Patents

Literature

817 results about "Composite process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes. There are three types of composite manufacturing processes: open molding, closed molding and cast polymer molding. There are a variety of processing methods within these molding categories, each with its own benefits.

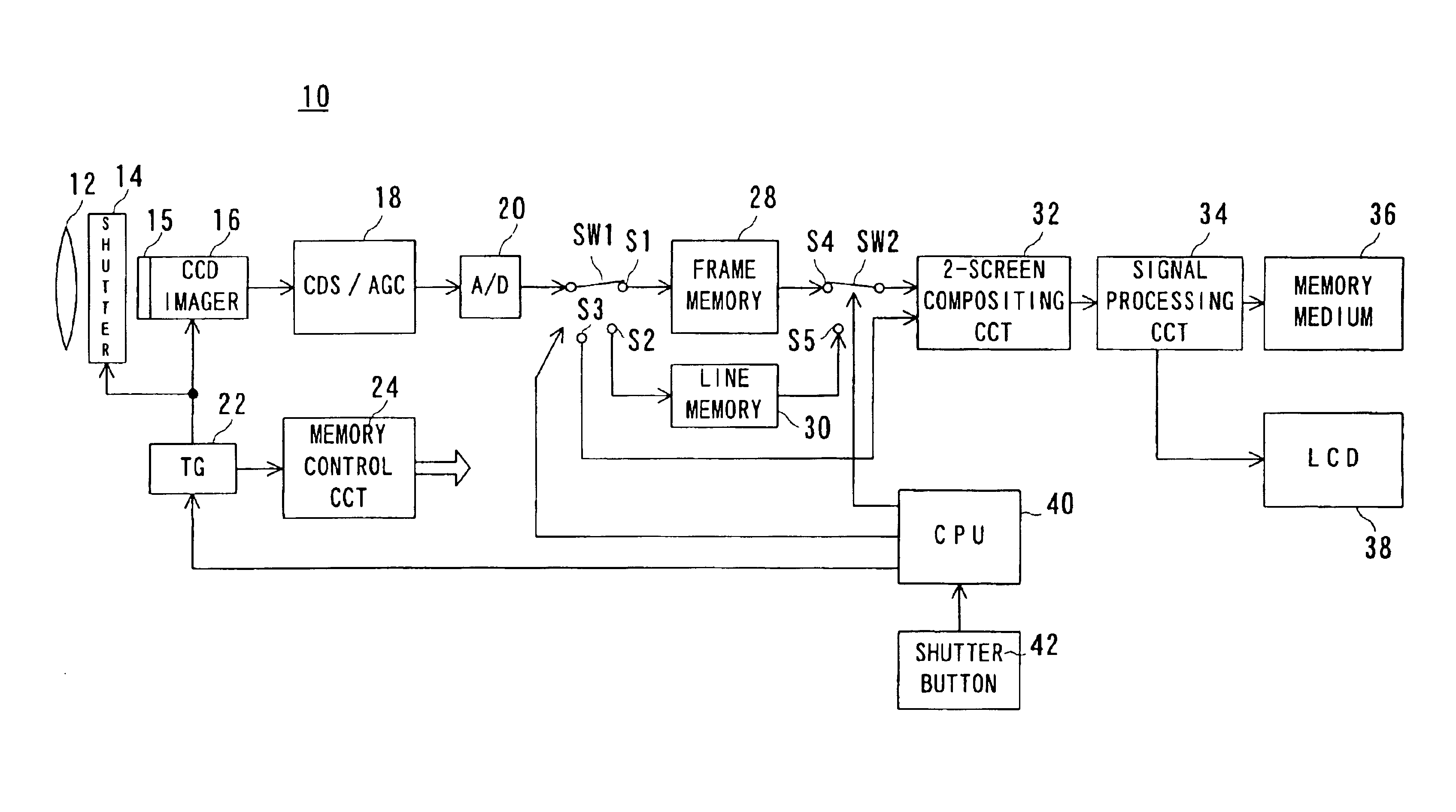

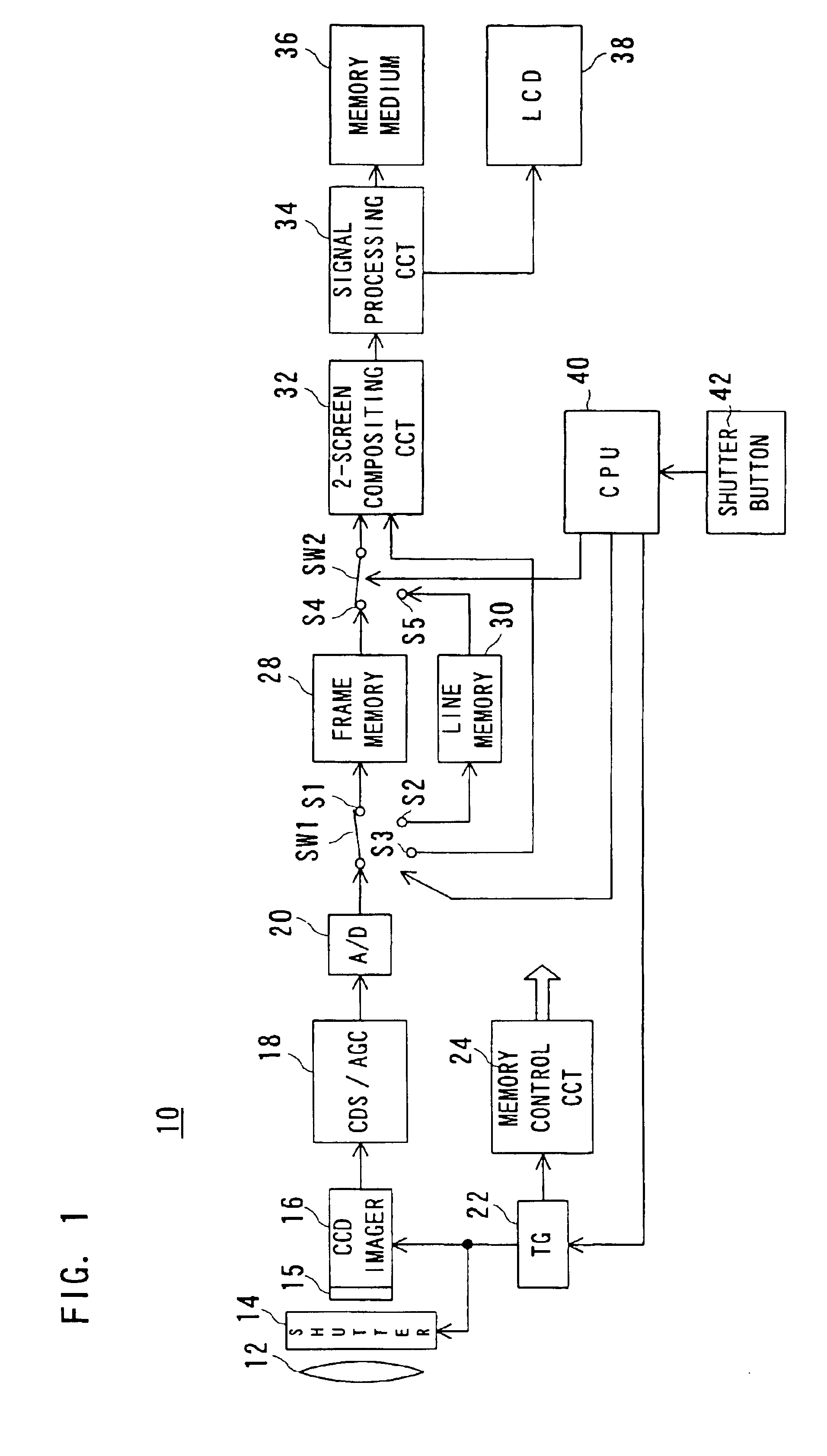

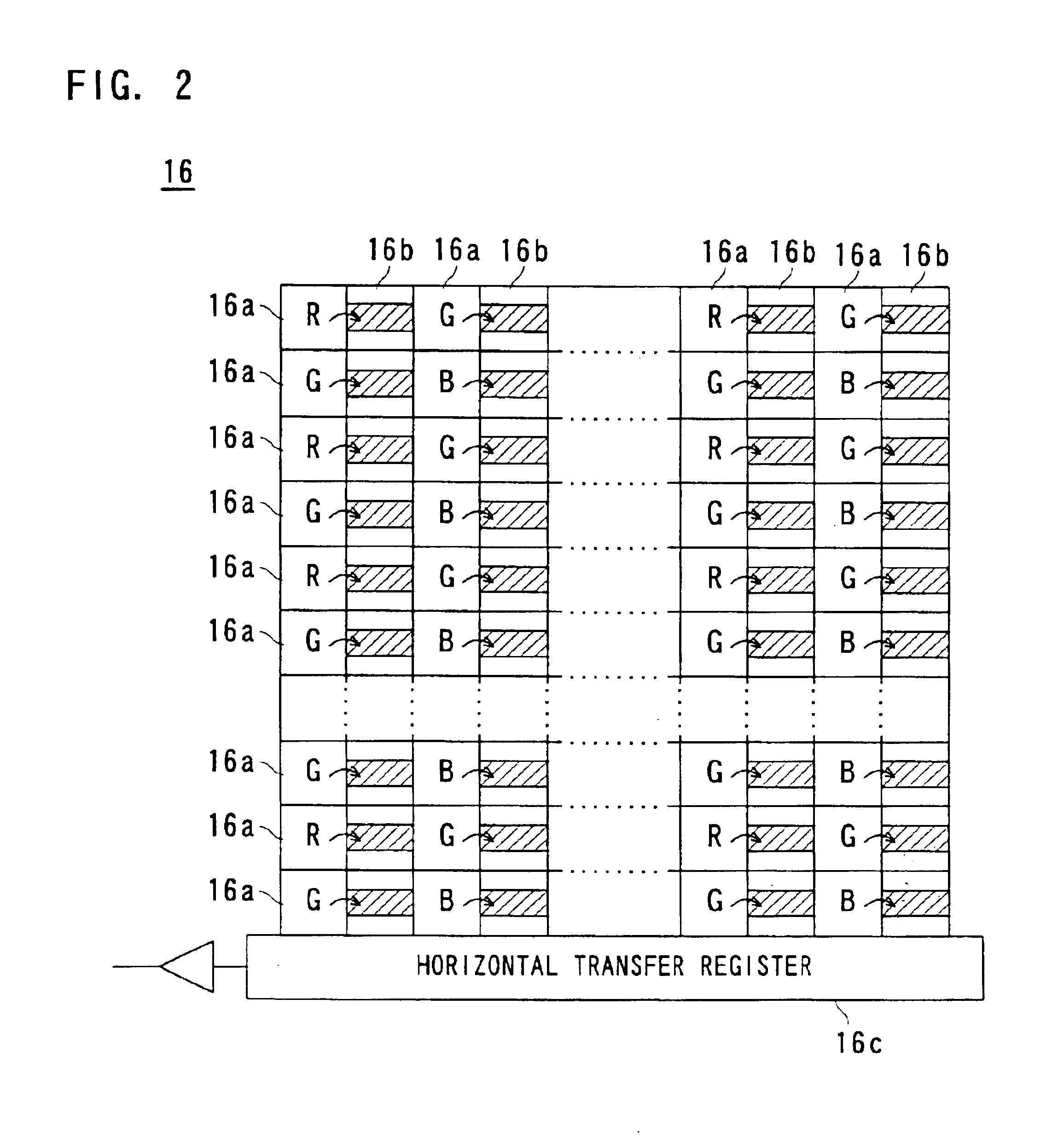

Digital camera which produces a single image based on two exposures

InactiveUS6903770B1Improve dynamic rangeTelevision system detailsTelevision system scanning detailsSingle imageSingle exposure

A digital camera includes a CCD imager having an interline transfer scheme. A first charge produced due to first exposure is read from light receiving elements positioned vertically intermittently. A second charge produced due to second exposure is also read from the same light receiving elements to vertical transfer regions. Here, the first charge is vertically moved simultaneously with or prior to reading out the second charge. The moving distance, at this time, is equal to or greater than a distance that the light receiving elements continue in the vertical direction. As a result of this, the second charge will not be mixed with the first charge. The first and second charges are subjected to a compositing process to display a composite image on an LCD.

Owner:XACTI CORP

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

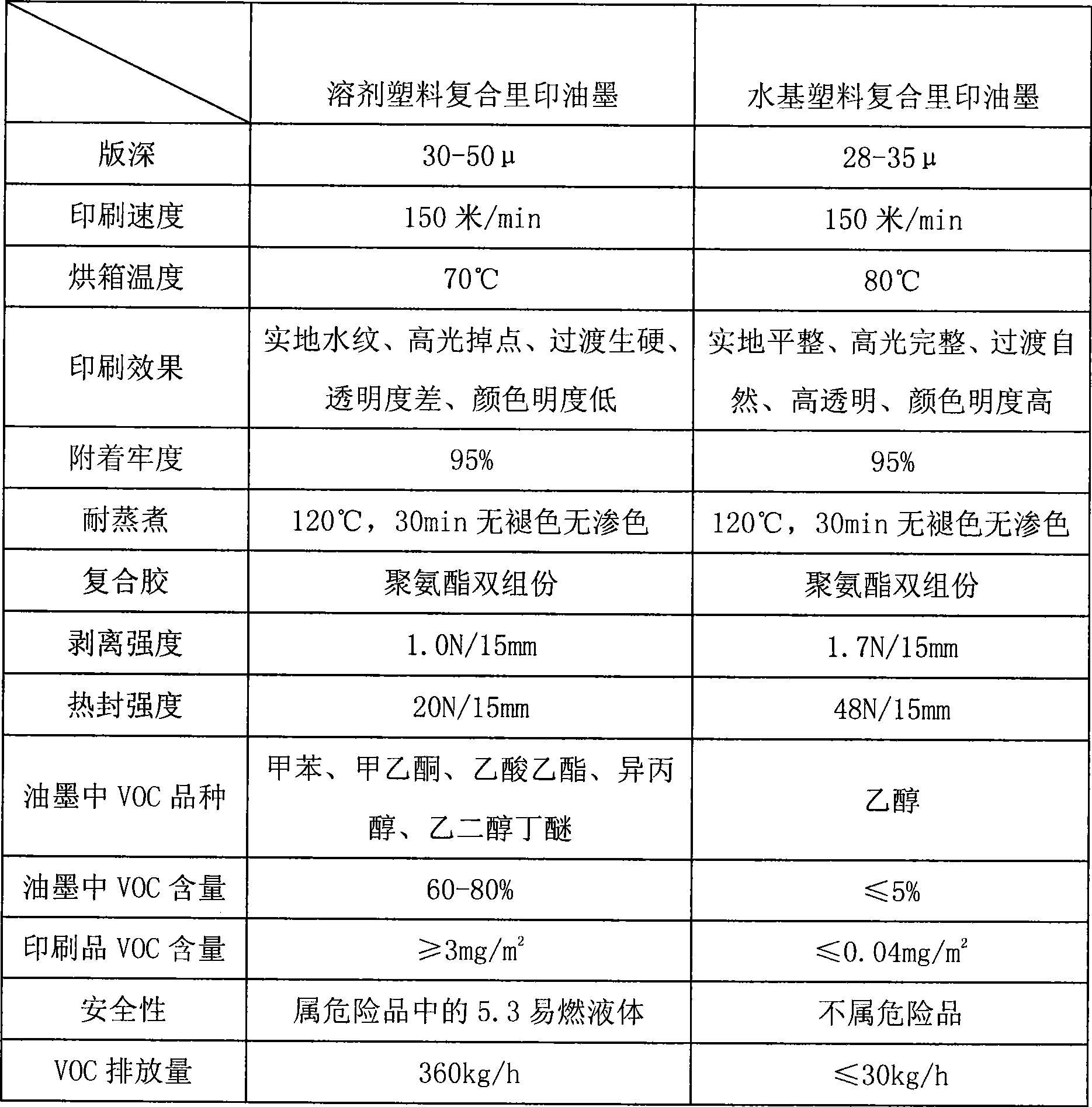

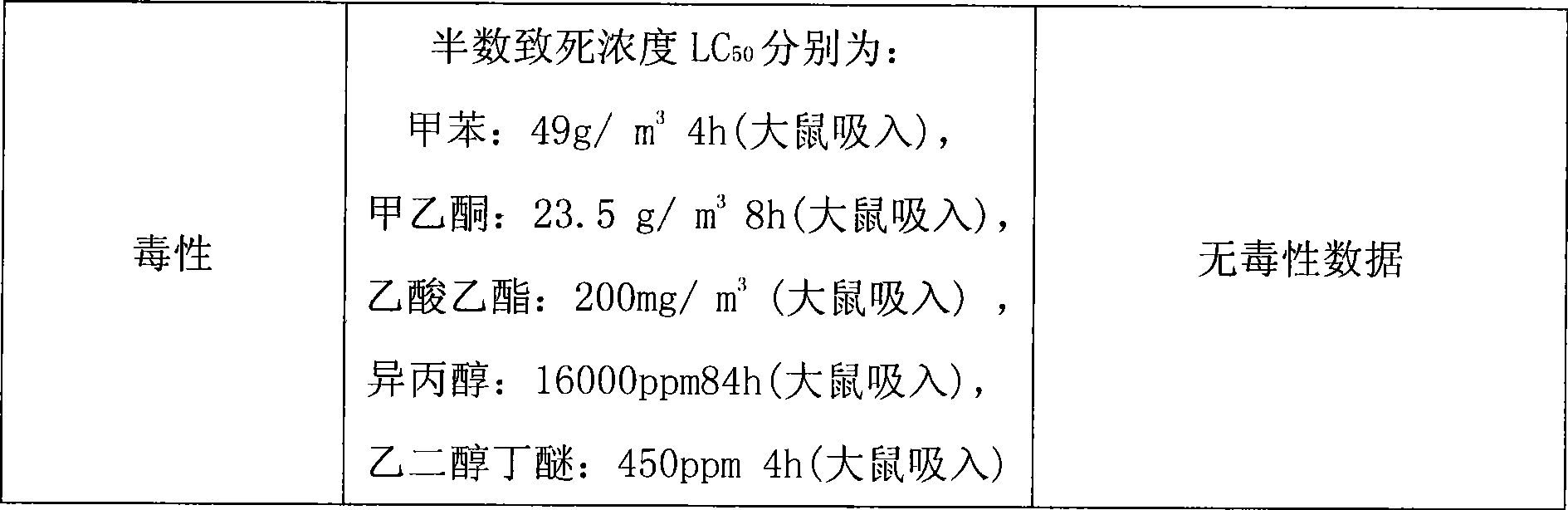

Water-based plastic composite inner-printing ink

The invention discloses a water-based plastic composite printing ink, in particular to a water-based ink needed in the plastic film intaglio printing composite process. To solve problems, the invention provides the water-based ink which remarkably improves composite strength, sealing strength and printing mass relative to the prior solvent ink on the premise of not reconstructing the prior printing equipment or adjusting the printing process; the water-based ink adopts the following technical proposal: the water-based plastic composite printing ink is prepared from the following raw materials in weight portion: 10 to 35 portions of aqueous polyurethane emulsion, 0 to 8 portions of aqueous acrylic resin, 0 to 7 portions of aqueous wetting dispersant, 0.2 to 2 portions of aqueous dampness levelling agent, 0.1 to 2 portions of aqueous defoaming agent, 0.1 to 5 portions of PH regulator, 6 to 30 portions of pigment, 0 to 5 portions of ethanol and 6 to 73.6 portions of water. The water-based ink can be widely applied in the field of ink manufacturing.

