Patents

Literature

417results about How to "High composite strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film made from graphene-carbon nanotube composite material and preparation method of film

InactiveCN103725263AHave flexibilityGood flexibilityHeat-exchange elementsCooling/ventilation/heating modificationsComposite filmLiquid-crystal display

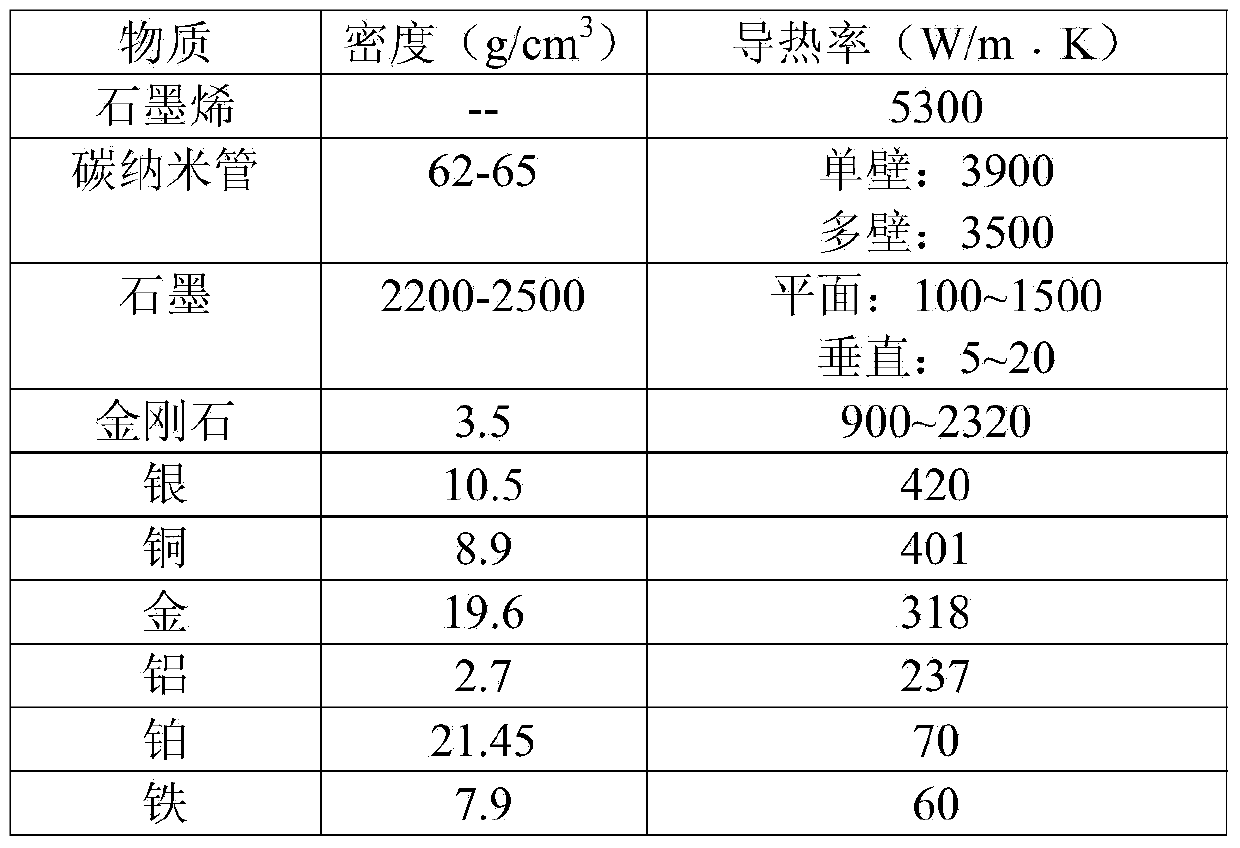

The invention discloses a film made from a graphene-carbon nanotube composite material and a preparation method of film. The preparation method comprises the following steps: mixing graphene and carbon nanotubes sufficiently and evenly via stirring and ultrasonic dispersion, reacting the graphene with the carbon nanotubes sufficiently via hydrothermal or solvothermal conditions, removing solvents after finishing the reaction to obtain the graphene-carbon nanotube composite materials which are preformed and tangled in a network structure, forming the film on the surfaces of various base materials via coating, spraying, spin-coating and filtering the obtained graphene-carbon nanotube composite materials to obtain the composite film made from the graphene-carbon nanotube composite materials and the base materials, and removing the base materials to obtain the film made from the graphene-carbon nanotube composite materials. According to the method, graphene-carbon nanotube composition is realized simply and effectively and dispersed in the solvents stably, and the two obtained films can be applied in the aspects of heat conduction and heat radiation systems of high calorific value electronic devices, LED (light-emitting diode) lamps and liquid crystal display products.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

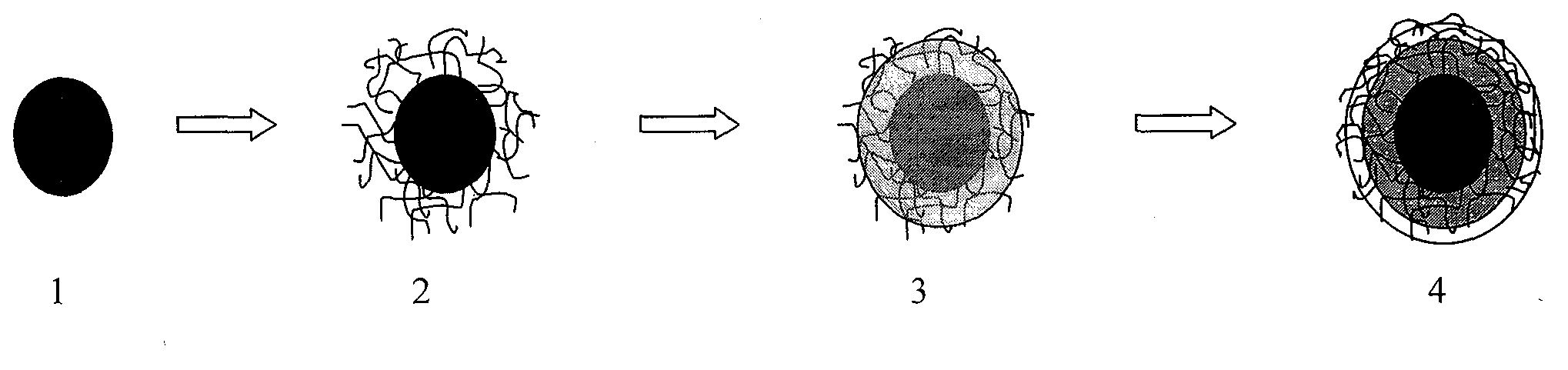

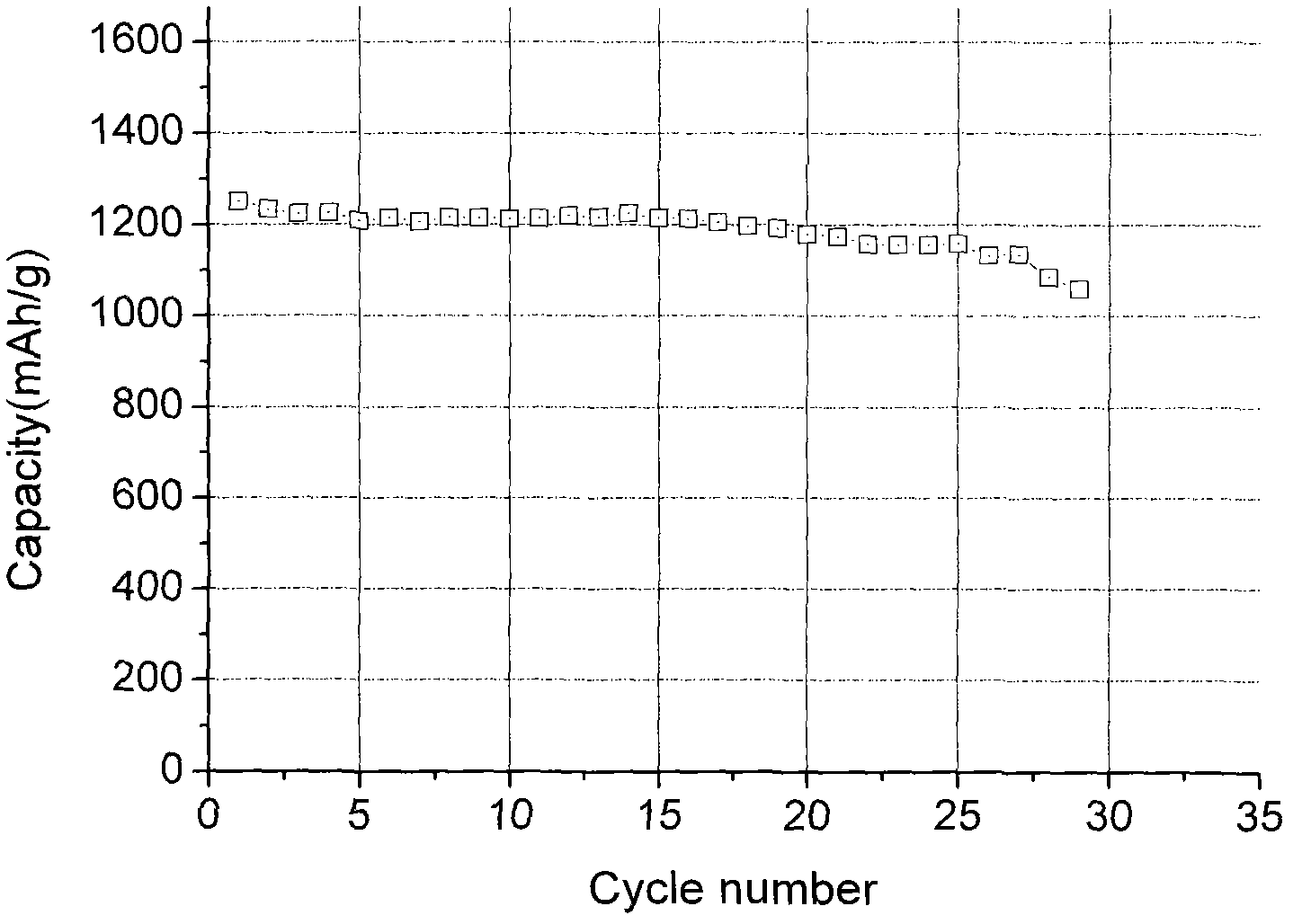

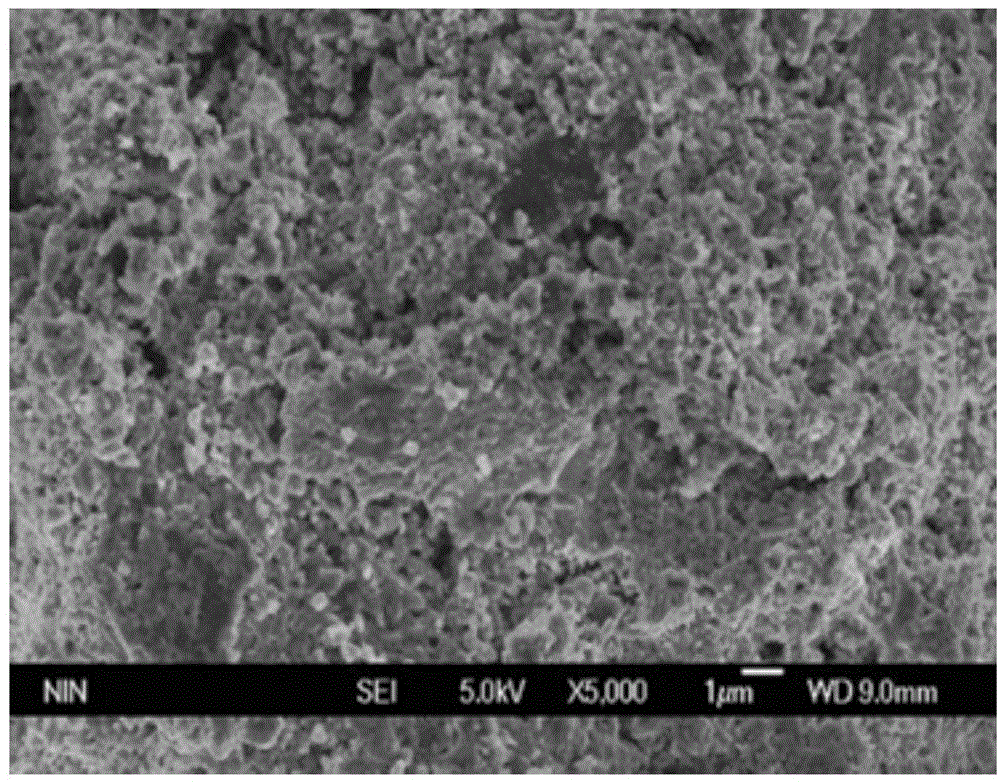

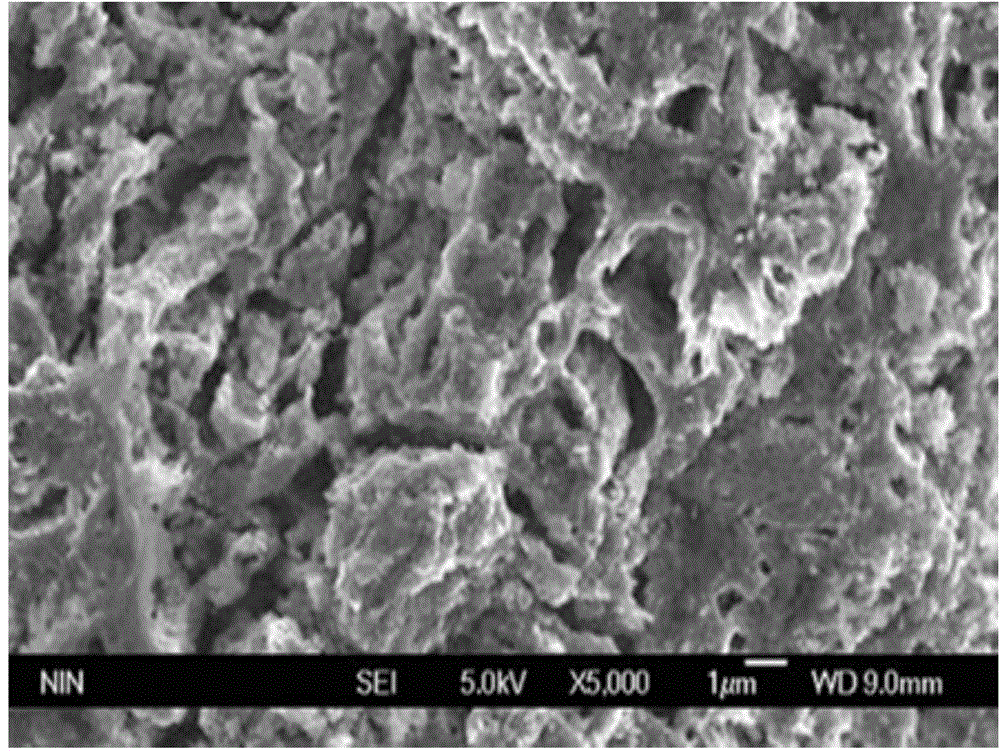

Nano carbon sulfur composite material with network structure and preparation method of nano carbon composite material

InactiveCN102142554AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCross-linkPorosity

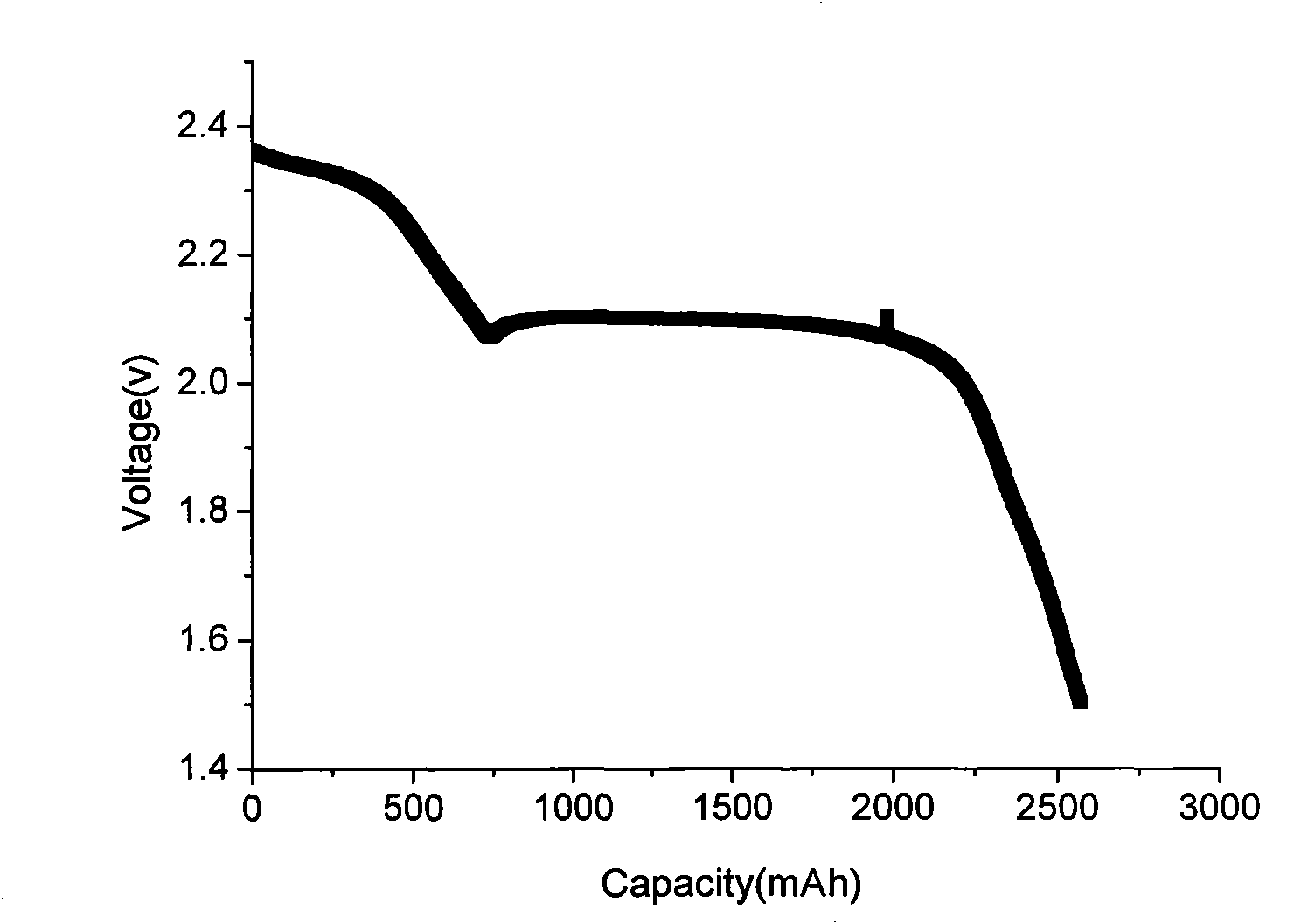

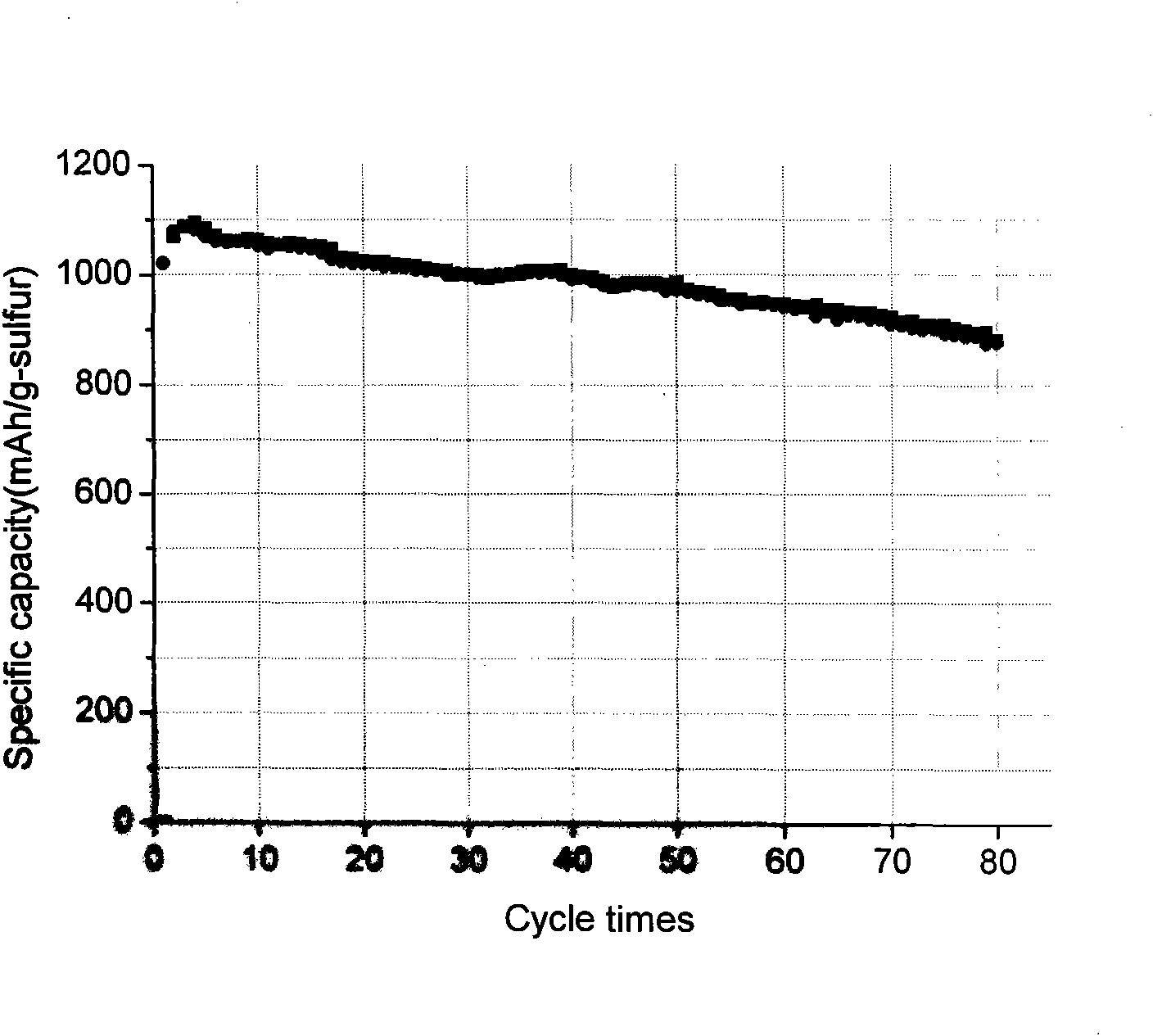

The invention relates to a nano carbon material with a network structure consisting of polymer chains, in particular to a nano carbon sulfur composite material with a network structure suitable to be used in a secondary lithium sulfur battery anode and a preparation method thereof. The carbon sulfur composite material is formed by adopting the following steps of: introducing functional groups onto carbon particles by adopting the electric conductivity and the porosity of a carbon material and the reaction capacity of similar condensed aromatics of the carbon material and by means of an irreversible chemical reaction; introducing the polymer chains, wherein the polymer chains are stretched, bent and cross-linked on the surfaces of the carbon particles to form a cross-linked network structure; and compounding a sulfur element or a polysulfide (m is more than 2) containing -Sm- structure into the network structure to form the nano carbon sulfur composite material with the network structure. The carbon sulfur composite material has a rich cross-linked network structure, nano-scale network pores constrain the sulfur element or the polysulfide (m is more than 2) containing the -Sm- structure in the network, and the active substances are limited in a certain region to react, so that the composite material has predominant electrochemical performance.

