Patents

Literature

270 results about "Matrix composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In structural applications, the matrix is usually composed of a lighter metal such as magnesium, titanium, or aluminum. In high temperature applications, cobalt and cobalt-nickel alloy matrices are common.

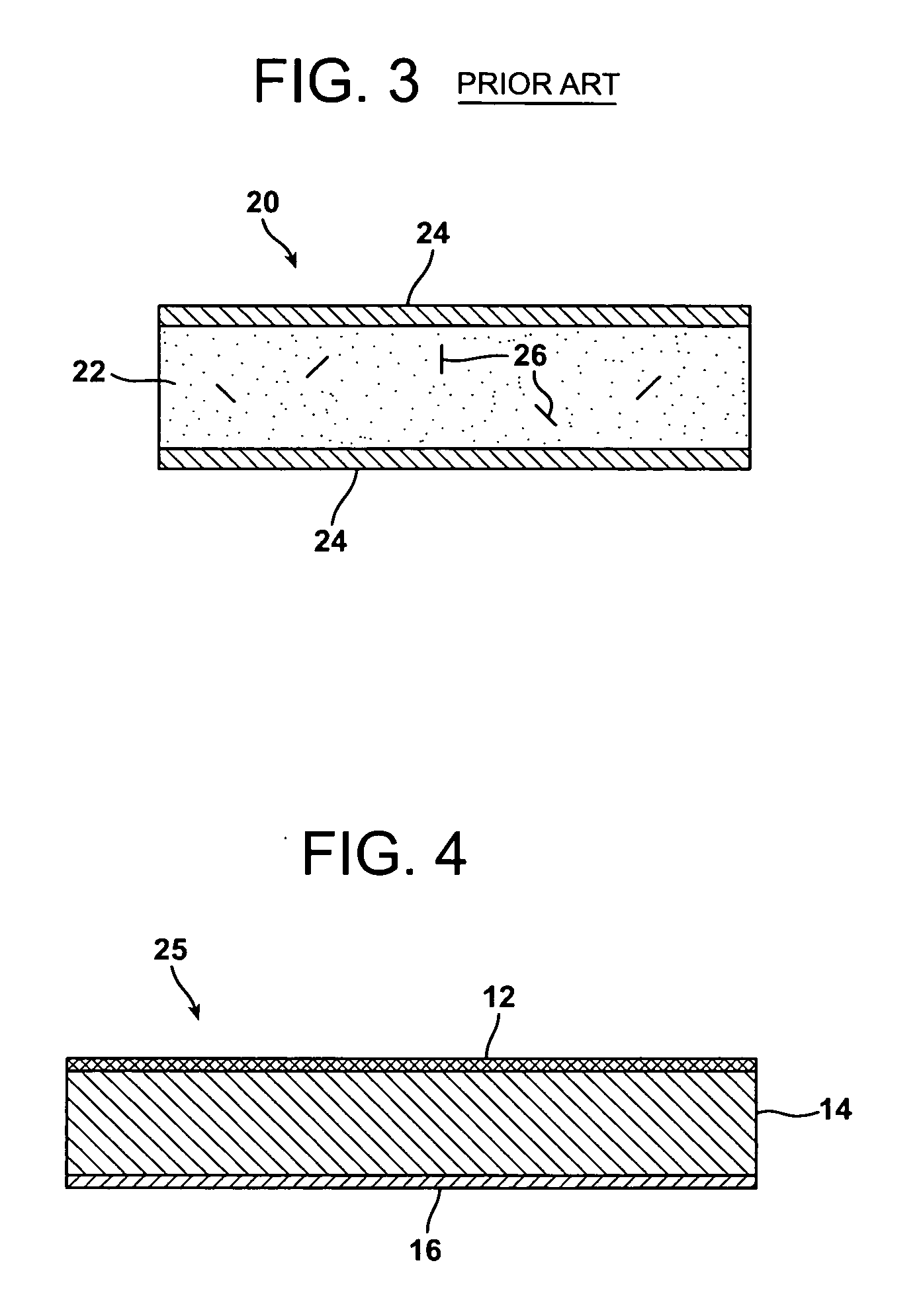

Frag shield

Fabric laminates having superior resistance to penetration of fragments, such as shrapnel. The fabrics are formed of high-strength fibers consolidated with from about 7% to about 15% by weight of an elastomeric matrix composition, and in combination with protective layers of a polymer film on each surface of the fabric. The fabrics achieve a significant improvement in fragment resistance compared to fabrics of the prior art, while also maintaining excellent ballistic resistant properties.

Owner:HONEYWELL INT INC

Methods for the manufacture of sheets having a highly inorganically filled organic polymer matrix

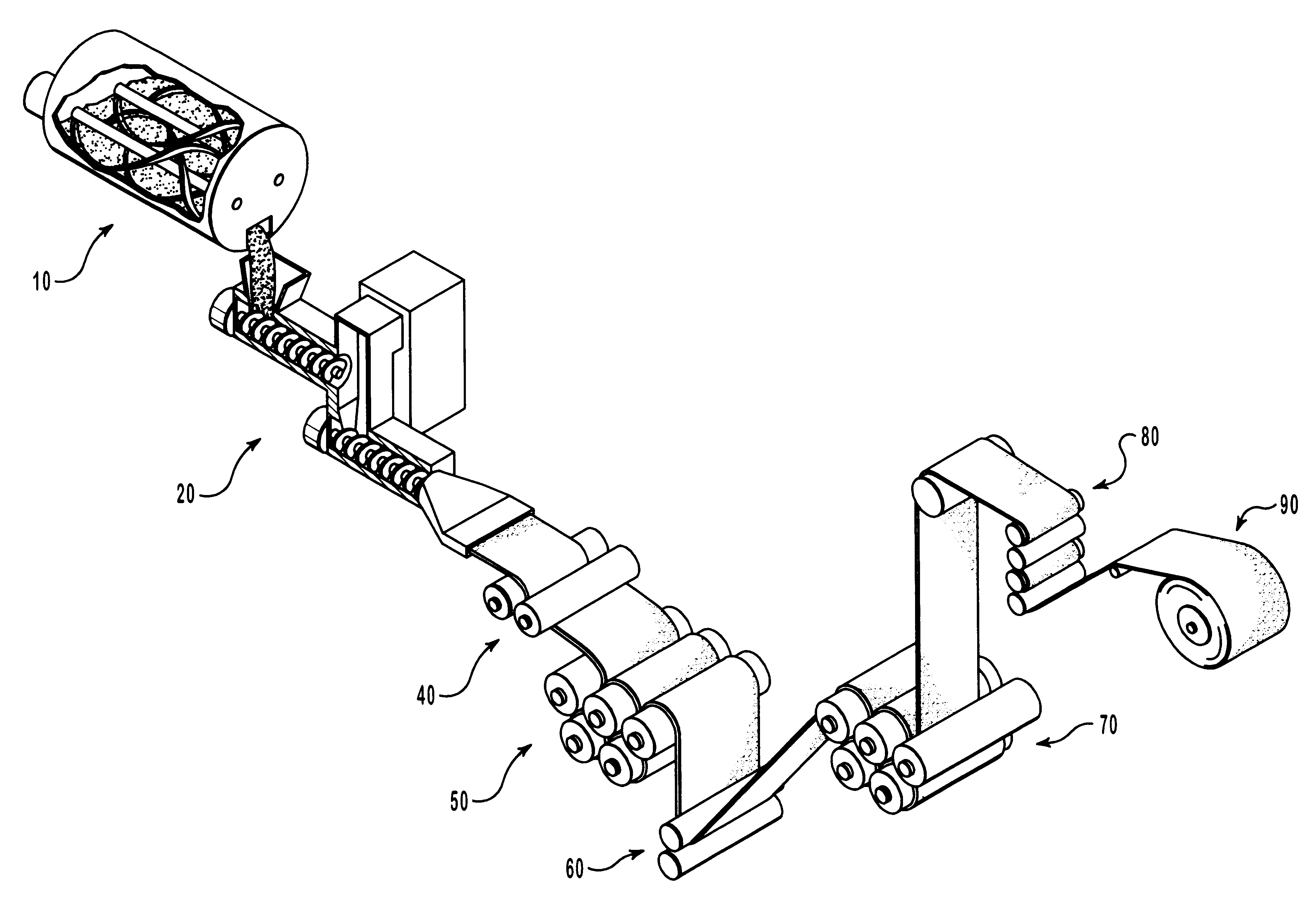

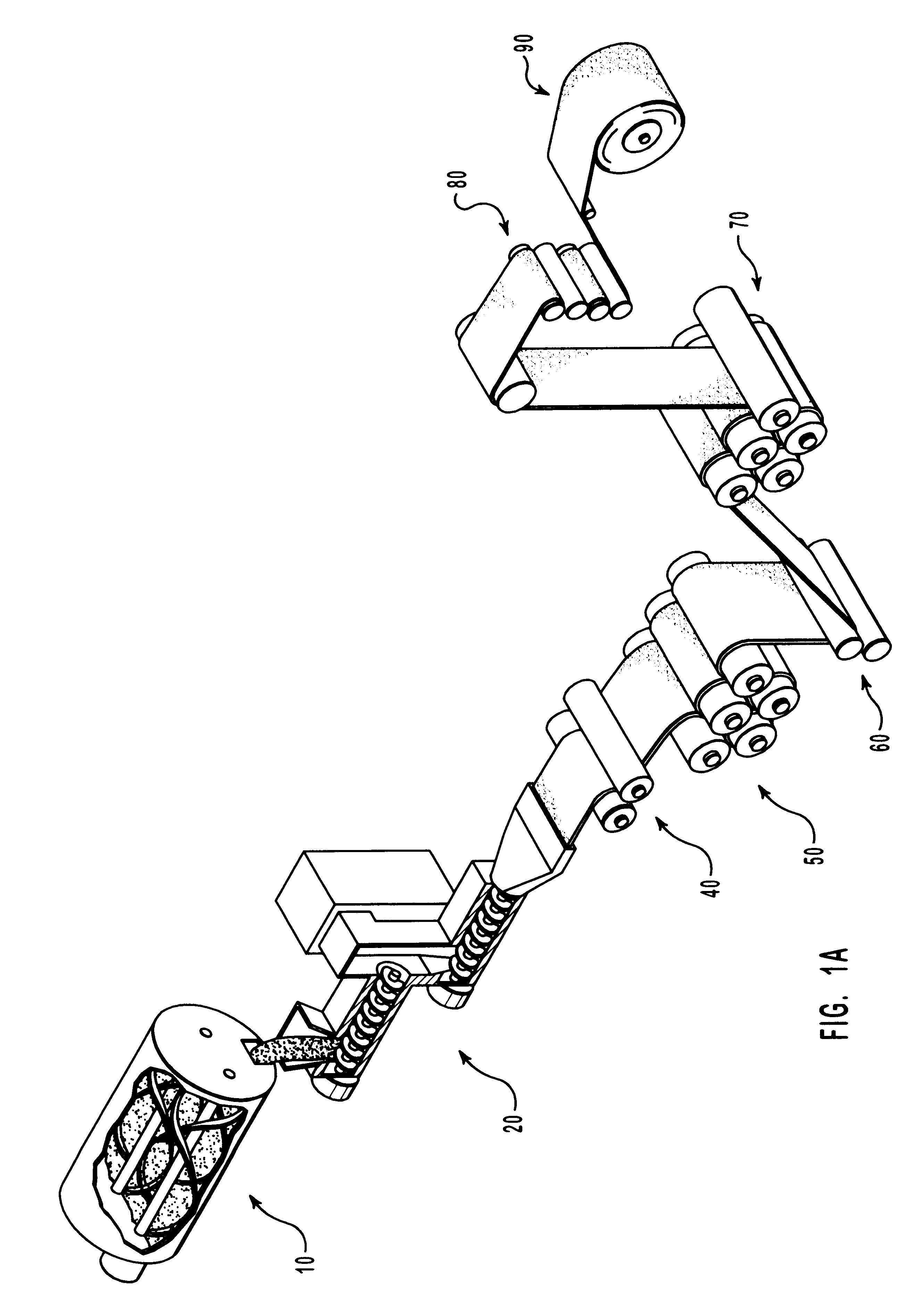

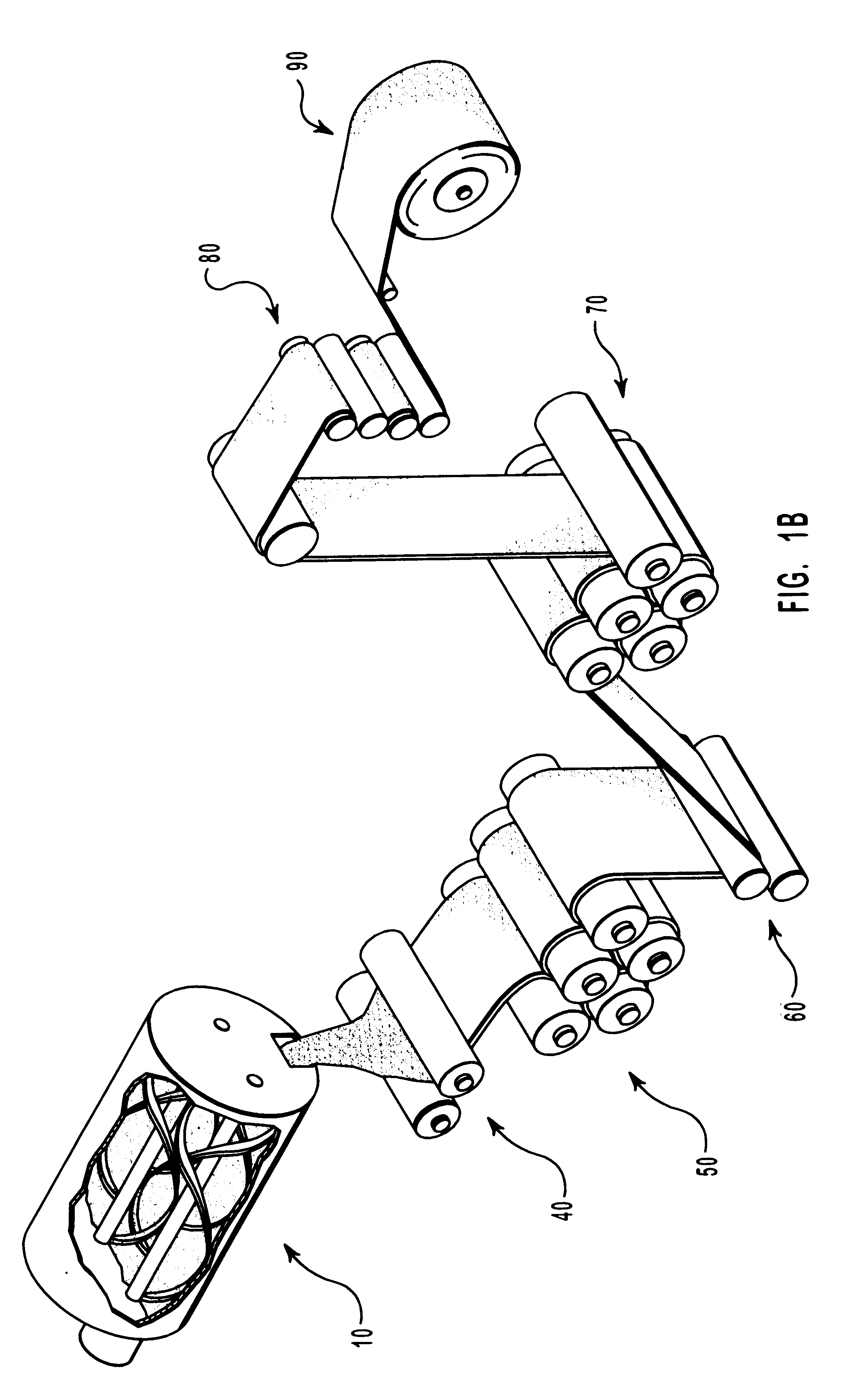

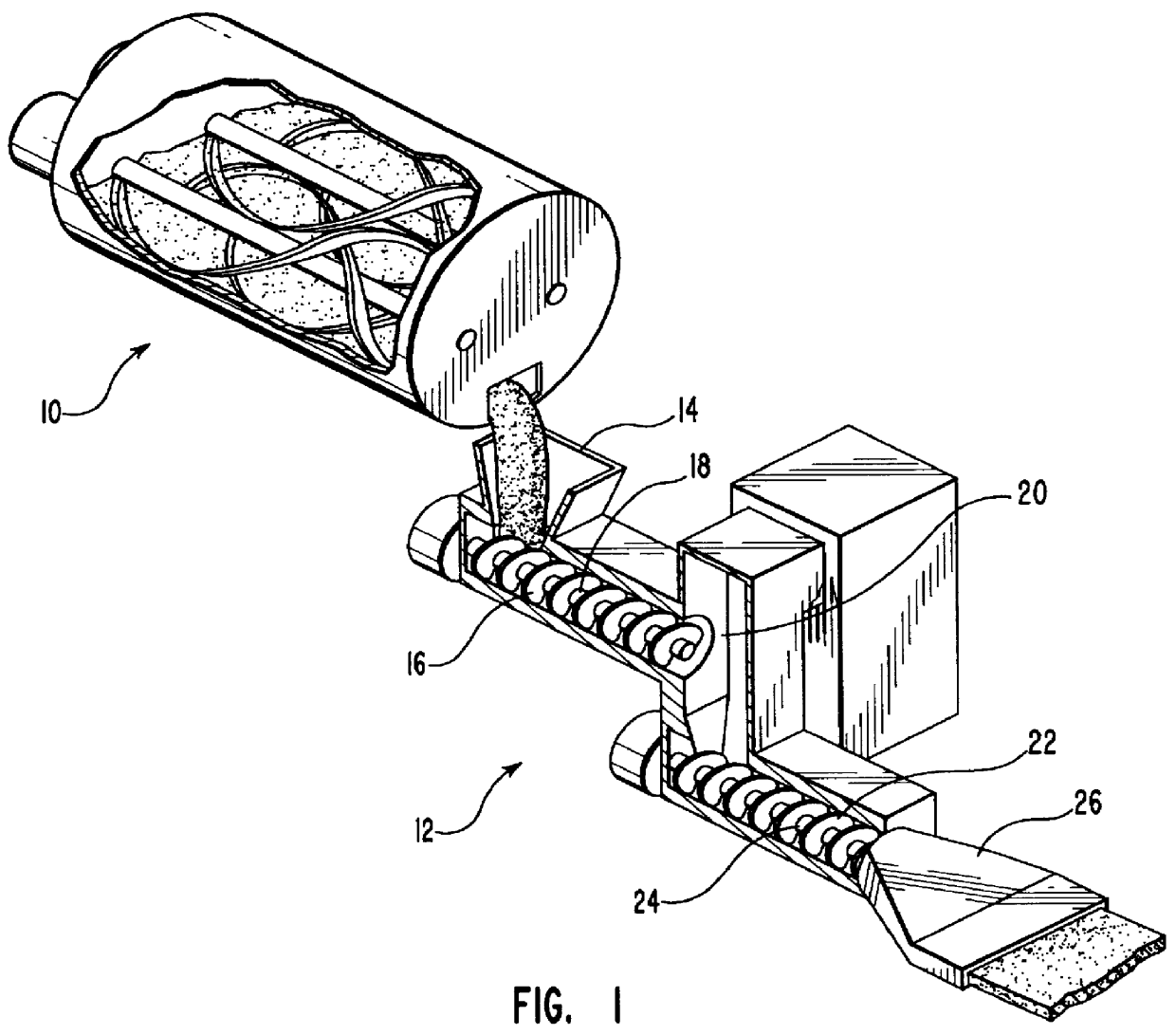

Compositions and methods for manufacturing sheets having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more inorganic aggregate materials, fibers, and optional admixtures in the correct proportions in order to form a sheet which has the desired performance criteria. The inorganically filled mixtures are formed into sheets by first extruding the mixtures and the passing the extruded materials between a set of rollers. The rolled sheets are dried in an accelerated manner to form a substantially hardened sheet, such as by heated rollers and / or a drying chamber. The inorganically filled sheets may have properties substantially similar to sheets presently made from traditional materials like paper, cardboard, polystyrene, plastic, or metal. Such sheets can be rolled, pressed, scored, perforated, folded, and glued. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:E KHASHOGGI INDS

Morphine controlled release system

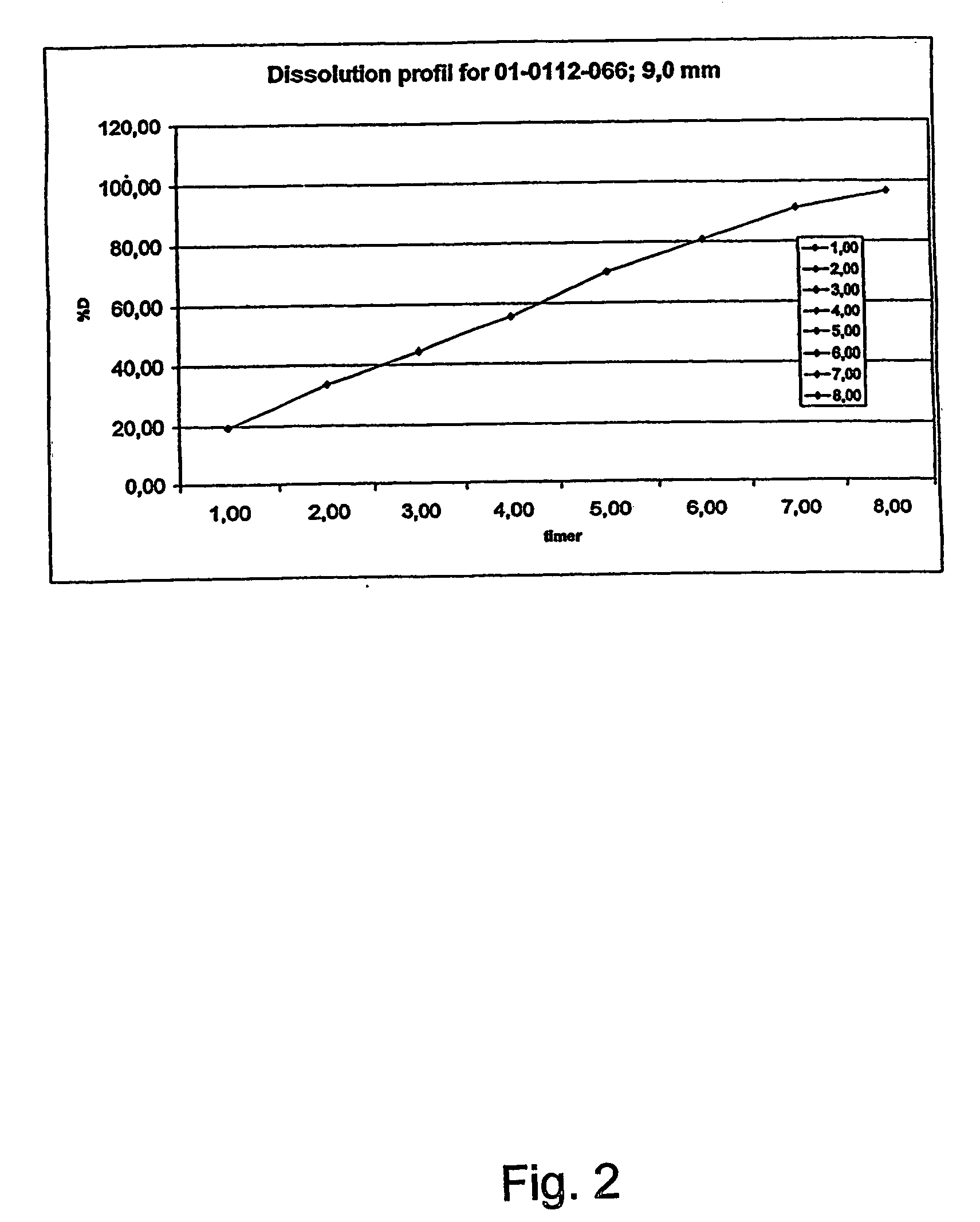

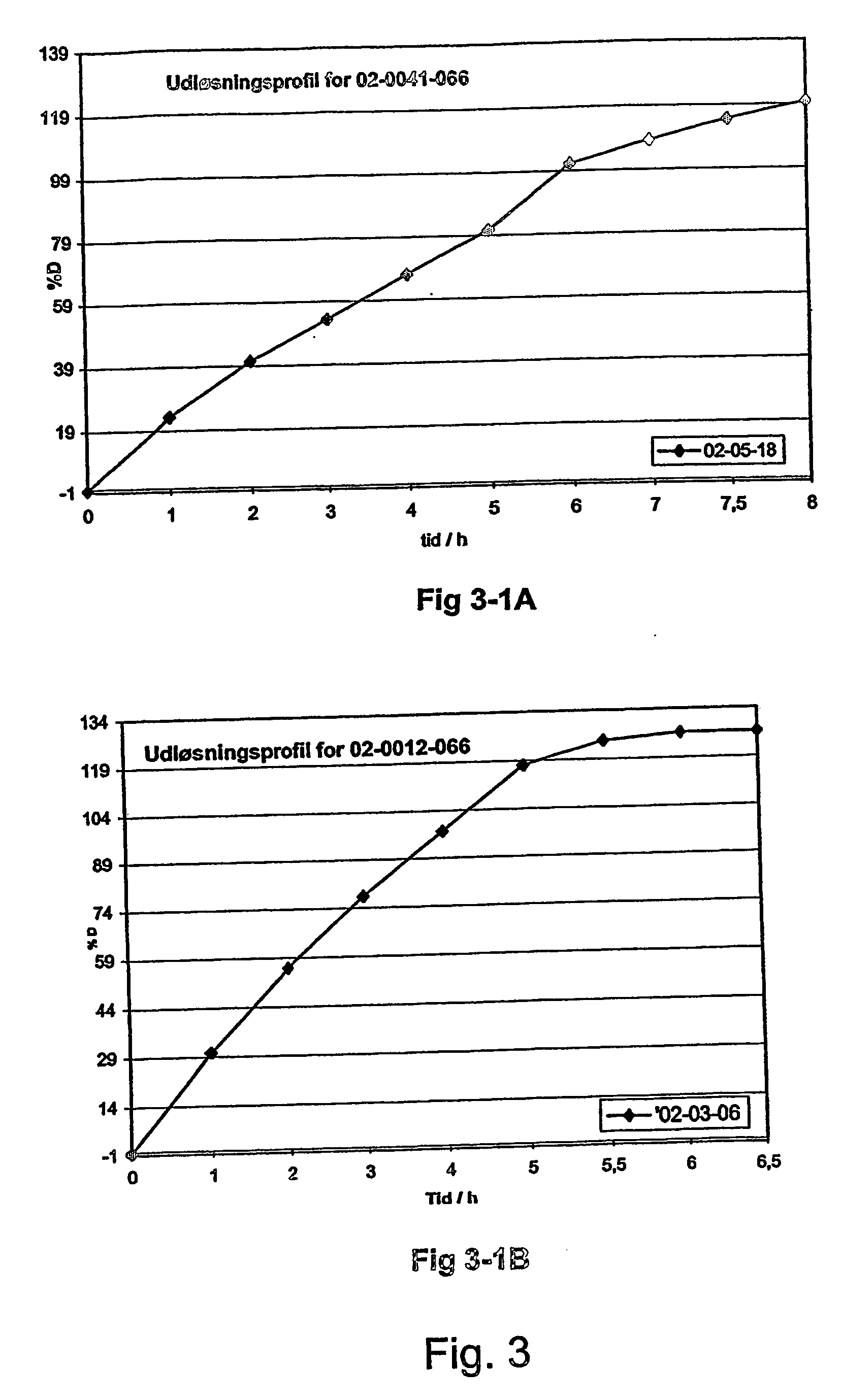

InactiveUS20070003617A1Low administration frequencyAffecting extent of drug bioavailabilityBiocideNervous disorderMorphineDissolution

