Patents

Literature

2259 results about "Melt blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ice melt blends are popular because they are economically priced while maintaining the ability to work quickly at extremely low temperatures. Typical blended ice melt contains a combination of sodium chloride, magnesium chloride or calcium chloride. These chlorides work in different ways to melt ice and snow.

Microporous PVDF films and method of manufacturing

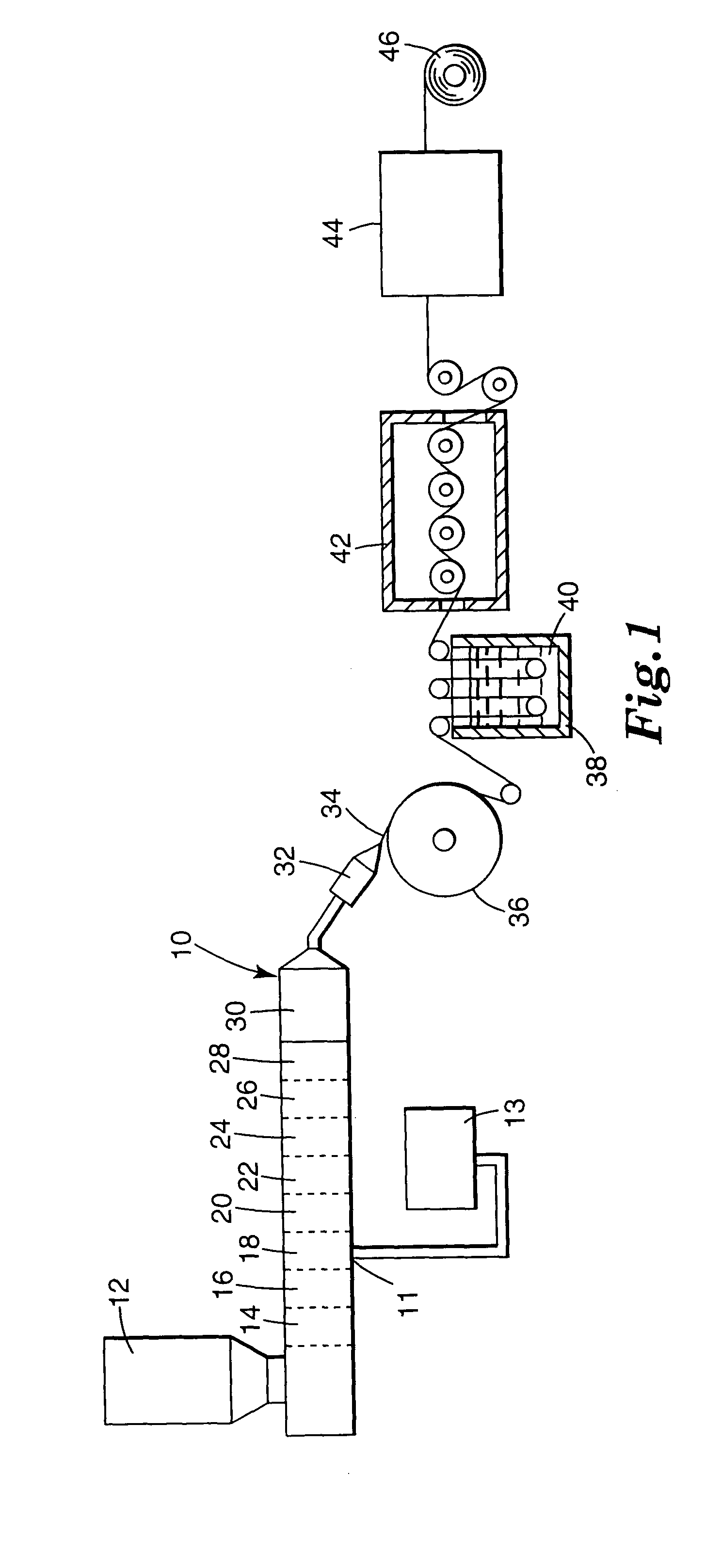

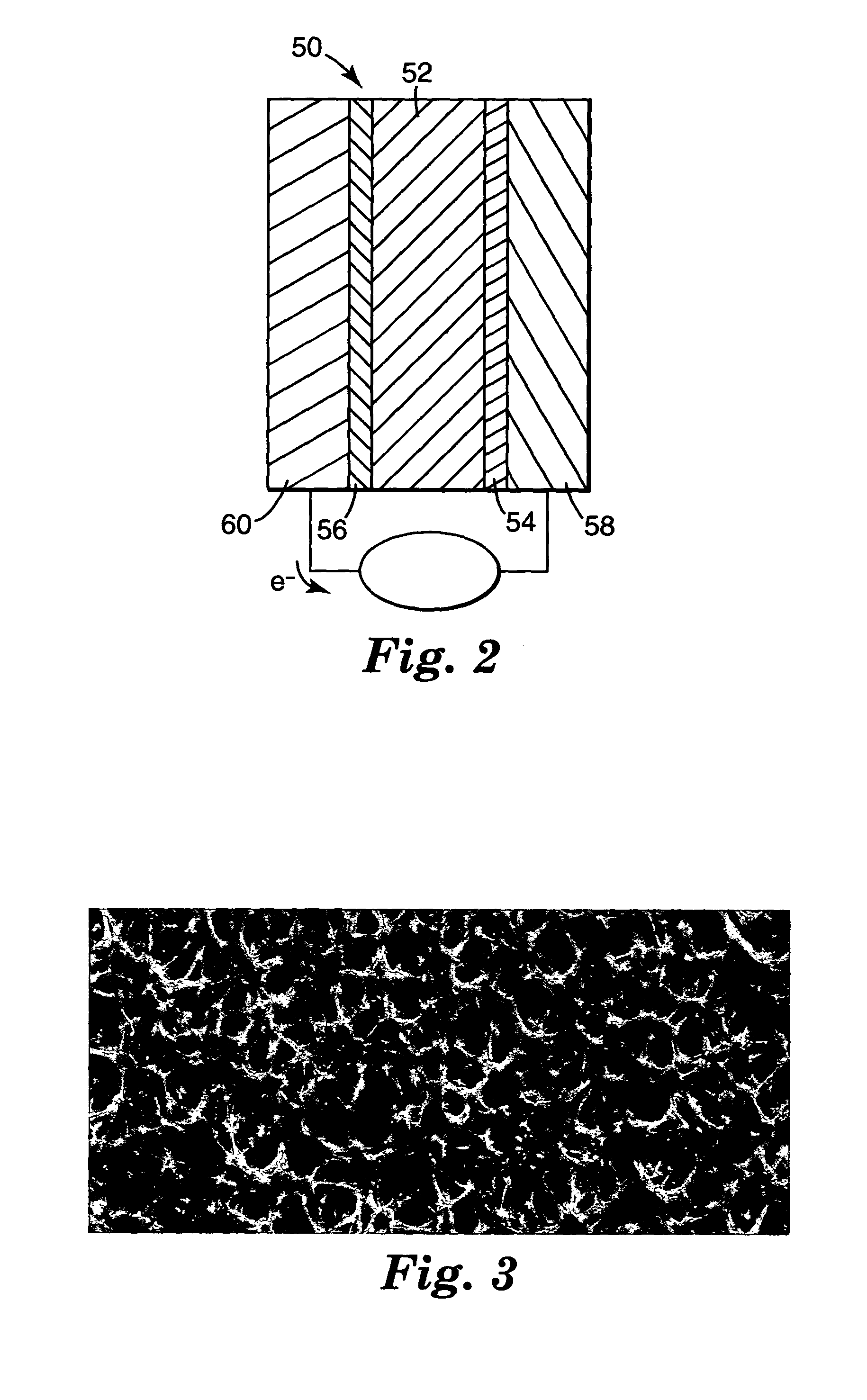

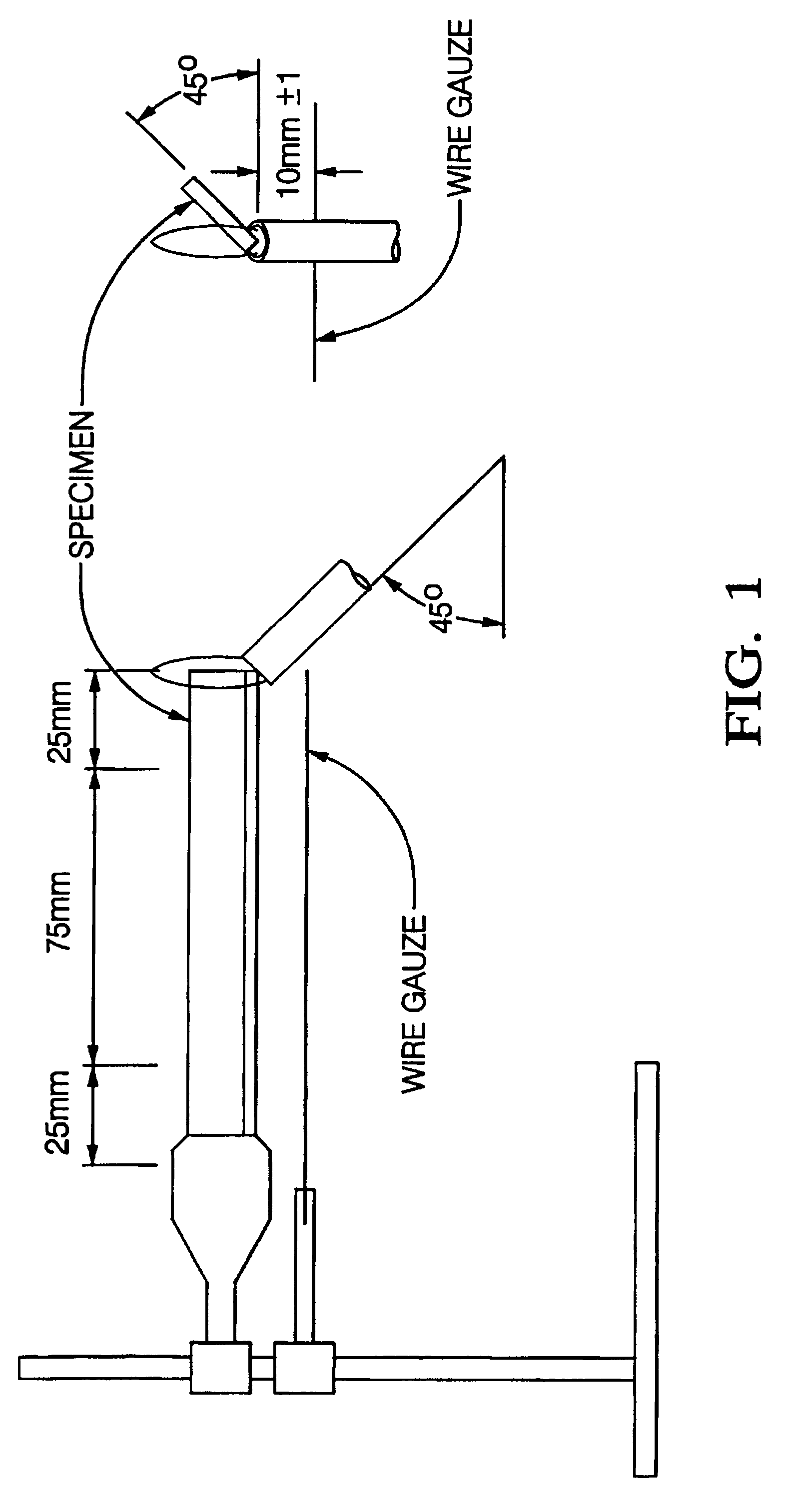

Shaped microporous articles are produced from polyvinylidene fluoride (PVDF) and nucleating agents using thermally induced phase separation (TIPS) processes. The shaped microporous article is oriented in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0. The shaped article may also comprise a diluent, glyceryl triacetate. The shaped microporous article may also have the micropores filled with a sufficient quantity of ion conducting electrolyte to allow the membrane to function as an ion conductive membrane. The method of making a microporous article comprises the steps of melt blending polyvinylidene fluoride, nucleating agent and glyceryl triacetate; forming a shaped article of the mixture; cooling the shaped article to cause crystallization of the polyvinylidene fluoride and phase separation of the polyvinylidene fluoride and glyceryl triacetate; and stretching the shaped article in at least one direction at a stretch ratio of at least approximately 1.1 to 1.0.

Owner:3M INNOVATIVE PROPERTIES CO

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

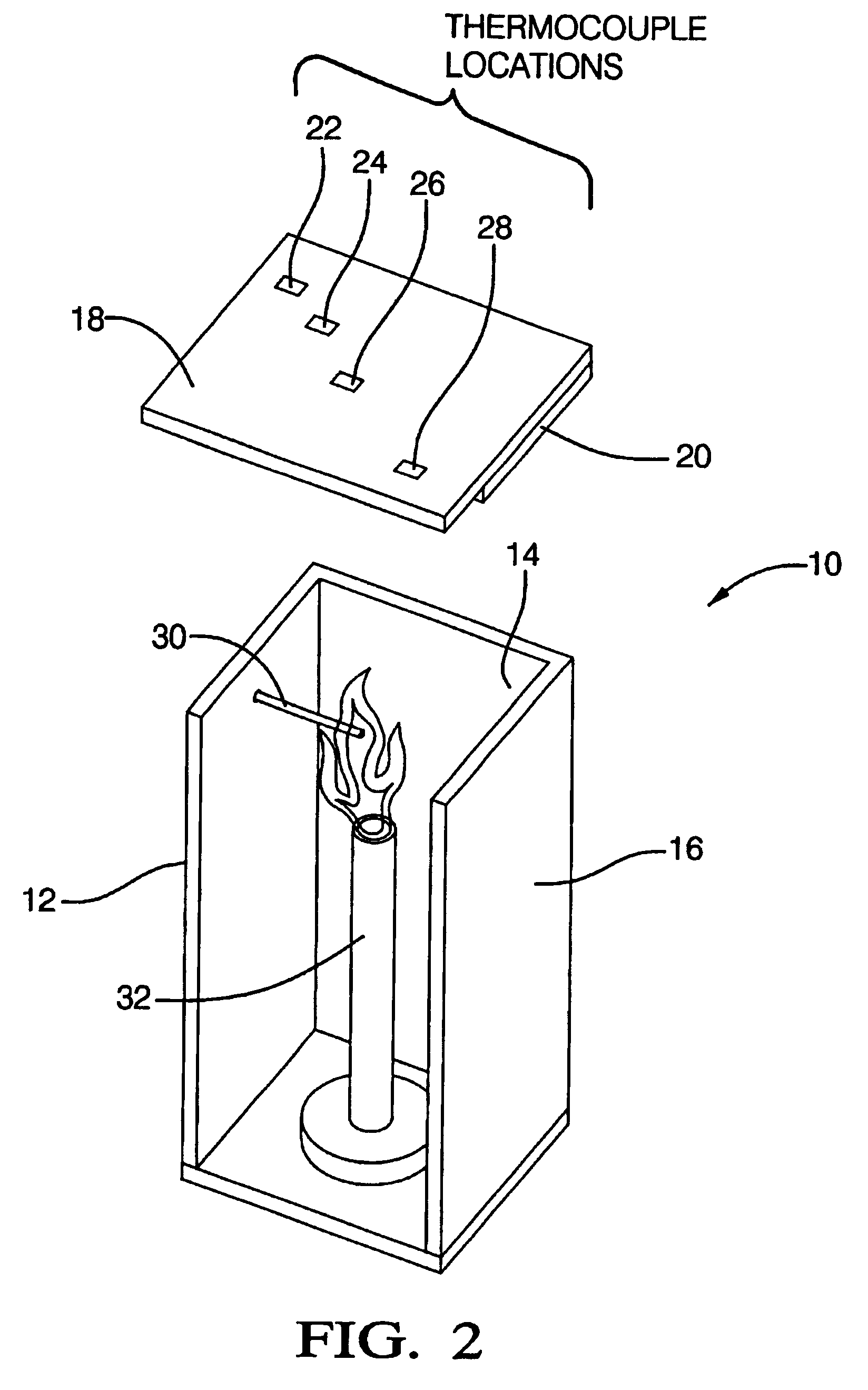

Intumescent fire retardant composition and method of manufacture thereof

InactiveUS6706793B2Improve flame retardant performanceHigh impact strengthFireproof paintsSpecial tyresGraphiteFire retardant

