Patents

Literature

248 results about "Toxic waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toxic waste is any unwanted material in all forms that can cause harm (e.g. by being inhaled, swallowed, or absorbed through the skin). Many of today's household products such as televisions, computers and phones contain toxic chemicals that can pollute the air and contaminate soil and water. Disposing of such waste is a major public health issue.

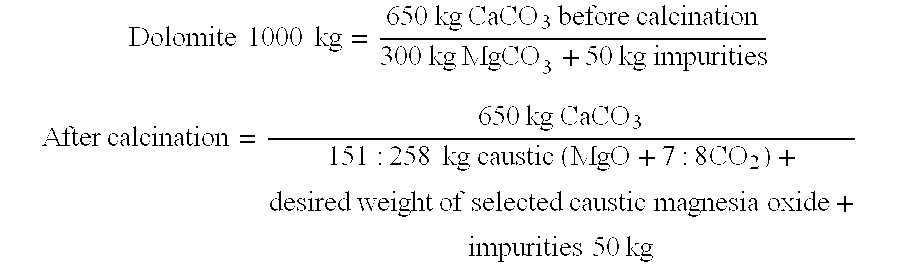

Settable composition and uses therefor

InactiveUS6200381B1Decrease decarbonisation temperaturePromote decompositionSolid waste managementWaste productSlurry

A dry powdered flowable cement composition contains calcium carbonate and a partially decarbonated magnesium carbonate. A slurry of the composition will set hard with various organic fillers including waste products and toxic waste. The composition can be slurried with contaminated water such as sea water, mineral laden ground water and muddy water. A high percentage of filler can be added while still having an acceptable set.

Owner:DOLOMATRIX INT LIMITED ACN 091 340 920

Delivery systems for mycotechnologies, mycofiltration and mycoremediation

The present invention utilizes fungal spore mass or hyphal fragments in burlap bags or sacks filled with biodegradable materials. The fungi may include saprophytic fungi, including gourmet and medicinal mushrooms, mycorrhizal fungi, entomopathogenic fungi, parasitic fungi and fungi imperfecti. The fungi function as keystone species, delivering benefits to both the microsphere and biosphere. Such fungal delivery systems are useful for purposes including ecological rehabilitation and restoration, preservation and improvement of habitats, bioremediation of toxic wastes and polluted sites, filtration of agricultural, mine and urban runoff, improvement of agricultural yields and control of biological organisms.

Owner:TURTLE BEAR HLDG LLC

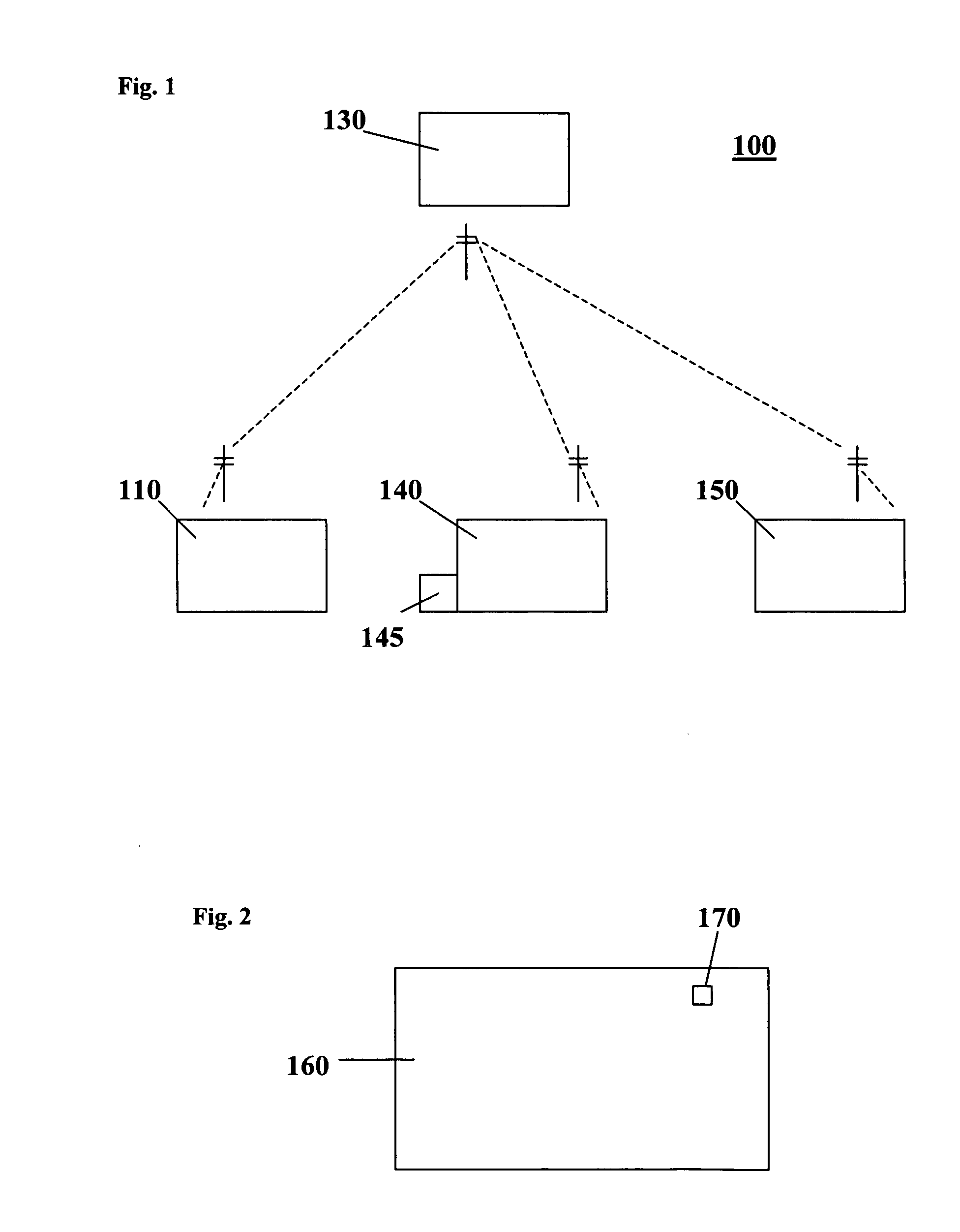

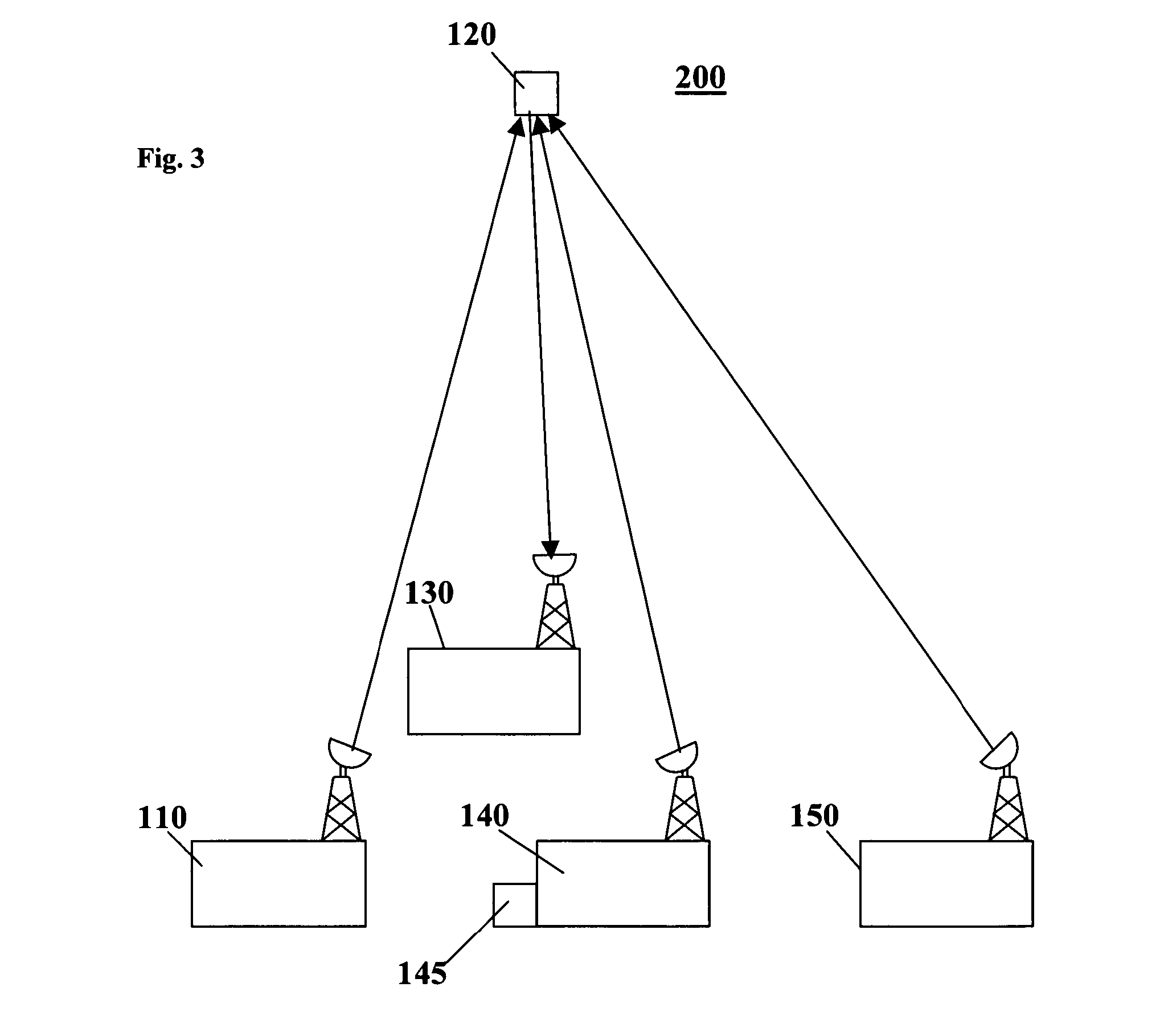

Method and system for tracking medical and other waste

InactiveUS20050228682A1Complete banking machinesSustainable waste treatmentMedical wasteToxic material

A system and method for tracking medical or toxic waste including a first container adapted to hold untreated medical waste, the container having a wireless tracking device attached thereto. The system also includes a tracking station capable of monitoring the movement of the medical waste by tracking the wireless tracking device.

Owner:SANITEC INDS

Process for recycling waste mineral oil without hazardous material emission

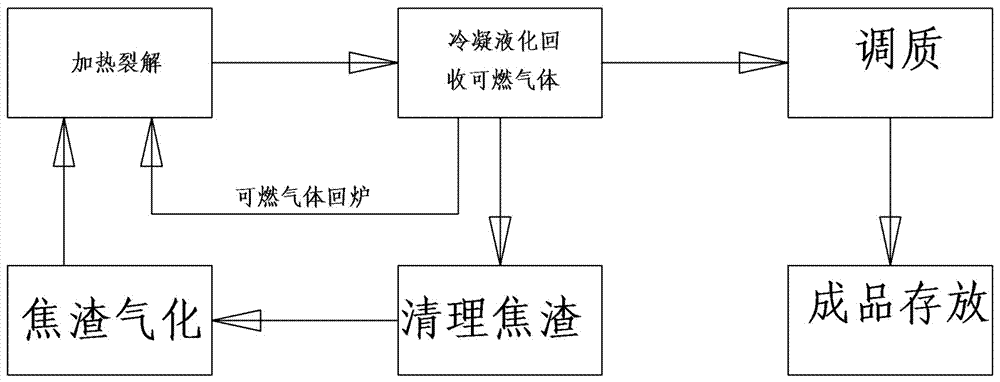

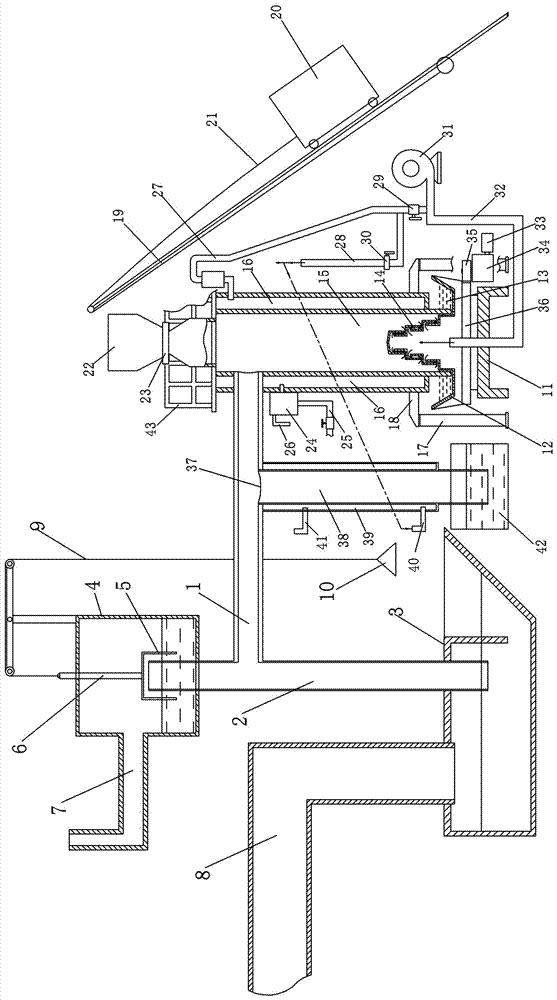

ActiveCN107099328ANo emissionsTake advantage ofTreatment with plural serial stages onlyGasification processes detailsClosed loopCombustible gas

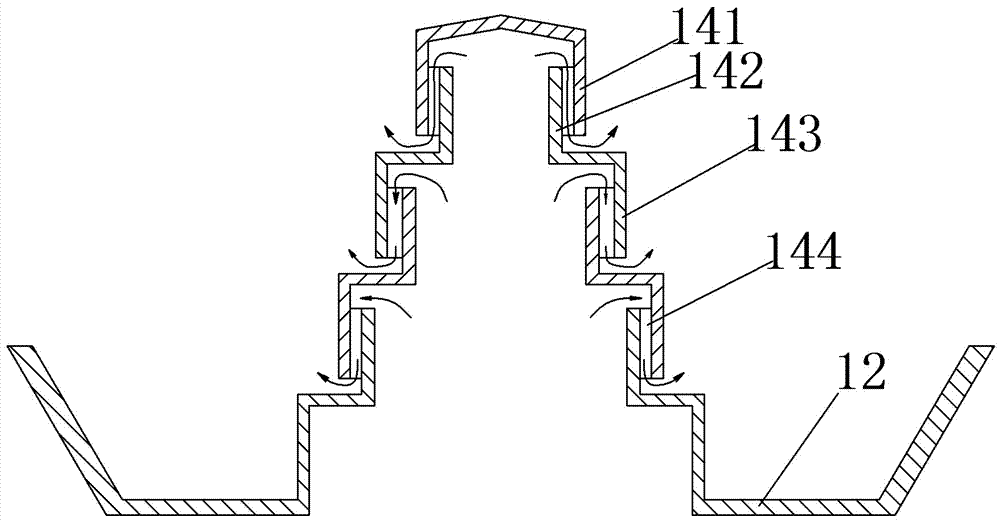

The invention discloses a process for recycling waste mineral oil without hazardous material emission. The process includes steps of 1, carrying out heating pyrolysis; 2, carrying out condensation and liquefaction and simultaneously recycling combustible gas; 3, carrying out conditioning; 4, storing finished products; 5, clearing coke residues, and to be more specific, clearing solid residual substances-coke residues obtained after clearing pyrolysis is carried out in reaction kettles; 6, gasifying the coke residues, to be more specific, crushing the coke residues cleared at the step 5 to obtain granules, then feeding the granules into a coke residue gasification furnace, gasifying the granules by the aid of the gasification furnace to obtain combustible gas, leading the combustible gas into a gas furnace used at the step 1 and combusting the combustible gas in the combustible furnace. The process has the advantages that certain waste gas and waste residues which are generated during pyrolysis on the waste mineral oil can be used as fuel to be fed into heating furnaces for the reaction kettles in closed-loop procedures, and accordingly the process is basically free of emission of toxic waste gas and toxic waste residues; all combustible substances in the waste mineral oil can be comprehensively sufficiently utilized, accordingly, environments can be protected, energy can be saved, and the process is favorable for society and people.

Owner:洛阳德正废弃资源再利用有限公司

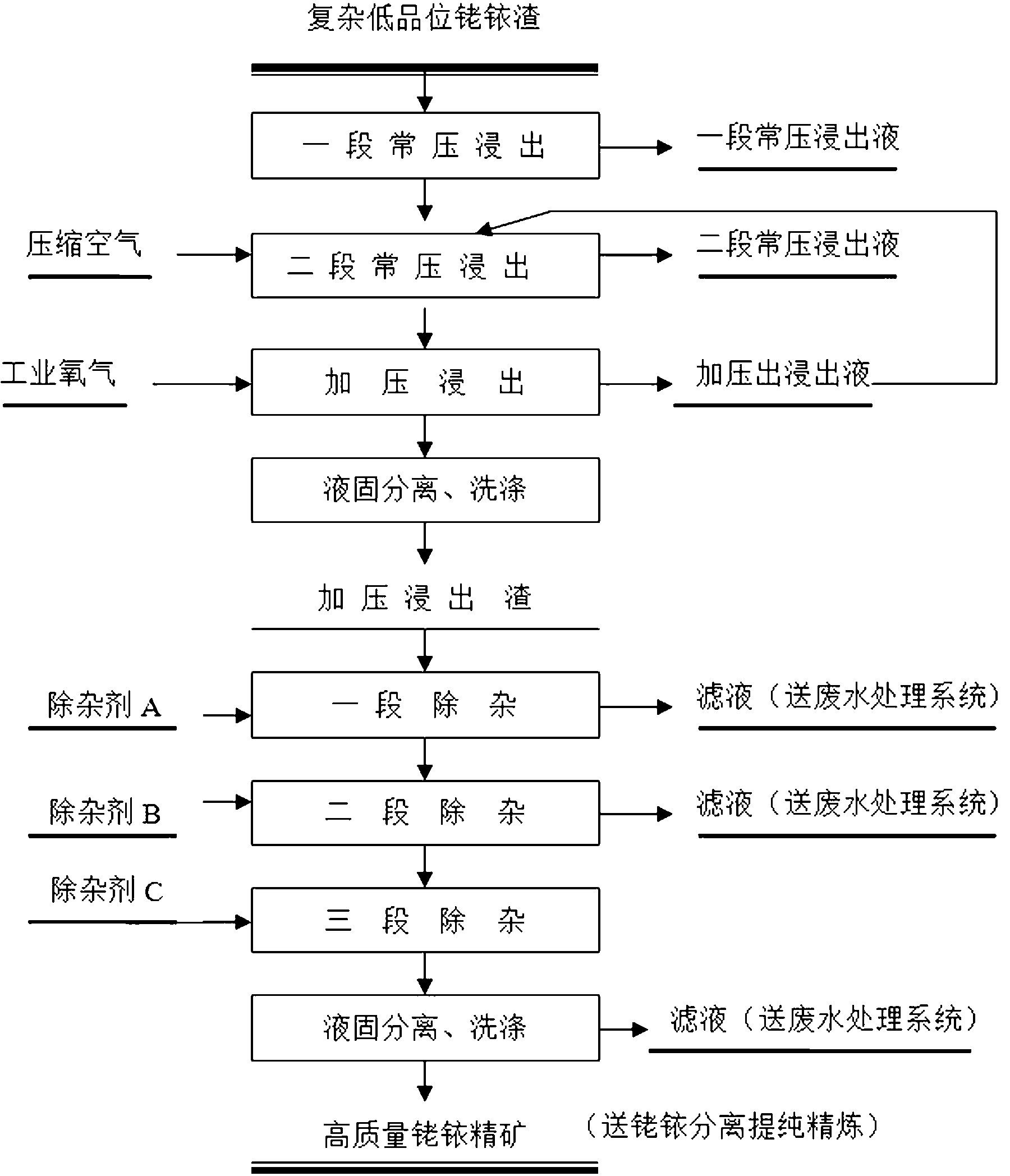

Method for efficiently enriching gold and platinum group metals from complex low-grade rhodium iridium residues

ActiveCN103320620AHigh recovery rateEliminate Scatter LossProcess efficiency improvementIridiumToxic material

The invention relates to a method for efficiently enriching gold and platinum group metals from complex low-grade rhodium iridium residues and belongs to the field of wet metallurgy of rare and precious metals. The method comprises the following steps that: primary normal pressure leaching, secondary normal pressure leaching and pressurization leaching are performed by using a low-concentration pure sulfuric acid solution, wherein an oxidizing agent is not introduced or added into the primary normal pressure leaching, air in the secondary normal pressure leaching serves as an oxidizing and leaching agent, industrial oxygen serves as an oxidizing and leaching agent in the pressurization leaching; the high-grade high-quality rhodium iridium concentrate is obtained by employing a three-step impurity removal process. The method is simple in process and environment-friendly, toxic waste gas, waste residues and the like are not generated in the process, a toxic agent is not used, the enrichment ratio and recovery rate of rare and precious metals such as rhodium and iridium are high, the grade of the precious metals in the enriched residue is 15 percent, the recovery rate of the precious metals is over 98 percent, and the method is conveniently linked with rhodium and iridium separating and refining.

