Thermoplastic konjac glucomannan/graphene oxide compound material and preparation method thereof

A konjac glucomannan and composite material technology is applied in the field of thermoplastic konjac glucomannan/graphene oxide composite material and its preparation, and achieves the effects of biodegradable source, high modulus and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

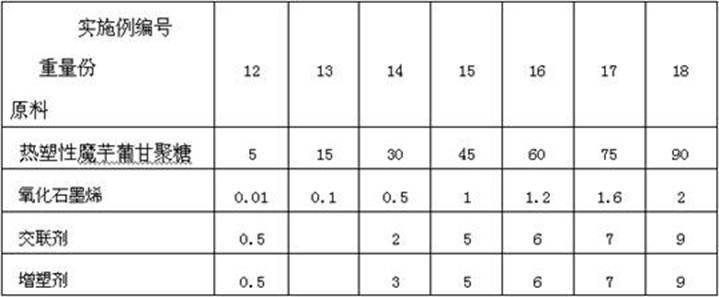

Examples

Embodiment 1

[0028] Take graphene oxide 0.1g by weight, be dissolved in ethanol, be mixed with the graphene oxide ethanol solution that concentration is 0.1g / L, then use the ultrasonic equipment that power is 500W to carry out sonication to described graphene oxide ethanol solution 2 hours, obtain the homogeneous stable graphene oxide ethanol solution; Then 50 parts of thermoplastic konjac glucomannans are added in the homogeneous stable graphene oxide ethanol solution after ultrasonic treatment, then mechanically stirred for 10 hours, After mixing and mixing, filter the solution and dry the mixture at 80°C for 3 hours; then mix the mixture with 10 parts of maleic anhydride in a high-speed mixer for 5 minutes, dry at 60°C for 8 hours, and control the temperature at 100 The blended material was melt-blended in a twin-screw extruder for 5 minutes, extruded and granulated at 1 MPa to obtain a thermoplastic konjac glucomannan / graphene oxide composite material.

Embodiment 2

[0030] Take graphene oxide 0.5g by weight, be dissolved in water, be mixed with the graphene oxide aqueous solution that concentration is 0.5g / L, then use the ultrasonic equipment that power is 600W to carry out ultrasonic treatment 3 hours to described graphene oxide aqueous solution, obtain A homogeneously stable graphene oxide aqueous solution; then add 15 parts of thermoplastic konjac glucomannan to the homogeneously stable graphene oxide aqueous solution after ultrasonic treatment, then mechanically stir for 10 hours, mix and mix, and filter solution, the mixture was dried at 90°C for 3 hours; then the mixture was stirred with 10 parts of glycerol in a high-speed mixer for 20 minutes, dried at a temperature of 50°C for 9 hours, and the blended material was placed in a double helix with temperature controlled at 120°C Melt and blend in an extruder for 10 minutes, extrude and granulate at 0.3 MPa, and obtain a thermoplastic konjac glucomannan / graphene oxide composite materia...

Embodiment 3

[0032] Take Graphene Oxide 1g by weight, be dissolved in ethanol, be mixed with the Graphene Oxide ethanol solution that concentration is 1g / L, then use the ultrasonic equipment that power is 400W to carry out ultrasonic treatment 5 hours to described Graphene Oxide ethanol solution, Obtain a homogeneous and stable graphene oxide ethanol solution; then add 30 parts of thermoplastic konjac glucomannan to the homogeneous and stable graphene oxide ethanol solution after ultrasonic treatment, then mechanically stir for 10 hours, mix and mix Finally, filter the solution, and dry the mixture at 100°C for 1 hour; then stir the mixture with 2 parts of tributyl citrate and 2 parts of polyethylene glycol in a high-speed mixer for 15 minutes, and dry at a temperature of 40°C for 10 hours, The blended material was melted and blended in a twin-screw extruder for 10 minutes under temperature control at 110° C., extruded and granulated at 1 MPa to obtain a thermoplastic konjac glucomannan / gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com