Owner:APTIV TECH LTD

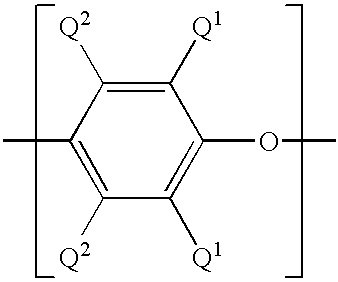

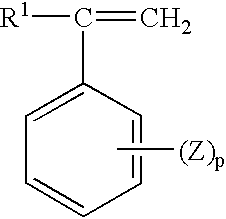

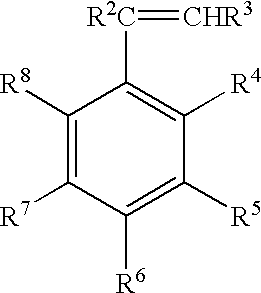

Method for the preparation of a poly(arylene ether)-polyolefin composition, and composition prepared thereby

A poly(arylene ether)-polyolefin composition is prepared by melt-blending a poly (arylene ether), a poly(alkenyl aromatic) resin, a hydrogenated block copolymer of an alkenyl aromatic compound and a conjugated diene, and an unhydrogenated block copolymer of an alkenyl aromatic compound and a conjugated diene to form a first blend, and melt-blending the first blend and a polyolefin to form a second blend. Reinforcing fillers may, optionally, be added during formation of the second blend or in an additional step. Multiple mixing elements, low throughput, and high extruder rotations per minute may be used to achieve high energy mixing of the first and second blends. Compositions prepared by the method exhibit an improved balance of impact strength, stiffness, and heat resistance, as well as reduced variability of physical properties.

Owner:SHPP GLOBAL TECH BV

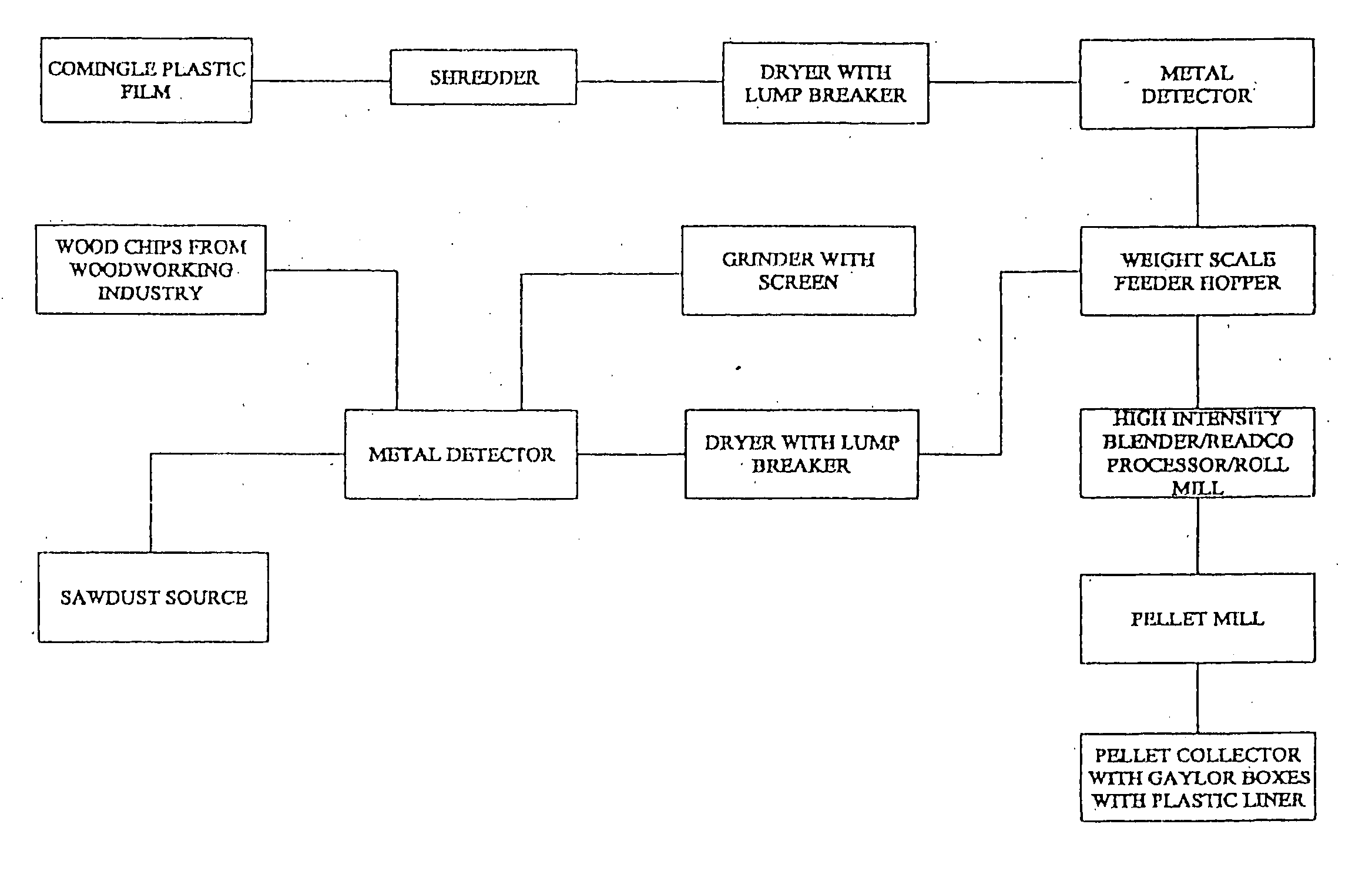

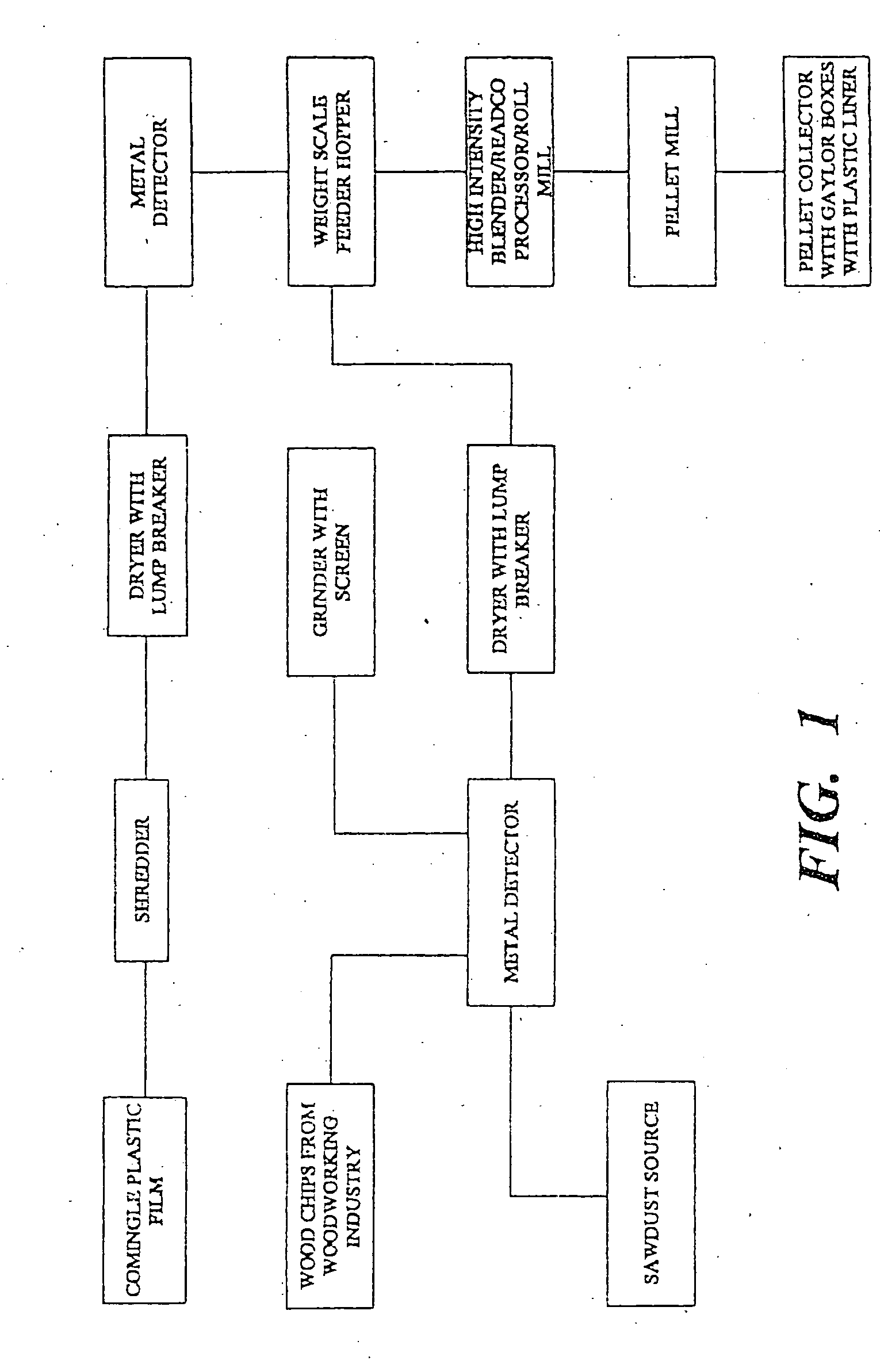

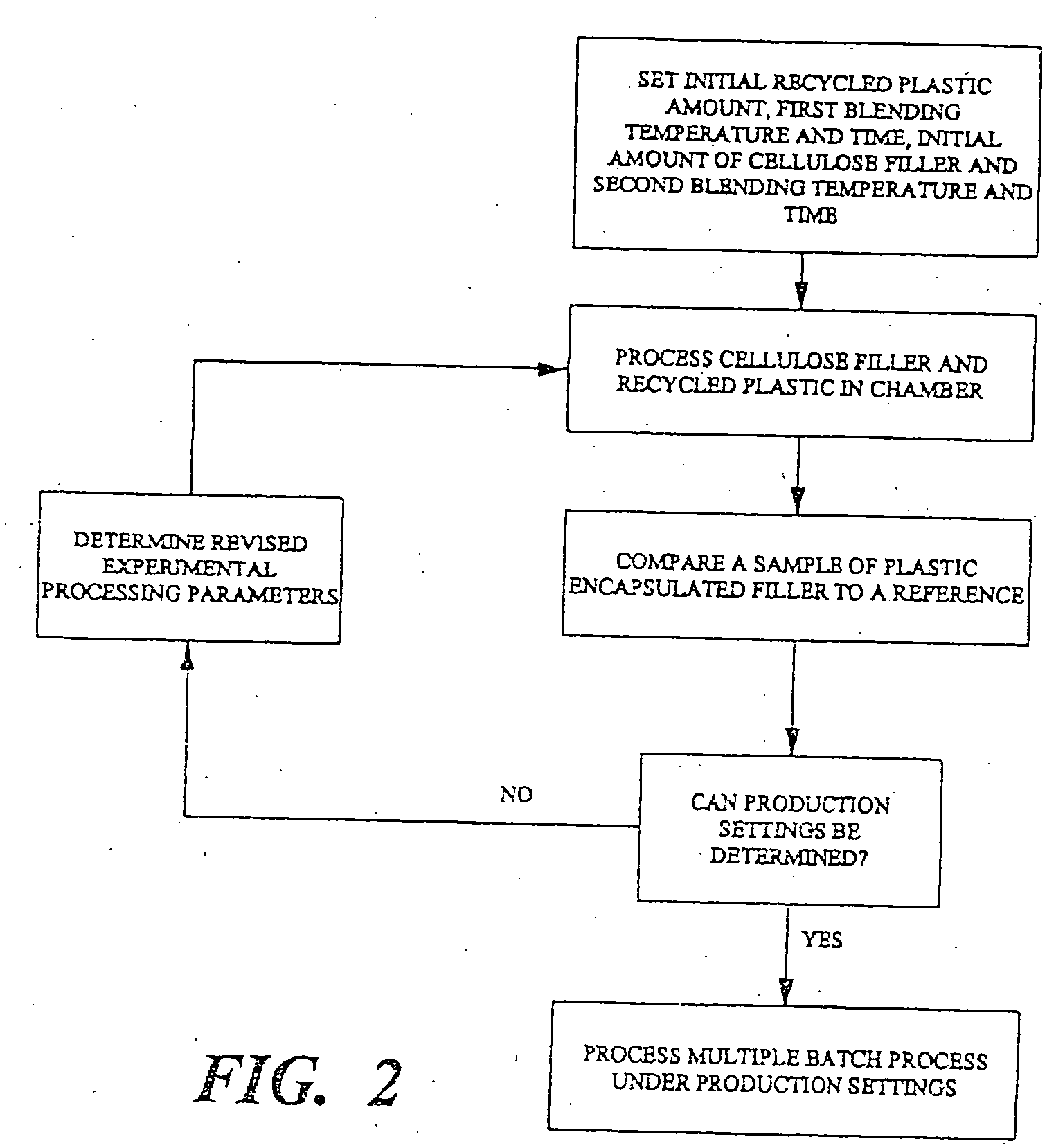

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20060006564A1Reduce the possibilityLower melting and softening temperaturePlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

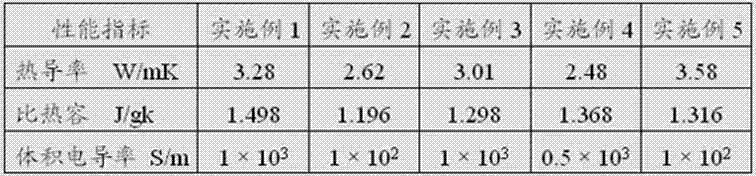

Graphene filled polymer matrix composite material and its preparation method

ActiveCN103087404AImprove conductivityImprove thermal conductivityIn situ polymerizationMechanical property

The invention discloses a graphene filled polymer matrix composite material. The composite material is prepared through using 90-99 parts by weight of a thermoplastic resin, 0.1-10 parts by weight of a graphene microchip, 0.01-1 part of a coupling agent, and 1-10 parts of a lubricant. The invention also discloses a preparation method of the graphene filled polymer matrix composite material. Compared with other carbon system filled composite materials, the graphene filled polymer matrix composite material has the advantages of easy processing, easy forming, less filler filling amount, wide raw material source, environmental protection and the like. The composite material has the characteristics of excellent electric conductivity, excellent thermal conductivity, good mechanical properties, good dimensional stability, good weather resistance and the like; and compared with present technologies for preparing a graphene / polymer composite material through in-situ polymerization or solution polymerization, the melt blending method for preparing the graphene filled polymer matrix composite material in the invention has the advantages of continuous production, suitableness for the large-scale production, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Essentially gas-impermeable thermoplastic elastomer

