Patents

Literature

23622results about "Solid waste management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

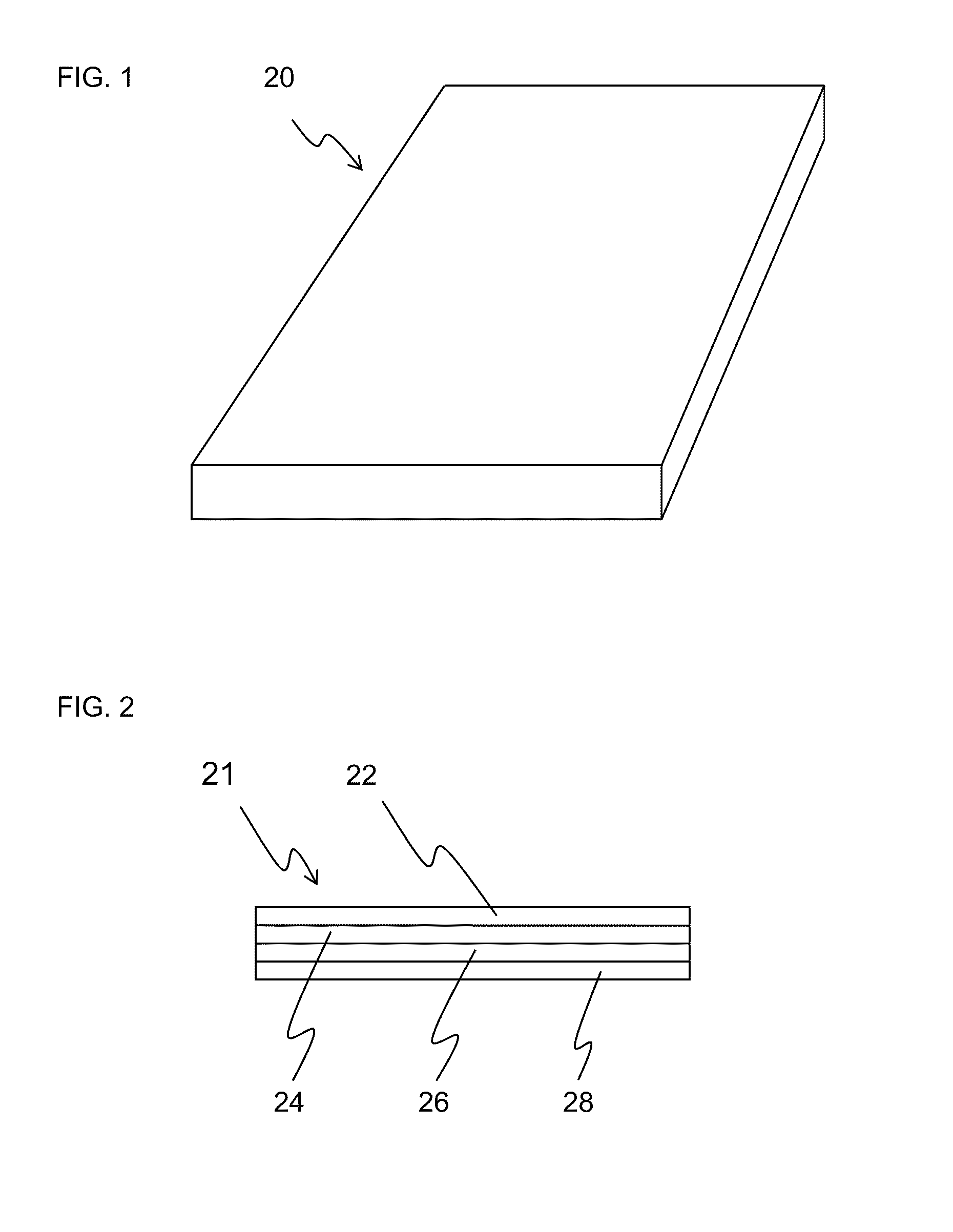

Fire-resistant panel and method of manufacture

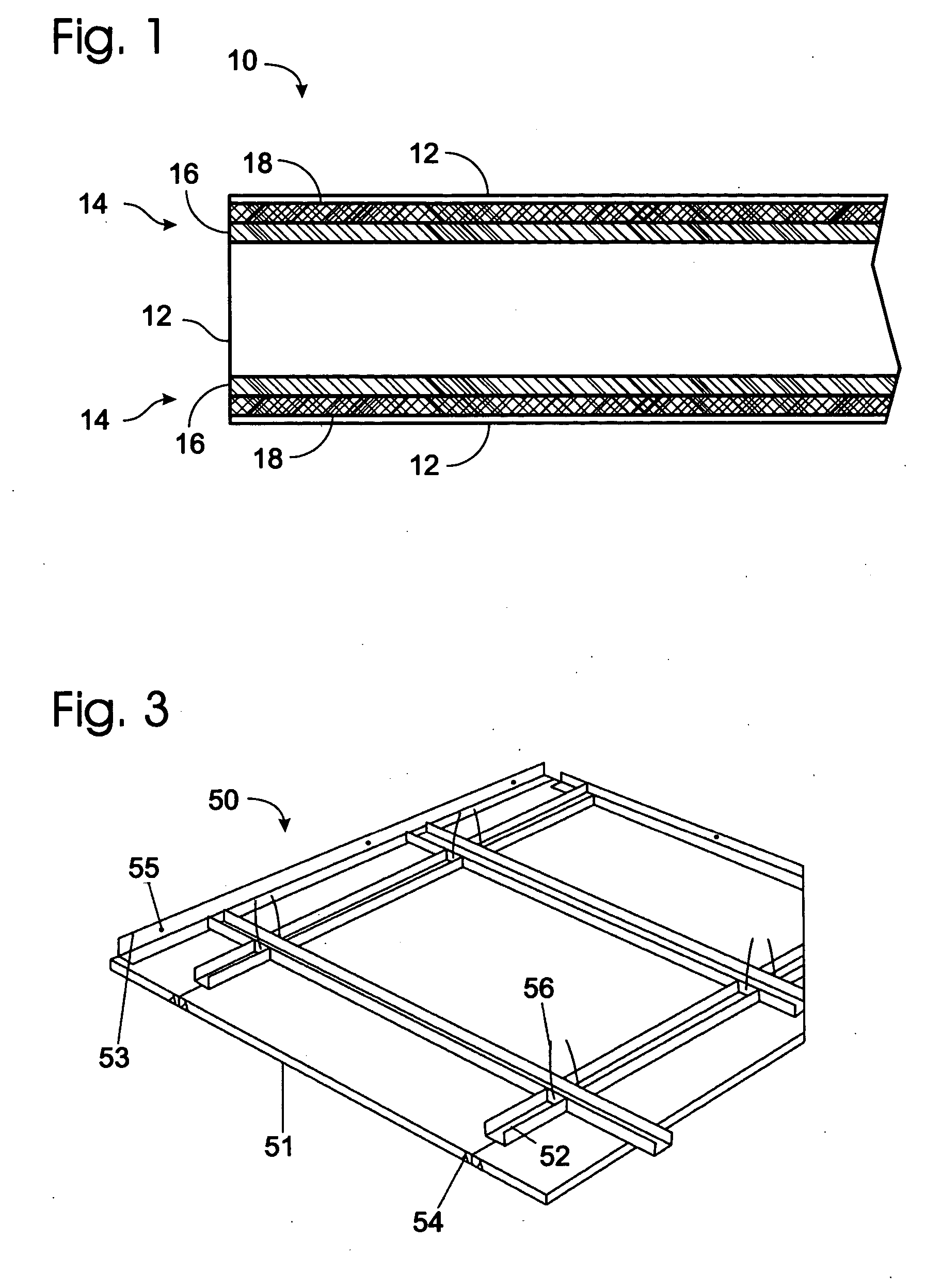

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

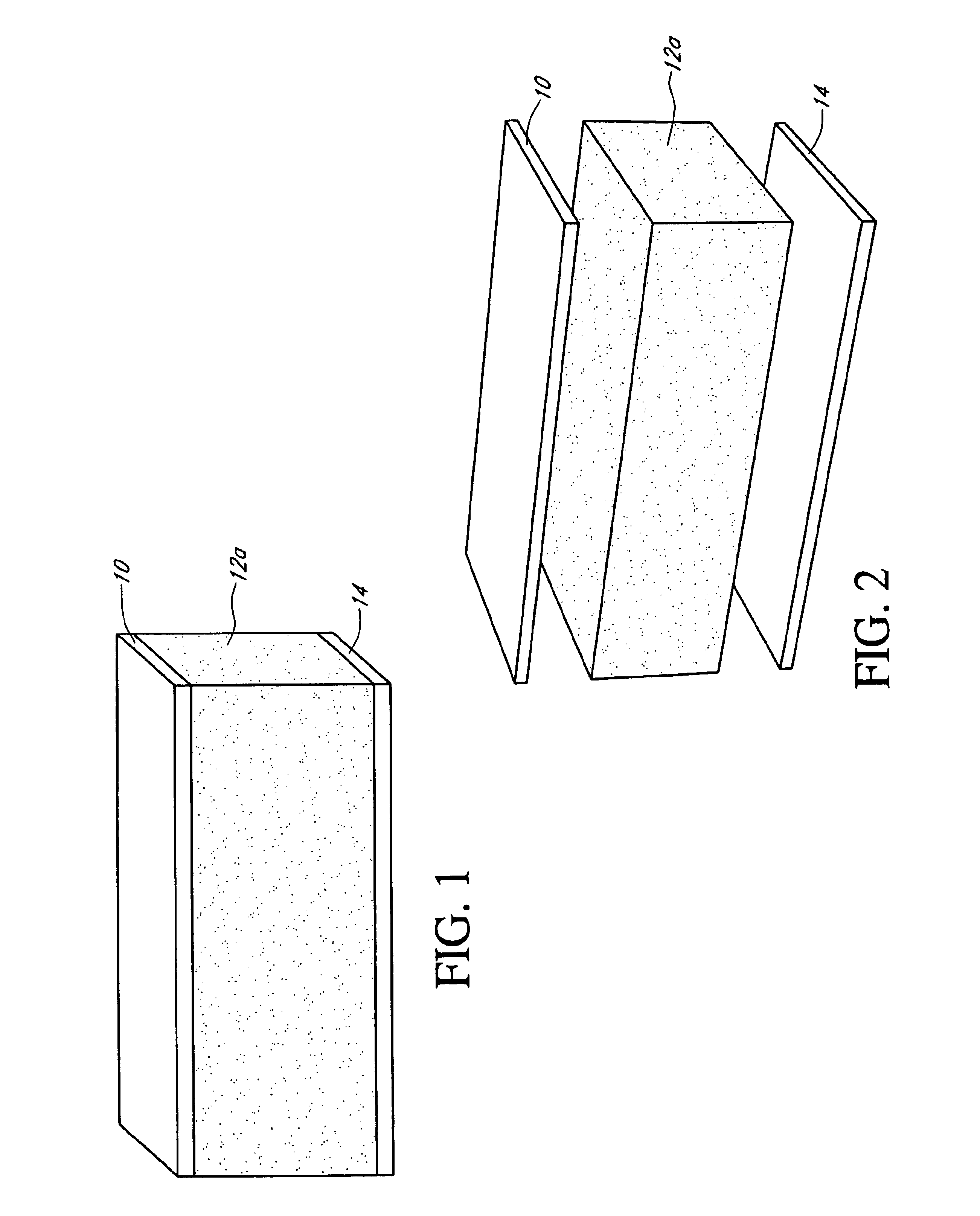

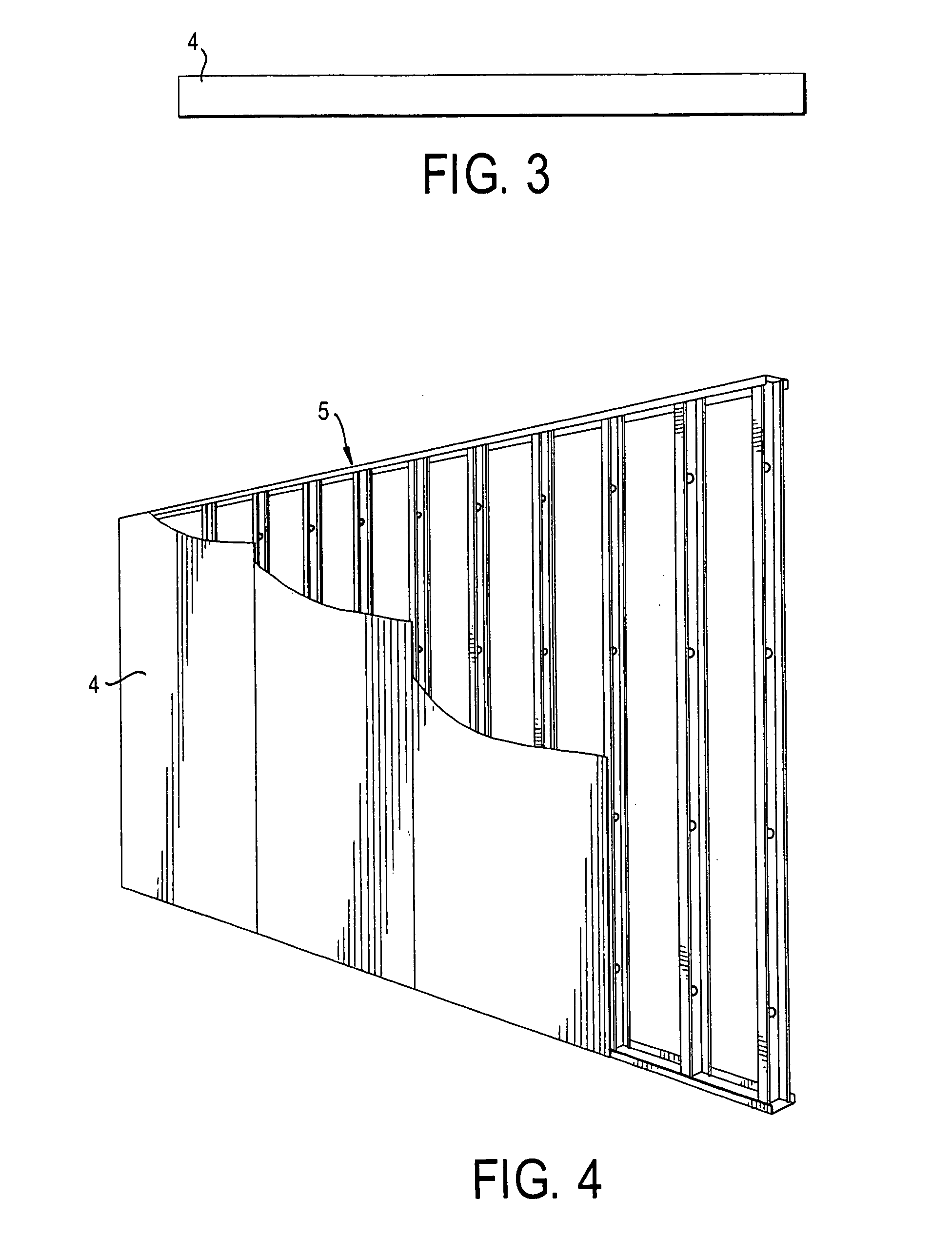

Composite building material

InactiveUS6941720B2Reduce noise transmissionLow acoustic transmissionConstruction materialSolid waste managementArchitectural engineeringPlastic property

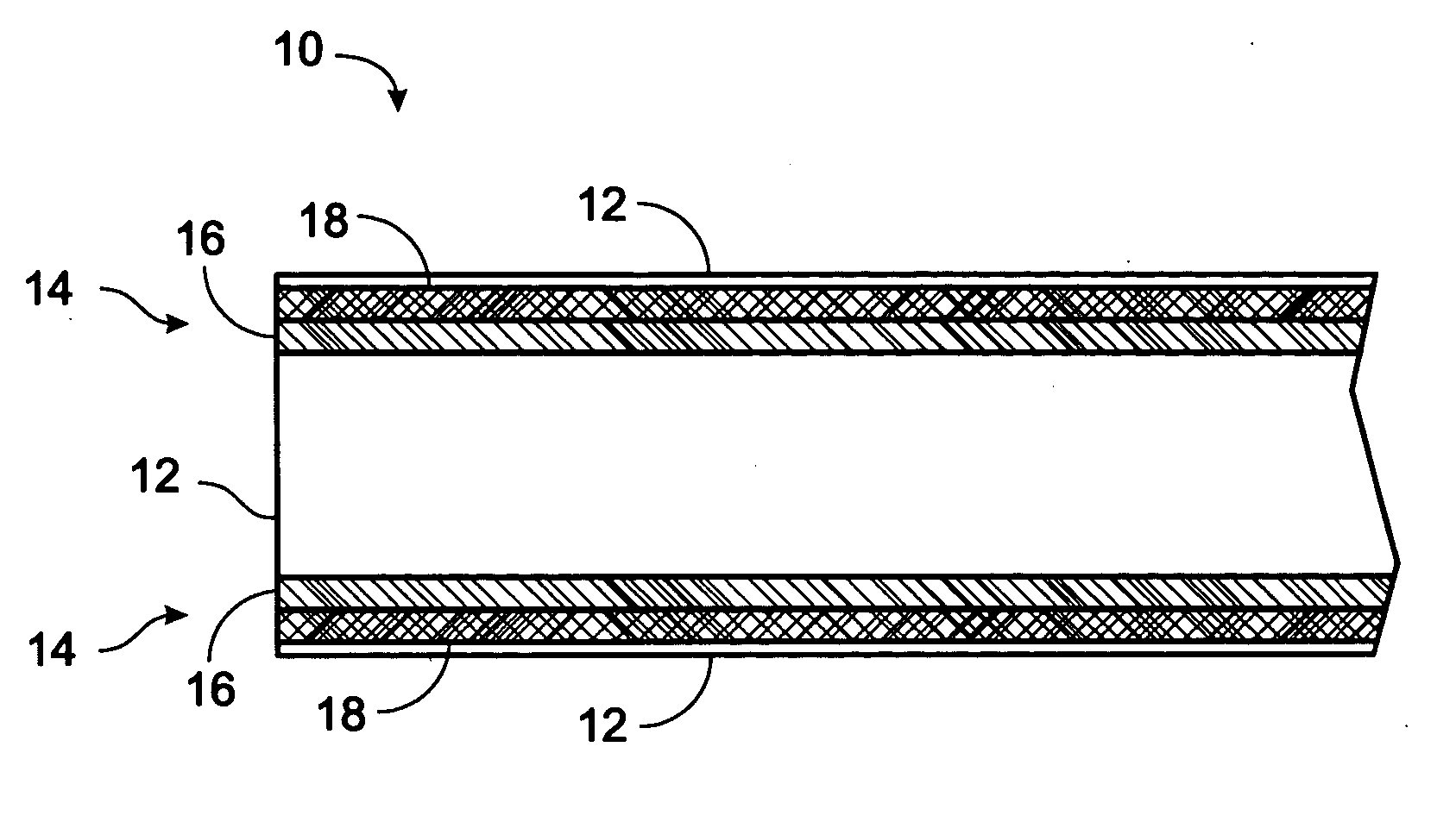

This invention generally pertains to a composite building material comprising a lightweight core with a thin fiber cement facing on one side of the core and a second facing material on the other side. The fiber cement facing that is used on at least one of the faces of the building material is 3 / 16″ or less, more preferably ⅛″ or less. The green fiber cement facing is preferably formed by a slurry-dewatering process to form a sheet that is in a plastic, uncured, state prior to manufacture of the composite. The composite building material is assembled in an uncured state and then cured.