Owner:JINCHUAN GROUP LIMITED

Rice-seedling mechanical-transplanting and raising matrix

The invention discloses a rice-seedling mechanical-transplanting and raising matrix, comprising the following components in parts by weight: 10-30 parts of fermentation straw coarse grains, 70-90 parts of non-toxic wastes in the fermentation industry and 0.1-2 parts of auxiliary materials, wherein the industrial non-toxic wastes are biogas residues generated in alcohol fermentation; the auxiliary materials are one or more of nutrient elements, a dwarfed strong seedling agent, a root growth promotion agent and a safety agent; and the nutrient elements are selected from one or more of nitrogen, phosphorus, potassium, zinc, boron and silicon. The rice-seedling mechanical transplanting and raising matrix disclosed by the invention has the advantages of easiness in obtaining materials, low production cost and good rice-seedling raising effect.

Owner:XINGHUA TIANYUAN MATRIX FERTILIZER CO LTD

Low-carbon high-performance concrete supplementary cementitious material

The invention discloses a low-carbon high-performance concrete supplementary cementitious material which is prepared from 20-70 parts of slag, 20-70 parts of coal ash, 5-10 parts of silica fume, 3-10 parts of desulfurized gypsum and 1-3 parts of water reducing agent by weight to form an admixture, wherein the slag, the coal ash, the silica fume and the desulfurized gypsum are micro aggregates of 100 nanometers to 100 microns; and the materials are sequentially placed in a mixer and stirred for 60-120 minutes at a speed of 60-120 rpm at normal temperature under normal pressure to obtain the supplementary cementitious material. The low-carbon high-performance concrete supplementary cementitious material disclosed by the invention can replace 70% of cement in concrete when applied to concrete; and even if the 70% of cement is replaced, the strength of the prepared concrete also can reach C15-C60. The low-carbon high-performance concrete supplementary cementitious material is suitable to be used as a building material and also has special purposes of back-fill grouting, toxic waste solidification and the like.

Owner:宁夏新丰益节能科技有限公司

Delivery systems for mycotechnologies, mycofiltration and mycoremediation

InactiveUS20050176583A1Promote decompositionEnhancing habitat recoveryBiocideFungiBiospherePlanting seed

The present invention utilizes fungal spore mass or hyphal fragments in landscaping cloths, fiber substrates, paper products, hydroseeders and agricultural equipment. The fungi may include saprophytic fungi, including gourmet and medicinal mushrooms, mycorrhizal fungi, entomopathogenic fungi, parasitic fungi and fungi imperfecti. The fungi function as keystone species, delivering benefits to both the microsphere and biosphere. Such fungal delivery systems are useful for purposes including ecological rehabilitation and restoration, preservation and improvement of habitats, bioremediation of toxic wastes and polluted sites, filtration of agricultural, mine and urban runoff, improvement of agricultural yields and control of biological organisms. The invention allow for a variety of methods and products including the use of cardboard boxes as a delivery system for fungi with or without the combination with plant seeds for starting gardens, for controlling insects, or for the process of ecological recovery.

Owner:CISCO TECH INC +1

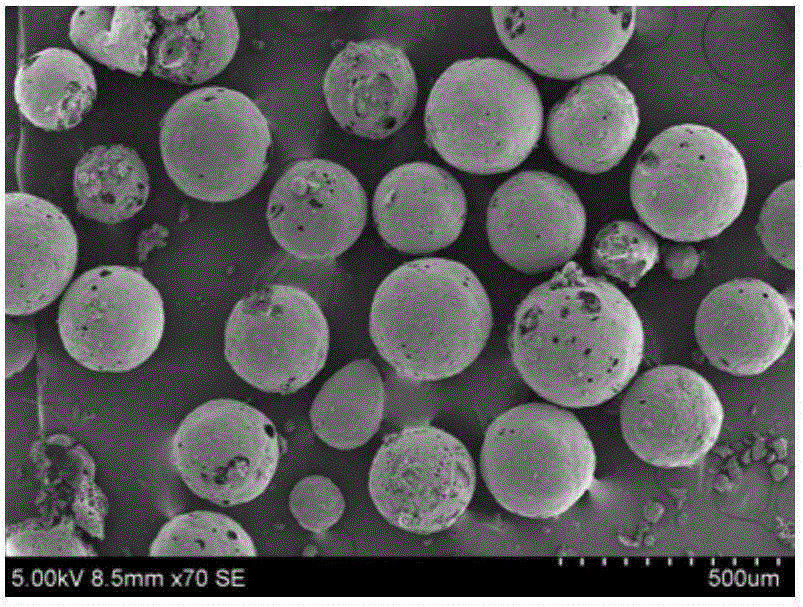

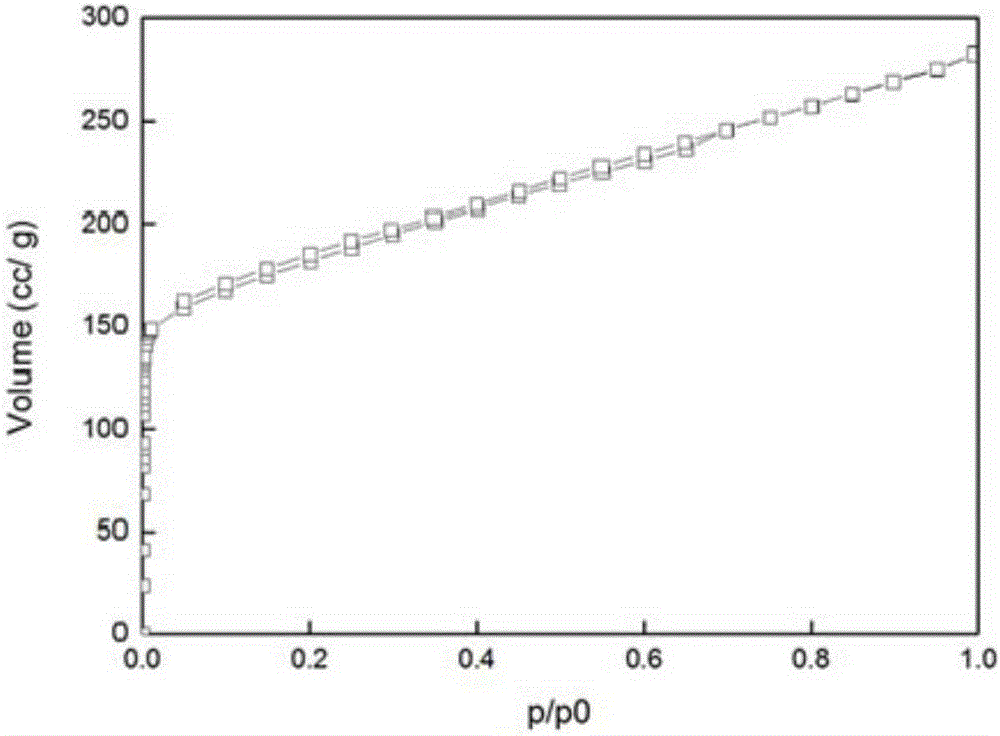

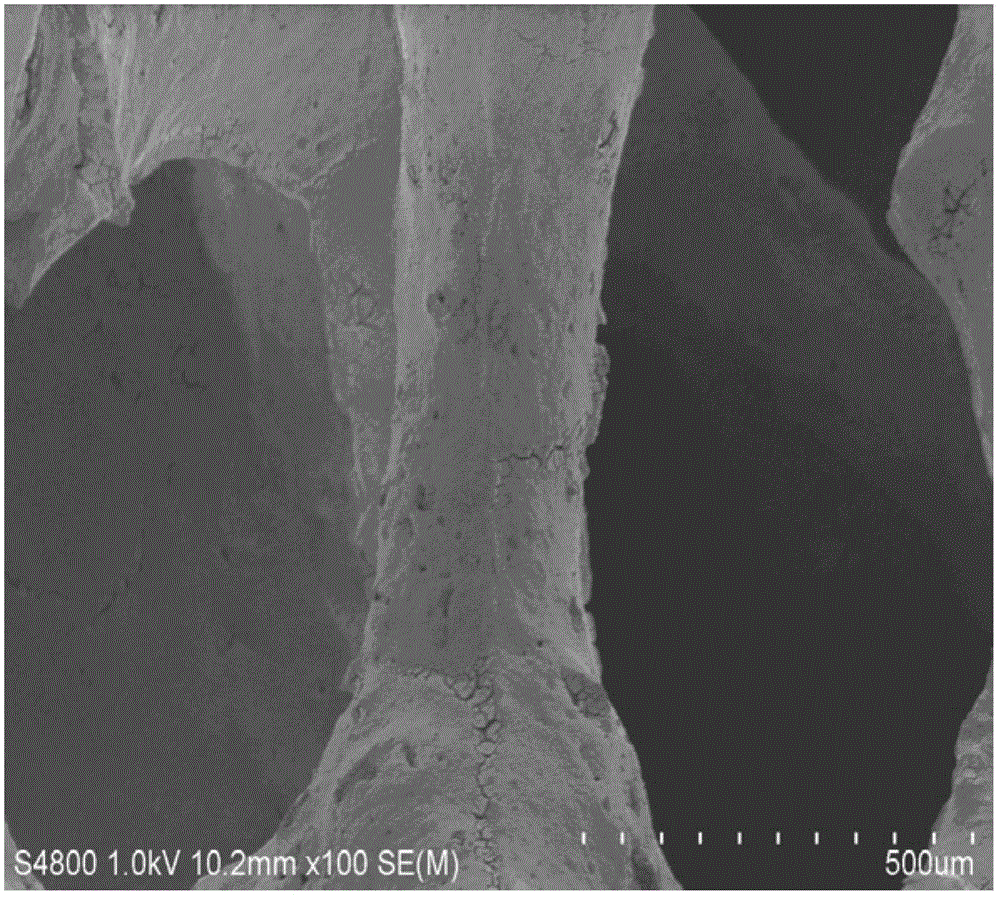

Lignin-based activated carbon microsphere and preparation method and application thereof

The invention provides a lignin-based activated carbon microsphere and a preparation method thereof. Wood powder and phenol are mixed and liquified under the condition that an acidic catalyst exists, then a stabilizer and a surfactant are added into the wood liquified matter to prepare a microsphere, then the microsphere is cured and carbonized, and the activated carbon microsphere is prepared. The prepared microsphere has the advantages of being uniform in surface, regular in shape, uniform in density during filling, large in internal pore number and the like, and can be used in the fields of adsorption materials and electrochemical materials. Wood serves as the raw material to prepare the lignin-based activated carbon microsphere, utilization additive value of wood is increased, and the problem that preparation of an activated carbon microsphere with phenolic resin as the raw material depends on fossil resources is reduced. In the curing process of the microsphere, formaldehyde does not need to be added, emission of toxic waste gas in the preparation process is reduced, and damage to human bodies and environment pollutions of harmful gas are avoided in the production process.

Owner:BEIJING FORESTRY UNIVERSITY

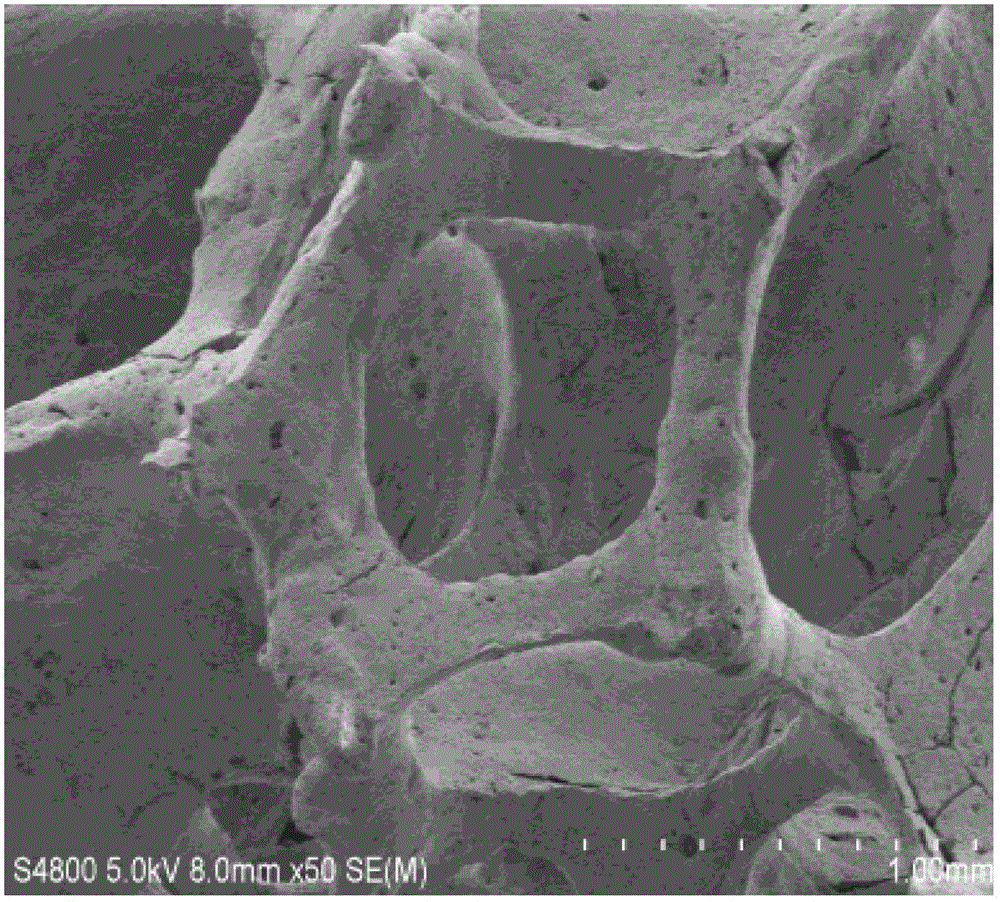

Foamed aluminum carried titanium dioxide catalyst, its preparation method and uses

InactiveCN1788839AConvenient sourceEasy to makeDispersed particle separationCatalyst activation/preparationWastewaterToxic material

The present invention is foamed aluminum supported titania catalyst and its preparation process and application, and features that the catalyst has foamed aluminum carrier and nanometer titania or nanometer doped titania on the surface of the carrier. The catalyst has simple preparation process, facile material, excellent stability, high catalytic activity, convenient use and convenient reuse, and may be used widely in various photocatalytic fields for purifying air, purifying water, treating toxic waste water, purifying atmosphere, sterilizing, etc.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