Owner:山西鹰鲲科技有限公司 +1

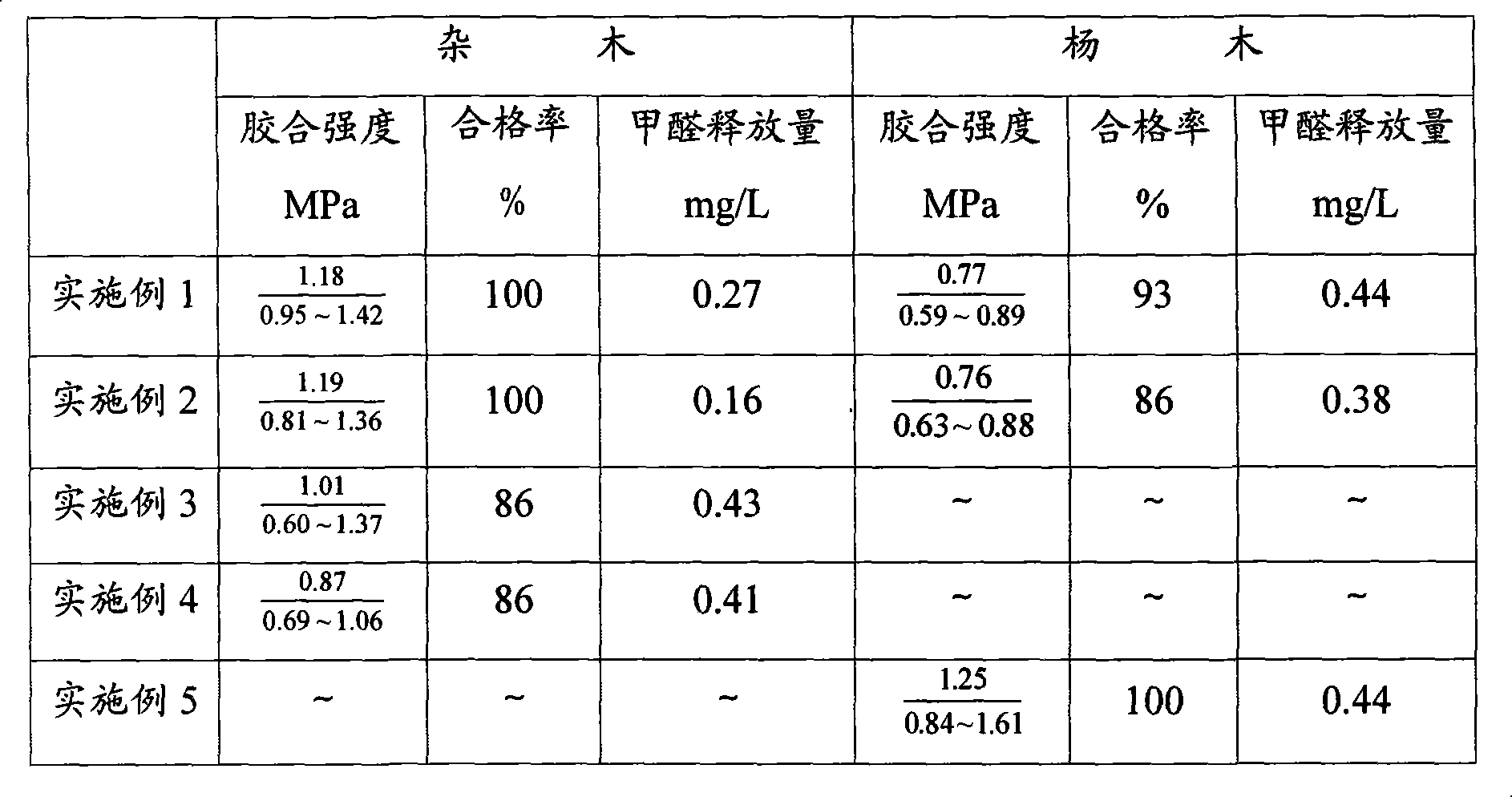

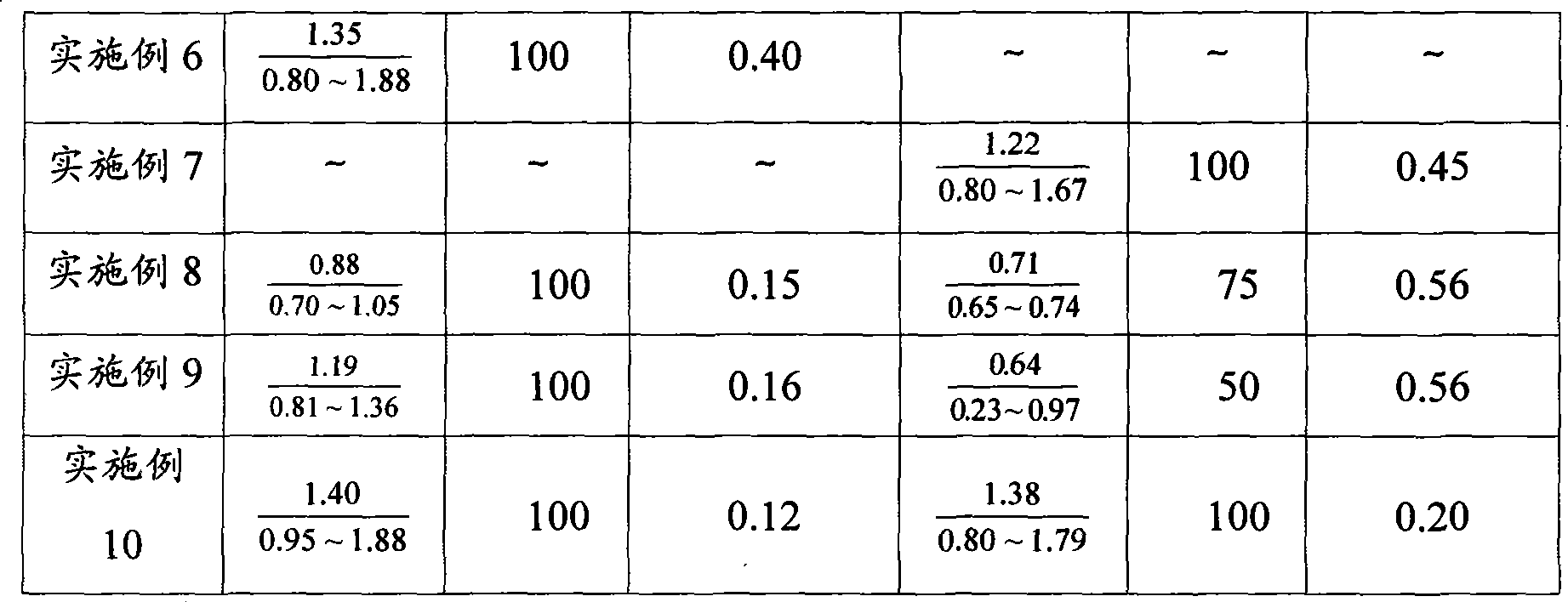

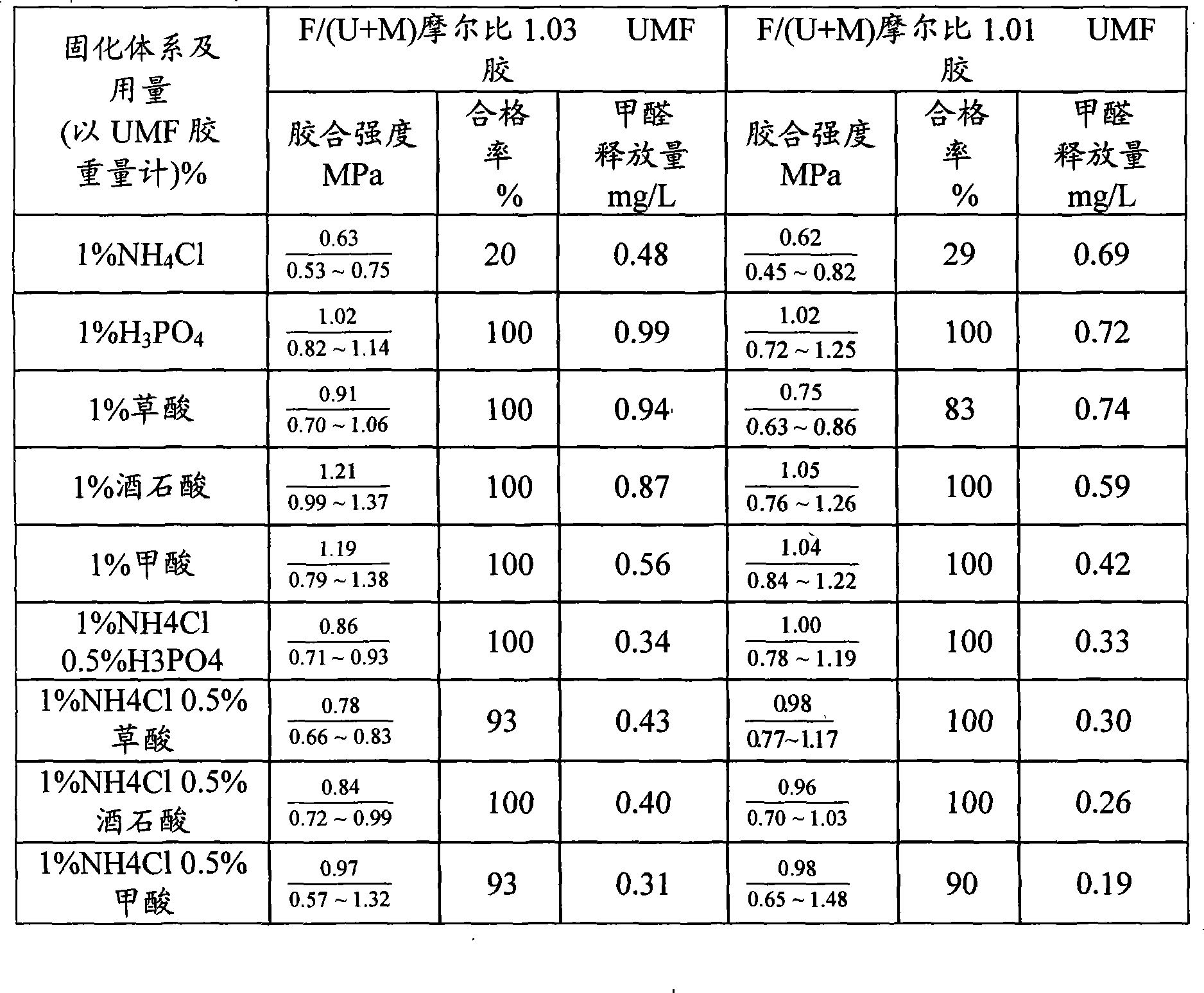

Method for manufacturing E0 level wood veneer

InactiveCN101244571AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesWood veneer joiningWood veneerEther

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

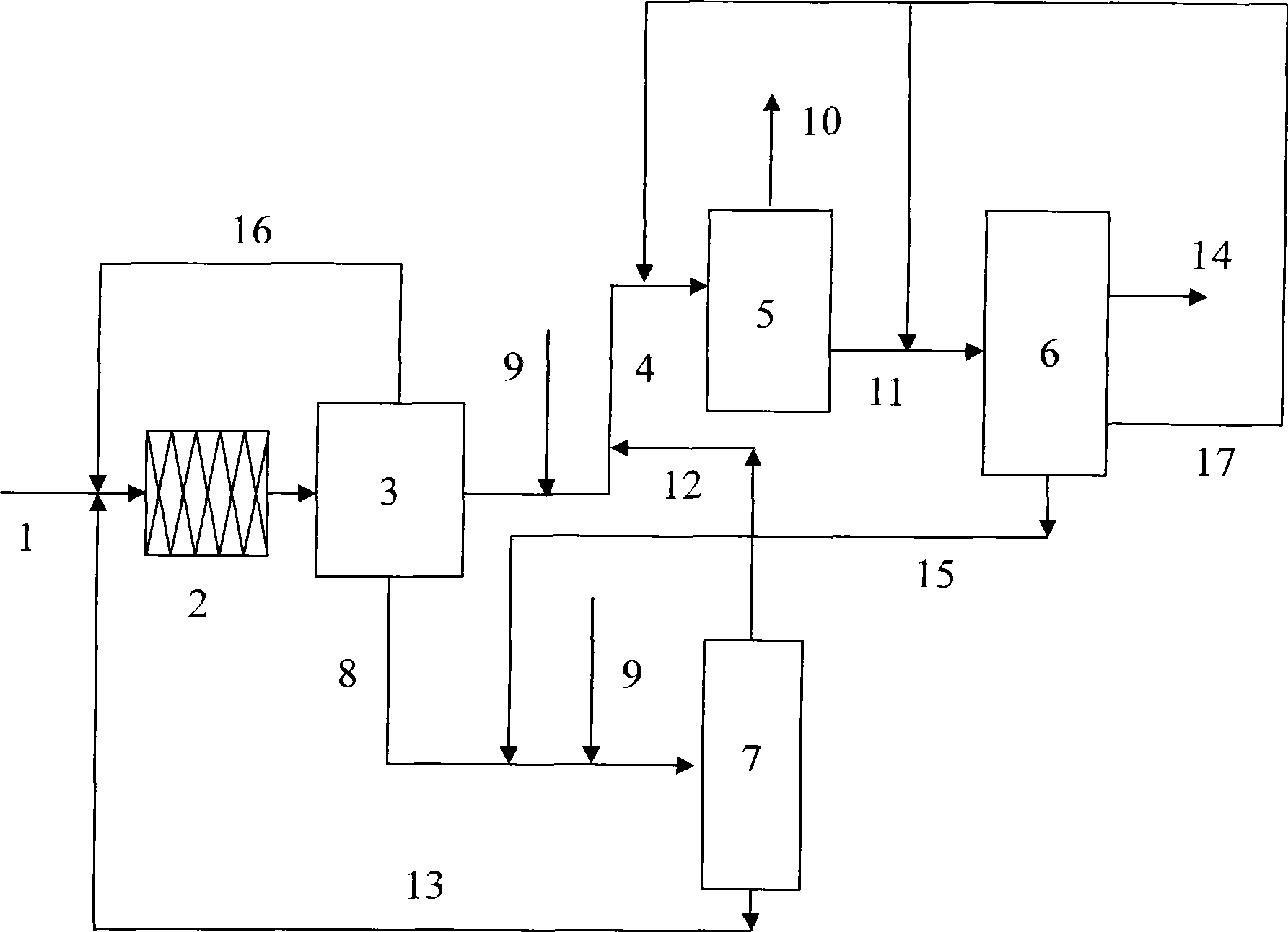

Composite process for treatment of inferior residual oil

ActiveCN101418222AWide adaptability of raw materialsAchieve maximum light weightTreatment with hydrotreatment processesTar working-up by solvent extractionDistillationHydrogenation process

The invention discloses a combined process method for treating inferior residual oil. The method comprises the following steps: a residual oil material enters a solvent deasphalting device to obtain DAO and deoil asphalt; the obtained DAO enters a hydrogenation device of a boiling bed and is treated to obtained a lightweight distillation fraction and hydrogenated tail oil; the hydrogenated tail oil enters a catalytic cracking device and is treated to obtain a lightweight distillation fraction and oil slurry; at least partial oil slurry and the deoil asphalt are mixed, enter a hydrogenation device of a suspension bed and are treated to obtain a lightweight distillation fraction and unconverted tail oil, wherein the unconverted tail oil circularly returns the solvent deasphalting device; and the lightweight distillation fraction and the DAO are mixed and enter the hydrogenation device of the boiling bed. The combined process course organically combines a decarbonization process and a hydrogenation process; and according to different properties of raw materials, a corresponding process and operation condition is adopted so as to maximize conversion of the residual oil material while minimizing equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

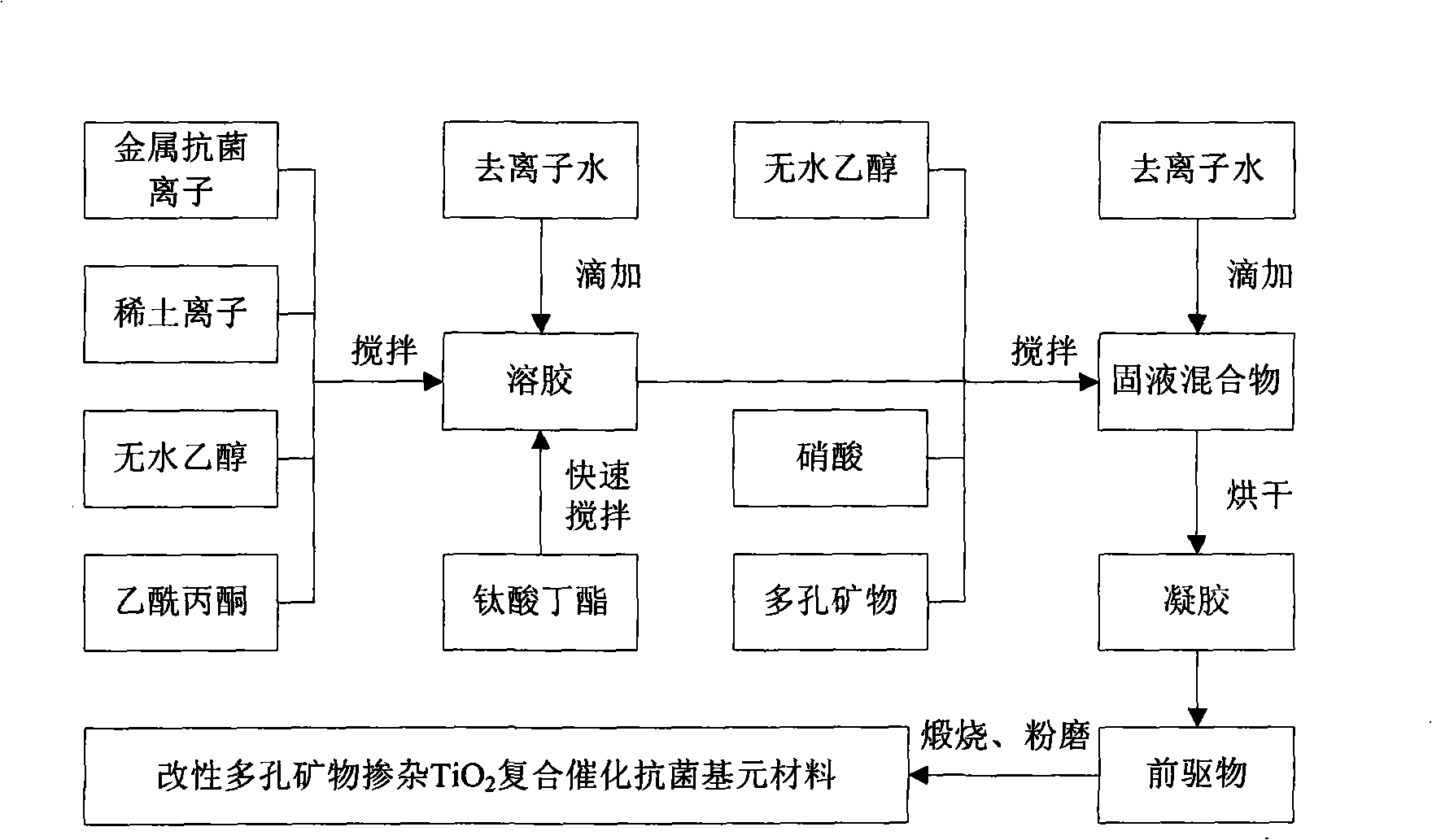

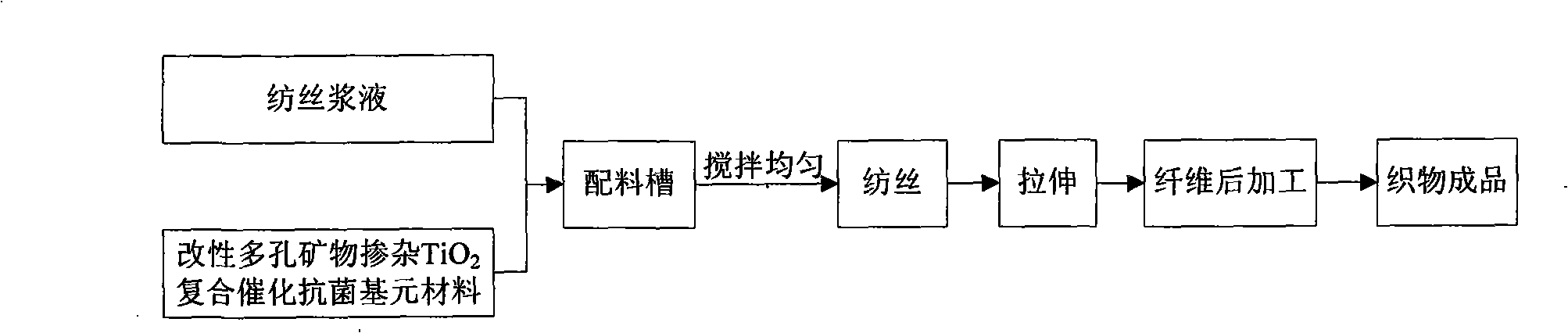

Active stephanoporate mineral TiO2-doped composite catalytic antimicrobial material preparation and using method

InactiveCN101322497AReduce consumptionSimple processBiocidePhysical/chemical process catalystsMaterials preparationPhoto catalytic

The invention discloses a preparation and using method of multiple active porous mineral doped nano-TiO2 composite catalytic anti-bacterial materials, and the preparation and using method belongs to the technical field of new material. The main technical key point of the invention is to combine the anti-bacterial mechanism of the ion modified porous minerals and the photo-catalytic anti-bacterial mechanism of the element doped nano-TiO2 to realize the synergistic anti-bacterial role, the modification of the porous minerals by the metal anti-bacterial ion (one of Ag<+>, Cu<2+>, Zn<2+> and Fe<3+>) and the rare earth ion and the nano-TiO2 doped synchronous composite process technology by the metal anti-bacterial ion and the rare earth ion are realized during the preparation process, thereby obtaining the composite catalytic anti-bacterial composite materials which are characterized by broad-spectrum, long-acting effect and safety, etc. The composite catalytic anti-bacterial products prepared by adopting the method and the technical process have low cost, anti-bacterial and long-acting effects, broad-spectrum and good synergistic anti-bacterial effect, the preparation process of the materials has the advantages of simpleness and strong operationality, and the like, so the preparation and using method can be widely applied in anti-bacterial coating, putty, fabric and other industries.