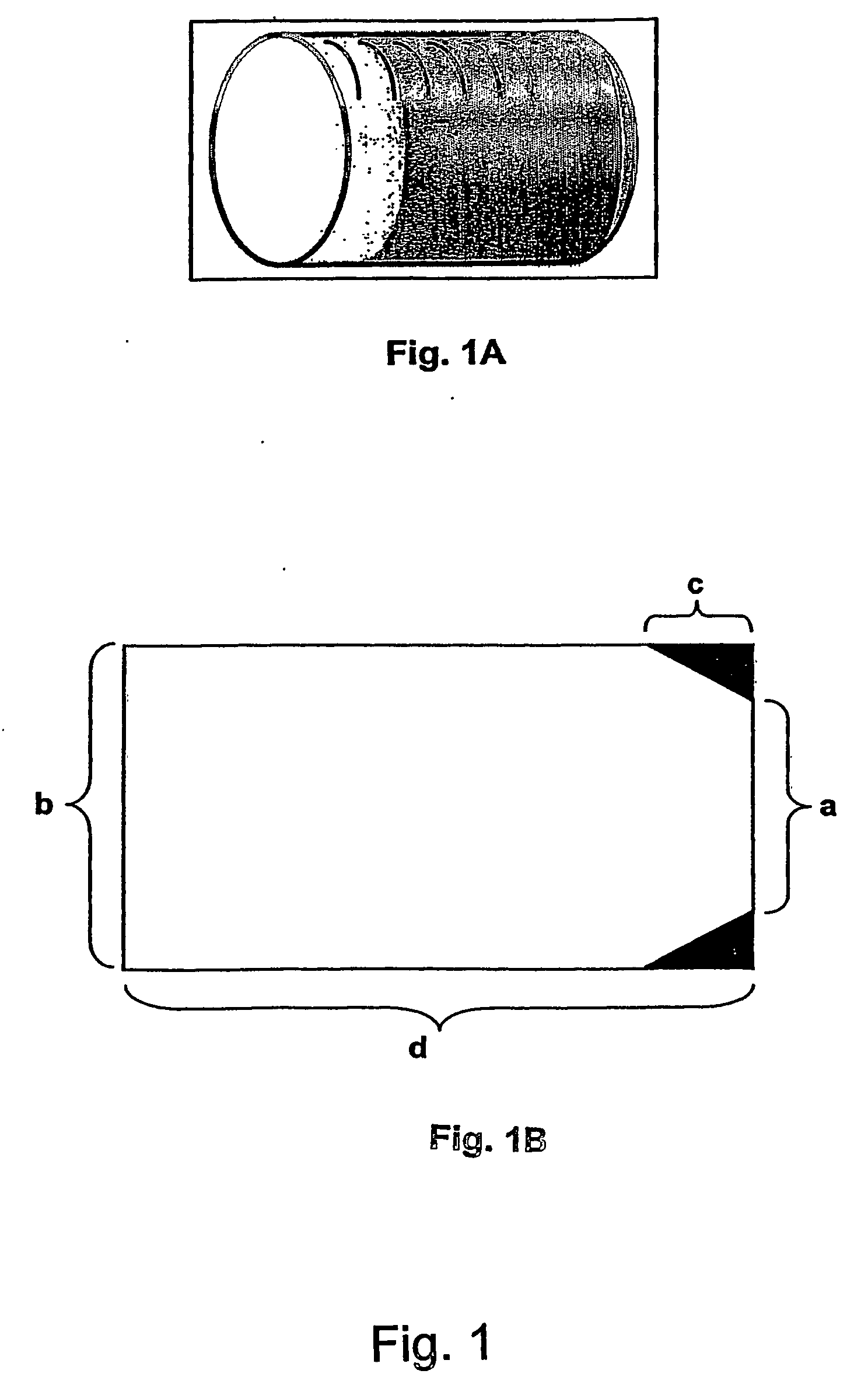

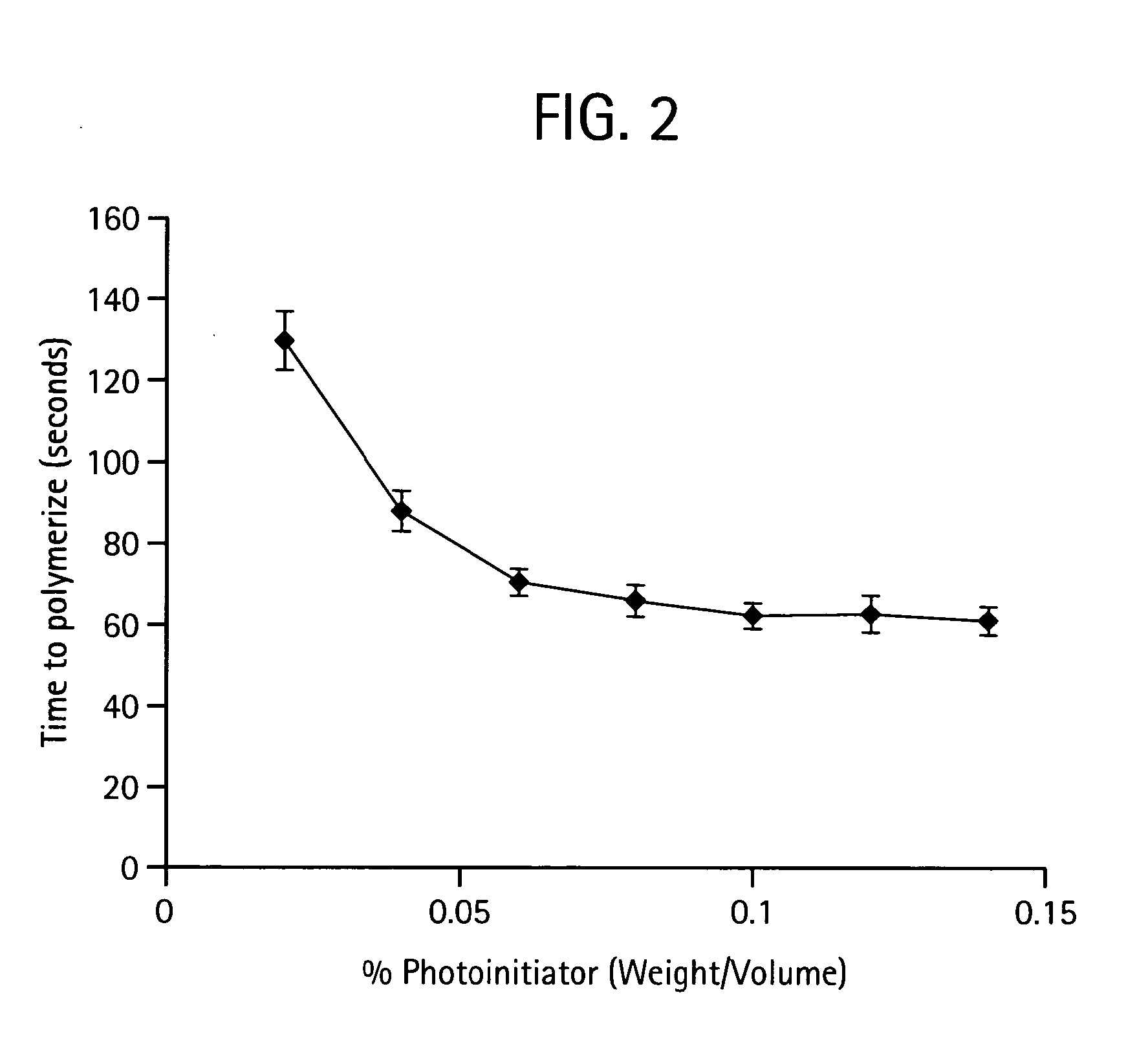

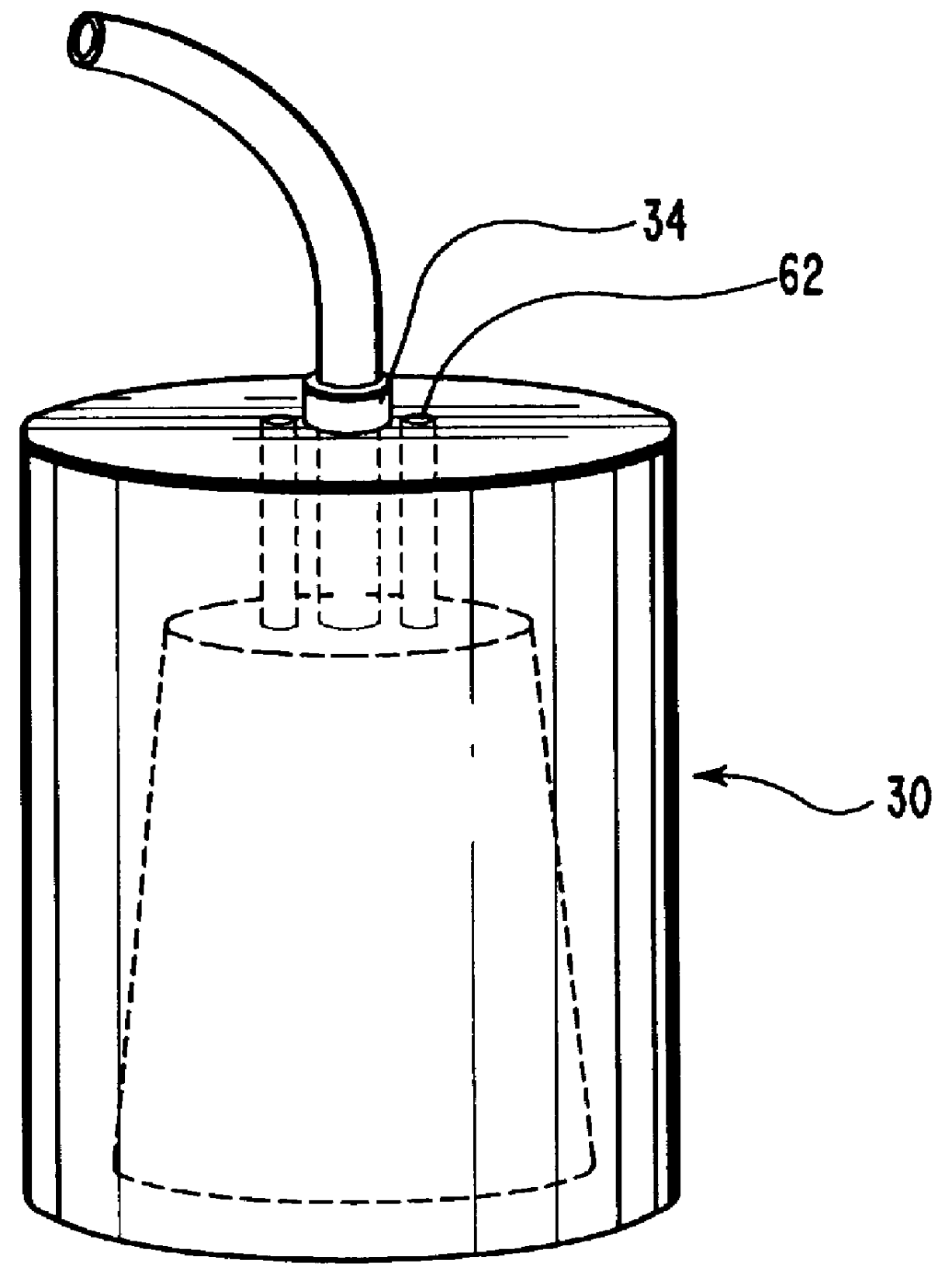

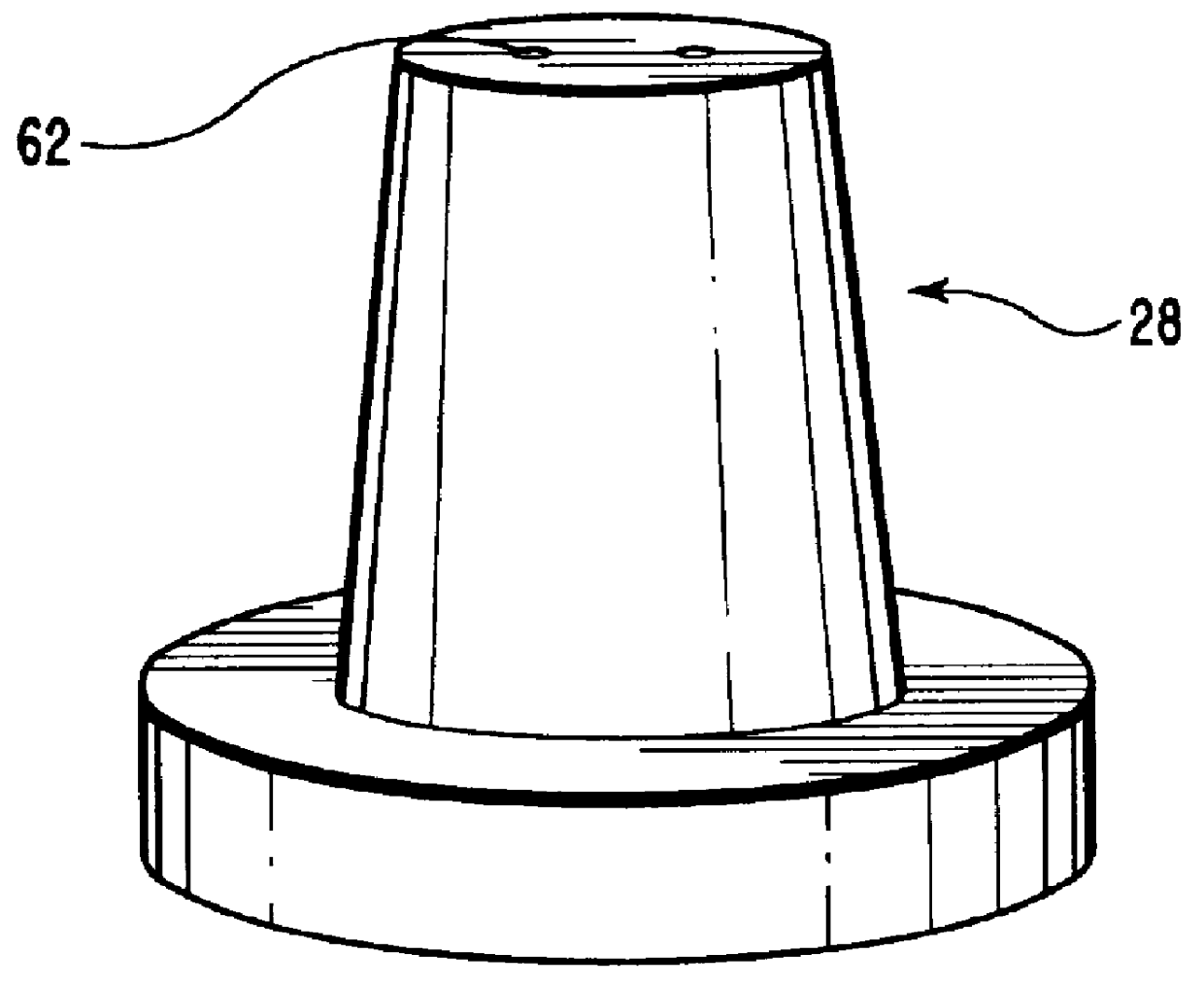

A composition for controlled release of an opioid from a pharmaceutical composition, the method comprises controlling the release of at least one opioid into an aqueous medium by erosion of at least one surface of a pharmaceutical composition comprising I) a matrix composition comprising a) polymer or a mixture of polymers, b) an opioid and, optionally, c) one or more pharmaceutically acceptable excipients, and (i) a coating. The matrix composition has a conus-like shape so the surface area exposed to the aqueous medium increases at least during initial erosion of the matrix composition, and the dissolution of the opioid-when tested in a Dissolution Test as described herein with or without application of sinkers-results in a zero order release of at least 80% of the opioid contained in the composition. Such compositions are especially suitable for controlled release of an opioid to obtain a delayed pead concentration and a prolonged therapeutically effective plasma concentration upon oral administration. Once or twice daily administration is possible. The matrix typically comprises PEO and the active substance is typically an opioid such as morphine or a glucuronide thereof.

Owner:EGALET LTD

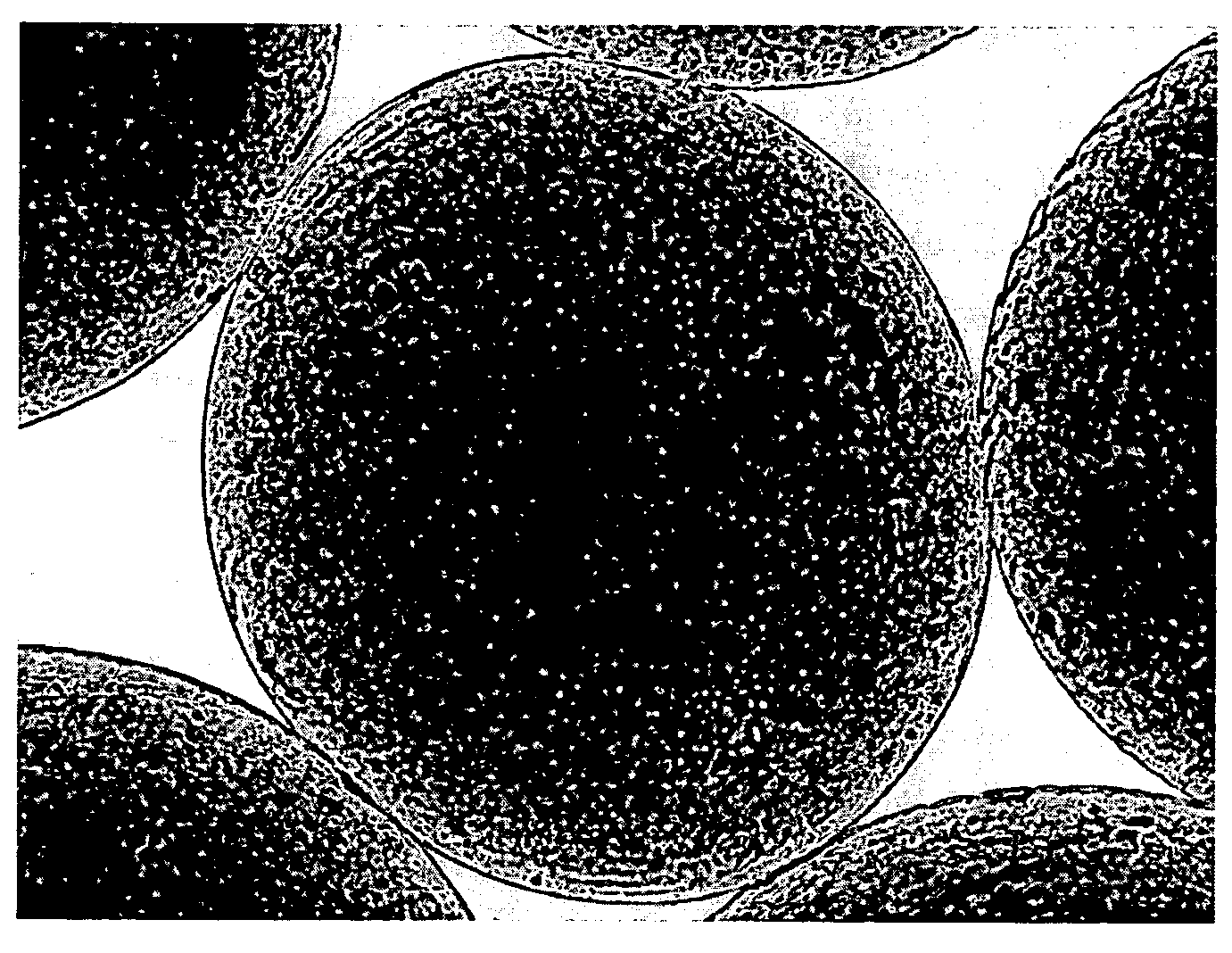

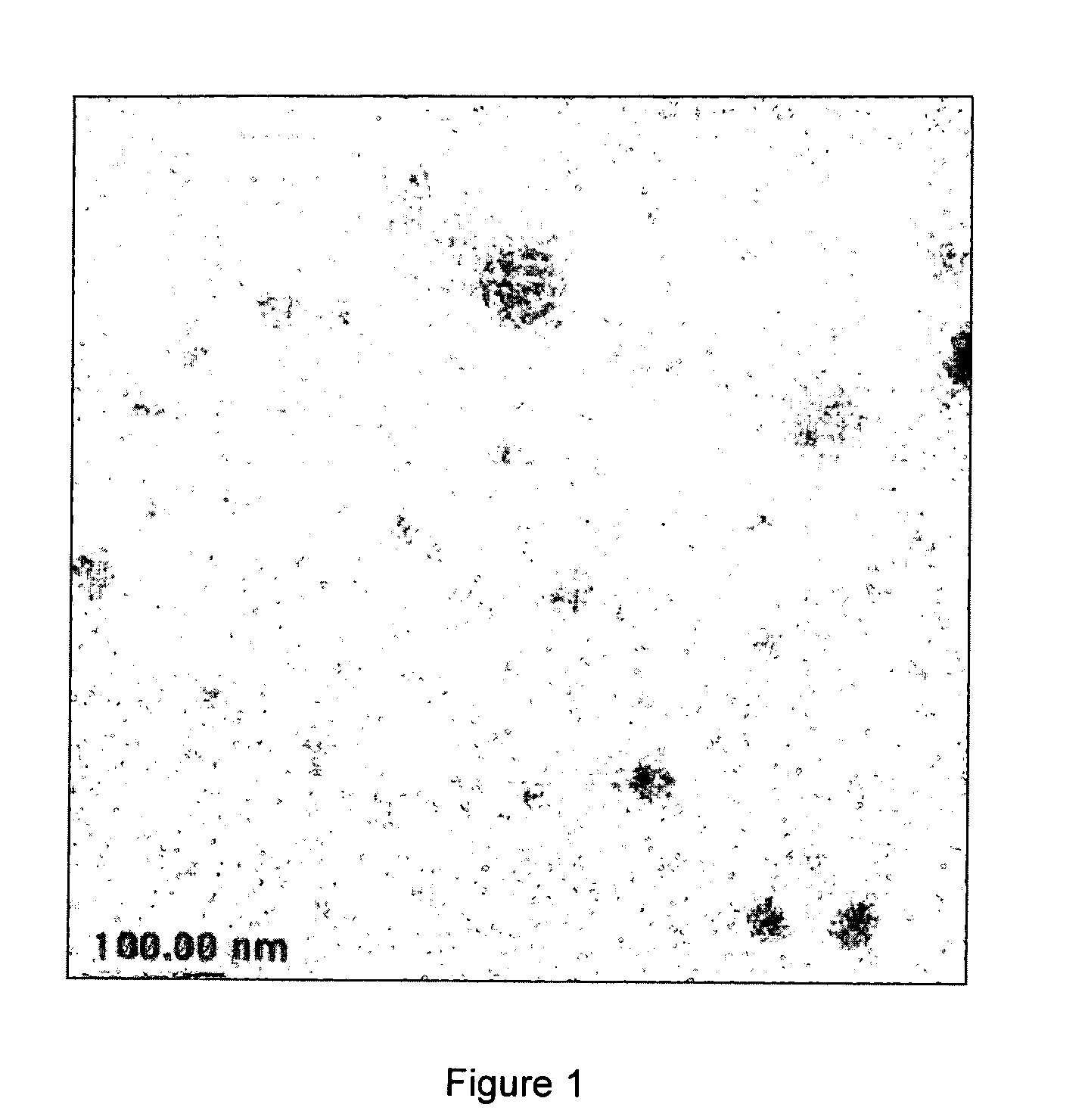

Methods of synthesis and use of chemospheres

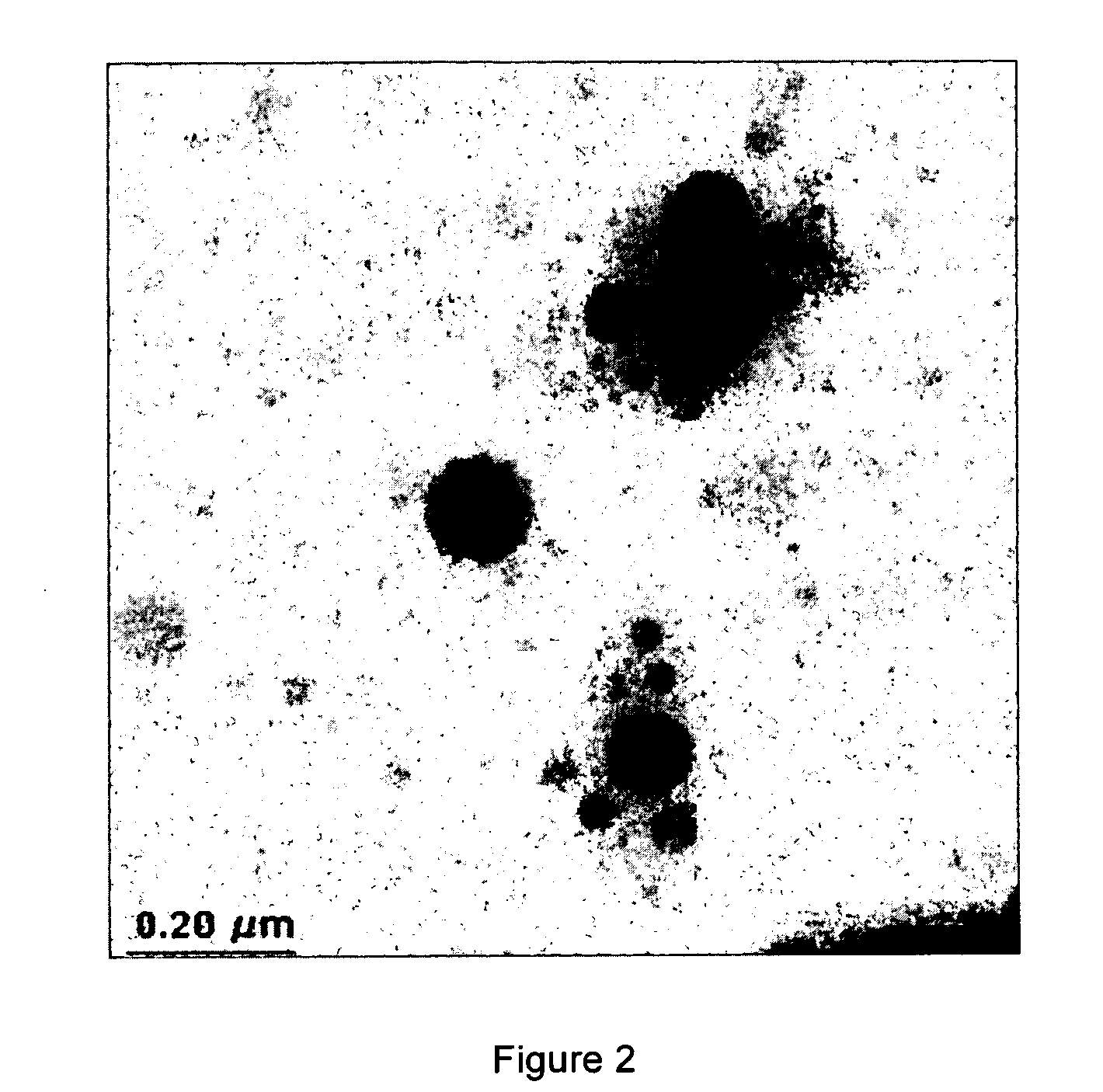

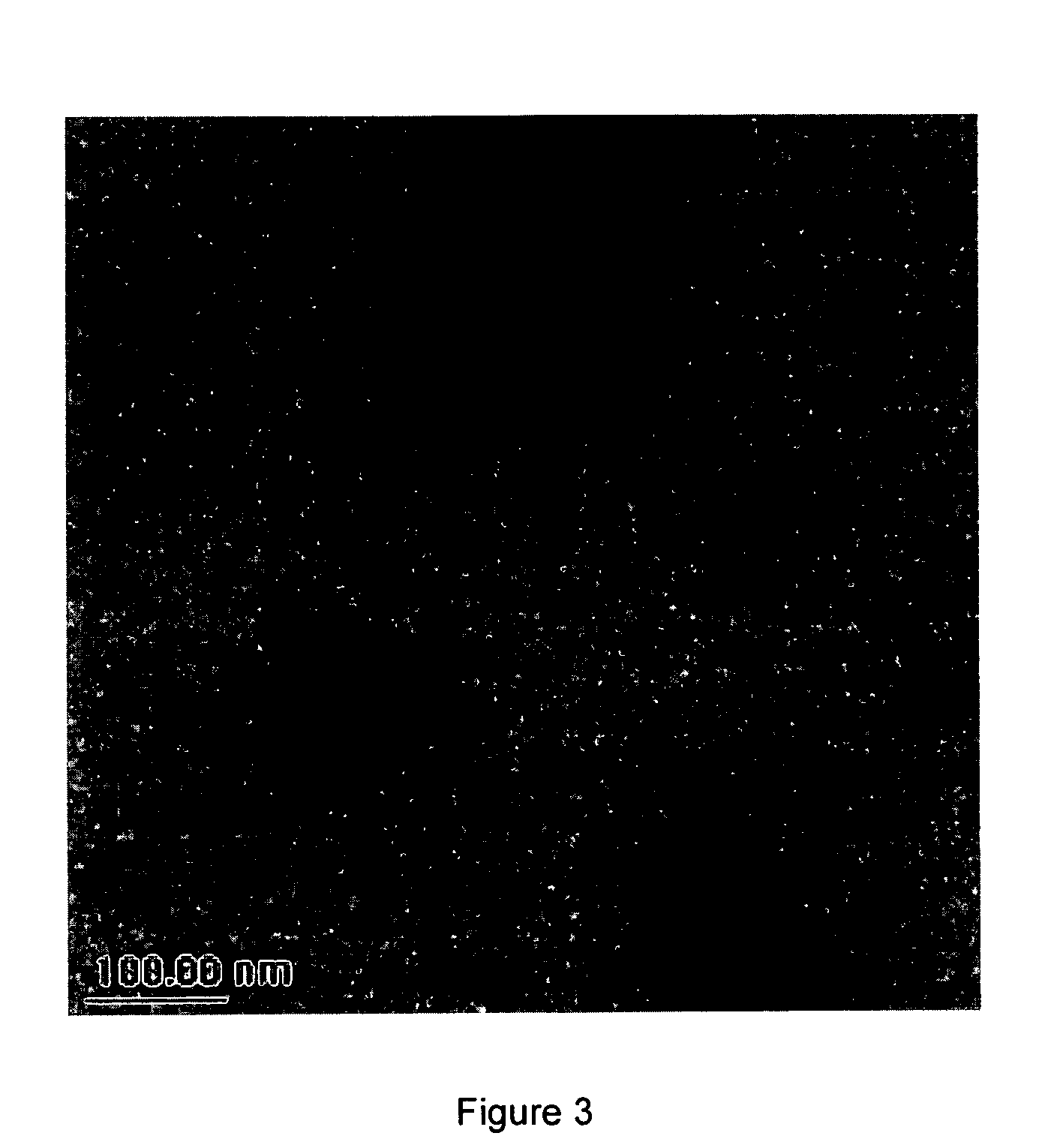

InactiveUS20110104052A1Prevents immunoclearanceExtended half-lifePowder deliveryBiocideDiagnostic agentComputed tomography

The present invention provides, in general, compositions comprising a hydrogel and an agent, for example a therapeutic agent or an imaging agent, for locoregional delivery. In certain preferred embodiments of the invention, the hydrogel compositions are detectable by Magnetic Responance and CT Scan and are used for locoregional delivery of therapeutic agents, for example chemotherapeutic agents. The invention also features polymer matrix compositions comprising nanoparticles that can be loaded after polymerization with bioactive agents, for example a diagnostic agent or therapeutic agent.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Compositions used in manufacturing articles having an inorganically filled organic polymer matrix

InactiveUS6090195AReadily and inexpensively mass producedHigh strengthClosure lidsWrappersFiberPolymer science

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more aggregate materials, fibers, and optional admixtures in the correct proportions in order to form an article which has the desired performance criteria. The inorganically filled mixtures are molded to fashion a portion of the mixture into a form stable shape for the desired article. Once the article has obtained form stability, such as by heating to remove water by evaporation, the article is removed from the mold and allowed to harden to gain strength. The articles may have properties substantially similar to articles presently made from traditional materials like paper, paperboard, polystyrene, plastic, or metal. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

