Patents

Literature

2650 results about "Methyl silicone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl Silicon. Methyl Silicon is an antifoaming material added to oils to inhibit general foaming and splattering when combined with heat. The chemical formula is C 2H 6OSi. It can be found in normal spray oils and cooking oils used often in fast food production.

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

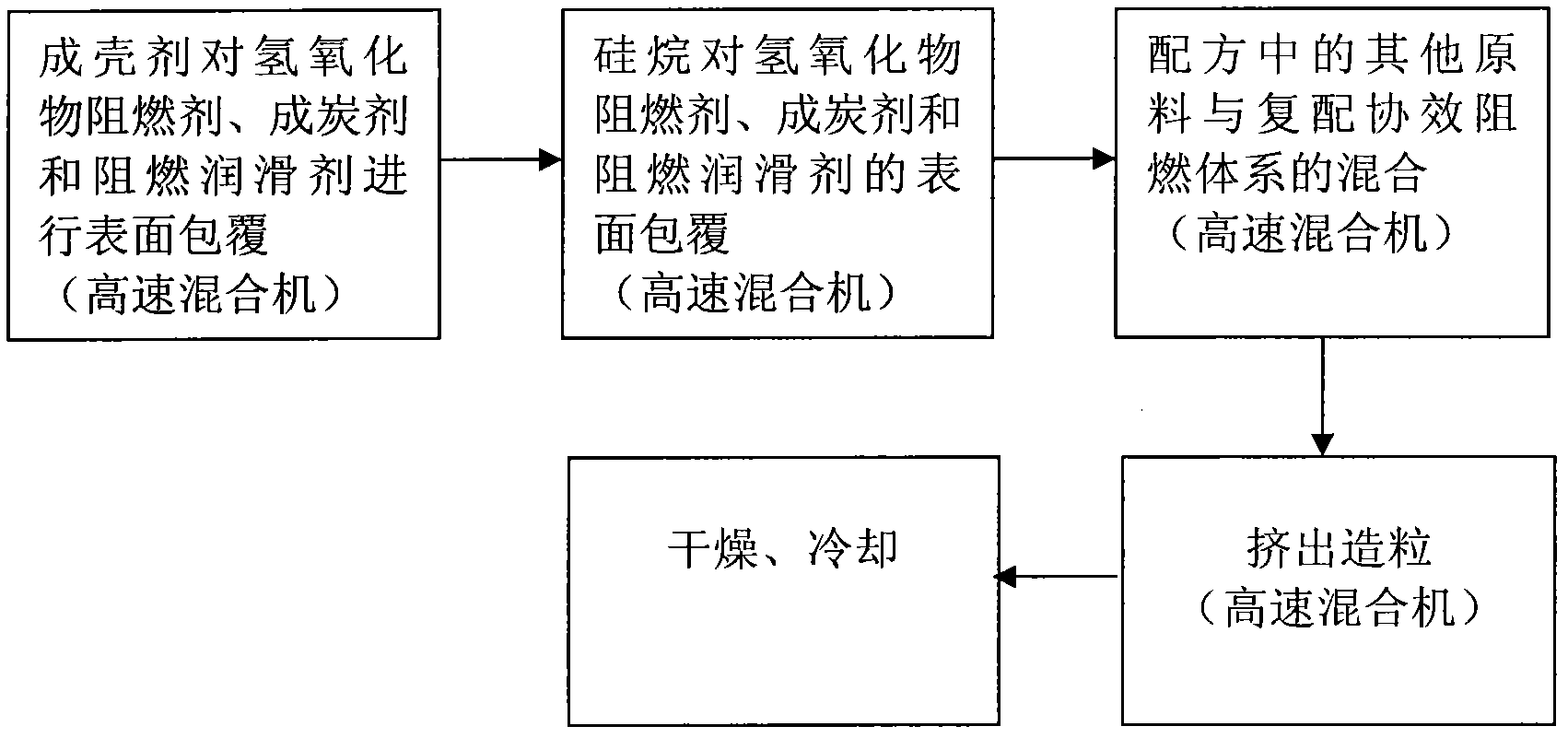

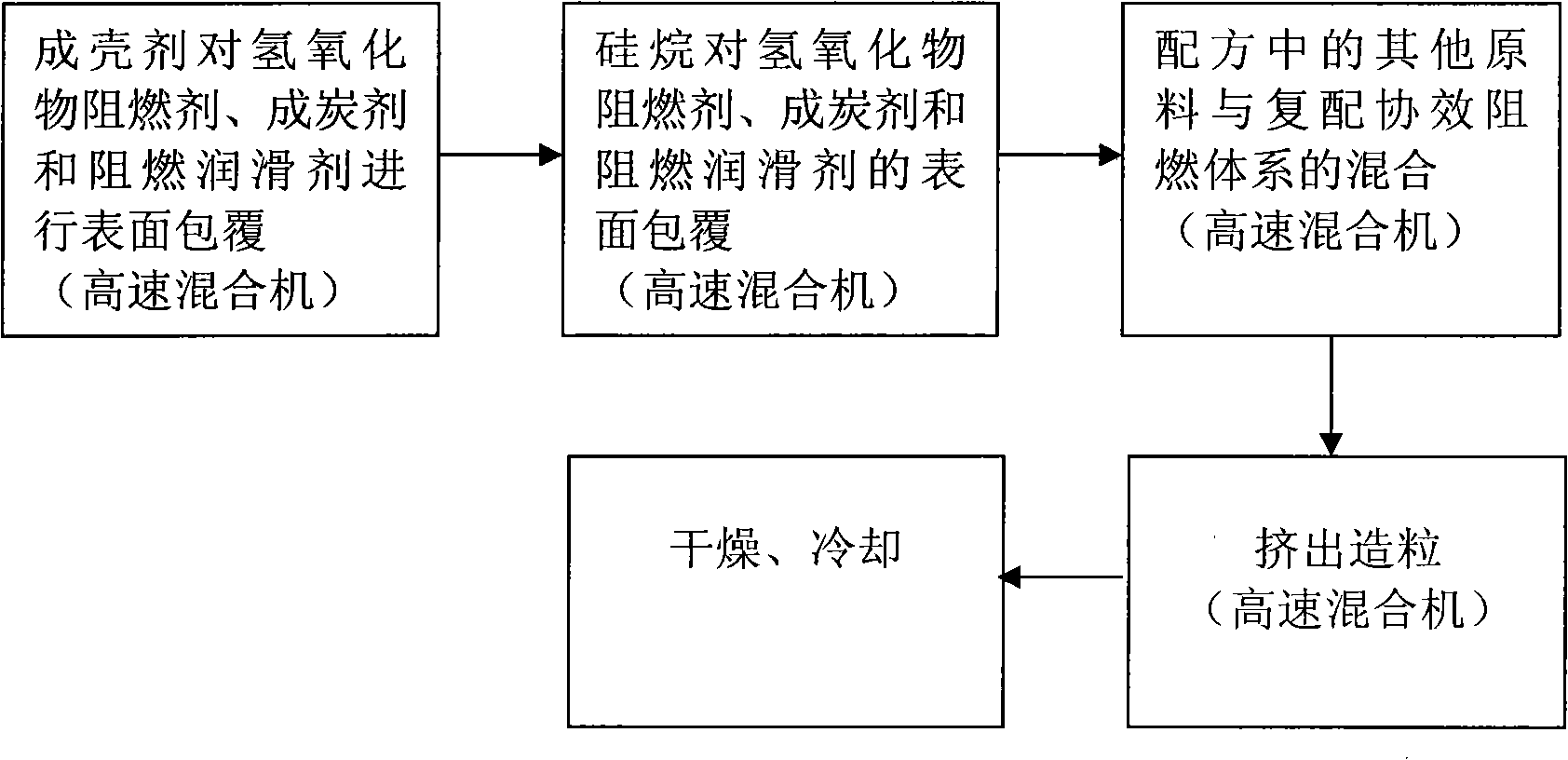

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

Porous silicon/carbon composite material and preparation method thereof

ActiveCN102208634AHigh specific capacityImprove cycle stabilityCell electrodesCarbon compositesNew energy

The invention discloses a porous silicon / carbon composite material and a preparation method thereof, and belongs to the fields of electrochemistry and new energy materials. The method comprises the following steps of: preparing porous silicon dioxide by using ethyl orthosilicate, silicon tetrachloride, methyl silicone oil and sodium silicide as raw materials, reducing the porous silicon dioxide into porous silicon, coating the porous silicon by adopting an organic carbon source, and performing thermal treatment under an inert atmosphere to prepare the porous silicon / carbon composite material. The material can be directly used as the lithium ion battery cathode material, the first discharge specific capacity of the material can reach 1,245mAh / g, the specific capacity can also reach 1,230mAh / g after 30 cycles, and the material has excellent charge / discharge performance.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

