Patents

Literature

1466 results about "Graft polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

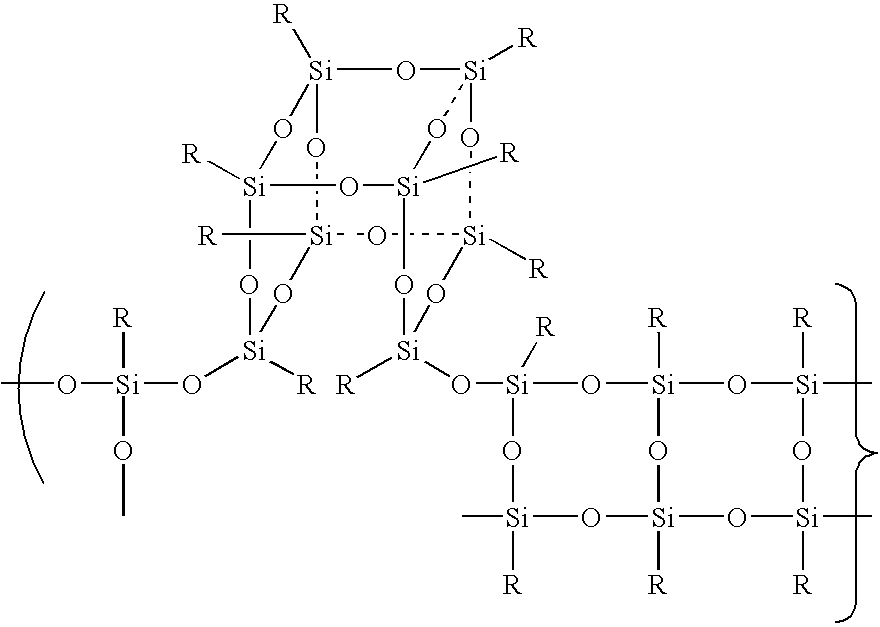

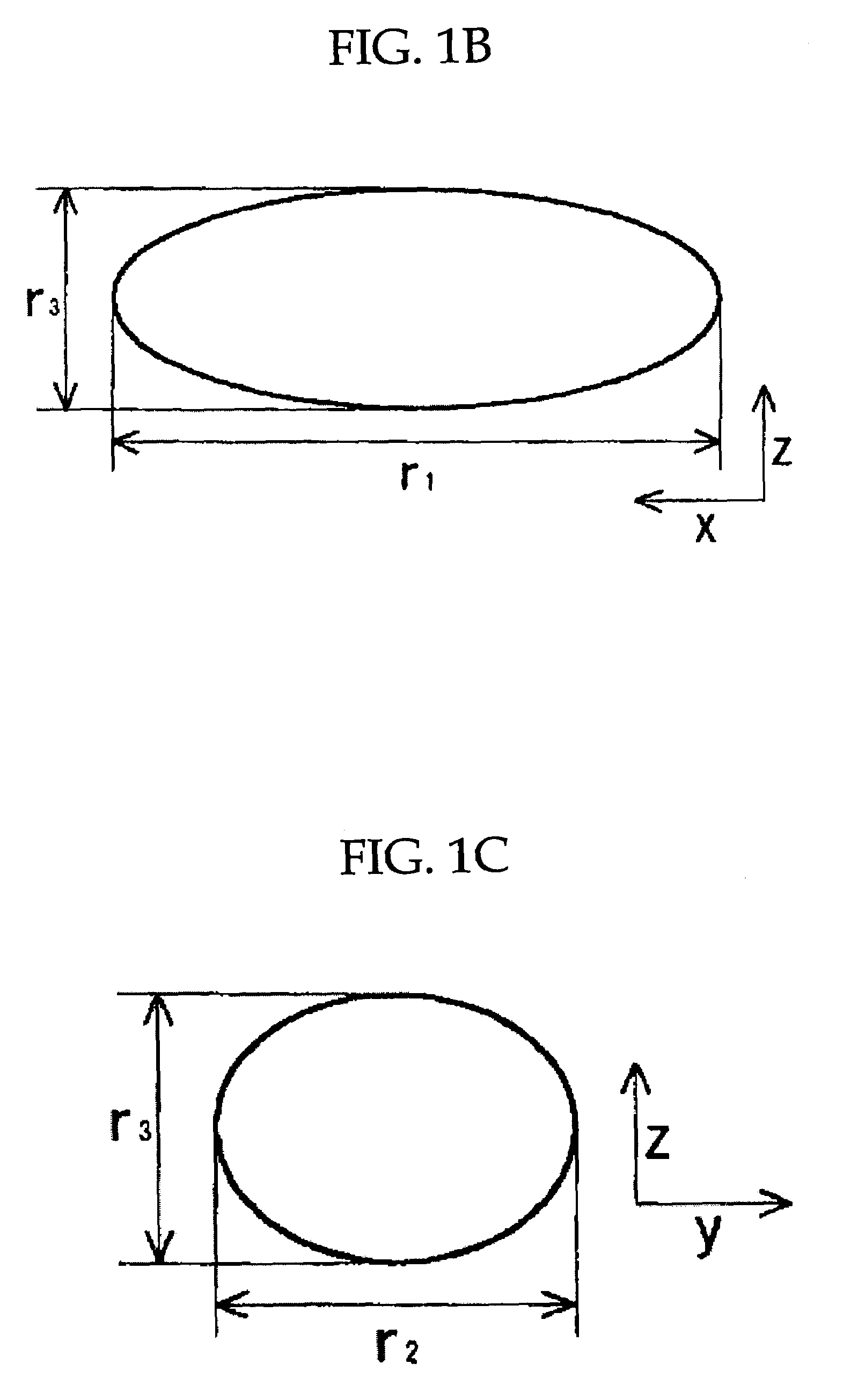

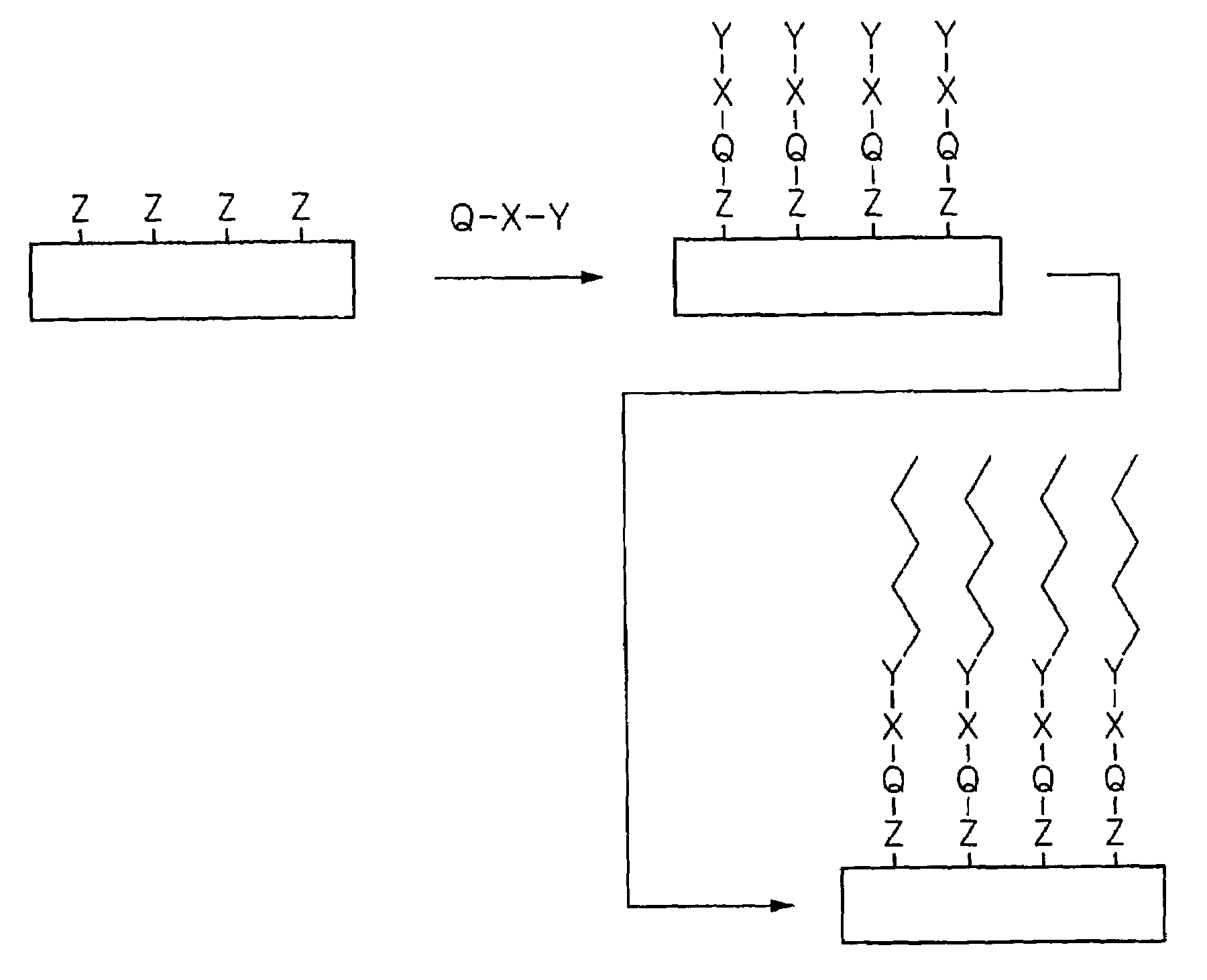

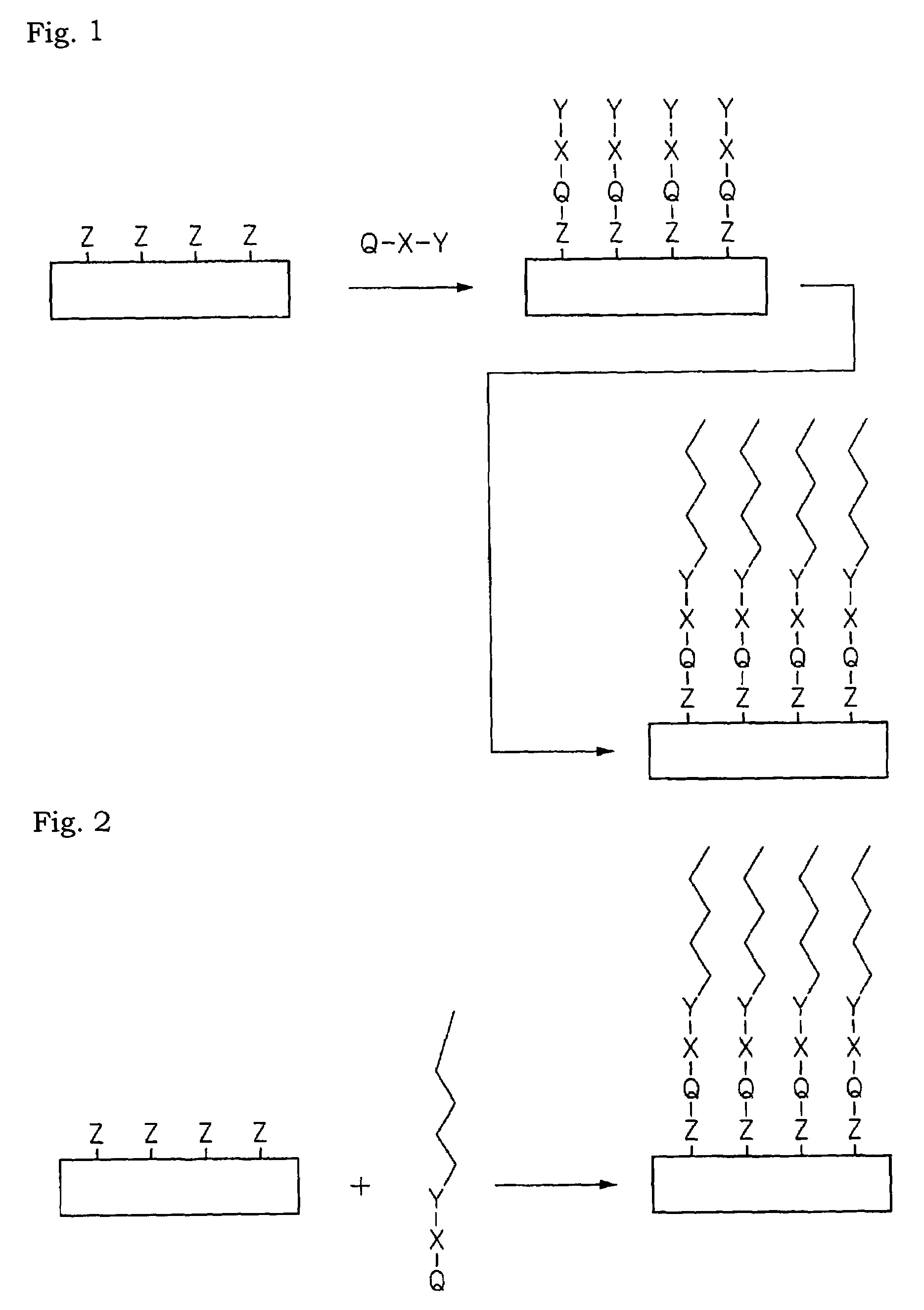

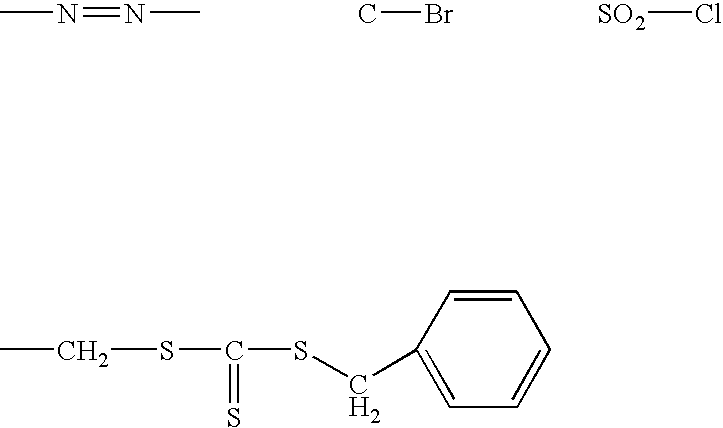

Graft polymers are segmented copolymers with a linear backbone of one composite and randomly distributed branches of another composite. The picture labeled "graft polymer" shows how grafted chains of species B are covalently bonded to polymer species A. Although the side chains are structurally distinct from the main chain, the individual grafted chains may be homopolymers or copolymers. Graft polymers have been synthesized for many decades and are especially used as impact resistant materials, thermoplastic elastomers, compatibilizers, or emulsifiers for the preparation of stable blends or alloys. One of the more well known examples of a graft polymer is high impact polystyrene, which consists of a polystyrene backbone with polybutadiene grafted chains.

Grafted polymers as gas hydrate inhibitors

InactiveUS6867262B1Low ground water pollution classificationReduce security risksThermal non-catalytic crackingUsing liquid separation agentPolymerHydrate

Owner:BASF AG

Hyaluronan and biodegradable high polymer modified material and preparation method