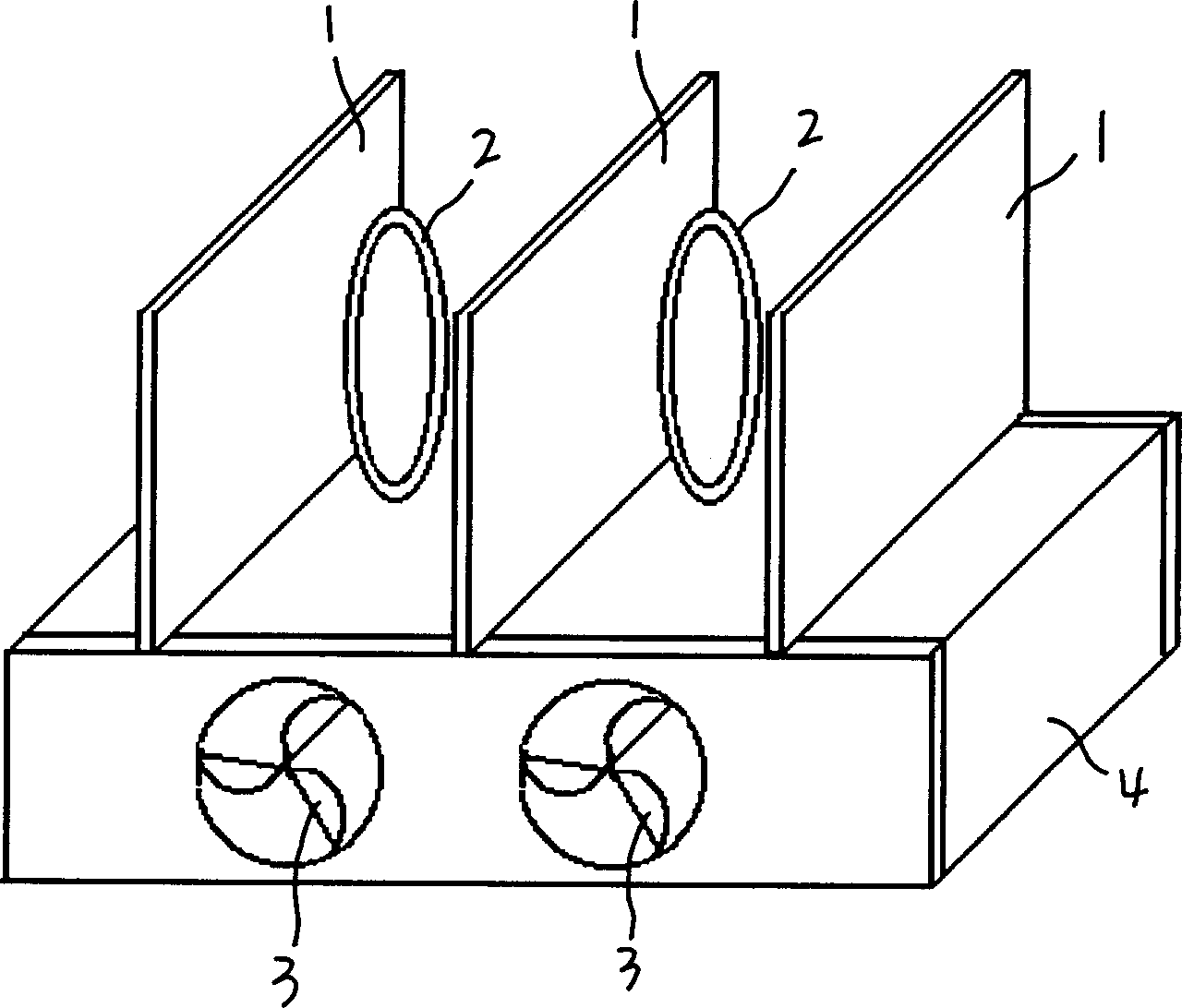

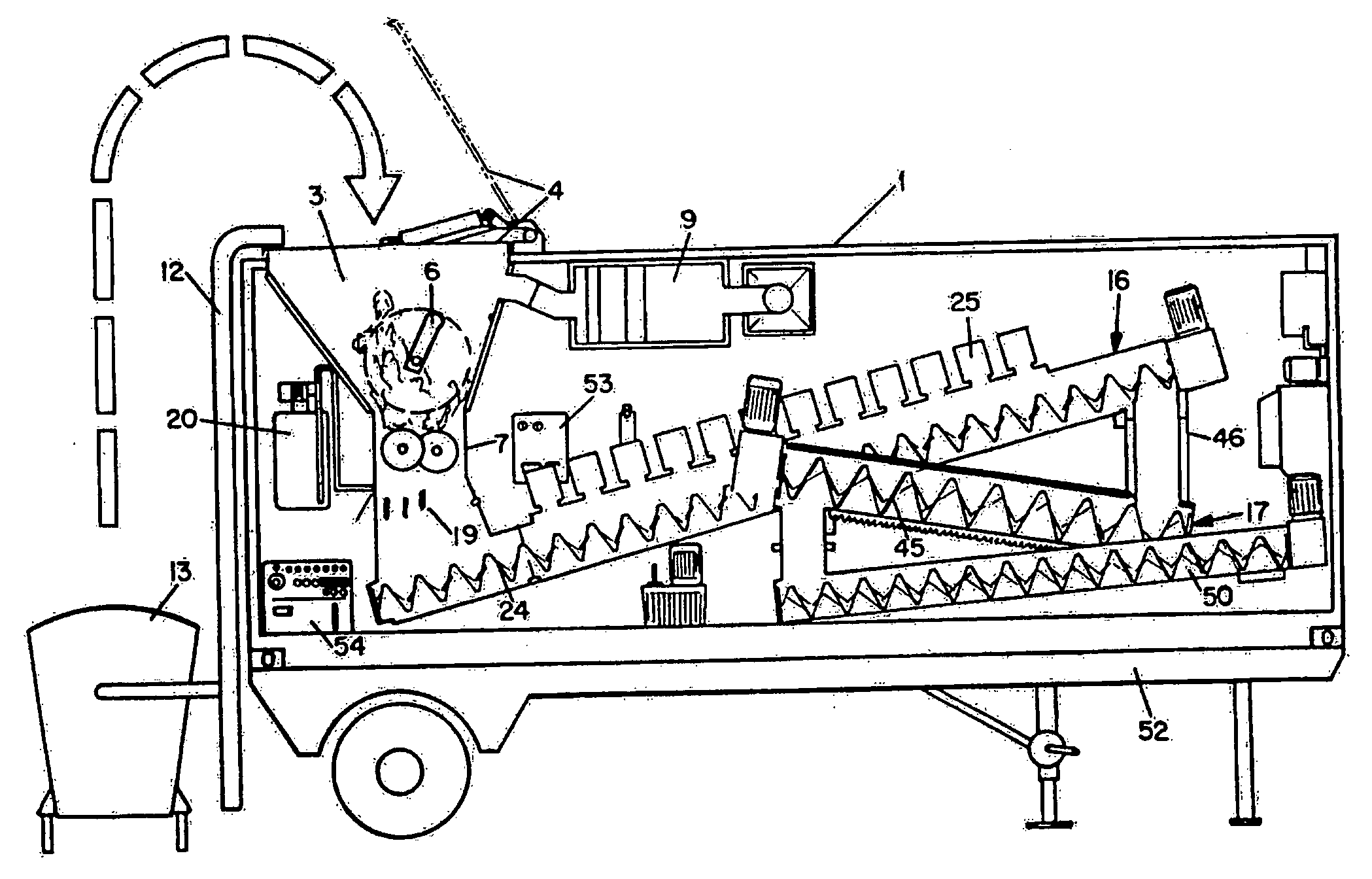

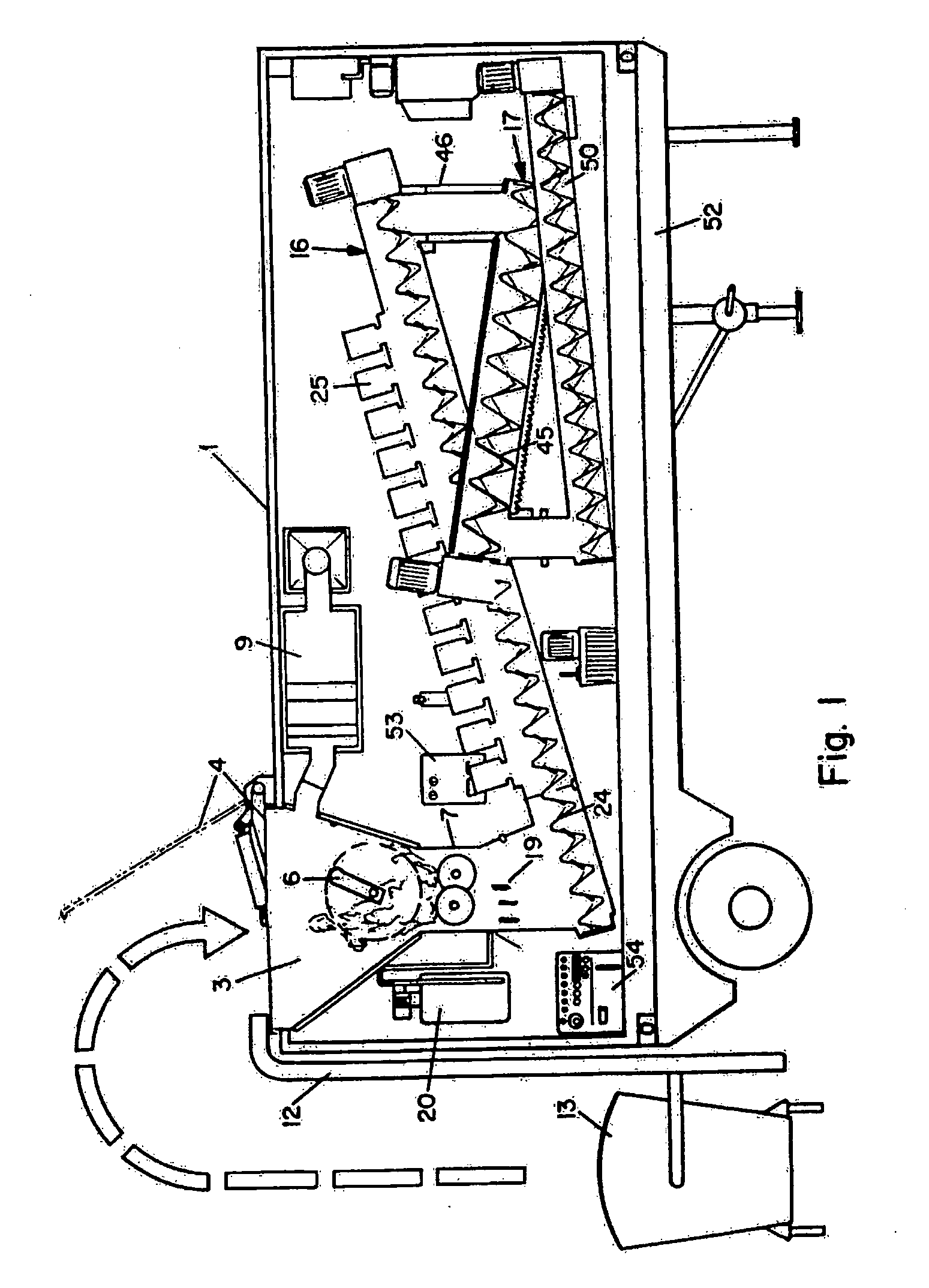

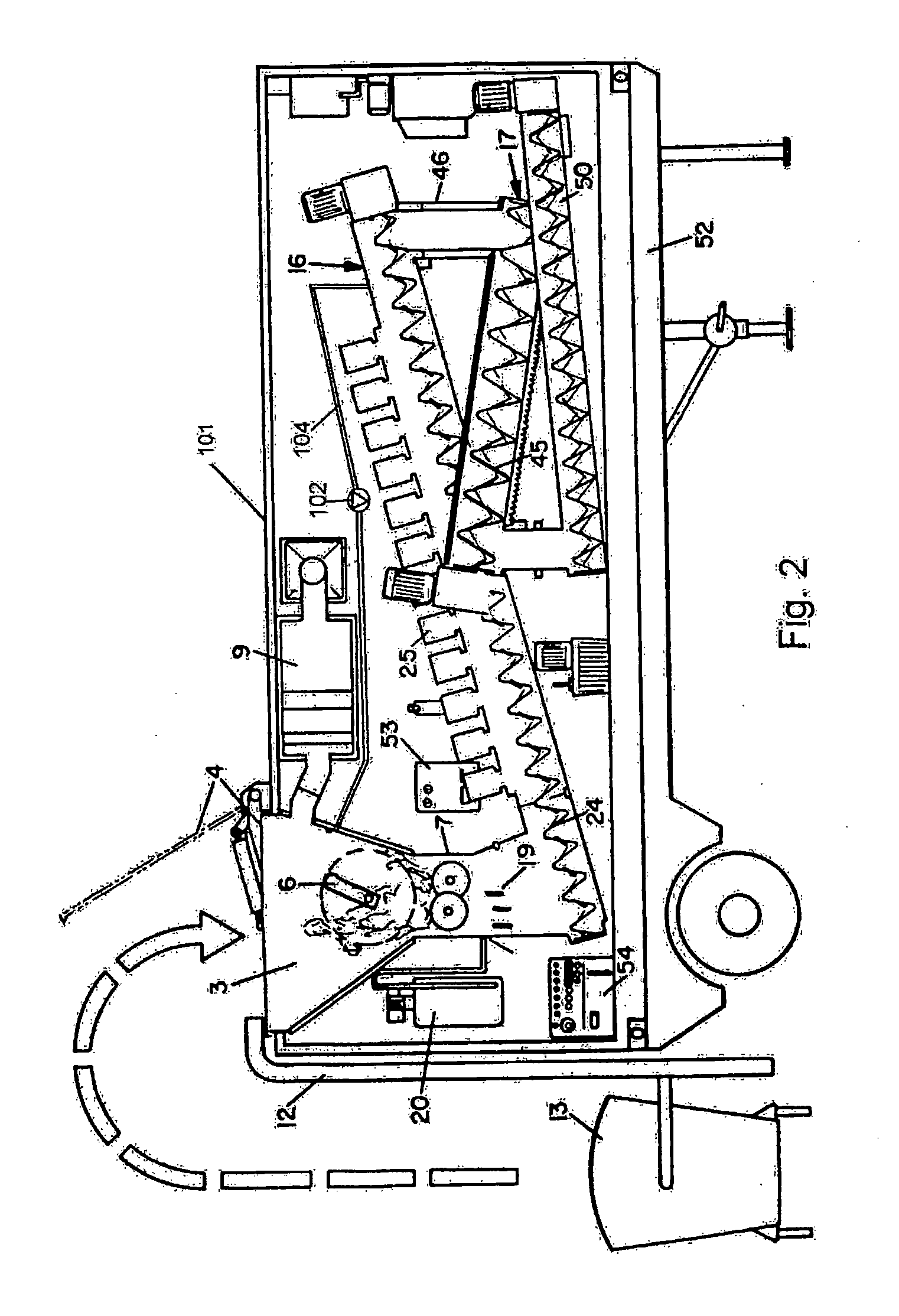

Processing of Documents with Medical and Other Waste

InactiveUS20090004051A1Toxic emissionSolid waste disposalDigital data processing detailsMedical wastePaper document

The invention relates to methods and apparatus for processing documents with medical and other waste. The method includes the steps of supplying the documents to an apparatus (1, 6) adapted to shred documents and medical waste, shredding the documents, and discharging the shredded documents from the apparatus (1). The apparatus (1) has little or no liquid effluent and little or no toxic air emissions. Also included is a system and method for tracking medical or toxic waste including a first container (13) adapted to hold untreated medical waste, the container having a wireless tracking device (170) attached thereto. The system also includes a tracking station capable of monitoring the movement of the medical waste by tracking the wireless tracking device (170).

