Patents

Literature

739 results about "Composite slab" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

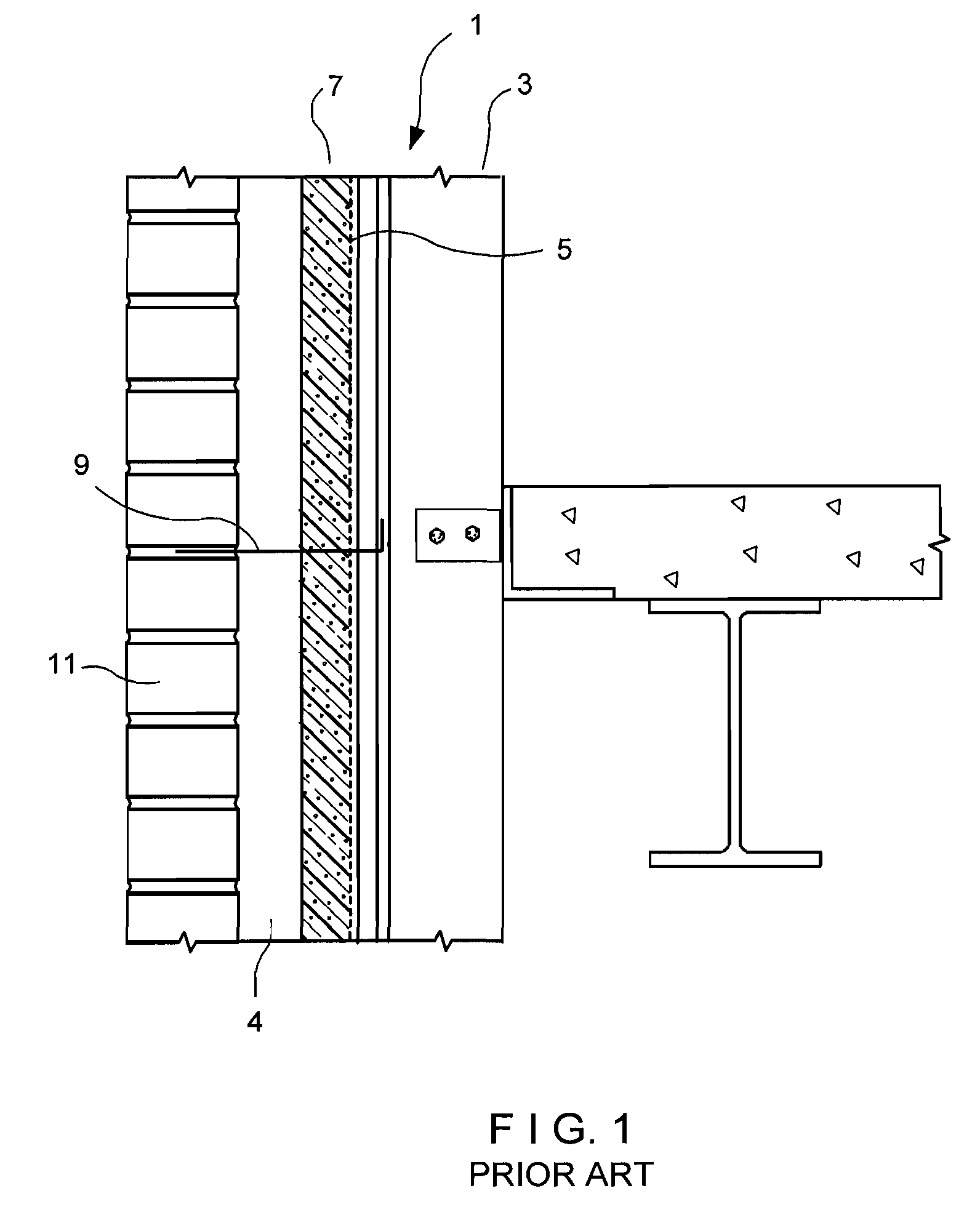

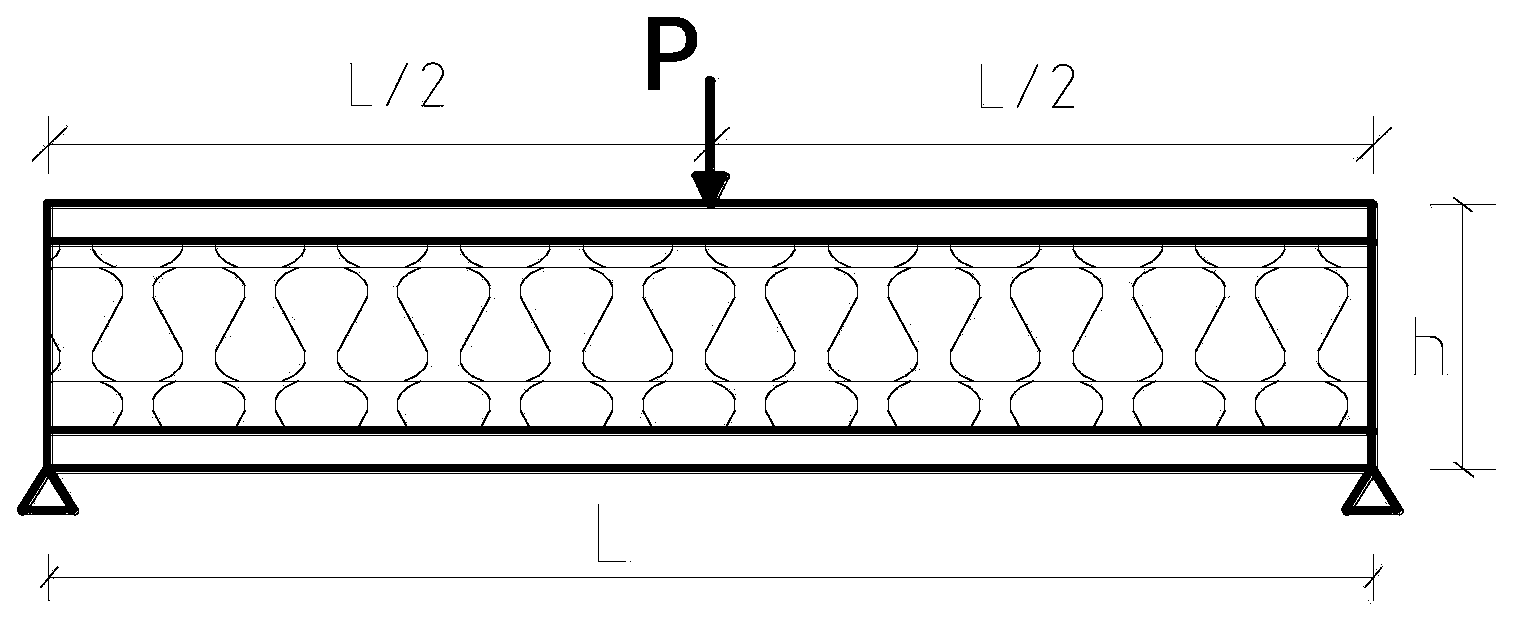

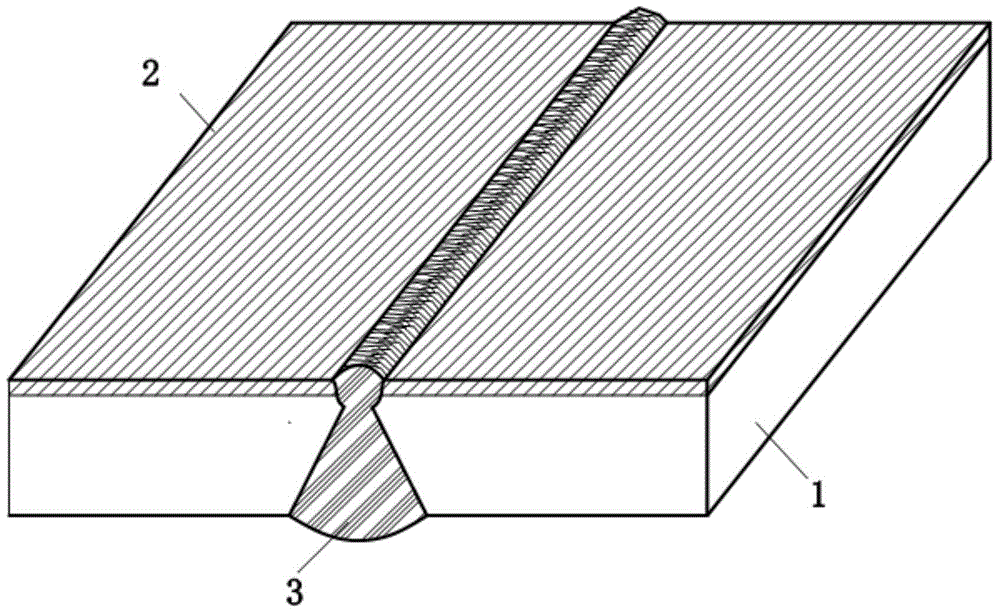

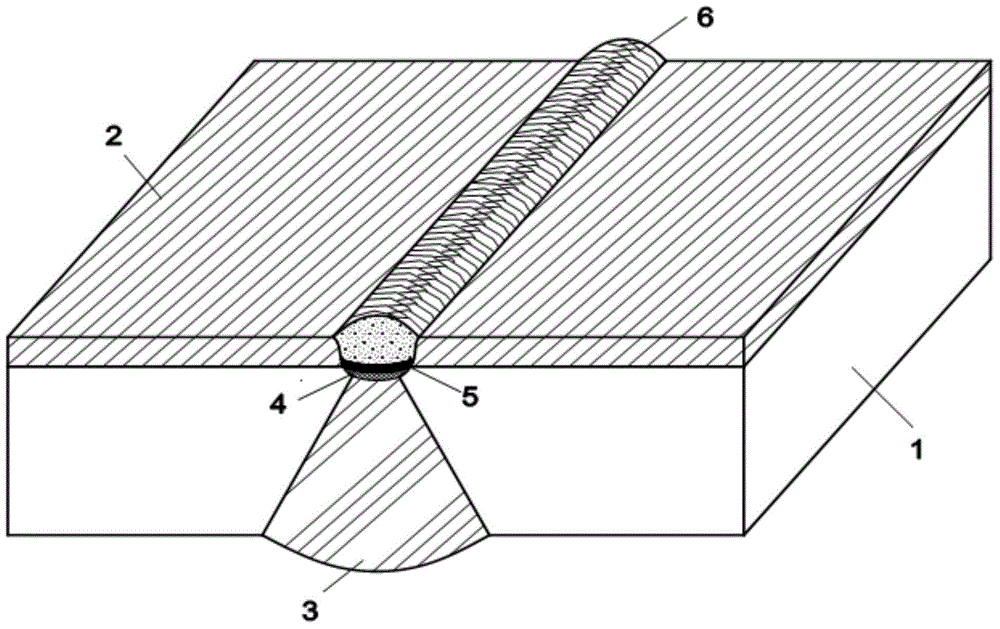

Composite slabs. Consist of profiled steel decking with an in-situ reinforced concrete topping. If the slab is unpropped during construction, the decking alone resists the selfweight of the wet concrete and construction loads. Subsequent loads are applied to the composite section.

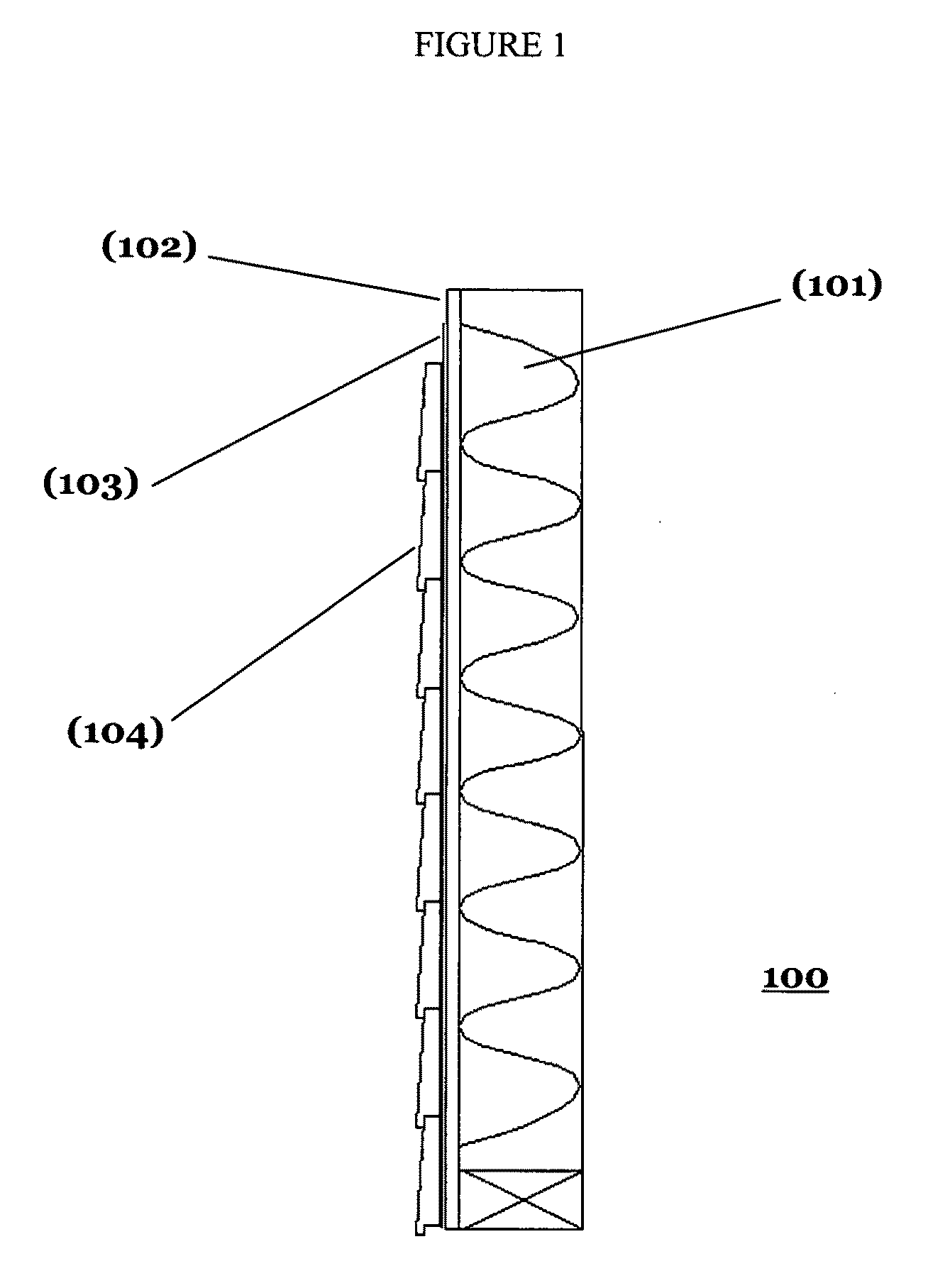

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

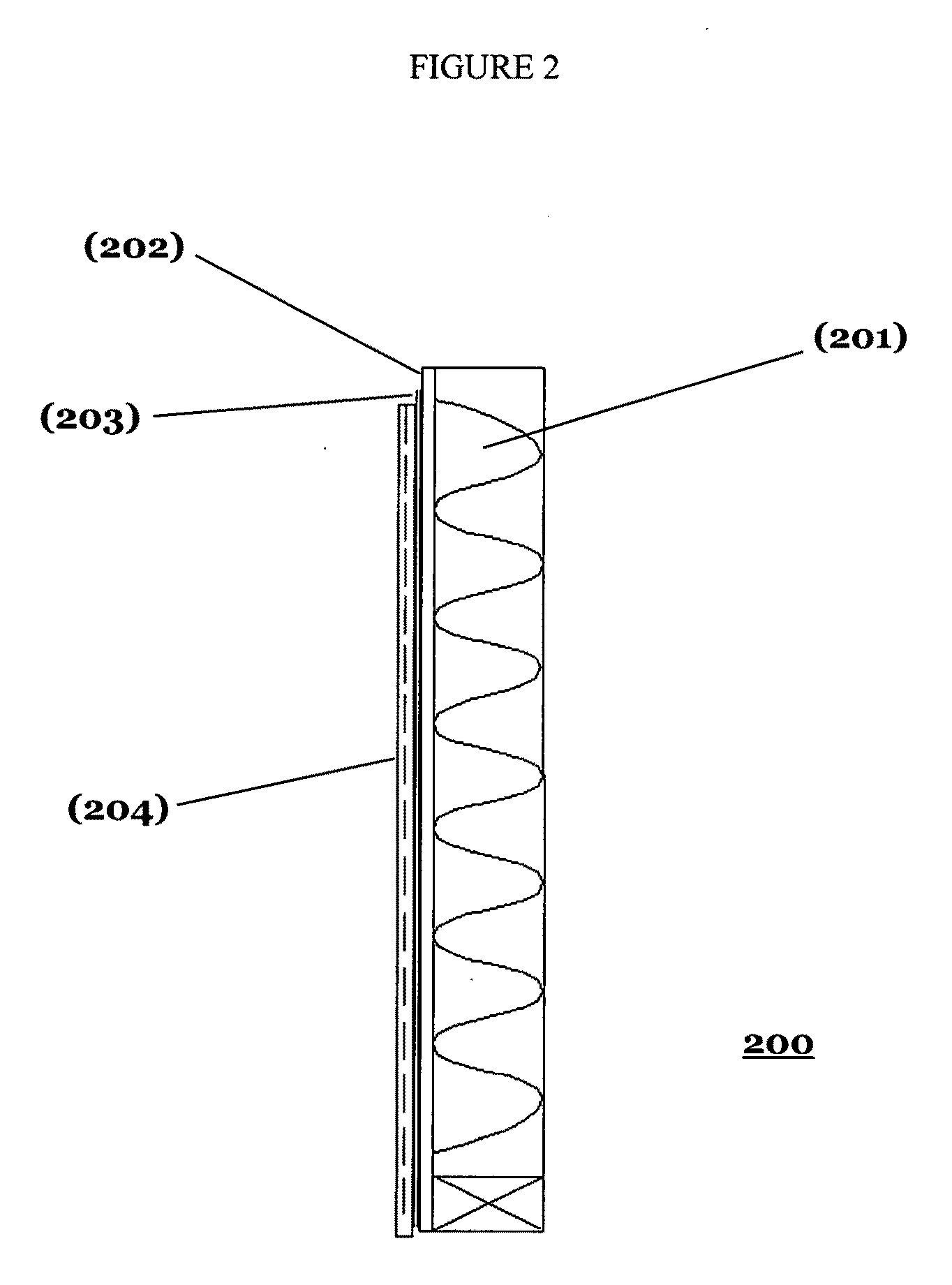

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

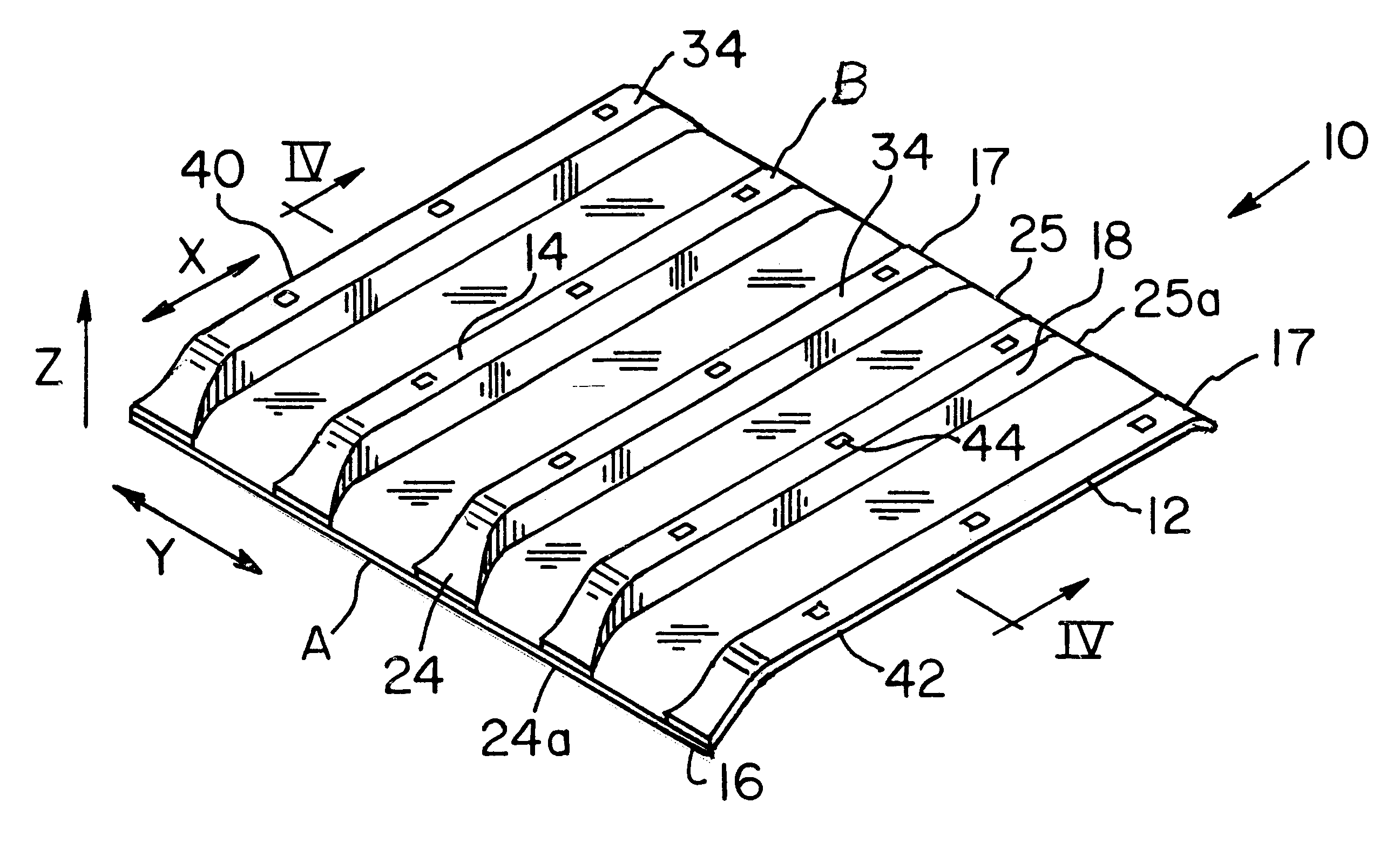

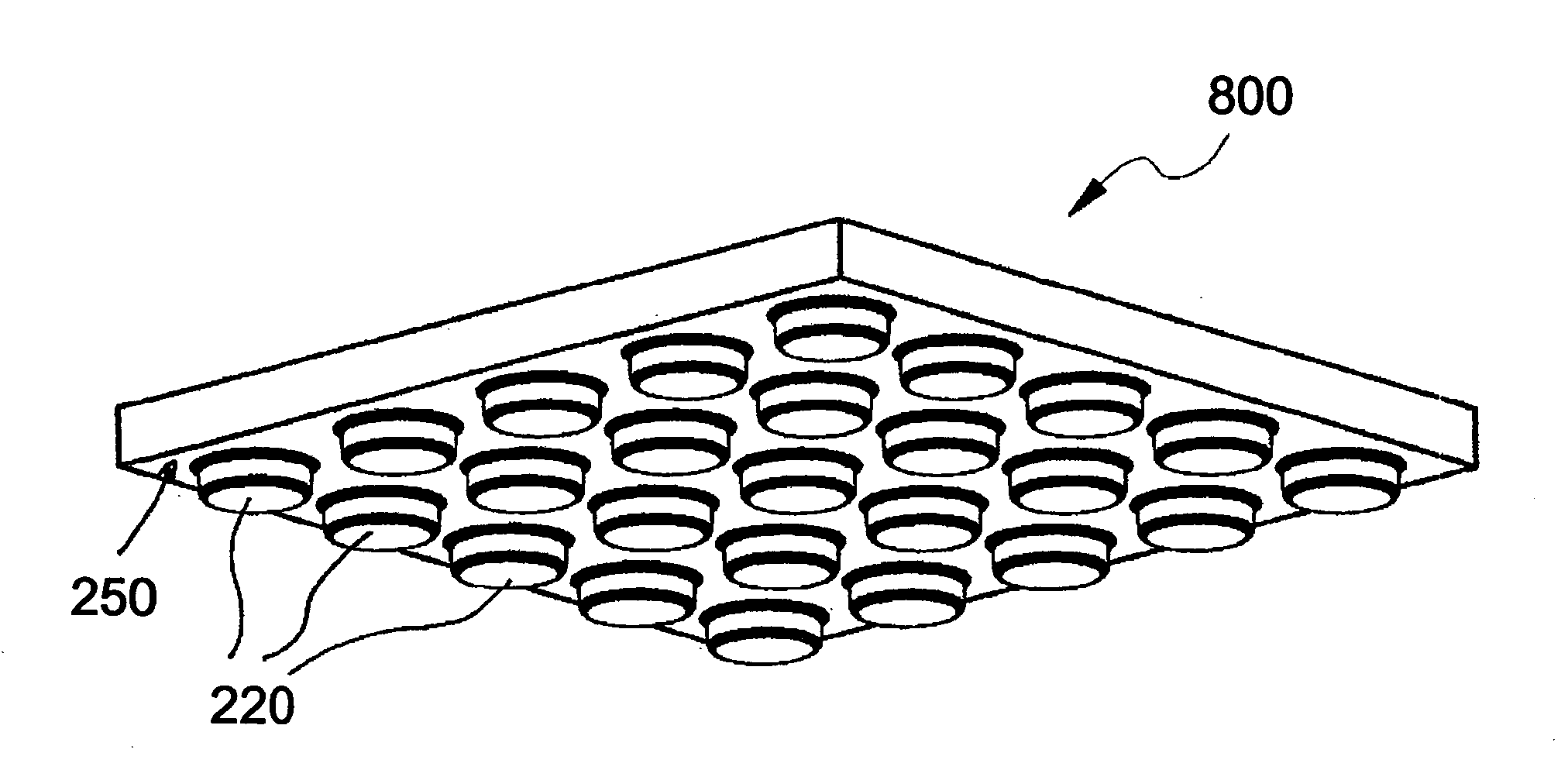

Composite deck

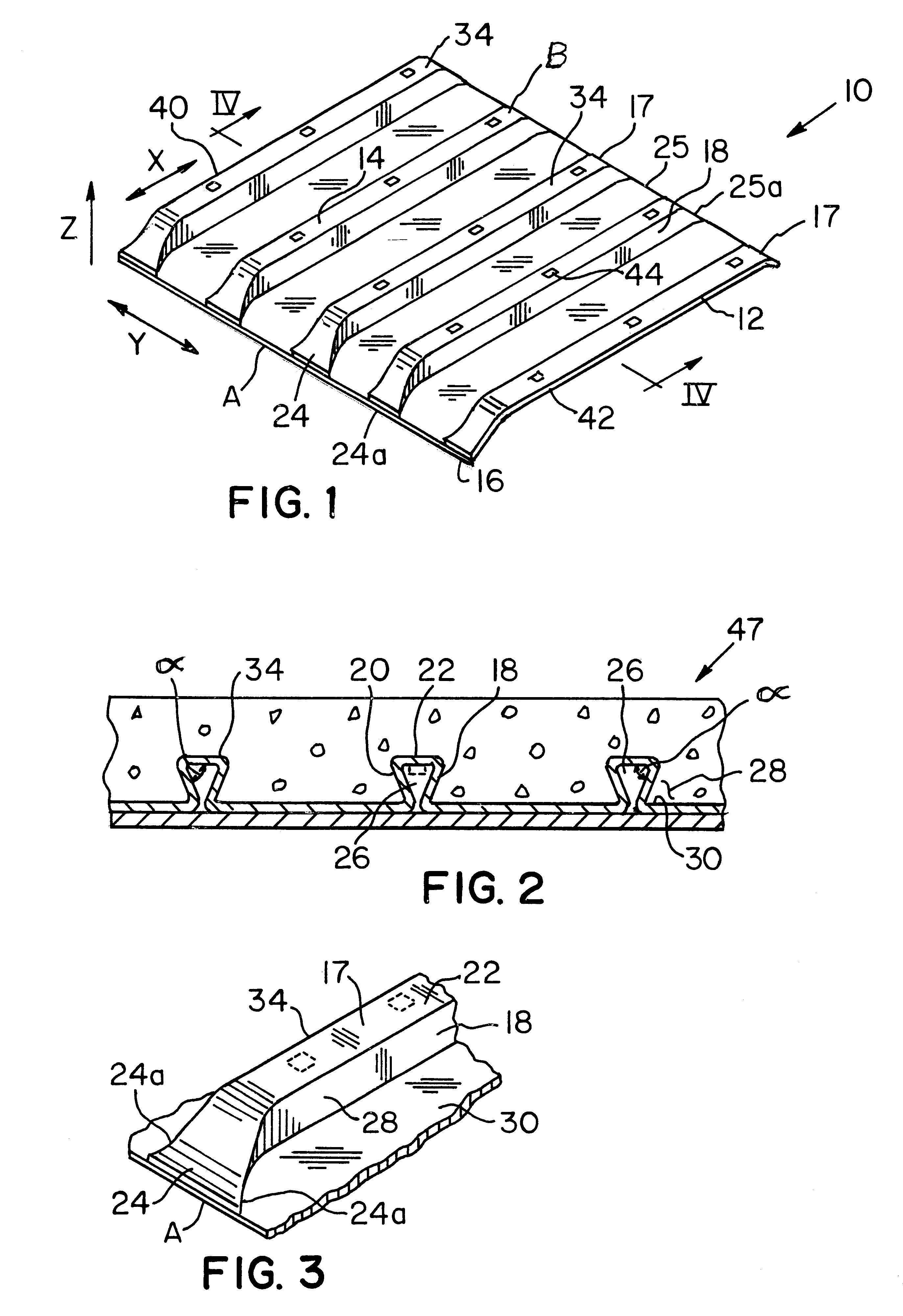

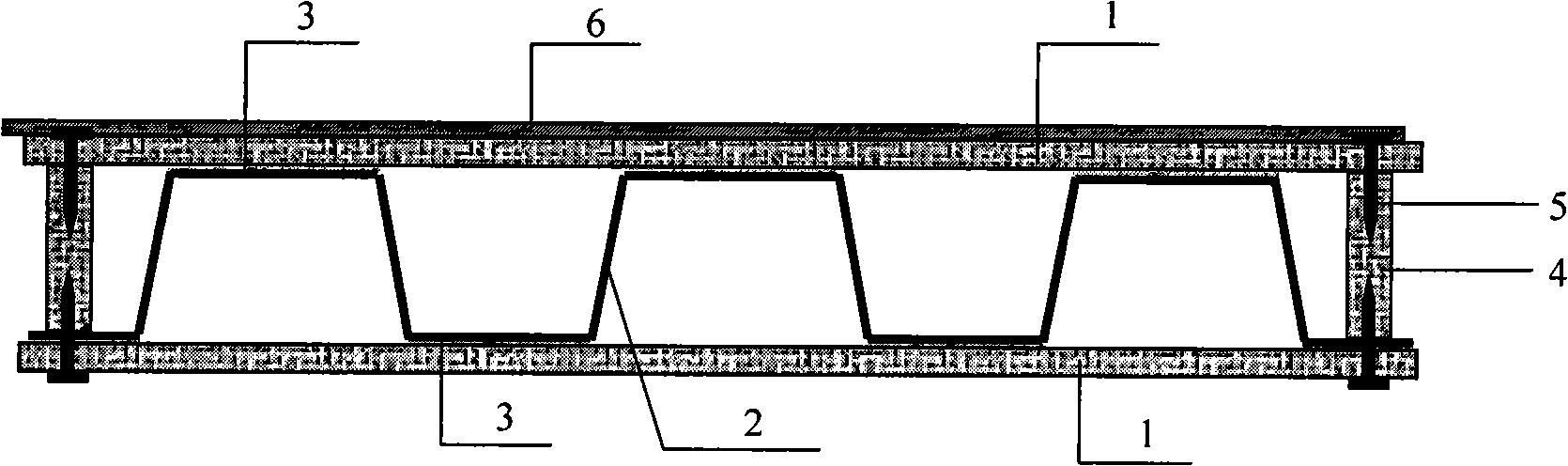

InactiveUS6357191B1Improve the quality of sound insulationImproved rodent and insect controlBuilding roofsCeilingsComposite slabMechanical engineering