Owner:SOUTHWEAT UNIV OF SCI & TECH

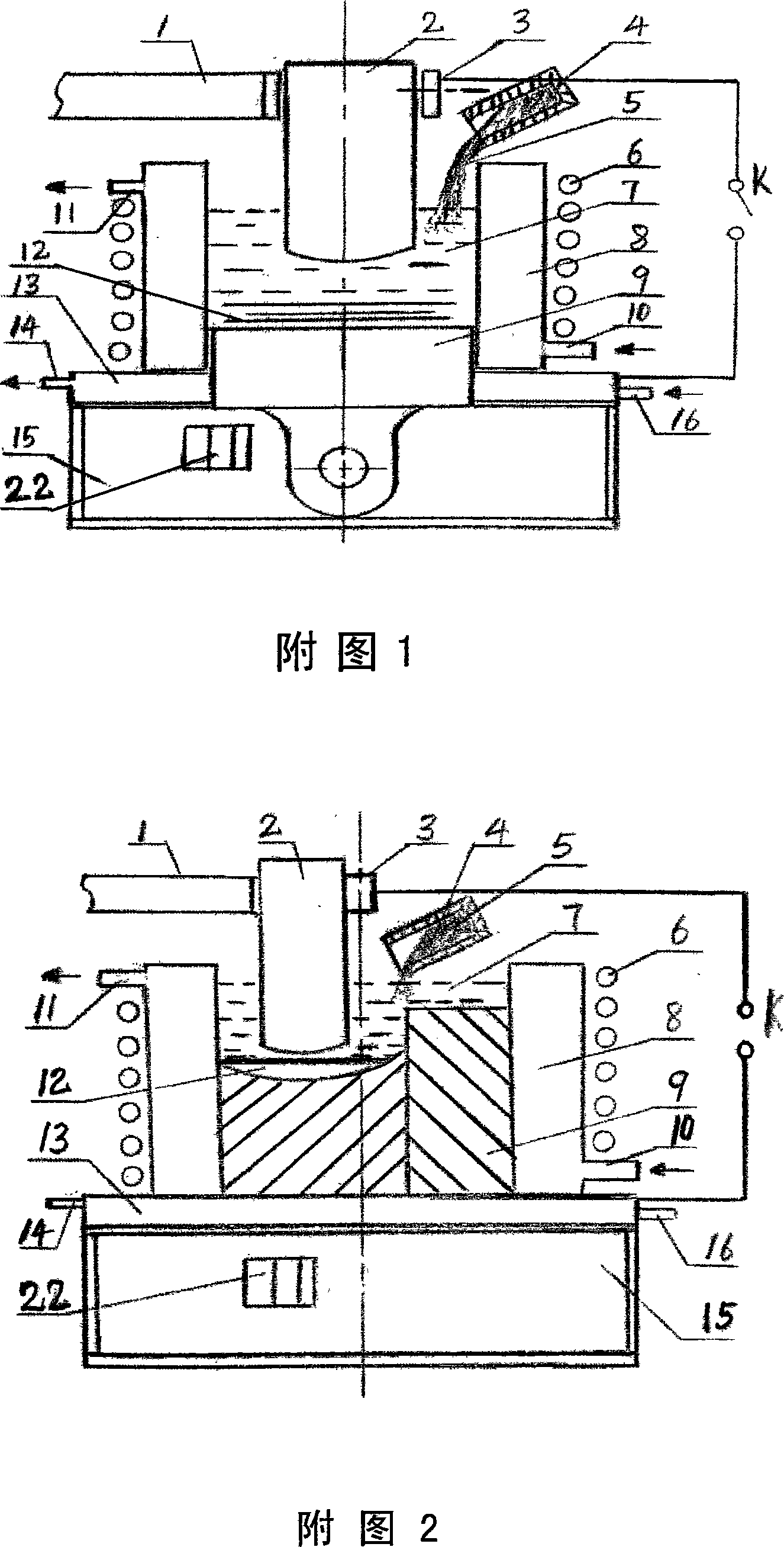

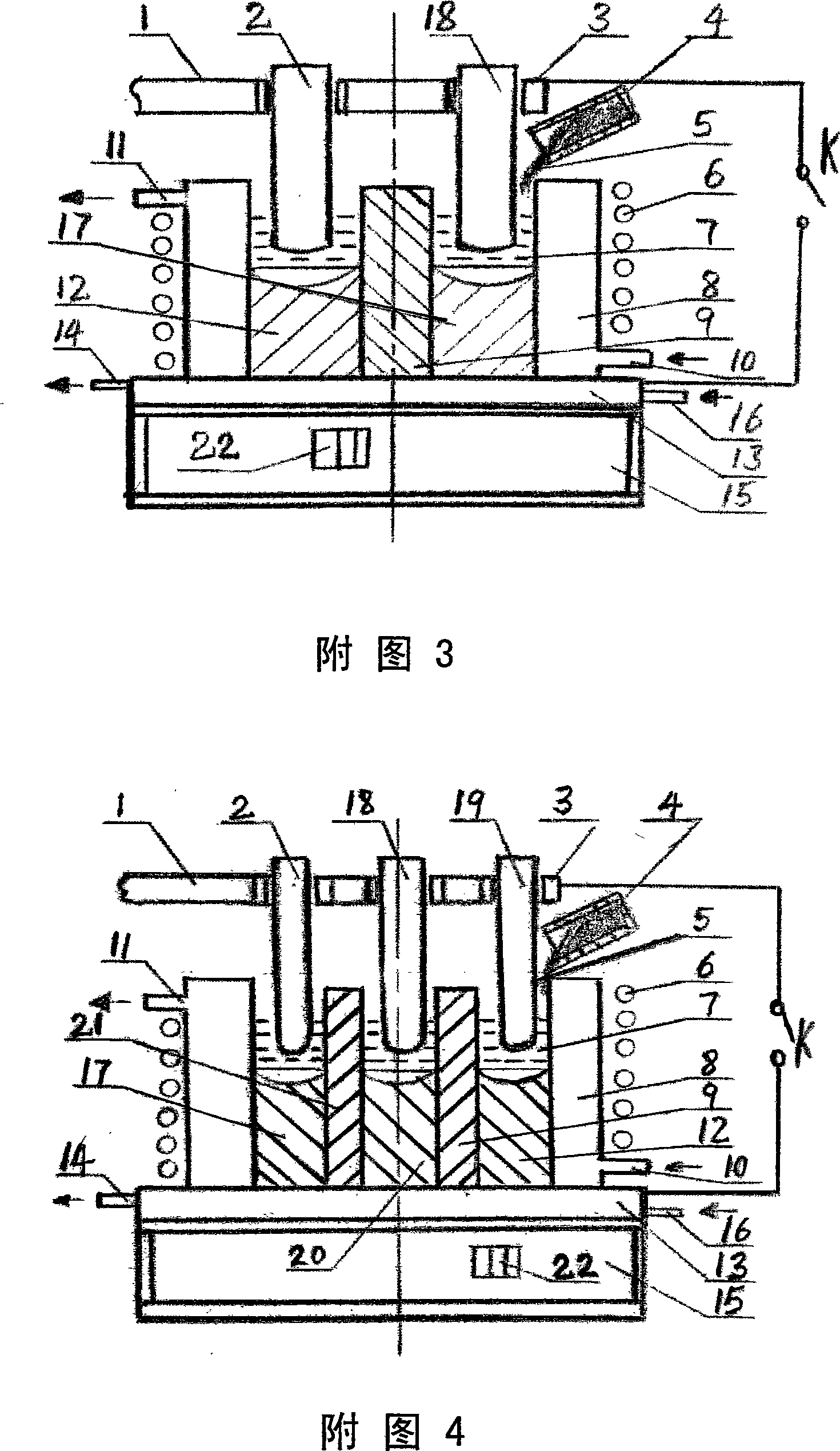

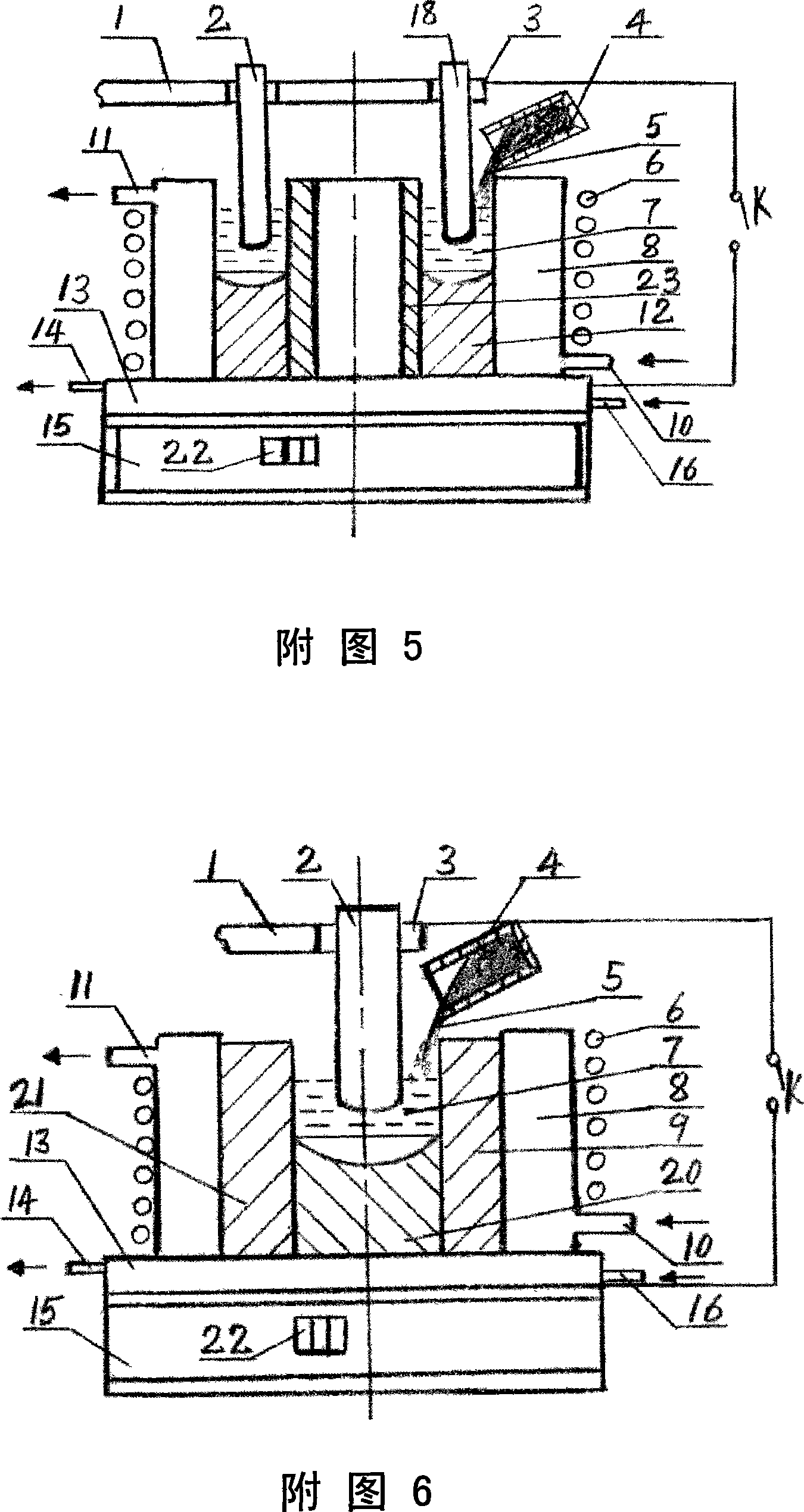

Casting method for manufacturing layered metal composite material technology and equipment

The present invention discloses a technique and relative equipment for casting laminated and composite metal material. Target material is heated to 300 DEG C to 1200 DEG C by an electromagnetic induction heater installed on exterior of a casting die or a water cooling crystallizer. Molten electroslag liquid is poured in the casting die or the water cooling crystallizer, and an electrode is inserted in for heating. The metal liquid is poured in the casting die or the water cooling crystallizer by top casting mode or bottom casting mode. After casting, the induction heater and the electrode conduct continuous heating for 3 to 20 minutes, then heating is stopped, and layered composite material with plane gradient, laminated composite material and coated composite material of all geometric shapes can be produced. The present invention can simplify production procedures of composite material and can realize the dynamic regulation of all technical parameters during composition. The interface of the composite layer is under eay control so as to achieve excelllent metallurgical combination. The present invention has wide optional range about materal of the composite layer, high productivity, simple production technique and low cost.

Owner:丁家伟 +1

Honeycomb composite silicon carbide mirrors and structures

Owner:FANTOM MATERIALS INC

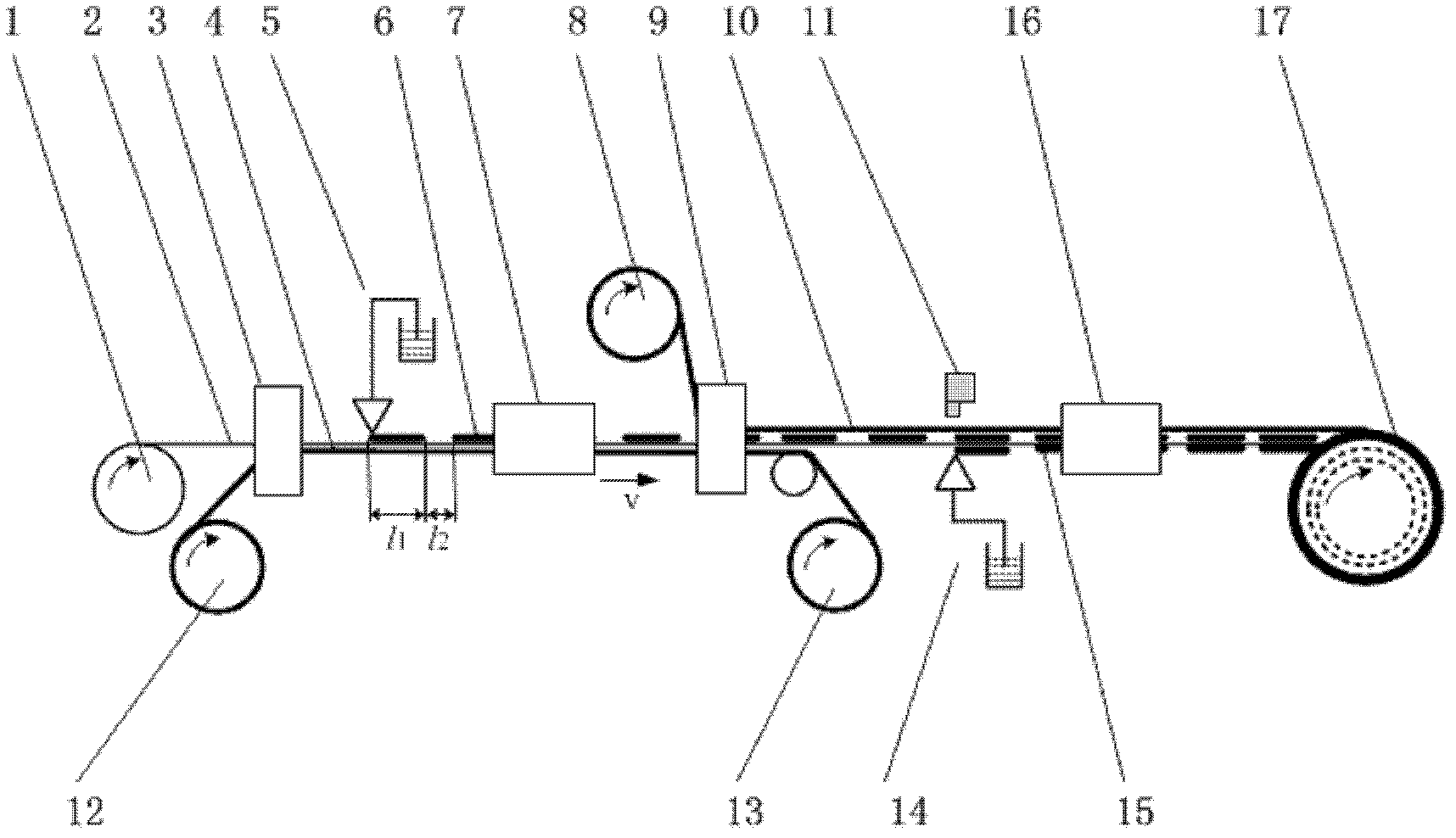

Method of manufacturing thin titanium/steel composite board

InactiveCN101428389AHigh bonding strengthGuaranteed Thickness RequirementsMetal rolling arrangementsNon-electric welding apparatusSheet steelTitanium

The invention discloses a method for preparing a thin-type titanium or steel composite plate, and particularly relates to a method for preparing a composite plate manufactured by the titanium steel-based composite plate through explosion and pack rolling. The method is characterized in that in the preparation process of the thin-type titanium or steel composite plate, the titanium or steel composite plate is compounded and formed by the titanium plate and the steel plate through explosion, then two composite plates are folded and welded into a billet body, and then the thin-type titanium or steel composite plate is formed through rolling. The preparation method adopts the explosive composite process, the rolling billet body has high bonding strength after explosive compounding, the titanium or steel composite plate billet is folded and welded for rolling, and the deformation amount is in 4 to 7 times; therefore, the preparation method not only ensures higher bonding strength of the titanium or steel composite plate after rolling, but also ensures the respective thickness requirements, the prepared titanium or steel composite plate has good processing technological property, the explosive composite billets of the titanium plate and the steel plate after pack rolling have good bonding property, the bending test is performed without layering, the titanium plate surface is free from cracks and impurities, and the method has the advantages of higher bonding strength, corrosion resistance and fatigue resistance.

Owner:XIAN TIANLI CLAD METAL MATERIALS

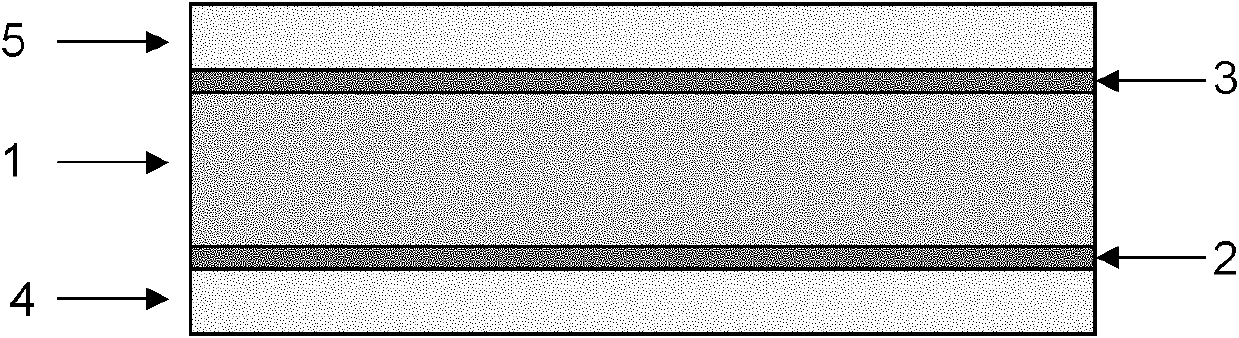

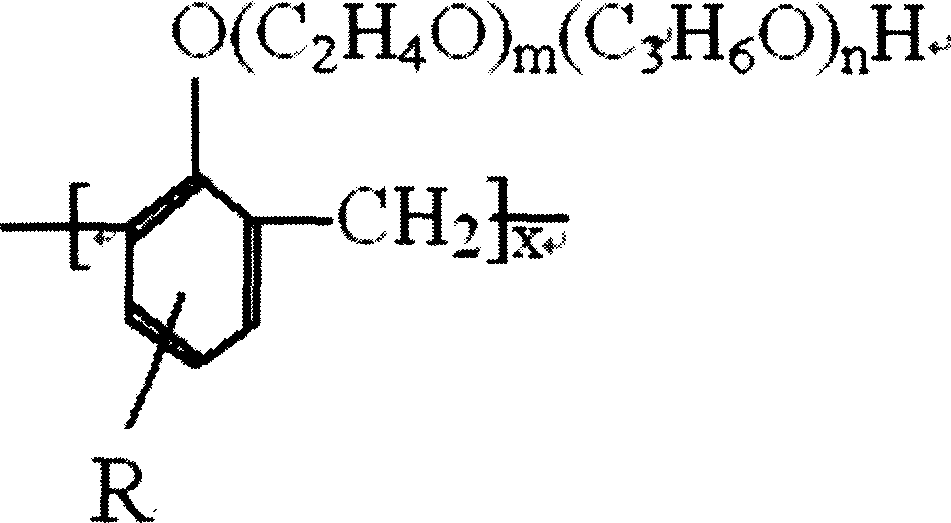

Polymer backsheet of solar cell assembly and manufacturing process thereof

InactiveUS20130209795A1Easy to processExcellent material mechanical performanceFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolymer alloy

A solar module polymer backsheet comprising a basement layer, tie layer on each side of the basement layer, a fourth film layer and a fifth film layer on the other side of the tie layer, the basement layer comprises at least one of the following components: polyamide polymers, polypropylene and propylene polymers, polyethylene and vinyl polymers, poly(vinylidene chloride), styrene polymers, ABS resins, liquid crystal polymers, acrylic polymers, polyphenylene oxides, polycarbonates, and polymer alloys of polycarbonates with poly(C2-6 alkylene glycol phthalates). The manufacturing process of the backsheet was provided, one polymer or a mixture of more polymers are used to form the film configuration in place of the former PET layer, thus excellent processability, material mechanical performances, barrier property and ageing resistance can be obtained; furthermore, the laminated films of the backsheet are formed via melt co-extrusion or extrusion composite process, which significantly upgraded the adhesion strength between the laminated films, and simplified manufacturing process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