Owner:NO 63971 TROOPS PLA

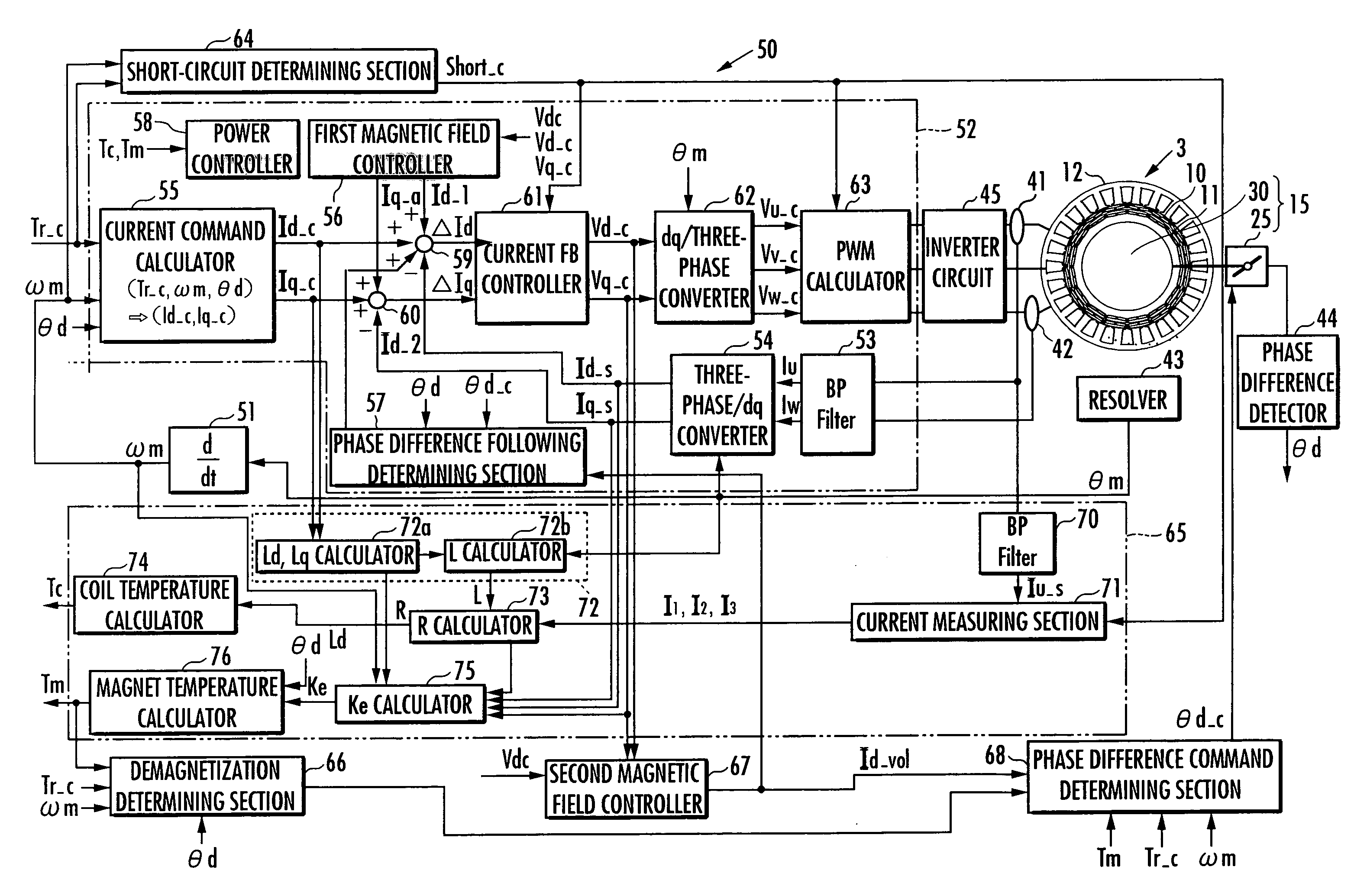

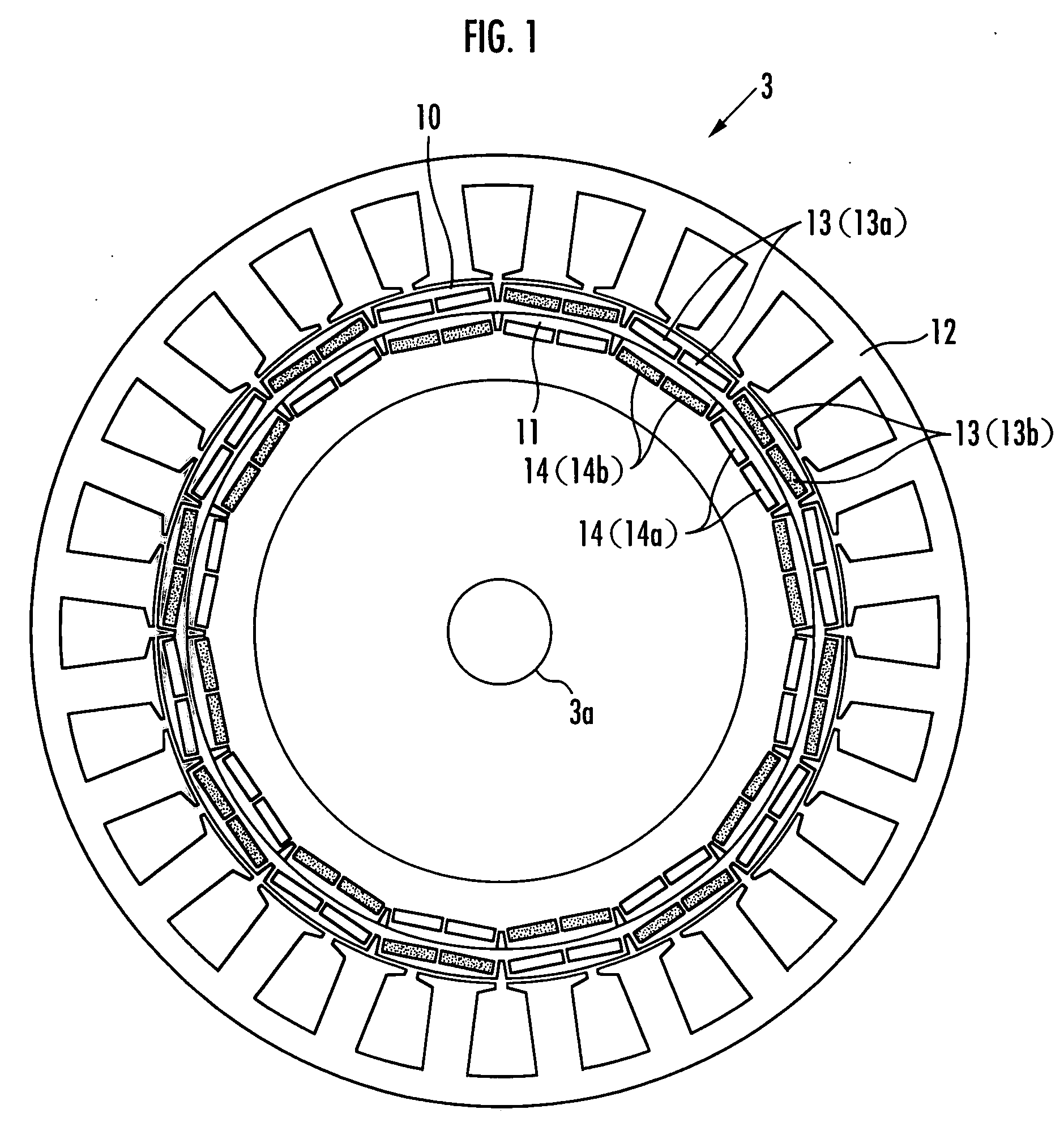

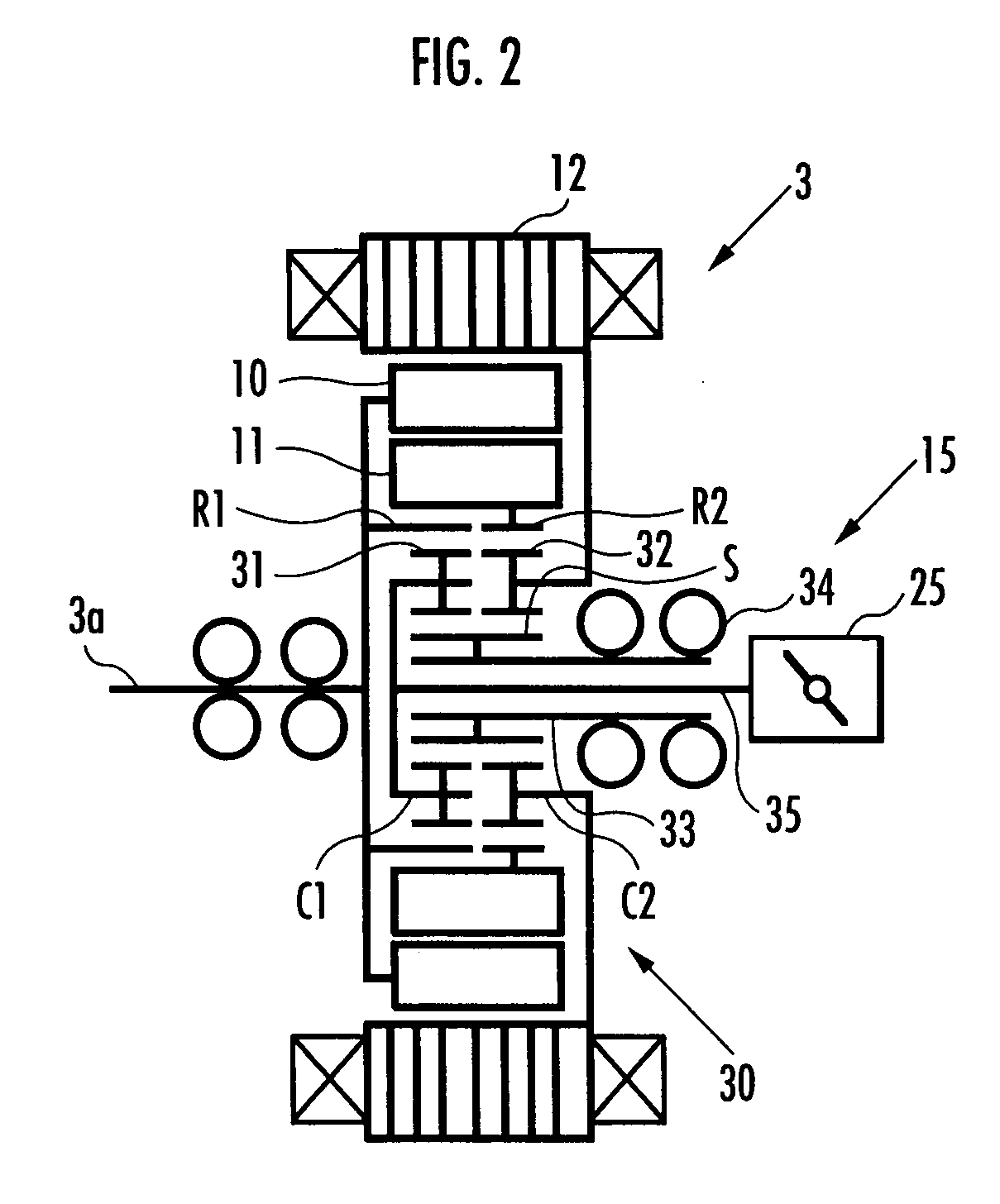

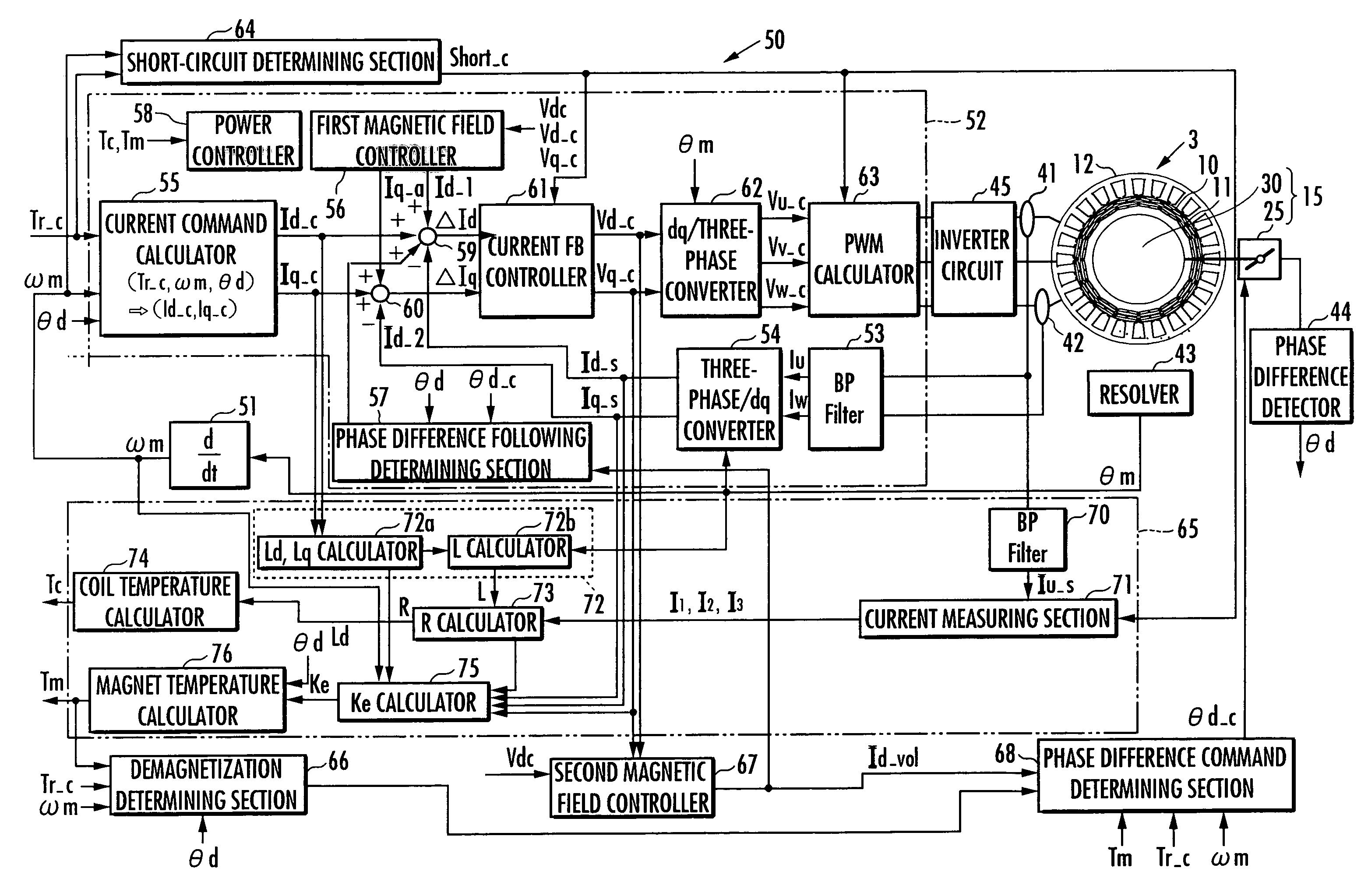

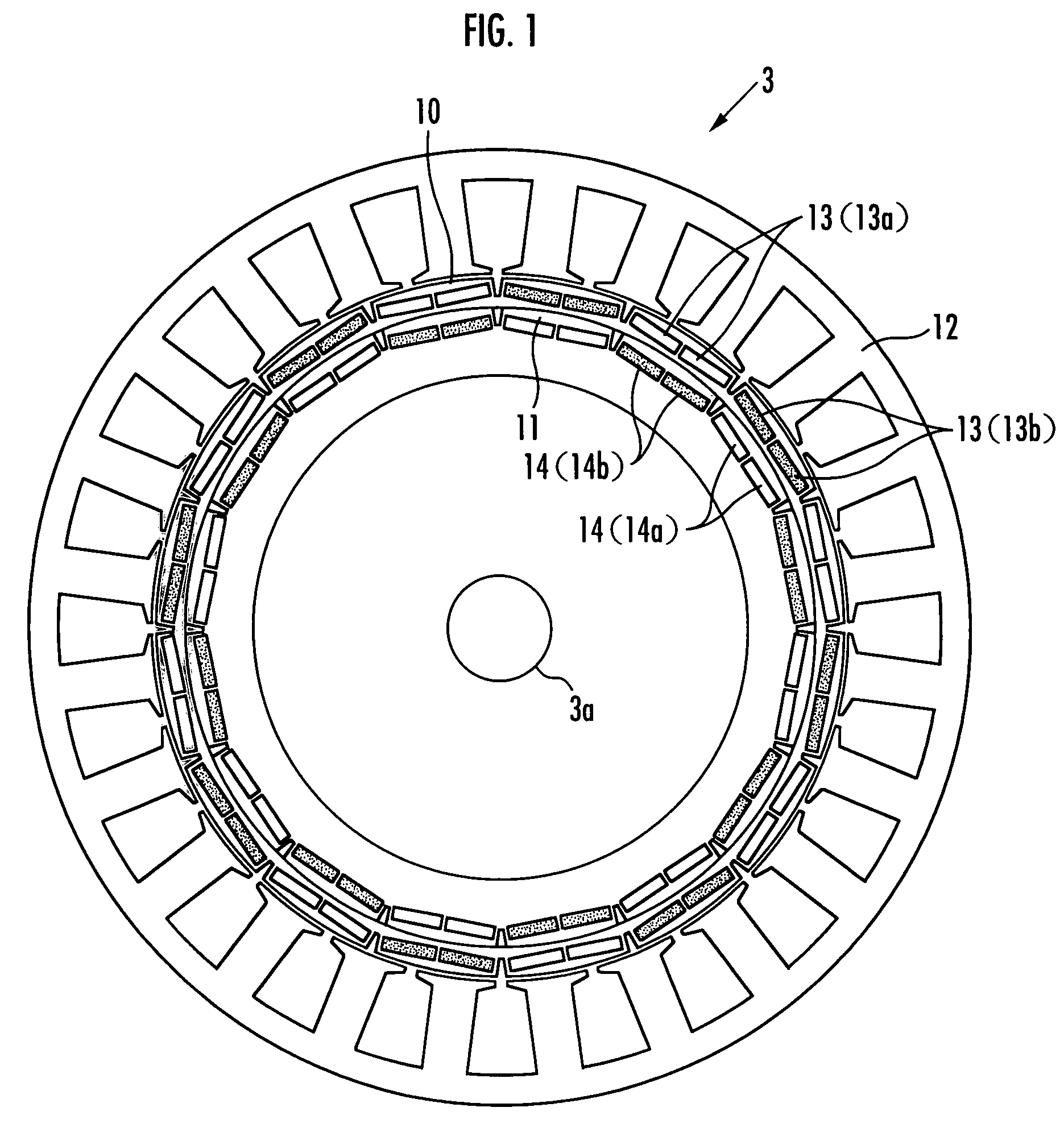

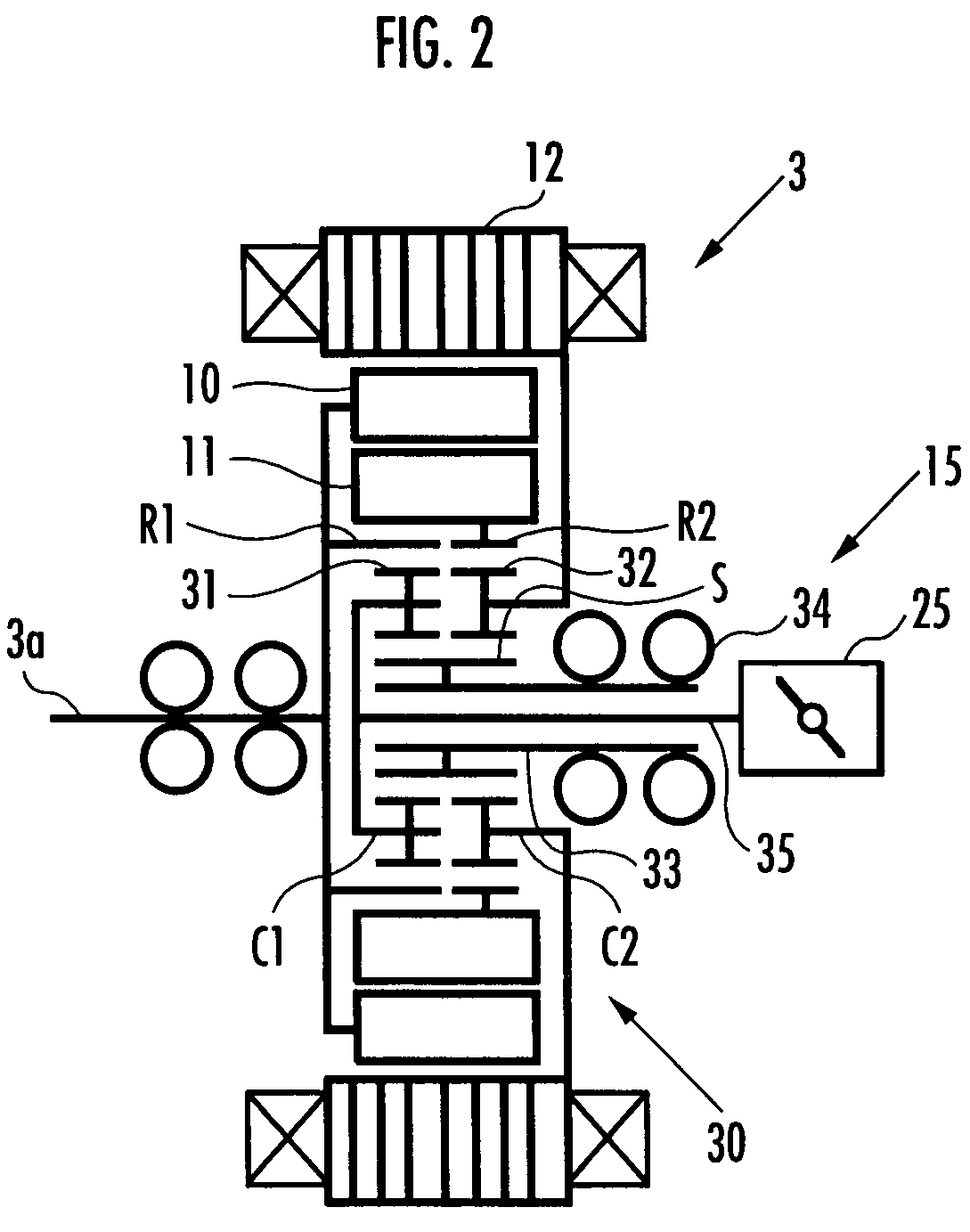

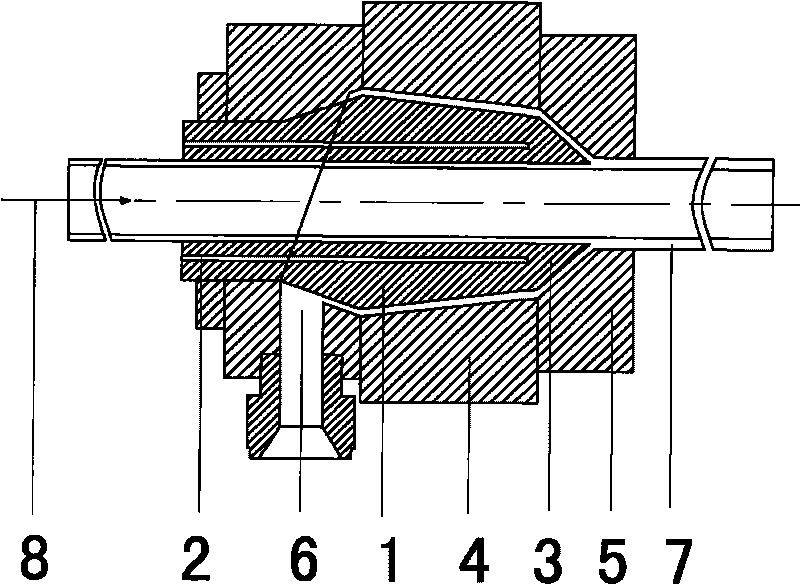

Controller for motor

InactiveUS20080036415A1High strengthHigh composite strengthSingle-phase induction motor startersSynchronous motors startersComposite fieldPhase difference

There is provided a controller for a motor capable of changing the phase difference between two rotors that can prevent demagnetization of permanent magnets or the rotors. The motor has two rotors each having a permanent magnet and phase difference changing driving means for changing the phase difference between the rotors. The controller has a demagnetization determining means for determining whether or not demagnetization of the permanent magnets of the rotors occurs during operation of the motor, and rotor phase difference controlling means for controlling the phase difference changing driving means to change the phase difference between the rotors from a current phase difference to a phase difference that results in a higher strength of a composite field of the permanent magnets if the result of determination by the demagnetization determining means is positive.

Owner:HONDA MOTOR CO LTD

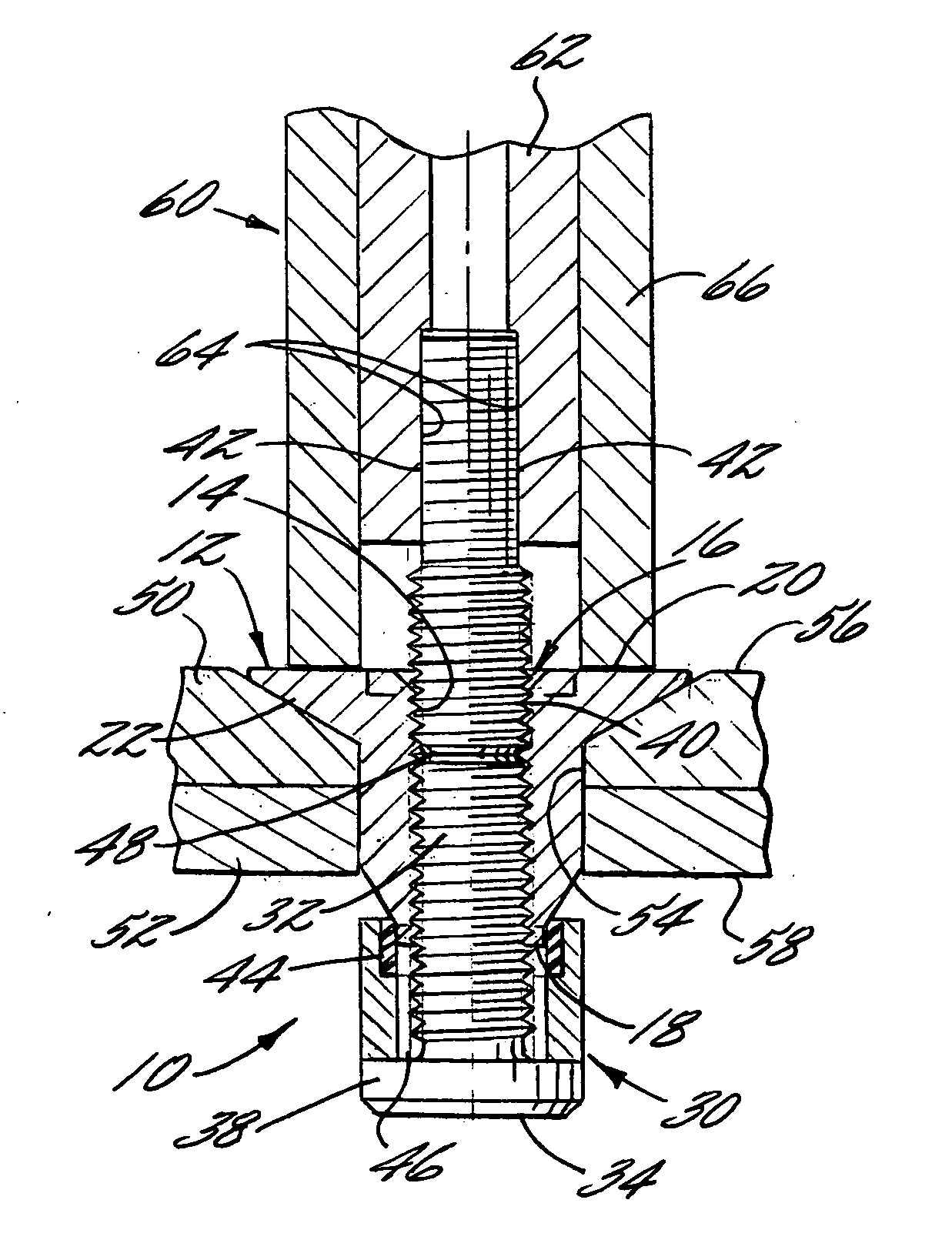

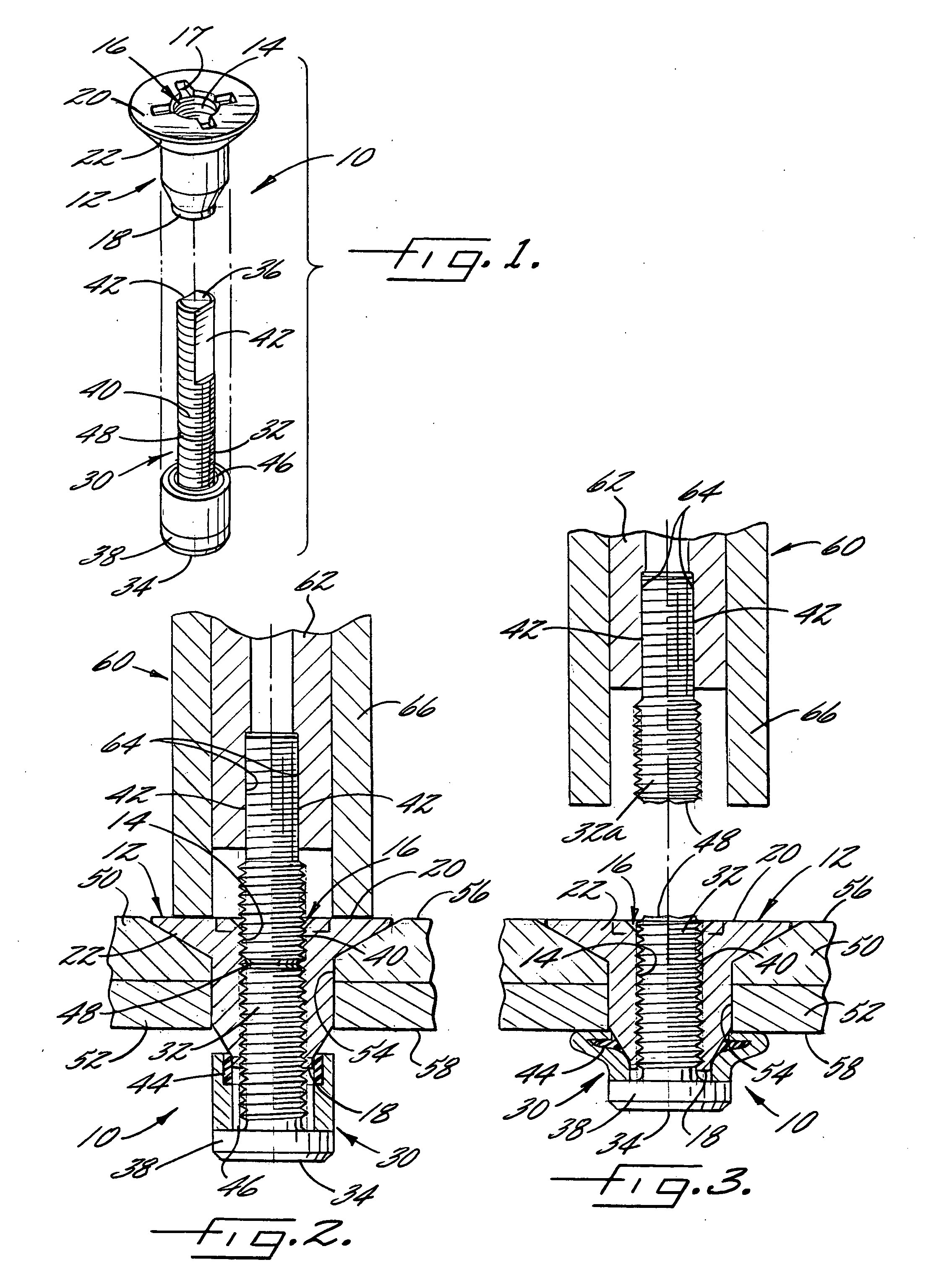

Hybrid fastener apparatus and method for fastening

InactiveUS20060062650A1Reduce galvanic corrosionEnhanced electrical continuityRivetsNutsFiberBiomedical engineering

A fastener and method for fastening structural members wherein the fastener comprises a metallic stem defining a shank extending between first and second ends, the stem defining a deformable first head at the first end of the shank, and a resin-fiber composite sleeve defining the second end of the shank. The sleeve defines an aperture longitudinally extending through the sleeve, and a portion of the sleeve has a cross-sectional dimension greater than a cross-sectional dimension of the aperture through the structural members. Tensile strength of the composite sleeve is increased by incorporation of a support washer into the composite sleeve and / or by substantially orienting the fibers of the resin-fiber sleeve composite in the longitudinal direction of the sleeve.

