Patents

Literature

18581 results about "Stabilizing Agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stabilizing agents are used for a number of functions in foods and the main function is to act as a thickening agent to gel the foods into the required consistency. Most stabilizing and thickening agents are polysaccharides (a kind of carbohydrate) examples of which are starches, gums, or proteins like gelatin.

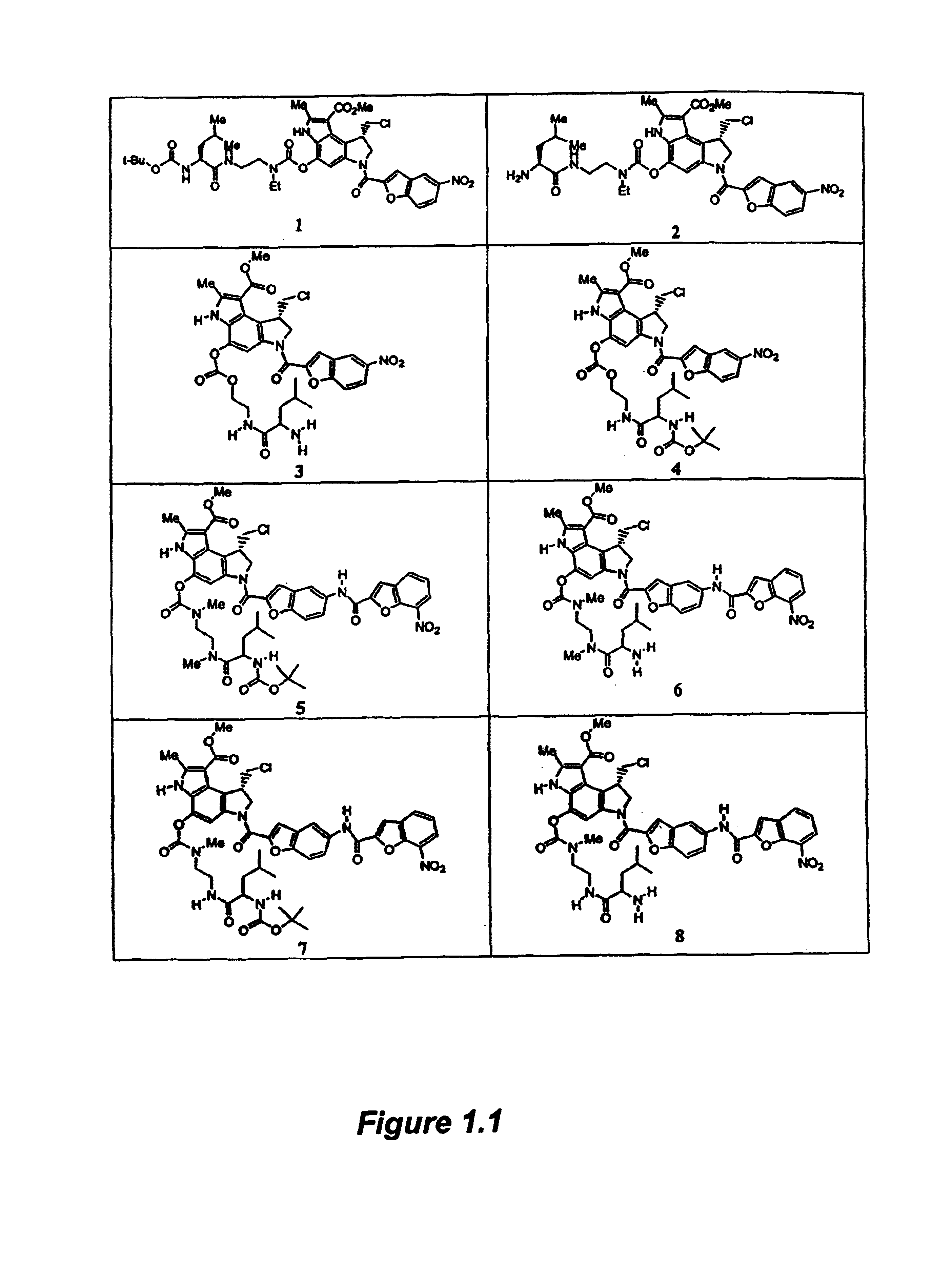

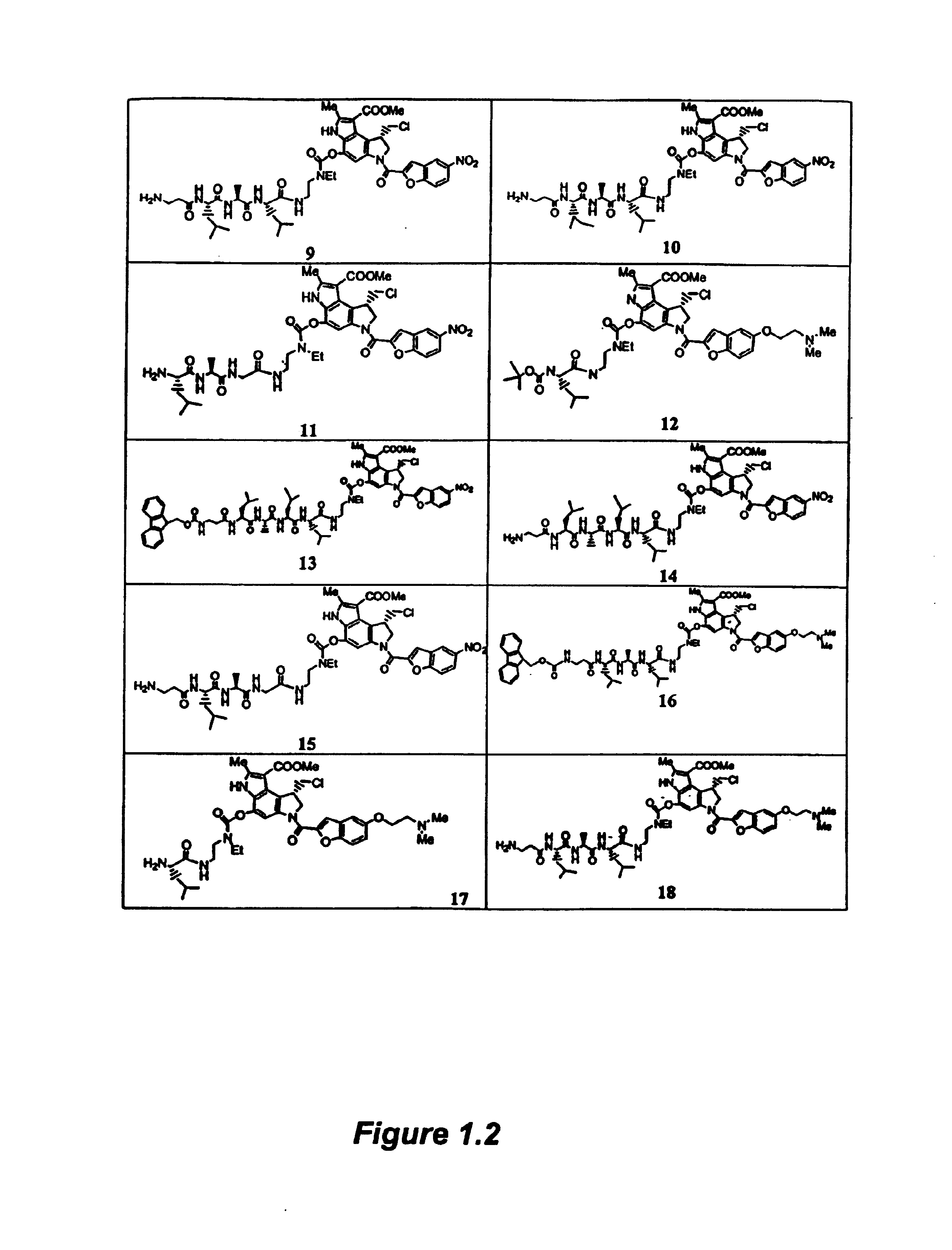

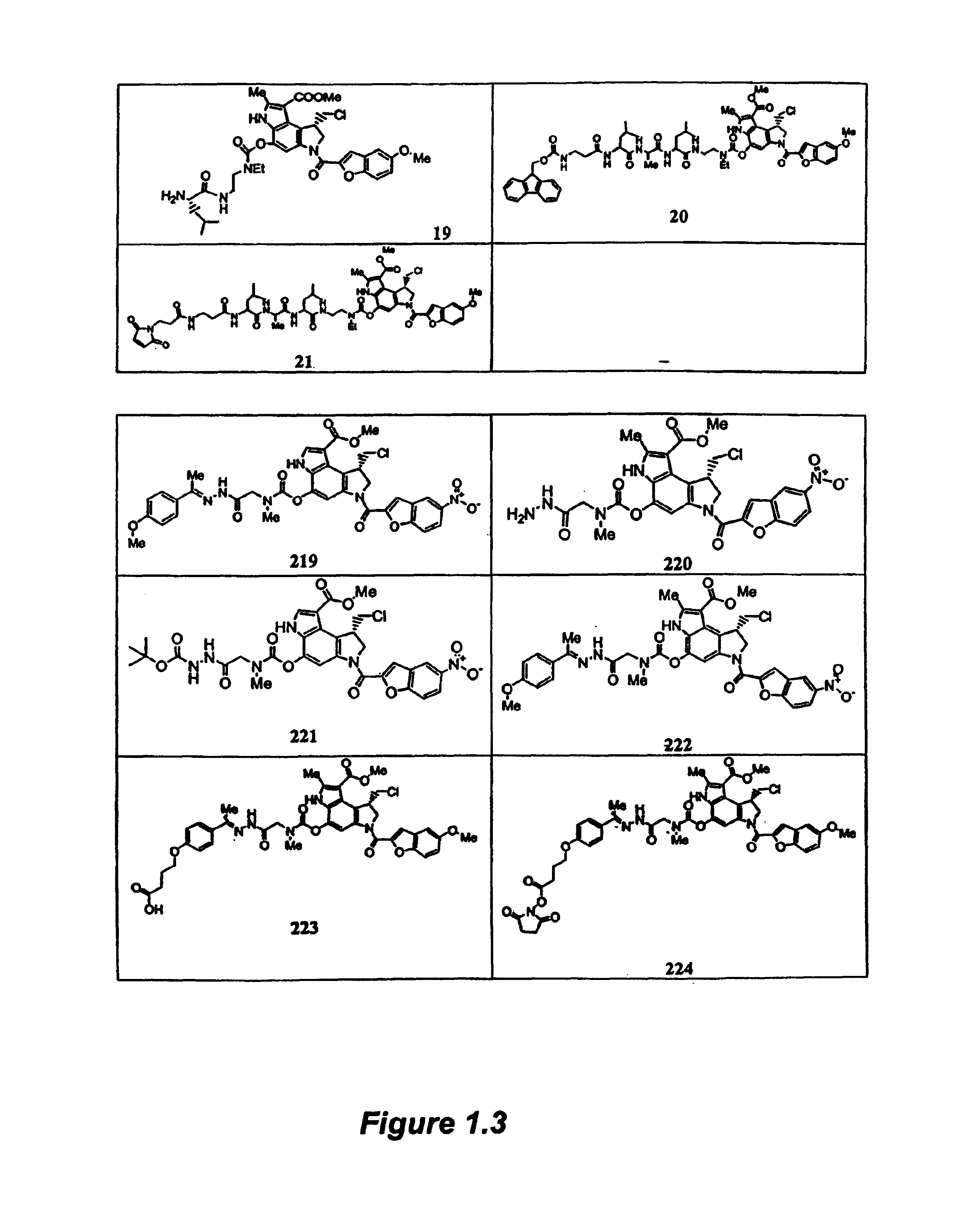

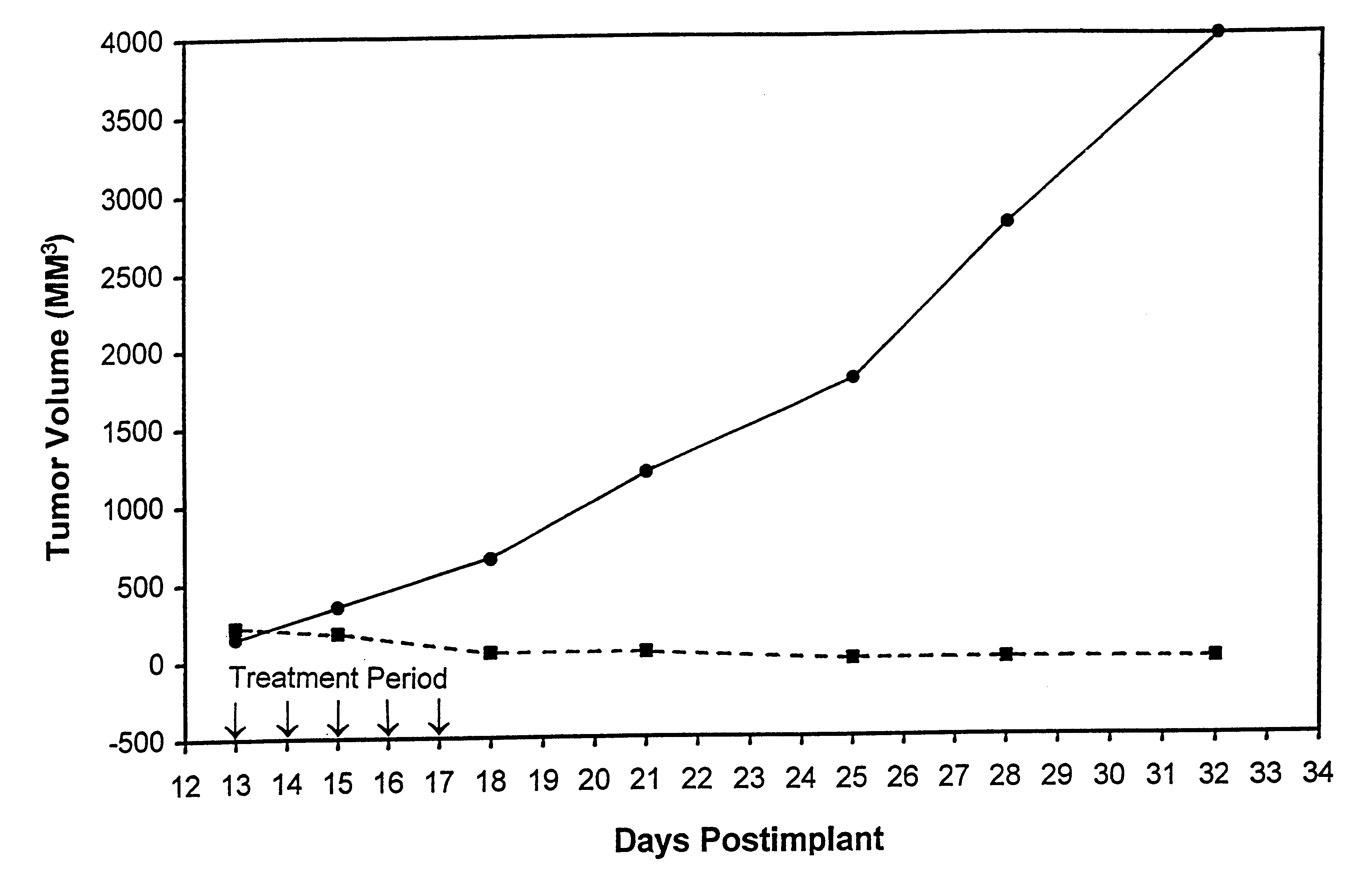

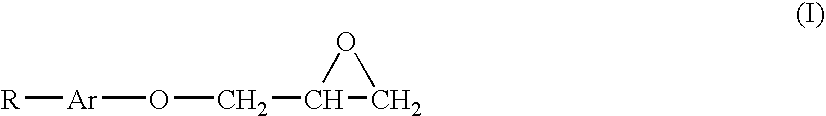

Disulfide prodrugs and linkers and stabilizers useful therefor

The present invention provides analogues of duocarmycins that are potent cytotoxins. Also provided are peptidyl and disulfide linkers that are cleaved in vivo. The linkers are of use in forming prodrugs and conjugates of the cytotoxins of the invention as well as other diagnostic and therapeutic moieties. The invention provides prodrugs and conjugates of the duocarmycin analogues with the linker arms of the invention.