Owner:JAMES HARDIE TECH LTD

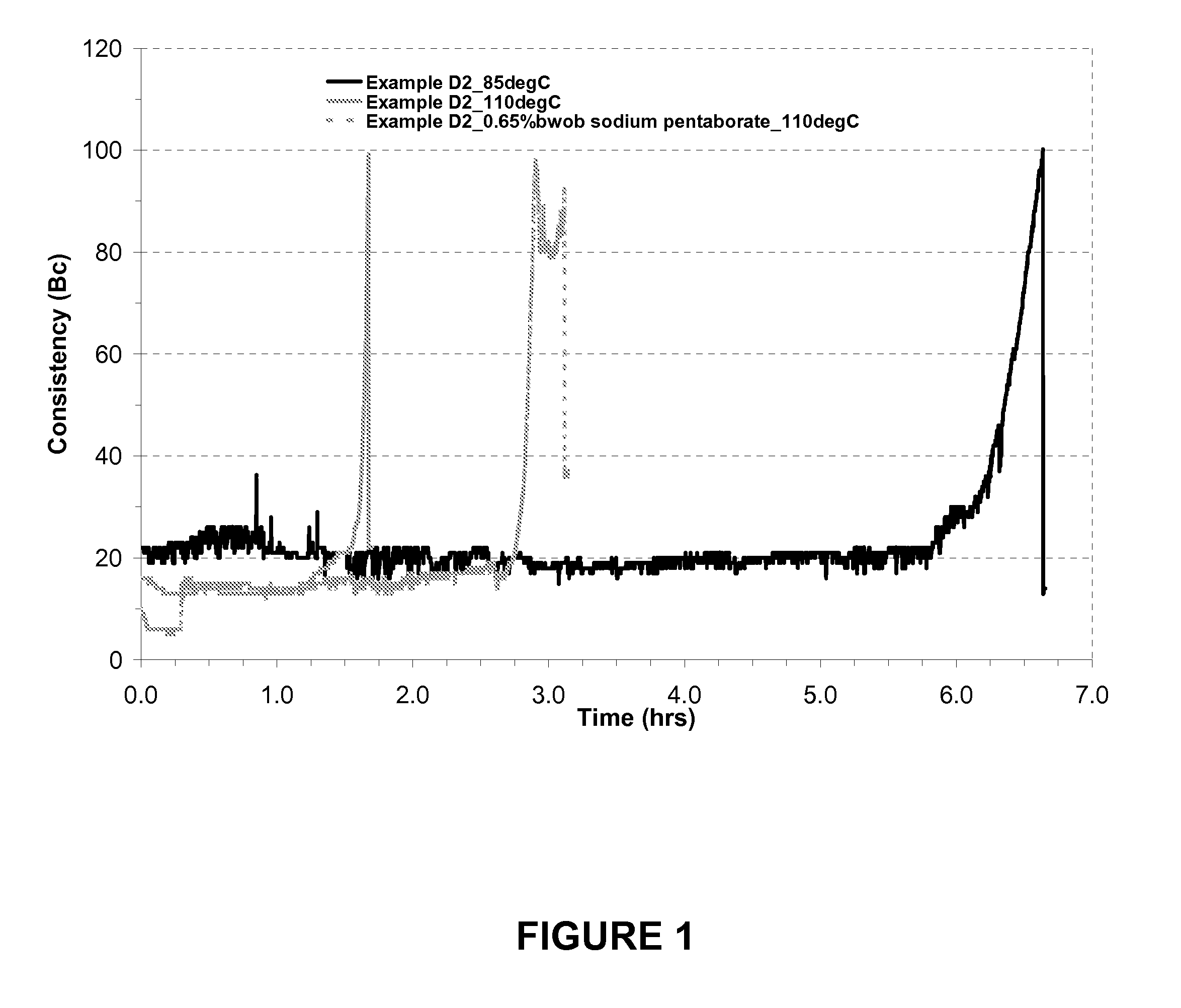

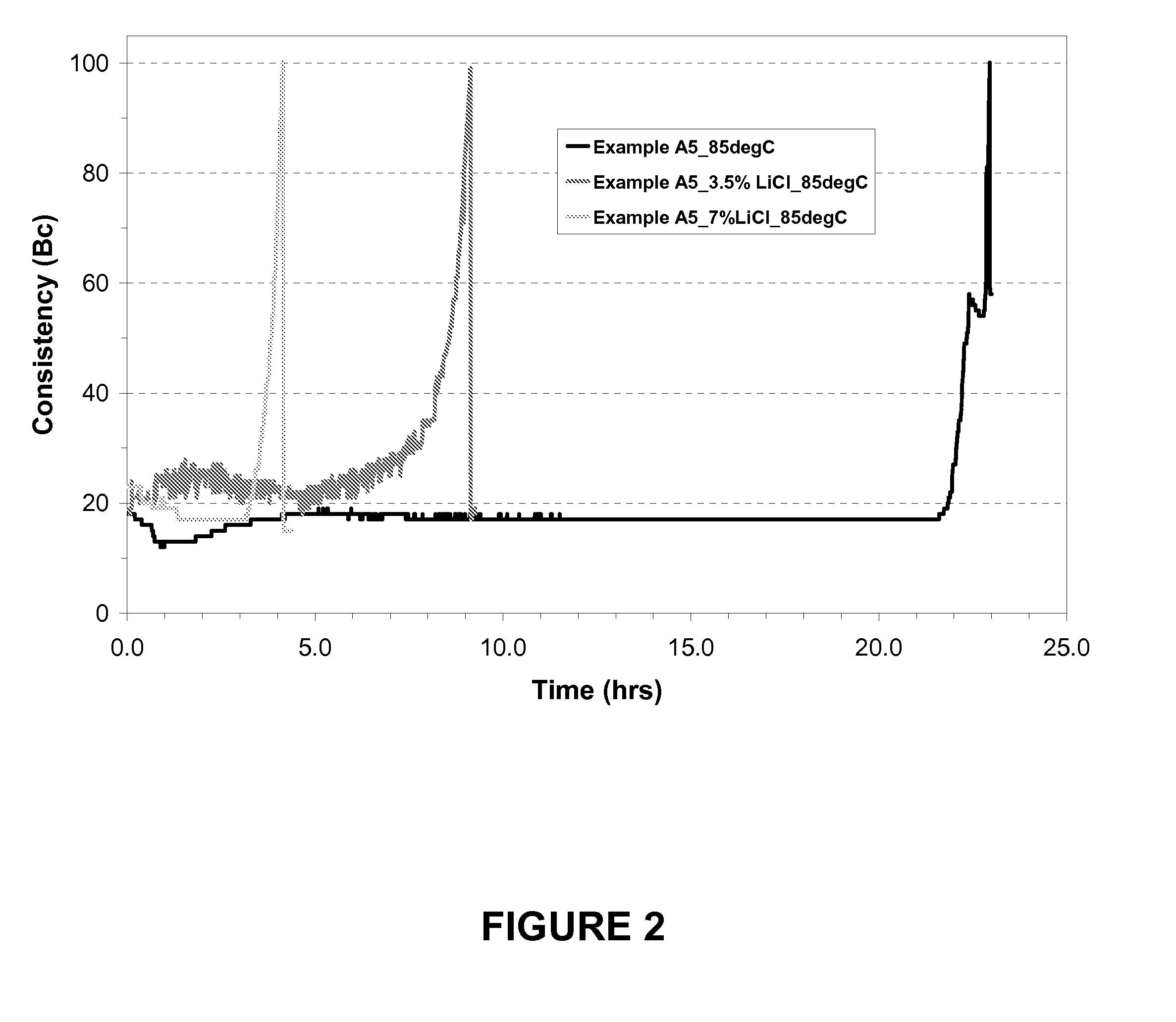

Contained micro-particles for use in well bore operations

Owner:HALLIBURTON ENERGY SERVICES INC

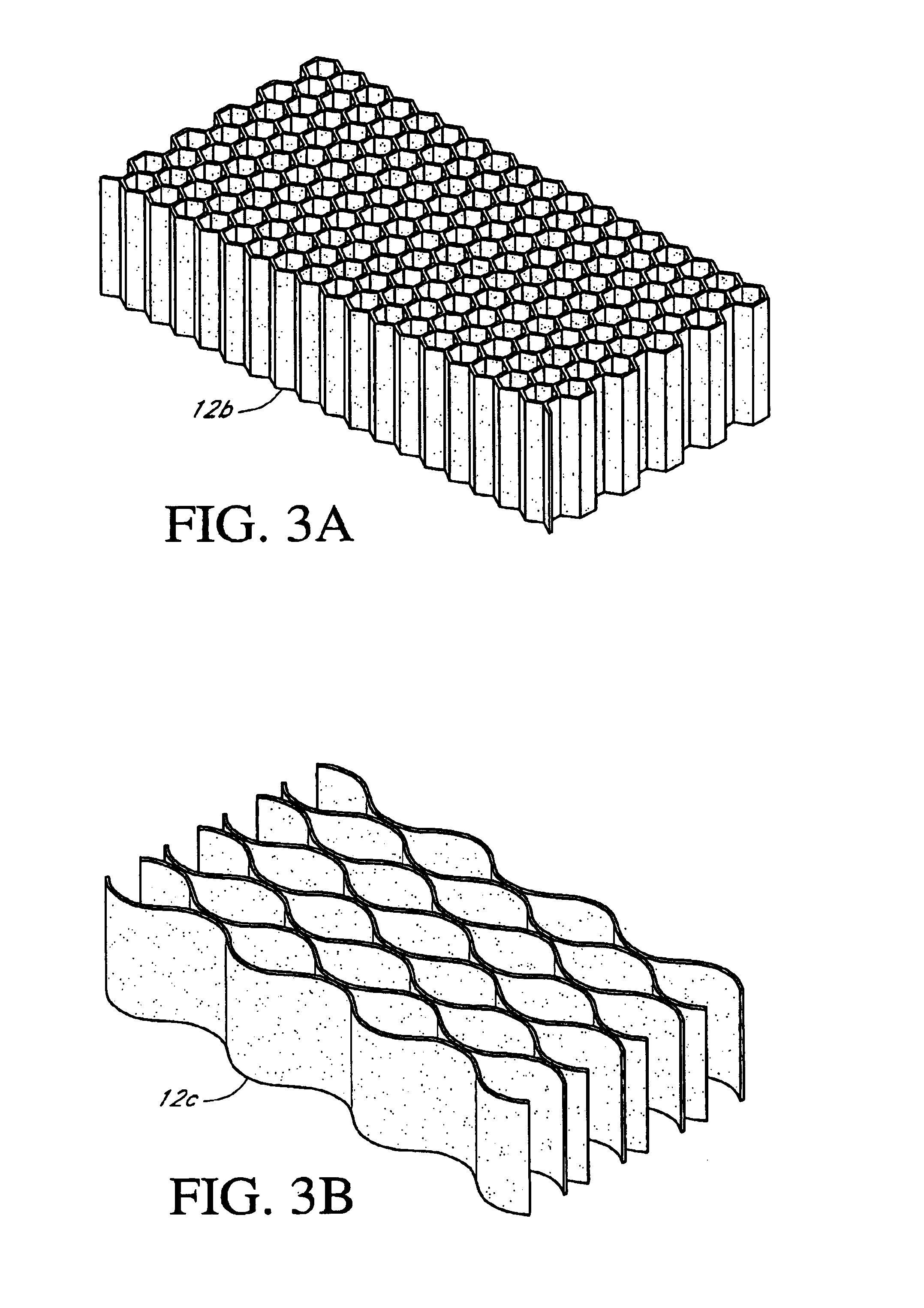

Molded starch-bound containers and other articles having natural and/or synthetic polymer coatings