Owner:THE BOEING CO

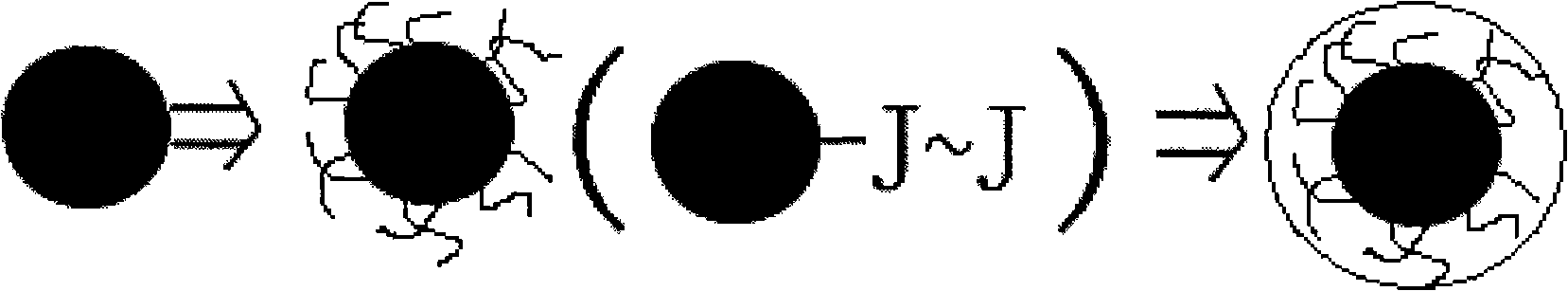

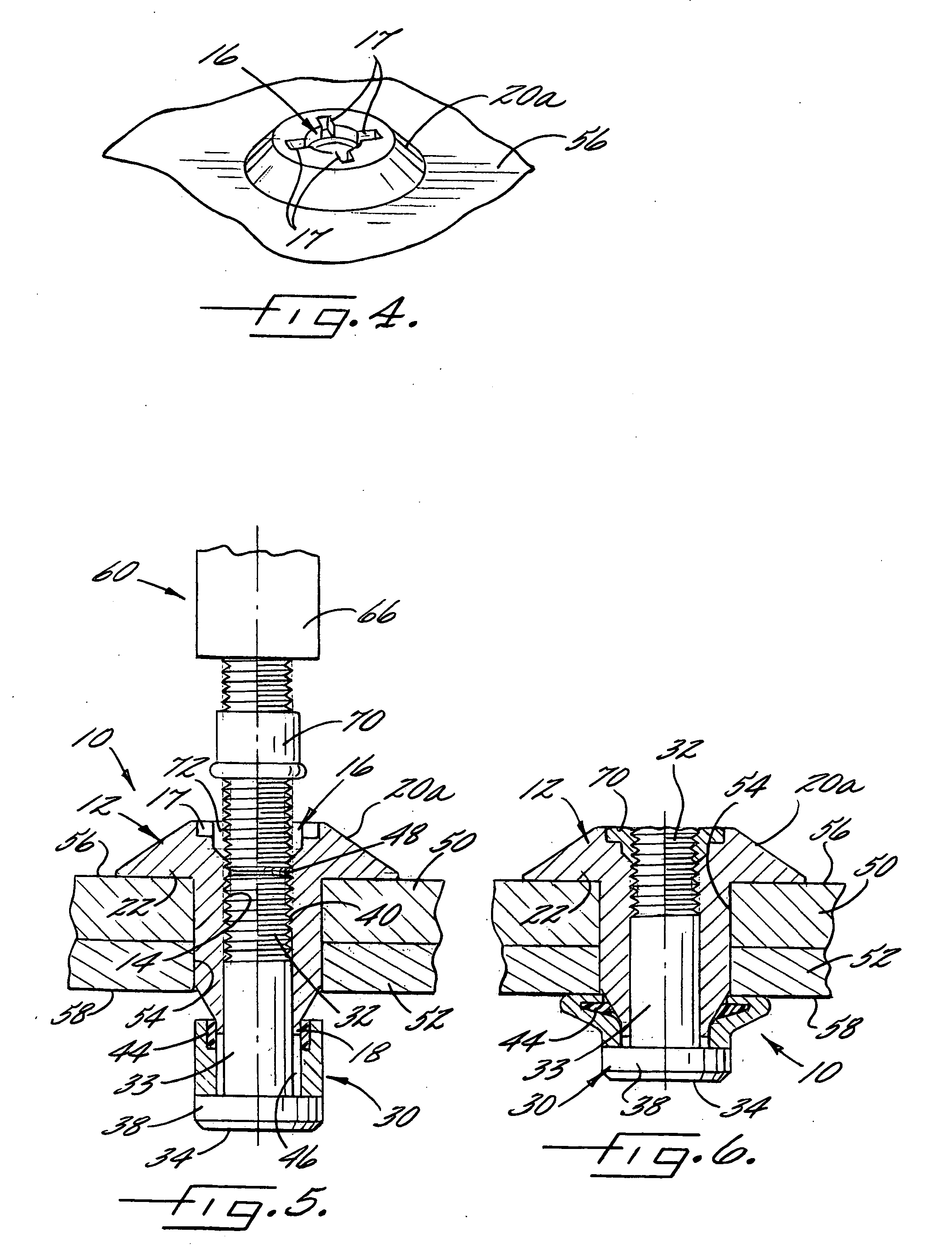

Carbon-sulfur-shell matter composite material having network dual-core shell structure and preparation method thereof

InactiveCN103474633AInhibition of dissolution and diffusion lossIncrease profitMaterial nanotechnologyElectrode manufacturing processesPolycyclic aromatic hydrocarbonLithium–sulfur battery

The invention relates to a carbon-sulfur-shell matter composite material having a network dual-core shell structure and a preparation method thereof. The carbon-sulfur-shell matter composite material has a carbon-sulfur-shell three layer structure, a central core (inner core) is nano carbon particles, sulfur elemental or a polysulfide containing-Sm-structure (m>2) is directly deposited on the nano carbon particles, or functional groups are introduced onto the nano carbon particles by use of polycyclic aromatic hydrocarbon like reaction capacity of the carbon material and through an irreversible chemical reaction, polymeric chains are introduced in, a crosslinked network structure is formed through stretching, bending and crosslinking of the polymeric chains on the surface of the nano carbon particles, the sulfur elemental or the polysulfide containing the-Sm-structure (m>2) is composited onto the crosslinked network structure to form a nano sulfur layer having a network structure, then a mono-core shell nano composite material having a network structure is obtained and is used as a second layer (outer core) of the carbon-sulfur-polymer composite material having the network dual-core shell structure, an outermost layer is a shell matter layer, electronic and / or ionic conductivity of the material are / is improved, dissolving loss of discharge products can be further inhibited, and structural stability of the material is improved. The material is suitable for positive poles of lithium sulfur batteries, and has a prominent effect on improvement of cycle stability of the lithium sulfur batteries.

Owner:NO 63971 TROOPS PLA

Production method of aluminum and copper composite metal band

ActiveCN101758071ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsCopperUltimate tensile strength

The invention discloses a production method of an aluminum and copper composite metal band. In the method, the aluminum and copper composite metal band is manufactured by anaerobic continuous casting and rolling of semisolid aluminum or aluminum alloy and a solid copper band. In the production method of the invention, the anaerobic metallurgical combination of the solid copper band and molten aluminum is realized, the aluminum oxidization problem is solved, the combined strength is high, and the aluminum and copper bonding strength is more than or equal to 100MPa; the continuous casting and rolling of the copper band and the molten aluminum are adopted to produce the aluminum and copper composite metal band, so the production efficiency is greatly improved by scores of times and the product quality is stable; the produced aluminum and copper composite metal band retains the original surface quality of the copper band, has a uniformly-thick copper layer and can be deeply processed by cold rolling; and the copper band and the molten aluminum, which comprise different components, can be used, and products are diversified and widely applicable. The method has the advantages that: the production process of the copper and aluminum composite band is advanced and comprises a few working procedures; and the energy-saving, material-saving and economic effects are obvious.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

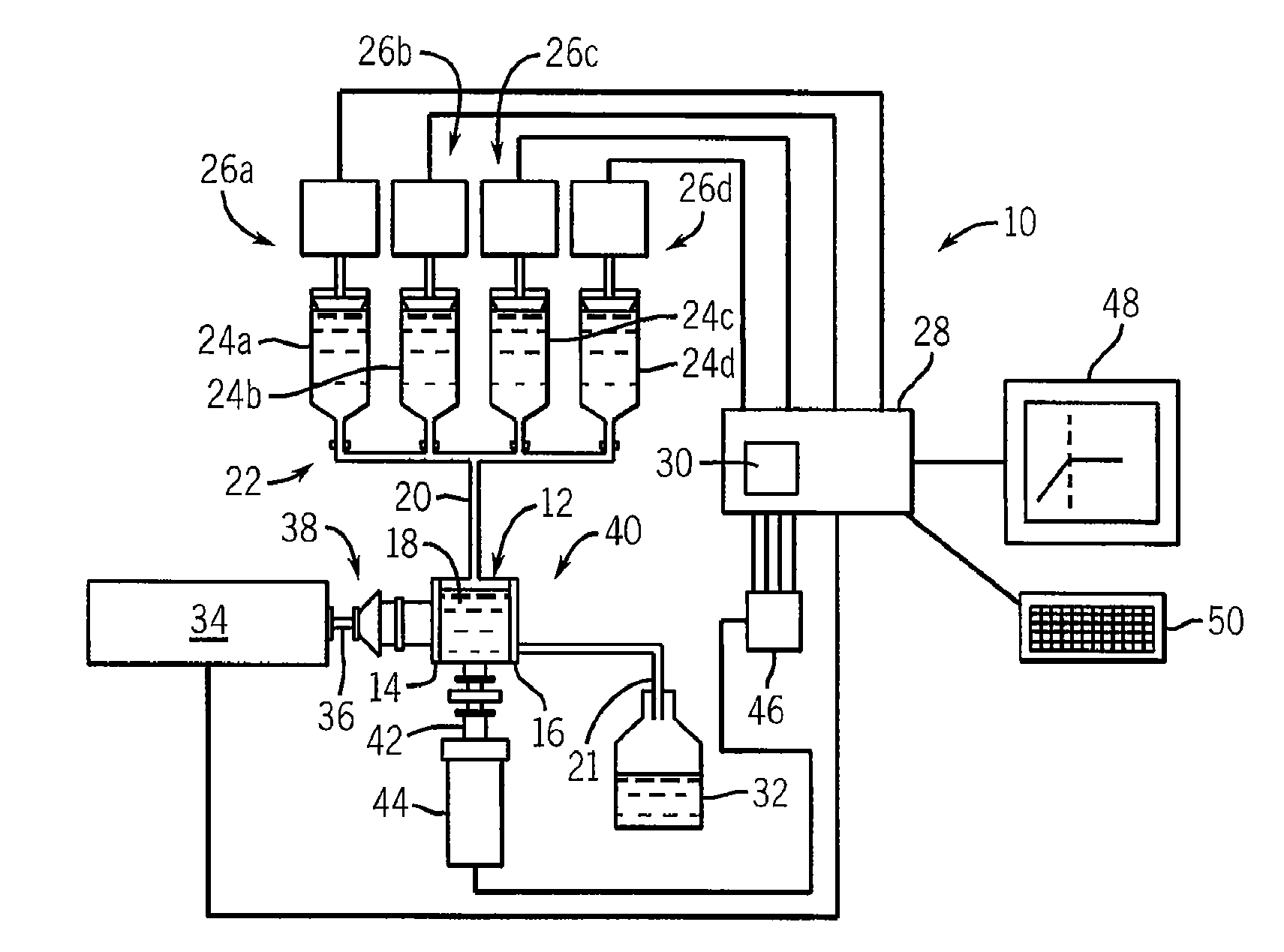

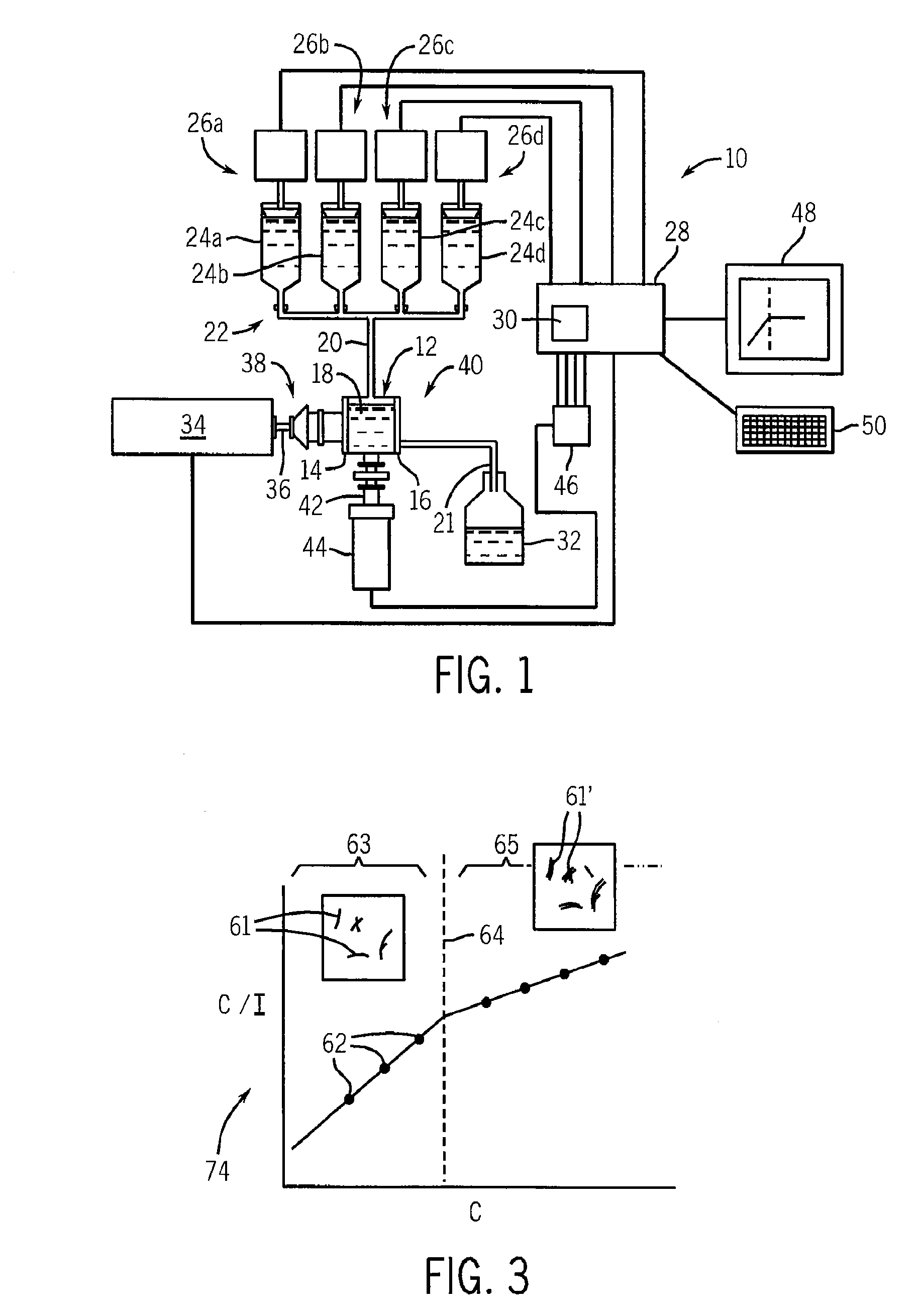

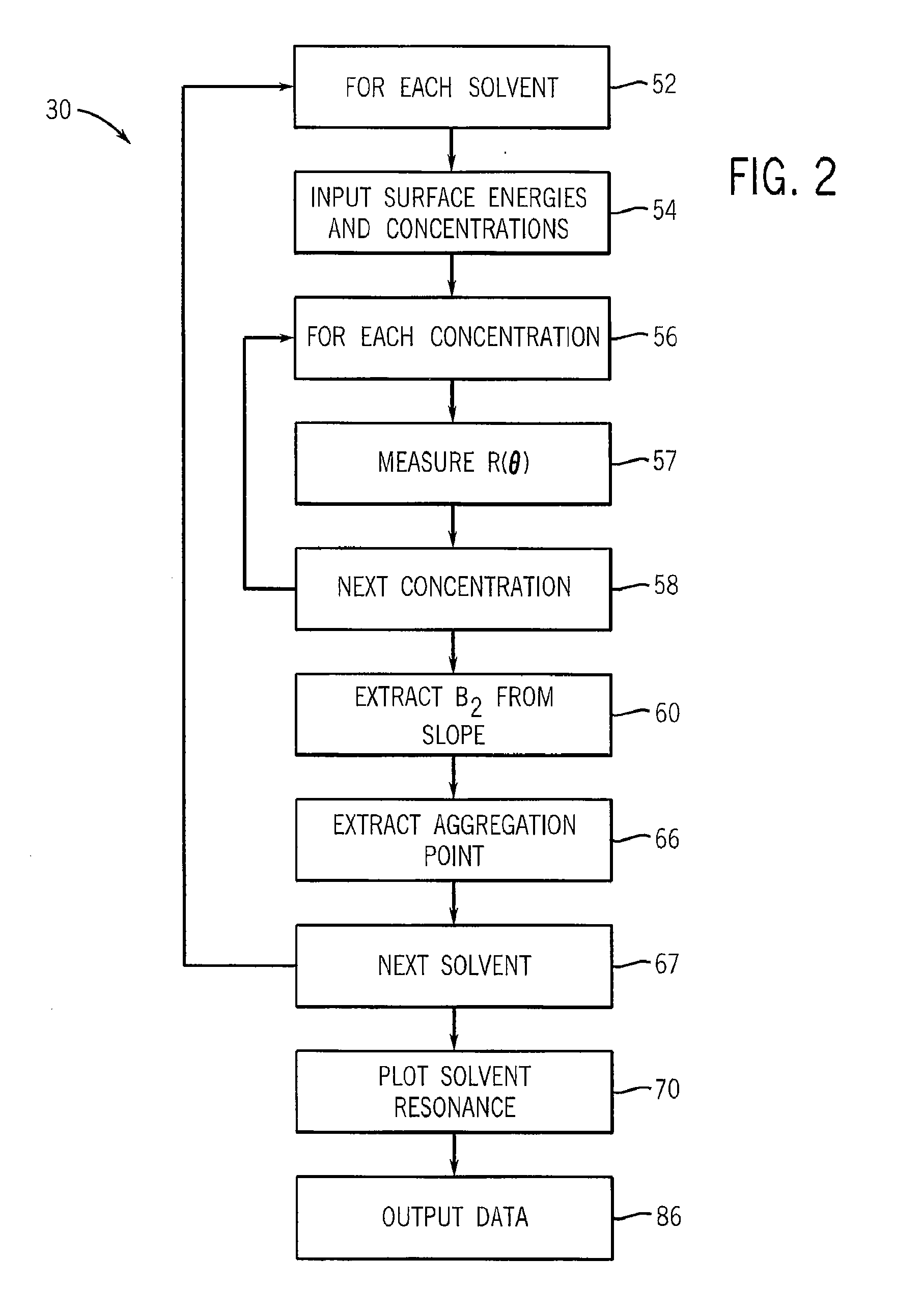

Method And Apparatus For Identifying And Characterizing Material Solvents And Composited Matrices And Methods Of Using Same

ActiveUS20110117361A1High composite strengthMaterial nanotechnologyElectrode manufacturing processesRayleigh scatteringRayleigh Light Scattering

Solvents for macromolecules generally believed to be insoluble in their pristine form are identified by generation of a ‘solvent resonance’ in the relationship between solvent quality (deduced by Rayleigh scattering) and an intrinsic property of solvents. A local extreme of the solvent resonance identifies the ideal intrinsic property of an ideal solvent which may then be used to select a particular solvent or solvent combination. A solvent for graphene is used in the production of transparent conductive electrodes.