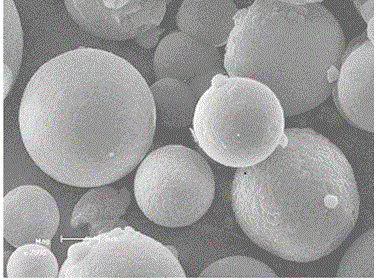

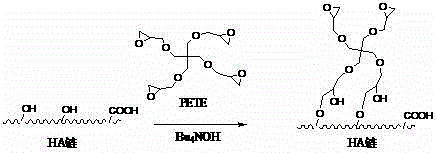

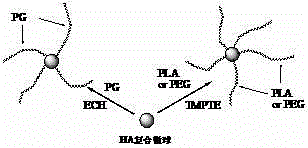

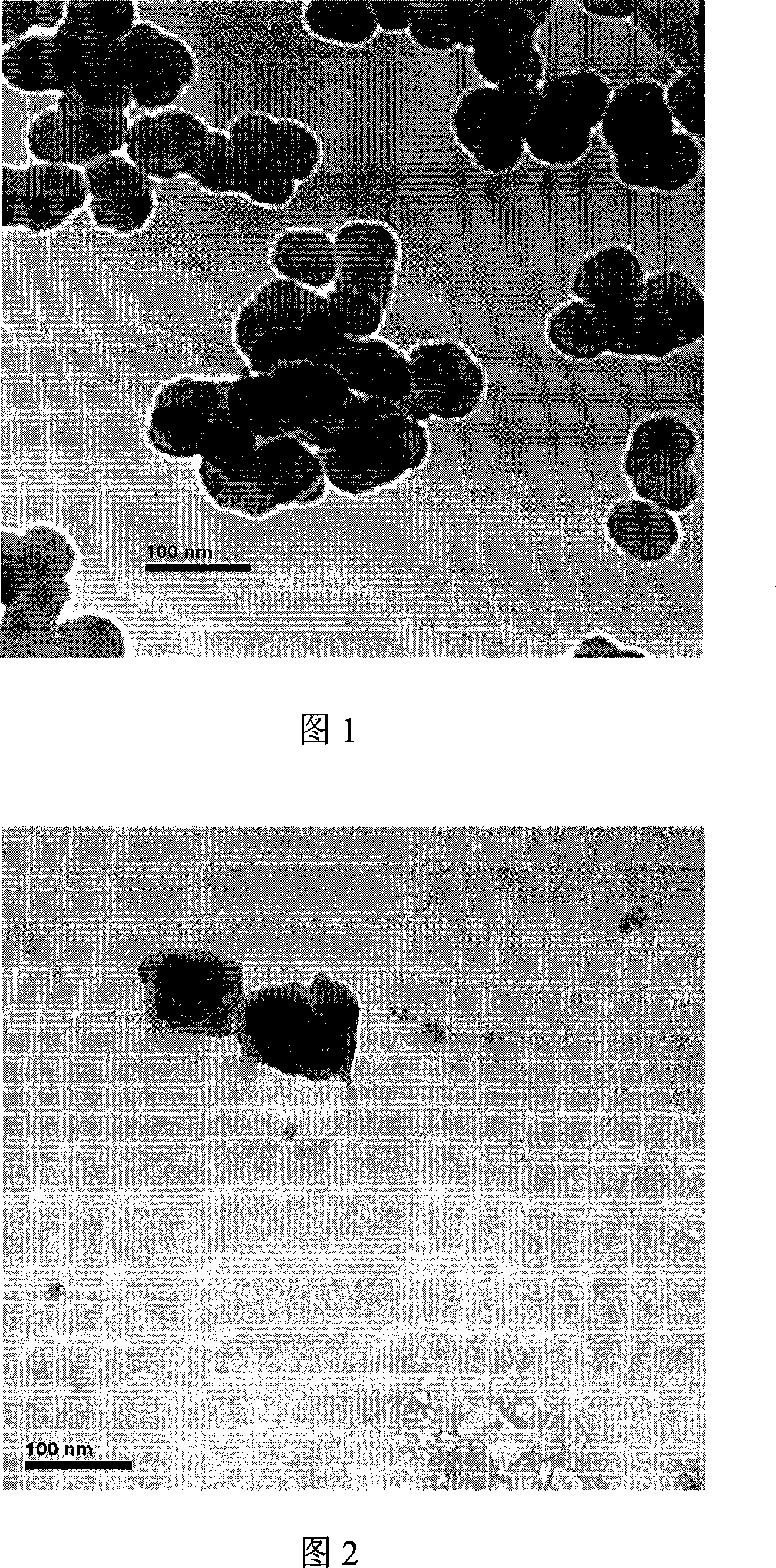

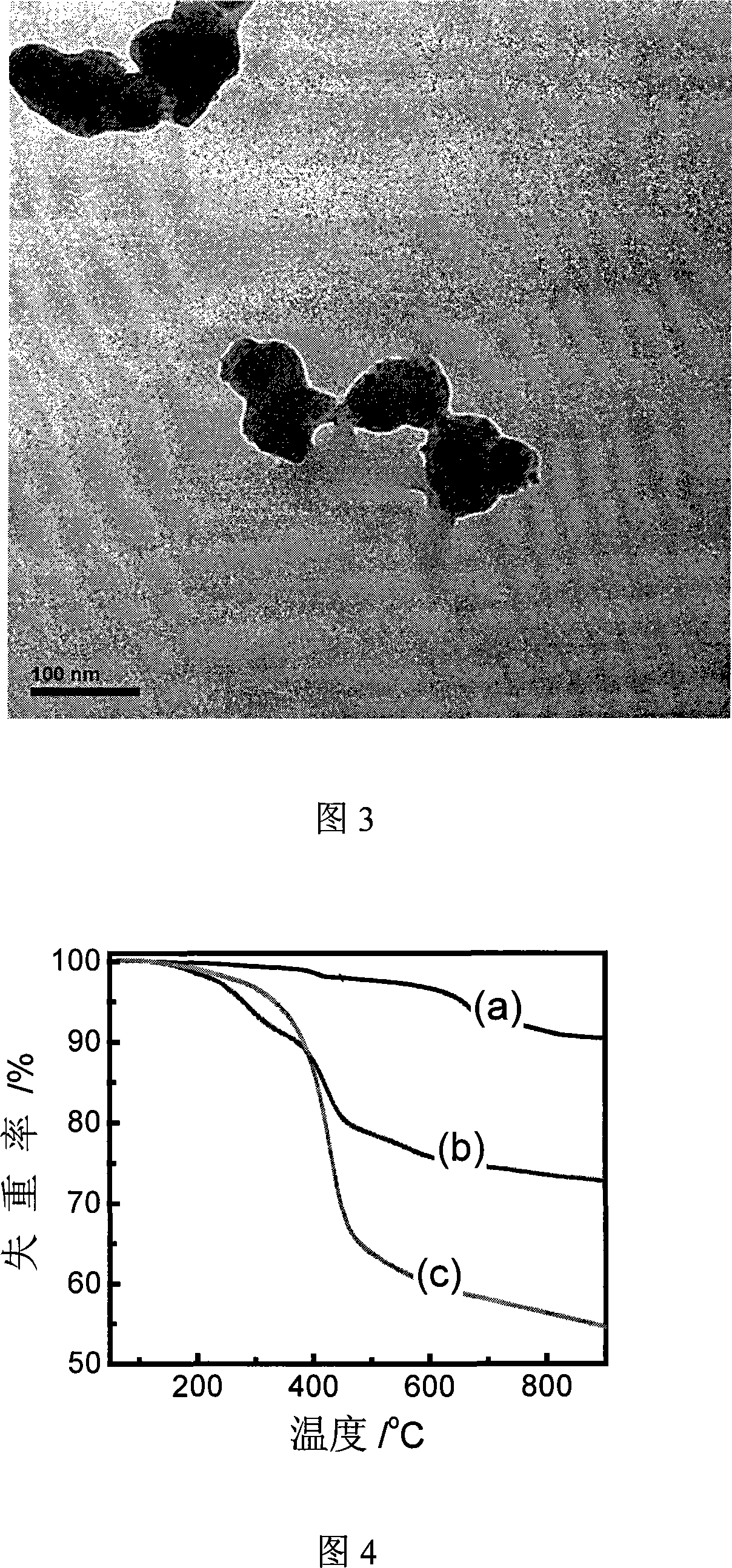

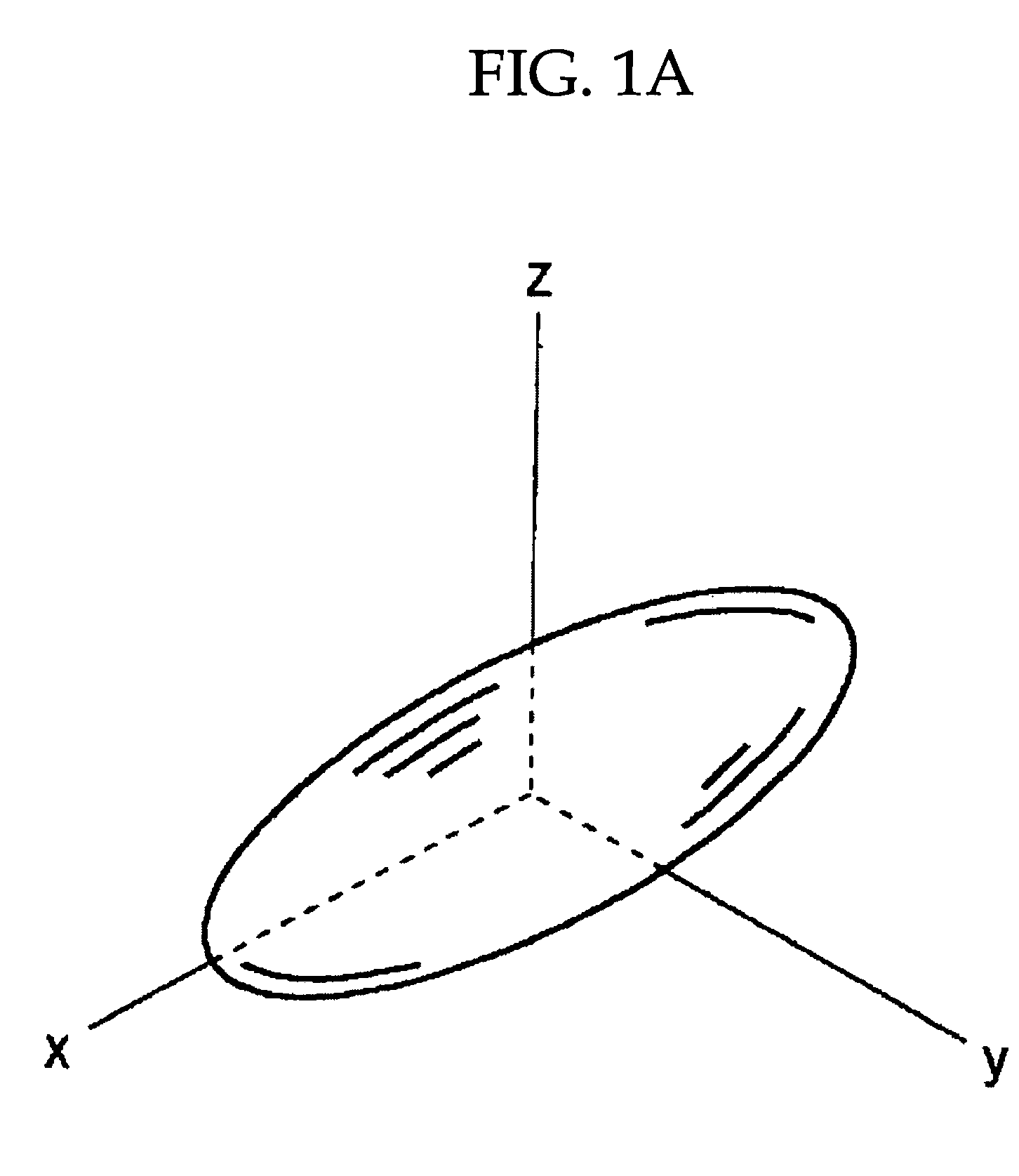

The invention relates to a hyaluronan and biodegradable high polymer modified material and a preparation method, in particular to a method for complex crosslinking and grafting of the hyaluronan and a derivative thereof with a biodegradable high polymer with active functional groups through a crosslinking agent. The method comprises the steps of taking the hyaluronan and the biodegradable high polymer as raw materials, conducting complex crosslinking or grafting reaction of a hyaluronan aqueous solution and at least one biodegradable high polymer solution with the presence of the crosslinking agent, and removing a solvent. According to the method, plural gel, an amphiphilic polymer, a graft polymer, a star polymer and a microsphere can be prepared. The method has the advantages that the reaction condition is simple, the utilization ratio of the crosslinking agent is high, the residual quantity of the crosslinking agent is small, and the gel is higher in thermostability and good in biological compatibility. The method is applicable to the fields of cosmetics, tissue filling and repair, biological stents, ophthalmonogy, sustained-release delivery and targeted drug delivery and the like, and has a wider application prospect.

Owner:IMEIK TECH DEV CO LTD

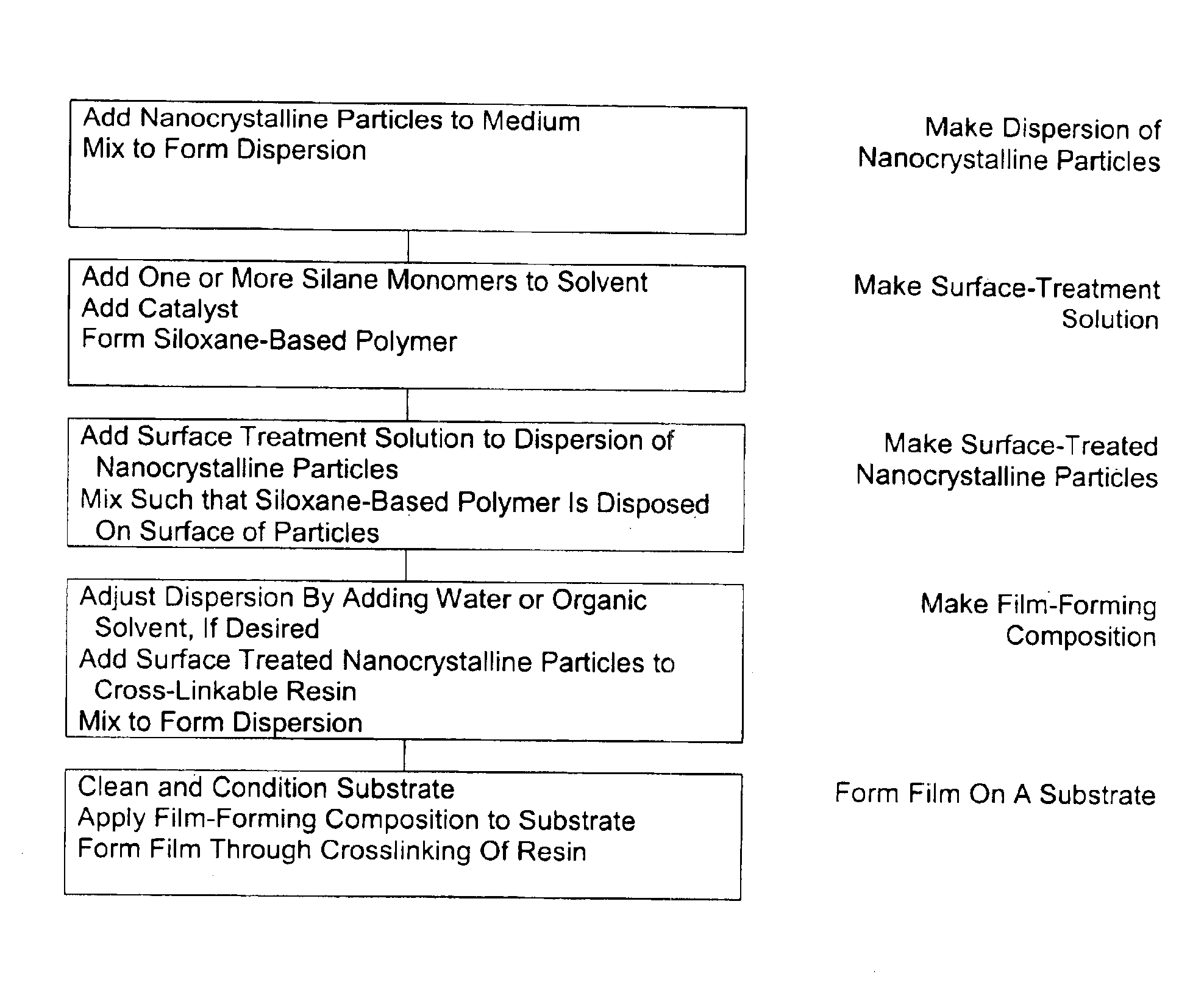

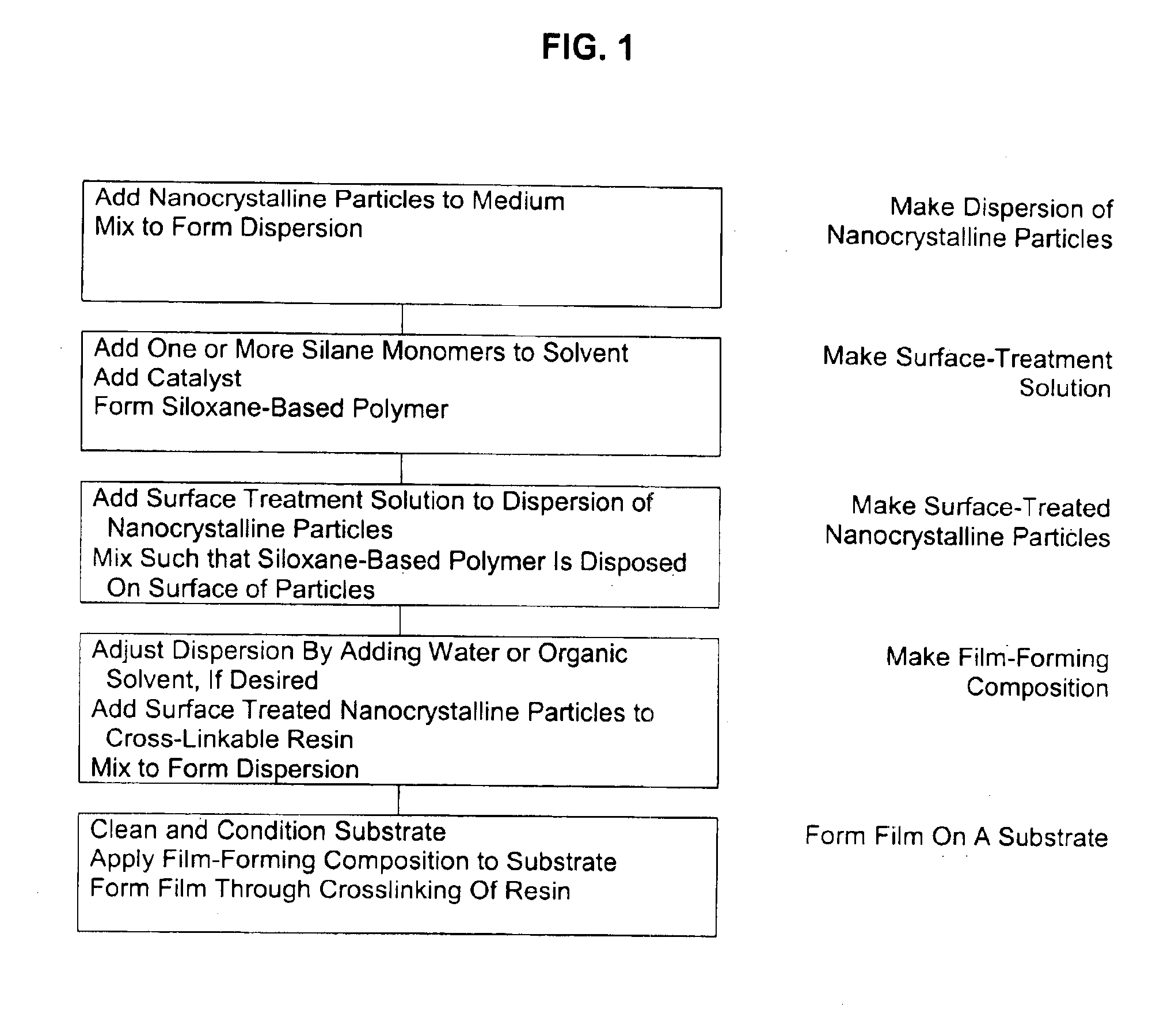

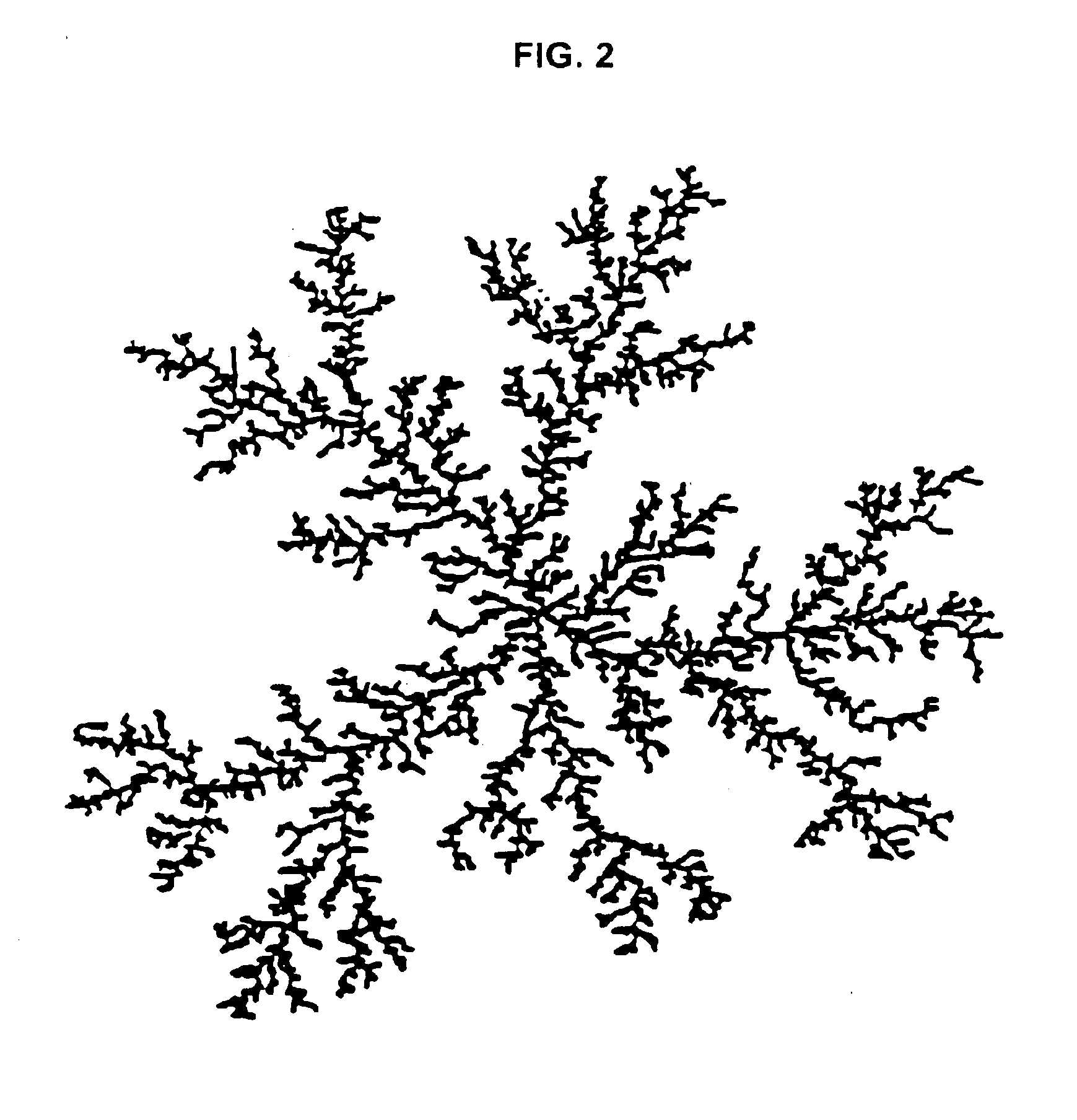

Substantially transparent, abrasion-resistant films containing surface-treated nanocrystalline particles

InactiveUS6896958B1Excellent abrasion resistanceHigh hardnessOther chemical processesMixing methodsNanocrystalPolymer chemistry

A film-forming composition contains surface-treated nanocrystalline particles dispersed in a cross-linkable resin. A substantially transparent, abrasion-resistant film is formed from the film-forming composition. Processes for preparing the film-forming composition and for preparing a substantially transparent, abrasion-resistant film are also included. The surface-treated nanocrystalline particles may be obtained by treating nanocrystalline particles with one or more siloxane species, such as a siloxane star-graft polymer coating.

Owner:NANOPHASE TECH CORP

Polymeric nanocomposites

InactiveUS20050191490A1Increase heightEnhanced interactionMaterial nanotechnologySynthetic resin layered productsEpoxyPolyolefin

Disclosed is a nanocomposite comprising a nano-reinforcing material (e.g., layered clay), a polymer matrix (e.g., a polyolefin), and, an epoxy-functionalized graft polymer compatible with the polymer matrix (e.g., epoxy-grafted polyolefin). Such nanocomposites are useful in the fabrication of a variety of materials including parts for the transportation and packaging industries, electronics, business equipment, building and construction materials.