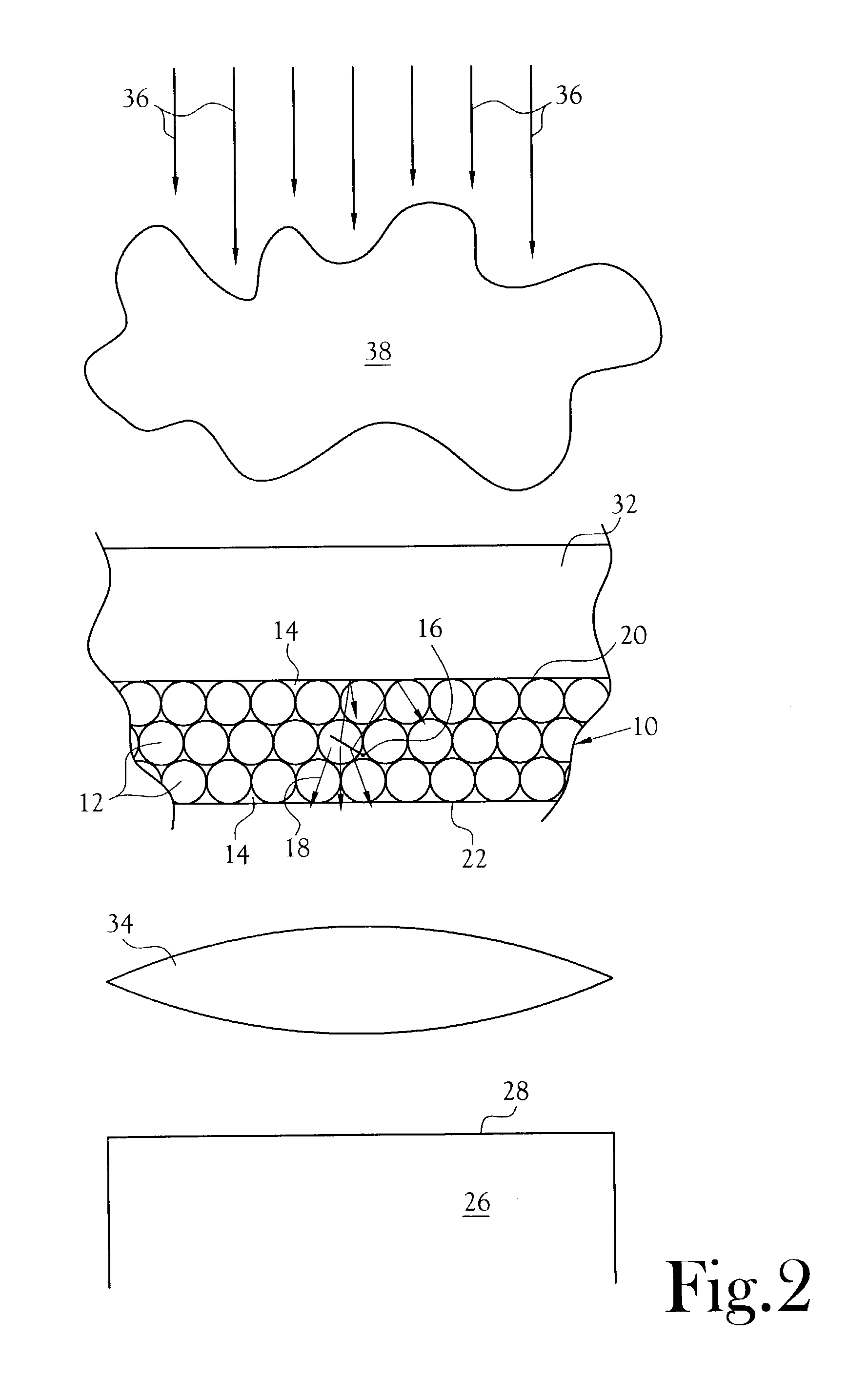

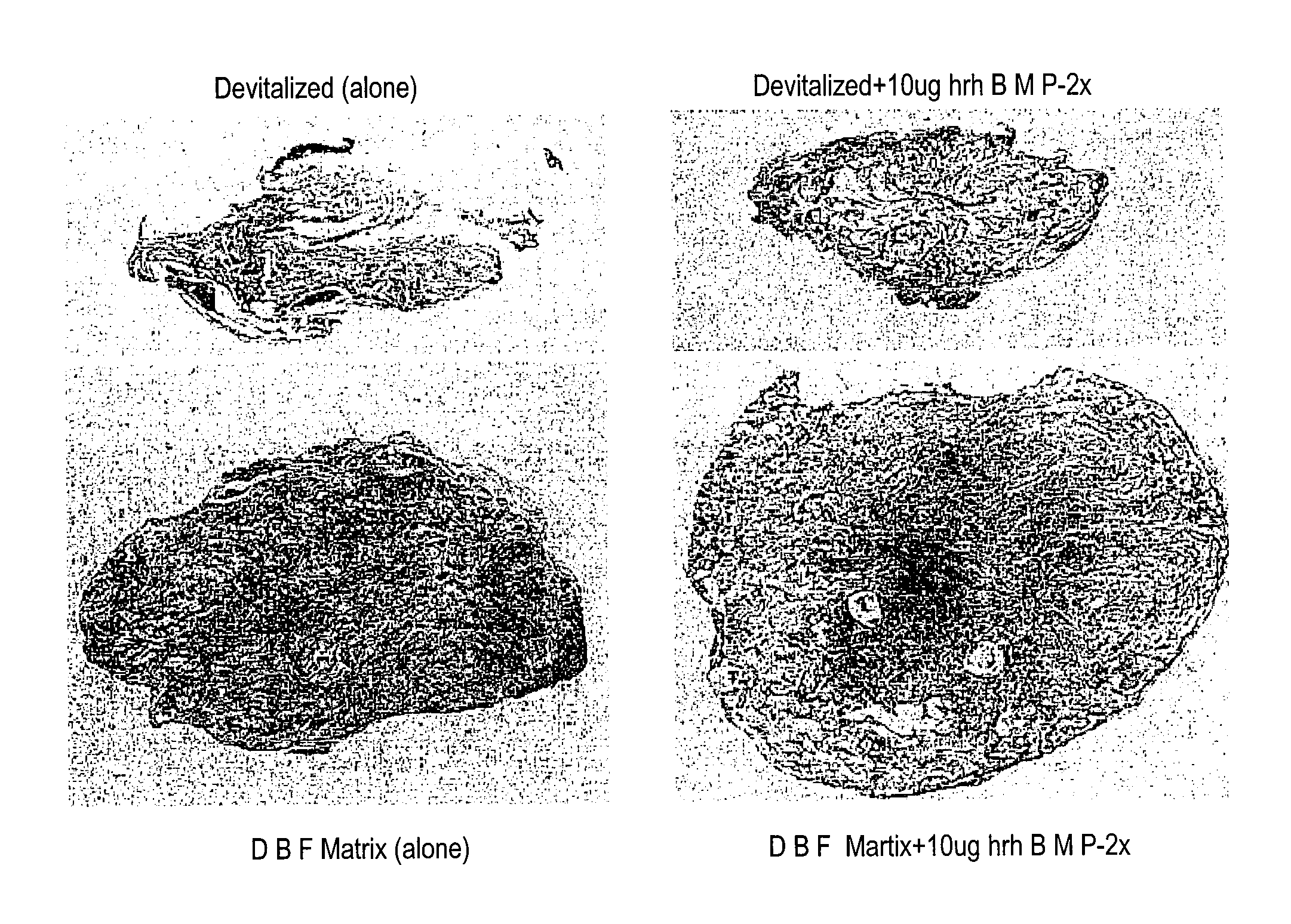

Bone graft

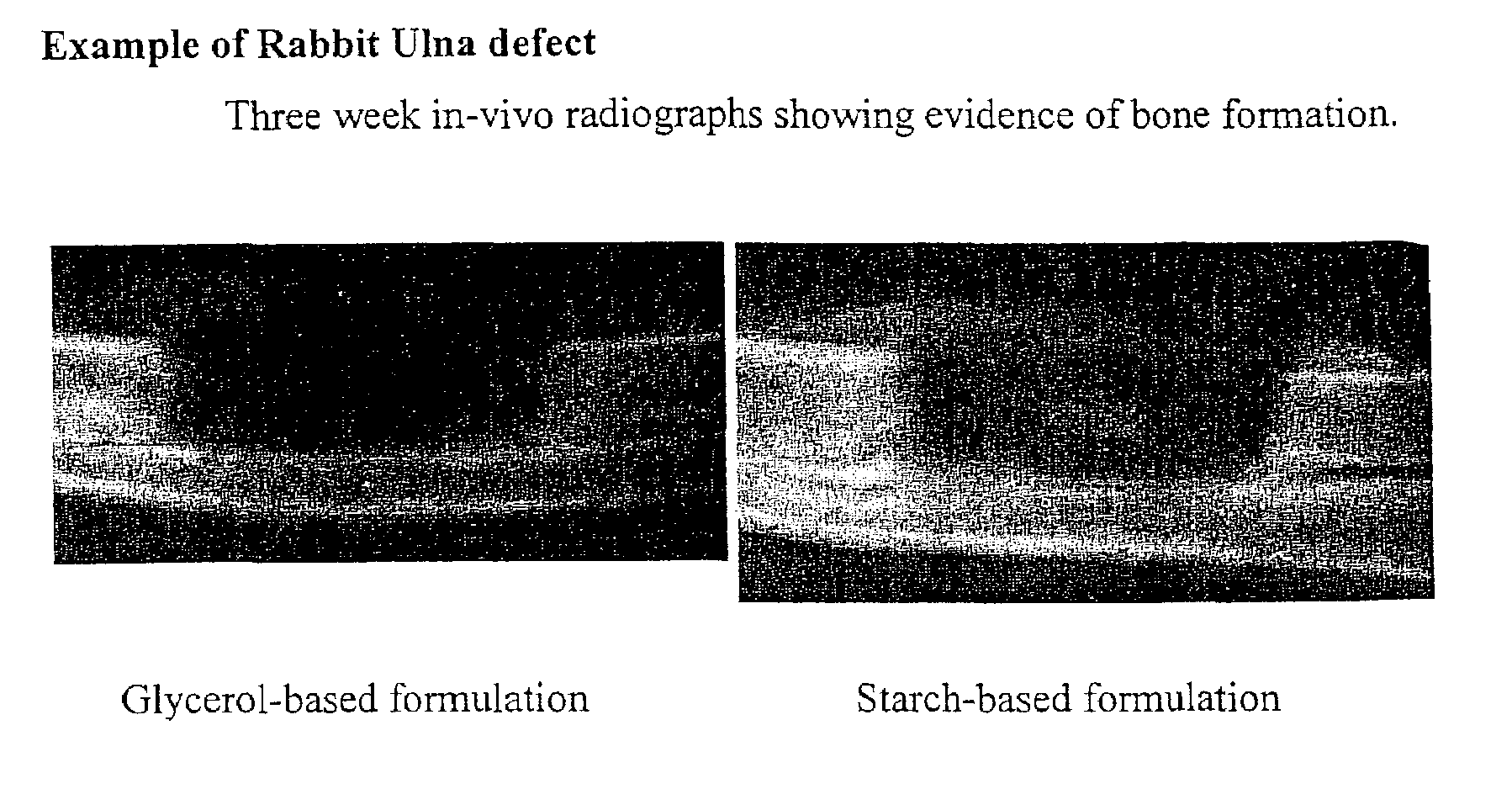

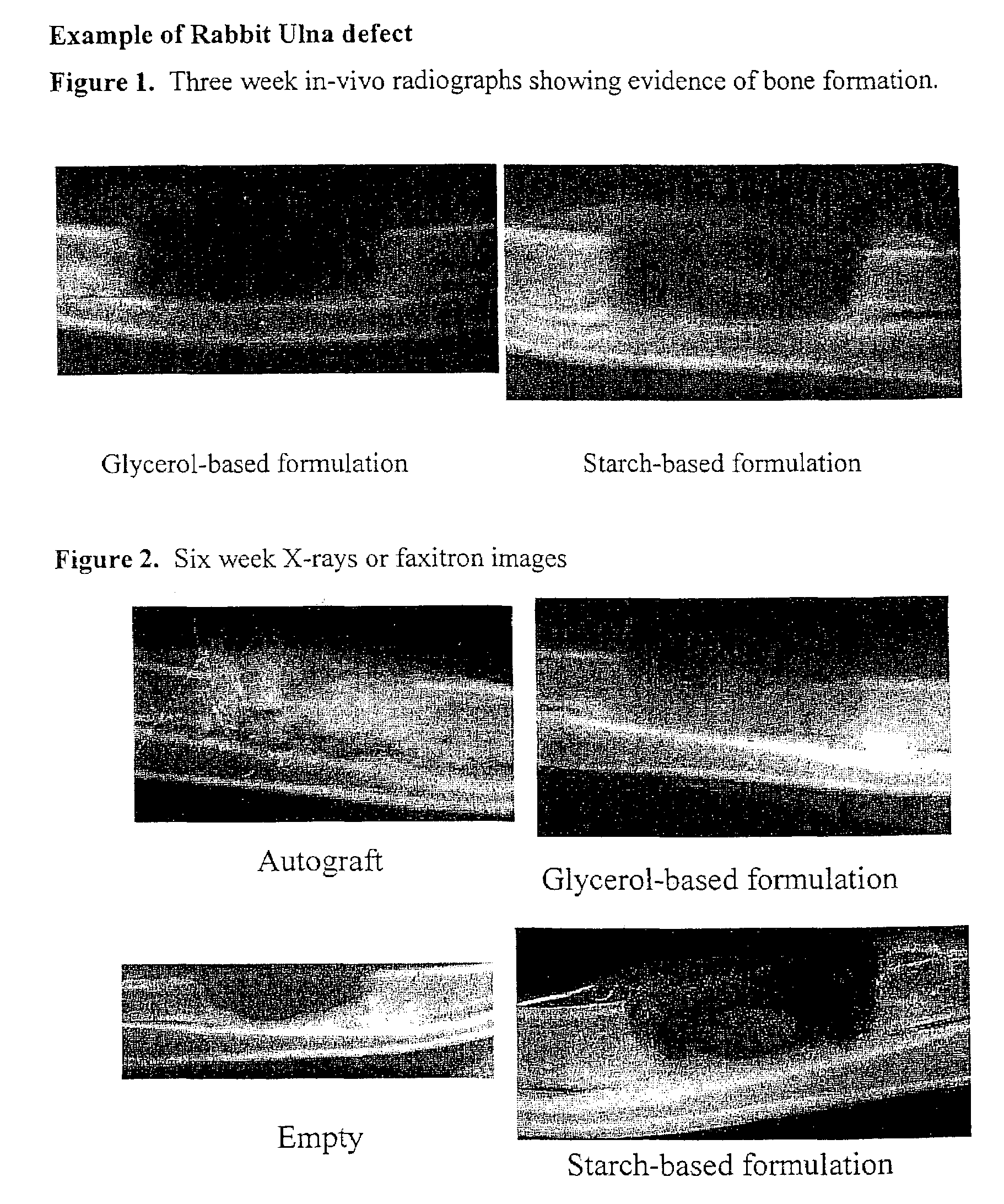

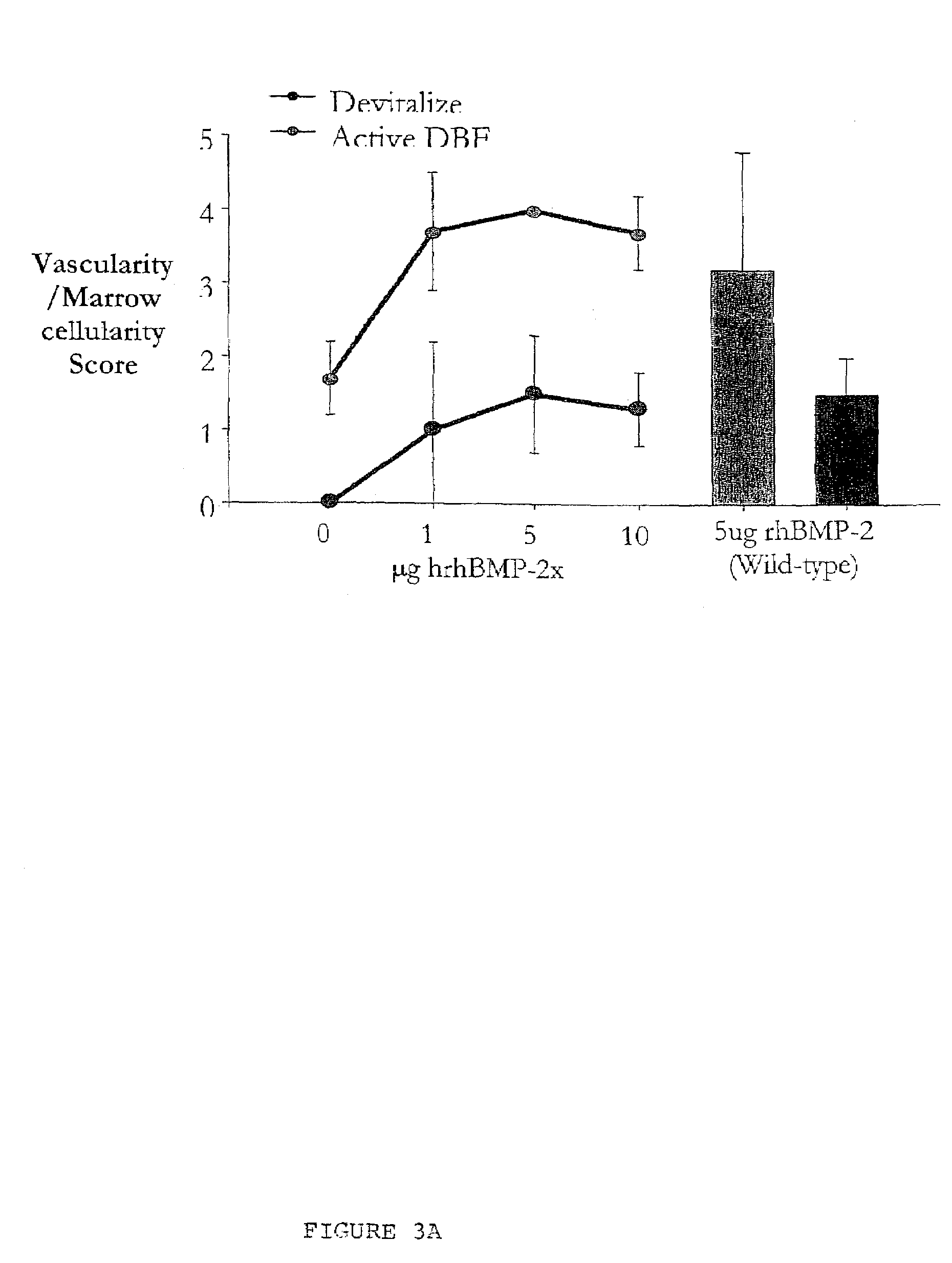

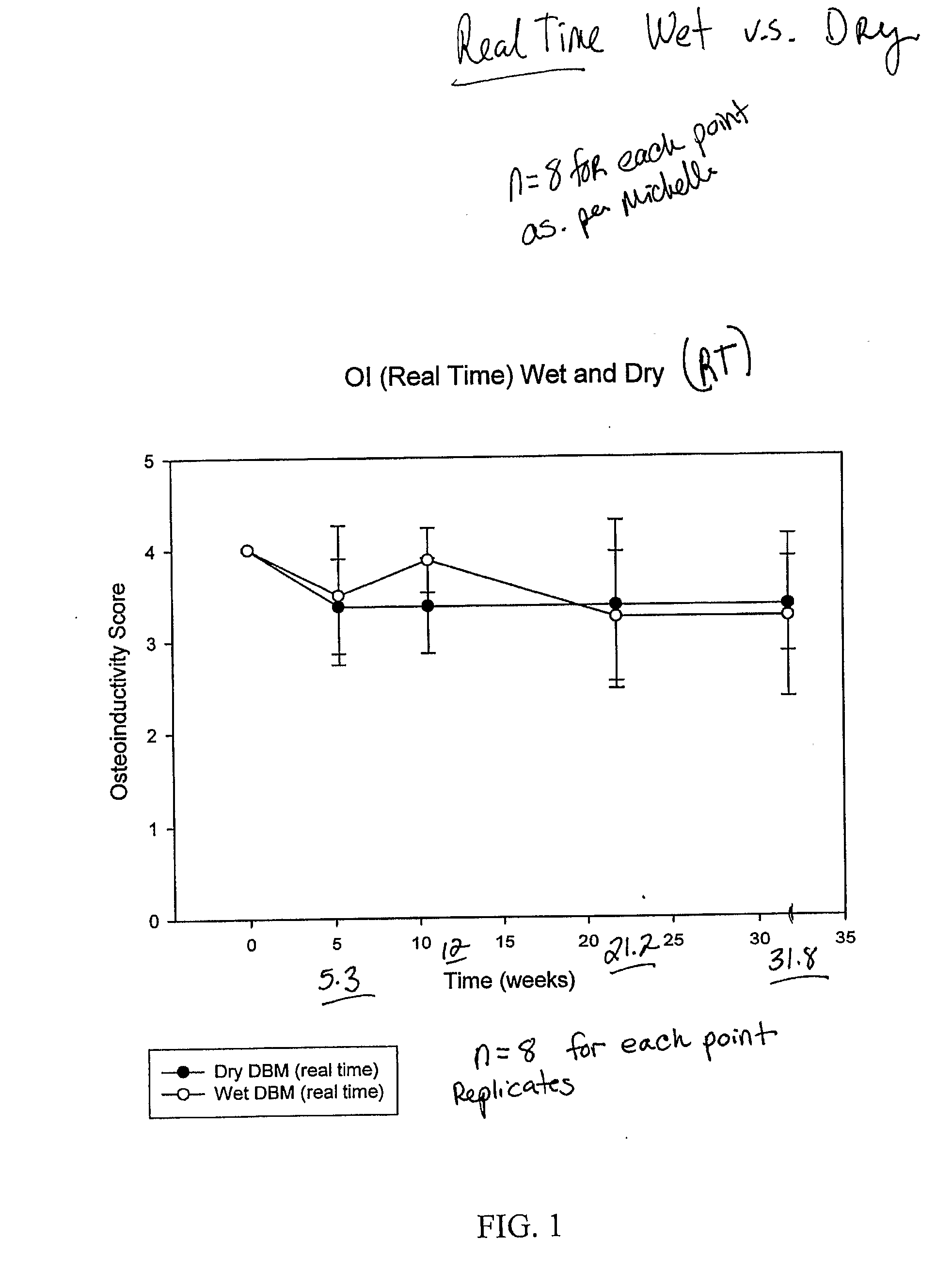

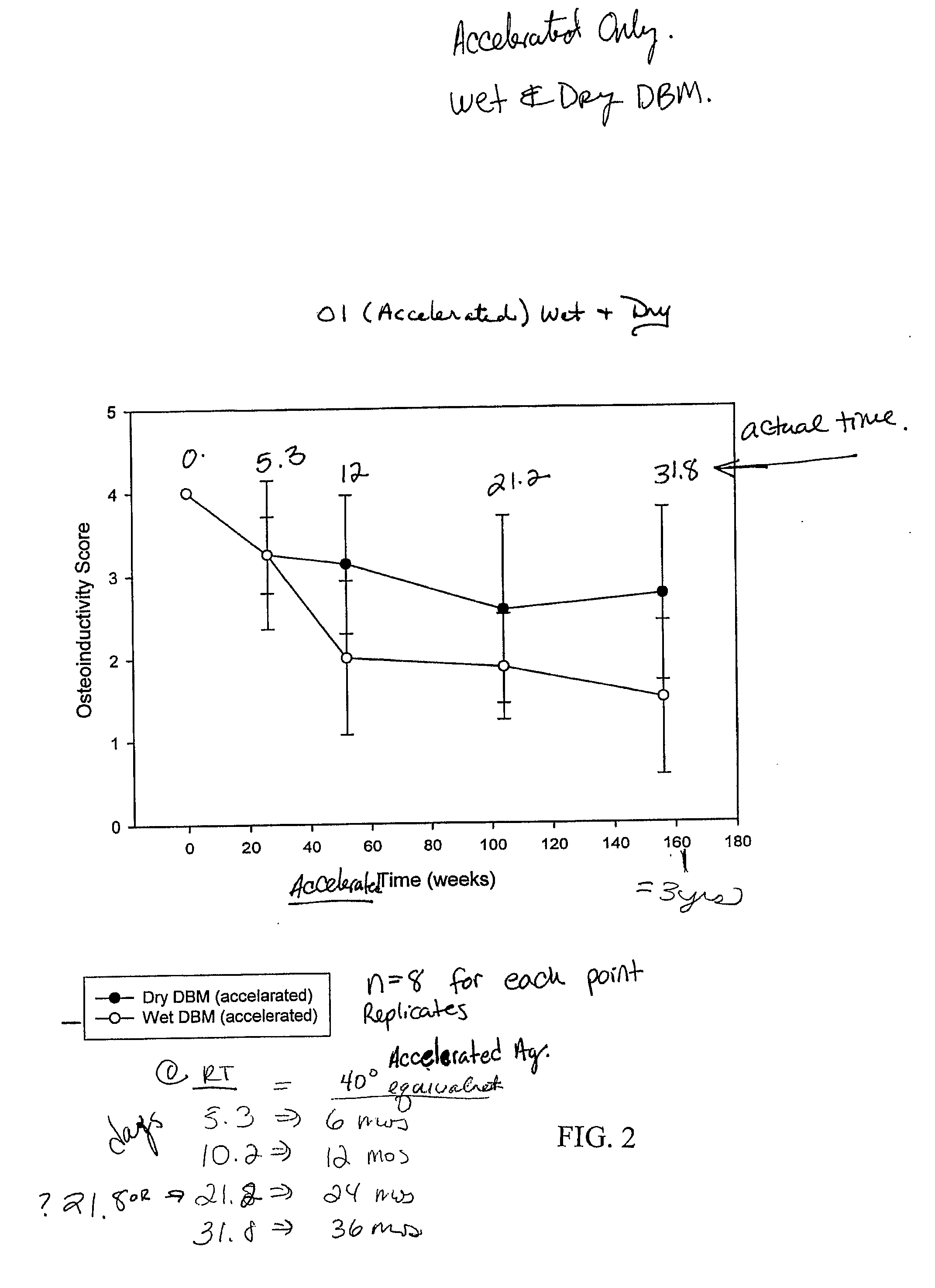

ActiveUS7163691B2Fast reduction in osteoinductiveGood curative effectOrganic active ingredientsImpression capsOSTEOINDUCTIVE FACTORIn vivo

An improved demineralized bone matrix (DBM) or other matrix composition is provided that has been mixed with a stabilizing agent that acts as (1) a diffusion barrier, (2) a enzyme inhibitor, (3) a competitive substrate, or (4) a masking moiety. A diffusion barrier acts as a barrier so as to protect the osteoinductive factors found in DBM from being degraded by proteolytic and glycolytic enzymes at the implantation site. Stabilizing agents may be any biodegradable material such as starches, modified starches, cellulose, dextran, polymers, proteins, and collagen. As the stabilizing agents degrades or dissolves in vivo, the osteoinductive factors such as TGF-β, BMP, and IGF are activated or exposed, and the activated factors work to recruit cells from the preivascular space to the site of injury and to cause differentiation into bone-forming cells. The invention also provides methods of preparing, testing, and using the inventive improved osteodinductive matrix compositions.