Owner:ER SQUIBB & SONS INC

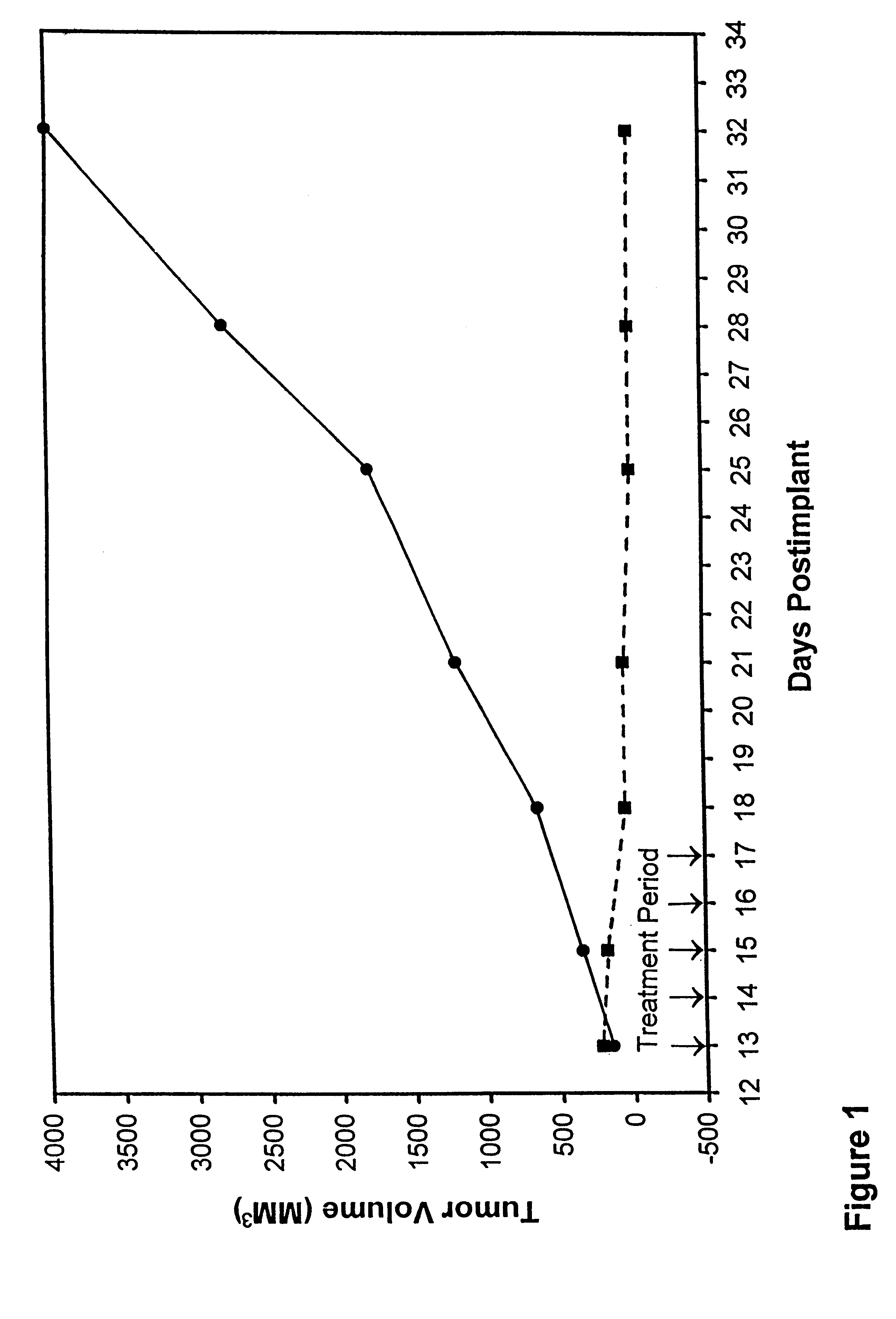

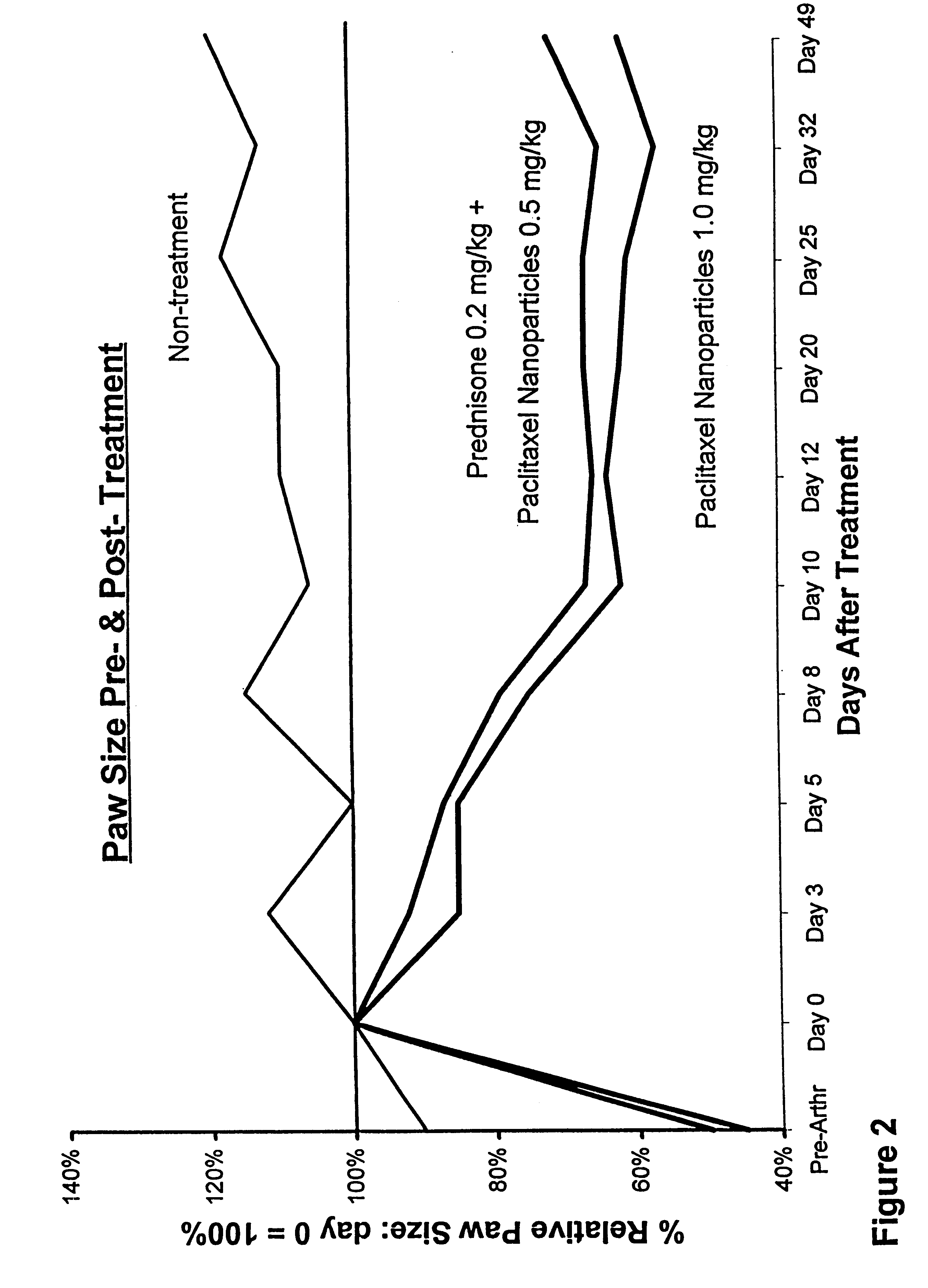

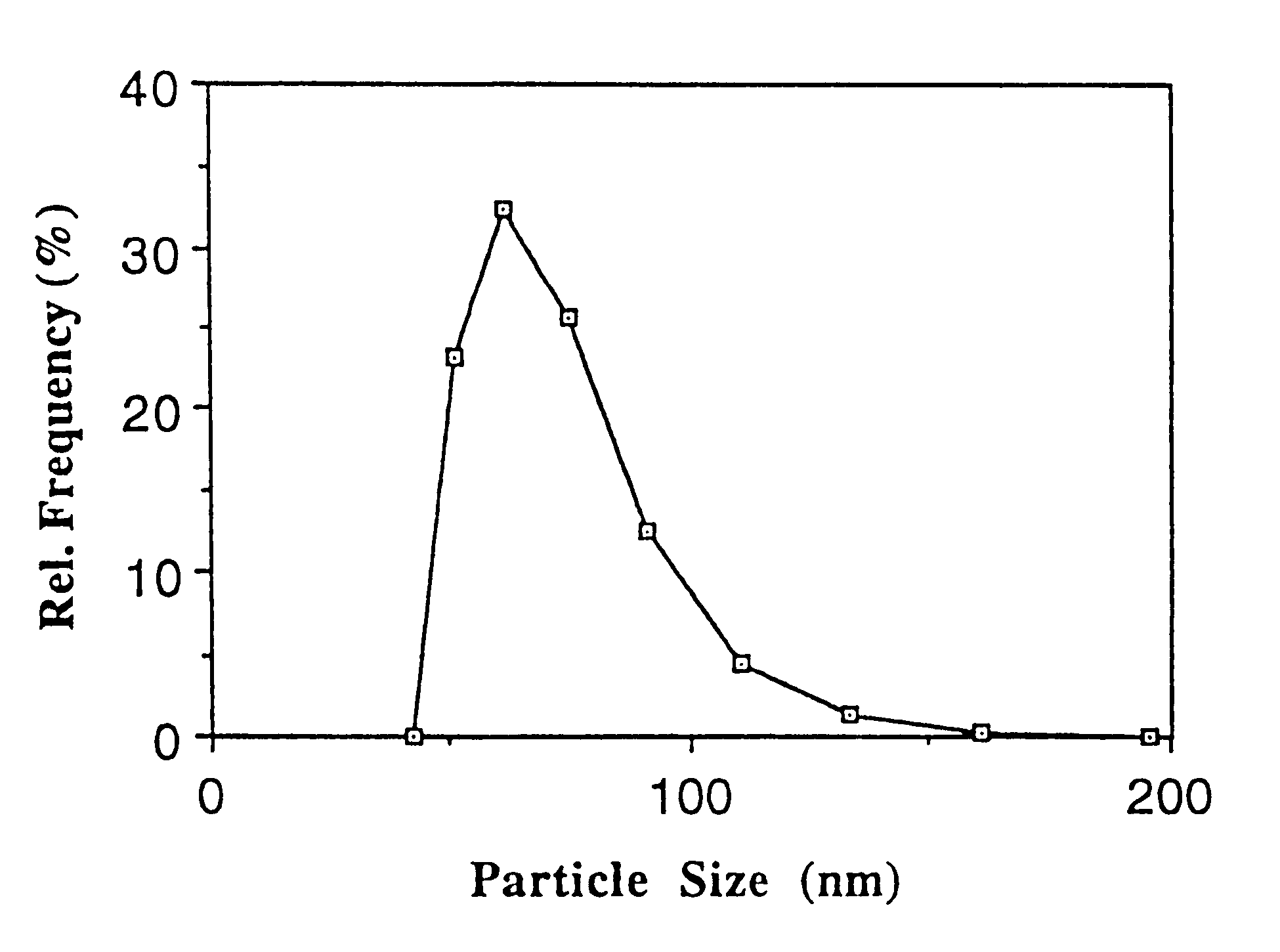

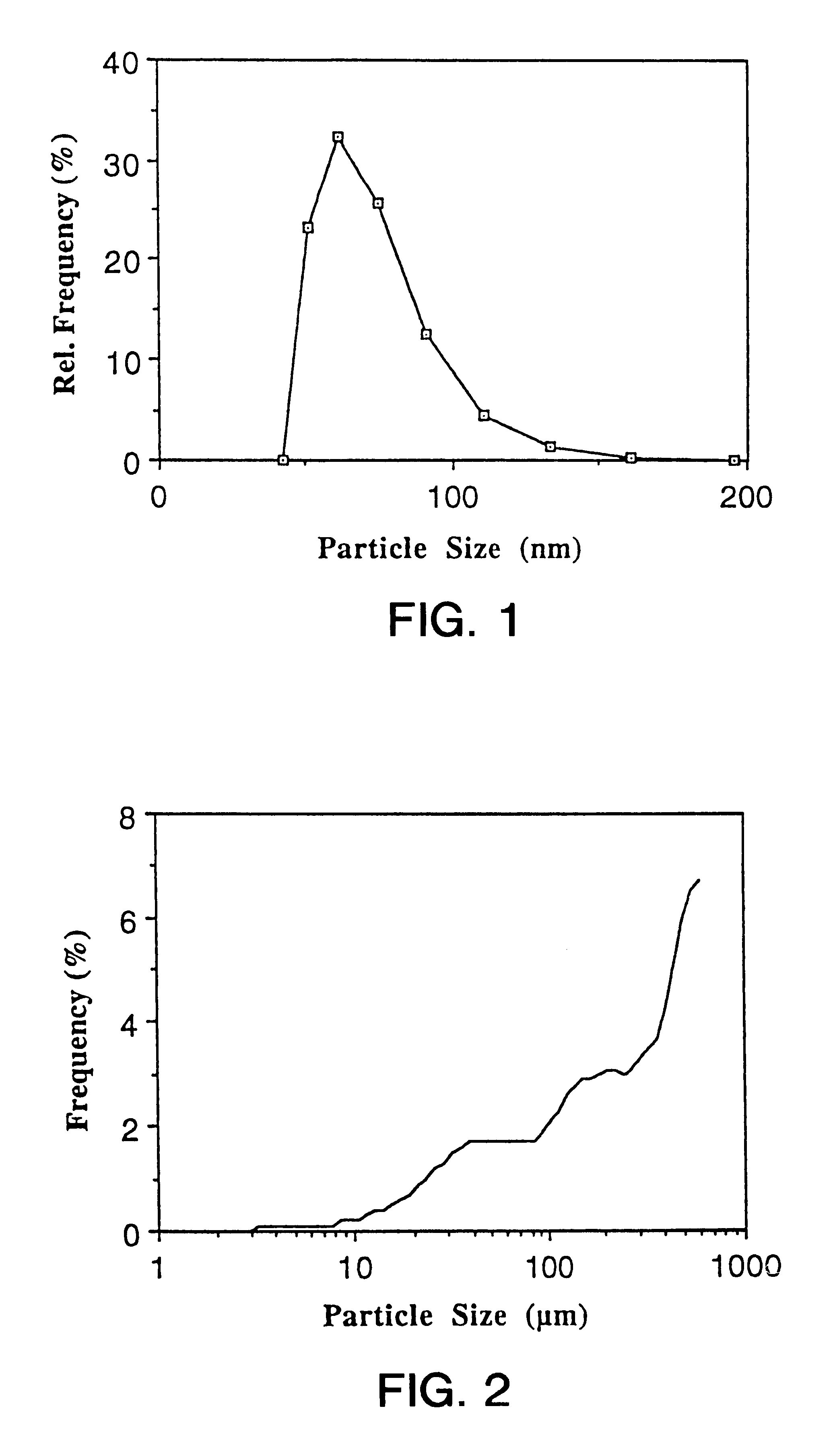

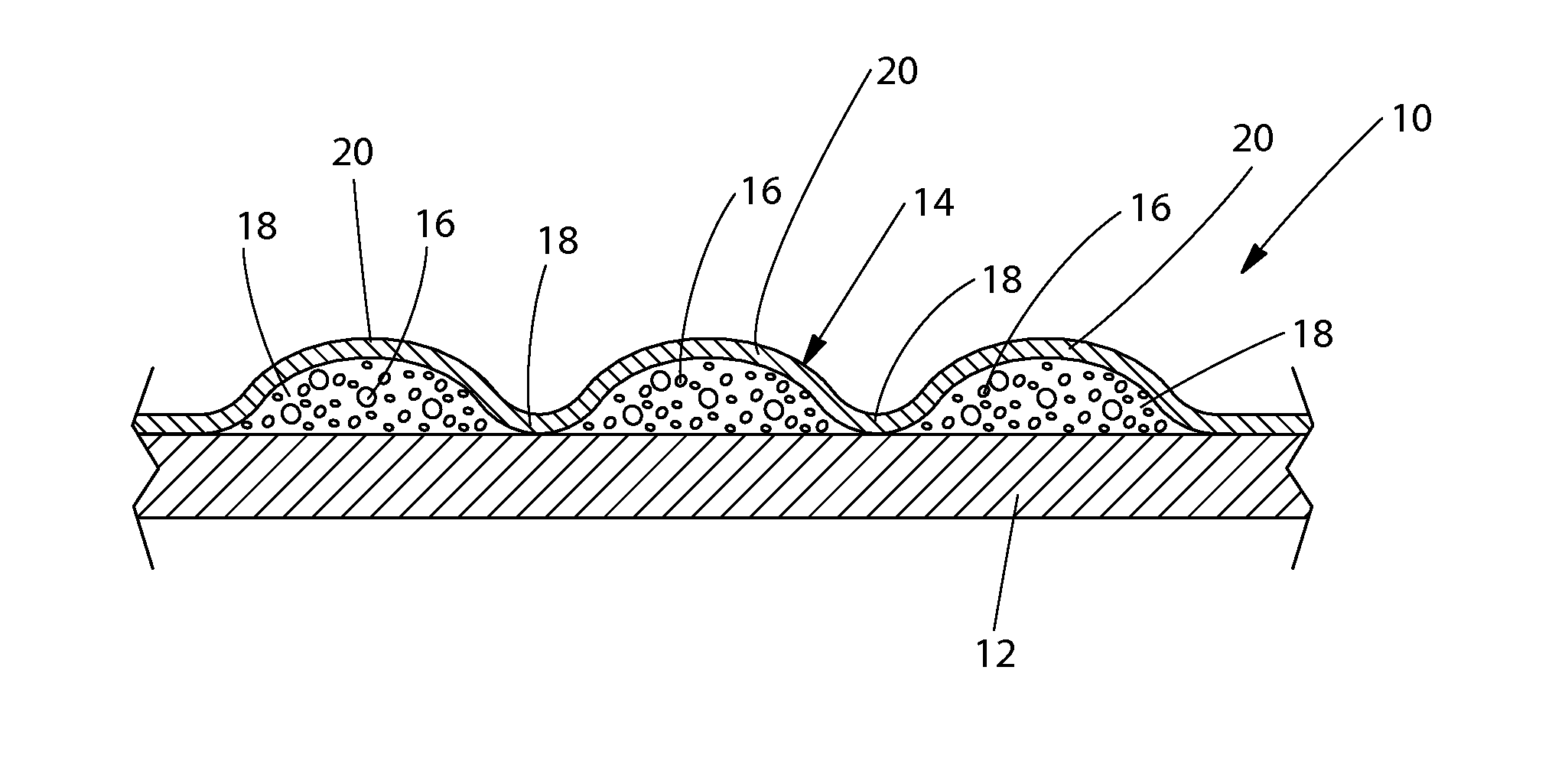

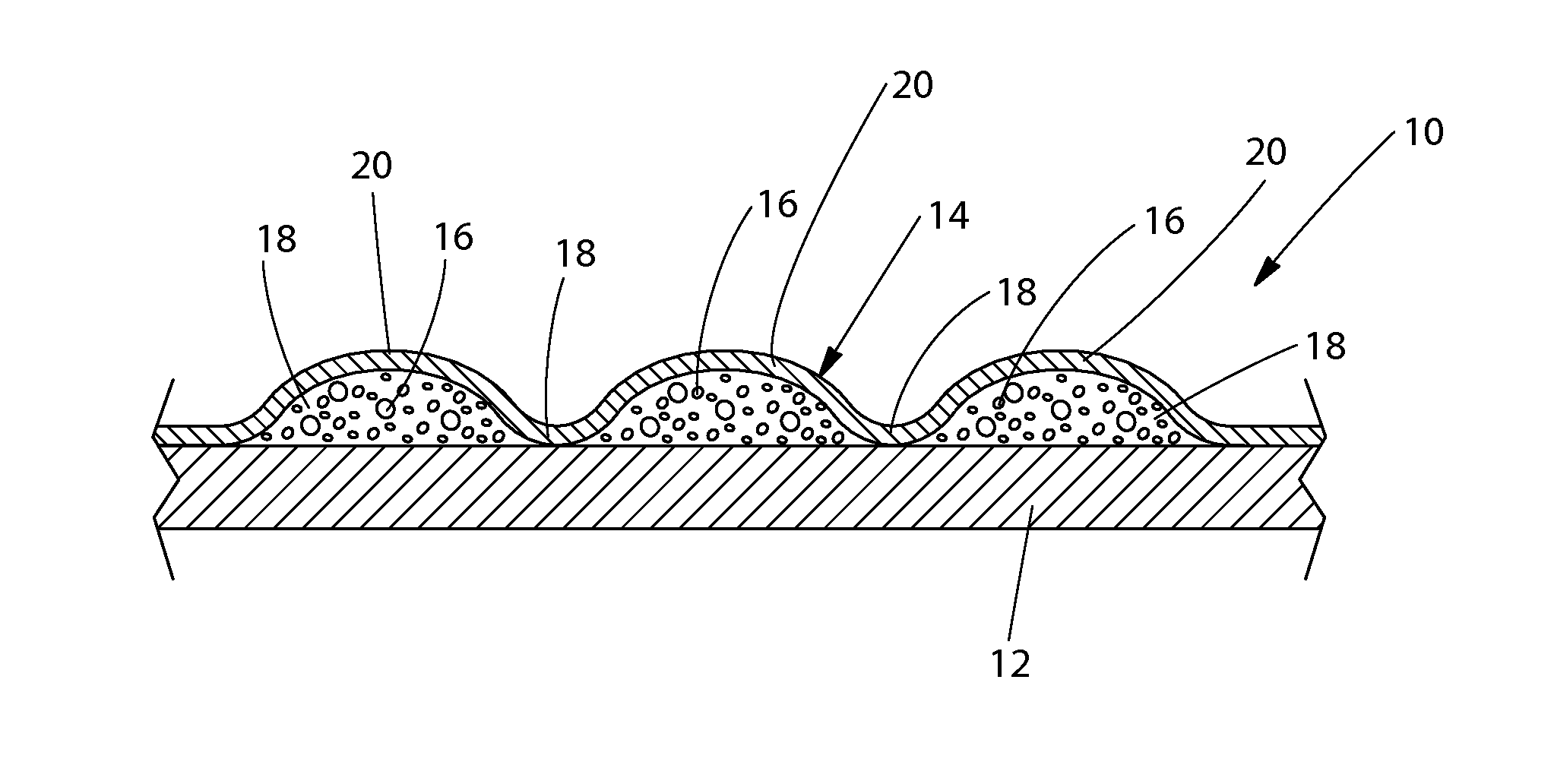

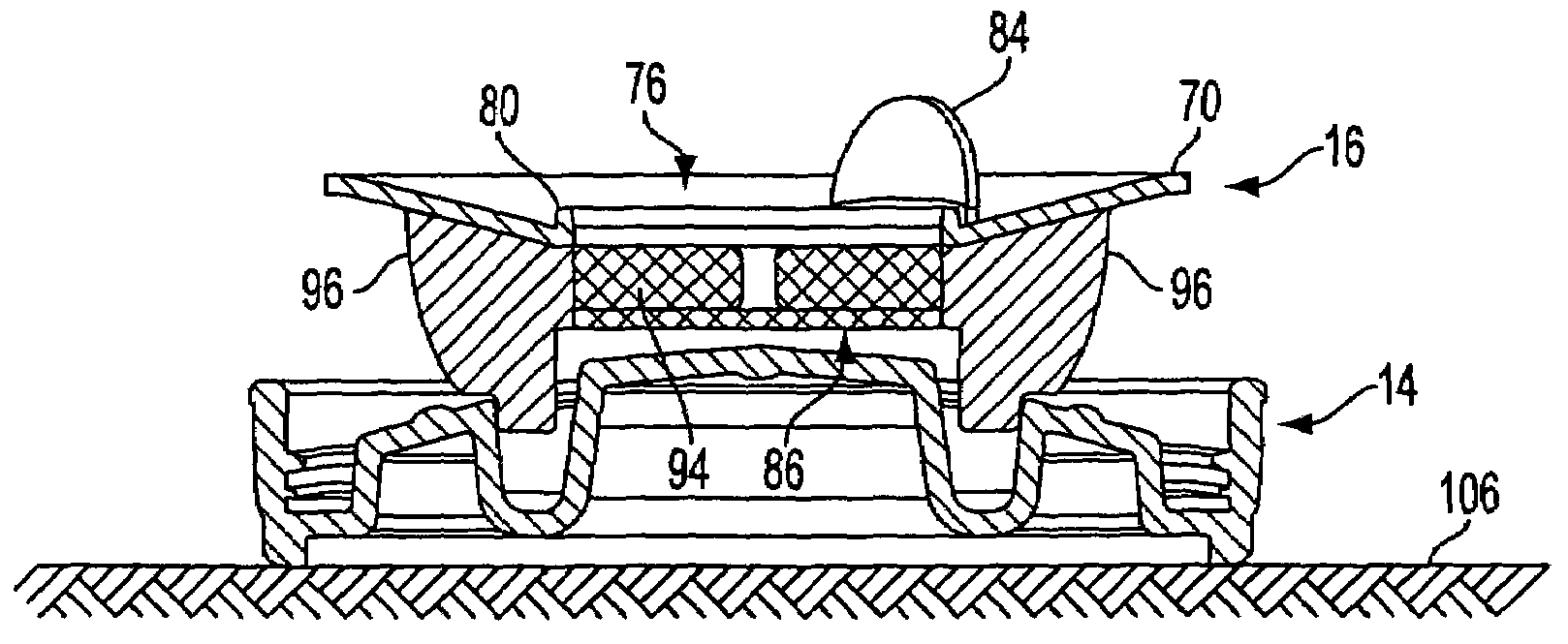

Protein stabilized pharmacologically active agents, methods for the preparation thereof and methods for the use thereof

InactiveUS6749868B1Low toxicityLong half-lifePowder deliveryEchographic/ultrasound-imaging preparationsSuspended particlesFree protein

