Patents

Literature

656 results about "Gold ore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

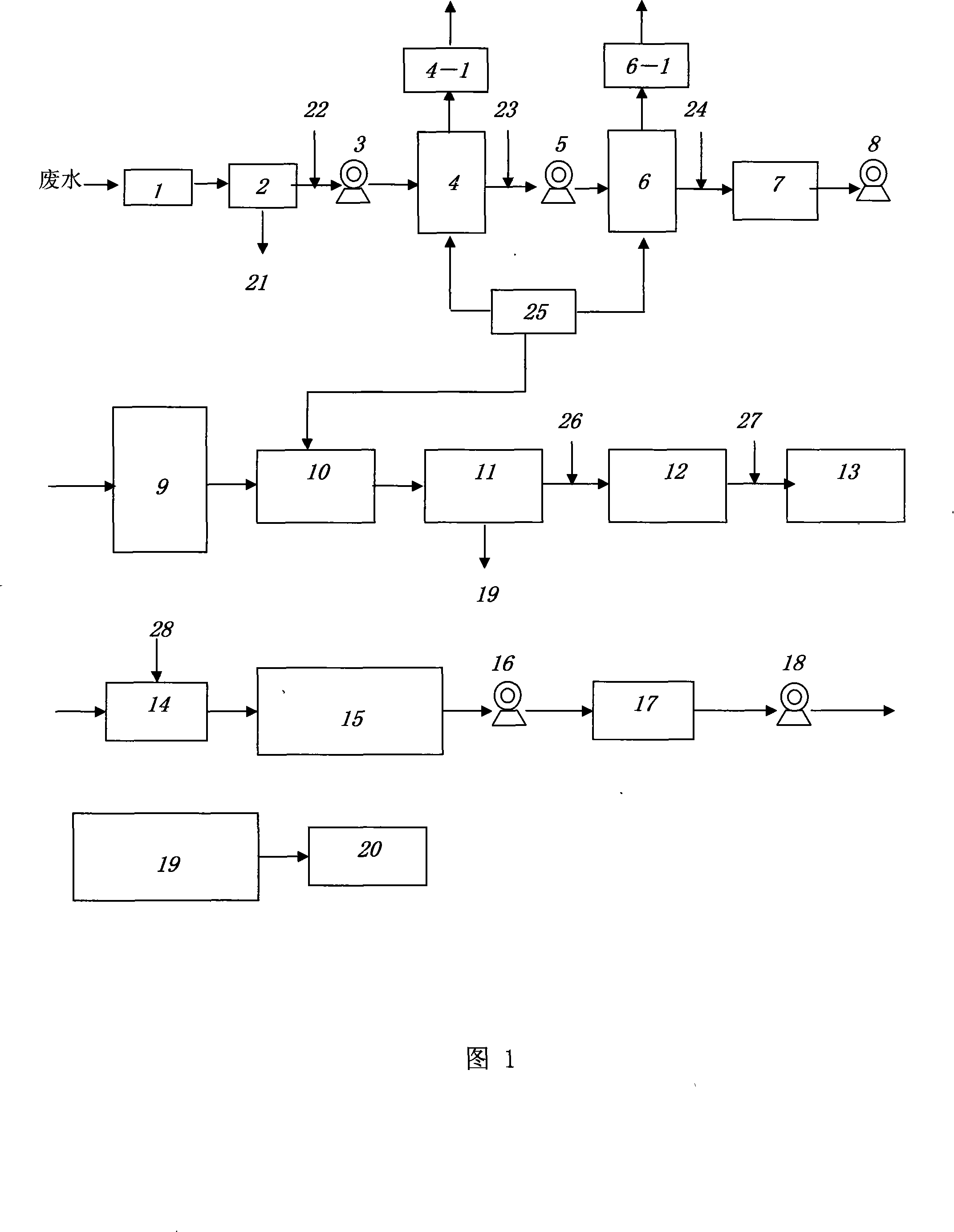

Combination technique for processing and recycling high-cyanogen high-ammonia high-salt organic waste water

InactiveCN101172743AProcess Combination ScienceReasonable process combinationWater contaminantsWater/sewage treatment bu osmosis/dialysisIndustrial waste waterCombined technique

The invention relates to a combined technique of treating and reusing the organic sewage which is rich in cyanogen, ammonia and salt, and adopts the combined techniques of acidified decyanation (with the sodium cyanide recollected), basified ammonia blowing (with ammonium salt recollected), oxidation by adding chlorine, biological treatment, precipitation and clarification, deep oxidation, biological active carbon filtering, one-time brine refining, microstraining film, and other combined techniques, and then the chlorine alkali is produced after the secondary brine refining in the chlorine alkali industry and the entrance into the ionic membrane electrobath. The combined technique can be used for treating the industrial sewage in the tricyanogen chloride, chlorine alkali, gold mine, galvanization and other industries and conduct recovery of the resources, thereby overcoming the disadvantages that the prior art has narrow applicability and treatment function and disappointing treatment result, cannot recollect the resources, and has high treatment cost and unobvious economical benefit. The combination of the technique is scientific and reasonable, the technique is novel, unique and mature, the treatment is good, and the combined technique has a plurality of functions, strong applicability, wide use range and remarkable environmental and economical benefit.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

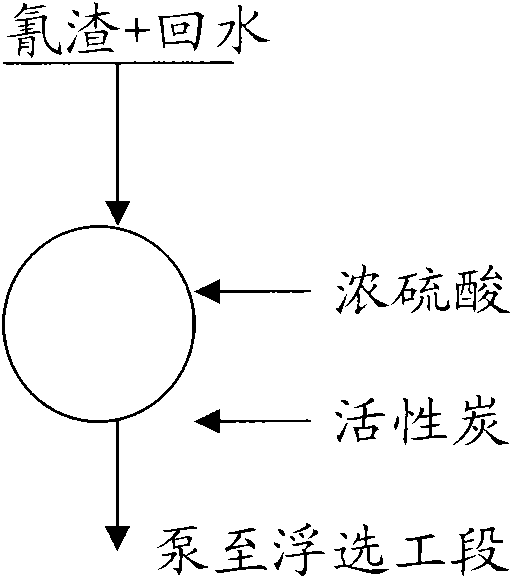

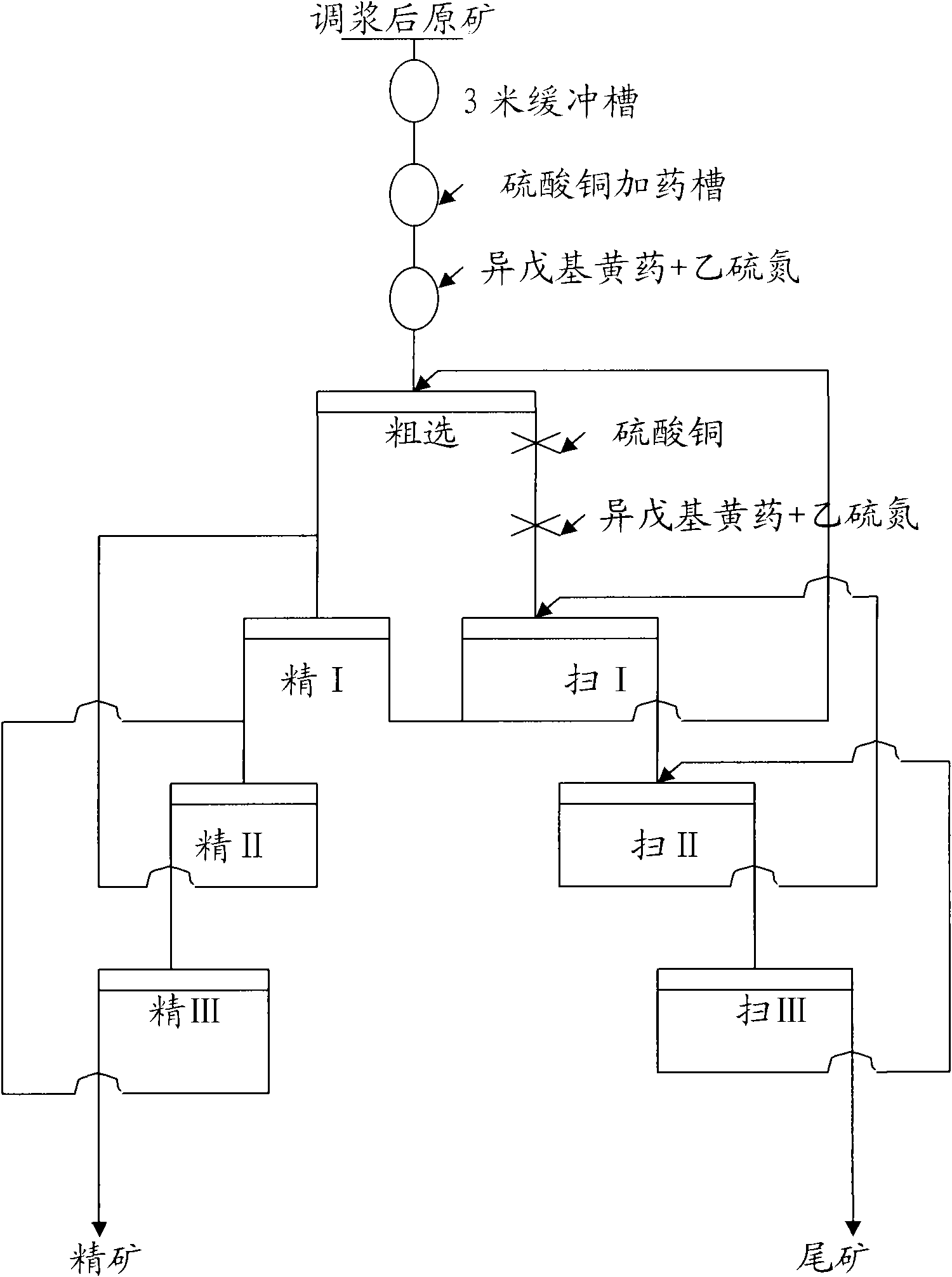

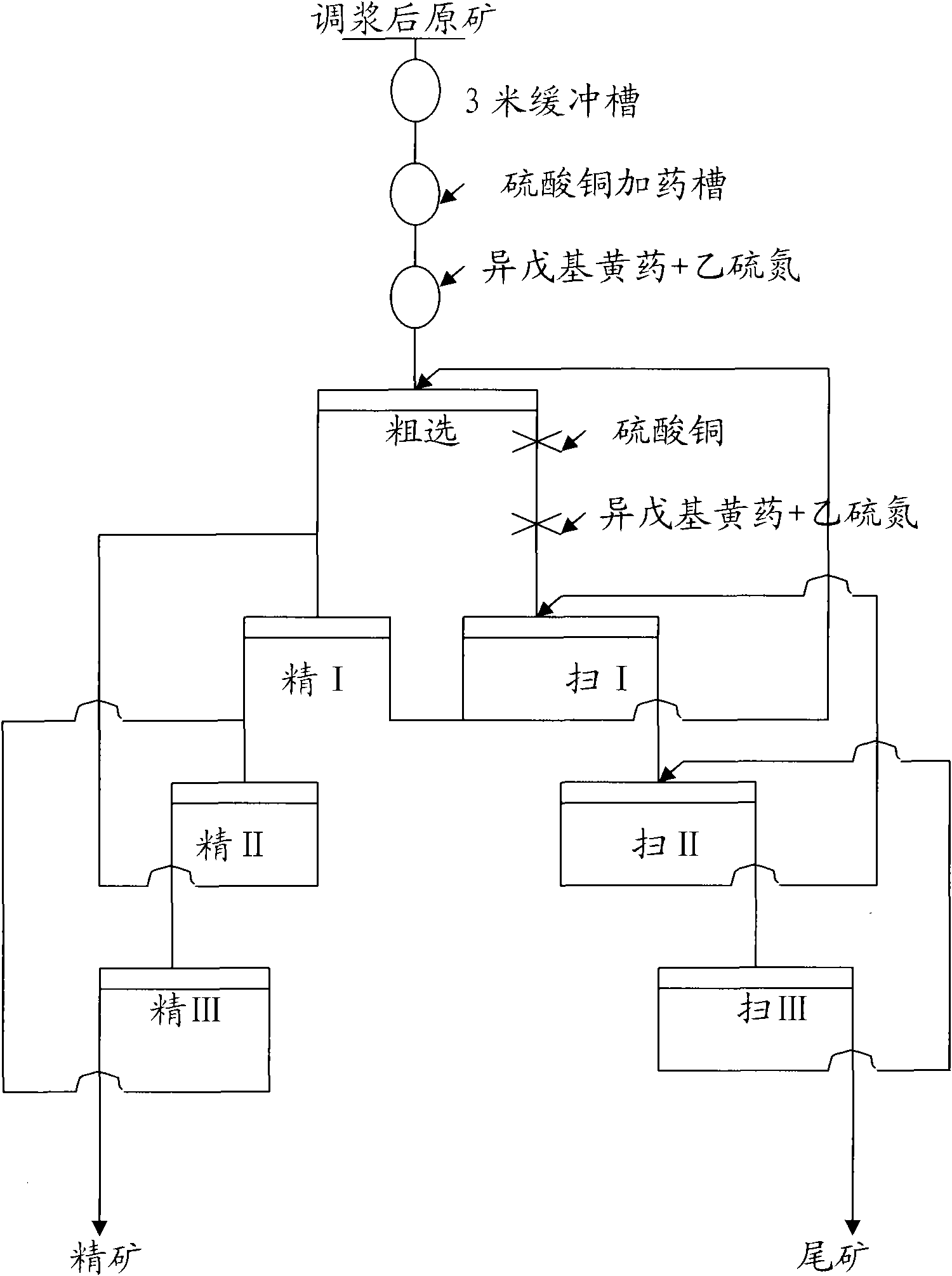

Method using mineral dressing backwater to float and to recover gold, silver, lead and zinc in cyanidation tailings of gold mine

The invention discloses a method using mineral dressing backwater to float and recover gold, silver, lead and zinc in cyanidation tailings of a gold mine. The method comprises the following working procedures: (1) pulp pre-processing stage: adding mineral dressing backwater in cyaniding tailings, adding concentrated sulfuric acid to stir for 5 minutes, reacting the concentrated sulfuric acid withthe pulp until smoke is completely generated, adding activated carbon to remove reagent for 55 minutes, and then pumping to a flotation workshop section; and (2) bulk flotation stage: pumping the pretreated pulp into a 3-meter stirring buffer slot, stirring for 30 minutes continuously, flowing into a medicine injecting slot 1 and a medicine injecting slot 2 by proper motion, sequentially adding copper sulfate and diethyldithiocarbamate, stirring fully, then entering a floatation unit to perform roughing on the pulp, further carrying out selection stage by stage on the rough concentrate obtained by roughing to obtain qualified lead and zinc bulk concentrate containing gold and silver, and further carrying out scavenging stage by stage on the roughed tailing to obtain floated tailing which is the sulphur concentrate. The invention realizes comprehensive utilization of mineral dressing tailings and zero exhaust of the tailings, thus realizing cleaner production of the mineral dressing process.

