Patents

Literature

396 results about "Gold leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings

ActiveCN106498177ARealize harmless treatmentLow toxicityProcess efficiency improvementSilicate mineralsGold leaching

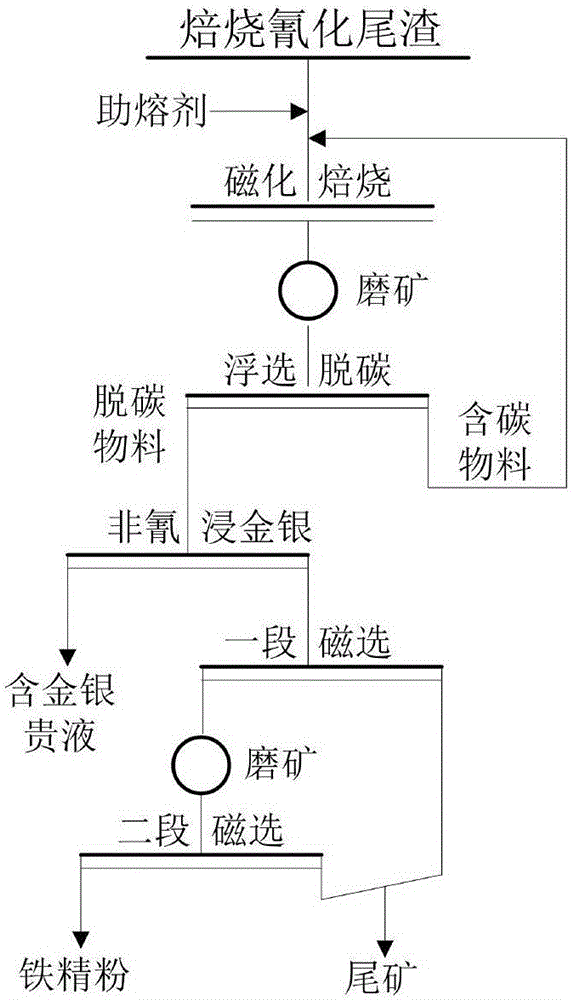

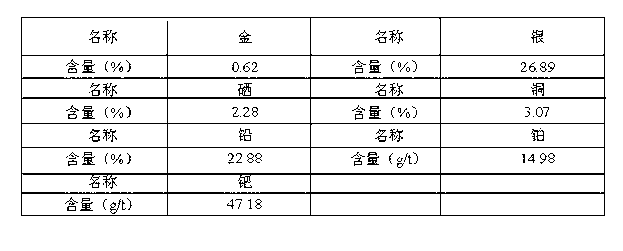

The invention provides a method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings, and belongs to the technical field of metallurgical waste residue utilization. The method comprises the following steps: mixing dried roasting-cyanidation tailings with a fluxing agent and a reducing agent; carrying out roasting at 750 to 900 DEG C for 3 to 5 hours; conducting water quenching on hot roasted sand for cooling; carrying out ore grinding and flotation to remove residual carbon; leaching gold and silver with an environment-friendly gold leaching agent; and conducting magnetic separation on the leaching residue to obtain fine iron powder. Containing no highly toxic cyanide, the rejects belong to general industry solid waste. As the fluxing agent is added for magnetic roasting, not only can gold and silver coated with an iron mineral be exposed, but also the fluxing agent can perform a solid-phase reaction with a silicate mineral to generate a dissoluble silicate, and gold and silver coated with the dissoluble silicate can also be exposed after ore grinding. According to the method, gold, silver and iron in the roasting-cyanidation tailings are recycled, harmless treatment is realized synchronously, and the purpose of clean production is realized.

Owner:UNIV OF SCI & TECH BEIJING

Method for extracting gold from waste printed circuit board

InactiveCN101392325AAchieve separationEliminate pollutionPhotography auxillary processesProcess efficiency improvementIodideIodine solutions

The invention provides a method for leaching gold from a deserted printed circuit board. The method comprises the specified steps: Step 1: the deserted printed circuit board is crushed and smashed to separate metals and plastics; Step 2: the metals obtained from the Step 1 are mixed with nitric acid solution, stirring and reaction are carried out for 1h to 6h at the constant temperature of 10 DEG C to 80 DEG C, products are filtered, copper is leached from the filtrate, and the filter residue is washed and dried; Step 3: the filter residue obtained from the Step 2 is added into the blended solution of first iodine solution and a pro-oxidant, a reaction pH value is controlled at 3 to 9 by an inorganic acid and alkaline solution, reaction is carried out for 2h to 5h in a constant temperature oscillator at the temperature of 10 DEG C to 60 DEG C; and Step 4: products obtained from the Step 3 are filtered, with the filtrate fed into the cathode region of an electrobath, second iodine solution composed of iodine, water-soluble iodide and water is used as the electrolyte and fed into the anode region of the electrobath, electrolysis is carried out, the solution at the cathode region is filtered, then the filter residue obtained is gold mud, and the second iodine solution at the anode region is recovered. The method has high gold leaching ratio, low cost and less environmental pollution.

Owner:DONGHUA UNIV

Method for pretreating refractory gold ore by employing microwave calcining

InactiveCN101225467AImprove leaching rateTo achieve the goal of green environmental protectionProcess efficiency improvementNitrogen gasMicrowave irradiation

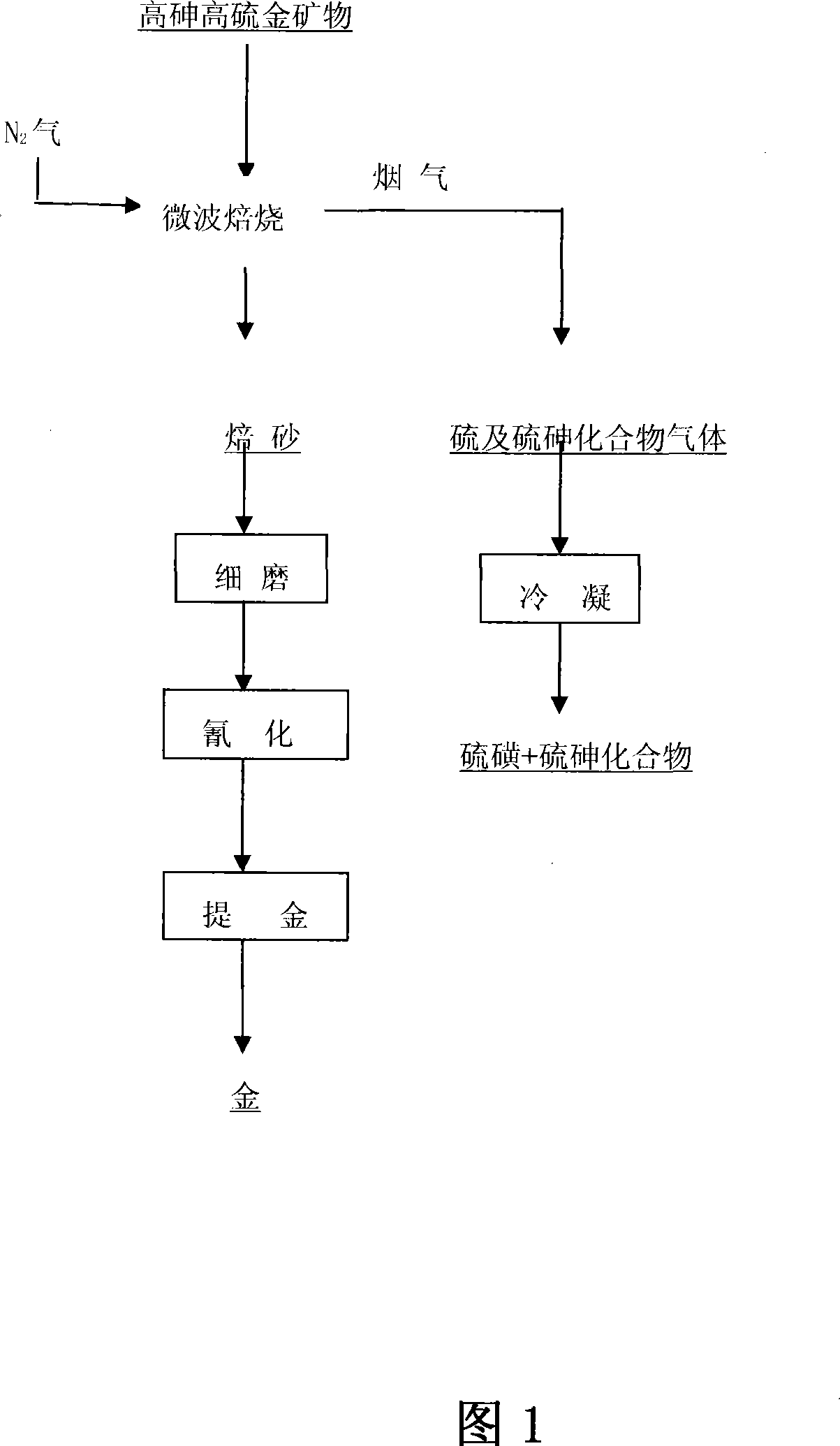

The invention relates to a method to pre-treat a hard-to-leach gold ores-pyrite by microwave roasting, which is characterized in that the gold ores-pyrite or fine gold ores-pyrite with the granularity being 200 meshes which takes 90% to 95% of the whole gold ores-pyrite is positioned in a reaction chamber of a microwave roasting oven, a nitrogen is filled fully into the reaction chamber, starting the microwave roasting oven, the gold ores-pyrite or fine gold ores-pyrite is radiated and roasted by the microwave in the nitrogen atmosphere, the roasting temperature is 450 to 580 degree centigrade, the power is 4 to 6kw, the microwave roasting oven stops working after roasting for 5 to 20 minutes, a roasted product is made when the roasting gold ore-pyrite is taken out. The method to pre-treat a hard-to-leach gold ores-pyrite by microwave roasting has the advantages of increasing the gold leaching yield of the hard-to-leach gold ores-pyrite up to over 90%, reaching purpose of the environment protection because the sulfur is precipitated as a free sulfur without the recovery process of smoke and dust, and saving the energy because the microwave roasting process is adopted and the pretreatment time is greatly shortened.

Owner:SHENYANG LIGONG UNIV

Method for extracting platinum-palladium out of copper anode mud

ActiveCN103305699ASimple configurationEasy to operateProcess efficiency improvementPlatinumProcess equipment

The invention discloses a method for extracting platinum-palladium out of copper anode mud. The method is characterized in that the platinum-palladium is extracted by employing a secondary gold dust chlorination gold leaching liquid, and the method comprises the following process steps of: firstly, carrying out sulfation roasting on the copper anode mud, carrying out primary chlorination gold leaching, carrying out sulfur dioxide gas reduction so as to obtain a primary reduction liquid, and subsequently carrying out zinc powder replacement so as to enrich gold, silver, platinum and palladium into secondary gold powder; secondly, dissolving the secondary gold powder, removing the impurities, filtering the obtained filtered residue, carrying out secondary chlorination gold leaching, adding ammonium chloride and a reduction inhibitor sodium chlorate into the filtered liquid, and reacting so as to obtain platinum and palladium precipitate; and finally reducing the filtered liquid by using a liquid sulfur dioxide to leach the gold. The method is simple in process equipment arrangement and convenient to operate; the recycling rate of the gold in the copper anode mud is increased; and meanwhile the platinum-palladium is effectively enriched in platinum-palladium concentrate.

Owner:SHANDONG HUMON SMELTING

Reinforced leaching method of fine-grained encapsulated gold

ActiveCN104694764APromote complexation dissolution reactionIncrease dissolved oxygen contentProcess efficiency improvementWater basedElectrolysis

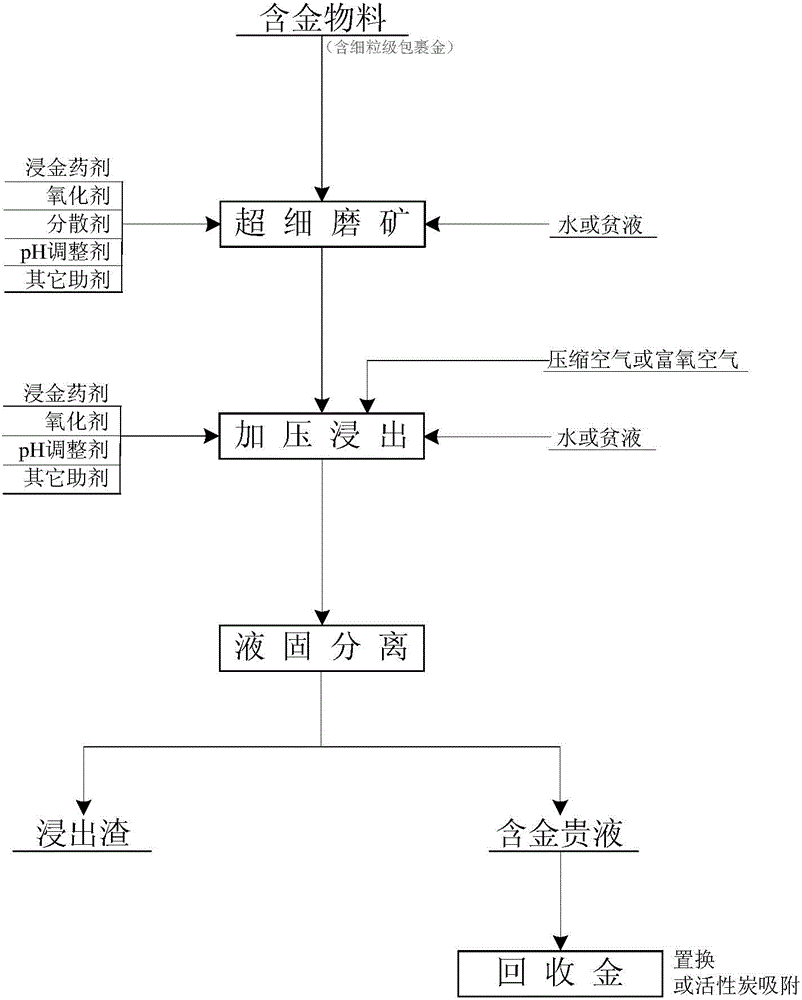

The invention discloses a reinforced leaching method of fine-grained encapsulated gold, which comprises the following steps: adding cyanation slag, calcined pyrite, pyrite cinder, auriferous sulfide ore roasted product or any other auriferous material, a gold leaching agent, a pH regulator, an oxidizer, a dispersing agent and the like into a water-base solvent, carrying out ball milling leaching to obtain extra-fine ground leaching slurry, transferring the extra-fine ground leaching slurry into a high-pressure reaction kettle, supplementing the gold leaching agent, oxidizer and water-base solvent, introducing air or oxygen-enriched air, carrying out pressure leaching, filtering and separating to obtain an auriferous pregnant solution and leaching slag. The method is simple in and convenient to operate, and can implement high-efficiency leaching of the fine-grained encapsulated gold; the obtained pregnant solution can be subjected to the existing technique composed of activated carbon adsorption, desorption, electrolysis, zinc powder (wire) reduction and the like to recover gold; and the method has high applicability and obvious economic benefits.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

