Patents

Literature

20197 results about "Hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydroxide is a diatomic anion with chemical formula OH⁻. It consists of an oxygen and hydrogen atom held together by a covalent bond, and carries a negative electric charge. It is an important but usually minor constituent of water. It functions as a base, a ligand, a nucleophile, and a catalyst. The hydroxide ion forms salts, some of which dissociate in aqueous solution, liberating solvated hydroxide ions. Sodium hydroxide is a multi-million-ton per annum commodity chemical. A hydroxide attached to a strongly electropositive center may itself ionize, liberating a hydrogen cation (H⁺), making the parent compound an acid.

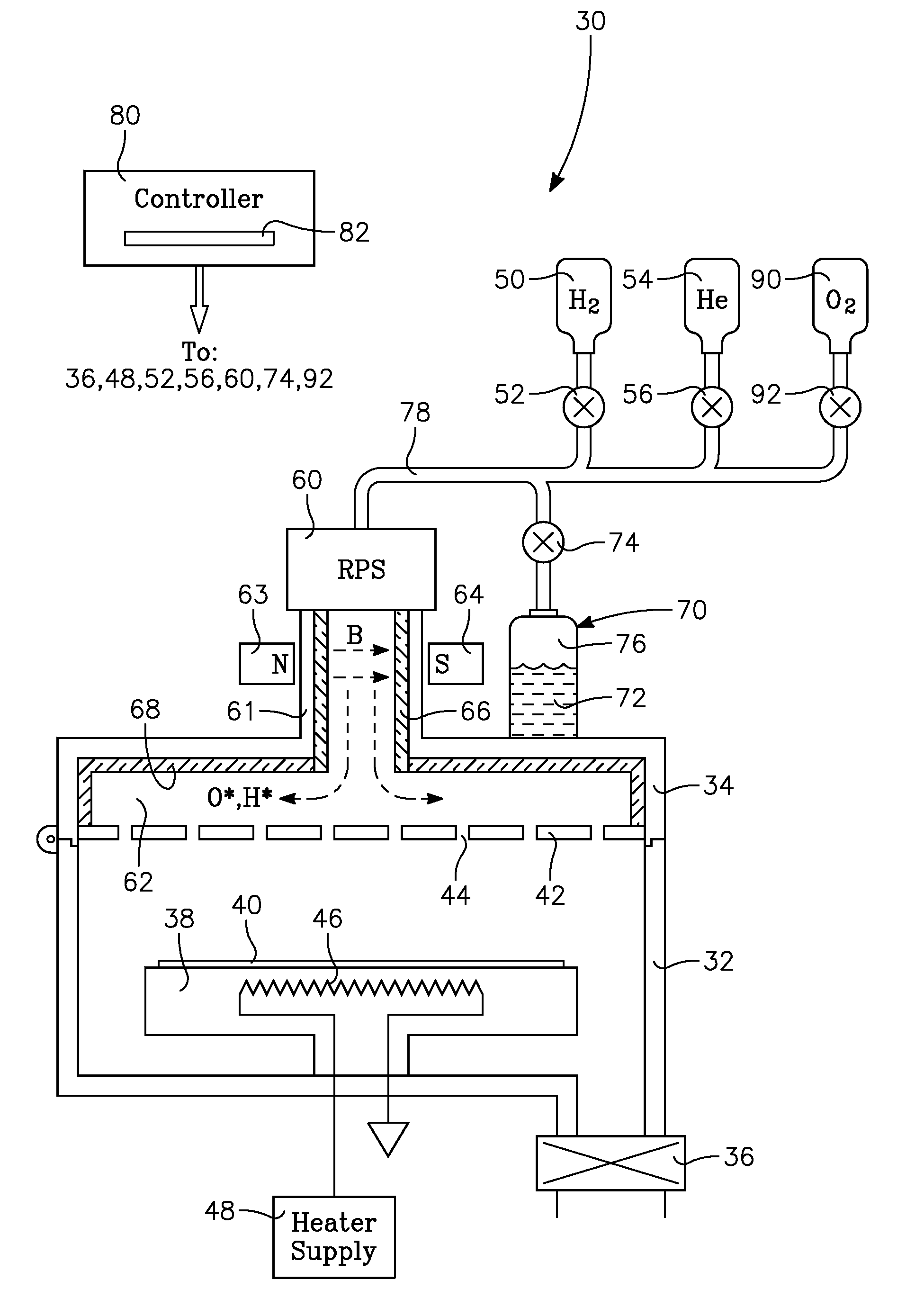

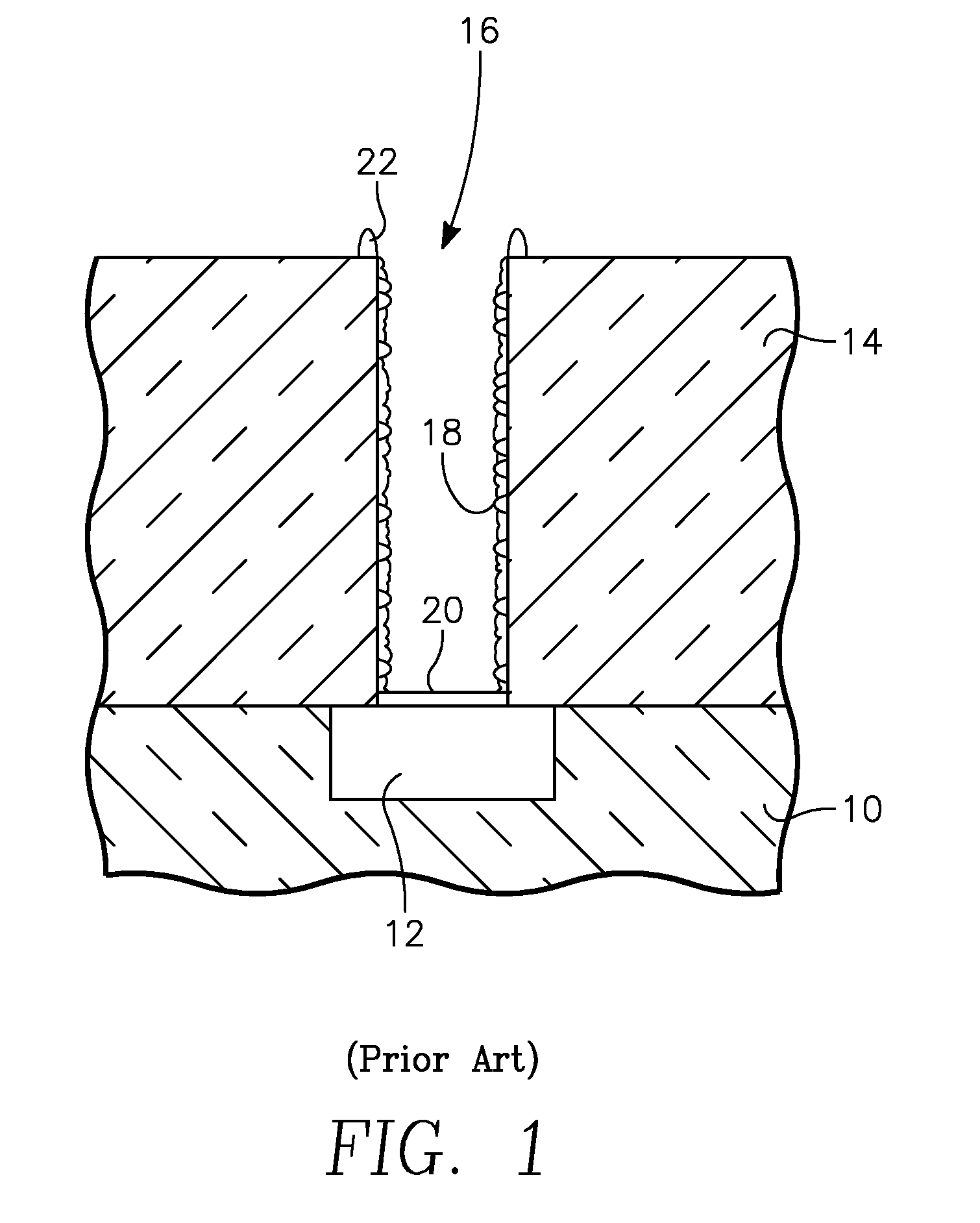

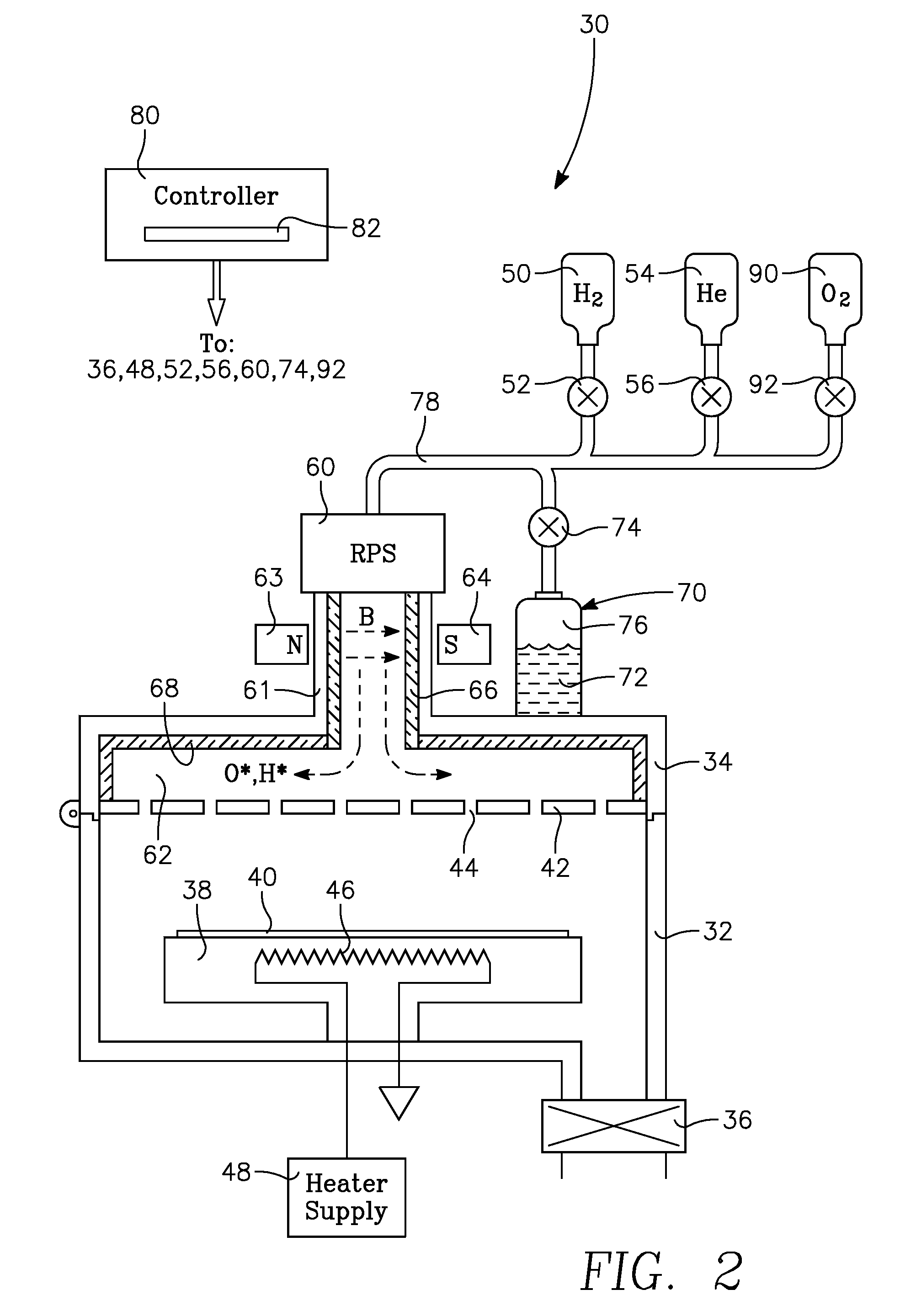

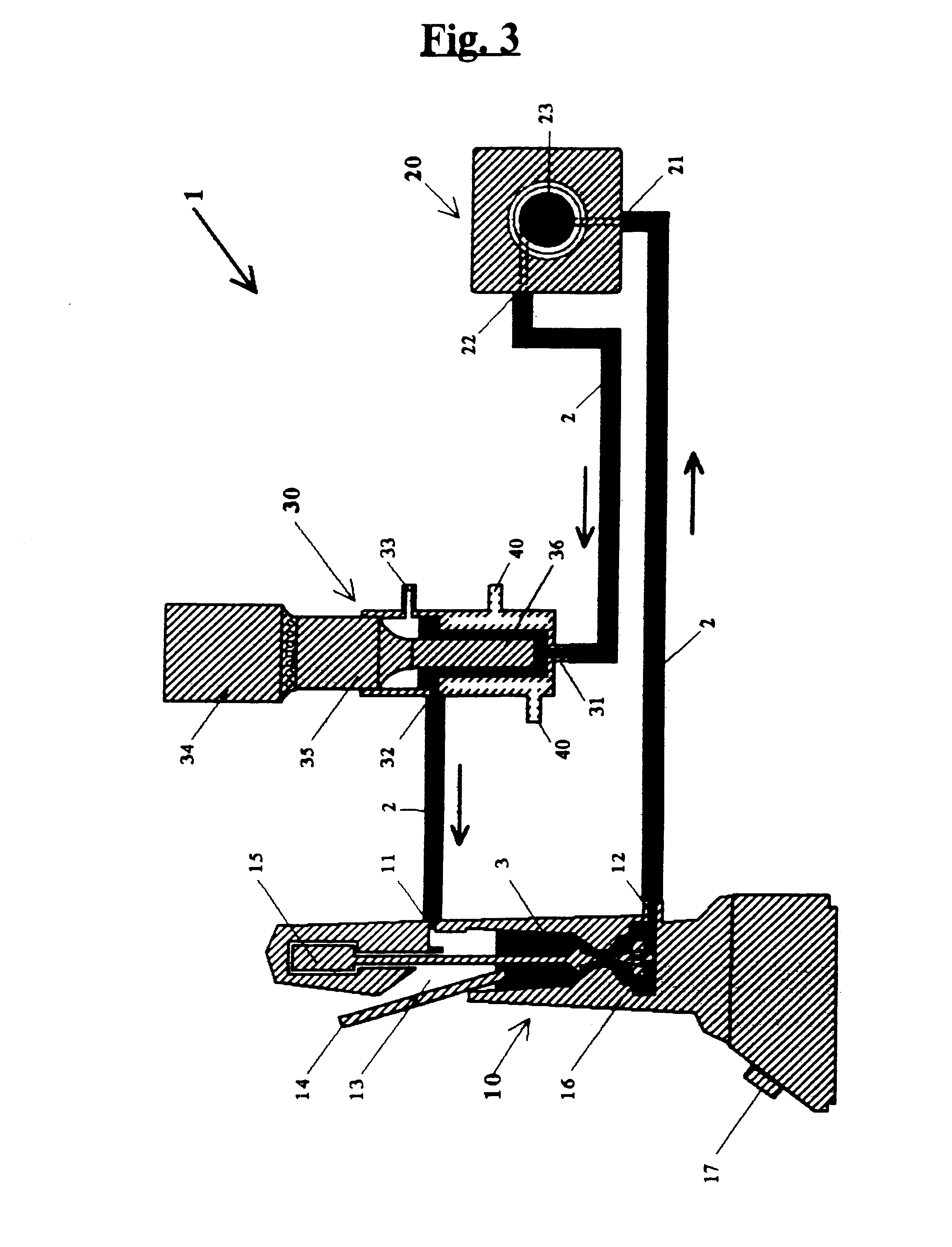

Remote Plasma Source for Pre-Treatment of Substrates Prior to Deposition

ActiveUS20090017227A1Electric discharge tubesSemiconductor/solid-state device manufacturingOxygenRefractory metals

A plasma processing chamber particularly useful for pre-treating low-k dielectric films and refractory metal films subject to oxidation prior to deposition of other layers. A remote plasma source (RPS) excites a processing gas into a plasma and delivers it through a supply tube to a manifold in back of a showerhead faceplate. The chamber is configured for oxidizing and reducing plasmas in the same or different processes when oxygen and hydrogen are selectively supplied to the RPS. The supply tube and showerhead may be formed of dielectric oxides which may be passivated by a water vapor plasma from the remote plasma source. In one novel process, a protective hydroxide coating is formed on refractory metals by alternating neutral plasmas of hydrogen and oxygen.

Owner:APPLIED MATERIALS INC

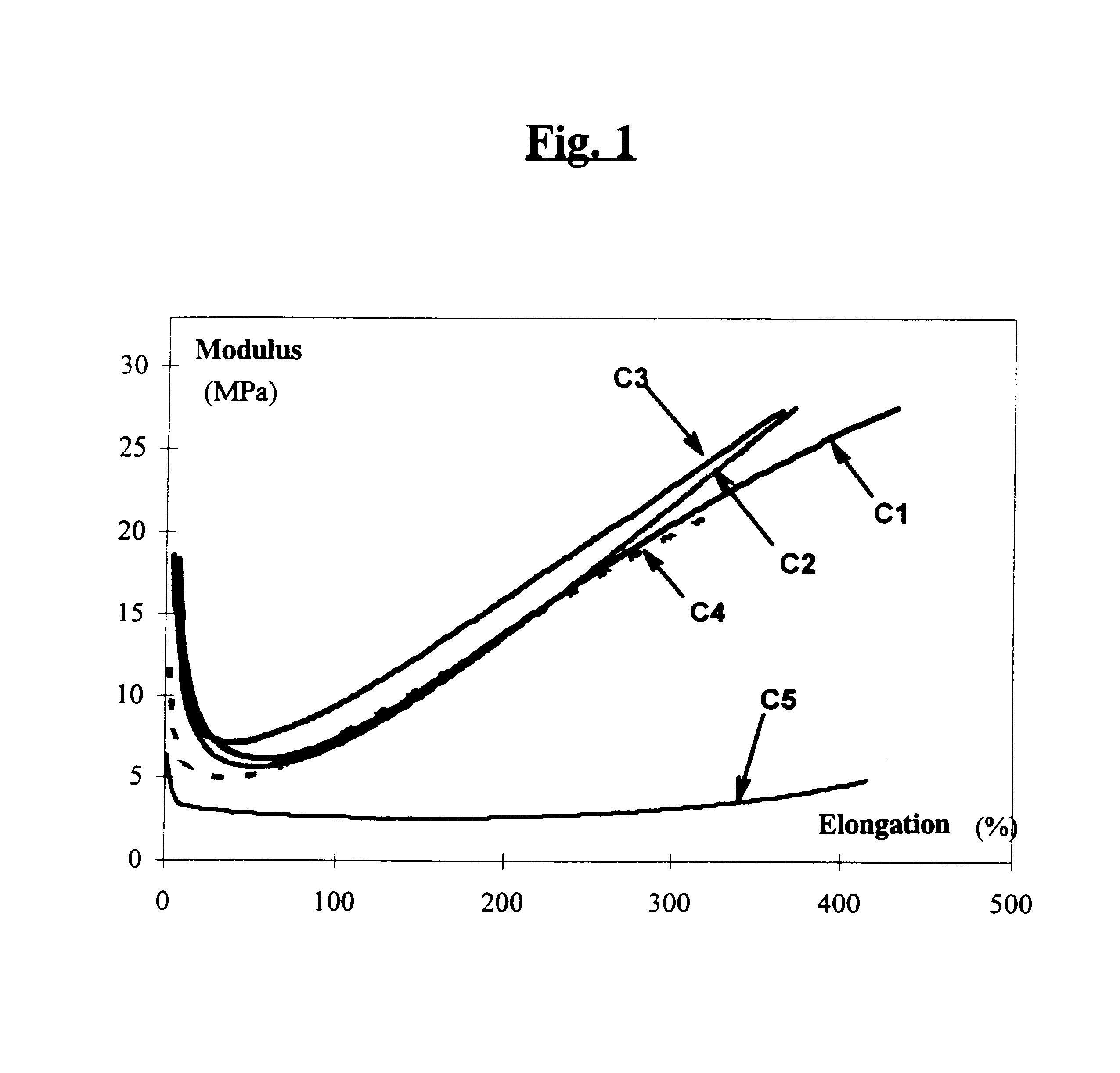

Reinforcing aluminum-based filler and rubber composition comprising such a filter

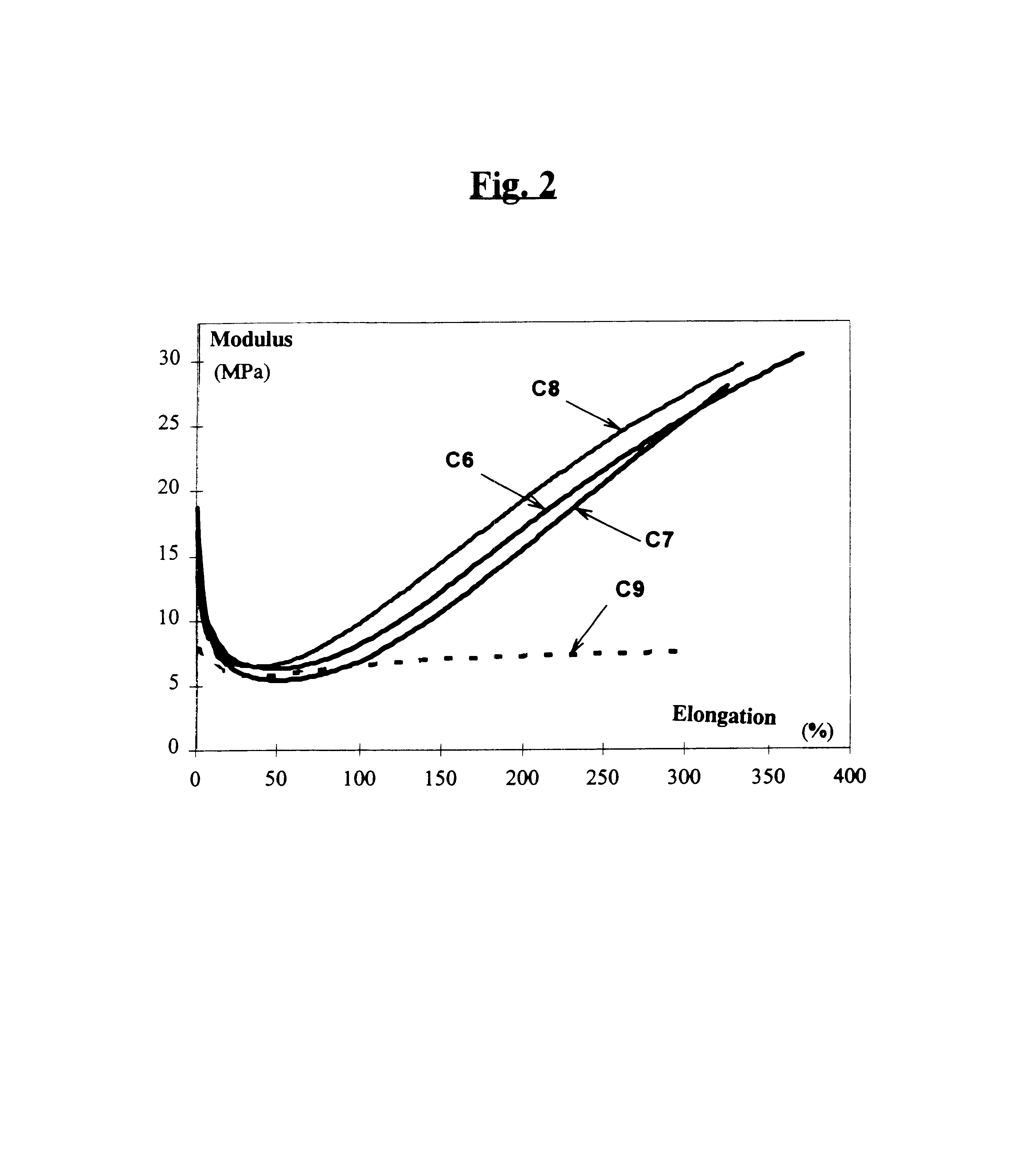

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers):the specific BET surface area of which is between 30 and 400 m2 / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10-3 mum-1 / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

