Patents

Literature

1654results about How to "Stable mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

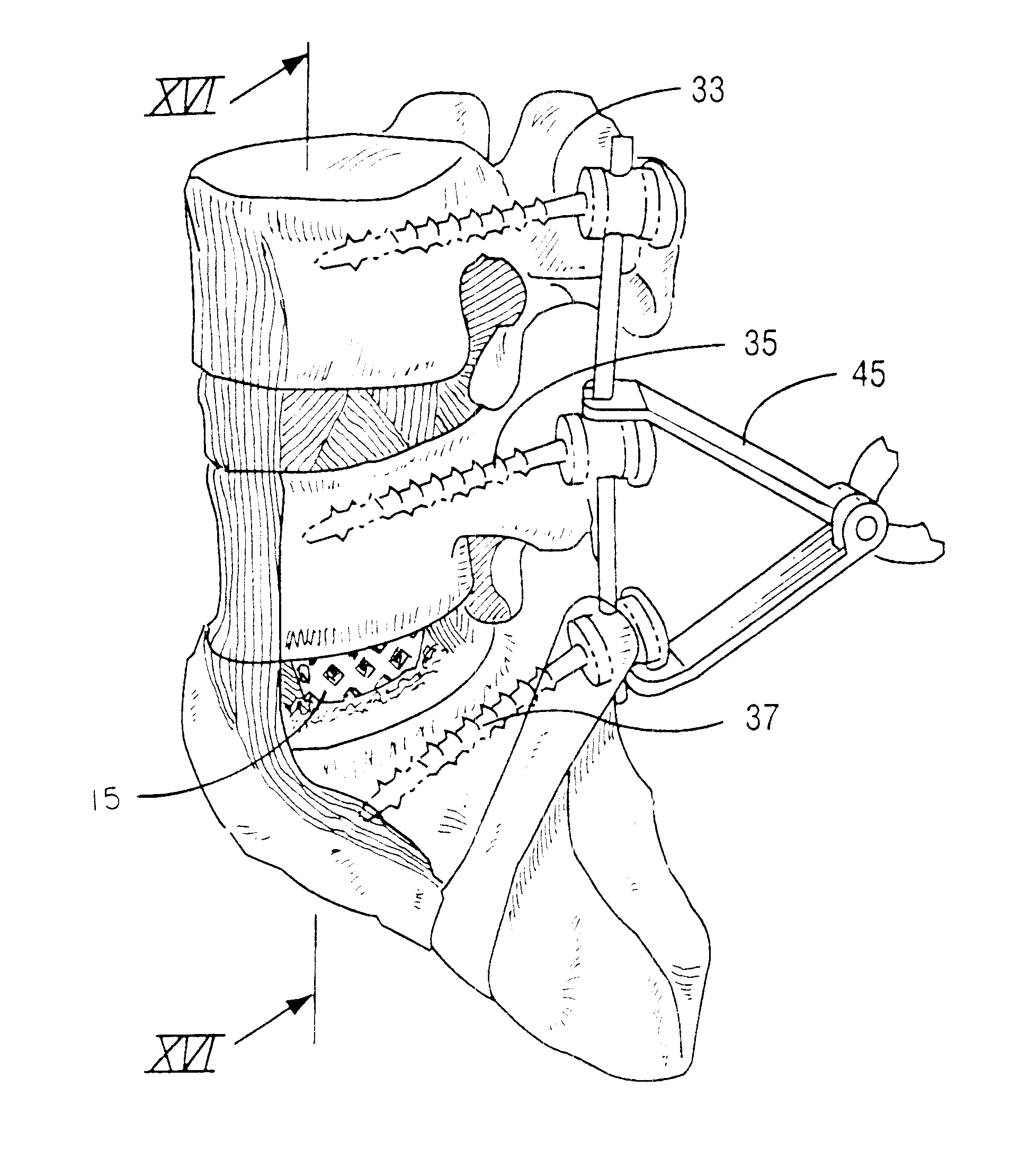

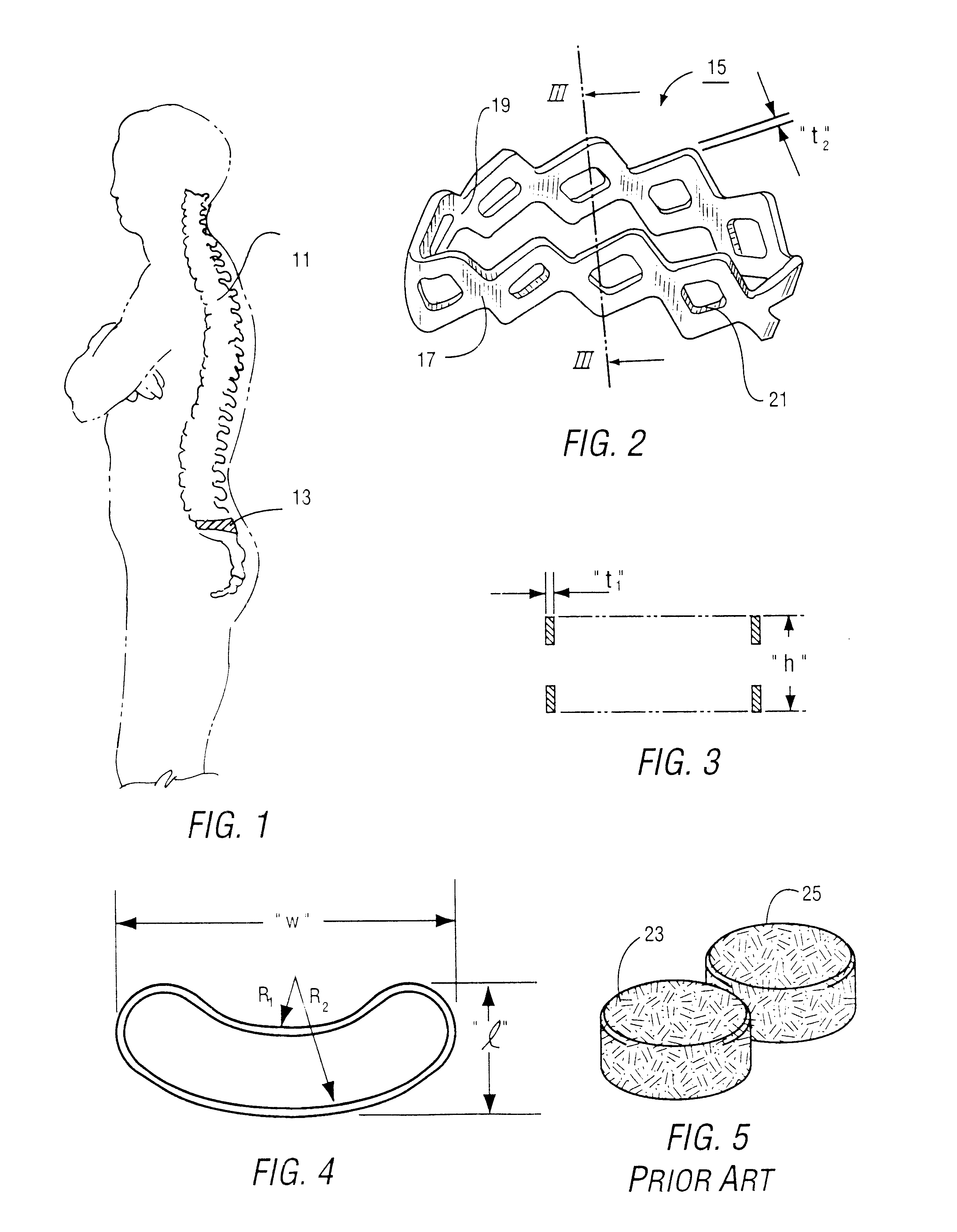

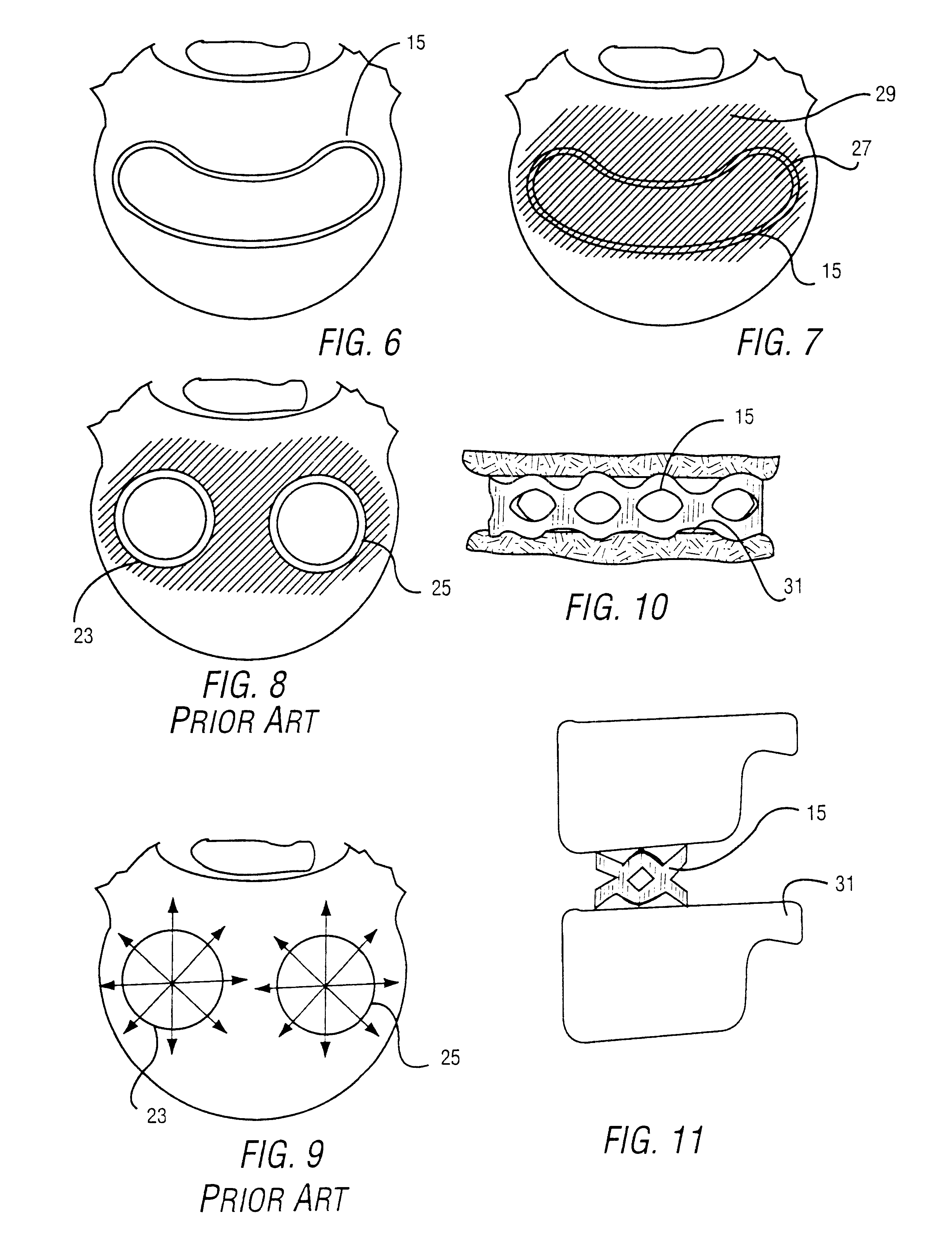

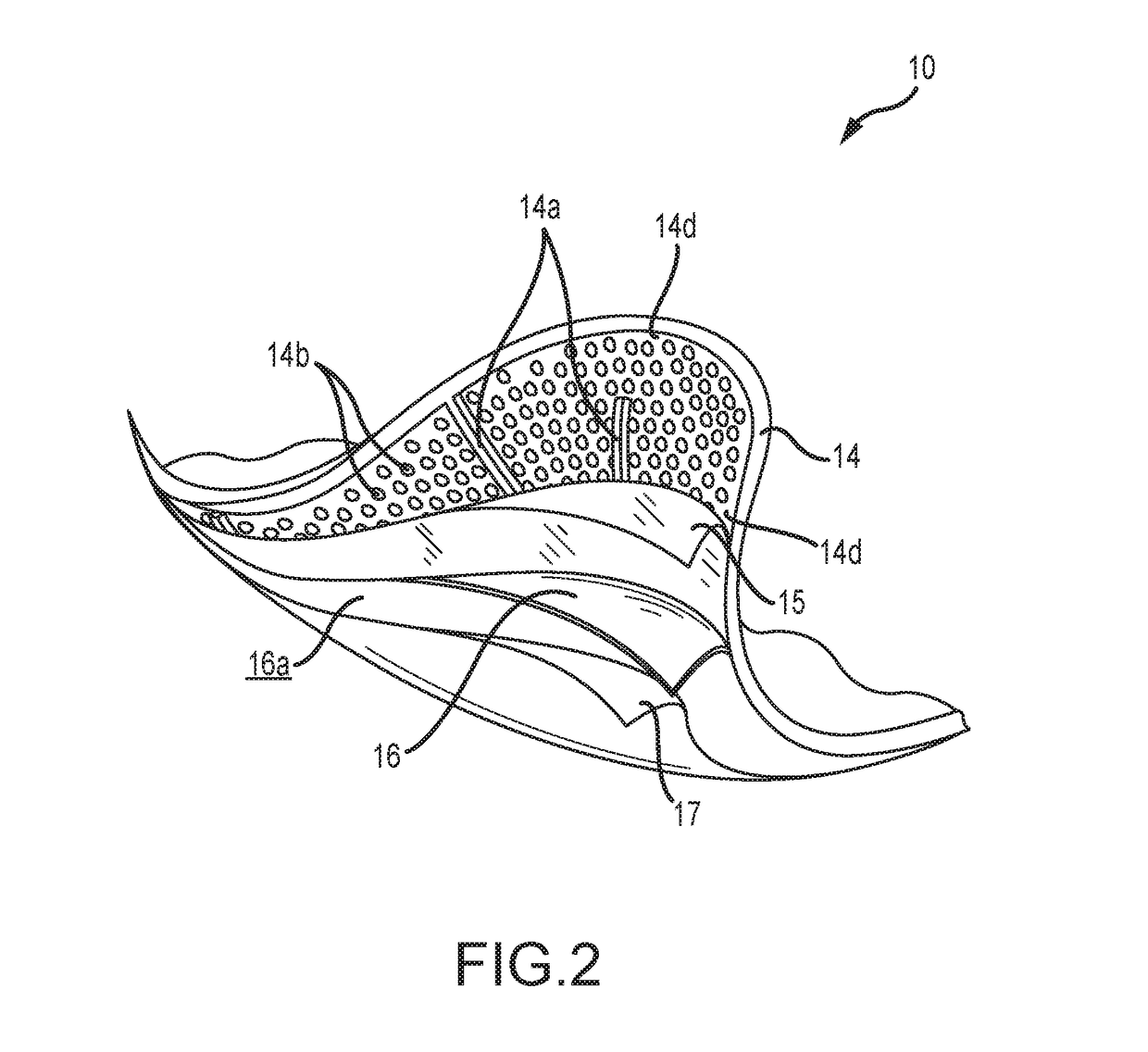

Intervertebral cage and method of use

InactiveUS6648915B2Restore tensionStable mechanical propertiesInternal osteosythesisBone implantSpinal columnHuman body

An intervertebral prosthesis for implantation between adjacent vertebrae of the human spine is shown. The prosthesis is formed as a unitary cage body configured and sized to be inserted between adjacent vertebrae in a single step implantation procedure. The cage body is banana shaped as viewed from above, the body having an exterior surface and an interior surface, the interior surface defining an internal recess for receiving cancellous bone material during an implantation procedure. The cage body can be formed as an interlinked mesh.

Owner:DEPUY ACROMED INC

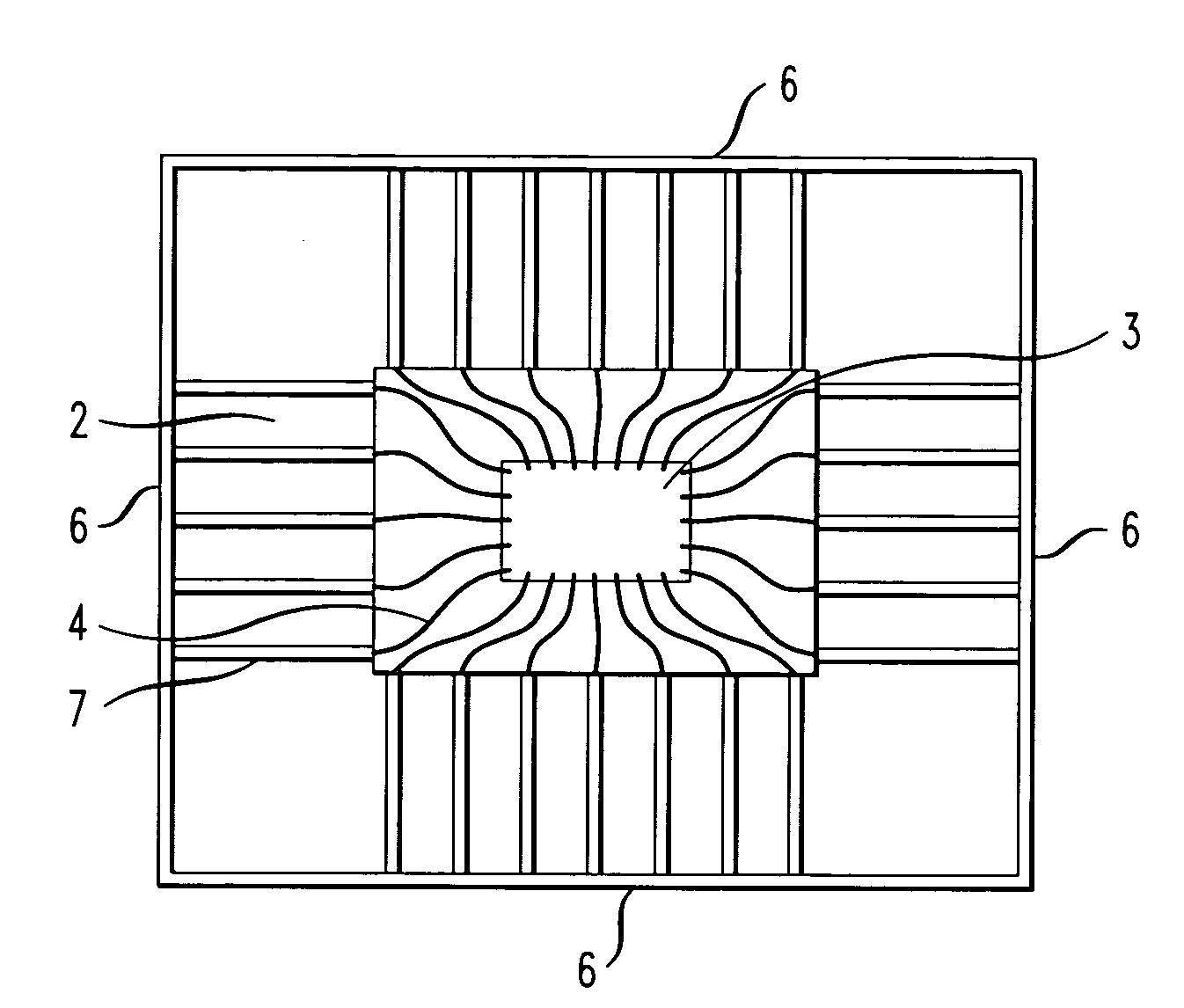

Method of making a product with improved material properties by moderate heat-treatment of a metal incorporating a dilute additive

InactiveUS6150186AStable mechanical propertiesImprove conductivitySemiconductor/solid-state device testing/measurementFinal product manufactureUltimate tensile strengthMechanical property

Deposition of metal in a preferred shape, including coatings on parts, or stand-alone materials, and subsequent heat treatment to provide improved mechanical properties. In particular, the method gives products with relatively high yield strength. The products often have relatively high elastic modulus, and are thermally stable, maintaining the high yield strength at temperatures considerably above 25 DEG C. This technique involves depositing a material in the presence of a selected additive, and then subjecting the deposited material to a moderate heat treatment. This moderate heat treatment differs from other commonly employed "stress relief" heat treatments in using lower temperatures and / or shorter times, preferably just enough to reorganize the material to the new, desired form. Coating a shape and heat treating provides a shaped deposit with improved material properties. Coating a shape with a portion connected to a base and a portion detached therefrom can provide a resilient, conductive contact useful for electronic applications.