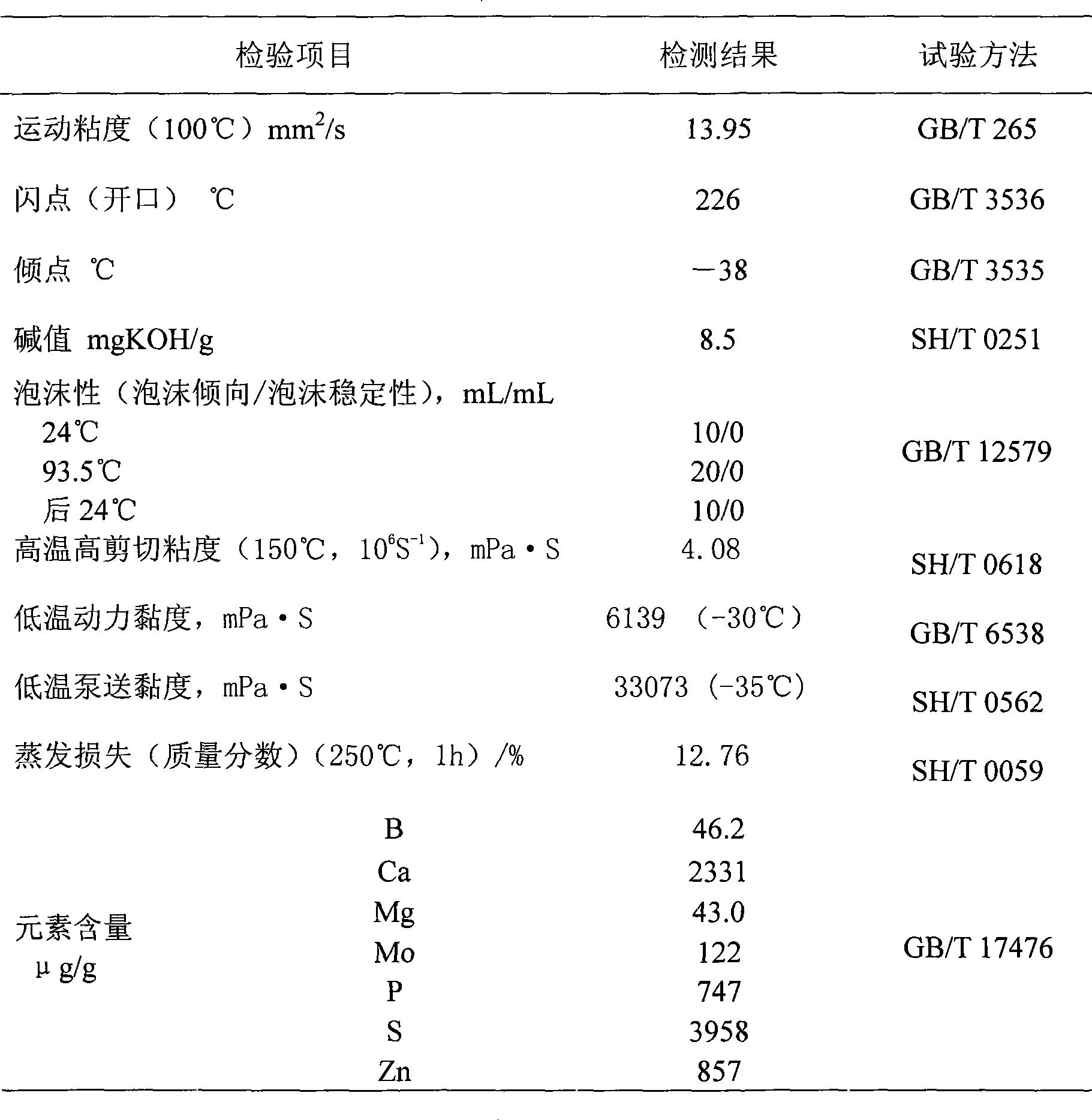

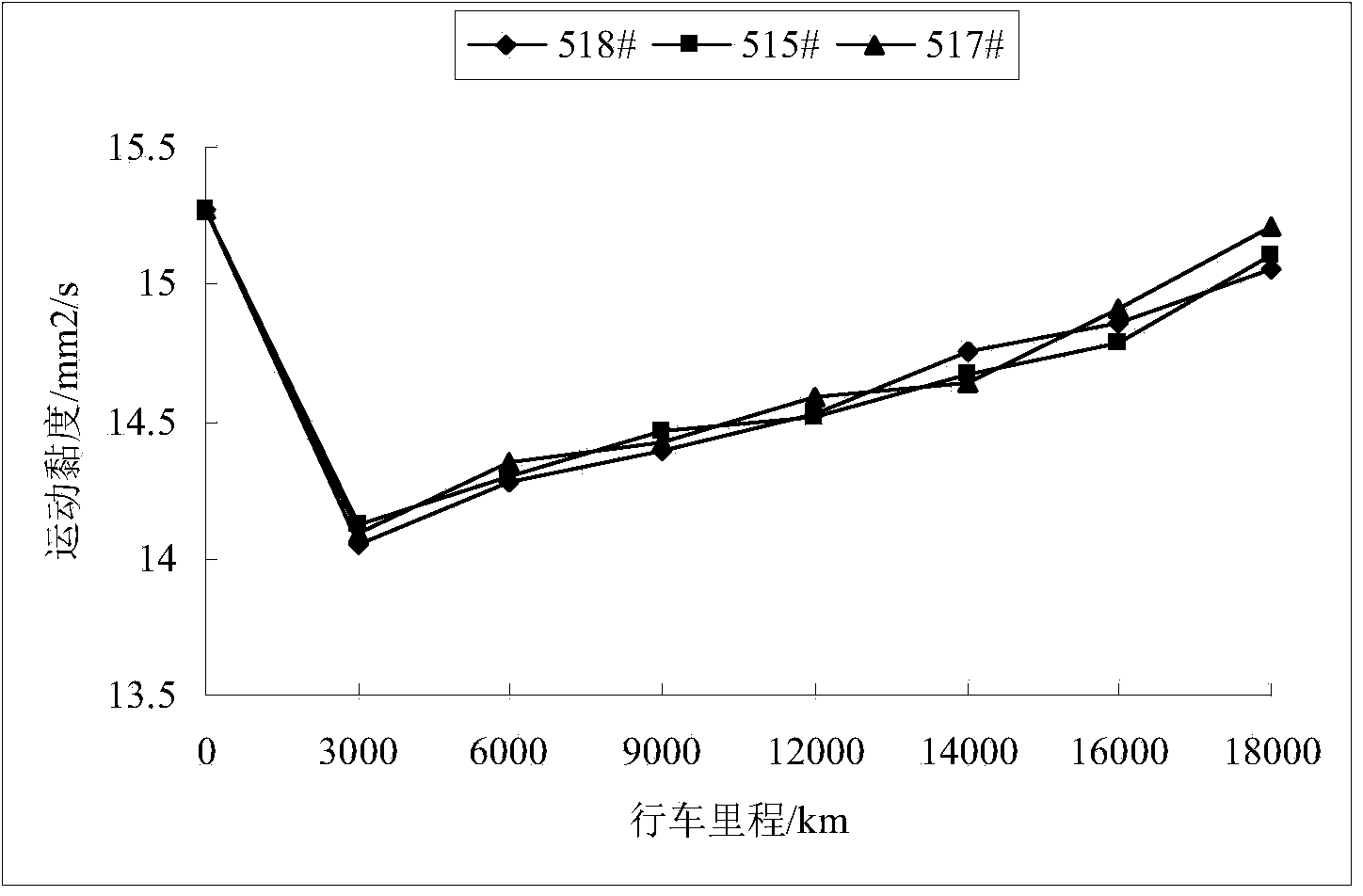

Engine oil suitable for pluralities of fuel

InactiveCN101418250AHave performance requirementsImprove anti-friction and anti-wear effectAdditivesBase-materialsPhenolDiesel engine

The invention relates to engine oil suitable for multiple fuels, and belongs to the field of engine oil for an automobile. The engine oil comprises the following raw materials in mass portion: 33 to 36 portions of base oil 150SN, 22 to 24 portions of base oil VHVI H350 (type III), 15 to 17 portions of poly alpha-alkene, 2 to 4 portions of ester oil of C8 to C10, 11 to 13 portions of ethylene-propylene copolymer the molecular weight of which is between 63,000 and 108,000 as viscosity index improver, 0.4 to 1.2 portions of zinc dialkyl dithiophosphate as additive for resisting oxidation and corrosion as well as abrasion, 1.1 to 4.8 portions of alkyl phenol calcium and 1.9 to 2.5 portions of calcium sulfonate as detergent, 3.8 to 5.0 portions of polyisobutene succimide as dispersant, and 0.001 to 0.003 portion of methyl silicone oil as antifoaming agent. The engine oil meets performance requirements of automobile and engine manufacturers at home and abroad on gasoline engine oil and sedan diesel engine oil.

Owner:CHANGCHUN YONGCHANG PETROCHEM

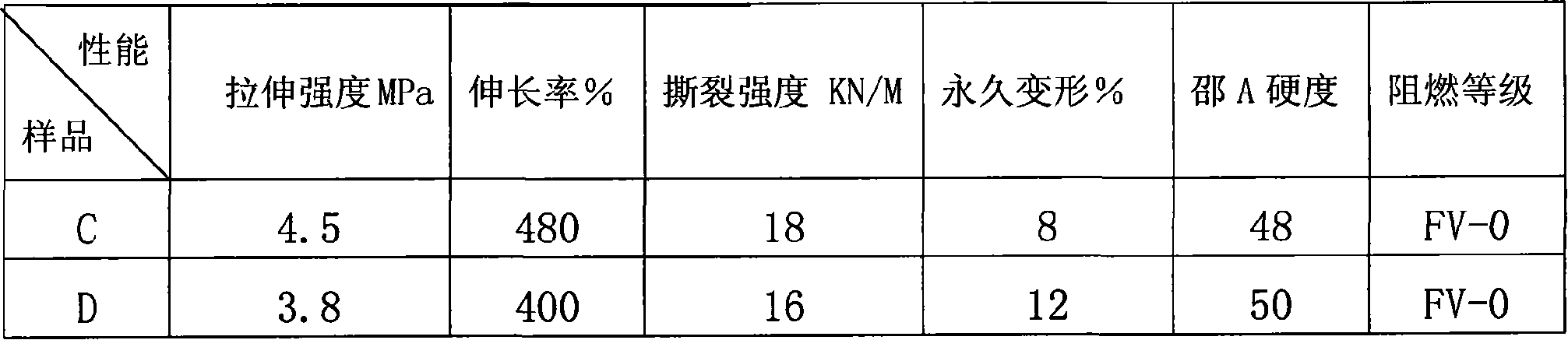

Halogen-free anti-flaming silicon rubber and its preparing method and use

A halogen-free flame retardant silicone rubber is made by the vulcanization of the compound with the methyl vinyl silicone rubber as the basic gel and the vulcanization agent; the compound consists of the two-component mixing gel; according to the weight shares, the compound includes: A component: 10 to 30 shares of methyl vinyl silicone rubber with the high content of vinyl, 20 to 40 shares of methyl vinyl silicone rubber with the low content of vinyl, 0.25 to 1 share of hydrogen silicone oil, 2 to 4 shares of hydroxy silicone oil, 20 to 40 shares of white carbon; B component: 90 to 110 shares of methyl vinyl silicone rubber with the low content of vinyl, 0.5 to 2 shares of methyl silicone oil, 0.25 to 1 share of hydrogen silicone oil, 50 to 70 shares of aluminum hydroxide and virgule or cyanuric melamine, and 2 to 5 shares of zinc borate. The preparation method is to mix and refine well the silicone rubber with the high and low content of vinyl; the hydrogen silicone oil, hydroxy silicone oil and white carbon are added to make the mixed and refined gel A; the silicone rubber with the low content of vinyl, the methyl silicone oil, hydrogen oil, aluminum hydroxide and virgule or cyanuric melamine, zinc borate are added to make the mixed and refined gel B; the mixed and refined gel A and B are mixed and vulcanized ; the fire-retardant performance can reach to the level of FV-0.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