Owner:NAT RES COUNCIL OF CANADA

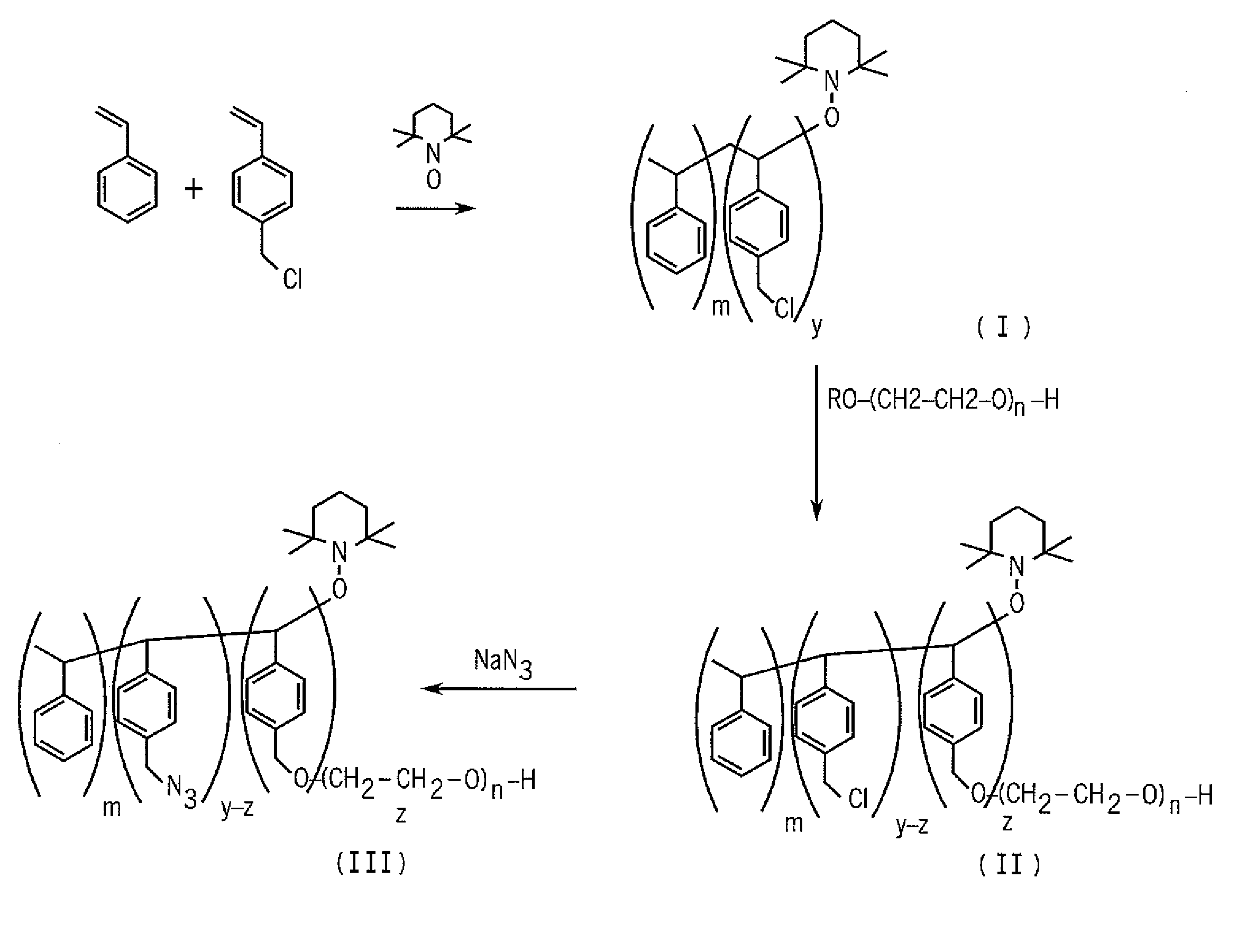

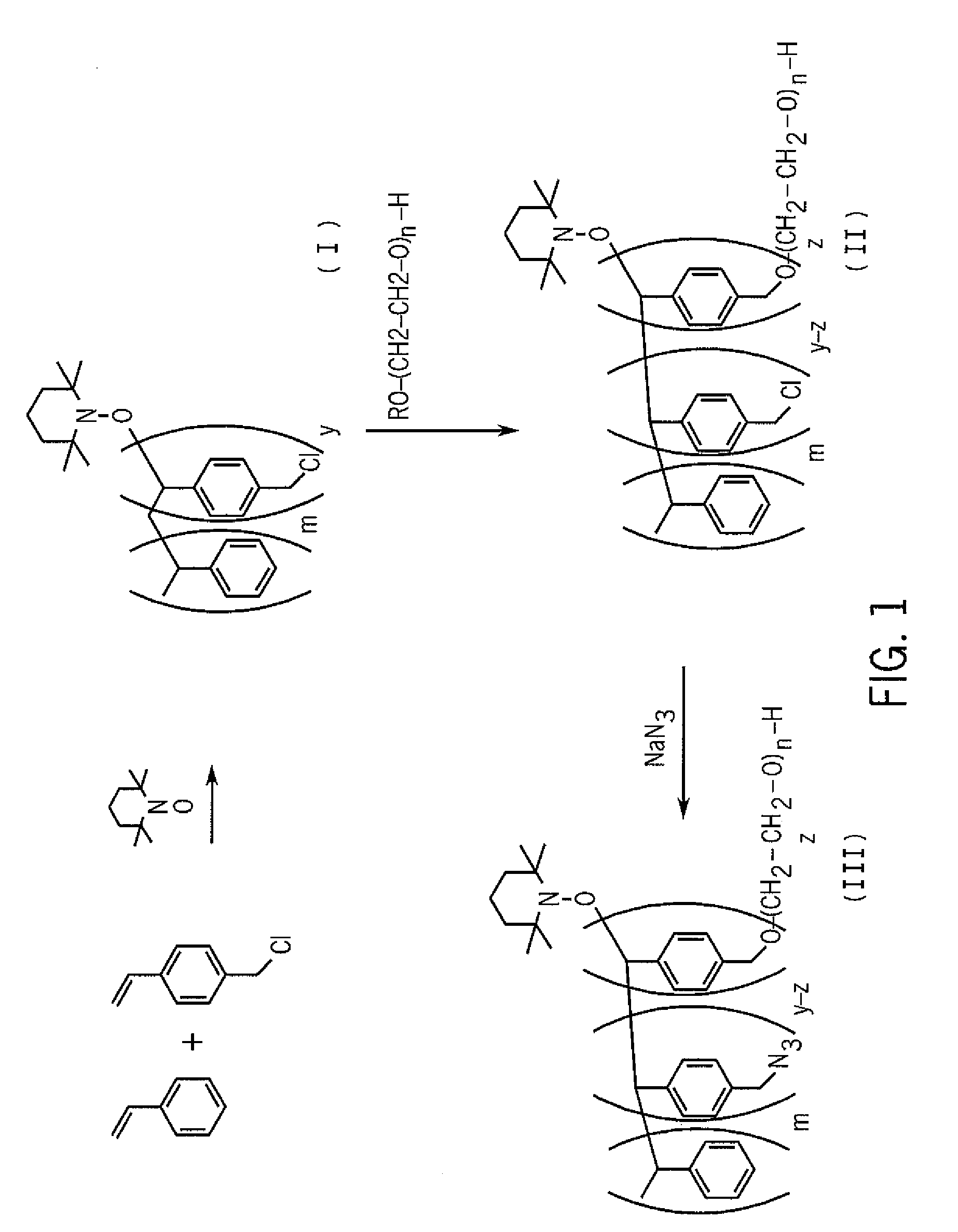

Crosslinkable Graft Polymer Non-Preferentially Wetted by Polystyrene and Polyethylene Oxide

ActiveUS20080318005A1Material nanotechnologyDecorative surface effectsPolyethylene oxidePolymer science

Methods for fabricating a random graft PS-r-PEO copolymer and its use as a neutral wetting layer in the fabrication of sublithographic, nanoscale arrays of elements including openings and linear microchannels utilizing self-assembling block copolymers, and films and devices formed from these methods are provided. In some embodiments, the films can be used as a template or mask to etch openings in an underlying material layer.

Owner:MICRON TECH INC

Non-fouling, Anti-microbial, Anti-thrombogenic graft-from compositons

ActiveUS20110305872A1Reduce microbial colonizationShorten the counting processLayered productsPretreated surfacesFibrinogenBlood plasma

A method for preparing and resulting articles of manufacture comprising a substrate having a surface, a bulk beneath the surface, and a grafted polymer layer on the substrate surface, the substrate surface and the grafted polymer layer, in combination, constituting a modified surface having a fibrinogen adsorption of less than about 125 ng / cm2 in a fibrinogen binding assay in which the modified surface is incubated for 60 minutes at 37° C. in 70 μg / mL fibrinogen derived from human plasma containing 1.4 μg / mL I-125 radiolabeled fibrinogen.

Owner:ARROW INT INC

Preparation method of polymer-grafted graphene

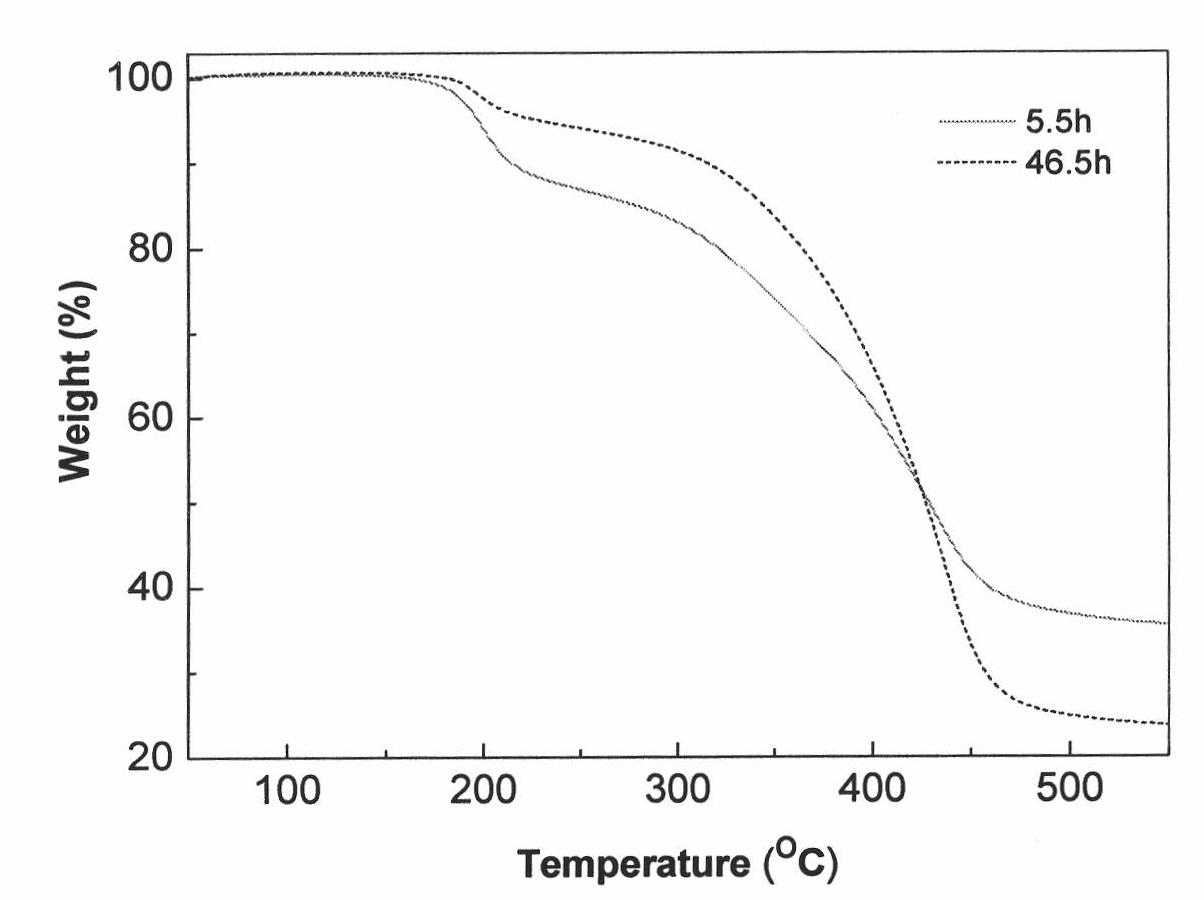

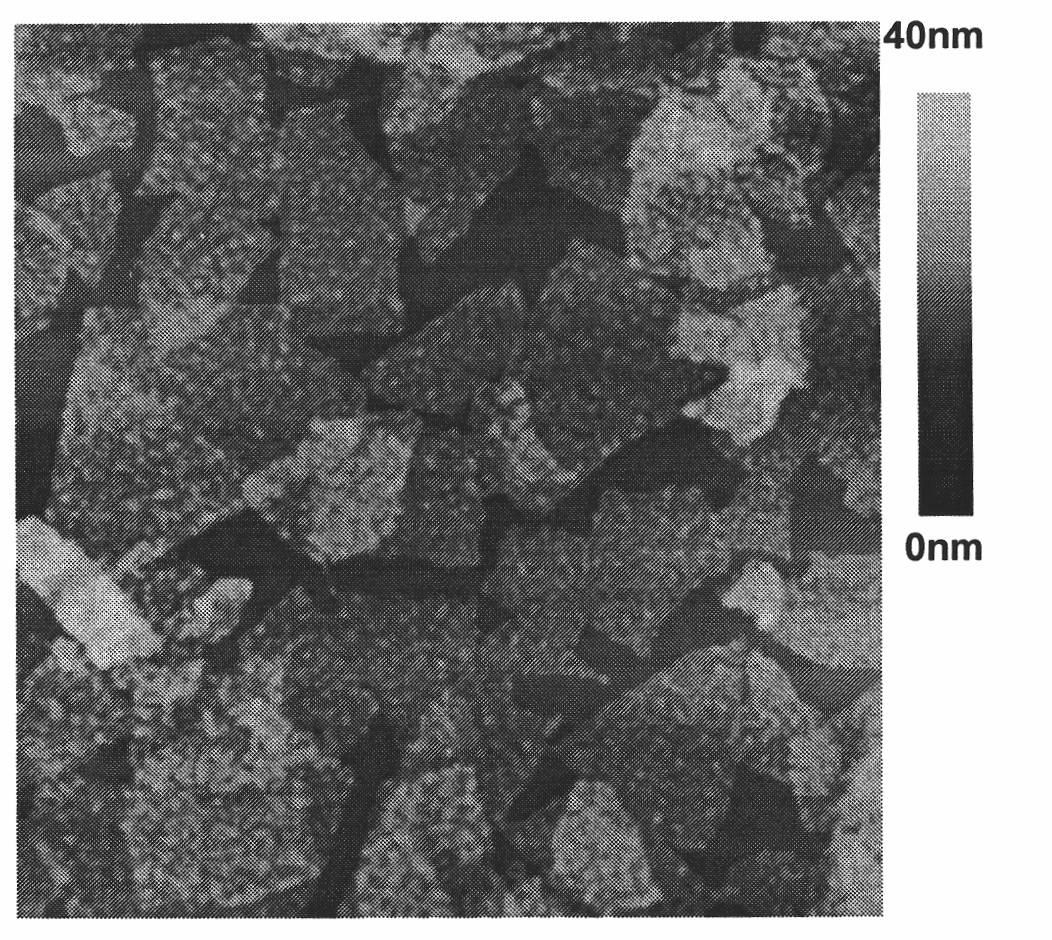

The invention discloses a method for grafting a polymer ona surface of graphene. The method comprises the following steps: adding 1 part by weight of graphene or graphene oxide, 10-1000 parts by weight of solvent and 10-1000 parts by weight of vinyl monomer, and adding 0.01-10 parts by weight of initiator under introduction of nitrogen; heating to 55-90 DEG C, and carrying out reaction for 1.5-60hours; and precipitating, centrifugating, washing, and drying, thus obtaining a product of polymer-grafted graphene. The method is convenient and simple in process, can be used for the large-scale production, is the universal method and ensures that a variety of polymers can be grated onto the graphene. The obtained functionalized graphene has good solubility and good solution processability, is conducive and has extensive application value in micro-nano electronics, machinery, chemical industry, high-performance materials and other fields.

Owner:杭州德烯科技集团有限公司

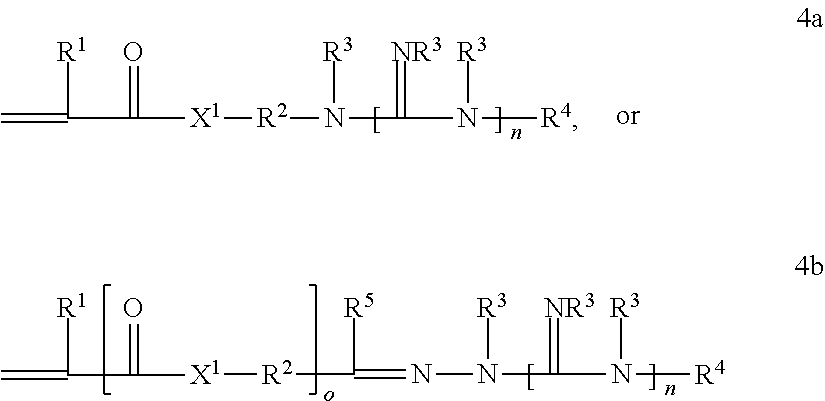

Ligand functional substrates

A substrate comprising a crosslinked polymer primer layer, and grafted thereto a ligand-functionalized polymer is provided. The grafted polymer has the requisite affinity for binding neutral or negatively charged biomaterials, such as cells, cell debris, bacteria, spores, viruses, nucleic acids, and proteins, at pH's near or below the pI's of the biomaterials.