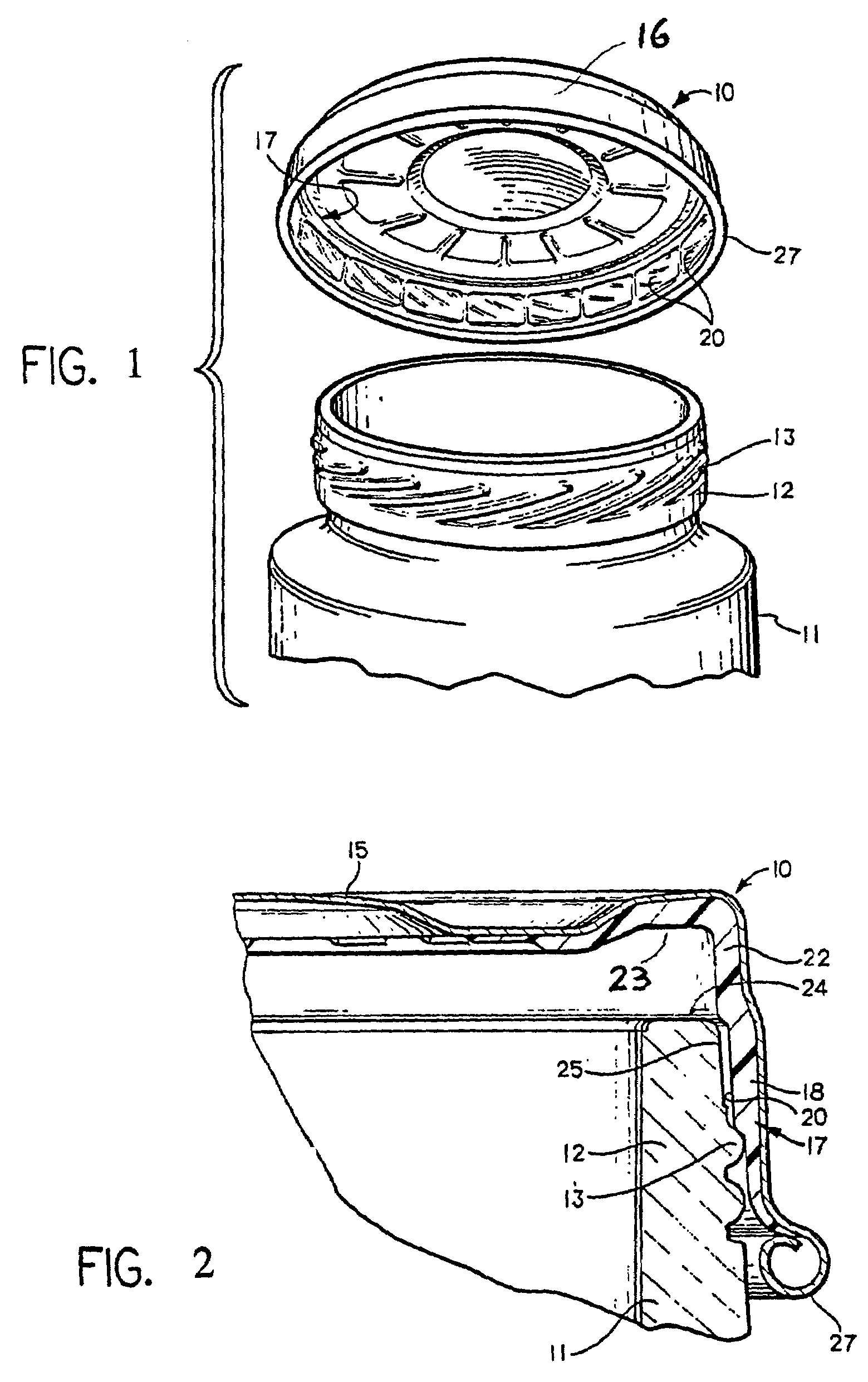

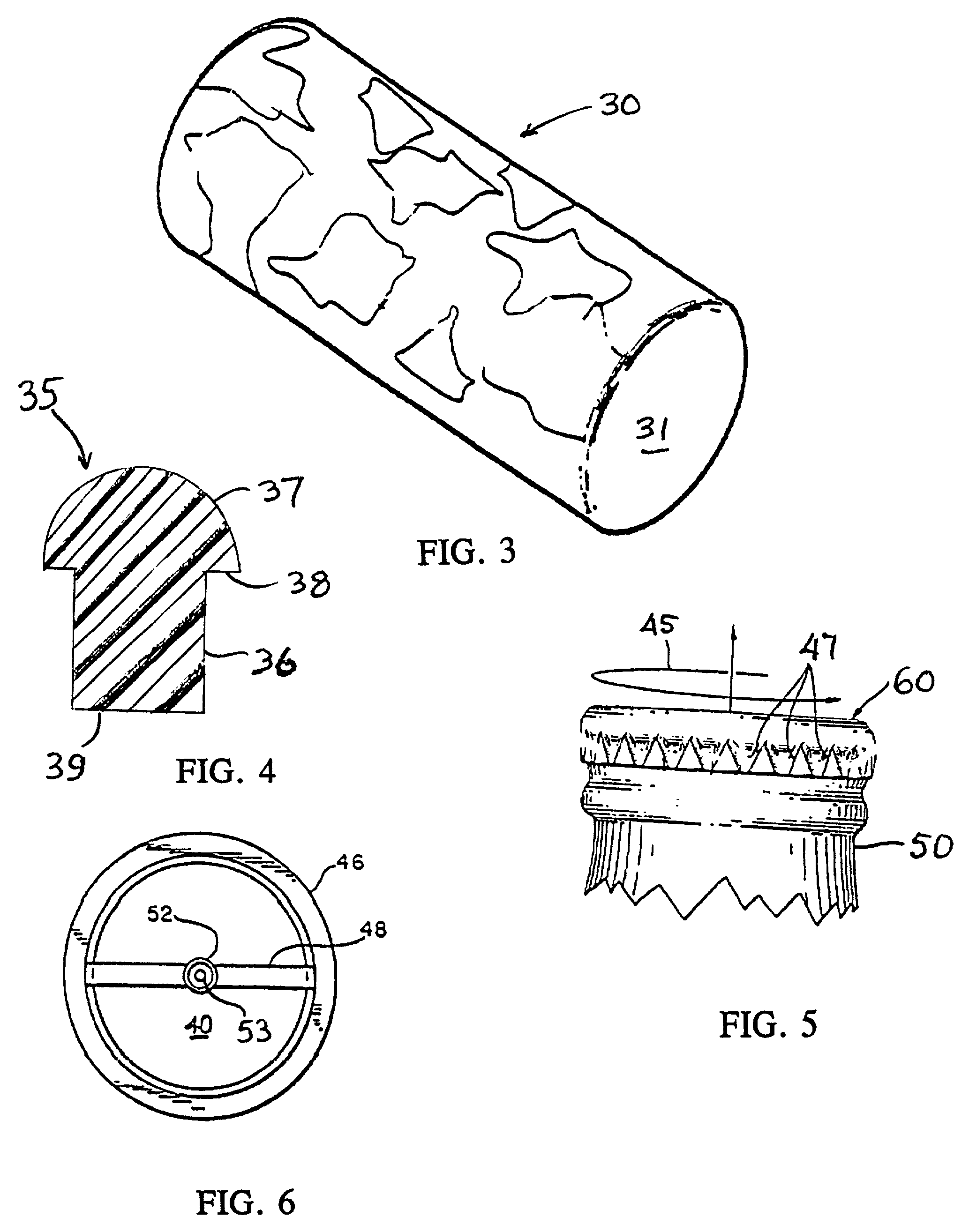

A thermoplastic elastomer (“TPE”) which is oxygen-permeable is provided with excellent barrier properties against oxygen by melt-blending with a liquid polyisobutene oil plasticizer in an amount insufficient to render the plasticized elastomer tacky. If made tacky, enough detackifier is used to allow the product to be formed into a removable seal. The TPE may be a conventional thermoplastic vulcanizate or a block copolymer of a vinylaromatic compound, typically styrene, and a conjugated diene, typically butadiene or isoprene, or mixtures thereof; the block may be a diblock, triblock or higher block, but the preferred polyblock copolymer is a triblock with styrene end-blocks and a butadiene / isoprene mid-block. Preferably the diene mid-block is hydrogenated to provide a poly(lower)monoolefin mid-block. When the TPE is a TPV, some or all of the mineral oil used to make the TPV processable may also be substituted with the polyisobutene plasticizer. The elastomeric product is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:AVIENT CORP