Owner:FORMFACTOR INC

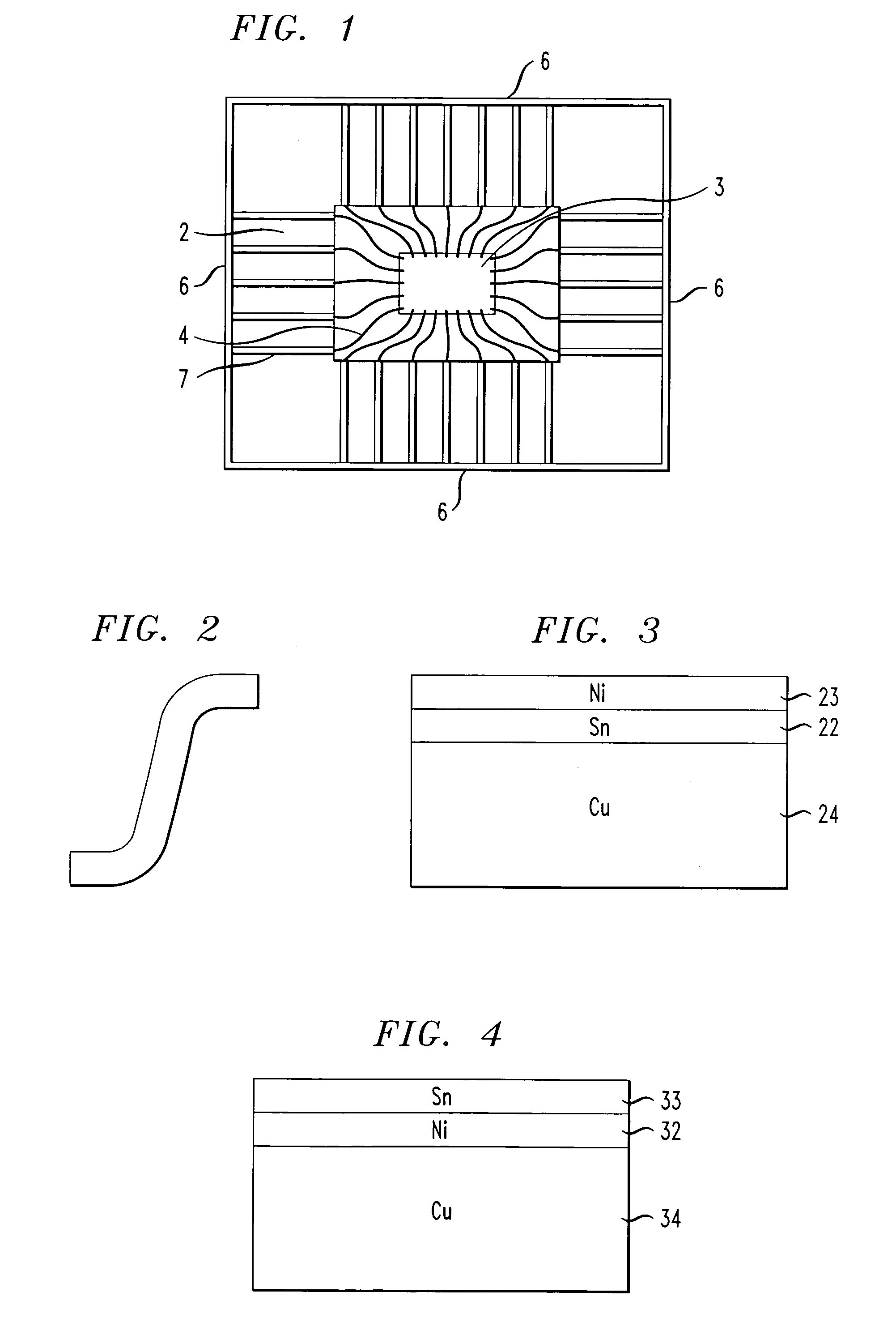

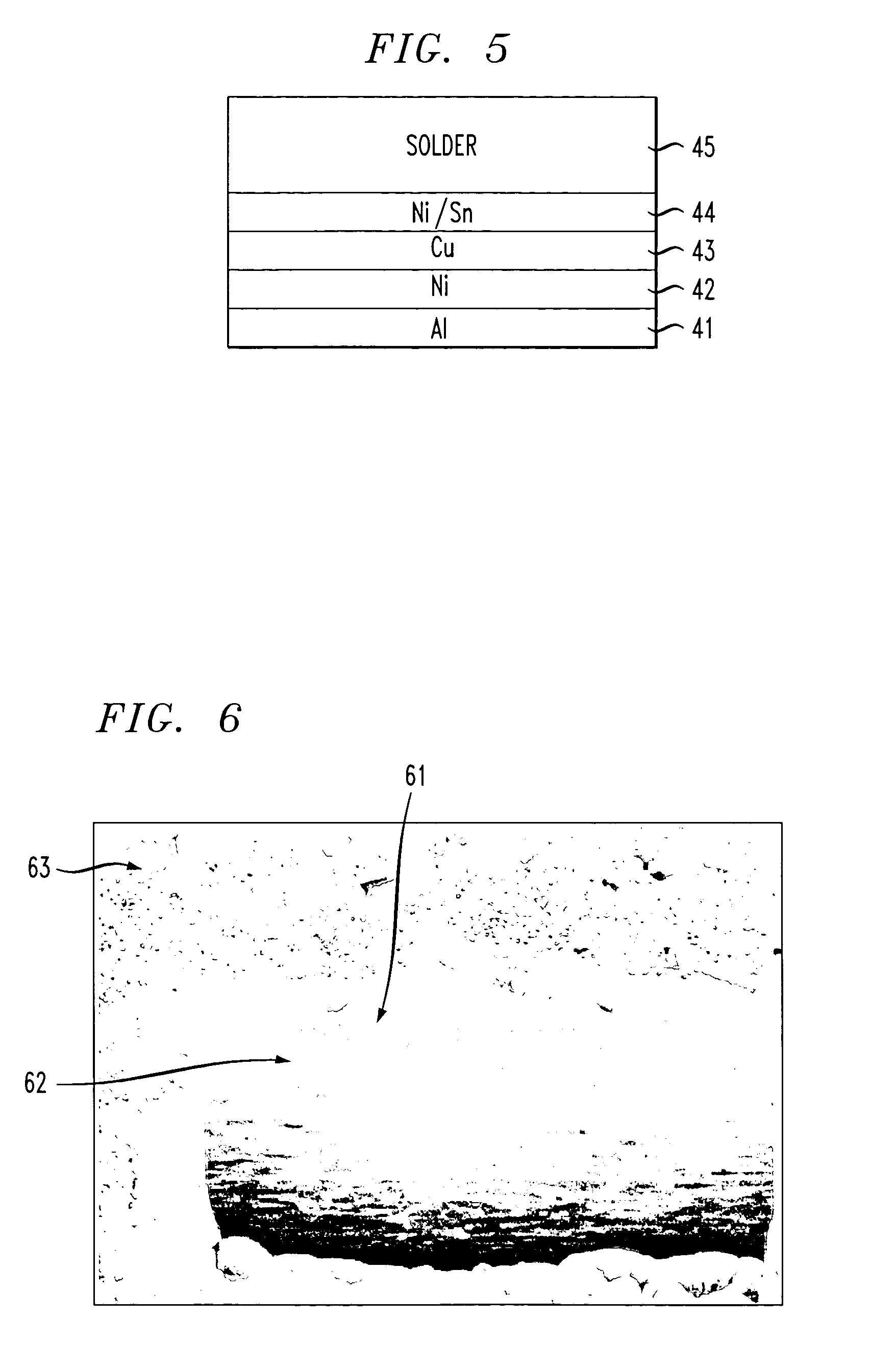

Whisker-free lead frames

InactiveUS20060068218A1Reduction tendencyStable mechanical propertiesMetallic material coating processesPrinted circuit manufactureCopperLead frame

The electrical and mechanical properties of structures such as lead frames and other electrical / electronic devices containing, during processing, copper / tin interfaces are improved by introduction of nickel to such interface. Typically, a weight percentage of nickel to tin in the range 1 to 12 weight percent yields upon melting of the tin, an intermetallic compound with essentially no occluded, unbound tin. Thus undesirable anomalous structures such as tin needles and substantially non-planar interface compositions are avoided. Advantageously a nickel / tin / copper intermetallic interface that is substantially planar is formed in the substantial absence of needle-like tin structures.

Owner:AGERE SYST INC +1

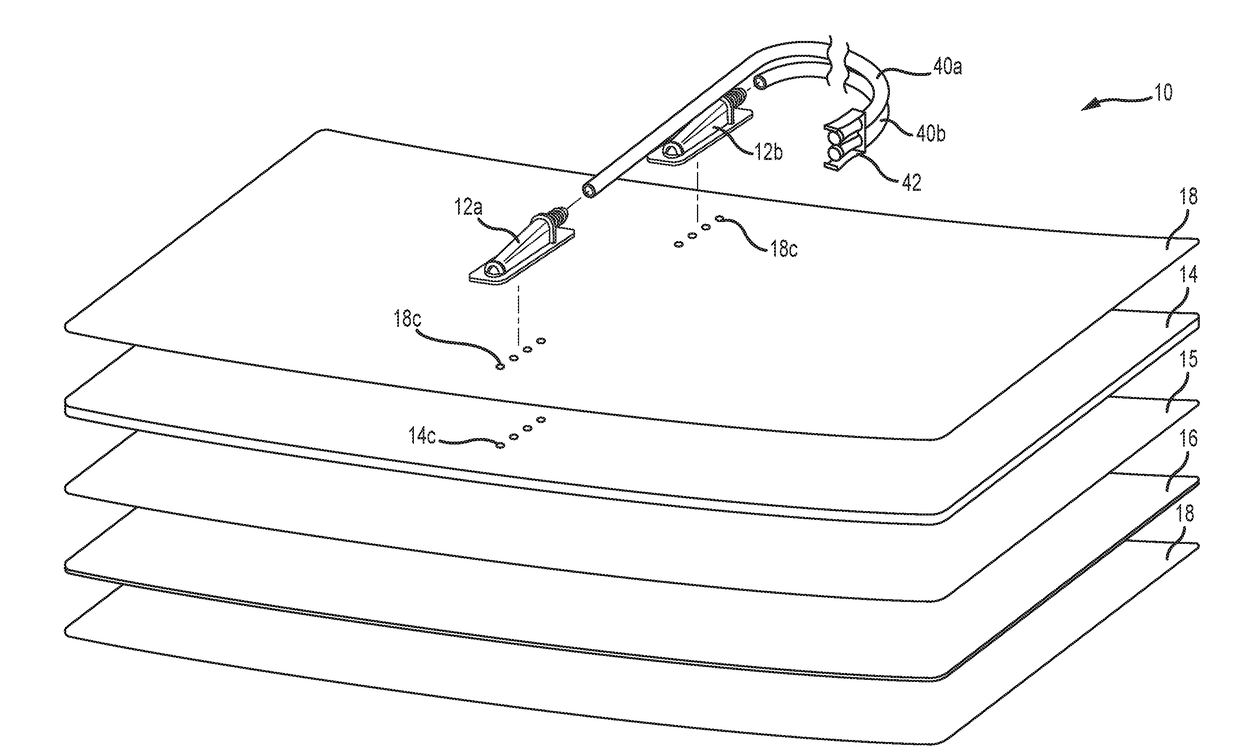

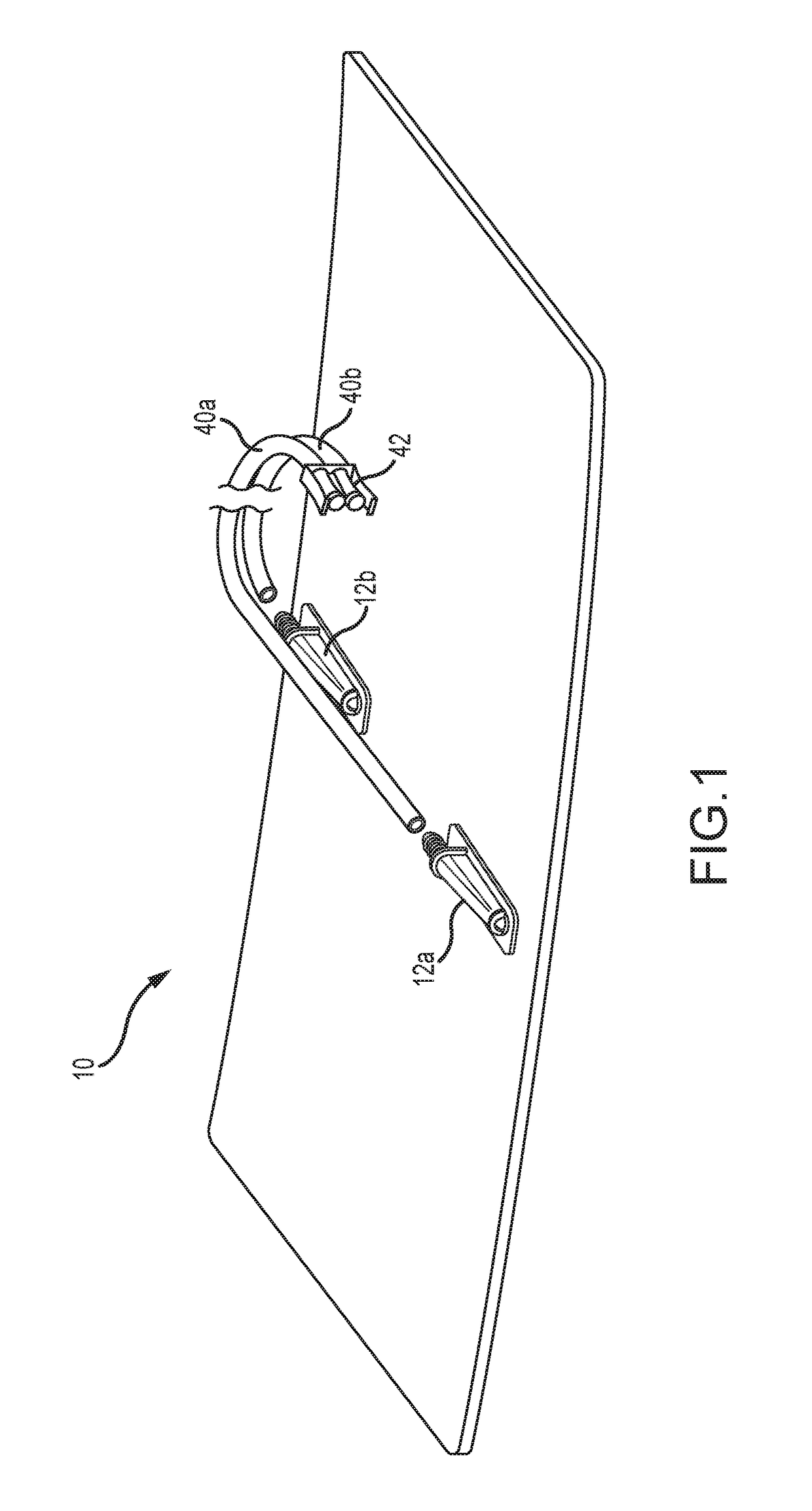

Medical pad and system for thermotherapy

ActiveUS20170189225A1Easy to implementDownsizing of facilityTherapeutic coolingTherapeutic heatingCross-linkEngineering

An improved medical pad for contact thermal exchange with a patient includes a fluid circulation layer for containing a thermal exchange fluid circulatable therethrough, a first port and a second port for circulating the thermal exchange fluid in to and out of the fluid circulation layer, and a hydrogel layer interconnected to and extending across one side of the fluid circulation layer to define an adhesive surface for adherence to a patient's skin. The hydrogel layer comprises an ultra violet light-cured composition that includes a cross-linking copolymer in an amount of between about 15% to 30% by weight of the composition, water in an amount of between about 15% to 40% by weight of the composition, and glycerol in an amount of between about 25% to 35% by weight of the composition. The hydrogel layer is provided to have a thermal conductivity of at least about 1.9 ca / / hr-cm-° C.

Owner:MEDIVANCE

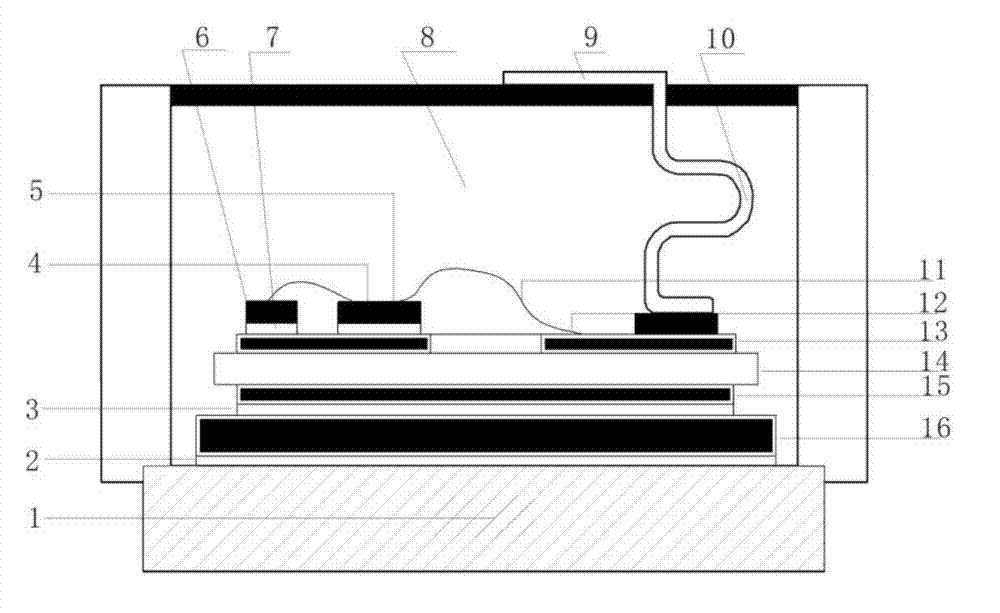

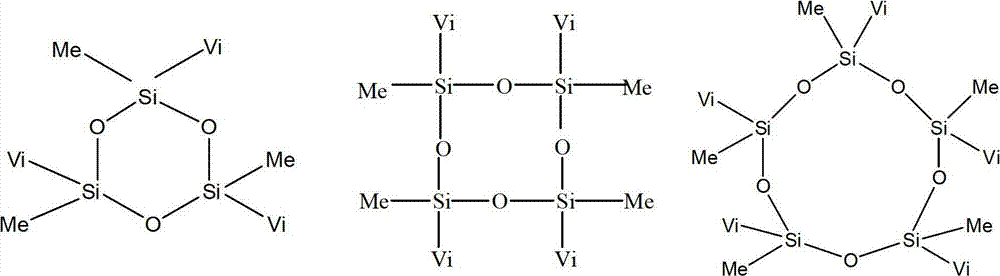

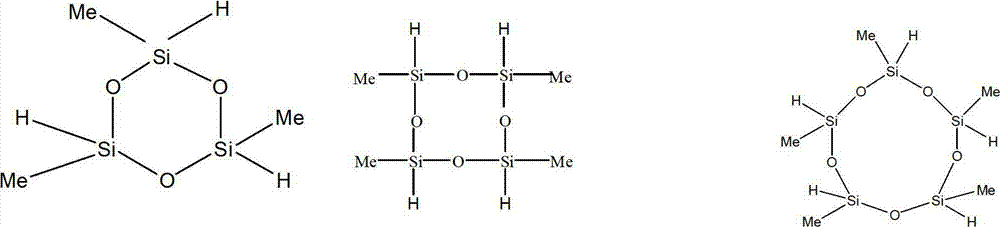

Organic silica gel used for packaging IGBT (insulated gate bipolar translator) module, and preparation method of organic silica gel

InactiveCN102807757AViscosity is convenient and controllableHigh reactivitySemiconductor/solid-state device detailsSolid-state devicesOptical propertyHigh intensity

The invention relates to an organic silica gel used for packaging an IGBT (insulated gate bipolar translator) module and a preparation method of the organic silica gel. The organic silica gel comprises a component A and a component B according to the weight proportion of 1:1, wherein the component A comprises the following raw materials by weight part: 94 to 99.89 parts of base material, 0.01 to 5 parts of silane coupling agent, and 0.1 to 1 part of catalyst; the component B comprises the following raw materials by weight part: 79 to 95 parts of base material, 5 to 15 parts of crosslinking agent, 0.01 to 5 parts of fire retardant and 0.1 to 1 part of inhibitor. The organic silica gel used for packaging the IGBT module has excellent optical property, high strength, low oil leakage, and fire resistance, is transparent, is solidified fast at high temperature, is capable of satisfying the long-term operating requirements under high and / or low temperature environments, and is mainly beneficial to sealing and encapsulation protection of the IGBT modules.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Barrier film

