Patents

Literature

53results about How to "Strong insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of modifying calcium silicate plate with water-base epoxy resin

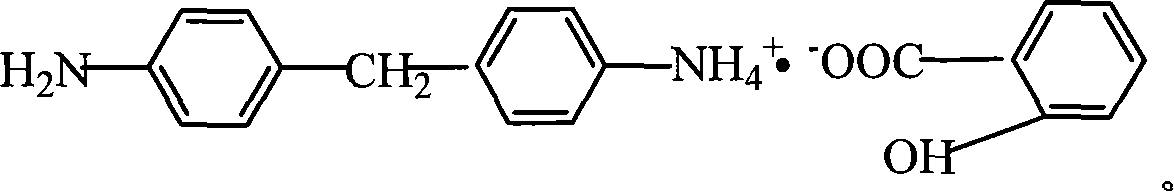

InactiveCN101066852AAchieve strengthMeet the requirements of autoclave curingWater basedCalcium silicate

The present invention relates to method of modifying calcium silicate plate with water-base epoxy resin. Water-base epoxy resin emulsion and curing agent are used in modifying calcium silicate plate product or material. The modified material consists of calcium silicate plate product 100 weight portions, water-base epoxy resin emulsion 3-10 weight portions, and curing agent 20-25 wt% of the water-base epoxy resin emulsion. The modified calcium silicate plate has excellent performances, including waterproof performance, shock resistance, compression strength and bending strength, higher than that of common calcium silicate plate, and is suitable for use in building.

Owner:GUANGDONG UNIV OF TECH

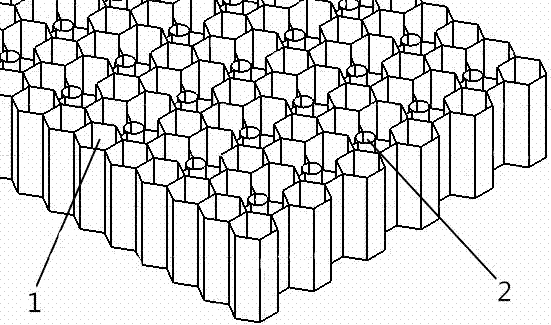

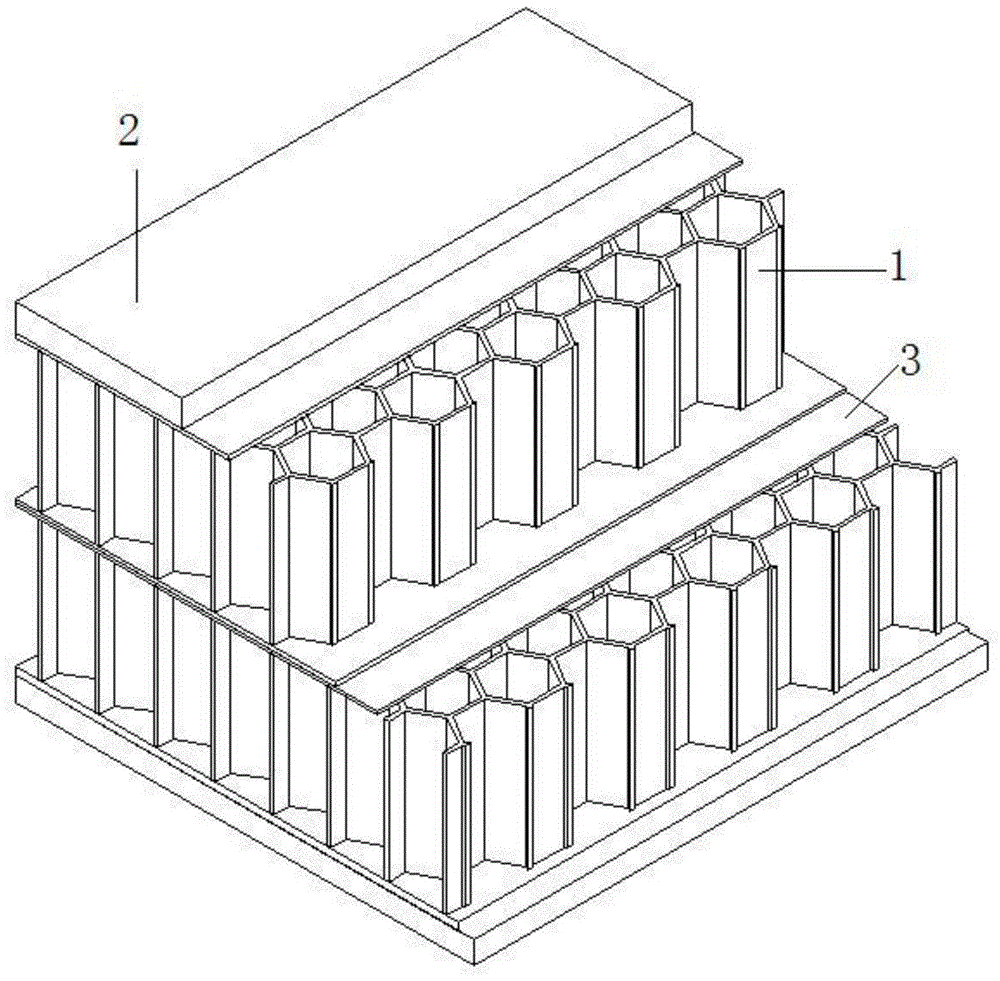

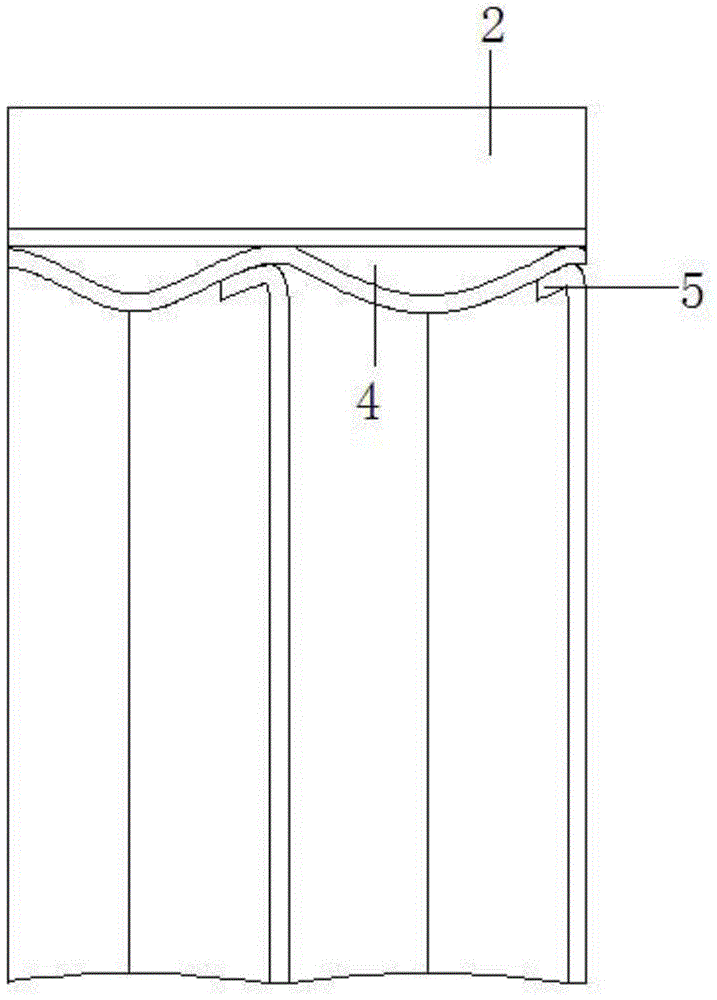

Honeycomb wall plate and mounting method thereof

The invention discloses a honeycomb wall plate and a mounting method of the honeycomb wall plate. The honeycomb wall plate is light in weight, high in strength, simple to construct, low in cost, high in sound and heat insulation and good in environment protection property and overcomes the problems that in the prior art a wall body has conspicuous defects in multiple aspects such as cost, weight, sound insulation and environment protection. The honeycomb wall plate comprises inner cores and two outer plates, wherein the plurality of inner cores are seamlessly spliced with one another to form a bottomless hexagonal prism; openings at two ends of the hexagonal prism are covered by two pieces of bottom sealing surface paper so as to form honeycomb paper cores; two honeycomb paper cores are connected in a manner of being adhered to one piece of bottom sealing surface paper, respectively; the bottom sealing surface paper is connected with the inner cores by virtue of an adhesive and is made of a material same as that of the inner cores; the two outer plates are arranged outside the honeycomb paper cores and are respectively connected with another piece of bottom sealing surface paper of the two honeycomb paper cores; the width of one outer plate is greater than that of the other outer plate. The honeycomb wall plate is applicable to occasions that a conventional building wall body is applicable to and has the advantages of light weight, good heat and sound insulation effects, good environment protection property and the like.

Owner:孔忻怡

Novel red mud decorating and heat-insulation integrated light wall material

A novel red mud decorating and heat-insulation integrated light wall material is characterized by consisting of colored glass and a red mud iron reduction slag high-temperature melt foaming material. The colored glass consists of from 25 to 45 % of potash feldspar, from 20 to 40% of quartz, from 5 to 25% of calcite, from 4 to 8% of sodium borate, from 2 to 8% of barium carbonate, from 2 to 8% of zirconium silicate, from 2 to 6% of potassium nitrate and from 0 to 10% of ceramic color agent. The forming steps of the red mud iron reduction slag high-temperature melt foaming material include forming metallic iron and silicate slag by means of carbothermic reduction of red mud wastes; melting the metallic iron and silicate slag at high temperature; obtaining high-temperature melt of silicate slag after separation of molten iron; and foaming. The novel red mud decorating and heat-insulation integrated light wall material can be colorful after being added with the ceramic color agent, is a multifunctional high-grade interior and exterior wall decorating material with functions of decoration, heat insulation, sound insulation, seismic proofing and the like, is low in production cost, reduces environmental pollution, and is economical and environment-friendly. The wastes can be reused.

Owner:SHANDONG UNIV OF TECH

Environment-friendly diatom sepiolite coating

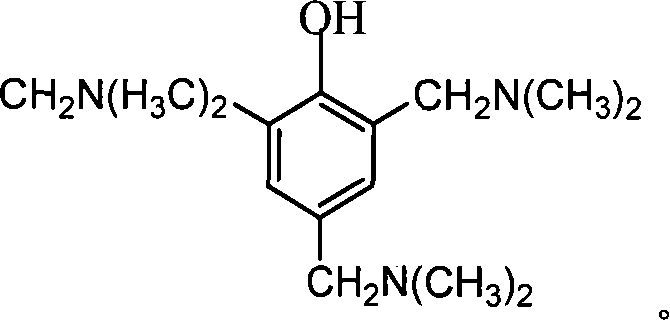

InactiveCN103172321AStrong bleachingStrong insulationDispersed particle separationSodium BentoniteMethyl cellulose

The invention provides an environment-friendly diatom sepiolite coating which is prepared by stirring the following components in percentage by weight: 20%-50% of diatomite, 5%-40% of sepiolite powder, 15%-30% of kaoline, 1%-5% of sodium bentonite, 5%-30% of quartz sand, 0.4%-0.8% of HPMC (Hydroxy Propyl Methyl Cellulose), 0.5%-6% of anion powder and 0.3%-3% of nanometer titanium dioxide. The environment-friendly diatom sepiolite coating provided by the invention has the advantages of good adsorptivity and decomposability and good effect on varnishing a wall body by matching with the usage method of the environment-friendly diatom sepiolite coating.

Owner:徐陈松

Heat insulation board capable of blocking hot and cold bridge, and preparation method thereof

The invention relates to the field of building materials, and particularly relates to a heat insulation board capable of blocking hot and cold bridge, and a preparation method thereof. At present, heat insulation materials used for outer walls are not ideal. The technical solution adopted by the invention is as follows: raw materials comprise, by weight, 40-45 parts of cement, 8-35 parts of redispersible rubber powder, 0.1-0.5 parts of cellulosic fiber, 10-15 parts of polyphenyl particles, 20-25 parts of fly ash, 5-10 parts of defoaming stone, 1-5 parts of light calcium carbonate, 1-5 parts of heavy calcium carbonate, 10-15 parts of a heat insulation material and 20-50 parts of expanded glass beads. The raw materials are distributed for three times and shaped in one time. The heat insulation board has the following beneficial effects of good flame retardant performance, incombustiblity, good heat insulation effect, good cohesiveness and high strength. Due to the board shape, the heat insulation board is convenient for construction and use, is reasonable in price, has the same service life with buildings, is suitable for being used by outer wall surfaces of various buildings, and has good economic benefits and social benefits.