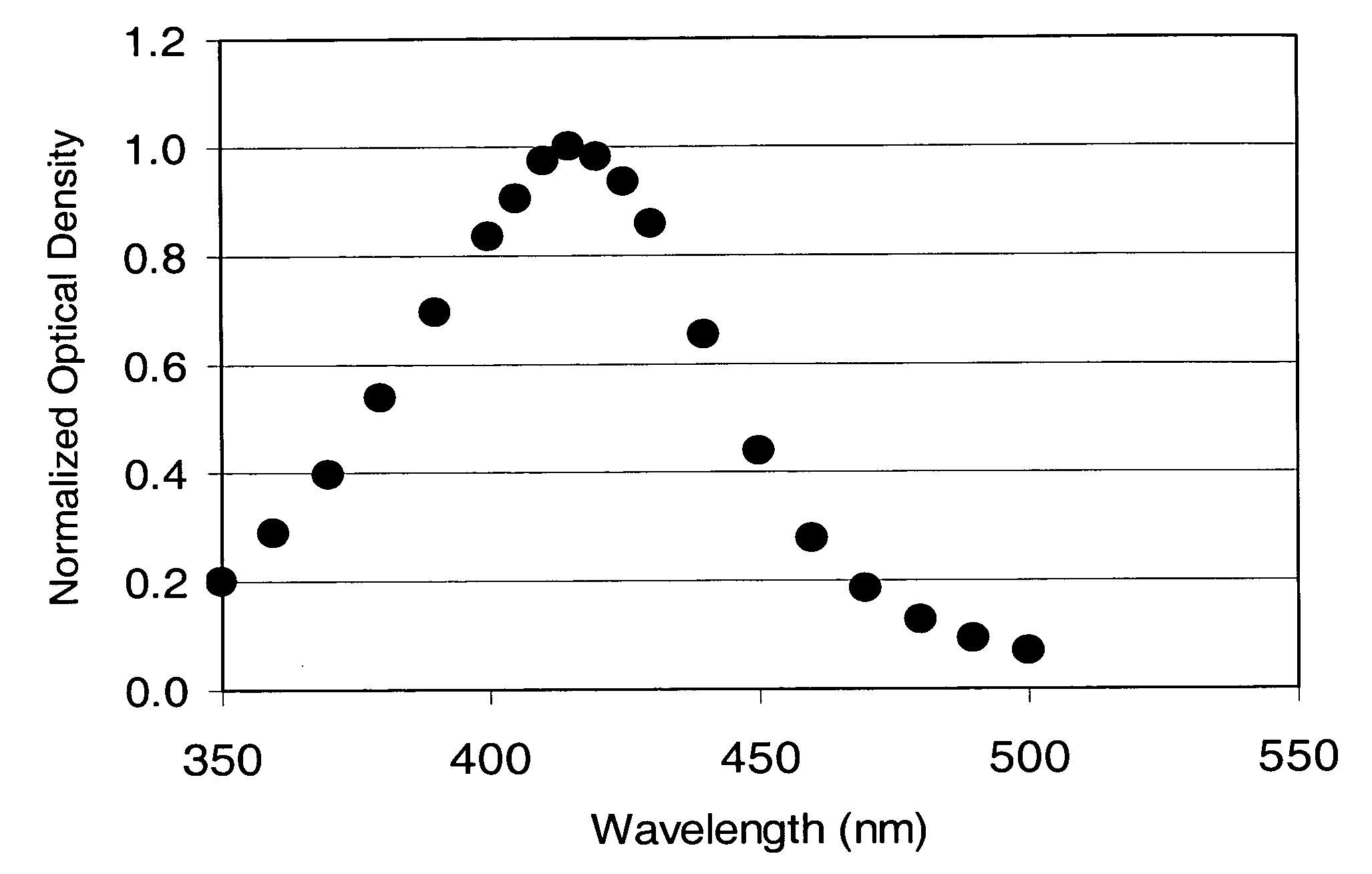

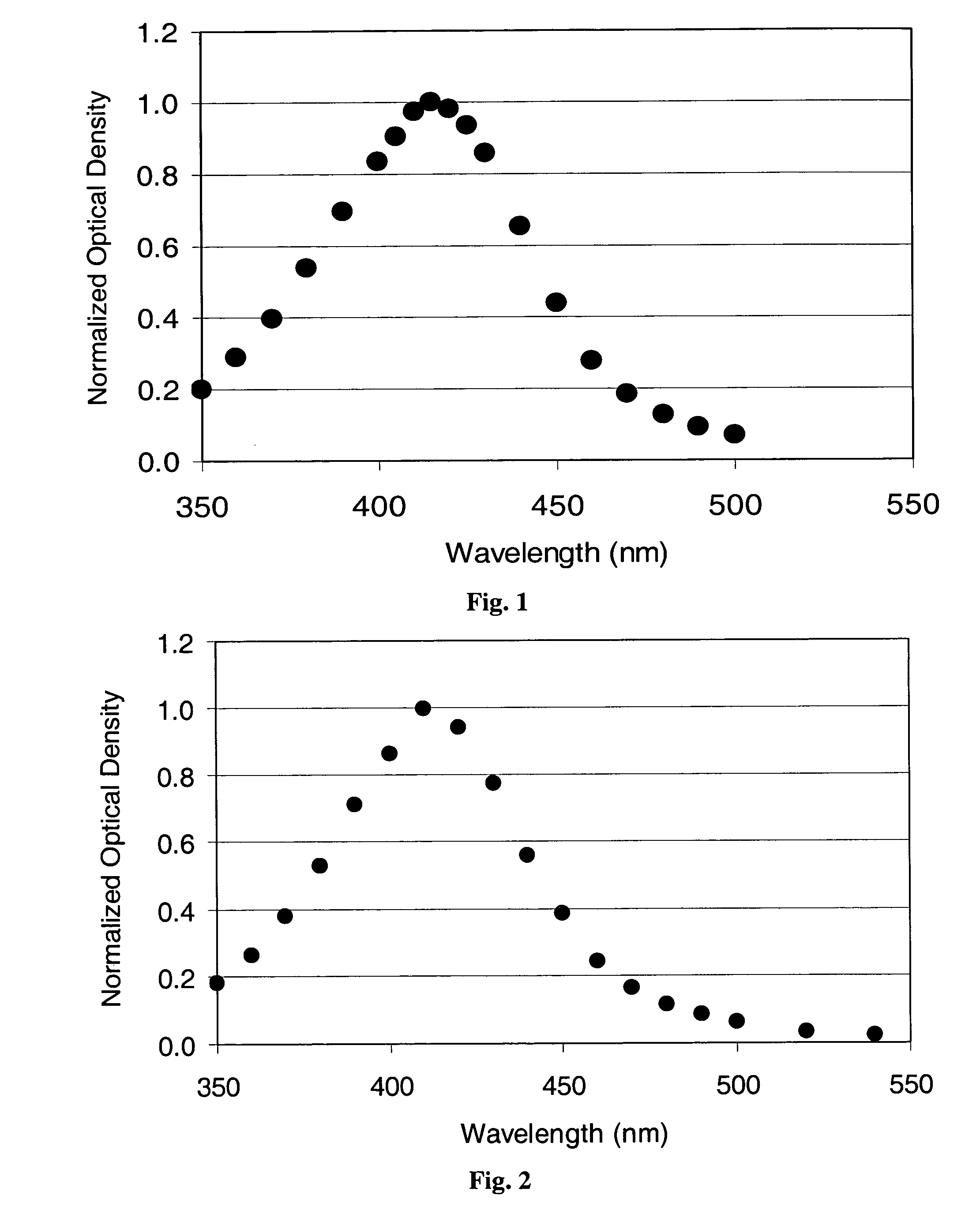

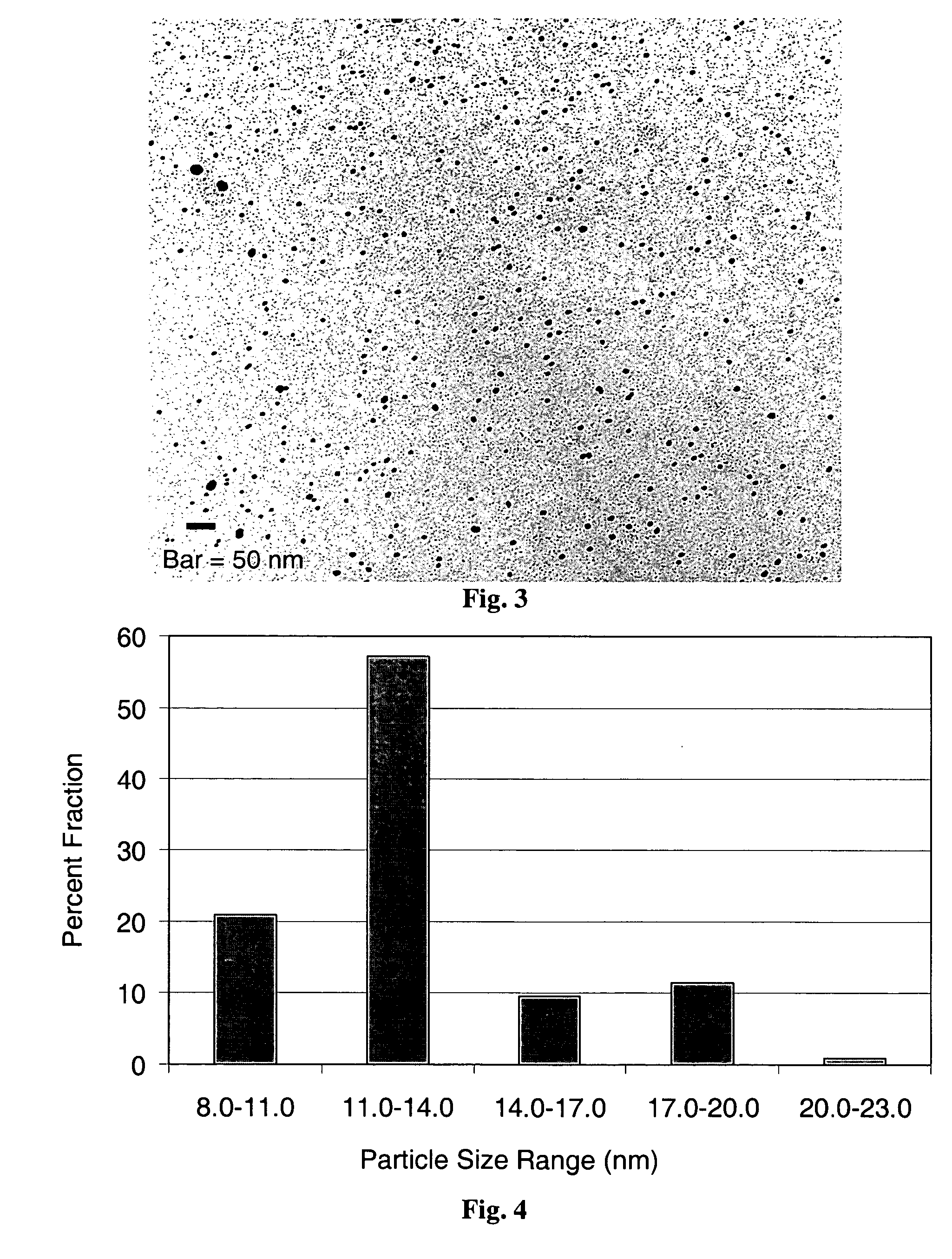

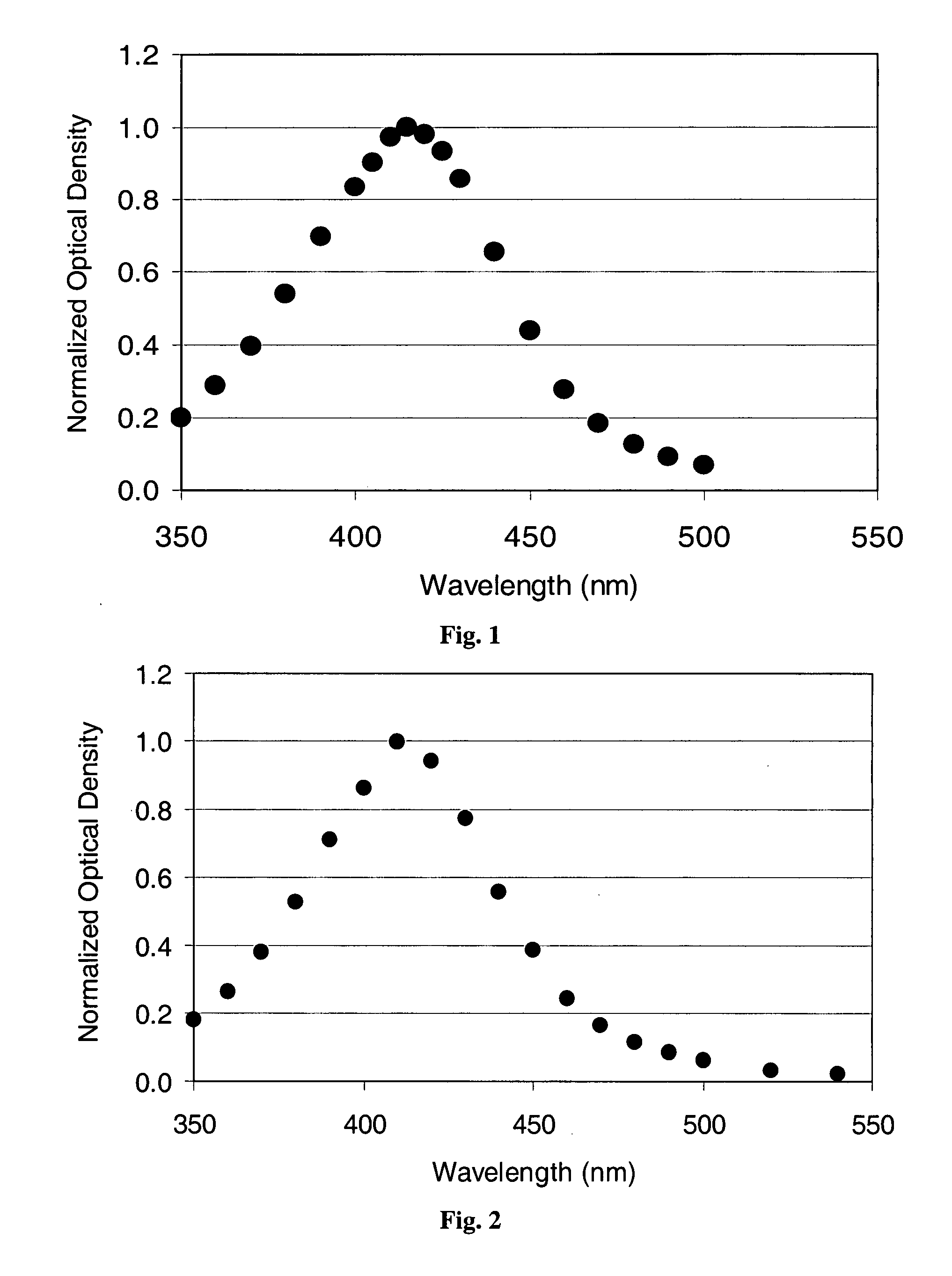

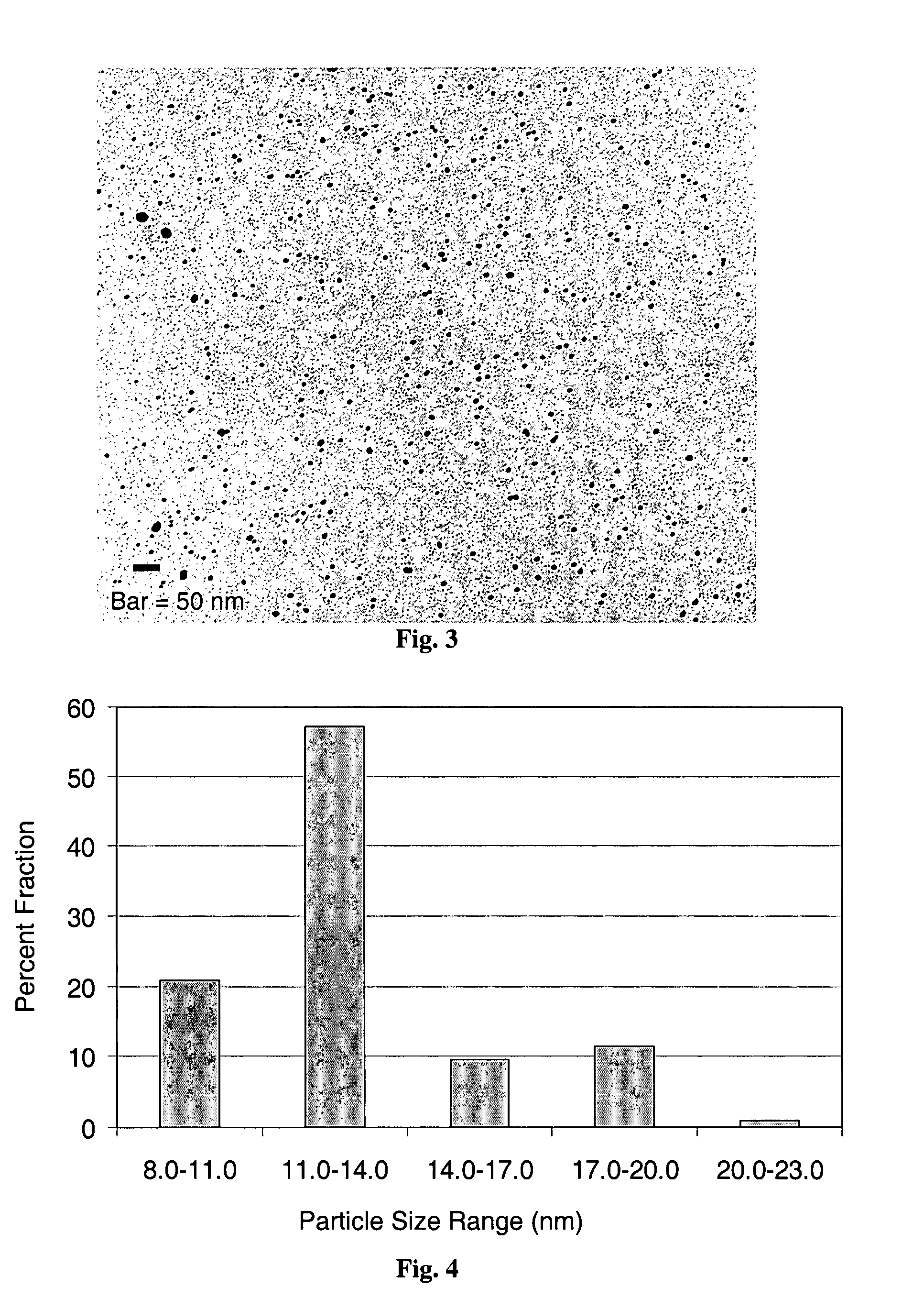

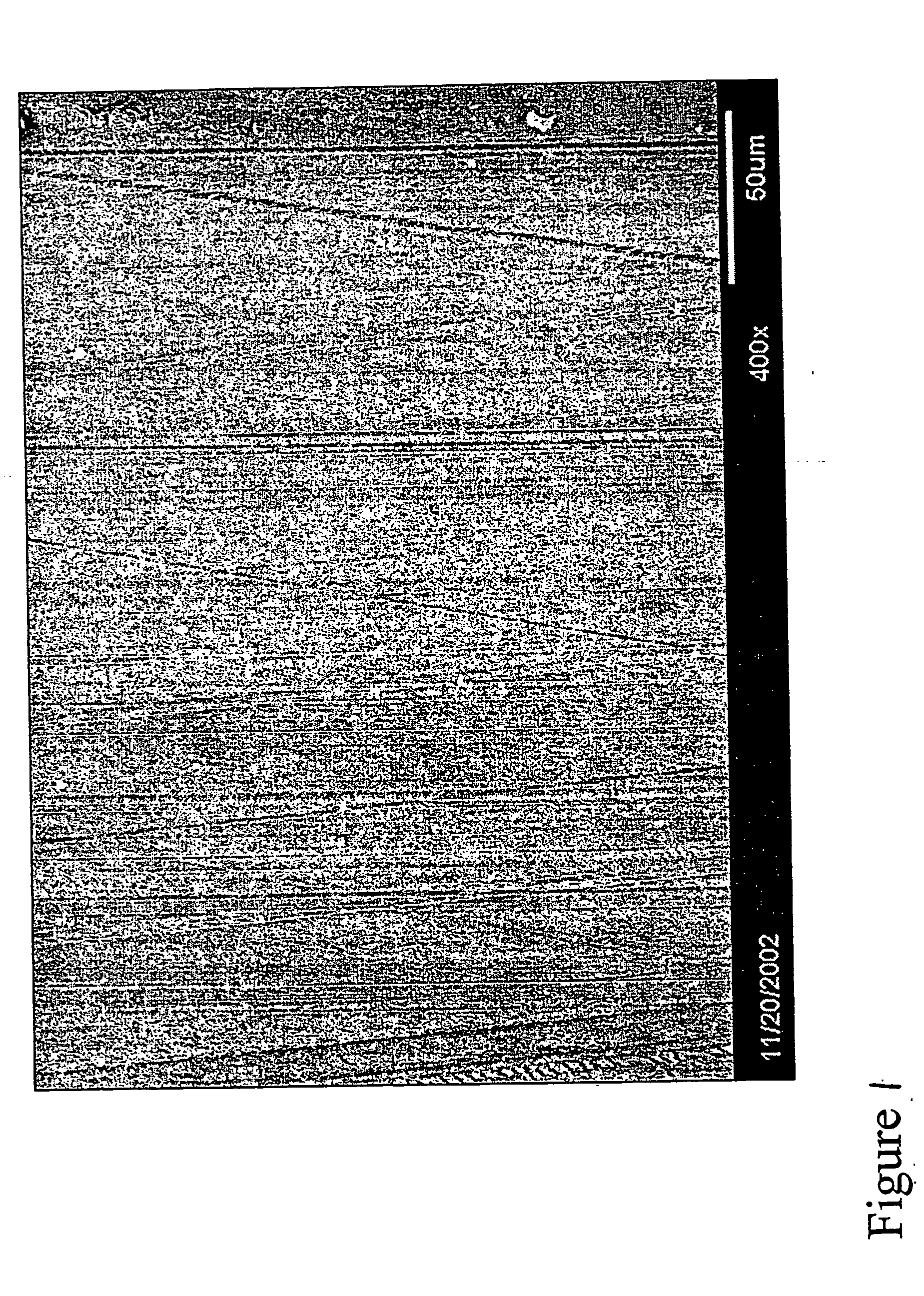

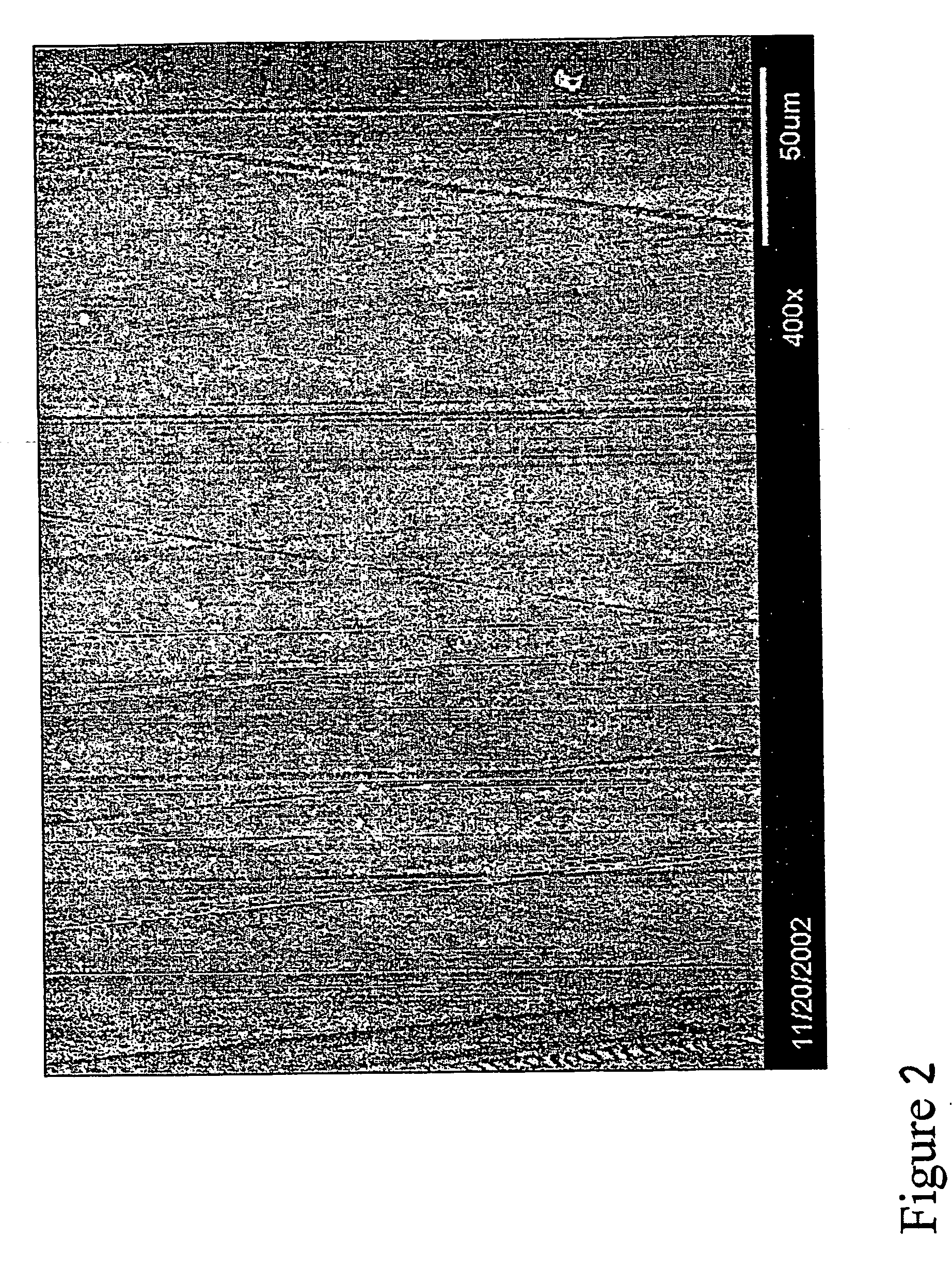

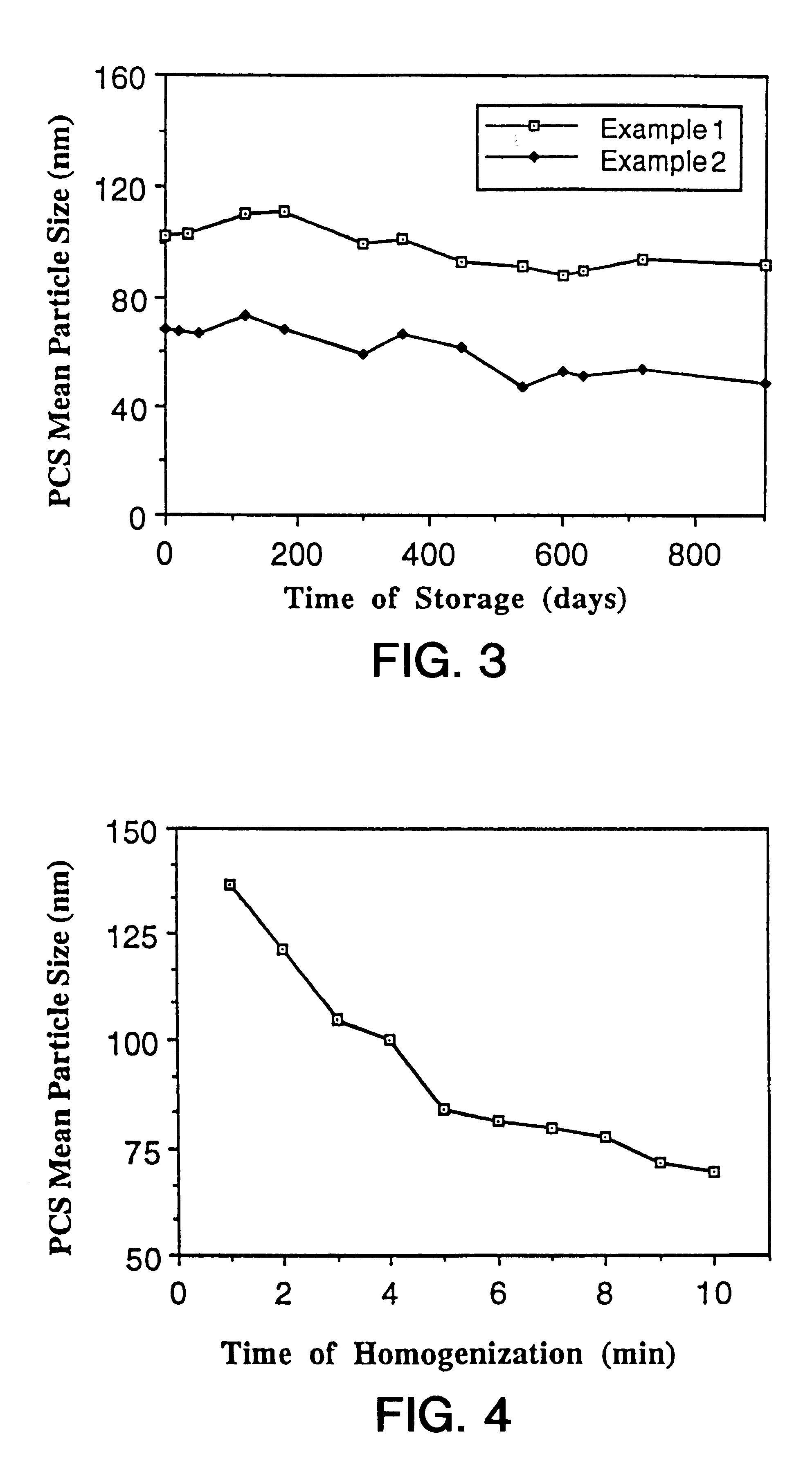

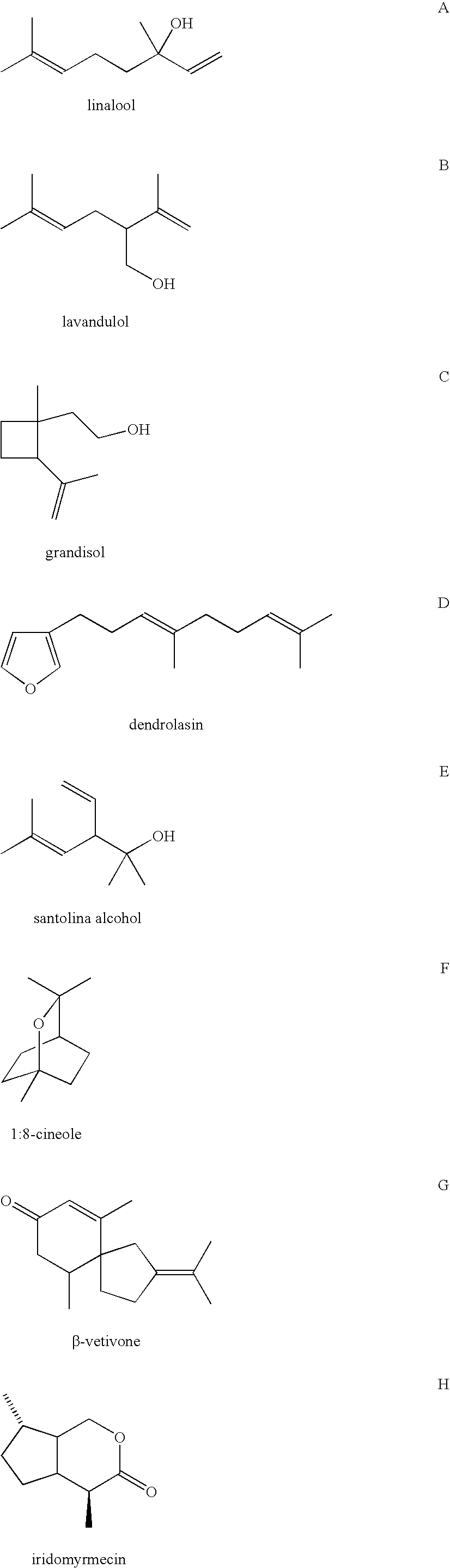

In accordance with the present invention, there are provided compositions and methods useful for the in vivo delivery of substantially water insoluble pharmacologically active agents (such as the anticancer drug paclitaxel) in which the pharmacologically active agent is delivered in the form of suspended particles coated with protein (which acts as a stabilizing agent). In particular, protein and pharmacologically active agent in a biocompatible dispersing medium are subjected to high shear, in the absence of any conventional surfactants, and also in the absence of any polymeric core material for the particles. The procedure yields particles with a diameter of less than about 1 micron. The use of specific composition and preparation conditions (e.g., addition of a polar solvent to the organic phase), and careful election of the proper organic phase and phase fraction, enables the reproducible production of unusually small nanoparticles of less than 200 nm diameter, which can be sterile-filtered. The particulate system produced according to the invention can be converted into a redispersible dry powder comprising nanoparticles of water-insoluble drug coated with a protein, and free protein to which molecules of the pharmacological agent are bound. This results in a unique delivery system, in which part of the pharmacologically active agent is readily bioavailable (in the form of molecules bound to the protein), and part of the agent is present within particles without any polymeric matrix therein.