A ribbed metal plate for a composite slab that includes a substantially planar plate having an upper surface and a lower surface and a plurality of laterally-spaced, longitudinally-extending ribs that have a keystone profile and wherein the sidewalls are angled toward each other. Ends of the ribs are integrally formed. The rib plate is secured to bearing walls in a structure and concrete is poured on the ribs to form a composite deck. The ends of the ribs extend in the lateral direction to form a composite structure retarding movement of cured concrete in a longitudinal direction. The ribbed plate can also be used in composite beams.

Owner:EPIC METALS

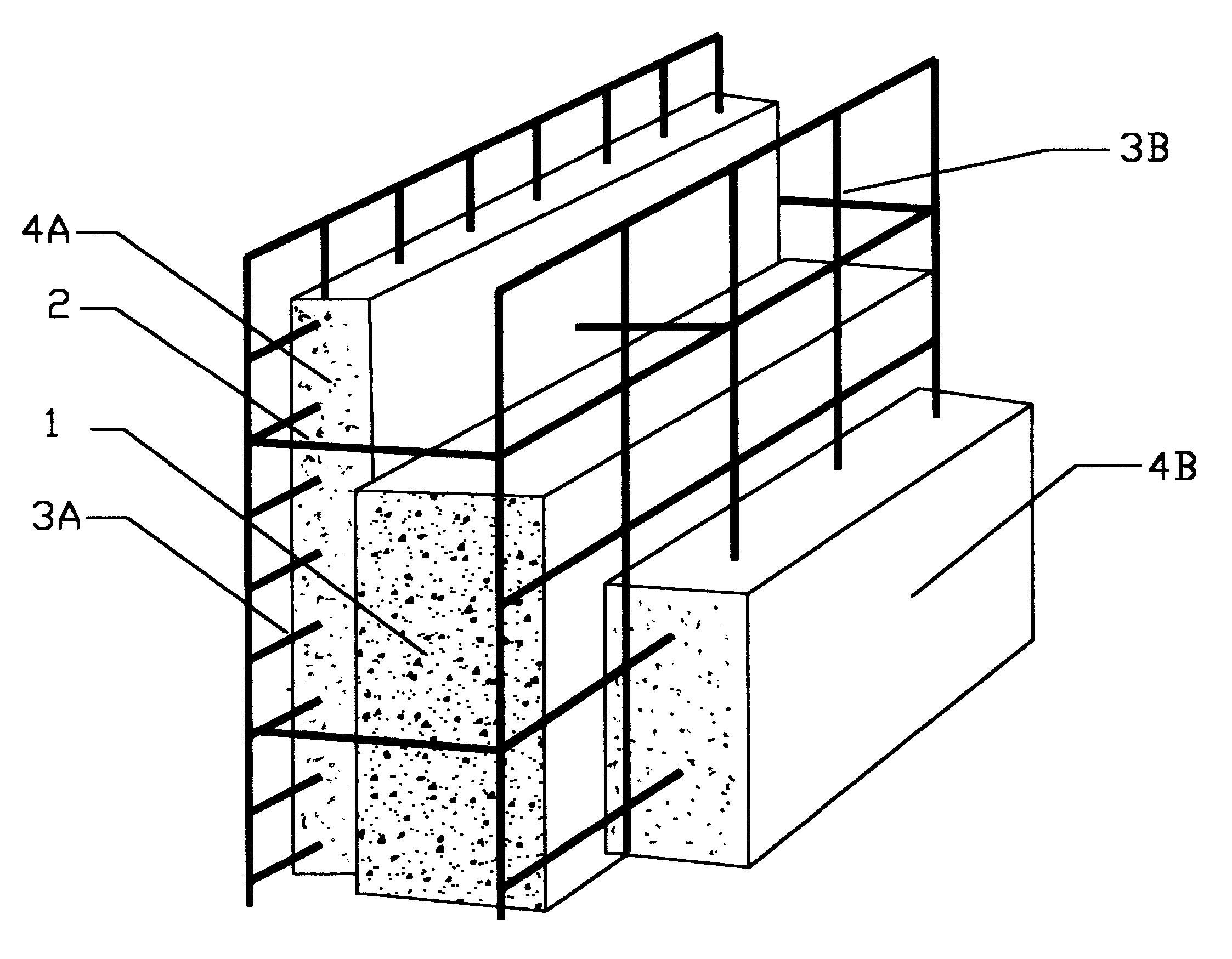

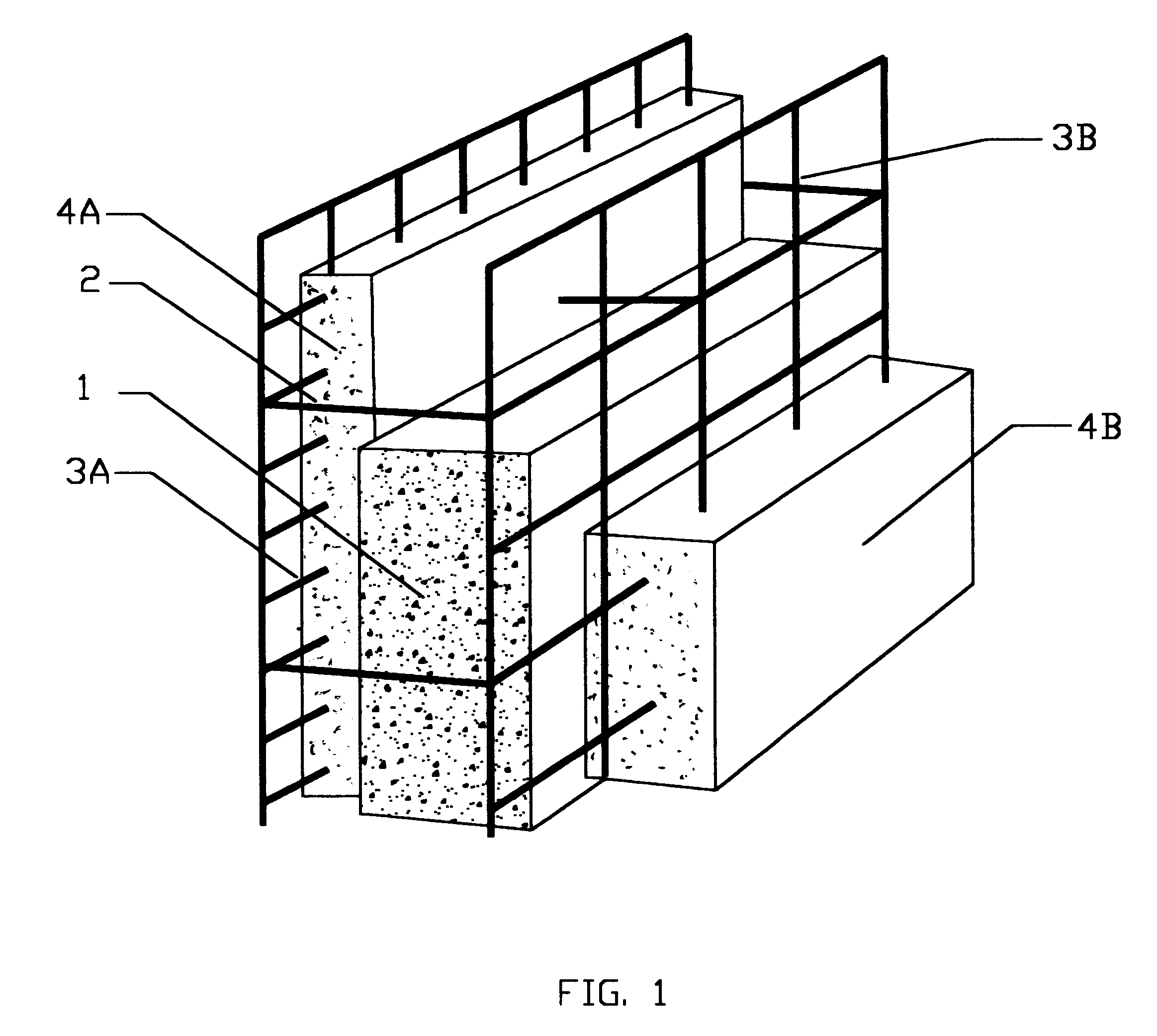

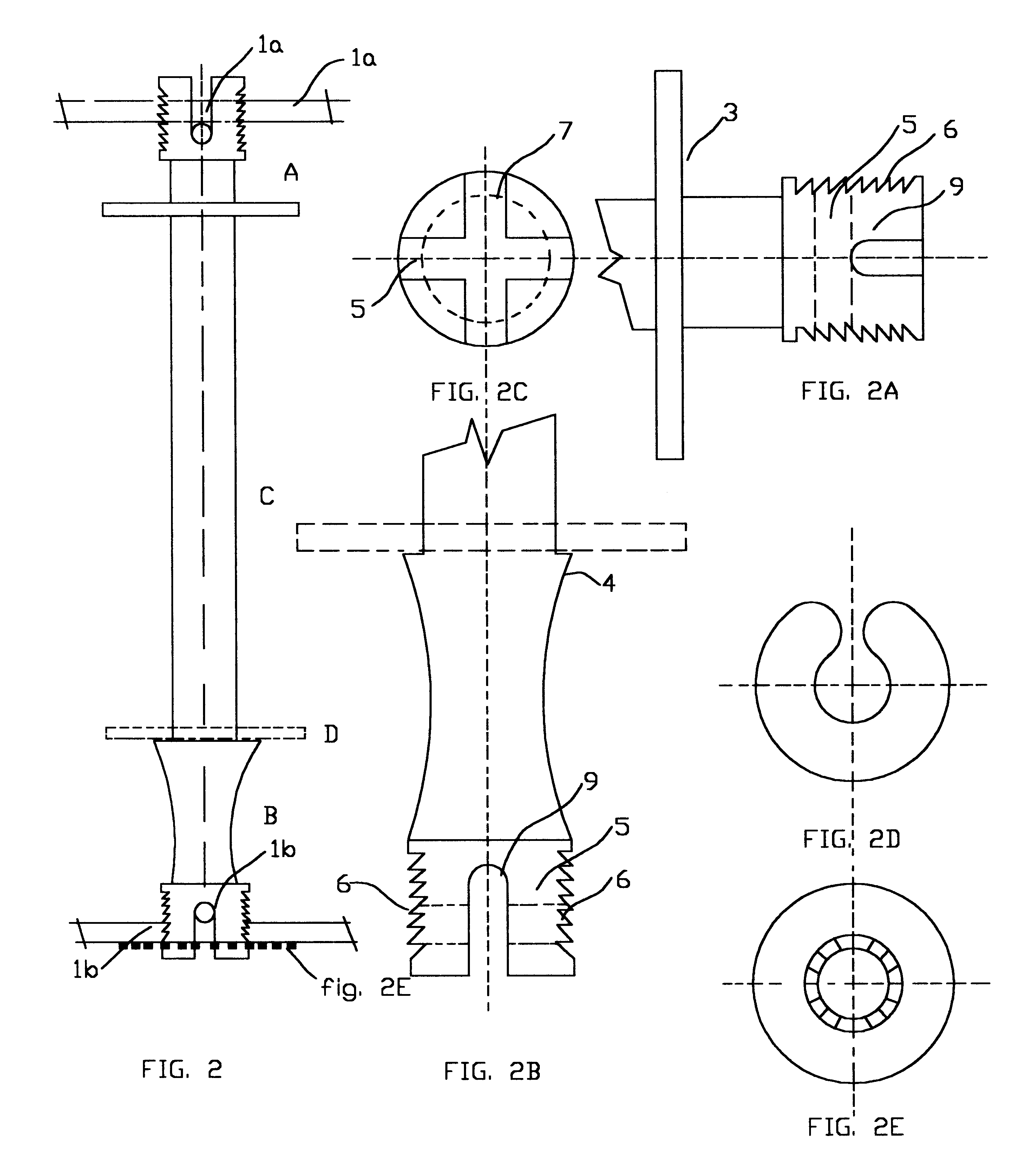

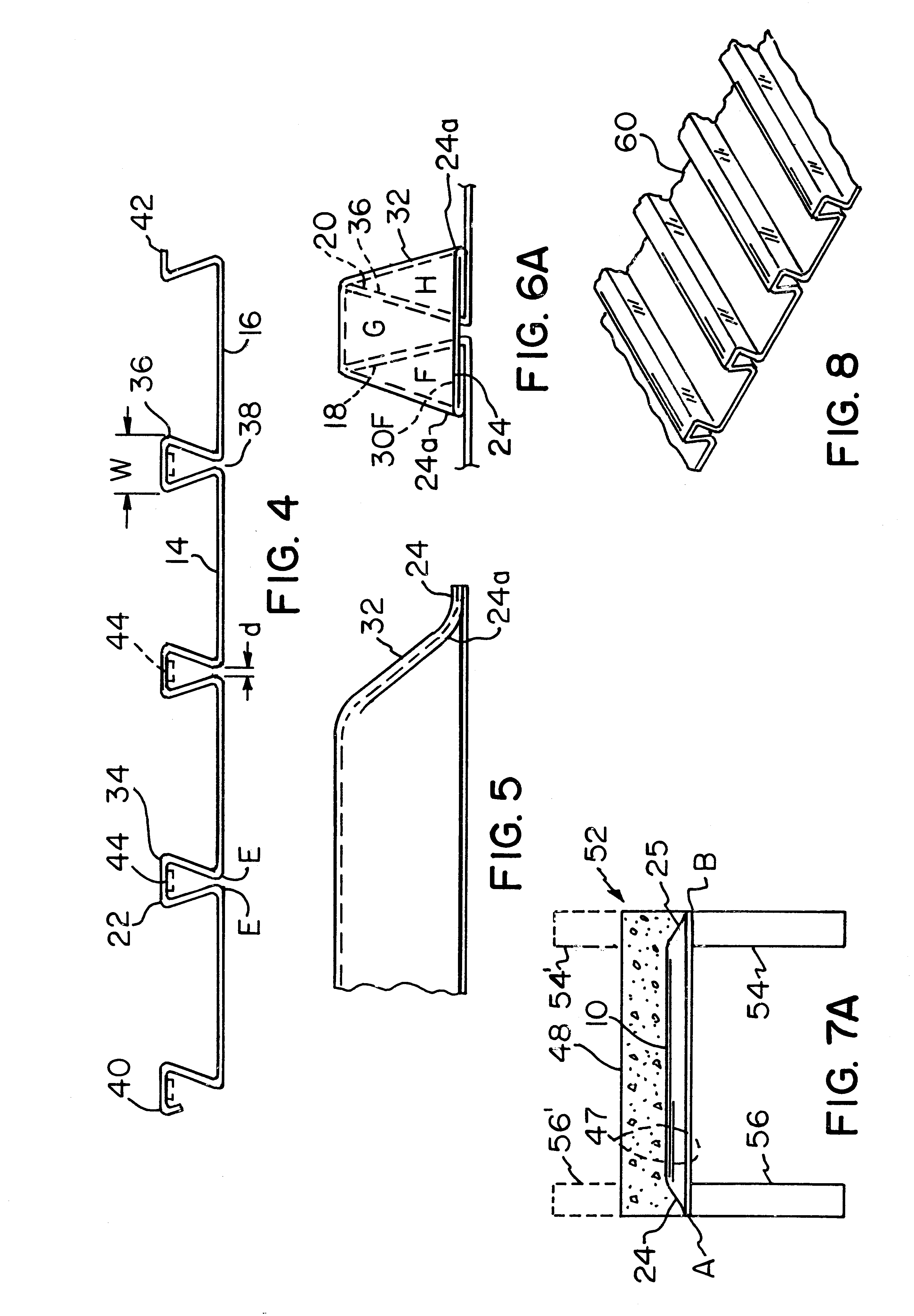

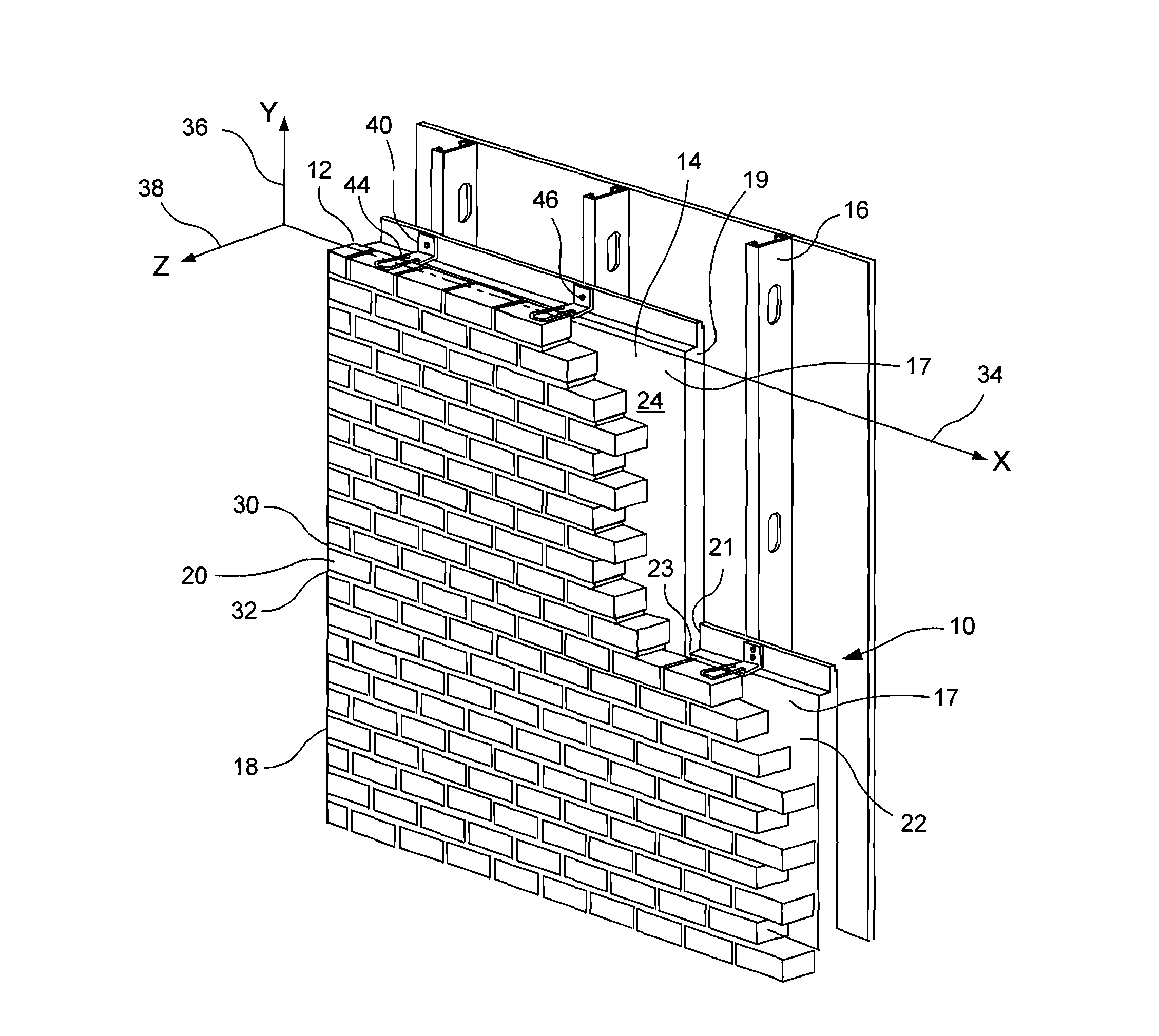

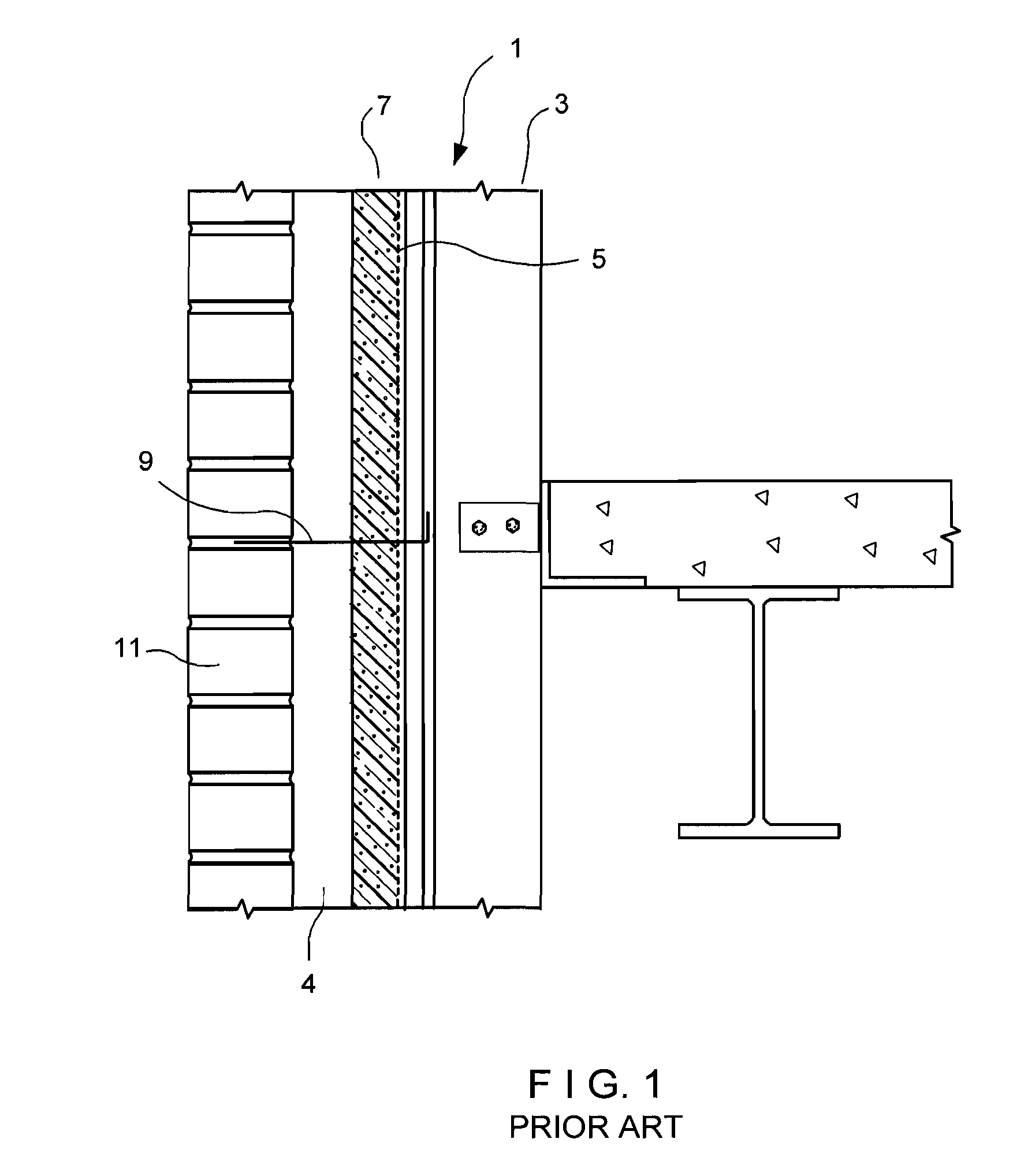

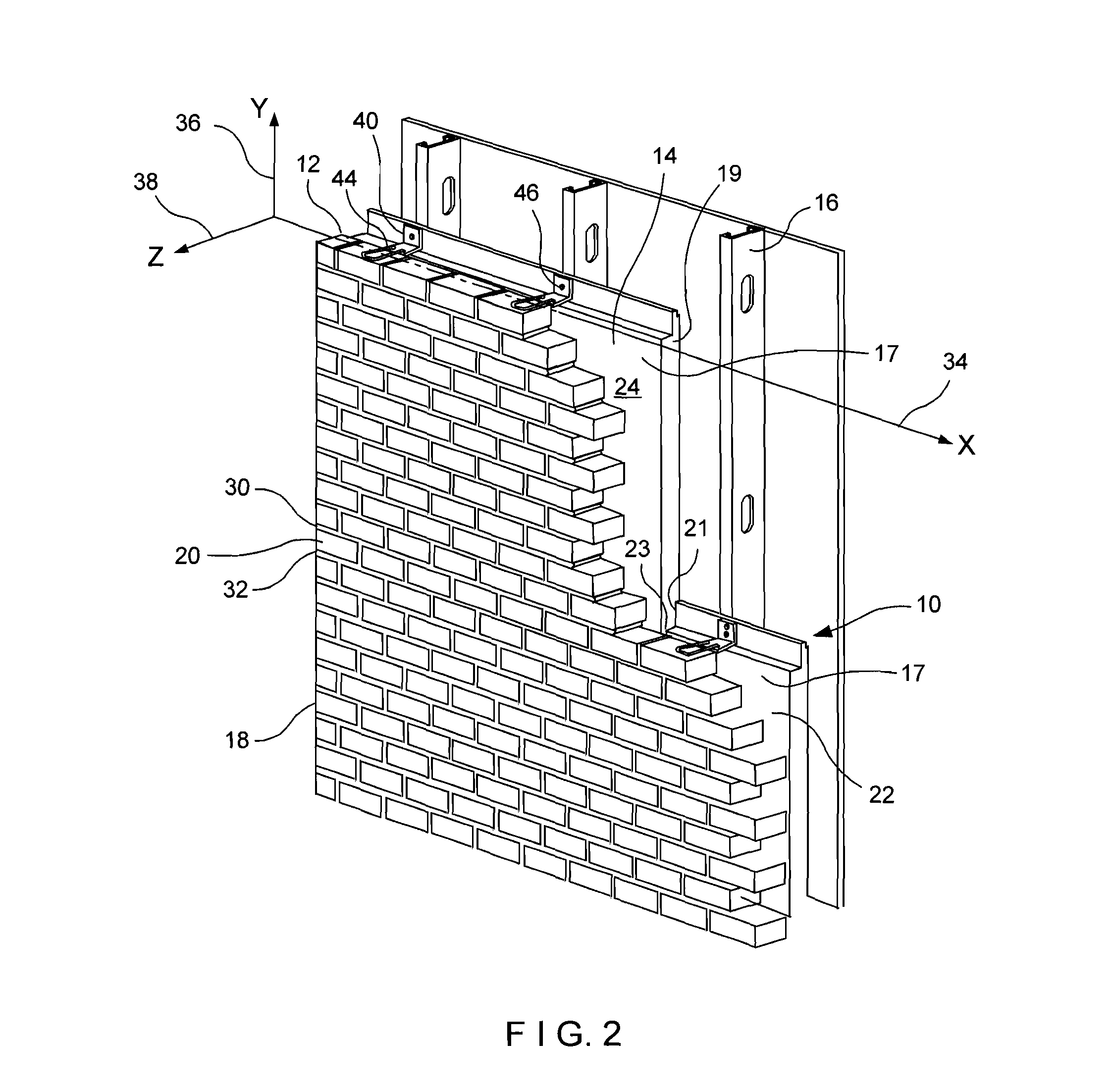

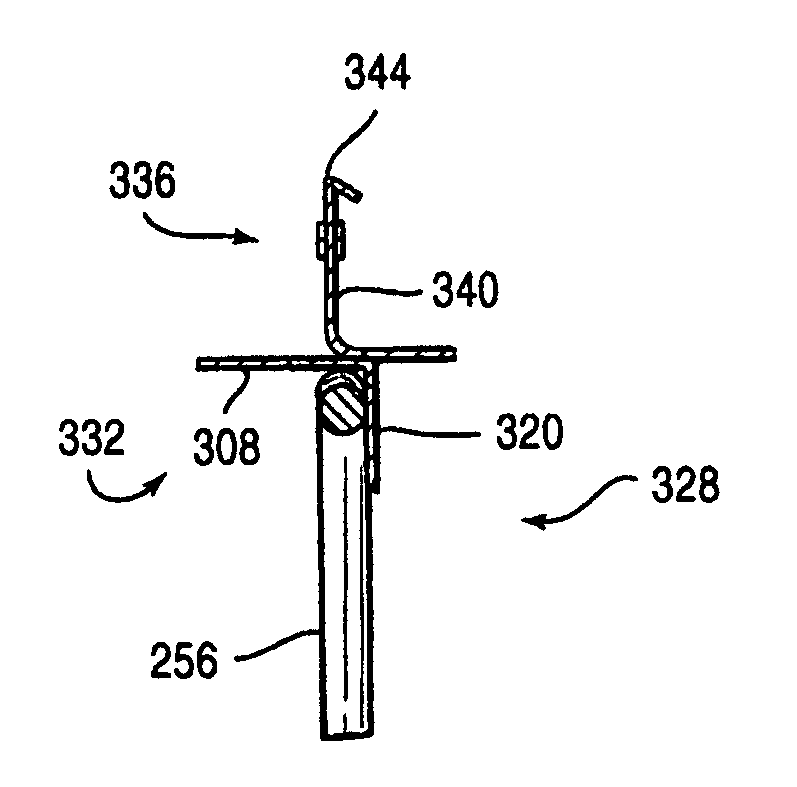

