Patents

Literature

810results about How to "Weak elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

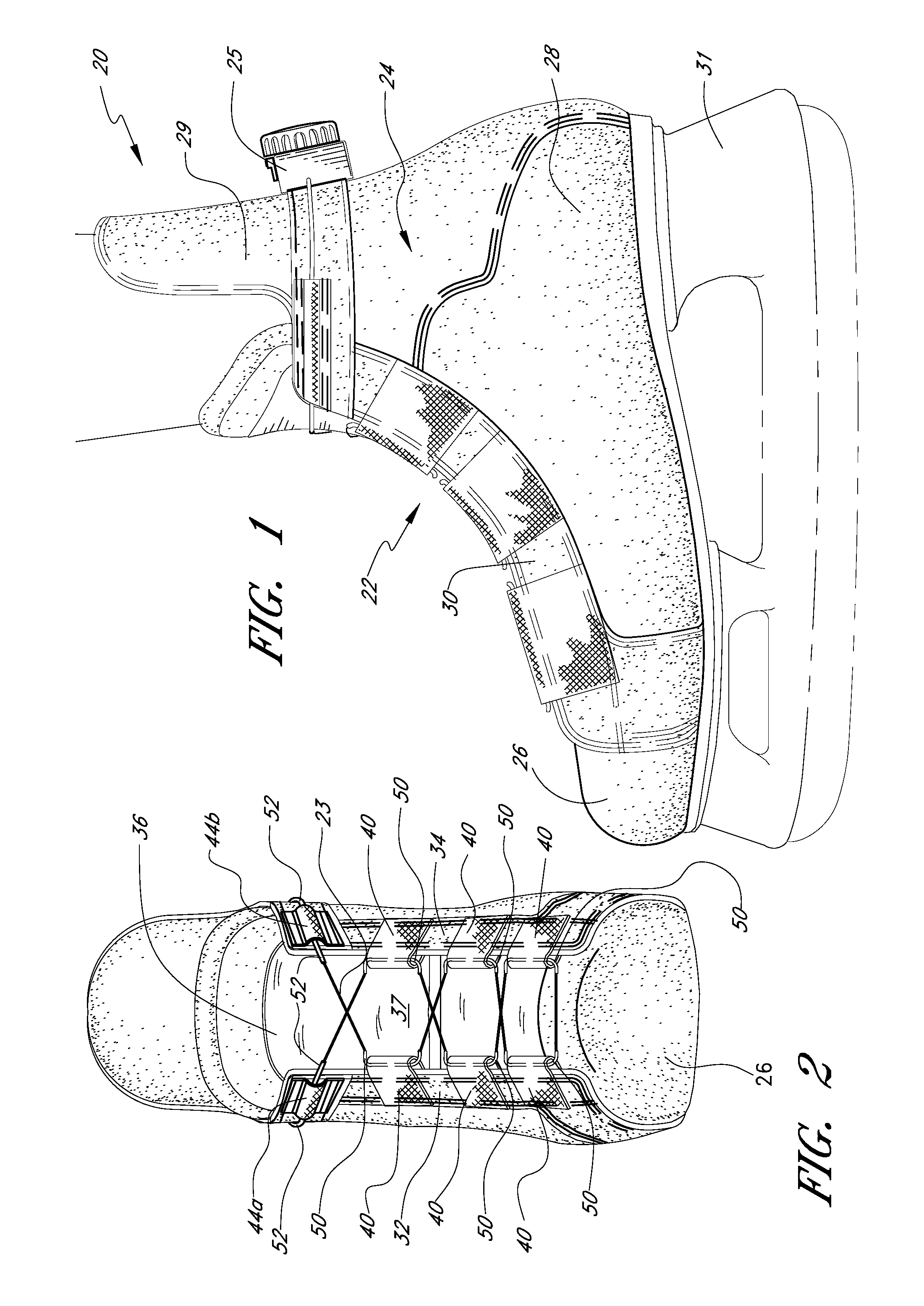

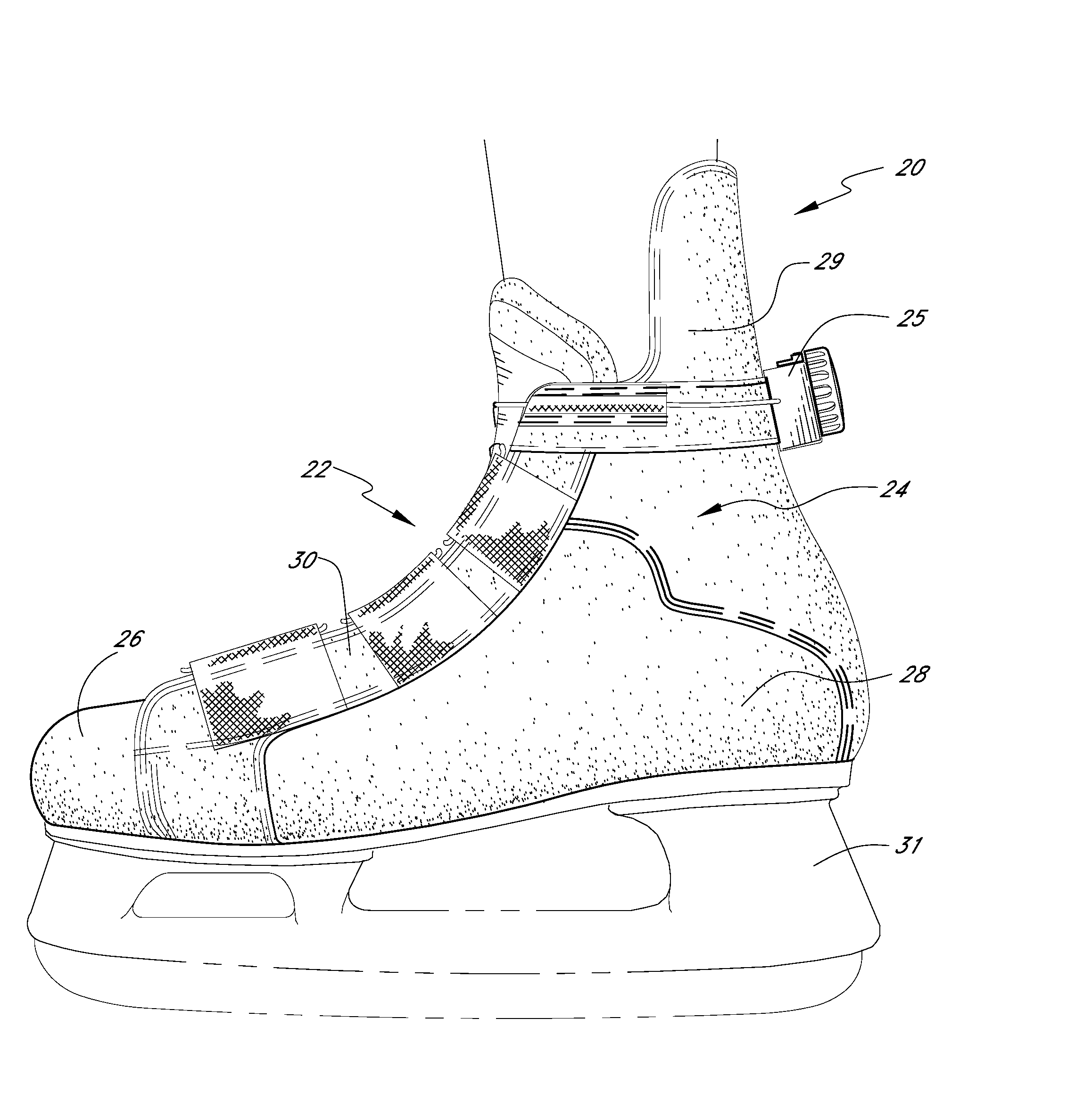

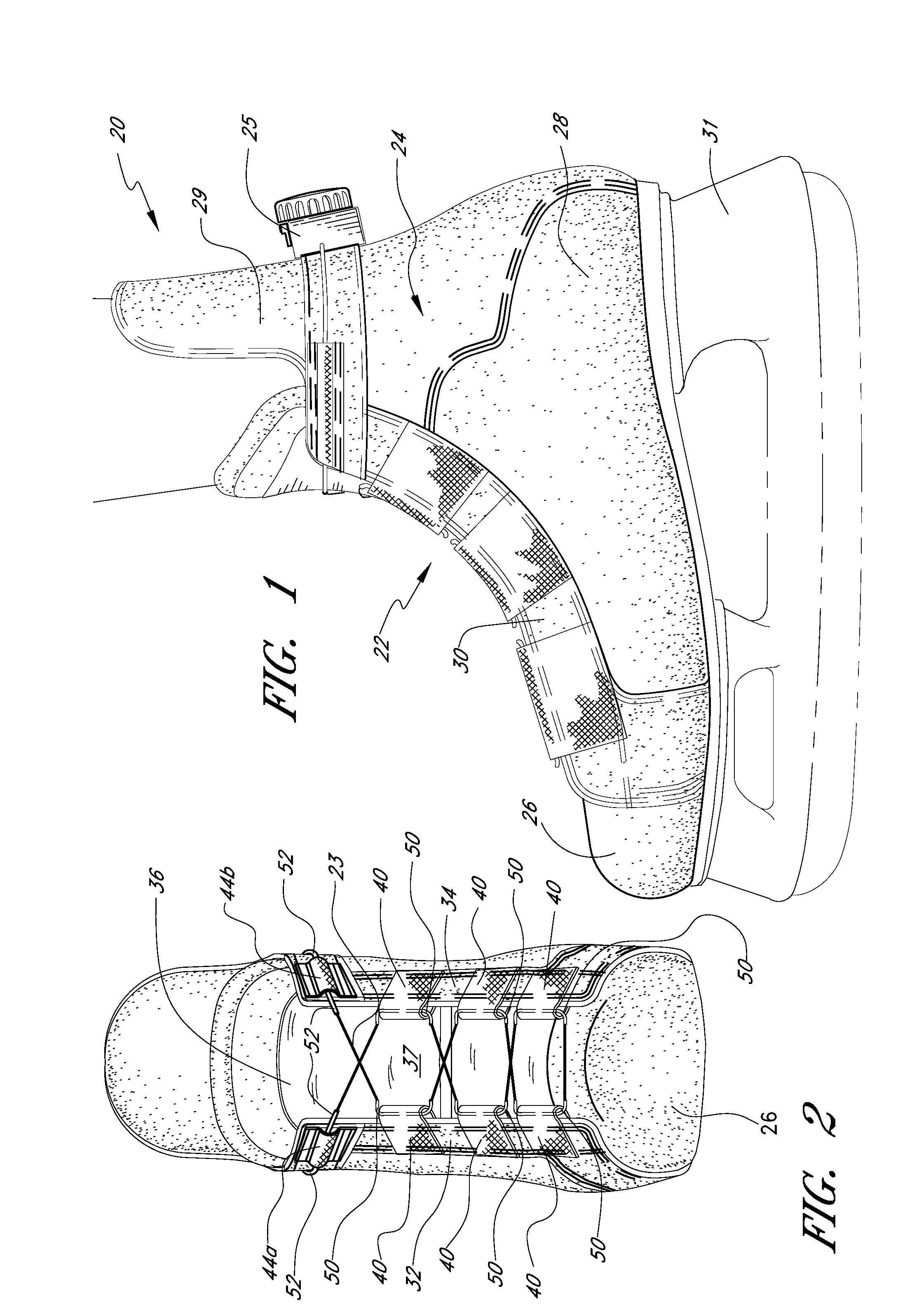

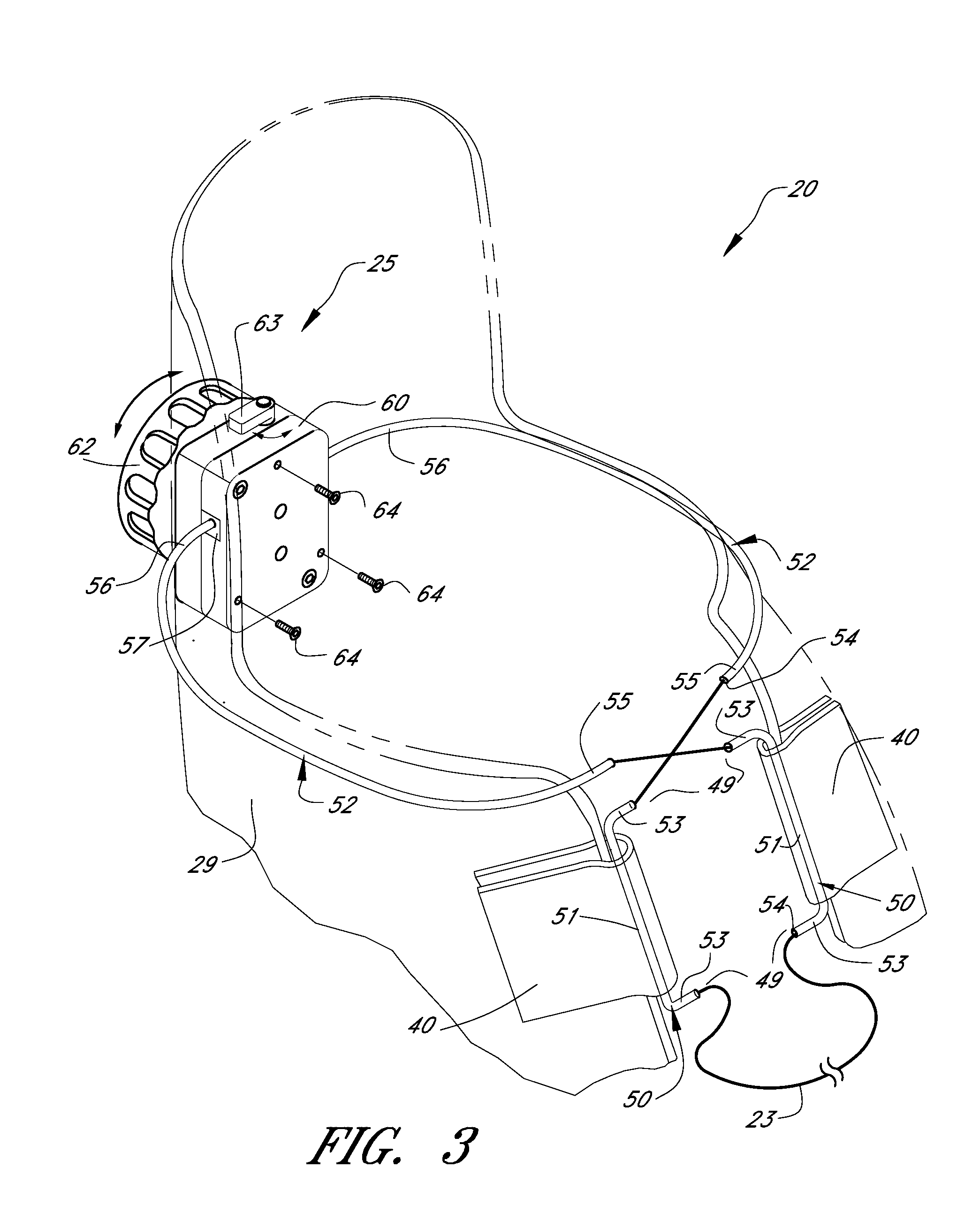

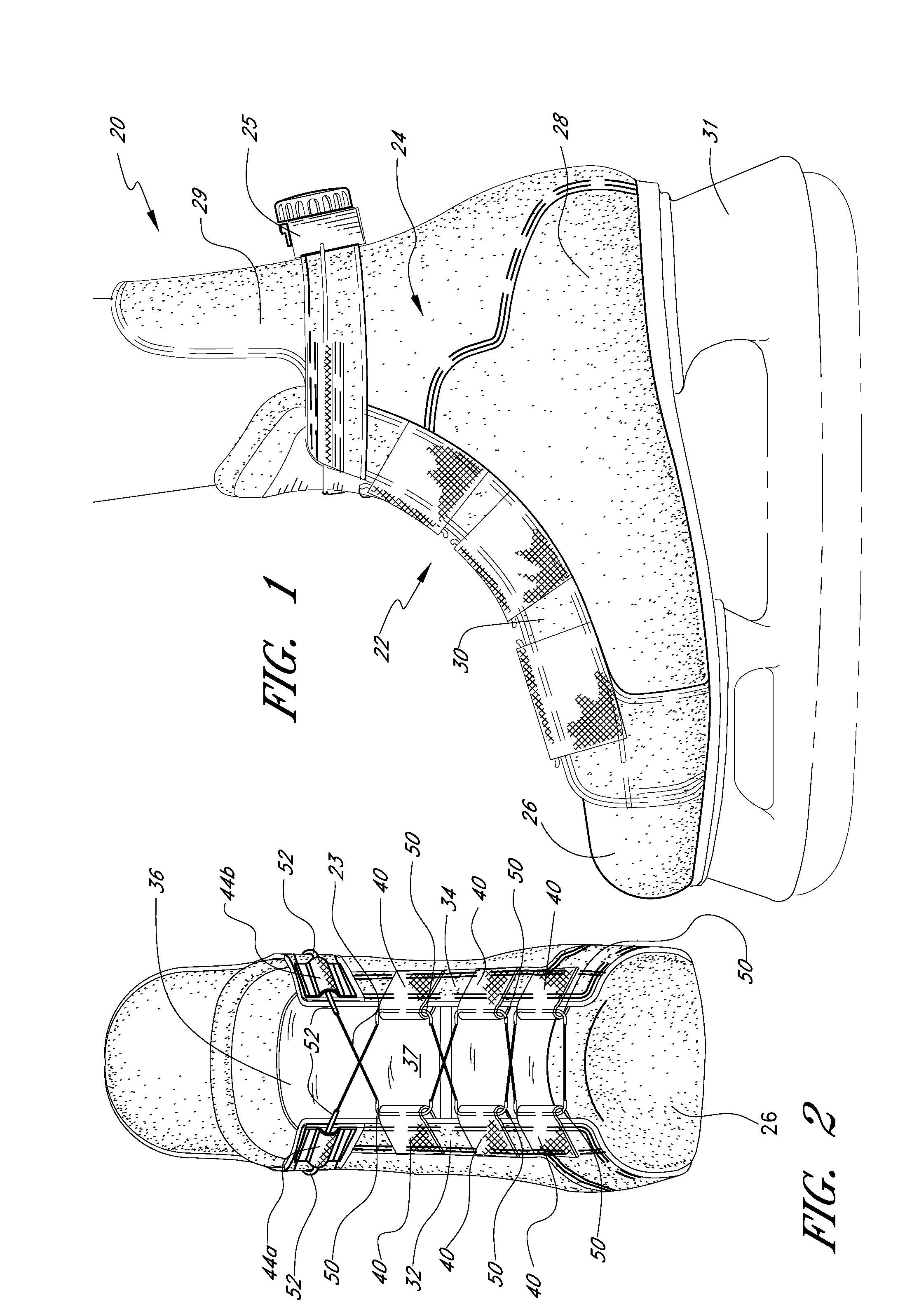

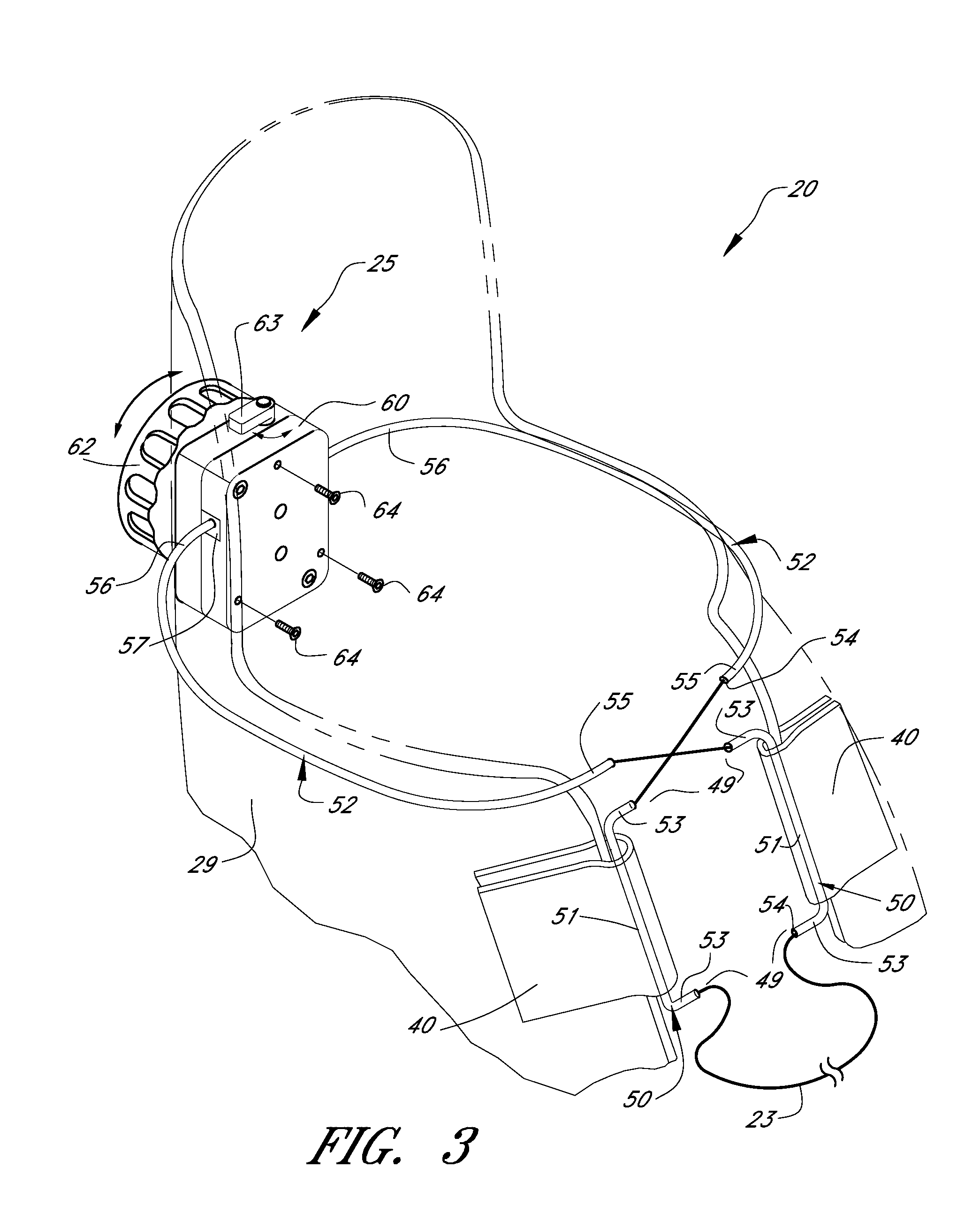

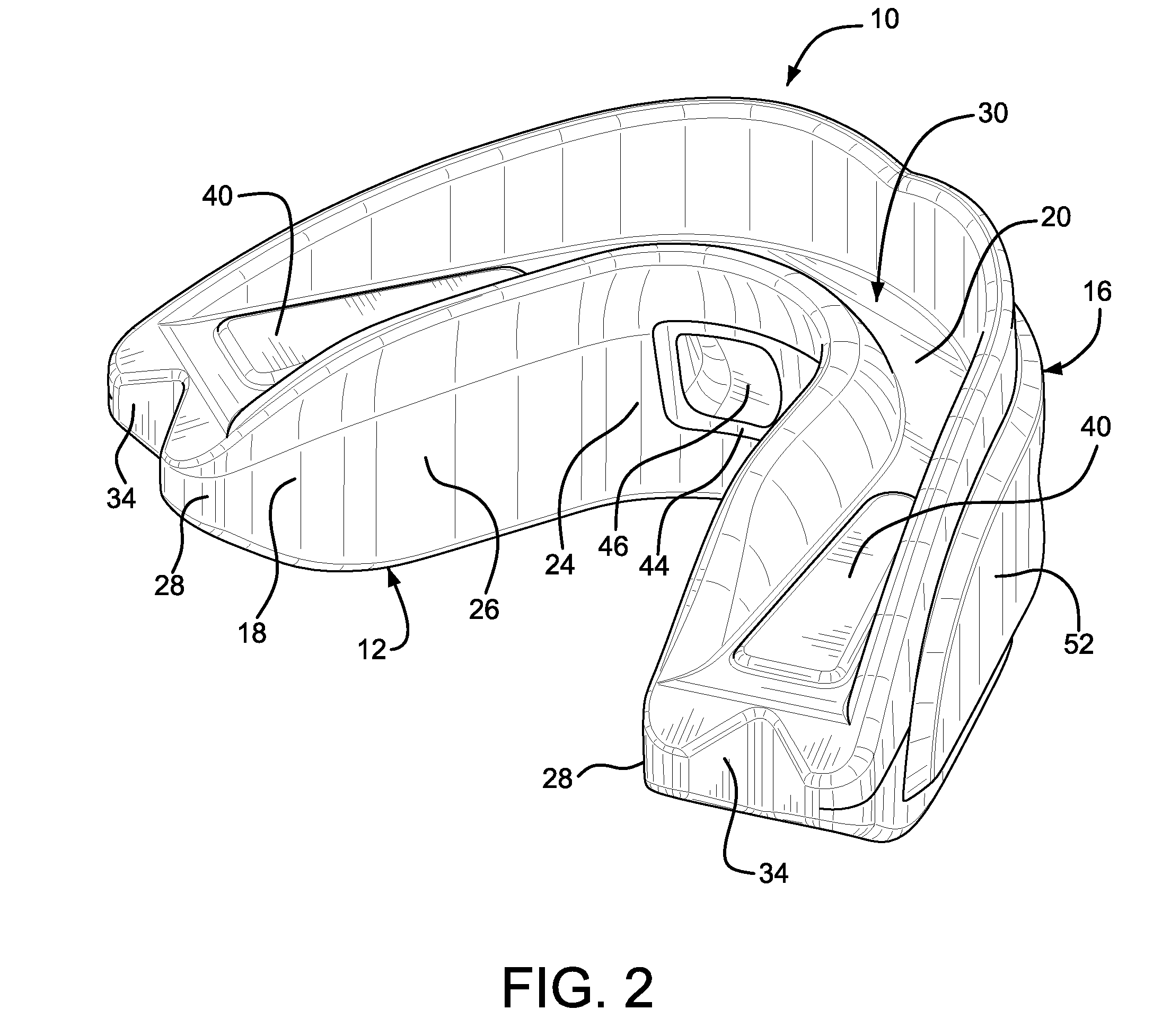

Reel based closure system

InactiveUS20080060167A1Weak elasticityHigh tensile strengthSnap fastenersShoe lace fasteningsEngineeringMechanical engineering

Disclosed is a closure system used in combination in any of a variety of applications including clothing, for example as a footwear lacing system comprising a lace attached to a tightening mechanism. The lace extends through a series of guide members positioned along two opposing footwear closure portions. The lace and guides preferably have low friction surfaces to facilitate sliding of the lace along the guide members so that the lace evenly distributes tension across the footwear member. The tightening mechanism allows incremental adjustment of the tension of the lace. The closure system allows a user to quickly loosen the lace and inhibits unintentional and / or accidental loosing of the lace.

Owner:HAMMERSLAG GARY R +2

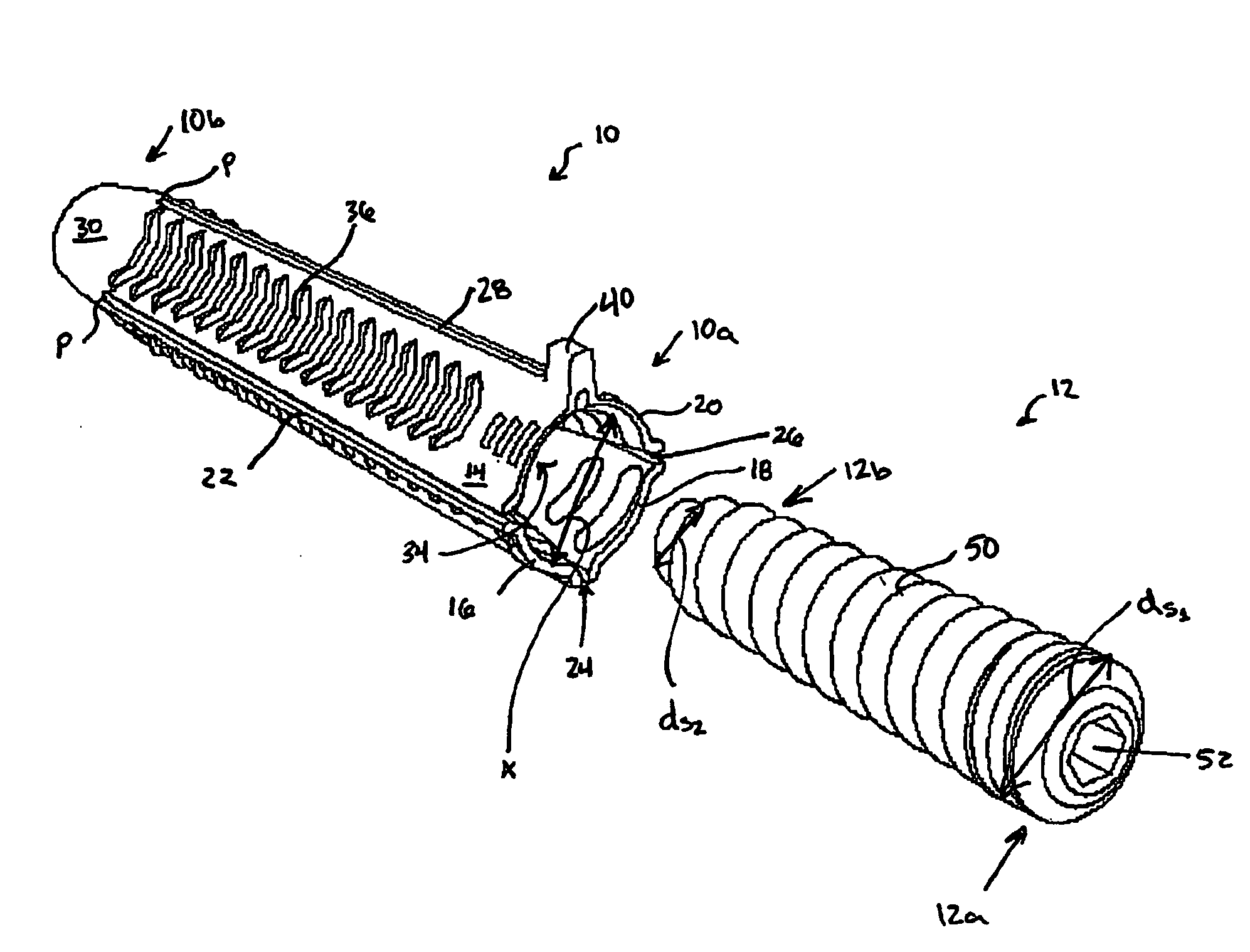

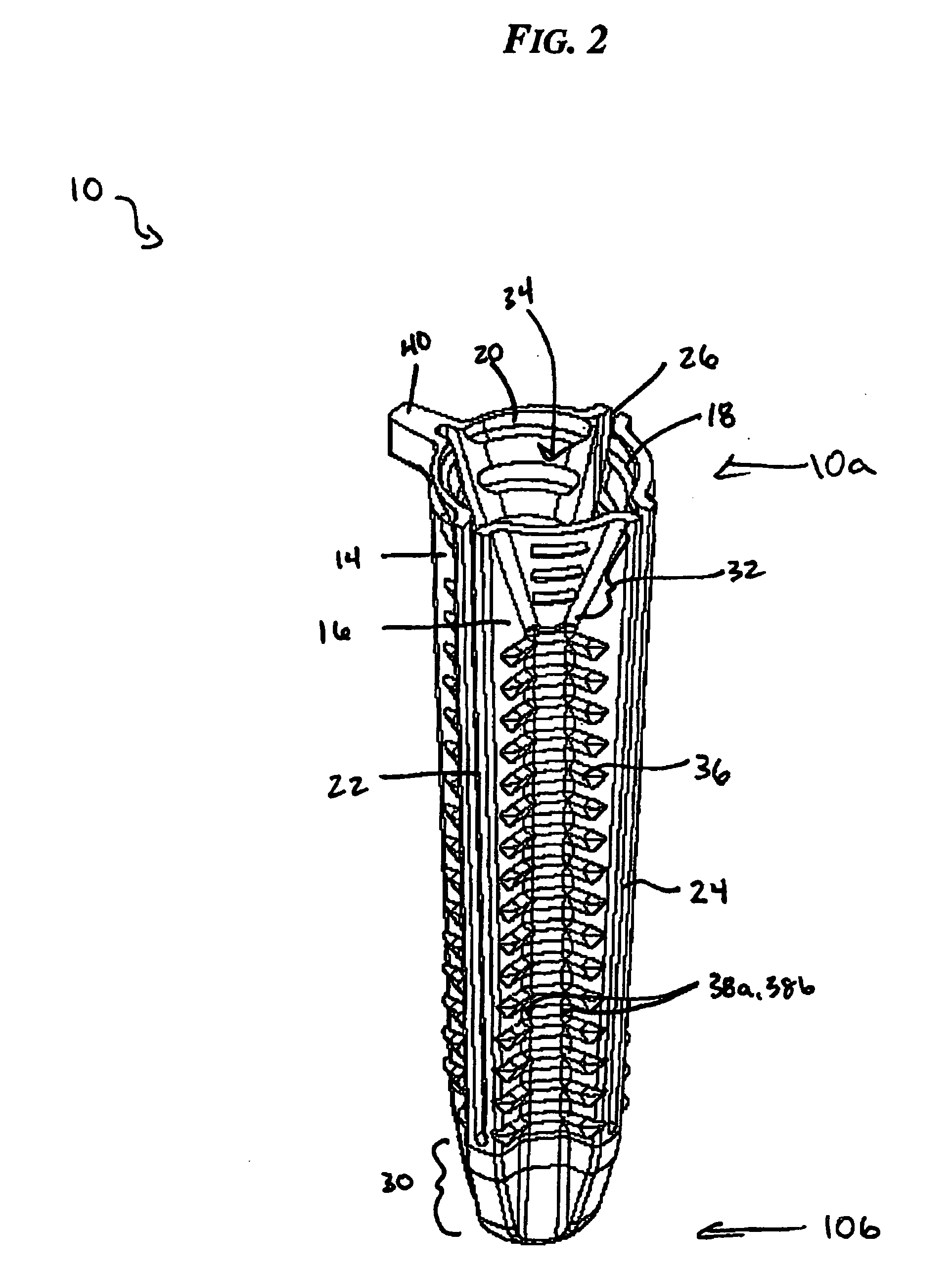

Flexible tibial sheath

InactiveUS20080133007A1Prevent over-insertionWeak elasticitySuture equipmentsBone implantBone tunnelDilator

A radially expandable sheath is provided having a substantially closed distal end with at least two sidewalls extending proximally therefrom and defining a central lumen. Each sidewall can have a substantially concave outer surface adapted to seat a graft member, and each side wall is at least partially separated by a longitudinally oriented slot that extends from a proximal end along a substantial length of each sidewall. The slot preferably terminates at a position just proximal to the distal end. The device can also include a sheath expander that is adapted to be disposed in the central lumen of the radially expandable sheath and that is configured to flex the sidewalls to radially expand the sheath so as to fix a graft member within a bone tunnel.