Owner:青岛黄金铅锌开发有限公司

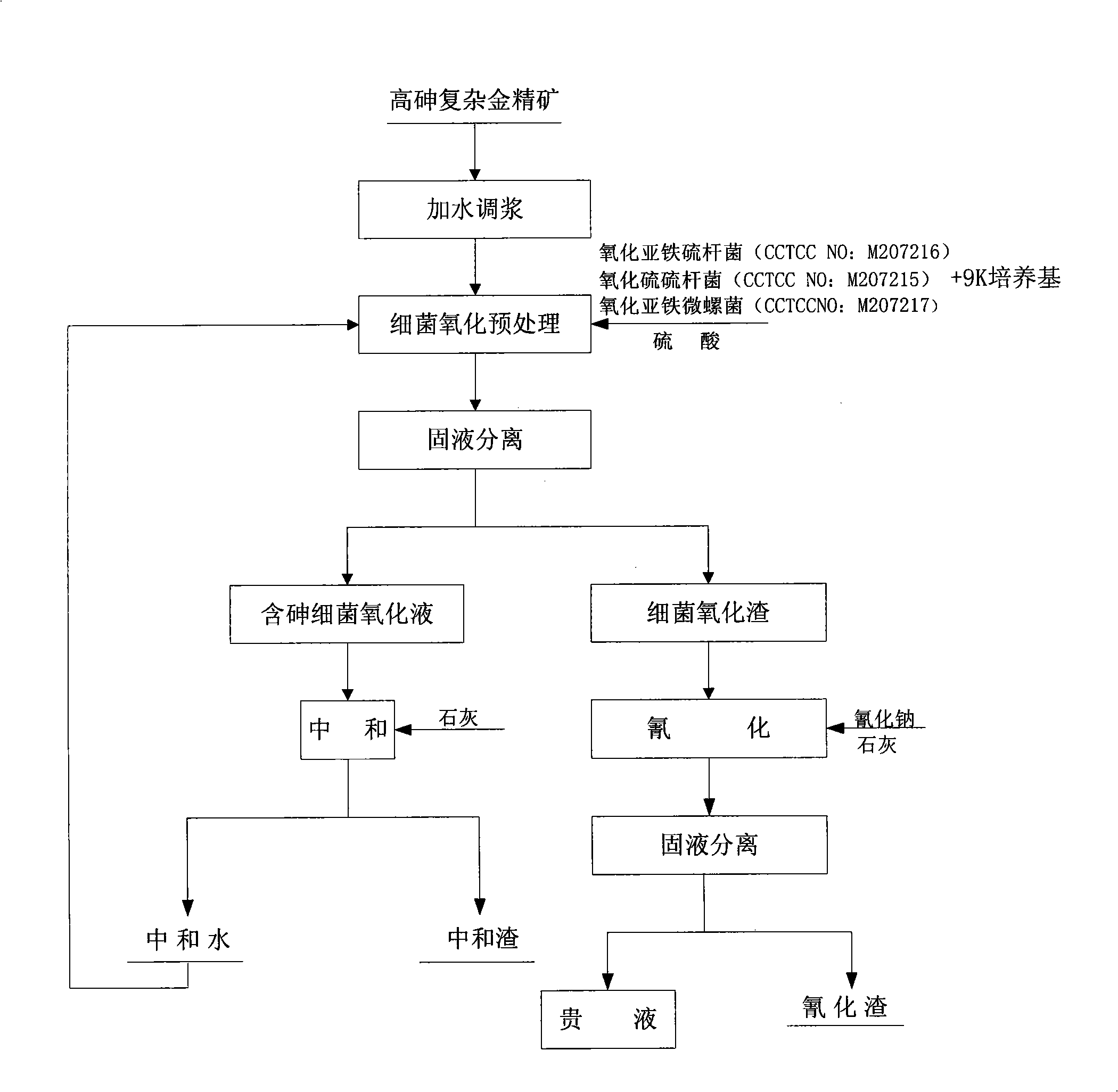

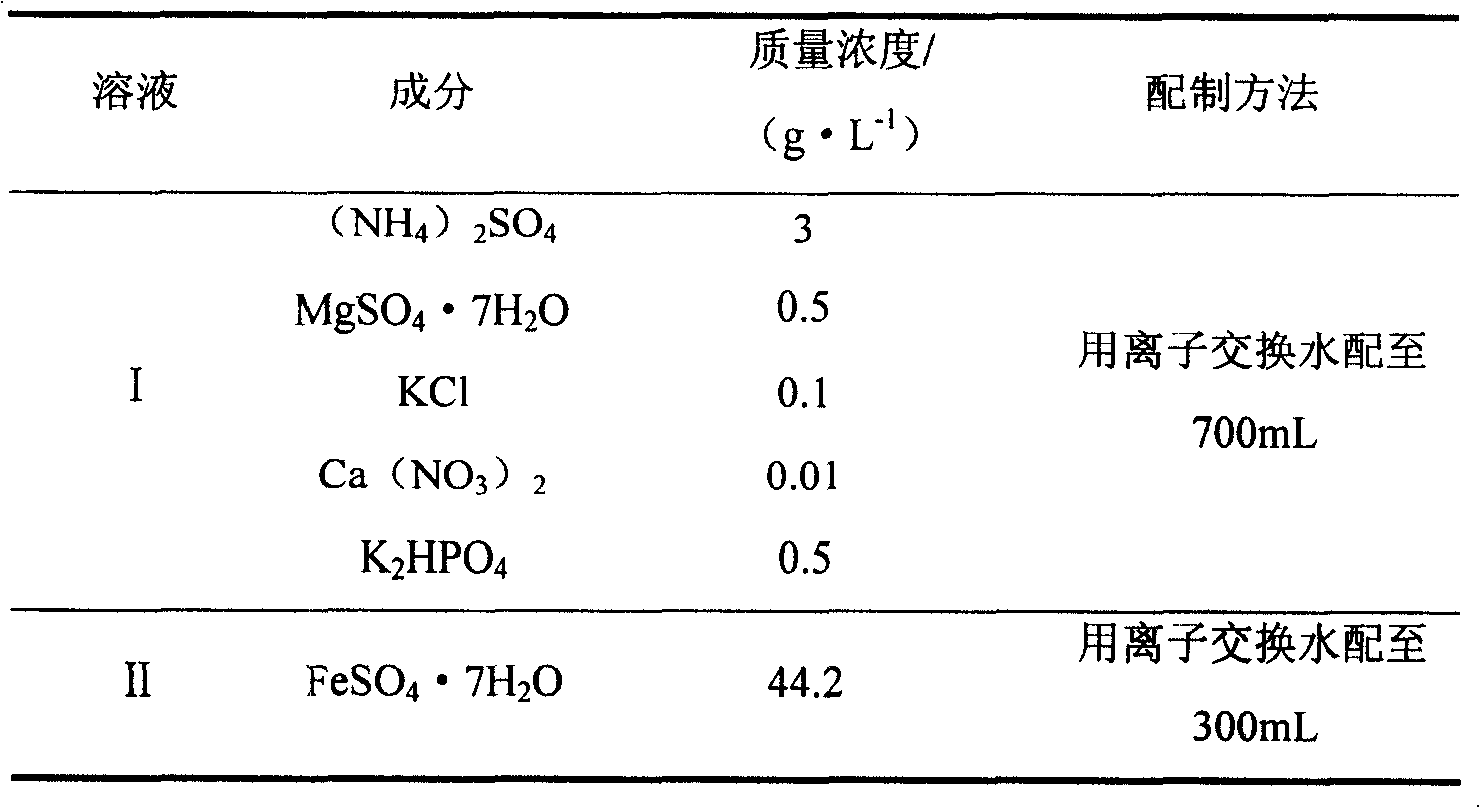

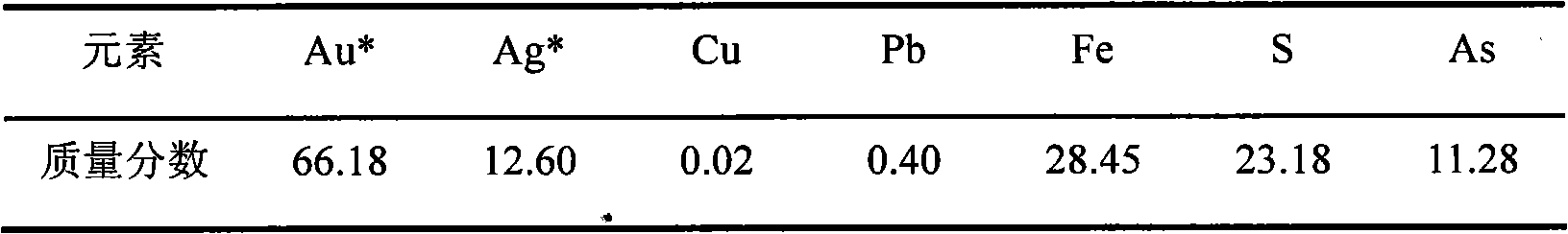

Cyanidation aurum-extracting method for preprocessing high-arsenic complex refractory gold ore by oxidation with arsenic resistant strains

InactiveCN101333599AIncrease growth temperatureStable temperatureProcess efficiency improvementThiobacillus ferrooxidansResistant strain

Disclosed is a cyaniding gold extraction method for pre-treating high-arsenic complex refractory gold ore by arsenic-resistant bacteria oxidation, comprising five steps of arsenic-resistant bacteria culture, flotation concentrate mixing, bacterial oxidation of flotation concentrates, solid-liquid separation and cyaniding gold extraction. The cyaniding gold extraction method adopts specific arsenic-resistant bacteria which are prepared by mixing Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, and conducts oxidation pretreatment of high-arsenic complex refractory gold ore. The high-arsenic complex gold ore containing 8 to 20 percent of arsenic can be pretreated, and the arsenic removal rate is 85 to 98 percent. The leaching rate of gold is up to 90 to 95 percent after cyaniding leaching. The cyaniding gold extraction method adopts unique bacteria for leaching ores, greatly saves cooling cost, conducts direct oxidation of high-arsenic complex gold ore containing 8 to 20 percent of arsenic, and has advantages of being widely adaptable, simple in operation, environmentally friendly and remarkably beneficial.