Owner:3M INNOVATIVE PROPERTIES CO

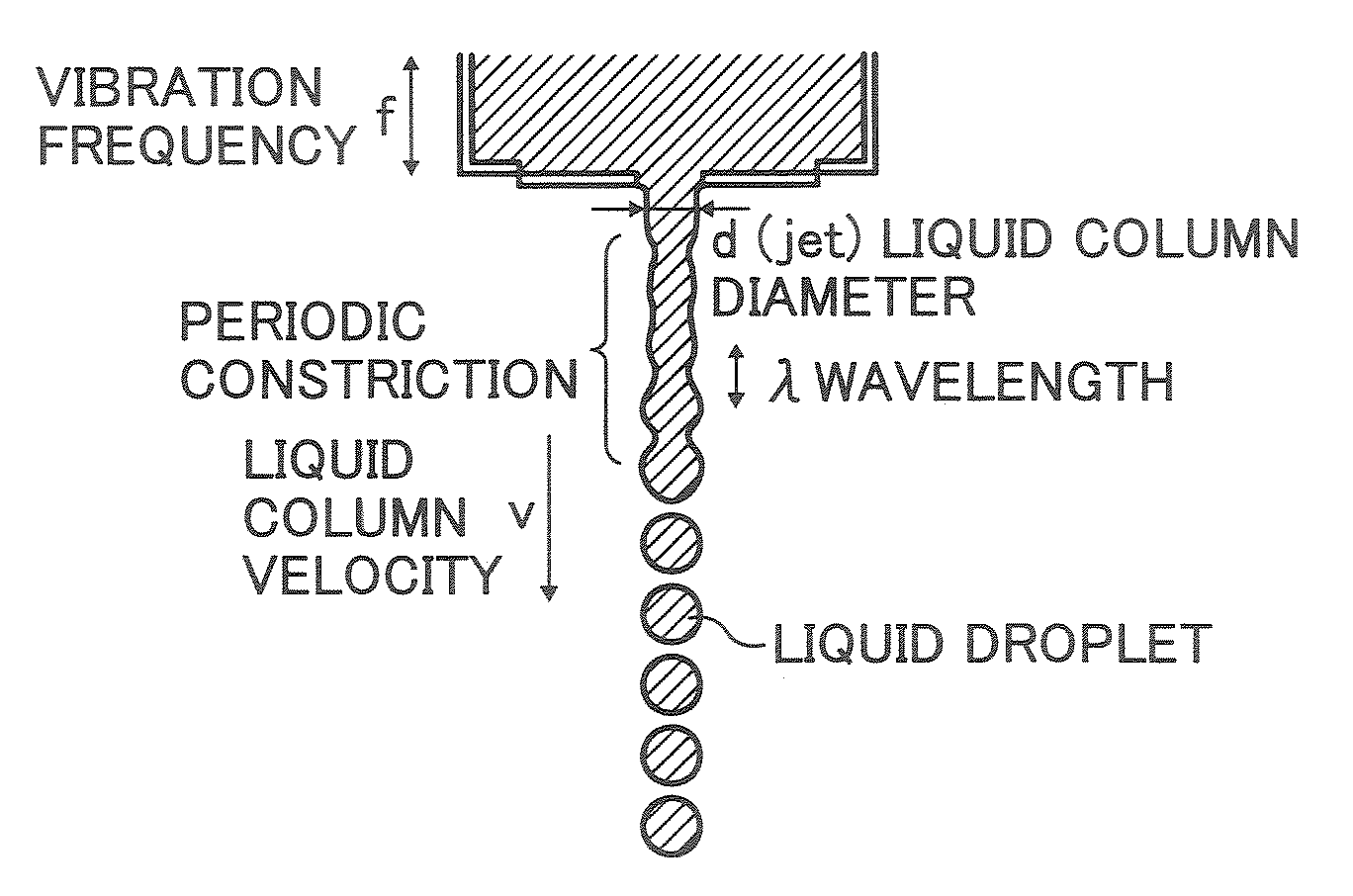

Method for manufacturing toner and toner

InactiveUS20080063971A1Efficient productionSmall particle sizeDevelopersLiquid spraying apparatusSolid massPolyolefin

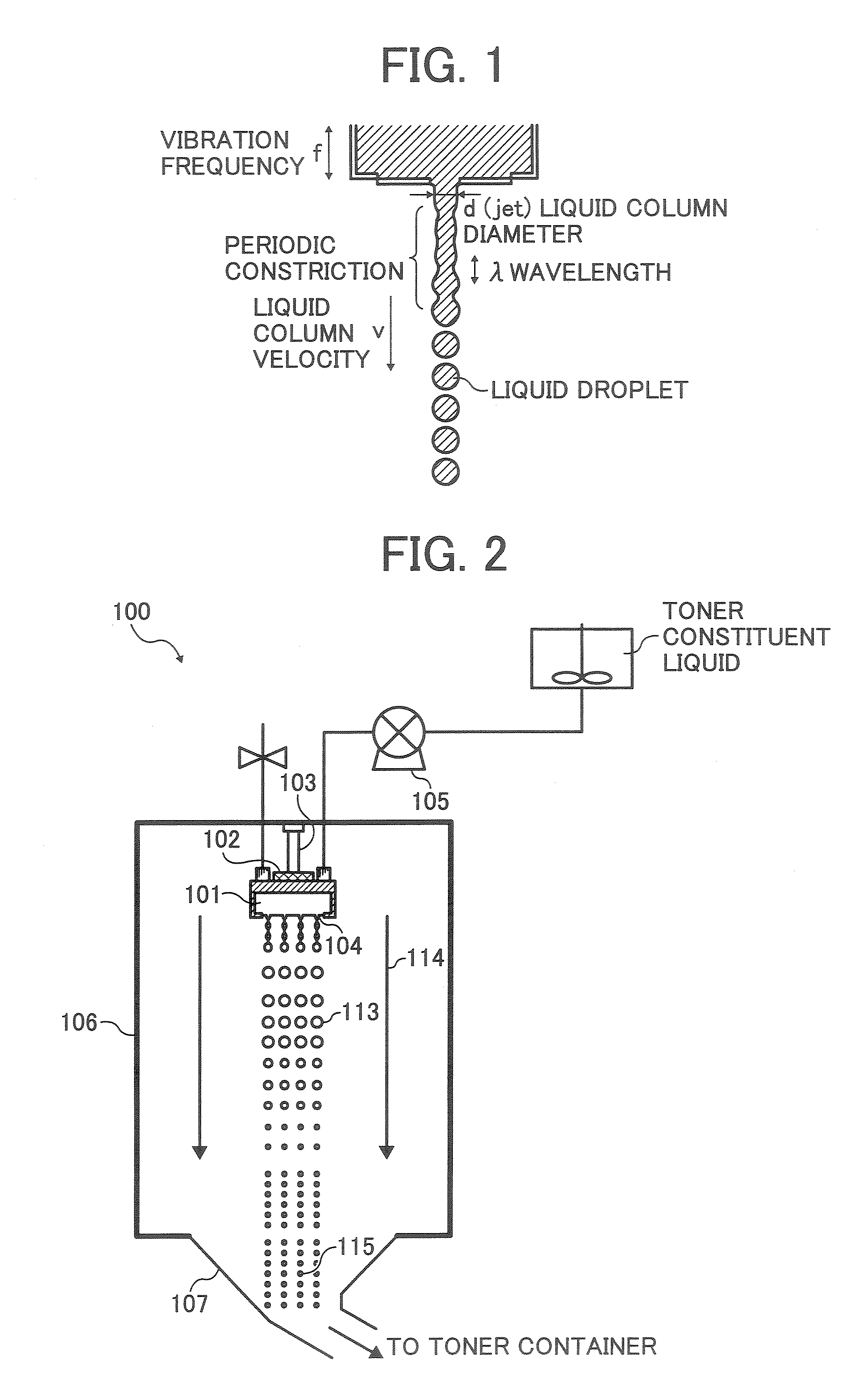

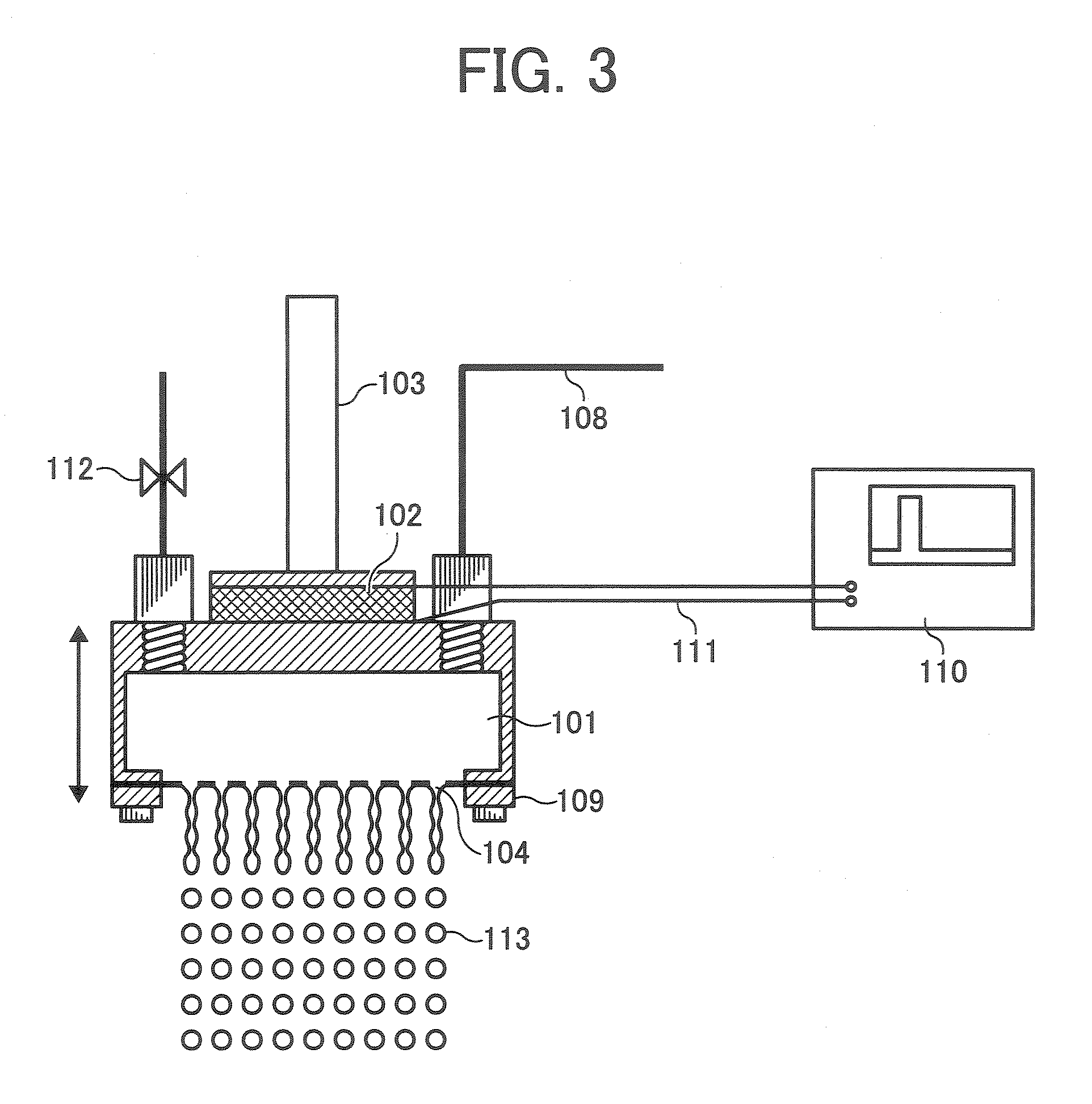

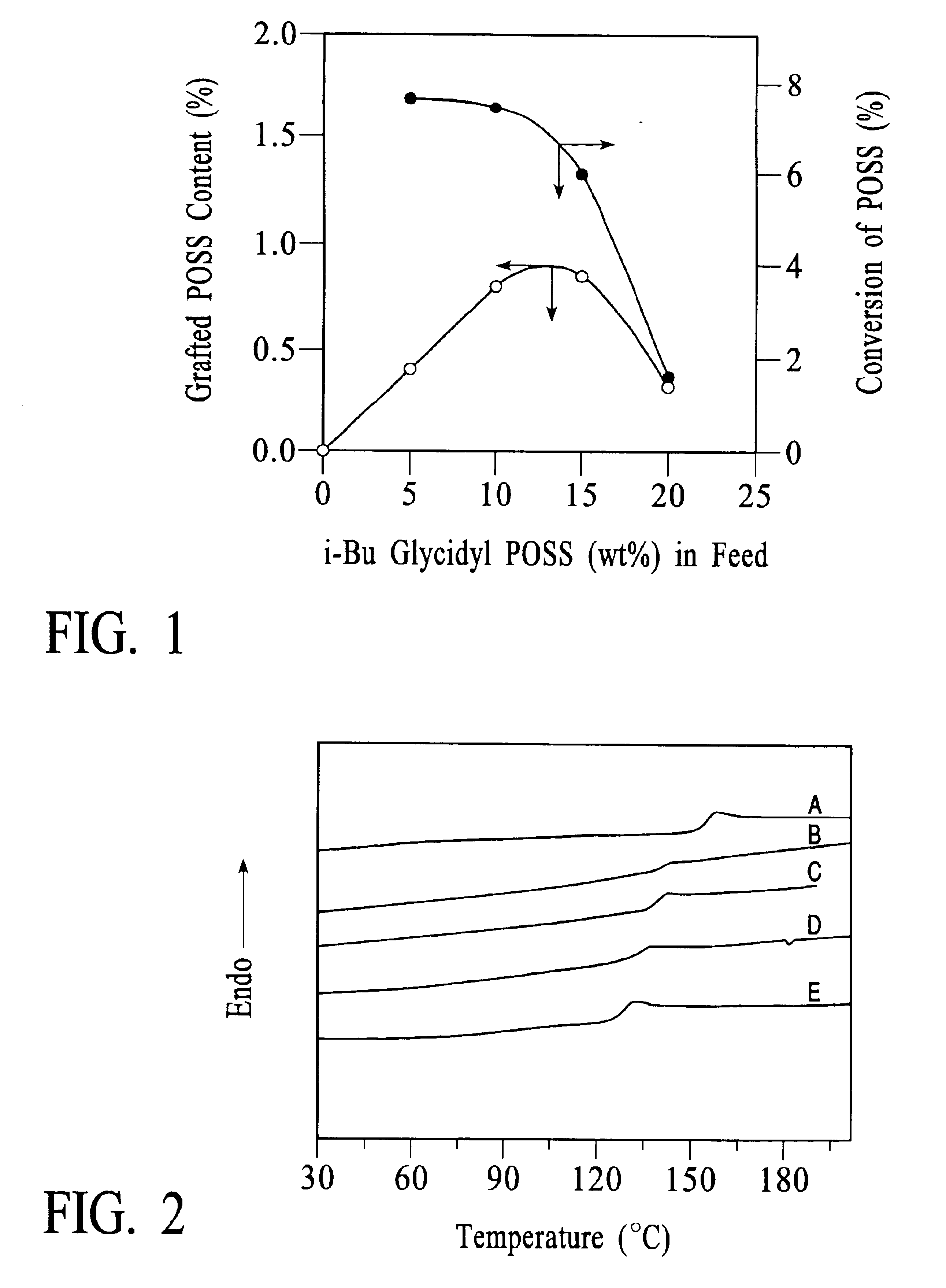

A method for manufacturing a toner, including: dissolving or dispersing toner constituents including a resin, a colorant, a release agent, and a graft polymer including a polyolefin resin unit and a vinyl resin unit in a solvent, to prepare a toner constituent liquid; supplying the toner constituent liquid to a retention part configured to retain the toner constituent liquid; discharging the toner constituent liquid from the retention part to a granulation space through plural holes arranged on the retention part, while exciting the toner constituent liquid by a vibration means in contact with a part of the retention part, so that the discharged columnar toner constituent liquid is constricted to form liquid droplets; and converting the liquid droplets into solid toner particles; together with a toner manufactured by the above method.

Owner:RICOH KK

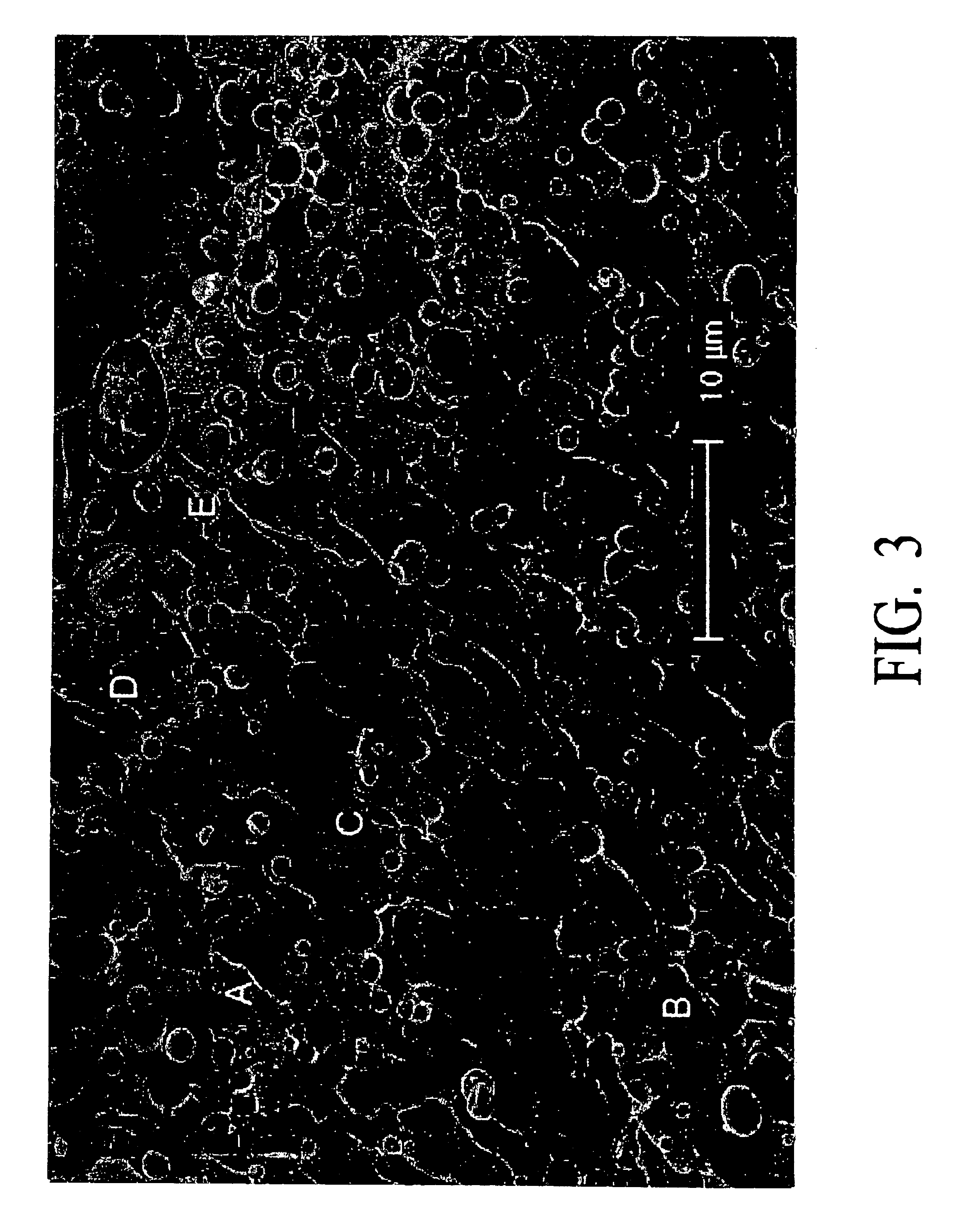

Reactive grafting and compatibilization of polyhedral oligomeric silsesquioxanes

InactiveUS6933345B1Rapid low cost modificationEasy to controlMaterial nanotechnologyFiberSilsesquioxane

The nanoscopic dimensions of polyhedral oligomeric silsesquioxanes (POSS) and polyhedral oligomeric silicates (POS) materials ranges from 0.7 nm to 5.0 nm and enables the thermomechanical and physical properties of polymeric materials to be improved by providing nanoscopic reinforcement of polymer chains at a length scale that is not possible by physically smaller aromatic chemical systems or larger fillers and fibers. A simple and cost effective method for incorporating POSS / POS nanoreinforcements onto polymers via the reactive grafting of suitably functionalized POSS / POS entities with polymeric systems amenable to such processes is described. The method teaches that the resulting POSS-grafted-polymers are particularly well suited for alloying agents by nongrafted POSS entitles such as molecular silicas. The successful alloying of POSS-polymers is aided because their interfacial tensions are reduced relative to non-POSS containing systems.

Owner:HYBRID PLASTICS INC

Method for grafting polymer on inorganic material surface

The present invention discloses a method of grafting a polymer on the surface of the inorganic materials. The polyethylene oxide or polyethylene glycol which contains amino or hydroxyl at the chain-end by a covalent bond or an ionic bond, or a compound containing glucose units is firstly fixed at the surface of the inorganic materials, so as to have a reductive organic chemical group on the surface; then a high cerium salt and a polymerizable monomer are added, the present invention makes use of the high cerium salt and the reductive organic group on the surface of the inorganic materials to constitute an oxidation-reduction initiation system, so as to initiate the monomer polymerization under the acidic condition, further to graft the polymer on the surface of the inorganic materials. The method of the present invention can graft the polymer on the surface of the inorganic materials easily, which has the advantages of simple reaction process, mild reaction condition and high grafting rate, so the present invention is particularly applicable for the grafting of a water-soluble polymer or a polymer hydrogel thin layer on the surface of the inorganic materials.

Owner:ZHEJIANG UNIV

Process for grafting a fluoropolymer and multilayer structures comprising this grafted polymer

The present invention relates to a process for grafting an unsaturated monomer onto a fluoropolymer, having the steps of:a) melt blending the fluoropolymer with the unsaturated monomer;b) forming the blend obtained in a) into films, sheets, granules or powder;c) exposing the products from step b), in the absence of air, to photon (γ) or electron (β) irradiation with a dose of between 1 and 15 Mrad; andd) optionally treating the product obtained at c) in order to remove all or part of the unsaturated monomer that has not been grafted onto the fluoropolymer.Structures made with these materials are barriers to many fluids and in particular to petrol and to air-conditioning fluids and may be formed into bottles, tanks, containers, pipes, hoses and vessels of all sorts. They may also be converted into films with which packaging is made.

Owner:ARKEMA FRANCE SA

Toner and developer for developing latent electrostatic images, and image forming apparatus

ActiveUS7129013B2Improved low-temperature image-fixing propertyImproved offset resistanceElectrographic process apparatusDevelopersOrganic solventPolyolefin

A toner for developing latent electrostatic images is in the form of particles prepared by dissolving or dispersing each component of a composition in an organic solvent to form a solution or dispersion, the composition containing at least a resin reactive with a compound having an active hydrogen group, a compound having an active hydrogen group, a coloring agent, a releasing agent, and a graft polymer C of a polyolefin resin A on which a vinyl resin B has been at least partially grafted; dispersing the solution or dispersion in an aqueous medium; reacting the reactive resin with the compound having an active hydrogen group; removing the organic solvent during or after the step of reacting; and washing and drying particles formed by removing the organic solvent.