Owner:ETHICON INC

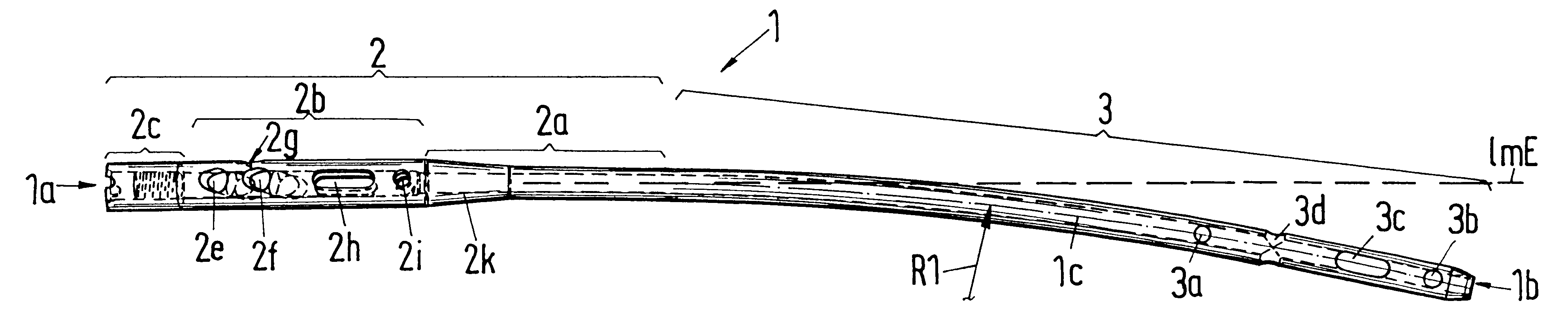

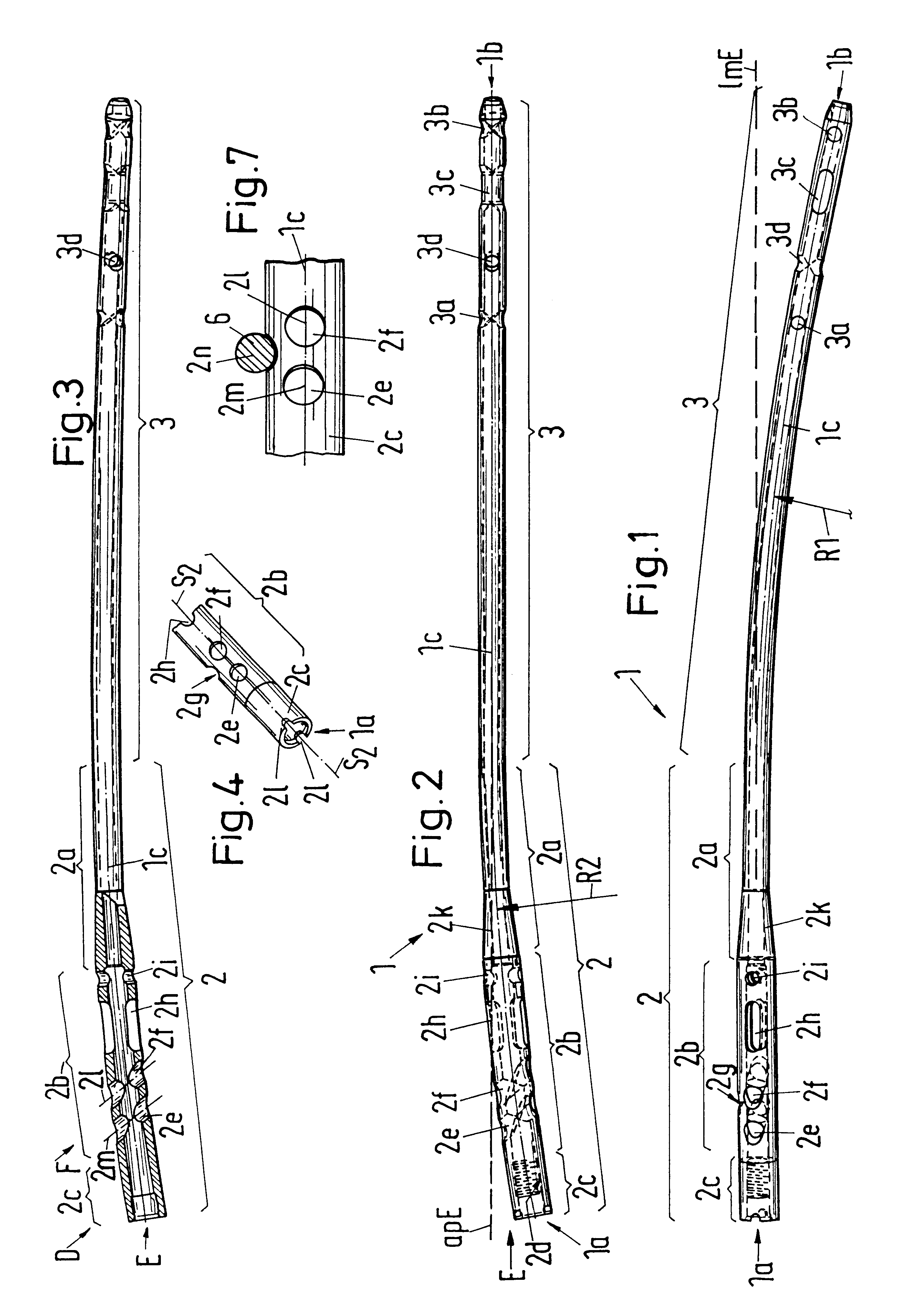

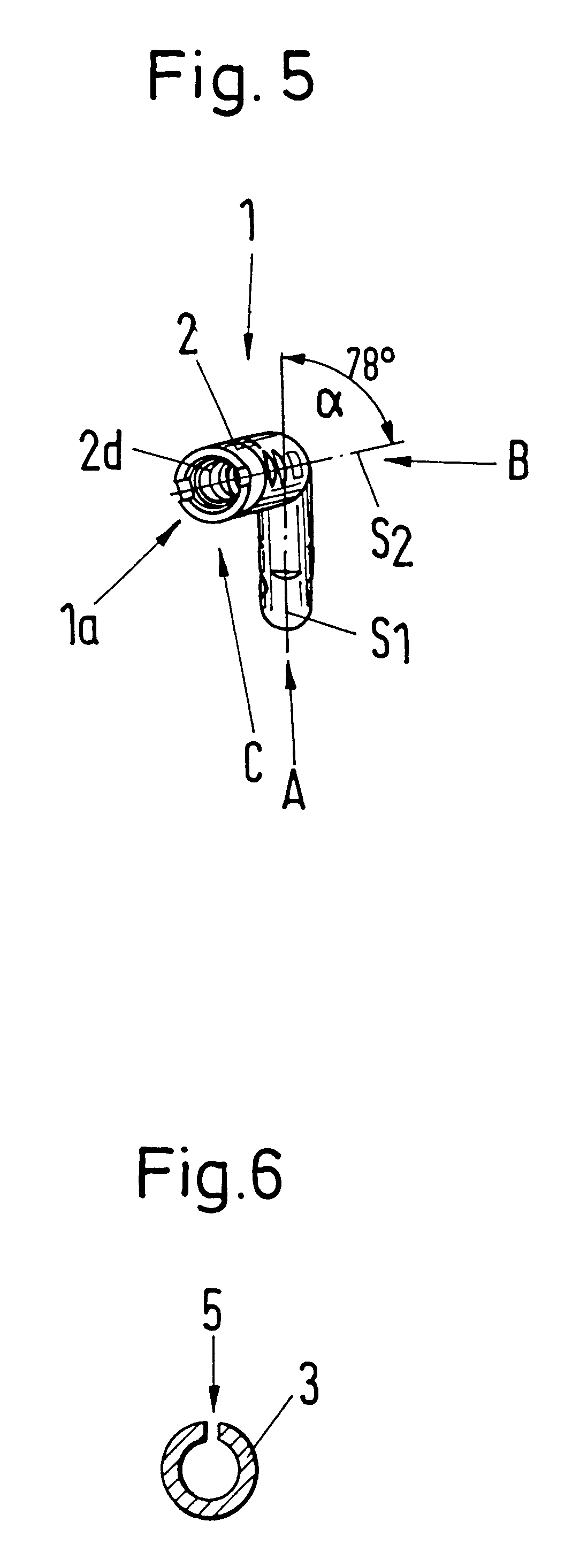

Locking nail for the repair of femur shaft fractures

InactiveUS6461360B1Great exertionGood mechanical holdInternal osteosythesisJoint implantsFEMUR SHAFTBone screws

The locking nail for the repair of femur shaft fractures, also in connection with trochanteric femur fractures, comprises a proximal nail section (2) and a distal nail section (3) adjoining the latter, with the nail sections (2, 3) having bores (2e, 2f, 2h, 2i, 3a, 3b, 3c) for the reception of bone screws, and with the distal nail section (3) having a curvature extending in an anterior-posterior plane (apE) and corresponding substantially to the antecurvature of the femur, with the proximal nail section (2) having at least over a partial section (2a, 2b) a continuous curvature, in particular with constant radius of curvature (R2), extending in a lateral-medial plane (lmE).

Owner:ZIMMER GMBH

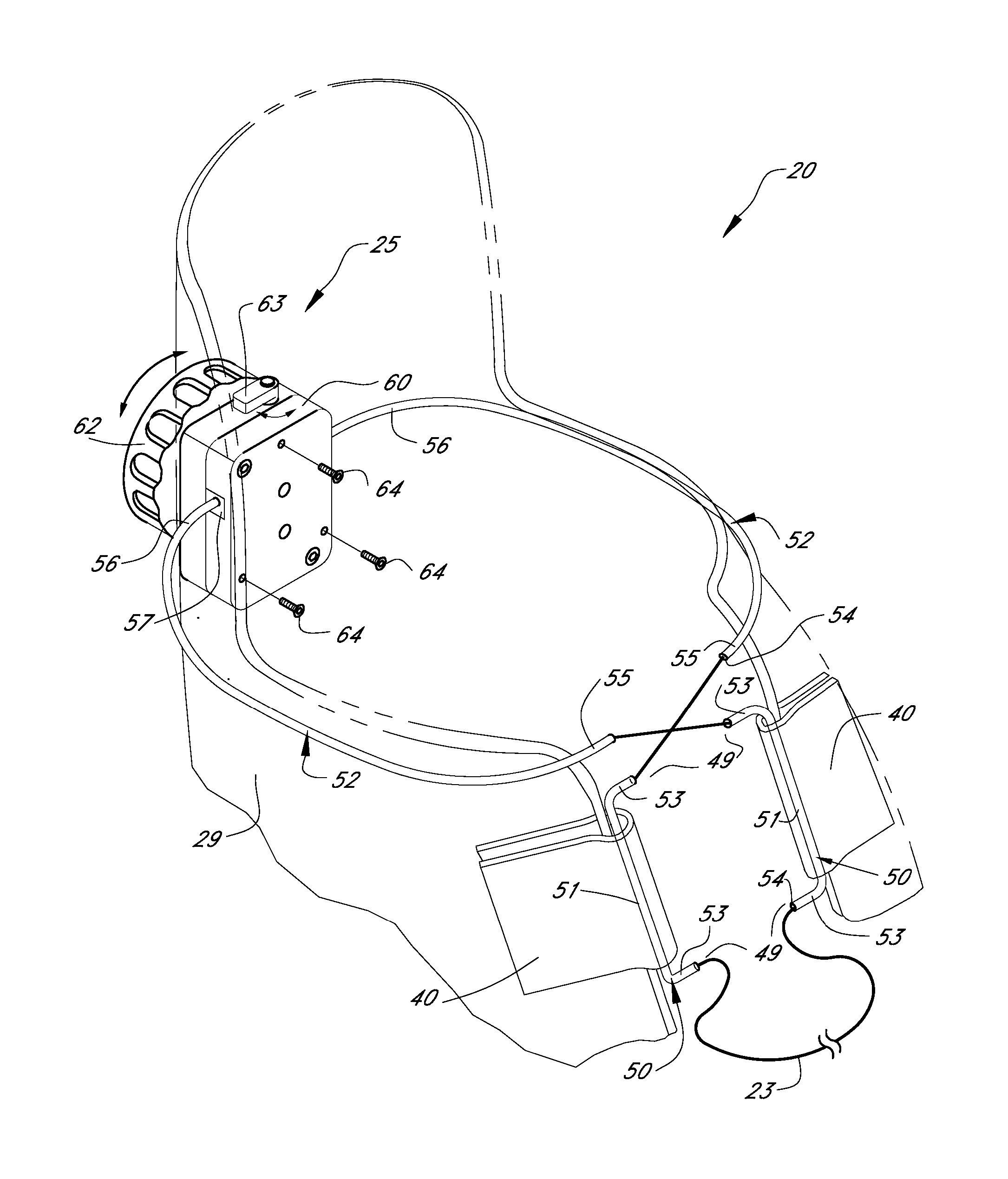

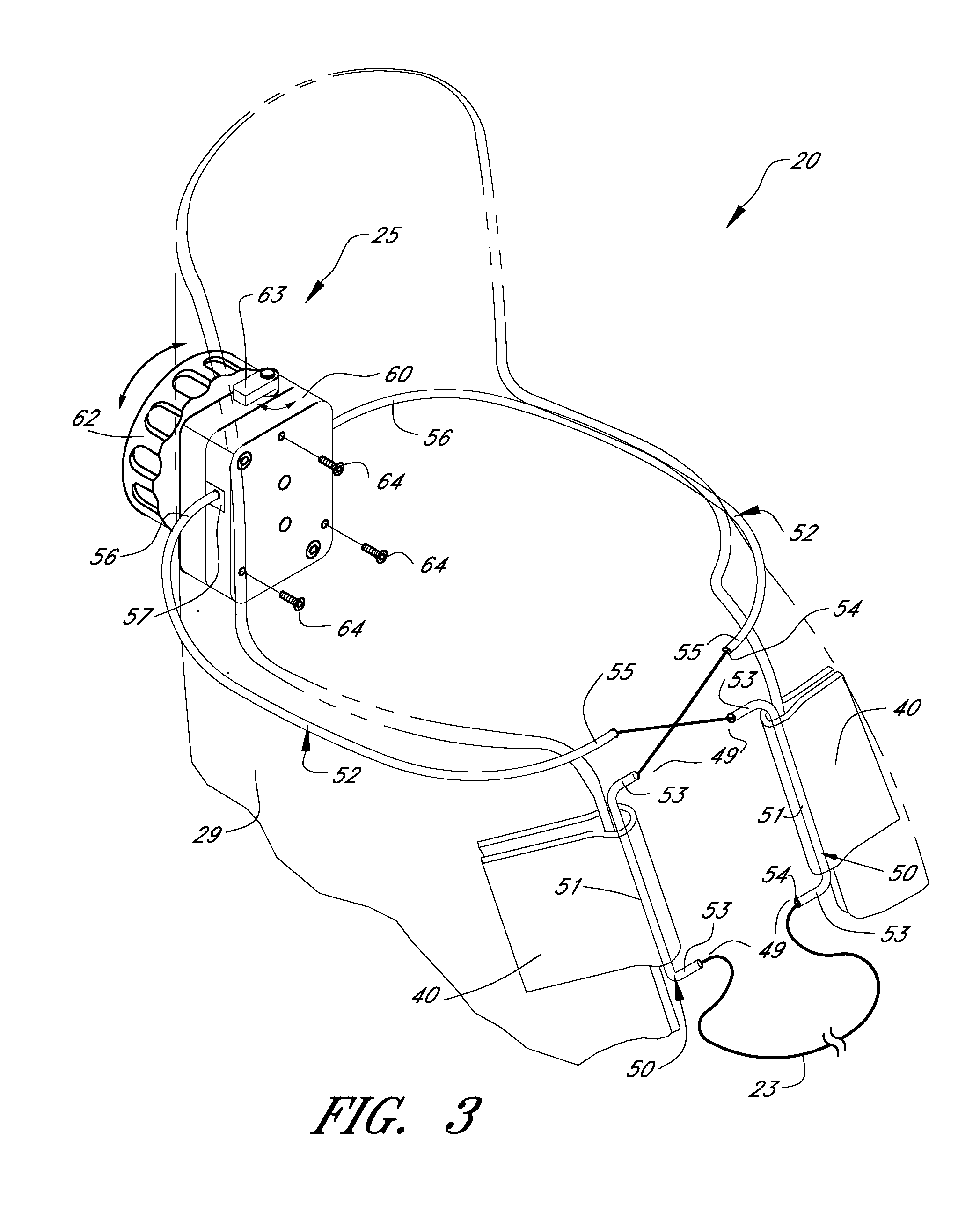

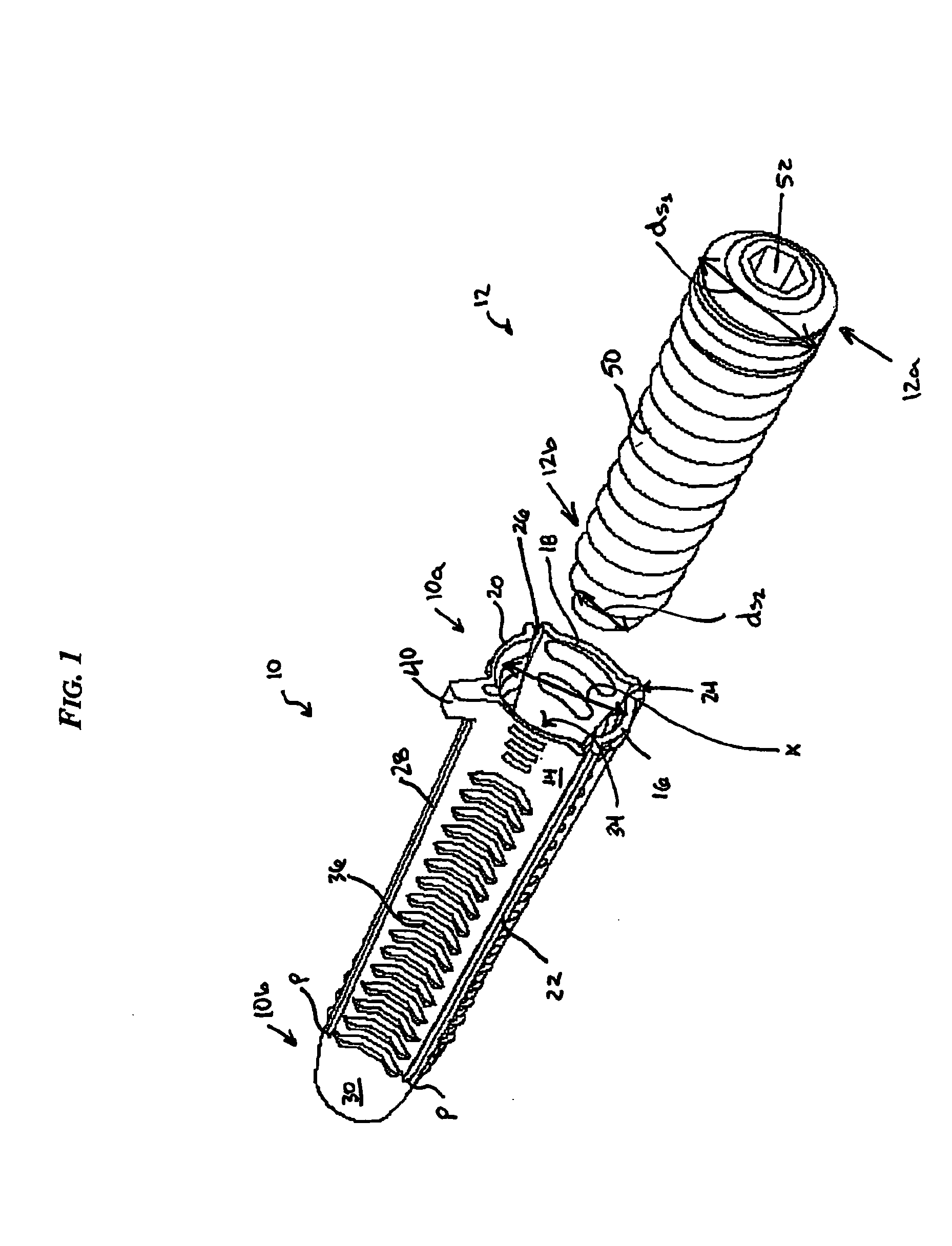

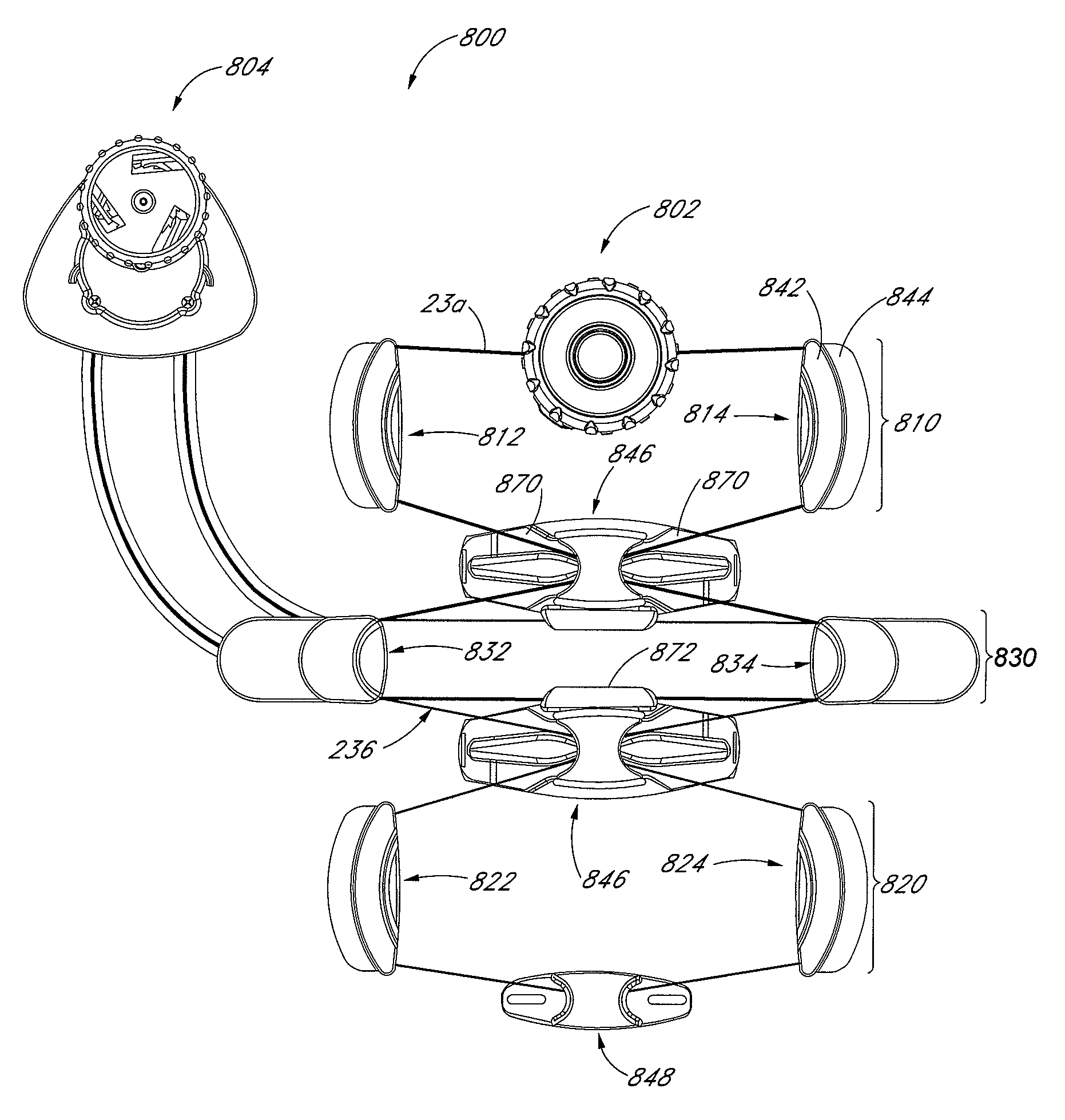

Reel based closure system

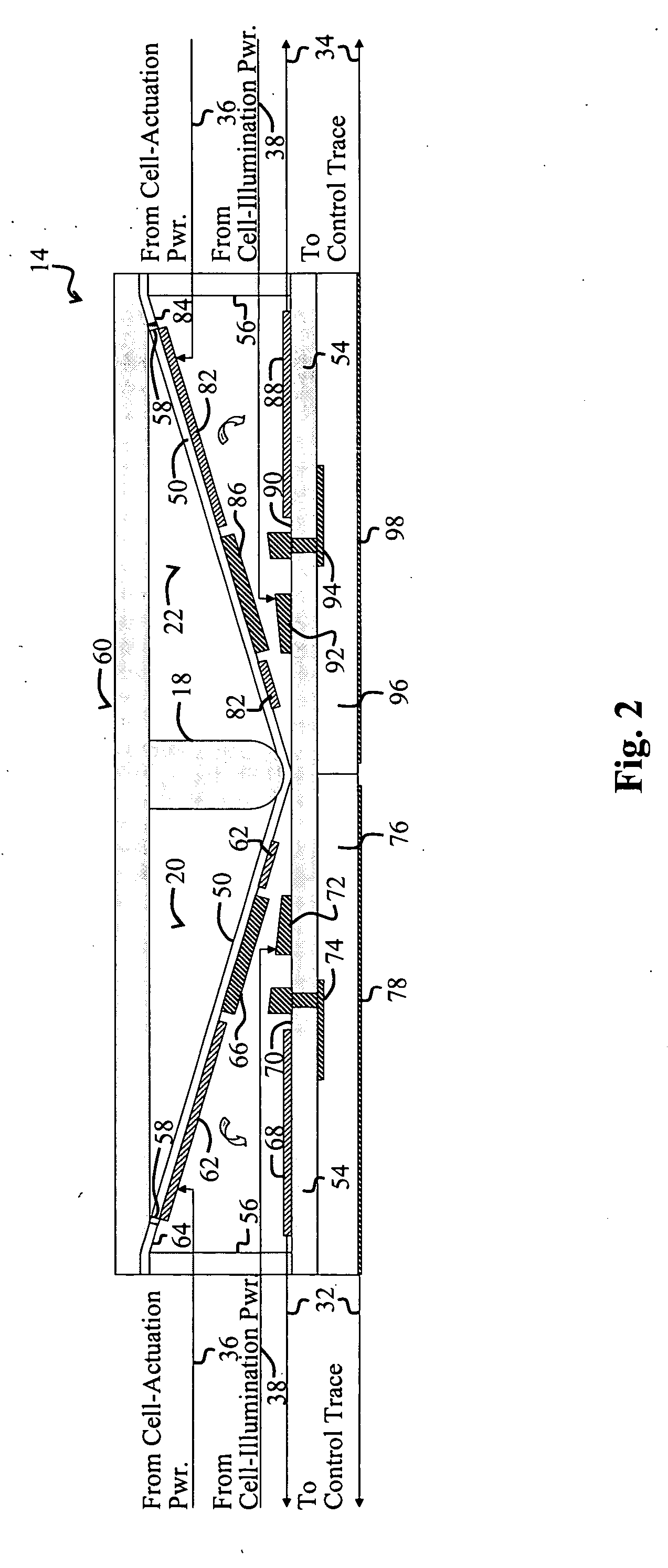

ActiveUS20100299959A1Weak elasticityHigh tensile strengthSnap fastenersShoe lace fasteningsEngineeringMechanical engineering

Disclosed is a closure system used in combination in any of a variety of applications including clothing, for example as a footwear lacing system comprising a lace attached to a tightening mechanism. The lace extends through a series of guide members positioned along two opposing footwear closure portions. The lace and guides preferably have low friction surfaces to facilitate sliding of the lace along the guide members so that the lace evenly distributes tension across the footwear member. The tightening mechanism allows incremental adjustment of the tension of the lace. The closure system allows a user to quickly loosen the lace and inhibits unintentional and / or accidental loosing of the lace.