Owner:NORTHEASTERN UNIV

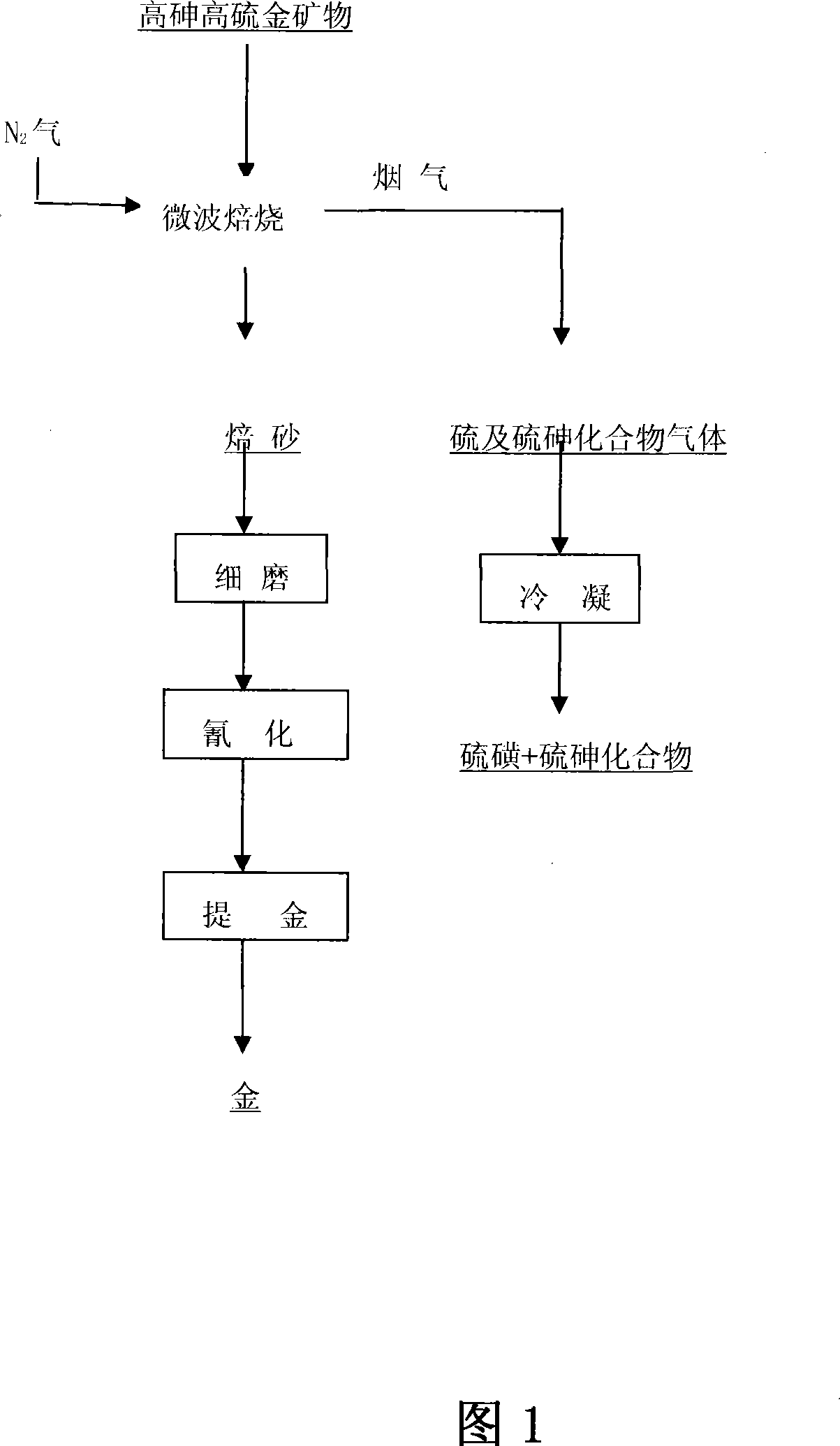

Method for pretreating refractory gold ore by employing microwave calcining

InactiveCN101225467AImprove leaching rateTo achieve the goal of green environmental protectionProcess efficiency improvementNitrogen gasMicrowave irradiation

The invention relates to a method to pre-treat a hard-to-leach gold ores-pyrite by microwave roasting, which is characterized in that the gold ores-pyrite or fine gold ores-pyrite with the granularity being 200 meshes which takes 90% to 95% of the whole gold ores-pyrite is positioned in a reaction chamber of a microwave roasting oven, a nitrogen is filled fully into the reaction chamber, starting the microwave roasting oven, the gold ores-pyrite or fine gold ores-pyrite is radiated and roasted by the microwave in the nitrogen atmosphere, the roasting temperature is 450 to 580 degree centigrade, the power is 4 to 6kw, the microwave roasting oven stops working after roasting for 5 to 20 minutes, a roasted product is made when the roasting gold ore-pyrite is taken out. The method to pre-treat a hard-to-leach gold ores-pyrite by microwave roasting has the advantages of increasing the gold leaching yield of the hard-to-leach gold ores-pyrite up to over 90%, reaching purpose of the environment protection because the sulfur is precipitated as a free sulfur without the recovery process of smoke and dust, and saving the energy because the microwave roasting process is adopted and the pretreatment time is greatly shortened.

Owner:SHENYANG LIGONG UNIV

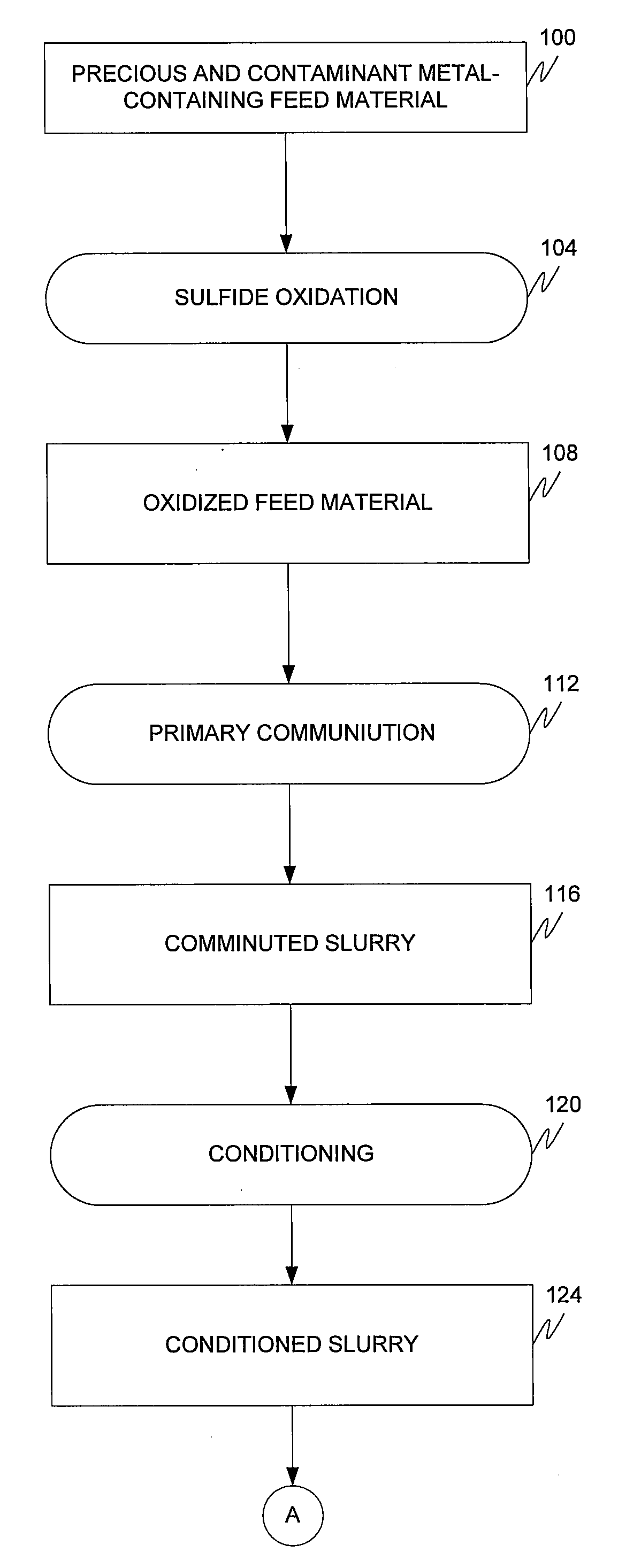

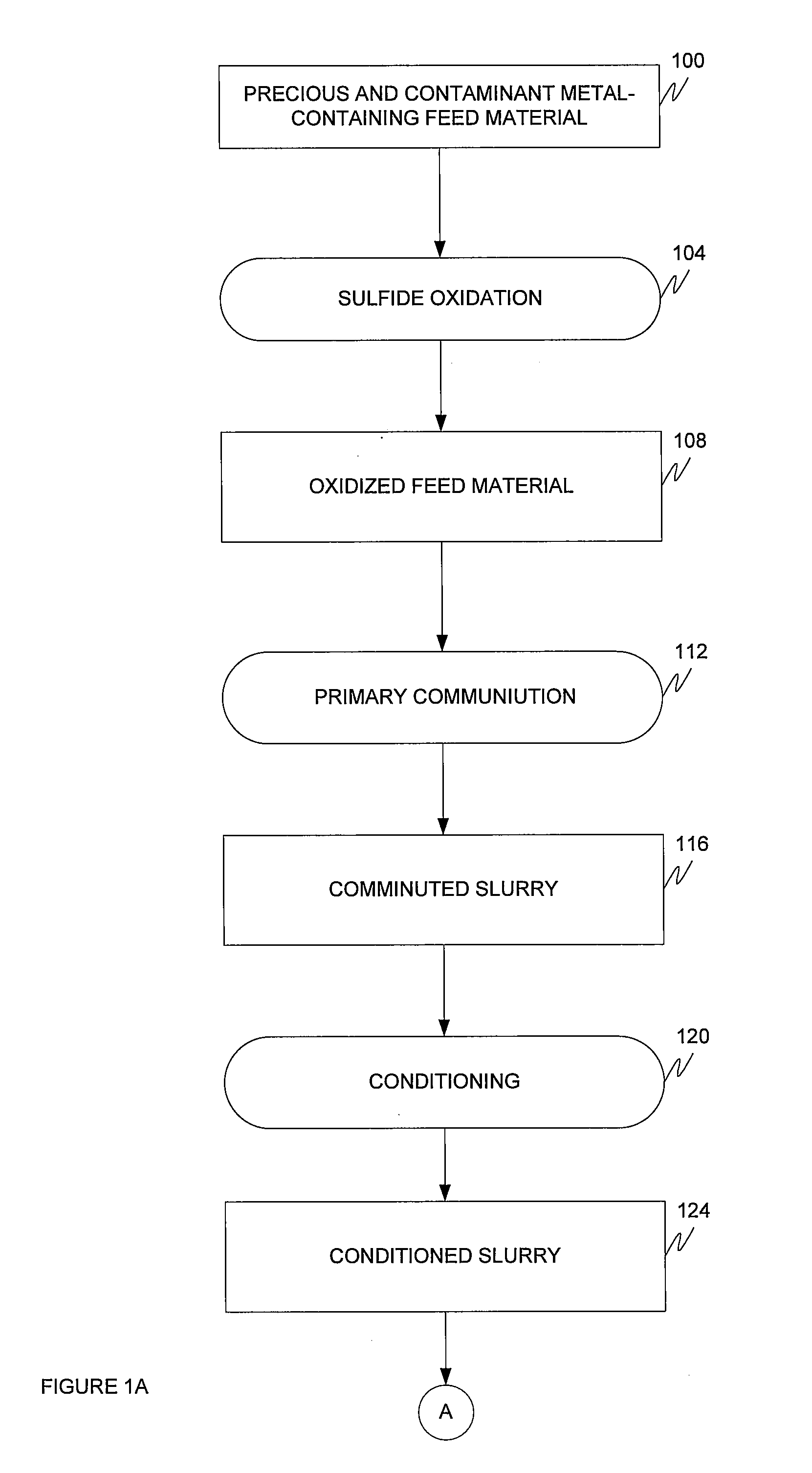

Method to improve recovery of gold from double refractory gold ores

ActiveUS20090071295A1Liberation of additionalReducing gold lossBlast furnace detailsFlotationSulfideGold ore

The present invention is directed to a precious metal recovery process in which carbonaceous material, such as preg robbing carbon, is floated after sulfide oxidation to separate the carbonaceous material from the precious metal.

Owner:BARRICK GOLD

Preparation method of special low-density grinding ball for cement grinding mill

The invention relates to a preparation method of a special low-density grinding ball for a cement grinding mill. The preparation method comprises the steps of with bauxite, alumina powder and the like as main raw materials and chromium oxide, zirconium oxide, calcium oxide, magnesium oxide, ferric oxide, manganese oxide, titanium oxide, silicon dioxide and the like as modified raw materials, adding alumina sol, silica sol and metal salt into slurry at a grinding stage; molding by rolling, isostatic pressing or machine pressing to obtain a green body; and calcining after drying the green body to obtain the low-density grinding ball. By virtue of scientific proportion design, strict process control and unique calcining system, the special low-density grinding ball disclosed by the invention is low in cost, excellent in wear resistance, lower in power load as comparison with a high-density metal grinding body, suitable for substituting a metal grinding body in cement grinding, iron ore grinding and gold ore grinding and capable of reducing the electric consumption for grinding by 30-50%.