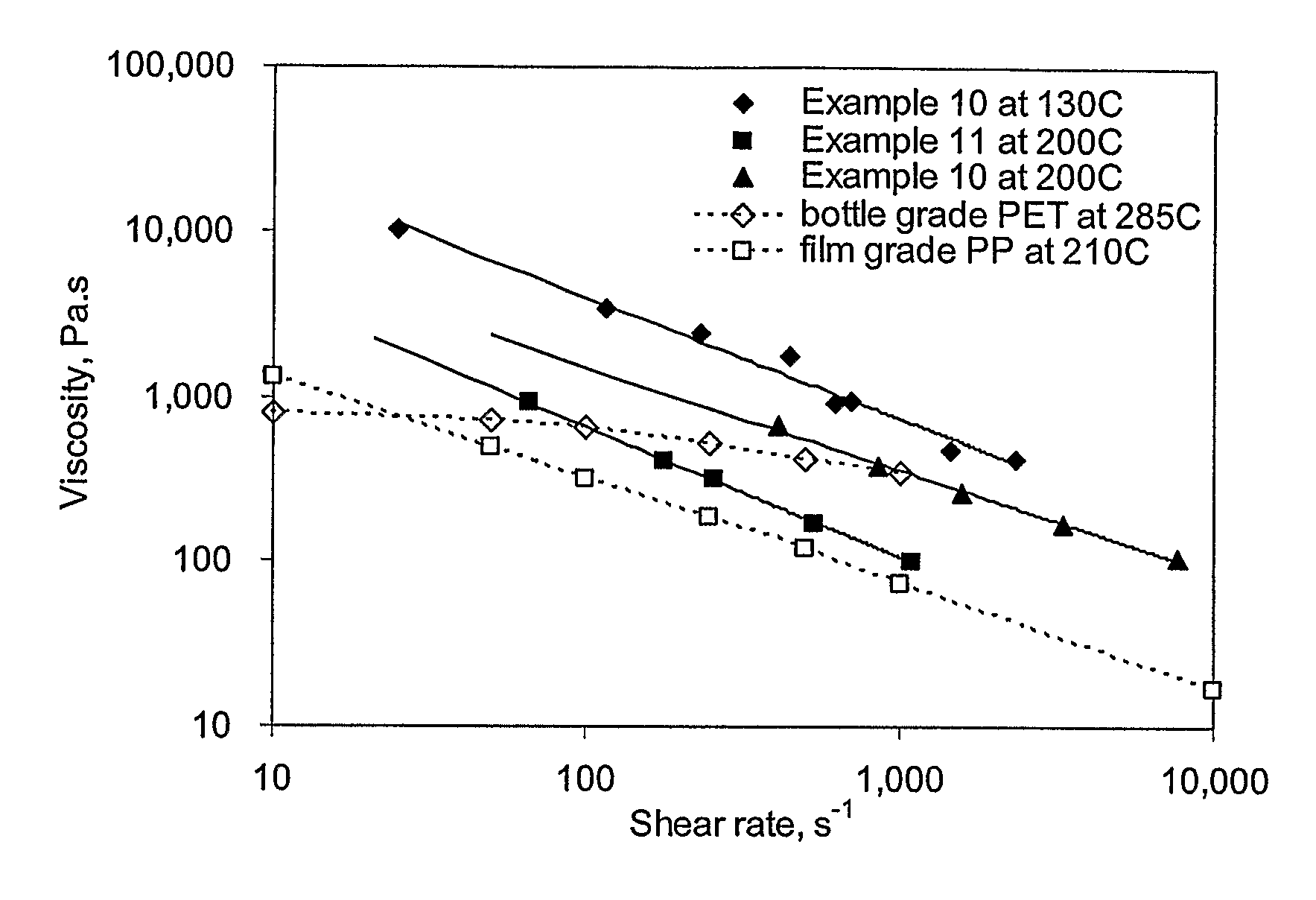

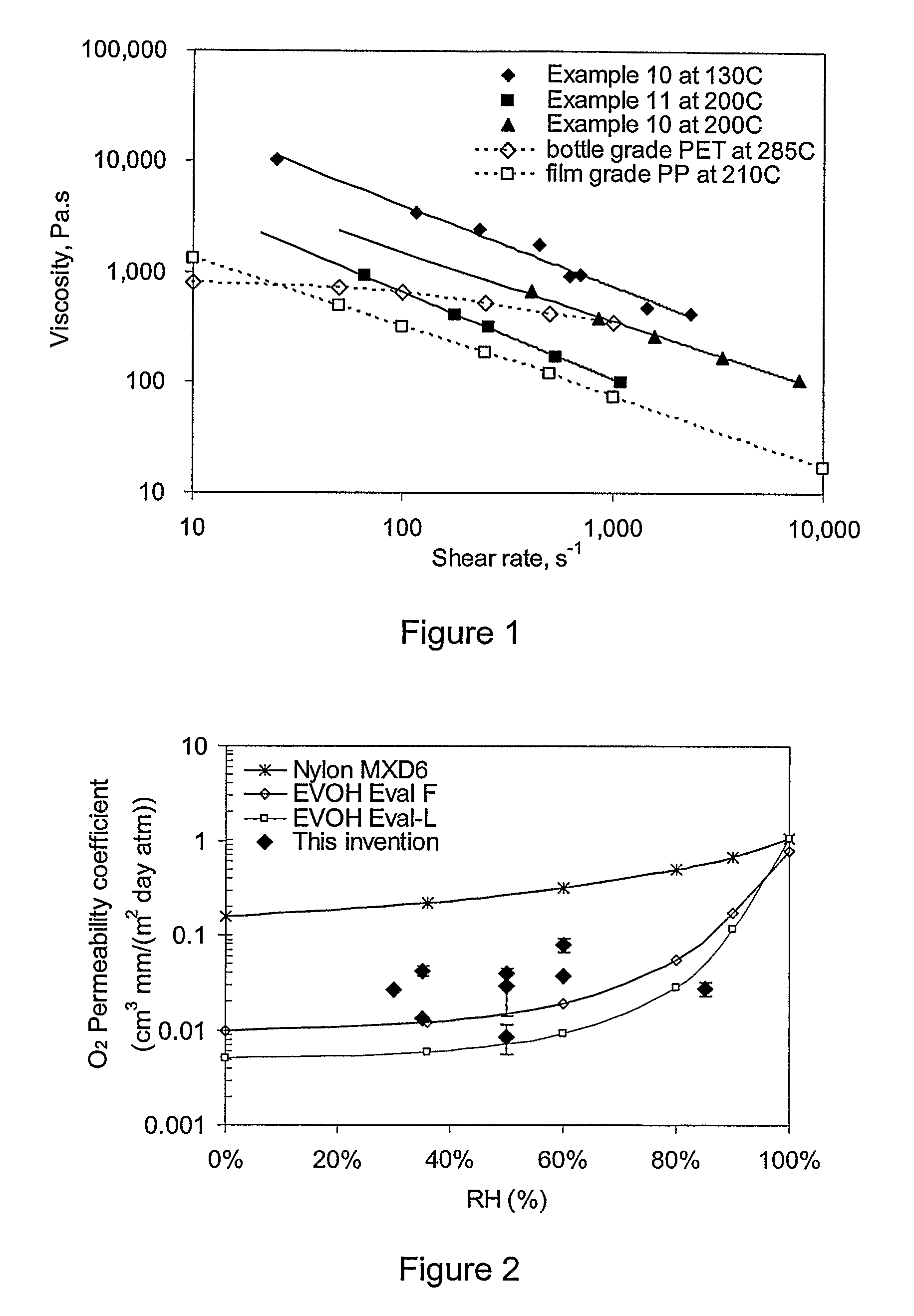

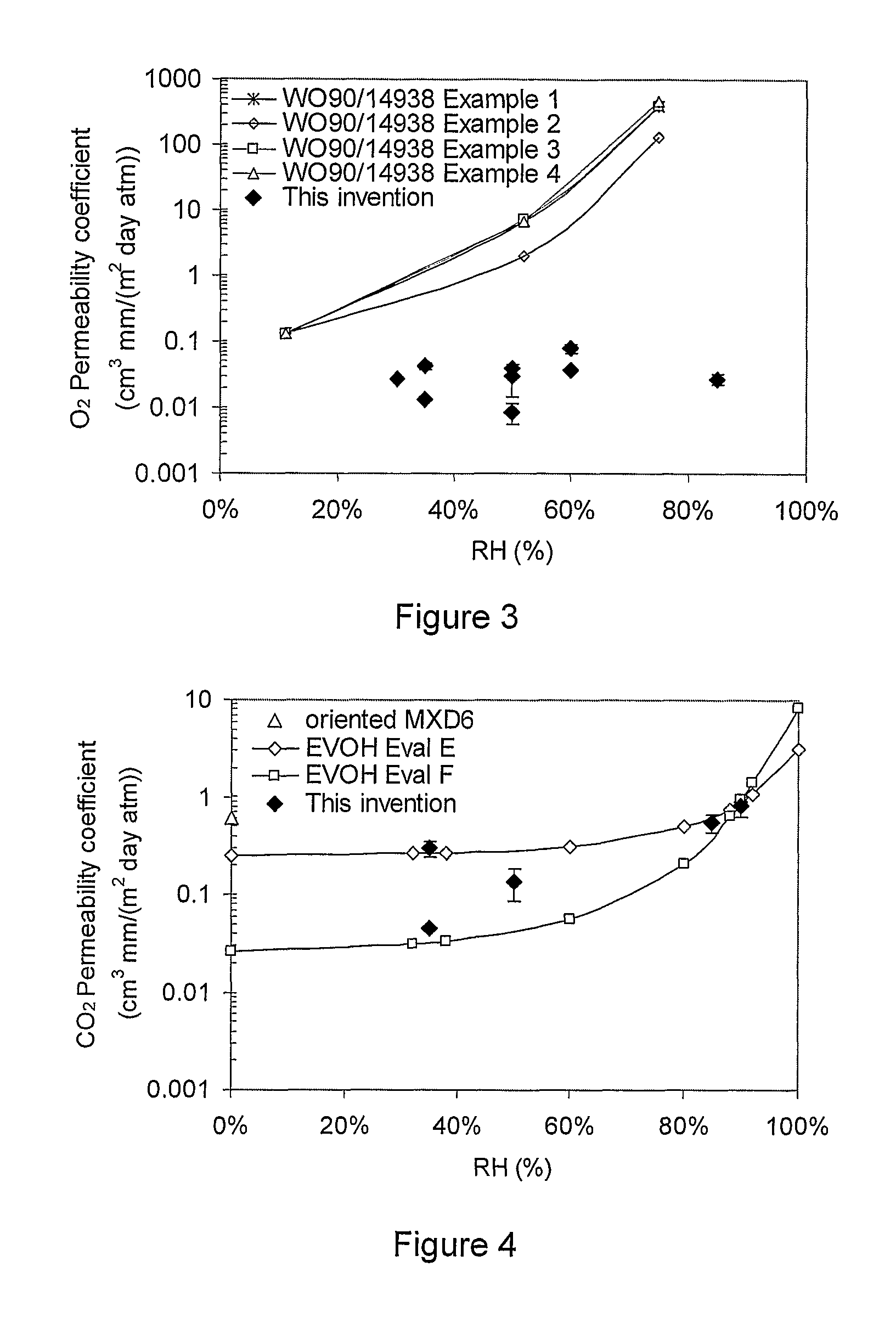

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

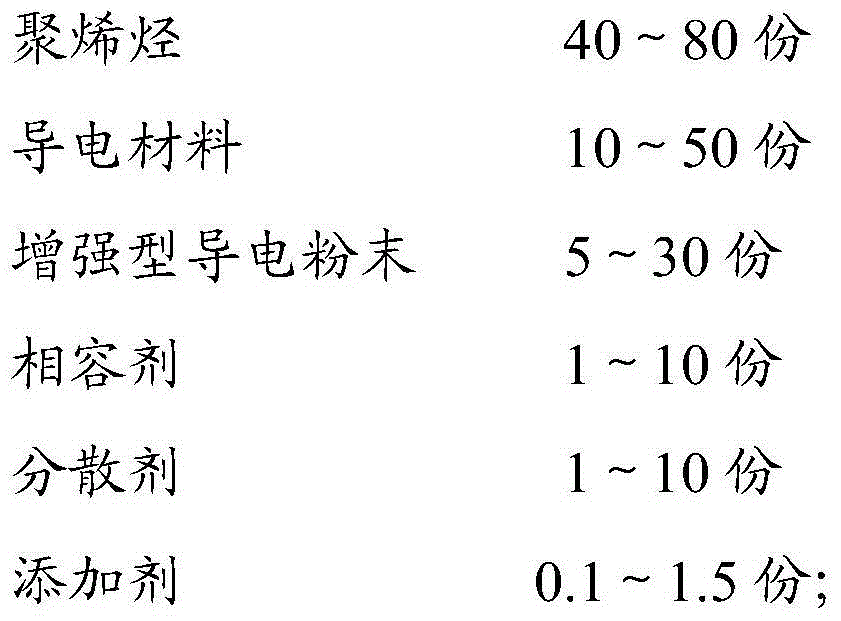

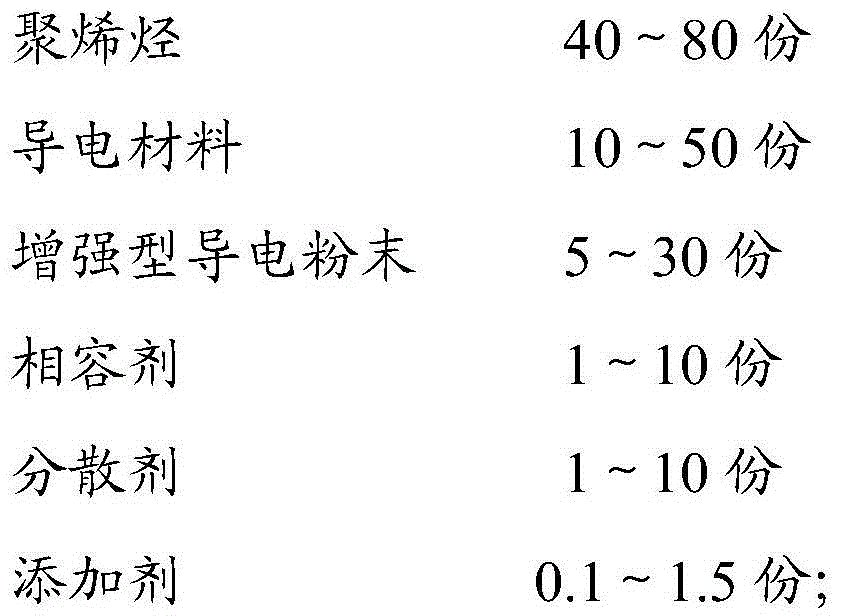

Permanently anti-static polyolefin master batch and preparation method thereof

The invention belongs to the technical field of high polymer materials, and particularly relates to a permanently anti-static polyolefin master batch and a preparation method thereof. The polyolefin master batch is prepared from the following components in parts by weight: 40-80 parts of polyolefin, 10-50 parts of conductive polymer or a composite material thereof, 5-30 parts of reinforcing conductive powder or fiber, 1-10 parts of a compatilizer, 1-10 parts of a dispersing agent, and 0.5-1.5 parts of other additives; the preparation method comprises the following steps: mixing the materials uniformly, then adding the mixture into a co-rotating twin screw extruder with a length to diameter ratio of 36-48, and extruding and pelletizing to obtain the product. The polyolefin master batch is good in dispersibility and compatibility; the good appearance, mechanical properties and stability of polyolefin can be maintained while the excellent anti-static effect can be achieved; the polyolefin master batch can be widely applied to membrane blowing, extrusion, blow molding and injecting molding products, and promotes the high-speed development of the electronic industry, the petroleum industry, the weapon industry and the military field in China.

Owner:DONGGUAN DICOLORS PLASTIC & METAL

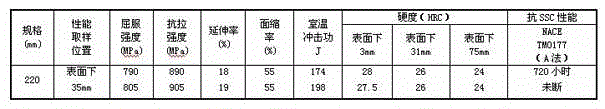

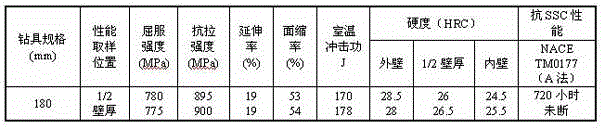

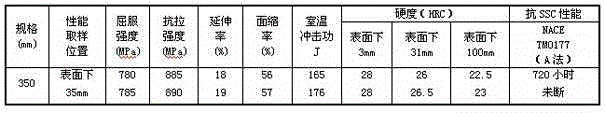

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

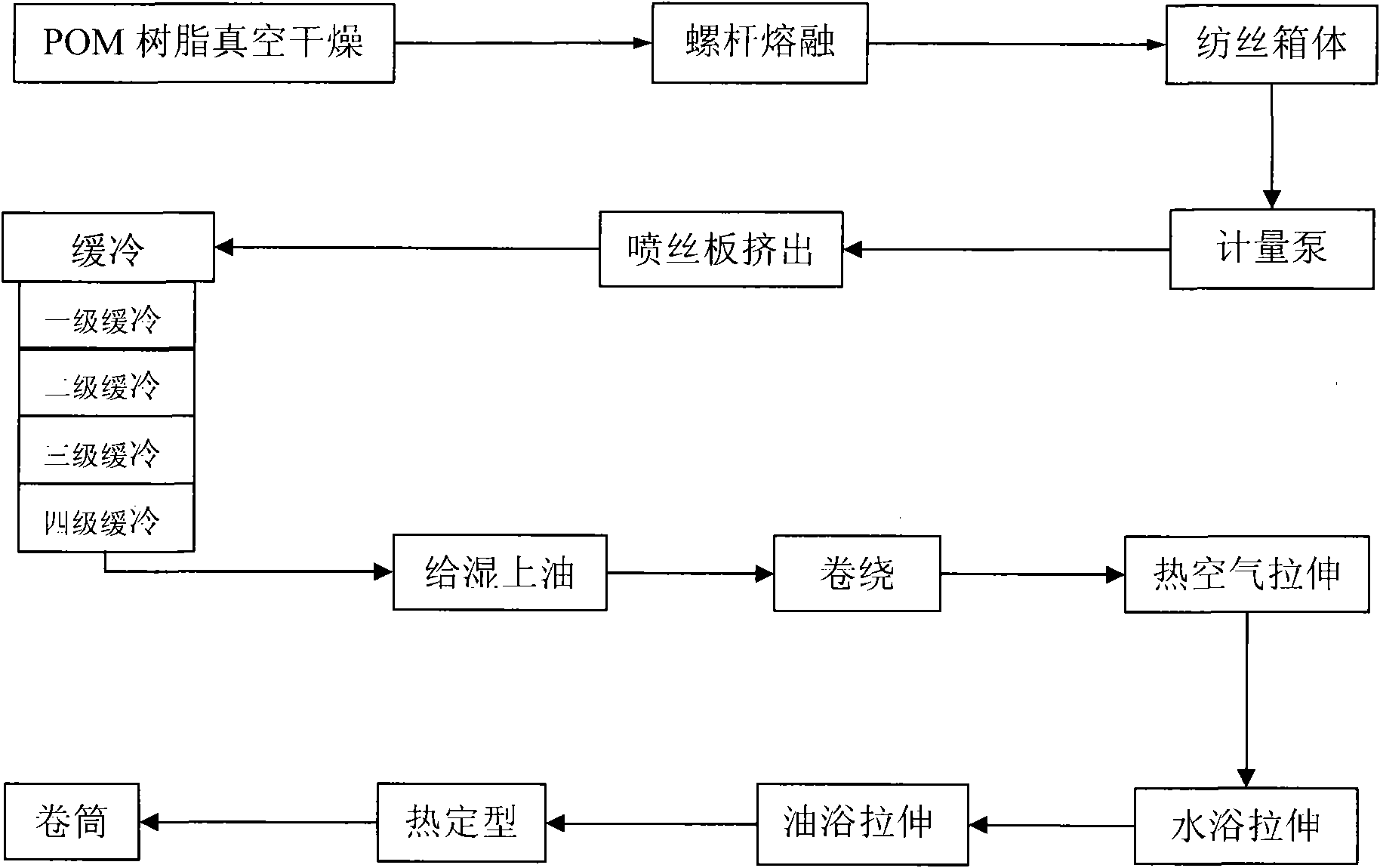

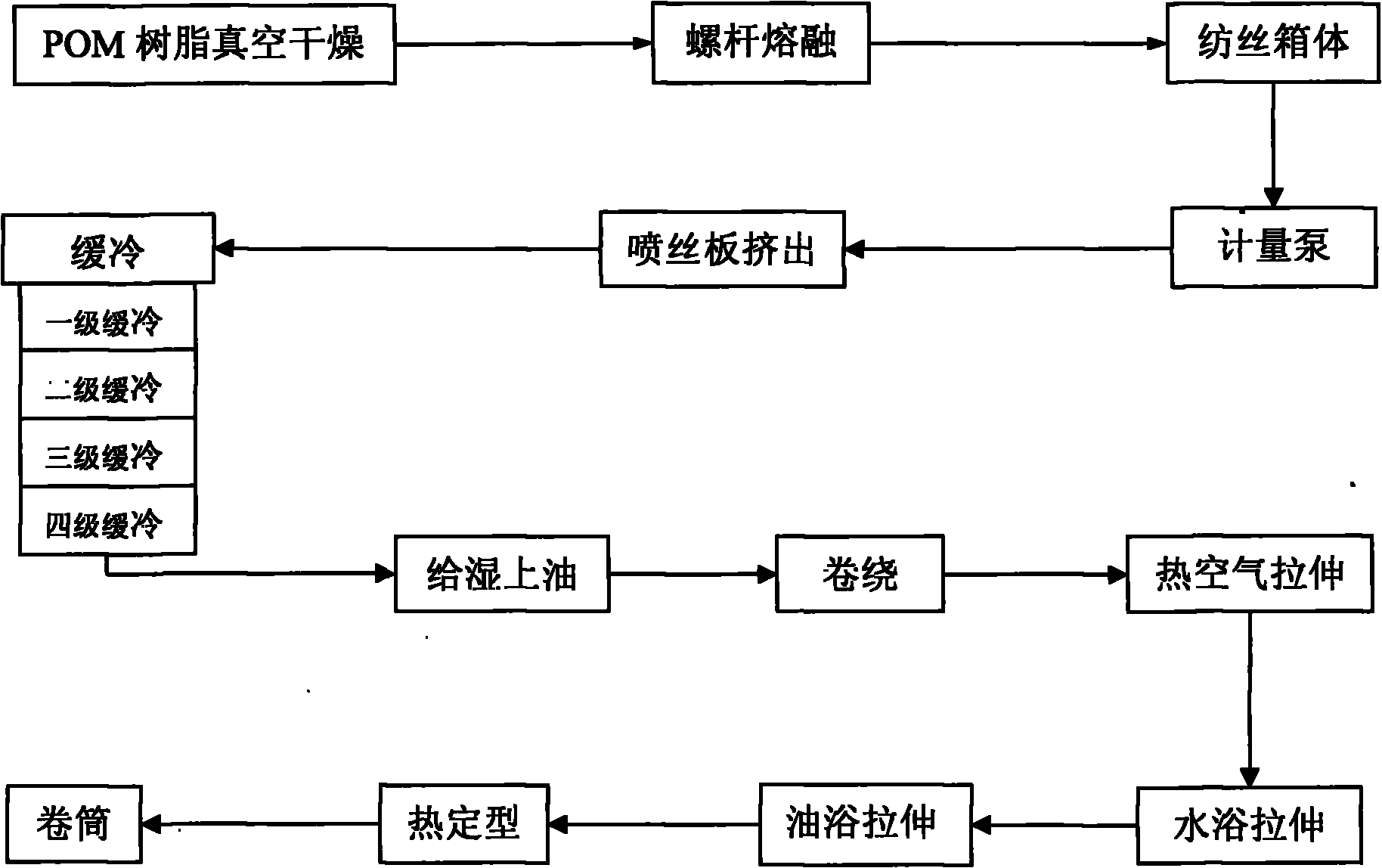

Novel preparation technology of polyoxymethylene fiber

InactiveCN101792938AStable structureReduce swellingArtificial filament heat treatmentStretch-spinning methodsFiberSolvent