Owner:BOA TECHNOLOGY

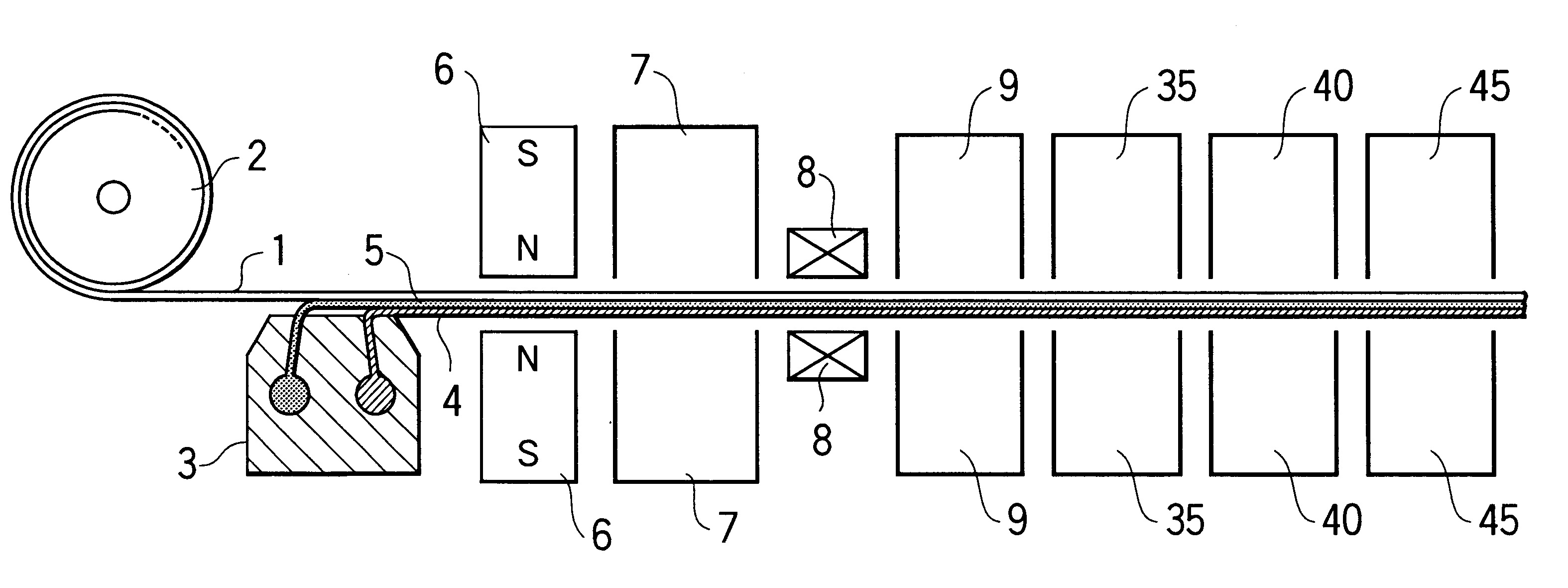

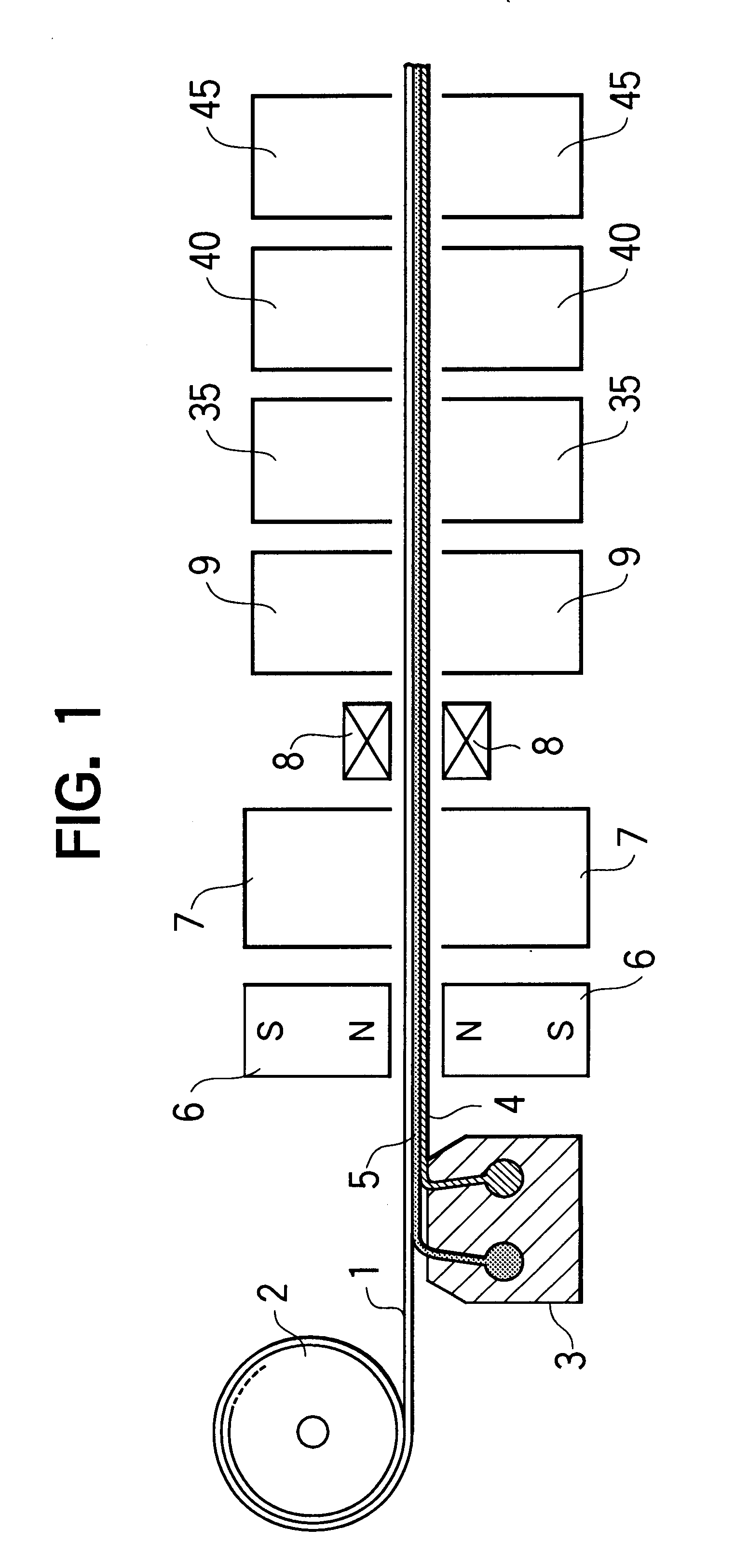

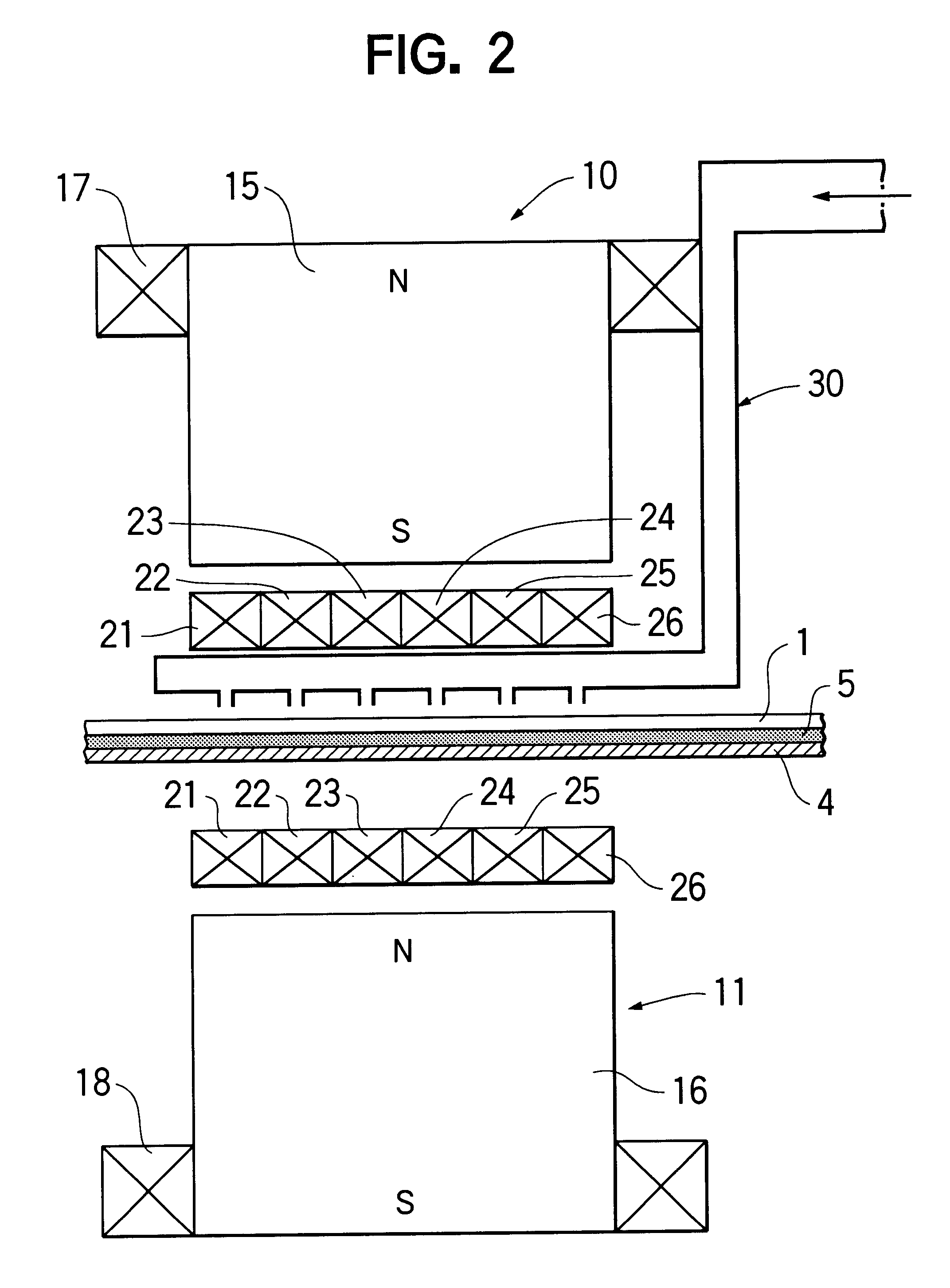

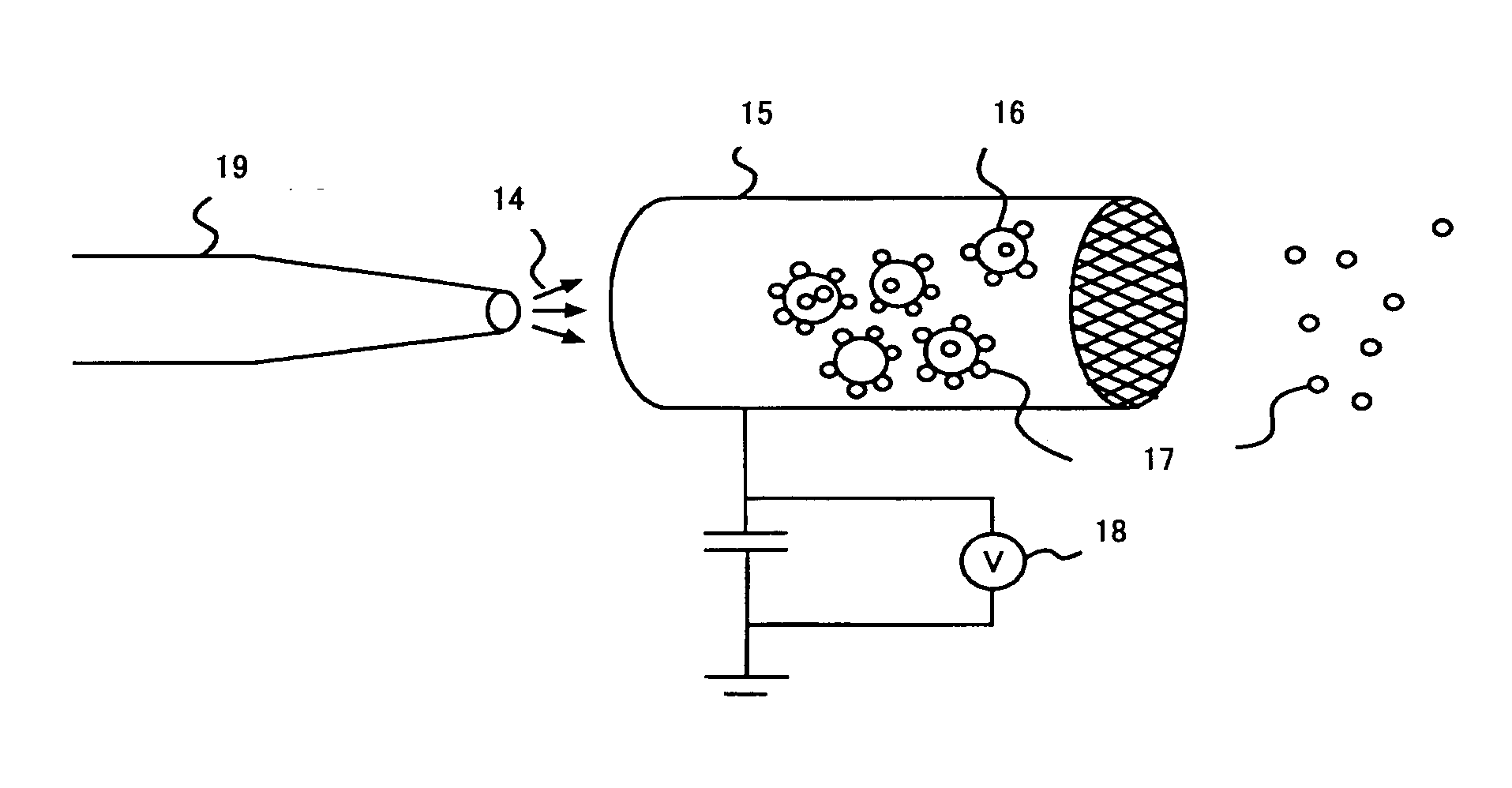

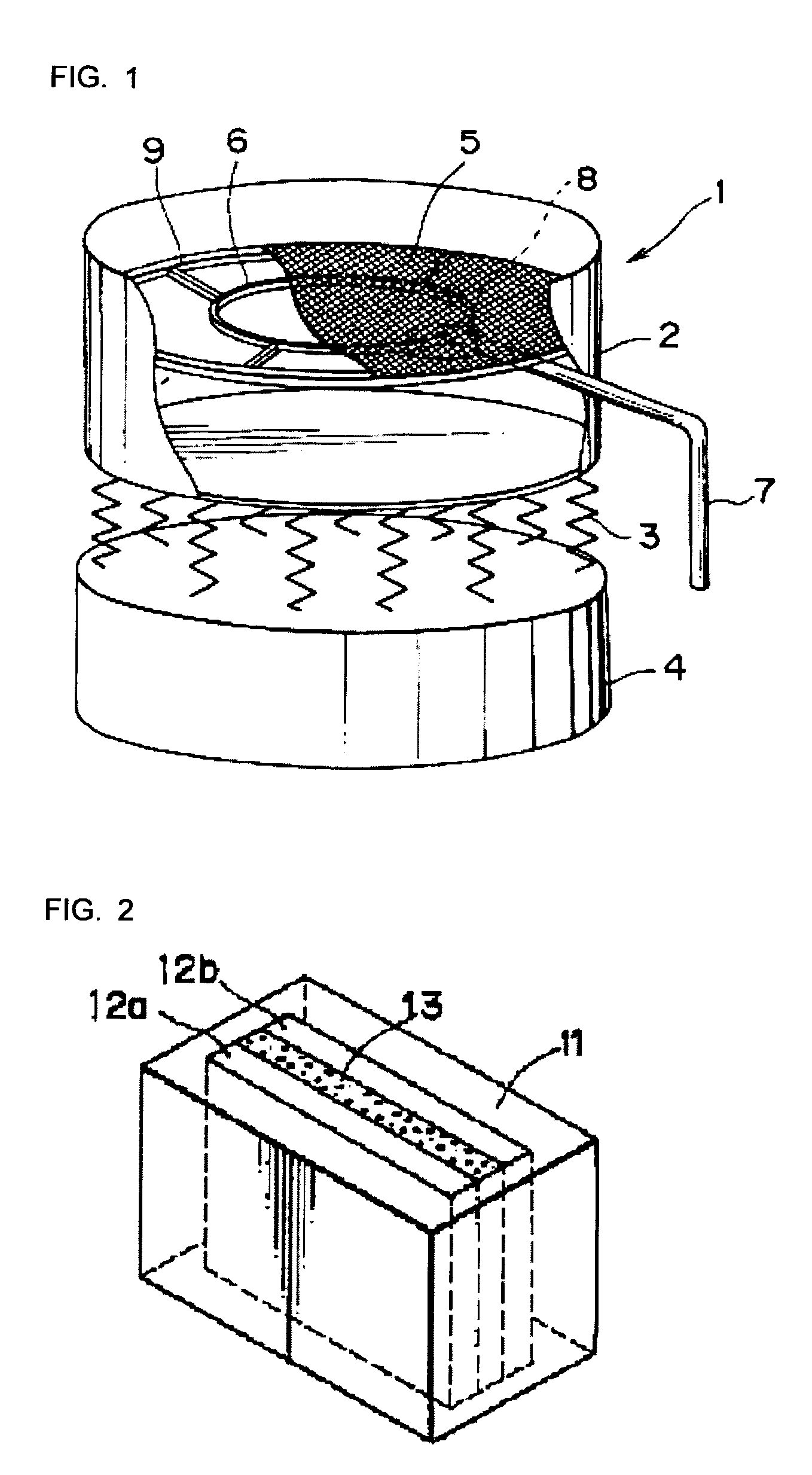

Method and apparatus for manufacturing magnetic recording medium

InactiveUS6261647B1Raise the ratioIncreased durabilityCoating by liquid dispersionMagnetic materialsEngineeringNon magnetic

A method for manufacturing a magnetic recording medium includes steps of forming a magnetic layer containing magnetic powder particles on a web-like non-magnetic support being continuously transported in one direction and applying a magnetic field to the magnetic layer by a plurality of magnets in such a manner that an angle of the magnetic field applied to the magnetic layer to the transporting direction of the non-magnetic support in a plane perpendicular to a surface of the magnetic layer and parallel to the transporting direction of the non-magnetic support gradually increases in the transporting direction of the non-magnetic support, thereby orienting the magnetic powder particles in an oblique direction with respect to the surface of the magnetic layer. According to this method, it is possible to orient magnetic powder particles in a desired direction with respect to the surface of a magnetic layer and to manufacture a magnetic recording medium having a high squareness ratio without increasing the size of the apparatus.

Owner:FUJIFILM CORP +1

Reel based closure system

ActiveUS8381362B2Weak elasticityHigh tensile strengthSnap fastenersShoe lace fasteningsMechanical engineeringLow friction

Owner:BOA TECHNOLOGY

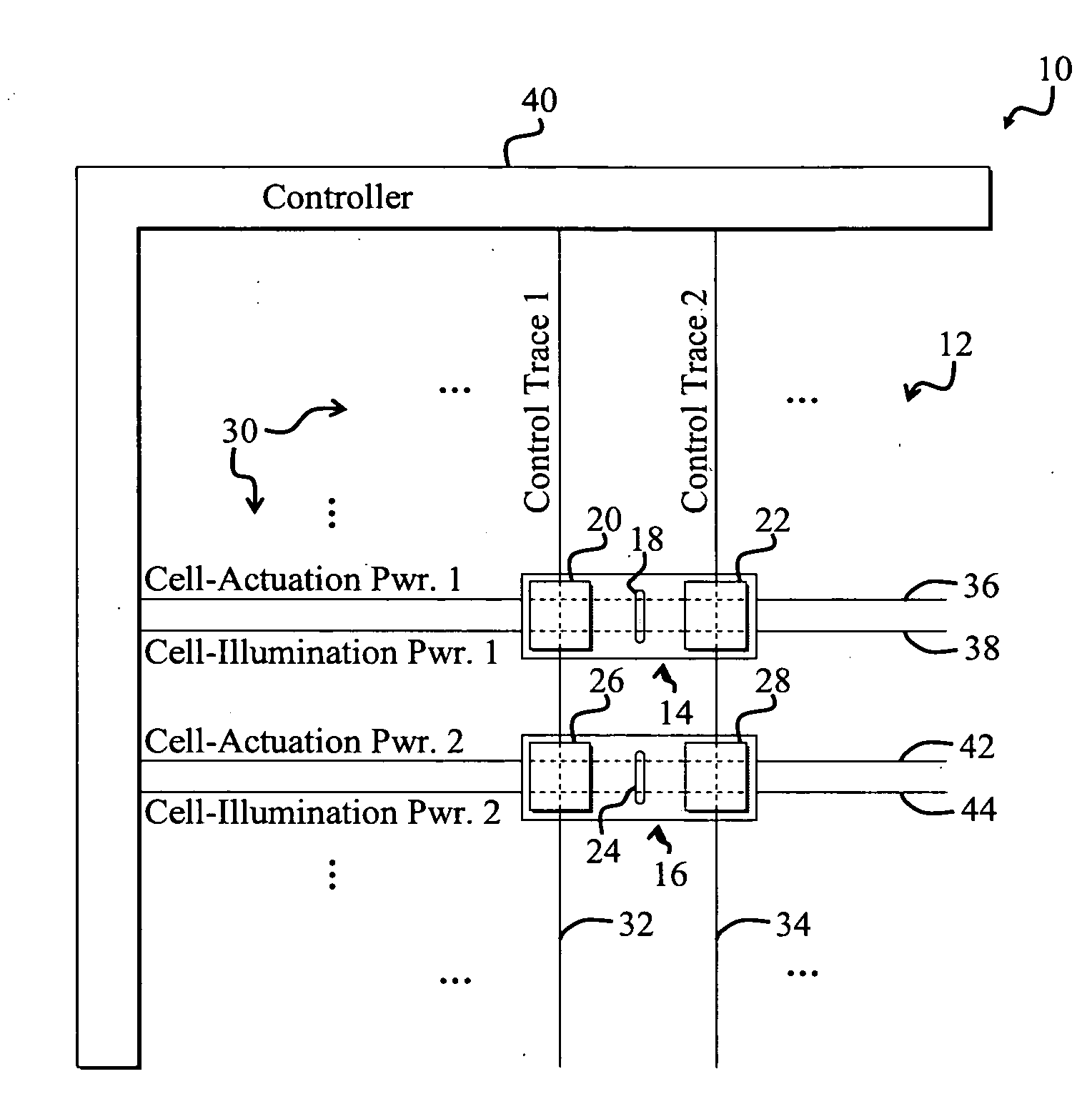

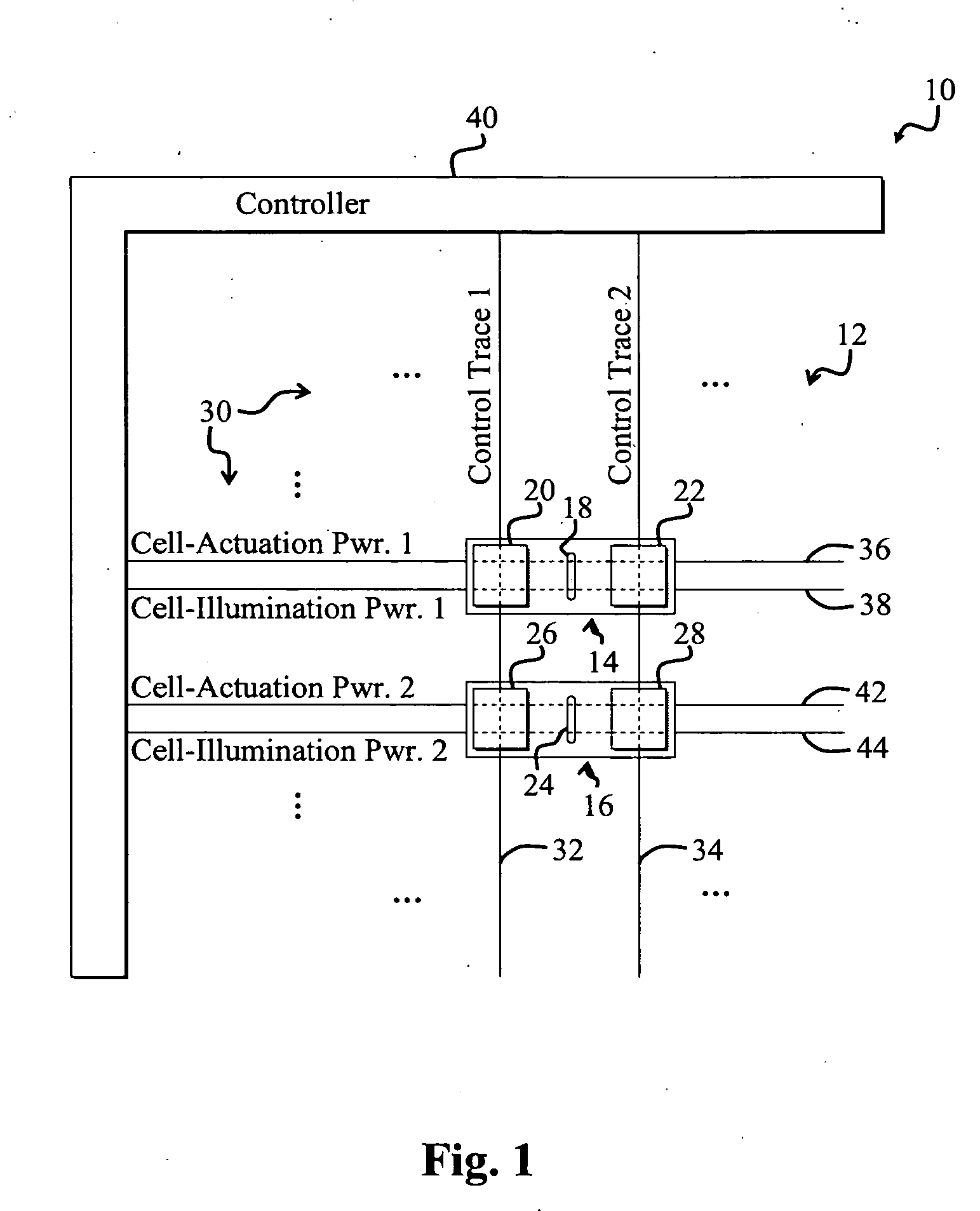

Picture element using microelectromechanical switch

InactiveUS20060202933A1Quality improvementImproved off-axis contrast contrastElectrostatic/electro-adhesion relaysStatic indicating devicesDisplay deviceEngineering

A robust microelectromechanical switch. In an illustrative embodiment, the switch is adapted for use in a display and includes a first flexible surface and a second surface. The second surface is angled relative to the first surface, forming a wedge the first surface and the second surface. A first terminal and a second terminal are positioned relative to the first flexible surface and the second surface so that selective flexing of the flexible surface electrically couples or uncouples the first terminal to the second terminal. In a more specific embodiment, the switch further includes a first mechanism for selectively applying an electrostatic force between the first flexible surface and the second surface. The first surface is positioned on a first elastic flexible layer, and the second surface is positioned on a second layer. The first mechanism includes a first actuator electrode that is coupled to the first surface, and a second actuator electrode that is coupled to the second surface. A sufficient charge differential applied between the first actuator electrode and the second actuator electrode will attract the first electrode to the second electrode, thereby flexing the flexible layer toward the second layer. The sidewalls define a perimeter of a cell that houses the switch. A protrusion extends from a third layer between the sidewalls, thereby indenting the first layer, and thereby forming the wedge.

Owner:SEERTECH CORP

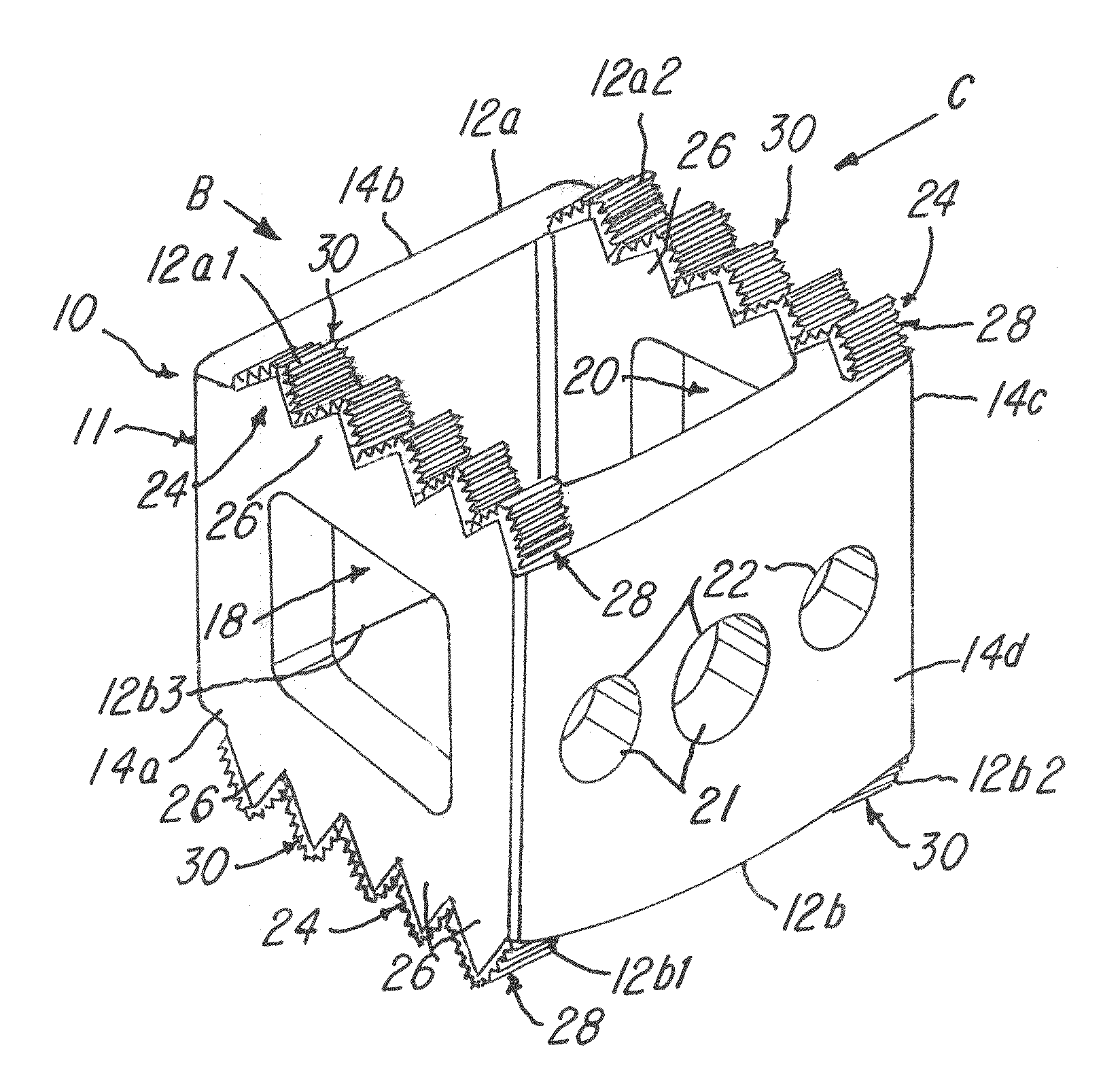

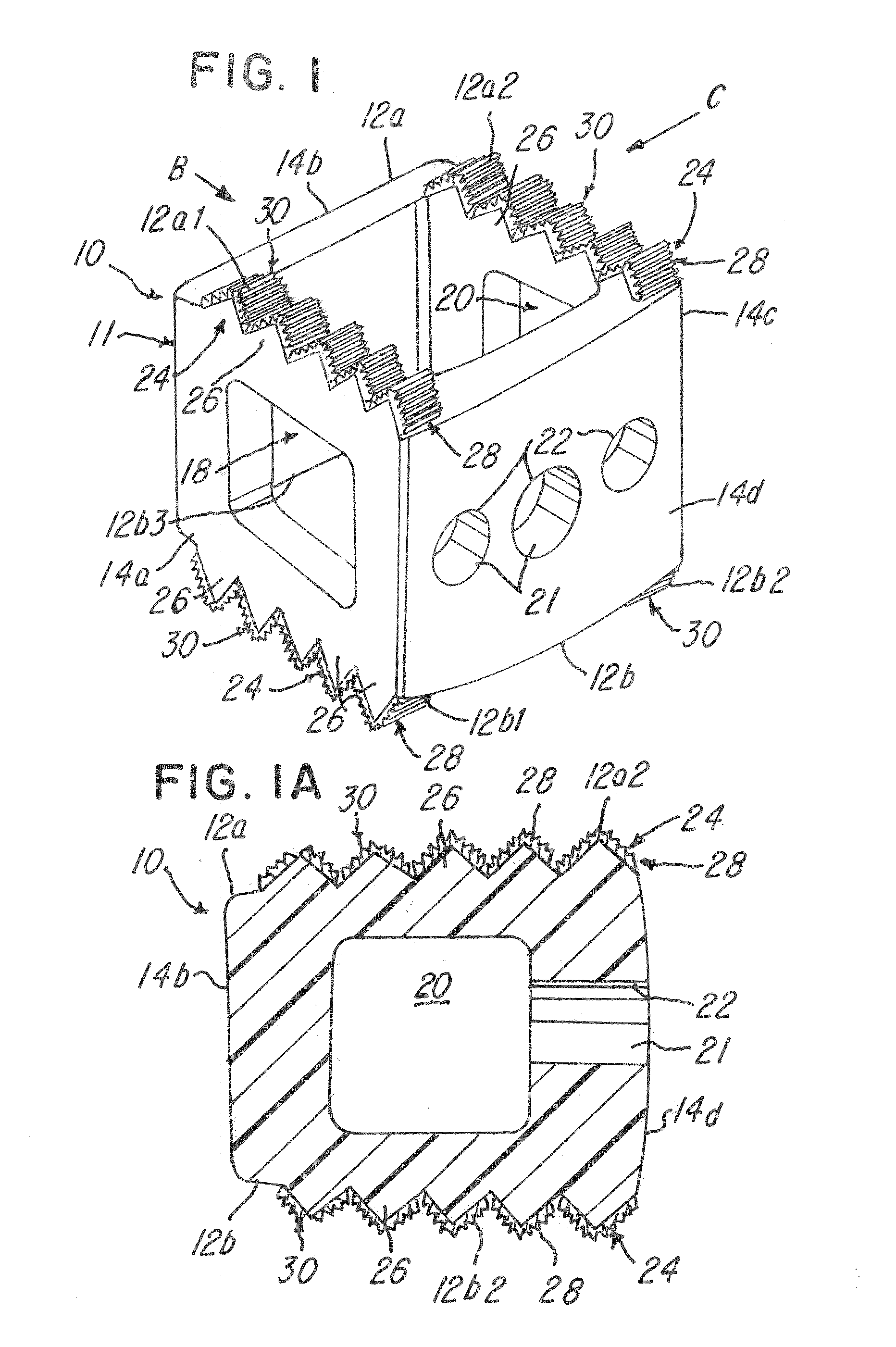

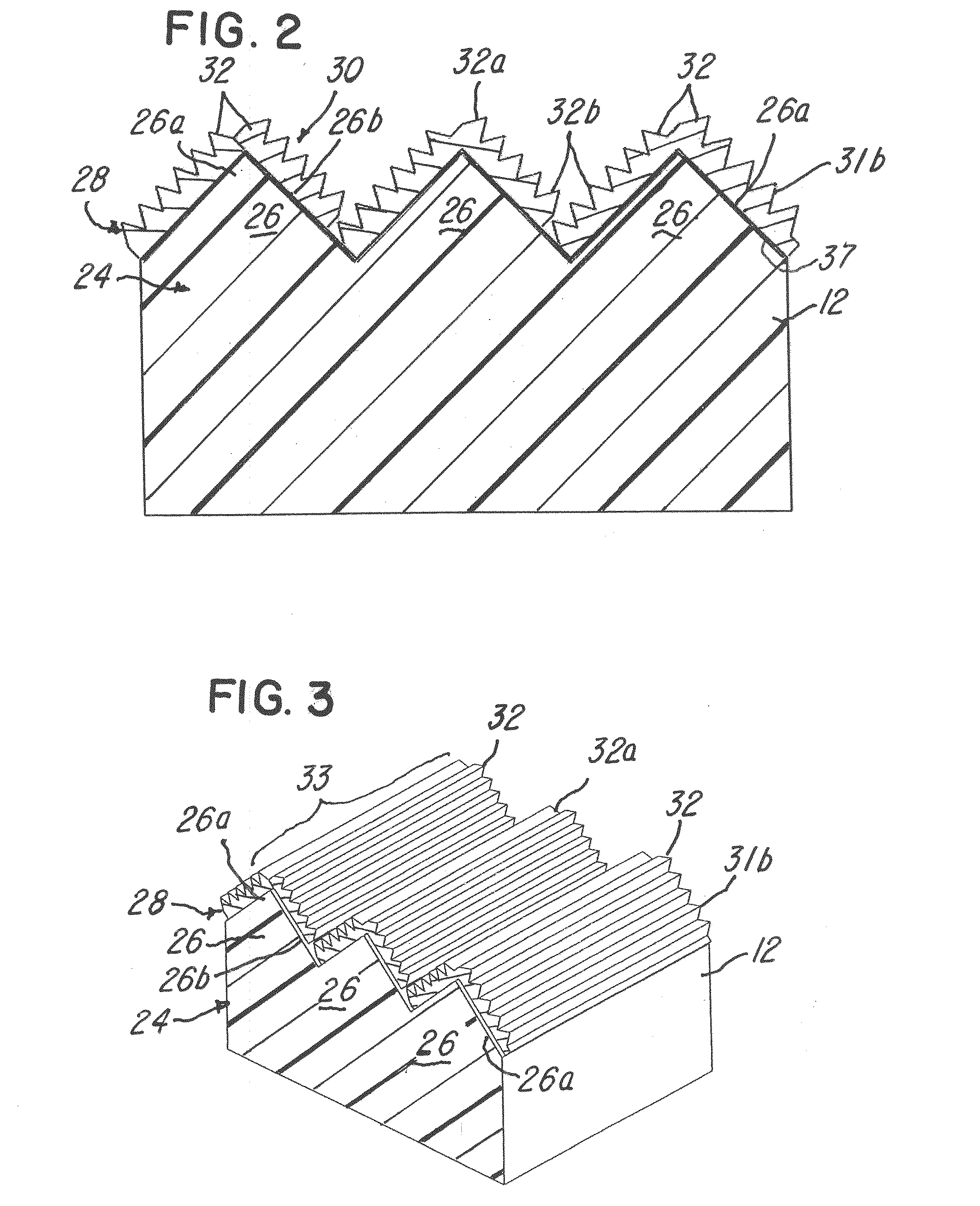

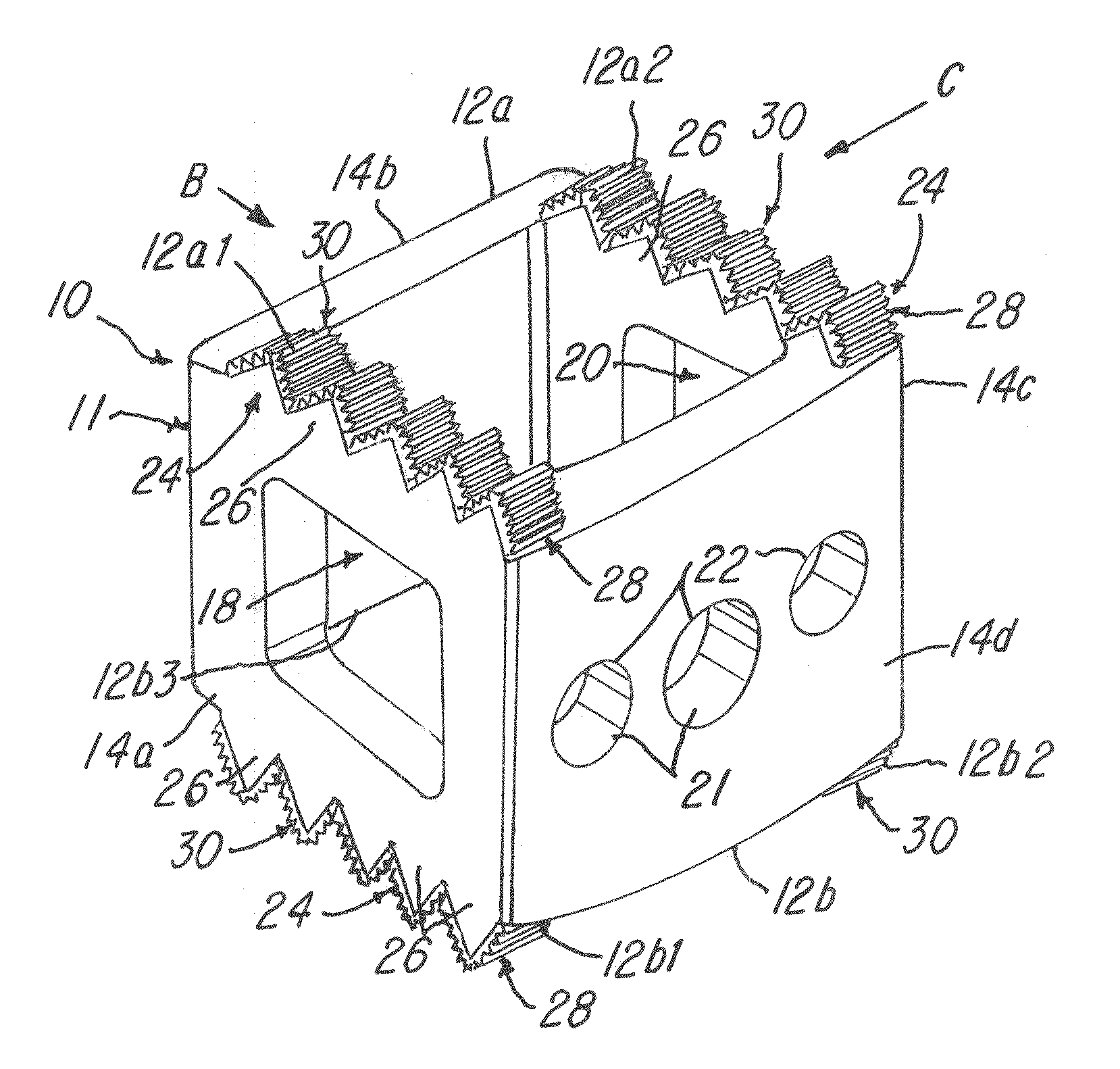

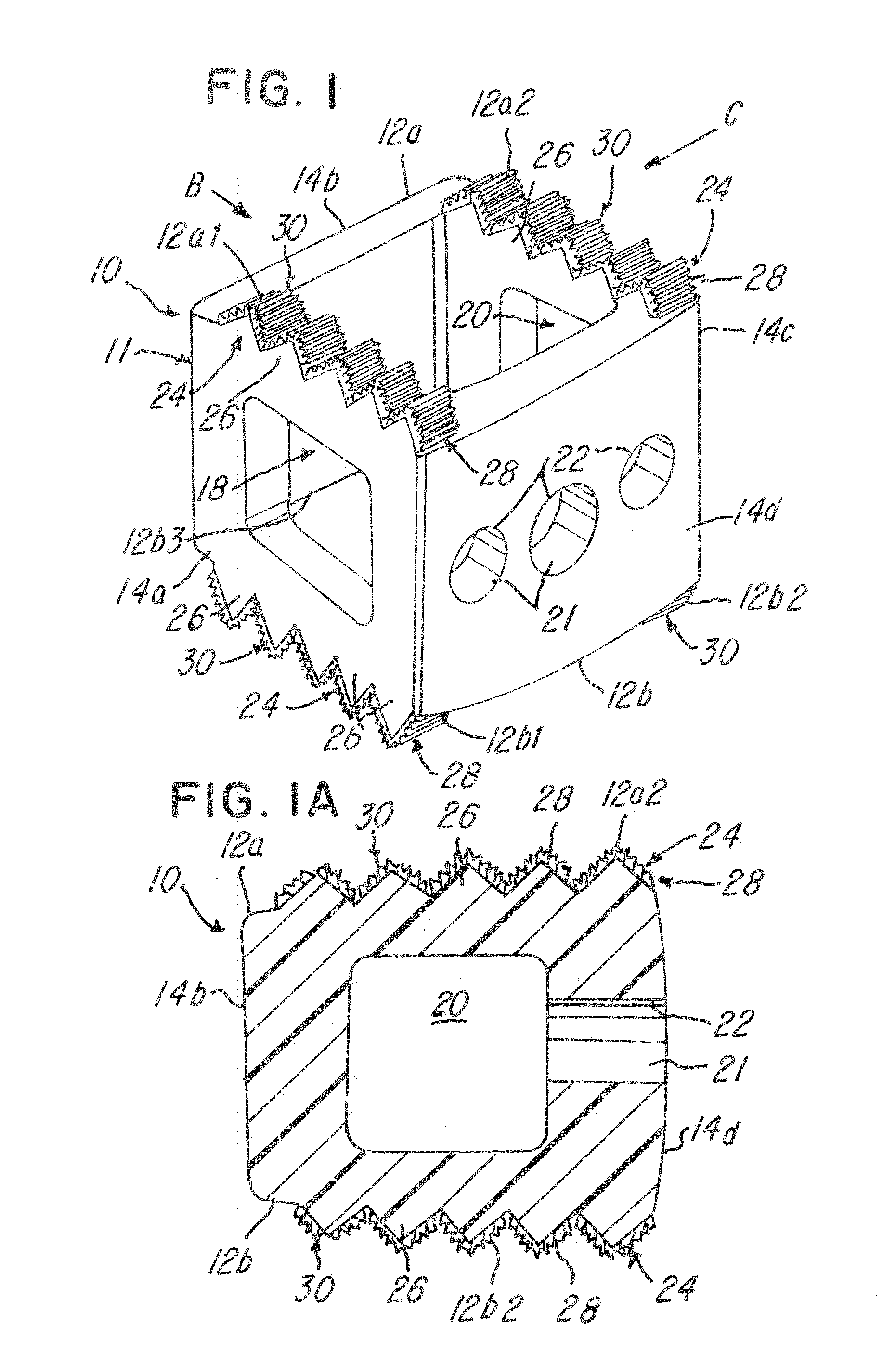

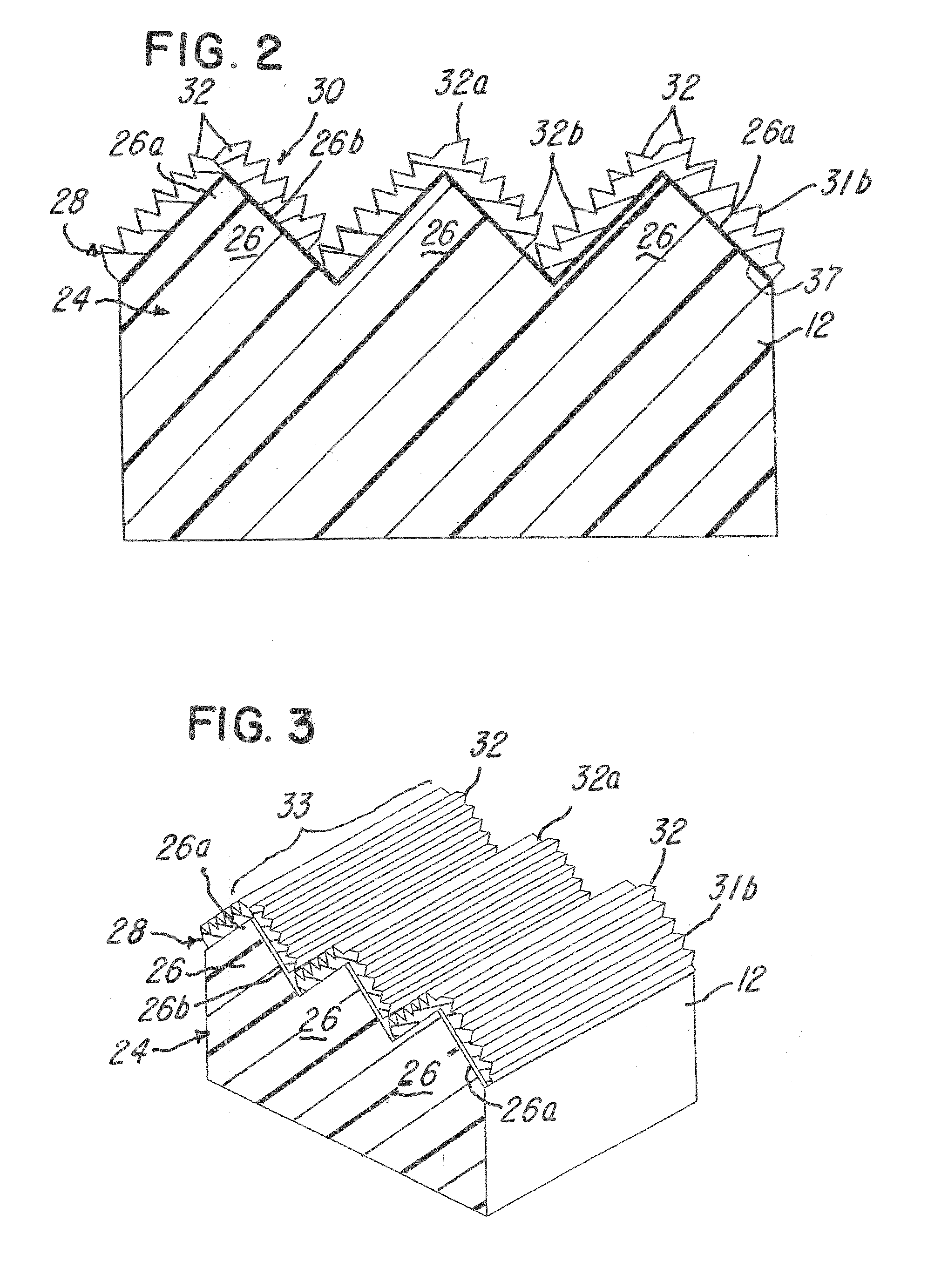

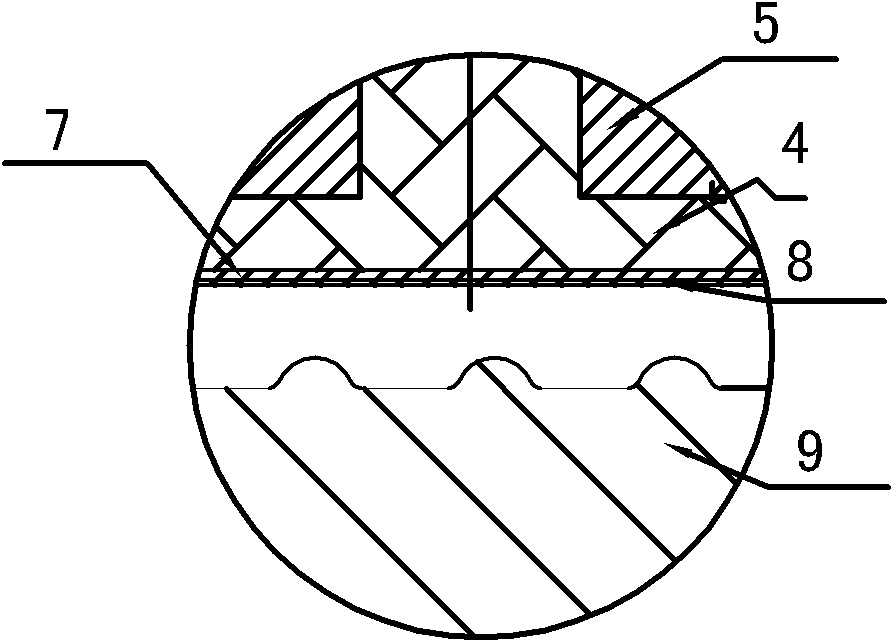

Composite orthopedic implant having a low friction material substrate with primary frictional features and secondary frictional features