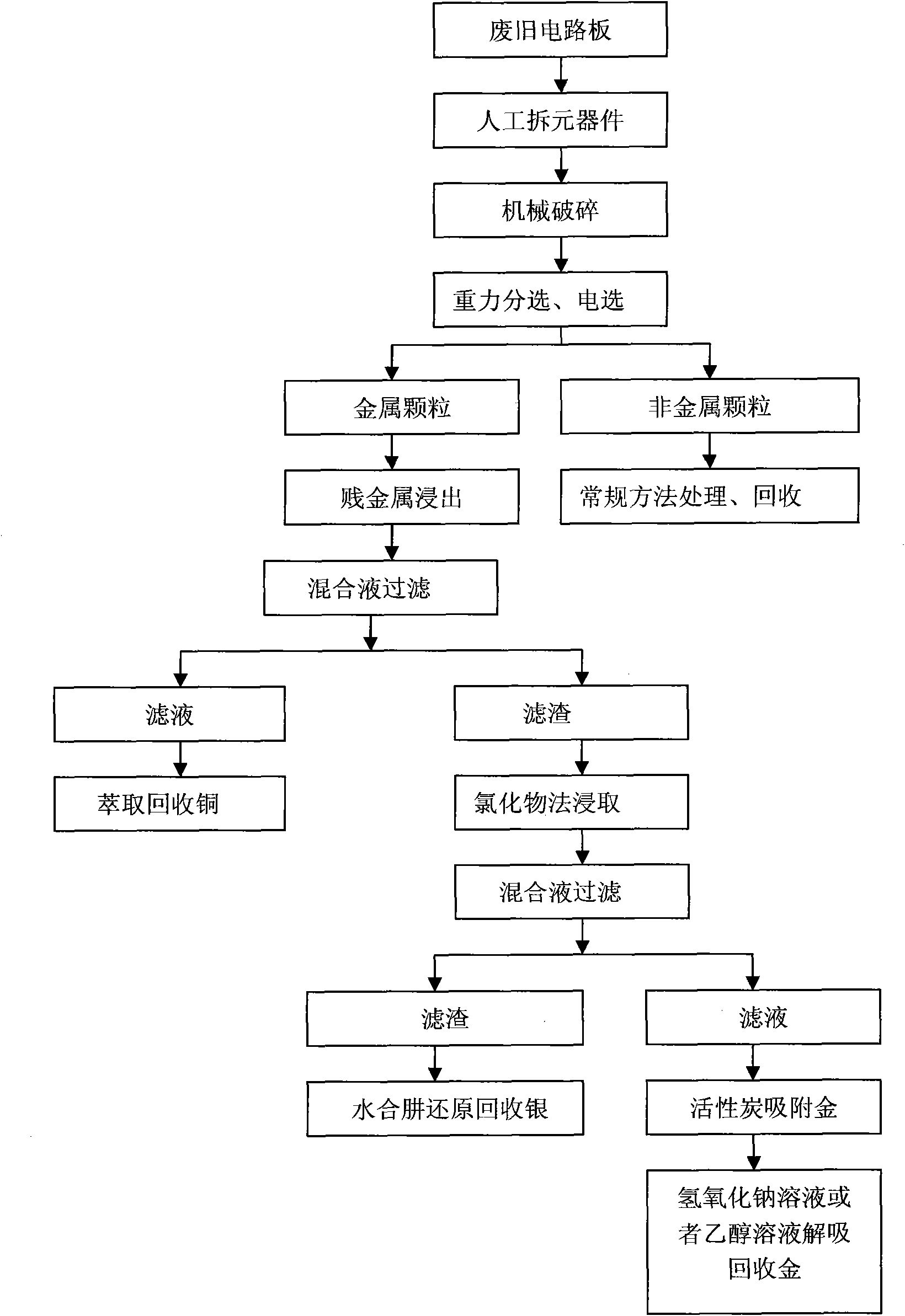

Method for recovering gold and silver from waste circuit boards

ActiveCN101928840ALow costGreen recyclingProcess efficiency improvementMetal particlePrinted circuit board

The invention relates to a method for recovering gold and silver from waste circuit boards which comprises: crushing the circuit boards, separating metal particles, adding sulfuric acid and oxidant to leach base metals from the metal particles, adding strong gold leaching agent BrCl2 into acidic solution which containing sodium chloride to leach gold, absorbing gold-containing solution by active carbon for two times, and desorbing in ethanol solution for two times to recover gold; directly reducing silver-containing filter residue, which is obtained by filtering, with hydrazine hydrate and recovering silver. The method is simple in operation and easy to promote industrially, avoids causing secondary pollution, effectively recover gold and silver from circuit boards, protecting environment from being polluted by directly discarded circuit boards and creates huge social and economic benefit.

Owner:TCL奥博(天津)环保发展有限公司

Preparation method and application of 2-mercaptobenzothiazole modified activated carbon

ActiveCN107215872ASimple processLow modification costOther chemical processesCarbon compoundsActivated carbonOrganic solvent

The invention discloses a preparation method and application of 2-mercaptobenzothiazole modified activated carbon, belonging to the fields of wet metallurgy and precious metal recovery. The preparation method comprises the steps of dissolving 2-mercaptobenzothiazole as an activated carbon modifying agent with an organic solvent or a strong base solution, and preparing 2-mercaptobenzothiazole modified activated carbon by virtue of an impregnation method, wherein the 2-mercaptobenzothiazole modified activated carbon is used for adsorbing Au(S2O3)2<3->. According to the preparation method, the disadvantages that cyanogen is polluted during adsorption recovery of activated carbon supported copper cyanide complex ions (Cu(CN)4<2->), a modifying process of loaded prussian blue is complicated, and continuous adsorption is difficultly realized, and the like are solved; the modified activated carbon is capable of adsorbing gold in thiosulfate gold leaching and has the advantages of multistage adsorption capacity and the like.

Owner:KUNMING UNIV OF SCI & TECH

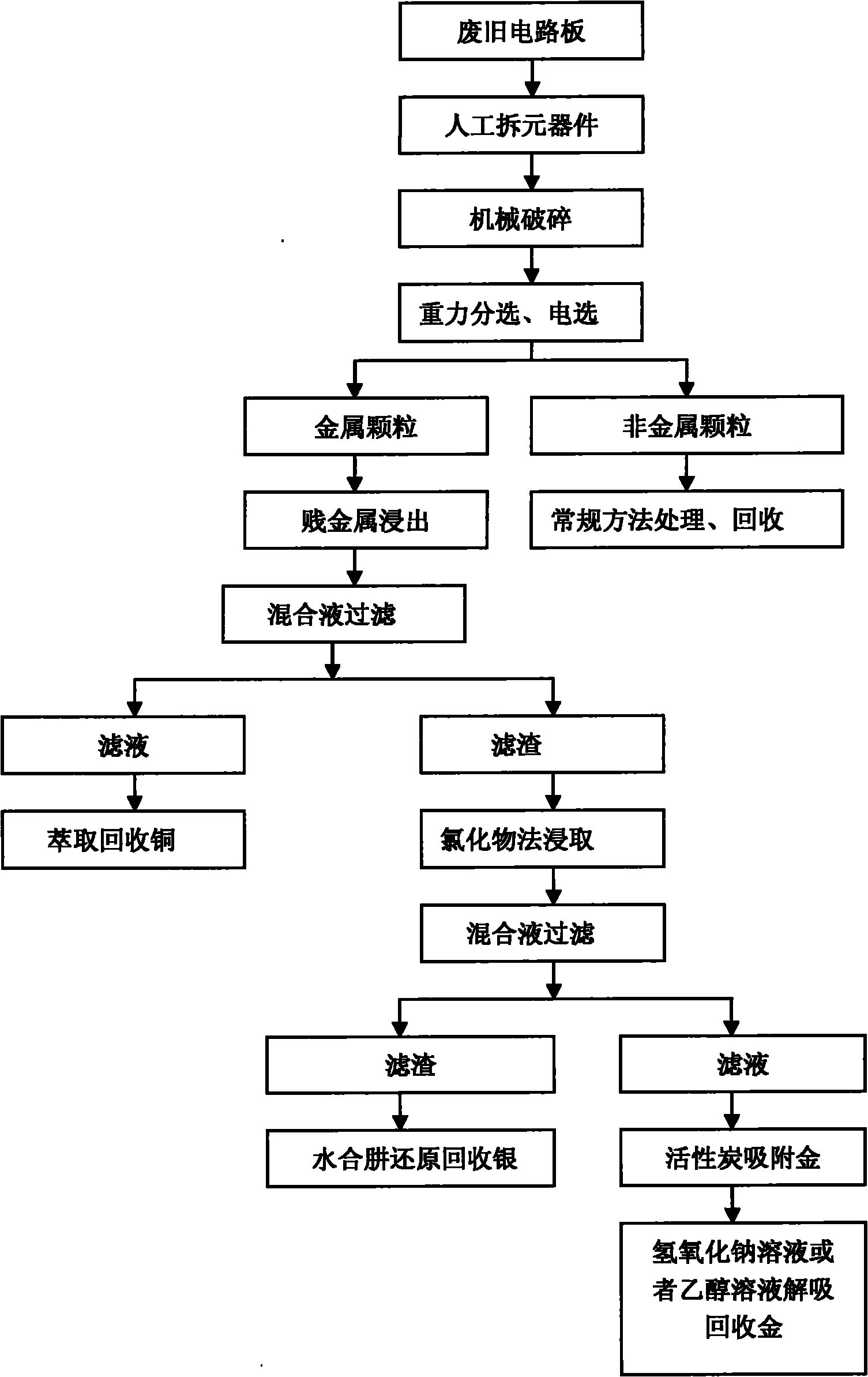

Beneficiation method for high-carbon micro-fine particle sub-microscopic gold ore

ActiveCN107326172AHigh recovery rateImprove leaching rateSolid separationProcess efficiency improvementHigh carbonPyrite

The invention discloses a beneficiation method for high-carbon micro-fine particle sub-microscopic gold ore, and belongs to the technical field of mineral processing. Roasted ore, namely, concentrated gold ore, is obtained by performing flotation after gold ore is ground, grinding and selecting the floated concentrated gold ore again, and performing oxidizing roasting on the floated concentrated gold ore. The content of carbon and sulphur in the floated concentrated gold ore is high; and when iron pyrite in the floated concentrated gold ore is enriched to a certain degree, the gold grade is difficult to improve. The concentrated gold core with high quality can only be obtained through the oxidizing roasting. Two-section oxidizing roasting is performed on floated tailings so as to prevent over-roasting or under-roasting, and a sulphide which coats the gold is damaged through roasting so that cracks appear on a gold-loaded mineral structure to inhibit negative impact of organic carbon on subsequent cyaniding gold extracting process; and therefore, the purpose of remarkably improving the leading rate of gold is achieved. The method has the characteristics of low production cost, high gold recovery rate, high adaptability, wide application range and the like; and recycling and utilization of the ore are realized.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