The invention relates to a novel preparation technology of polyoxymethylene fiber, in particular to the novel preparation technology of the polyoxymethylene fiber via multi-stage slow cooling and three-stage drawing with different media, which comprises the following steps: vacuum-drying polyoxymethylene granular materials, heating and melting via a screw extruder, melting and extruding by a spinneret, leading small melt flow to pass through the multi-stage slow cooling, carrying out high-speed traction, passing through a moistening and oiling cluster, winding, then obtaining as-spun fiber, carrying out hot air drawing and two times of drawing with different types of solvent, then carrying out hot molding and finally preparing the polyoxymethylene fiber. The novel prepration technology can solve the problems of matching between the multiple sections of atmosphere and temperature and the spinning process control and the control of the drawing with multiple media and make up for the deficiencies that the single atmosphere and temperature and the single medium drawing of the prior art lead the structure to be difficult to stable and uniform.

Owner:DONGHUA UNIV +1

High-strength rebar and manufacturing process thereof

InactiveCN101275197AImprove the strength of steel barsStable mechanical propertiesTemperature control deviceProcess efficiency improvementChemical IngredientsRebar

A high intensity deformed steel bar and a manufacturing procedure thereof are disclosed, belonging to the field of steel metallurgy and suitable for the deformed steel bar with 12mm to 40mm production standard. The high intensity deformed steel bar of the invention comprises the ingredients: C: 0.12-0.25%; Si; 0.12-0.80%; Mn: 0.30-1.55%, P: 0.01-0.035%, S: 0.01-0.040%, equivalent weight of carbon: 0.19-0.51% the rests are Fe. The procedure flow of the invention comprises the steps of: squaring billet, heating, roughly and intermediately rolling, precisely rolling, performing QTB water penetration, placing on a cooling bed (cooling naturally), scaling, checking and putting into storage. The invention has the advantage that: chemical ingredients are designed diversely according to the diverse production standards of the deformed steel bar, the after-rolling remaining heat treatment procedure is used to keep the steel bar in a good plasticity and toughness.

Owner:TIANJIN IRON & STEEL GRP

Hardened and tempered ultrahigh-strength steel with 1000MPa-grade yield strength and production method thereof

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

Method for producing steel plate of petroleum storage tank by using direct quenching process

The invention discloses a method for producing a steel plate of a petroleum storage tank by using a direct quenching process. The invention provides a chemical composition of special petroleum storage tank steel and adopts a direct quenching process. The method comprises the following steps of: heating a steel blank to 1100 to 1280 DEG C, rolling into a steel plate in re-crystallization and non-recrystallization stages; carrying out on-line quenching operation under the conditions that the temperature of the steel plate is between 780 DEG C and 900 DEG C, the average cooling rate ranges from 25 DEG C / s to 60 DEG C / s, the cooling terminal temperature is less than or equal to 350 DEG C, and performing off-line tempering on the steel plate subjected to quenching. Compared with the conventional high-energy-consumption hardening process based on the combination of off-line tempering and tempering, the method provided by the invention has the advantages of short production flow and low energy consumption and the prepared steel plate has good general mechanical properties and high heat input welding property. The yield strength of the steel plate is more than 490 MPa and the tensile strength of the steel plate is more than 610 MPa. In case of high heat input welding (less than or equal to 400 KJ / cm), a welding heat affected zone maintains excellent low-temperature toughness, and the mean value of work done by impact at -20 DEG C is more than 50 J.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

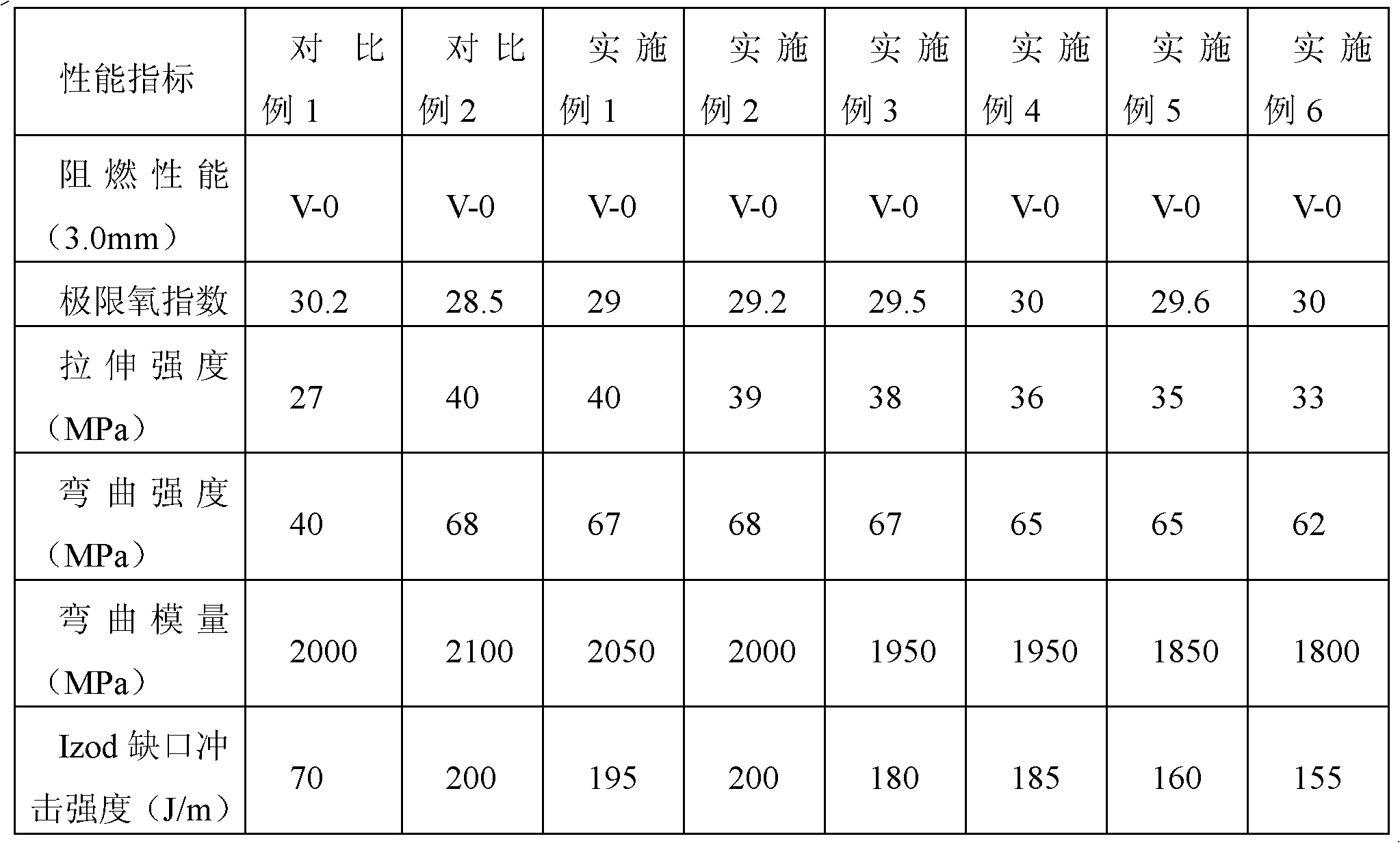

Polyolefin/styrene resin composition and preparation method thereof

The invention relates to the technical field of polymer / styrene resin composition and a preparation method thereof. The composition comprises the following compositions, by weight, 100-800 parts of polyolefin, 100-800 parts of styrene resin, 30-100 parts of compatilizer, 30-200 parts of flexibilizer, 50-200 parts of flame retardants, 40-80 parts of effect assisting flame retardants, 10-100 parts of compound flame retardants, 0-30 parts of enhancer, 0-10 parts of anti-oxidation additives and 0-5 parts of processing aids. The preparation method of the composition comprises the steps of placing the compositions of the proportion in a high-speed mixer and mixing the compositions for 1-3 minutes; conveying evenly-mixed materials into a double-screw extruder through a precise metering material-conveying device; sufficiently mixing the materials through the shearing function of screw rods, and feeding the compound flame retardants and the enhancer into the extruder in a melting section of the extruder through a side direction forced feeding device; and packing the melted mixing materials into finished products after extrusion, strip pulling, cooling and dicing. The composition has remarkable flame retarding effect and is stable in mechanical performance.

Owner:HEFEI GENIUS NEW MATERIALS

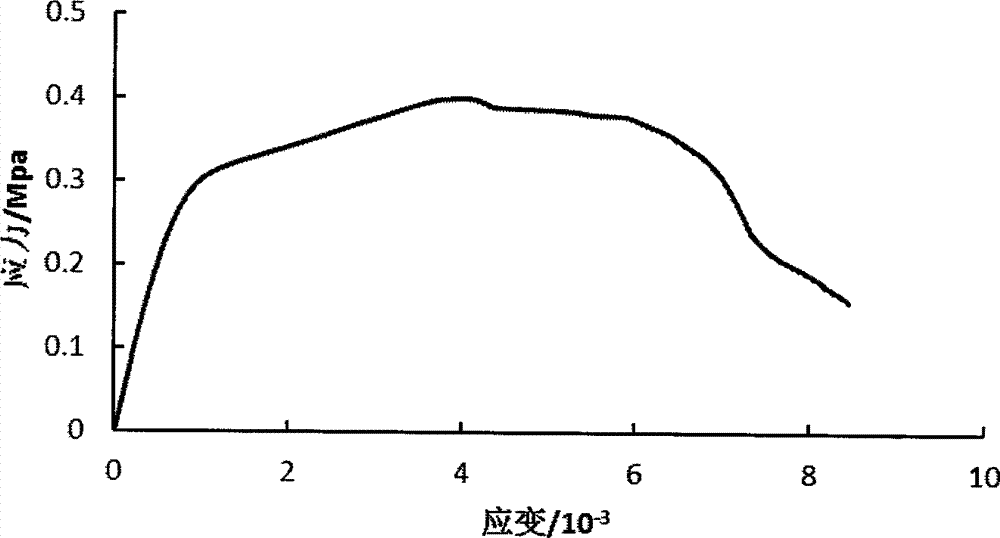

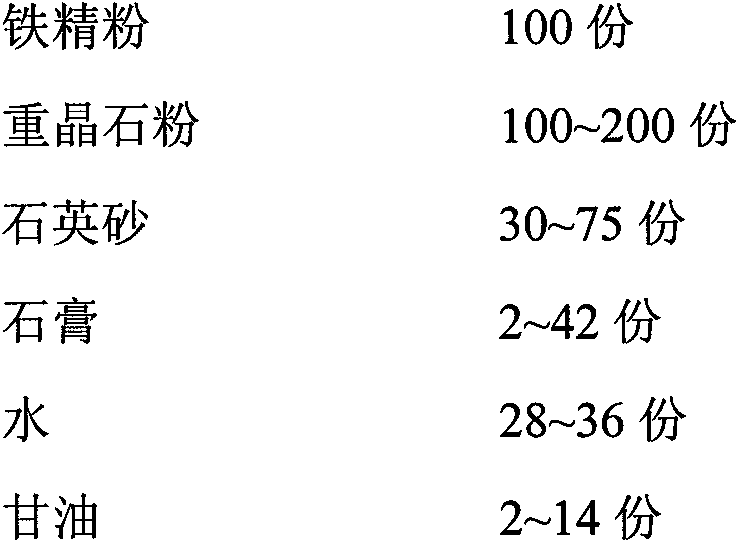

Rock soil similar material and preparation method thereof

InactiveCN103043986AEasy to processOvercome the disadvantage of low densityHigh densityRoom temperature

The invention relates to a rock soil similar material and a preparation method thereof, and the rock soil similar material is particularly suitable for a geotechnical engineering geomechanics model test and a seismic modeling vibrating table physical model test. According to the rock soil similar material, powdered iron and barite powder are selected as fine aggregates, quartz sand is selected as a coarse aggregate, gypsum is selected as a cementing agent, and glycerin is selected as a conditioning agent. The preparation method comprises the following steps of: weighing and uniformly stirring all the components of the rock soil similar material according to the mass part; pouring the stirred mixture in a rigid mould and compacting the mixture by layers; and after the mould is removed, naturally airing a test piece which is taken down at a normal temperature for 5-7 days. The rock soil similar material has the advantages of high density, large strength and deformation parameter change range, wide raw material source, simple preparation method, stable mechanical property at the room temperature, no harm to a human body, and the like; and the test piece is easily processed and formed, and is naturally aired without curing.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Halogen-free flame retardant sheath material for nuclear cable, cable sheath, preparation method and application

ActiveCN102875947AImprove performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