Owner:WARSAW ORTHOPEDIC INC

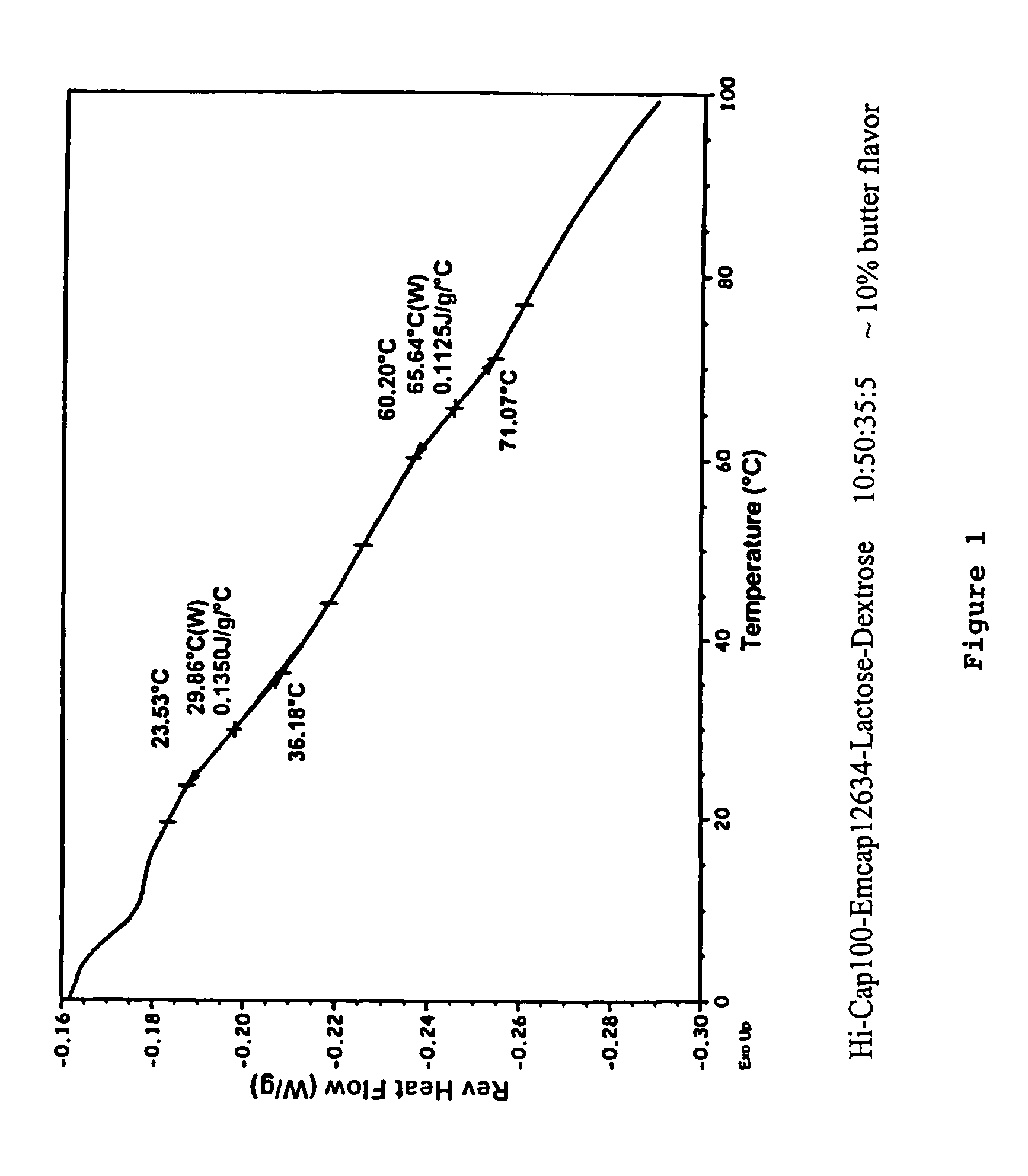

Encapsulation compositions and processes for preparing the same

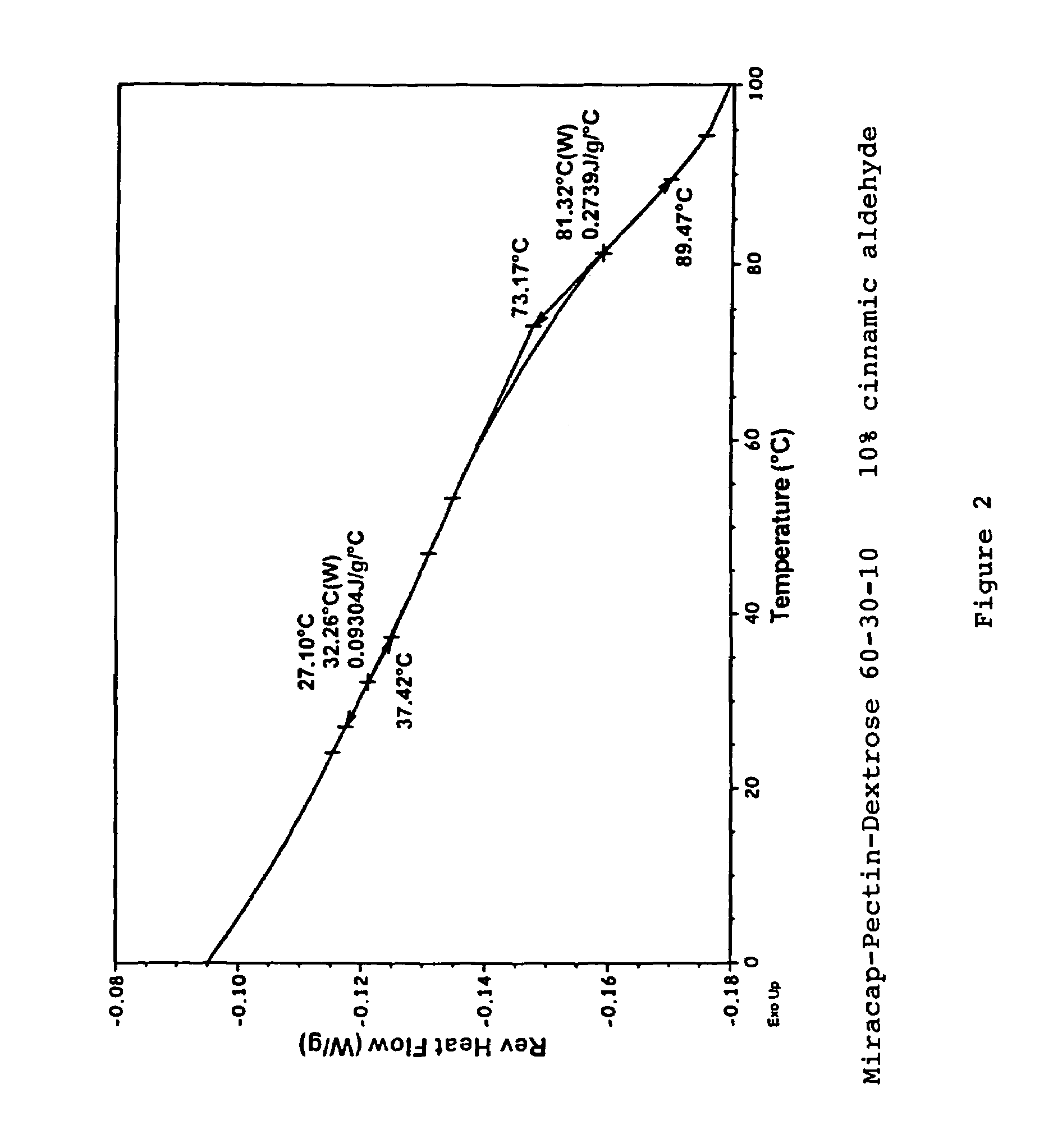

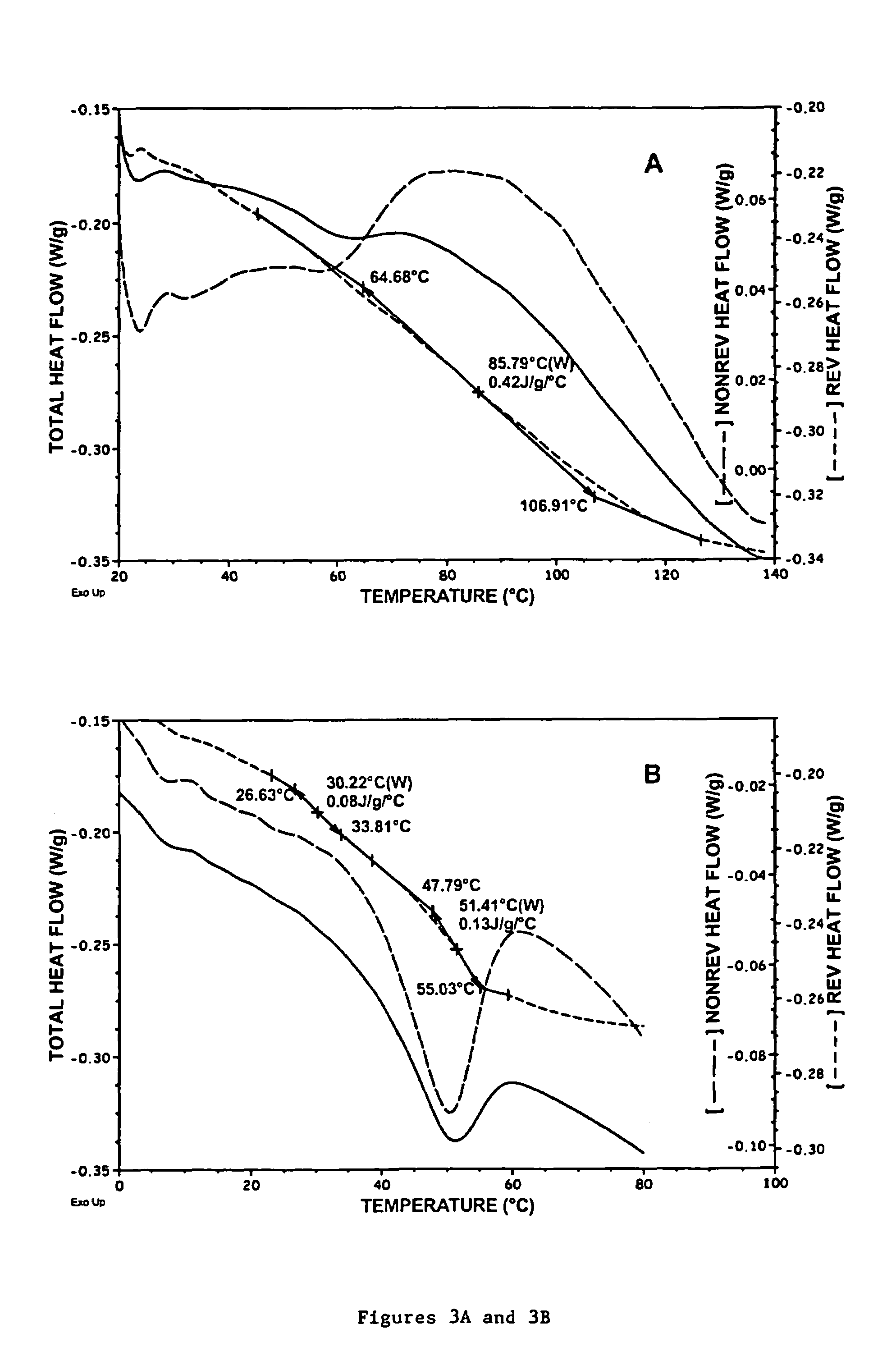

Matrix compositions which contain a mixture of two different food polymers are useful for encapsulating encapsulates, such as flavoring agents.

Owner:MCCORMICK & CO INC

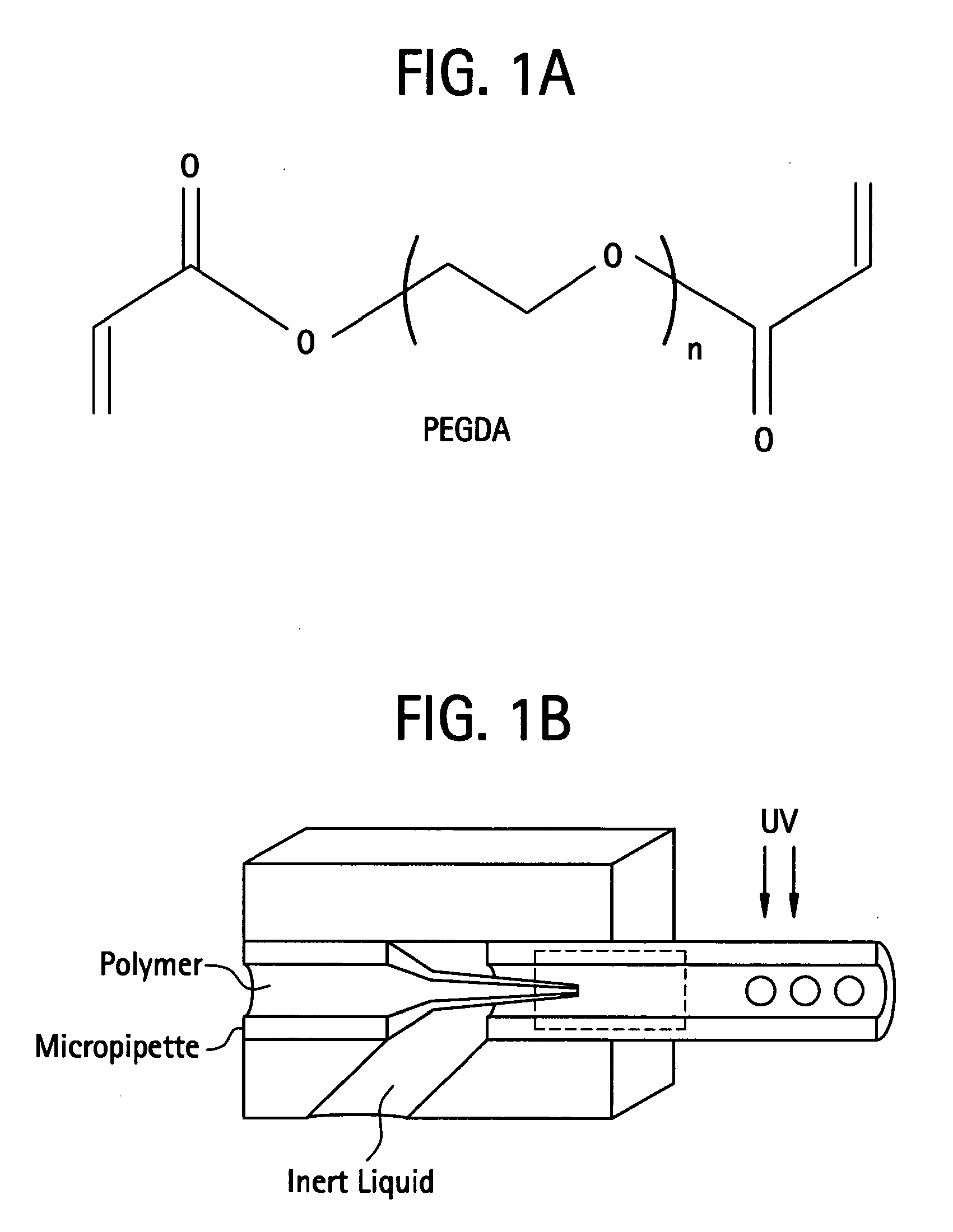

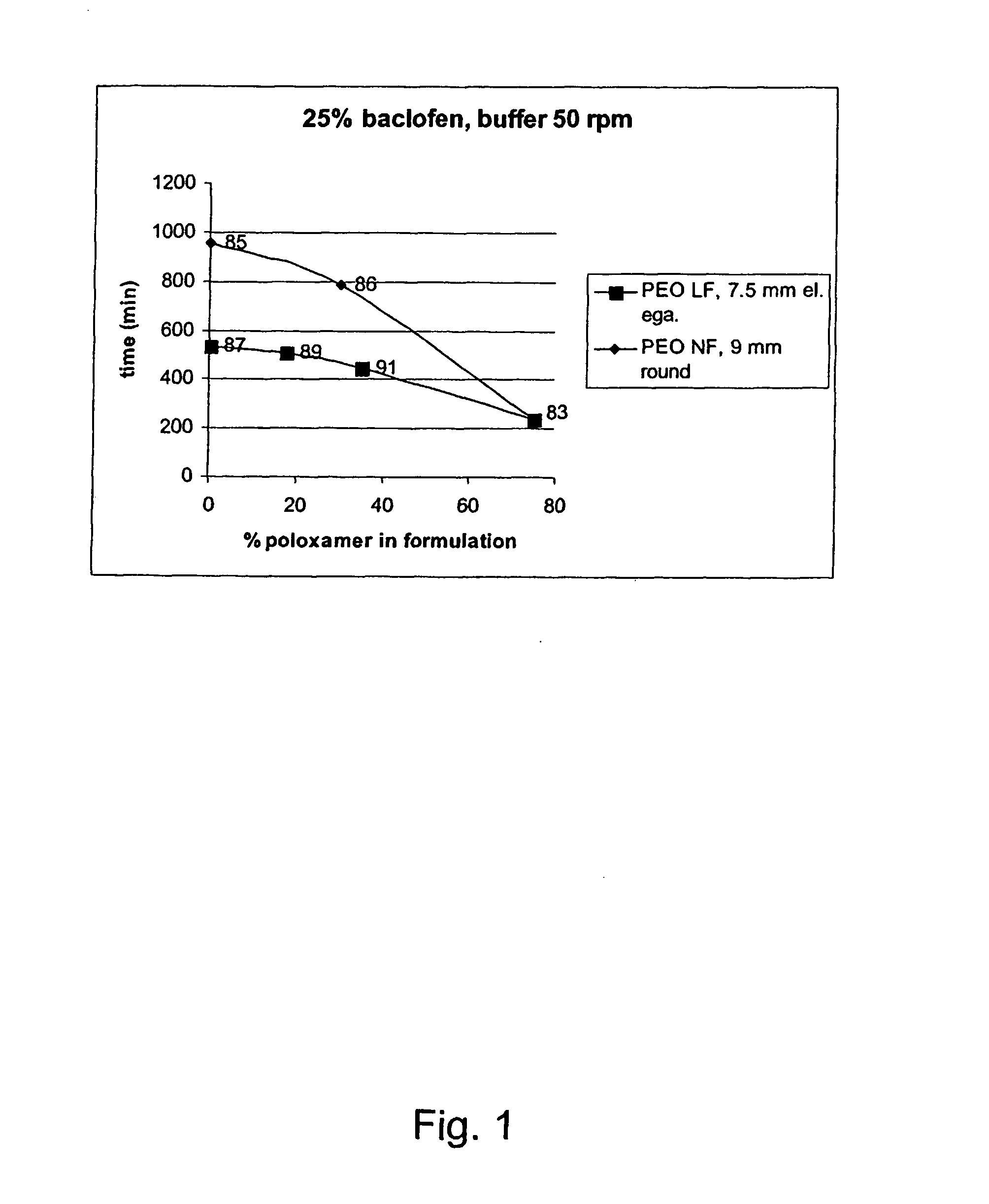

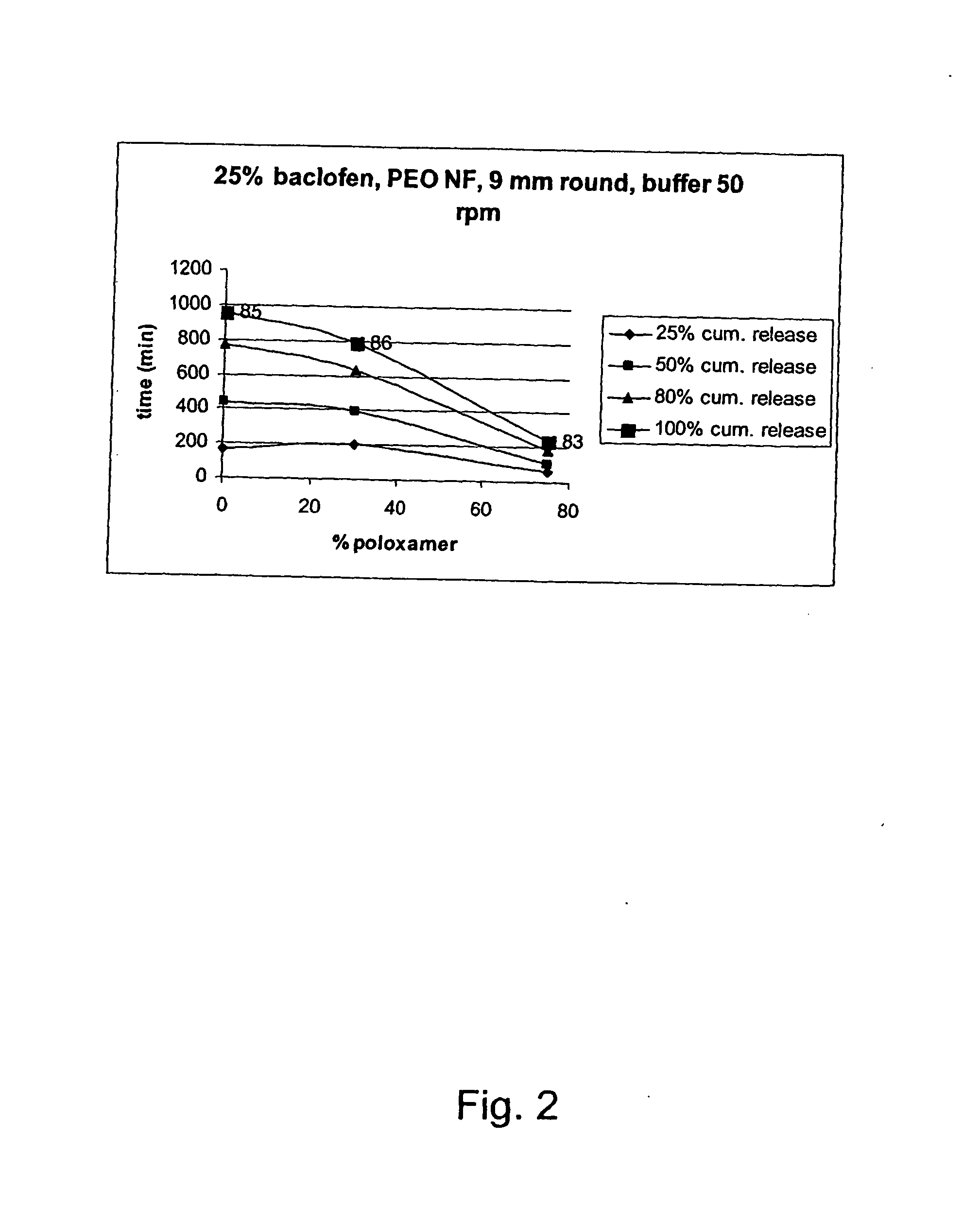

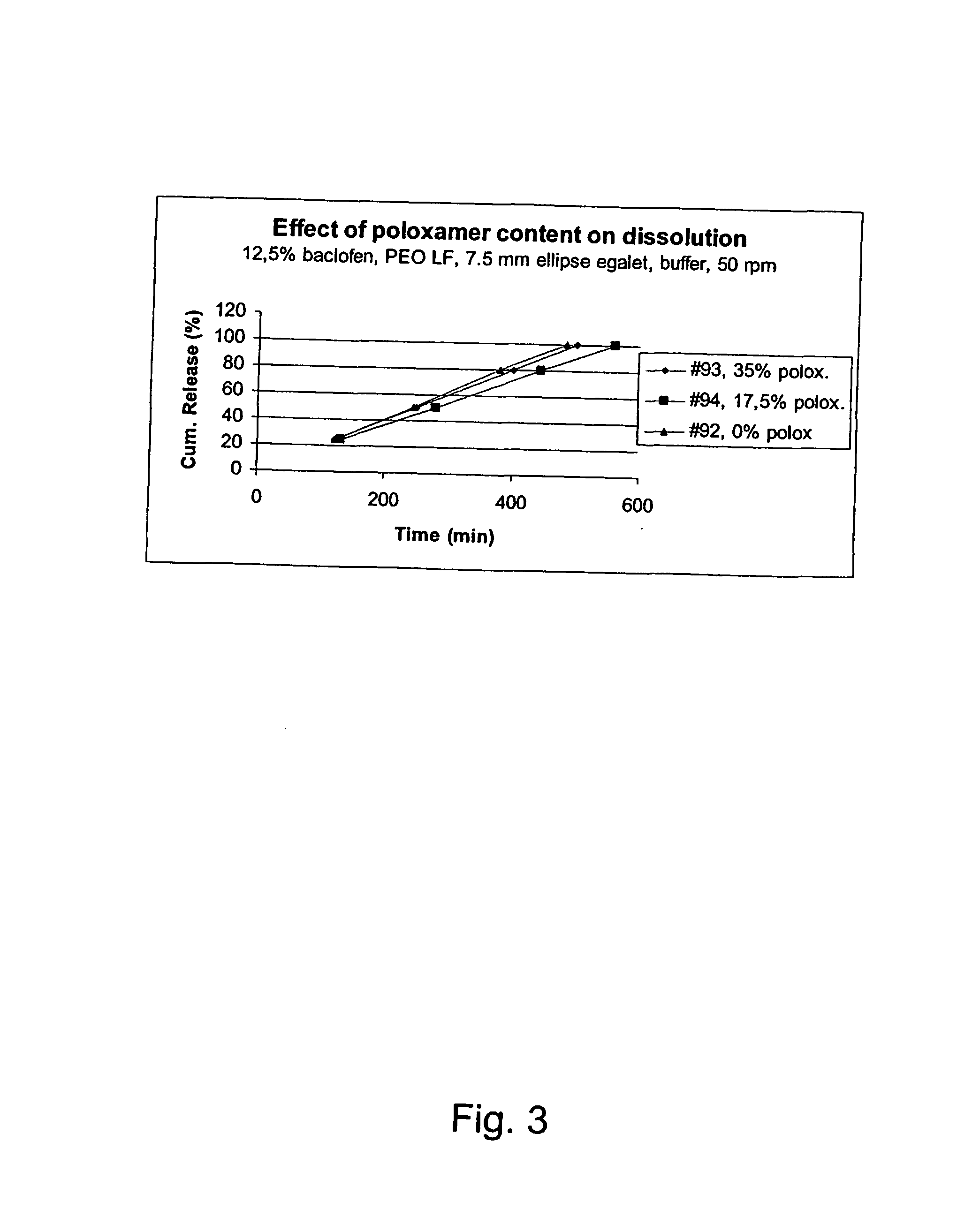

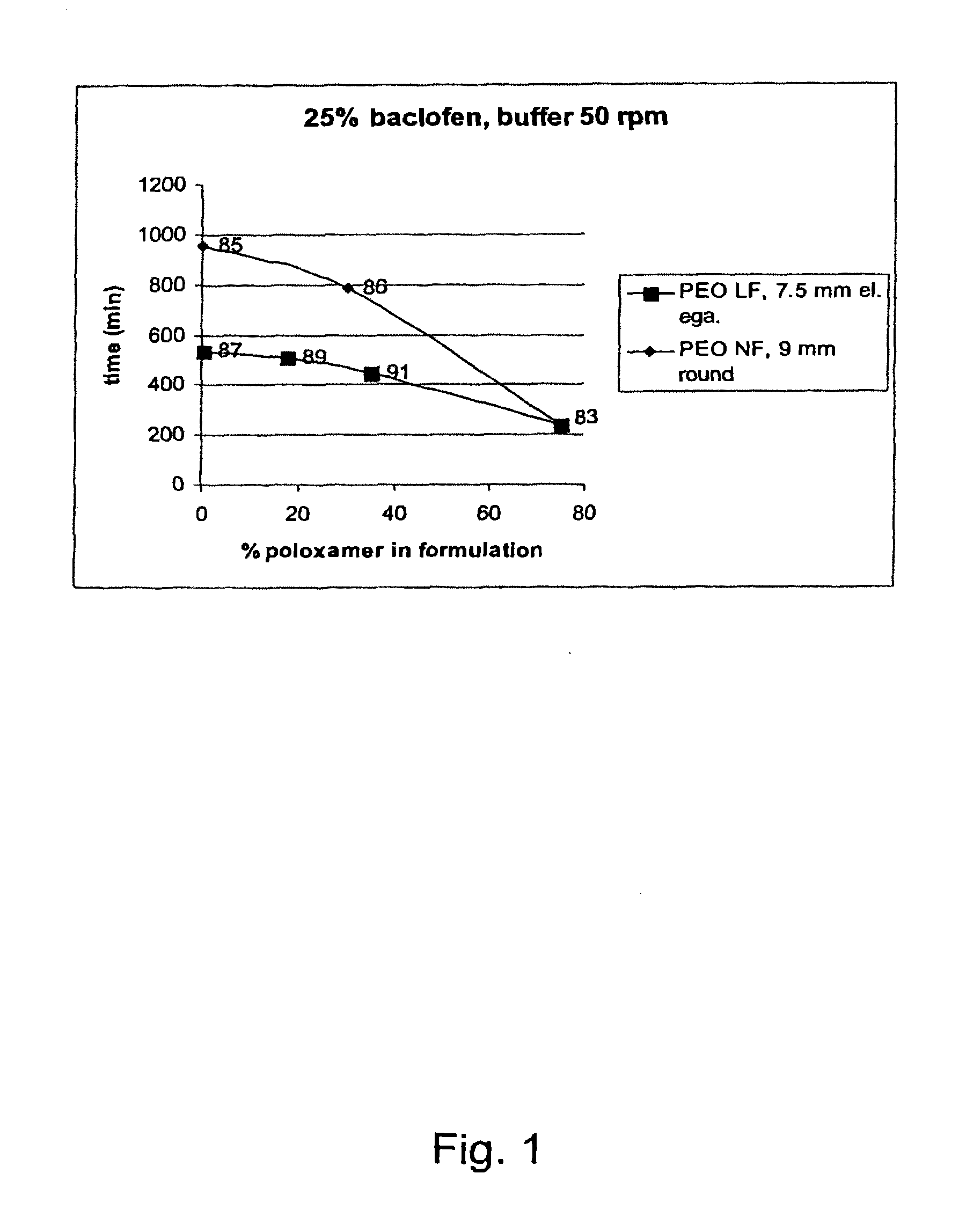

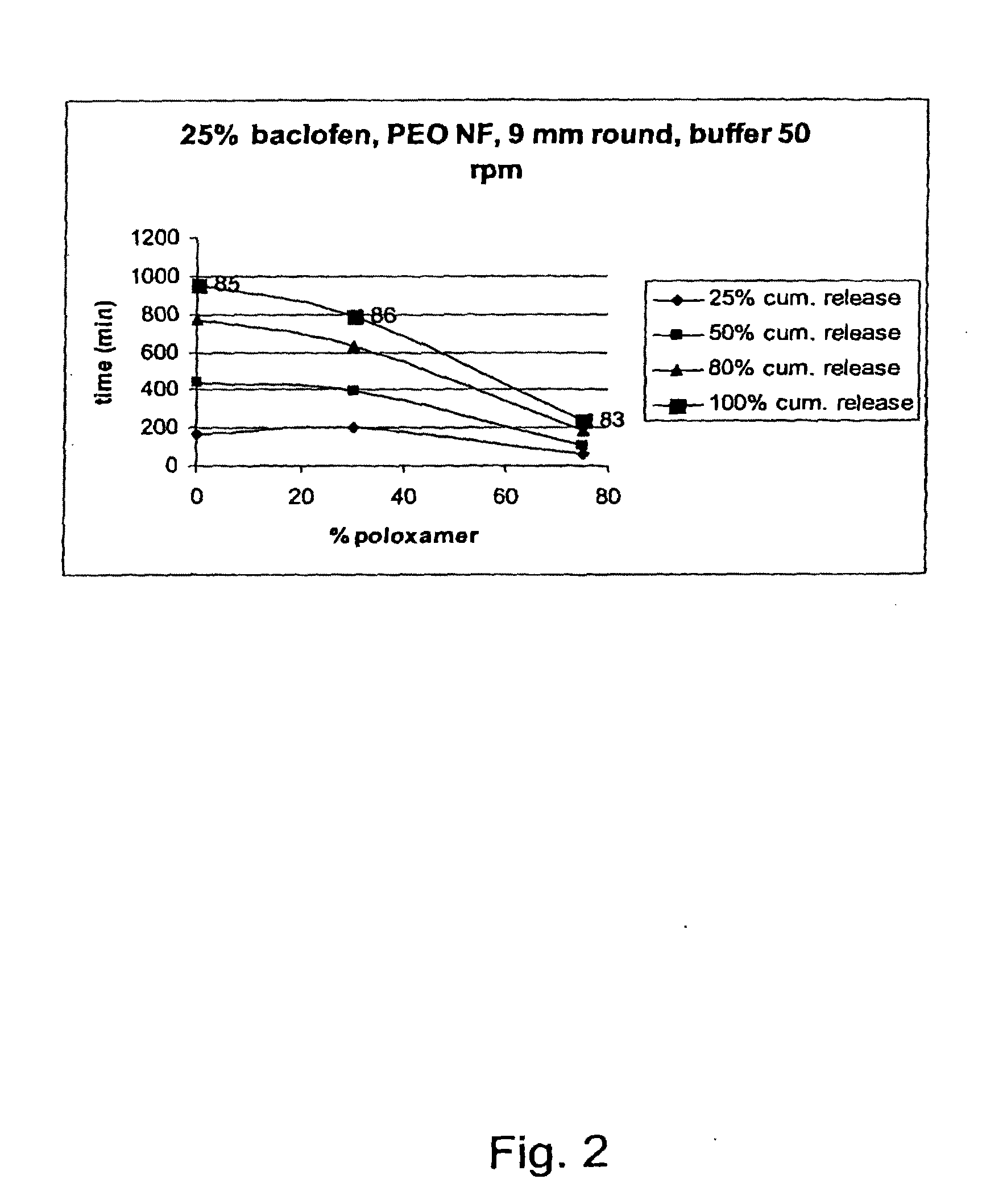

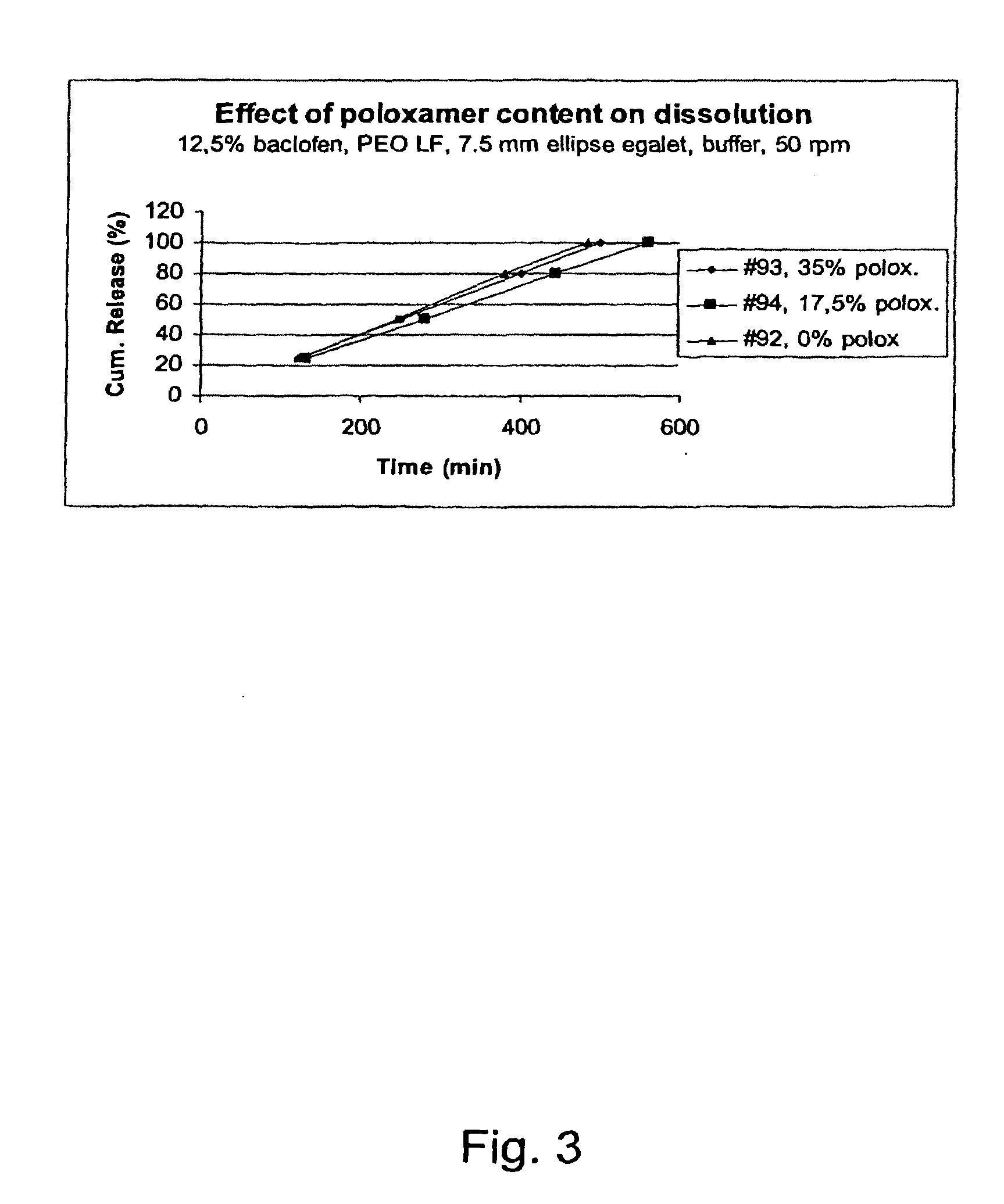

Matrix compositions for controlled delivery of drug substances

InactiveUS20070042044A1Improve solubilityImprove oral bioavailabilityBiocidePowder deliveryPolyethylene oxidePEG-PLGA-PEG

A novel matrix composition for pharmaceutical use. The matrix composition has been designed so that it is especially suitable in those situation where an improved bioavailability is desired and / or in those situation where a slightly or insoluble active substance is employed. Accordingly, a controlled release pharmaceutical composition for oral use is provided in the form of a coated matrix composition, the matrix composition comprising i) a mixture of a first and a second polymer that have plasticizing properties and which have melting points or melting intervals of a temperature of at the most 200° C., the first polymer being selected from the group consisting of polyethylene glycols and polyethylene oxides, and the second polymer being selected form block copolymer of ethylene oxide and propylene oxide including poly(ethylene-glycol-b-(DL-lactic acid-co-glycolic acid)-b-ethylene glycol (PEG-PLGA PEG), poly((DL-lactic acid-co-glycolic acid)-g-ethylene glycol) (PLGA-g-PEG), poloxamers and polyethylene oxide-polypropylene oxide (PEO-PPO), ii) a therapeutically, prophylactically and / or diagnostically active substance, the matrix composition being provided with a coating having at least one opening exposing at one surface of said matrix, wherein the active substance is released with a substantially zero order release.