ActiveUS20140128980A1Reduce lubricationSimple featuresImpression capsPretreated surfacesSurgical implantPlastic surgery

An orthopedic implant comprising a substrate material adapted to provide the orthopedic implant. The implant has a primary friction area located on or integral with the substrate material. The primary friction area defining an engagement surface having a primary frictional feature. A secondary friction area is located on or integral with the engagement surface and defining a second frictional feature. The primary friction area and the secondary friction area defining a friction interface zone between the orthopedic implant and at least one bone. The secondary friction area increases a friction of the engagement surface and modulus of elasticity to enhance the frictional engagement between the engagement surface and the at least one bone.

Owner:X SPINE SYST

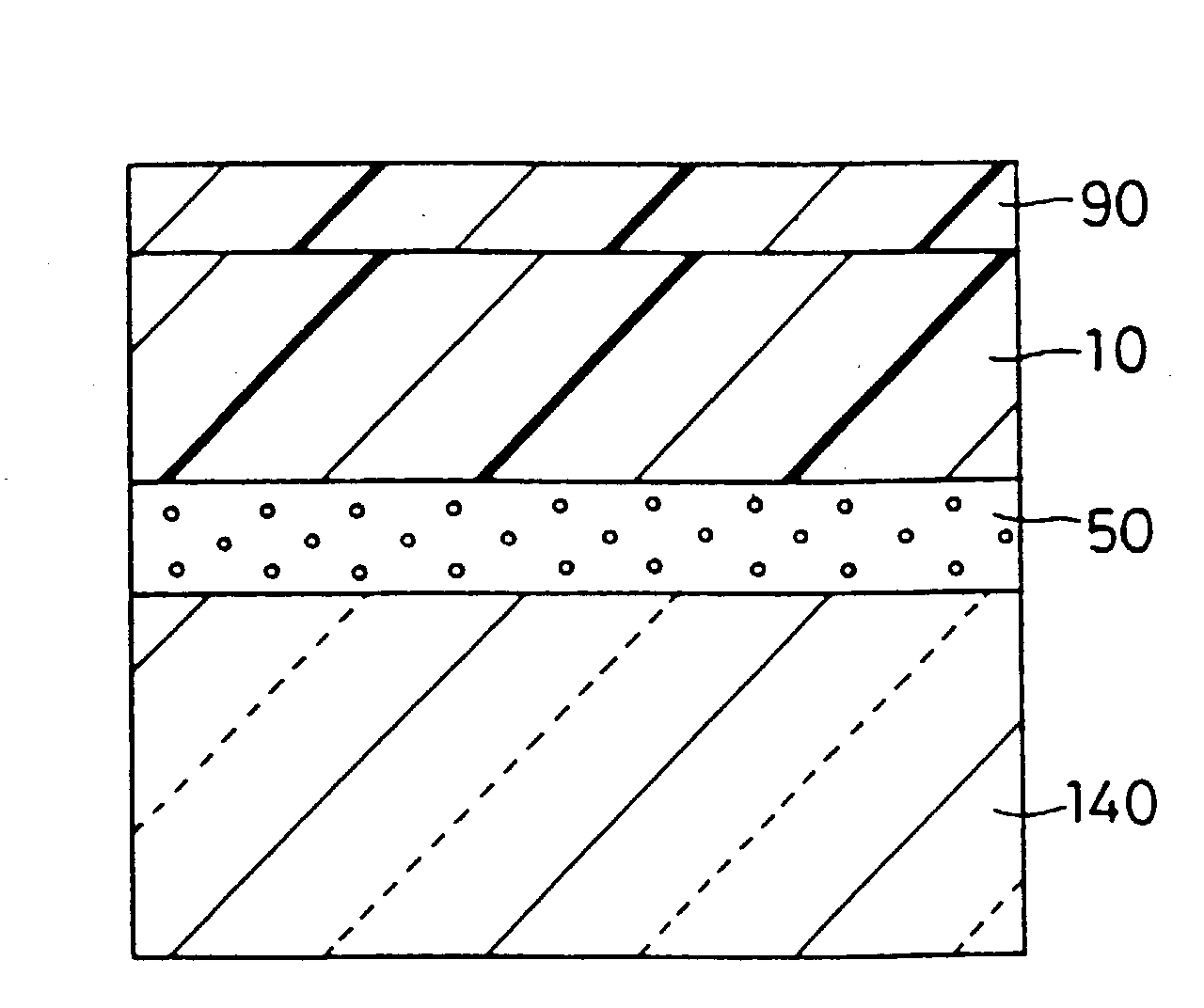

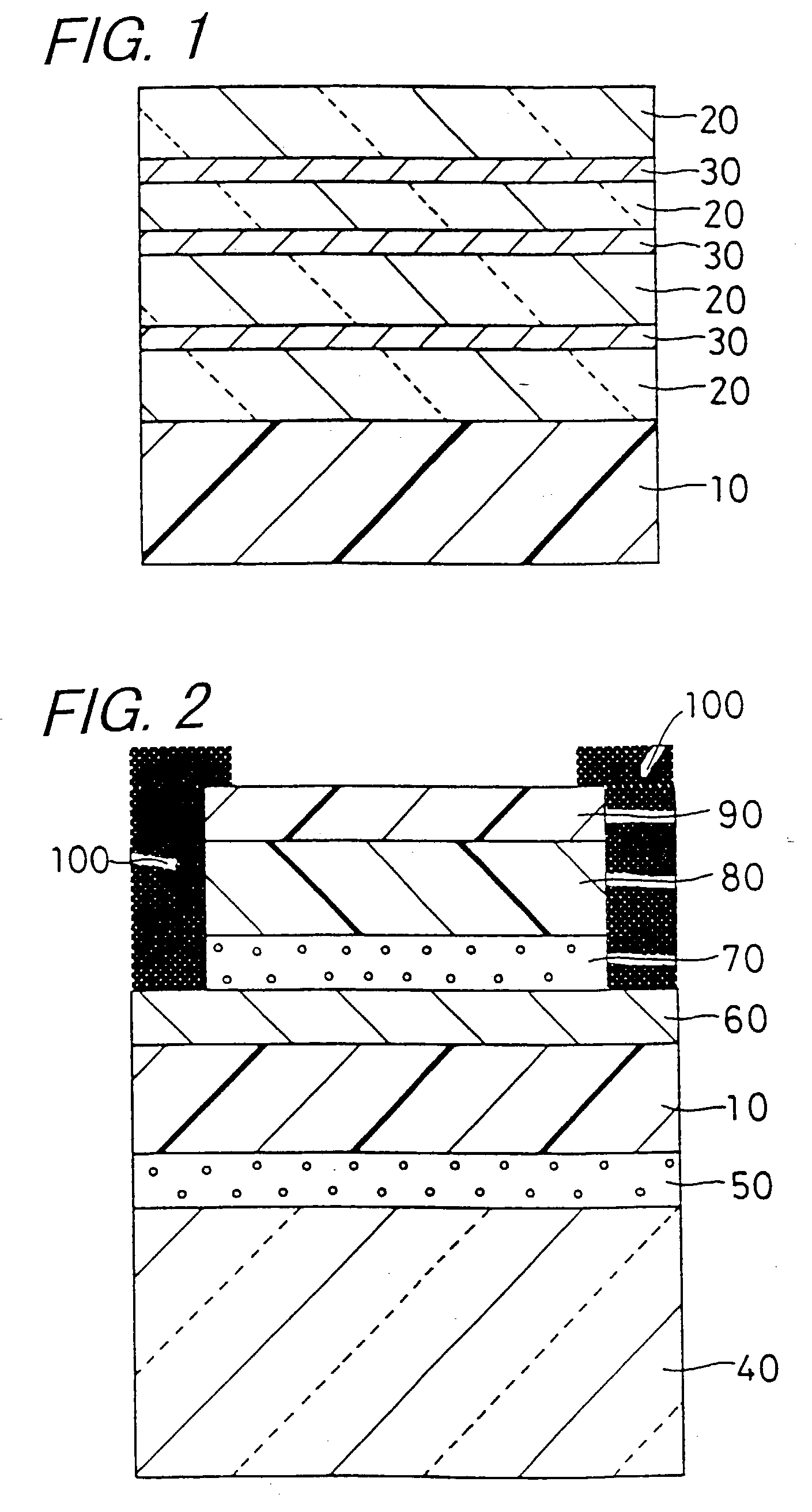

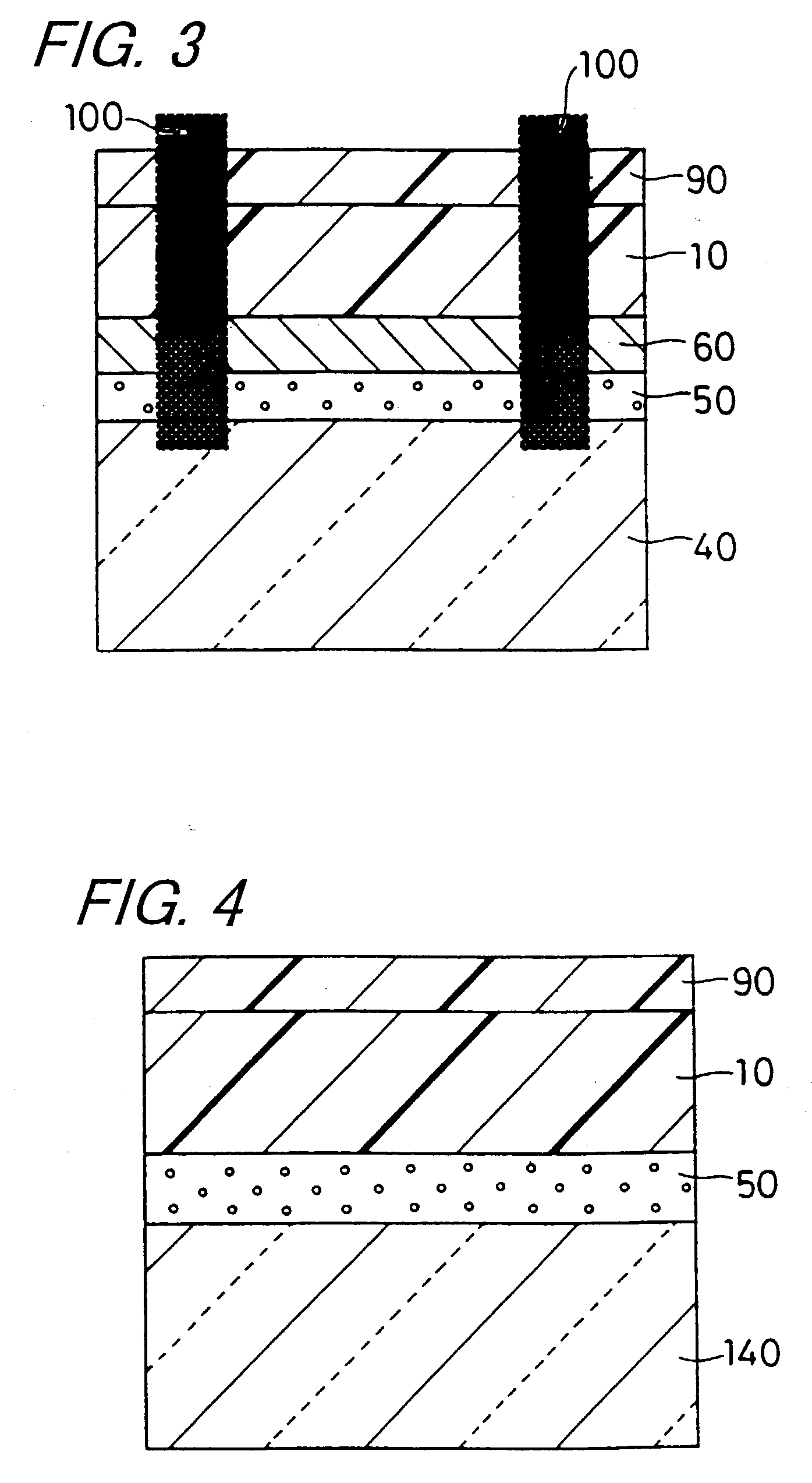

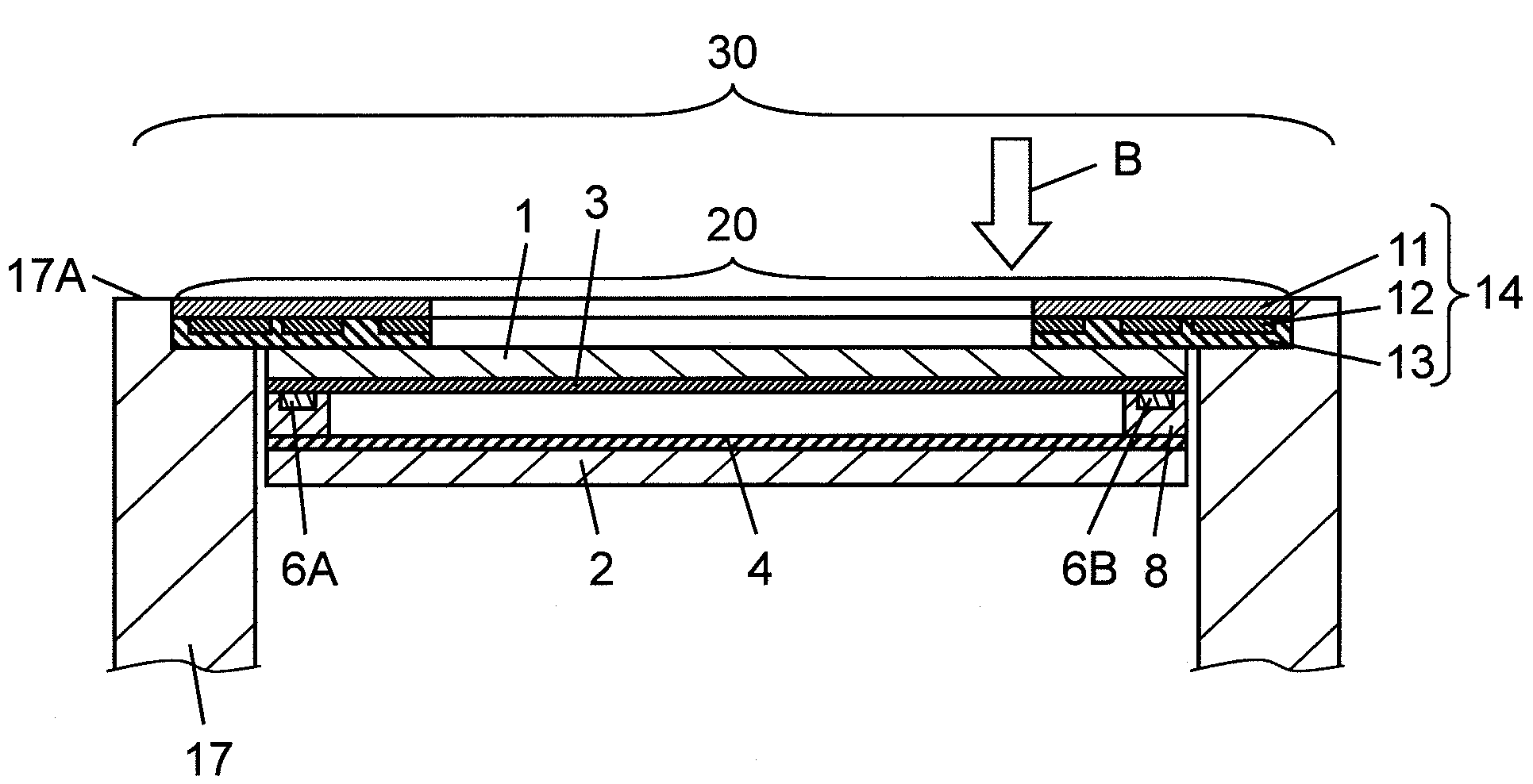

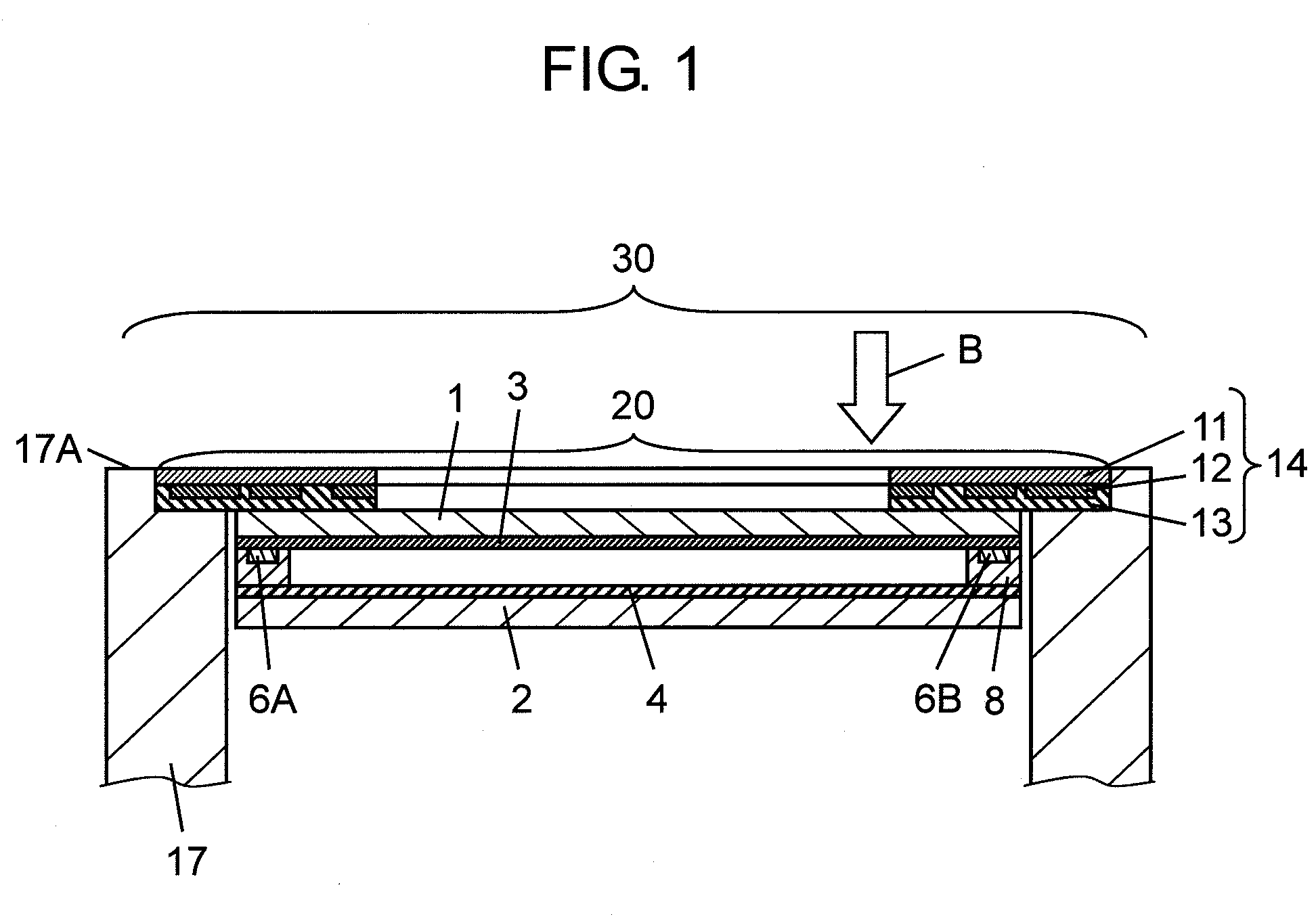

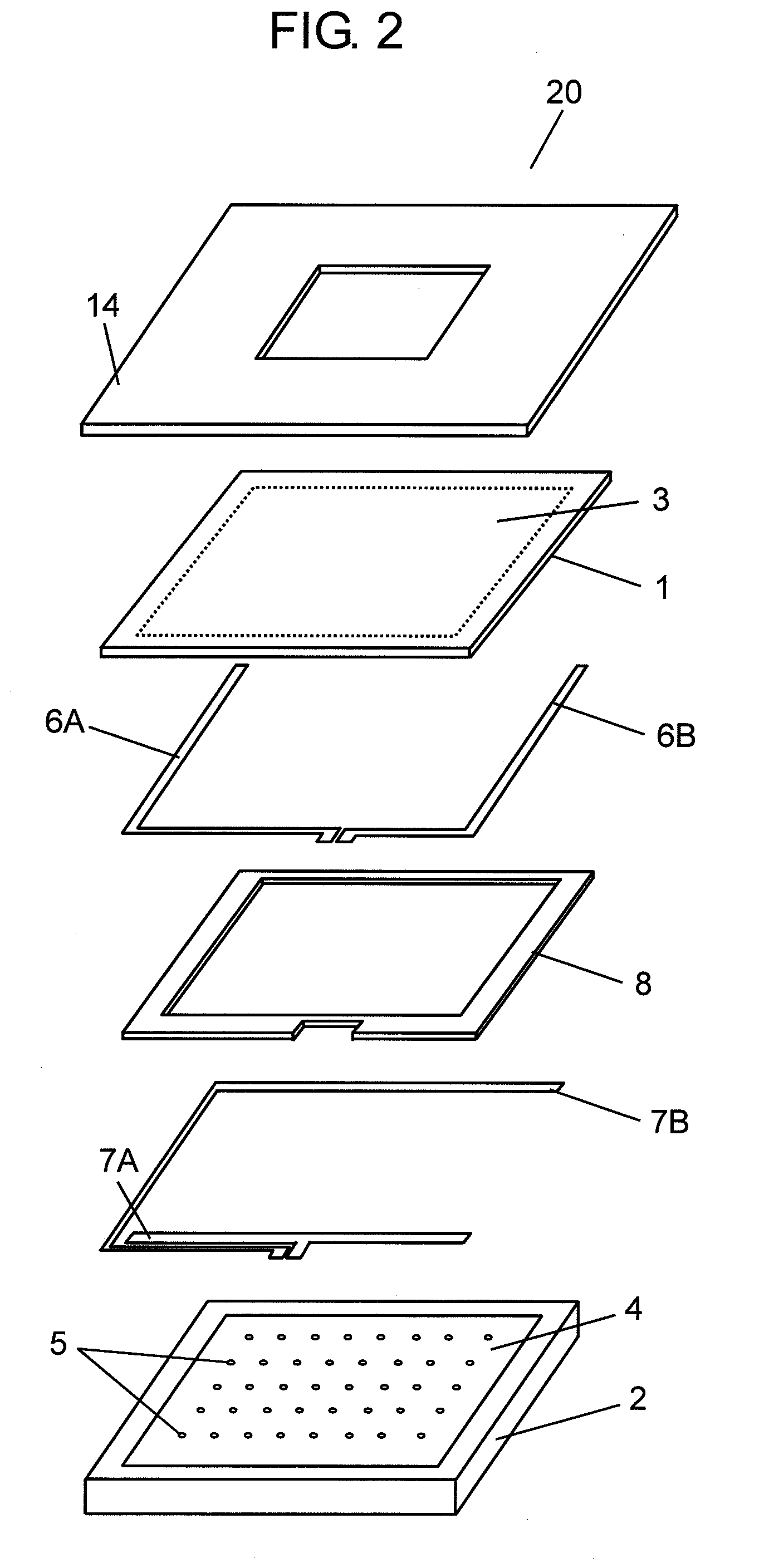

Laminate body and display device using the laminated body

InactiveUS20030176124A1Reduce deteriorationWeak elasticityCathode ray tubes/electron beam tubesMagnetic/electric field screeningDisplay deviceYoung's modulus

A laminate which can easily attain safety standards such as impact resistance, while cost reduction is aimed for, for example, when the laminate is provided on a display viewing surface, and a display apparatus using this laminate are provided. By using a filter for a display having a specified parameter and a specified thickness, the impact resistance is enhanced. By using the filter for the display containing a transparent adhesive layer having a specified Young's modulus and a specified thickness, the impact resistance is enhanced. By using the filter for the display containing a transparent resin layer having a specified Young's modulus and a specified thickness, the impact resistance is enhanced. By using the filter for the display containing an impact absorption layer having a specified penetration and a specified thickness, the impact resistance is enhanced.

Owner:MITSUI CHEM INC

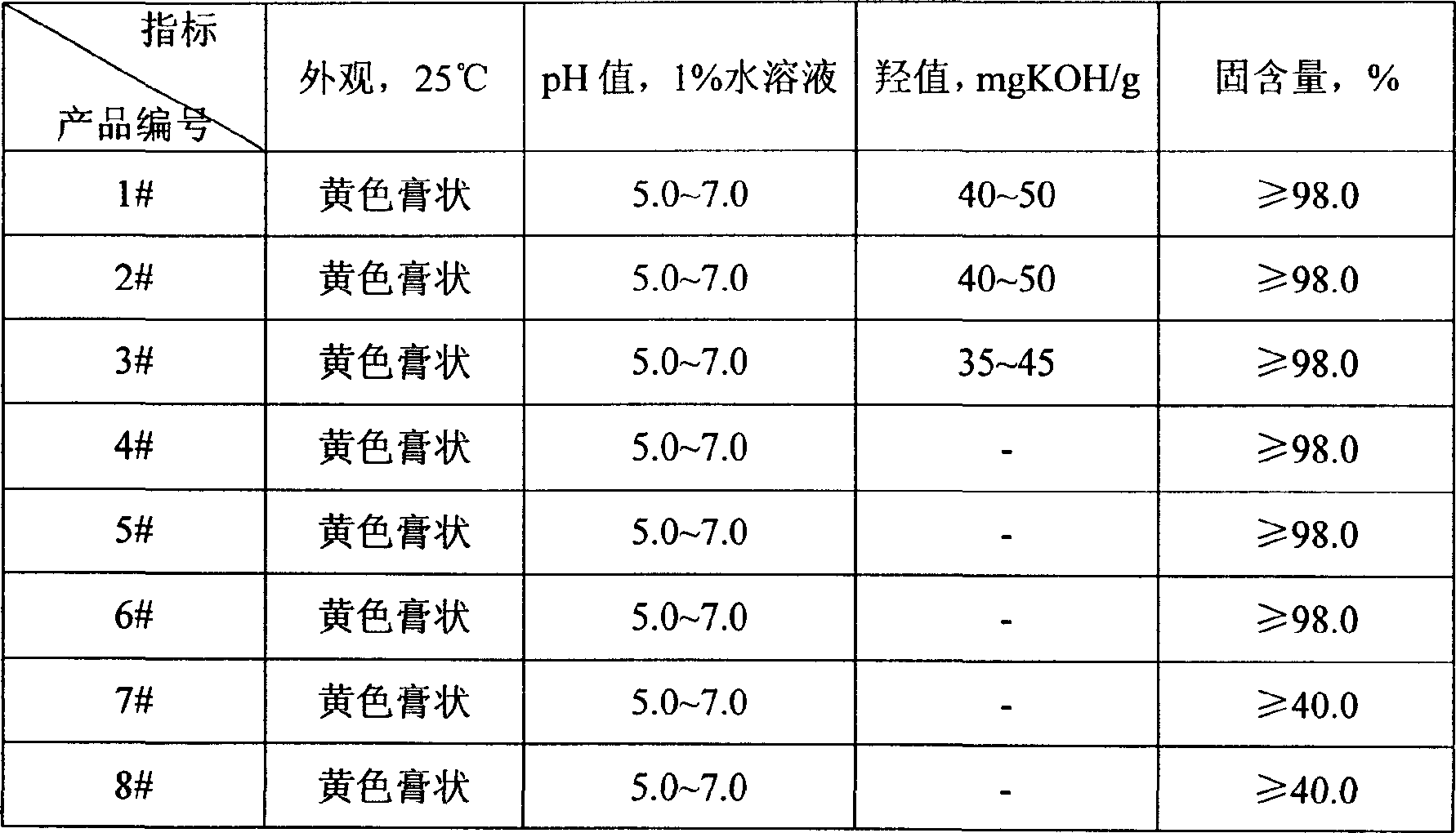

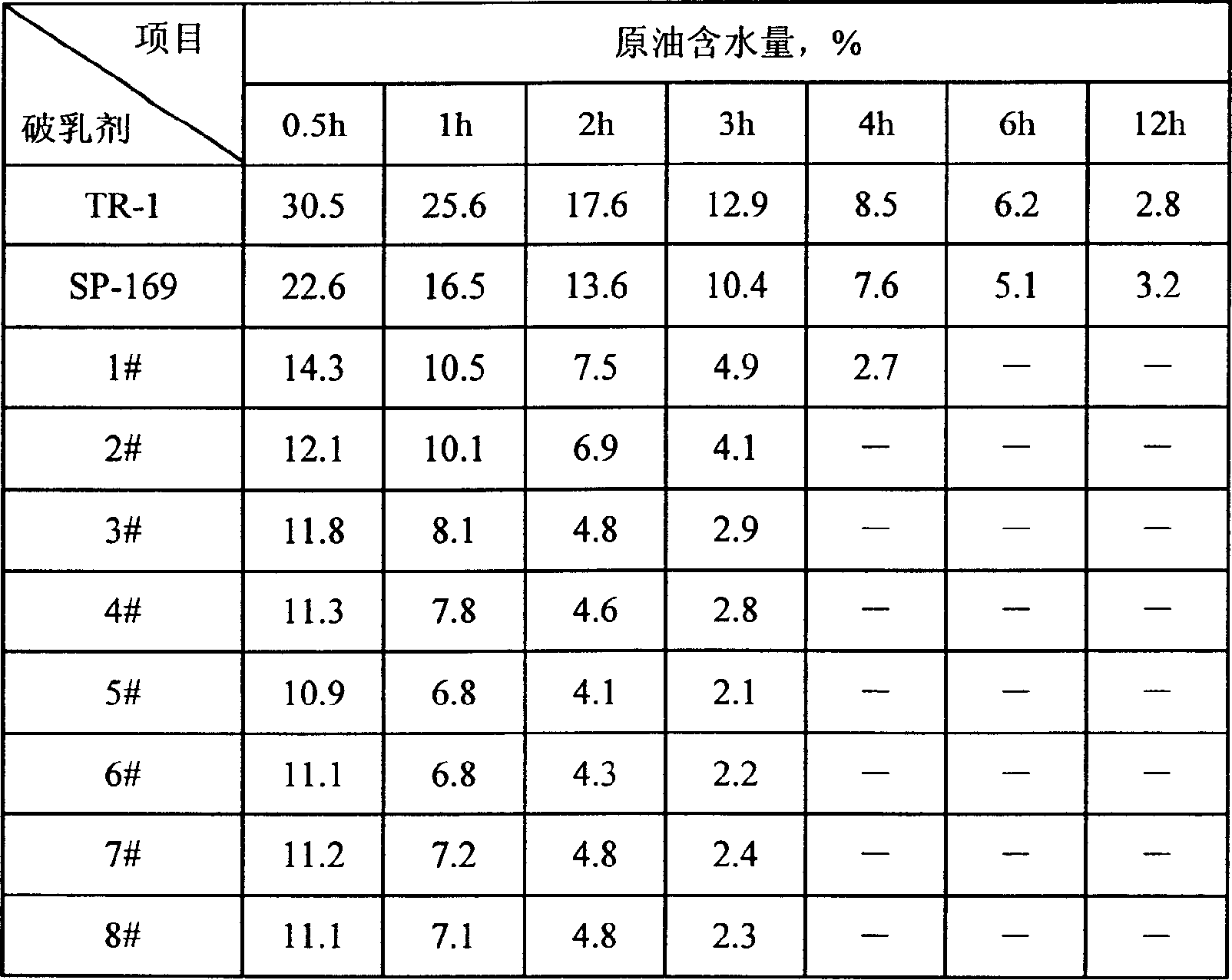

Thick oil demulsifier and its prepn

ActiveCN1810933ALow densityIncrease viscosityHydrocarbon oil dewatering/demulsificationEpoxyDemulsifier

The present invention is one kind of thick oil demulsifier and its preparation process, and belongs to the field of petrochemical technology. The present invention features that phenol-amine resin as the initial material is block polymerized with epoxy propane ad epoxy ethane under the action of catalyst to obtain stereo netted macromolecular polyether as the thick oil demulsifier. The polyether as the thick oil demulsifier may be further chain expanded for even high demulsifying effect. The thick oil demulsifier can reach the oil-water interface fast to lower the elasticity and viscosity of the interface film, speed the aggregation of liquid drops and demulsify effectively. The thick oil demulsifier has simple preparation process, is suitable for industrial production, and may be used in the efficient dewatering of oil field produced liquid with different water contents.