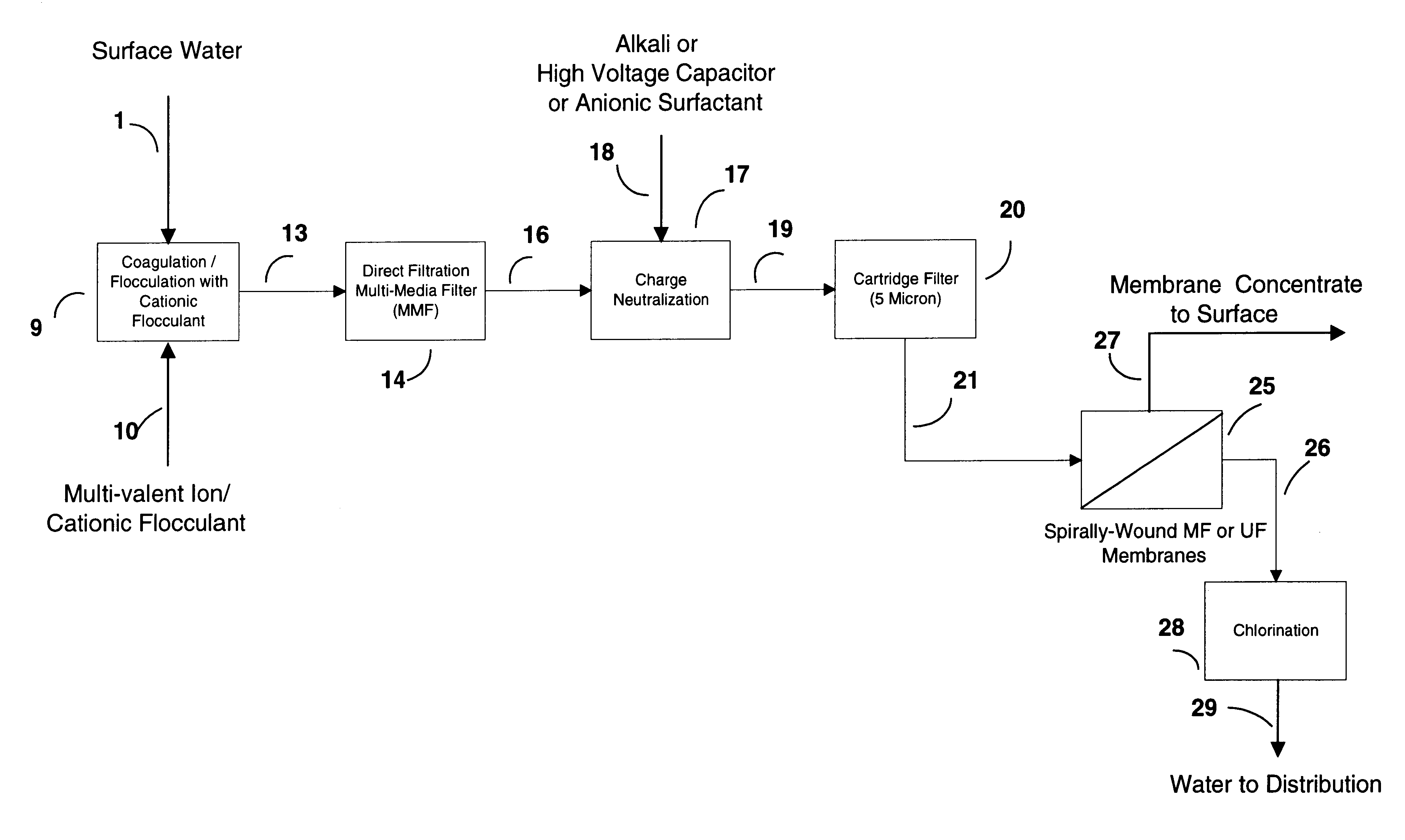

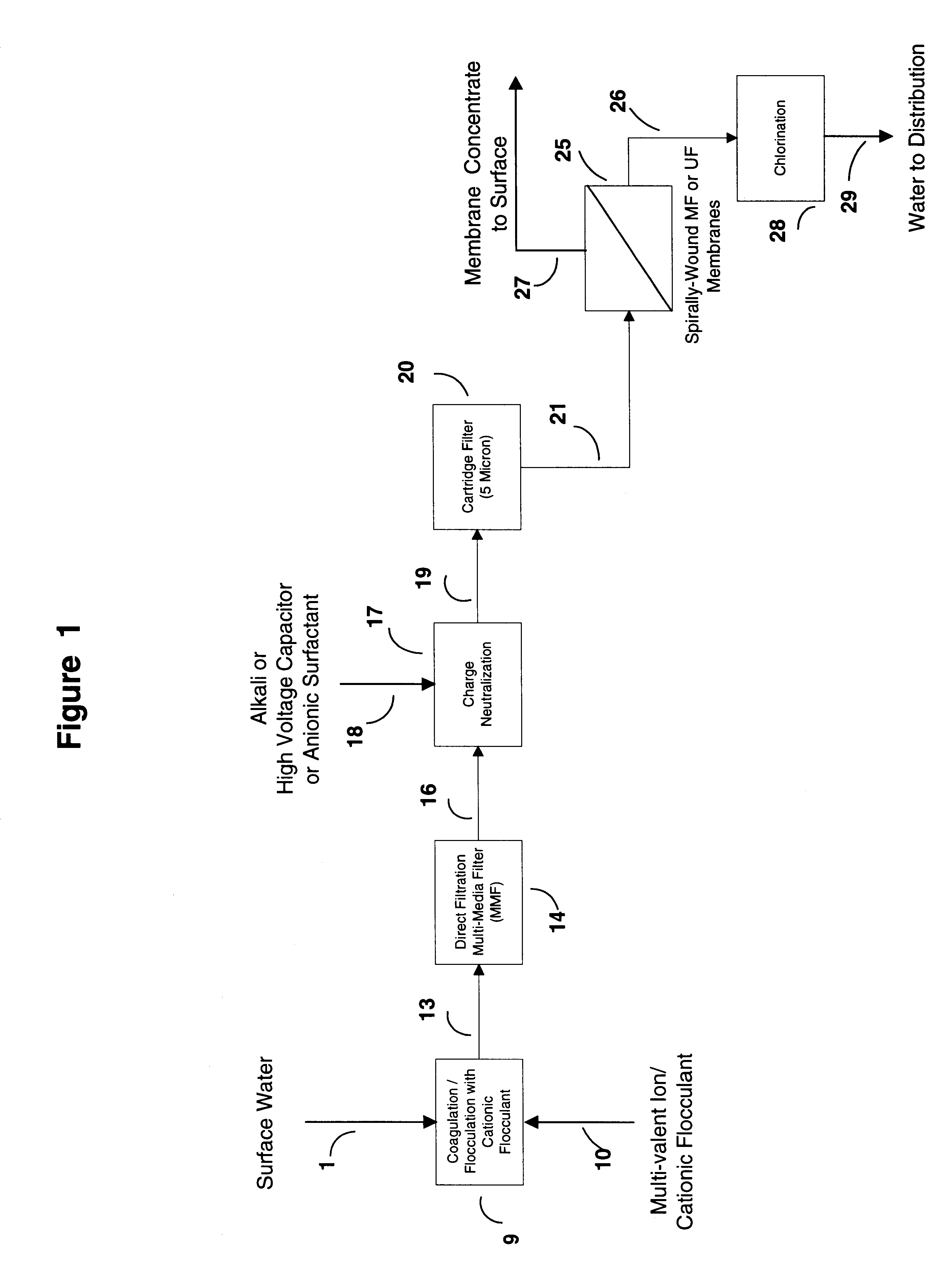

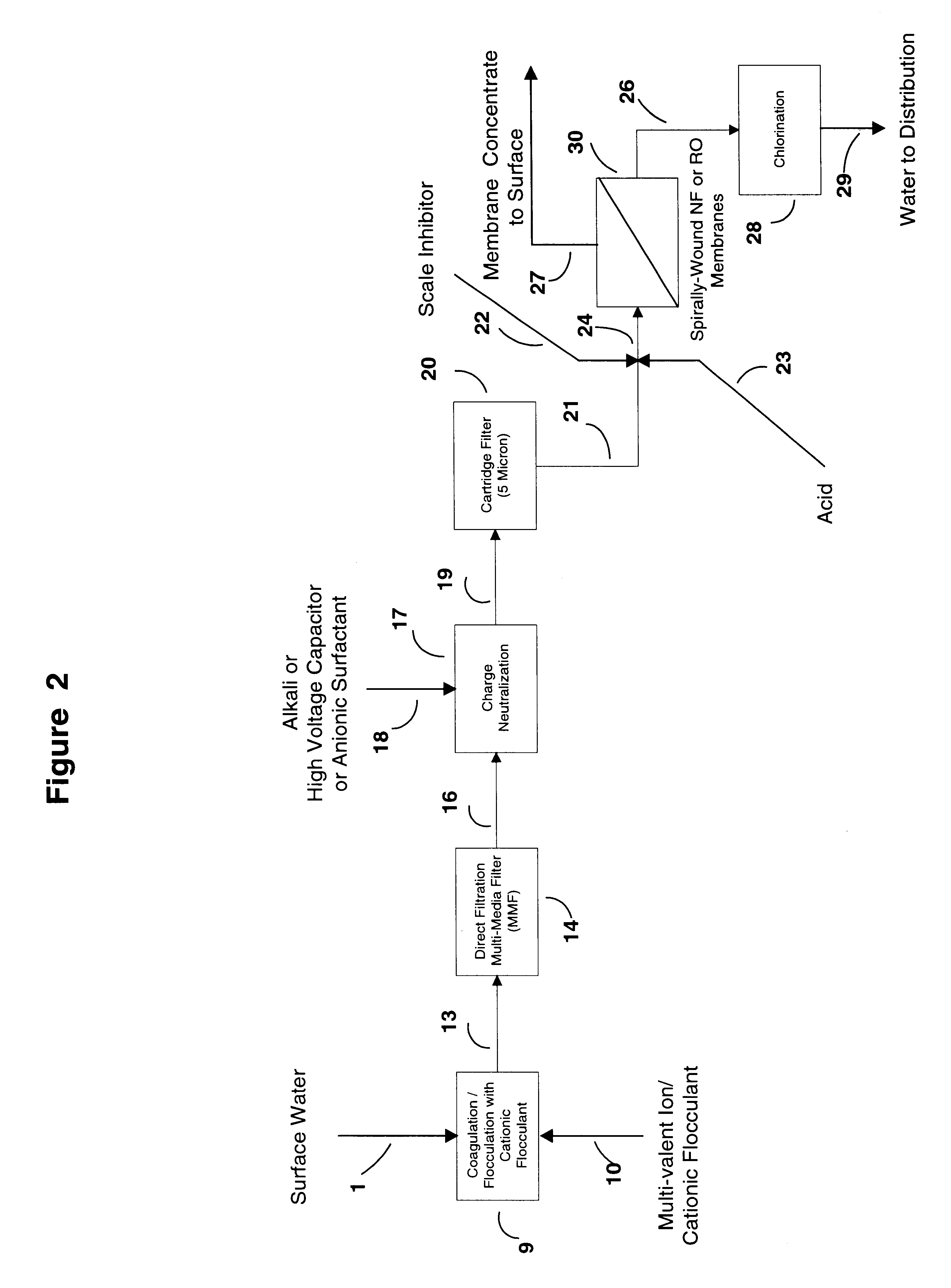

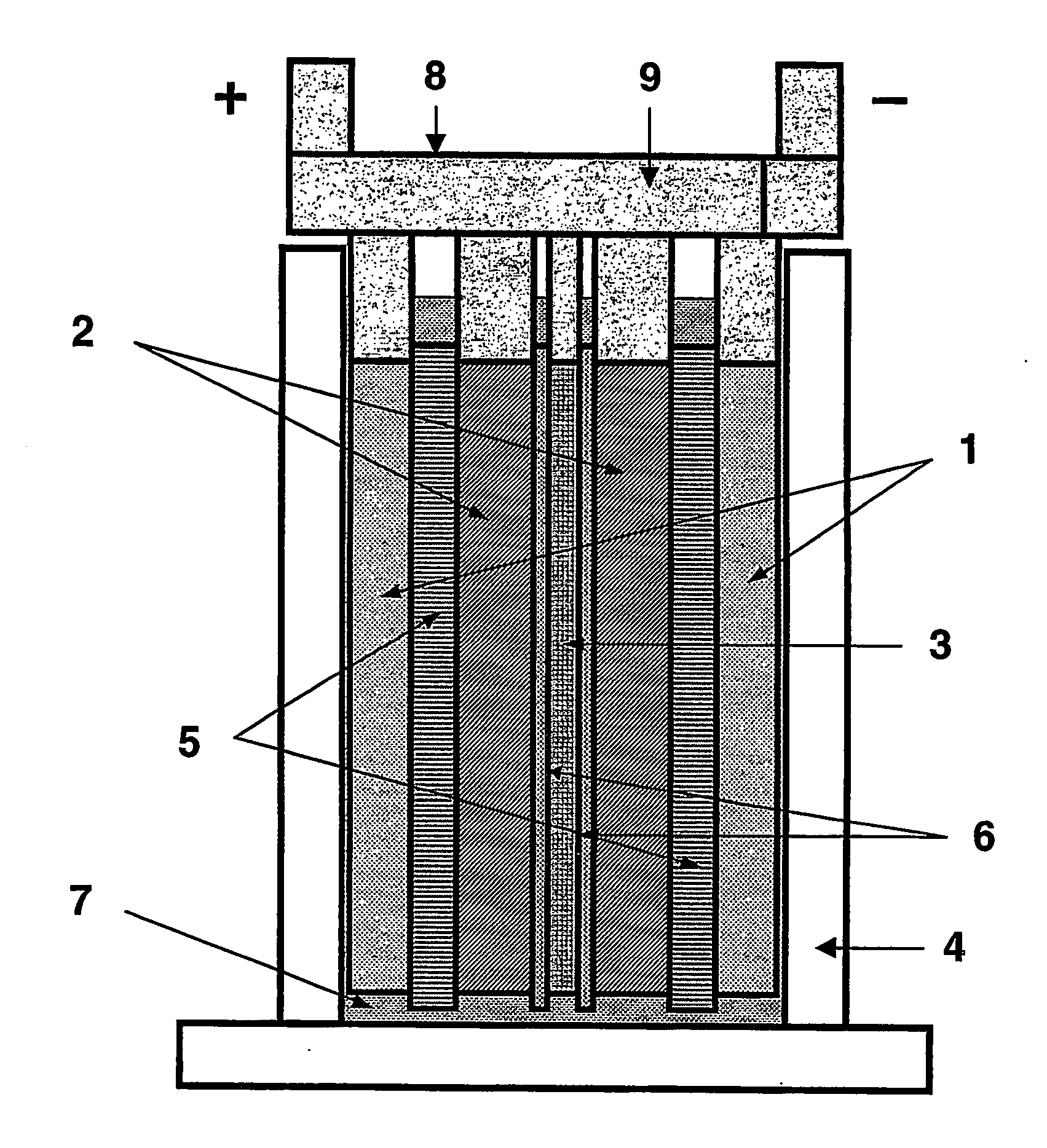

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

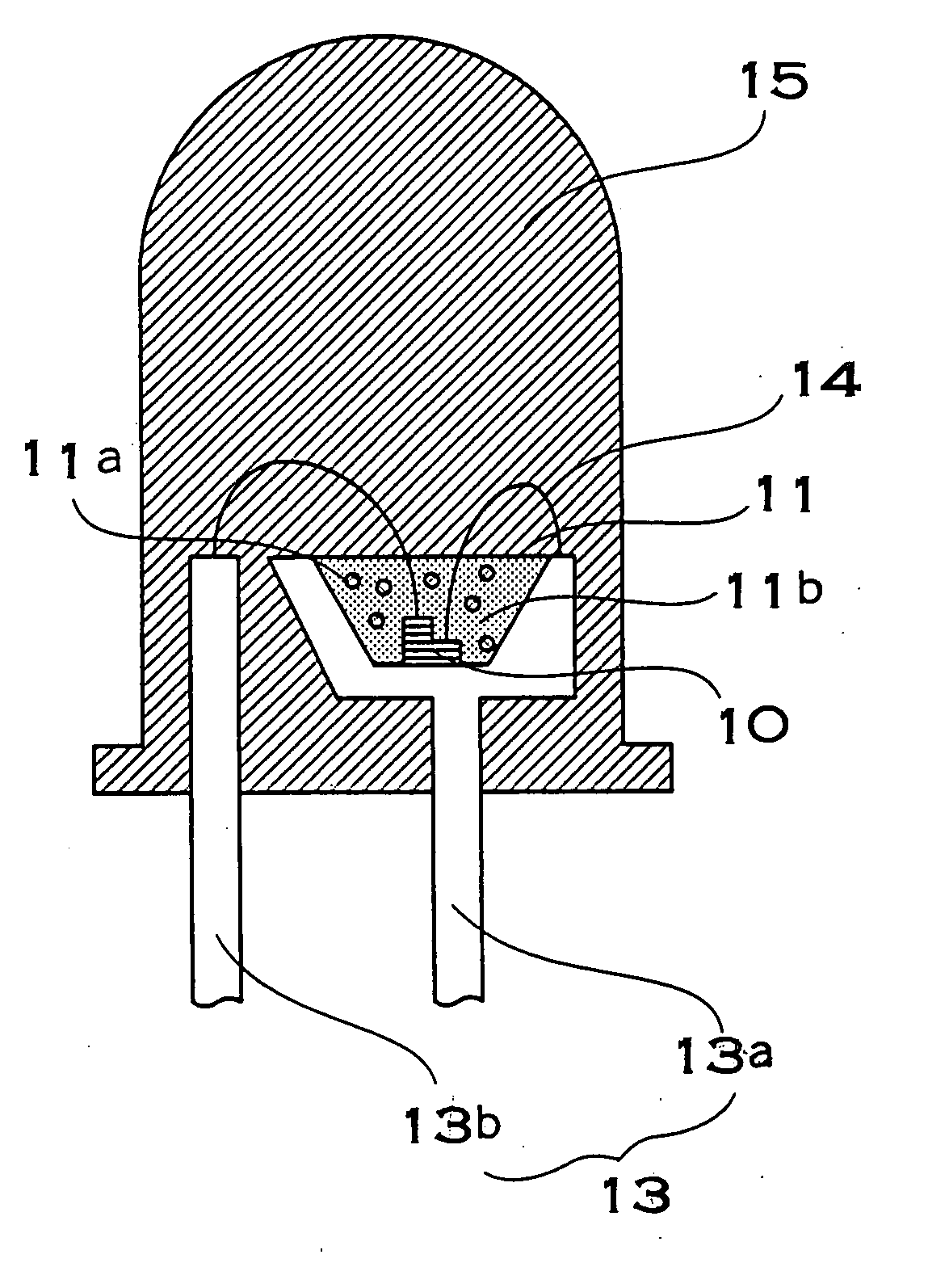

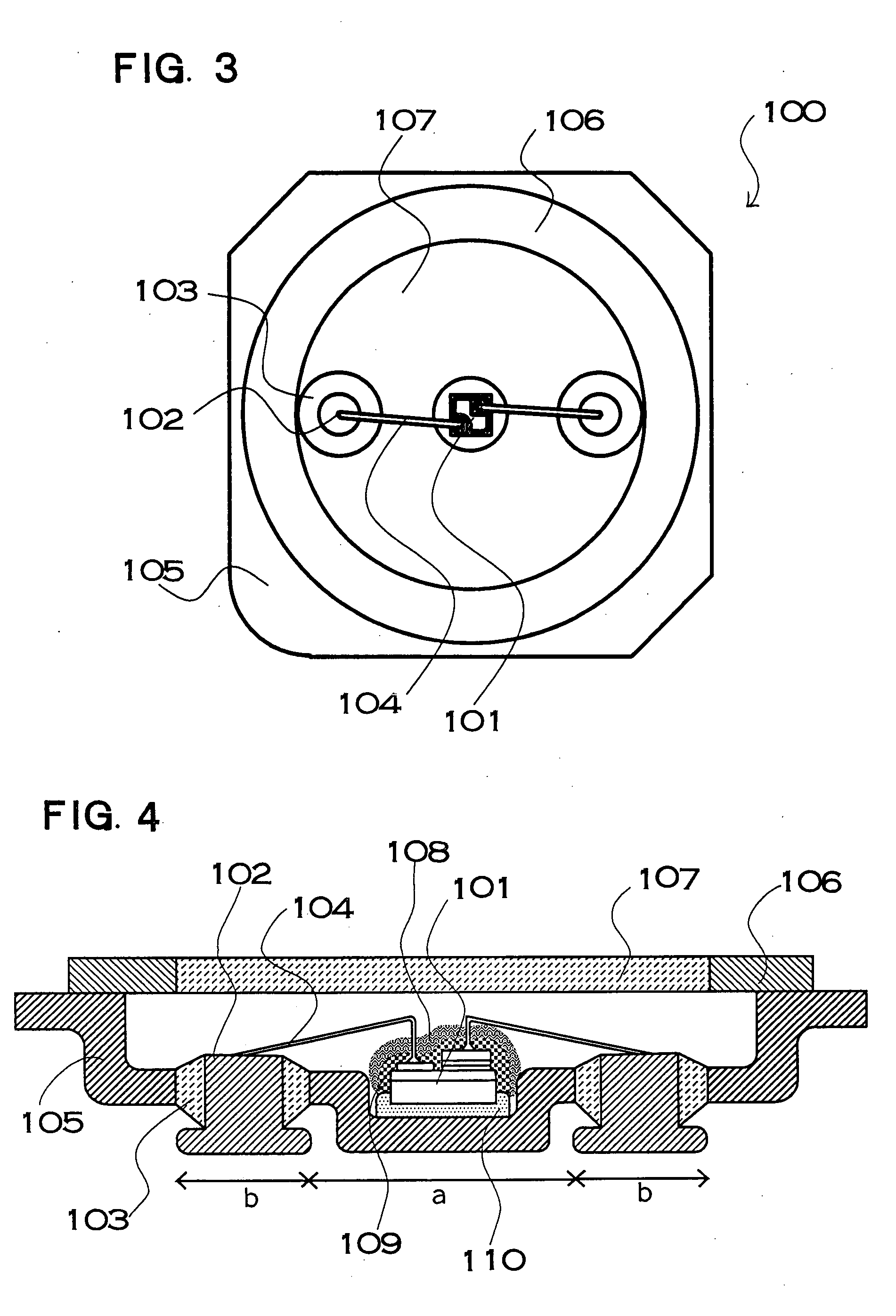

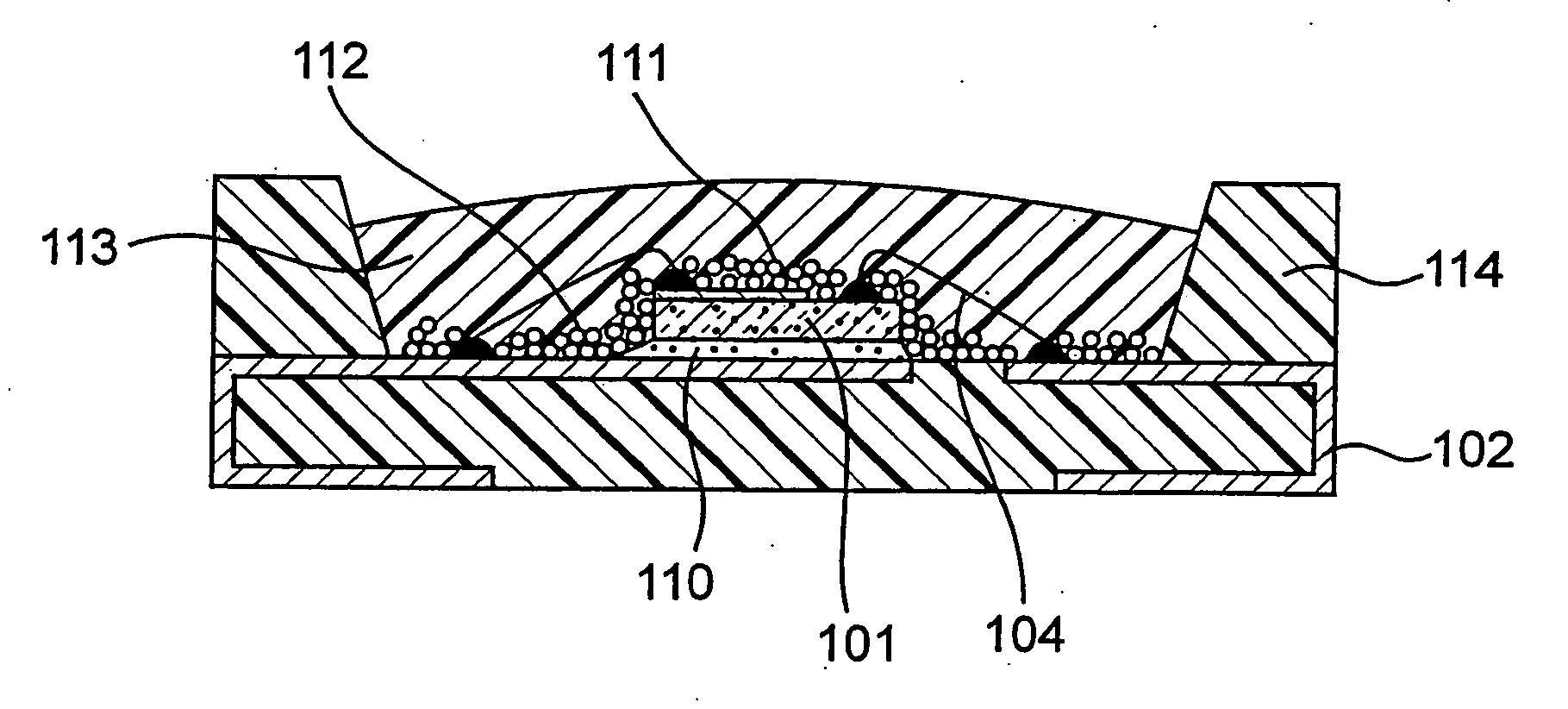

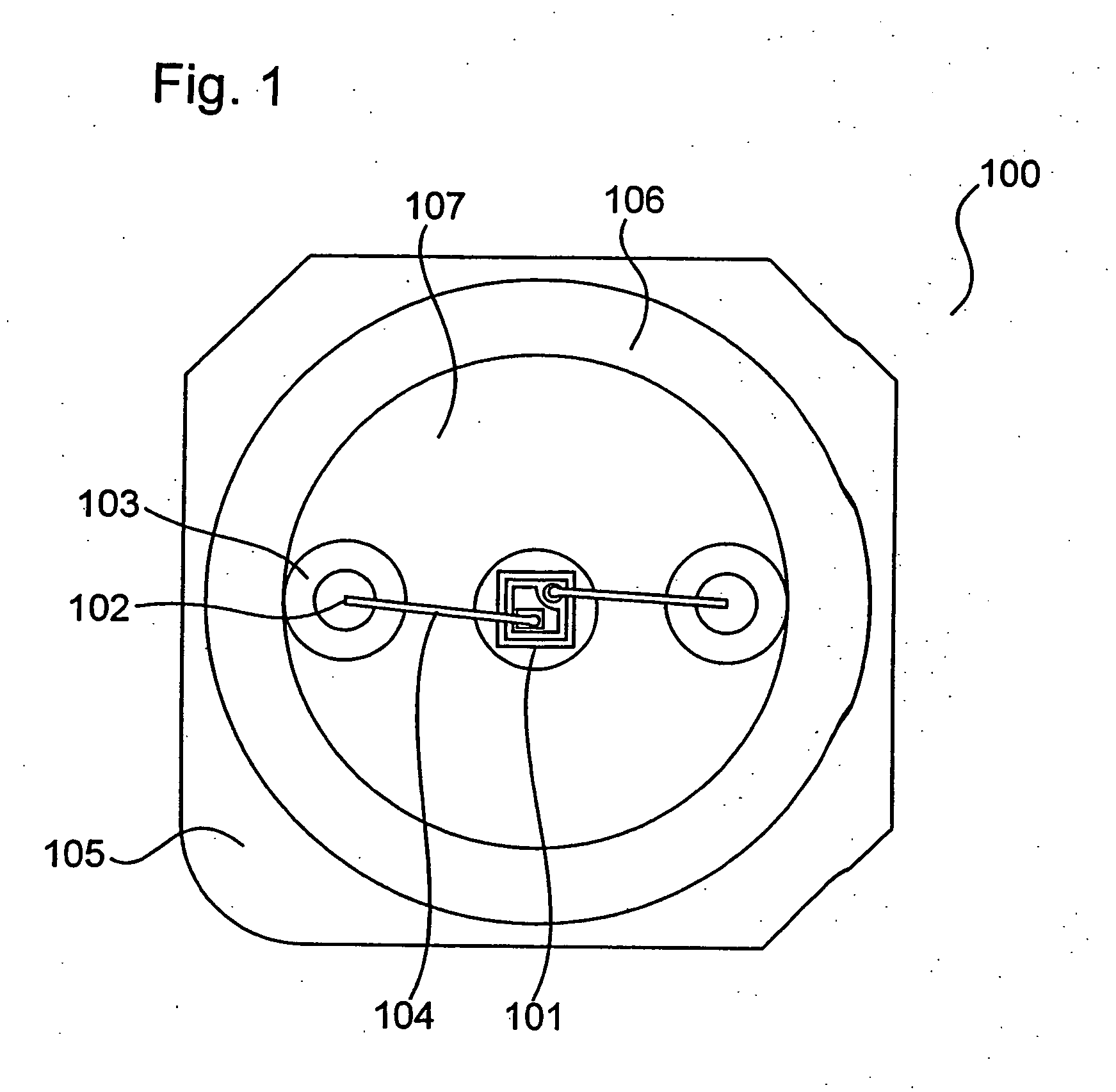

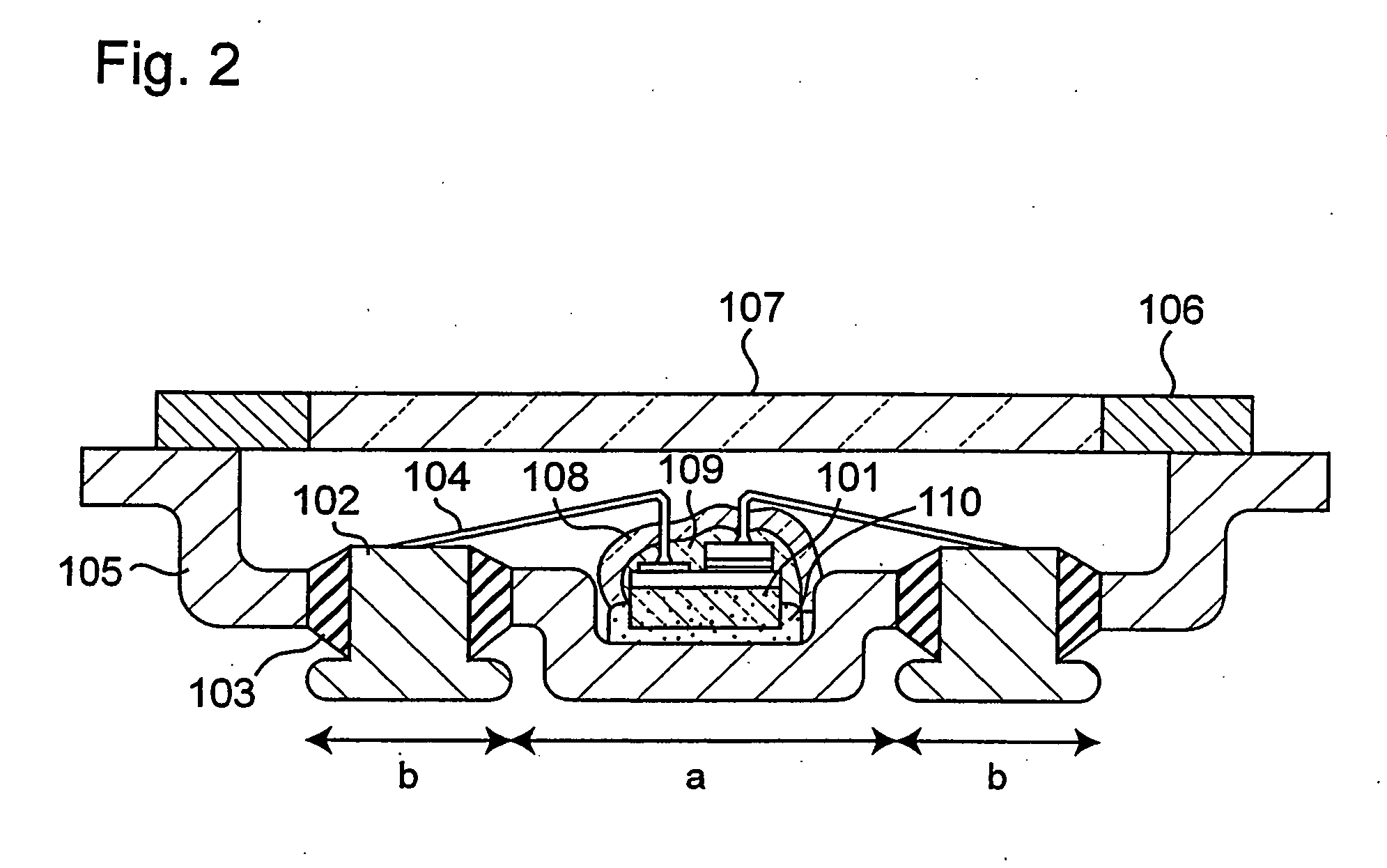

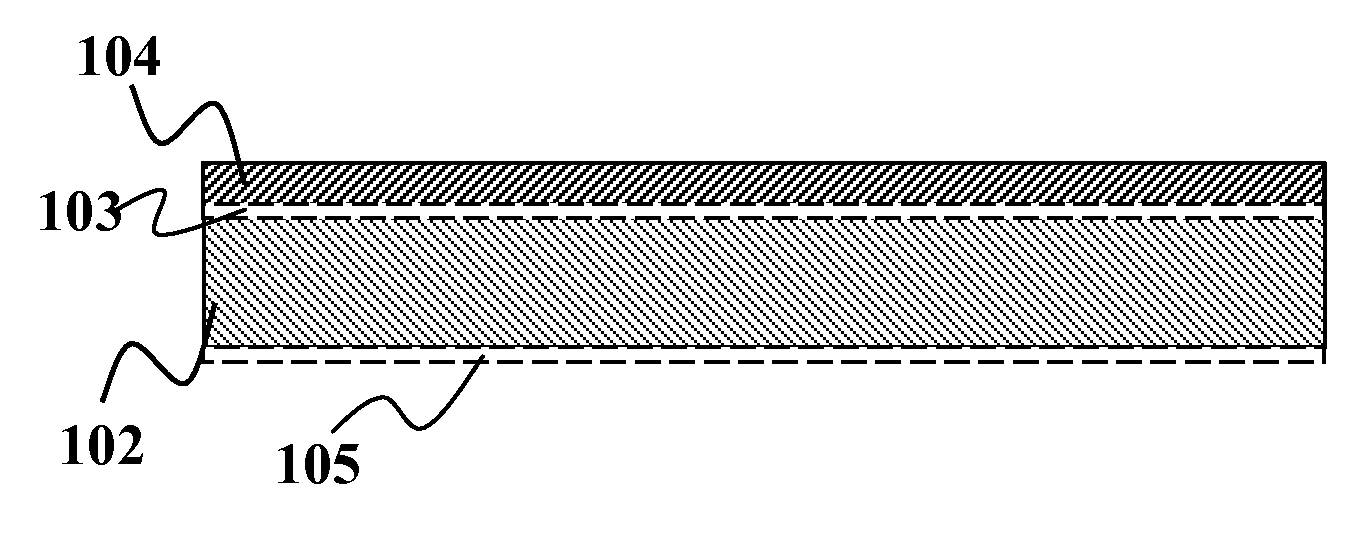

Light emitting apparatus and method of manufacturing the same

ActiveUS20040061433A1Facilitated DiffusionLarge particle sizeDischarge tube luminescnet screensLamp detailsAlkaline earth metalFluorescence

A light emitting apparatus comprising a light emitting device (101) disposed on a supporting body (105), and coating layers ((108, 109) that bind a fluorescent substance that absorbs light emitted by the light emitting device (101) and emits light of a different wavelength and secures the fluorescent substance onto the surface of the light emitting device (101). The coating layers (108, 109) are made of an inorganic material including an oxide and a hydroxide, each containing at least one element selected from the group consisting of Si, Al, Ga, Ti, Ge, P, B, Zr, Y, Sn, Pb and alkali earth metals. Also an adhesive layer (110) is made of the same inorganic material as that of the coating layers (108, 109).

