Compound technique of film filtering material and equipment

A membrane filtration and process technology, which is applied in the composite process and equipment field of new membrane filter materials, can solve the problems of easy separation of membrane and base cloth, reduce the service life of membrane filter materials, and poor high temperature resistance of viscose, so as to improve air permeability Sex and filtration efficiency, reduce operating costs, and ensure the effect of production and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

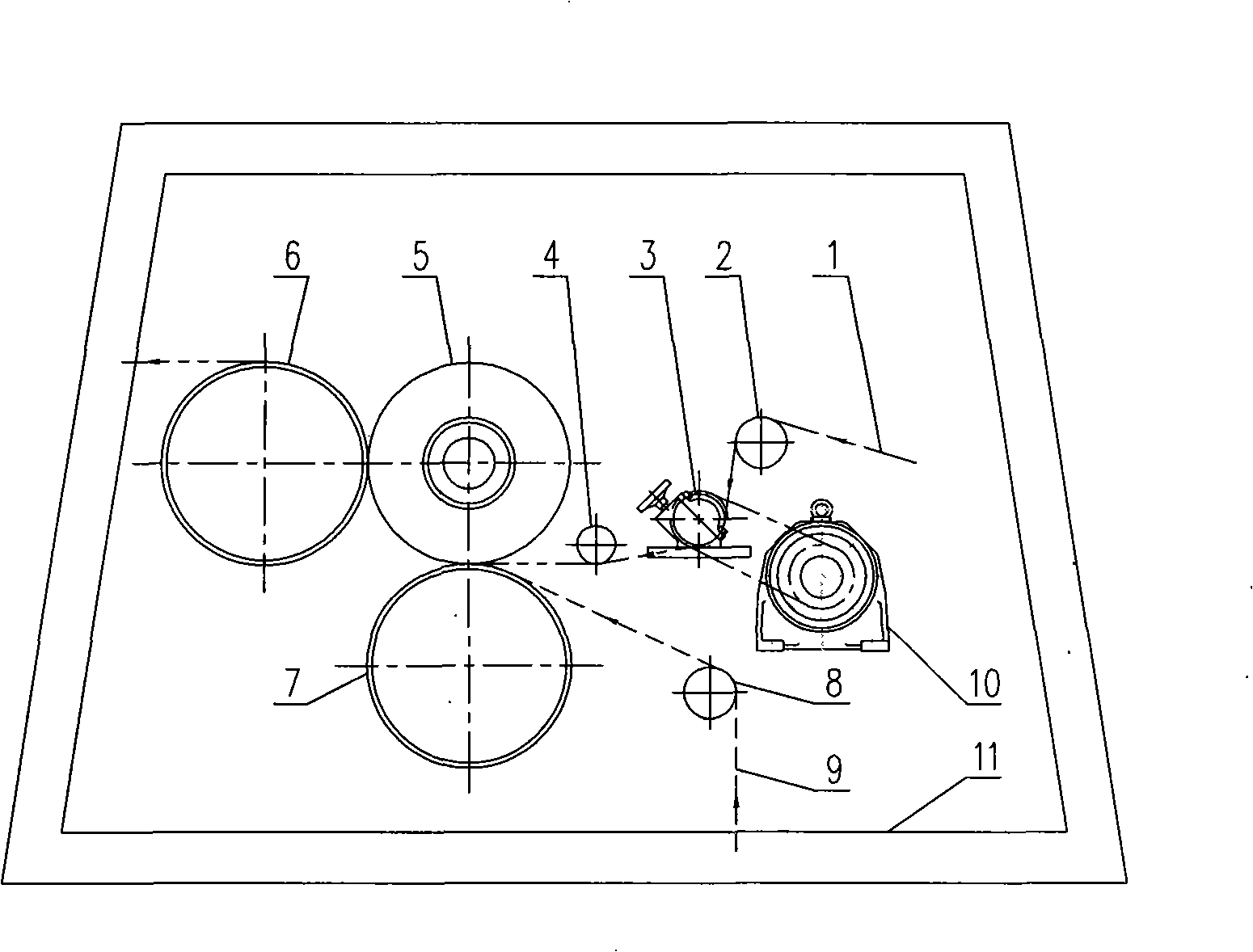

[0019] Embodiment 1: Take the thermocompression composite of polytetrafluoroethylene film and glass fiber cloth as an example.