Owner:LIAONING OXIRANCHEM INC

Total-biodegradation plastic film and preparation method thereof

InactiveCN101240086AQuality improvementImprove performanceFlat articlesPlastic filmMechanical property

A full-biodegradable plastic membrane, which uses thermoplastic starch with diameter of 1-9 mu m, biodegradable polymer and auxiliary component as raw material, processed by screw extruding apparatus and membrane producing apparatus. The raw material comprises 30-70 parts by weight of thermoplastic starch with diameter of 1-9 mu m, 10-40 parts by weight of biodegradable polymer, 5-10 parts by weight of compatible modified component, 3-5 parts by weight of complex plasticized component, 10-30 parts by weight of lubricant. These materials are mixed and processed by screw extruding apparatus and membrane producing apparatus, wherein the lubricant is at least adding into other materials for mixture before process by screw extruding apparatus and during melt blending, and the adding amount of lubricant before process by screw extruding apparatus is not more than 1 / 3 of the total amount thereof. By highly increasing dosage of lubricant and changing mixing way, thermoplastic degree of starch is increased, rheological property of the system and processing quality of product are dramatically improved, mechanical property of the product is enhanced.

Owner:上海悦仕生物材料有限公司 +1

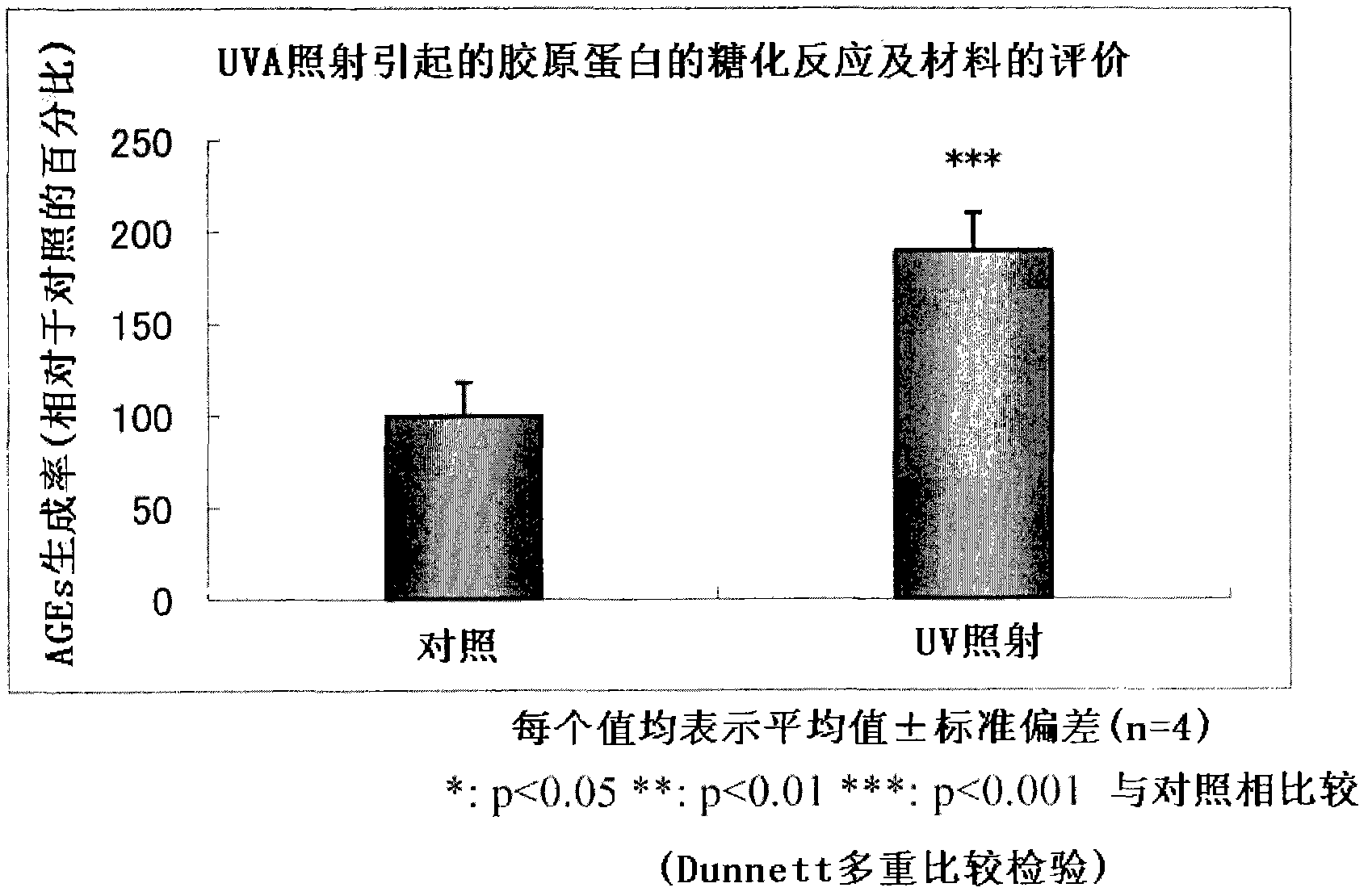

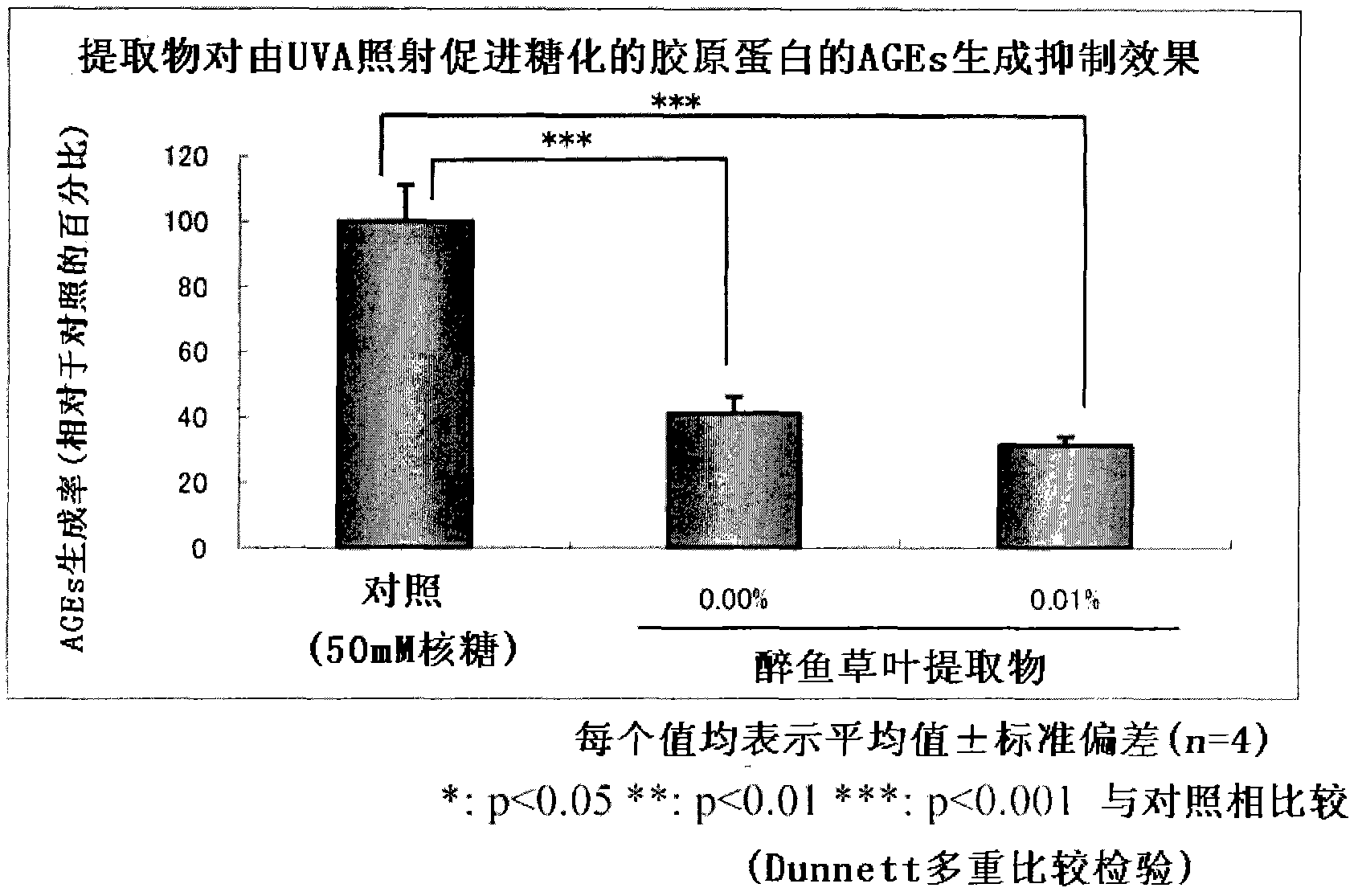

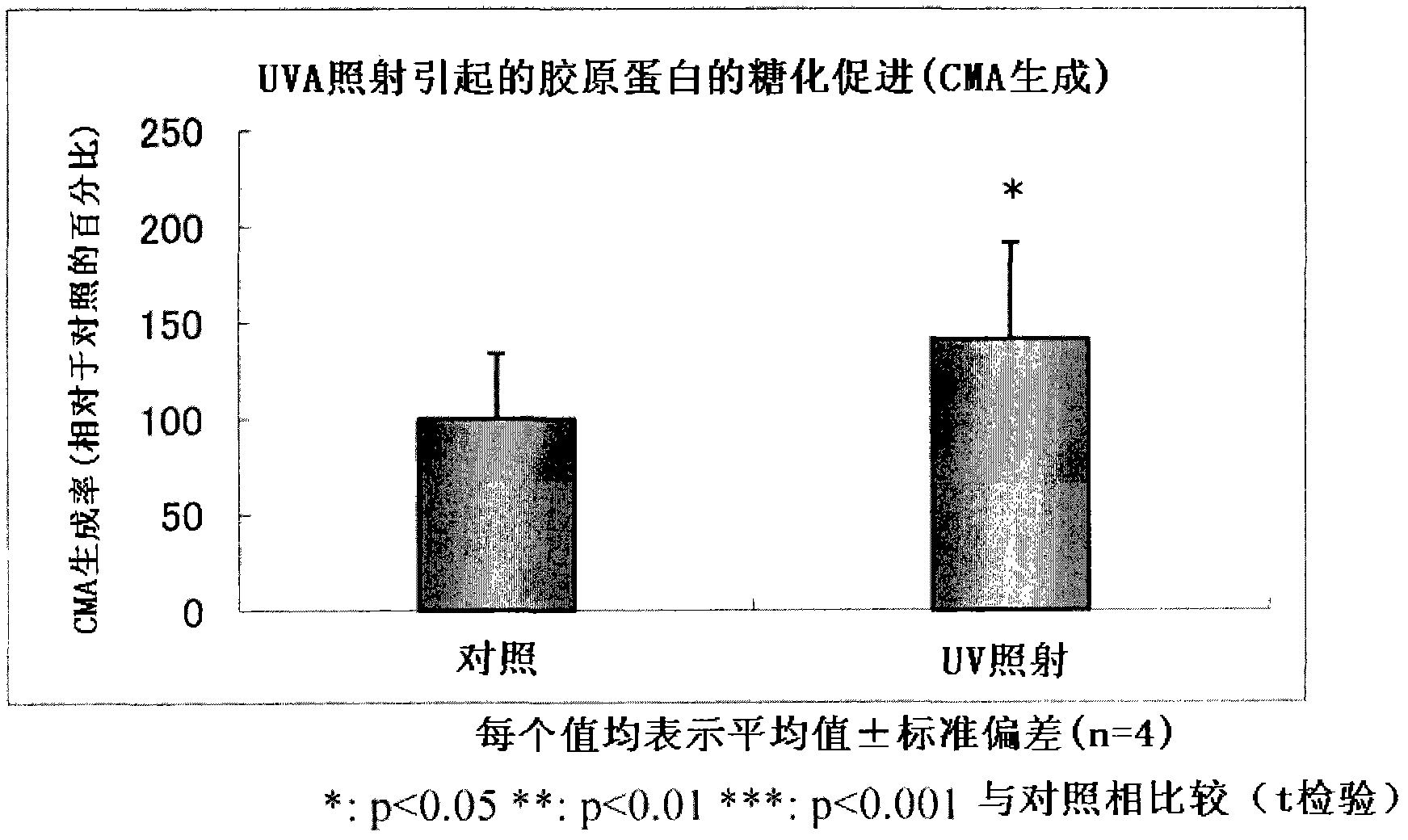

Anti-saccharification agent

InactiveCN102058504AInhibit damagePrevent skin agingCosmetic preparationsToilet preparationsWrinkleSkin wrinkle

The invention provides the application of extracts of buddleja blades, and the extracts of buddleja blades are used to produce anti-saccharification agents, anti-aging agents, skin collagen damage inhibitors, or agents for inhibiting, preventing or improving the decrease in skin firmness or elasticity or skin wrinkles.

Owner:ROHTO PHARM CO LTD

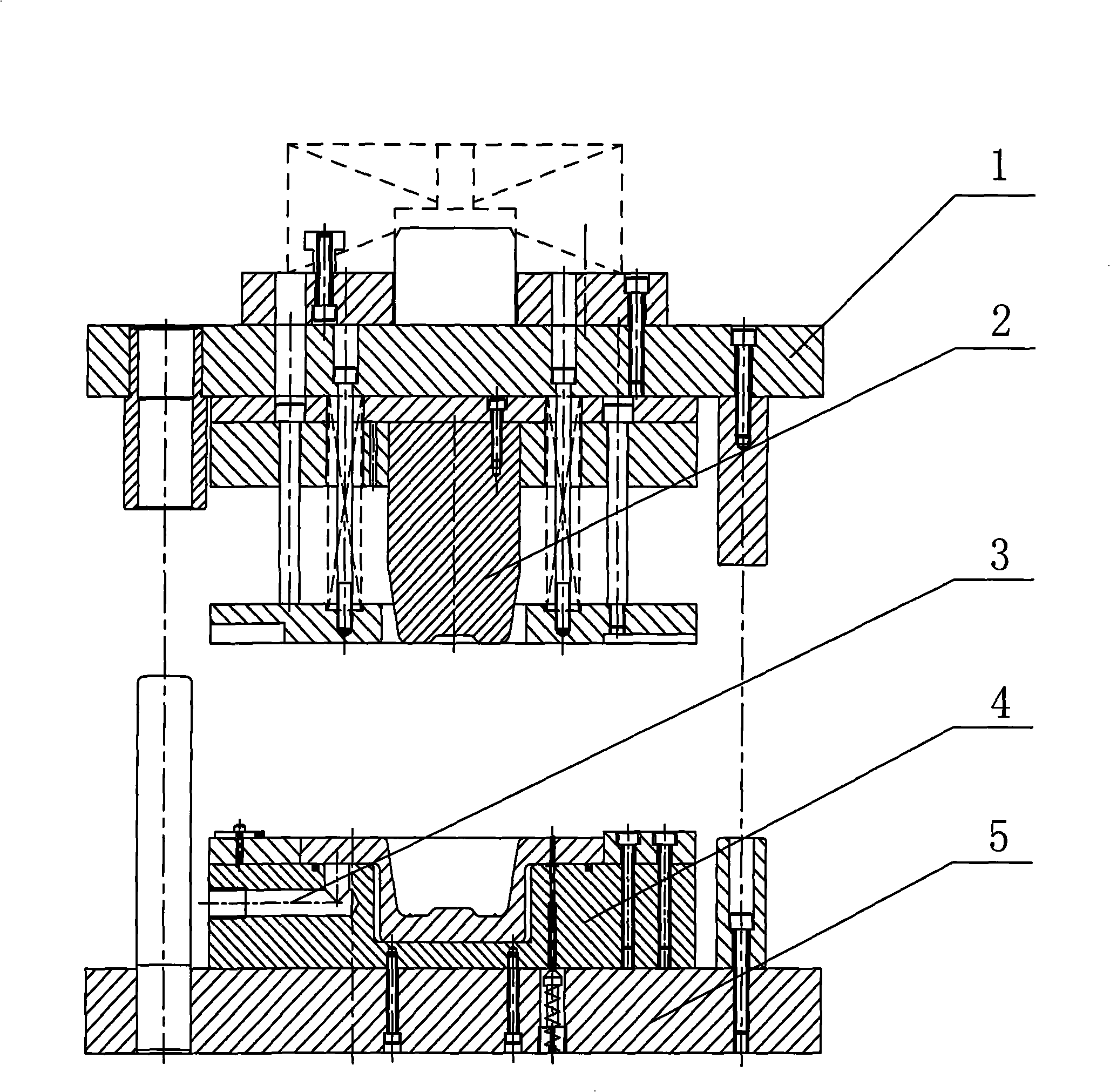

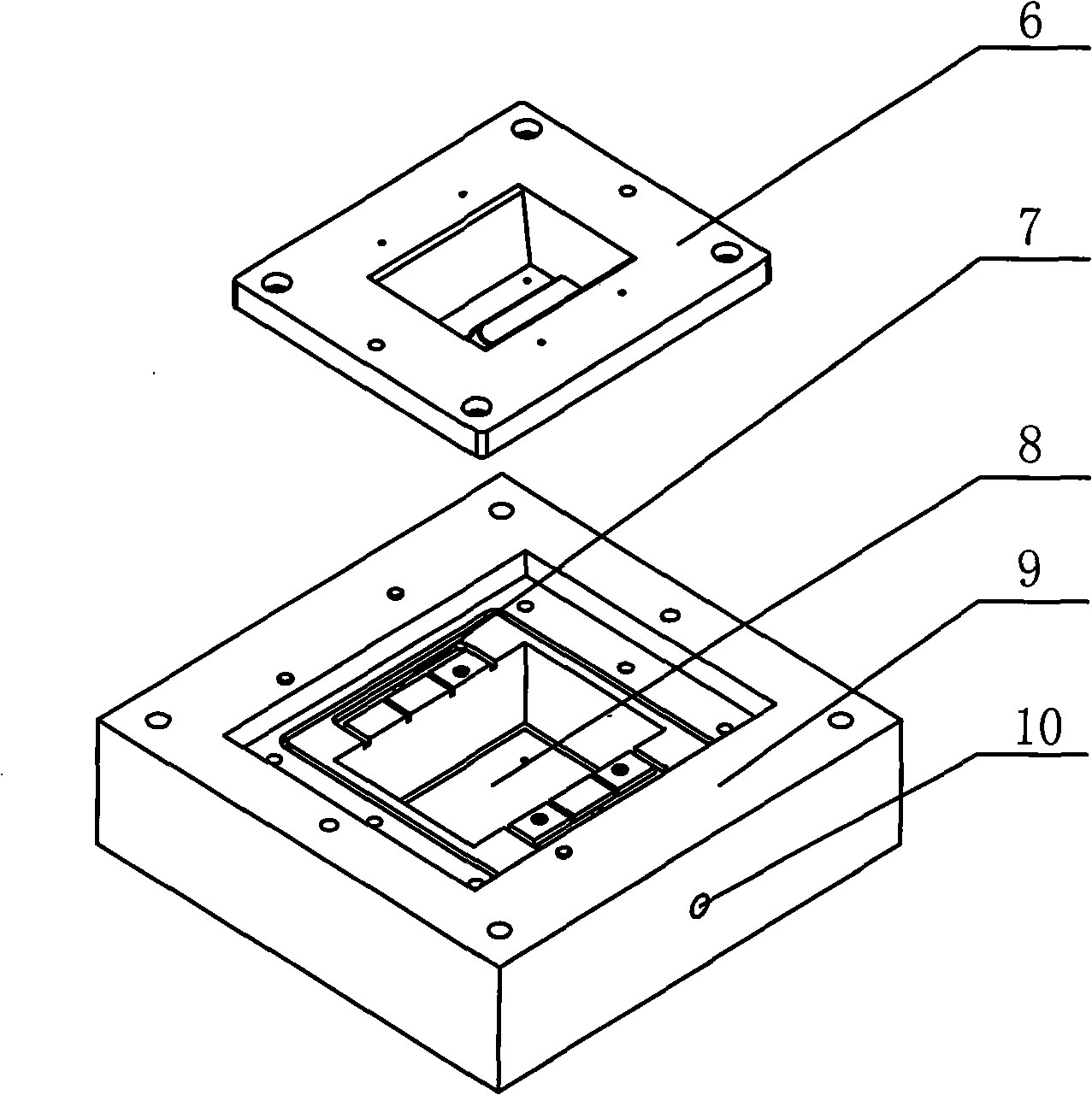

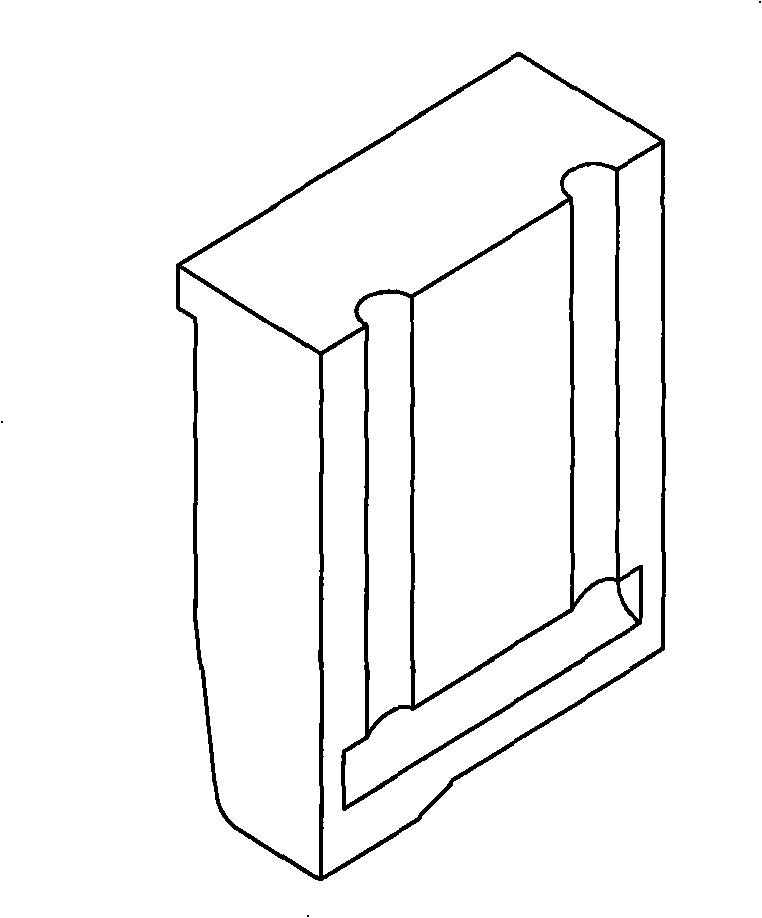

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

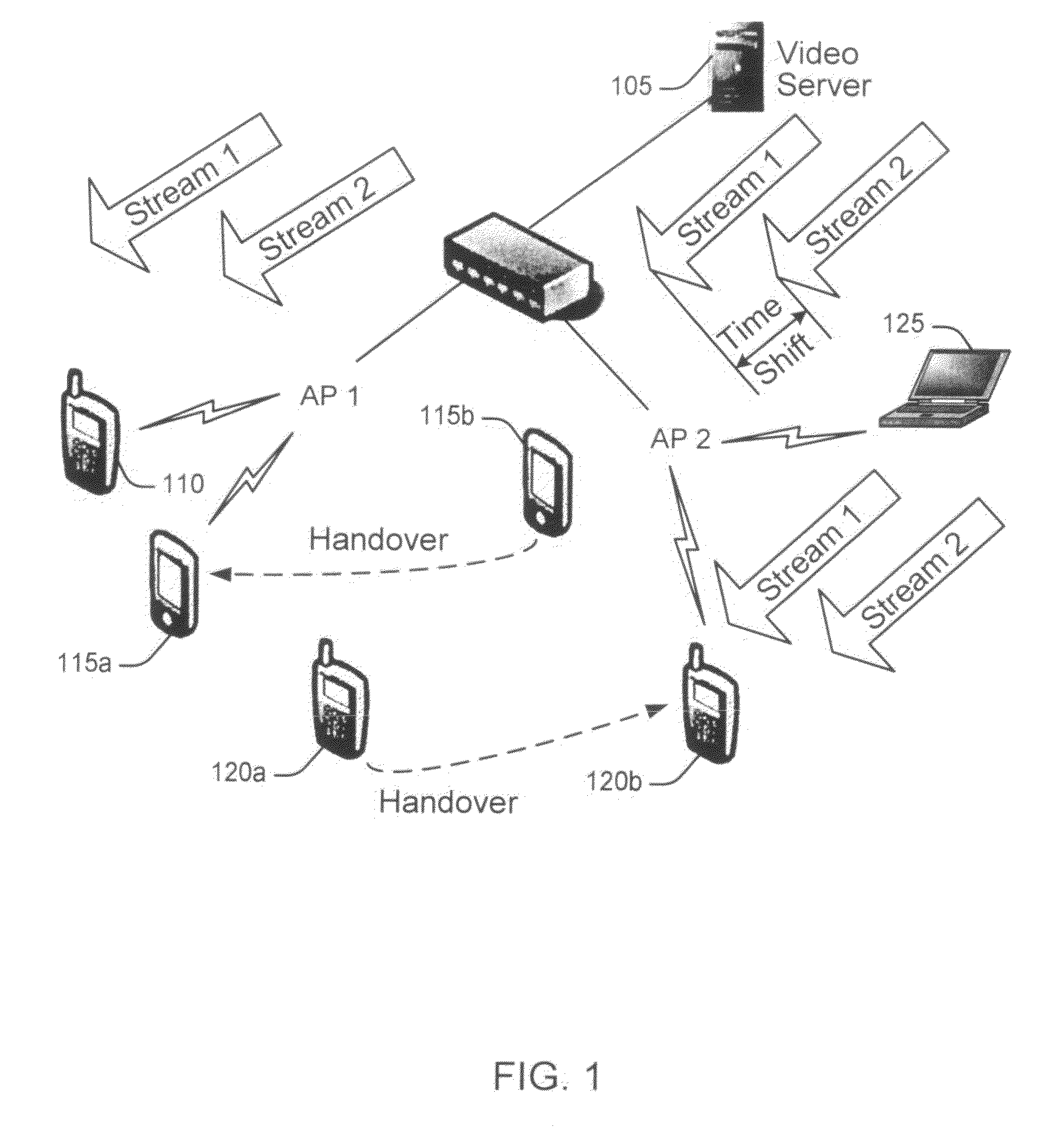

Seamless Handover of Multicast Sessions in Internet Protocol Based Wireless Networks Using Staggercasting

ActiveUS20090319845A1Low resilienceWeak elasticityTransmission systemsCode conversionHandoverPacket loss

A method and apparatus are described for recovering from loss of an original data packet, including detecting data packet loss, joining a delayed multicast group, receiving a delayed data packet and using the delayed data packet to recover the original data packet that was lost. The delayed data packet is one of a copy of the original data packet, a copy of the original data packet encoded at a lower bit rate or a parity packet. Also described are a method and apparatus for staggercasting including encoding and compressing a first data sequence, packetizing the compressed encoded data sequence to form a data packet, multicasting the data packet to a first multicast group, encoding and compressing a second data sequence, packetizing the compressed encoded second data sequence to form a packet and multicasting the packet delayed by an offset time to a second multicast group.

Owner:INTERDIGITAL CE PATENT HLDG

Touch panel and input device using same

InactiveUS20090284487A1Improve stabilityWeak elasticityInput/output processes for data processingEngineeringTouch panel

A touch panel including a top substrate provided with an upper conductive layer formed on a lower surface thereof, a bottom substrate provided with a lower conductive layer formed on an upper surface thereof in a position confronting the upper conductive layer with a predetermined space, and a spacer of a frame-like shape formed at a periphery of at least one of the top substrate and the bottom substrate, and formed therebetween, wherein the touch panel further has a decorative sheet disposed on an upper surface of the top substrate so that a peripheral edge of the decorative sheet protrudes outward beyond the periphery of the top substrate.

Owner:PANASONIC CORP

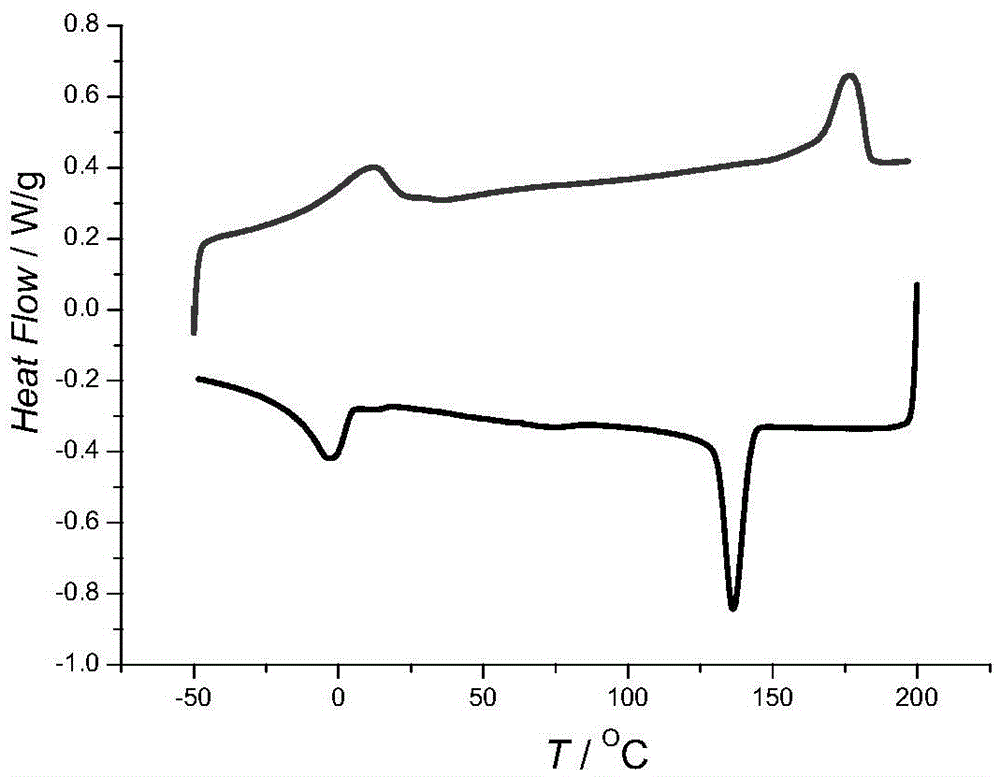

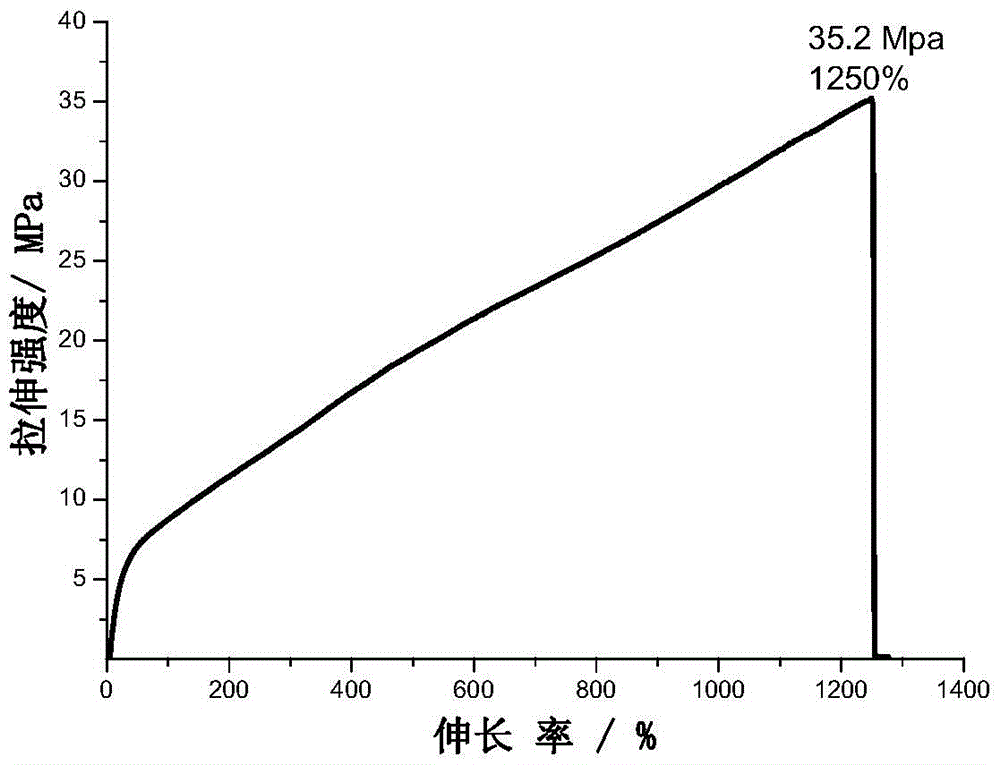

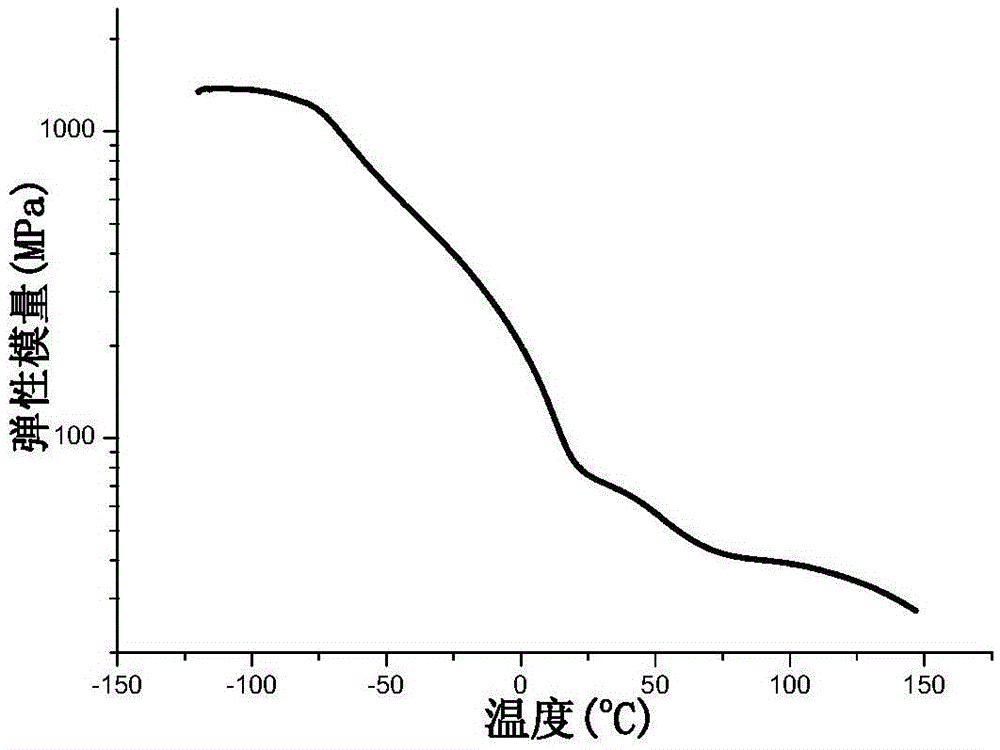

Polyamide 1012 serial thermoplastic elastomer material and preparation method thereof

Provided are a long-carbon-chain polyamide 1012 serial thermoplastic elastomer material and a preparation method thereof. The thermoplastic elastomer material is a block copolymer, wherein long-carbon-chain polyamide 1012 blocks serve as hard segments of the block copolymer, and polyether blocks and / or polyester diol blocks serve as soft segments of the block copolymer. The preparation method of the long-carbon-chain polyamide 1012 serial thermoplastic elastomer is a body melt phase polycondensation method under the control of certain temperature and pressure. The preparation cost of the long-carbon-chain polyamide 1012 serial elastomer is lower, and the performance-cost ratio is better; meanwhile, the long-carbon-chain polyamide 1012 serial elastomer has the multiple advantages of long-carbon-chain polyamide and polyether and / or polyester materials, has the advantages of being good in thermal stability, good in solvent resistance, low in water absorbing capacity, good in elasticity, good in wear-resisting property and the like and can be applied in the fields such as soles of high-end sports shoes, medical catheter materials, micro-drive mechanical parts, vibration-absorptive materials for sports equipment and damping and sound insulating materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Silicone rubber composition, light-emitting semiconductor embedding/protecting material and light-emitting semiconductor device

ActiveUS7521813B2Eliminates surface tackImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesPolymer sciencePtru catalyst

A silicone rubber composition comprising (A) an organopolysiloxane containing at least two aliphatic unsaturated bonds, (B) an organopolysiloxane of resin structure comprising SiO2 units, R3nR4pSiO0.5 units and R3qR4rSiO0.5 units wherein R3 is vinyl or allyl, R4 is a monovalent hydrocarbon group free of aliphatic unsaturation, n is 2 or 3, p is 0 or 1, n+p=3, q is 0 or 1, r is 2 or 3, q+r=3, (C) an organohydrogenpolysiloxane having at least two SiH groups, and (D) a platinum catalyst cures into a silicone rubber having excellent rubbery and strength properties and little surface tack.

