Patents

Literature

1568 results about "Shotcrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shotcrete, gunite /ˈɡʌnaɪt/ or sprayed concrete is concrete or mortar conveyed through a hose and pneumatically projected at high velocity onto a surface, as a construction technique, first used in 1914. It is typically reinforced by conventional steel rods, steel mesh, or fibers.

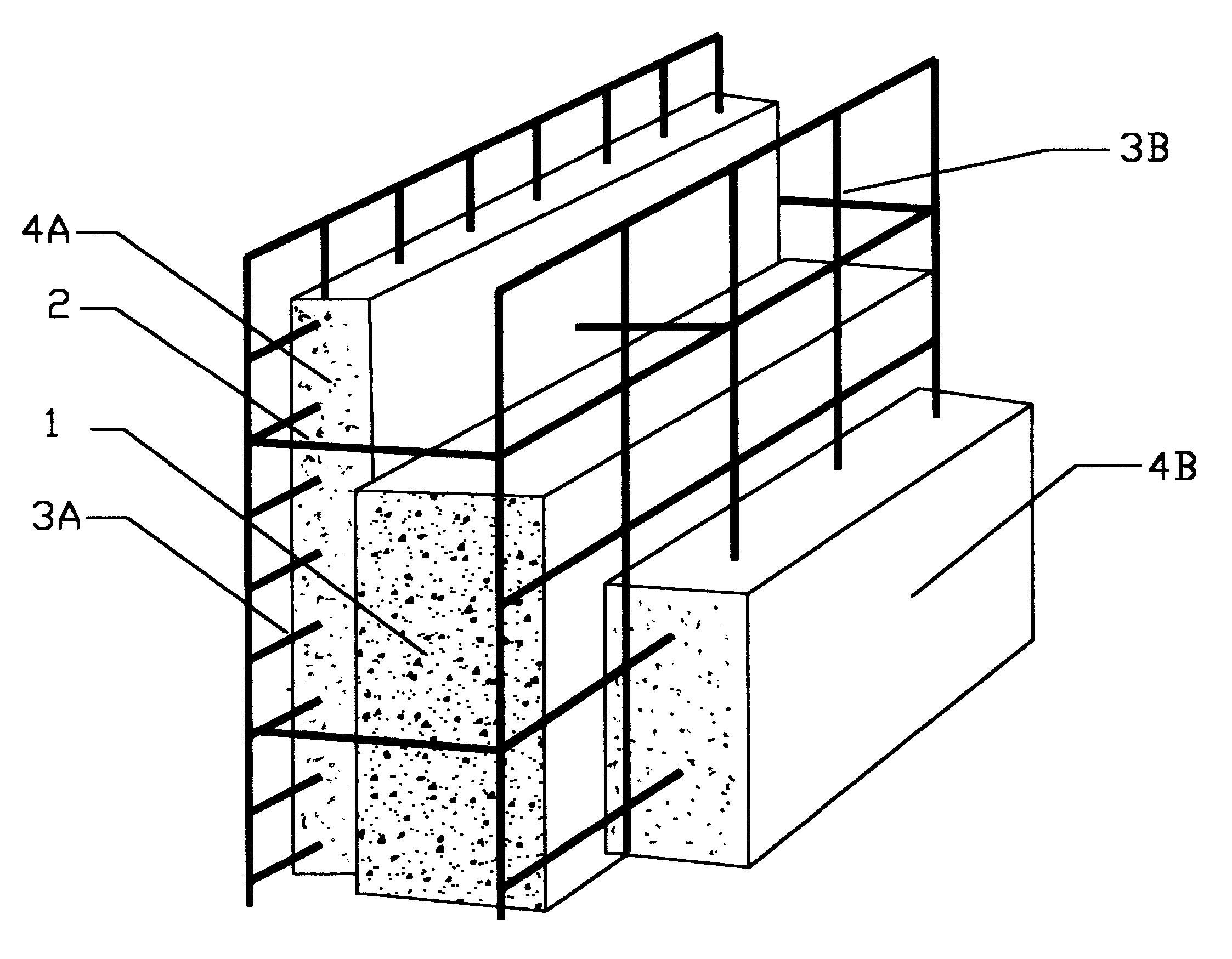

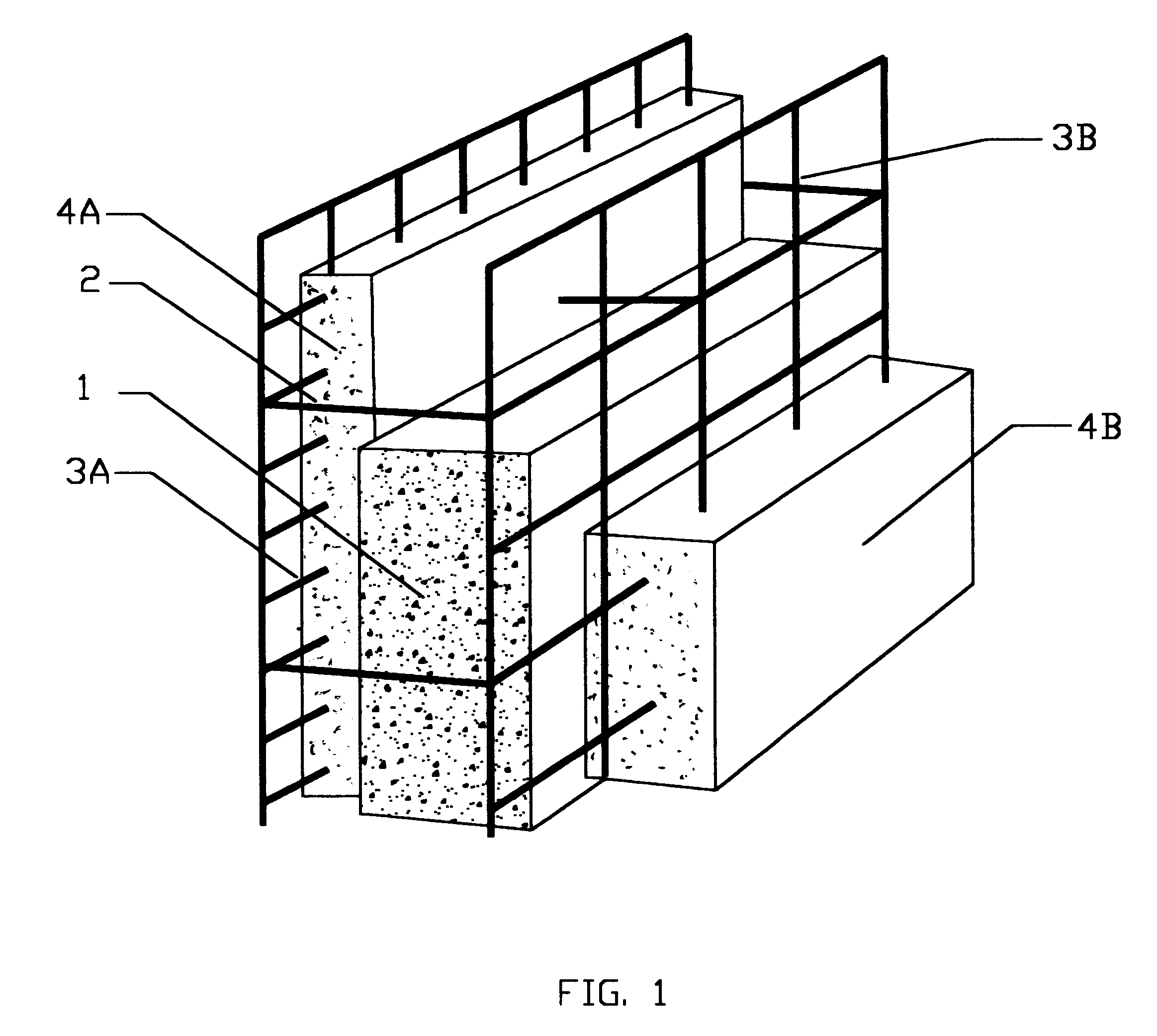

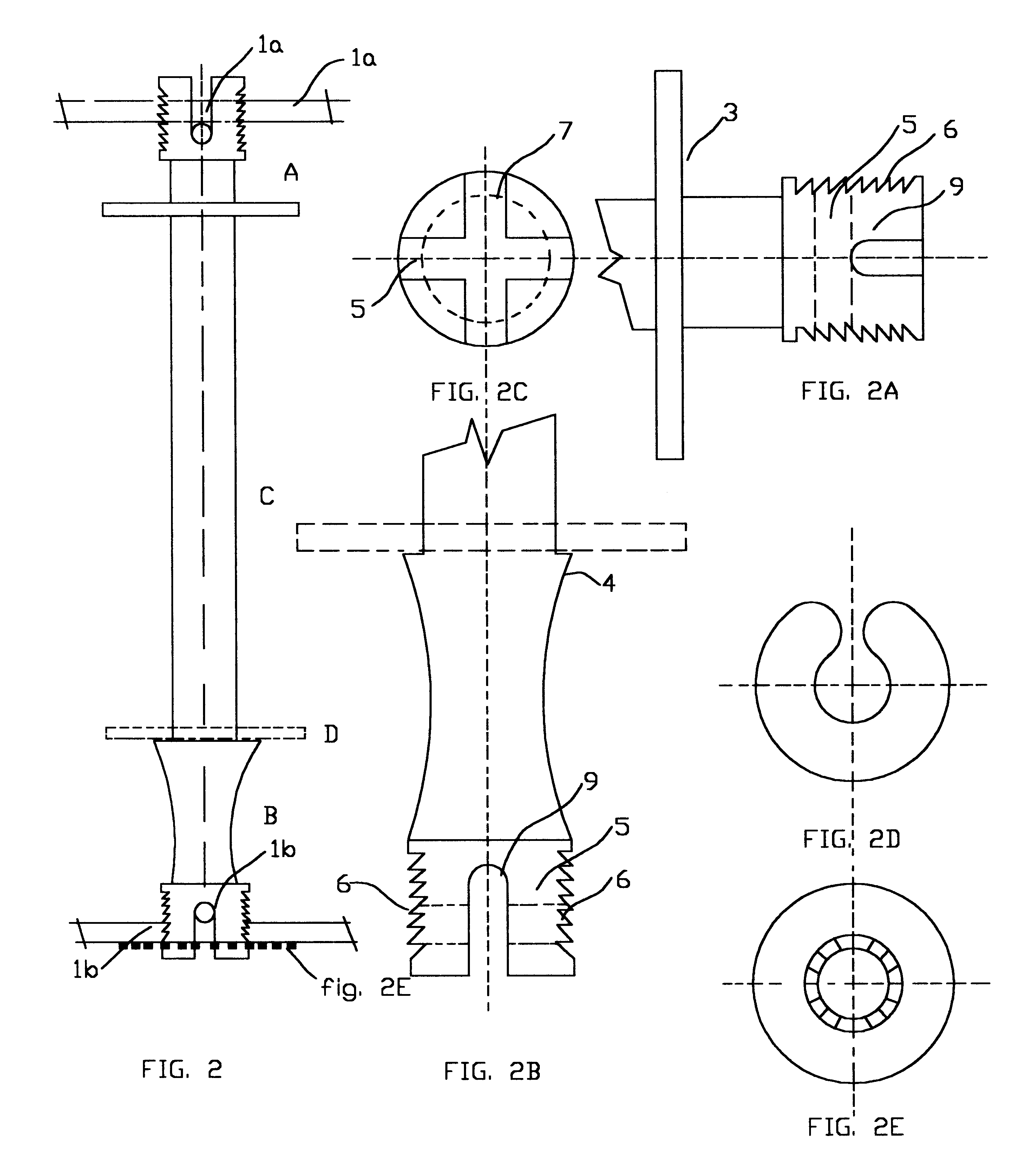

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

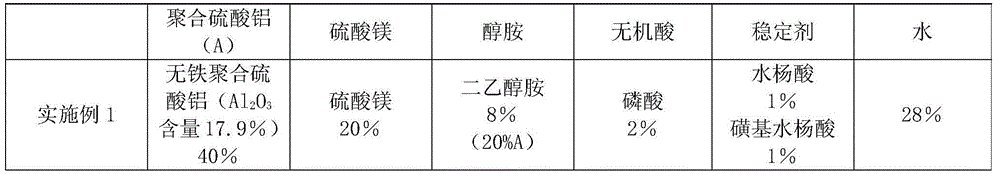

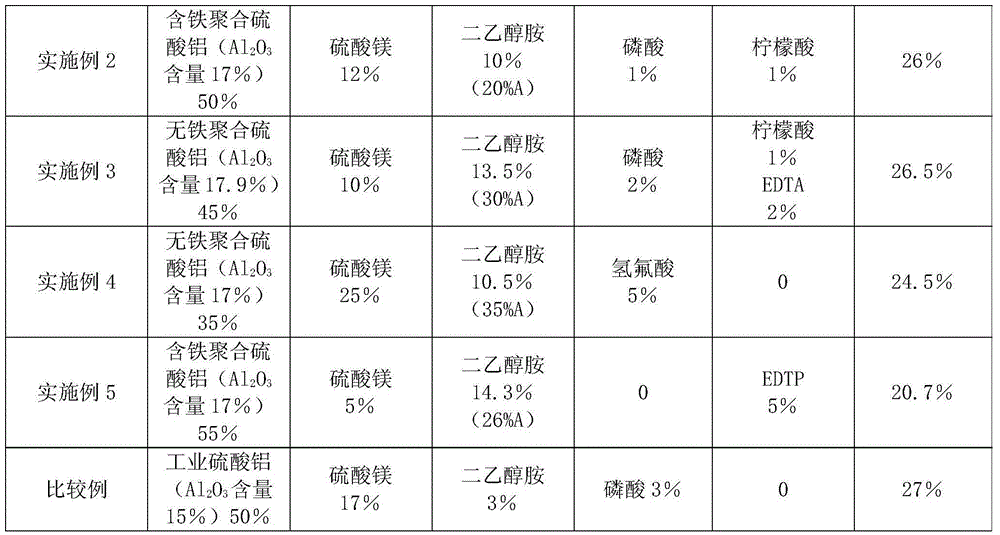

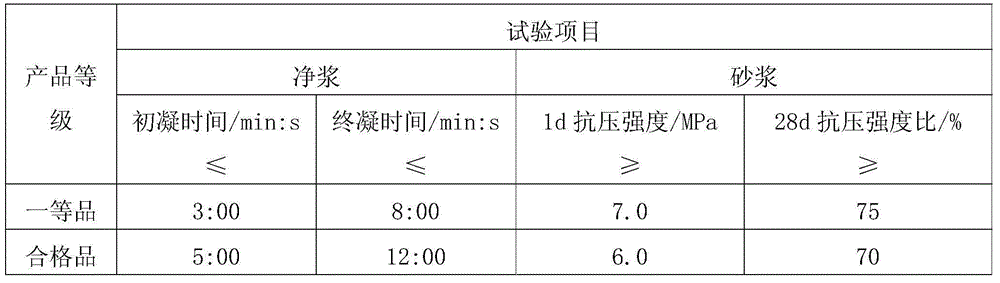

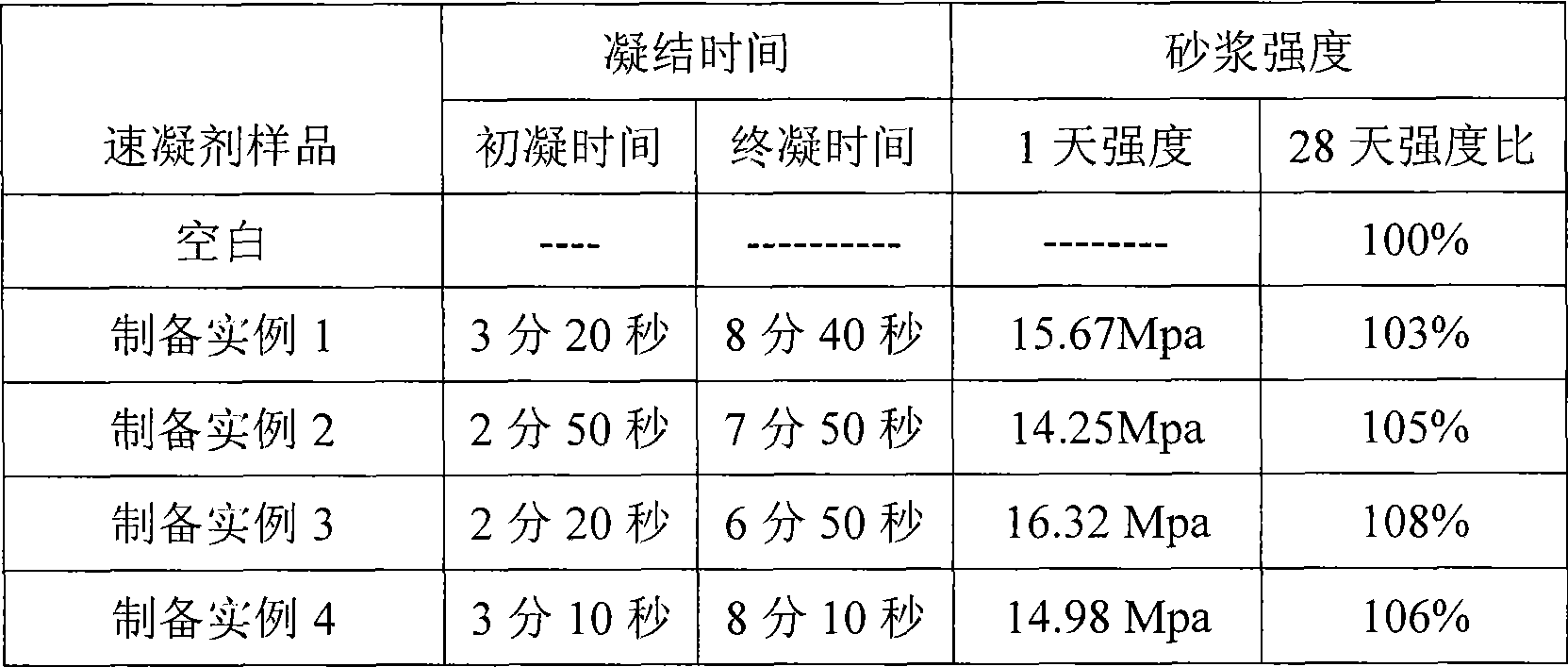

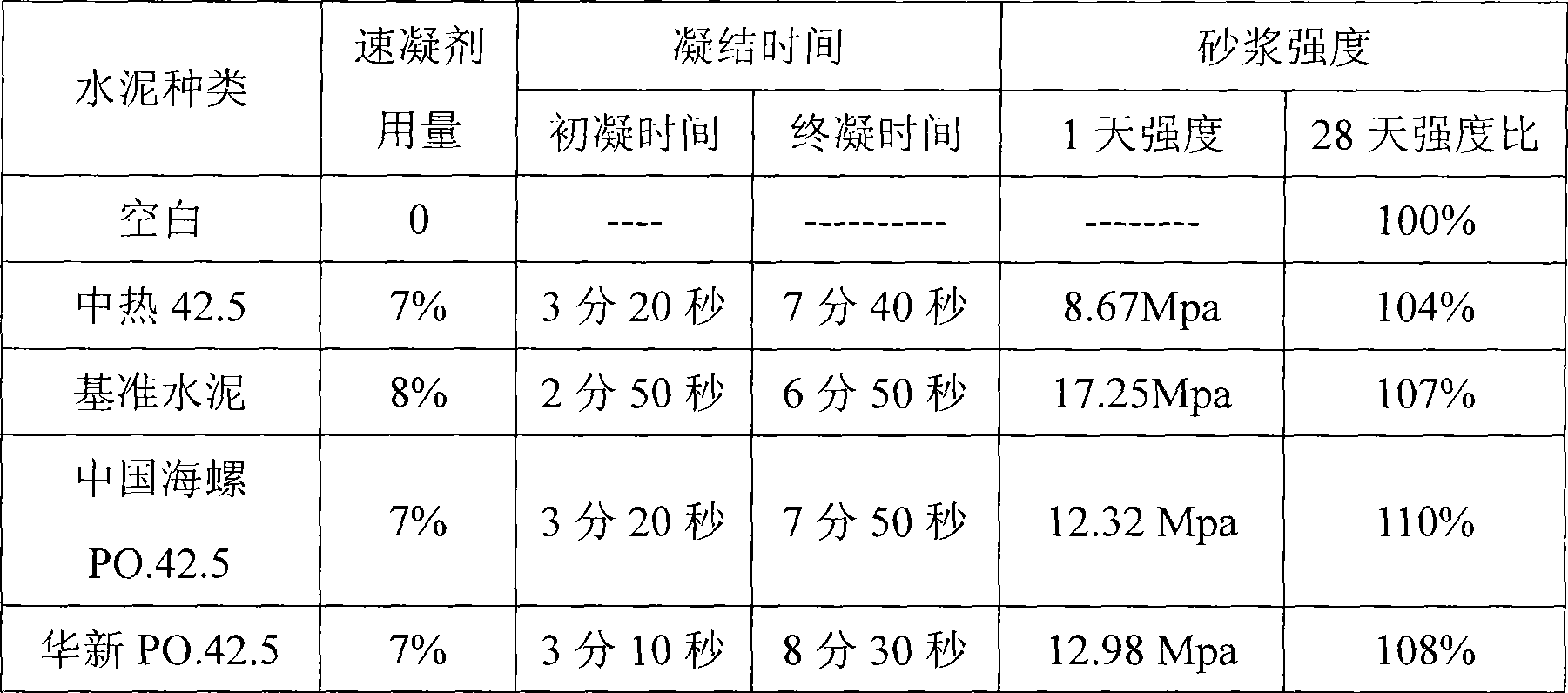

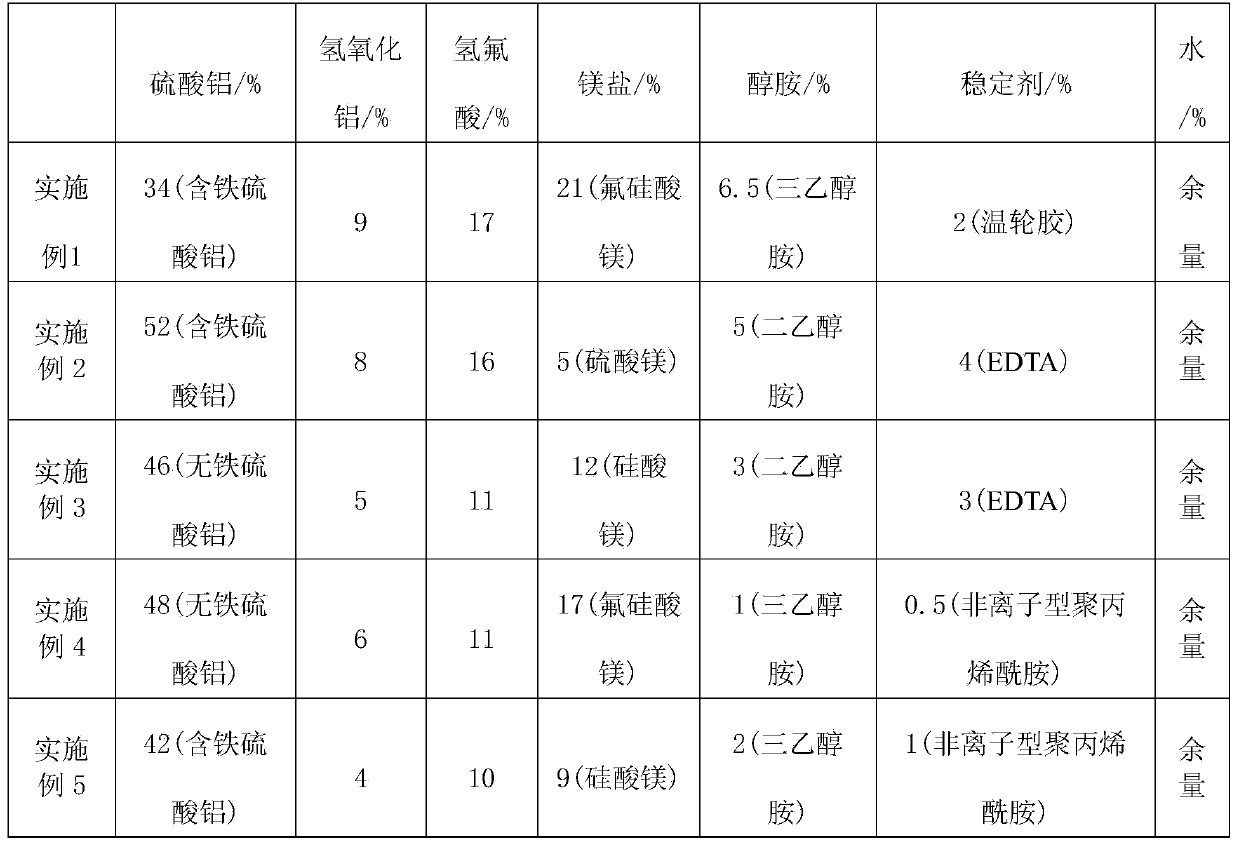

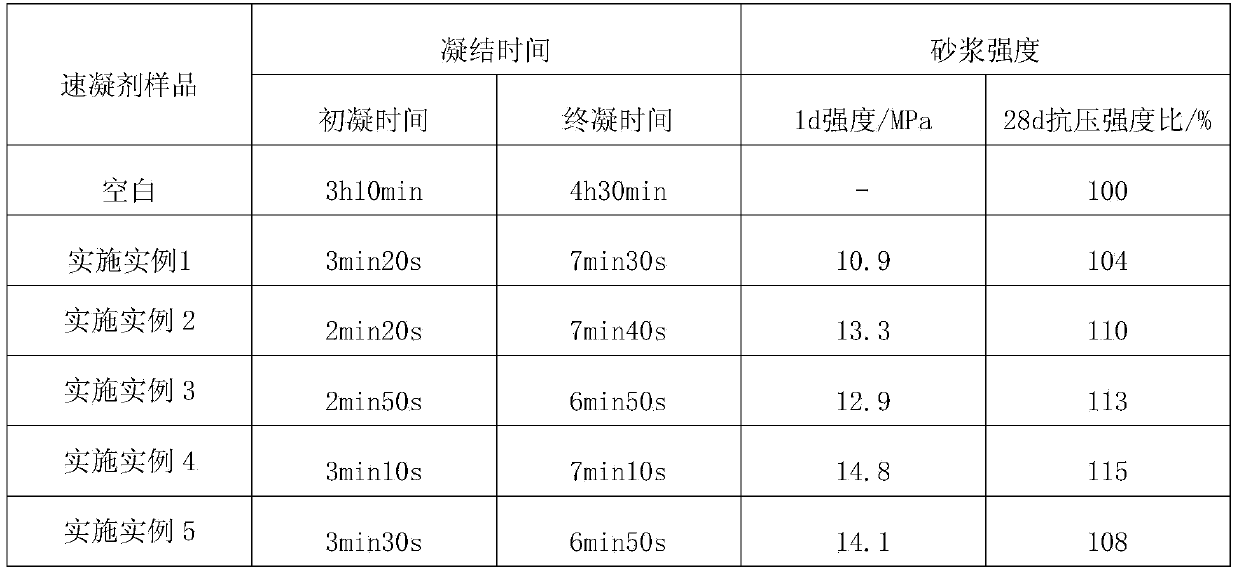

Alkali and chlorine-free liquid setting accelerator based on industrial polyaluminium sulfate and its preparation method

The invention discloses an alkali and chlorine-free liquid setting accelerator based on industrial polyaluminium sulfate. The liquid setting accelerator comprises the following raw materials by weight: 35-55% of polyaluminium sulfate, 5-25% of magnesium sulfate, alcohol amine accounting for 15-30% of the polyaluminum sulfate, 0-5% of an inorganic acid, 0-5% of a stabilizer, and the balance water. The liquid setting accelerator provided by the invention can be used in the wet jetting industry of sprayed concrete, belongs to alkali and chlorine-free liquid setting accelerators, has a stable period of more than 6 months, a 28d compressive strength ratio of greater than 100%, and good adaptability to different cement. When the dosage is 4.5%, the technical requirements of the JC477-2005 ''setting accelerators for sprayed concrete'' can be satisfied. The liquid alkali-free setting accelerator has superior performance, and can be widely used in tunnels, bridges, first-aid repair and other projects.

Owner:CHINA BUILDING MATERIALS ACAD

Alkali-free liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to an alkali-free liquid accelerating agent for tunnel wet jet concrete and a preparation method thereof. The alkali-free liquid accelerating agent is characterized in that aluminium sulphate is adopted to serve as a main accelerating component; aluminium is added to an aluminium sulphate solution to be polymerized in a form of aluminium fluoride; aluminium ions are introduced to the greatest extent so as to reduce other ion introduction; and the accelerating effect is ensured. The alkali-free liquid acceleratingagent comprises the following components in percentage by mass: 30-55% of aluminium sulphate, 5-15% of aluminium hydroxide, 10-30% of hydrofluoric acid, 0.5-5% of water glass, 0-0.2% of stabilizing agent, and the balance of water. For jetting concrete, the alkali-free liquid accelerating agent disclosed by the invention has the positive effects that: ordinary cement can be initially solidified within 2 min in lower doping quantity and finally solidified within 4 min; the 1d strength of cement plaster can achieve above 15 MPa; the 28d compressive strength ratio is more than 100%; and the alkali-free liquid accelerating agent has good adaptability to different types of cements.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