Owner:陕西亿丰绿色建筑材料有限公司

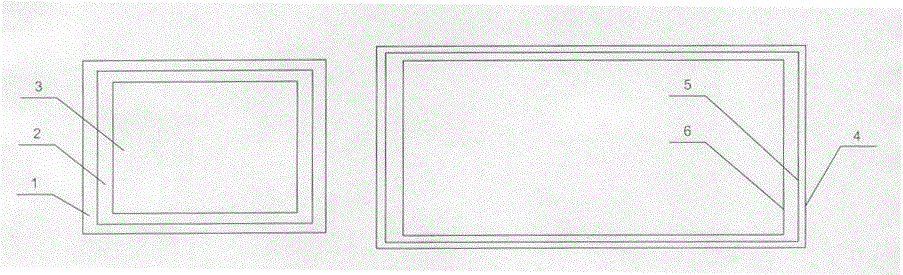

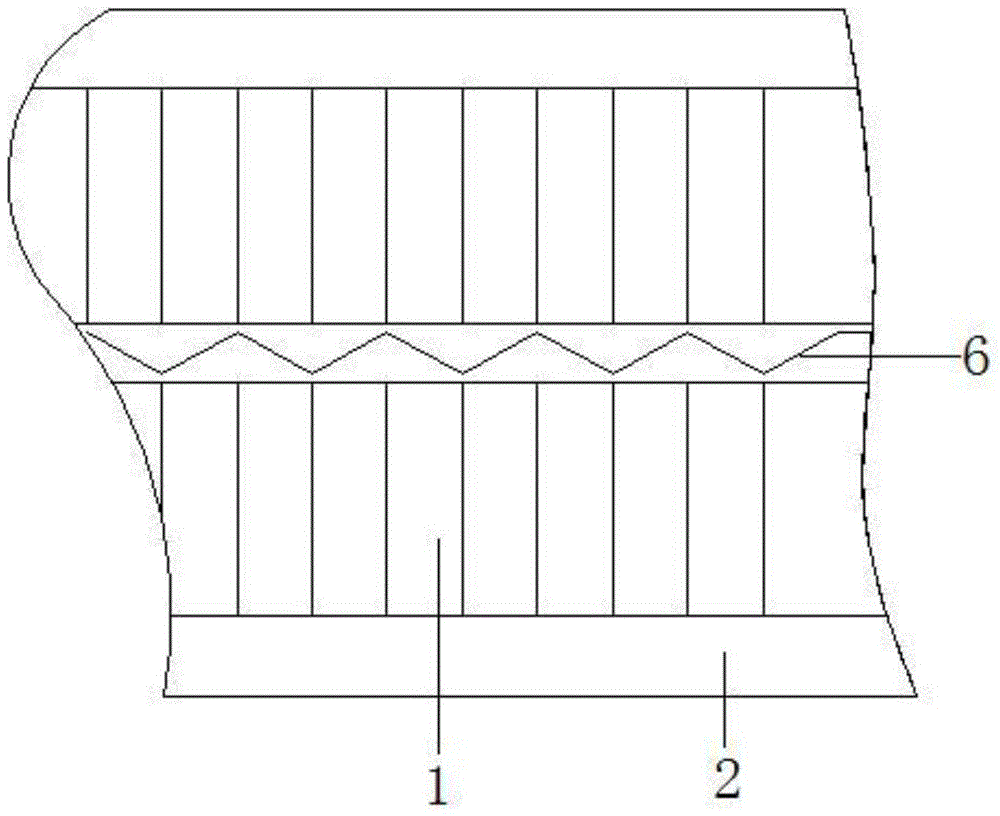

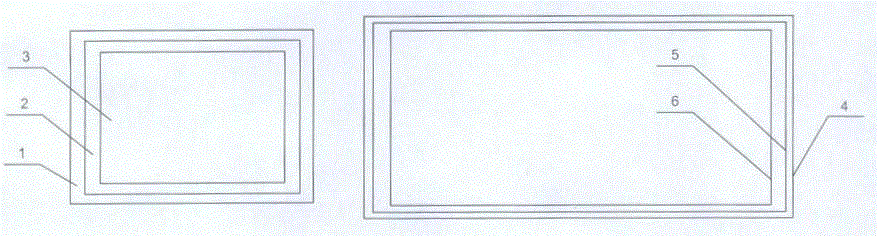

Preparation method of red mud combined expanded vermiculite polyhedral color decorative lightweight wall material

InactiveCN104309184AImprove the decorative effectImprove insulation effectLayered productsDomestic wallsInsulation layerRed mud

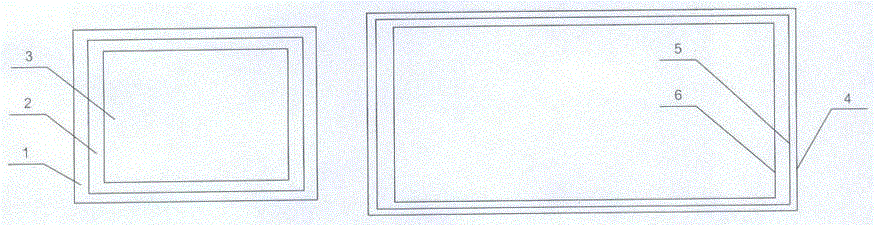

The invention discloses a preparation method of red mud combined expanded vermiculite polyhedral color decorative lightweight wall material. The method is characterized in that the red mud combined expanded vermiculite polyhedral color decorative lightweight wall material is composed of a color decorative layer (1), a transition layer (2) and an insulating layer (3). The red mud combined expanded vermiculite polyhedral color decorative lightweight wall material prepared by the invention adopts one-time firing, and the transition layer is added between the color decorative layer and the insulating layer, so that the defects that the pore diameter is oversize, the bonding strength and the heat impact resistance are low caused by inconsistent material melting points of the color decorative layer and the insulating layer are effectively solved; the inner wall and outer wall decorative material in single-color, composite color and various patterns are prepared by adding ceramic toner without adding extra decoration; the production process is simple, the cost is low, the building insulating effect is good, and the material is energy-saving, waterproof and environment-friendly; the produced color decorative red mud combined expanded vermiculite lightweight wall material has all-in-one function of decorating, insulating, heat insulating, sound insulating and shockproof.

Owner:SHANDONG UNIV OF TECH

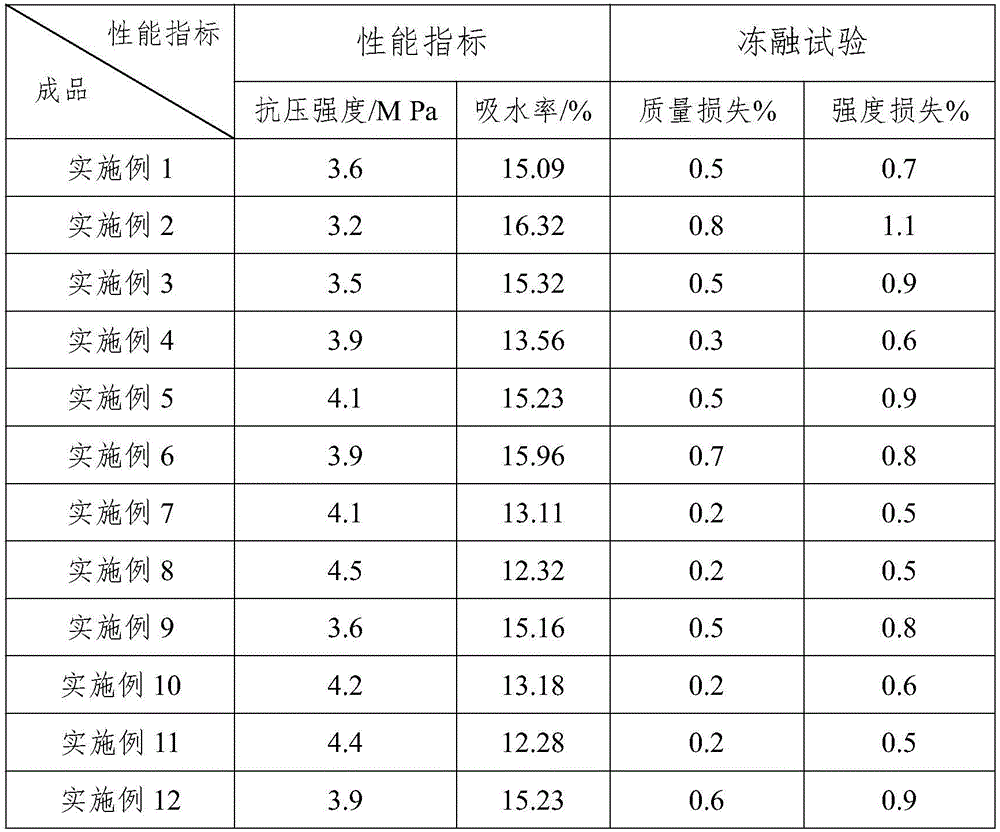

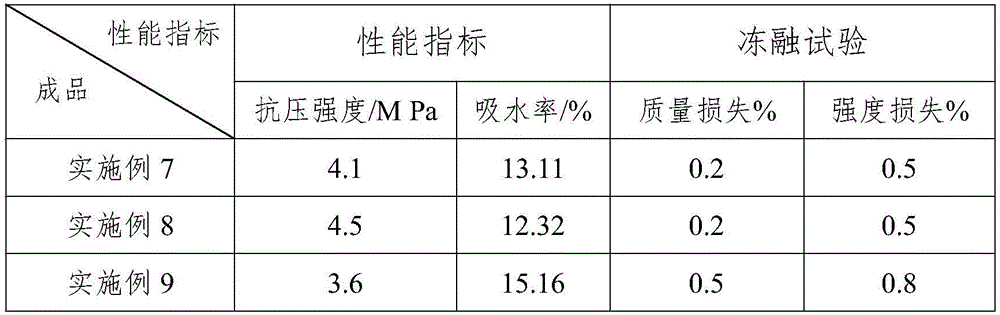

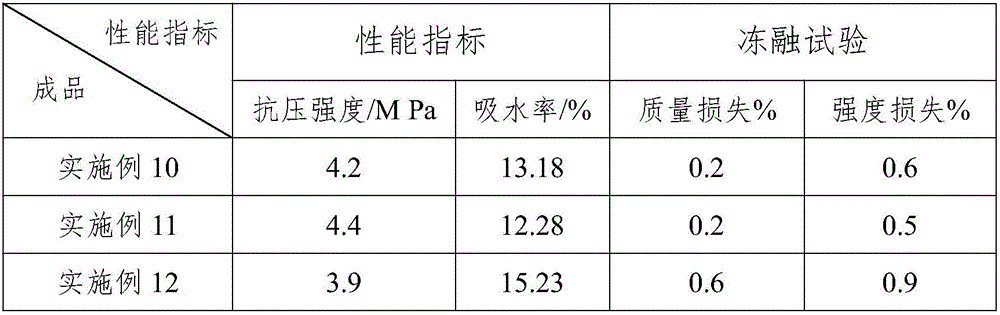

Preparation method of porous red mud cement brick

The invention relates to a preparation method of a porous red mud cement brick, which comprises the following steps: grinding 30-50% of red mud, 20-30% of sandstone, 20-40% of limestone and 4-10% of iron powder into a raw slurry, regulating until the raw slurry conforms to the technical indexes, removing most water by an inflow process with an evaporator, directly spraying into a rotary kiln, firing into cement clinker at 1400-1450 DEG C, carrying mix grinding on the clinker, 20-30% of blast furnace grain slag and 10-20% of gypsum in a cement grinder to a certain fineness, adding water into the mixture, stirring, adding 10-20% of straw powder, grinding, injecting into a mold, oscillating, molding, airing, calcining the aired brick in the kiln for 30-100 minutes, and curing under the pressure of 0.08-0.12 Mpa for 48-72 hours to obtain the required red mud cement brick. The method has the advantages of high utilization ratio of industrial waste residue, low cost, short maintenance time and low curing conditions.

Owner:苏州负碳谷材料科技有限公司

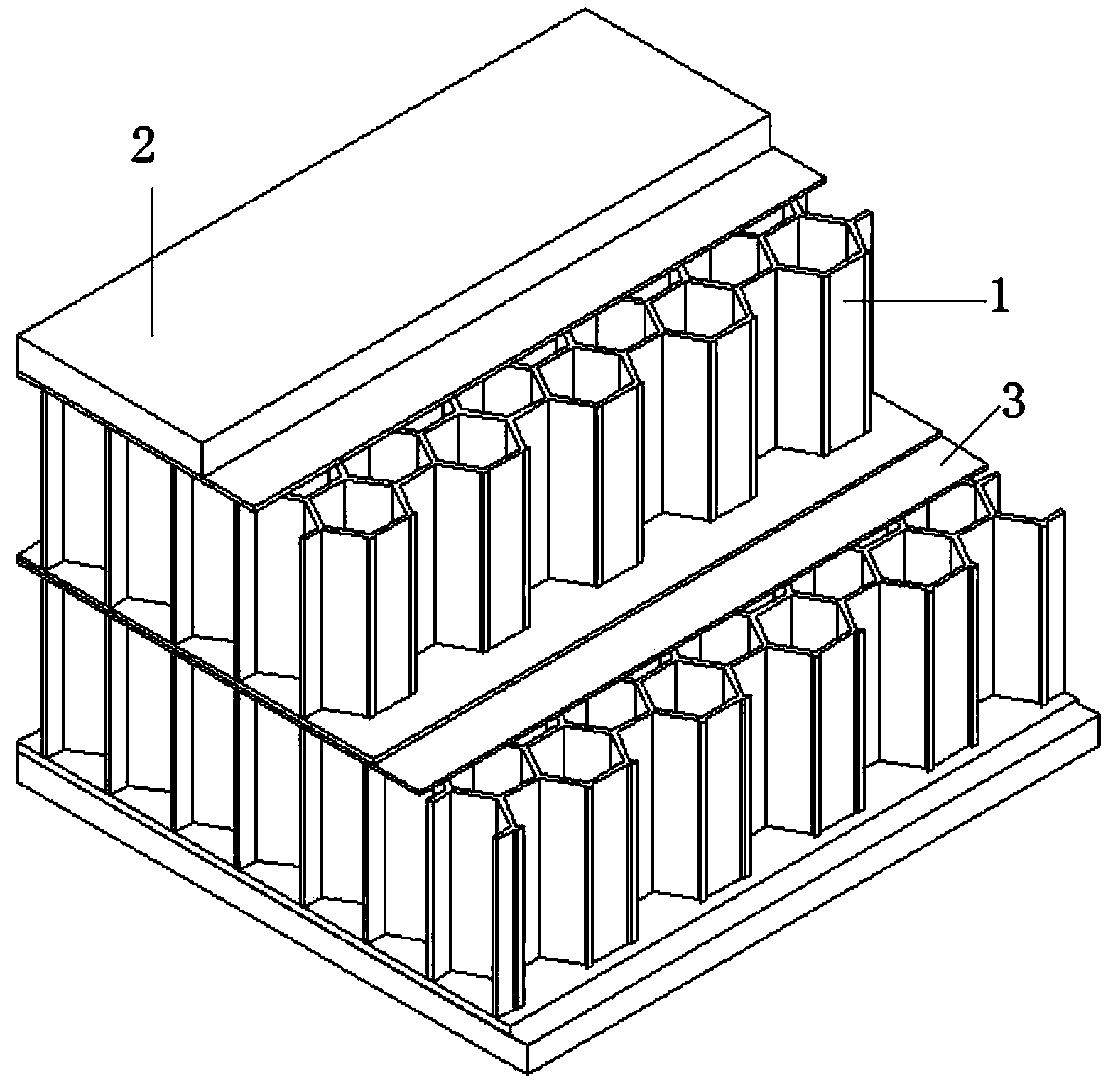

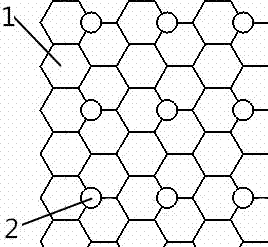

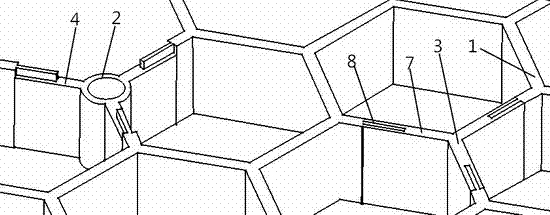

Regular-hexagon honeycomb core with detachable circular noise-reducing structures