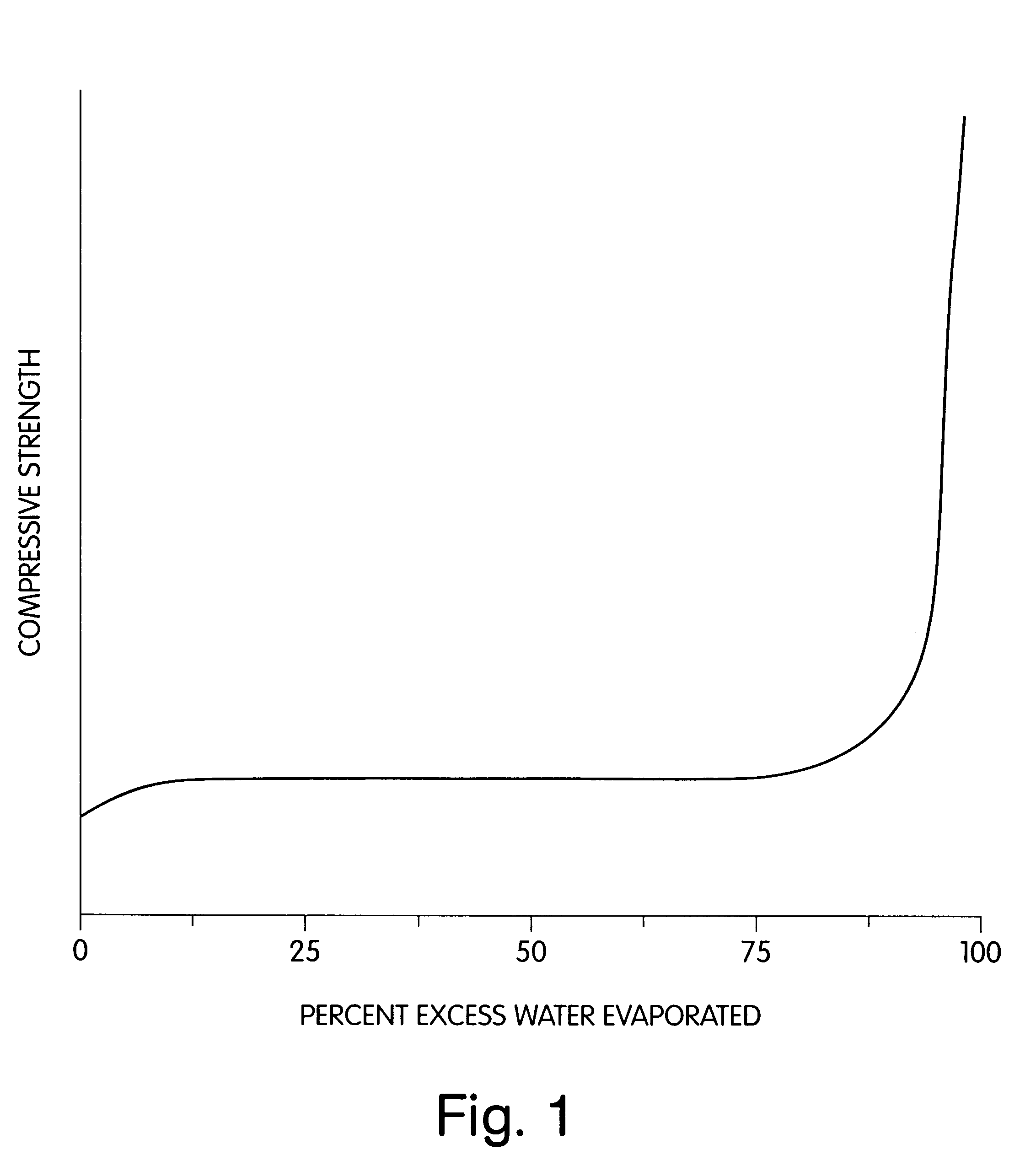

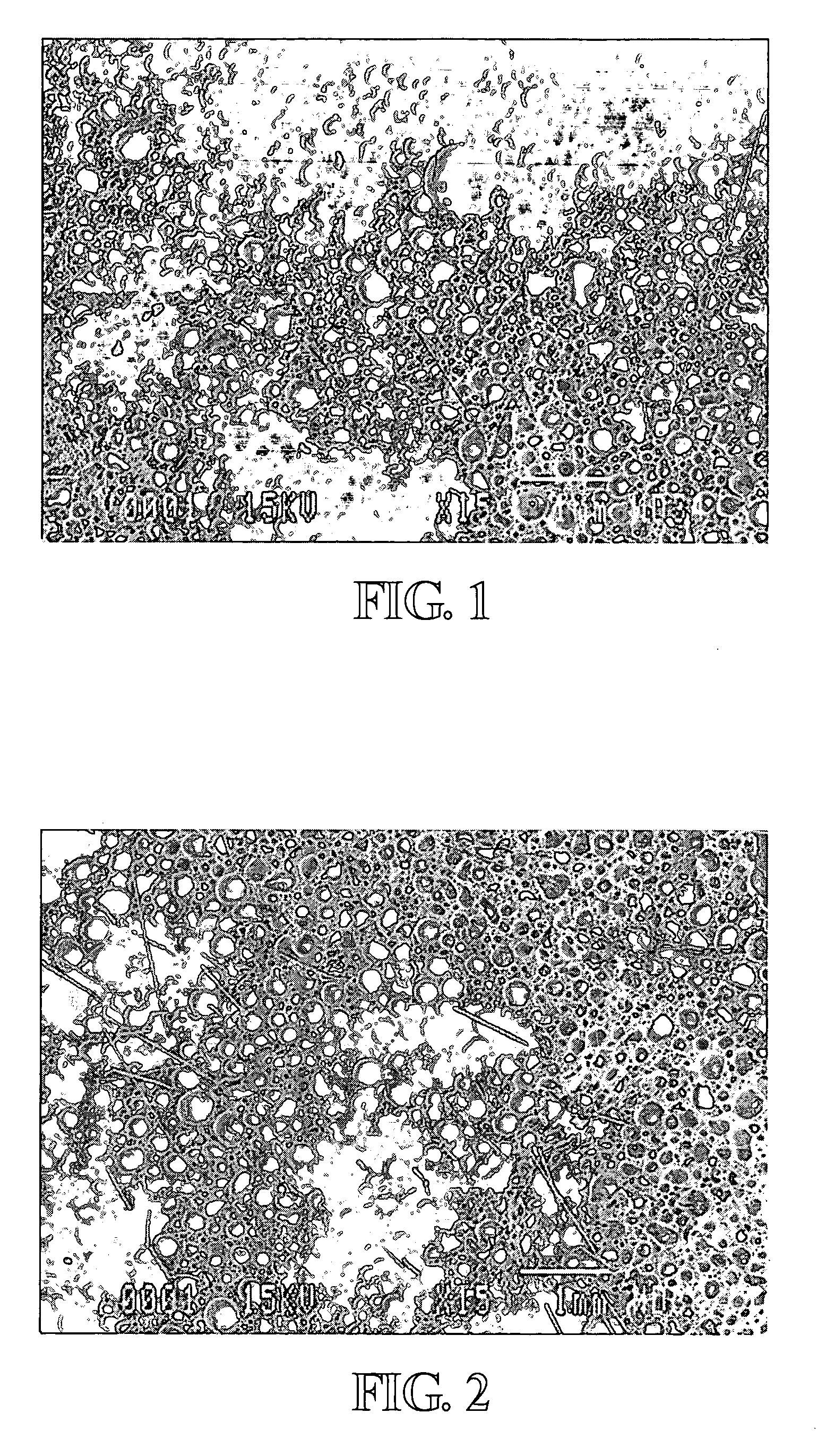

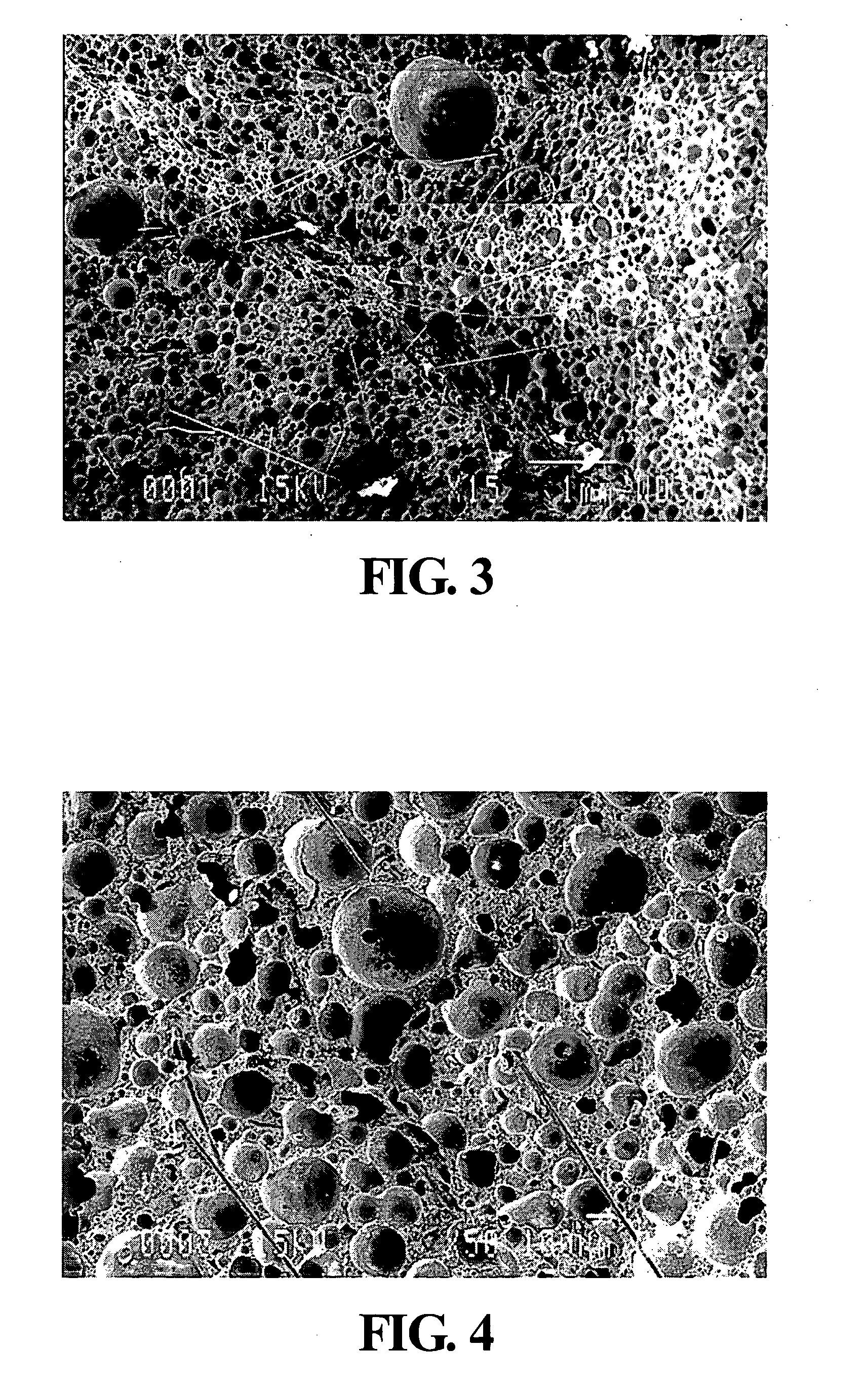

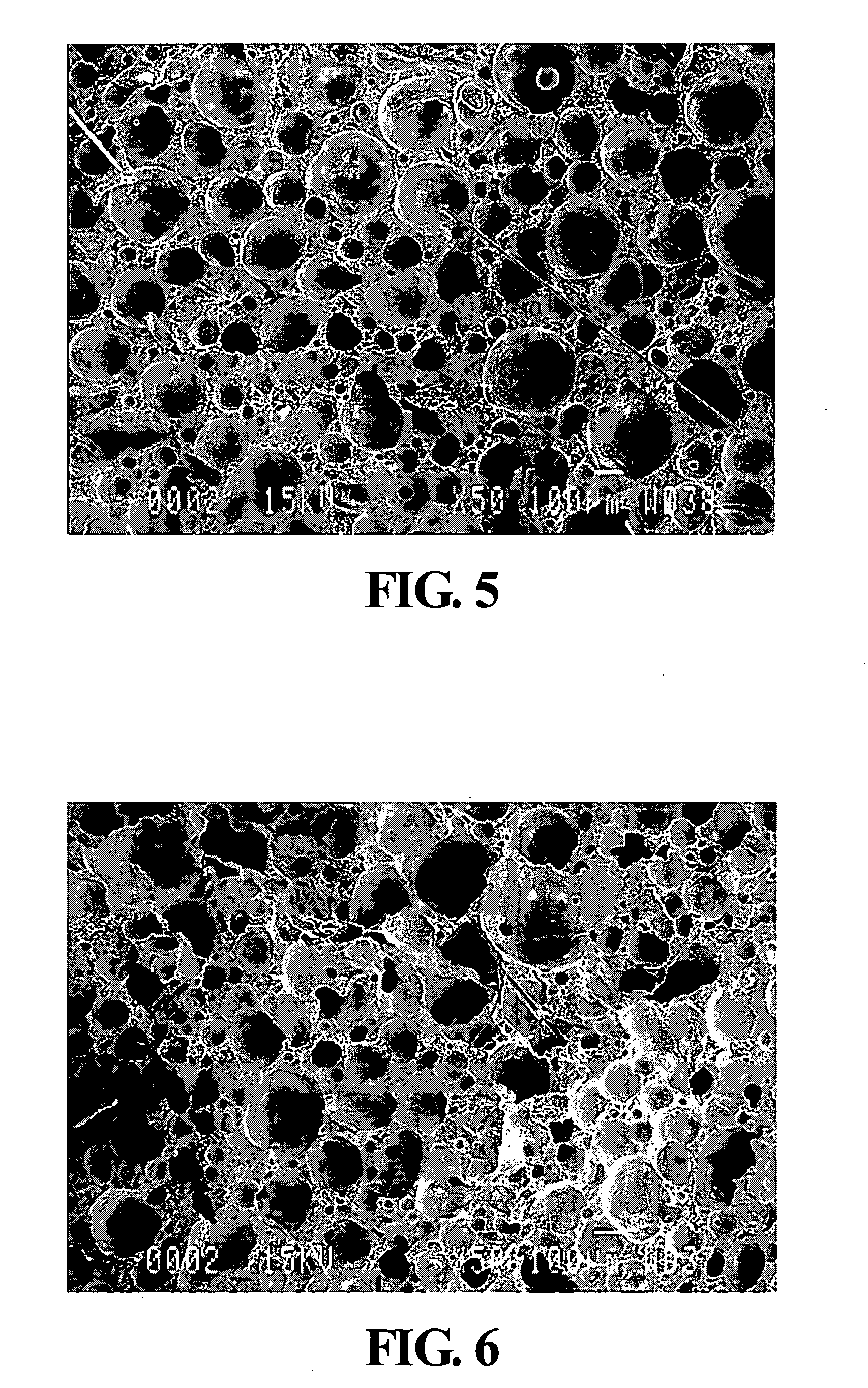

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a particle packed, highly inorganically filled, cellular matrix are disclosed. Suitable inorganically filled mixtures are prepared by mixing together a starch-based binder, a solvent, inorganic aggregates, and optimal admixtures, e.g., fibers, mold-releasing agents, rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The inorganically filled mixtures have a predetermined viscosity and are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled cellular, structure matrix. The molded articles may be placed in a high humidity chamber to obtain the necessary flexibility for their intended use. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic materials. They have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