Owner:WISYS TECH FOUND

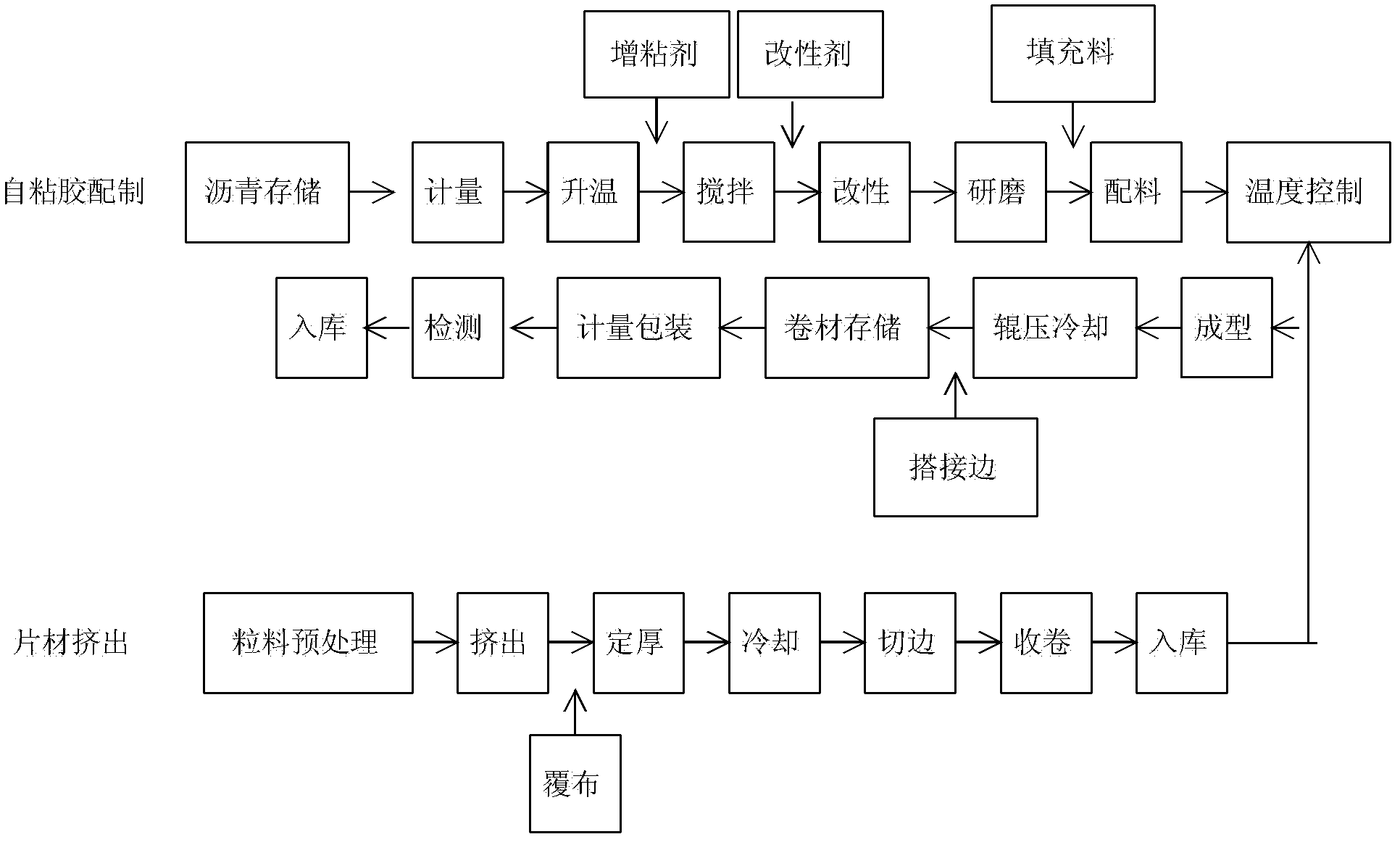

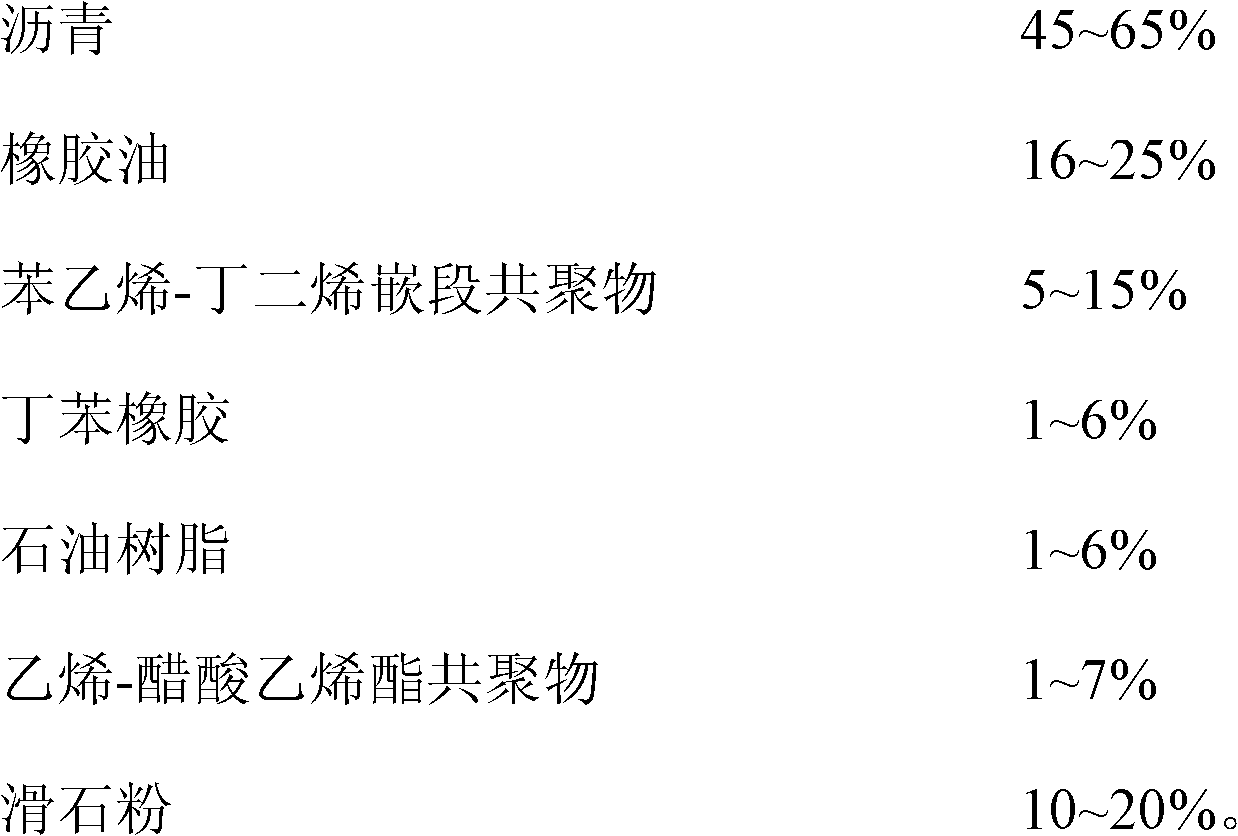

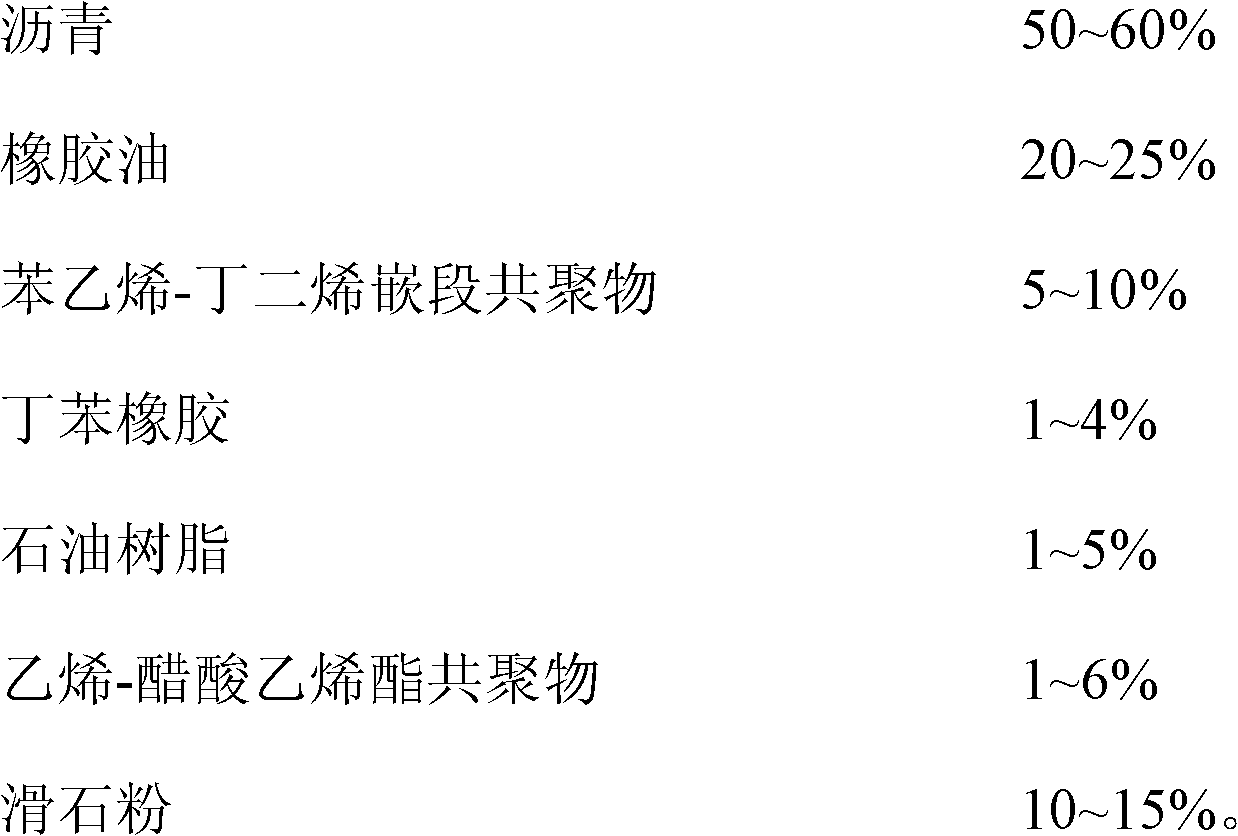

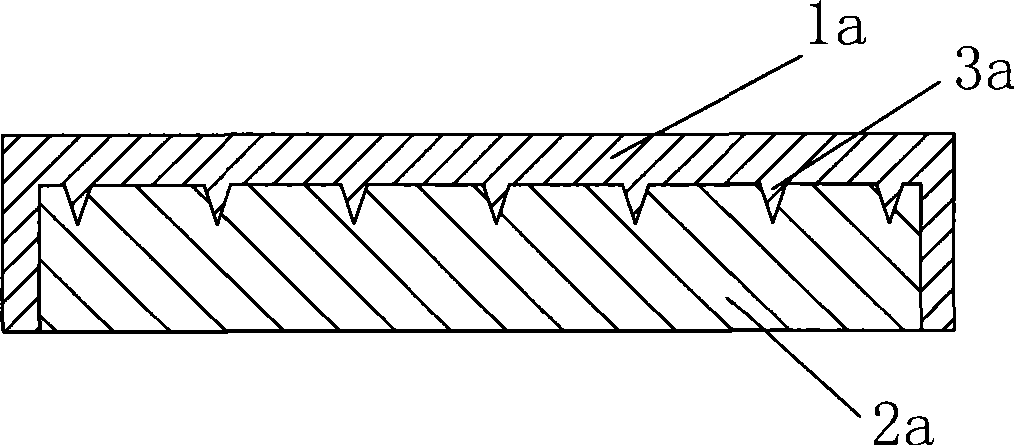

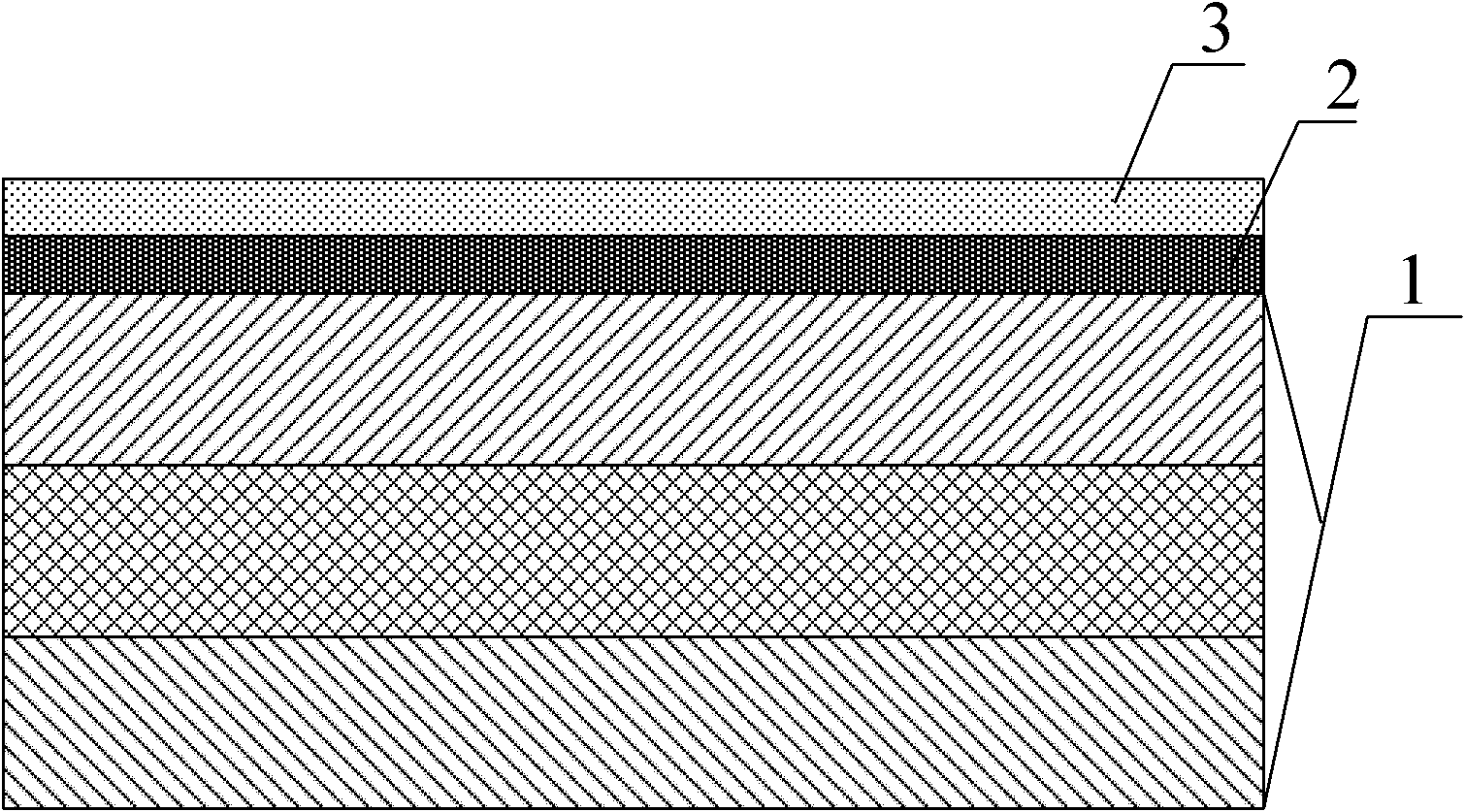

Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

InactiveCN102559135AGood compatibilityHigh composite strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesUltimate tensile strengthButadiene-styrene rubber

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Owner:SHENZHEN ZHUOBAO TECH

Graphitized wetable cathode carbon block for aluminium electrolysis bath and production method thereof

InactiveCN101158048AGood electrical and thermal conductivityHigh degree of graphitizationShaping pressAluminium electrolysisGraphite

The invention relates to a graphitized wettable cathode carbon block used in an aluminum electrolytic tank and a production method thereof, and is characterized in that the graphitized wettable cathode carbon block consists of a graphitized carbon block matrix and a TiB2 compound layer integrated on the matrix. The production method of the graphitized wettable cathode carbon block is characterized in that when the cathode carbon block is produced through vibration molding, the working surface of the cathode carbon block is integrated with and molded by a TiB2 compound layer; a pressing molded greed block is roasted, leached, graphitized and processed by machine and a graphitized wettable cathode carbon block is prepared. The carbon block matrix of the graphitized wettable cathode carbon block used in the aluminum electrolytic tank of the invention has good electric and heat conductivity, and the TiB2 compound layer integrated and molded on the matrix is roasted and treated by high temperature heat process, thus the compound intensity can be effectively improved, so the graphitized wettable cathode carbon block used in aluminum electrolytic tank has excellent electrolyte corrosion resistance and aluminum liquid scouring resistance as well as good electric and heat conductivity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

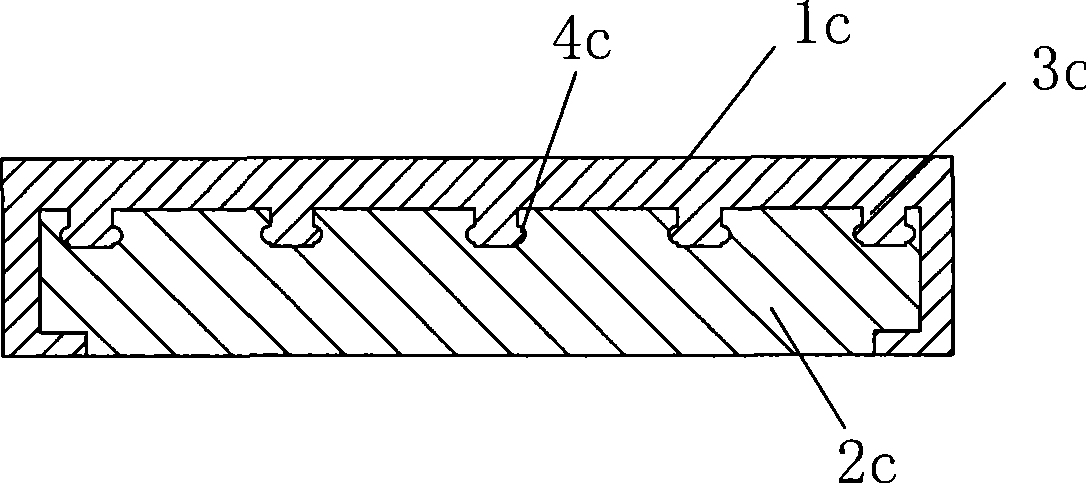

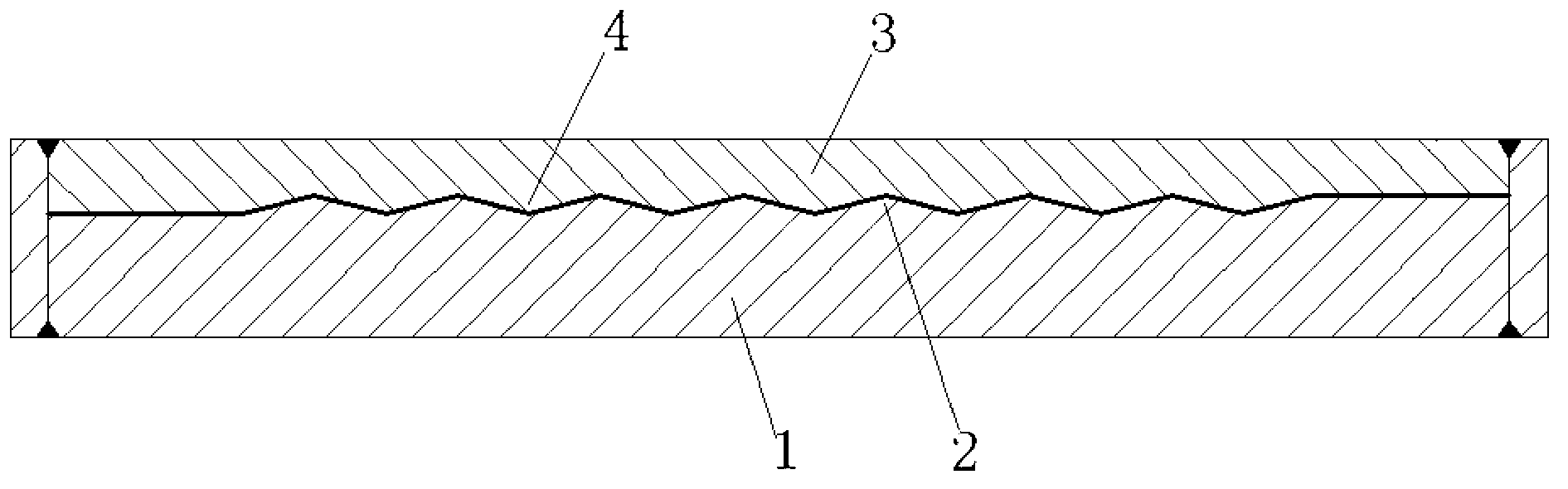

Magnalium composite board and method for producing the same

The invention discloses a magnesium-aluminum composite board and a method for manufacturing the same. The magnesium-aluminum composite board comprises at least one layer of magnesium or magnesium alloy plate and at least one layer of aluminum or aluminum alloy plate which are cast together by vacuum die-casting, and at least one two-layer joint surface which is provided with a mutually occlusive zigzag structure, namely the magnesium-aluminum composite board consists of a magnesium plate and an aluminum plate, or the magnesium alloy plate and the aluminum plate, or the magnesium plate and the aluminum alloy plate, or the magnesium alloy plate and the aluminum alloy plate by vacuum die-casting, and can be a structure with two layers, three layers or more than three layers. The method for manufacturing the composite board comprises the following steps: preheating a manufactured aluminum or aluminum alloy plate finished product as an insert of a die to certain temperature, and then putting the insert into a magnesium or magnesium alloy vacuumized die; matching the die in a vacuum pressure casting machine; pouring the molten magnesium or magnesium alloy molten; performing vacuumizing injection; and finally forming the magnesium-aluminum composite board. The joint surface of the composite board is provided with the mutually occlusive zigzag structure so that the layers are closely connected with each other sequentially and the combined strength is higher.

Owner:青岛地恩地材料科技有限公司

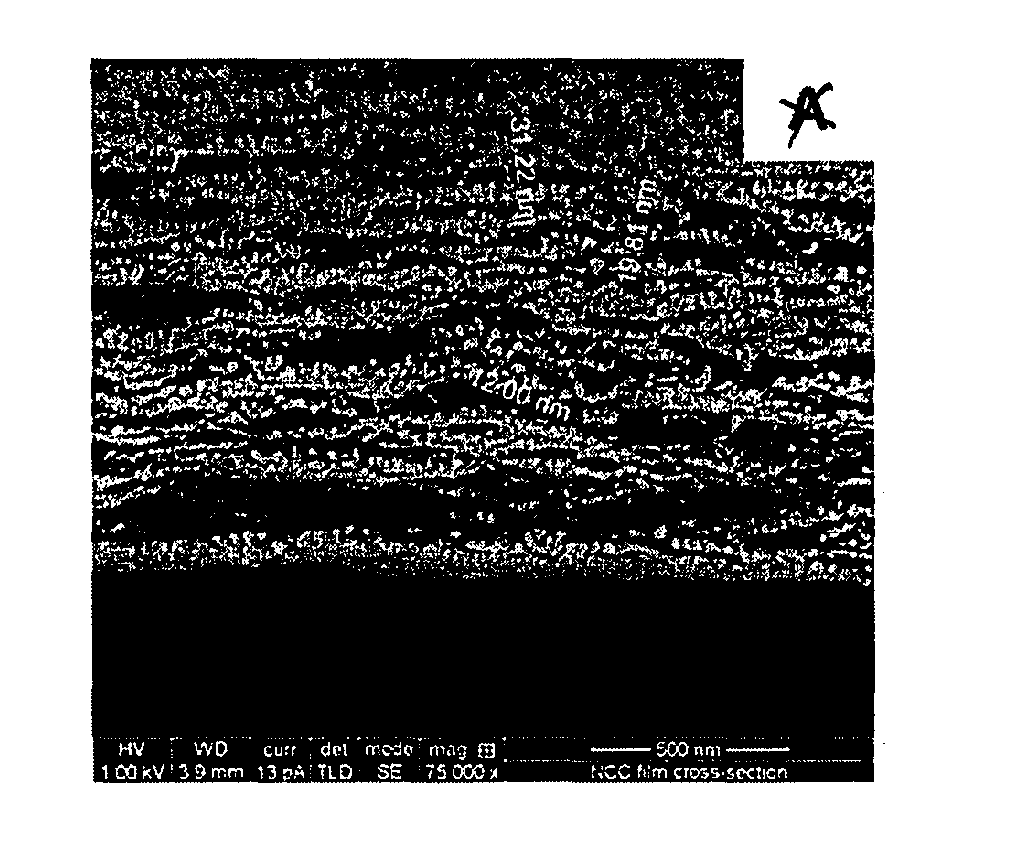

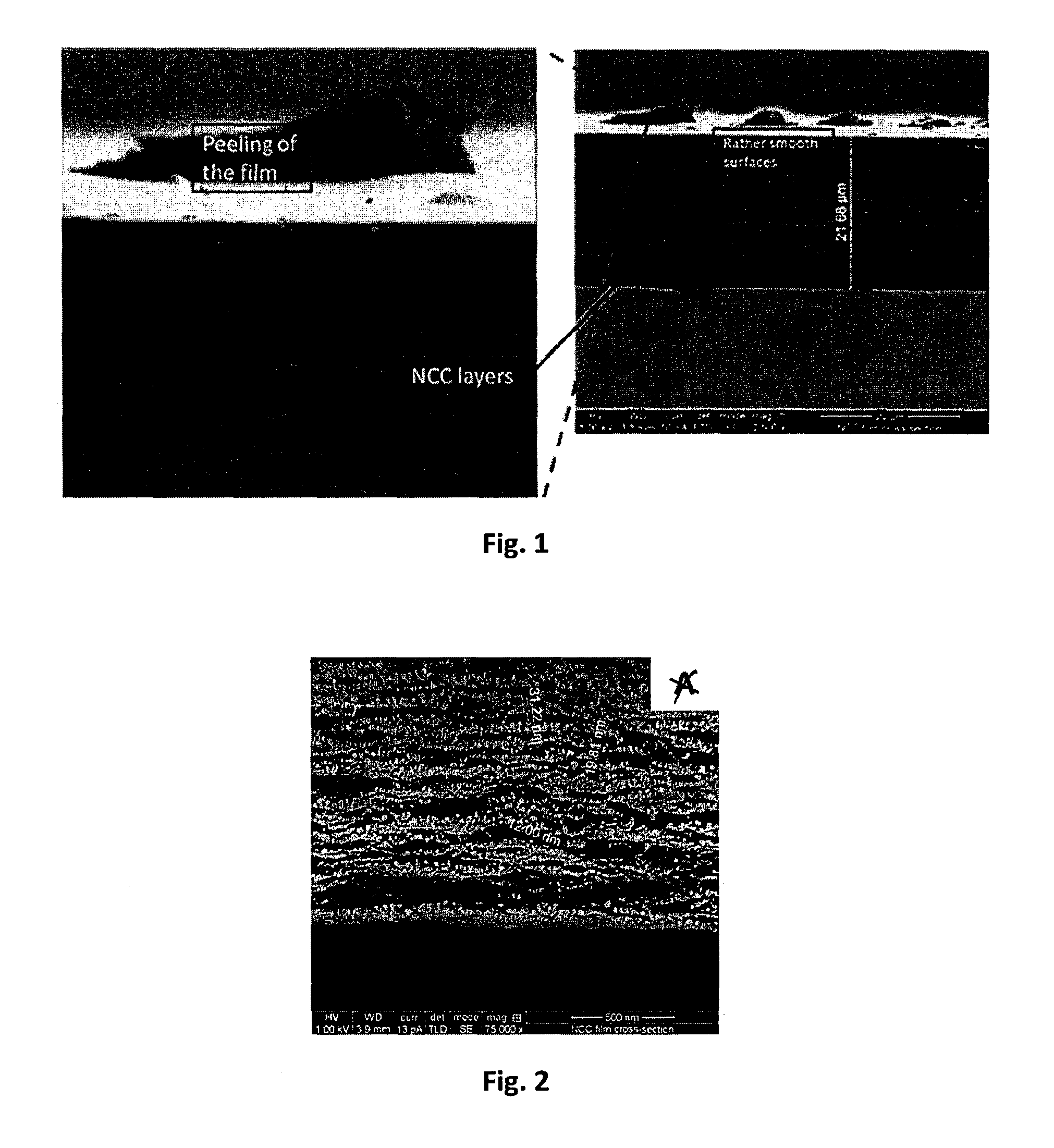

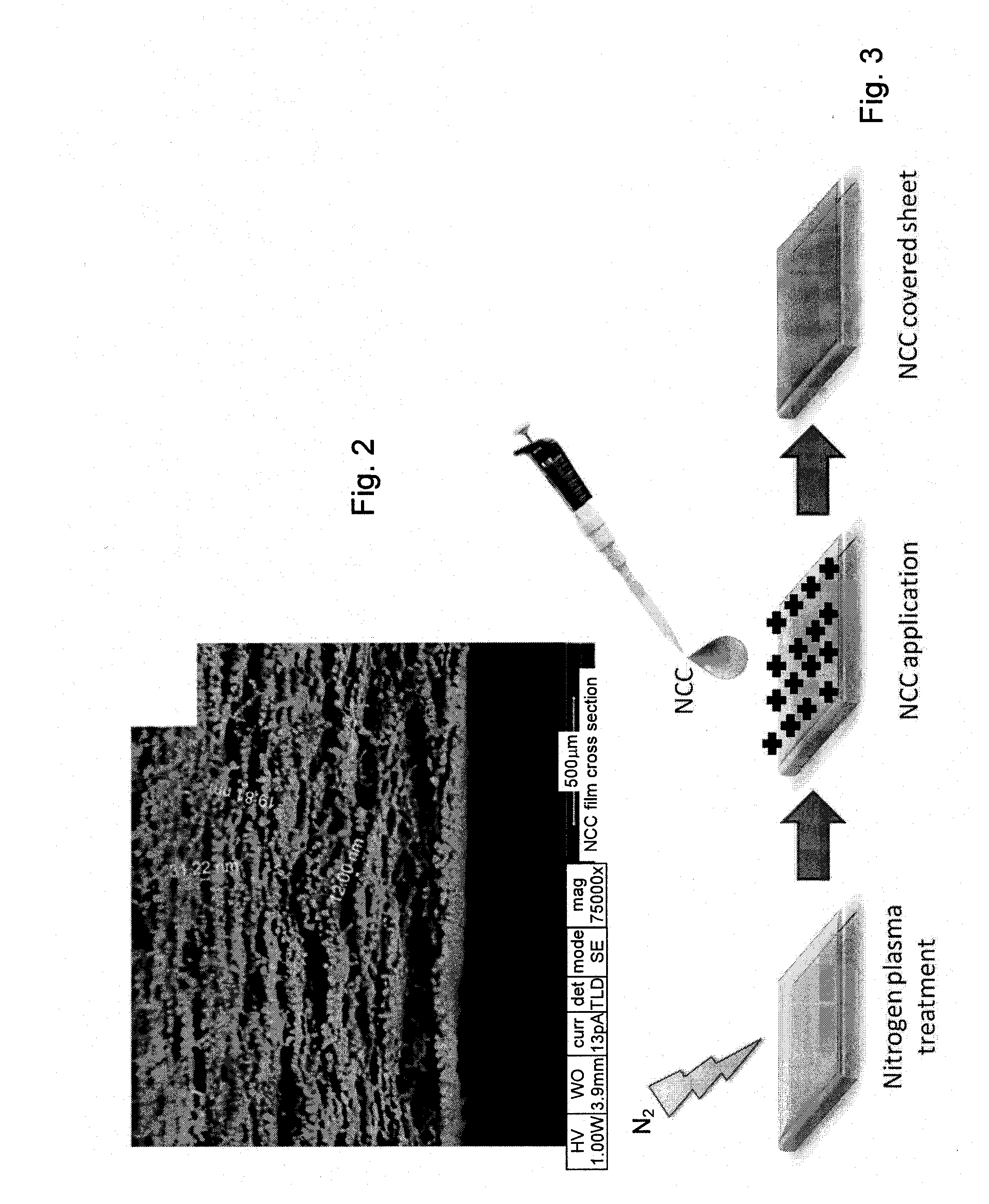

Coating layers of a nanocomposite comprising a nano-cellulose material and nanoparticles

InactiveUS20150017432A1Good effectImprove efficiencyMaterial nanotechnologyOptical filtersNanoparticleNanocomposite

The invention provides articles and methods for making such articles including a substrate coated on at least one region thereof with a layer of nanocomposites nano-cellulose materials and nanoparticles.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