Owner:SHIN ETSU CHEM CO LTD

Composite orthopedic implant having a low friction material substrate with primary frictional features and secondary frictional features

InactiveUS20120022653A1Reduce lubricationSimple featuresSpinal implantsCoatingsEngineeringSurgical implant

An orthopedic implant comprising a substrate material adapted to provide the orthopedic implant. The implant has a primary friction area located on or integral with the substrate material. The primary friction area defining an engagement surface having a primary frictional feature. A secondary friction area is located on or integral with the engagement surface and defining a second frictional feature. The primary friction area and the secondary friction area defining a friction interface zone between the orthopedic implant and at least one bone. The secondary friction area increases a friction of the engagement surface and modulus of elasticity to enhance the frictional engagement between the engagement surface and the at least one bone.

Owner:X SPINE SYST

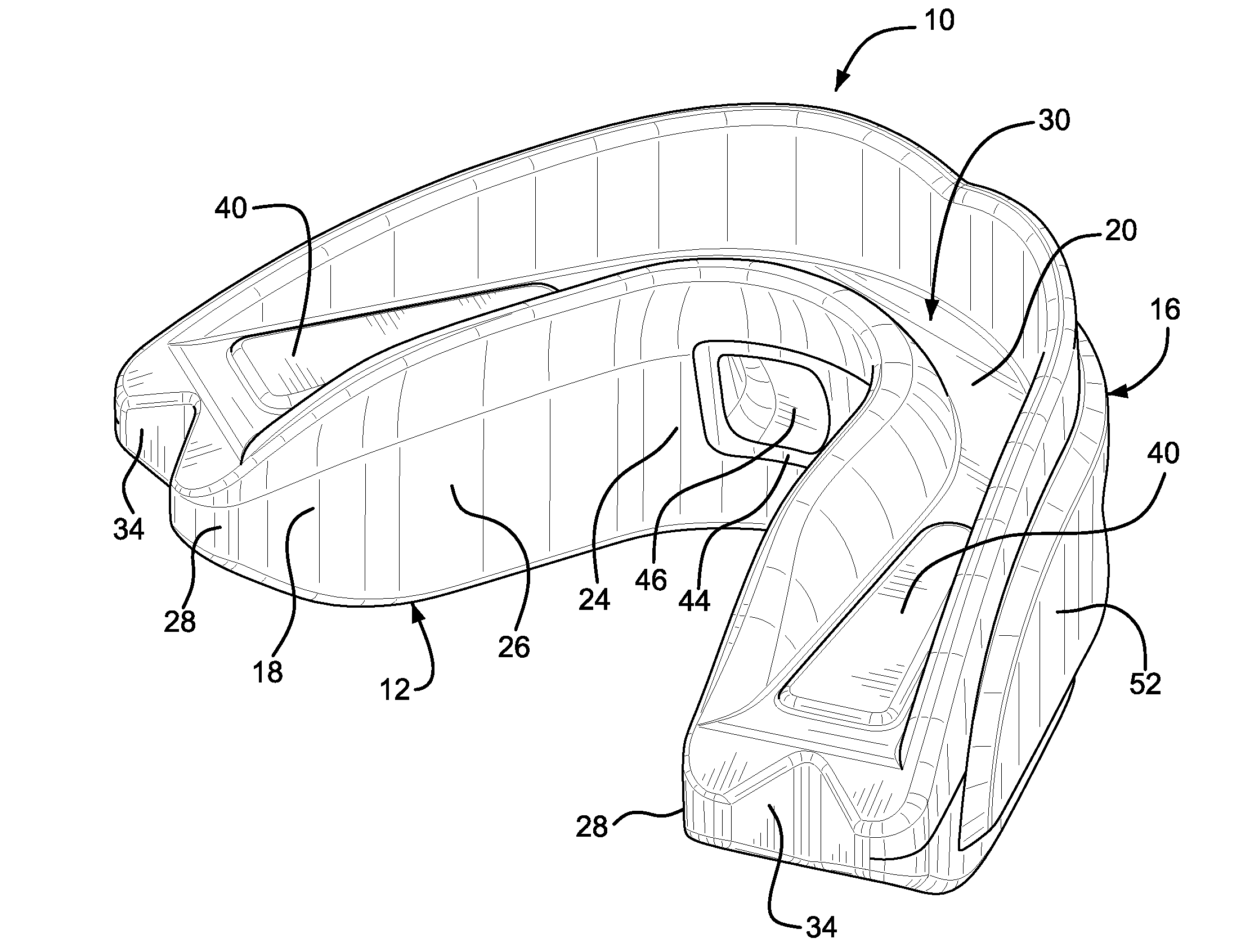

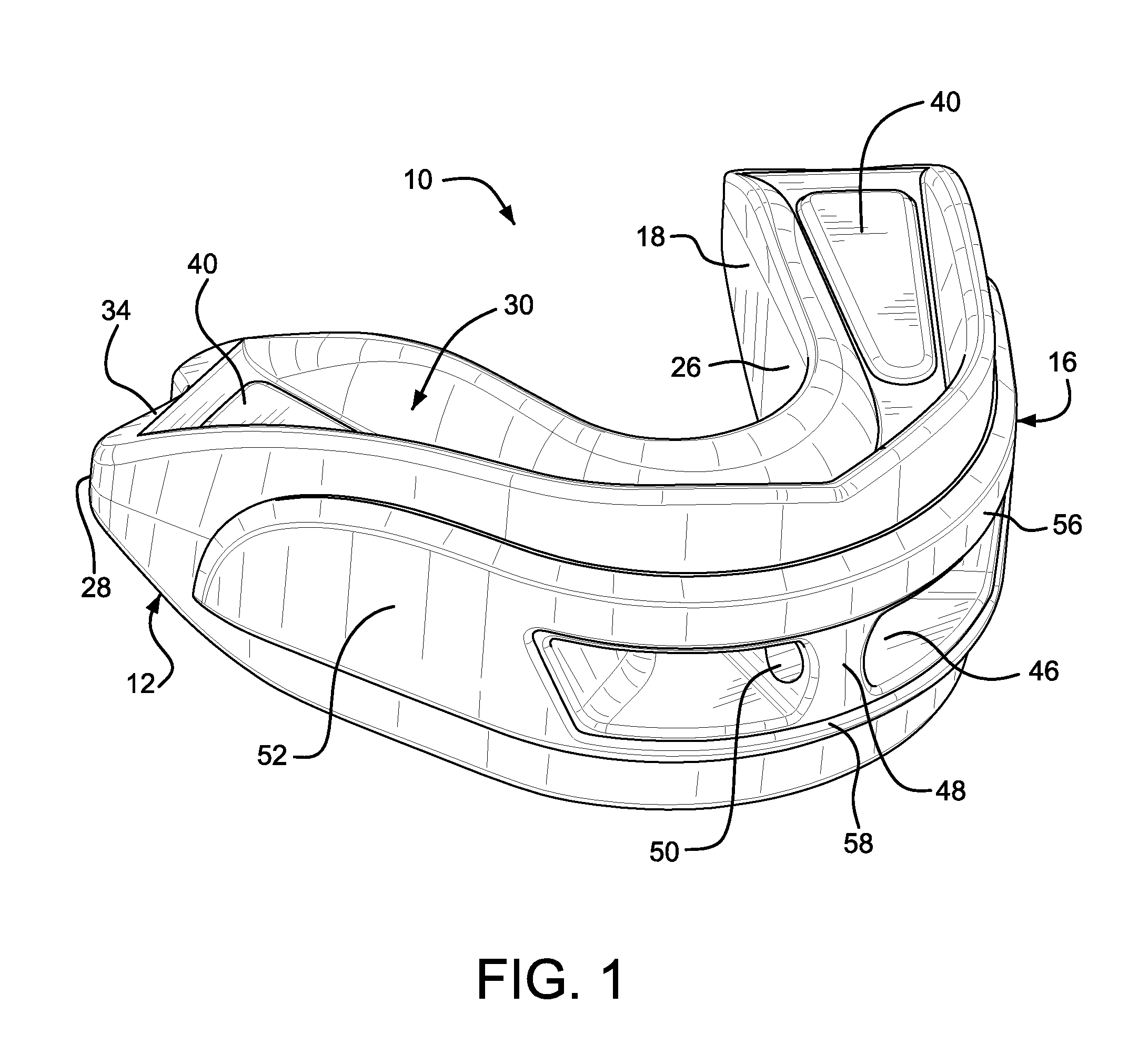

Shock absorbing dental appliance

InactiveUS20110005531A1Improve impact absorption performanceTransfer shockRespiratorsTeeth fillingPlastic materialsEngineering

A dual arch dental appliance including a body which contains a pair of impact absorbing members located in molar regions of the arches. The impact absorbing members are selected from plastic material that exhibits high impact absorption coupled with low resilience or rebound. The result is an appliance which transfers minimal shock to the wearer. The appliance preferably further includes a bumper for providing enhanced impact protection to all of the user's upper and lower teeth. An airway opening is preferably provided to facilitate breathing when the appliance is clenched between the teeth. A post may be provided for structural reinforcement of the airway opening and, optionally, for receiving a tether for fastening the device to a helmet.

Owner:MANZO JOSEPH S

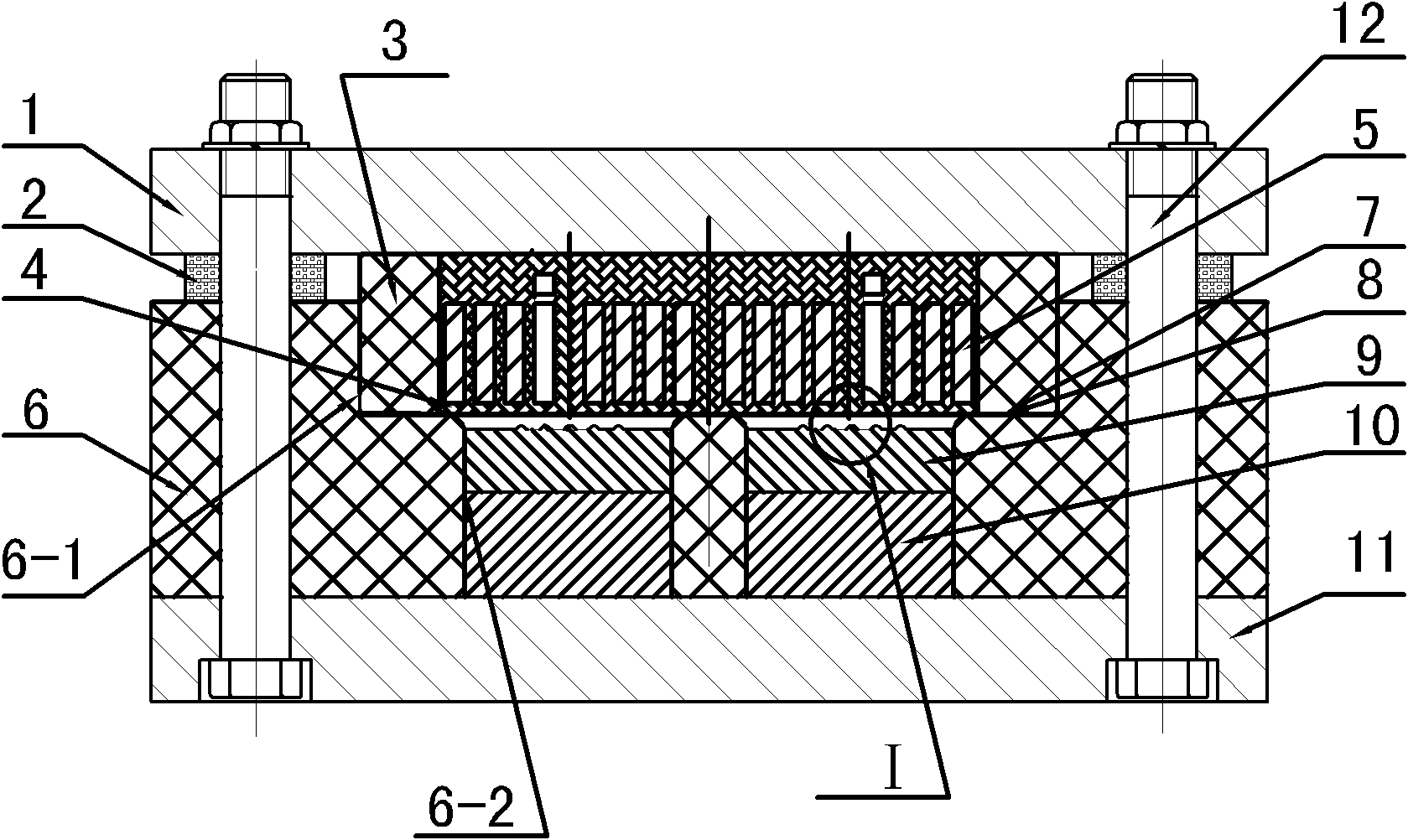

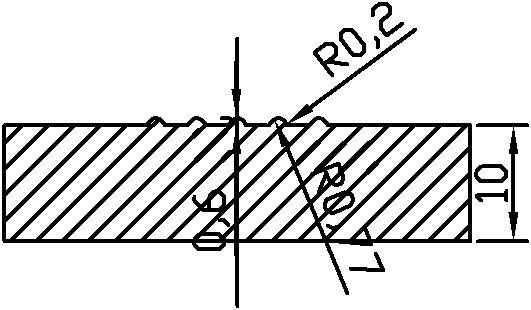

Electromagnetic forming device and method for micro fuel cell metal bipolar plate microchannel

The invention discloses an electromagnetic forming device and an electromagnetic forming method for a micro fuel cell metal bipolar plate microchannel, and relates to a micro fuel cell metal bipolar plate microchannel forming device and a micro fuel cell metal bipolar plate microchannel forming method so as to solve the problem of matching difficulty between micro male and female dies in the process of forming a microstructure on a metal thin plate based on stamping and other conventional plastic deformation means. The device comprises an upper template, a coil, a driving sheet, a die, a lower template and a fastening bolt; a groove is formed on the surface of a supporting frame so as to accommodate the coil; a circular through hole is formed in the center of the bottom of the groove so as to accommodate the die; the driving sheet is arranged above the die; and an axial lead of the coil is in upper and lower directions. The method comprises the following steps of: discharging to the coil to excite a strong pulsed magnetic field; generating induced eddy on the surface of the driving sheet so as to generate a magnetic field opposite to the magnetic field of the coil in the transient strong pulsed magnetic field; and driving a plate blank to make die attaching motion by using the driving sheet under repellent applied force between the magnetic fields. The invention is used for micro-forming.

Owner:HARBIN INST OF TECH

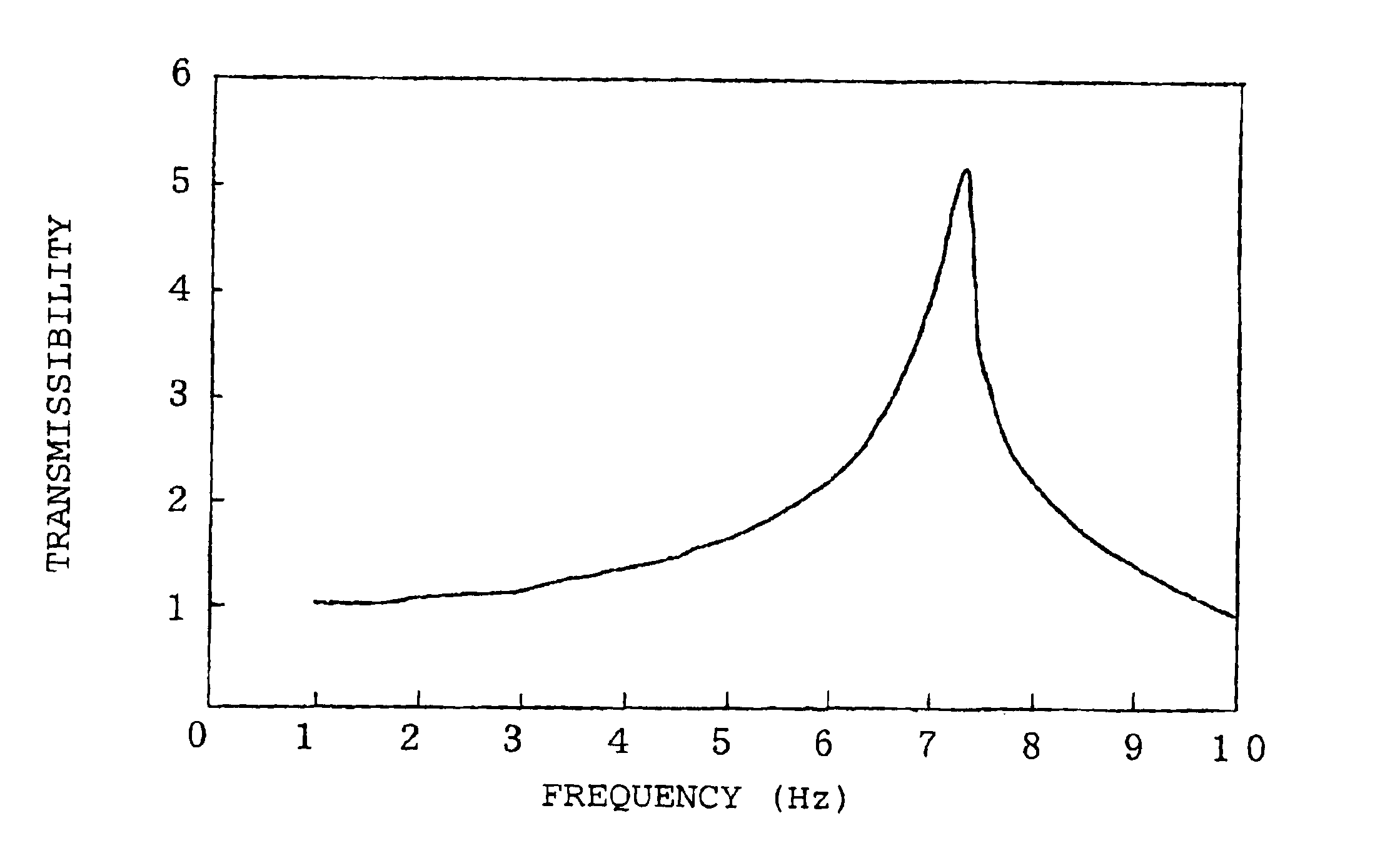

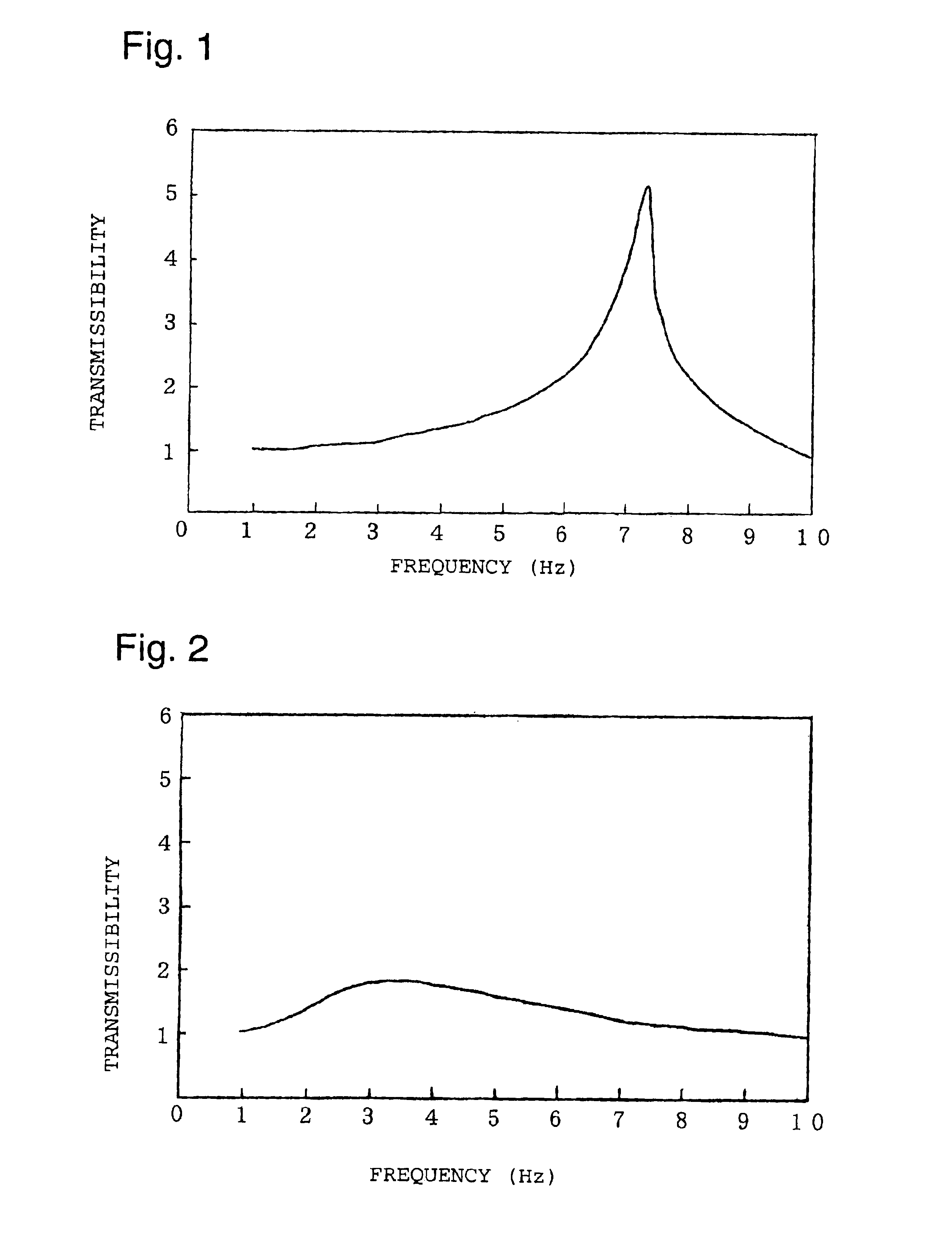

Flexible polyurethane foam and method for its production

A flexible polyurethane foam having a core impact resilience of at most 40%, of which the half-width of the resonance transmission peak in the resonance curve is at most 1 Hz.

Owner:ASAHI GLASS CO LTD

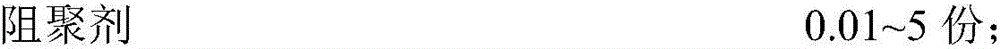

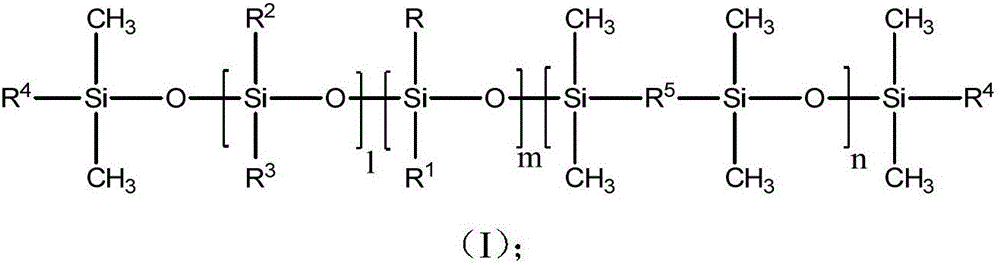

Ultraviolet-curing liquid optical silica gel used for reworkable gluing as well as preparation method and application thereof

InactiveCN106497505AReduce scrap rateAnti-yellowing and agingNon-macromolecular adhesive additivesAdhesiveOptical transmittance

The invention belongs to the technical field of preparation of adhesives and specifically discloses an ultraviolet-curing liquid optical silica gel used for reworkable gluing. The ultraviolet-curing liquid optical silica gel used for reworkable gluing comprises the following ingredients in parts by weight: 100 parts of methacryloyloxyethyl modified polysiloxane; 0-90 parts of MQ silicon resin, 0.1-10 parts of a photoinitiator, 0.01-5 parts of a coupling agent, 0.01-5 parts of a stabilizer and 0.01-5 parts of a polymerization inhibitor. The liquid optical silica gel provided by the invention has high light transmittance, small shrinking percentage, small yellowing index and good reworkable performance; the liquid optical silica gel can be repeatedly used for gluing an optical element and a screen; meanwhile, the rejection rate of materials can be effectively controlled, the production cost of enterprises is greatly reduced, and the application prospect is wide.

Owner:矽时代材料科技股份有限公司

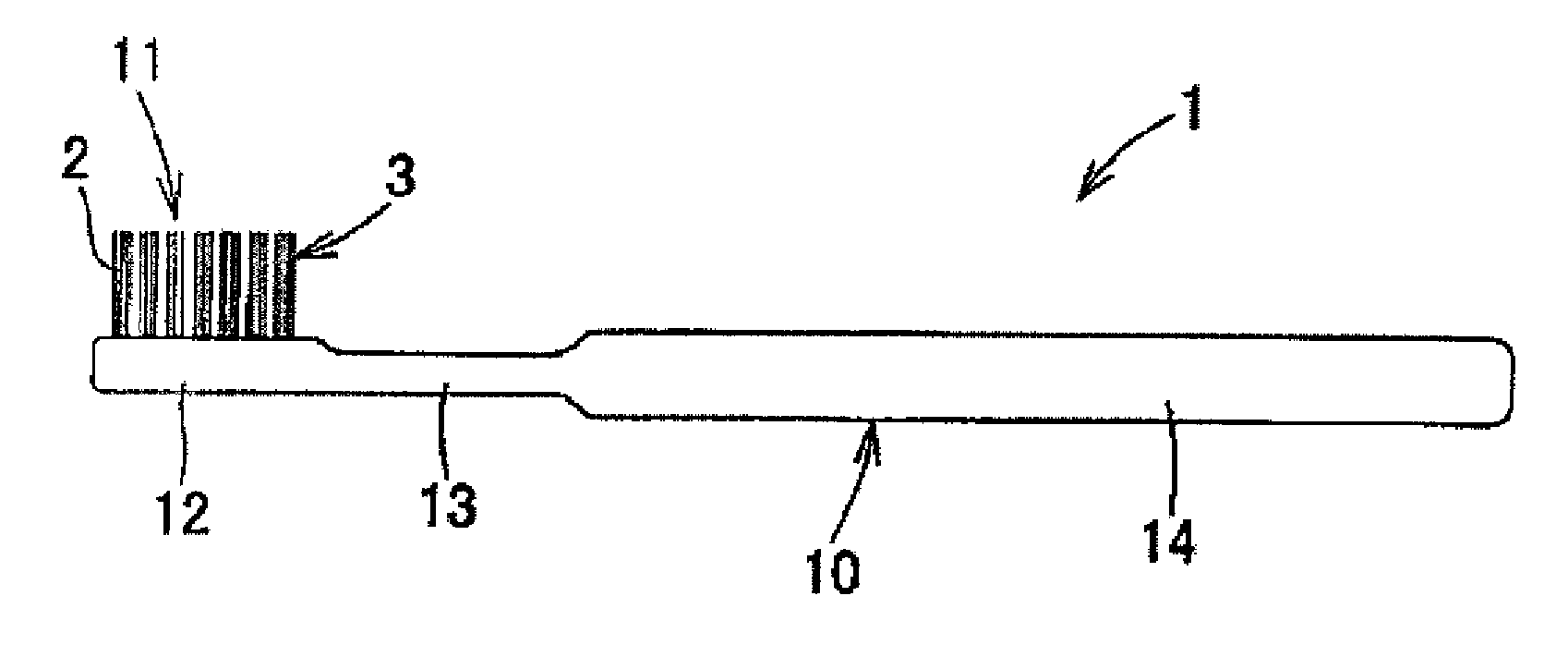

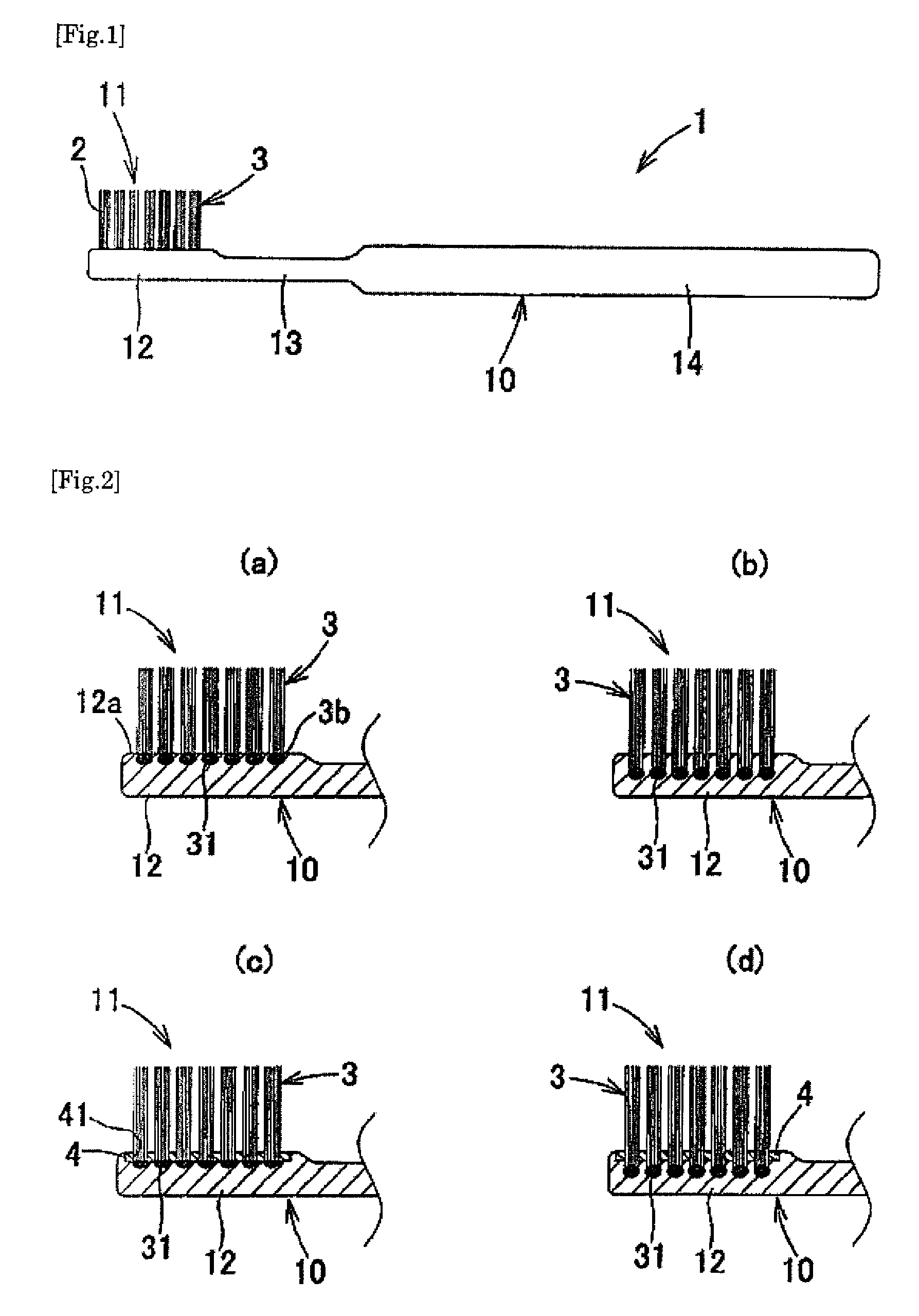

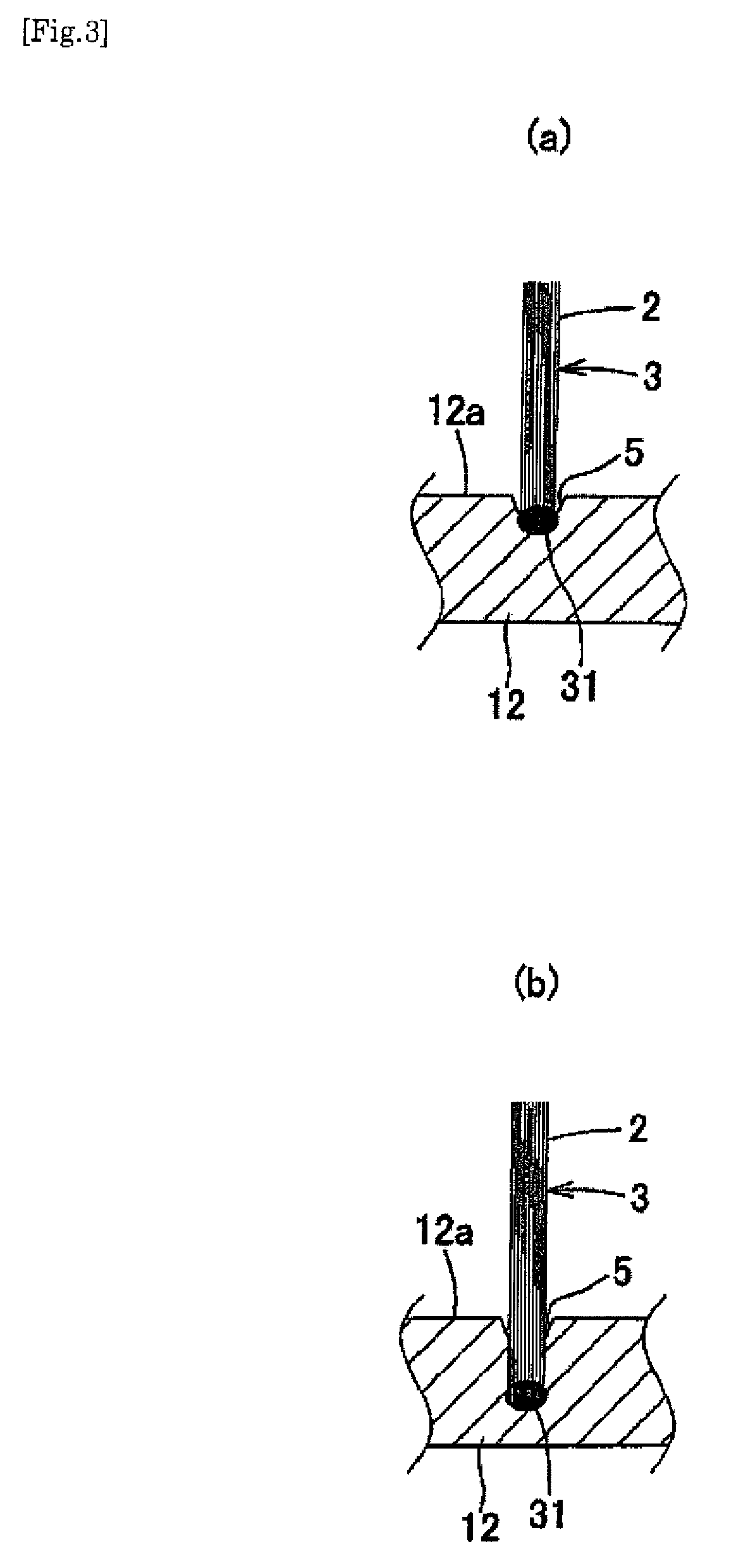

Toothbrush

InactiveUS20090013488A1Easy to useHighly attractive appearanceBristleDomestic articlesBristleEngineering

A toothbrush which comprises a brush main body made of a synthetic resin and having a bristle base and bristles made of a thermoplastic resin which have been fusion-bonded to the bristle base to constitute a bristled part, wherein the bristles constituting the bristled part at least partly comprise: tapered bristles which are bristles having split free ends, the split free ends having been tapered beforehand; tapered bristles which have a sectional shape having a core-sheath structure or islands in a sea structure; or tapered bristles in each of which a core bristle comprising a core or island part has been formed beforehand so as to be exposed at the free end. The toothbrush has excellent suitability for bristle insertion into narrow parts. It is highly effective in removing dental plaque and cleaning the teeth. It is highly easy to use in the oral cavity. It further has a highly attractive appearance.