Owner:NICHIA CORP

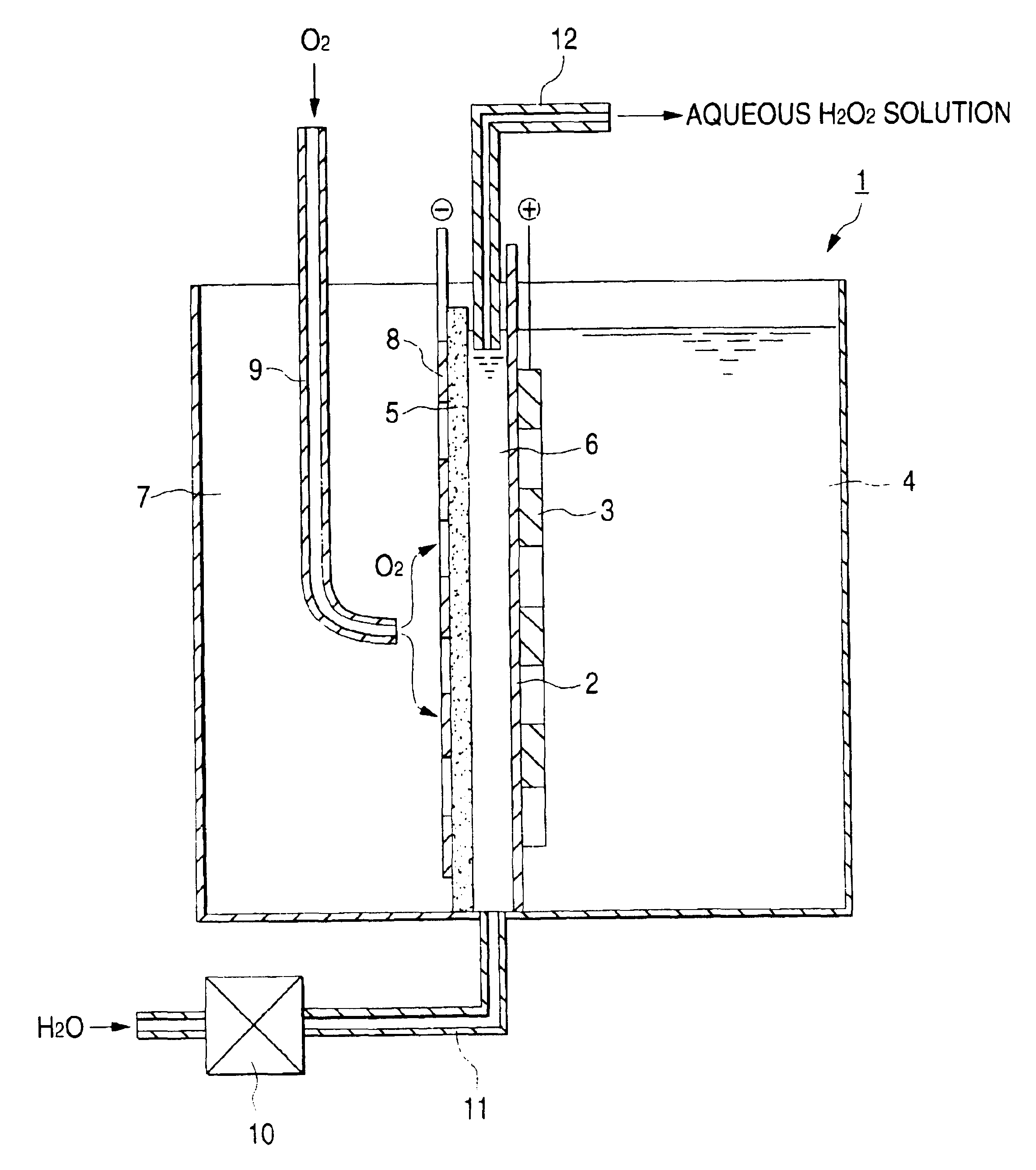

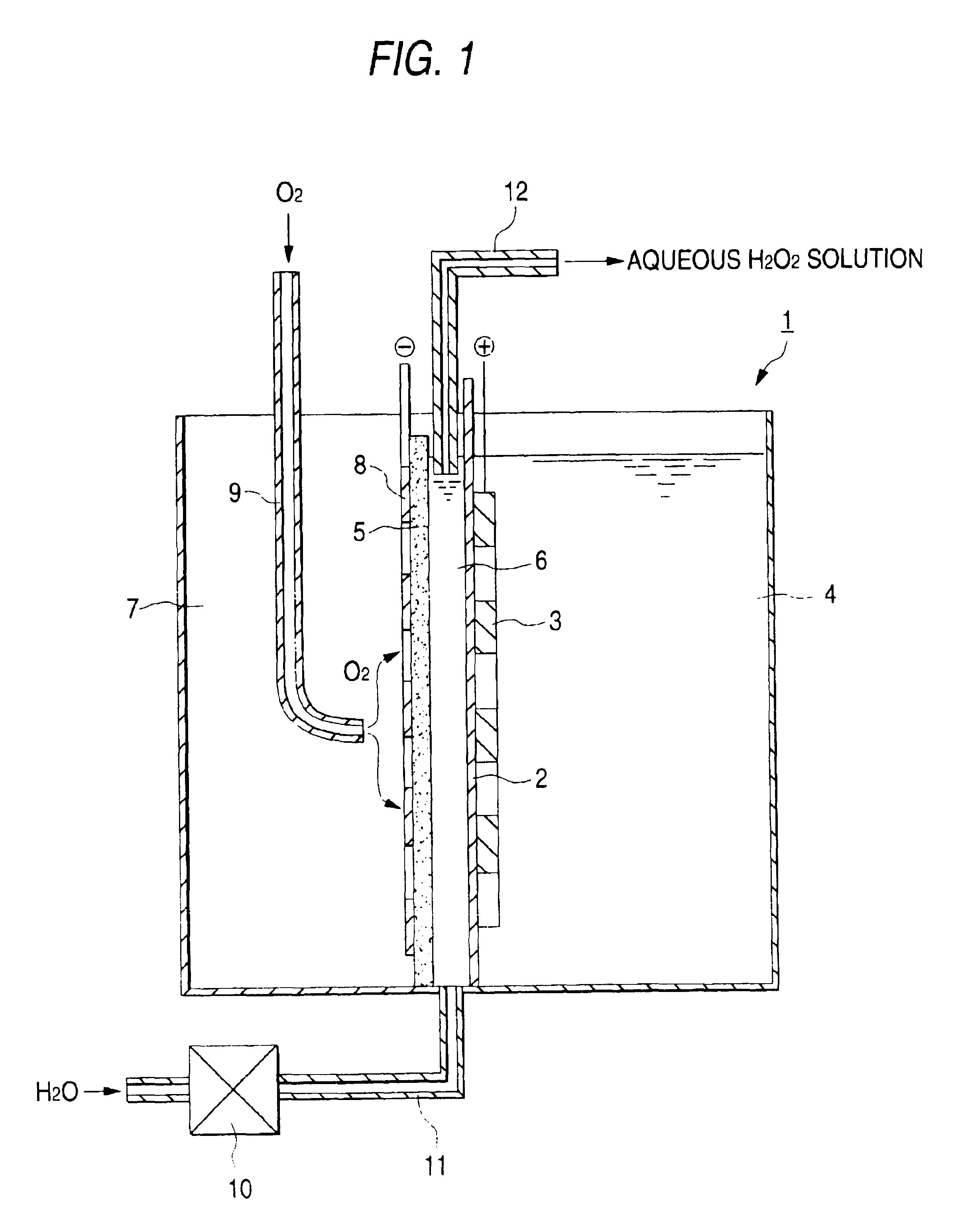

Electrolytic cell for hydrogen peroxide production and process for producing hydrogen peroxide

InactiveUS6767447B2CellsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSodium sulfateNuclear chemistry

An electrolytic cell and method of electrolysis for producing hydrogen peroxide at a moderate current density while preventing metal deposition on the cathode surface. A feed water from which multivalent metal ions have been removed and in which a salt of a univalent metal, e.g., sodium sulfate, has been dissolved in a given concentration is prepared with an apparatus for removing multivalent metal ions and dissolving a salt in low concentration. The feed water is supplied to an electrolytic cell. Even when electrolysis is continued, almost no deposition of a hydroxide or carbonate occurs on the cathode because multivalent metal ions are not present in the electrolytic solution. Due to the dissolved salt, a sufficient current density is secured to prevent an excessive load from being imposed on the electrodes, etc. Thus, stable production of hydrogen peroxide is possible over a long period of time.

Owner:DE NORA PERMELEC LTD

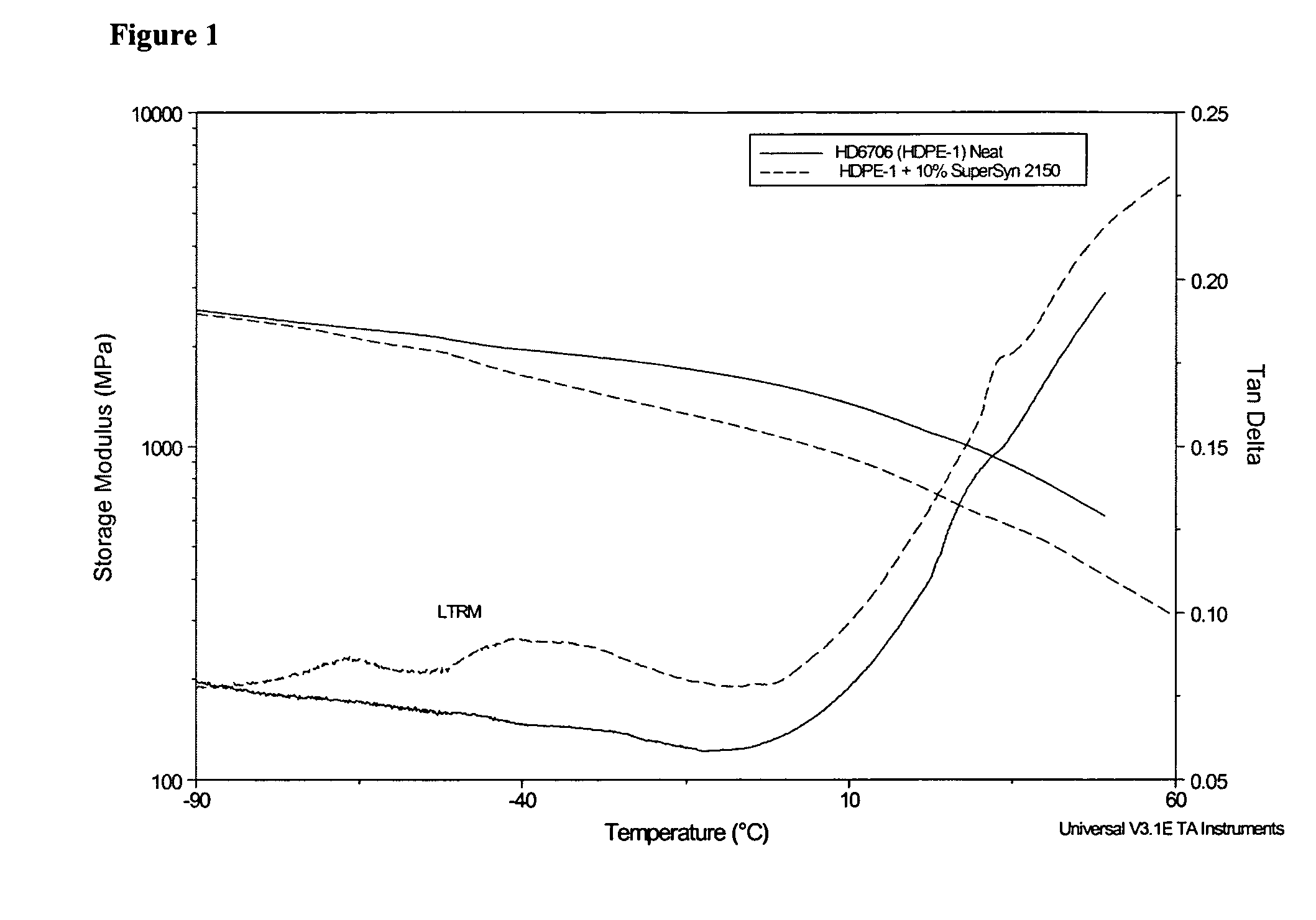

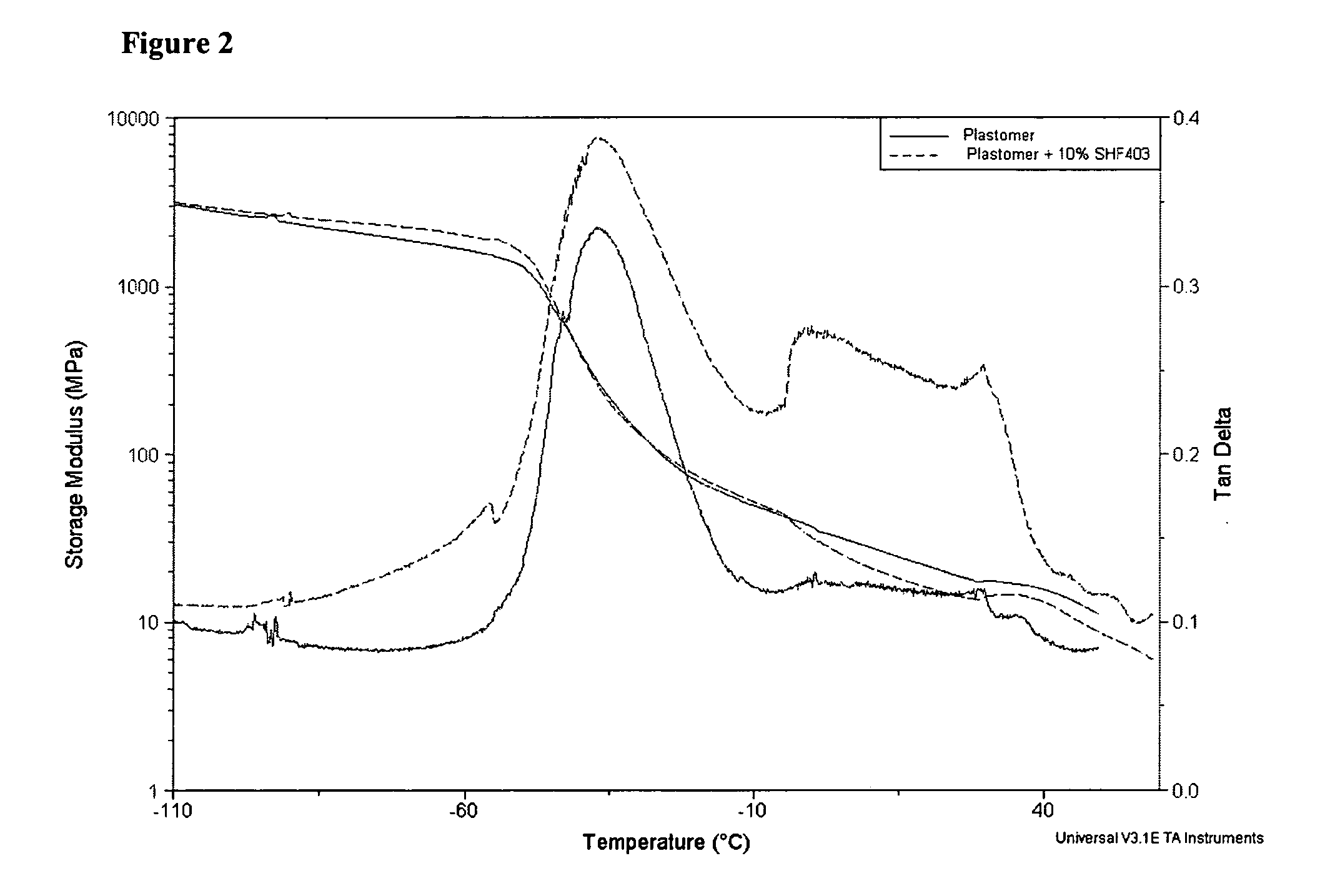

Modified polyethylene compositions

The present invention relates to a composition comprising more than 25 weight % (based on the weight of the composition) of one or more ethylene polymers having an Mw of 20,000 g / mole or more and at least 0.1 weight % of a liquid hydrocarbon modifier where the modifier has: 1) a viscosity index of 120 or more, and 2) an kinematic viscosity of 3 to 3000 cSt at 100° C., and 3) a pour point of −10° C. or less, and 4) a flash point of 200° C. or more; and wherein the modifier contains less than 5 weight % of functional groups selected from hydroxide, aryls, substituted aryls, halogens, alkoxys, carboxylates, esters, acrylates, oxygen, nitrogen, and carboxyl, based upon the weight of the modifier.