Owner:EGALET LTD

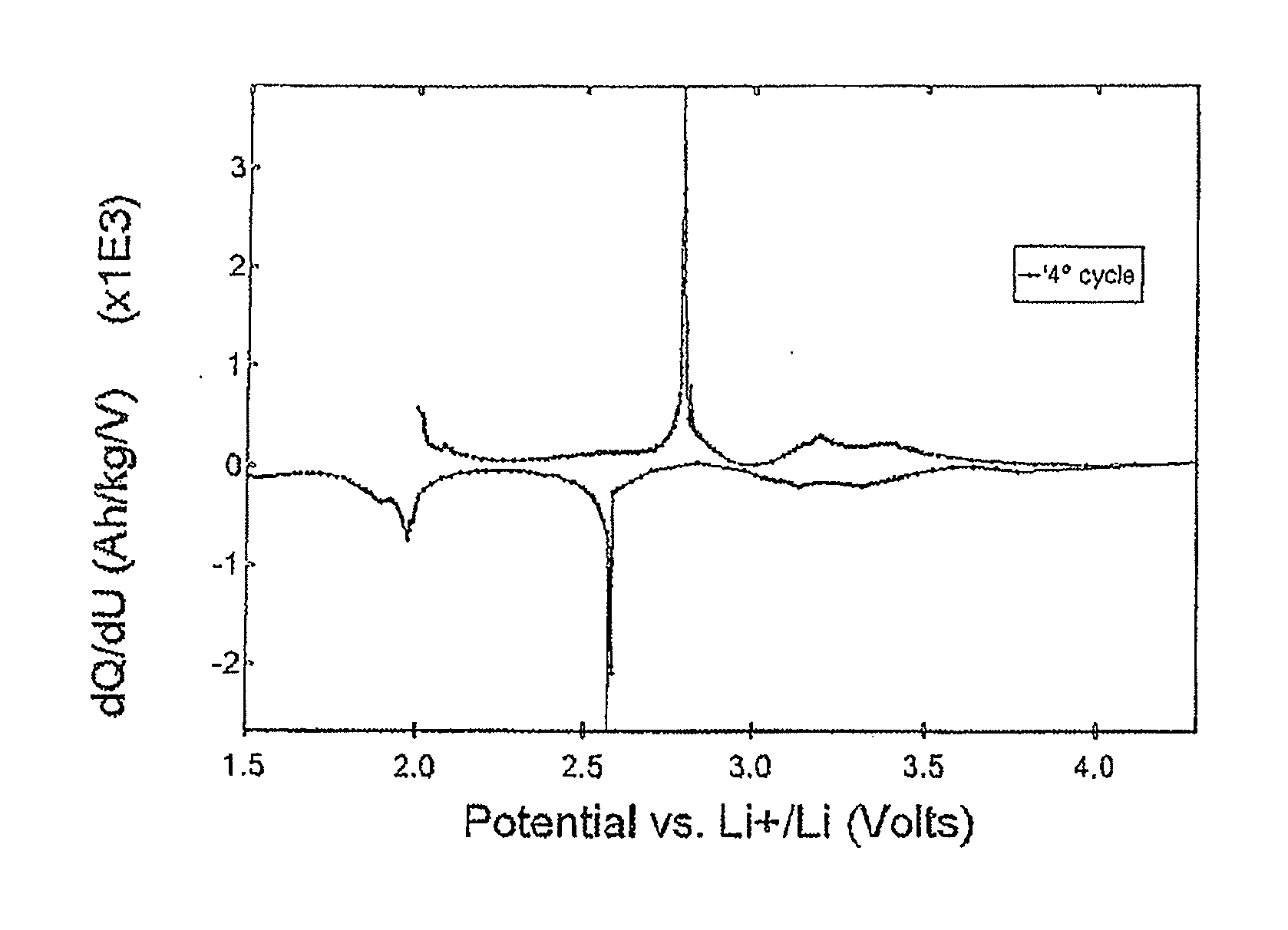

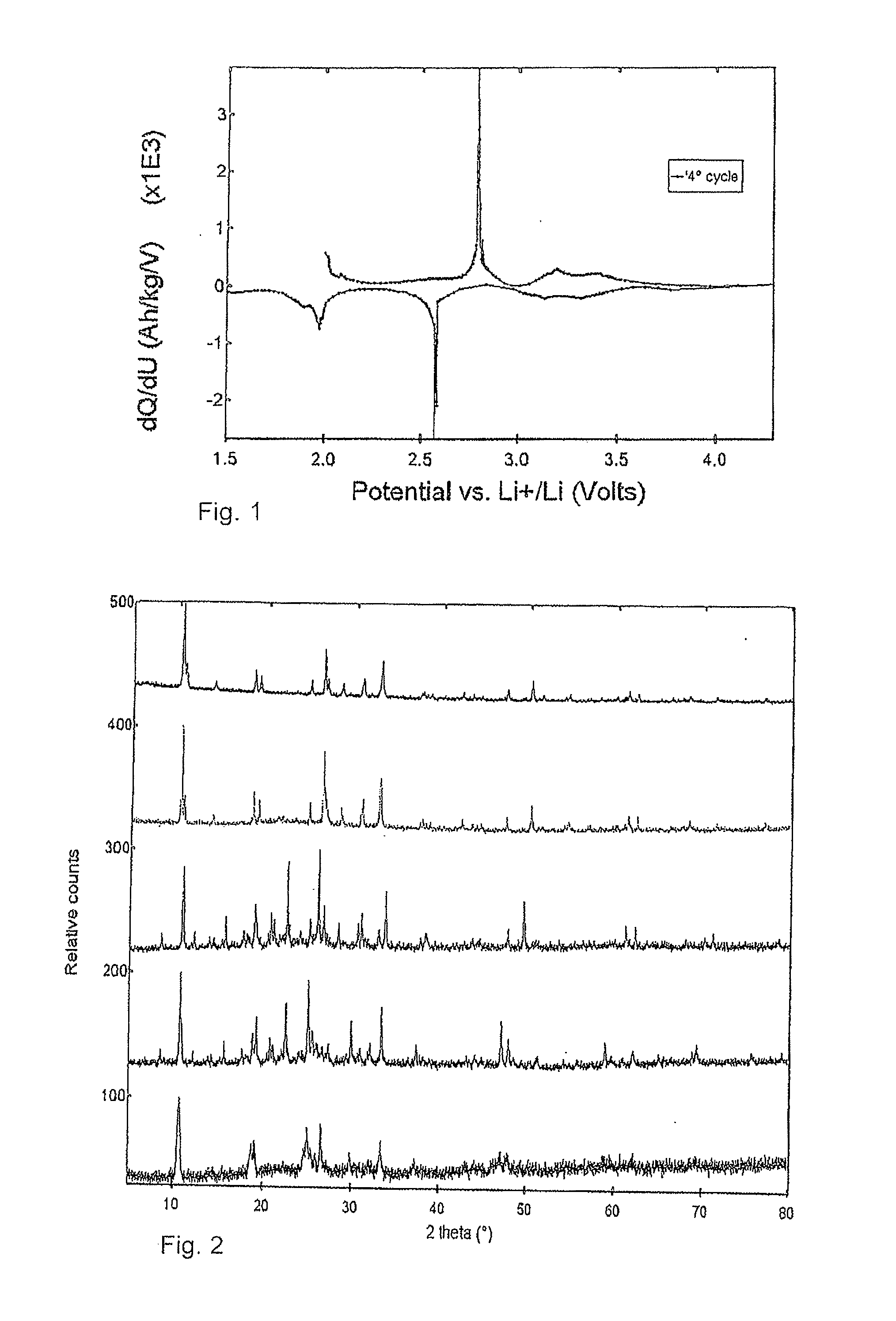

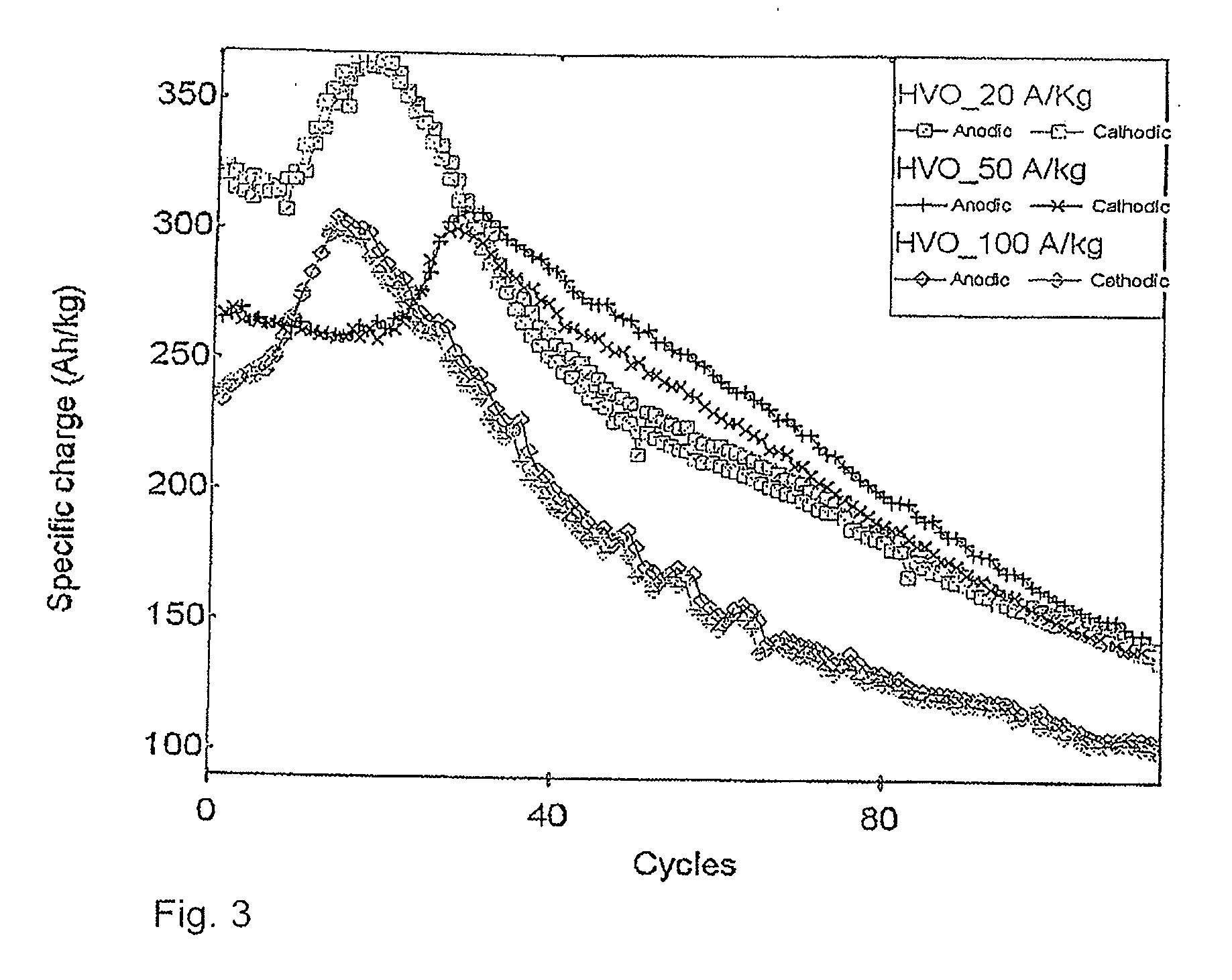

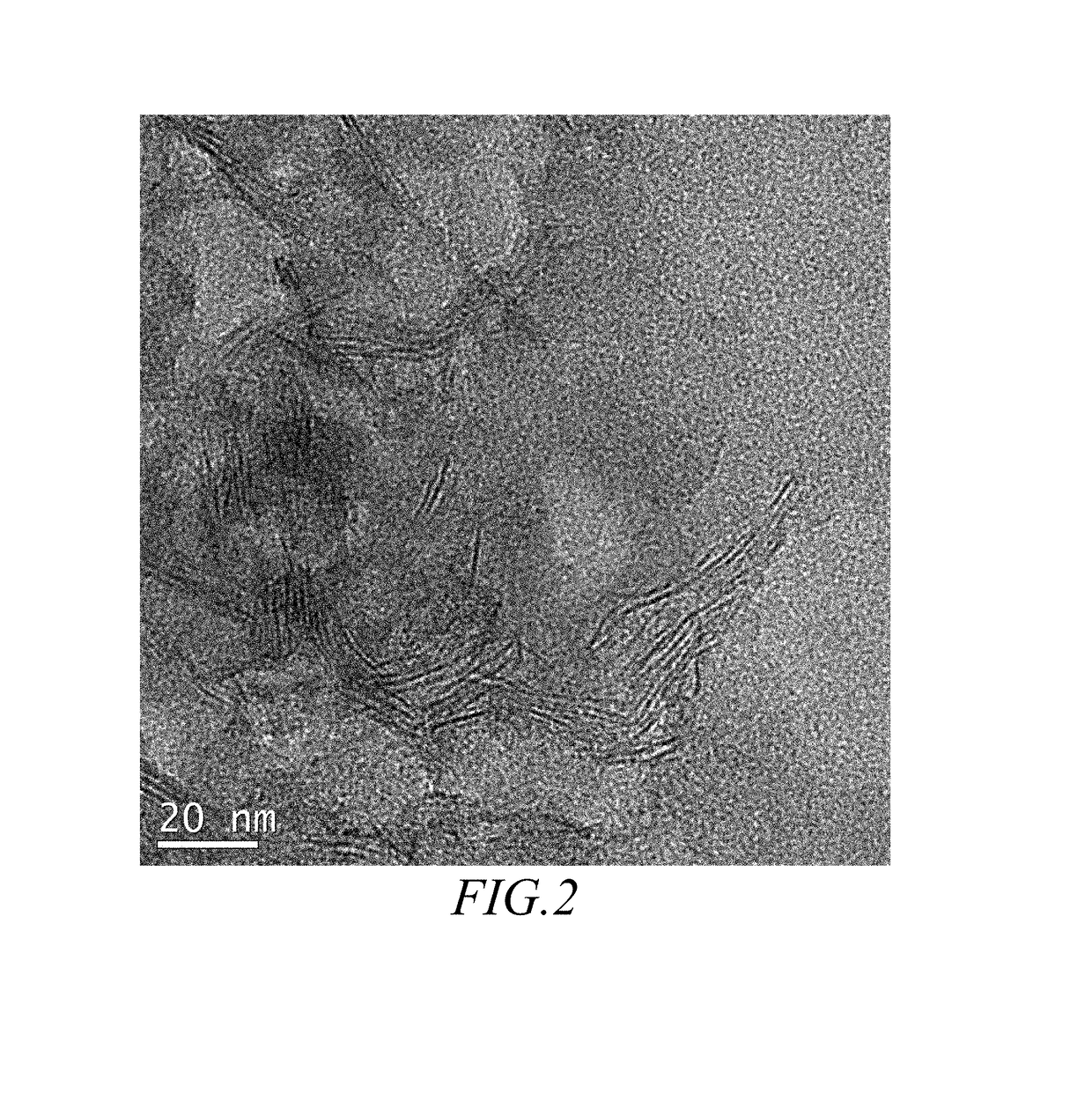

Electrode (anode and cathode) performance enhancement by composite formation with graphene oxide

ActiveUS20120100402A1Low and reduced matrix contentHigh matrix conductivityMaterial nanotechnologyBatteries circuit arrangementsFiberPerformance enhancement

Described is an electrode comprising and preferably consisting of electronically active material (EAM) in nanoparticulate form and a matrix, said matrix consisting of a pyrolization product with therein incorporated graphene flakes and optionally an ionic lithium source. Also described are methods for producing a particle based, especially a fiber based, electrode material comprising a matrix formed from pyrolized material incorporating graphene flakes and rechargeable batteries comprising such electrodes.

Owner:BELENOS CLEAN POWER HLDG

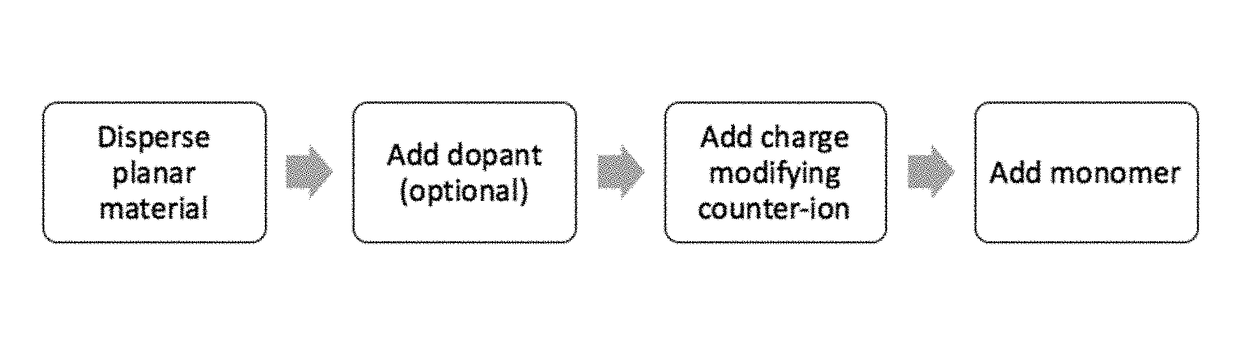

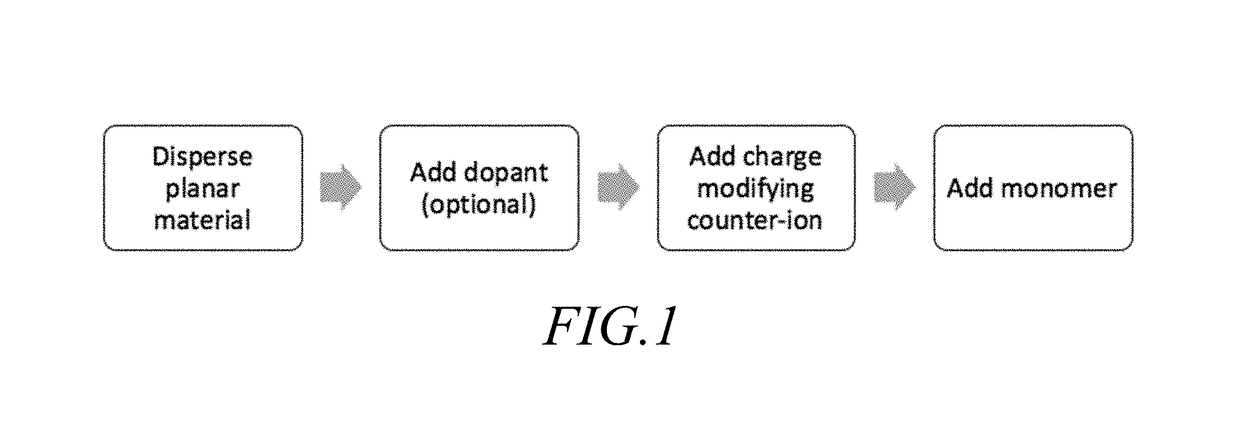

Conductive polymer-matrix compositions and uses thereof

A rubber composition comprising a plurality of composite particles and an elastomer is provided. A composite comprising a conductive polymer and a clay particle are also provided. Use of each in various applications and methods of preparing each are also provided.

Owner:POLYDROP LLC

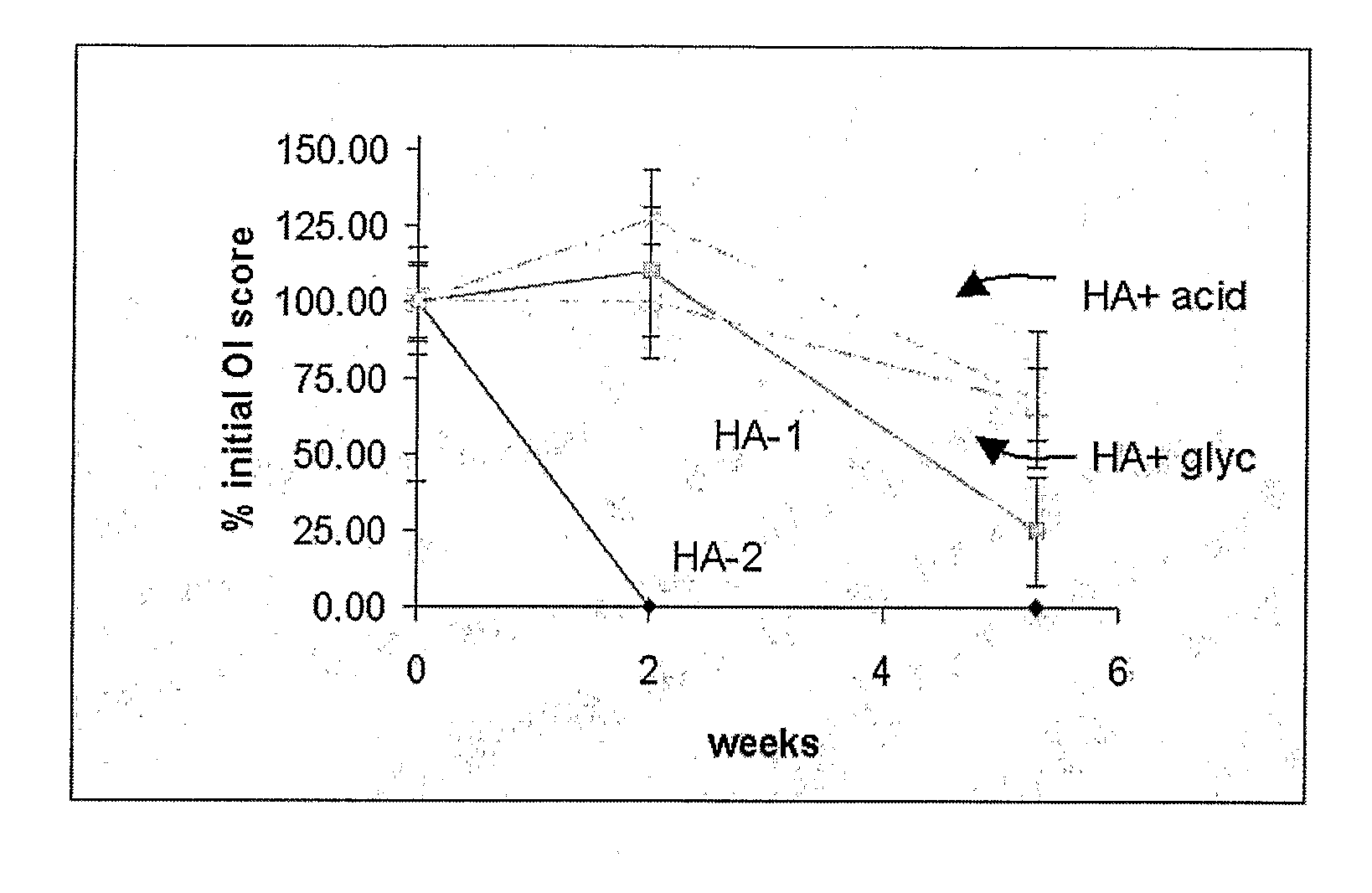

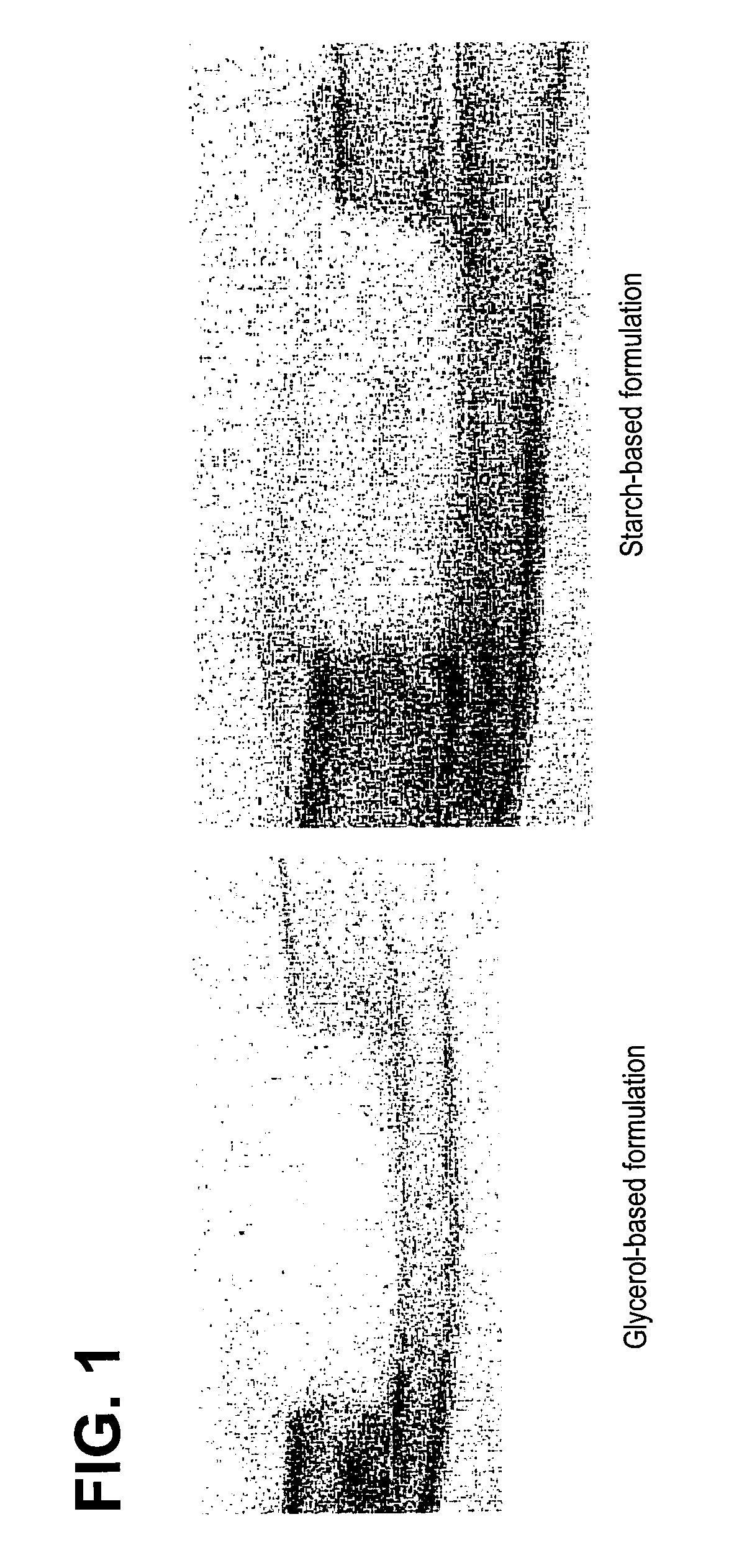

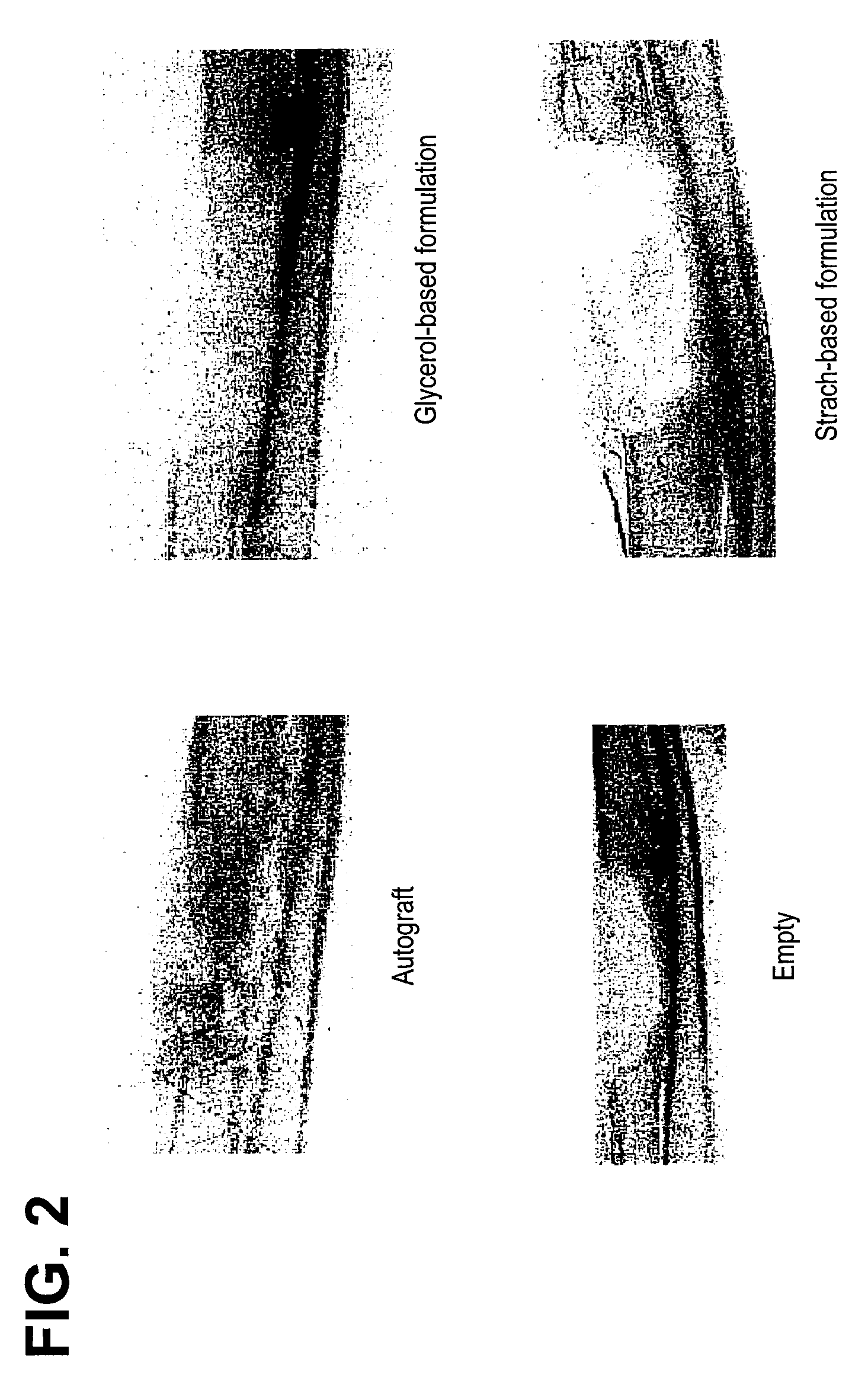

Stabilized bone graft

ActiveUS20070178158A1Good osteoinductivityImprove stabilityOrganic active ingredientsBiocideProteinase activityGlycerol

A demineralized bone matrix (DBM) or other matrix composition is provided that has been stabilized by lowering the pH of the composition, reducing the water content, adding water substitutes, and / or increasing the amount of deuterated water present in the composition in order to reduce the activity of endogenous degrading enzymes such as proteases. A hydrated form of a stabilized DBM composition may be stable up to a year at room temperature at acidic pH. The acidified DBM compositions may be further stabilized by the addition of a stabilizing agent such as deuterated water, water substitutes, polymers, protease inhibitors, glycerol, hydrogels, etc. The invention also provides methods of preparing, testing, and using the inventive stabilized osteodinductive matrix compositions.