Owner:UNIV OF JINAN

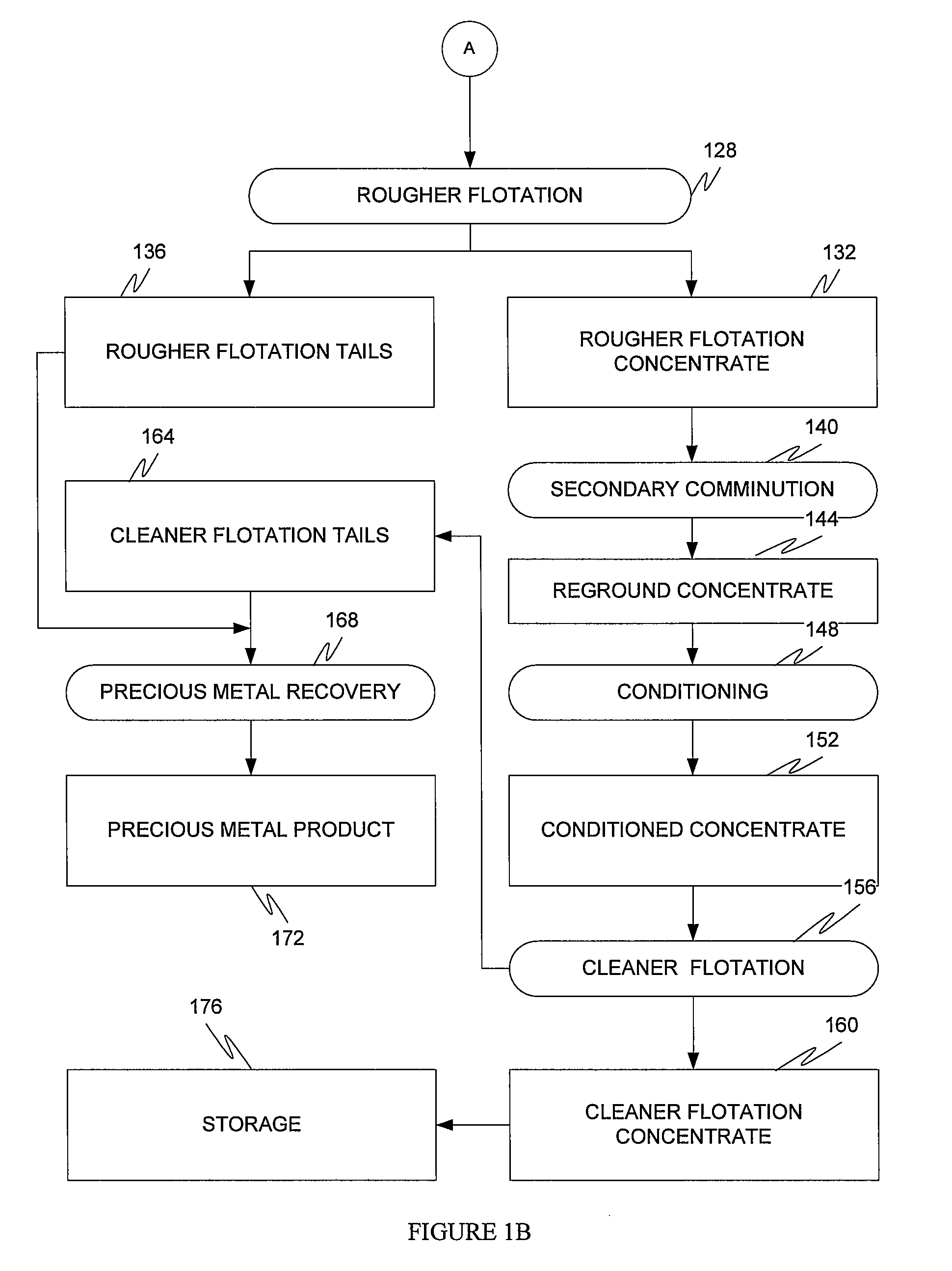

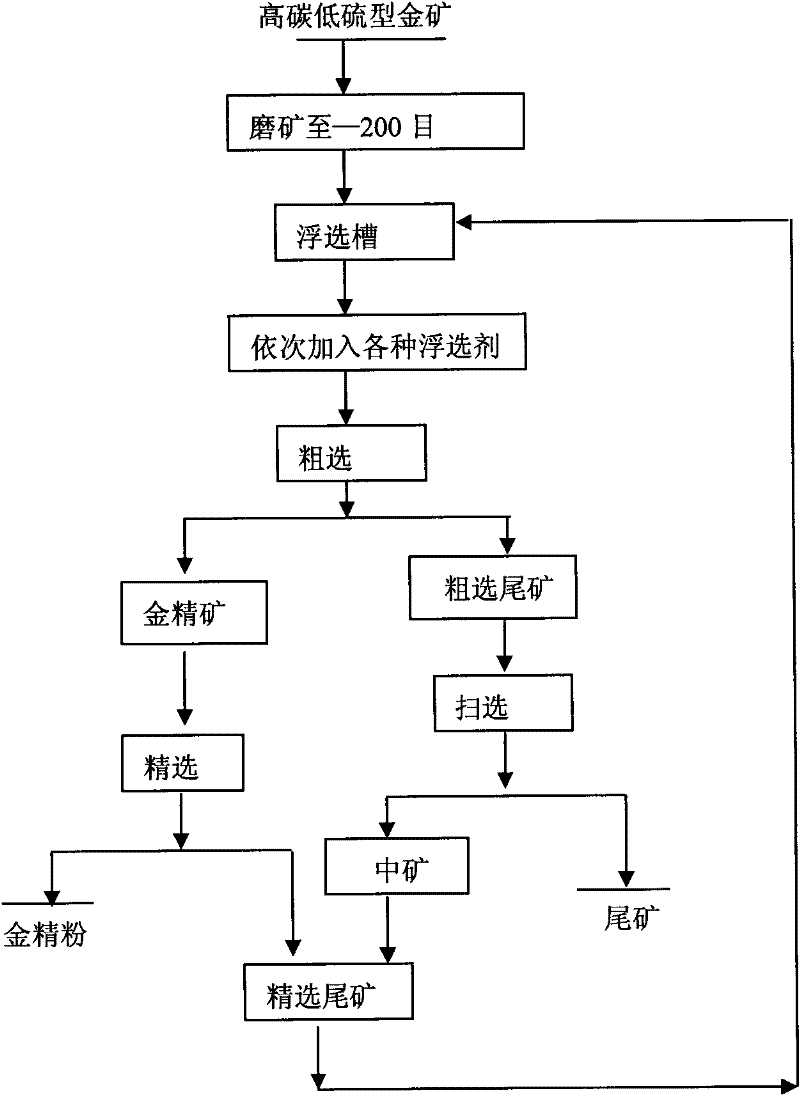

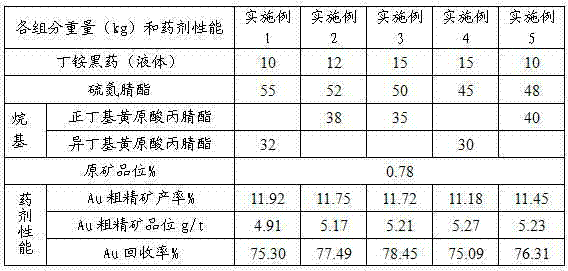

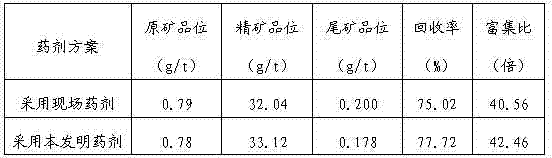

High-carbon and low-sulfur type gold ore floating agent and floating method thereof

InactiveCN102049355ASolve difficult dippingSolving Difficult Flotation ProblemsFlotationScavengerFoaming agent

The invention relates to a high-carbon and low-sulfur type gold ore floating agent and a floating method thereof. The floating agent comprises an activating agent, an adjusting agent, a foaming agent and a collecting agent. The floating method comprises the following steps: smashing and grinding each of high-carbon and low-sulfur type gold ores into 200 meshes and adding the activating agent, theadjusting agent, the foaming agent and the collecting agent in sequence for uniform agitation after size mixing; roughing to obtain gold concentrate ores and rougher tailings, obtaining gold concentrate powder and cleaner tailings after the gold concentrate ores are chosen; obtaining scavenger gold ores and tailings after the rougher tailings are scavenged; discarding the tailings; and returning the scavenger gold ores and the cleaner tailings into a flotation tank for re-separation. The invention solves the problem that the high-carbon and low-sulfur type gold ore is hard to soak and float, so that the explored high-carbon and low-sulfur type gold ore is developed and utilized. Compared with the prior art, the floating method has short sorting process, simple process, relatively low sorting cost, high recovery rate and easiness in operation.