Owner:EXXONMOBIL CHEM PAT INC

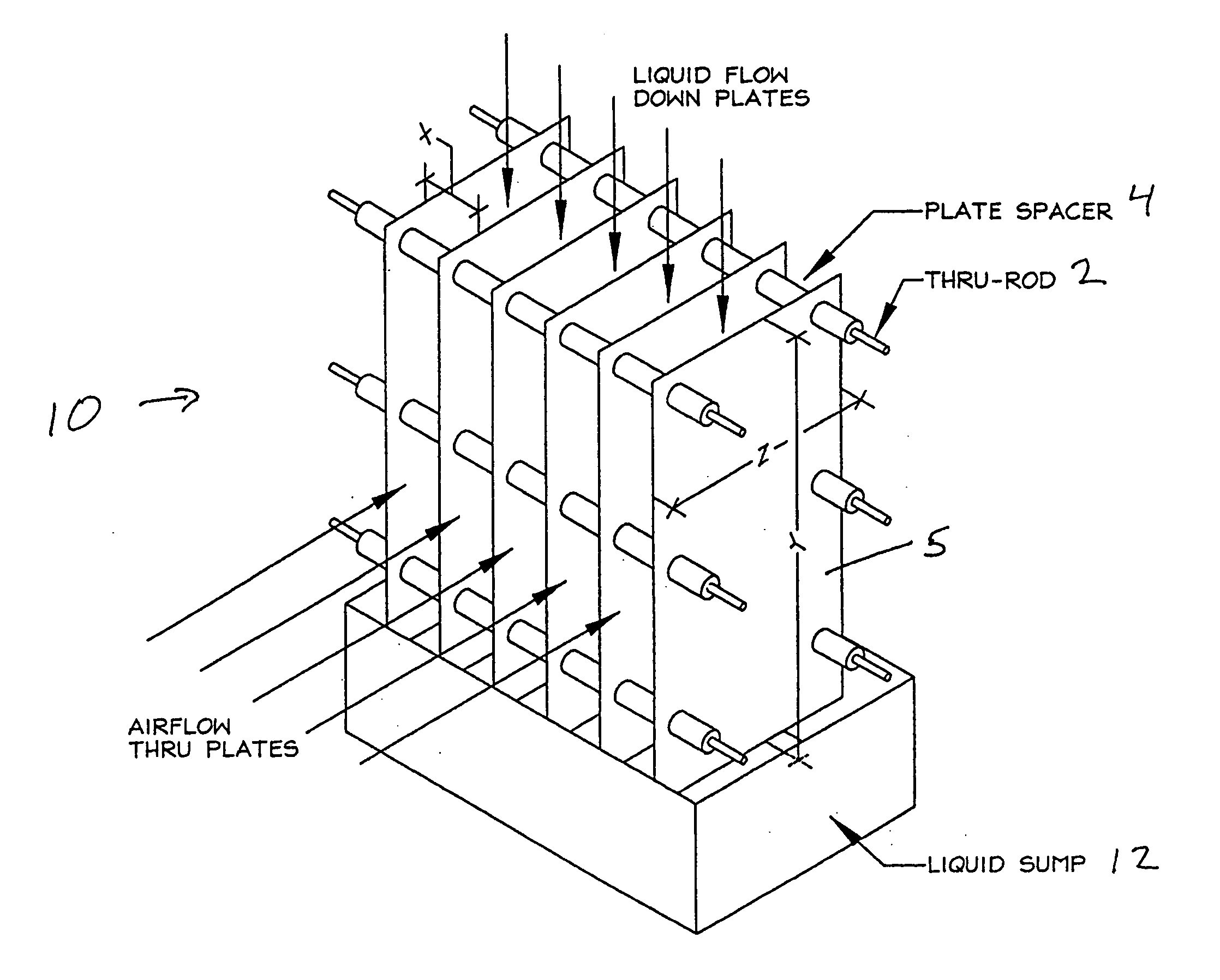

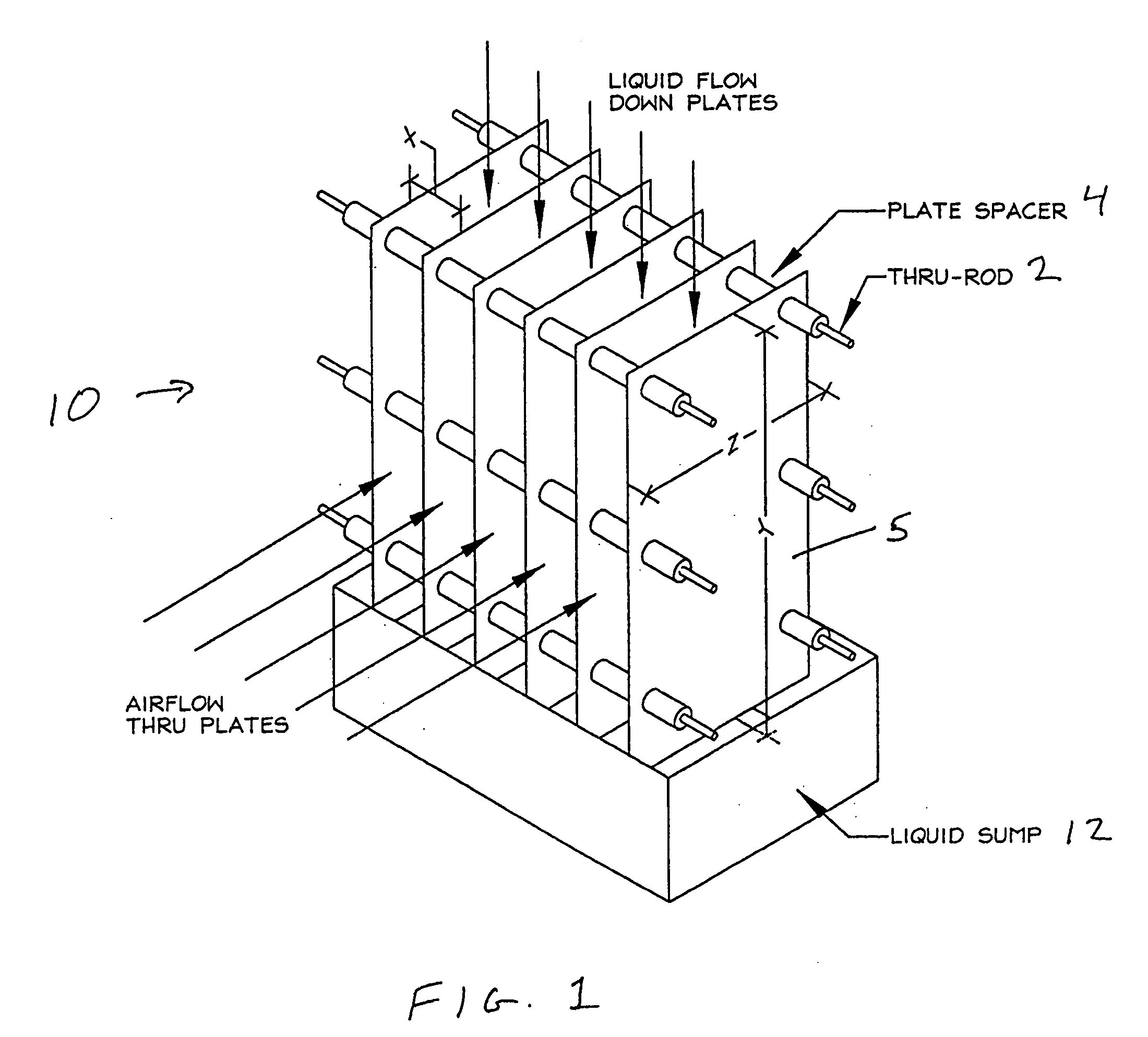

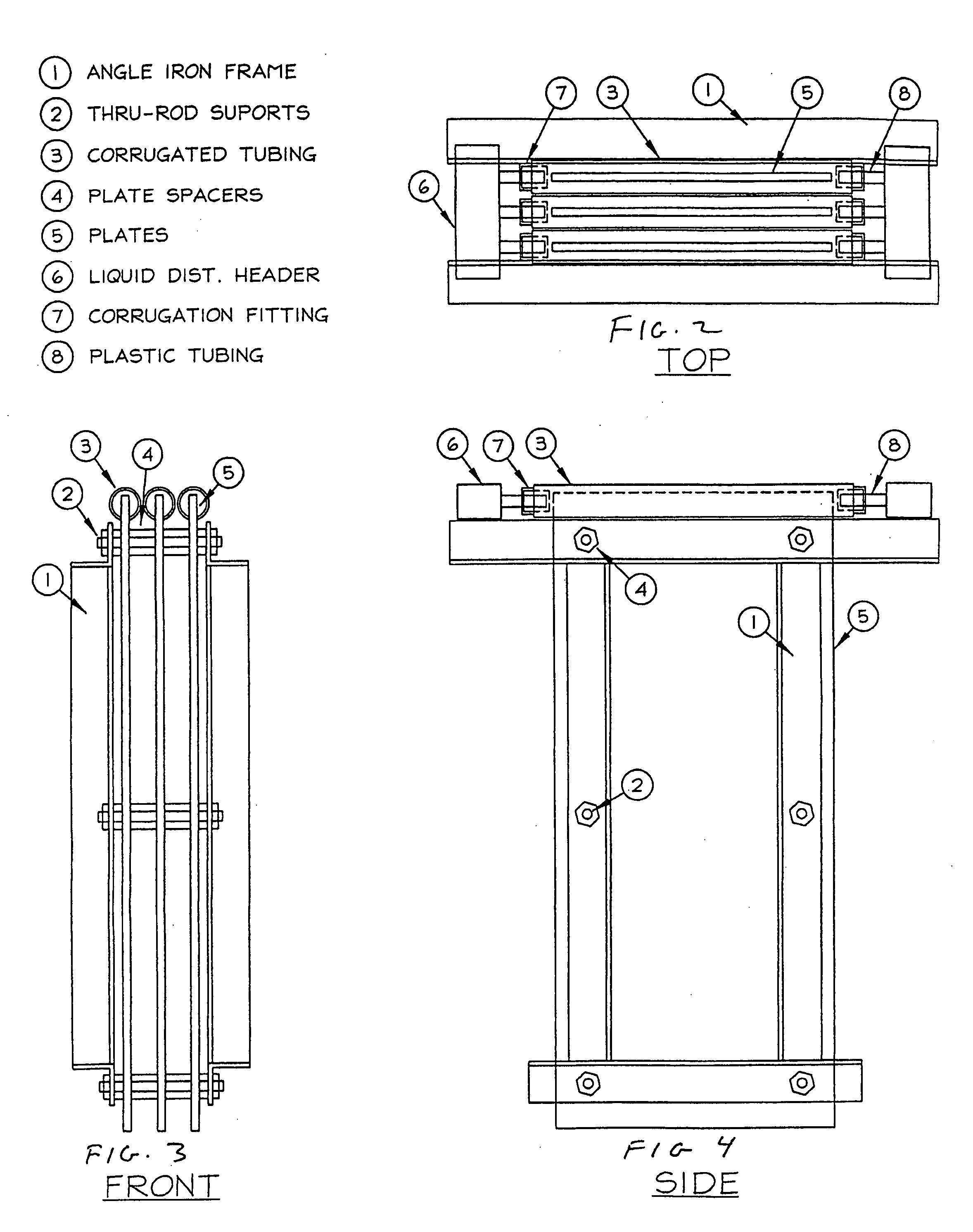

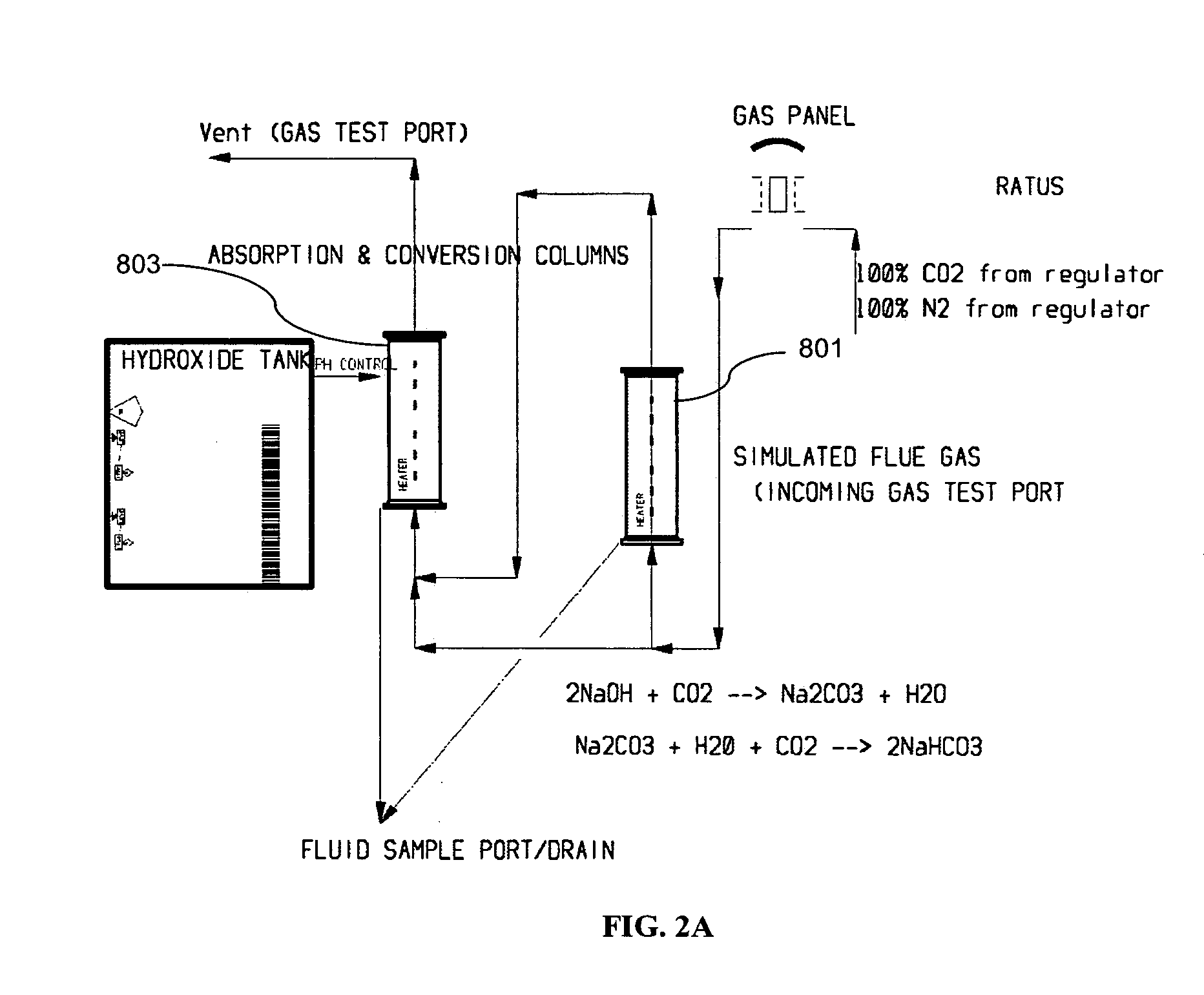

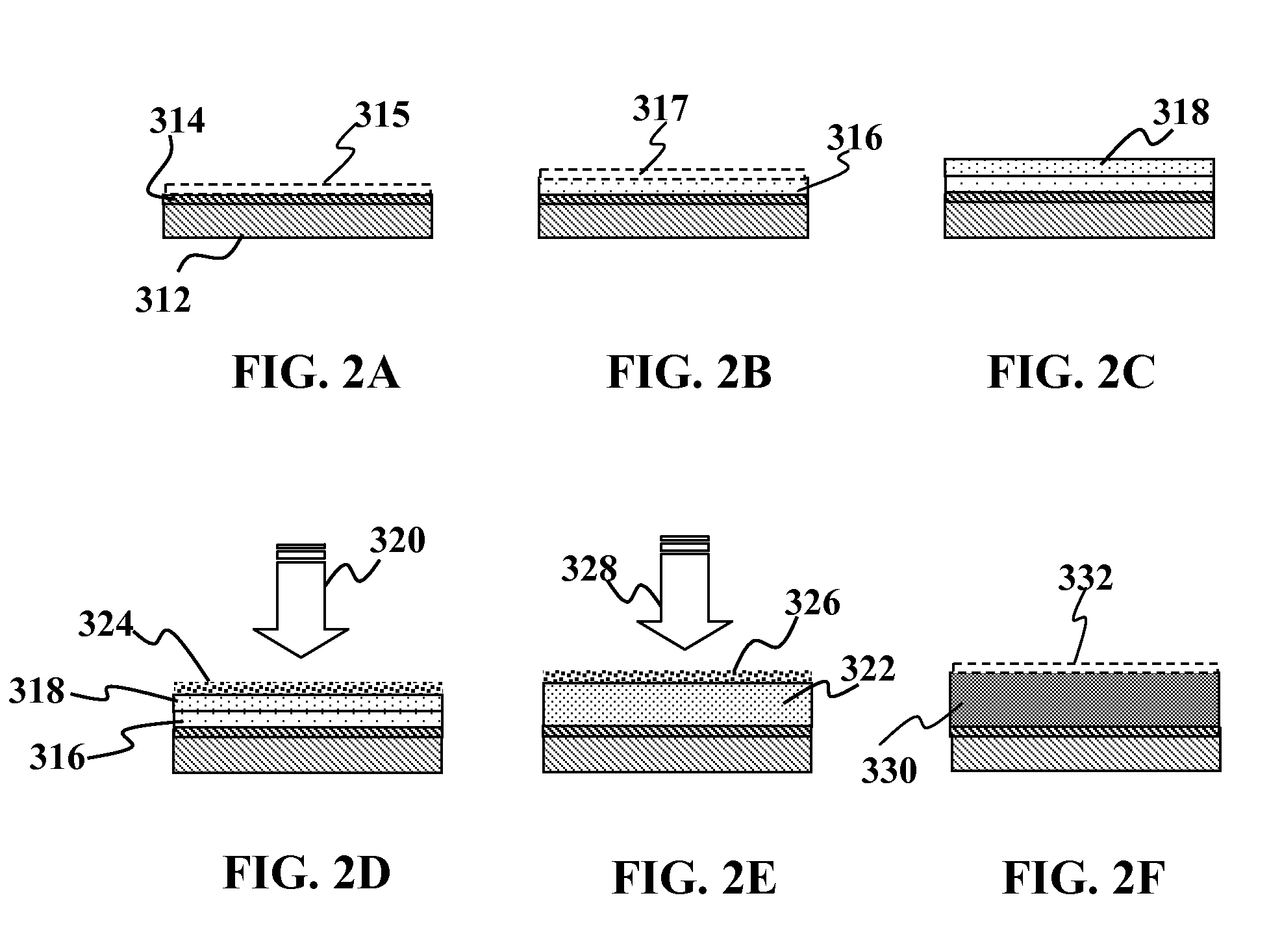

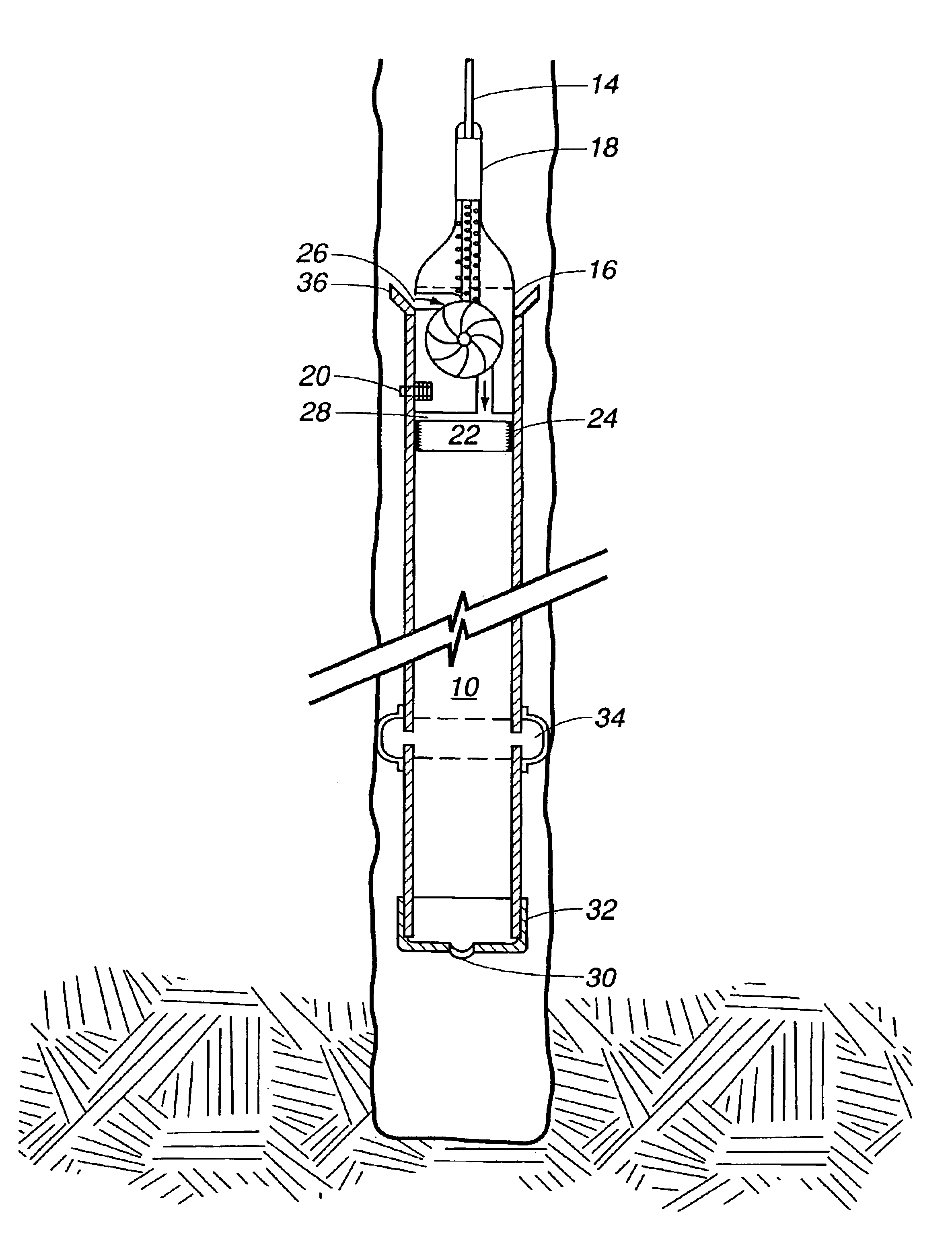

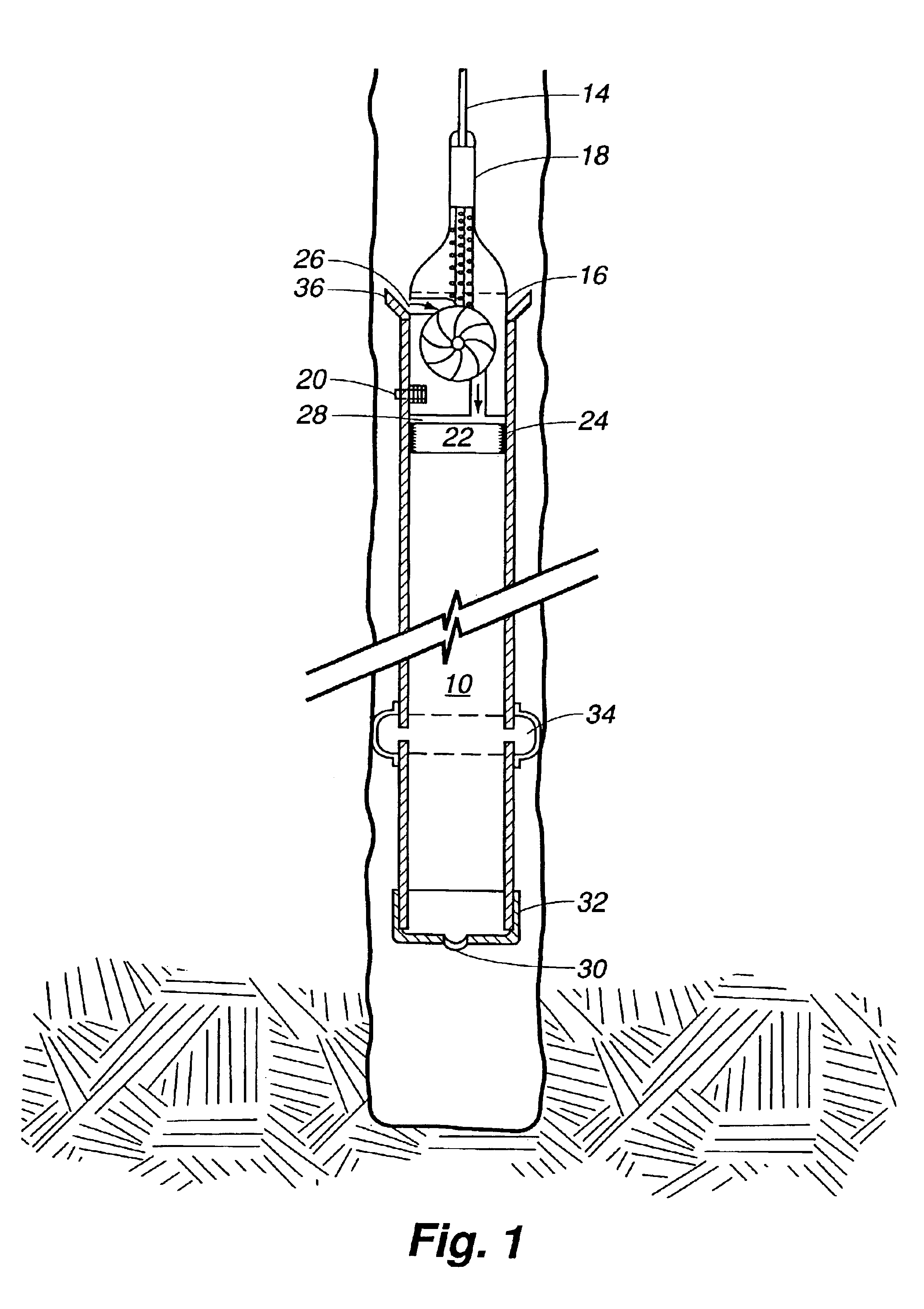

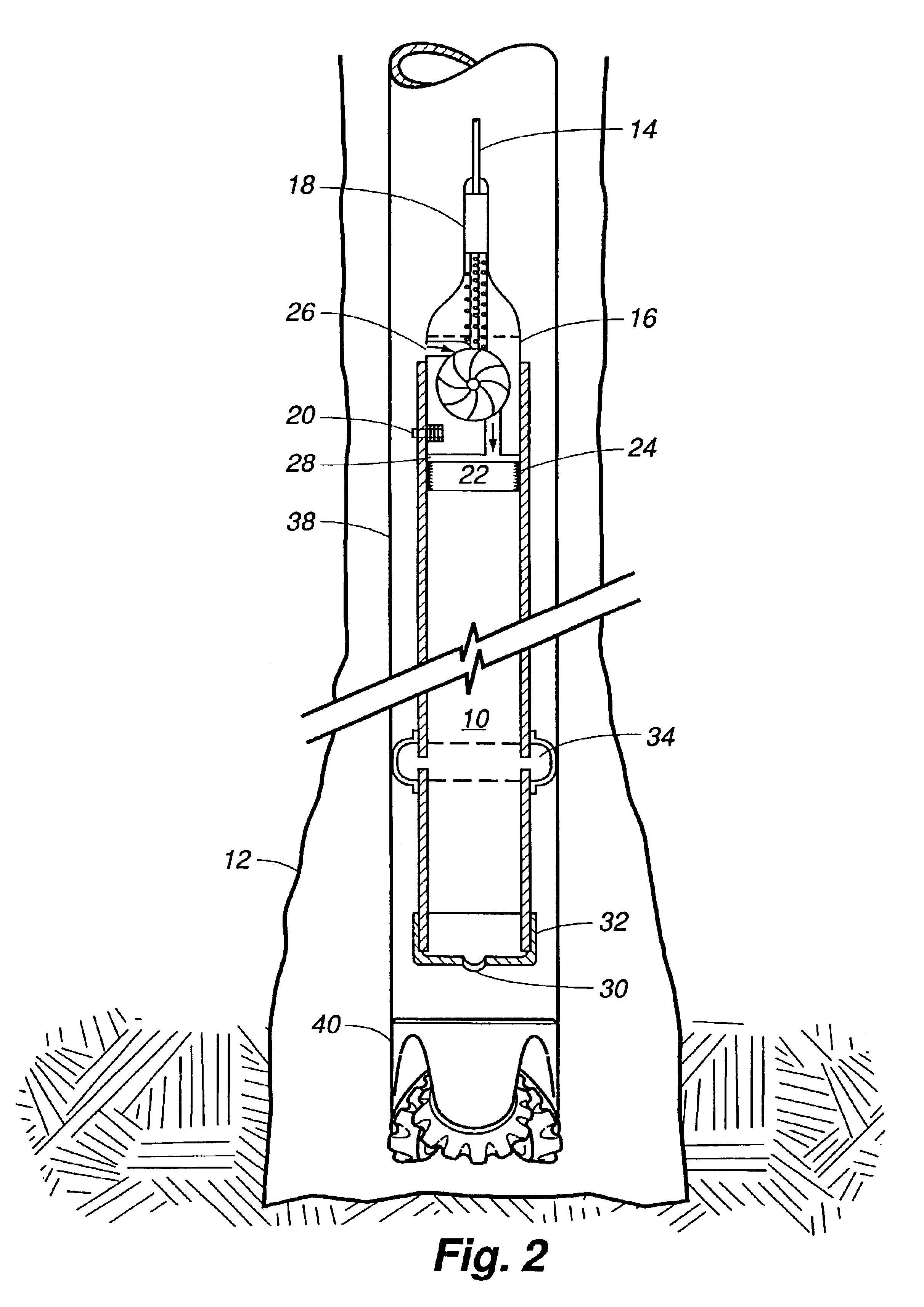

Removal of carbon dioxide from air

InactiveUS20060051274A1Simple processReduce energy consumptionSemi-permeable membranesHydrogen sulfidesSolventCarbon dioxide binding

The present invention is directed to methods for removing carbon dioxide from air, which comprises exposing solvent covered surfaces to air streams where the airflow is kept laminar, or close to the laminar regime. The invention also provides for an apparatus, which is a laminar scrubber, comprising solvent covered surfaces situated such that they can be exposed to air stream. In another aspect, the invention provides a method and apparatus for separating carbon dioxide (CO2) bound in a solvent. The invention is particularly useful in processing hydroxide solvents containing CO2 captured from air.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +2

Light emitting film, luminescent device, method for manufacturing light emitting film and method for manufacturing luminescent device

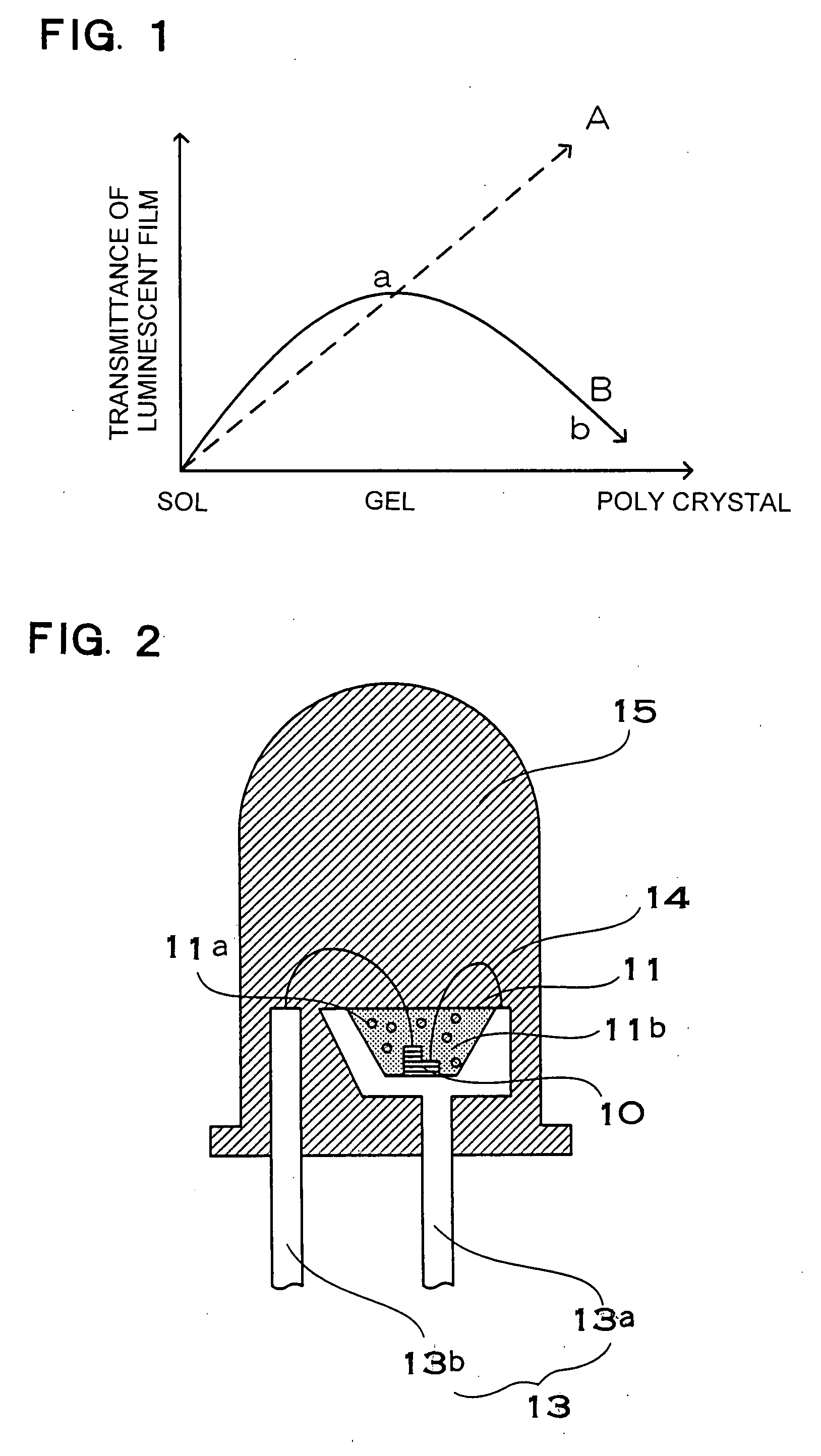

InactiveUS20060170332A1High light-outgoing efficiencyHardness is easy to controlDischarge tube luminescnet screensLamp detailsPhosphorTransmittance

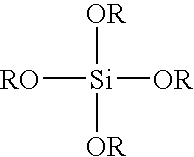

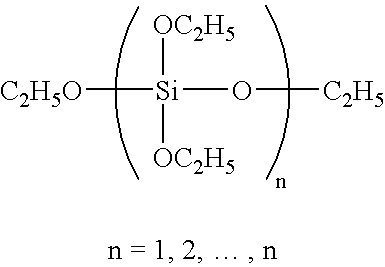

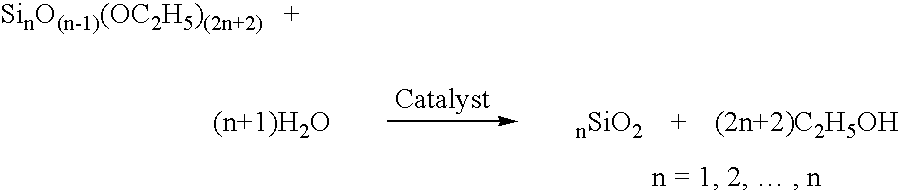

The present invention provides a reliable, long-life phosphor, or the like, which is prevented from darkening due to aging. A light emitting apparatus has a light emitting element and a phosphor layer. The phosphor layer has a phosphor excited by light from the light emitting element, and a binder which binds the phosphor. The binder is hydroxide oxide gel obtained by curing sol of a hydroxide oxide mixed with sol containing at least one metallic element selected from the group consisting of Al, Y, Gd, Lu, Sc, Ga, In, and B. Transmittance of hydroxide oxide in a gel state is higher than the transmittance in the polycrystal state where the sol-gel reaction is proceeded. In addition, the content of hydroxyl group or water of crystallization in the hydroxide oxide is 10% or less by weight.