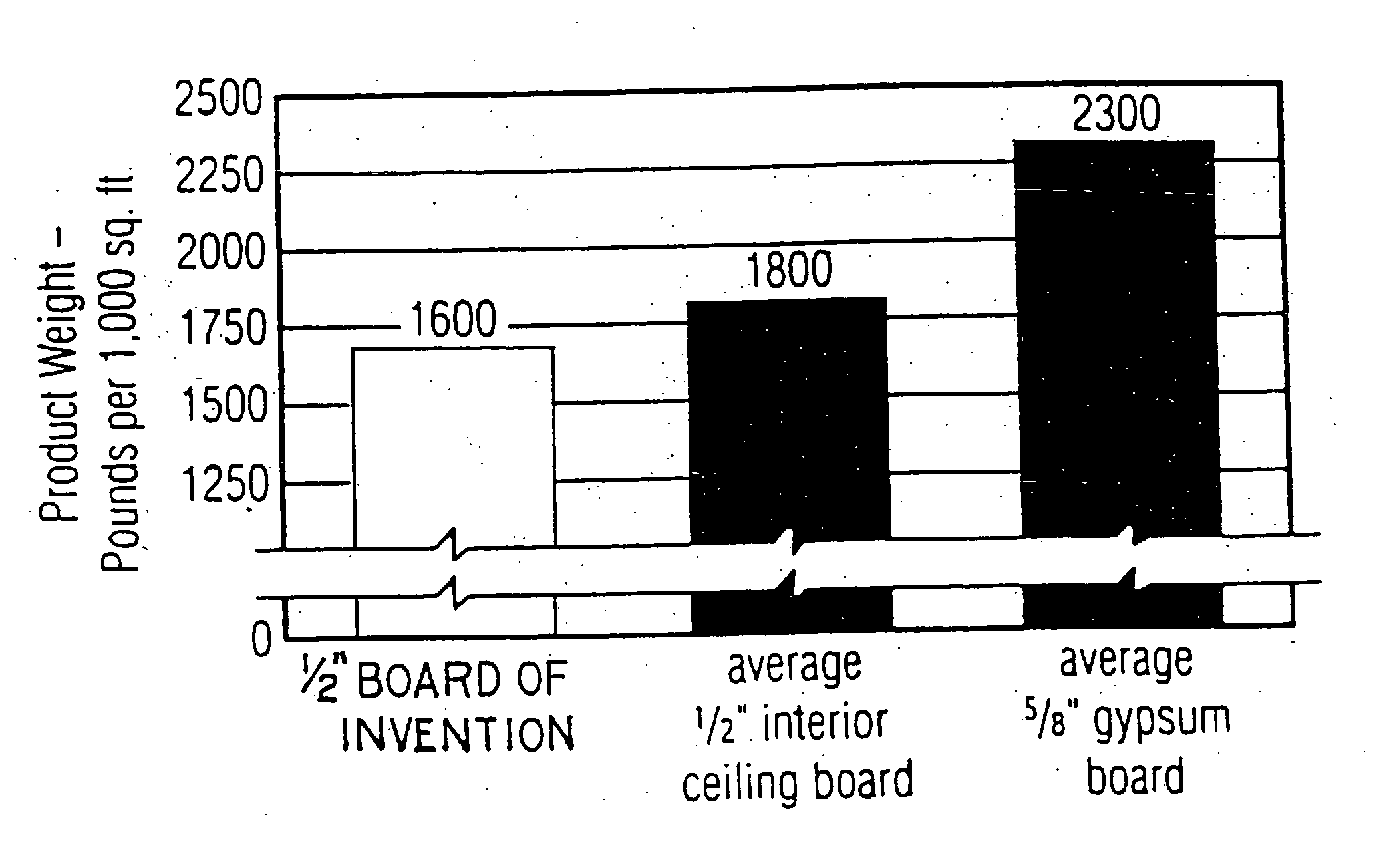

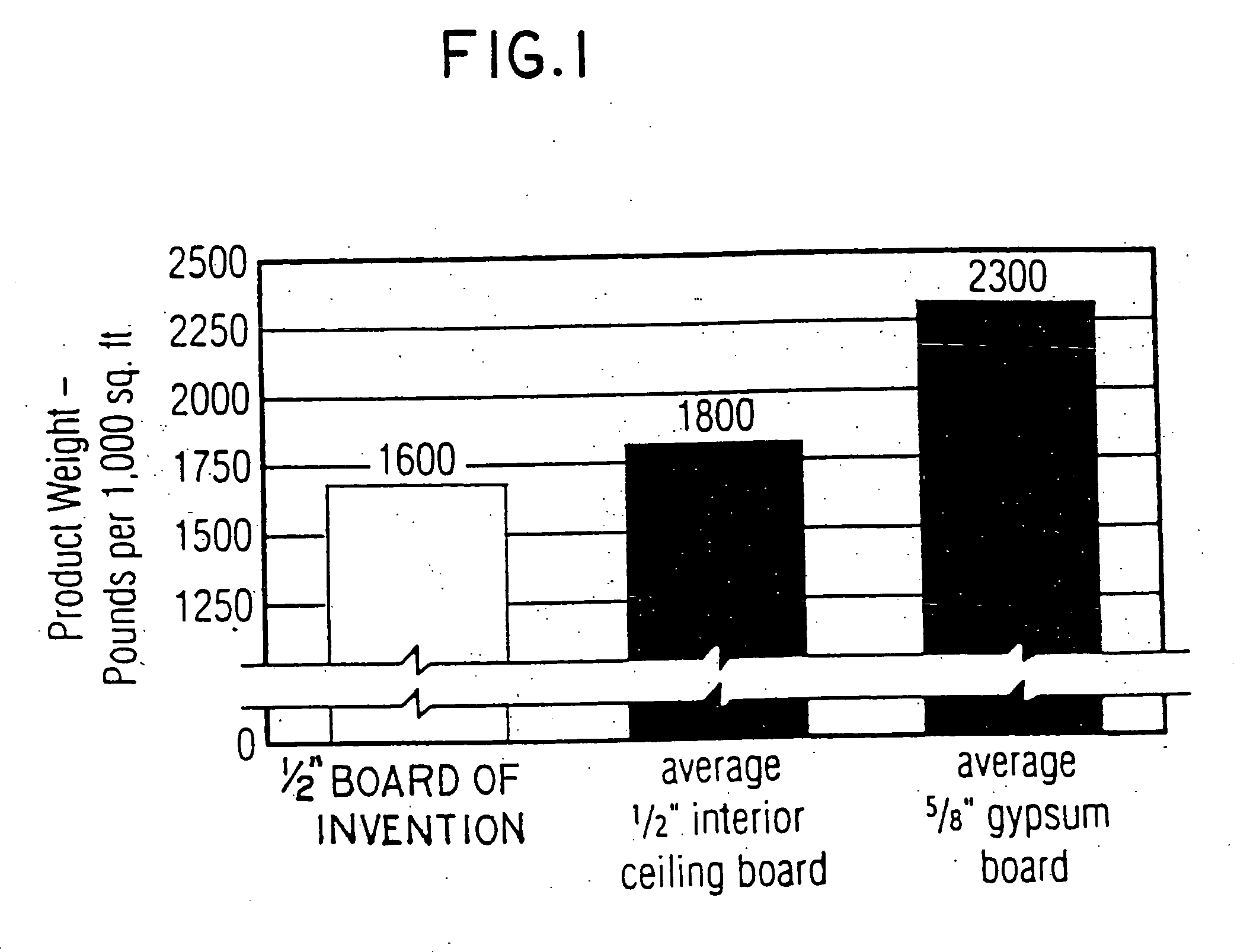

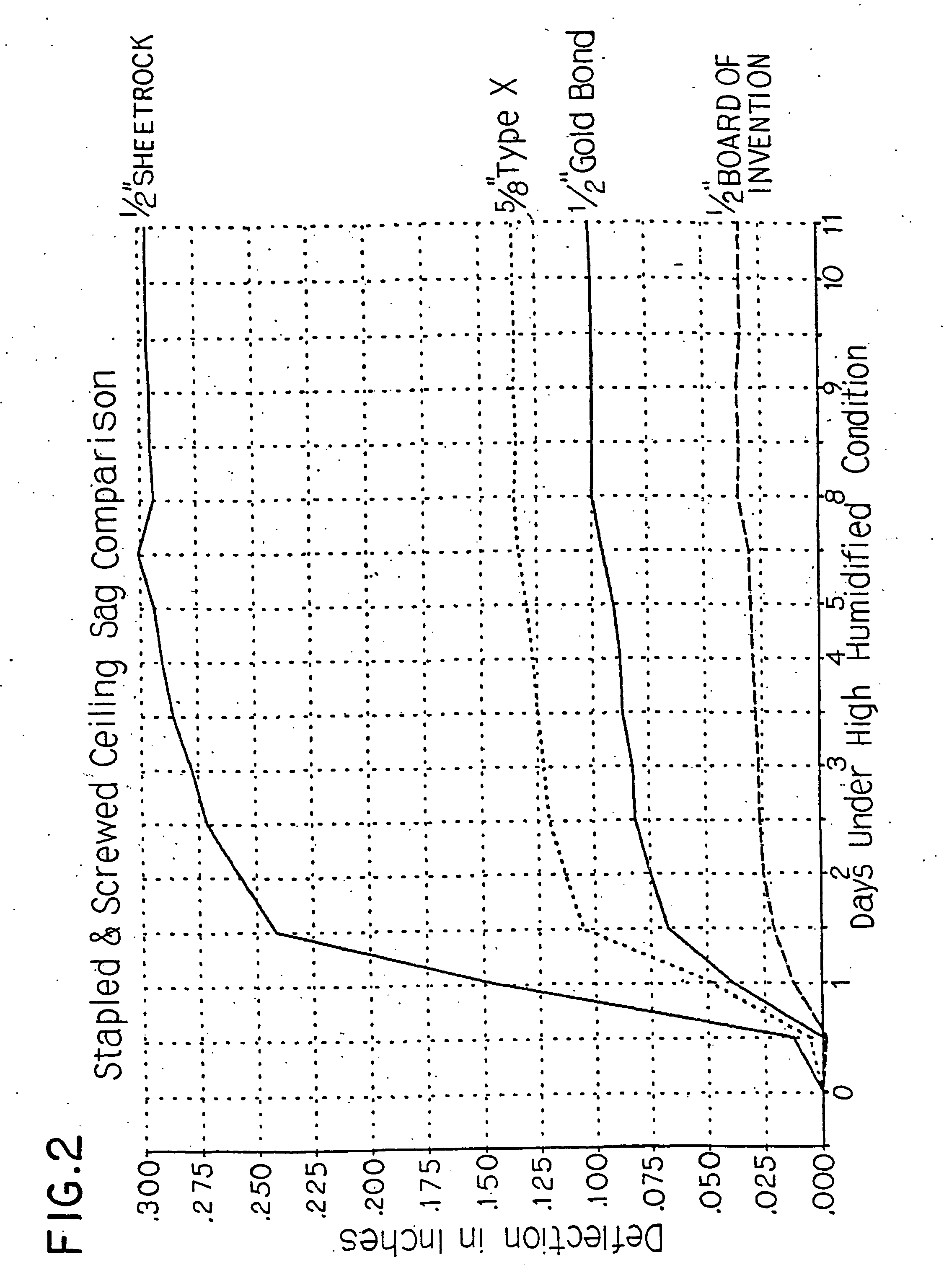

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

Masonry cement having higher strength and water retention

InactiveCN101182139AHigh strengthSolve the difficult problem of preparing high-strength grade building mortarSolid waste managementCelluloseLower grade

The invention discloses a masonry cement with high strength and water retention. According to the weight percentage, the masonry cement consists of 21-98.99 percent of porland cement clinker, 0-50 percent of blending materials, 1-12 percent of gypsum, 0.01-2 percent of cellulose ether and 0-15 percent of other additives. With the cellulose ether of high water retention material added, the water retention of the masonry cement is greatly improved. At the same time, through breaking through the limitation that the using amount of the blending materials in the original masonry cement is not less than 50 percent, the using amount of the blending materials is lowered to be 50 percent below to improve the strength of novel masonry cement. The strength of the prepared masonry cement is high, and the masonry cement with the strength grades of 12.5, 22.5, 52.5R, 62.5, 62.5R, etc. can be made. The hard problems of using low-grade blending materials to produce masonry cement with high water retention and using low- grade strength masonry cement of 12.5 and 22.5 to produce high-grade strength building mortar are solved.

Owner:SOUTH CHINA UNIV OF TECH

Cement compositions with improved corrosion resistance and methods of cementing in subterranean formations

InactiveUS6904971B2Improve corrosion resistanceSolid waste managementDrilling compositionPhosphateSlurry

Owner:HALLIBURTON ENERGY SERVICES INC

Alkali activated supersulphated binder

The invention describes an activated supersulphated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts, wherein the aluminosilicates are selected from the group consisting of blast furnace slag, clay, marl and industrial by-products such as fly ash with the proviso that the Al2O3 content is greater than 5% by weight, wherein blast furnace slag is present in an amount exceeding 35% by weight and clay, marl and / or fly ash is present in an amount exceeding 5% per weight and wherein cement kiln dust in an amount of from 3 to 10% by weight is added to the mixture as an activator and calcium sulphate is used in an amount exceeding 5% by weight.

Owner:HOLCIM

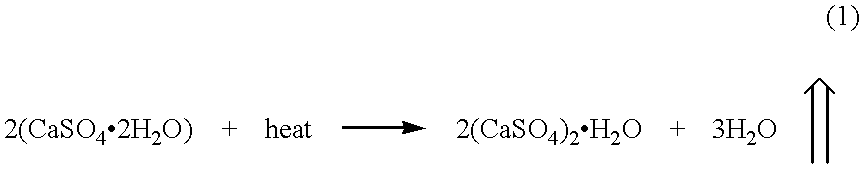

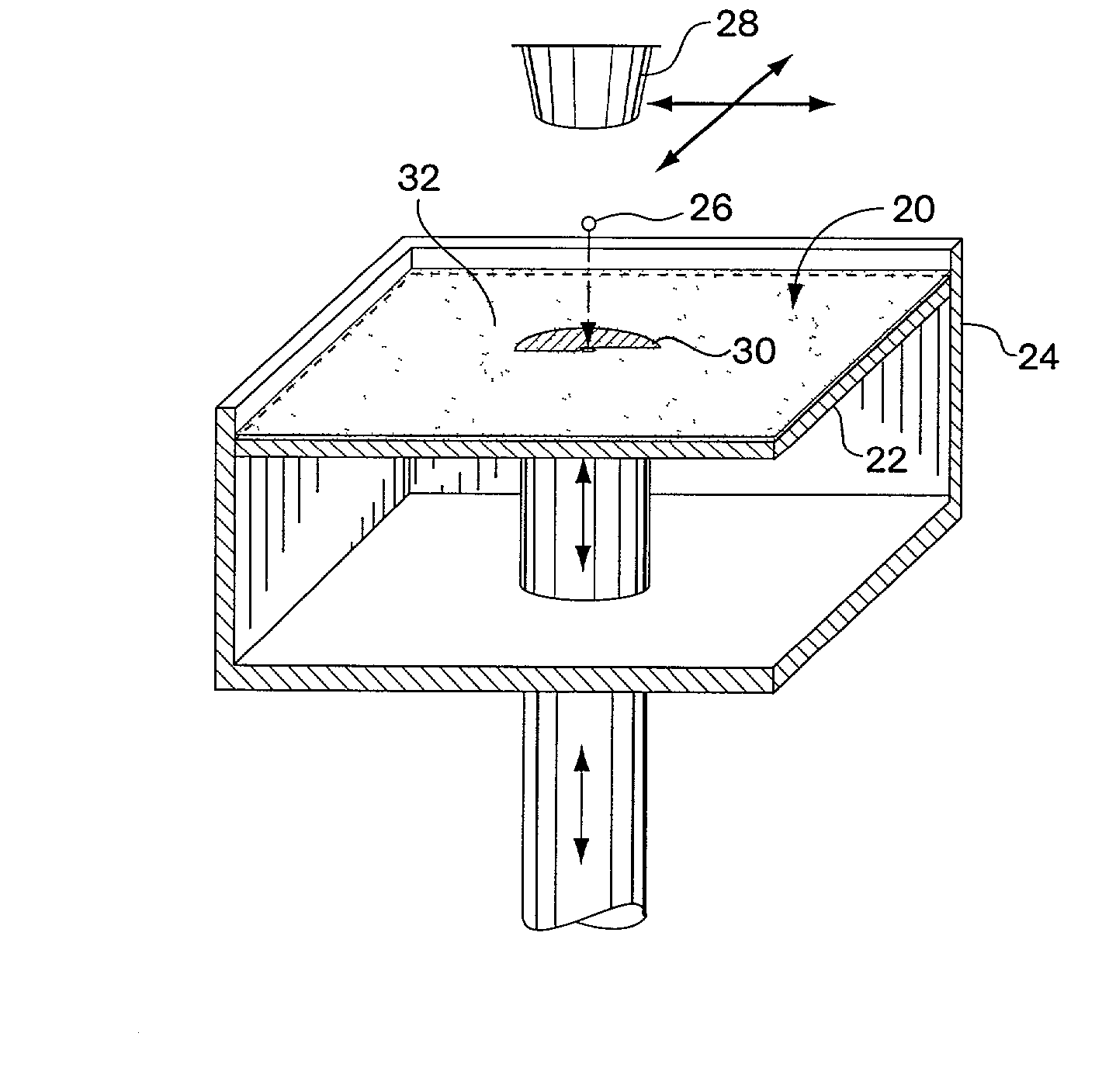

Three dimensional printing material system and method

InactiveUS6610429B2High strengthReduce the amount of solutionAdditive manufacturing apparatusLamination ancillary operationsEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

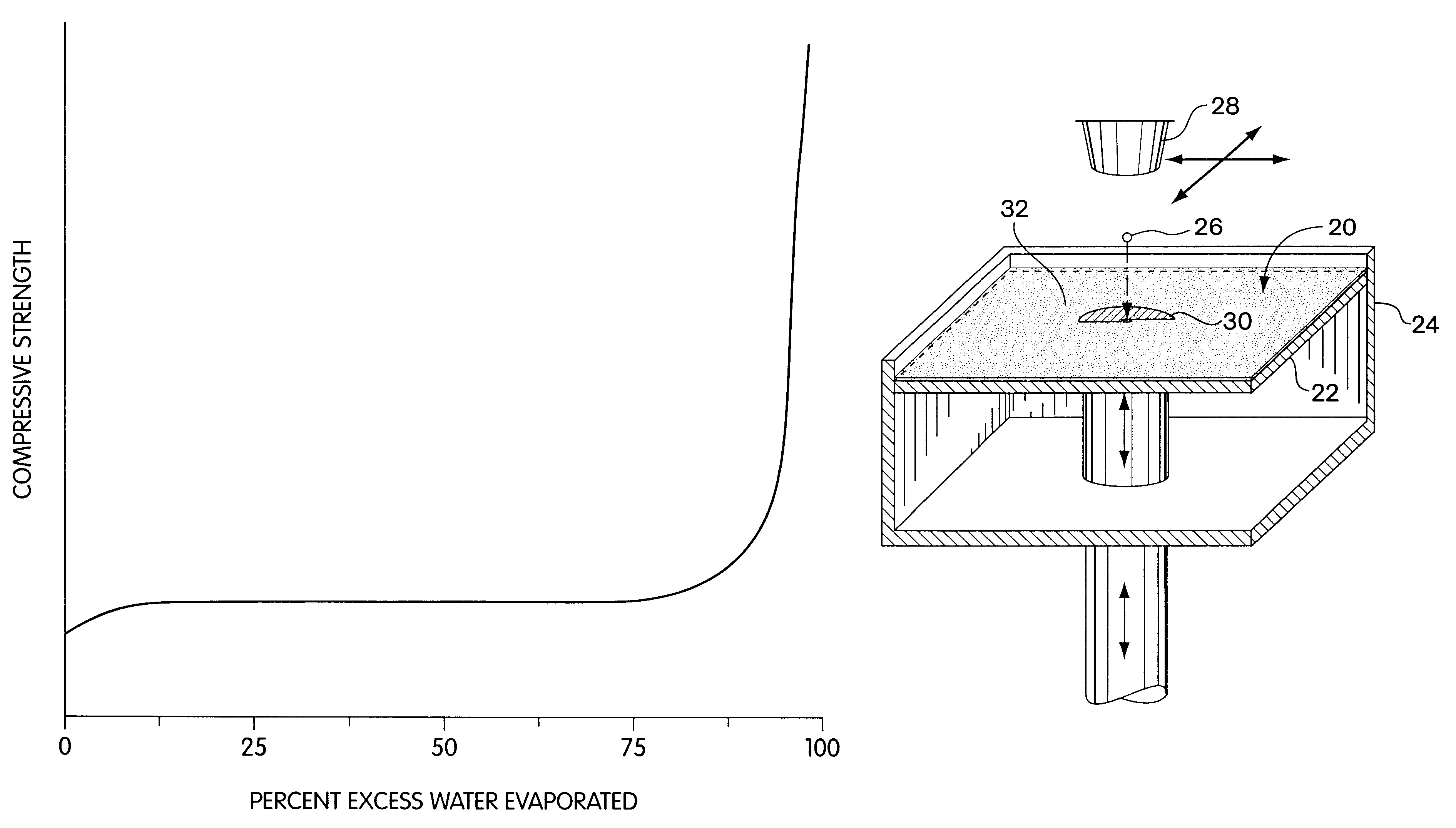

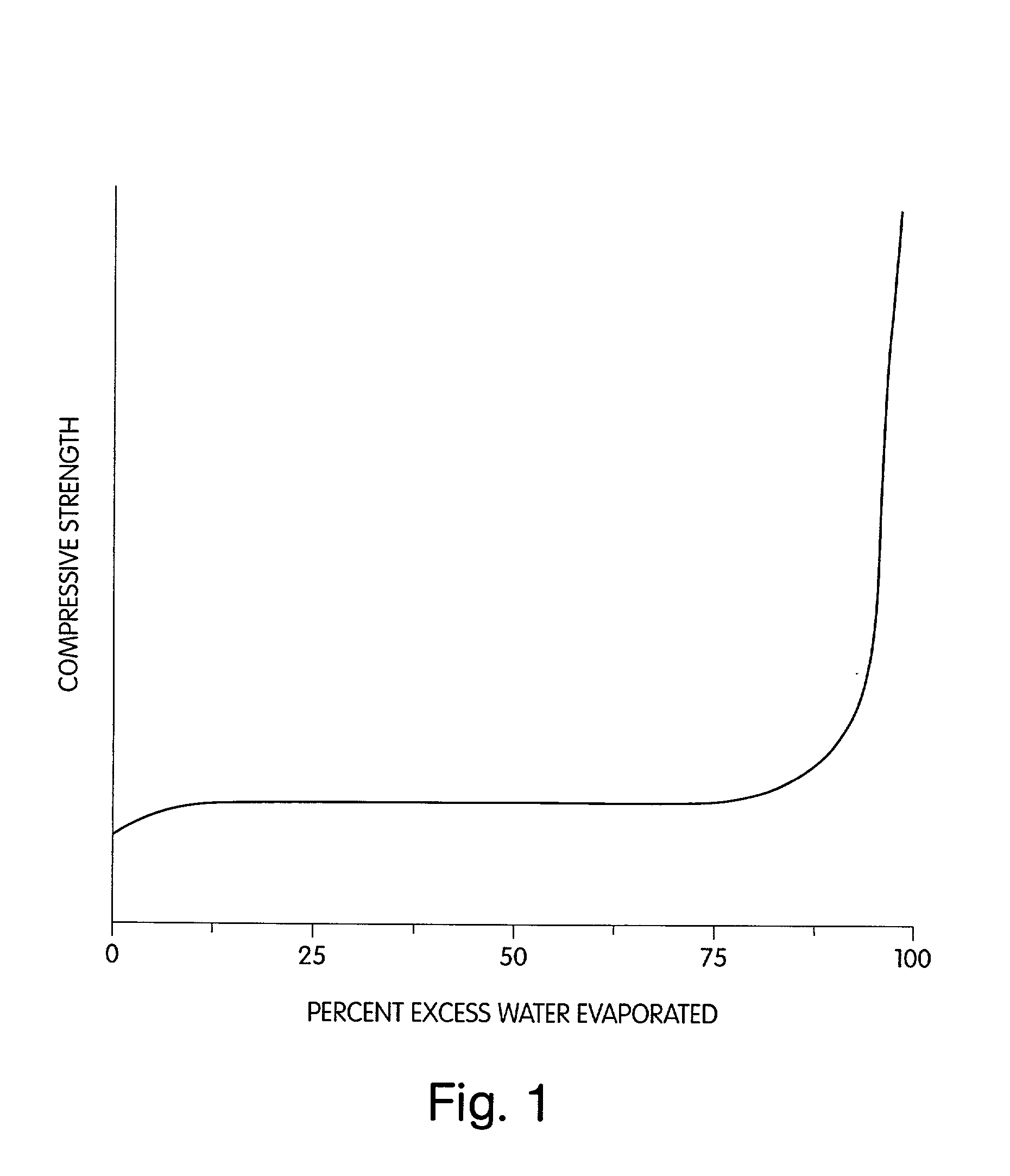

Low dust gypsum wallboard

ActiveUS20070048490A1High strengthReduce weightConstruction materialCovering/liningsDust controlSlurry

This invention provides low dust low density gypsum wallboard products having high total core void volumes, corresponding to low densities in the range of about 10 to 30 pcf. The wallboards have a set gypsum core formed between two substantially parallel cover sheets, the set gypsum core preferably having a total void volume from about 80% to about 92%, and made from a slurry including stucco, pregelatinized starch, and a naphthalenesulfonate dispersant. The combination of the pregelatinized starch and the naphthalenesulfonate dispersant also provides a glue-like effect in binding the set gypsum crystals together. The wallboard formulation, along with small air bubble voids (and water voids) provides dust control during cutting, sawing, routing, snapping, nailing or screwing down, or drilling of the gypsum-containing products. This invention also provides a method of making the low dust low density gypsum products including the introduction of soap foam in an amount sufficient to form a total void volume, including air voids, preferably from about 80% to about 92% in the set gypsum core, corresponding to a set gypsum core density from about 10 pcf to about 30 pcf. The wallboards produced by the method generate significantly less dust during working.