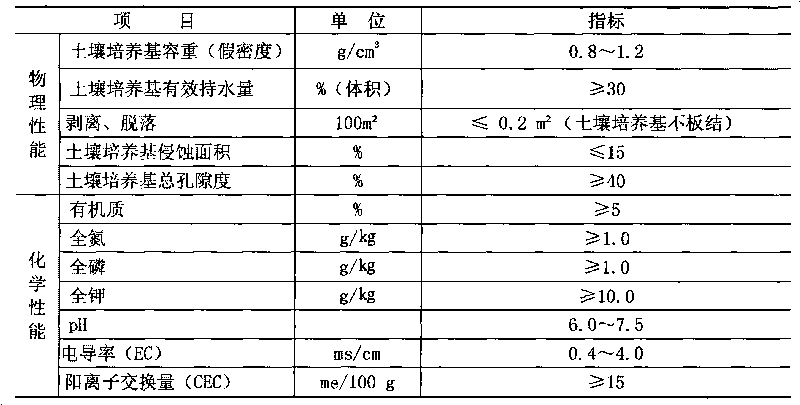

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

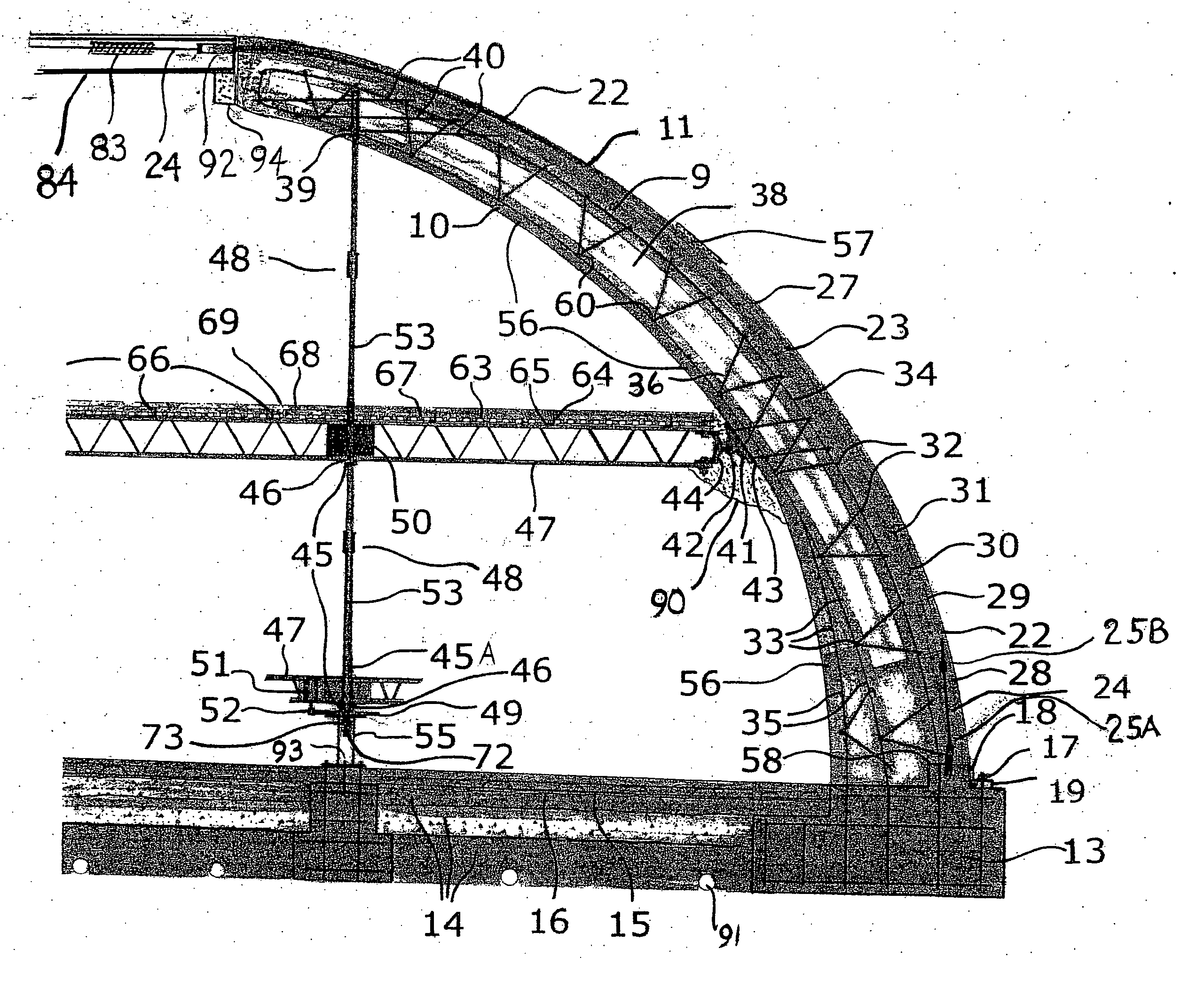

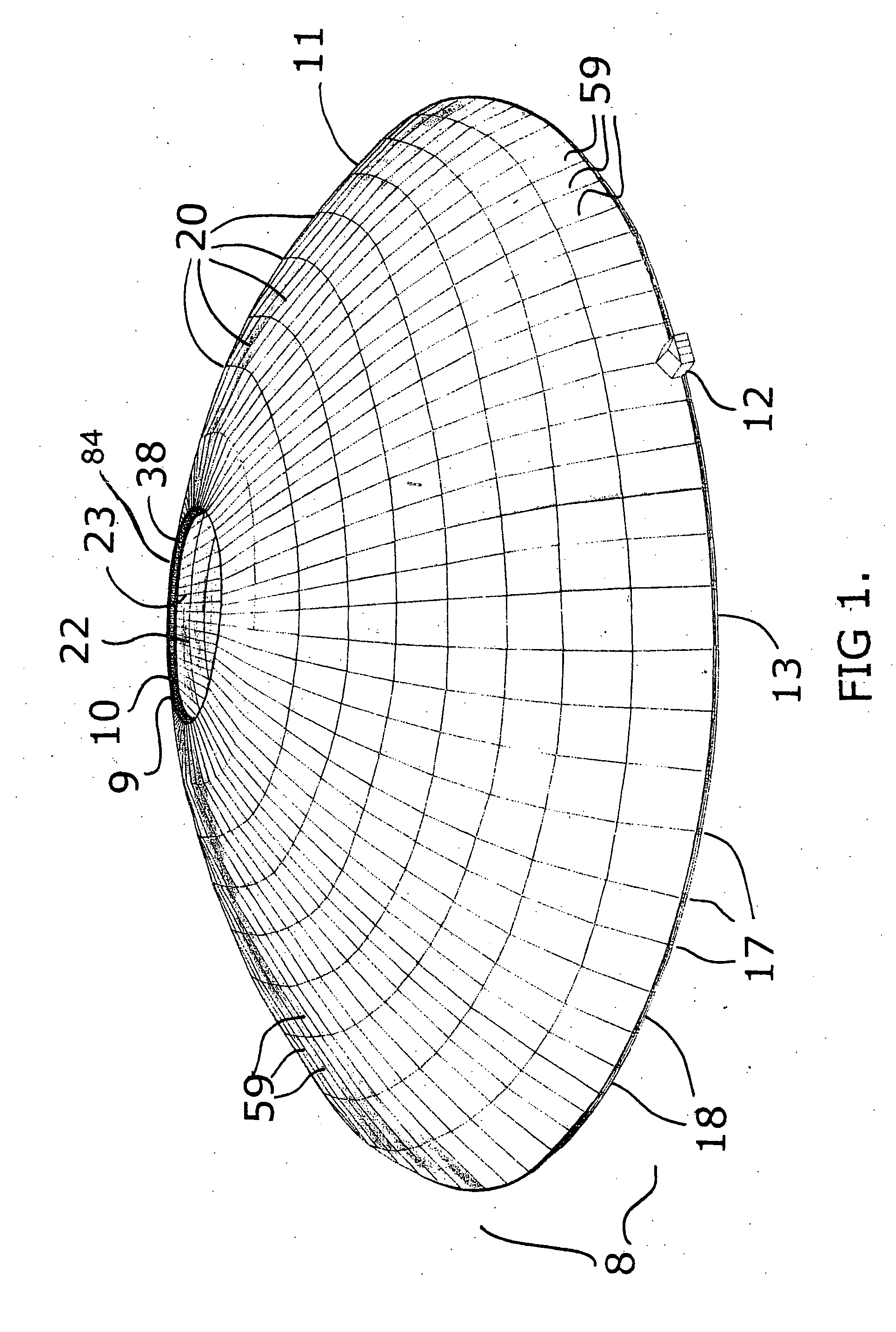

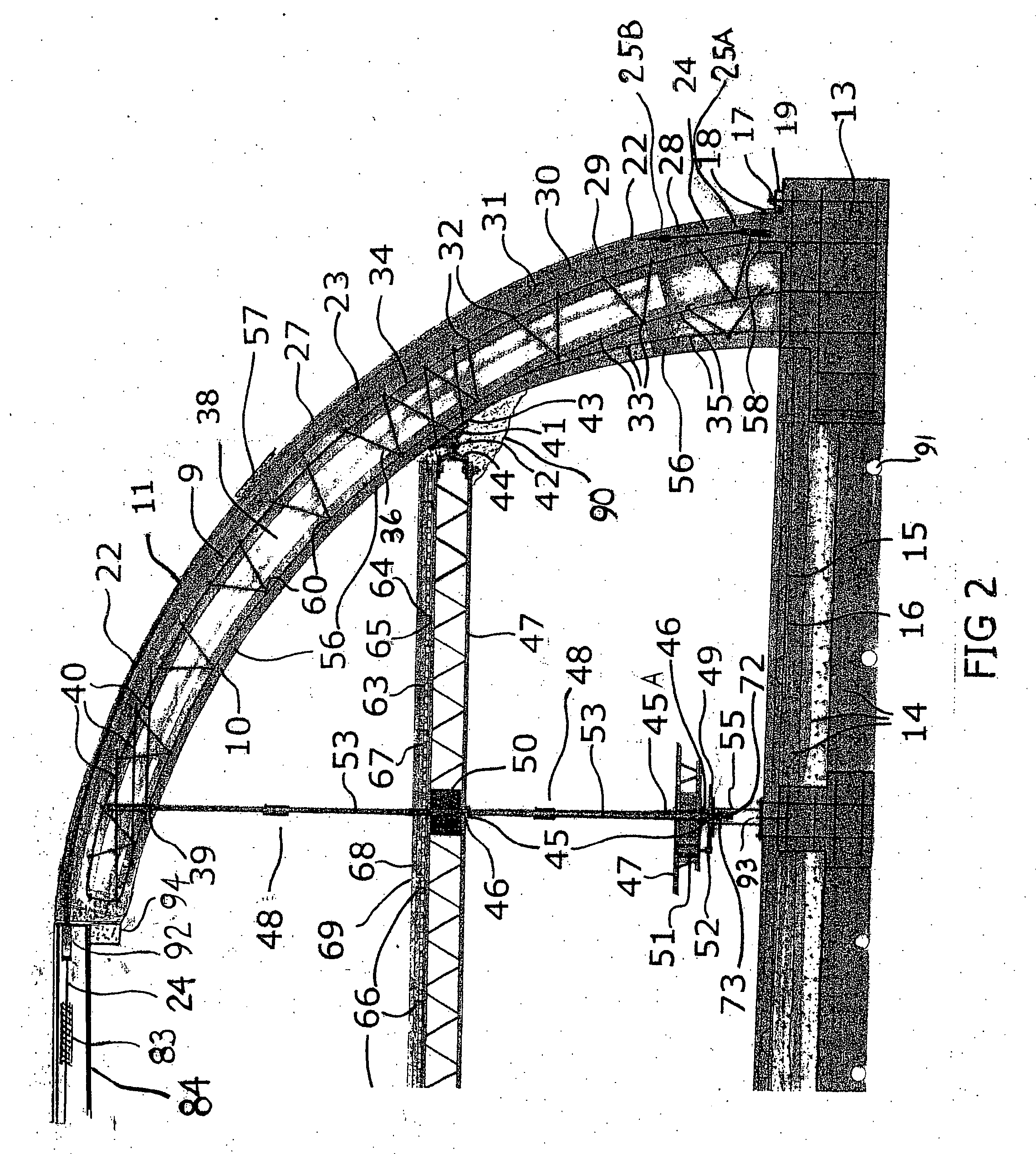

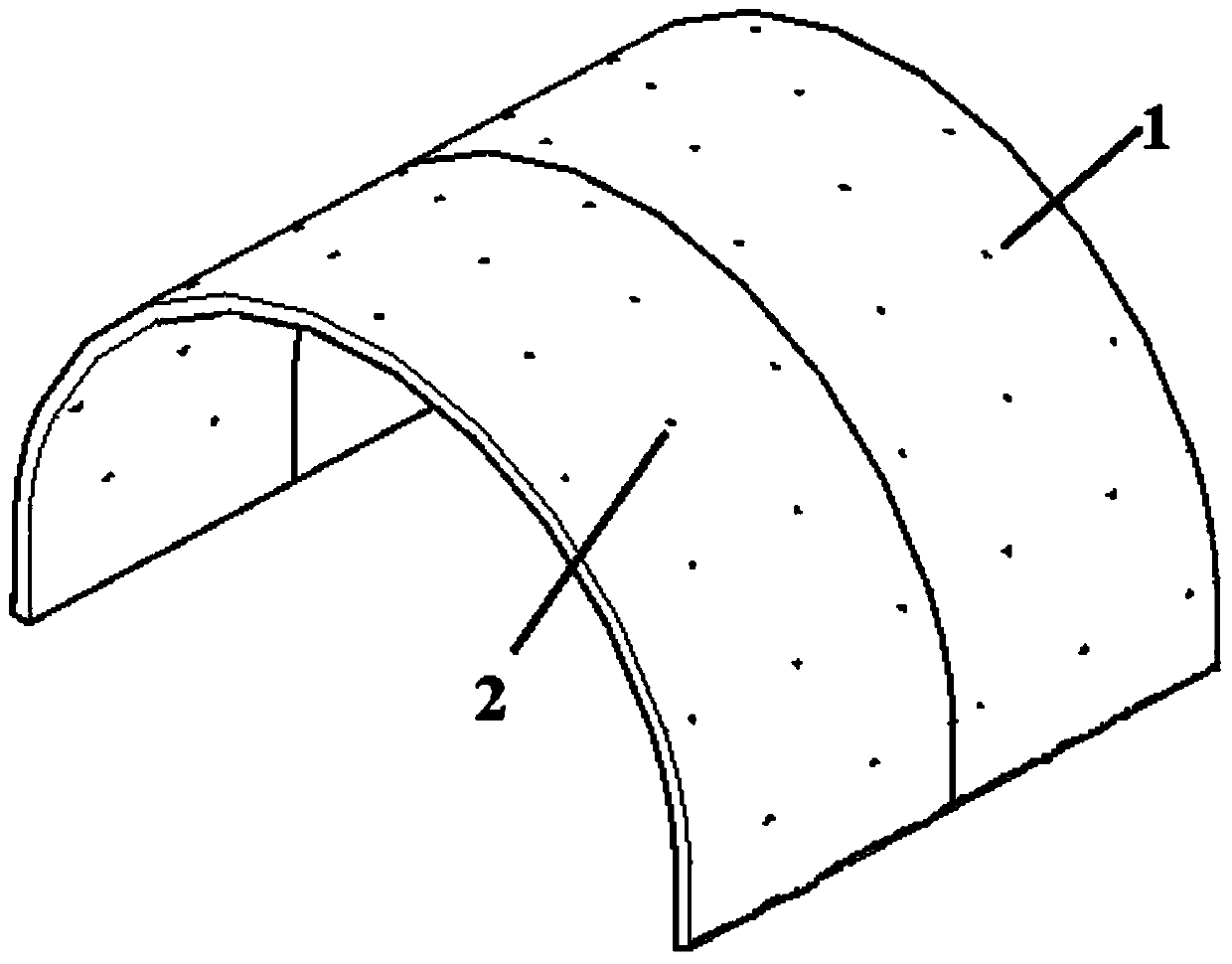

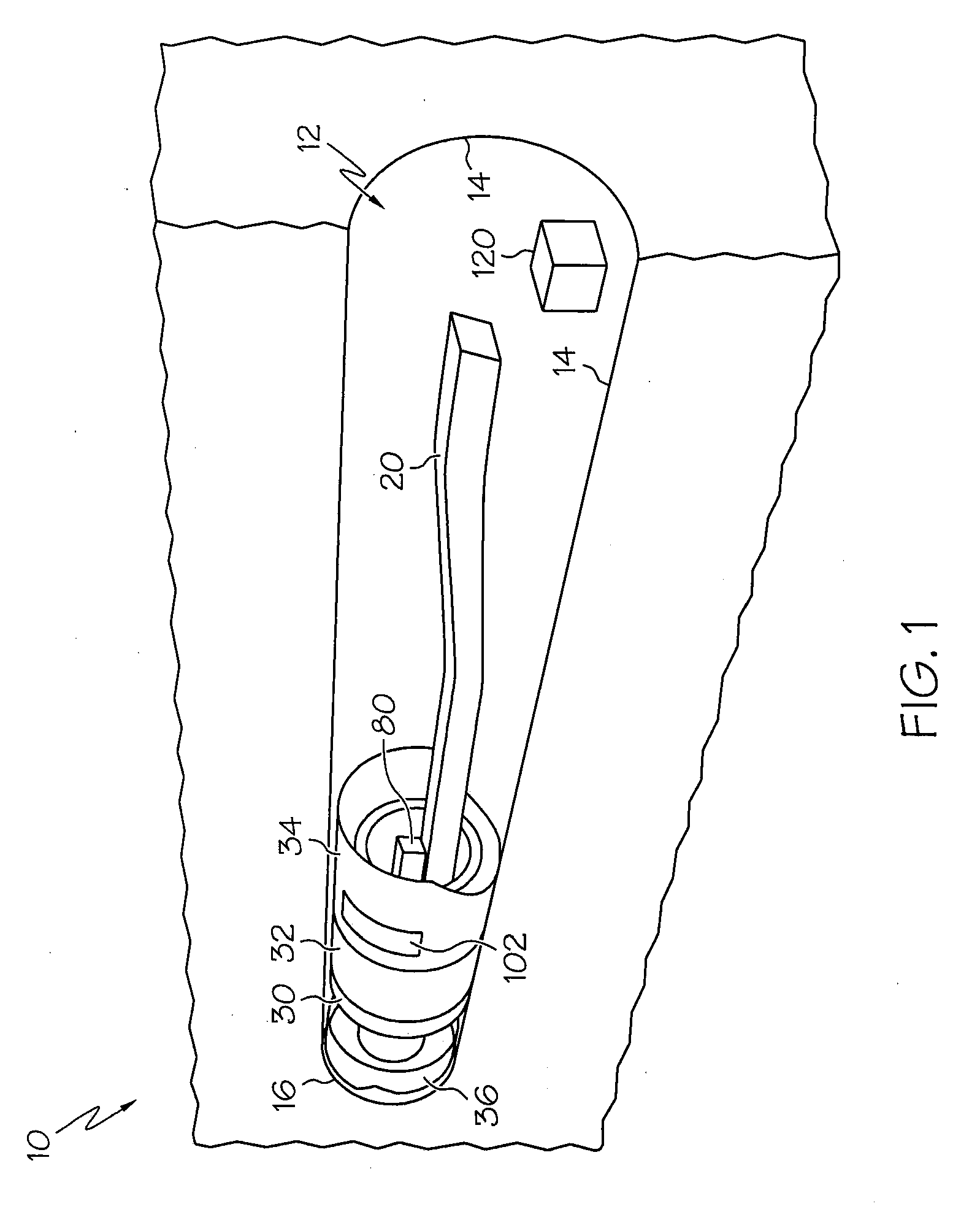

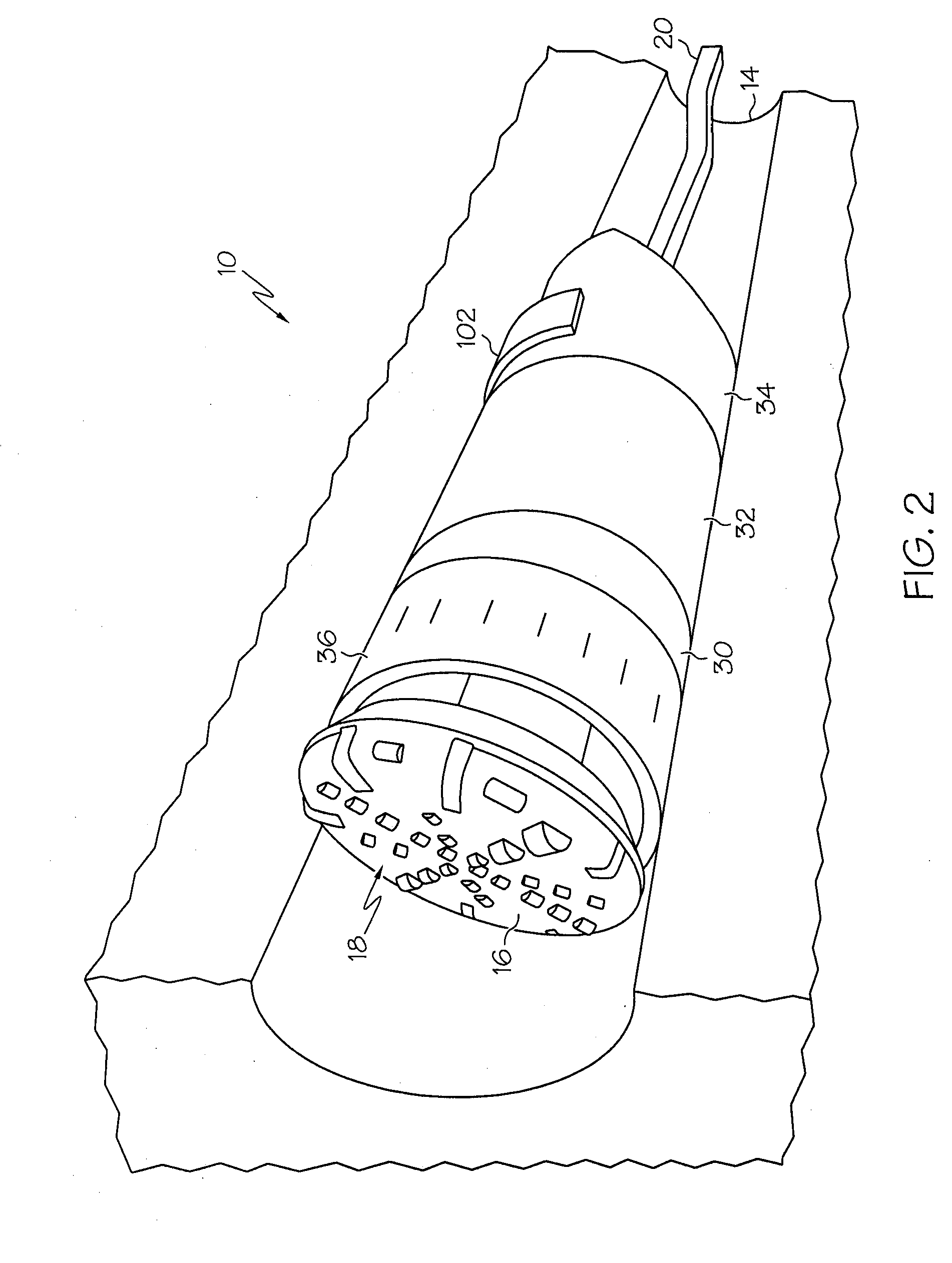

Trilithic and/or twin shell dome type structures and method of making same

InactiveUS20050210767A1Quick connectionImprove load-bearing strengthBuilding roofsArched structuresShotcreteThin shells

Trilithic Shell, Twin Shell, Multiple Shell, Curvilinear Shell as well as Free-formed Structures described herein each employ an inflatable membrane having a peripheral edge secured to an outer foundation base. An ultra-light membrane (air-form) having a network of internal cross connecting restraints is additionally secured to the inner foundation base to permit a novel and unique curvilinear surface. Pressurization then creates the backdrop upon which various urethane layers are applied which when laced with rigidifying tubes become the defining backdrop beneath which numerous cross connecting braces which when snapped into position effectively lock an inner framework to an outer framework thereby producing a self supporting truss like structure both compatible with either current dome construction and / or conventional construction practices. Shotcrete being then sprayed from the interior over said urethane coated backdrop forms highs at framework intersections and natural lows in between followed by the insertion of inflated cell tubes which span the created network of horizontal and vertical cavities are next over sprayed with urethane foam necessary to form the next natural backdrop over which two or more shotcrete / steel reinforced separate yet cross connected planes may be achieved. Such multiple yet independent rigid layers now having thousands of inner-connecting cross braces through which interior voids become natural chase-ways effectively displace 50% or more of what might otherwise be solid concrete as would be the case with all prior art thin shell structures and / or conventional stem wall construction practices. Such Free Formed curve-linear structures effectively reduce material and labor costs by as much as 50%, eliminate snap-through or oil-can buckling tendencies, enhance overall structural capacity, eliminate all height to diameter restraints, permit larger structures, facilitate floor suspension and attachment, and allow mechanical, electrical and HVAC distribution through interior chase-ways which cannot be achieved with prior art concrete thin shell single thickness structures and / or conventional stem wall, construction practices to date.