Owner:NICHIA CORP

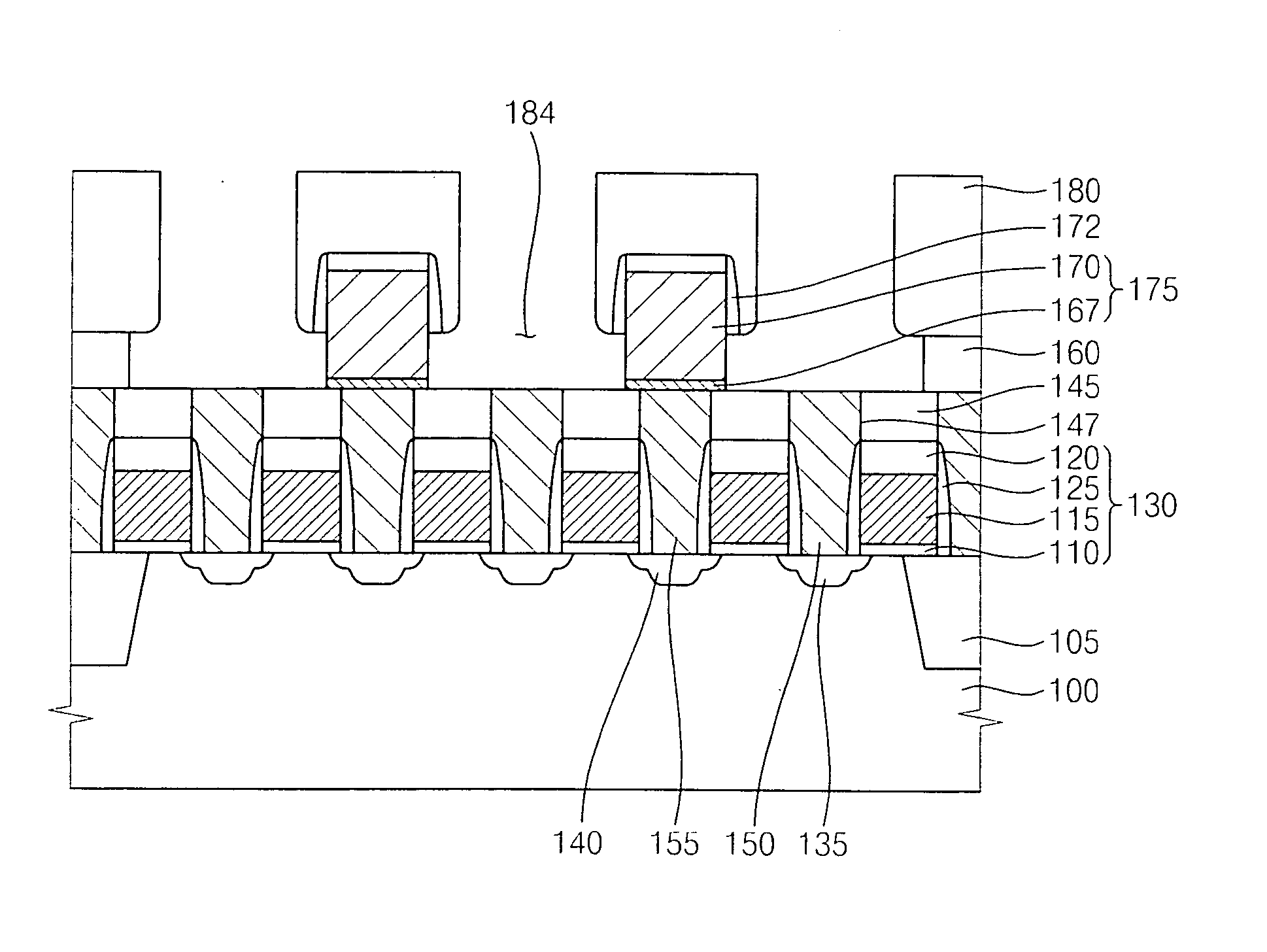

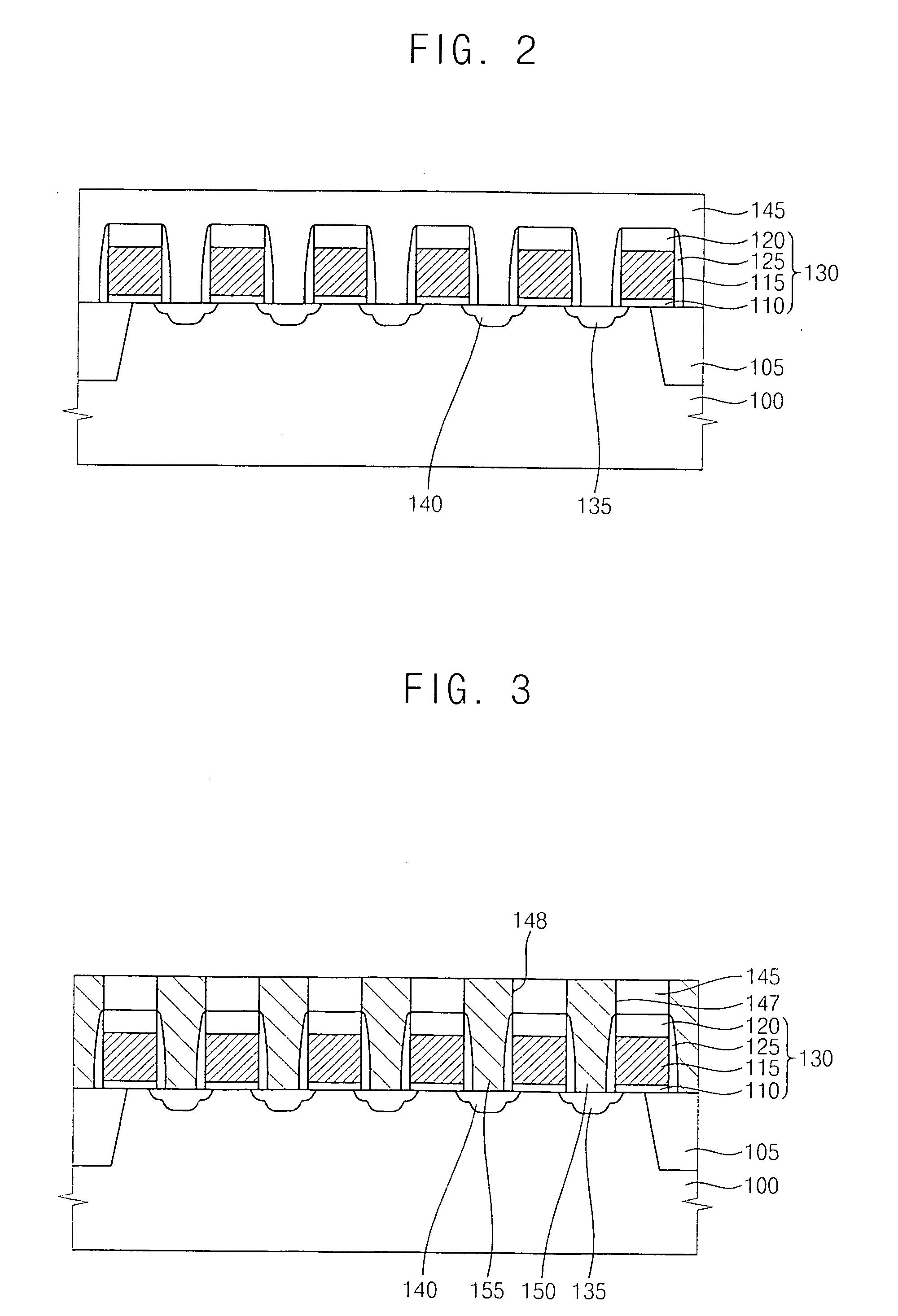

Etching solution for silicon oxide and method of manufacturing a semiconductor device using the same

InactiveUS20070090325A1Efficient removalAvoid damageDecorative surface effectsSolid-state devicesHydrogen fluorideDevice material

An etching solution for silicon oxide may be used in a process for enlarging an opening formed through a silicon oxide layer. The etching solution includes about 0.2 to about 5.0 percent by weight of a hydrogen fluoride solution, about 0.05 to about 20.0 percent by weight of an ammonium fluoride solution, about 40.0 to about 70.0 percent by weight of an alkyl hydroxide solution and remaining water. The etching solution may etch the silicon oxide layer without damage to a metal silicide layer exposed by the opening.

Owner:CONVERSANT INTPROP MANAGEMENT INC

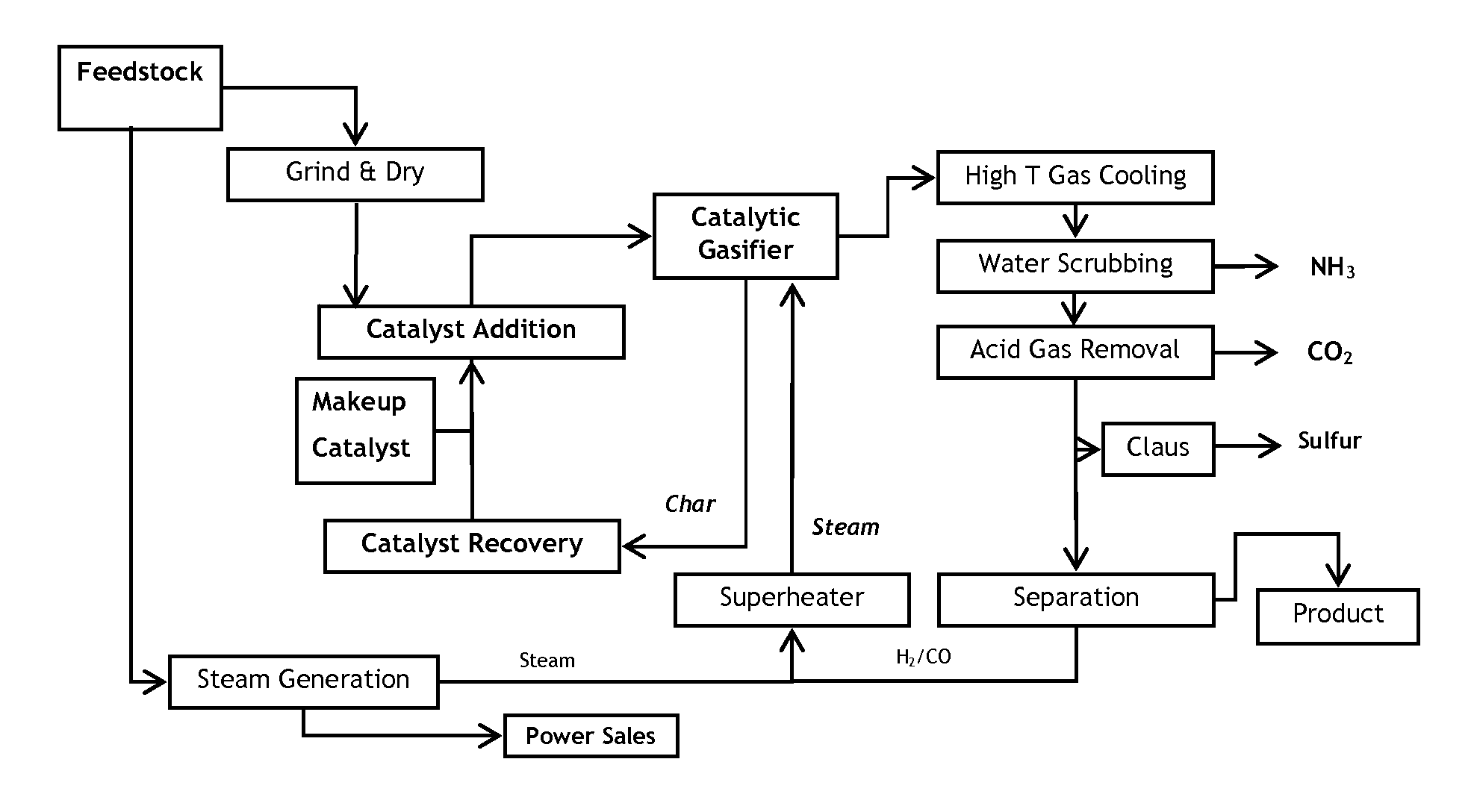

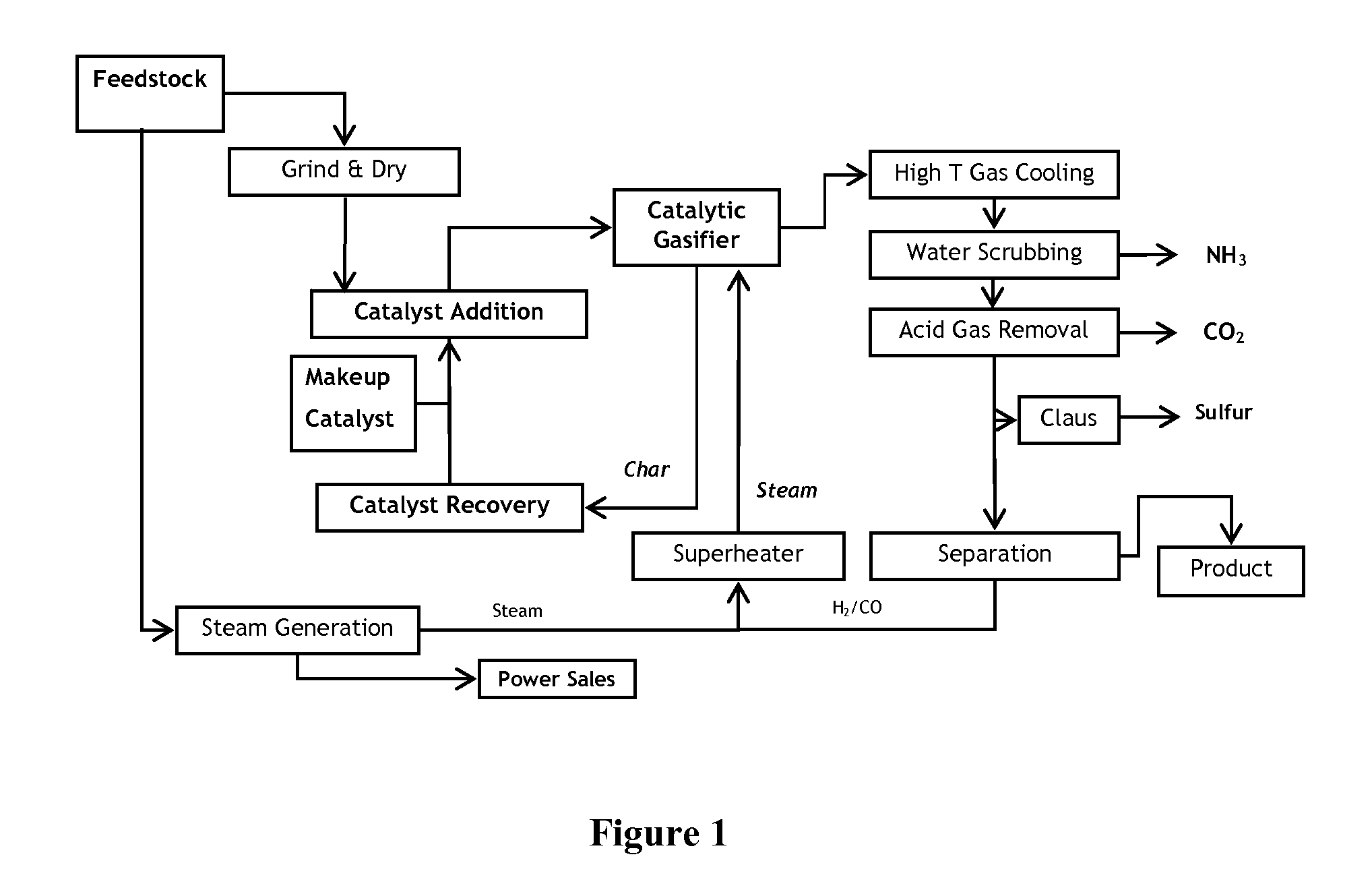

Petroleum Coke Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a petroleum coke and an alkali metal gasification catalyst, where the alkali metal gasification catalyst comprises a combination of an alkali metal hydroxide and one or more other alkali metal compounds are loaded onto coke for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

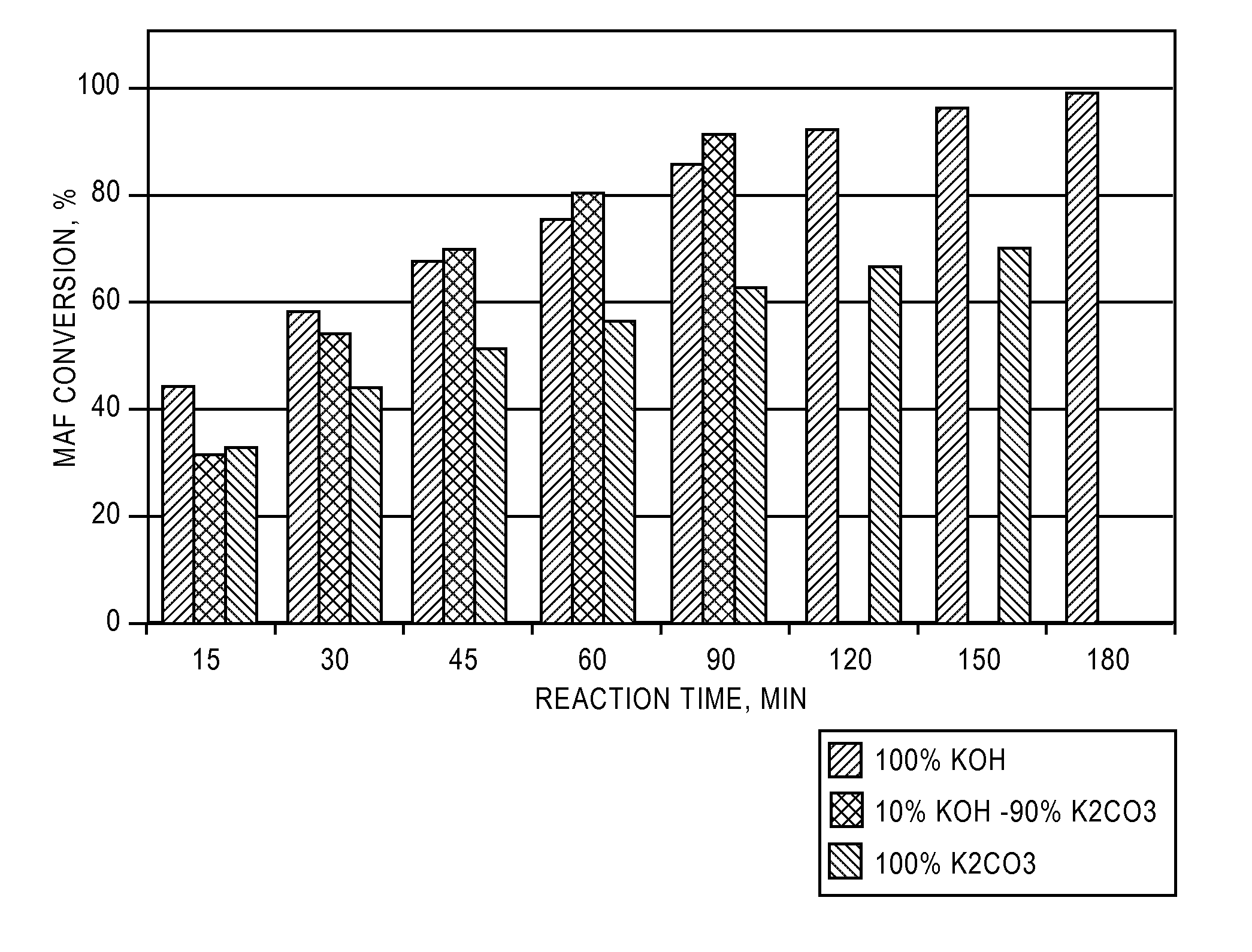

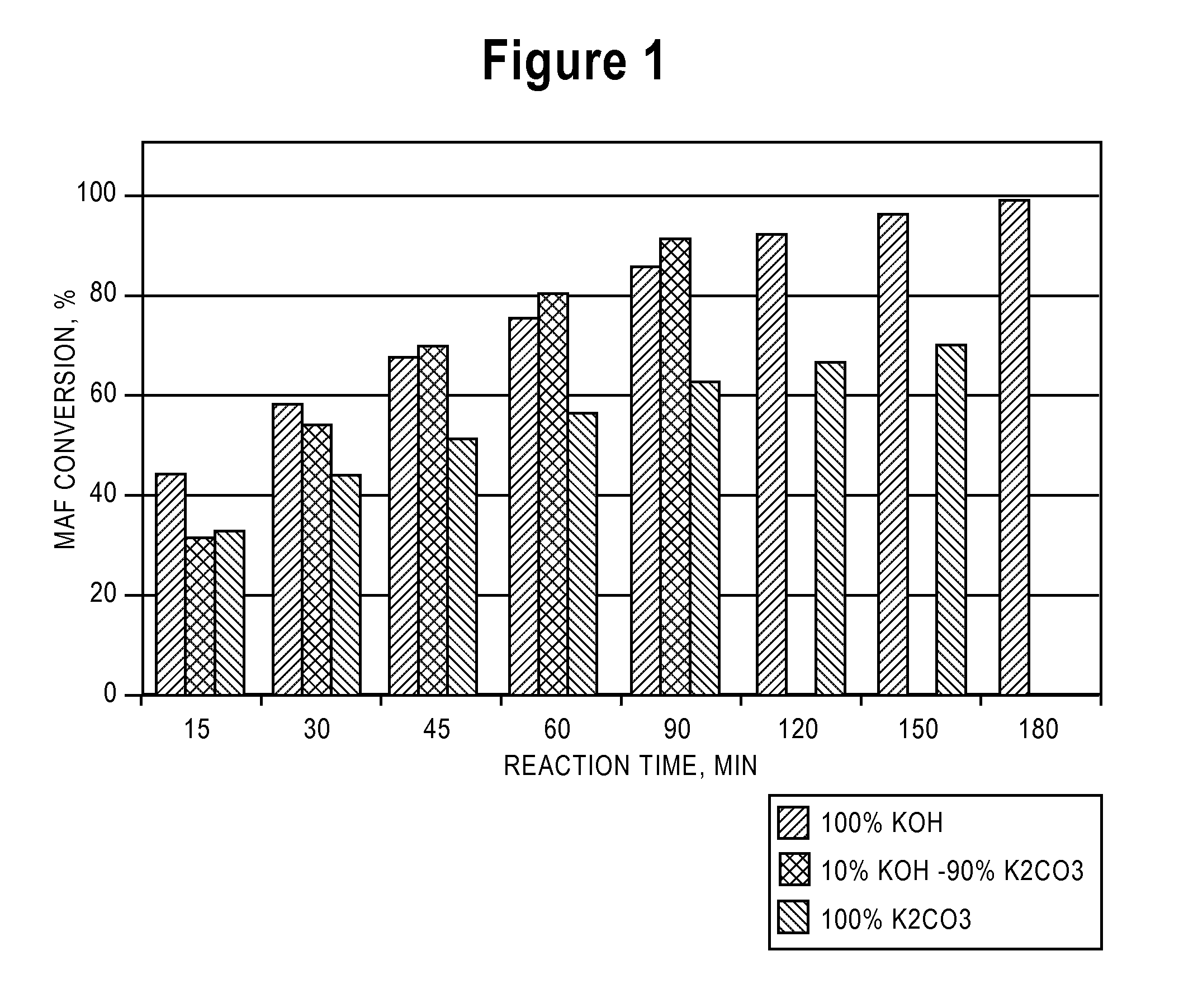

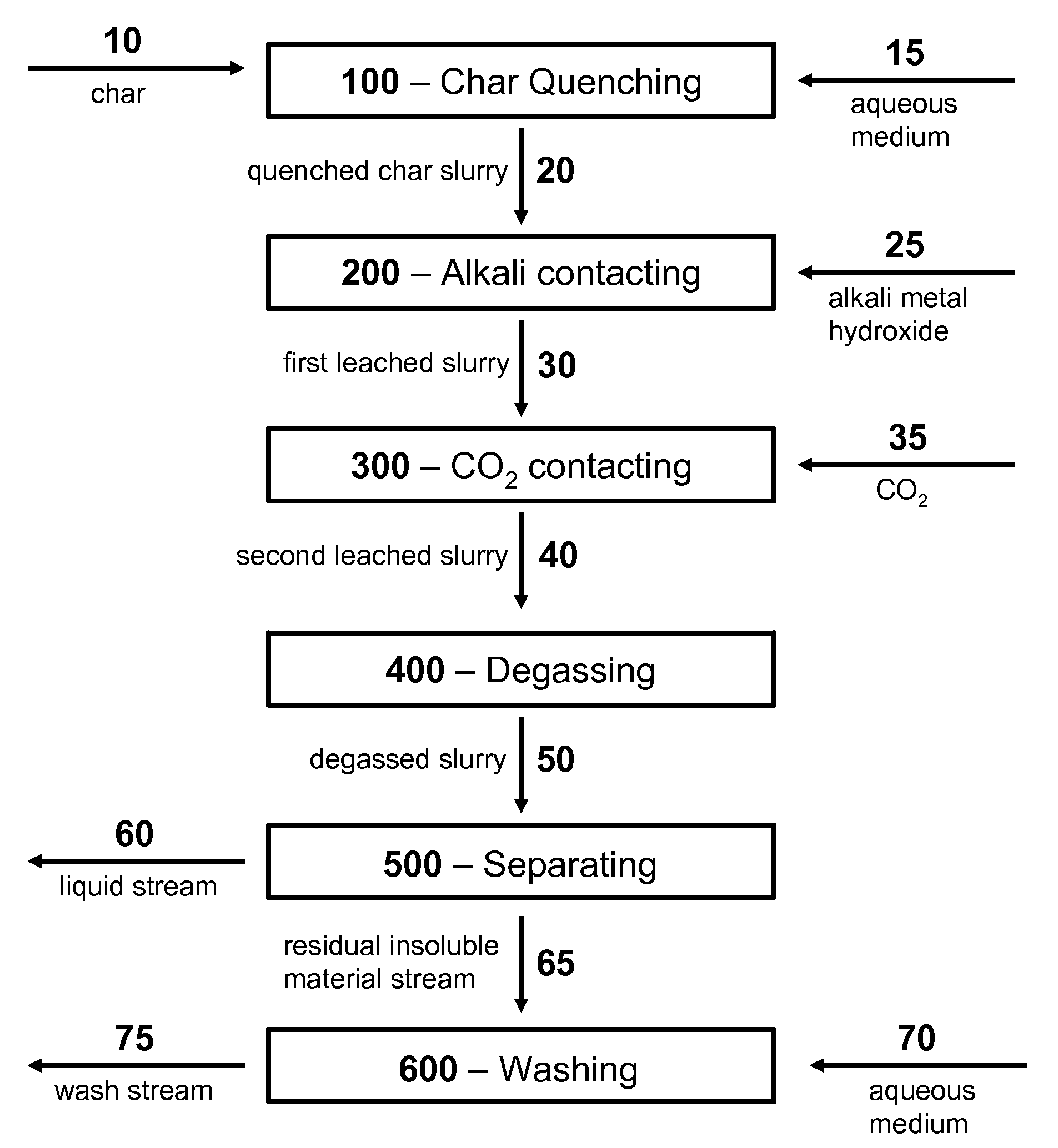

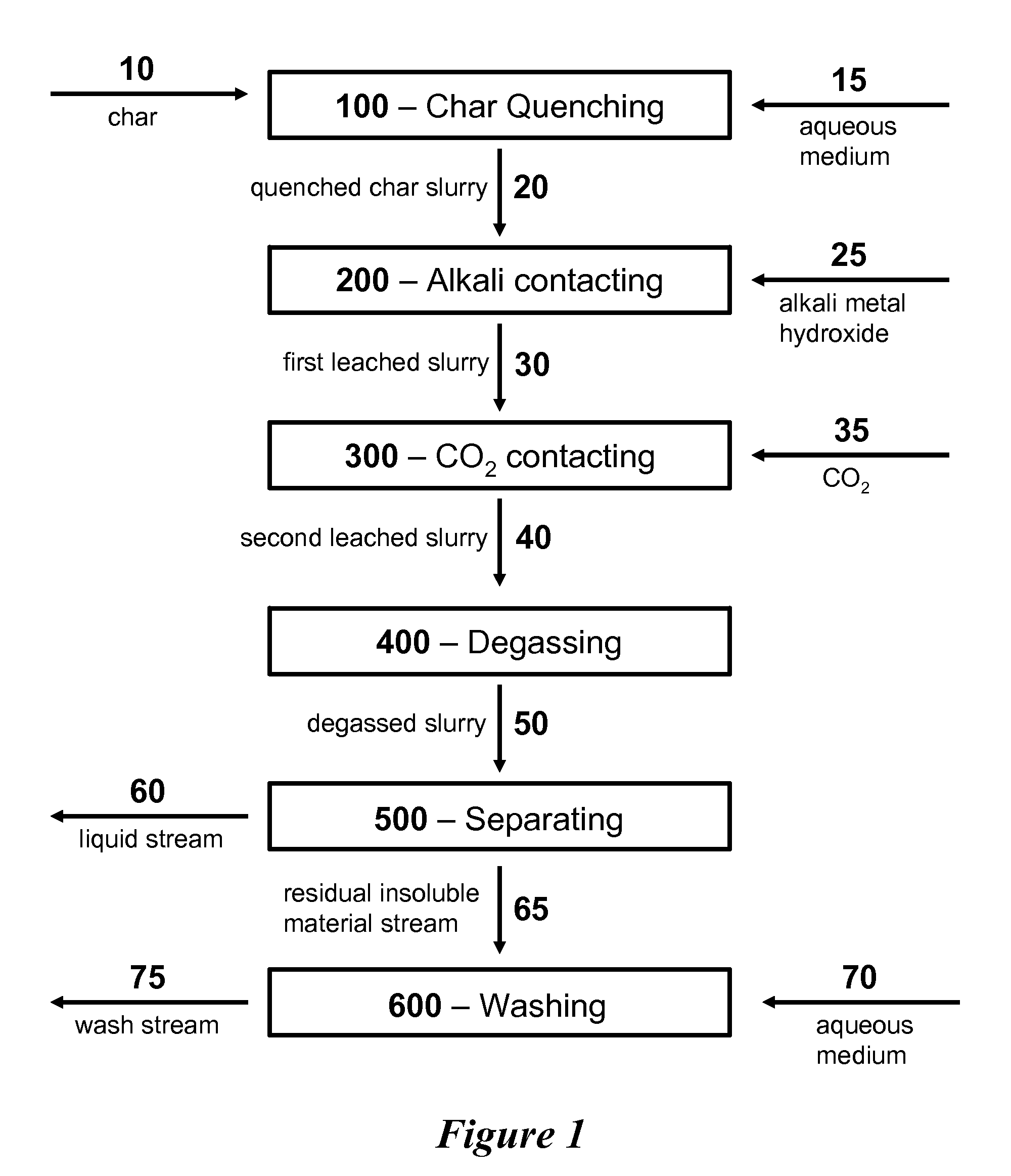

Catalytic Gasification Process with Recovery of Alkali Metal from Char

InactiveUS20090165382A1Quantity minimizationGaseous fuelsGasification processes detailsMetalCarbon dioxide

Processes for extracting and recycling alkali metal compounds present in the char produced from the catalytic gasification of carbonaceous materials are provided involving at least contacting the char with and alkali metal hydroxide followed by carbon dioxide. Both the alkali metal hydroxide and carbon dioxide treatments serve to convert at least a portion of the insoluble alkali metal compounds in the char into soluble species which can be recovered and recycled.