Owner:ABRAXIS BIOSCI LLC

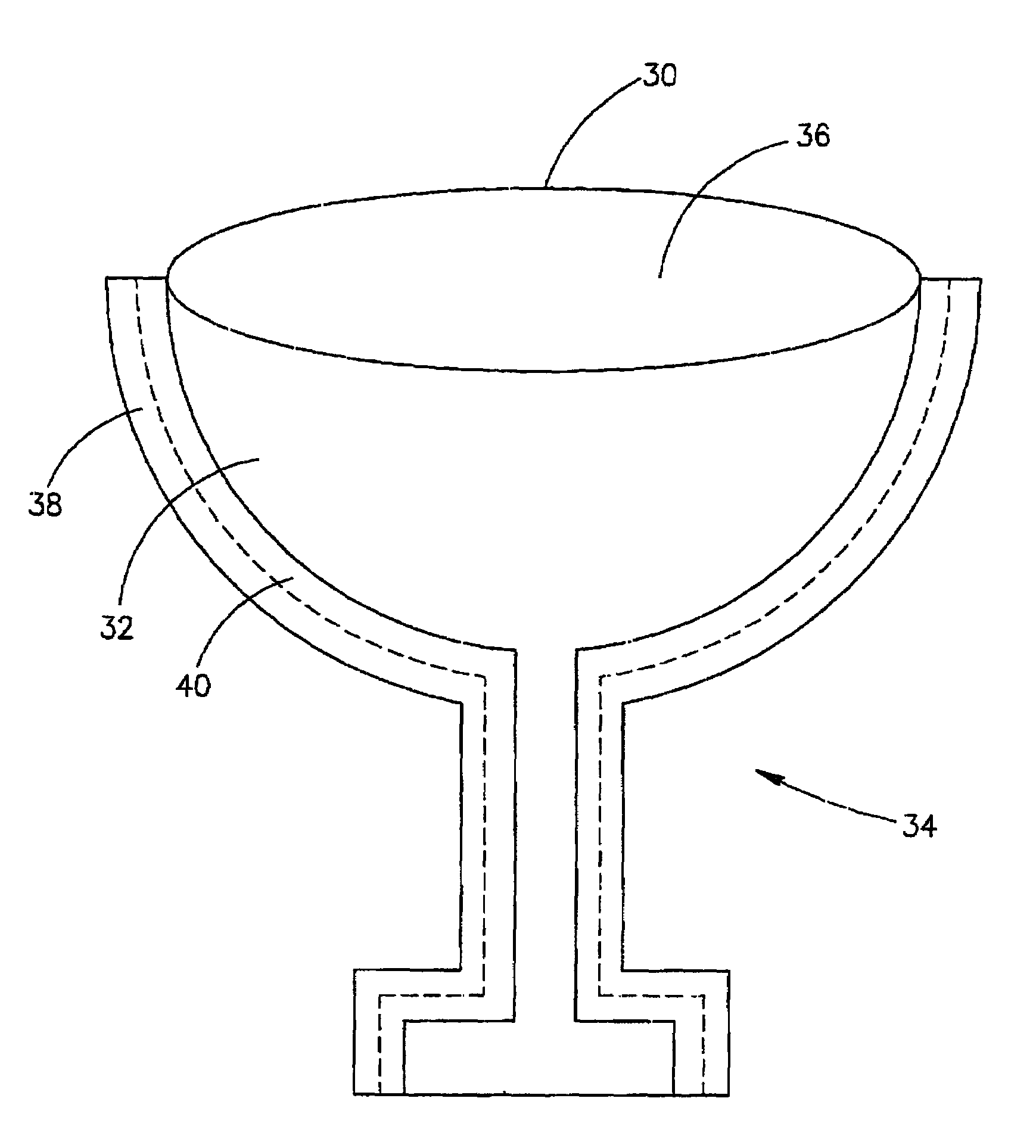

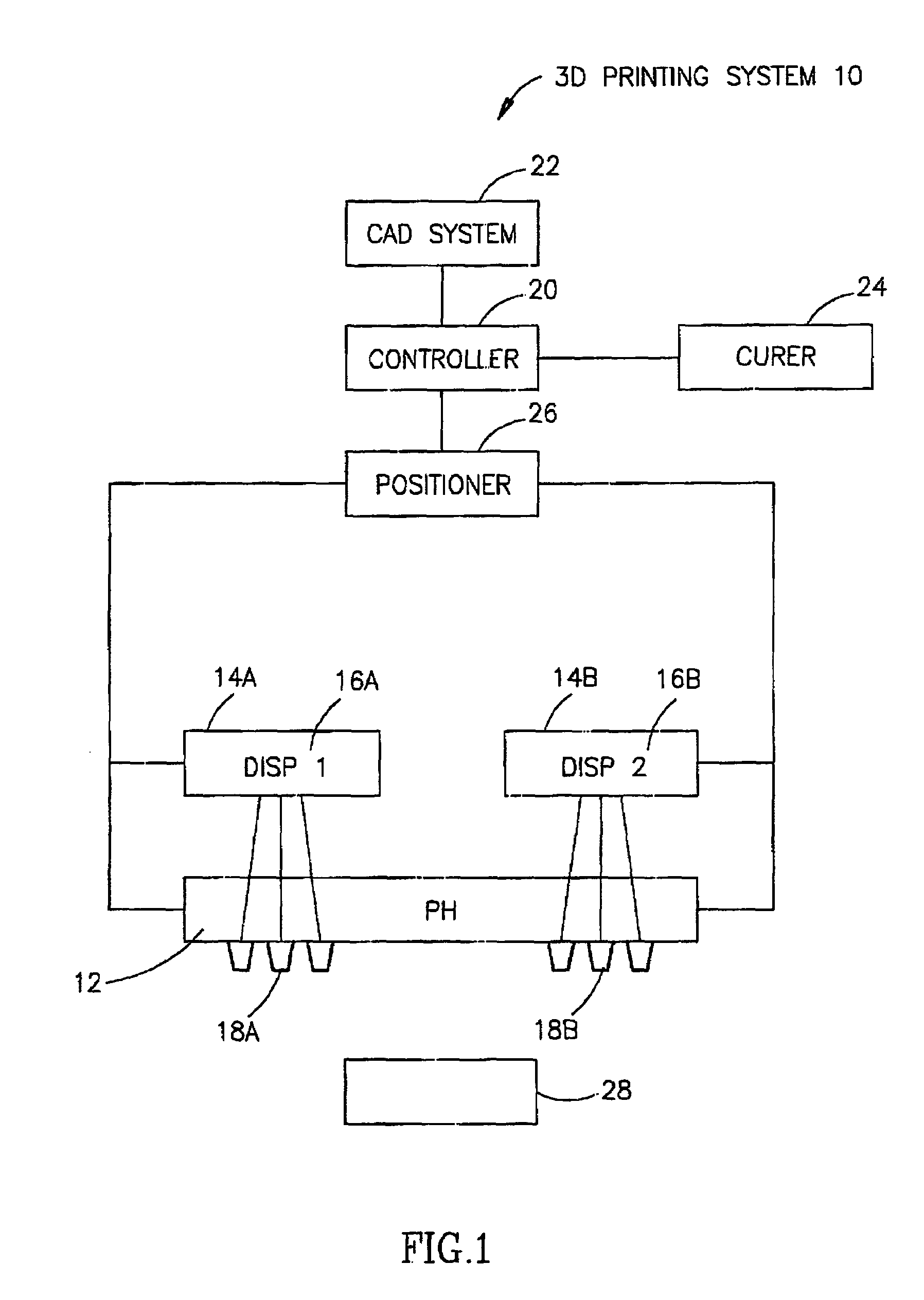

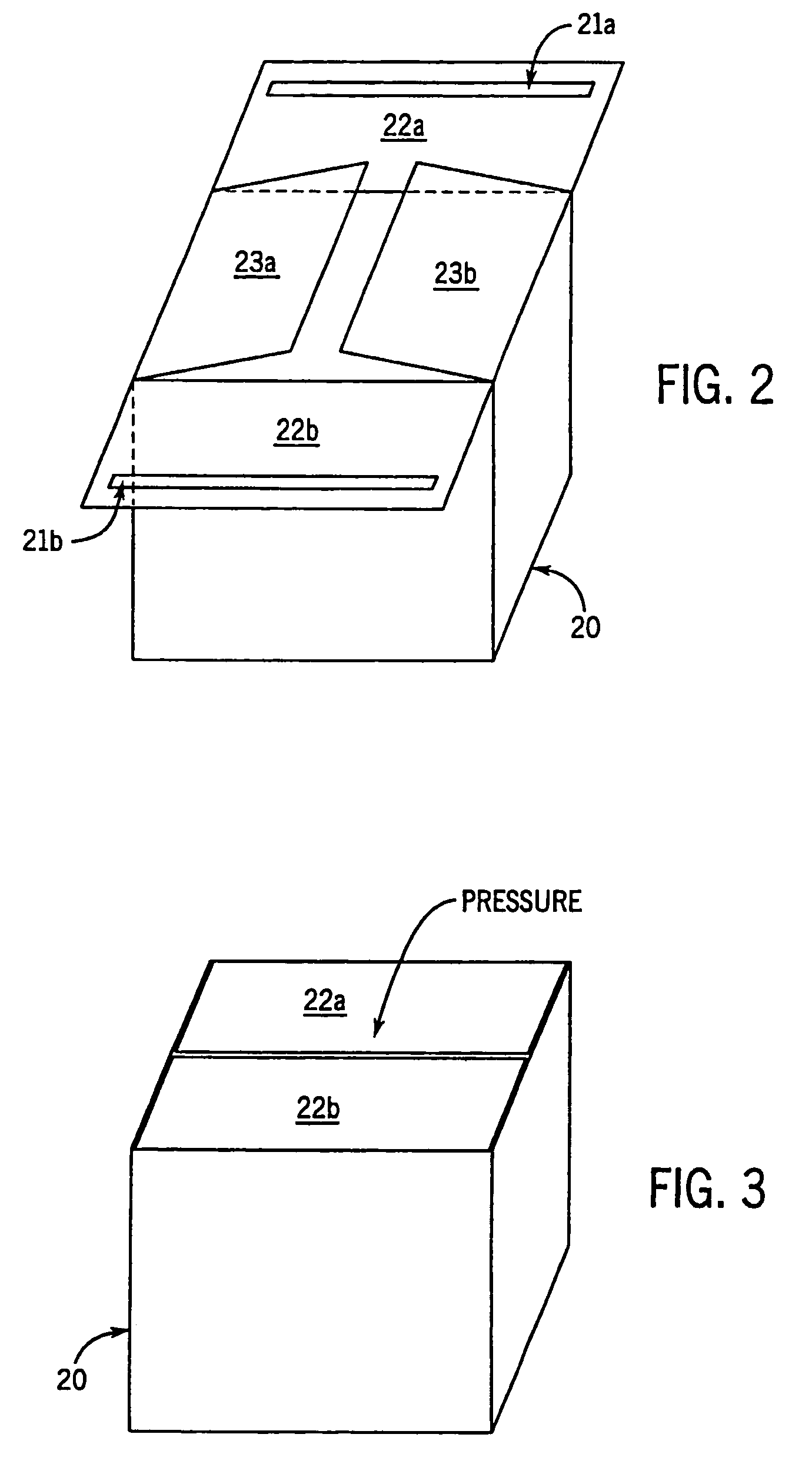

Compositions and methods for use in three dimensional model printing

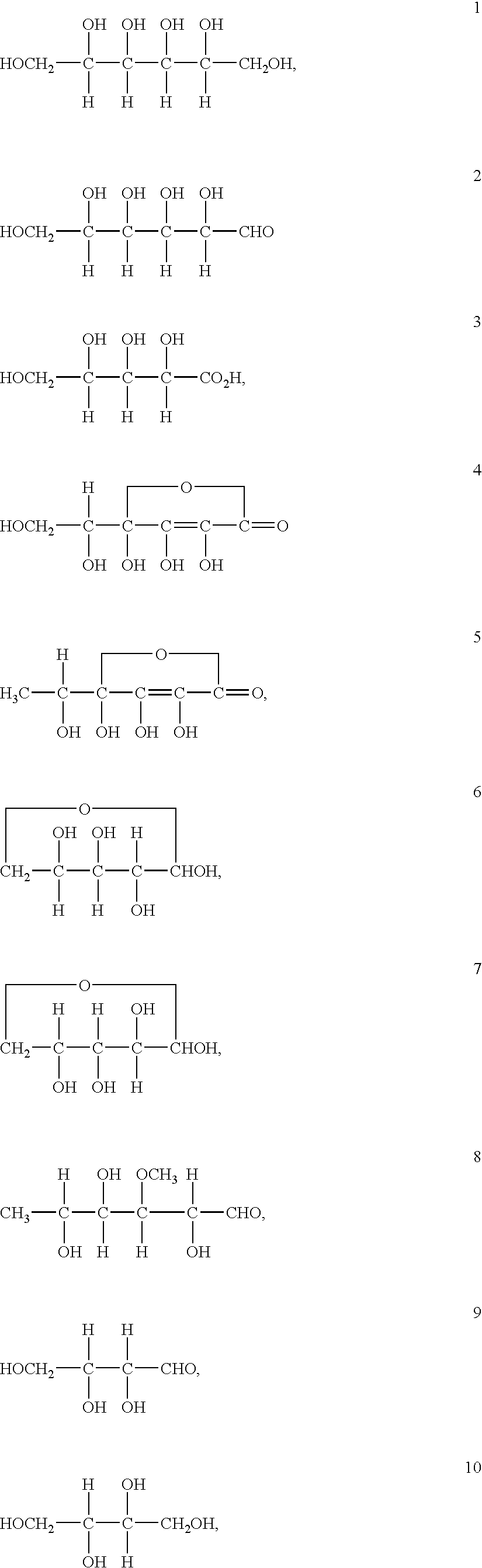

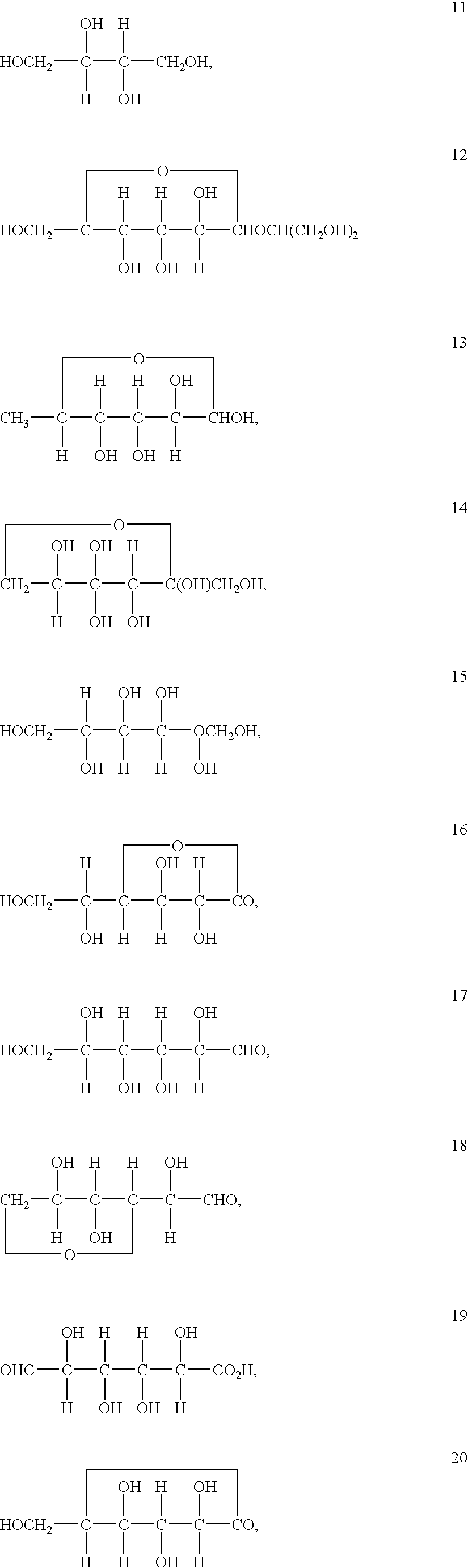

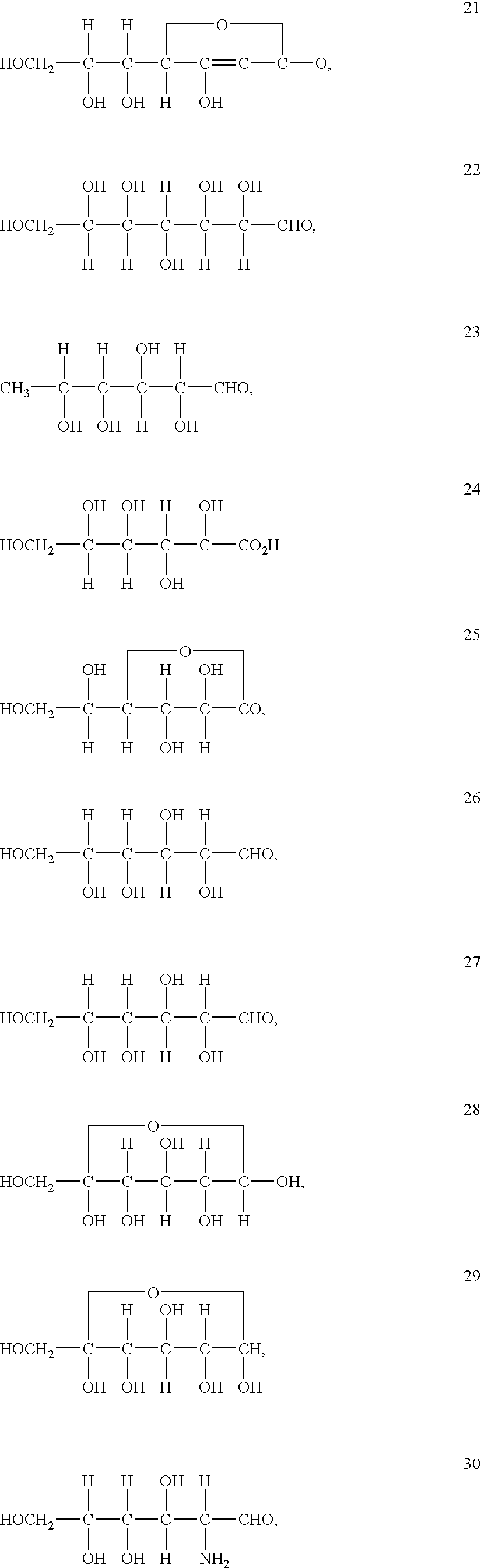

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

Antimicrobial silver compositions

The present invention comprises methods and compositions for antimicrobial silver compositions comprising silver nanoparticles. The present invention further comprises compositions for preparing silver nanoparticles comprising at least one stabilizing agent, one or more silver compounds, at least one reducing agent and a solvent. In one aspect, the stabilizing agent comprises a surfactant or a polymer. The polymer may comprise polymers such as polyacrylamides, polyurethanes, and polyamides. In one aspect, the silver compound comprises a salt comprising a silver cation and an anion. The anion may comprise saccharinate derivatives, long chain fatty acids, and alkyl dicarboxylates. The methods of the present invention comprise treating devices with the silver nanoparticle compositions, including, but not limited to, such devices as woven wound care materials, catheters, patient care devices, and collagen matrices. The present invention further comprises treatment of humans and animals wacr6ith the antimicrobial devices described herein.

Owner:AVENT INC

Stabilized silver nanoparticles and their use

A process comprising: reacting a silver compound with a reducing agent comprising a hydrazine compound in the presence of a thermally removable stabilizer in a reaction mixture comprising the silver compound, the reducing agent, the stabilizer, and an optional solvent, to form a plurality of silver-containing nanoparticles with molecules of the stabilizer on the surface of the silver-containing nanoparticles.

Owner:XEROX CORP

Methods and compositions for metal nanoparticle treated surfaces

ActiveUS20070207335A1Extended shelf lifeConvenient coatingMaterial nanotechnologyBiocidePolyamideSolvent

The present invention comprises methods and compositions comprising metal nanoparticles. The invention comprises metal nanoparticles and surfaces treated with a metal nanoparticle coating. The present invention further comprises compositions for preparing nanoparticles comprising at least one stabilizing agent, one or more metal compounds, at least one reducing agent and a solvent. In one aspect, the stabilizing agent comprises a surfactant or a polymer. The polymer may comprise polymers such as polyacrylamides, polyurethanes, and polyamides. In one aspect, the metal compound comprises a salt comprising a metal cation and an anion. The anion may comprise saccharinate derivatives, long chain fatty acids, and alkyl dicarboxylates.