Owner:UNITED STATES GYPSUM CO

Methods of cementing high temperature wells and cement compositions therefor

Owner:HALLIBURTON ENERGY SERVICES INC

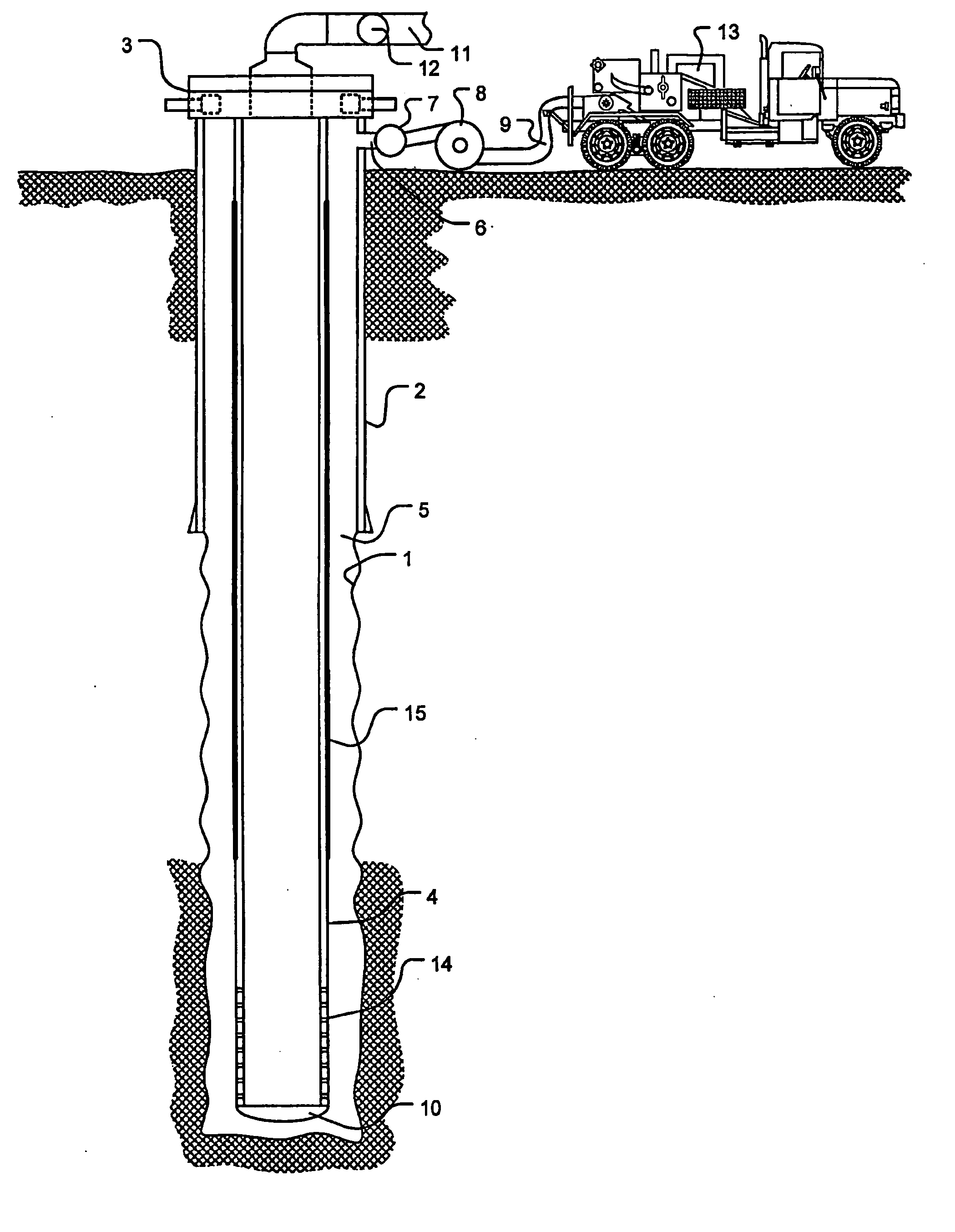

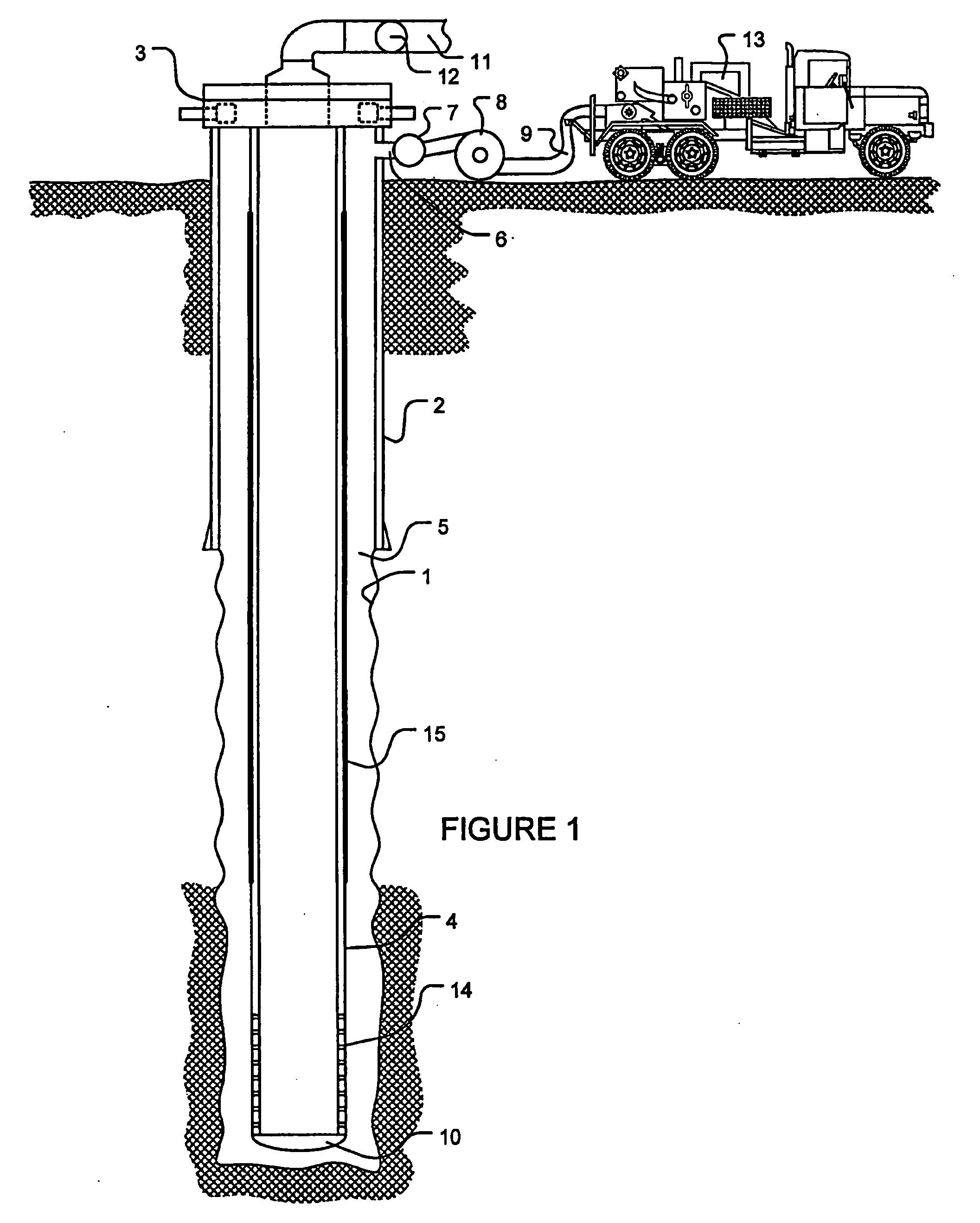

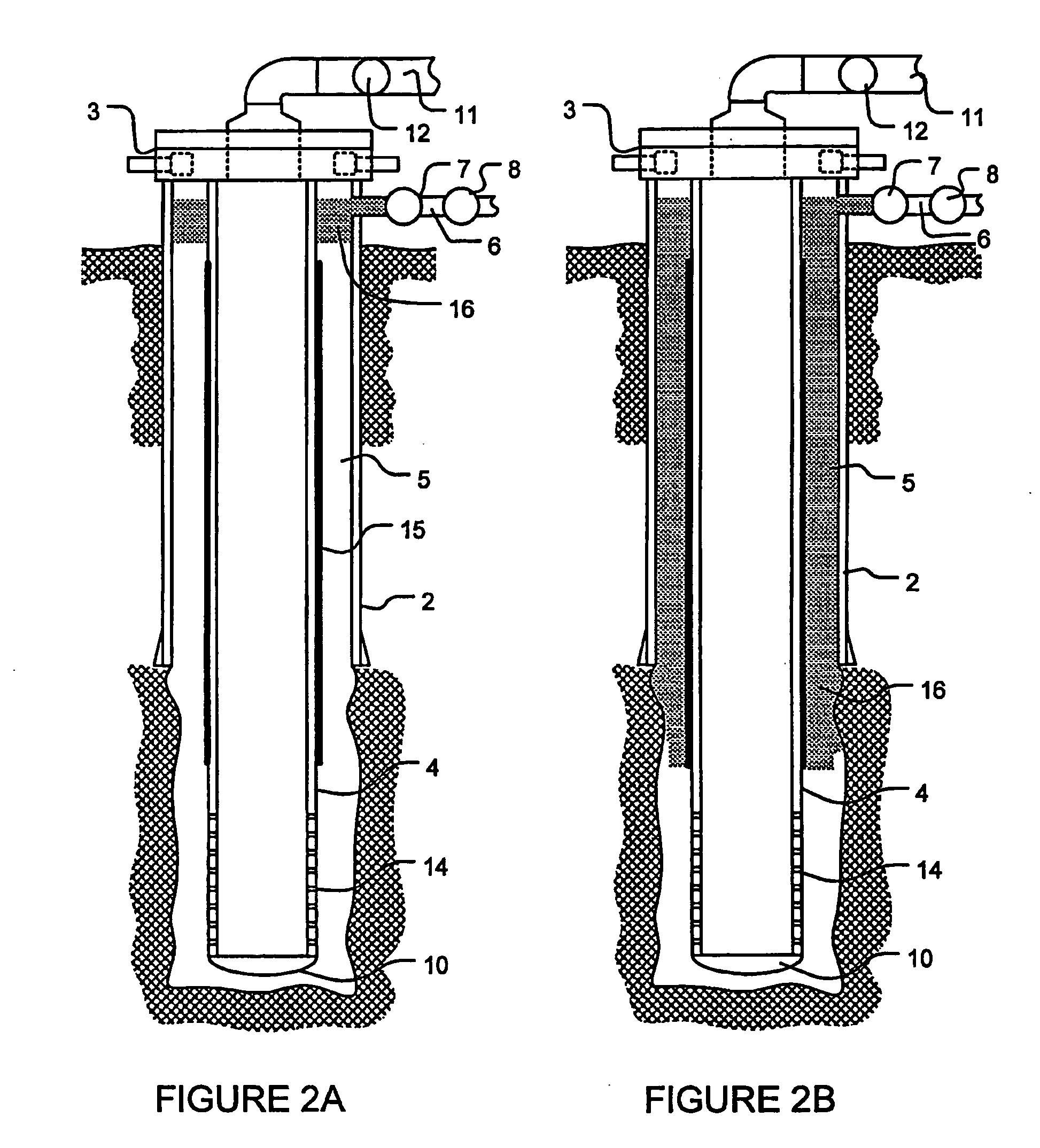

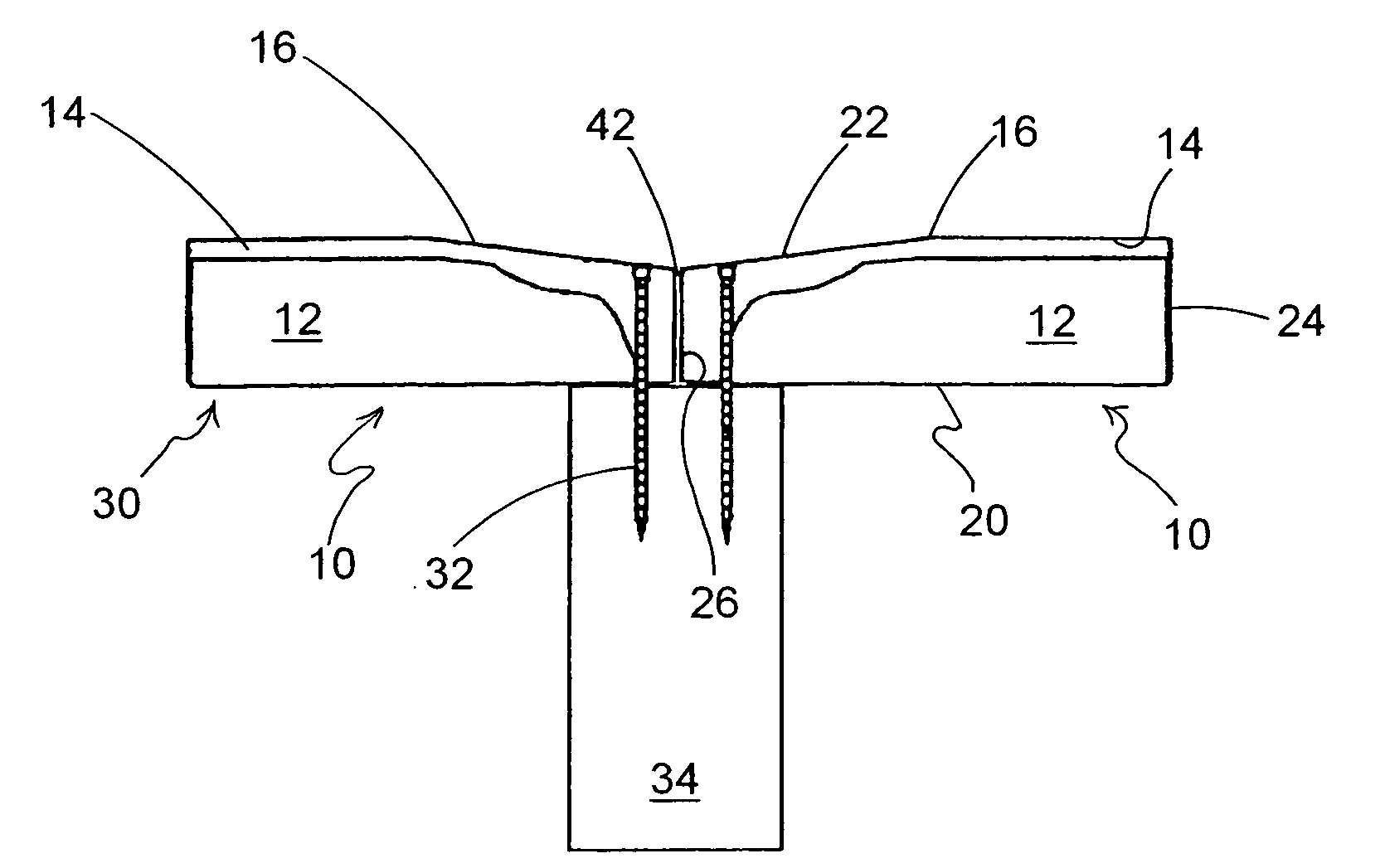

Casing strings and methods of using such strings in subterranean cementing operations

ActiveUS20060086503A1Extension of timeSolid waste managementFluid removalCasing stringWell cementing

Improved casing strings, and methods of using improved casing strings in subterranean cementing operations, are provided. An example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of an activator. Another example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of a set retarder. An example of a method is a method of cementing in a subterranean formation. Other examples of methods are methods of cementing in a subterranean formation comprising a well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

Synthesis-reactivation technique for preparing inorganic coagulation material

InactiveCN1990413ASimple processImprove adjustabilitySolid waste managementSlagBiological activation

The invention relates to a process of preparing inorganic cementing material. It comprises following steps: mixing industrial slag, silicon-containing material, lime, plaster, addictive and water according to a certain proportion; pressing mixed material or compressing it into briquetting, maintaining naturally for thorough reaction, heat treating for activation under 450-850 Deg. C, adding addictive and grinding until sifting leaves is less than 15% with screen of 80 um, and getting inorganic cementing material, which is used as special cement or expansive agent. The invention is characterized by good physical property, stable volume, long durability and workability, low energy consumption and cost and environmental friendly.