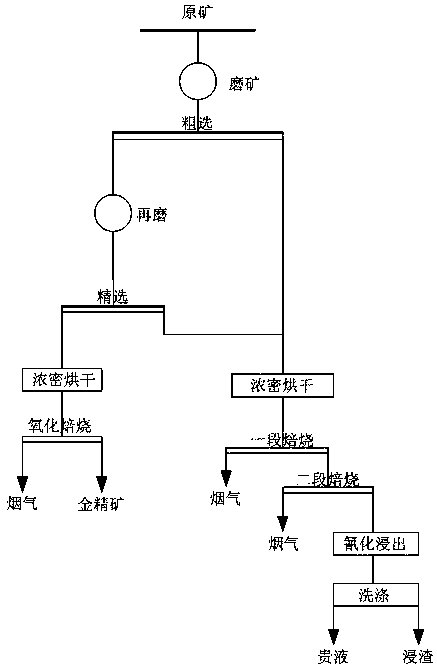

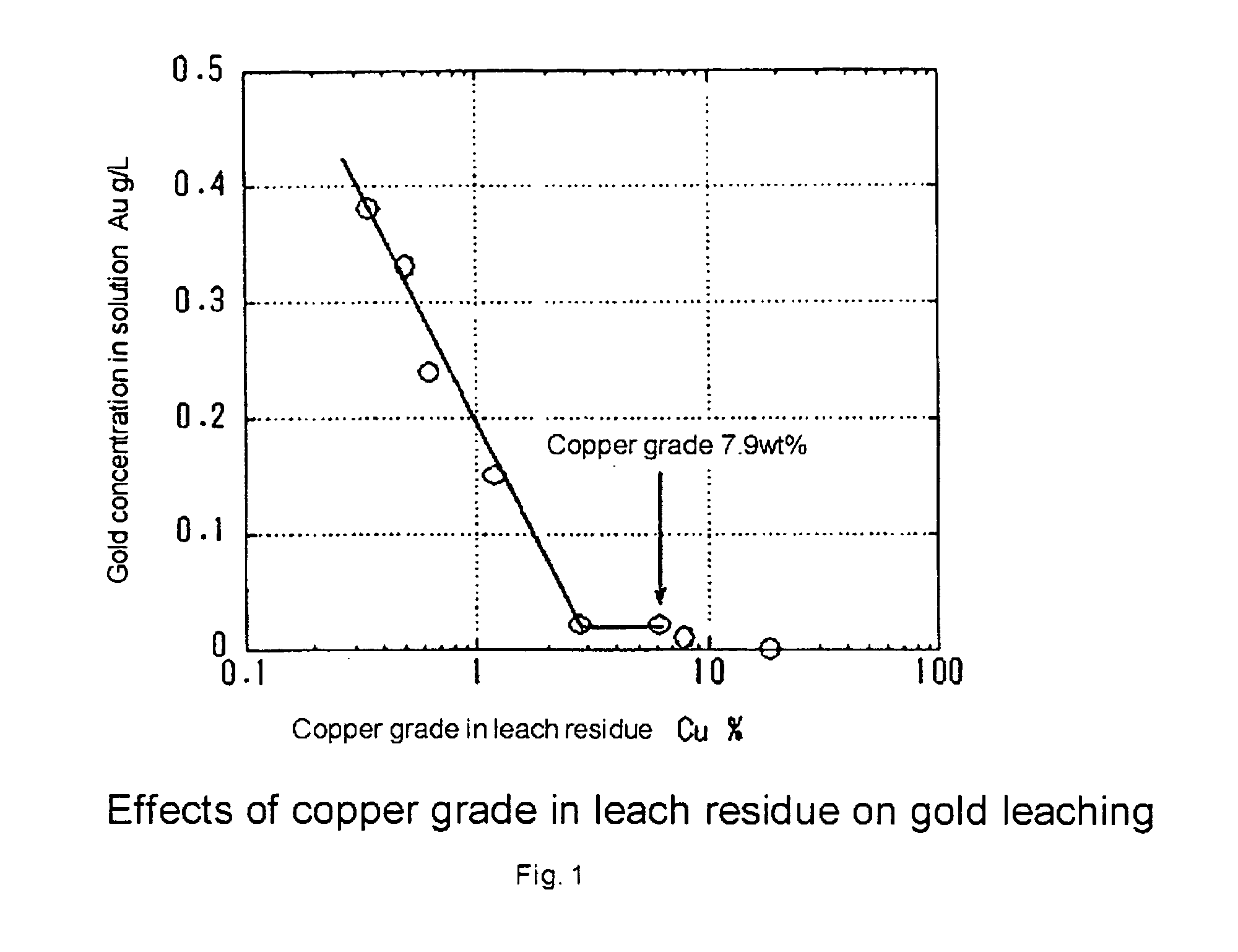

Process of leaching gold

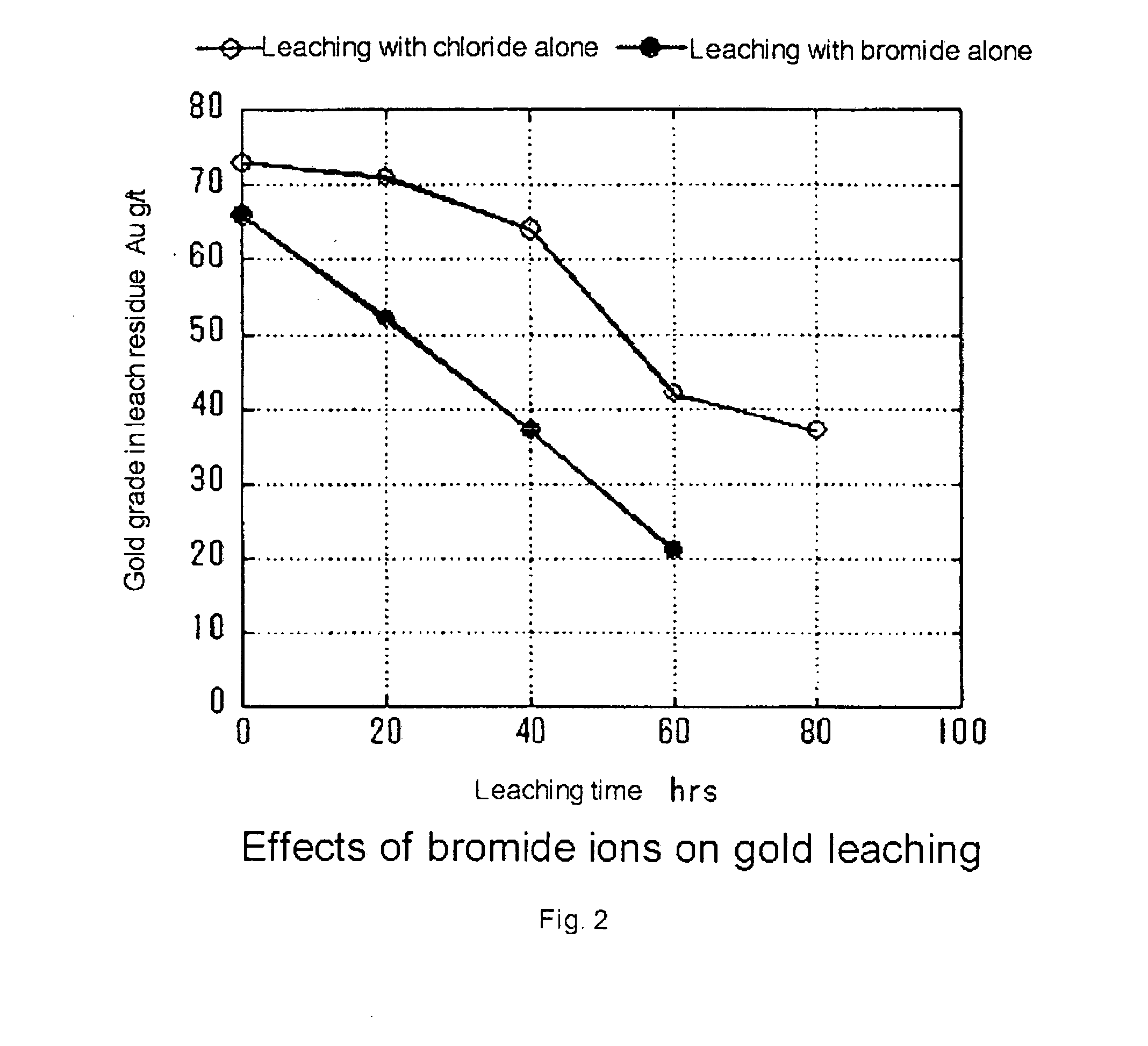

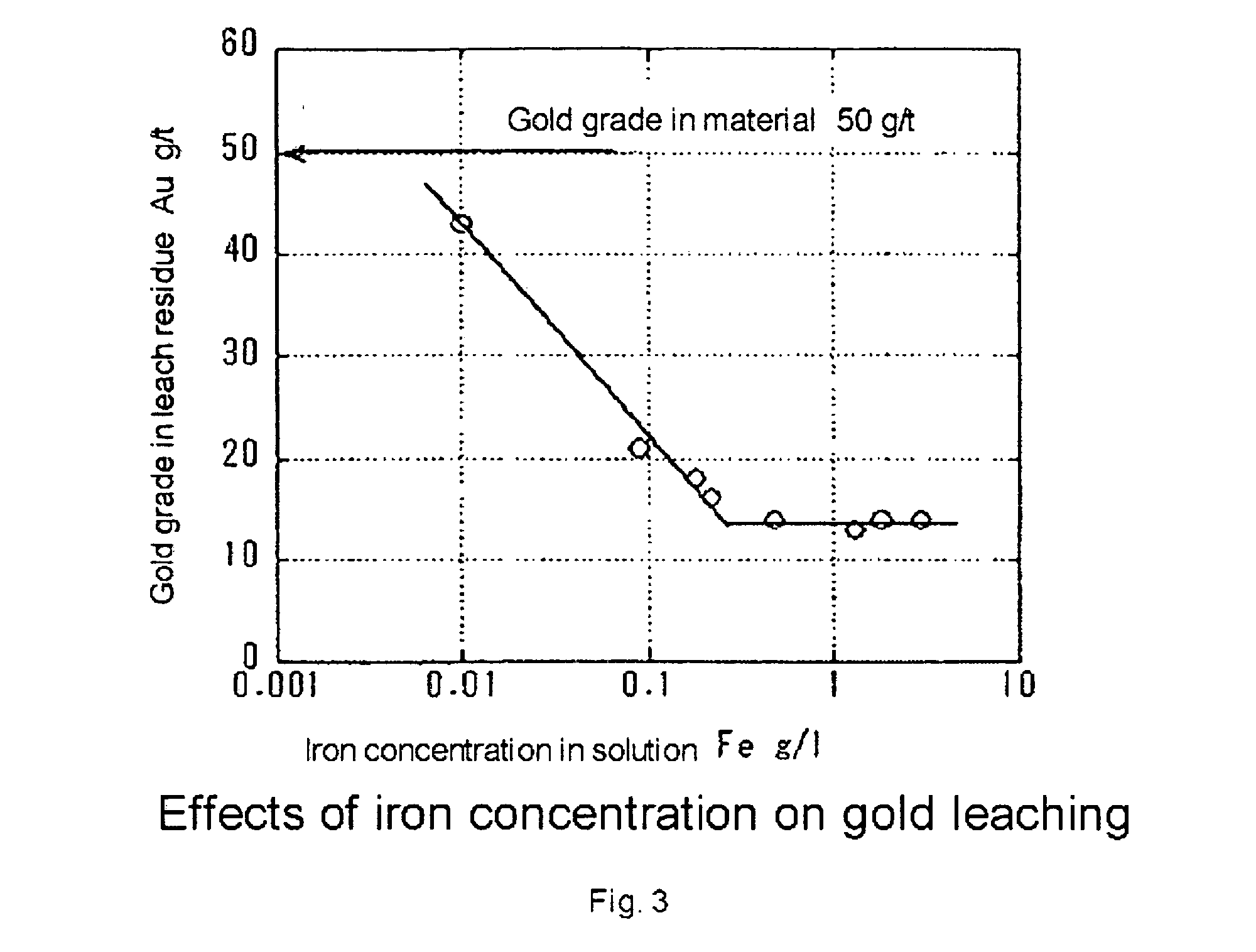

ActiveUS20090241735A1Improve efficiencyProcess efficiency improvementPregnant leach solutionChloride

A process of leaching gold comprising the steps of: a) leaching copper from copper sulfide ore material that contains gold or contains silicate ore containing gold until the copper grade is reduced to 7.9 wt % or less; b) mixing the resulting material having a copper grade of 7.9 wt % or less with a gold leaching solution selected from the group consisting of a first solution containing chloride ions and ferric ions, and a second solution containing chloride ions and iron ions, the iron ions having been oxidized to trivalent ferric ions by air bubbled into the second solution; c) adjusting the pH of the gold leaching solution to 1.9 or less with stirring to leach at least gold in the material into the gold leaching solution by the oxidative activity of the ferric ions contained in the gold leaching solution, wherein the concentration of gold is reduced by selectively removing gold from part or all of the gold leaching solution during gold leaching. This process efficiently leaches at least copper and gold from a copper sulfide ore.

Owner:JX NIPPON MINING& METALS CORP

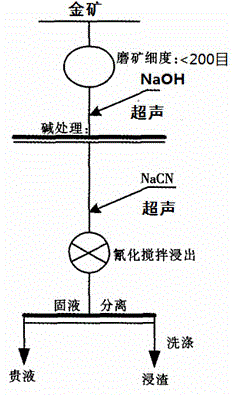

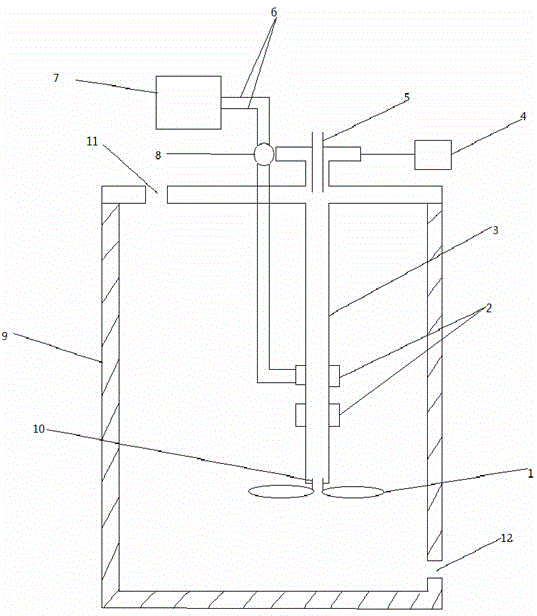

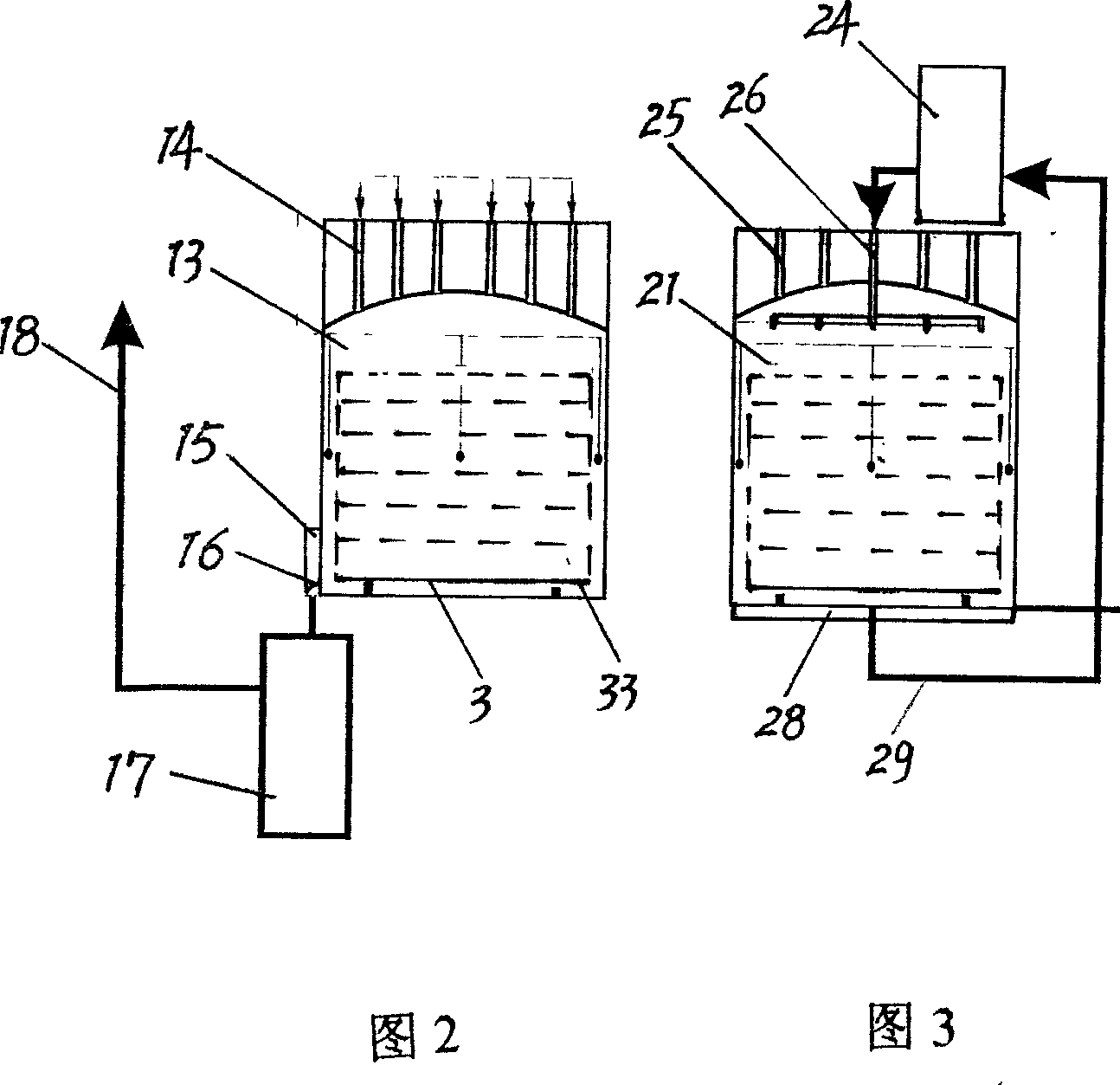

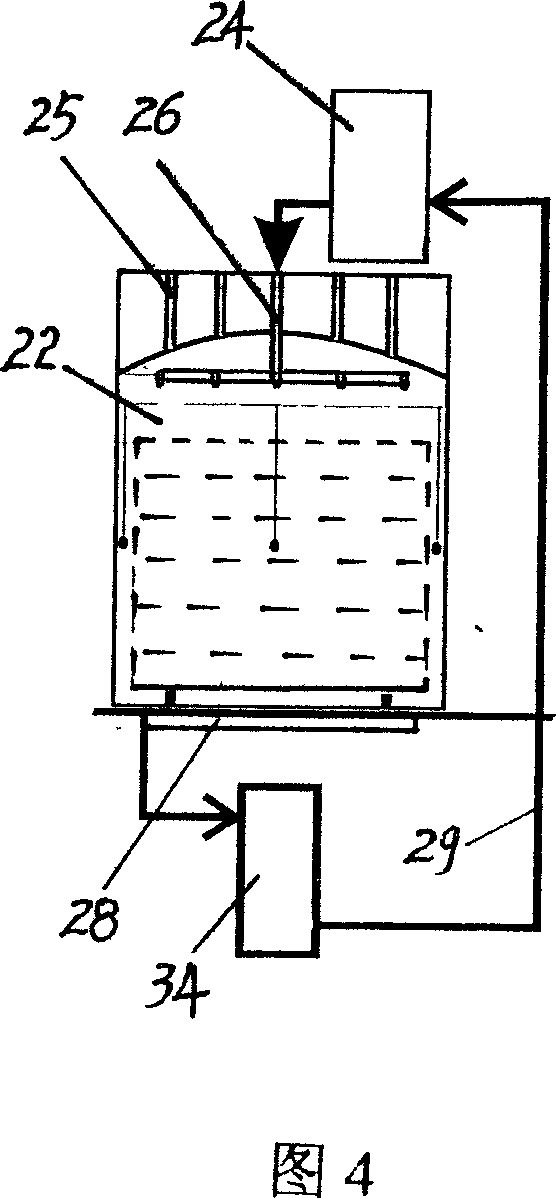

Ultrasonic intensified leaching method for refractory gold ores and ultrasonic intensified gold leaching stirrer

InactiveCN104131160AAccelerated gas stirringReduce disassemblyProcess efficiency improvementImpellerGas phase

Belonging to the technical field of wet metallurgy, the invention relates to an ultrasonic intensified leaching method for refractory gold ores and an ultrasonic intensified gold leaching stirrer. The method includes: firstly crushing gold ores to prepare an ore pulp, and then subjecting the ore pulp to pretreatment and leaching processes, in which ultrasonic intensified treatment is adopted. The ultrasonic intensified gold leaching stirrer includes a trough body, a feed inlet, a discharge port, a stirring structure, an ultrasonic structure and a ventilation structure. In the pretreatment and leaching processes, the method employs the ultrasonic method to perform intensified treatment on refractory gold ores, especially by adopting the ultrasonic method in the pretreatment process, the reaction time is shortened, and the leaching effect is intensified. The transmission shaft and stirring impellers of the ultrasonic intensified gold leaching stirrer deviate from the trough body center, thus effectively preventing the swirling phenomena, being beneficial to uniform mixing of solid-liquid-gas phase, and increasing the mass transfer rate.