Owner:RICOH KK

Surface graft material, conductive pattern material, and production method thereof

InactiveUS7291427B2Promote generationWell formedInsulating substrate metal adhesion improvementPhotosensitive materialsMetal particleChemistry

A surface graft material including a substrate and a surface graft polymer chain, wherein the surface graft polymer chain includes a photocleavable moiety at one of its terminals, and the surface graft polymer chain is directly bonded to a surface of the substrate by a covalent bond between the photocleavable moiety and the substrate. A graft pattern formation method comprising exposing the graft material to cleave the photocleavable moiety in the exposed area, and removing the graft polymer chain from the exposed are to form a surface graft polymer chain pattern. A conductive pattern material and a metal particle pattern material using the graft pattern.

Owner:FUJIFILM HLDG CORP +1

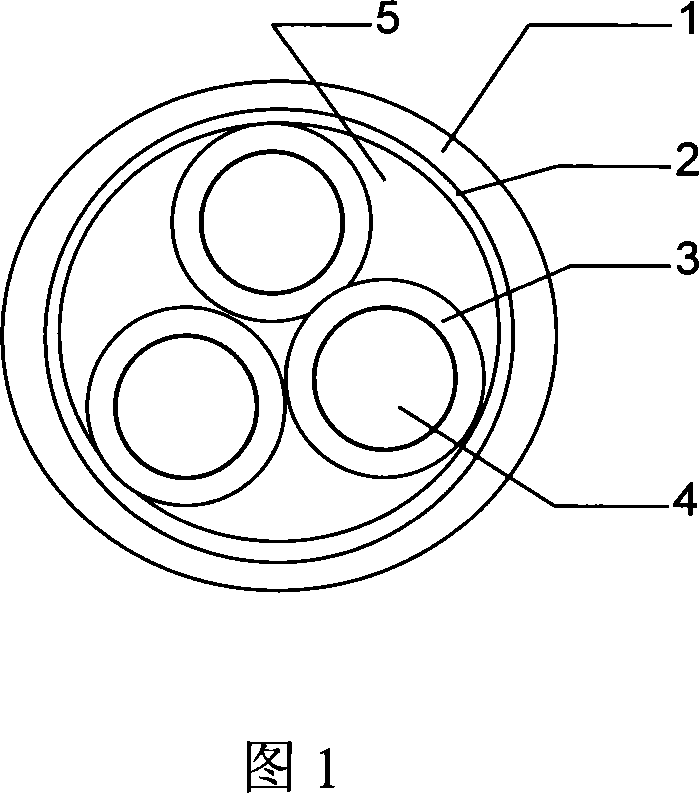

Halogen-free flame-retardant electric wire and cable sheath polymer material and uses thereof

ActiveCN101205324ASolve the problem of unsatisfactory flame resistanceNormal channel workInsulated cablesInsulated conductorsMolecular materialsElectrical polarity

The invention relates to a high molecular material of the halogen-free fire retardant sheath for wire cable and the application thereof. The invention solves the problem of bad fire retardant performance of the existing flame-retardant wire cable. The high molecular material of the invention is characterized in that the material comprises the following components by weight: a) 8-50 per cent of halogen-free expansive flame retardant pretreated by coupling agent occupying 0.1-3 wt per cent of the halogen-free expansive flame retardant; b) 0.5-10 per cent of graft polymer of the polar compound; c) 5-30 per cent of inorganic padding pretreated by coupling agent occupying 0.1-3 wt per cent of the inorganic padding; and d) at least one organic polymer for the rest.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

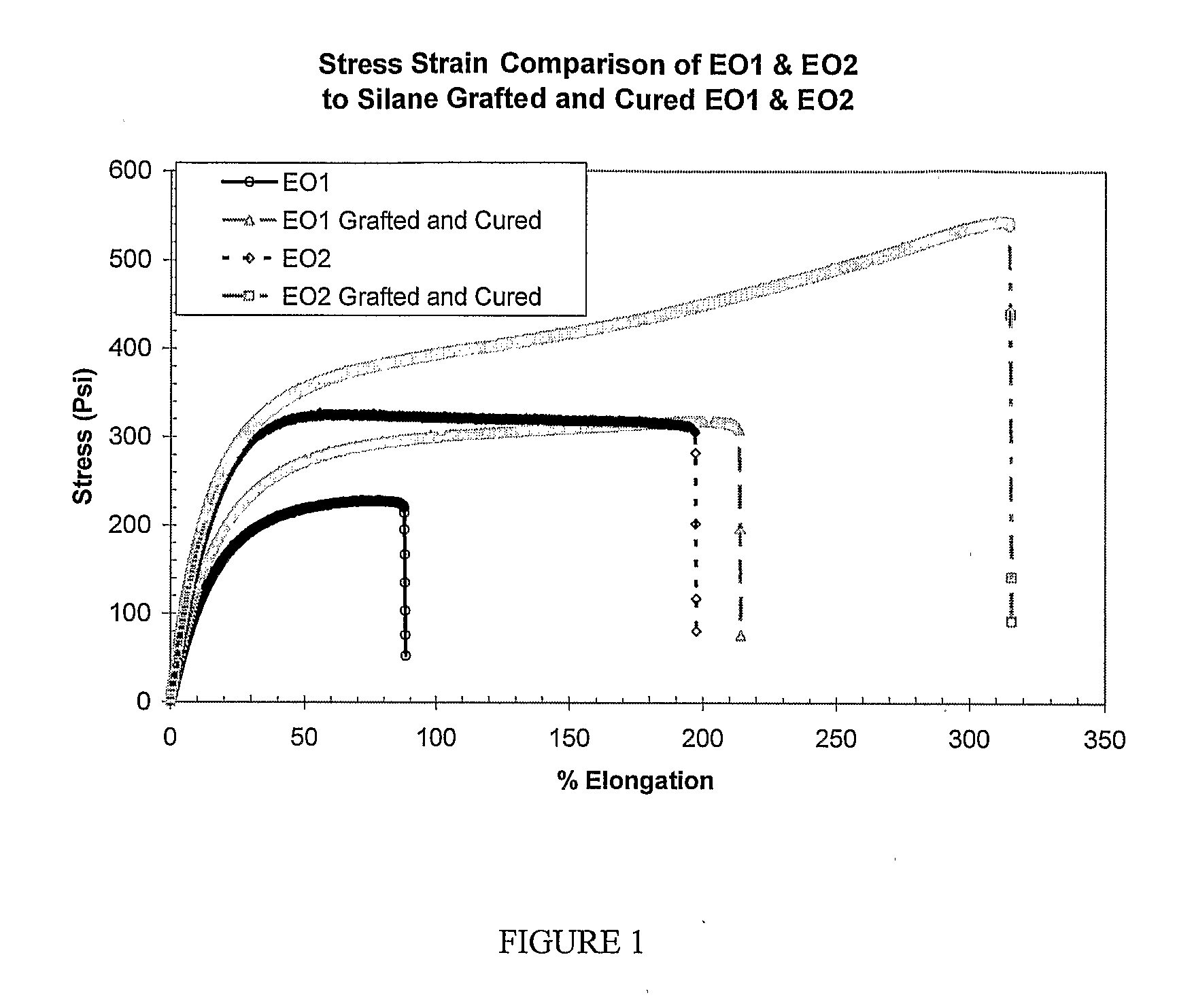

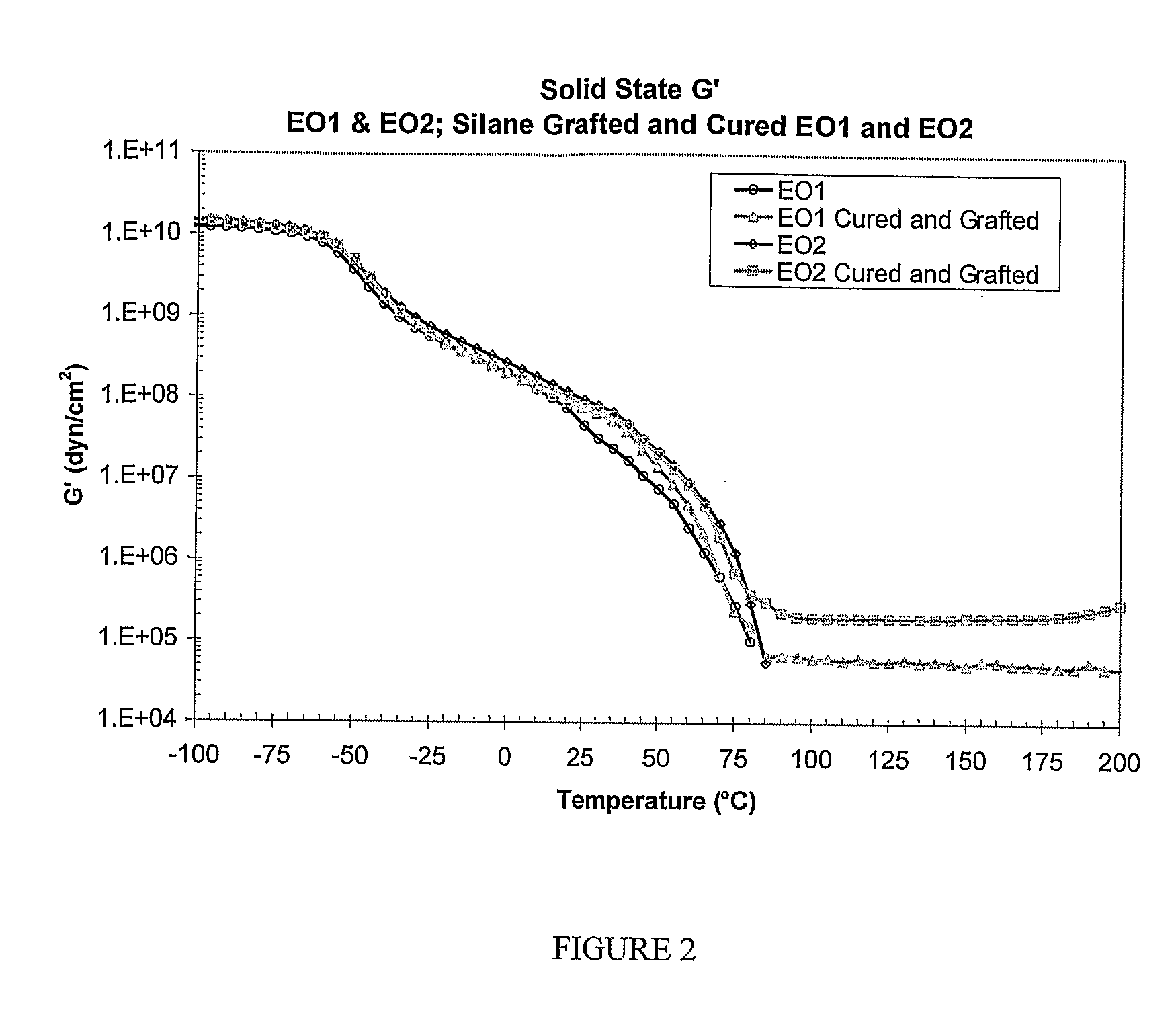

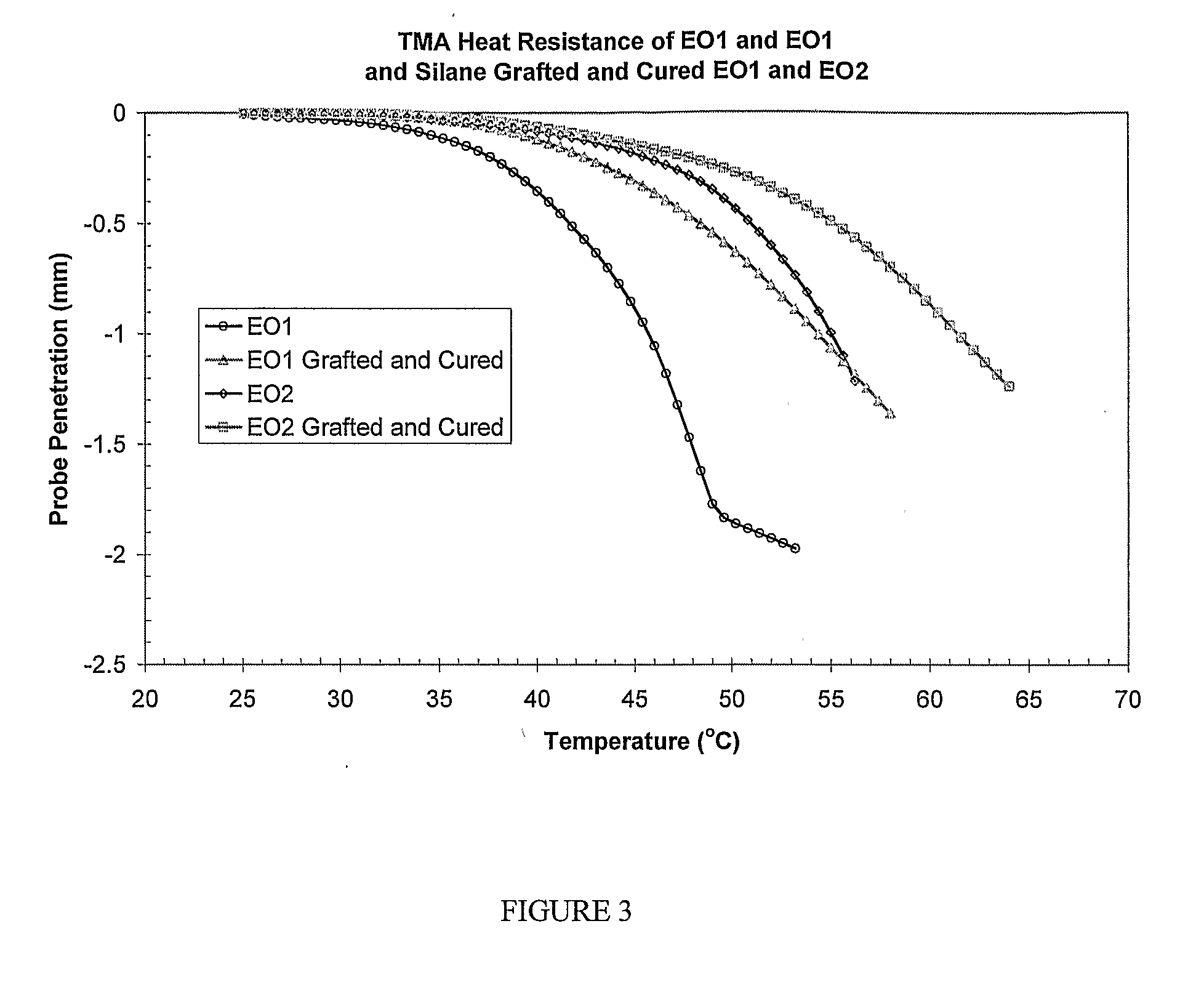

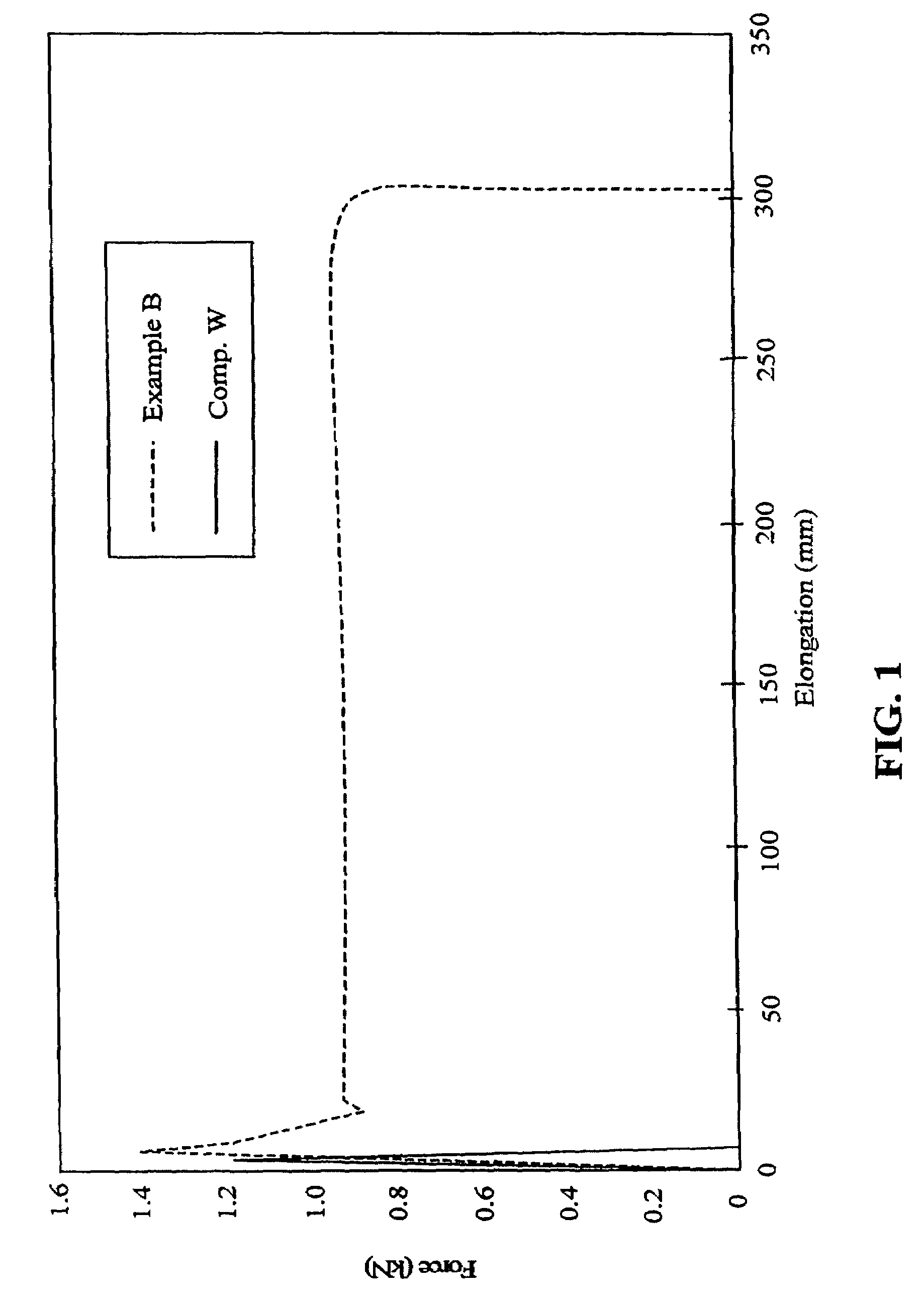

Silane-Grafted Olefin Polymers, Compositions and Articles Prepared Therefrom, and Methods For Making the Same

ActiveUS20080167421A1Improve adhesionReduce crystallinitySpecial tyresGraft polymer adhesivesSilane compoundsPolyolefin

The invention relates compositions containing at least one silane-grafted polyolefin, and in particular, to compositions containing at least one silane-grafted ethylene / α-olefin polymer, which has a melt viscosity less than 50,000 cP, and adhesives containing the same. In one embodiment, the at least one silane-grafted ethylene / α-olefin polymer is formed from an ethylene / α-olefin polymer that has a molecular weight distribution from 1 to 3.5. The invention also relates to the preparation of the silane-grafted polymers, by reacting, for example, an ethylene / α-olefin polymer with at least one silane compound and at least one initiator.