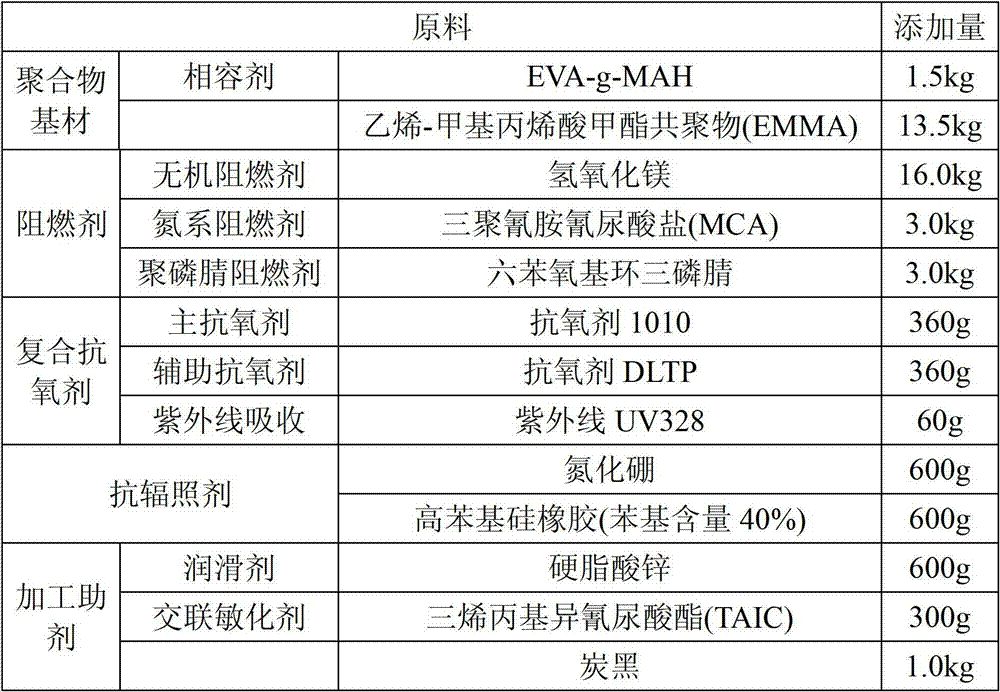

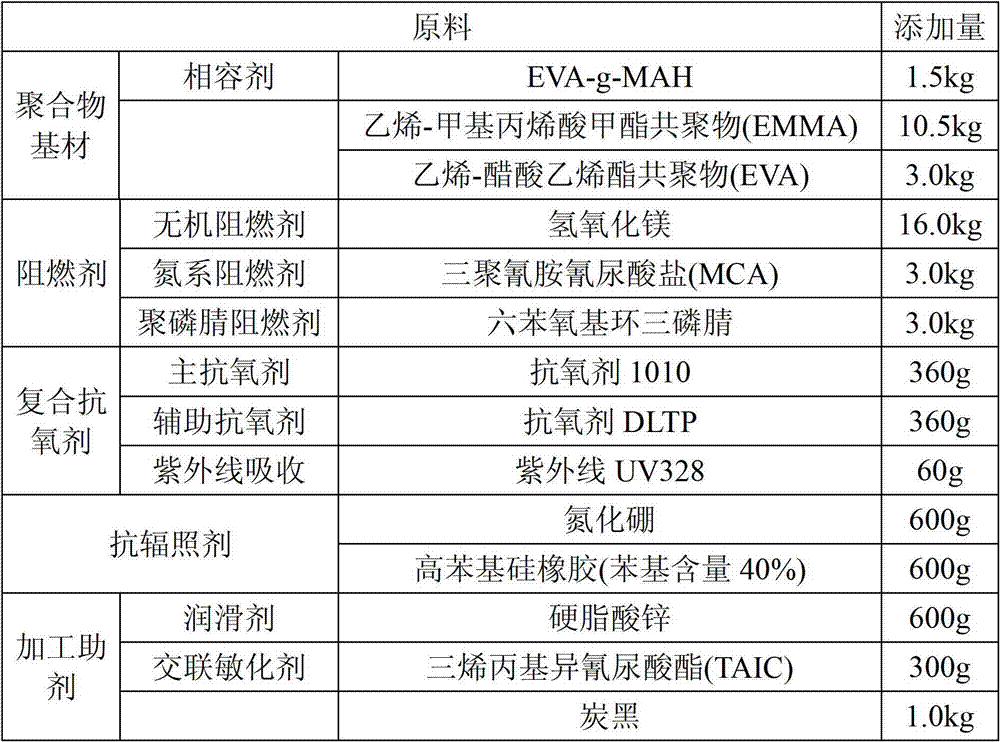

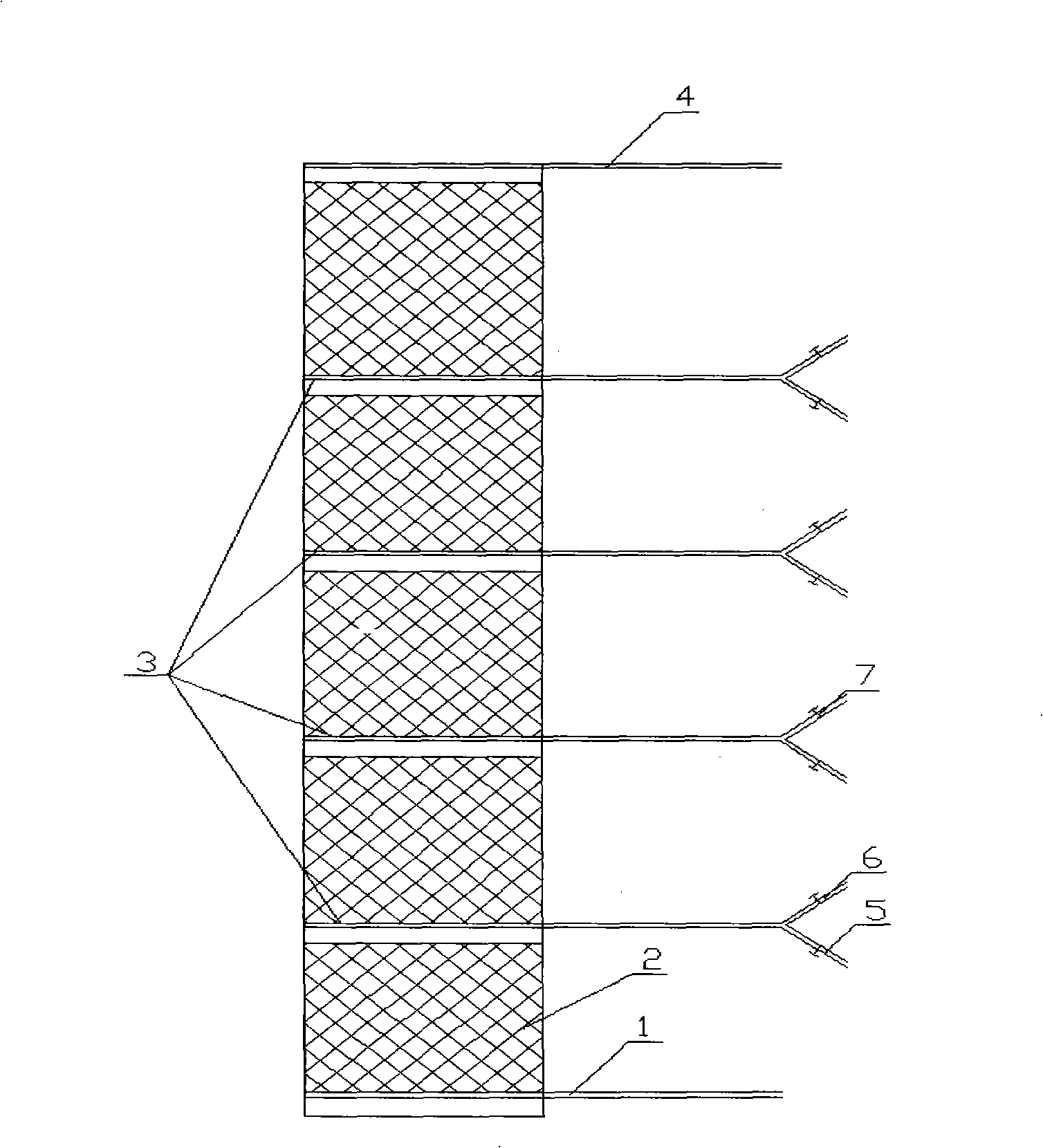

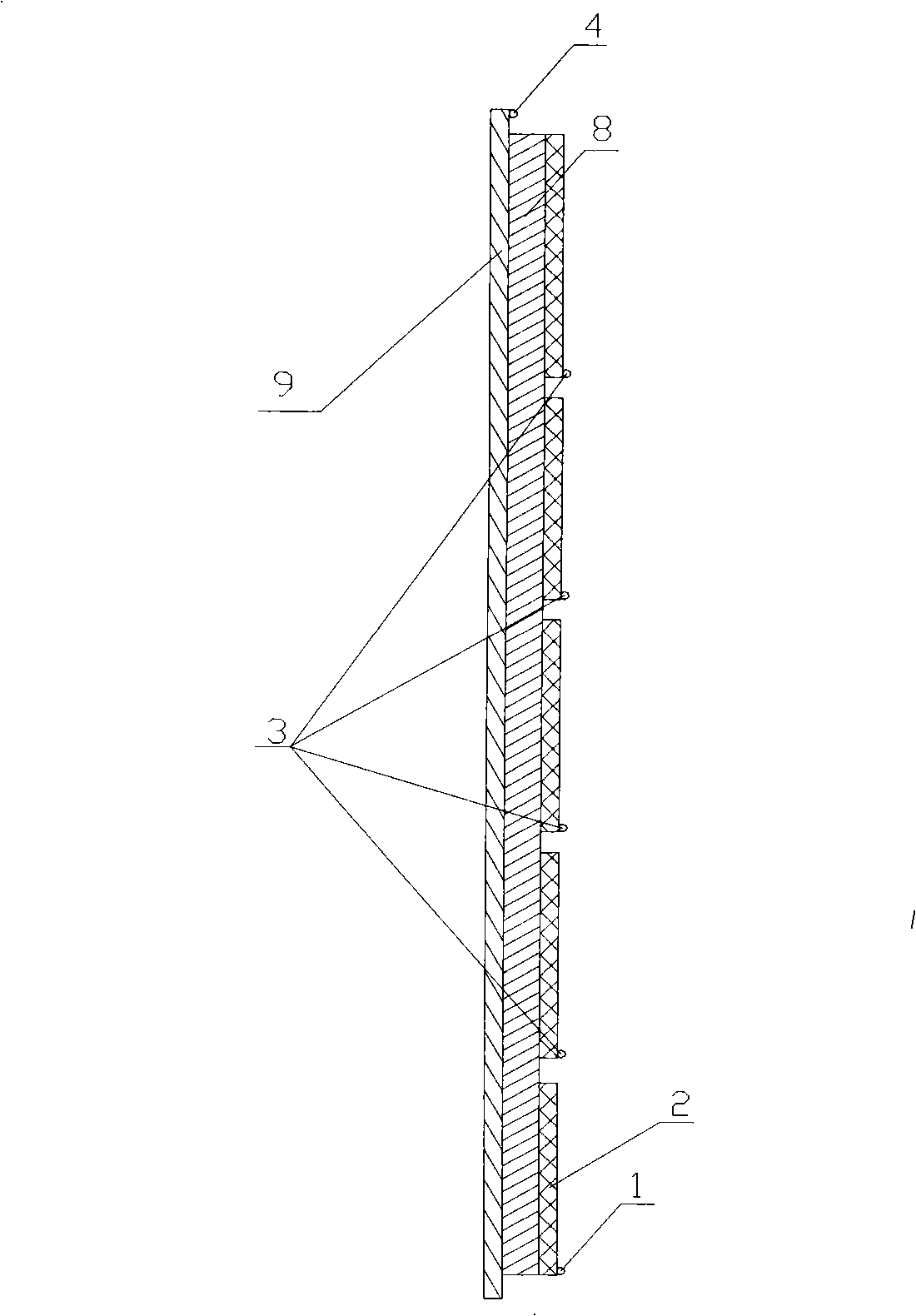

The invention discloses a halogen-free flame retardant sheath material for a nuclear cable, a cable sheath, and a preparation method and an application of the cable sheath. The halogen-free flame retardant sheath material for the nuclear cable comprises the following raw materials: 100 parts of a polymer base material comprising ethylene vinyl acetate copolymer and ethylene methyl methacrylate copolymer, 100-140 parts of an inorganic fire retardant comprising magnesium oxide, 15-25 parts of phenoxycycloposphazene; 15-30 parts of nitrogen fire retardant comprising melamine cyanurate, 4-8 parts of a compound antioxidant comprising a main antioxidant, an auxiliary antioxidant and an ultraviolet light absorber, 5-15 parts of an anti-radiation agent comprising high phenyl siloxane rubber and an anti-radiation agent A, and 6-12 parts of a processing aid comprising a cross-linking sensitizing agent and a lubricant, wherein the anti-radiation agent A is boron carbide and / or boron nitride. The halogen-free sheath material for the nuclear cable disclosed by the invention is good in superior performance, good fire retardant performance, and stable anti-radiation performance, electrical performance and mechanical performance.

Owner:青岛中科汉缆高分子材料有限公司

Method for manufacturing aluminium alloy sheet for automobile fuel tank

ActiveCN104294113AStable mechanical propertiesPrecise dimensional tolerancesFuel tankEconomic benefits

The invention provides a method for manufacturing an aluminium alloy sheet for an automobile fuel tank. The method comprises the steps of batching, smelting, refining, grain refining, degassing, filtering, casting, saw-cutting, milling, homogenized heating, hot-rolling, cold-rolling, cleaning, low-temperature stabilized annealing, transverse shearing, edge straightening, board cutting, inspecting and the like. The aluminium alloy sheet for the automobile fuel tank has the advantages of stable mechanical property, precise dimensional tolerance, finish surface and the like. Compared with the present plastic fuel tank, the automobile fuel tank manufactured by the aluminium alloy sheet produced by the method has the advantages of high strength, sun exposure resistance, aging resistance, breakage prevention, environmental protection and the like, and also has the advantages of corrosion resistance, rusting avoidance, light weight, good economic benefits within the product life cycle, high material reutilization ratio and the like in comparison with a copper fuel tank.

Owner:DALISHEN ALUMINUM

Vacuum auxiliary molding technique produced by high-facade composite material for ship

The invention discloses a vacuum assistant resin infused method for molding a high elevation part of composite materials used on ship and comprises the working procedures of raw material preparation, forming process, etc. The invention is characterized in that in the forming process, the direction of a resin channel is the same as the height direction of the product; a plurality of glue-injection pipes or exhaust pipes parallel to the width direction of the product are arranged in the height direction of the product; the product is divided into a plurality of forming units by the glue-injection pipes or exhaust pipes in the height direction; the distance between the edge of permeable medium and the glue-injection pipes or exhaust pipes is controlled and each unit comprises a flood protection material system of stream guidance, glue injection and gas exhaust, and the like; in the forming process, each unit is immersed successively from bottom to top in a relay style. The invention is used for molding the high elevation part of composite materials used on ship, increases the penetration degree and uniformity of the resin, raises the product quality, and gives good mechanical and sea-water proof property to the product with greatly reduced weight, thereby improving the loading capacity and ample stability of the operation platform on water surface and under water.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Cranioplasty prosthesis with biological activity and preparation method of cranioplasty prosthesis

InactiveCN104667345AFast productionSmall sizeAdditive manufacturing apparatusCoatingsBiocompatibility TestingDrug biological activity

The invention relates to cranioplasty prosthesis with biological activity and a preparation method of the cranioplasty prosthesis. The cranioplasty prosthesis with biological activity sequentially comprises an unmodified cranioplasty prosthesis layer, a modified cranioplasty prosthesis layer and a nanofiber membrane layer from inside to outside. The invention further provides a preparation method of the cranioplasty prosthesis. By virtue of a three-layer structure and polyaryletherketone materials which are equivalent to a bone of a human body in hardness, strength and weight, are good in biocompatibility, and a 3D printing technology, a cranioplasty prosthesis implant has reliably safety and effectivity and high matching degree. The cranioplasty prosthesis provided by the invention is capable of loading a plurality of bionic scaffolds and bioactive substances, and promoting exchange of nutrient substances inside and outside the prosthesis, and is beneficial to growth of tissues.

Owner:MEDPRINSHENZHEN REGENERATIVEA MEDICAL TECH CO LTD

Light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and preparation method

InactiveCN102181754AReduced responseLess rigidRoll mill control devicesMetal rolling arrangementsMaterials preparationFiltration

The invention relates to a light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and a preparation method. The iron-silicon rate of the woolen ranges between 4.3-5.3. The process of the preparation technology is sequentially as follows: material preparation, batching, feeding, melting, stirring, primary refining of a smelting furnace, drossing, sampling, ingredient adjustment, secondary refining of the smelting surface, drossing, converter, primary refining in a holding furnace, intensified refining in the holding furnace, online addition of AL-Ti-C wire intermediate alloy refiner, Ar online degassing, filtration, continuous casting into 7.0-7.5mm cast rolling plates, cold rolling, high-temperature homogenizing annealing of a primary sheet strap, cold rolling, trimming of a rereeling machine, cold rolling, intermediate annealing of a secondary sheet strap, cold rolling to 0.26-0.32mm, trimming of the rereeling machine, and packaging. The cost is low, the quality is stable, the calendaring of the aluminum foil and grain refining are good in effect, and the probability of generating pinholes is low during production.

Owner:江阴新仁铝业科技有限公司

Water swelling polyurethane elastomer sealing product material and preparation method

ActiveCN101565602AStable physical and chemical propertiesStable physical and chemical properties (hardnessOther chemical processesPolyurethane elastomerPolyol

The invention relates to a water swelling polyurethane elastomer sealing product material and a preparation method. The material is prepared from the following three components (A), (B) and (C) through polymerization reaction of two steps, the elastomer material has water swelling property, and a main chain structure of material molecules absorbs water, wherein the (A) is hydrophilic polyether type polymer1polyol; the (B) is polyisocyanates; and the (C) is low-molecular polyol and amino chain-extended crosslinker. The molar ratio of the (B) to the (A) in an isocyanate end capping reaction is 1.3 to 2.8; and the molar ratio of a product of the isocyanate end capping reaction of the (A) and the (B) to the (C) in a chain-extended crosslinking reaction is 0.75 to 1.05. In the preparation method for the material, the reaction of the two steps is a reaction process of liquid polymerization, and the production of a product is an elastomer casting-molding process. The material has the characteristics of small mass variation rate and stable physical performance after the material absorbs the water repeatedly to swell, and permanent compression deformation and small stress relaxation.

Owner:NORTHWEST RUBBER & PLASTIC RES & DESIGN INST CO LTD

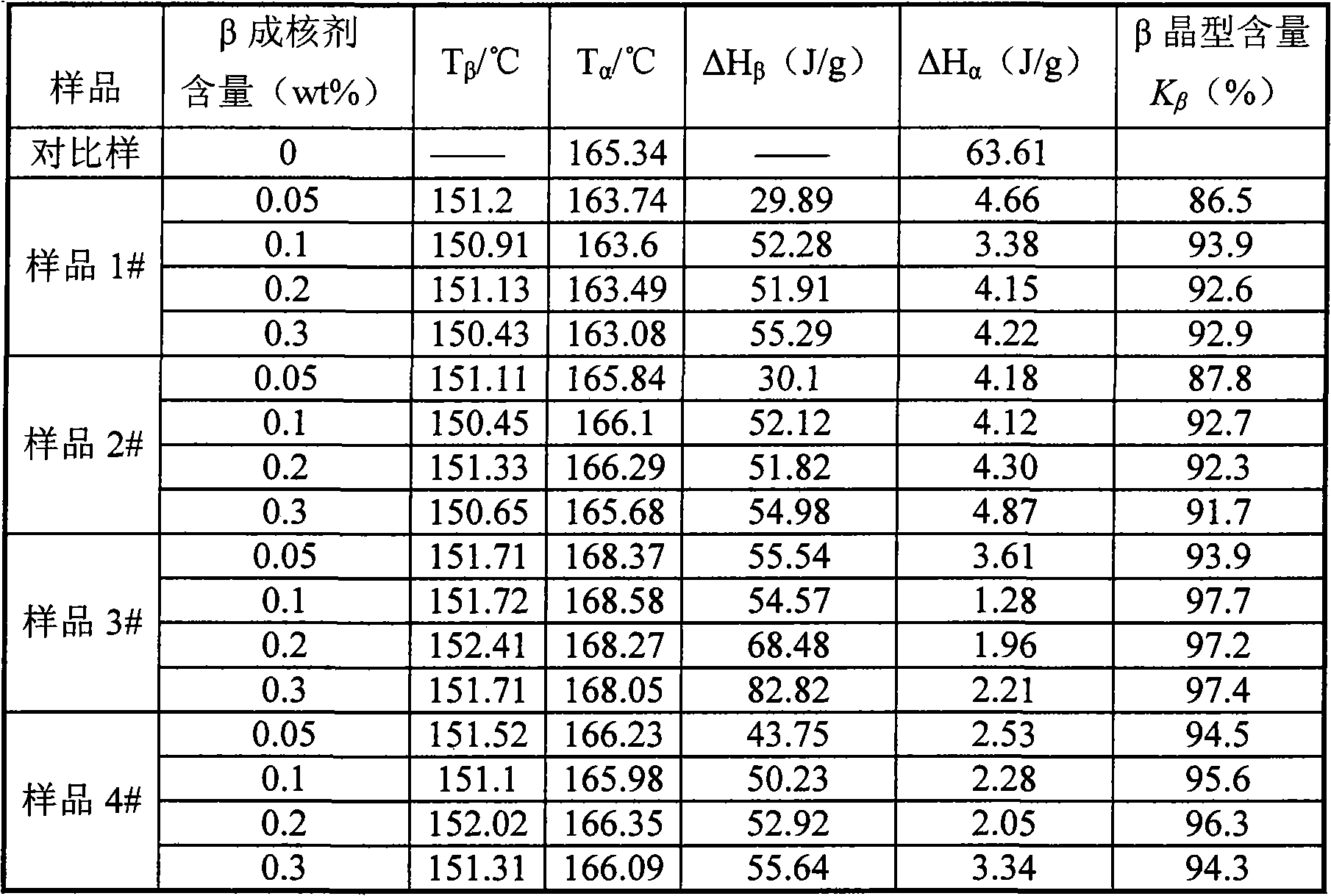

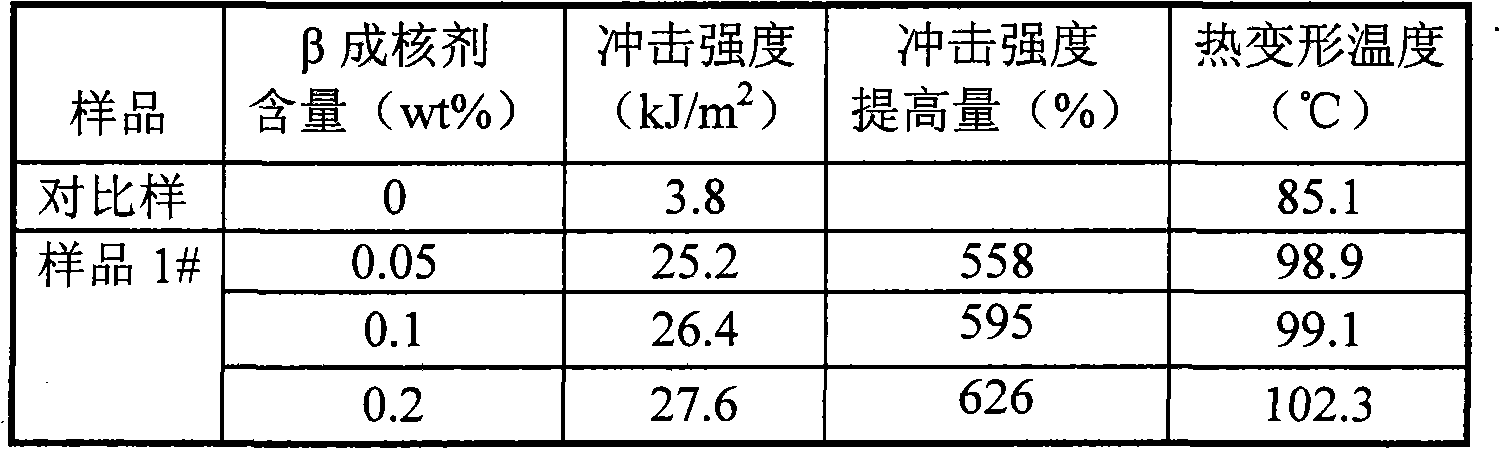

Application of carboxylic acid metal salt of tetrahydrophthalic anhydride as nucleating agent for polypropylene beta crystal form

ActiveCN102181092AHigh impact strengthHigh heat distortion temperatureDispersityHeat deflection temperature

The invention provides an application of a carboxylic acid metal salt of tetrahydrophthalic anhydride as a nucleating agent for a polypropylene beta crystal form. By adopting the carboxylic acid metal salt of tetrahydrophthalic anhydride as the nucleating agent, the generation of beta crystal form polypropylene can be induced efficiently; as tested by differential scanning calorimetry (DSC), the content of a beta crystal form is up to 86-97.7 percent; after nucleation modification by using the carboxylic acid metal salt of the tetrahydrophthalic anhydride, the punching strength of polypropylene is increased by 5-8 times, the heat deflection temperature is increased greatly, and high mechanical property is achieved; and moreover, the carboxylic acid metal salt has the advantages of chemical stability, high dispersity, coloring resistance, capability of improving the working quality of a product and wide application range in the field of materials special for polypropylene.