Owner:KUNMING UNIV OF SCI & TECH

Method for reducing consumption of thiosulfate in gold leaching system

The invention provides a method for reducing consumption of thiosulfate in a gold leaching system. According to the method, the additive is humic acid extracted from coal and adopting fulvic acid , and humin acid as main components; during application, the humic acid is added into a copper-ammonia-thiosulfate system, wherein the adding amount of the humic acid is in the range of 20-120 mg / dm3, preferably 80mg / L, the copper-ammonia-thiosulfate system comprises 0.01-0.05mol / dm<3> of copper (II) ion, 0.3-2mol / dm <3> of aqua ammonia and 0.3-1mol / dm <3> of thiosulfate, and the pH value of pulp is 10-11. By using the leaching solution (namely the copper-ammonia-thiosulfate) to extract gold from ore, the consumption of the thiosulfate can be remarkably reduced on the premise of not affecting the leaching rate of gold.

Owner:CENT SOUTH UNIV

Selective heap leaching gold extraction process for gold mine containing copper

ActiveCN101818247AReduce consumptionImprove leaching rateProcess efficiency improvementSelective leachingHydrometallurgy

The invention discloses a selective heap leaching gold extraction process for gold mine containing copper, belonging to the field of hydrometallurgy. The process comprises the steps of: smashing and heaping gold mine containing copper; carrying out alkali treatment on the mine; then adding ammonium salt and sodium cyanide according to a certain proportion to realize the selective leaching of the gold and the restriction to the leaching of the copper; and finally absorbing and extracting the gold from leaching solution by conventional active carbon. The invention has the advantages of simple process method, short procedure, simple equipment, easy implementation, high gold leaching efficiency, low consumption of sodium cyanide, low energy consumption, little investment and low cost, and is the gold extraction method with easy realization of industrialized production and favorable economical benefit.

Owner:ZIJIN MINING GROUP

Modified lime sulphur and application thereof in gold leaching technology

ActiveCN103243222AReduce dosageImprove stabilityProcess efficiency improvementLead nitrateCalcium peroxide

The invention discloses a modified lime sulphur and an application thereof in a gold leaching technology. The modified lime sulphur comprises a stabilizer sodium-hexametaphosphate, oxidants-calcium peroxide and potassium cyanate, and additives-lead nitrate and soluble bromides (such as sodium bromide, potassium bromide, calcium bromide and the like). The modified lime sulphur is used as a gold leaching agent so as to effectively recover gold from gold-containing ores, gold concentrate powder and gold-containing wastes. The modified lime sulphur has the characteristics that the modified lime sulphur is easy to synthesize; the preparation cost is low; the preparation process is environment-friendly and toxic-free; and when the prepared modified lime sulphur is used for gold leaching, the gold leaching technology is simple, and the gold leaching velocity is high; and moreover, the modified lime sulphur is suitable for more ores than cyaniding gold leaching.

Owner:CENT SOUTH UNIV

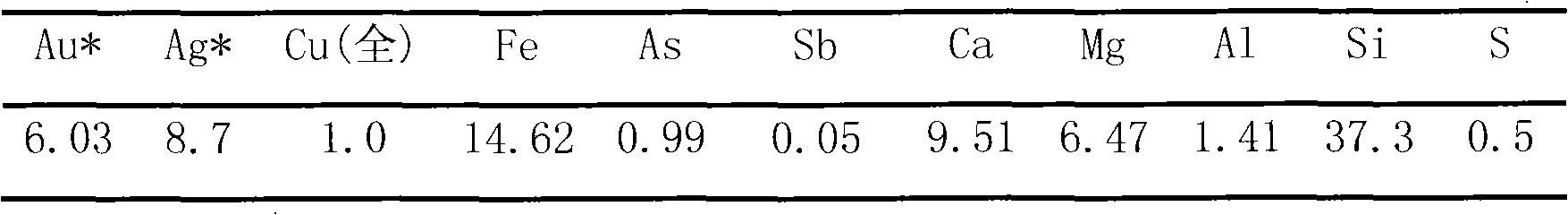

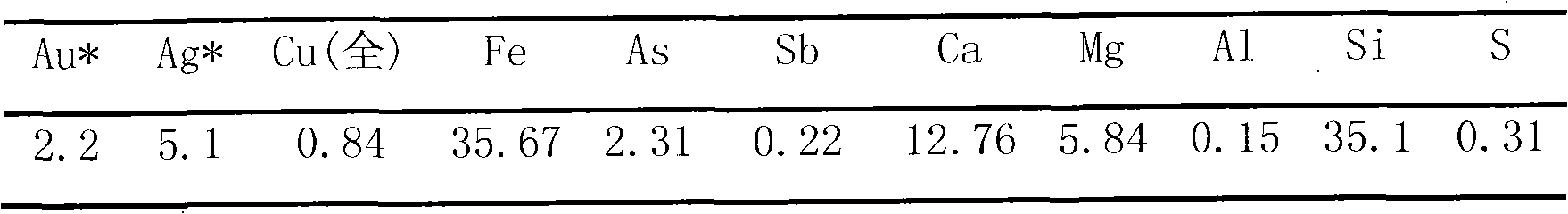

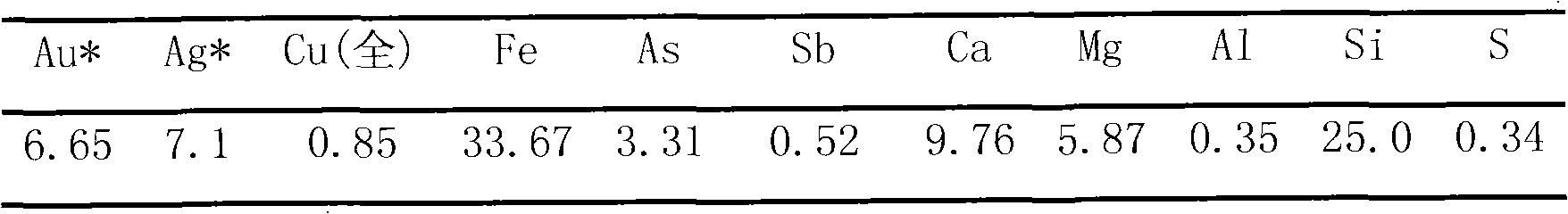

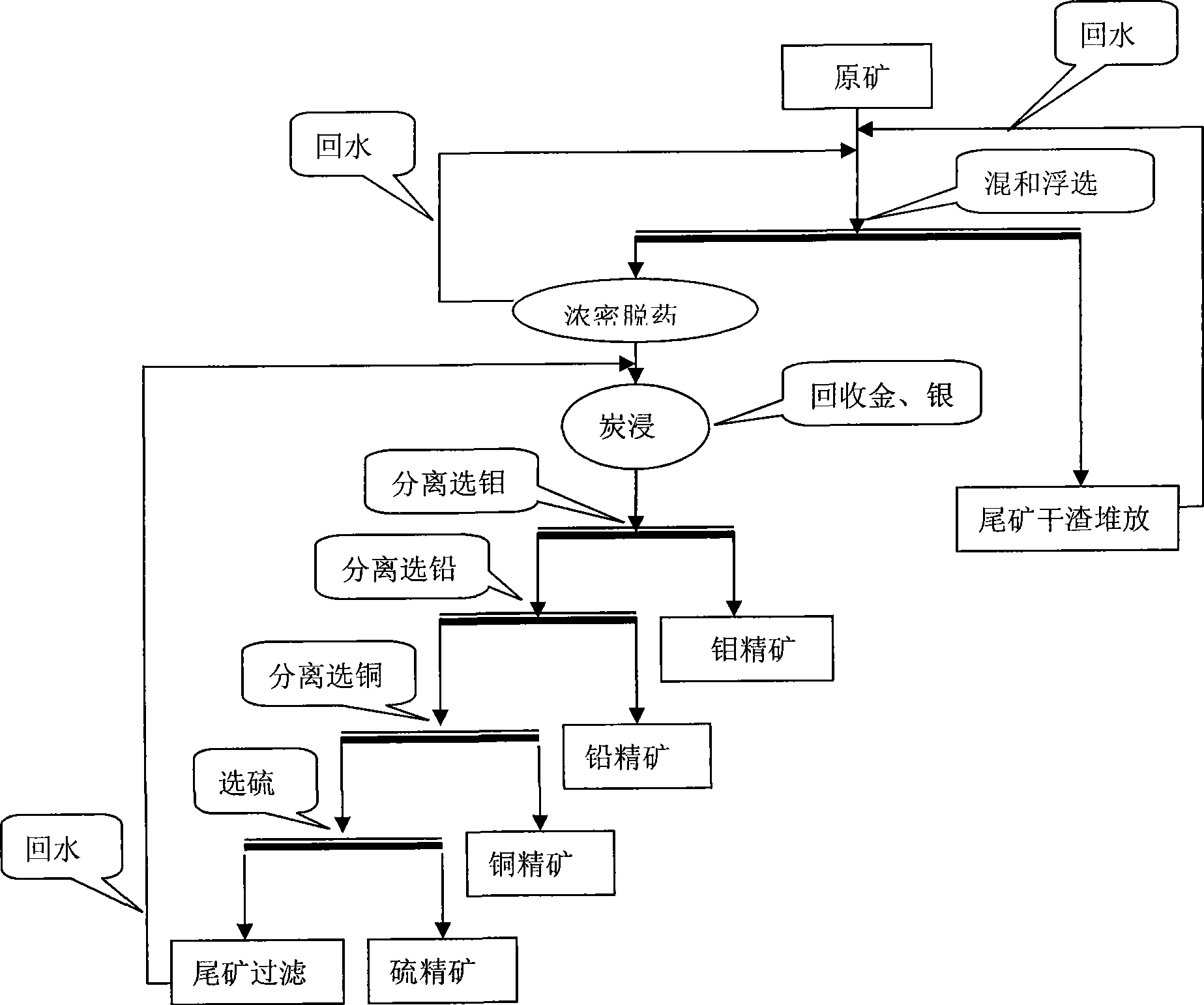

Comprehensive recovery method of gold ore resource containing molybdenum multi-metal

ActiveCN101451187AHigh Filtration AutomationReduce labor intensityFlotationProcess efficiency improvementRecovery methodFiltration

The invention discloses a method for comprehensively recovering molybdenum-containing polymetallic gold ore resources, which comprises the following steps: firstly, crushing and grinding molybdenum-containing gold ores first, performing floatation on useful metallic elements to obtain bulk concentrate by a complete mixing floatation method, and discarding tailings; secondly, leaching out and recovering gold and silver from the bulk concentrate by CCL carbon paste wet-method gold leaching technology, and using tailings after gold leaching for preferred selection of molybdenum in the next step; thirdly, performing preferred separation and floatation of the molybdenum on the gold leaching tailings to obtain qualified molybdenum concentrate; fourthly, activating molybdenum-selecting tailings, and performing separation and floatation of lead to obtain lead concentrate; fifthly, performing separation and floatation of copper on lead-selecting tailings to obtain copper concentrate; and sixthly, performing floatation of sulfur on copper-selecting tailings to obtain sulfur concentrate, performing filtration and backwater circulation on sulfur-selecting tailings, and applying the sulfur-selecting tailings to the carbon paste wet-method gold leaching technology for recovery of the gold and the silver. The method greatly improves the grade of separated metals. The following products can be obtained by utilization of the method: more than or equal to 95 percent of alloyed gold, more than or equal to 45 percent of the molybdenum concentrate, more than or equal to 40 percent of the lead concentrate and more than or equal to 35 percent of the sulfur concentrate. The tailings after floatation are filtered by a ceramic filter (the moisture content is less than or equal to 15 percent), subjected to dry-type stacking, and used for soil sealing and land rehabilitation in late stage.

Owner:LINGBAO CITY JINYUAN MINING

Integral gold refining kiln oxidizing roasting process for refractory gold ore

InactiveCN1932052ALarge amount of processingWide adaptabilityProcess efficiency improvementTunnel kilnSulfur

The present invention provides integral kiln type oxidizing, roasting and gold refining process for refractory gold ore. The roasting, the cyanating and the gold refining are completed in the same tunnel kiln. The present invention has low investment, simple apparatus making, short technological process, easy control, high gold leaching rate, high S and As oxidizing rate, low production cost, easy waste treatment and other advantages.

Owner:云南省地质科学研究所

Process of nickel citrate for catalyzing thiosulfate to leach gold

ActiveCN104789792AReduce consumptionReduce the amount of decompositionProcess efficiency improvementSulfateAmmonia

The invention discloses a novel process of nickel citrate for catalyzing thiosulfate to leach gold. The novel process is characterized in that the nickel citrate catalysis is used for substituting the traditional copper ammonia catalysis, namely the nickel sulfate and the citric acid (or sodium citrate) are added in the thiosulfate gold leaching pulp to substitute the adding of the copper sulfate and the ammonia. By adopting the process, the oxygenolysis effect of the Cu(NH3)4<2+> and S2O3<2-> is eliminated so that the consumption of the thiosulfate is obviously reduced; and besides, the use of the ammonia is cancelled so as to avoid the risk of the NH3 on the environment. The gold leaching rate is equal to that of the copper ammonia catalysis.