Owner:DEFEVER MICHAEL D +1

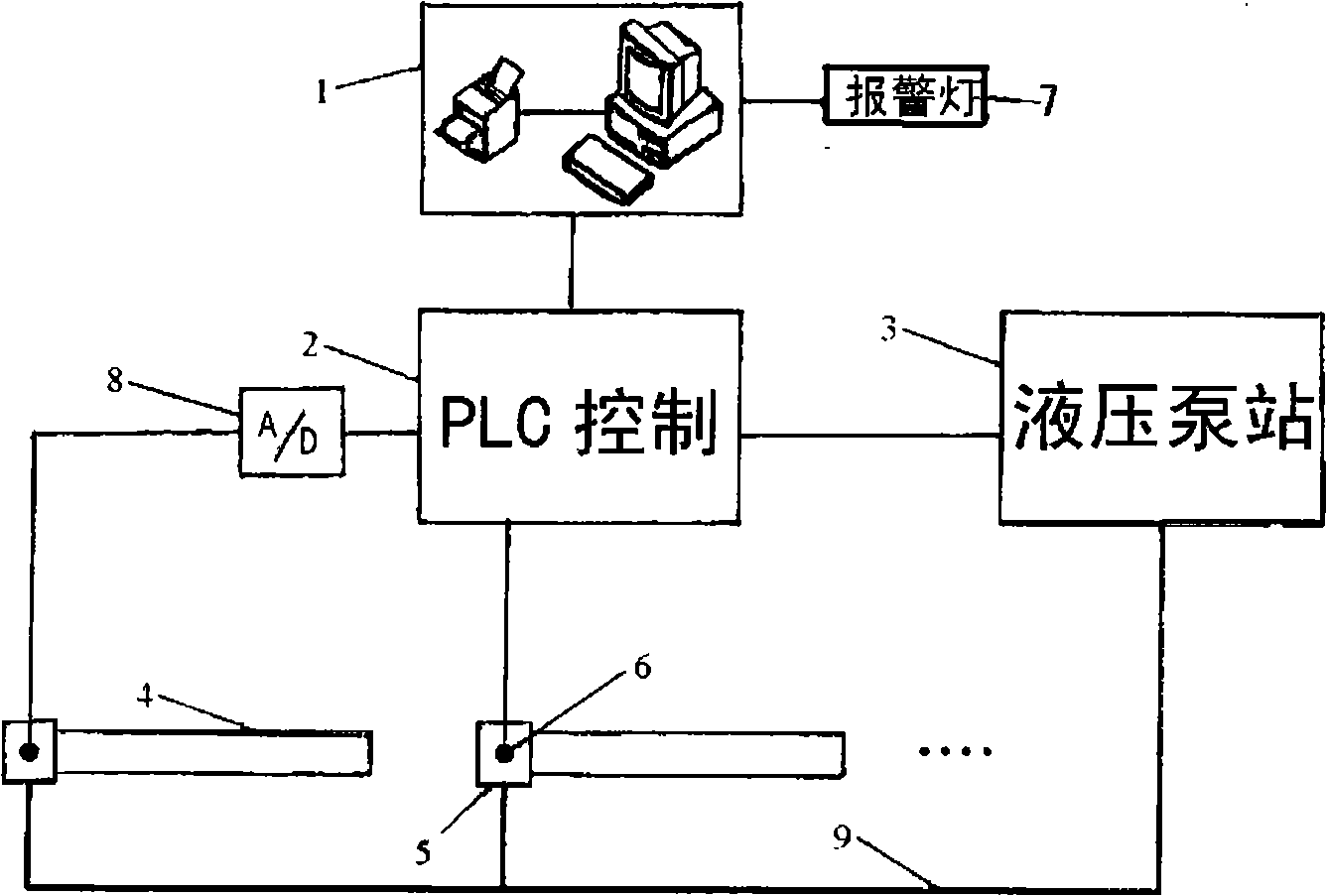

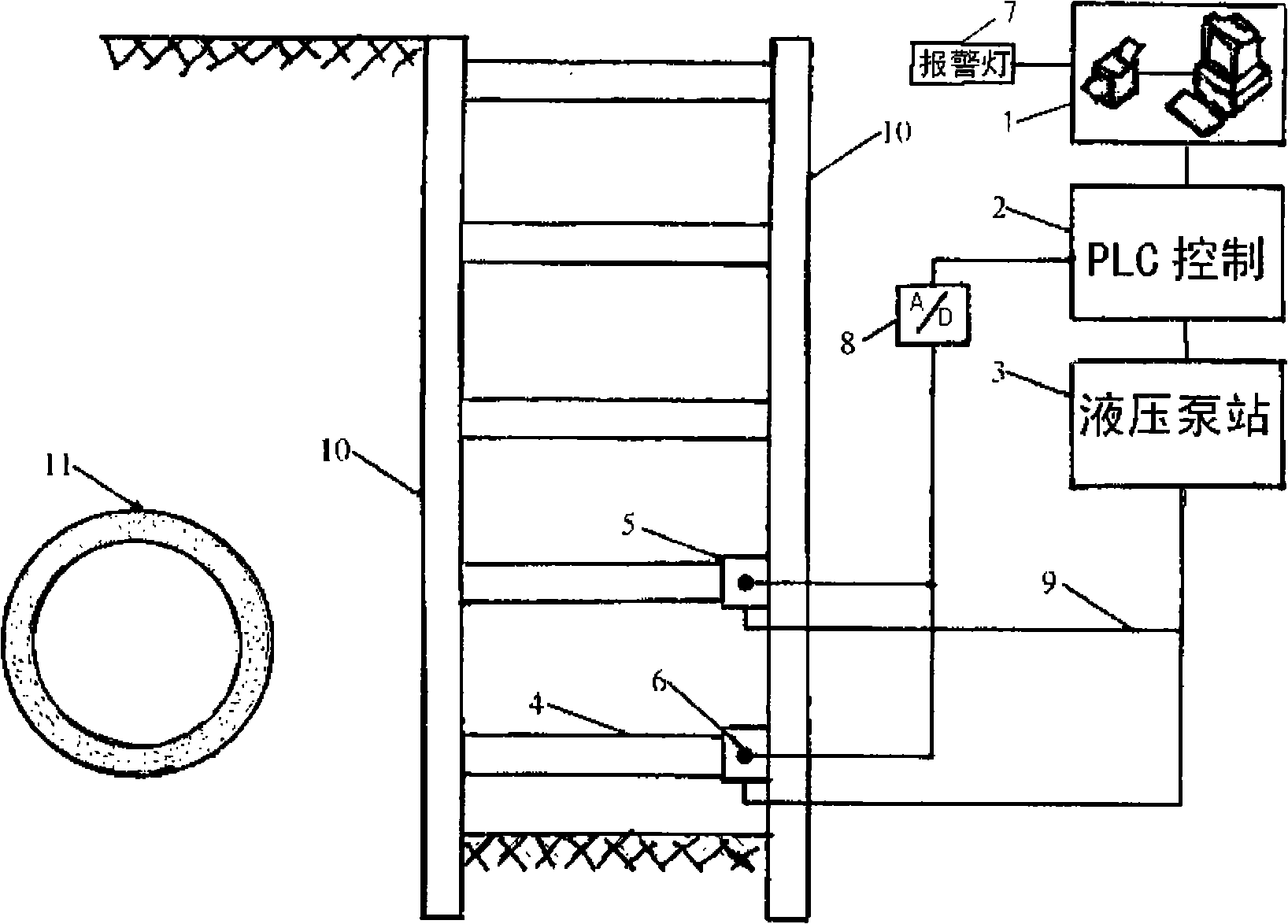

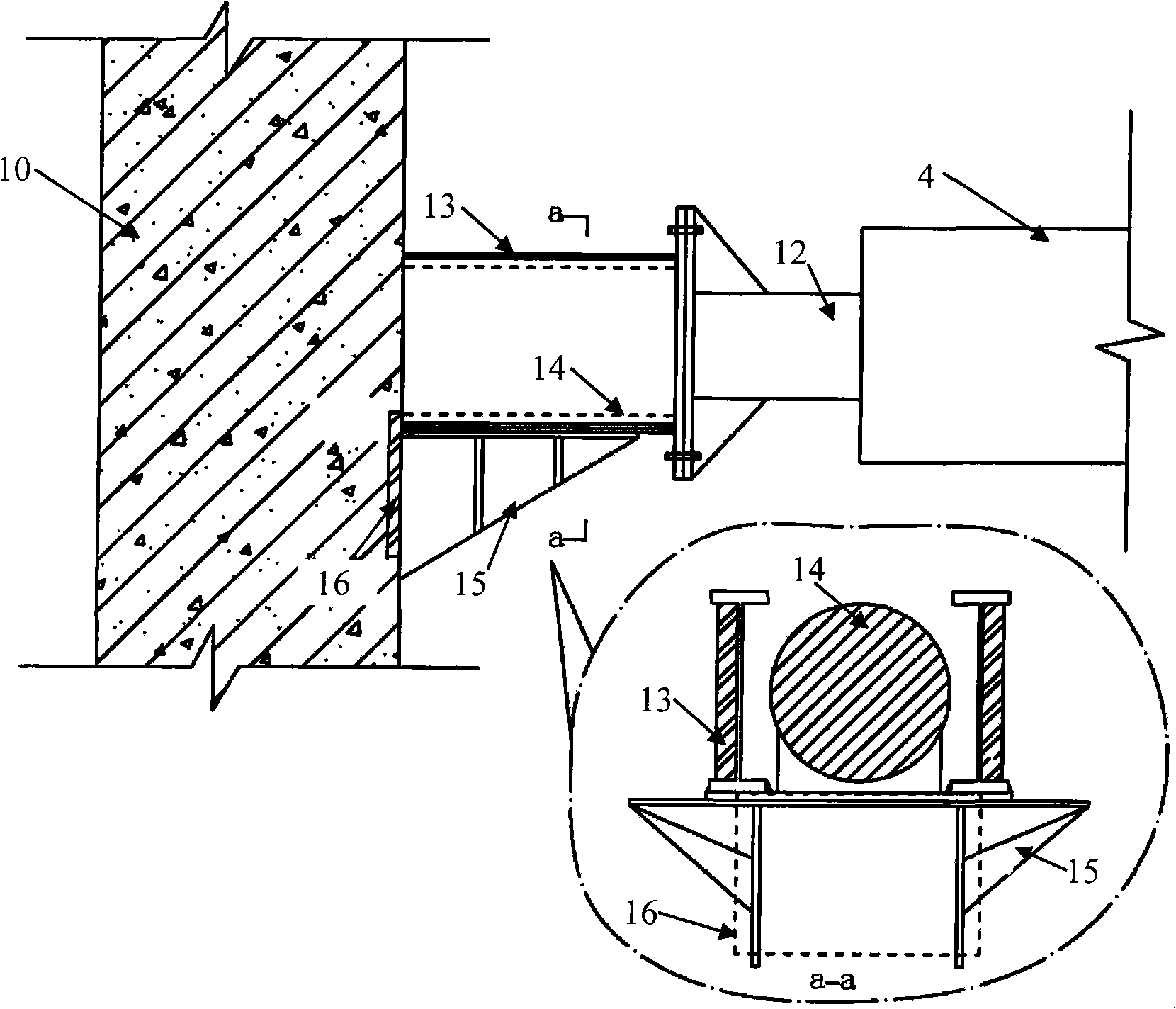

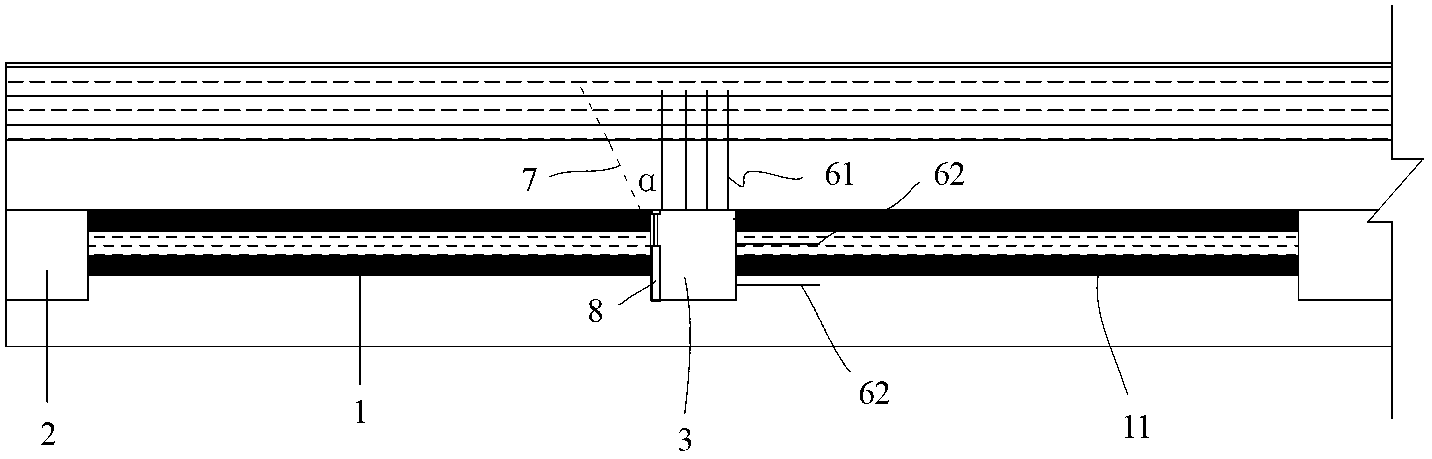

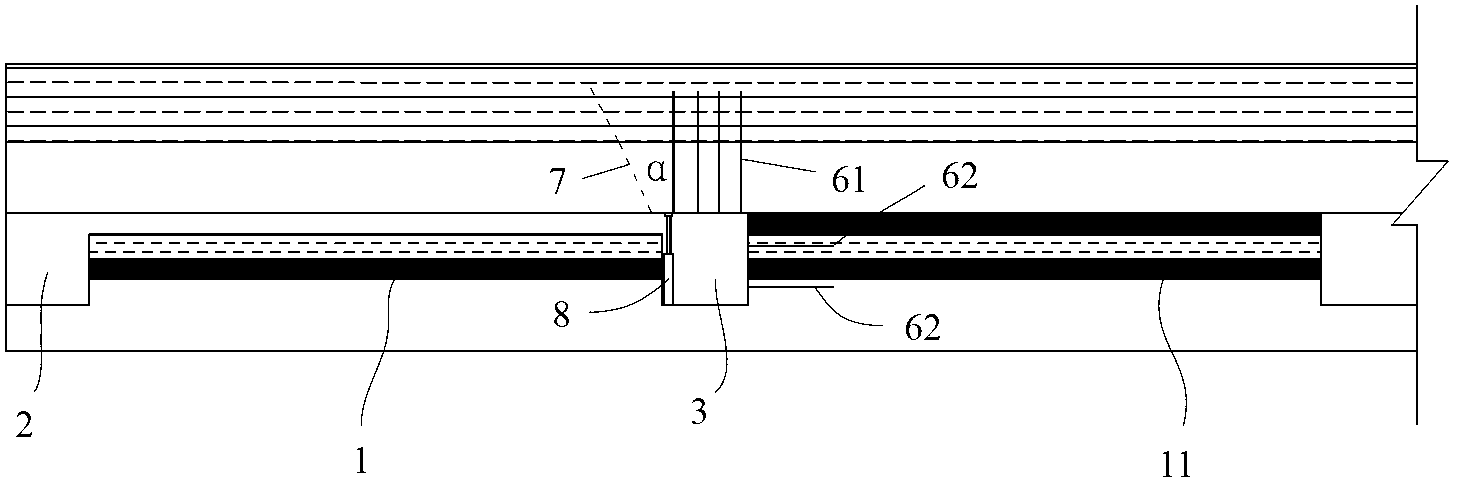

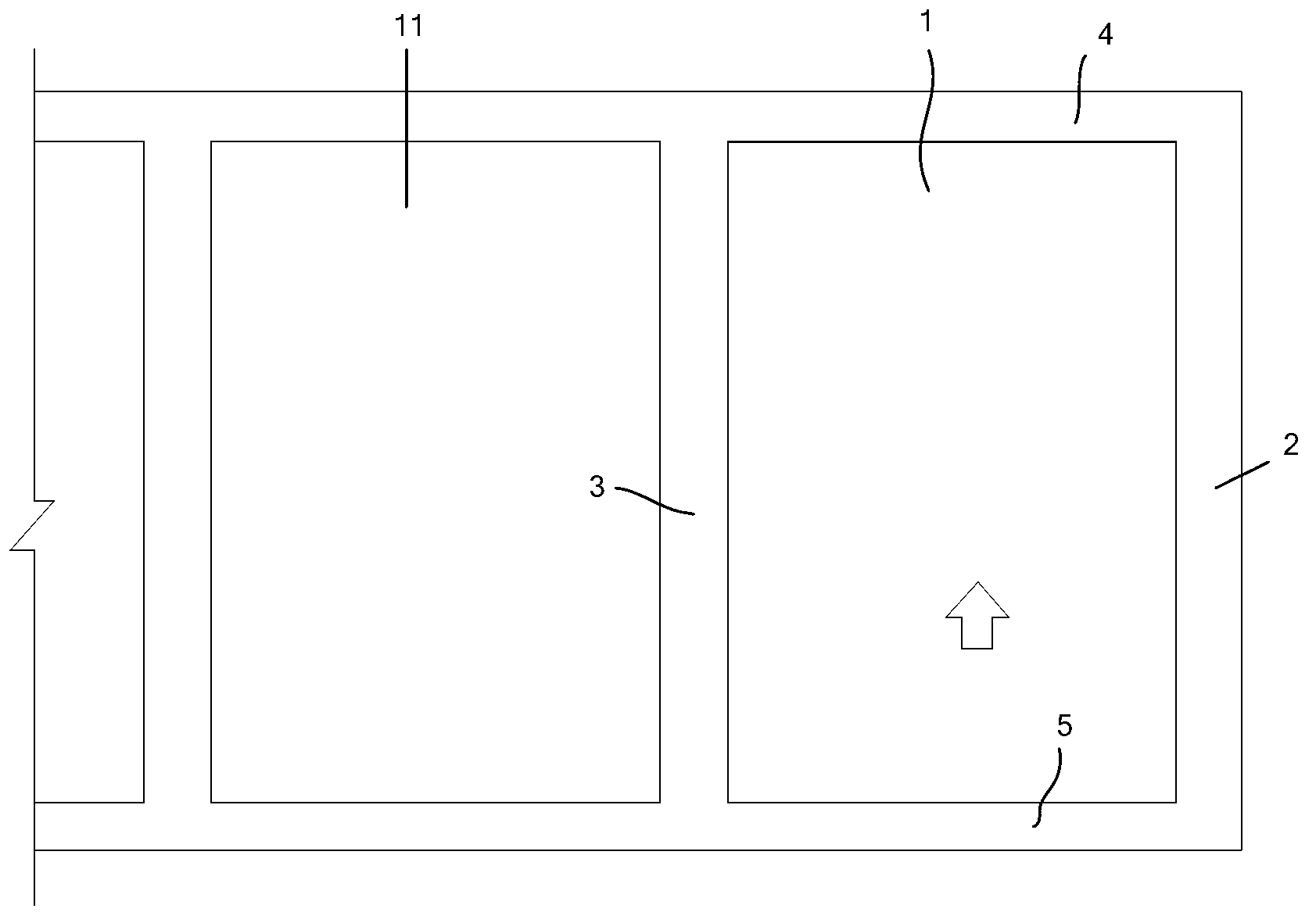

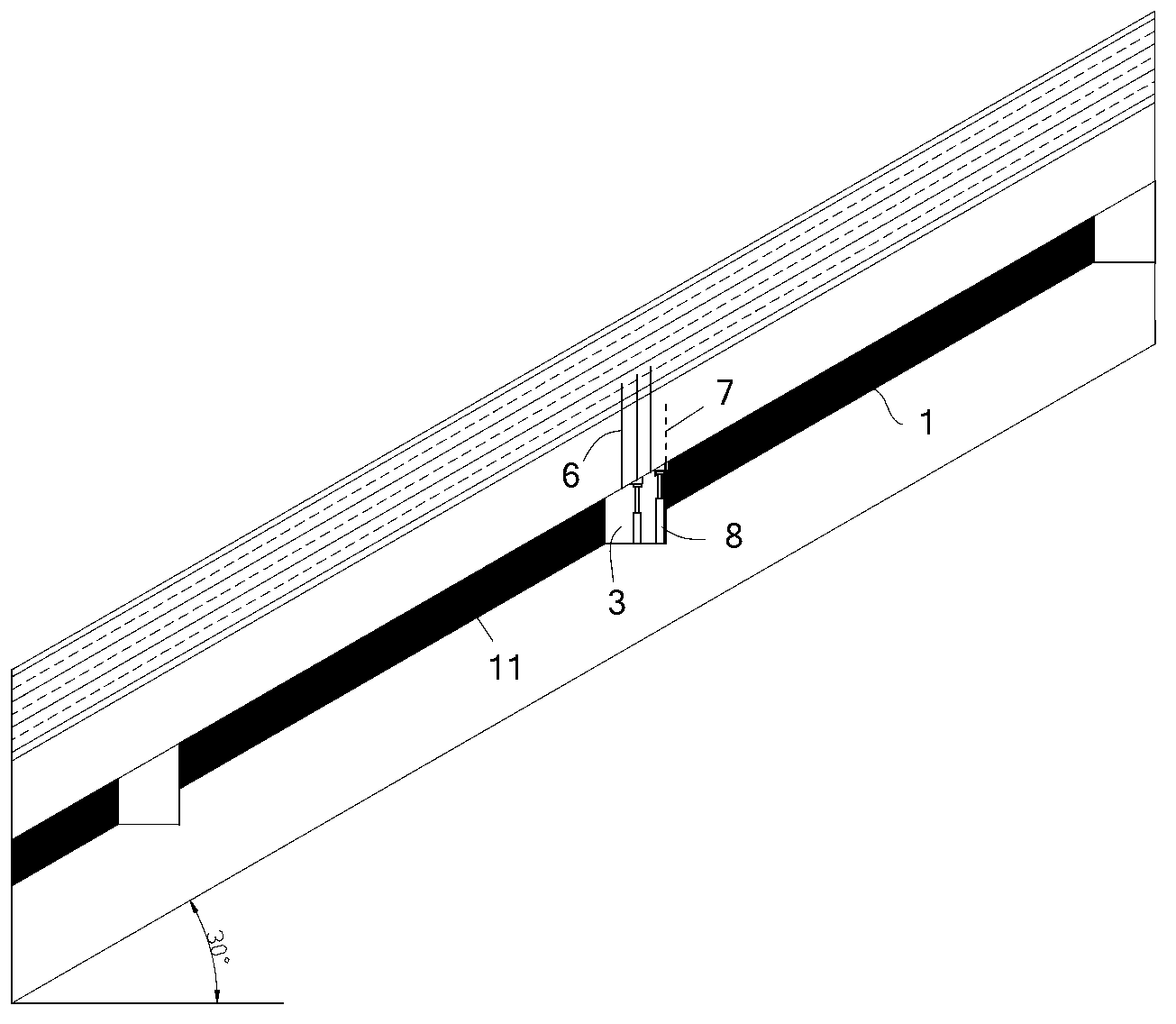

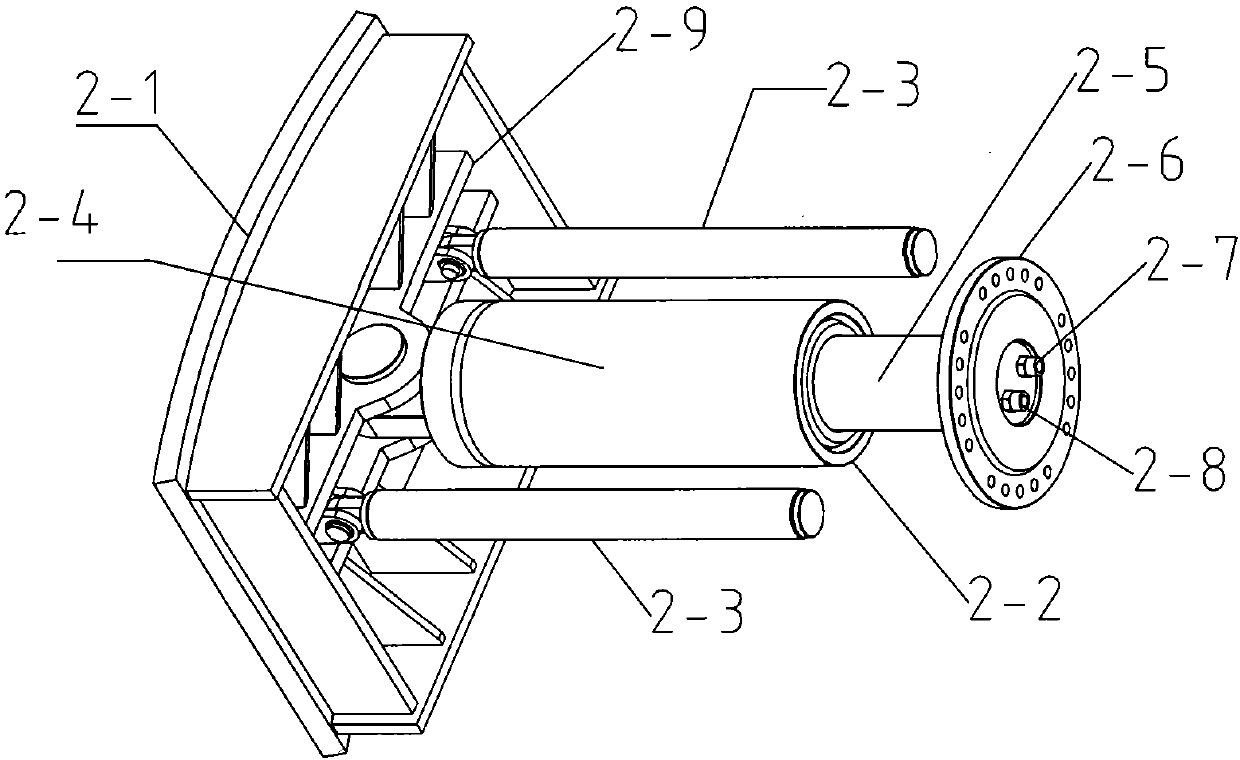

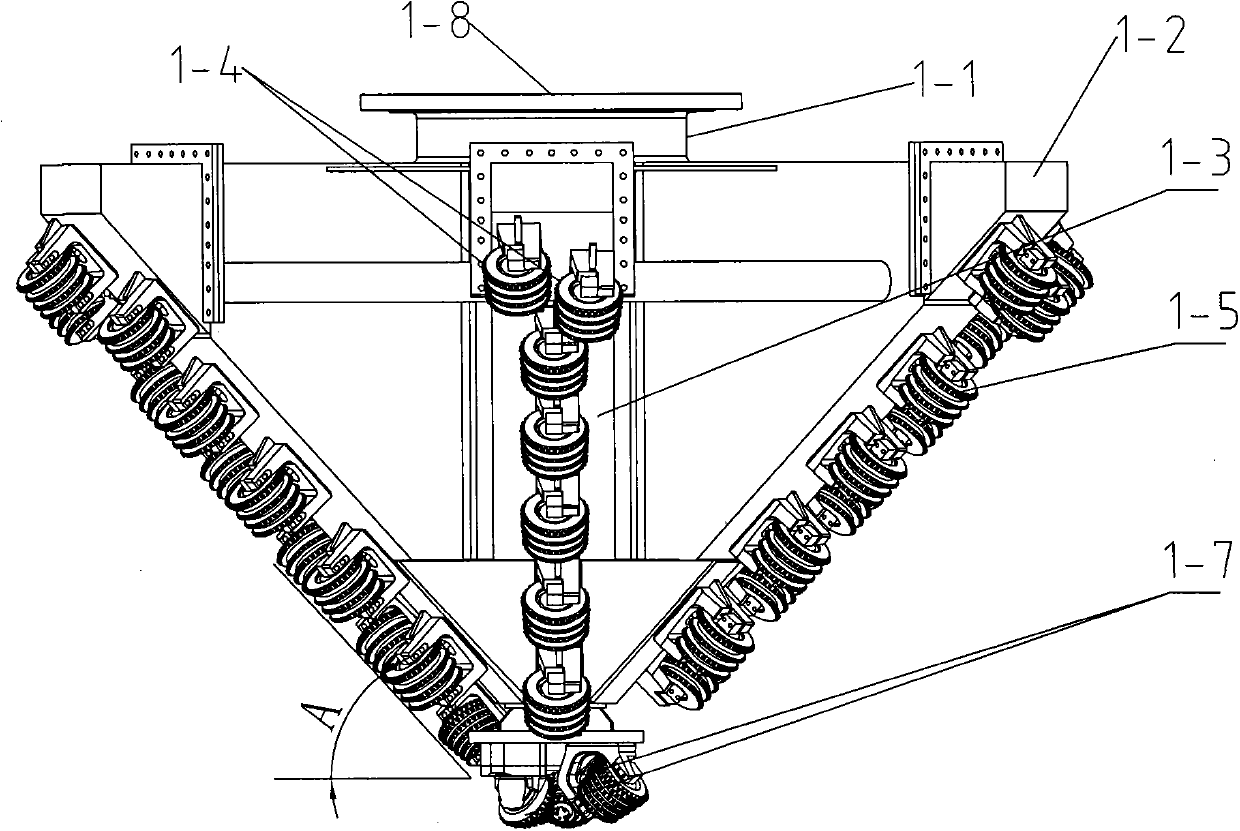

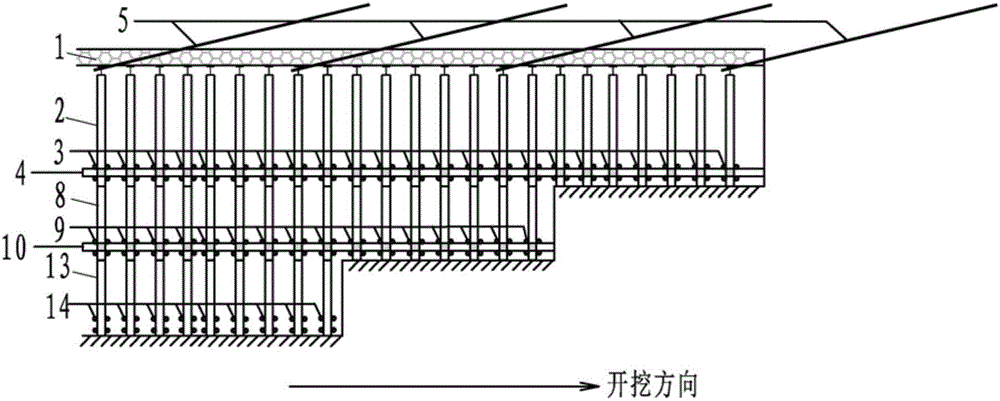

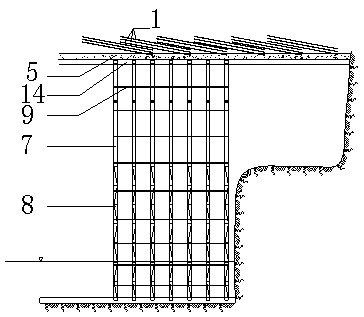

Steel shotcrete support internal force self-compensation, displacement control system and control method

InactiveCN101294389AImprove the force deformation performanceControl deformationExcavationsShotcreteAutomatic control

The invention belongs to the building support component technology field including the stress automatic control and monitoring as well as the structural safety, and relates to a steel tube supporting internal force automatic compensating and displacement controlling system. The system comprises an upper system, a PLC control system module and a field executive system. A steel support is arranged on a reinforced concrete diaphragm wall, a hydraulic jack is arranged on the steel support, and real time pressure monitoring values are fed back through a pressure sensor. The steel support and the hydraulic jack form a pre-stressed steel support structure, the hydraulic jack is connected with a hydraulic pump station through an oil circuit, and is connected with the PLC control system module through the pressure sensor, the hydraulic pump station is connected with the PLC control system module, and a PLC controlling device is connected with the upper system. Through auto-control software and a PLC control system, the automatic control to the axial force of the steel support is realized, thereby controlling the displacement and the settlement of the deep excavation supporting structure and the adjacent basic facilities.

Owner:CSCEC INT CONSTR +1

Alkali-free liquid setting accelerator for spray concrete