Owner:GCH TECH

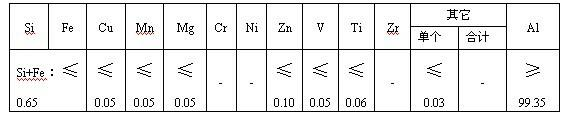

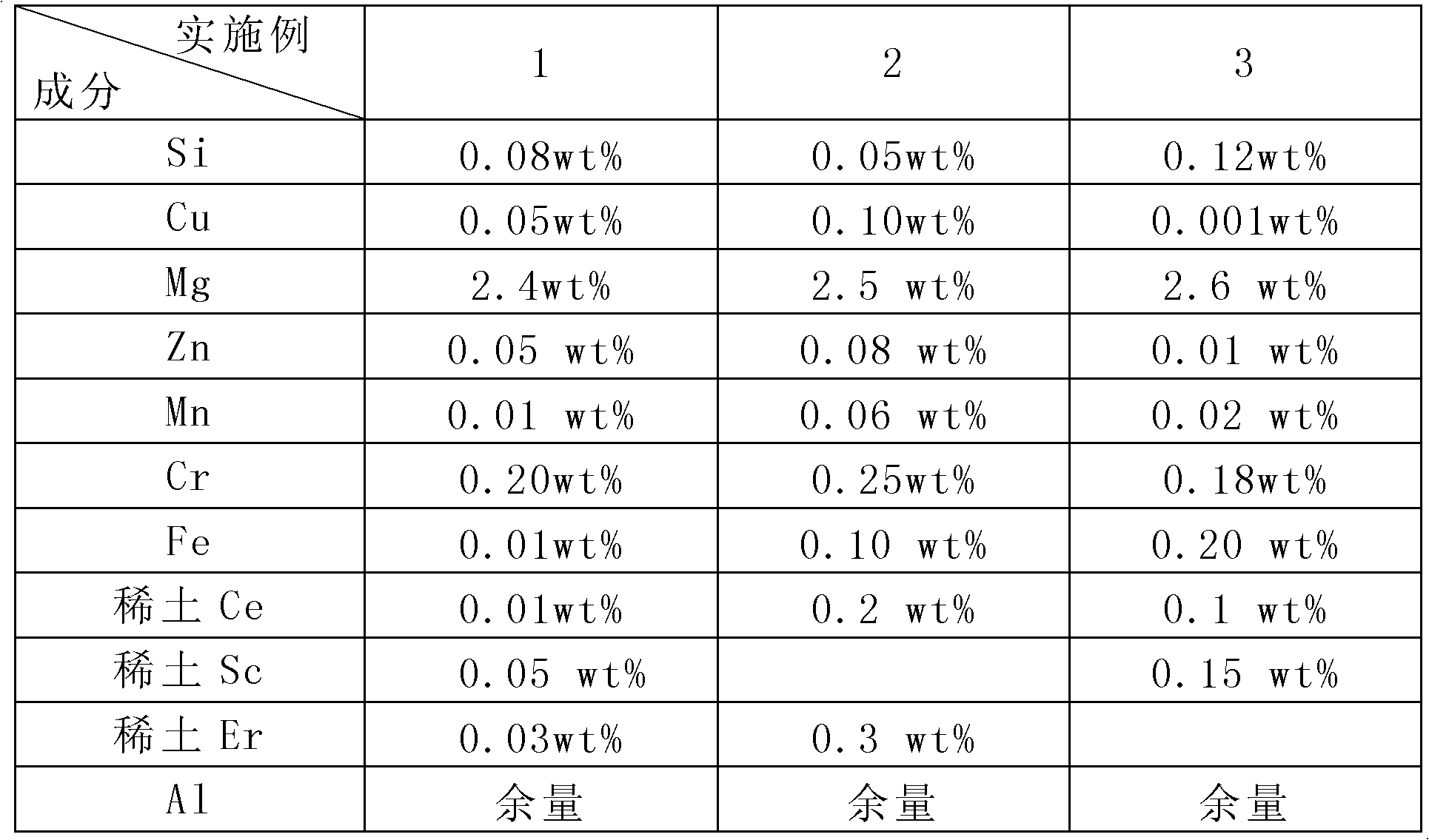

Aluminum alloy 5052 having high corrosion resistance and manufacturing method thereof

The invention provides an aluminum alloy 5052 having high corrosion resistance and a manufacturing method thereof, which belongs to the technical field of alloy materials and solves the problem of low corrosion resistance of the traditional aluminum alloy 5052 material. The aluminum alloy 5052 having high corrosion resistance comprises the following components in percentage by weight: no more than 0.20% of Si, no more than 0.20% of Cu, 2.4-2.6% of Mg, no more than 0.10% of Zn, no more than 0.10% of Mn, 0.18-0.30% of Cr, 0.01-0.40% of Fe, no more than 0.05% of single other element, no more than 0.15% of total other elements, 0.01-0.8% of rare earth elements and the balance of Al. The aluminum alloy 5052 having high corrosion resistance can improve the corrosion resistance and simultaneously maintain the stabilization of mechanical properties.

Owner:ZHEJIANG GKO ALUMINUM

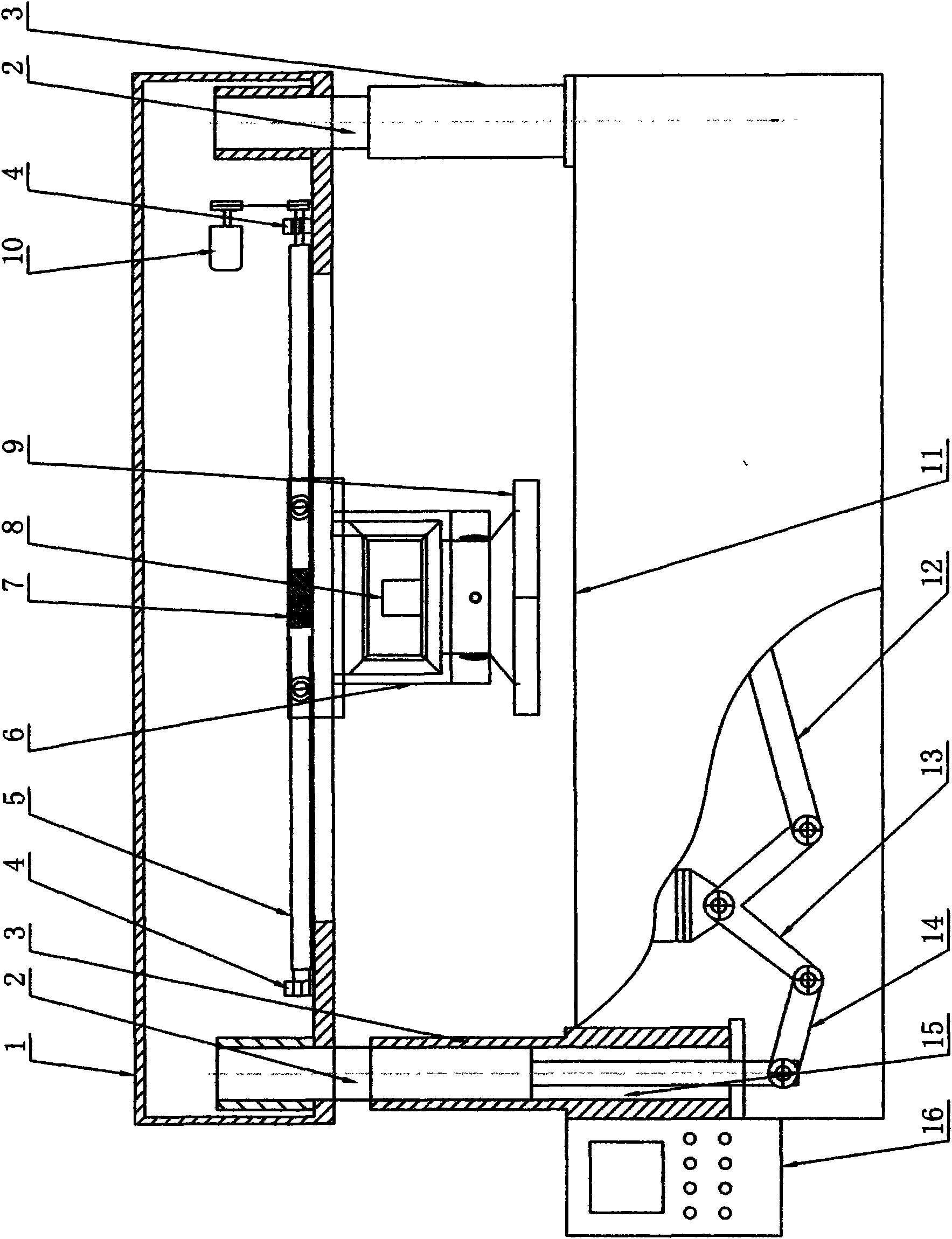

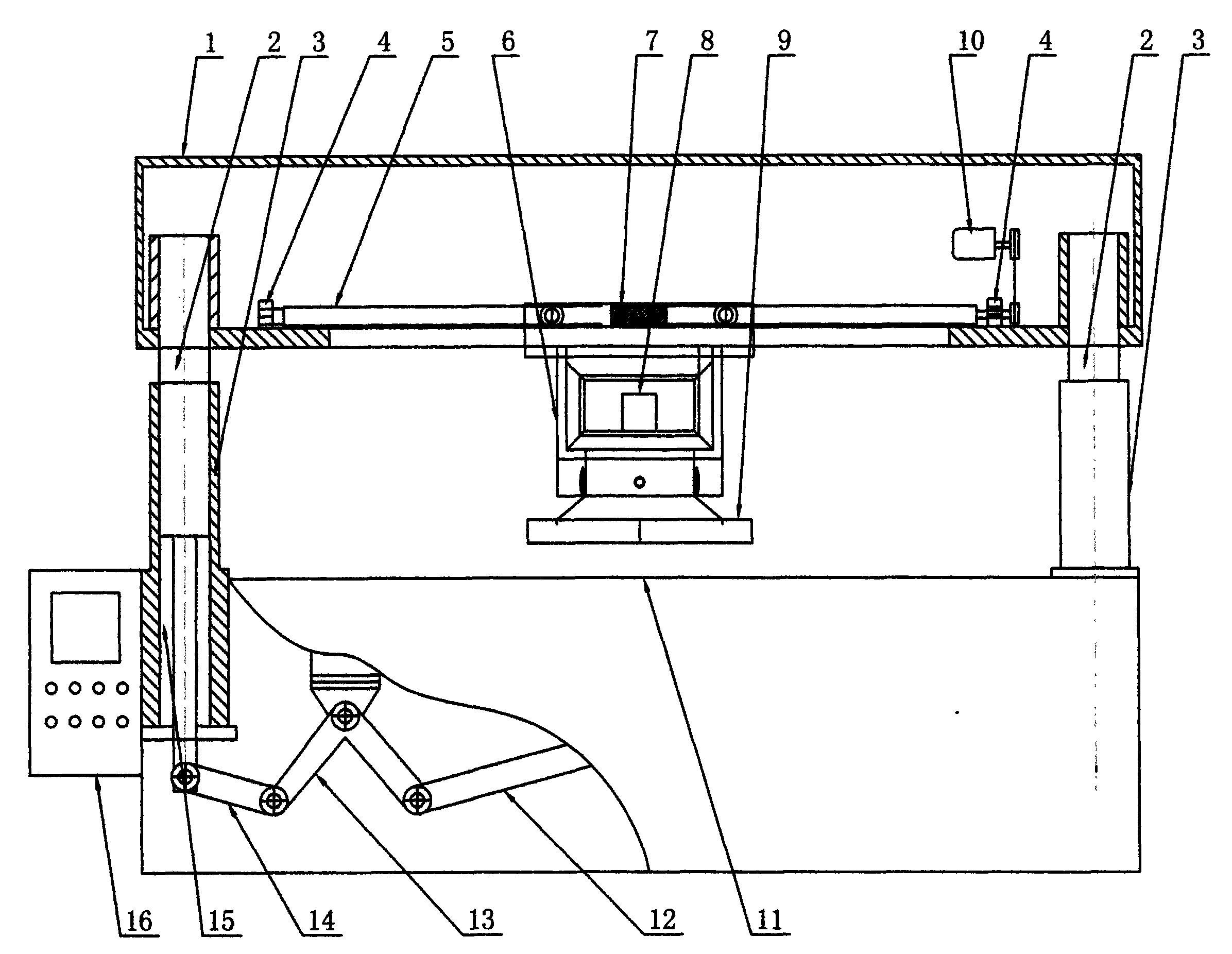

Numerical control cutting machine

InactiveCN101987464ARealize mobile cuttingRealize automatic croppingMetal working apparatusFailure rateNumerical control

The invention discloses a numerical control cutting machine, which comprises an upper workbench, a guide post, a guide sleeve, a screw support, a ball screw, a numerical control moving head, a connecting seat, a step motor, a rotary die holder, a servomotor, a workbench, a balancing connecting rod, a swing plate, a connecting plate, an oil cylinder, and a numerical control box. The computer programming control technology and a human-computer interface are adopted by the machine, a chain wheel on the servomotor drives a chain wheel on the ball screw through a chain, so that the connecting seat on the ball screw drives the numerical control moving head to advance and retreat in the longitudinal direction to realize mobile cutting; the rotary die holder on the numerical control moving head driven by the step motor can rotate 360 DEG; layout and blanking are carried out digitally; and the computer controls a hydraulic system to push the guide post on the oil cylinder to drive a balance mechanism, so that the upper workbench drives the numerical control moving head ascend and descend to realize automatic cutting. The machine has quick response, high precision, stable mechanical properties, low failure rate, high automation degree, and high production efficiency without waste and ungraded product, is convenient and safe to operate, and obviously saves energy.

Owner:陆存林

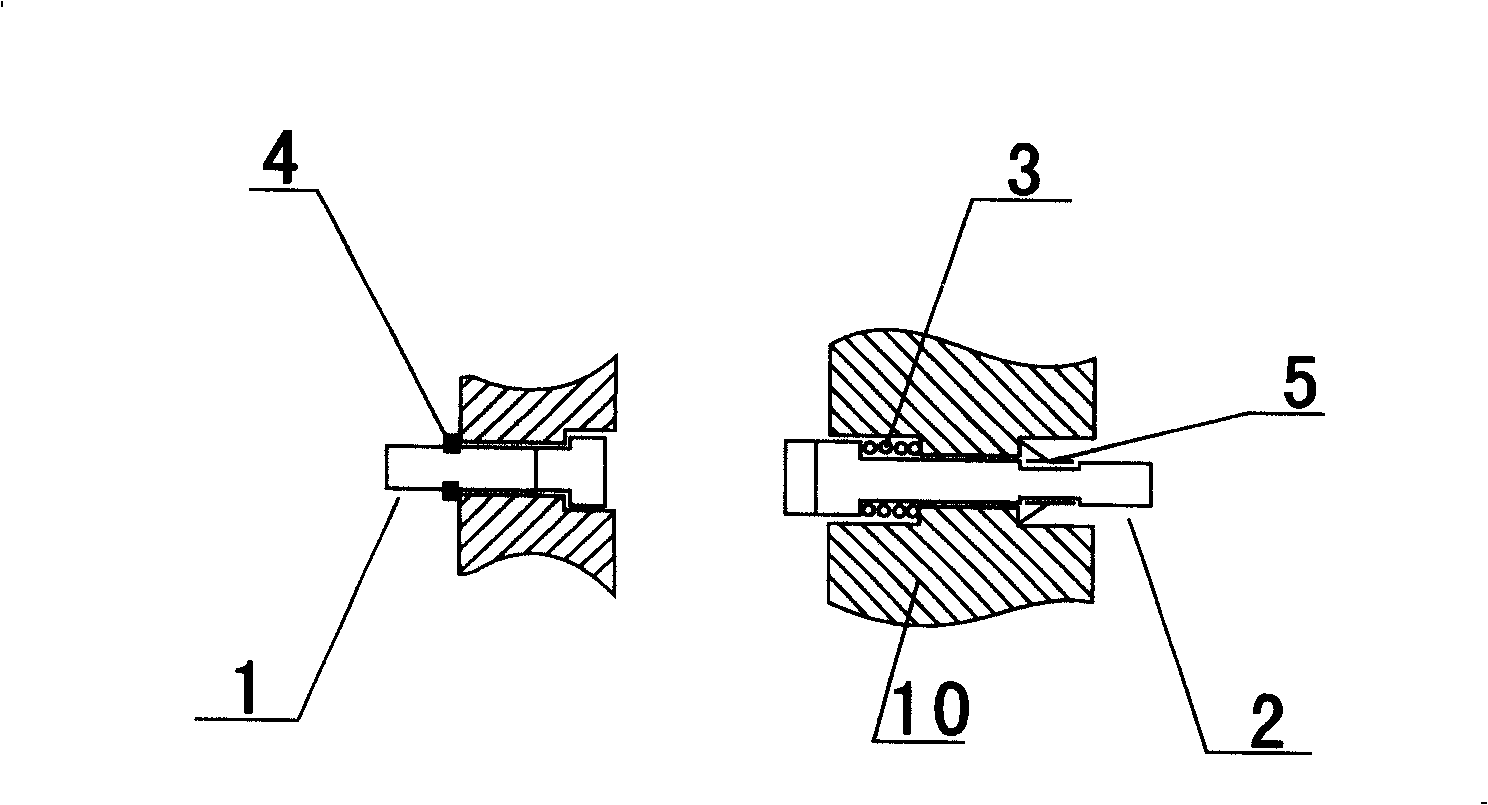

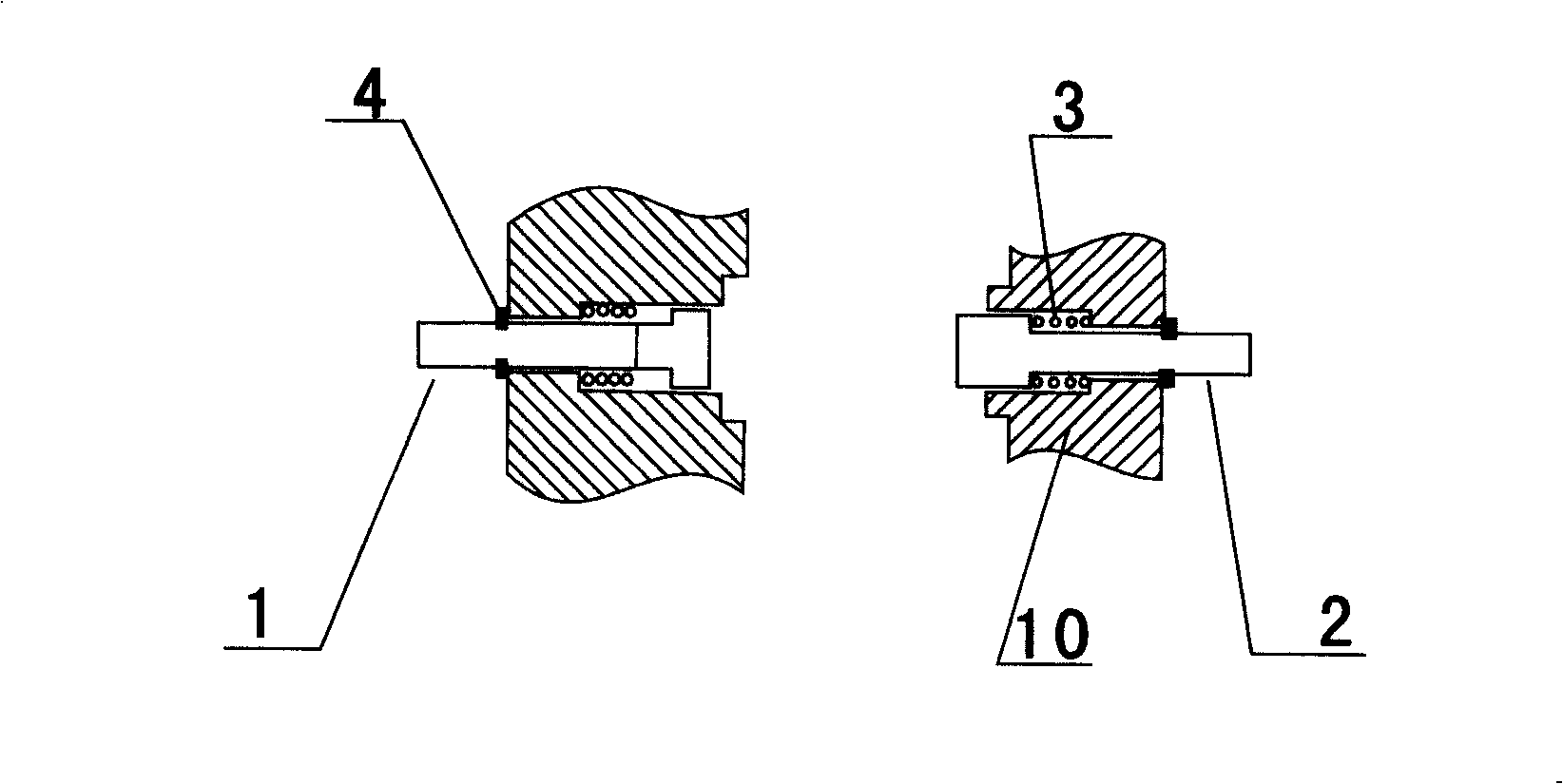

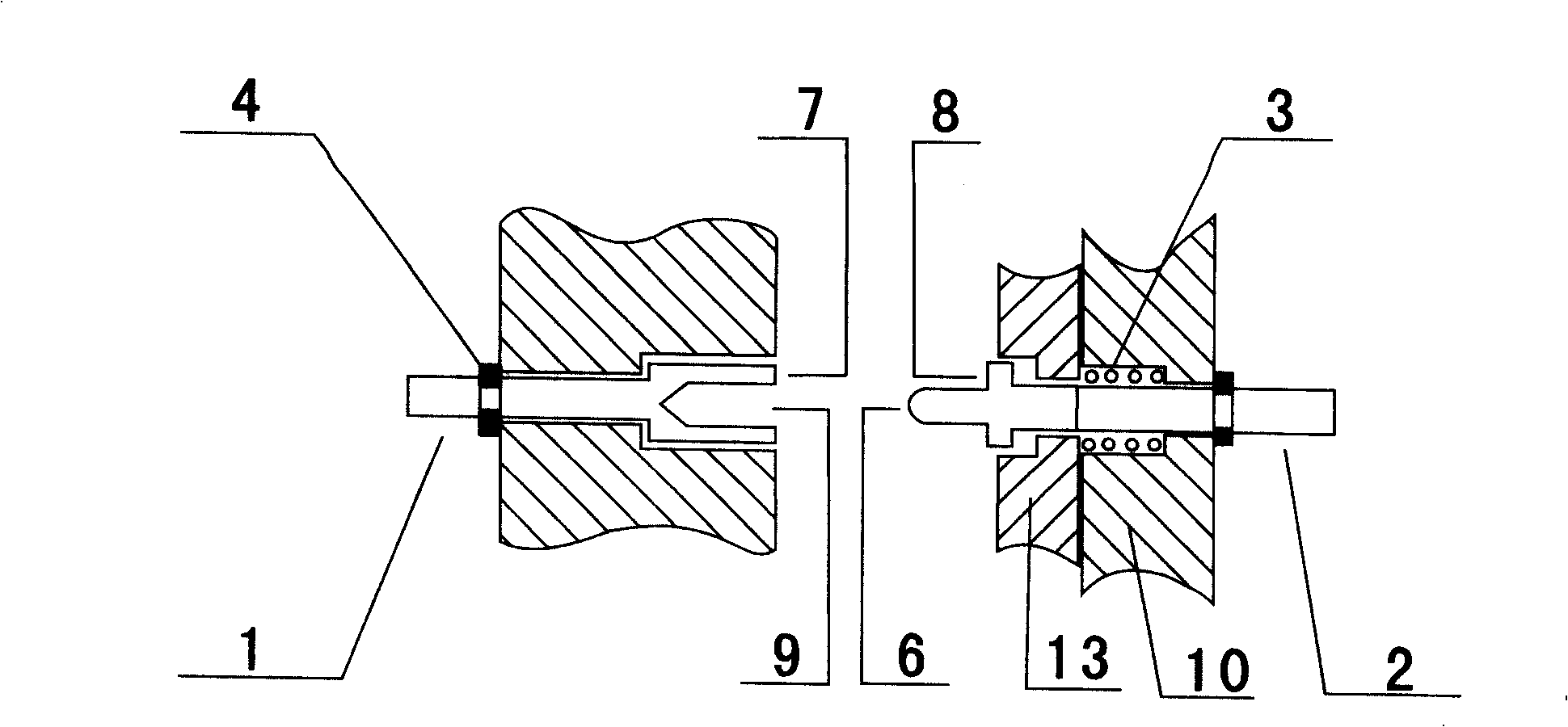

Axial elastic force-applying connection method for electric connector contact pair