Owner:尹小林

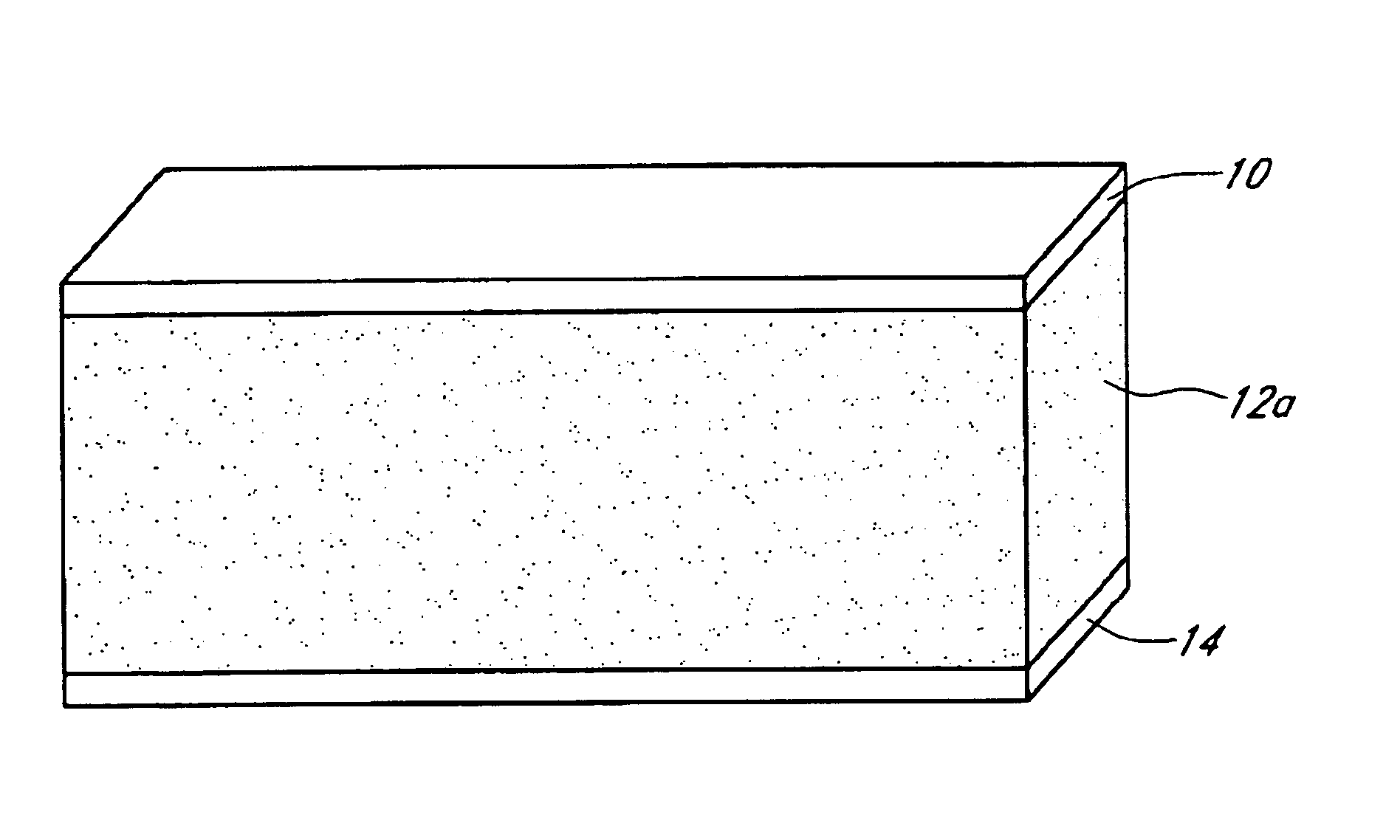

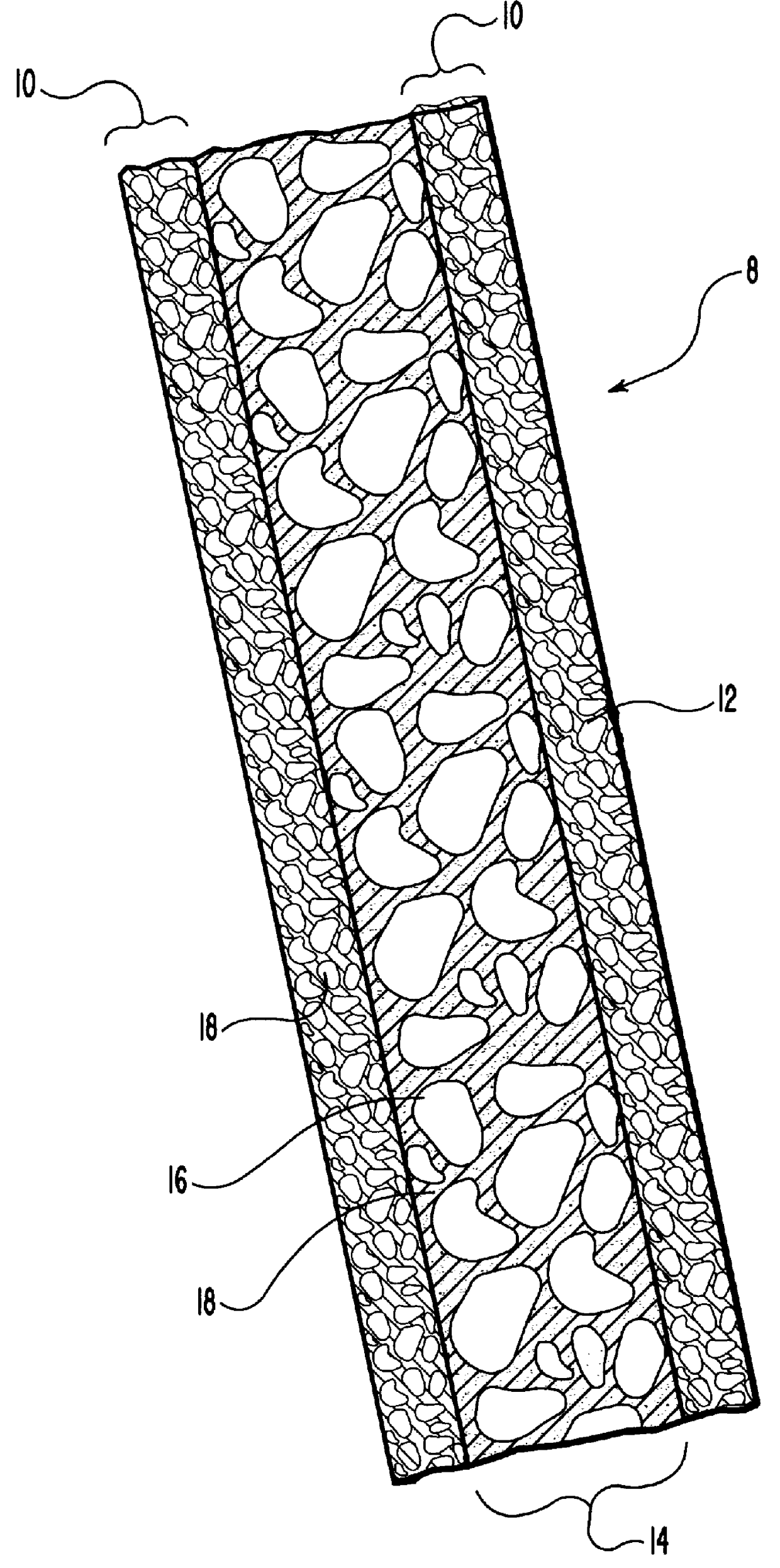

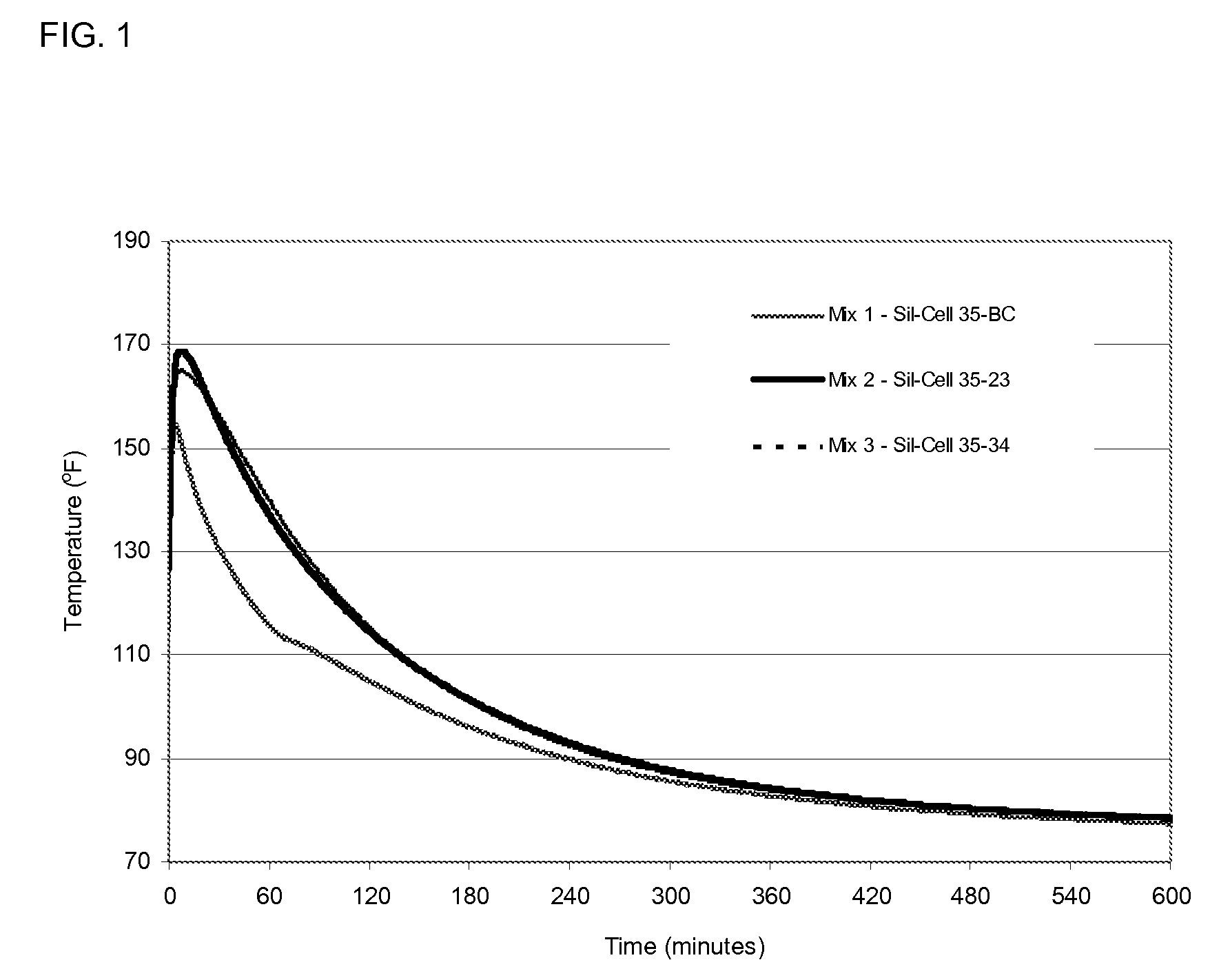

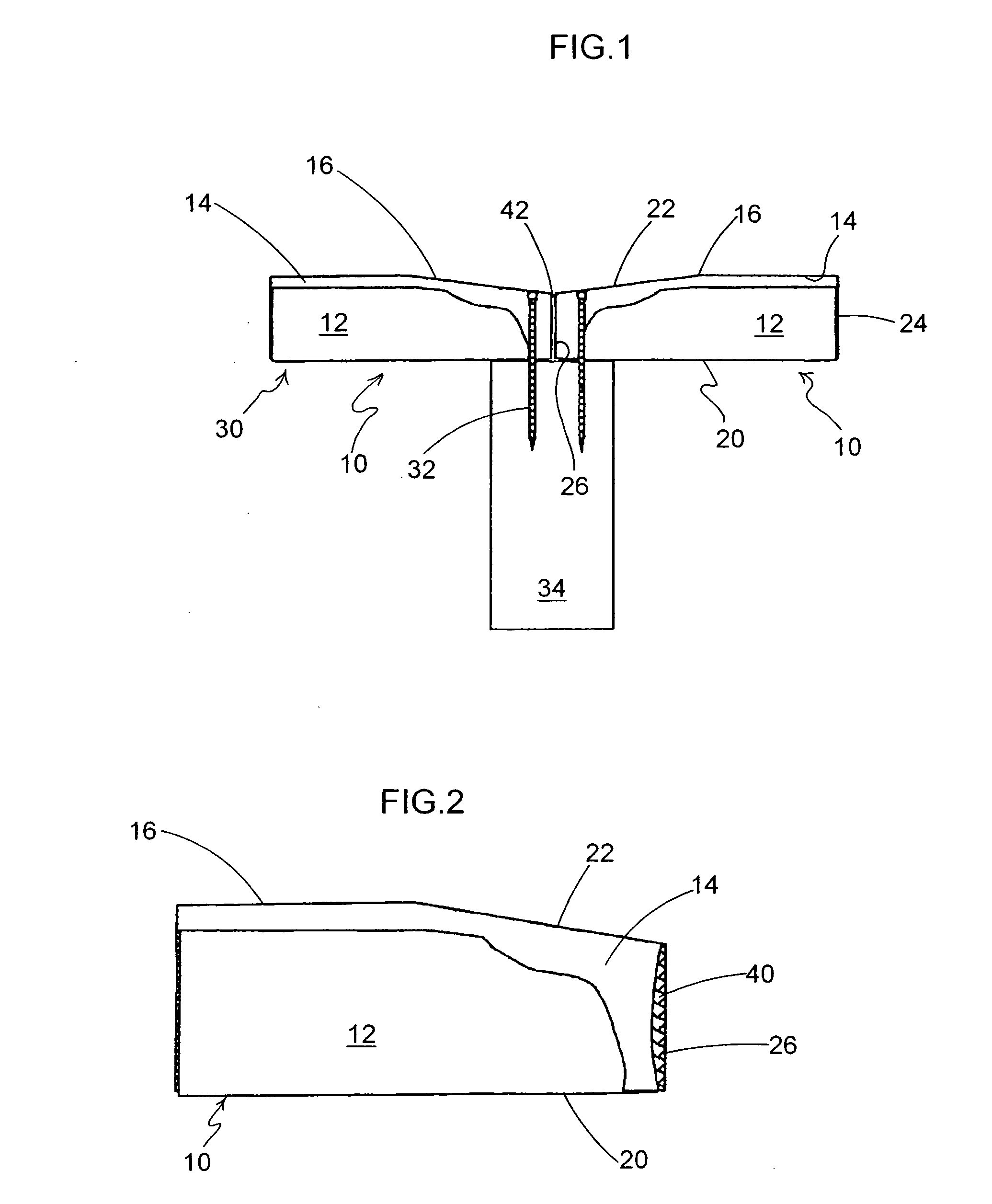

High performance non-combustible gypsum-cement compositions with enhanced water durability and thermal stability for reinforced cementitious lightweight structural cement panels

ActiveUS8038790B1Reduce weightPerformance requirementConstruction materialSolid waste managementOperating energyAir entrainment

Structural cement panel for resisting transverse and shear loads equal to transverse and shear loads provided by plywood and oriented strain board, when fastened to framing for use in shear walls, flooring and roofing systems. The panels provide reduced thermal transmission compared to other structural cement panels. The panels employ one or more layers of a continuous phase resulting from curing an aqueous mixture of calcium sulfate alpha hemihydrate, hydraulic cement, coated expanded perlite particles filler, optional additional fillers, active pozzolan and lime. The coated perlite has a particle size of 1-500 microns, a median diameter of 20-150 microns, and an effective particle density (specific gravity) of less than 0.50 g / cc. The panels are reinforced with fibers, for example alkali-resistant glass fibers. The preferred panel contains no intentionally added entrained air. A method of improving fire resistance in a building is also disclosed.

Owner:UNITED STATES GYPSUM CO

Cementing compositions and methods of cementing in a subterranean formation using an additive for preventing the segregation of lightweight beads.

Cementing compositions and methods of cementing in a subterranean formation are provided. The cement composition includes a hydraulic cement, lightweight beads, and a desegregating agent for inhibiting segregation of the beads. The lightweight beads may be, for example, cenospheres, glass spheres, and ceramic spheres. The desegregating agent comprises a particulate substrate such as precipitated silica. It also comprises a polar molecule producing chemical disposed on the particulate substrate. Preferably, the polar molecule producing chemical is absorbed on the particulate substrate. The polar molecule producing chemical comprises at least one of a polar molecule producing acid such as glacial acetic acid, a salt of such an acid, and an acid anhydride. The method of cementing includes forming a pumpable slurry using the cement composition, pumping the slurry into a subterranean formation, and allowing the slurry to set.

Owner:HALLIBURTON ENERGY SERVICES INC

Self adaptive cement systems

InactiveUS20070137528A1Avoid seizuresInhibit migrationSolid waste managementDrilling compositionSelf-healingChemical products

A self-adaptive cement system includes cement, water and at least one additive that reacts or and expands in contact with oil and gas. Several chemical products have been identified including rubber alkylstyrene, polynorbornene, resins such precrosslinked substituted vinyl acrylate copolymers and diatomaceous earth. These additives have the effect of making the cement self-healing in the event of physical failure or damage such as micro-annuli. The self healing property is produced by the contact with subterranean hydrocarbon fluids, the potential repair mechanism is thus activated if and when needed in case of start of loss of zonal isolation. In another embodiment, the expansion is deliberately induced by pumping a hydrocarbon fluid in the vicinity of the set cement.