The alkali-free liquid setting accelerator for spray concrete is compounded with aluminum sulfate 40-70 wt%, magnesium sulfate in 5-50 wt% of the aluminum sulfate, alcohol amine 2-10 wt%, stabilizer 0-10 wt%, defoaming agent in 0-10 wt% of the stabilizer, glycerin 0-1 wt%, and water for the rest. The present invention has excellent cement adaptability, and can provide excellent early strengthening performance and spray construction performance even if to difficult cement with lower C3A content, such as modified cement.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

High ground stress soft rock stress-relief construction method

InactiveCN101644160AMature technologyGood effectUnderground chambersTunnel liningShotcretePolystyrene

The invention discloses a high ground stress soft rock stress-relief construction method which comprises the following steps: A. anchor shotcreting constructing, tagging the anchor shotcreting constructing with heading, and eliminating dangerous rock; B. cystosepiment hanging, carrying out hanging construction on polystyrene cystosepiment; C. inverted arch excavating and U shape steel spanning, lining tunnel to a ring, and carrying out re-spraying with shotcrete on clearance of steel racks; D. inverted arch backfilling, carrying out construction of a waterproof barrier layer after completing spanning of the U shape steel so as to conserve concrete; E. waterproof barrier layer constructing, carrying out waterproof barrier layer constructing when the convergence rate of tunnel is stabilized;F. secondary lining constructing, carrying out secondary lining constructing when the waterproof barrier layer constructing is completed; and G. prestress anchor line constructing, determining a holesite of an anchor line and the drilling direction through field lofting, and clearing the location of the hole site. The construction method has obvious effect for controlling large deformation of the soft rock with the high ground stress, is simple and convenient, and has the advantages of simple operation, obvious effect and relatively low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