Owner:AVENT INC

Jettable compositions

ActiveUS20050171237A1Prevent long-term corrosionReaction is slowAdditive manufacturing apparatusLiquid surface applicatorsMeth-Oligomer

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabiliser for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

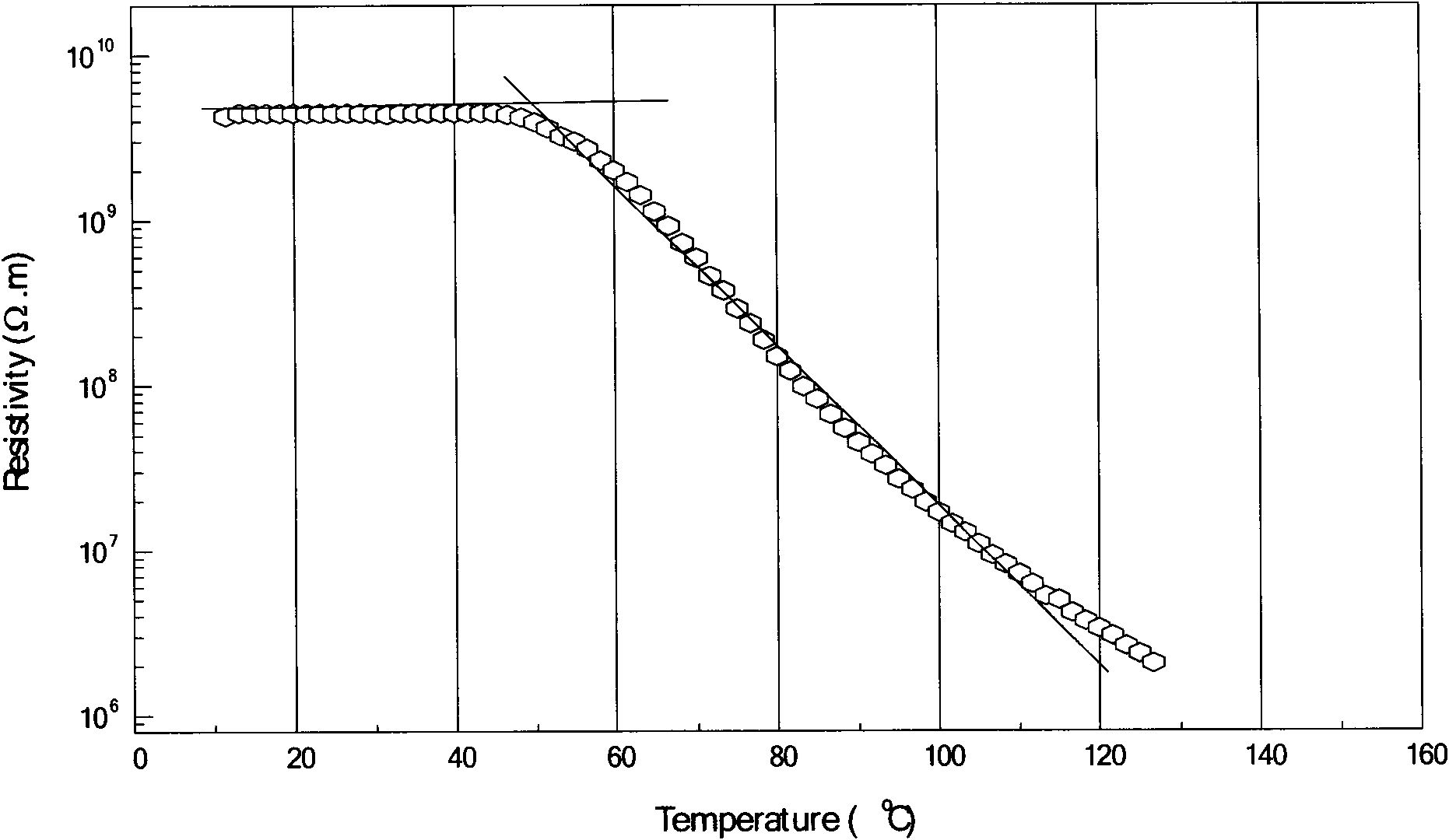

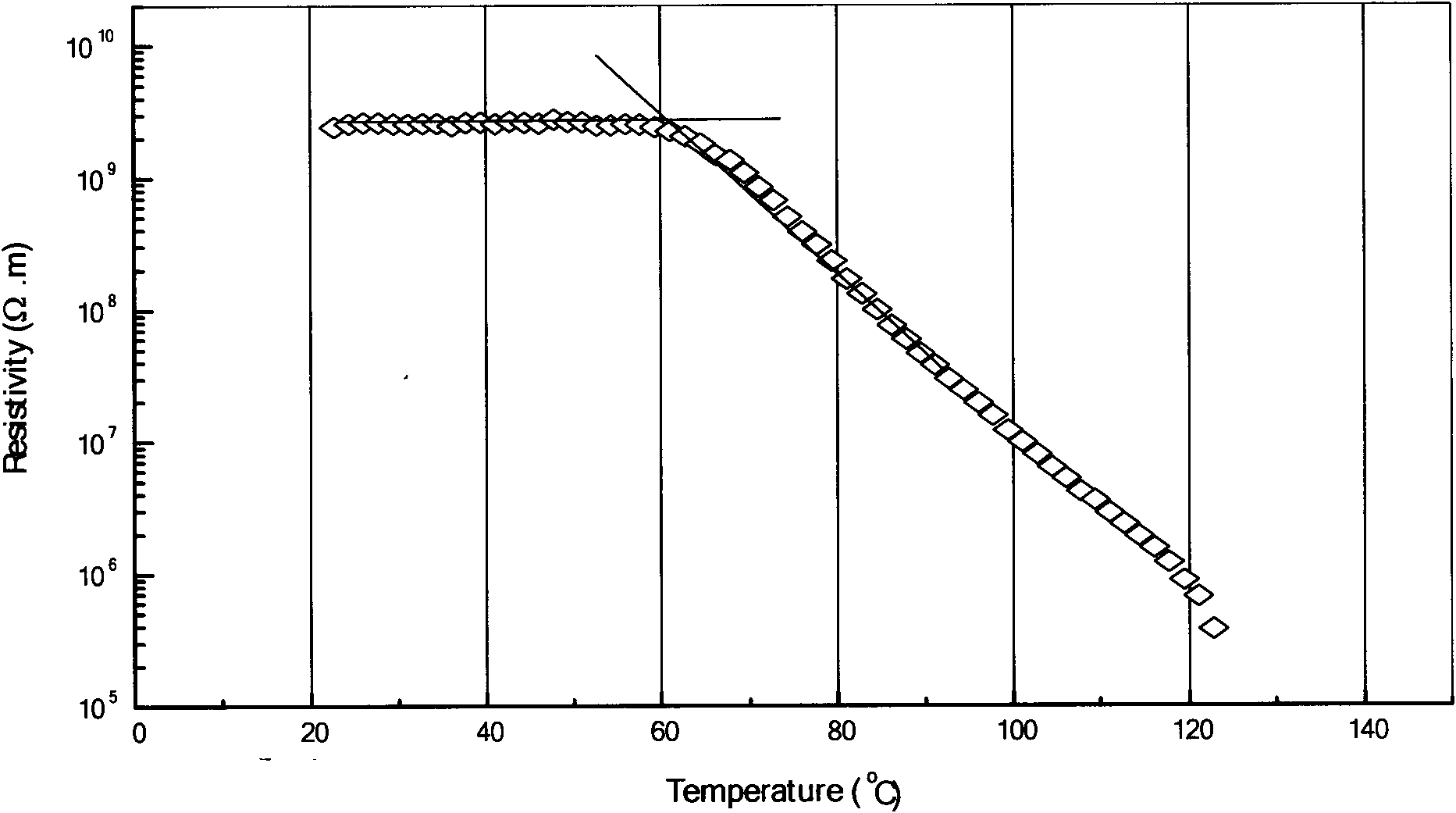

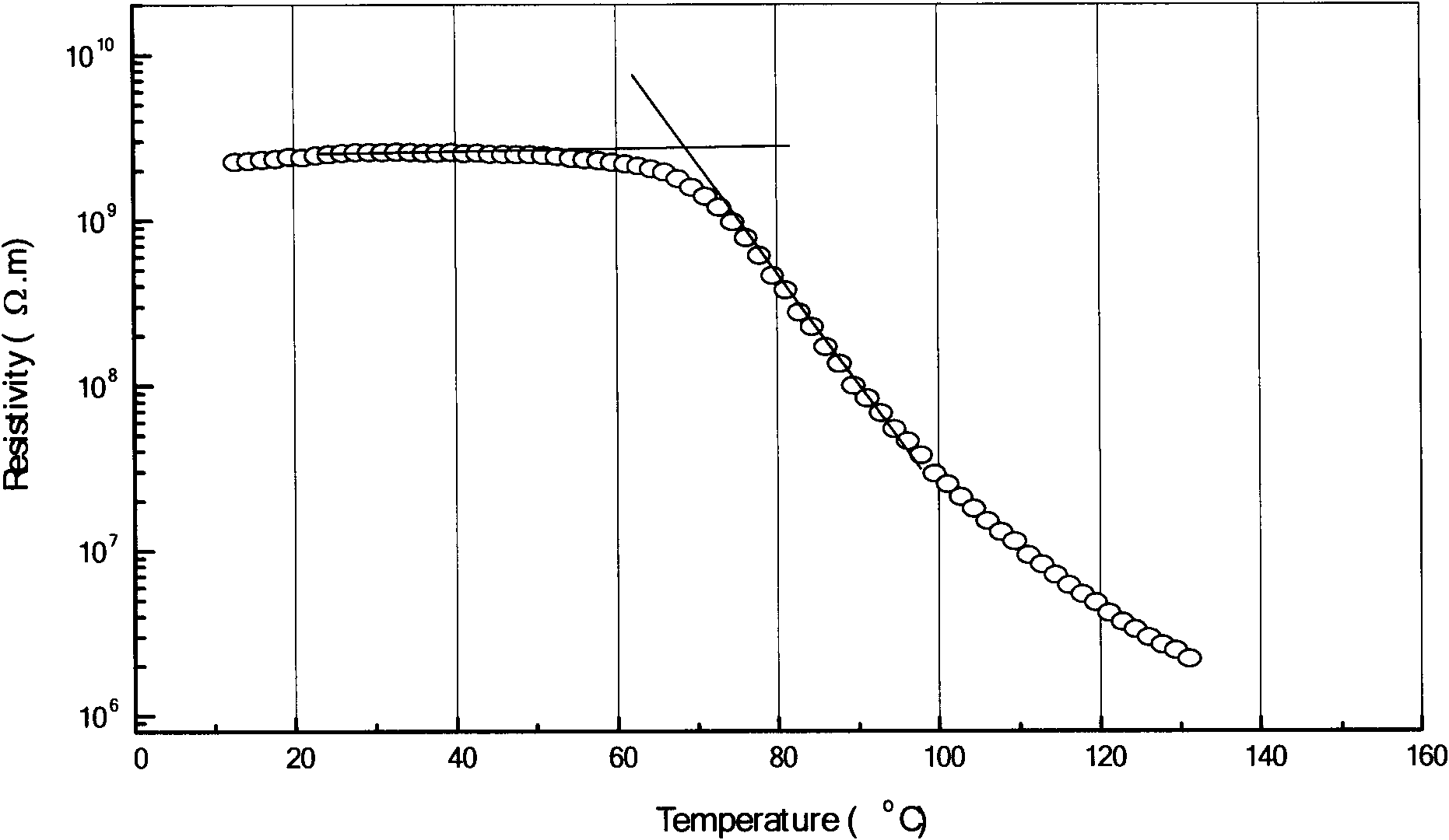

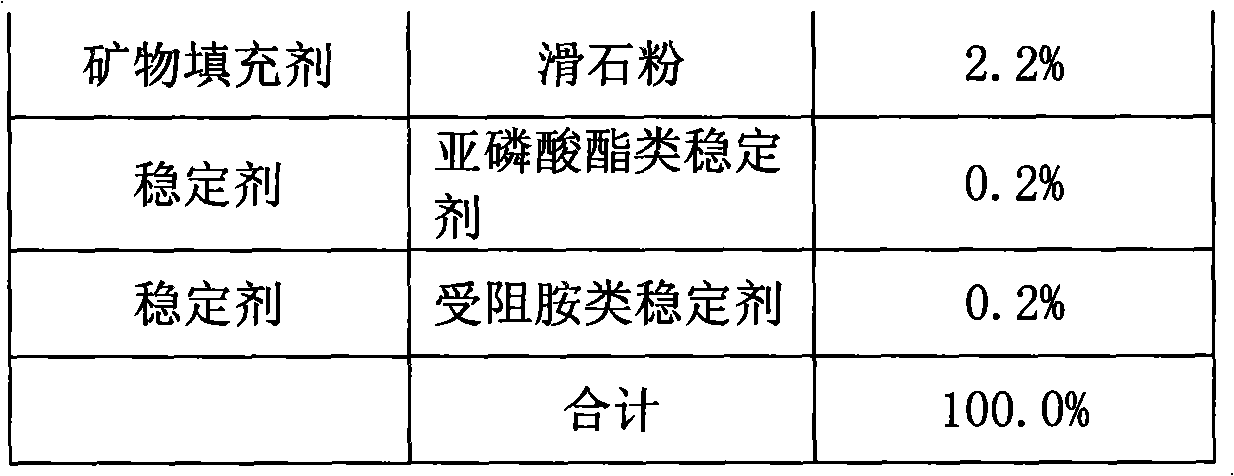

Temperature sensing cable material with CRT characteristics and preparation method thereof

ActiveCN101613504AWith CTR featureFlexibleRubber insulatorsPlastic/resin/waxes insulatorsProcedure AgentsAntioxidant

The invention relates to technical fields of materials, chemical engineering and electronics, in particular to a cable material with a polymer substrate and CTR effect and a preparation method thereof. The temperature sensing cable material with CRT characteristics consists of thermoplastic polymer, a filling agent, a plasticizer, functional additives, a stabilizing agent, a flame retardant, a lubricant, an antioxidant and a processing agent, has the use temperature range between -30 and 150 DEG C, and can be applied on occasions such as recoverable line-type temperature sensing cables, fire prewarning and alarm devices, temperature measurement, overheating alarm and protection and the like. The temperature sensing cable material with the CRT characteristics takes a polymer material as a substrate, and is added with multiple organic and inorganic compounds with special CTR characteristics taken as the functional additives, and has the characteristics of flexibility, and capacities of being continuously processed and being used like a common cable material.

Owner:QINGDAO SUNYFIRE TECHNOLOGE

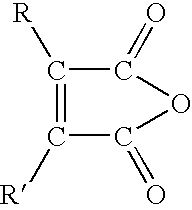

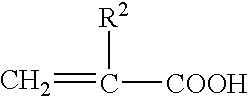

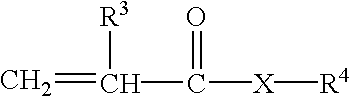

Rheology modifying copolymer composition

A rheology modifying copolymer composition containing a cross-linked copolymer of unsaturated carboxylic acid, a hydrophobic monomer, a hydrophobic chain transfer agent, a cross linking agent, and, optionally, a steric stabilizer, provides increased viscosity in aqueous electrolyte-containing environments.

Owner:NOVEON IP HLDG CORP

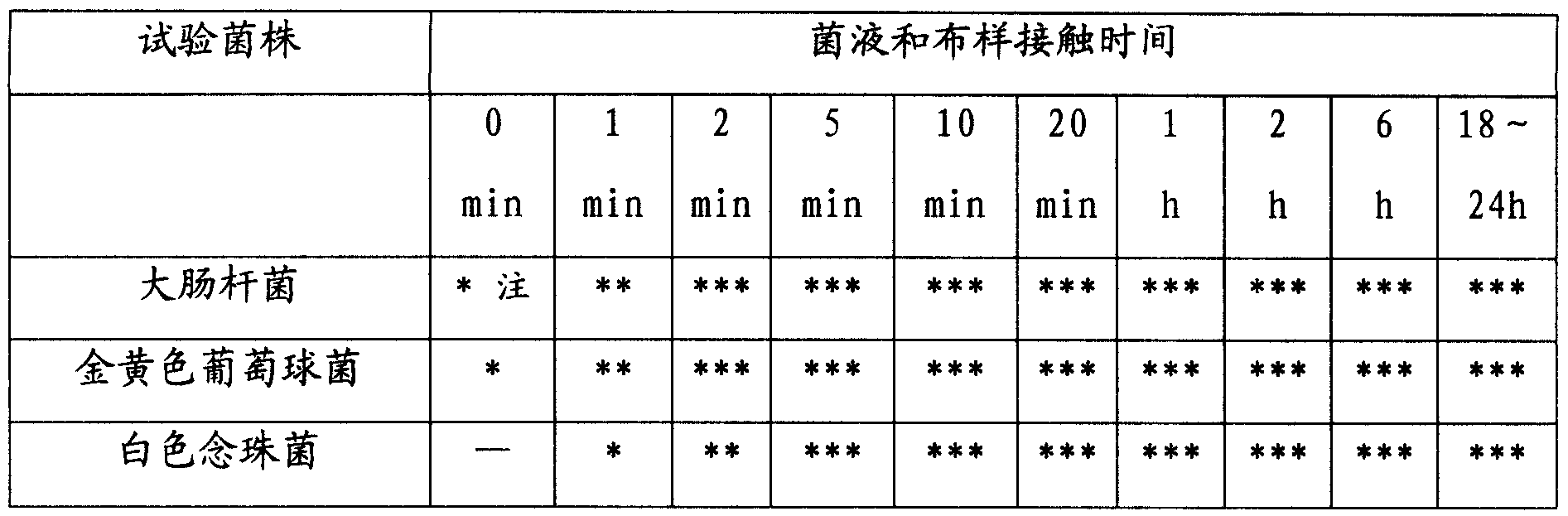

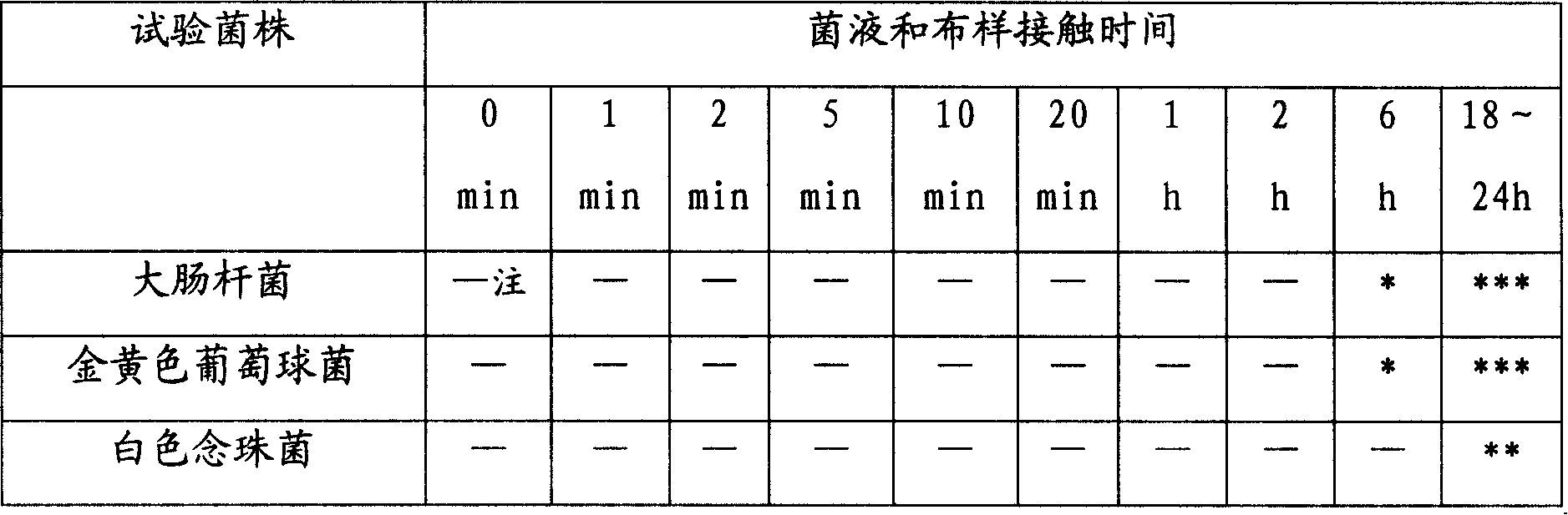

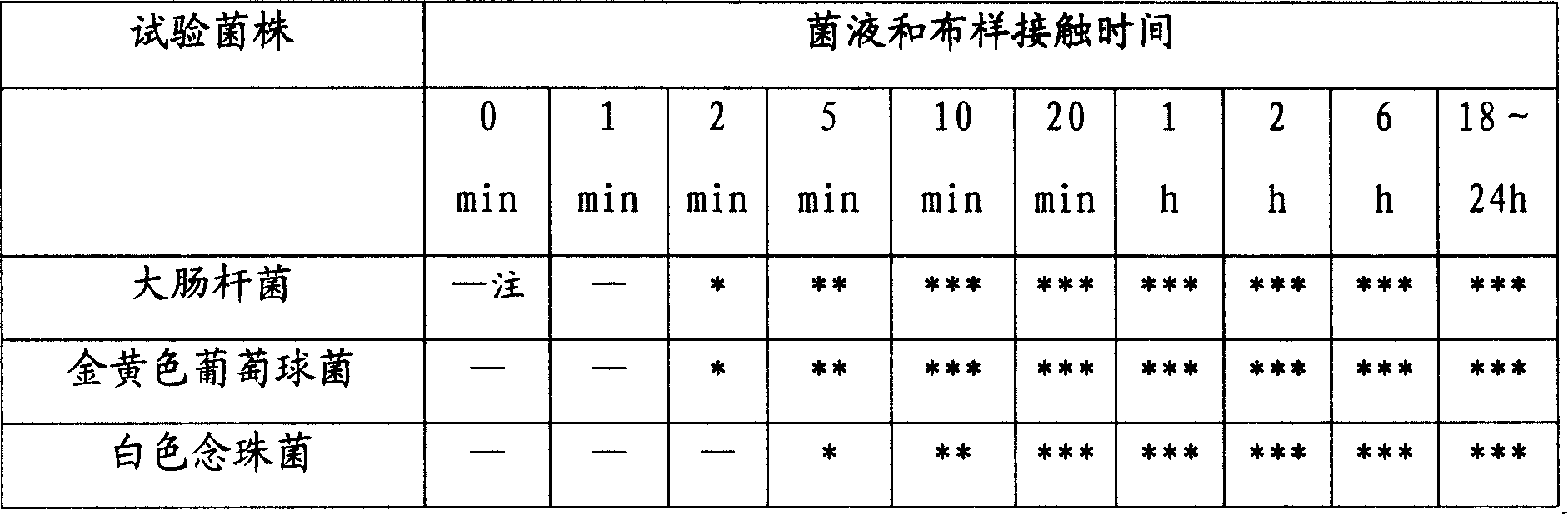

Inorganic/organic nano composite antibacterial agent and its fabric product application

The invention relates to an inorganic / organic nano-composite antibacterial and application of fiber product thereof. 0.01-20 proportions of inorganic antibacterial, 0.01-35 proportions of organic antibacterial, 0.0001-0.4 proportion of inorganic / organic antibacterial compatibility finishing agent, 0.05-40 proportions of macromolecule bond, 0.0001-0.4 proportion of stabilizer that prevents color change of the inorganic antibacterial, 0.1-30 proportions of high efficiency emulsifying agent and 100 proportions of distilled water are added in sequence by weight proportion, wetted, dispersed, ground, dispersed at high-speed, stirred, etc., so as to acquire the nano-composite antibacterial. The antibacterial can process the fiber product by a dip-dye method, a roll-dye method, a spray method, etc. Dresses, socks and socks, blankets, beddings, gowns, patient wears, masks, medicinal gauzes, air filtering nettings, etc., made from the inorganic / organic nano-composite antibacterial of the invention are characterized by high antibacterial efficiency, rapid antibacterial function, long lasting antibacterial performance, laundering durability, etc., and the inorganic / organic nano-composite antibacterial of the invention is applicable to life, medical care, etc., and has the functions of preventing the occurrence and transmission of diseases, protecting the health of people and improving life quality.

Owner:BEIJING CHAMGO NANO TECH

Crystalline hydroxy waxes as oil in water stabilizers for skin cleansing liquid composition

The present invention relates to a stress stable lathering skin cleansing liquid composition comprising by weight parts of the liquid composition: (a) from about 0.5 parts to 10 parts of a stabilizer; for example trihydroxystearin; (b) from about 1 part to about 80 parts of lipid skin moisturizing agent; (c) from about 1 part to about 30 parts of surfactant having a combined CMC equilibrium surface tension value of from 15 to 50; (d) water; wherein said stress stable lathering skin cleansing liquid composition has a Lipid Deposition Value (LDV) of from about 5 to about 100 and wherein said composition is stable for at least two weeks at 100 F.