Owner:DOW GLOBAL TECH LLC

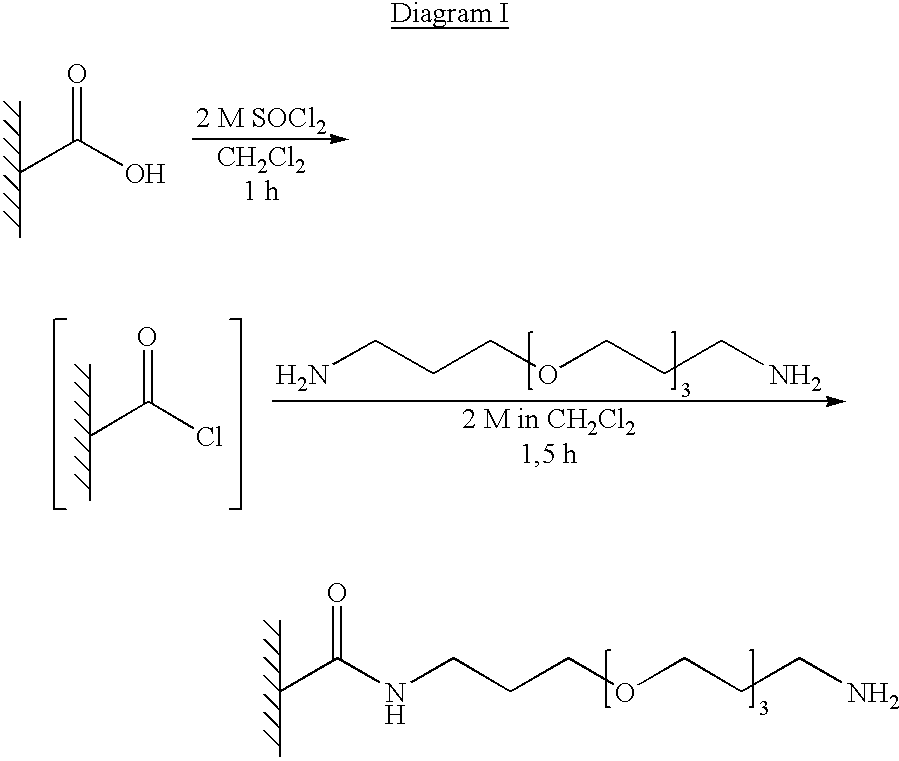

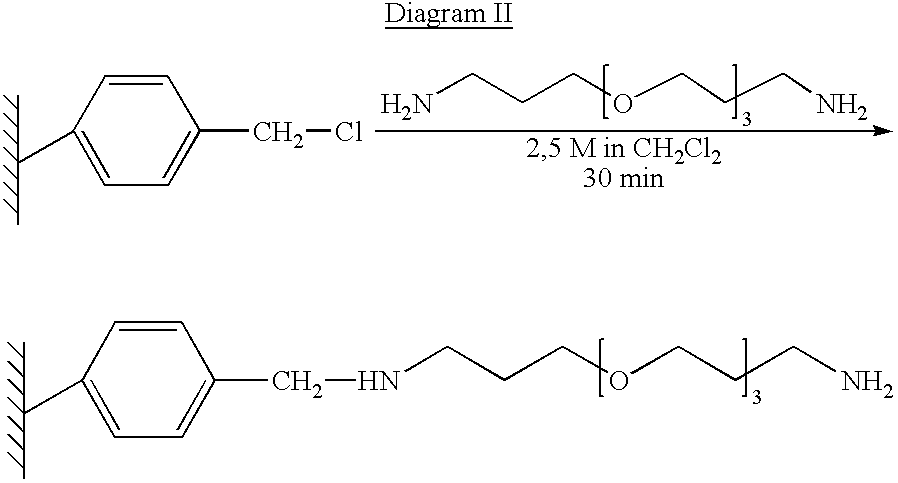

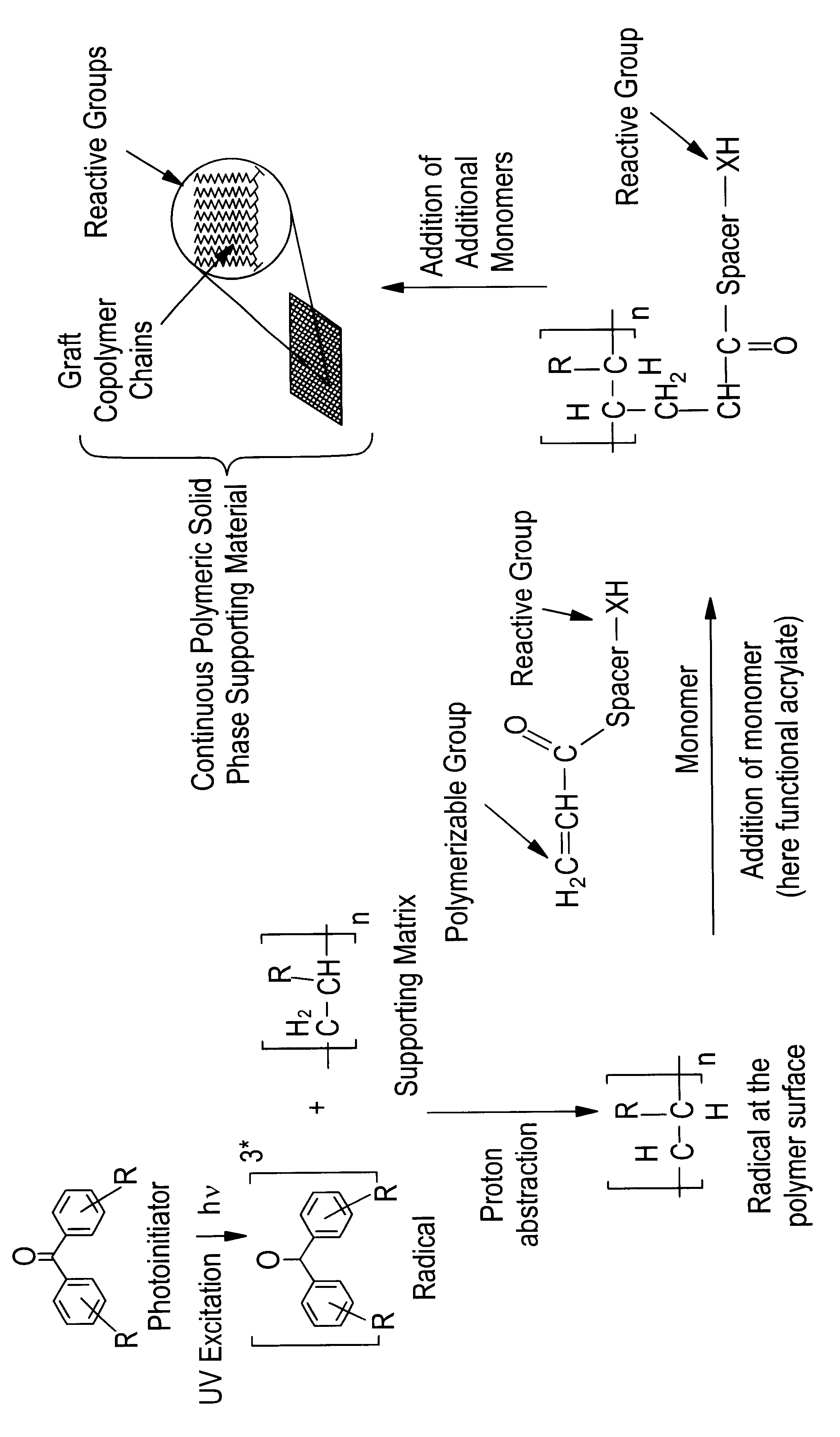

Method for the parallel and combinatory synthesis of compounds bound to a continuous polymeric solid phase supporting material

InactiveUS6515039B1Improve performanceImprove accessibilitySequential/parallel process reactionsMacromolecular librariesSimple Organic CompoundsPolymer science

The invention relates to a method for the parallel and combinatory synthesis of compounds bound to a continuous polymeric solid phase supporting material. According to the method, a continuous polymeric solid phase supporting material is prepared, the material comprising a matrix of a supporting polymeric material and graft copolymer chains covalently bound to the supporting matrix, the graft copolymer chains having reactive groups being able to react with organic compounds, thereby forming spatially defined reaction sites. The method then comprises the sequential spotting of synthesis building blocks or reagents at the various reaction sites on the continuous solid phase supporting material to yield a substrate library of compounds bound to the solid phase supporting material, whereby each reaction site on the continuous solid phase supporting material determines the composition of the synthesized compound, which is bound directly on the supporting matrix via the reactive groups of the graft polymer chain.

Owner:POLY AN

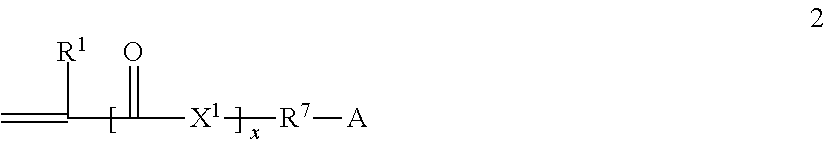

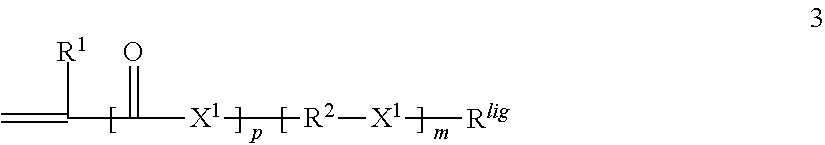

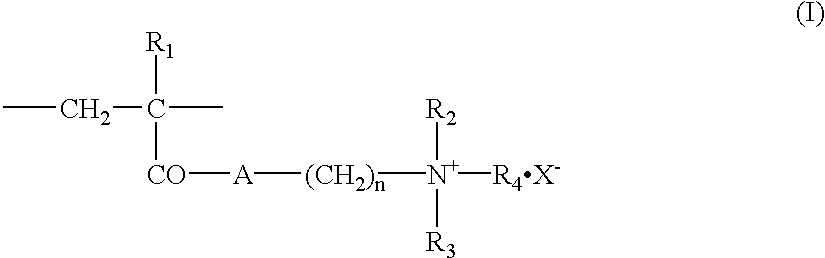

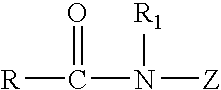

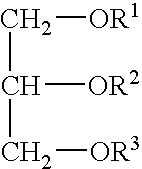

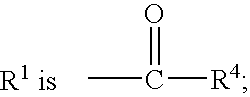

Graft polymer and moulded medical articles employing this

The present invention relates to graft polymer which is characterized in that it is formed by graft polymerization of structural units containing. a quaternary ammonium group represented by general formula (A),(R2 and R3 each represent an alkyl group with from 1 to 3 carbons, and R4 represents an alkyl group with from 3 to 18 carbons. X represents at least one type of ion selected from halogen, sulphate, hydroxide and carboxylic acid ions.),preferably to graft polymer where the structural units containing a quaternary ammonium group represented by general formula (A) are structural units which are represented by general formula (I),(R1 represents at least one species selected from hydrogen, the methyl group and the ethyl group, and n represents an integer in the range 1 to 12. A represents at least one species selected from O, S and NR5. R5 represents hydrogen or an alkyl group with 1 to 12 carbons.) orgraft polymer formed by the graft polymerization of structural units containing a quaternary ammonium group and structural units containing an alkoxypolyalkylene glycol moiety represented by the general formula (B),(n represents an integer in the range 1 to 100. R5 represents a straight-chain or branched alkylene group with from 1 to 4 carbons, and R6 represents at least one species selected from hydrogen and straight-chain or branched alkyl groups with from 1 to 4 carbons.).By applying or incorporating the graft polymer to / in medical devices which are left in the body for a long period, it is possible to prevent microbial infection arising via these medical devices.

Owner:TORAY IND INC

Barrier film

InactiveUS20090110942A1Stable mechanical propertiesImprove homogeneityFireproof paintsFibre treatmentMolten statePolyethylene oxide

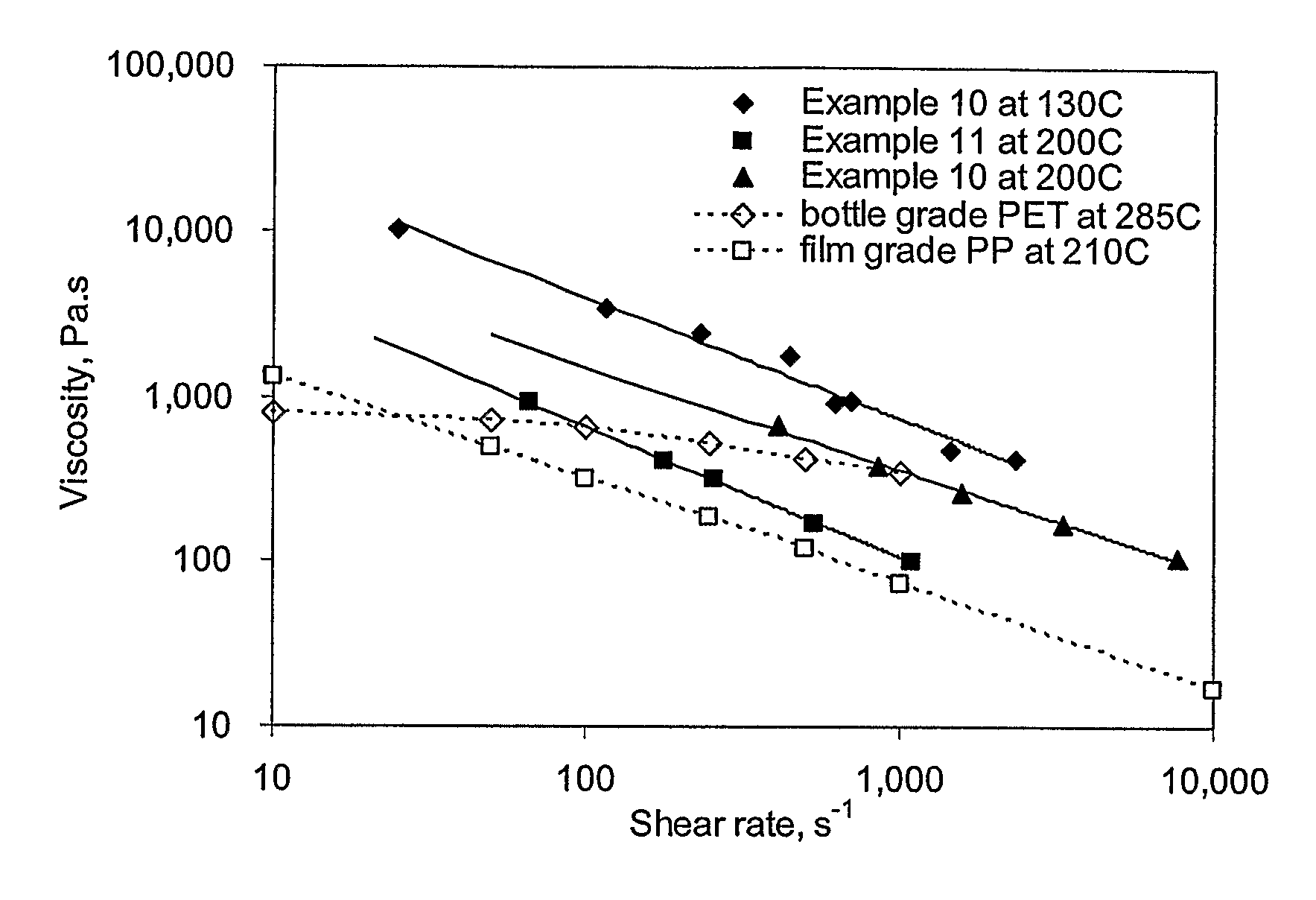

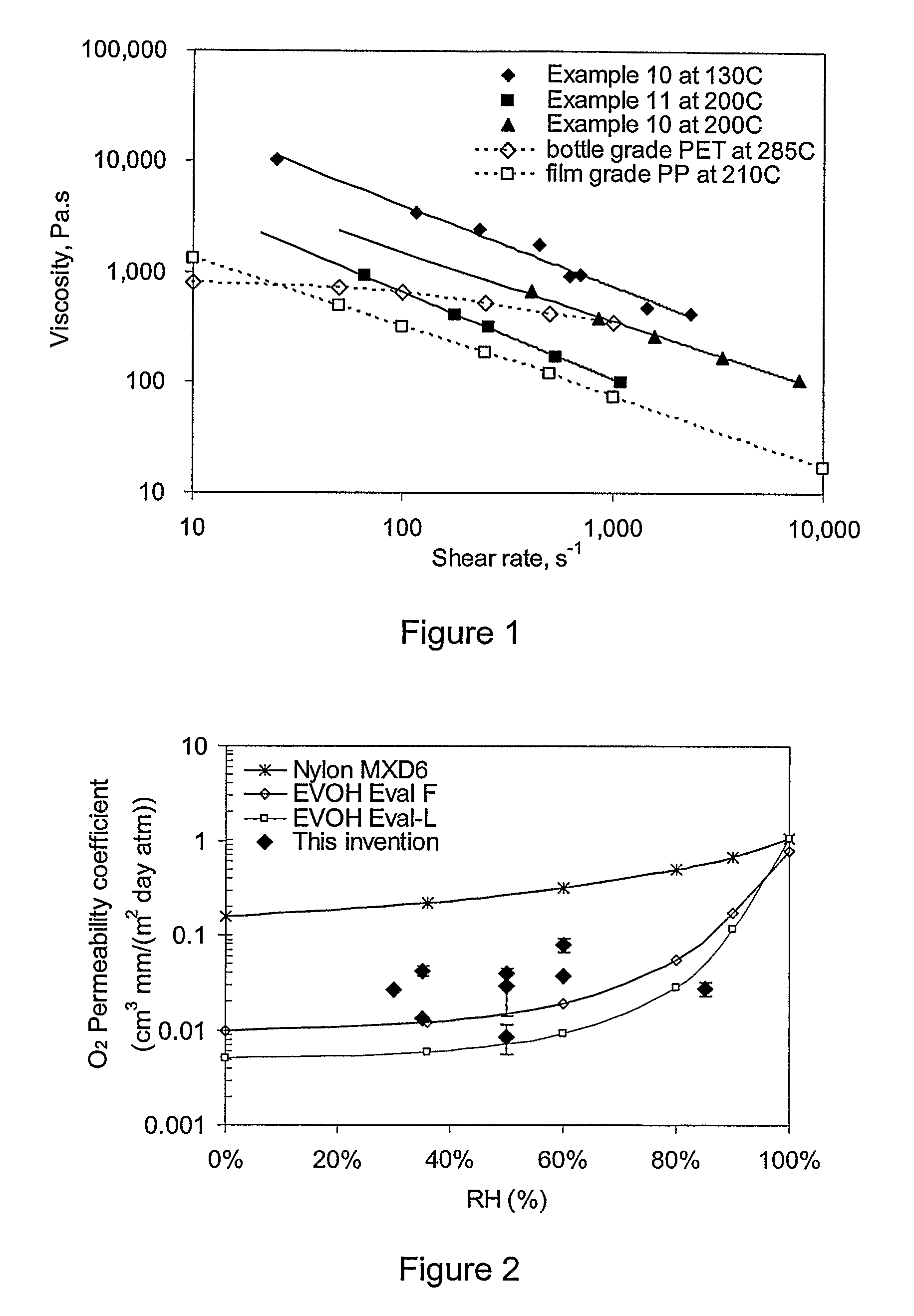

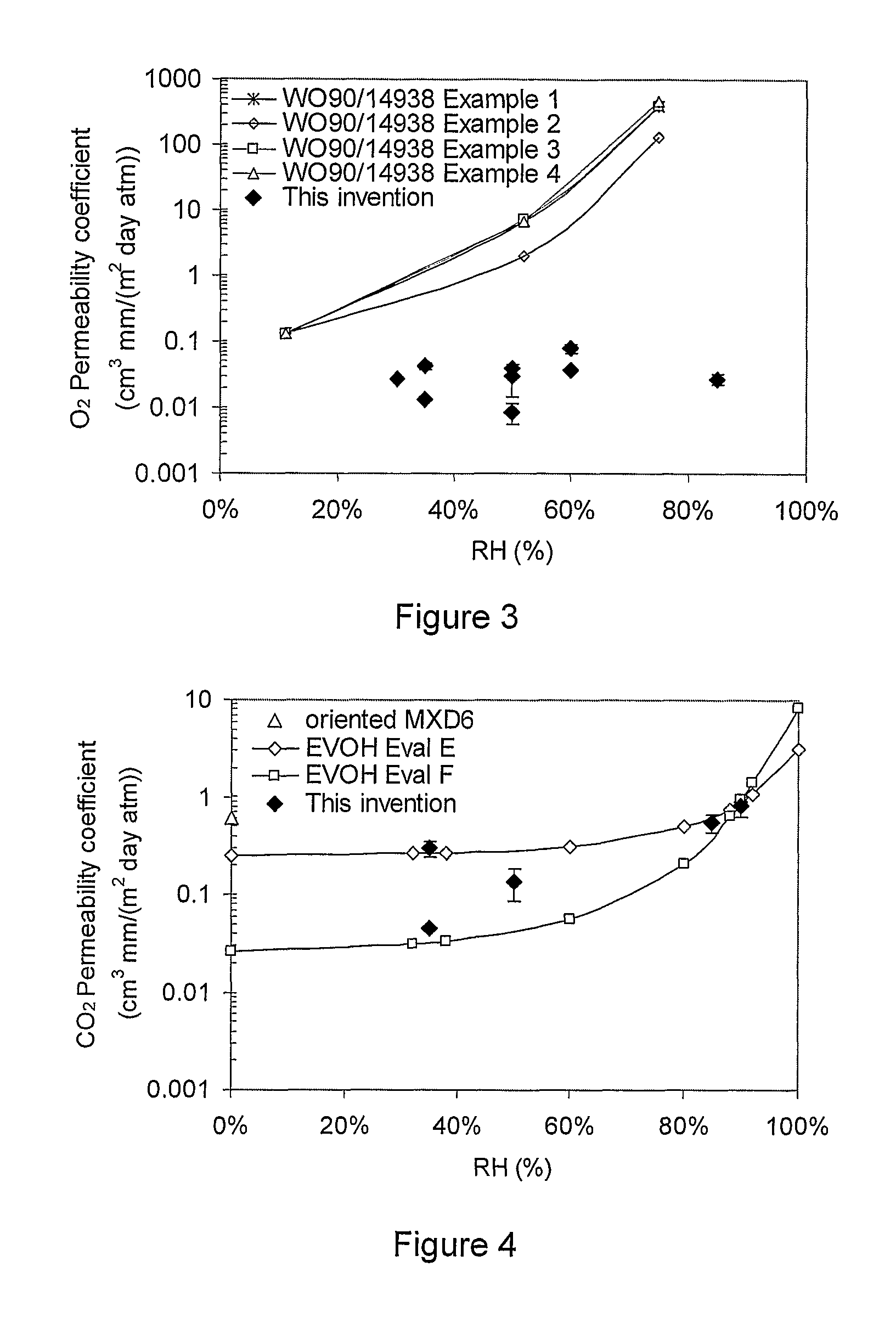

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5 % by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