Owner:SUNSTAR INC

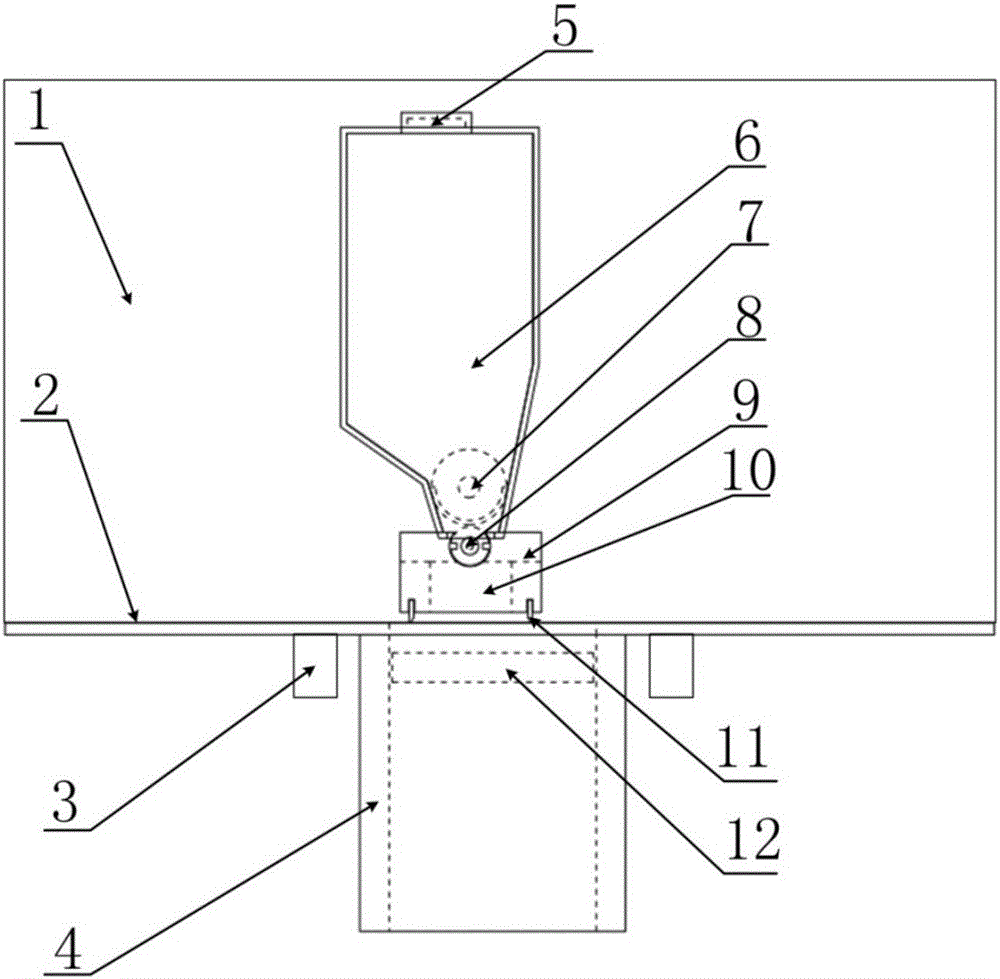

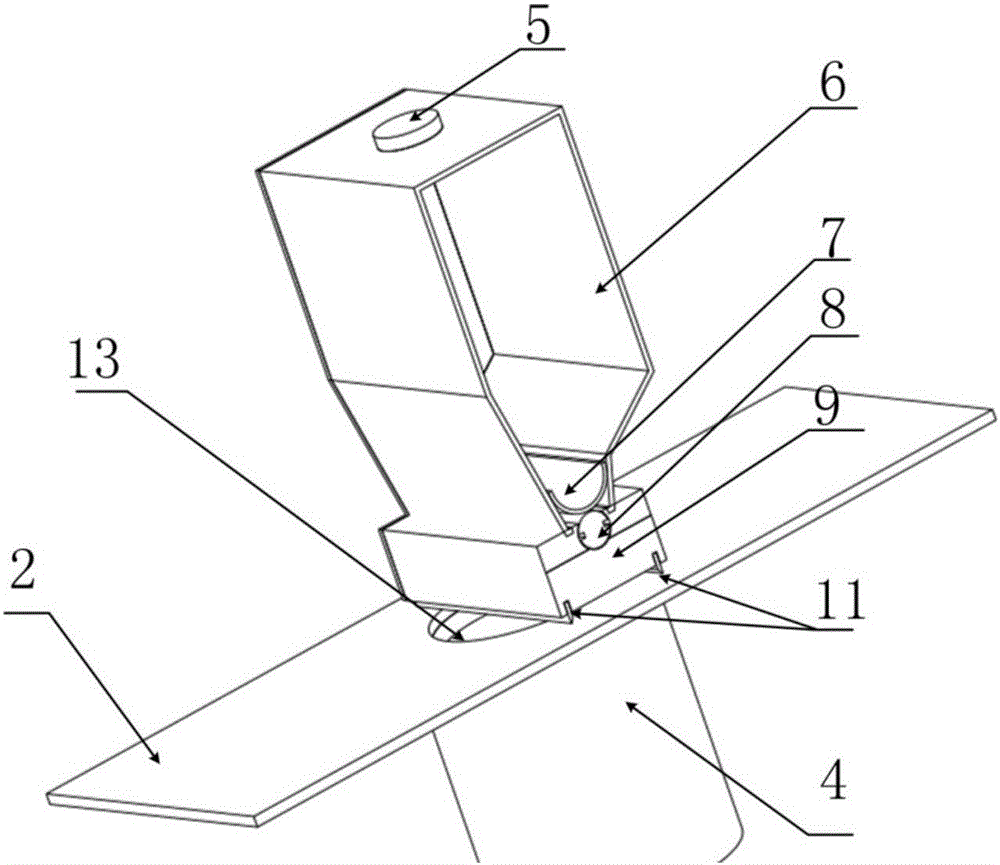

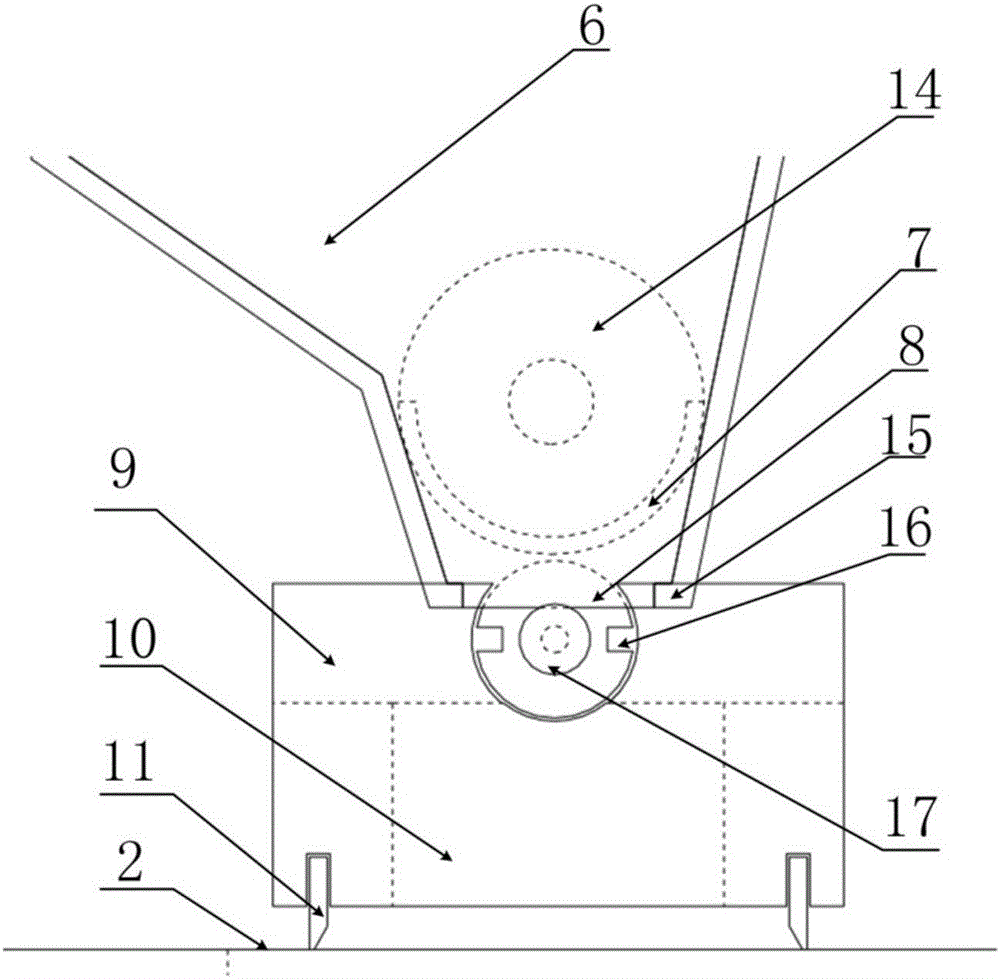

Internally-arranged automatic coating device and method based on 3D printing of precious metal

ActiveCN105903966AReduce wasteReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencyChinese charactersPowder coating

The invention discloses an internally-arranged automatic coating device and method based on 3D printing of precious metal. The device comprises a forming chamber, a powder laying mechanism and a datum horizontal plate; a closed powder storage box is arranged below a powder outlet of a powder box body, and a quantitative powder feeding mechanism is arranged between the powder outlet of the powder box body and the closed powder storage box; a structure shaped like a Chinese character 'hui' is formed by the enclosure of the peripheral side walls of the closed powder storage box, and two powder coating scrapers are installed on the front side wall and the rear side wall of a lower opening in the powder laying direction; the peripheral side walls of the closed powder storage box, the two powder coating scrapers and the datum horizontal plate form powder storage space; the powder coating scrapers flattens powder from the powder box body uniformly back and forth with the datum horizontal plate as the datum plane. The device integrates the quantitative powder feeding function and the efficient powder laying function and can effectively increase the utilization rate of the precious metal and reduce material waste when applied to the 3D printing process of the precious metal.

Owner:SOUTH CHINA UNIV OF TECH

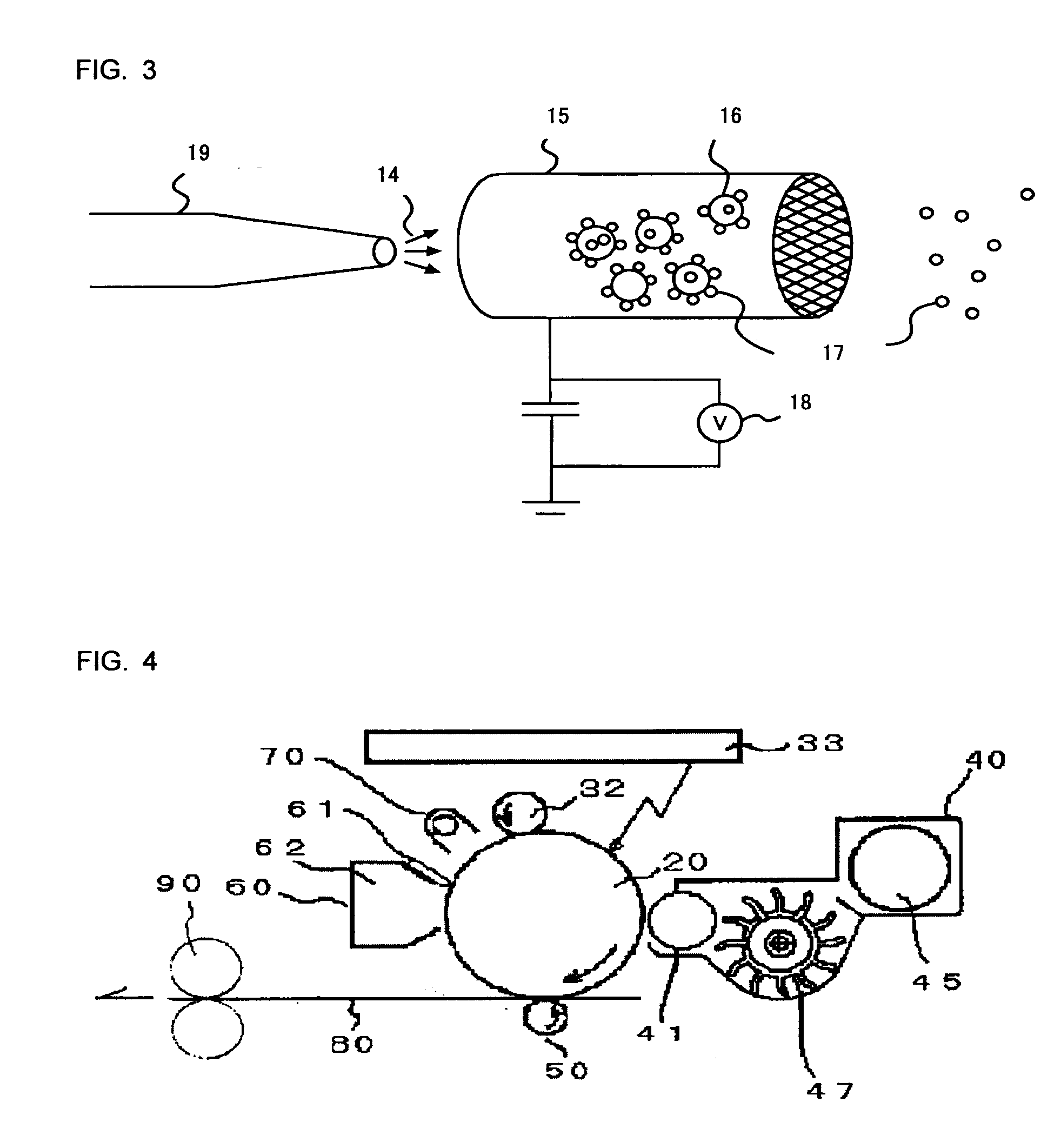

Electrophotographic developer and carrier therefor, core material particle for carrier for electrophotographic developer and production method thereof and image forming method

ActiveUS20070243482A1Minimize toner spentImprove image qualityElectrographic process apparatusDevelopersCost effectivenessEngineering

The present invention can provide small-diameter core material particles for electrophotographic carrier, the particles that can prevent occurrences of carrier adhesions and reduce toner spent, have excellent durability and cause little fluctuations in image density with a narrow particle diameter distribution, and an efficient, cost-effective production method thereof. That is, the core material particles for electrophotographic carrier are particles wherein the weight average particle diameter, Dw, is in the range of 22 μm to 32 μm, the ratio of Dw to the number average particle diameter, Dp, satisfies the condition, 1<Dw / Dp<1.20, the content of particles smaller than 20 μm in diameter is in the range of 0% by mass to 7% by mass and smaller than 36 μm is in the range of 90% by mass to 100% by mass, and the BET specific surface area is in the range of 300 cm2 / g to 900 cm2 / g.

Owner:RICOH KK

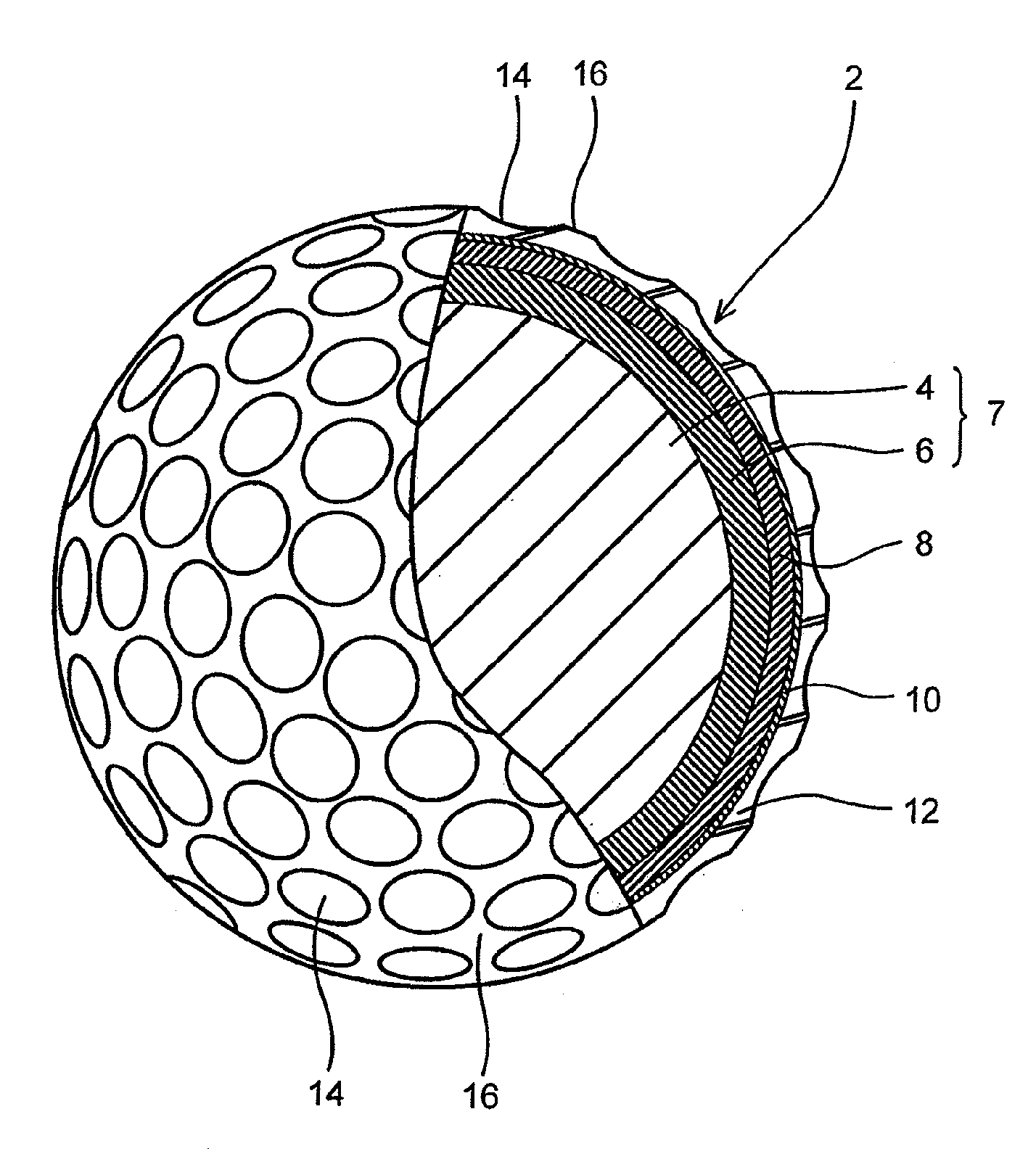

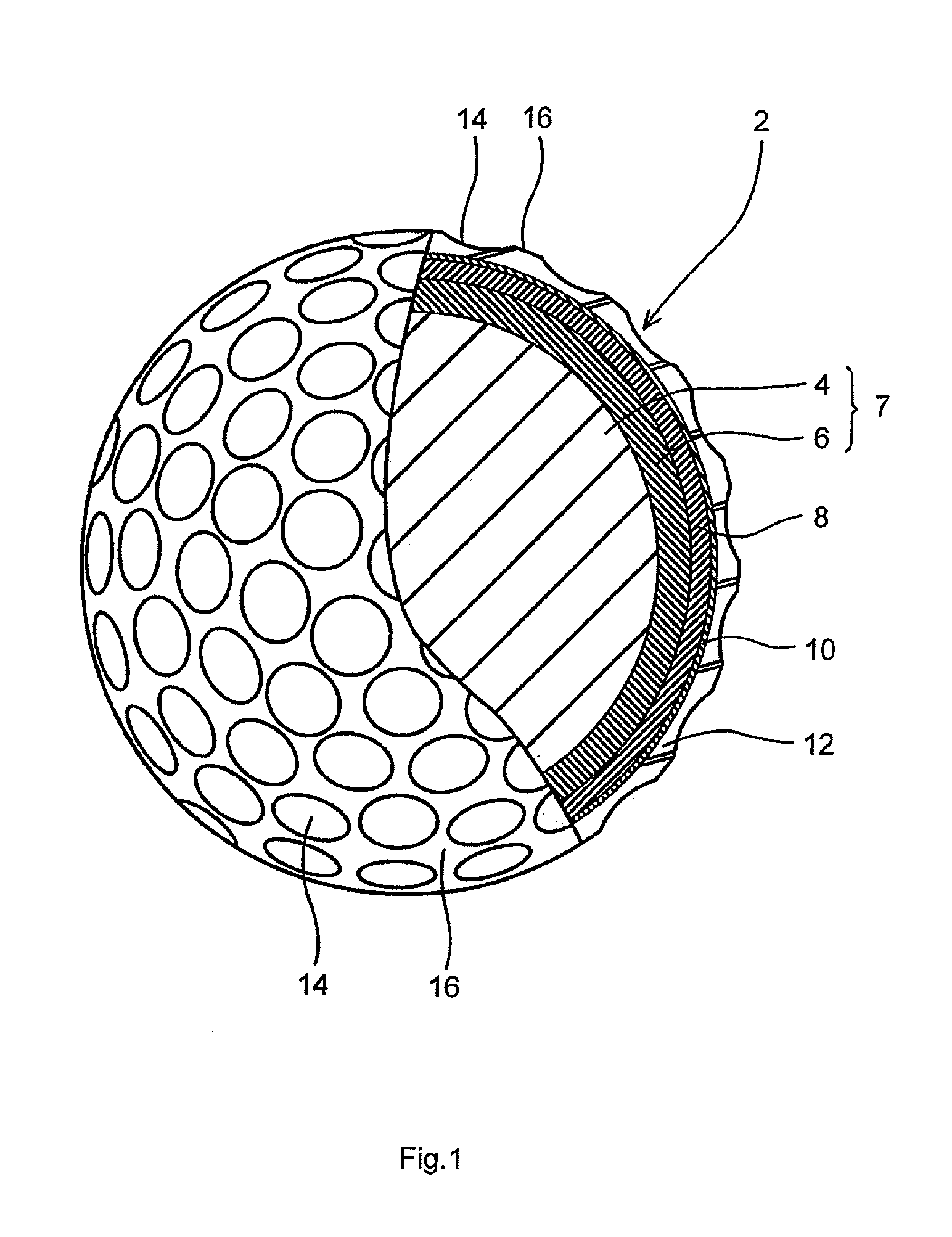

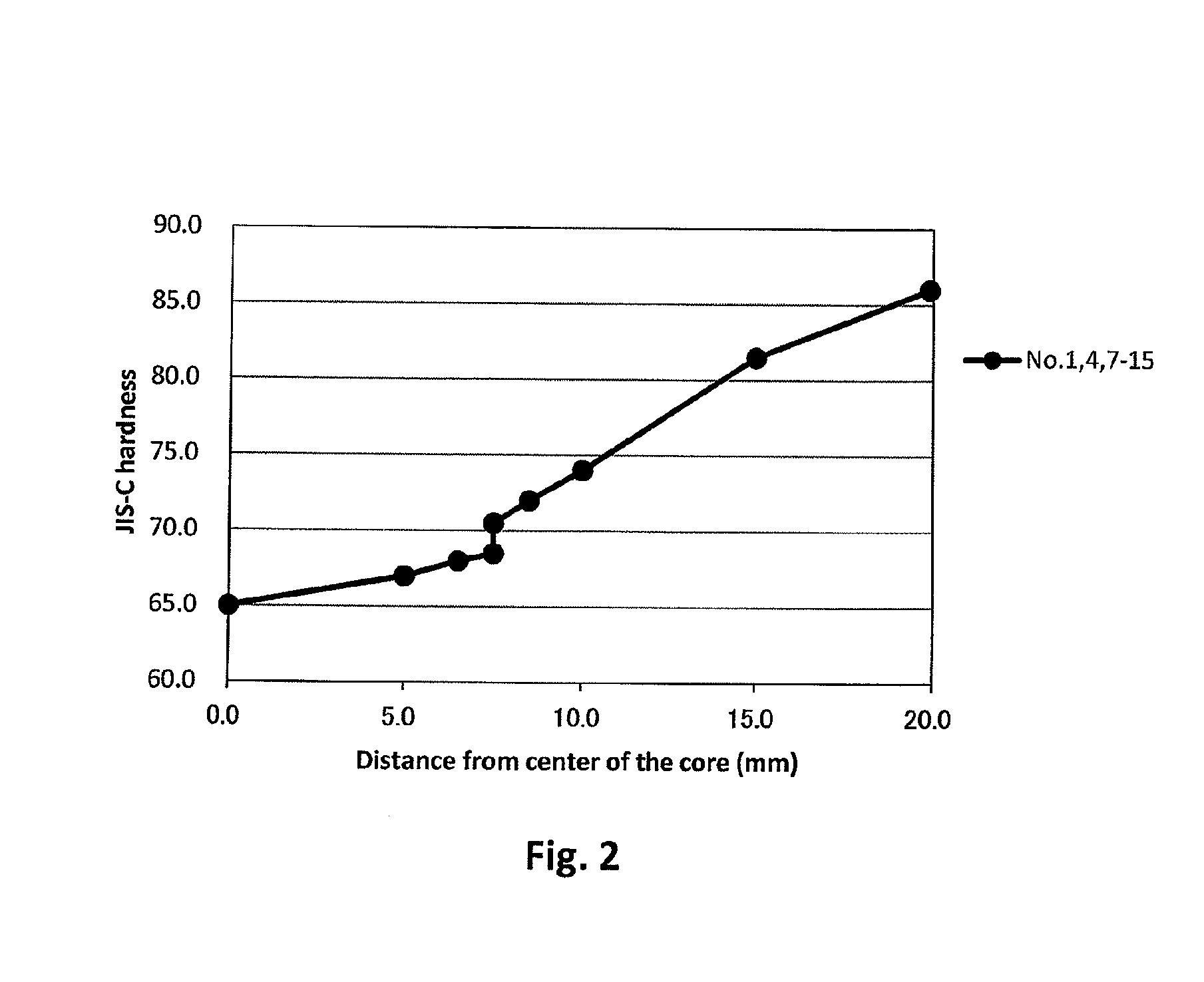

Golf ball

An object of the present invention is to provide a golf ball having an improved controllability and shot feeling while maintaining a flight distance on driver shots. The present invention provides a golf ball having a core, an intermediate layer disposed around the core, and a cover disposed around the intermediate layer, wherein the core has a center and an envelope layer disposed around the center, and has a specific hardness distribution, and the intermediate layer is formed from an intermediate layer composition comprising, as a resin component, (A) a modified polyester elastomer and (B) a binary ionomer resin, and having a flexural modulus ranging from 150 MPa to 450 MPa, a maximum loss factor (tan δ) between −20° C. and 0° C. of 0.08 or less, a repulsive modulus of 55% or more, and a slab hardness ranging from 60 to 90 in JIS-hardness.

Owner:SUMITOMO RUBBER IND LTD

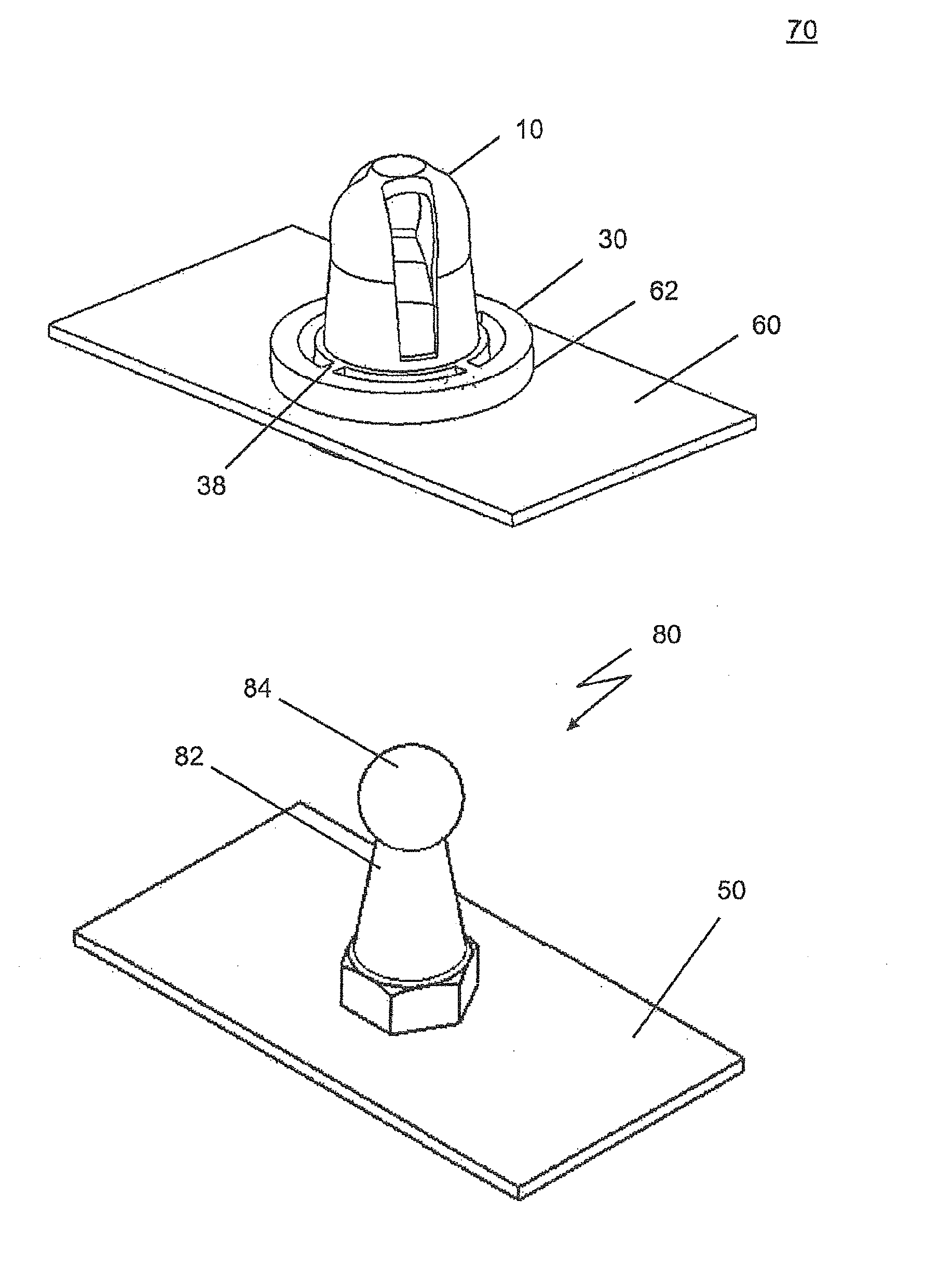

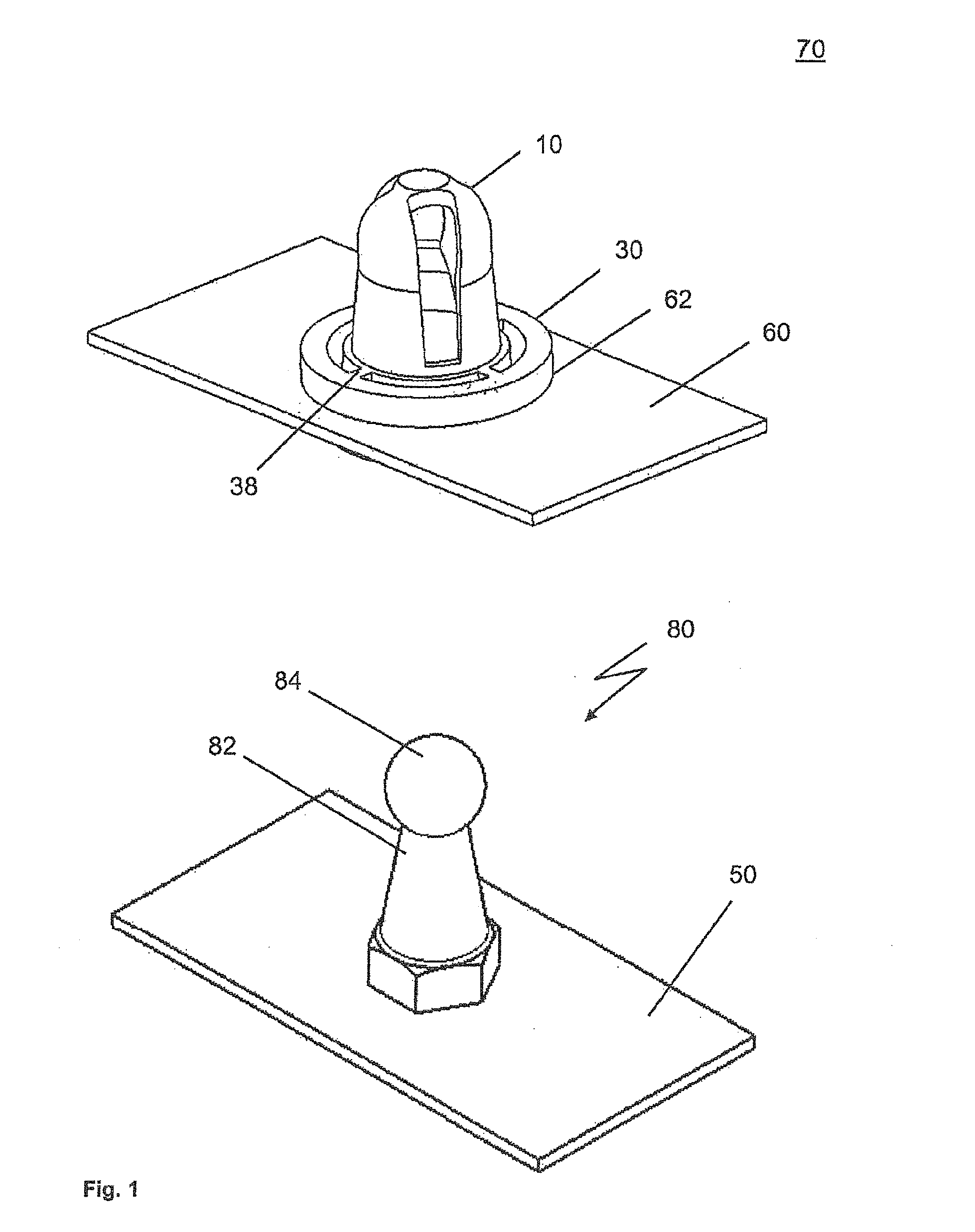

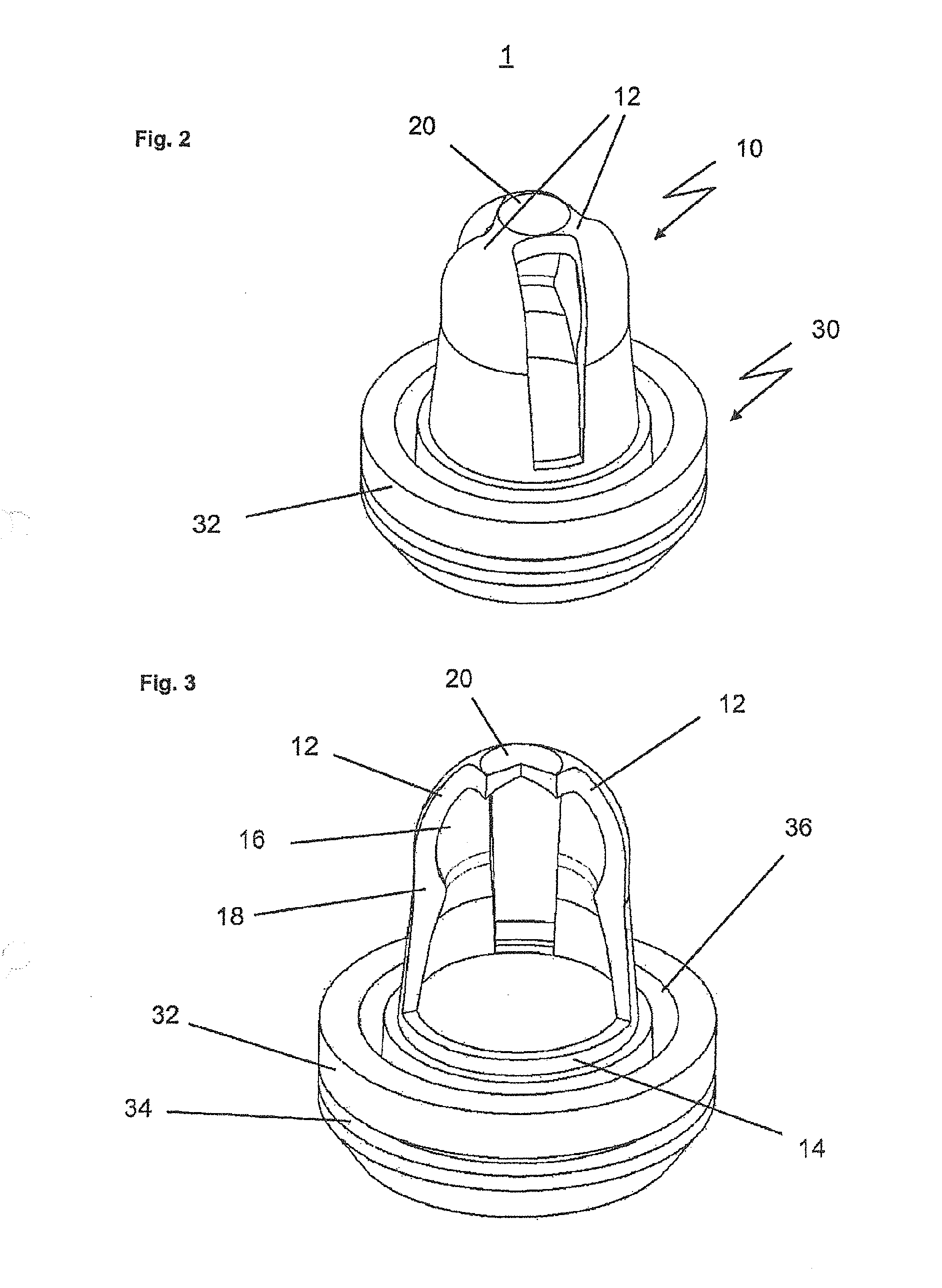

Plug-in coupling and method for the production thereof

ActiveUS20140199116A1Improve stabilityReliable holdControlling membersSnap-action fastenersCouplingEngineering