Owner:CENT SOUTH UNIV

Method for leaching gold in alkaline thiourea system efficiently and stably

ActiveCN103276206AImprove stabilityReduce dosageProcess efficiency improvementThioureaSodium phosphates

The invention discloses a method for leaching gold in an alkaline thiourea system efficiently and stably. According to the method, under an alkaline condition, thiourea is taken as a gold leaching reagent, sodium hexametaphosphate or trisodium phosphate is taken as a stabilizing agent, calcium peroxide is taken as an oxidizing agent, EDTA (ethylene diamine tetraacetic acid) is taken as a leaching auxiliary, and gold in auriferous ores (tailings), gold fine powder and auriferous waste are recycled rapidly and efficiently. The method is characterized in that the stability of the thiourea under the alkaline condition is guaranteed, the gold leaching efficiency and the speed are high, the gold leaching system is non-toxic, the gold leaching process is simple, no corrosiveness is produced to devices, and the method is almost suitable for leaching gold in all auriferous materials.

Owner:CENT SOUTH UNIV

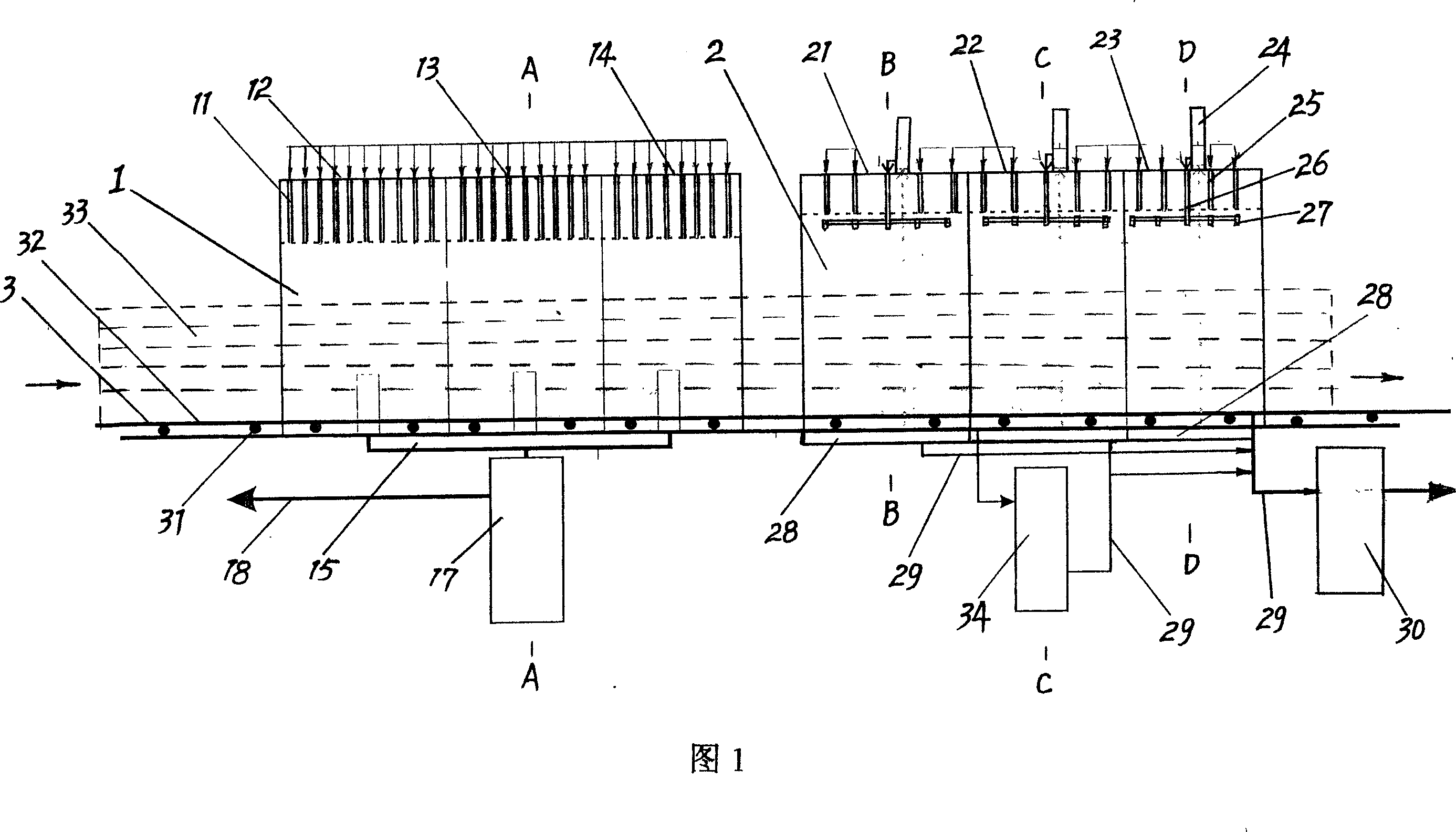

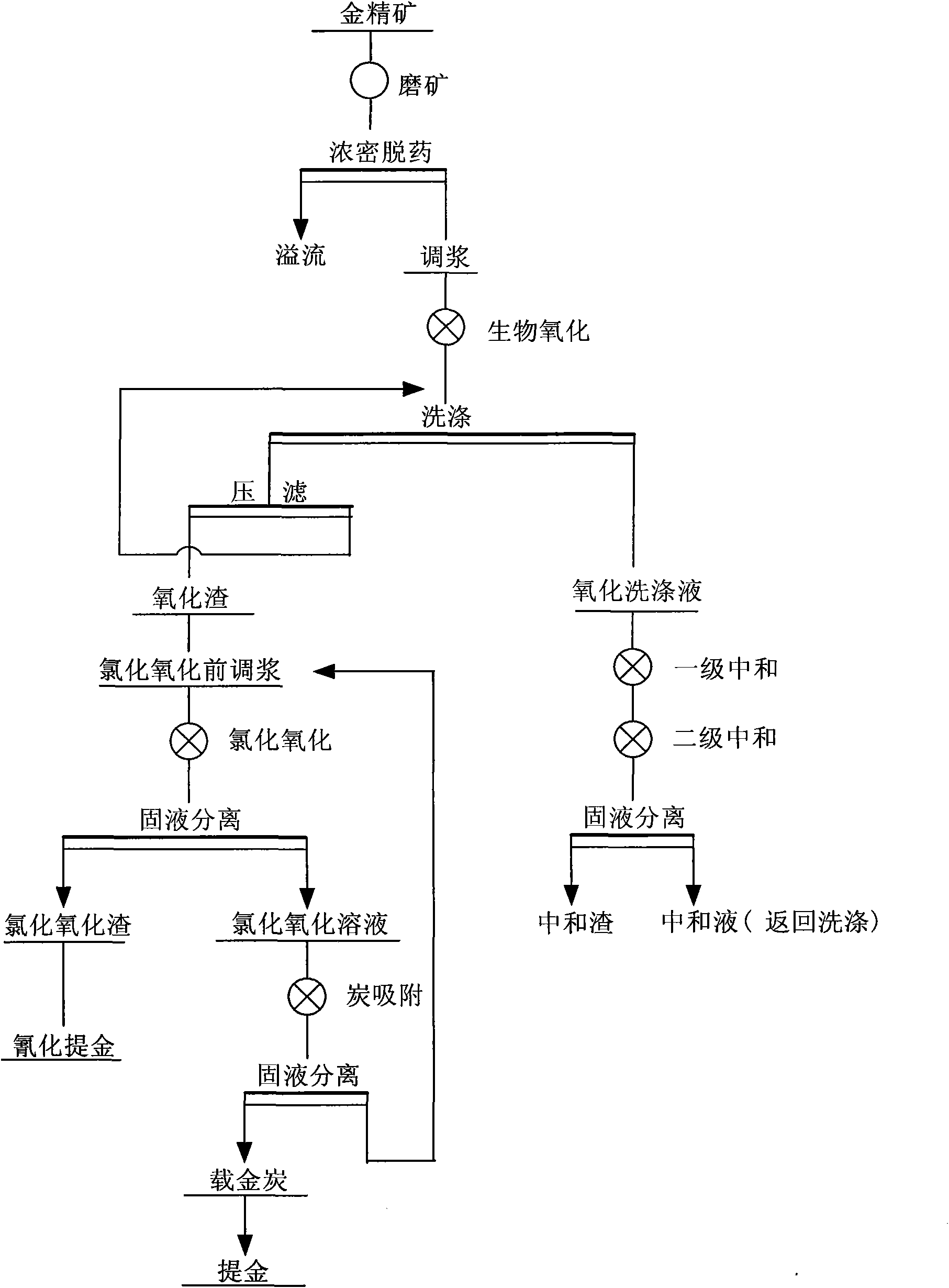

Secondary oxidation pretreatment process for arsenic, sulphur and carbon-containing difficultly treated gold concentrate

InactiveCN102011013ASolve the technical bottlenecks that are not suitable for processing carbon-containing refractory concentratesNo pollution in the processProcess efficiency improvementHypochloriteBiological oxidation

The invention discloses a secondary oxidation pretreatment process for arsenic, sulphur and carbon-containing difficultly treated gold concentrate. The process sequentially comprises the following steps of: grinding concentrate again, removing a reagent, performing biological oxidation, chloridizing and oxidizing and cyaniding to leaching gold. In the process, the gold concentrate is oxidized by a biological oxidation process, and oxidizing slag is treated by using hypochlorite, so that the harmful influence of carbonaceous matter on the cyaniding and gold leaching is reduced greatly by chloridizing and oxidizing; and the process can effectively improve gold recovery rate, and is simple and environmental-friendly.

Owner:CHANGCHUN GOLD RES INST +1

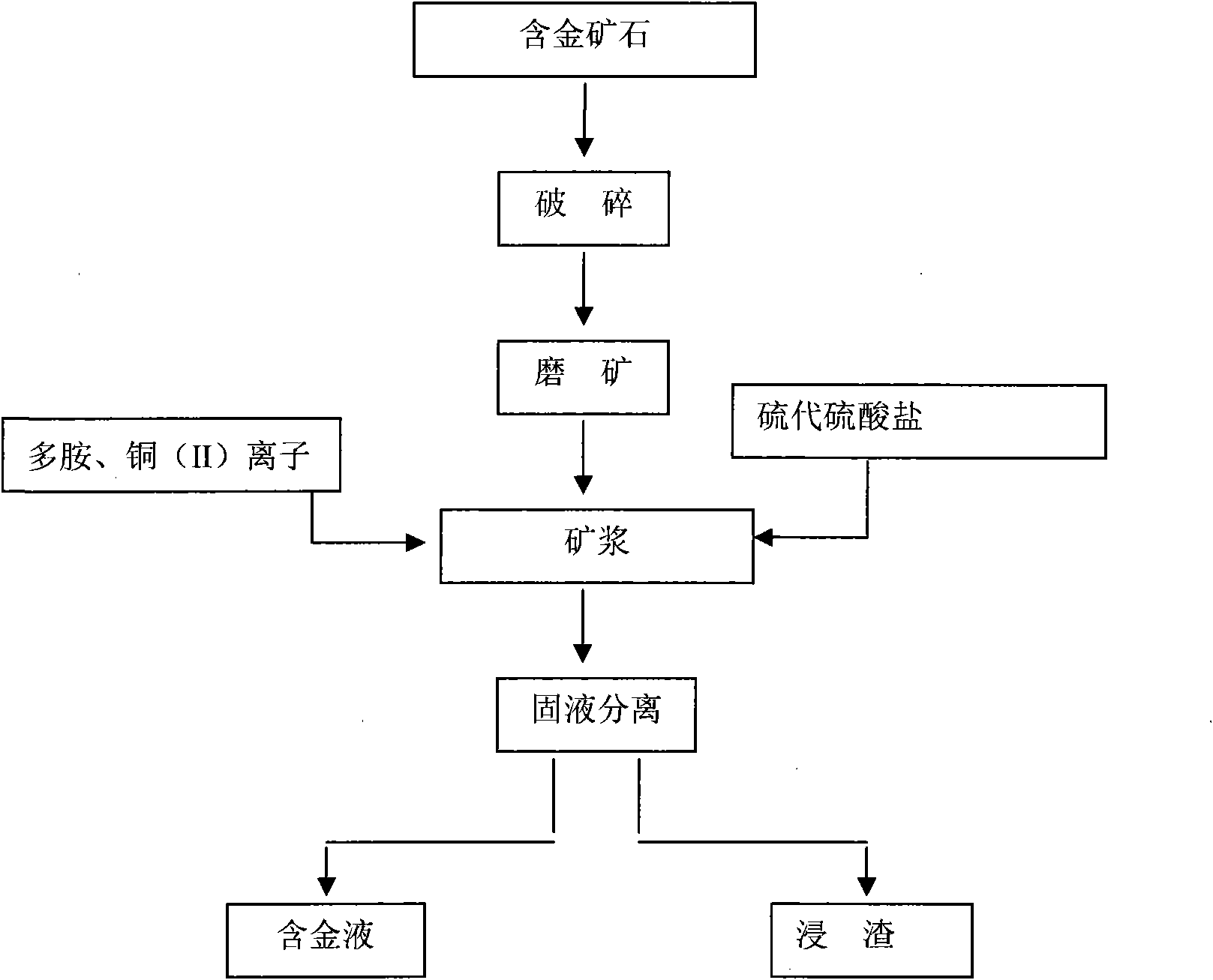

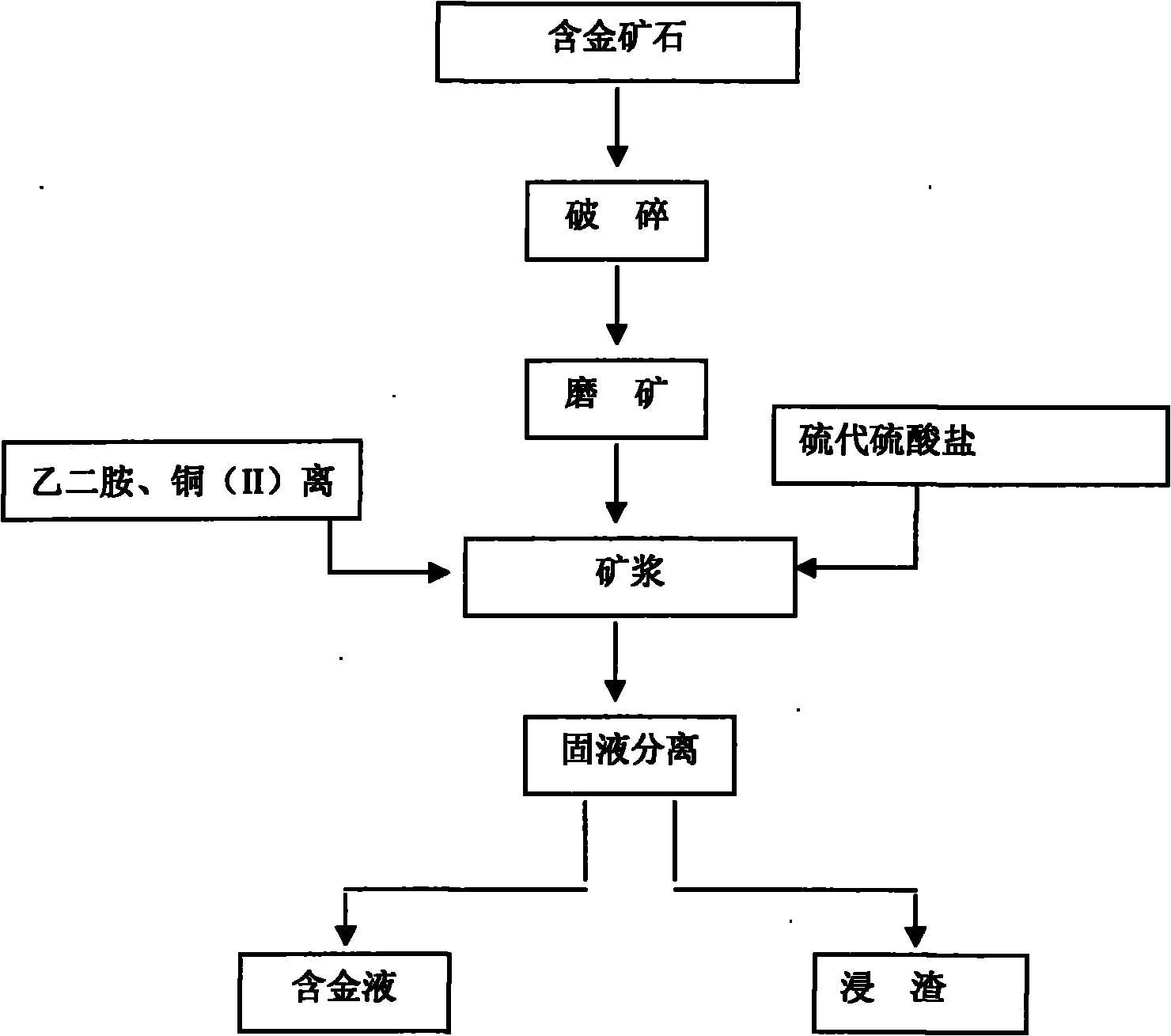

Gold extracting method by thiosulfate using polyamine compoud as additive

InactiveCN101775490AReduce consumptionLittle effect of leachingProcess efficiency improvementToxic materialSodium cyanide