InactiveCN107023743ACompressive strengthStrong insulationElongated constructional elementsActive forceHoneycomb structure

The invention discloses a regular-hexagon honeycomb core with detachable circular noise-reducing structures. The regular-hexagon honeycomb core comprises regular-hexagon honeycomb main structures, circular honeycomb structures and Y-shaped aluminum components, wherein the circular honeycomb structures are added among the regular-hexagon honeycomb main structures; part of wall plates at the positions, where the circular honeycomb structures and the Y-shaped aluminum components are mounted, of the regular-hexagon honeycomb main structures are lacking; the extra spaces are suitable for the mounting of the detachable circular honeycomb structures; the radiuses, the heights and the mounting density of the circular honeycomb structures can be adjusted as required; once one circular honeycomb structure is not needed, the circular honeycomb structure can be replaced by one Y-shaped aluminum component; not only the regular-hexagon honeycomb main structures and the circular honeycomb structures but also the regular-hexagon honeycomb main structures and the Y-shaped aluminum components can be fastened by adopting the mutually active force generated from material plasticity deformation; and accordingly, the Y-shaped aluminum components can also be detached.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of polished tile waste and expanded perlite combined multi-surface colorful decorating wall body material

InactiveCN104314256ASimple processStrong decorationCovering/liningsSolid waste managementPerliteWaste material

The invention relates to a preparation method of a polished tile waste and expanded perlite combined multi-surface colorful decorating wall body material. The preparation method of the polished tile waste and expanded perlite combined multi-surface colorful decorating wall body material is characterized in that the polished tile waste and expanded perlite combined multi-surface colorful decorating wall body material consists of three parts, i.e., a colorful decorating layer (1), a transition layer (2) and a heat insulating layer (3). The polished tile waste and expanded perlite combined multi-surface colorful decorating wall body material prepared by adopting the preparation method disclosed by the invention has the advantages that since a one-step sintering method is adopted and the transition layer is added between the colorful decorating layer and the heat insulating layer, the disadvantages that the air hole diameter is too large and the bonding strength and thermal impact resisting capacity are reduced due to a reason that the melting points of the materials of the colorful decorating layer and the heat insulating layer are not consistent are effectively overcome; by adding ceramic color agent to prepare interior and exterior wall decoration materials in a single color, combined colors and patterns, additional decoration is not needed, the production process is simple, the cost is low, the building heat insulating effect is good, the material is energy-saving and environmental-friendly, and the produced polished tile waste and expanded perlite combined multi-surface colorful decorating wall body material is integrated with functions such as decoration, heat preservation, heat insulation, water prevention, sound insulation and shock resistance.

Owner:SHANDONG UNIV OF TECH

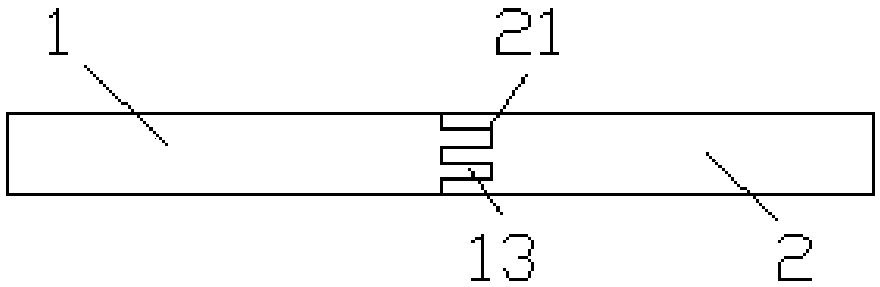

Sound elimination pad with air purifying function on car roof

ActiveCN104290680AStrong insulationIncrease circulation spaceAir-treating devicesAdhesiveRegenerating fibers

The invention provides a sound elimination pad with an air purifying function on a car roof. The sound elimination pad comprises a regenerated fiber layer which is hot-pressed into a half-frame shape. An opening of the half-frame-shaped regenerated fiber layer is arranged downwards. A PEF layer is bonded to the upper end face of the regenerated fiber layer through polyene adhesives. A half-frame-shaped pure cotton layer is arranged on the inner surface of the half-frame-shaped regenerated fiber layer 1. An opening of the half-frame-shaped pure cotton layer is also arranged downwards. A half-frame-shaped purifying layer with a downward opening is arranged on the inner surface of the half-frame-shaped pure cotton layer. According to the sound elimination pad, by the adoption of the half-frame-shaped arrangement, the air purifying effect can be very good, diffusion of fragrance is slow, the service life can be prolonged when the sound elimination pad is used in an effective space, and the cost is lowered; as a result of the arrangement, the structure is simple, the space is saved, the sound insulation effect can be enhanced, the air can be purified, fresh fragrance can be diffused, the car roof is more resistant to a high temperature, and the heat insulation effect is enhanced.

Owner:GUANGDE TIANYUN NEW TECH

Method for preparing red mud-expanded perlite multi-face colored decoration lightweight wall material

InactiveCN104309185AImprove the decorative effectImprove waterproof performanceLaminationLamination apparatusCeramic colorantsInsulation layer

The invention discloses a method for preparing a red mud-expanded perlite multi-face colored decoration lightweight wall material. The red mud-expanded perlite multi-face colored decoration lightweight wall material is characterized by consisting of three parts, namely a colored decoration layer (1), a transition layer (2) and a thermal insulation layer (3). The red mud-expanded perlite multi-face colored decoration lightweight wall material disclosed by the invention is subjected to once-firing, and the transition layer is added between the colored decoration layer and the thermal insulation layer, so that the defects that the pore diameter is extremely large and the bonding strength and thermal shock resistance are reduced between the colored decoration layer and the thermal insulation layer due to inconsistent melting points of materials are effectively overcome. Ceramic colorants are added, so that interior and exterior wall decoration materials of a single color, composite colors and various colors and patterns are prepared, and extra decoration is not needed. The method is simple in production process and low in cost and has a good building heat preservation effect and energy-saving and environment-friendly effects, and the produced red mud-expanded perlite multi-face colored decoration lightweight wall material integrates multiple functions such as decoration, heat preservation, heat insulation, sound insulation, shock resistance and the like.

Owner:SHANDONG UNIV OF TECH

Sprayed concrete for roadway

The invention provides sprayed concrete for a roadway. The sprayed concrete is prepared from the following raw materials in parts by weight: 80-120 parts of cement, 40-60 parts of superfine aggregate, 80-100 parts of fine sand, 10-20 parts of fibers, 6-12 parts of rubber powder, 7-10 parts of nano aluminum oxide, 3-8 parts of polyacrylamide, 8-14 parts of an MK-1 reinforcing agent, 1.5-5 parts of a water reducing agent, 6-10 parts of a flame retardant and 10-18 parts of an accelerator. According to the invention, an inorganic-organic co-hybrid polymer dispersion group system is formed on the basis of the principle of an inorganic-organic ultrafine powder assembly, coating and dispersion system, so that moderate toughness and rigidity can be achieved, excellent guniting material indexes such as high adhesion, cracking resistance, impermeability, reinforcement and support and the like are achieved, and the concrete also has relatively strong toughness, ductility, heat insulation and shock absorption performance.