Owner:SANITEC INDS

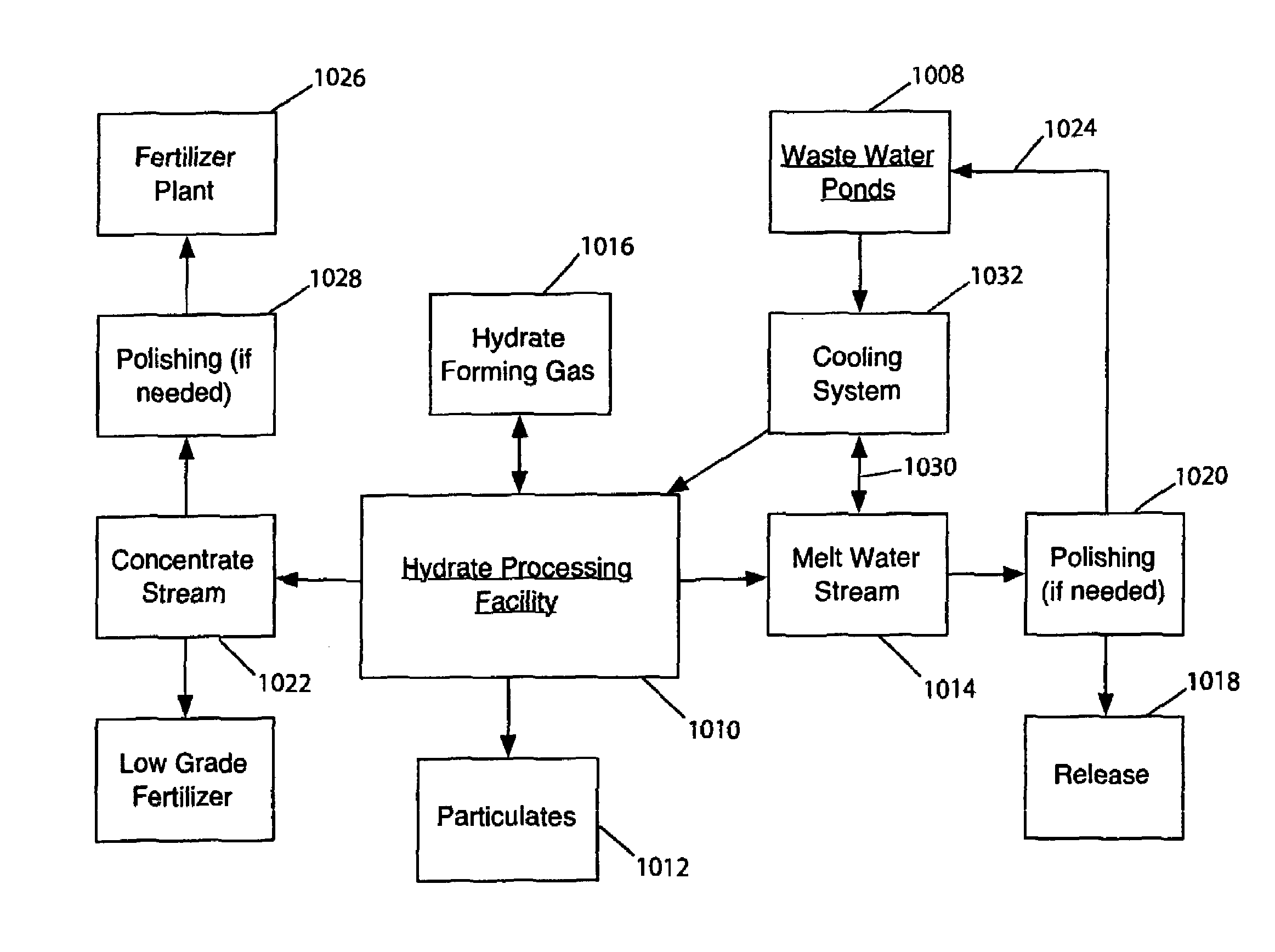

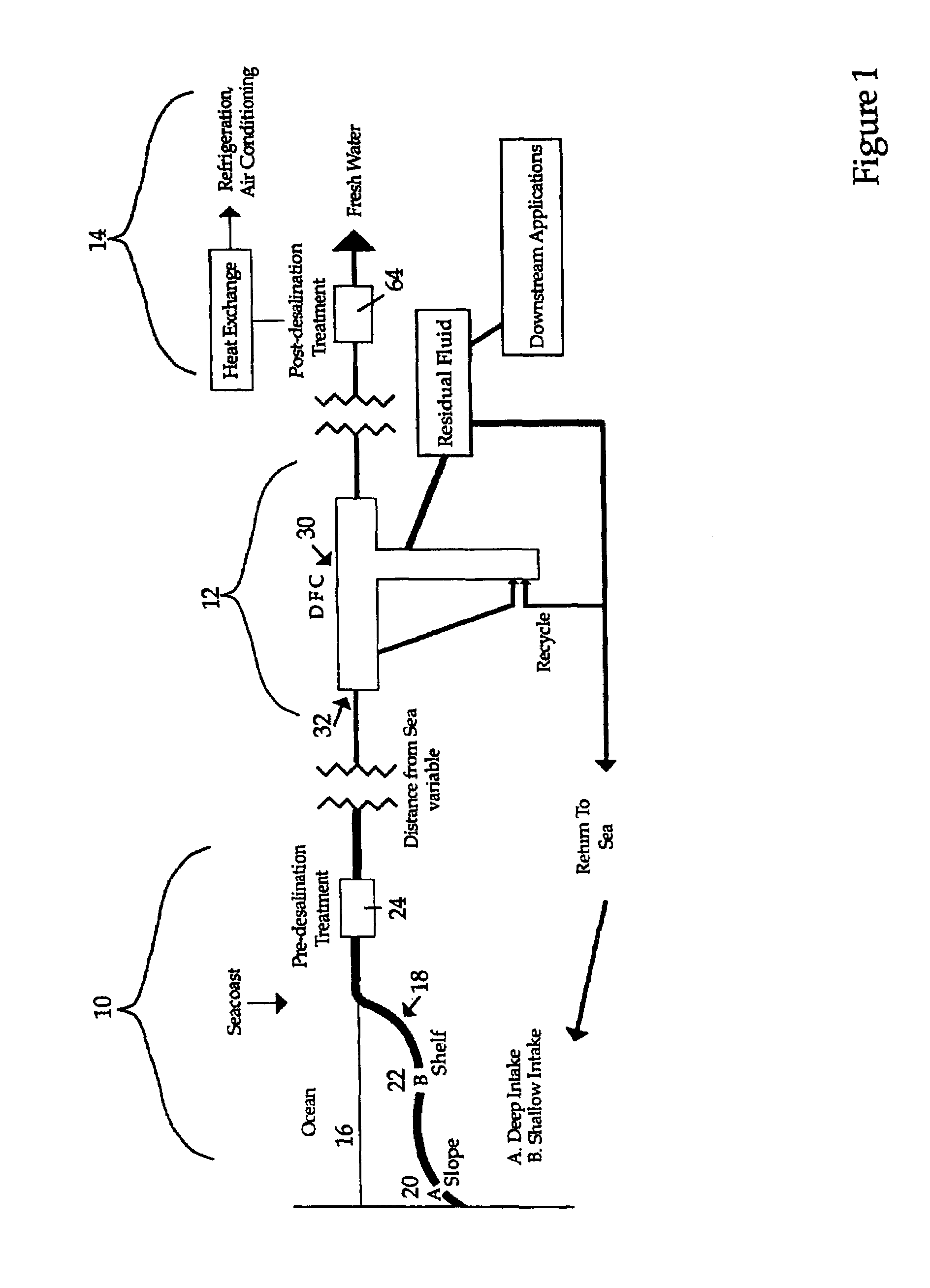

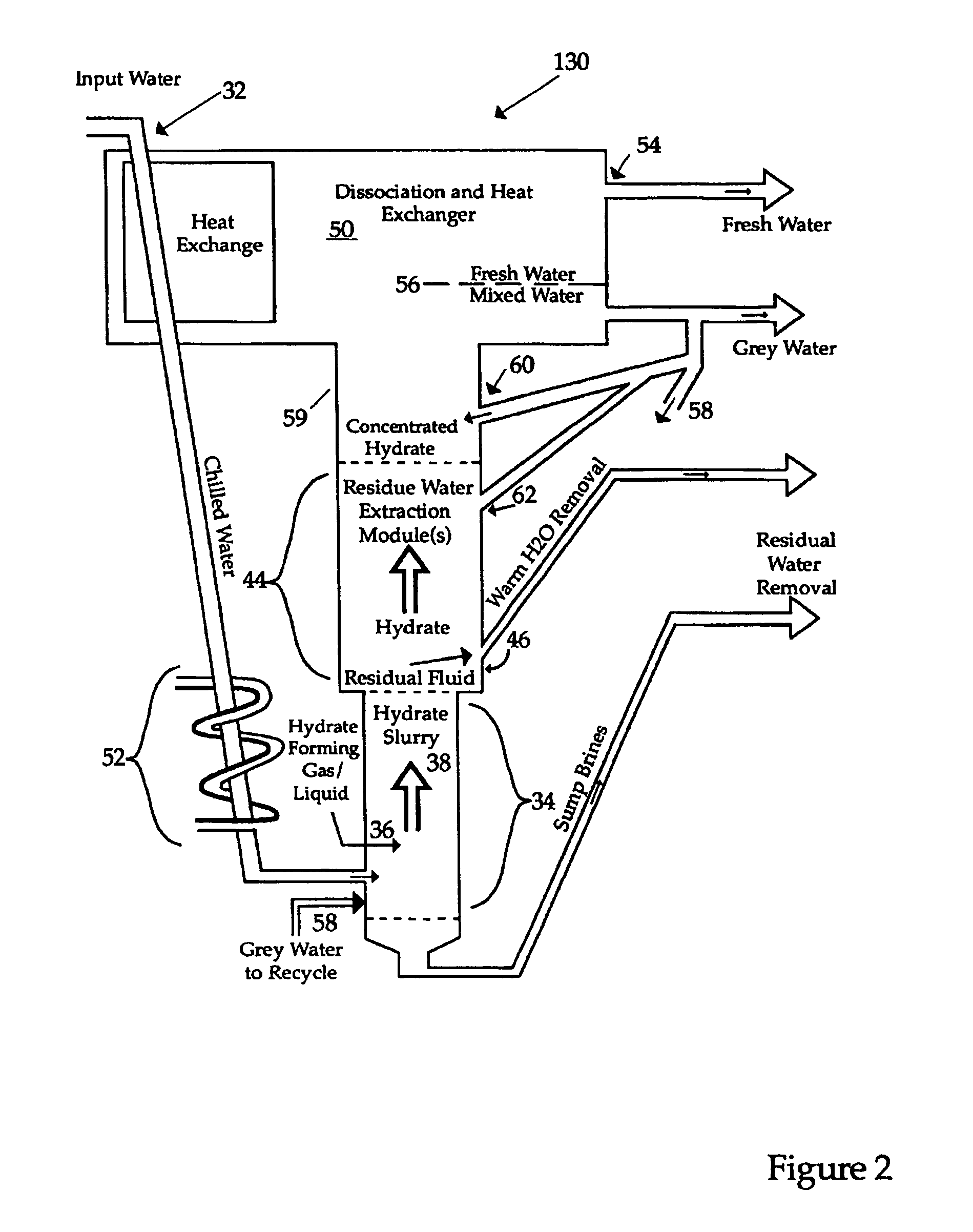

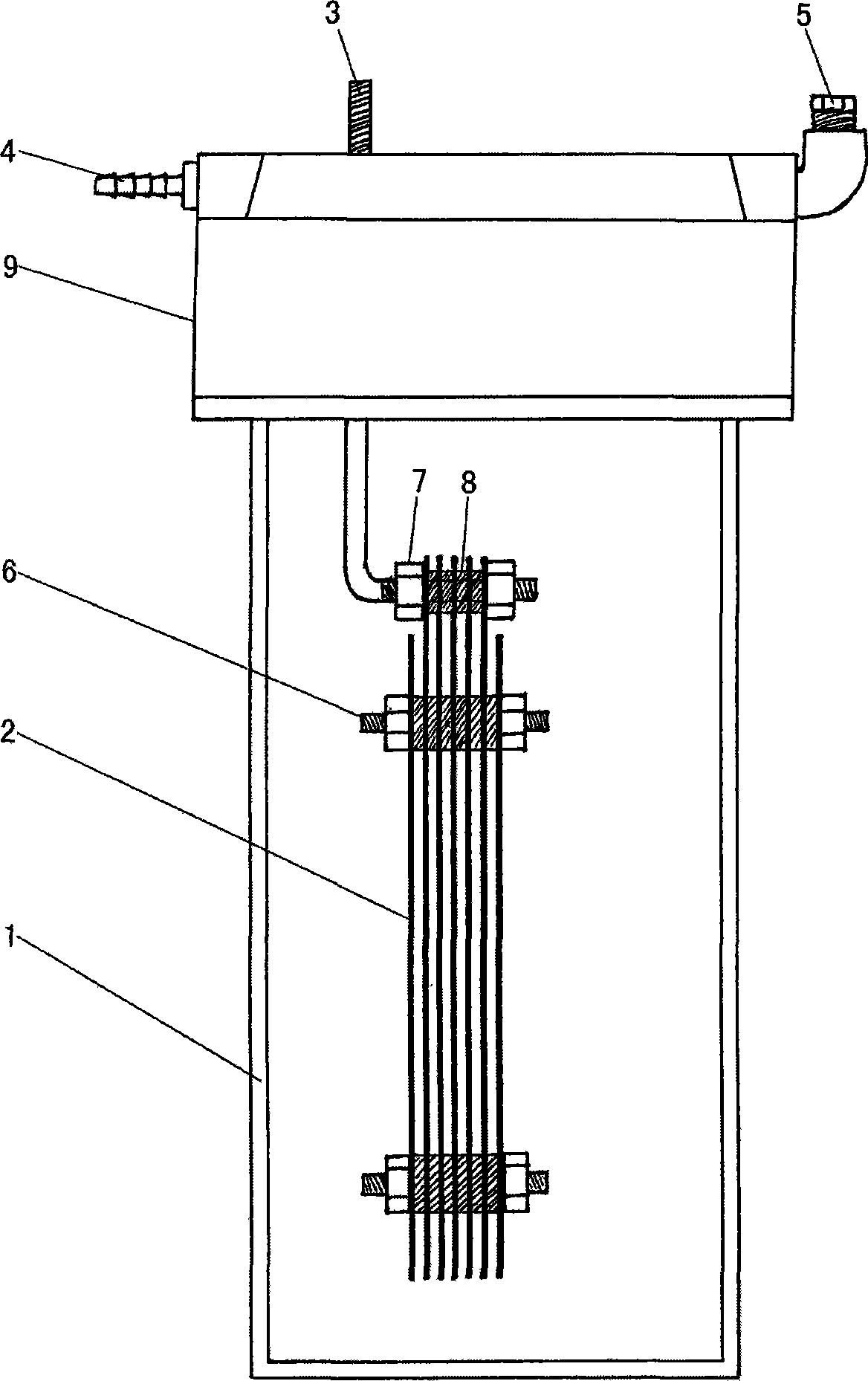

Hydrate-based reduction of fluid inventories and concentration of aqueous and other water-containing products

InactiveUS7255794B2Lower the volumeEfficient and cost-effectiveOrganic chemistryGeneral water supply conservationToxic materialFood products

Toxic waste waters polluted with high levels of chemical byproducts of various industrial processes (e.g., waste water held in industrial holding ponds) are treated using gas hydrate to extract and remove fresh water from the polluted water, thus reducing the volume of toxic waste water inventories. Extracting fresh water by forming and removing the hydrate raises the concentration of dissolved materials in the residual concentrated brines to levels at which the residual fluid is suitable for use as an industrial feedstock. Furthermore, so raising the concentration of the residual brine will cause certain mineral species to precipitate out of solution, which mineral species are separated from the fluid and may be put to other uses, as appropriate. Food products are also advantageously concentrated by means of gas hydrates.

Owner:WATER REGENERATION SYST +1

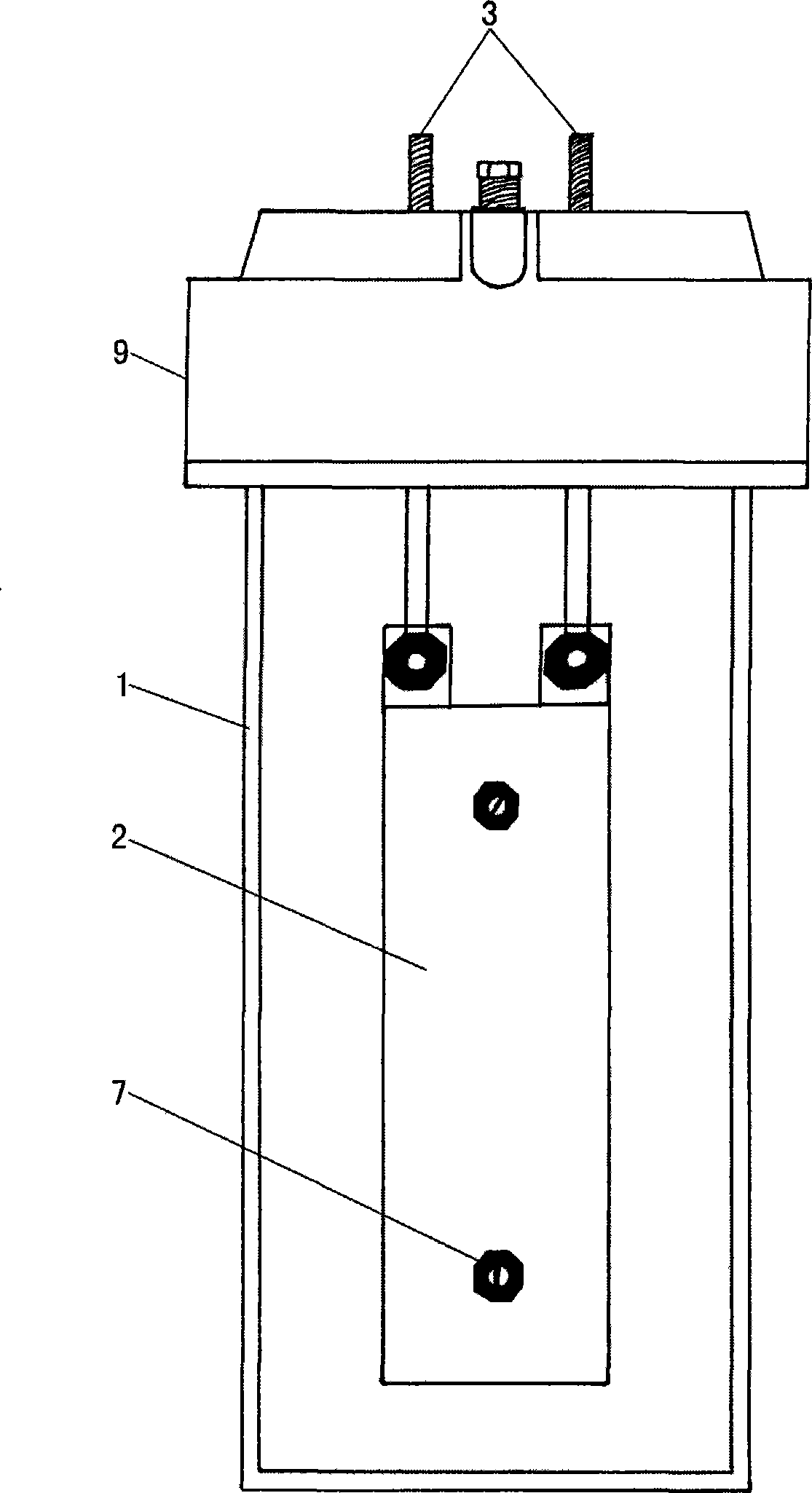

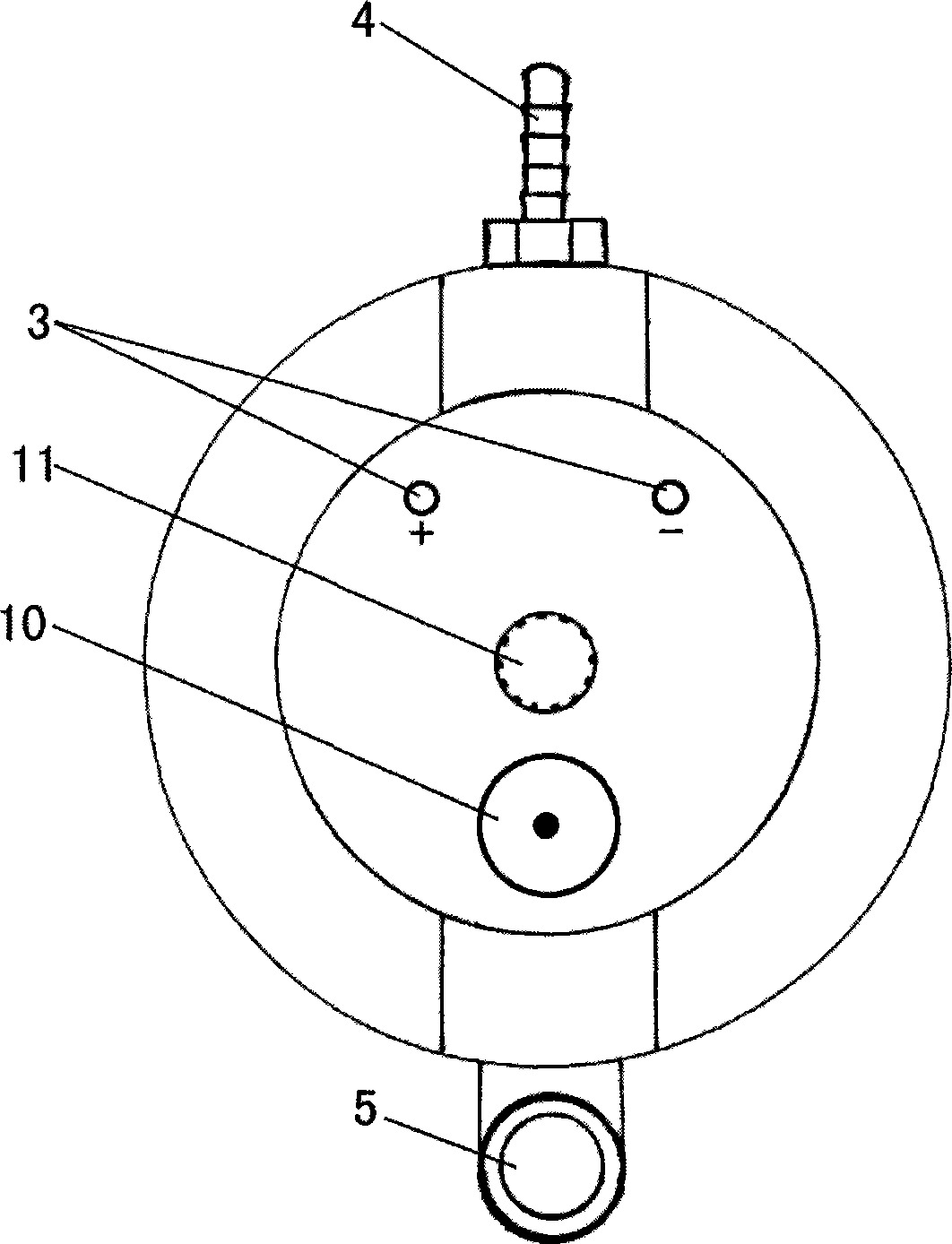

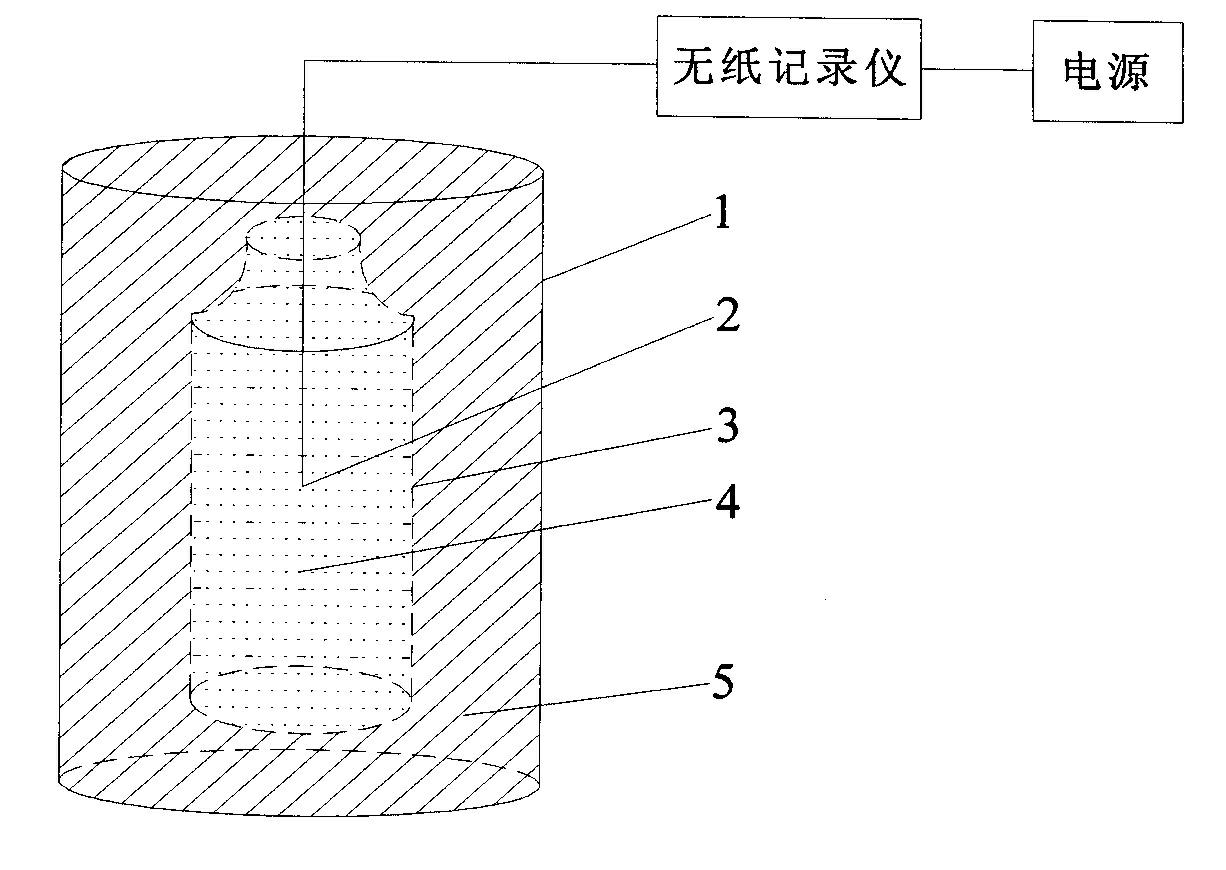

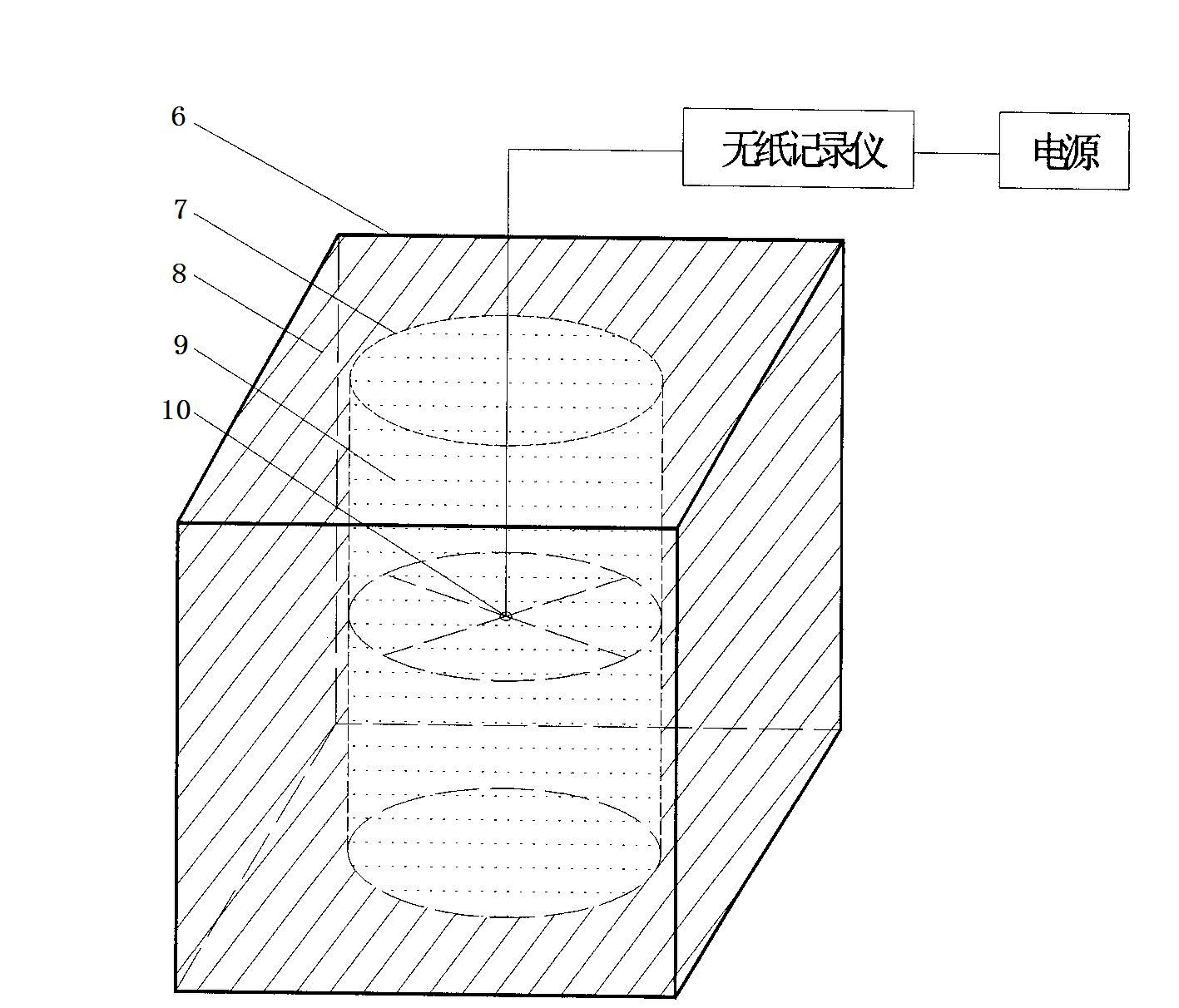

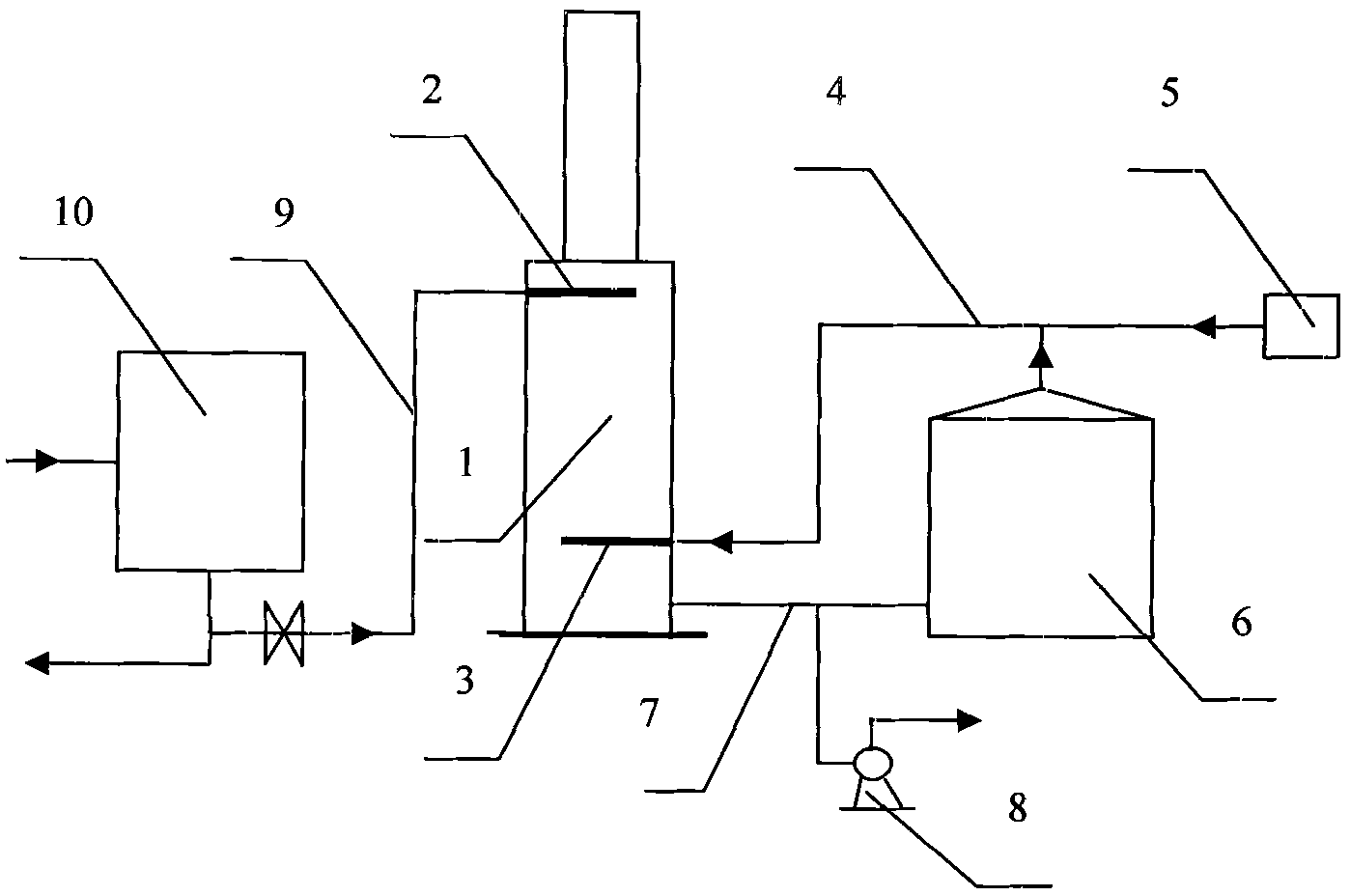

Energy-saving device for producing oxyhydrogen combustion-supporting gas and method thereof

InactiveCN101445940AProduce efficientlyImprove performanceCellsNon-fuel substance addition to fuelElectrolysisCombustion

The invention discloses an energy-saving device for producing oxyhydrogen combustion-supporting gas and a method thereof. The device is characterized in that: an electrolytic tank of the device comprises a plurality of negative electrode plates, positive electrode plates and neutral electrode plates; the different electrode plates do not mutually contact and are adjacently and alternately arranged to form an electrolytic electrode plate, and the two electrode plates positioned at the outermost of the electrolytic electrode plate are neutral electrode plates; an electronic drive unit in the device is an adjustable pulse-width modulator, an input terminal of the modulator is connected with DC power supply, and an output terminal of the modulator is respectively connected with the negative electrode plates and the positive electrode plates of the electrolytic tank. The method for producing the oxyhydrogen combustion-supporting gas by the device comprises the following steps: (1) supplying power to the adjustable pulse-width modulator; (2) adjusting the frequency and the duty ratio of the adjustable pulse-width modulator to cause the electrolytic tank to electrolyze out oxyhydrogen gas; and (3) outputting the oxyhydrogen gas without storage. The energy-saving device is safe, has convenient installation, can efficiently produce the oxyhydrogen gas, causes a combustion engine or an engine to obtain considerable and definite performance improvement, saves fuel and reduces the discharge of toxic waste gas.