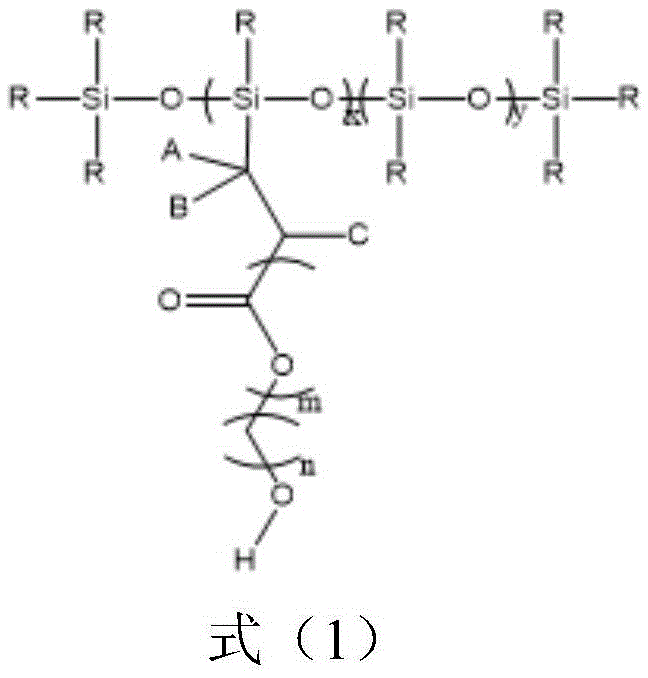

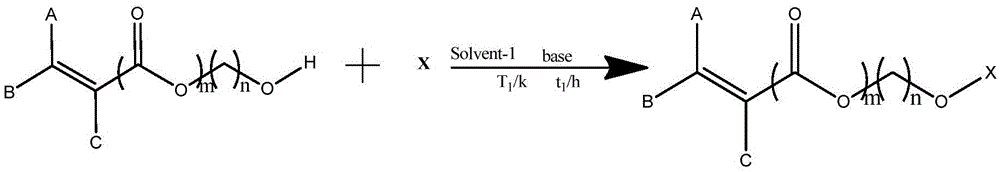

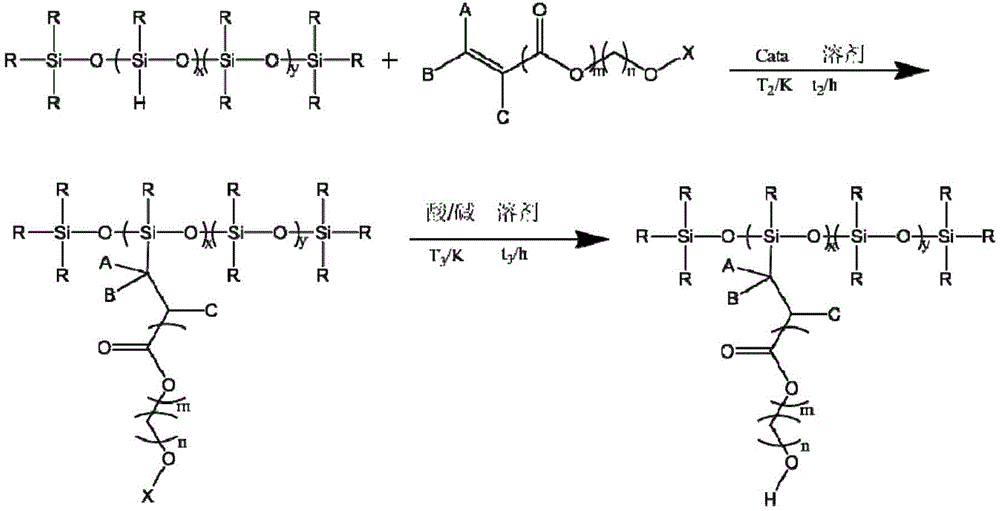

Polyhydroxy polysiloxane and wear-resisting super-hydrophobic coating and preparation method

ActiveCN105646884AImprove wear resistanceHigh temperature resistantLiquid repellent fibresAnti-corrosive paintsPolymer scienceSide chain

The invention discloses a polyhydroxy polysiloxane and wear-resisting super-hydrophobic coating and a preparation method, and belongs to the field of super-amphiphobic materials. A structural formula of polyhydroxy polysiloxane is shown in the following formula of the description. According to the method, an active hydroxyl group is introduced onto a flexible silica main chain through over protection and deprotection processes, polymethylsiloxane with active hydroxyl group on a side chain is compounded, then the polymethylsiloxane with an active hydroxyl group on a side chain is cross-linked with diisocyanate to form a three dimensional net structure, methyl is orderly and densely arranged on the surface of a substrate, the methyl is very small in polarity and volume, and low in surface tension, thus, a compact low surface energy layer is formed, and a wear-resisting super-hydrophobic material is formed by utilizing cohesive action of isocyanate.

Owner:国科广化(南雄)新材料研究院有限公司 +1

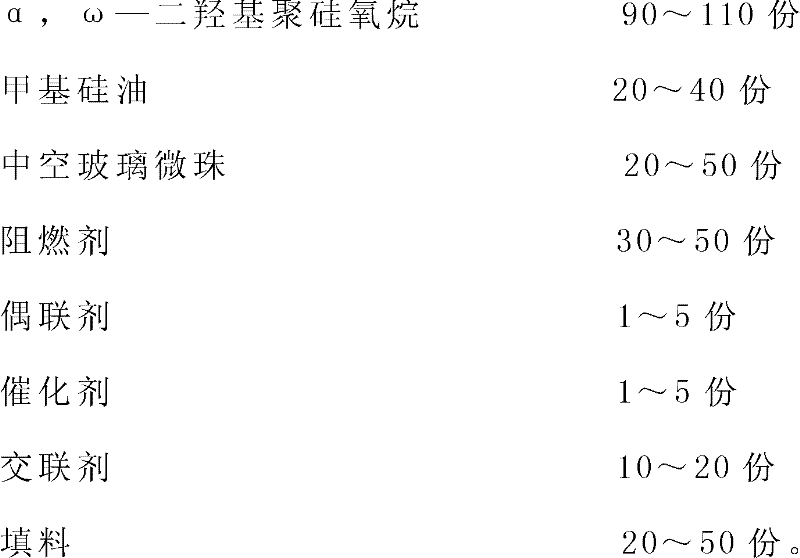

Mono-component room-temperature vulcanized silicone heat-insulation refractory sealant and preparation method thereof

InactiveCN102516925AImprove flame retardant performanceImprove radiation resistanceNon-macromolecular adhesive additivesOther chemical processesRefractoryRoom temperature

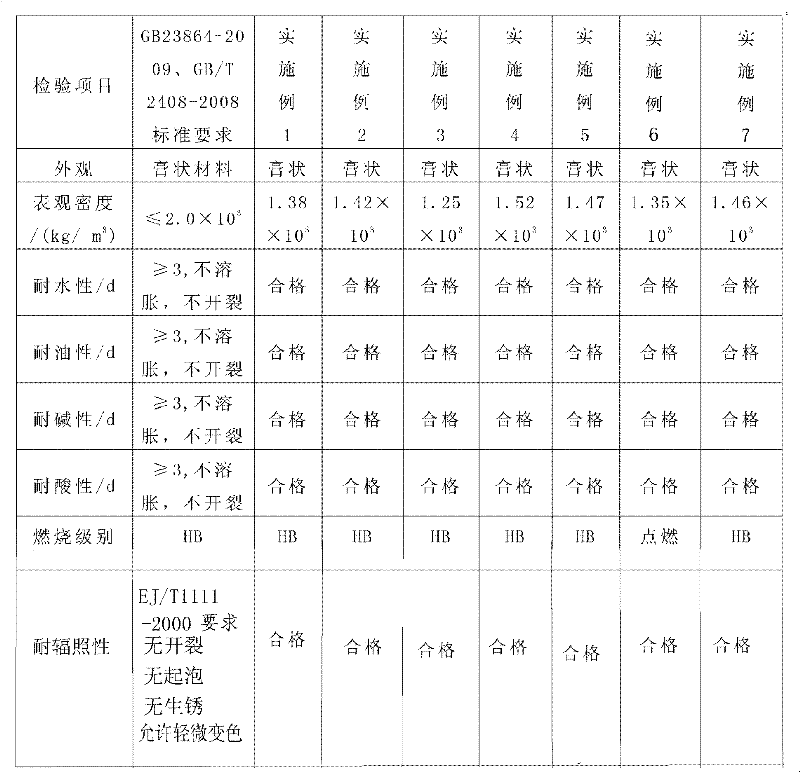

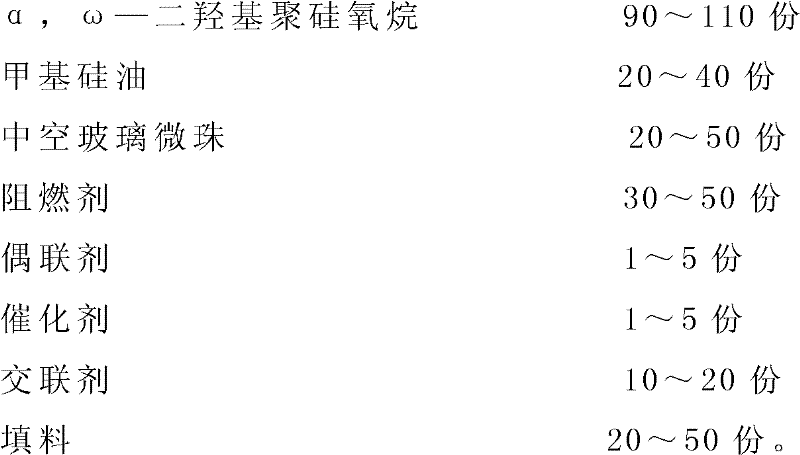

The invention relates to preparation of a mono-component room-temperature vulcanized silicone heat-insulation refractory sealant. The mono-component room-temperature vulcanized silicone heat-insulation refractory sealant is prepared by the following steps of: sequentially adding 90-110 parts of alpha, omega-dihydroxy polysiloxane, 20-40 parts of methyl silicone oil, 20-50 parts of hollow glass microbeads, 30-50 parts of flame retardant, and other fillers to a vacuum stirrer, and stirring at vacuum degree of 0.06-0.08MPa and temperature of 100-150 DEG C for 4-6h; and then sequentially adding 1-5 parts of coupling agent, 1-5 parts of catalyst and 10-20 parts of crosslinking agent to the base materials in the stirrer, and stirring at vacuum degree of 0.06-0.08MPafor 40-100min. The prepared sealant has good flame retardancy, flame resistance and heat-insulation performance and greatly increased radiation resistance, and is an excellent sealing block material for nuclear power and building industries.