Owner:河南省宜居建材科技有限公司

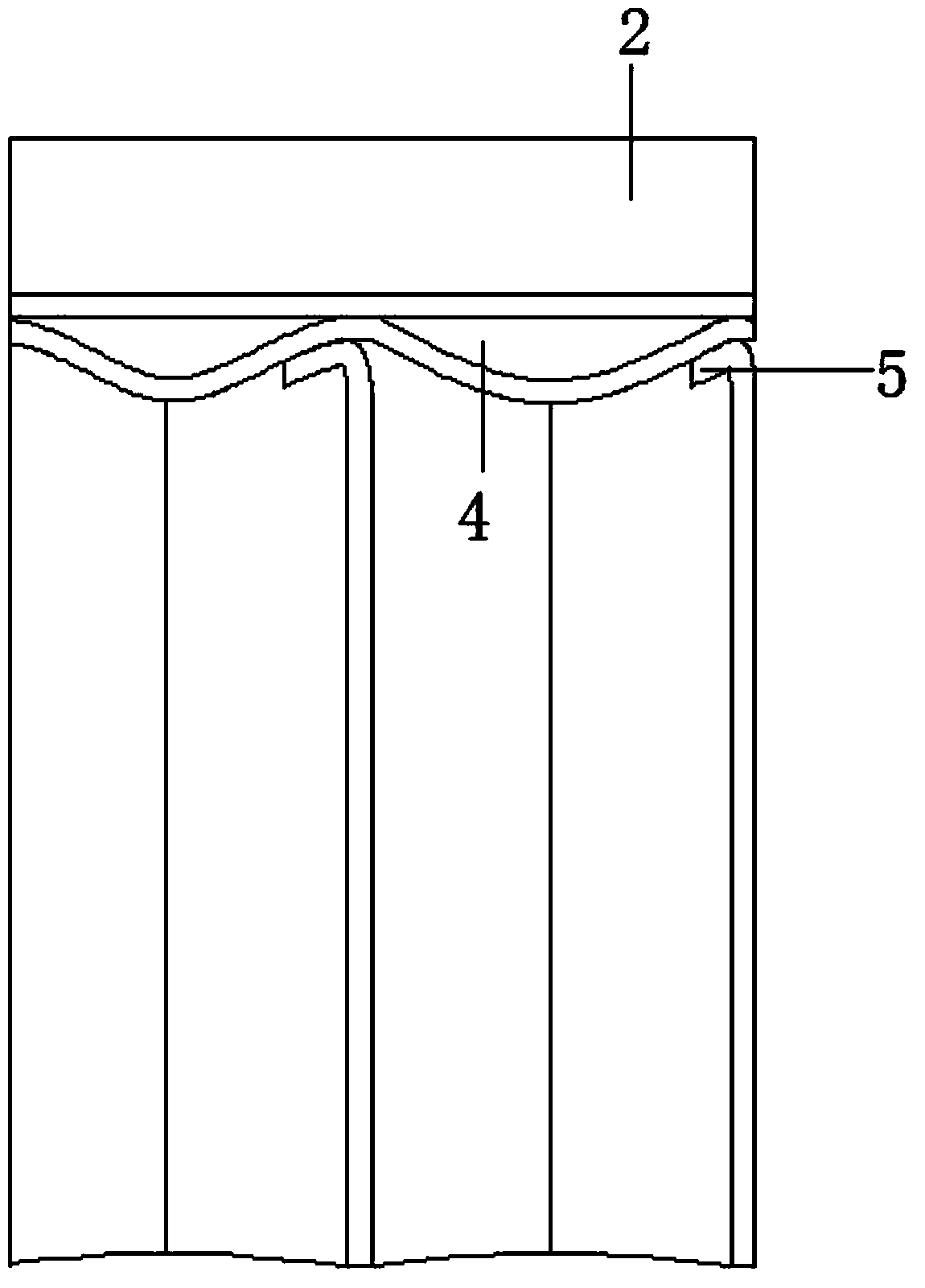

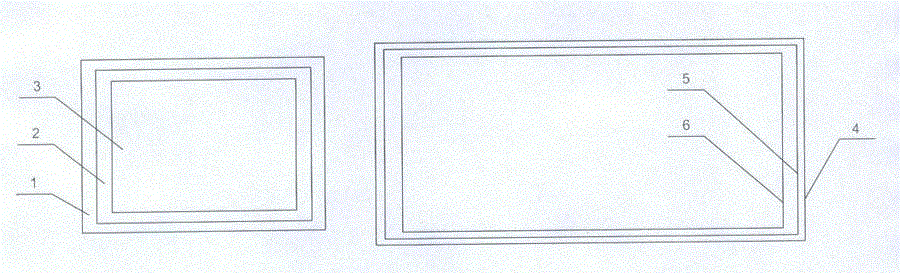

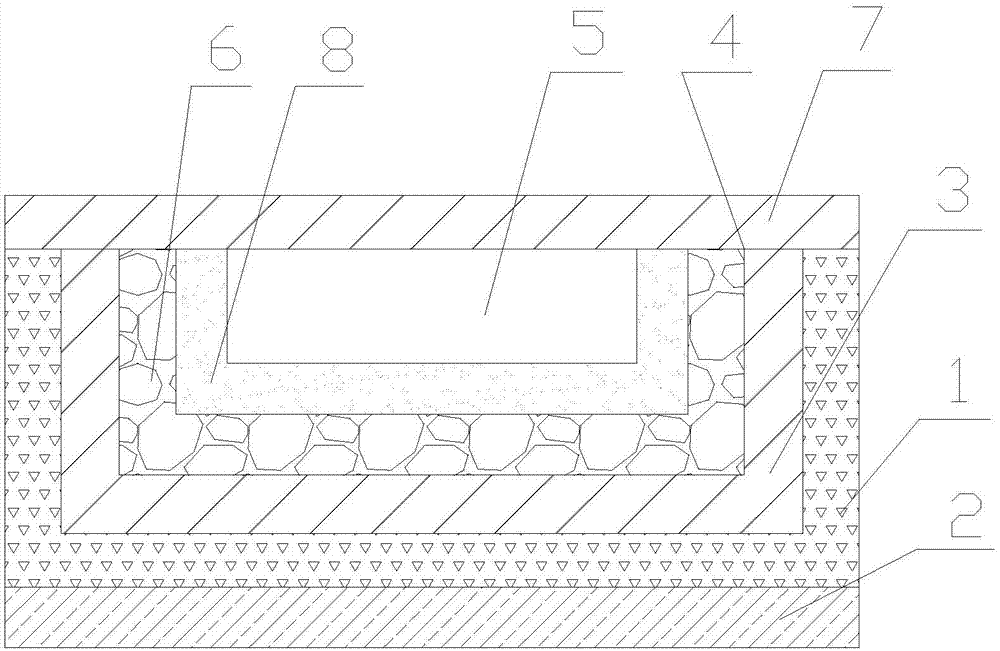

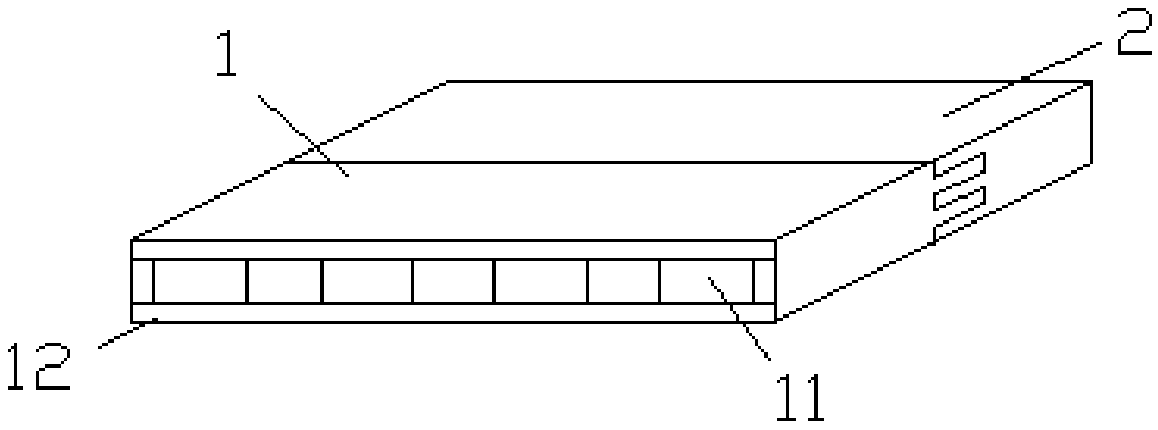

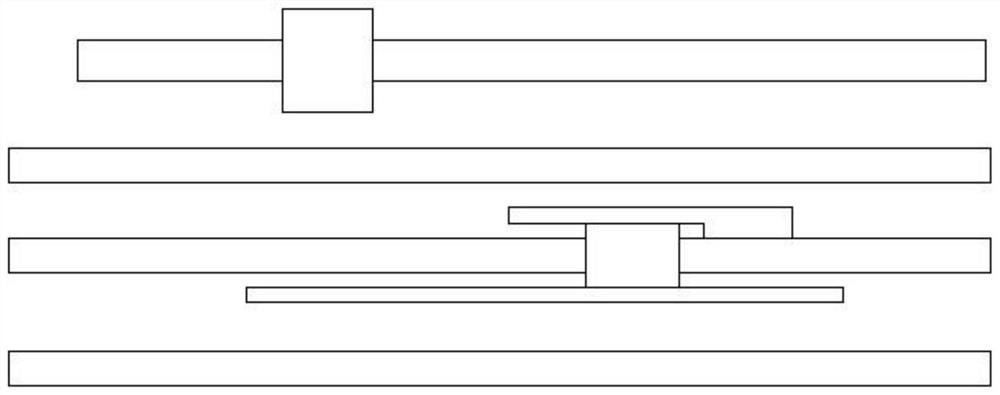

Novel thermal insulation building inner wall board

InactiveCN108442633AImprove insulation performanceStrong insulationCovering/liningsFlooringThermal insulationPolystyrene

The invention discloses a novel thermal insulation building inner wall board. The novel thermal insulation building inner wall board structurally comprises a first building inner wall board and a second building inner wall board. Through holes, a decorative board, a convex block, a first thermal insulation layer, a first reinforcement layer, a first heat preservation layer, a second heat preservation layer, a second reinforcement layer and a second thermal insulation layer are arranged on the first building inner wall board. A groove is formed in the first building inner wall board. The firstbuilding inner wall board is arranged on the left side of the second building inner wall board, and is connected with the groove in a matched mode through the convex block. The novel thermal insulation building inner wall board has the advantages of good thermal insulation, good heat preservation, low cost and non-polluting material. The first thermal insulation layers are made from rock wool materials to prevent the temperature infiltrated from the outside world, and a good thermal insulation effect is achieved; the heat preservation layers are made from polystyrene foam materials, so that indoor temperature is not easy to lost, and the heat preservation effect is excellent; and the convex block and the groove are formed, so that the installation and disassembly of the building interior wall board is facilitated, the structure is simple, and the operation is simple.

Owner:FOSHAN TIANLI TONGSE DECORATION MATERIAL CO LTD

Method for preparing soundproof brick body

InactiveCN101100088ACancel sound wavesImprove sound insulationCeramic shaping apparatusFoaming agentBrick

The present invention discloses process of making sound insulating brick, and belongs to the field of building material technology. The process includes the following steps: preparing foam with foaming agent and water; preparing slurry with cement, fly ash and water in certain proportion; pressurizing the foam into the slurry; pumping the foamed slurry with a high pressure pump to depositing mold; naturally curing and demolding to obtain product. By means of Heln. Holtn resonance principle, the sound insulating brick can eliminate sound wave through absorbing vibrating energy. The process is simple and low in cost, and may have different molds adopted.

Owner:南京长湖机电设备有限公司

Lime-based plaster formula

The invention discloses a lime-based plaster formula, wherein the components comprise, by weight, 74-82 g of building lime, 294-306 g of building gypsum, 611-629 g of heavy calcium powder, 1-4 g of wood fiber, 1-3 g of cellulose ether, 0.2-1 g of a retarder, 1-3 g of poly-acid styrene, 1-3 g of foamed polystyrene, 1-4 g of starch ether, and 1-3 g of a hydrophobic agent. The lime-based plaster of the present invention has advantages of reasonable ratio design, low cost, moisture prevention, weathering prevention and extremely strong heat insulation capability.

Owner:彭龙喜

Roof rock wool board production method

InactiveCN108979013AHigh compressive strengthImprove insulation effectRoof covering using slabs/sheetsGlass making apparatusFiberThermal insulation

The invention discloses a roof rock wool board production method. The method comprises the following steps that 1, raw materials are prepared; 2, hydrophobic liquid is prepared; 3, fiber is prepared;4, a fibrous body is prepared; 5, the fibrous body is compressed, wherein a flat extrusion machine is adopted for extruding the fibrous body; 6, a finished product is prepared, wherein the extruded fibrous body is cut into a roof rock wool board with the preset size through a cutting tool. Accordingly, the prepared roof rock wool board has high compressive strength and point load capacity, the loading requirements of construction personnel and equipment can be met, and the roof rock wool board has the effects of heat preservation, thermal insulation, fire prevention, sound insulation and noisereduction.

Owner:江苏振威新材料科技有限公司

Gypsum block and processing method thereof

The invention relates to a gypsum block and a processing method thereof. During processing, the gypsum block is prepared from the following raw materials in part by weight: 172 to 176 parts of gypsum powder, 60 to 65 parts of fly ash, 180 to 185 parts of water, 2 to 5 parts of early strength agent and 1 to 1.5 parts of adhesive. During processing production, the raw materials are mixed in the reasonable ratio and stirred, and the mixture is subjected to mould pressing to form the gypsum block. The gypsum block has strong sound-insulating, heat-insulating, heat-preserving and moisture-preserving effects, and high earthquake resistance.

Owner:池州市新科建材有限公司

Preparation process of nano thermal insulation coating

InactiveCN111607328AImprove insulation effectStrong insulationFireproof paintsAntimony oxides/hydroxides/oxyacidsThermal insulationPhysical chemistry

The invention discloses a preparation process of a nano thermal insulation coating. The method comprises the following steps: preparation of nano antimony pentoxide: adding 14-15 parts of antimonous oxide and 19-20 parts of deionized water into a stirring reaction kettle to be stirred, so that the antimonous oxide and the deionized water are fully mixed into a slurry; then heating the slurry to raise the temperature to 90-95 DEG C, after the heating is finished, adding inlet water into the kettle and stirring for 5 to 7 minutes; slowly dropwise adding 11-12 parts of hydrogen peroxide into a mixture after stirring; after hydrogen peroxide is added completely, continuing to stir for 2-4 minutes to fully mix a slurry with hydrogen peroxide; after mixing, heating and refluxing an obtained mixture for 43 to 48 minutes to prepare a white thick paste, slightly cooling the white thick paste, filtering the white thick paste to remove aggregates or block particles in the white thick paste, and drying the obtained white thick paste in an oven at 80-90 DEG C to obtain the nano antimony pentoxide.