Owner:JILIN UNIV

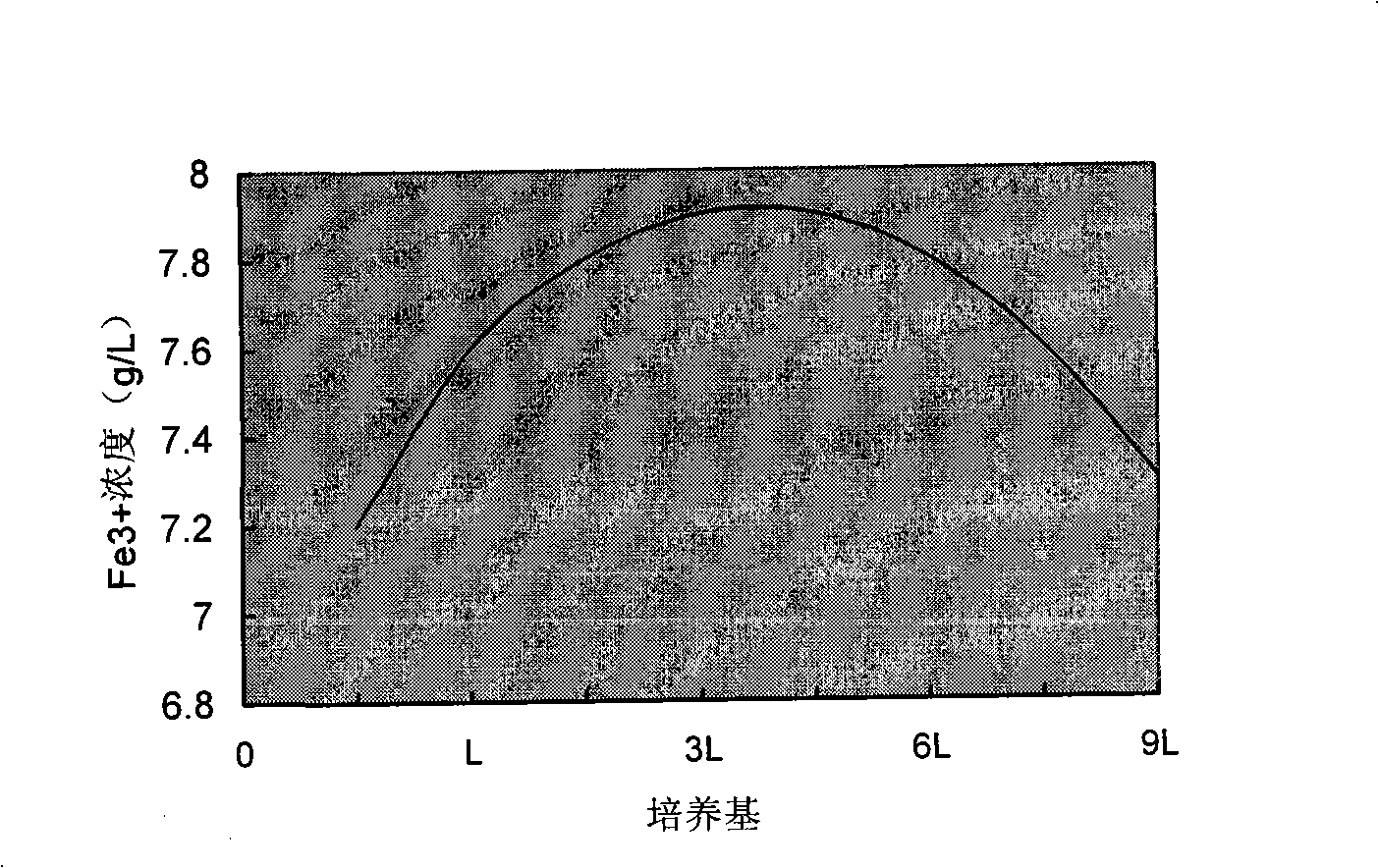

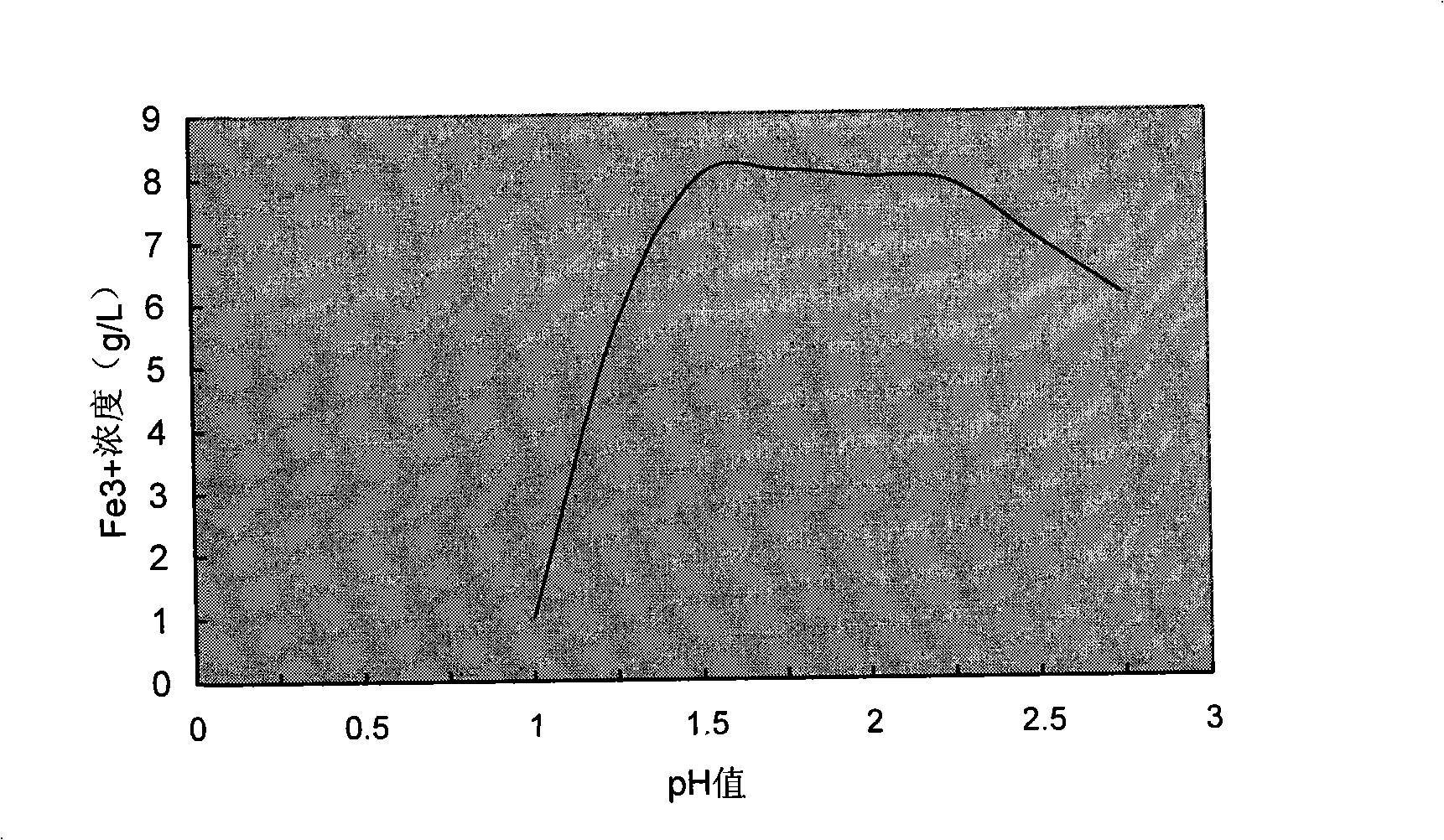

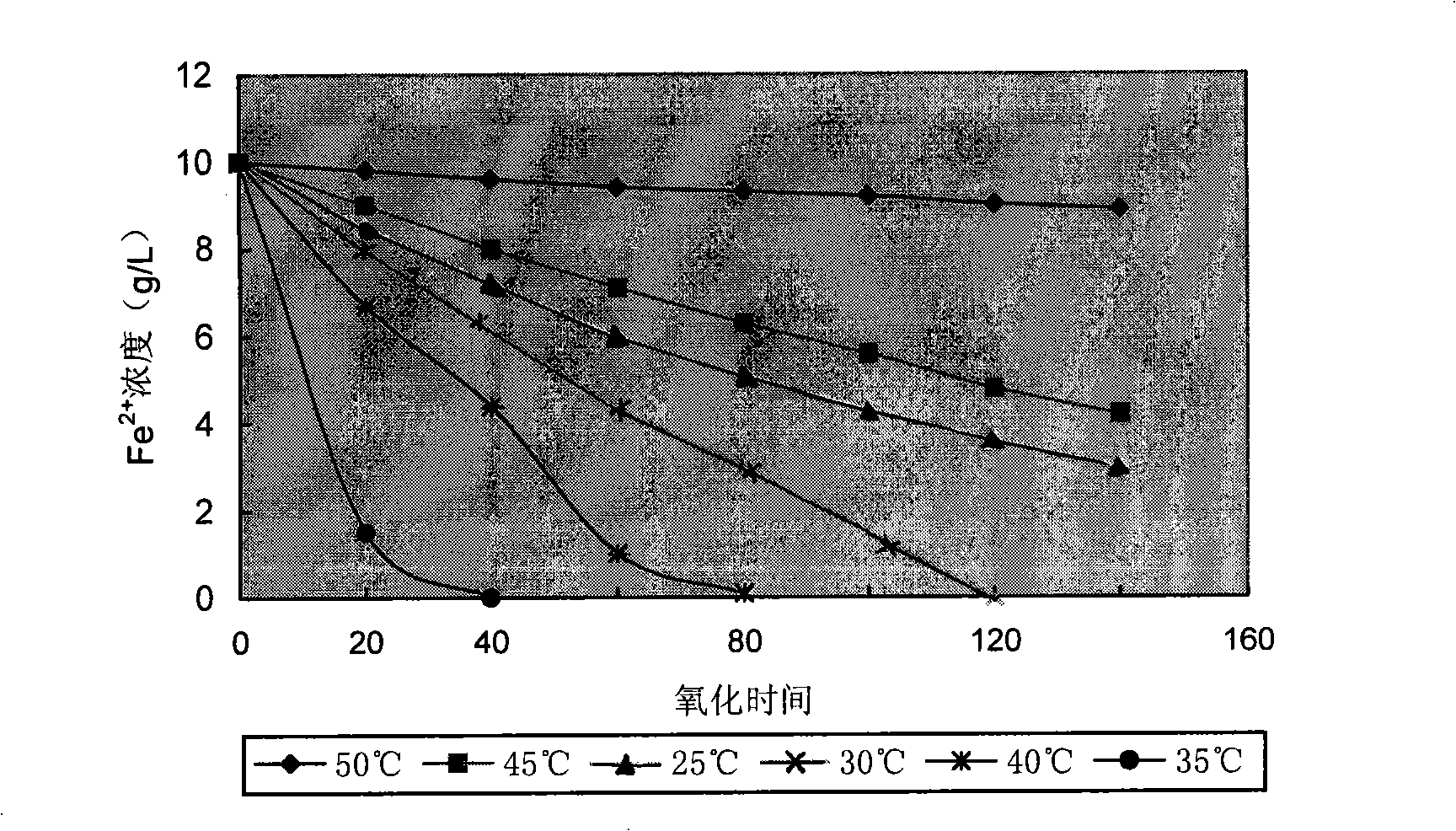

Composite mineral-leaching bacteria colony and use of same in biological metallurgy

ActiveCN101538540AImprove efficiencyBroaden the scope of ore processingBacteriaMicroorganism based processesIonLaboratory culture

The invention relates to a composite mineral-leaching bacteria colony and use of the same in biological metallurgy. The composite mineral-leaching bacteria colony has a preserving number of CGMCC No.2395 in the Common Micro-organism Center of China General Microbiological Culture Collection Center. The composite mineral-leaching bacteria colony has strong oxidative activity within a temperature range from 30 to 52 DEG C as well as a working pH value of between 0.8 and 2.25 and an arsenic ion tolerance of 0 to 20 g / L. The composite mineral-leaching bacteria colony is used for extracting and recovering gold or copper, and greatly expands the use range of biological metallurgy in gold mines. Meanwhile, due to the wide temperature adaptation range, the composite mineral-leaching bacteria colony improves the oxidation speed and reduces production cost. Therefore, the composite mineral-leaching bacteria colony has a significant application prospect in biological metallurgy industry.