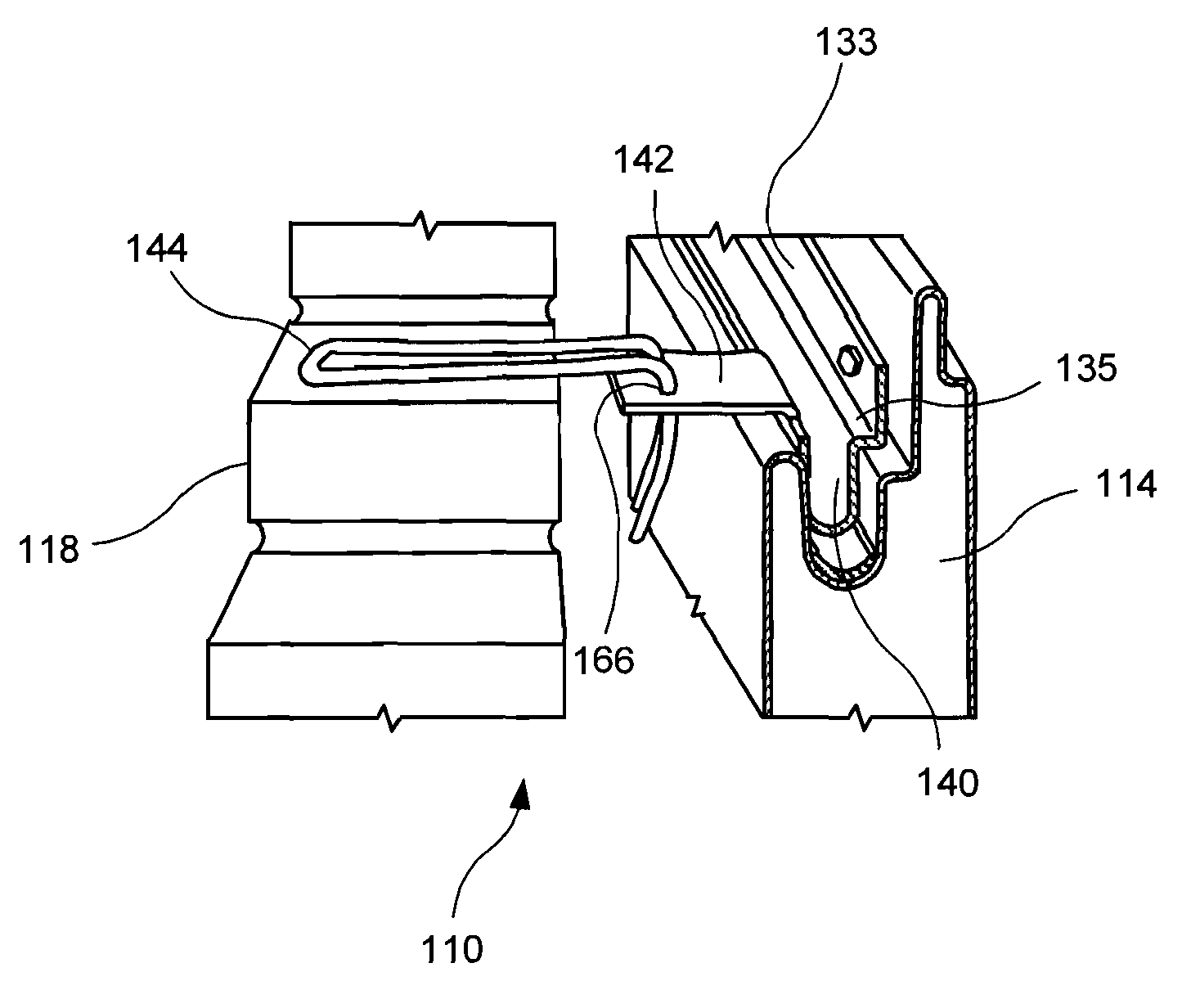

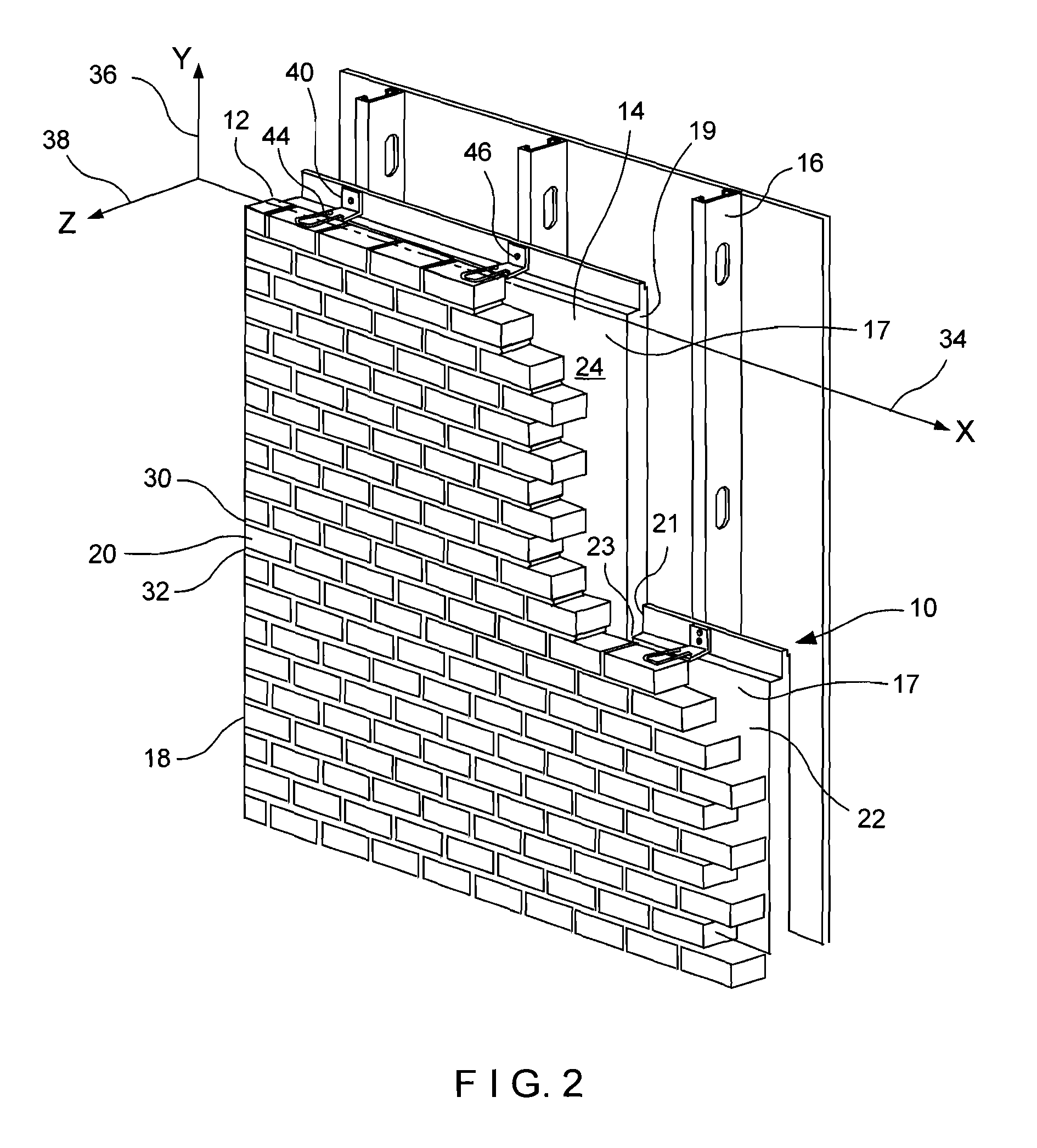

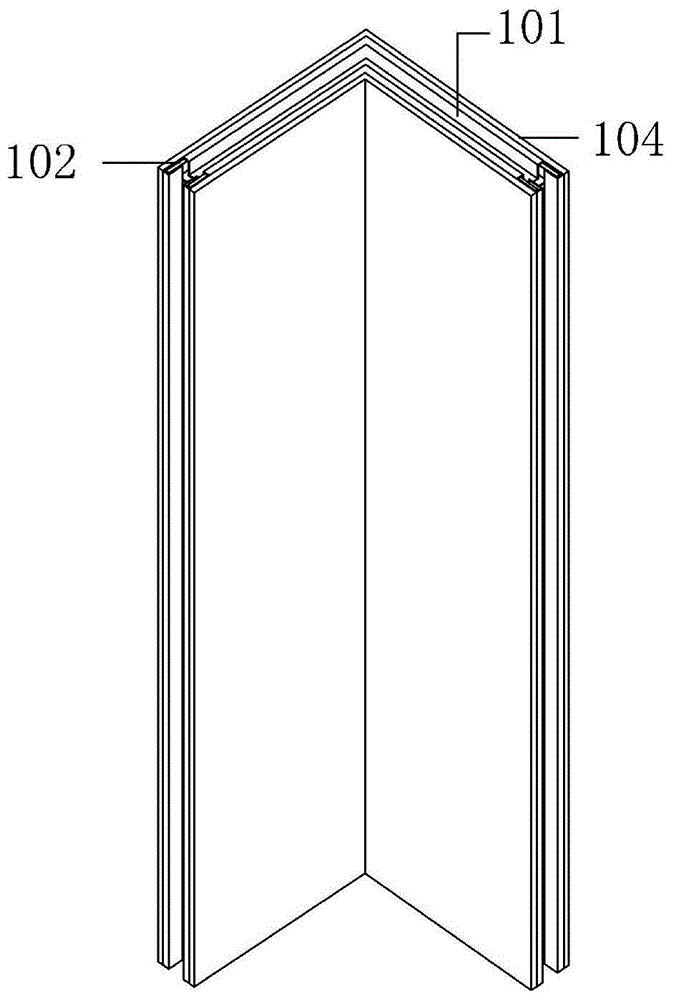

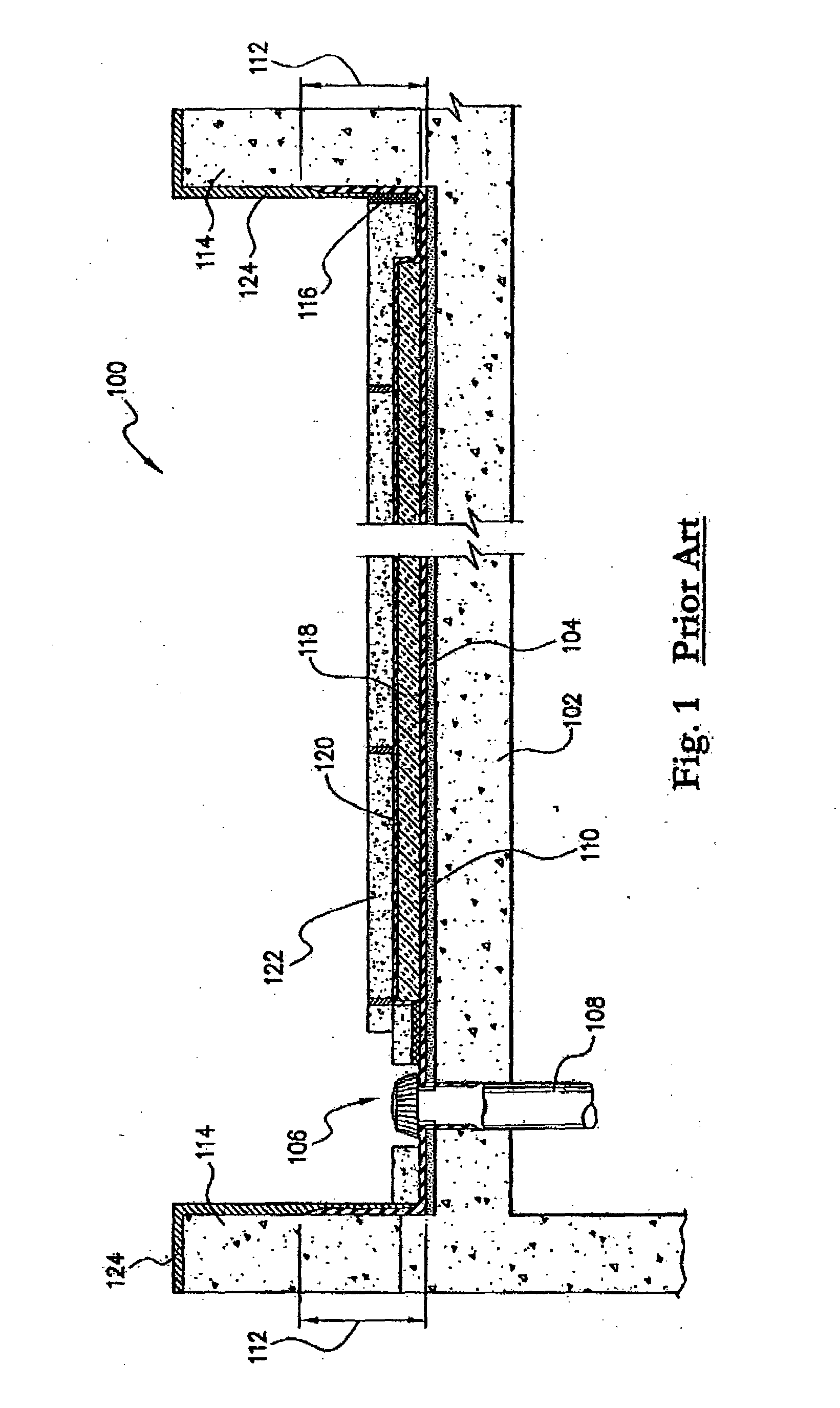

Anchor System for Composite Panel

Anchoring systems for use in cavity wall structures having an inner wythe constructed of interengaged composite panels and a veneer outer wythe are disclosed. The wall anchor is disposed within the juncture of the interengaged composite panels and fastened to the frame. The wall anchor maintains a strong interlock with the composite panels and backup wall, maintains insulation integrity and limits thermal transfer, without obstructing the juncture of the composite panels. The anchoring system interlocks with varied veneer ties, allowing vertical and horizontal adjustment for alignment with the bed joints. The anchoring system for composite panels provides an economical, high strength, low weight, insulated backup wall construction for interengagement with a veneer outer wythe.