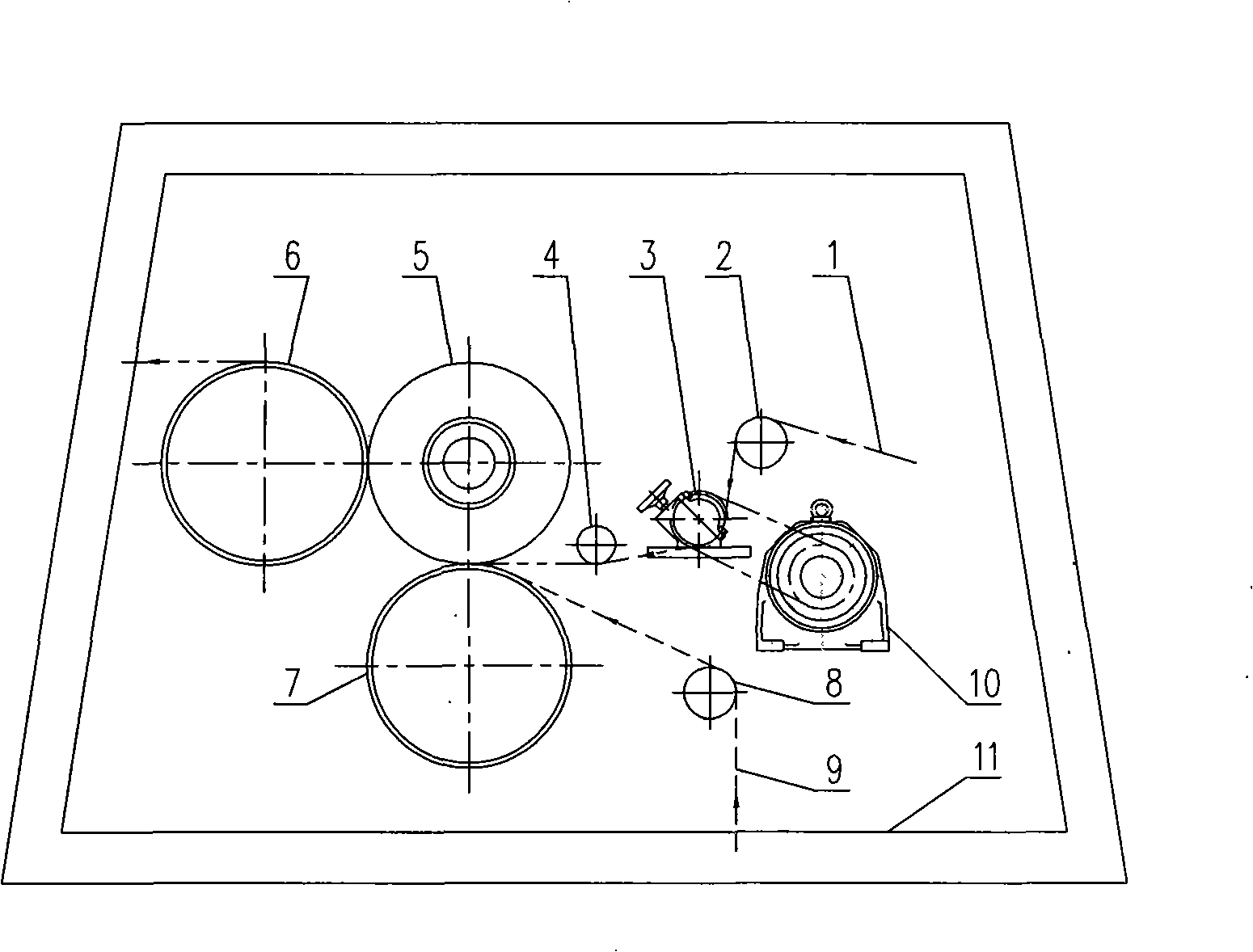

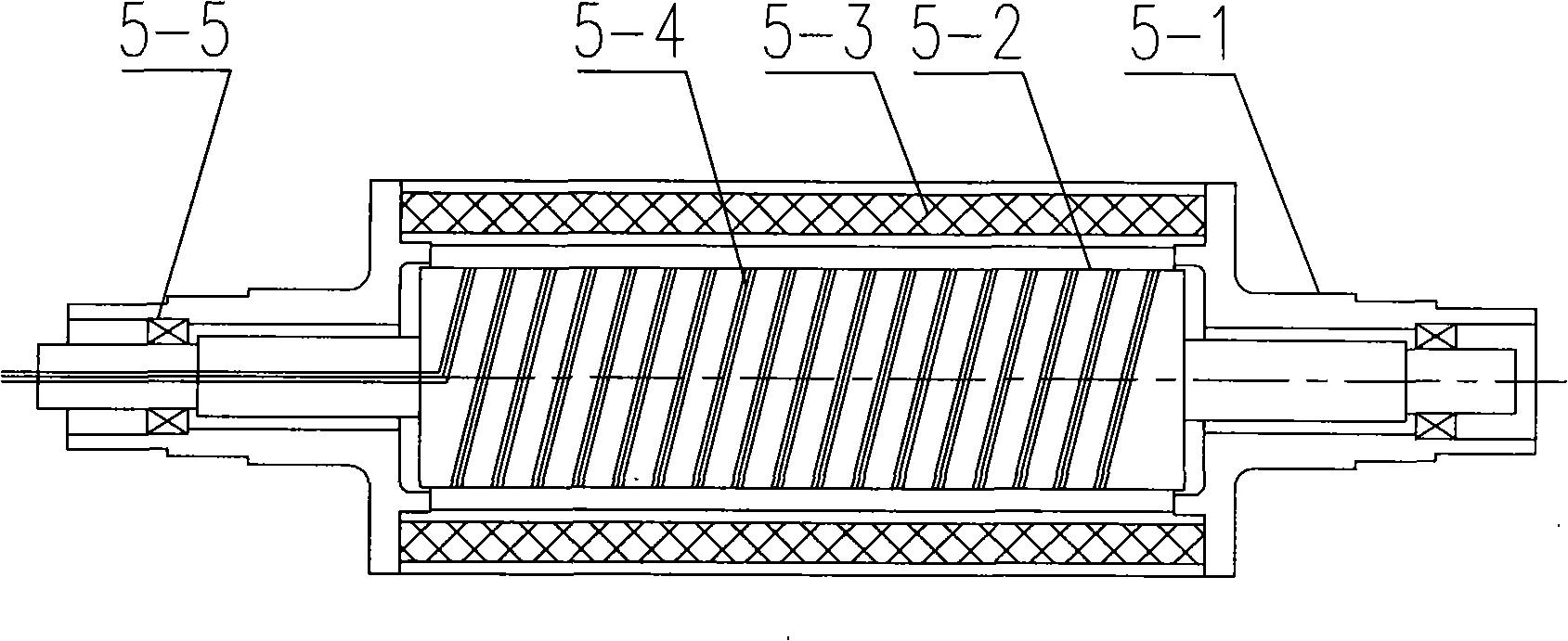

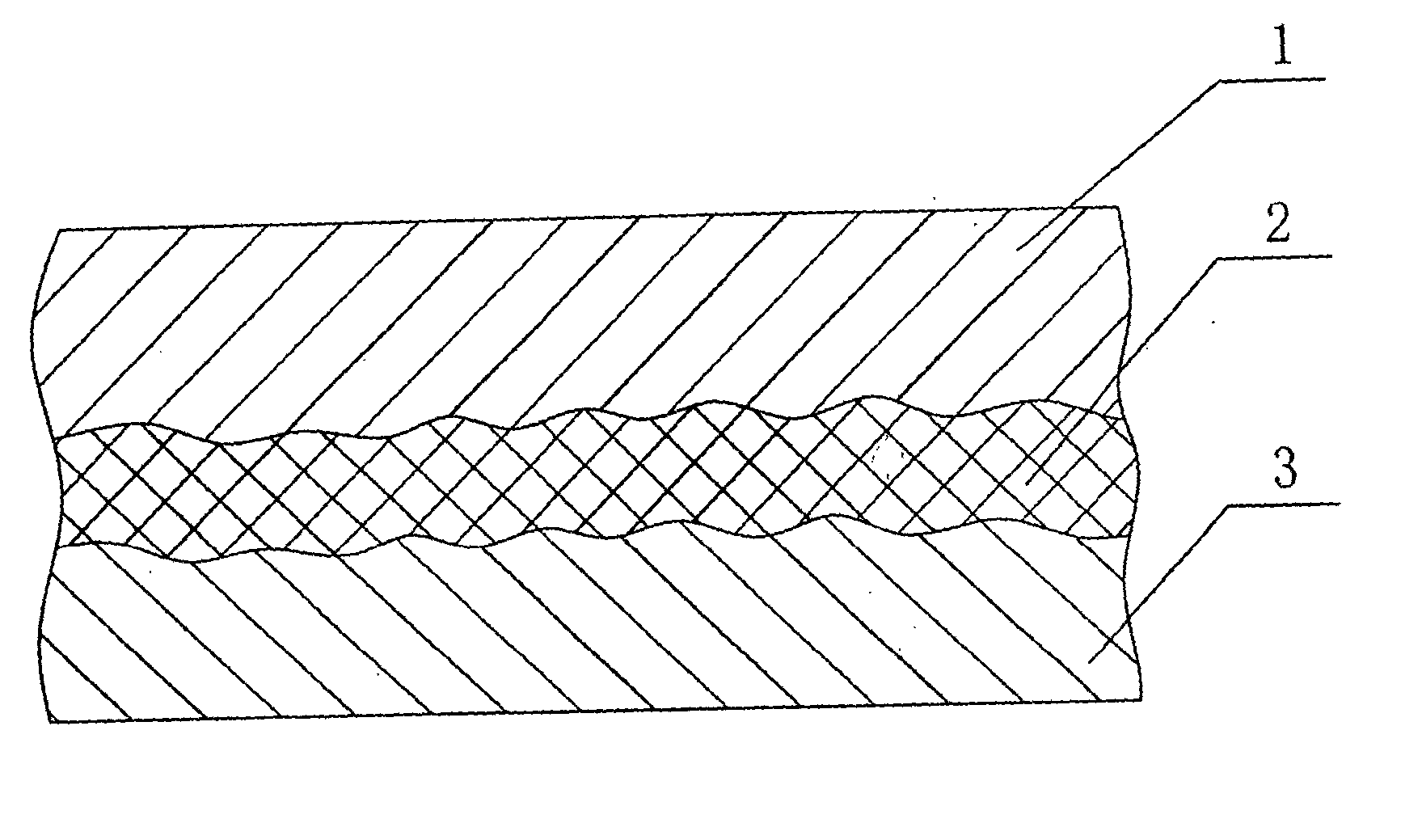

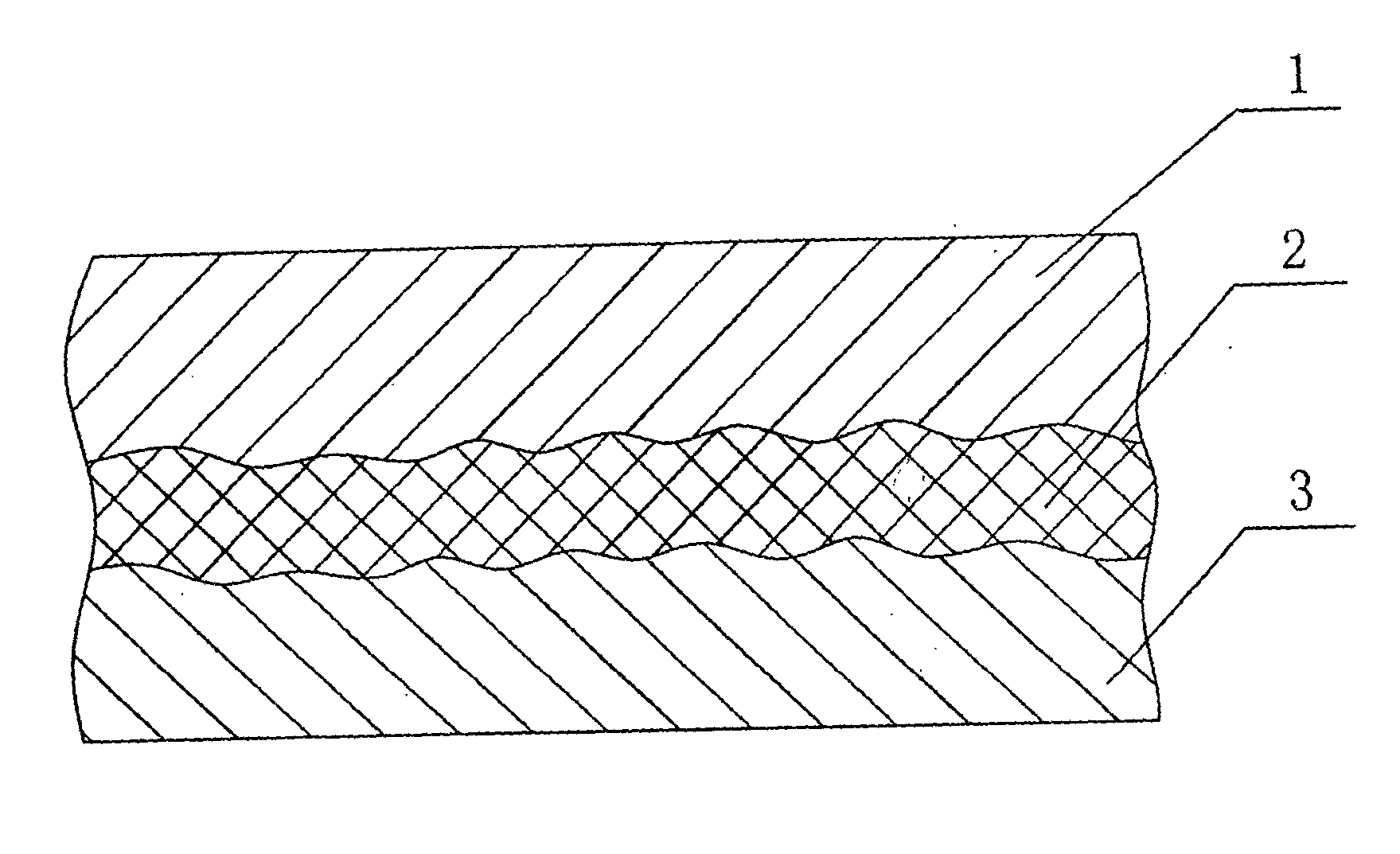

Compound technique of film filtering material and equipment

ActiveCN101279524APreserve physical and chemical propertiesImprove breathabilitySynthetic resin layered productsLaminationComposite strengthGlass fiber

The invention provides a composite technique for membrane filter material and an equipment. Polytetrafluoroethylene membrane and glass fiber base cloth are synchronously input between the heating roller and the press roller of a composite equipment at a speed ranging from 3 to 5m per min, and the polytetrafluoroethylene membrane is input in the direction of the tangent between the heating roller and a lower press roller and is formed by hot pressing with a linear pressure ranging from 15 to 30kN / m at the temperature ranging from 260 to 360 DEG C; after the membrane filter material formed by the hot press is heated by the one-fourth surface of the heating roller and then is formed by hot pressing with a linear pressure ranging from 15kN / m to 20kN / m. The technique method realizes rubber-free hot pressing compounding of the polytetrafluoroethylene membrane and the glass fiber base cloth, thus effectively saving the original physical and chemical property of the polytetrafluoroethylene membrane, enhancing the permeability and filtration efficiency of the membrane filter material, strengthening the composite strength of the membrane filter material and extending the service life of the membrane filter material; simultaneously, the hot pressing composite equipment has reasonable structure, thus ensuring the production and preparation of the membrane filter material.

Owner:中材科技膜材料(山东)有限公司

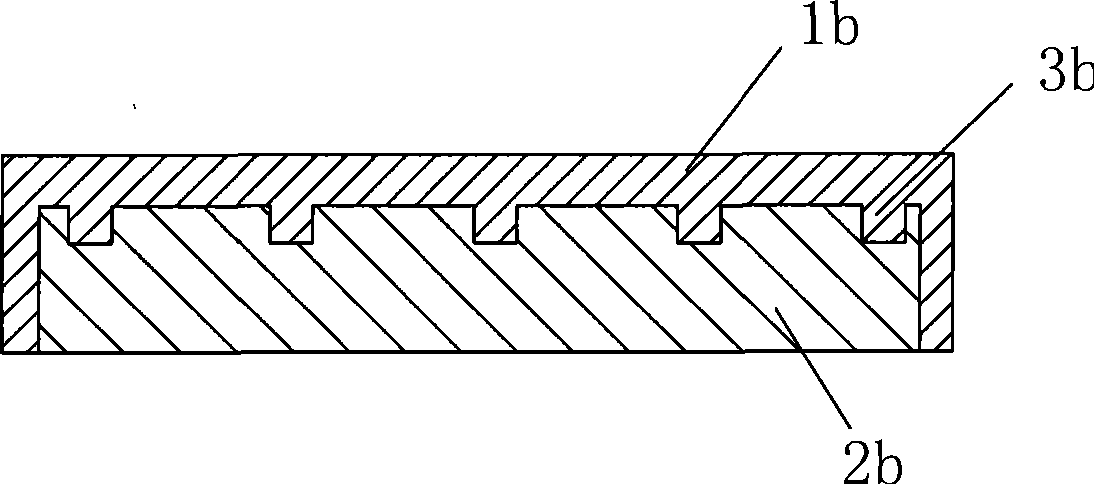

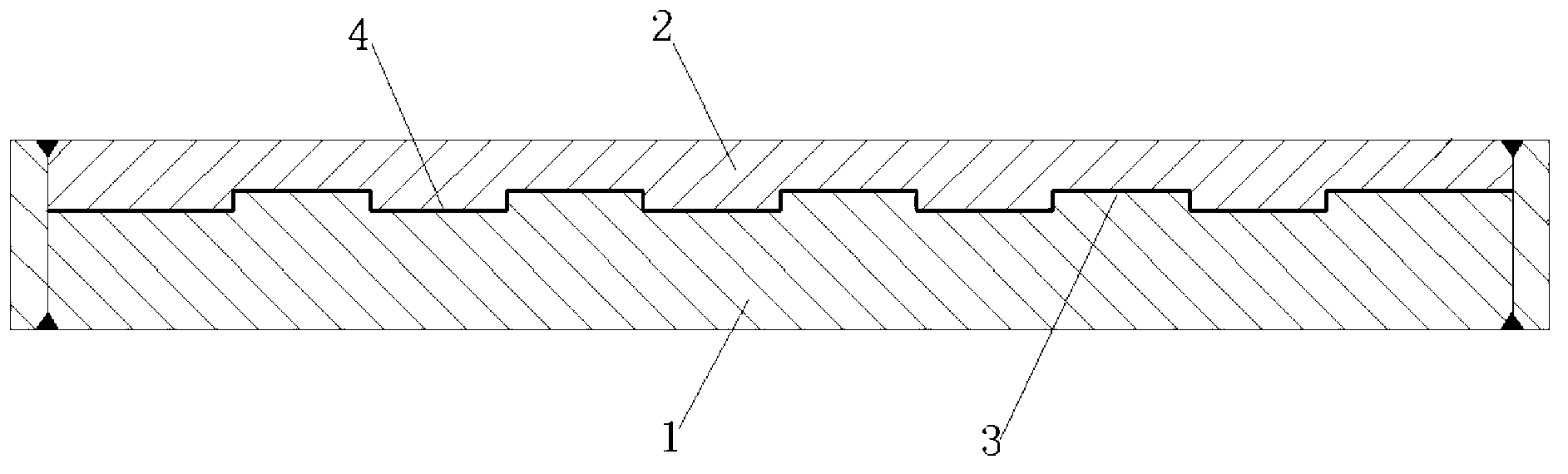

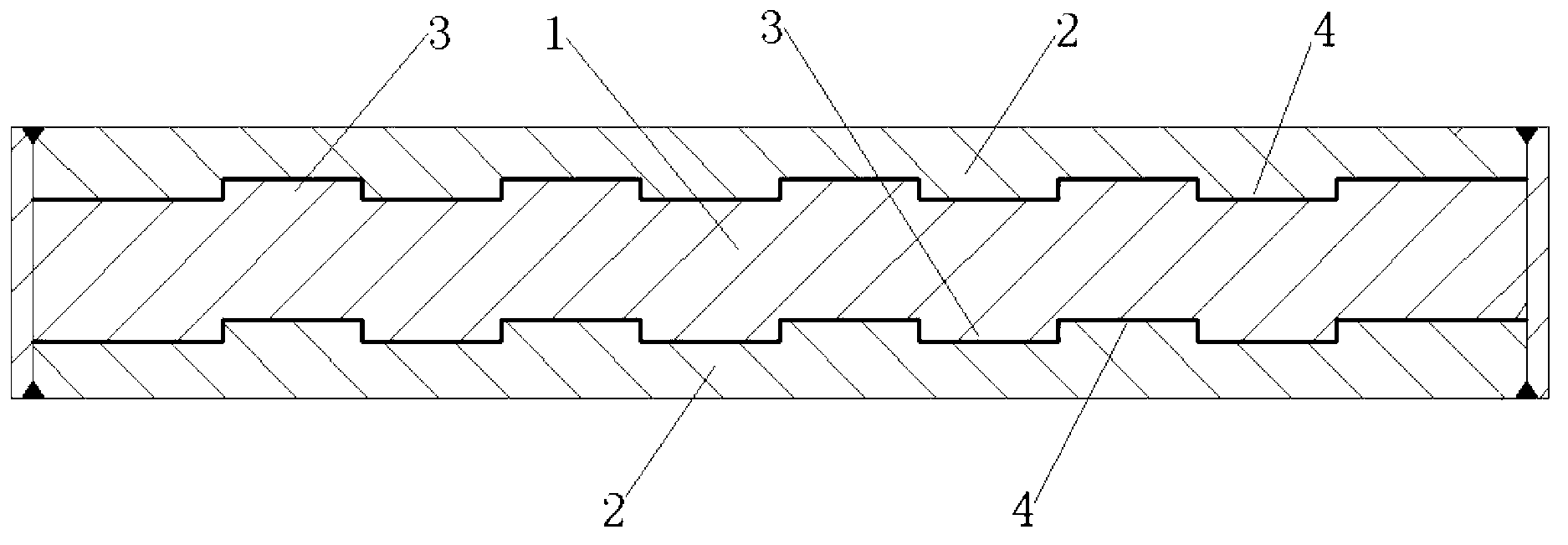

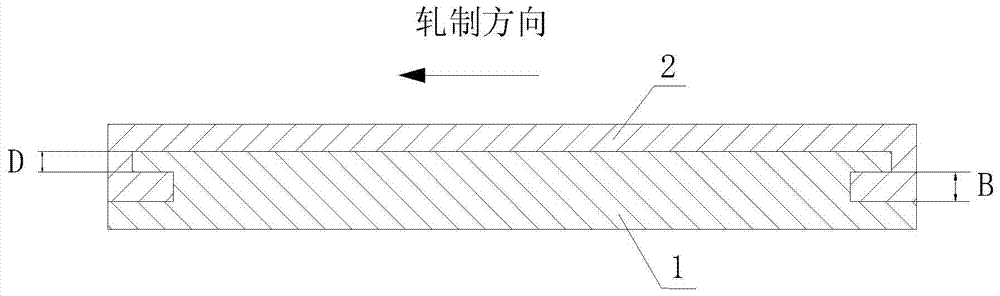

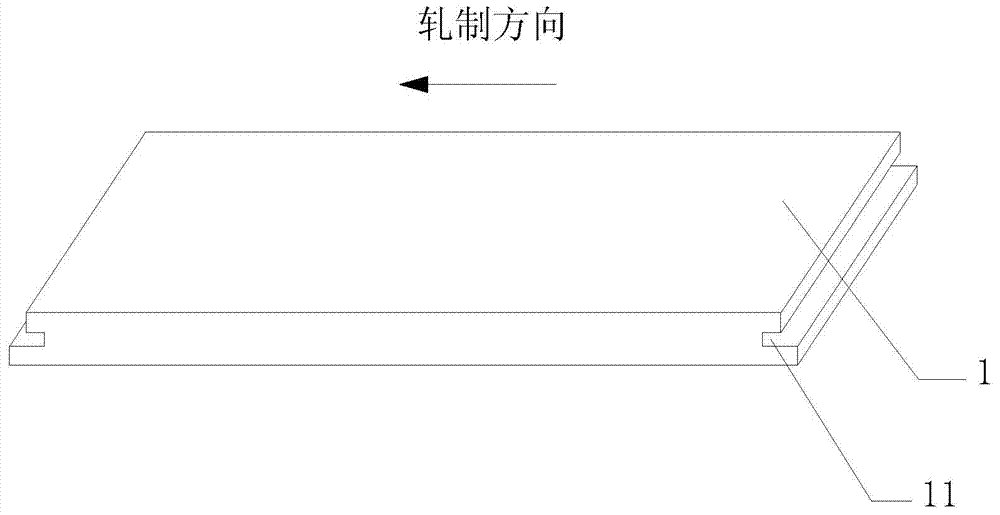

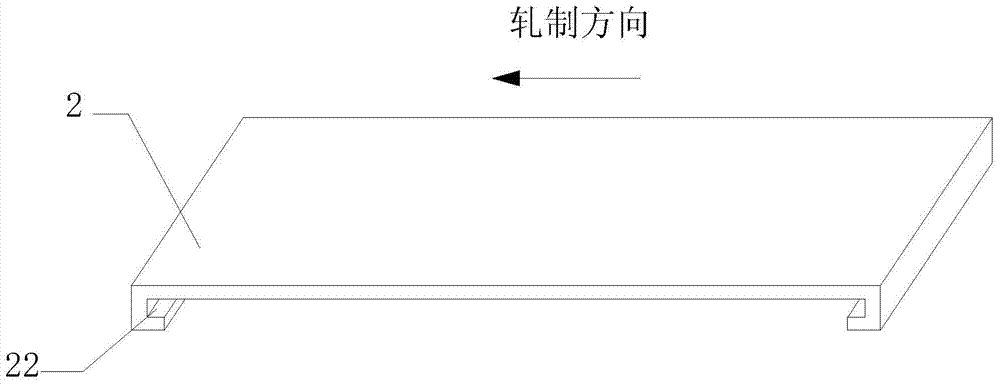

Meshing type composite plate vacuum rolling preparation method

InactiveCN103272842AImprove fitAvoid separationAuxillary arrangementsMetal rolling arrangementsComposite strengthComposite filter

The invention discloses a meshing type composite plate vacuum rolling preparation method. The meshing type composite plate vacuum rolling preparation method includes the steps: processing base plate protrusions and covering plate protrusions, which are matched mutually, on compositing surfaces of a base plate and a covering plate respectively; cleaning the compositing surfaces of the base plate and the covering plate; overlaying the base plate and the covering plate, and enabling the base plate protrusions on the base plate and the covering plate protrusions on the covering plate to be meshed mutually; obtaining a composite plate blank by means of blank assembly; and performing hot rolling so that a composite plate is obtained. The meshing type composite plate vacuum rolling preparation method has the advantages that the base plate protrusions and the covering plate protrusions which are matched mutually are processed on the compositing surfaces of the base plate and the covering plate respectively, so that fitting force between the base plate and the covering plate is increased by the aid of meshing force among the base plate protrusions and the covering plate protrusions, separation of the base plate from the covering plate during rolling is avoided, and rolling quality is improved while process is simple; meanwhile, contact area between the base plate and the covering plate is enlarged (namely, the area of a compositing interface is enlarged), so that compositing strength of the composite plate is enhanced; and the meshing type composite plate vacuum rolling preparation method is applicable to preparation of composite plates.