Owner:JIANGSU BAOPING ANTI THEFT TECH CO LTD

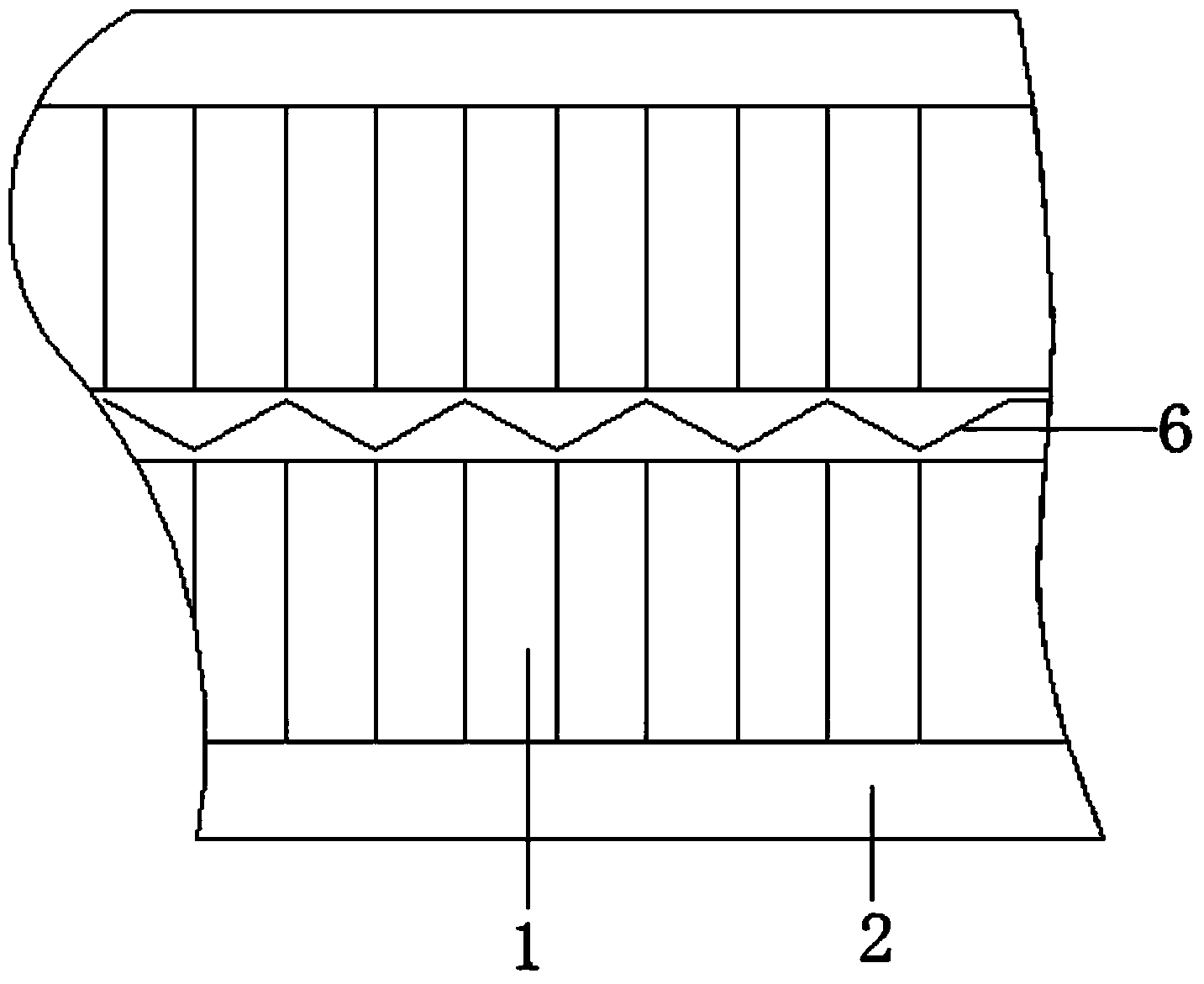

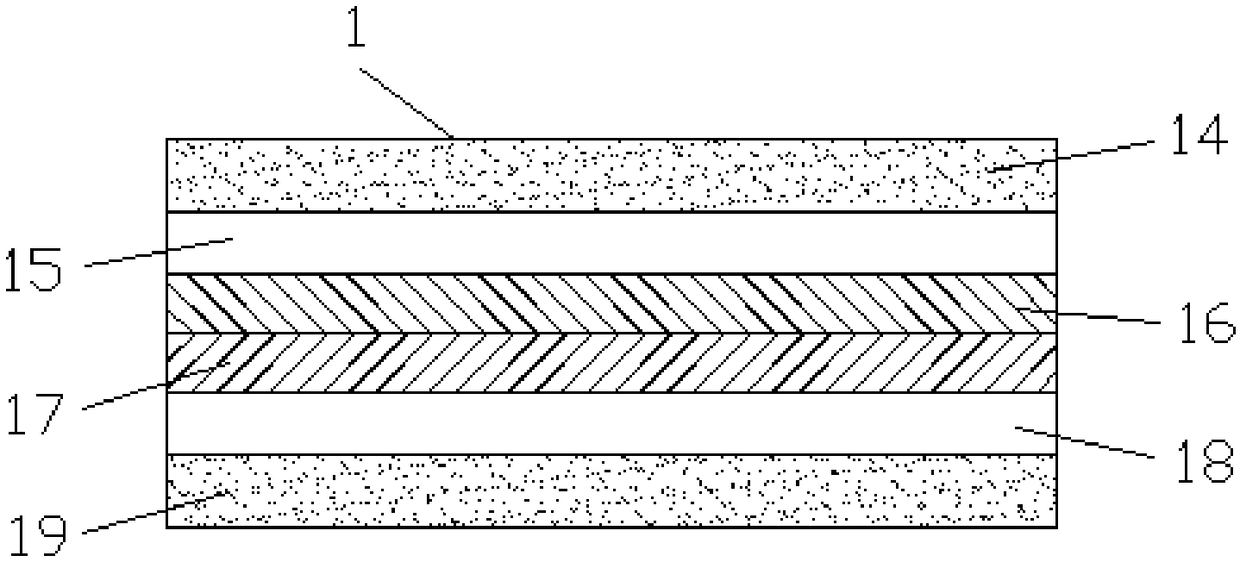

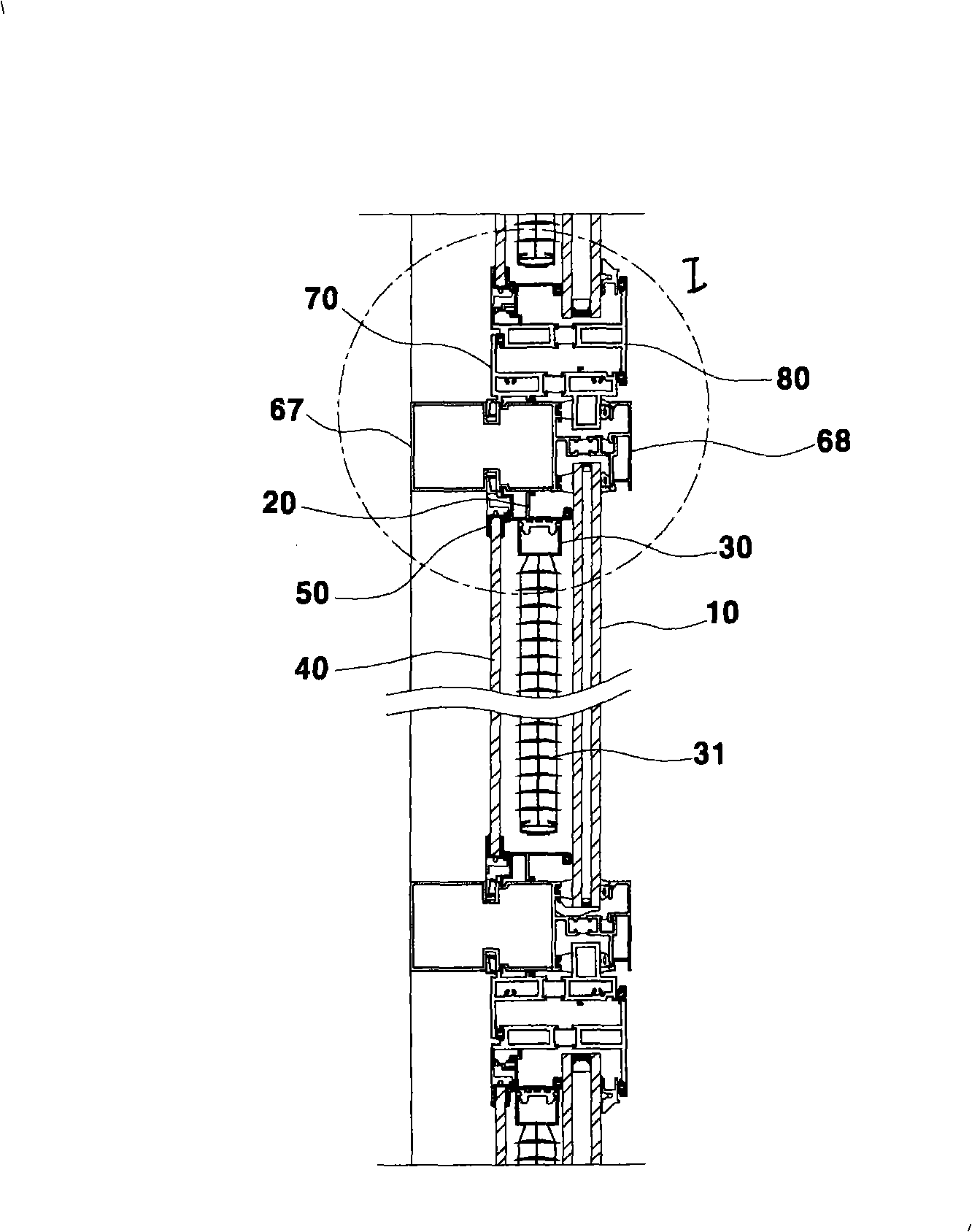

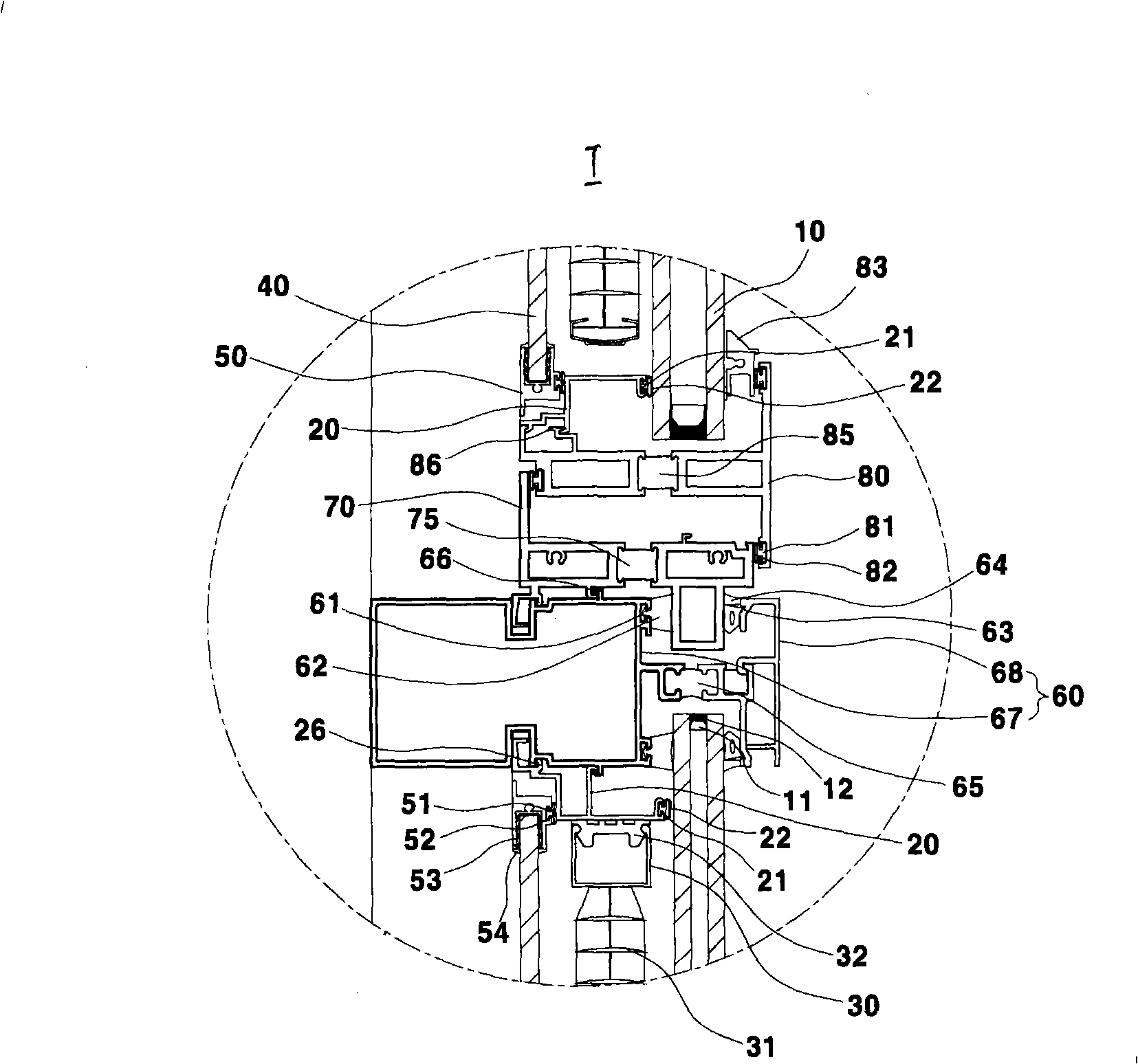

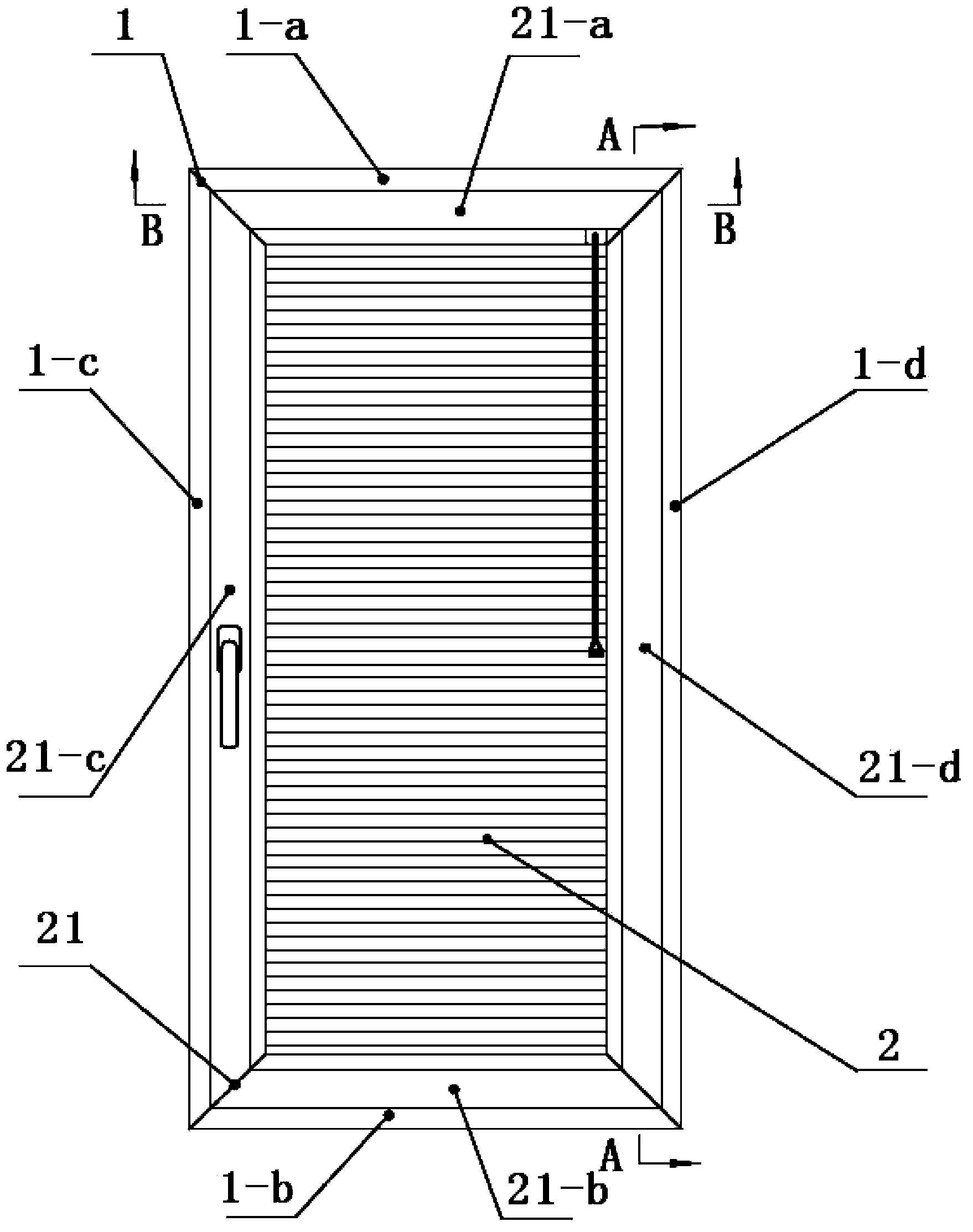

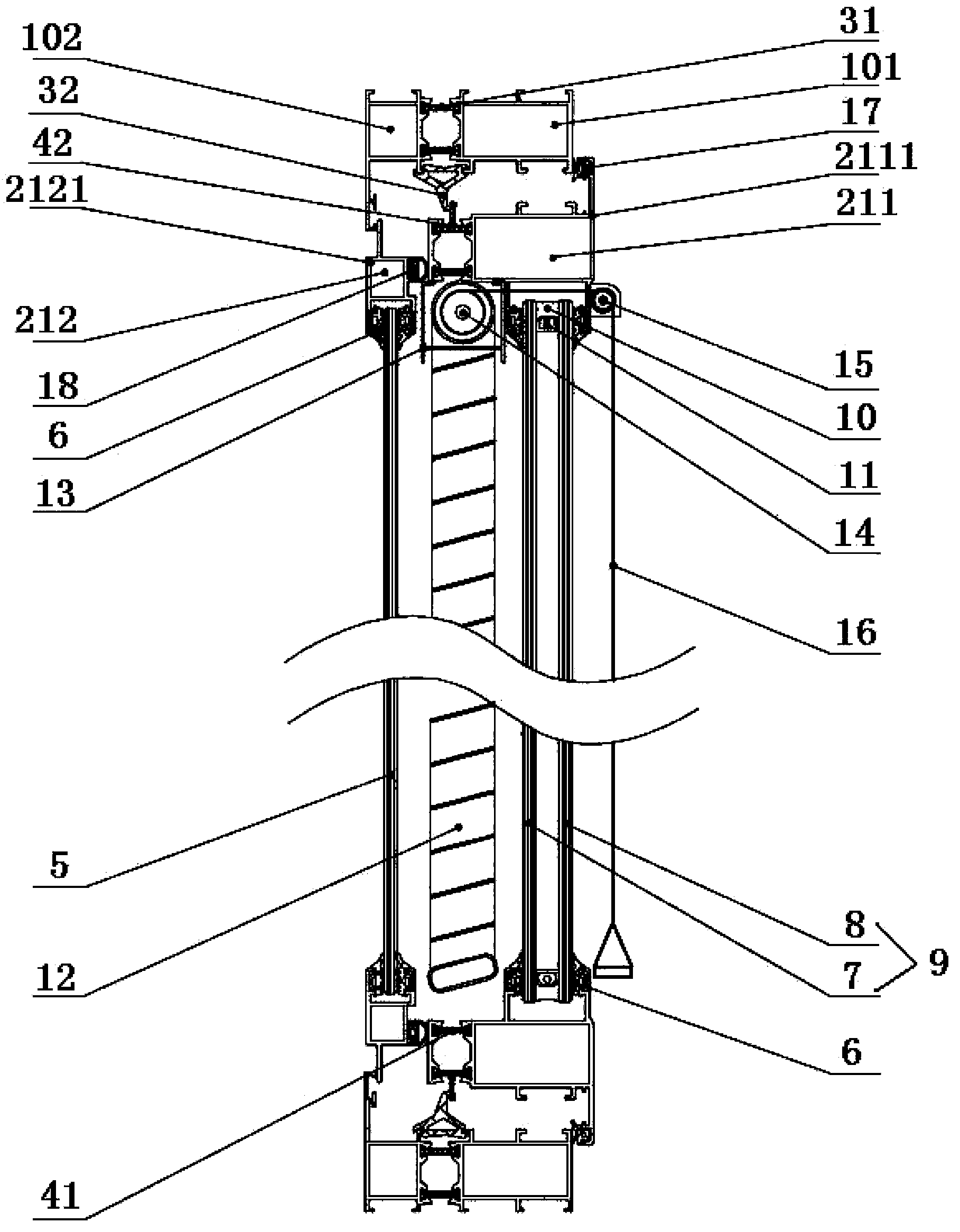

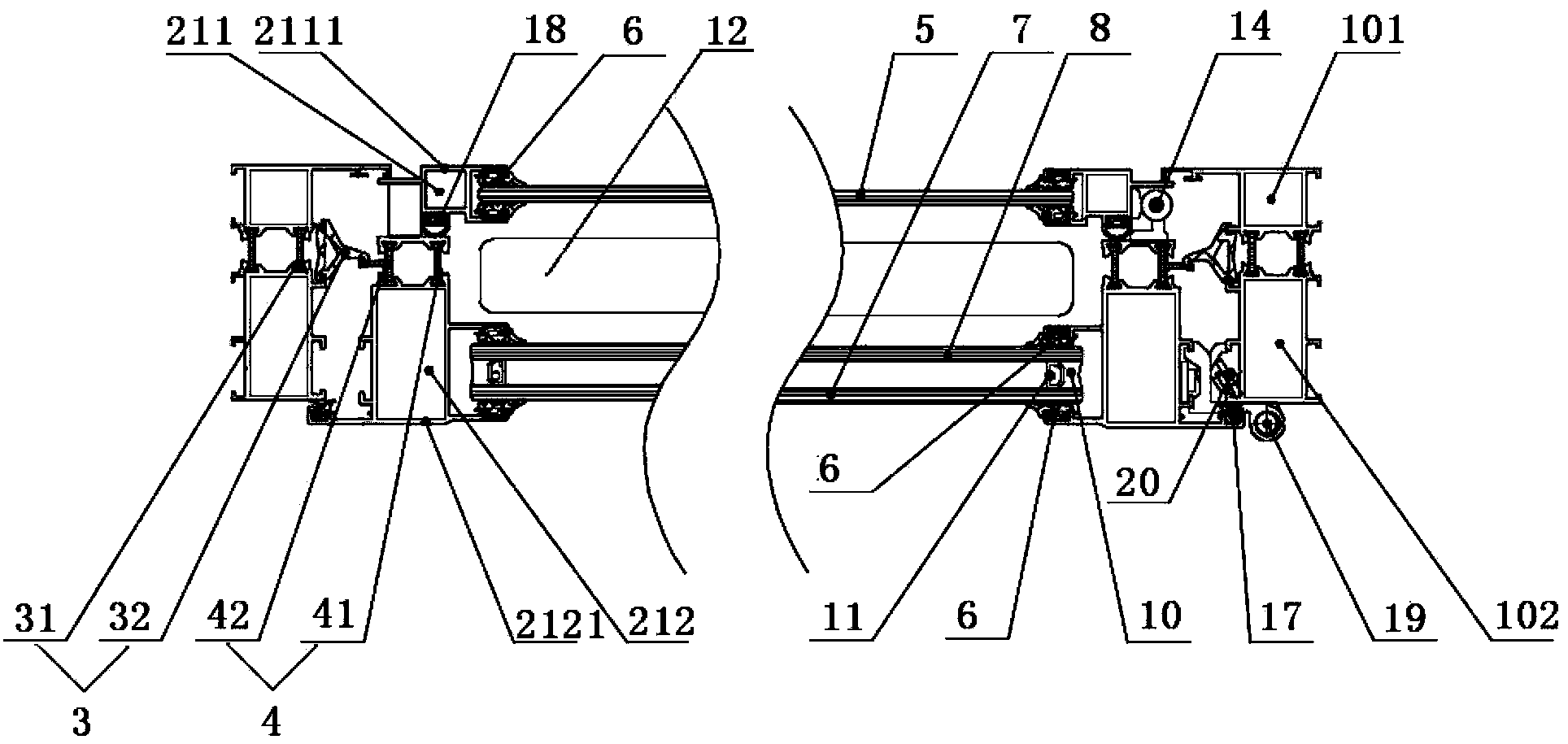

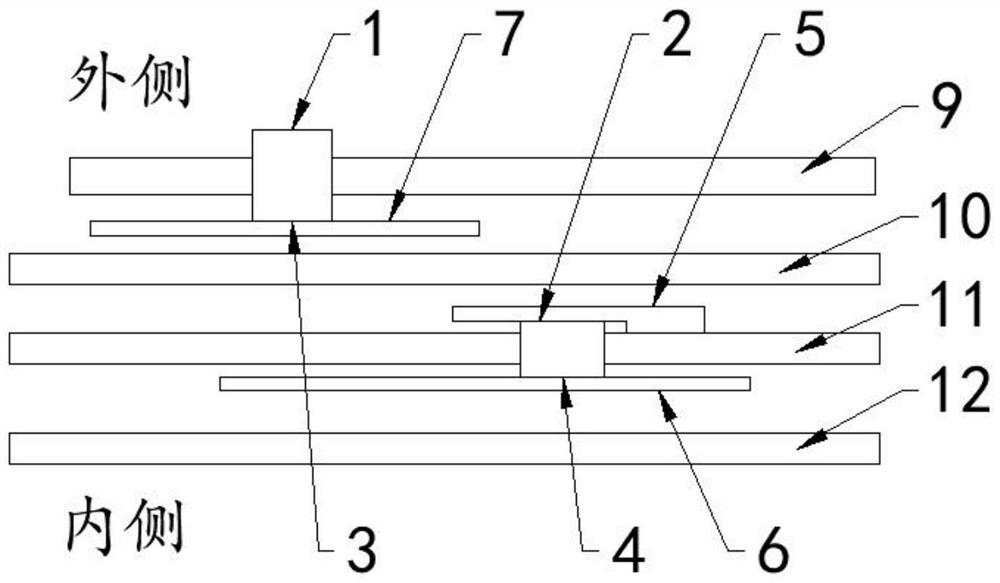

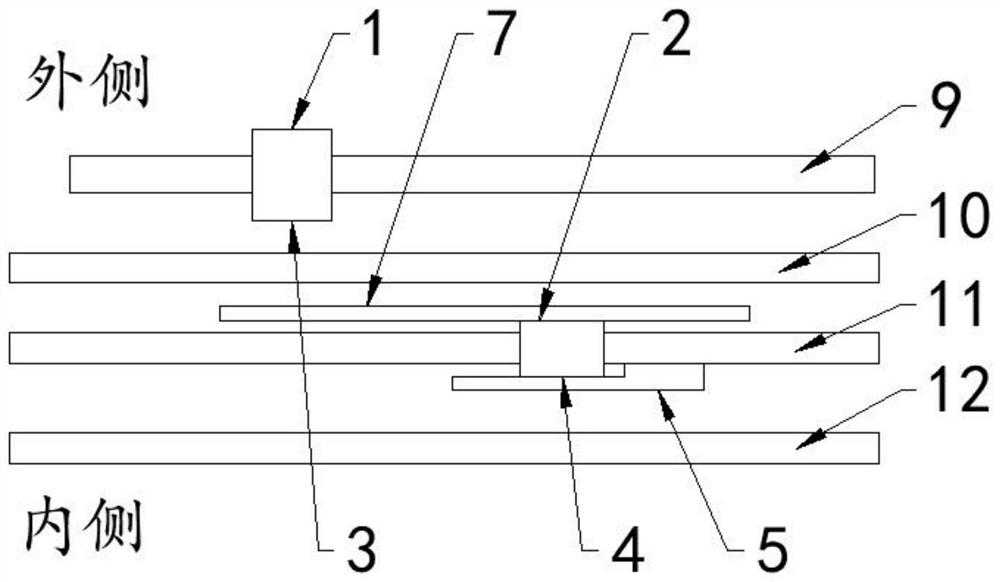

Ternary heat insulation glass window with built-in louvre window

InactiveCN101333905AAvoid Dust ProblemsAvoid pollutionDoor/window protective devicesUnits with parallel planesSash windowWindow shutter

Disclosed is a three-layer heat insulation glass window with an inner louver, comprising a double-layer glass window, a first window sash in the window bore formed by the insertion of a heat insulation seal gasket along the length direction on the position that the double-layer glass window is connected, an inner louver, a lifting device used for controlling the lifting of the louver, a heat insulation box fixed on the first window sash according to the combination means, an inner side glass window designed for the inner louver and the heat insulation box, a second window sash which is formed that the inner side glass window is inserted into the window bore formed by the insertion of the insulation seal gasket along the length direction on the position that the first window sash is connected, and is fixed by a fixing seal gasket, and a main window sash; the main window sash includes an inside window sash and an outside window sash; the outside window sash is clung tightly with the lateral side of the double-layer glass window through a rubber damper; the inside window sash is connected with the inner side of double-layer glass window with the connection part thereof form a window bore along the length direction of the main window sash; a fixing seal gasket is inserted into the window bore to enable the inside window sash to be clung tightly with the double-layer glass window through the fixing seal gasket; the inside window sash is connected with the outside window sash through a heat insulation handle.

Owner:苏州汉斯新型建材有限公司

A kind of environment-friendly diatom sea foam mud coating

InactiveCN103172321BStrong bleachingStrong insulationDispersed particle separationSodium BentoniteKaolin clay

The invention provides an environment-friendly diatom sepiolite coating which is prepared by stirring the following components in percentage by weight: 20%-50% of diatomite, 5%-40% of sepiolite powder, 15%-30% of kaoline, 1%-5% of sodium bentonite, 5%-30% of quartz sand, 0.4%-0.8% of HPMC (Hydroxy Propyl Methyl Cellulose), 0.5%-6% of anion powder and 0.3%-3% of nanometer titanium dioxide. The environment-friendly diatom sepiolite coating provided by the invention has the advantages of good adsorptivity and decomposability and good effect on varnishing a wall body by matching with the usage method of the environment-friendly diatom sepiolite coating.

Owner:徐陈松

Heat-insulation anti-ablation silicone rubber for cable

InactiveCN106543722AHigh strengthHigh heat distortion temperatureRubber insulatorsInsulated cablesPolyethylene glycolTemperature resistance