InactiveCN101355208AEmission reductionSimple structureCoupling contact membersRelative displacementElectrical resistance and conductance

The invention provides a method for the axial elastic force application connection of electrical connector contact pairs. The method adopts an elastic element to apply axial external force to a contact pair consisting of a contact piece A (1) and a contact piece B (2), so as to combine the two tightly, thereby forming the electric connection with lower conductive resistance. One end of the elastic element is in contact with an insulating base so as to turn into a relative fixed end; and the other end of the elastic element directly acts on a preset fixed end face of an electric conductor contact piece, and is a relative displacement end during axial force application. The contact pair is independently formed by the end planes of the two contact pieces with simple structure. As axial elastic connection can not be affected by shock or other external factors, the connection reliability is higher. The contact pair can be formed by a positive contact piece and a negative contact piece as well, which ensures that the radial and axial directions of the contact pair are uniform in stress and contact.

Owner:徐志

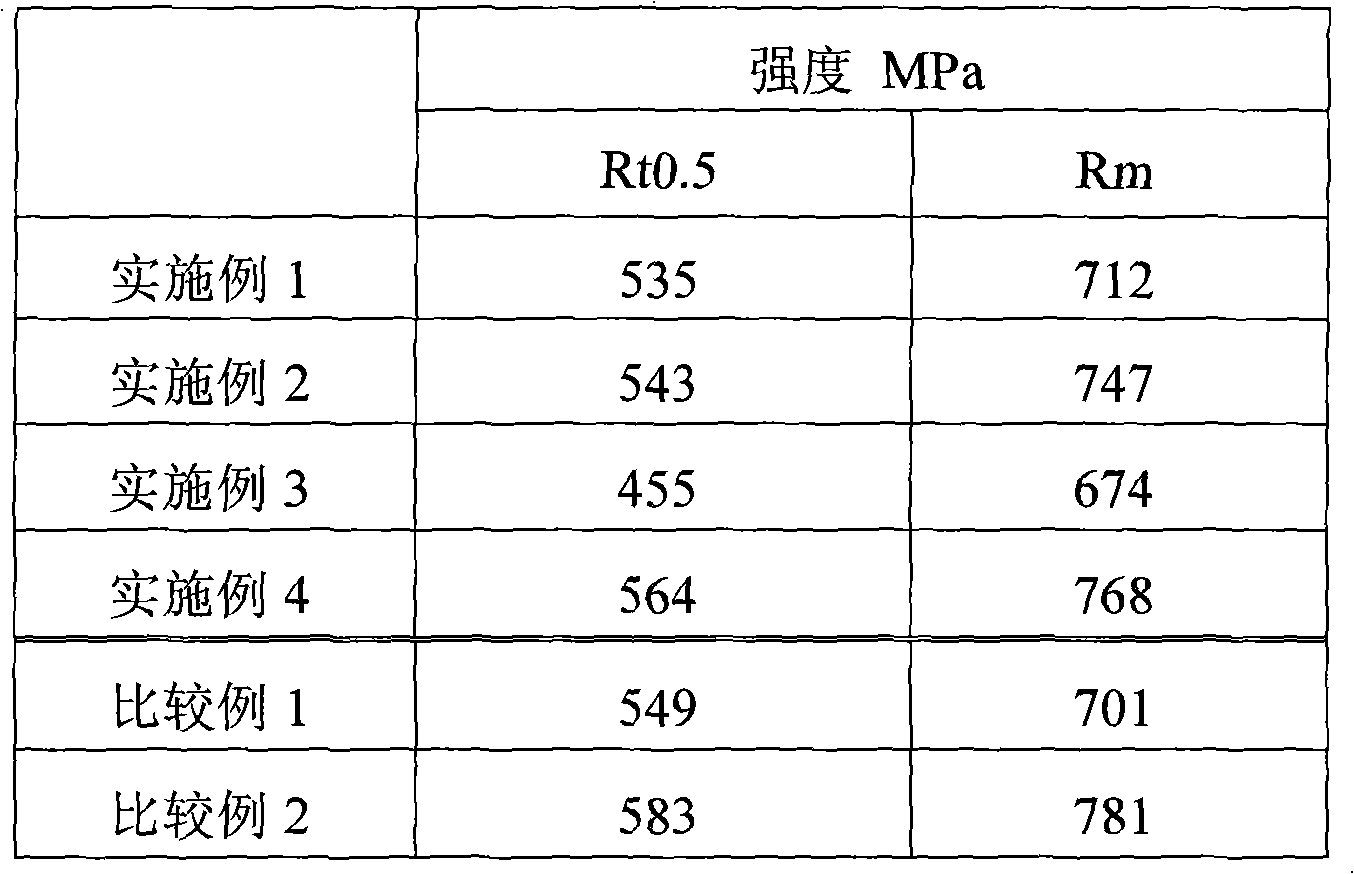

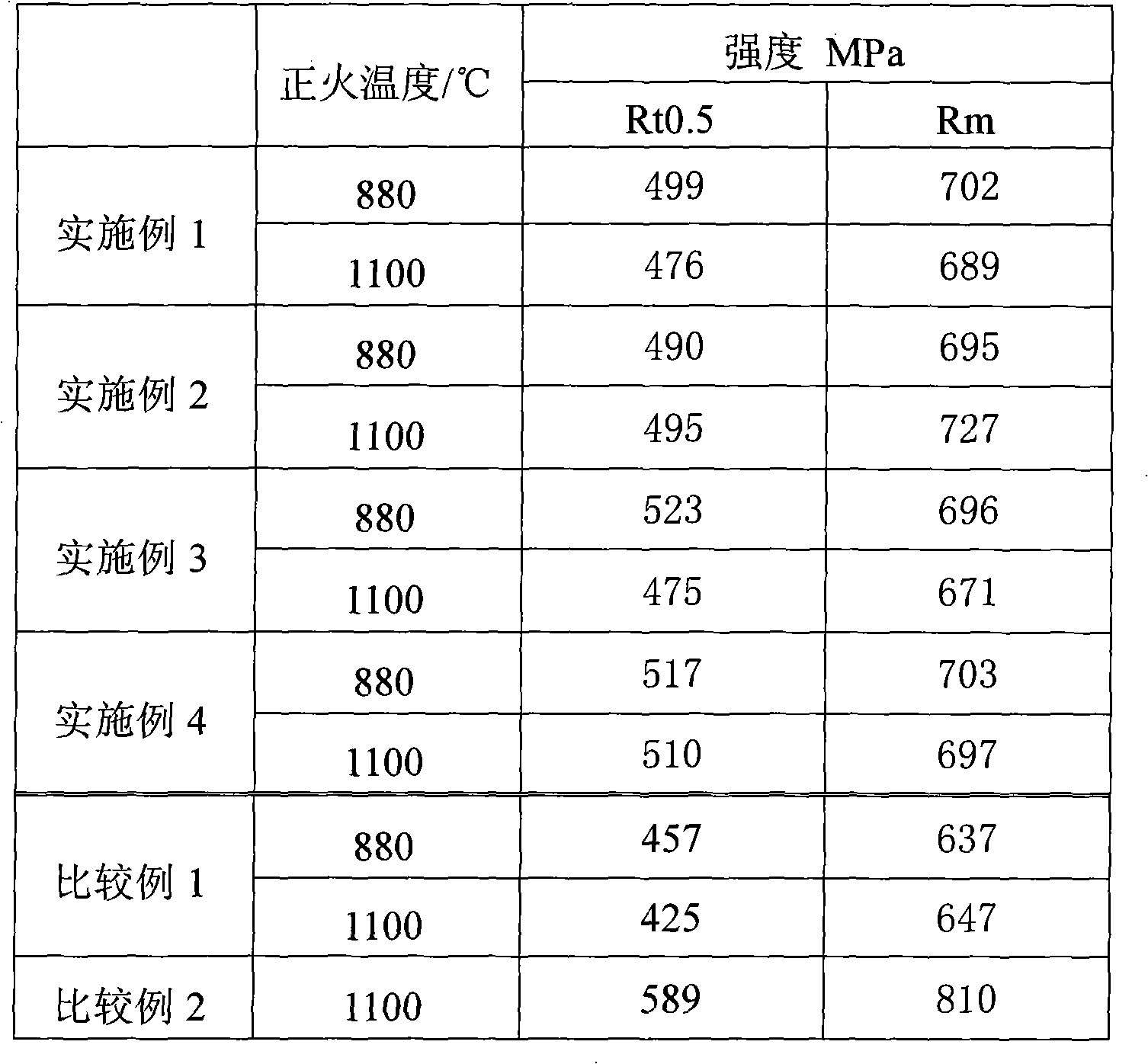

Normalized steel for resistance welding petroleum case pipe with low yield ratio, resistance welding casing tube and its manufacturing method

ActiveCN101270438ASimple processStable mechanical propertiesDrilling rodsTemperature control devicePetroleumCalcium

The invention provides an air hardening steel for oil casing with low yield ratio electrical resistance welding (ERW), an oil casing with low yield ratio electrical resistance welding which is made of the air hardening steel and a preparation method of oil casing. The components of the air hardening steel for oil casing with low yield ratio electrical resistance welding (ERW) in weight percent comprises: 0.19 to 0.29 percent of Carbon, 0.1 to 0.4 percent of Silicon, 1.0 to 1.3 percent of Manganese, less than or equal to 0.015 percent of Phosphorus, smaller than 0.008 percent of Sulfur, 0.002 to 0.04 percent of Aluminum, 0.001 to 0.01 percent of Calcium, 0.08 to 0.14 percent of Vanadium, the remaining part is Ferrum and other inevitable purities. The air hardening steel of the chemical proportion is adopted, continuously casted to form blank, the normalizing heat treatment is carried out for the entire casing after ERW of casing, and then the oil casing with low yield ratio electrical resistance welding of the invention is fabricated out. The yield strength of the oil casing is between 379 to 552 Megapascal, the tensile strength is greater than or equal to 655 Megapascal, and the oil casing has the moderate carbon equivalent and the stable mechanical property of the entire casing.

Owner:BAOSHAN IRON & STEEL CO LTD

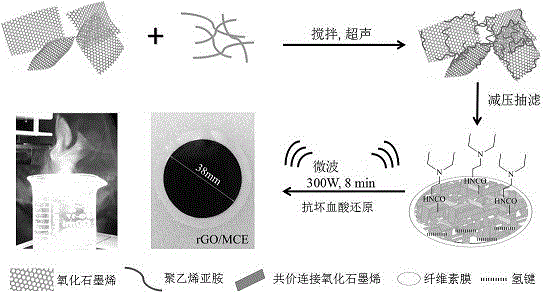

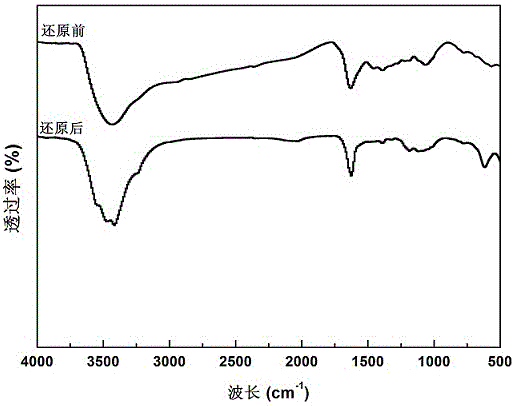

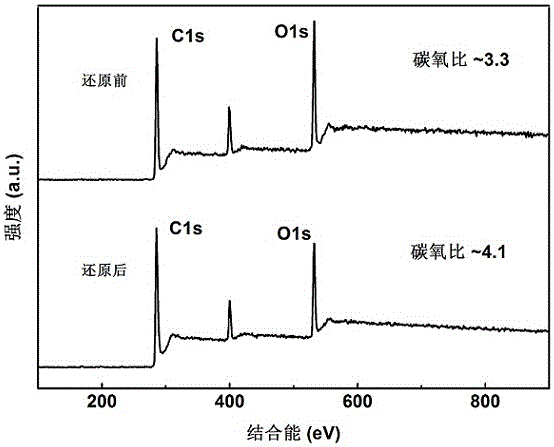

Reusable reduced graphene oxide-based photothermal conversion film and preparation method thereof

InactiveCN106744831AReduce usageEnhanced light absorptionSolar heating energySolar heat devicesCelluloseFiltration

The invention relates to a reusable reduced graphene oxide-based photothermal conversion film and a preparation method thereof. The method comprises the steps of firstly connecting a graphene oxide sheet by adopting a crosslinking agent under the action of agitation and ultrasound and then carrying out vacuum suction filtration on the mixed dispersion liquid to a mixed cellulose filter film; and quickly reducing the prepared graphene oxide / mixed cellulose film by using a reducing agent under a microwave assist to obtain the reduced graphene oxide-based double-layer photothermal conversion film. A steam performance test shows that the reduced graphene oxide-based double-layer photothermal conversion film achieves 60% of steam conversion efficiency under illumination of 1Kw / m<2>. A cyclic test result shows that the reduced graphene oxide-based double-layer photothermal conversion film still keeps the stable performance after repeated experiments for 30 times. The prepared photothermal conversion film is capable of directly converting solar energy into steam energy, is high in photothermal conversion efficiency, wide in application prospect, simple in preparation technology and low in cost, and has excellent mechanical stability and reusability.

Owner:HUBEI UNIV

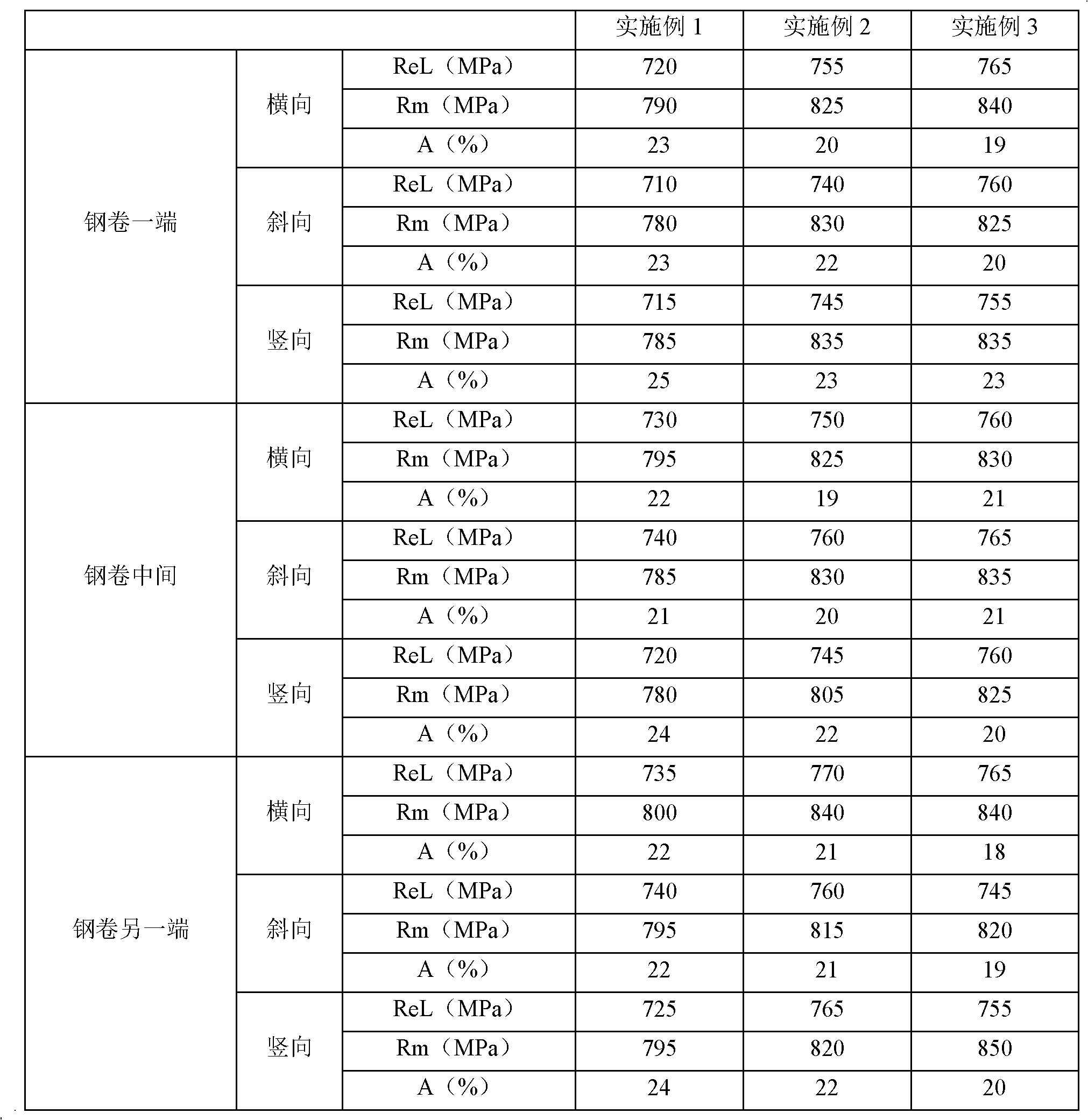

Hot rolling steel plate for automobile girder, and manufacturing method thereof

The present invention provides a manufacturing method of a hot rolling steel plate for an automobile girder. The production method comprises a steelmaking step, a continuous casting step, a heating step, a hot continuous rolling step and a coiling step, and is characterized in that components of the molten steel after steelmaking comprise 0.05-0.1 wt% of C, 0.15-0.35 wt% of Si, 1-2 wt% of Mn, 0.01-0.1 wt% of Nb, 0.03-0.12 wt% of Ti, less than or equal to 0.025 wt% of P, less than or equal to 0.01 wt% of S, and the balance of Fe and unavoidable impurities, a finish rolling temperature in the hot continuous rolling step is 830-900 DEG C, and a coiling temperature is 600-700 DEG C. The present invention further provides the hot rolling steel plate prepared by using the method and provided for the automobile girder. With the manufacturing method, production cost is reduced, and rolling process control is simple. With the hot rolling steel plate for the automobile girder, hot rolling product structures are substantially enriched and improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Rotary swaging forming method for automobile aluminum alloy wheel hubs

The invention relates to a rotary swaging forming method for automobile aluminum alloy wheel hubs. By utilizing the capability of deformation allowance of a material under a certain temperature, and by the aid of the rotary swaging forming method, an aluminum alloy material is forced to form a shape according to a preset mould shape. The rotary swaging forming method includes: preparing a rough material, cleaning, preheating the rough material (enabling the rough material to be semi-solid), forging and pressing to form a shape, expanding an opening, and rotating and pressing to form a shape. The automobile aluminum alloy wheel hubs manufactured by the rotary swaging forming method are high in yield and stable in mechanical property, mechanical processing quantity and energy consumption for the wheel hubs are obviously lowered, raw material is saved, and production efficiency is improved.

