Method of rolling composite plate and strip by slanting corrugating roll

A technology of rolling compounding and oblique corrugation, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of instantaneous impact on the strip, deviation, etc., to increase the bonding force, increase the bonding area, and improve the composite The effect of strength and compounding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

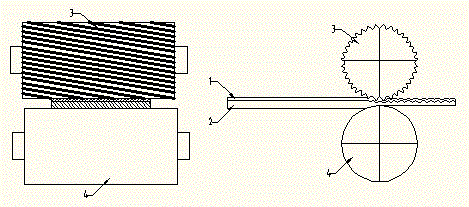

Method used

Image

Examples

Embodiment 1

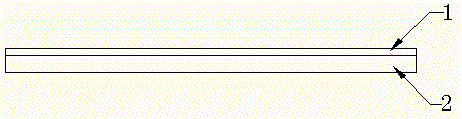

[0032] Example 1: Preparation of titanium steel-carbon steel single-sided composite panel

[0033] Billet making: Select TC3 titanium steel plate and Q345R carbon steel plate to assemble blanks according to the ratio of 1:4. The size of titanium steel plate is 40mm thick×1500mm wide×3000mm long, which is used as double plate 1; the size of carbon steel plate is 160mm thick×1500mm wide×3000mm long. As the base plate 2; clean the carbon steel plate and titanium steel plate until the metal base is seen; stack the double plate 1 and the base plate 2, send them to the press for compaction, and use 15mm thick carbon steel plates to spot weld around the stacked composite slabs Afterwards, submerged arc welding is used to package and weld, and the end of the welded composite slab blank is drilled to evacuate, and then the hole is closed to obtain a composite slab, such as figure 1 , the thickness of the composite slab is 200mm;

[0034] Heating: Send the qualified composite slab to t...

Embodiment 2

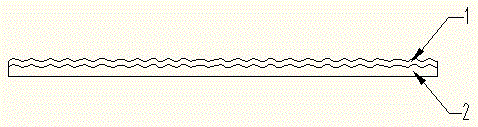

[0038] Embodiment 2: Preparation of copper plate-aluminum plate-copper plate double-sided composite board:

[0039] Blank making: Select T2 copper plate, LY2 aluminum plate and T2 copper plate to assemble blanks according to the ratio of 1:3:1. The size of the aluminum plate is 120mm thick×800mm wide×3000mm long as the base plate 2, and the size of the copper plate is 40mm thick×800mm wide×3000mm long. as the upper cladding board 1 and the lower cladding board 1'; clean the aluminum board and two copper boards until the metal base is seen; stack the lower cladding board 1', the base board 2 and the upper cladding board 1, and send them to the press Machine compaction, spot welding around the stacked composite slabs to obtain composite slabs, such as Image 6 , the thickness is 200mm;

[0040] Cleaning: Send the qualified composite slab to the cleaning equipment for cleaning;

[0041] Rough rolling: Send the cleaned composite slab to the composite rough rolling mill for rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com