Owner:SURE CHAMPION INVESTMENT LTD

Continuous Process for Converting Carbonaceous Feedstock into Gaseous Products

Continuous processes for converting a carbonaceous feedstock into a plurality of gaseous products are described. The continuous processes include, among other steps, recovering a substantial portion of alkali metal from the solid char that results from the gasification of a carbonaceous feedstock. The alkali metal is recovered as an alkali metal carbonate. A gasification catalyst for a subsequent gasification step may comprise the recovered alkali metal carbonate and a makeup amount of alkali metal hydroxide.

Owner:SURE CHAMPION INVESTMENT LTD

Light emitting apparatus and method of manufacturing the same

ActiveUS20060267042A1Improve reliabilityLess variabilitySolid-state devicesSemiconductor/solid-state device manufacturingAlkaline earth metalFluorescence

A light emitting apparatus comprising a light emitting device (101) disposed on a supporting body (105), and coating layers ((108, 109) that bind a fluorescent substance that absorbs light emitted by the light emitting device (101) and emits light of a different wavelength and secures the fluorescent substance onto the surface of the light emitting device (101). The coating layers (108, 109) are made of an inorganic material including an oxide and a hydroxide, each containing at least one element selected from the group consisting of Si, Al, Ga, Ti, Ge, P, B, Zr, Y, Sn, Pb and alkali earth metals. Also an adhesive layer (110) is made of the same inorganic material as that of the coating layers (108, 109).

Owner:NICHIA CORP

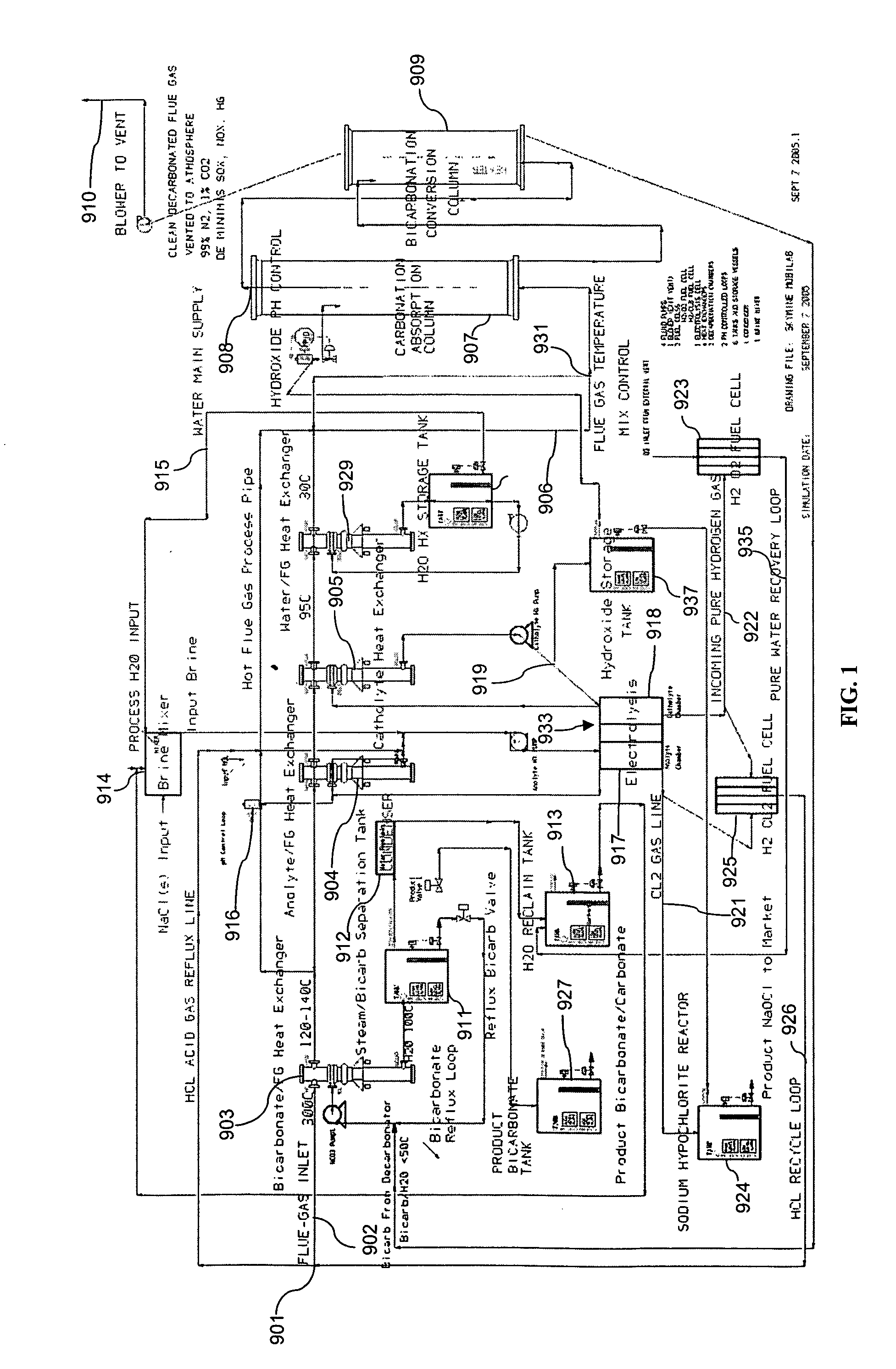

Removing carbon dioxide from waste streams through co-generation of carbonate and/or bicarbonate minerals

ActiveUS20060185985A1Improve ecologic efficiency of processEcologic efficiencyCalcium/strontium/barium carbonatesElectrolysis componentsElectrolysisWaste stream

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

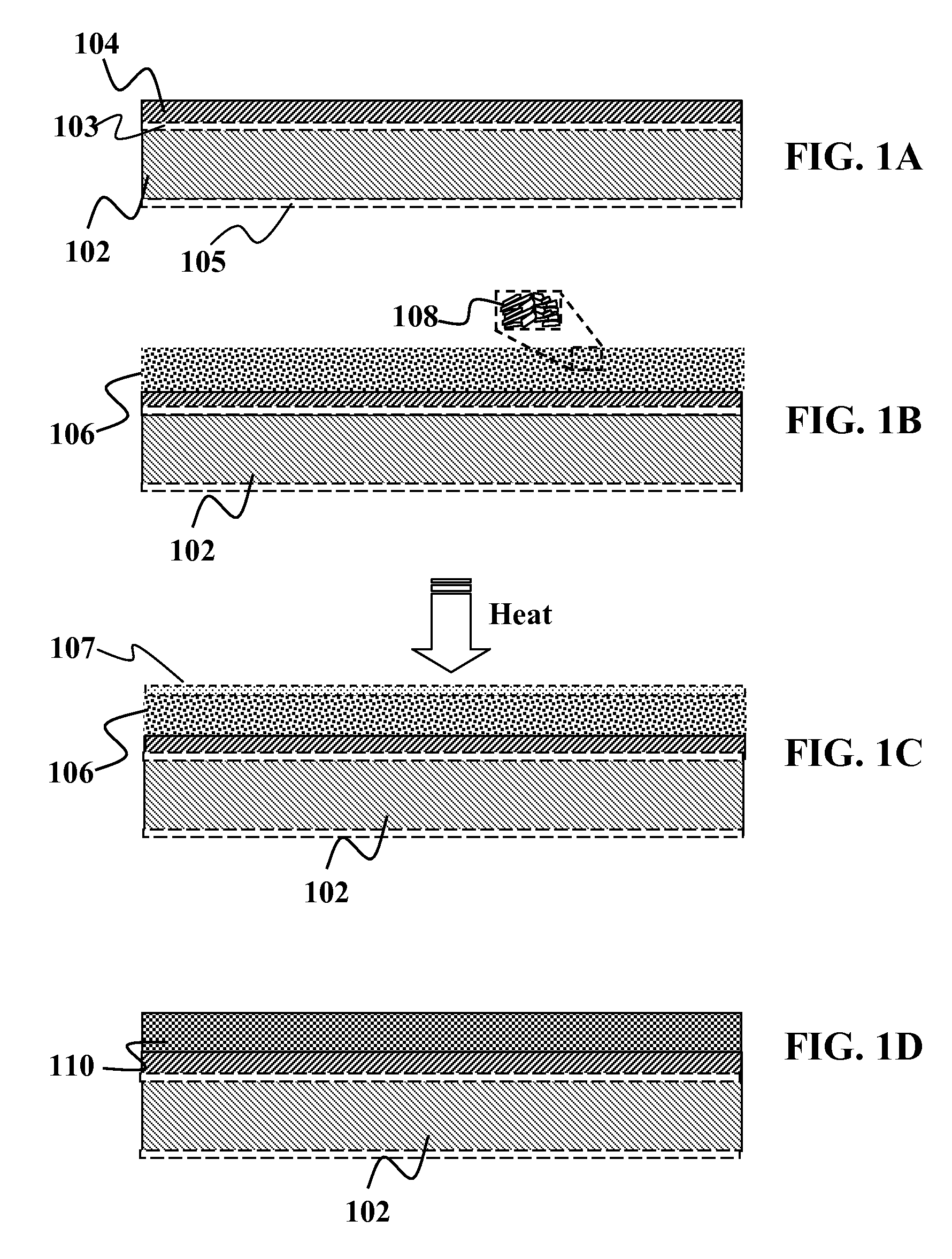

Solar cell absorber layer formed from metal ion precursors

Methods and devices are provided for forming an absorber layer. In one embodiment, a method is provided comprising of depositing a solution on a substrate to form a precursor layer. The solution comprises of at least one polar solvent, at least one binder, and at least one Group IB and / or IIIA hydroxide. The precursor layer is processed in one or more steps to form a photovoltaic absorber layer. In one embodiment, the absorber layer may be created by processing the precursor layer into a solid film and then thermally reacting the solid film in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer. Optionally, the absorber layer may be processed by thermal reaction of the precursor layer in an atmosphere containing at least an element of Group VIA of the Periodic Table to form the photovoltaic absorber layer.

Owner:AERIS CAPITAL SUSTAINABLE IP

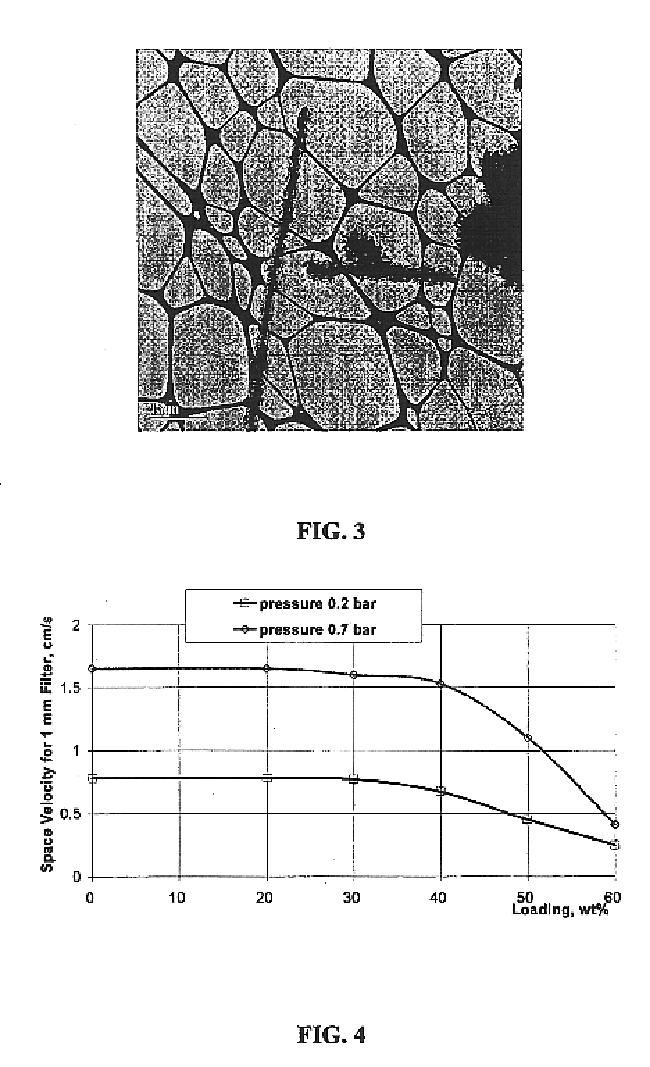

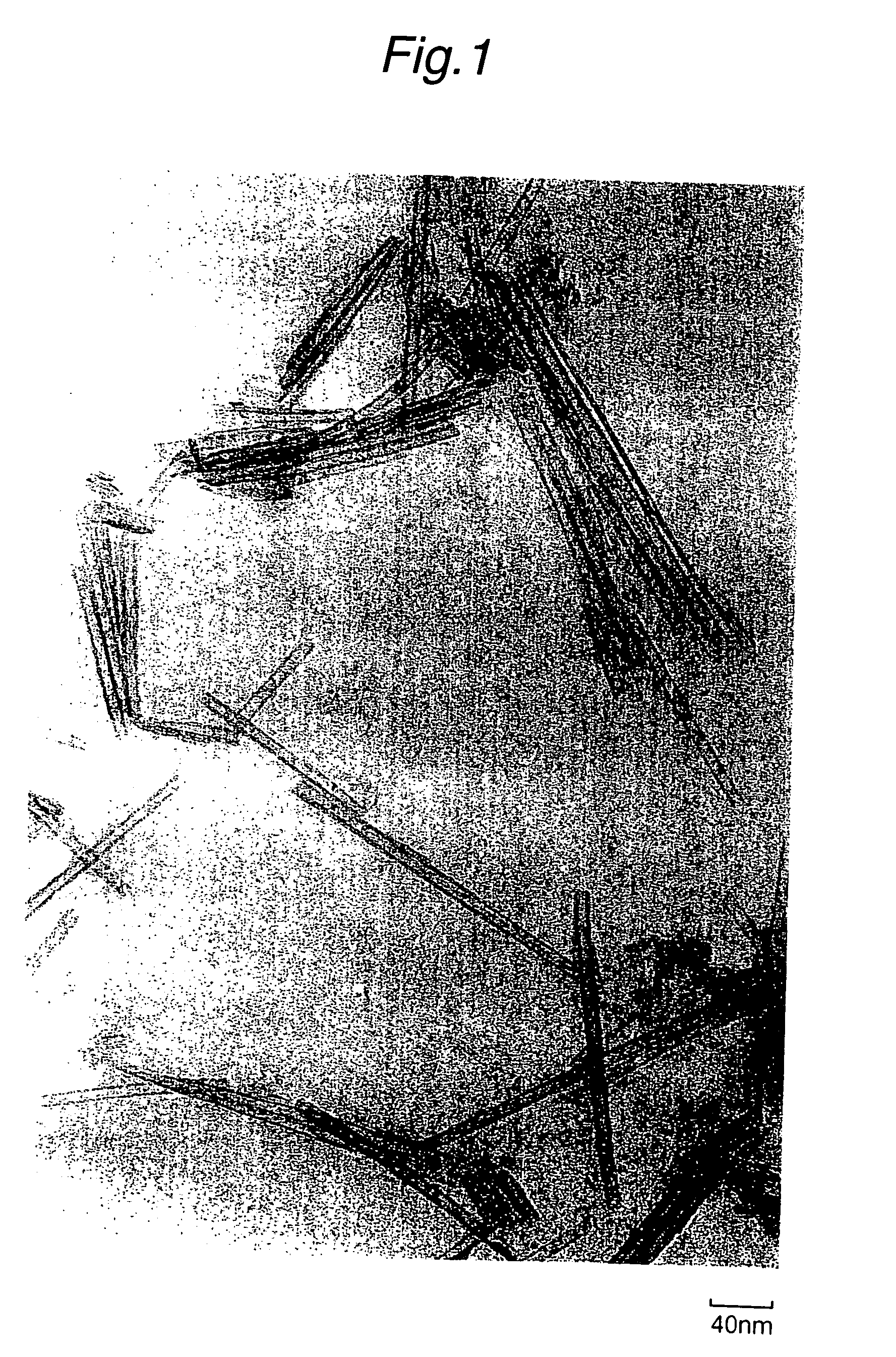

Nanosize electropositive fibrous adsorbent

InactiveUS6838005B2Improve the immunityEfficient precipitationIon-exchanger regenerationLoose filtering material filtersFiberParticulates

Aluminum hydroxide fibers approximately 2 nanometers in diameter and with surface areas ranging from 200 to 650 m2 / g have been fount to be highly electropositive. When dispersed in water they are able to attach to and retain electronegative particles. When combined into a composite filter with other fibers or particles they can filter bacteria and nano size particulates such as viruses and colloidal particles at high flux through the filter. Such filters can be used for purification and sterilization of water, biological, medical and pharmaceutical fluids, and as a collector / concentrator for detection and assay of mirobes and viruses. The alumina fibers are also capable of filtering sub-micron inorganic and metallic particles to produce ultra pure water. The fibers are suitable as a substrate for growth of cells. Macromolicules such as proteins may be separated from each other based on their electronegative charges.

Owner:ARGONIDE CORP

High performance energy storage devices

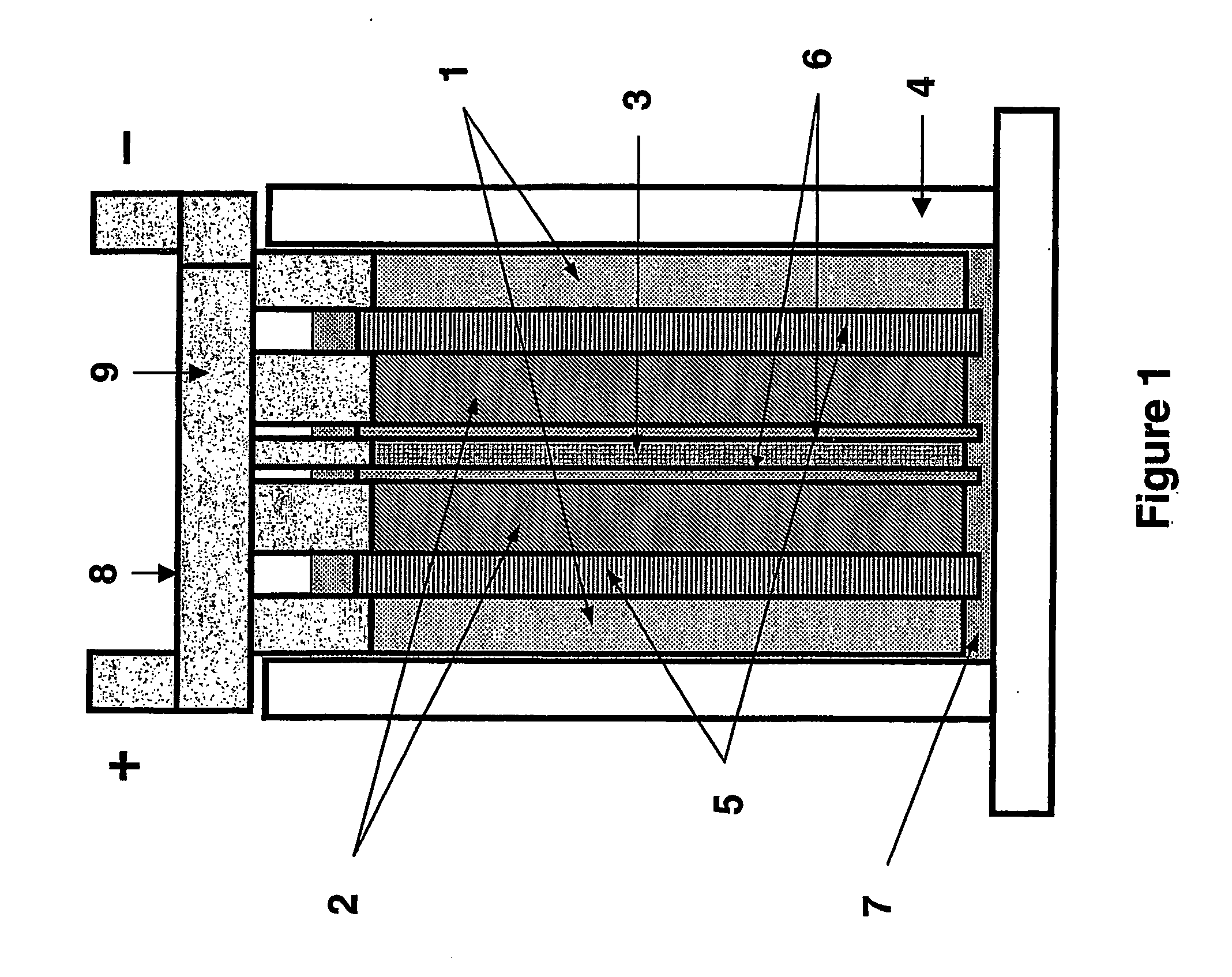

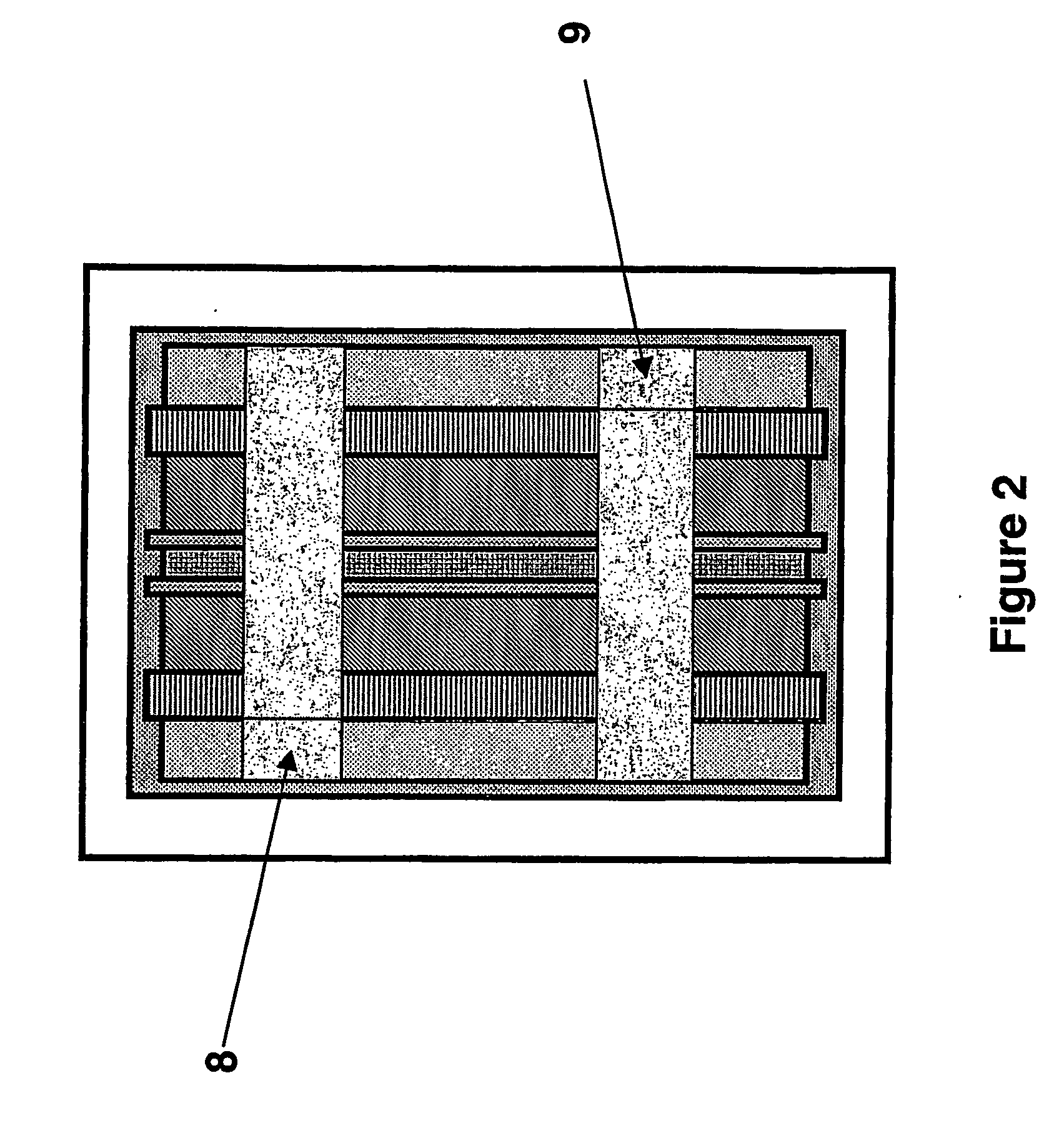

ActiveUS20070104981A1Avoid gasLower internal resistanceHybrid capacitor electrolytesCapacitor and primary/secondary cellsLead dioxideBusbar

A lead-acid battery comprising: at least one lead-based negative electrode; at least one lead dioxide-based positive electrode; at least one capacitor electrode; and electrolyte in contact with the electrodes; wherein a battery part is formed by the lead based negative electrode and the lead dioxide-based positive electrode; and an asymmetric capacitor part is formed by the capacitor electrode and one electrode selected from the lead based negative electrode and the lead-dioxide based positive electrode; and wherein all negative electrodes are connected to a negative busbar, and all positive electrodes are connected to a positive busbar. The capacitor electrode may be a capacitor negative electrode comprising carbon and an additive mixture selected from oxides, hydroxides or sulfates of lead, zinc, cadmium, silver and bismuth, or a capacitor negative electrode comprising carbon, red lead, antimony in oxide, hydroxide or sulfate form, and optionally other additives. The capacitor electrode may be used in asymmetric capacitors and batteries of other types.

Owner:COMMONWEALTH SCI & IND RES ORG

Alkaline, post plasma etch/ash residue removers and photoresist stripping compositions containing metal-halide corrosion inhibitors

InactiveUS20070060490A1Avoiding consequenceAvoid expensesDetergent mixture composition preparationElectrostatic cleaningAlkaline earth metalMetal halides

The invention provides alkaline compositions useful in the microelectronics industry for stripping or cleaning semiconductor wafer substrates by removing photoresist residues and other unwanted contaminants. The compositions contain (a) one or more bases and (b) one or more metal corrosion inhibiting metal halides of the formula: WzMXy where M is a metal selected from the group Si, Ge, Sn, Pt, P, B, Au, Ir, Os, Cr, Ti, Zr, Rh, Ru, and Sb; X is a halide selected from F, Cl, Br and I; W is selected from H, to an alkali or alkaline earth metal, and a metal ion-free hydroxide base moiety; y is a numeral of from 4 to 6 depending on the metal halide; and z is a numeral of 1, 2 or 3.