Owner:HOHMANN & BARNARD INC

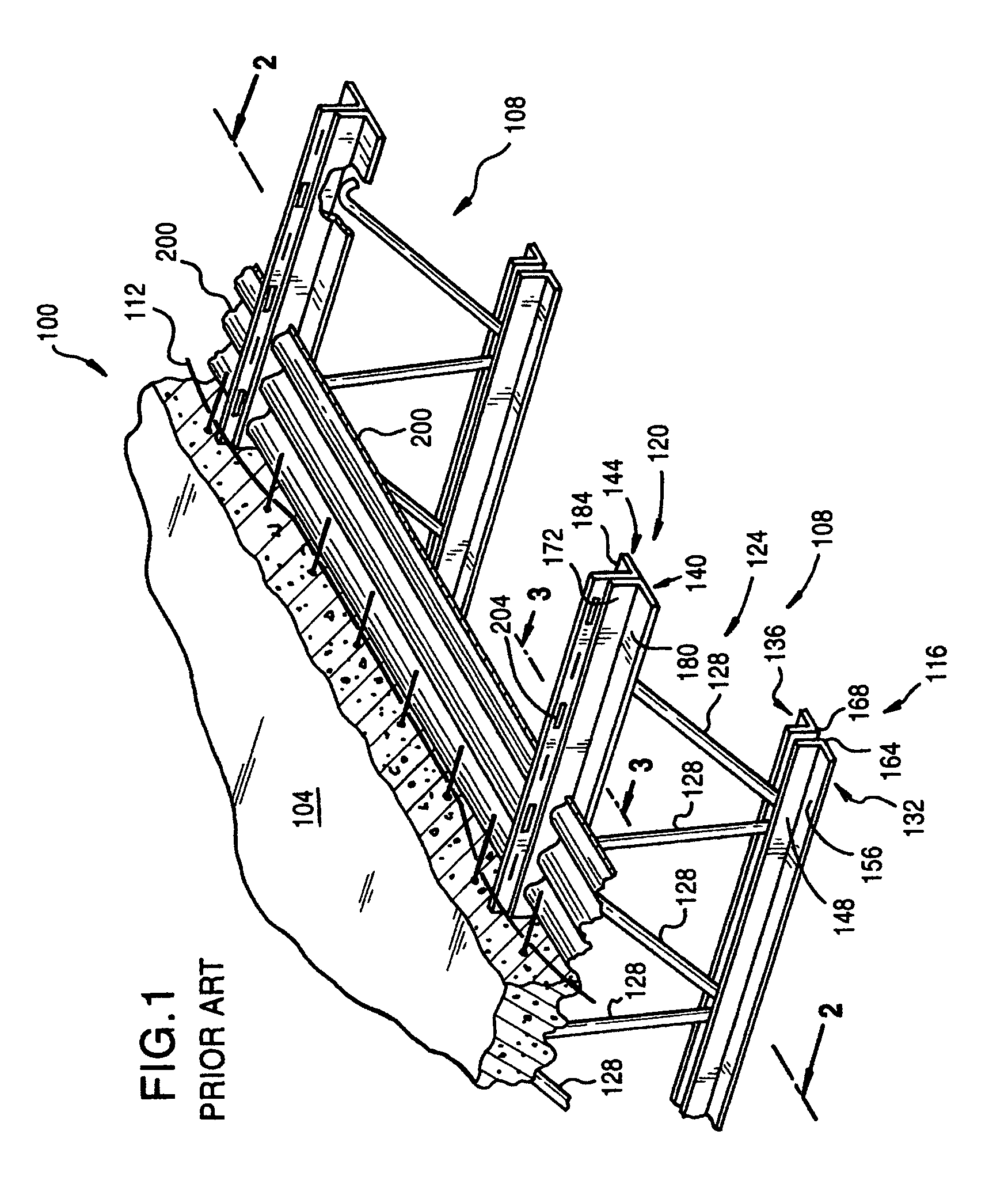

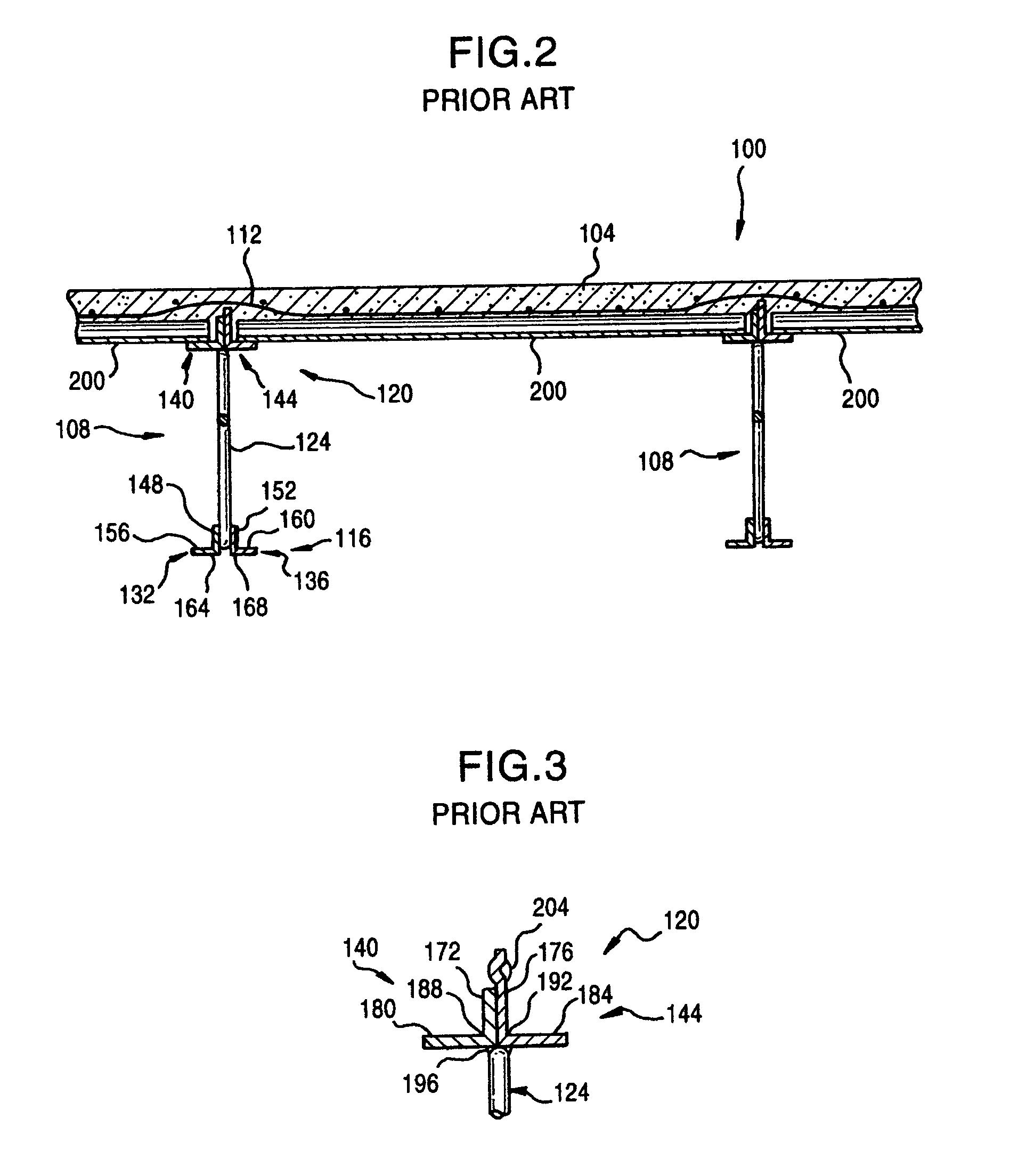

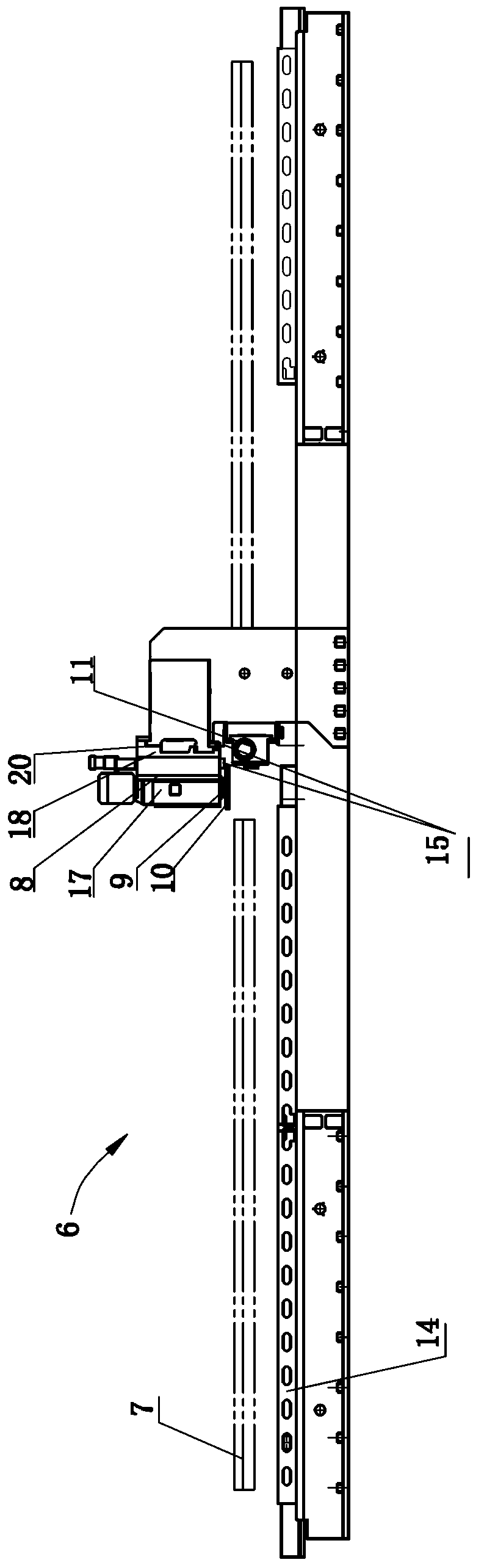

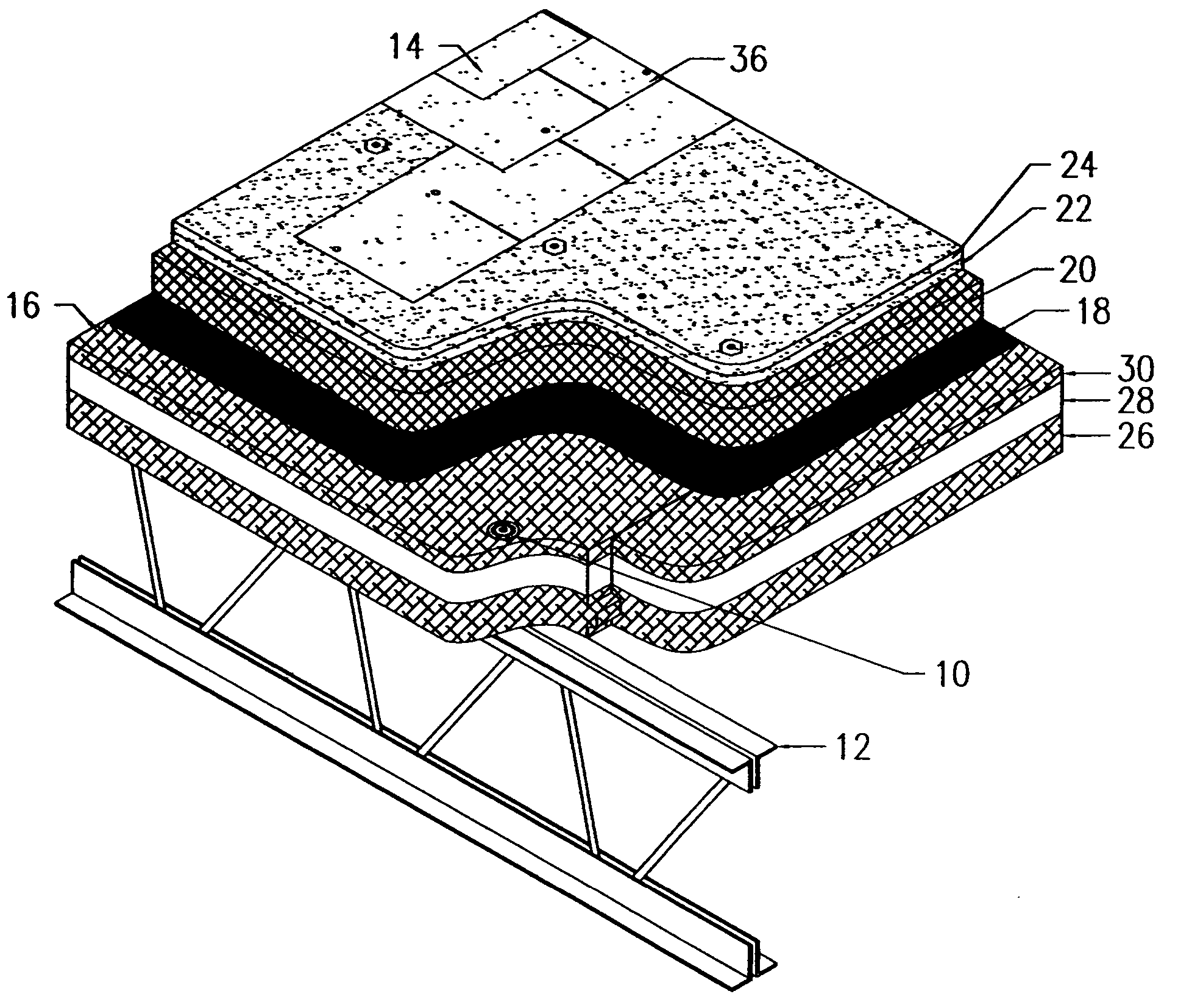

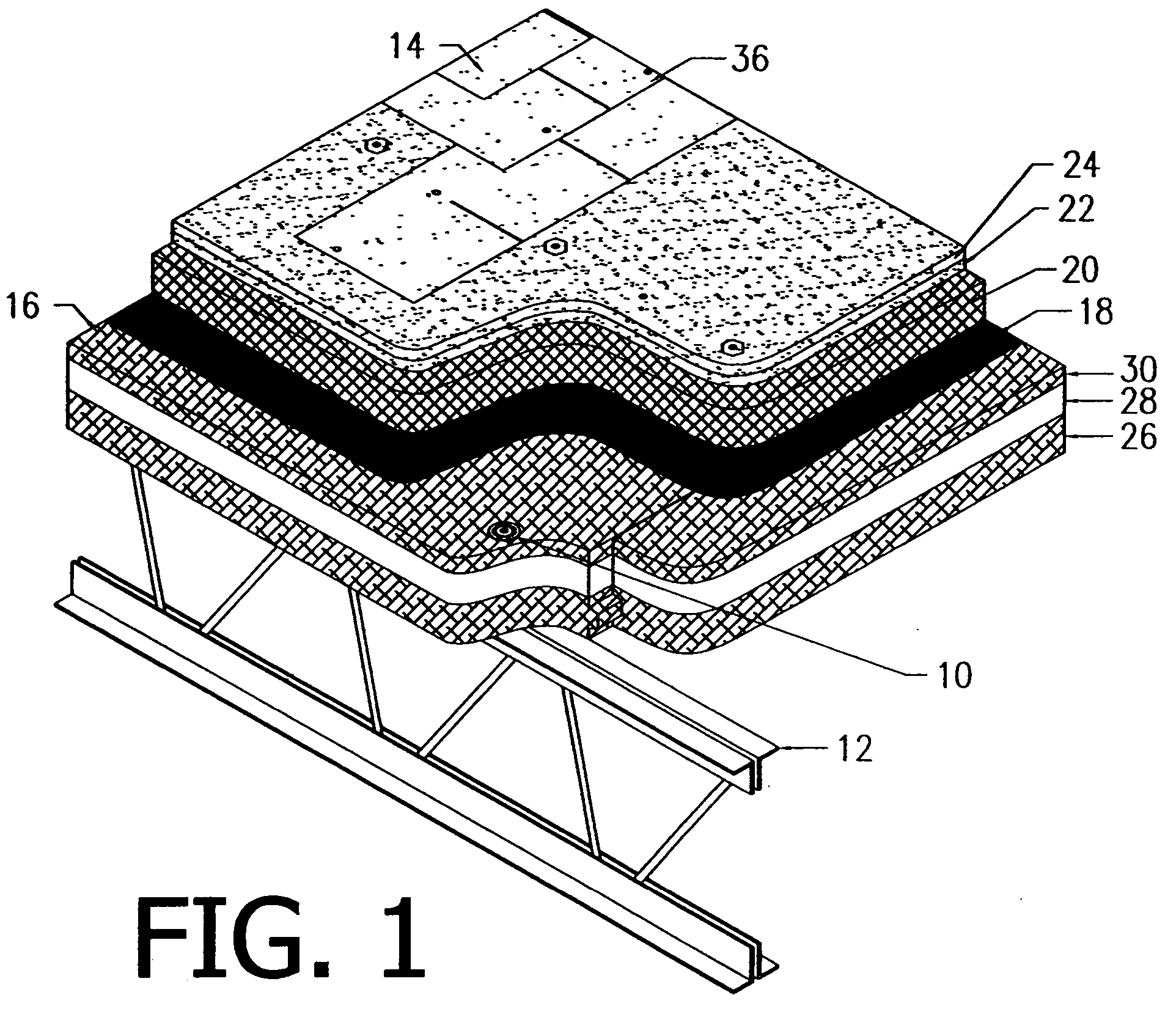

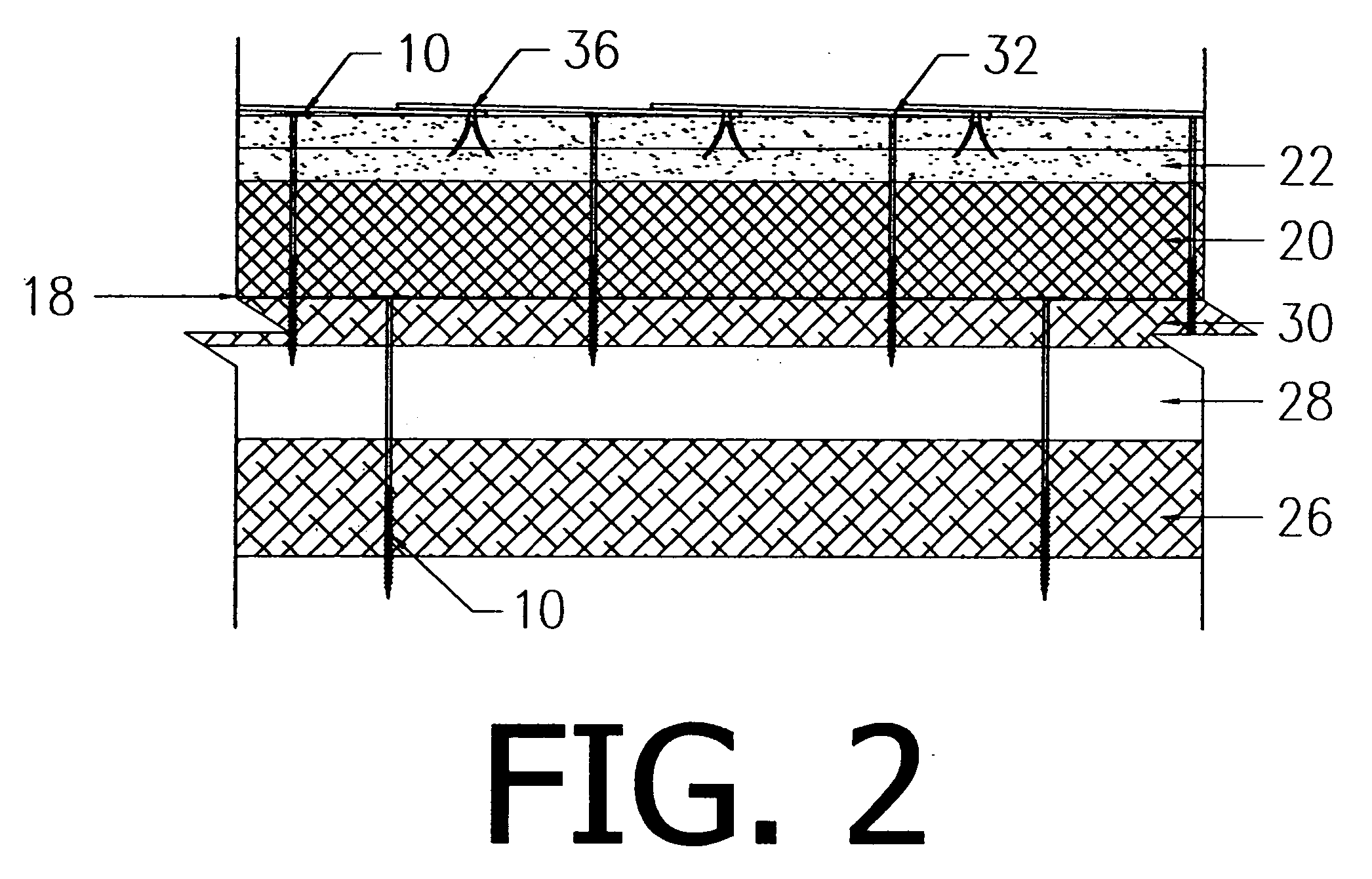

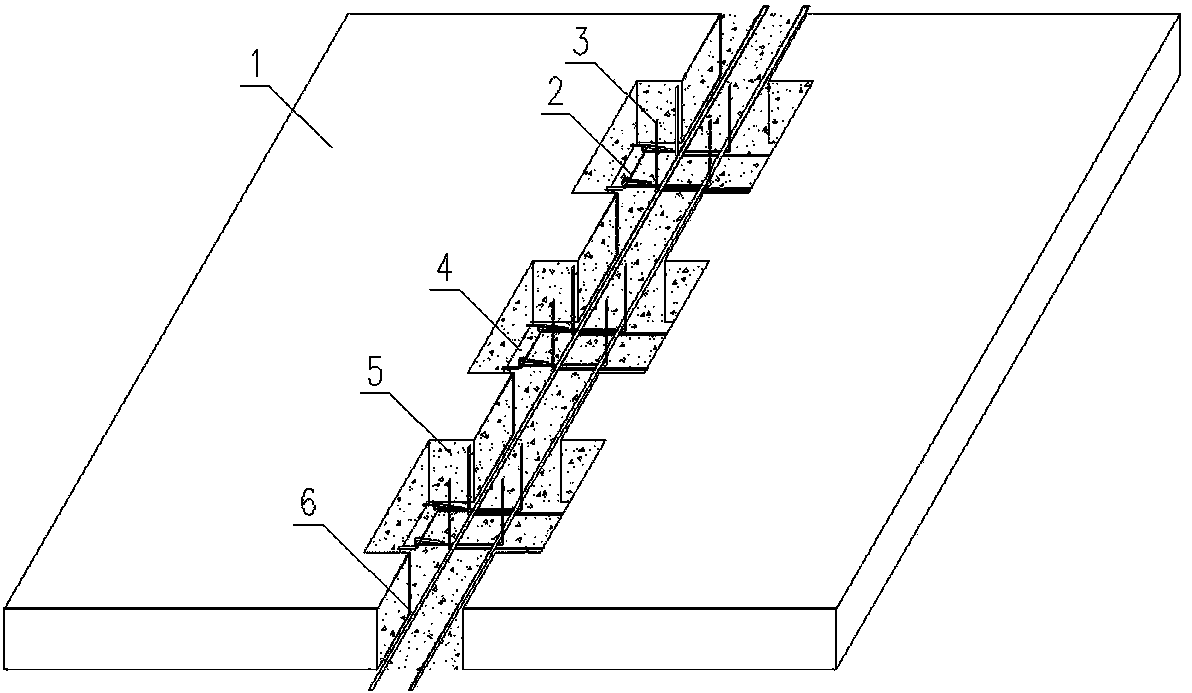

Composite slab and joist assembly and method of manufacture thereof

A composite slab and joist assembly includes a joist, at least one deck panel on the joist, slab reinforcement above the joist and dock panel, and a slab of concrete formed on the deck panel and joist such that the slab encloses the slab reinforcement and a top portion of the joist. The joist includes a bottom chord, a top chord, and a web affixed therebetween. The top chord has first and second structural angles. The first structural angle has in cross-section a horizontally-extending leg and an upwardly-extending leg meeting at a corner. The second structural angle has in cross-section a horizontally-extending leg and a downwardly-extending leg meeting at a corner. The upper portion of the web is joined to the second structural angle against the downwardly-extending leg.

Owner:SWIRNOW R & D

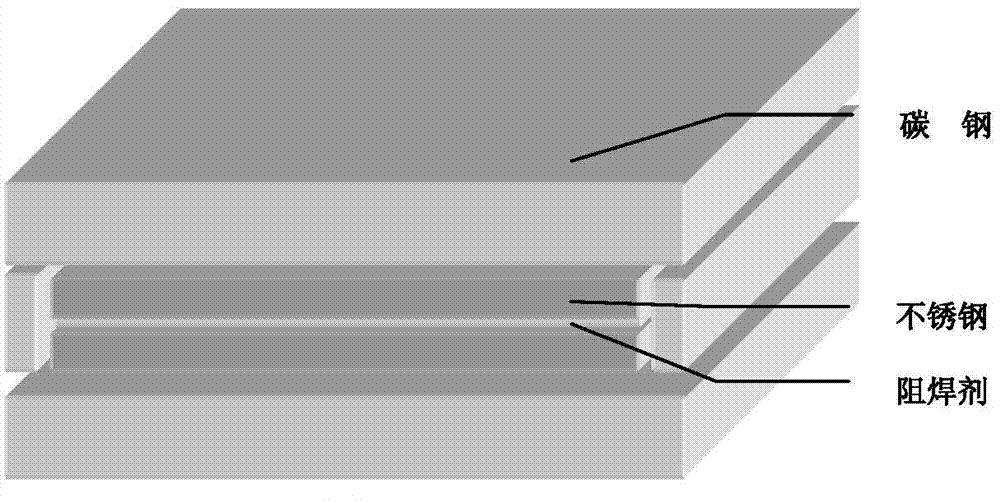

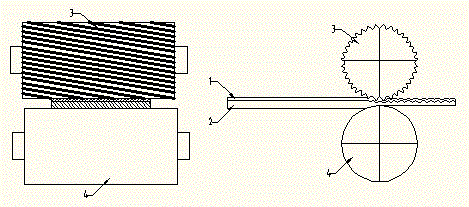

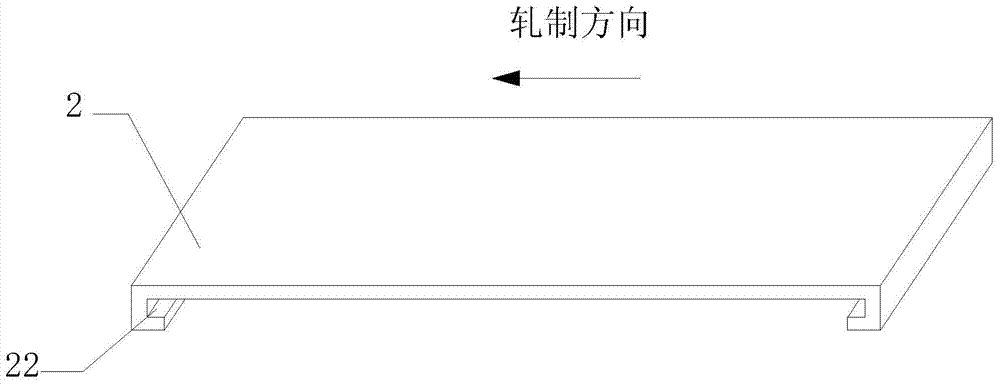

Manufacturing technique and device for composite board

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

Anchor system for composite panel

Anchoring systems for use in cavity wall structures having an inner wythe constructed of interengaged composite panels and a veneer outer wythe are disclosed. The wall anchor is disposed within the juncture of the interengaged composite panels and fastened to the frame. The wall anchor maintains a strong interlock with the composite panels and backup wall, maintains insulation integrity and limits thermal transfer, without obstructing the juncture of the composite panels. The anchoring system interlocks with varied veneer ties, allowing vertical and horizontal adjustment for alignment with the bed joints. The anchoring system for composite panels provides an economical, high strength, low weight, insulated backup wall construction for interengagement with a veneer outer wythe.

Owner:HOHMANN & BARNARD INC

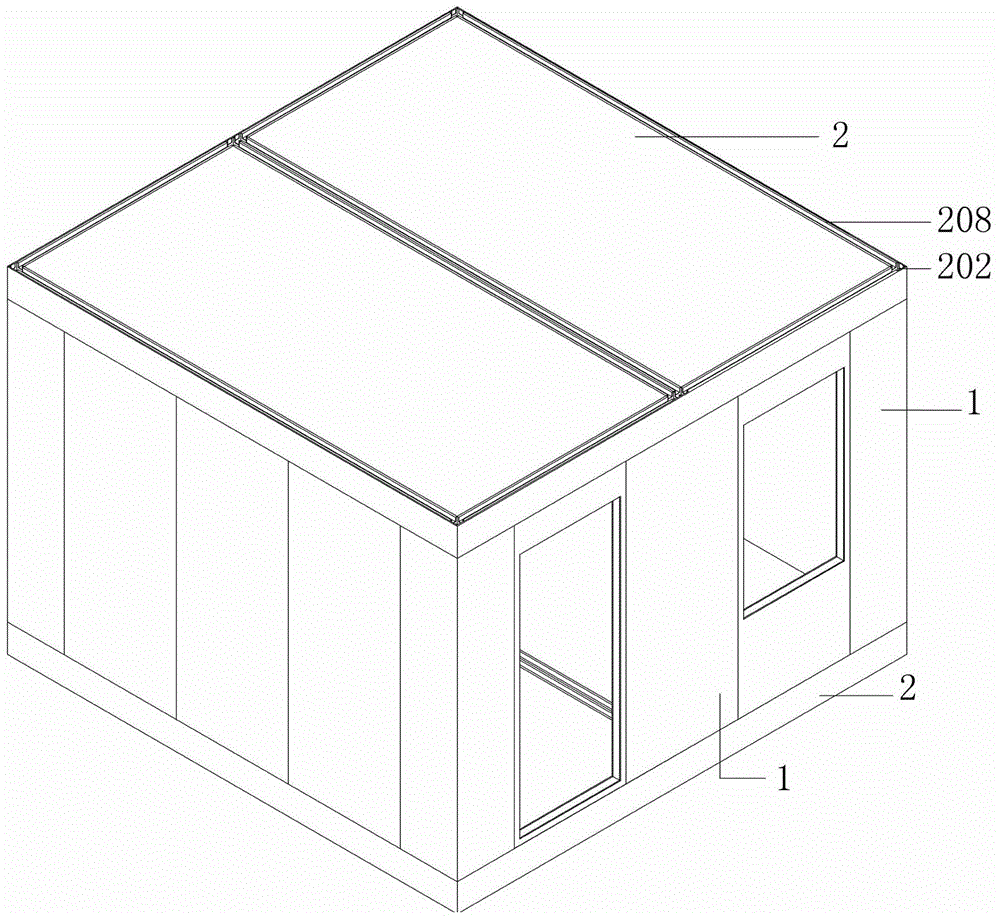

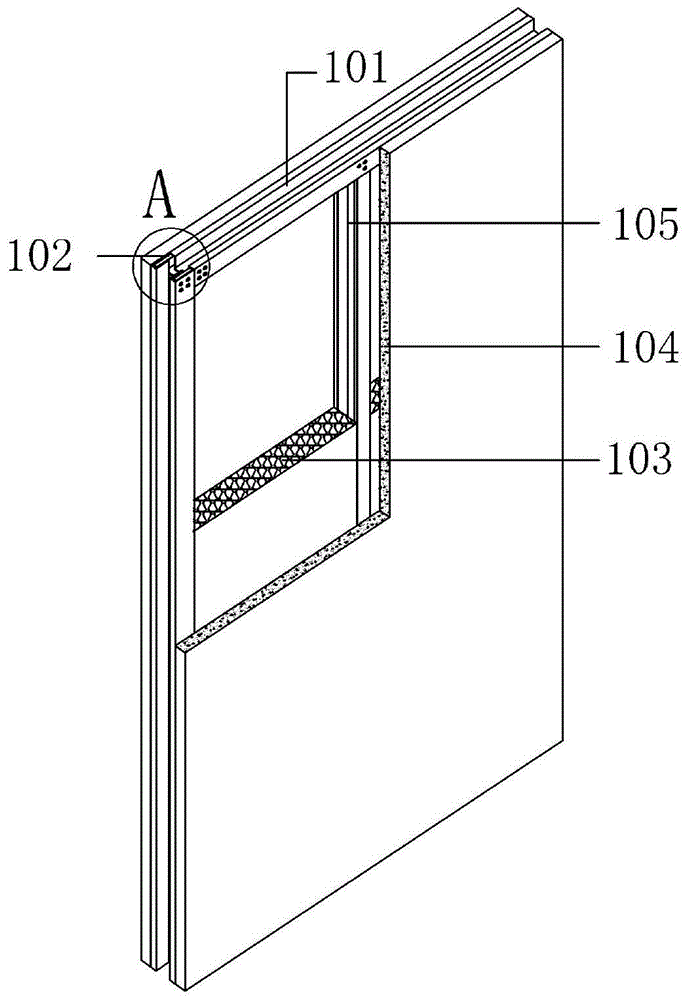

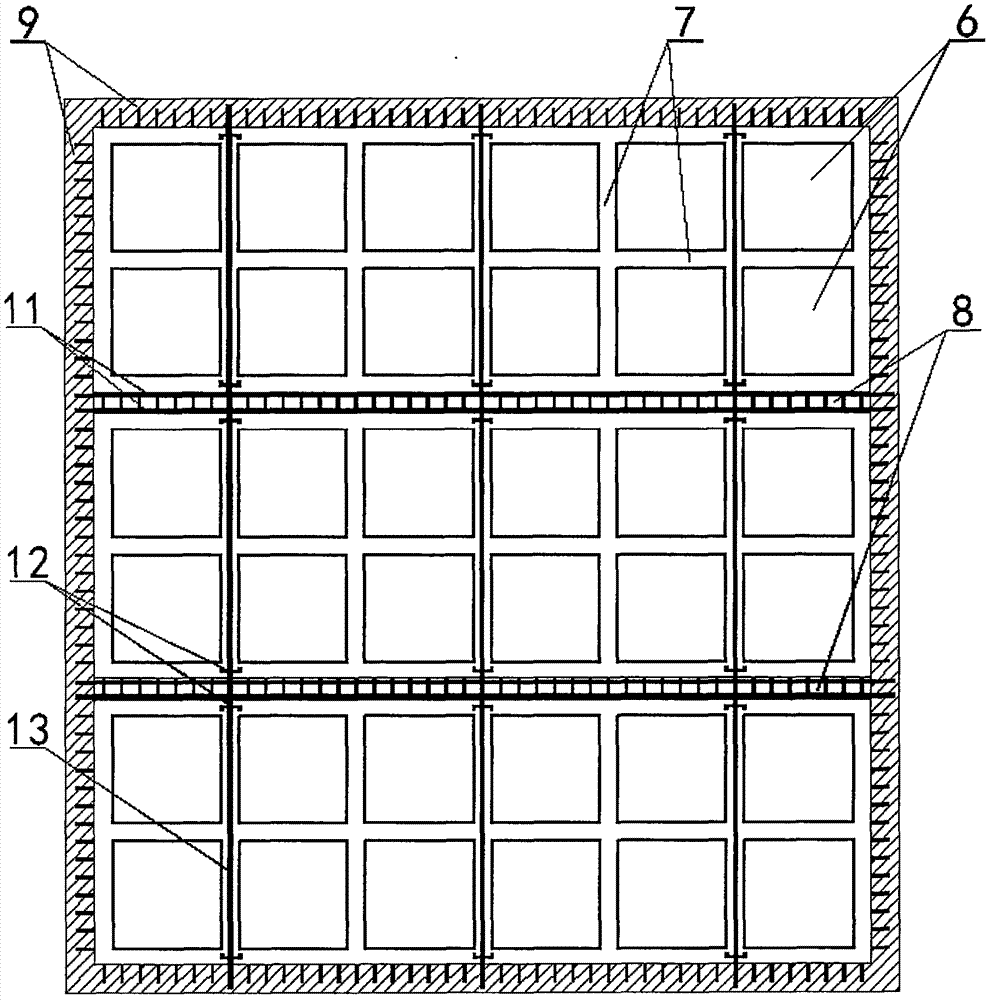

DGC modular fabricated building system and building method thereof

Provided are a DGC modular fabricated building system and a building method thereof. Wallboards are composite boards prefabricated in a factory. Light steel profiles and light steel keels are connected through self-tapping screws. The corners of the light steel profiles with grooves in frames are connected through self-tapping screws and light steel keel connecting pieces. The interiors of the wallboards are filled with heat preservation materials. Pouring layers of modified cement mortar or light aggregate concrete materials are arranged on the outermost sides of the wallboards. Floors are composite boards prefabricated in the factory, and each composite board is a foundation bottom plate or a floorboard or a roof panel of the DGC modular fabricated building system. The wallboards are connected through board connecting pieces, the wallboards and the floors are connected through board connecting pieces, and the floors are connected through board connecting pieces. The DGC modular fabricated building system is simple in structure, convenient to mount and low in cost, the construction period can be saved, and therefore the defects that an existing fabricated building is single in structure, complex in mounting process and high in manpower cost are overcome.