Owner:WARSAW ORTHOPEDIC INC

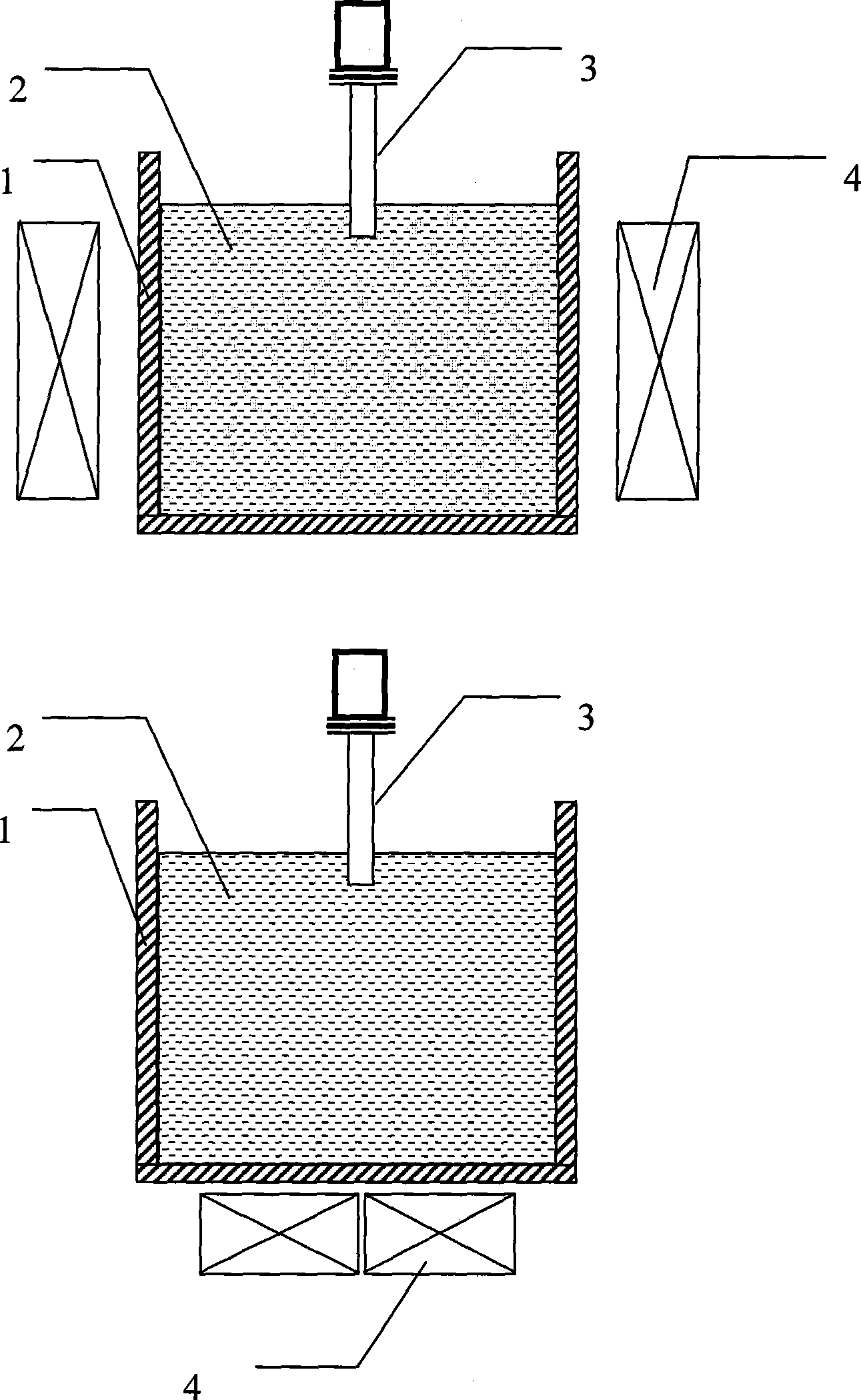

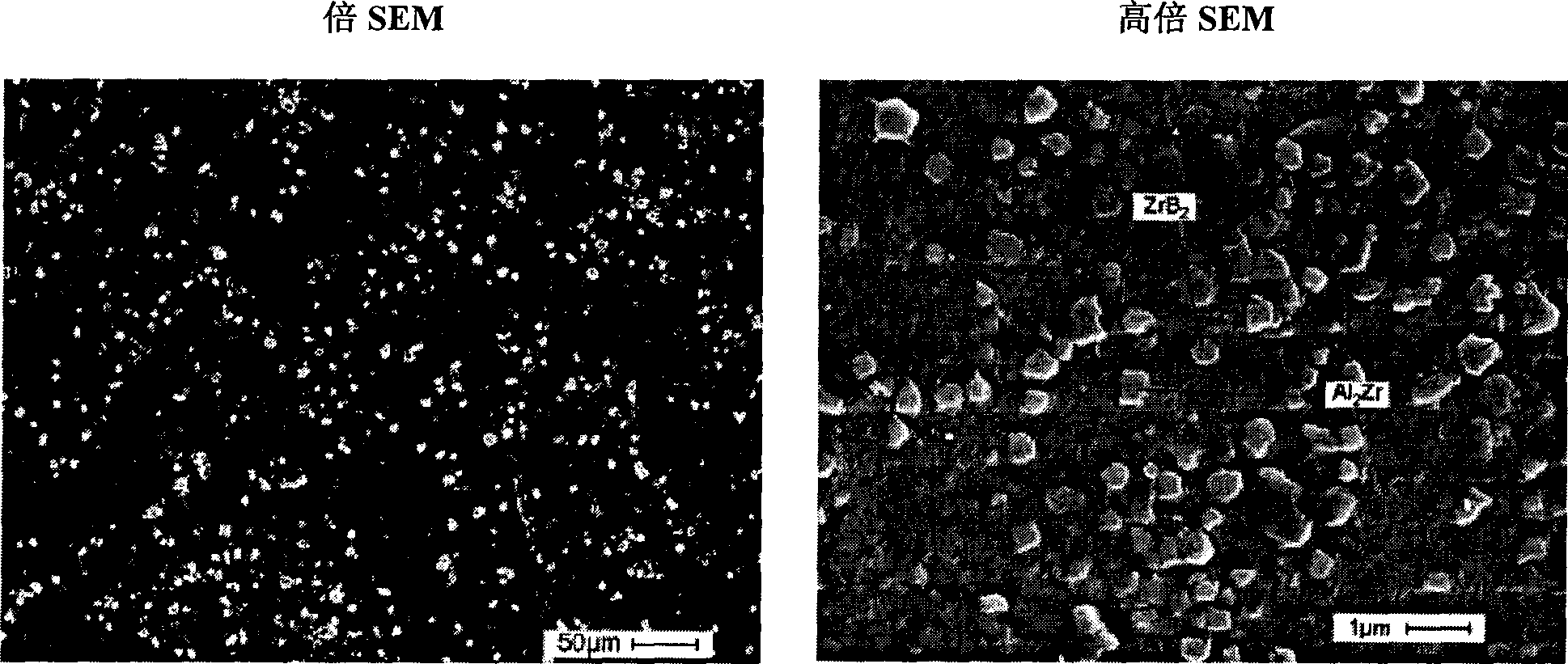

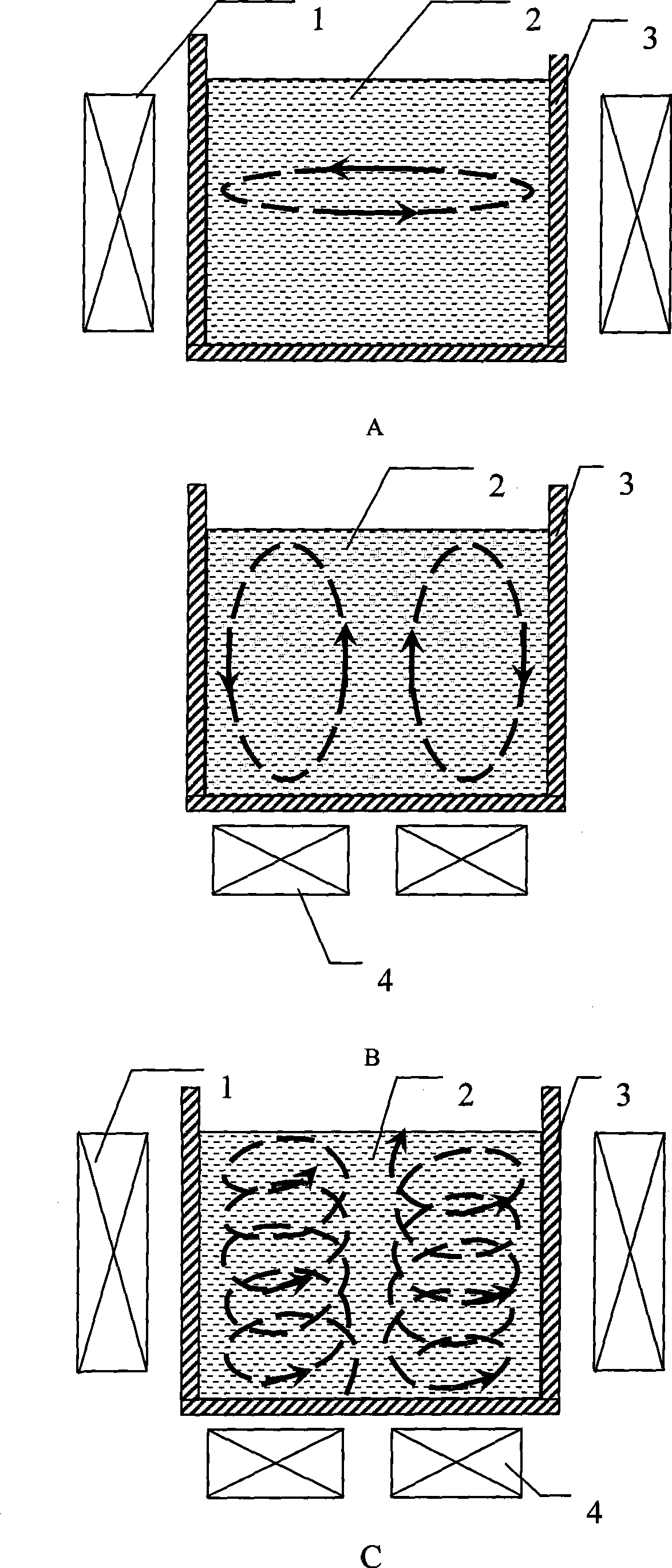

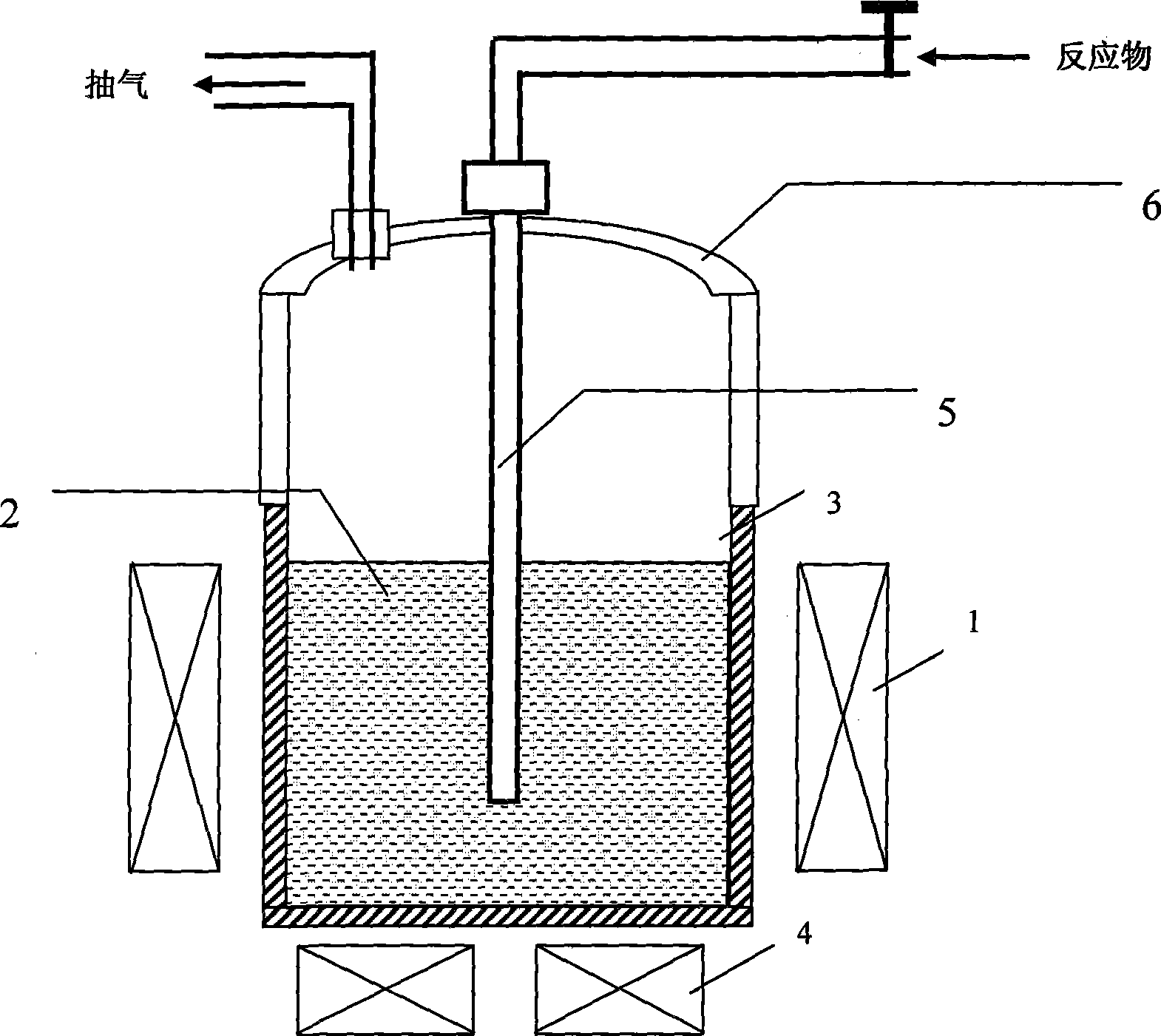

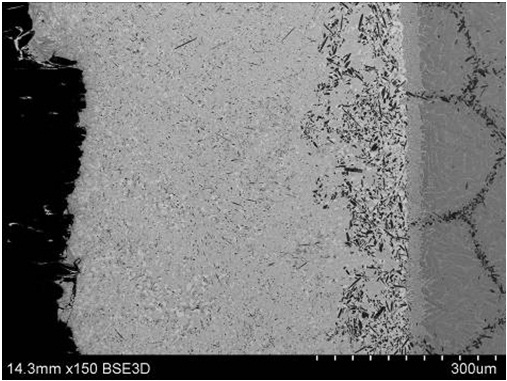

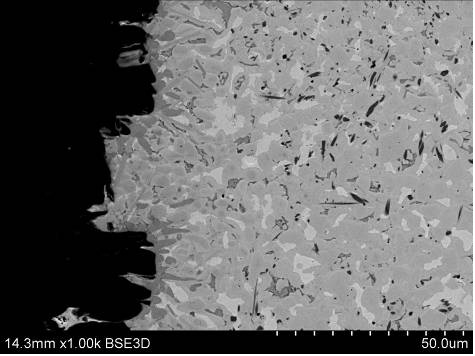

Method for synthesizing metal matrix composition using metal reaction under the coupling action of magnetic field and ultrasonic field

The invention relates to a method for preparing endogenetic particle reinforced metal matrix composites under the coupling effect of a magnetic field and supersonic waves. The method comprises: adjusting the temperature of a metal matrix fused mass to the reaction initial temperature after refining, adding a reactant which can generate a particle phase with the fused mass through the reaction in situ for implementing the synthesis reaction, standing the mixture after the reaction is over, and cooling the mixture to the pouring temperature for pouring; and the method is characterized in that: the magnetic field and the high-intensity ultrasonic field are simultaneously exerted in the reaction synthesis process to realize the synthesis of endogenetic particle reinforced metal matrix composites under the coupling effect of the magnetic field and the high-intensity ultrasonic field. The magnetic field can be an intense pulse magnetic field, a high frequency oscillation magnetic field or a low frequency alternating magnetic field. In the method, the coupling effect of the magnetic field and the ultrasonic field makes the particle sizes be thinned and dispersed evenly; the ultrasonic vibration agitation and electromagnetic stirring functions improve the composite dynamic condition, and the compounding of the particle phase and a base metal interface is better; and the co-action of magnetochemistry and sonochemistry improves the thermodynamic condition of the reaction in situ, as well as speeding up the reaction in situ and controlling the growth of the particle phase.

Owner:JIANGSU UNIV

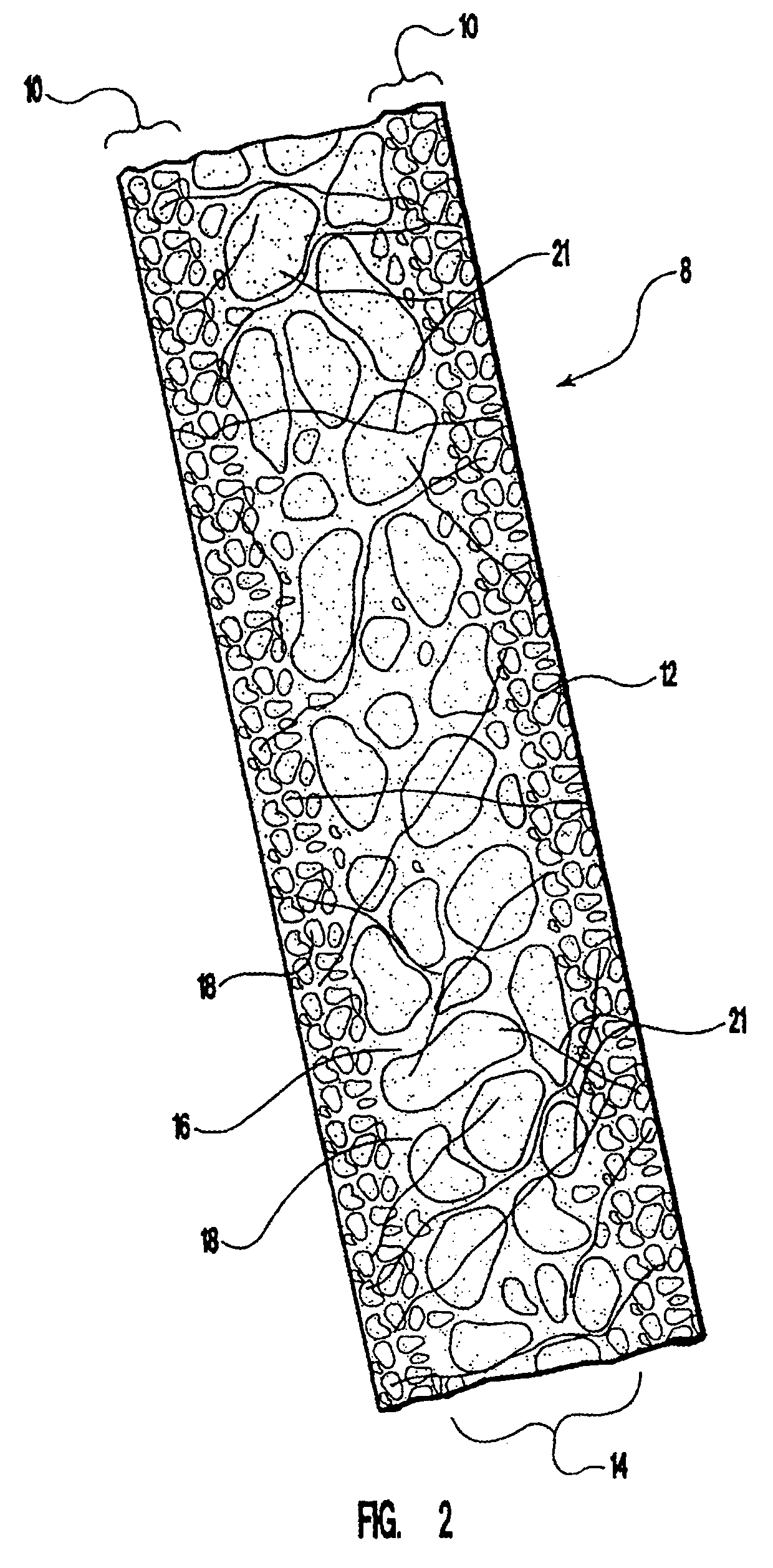

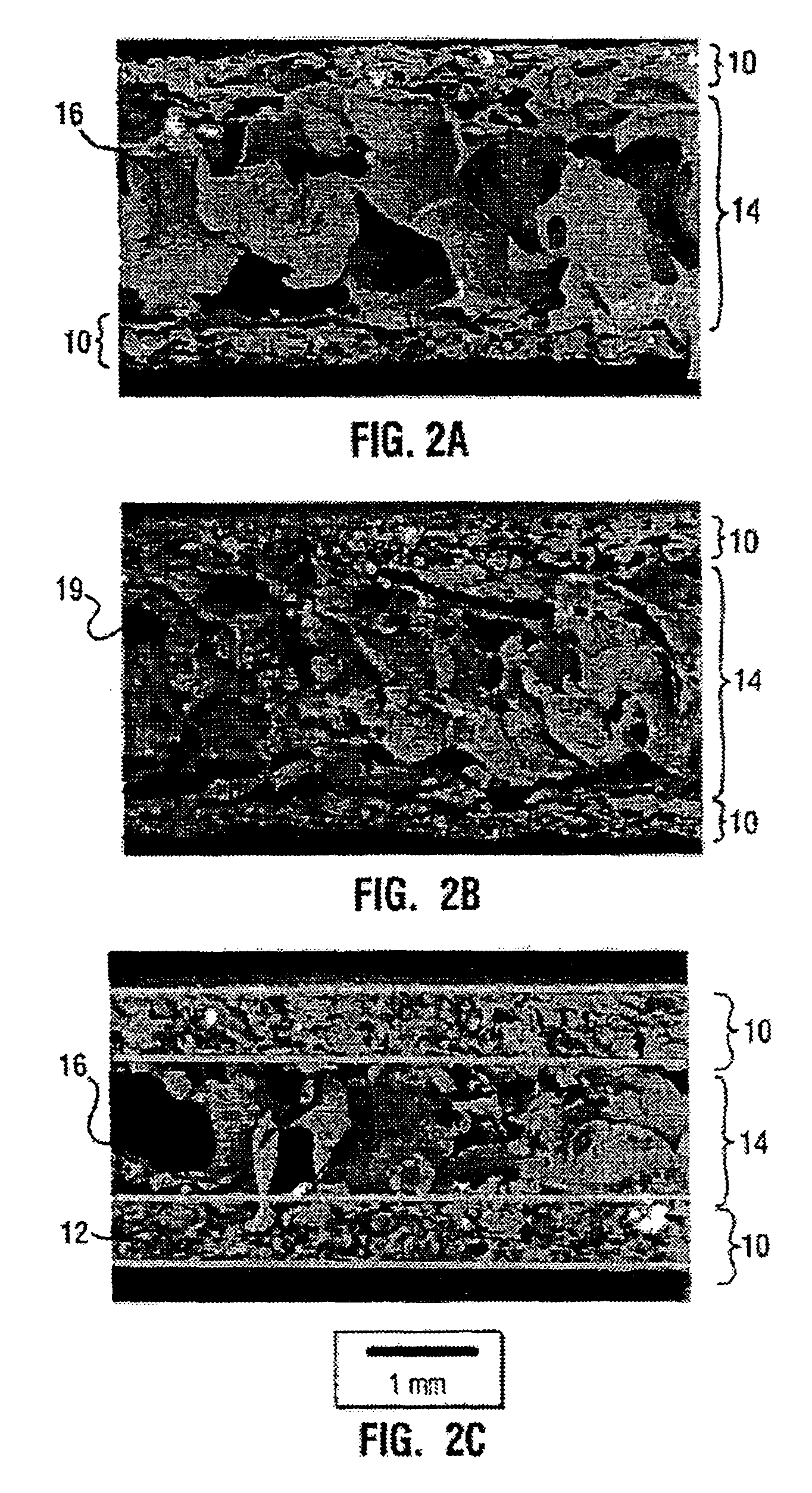

Compositions for manufacturing fiber-reinforced, starch-bound articles having a foamed cellular matrix

InactiveUSRE39339E1Avoid lack of toughnessHigh strengthClosure lidsSolid waste managementPolymer sciencePaperboard

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a fiber-reinforced, starch-bound cellular matrix. Suitable mixtures used to form the articles are prepared by first preparing a viscous preblended mixture comprising water, a gelatinized starch-based binder, and fibers having an average length greater than about 2 mm. The highly viscous preblended mixture effectively transfers the shearing forces of the mixer to the fibers. The final moldable mixture is then prepared by mixing into the preblended mixture the remaining starch-based binder, water, and other desired admixtures, e.g., mold-releasing agents, inorganic filler rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The moldable mixtures are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled foamed structural matrix. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic-based materials and have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

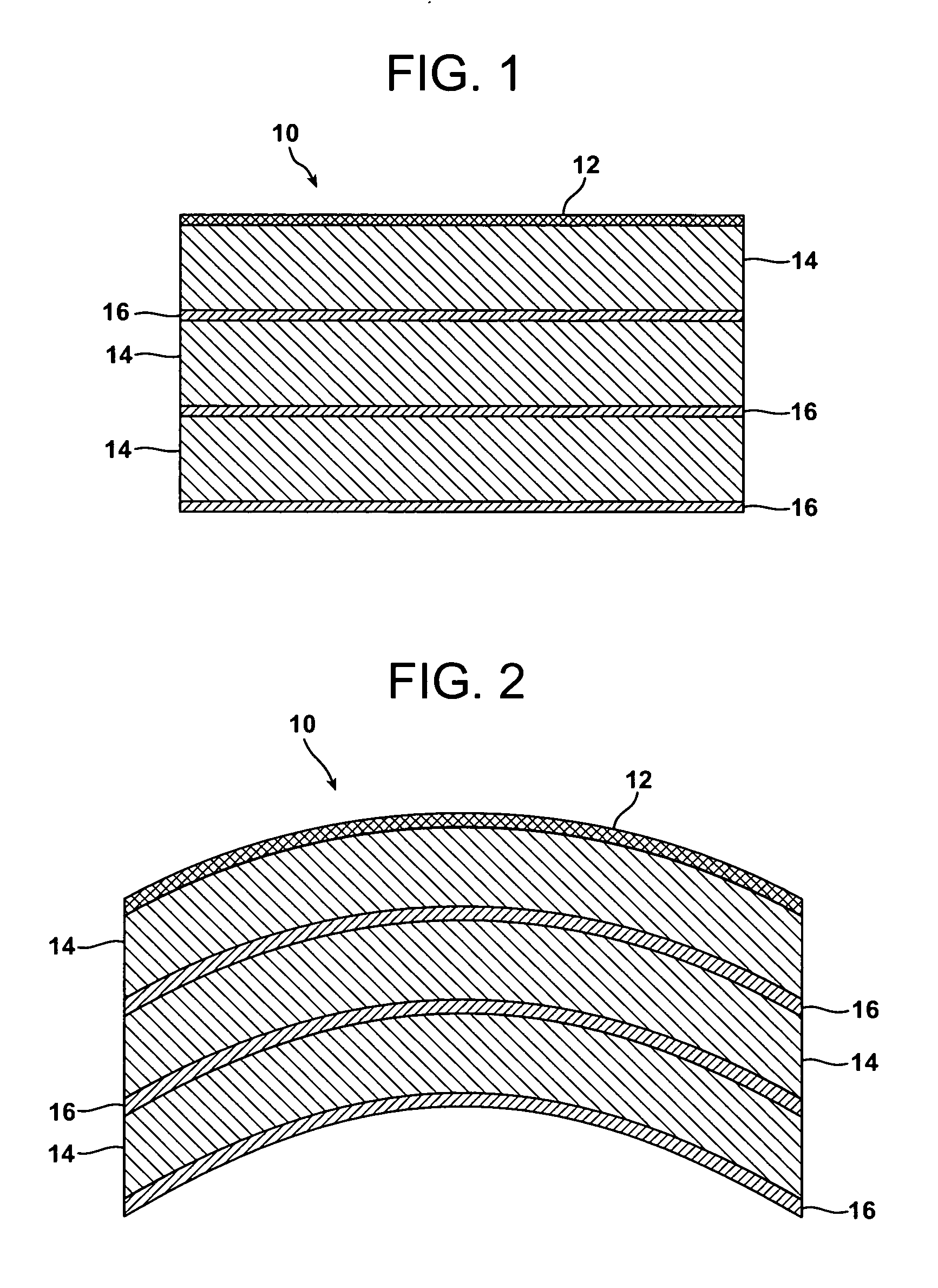

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

Inorganic matrix compositions and composites incorporating the matrix composition

InactiveUS20050022698A1Maintain good propertiesExcellent thermalAlkali metal silicate coatingsCement productionCompression moldingInorganic composition

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

Low density drywall

InactiveUS20080057318A1Good physical propertiesImprove impact resistanceLiquid surface applicatorsBuilding componentsFiberWater dispersible

A thin drywall board that includes a gel coat, at least one polymer / gypsum layer, and a wet glass fiber layer is provided. The gel coat is formed of a gel coat composition that includes a water dispersible polymer, gypsum, and optionally a crosslinking agent and / or a coupling agent. The polymer / gypsum layer is formed of a matrix composition that includes a water dispersible polymeric resin and gypsum. Components including melamine formaldehyde, a filler material, coupling agents, acetic acid, an accelerator, and / or a hardener may also be added to the matrix composition. The wet glass fiber layer is preferably a glass fiber mat. The combination of the water dispersible polymeric resin and the gypsum in the matrix composition have a synergistic effect that creates a thin drywall board that is water resistant, fire resistant, and has improved mechanical properties. A method of forming the inventive thin drywall boards is also provided.