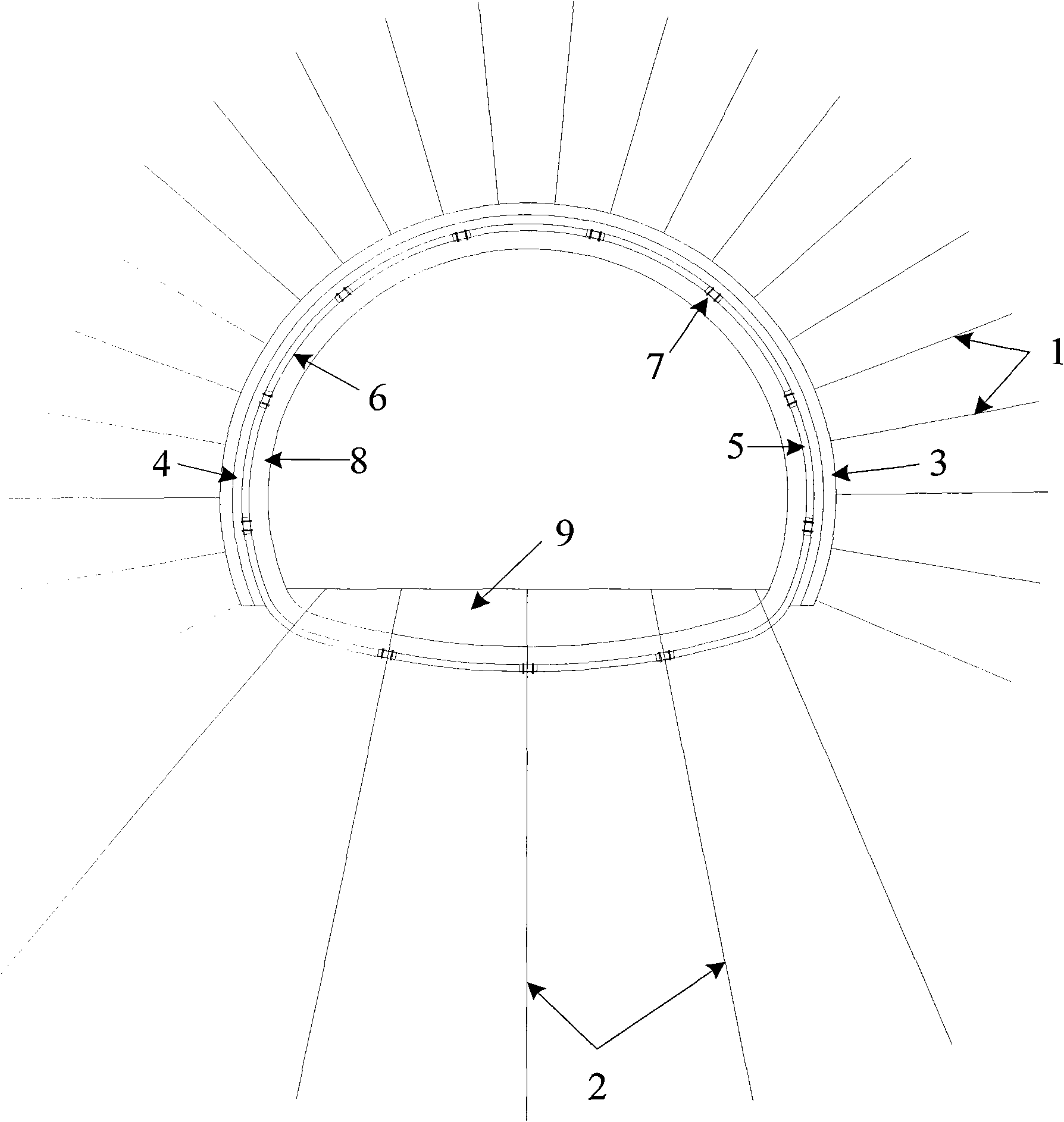

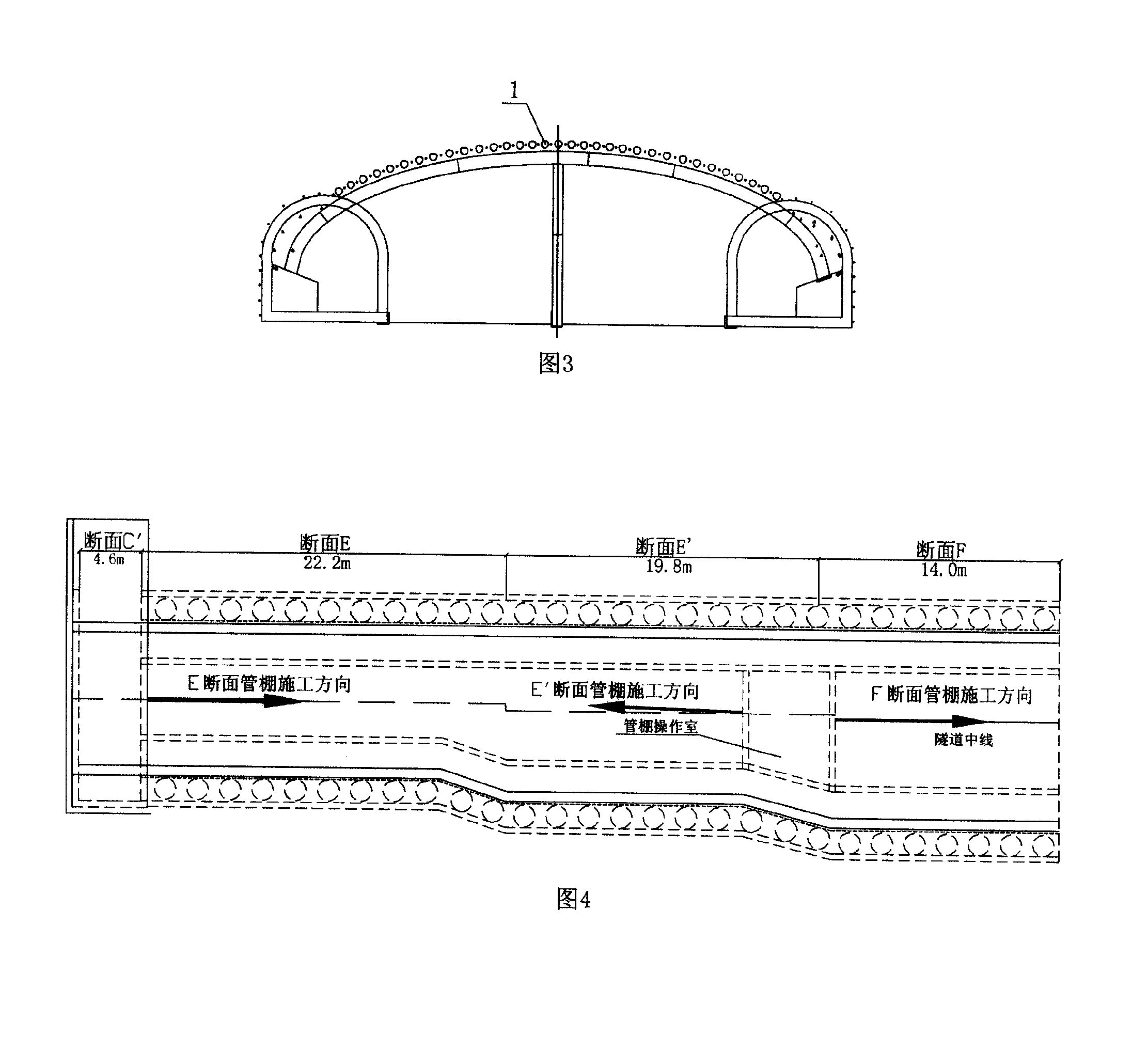

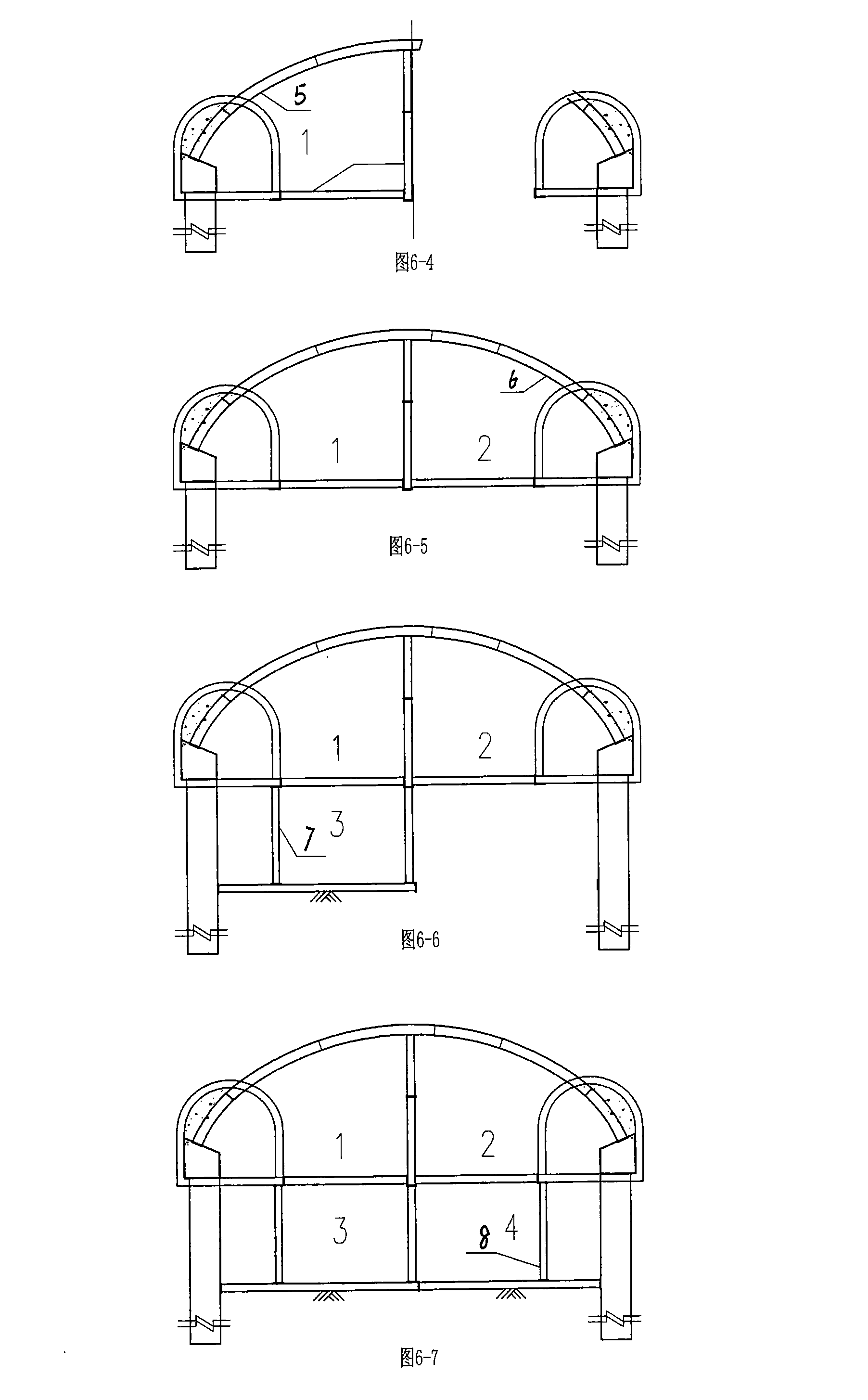

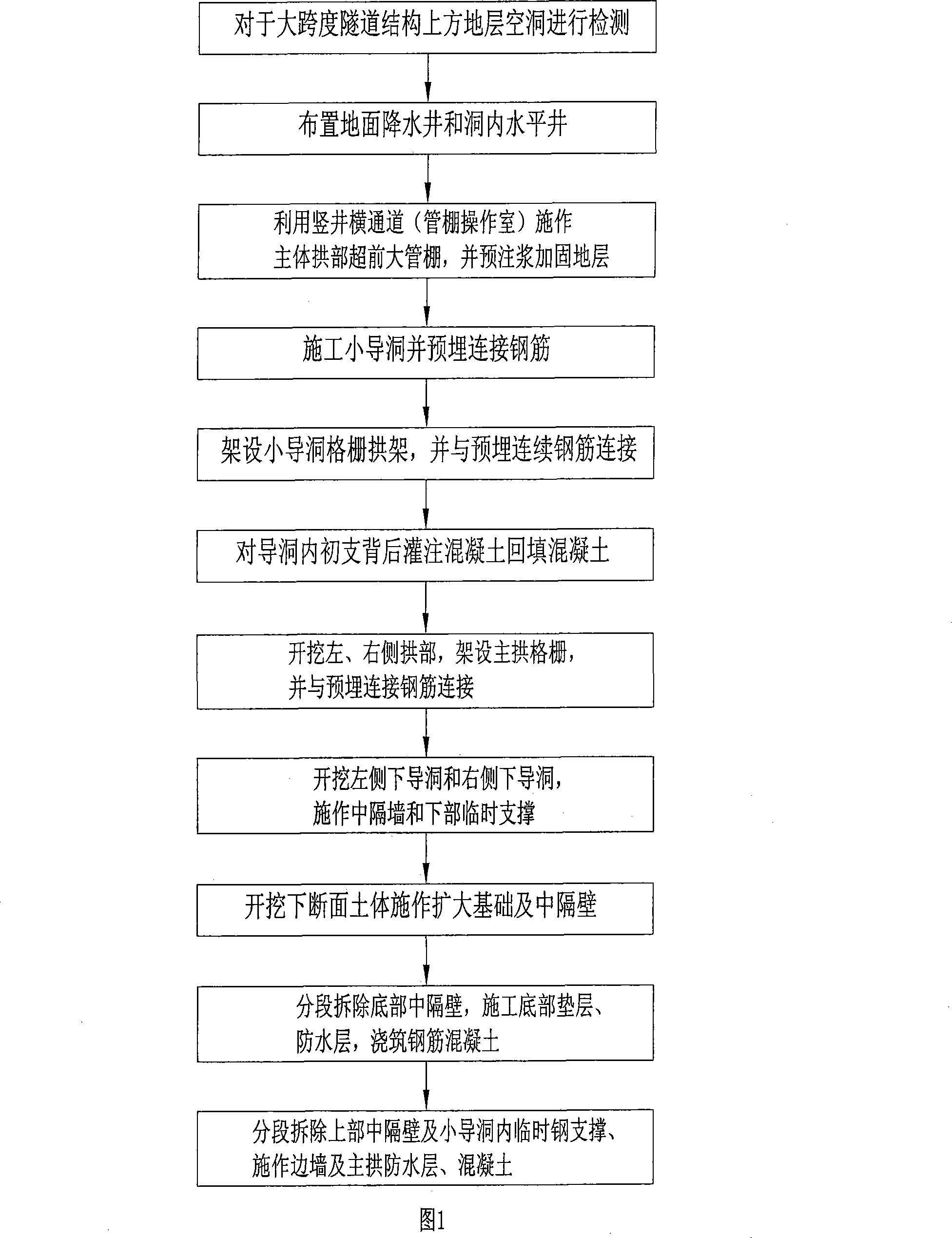

Construction method of shallow buried underground excavating tunnel super large section using PBA method

ActiveCN101225742ASolve comprehensive technical problemsSolve processing problemsUnderground chambersTunnel liningShotcreteTerrain

The invention relates to a method of shallow embedment and concealed excavation based on the PBA method for construction on super large cross-section of tunnel, comprising the following steps: 1. to detect the geologic cavity over the wide span tunnel structure; 2. to arrange the ground dewatering well and the tunnel horizontal well; 3. to take the horizontal channels of vertical well as the front large pipe shed on the arch part of the main body and to inject for strengthening the terrain formation; 4. to carry out the supporting arch construction on the side span of small pilot tunnel and the supporting major arch construction on the main body; 5. to excavate the soil mass of lower cross section as the extended foundation and the central partition wall; 6. to remove the bottom central partition wall section by section, construct bottom underlayer and waterproof layer, pour the reinforced concrete; 7. to remove the central partition wall of the upper part section by section and temporary steel shotcrete in the small pilot tunnel, construct the waterproof layer and concrete of the side wall and the main arch. The method of shallow embedment and concealed excavation based on the PBA method for construction on super large cross-section of tunnel has the advantages of guaranteeing the safety, quality and time limit of the construction, saving cost and enhancing work efficiency.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Liquid accelerator for sprayed concrete and preparation thereof

The invention relates to a liquid accelerator for shotcrete and a method for preparing the same. The liquid accelerator is prepared from the following components in percentage by weight: 25 to 70 percent of aluminum sulfate, 0 to 8 percent of metal fluoride, 1 to 10 percent of amine substance, 0.5 to 7 percent of pH regulator, 0.01 to 1 percent of thickening agent, and the balance being water. The method for preparing the liquid accelerator comprises the following steps: firstly, dissolving the fluoride into the water; secondly, adding the amine substance to the mixture and heating the solution to a temperature of between 40 and 80 DEG C; thirdly, adding the aluminum sulfate to the solution to perform heat preservation reaction until the solution becomes a uniform liquid; and fourthly, adding the pH regulator and the thickening agent to the uniform liquid and stirring the mixture evenly to finally obtain a uniform liquid substance which is the liquid accelerator for the shotcrete. The liquid accelerator is free from corrosion, has no penetrating odor, has good storage stability so that the phenomena of deposition, crystallization and the like do not appear after the storage of more than 6 months at a temperature of between 0 and 35 DEG C, and does not influence the effect in practice. Using the liquid accelerator with lower mixing proportion (5 to 8 percent), cement can be initially set within 4 minutes and finally set within 10 minutes, and the strength of cement mortar within one day is more than 10 MPa and the storage rate of the strength within 28 days is more than 100 percent.

Owner:JIANGSU SUBOTE MATERIAL

Heating-free non-alkali liquid accelerator for jetting concrete and preparation method of heating-free non-alkali liquid accelerator

The invention discloses a heating-free non-alkali liquid accelerator for jetting concrete and a preparation method of the heating-free non-alkali liquid accelerator. The liquid accelerator is prepared from the following components in percentage by mass: 30%-55% of aluminum sulfate, 3%-10% of aluminium hydroxide, 10%-18% of hydrofluoric acid, 8%-25% of magnesium salt, 1%-8% of alkylol amine, 0.5%-4% of a stabilizer, and 10%-33% of water. The preparation method is characterized by comprising the following processing steps: putting aluminium hydroxide into a reaction kettle; adding water to the reaction kettle, and stirring aluminium hydroxide into paste; slowly adding hydrofluoric acid, and when the temperature reaches 50-55 DEG C, adding aluminum sulfate to stir in batches; after hydrofluoric acid is completely added, adding residual aluminum sulfate and supplementing residual water, so as to obtain reaction liquid; adding the magnesium salt to the reaction liquid, and then adding the alkylol amine and the stabilizer, so that the solution becomes evenly mixed liquid. The accelerator disclosed by the invention has strong adaptability with cement, low energy consumption and good performance, and does not need to be heated in the use procedure.

Owner:刘翠芬 +1

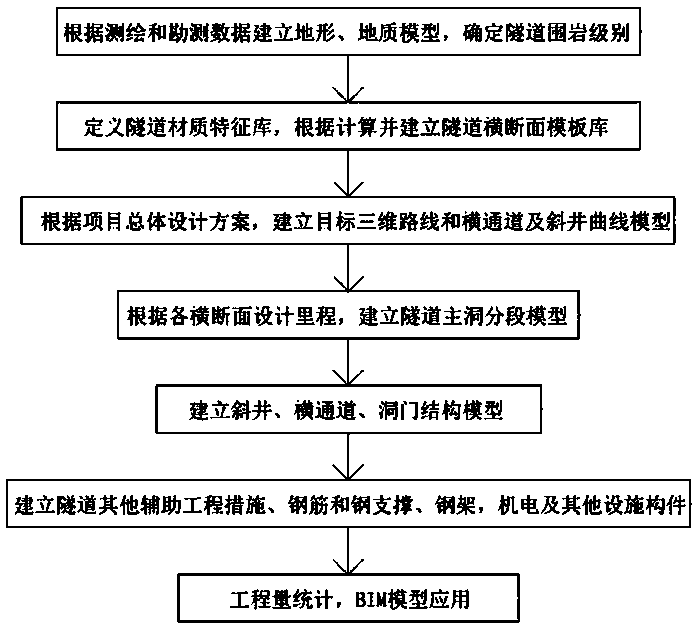

Highway tunnel designing method based on BIM

The invention discloses a highway tunnel designing method based on BIM. The highway tunnel designing method based on the BIM includes the steps that 1, according to mapping and reconnaissance data, aterrain model and a geologic model are built, and tunnel surrounding rock grades are determined; 2, a tunnel texture feature library is defined, and a tunnel cross section model library is establishedthrough calculation; 3, according to a project overall design scheme, a tunnel three-dimensional path and cross aisle and inclined shaft space curve model is built; 4, according to design kilometersof all tunnel cross sections, a tunnel main cave subsection model is built; 5, an inclined shaft model, a cross-aisle model and a tunnel portal structure model are built; 6, other tunnel auxiliary engineering measure components including reinforcing steel bars, steel shotcrete, steel frames and electromechanical parts are built; 7, tunneling work amount accounting is conducted, and a BIM model isapplied. According to the highway tunnel designing method based on the BIM, the terrain model and the geologic model are fused with a tunnel main body, three-dimensional paths can be modified in realtime, related drawings are automatically modified, therefore, the purpose is achieved that engineering design information is completely reflected in the BIM model, and model information transfer and application in the later period are facilitated.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

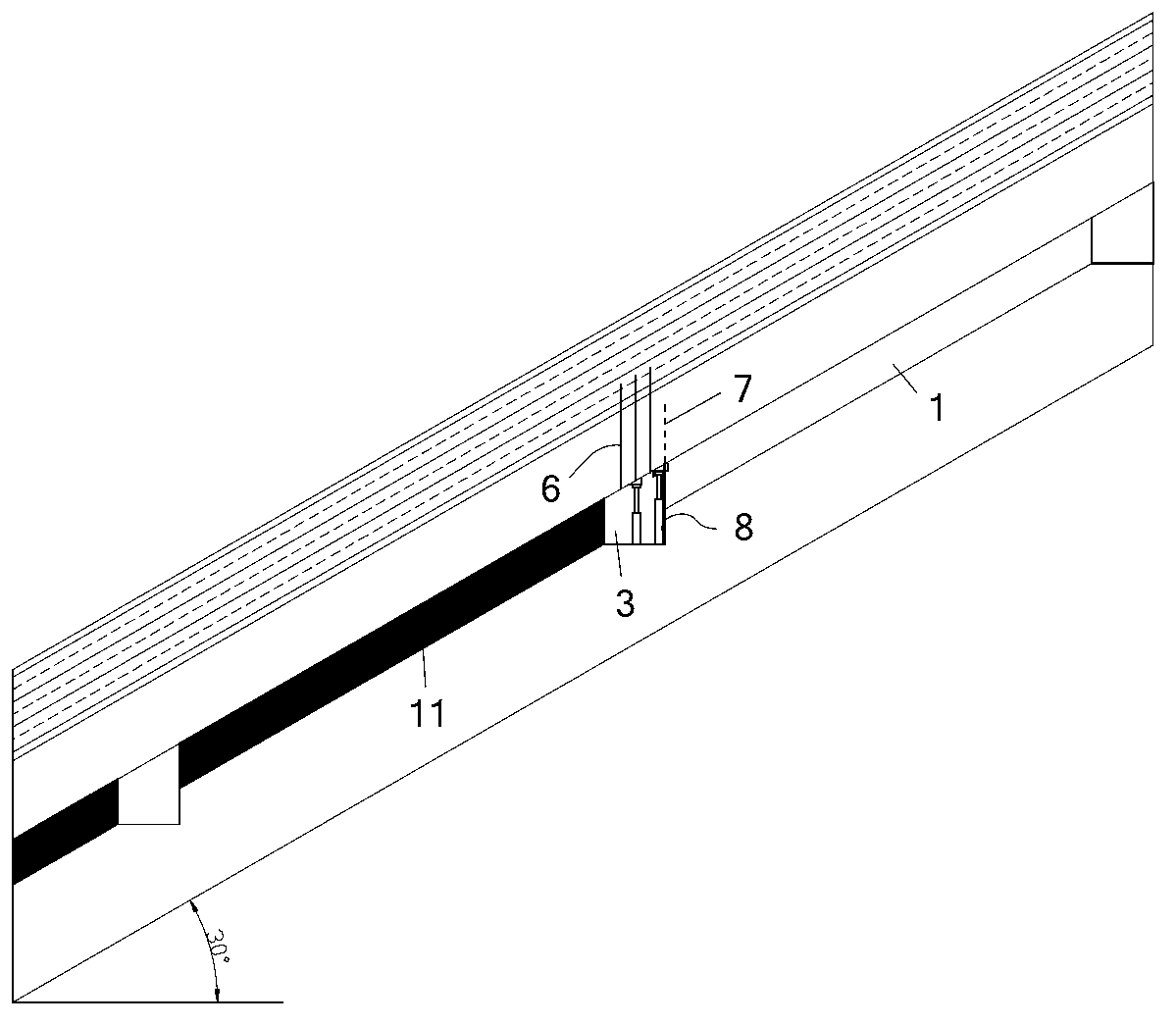

Top-cutting roadway coal-pillar-free mining method of close-range thin coal seam

ActiveCN103233740AAvoid destructionDoes not cause prominenceUnderground miningSurface miningShotcreteCoal pillar

The invention discloses a top-cutting roadway coal-pillar-free mining method of a close-range thin coal seam. The method comprises the following steps of: (1), excavating an upper crossheading roadway and a lower crossheading roadway; (2), mounting a grouting constant-resistance anchor rope and a grouting constant-resistance anchor rod without grouting at first, and a monomer hydraulic pillar, machining energy-accumulation presplitting top-cutting holes, and blasting to obtain presplitting cutting joints; (3), extracting an upper coal seam till unavailable; (4), allowing a mining field ejection plate to collapse along the shallow energy-accumulation presplitting cutting joints; (5), spraying a concrete spray layer to the rise side wall of the lower crossheading roadway, and grouting the grouting constant-resistance anchor rope and the grouting constant-resistance anchor rod; (6), extracting a lower coal seam till unavailable, and allowing the mining field ejection plate to collapse along the deep energy-accumulation presplitting cutting joints; (7), taking a roadway automatically formed at the original lower crossheading roadway as the upper crossheading roadway of a next mining surface; and (8), repeating steps (2) to (7). According to the method, by using the cutting joints formed by the energy-accumulation presplitting top-cutting holes for blasting the ejection plate, shallow breakage and deep breakage can be performed twice, and twice collapse of the mining field ejection plate is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Steep-coal-seam long wall face non-pillar coal mining method

ActiveCN103195426AAvoid destructionAvoid enteringUnderground miningSurface miningShotcreteEngineering

The invention discloses a steel-coal-seam long wall face non-pillar coal mining method. The method comprises the steps of (1) excavating an upper crossheading roadway and a lower crosshead roadway; (2) mounting a constant-resistance large-deformation anchor rod, processing a row of vertical energy-gathering blasting holes, and implementing blasting and presplitting; (3) erecting a column body for supporting a top plate, and arranging a protective layer on the back of the column body; and (4) carrying out recovery, slipping the top plate of a recovery face along a presplitting kerf; (5) withdrawing the column, hanging a net and spraying concrete to form a support layer; (6) mounting a slip-casting constant-resistance long anchor rod, and grouting; (7) forming a roadway automatically in the original crosshead roadway and taking the roadway as the upper crosshead roadway of the next mining face; and (8) repeating the steps (2)-(7). According to the method, the top plate at a worked out section collapses along the presplitting kerf, and meanwhile, a lower crosshead top plate is prevented from being damaged, and small caving waste rocks are prevented from entering the lower crosshead roadway, so that the roadway is automatically formed in the original crosshead roadway.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Sinking technology for expanding pilot well drilled by raise-boring machine, by using vertical well heading machine

The invention discloses a sinking technology for expanding a pilot well drilled by a raise-boring machine, by using a vertical well heading machine, which comprises the following steps of (a) drilling the pilot well by using the raise-boring machine; (b) drilling by using the vertical well heading machine to enable the pilot well to be enlarged into a vertical well at a desirable diameter in a brushing way; (c) hanging a net on and jetting concrete onto the wall of the vertical well to form a temporary supporting well wall; (d) after enlarging in the brushing way and heading to a lower tunnel by using the vertical well heading machine, gradually removing components of the vertical well heading machine from top to bottom. By the adoption of the technology provided by the invention, in the presence of the pilot well, a vertical well hole at a design diameter is formed through the one-time drilling of the vertical well heading machine; therefore the technology is applicable for the construction of underground mine vertical well holes for coal mining, metal, nonmetal and the like.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Low-alkaline liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to a low-alkaline liquid accelerating agent and a preparation method thereof. For the low-alkaline liquid accelerating agent, aluminium sulfate solution is neutralized with sodium aluminate solution to produce aluminium hydroxide collosol, and then aluminium sulfate and aluminium hydroxide collosol conduct polymerization reaction in an original solution system to produce polymerized aluminium sulfate, so that the accelerating agent solution has higher aluminium ion content and liquid stability; the low-alkaline liquid accelerating agent is prepared by aluminium sulfate, sodium aluminate and stabilizing agent; and the mass percentage of the components are as follows: 40 to 60 percent of aluminium sulfate, 6 to12 percent of sodium aluminate, 0 to 0.2 percent of stabilizing agent, and the balance of water. The invention has the following positive effects to sprayed concrete: initial set of common cement can be realized in five minutes and final set of the common cement can be realized in eight minutes under lower doping amount; the 1d strength of cement mortar can reach more than 12MPa, and the 28d compression strength ratio of the cement mortar is more than 100 percent; and the invention has good adaptability to cement of different varieties.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