Owner:氢汇创新(深圳)科技有限公司

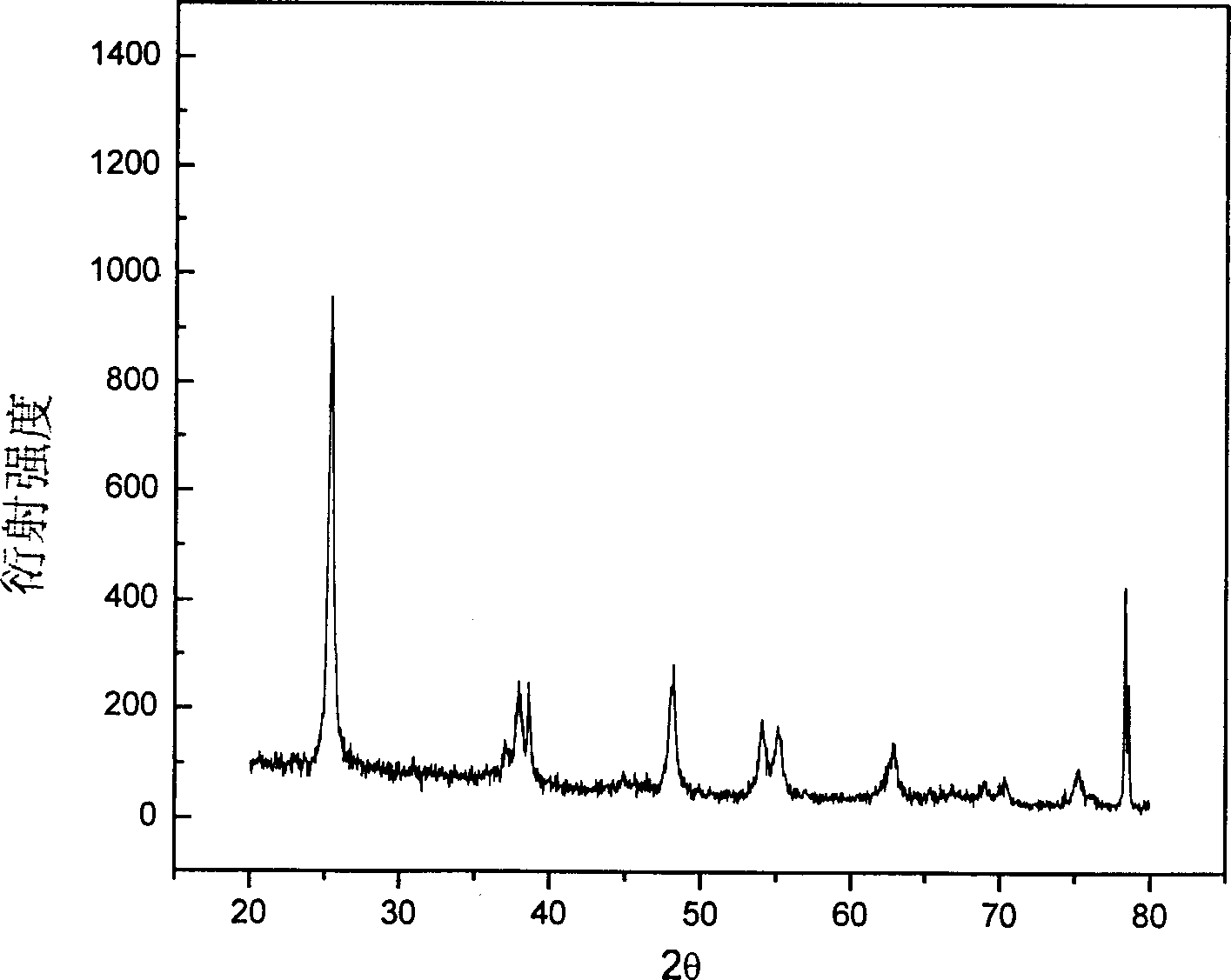

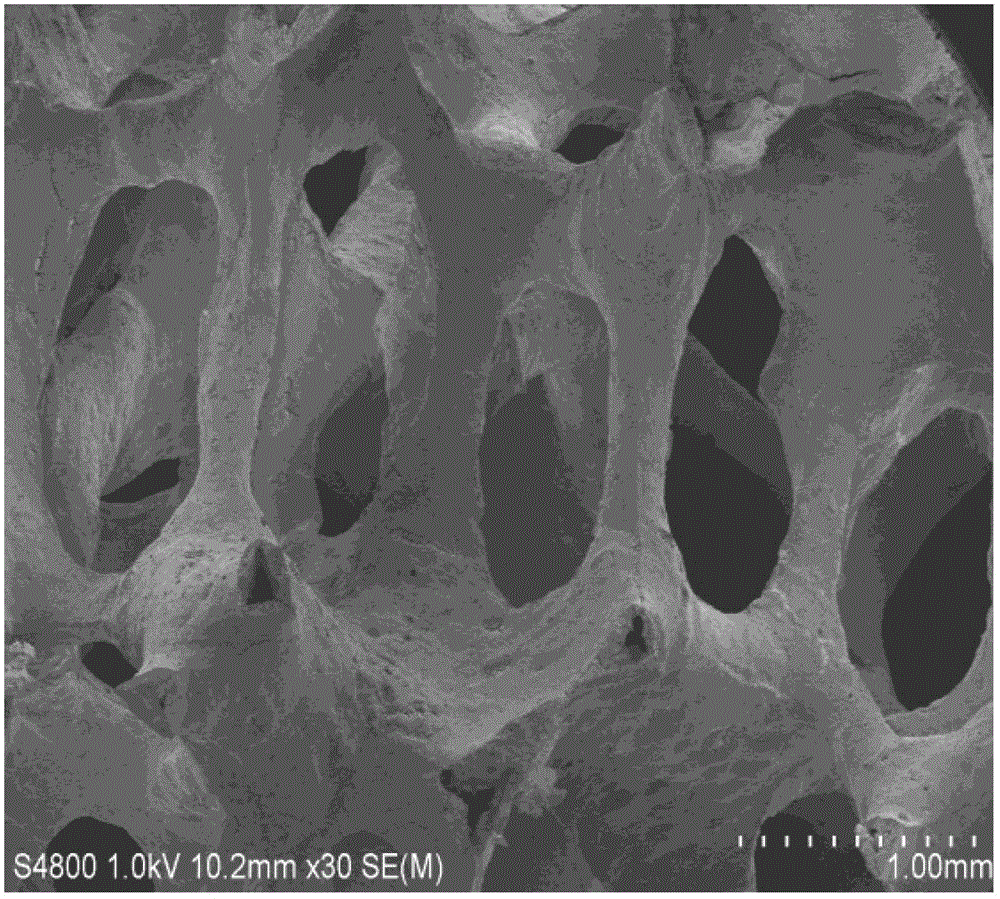

Process for preparing TiO2 (titanium dioxide) film on aluminum-oxide foamed ceramic

InactiveCN102744049AIncrease the effective areaImprove acid and alkali corrosion resistancePhysical/chemical process catalystsIndustrial waste waterPtru catalyst

The invention discloses a process for preparing a TiO2 (titanium dioxide) film on aluminum-oxide foamed ceramic. The process adopts a concrete implementation scheme that coating aluminum oxide slurry is coated on a foam rib by dipping and extruding, then foam is burned up, and finally, the aluminum-oxide foamed ceramic with high porosity is obtained in a high-temperature sintering manner; Ti collosol is uniformly coated on a pore wall of an aluminum-oxide foamed ceramic carrier by negative-pressure infiltration; and the TiO2 film which is uniformly and continuously distributed on the pore wall of the aluminum-oxide foamed ceramic is prepared by drying and thermal treatment. According to materials disclosed by the invention, the porous aluminum-oxide foamed ceramic serves as a base body; meanwhile, the base body has good resistance to acid and alkali corrosion due to the stable chemical properties of the Al2O3 (aluminum oxide) ceramic; in addition, the carrier material has good high-temperature resistance and oxidation resistance by virtue of a high-melting point of the Al2O3 ceramic. These properties of the materials well meet the requirements on properties of catalysts and the carrier which are used for purifying industrial wastewater, domestic sewage and toxic waste gas in extremely serious corrosive environments.

Owner:CHANGAN UNIV

Compositions for improved recovery of metals

InactiveUS6908570B2Effective dissolutionEasy to separateOther chemical processesContaminated soil reclamationSteelmakingElectrolysis

Liquor compositions for the extraction of metallic elements from solid and liquid metal-contaminated starting material such as mineral ores, recyclable wastes, contaminated soils, engraving solutions, metal finishing solutions, battery manufacturing solutions, toxic wastes such as dusts producing through steelmaking processes by effectuating preferably prolonged contacting of such starting material with the liquor to cause the underlying structure of the starting material to be broken down. The contaminated starting materials are more susceptible to metal separation because the released metallic element are readily solubilized in the contacting liquor. Compositions of the contacting liquor comprise caustic silicate solutions containing essentially saturating levels of silica. Once the plurality of metallic elements contained in the starting material have been solubilized, they tend to remain in solution, and then may be routinely extracted and removed using conventional extraction methodologies such as precipitation of insoluble salts, electrowinning, or electrodeposition.

Owner:DISCOVERY RESOURCES

Low heat composite cementing material

InactiveCN102617057AHeat of hydrationSolve the high temperature riseCement productionToxic materialCement paste

The invention provides a low heat composite cementing material, the raw materials of which comprise, by weight: 20-50 parts of cement, 40-70 part of fly ash, 5-25 parts of metakaolin, and 0-8 parts of an exciting agent. The cementing material is prepared by placing the above materials into a material mixer in order, and stirring them for 5-15m at a speed of 60-120 r / m under normal temperature and pressure. Application of the cementing material consists of the steps of: placing 88-97 parts by weight of the cementing material, 3-12 parts by weight of an expanding agent 1.0-1.5 parts by weight of a water reducer, and 24-32 parts by weight of tap water into a cement paste blender for blending based on the speed and procedure prescribed by the national building material industry standard JC / T729-2005: carrying out slow stirring for 117-123s at a rotation speed of 135-145 r / m and a revolution speed of 57-67 r / m, then stopping stirring for 14-16s, and then performing stirring again rapidly for 117-123s at a rotation speed of 275-295 r / m and a revolution speed of 115-135r / m for molding. The material provided in the invention is not only suitable to be used as a building material, and also can be used in backfill grouting, toxic waste curing and other special aspects.

Owner:63653 FORCES PLA

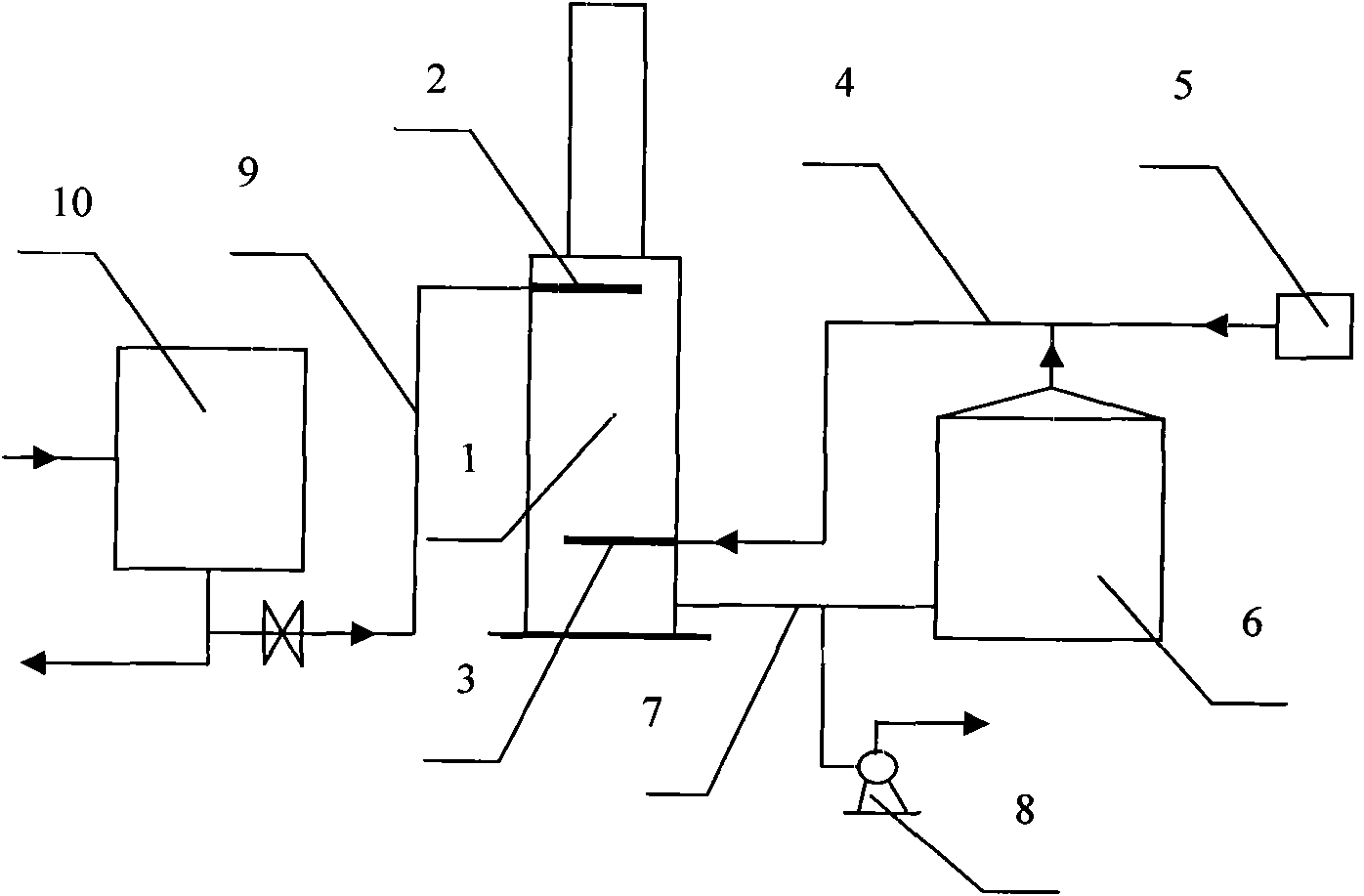

Recovery process of coking crude benzene dispersing gas and device thereof

ActiveCN101879398AEmission reductionSimple processDispersed particle separationDistillation purification/separationToxic materialNaphthalene

The invention belongs to the technical field of coke oven gas purification, and in particular relates to the recovery process of coking crude benzene dispersing gas and a device thereof. The recovery process comprises the following steps: the dispersing gas in each storage tank in a crude benzene production area is intensively recovered through a pipeline and then introduced into a special washing tower; wash oil at the temperature of 25-28 DEG C is sprayed from the top of the washing tower so as to absorb benzene, naphthalene and other organic matters from the dispersing gas; the wash oil absorbing benzene, naphthalene and other organic matters flows automatically into the bottom of the tower and then enters a front pipe of a rich oil pump through a communicating pipe at the bottom of the tower to be mixed with rich oil; and finally the obtained mixed oil is treated in a debenzolization tower. The invention requires no operating cost, greatly reduces toxic waste gas generated in the existing coking crude benzene production area, and improves operating environment.