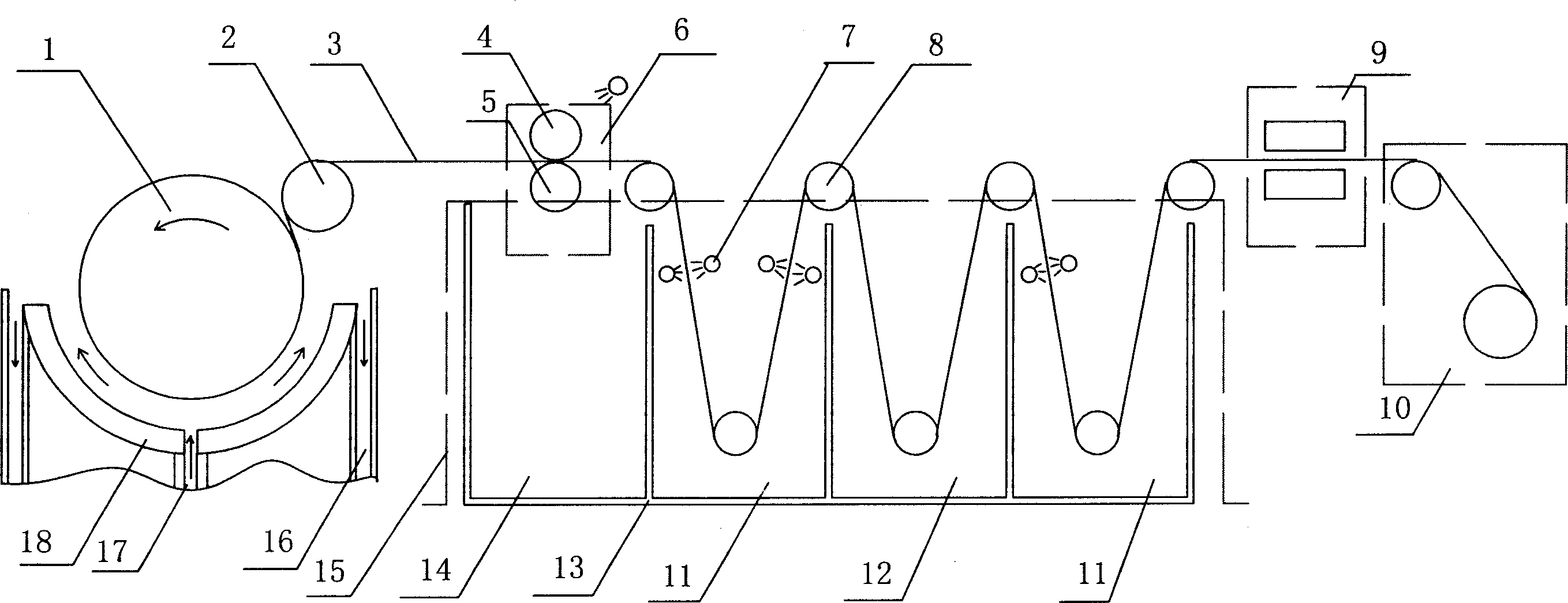

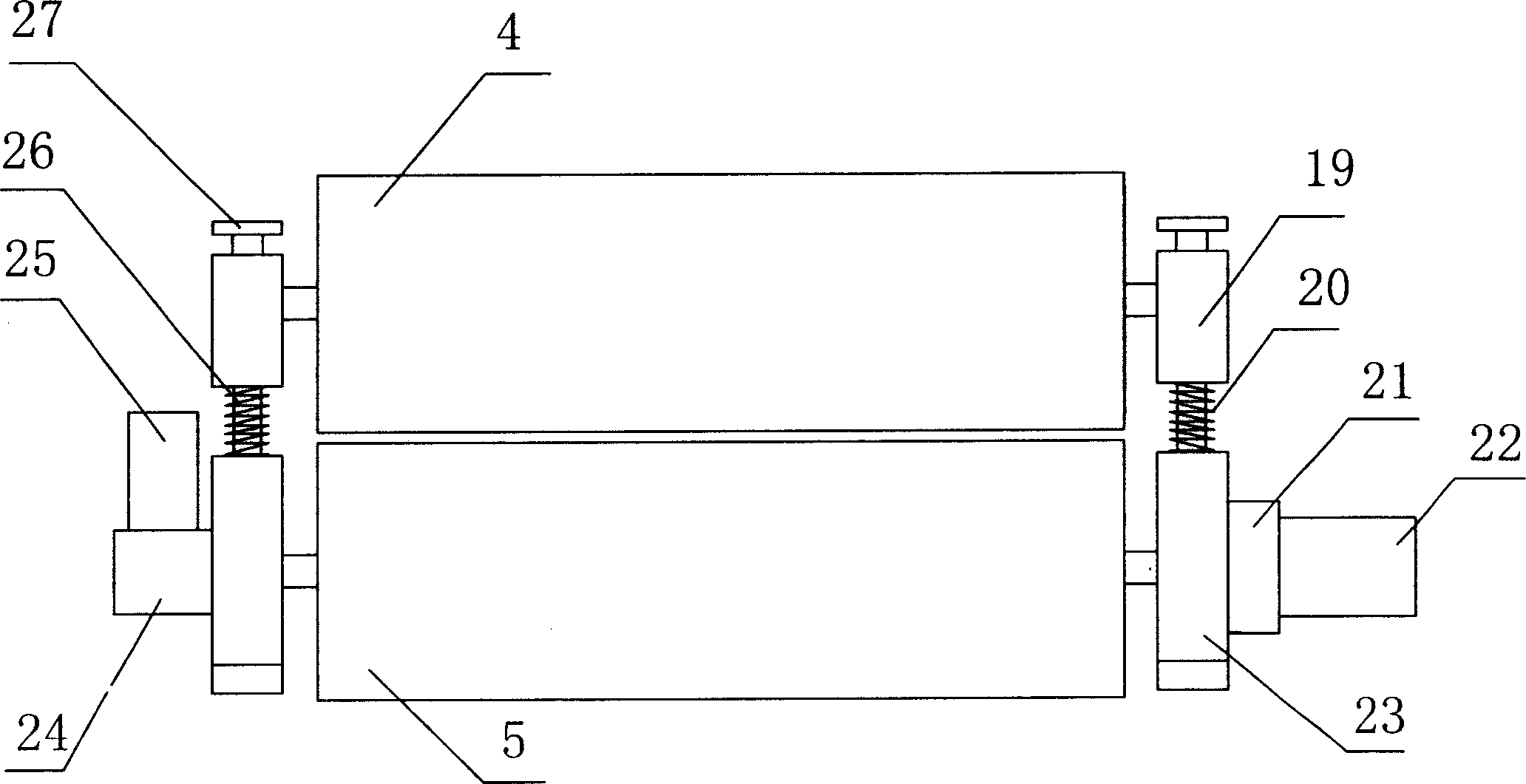

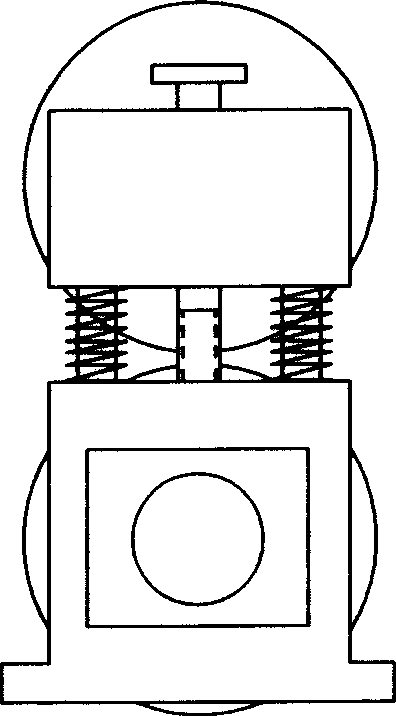

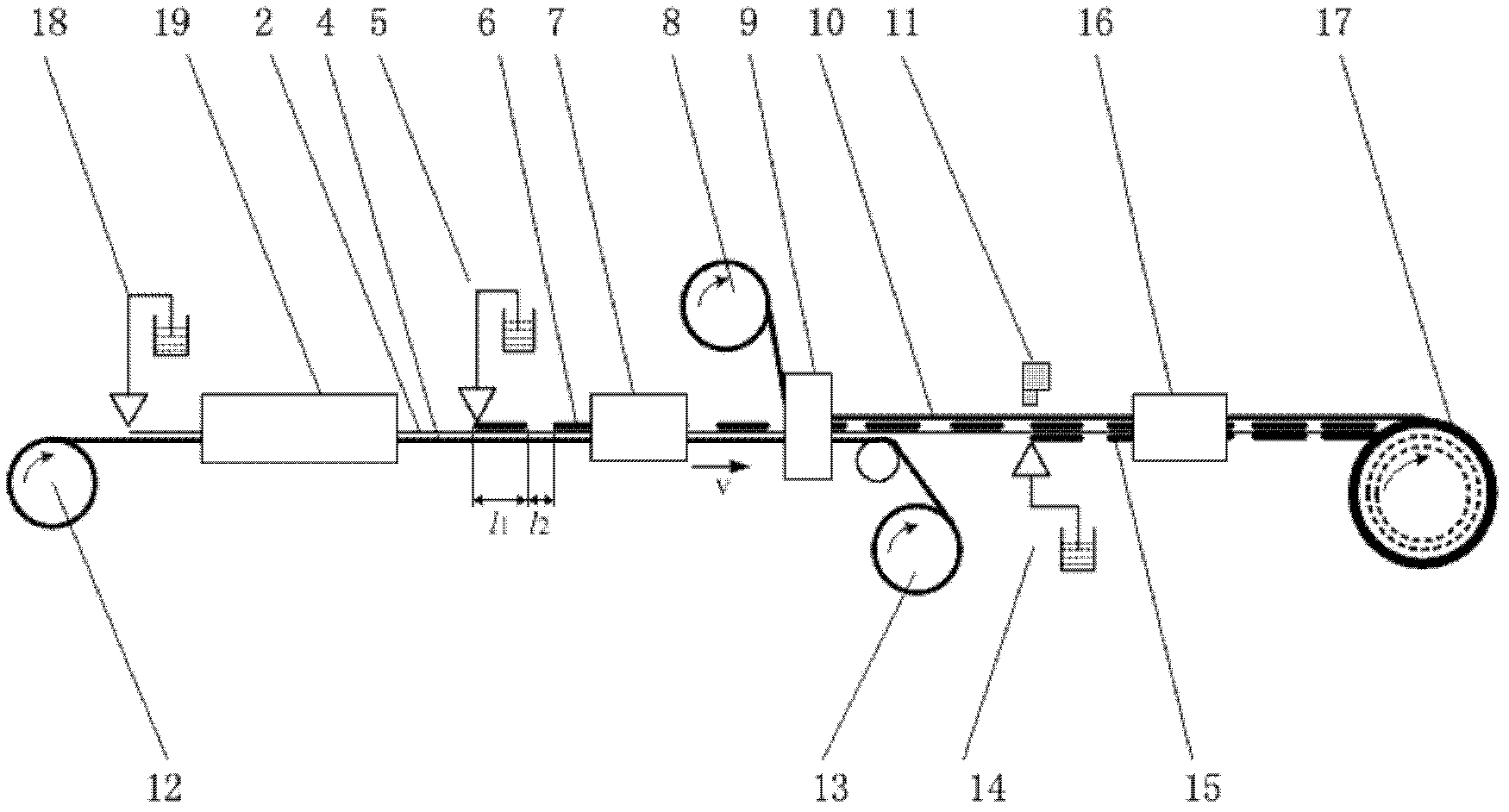

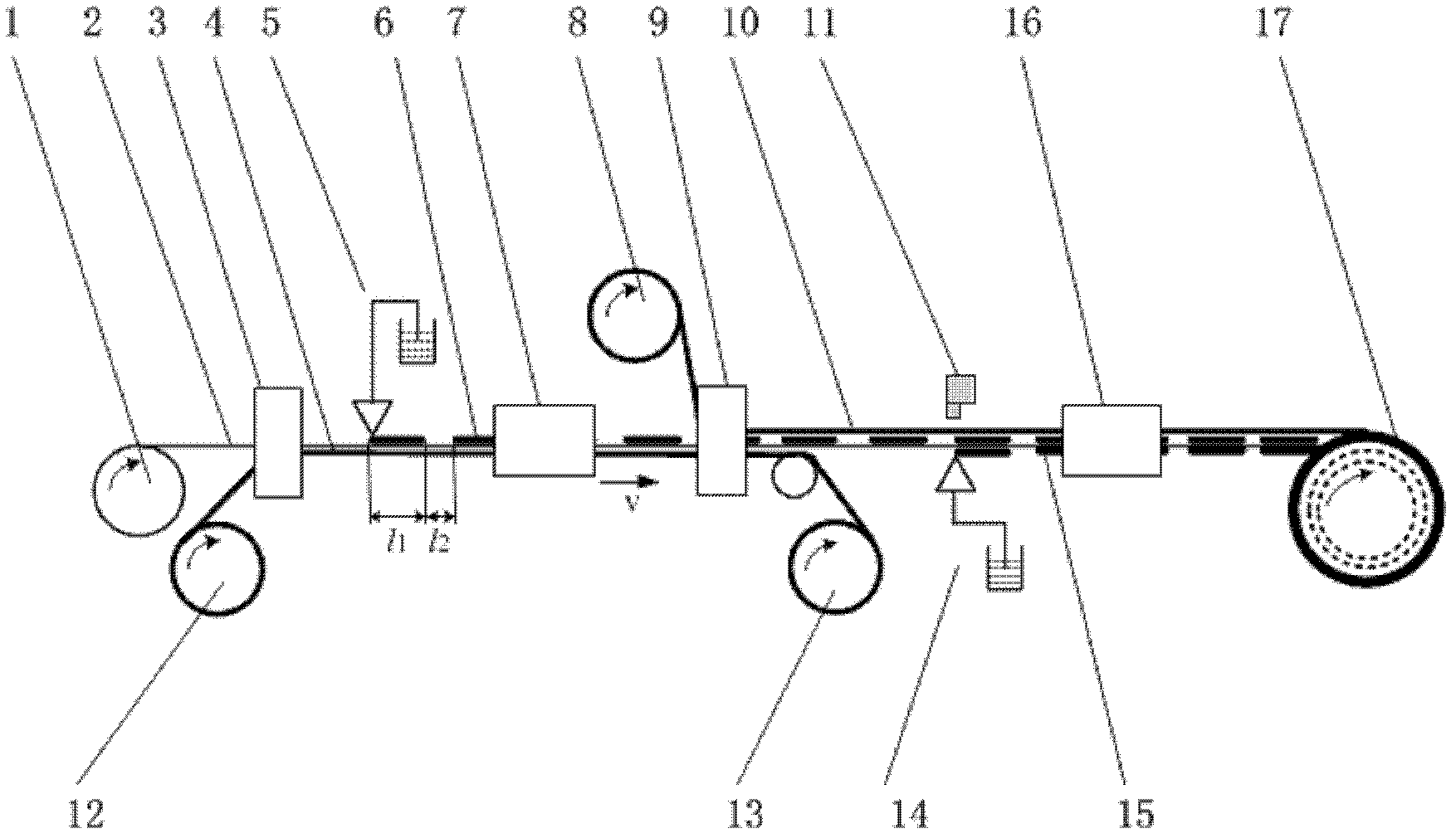

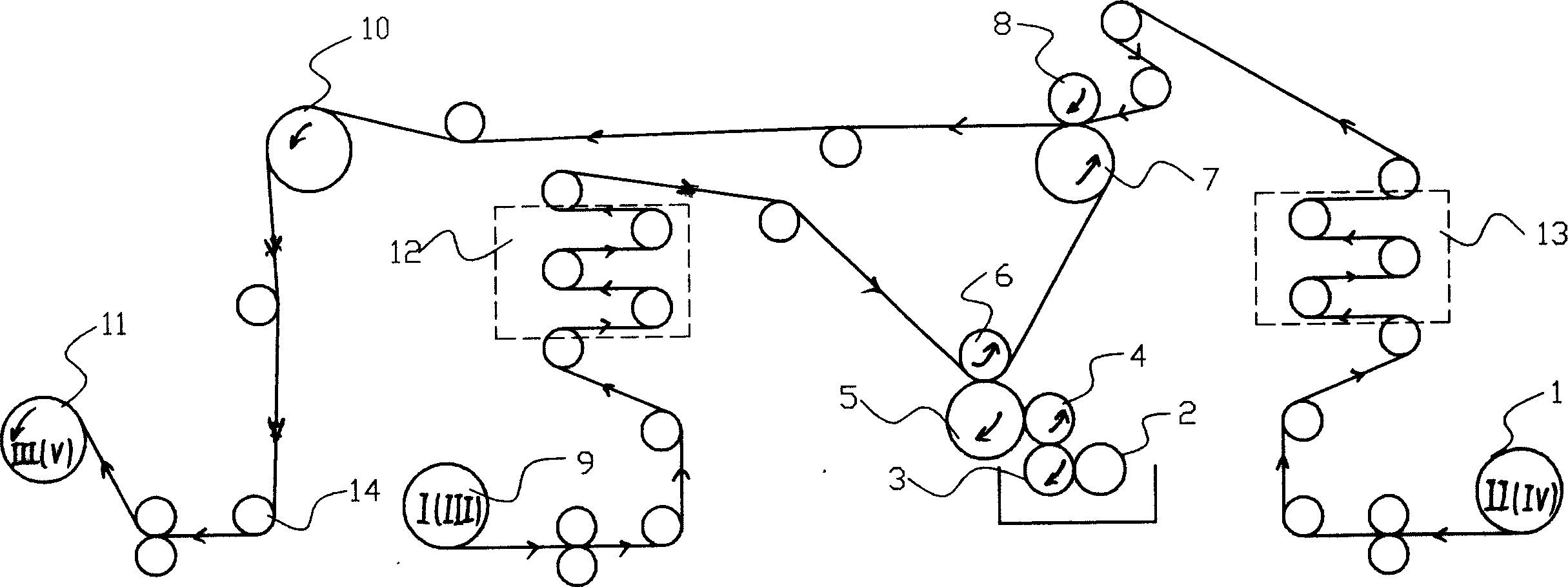

210-400 um superthick electrolytic copper foil, its composite process and apparatus

ActiveCN1854348ASolve the problem of large-area pinholesSolve technical problems that cannot be formedElectroforming processesElectrolysisBraced frame

An extra-high build electrolytic copper foil with roughness Ra<= 20 mum and thickness 210-400 mum and its preparation technology and equipment. The equipment consists of cathode roll, overflow launder, anode launder, wipe roll, cleaning shop, braced frame and so on. It has the following characters: flexible materials were adopted between wipe roll and copper foil; on-line rubbing down equipment with press roll and polishing roll were fixed behind the wipe roll. The preparation technology includes copper foil peel off, polish, cleanout, antioxidate treatment, dry, wind-up and the final product.

Owner:惠州联合铜箔电子材料有限公司

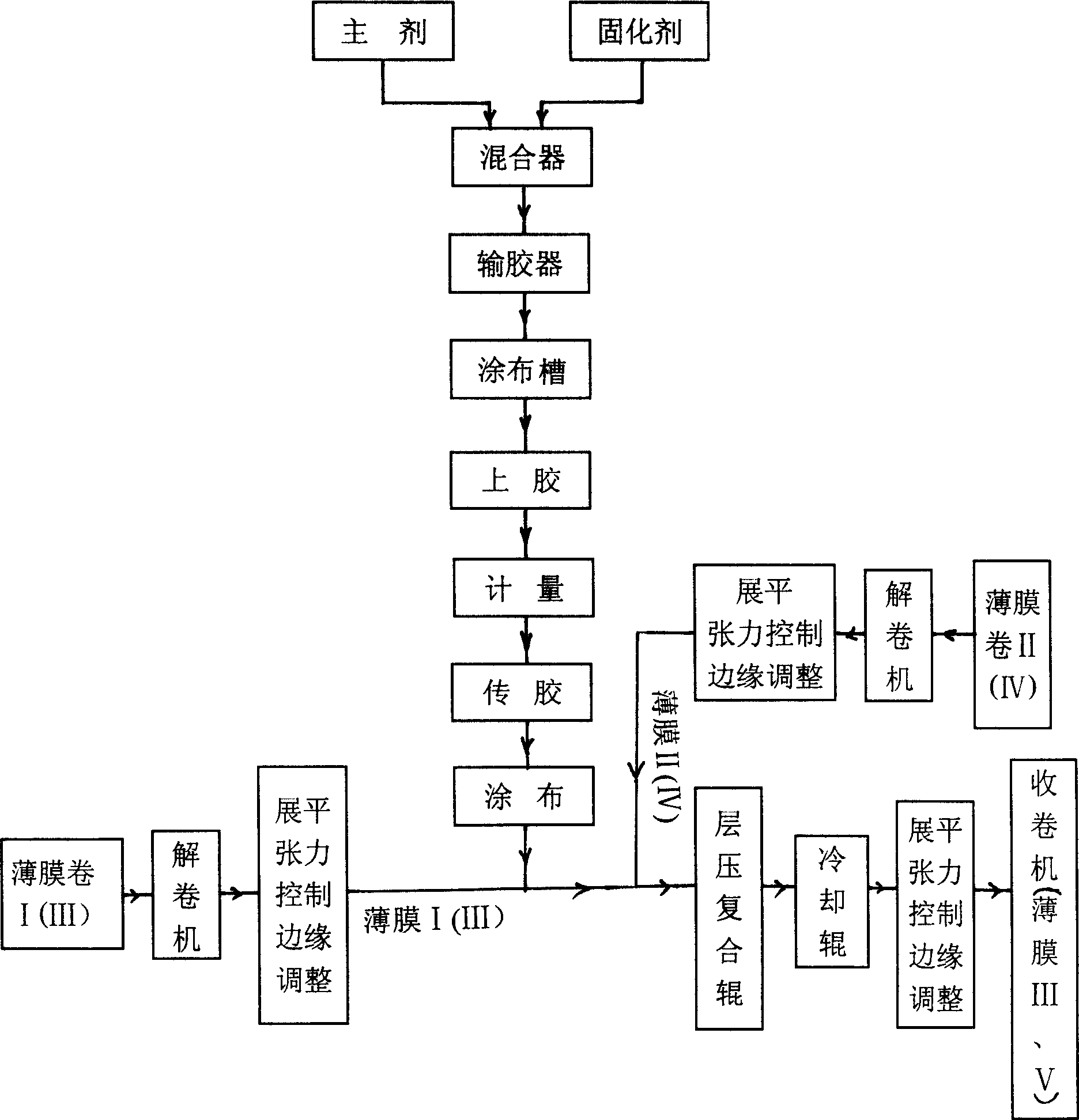

Method for continuously manufacturing 3-CCM (three Catalyst Coated Membranes) of fuel cell

InactiveCN102544558AEasy Tension ControlEasy towingFinal product manufactureSolid electrolyte fuel cellsTectorial membraneFuel cells

The invention discloses a method for continuously manufacturing 3-CCM (three Catalyst Coated Membranes) of a fuel cell. The method is characterized by comprising the following step of: under a condition that a protective membrane is adhered on one side of a proton exchange membrane, compositing a catalyst on the other side of the proton exchange membrane by utilizing a process manner, such as a direct coating manner, a printing manner, an indirect coating manner, a spray coating manner, a slit extrusion manner and a physicochemical deposition manner. The method for continuously manufacturing the 3-CCM of the fuel cell, disclosed by the invention, has the advantages that: (1) coil-to-coil easy continuous batch manufacturing can be realized; (2) the size precision is better and composite defects are fewer in the manufacturing procedure because the proton exchange membrane adhered with the protective membrane has excellent size stability in a compositing process of a catalyst layer and the proton exchange membrane; and (3) the manufacturing of the 3-CCM of the fuel cell with slotted catalyst layer can be continuously realized. When the 3-CCM are manufactured by utilizing the method for continuously manufacturing the 3-CCM of the fuel cell, disclosed by the invention, batch production is easier, and the yield is higher at the same time.

Owner:武汉理工新能源有限公司

Manufacturing method of metal matrix nanocomposites with high toughness

The invention relates to the composite technical field, in particular to a manufacturing method of metal matrix nanocomposites with high toughness. According to the manufacturing method, the size, distribution, interface structure of reinforcement bodies and the metal matrix micro-structure are effectively controlled by the combined composite process of twice ball-milling, discharging plasma in situ reaction sintering and the large strain plastic deformation technology, so that ultra-fine grain metal matrix composites with evenly distributed in situ authigenic nanoparticles and good interface combination are manufactured, and good matching of intensity and toughness is obtained.

Owner:泰州赛龙电子有限公司

Method for preparing nano hydroxyapatite/polylactic acid composite microspheres

InactiveCN101590388AEvenly dispersedImprove mechanical propertiesMicroballoon preparationMicrocapsule preparationMicrosphereFiltration

The invention discloses a method for preparing nano hydroxyapatite / polylactic acid composite microspheres, which uses nano hydroxyapatite (n-HA) and polylactic acid (PLA) as raw materials and adopts an ultrasonic blending composite process and an emulsification-solvent evaporation method to prepare the microspheres of a nano hydroxyapatite / polylactic acid composite material. The preparation method comprises the following steps: nano-crystallizing hydroxyapatite, proportionally preparing complex liquid, performing ultrasonic dissolving and blending, emulsifying the mixture into small liquid drops, reducing pressure to volatilize a solvent, performing refrigeration and filtration, performing washing, and performing freeze-drying to obtain the composite microspheres. Compared with like products, the composite microspheres have the characteristics that the method has simple and easy operation, the size of the microspheres is easy to control, and the prepared microspheres have large surface holes and specific area, and good mechanical property. The prepared nano hydroxyapatite / polylactic acid composite microspheres are mainly applied to microsphere bonding type brackets in bone tissue engineering and cell micro-carriers in cell engineering, and can be applied to conveying medicaments and bioactive molecules.