The invention discloses a heat-insulation anti-ablation silicone rubber for a cable. The heat-insulation anti-ablation silicone rubber for the cable is prepared from the following raw materials: MVQ (Methyl Vinyl Silicone Rubber), a polyurethane elastomer, maleic anhydride-grafted polystyrene, tetrapropyl fluoro elastomer, photoinitiator benzophenone, a cross-linking agent (TAIC), ferrous chloride, ferric trichloride, mica, low-melting-point glass powder, polyethylene glycol, ferrous sulfate, ammonium bicarbonate, graphite, attapulgite, a silane coupling agent A172, phenolic resin, phenoxyl polyphosphazene, dioctyl sebacate, absolute ethyl alcohol and appropriate amount of deionized water. The cable material provided by the invention is good in abrasive resistance, high in heat insulation, and good in flame retardant property, has favorable high-temperature resistance and chemical resistance, and is low temperature resistant, ageing resistant, superior in mechanical performance, green and environmentally friendly, and worth popularizing.

Owner:ANHUI LVHUAN ELECTRIC CO LTD

Autoclave plaster brick and preparation method thereof

The invention provides an autoclave plaster brick and a preparation method thereof, and relates to the technical field of construction materials. The autoclave plaster brick is prepared from the following raw materials: phosphogypsum, carbide slag, pulverized fuel ash, aggregate, slag ash and a compound exciting agent. The autoclave plaster brick adopts the high-addition phosphogypsum as a raw material, and the new compound exciting agent is added, so that pretreatment does not need to be performed on the raw material phosphogypsum in advance, the phosphogypsum addition quantity can be improved, and the prepared autoclave plaster brick product is good in performance; the autoclave plaster brick has high sound insulation, heat insulation and heat preservation effects; the preparation method is capable of lowering the production cost, improving the utilization ratio of the phosphogypsum, and reducing land occupation and environmental pollution caused by accumulation of a large amount of phosphogypsum.

Owner:中盐安徽红四方新型建材科技有限公司

Built-in louver broken bridge aluminum window

InactiveCN103437684AStrong waterproof performancePrevent from dusting or contaminationDoor/window protective devicesEngineeringFirst glasses

The invention discloses a built-in louver broken bridge aluminum window, which comprises a window frame and a window sash, wherein the window sash is provided with a first glass plate and a hollow glass layer, wherein the hollow glass layer consists of a second glass plate and a third glass plate, and a built-in louver window curtain is arranged between the first glass plate and the hollow glass layer. The window has the advantages that the space between the window glasses is free from any limitation, the heat isolation, sound isolation and waterproof performances are high, the buffer function on the exterior temperature or press change is sufficiently realized, the appearance is attractive, and the dust falling or the pollution to the louver window is effectively prevented.