Owner:武钢集团有限公司

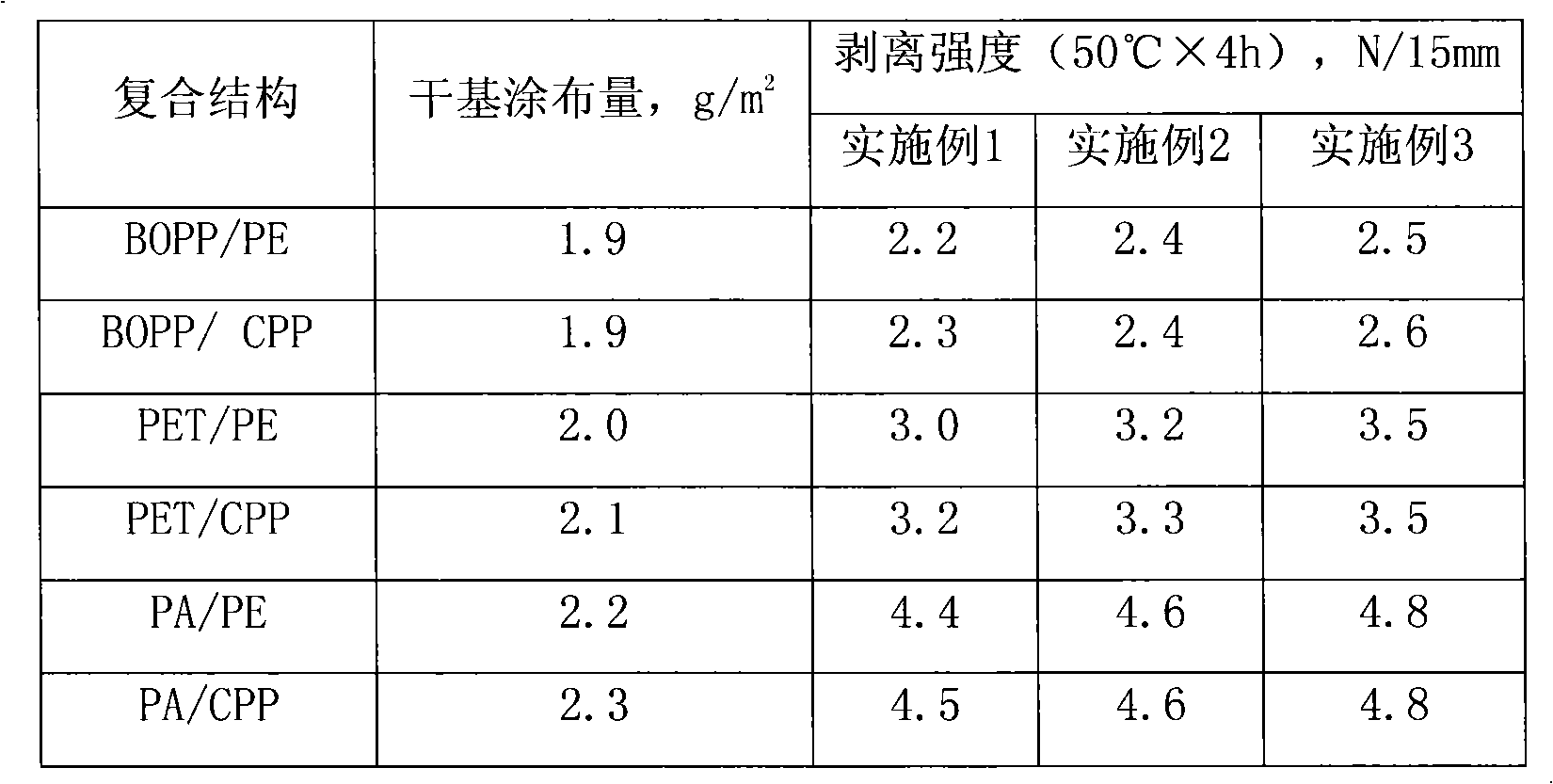

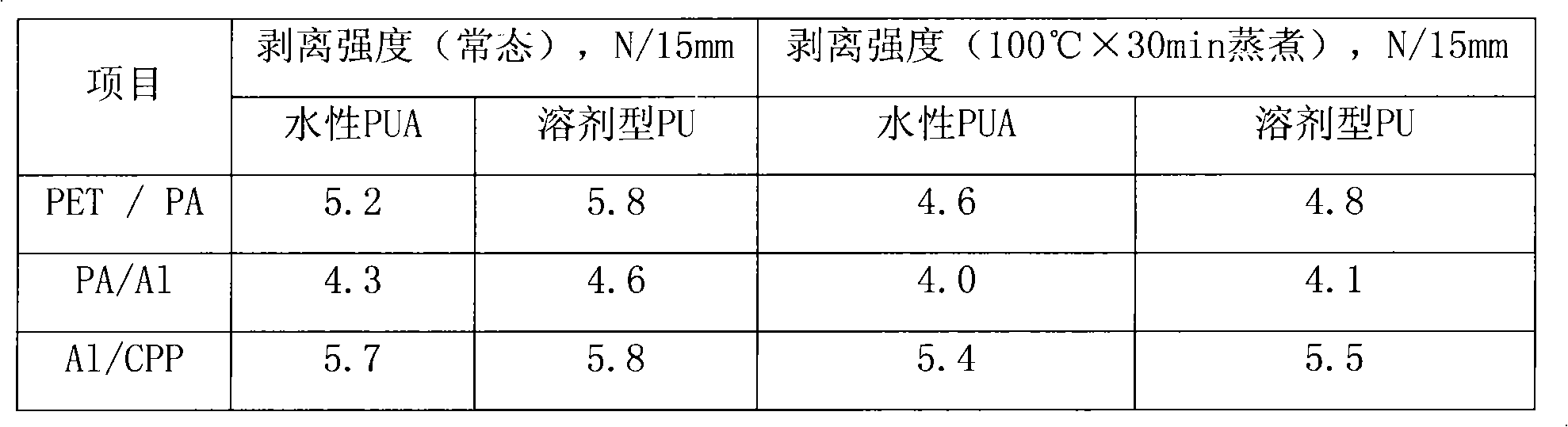

Aqueous composite adhesive and preparation method and use thereof

InactiveCN101768416AImprove water resistanceHigh composite strengthGraft polymer adhesivesIonChemistry

The invention discloses an aqueous composite adhesive and a preparation method thereof, and belongs to the field of high molecular materials. The adhesive is polyurethane / acrylate PUA composite emulsion, wherein based on the total weight of the PUA composite emulsion, the content of the polyurethane is 5 to 20 percent; the content of the polyacrylate is 25 to 45 percent; the content of water is 50 to 70 percent; and the solid content of the PUA composite emulsion is 30 to 50 percent. The preparation method comprises the following steps: preparing the aqueous polyurethane emulsion; preparing the aqueous polyurethane / acrylate PUA composite emulsion from the aqueous polyurethane emulsion; and finally, regulating the solid content of the aqueous polyurethane / acrylate PUA composite emulsion by using de-ionized water, and adding an antifoaming agent, a wetting agent and an antiseptic to prepare the aqueous composite adhesive. In the prepared aqueous PUA composite emulsion, emulsion particles have complex phase structures, a carbamic acid ester chain is knitted tightly with an acrylicacid chain at the molecular level, and the synergic effect between the two makes the performance of a coating better than that of a physically blended coating, so that the aqueous PUA composite emulsion has high performance and environmental protection property.

Owner:BEIJING COMENS NEW MATERIALS

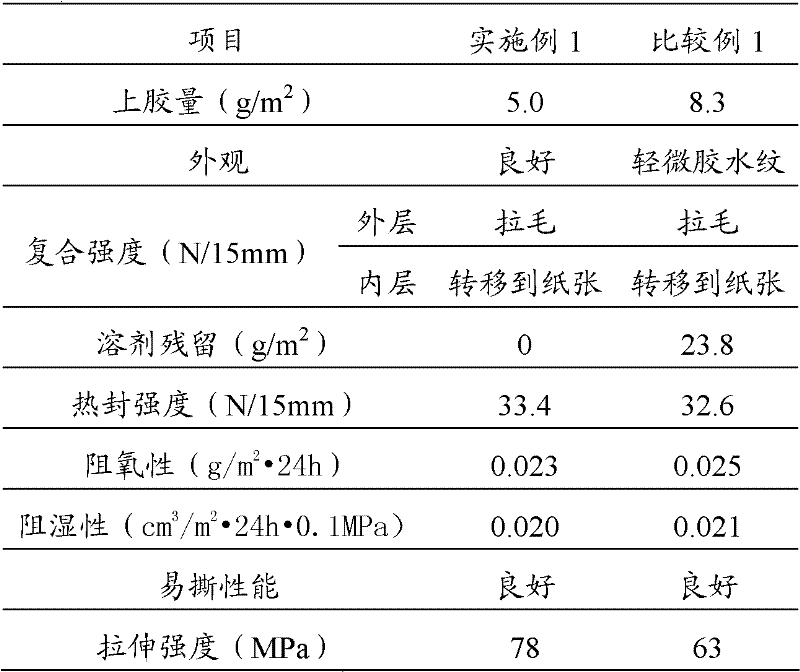

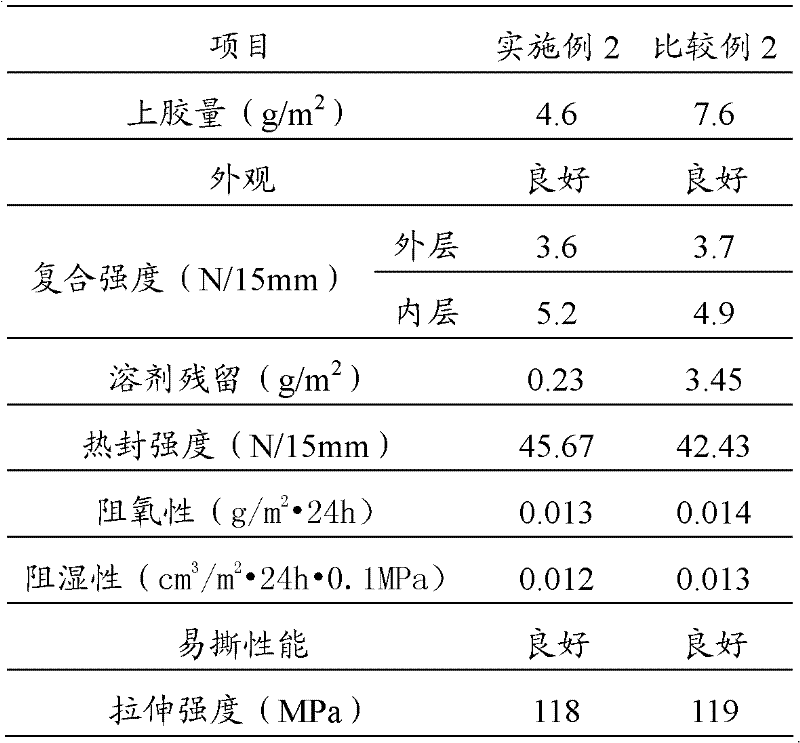

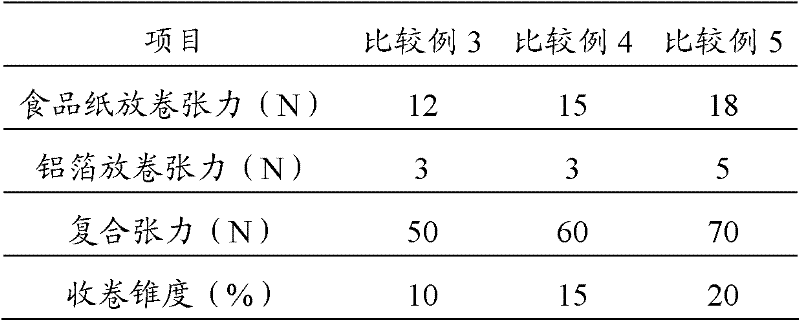

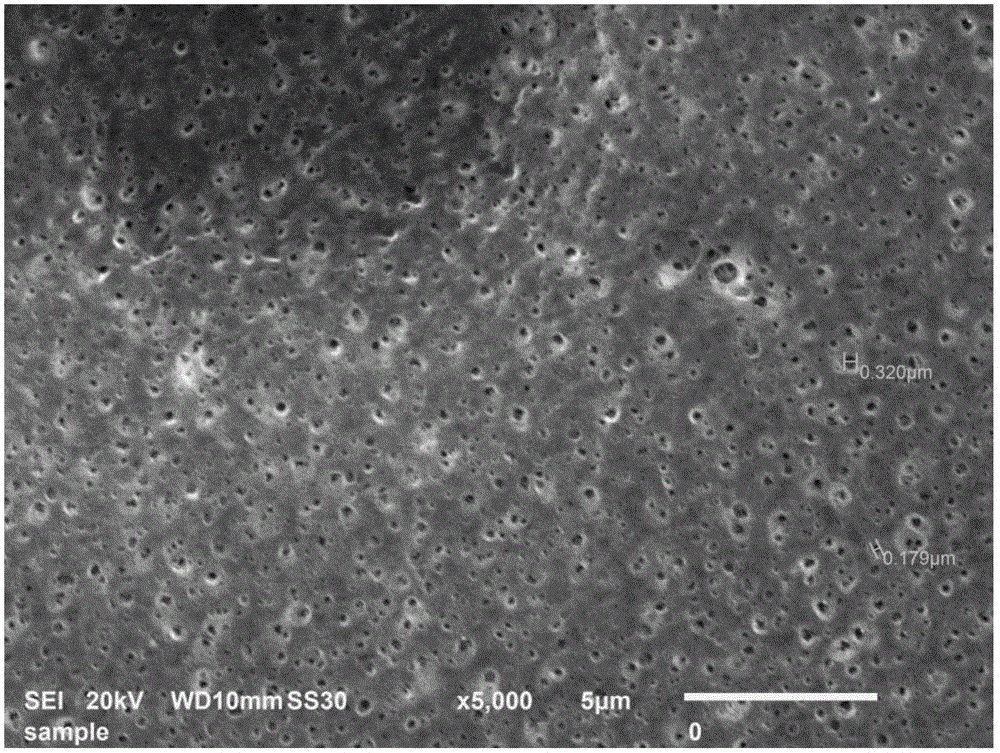

Preparation method of aluminum foil composite packaging material

The invention provides a preparation method of an aluminum foil composite packaging material. The method comprises the following steps of: coating a solventless adhesive on a surface of a substrate, wherein the substrate is paper or a high polymer film, and the coating amount of the solventless adhesive is 2.4 -3.4 g / m<2>; compositing the substrate coated with the solventless adhesive with the aluminum foil with a composite tension of 75-85 N; rolling the obtained composite material; and curing the rolled composite material to obtain the aluminum foil composite packaging material. An experiment express that the coating amount of dry basis of 40g of food paper / Al / PE (polyethylene) composite film prepared by the method in the invention is 5.0 g / g / m<2>, the solvent residual amount is 0, the oxygen-resistance property can be 0.023 (g / g / m<2>.24 h), the moisture-resistance property can be 0.020 (cu.cm / g / m<2>.24 h.0.1 MPa), and the tensile strength can be 78 MPa.

Owner:HUANGSHAN NOVEL

Pervaporation separation membrane and preparation method thereof

InactiveCN106110910AImprove hydrophilicityEasy to separateSemi-permeable membranesMembranesPervaporationEthyl ester

The invention discloses a pervaporation separation membrane and a preparation method thereof. The pervaporation separation membrane is prepared by stably polymerizing dopa or dopamine on the surface of a base membrane, and performing grafting and cross-linking. According to the pervaporation separation membrane and the preparation method thereof, a polydopa or polydopamine composite layer which can be firmly combined with the base membrane on the basis of a biological bonding principle is obtained; the composite layer is directly cross-linked with hydroxyls in a long-chain molecule, so that the pervaporation separation membrane which is high in hydrophility, permeation flux, separation performance and membrane stability is prepared. The preparation process is simple and convenient; raw materials are easy to obtain; the condition is mild; the prepared pervaporation membrane is used for separating ethyl acetate from water, and has relatively high permeation flux and membrane stability.

Owner:JIANGSU SOPO GRP +2

Microcrystalline foamed wall block produced by use of tailings and manufacturing method of microcrystalline foamed wall block

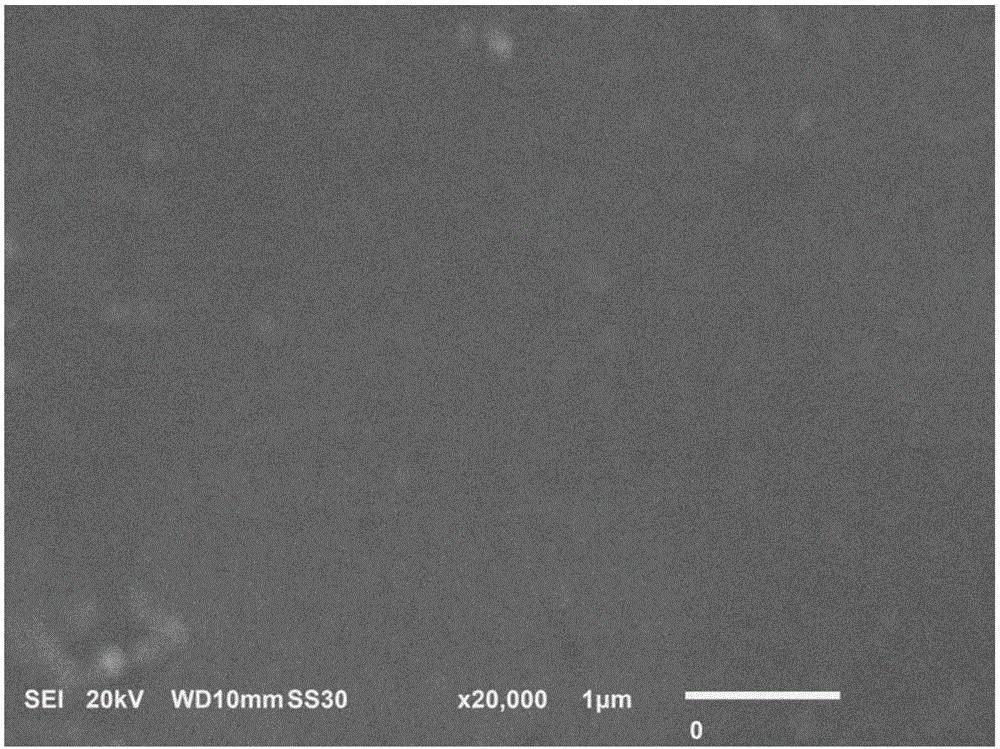

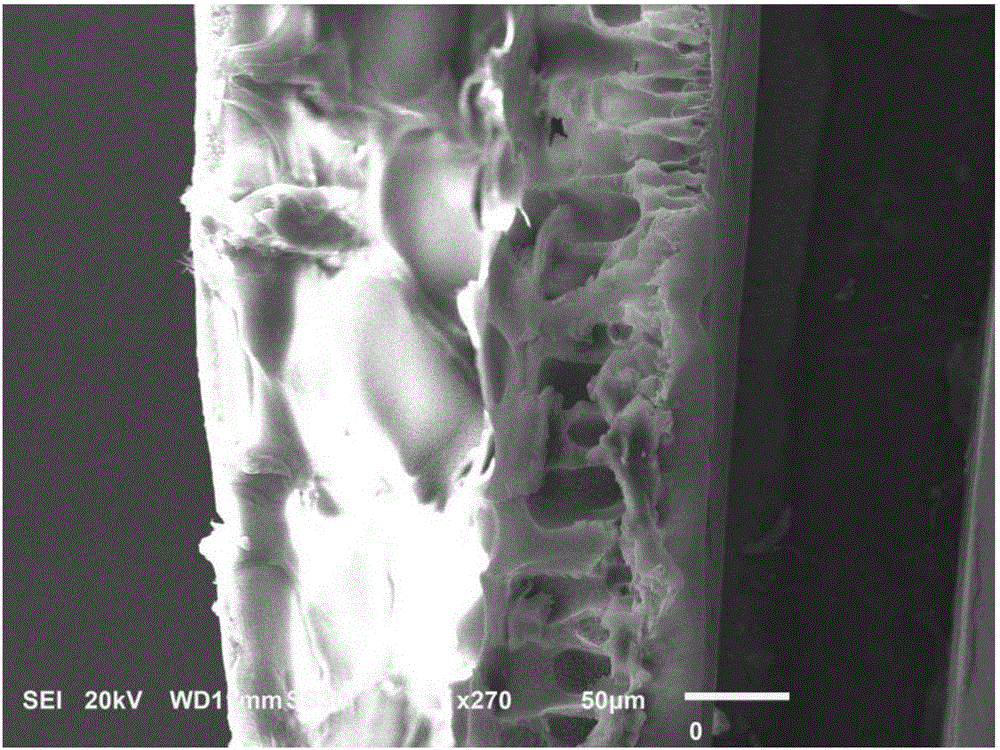

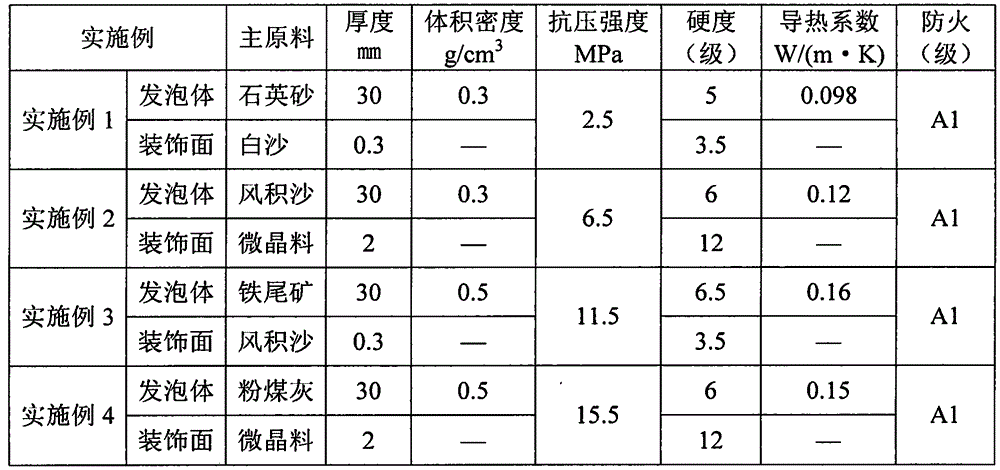

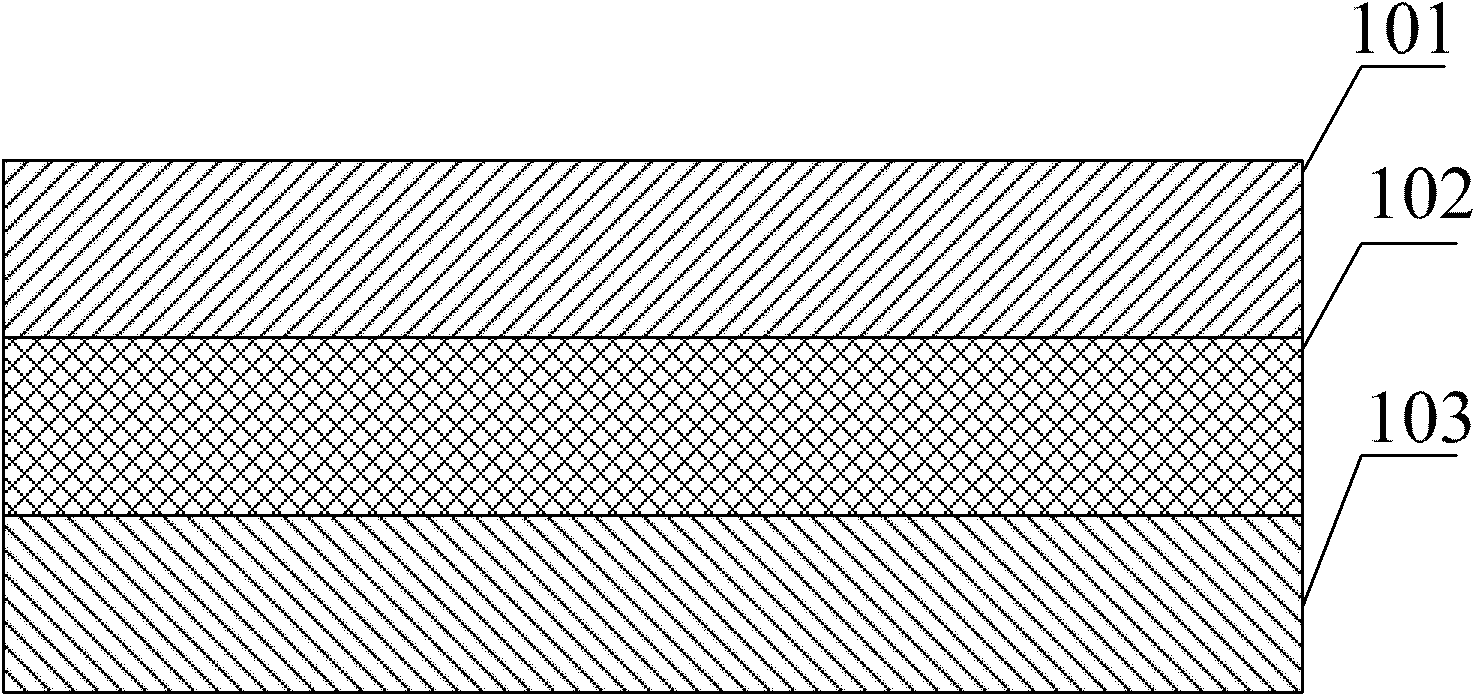

ActiveCN104631688AProduced noRelieve pressureBuilding componentsCeramicwareWeather resistanceSurface layer

The invention discloses a microcrystalline foamed wall block produced by use of tailings and a manufacturing method of the microcrystalline foamed wall block. According to the microcrystalline foamed wall block, a decorative surface layer is sintered on a tailing microcrystalline foamed base body manufactured by use of a tailing composite material at a high temperature. The manufacturing method comprises the following steps: (1) preheating, namely increasing the temperature to the range of 800-950 DEG C and preserving heat for 10-40 minutes; (2) integrated sintering, namely increasing the temperature to the range of 1000-1350 DEG C and preserving heat for 30-120 minutes; (3) annealing cooling, namely cooling to below 280 DEG C and then taking out of a kiln; (4) naturally cooling to below 100 DEG C and then performing mold stripping, thereby obtaining a microcrystalline foamed wall block board; naturally placing the microcrystalline foamed wall block board for more than 60 hours to eliminate stress, and then grinding or polishing, cutting and drying to obtain the microcrystalline foamed wall block. The microcrystalline foamed wall block has a plurality of functions of high strength, fire resistance, heat preservation and thermal insulation, moisture and water proofing, decoration, light weight, weathering resistance, environmental protection and the like.

Owner:BEIJING HUIERJIU MATERIAL TECH

Polyethylene (PE) film and preparation method thereof

ActiveCN102179985AImprove mechanical propertiesGood solvent resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a polyethylene (PE) film and a preparation method thereof. The PE film sequentially comprises a composite layer, an intermediate layer and a heat-seal layer, wherein the composite layer comprises 25 to 40 weight percent of low-density PE, 25 to 40 weight percent of linear low-density PE and 33 to 45 weight percent of modified metallocene linear low-density PE; the intermediate layer comprises 25 to 50 weight percent of the low-density PE and 50 to 75 weight percent of the linear low-density PE; and the heat-seal layer comprises 28 to 35 weight percent of the low-density PE and 65 to 72 weight percent of the linear low-density PE. The invention also provides a cleaning solution packaging composite film and a cleaning solution packaging bag, wherein the cleaning solution packaging composite film is prepared from the PE film. Correspondingly, the invention also provides a preparation method of the cleaning solution packaging composite film which is prepared from the PE film. A product is packaged by the PE film provided by the invention, so the packaging bag has certain solvent resistance and excellent heat-seal performance, the relatively high sealing property and tensile strength of a material subjected to heat sealing are guaranteed, and the leakage resistance and falling resistance of the composite film which is prepared by the material are further improved.