Owner:CHONGQING UNIV OF ARTS & SCI

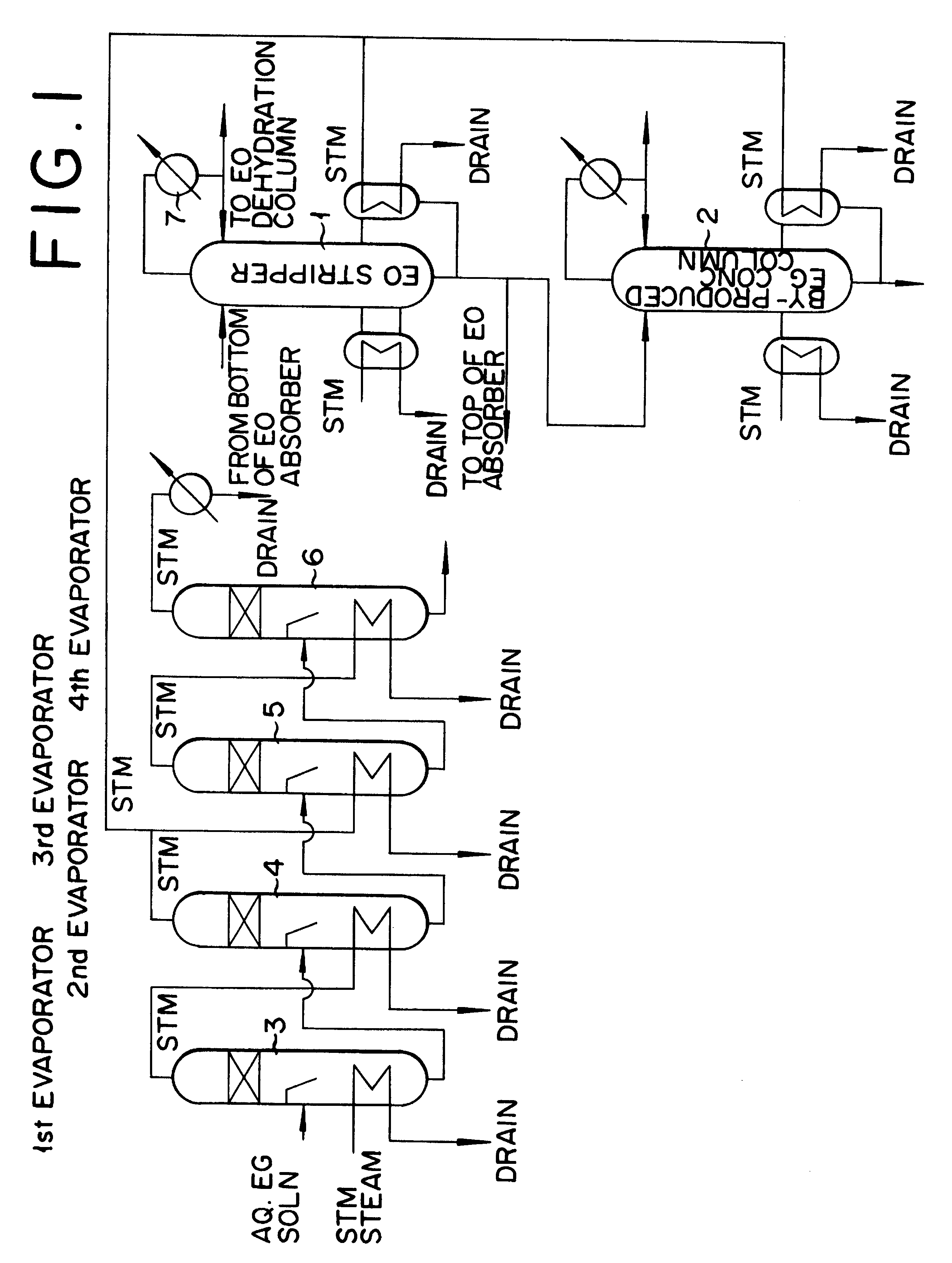

Method for production of ethylene glycol

InactiveUS6417411B2Efficient comprehensive utilizationSmall consumptionOxygen-containing compound preparationOrganic compound preparationGas phaseEthylene oxide

In a composite process for subjecting ethylene to catalytic gas phase oxidation thereby obtaining ethylene oxide and causing this ethylene oxide to react with water thereby obtaining ethylene glycol, a method for producing the ethylene glycol is provided which permits effective utilization of the energy at the step for dehydrating and concentrating the resultant aqueous ethylene glycol solution. In the production of ethylene glycol by the supply of the aqueous ethylene glycol solution to a concentrating treatment at the multi-effect evaporator, the method contemplated by this invention for the production of ethylene glycol comprises utilizing as the source of heating at least one specific step the steam generated in the multi-effect evaporator.

Owner:RECOVERYCARE COM +1

Novel cathode material for lithium ion battery and preparation method thereof

ActiveCN102522532AIncrease gram capacityImprove efficiencyCell electrodesPetroleumCharge and discharge

The invention provides a novel cathode material for a lithium ion battery and a preparation method thereof. The material is compounded by natural graphite, oil coke and pitch. The compound process comprises mixing, pinching, rolling sheets, smashing, forming, carbonizing, graphitizing, spherizing and the like. By weight, the natural graphite is 35 to 55 parts, the oil coke is 25 to 45 parts, and the pitch is 15 to 25 parts. Compared with the prior art, the cathode material has the advantages of synthetic graphite and natural graphite and is large in volume, high in first efficiency and circulation efficiency and excellent in charging and discharging performance. Furthermore, the natural graphite adopts secondary products discharged and collected by a dust remover after natural crystalline flake graphite is smashed in spherical mode. Thus, secondary products are reasonably used, and production cost is remarkably reduced.

Owner:湖北联投恒达石墨有限公司

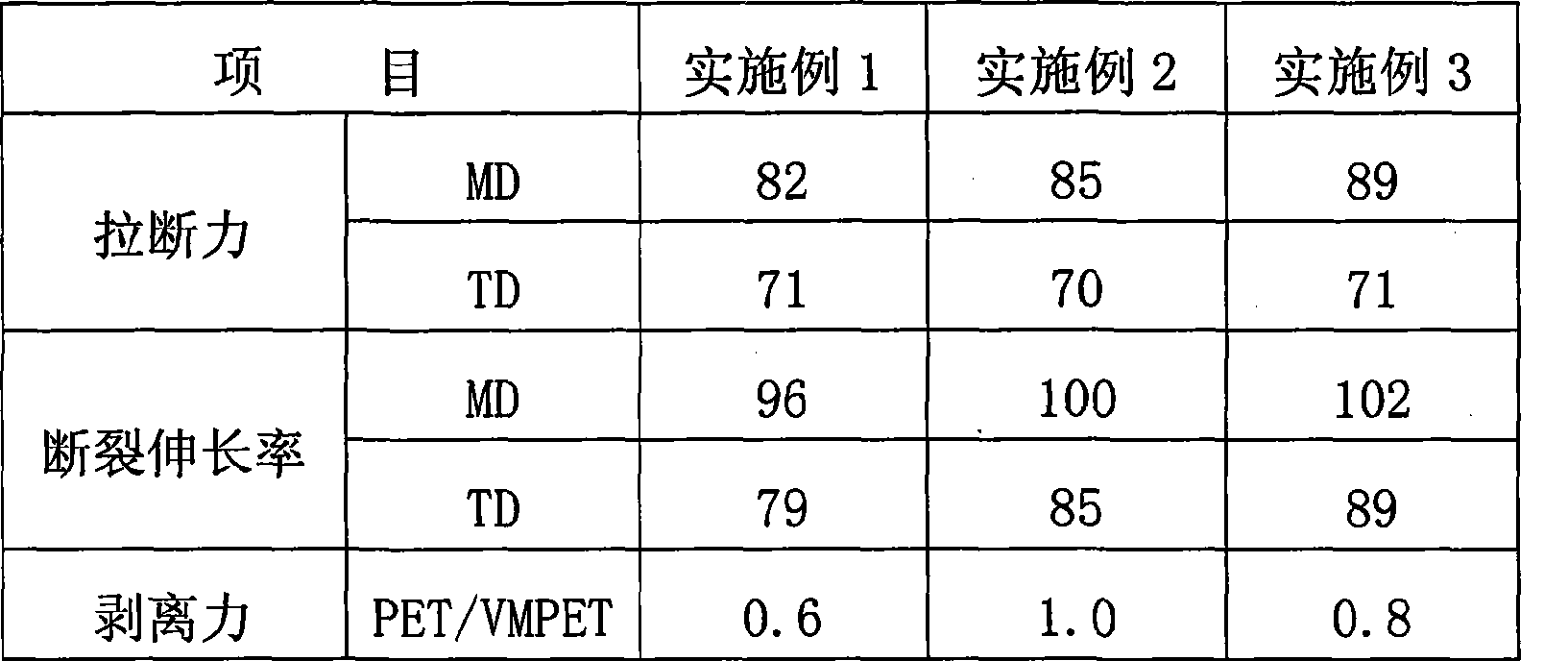

Milk powder packing bag and preparing method thereof

The invention discloses a milk powder packing bag and a preparation method thereof. The packing bag includes an antibacterial inner-film layer, a high-obstruction vacuum aluminum plating film layer and a PET polyester film layer from inside to outside. The preparation method includes steps of a) PET film printing process; b) preparation process of the high-obstruction vacuum aluminum plating film; c) preparation process of the antibacterial inner-film; and d) composite process Compared with the prior art, the packing bag of the present invention has residual solvent mount less than 8mg / m<2>, and has no phenomenon of tainting by odour and peculiar smell.

Owner:HUANGSHAN NOVEL

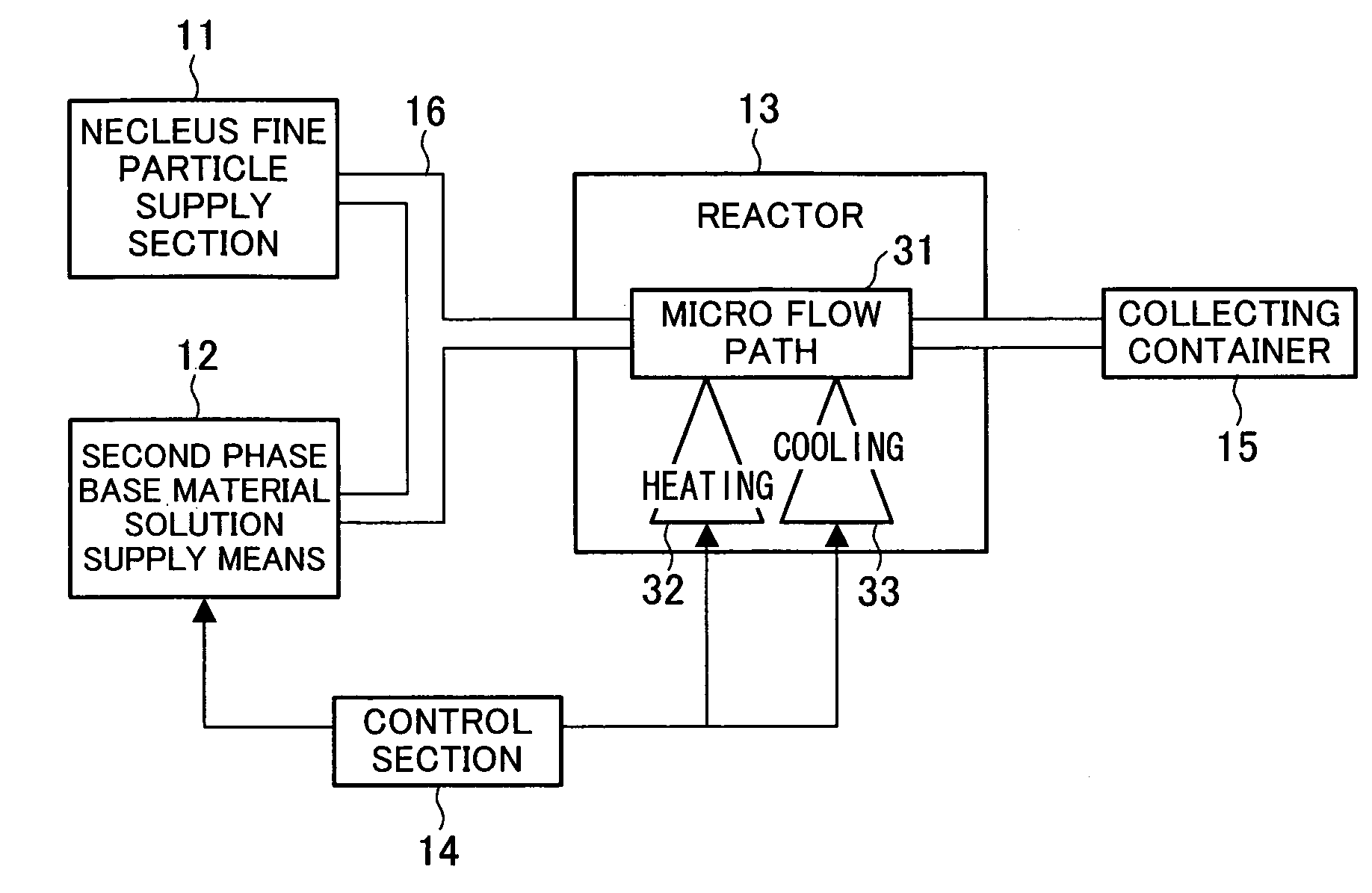

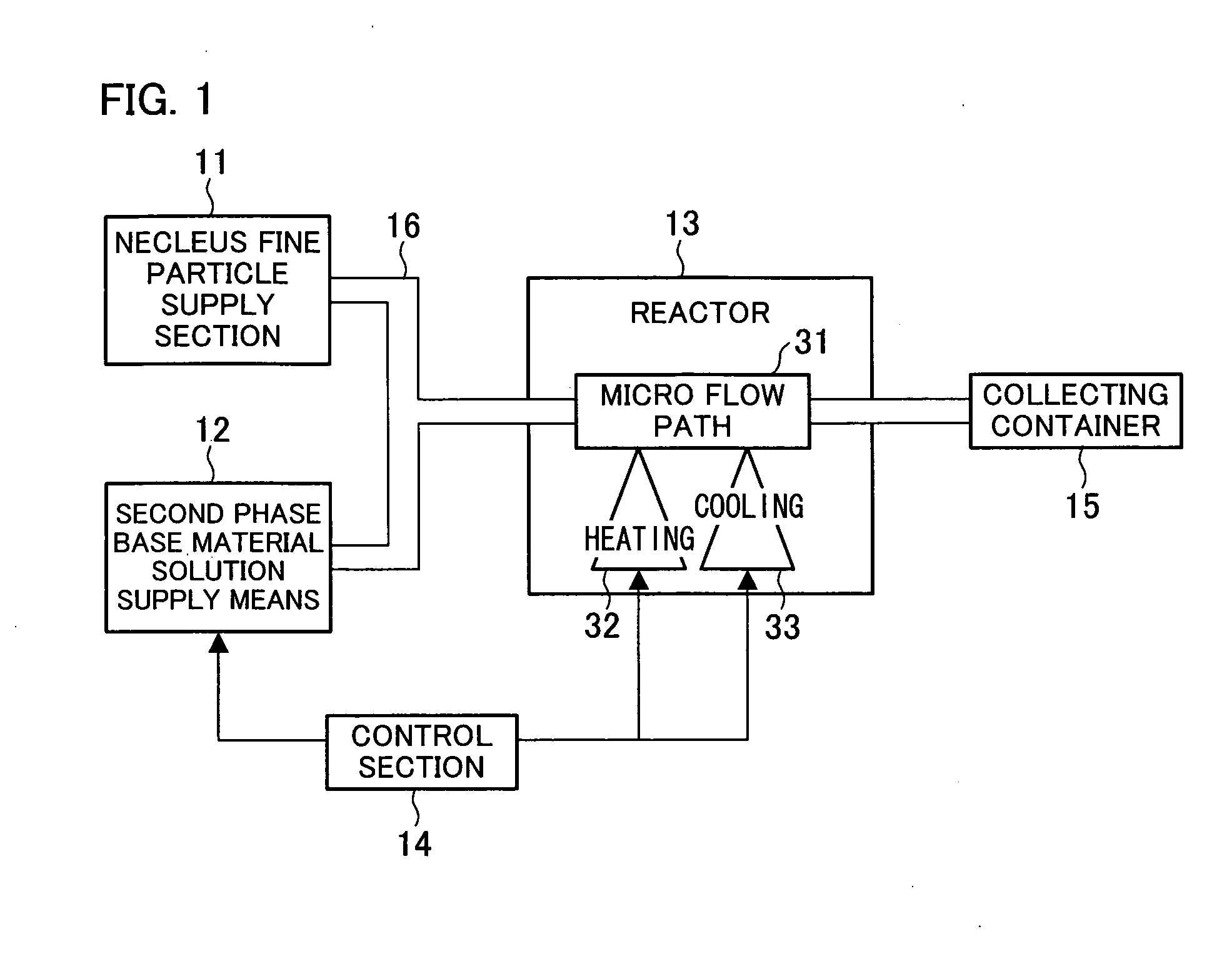

Method for manufacturing fine composite particles, apparatus for manufacturing fine composite particles, and fine composite particles

ActiveUS20070128350A1Easy to controlContinuous productionPigmenting treatmentMaterial nanotechnologyMicroparticleCore Particle

In the present invention, the fine particle composite process is carried out with the step of reacting fine core particles and a raw material for coating layer by mixing them and continuously supplying a resulting mixture into a micro flow path. The micro flow path is specified to 1-4000 in Reynolds number. With this arrangement, the present invention ensures, in a technology using a reactor having a micro flow path, accurate control of reaction condition, uniformity of coating amount distribution, easy layer formation, and successive production of fine composite particles.

Owner:NAT INST OF ADVANCED IND SCI & TECH

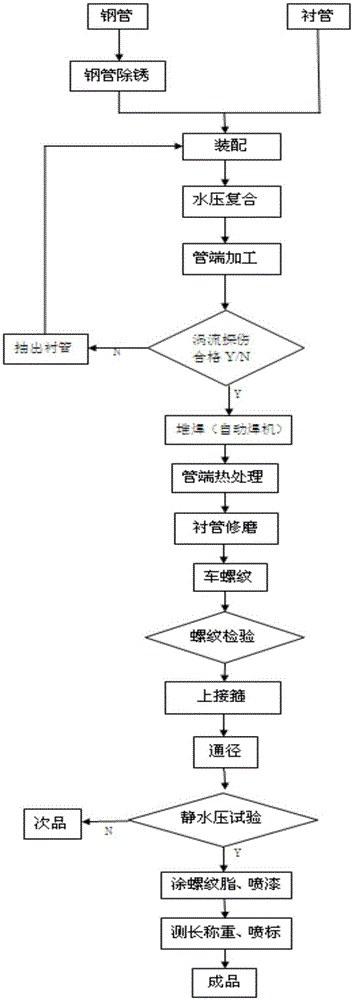

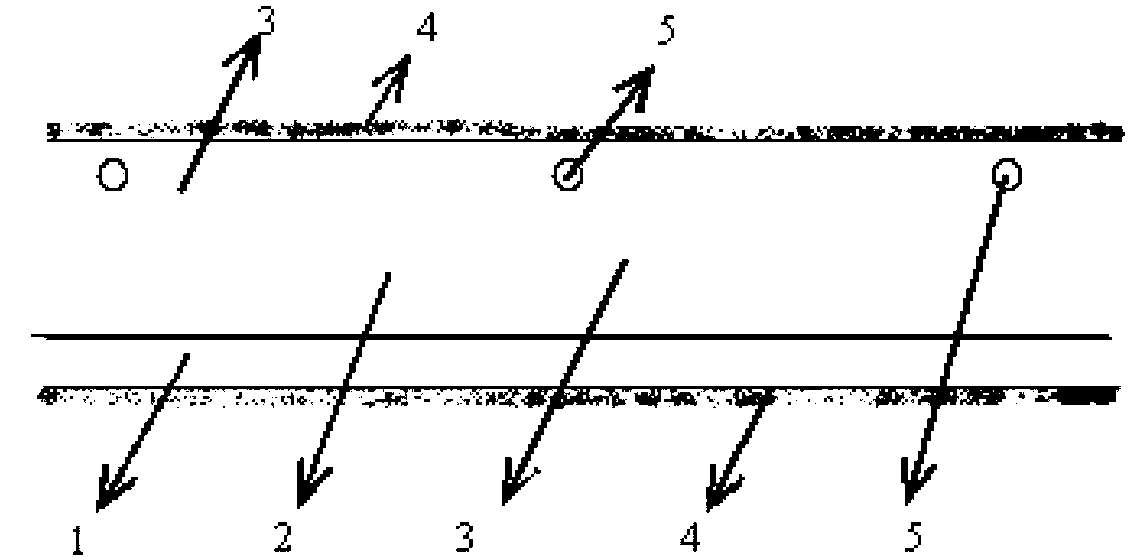

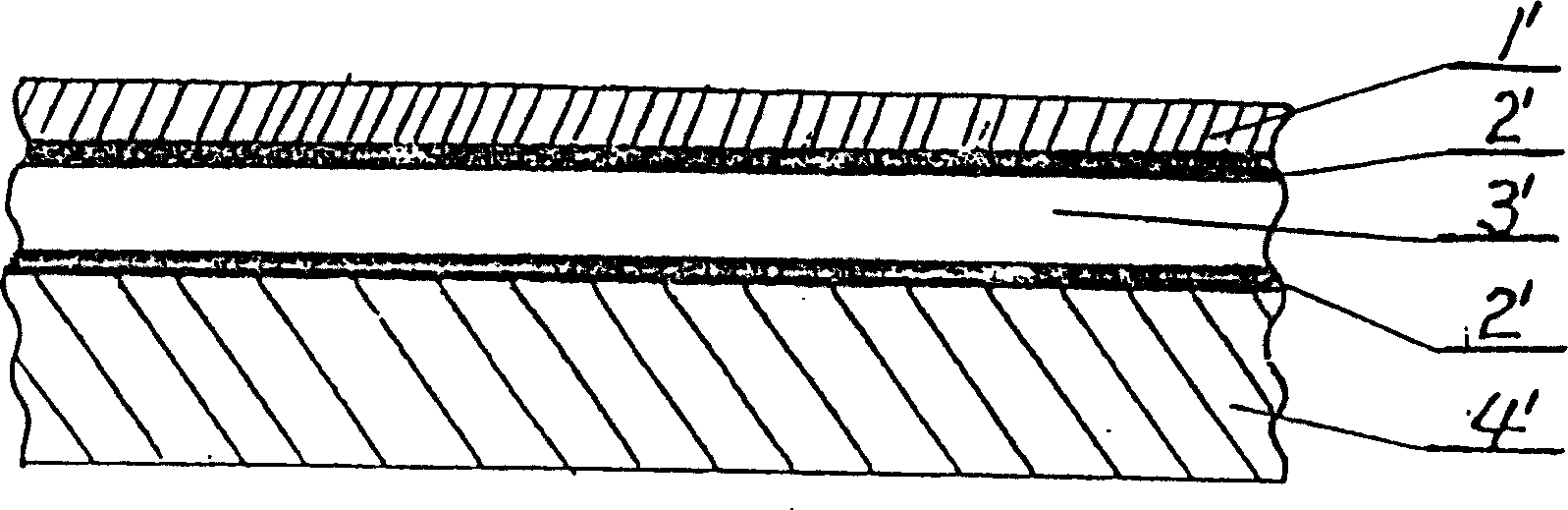

Preparation method for hydraulic pressure composite thermometal oil pipe

InactiveCN105171349AAnti-corrosion and wear-resistantStrong enoughDrilling rodsOther manufacturing equipments/toolsWelding residual stressMaterials science

The invention relates to a preparation method for a hydraulic pressure composite thermometal oil pipe. A carbon steel outer pipe is subjected to abrasive blasting and derusting, and the cleaning of the inner surface of the carbon steel outer pipe and the outer surface of a stainless steel inner pipe is ensured; the inner pipe penetrates into the outer pipe, and hydraulic pressure composite is conducted through a hydraulic press after the penetration is completed; the carbon steel outer pipe is made to deform elastically and the stainless steel inner pipe is made to deform plastically in the composite process, so that the inner pipe and the outer pipe are made to combined closely. After the composite process, pipe end machining is conducted before welding, and eddy current inspection is conducted on the whole oil pipe after the pipe end machining is completed; if the oil pipe is qualified through the inspection, the two pipe ends are subjected to bead welding which is completed through an automatic welder, and the bonding strength of the pipe ends are ensured. Pipe end heat treatment is conducted for removing the residual stress of the welding after the welding is completed. After the stress is removed, coping of a screened pipe and turning of threads are conducted, and inspection is conducted after the turning of threads is completed. Coupling and path opening are conducted after the oil pipe is qualified. The whole inner surface of the product prepared through the preparation method is corrosion resistant, and the corrosion-resistance strength is high; the outer pipe ensures that the strength of the composite oil pipe is enough, so that the stainless steel composite oil pipe has the characteristics of anticorrosion and abrasion resistance. Besides, the cost is low and the service life is long.