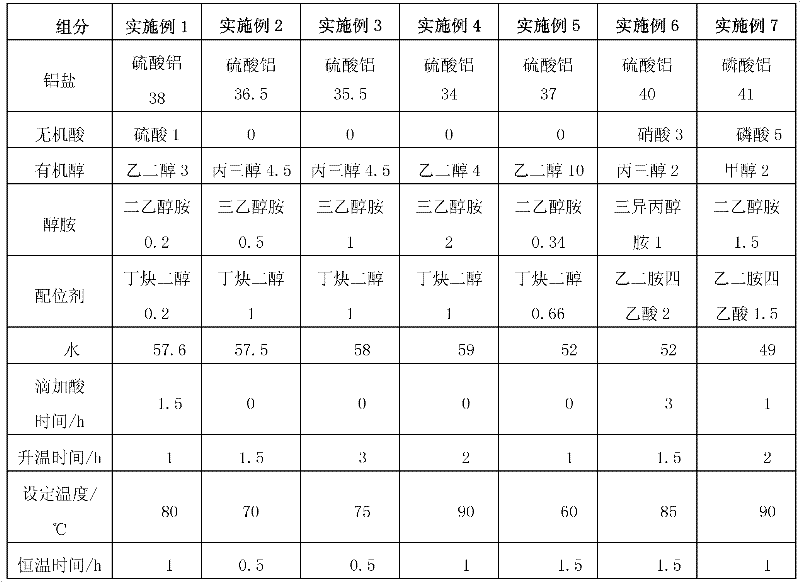

Alkali-free and chlorine-free liquid concrete accelerating agent as well as preparation method and application thereof

The invention discloses an alkali-free and chlorine-free liquid concrete accelerating agent as well as a preparation method and an application thereof. The product disclosed by the invention comprises the following components in parts by weight: 34-41 parts of aluminum salt, 0-5 parts of inorganic acid, 2-10 parts of organic alcohol, 0.2-2 parts of alcohol amine, 0.2-2 parts of coordination agentand 9-59 parts of water. The alkali-free and chlorine-free liquid concrete accelerating agent disclosed by the invention plays an important role in engineering such as sprayed concrete and sprayed mortar of various wells, tunnels, culverts, supports and other underground engineering, concrete emergency repair engineering, anchoring, sealing and plugging engineering and the like, and has wide application prospects.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Treatment method for fault fracture zone collapse in tunnel construction process

InactiveCN104196546AReduce the risk of secondary landslidesLess investmentUnderground chambersTunnel liningShotcreteFracture zone

The invention discloses a treatment method for fault fracture zone collapse in the tunnel construction process. The method includes the steps that firstly, arch reinforcement is conducted on every two adjacent surrounding rocks in a collapse segment; secondly, a collapse body is removed, and concrete is jetted to the collapse tunnel face after the collapse body is removed to close the collapse segment; thirdly, a lifting jack acts on the four corners of each bottom of racks of formworks, the interval identical to the width of a steel arch is reserved between the formworks, formwork erection is conducted in time, and the formworks and the steel arch jointly form a supporting layer; fourthly, through holes reserved in the formworks in advance, an arch apex concrete layer is formed in a high-pressure grouting mode, and small grouting guide pipes are punched into arch springs and the side walls of the steel arch; fifthly, the front end of a bottom die composed of the formworks and the steel arch is grouted and reinforced through the small guide pipes, operation of the next construction circulation stage of the collapse segment is conducted, and the first step, the second step, the third step and the fourth step are specifically repeated; sixthly, after second circulation is finished, supports of arch protecting layer concrete are formed through conveying ports embedded through the second step.

Owner:SHANDONG UNIV

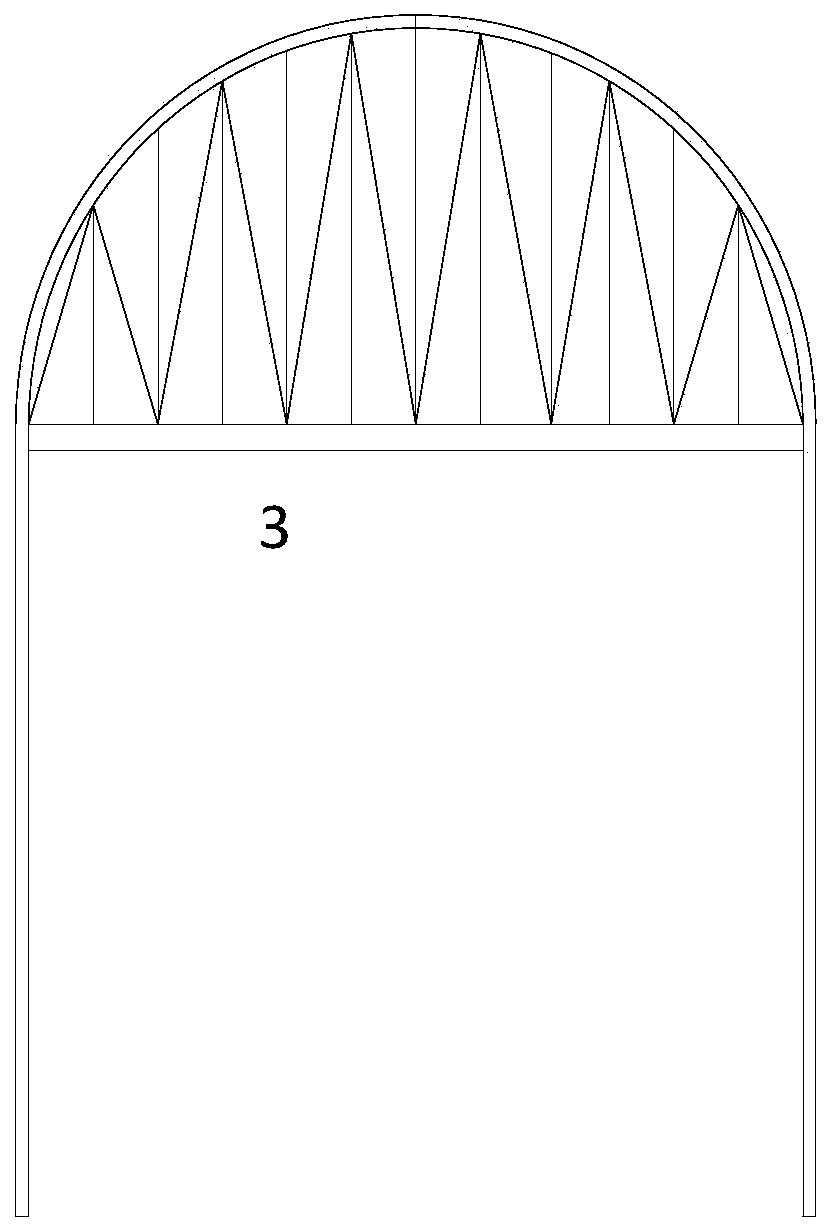

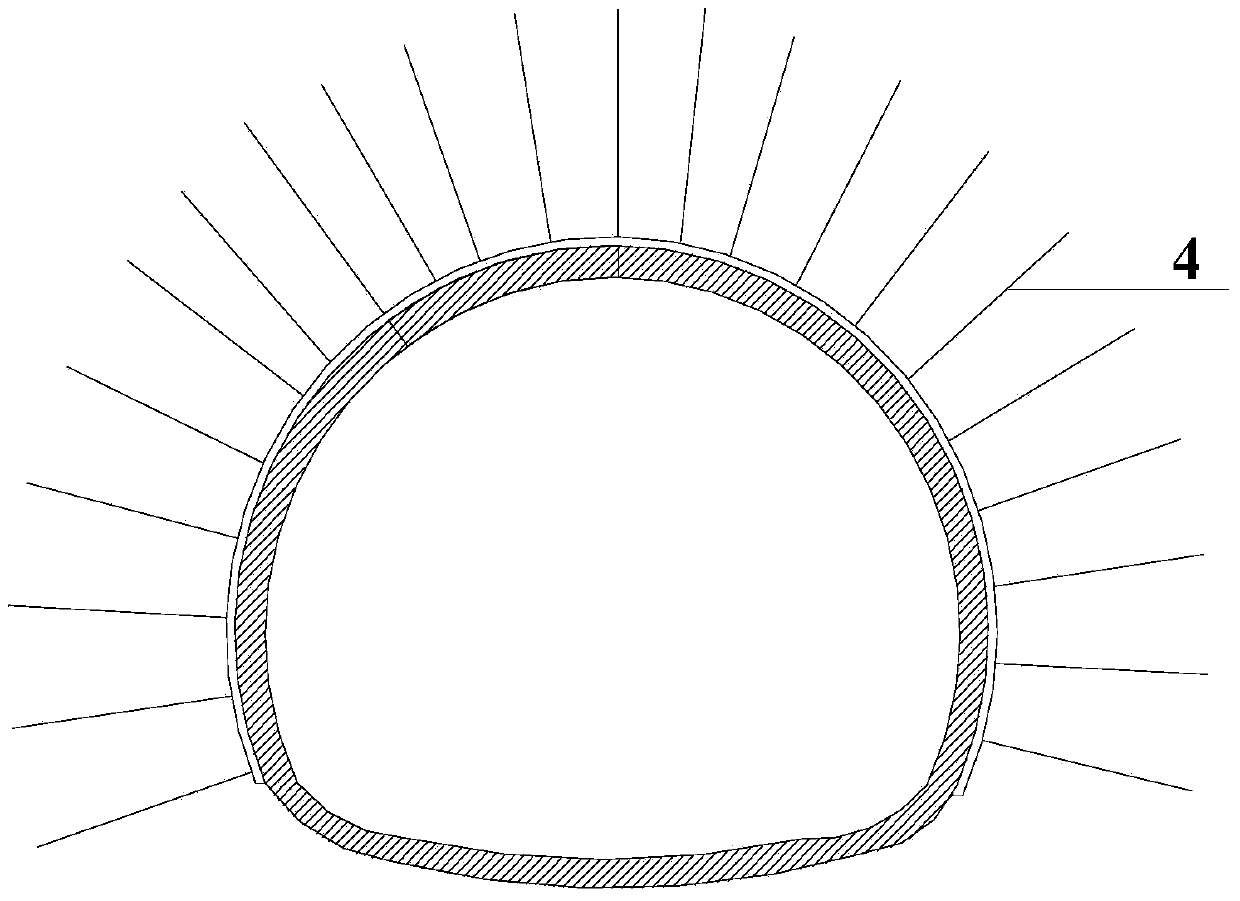

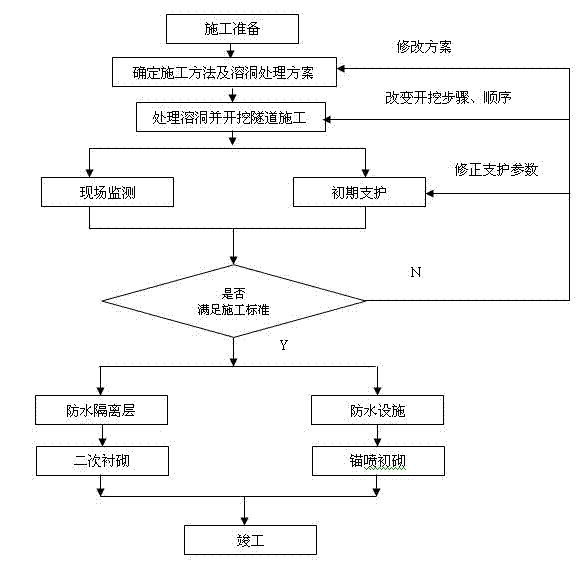

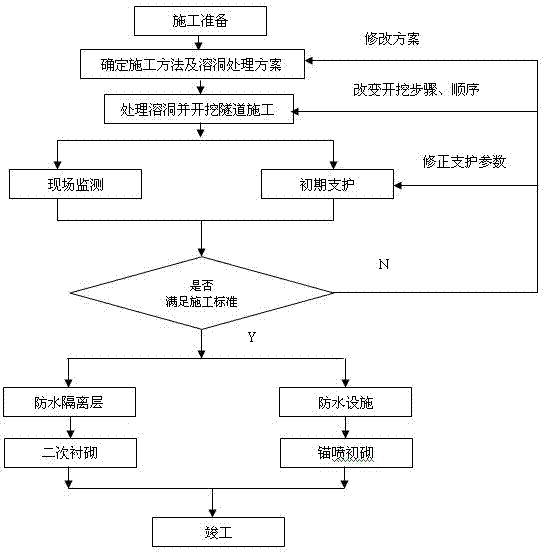

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

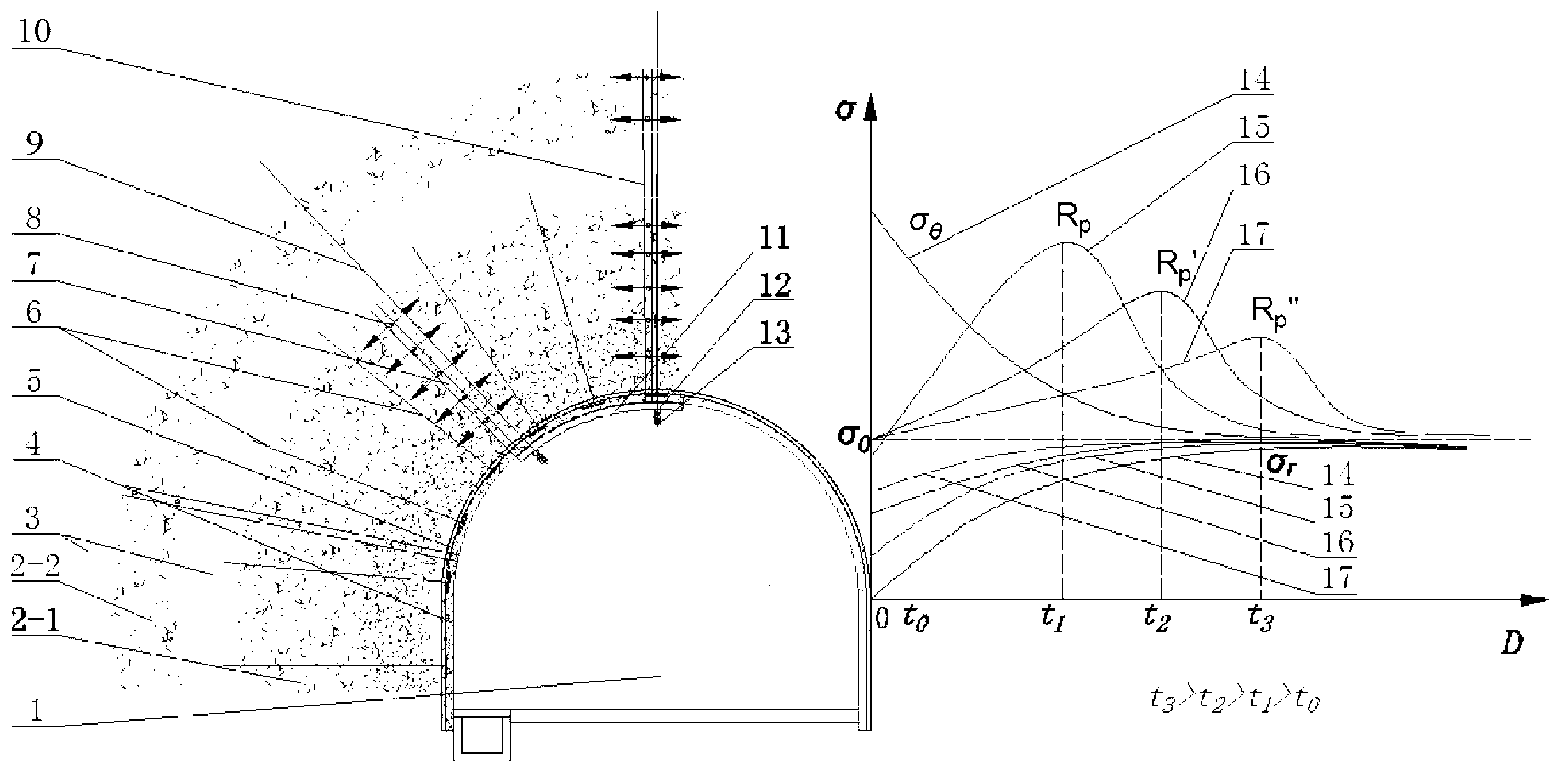

Bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock

The invention specifically discloses a bolting-grouting integrated support method for zonal disintegration of deep roadway surrounding rock, and the method comprises the following steps of: (1) after the roadway is excavated, immediately shotting concrete to close the surrounding rock, employing a high-pretightening force overstrength anchor bolt for supporting in the first disintegration zone, and arranging a steel bar net on the inner wall of the roadway surrounding rock and shotting concrete again; (2) applying a pretightening force anchor cable on the top plate of the roadway surrounding rock such that the anchoring end of the anchor cable is located in the deep intact rock mass, arranging a steel I-beam closely to the surrounding rock, passing the anchor cable through the shotcrete, the steel I-beam and a yielding ring and fixing the anchor cable on the inner wall of the roadway surrounding rock by using an anchor cable lock, thereby realizing coupling and supporting of the anchor bolt and the anchor cable; and (3) according to the monitoring result of the zonal disintegration of the surrounding rock, performing the delayed anchor bolt support for about 20-30 days, and performing grouting reinforcement on each disintegration zone by virtue of long and short combined injection pipes or a hollow sectional spiral grouting anchor bolt. The bolting-grouting integrated support method is capable of effectively performing bolting-grouting integrated reinforcement on the disintegrated surrounding rock of the deep roadway and thereby obviously enhancing the stability of the roadway.