Owner:OCV INTELLECTUAL CAPITAL LLC

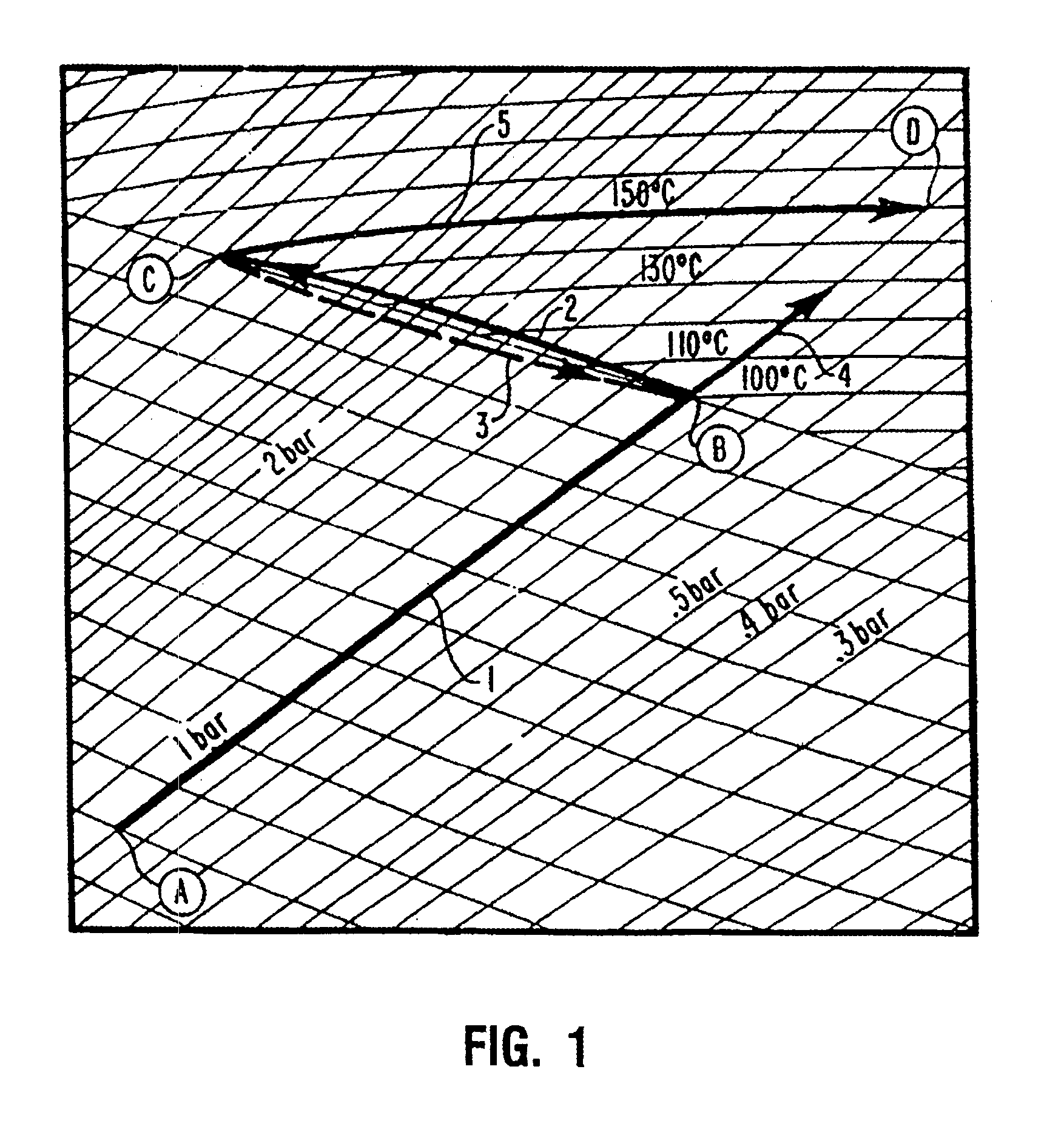

Thermally conductive adhesive composition and process for device attachment

InactiveUS20080207814A1Non-macromolecular adhesive additivesConductive materialPolymer sciencePolymer resin

A thermally conductive adhesive composition includes a powder of a high melting point metal or metal alloy, a powder of a low melting point metal or metal alloy, and a polymerizable fluxing polymer matrix composition having a polyepoxide polymer resin and a low-melting solid or liquid acid-anhydride and a polymer diluent or diluents with carbon carbon double bonds and / or functional hydroxyl groups. The ratio by weight of the low melting point powder to high melting point powder ranges from about 0.50 to about 0.80, and may range from about 0.64 to about 0.75, and may be 0.665. Heretofore unpredicted substantially higher thermal conductivity improvements in performance have been found using these ratios of low melting point powder to high melting point powder.

Owner:CREATIVE ELECTRON

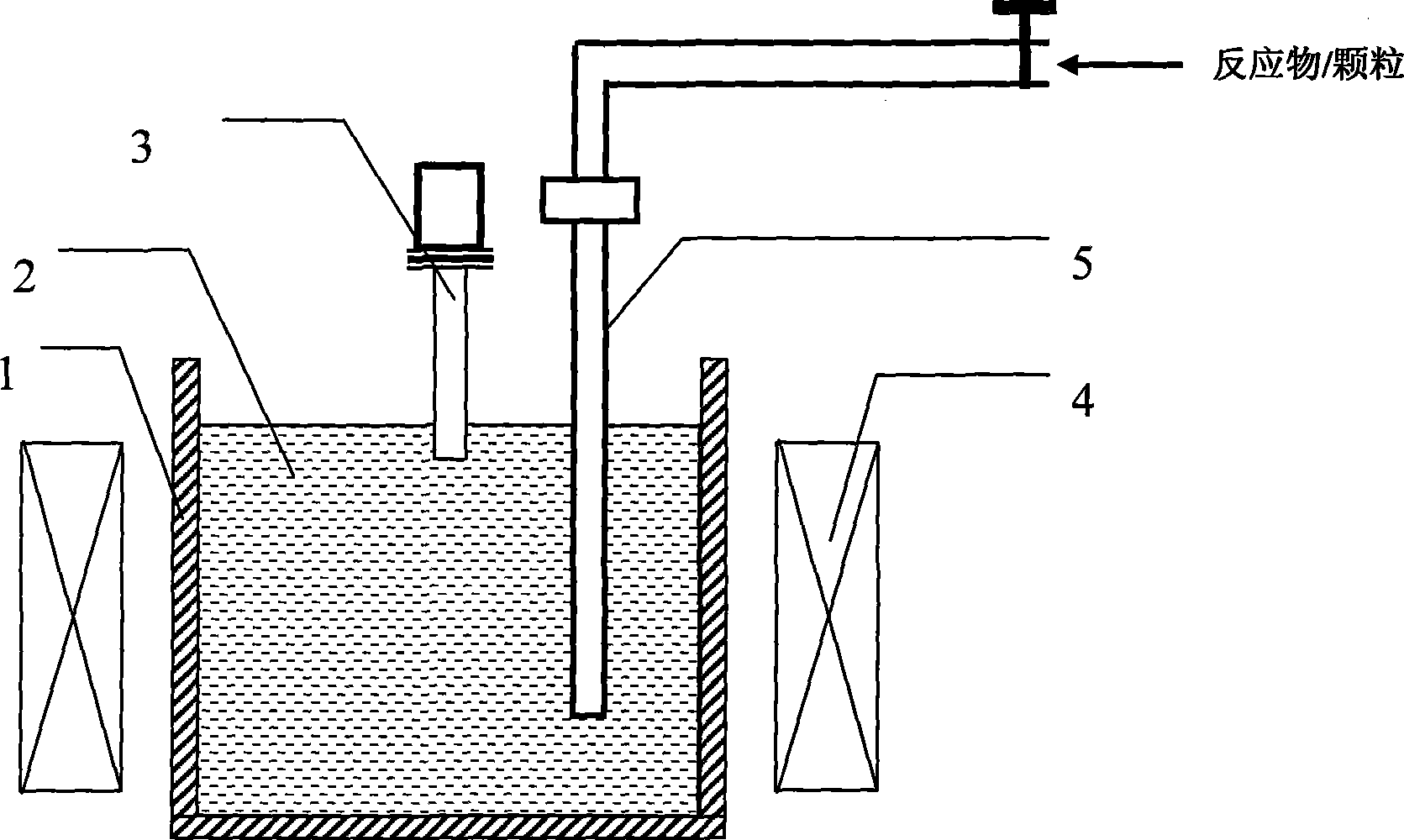

Metal matrix composition home-position synthesizing method in combined electric magnetic field

The invention provides a method for continuously producing particle reinforced metal matrix composites in an industrial scale, which adopts the synthesis of metal matrix composites in a combination magnetic field. The method is characterized in that: the combination of a rotating magnetic field and a travelling wave magnetic field is adopted to synthesize a preparation particle reinforced metal matrix composite fused mass in the in-situ synthesis process of composites. The low frequency rotating magnetic field is placed at the outer side of a composite material molten pool, and the center of a coil of the magnetic field and the center of the fused mass are at the same height; and the travelling wave magnetic field is exerted at the bottom part of the composite material molten pool, and the coil center of the travelling wave magnetic field and the center of the composite material molten pool are at the same position. The composite material particle reinforced phases prepared by the method are distributed evenly and thinned, interior tissues are compact and have no structural defects such as loosening and hole shrinkage, the degree of finish of external surfaces of casting blanks is high, defects are eliminated, and the friction resistance and the abrasion resistance of the composites are obviously improved.

Owner:JIANGSU UNIV

Secured documents indentified with anti-stokes fluorescent compositions

The present invention provides a secured document including a composition capable of anti-Stokes fluorescence containing an ion capable of absorption of electromagnetic radiation, an ion capable of emitting electromagnetic radiation, and a matrix composition comprising gadolinium, yttrium, lanthanum, and luetium, wherein the wavelength of the emitted electromagnetic radiation is shorter than the wavelength of the absorbed electromagnetic radiation, and wherein the concentrations of the absorbing and emitting ions are adjusted to achieve concentration quenching of anti-Stokes luminescence.

Owner:BUNDESDRUCKEREI GMBH

A kind of seedling raising substrate using cassava residue as raw material and preparation method thereof

InactiveCN102276332AFermentation heats up fastDeodorize quicklyBio-organic fraction processingOrganic fertiliser preparationSlagMicrobial agent

The invention relates to a seedling raising substrate using cassava residue as a raw material and a preparation method thereof. The composition and weight percentage of the substrate are: cassava bagasse 40-70%, bagasse 10-30%, peat soil 10-20%, perlite 3-5%, superphosphate 1-2%, potassium chloride 0.2- 0.5%, 0.2-0.5% urea, pH 6-7, 5-10% starter; the starter is the pre-fermented product of cassava bagasse, bagasse, bran and microbial compound bacteria. This substrate is suitable for raising seedlings in nutritional cups and plug trays for vegetables, flowers, etc. It has excellent physical properties, excellent porosity, early, uniform and strong seedlings, suitable particle size composition, and good agglomeration performance. Cassava residue does not need to be crushed and processed, the preparation process is simple, and the cost is low; it can provide a new way for the harmless treatment and resource utilization of cassava residue, and at the same time alleviate the excessive exploitation of non-renewable natural resources such as peat, which is conducive to protecting the ecological environment.

Owner:MICROBIOLOGY RES INST GUANGXI ZHUANG AUTONOMOUS REGION ACADEMY OF AGRI SCI

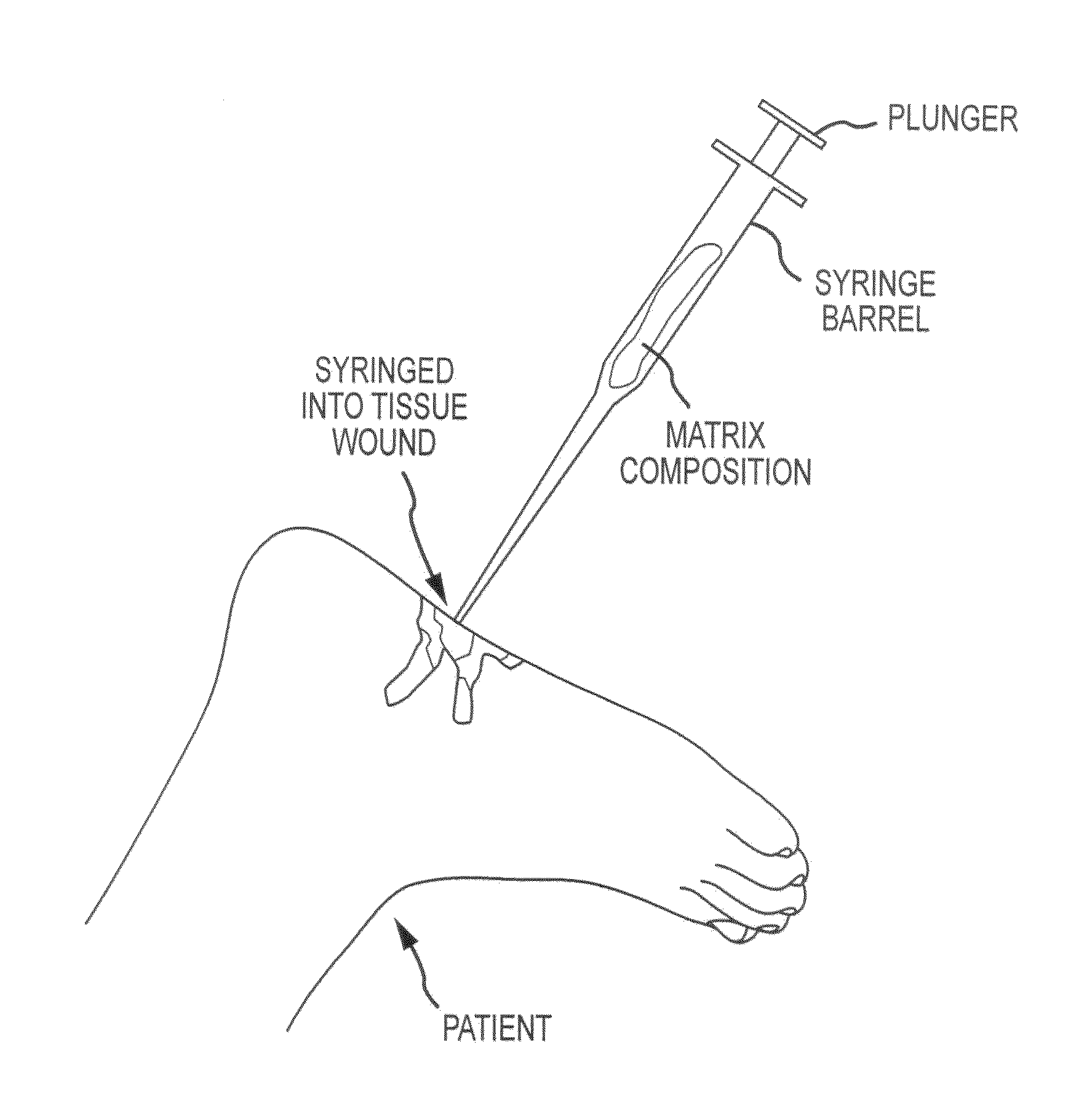

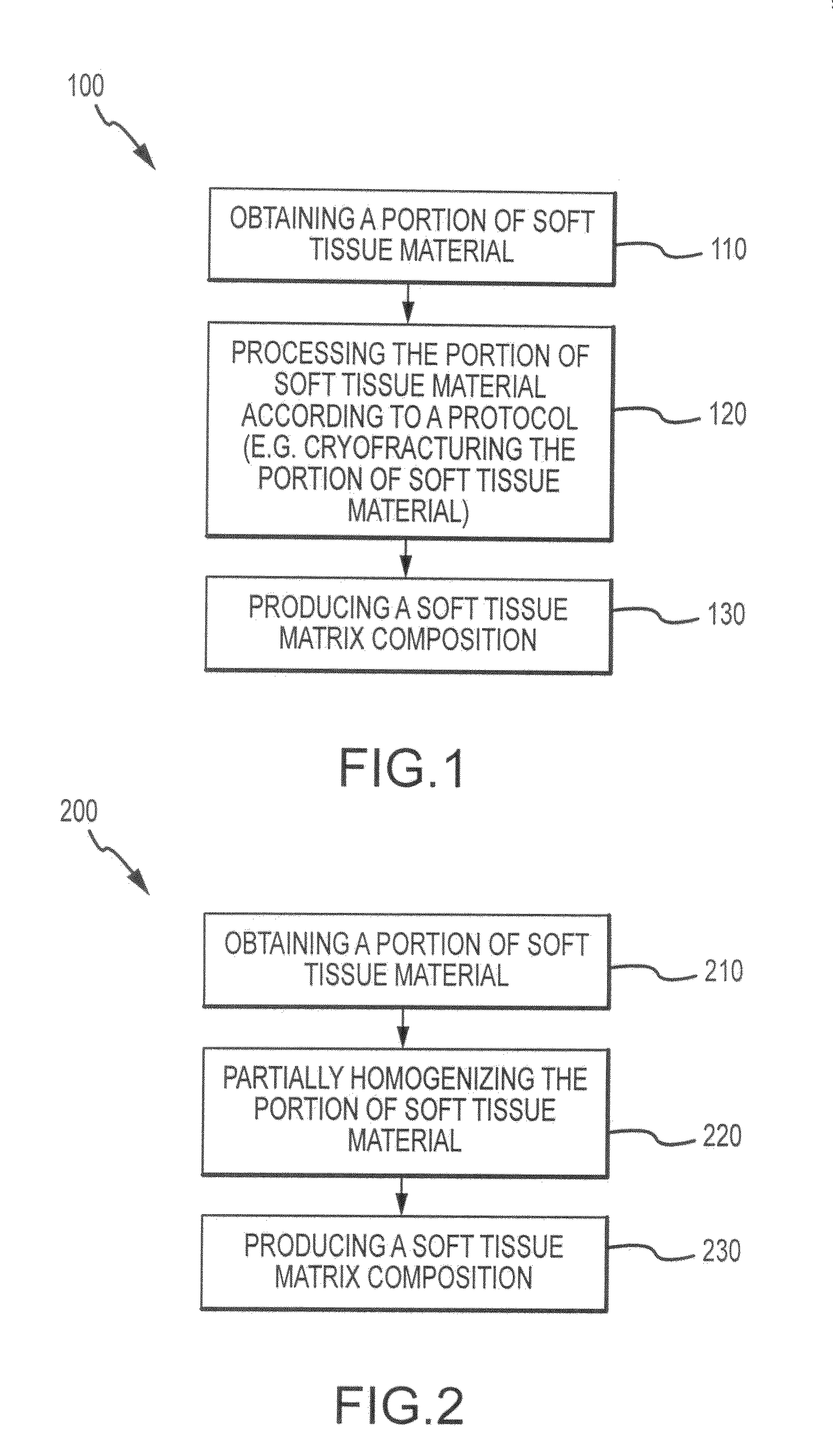

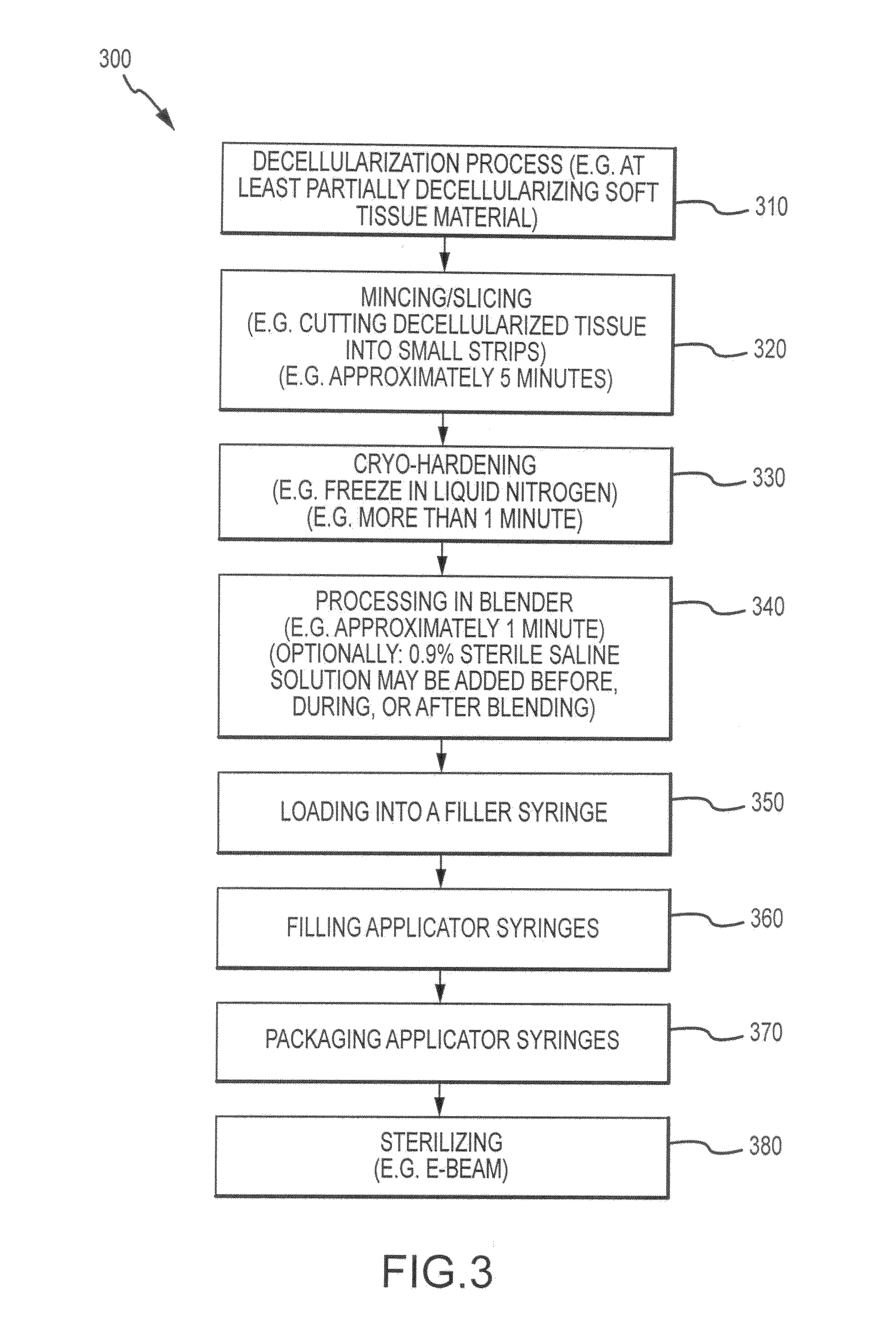

Flowable matrix compositions and methods

Flowable matrix compositions and methods of their use and manufacture are provided. Exemplary compositions may include a flowable, syringeable, putty-like form of acellular human dermal matrix. In some cases, compositions may include a moldable acellular collagen extracellular matrix. In use, the matrix compositions can be used to fill or treat skin voids, channel wounds, and other soft tissue deficiencies.

Owner:ALLOSOURCE

Polymer nano-particle with polar core and method for manufacturing same

The present invention provides a nano-particle comprising a shell and a polar core, their preparation, and their applications in ER fluids, polymeric product, rubber composition, tire product, hard disk drive gasket, matrix composition, and engine mount etc. The shell comprises a polymer formed from formula (I) monomers and the core comprises a polymer formed from formula (II) monomers, in which R1 and R2 are hydrogen; R3, R4, R5, R6, and up to three of R7, R8, R9, and R10 are each independently selected from the group consisting of hydrogen, methyl, ethyl, propyl, and isopropyl; and at least one of R7, R8, R9, and R10 is a polar group that is more polar than any one of R1, R2, R3, R4, R5, and R6 groups.

Owner:BRIDGESTONE CORP

Matrix compositions for controlled delivery of drug substances

InactiveUS20100166866A1Improve solubilityImprove oral bioavailabilityPowder deliveryBiocidePolyethylene oxidePEG-PLGA-PEG