Owner:SHANGHAI HILONG CRA LINED STEEL PIPE MFR

Composite quartz board and manufacturing process thereof

InactiveCN105415764AElasticFully bondedSynthetic resin layered productsLaminationFiberComposite plate

The invention relates to the technical field of a stone decoration material, and particularly relates to a composite quartz board and a manufacturing process thereof. The manufacturing process comprises the following steps: weighing a mortar raw material for molding a quartz layer, and stirring for standby application; laying a layer of kraft paper or PVC film on the bottom surface of a mold, uniformly pouring the stirred mortar raw material into the mold, laying a piece of fibrous web on the surface of the flattened mortar raw material, then laying a layer of kraft paper or PVC film on the fibrous web, and vacuumizing, vibrating and compacting to obtain an uncured quartz mortar layer; and removing the kraft paper or PVC film on the fibrous web, attaching a ceramic tile coated with modified glue onto the surface of the fibrous web, then compacting, curing at a high temperature, cooling, molding, and grinding for determining the size to obtain the composite quartz board. The quartz layer is unlikely to separate from the ceramic tile, the adhesive strength is high, the production process is simple, no air bubble is produced during the compositing process, and the prepared composite quartz board is high in strength and long in service life.

Owner:东莞友联建筑材料有限公司

Method for distributing low-bit-rate video streaming composite high definition graphic data and bandwidth of low-bit-rate video streaming composite high definition graphic data

InactiveCN103647980AHigh utility valueImprove accuracyDigital video signal modificationSelective content distributionComputer graphics (images)Data transmission

The invention relates to a method for distributing low-bit-rate video streaming composite high definition graphic data and bandwidth of the low-bit-rate video streaming composite high definition graphic data. Under the condition of the low bit rate, the transmission is completed through the bandwidth distribution, the priority of audio interaction is the highest, the priority of transmission of low-bit-rate video streaming is higher, and the priority of transmission of composite high definition graphic data is the lowest. Each frame of the composite high definition graphic data corresponds to the assigned frame of the low-bit-rate video streaming according to time stamp logos, and synchronization of two paths of data is kept from the frame. Each frame of the composite high definition graphic data is shown through blocking, coding compression, transmission and showing. Each of blocks covers low-bit-rate video frames synchronous with the blocks which are amplified to show corresponding positions according to position information after transmission is completed, and the composite process is reverted to a high definition image gradually. The method can guarantee audio interaction and low-bit-rate video and transmit the high definition graphic data synchronously under the low bandwidth condition.

Owner:HEFEI UNIV OF TECH +2

Hole-containing fiber reinforced ion exchange membrane for chlor-alkali industry and preparation method thereof

The invention relates to a hole-containing fiber reinforced ion exchange membrane for the chlor-alkali industry and a preparation method thereof. The membrane is a multi-layer composite membrane composed of a perfluorinated sulfonic acid ion exchange resin layer, a perfluorinated carboxylic acid ion exchange resin layer, a reinforced mesh and a gas release coating, wherein the perfluorinated sulfonic acid resin layer contains reinforced fibers and nano holes. The membrane is prepared through a melt coextrusion or multi-layer hot pressing composite process. The membrane can be used as an ion exchange membrane for the chlor-alkali industry, and has good mechanical properties and electrochemical properties.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

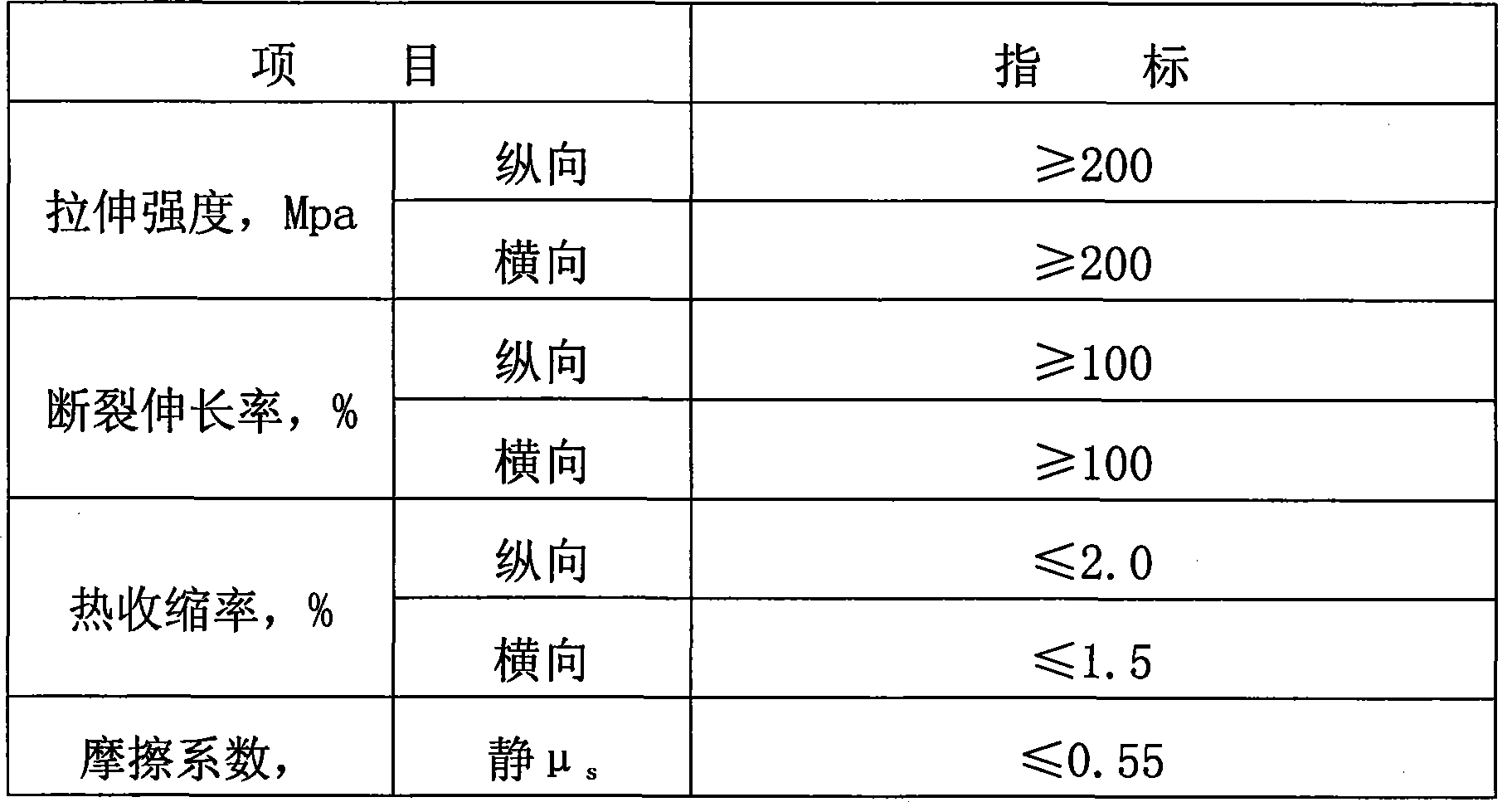

PVDC laminated composite high-temp-resistant steamed and boiled food packaging film and its preparation method

InactiveCN1535814AExtended shelf lifeEasy to buySynthetic resin layered productsSolvent freeBoiled food

The present invention relates to a PVDC laminated composite high-temp.-resistant cooked food packaging film and its preparation method. Its intermediate layer PVDC (chlorovinylidene and vinyl chloride copolymer) is respectively connected with two layers of two sides by means of binder, the described binder is a double-component polyurethane type solvent-free binder. The product can be produced by adopting said double-component polyurethane type solvent-free binder combination process and utilizing solvent-free combining machine. Said invented packaging film can meet the requirements for cooking above 121 deg.C.

Owner:郑州宝蓝包装技术有限公司

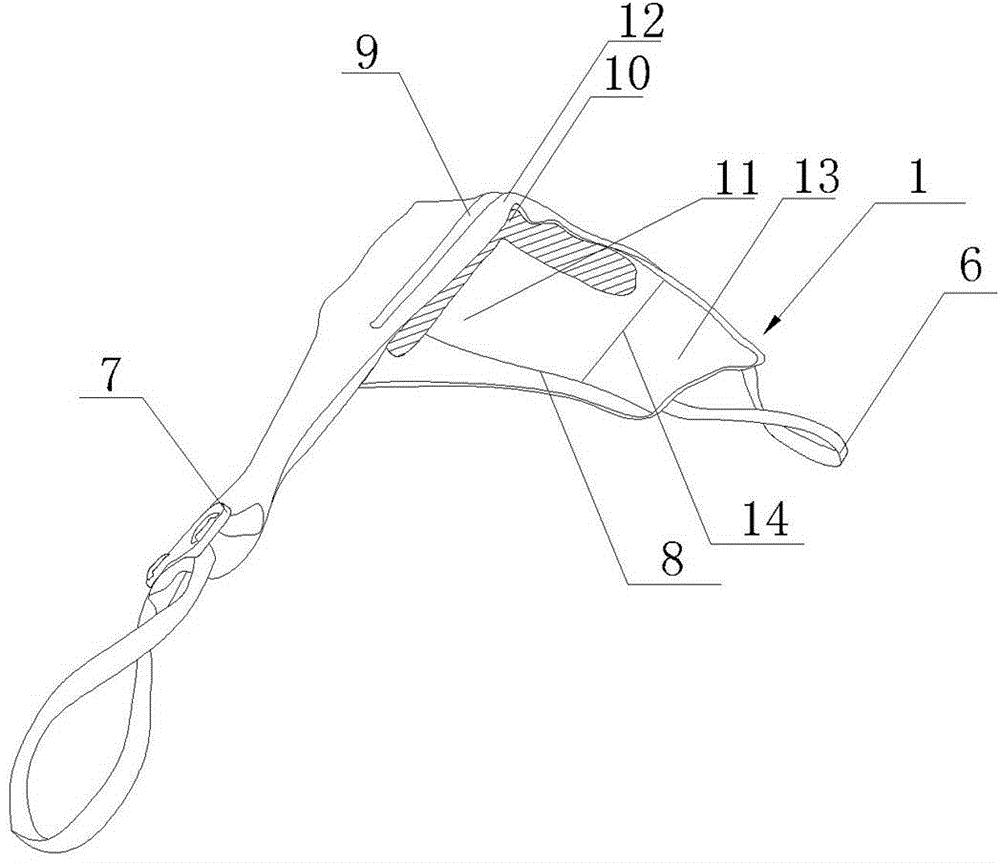

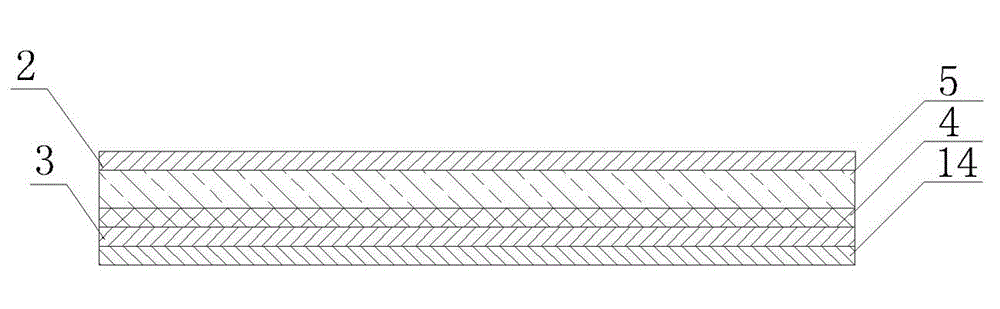

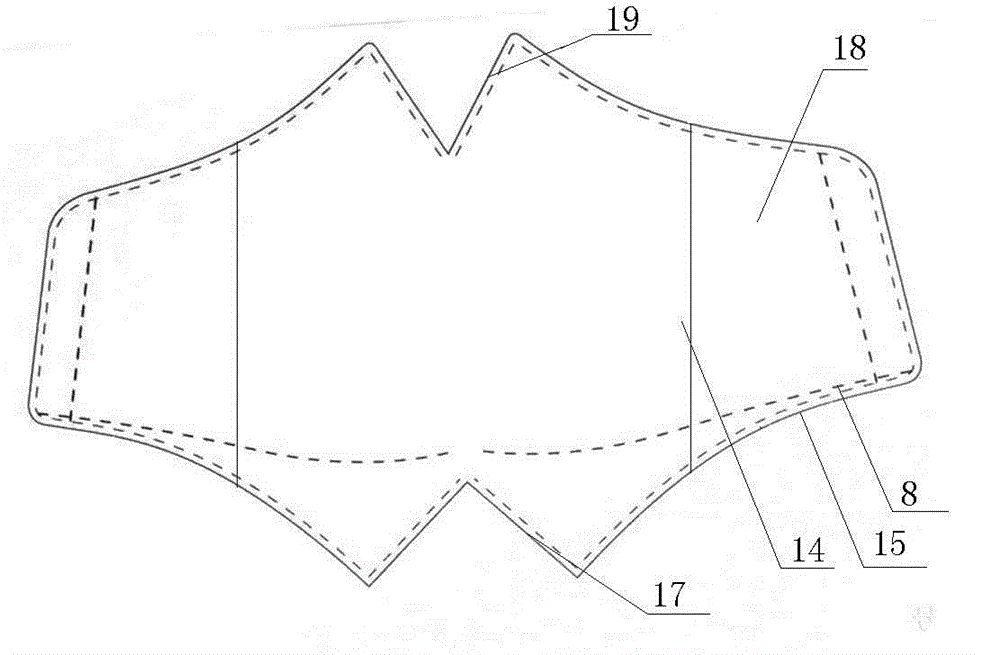

Easy-to-composite multi-layer composite mask and manufacturing method thereof

InactiveCN104585924AImprove filtering effectImprove comfortProtective garmentSpecial outerwear garmentsSurface layerBiochemical engineering

The invention relates to a protective article and particularly relates to an easy-to-composite multi-layer composite mask and a manufacturing process thereof. The mask comprises a mask body; the mask body consists of a surface layer, an intermediate layer and an inner layer; both the surface layer and the inner layer are non-woven fabric layers; the intermediate layer is an electrostatically-loaded and melt-blown filter material layer; a pure cotton fabric layer is arranged between the surface layer and the intermediate layer; outer edges of the surface layer, the electrostatically-loaded and melt-blown filter material layer and the inner layer are composited by hot melting; the surface layer, the pure cotton fabric layer, the electrostatically-loaded and melt-blown filter material layer, and the inner layer are welded ultrasonically. According to the mask disclosed by the invention, because the electrostatically-loaded and melt-blown filter material layer is adopted by the intermediate layer and the cotton fabric layer can be fused between the surface layer and the intermediate layer, the mask has good filtering effect, low resistance, nice comfort and strong air permeability and water absorption; meanwhile, the multiple layers of materials are composited through ultrasonic welding, so the stitching with threads is avoided and the composite process is simplified.

Owner:ZHEJIANG JIANDE CHAOMEI DAILY CHEM

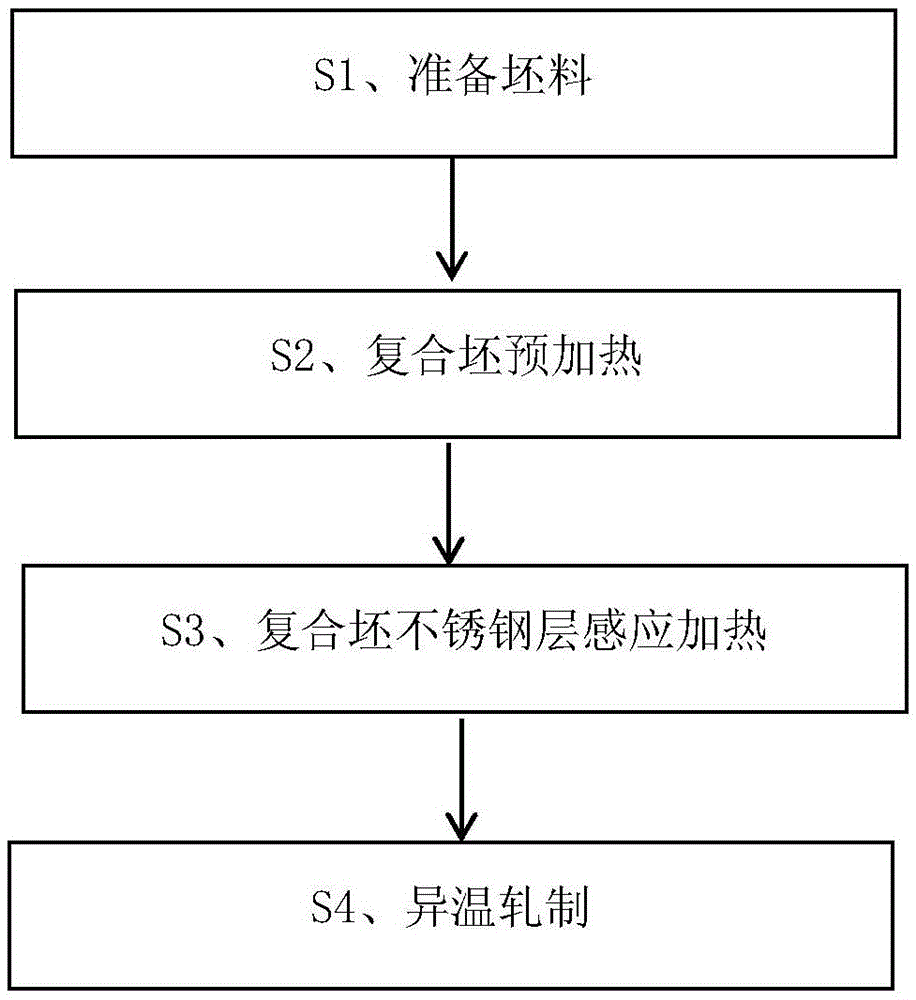

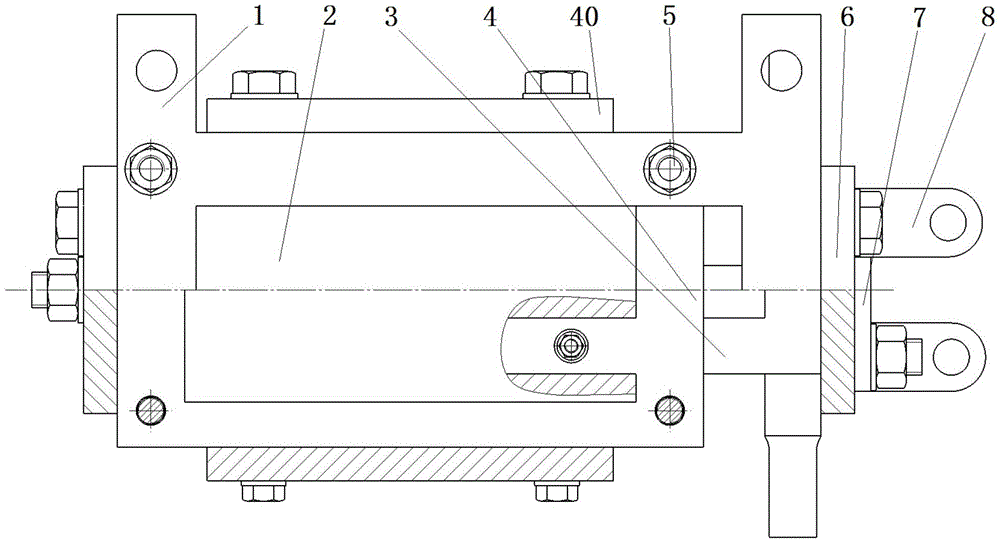

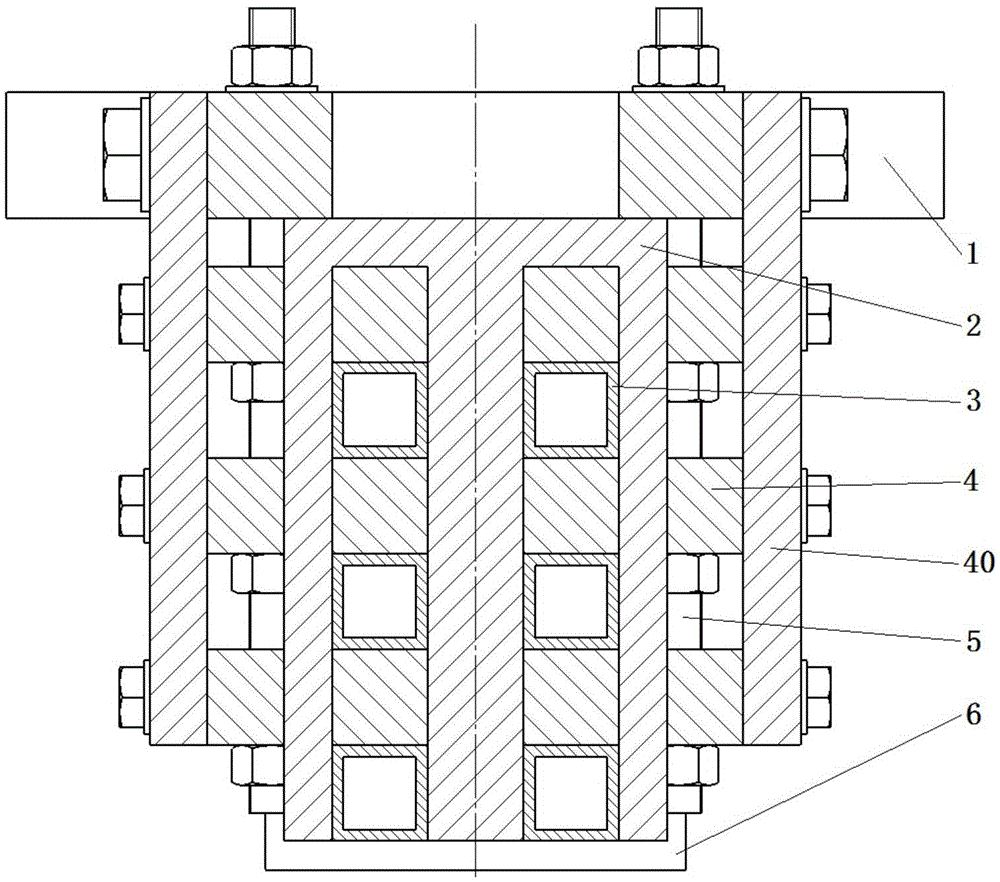

Different-temperature rolling method for preparing stainless steel and carbon steel composite board

ActiveCN105598166AReduce the difference in deformation resistanceMorph coordinationTemperature control deviceWork heating devicesTemperature differenceCarbon steel

The invention provides a different-temperature rolling method for preparing a stainless steel and carbon steel composite board. The different-temperature rolling method comprises the following steps: S1, blank preparation; S2, composite blank pre-heating; S3, composite blank induction-heating; S4, different-temperature rolling. An electromagnetic induction heating method is introduced into a hot-rolling composite process for preparing the stainless steel and carbon steel composite board to perform secondary heating on a stainless steel layer of an integrally-heated composite blank; the deformation resistance difference between the stainless steel layer and a carbon steel layer is reduced through controlling the temperature difference between the stainless steel layer and the carbon steel layer of the composite blank, so that the deformation of the stainless steel layer and the carbon steel layer in the rolling deformation process is more coordinated, therefore, the warping after a single-sided stainless steel composite blank is rolled can be reduced, even eliminated, and the internal residual stress after a double-sided stainless steel composite blank is rolled can be reduced.