The invention relates to a gold extracting method by thiosulfate using a polyamine compound as an additive, which comprises the steps: after ores are crushed and wet-ground until the fineness is over 90 percent of -200 meshes, 0.03-3mol / dm3 thiosulfate is added to be used as a leaching agent, and then 0.0015-0.09mol / dm3 polyamine compound and 0.0015-0.03mol / dm3 copper (II) ion are added to form a complex ion to be used as an additive to be stirred and leached; and after gold ores are leached, gold from a leaching solution is recovered. The leaching solution is used to extract gold from the ores, so that the gold leaching rate is high, the process operation is simple, the control is easy, the consumption of thiosulfate is extremely low, and the compositions of the gold leaching solution are simple and are favorable for the recovery of the gold; and the application range is wide, the leaching effect is good when the pH value is between 10 and 12, the leaching speed is quick for copper-containing, carbon-containing and other refractory gold ores, quite high gold leaching rate can be maintained, and sodium cyanide and other toxic substances are not used and toxic waste is not discharged in the whole gold extraction process, so the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

Method for strengthening gold extraction of iron gold concentrate roasted product containing sulphur and arsenic

The invention discloses a method for strengthening gold extraction of an iron gold concentrate roasted product containing sulphur and arsenic. The high-iron gold concentrate containing sulphur and arsenic, especially high sulphur and high arsenic, hinders the subsequent chemical gold leaching process after being subjected to oxidation roasting pretreatment because of the problem that iron oxide is inevitably generated to wrap gold in a high-temperature reaction process. The invention proposes a new method for strengthening gold extraction of the iron gold concentrate roasted product containing sulphur and arsenic by a flow of 'metallized reduction roasting-acid leaching-gold leaching', namely a method for strengthening gold extraction of the iron gold concentrate roasted product containing sulphur and arsenic aiming at the problem. The method comprises the steps of firstly, carrying out metallized reduction roasting on the iron gold concentrate roasted product containing sulphur and arsenic with a reducing agent, carrying out acid leaching on the metalized roasted product, and finally carrying out chemical leaching with an acid slag. By adopting the method disclosed by the invention, the leaching rate of the iron gold concentrate roasted product containing sulphur and arsenic is higher than 95%; and important theory and technical guidance are provided for effective gold extraction of the gold roasted product.

Owner:CENT SOUTH UNIV

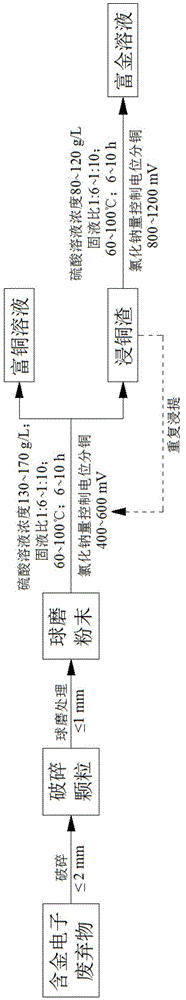

Leaching method of gold and copper in gold-contained electronic waste

InactiveCN104894383AHigh extraction rateHigh degree of resource utilizationProcess efficiency improvementSlagOxidation-Reduction Agent

The invention discloses a leaching method of gold and copper in a gold-contained electronic waste. The gold-contained electronic waste is crushed, and the particle size of crushed particles is not more than 2 mm; then, the ball-milling treatment is performed, and the particle size is not more than 1 mm after the ball-milling treatment; powder obtained by the ball-milling treatment is added in sulfuric acid solution with a concentration of 130-170 g / L for copper leaching to obtain copper-enriched solution and copper leaching slag; and finally, the chlorination gold leaching is performed for the copper leaching slag to obtain gold-enriched solution. The method realizes the separation of copper and gold; the obtained copper-enriched solution and gold-enriched solution can be deeply treated to obtain gold and copper simple substances; and in the separation process, such other metals as lead and tin can be separated through controlling the redox potential.

Owner:SHANGHAI JIAO TONG UNIV

Method for extracting gold from waste and old circuit board

The invention relates to a method for extracting gold from a waste and old circuit board, which comprises the following specific steps of: adding an oxidizing agent and a corrosion inhibiting agent into a potassium iodide solution to prepare into a mixed potassium iodide solution; immersing the circuit board in the mixed potassium iodide solution, and reacting for 3-5 min under the condition of 10-80 DEG C while stirring; then, washing the circuit board with clean water, guiding the obtained washing liquid into the mixed potassium iodide solution to obtain a mixed washing liquid; and filtering the mixed washing liquid, absorbing foreign ions through ion exchange, and adding a reducing agent to obtain sponge gold after a reduction reaction. In the invention, the method for leaching gold by using nontoxic iodide is adopted, so that high gold leaching rate is realized, the hazard-free, reduction and recycling treatment of electronic waste is realized, and the treatment cost is low. The used iodide solution can be recycled after reduction, the secondary gold leaching effect is unchanged, environmental pollution can be further reduced, and the treatment cost is lowered.

Owner:HUAXING GROUP ENVIRONMENTAL PROTECTION IND DEV

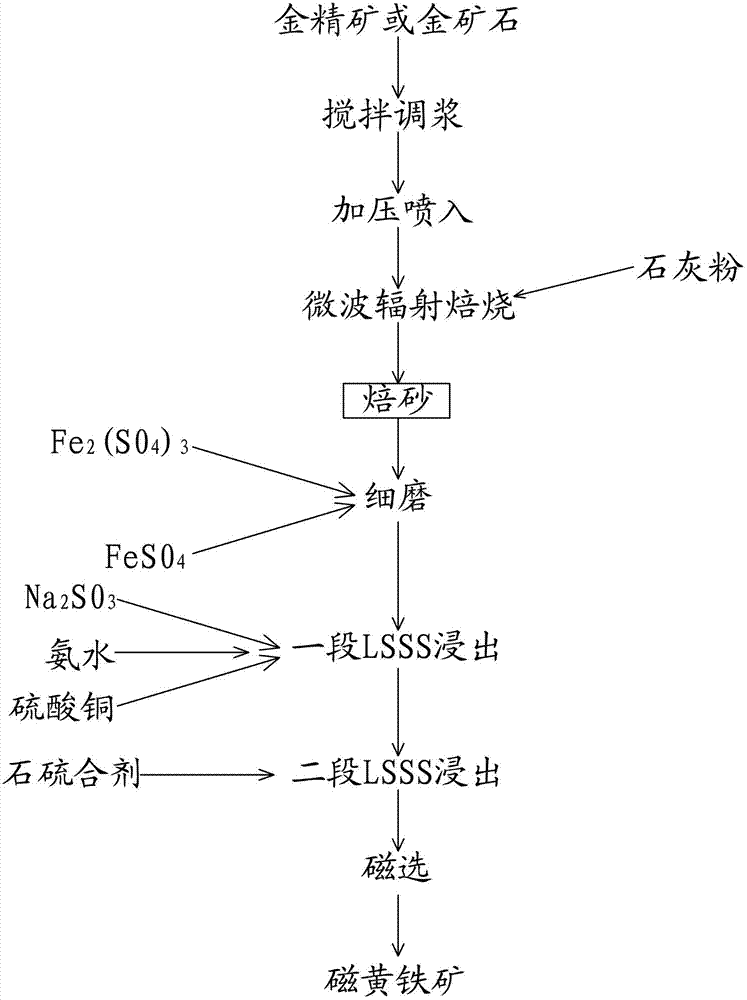

Energy-saving optimizing technology for microwave roasting and non-cyanogen gold leaching of sulfur-bearing gold mineral

InactiveCN102758079AImprove leaching rateLow costProcess efficiency improvementCopper sulfateSulfur containing

The invention discloses an energy-saving optimizing technology for microwave roasting and non-cyanogen gold leaching of sulfur-bearing gold mineral, which includes the following steps: 1) feeding water to blend gold concentrate or gold ores into ore pulp; 2) spraying the newly-pressurized the ore pulp into the reaction chamber of a microwave roasting furnace to form spray, and simultaneously spraying lime powder to carry out microwave radiation roasting in the reaction chamber; 3) discharging the calcine from the microwave roasting furnace, feeding Fe2(SO4) 3 and FeSO4 into the calcine, and feeding water for fine grinding; and 4) feeding Na2SO3, copper sulfate and ammonia water into the fine ground ore pulp, and carrying out first-stage LSSS leaching; adding lime sulfur into the washed leaching residue after the first-stage LSSS leaching for second-stage LSSS leaching; and recovering the pyrrhotite from the leaching residue through the magnetic separation method after the second-stage LSSS leaching. By adopting the technical scheme, the leaching rate of the gold in the sulfur-bearing gold mineral or the gold concentrate can be improved to more than 97%.

Owner:FUJIAN SHUANGQISHAN MINING

Method for recycling gold from refractory gold concentrate

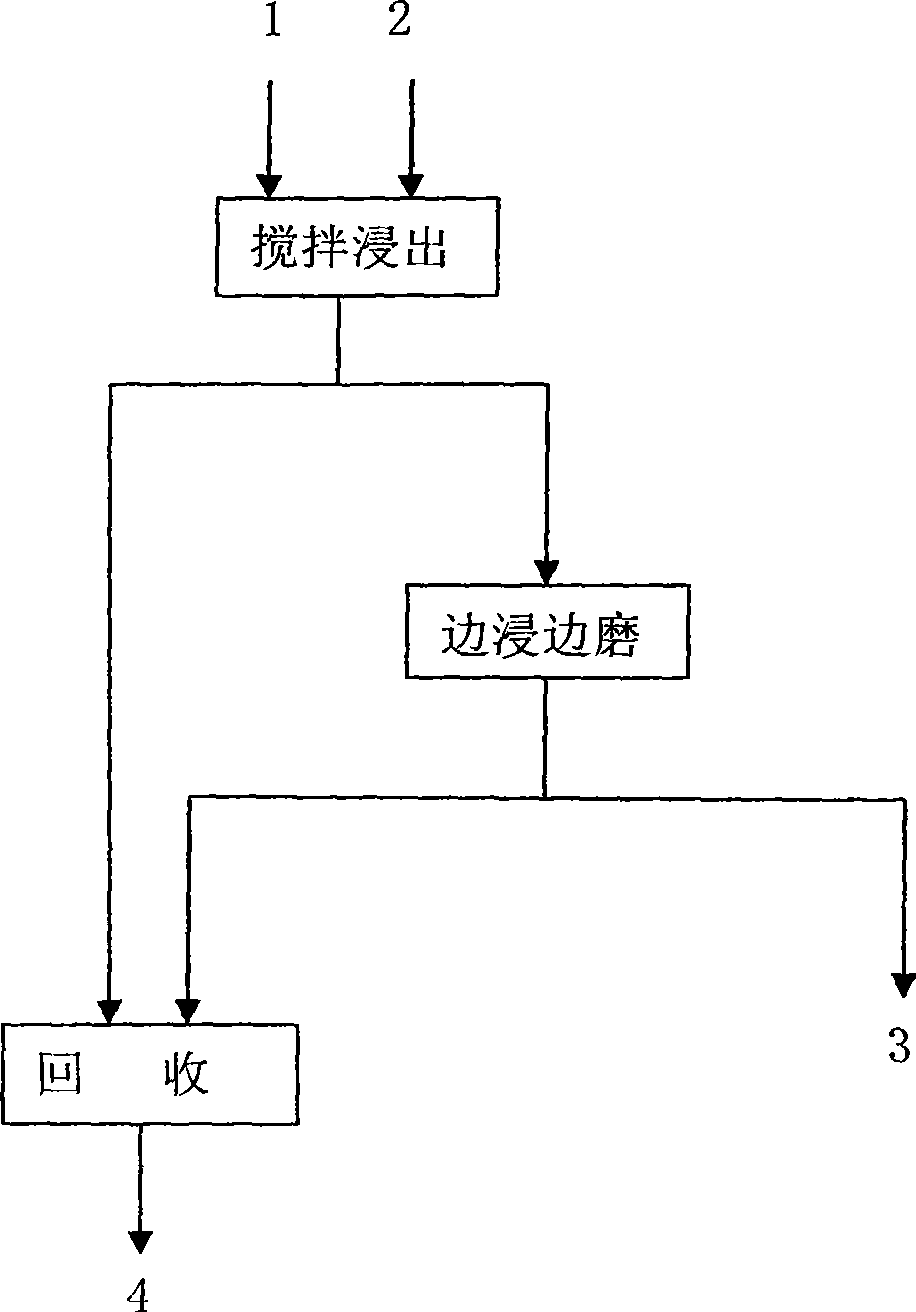

The invention relates to a method for recovering gold from unmanageable gold concentrate, which comprises the steps in the following process order: a. stirring and leaching: sodium cyanide solution is added into the gold concentrate to be stirred and leached; the liquid-solid ratio of the ore pulp is 1 to 4:1, the concentration of the sodium cyanide is 0.5 millesimal to 4 millesimal of the weight of the ore pulp, the leaching time is 12h to 36h, and pregnant solution 1 and leaching slag 1 are filtered; b. leaching while milling: the leaching slag 1 after stirring and leaching is put into a milling and leaching machine to be leached and milled; the liquid-solid ratio of the ore pulp is 1 to 4:1, the concentration of the sodium cyanide is 0.5 millesimal to 4 millesimal of the weight of the ore pulp, the milling and leaching time is 1h to 6h, and pregnant solution 2 and waste slag are filtered; c. recovery: the pregnant solution 1 and the pregnant solution 2 are recovered, to obtain sponge gold. The method is characterized by high gold leaching rate, low-grade gold in cyanidation tailing, short technological process, short treatment and recovery time, low sodium cyanide consumption, low requirement for the corrosion resistance of the equipment and the like, and is in particular applicable in the recovery and application of the gold in gold concentrate with complicated package.