Owner:江苏保力装配式住宅工业有限公司

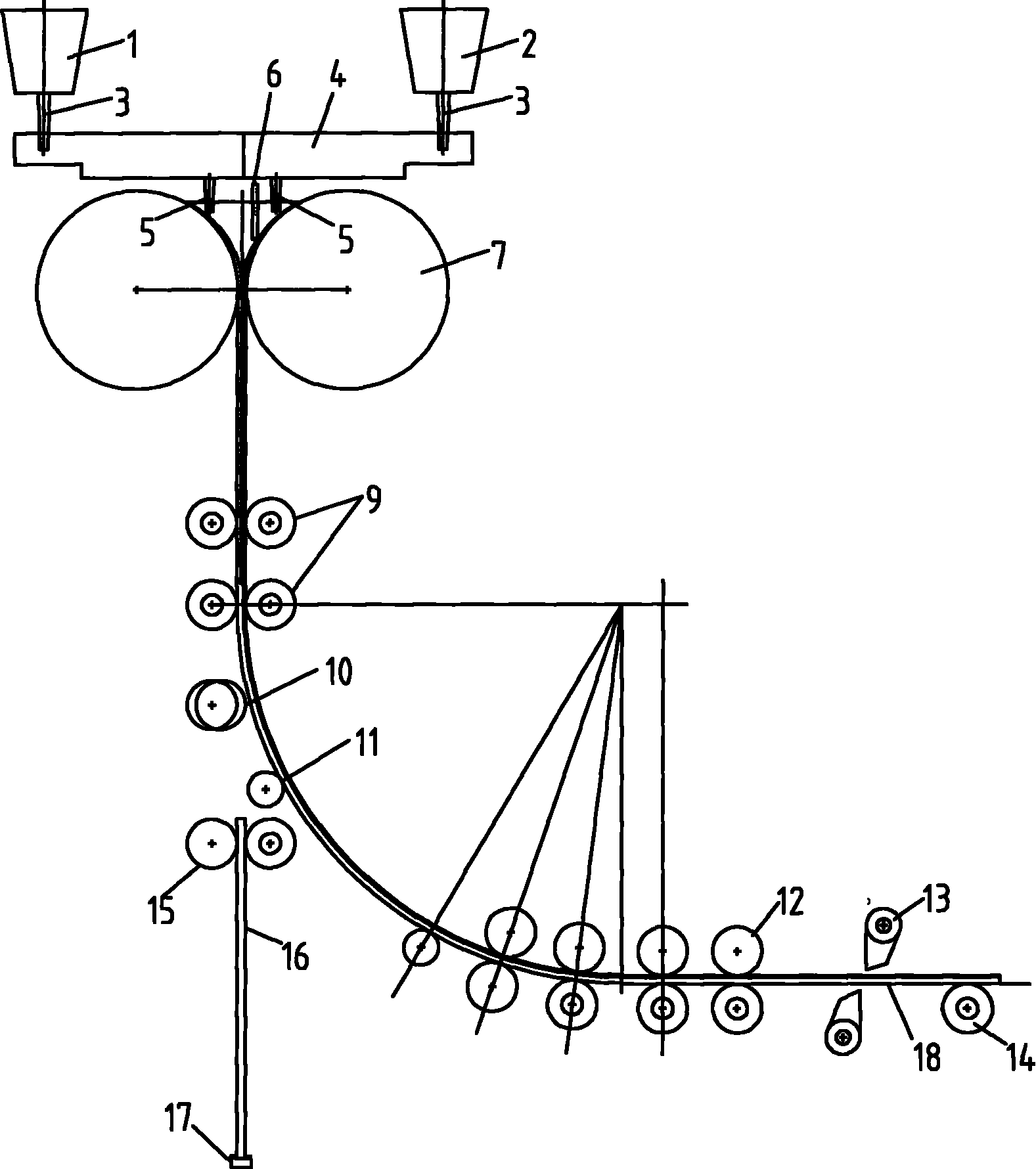

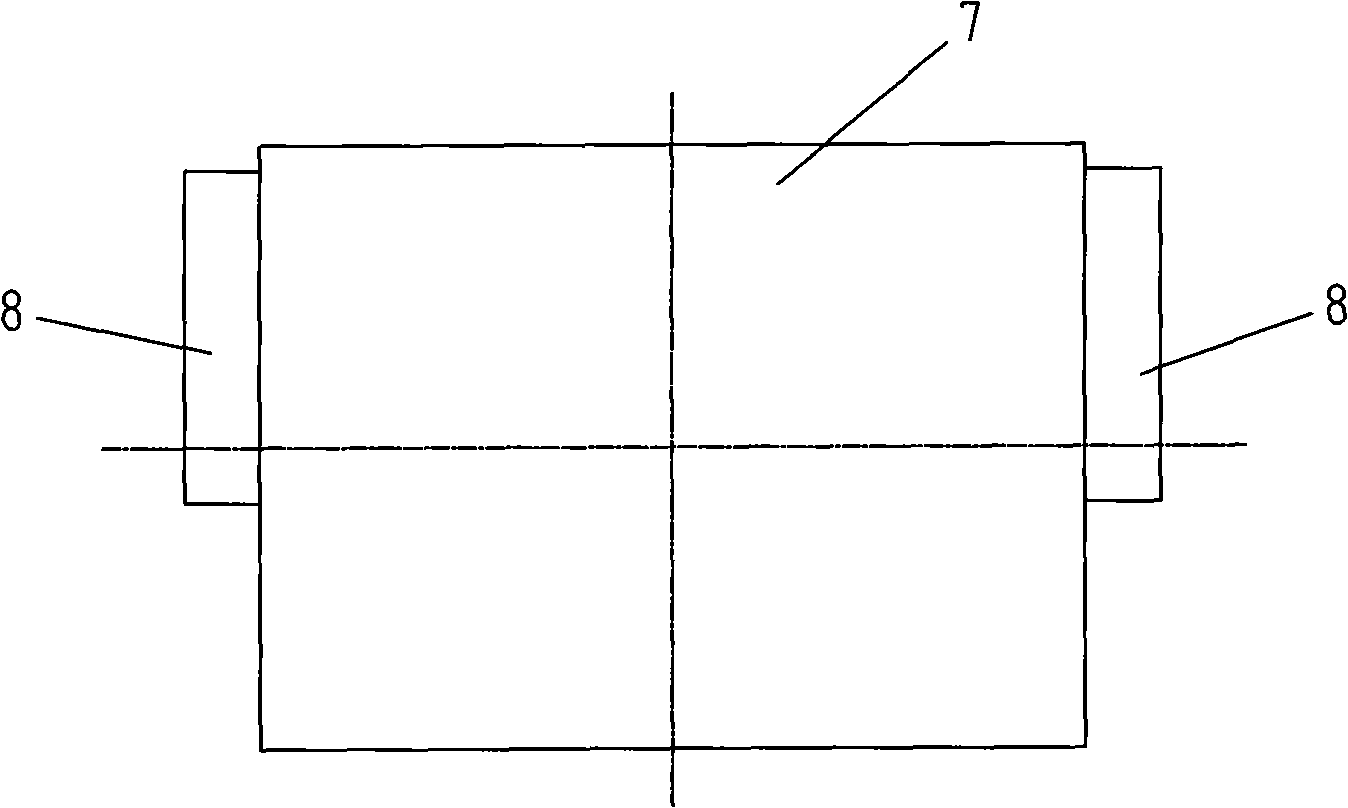

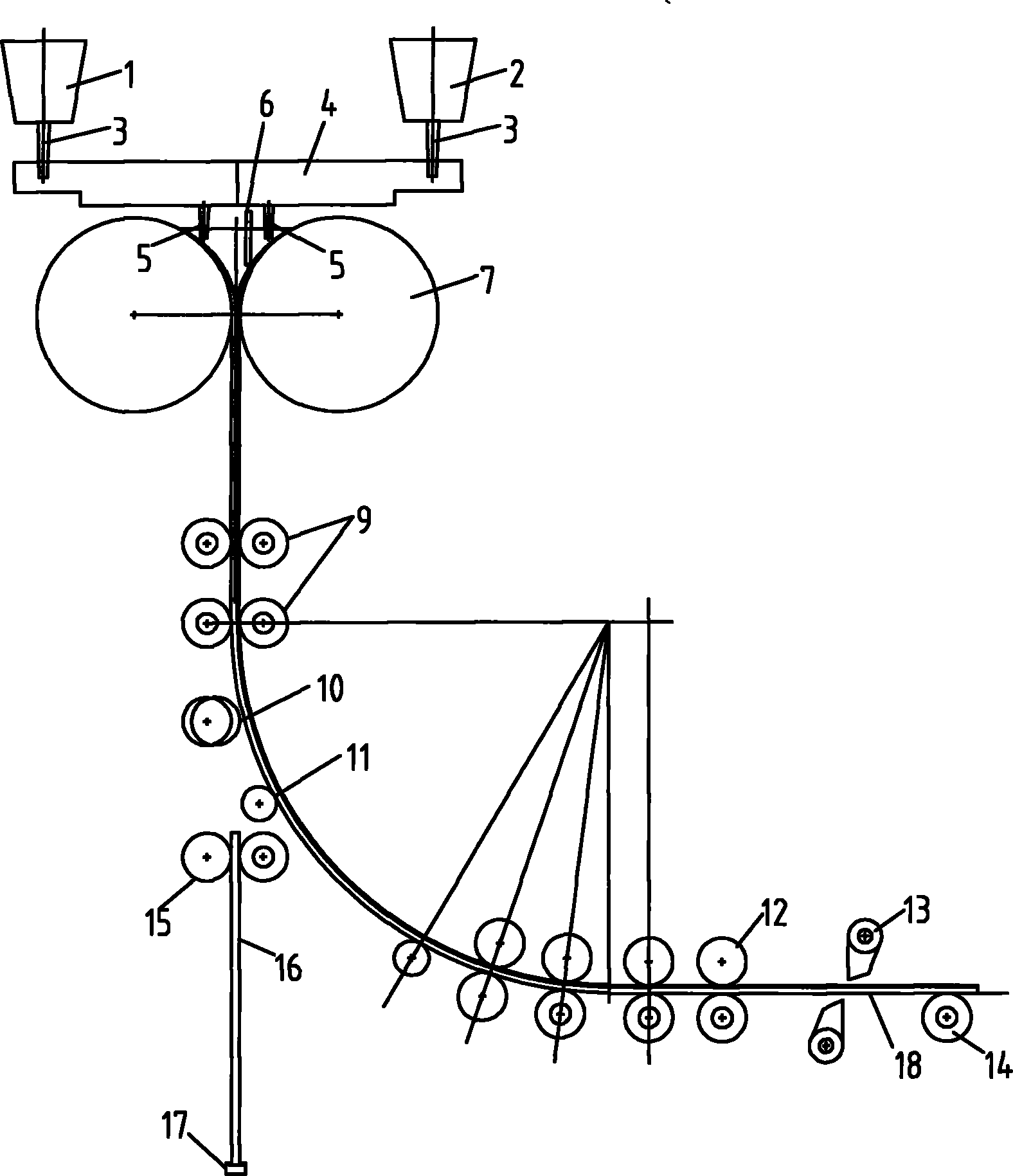

Continuous casting method of liquid-phase composite slab

The invention provides a continuous casting method of a liquid-phase composite slab. A continuous casting device comprises a composite casting system, a roll type crystallizer, a pinch and bending device, a withdrawing-straightening device, a shearing device and a dummy bar system. A base material metal pouring ladle and a composite material metal pouring ladle pour metal solution into a roll type crystallizer molten pool formed by crystallizing rolls and side seal plates via submerged nozzles. An intermediate diaphragm separates the molten pool into a base material dissolved cavity and a composite material dissolved cavity. The base material metal solution and the composite material metal solution are respectively solidified into slab shells on the crystallizing rolls, the crystallizing rolls synchronously rotate in the reverse direction and the metal slab shells move downward along with rotation of the crystallizing rolls. The base material metal liquid interacts with the composite material metal solid-liquid interface to realize metallurgical fusion and composition of the interface, and is bonded into the composite slab at the exit of the roll crystallizer. The composite casting slab is transferred by pinch rolls and bent into arc by a bending roll, and then enters the withdrawing-straightening section through a guide roll to be horizontally straightened. The composite casting slab keeps on moving forward to the roll way in a shear zone to be cut to length by swinging shears and then is moved out.

Owner:CHINA FIRST HEAVY IND +1

Phosphate base cementing agent

The invention discloses phosphate base cementing agent which is formed by uniformly mixing phosphate cementing mixture and water. The phosphate cementing mixture comprises the following component according to mass percent: 65 to 80 percent of phosphate cementing mixture and 20 to 35 percent of water; the phosphate cementing mixture comprises the following components according to mass percent: 20 to 60 percent of dihydric phosphate, 20 to 40 percent of magnesite, and 0 to 40 percent of inorganic mineral filler, wherein the mass of retarder occupies 5 to 15 percent of that of the magnesite; and the mass of sand occupies 0 to 30 percent of that of the phosphate cementing mixture. Phosphate gelling slurry can be served as structural adhesive to prepare fibrous composite material for concrete reinforcement, to improve the compatibility between the phosphate gelling slurry and concrete, and can also be served as gelling material to prepare artificial composite board material, self-leveling slurry, protective paint and the like.

Owner:SHENZHEN UNIV

Low noise roof deck system

A low noise roof deck system eliminates the thermal expansion noises associated with metal decking and includes structural features that permit installation of composite roofing shingles directly over the deck without venting. The system includes a composite panel base layer surmounted by a layer of water resistant material, a layer of foam synthetic resin insulation and a layer of mineral board. A second layer of mineral board may be overlaid on the first mineral board layer. The system is easily installed over a system of conventional underlying supports to provide a strong, rigid deck for supporting a waterproof composite shingle roof membrane and forming a quiet weatherproof roof system. The composite base panel has a layer of synthetic resin foam insulation sandwiched between a base layer of wood fibers bonded with an inorganic cement and an upper layer of a resin bonded wood product.

Owner:BONTRAGER II ARLEY L

Composite board and manufacturing method thereof

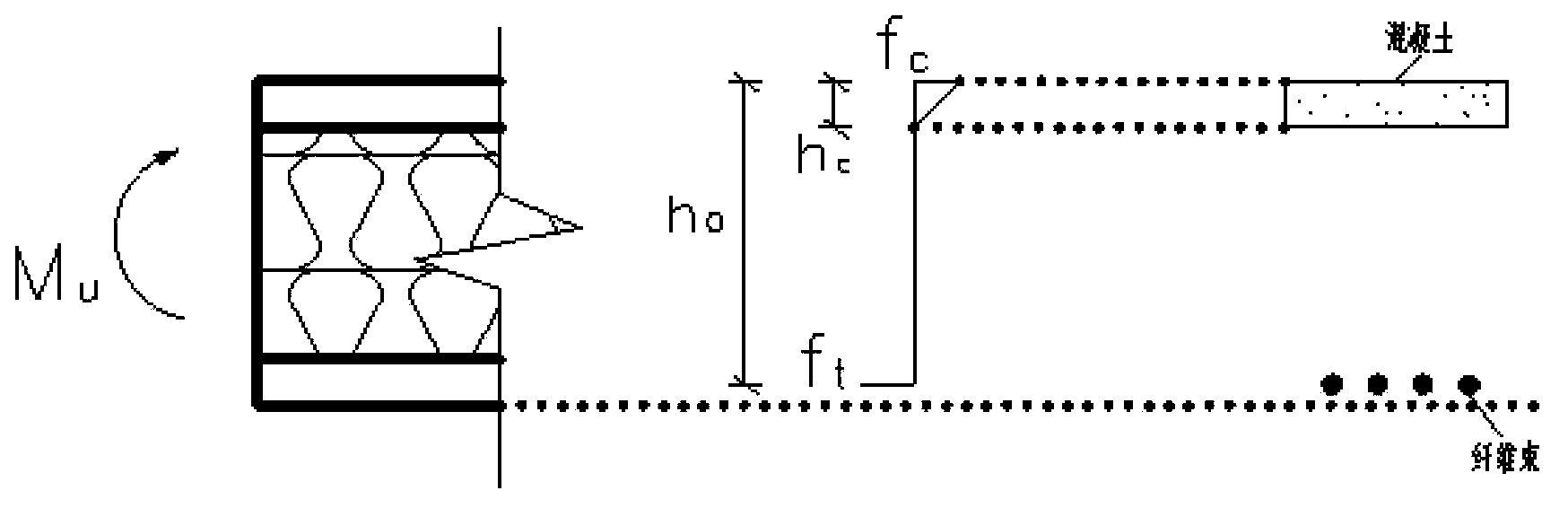

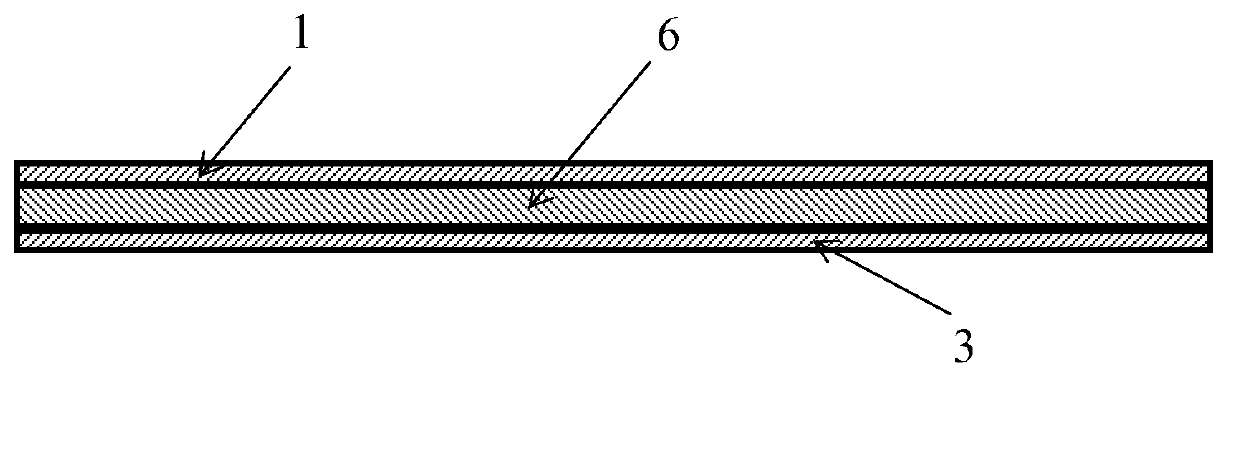

The invention discloses a composite board and a manufacturing method thereof, and belongs to composite boards of building materials and design and manufacturing methods of the composite boards. The composite board comprises fiber woven nets, chopped fiber, fine concrete and an insulating material. The composite board is designed based on certain hypothesis. The manufacturing method of the composite board comprises the following steps: 1, mixing and stirring an epoxy resin, a curing agent and a diluting agent according to a ratio, and uniformly coating the mixture on the surface of a fiber woven net; 2, fixing a wooden template, firstly stirring cement, coal ash, silica ash and silica sand, subsequently adding water to stir, adding a water reducing agent, stirring, adding the chopped fiber, and further stirring; 3, firstly casting the stirred fine concrete on the template, subsequently laying another fiber woven net, further casting the fine concrete and laying another fiber woven net; 4, casting the fine concrete on the fiber woven nets, and laying the insulating plate which is subjected to surface roughening treatment; 5, casting the fine concrete on the roughened insulating plate, laying another fiber woven net, further casting the fine concrete, laying another fiber woven net and further casting the fine concrete; 6, demolding and maintaining. The composite board has the advantages that the weight is light, the thickness is large, the bearing capacity is large, and the construction is simple.

Owner:CHINA UNIV OF MINING & TECH

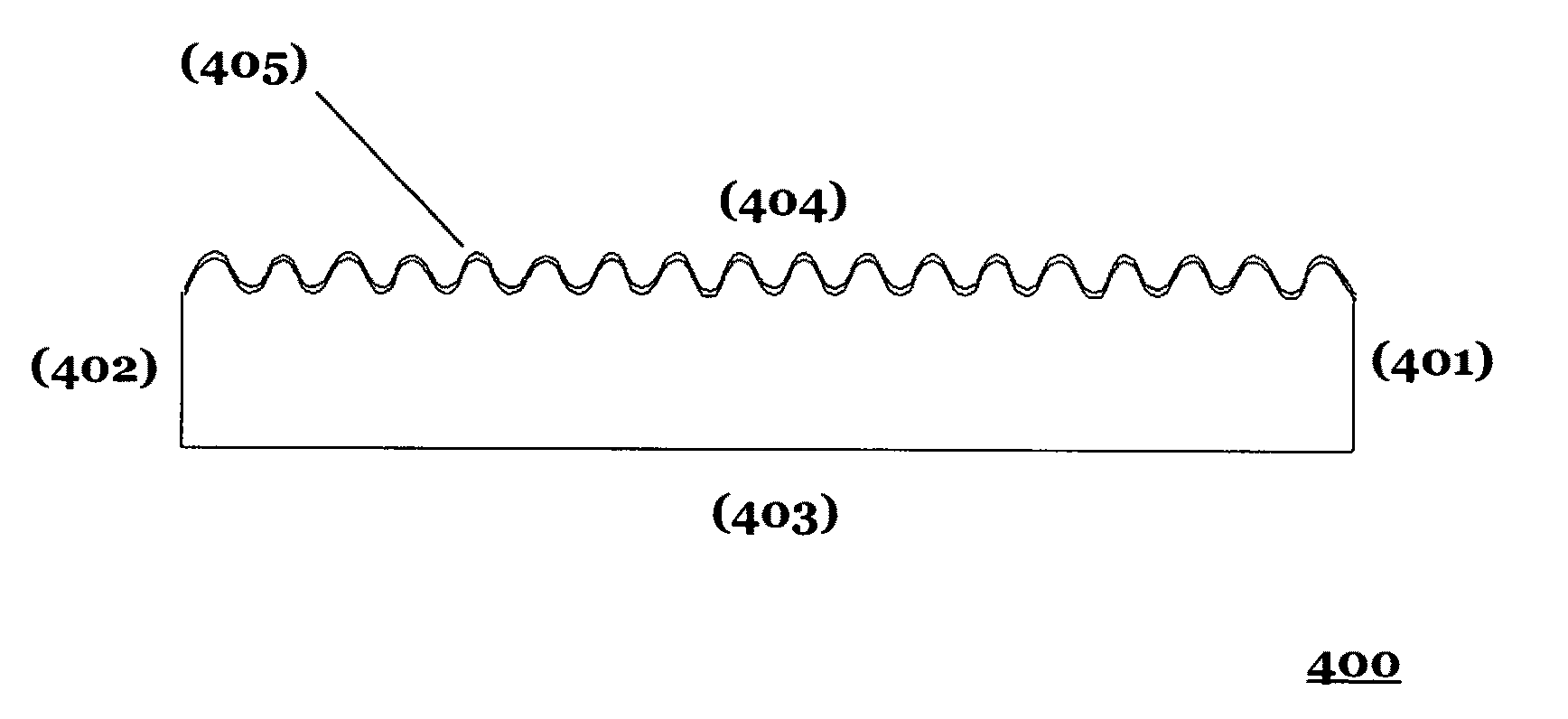

Structural boards having integrated water drainage channels

InactiveUS20090113838A1Improve waterproof performanceCost time be reducedWallsDecorative surface effectsWater trapEngineering

A water resistant structural board suitable for use in a wall system is disclosed. The structural board has water drainage channels on at least one of its surfaces to drain any water trapped behind the sealed wall system. The water drainage channels may be imparted into the structural board during or applied subsequent to a board production process, and the produced board is shipped to the construction site for a wall installation. When desired, the channeled surface of the structural board may be laminated, coated, or sprayed with a water resistant layer to further enhance the water resistant property of the board. A wall system including the disclosed structural board does not require a layer-by-layer installation of a component having water resistant property and a component having water drainage channel structure at a work site; therefore, labor cost and installation time may be reduced significantly. Examples of structural boards are oriented strand board, plywood, particle board, oriented strand lumber, dimensional lumber, fiberboard, wafer board, chipboard, laminated veneer lumber, and any substantially equivalent wood composite board known in art.