Owner:TIANYUAN HUAWEI GRP

Cement-based capillary crystalline waterproof coating and preparation method thereof

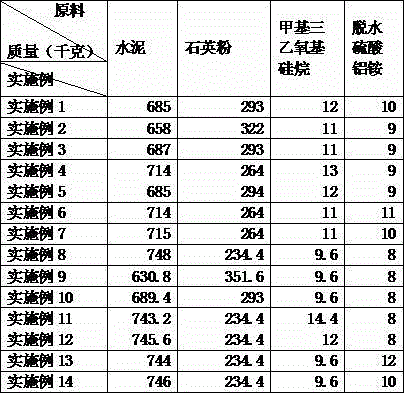

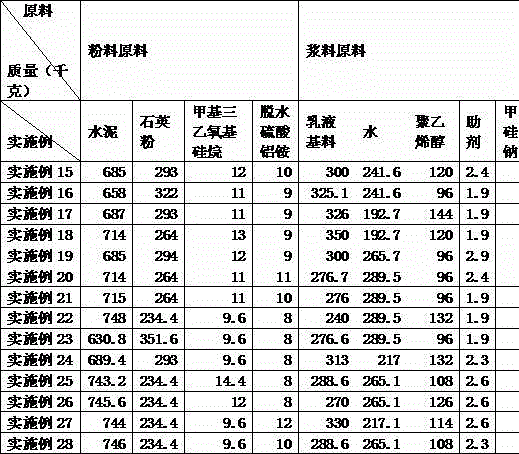

The invention discloses a cement-based capillary crystalline waterproof coating. A preparation method of the cement-based capillary crystalline waterproof coating comprises the steps of taking 630.8-748 parts of cement, 234.4-351.6 parts of quartz powder, 9.6-14.4 parts of methyl triethoxysilane, 8-12 parts of dehydrated ammonium aluminum sulfate, 240-350 parts of an emulsion binder, 192.7-289.5 parts of water, 96-144 parts of polyvinyl alcohol, 1.9-2.9 parts of an assistant and 2.4-3.6 parts of sodium methyl silicate; mixing the cement, the quartz powder, methyl triethoxysilane and dehydrated ammonium aluminum sulfate and stirring to obtain a powder material; mixing the emulsion binder, water, polyvinyl alcohol, the assistant and sodium methyl silicate and stirring to obtain a slurry; and mixing the powder material, the slurry and water according to a mass ratio of 6-6.5:4-4.5:4-4.5, and thus a cement-based capillary crystalline waterproof coating capable of being used instantly is obtained. The cement-based capillary crystalline waterproof coating can form a cement crystalline layer on building cement, so that self-waterproof cement concrete can be obtained.

Owner:王福刚

Ester type fire-resistant hydraulic fluid and preparation method thereof

InactiveCN103013635AInhibition of catalytic oxidationImprove stabilityLubricant compositionPhosphoric acidTriazole derivatives

The invention relates to an ester type fire-resistant hydraulic fluid. The hydraulic fluid comprises the following raw materials by weight percent: 95-99% of base oil, 1.0-5.0% of diphenol propane, 0.005% of dimethylsilicone fluid or dimethylsilicone grease, 0.05% of tricresyl phosphate, 0.1% of benzotriazole, 100 parts per million (PPM) demulsifying agent T1001 or LZ5957 and 0.2-0.3% of triazole derivative, thiadiazole derivative, N-salicylidene ethylamine, N, N'-bis(salicylidene)ethylenediamine, N, N'-bis(salicylidene)propylene diamine or ethylenediamine tetraacetic acid. A preparation method of the ester type fire-resistant hydraulic fluid comprises the following steps of sufficiently and evenly stirring various materials at room temperature according to a formula, and then filtering. The ester type fire-resistant hydraulic fluid has the beneficial effects that the high temperature use performance of the product is greatly improved, the service life of a hydraulic system and the oil changing period of oils are prolonged, and the ester type fire-resistant hydraulic fluid has a good flame-retardant effect and is safe to use. The preparation method has the advantages that operation is convenient, technology and equipment are simple, energy consumption is low, cost is low, and the like.

Owner:ANLU AOSEN PETROCHEM

Prepn of stone material surface protecting agent

InactiveCN1506426AImprove breathabilityPrevent intrusionCoatingsStone-like material working toolsWater vaporSilanes

The present invention is the preparation process of stone material surface protecting agent. The preparation process includes adopting absolute ethyl alcohol as solvent, mixing with long chain alkyl alkoxy silane and hydrogenous methyl silicone oil at room temperature, and adding dibutyltin dilaurate as organic catalyst through stirring. When it is used, the stone material surface protecting agent is painted directly before letting stand for 24 hr and further construction without needing heating for crosslinking. It may be used in repairing fine holes and cracks without blocking the capillary tracts, and it can form excellent hydrophobic effect while not blocking inside water vapor to diffuse outwards.

Owner:曾繁杰 +1

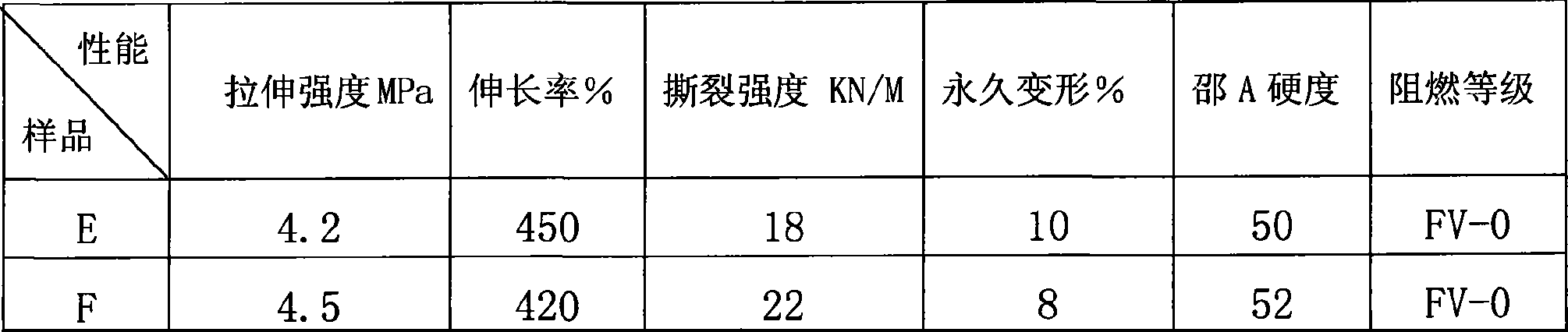

One-component room temperature vulcanizing silicone fireproof sealant and preparation method thereof

InactiveCN101985550ANo pollutionLess corrosiveNon-macromolecular adhesive additivesOther chemical processesRoom temperatureOmega

The invention relates to one-component room temperature vulcanizing silicone fireproof sealant. A preparation process comprises the following steps of: sequentially adding 90 to 110 weight parts of alpha, omega-dihydroxy polysiloxane, 20 to 40 weight parts of methyl silicone oil, 70 to 90 weight parts of filler and 30 to 50 weight parts of flame retardant into a vacuum kneading machine, and stirring at the temperature of between 100 and 150 DEG C under the vacuum degree of 0.06 to 0.08MPa for 2 to 4 hours to obtain a base material; and adding the base material into a vacuum high-speed stirrer, sequentially adding 1 to 5 weight parts of coupling agent, 1 to 5 weight parts of catalyst and 10 to 20 weight parts of cross-linking agent, and reacting under the vacuum degree of 0.06 to 0.08MPa at the rotating speed of 20 to 100rpm for 40 to 100 minutes with stirring to obtain the one-component room temperature vulcanizing silicone fireproof sealant. The prepared sealant has good flame retarding effect and high physicochemical property and is a novel high-performance fireproof material in nuclear power and building industries.

Owner:TIANYUAN HUAWEI GRP

Low-superficial area ratio marine antifouling coating of silicofluoride block polymer and its production

InactiveCN101029207ALower surface energyLow costAntifouling/underwater paintsPaints with biocidesMethacrylatePolydimethyl siloxane

A fluosilicate block polymer low-surface energy marine anti-fouling coating and its production are disclosed. The coating consists of base material polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer, accessory methyl silicone oil and di-n-octyl ester phthalate and coating solvent butyrin acetate. The process is carried out by mixing methyl silicone oil with di-n-octyl ester phthalate to obtain coating accessory, mixing polydimethyl siloxane-b-polymethylmethacrylate-b-polyfluobutyl metacrylic acid ester ternary fluosilicate block copolymer with pigment to obtain coating base material and pigment mixture, adding coating accessory into mixture of coating base material and pigment, mixing, dissolving it into butyrin acetate and laying aside. It has excellent anti-fouling effect and no environmental pollution.

Owner:XIAMEN UNIV

AC wet capacitor impregnating agent

InactiveCN102290234AImpact on life performanceExtended service lifeFixed capacitorsSilicone oilCapacitor

The invention discloses an impregnating agent for an AC wet capacitor, which comprises castor oil, salad oil and other vegetable oils or methyl silicone oil, benzyl silicone oil, PO oil and other mineral oils and hydrated magnesium silicate superfine powder. The content of the hydrated magnesium silicate superfine powder is preferably 3-8% (by weight). The hydrated magnesium silicate superfine powder is mixed with vegetable oil or mineral oil to form a suspension after stirring. The invention absorbs the moisture in the impregnating agent by adding hydrated magnesium silicate superfine powder in the impregnating agent. In this way, the moisture contained in the impregnating agent is absorbed, which cannot affect the service life of the capacitor, and can effectively improve the service life of the capacitor.