Owner:AVANTOR PERFORMANCE MATERIALS INC

Canister, sealing method and composition for sealing a borehole

Owner:TRIAD NAT SECURITY LLC

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

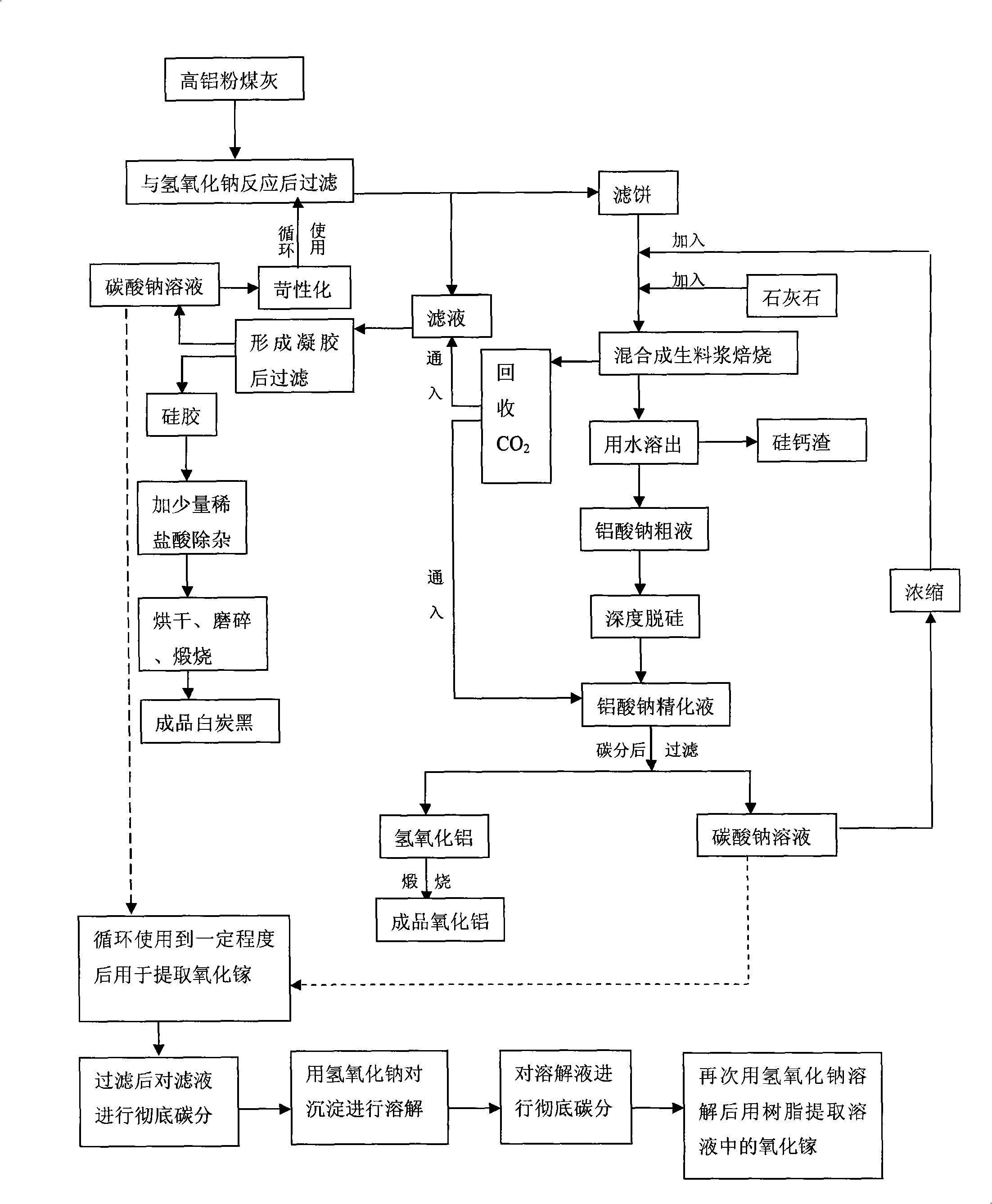

Process for abstracting earth silicon, oxide of alumina and gallium oxide from high-alumina flying ash

ActiveCN101284668AReduce the total massLow firing temperatureGallium/indium/thallium compoundsSilicon oxidesChemical industryFiltration

A method for extracting silicon dioxide, alumina and gallium oxide from high-alumina fly ash relates to the technology fields of environmental mineralogy and material, chemical industry and metallurgy. The method comprises the main steps as follows: causing the high-alumina fly ash to react with sodium hydroxide solution; filtering the solution; introducing CO2 to the filtrate for full gelation; cleaning, purifying, drying, grinding and calcining the silica gel after gel filtration to obtain finished white carbon black; adding limestone and a sodium carbonate solution into the filter mass after the reaction and filtration of the high-alumina fly ash and the sodium hydroxide solution; ball grinding the mixture into raw slurry; dissolving out the clinker obtained by baking the raw slurry; subjecting the filtrate to deep desiliconization to obtain sodium aluminate extraction liquid; filtrating the sodium aluminate extraction liquid after subjecting the sodium aluminate extraction liquid to carbon dioxide decomposition; baking the aluminum hydroxide after washing the filter mass to form the aluminum hydroxide product; and extracting the gallium oxide from the carbon dioxide decomposition mother solution and desiliconized solution. The method has the advantages of low material price, simple operating procedures, low investment, low production cost, low energy consumption and less slag.

Owner:TSINGHUA UNIV +1

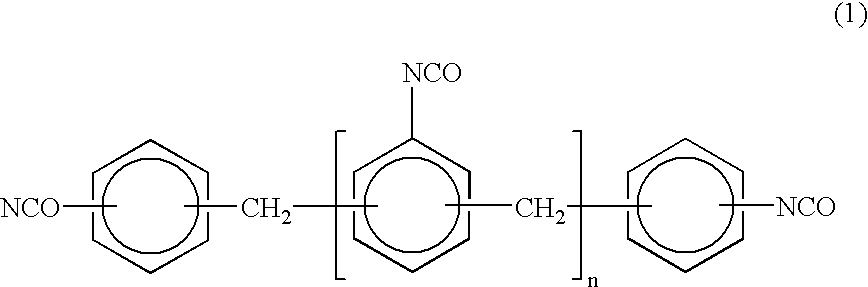

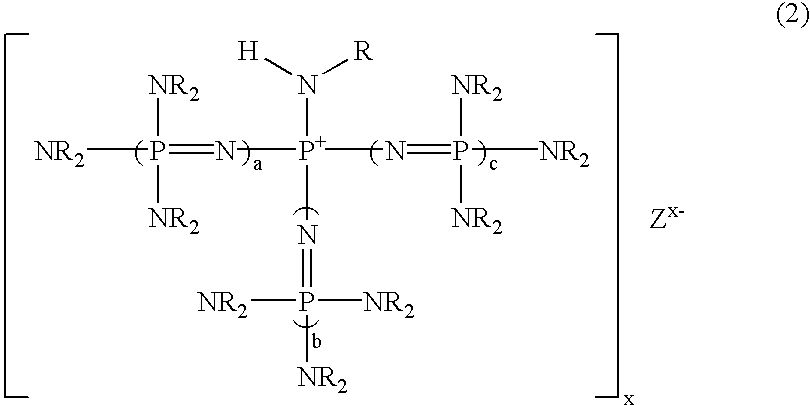

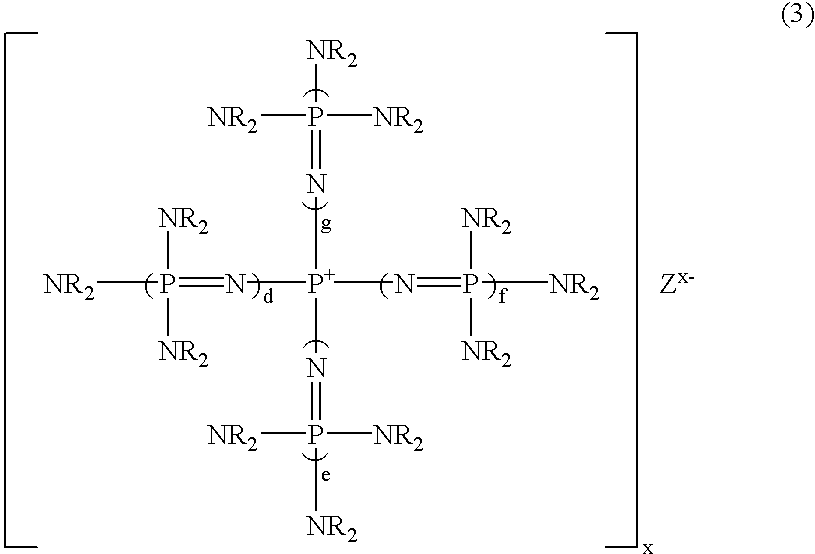

High-durability flexible polyurethane cold cure molded foam and process for producing the same

The high-durability flexible polyurethane cold cure molded foam of the invention has an overall density of not less than 35 kg / m3 and not more than 45 kg / m3 and a wet heat compression set of not more than 15%, and preferably has a hardness change ratio, as determined in a repeated compression test, of not more than 15%. This foam can be obtained by the process of the invention. The process of the invention is a process for producing a flexible polyurethane cold cure molded foam obtained from a polyol and / or a polymer polyol containing dispersed polymer microparticles obtained by radical polymerizing a compound having an unsaturated bond in the polyol, water, a catalyst and a polyisocyanate, wherein the polyol is a polyol synthesized by the use of a catalyst containing at least one compound selected from the group consisting of a compound having a nitrogen-phosphorus double bond, cesium hydroxide and rubidium hydroxide. The foam of the invention has a low density and is excellent in durability, particularly in hardness change ratio in a repeated compression test and wet heat compression set. According to the process of the invention, such a foam can be obtained.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

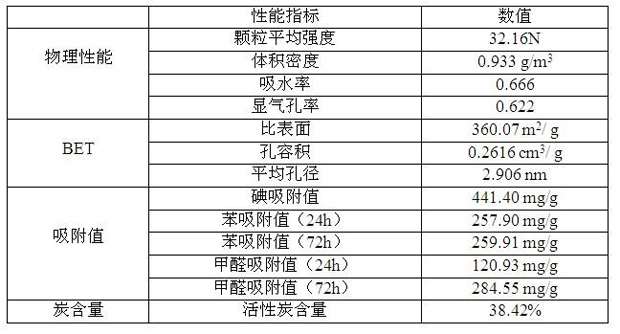

Activated alumina and activated carbon compounded material and preparation method thereof

InactiveCN101890336AAchieve the perfect combinationEasy to useCatalyst carriersOther chemical processesActivated carbonAir purification

The invention provides an activated alumina and activated carbon compounded material and a preparation method thereof. According to a formula, the material comprises the following raw materials in percentage by mass: 40 to 99 percent of aluminum hydroxide, 1 to 60 percent of activated carbon, and 15 to 35 percent of binder. The material is prepared by uniformly mixing, pelleting, ageing, molding, airing, sintering, rinsing, drying and the like. The invention aims to compound the activated carbon with the activated alumina; on the one hand, the material with a certain shape can be processed, the defects of loose shape, low strength, difficult recovery and the like of the activated carbon are overcome, and the material is easy to recycle; and on the other hand, the adsorption property of the activated alumina material is greatly improved. The method has the advantages of simpleness, practicality, readily available raw materials, low cost and suitability for industrial mass production, and can be widely applied to various fields such as industry, agriculture, environmental protection, air purification, water treatment and the like.

Owner:FUZHOU UNIV

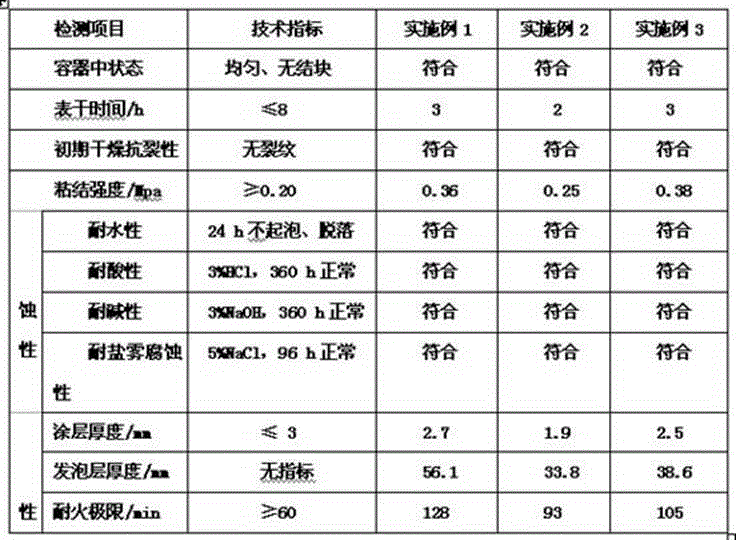

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

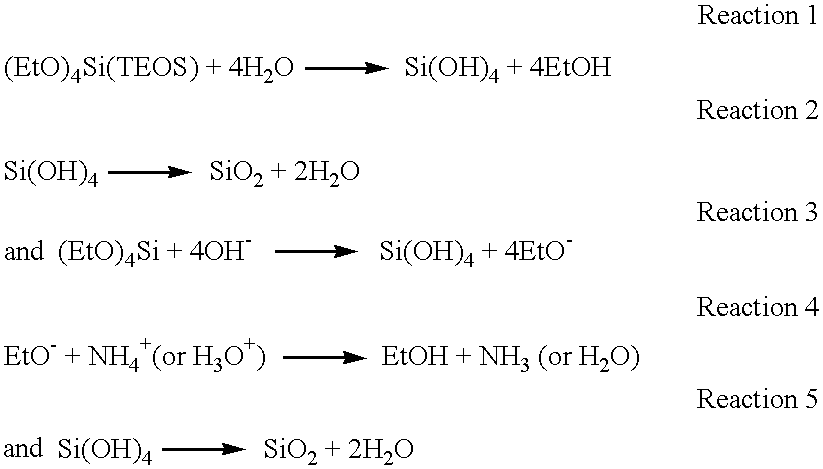

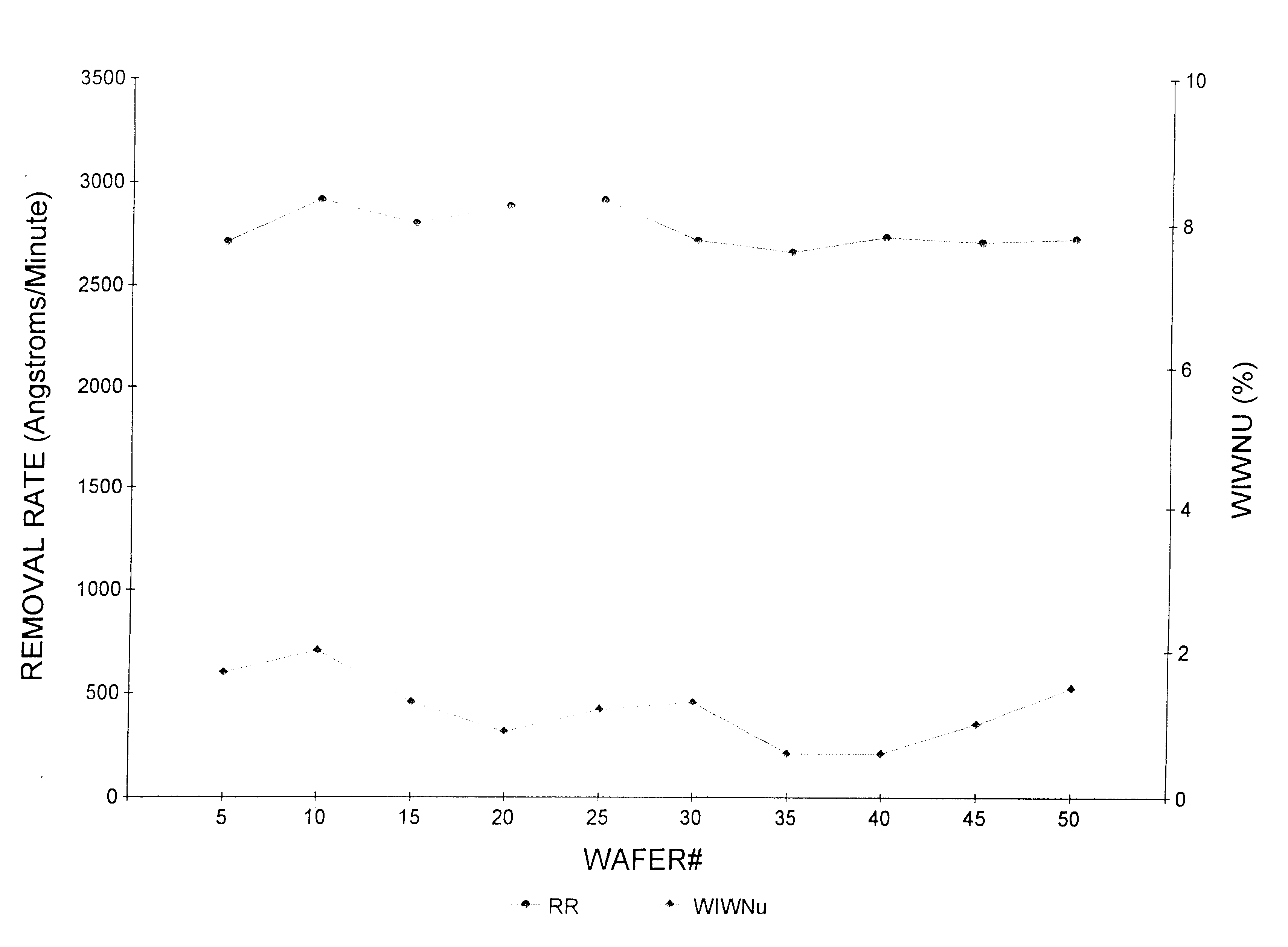

Planarization compositions and methods for removing interlayer dielectric films

InactiveUS6322600B1Improve planarization qualityQuality improvementPigmenting treatmentOther chemical processesThinningDielectric thin films

A planarization composition is set forth for chemical mechanical planarization of dielectric layers for semiconductor manufacture. The composition comprises spherical silica particles having an average diameter of from 30 nm to about 400 nm, and a narrow range of particle sizes, wherein about 90% of the particles is within 20% of the average particle diameter. The composition includes a liquid carrier comprising up to about 9% alcohol and an amine hydroxide in the amount of about 0.2 to about 9% by weight. The pH of the composition is in the range of about 9 to about 11.5, and the remainder of the solution is water. The composition has low amounts of metal ions, and the composition is used for thinning, polishing and planarizing interlayer dielectric thin films, shallow trench isolation structures, and isolation of gate structures. The invention also comprises methods for using the planarization composition in the manufacture of semiconductor devices.

Owner:ADVANCED TECH MATERIALS INC

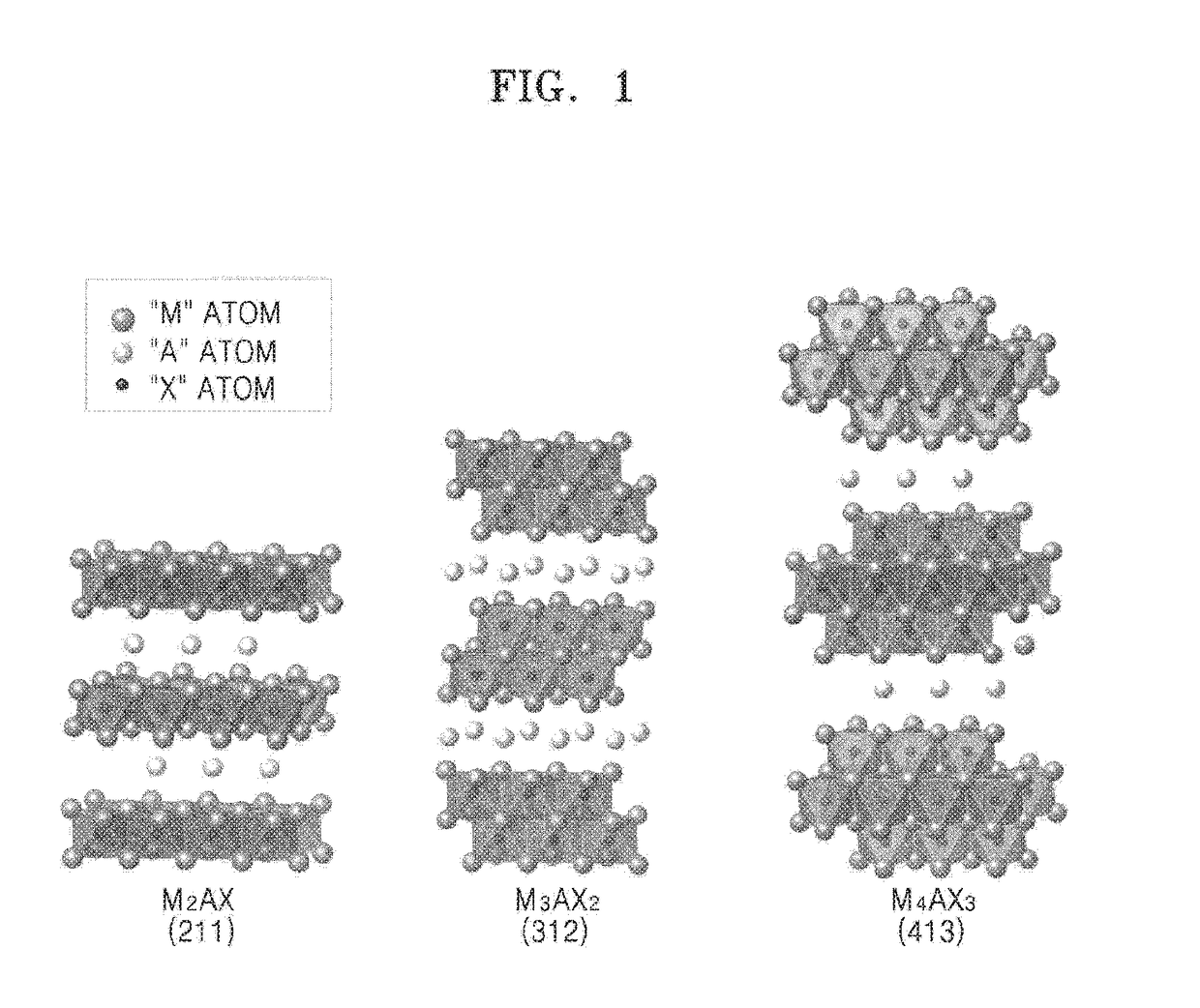

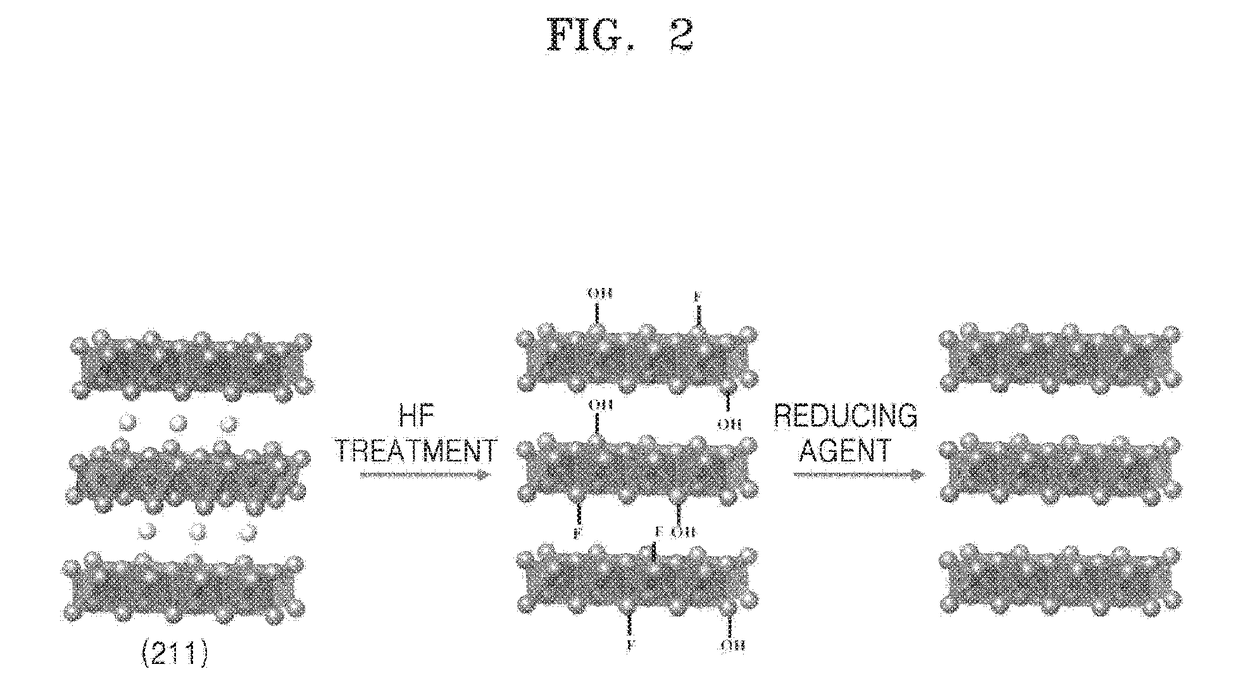

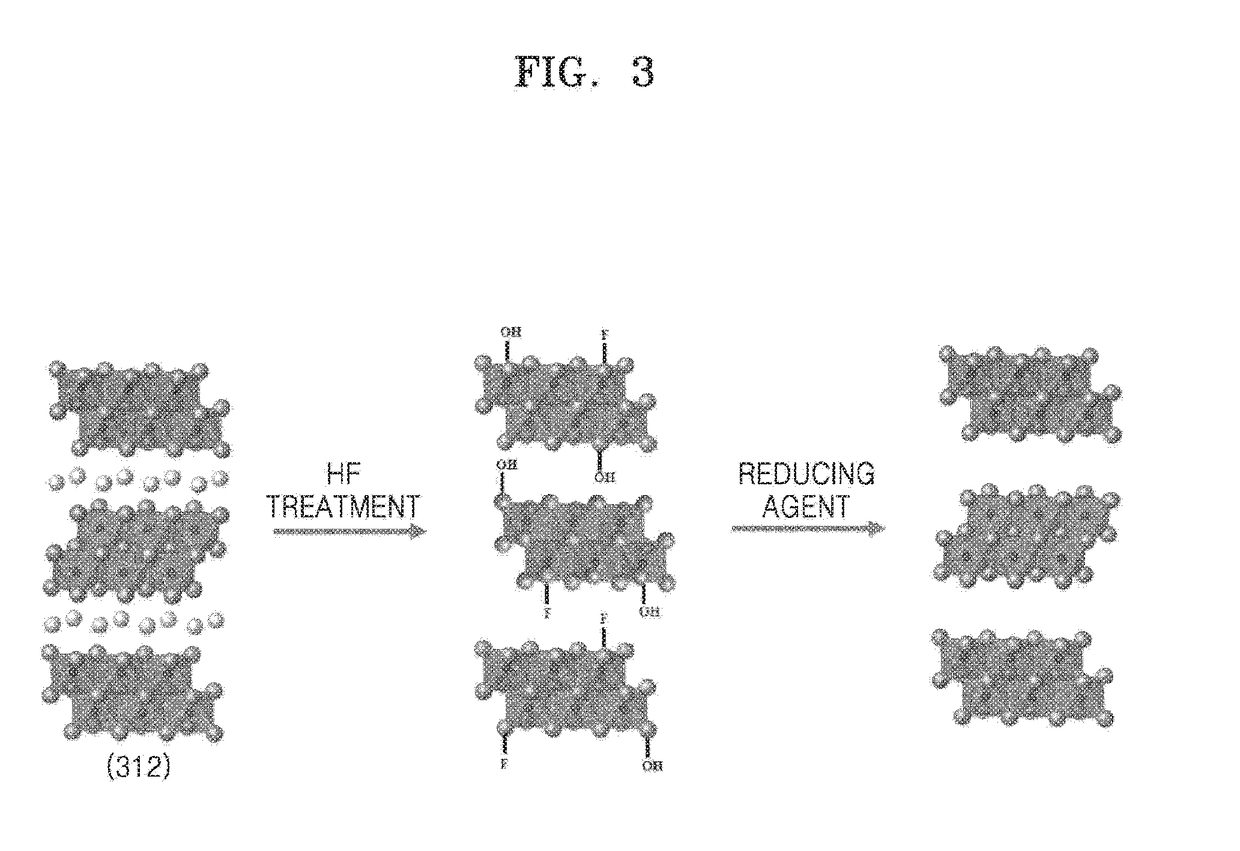

Mxene nanosheet and manufacturing method thereof

ActiveUS20170088429A1Material nanotechnologyNitrogen-metal/silicon/boron binary compoundsIodideInorganic compound

A method of manufacturing a MXene nanosheet includes removing an A atomic layer from an inorganic compound having a formula of Mn+1AXn to form a nanosheet, the nanosheet having a formula of Mn+1XnTs, and reducing the nanosheet having a formula of Mn+1XnTsto form an MXene nanosheet, the MXene nanosheet having a formula of Mn+1Xn, wherein M is at least one of Group 3 transition metal, Group 4 transition metal, Group 5 transition metal, and Group 6 transition metal, A is at least one of a Group 12 element, Group 13 element, Group 14 element, Group 15 element and Group 16 element, X is one of carbon (C), nitrogen (N) and a combination thereof, Ts is one of oxide (O), epoxide, hydroxide (OH), alkoxide having 1-5 carbon atoms, fluoride (F), chloride (Cl), bromide (Br), iodide (I), and a combination thereof, and n is one of 1, 2 and 3.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

Stripping liquid for semiconductor device, and stripping method

A stripping liquid for a semiconductor device is provided that includes an aqueous solution containing a quaternary ammonium hydroxide, an oxidizing agent, an alkanolamine, and an alkali metal hydroxide. There is also provided a stripping method that includes a stripping liquid preparation step of preparing the stripping liquid and a stripping step of removing at least one deposit selected from the group consisting of a photoresist, an anti-reflection film, and an etching residue by means of the stripping liquid obtained in the stripping liquid preparation step.