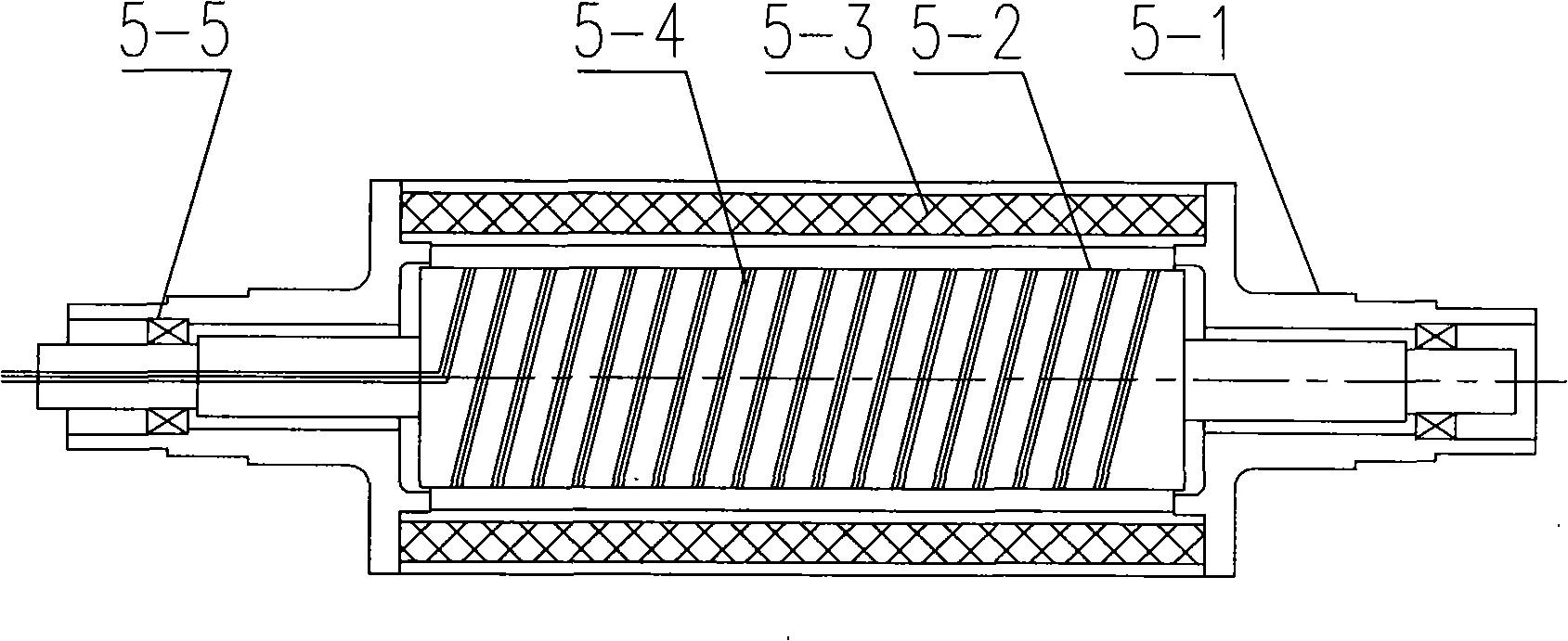

[0020] The composite process of the membrane filter material is as follows: the polytetrafluoroethylene membrane 1 and the glass fiber cloth 9 are synchronously input between the heating roller 5 and the lower pressure roller 7 of the hot pressing composite equipment at a speed of 4m / min, and the polytetrafluoroethylene membrane 1 Input from the tangential direction of the heating roller 5 and the lower pressure roller 7 to realize the line contact of hot pressing; the polytetrafluoroethylene film 1 and the glass fiber cloth 9 are hot pressed at a linear temperature of 270°C with a line pressure of 25kN / m forming. After the membrane filter material formed by linear hot pressing is heated by a quarter surface of the heating roller 5, it is hot-pressed and shaped with a linear pressure of 18kN / m. The axial temperature difference between the polytetraf...

Embodiment 2

[0023] Embodiment 2: Take the thermocompression compounding of polytetrafluoroethylene film and glass fiber needle felt as an example.

[0024] The composite process of the membrane filter material is as follows: the polytetrafluoroethylene membrane 1 and the glass fiber needle felt 9 are synchronously input between the heating roller 5 and the lower pressure roller 7 of the hot pressing composite equipment at a speed of 3.5m / min, and the polytetrafluoroethylene The film 1 is input from the tangential direction of the heating roller 5 and the lower pressure roller 7 to realize the line contact of hot pressing. The polytetrafluoroethylene film 1 and the glass fiber needle felt 9 are heated at a linear temperature of 280°C at a temperature of 20kN / m. Line pressure thermoforming. After the membrane filter material formed by linear hot pressing is heated by a quarter surface of the heating roller 5, it is hot-pressed and shaped with a linear pressure of 16kN / m. The composite temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com