Owner:ANHUI SAFE ELECTRONICS

Preparation method and use for ultra-hydrophobic cotton fibrous material or ultra-hydrophobic paper fibrous material

The invention relates to super hydrophobic cotton or paper fiber material manufacturing method and their use. It is processed surface modification for the cellulose by silicon material which can be methane sodium silicate, methane potassium silicate, or chlorosilane. Thus the processed cellulose has good super hydrophobic property and air permeability, can be used in garment material, package, health aids fields etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

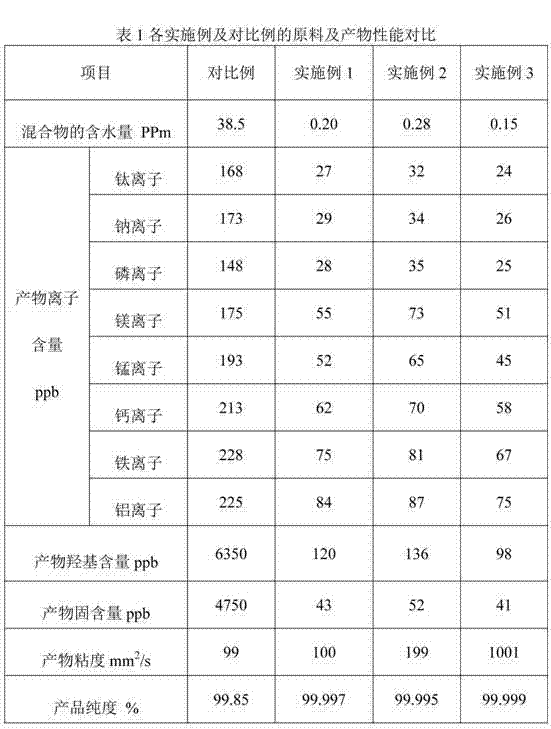

Continuous preparation technology of high-purity low-viscosity dimethicone

ActiveCN103073722AHigh purityMaintain catalytic activityChemical recyclingPtru catalystSilicone fluid

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

Foamed silicon rubber and preparation method thereof

The invention belongs to the technical field of the silicon rubber and particularly relates to a foamed silicon rubber and a preparation method thereof. The foamed silicon rubber consists of the following raw materials in part by weight: 200 parts of crude rubber, 0.5 to 2 parts of foaming agent, 30 to 40 parts of methyl silicone oil, 1.8 to 2.2 parts of hydroxyl silicone oil, 0.2 to 0.5 part of hydrogen-containing silicone oil, 0.05 to 0.15 part of Pt coordination compound, 54 to 66 parts of white carbon black and 0.05 to 0.1 part of retardant, and is prepared under a certain process conditions. The prepared foamed silicon rubber has the advantages of uniform foaming, long storage period and simple process.

Owner:东莞新东方科技有限公司

Preparation method of methylsilicone oil

The invention discloses a preparation method of methylsilicone oil, and specifically relates to methyl silicone oil with different viscosity (molecular weight) prepared by using supported solid superacid SO4<2-> / ZrO2-ZSM-5 as a catalyst and by adopting inexpensive and commercially available methylsilicone oil (Dn), octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM), so as to fit various needs. Compared with a conventional catalyst for producing methylsilicone oil, the supported solid superacid catalyst provided by the invention has higher catalytic activity, higher stability, lower cost and the like. More importantly, the supported solid superacid catalyst is in a solid state and can be separated via simple filtration and reused, thereby enabling the production to have the advantages of simple process, convenient operation, no pollutions, no corrosion toward equipment, and the like.

Owner:JIANGNAN UNIV

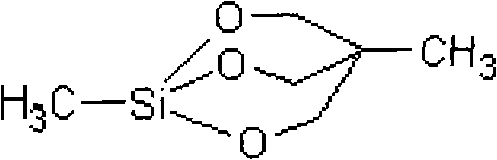

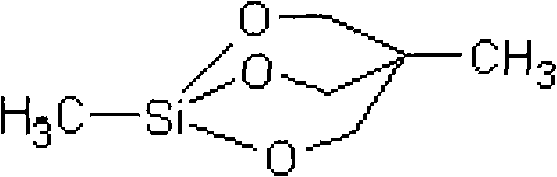

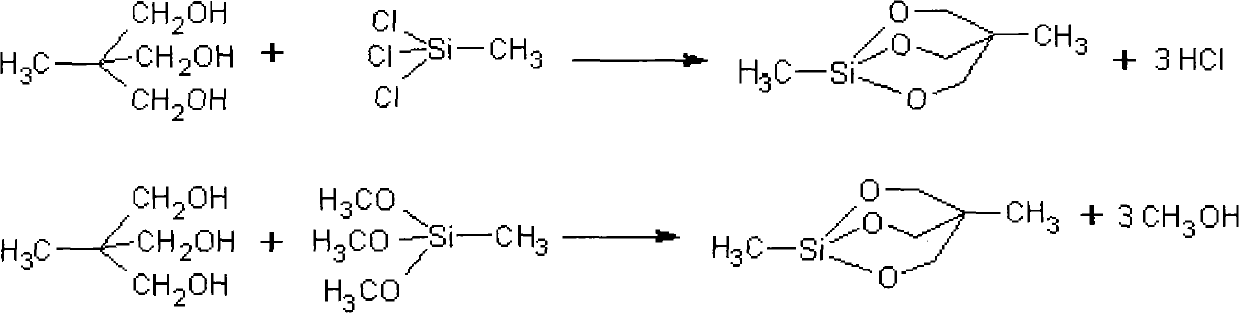

Cage-shaped organic silicon flame retardant charring agent and preparation method thereof

ActiveCN102146093ACompact and stable structureStrong insulationGroup 4/14 element organic compoundsCoatingsMethyltrimethoxysilanePhysical chemical

The invention relates to a cage-shaped organic silicon flame retardant charring agent, i.e. a 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane compound, and a preparation method thereof. The compound has a structure shown as the following formula in the specification. The preparation method comprises the step of: reacting methyl trichlorosilane or methyltrimethoxysilane with trimethylolethane in an organic solvent to prepare 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane. The cage-shaped organic silicon flame retardant charring agent is a novel halogen-free non-toxic flame retardant charring agent, which has high flame retardant performance and good charring performance, can effectively prevent the melting and the dropping of high polymer during combustion, and is stable in physical and chemical properties, good in compatibility with macromolecular materials, high in raw material availability, simple in process and easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