Owner:FUJIFILM CORP

Thermosettable adhesive

Owner:3M INNOVATIVE PROPERTIES CO

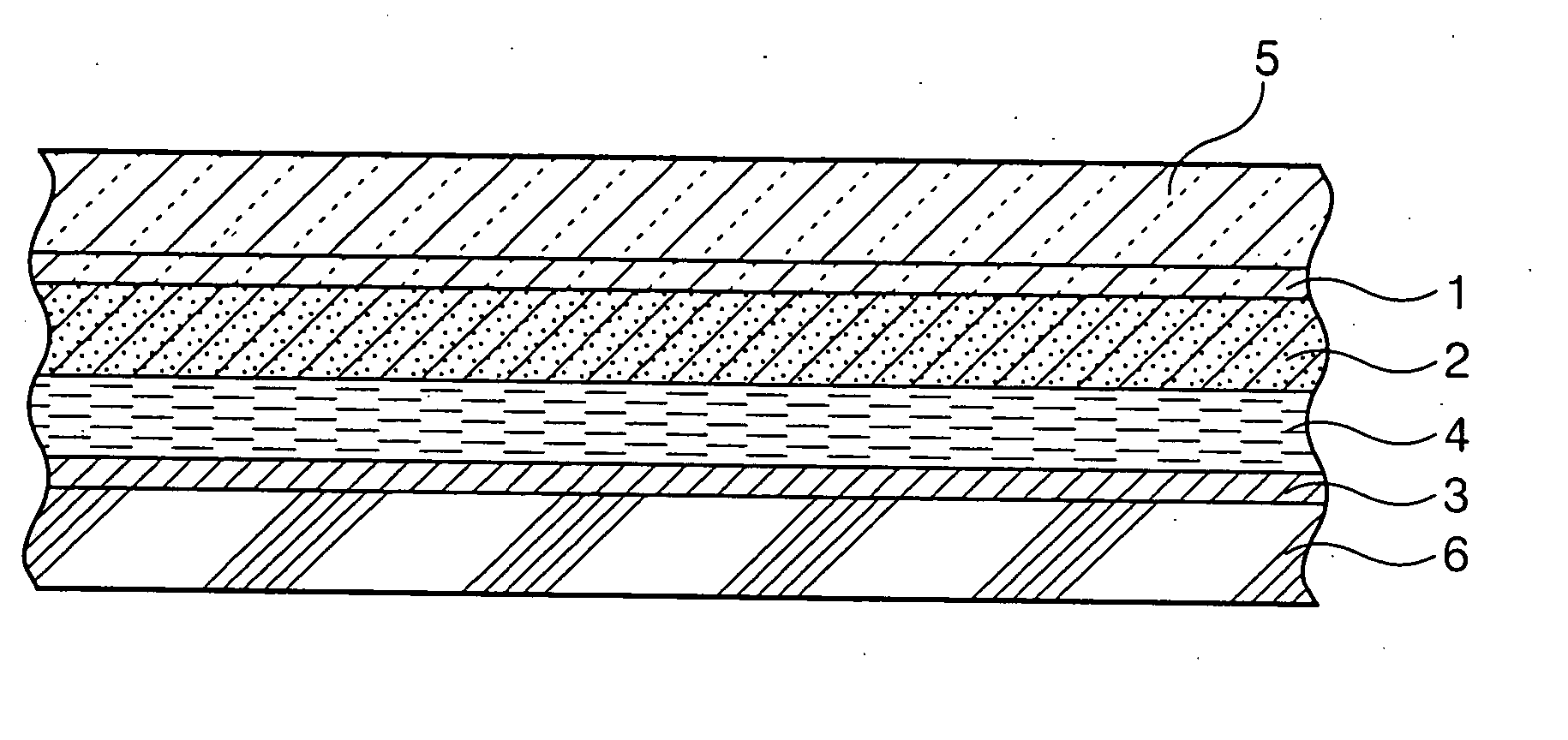

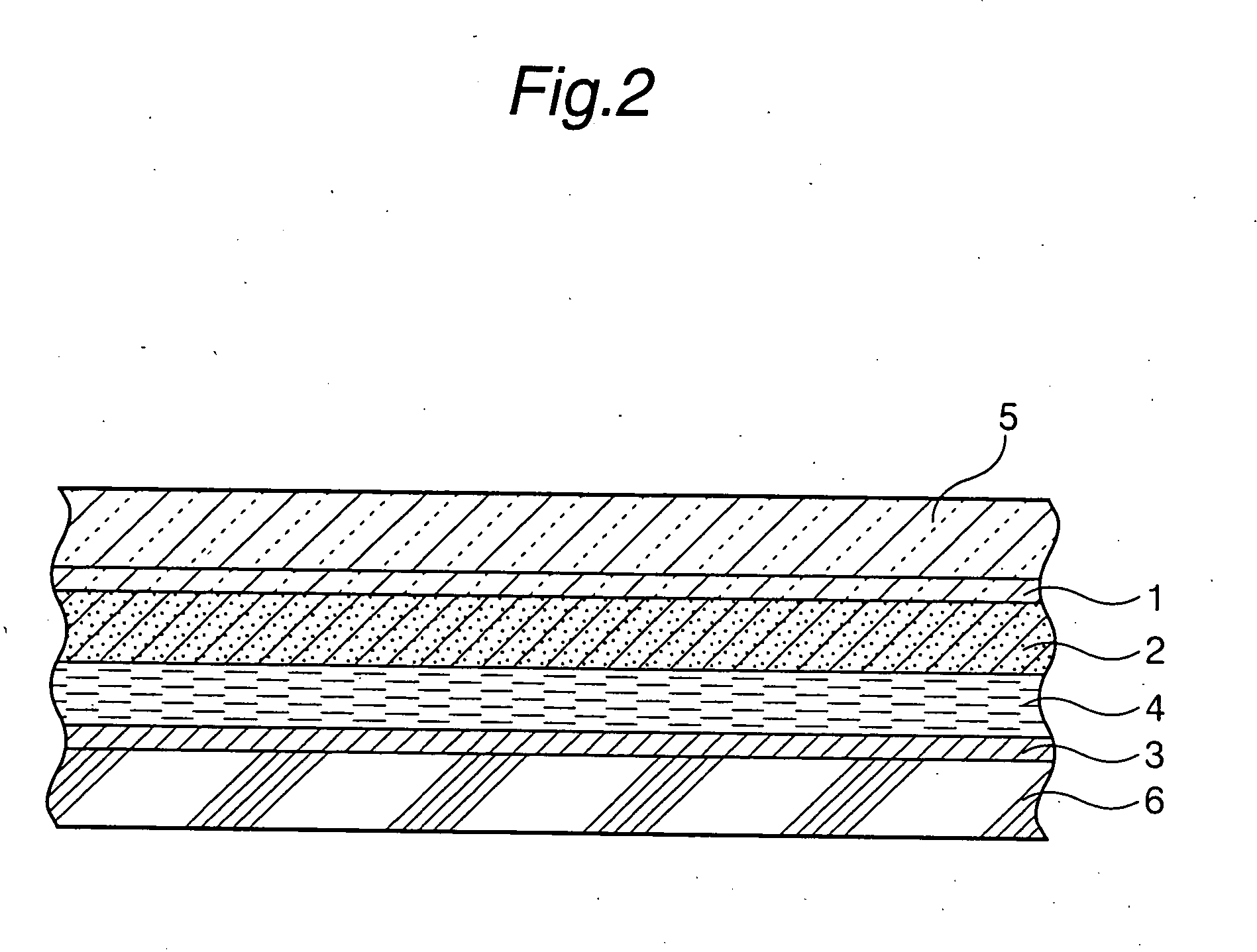

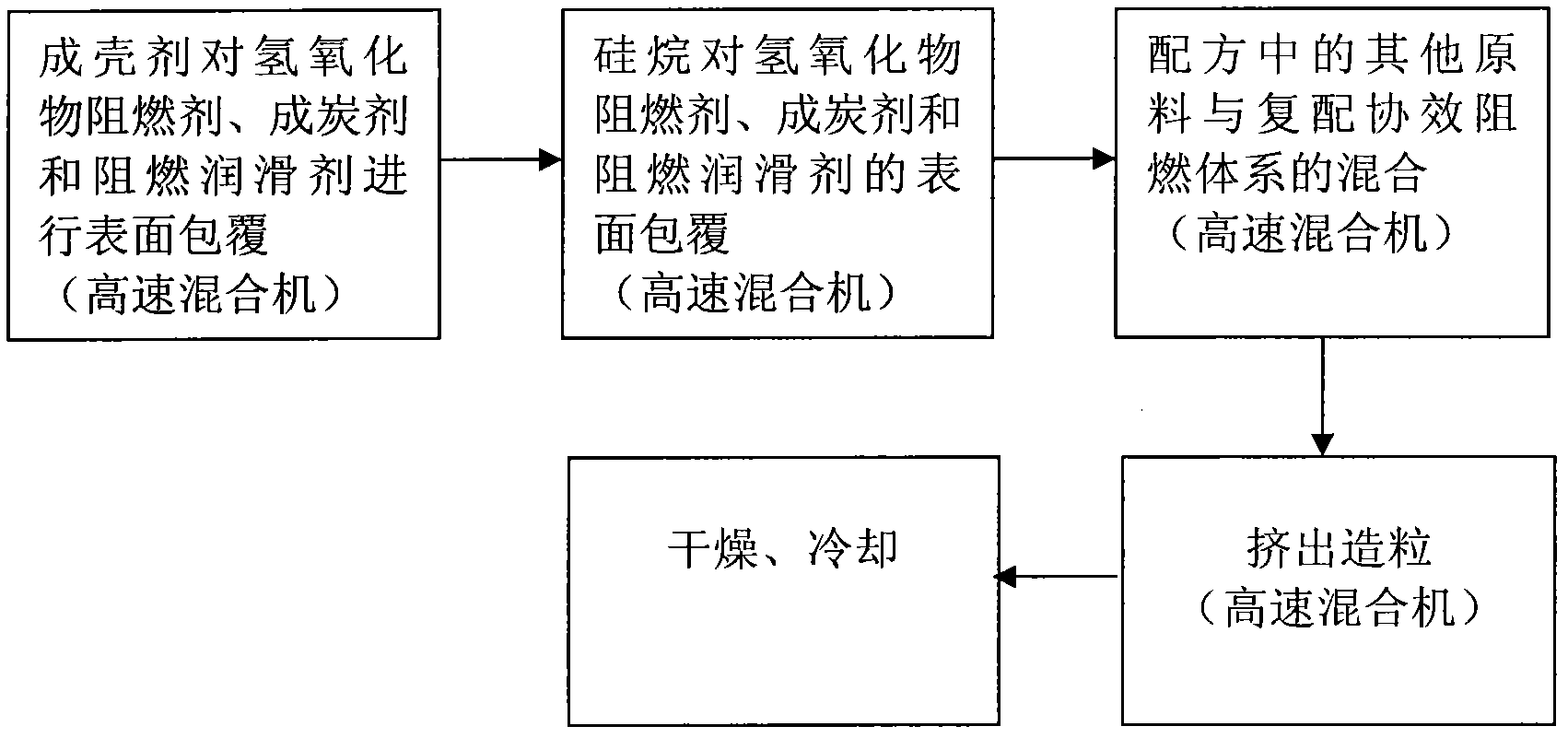

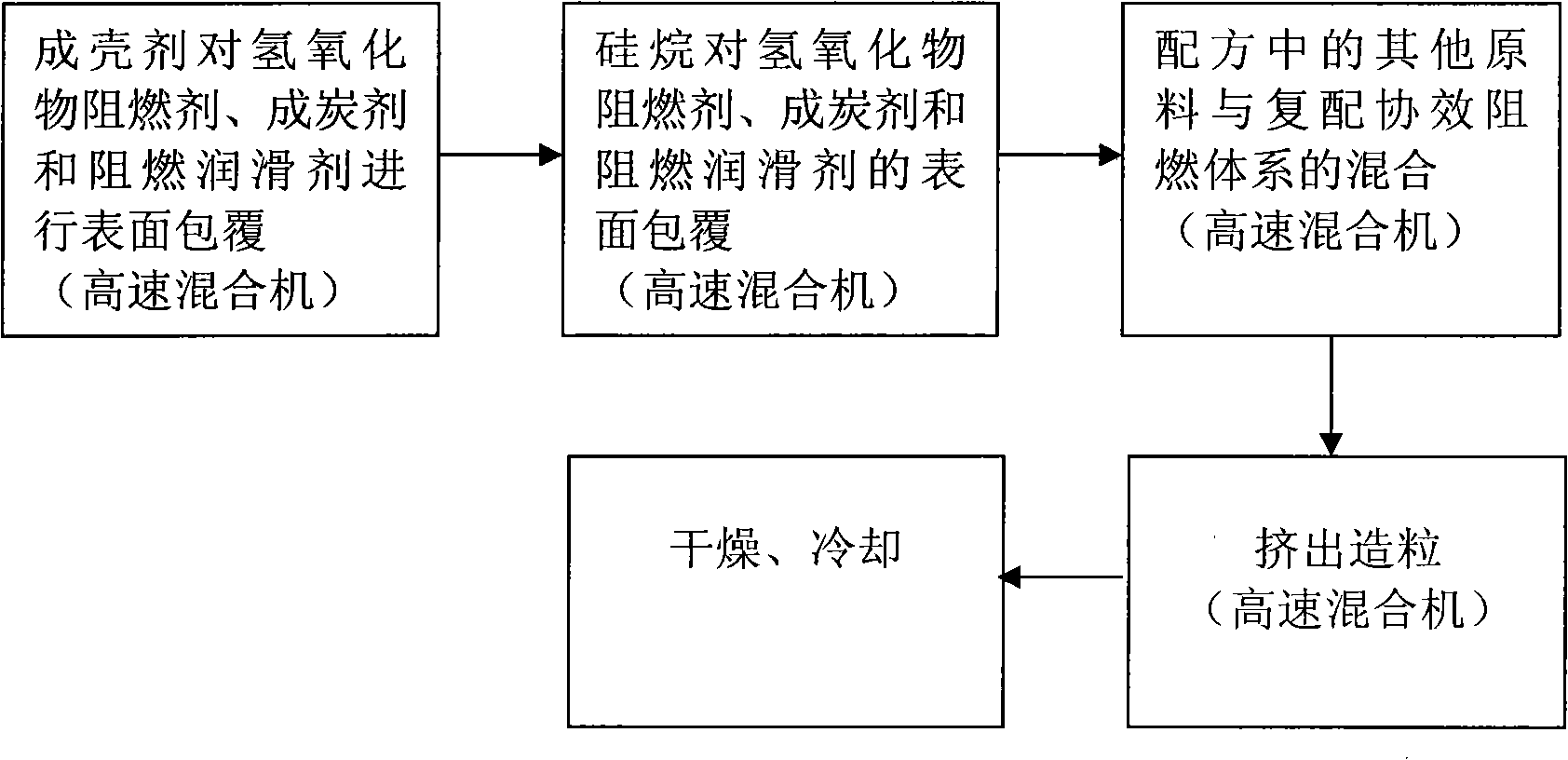

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

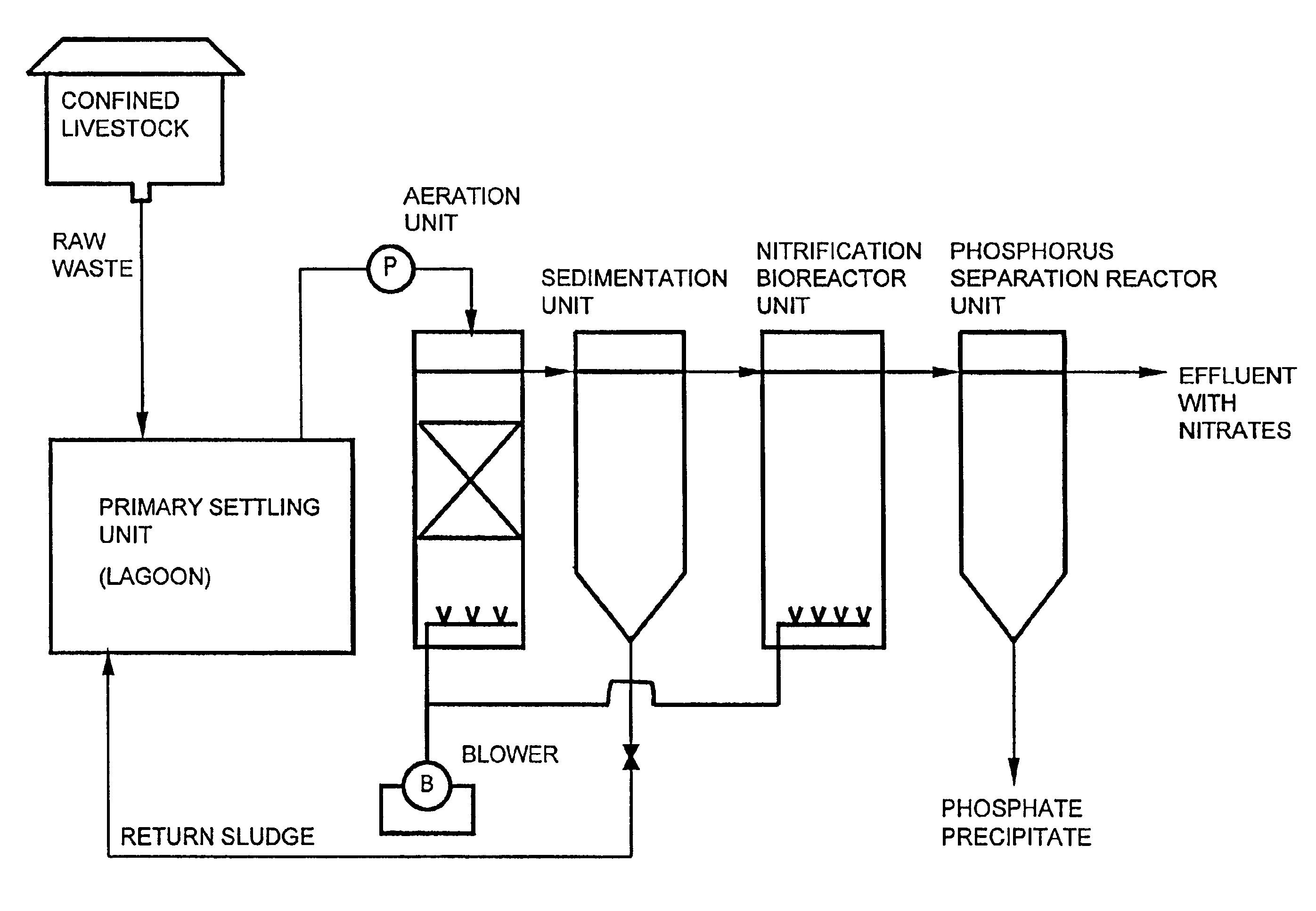

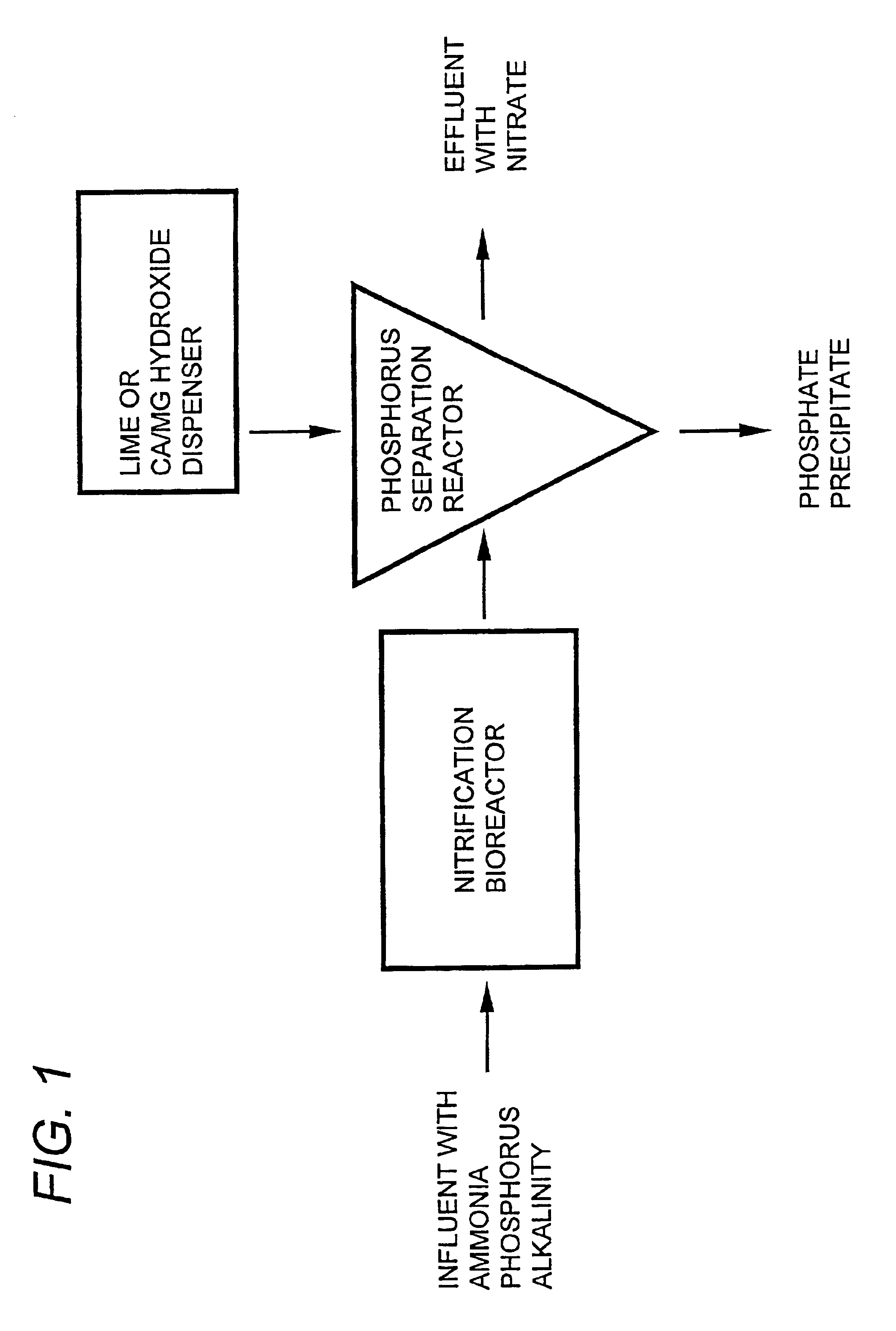

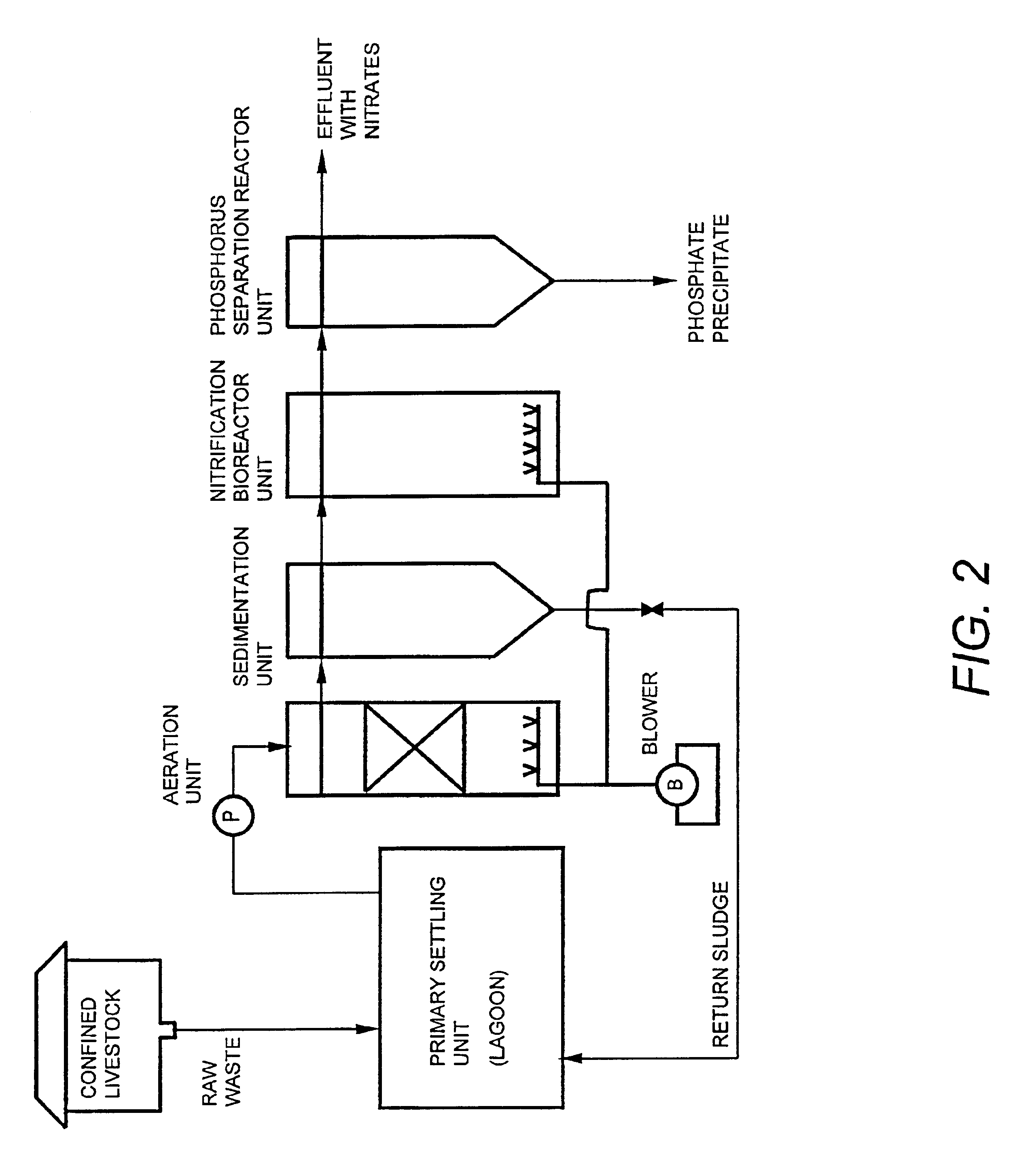

Wastewater treatment system

InactiveUS6893567B1Expand the populationShorten treatment timeTreatment using aerobic processesMixing methodsEnteropathogenic bacteriaTreatment system

Wastewater treatment systems and processes for: removal of solids, pathogens, nitrogen, and phosphorus from municipal and agricultural wastewater include nitrification of wastewater and increasing the pH of the nitrified wastewater by adding a metallic-containing salt and hydroxide to precipitate phosphorus to form a useable effluent having a specified nitrogen:phosphorus ratio that is useful as a fertilizer or spray for remediation of contaminated soils. The presence of infectious microorganism such as enteropathogenic bacteria and picarnoviruses will be reduced in the useable effluent. The precipitated phosphorus is recovered and used to form useable phosphorus products.

Owner:AGRI UNTED STATES OF AMERICA THE AS REPRESENTED BY THE SEC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com