Owner:金刚

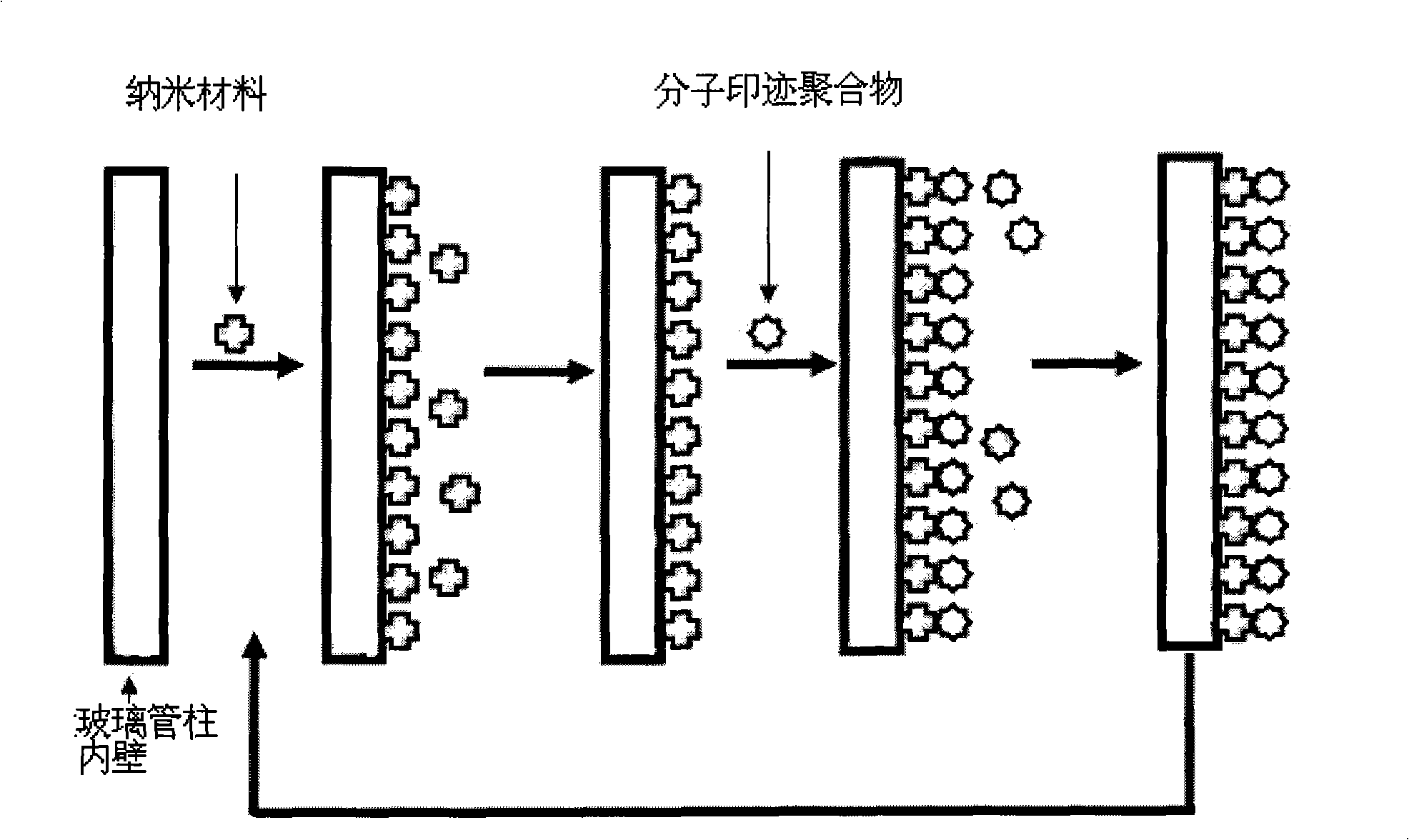

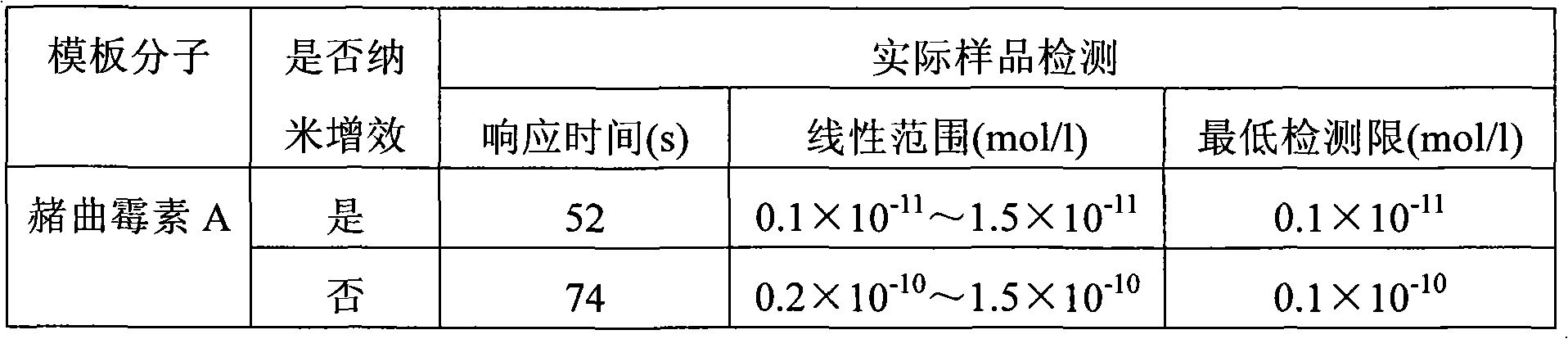

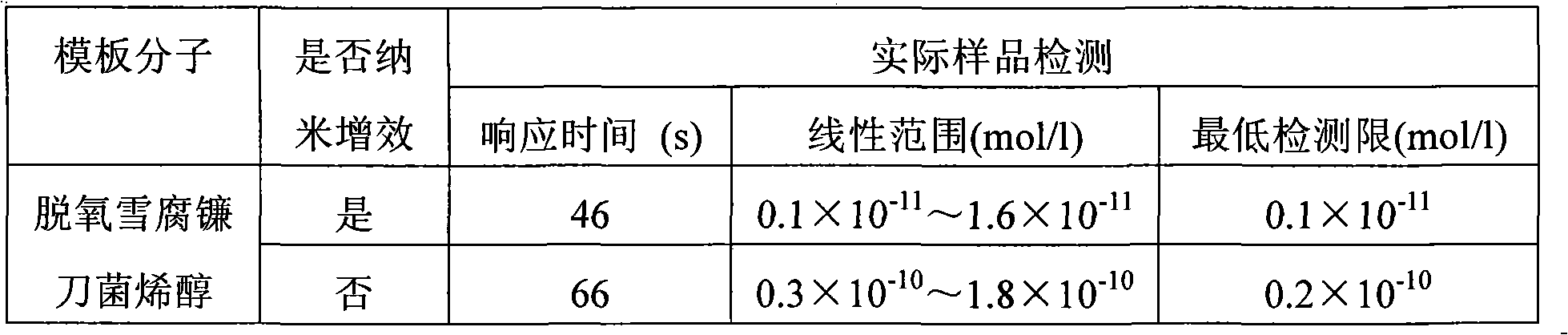

Trace amount mycotoxins molecular blotting column preparation method and application

InactiveCN101308066AIncreased sensitivityExpand the scope of detectionComponent separationChemiluminescene/bioluminescenceCross-linkFunctional monomer

The invention discloses a process for preparing a trace amount mycotoxin molecular imprinted column, which comprises the following steps of: selecting a functional monomer; evenly mixing a mycotoxin template molecule, the functional monomer, a cross-linking agent, a pore-forming agent, an initiator and an organic solvent by a certain molar ratio to prepare a molecular imprinting polymer solution; preparing a nano-solution; and dressing the nano-material and a molecular imprinting polymer on the internal surface of a glass pipe column. A method for detecting the trace amount mycotoxins includes: pumping a chemiluminescence system solution and a sample solution into a chemiluminescence analyzer respectively and detecting the mycotoxins in the sample. The molecular imprinted column of the invention has advantages of high sensitivity and accuracy. The nano-enhanced trace amount mycotoxin molecular imprinted column obtained in the invention is connected to the chemiluminescence analyzer for detecting mycotoxins, and purposes of high specificity, high sensitivity and fast detection to mycotoxins in the sample can be realized.

Owner:UNIV OF JINAN

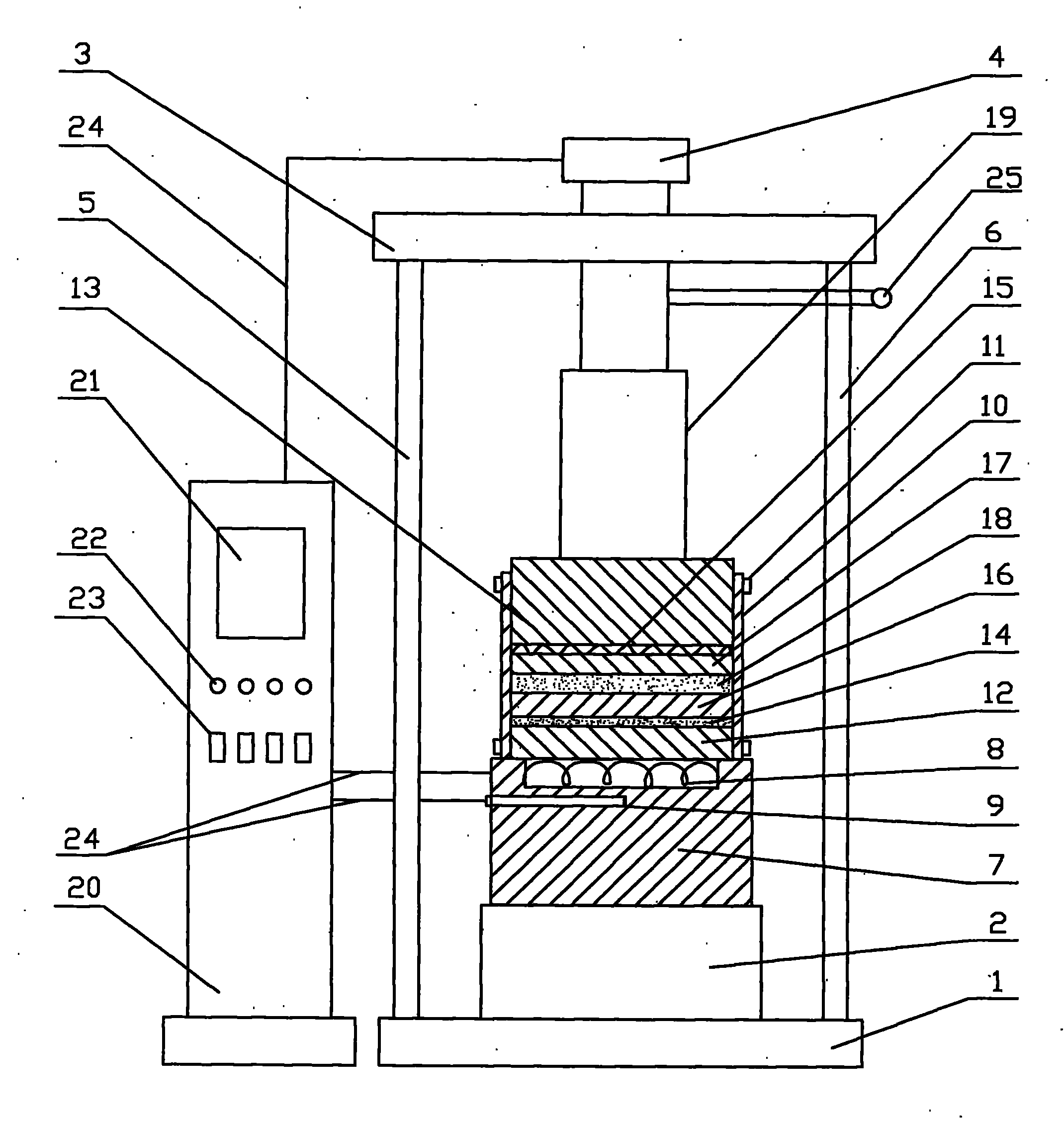

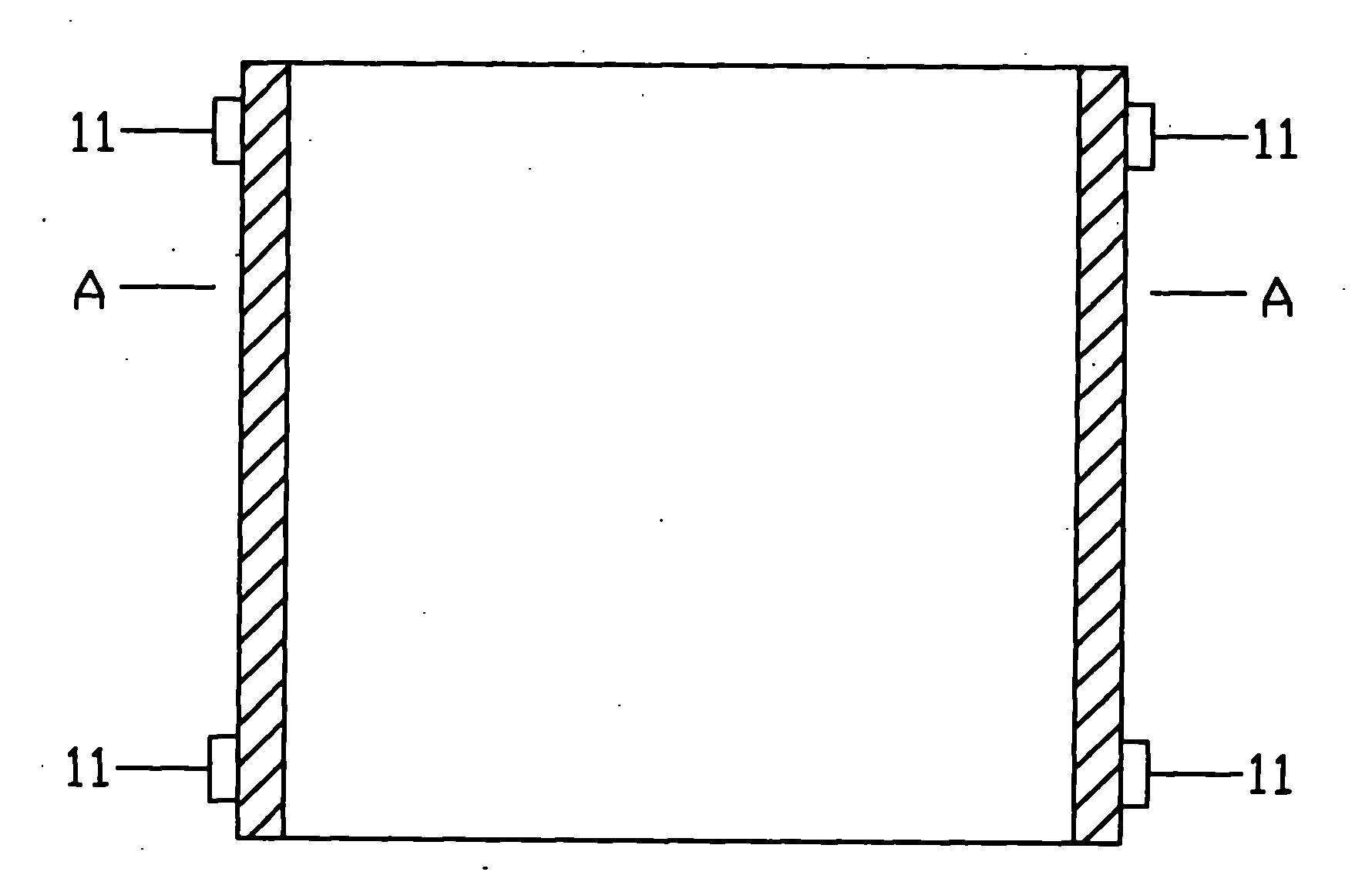

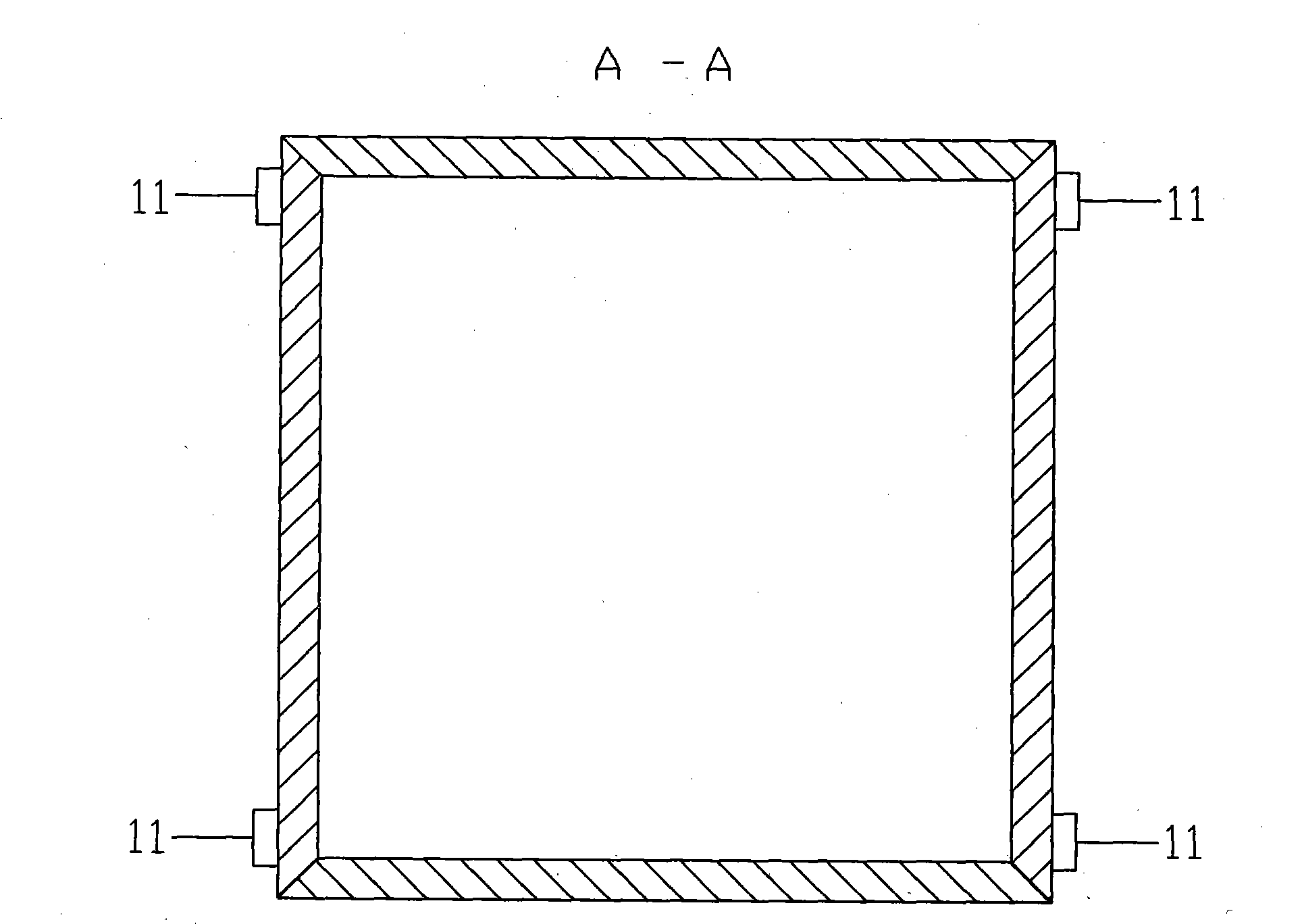

Preparation method of magnesium-aluminum layered composite plate

InactiveCN102166846AStable mechanical propertiesImprove corrosion resistanceLaminationLamination apparatusAlloyComposite plate

The invention relates to a preparation method of a magnesium-aluminum layered composite plate, aiming at solving the problems that the magnesium-aluminum alloy plate is light in weight, low in strength and poor in corrosion resistance. The method comprises the steps of: pressing and labeling a layer of aluminum plate on the magnesium-aluminum alloy plate; taking magnesium-aluminum eutectic alloy powder as a pressing and labeling material; pressing and labeling the magnesium-aluminum alloy plate+the magnesium-aluminum eutectic alloy powder+the aluminum plate into a magnesium-aluminum layered composite plate in an open-close through groove mould on a press machine under the temperature of 480 DEG C and the pressure of 30M Pa for 60s; and performing the low-temperature thermal treatment, so that an internal metallographic phase tissue of the magnesium-aluminum layered composite plate is more compact and stable. The method is advanced and reasonable, small in use equipment, short in technological process, and fast in speed. The mechanical property tensile strength of the magnesium-aluminum layered composite plate can reach 24MPa. Compared with the prior art, the mechanical property tensile strength can be improved by 95%, and the corrosion resistant performance can be improved by 94%, therefore, the preparation method of the magnesium-aluminum layered composite plate is very ideal.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com