Owner:ZIJIN MINING GROUP

Gold extraction method employing gold cyanided tailing roasting-ultrasonic intensification thiourea gold leaching-activated carbon enrichment

InactiveCN102676838AImprove leaching rateShorten gold immersion timeProcess efficiency improvementActivated carbonThiourea

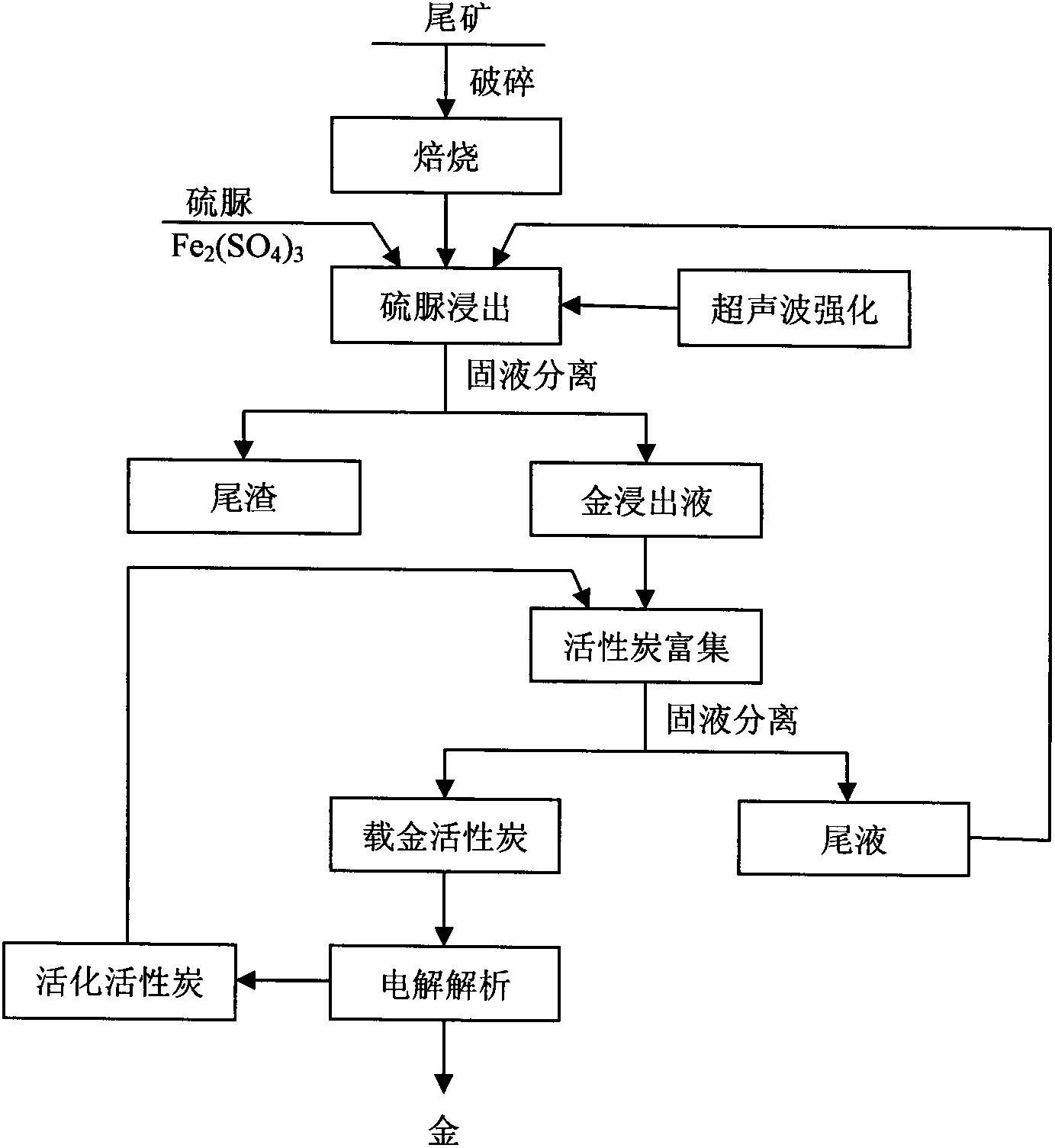

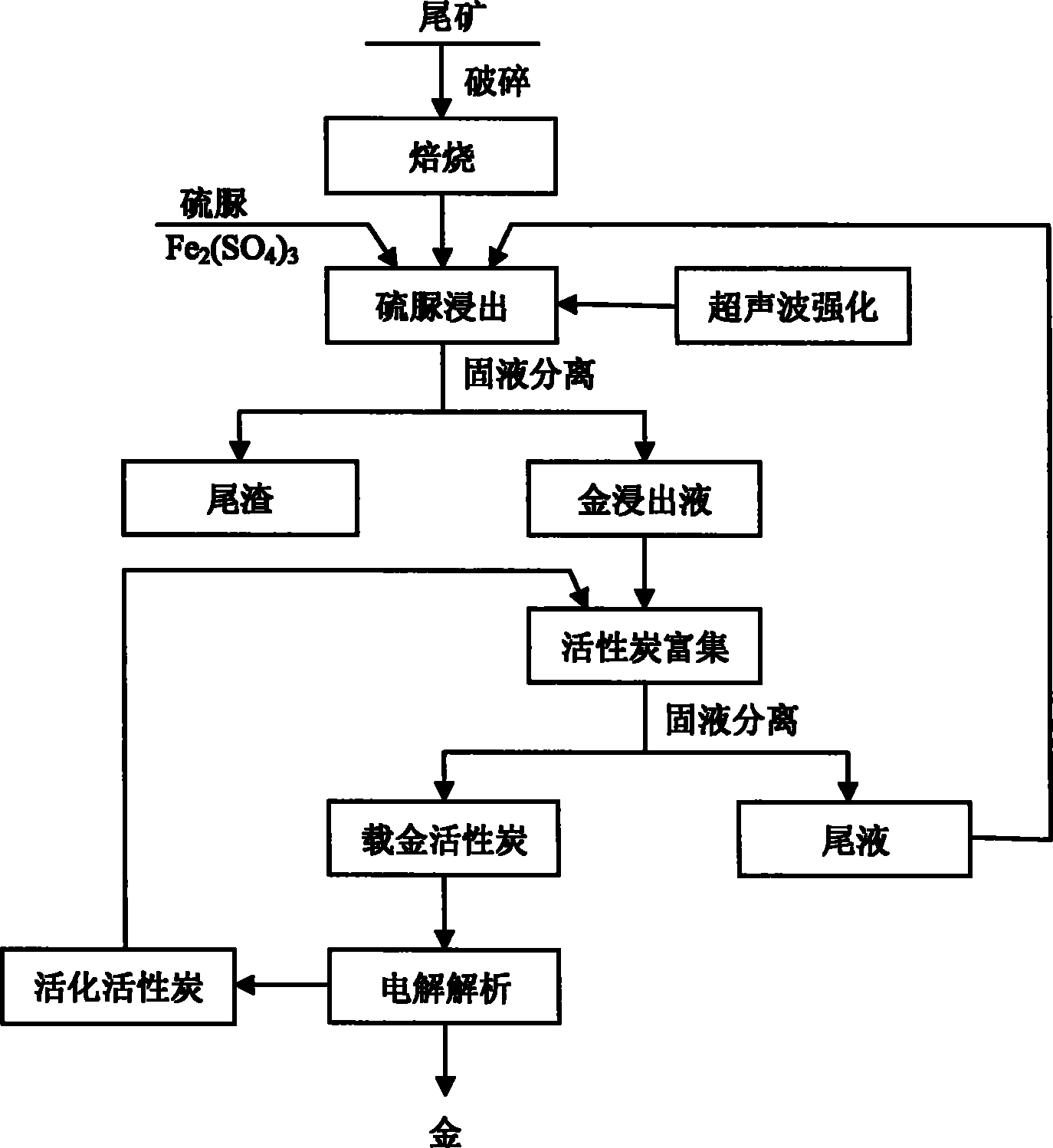

The invention relates to a gold extraction method employing gold cyanided tailing roasting, ultrasonic intensification thiourea gold leaching and activated carbon enrichment, and belongs to the field of wet method metallurgy. According to the gold extraction method, gold-containing cyanided tailing is subjected to roasting treatment, then thiourea is used for leaching gold, meanwhile the ultrasonic intensification treatment is carried out, solid-liquid separation is performed after the gold leaching, gold contained in the liquid phase is gathered by the activated carbon through enrichment, solid-liquid separation is performed after the enrichment, the activated carbon is used for extracting and resolving gold, after resolving, the activated carbon is activated to be recycled repeatedly, a large quantity of thiourea exits in the tail liquid, and the thiourea can be circularly used for the leaching process after being simply treated. The gold extraction method is used for extracting gold in the cyanided tailing through leaching, the leaching speed is high, the extraction rate can be more than 90%, the cycle is short, and the activated carbon and the tail liquid can be recycled, so the production cost is greatly reduced, the economical benefit on the utilization of gold cyanided tailing is improved, and meanwhile, the environmental protection is facilitated.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

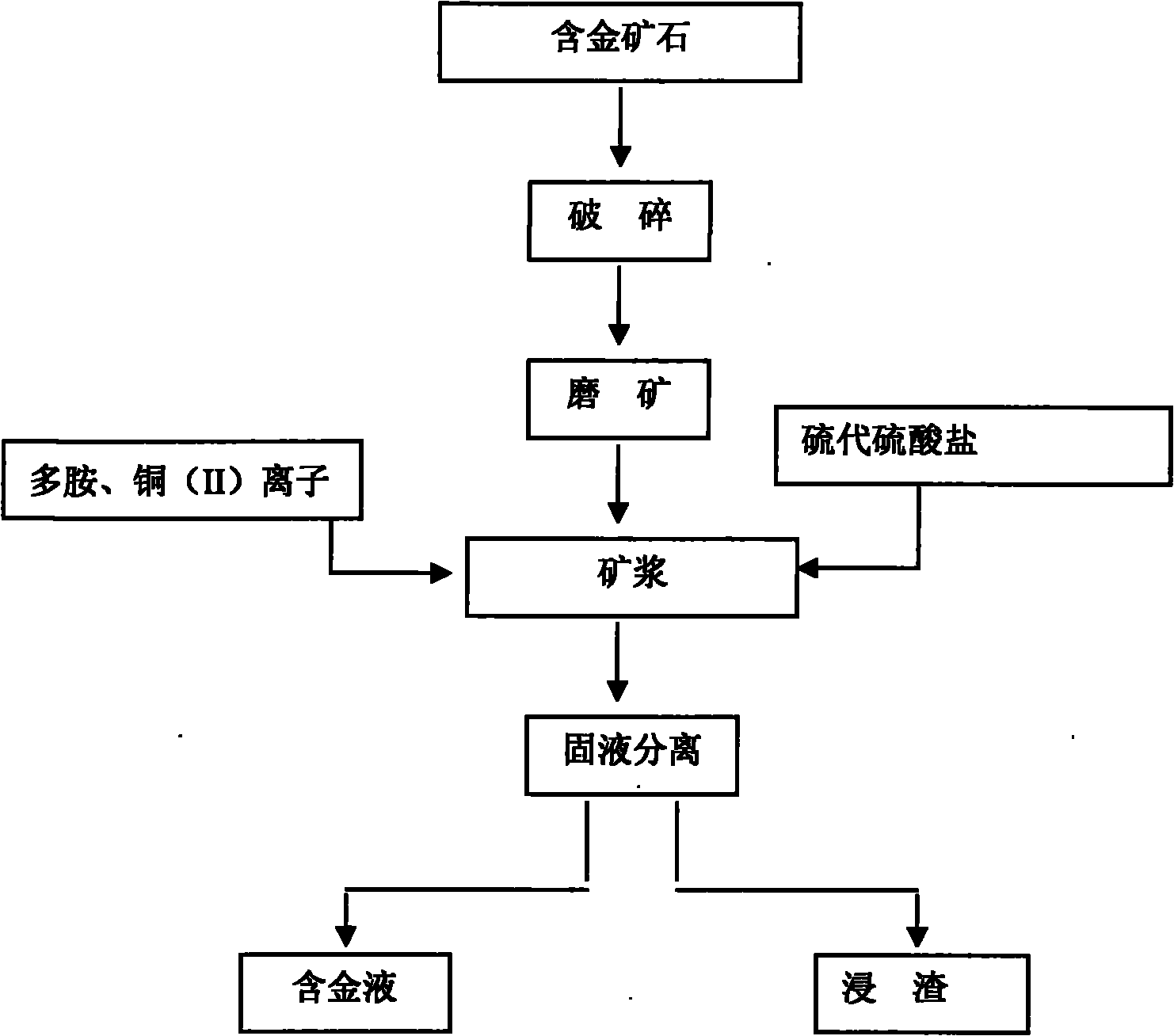

Method for extracting gold from thiosulfate adopting ethanediamine as additive

InactiveCN101824545AReduce consumptionLittle effect of leachingProcess efficiency improvementEthylenediamineToxic material