Owner:THE PROCTER & GAMBLE COMPANY

Particles with modified physicochemical properties, their preparation and uses

InactiveUS6197349B1Easy to handleImprove bioavailabilityPowder deliveryOrganic active ingredientsActive agentDelivery system

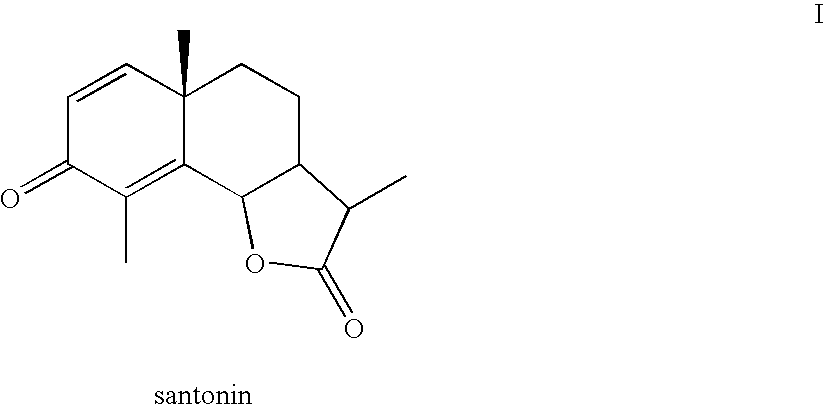

Particles comprising(a) a supercooled melt of a poorly water-soluble substance and(b) a stabilizing agent,which have a mean particle size of between 30 and 500 nm, and disperse compositions containing them, as administration forms and delivery systems for drugs, vaccines and other biologically active agents such as herbicides, pesticides, insecticides, fungicides, fertilizers, vitamins, nutrition additives and cosmetics.

Owner:MSE PHARMA

Stabilized Iodocarbon Compositions

InactiveUS20080157022A1Reduce environmental damageLow propertyHalogenated hydrocarbon separation/purificationHeat-exchange elementsStabilizing AgentsSolvent composition

Disclosed are compositions comprising at least one iodocarbon compound and preferably at least one stabilization agent comprising a diene-based compound. These compositions are generally useful as refrigerants for heating and cooling, as blowing agents, as aerosol propellants, as solvent composition, and as fire extinguishing and suppressing agents.

Owner:HONEYWELL INT INC

Stabilized vanadium electrolyte solutions for all-vanadium redox cells and batteries

InactiveUS6562514B1Effective amountEasy to modifyFinal product manufactureRegenerative fuel cellsRedoxPhysical chemistry

Owner:JD HLDG INC

Stabilized silver nanoparticles and their use

A process comprising: reacting a silver compound with a reducing agent comprising a hydrazine compound in the presence of a thermally removable stabilizer in a reaction mixture comprising the silver compound, the reducing agent, the stabilizer, and an optional solvent, to form a plurality of silver-containing nanoparticles with molecules of the stabilizer on the surface of the silver-containing nanoparticles.