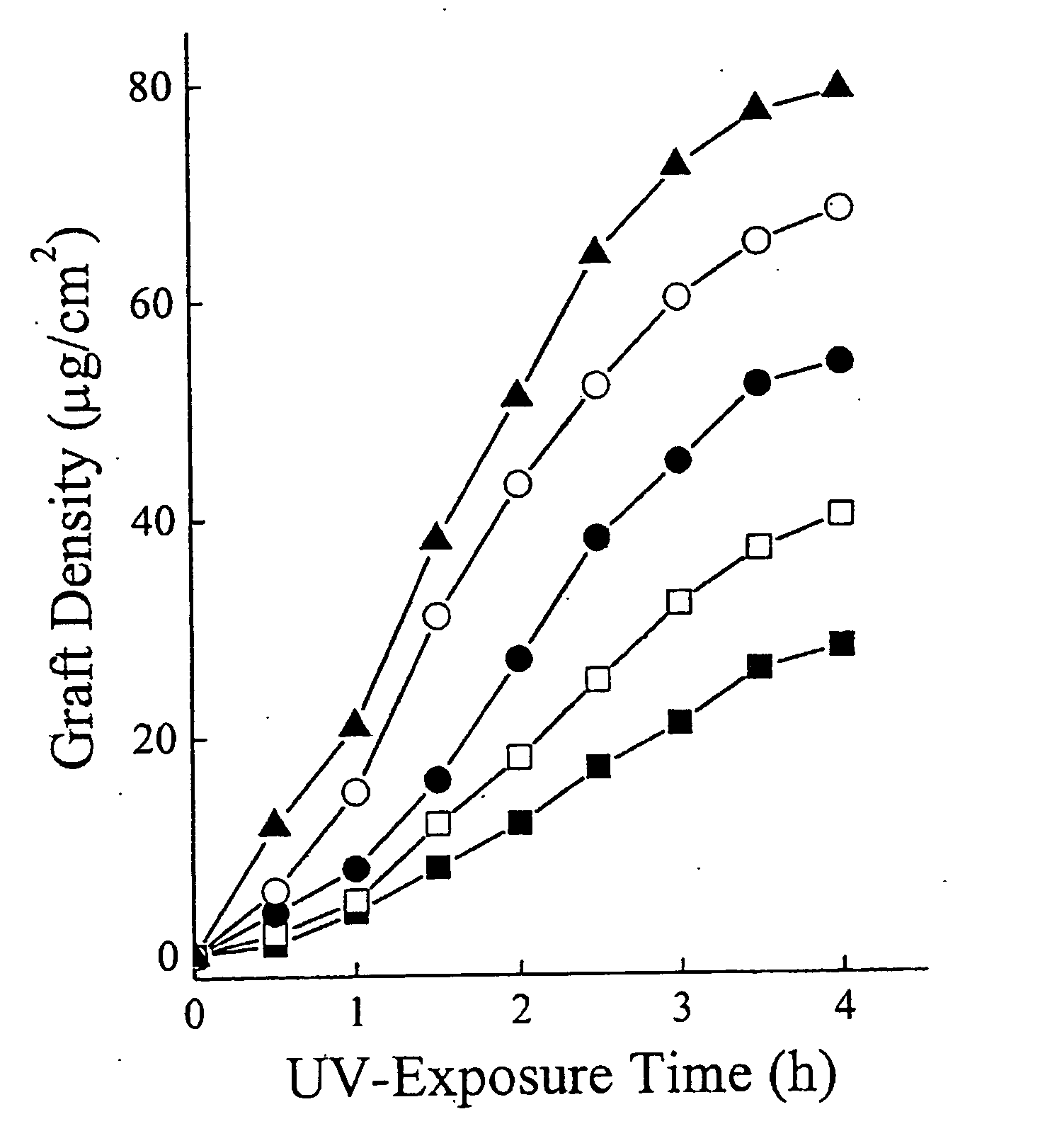

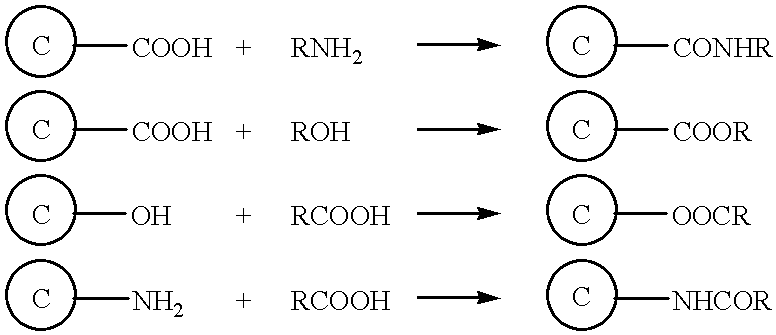

Chemical modifications to polymer surfaces and the application of polymer grafting to biomaterials

InactiveUS20050237480A1Numerous polymerizationQuality improvementMaterial analysis by electric/magnetic meansOptical partsPolymeric surfacePolymer science

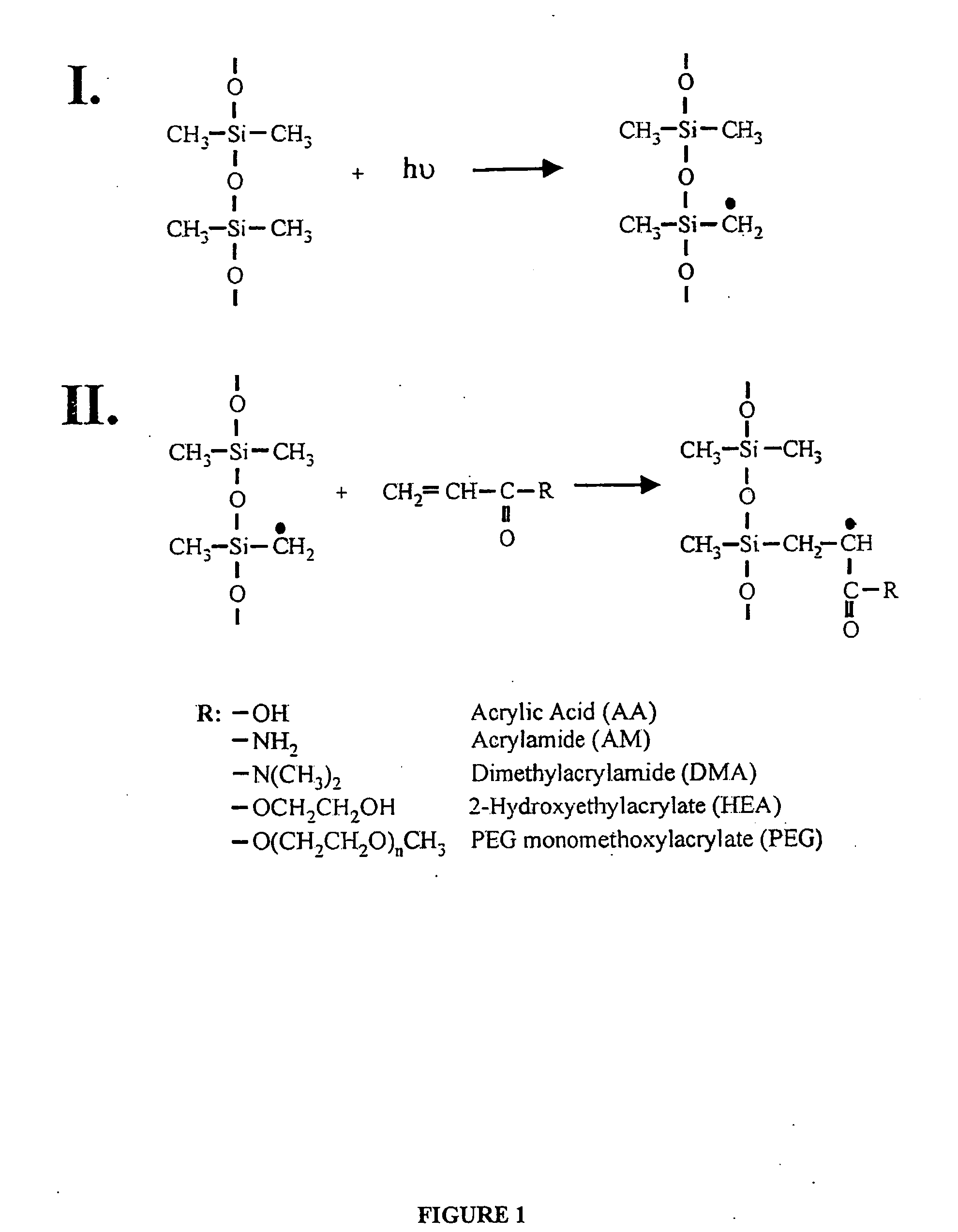

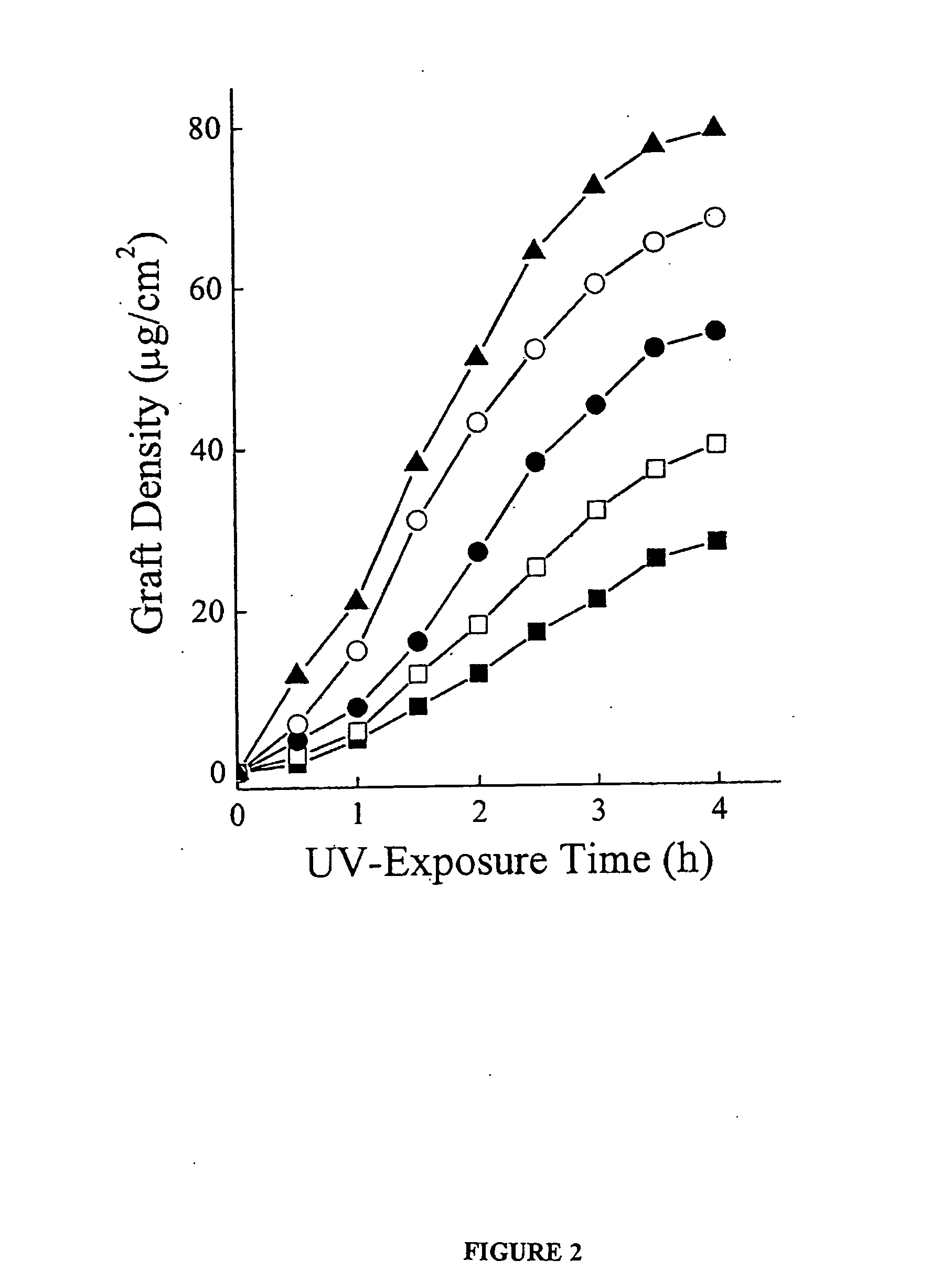

Polymer-based biomaterials are popular due to ease of fabrication and low costs. However, many polymer substrates have undesirable surface properties. The invention provides a procedure to covalently apply a graft polymer to the surface of a polymer substrate by ultraviolet graft polymerization. The graft polymer is formed from monomers such as PEG, AA, monomethoxy acrylate PEG, HEMA, or DMA. Also, mixed monomers may be used to create the graft and the surface properties of the graft may be tailored for different properties, including hydrophobicity, friction coefficient, electroosmotic mobilities and electrophoretic separations. The invention has particular utility in tailoring surface chemistries in ocular lenses and polymer microdevices. I.II.R:—OHAcrylic Acid(AA)—NH2Acrylamide (AM)—N(CH3)2Dimethylacrylamide (DMA)—OCH2CH2OH2-Hydroxyethylacrylate (HEA)—O(CH2CH2O)nCH3PEG monomethyoxylacrylate (PEG)

Owner:RGT UNIV OF CALIFORNIA

Laundry detergent compositions comprising amphiphilic graft polymers based on polyalkylene oxides and vinyl esters

InactiveUS20090005288A1Negatively impacting general cleaning capabilityLower surfactant levelOrganic detergent compounding agentsDetergent solventsOrganic solventPolybutylene

A laundry detergent composition comprising a graft copolymer of polyethylene, polypropylene or polybutylene oxide with vinyl acetate in a weight ratio of from about 1:0.2 to about 1:10; from about 0.2% to about 8% of organic solvent; and from about 2% to about 20% of a surfactant system; wherein said detergent composition is in a form selected from: liquid; gel; and combinations thereof.