Owner:PAULSEN FRITZ G +1

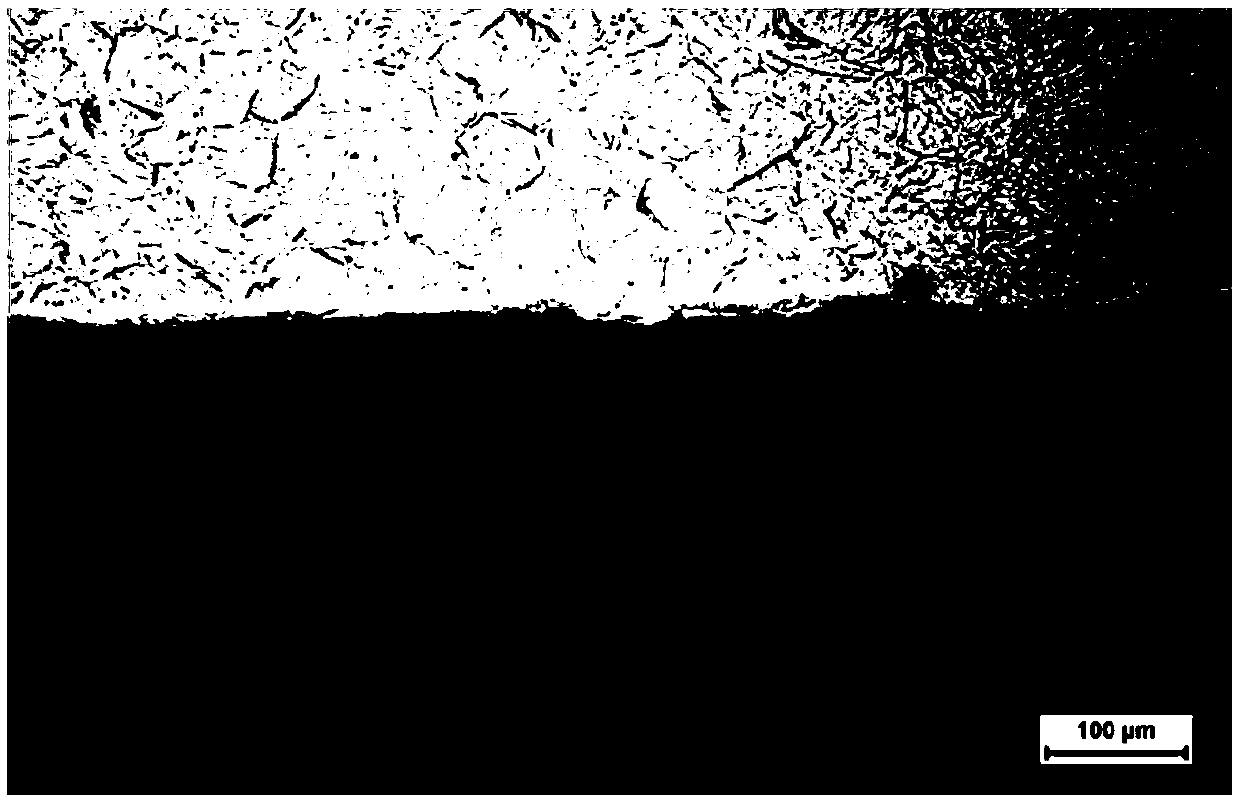

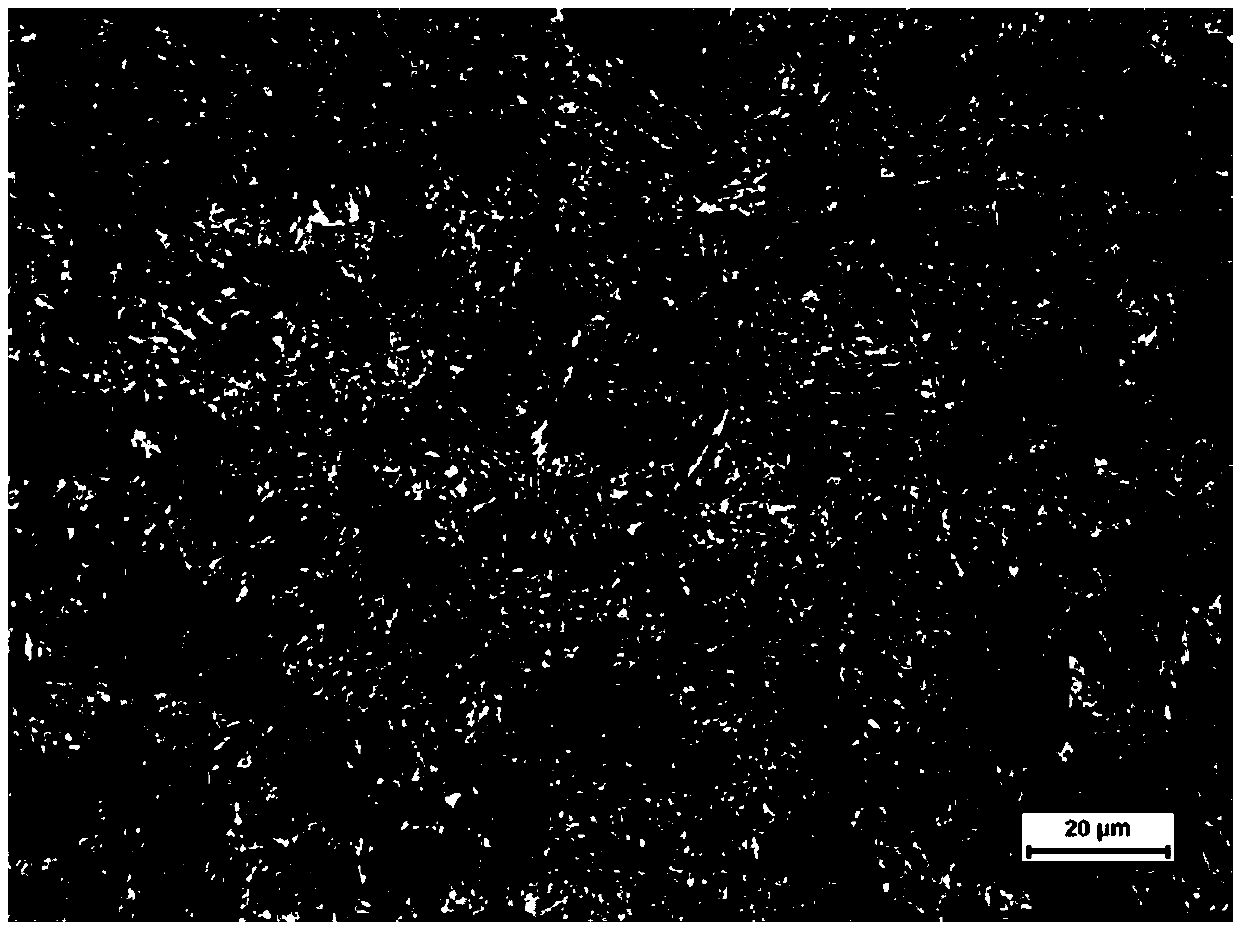

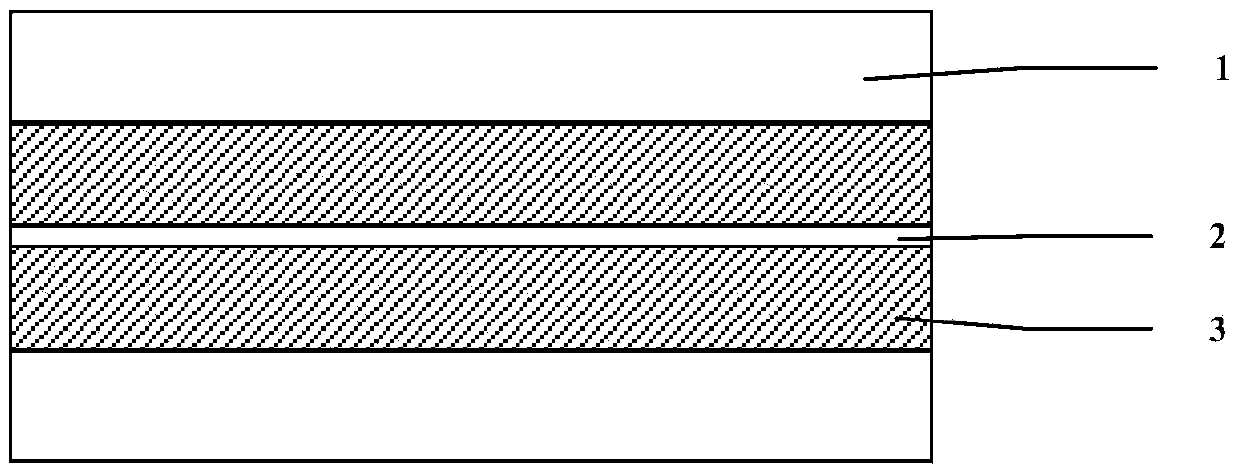

Titanium and steel and stainless steel composite board and preparation method

InactiveCN102922816AHigh composite strengthEasy to paintAuxillary arrangementsMetal rolling arrangementsSheet steelTitanium

The invention relates to the field of metal composite materials, particularly relates to a titanium and steel and stainless steel composite board and a preparation method, and solves the problems that in a process that an explosive composite board is rolled to a thin board, an existing bonding surface is a wavy structure, a substrate of a steel plate is easily exposed in the rolling process, bonding intensity is also low, and the like. The composite board adopts a composite structure composed of a titanium plate, a common steel plate and a stainless steel plate, the common steel plate serves as an intermediate layer, planes of two sides of the common steel plate are respectively composited with the titanium plate and the stainless steel plate, the common steel plate and the stainless steel plate are in a hot rolling extension composite structure, and the common steel plate and the titanium plate are in a hot rolling composite structure. The composite board adopts a method that mild steel with a small brittle phrase produced at a high temperature and the titanium and the stainless steel are heated and rolled, mainly achieves a purpose that ferritic stainless steel is rapidly taken out so as to mutually reach to the hot inlaying combination, and finally the titanium-steel stainless steel composite board is manufactured. According to the preparation method, the titanium and steel and stainless steel composite thin board is manufactured and can be widely applied to industries and civilians for use.

Owner:刘鸿彦 +2

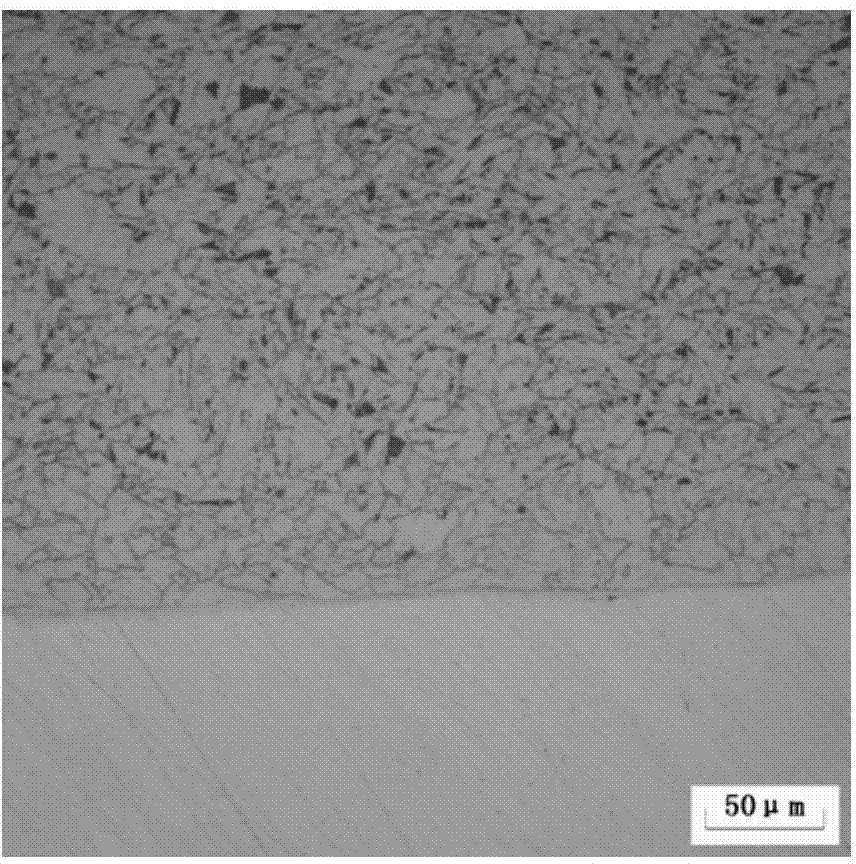

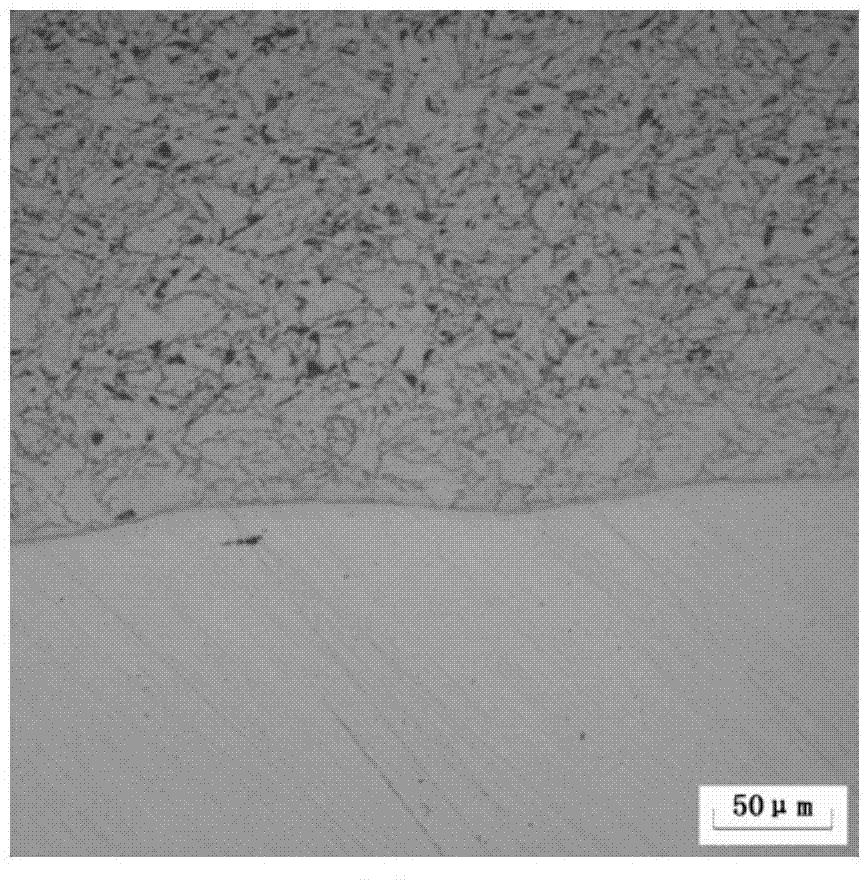

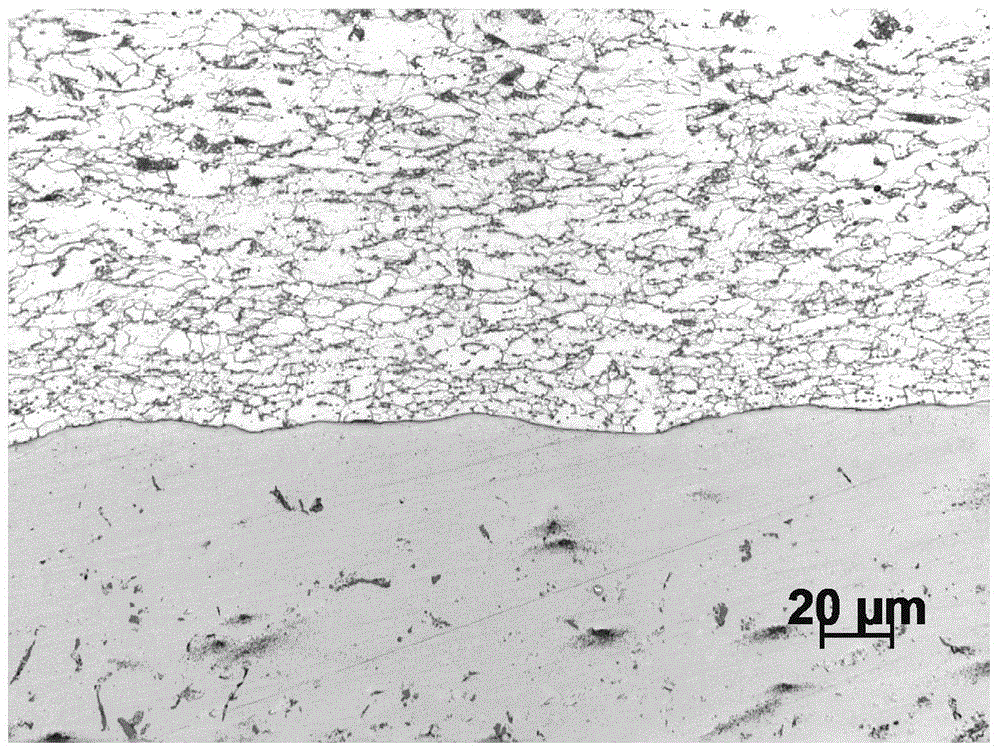

Carbon steel and austenitic stainless steel combined steel plate and production method thereof

InactiveCN104760351AImprove toughnessAccelerated corrosionMetal layered productsSheet steelComposite plate

The invention discloses a carbon steel and austenitic stainless steel combined steel plate and a production method thereof, and belongs to the technical field of metal composite plate production. A steel blank is adopted for symmetrical combination (dual-blank lamination) for the combined steel plate; the upper and lower layers are made from carbon steel made from X70 materials; the two middle layers are made from 316L stainless steel; scaling powder is not added between the carbon steel and the stainless steel; an insulation agent is added between stainless steel; then four edges of the steel blank are welded and sealed, and vacuumization treatment is carried out by using a vacuum dispersion pump. The blank assembling technology of the steel blank is that smelted X70 and 316L steel blanks are respectively subjected to blooming forging to the designed middle size; then the steel blank is subjected to surface polishing treatment; and then welding, edge sealing and vacuumization are carried out. The carbon steel and austenitic stainless steel combined steel plate and the production method thereof have the advantages that the use safety of a petroleum pipeline is improved, and great significance is achieved for the pipeline development of China.

Owner:SHOUGANG CORPORATION

Composite board produced with waste and old plastic and industrial gypsum, and producing method thereof

The invention discloses a composite board produced by waste plastics and industrial gypsum and a production method thereof. The composite board is prepared by the waste plastics and the industrial gypsum according to certain weight ratio. The invention adopts waste plastics such as waste polypropylene plastic, waste polyethylene plastic, waste polystyrene plastic, waste polyvinyl chloride plastic and so on discarded by industrial production and human life and the industrial gypsum as main raw materials to produce the composite board through the crushing and hot pressing, the composite board achieves the standard of the national building formwork, reduces the pollution of the industrial gypsum and plastic wastes to the environment, can also be used to substitute a wood building formwork or a steel building formwork which is widely used for the prior building construction, has low production cost, light weight, high strength, shock resistance, and easy mold stripping, can turn the harmful into the beneficial and turn waste into valuables, and greatly accelerate the progress of waste resource recovery in our country.

Owner:GUIZHOU UNIV

Composite cement panel

InactiveUS20100189953A1Roof covering using slabs/sheetsConstruction materialComposite slabEngineering

This invention relates to a composite panel for a rooftop surface having a core material board having a top surface and a bottom surface with a plurality of openings through said core material board extending from said top surface to said bottom surface; a rigid outer shell of solid material that encapsulates said core material board; a plurality of supports of said solid material wherein each of said plurality of supports extends through one of said plurality of openings in said core material board; and a plurality of legs on a portion of said rigid outer shell covering said bottom surface of core board material.

Owner:LIM CO LTD

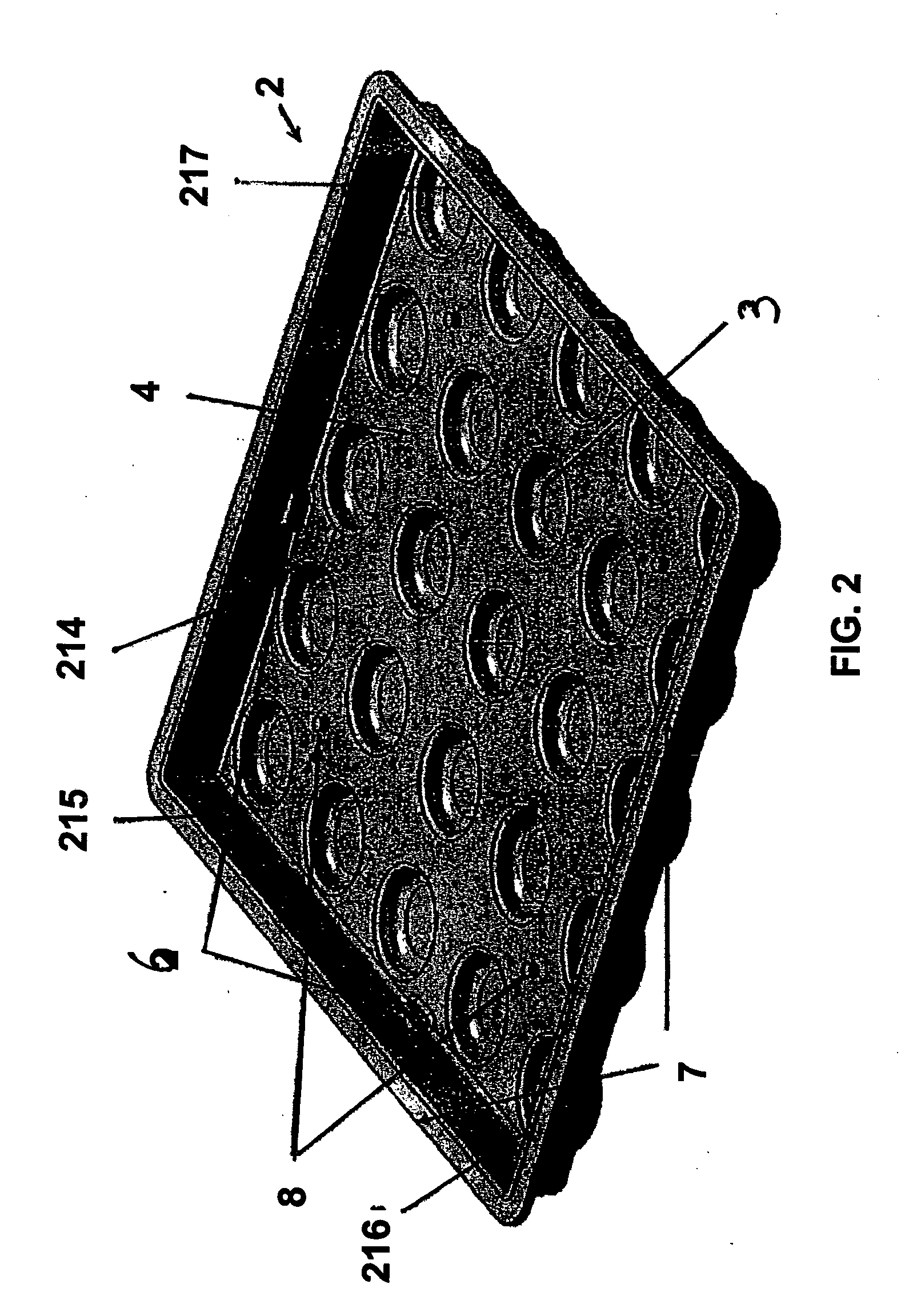

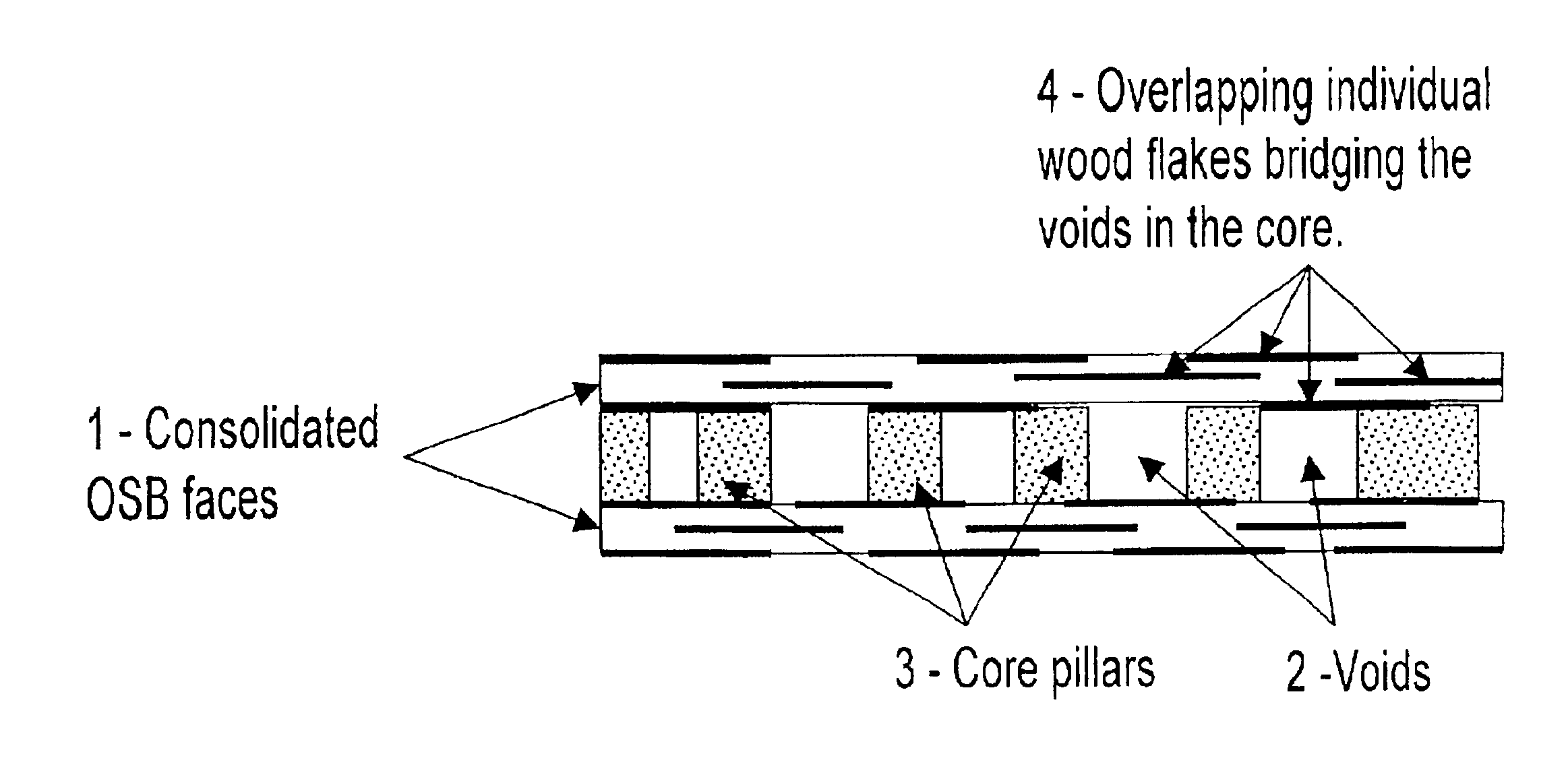

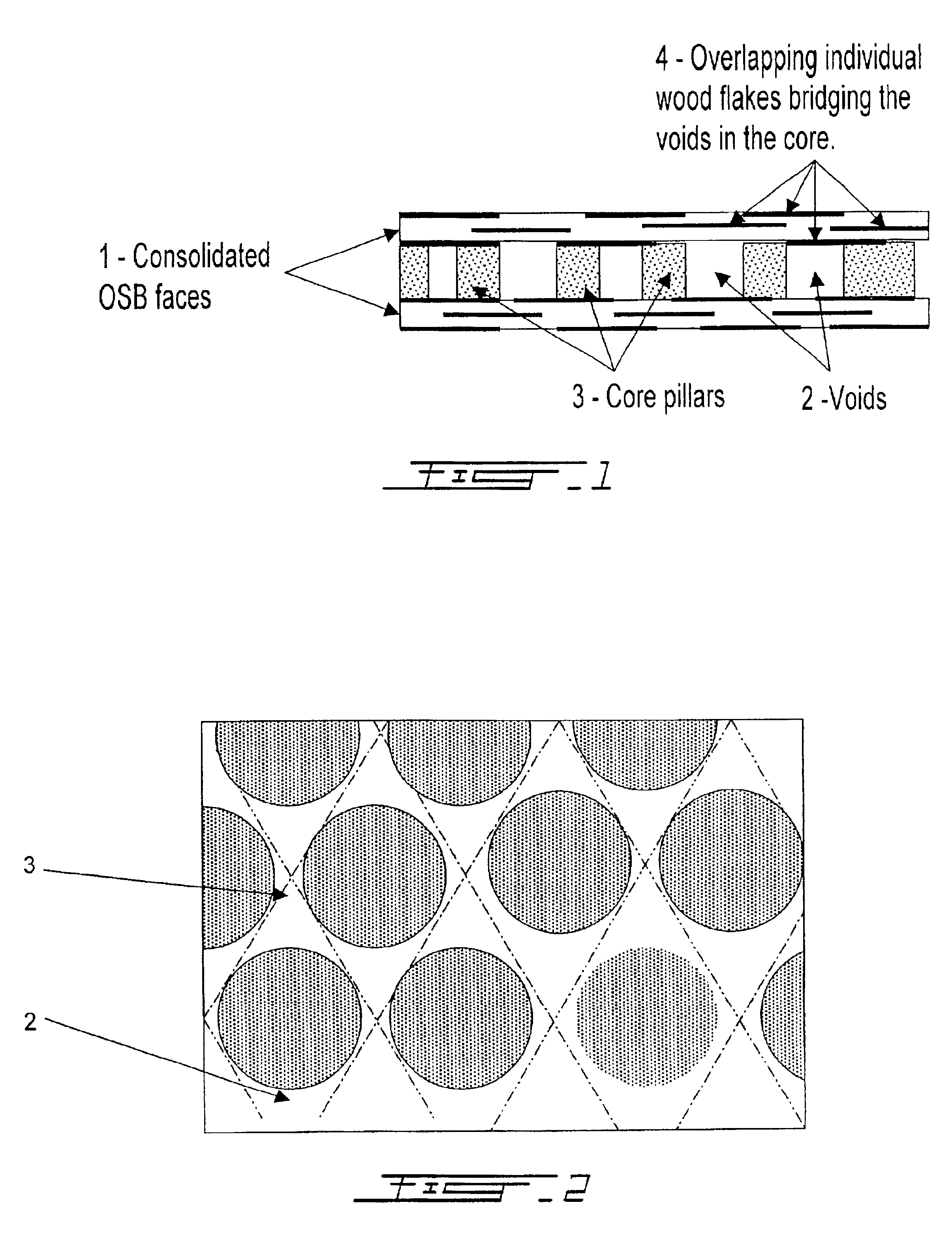

Composite board with OSB faces

InactiveUS6852386B2Reduce weightSolve the lack of resistanceLayered productsWood working apparatusPulp and paper industryComposite slab

Owner:NEXFOR

Vanadium/copper solid solution transition connection-based welding process for titanium-containing metal layer/pipeline steel layer composite board

ActiveCN105014207AEffective Butt Weld LinksImprove barrier propertiesArc welding apparatusWelding/soldering/cutting articlesButt weldingTitanium

The invention discloses a vanadium / copper solid solution transition connection-based welding process for a titanium-containing metal layer / pipeline steel layer composite board. The titanium-containing metal layer / pipeline steel layer composite board is formed in the way that an industrial pure titanium and titanium alloy board and a pipeline steel board are connected together by the explosive welding process and the connected boards are rolled by use of the controlled rolling and controlled cooling technology, so that an industrial pure titanium and titanium alloy layer is arranged on one side of the titanium-containing metal layer / pipeline steel layer composite board, and a pipeline steel layer is arranged on the other side. The welding process provided by the invention is simple in process implementation, can realize metallurgical butt-welding engineering production of the titanium-containing metal layer / pipeline steel layer composite board, enables a metallurgically connected seam to be relatively good in appearance and favorable in mechanical property index, and achieves reliable connection of the titanium-containing metal layer / pipeline steel layer composite board while guaranteeing the decay resistance of the titanium-containing metal layer / pipeline steel layer composite board.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