Owner:EGALET LTD

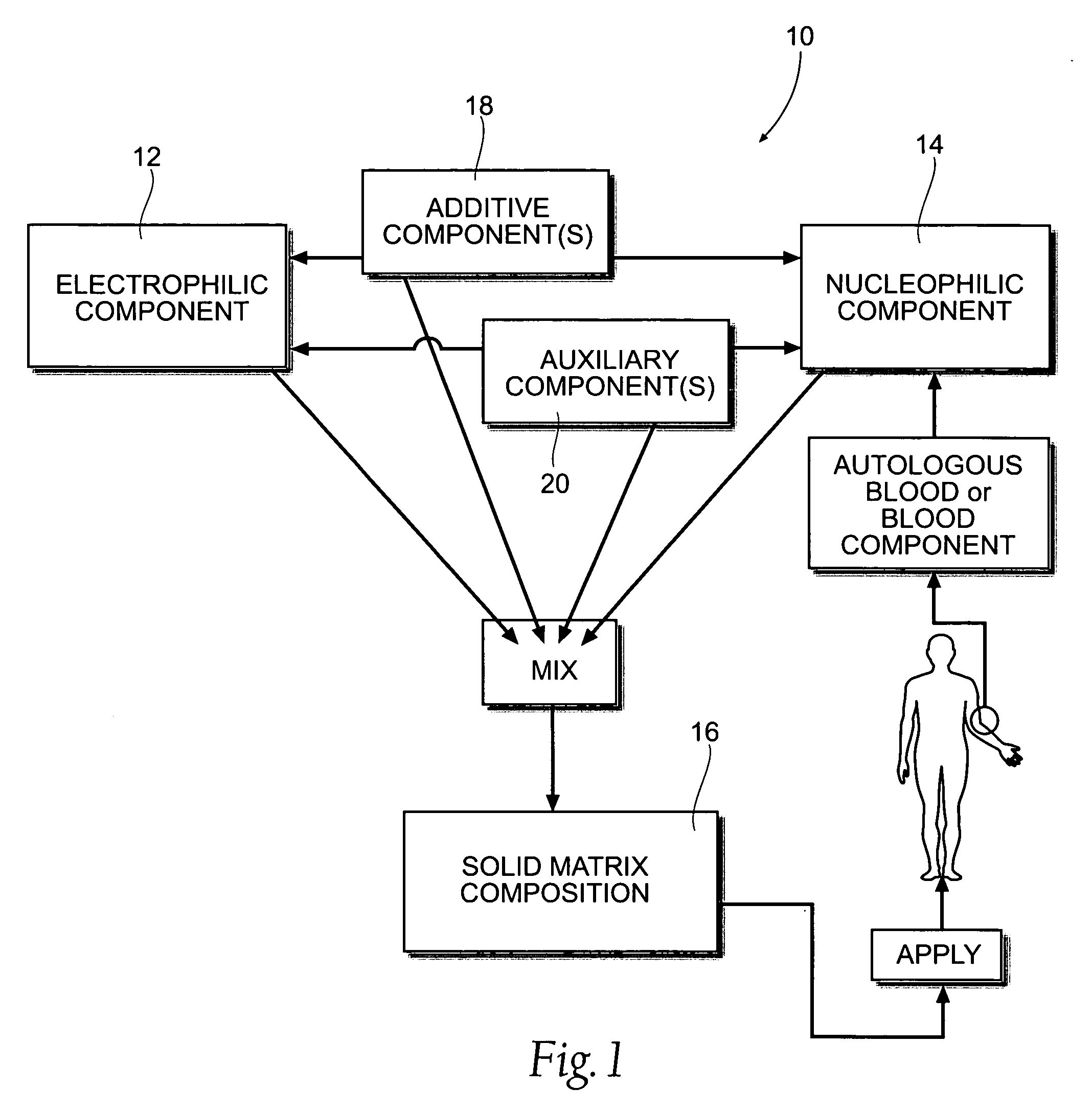

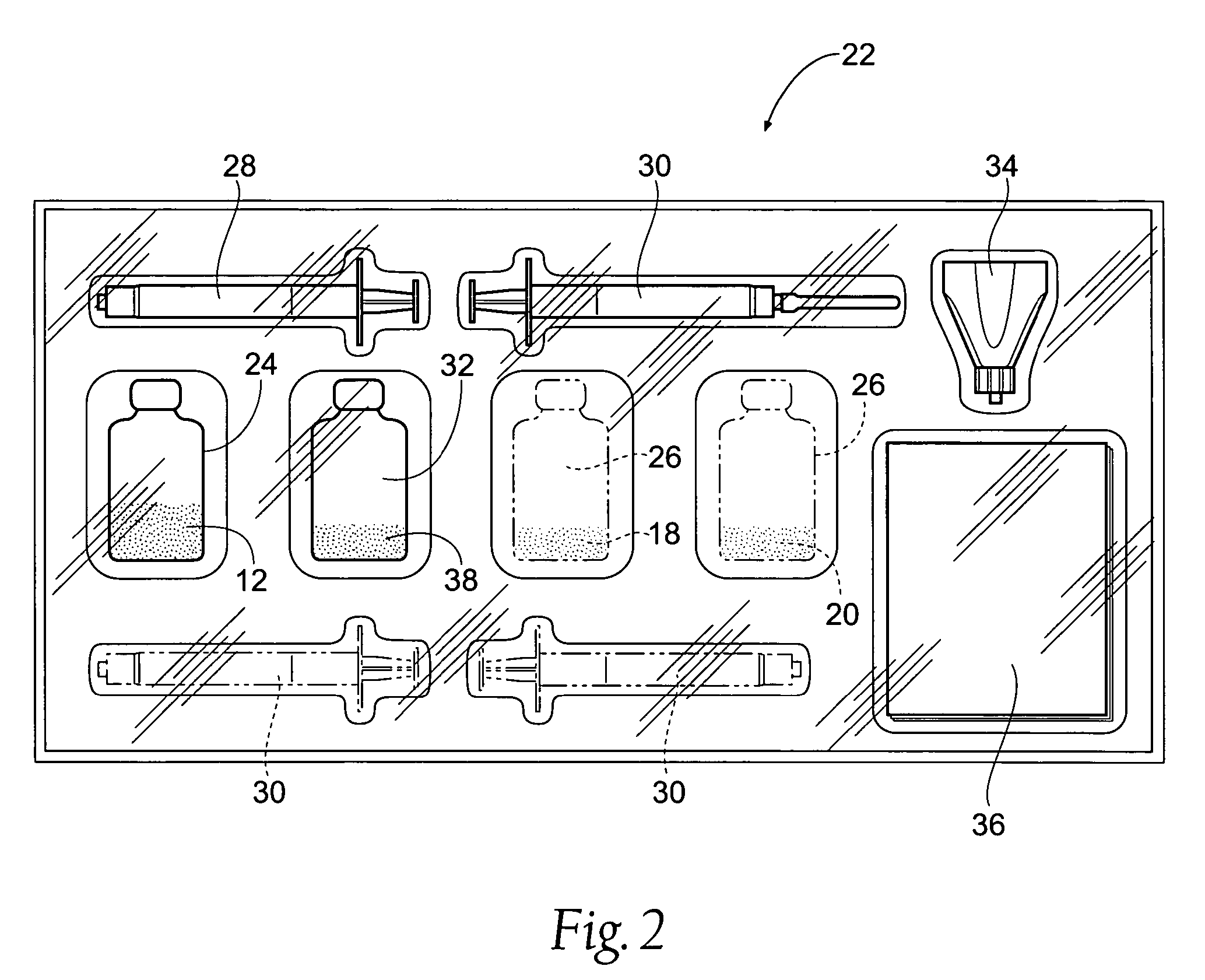

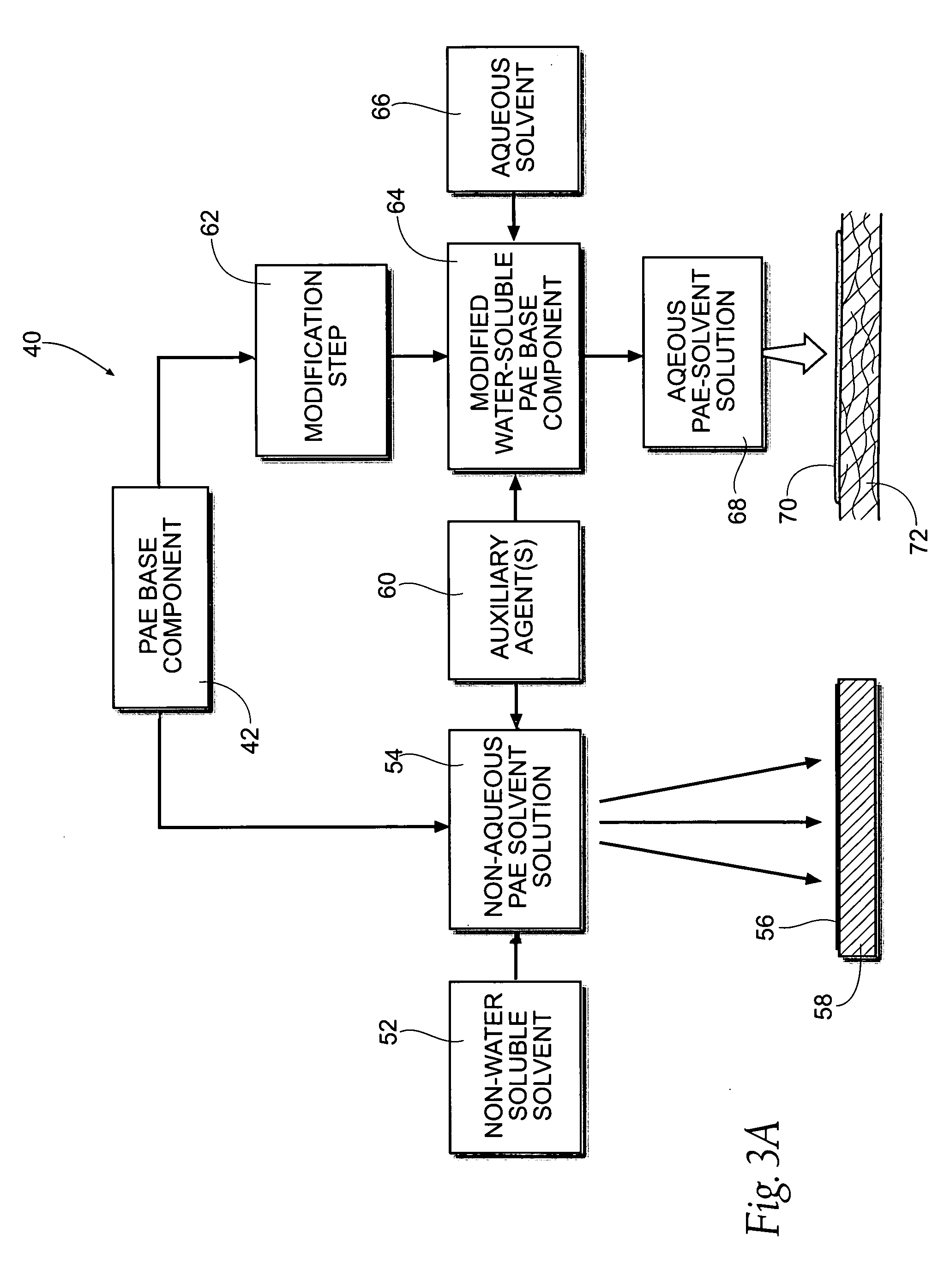

Biocompatible hydrogel compositions

Compositions, instruments, systems, and methods are providing for creating families of materials having diverse therapeutic indications and possessing enhanced biocompatibility. One genus platform for the families includes a biocompatible synthetic electrophilic component mixed with a nucleophilic component. The electrophilic component can include a functionalized electrophilic poly (anhydride ester) material. The nucleophilic material can include a natural, autologous protein. The components, when mixed in a liquid state, react by cross-linking, forming a solid matrix composition, or hydrogel.

Owner:HNOJEWYJ OLEXANDER

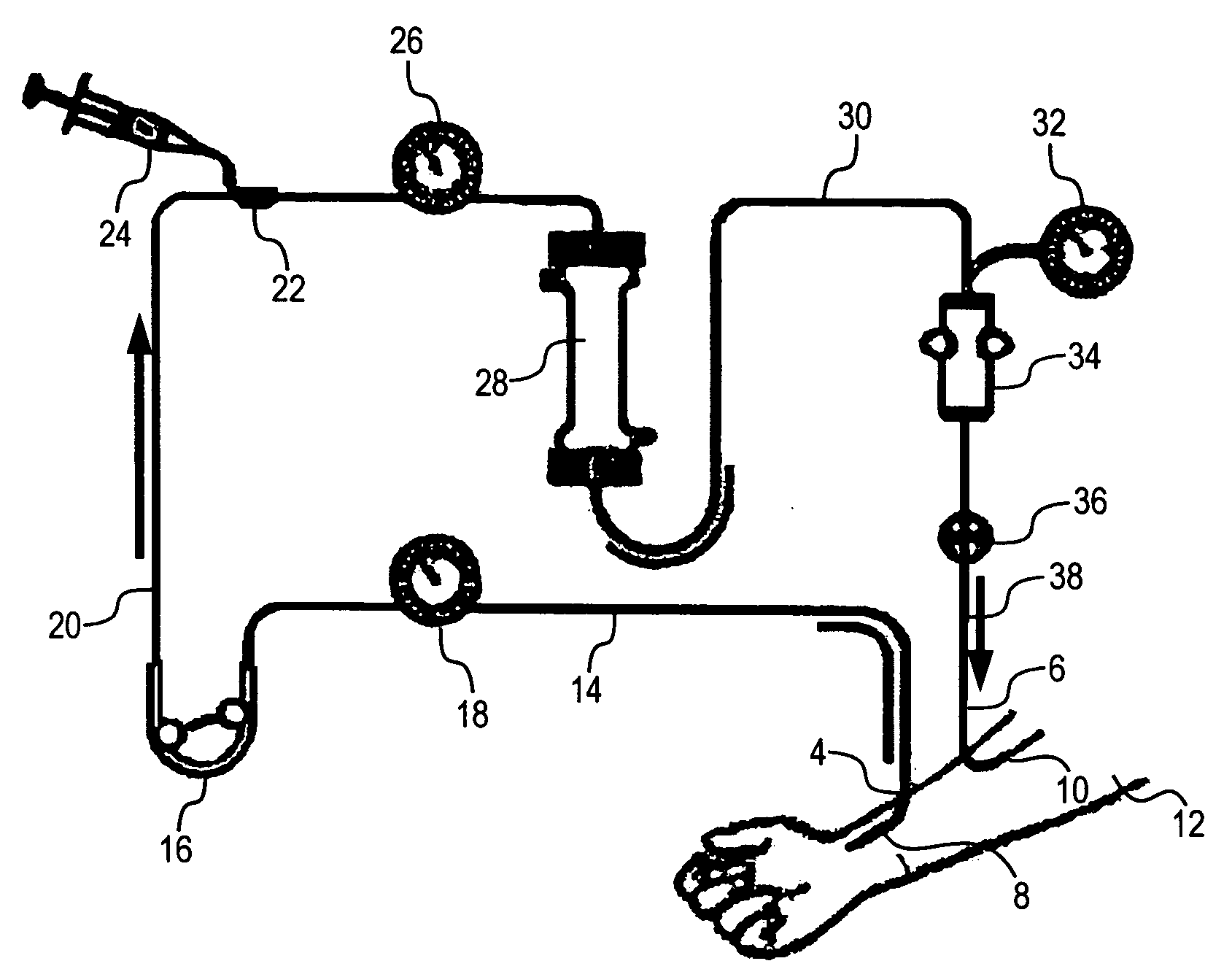

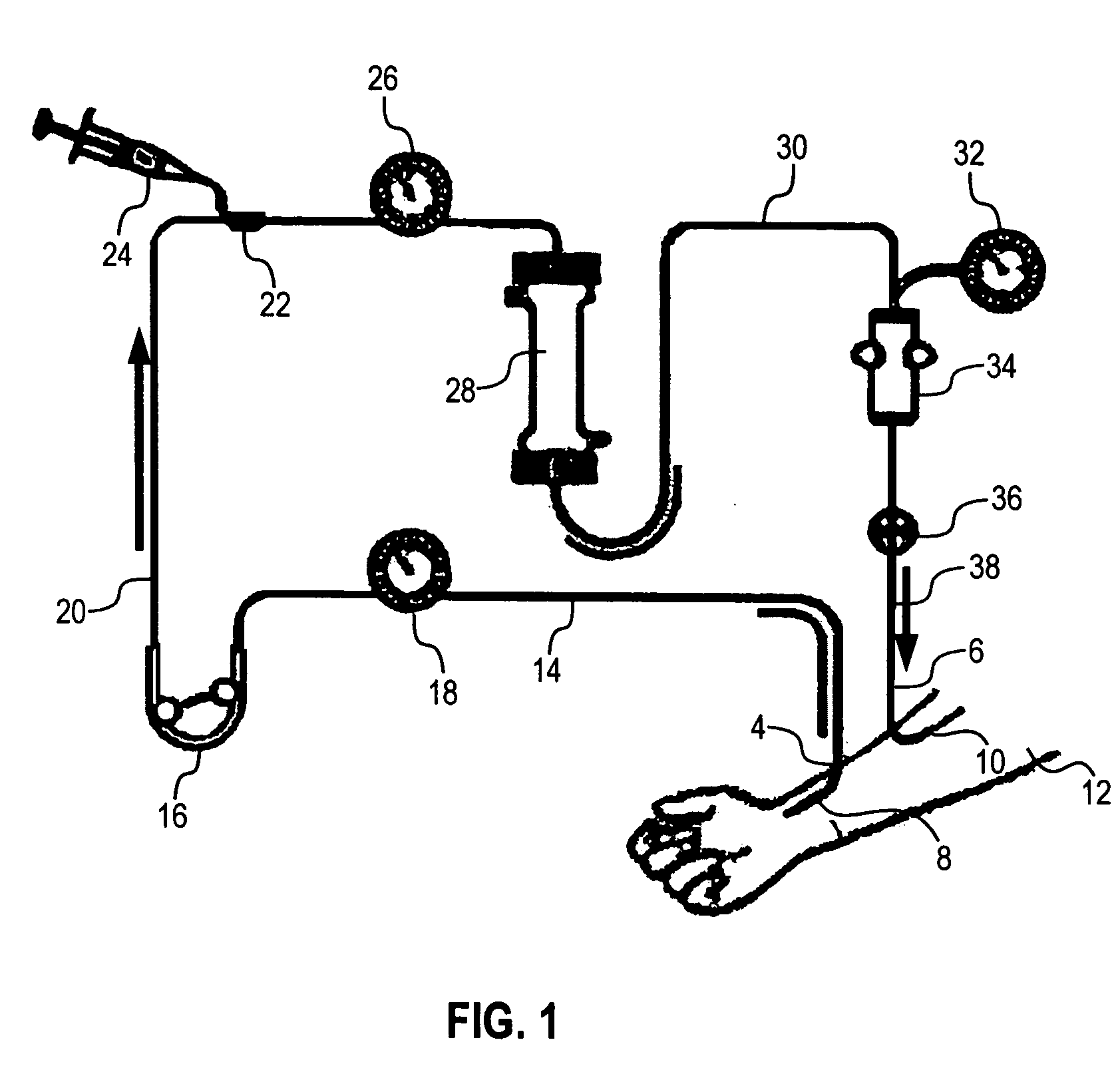

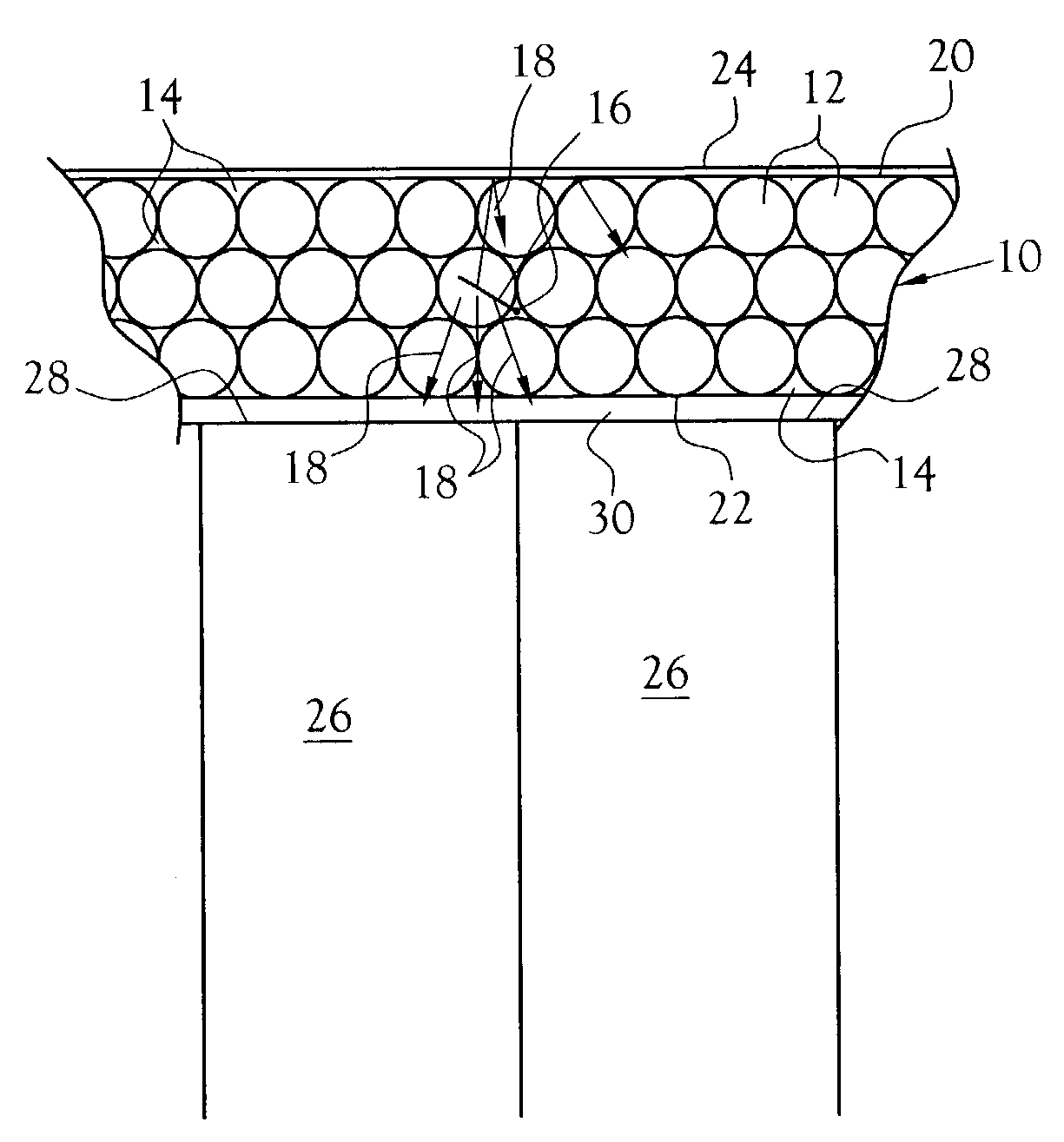

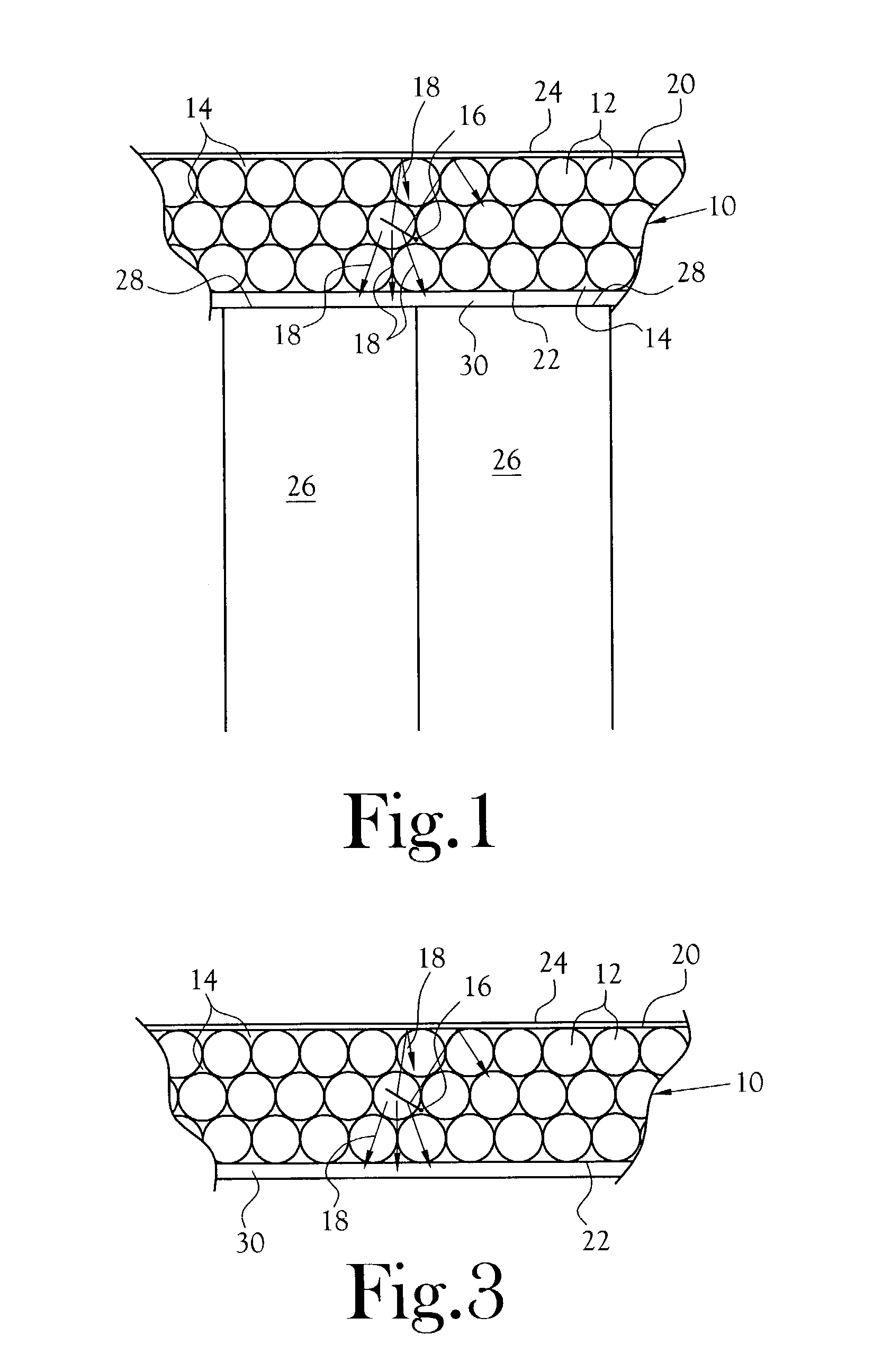

Capture and removal of biomolecules from body fluids using partial molecular imprints

InactiveUS20060030027A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBlood componentBlood plasma

The invention provides methods and devices for the capture and removal of target biomolecules from a patient's body fluid, particularly blood or a blood component, using a partial imprint material. The partial imprint material is composed of a matrix composition having partial imprint cavities that correspond to a segment of a target biomolecule but which are capable of removing the entire target biomolecule from the body fluid. The method can be implemented by removing a volume of a patient's body fluid, e.g., blood, bringing the body fluid or a component thereof into contact with the partial imprint material under conditions effective to capture the target biomolecule, and returning the body fluid to the patient. A modified dialysis or apheresis device can be used in which the body fluid is removed, continuously passed through a circuit containing the partial imprint material, and re-introduced into the patient's body following treatment.

Owner:ASPIRA BIOSYST

Alkali free glass and process for its production

InactiveUS20080076656A1Deterioration of of resistanceDeterioration of strainGlass furnace apparatusAlkali freeSulfur

To provide an alkali free glass which is suitable as a glass substrate for LCD and has few defects of bubbles and an undissolved starting material, and a process for producing an alkali free glass which can readily lower the defects in bubbles and an undissolved starting material. An alkali free glass with a matrix composition comprising SiO2, Al2O3, B2O3, MgO, CaO, SrO and BaO and containing substantially no alkali metal oxide, of which the temperature at which the viscosity becomes 102 dPa·s, is at most 1,600° C. and which contains sulfur in an amount of from 0.001 to 0.1% as calculated as SO3, as represented by the mass percentage, per 100% of the total amount of the above matrix composition, and a process for producing a glass which comprises preparing a starting material and melting it so that a sulfate be incorporated to the starting material in an amount of from 0.01 to 5% as calculated as SO3, as represented by the mass percentage, per 100% of the total amount of the above matrix composition.

Owner:ASAHI GLASS CO LTD

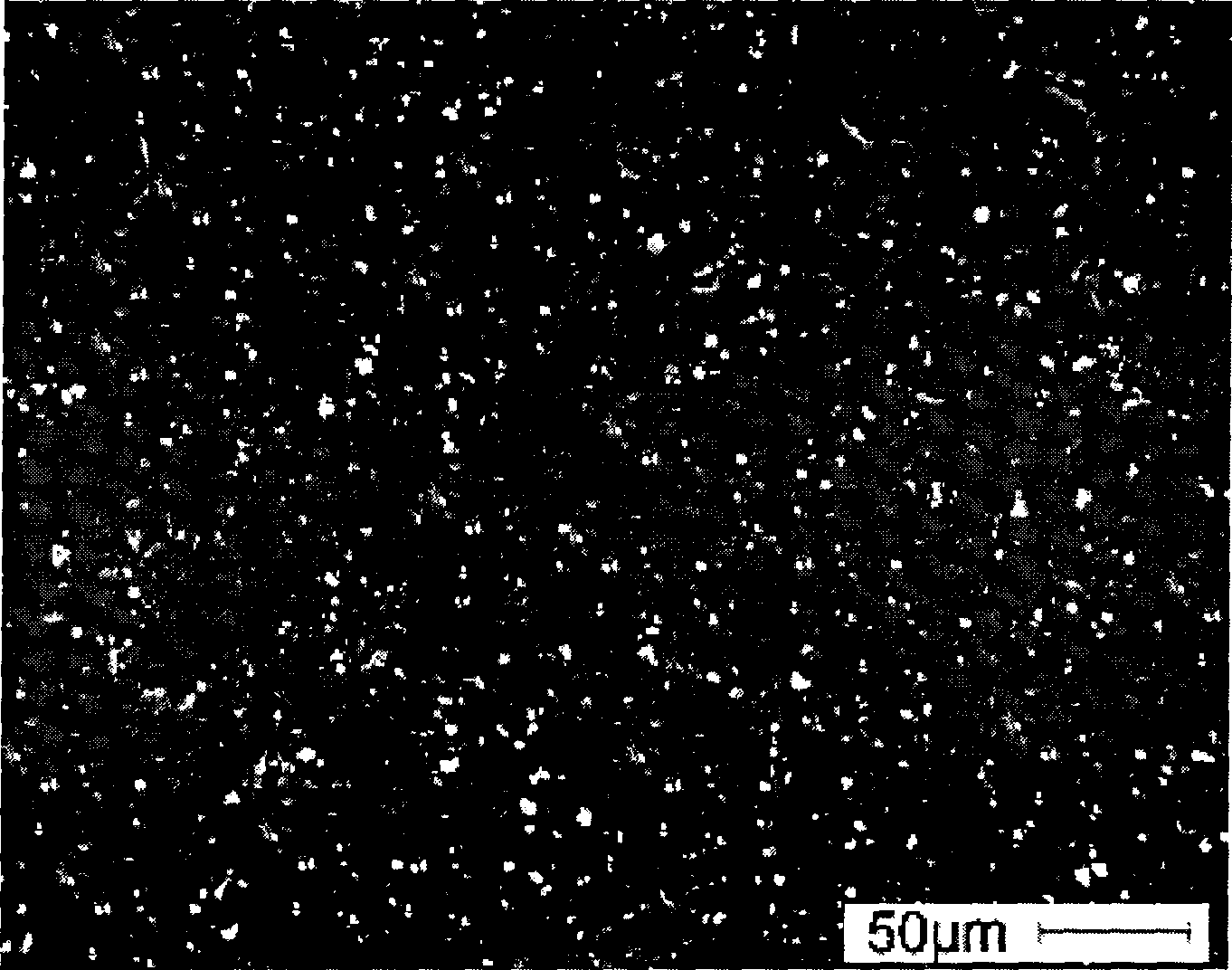

Neutron detector using lithiated glass-scintillating particle composite

InactiveUS7582880B2Improve overall utilizationPhotosensitive materialsMeasurement with scintillation detectorsLithiumNinetieth percentile

A neutron detector composed of a matrix of scintillating particles imbedded in a lithiated glass is disclosed. The neutron detector detects the neutrons by absorbing the neutron in the lithium-6 isotope which has been enriched from the natural isotopic ratio to a commercial ninety five percent. The utility of the detector is optimized by suitably selecting scintillating particle sizes in the range of the alpha and the triton. Nominal particle sizes are in the range of five to twenty five microns depending upon the specific scintillating particle selected.

Owner:NEUTRON SCI +2

Bone Graft

ActiveUS20080145392A1Good curative effectSimple compositionAdditive manufacturing apparatusBone implantOSTEOINDUCTIVE FACTORIn vivo

An improved demineralized bone matrix (DBM) or other matrix composition is provided that has been mixed with a stabilizing agent that acts as (1) a diffusion barrier, (2) a enzyme inhibitor, (3) a competitive substrate, or (4) a masking moiety. A diffusion barrier acts as a barrier so as to protect the osteoinductive factors found in DBM from being degraded by proteolytic and glycolytic enzymes at the implantation site. Stabilizing agents may be any biodegradable material such as starches, modified starches, cellulose, dextran, polymers, proteins, and collagen. As the stabilizing agents degrades or dissolves in vivo, the osteoinductive factors such as TGF-.beta., BMP, and IGF are activated or exposed, and the activated factors work to recruit cells from the preivascular space to the site of injury and to cause differentiation into bone-forming cells. The invention also provides methods of preparing, testing, and using the inventive improved osteodinductive matrix compositions

Owner:WARSAW ORTHOPEDIC INC

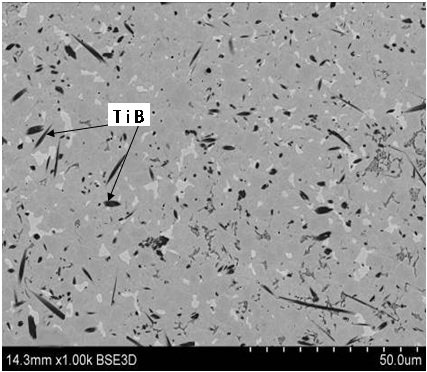

Composite soldering material for soldering titanium alloy and ceramic or ceramic matrix composition material and method for soldering by using same

ActiveCN101890590AGuaranteed wettabilityEasy to manufactureWelding/cutting media/materialsWelding/soldering/cutting articlesCrazingTitanium alloy

The invention discloses a composite soldering material for soldering a titanium alloy and a ceramic or a ceramic matrix composition material and a method for soldering by using the same, and solves the problems that a welding joint obtained by soldering the titanium alloy and the ceramic or the ceramic matrix composition material through the conventional soldering material is easy to crack and has low strength, and the introduction of a ceramic phase in a method of introducing the ceramic phase into the soldering material causes reduction of wettability of a connecting layer for a base metal. The composite soldering material consists of Cu, Ni and a reinforced phase, wherein the reinforced phase is TiB2 powder or SiC powder. The method comprises the following steps of: performing ball milling on the Cu, Ni and TiB2 or SiC powder, uniformly mixing, and coating to-be-welded surfaces of the titanium alloy and the ceramic to obtain to-be-welded parts; and putting the to-be-welded parts into a vacuum brazing furnace for vacuum brazing treatment. In the soldering process, the composite soldering material has good wettability for the ceramic and ceramic materials, and the obtained welding joint has no crack, the shear strength between 16 and 45MPa, and good mechanical properties.

Owner:HARBIN INST OF TECH

Compositions and methods for the preparation of composite photochromic polycarbonate lenses

InactiveUS20050089630A1Attractive photochromic performanceDiffusing elementsPretreated surfacesMethacrylateMeth-

Photochromic matrix compositions and tie layer compositions useful for the preparation of photochromic polycarbonate lenses are disclosed. The tie layer compositions facilitate adhesion of the photochromic matrix composition to the polycarbonate lens. The photochromic matrix compositions can contain a flexible hydrophilic dimethacrylate monomer, one or more hydrophobic monomers, a flexible hydrophobic multi(meth)acrylate monomer, one or more urethane methacrylate oligomers, and one or more photochromic dyes. The tie layer compositions can contain one or more methacrylate monomers, a (meth)acrylated oligomer with a polycarbonate backbone, one or more urethane methacrylate oligomers, and a solvent or solvent mixture. Methods of preparing photochromic polycarbonate lenses are also disclosed, involving the serial application of the tie layer composition, then the photochromic matrix composition to the lens.

Owner:SIGNET ARMORLITE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com