Owner:南京金瀚环保科技有限公司

Composition for building material and a process for the preparation thereof

ActiveUS8257486B2Simple methodHigh compressive strengthSolid waste managementOther chemical processesPotassiumBound property

Owner:COUNCIL OF SCI & IND RES

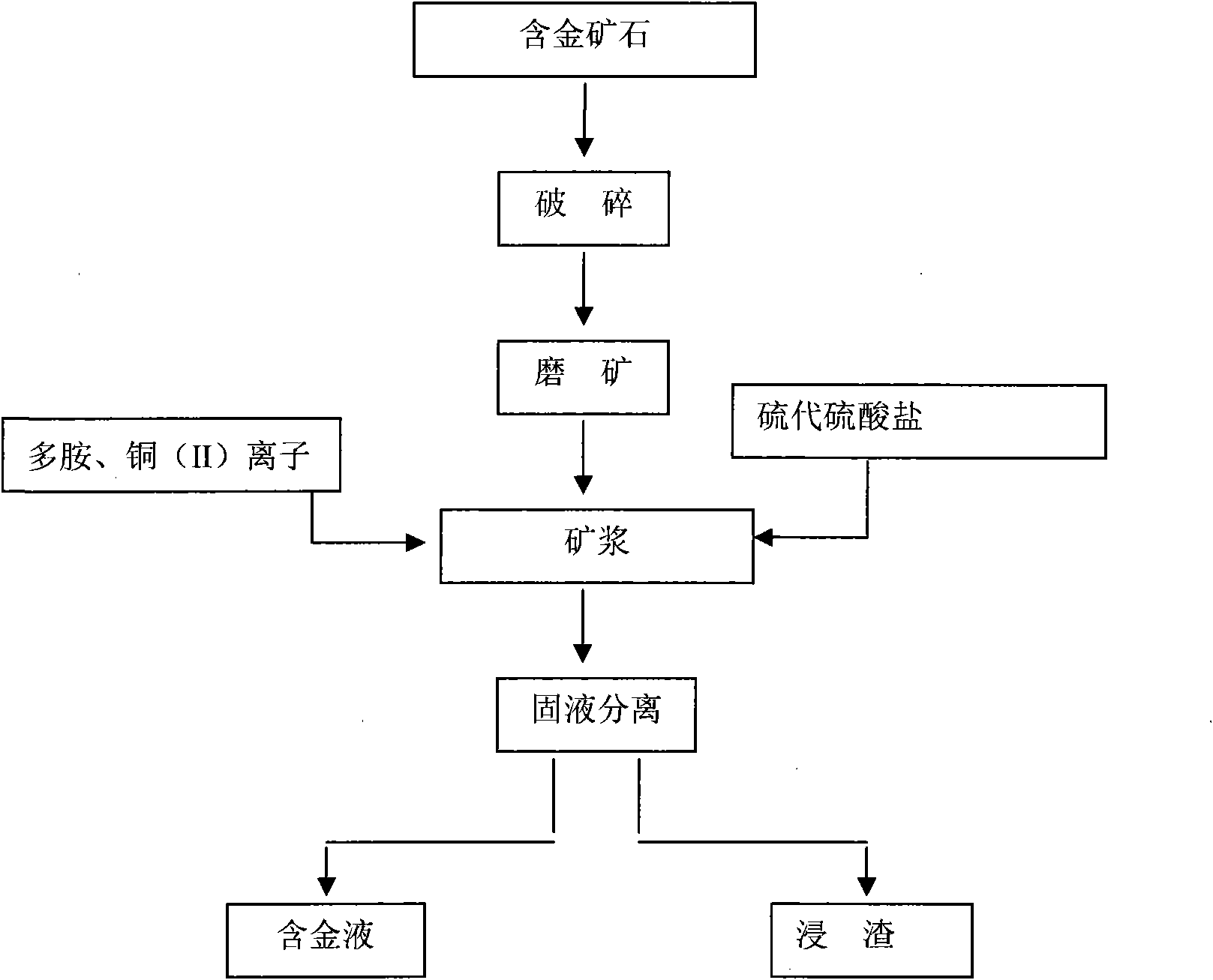

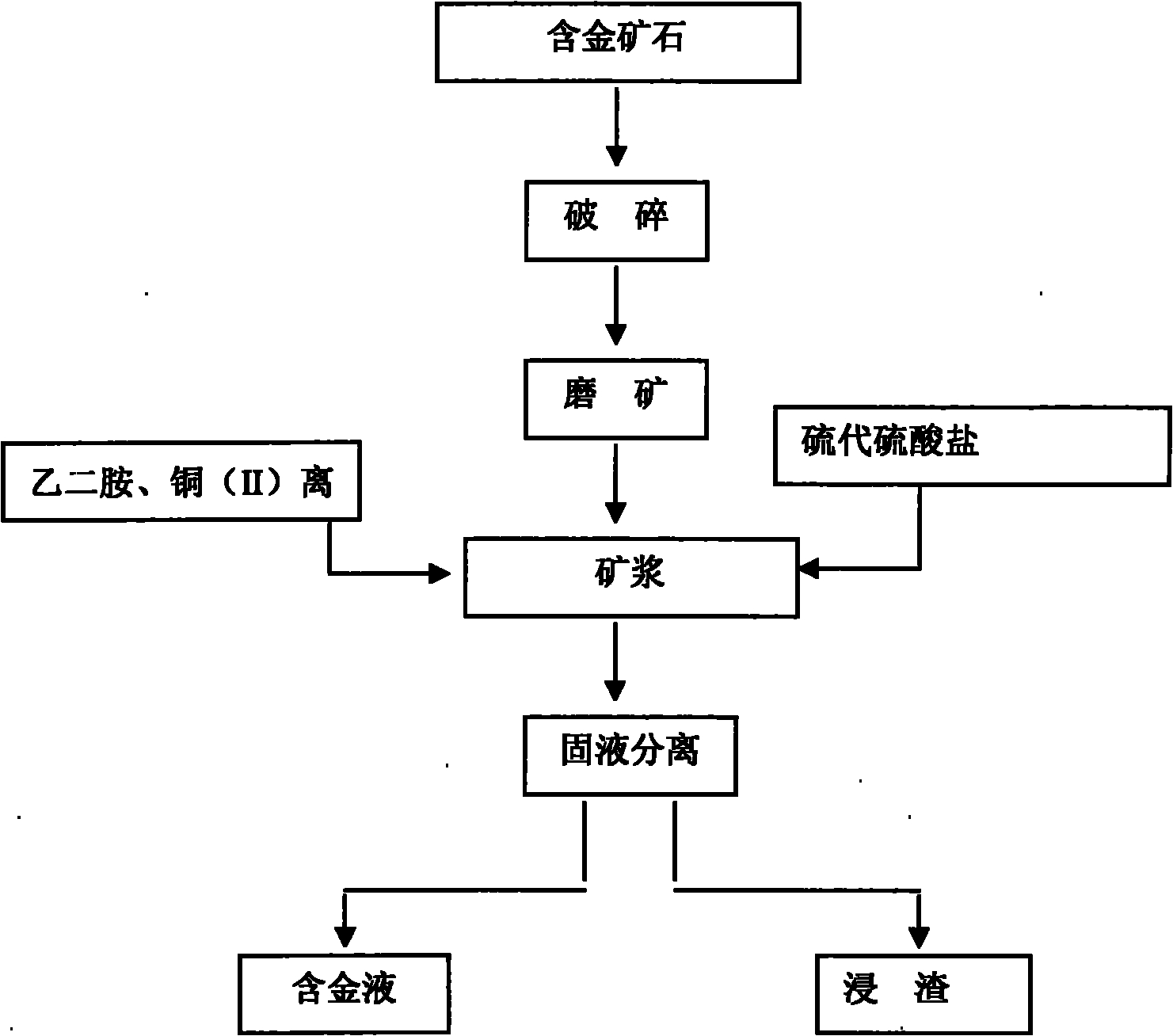

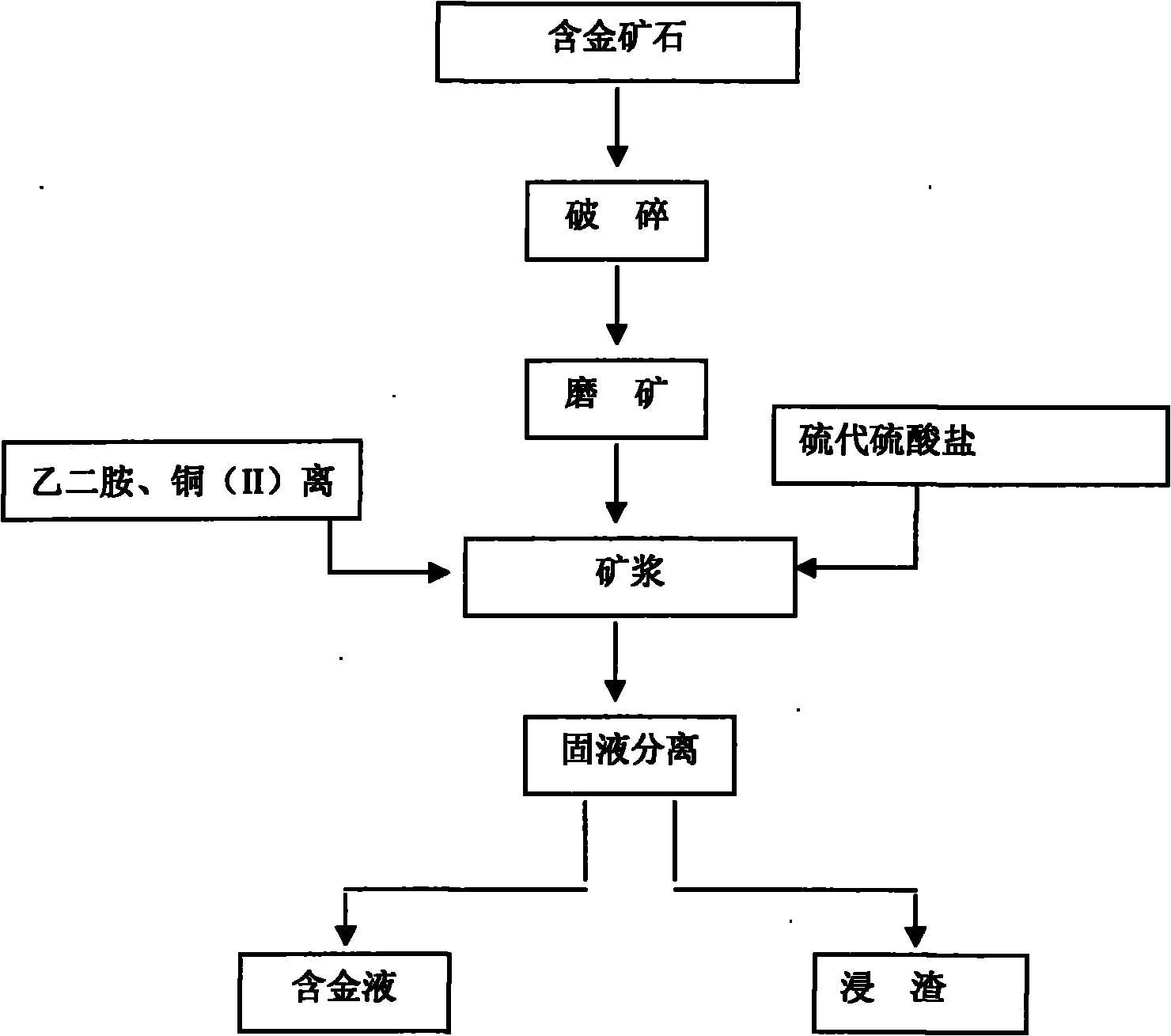

Gold extracting method by thiosulfate using polyamine compoud as additive

InactiveCN101775490AReduce consumptionLittle effect of leachingProcess efficiency improvementToxic materialSodium cyanide

The invention relates to a gold extracting method by thiosulfate using a polyamine compound as an additive, which comprises the steps: after ores are crushed and wet-ground until the fineness is over 90 percent of -200 meshes, 0.03-3mol / dm3 thiosulfate is added to be used as a leaching agent, and then 0.0015-0.09mol / dm3 polyamine compound and 0.0015-0.03mol / dm3 copper (II) ion are added to form a complex ion to be used as an additive to be stirred and leached; and after gold ores are leached, gold from a leaching solution is recovered. The leaching solution is used to extract gold from the ores, so that the gold leaching rate is high, the process operation is simple, the control is easy, the consumption of thiosulfate is extremely low, and the compositions of the gold leaching solution are simple and are favorable for the recovery of the gold; and the application range is wide, the leaching effect is good when the pH value is between 10 and 12, the leaching speed is quick for copper-containing, carbon-containing and other refractory gold ores, quite high gold leaching rate can be maintained, and sodium cyanide and other toxic substances are not used and toxic waste is not discharged in the whole gold extraction process, so the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

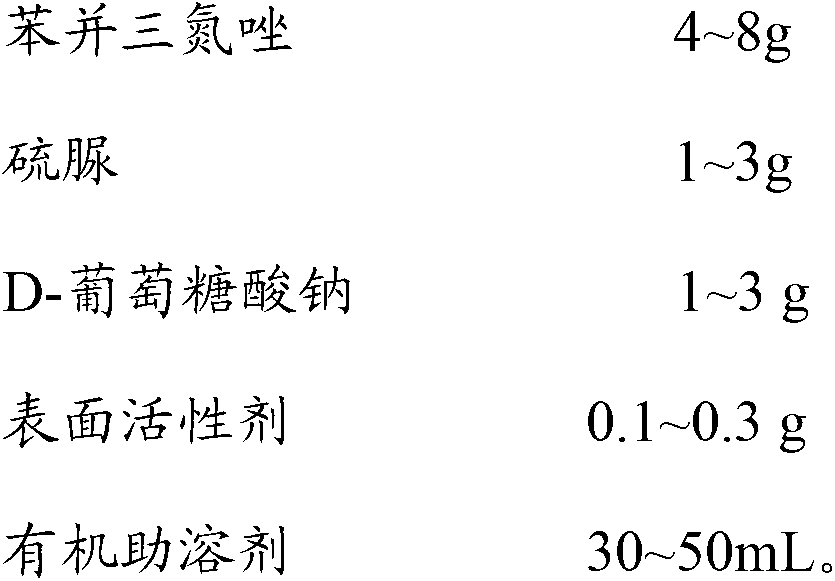

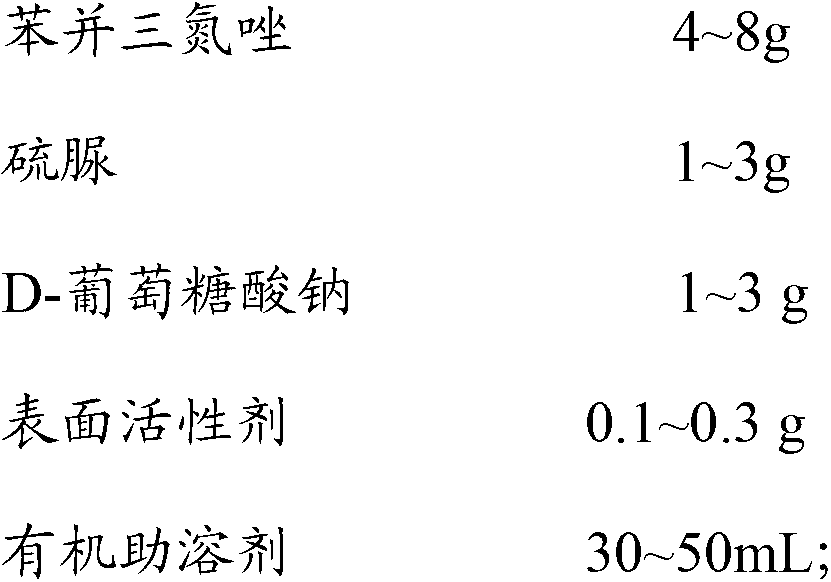

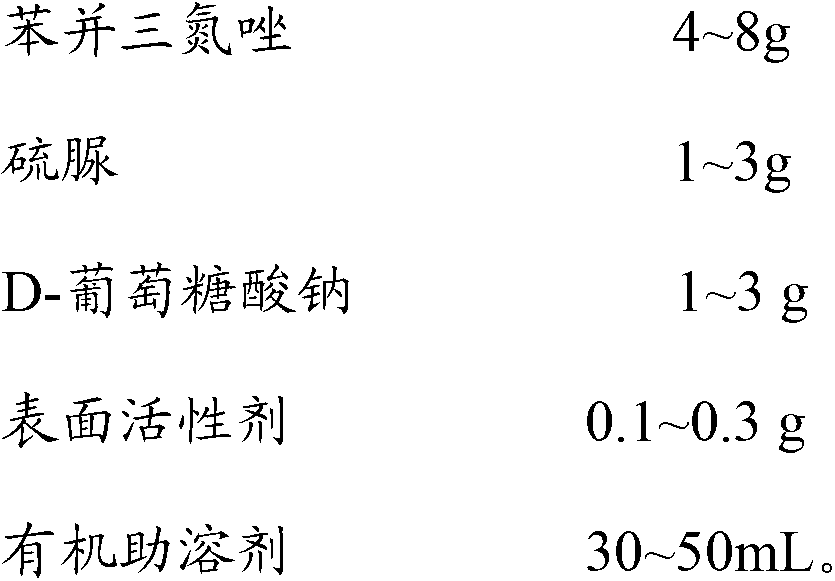

Copper oxidation discoloration resistant agent and preparation method thereof

The invention discloses a copper oxidation discoloration resistant agent and a preparation method thereof. Solvent of the copper oxidation discoloration resistant agent is water, one liter of the copper oxidation discoloration resistant agent comprises, by proportion, 4g-8g of benzotriazole, 1g-3g of thiocarbamide, 1g-3g of D-glucose acid sodium, 0.1g-0.3g of surface active agent and 30mL-50mL of organic cosolvent. According to the copper oxidation discoloration resistant agent, no toxic component is included, no toxic waste is discharged to environment in the processes of preparation and application, and thus environmental protection is benefited, the benzotriazole is used as a main component of a molecular self-assembly membrane, meanwhile, corrosion inhibitor thiourea and the D-glucose acid sodium are combined with the copper oxidation discoloration resistant agent to form a hydrophobic adsorption layer on the surface of a copper base material, and thus the copper base material is effectively isolated from outer corrosive environment, and a good copper oxidation discoloration resistant function is achieved.

Owner:厦门金越电器有限公司

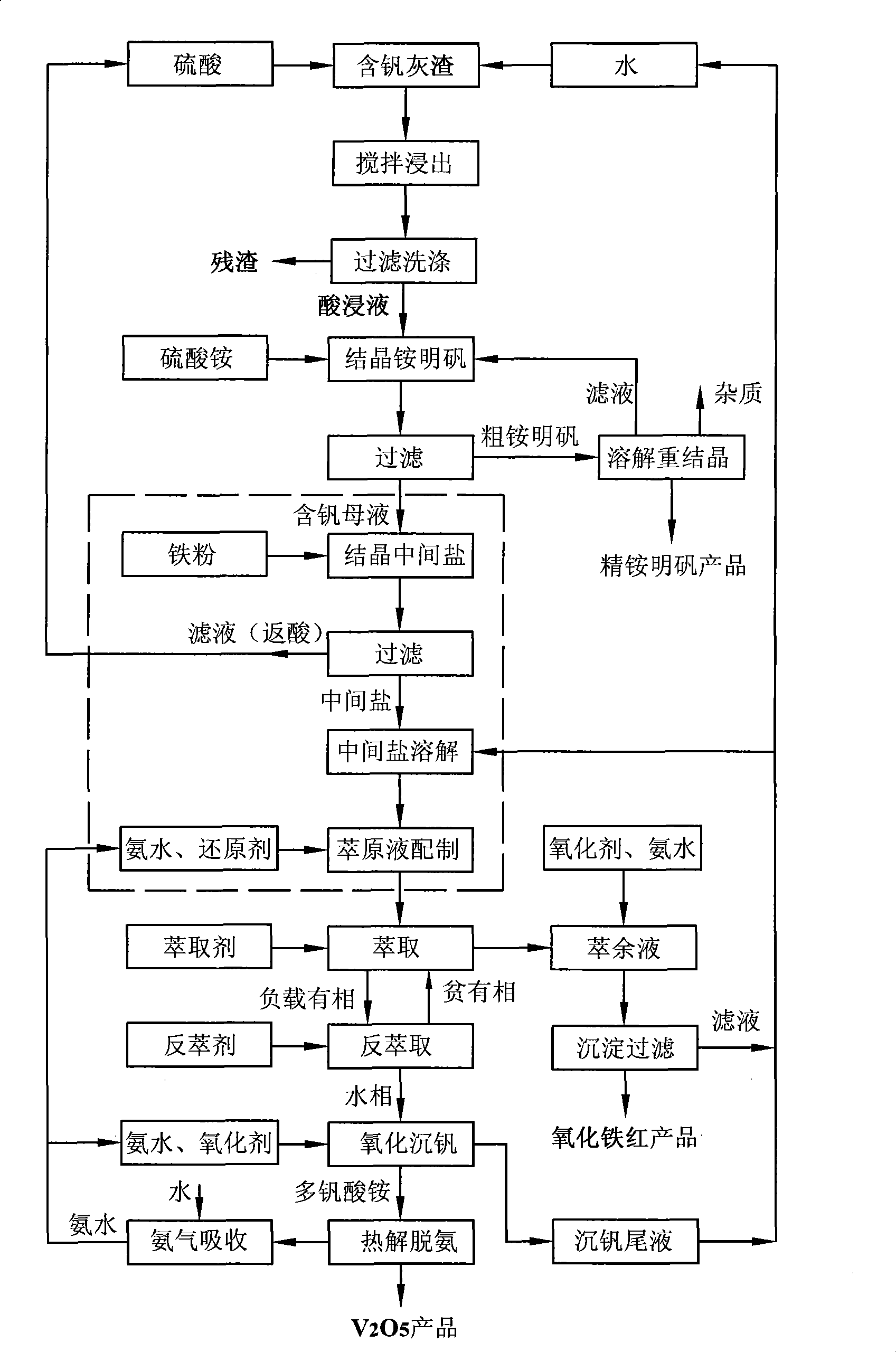

Method for preparing intermediate salt during acid leaching and extraction of vanadium pentoxide from vanadium-containing stone coal ash

InactiveCN101381818ASimple methodImprove the operating environmentVanadium oxidesProcess efficiency improvementFiltrationToxic material

The invention provides a preparation dissolution method for intermediate salt during the process of acid leaching extraction of vanadium pentoxide from vanadium-containing stone coal clinker. The method comprises the following steps: the vanadium-containing stone coal clinker undergoes acid leaching, so as to obtain an acid leaching solution; ammonium sulfate is added into the acid leaching solution to separate out tschermigite, so as to obtain a vanadium-bearing mother liquor as a raw material; the vanadium-containing mother liquor and iron elementary substance are added into a reaction vessel, wherein the mass of the iron elementary substance is 1 to 60 percent of that of the vanadium pentoxide in the vanadium-containing mother liquor; the mixture is stirred for full reaction, and is heated, evaporated and concentrated until the concentration of H<+> in the solution is between 18 and 22 mol per liter; after complete crystallization, the solution is cooled to the room temperature, and filtrate and filter residue are obtained through filtration; and the filter residue is taken, and intermediate salt solid is obtained. The method has the advantages that the method is simple; the operating environment is good; the whole process undergoes full-liquid phase operation; no pollution of toxic waste gas exists; more than 98 percent of vanadium in the mother liquor is enriched into the intermediate salt, thereby greatly simplifying the subsequent extraction operation; and a residual acid after preparation of the intermediate salt can be recovered, thereby greatly reducing the cost.