Owner:CHINA NAT GOLD GROUP CORP TECH CENT +1

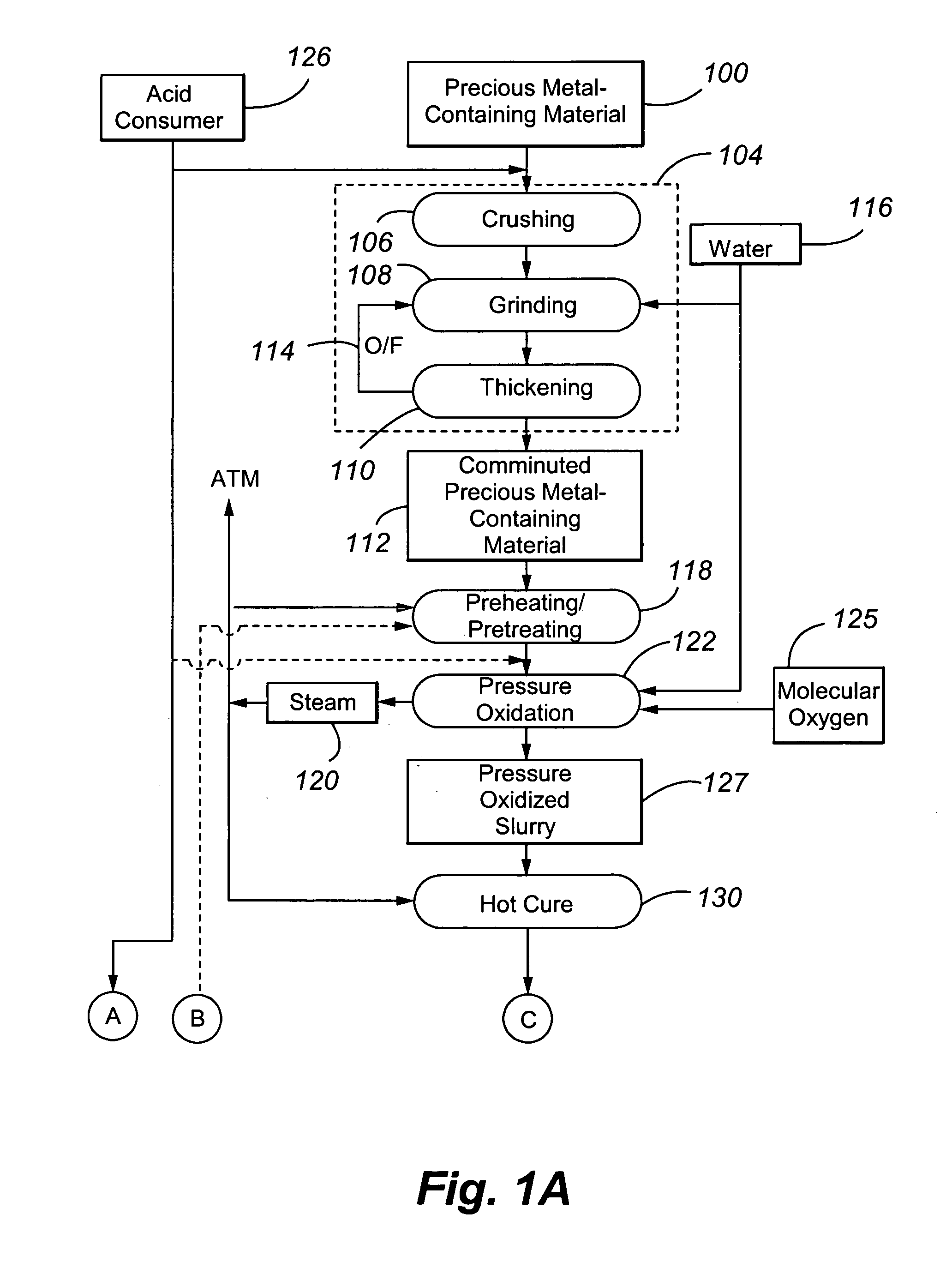

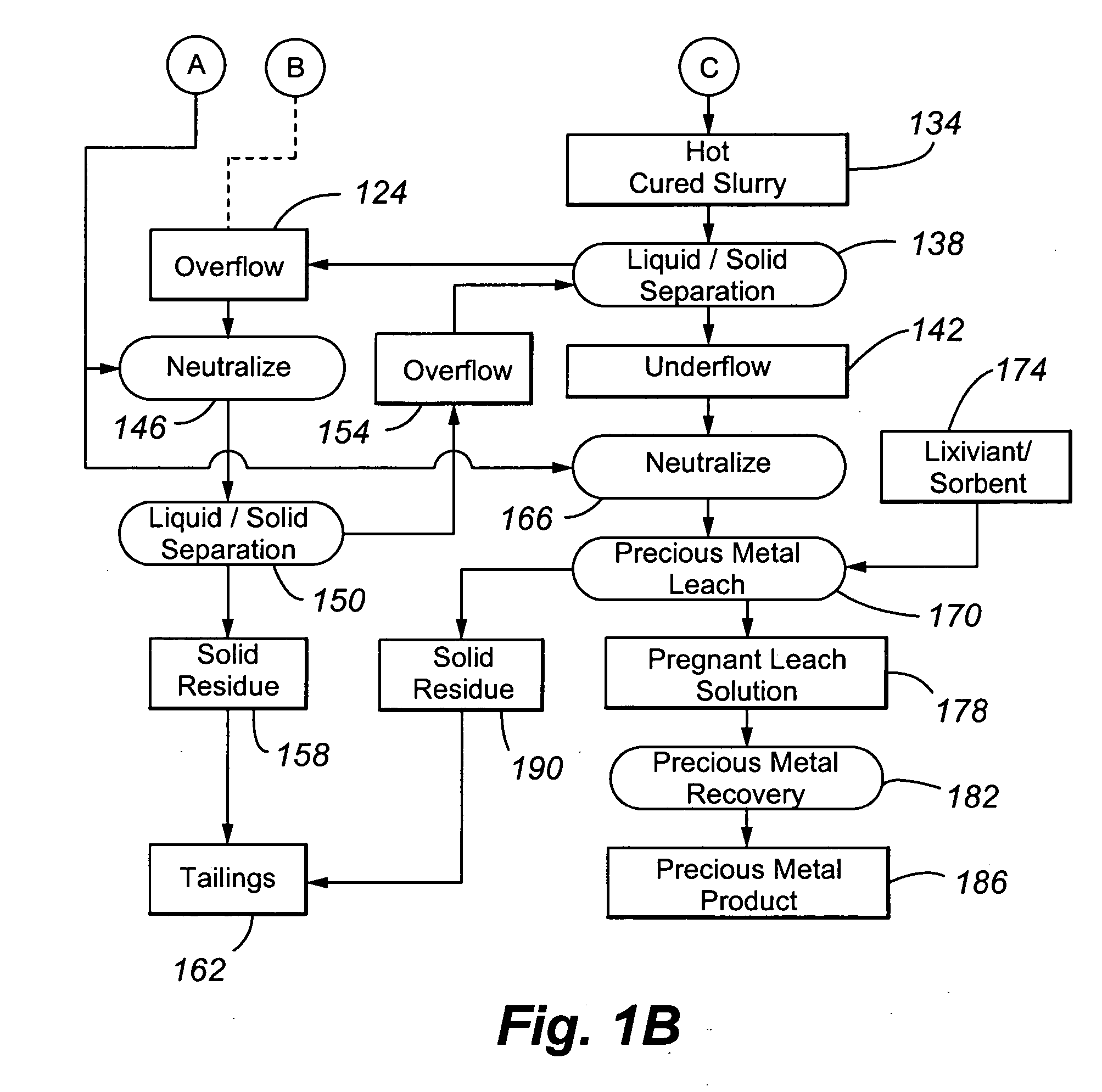

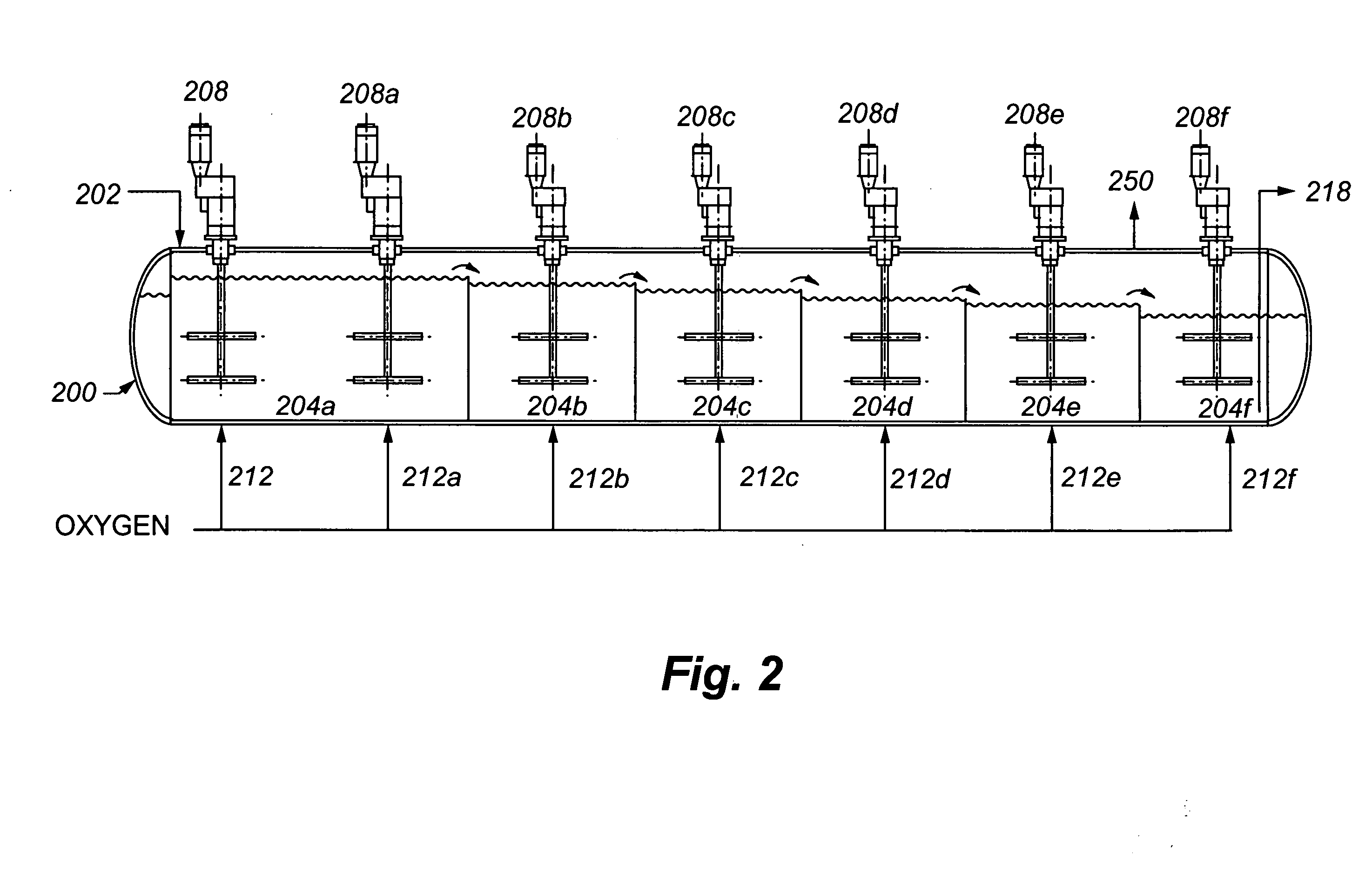

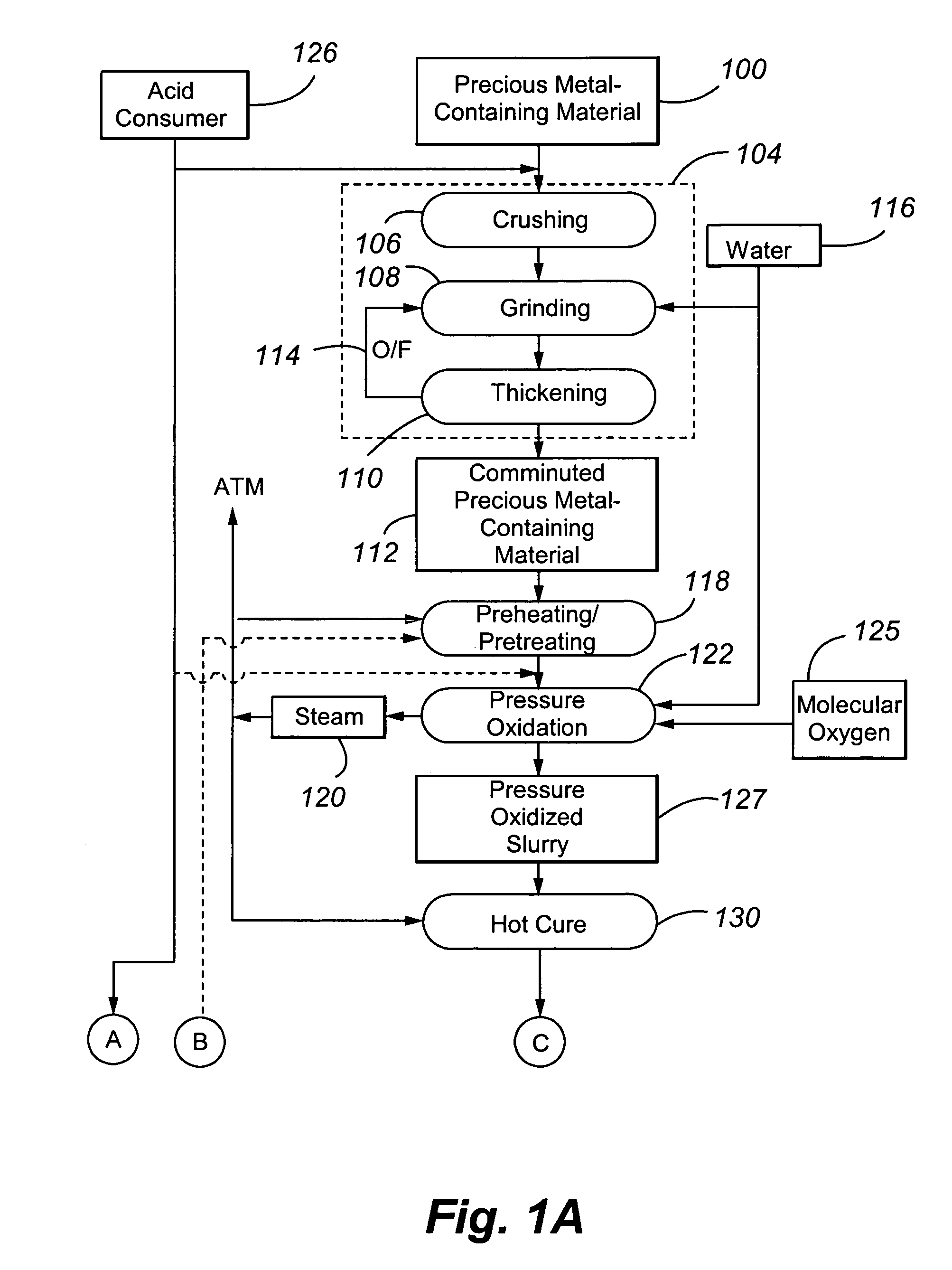

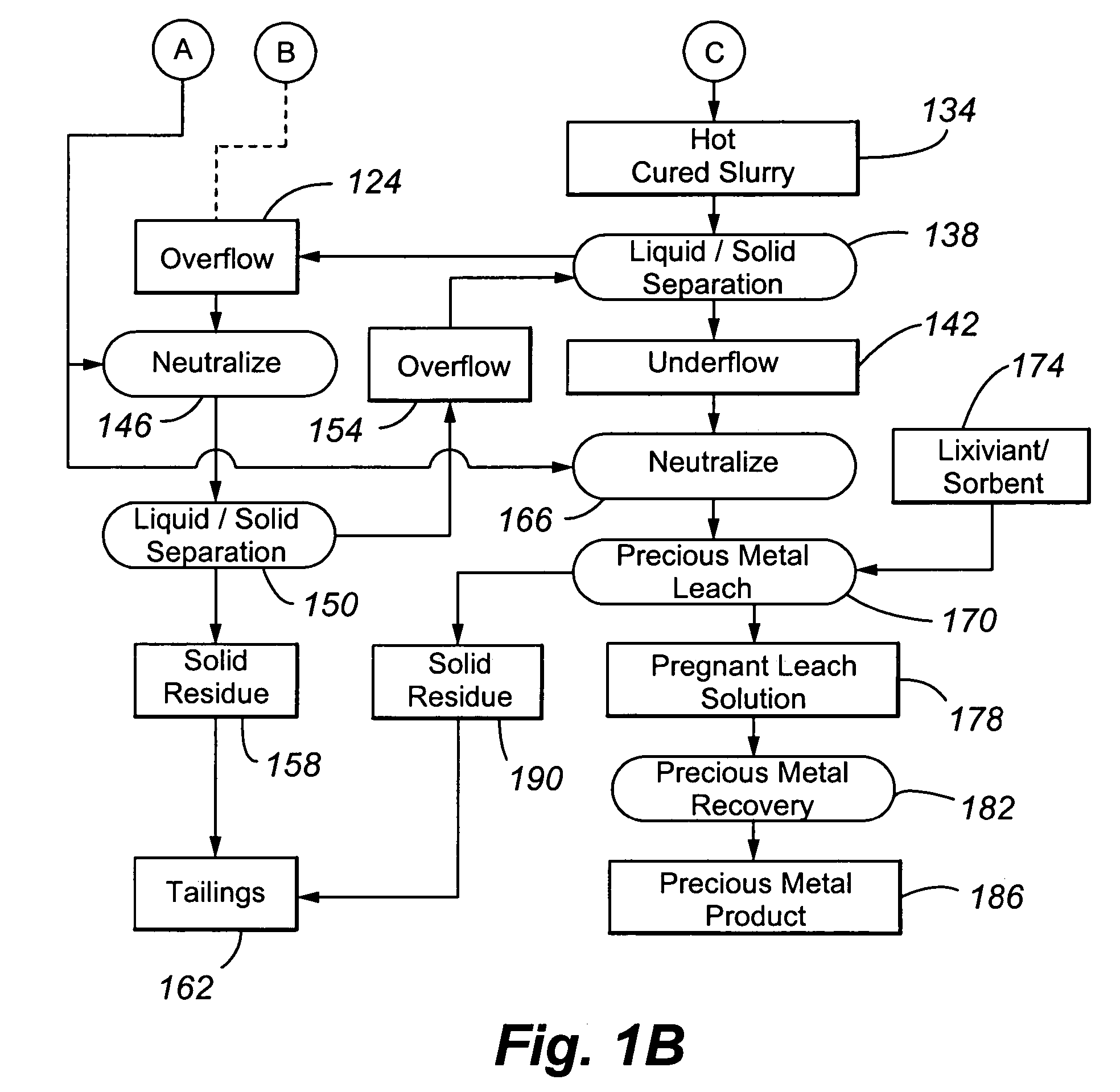

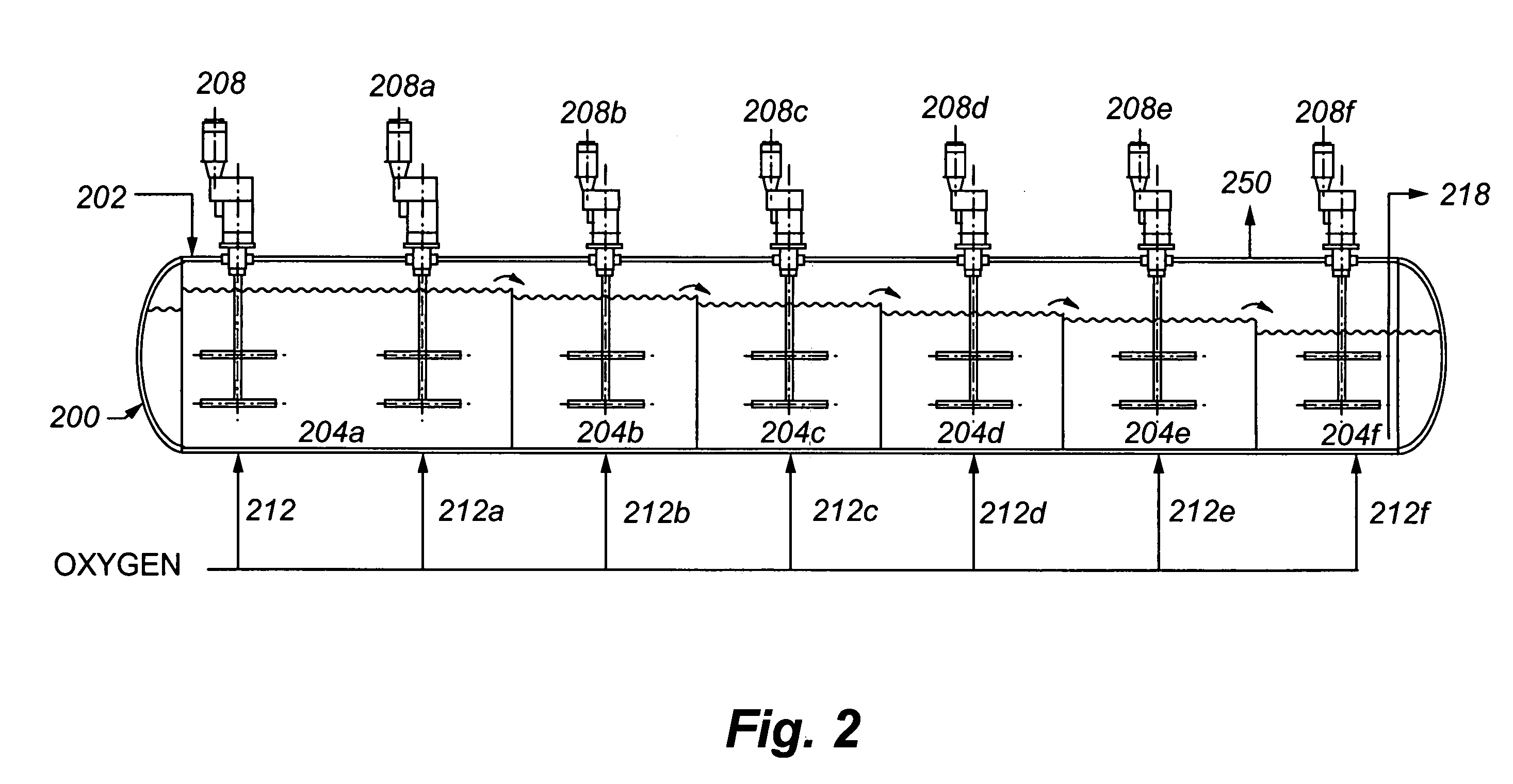

Reduction of lime consumption when treating refractory gold ores or concentrates

ActiveUS20060133974A1Improve the level ofReduce operating costsSolvent extractionGold compoundsSlurryGold ore

The present invention is directed to a precious metal recovery process in which basic ferric sulphates and / or jarosites are controlled by a number of mechanisms, including control of the oxidation reaction conditions in the first autoclave compartment, hot curing of the autoclave discharge slurry, and / or contacting of the autoclave feed slurry with the hot cured discharge liquid.

Owner:PLACER DOME TECHN SERVICES

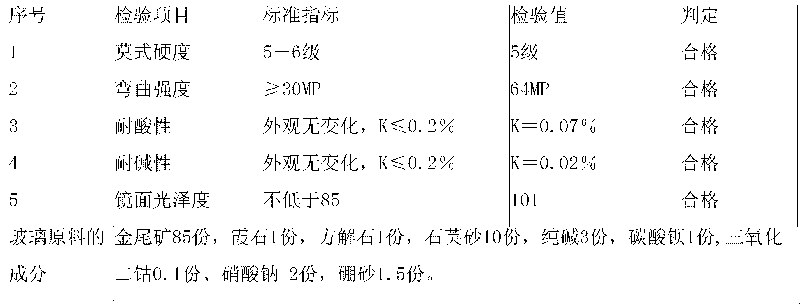

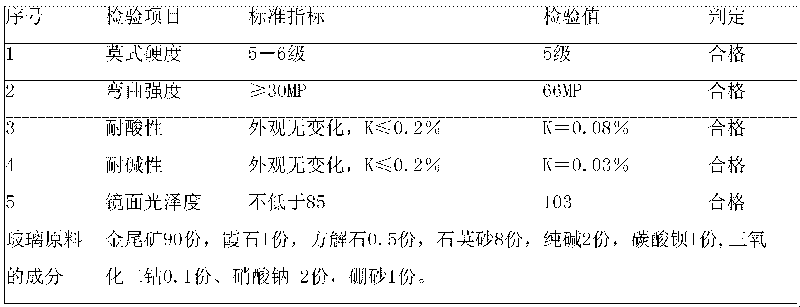

Black micro-crystalline glass plate made of gold ore tailings and manufacturing method thereof

The invention discloses a black micro-crystalline glass plate made of gold ore tailings, which is prepared from the following raw materials in part by mass: gold ore tailings 60-90, quartz sand 8-20, calcite 0.5-2, nepheline 1-2, sodium carbonate 2-5, borax 1-2, barium carbonate 1-8, sodium nitrate 2-6 and cobalt oxide 0.1-0.5. A manufacturing method comprises: crushing and screening the gold ore tailings, the quartz sand, the calcite and the nepheline; removing cyanides from the gold ore tailings by an iron exchange method; weighing the raw materials in proportion and preparing a mixed material; melting the mixed material at 1,250 to 1,350 DEG C to form vitreous humour; allowing molten vitreous humour directly to flow into water to be quenched by water into glass grains; flatly spreading the glass grains in a refractory mould for crystallization; and grinding and cutting an obtained black crystalline glass sample. Compared with the traditional black crystalline glass, the product has more higher quality, and has the advantages of high Mohs' hardness, high bending strength, high chemical stability and pure color.

Owner:君达环保科技(宝鸡)有限公司

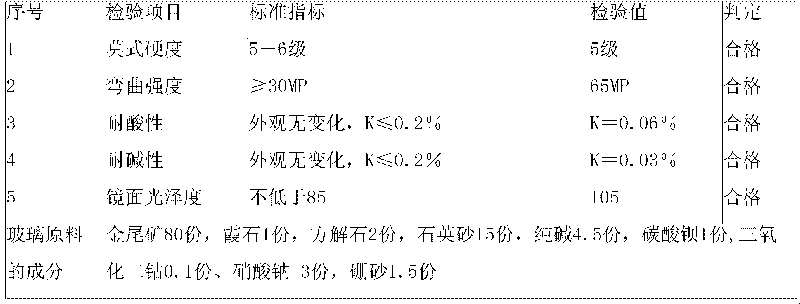

Comprehensive recovery method for directly cyanating and intensified leaching multi-metal gold ore concentrate

ActiveCN101451192AHigh recovery rateReduce backlogProcess efficiency improvementRecovery methodFiltration

The invention discloses a comprehensive recovery method for directly cyaniding, consolidating and leaching polymetallic gold concentrate, which comprises the following steps: after the gold concentrate is pulped, fractionated and grinded, qualified grinded and fractionated products are subjected to dehydration and reagent removal operation, and underflow is subjected to pre-alkaline leaching operation; pulp after alkaline leaching is subjected to alkaline leaching and pressure filtration; pulp after primary cyaniding leaching is subjected to primary washing, and 99.9 percent of finished products, namely gold ingots / silver ingots are produced; the underflow after primary washing is subjected to secondary leaching operation, and leached pulp is subjected to countercurrent washing; washed underflow pulp is subjected to pressure filtration; pulp