Owner:SCHLUMBERGER TECH CORP

Settable fluids and methods for use in subterranean formations

The present invention relates to subterranean operations, and more particularly, to settable fluids comprising vitrified shale and hydrated lime and methods of using such settable fluids in subterranean applications. In an exemplary embodiment, the settable fluids of the present invention may be used as a displacement fluid. In another exemplary embodiment, the settable fluids of the present invention may be used as a drilling fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

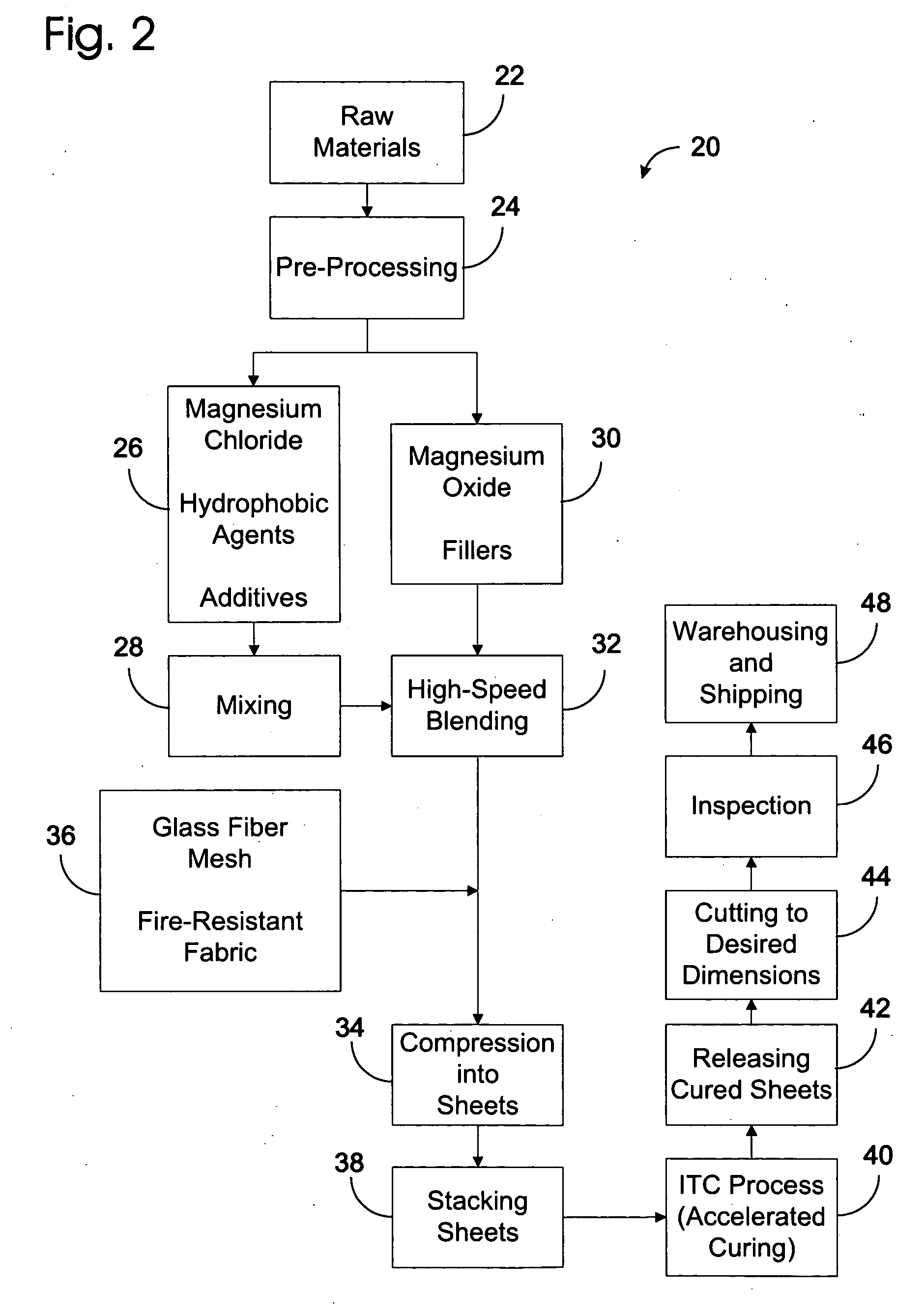

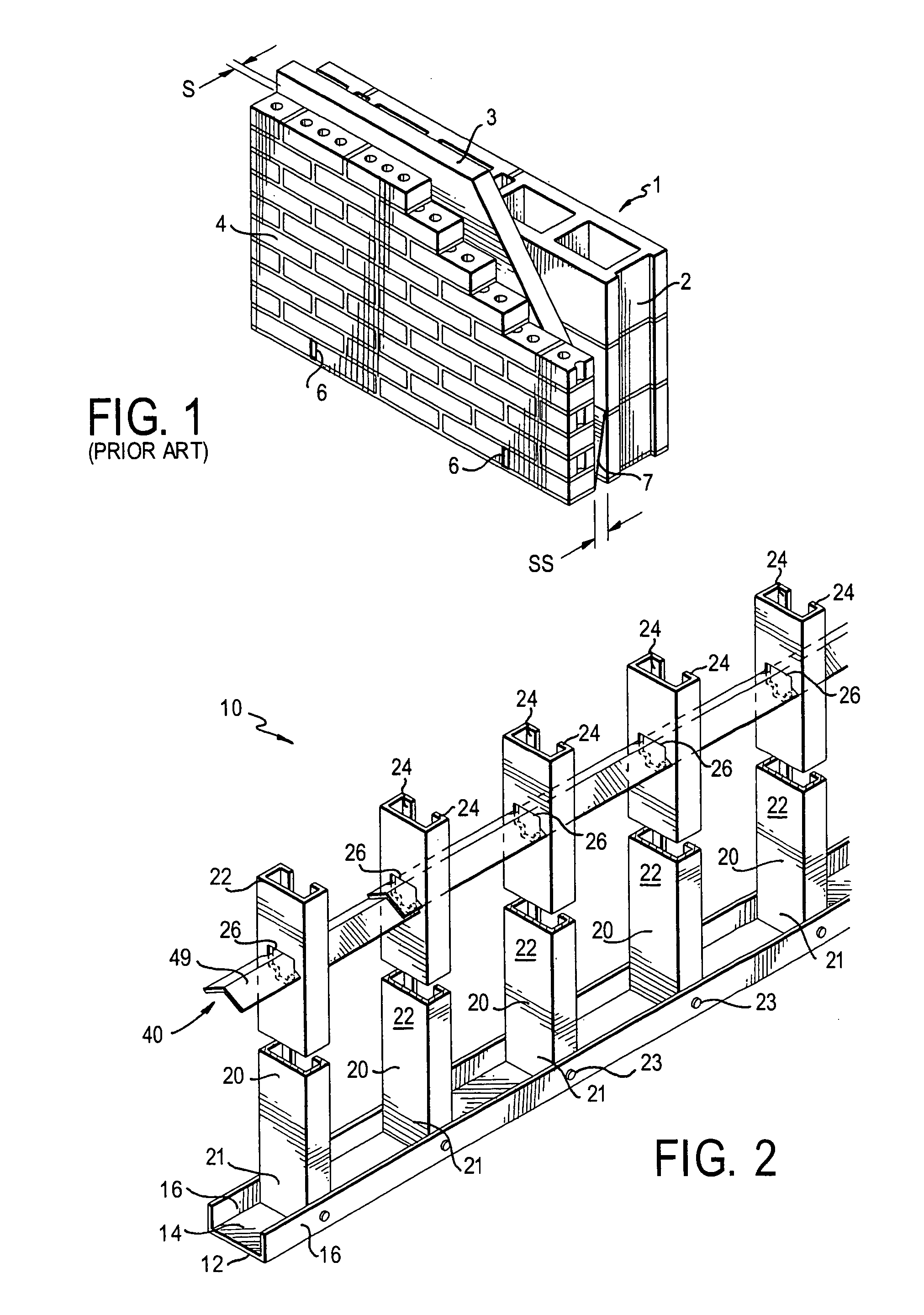

Non-combustible reinforced cementitious lighweight panels and metal frame system for a fire wall and other fire resistive assemblies

ActiveUS20060168906A1Reduce buildReduce capacityBuilding roofsSolid waste managementMicrosphereMetal framework

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

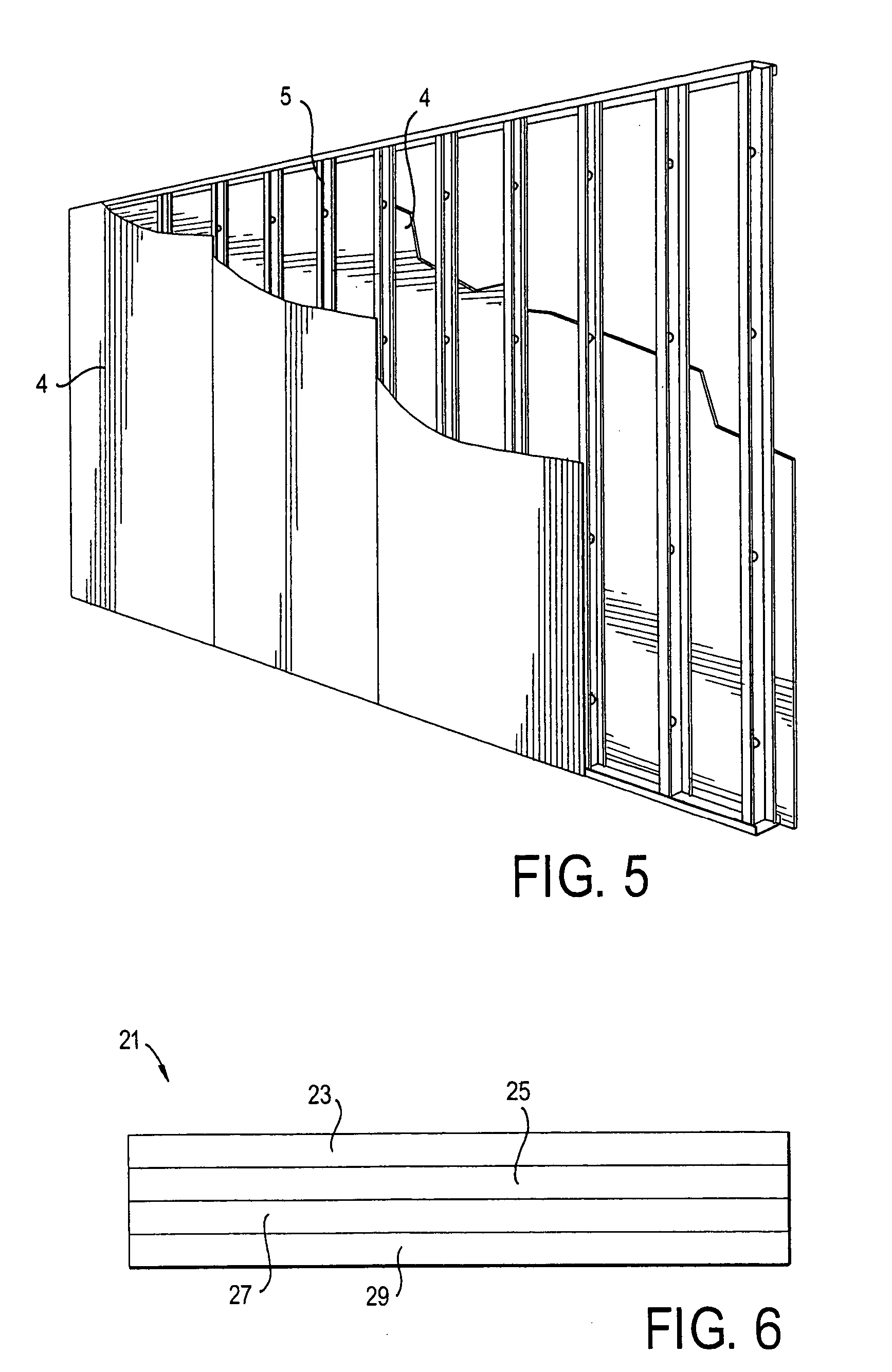

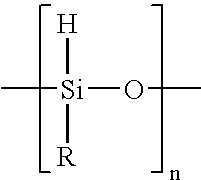

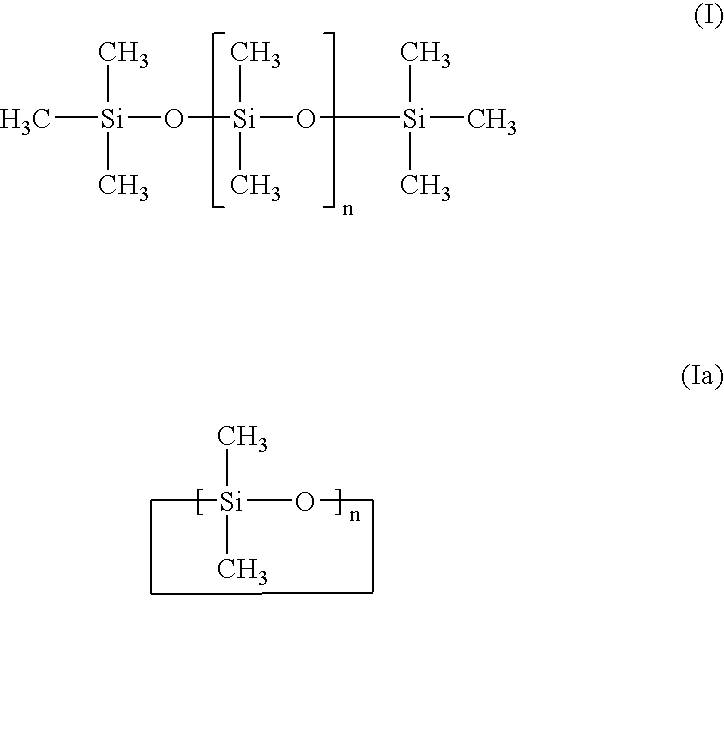

Siloxane polymerization in wallboard

ActiveUS20070022913A1Small expansionDimensional stabilitySolid waste managementWoven fabricsDihydrate Calcium SulfateSlurry

Polymerization of siloxane is improved using a gypsum-based slurry that includes stucco, Class C fly ash, magnesium oxide and an emulsion of siloxane and water. This slurry is used in a method of making water-resistant gypsum articles that includes making an emulsion of siloxane and water, then combining the slurry with a dry mixture of stucco, magnesium oxide and Class C fly ash. The slurry is then shaped as desired and the stucco is allowed to set and the siloxane polymerizes. The resulting product is useful for making a water-resistant gypsum panel having a core that includes interwoven matrices of calcium sulfate dihydrate crystals and a silicone resin, where the interwoven matrices have dispersed throughout them a catalyst comprising magnesium oxide and components from a Class C fly ash.

Owner:UNITED STATES GYPSUM CO

Methods of cementing in subterranean formations using cement kiln dust in compositions having reduced Portland cement content

The present invention includes methods of cementing in subterranean formations using cement kiln dust in compositions having reduced Portland cement content. An embodiment of a method comprises placing a sealant composition that comprises cement kiln dust and is essentially free of Portland cement in a subterranean formation; and allowing the sealant composition to set.

Owner:HALLIBURTON ENERGY SERVICES INC

Three dimensional printing material system and method

InactiveUS20020026982A1High strengthReduce the amount of solutionSolid waste managementCeramic shaping apparatusEngineeringLayer wise

The present invention is directed to a 3DP(TM) material system ad method, and an article made therefrom. The method of the present invention includes building cross-sectional portions of a three-dimensional article, and assembling the individual cross-sectional areas in a layer-wise fashion to form a final article. The individual cross-sectional areas are built by using an ink-jet printhead to deliver an aqueous fluid to a particulate material that includes plaster.

Owner:3D SYST INC

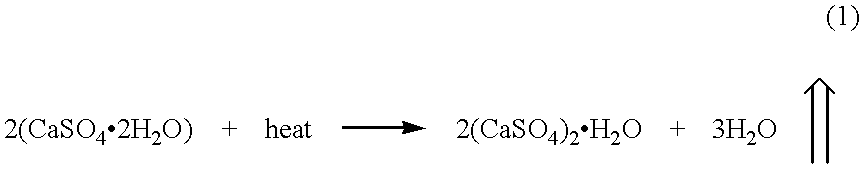

Gypsum-containing board and tile, and method for producing same

InactiveUS20050019618A1Improve the immunitySave a lot of costLiquid surface applicatorsConstruction materialO-Phosphoric AcidBrick

A method for producing a set gypsum-containing product comprising an interlocking matrix of set gypsum wherein said method comprises applying to said set gypsum one or more enhancing materials selected from the group consisting of phosphoric acid; condensed phosphoric acids, each of which comprises 2 or more phosphoric acid units; and salts or ions of condensed phosphates, each of which comprises 2 or more phosphate units, and monobasic salts or monovalent ions of orthophosphates.