Owner:ZHEJIANG UNIV +1

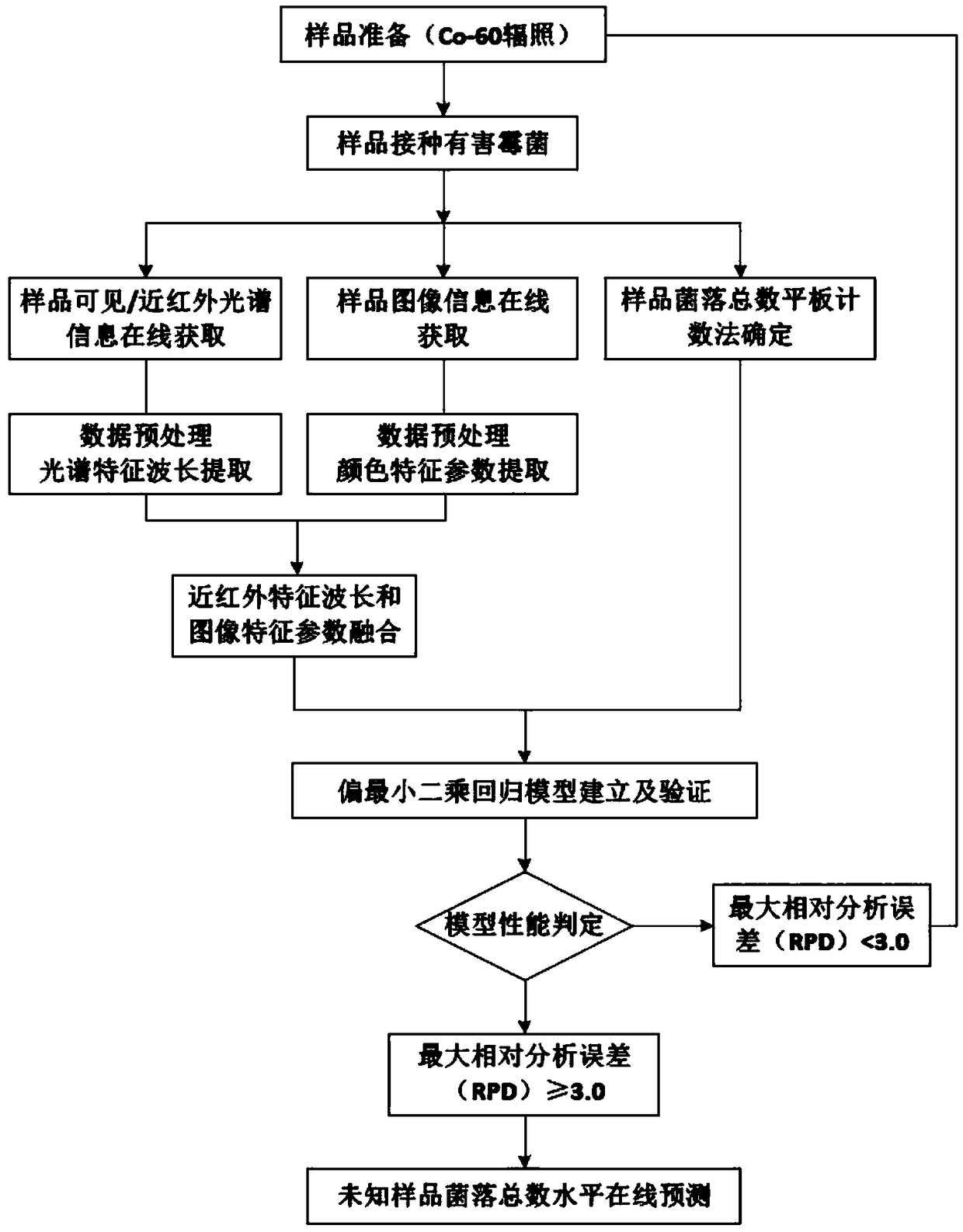

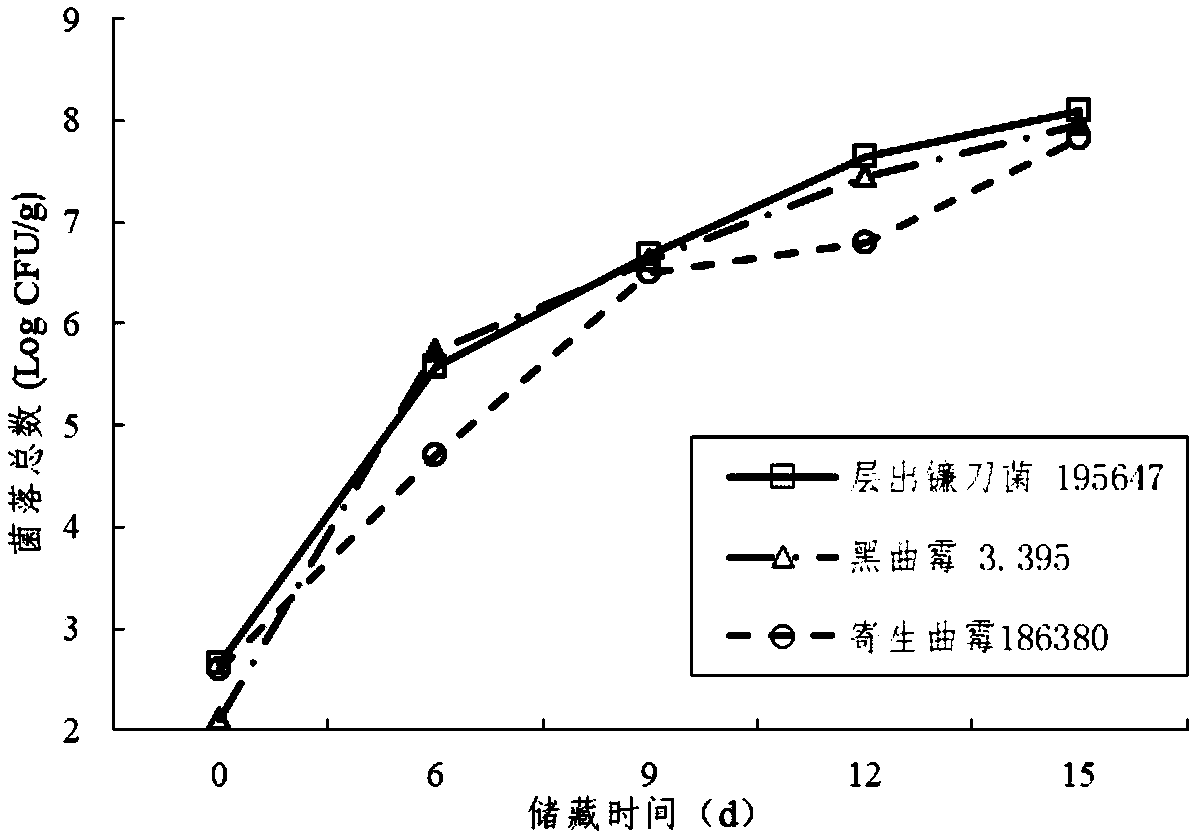

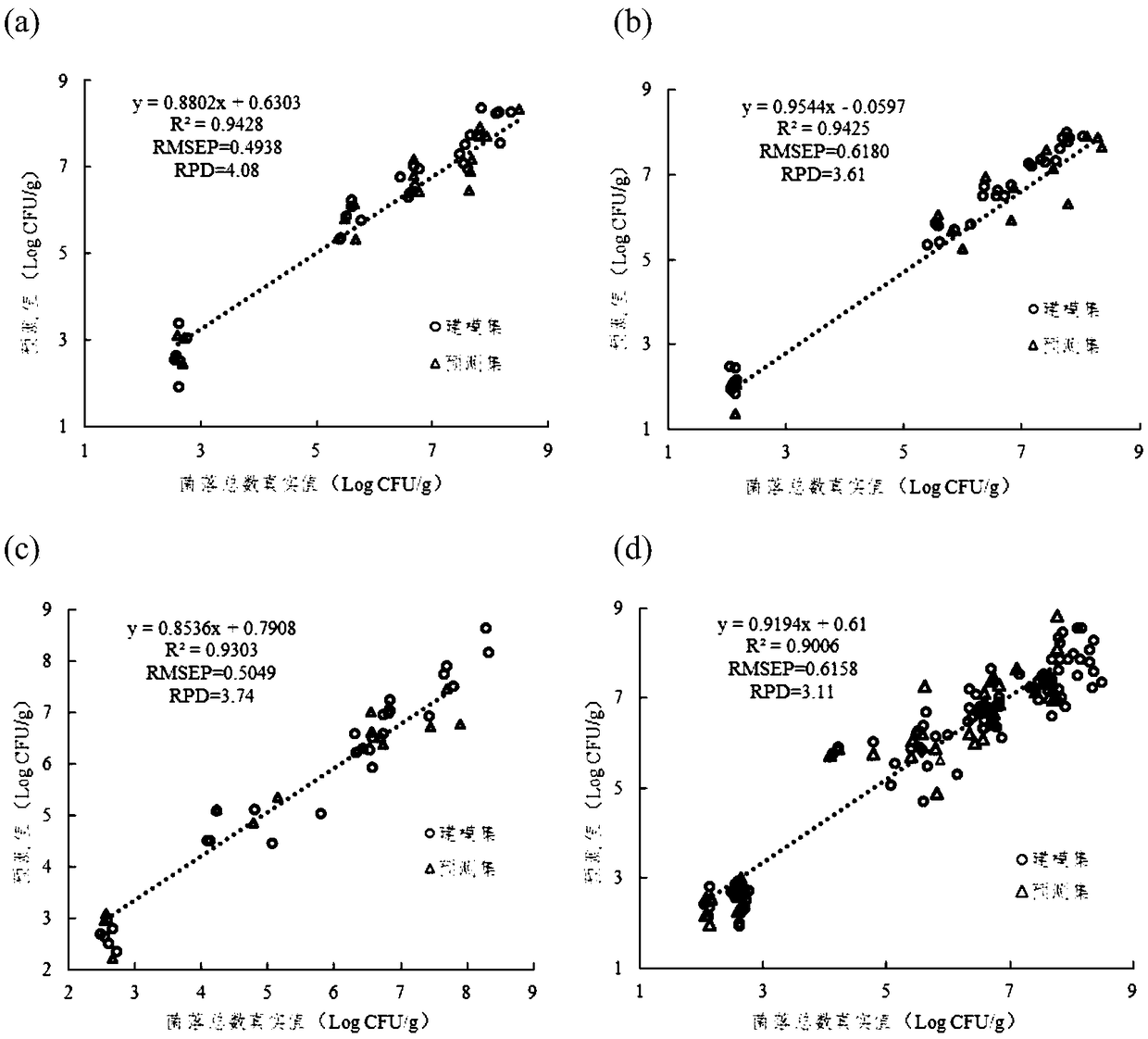

On-line detection method of mildew corn, based on spectrum and image information fusion

The invention discloses an on-line detection method of a mildew corn, based on spectrum and image information fusion, and relates to the technical field of corn colony total count detection. The method comprises the following steps: performing irradiation sterilization on a corn sample; inoculating harmful mildew to the corn sample and storing the corn sample; performing on-line collection on cornsample spectrum and image information; measuring the total number of corn colony; performing rapid determination, outputting actual content of molds through an established model and spectrum and image fusion information of a corn to be detected, so as to judge corn mildew state. The method is convenient for detection, does not need to perform traditional counting on mildew in the corn, and only need to collect characteristic spectrum information and image parameter information of corn mildew pollution through a near infrared spectrum and image technology. The method does not damage the sample, is energy-saving and environmentally friendly, does not need to prepare chemical reagents, does not produce toxic waste liquor, and reduces harm to human body and the environment. The method is lowin detection cost, and does not need to buy expensive chemical reagents and various analysis instruments.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

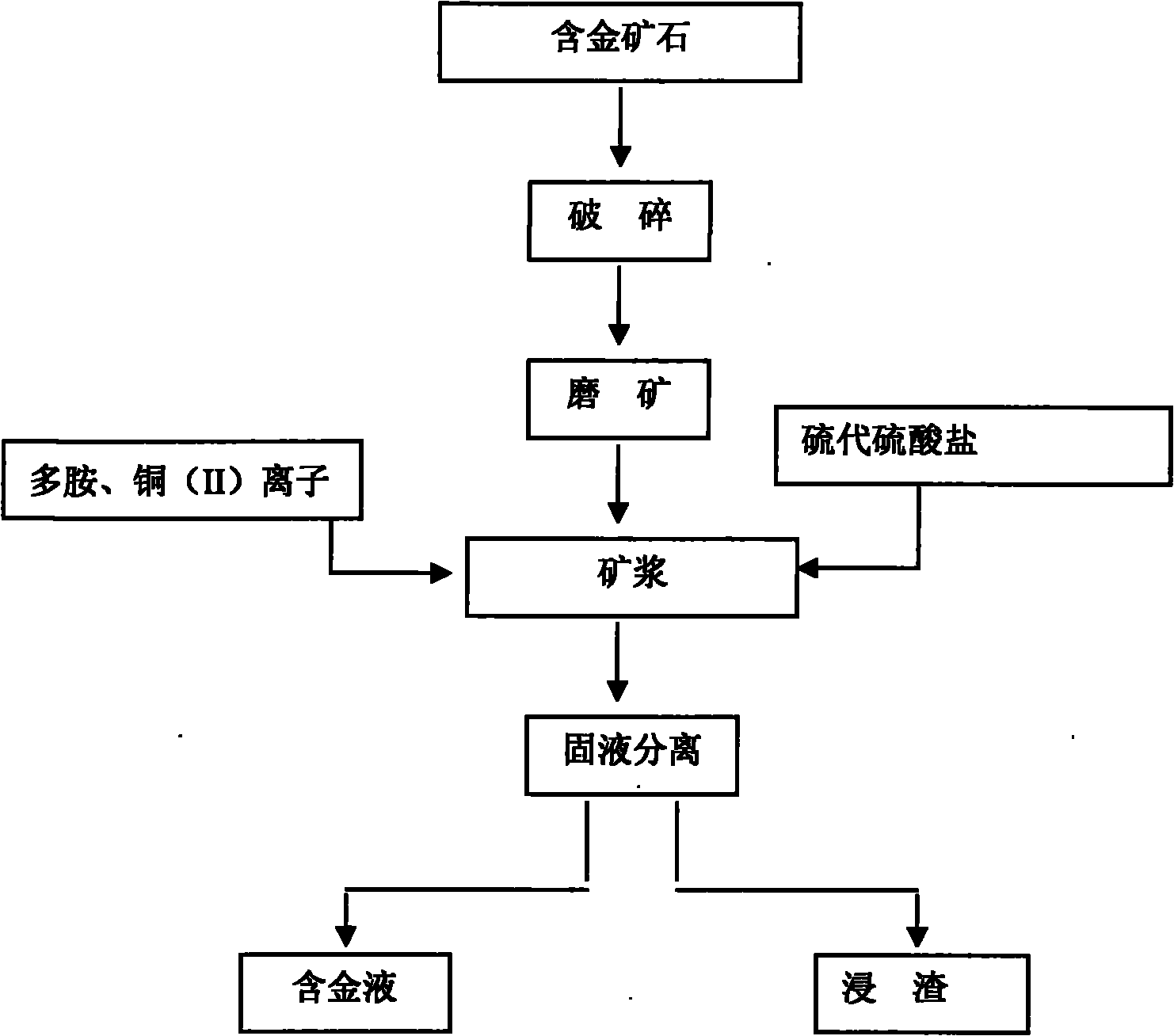

Method for extracting gold from thiosulfate adopting ethanediamine as additive

InactiveCN101824545AReduce consumptionLittle effect of leachingProcess efficiency improvementEthylenediamineToxic material

The invention relates to a method for extracting gold from thiosulfate adopting ethanediamine as an additive. The method comprises the following steps that: the ethanediamineas is adopted as ligand and forms ethanediamine copper (II) complex ion with copper (II) ion, the formed ethanediamine copper (II) complex ion is used as the additive, and the thiosulfate is used as a leaching agent and is used for extracting the gold from ore pulp; and calculated by water amount, the adding amount of the thiosulfate is 0.03-3mol / dm<3>, the adding amount of the ethanediamine is 0.0015-0.09mol / dm<3>, and the adding amount of copper (II) ion is 0.0015-0.03mol / dm<3>. The leachate is used for extracting the gold from the ore, the leaching rate of the gold is high, the technique operation is simple, the control is easy, the consumption amount of the thiosulfate is extremely low, and the ingredients of the gold leachate are simple and are beneficial to recovery of the gold therein. The method has wide application range, has good leaching effect when the pH is between 10 and 12, also has fast leaching speed of gold ores which contain copper, carbon and the like and are difficult to treat, can maintain quite high gold leaching rate, and the whole gold extracting process does not use toxic substances of sodium cyanide and the like, also does not discharge toxic waste, and is environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

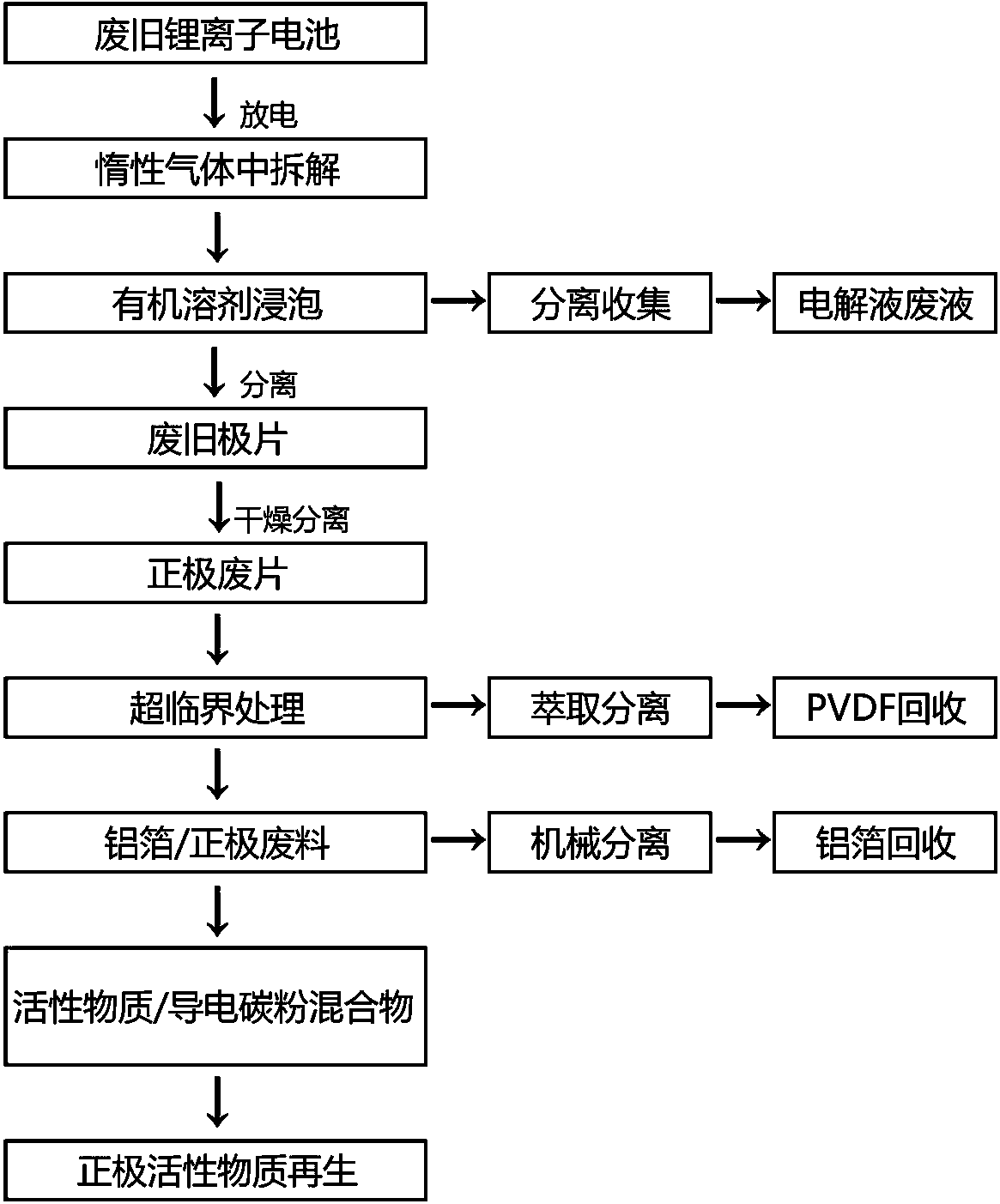

Lithium ion battery waste cathode piece recycling method

InactiveCN108736086ACost-effective recycling methodGreen recycling methodWaste accumulators reclaimingBattery recyclingToxic materialSodium-ion battery

The invention discloses a method for recycling polyvinylidene fluoride (PVDF), aluminum and cathode wastes (a mixture of active substances and conductive carbon powder) in waste battery cathode piecesof lithium ion batteries by virtue of a supercritical fluid extraction process. The method comprises the following steps: firstly disassembling cathodes of the lithium ion batteries, soaking in an organic solvent, taking out, carrying out drying treatment, and obtaining cathode pieces which do not contain electrolyte; then carrying out supercritical extraction treatment on the treated cathode pieces, namely dissolving a binder PVDF in the cathode pieces into a supercritical fluid, and extracting and separating the binder PVDF; mechanically separating remaining aluminum foils and the cathode wastes which lose cohesiveness and are mutually stripped; and directly taking the separated cathode wastes as a raw material for producing a lithium ion battery cathode material. The method disclosed by the invention does not use an acid-base fluid to treat electrodes or carry out high-temperature incineration, so that chemical waste liquor or toxic waste gas is not produced; and by virtue of the supercritical extraction treatment way, the recycled aluminum foils, PVDF and cathode wastes can be directly taken as the raw material to be recycled, so that the method has the advantages of economy,high efficiency and environmental friendliness.