after pulping is subjected to cyanide residue floatation operation, and gold lead concentrate, copper concentrate and sulfur concentrate are respectively recovered by floatation and taken as concentrate goods for sale; and tailings after floatation are subjected to pressure filtration and discharged as waste tailings. The method improves the recovery rate of difficulty leached gold concentrate to more than 96 percent, simultaneously reduces equipment investment, shortens the leaching technological flow, and reduces the metal overstock flow. The direct cyanidation recovery rate of gold reaches more than 96 percent, and the comprehensive recovery rate of the gold reaches more than 98 percent, so as to reach the advanced level in the same industry in China.

Owner:LINGBAO CITY JINYUAN MINING

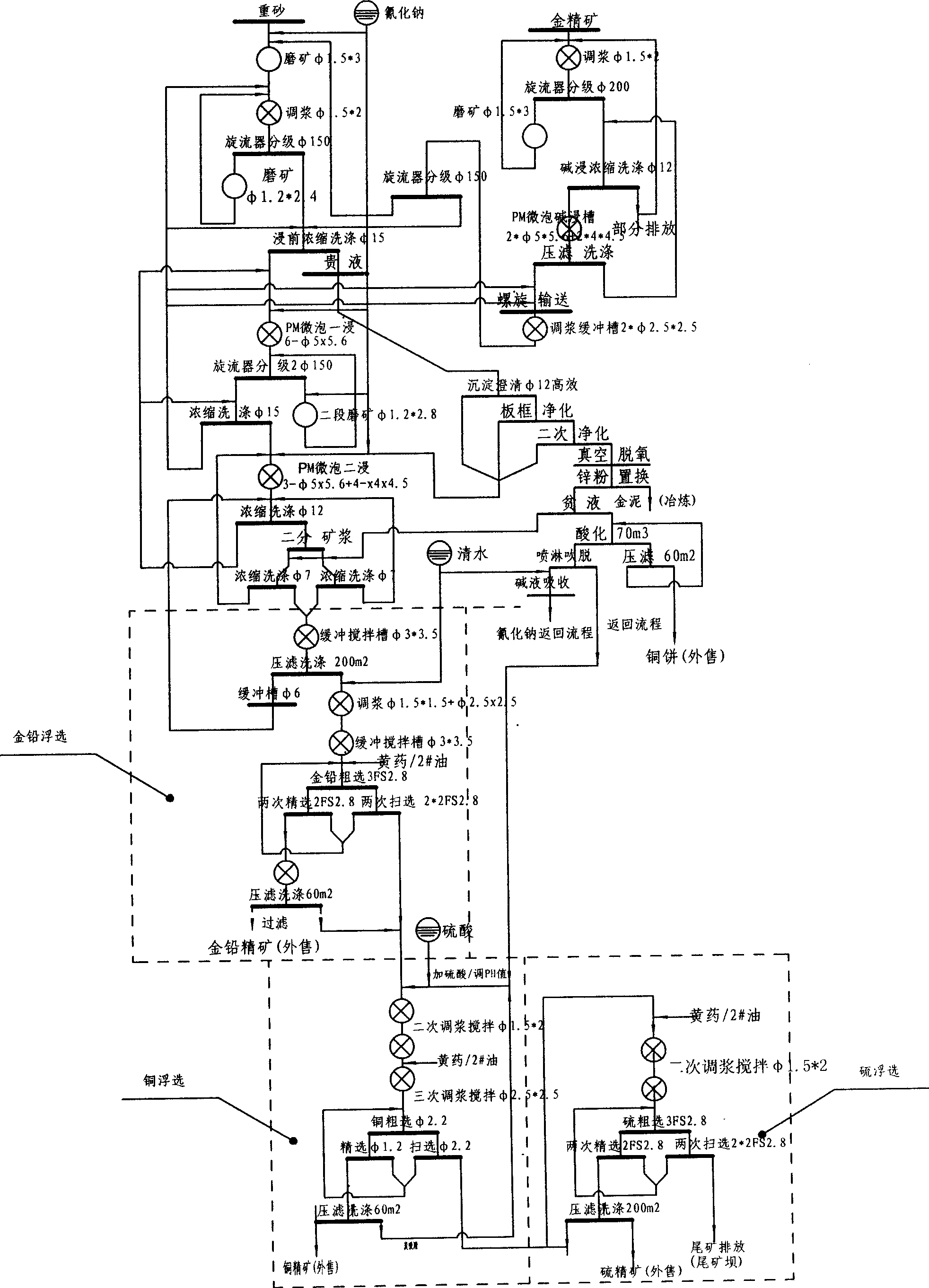

Novel martensitic wear resistant steel and production technology for steel casting thereof

The invention particularly relates to novel martensitic wear resistant steel and a production technology for steel casting thereof, belonging to the technical field of wear resistant steel in iron and metal metallurgy and foundry industry. Chemical components in the novel martensitic wear resistant steel comprise, by weight, C 0.3% to 0.5%, Si 0.8% to 1.5%, Cr 2.1% to 2.5%, Mn 0.8% to 1.5%, Ni 0.7% to 1.2%, Mo, 0.6% to 1.0%, Nb 0.1% to 0.3%, Ti 0.1% to 0.5%, Re 0.04% to 0.05%, and P and S no more than 0.04, with the balance being Fe. The production technology for steel casting comprises a smelting process, a casting process, a heat treatment process and quality inspection. The novel martensitic wear resistant steel provided in the invention can be used for liner plates of ball mills, hammerheads of hammer mills or the like used in metallurgic mines under the condition of low impact, is applicable to wear resistant products used in various mines like gold mines, iron mines and cement quarries, and is a novel wear resistant material capable of substituting conventional high manganese steel. According to results of utilization in ore dressing factories for iron ore and cement, the novel martensitic wear resistant steel has an improved service life 2 to 2.3 times longer than the high manganese steel.

Owner:ANSTEEL GRP MINING CO LTD

Method for quickly leaching gold and silver by using mixed leaching agent

The invention discloses a method for quickly leaching gold and silver by using a mixed leaching agent, which comprises the following steps of: crushing gold-containing pyrite smelting slag, a sulfide-containing visible gold ore or / and a gold-containing oxidized ore serving as raw materials, conditioning the raw materials with water to form slurry, adding ammonium thiocyanate, thiocarbamide, urea and an oxidant, namely manganese dioxide or ferric chloride, into the ore slurry and stirring and leaching the mixed slurry to leach the gold and silver out. The method has the advantage that: the mixed leaching agent formed by adding the urea into the ammonium thiocyanate can quickly leach the gold and the silver out of the sulphur and arsen-containing gold ore by adding the urea with a low cost, particularly the gold and the silver which are contained in pyrolusite can be leached out with a lower cost. At the same time, beneficial elements in the ores can be comprehensively used.