Owner:浙江雅德居实业有限公司

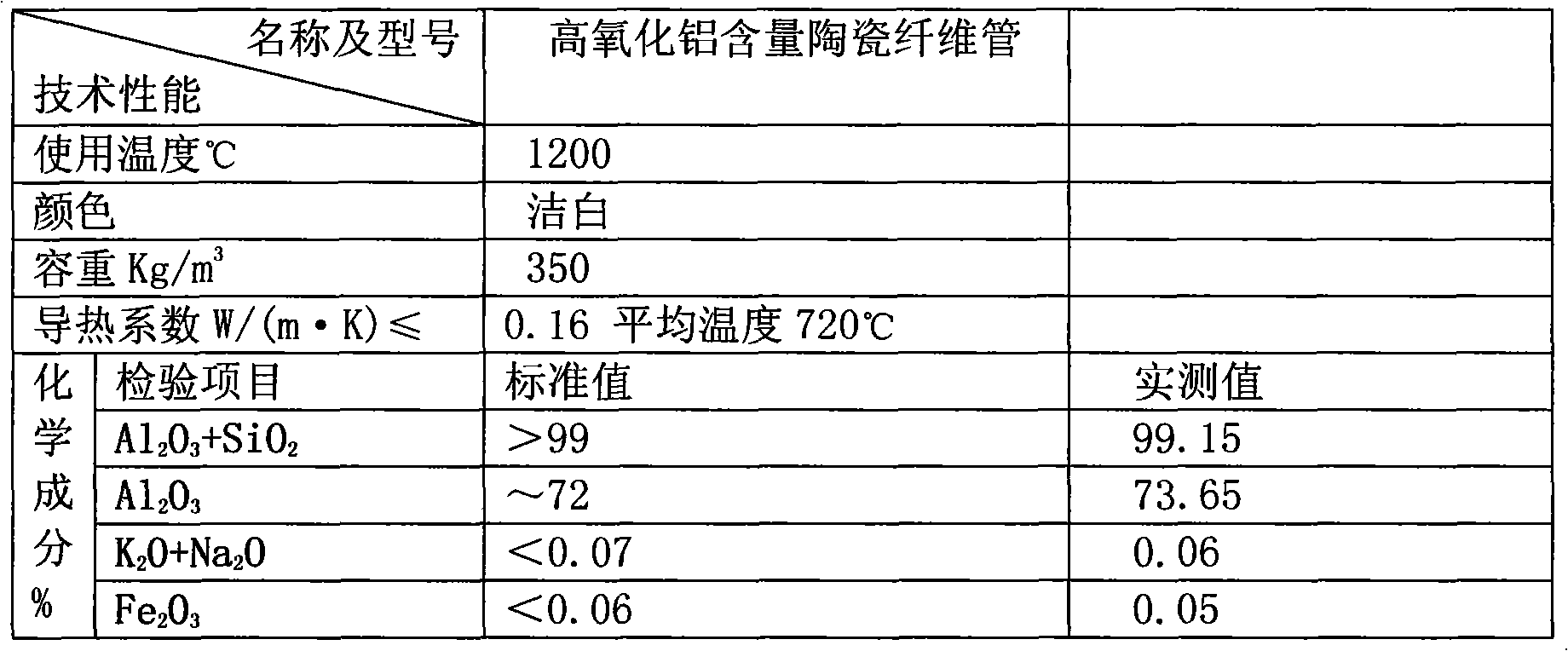

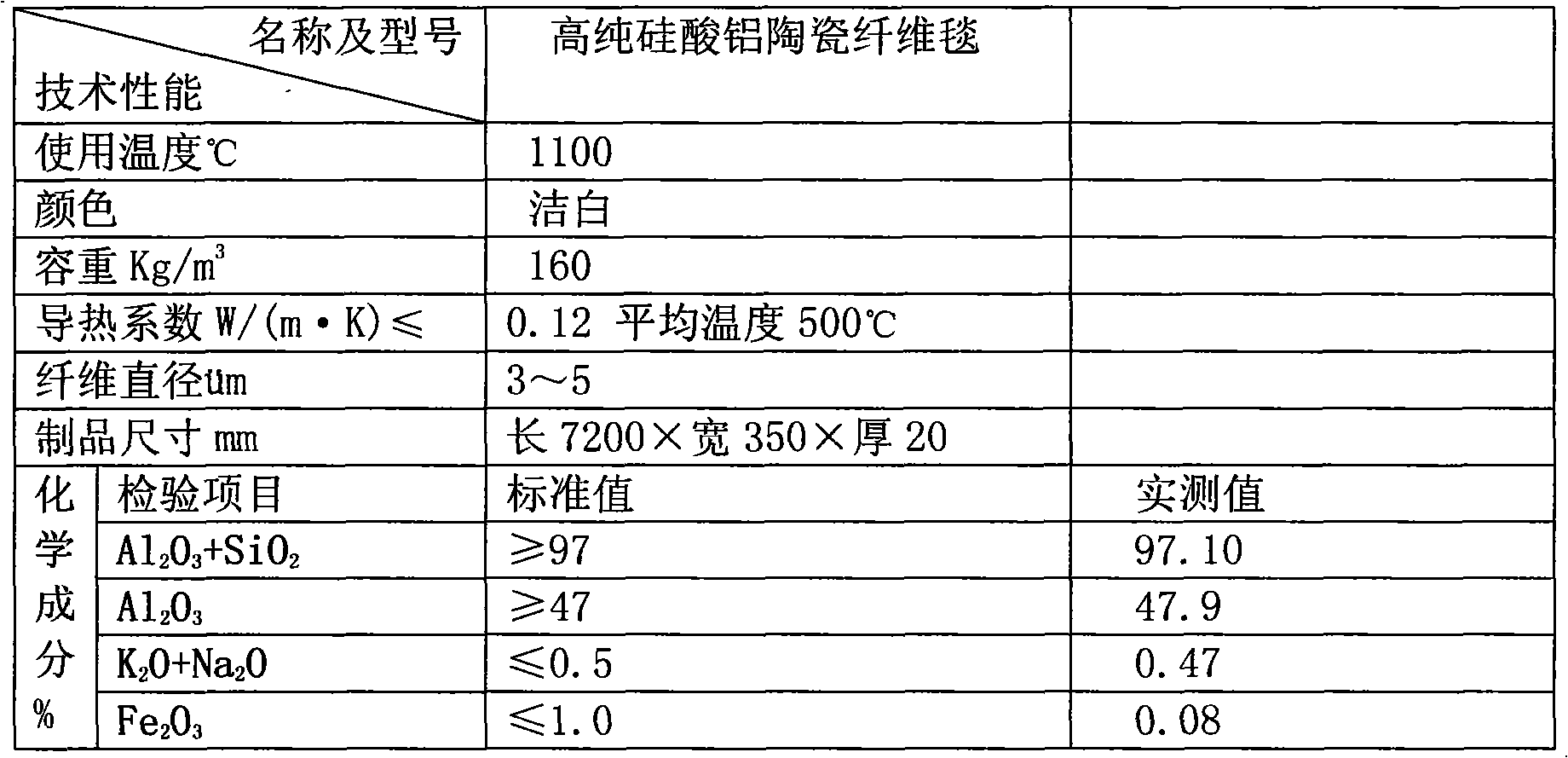

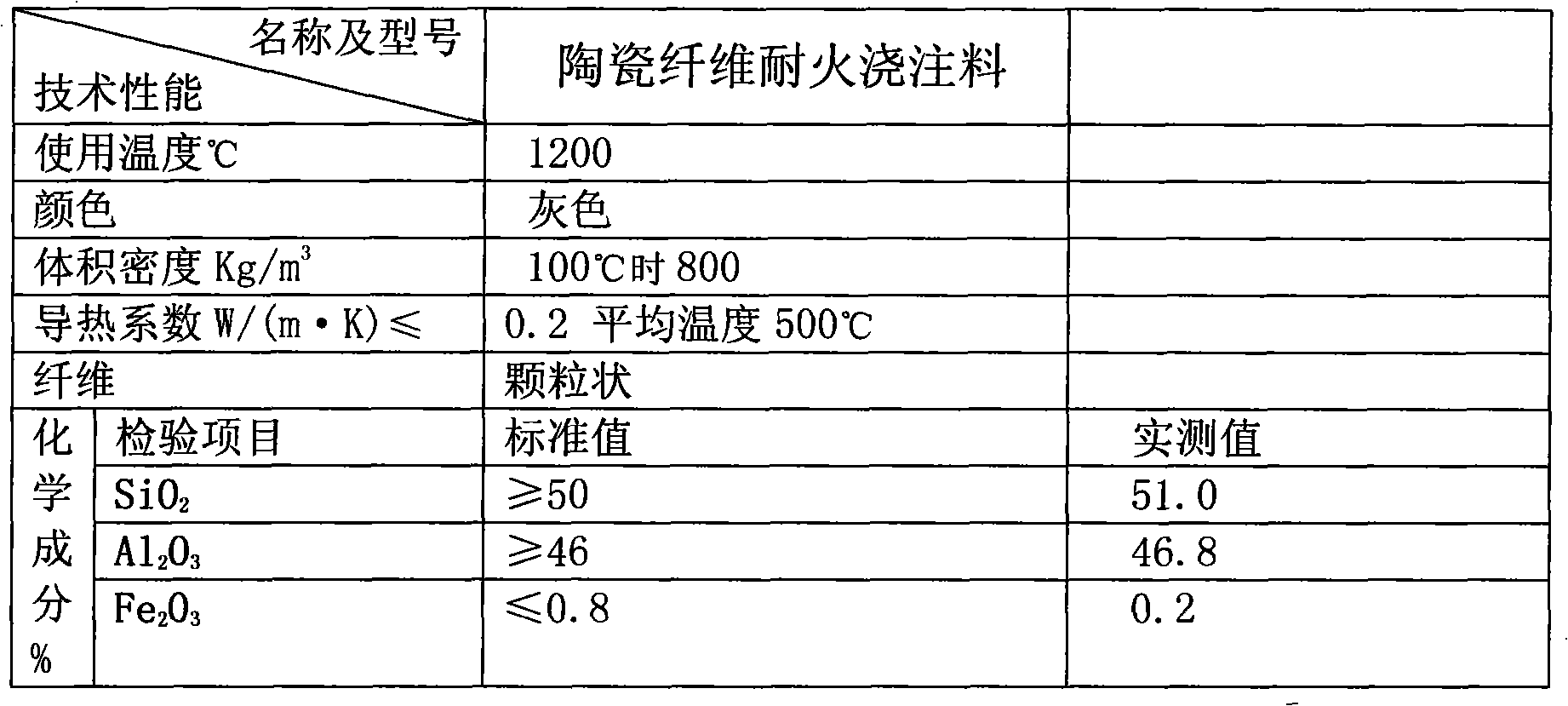

Optical-fiber temperature measuring probe and optical cable cooling method in high-temperature environment

InactiveCN101620009BReduce the burden of cold insulationStrong insulationRadiation pyrometryFibre mechanical structuresFiberOxide ceramic

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A kind of honeycomb wall panel and its installation method

The invention discloses a honeycomb wall panel with light weight, high strength, simple construction, low cost, strong sound insulation and heat insulation ability, and good environmental protection and an installation method thereof, which overcomes the problems of cost, weight, sound insulation, and There are obvious defects in many aspects such as environmental protection. The honeycomb wallboard includes an inner core and two outer panels. The inner core is in the shape of a plurality of bottomless hexagonal columns that are seamlessly spliced with each other. A honeycomb paper core is formed, each of the two honeycomb paper cores is connected with a back cover paper surface, the back cover paper is glued to the inner core and has the same material, and the two outer panels are arranged outside the honeycomb paper core , and each connected with the other back cover paper of the two honeycomb paper cores, one of the outer panels is wider than the other. The invention is suitable for the occasions where the building walls are used in the past, and has the advantages of light weight, strong heat and sound insulation effects, good environmental protection and the like.

Owner:孔忻怡

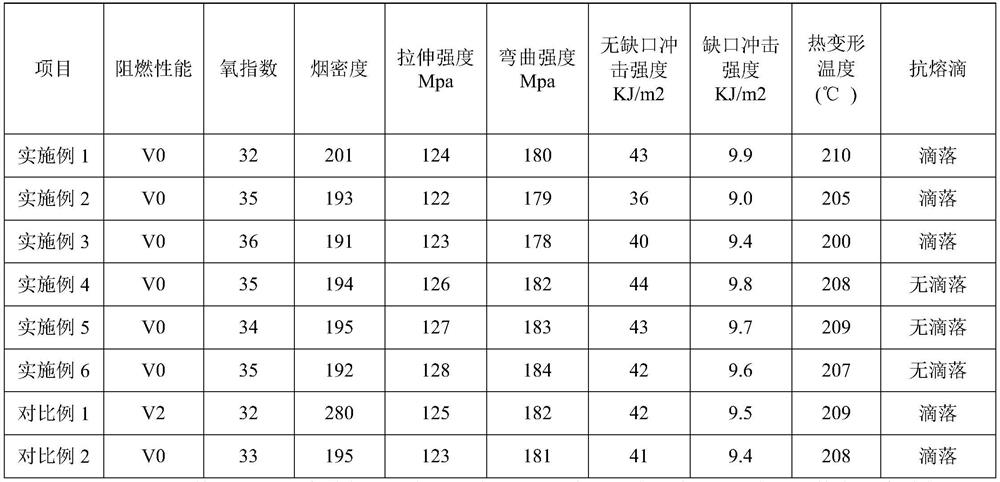

A kind of fire-retardant and smoke-suppressing PTT polyester composite material and preparation method thereof

ActiveCN111363318BReduce generationHave a smoke suppressing effectChemical recyclingGlass fiberPolymer science

The invention discloses a flame-retardant and smoke-suppressing PTT polyester composite material and a preparation method thereof, relates to the field of polyester preparation, and comprises the following raw materials in parts by mass: 100 parts of PTT polyester, 5-80 parts of modified polyester, glass fiber 5-50 parts, 10-30 parts of nanocomposite flame retardant containing hydroxide, 5-30 parts of carbon forming agent, 1-30 parts of toughening agent, 1-30 parts of coupling agent, 0.1-1 parts of antioxidant Parts, 0.01-4 parts of nucleating agent. In the present invention, the carbon forming agent and the nanocomposite flame retardant containing hydroxide are used in combination, which not only can prevent flames, but also reduces the generation of toxic smoke, and has the effect of suppressing smoke. While polluting the environment, it takes away a lot of heat.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

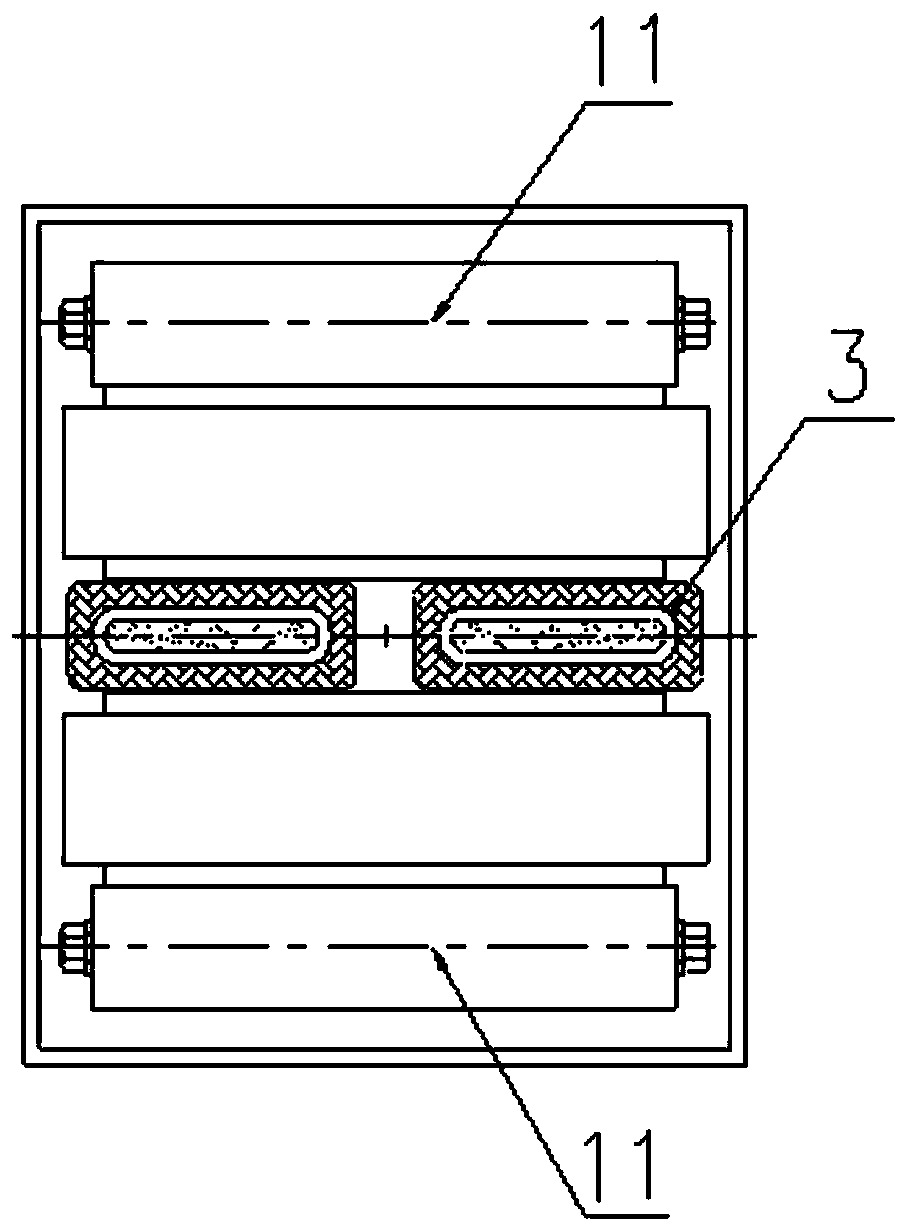

Manufacturing method of high-current-impact-resistant lead-type aluminum electrolytic capacitor