Owner:XEROX CORP

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

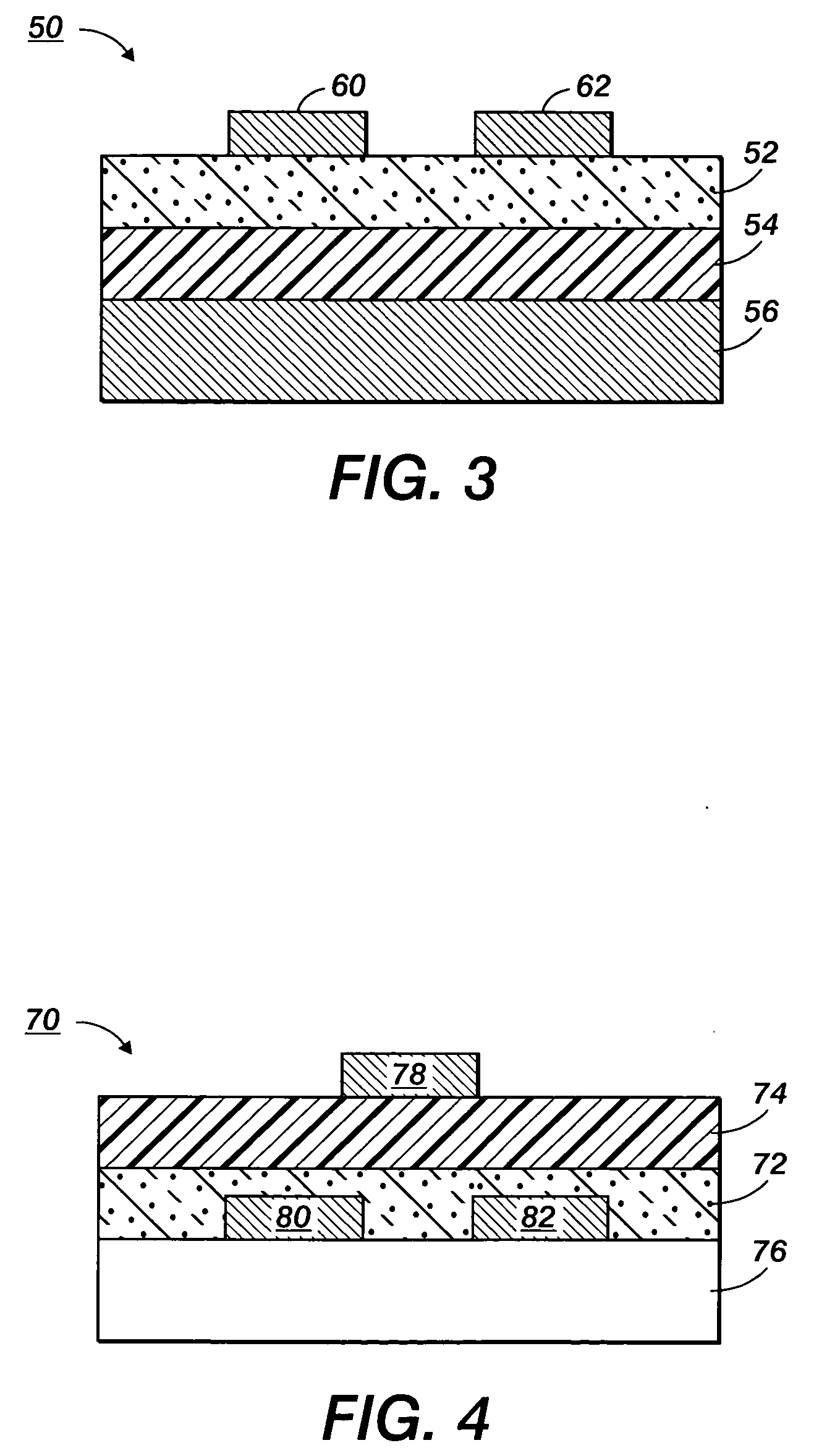

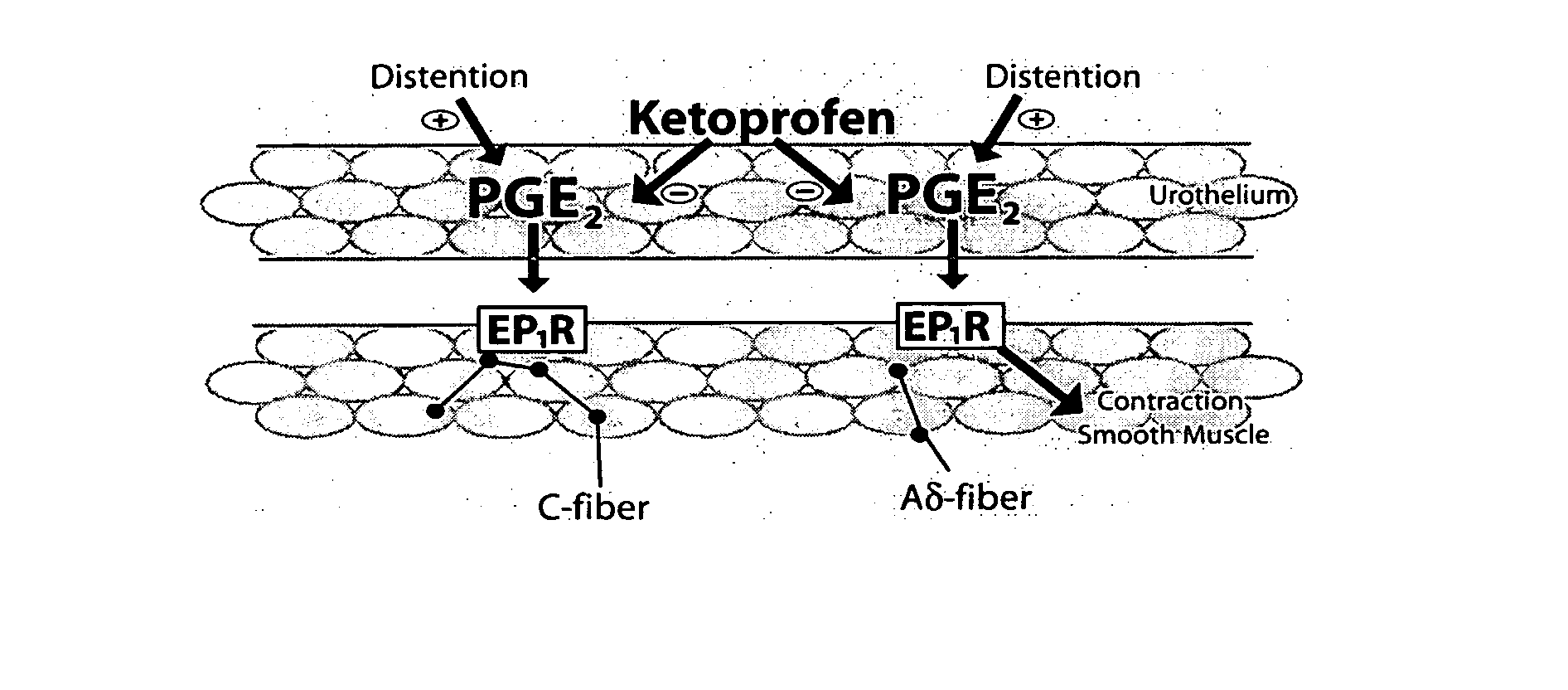

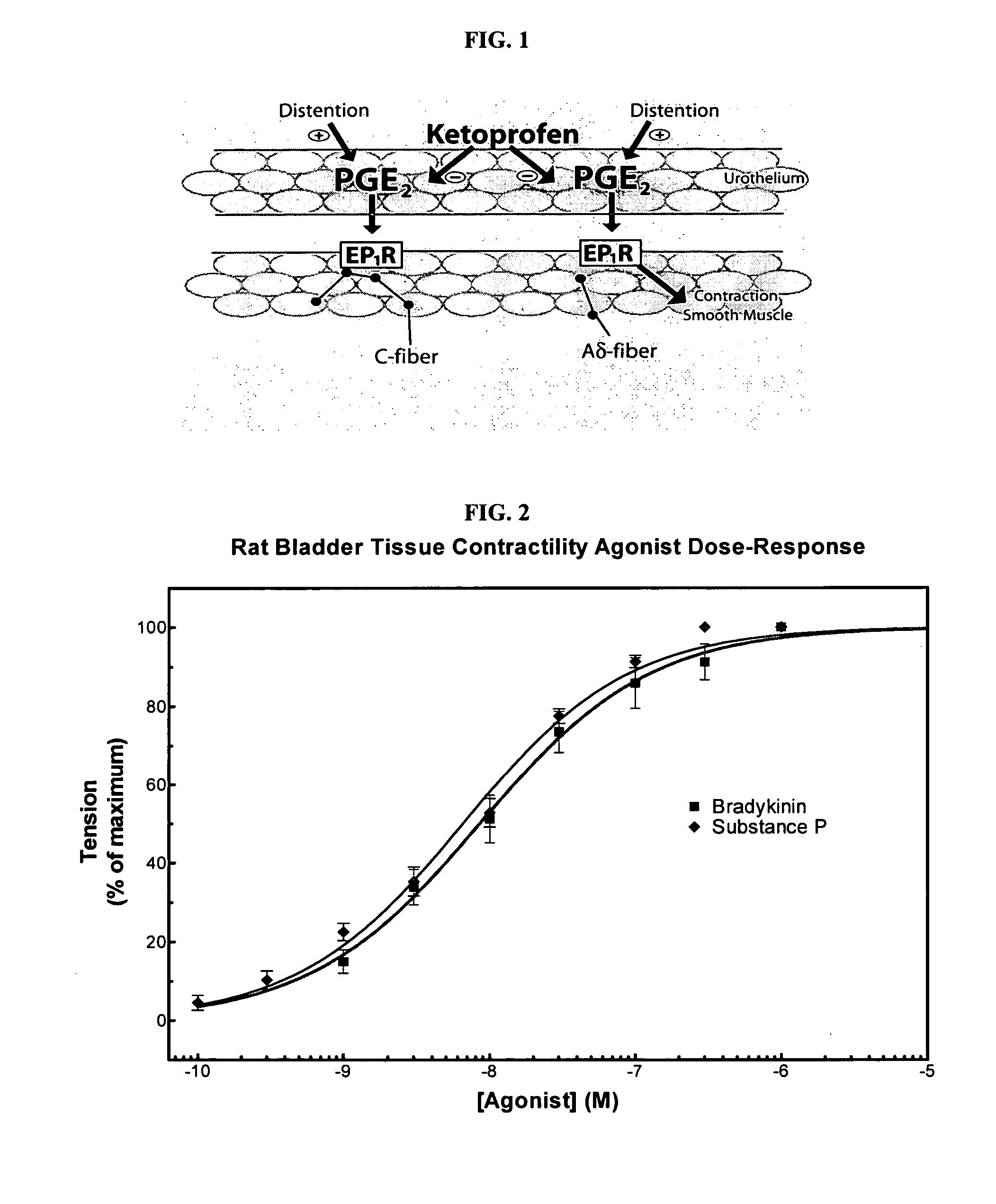

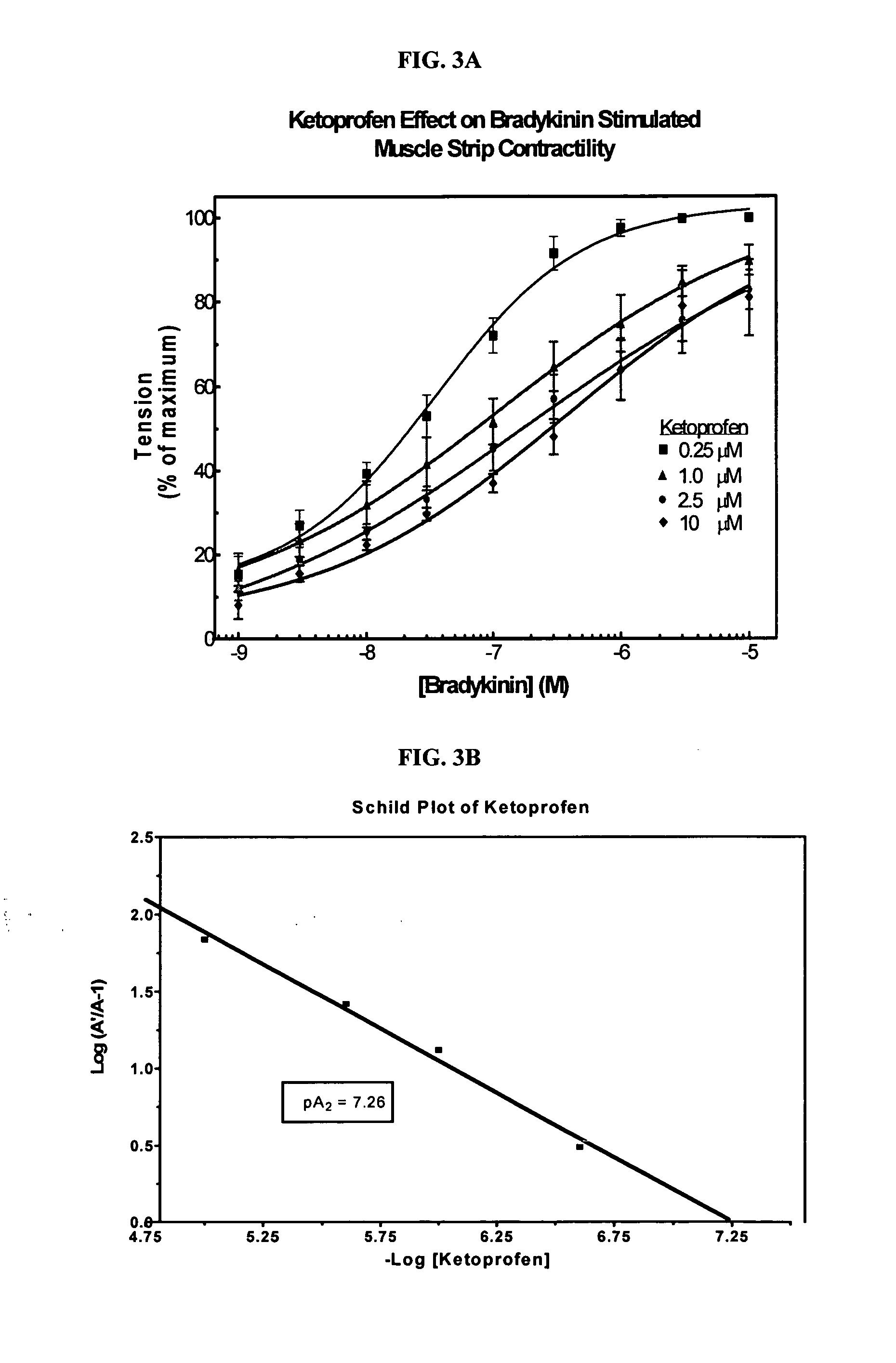

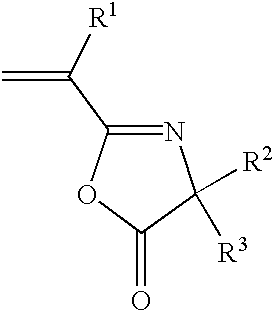

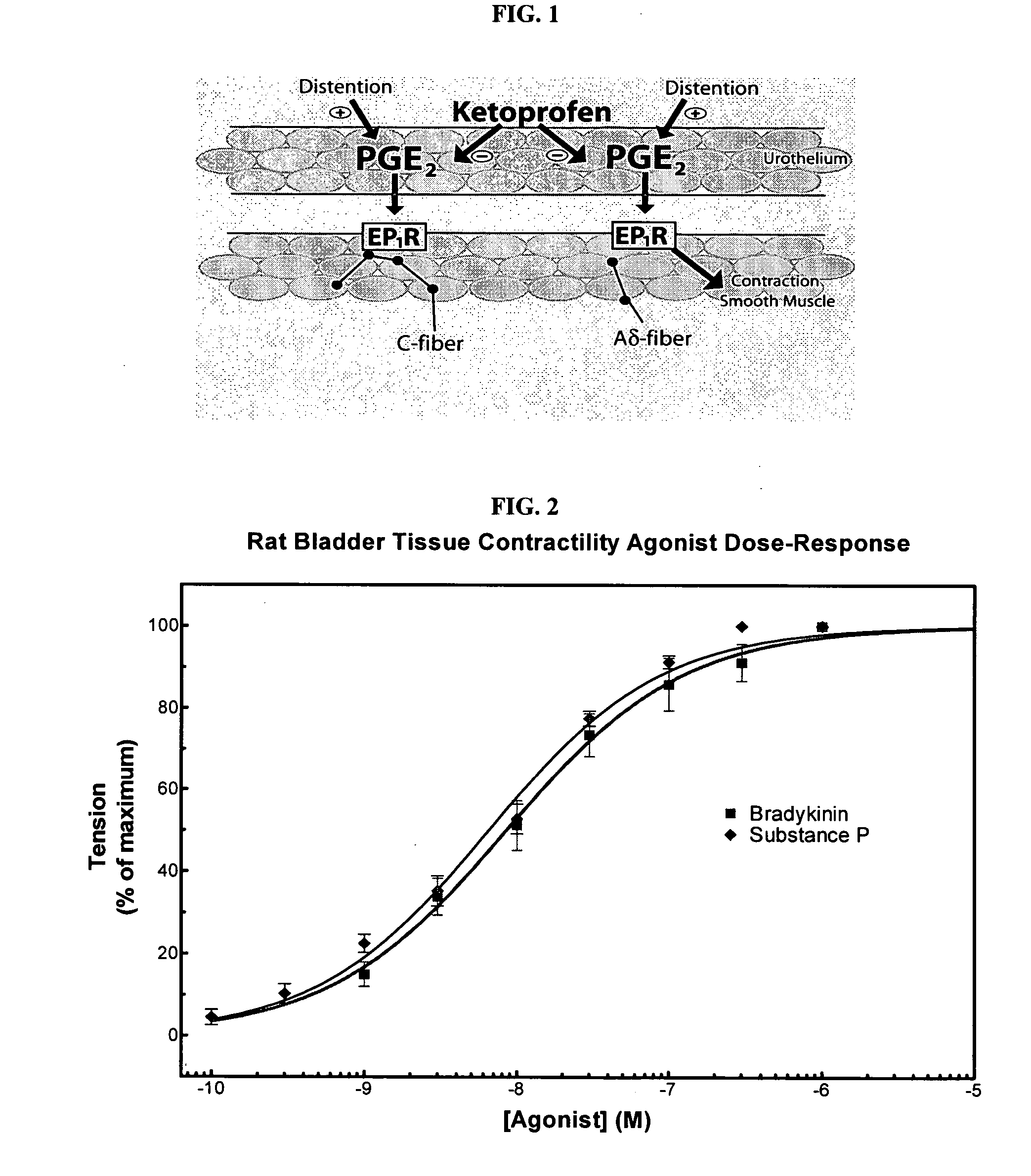

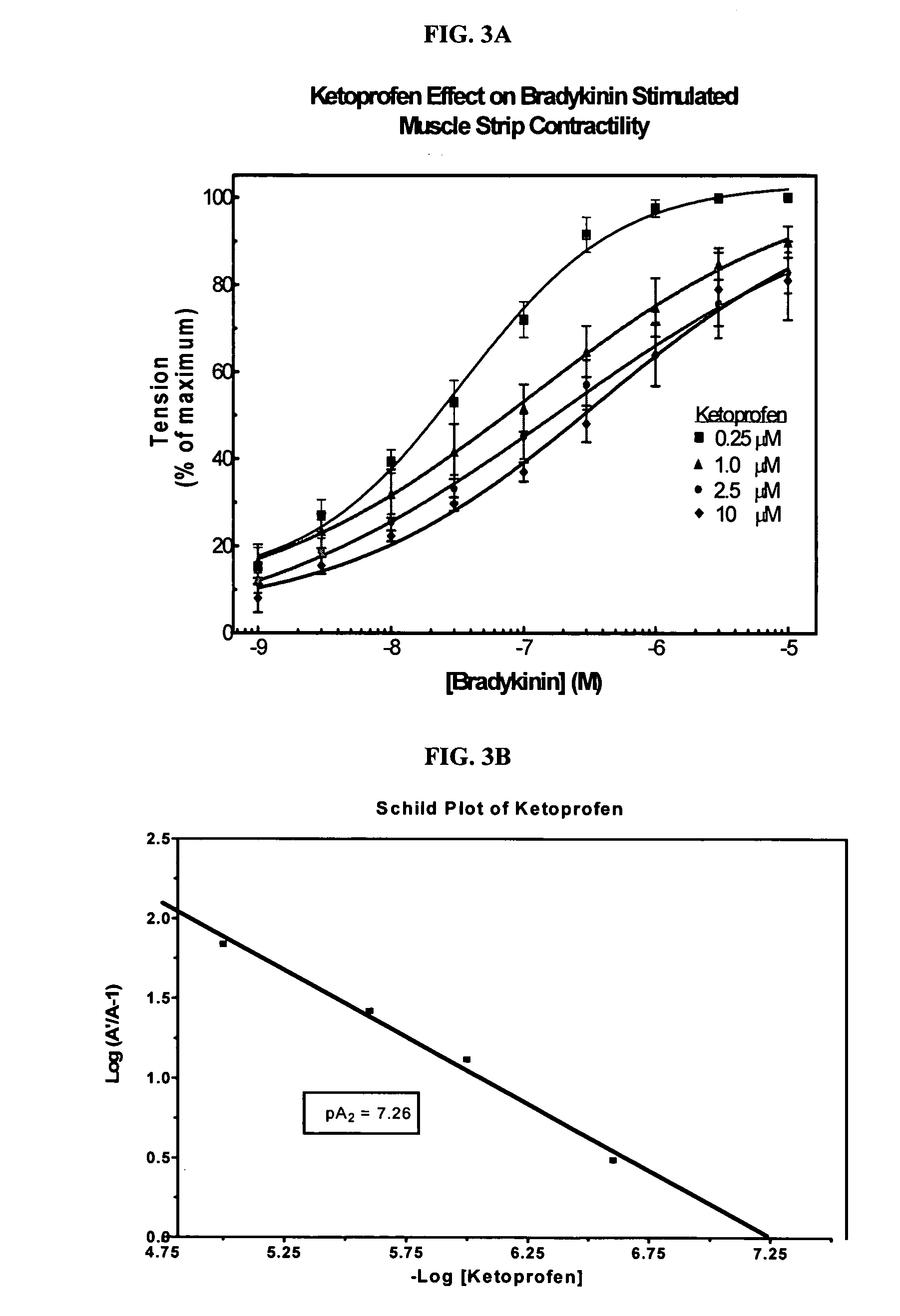

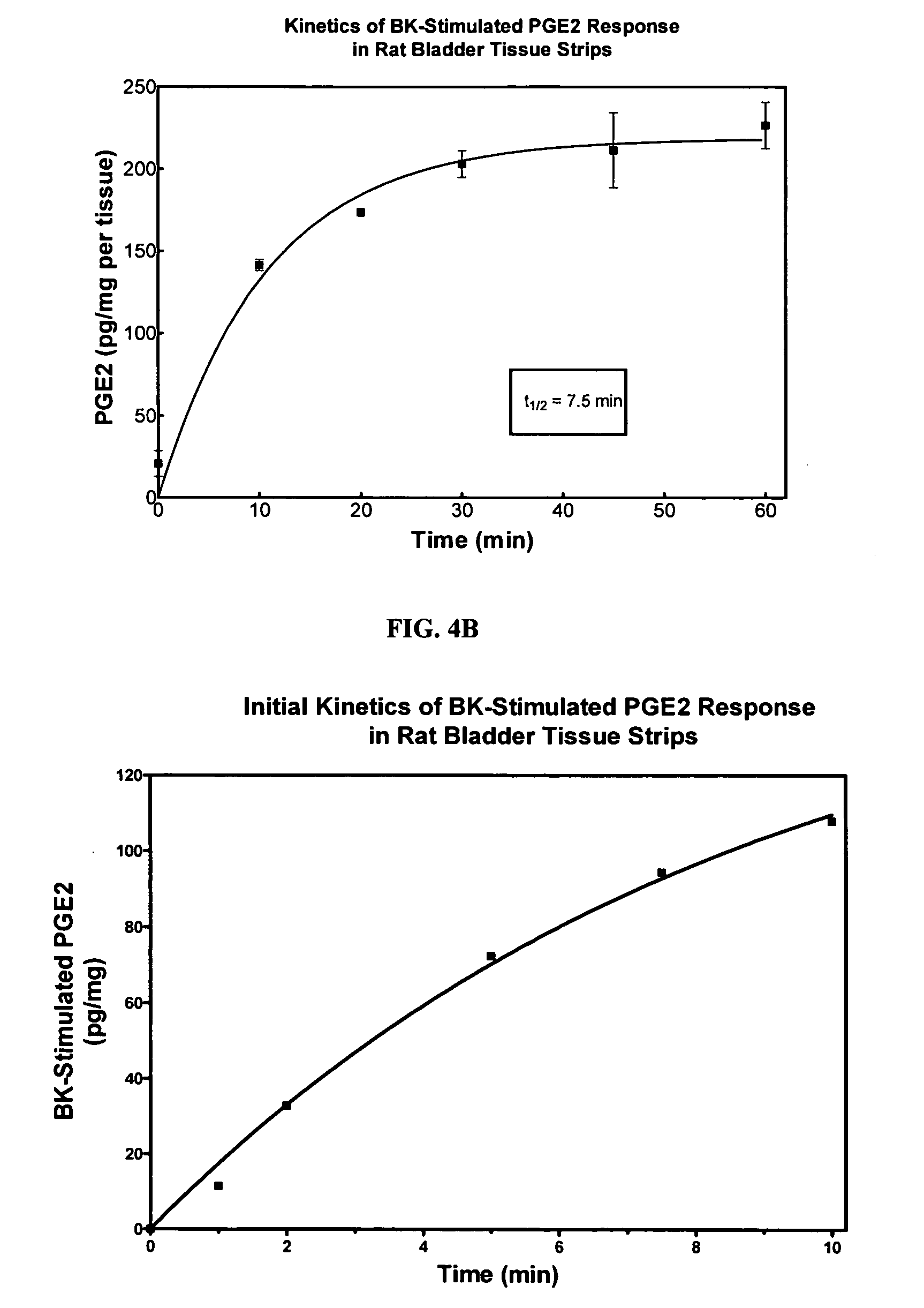

Cyclooxygenase inhibitor and calcium channel antagonist compositions and methods for use in urological procedures

InactiveUS20070248639A1Inhibiting pain/inflammationPrevent spasmsBiocideNervous disorderNifedipineCyclooxygenase

Compositions of a cyclooxygenase inhibitor and a calcium channel antagonist in a liquid carrier. The composition may be administered the the urinary tract during urological diagnostic, interventional, surgical and other medical procedures. One disclosed composition comprises ketoprofen and nifedipine in a liquid irrigation carrier, and includes a solubilizing agent, stabilizing agents and a buffering agent.

Owner:OMEROS CORP

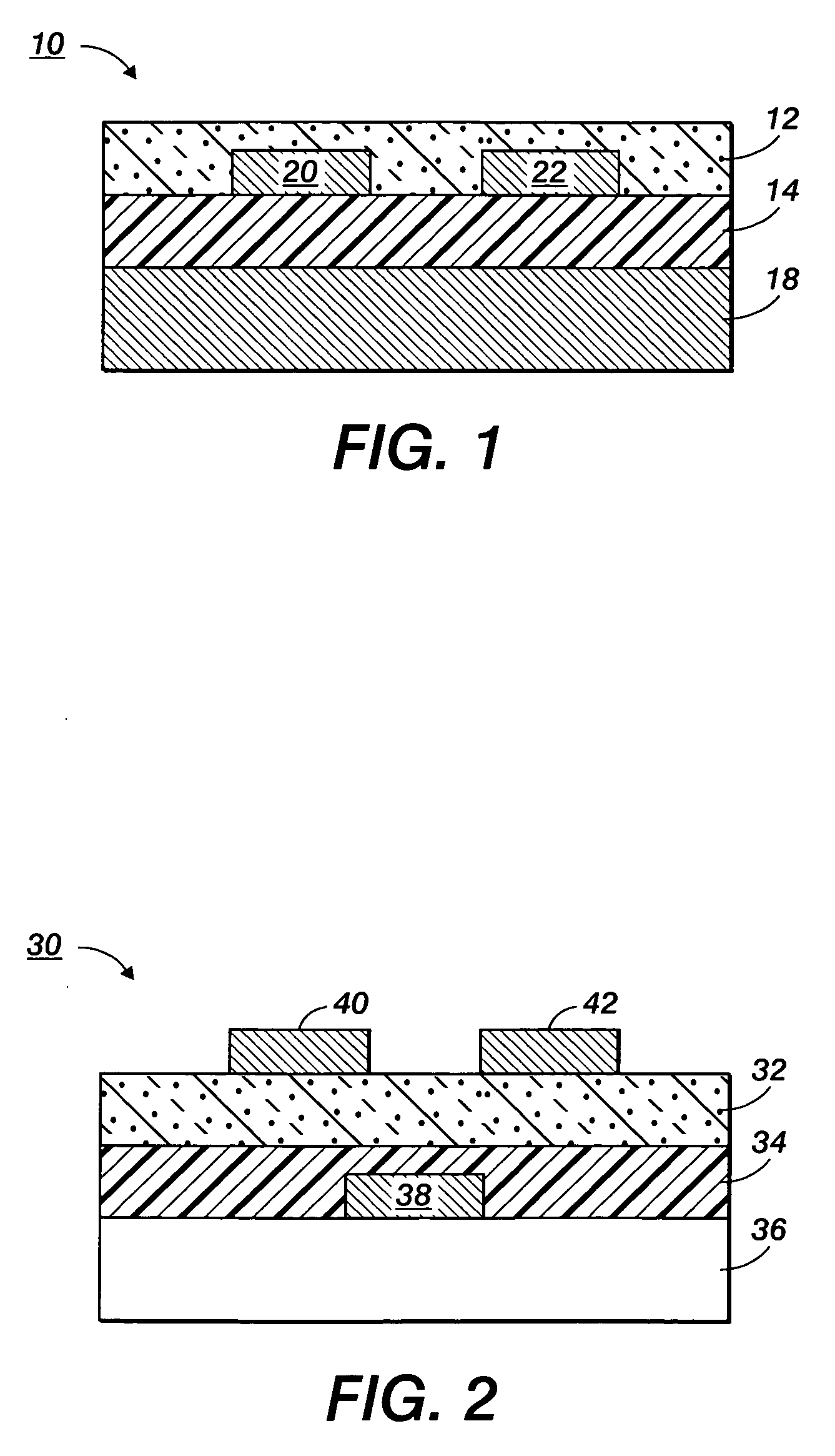

Stabilized alkaline compositions for cleaning microelectronic substrates

InactiveUS6599370B2Eliminate contaminationLong lastingInorganic/elemental detergent compounding agentsLighting and heating apparatusWater solubleSURFACTANT BLEND

The invention provides aqueous alkaline compositions useful in the microelectronics industry for stripping or cleaning semiconductor wafer substrates by removing photoresist residues and other unwanted contaminants. The compositions typically contain (a) one or more metal ion-free bases at sufficient amounts to produce a pH of about 10-13 and one or more bath stabilizing agents having at least one pKa in the range of 10-13 to maintain this pH during use; (b) optionally, about 0.01% to about 5% by weight (expressed as % SiO2) of a water-soluble metal ion-free silicate; (c) optionally, about 0.01% to about 10% by weight of one or more chelating agents; (d) optionally, about 0.01% to about 80% by weight of one or more water-soluble organic co-solvents; and (e) optionally, about 0.01% to about 1% by weight of a water-soluble surfactant.

Owner:AVANTOR PERFORMANCE MATERIALS LLC

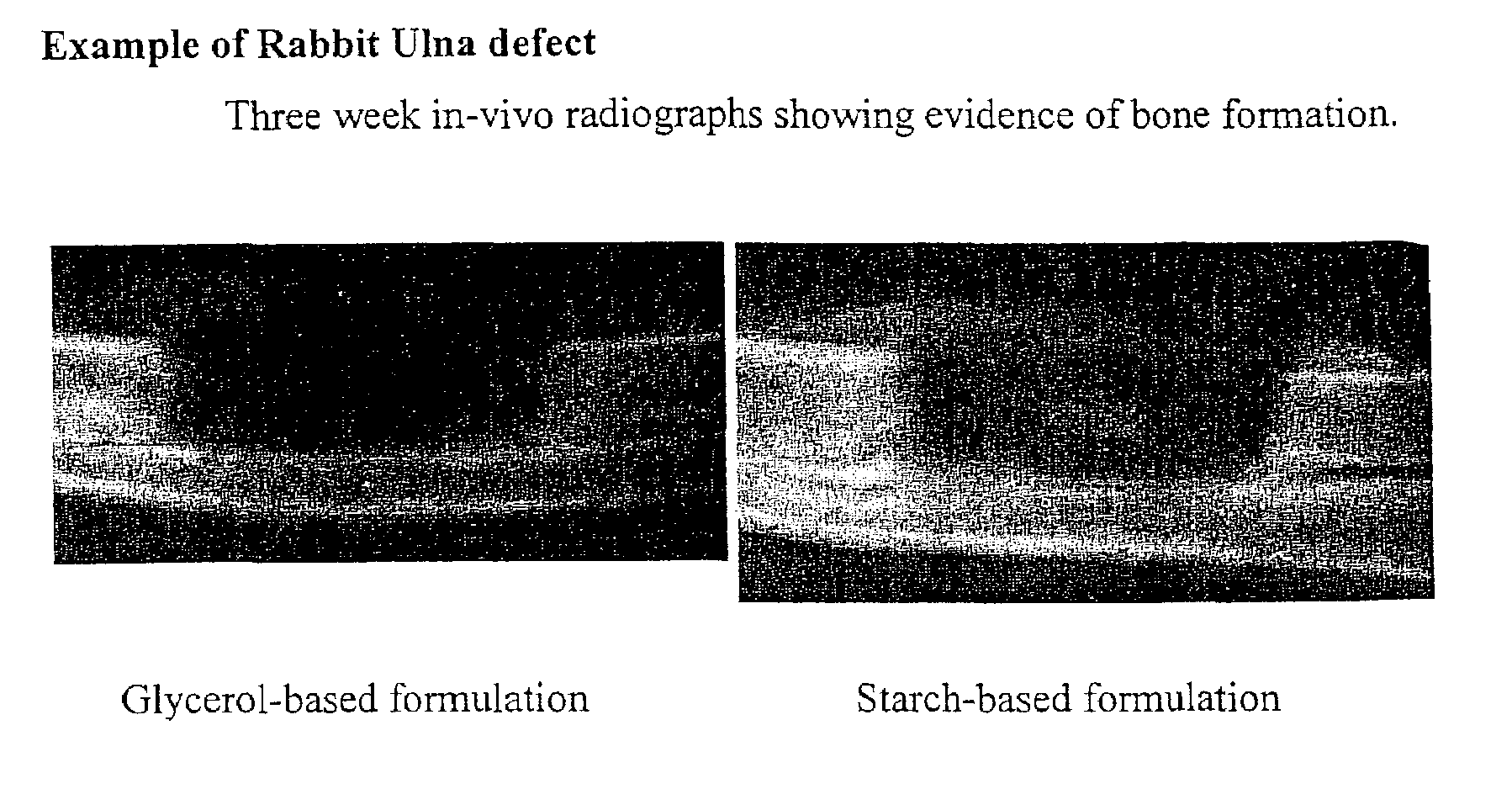

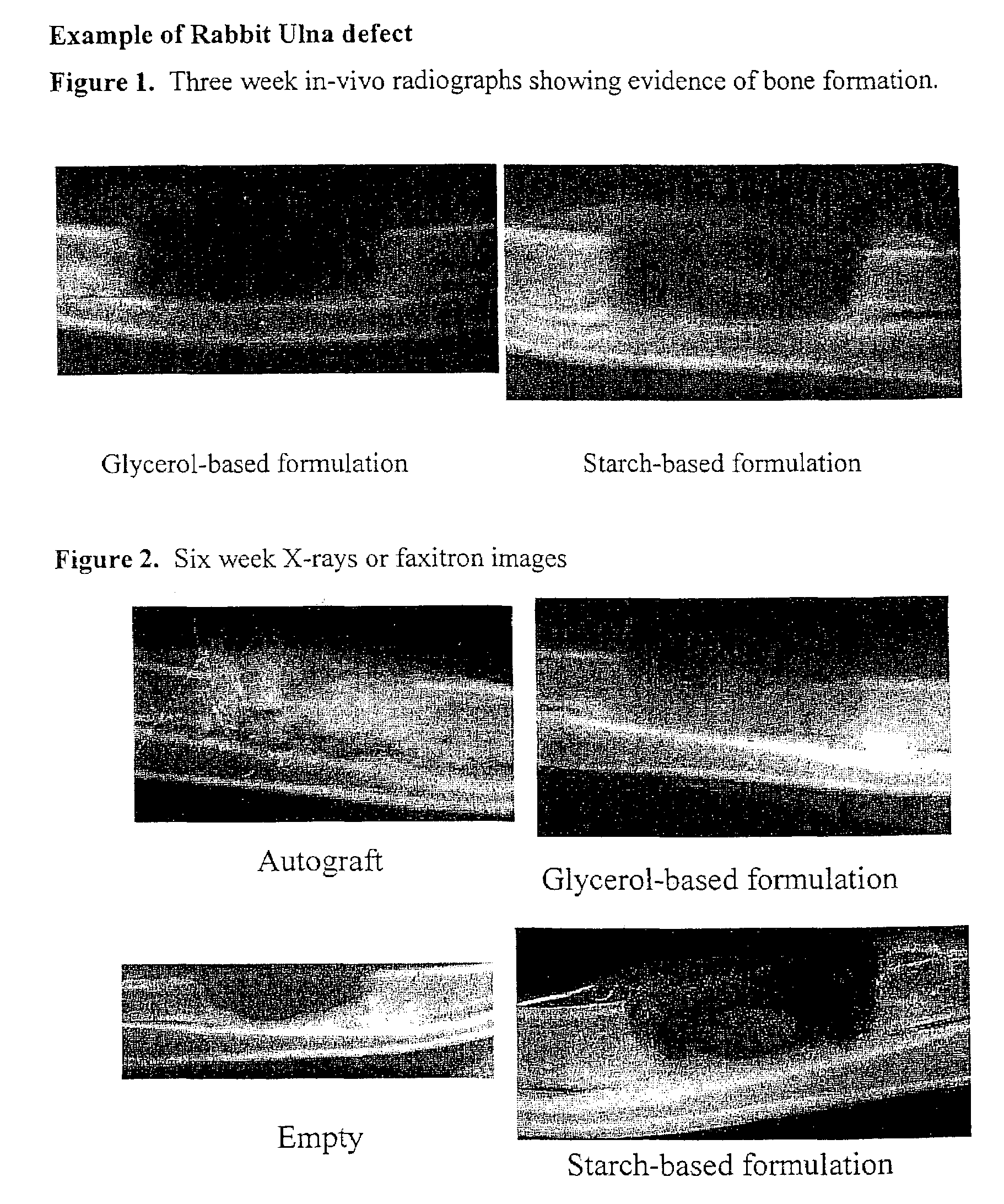

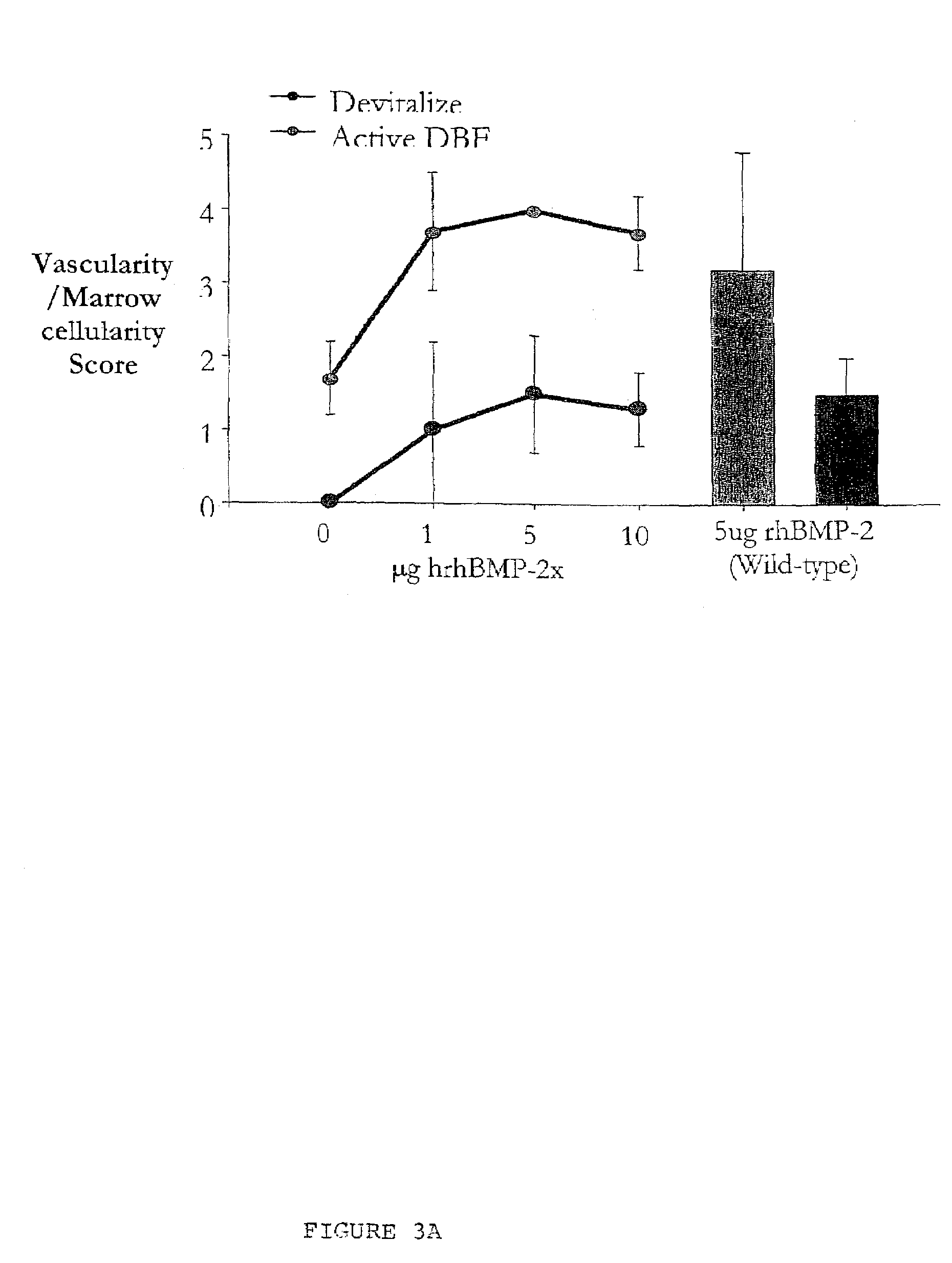

Bone graft

ActiveUS7163691B2Fast reduction in osteoinductiveGood curative effectOrganic active ingredientsImpression capsOSTEOINDUCTIVE FACTORIn vivo

An improved demineralized bone matrix (DBM) or other matrix composition is provided that has been mixed with a stabilizing agent that acts as (1) a diffusion barrier, (2) a enzyme inhibitor, (3) a competitive substrate, or (4) a masking moiety. A diffusion barrier acts as a barrier so as to protect the osteoinductive factors found in DBM from being degraded by proteolytic and glycolytic enzymes at the implantation site. Stabilizing agents may be any biodegradable material such as starches, modified starches, cellulose, dextran, polymers, proteins, and collagen. As the stabilizing agents degrades or dissolves in vivo, the osteoinductive factors such as TGF-β, BMP, and IGF are activated or exposed, and the activated factors work to recruit cells from the preivascular space to the site of injury and to cause differentiation into bone-forming cells. The invention also provides methods of preparing, testing, and using the inventive improved osteodinductive matrix compositions.

Owner:WARSAW ORTHOPEDIC INC

Process and composition for cleaning soft tissue grafts optionally attached to bone and soft tissue and bone grafts produced thereby

InactiveUS6024735AEfficient removalEfficient formationSurgical needlesVaccination/ovulation diagnosticsPresent methodAdditive ingredient

The invention relates to compositions effective for the cleansing of mammalian soft tissue optionally attached to bones, and particularly the removal of blood deposits and bone marrow therefrom. The compsotions are composed of an aqueous solution containing as its essential ingredients a detergent having a functionality of the nature of a polyoxyethylene-23-lauryl either, a detergent having a functionality of the nature of exyethylated alkylphenol, and water, where the compositions are free from any membrane stabilizers. The present invention is also directed to a method and composition for cleaning cadaveric soft tissue optionally attached to bone to produce soft tissue grafts optionally attached to bone suitable for transplantation into a human. The present method involves removing bone marrow elements, blood deposits and any bacteria, virus or fungi contamination, from the donor bone and / or associated soft tissues.

Owner:LIFENET HEALTH

Stable probiotic microsphere compositions and their methods of preparation

The invention relates to viable and stable probiotic formulations for intestinal targeting made of microspheres comprising each a core of one or more probiotic bacteria, microcrystallline cellulose with a degree of polymerization from 165-365 and mean diameter from 45 to 180 μm, a disintegrant and a stabilizer, the core being coated with a non-enteric coating and further coated with an enteric coating. Each probiotic microsphere has a residual moisture level of less than 5% and a water activity (aw) between 0.1 and 0.5. Such a probiotic microsphere shows no reduction in viable bacteria after one hour in simulated gastric fluid. The present invention also relates to the process of preparing such formulation.