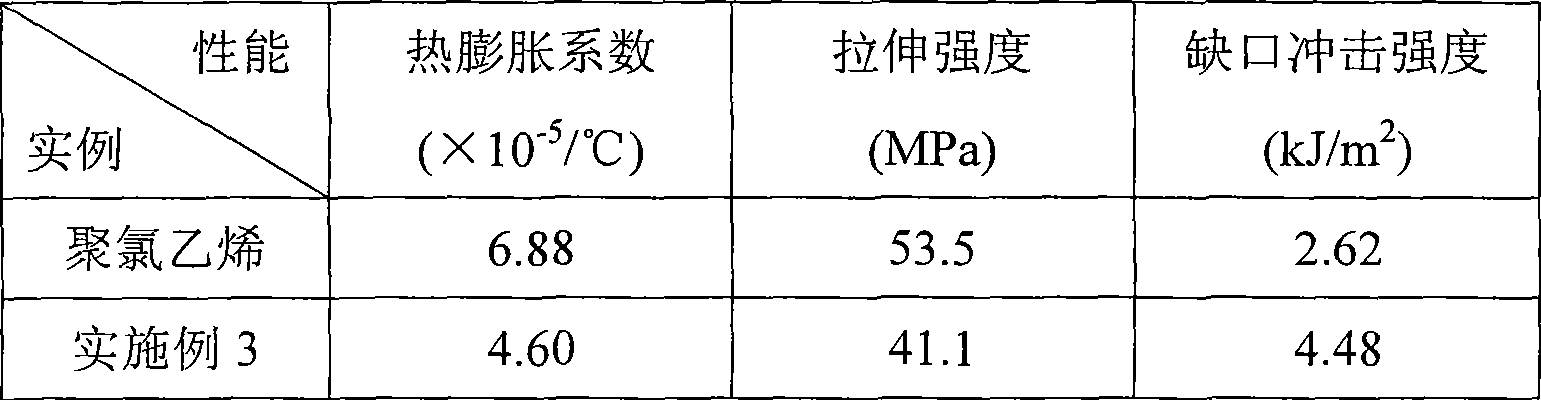

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

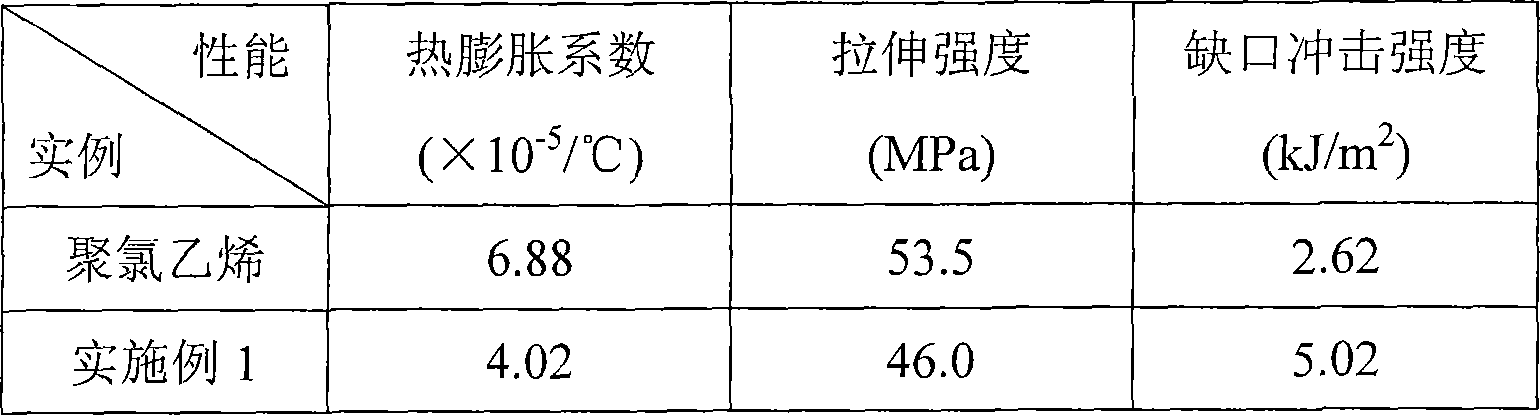

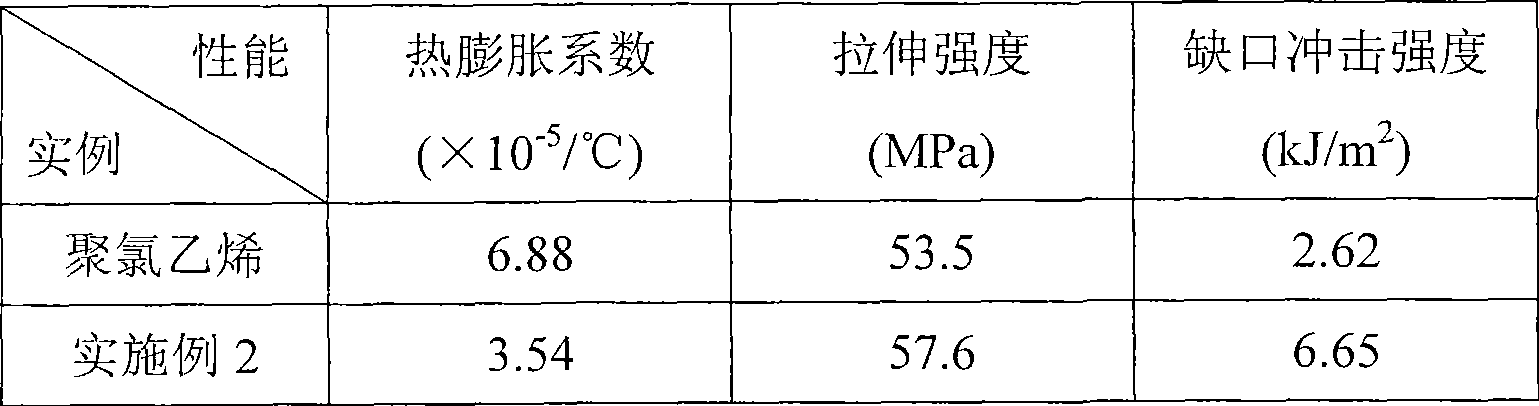

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

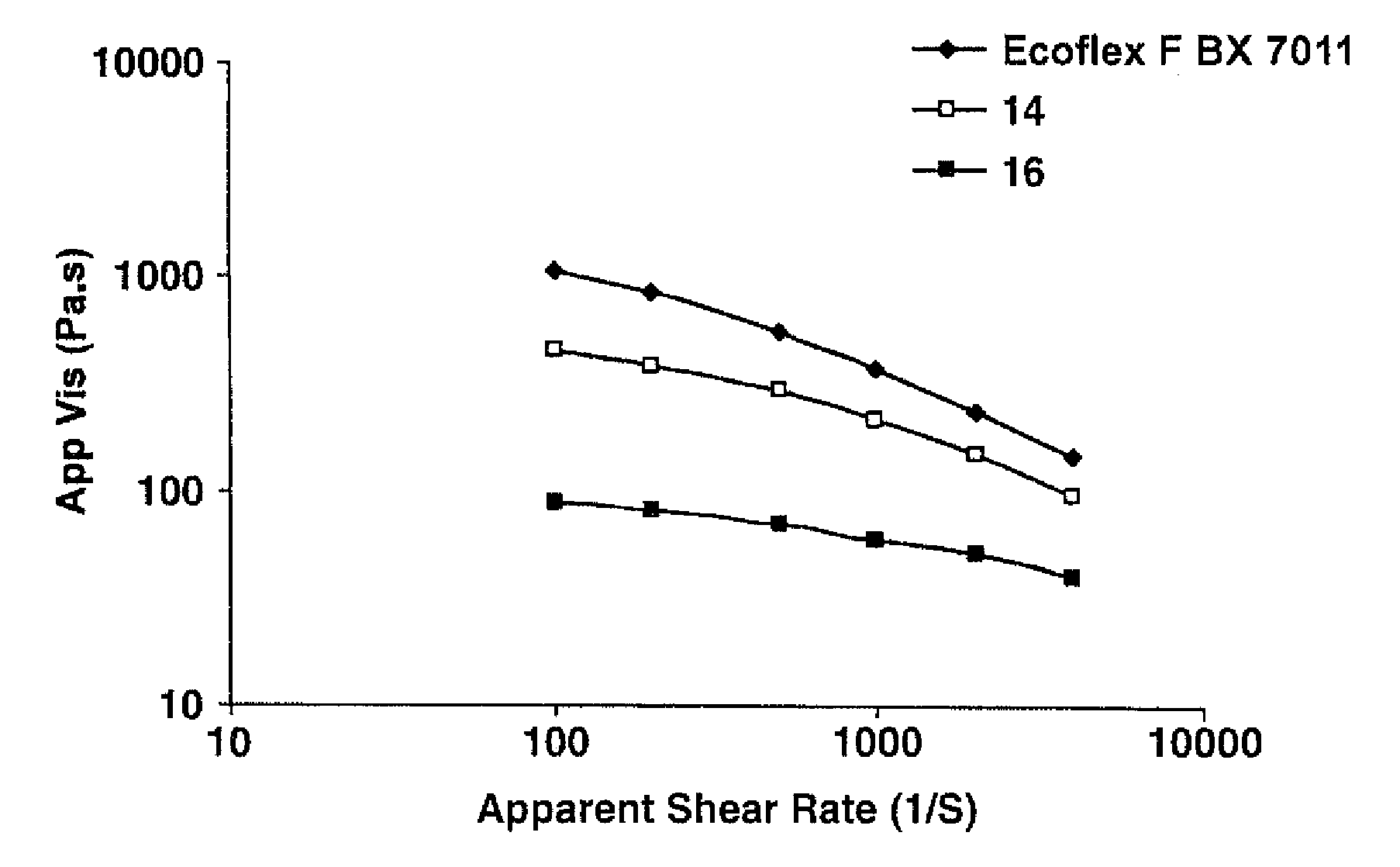

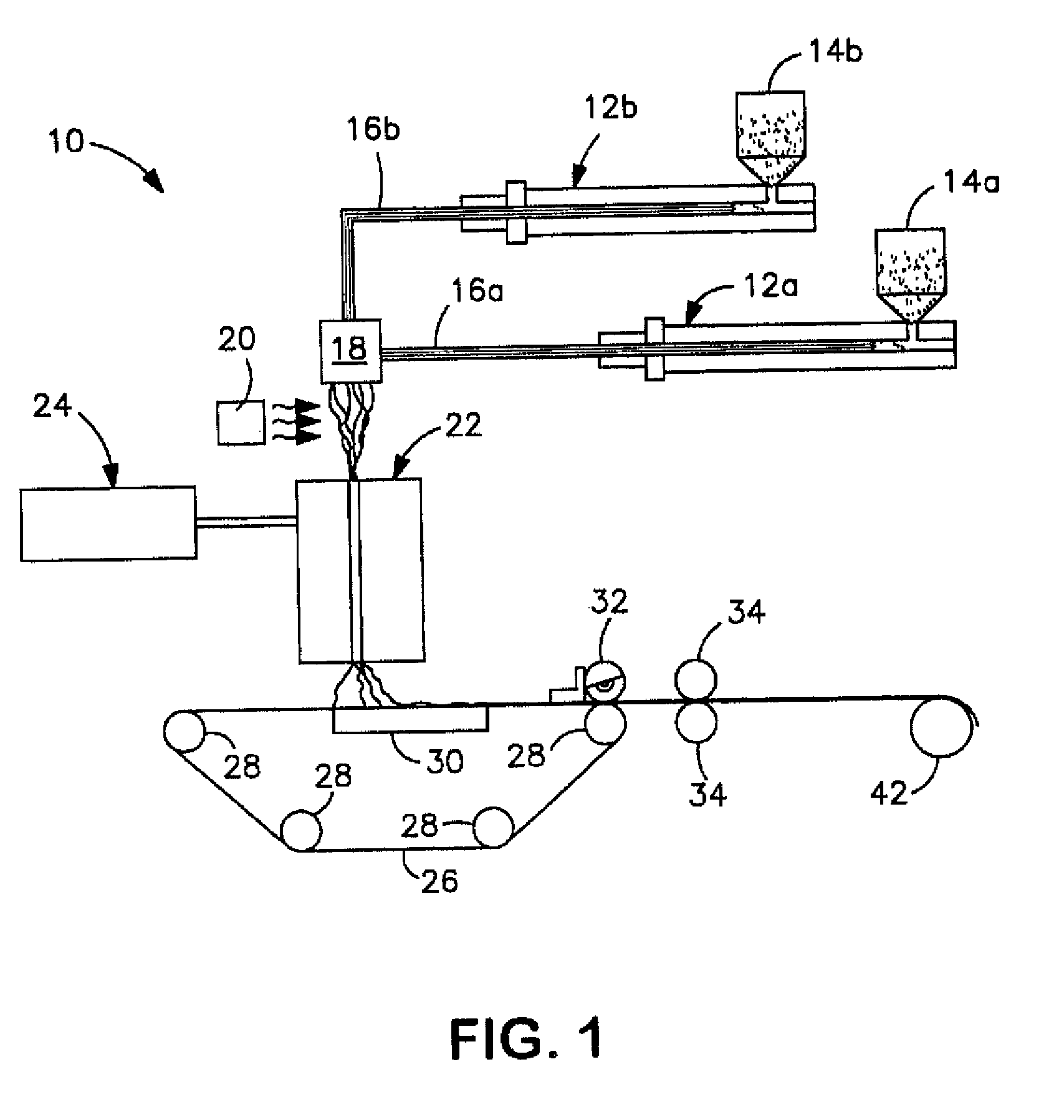

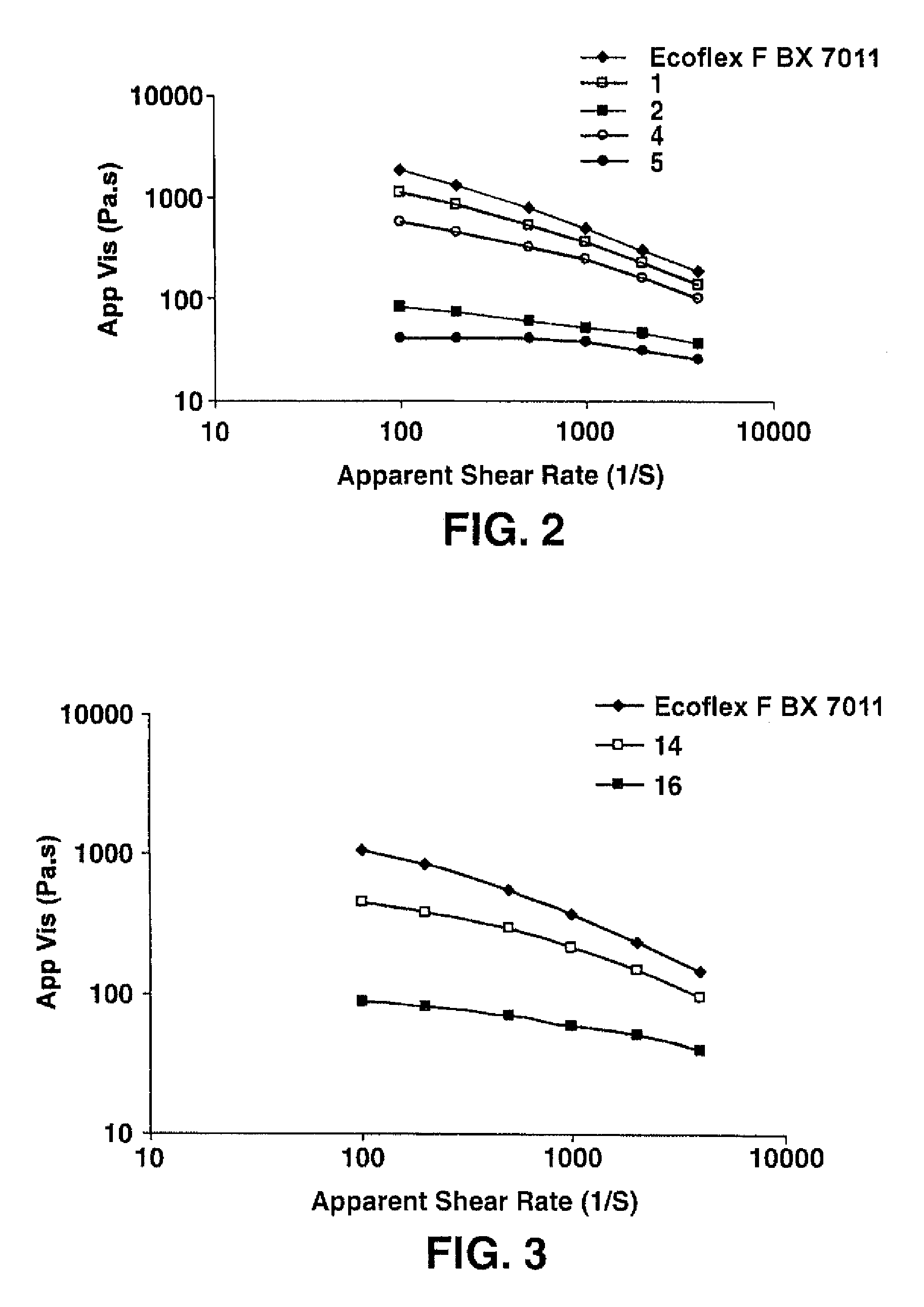

Multicomponent biodegradable filaments and nonwoven webs formed therefrom

A biodegradable, substantially continuous filament is provided. The filament contains a first component formed from at least one high melting polyester and a second component formed from at least one low melting polyester. The low melting point polyester is an aliphatic-aromatic copolyester formed by melt blending a polymer and an alcohol to initiate an alcoholysis reaction that results in a copolyester having one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the alcoholysis conditions (e.g., alcohol and copolymer concentrations, catalysts, temperature, etc.), a modified aliphatic-aromatic copolyester may be achieved that has a molecular weight lower than the starting aliphatic-aromatic polymer. Such lower molecular weight polymers also have the combination of a higher melt flow index and lower apparent viscosity, which is useful in the formation of substantially continuous filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Recycled carbon fiber reinforced thermoplastic resin composite material and preparation method thereof

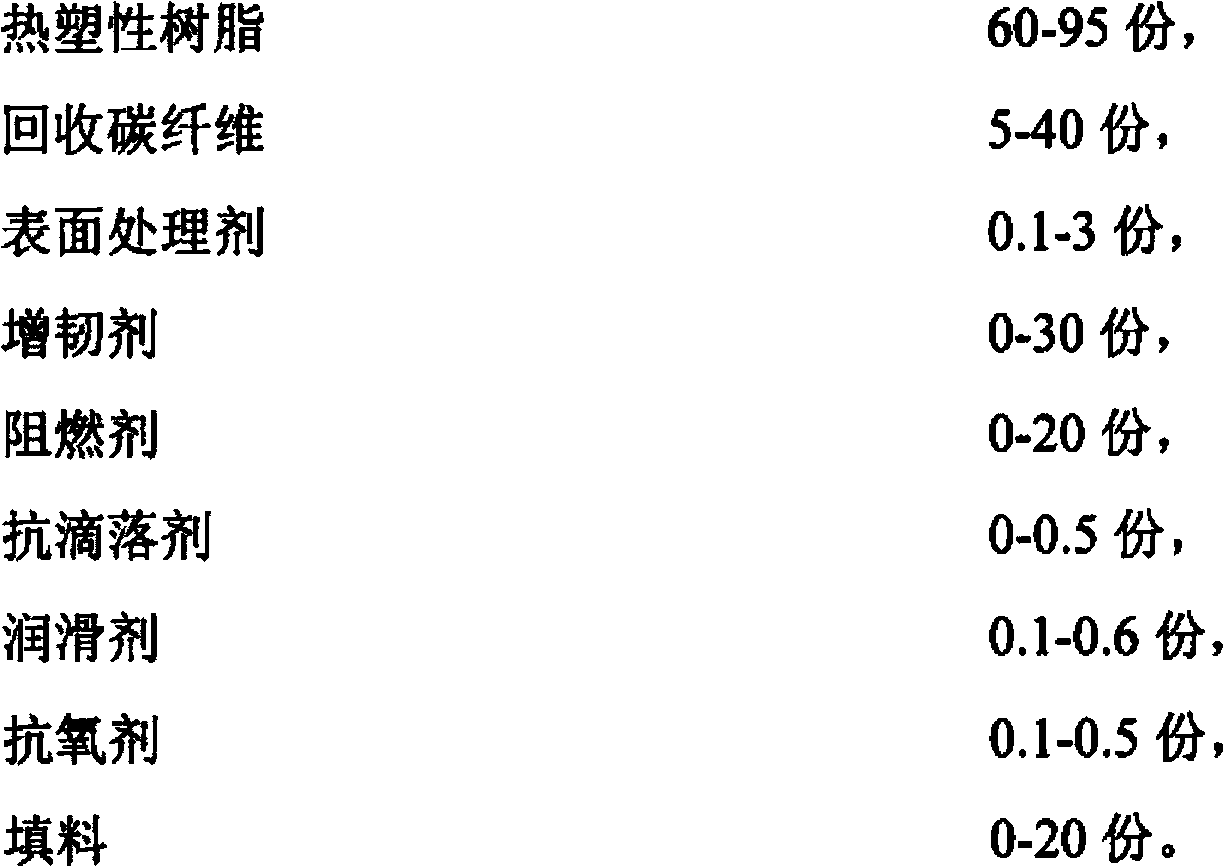

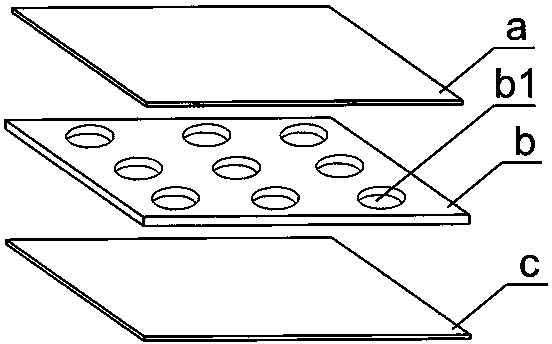

The invention relates to a recycled carbon fiber reinforced thermoplastic resin composite material and a preparation method thereof. The preparation method comprises the following steps: (1) weighing 5-40 parts of recycled carbon fiber according to a proportion, adding the recycled carbon fiber into a high-speed mixer, adding 0.1-3 parts of surface treating agent, and performing surface treatment on the recycled carbon fiber; (2) weighing 60-95 parts of thermoplastic resin, 0-30 parts of flexibilizer, 0-20 parts of fire retardant, 0-0.5 part of anti-drip agent, 0.1-0.6 part of lubricant, 0.1-0.5 part of antioxidant and 0-20 parts of filler according to the proportion, adding the raw materials into the high-speed mixer, and uniformly mixing the raw materials; (3) adding the uniformly mixed raw materials into a double-screw machine, and performing melt blending, extrusion, water cooling and strand pelletizing to obtain the recycled carbon fiber reinforced thermoplastic resin composite material. Compared with the prior art, the recycled carbon fiber reinforced thermoplastic resin composite material has the advantages of low density, excellent mechanical performance, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

High melt strength polypropylene material and preparation

InactiveCN101486817AOther physical and mechanical properties remain unchangedPhysical and mechanical properties unchangedPolymer sciencePolypropylene

The invention relates to a high melt strength polypropylene material and a preparation method. The high melt strength polypropylene material consists of 100 parts of polypropylene, 5-60 parts of high-melting point crystalline polymer, 2-50 parts of compatilizer, 0-40 parts of polyethylene and other additives according to parts by weight. The preparation method includes the following steps of: measuring the polypropylene, the high-melting point crystalline polymer, the compatilizer, the polyethylene and a processing agent according to formula amount, premixing the materials uniformly and then melting and blending the materials by a screw extruder at controlled temperature and rotating speed, thus obtaining the high melt strength polypropylene material which is applicable to extrusion foaming and other hot forming technologies.