The plug-in coupling comprises a negative coupling part and a positive coupling part consisting of a pin having a ball head. The negative coupling part comprises a coupling construction made of a first material for accommodating and detachably fastening the positive coupling part, and a retaining construction made of a second material, which surrounds the coupling construction, for fastening the negative coupling part to the second component, wherein the second material has a higher elasticity than the first material, such that component vibrations can be absorbed by the retaining construction.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

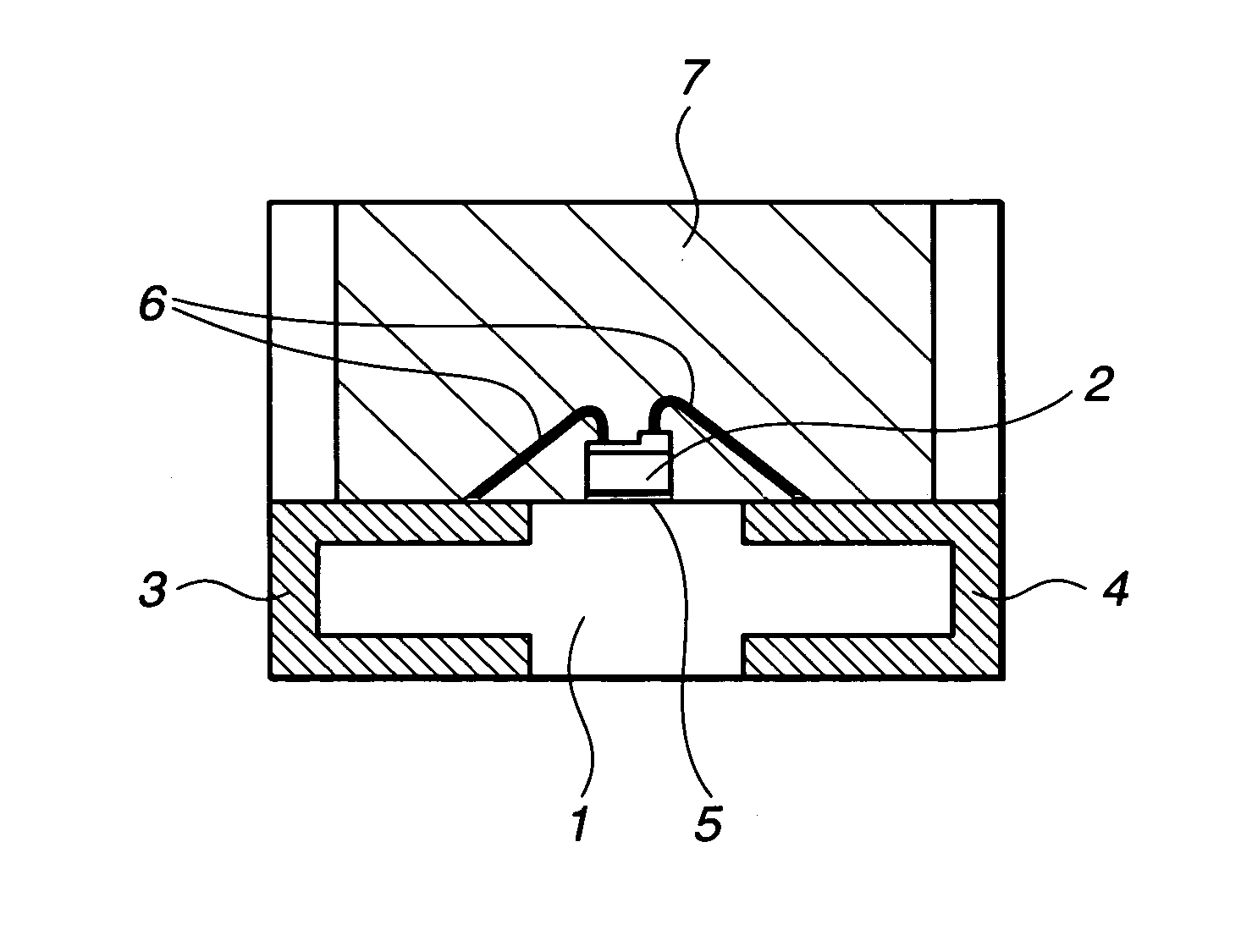

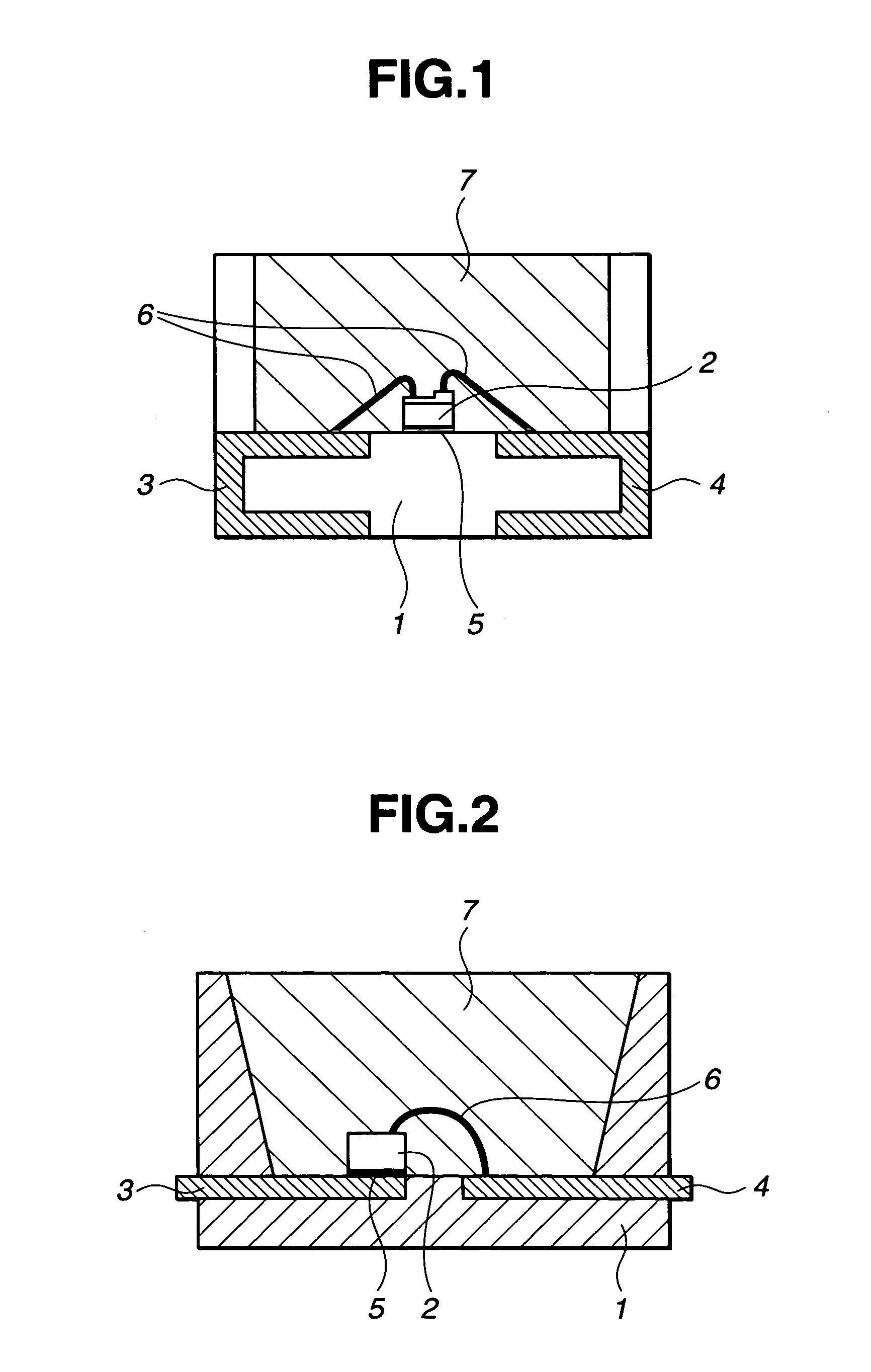

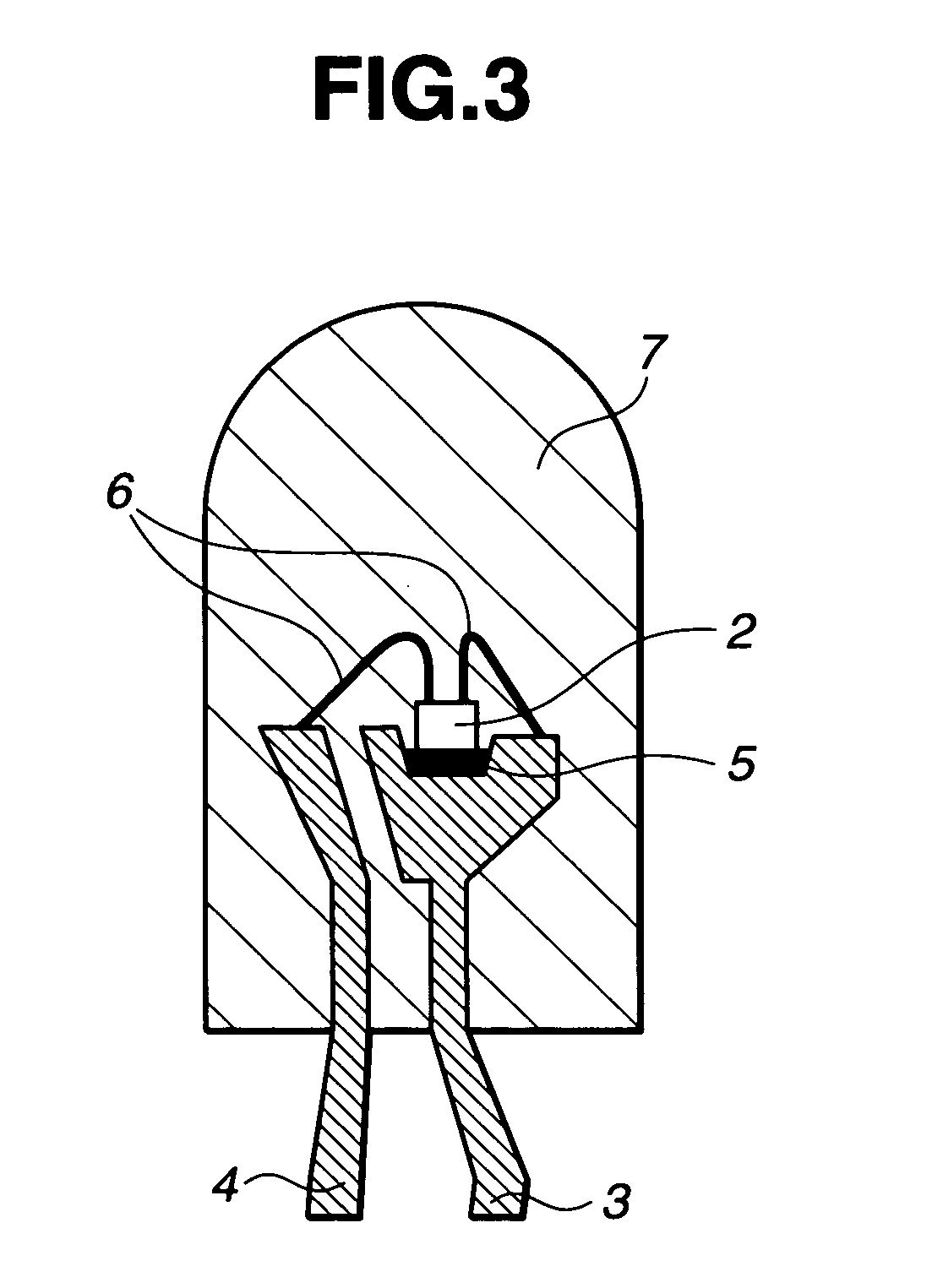

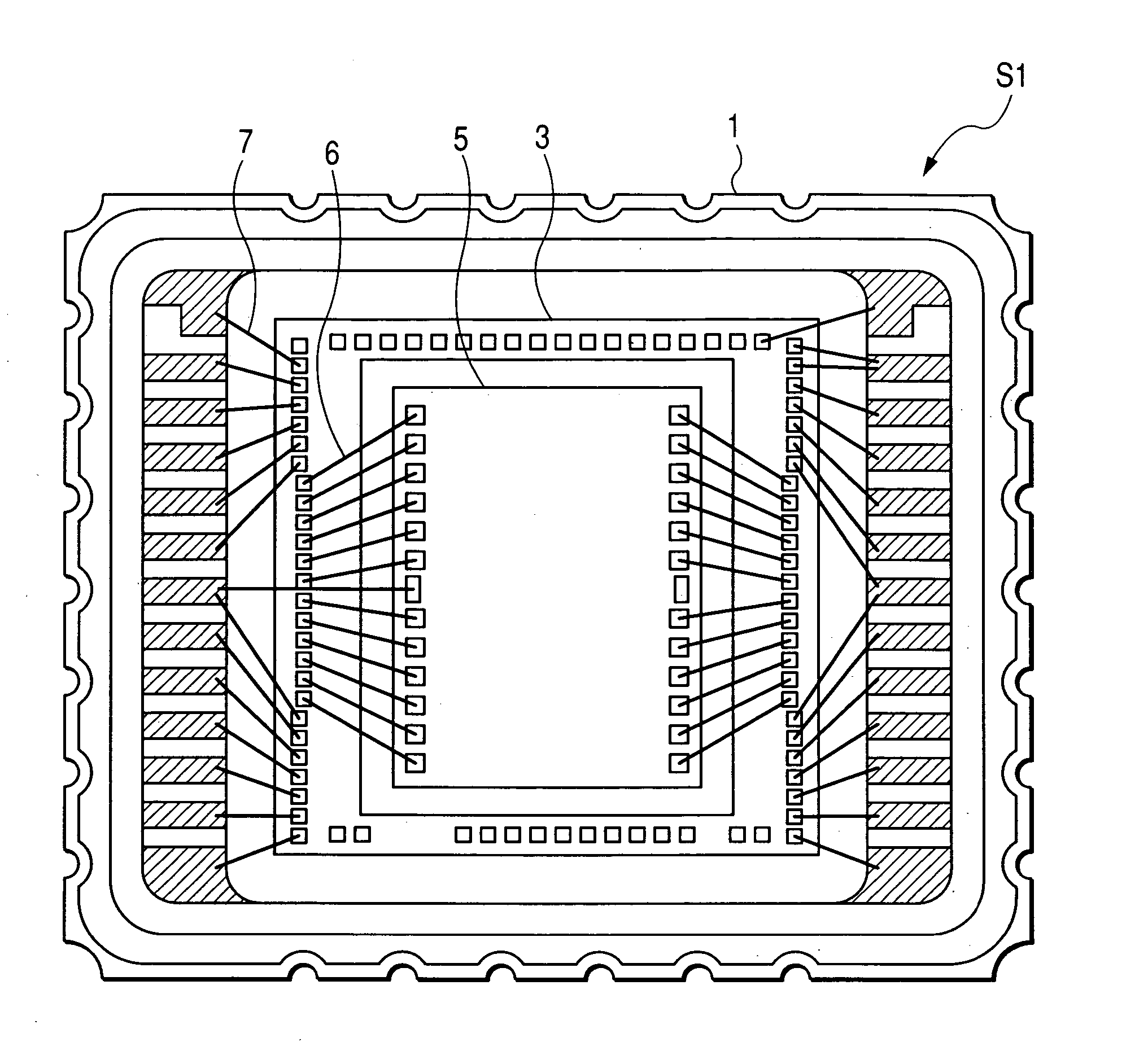

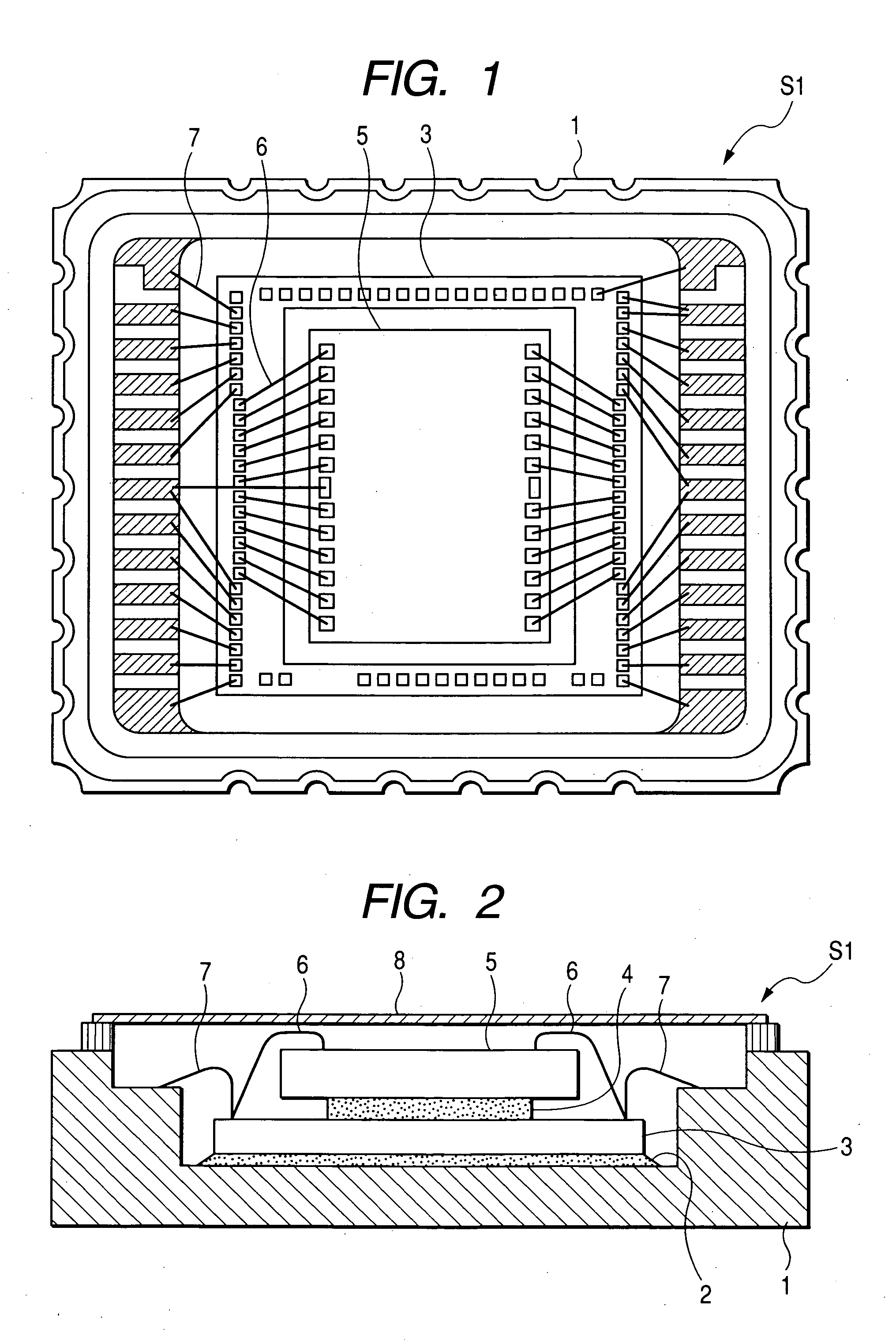

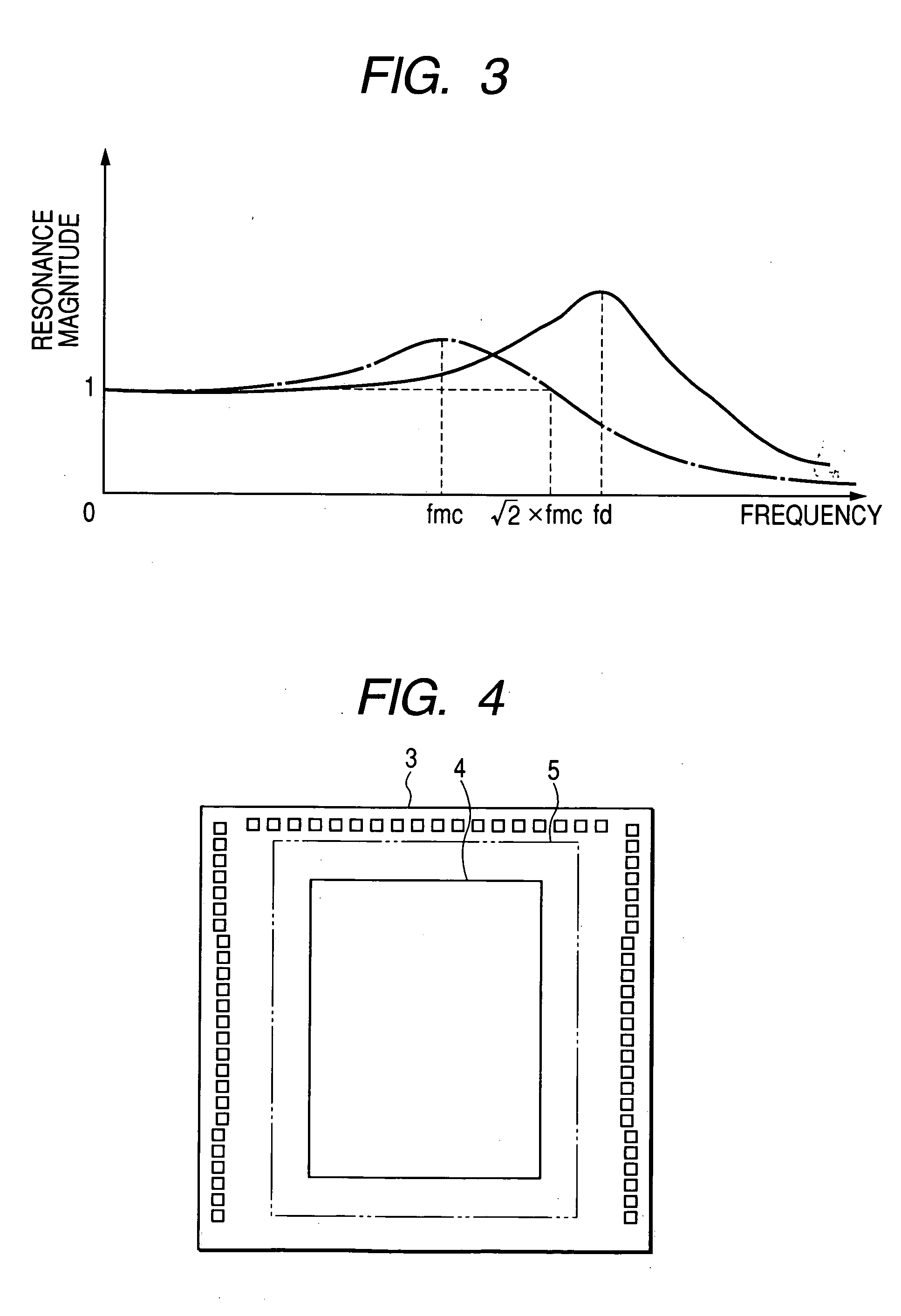

Vibration-type angular rate sensor

InactiveUS20050257615A1Secure vibration-proof propertyImprove seismic performanceAcceleration measurement using interia forcesSolid-state devicesResonanceAngular rate sensor

An angular rate sensor includes a sensor chip having an oscillator vibrating at a predetermined frequency and detecting an angular velocity applied to this oscillator around a predetermined rotation axis. A circuit chip, laminated with the sensor chip, has a circuit formed on a surface thereof to detect the angular velocity based on a signal obtained from the sensor chip. The sensor chip and the circuit chip are bonded with an adhesive film. A resonance frequency of the sensor chip is smaller than (½)1 / 2 times a driving frequency of the oscillator in a condition that adjustment is applied to at least one of configuration or elastic coefficient of the adhesive film.

Owner:DENSO CORP

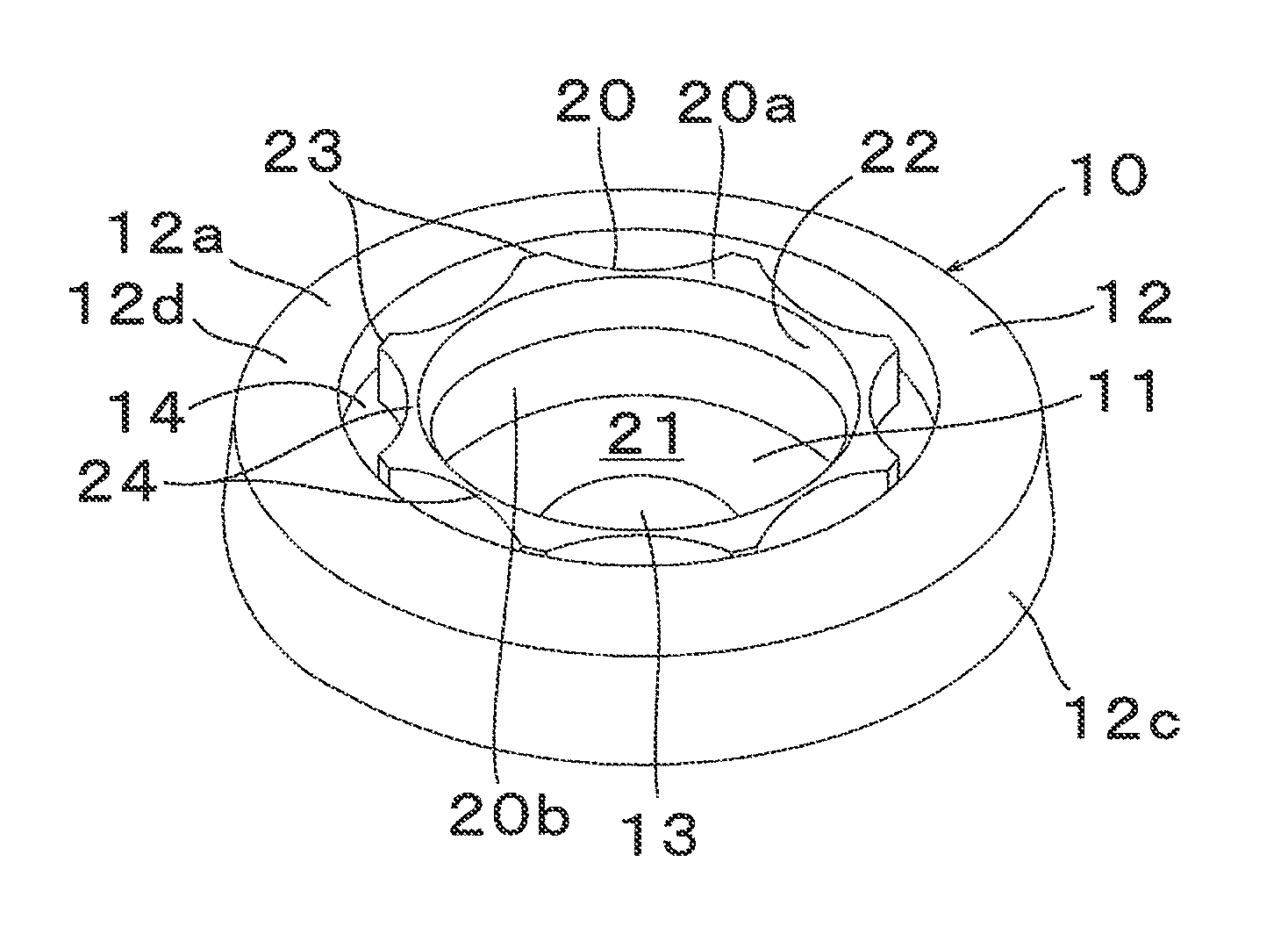

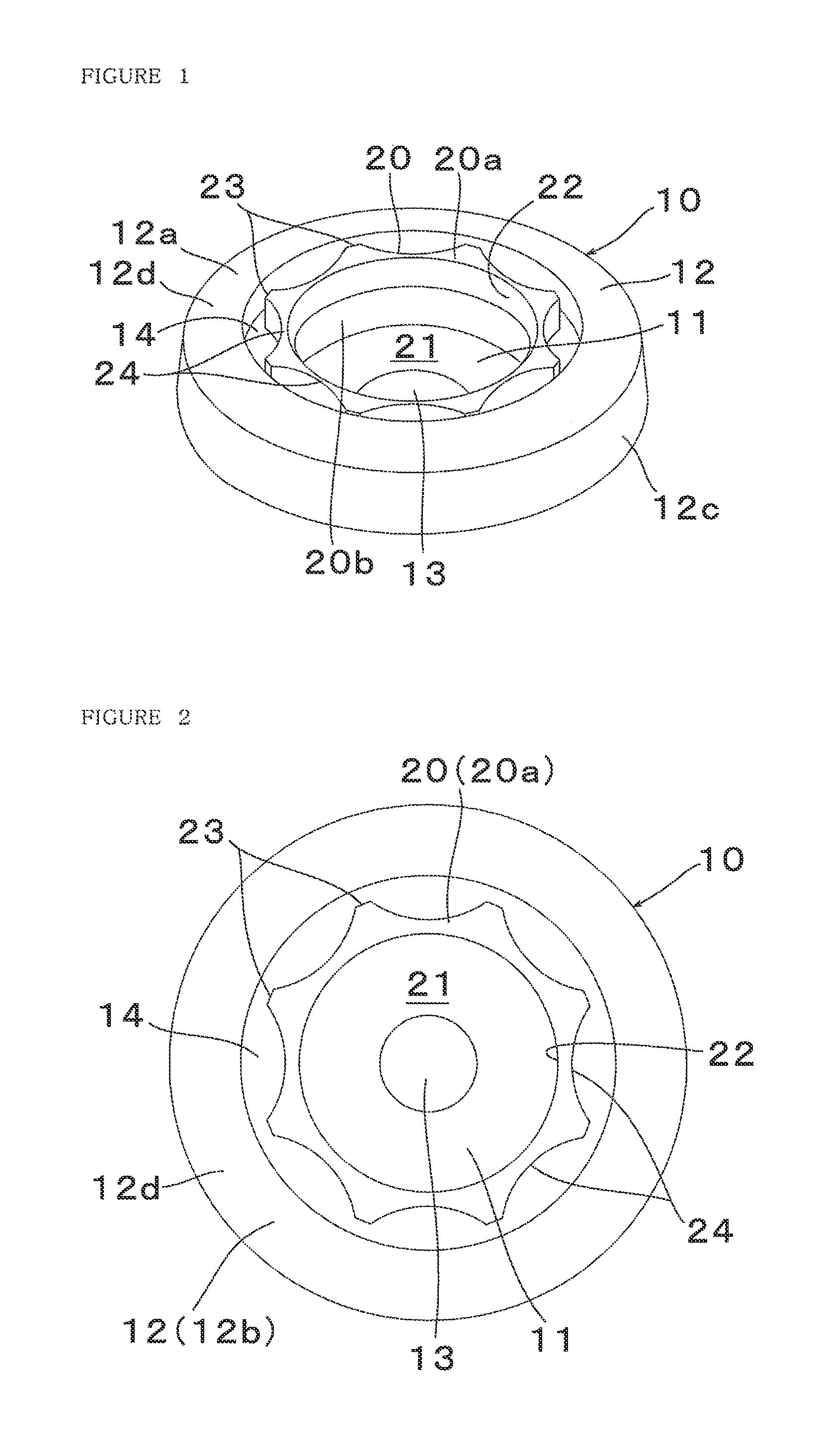

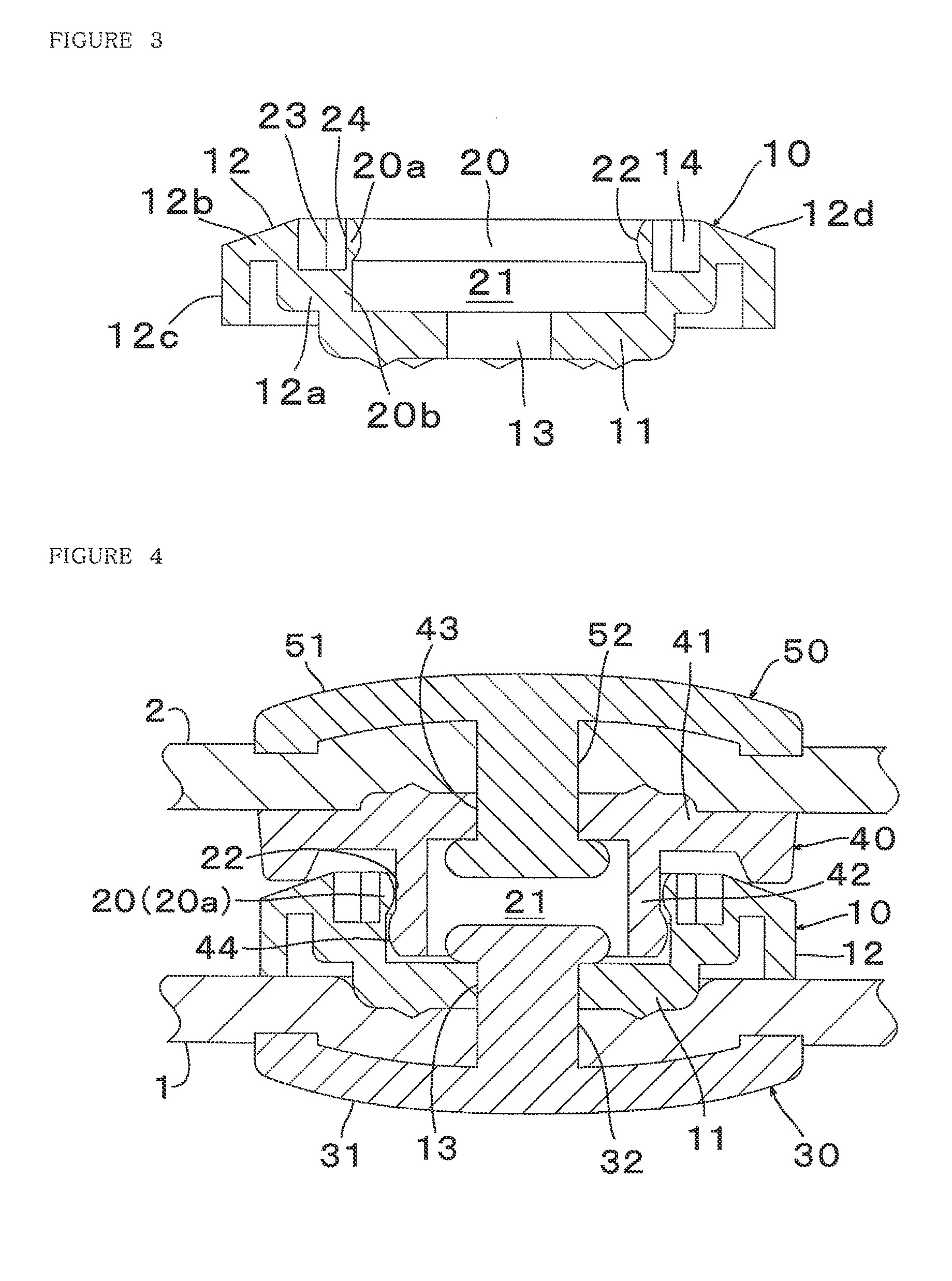

Female snap button

ActiveUS8561264B2Increase the differenceMaintain resistanceSnap fastenersClothes buttonsEngineeringThin walled

Owner:YKK CORP

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com