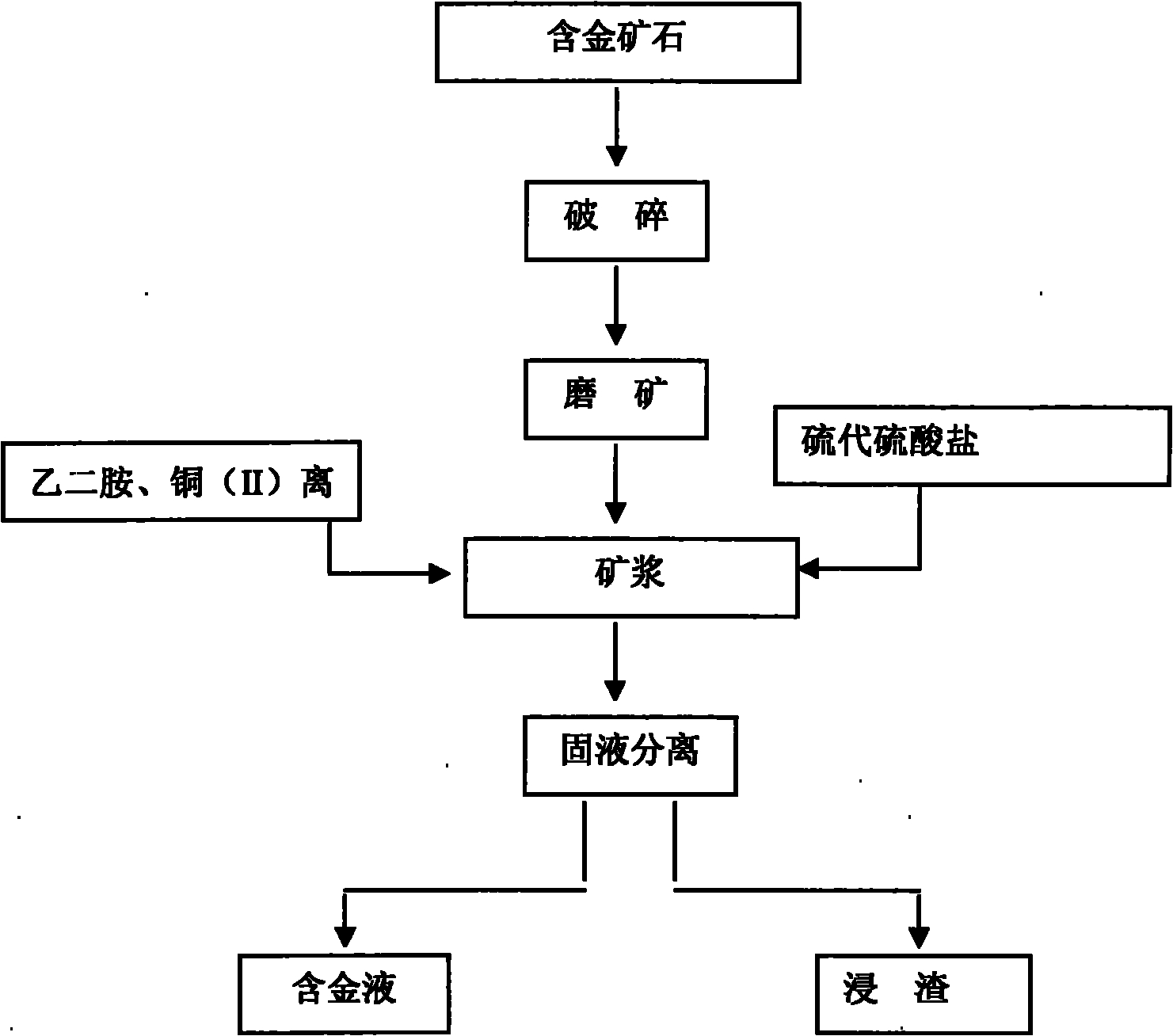

The invention relates to a method for extracting gold from thiosulfate adopting ethanediamine as an additive. The method comprises the following steps that: the ethanediamineas is adopted as ligand and forms ethanediamine copper (II) complex ion with copper (II) ion, the formed ethanediamine copper (II) complex ion is used as the additive, and the thiosulfate is used as a leaching agent and is used for extracting the gold from ore pulp; and calculated by water amount, the adding amount of the thiosulfate is 0.03-3mol / dm<3>, the adding amount of the ethanediamine is 0.0015-0.09mol / dm<3>, and the adding amount of copper (II) ion is 0.0015-0.03mol / dm<3>. The leachate is used for extracting the gold from the ore, the leaching rate of the gold is high, the technique operation is simple, the control is easy, the consumption amount of the thiosulfate is extremely low, and the ingredients of the gold leachate are simple and are beneficial to recovery of the gold therein. The method has wide application range, has good leaching effect when the pH is between 10 and 12, also has fast leaching speed of gold ores which contain copper, carbon and the like and are difficult to treat, can maintain quite high gold leaching rate, and the whole gold extracting process does not use toxic substances of sodium cyanide and the like, also does not discharge toxic waste, and is environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

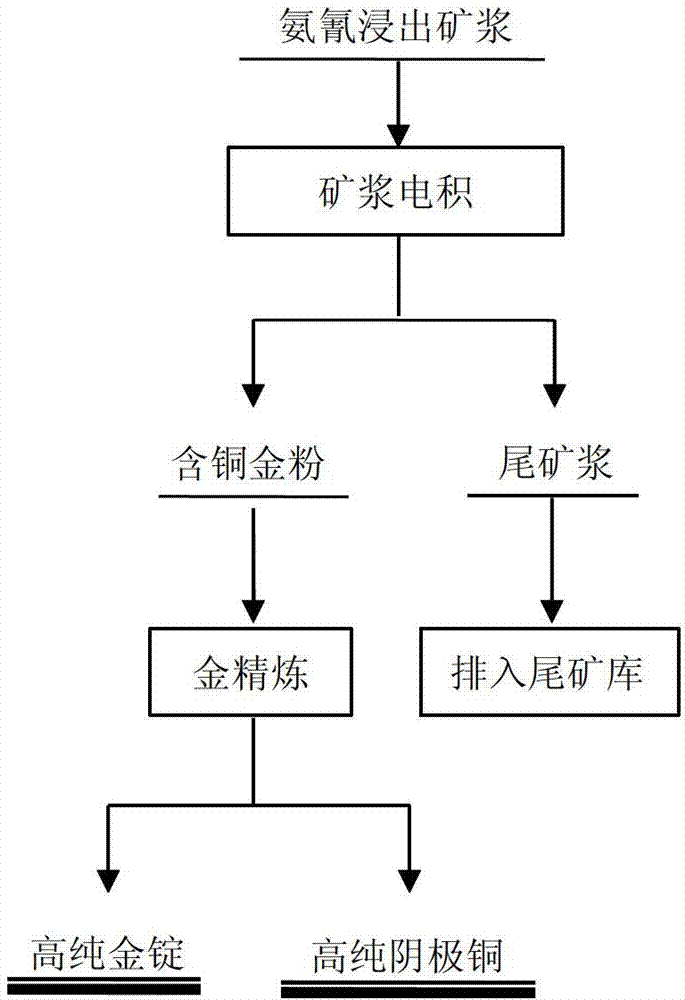

Process for extracting gold from low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp via electrodeposition

ActiveCN103194770AHigh recovery rateShort processPhotography auxillary processesDesorptionCyanide leaching

The invention relates to a process for extracting gold from a low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp via electrodeposition. The process comprises the following steps: diluting the low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp to the proper pulp concentration; leading the pulp into an electrodeposition tank and performing the electrodeposition on the pulp; refining the copper-containing gold powder obtained from a cathode, thereby obtaining a high-purity gold ingot and high-purity cathode copper; and discharging the pulp after the electrodeposition into a tailings pond. The process has the advantages that the technological process is short; the gold recovery rate is high; the production cost is low; the comprehensive recovery of copper is realized; the steps of countercurrent washing, carbon adsorption, gold-carrying carbon desorption-electrodeposition and the like in the conventional gold leaching process are omitted; the investment cost is lowered greatly; and the like.

Owner:ZIJIN MINING GROUP

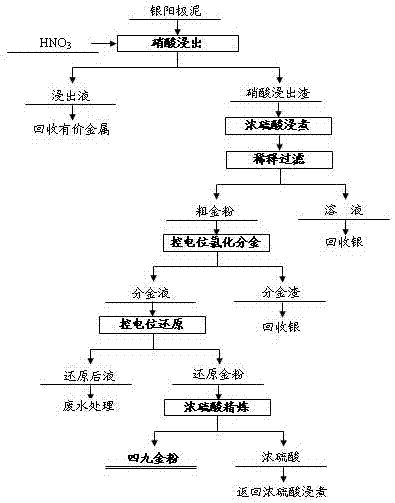

Method for preparing pure gold from silver anode mud through potential control

ActiveCN107460324AHigh purityGold powder with a purity of 99.99%, high direct recovery rate of goldProcess efficiency improvementSulfite saltSlurry

Provided is a method for preparing pure gold from silver anode mud through potential control. The silver anode mud is leached out in a nitric acid solution, after nitric acid leaching residue is immersed and digested in concentrated sulfuric acid, coarse gold powder is obtained, hydrogen peroxide is added into a hydrochloric acid solution containing the coarse gold powder to conduct potential controlling and gold leaching by chlorination, slurry is subjected to solid-liquid separation after being cooled, gold leaching liquid is added into sodium hydroxide and sodium sulfite to conduct potential controlling and reduction, and reduction gold powder is obtained, and after the reduction gold powder is subjected to concentrated sulfuric acid refining, pure gold powder is obtained. According to the method for preparing the pure gold from the silver anode mud through potential control, a potential control mode is adopted to achieve adjustment and controllability of the process for preparing the pure gold from the silver anode mud, the gold powder with the purity being 99.99% is prepared, the direct recovery rate of gold reaches to over 99.9%, the method has the advantages of being high in gold direct recovery rate, stable in technological process and high in product purity, and the environmental pollution problem existing in a traditional aqua regia dissolution method is solved.

Owner:CENT SOUTH UNIV

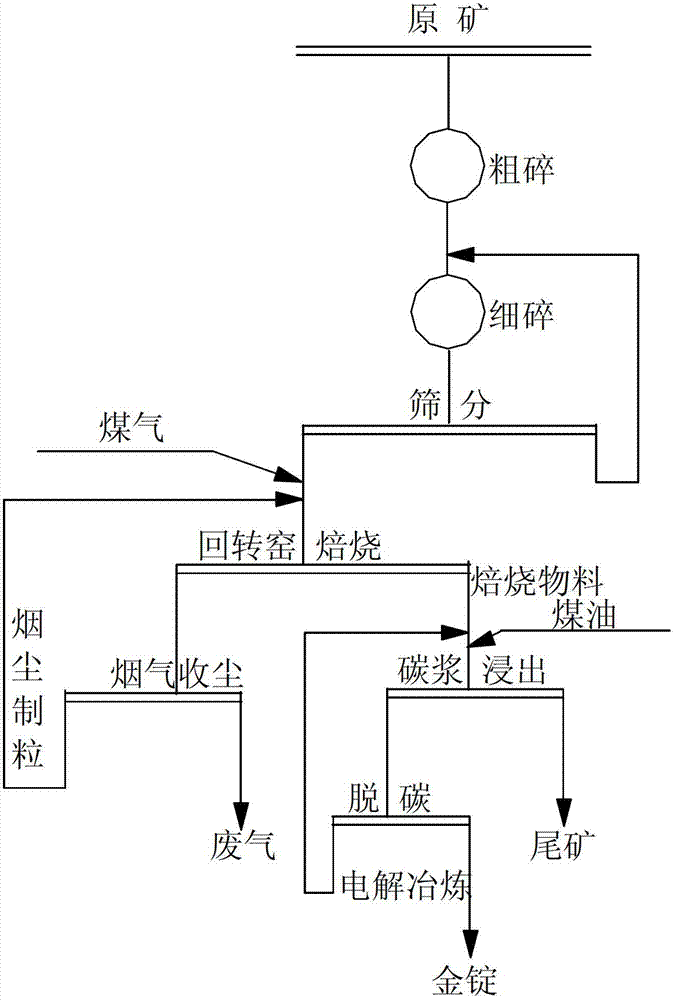

Beneficiation method for high-carbon fine particle embedded gold ore

The invention provides a beneficiation method for a high-carbon fine particle embedded gold ore. The method comprises the following steps of: crushing and screening a raw ore; baking the crushed and screened raw ore in a rotary kiln by gas at 650 DEG C for 2-3 h, wherein the gas is produced by coal-to-gas equipment; water quenching the baked gold ore to no more than 50 DEG C, adding 400 g / t kerosene to shield insufficiently-combusted carbon; and finally leaching the gold ore by using a cyanide process. According to the method provided by the invention, the baking temperature is lowered from 750 DEG C to 650 DEG C under the condition that the recovery rate is ensured, and thus, the combustion cost is reduced, the service life of the equipment is prolonged and the labor intensity of workers is reduced; as the insufficiently-combusted carbon is shielded, the leaching rate of the gold is increased, and the gold leaching rate is more than 85 percent; in addition, the pulverized coal injection is replaced by the rotary kiln and the coal-to-gas process, the temperature control efficiency is increased, the secondary pollution of the carbon is removed, and the industrialization becomes possible.

Owner:SHANYANG TAIJIN MINING

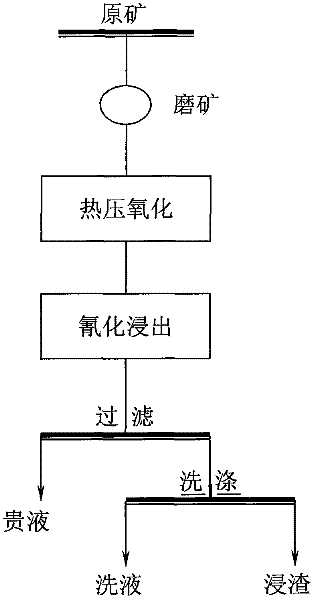

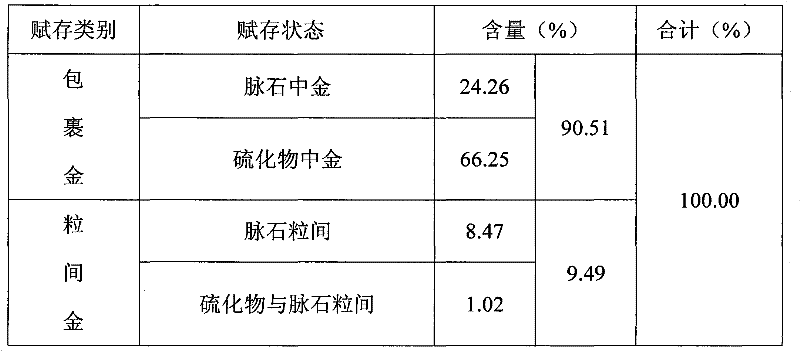

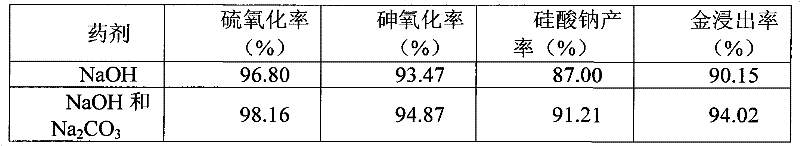

Process for extracting gold by modified pressure oxidation-cyaniding

InactiveCN102127653AAvoid secondary packagingImprove leaching rateProcess efficiency improvementSulfurHigh pressure

The invention discloses a process for extracting gold by modified pressure oxidation-cyaniding. The pressure oxidation technology and alkali silicon dissolving technology are organically combined and a technological scheme of mixed medicament of NaOH and Na2CO3 is adopted to process Carlin dipped-type obstinate gold-containing ore, and the pressure oxidation process is adopted, thus sulphide mineral can be fully oxidized and decomposed and gold wrapped in the ore can be fully exposed and dissociated; under the conditions of higher temperature and higher pressure, NaOH reacts with SiO2 to effectively decompose gangue, thus gold wrapped in the ore is fully exposed and dissociated; wraps of the sulphide mineral and gangue are opened, and harmful elements enter into a liquid phase in a soluble salt form, thus secondary wrapping to gold is avoided; and most harmful substances such as sulphur and arsenic are oxidized and then enter into the liquid phase to be neutralized and recycled. By applying the process disclosed by the invention, the gold leaching rate is improved to 96.5% from 5% of the conventional process, thus the gold leaching rate is obviously improved; and the pollution to the environment is greatly reduced.

Owner:CHANGCHUN GOLD RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com