Owner:SOUTH CHINA UNIV OF TECH

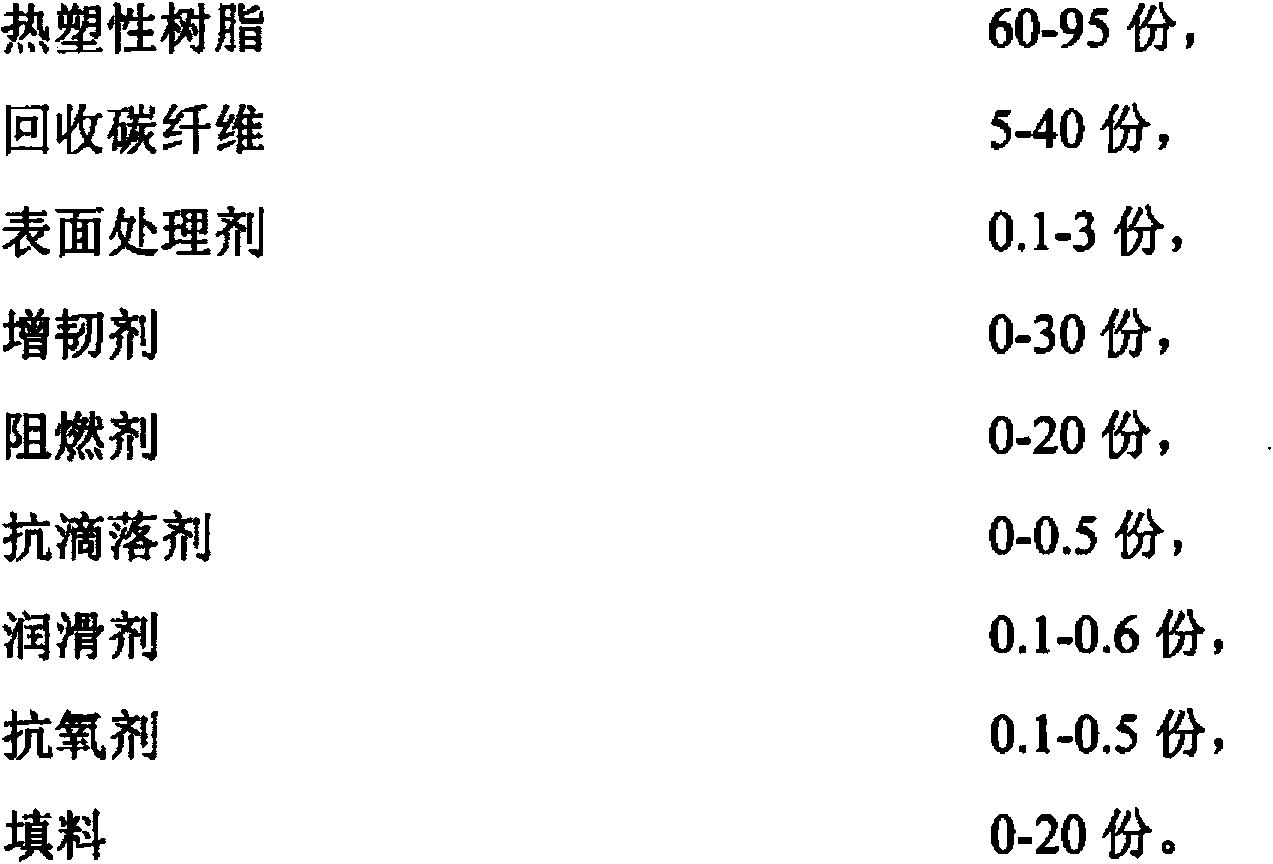

Nylon 6/graphene nanometer composite material with high thermal conductivity and preparation method thereof

The invention relates to a nylon 6 / graphene nanometer composite material with high thermal conductivity and a preparation method thereof. The composite material is composed of a nylon 6 matrix and nanometer graphene and is prepared by carrying out in situ polymerization and melt blending and banburying on obtained master batches and pure nylon 6. The nanometer graphene oxide adopted in the preparation method has a high radius-thickness ratio, a small amount of nanometer graphene oxide is added and is thermally reduced to form heat-conducting master batches, and an effective graphene heat conducting path can be formed effectively in the nylon 6. The small amount of nanometer graphene oxide heat conducting fillers and the master batches are added into the pure nylon 6 to be mixed and compounded so as to keep the good mechanical properties of the nylon 6 in the heat-conducting composite material. The nylon 6 / graphene nanometer composite material with high thermal conductivity, provided by the invention, is excellent in heat conducting property, simple in preparation process and low in cost, thereby being capable of being widely applied in the field of heat dissipation of automobiles, computers, LEDs (Light Emitting Diode), etc.

Owner:SHANGHAI UNIV

Preparation method of polylactic acid/nano-cellulose composite material

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

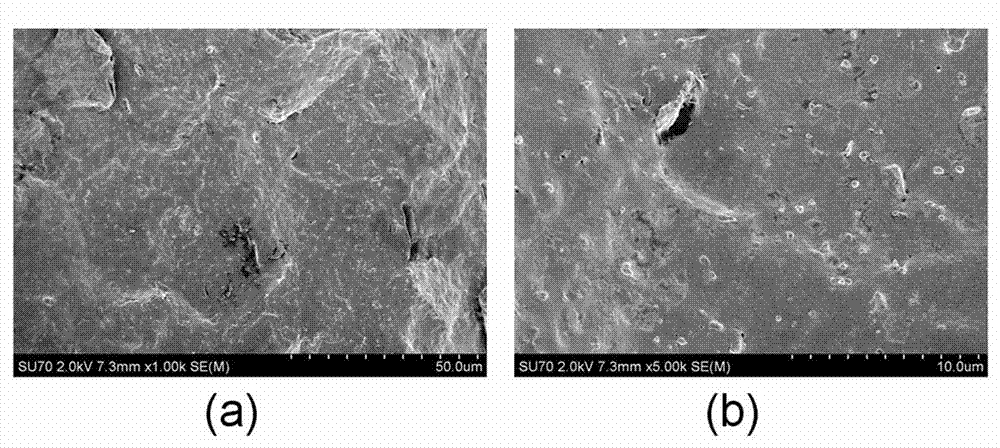

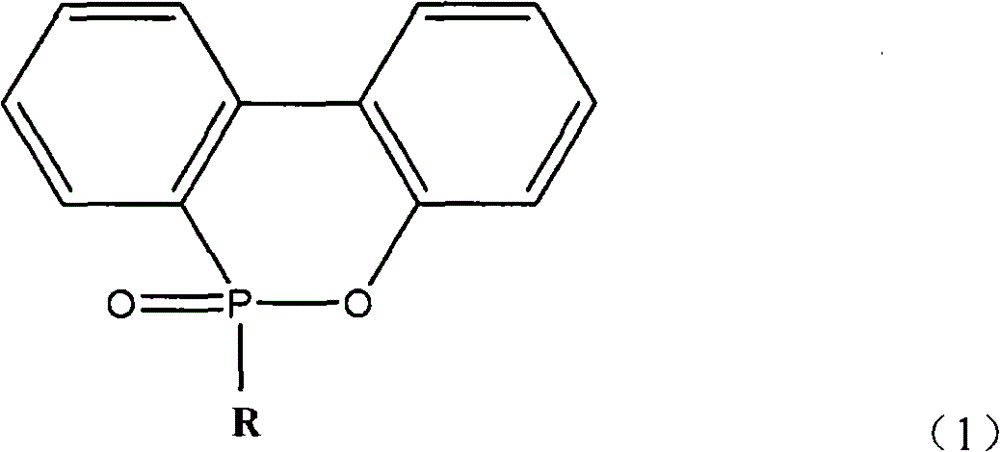

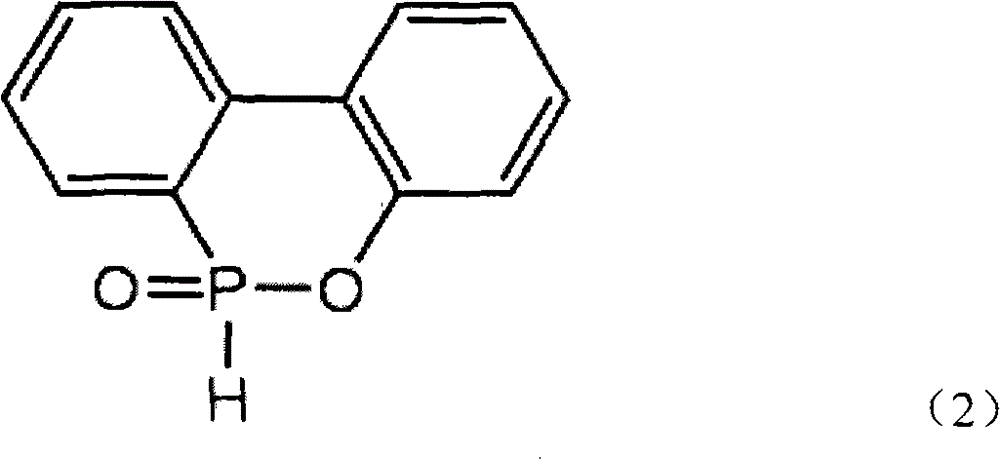

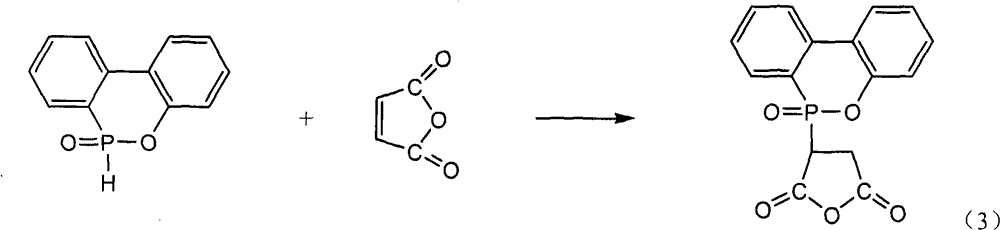

In-situ modified halogen-free flame retardant thermoplastic resin composition and preparation method thereof

InactiveCN102875982AImprove flame retardant performanceImprove mechanical propertiesPolyesterPolymer science

The invention discloses a halogen-free flame retardant thermoplastic engineering plastic composition prepared by in-situ modification, and a preparation method for the halogen-free flame retardant thermoplastic engineering plastic composition. According to the composition, polyester or polyamide is used as a base material, and reactive type halogen-free flame retardant, namely a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) composition is added, so that the halogen-free and flame retardant aims are fulfilled. The invention also discloses the preparation method for the halogen-free flame retardant engineering plastic composition. According to the method, the reactive type flame retardant and end groups or other functional groups of molecular chains of thermoplastic polymer are reacted in the melt blending process, so that the dispersibility and the compatibility between the flame retardant and a material are improved, the using amount of the flame retardant is reduced, the material is excellent in flame retardant property and high in heat resistance, and a large amount of toxic gas and fume can be prevented from being released in the combustion process.