Owner:SHANDONG UNIV

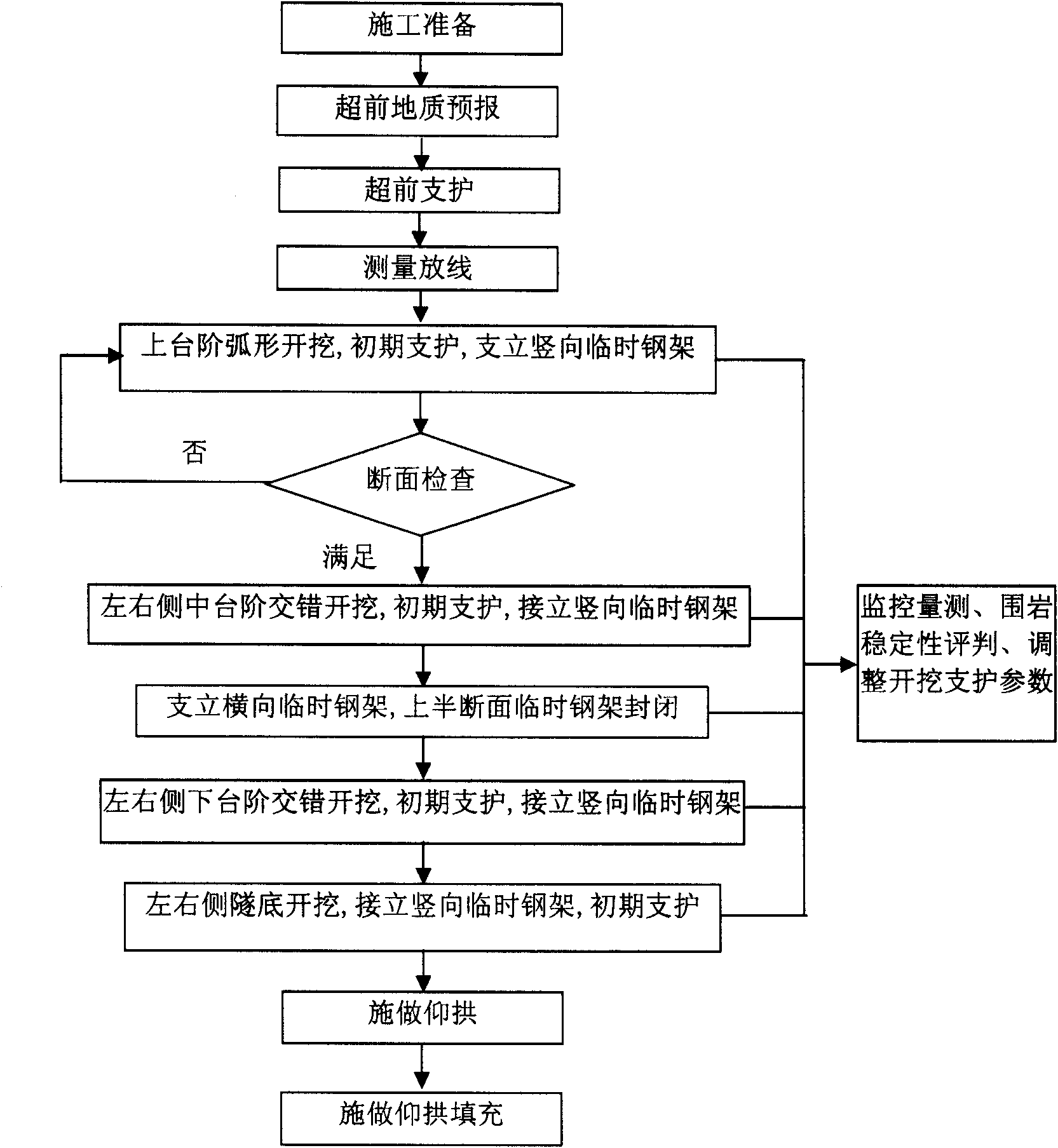

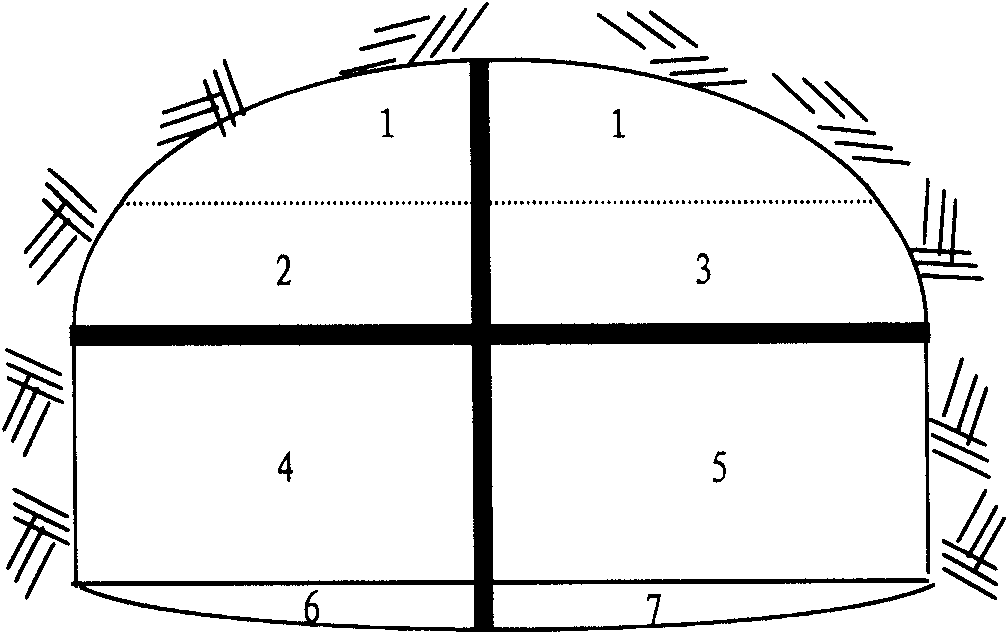

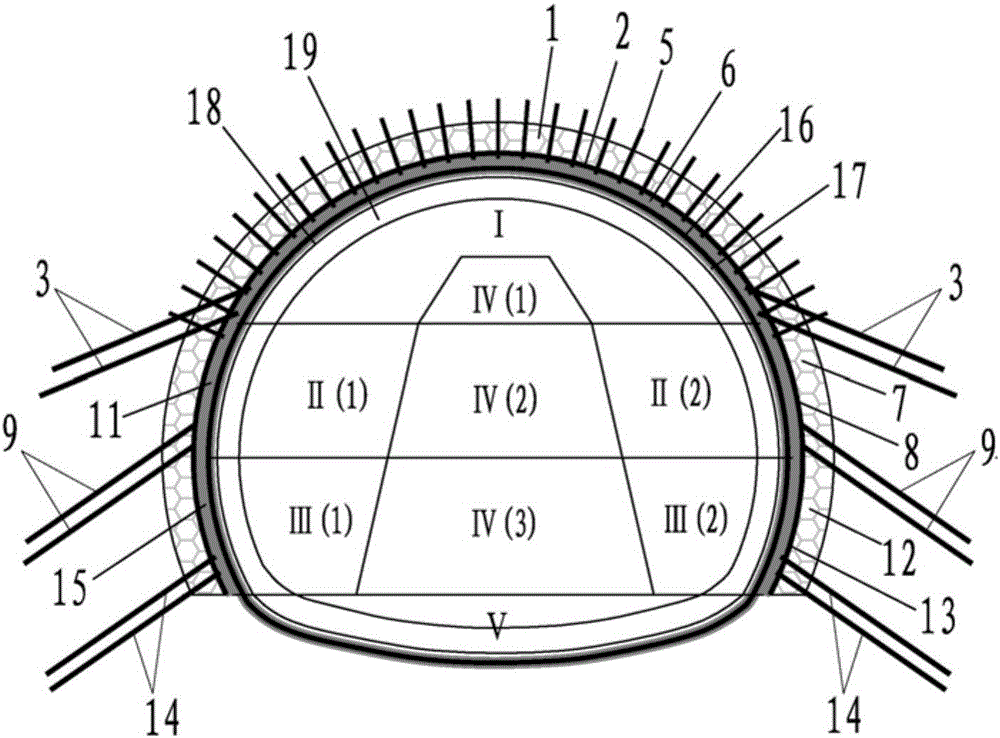

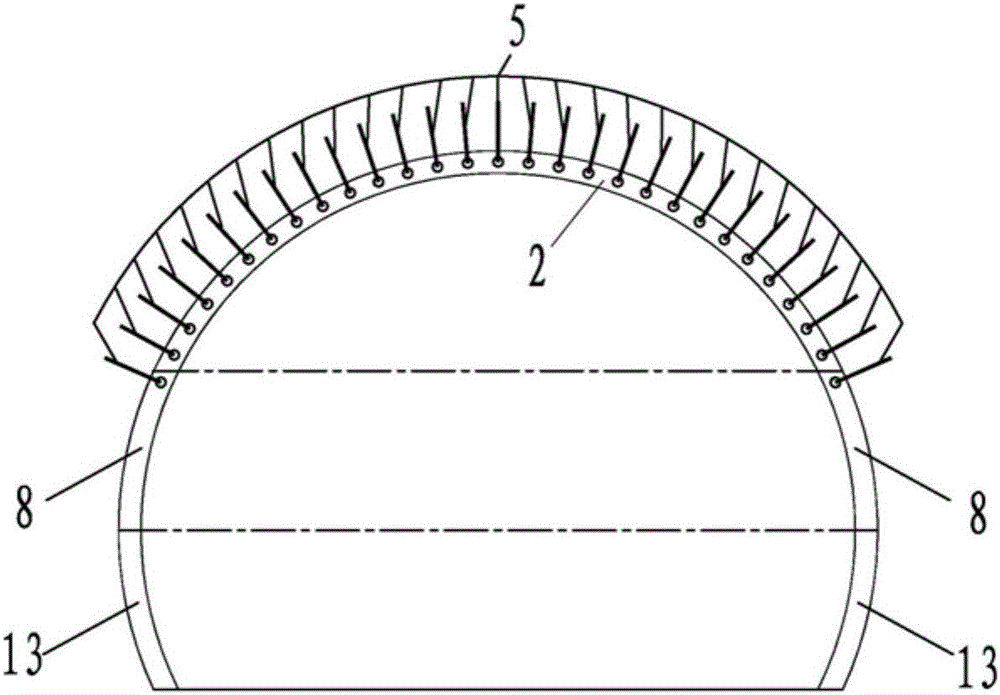

Excavation supporting method for tunnel construction

InactiveCN101769154AReduce labor intensityFast formingUnderground chambersTunnel liningSupporting systemShotcrete

The invention discloses an excavation supporting method for tunnel construction. In the method, the tunnel is excavated in parts and blocks, arch part primary support and temporary steel frame support are erected to form reticular closed stable support system, and finally a complete tunnel section is formed, the excavation and support of each part are in vertical staggered manner along tunnel and are carried on through parallel advancing construction method. The excavation supporting method has large excavation part section, facilitates the operation of construction machinery, has simple primary-support process, easy operation, reduces the arch jack fabrication, anchor rod mounting and concrete spraying processes for middle partition and temporary inverted arch construction, reduces the construction period and the construction cost.

Owner:HOHHOT RAILWAY CONSTR OF THE SIXTH ENG BUREAU CREC +1

Top breaking gob-side entry retaining method for tender roofs

InactiveCN104929666ACollapse accident preventionAvoid damageUnderground chambersMine roof capsShotcreteStone wall

The invention discloses a top breaking gob-side entry retaining method for tender roofs. The top breaking gob-side entry retaining method includes steps of firstly, reinforcing and supporting the tender roofs of roadways jointly supported by original anchor meshes and cables or supported by sheds; secondly, laying wire meshes on gob sides; thirdly, preliminarily breaking the roofs of the roadways on the gob sides; fourthly, piling up preliminarily broken caved gangue until the caved gangue reaches rock of upper-end hard roofs to form gangue piled walls; fifthly, burying perforated grouting pipes in the formed gangue walls, spraying concrete on the surfaces of the wire meshes and the surfaces of the gangue walls to form concrete sprayed supporting layers; sixthly, injecting concrete grout in each preliminarily buried grouting steel pipe by the aid of a grouting pump after the concrete sprayed supporting layers are solidified; seventhly, sequentially detaching falling preventing devices and dense reinforcing columns along with advancing of working faces; eighthly, reinforcing and supporting the roofs under special conditions. The top breaking gob-side entry retaining method has the advantages that active bearing supporting effects can be realized for inherent characteristics of the tender roofs, supporting forms are simple, the cost is low, and entry retaining effects can be efficiently realized.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of low-alkaline liquid accelerating agent

The invention relates to a preparation method of low-alkaline liquid accelerating agent, comprising the following steps: 1) preparing sodium aluminate liquid; 2) modifying sodium aluminate liquid; 3)carrying out a reaction between the modified sodium aluminate and the aluminum sulfate; and 4) adding hydramine and hydroxycarboxylic acid and stirring evenly to prepare the finished product. The low-alkaline liquid accelerating agent prepared by the invention has low alkali content, namely, the sum of Na2O and K2O is less than 5%, low preparation cost, is suitable for cement such as ordinary Portland cement, moderate-heat cement, low-heat cement and other brands and types, is applicable to the sprayed concrete construction, can significantly improve initial strength and ensure later strength.

Owner:JIANGSU SOBUTE NEW MATERIALS

All-conditions tunnel boring machine

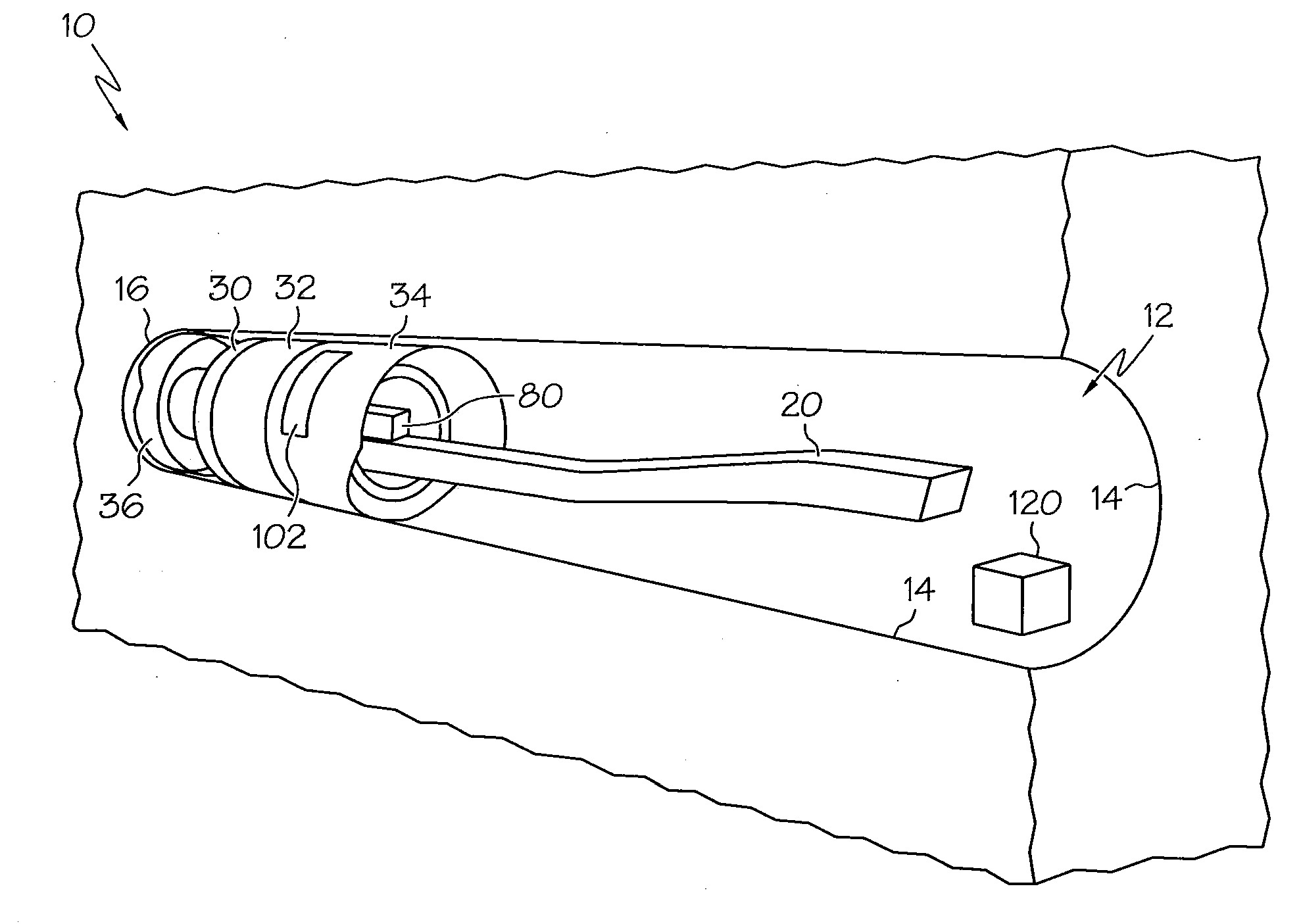

A tunnel boring machine is provided comprising a cutter head, a main beam, a first, second, and third shield; and a ground conditioning work zone within the first shield, a gripper assembly, a segment erector arm for lining the tunnel, and at least one propulsion mechanism. The ground conditioning work zone includes at least one probing device for probing the terrain ahead of the cutter head. The first shield is configured to be retracted relative to the second shield to provide access for the ground conditioning work zone to apply at least one ground support device. The at least one propulsion mechanism moves the cutter head, the first and the second shield forward while the third shield and the gripper assembly remain stationary. The ground support devices can include filling a hole with a ground conditioning agent; and placing a bolt, ring beam, mesh, or shotcrete in / on the tunnel wall.

Owner:THE ROBBINS CO

Alkali-free liquid accelerator, and preparation method and application method thereof

InactiveCN106082763AIncrease the concentration of aluminum ionsImprove solubilityShotcreteAlkali free

The invention discloses an alkali-free liquid accelerator, and a preparation method and an application thereof. The alkali-free liquid accelerator is prepared from, by weight, 35-60% of aluminum sulfate, 2-8% of aluminum hydroxide, 1-5% of alcohol amine, 0.5-1% of a dispersant, 0.1-0.5% of a stabilizer, and the balance of water. The accelerator is neutral, effectively avoids later alkali-aggregate reactions and avoids hidden safety troubles; the accelerator has low admixture and superior performances, and is far better than first-grade accelerators in initial setting time, final setting time and later strength; and the accelerator has the advantages of small rebounding amount, low dust concentration, provision of safe and healthy operating environment for construction personnel, engineering cost reduction, construction progress acceleration and good economic and social benefits in the concrete jet construction process.

Owner:SHANDONG YUANLIHUA MINING EQUIP

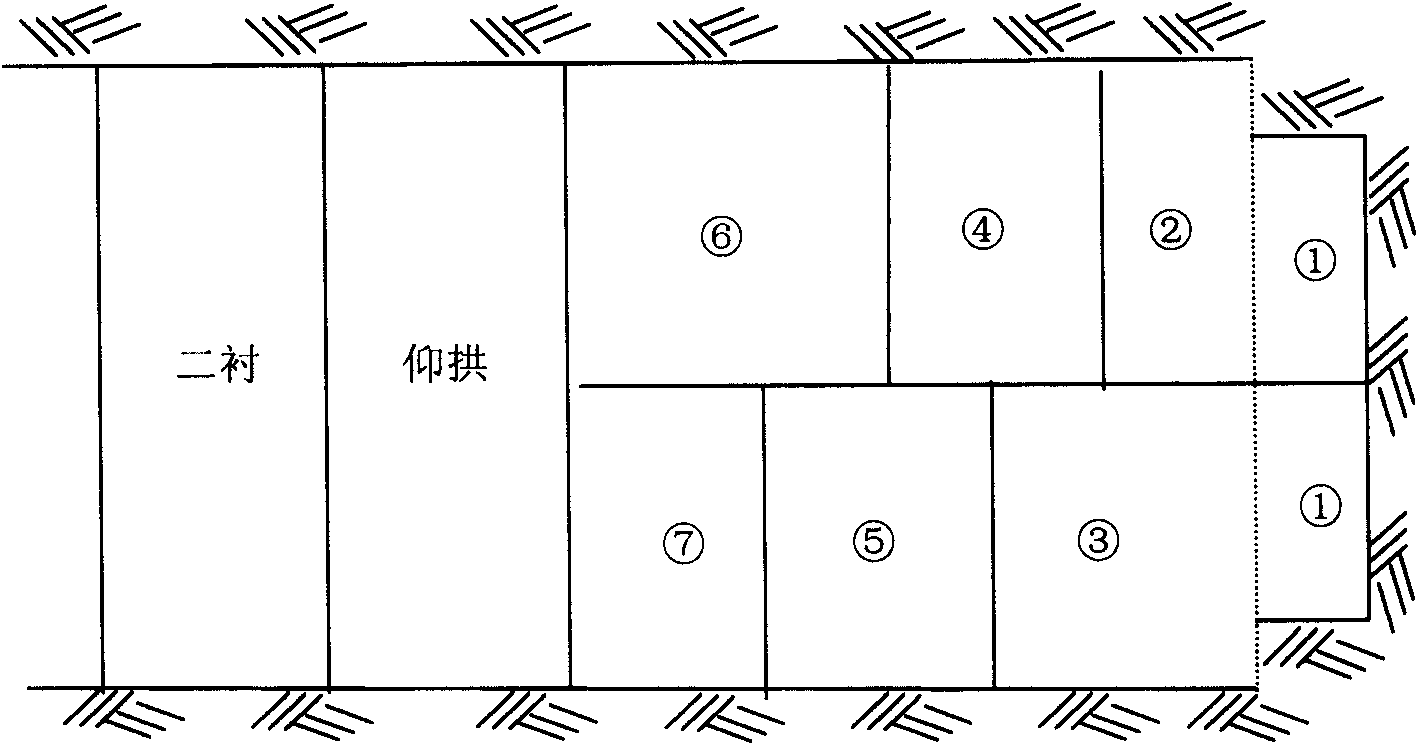

Construction process for large-section soft rock large-deformation tunnel

ActiveCN106761769AReduce stressImprove bearing capacityUnderground chambersTunnel liningShotcreteSteel frame

The invention relates to the field of tunnel engineering, in particular to a construction process for a large-section soft rock large-deformation tunnel. The adopted construction process comprises the steps that (1) an upper step is constructed; (2) a middle step is constructed; (3) a lower step is constructed; (4) reserve core soil is excavated; (5) an inverted arch is excavated, specifically, every time cycle excavation is conducted for 3 m, primary spraying is conducted immediately after the inverted arch part is excavated; (6) an inner layer steel frame is erected in time, HW200*200 profile steel is adopted, after closing ring formation, an inner layer is made, and concrete is sprayed to the designed thickness; (7) a concrete inner surface is sprayed on the inner layer, and a waterproof board is laid; (8) after tunnel deformation reaches designed reserved deformation, secondary lining is made; and (9) under supporting of advanced grouting small duct, the next cycle of construction is conducted till the tunnel is made through. The construction process meets the requirement of soft rock large deformation, limit intrusion is avoided, meanwhile, stress of a support structure can be reduced, and safety of the support structure is ensured.

Owner:CHANGAN UNIV

Sprayed concrete with microorganism crack self-repairing capacity and preparation method of sprayed concrete

InactiveCN108017337AStrong adaptability to high alkaline environmentIncreased durabilityPorosityShotcrete

The invention discloses sprayed concrete with microorganism crack self-repairing capacity and a preparation method of the sprayed concrete. The sprayed concrete is prepared from components as follows:self-repairing particles carrying a microorganism repair agent and nutrients, cement, pebbles, sand, silica fume, water, polypropylene fibers, a sodium aluminate liquid accelerator and a polycarboxylate superplasticizer. The microorganism with mineralization and sedimentation characteristics is taken as the crack repair agent of the sprayed concrete, and expanded perlite or flyash pottery sand with high porosity is taken as a carrier of the repair agent; the carrier is coated with the nutrients and is isolated from a cement-based material by an isolating layer. The concrete cracks are repaired by calcium carbonate precipitate produced by the microorganism repair agent in a metabolism process, and the crack self-repairing capacity of the sprayed concrete in the service is improved, so thatimpervious performance and durability of the sprayed concrete are improved. The sprayed concrete with crack self-repairing capacity as a sprayed concrete material with crack self-diagnosis and self-repairing functions has great research value and application potential.

Owner:李珠

Preliminary bracing construction method for tunnel with surrounding rocks containing collapsible loess and soft rocks

InactiveCN103410527AEasy to operateEconomically reasonableUnderground chambersTunnel liningShotcreteMesh reinforcement

The invention discloses a preliminary bracing construction method for a tunnel with surrounding rocks containing collapsible loess and soft rocks. The method includes the following steps that a plurality of layers of advanced pipe sheds are arranged on a collapsible loess layer, and a single layer of advanced pipe shed is arranged on a soft rock layer; after the advanced pipe shed is set up, a working face is closed through sprayed concrete, a system anchor bolt is arranged on the soft rock layer, a foot locking small guide pipe is arranged at the arch springing position of the tunnel, and grouting is conducted on the rocks through permeation of the system anchor bolt and the foot locking small guide pipe; a pre-fabricated reinforcing mesh is paved on a concrete initial spraying layer formed by concrete initial spraying in a fluctuation mode, and a reinforcing mesh arranged at the collapsible loess layer is encrypted; a steel arch support is set on the collapsible loess layer, a reinforcing steel bar grid is set up at the soft rock layer, and the connecting position of the reinforcing steel bar grid and the steel arch support is welded; repeated spraying is conducted by adopting concrete spraying, and construction of tunnel preliminary bracing is finished. By means of the method, stress releasing and deformation coordination of two layers of surrounding rocks can be well controlled, operability is good, construction cost is low, and the safety is good.

Owner:CENT SOUTH UNIV

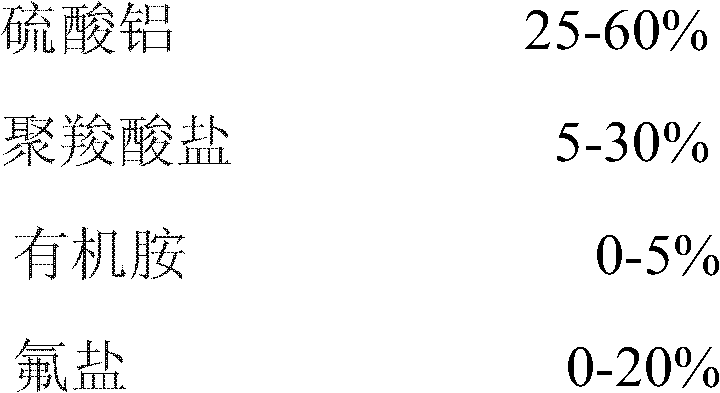

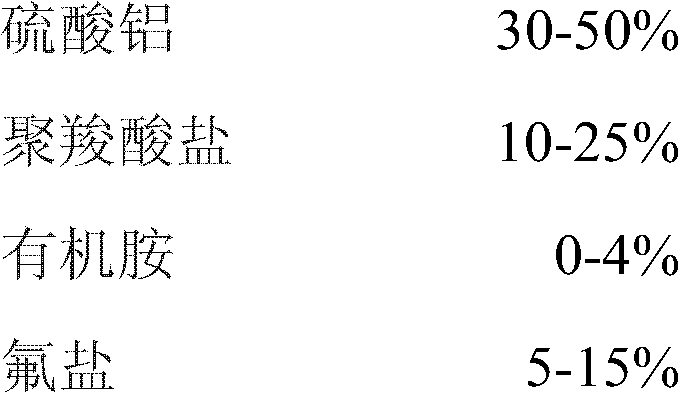

Alkali and chlorine free liquid setting accelerator

The invention relates to an environment-friendly alkali and chlorine free liquid setting accelerator used for sprayed concrete. The setting accelerator is composed of the following components by weight: 25-60% of aluminum sulfate, 5-30% of a polycarboxylic acid salt, 0-5% of organic amine, 0-20% of a fluoride salt, and the balance water. The dosage of the setting accelerator doped into sprayed concrete accounts for 3-7 wt% of cement. The initial setting time is less than 4 minutes, and the final setting time is not more than 9 minutes. The invention also relates to a preparation method of the environment-friendly alkali and chlorine free liquid setting accelerator.