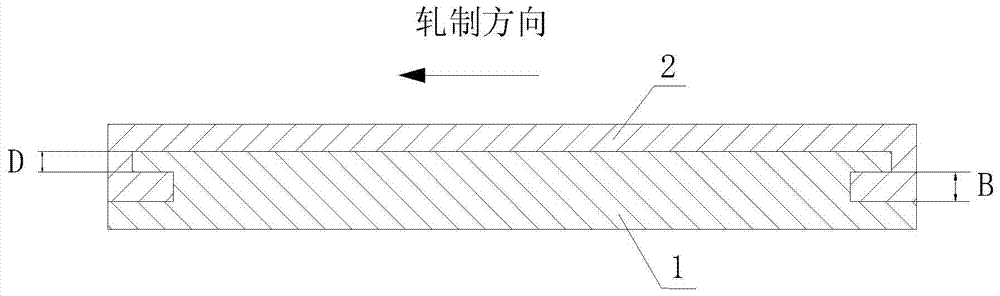

Method of rolling composite plate and strip by slanting corrugating roll

ActiveCN105798062AImprove bindingHigh composite strengthRollsMetal rolling arrangementsComposite strengthAxial force

The invention discloses a method of rolling composite plate and strip by a slanting corrugating roll. The method is characterized by comprising the following steps that a composite slab which is composed of a basal plate and a multilayer plate is rolled by a composite roughing mill with the slanting corrugating roll to prepare a semi-finished slanting corrugated composite plate, and then the semi-finished slanting corrugated composite plate is rolled by a composite finishing mill with a flat roll until the needed thickness to obtain a composite plate, wherein an axial included angle between slanting corrugation and the roll is 10-80 degrees. According to the method, the problems that instant impact is generated during rolling of a transverse corrugating roll, and the plate and strip are in deviation due to the axial force during rolling of a longitudinal corrugating roll are solved, and meanwhile, the combination area of the composite plates after being roughly milled is increased, so that the binding force between the basal plate and the multilayer plate is improved, and the composite strength and the composite efficiency of the composite plate are greatly improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

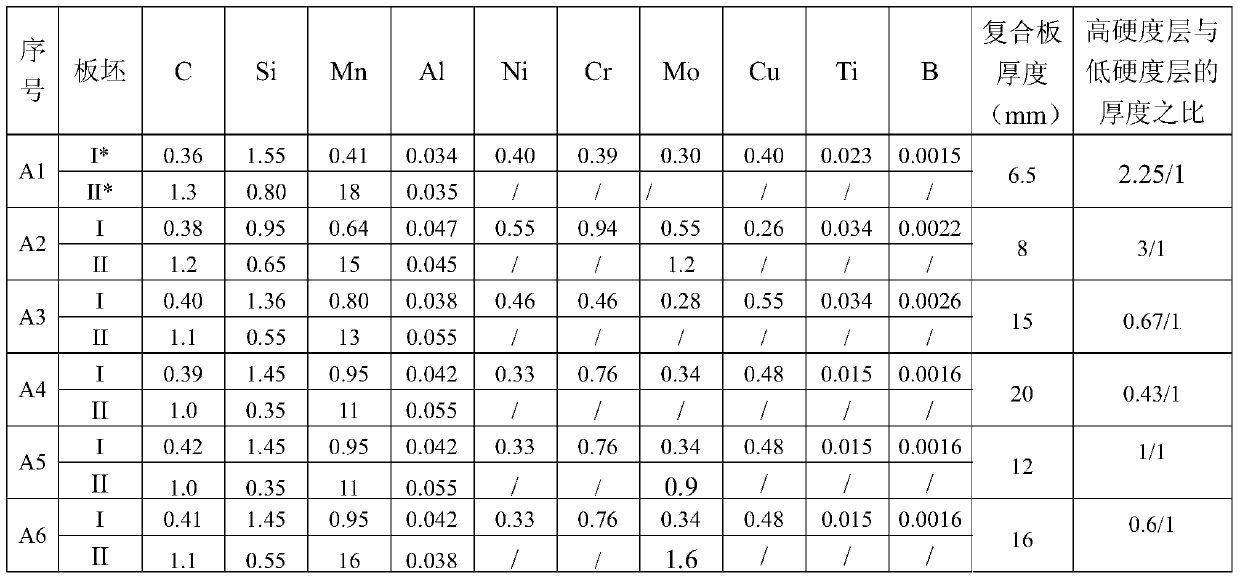

Dual-hardness clad steel plate and production method thereof

InactiveCN105499269AEasy to controlDifferent hardness characteristicsArmourTemperature control deviceHeating timeSheet steel

The invention discloses a dual-hardness clad steel plate. One surface of the steel plate is a high-hardness layer, the other surface of the steel plate is a low-hardness layer, and atom combination is achieved between the high-hardness layer and the low-hardness layer by rolling bonding, wherein Mn13 steel is adopted for the low-hardness layer, and the Brinell hardness of the high-hardness layer is greater than 600. The invention further discloses a production method of the dual-hardness clad steel plate, comprising the following steps: 1. respectively preparing a high-hardness layer slab and a low-hardness layer slab; 2. assembly: preprocessing the combined surface of the slabs, carrying out spherical welded sealing on the binding faces of the slabs, and carrying out vacuumizing treatment on a composite slab after welded sealing; 3. heating; 4. carrying out composite rolling; 5. cooling; and 6. carrying out thermal treatment, wherein the heating temperature is 1050-1100 DEG C, the heating time is 2-3min / mmx thickness, water cooling is performed on the heating slab, and the water temperature is lower than 40 DEG C. The steel plate has different hardness characteristics and good low-temperature toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

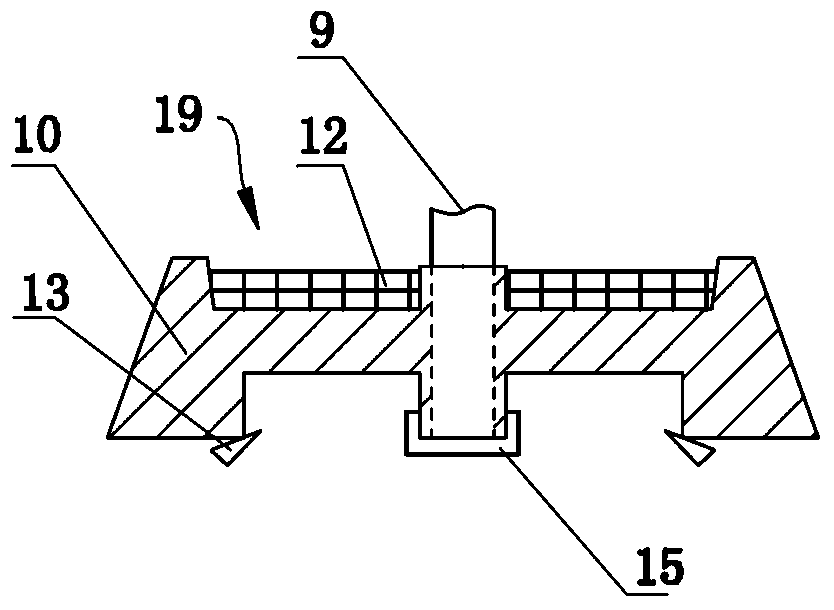

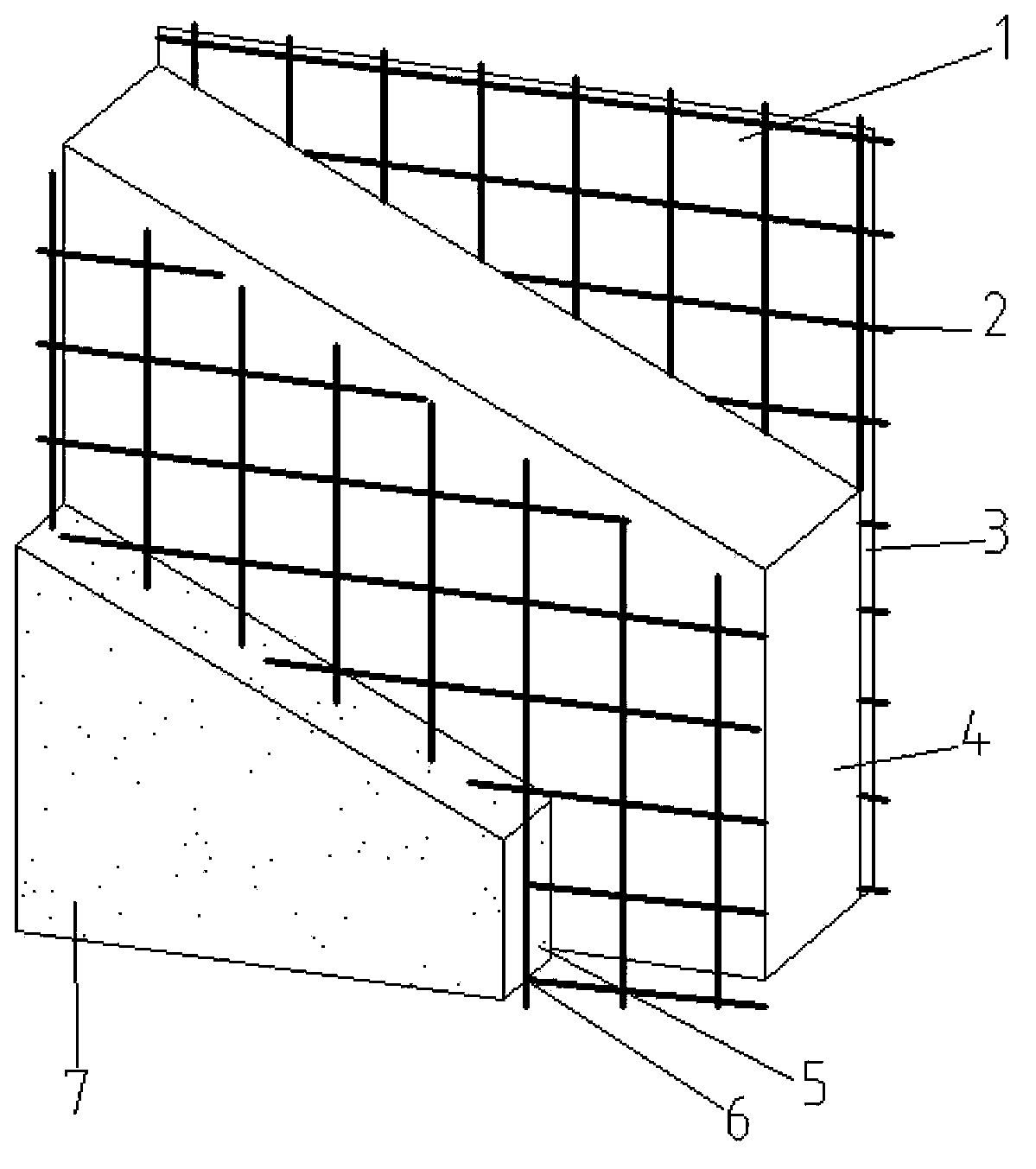

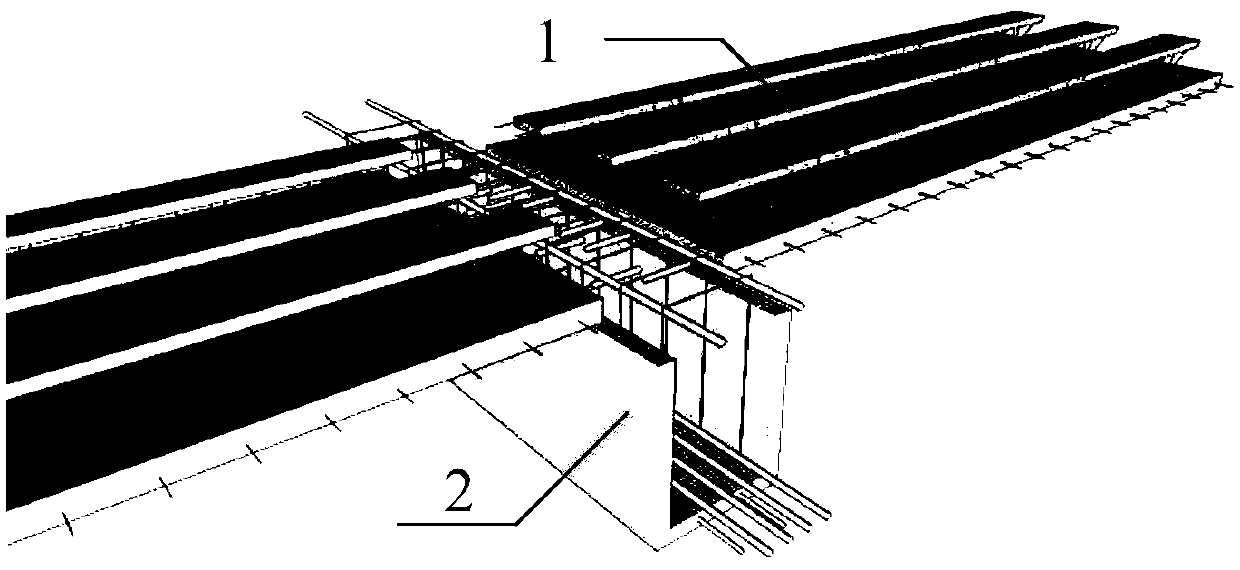

Pre-stressed concrete truss composite slab and manufacturing method thereof

The invention relates to a pre-stressed concrete truss composite slab and a manufacturing method thereof. The pre-stressed concrete truss composite slab comprises a concrete base plate. A truss is arranged on the concrete base plate. The truss comprises an upper chord, first webs and second webs are respectively arranged on two sides of the upper chord, the first webs and the second webs are continuously-bent reinforced steel bars, and the top bent parts of the first webs and the second webs are connected with the outer wall of the upper chord. When hoisting equipment grabs the upper chord for hoisting, the webs, transverse assisting reinforced steel bars and pre-stressed longitudinal ribs are stressed, and the webs are prevented from being stressed independently and falling out of the concrete base plate 10.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

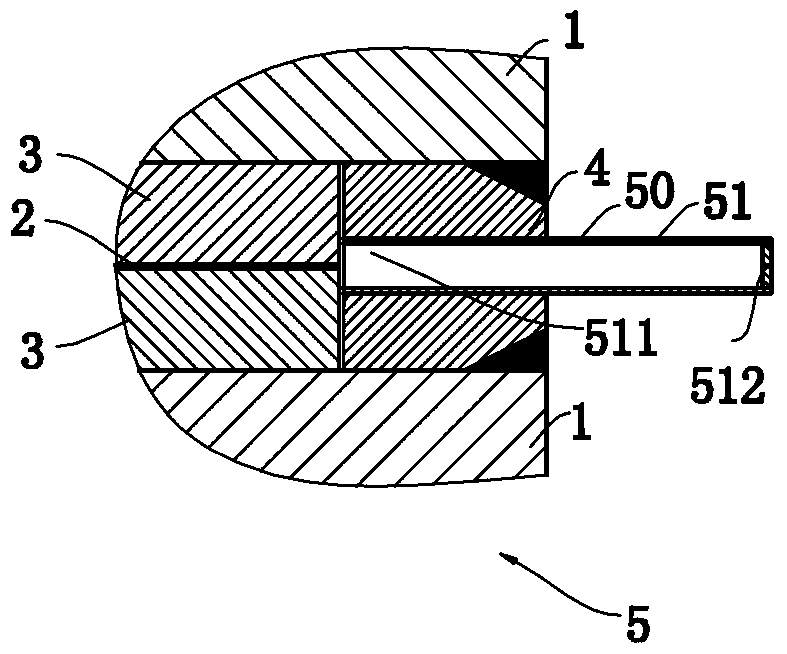

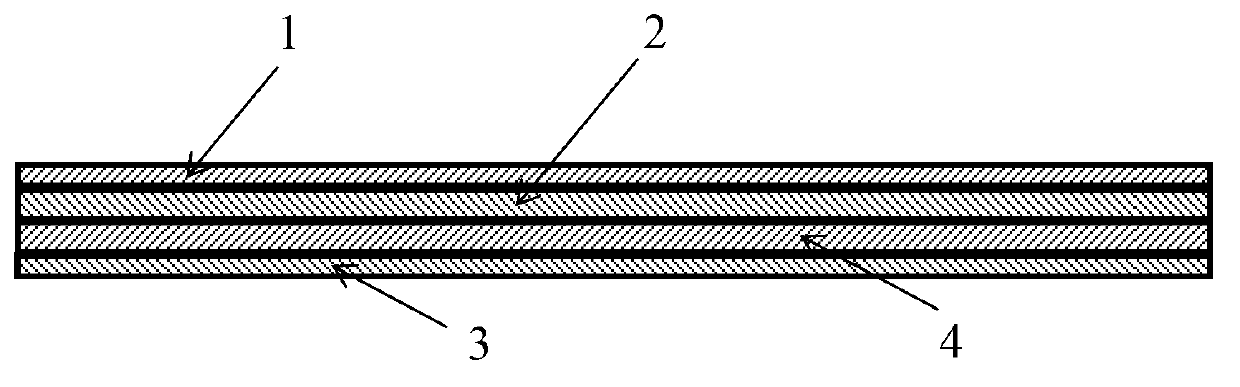

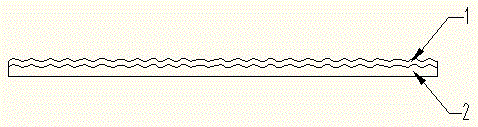

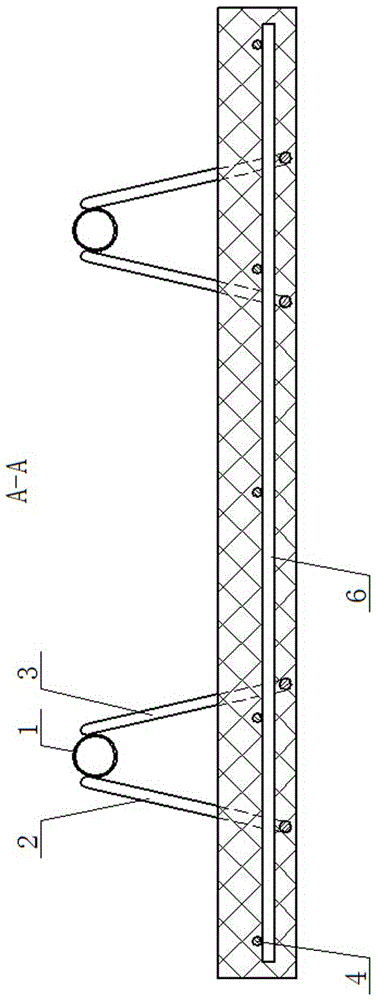

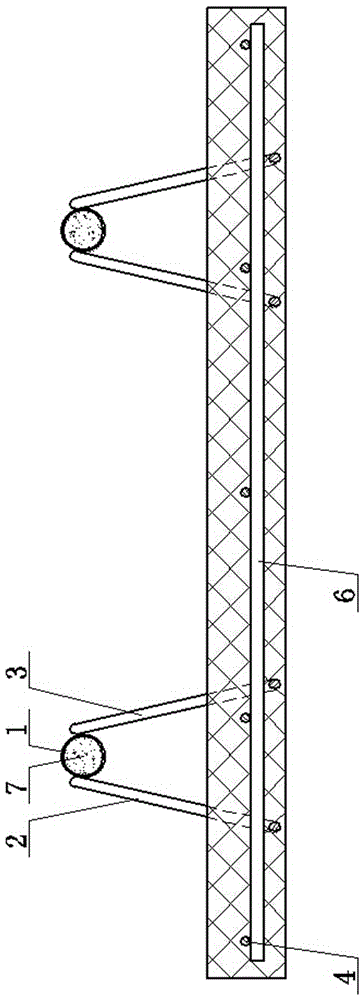

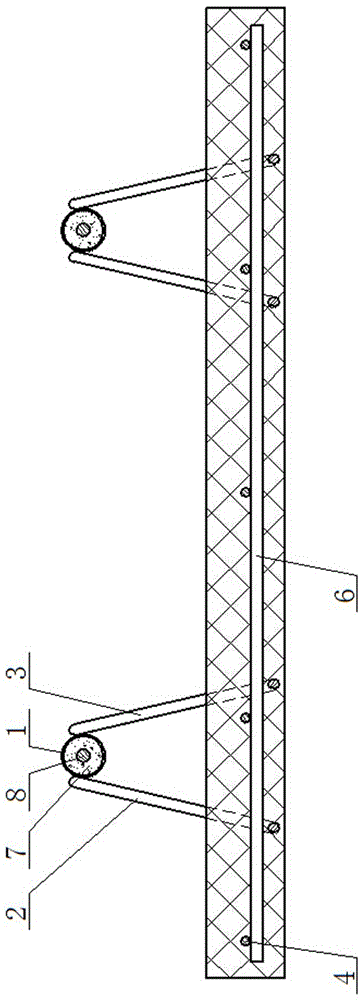

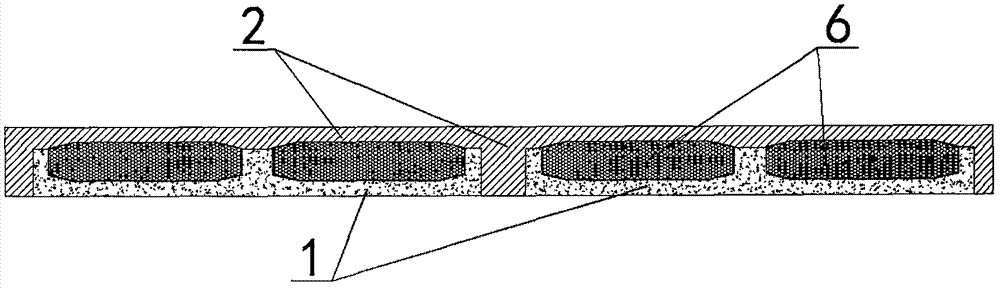

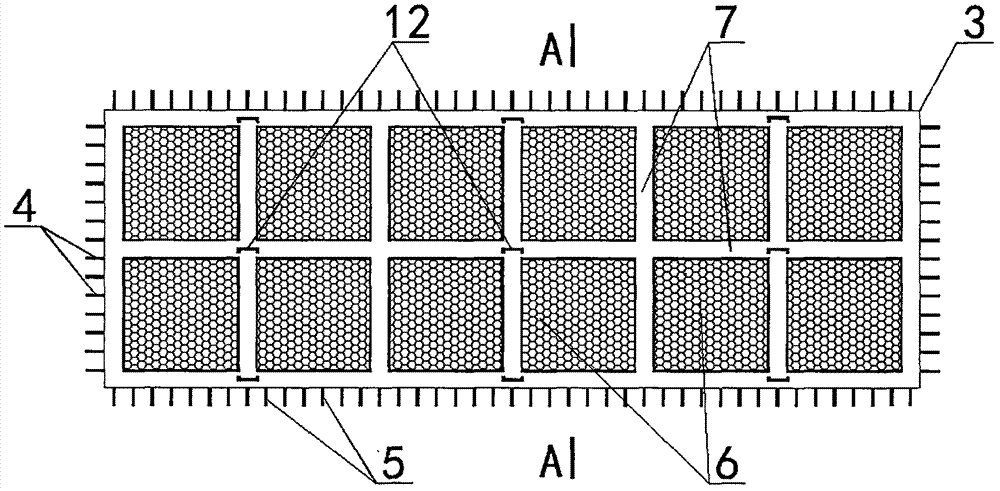

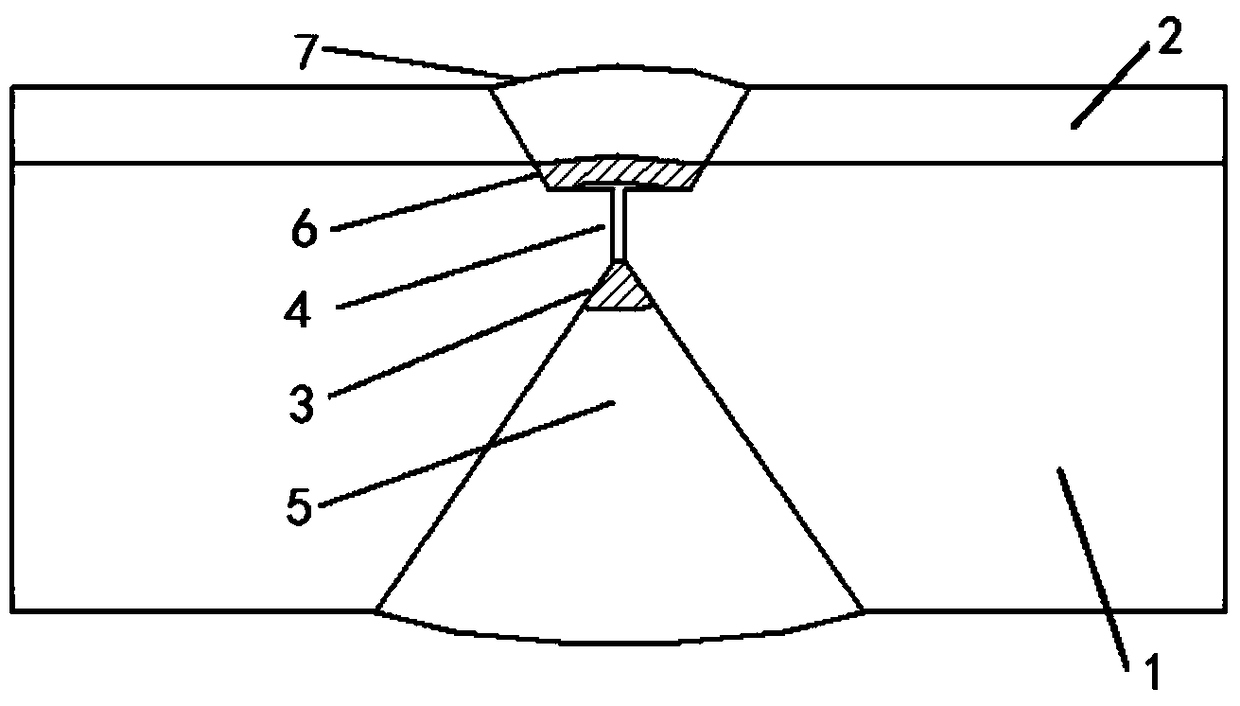

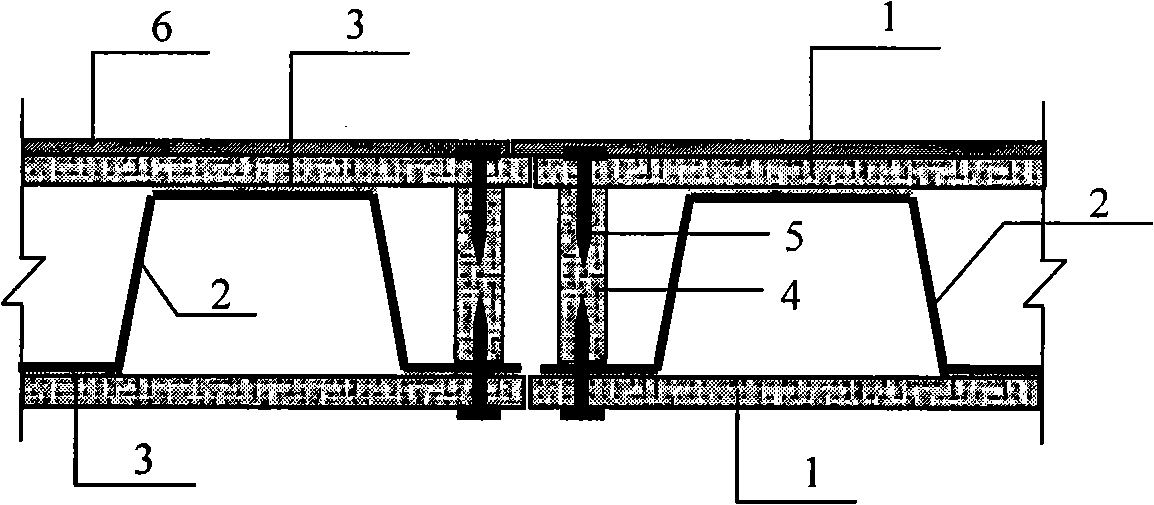

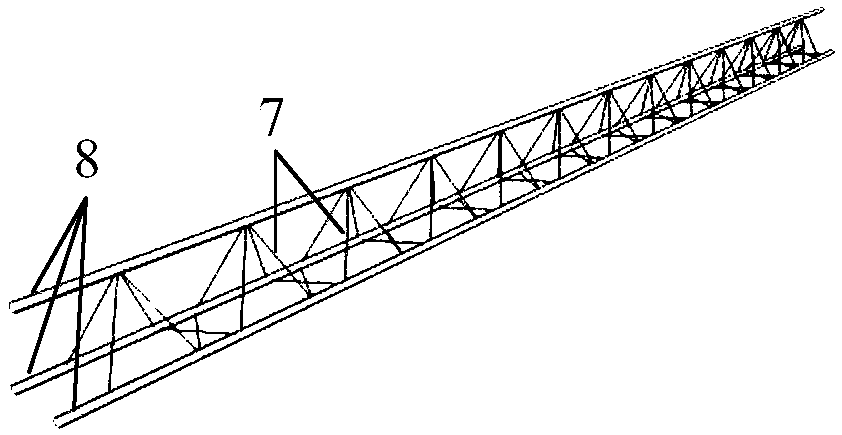

Prestressed hollow composite slab

ActiveCN107313539ALight weightApplicable span is largeFloorsBuilding reinforcementsPre stressComposite slab

The invention relates to a prestressed hollow composite slab and a manufacturing method thereof, and belongs to the field of normal building construction. The composite slab comprises prefabricated pieces (1) and composite layers (2). Thickness of a bottom plate (3) of each prefabricated piece (1) is greater than or equal to 35 mm and less than or equal to 60 mm, prestressed steel wires (4) in the bottom plate are located at the upper parts of transversal steel bars (5), and the length of each prestressed steel wire (4) and each transversal steel bar (5) extending out of the corresponding bottom plate (3) is greater than or equal to 50 mm; the width of each prefabricated piece is greater than or equal to 1500 mm, light-weight material filling pieces (6) are arranged at the upper part of each prefabricated piece (1); the heights of concrete solid ribs (7) between adjacent filling pieces are greater than or equal to 50 mm; the transversal steel bars (5) between adjacent prefabricated pieces (1) are overlaid in a joint area (8), upper part steel bars (10) of the composite slab are bound, composite layer concrete is poured, and the composite slab is formed. According to the prestressed hollow composite slab and the manufacturing method thereof, the self-weight of the composite slab is light, the stiffness in the longitudinal direction and the transversal direction is high, the application range is large, and transportation and installation are convenient. The prestressed hollow composite slab and the manufacturing method thereof have good economic efficiency and applicability, and play a role on promoting the development of building technology.