Owner:YANSHAN UNIV

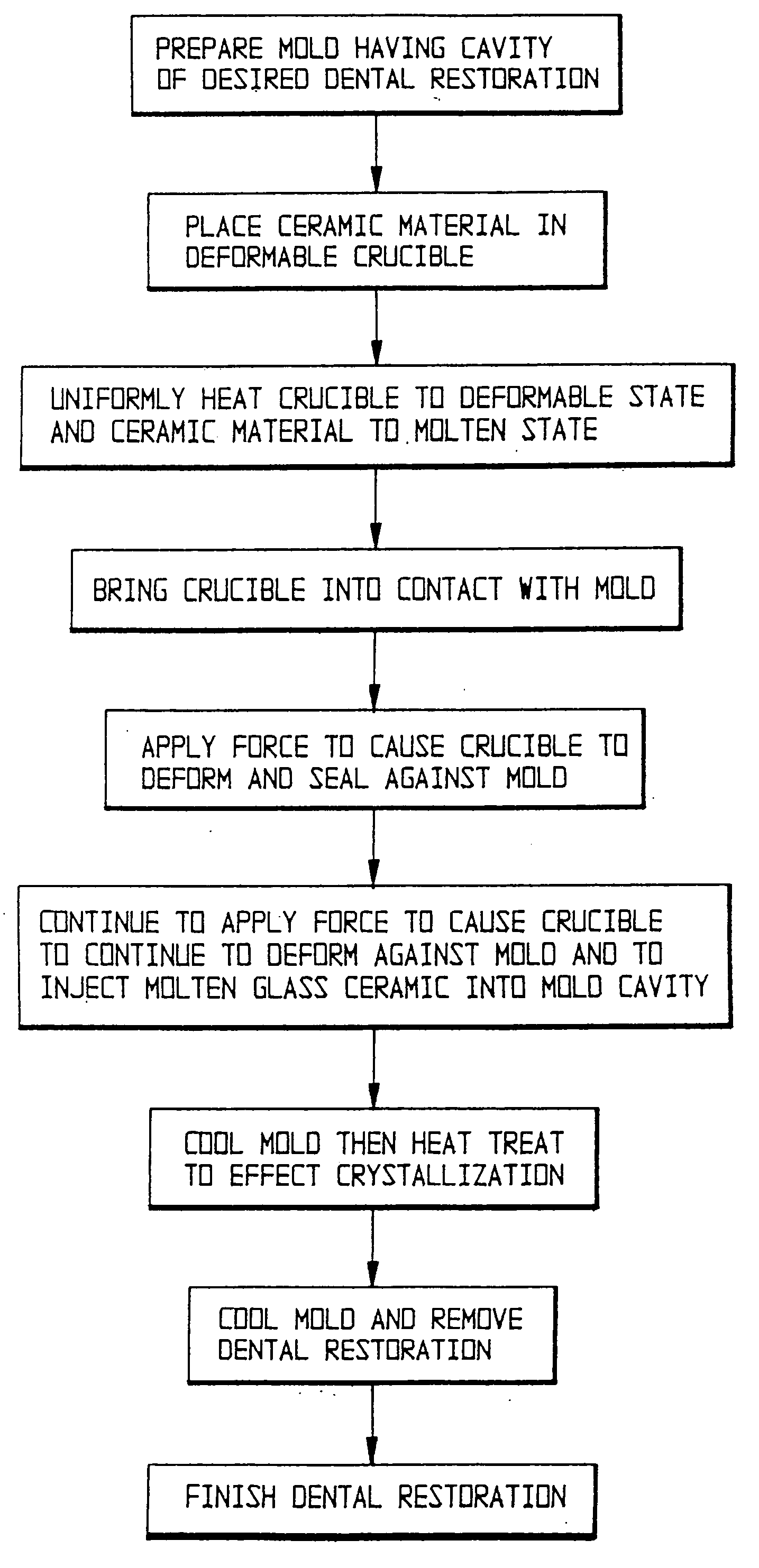

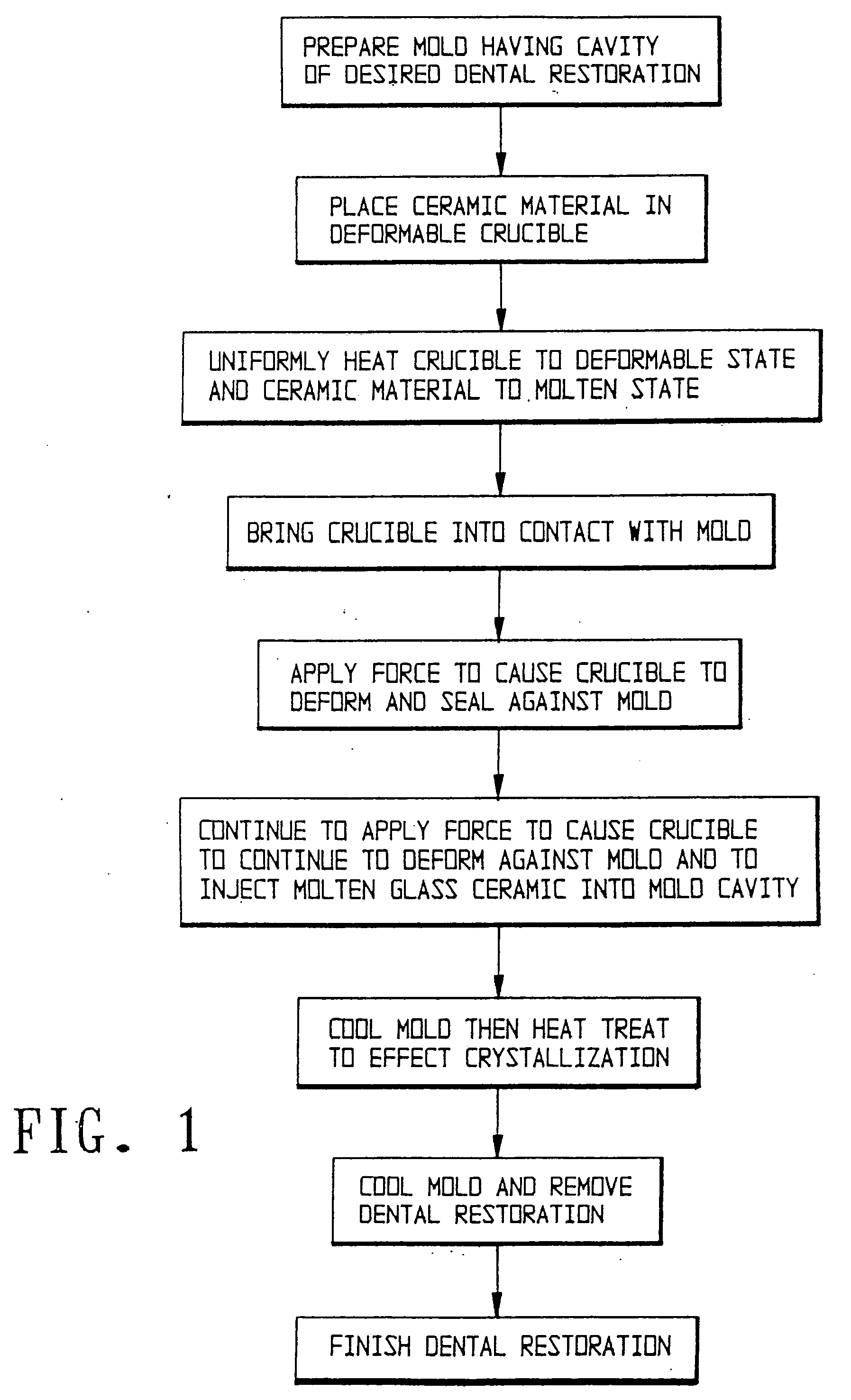

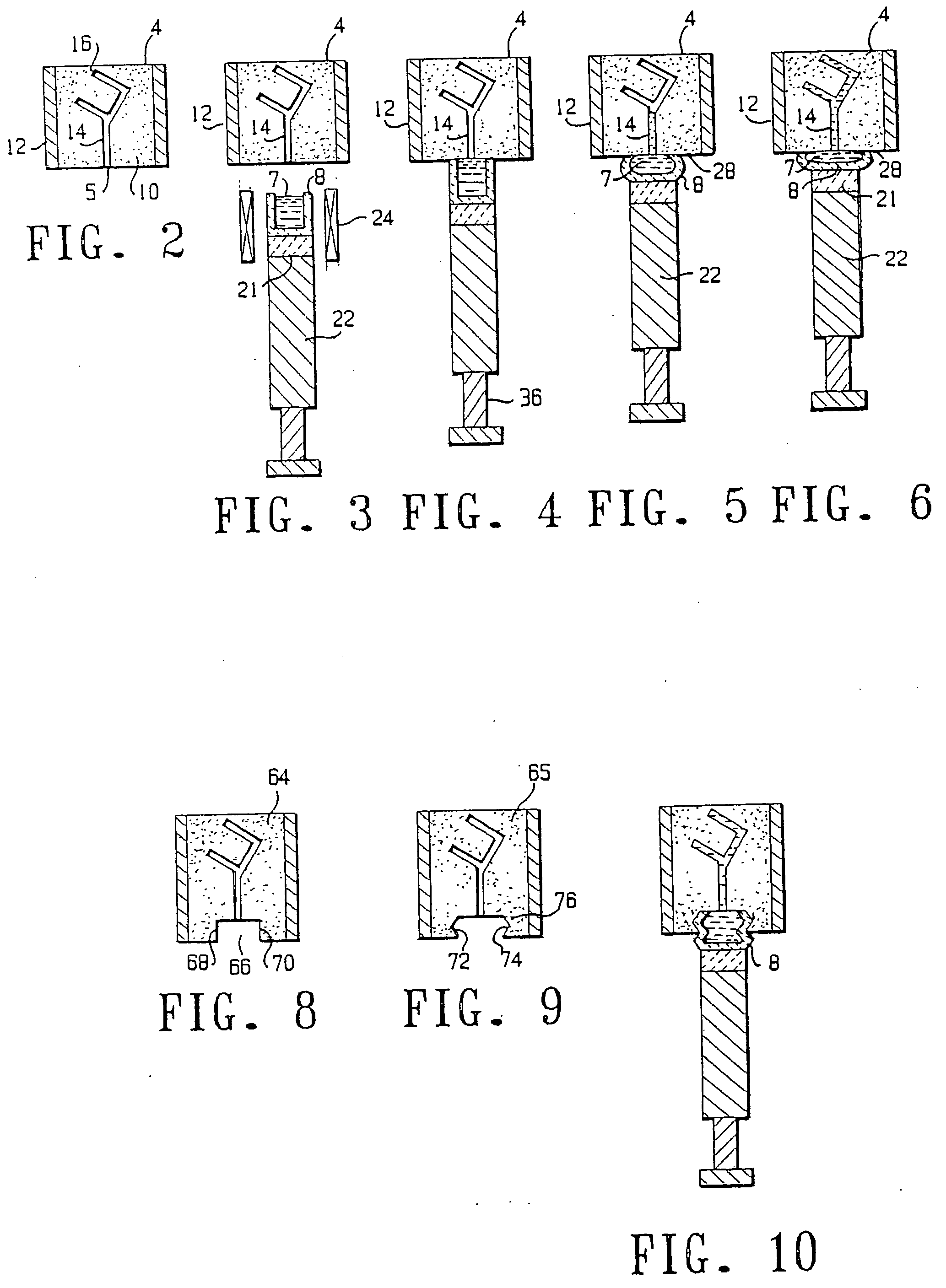

Method for molding dental restorations and related apparatus

InactiveUS20050115460A1Readily molded into dental restorationEasy to useImpression capsOther chemical processesWorking temperatureDental restoration

The present invention is concerned with a process for the formation of dental restorations from glass-ceramic materials, and the resulting dental restorations. In this invention, a dental restoration is prepared by placing a glass-ceramic material in a heat-pressure deformable crucible. Heat is then applied to the crucible in order to bring the glass-ceramic material to working range at temperatures above its liquidus temperature. The crucible in which the glass-ceramic material is placed has heat-pressure deformation properties which are matched to the working temperature of the glass-ceramic material being heated. The heat deformation properties of the crucible must be such that when the glass-ceramic material in the crucible is in the working range, the crucible is heat-pressure deformable without rupturing. Once the glass-ceramic material is heated to its working temperature, the crucible is brought into contact with a mold having a preformed cavity therein, the cavity being in the shape of the desired dental restoration. As the distance between the heated glass-ceramic material and the mold is decreased, the crucible is deformed to form a seal with the mold, thereby facilitating the injection of the molten glass-ceramic material into the mold cavity. An interactive seal between the crucible and the mold may be provided for. The composite process may be carried out in a vacuum. The resulting dental restoration has superior optical esthetic and strength properties. The invention further includes the heat-pressure deformable crucible. The invention includes dental restorations which are formed from particular lithium-disilicate glass-ceramics. In addition to forming dental restorations by the process of this invention, the dental restorations may be milled.

Owner:PETTICREW RICHARD W

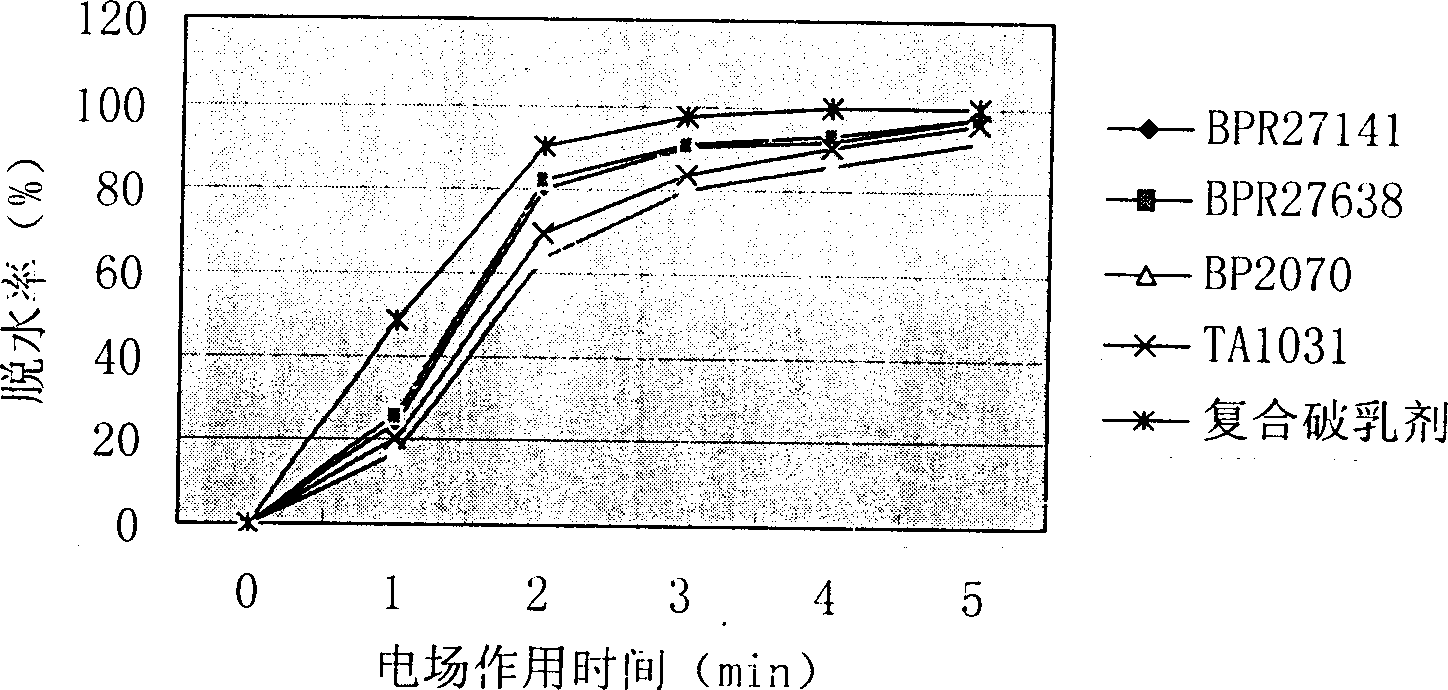

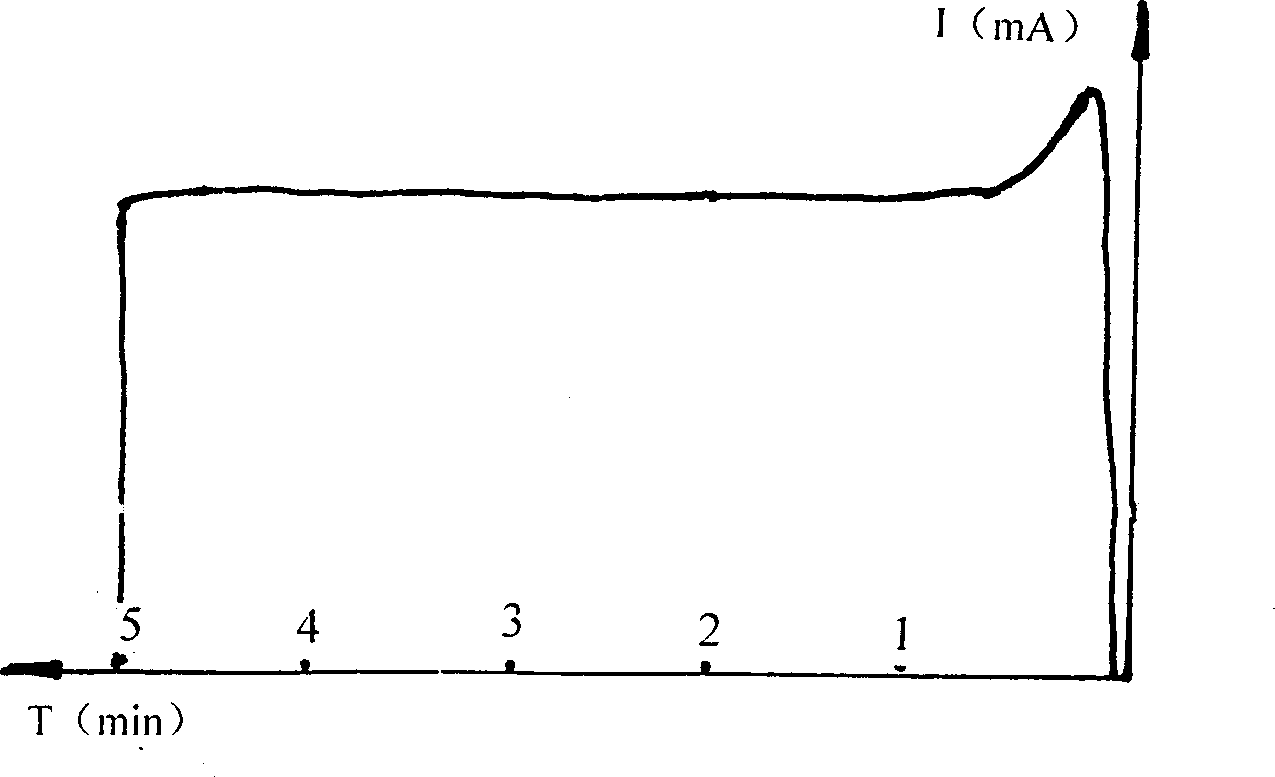

Composite oil-soluble demulsifier product and its production method

ActiveCN1807557AImprove performanceReduce dosageHydrocarbon oil dewatering/demulsificationDemulsifierOrganic solvent

This invention provides a kind of composite oil-soluble demulsifier and its preparing method. The composite oil-soluble demulsifier is composed by mixed solvent and functional demulsifier. The mixed solvent is made of one or several kinds of organic solvents in dimethylbenzene, methanol, isopropanol, solvent oil, dimethyl carbonate, while the functional demulsifier is made of non-ionic surfactant. The mass percent of the mixed solvent is 30-70 while that of the functional demulsifier is 70-30. The composite process is proceeded in agitated still which has heat-insulating cover, and controlled conditions are as follows: composite mixing temperature 20-80 deg C; agitating speed 30-150r / min; agitating time 20-60min plugging temperature30-40deg C.