Owner:NINGBO ECOT SCI & TECH

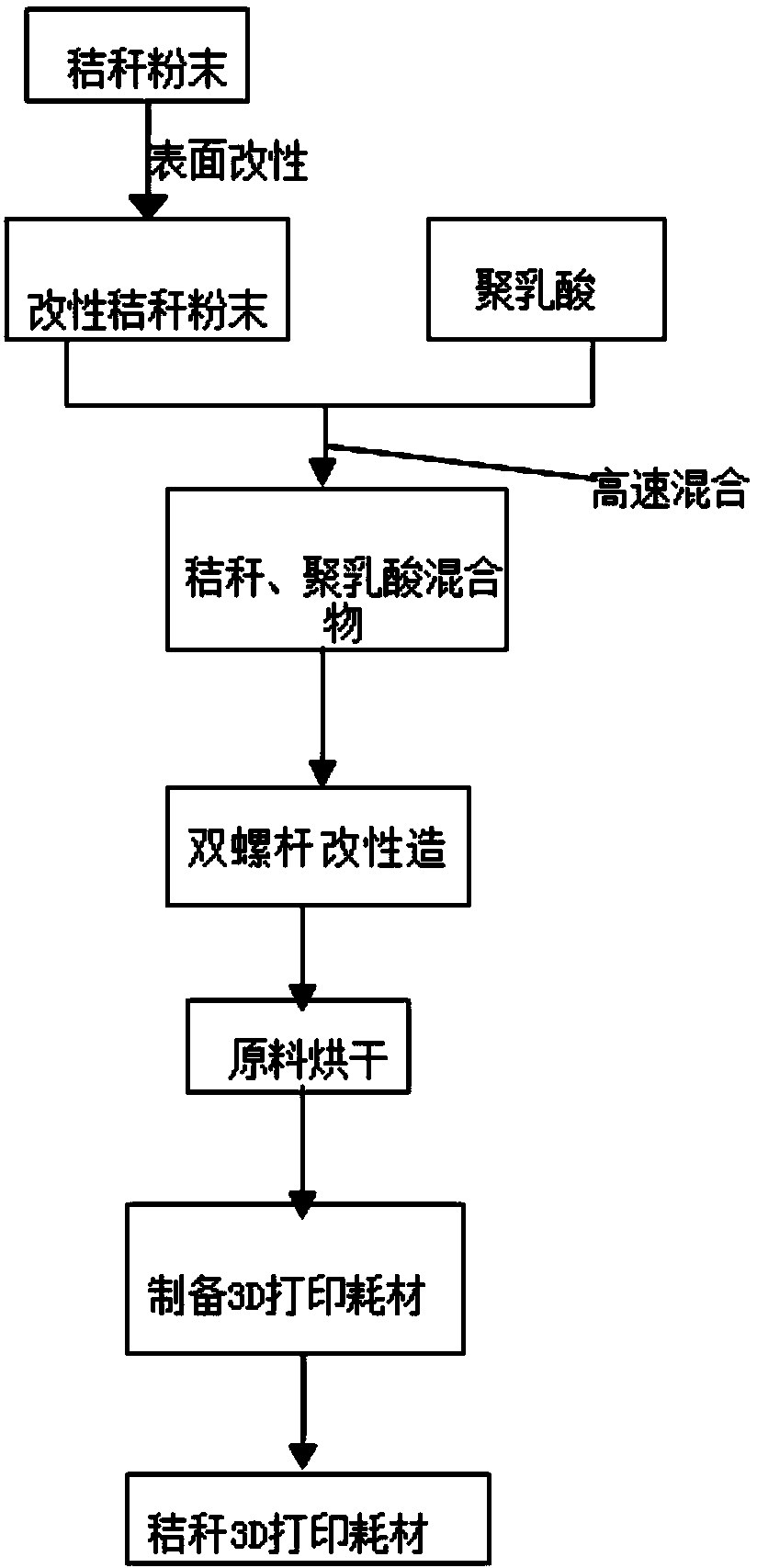

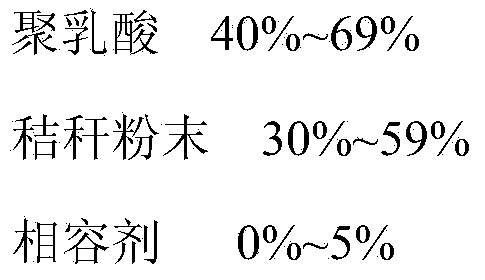

Straw 3D printing consumable and preparation method thereof

The invention provides a straw 3D printing consumable and a preparation method thereof. The formula includes the following raw materials in mass percentage: 40 to 69 percent of polylactic acid, 30 to 59 percent of straw powder, 0 to 5 percent of a compatilizer, and 0.2 to 3 percent of other additives. Straws, a crop byproduct, are fully utilized by the straw 3D printing consumable for surface modification, and the degradable material polylactic acid is added for melt blending. Compared with the prior art, the 3D printing material provided by the invention has stable performances, can replace common 3D plastic consumables in 3D printing, is non-toxic, low-carbon and environment-friendly, and has superior comprehensive performances, thereby achieving considerable economic value and broad market prospects.

Owner:芜湖瀚博电子科技有限公司

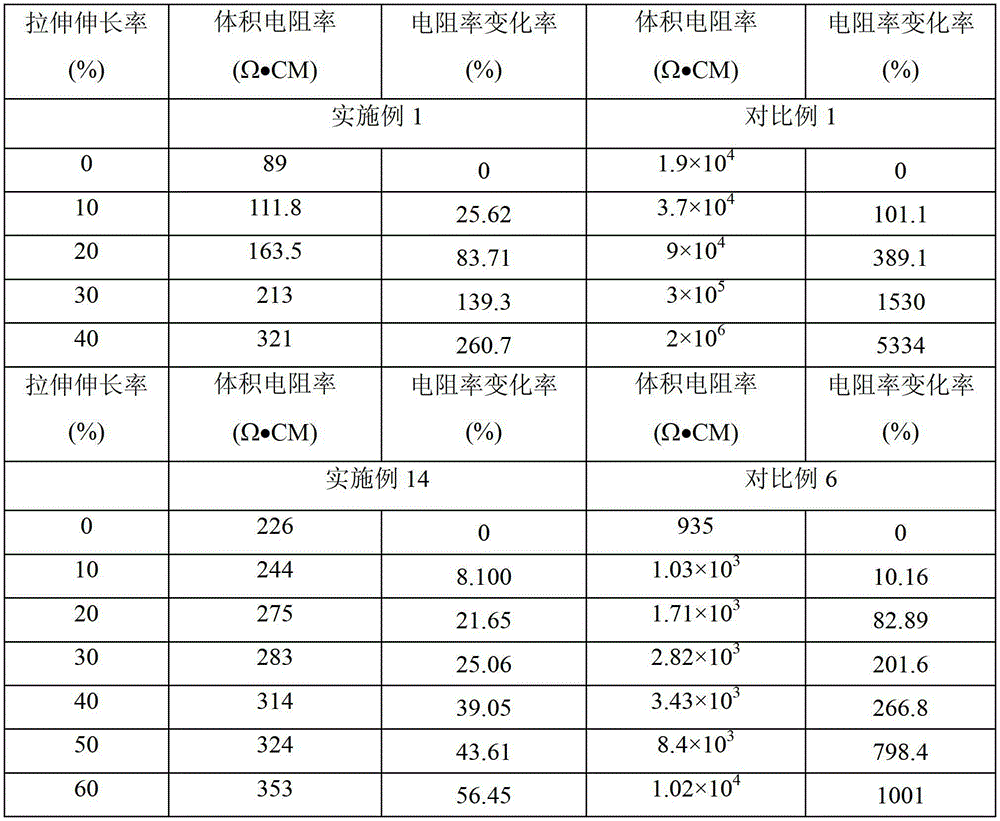

Conductive polymer composite material and preparation method thereof

The invention provides a conductive polymer composite material and a preparation method thereof. The composite material includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is more excellent in conductive performance, can be prepared through a conventional melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Poly(arylene ether) compositions and methods of making the same

A method of making a resin composition comprises melt mixing a first polymer comprising a polyamide powder or a polyester powder with a fluoropolymer at a temperature below a softening temperature of the fluoropolymer to form a first melt blend; fibrillating the fluoropolymer in the first melt blend to form a fibrillar network in the first melt blend; and melt mixing the first melt blend having the fibrillar network with i) a poly(arylene ether) and a compatibilizing agent or ii) a poly(arylene ether) and a reaction product of the poly(arylene) and a compatibilizing agent.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Antibacterial polyester fibers and preparation method for same

InactiveCN104963028ASolve the problem of uniform distribution of small particle sizeSimple methodMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterPolyethylene terephthalate glycol

The invention belongs to the field of textile, and particularly relates to antibacterial polyester fibers, which are prepared by melting-spinning the following materials in parts by weight: 100 parts of PET (polyethylene terephthalate) polyester chips and 2 to 5 parts of antibacterial polyester masterbatches, wherein the antibacterial polyester masterbatches are prepared by melt-blending and extruding the PET polyester chips, and 2 to 5 percent of a pre-treatment nanometer silver antibacterial agent, 2 to 3 percent of an antioxidant, 0.1 to 2 percent of a lubricant and 1 to 3 percent of a dispersant, which are counted based on the weight of the PET polyester chips; the pre-treatment nanometer silver antibacterial agent is a nanometer silver antibacterial agent obtained by wrapping treatment with polyethylene wax. According to the antibacterial polyester fibers, the small particle size uniform distribution of the nanometer silver antibacterial agent in a PET matrix is realized, the antibacterial polyester fibers are prepared by melt-spinning, and are efficient and long in service life, and the method is simple, easy and suitable for industrial popularization and application.

Owner:YIWU HUIHANG CHEM FIBER

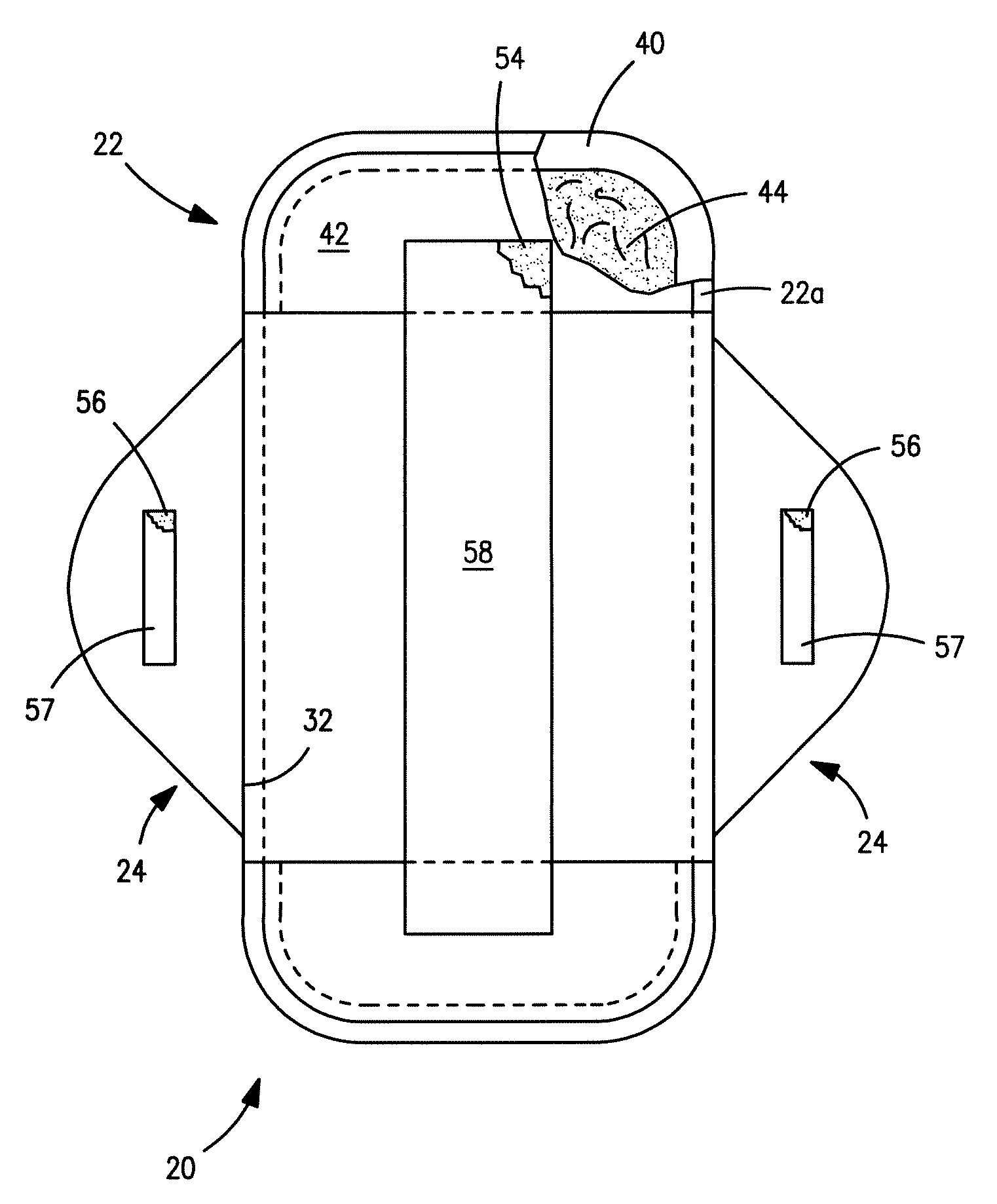

Melt-blended protein composition

A melt-processed protein composition formed from a protein, plasticizer, and an electrophilic reagent is provided. The electrophilic reagent, for instance, may be selected to undergo a nucleophilic addition reaction with free sulfhydryl and / or thiyl radicals to help minimize the formation of disulfide crosslinking bonds that could otherwise lead to protein aggregation during melt processing. To enhance the degree to which the electrophilic reagent can limit crosslinking, a plasticizer is also employed that helps to mediate the adsorption of the electrophilic reagent into the internal structure of the protein, where it can be more stably retained. Furthermore, the temperature and shear rate employed during melt blending may also be selected to be relatively low to help limit polypeptide dissociation, thereby minimizing the impact of aggregation and embrittlement.

Owner:KIMBERLY-CLARK WORLDWIDE INC

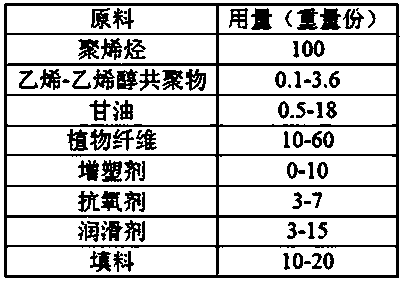

Polyolefin wood-plastic composite and preparation method thereof

The invention discloses a polyolefin wood-plastic composite and a preparation method thereof. Polyolefin and plant fiber modified by EVOH (ethylene-vinyl alcohol copolymer) are taken as main raw materials, a plasticizer, a stabilizer, a lubricating agent and the like are added, and the environment-friendly wood-plastic composite with excellent mechanical property is prepared with a melt blending method commonly used during plastic processing. The wood-plastic composite can be used in conventional fields such as building materials, decorative materials, foam materials, boards, packaging materials, toys, automobile parts and the like, and the application range of the EVOH is enlarged.

Owner:FUJIAN NORMAL UNIV

Conductive thermoplastic elastomer and preparation method thereof

ActiveCN104098795AConductiveEvenly dispersedNon-conductive material with dispersed conductive materialThermoplasticConductive polymer composite

The invention provides a conductive thermoplastic elastomer and a preparation method thereof. The thermoplastic elastomer includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. A weight ratio of the component b to the component a is more than 30:70 and is lower than 75:25. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is excellent in conductive performance, can be prepared through a melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of carbon nanotubes/nano ATO (antimony tin oxide)/polypropylene electroconductive fibers

InactiveCN102409421AImprove fill factorImprove electrical performanceElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentPolypropylene compositesOrganic solvent

The invention discloses a preparation method of carbon nanotubes / nano ATO (antimony tin oxide) / polypropylene electroconductive fibers. The preparation method comprises the following steps of: (1) mixing nano ATO and carbon nanotubes, placing in an organic solvent together with a dispersant, and carrying out surface treatment to obtain a double-component nano electroconductive agent; (2) mixing the double-component nano electroconductive agent with polypropylene slices, and carrying out melt blending and strip preparation and granulation with a screw extruder to obtain double-component nano electroconductive agent / polypropylene composite electroconductive slices; (3) carrying out melt spinning on the composite electroconductive slices to obtain carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers; and (4) stretching and shaping the carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers to obtain the carbon nanotubes / nano ATO / polypropylene electroconductive fibers. By using the preparation method, the filling factor of a filler is increased, the content of an electroconductive filler in the material is reduced, the electric conductivity of the material is improved, and the electric performance stability of the material is simultaneously improved; and the preparation method has low price and no special requirement on equipment, has a economicand simple process route, and is suitable for industrial production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