InactiveCN113470978AHigh dielectric strengthImprove impact performanceSolid electrolytic capacitorsWinding capacitor machinesElectrolysisMetallurgy

The invention relates to the technical field of lead-type capacitors, in particular to a manufacturing method of a high-current-impact-resistant lead-type aluminum electrolytic capacitor, and solves the problem that the current impact resistance of a lead-type aluminum electrolytic capacitor in the prior art needs to be improved. The manufacturing method of the high-current impact resistant lead type aluminum electrolytic capacitor comprises the following steps of: winding a negative electrode foil outside a second electrolytic paper layer, winding a first electrolytic paper layer outside the negative electrode foil, and winding a positive electrode foil outside the first electrolytic paper layer, wherein both the cathode foil and the anode foil are provided with electrode nails. According to the invention, the petal end face of the positive electrode nail and the petal end face of the negative electrode nail are respectively provided with the insulating layers, namely the second insulating layer and the first insulating layer, and the second insulating layer is additionally arranged on the petal end face of the positive electrode nail, so that the insulating strength between burrs on the petal end faces and the negative foil is improved, the impact endurance capability of instant large current or instant large voltage is improved, and thus the occurrence probability of point discharge is reduced.

Owner:CHANGZHOU HUAWEI ELECTRONICS

A preparation method of multi-faceted color decorative light wall material

InactiveCN104309228BImprove the decorative effectImprove insulation effectNatural mineral layered productsDomestic wallsInsulation layerMonochromatic color

The invention discloses a preparation method of polyhedral color decorative lightweight wall material. The preparation method is characterized in that the polyhedral color decorative lightweight wall material is formed by a color decorative layer (1), a transition layer (2) and an insulating layer (3). The prepared polyhedral color decorative lightweight wall material adopts one-time firing, and the transition layer is added between the color decorative layer and insulating layer, the defects that the pore diameter is oversize and the bonding strength and the heat impact resistance are low caused by inconsistent material melting points of the color decorative layer and the insulating layer are effectively solved; the inner wall and outer wall decorative material in single-color, composite color, and various patterns are prepared by adding ceramic toner without adding extra decoration; the production process is simple, the cost is low, the building insulating effect is good, and the material is energy-saving, waterproof and environment-friendly; the produced polyhedral color decorative lightweight wall material has all-in-one function of decorating, insulating, heat insulating, sound insulating and shockproof.

Owner:SHANDONG UNIV OF TECH

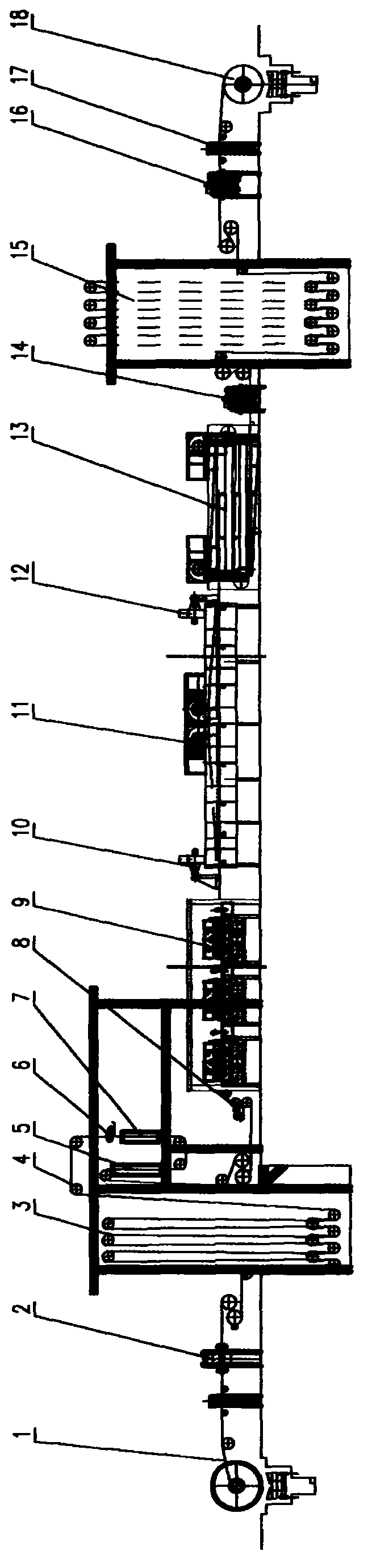

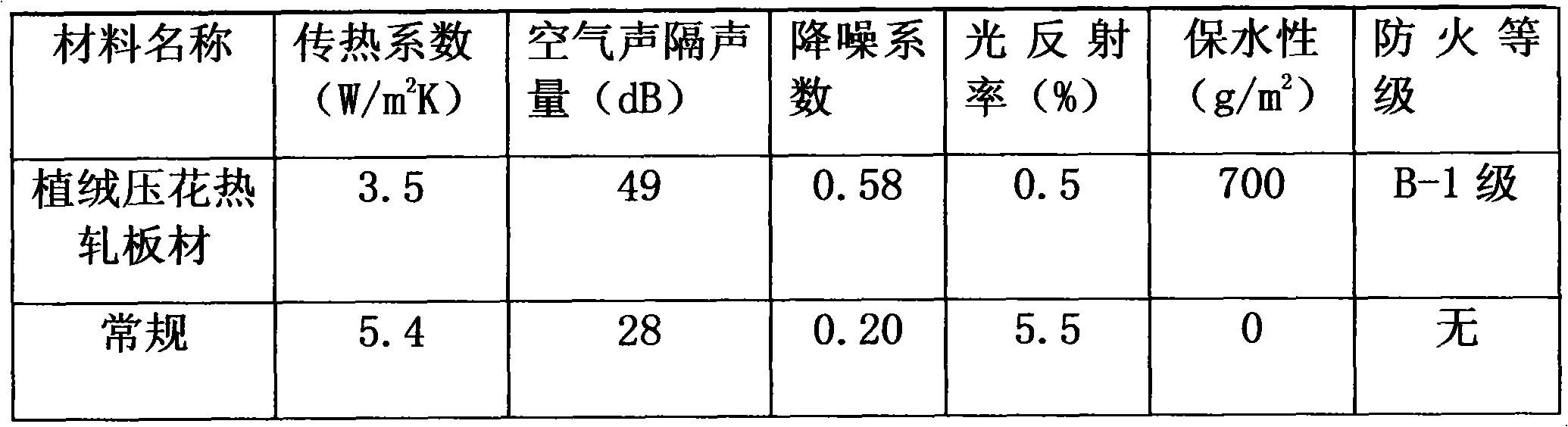

Hot-rolled steel plate flocking and embossing process and special equipment for same

InactiveCN103538345AImprove utilization efficiencyQuality improvementLamination ancillary operationsLaminationSheet steelHigh volume manufacturing

The invention relates to a hot-rolled steel plate flocking and embossing process and special equipment for the same. The process comprises the following steps: unreeling; front storage and deviation correction; material pretreatment; glue spreading; flocking; fluff absorption; drying; fluff recovery; cooling and brushing; back storage; embossing; reeling. The special equipment provided by the invention comprises an unreeling device, a front storage device, a double-roller deviation correcting device, a cooling tank, a passivating device, a passivating and drying device, a roller glue spreader, an electrostatic flocking machine, a fluff absorbing device, a drying room, a fluff recovery device, an air cooling room, a first brushing box, a back storage device, a second brushing box, an embossing device and a reeling device which are connected in sequence. By using the process and special equipment provided by the invention, hot-rolled flocked and embossed plates can be continuously produced in a large scale, the production efficiency is high, and the product quality is reliable. A product produced by using the special equipment provided by the invention is strong in upright pile feeling, attractive and bright in color, soft in touch, environment-friendly, fireproof, anti-sweat, capable of absorbing sound and light, and favorable in ray diffuse reflection effect.

Owner:无锡市鹏程植绒机械有限公司

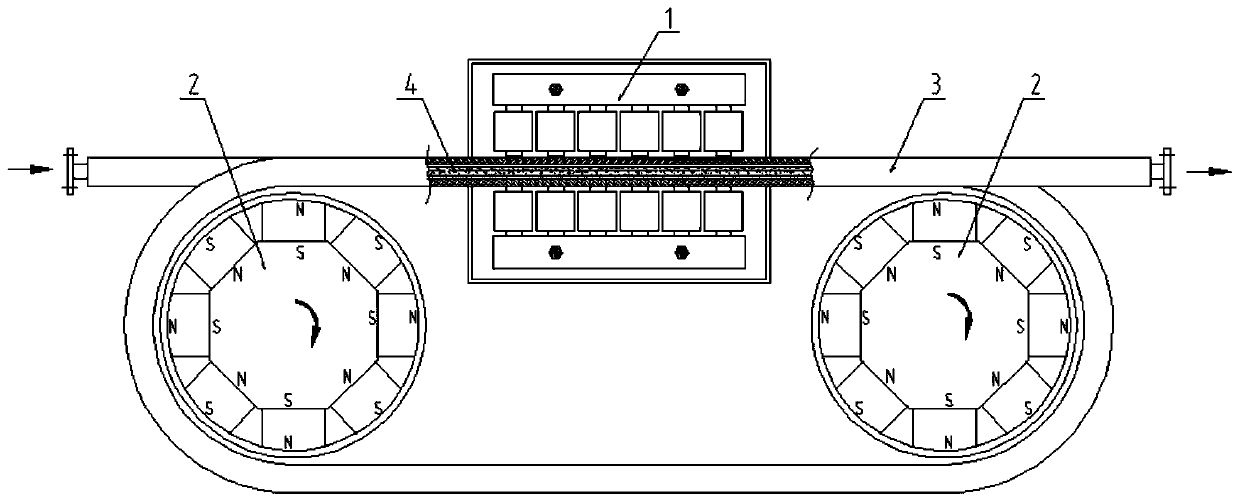

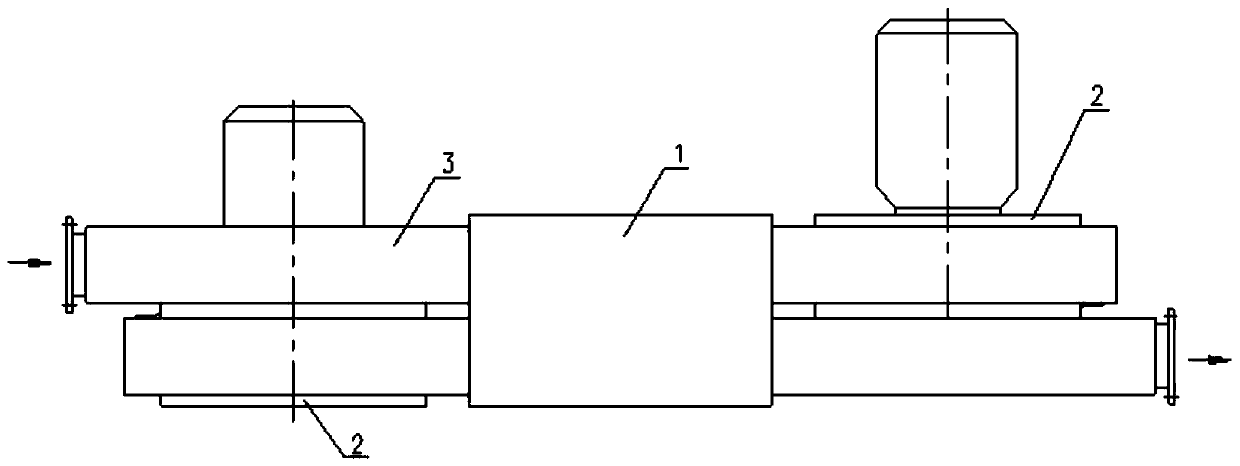

A liquid metal magnetic conveying device

ActiveCN106961205BIncrease delivery speedImprove delivery capacityDynamo-electric machinesMagnetic tension forceThermal insulation

The invention discloses liquid metal magnetic force transmission equipment. The liquid metal magnetic force transmission equipment comprises a magnetic force transmission pump unit and a transmission pump groove. The magnetic force transmission pump unit comprises at least one electromagnetic pump and at least one permanent magnet pump. The electromagnetic pump is disposed on the transmission pump groove, and the permanent magnet pump is disposed on the transmission pump groove. The liquid metal magnetic force transmission equipment is advantageous in that by adopting multi-stage push, the transmission speed of the liquid metal is accelerated, and a transmission capability is improved, and the liquid metal magnetic force transmission equipment is adapted to a fast production rhythm; the electromagnetic transmission of the liquid metal having a large proportion and low conductivity is realized; the whole transmission equipment is more energy-saving by adopting the permanent magnet pump; strong thermal insulation is realized by small space via nano-meter thermal insulation materials, and therefore the operating air gap of the electromagnetic pump and the operating air gap of the permanent magnet pump are reduced, and the working efficiency of the electromagnetic pump and the working efficiency of the permanent magnet pump are improved.

Owner:HUNAN KEMEIDA ELECTRIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com