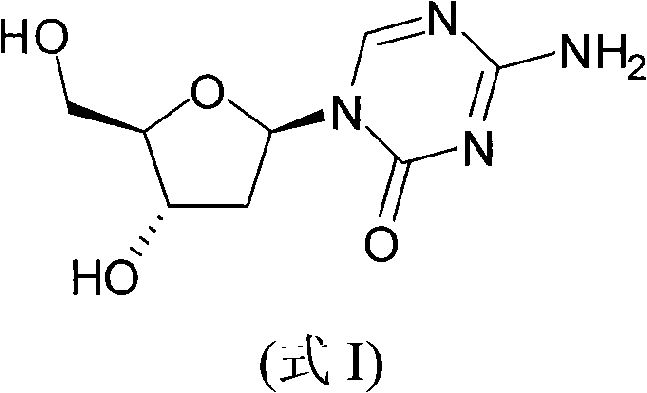

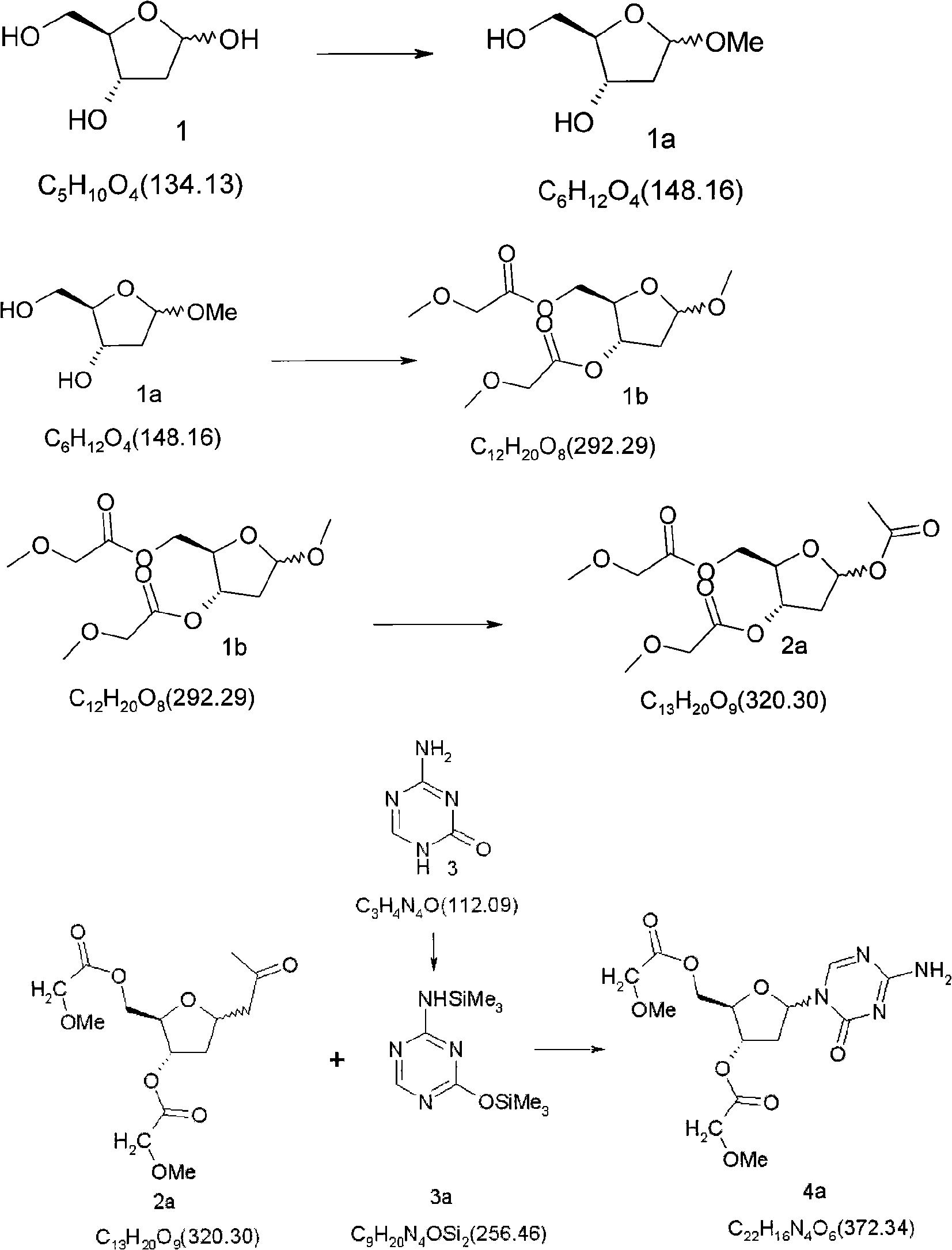

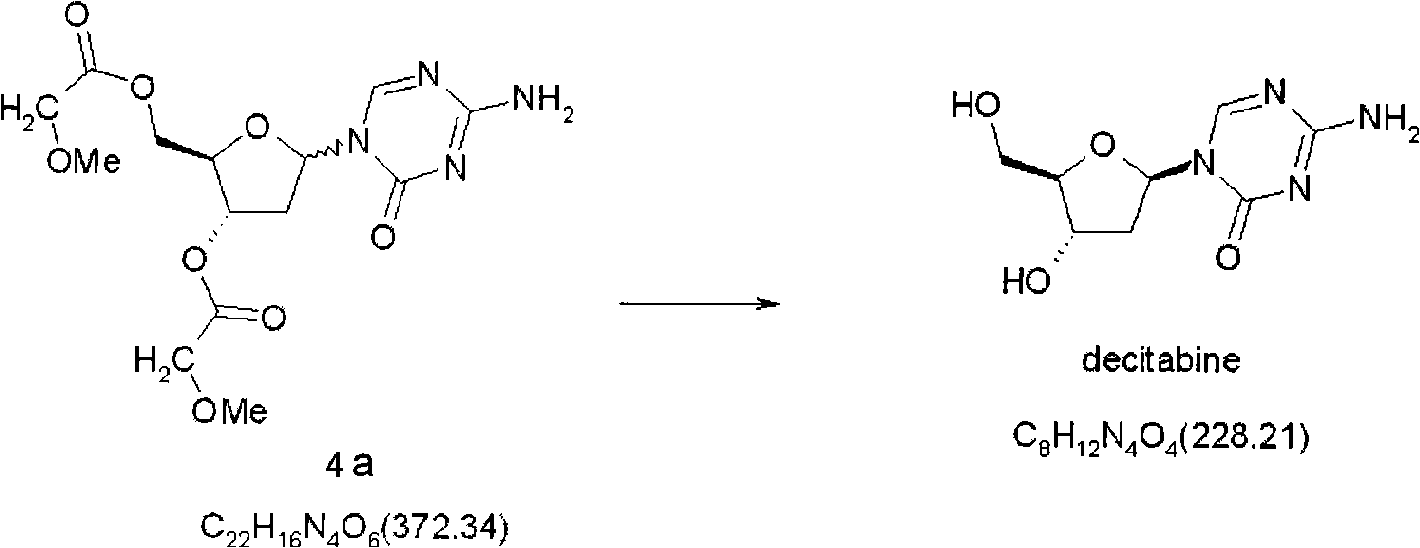

Synthetic process of decitabine

The invention relates to a method for preparing Decitabine. The particular proposal for solving the technical problem is as follows: 2-deoxidtion-D-ribose, 10 percent of HCL methanol solution, methoxyacetic acetic anhydride, HMDS, acetic anhydride, tri-silicyl tri-fluorine methane sulfonic acid ester, acetic acid amine, etc. are adopted as raw materials to synthesize the Decitabine; the target product of the Decitabine is obtained through the five steps of reactions, namely, methylation, acylation, trimethyl silication, ammoniation and deacylation with a total yield of above 18.4 percent and a product purity of above 99.7 percent.

Owner:GUIZHOU UNIV

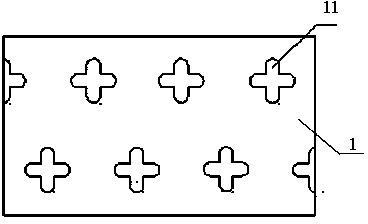

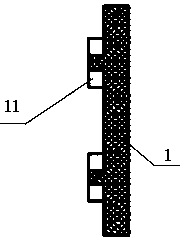

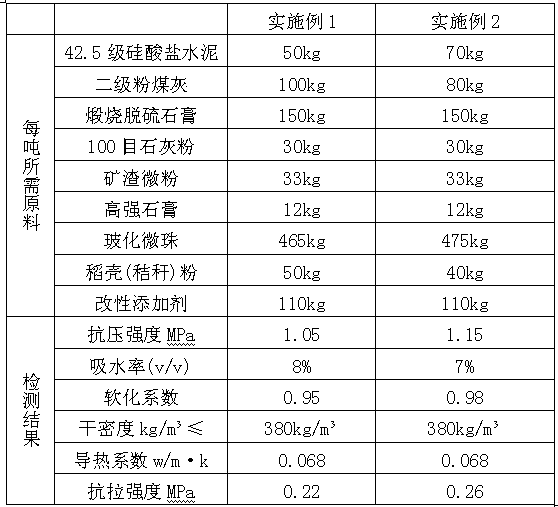

Insulation board for external wall of building

The invention discloses an insulation board for an external wall of a building. The insulation board is prepared by mixing a binding material, insulating lightweight aggregate and a modified additive according to a weight ratio of (30-50):(40-55):11, wherein the binding material is prepared from the following components in parts by weight: 5-10 parts of cement, 8-16 parts of coal ash, 15-28 parts of calcined desulfurization gypsum, 2-8 parts of lime powder, 2-9 parts of superfine slag powder and 1-8 parts of high-strength gypsum. The insulating lightweight aggregate is prepared from the following components in parts by weight: 30-56 parts of glass beads and 2-8 parts of rice hull powder or straw powder. The modified additive is prepared from the following components in parts by weight: 16 parts of a tripolycyanamide resin water reducer, 4 parts of an air entraining agent, 2 parts of methyl cellulose ether, 6 parts of sodium methylsilicate, 15 parts of polymer resin rubber powder, 12 parts of acrylate emulsion, 16 parts of polyvinyl alcohol liquor and 68 parts of inorganic salt compounds. The toughness, viscosity and water-resistance of the insulation board are enhanced, the performance of a composite material is optimized, and the utilization ratio of renewable resources is high, and the cost is low.