Owner:苏州威星能源科技有限公司

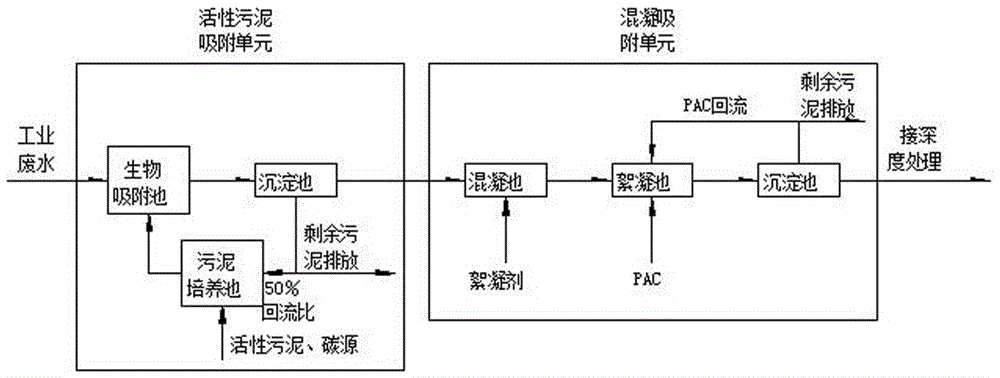

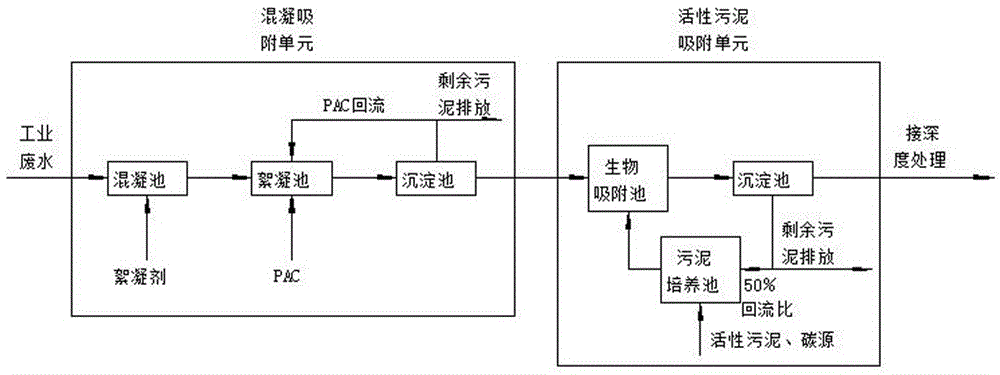

Highly toxic waste water pre-treatment device and use method thereof

InactiveCN106430811AReduce concentrationGood removal effectMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationChemical oxygen demandSludge

The invention discloses a highly toxic waste water pre-treatment device and a use method thereof. The device comprises an active sludge adsorption unit and a coagulation absorption unit. In a use process, the active sludge adsorption unit removes COD (chemical oxygen demand) and partial heavy metal; the coagulation absorption unit removes most of the heavy metal. According to the practical use conditions, the installation and use sequence of the active sludge adsorption unit and the coagulation absorption unit can be freely arranged. The highly toxic waste water pre-treatment device disclosed by the invention has the advantages that heavy metal ions and the organic matter concentration of aromatic organic matters, phenol organic matters, ether organic matters and the like in industrial waste water can be greatly reduced; the total COD removal rate reaches 60 to 80 percent; the heavy metal removal rate reaches 80 percent; the beneficial conditions are provided for subsequent deep treatment of industrial waste water.

Owner:陈亚松

Bamboo charcoal/carbon aerogel composite material and preparation method thereof

InactiveCN102430369AHigh specific surface areaLarge specific surface areaColloidal chemistry detailsToxic materialNitrogen gas

The invention discloses a method for preparing bamboo charcoal / carbon aerogel composite material, comprising the following steps: 1) mixing m-dihydroxybenzene with formaldehyde, dissolving in water, and stirring to obtain mixed liquid A; 2) adding the bamboo charcoal to the mixed liquid A and sealing; firstly standing at room temperature, then standing at 70-80 DEG C, and filtering to obtain mixture B; 3) putting the mixture B in trifluoroacetic acid liquor of which the mass concentration is 0.4-0.6% to soak, then taking outside and putting in acetone to soak, wherein the acetone is changed every day; and 4) putting the mixture after being dried in a nitrogen atmosphere furnace, insulating at 800-1000 DEG C for 1-3 hours, and obtaining the bamboo charcoal / carbon aerogel composite material. The composite material can be widely applied to industries for purifying air, processing waste water, processing toxic waste water, chemical catalyst carrier, purifying tail gas of cars, preparing sugar and wine, and preparing food.

Owner:ZHEJIANG UNIV

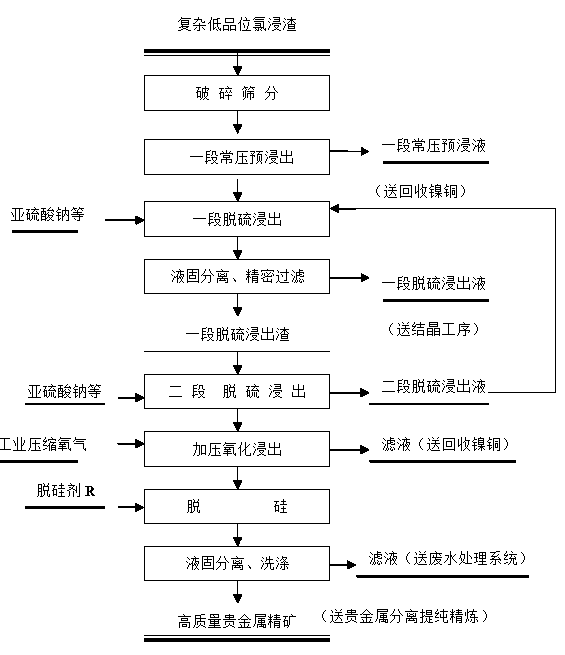

Method for high-efficiently enriching gold and platinum metal from complex low-grade chlorine soaked slag

A method for high-efficiently enriching gold and platinum metal from complex low-grade chlorine soaked slag relates to the key technology development field of high-efficient processing of low-grade assisted mineral resource and separation and extraction of scarce and precious metal. Complex low-grade chlorine soaked slag is subjected to the processes of slurry washing, first-stage normal-pressure leaching desulfurating, second-stage normal-pressure leaching desulfurating, pressure leaching, silicon-removing, and solid-liquid separating, while controlling appropriate technology parameters such as solid-liquid ratio, leaching reaction temperature, leaching time, acidity, addition amount of desulfurizer at the same time. Finally the silicon removed slag is high-grade, high-qualified precious metal concentrate. Compared to conventional methods, the method for high-efficiently enriching gold and platinum metal from complex low-grade chlorine soaked slag has the advantages of simple technology, environmental-friendliness, no generation of toxic waste gas or waste slag during production process, no use of toxic reagents, and high recovery rate and enrichment ratio of precious metals such as gold and palladium. The grade of enriched precious metals reaches 9000 to 15000 g / t, the recovery rate of precious metals reaches 98% or more, which is convenient for connecting the separation and refine processes of precious metals.

Owner:JINCHUAN GROUP LIMITED

Combustion gas catalyst, catalytic burner as well as preparation methods and application thereof

InactiveCN103111291ABurn fullyNothing producedGaseous fuel burnerMetal/metal-oxides/metal-hydroxide catalystsPtru catalystGas heater

The invention relates to a combustion gas catalyst, a preparation method and application thereof, a catalytic burner and a preparation method thereof. The combustion gas catalyst comprises a carrier, a catalytic active component and a modifier, wherein the carrier is mainly prepared from Al2O3, and the catalytic active component consists of either or both of Pt and Pd. The combustion gas catalyst disclosed by the invention has the characteristics that the catalytic activity is high, the performance is stable, no naked fire exists during burning, the burning is sufficient, toxic waste gases are hardly produced, and the like, and the service life is long under the normal working temperature of 1,100 DEG C. The catalytic burner disclosed by the invention has very high infrared radiation efficiency, polluting gases of burnt gas are few, the cost is low, the burner is less prone to backfiring, and the use safety performance of combustion gas is high, so that the catalytic burner can be applied to the manufacture of gas stoves, gas water heaters, gas heaters, gas boilers or industrial gas drying equipment and the like.

Owner:惠州市奥能科技有限公司

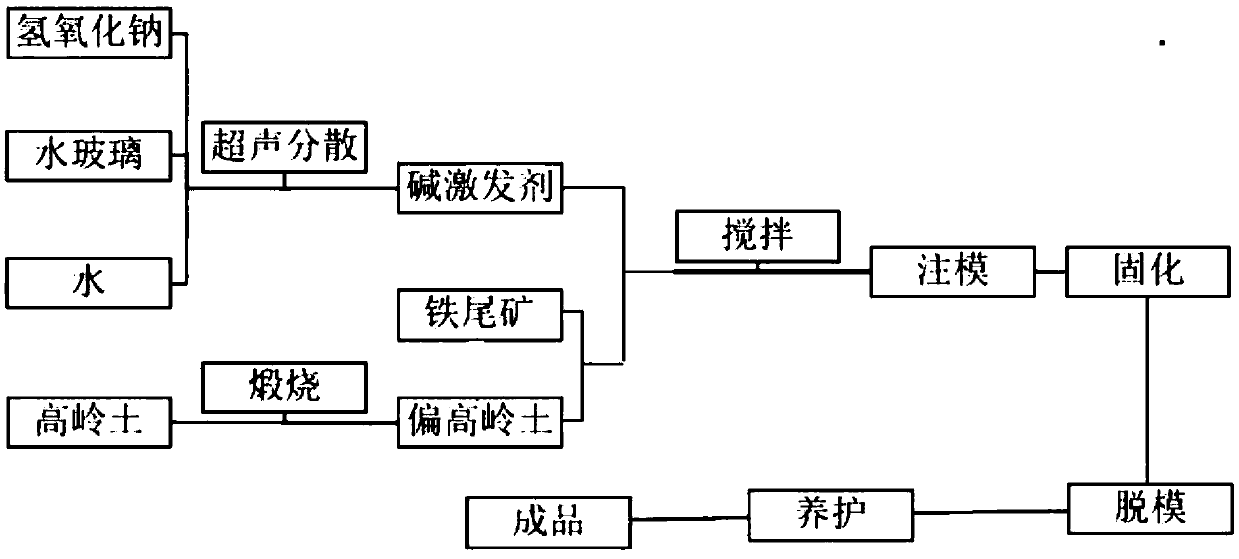

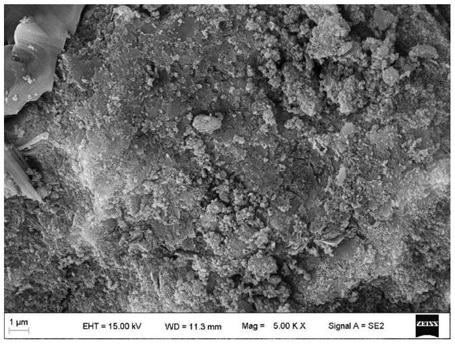

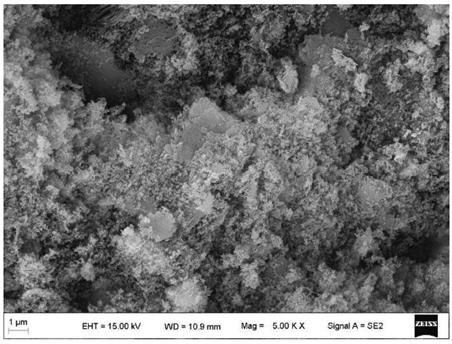

Iron tailings based geopolymer porous material and preparation method thereof

PendingCN109574558AHigh economic valueSolve the problem of resource utilizationCement productionCeramicwareKaolin clayToxic material

The invention relates to an iron tailings based geopolymer porous material and a preparation method thereof. The preparation method includes, grinding and activating iron tailings, which serve as themain raw material, adding in a certain proportion of Kaolin to regulate components, uniformly mixing with sodium hydroxide and a sodium silicate composite alkali activator to obtain a mixture, injecting the mixture into a mold while sealing and curing, releasing, and maintaining on the condition with a certain temperature and humidity, so as to obtain a finished product. The geopolymer porous material has the special three-dimensional grid structure with high strength, large specific surface ratio, good corrosion resistance and long durability, and can be applied to the fields such as buildingmaterials, sealing of heavy-metal ion or toxic waste, porous adsorbent materials and the like. Raw materials are rich in sources and cost is low; the preparation method is simple, green and environmental friendly, realizes recycled comprehensive utilization of iron tailings, and has a great significance in sustainable development and energy conservation and emission reduction.

Owner:东北大学秦皇岛分校

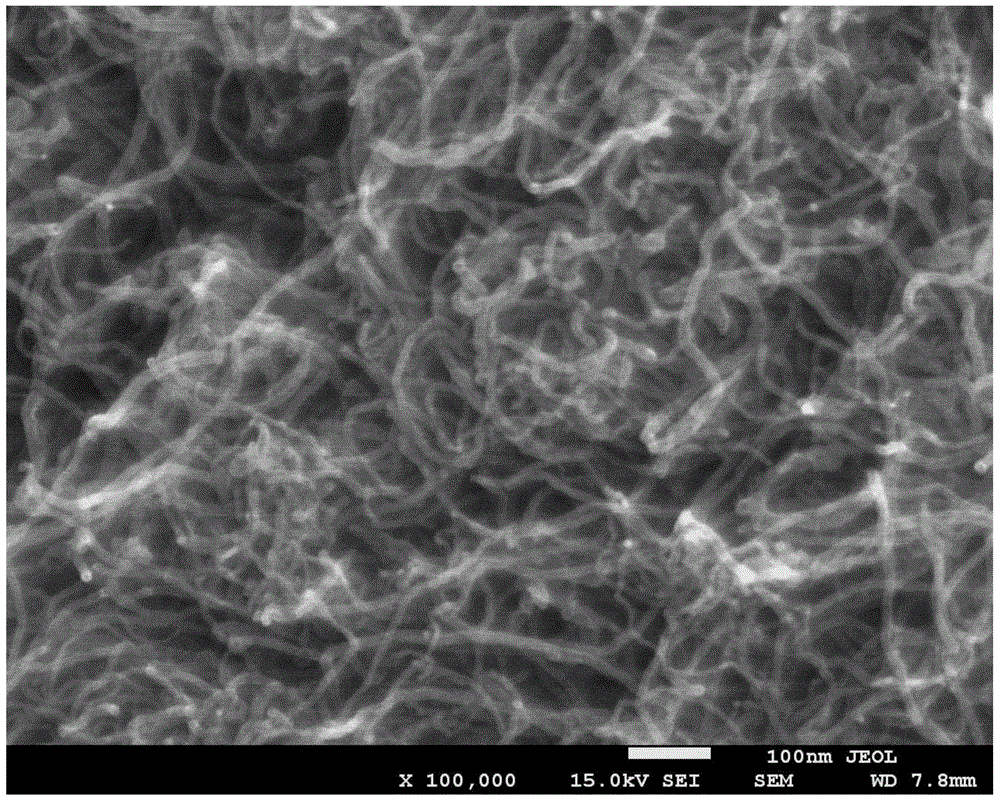

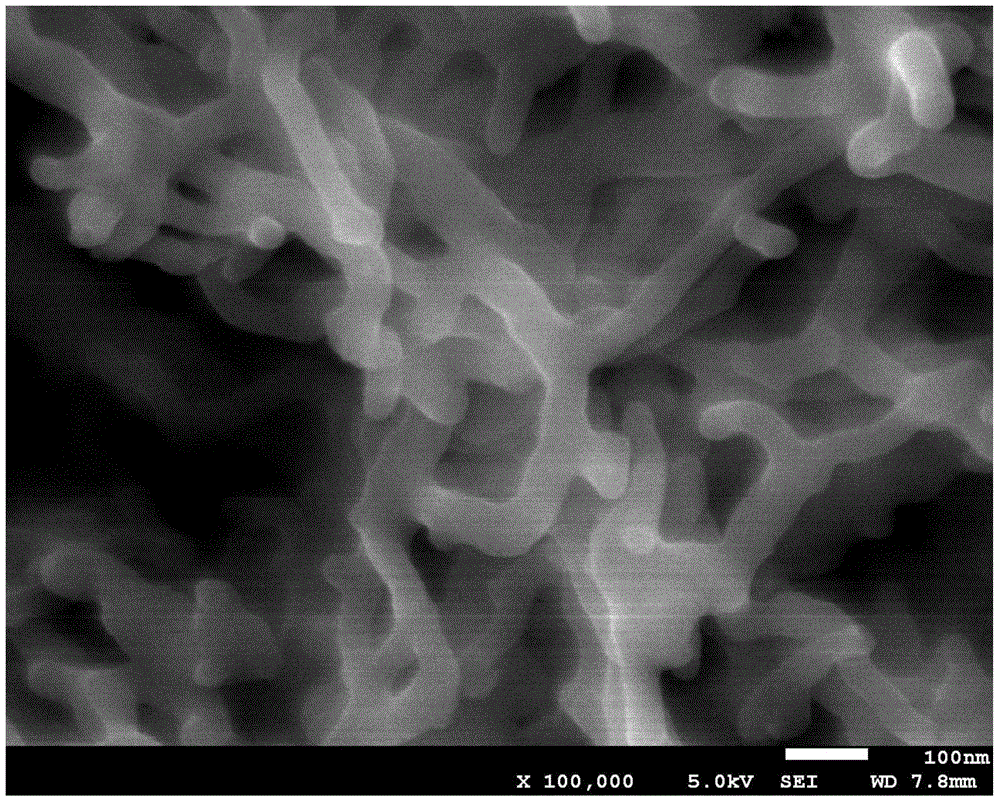

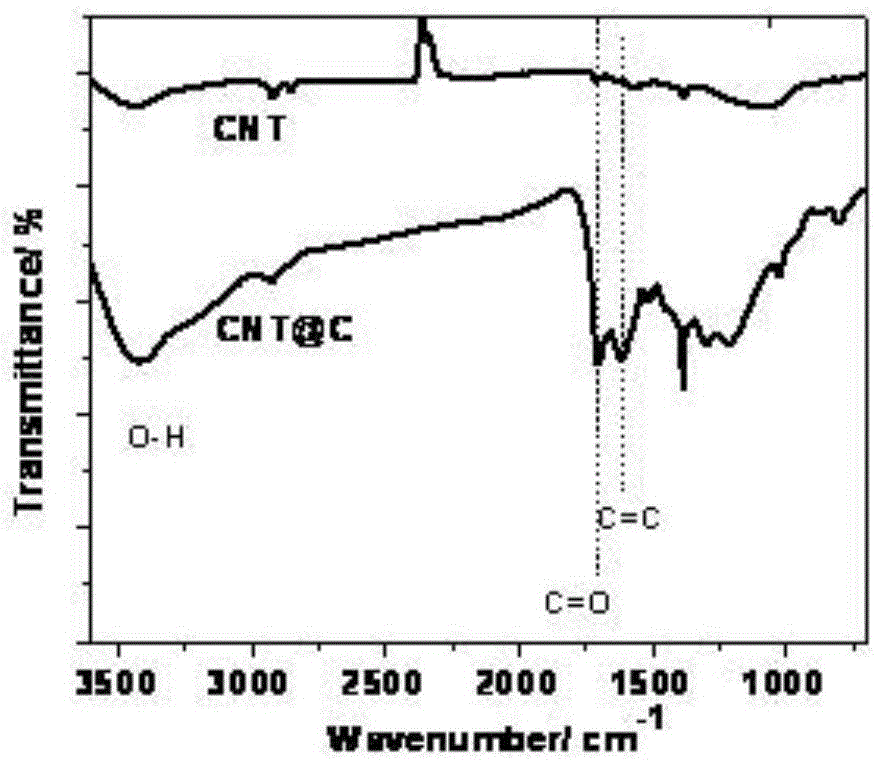

Method for surface modification of carbon material

The invention discloses a method for surface modification of a carbon material. By adopting a safe, low-cost, non-toxic environment-friendly structure-directing agent and a one-pot hydrothermal method, functionalized radicals are simply and efficiently introduced into surfaces of carbon nanotubes and graphene so that the surface of the carbon material is significantly modified, the structure stability of the carbon material is maintained to the greatest extent, the dispersion of the carbon material in a solution is improved, the carbon material has good dispersing effect in the process that a dispersion liquid is maintained for a long time and thus the carbon nanotubes and graphene can be uniformly dispersed and stably exist in different matrix materials and the mechanical property, electrical conductivity and the like of a composite material can be significantly improved. Compared with the prior art, the method disclosed by the invention has the advantages that environmental friendliness is achieved, large-scale production can also be achieved and no highly toxic waste is produced and the method is simple, efficient and safe and, thus being a very promising and efficient modification method of carbon material.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com