Owner:THE PROCTER & GAMBLE COMPANY

Surface modified carbonaceous materials

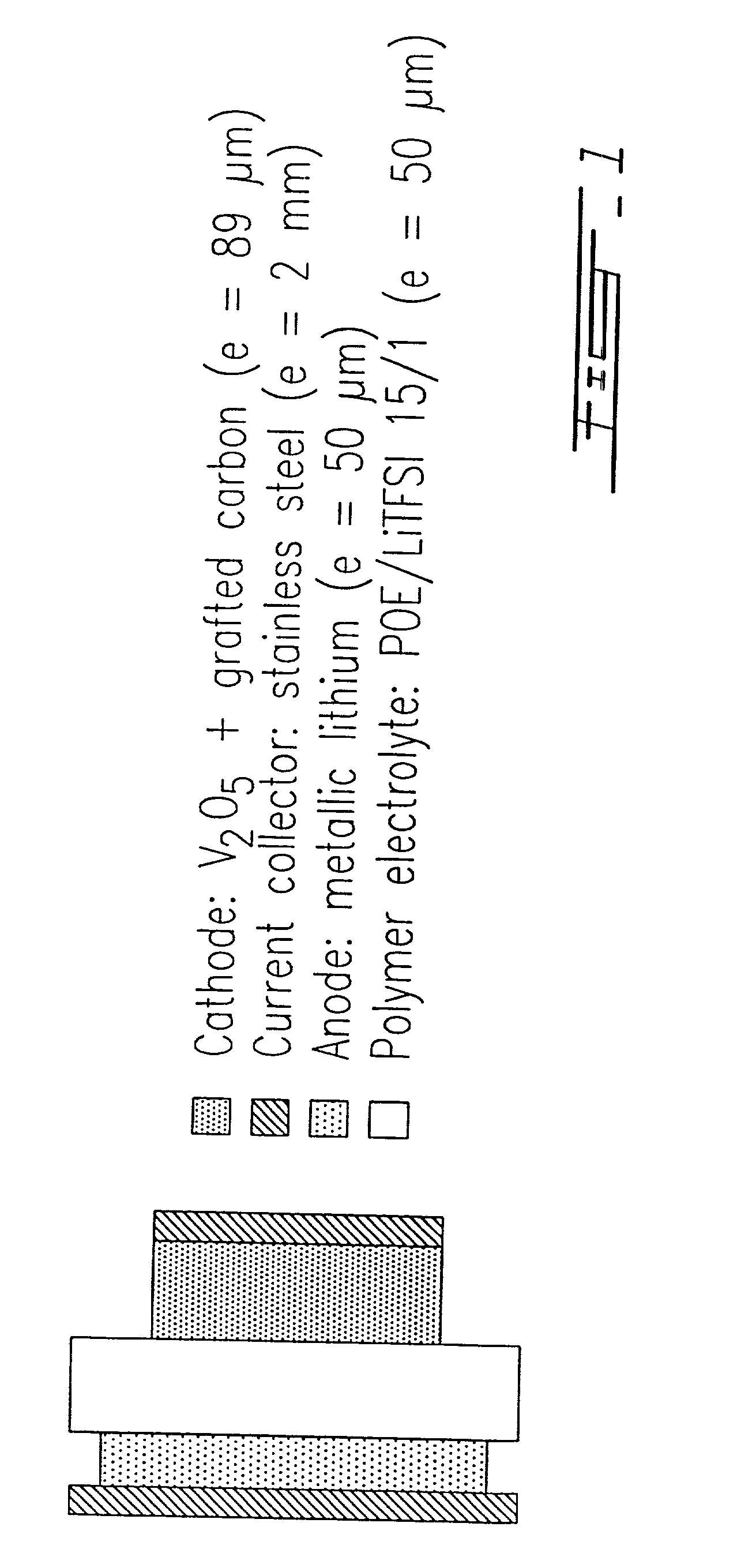

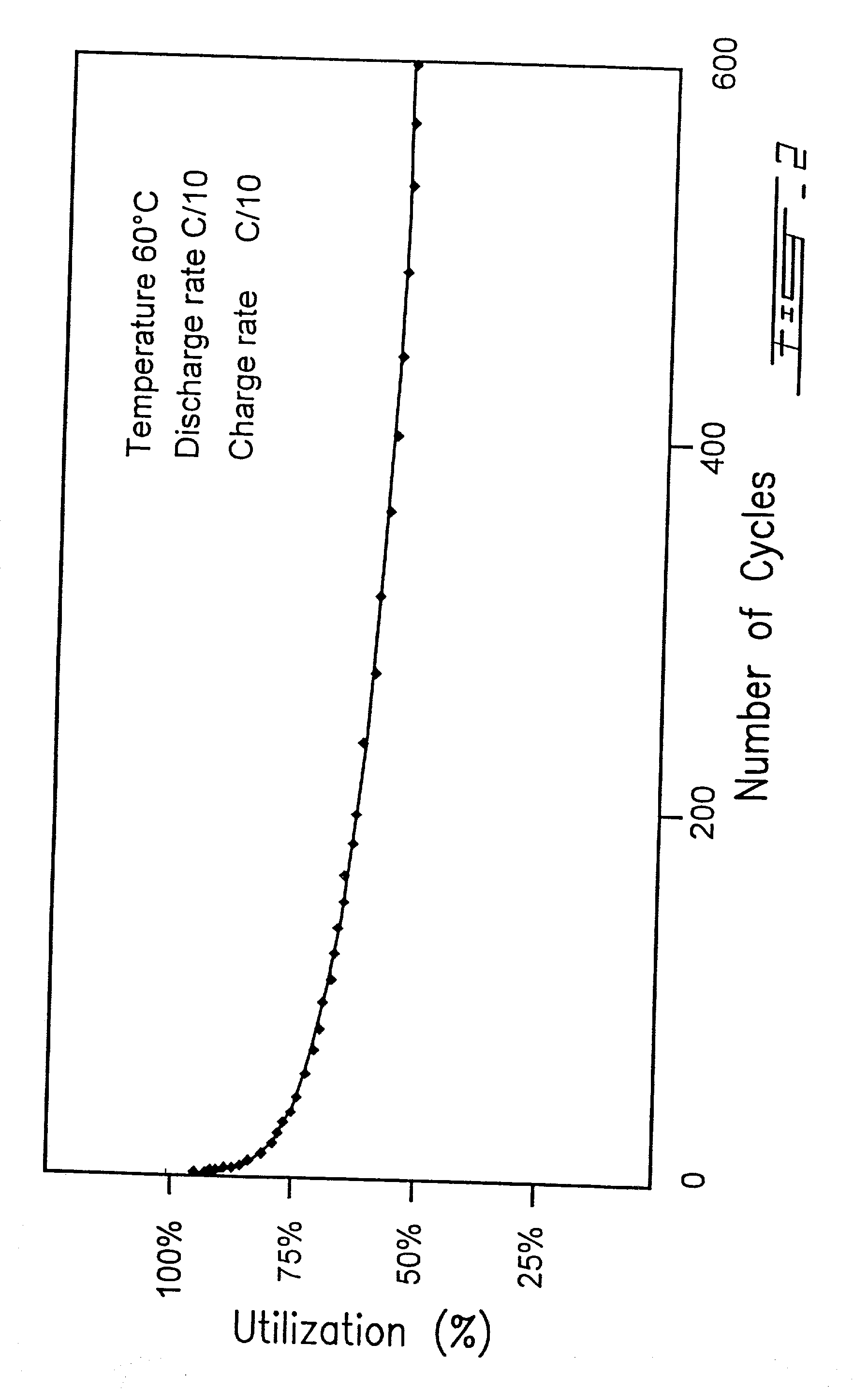

Grafting a polymer at the surface of a carbonated material containing carboxyl, amine and / or hydroxyl functions at its surface. This material is suspended in a solution comprising the polymer to be grafted, which includes a carboxyl, amine and / or hydroxyl function, the solution also comprising a solvent of the polymer. This is followed by a treatment causing dehydration into a carboxyl function, an amide and / or hydroxyl function and the polymer is thus grafted on the carbonated material by means of ester or amide bonds. Utilization in the cathode or anode of an electrochemical generator, in a polymer material with low polarity, in an ink, and as a conductive deposit on flexible plastic used as electrical contact, electromagnetic protection and antistatic protection.

Owner:HYDRO QUEBEC CORP +1

A kind of stress whitening resistant polypropylene composition and its preparation method

ActiveCN102295808AImprove mechanical propertiesGood resistance to stress whiteningPolymer scienceProcedure Agents

The invention discloses a stress whitening resistant polypropylene composition and a preparation method thereof. The stress-whitening-resistant polypropylene composition comprises the following components calculated by weight percentage: 35%-82% polypropylene resin; 2%-12% compatibilizer; 5%-15% stress-whitening-resistant agent; 10%-40% filler; 0.2%-1.0% antioxidant; 0.2%-1.0% processing aid; the polypropylene resin is a mixture of homopolymerized polypropylene and random copolymerized polypropylene; The whitening agent is a mixture of polyethylene and thermoplastic elastomer; the compatibilizer is a graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The stress-whitening-resistant polypropylene composition of the present invention has both good comprehensive mechanical properties and good stress-whitening resistance, and can be applied to the fields of household appliances, toys, auto parts, electric tools and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Method of preparing polypropylene graft polymer

The invention relates to a polypropylene graft polymer preparing method which is characterized in that: (a) calculated by weight parts, the polypropylene graft polymer comprises 100 parts of polypropylene, 0.1-20 parts of graft monomer maleic anhydride, 0.1-20 parts of graft monomer styrene monomer or vinyl acetate monomer, 0.01-10 parts of peroxide initiator and 1-20 parts of other vinyl monomers; (b) the graft monomers, the initiator and the polypropylene are evenly mixed; (c) the reactants are heated to reach a temperature of 70-120 DEG C and then react for 1-10 hours; and (d) after the reaction, the polypropylene graft polymer can be obtained through cooling. During the implementation of the method, no solvent, suspending medium or interfacial agent needs to be used, the obtained product can be applied without needing further treatment, for example, a compatilizer for a polypropylene composite material; and the obtained product is particularly used for improving the interfacial compatibility and dispersivity of inorganic filler and polyolefine. The conversion rate of the graft monomers of the invention is greater than 95 percent, and at least 55 percent of the graft monomers form graft polypropylene.

Owner:BEIJING UNIV OF CHEM TECH

Functionalized materials and methods of using same

InactiveUS20060040280A1Reduce concentrationPrevent disengagementBioreactor/fermenter combinationsBiological substance pretreatmentsCompound (substance)Hydrolysis

Owner:LEE WILLIAM +1

Toner

ActiveUS9377705B2Satisfactory heat-resistant storabilityLow-energy fixingDevelopersHeat flowAcrylic resin

A toner containing a toner particle containing a binder resin, wherein the binder resin contains a styrene-acrylic resin and a crystalline resin, and the crystalline resin is a block polymer or a graft polymer in which the mass ratio between the crystalline segment and an amorphous segment is 30:70 to 90:10, and wherein, in the total heat flow measured for the binder resin by a temperature-modulated differential scanning calorimeter, the peak temperature of an endothermic peak is from 55.0° C. to 90.0° C., and the percentage of the endothermic quantity of the endothermic peak in the reversing heat flow with respect to the endothermic quantity of the endothermic peak in the total heat flow is from 0.0% to 35.0%.

Owner:CANON KK

Barrier film

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

Ultraviolet crosslinking and curing EVA (ethylene vinyl acetate copolymer) optical adhesive film and preparation method thereof

ActiveCN103525319AShort operating timeLess investmentNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceUltraviolet

The invention relates to an ultraviolet crosslinking and curing EVA (ethylene vinyl acetate copolymer) optical adhesive film and a preparation method thereof. The ultraviolet crosslinking and curing EVA optical adhesive film takes EVA or a mixture of the EVA and an EVA-modified graft polymer as a base material; in the mixture, the weight ratio of the EVA to the EVA-modified graft polymer is 1: 0-0.2; and according to 100 parts of the of the base material by total weight, the EVA optical adhesive film further comprises the following raw materials in part by weight: 0.1-5 parts of photoinitiator, 0.1-5 parts of multifunctional crosslinking agent, 0.1-1 part of antioxidant, 0.1-1 part of light stabilizer, 0.1-2 parts of coupling agent and 0.1-10 parts of bonding resin. The preparation method is short in operating time, small in required equipment investment, simple in process, convenient in operation and maintenance, energy-saving, environment-friendly and high in production efficiency; the production cost is reduced; the ultraviolet crosslinking and curing EVA optical adhesive film is low in defective ratio and excellent in mechanical properties; and during use, the ultraviolet crosslinking and curing EVA optical adhesive film can be crosslinked and adhered through radiation of specific ultraviolet, so that optical adhesive OCA and liquid optical adhesive LOCA for adhering a display in the traditional electronic industry can be replaced.

Owner:GUANGZHOU HUICHI GLASS TECHNICAL CO LTD

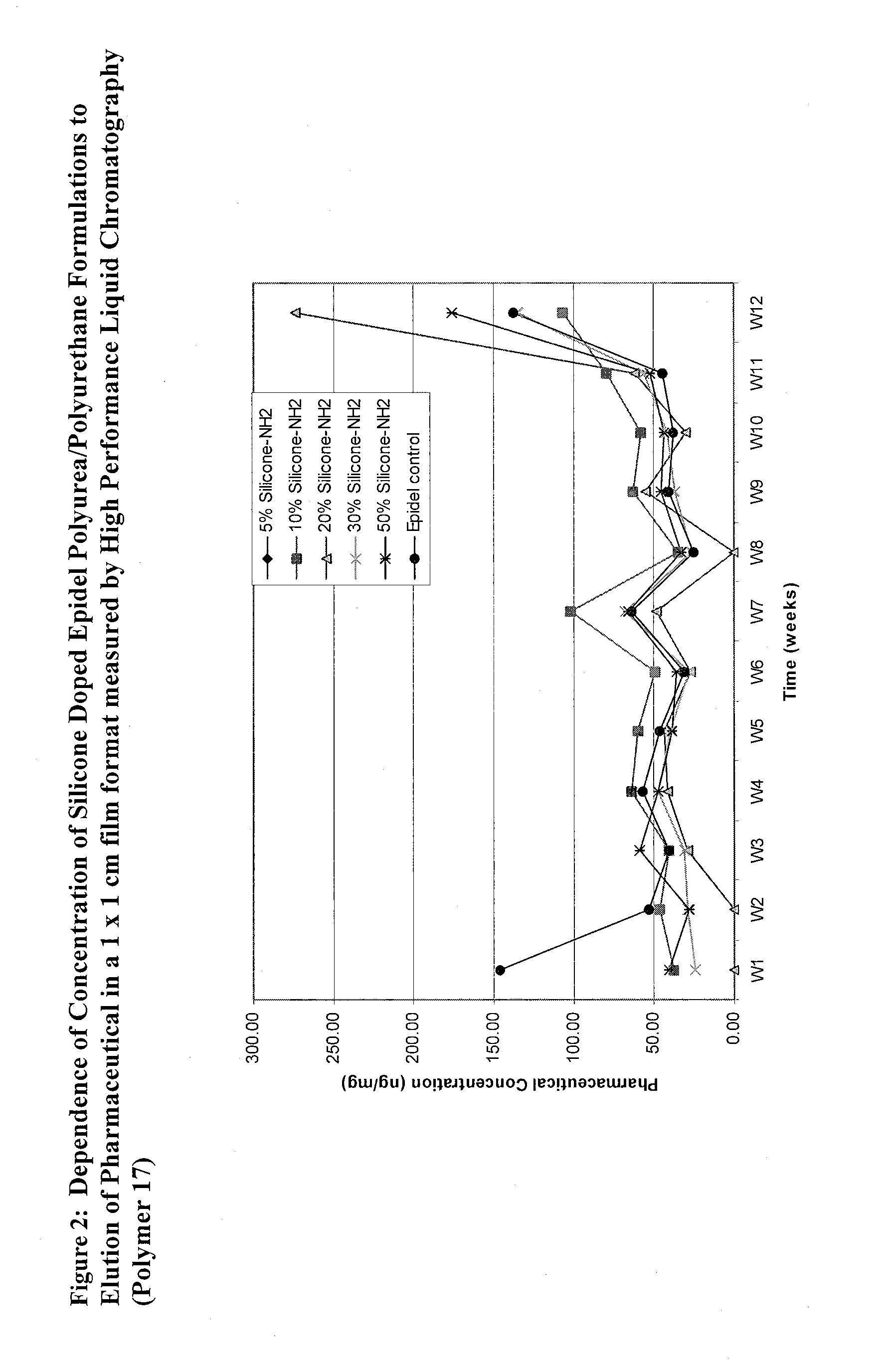

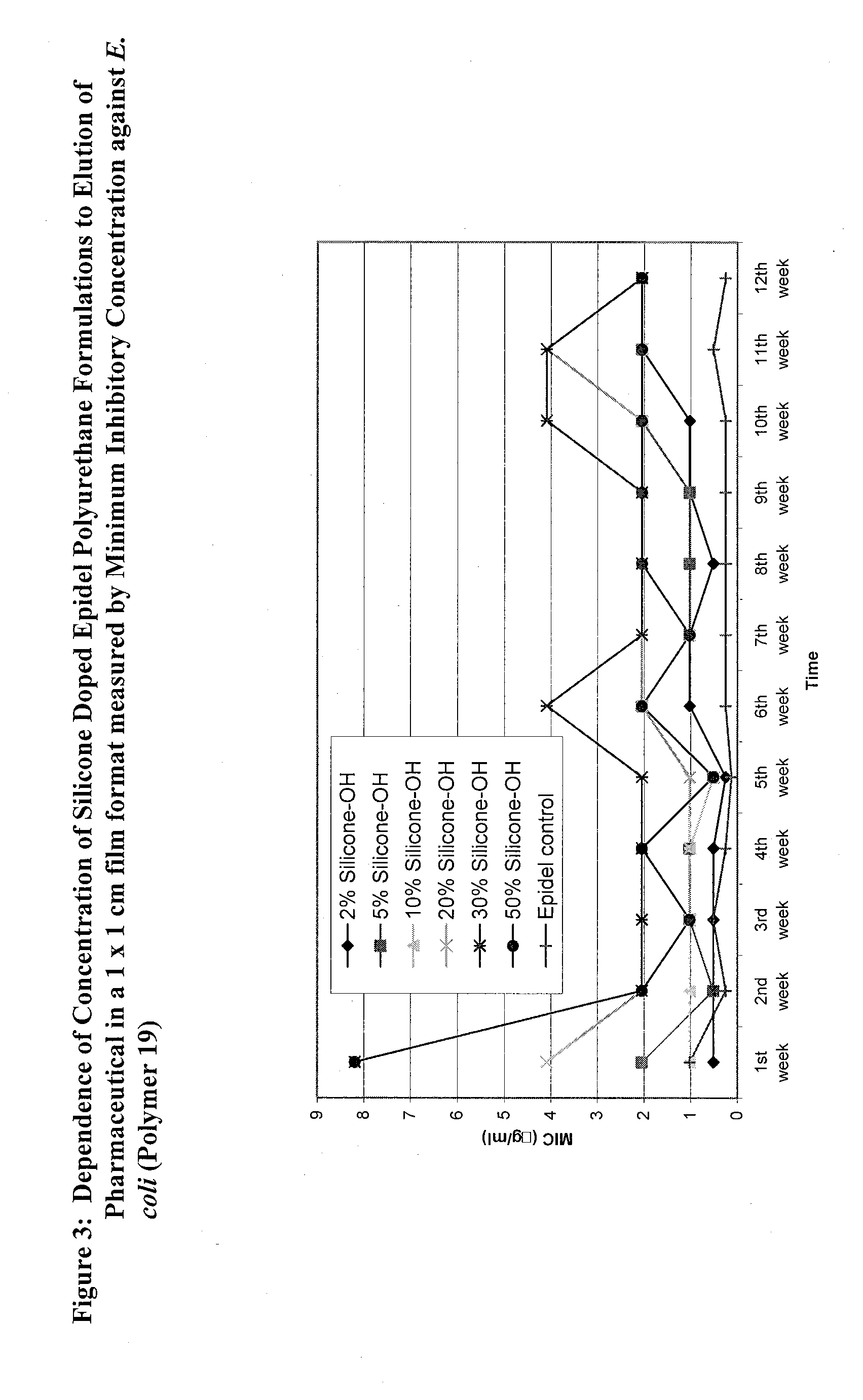

Covalently grafted pharmaceutically active polymers

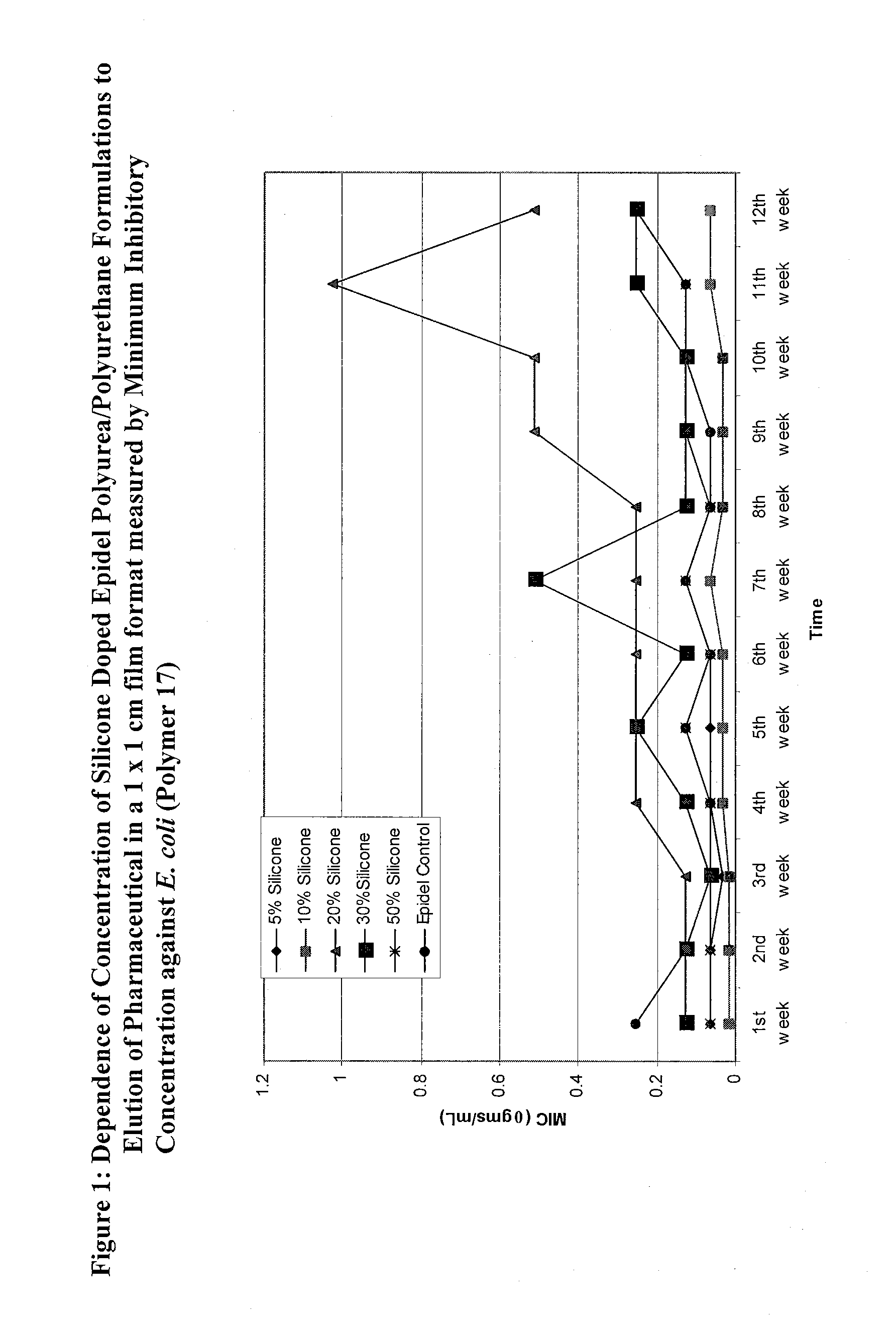

ActiveUS20100034862A1Reduce adverse side effectsHigh elution rateBiocideSurgeryActive polymerActive agent

The invention relates to graftable polymers comprising biologically active agents and the use of such polymers in the manufacture of shaped articles, such as implantable medical devices and catheters. The graftable polymers are covalently grafted to a surface via one or more grafting moieties incorporated into the pharmaceutically-active graftable polymer. The coated articles of the invention can further comprise tie-coats, and the ratio of polymer:tie coat can be used to adjust the rate of drug elution.

Owner:RIPPLE THERAPEUTICS CORP

Polymeric nanocomposites comprising epoxy-functionalized graft polymer

InactiveUS7220484B2Increase heightEnhanced interactionMaterial nanotechnologySynthetic resin layered productsEpoxyPolyolefin

Disclosed is a nanocomposite comprising a nano-reinforcing material (e.g., layered clay), a polymer matrix (e.g., a polyolefin), and, an epoxy-functionalized graft polymer compatible with the polymer matrix (e.g., epoxy-grafted polyolefin). Such nanocomposites are useful in the fabrication of a variety of materials including parts for the transportation and packaging industries, electronics, business equipment, building and construction materials.

Owner:NAT RES COUNCIL OF CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com