Owner:UNITED STATES GYPSUM CO

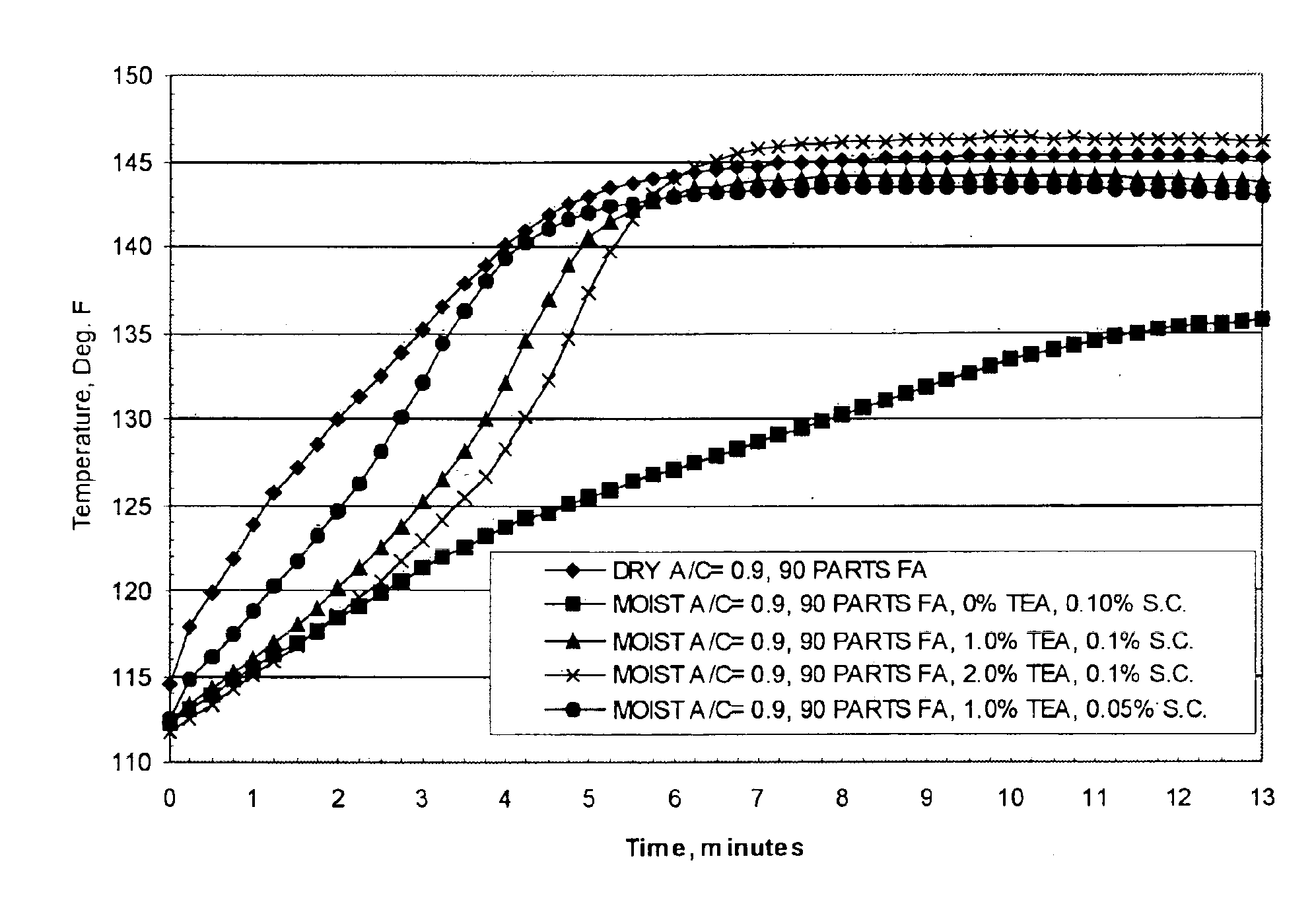

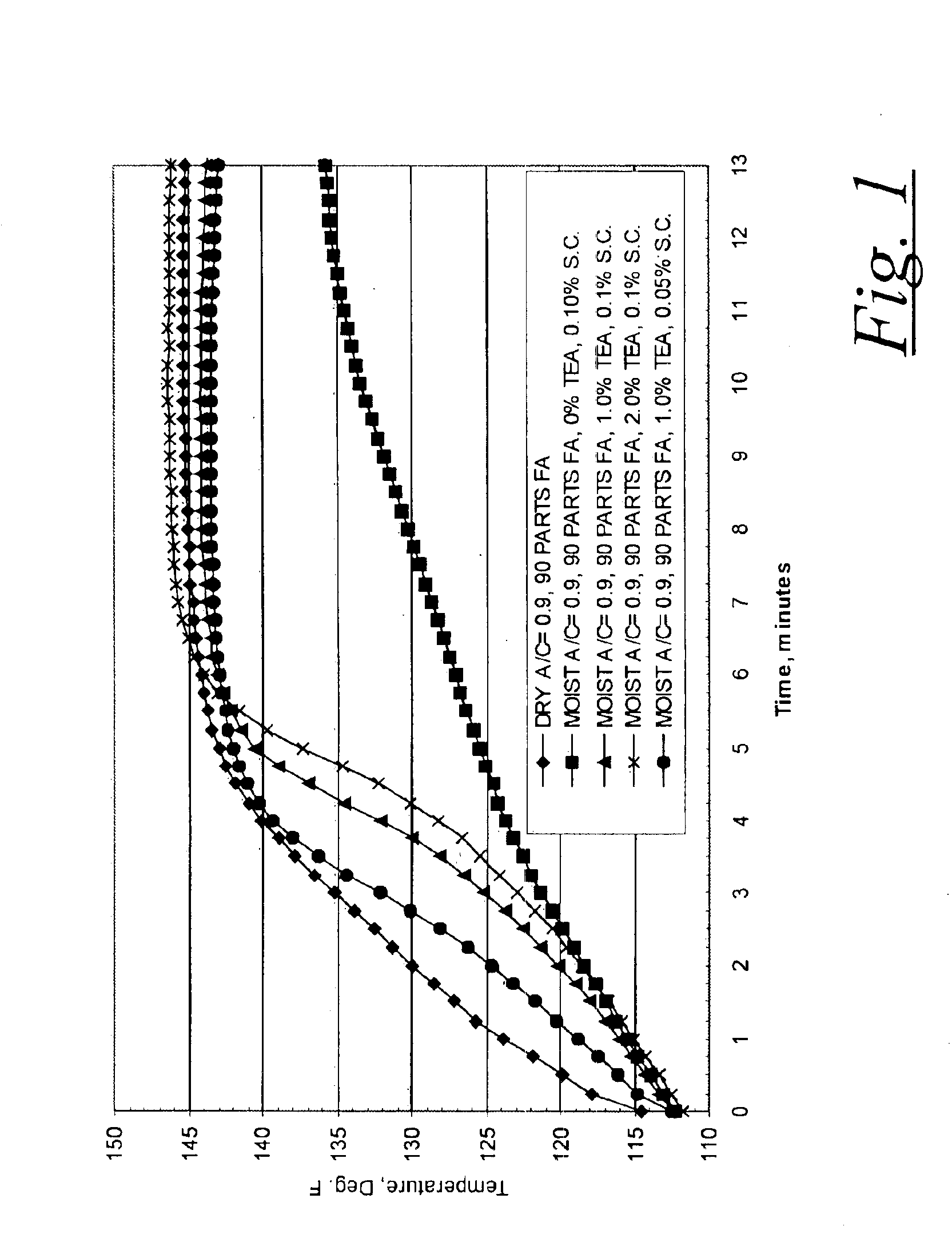

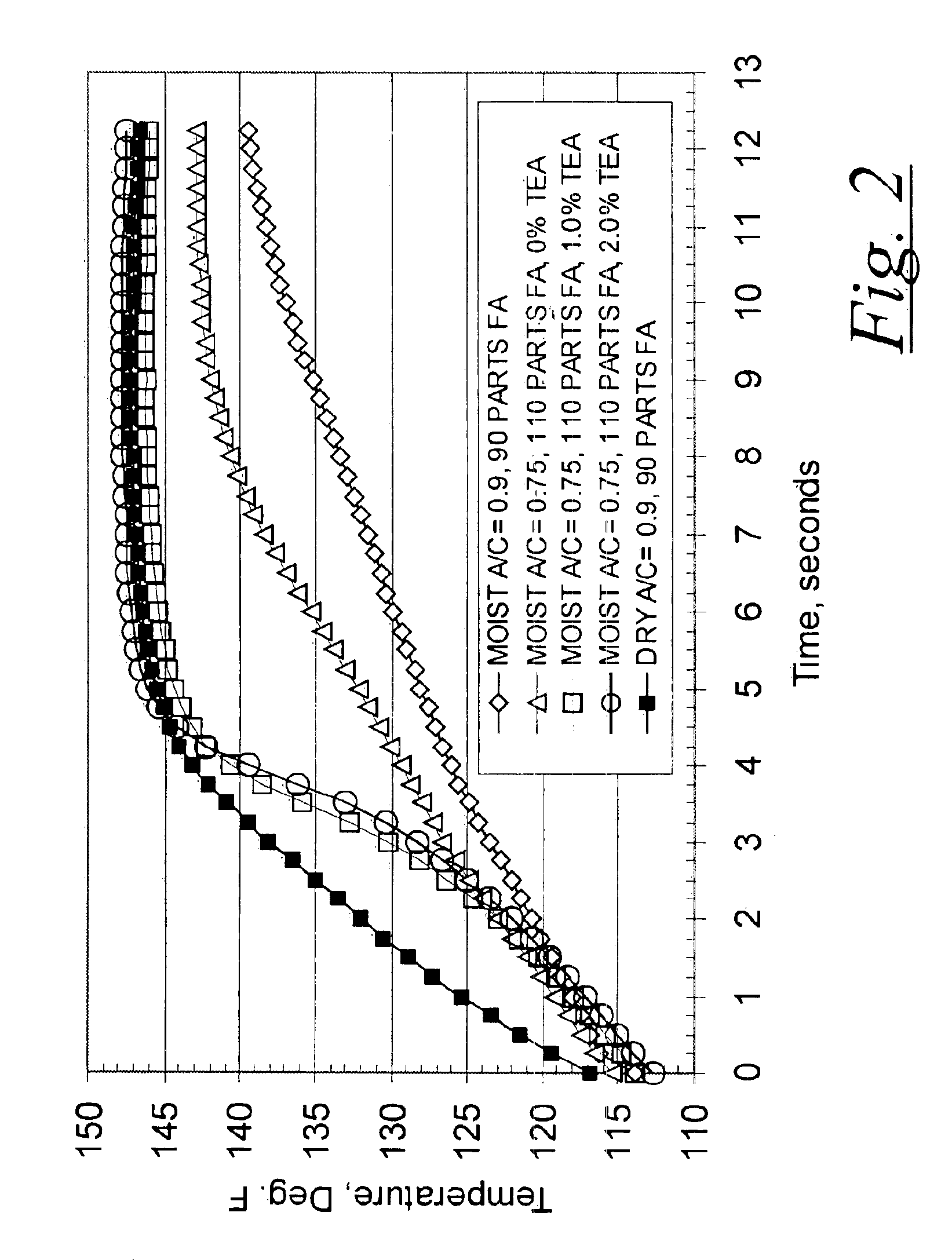

Very fast setting cementitious composition

Extremely fast setting of cementitious compositions for producing cement-based products such as cement boards is made possible by adding an alkanolamine to a hydraulic cement such as portland cement, and forming a slurry with water under conditions that provide an initial slurry temperature of at least 90° F. Use of alkanolamine under conditions disclosed herein allows an extremely rapid setting of the cementitious composition. Additional reactive materials may be included such as high alumina cement, calcium sulfate and a pozzolanic material such as fly ash. The extremely fast rapid set permits rapid production of cementitious products.

Owner:UNITED STATES GYPSUM CO

Gypsum wood fiber product having improved water resistance

InactiveUS6010596AImprove water resistanceHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberWax

An improved water resistant gypsum board is made by adding an aqueous wax emulsion containing a cationic surfactant to an aqueous slurry containing calcium sulfate and host particles at a slurry temperature which maintains calcium sulfate hemihydrate crystals. The wax emulsion is stable at the temperature of slurry which maintains the calcium sulfate hemihydrate. The slurry is then dewatered and rehydrated to form a gypsum board and dried at a temperature to melt the wax.

Owner:UNITED STATES GYPSUM CO

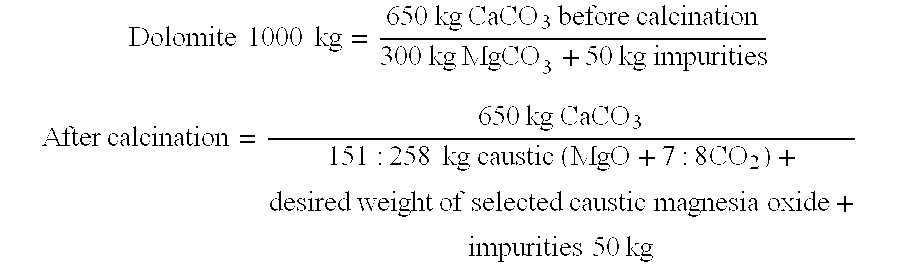

Settable composition and uses therefor

InactiveUS6200381B1Decrease decarbonisation temperaturePromote decompositionSolid waste managementWaste productSlurry

A dry powdered flowable cement composition contains calcium carbonate and a partially decarbonated magnesium carbonate. A slurry of the composition will set hard with various organic fillers including waste products and toxic waste. The composition can be slurried with contaminated water such as sea water, mineral laden ground water and muddy water. A high percentage of filler can be added while still having an acceptable set.

Owner:DOLOMATRIX INT LIMITED ACN 091 340 920

Processes for incorporating inert gas in a cement composition containing spherical beads

ActiveUS20050098317A1High densityModifies its propertySolid waste managementFluid removalAl powderPhysical chemistry

The present invention provides a process for forming cement in a well bore. In this process, a cement composition is formed that comprises a cement and one or more beads mixed with the cement. The cement composition containing the beads is displaced into the well bore, and an inert gas phase is introduced to the cement composition to control a density of the cement composition. The inert gas phase can be introduced by adding a gas generating material to the cement composition and / or a porous material to the cement composition. In an embodiment, the gas generating material is a nitrogen generating material that may be activated by an oxidizing agent. In another embodiment, the gas generating material is a hydrogen generating material, e.g., an aluminum powder. The present invention further provides a cement composition comprising a cement, one or more beads combined with the cement, and an inert gas phase created by, e.g., a gas generating material and / or a porous material.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods of cementing in subterranean formations using crack resistant cement compositions

The present invention relates to subterranean cementing operations, and more particularly, to methods of cementing in subterranean formations using cement compositions that autogenously cure voids that may form in such cement compositions. In one embodiment, the present invention provides a method of cementing in a subterranean formation penetrated by a well bore comprising the steps of: placing a cement composition into the well bore, wherein the cement composition comprises a first cementitious component having a first set time and a second cementitious component having a second set time that is delayed relative to the first set time of the first cementitious component; allowing the first cementitious component to at least partially set; and allowing the second cementitious component to set after a delay period.

Owner:HALLIBURTON ENERGY SERVICES INC

Geopolymer composition and application in oilfield industry

ActiveUS20080028994A1Enhanced pumpabilityImprove stabilitySolid waste managementAlkali metal silicate coatingsGeopolymerSlurry

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, lightweight or heavyweight fillers and a carrier fluid wherein the suspension of said geopolymeric composition is pumped in a well and allowed to set.

Owner:SCHLUMBERGER TECH CORP

Fire-resistant gypsum panel

InactiveUS20080087366A1Improve fire resistanceImprove fire performanceConstruction materialCovering/liningsFire protectionSlurry

A method of continuously forming a multilayer panel includes making a gypsum slurry, then dividing the gypsum slurry into at least a primary gypsum slurry and a secondary gypsum slurry. An additive slurry having water and an intumescent material is created, then added to the secondary gypsum slurry to make an expandable layer slurry that is spread over at least a portion of a facing material. The primary gypsum slurry is distributed over the secondary gypsum slurry over the facing material and the expanding layer slurry to form a core. Optionally, another layer, an edge coating, is applied to the expanding layer for additional fire protection. The edge coating includes a second intumescent material. During a fire, the expanding layer expands to increase the thickness of the fire exposed gypsum panel and the edge coating expands to seal the gap between adjoining gypsum panels.

Owner:UNITED STATES GYPSUM CO

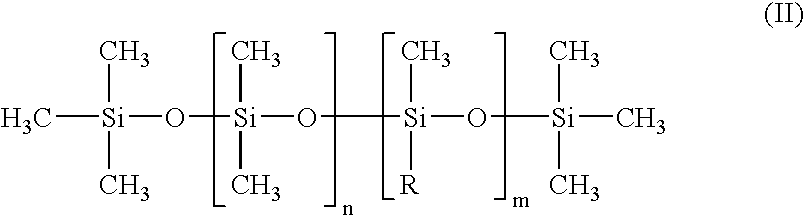

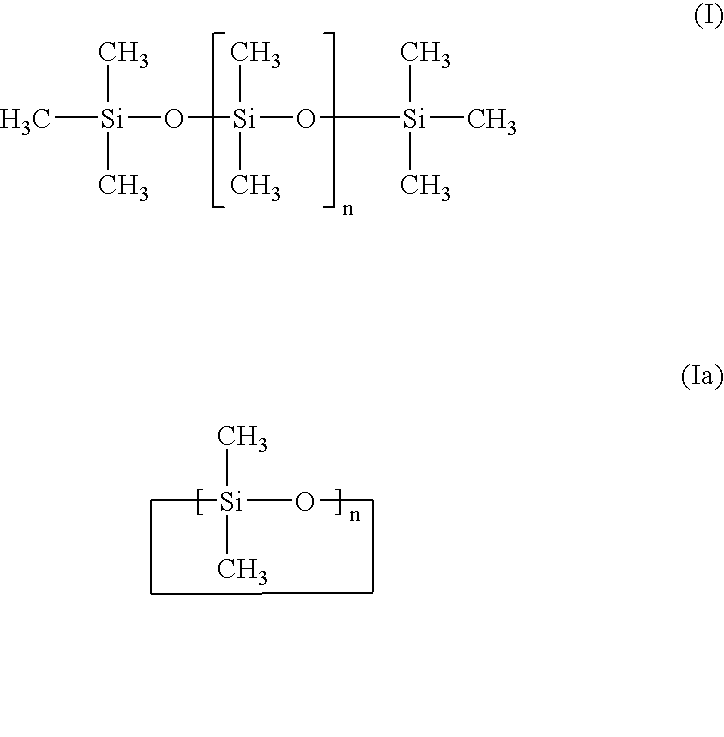

Process for producing detachable dirt- and water-repellent surface coatings

ActiveUS7083828B2Good removal effectSimple wayFouling preventionSolid waste managementWaxSurface structure

Process for producing detachable dirt- and water-repellent surface coatings on articles, wherein during the coating process, hydrophobic particles are applied to the surface of the articles, thus generating a surface structure with elevations on that surface of the articles that has dirt- and water-repellent properties, which comprises suspending the hydrophobic particles in a solution of a silicone wax in a highly volatile siloxane, and applying this suspension to at least one surface of an article, and then removing the highly volatile siloxane.

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com