Owner:徐焱

Welding method of stainless steel lining composite board

ActiveCN108705200AWell formedSmall weld widthWelding/soldering/cutting articlesMetal working apparatusCorrosion resistant alloyComposite slab

The invention discloses a welding method of a stainless steel lining composite board. The welding method comprises the steps that double V-shaped grooves are formed; welding is carried out on the bottom of the V-shape groove in one side of a carbon steel layer by adopting MAG welding, and a pre-welding joint is formed; welding is carried out on a groove between the V-shaped groove in one side of acorrosion-resistant alloy layer and the V-shape groove in one side of a carbon steel layer by adopting plasma welding, laser welding or TIG, and a base layer inner weld joint is formed; welding is carried out on exterior of the pre-welding joint on one side of the carbon steel layer by adopting submerged arc welding to form a base layer outer weld joint; welding is carried out on the bottom of the V-shaped groove at one side of the corrosion-resistant alloy layer by adopting the MAG or the TIG, and a transition layer welding joint is formed; and welding is carried out on the exterior of the transition layer welding joint by adopting the MAG or the TIG, and a composite welding joint is formed. According to the welding method, through the matching of the reasonable groove design and the welding process, high-quality and efficient welding of the stainless steel lining composite board is achieved, the performance is excellent, automatic production is easy to realize, and the wide market prospect is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

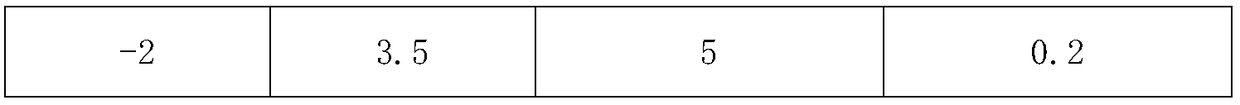

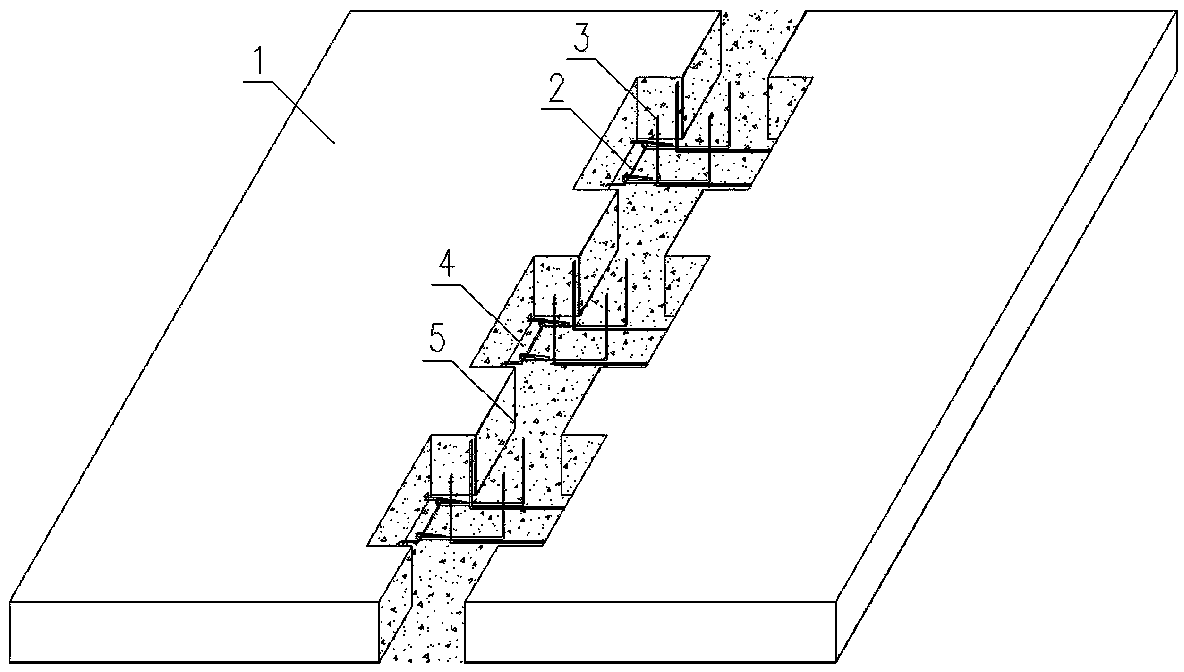

Connection method of precast reinforced concrete slabs

The invention discloses a connection method of precast reinforced concrete slabs, and belongs to the technical field of building structures. The connection method is characterized in that reinforcing steel bars which are fully anchored and of which exposed parts are in a shape of a half ring are embedded on lateral sides of the precast reinforced concrete slabs, transverse reinforcing steel bars are hung on the reinforcing steel bars in the shape of the half ring, and lapped in a reserved gap among the precast reinforced concrete slabs; a template is arranged at the lower part of the reserved gap, the precast reinforced concrete slabs are connected as a whole by pouring concrete in the reserved gap; or the template is arranged at the lower part of the reserved gap, and the concrete is poured in the reserved gap and at the upper parts of the precast reinforced concrete slabs to form a precast concrete composite slab. The connection method disclosed by the invention can improve the integrity of an assembled monolithic concrete structure and promote the development of building industrialization.

Owner:初明进

Plain carbon steel and wear-resistant steel clad steel plate and production method thereof

InactiveCN105363780AGuaranteed Performance RequirementsComposite goodTemperature control deviceMetal rolling arrangementsWear resistantQuenching

The invention relates to a plain carbon steel and wear-resistant steel clad steel plate and a production method thereof and belongs to the technical field of metal clad plate production. Plain carbon steel meets the requirement of GBT700-2006, wear-resistant steel meets the requirement of GBT24186-2009, and an isolation agent comprises MgO and Al2O3. A smelted plain carbon steel billet and a smelted wear-resistant steel billet are break-down rolled, the four edges of each billet are welded and sealed, and vacuumization is performed; after being rolled, the billets with heat are put into water or cooled in the air; and the water entering temperature is controlled between 780 DEG C and 820 DEG C, and an air-cooled plate is subjected to offline quenching and tempering heat treatment. The steel plate has the advantages that the wear-resistant quality of the wear-resistant plate is improved, the service life of the wear-resistant plate is prolonged, and important significance in energy conservation, energy consumption reduction and the like is achieved.

Owner:SHOUGANG CORPORATION

Profiling steel plate - bamboo slab rubber combining floor and manufacturing method thereof

The invention relates to a composite slab of profiled steel sheet-bamboo plywood and a making method thereof. The structure of the invention is that a profiled steel sheet is held between two bamboo plywood; the interface of the bamboo plywood and the steel plate are connected by adhesive with high intensity; periphery of the board are sealed with bamboo lath and fixed by bolts; the upper surface of the composite slab is bonded with rearranged bamboo-made panel by adhesive, causing the composite slab to have the function of structure function as well as decoration function. The composite slab produced in the method of the invention is characterized by small dead weight, high intensity, large rigidity, thin board body, good extensity, excellent anti earthquake performance, requiring no secondary decoration, fast construction speed and high industrialization degree. The composite slab of the invention can also be used as construction wall, has good force-bearing performance, can realize the purpose of substituting wood, steel and other materials by using bamboo, be widely applied to various light construction, mobile house, floor-increase building, ship, etc. and has good market development prospect.

Owner:NINGBO UNIV

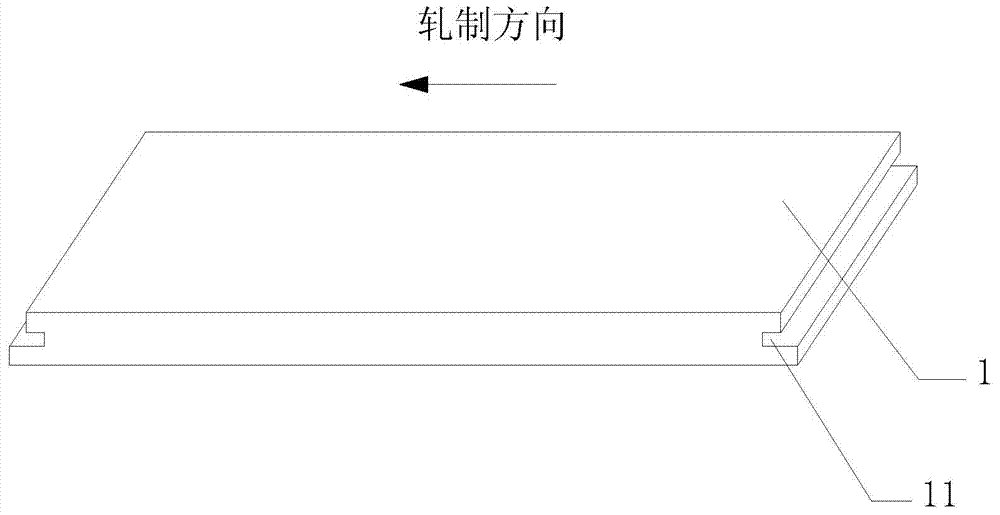

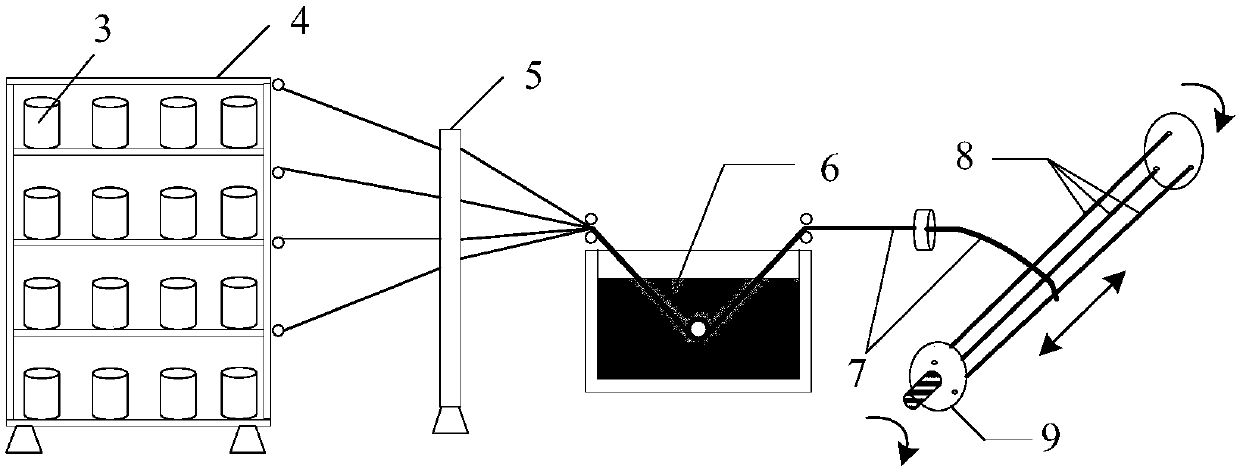

Method of lock catch type vacuum rolling metal composite plate

InactiveCN103495604AHigh composite strengthEasy to separateAuxillary arrangementsMetal rolling arrangementsComposite strengthVacuum pumping

A method of a lock catch type vacuum rolling metal composite plate comprises the following steps that penetrated grooves are machined in the end faces of the two ends, vertical to the rolling direction, of a base plate respectively, and correspondingly, L-shaped embedding strips are welded to corresponding positions at the two ends of a shroud plate respectively; greasy dirt on the surface to be compounded is cleaned; the L-shaped embedding strips at the two ends of the shroud plate slide into the grooves in the two ends of the base plate to enable a composite slab formed by the shroud plate and the base plate to be in an embedded state. Sealing plates are connected to the periphery of the composite slab in a welded mode to enable composite space to be sealed; holes are formed in the sealing plates, air between the shroud plate and the base plate is extracted through the holes, and the holes are blocked after vacuum pumping is carried out; the composite slab is heated to 950-1300 DEG C to be rolled until the composite slab reaches a needed thickness to form the metal composite plate; edge cutting is carried out on the rolled metal composite plate, the sealing plates are removed, and rolling of the composite plate is completed. According to the method, mutual movement of adjacent slabs in the rolling direction and the slab thickness direction can be effectively constrained, rolling stability is improved, and meanwhile composite strength of the metal composite plate is greatly increased.

Owner:武汉钢铁有限公司

Beam-slab structure for marine environment and building method thereof

The invention discloses a beam-slab structure for marine environment. The beam-slab structure comprises a prefabricated UHPC(ultrahigh performance concrete) formwork composite beam and a prefabricatedFRP(fiber reinforce plastic) rebar truss composite slab ; the prefabricated UHPC formwork composite beam comprises an UHPC formwork, beam bottom formwork internal prestress FRP rebars are arranged inside the U-shaped UHPC formwork, FRP stirrups are arranged in a U-shaped area of the U-shaped UHPC formwork, FRP bearing rebars are arranged on the top of the FRP stirrups, and FRP tensile longitudinal rebars are arranged at the bottom of the FRP stirrups; the prefabricated FRP truss composite slab comprises an FRP rebar truss, slab bottom formwork internal prestress FRP rebars are arranged at thebottom of the FRP rebar truss, slab bottom transverse FRP rebars are arranged on the slab bottom formwork internal prestress FRP rebars, UHPC bottom plates are arranged on the slab bottom transverseRFP rebars, and prefabricated concrete ribbed slabs are arranged on the top of the DRP rebar truss. The invention further discloses a building method of the beam-slab structure. Local materials such as sea water and sand can be used for mixing sea water and sand concrete which can be used for hoisting construction immediately, and meanwhile, the beam-slab structure has excellent chloride ion erosion resistance capacity.

Owner:SOUTHEAST UNIV

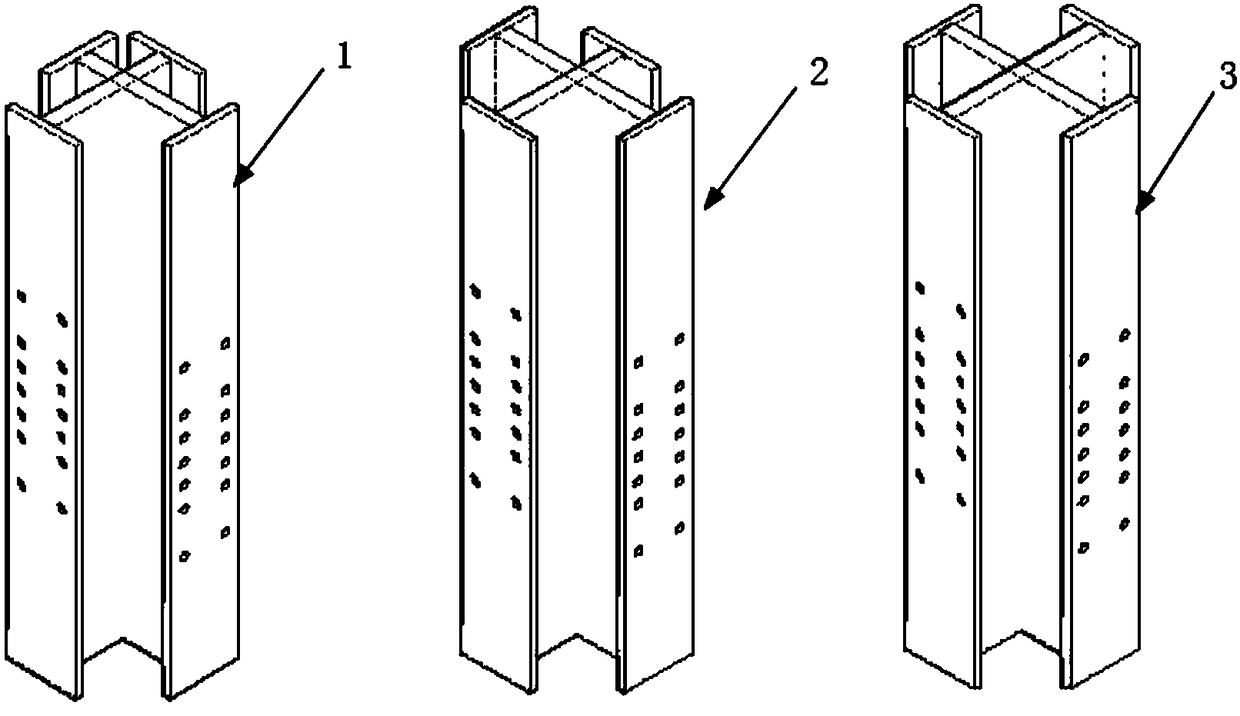

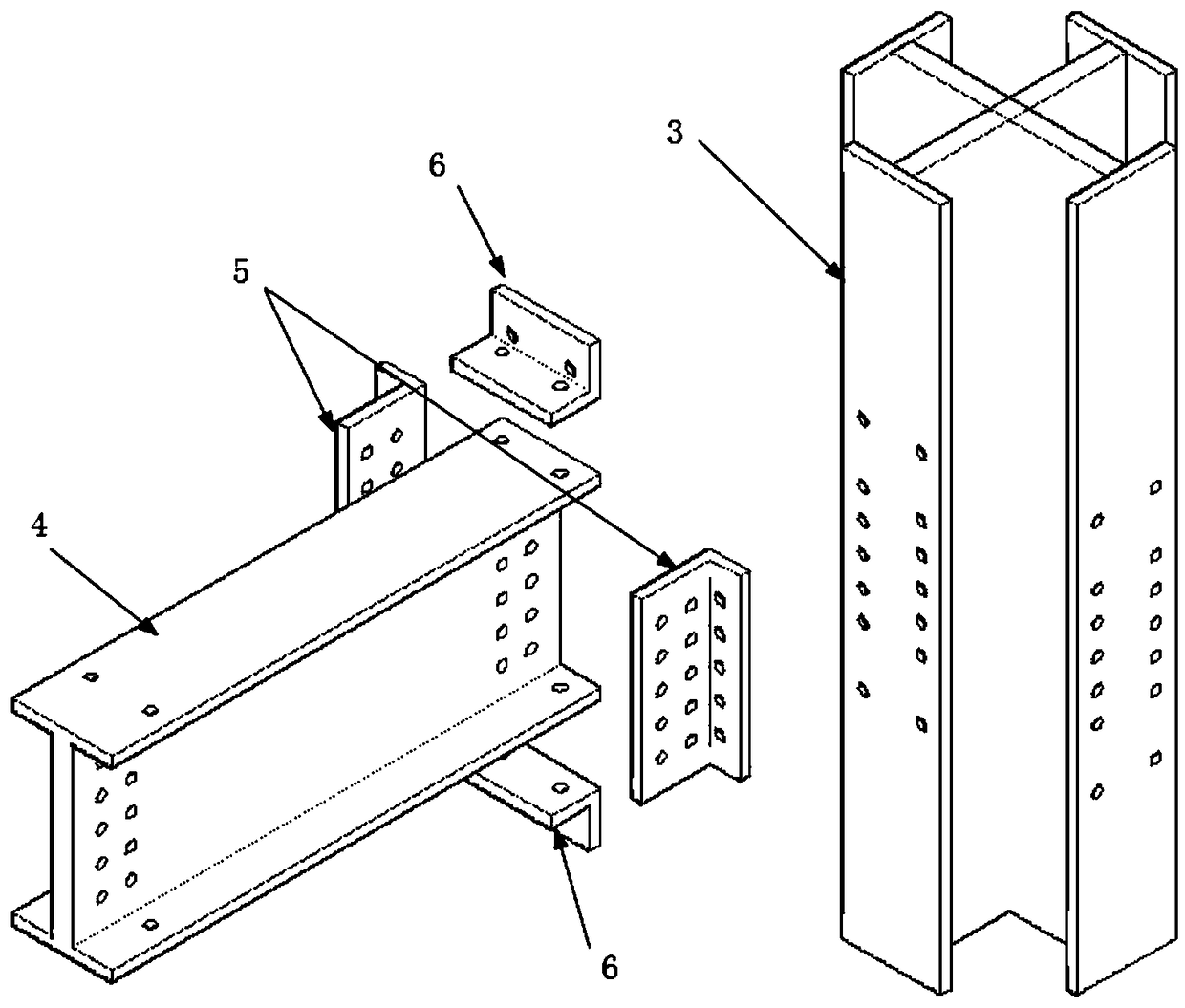

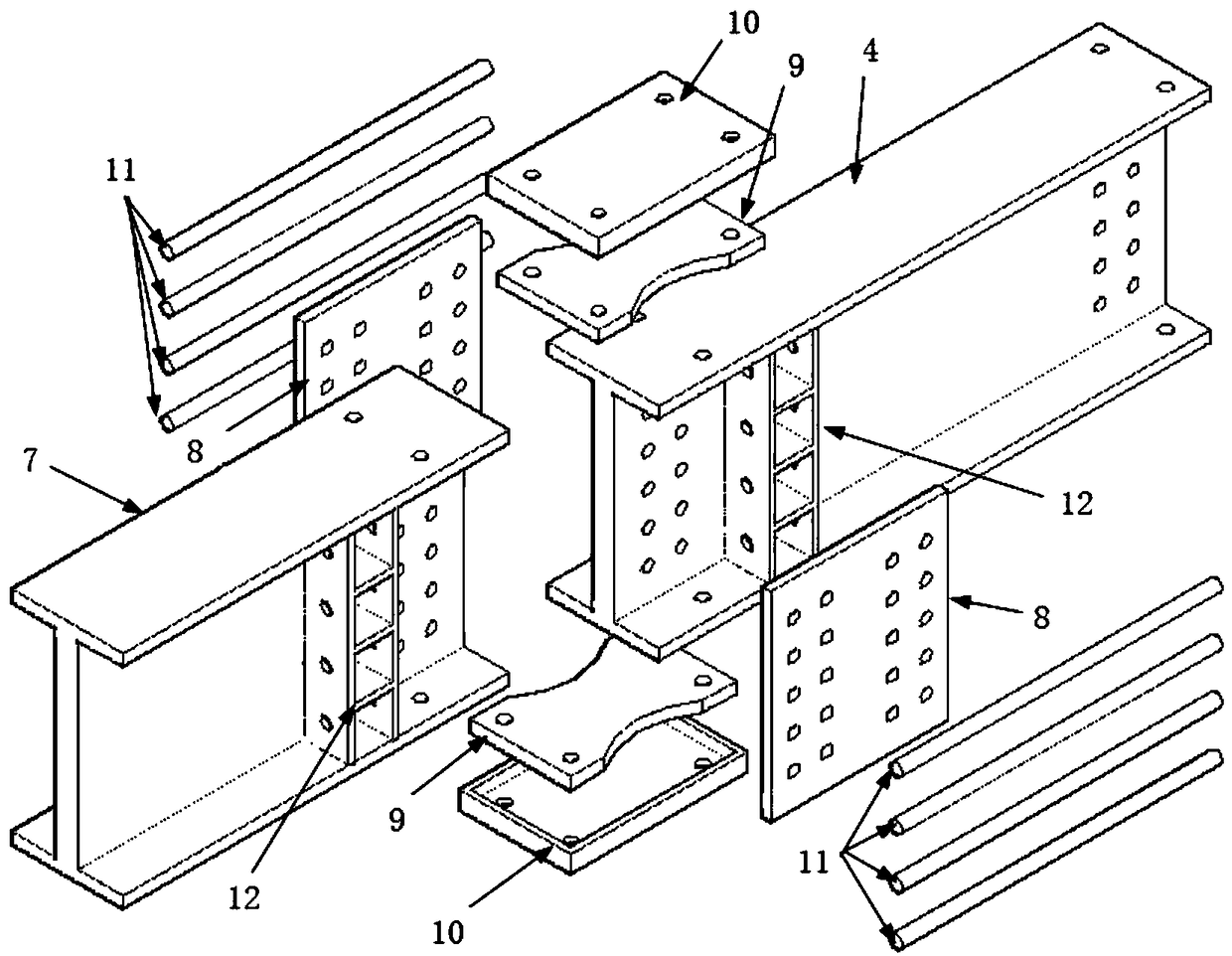

Assembling multi-section beam center support steel frame capable of self-centering after earthquake

The invention discloses an assembling multi-section beam center support steel frame capable of self-centering after earthquake. An I-beam is connected with special-shaped columns of different forms through a web angle steel and a flange angle steel to form a connecting form of full bolts without weld seams; a middle I-beam is connected with an end I-beam through a web connecting plate and a high-strength silicone rubber plate to form a connecting form of full bolts without weld seams with good ductility and high energy consumption; a prestressed steel cable is applied at the connecting part ofthe full bolts without the weld seams of the middle I-beam and the end I-beam to form self-centering nodes after the prestressed earthquake, and after the nodes are connected in sequence, a precast concrete-profiled steel plate composite slab or a poured concrete slab is assembled to form an assembling multi-section beam center support steel frame structure system capable of self-centering afterthe earthquake.

Owner:BEIJING UNIV OF TECH

Method for preparing titanium steel cladding board with thin coating

InactiveCN104368600ALow investment costAvoid discountingTemperature control deviceWork treatment devicesProduction lineExplosive cladding

The invention discloses a method for preparing a titanium steel cladding board with a thin coating. The method comprises the steps that (1) an explosive cladding blank with a titanium plate as the upper layer and a steel plate as the lower layer is selected; (2) surfacing cleaning is conducted on the cladding blank; (3)the cleaned cladding blank is put in a stepping type heating furnace to be heated, and steel is loaded at the furnace tail of the stepping type heating furnace; (4) the evenly-heated cladding blank penetrates through a conveying roller table to a rolling mill to be descaled and rolled, the press-down rate of a first gate of rolling is controlled to be 20% or higher, the press-down rate of the rolling of the last gate is controlled to be 10% or lower, and the total press-down rate is 60%-90%. Air cooling is conducted on the cladding board after rolling is completed, and then the rolled cladding board is straightened. According to the method for preparing the titanium steel cladding board with the thin coating, under the premises that other auxiliary devices are not added, the descaling gates and the press-down amount in the rolling process are effectively controlled by using existing equipment of a moderate thickness board production line and by adopting the stepping type heating furnace for heating, and it is ensured that the rolled titanium steel cladding board is good in shape and good in comprehensive performance.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com