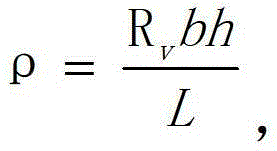

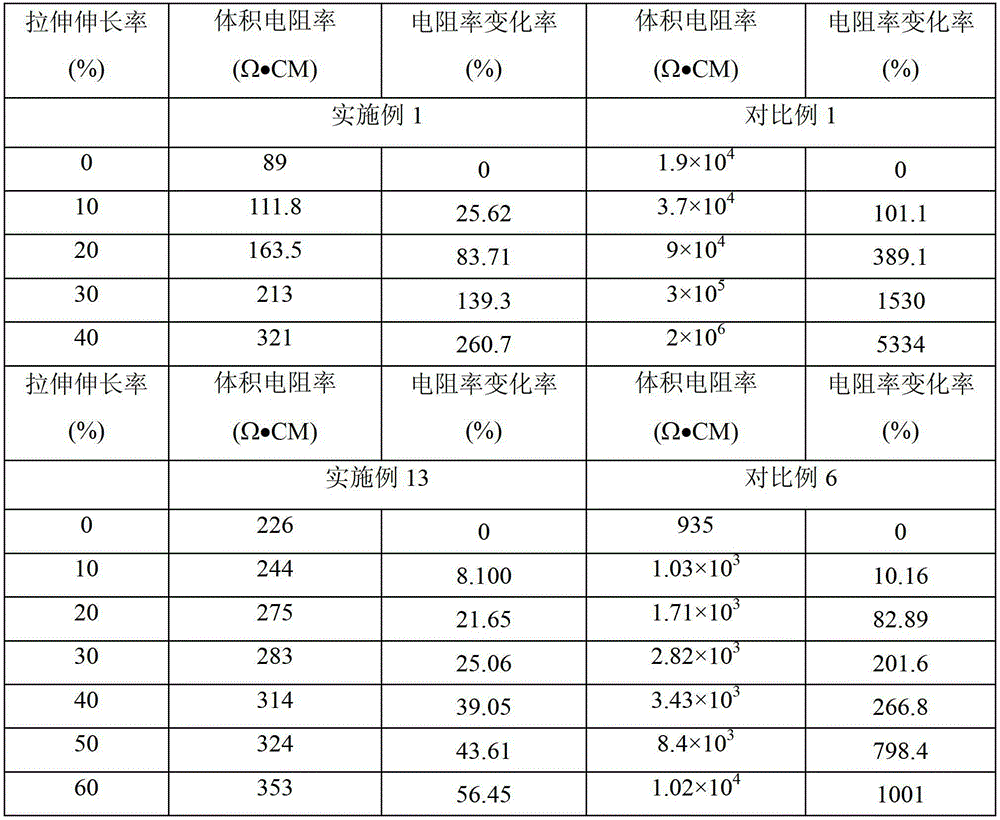

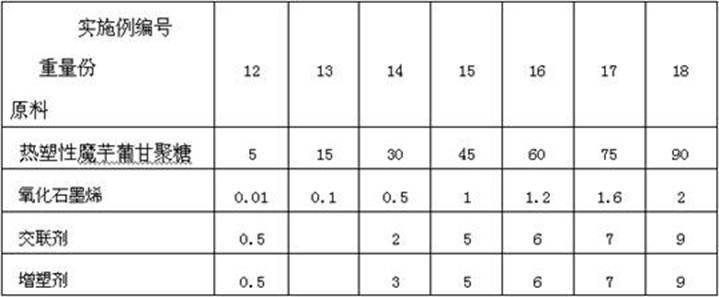

Thermoplastic konjac glucomannan/graphene oxide compound material and preparation method thereof

The invention discloses a thermoplastic konjac glucomannan / graphene oxide compound material and a preparation method thereof. The invention is characterized in that the compound material comprises the following components according to parts by weight: 1 to 99 parts of thermoplastic konjac glucomannan, 0.001 to 2 parts of graphene oxide, 0 to 10 parts of cross-linking agent and 0 to 10 parts of plasticizing agent; and the preparation method comprises the following steps of: proportioning; adding the thermoplastic konjac glucomannan into an ethanol or water solution of the graphene oxide, stirring for 5 to 10 hours, filtering and drying solid substances; then, drying after stirring and mixing with the cross-linking agent and the plasticizing agent in a mixing machine evenly; and afterwards, placing into a double-screw extrusion machine, extruding after carrying out melt blending at the temperature of 100 to 140 DEG C for 5 to 15 minutes, and granulating so as to prepare the compound material. The compound material has favorable processing performance, has excellent adsorbability, thermal stability and mechanical toughness, can be biologically degraded, can be regenerated, has no pollution to the environment and can be widely applied to the fields of chemical engineering, medicine, environmental protection, capital construction and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Modified polylactic acid fiber and preparation method thereof

ActiveCN103225125ASave raw materialsRich sourcesMelt spinning methodsMonocomponent polyesters artificial filamentEnvironmental resistanceCellulose diacetate

The invention discloses a modified polylactic acid fiber and a preparation method thereof. The modified polylactic acid fiber is prepared through blending polylactic acid, a cellulose derivative, a cellulose diacetate grafted polylactic acid copolymer, a lubricant, inorganic nanoparticles, a nucleating agent and an antioxidant. The preparation method comprises the following steps: adding partial polylactic acid slices and all other raw materials to a high speed mixer according to a mass component ratio, carrying out high speed dispersion, and carrying out melt blending and extrusion through a double screw extruder to obtain modified polylactic acid master batch slices; and carrying out dry mixing of the modified polylactic acid master batch slices and residual polylactic acid slices in the high speed mixer, carrying out melt spinning through a melt spinning machine, and stretching to obtain the modified polylactic acid fiber. The prepared polylactic acid fiber has the advantages of low cost, complete biodegradation, environmental protection, good spinning performance, stable filament bundle quality, excellent flexibility, excellent antifriction, excellent dyeing property and excellent comfortableness, and is a very good high-performance environmentally-friendly fiber material. The preparation method has the advantages of simplicity, low equipment requirement, and environmental protection in the production process, and is in favor of the industrialized production.

Owner:长沙乐远化工科技有限公司

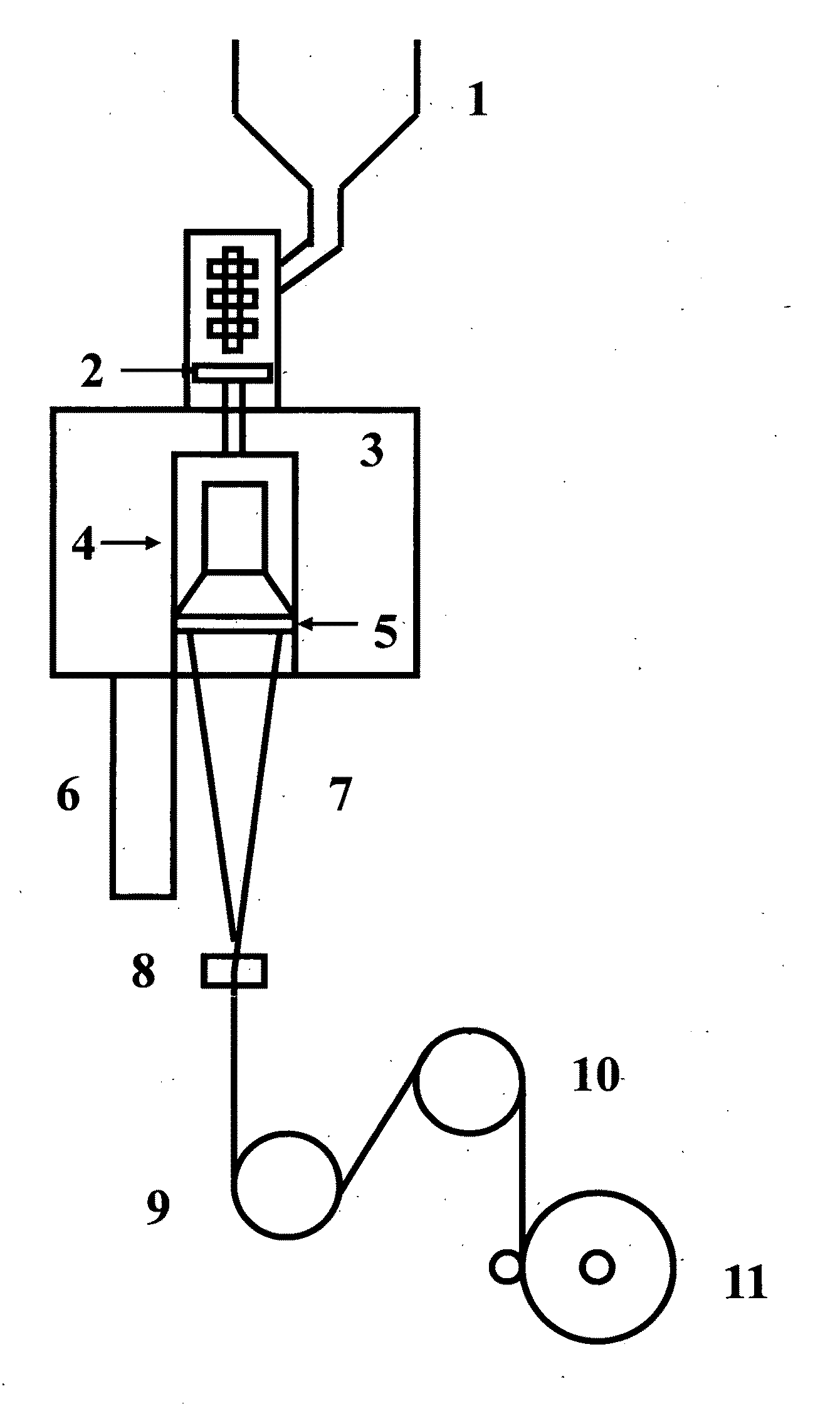

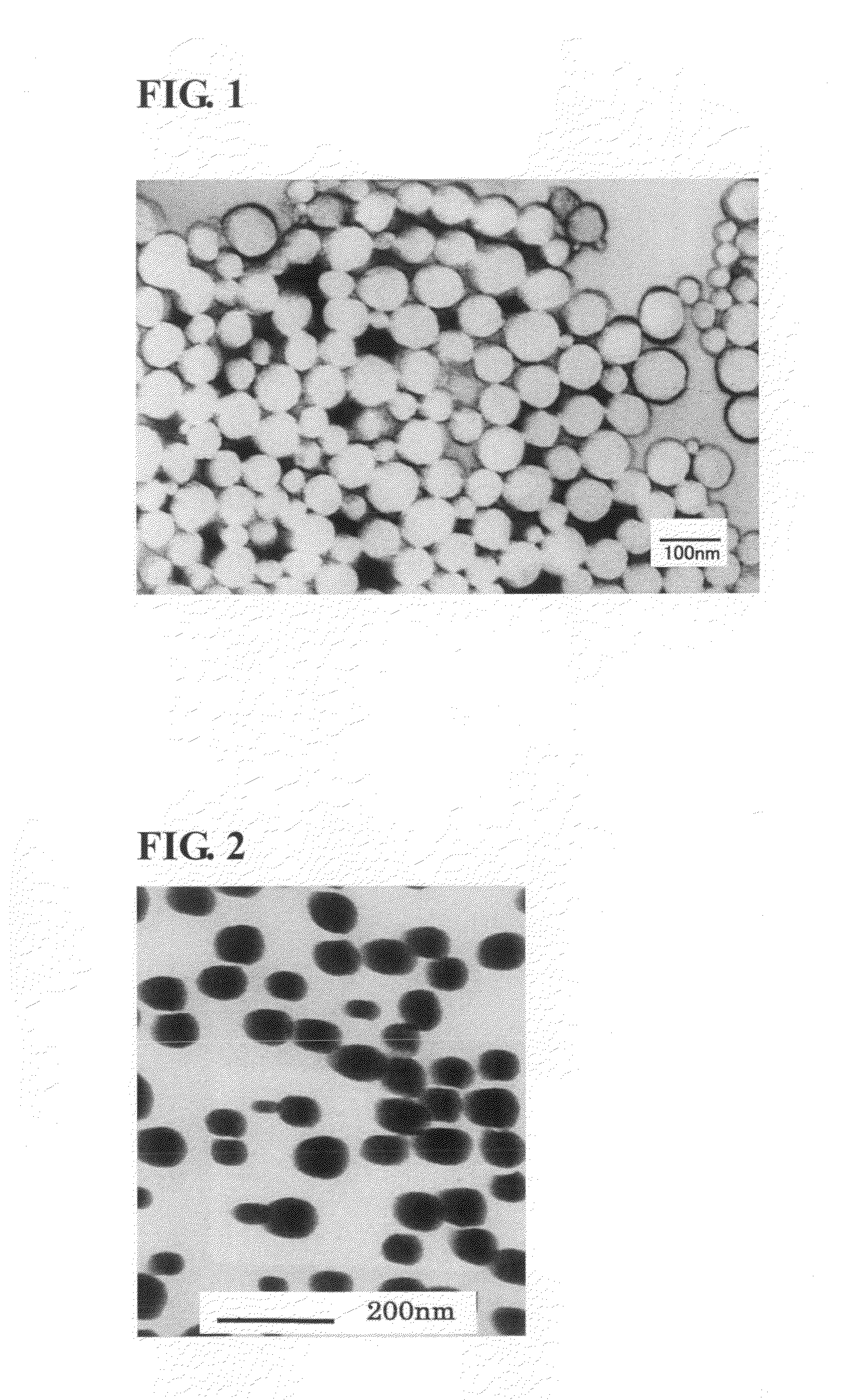

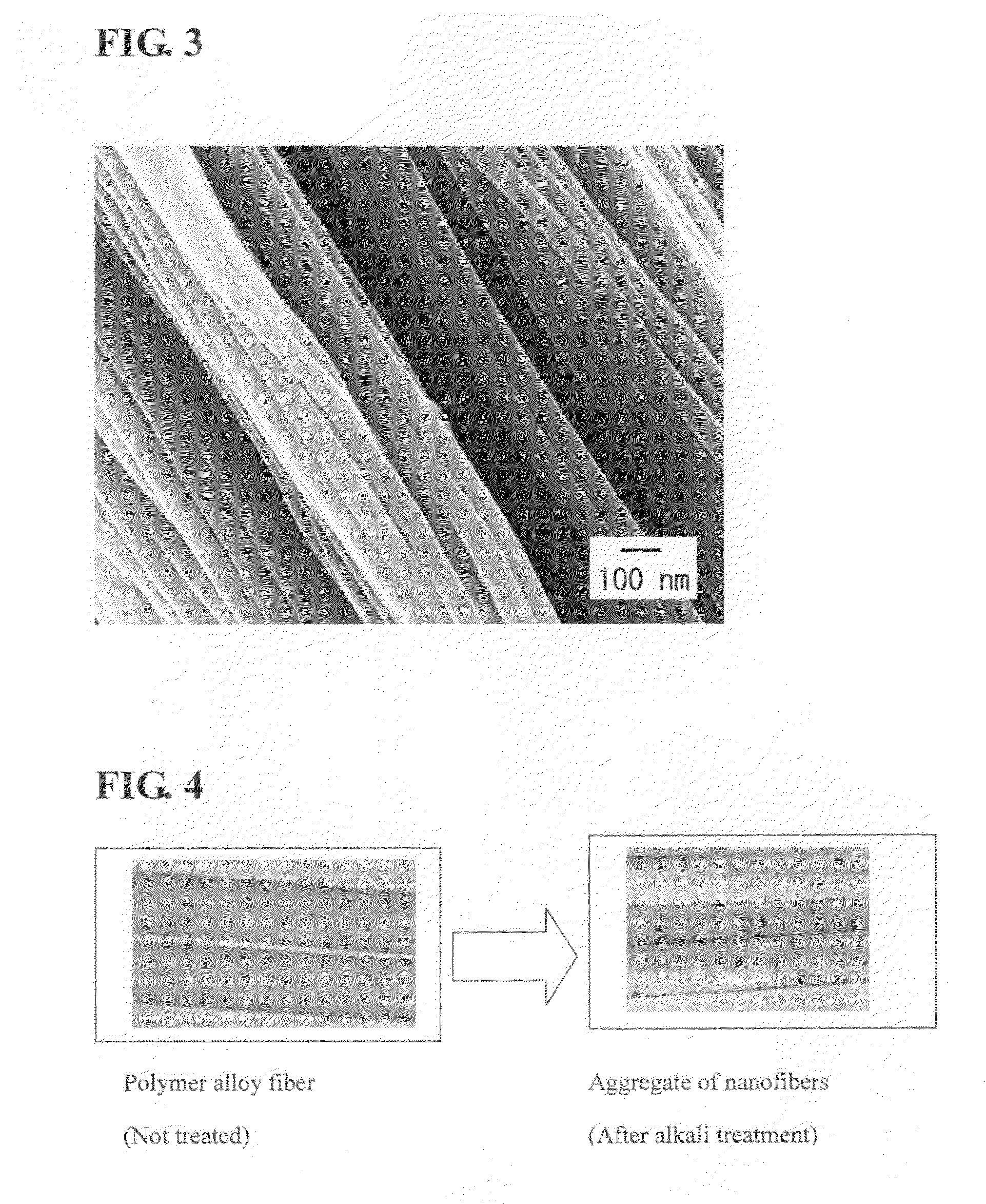

Polymer alloy fiber, fibrous material, and method for manufacturing polymer alloy fiber

InactiveUS20110183563A1Less spreadingWide applicationWarp knittingFilament/thread formingSolubilityPolymer science

A polymer alloy fiber that has an islands-in-sea structure of two or more kinds of organic polymers of different levels of solubility, wherein the island component is made of a low solubility polymer and the sea component is made of a high solubility polymer, while the diameter of the island domains by number average is in a range from 1 to 150 nm, 60% or more of the island domains in area ratio have sizes in a range from 1 to 150 nm in diameter, and the island components are dispersed in a linear configuration. A method for manufacturing the polymer alloy fiber includes melt spinning of a polymer alloy that is made by melt blending of a low solubility polymer and a high solubility polymer.