Owner:江苏宇辉新材料集团有限公司

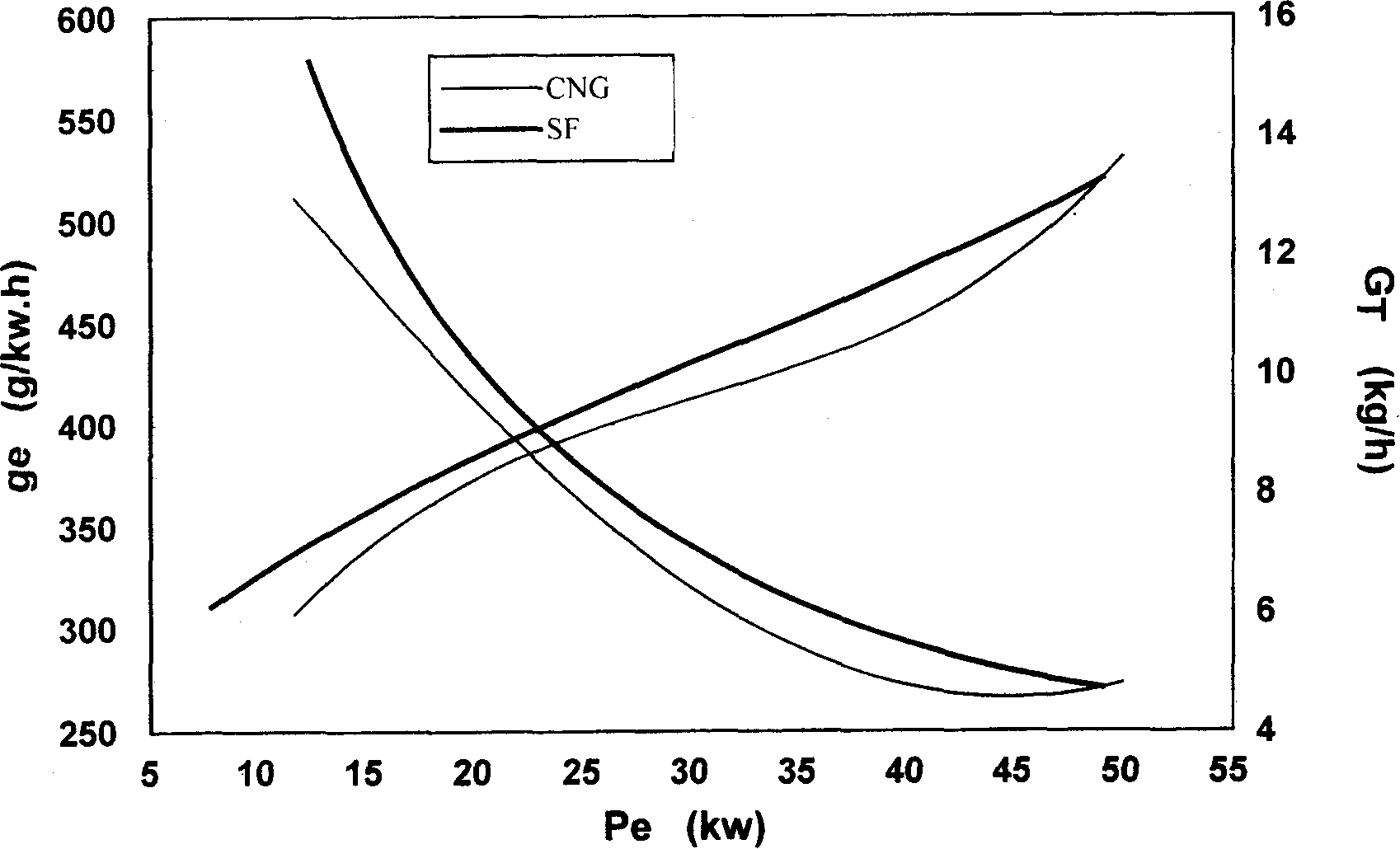

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

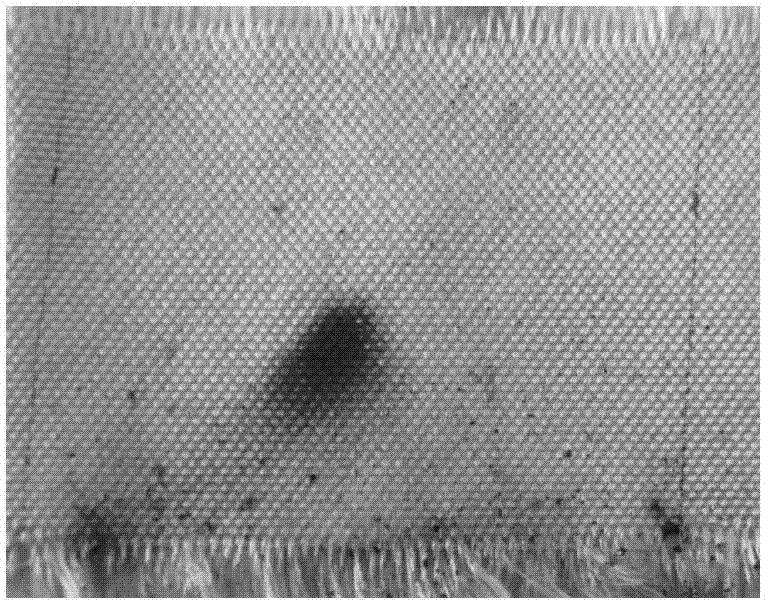

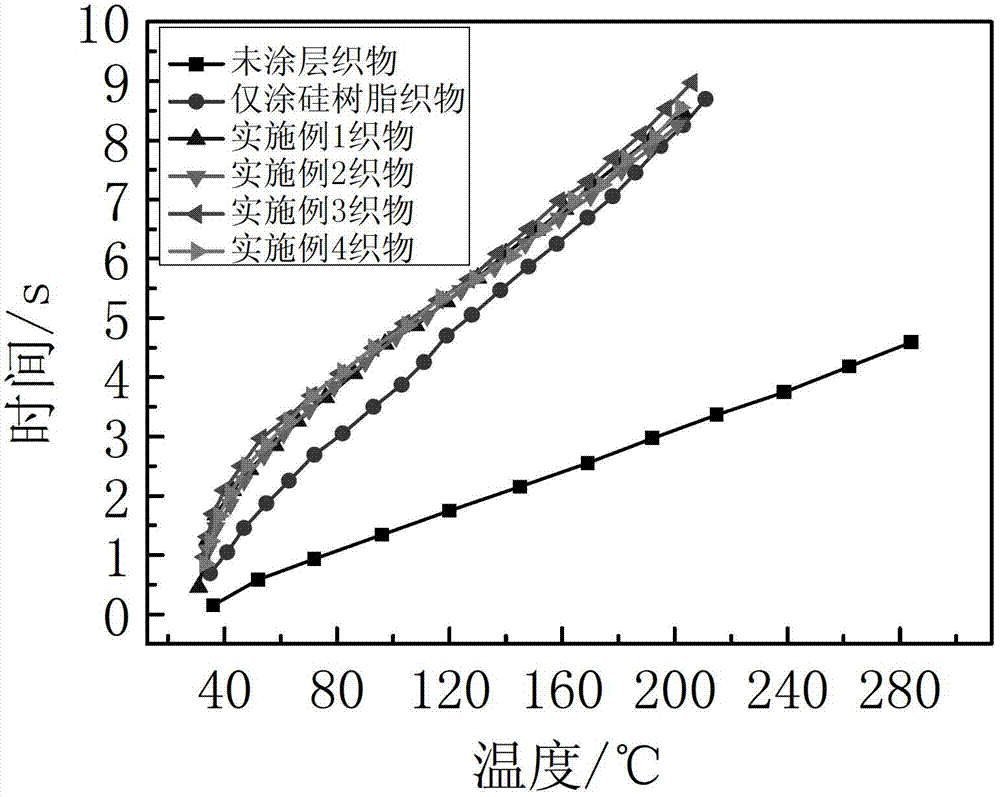

Heat-insulating and ablation-resistant glass fiber fabric and preparation method thereof

ActiveCN103205896AImprove heat resistanceImprove crack resistanceFibre treatmentResin coatingEngineering

The invention provides a heat-insulating and ablation-resistant glass fiber fabric and a preparation method thereof, belonging to the technical field of thermal protection fabrics and preparation thereof. The heat-insulating and ablation-resistant glass fiber fabric product comprises a fabric layer and coating layers on the front and back surfaces of the fabric layer, wherein the thicknesses of the coating layers on the front and back surfaces of the fabric layer are controlled at 30-80 micros; the fabric layer is made from glass fiber fabrics; the coating layers are composite organic silicon resin coating layers which are prepared by mixing an organic silicon resin solution, white carbon black, mica powder and the like in certain percentage by weight; a solute of the organic silicon resin solution is phenyl methyl silicone, a solvent of the organic silicon resin solution is dimethylbenzene, toluene or a mixture of the two, and the mass ratio of the solvent to the solute is 1:1; and a preparation method of a composite organic silicon resin coating layer solution comprises the following steps of: sequentially adding the white carbon black, the mica powder, wollastonite in powder and metallic oxide into the organic silicon resin solution, and stirring to ensure that the substances are uniformly dissolved. The heat-insulating and ablation-resistant glass fiber fabric is simple in process, easy to operate, and excellent in heat resistance, weather resistance, insulating property, reinforcement performance, scrubbing resistance and weathering resistance.

Owner:赵晓明 +1

Method for using soft attapulgite ceramic powder

The invention discloses a method for using soft attapulgite ceramic powder. The method comprises the following steps of: putting the soft attapulgite ceramic powder into a container; slowly adding hot water to the soft attapulgite ceramic powder, stirring the powder in time and kneading into a strip-shaped mud cake; coating methyl silicone oil onto the outer surface of the strip-shaped mud cake and kneading once again; and pressing the strip-shaped mud cake into soft attapulgite ceramic mud. The soft attapulgite ceramic powder comprises purified attapulgite clay, bentonite, sepiolite, calcium chloride, sodium polyacrylate, sodium carboxymethylcellulose and sodium stearoyl lactate. The soft attapulgite ceramic mud prepared by adding the water and the methyl silicone oil to the soft attapulgite ceramic powder has the characteristics of high viscosity, good soft plasticity, small shrinkage, no deformation, hardening after natural drying, no need of roasting, no cracks, no mildew, no deterioration, no irritation to skin, no toxicity, no corrosivity and no oily feel. The using method of the soft attapulgite ceramic powder is suitable for manufacturing the soft attapulgite ceramic mud on site by adopting the soft attapulgite ceramic powder.

Owner:JIANGSU DAHAI PLASTIC

Preparation method of binary acid refined adsorbing material

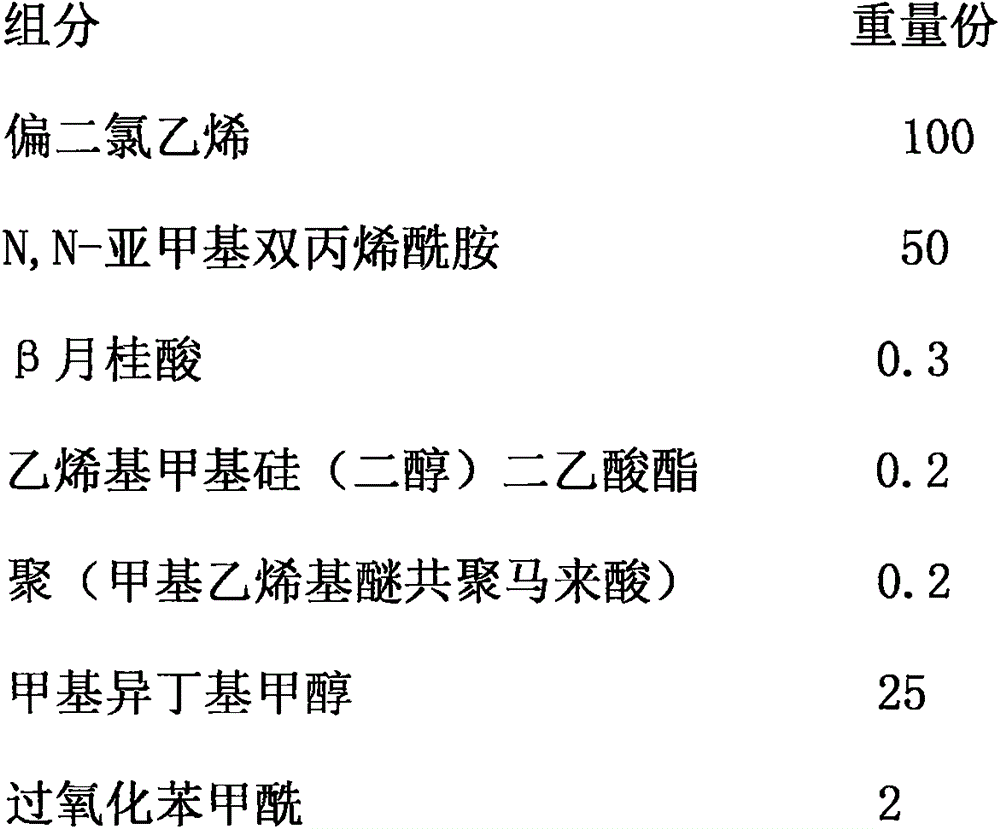

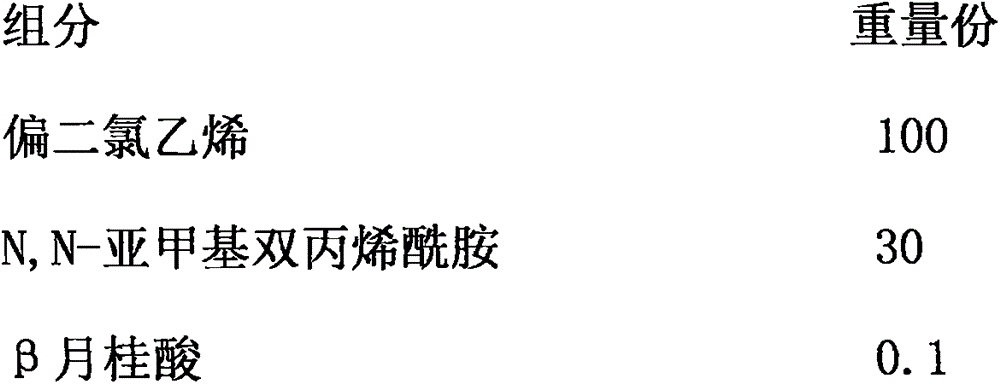

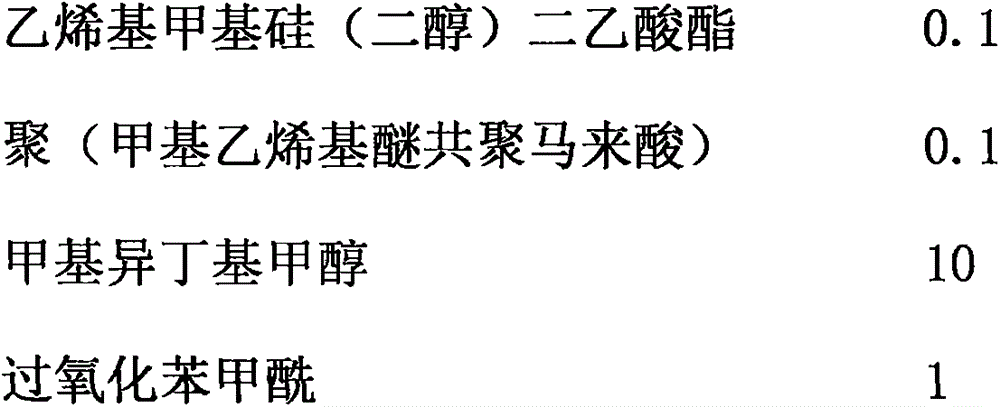

The invention relates to a preparation method of a binary acid refined adsorbing material. According to the preparation method, co-monomers, namely beta-myrcene, vinyl methyl silicone (diol) diacetate and N,N-methylene bisacrylamide, are added into vinylidene chloride, a dispersing aid (methyl vinyl ether copolymerized maleic acid) is added to generate a polymer, and the polymer is utilized for extracting decolored binary acid with a long carbon chain. The preparation method has the advantages that the adsorbing capacity is high, and the loss of binary acid caused by the repeated crystallization and filtration can be reduced.