Owner:HUANGSHAN NOVEL

Carbon fiber, process for production thereof, prepregs, and golf club shafts

InactiveUS20070196648A1High compressive strengthTensile modulusSynthetic resin layered productsMonocomponent synthetic polymer artificial filamentCarbonizationGolf Ball

A carbon fiber tow composed of many carbon filaments and having a strand tensile strength of 3.8 to 5.5 GPa, a strand tensile modulus of 180 to 220 GPa and a carbon crystal size (Lc) of 13 to 18 Å. This carbon fiber tow can be produced by subjecting a precursor fiber tow composed of many polyacrylonitrile filaments which have a lightness difference (ΔL) of 50 or below and fineness of 1.1 to 1.7 dtex to oxidative stabilization and subjecting the stabilized fiber tow to carbonization with the maximum temperature within the range of 1,100 to 1,300° C. in an inert atmosphere while raising the temperature from 1,000° C. to the maximum temperature at a temperature rise rate of 100 to 2,000° C. / min.

Owner:TORAY IND INC

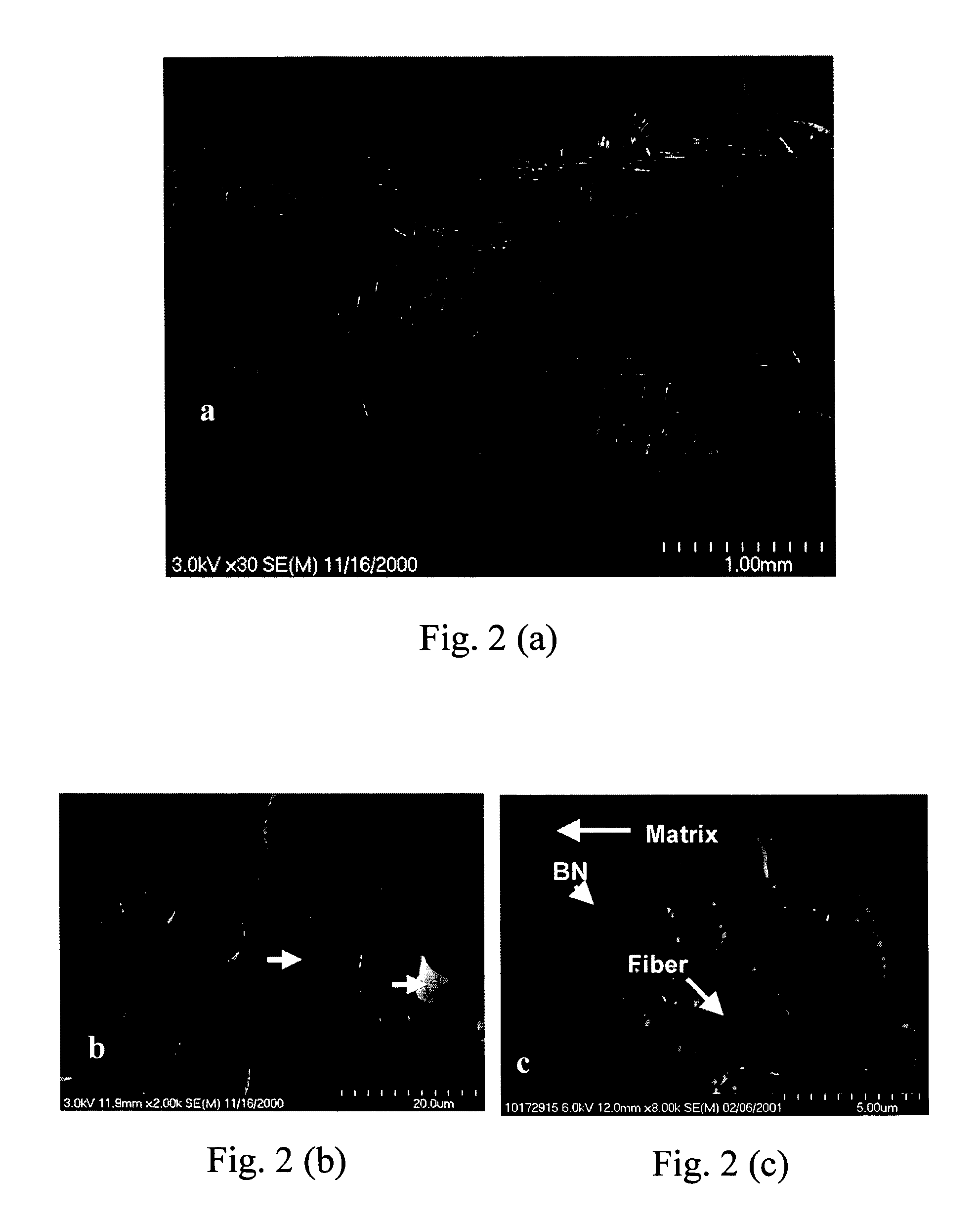

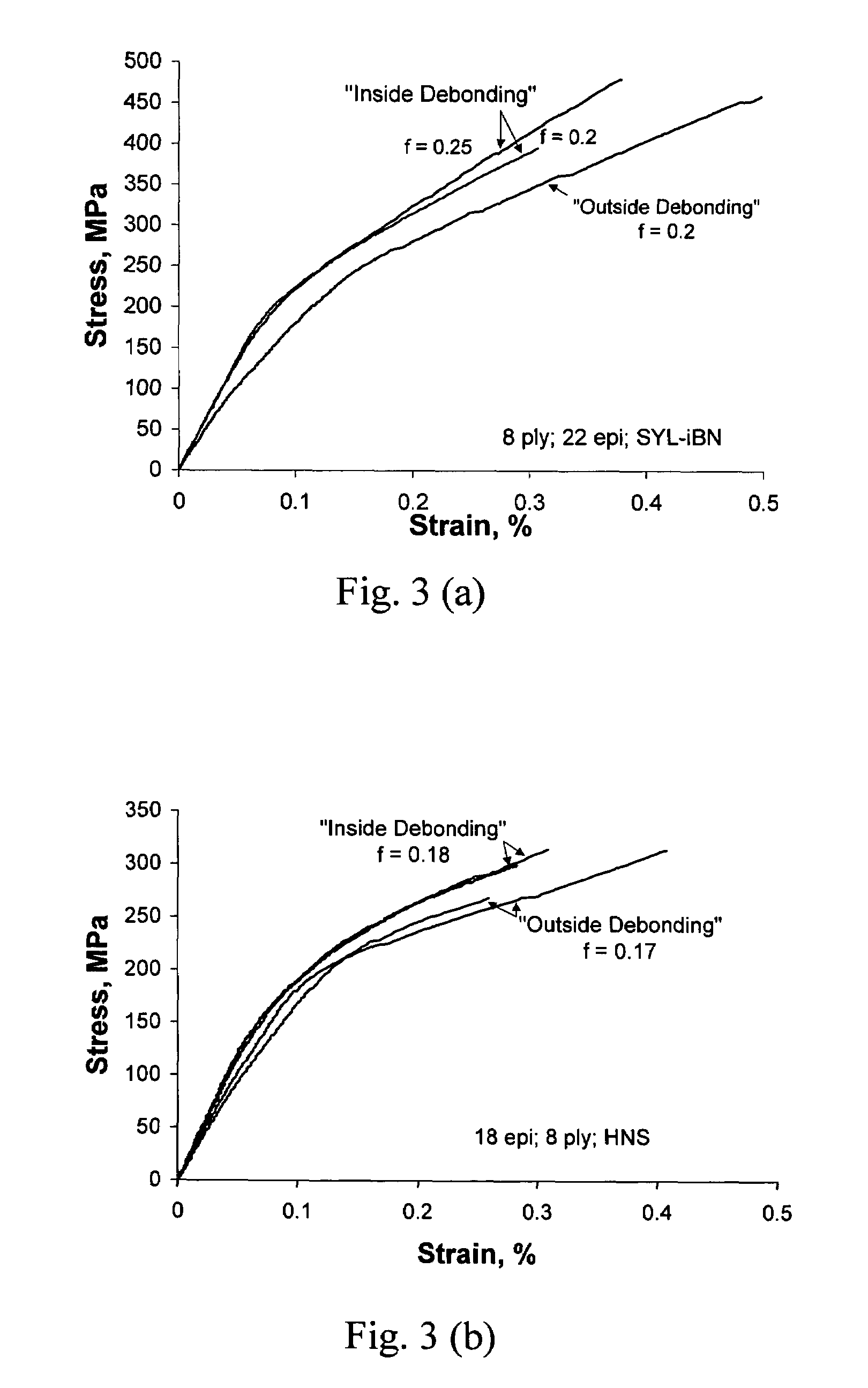

Interphase for ceramic matrix composites reinforced by non-oxide ceramic fibers

ActiveUS7427428B1Improve the oxidative durability of ceramic matrix composite materialsMaintain reliabilityLayered productsPretreated surfacesOxide ceramicNon oxide ceramics

A ceramic matrix composite material is disclosed having non-oxide ceramic fibers, which are formed in a complex fiber architecture by conventional textile processes; a thin mechanically weak interphase material, which is coated on the fibers; and a non-oxide or oxide ceramic matrix, which is formed within the interstices of the interphase-coated fiber architecture. During composite fabrication or post treatment, the interphase is allowed to debond from the matrix while still adhering to the fibers, thereby providing enhanced oxidative durability and damage tolerance to the fibers and the composite material.

Owner:NASA UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE

Method of rolling composite plate and strip by slanting corrugating roll

ActiveCN105798062AImprove bindingHigh composite strengthRollsMetal rolling arrangementsComposite strengthAxial force

The invention discloses a method of rolling composite plate and strip by a slanting corrugating roll. The method is characterized by comprising the following steps that a composite slab which is composed of a basal plate and a multilayer plate is rolled by a composite roughing mill with the slanting corrugating roll to prepare a semi-finished slanting corrugated composite plate, and then the semi-finished slanting corrugated composite plate is rolled by a composite finishing mill with a flat roll until the needed thickness to obtain a composite plate, wherein an axial included angle between slanting corrugation and the roll is 10-80 degrees. According to the method, the problems that instant impact is generated during rolling of a transverse corrugating roll, and the plate and strip are in deviation due to the axial force during rolling of a longitudinal corrugating roll are solved, and meanwhile, the combination area of the composite plates after being roughly milled is increased, so that the binding force between the basal plate and the multilayer plate is improved, and the composite strength and the composite efficiency of the composite plate are greatly improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Controller for motor

InactiveUS7622883B2Avoid demagnetizationHigh strengthSingle-phase induction motor startersSynchronous motors startersComposite fieldPhase difference

There is provided a controller for a motor capable of changing the phase difference between two rotors that can prevent demagnetization of permanent magnets or the rotors. The motor has two rotors each having a permanent magnet and phase difference changing driving means for changing the phase difference between the rotors. The controller has a demagnetization determining means for determining whether or not demagnetization of the permanent magnets of the rotors occurs during operation of the motor, and rotor phase difference controlling means for controlling the phase difference changing driving means to change the phase difference between the rotors from a current phase difference to a phase difference that results in a higher strength of a composite field of the permanent magnets if the result of determination by the demagnetization determining means is positive.

Owner:HONDA MOTOR CO LTD

Ultrahigh molecular weight polyethylene/polyvinyl chloride composite pipe and manufacture method thereof

InactiveCN101696754AHighlight substantiveSignificant progressFlexible pipesPolyvinyl chlorideUltrahigh molecular weight

The invention relates to an ultrahigh molecular weight polyethylene / polyvinyl chloride composite pipe and a manufacture method thereof. The ultrahigh molecular weight polyethylene / polyvinyl chloride composite pipe is manufactured by compounding an ultrahigh molecular weight polyethylene inner pipe and a polyvinyl chloride outer wall, wherein the ultrahigh molecular weight polyethylene inner pipe comprises the following raw material components in parts by weight: (1) 100 parts of the ultrahigh molecular weight polyethylene with viscosity-average molecular weight larger than or equal to 1.5 million, 2.1-10 parts of polyvinyl chloride with the molecular weight of 2,000-10,000; and the polyvinyl chloride outer wall comprises 100 parts of polyvinyl chloride resin (PVC), 5-15 parts of impact modifiers, 0.5-8 parts of heat stabilizers, 0.07-1 part of lubricants and the balance of dyestuff. The invention provides an ideal ultrahigh molecular weight polyethylene / polyvinyl chloride composite pipe with friction resistance, corrosion resistance, high strength, creep resistance and firm fastening of the inner pipe and the outer wall and the manufacture method thereof with firm compound and low production cost. The invention is suitable for transporting corrosive, adhesive, high abrasive materials.

Owner:SHANDONG KELI NEW MATERIAL CO LTD

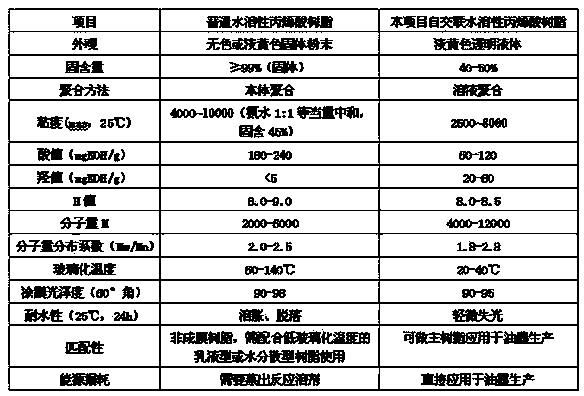

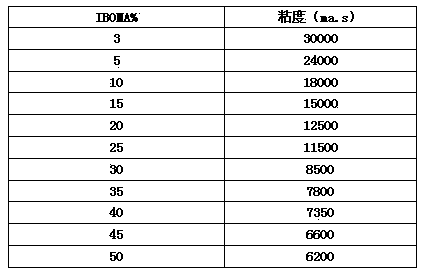

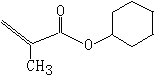

Water-soluble self-crosslinking acrylic resin composition and preparation method thereof

ActiveCN103387637AImprove water resistanceGood scrub resistancePolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides a water-soluble self-crosslinking acrylic resin composition. The water-soluble self-crosslinking acrylic resin composition is prepared from the following raw materials in percentage by mass: 40-50% of acrylic acid and derivative thereof as well as non-acrylic carboxyl monomers, 20-40% of solvent, 8-15% of water, 0.5-1.5% of initiating agent, 0.03-0.4% of molecular weight regulator, 3-8% of neutralizing agent and 0.1-0.5% of crosslinking agent, wherein the acrylic acid and derivative thereof as well as non-acrylic carboxyl monomers contain 0.2-1% of monomers containing carbonyl structures, 2-5% of monomers containing ring structures, 0-2.5% of acrylic acid carboxyl monomers, 2.5-5% of non-acrylic carboxyl monomers and 2.5-5% of hydroxyl monomers. The invention also discloses a preparation method of the water-soluble self-crosslinking acrylic resin composition. The water-soluble self-crosslinking acrylic resin composition is low in monomer residual quantity, wide in molecular weight distribution and good in resin resolubility, and basically reaches an industrial 0.8N / 15mm standard for the combined strength of OPP (oriented polypropylene) and PET (polyethylene terephthalate), so that the water-soluble self-crosslinking acrylic resin composition not only is suitable for PET composite packaging with compound printing ink printed in the OPP and low requirement for the combined strength, but also is suitable for paper printing.

Owner:江苏泰格油墨有限公司

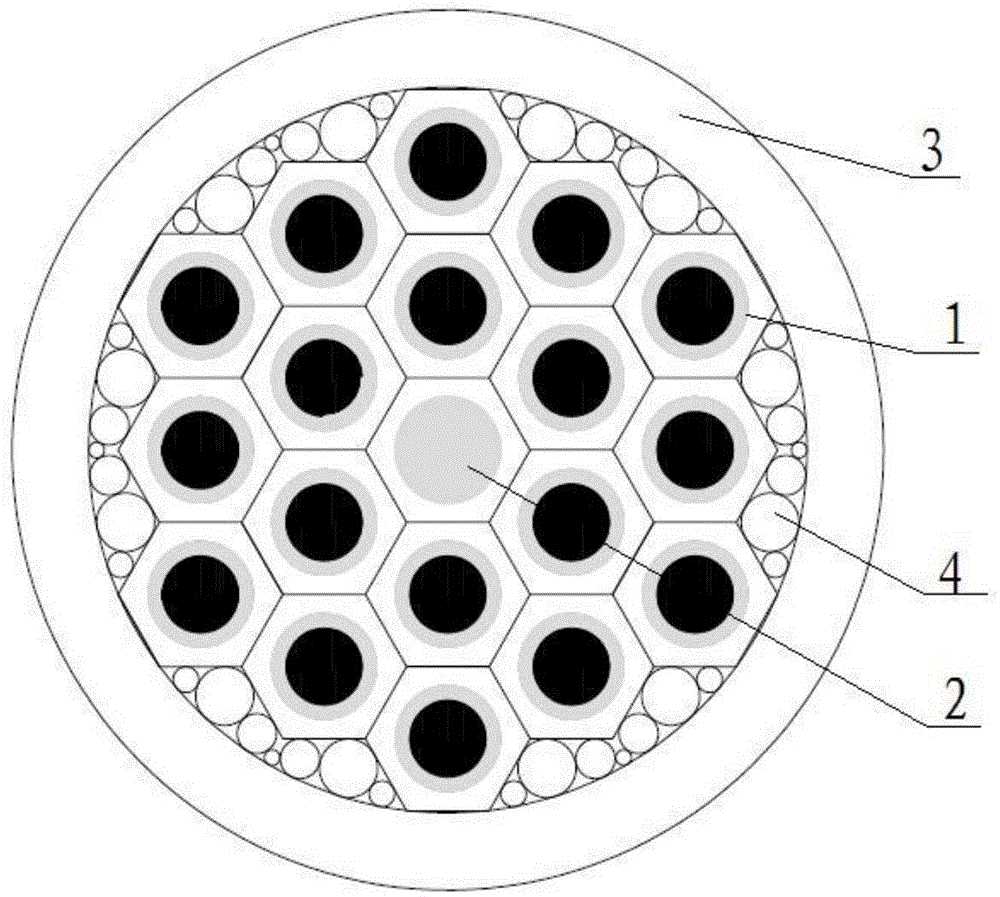

Method for manufacturing multi-core MgB2 superconductive wires through extrusion technology

ActiveCN104091651AImprove compactnessHigh yield strengthCable/conductor manufactureComposite strengthMachining deformation

The invention discloses a method for manufacturing multi-core MgB2 superconductive wires through the extrusion technology. The method includes the steps that first, precursor powder is prepared; second, the precursor powder is installed in a pipe to prepare a primary complex, and single-core wires are obtained through drawing machining; third, the precursor powder is installed in a pipe to prepare a secondary complex; fourth, the secondary complex processed through pre-heating seal welding is extruded, and multi-core rods are obtained; fifth, the multi-core rods are stripped and drawn to obtain multi-core wires, the multi-core wires are subjected to heat treatment, and then the multi-core MgB2 superconductive wires are obtained. According to the method, on the basis of a traditional power pipe-installing technology, a large single-pass machining deformation amount is adopted for manufacturing the multi-core MgB2 superconductive wires, in other words, the extrusion technology is adopted for manufacturing the multi-core MgB2 superconductive wires, because the secondary complex is in a very favorable three-dimensional stress state in extrusion, good metallurgical bonding will be achieved between different metal interfaces in the secondary complex along with the large extrusion deformation amount, the manufactured multi-core rods are high in composite strength, and the compactness and the yield strength of the multi-core MgB2 superconductive wires can be significantly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

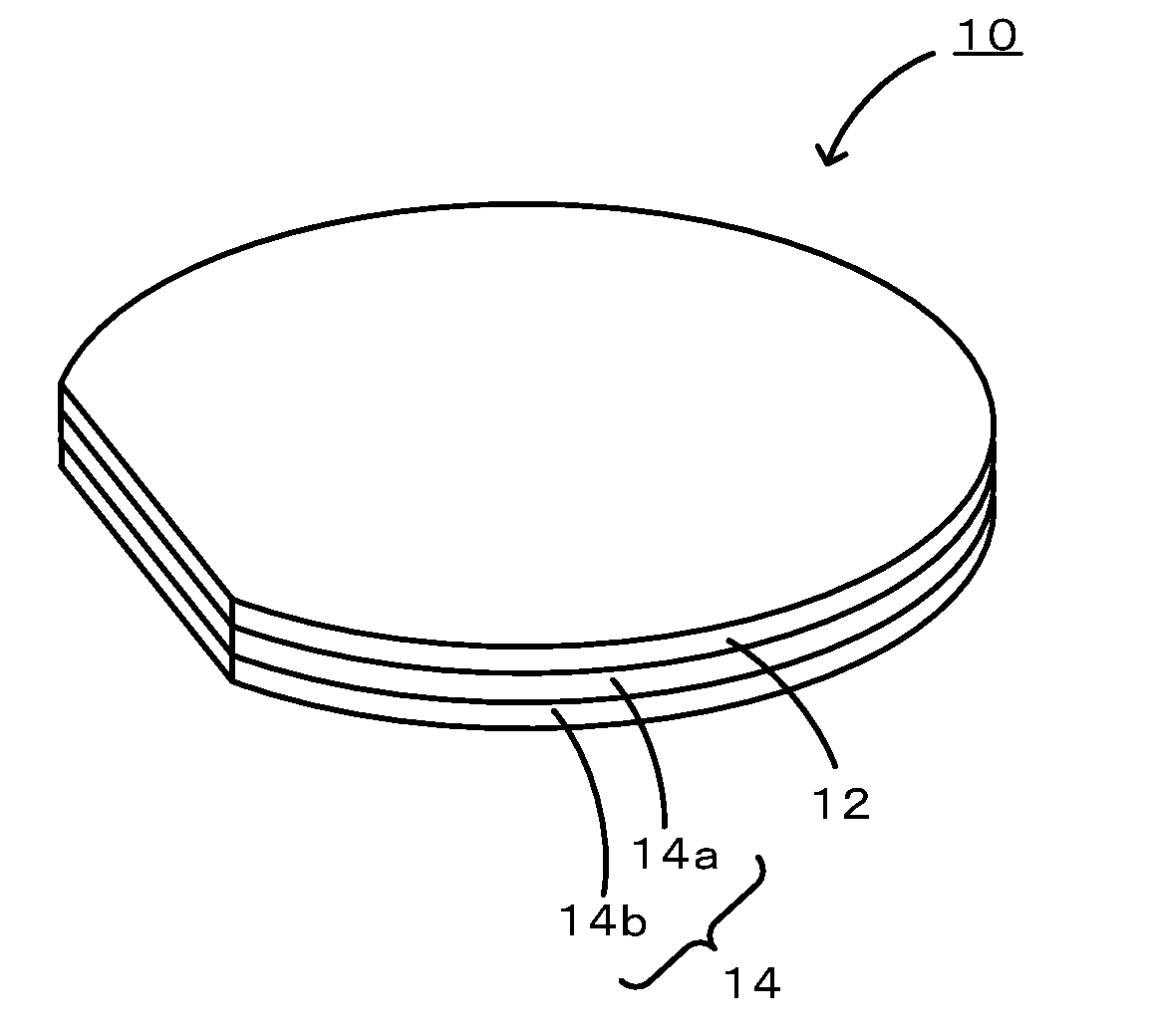

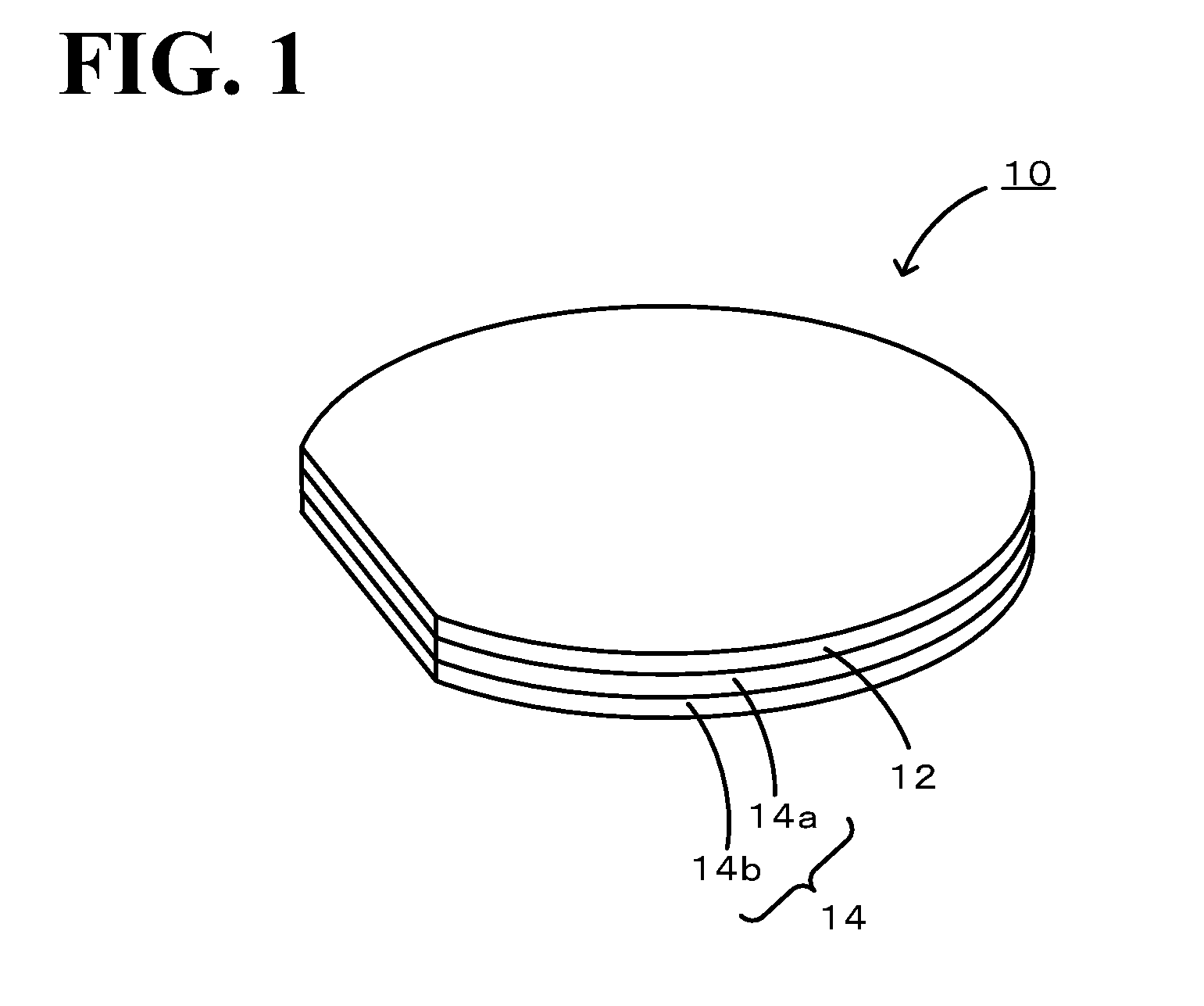

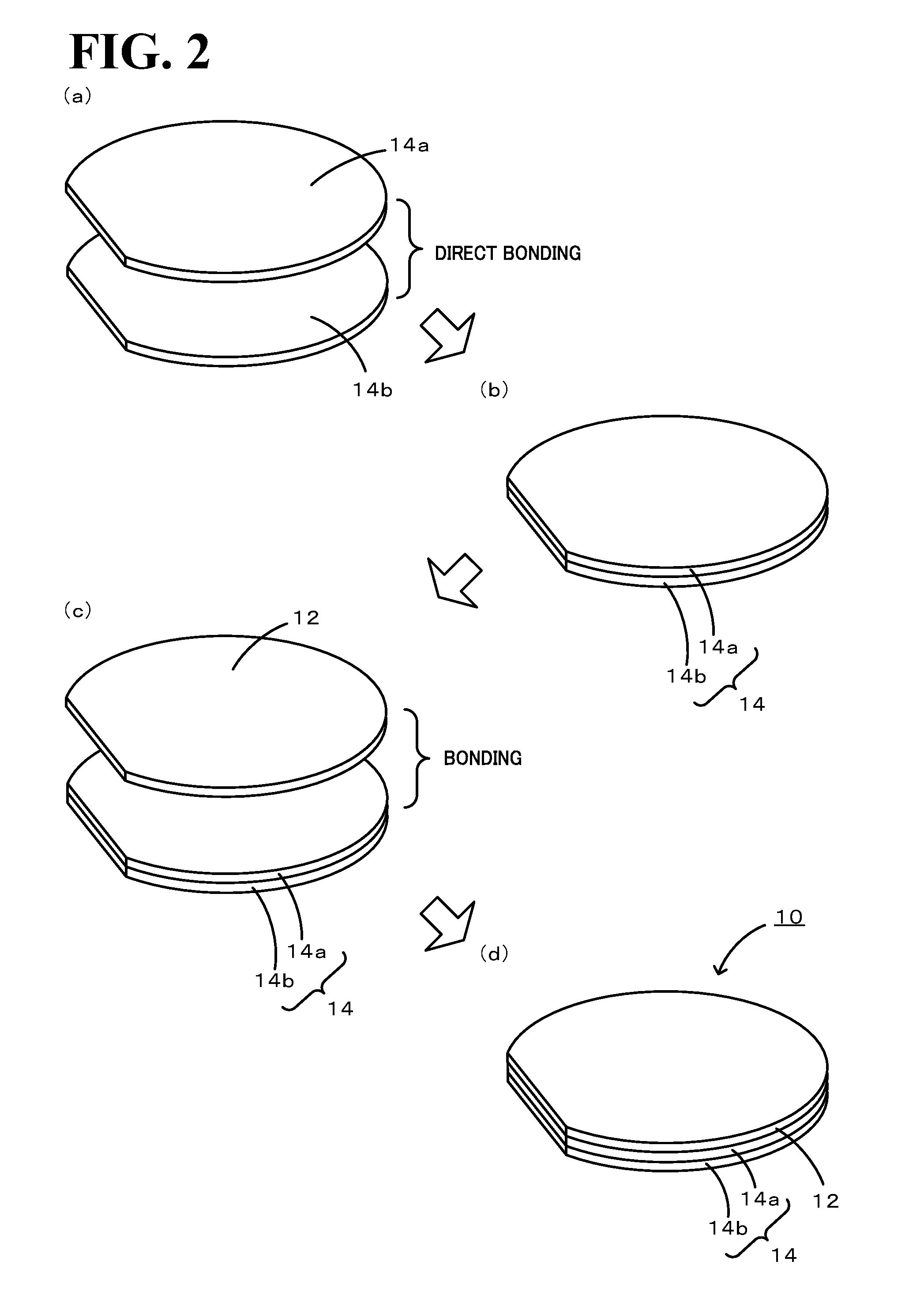

Composite Substrate, Elastic Wave Device, and Method for Producing Elastic Wave Device

ActiveUS20150328875A1Reduce warpageHigh strengthLamination ancillary operationsPiezoelectric/electrostriction/magnetostriction machinesComposite substrateThermal expansion

A composite substrate 10 is formed by bonding together a piezoelectric substrate 12 and a support substrate 14 that has a lower thermal expansion coefficient than the piezoelectric substrate. The support substrate 14 is formed by directly bonding together a first substrate 14a and a second substrate 14b at a strength that allows separation with a blade, the first and second substrates being formed of the same material, and a surface of the first substrate 14a is bonded to the piezoelectric substrate 12, the surface being opposite to another surface of the first substrate 14a bonded to the second substrate 14b.

