Reusable reduced graphene oxide-based photothermal conversion film and preparation method thereof

A light-to-heat conversion, graphene-based technology, applied in the field of preparation of nanocomposite materials, can solve the problems of assembly material stability limitation, non-reusability, heat energy loss, etc., achieve excellent local heat generation ability, improve vaporization Conversion efficiency, the effect of reducing the loss of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of graphene oxide: Mix 360ml of concentrated sulfuric acid and 40ml of concentrated phosphoric acid evenly and pour it into a three-necked flask filled with 3g of flake graphite. Under the condition of magnetic stirring at 50 ℃, slowly add 18g of potassium permanganate and continue stirring 12 hours; then after the mixture is cooled to room temperature, pour it into about 400ml of ice containing 3ml of 30% hydrogen peroxide, and continue to drop hydrogen peroxide until it does not change color; then the product is centrifuged to remove the supernatant, and the obtained product is washed , after ultrasonic stripping, flocculate with sodium hydroxide, dry at 20-80°C for 2-10 hours, and grind to obtain graphene oxide solid powder;

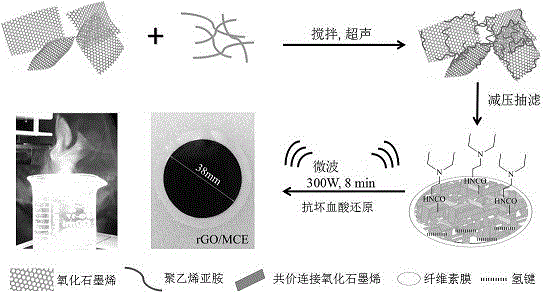

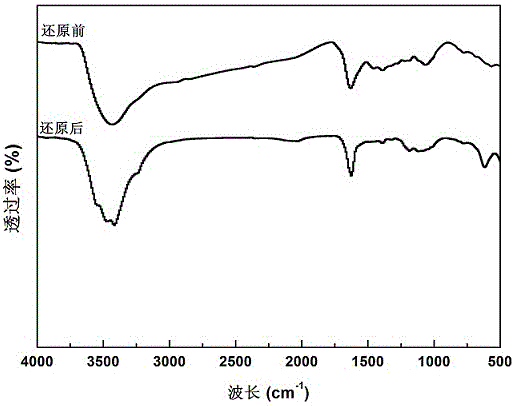

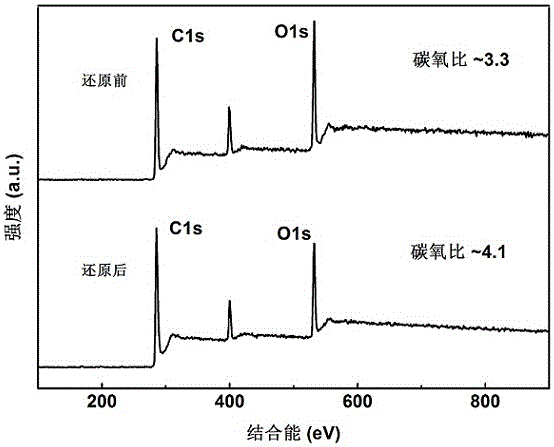

[0039] (2) Preparation of graphene oxide-based light-to-heat conversion film: add 20 mg graphene oxide and 0.5 g polyethyleneimine to 20 ml deionized water, stir the mixture magnetically at room temperature for 2 hours, then tran...

Embodiment 2

[0042] Press the preparation method of embodiment 1, just the usage amount of polyethyleneimine is adjusted to 0.2g or 0.6g by 0.5g, obtain as follows Figure 4 The results shown.

Embodiment 3

[0044] Press the preparation method of embodiment 1, just adjust polyethylenimine to polyvinylamine or polyacrylamide, obtain such as Figure 4 The results shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com