Owner:OCHI TAKASHI +1

Dynamic vulcanization process for preparing thermoplastic elastomers

Described in one aspect is a process for preparing a low durometer thermoplastic vulcanizate composition comprising melt blending one or more thermoplastic polymer(s) with a cross-linkable elastomer under conditions of dynamic vulcanization; adding at or after the start of the melt blending at least one curative agent for the elastomer so as to cross-link the elastomer during the melt blending; introducing process oil into the melt blending before, during and / or after the addition of the curative agent; and, extruding a fully crosslinked thermoplastic vulcanizate having a Shore A Hardness of less than 25.

Owner:CELANESE INT CORP

Antistatic polymer blending composition

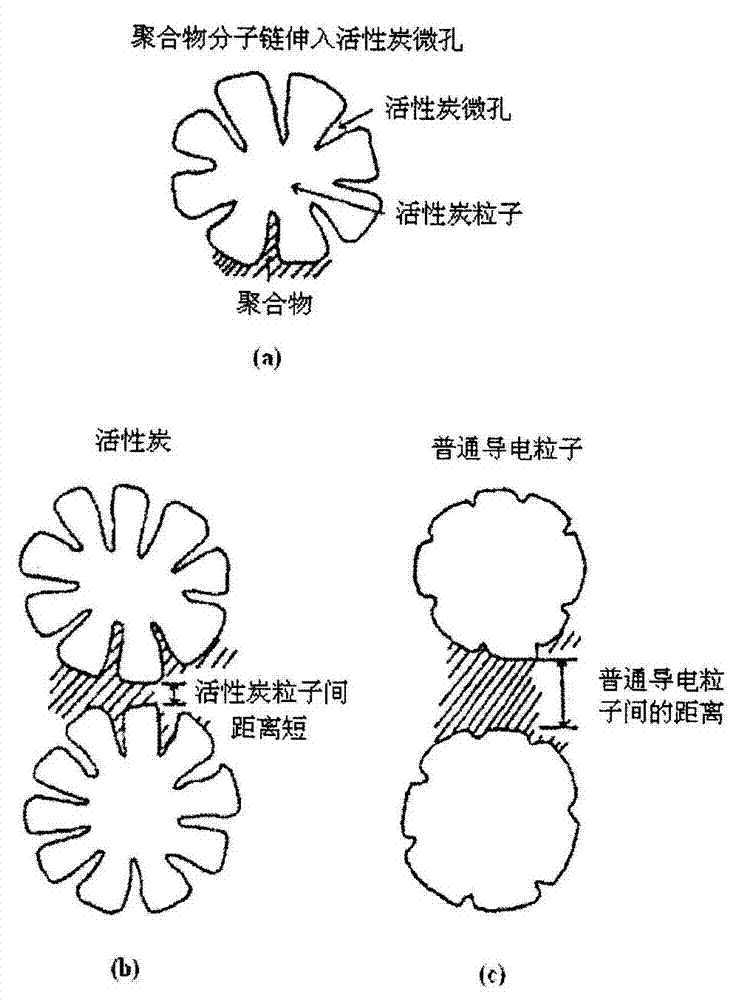

InactiveCN103087391AHas permanent antistatic propertiesMaintain antistatic propertiesPolymer scienceNetwork structure

The invention relates to an antistatic polymer blending composition. The antistatic polymer blending composition is characterized by comprising the following raw materials in parts by mass: 100 parts of thermoplastic polymer, 6 to 20 parts of active carbon and 0.5 to 6 parts of auxiliary agent, wherein the raw materials are subjected to melt blending to obtain the antistatic polymer blending composition of which the surface resistance is 106 to 1,012 ohms. In the antistatic polymer blending composition, the conductive active carbon forms a three-dimensional network structure in a polymer matrix to ensure that the surface resistance of the polymer blending composition reaches 106 to 1,012 ohms; and the used technology and the preparation process are simple and easy to control.

Owner:HENAN POLYTECHNIC UNIV

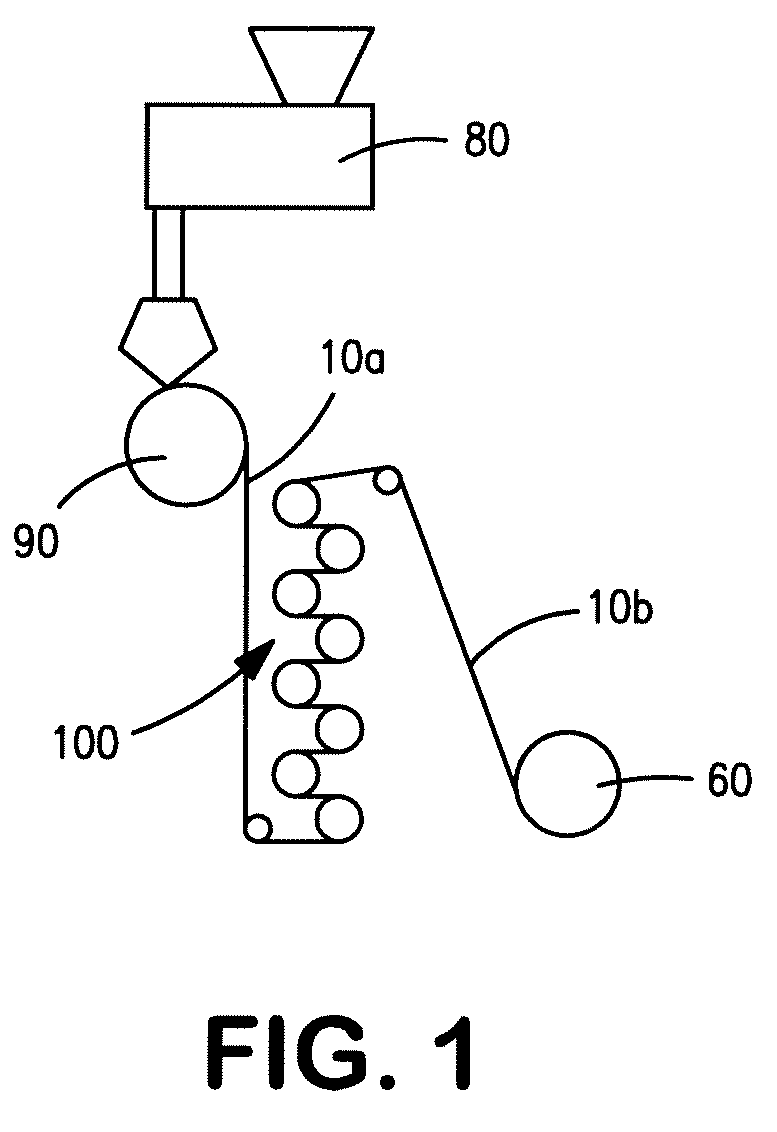

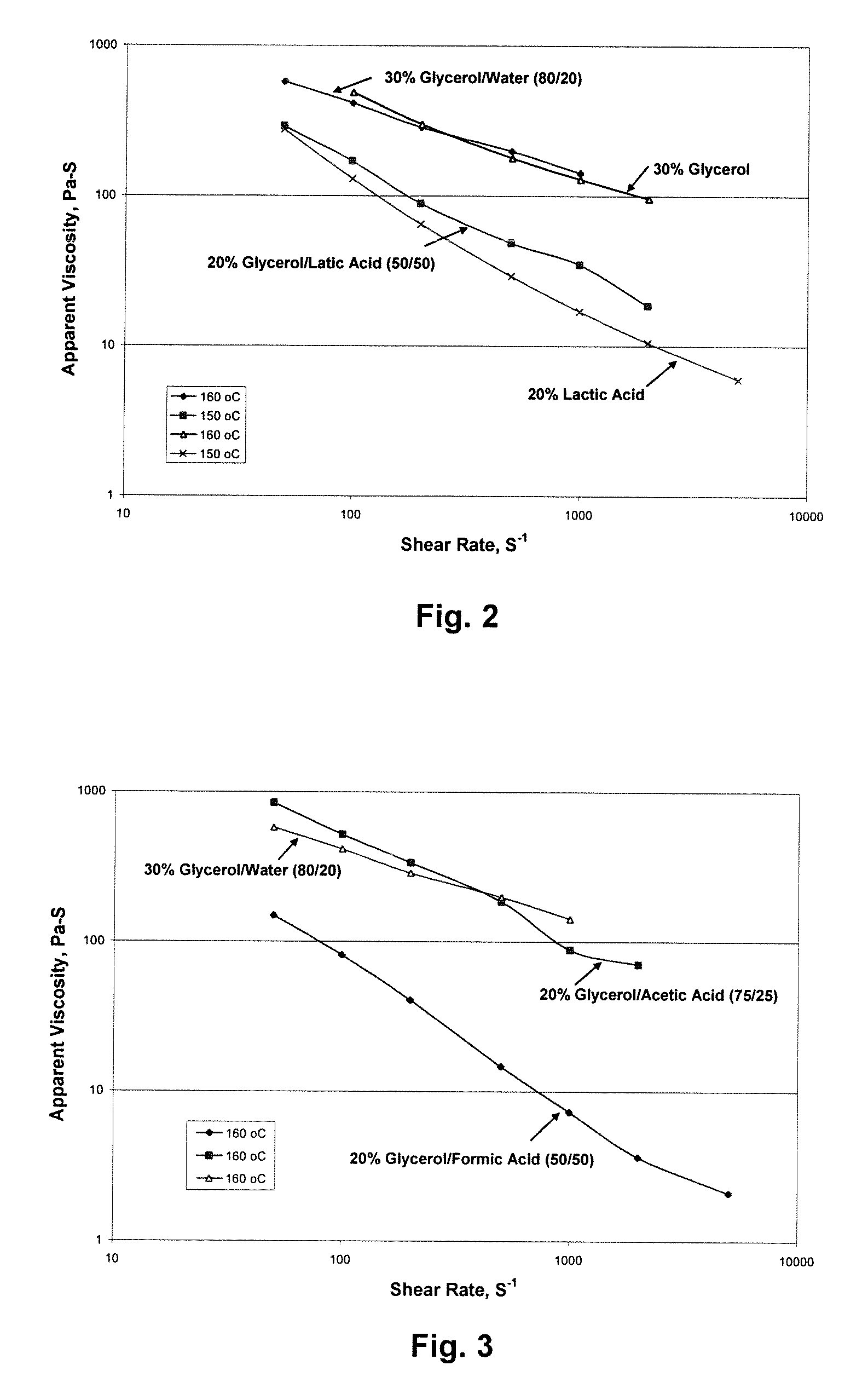

Thermoplastic Starch for Use in Melt-Extruded Substrates

A melt-extruded substrate (e.g., film, nonwoven web, etc.) that contains a thermoplastic starch formed from a starch and plasticizer is provided. The starch and plasticizer are melt blended together in the presence of a weak organic acid (e.g., lactic acid, formic acid, acetic acid, etc.). By selectively controlling certain parameters of the melt blending process (e.g., extrusion temperature, content of the components, etc.), the present inventors have discovered that the starch may be hydrolyzed in a highly efficient manner to form compositions having a comparably lower weight average molecular weight, polydispersity index, and viscosity, which are particularly suitable for use in the formation of melt-extruded substrates.

Owner:KIMBERLY-CLARK WORLDWIDE INC

High-intensity wood plastic composite board and fabrication method thereof

InactiveCN101708614AEasy to produceHigh strengthWood veneer joiningFlat articlesMechanical propertyWhite oil

The invention relates to a wood plastic composite, in particular to a high-intensity wood plastic composite board and a fabrication method thereof. The method for fabricating the high-intensity wood plastic composite board comprises the following steps: treating nano titanium dioxide with silane coupling agent to obtain modified nano titanium dioxide; mechanically stirring the modified nano titanium dioxide, plastic particles, maleic anhydride grafted plastic particles, calcium stearate and the like, and extruding and pelleting all the materials to obtain modified plastic particles; mechanically stirring the modified plastic particles, wood flour, terpene resin, chopped glass fiber, white oil, antioxidant and the like, and extruding, melt-blending and pelleting all the materials to obtain high-intensity wood plastic composite particles; and finally extruding the high-intensity wood plastic composite particles with a machine to mold the high-intensity wood plastic composite board. The high-intensity wood plastic composite board has extremely wide application range, and is applied to the fields such as transportation, construction, decoration, ornament, municipal works, garden and park, packaging and the like. The high-intensity wood plastic composite board has the advantages of reproducibility, low cost and higher mechanical properties such as static bending strength and the like, thereby being an ideal material for replacing wood. Compared with traditional wood plastic composites, the high-intensity wood plastic composite board has longer service life, and is a novel upgrade product of the present wood plastic composites.

Owner:江苏森诺塑胶科技有限公司

Preparation of material for bone plate, bone peg and bone block

The invention discloses a preparation method of materials which are used for bone plates, bone nails and bone blocks, including the following steps: biomedical fiber, hydroxyapatite, polylactic acid and compatibilizer are arranged at a twin-screw extruder or a torque rheometer for melt blending; or the polylactic acid and the hydroxyapatite which is grafted by using the polylactic acid macromonomer are dissolved in chloroform, the biomedical fiber is added for even dispersion, and the thin film can be obtained by vacuum drying after the volatilization of the chloroform; or the polylactic acid and the biomedical fiber are woven into mesh structure, then the mixed solution of hydroxyapatite powder which is grafted by using the polylactic acid macromonomer and the polylactic acid is added, and the vacuum drying is carried out after the volatilization of the solvent; finally, the materials which are obtained by the method are done with the pressing forming on a flat sulphuration machine or done with the injection forming by using a precise injection machine. The preparation method of the materials which are used for the bone plates, bone nails and bone blocks of the invention has strong practicality, easy industrial production and can significantly improve the mechanical properties of the bone repair materials.

Owner:JINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com