Owner:NGK INSULATORS LTD

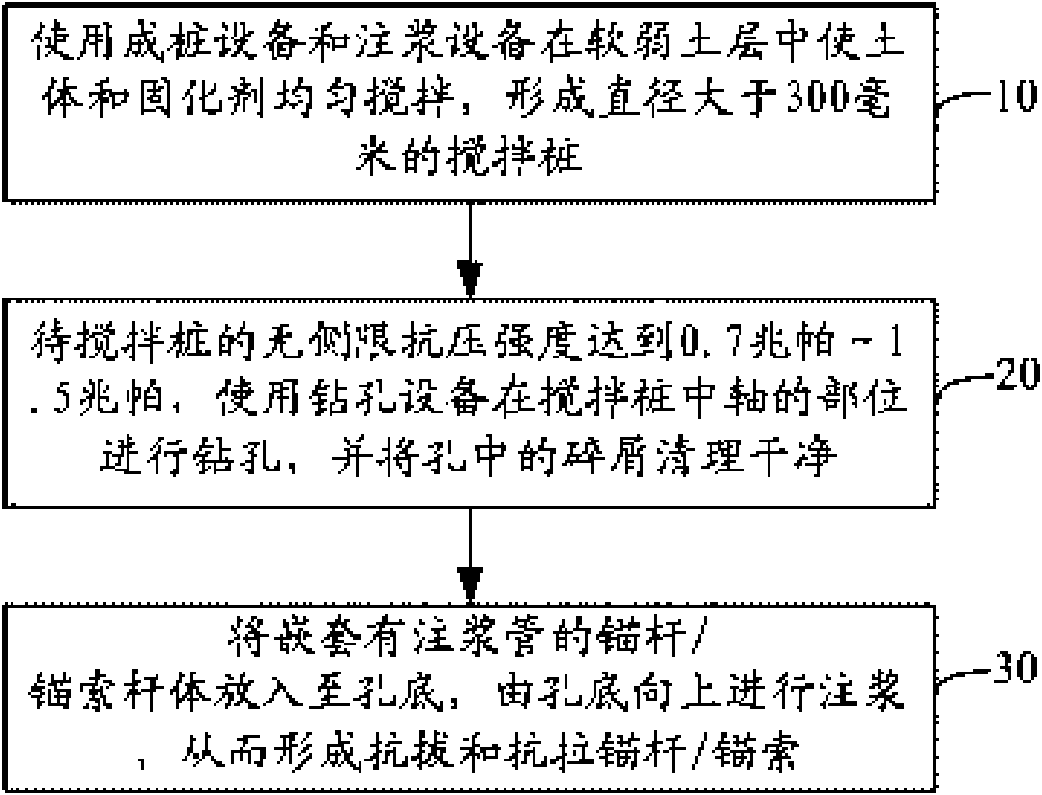

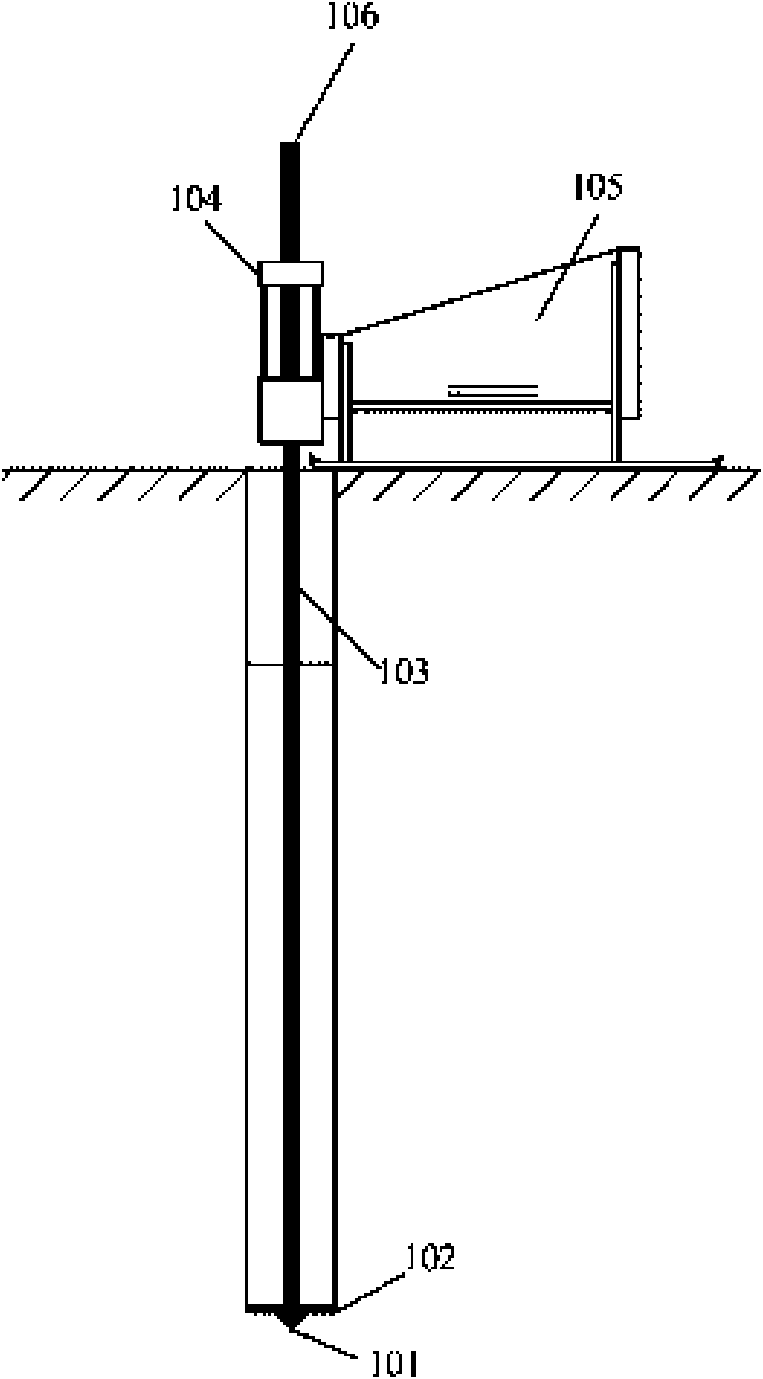

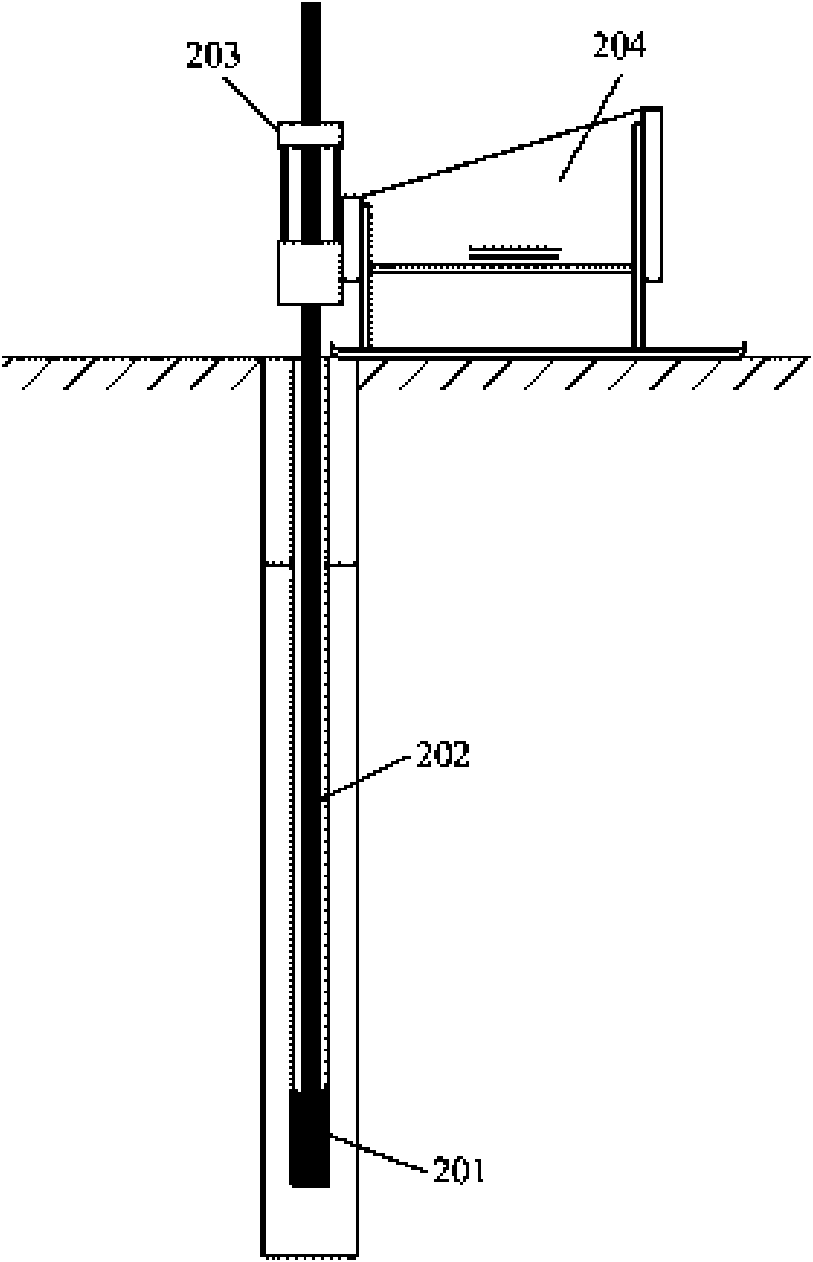

Method for enhancing pulling-resistant and tensile-resistant capability of soft and weak soil layer anchor rod/anchor rope

The invention relates to a method for enhancing pulling-resistant and tensile-resistant capability of a soft and weak soil layer anchor rod / anchor rope. The method comprises the following steps: evenly stirring soil body and a solidifying agent in the soft and weak soil layer by using pile-forming equipment and grout injecting equipment, and forming a stirring pile; drilling holes at the positionof a central shaft in a stirring pile by using drilling equipment when unconfined compressive strength of the stirring pipe reaches 0.7MPa to 1.5MPa, and cleaning detritus in the holes; and placing the anchor rod / anchor rope rod body embedded with a grout injecting pipe into the bottom of the holes, and carrying out grout injection from the hole bottom to top to form the pulling-resistant and tensile-resistant anchor rod / anchor rope. The method solves the problem that the soil layer anchor rod / anchor rope can not be used in soft soil areas, solves a series of problems of slurry pollution, longconstruction period, complex technique, high cost and the like due to pile injecting by the use of the pulling-resistant drilling and solves the problems of easy corrosion and nondurability of a reinforced pile anchor.

Owner:凌光荣 +1

Method of lock catch type vacuum rolling metal composite plate

InactiveCN103495604AHigh composite strengthEasy to separateAuxillary arrangementsMetal rolling arrangementsComposite strengthVacuum pumping

A method of a lock catch type vacuum rolling metal composite plate comprises the following steps that penetrated grooves are machined in the end faces of the two ends, vertical to the rolling direction, of a base plate respectively, and correspondingly, L-shaped embedding strips are welded to corresponding positions at the two ends of a shroud plate respectively; greasy dirt on the surface to be compounded is cleaned; the L-shaped embedding strips at the two ends of the shroud plate slide into the grooves in the two ends of the base plate to enable a composite slab formed by the shroud plate and the base plate to be in an embedded state. Sealing plates are connected to the periphery of the composite slab in a welded mode to enable composite space to be sealed; holes are formed in the sealing plates, air between the shroud plate and the base plate is extracted through the holes, and the holes are blocked after vacuum pumping is carried out; the composite slab is heated to 950-1300 DEG C to be rolled until the composite slab reaches a needed thickness to form the metal composite plate; edge cutting is carried out on the rolled metal composite plate, the sealing plates are removed, and rolling of the composite plate is completed. According to the method, mutual movement of adjacent slabs in the rolling direction and the slab thickness direction can be effectively constrained, rolling stability is improved, and meanwhile composite strength of the metal composite plate is greatly increased.

Owner:武汉钢铁有限公司

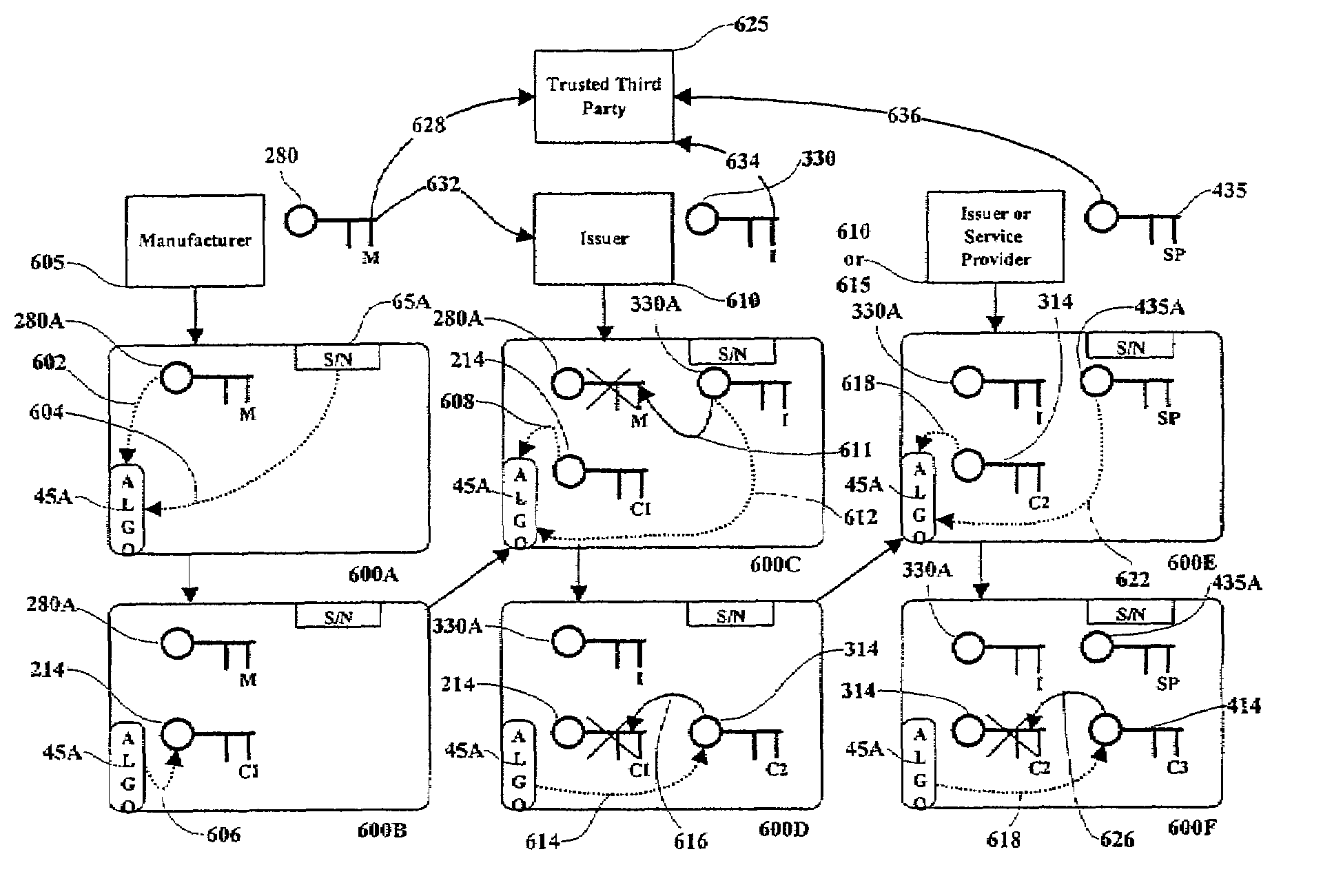

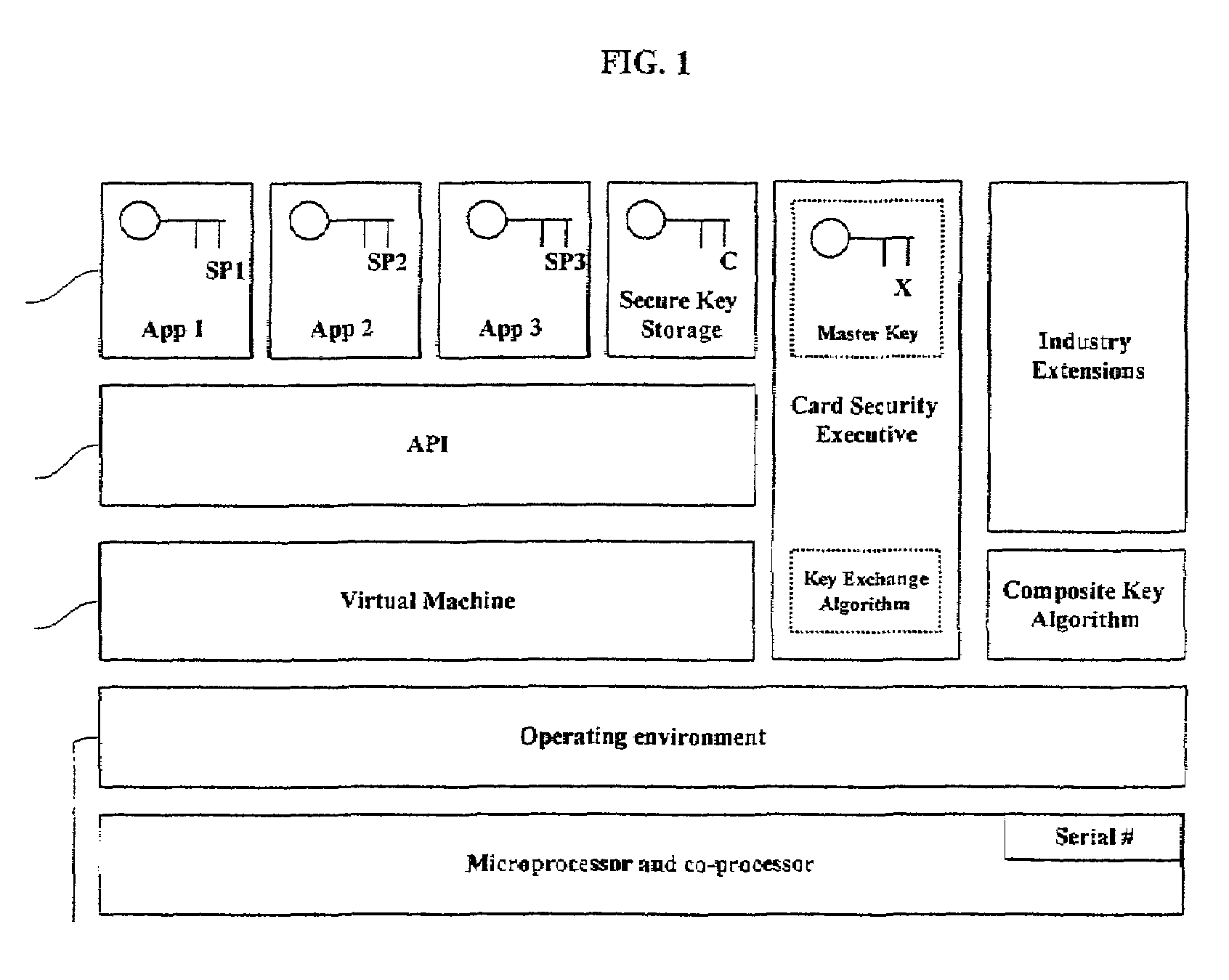

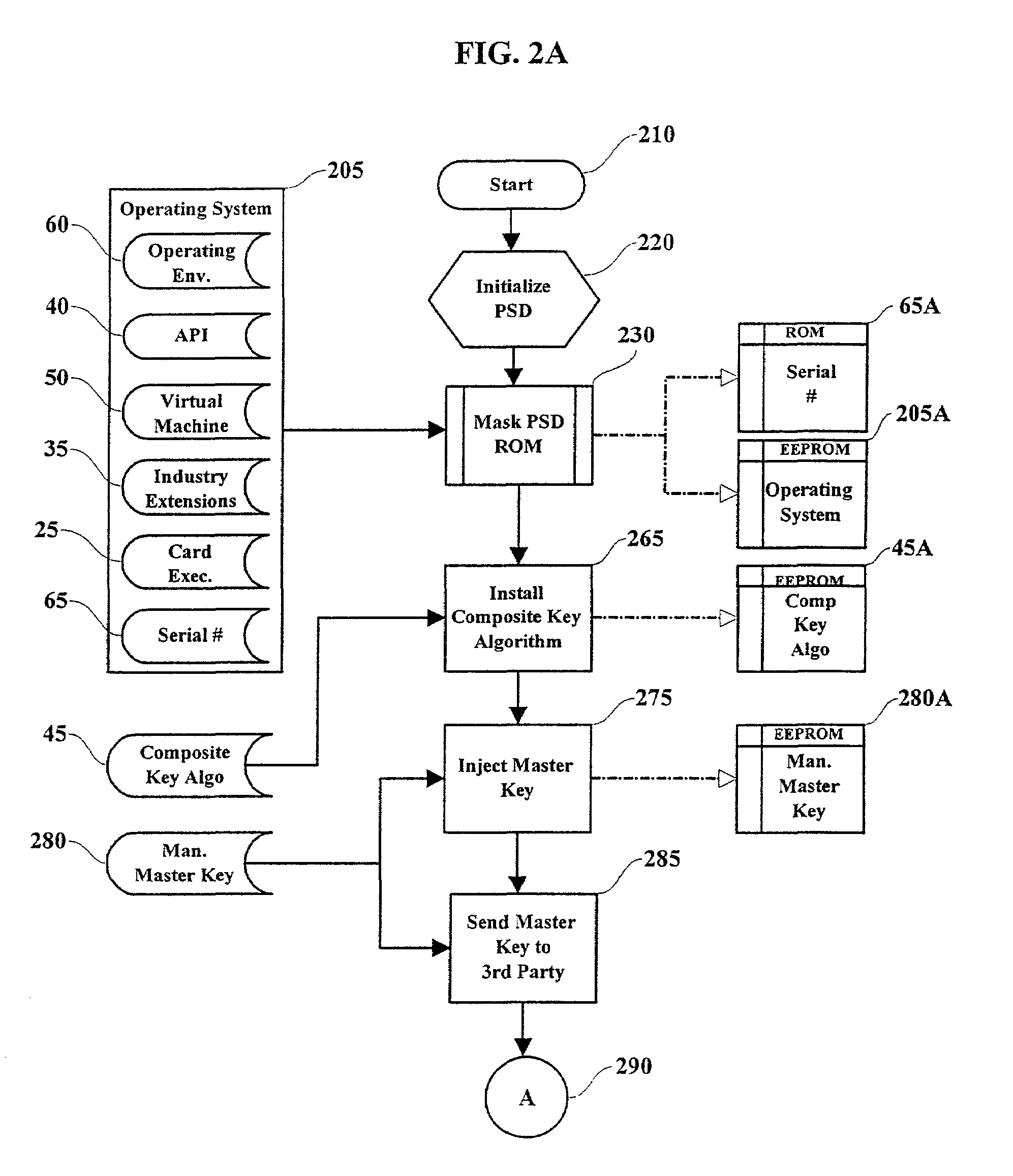

System and method for generating symmetric keys within a personal security device having minimal trust relationships

ActiveUS6973191B2Reducing trust relationshipHigh composite strengthKey distribution for secure communicationDigital data processing detailsService provisionTrusted third party

Owner:ASSA ABLOY AB

Hot melt adhesives bonding fiber

InactiveUS20050170143A1Easy to manufactureHigh strengthSynthetic resin layered productsLaminationSecondary layerThree dimensional shape

A hot melt adhesive bonding fiber of the invention, which comprises at least one layer of thermal activation fiber cloth, which is interposed between a first layer of material and a second layer of material. The fiber cloth has a three-dimensional shape constituted by alternate protrusions and concaves, which is bonded with the first or second layer of material by hot-pressing, perfusion, or molding injection. The composite of the invention can be used for bonding all kinds of polyurethane materials with rubber (plastic) to strengthen the bonding intension.

Owner:BISQUIT DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com