Owner:CANACURE CORP

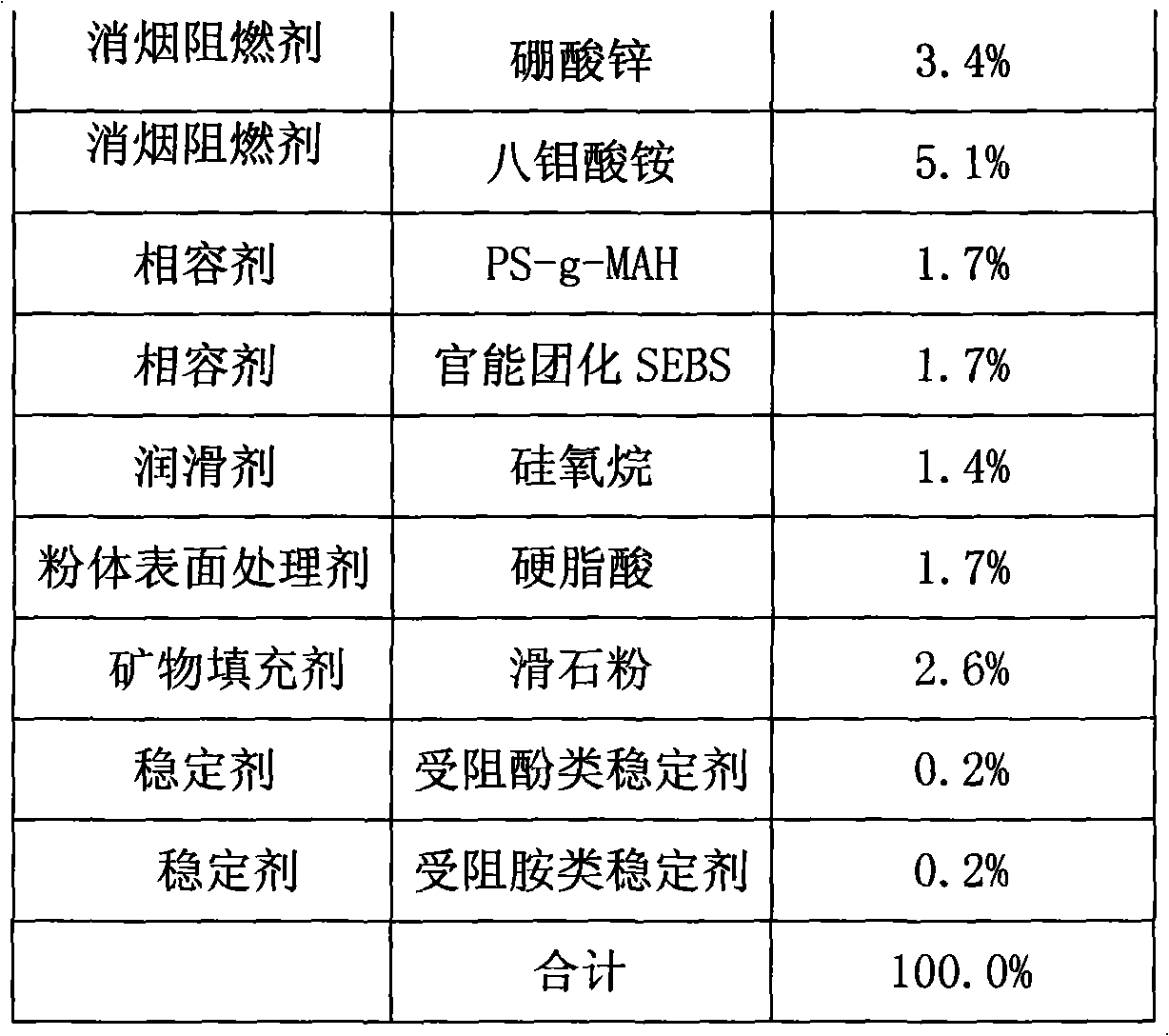

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

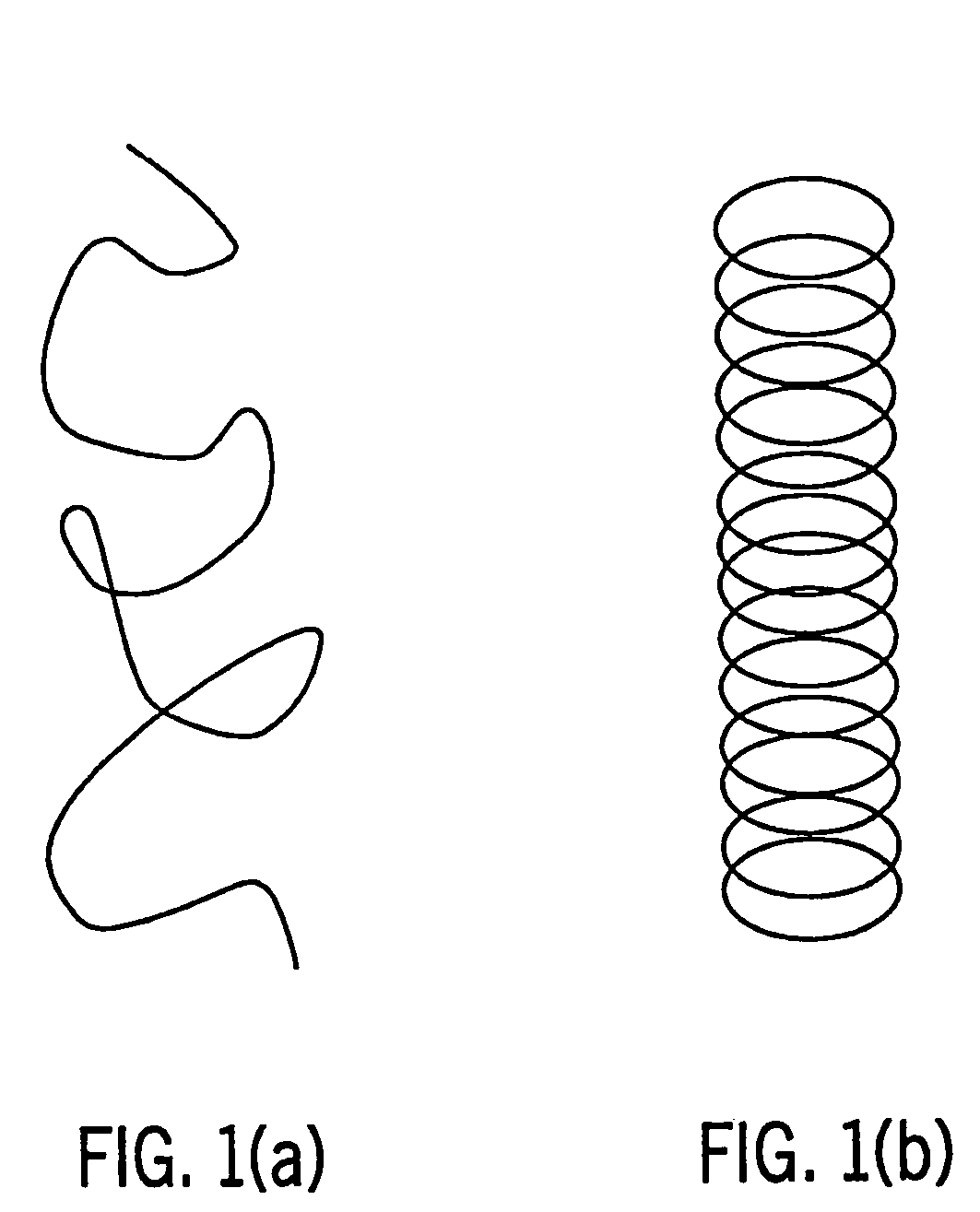

Liquid inks comprising a stable organosol

InactiveUS20020128349A1Good dispersionAvoid resistanceDuplicating/marking methodsInksMethacrylateDispersion stability

A liquid ink comprises (a) a carrier liquid having a Kauri-Butanol number less than 30; (b) a graft copolymer comprising a (co)polymeric steric stabilizer covalently bonded to a thermoplastic (co)polymeric core that is insoluble in the carrier liquid; and (c) a colorant, wherein the steric stabilizer comprises units derived from 3,3,5-trimethylcyclohexyl methacrylate, and the thermoplastic (co)polymeric core comprising units derived from at least a polymerizable monomer selected from the group consisting of (meth)acrylates having aliphatic amino radicals, nitrogen-containing heterocyclic vinyl monomers, N-vinyl substituted ring-like amide monomers, aromatic substituted ethylene monomers containing amino radicals, and nitrogen-containing vinylether monomers. The organosol provides improved liquid electrophotographic and electrographic ink compositions with improved dispersion stability, chargeability, and blocking resistance so that improved print quality or ink transfer performance are obtained.

Owner:S PRINTING SOLUTION CO LTD

Cyclooxygenase inhibitor and calcium channel antagonist compositions and methods for use in urological procedures

ActiveUS20060263393A1Inhibits pain/inflammation and spasmInhibiting pain/inflammationBiocideNervous disorderNifedipineCyclooxygenase

Compositions of a cyclooxygenase inhibitor and a calcium channel antagonist in a liquid carrier. The composition may be administered the the urinary tract during urological diagnostic, interventional, surgical and other medical procedures. One disclosed composition comprises ketoprofen and nifedipine in a liquid irrigation carrier, and includes a solubilizing agent, stabilizing agents and a buffering agent.

Owner:OMEROS CORP

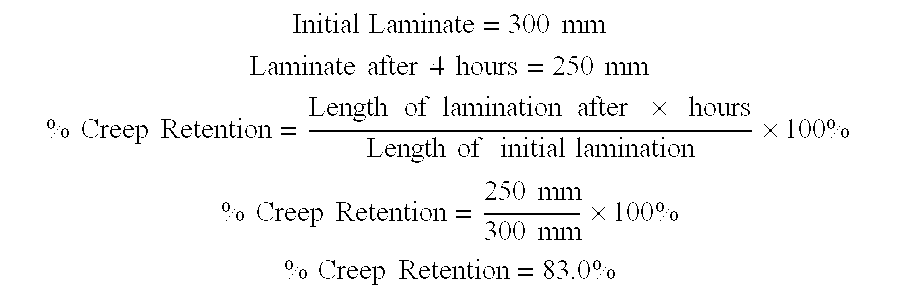

Hot Melt Adhesive Based on Olefin Block Copolymers

ActiveUS20110021103A1Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene and a secondary polymer

InactiveUS7262251B2Broad processibilityImprove thermal stabilityOther chemical processesFilm/foil adhesivesWaxPlasticizer

Owner:ATO FINDLEY

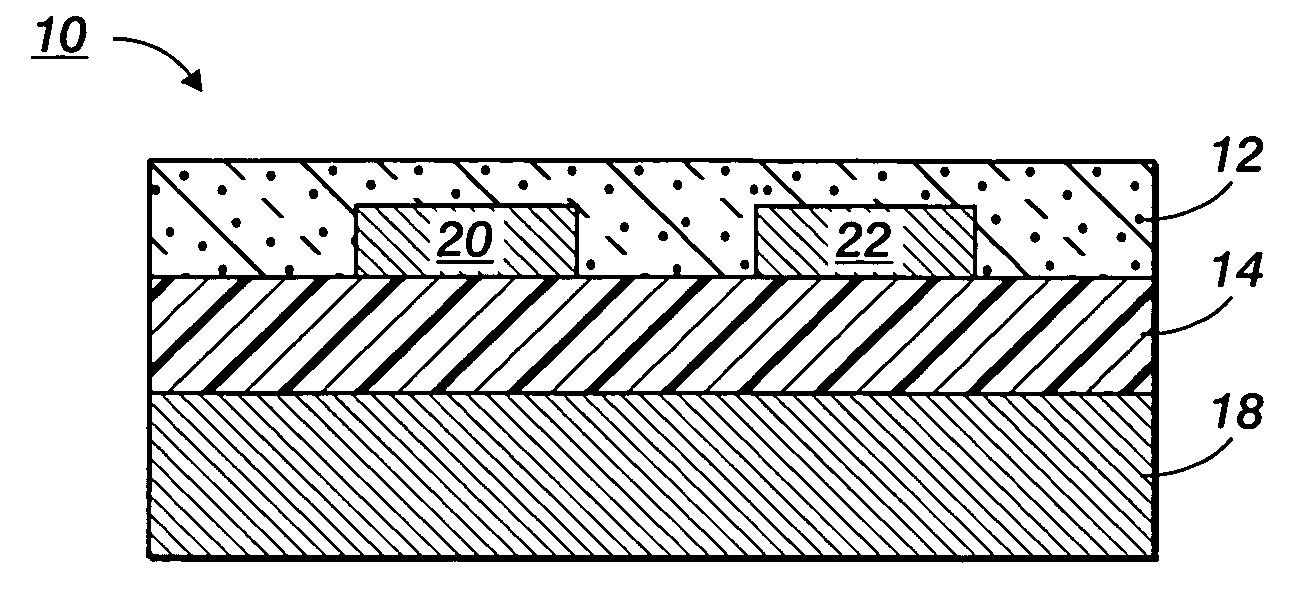

Absorbent articles comprising wetness indicators

An absorbent article of the present invention may comprise a backsheet, a wetness indicator composition, and an absorbent core. The wetness indicator composition may comprise a stabilizer, a colorant, and a matrix. The absorbent core may comprise a nonwoven layer and a complex of absorbent polymer material and thermoplastic adhesive material. The wetness indicator composition may be in direct contact with an inner surface of the backsheet and an outer surface of the nonwoven layer. And, the complex of absorbent polymer material and thermoplastic adhesive material may be in direct contact with an inner surface of the nonwoven. Further, the absorbent core may be cellulose free.

Owner:THE PROCTER & GAMBLE COMPANY

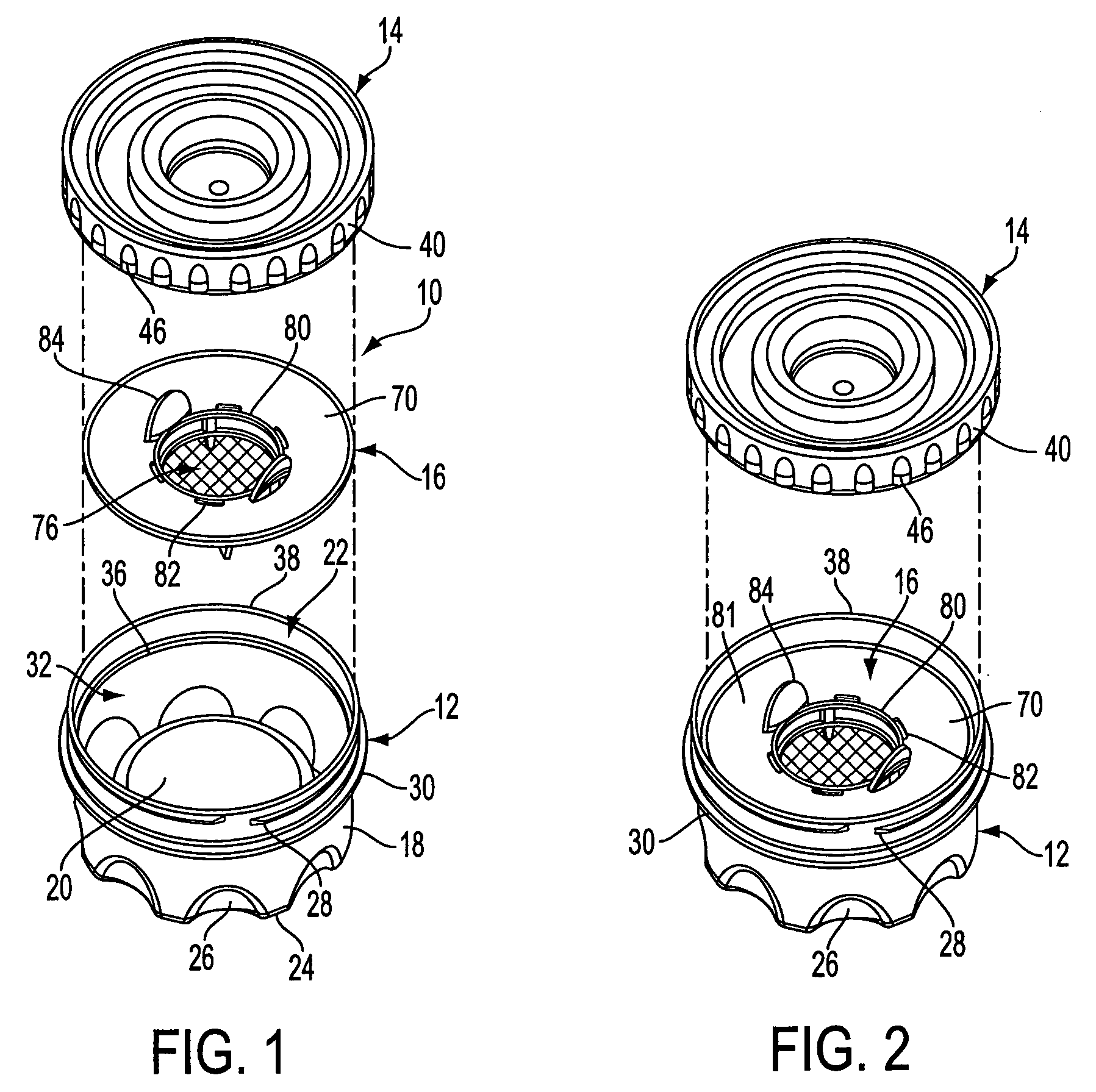

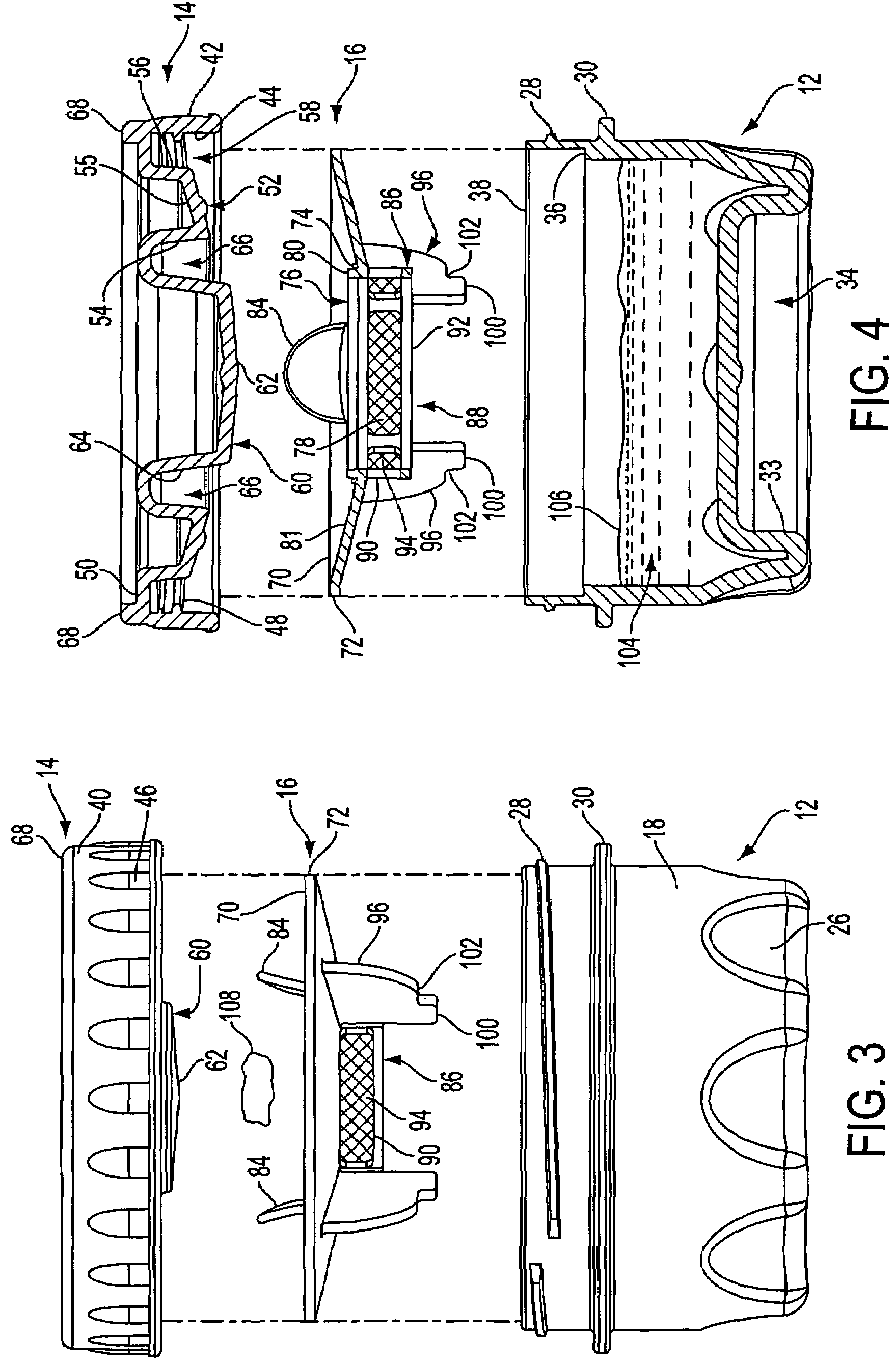

Method and apparatus for transporting biological samples

InactiveUS7147826B2Linear movement is impededRestrict movementBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringReagent

A container assembly and method for storing, treating, transporting and stabilizing a biological sample includes a container, a closure member and a sample holder removably received in the container. The sample holder can be a platform-like device dimensioned to be supported on a ledge formed in the side wall of the container. The sample holder includes a central cavity for receiving the sample and immersing the sample in the stabilizing agent in the container. The closure member includes a body member to close the top end of the central cavity of the sample holder and to limit movement of the sample holder in the container. In another embodiment, the sample holder has a closure cap for closing the open top end of the cavity. The container includes a liquid reagent in an amount sufficient to treat the biological sample. The biological sample is retained in a predetermined containment area of the container to maintain the biological sample immersed in the reagent without regard to the orientation of the container.

Owner:BECTON DICKINSON & CO

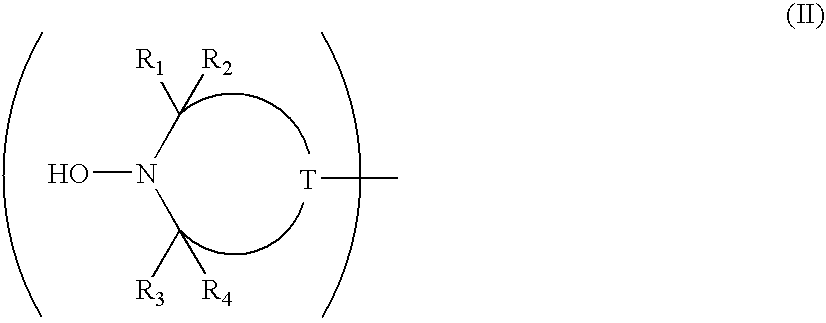

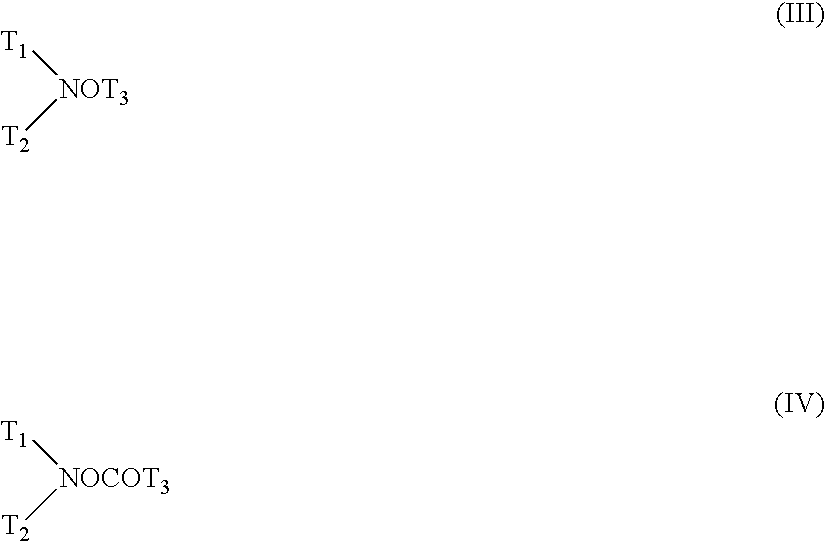

Polyester and polyamide compositions of low residual aldehyde content

A mixture of a polyester, such as poly(ethylene terephthalate) PET, or a polyamide, and a suitable stabilizer selected from the group consisting of hydroxylamine stabilizers, substituted hydroxylamine stabilizers, nitrone stabilizers and amine oxide stabilizers, when extrusion compounded exhibits a lower residual acetaldehyde content than does polyester or polyamide alone when similarly treated. The invention pertains to any polyester or polyamide used in the manufacture of molded articles, fibers or films, for instance bottles or containers which are used to store consumer materials, for example food, beverages and water.

Owner:CIBA SPECIALTY CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com