Owner:长江三星能源科技股份有限公司

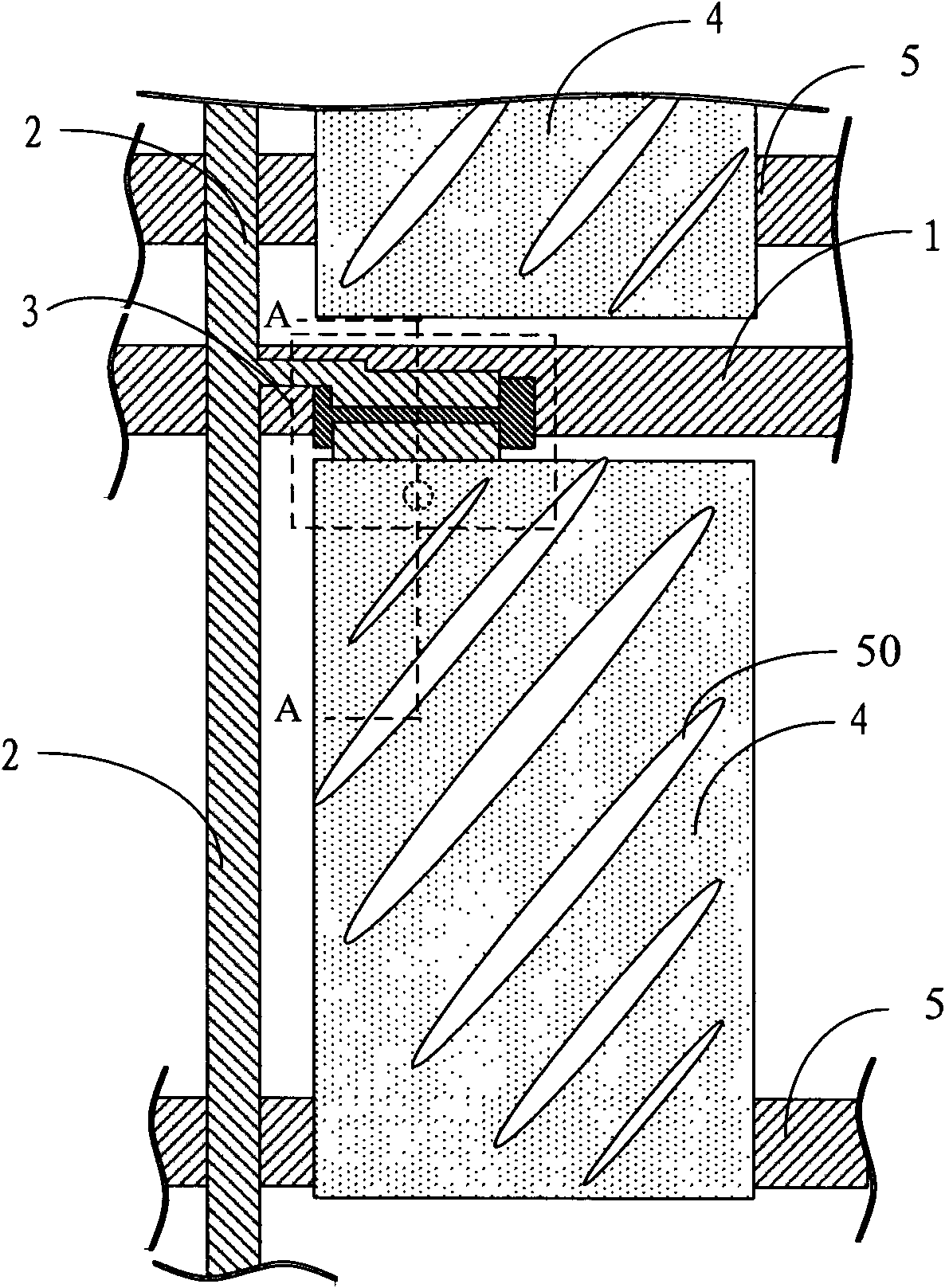

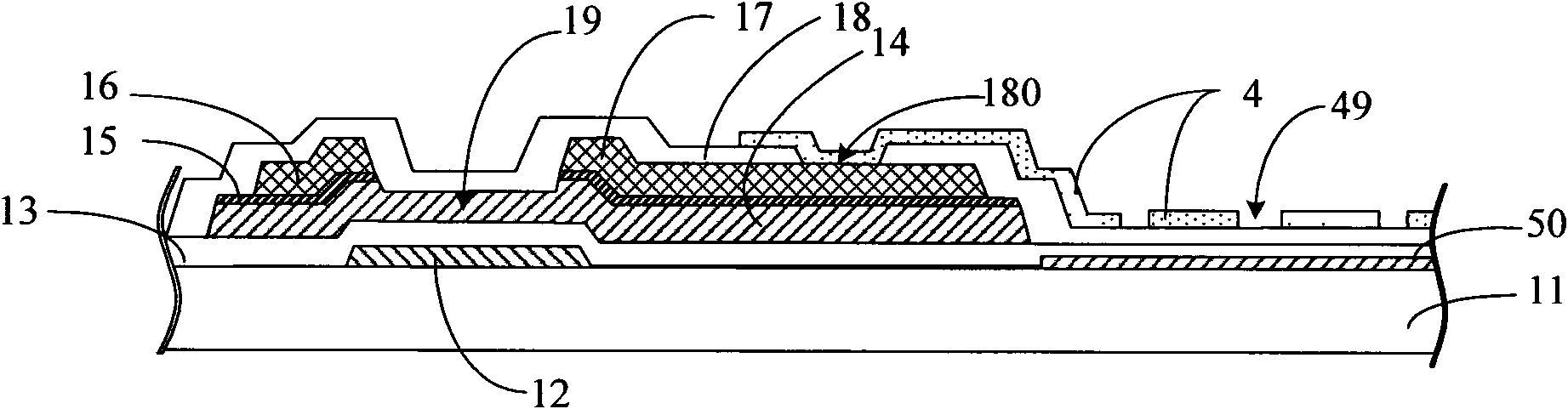

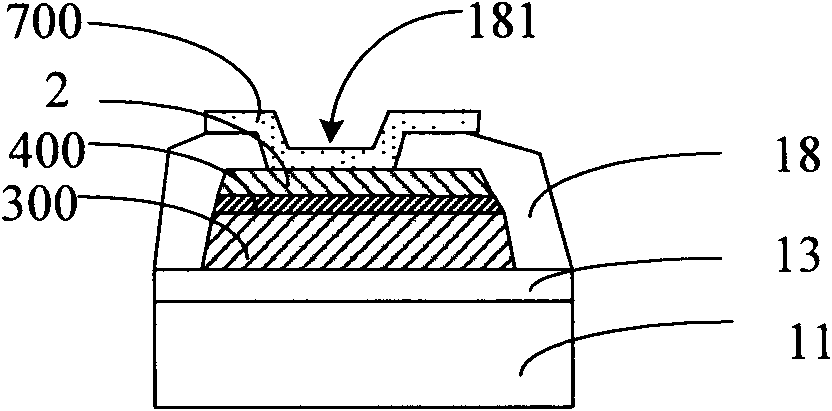

TFT-LCD (thin film transistor-liquid crystal display) array substrate and manufacturing method therefor

ActiveCN102148196AReduce the number of processesLow costSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayThin-film-transistor liquid-crystal display

The invention discloses a manufacturing method for a TFT-LCD (thin film transistor-liquid crystal display) array substrate, which comprises the following steps: sequentially depositing a first transparent conductive film, a second metallic film and a doped semiconductor film on a transparent substrate and compositing a pattern for an established region so as to form the pattern comprising a source electrode, a drain electrode, a data line and a pixel electrode; depositing a semiconductor film and compositing a pattern for an established region so as to form the pattern comprising a doped semiconductor layer, a TFT (thin film transistor) channel and a semiconductor layer; depositing an insulating film and a second metallic film and compositing a pattern for an established region so as to form the pattern comprising a connecting hole of a PAD region data line, a grid line, a gate electrode and a public electrode line; and depositing a second transparent conductive film and compositing apattern for an established region so as to form the pattern comprising a public electrode. In the manufacturing method, the TFT-LCD array substrate is manufactured by a four-time pattern compositing process; and compared with the prior art, the manufacturing method reduces the process number, greatly saves the cost and improves the market competitiveness.

Owner:BOE TECH GRP CO LTD +1

Laser auxiliary pre-stress shot blasting forming-strengthening composite process

The invention discloses a laser-assisted prestressed composite method for shot blasting, forming and strengthening. The method is as follows: firstly, a workpiece is deformed as expected in an elastic range through a mechanical preloading method; secondly, the elastic energy concentration region of a part is scanned with a laser beam; thirdly, shot blasting is carried out to the workpiece along a laser scanning path. When the method is adopted for forming, the thermal effect of the interaction between the laser and a material can reduce the deformation resistance (elastic modulus and yield strength) of the material in a laser action region, and can assist the part in shaping through an inhomogeneous thermal stress field established in the thickness direction of the part, thereby the compression bending forming amount, forming efficiency and forming precision of a shaped part can be remarkably improved; moreover, the shot blasting immediately carried out later can strengthen the strain of a heat action region, so as to improve structural mechanical property.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

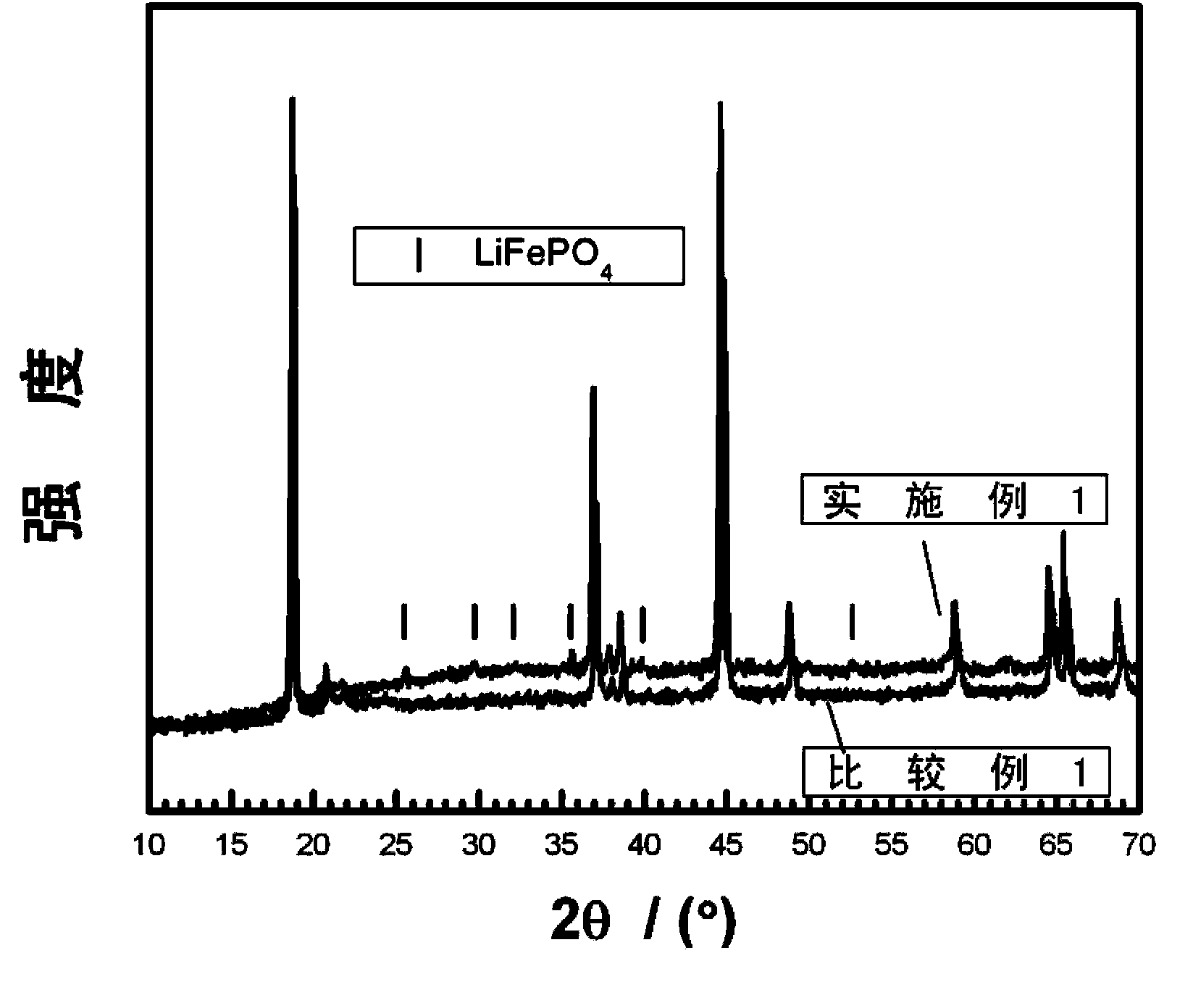

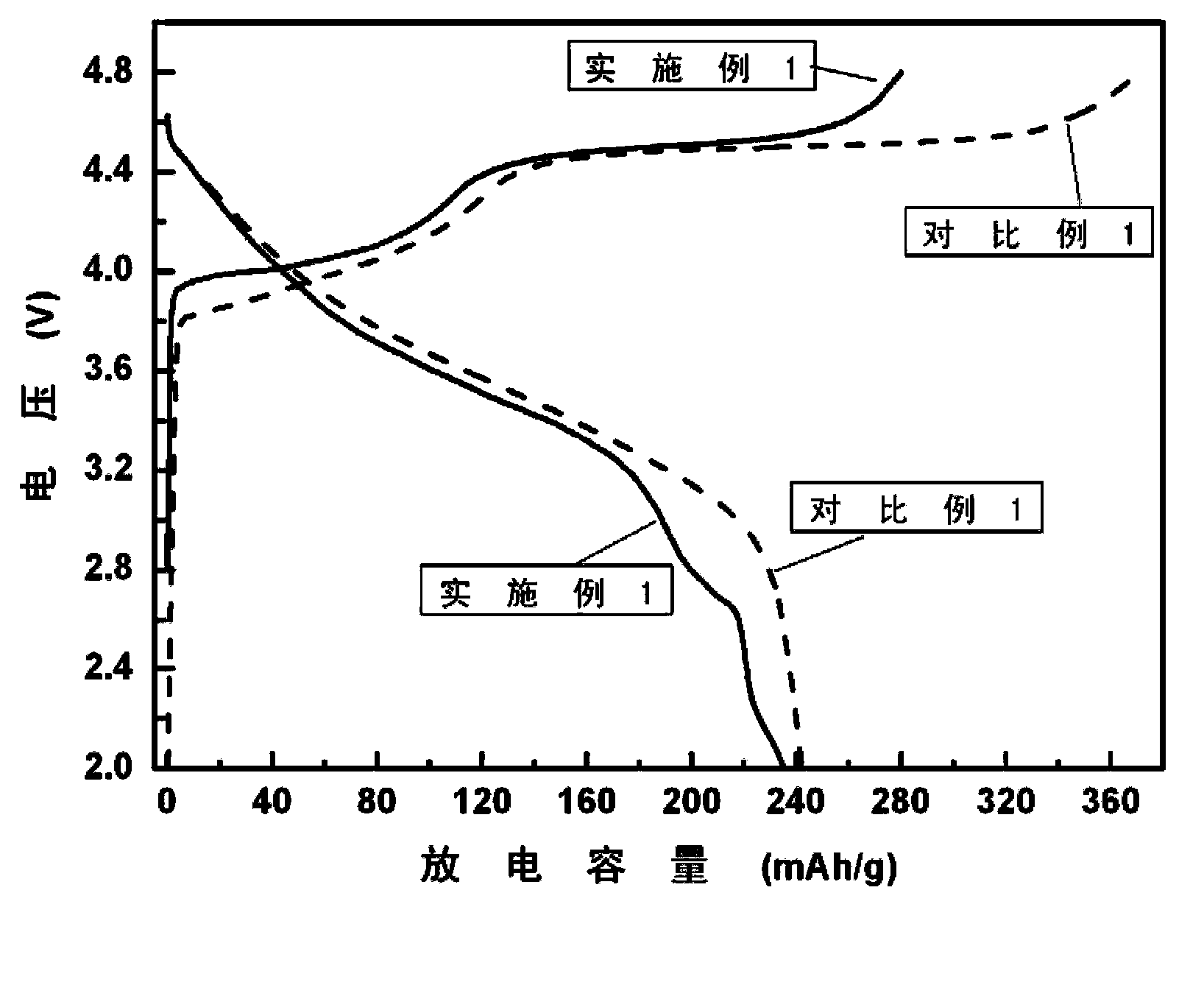

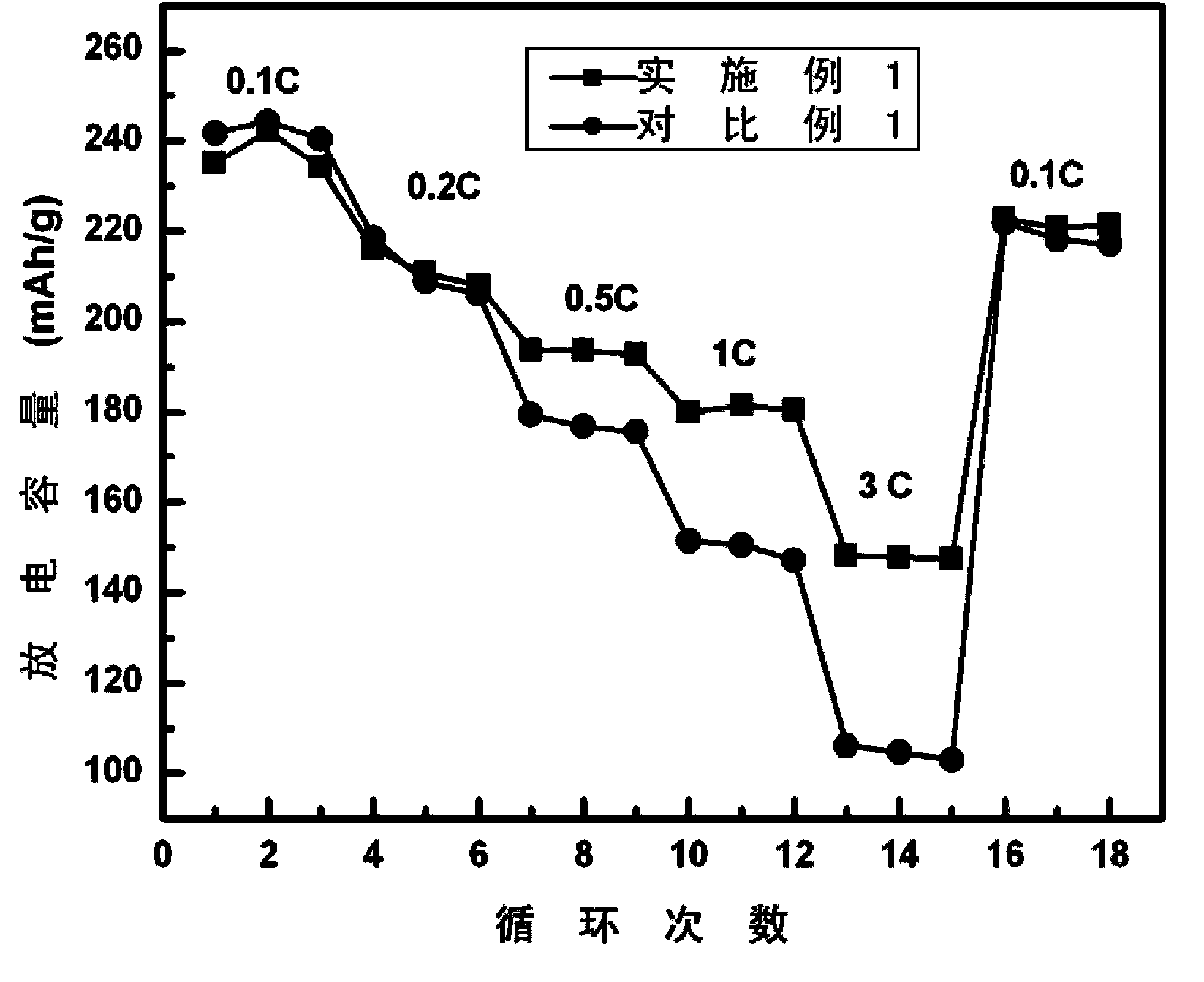

Surface coating and compounding lithium-rich manganese-based positive electrode material and preparation method of positive electrode material

ActiveCN103904311AImprove the first charge and discharge efficiencyHigh initial charge and discharge capacityCell electrodesSecondary cellsDischarge efficiencyLithium iron phosphate

The invention provides a positive electrode material which is applicable to lithium secondary batteries with high capacity, high charging and discharging efficiency and excellent rate capability. The positive electrode material which is applicable to the lithium secondary batteries is a surface coating and compounding lithium-rich manganese-based positive electrode material. The surface coating and compounding lithium-rich manganese-based positive electrode material is characterized in that an inner layer is made of a lithium-rich manganese-based material; a surface coating and compounding layer is made of a lithium iron phosphate material; the lithium iron phosphate of the surface coating and compounding layer is a novel phase which is generated in a coating and compounding process; a lithium source is selected from the lithium-rich manganese-based positive electrode material and is expressed by a general formula shown as Li[Li<x / 3-y>Me<1-x>Mn<>2x / 3.yLiFePO4; in the general formula, x is greater than 0 and less than 0.8; y is greater than 0 and less than x / 3; Me is selected from at least one of chemical elements comprising Ni, Co, Mn, Cr, Fe, Zn, Al, Mg and Cd. The invention also provides a preparation method of the positive electrode material and a lithium ion secondary battery positive electrode and a lithium-ion secondary battery using the positive electrode material.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com