Owner:XUZHOU HONGFENG HIGH MOLECULAR MATERIAL CO LTD

Binder systems derived from amorphous silica and bases

InactiveUS6866709B1Excellent binder systemProcess stabilityGas treatmentSolid waste managementFiberPorosity

The present invention relates to compositions comprising the reaction product of amorphous silica or ultra-fine silica and one or more bases. The present invention also relates to materials and method involving the use of such products. In particular, the present invention i.a. relates to new mineral wool products, e.g. products comprising man-made vitreous fibres (such as glass fibres, slag fibres, stone fibres and rock fibres) or perlite, having included therein a binder component which comprises amorphous silica and aklali metal organosiliconates, e.g. potassium methyl siliconate. An important feature of such products is the preparation of the binder systems under vigorous mixing. Such products provide good fire, heat and sound insulating properties. The present invention also provides to a method for removing odorous substances from a gas where materials prepared from ultra-fine silica, water, and one or more components enabling porosity-conferring binding of the material, e.g. a base or bases. Furthermore, the invention provides methods for thixotroping bitumen.

Owner:HOLBEK KJELD

Water-based paint

ActiveCN103614032APhenomena that reduce the apparent effectPhenomena that affect the appearanceAntifouling/underwater paintsPaints with biocidesCoated surfaceEmulsion

The invention provides a water-based paint. The water-based paint comprises potassium methyl silanolate and a wetting agent with an emulsification function. After the water-based paint provided by the invention is coated on a wall surface polluted by greasy dirt, the wetting agent penetrates into the surface of the greasy dirt for emulsifying oil into small liquid drops, the small liquid drops enter into a coating to react with the potassium methyl silanolate in the coating to be cured into the coating as filler of the coating, so that a purpose of beautifying and cleaning is achieved, and pre-treatments for refreshing the wall surfaces can be reduced. Meanwhile, an emulsion with high stain resistance is selected to co-act with organic silicon, so that the formed coating surface is easy to clean, and long-term decorative and protective functions are provided. Besides, as the organic silicon component is contained, the water-based paint provided by the invention has better pollution resistance.

Owner:广州富美奥涂料有限公司

Lubricating oil for natural gas and gasoline dual purpose fuel engine

Owner:CHANGAN UNIV

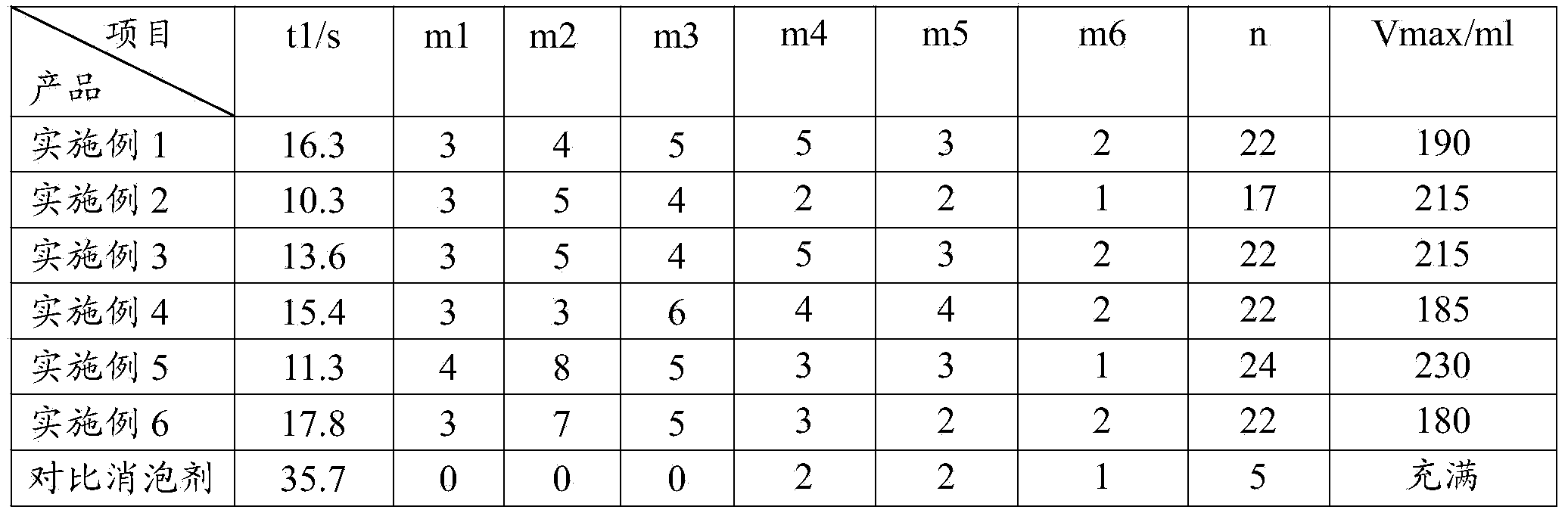

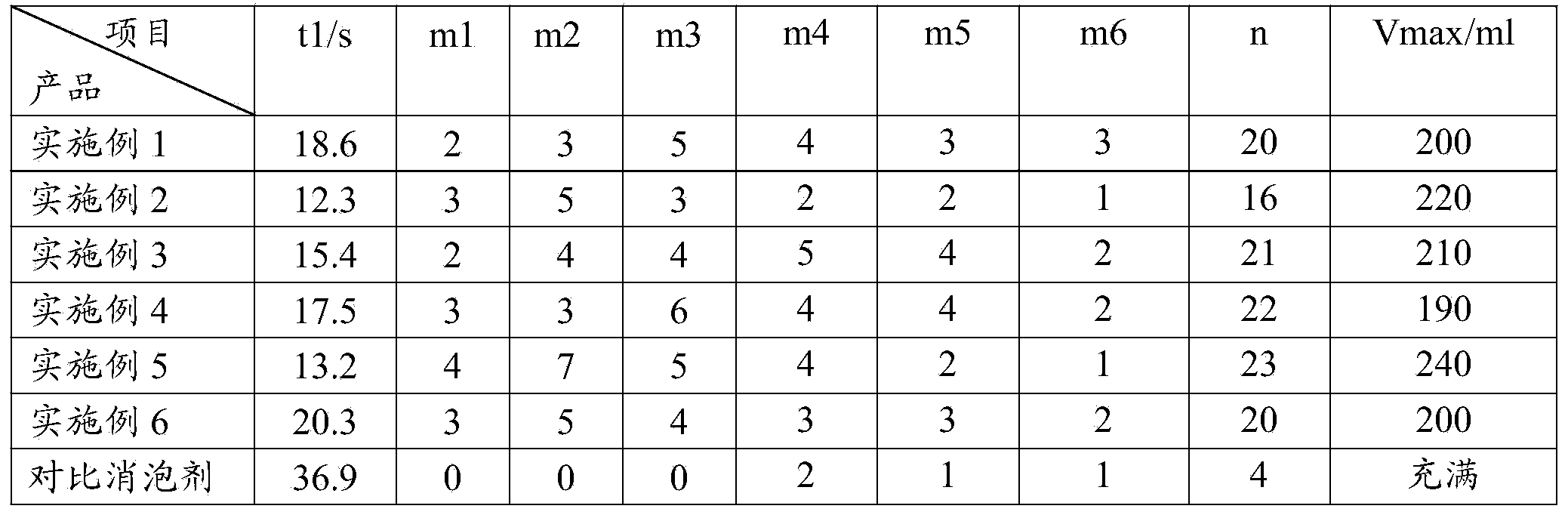

Organic silicon defoamer and preparation method thereof

ActiveCN103641195AFast defoaming speedLong foam suppression timeWater/sewage treatment by degassingPolypropylene glycolSilicone oil

The invention discloses an organic silicon defoamer and a preparation method thereof. The organic silicon defoamer is obtained by emulsifying an organic silicon defoaming composition. The organic silicon defoaming composition comprises a silicon paste composition, emulsifiers and auxiliaries, wherein the silicon paste composition comprises polysiloxane, hydrophobic fumed silica and MQ silicon resin particles; polysiloxane is methyl silicone oil or hydroxyl silicone oil with viscosity of 10000-500000mPa.s; the particle sizes of the MQ silicon resin particles are 5-20mu m; the specific surface area of hydrophobic fumed silica is 100-300m<2> / g; the auxiliaries include tributyl phosphate and / or polypropylene glycol. The invention further provides the preparation method of the organic silicon defoamer. The organic silicon defoamer with high defoaming speed, long foam inhibition time, excellent dispersing performance and prominent defoaming permanence is prepared by a special method, has good storage and dilution stability, is not easy to demulsify and is free from floating oil. The preparation method is simple and is low in cost.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

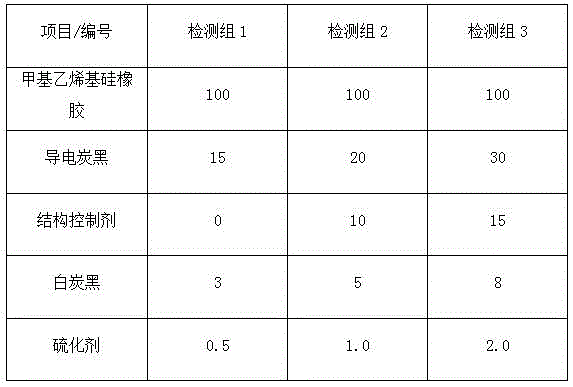

Semiconductive silicon rubber screening material for traveling cable and preparation method thereof

The invention relates to a semiconductive silicon rubber screening material for a traveling cable and a preparation method thereof, and belongs to the technical field of cable screening materials. The semiconductive silicon rubber screening material comprises the following raw materials by weight: 100 parts of silicon rubber, 15-30 parts of conductive carbon black, 3-8 parts of white carbon black, 0.5-2 parts of dicumyl peroxide and 5-15 parts of hydroxyl silicone oil, wherein the silicon rubber is methyl vinyl silicone rubber, dimethyl silicone rubber or methyl phenyl vinyl silicone rubber; and the conductive carbon black has an average particle size of less than 20 nm and specific resistance of 0.35-0.50 omega.cm. The selected silicon rubber is high in plasticity and good in softness and serves as a base material of the semiconductive screening material, so that the disadvantage of film hardening due to strong constitutive property of the conductive carbon black can be avoided, thereby enabling the semiconductive screening material to be good in production and processing performance.

Owner:SICHUAN MINGXING CABLE

Fire-resistant rubber

Owner:山东中一橡胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com