Owner:高永会

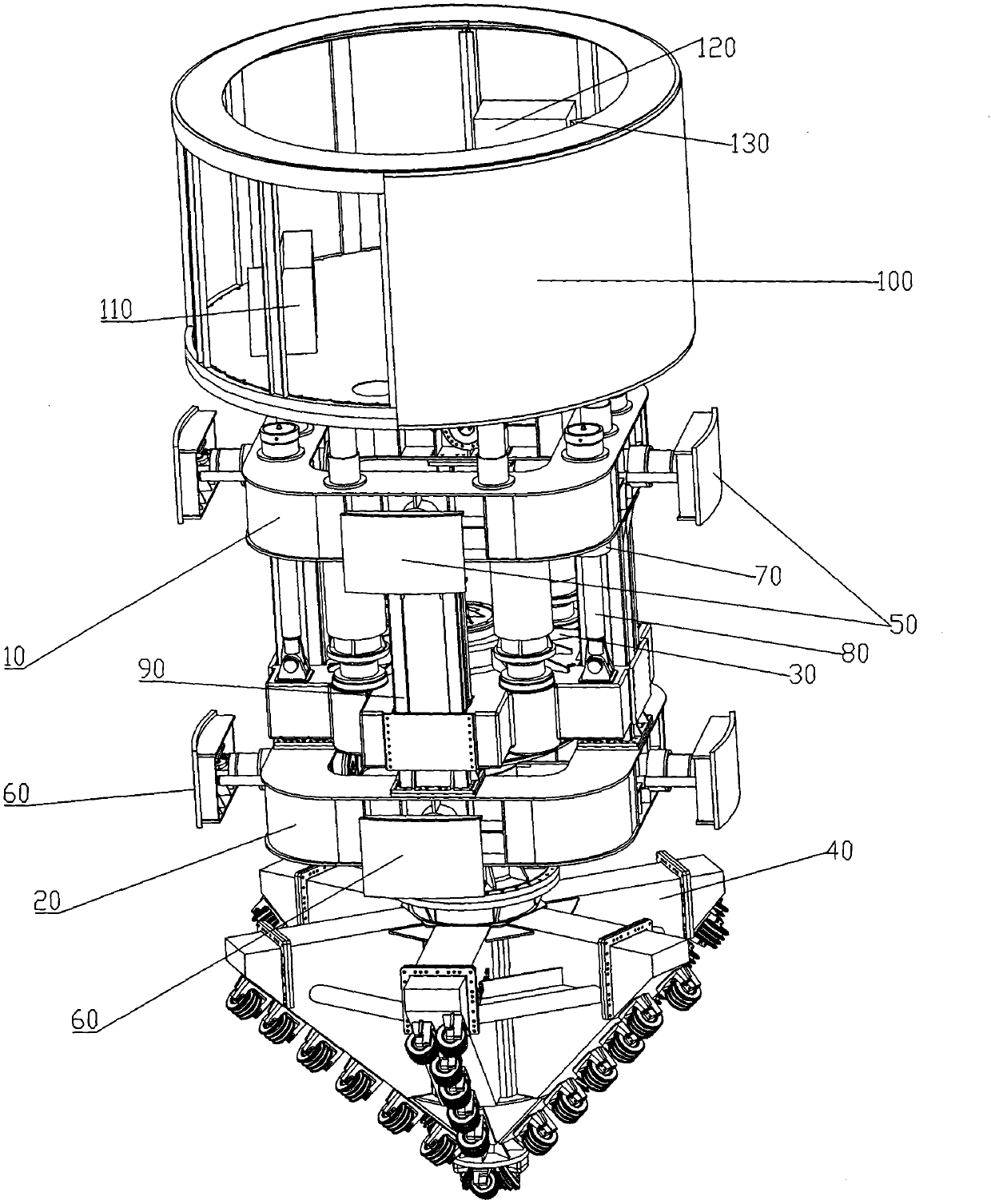

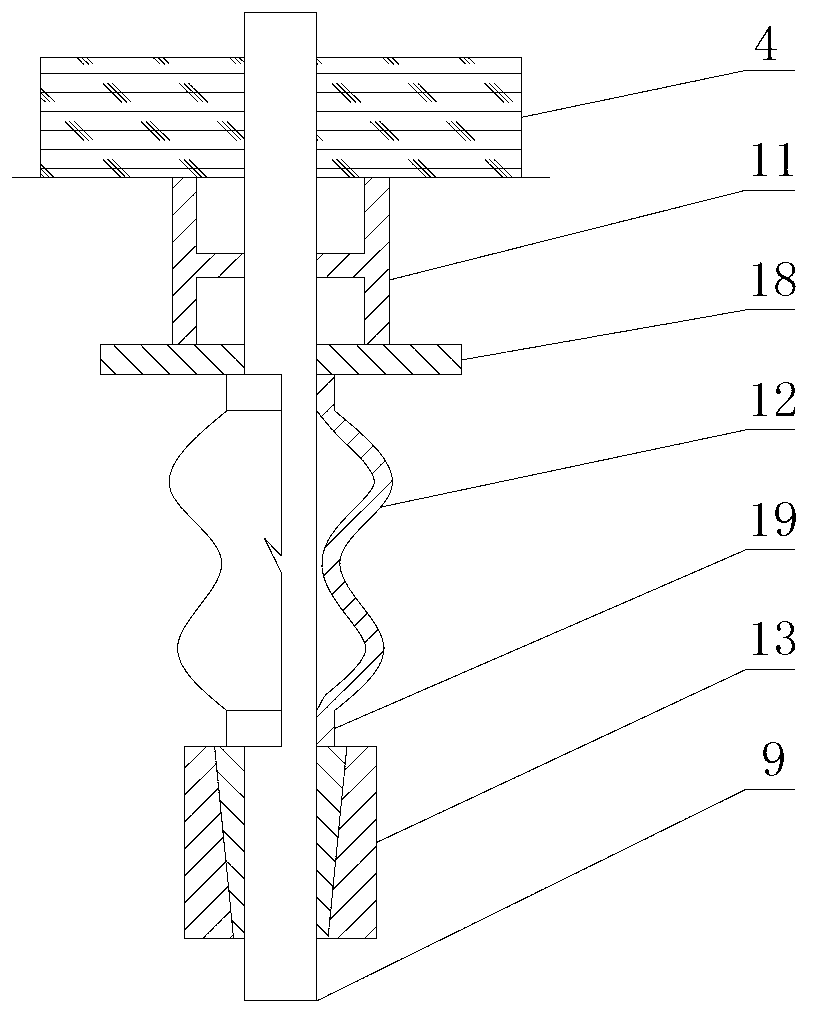

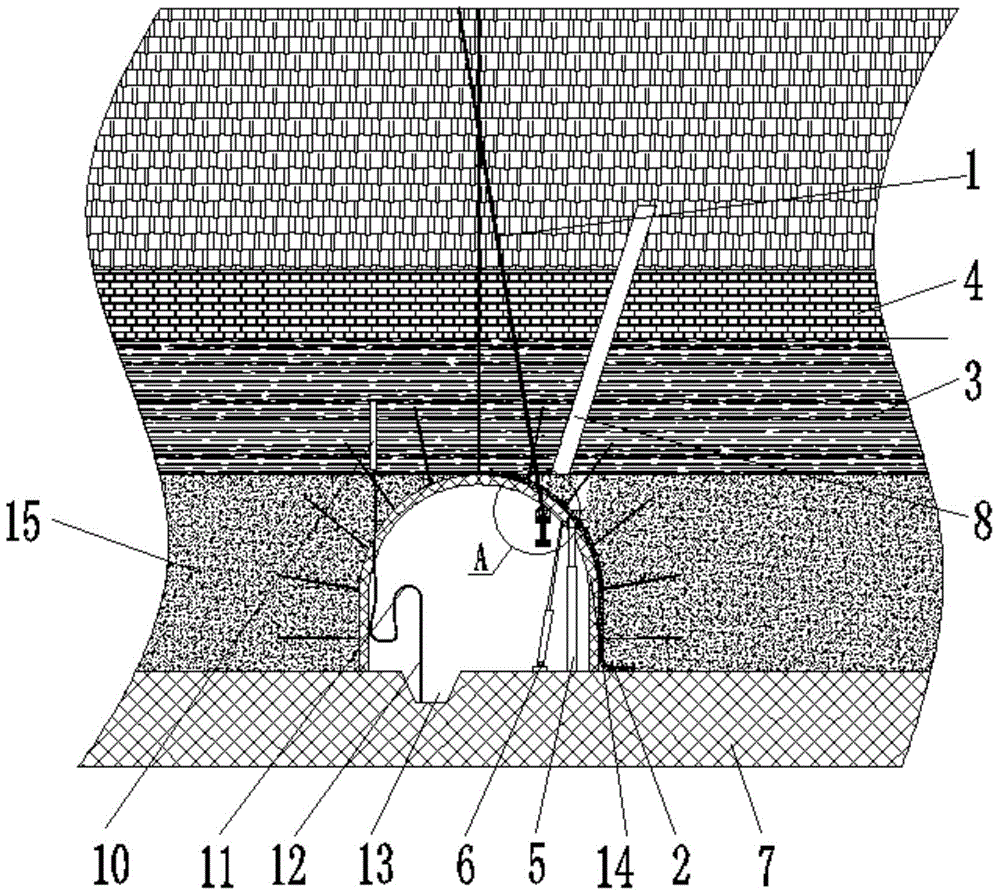

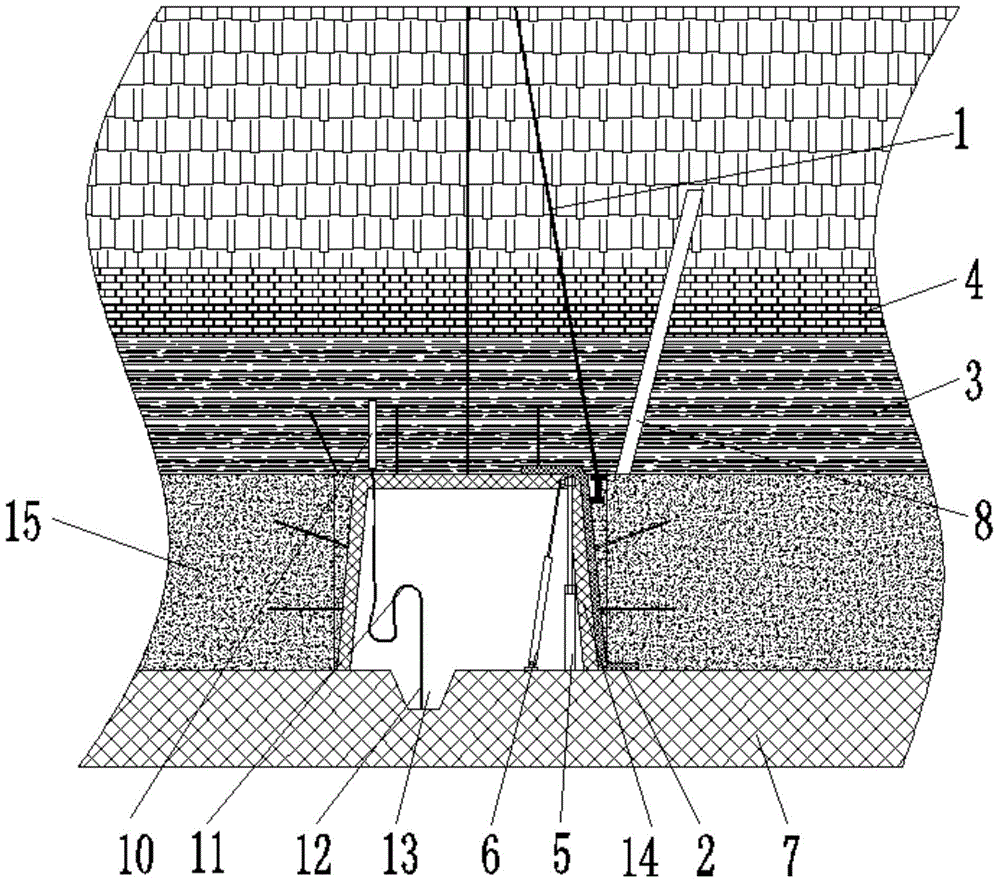

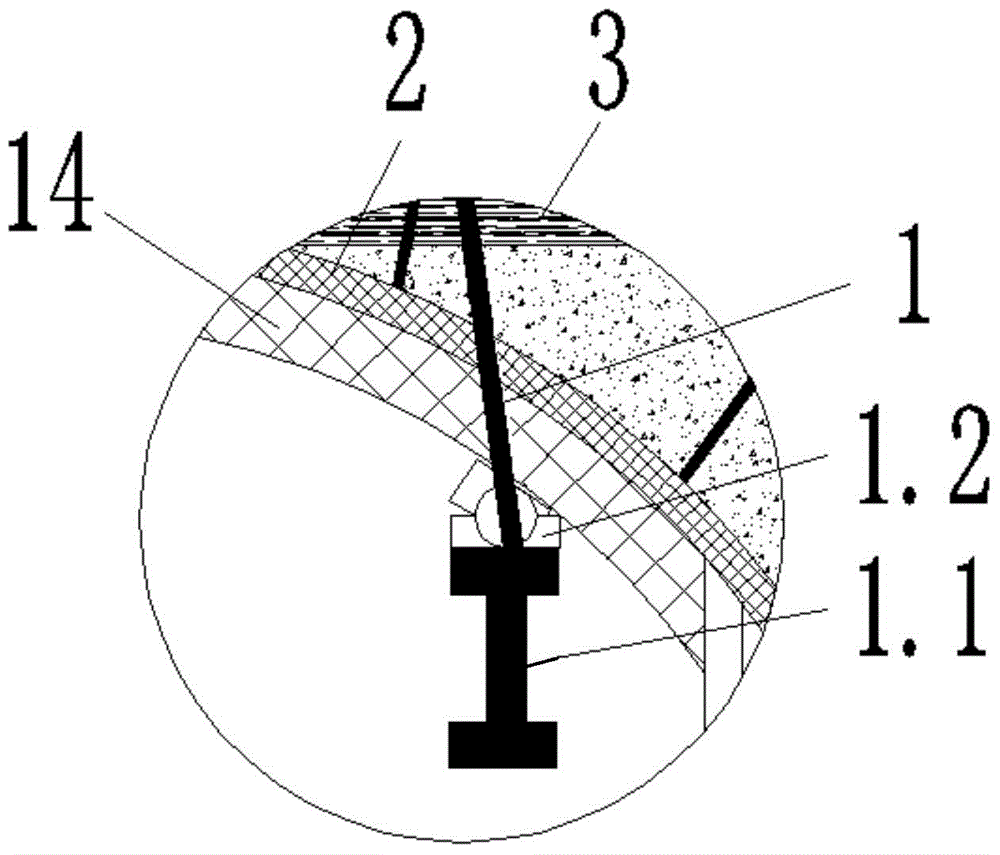

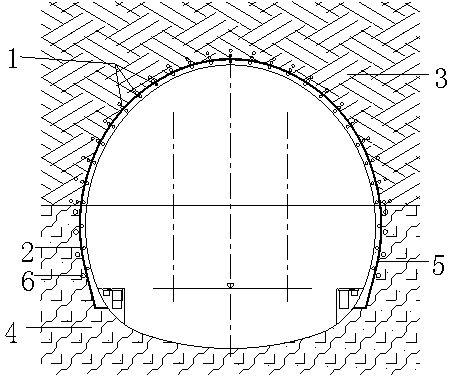

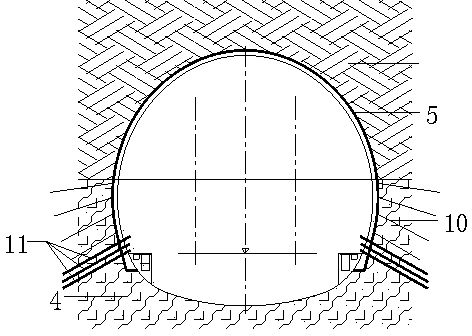

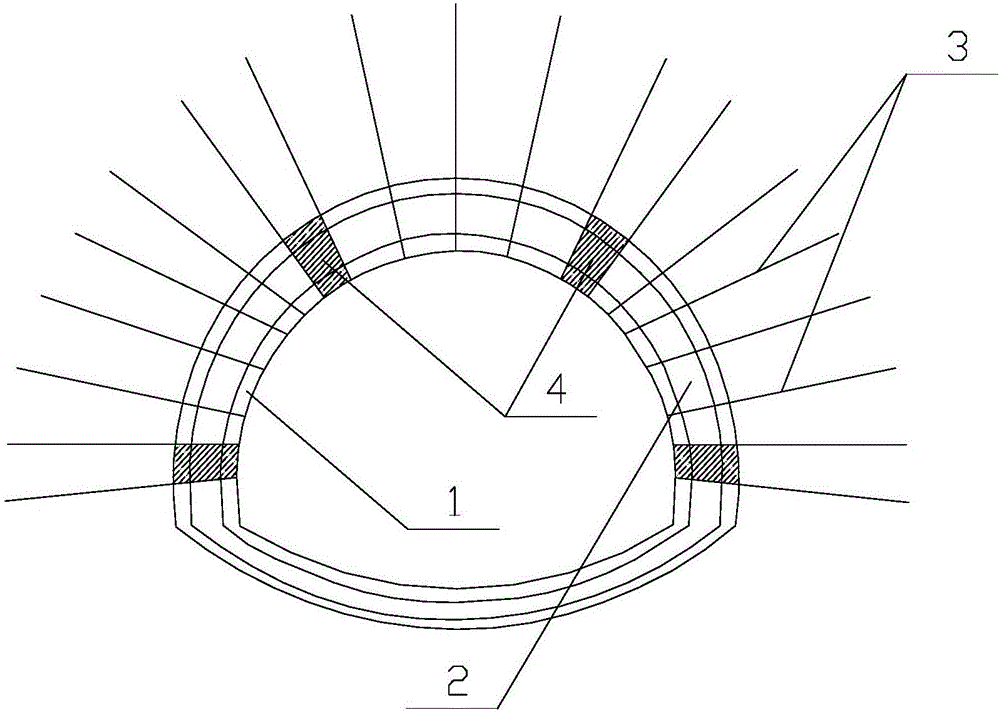

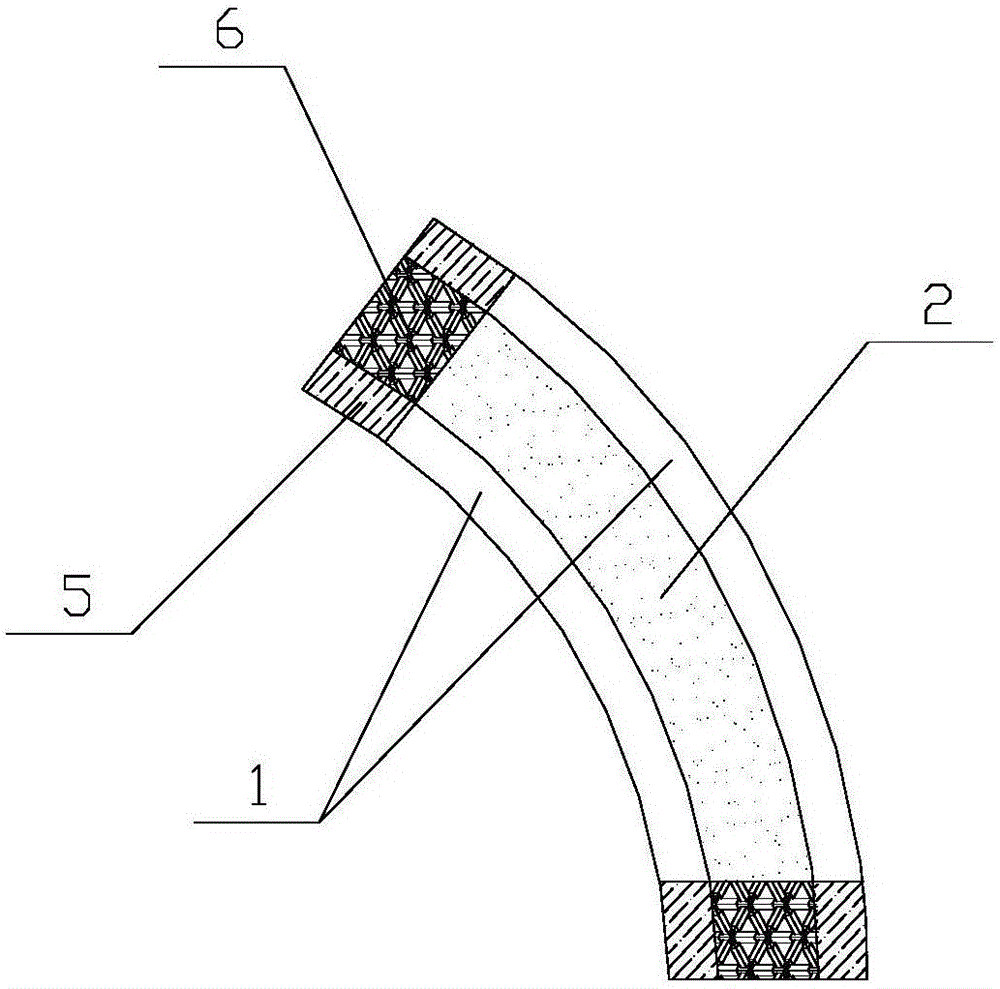

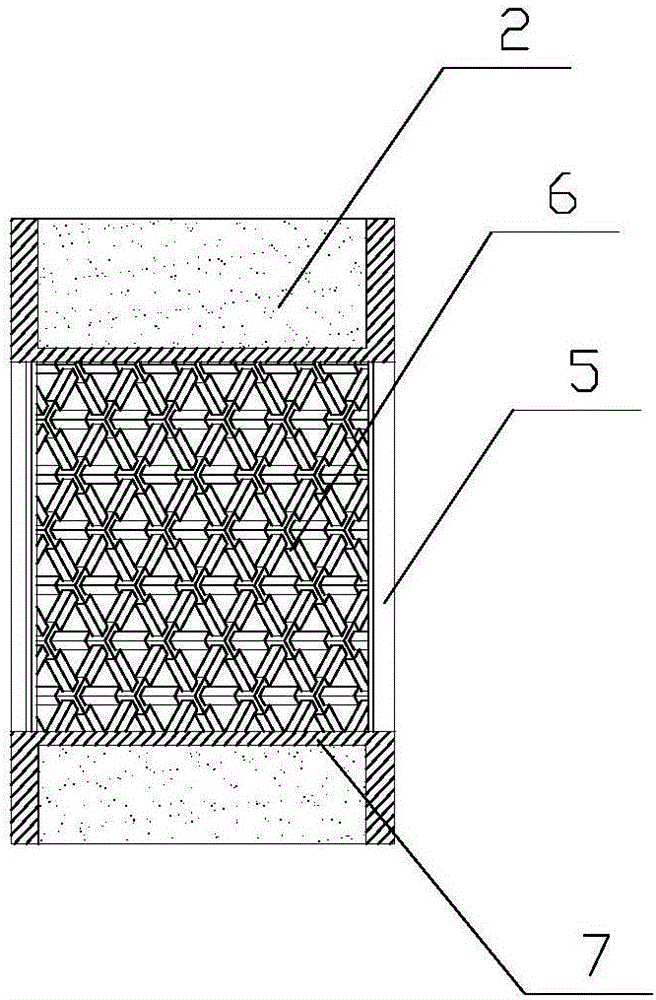

Tunnel yielding type shoring system

ActiveCN106285724AReach pressureReach uninstallUnderground chambersTunnel liningShotcreteLarge deformation

The invention discloses a tunnel yielding type shoring system and relates to the field of traffic and mining soft rock large-deformation tunnels. Stretchable units are arranged on a shoulder part and a waist part of each steel arch frame; the stretchable units are connected with the steel arch frame through flanges; each stretchable unit is composed of a stretchable component and a rectangular rubber damper; stretchable components are arranged at the two ends of each steel arch frame; a deforming slot is reserved between the stretchable components; the rectangular rubber damper is arranged in the deforming slot; a separating plate is arranged between the rectangular rubber damper and a sprayed concrete layer; a plurality of yielding anchor rods are arranged on the sprayed concrete layer at intervals. According to the invention, a combined body composed of the yielding anchor rods, the stretchable components, the steel arch frame, the rectangular rubber damper and the sprayed concrete generates uniformly harmonious deformation with the surrounding rock, so that the surrounding rock stability can be effectively maintained by a certain supporting resistance, and meanwhile, the shoring system is allowed to generate a certain displacement, and the functions of shoring, yielding and unloading can be achieved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com