Owner:梁伟基 +1

Beneficiation method for high-carbon micro-fine particle sub-microscopic gold ore

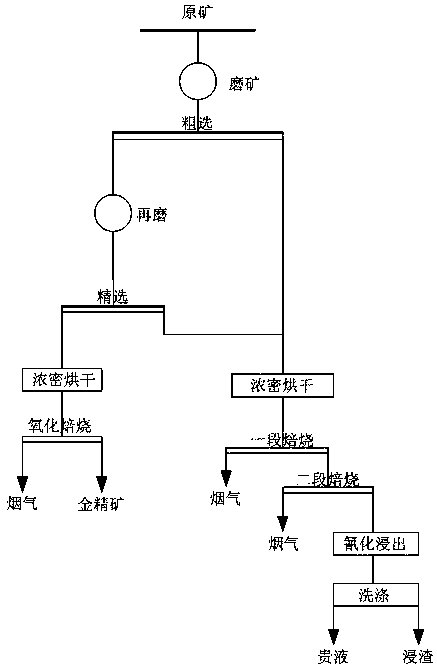

ActiveCN107326172AHigh recovery rateImprove leaching rateSolid separationProcess efficiency improvementHigh carbonPyrite

The invention discloses a beneficiation method for high-carbon micro-fine particle sub-microscopic gold ore, and belongs to the technical field of mineral processing. Roasted ore, namely, concentrated gold ore, is obtained by performing flotation after gold ore is ground, grinding and selecting the floated concentrated gold ore again, and performing oxidizing roasting on the floated concentrated gold ore. The content of carbon and sulphur in the floated concentrated gold ore is high; and when iron pyrite in the floated concentrated gold ore is enriched to a certain degree, the gold grade is difficult to improve. The concentrated gold core with high quality can only be obtained through the oxidizing roasting. Two-section oxidizing roasting is performed on floated tailings so as to prevent over-roasting or under-roasting, and a sulphide which coats the gold is damaged through roasting so that cracks appear on a gold-loaded mineral structure to inhibit negative impact of organic carbon on subsequent cyaniding gold extracting process; and therefore, the purpose of remarkably improving the leading rate of gold is achieved. The method has the characteristics of low production cost, high gold recovery rate, high adaptability, wide application range and the like; and recycling and utilization of the ore are realized.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

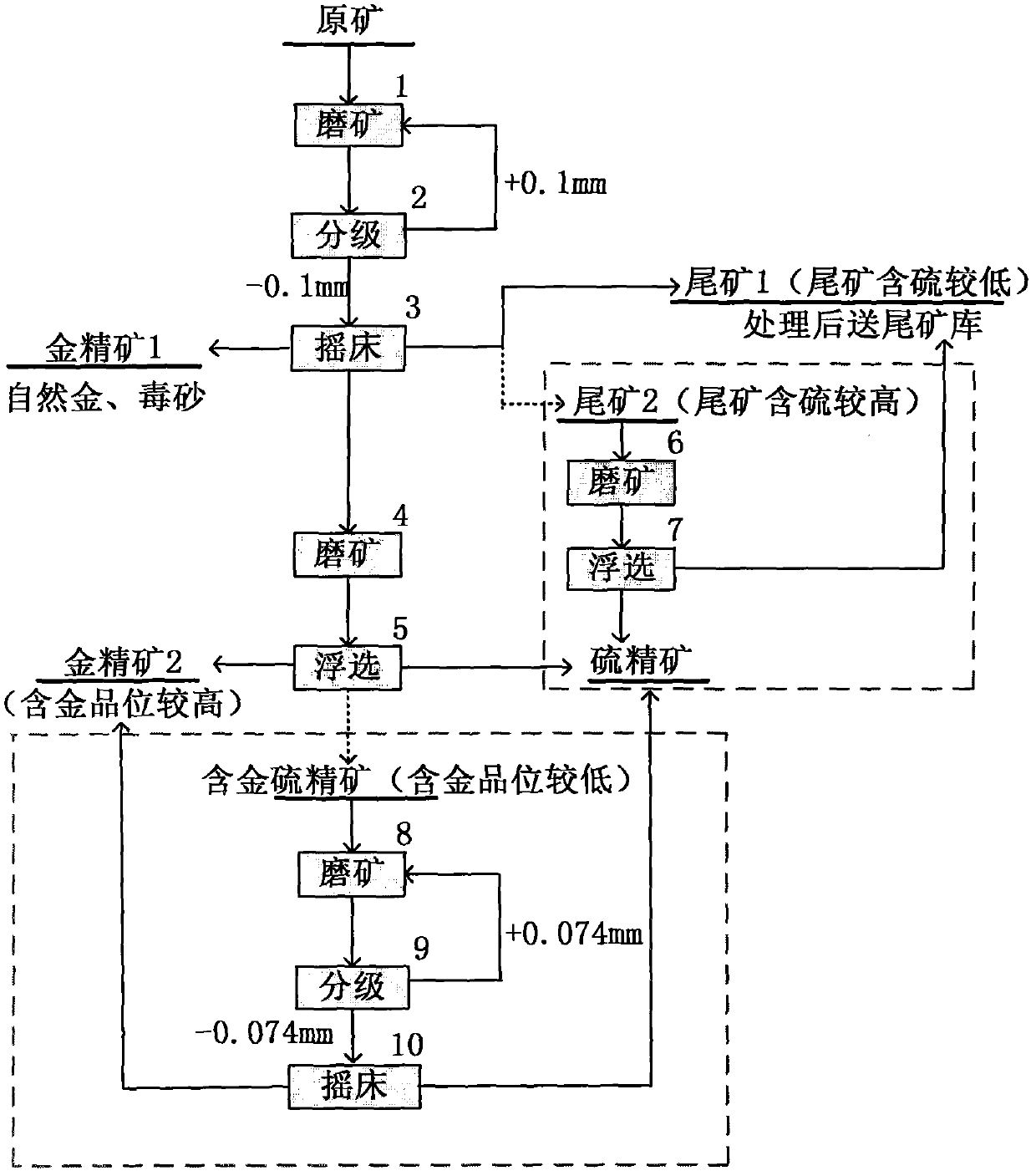

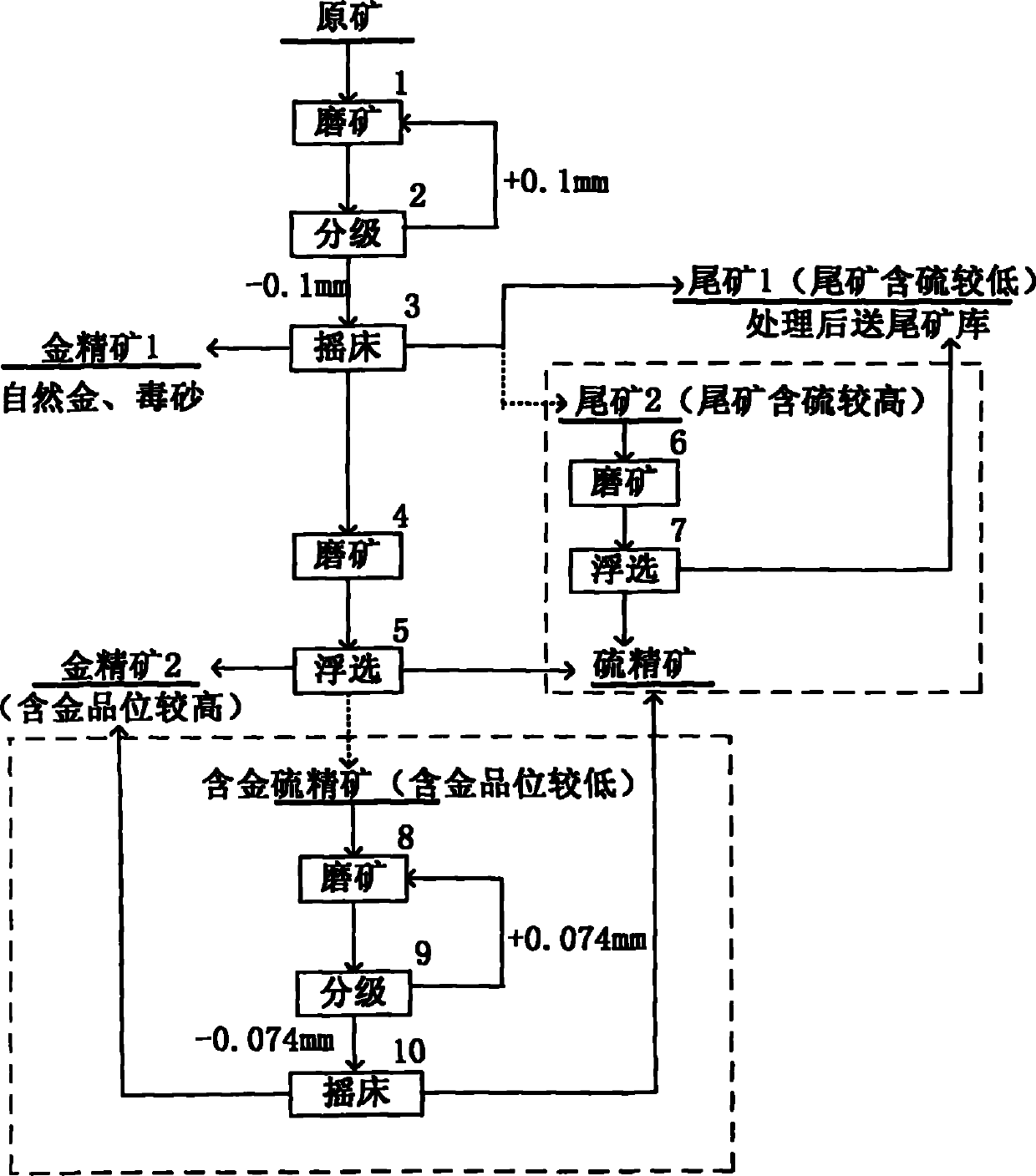

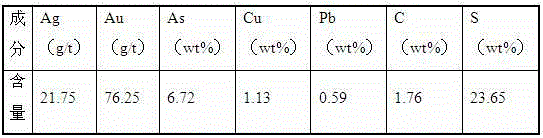

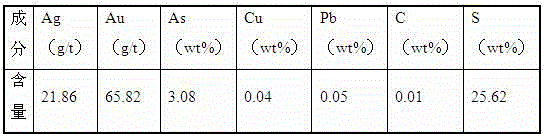

Process for recycling gold from high-arsenic and high-sulfur difficultly treated gold ore

The invention relates to a process for recycling gold from a high-arsenic and high-sulfur difficultly treated gold ore. The process comprises the following steps of: separating natural gold and arsenopyrite from a raw ore through an ore grinding and grading table to obtain gold concentrate 1, tailings 1 or tailings 2; wherein when the content of sulfur in the tailings is low, the tailings 1 are obtained, processing the tailings 1, and directly conveying the tailings 1 to a tailing warehouse; when the content of sulfur in the tailings is high, the tailings 2 are obtained, performing ore grinding floatation on the tailings 2 to obtain sulfur concentrate and the tailings 1; further performing sulfur fine grinding floatation on the ore in the table, wherein the floatation tailings are sulfur concentrate, and the flotation concentrate is gold concentrate 2 or gold-containing sulfur concentrate; when the gold-containing grade of the flotation concentrate is relatively high, obtaining the gold concentrate 2; and when the gold-containing grade of the flotation concentrate is relatively low, obtaining the gold-containing sulfur concentrate, and after ore grinding and grading, further collecting through the table to obtain the gold concentrate 2, wherein the tailings are sulfur concentrate. The grade of the gold concentrate is greatly improved in a processing way that repeated selectionand floatation are combined in the new process; and a large amount of arsenic is collected into the gold concentrate simultaneously, so the utilization rate of sulfur is improved. When an ore sample of which the pyrite grade is relatively high and gold with a large amount is distributed in the pyrite is treated, qualified gold concentrate with certain amount can be still obtained.

Owner:有研资源环境技术研究院(北京)有限公司

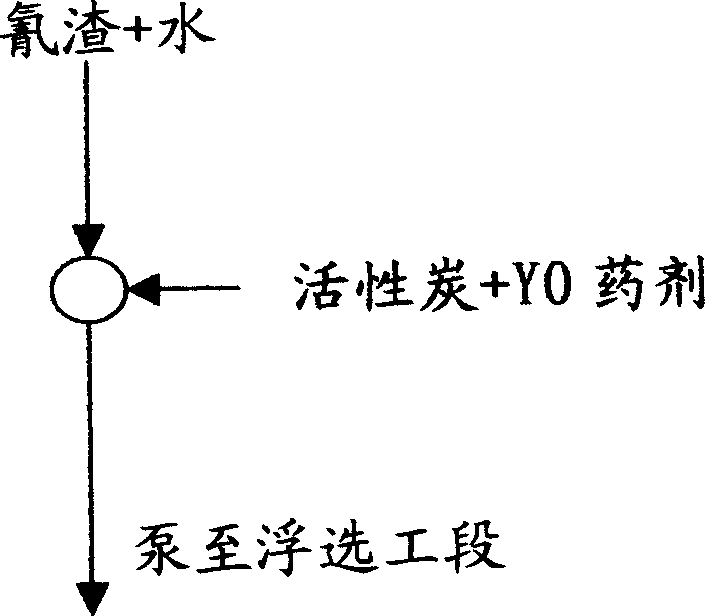

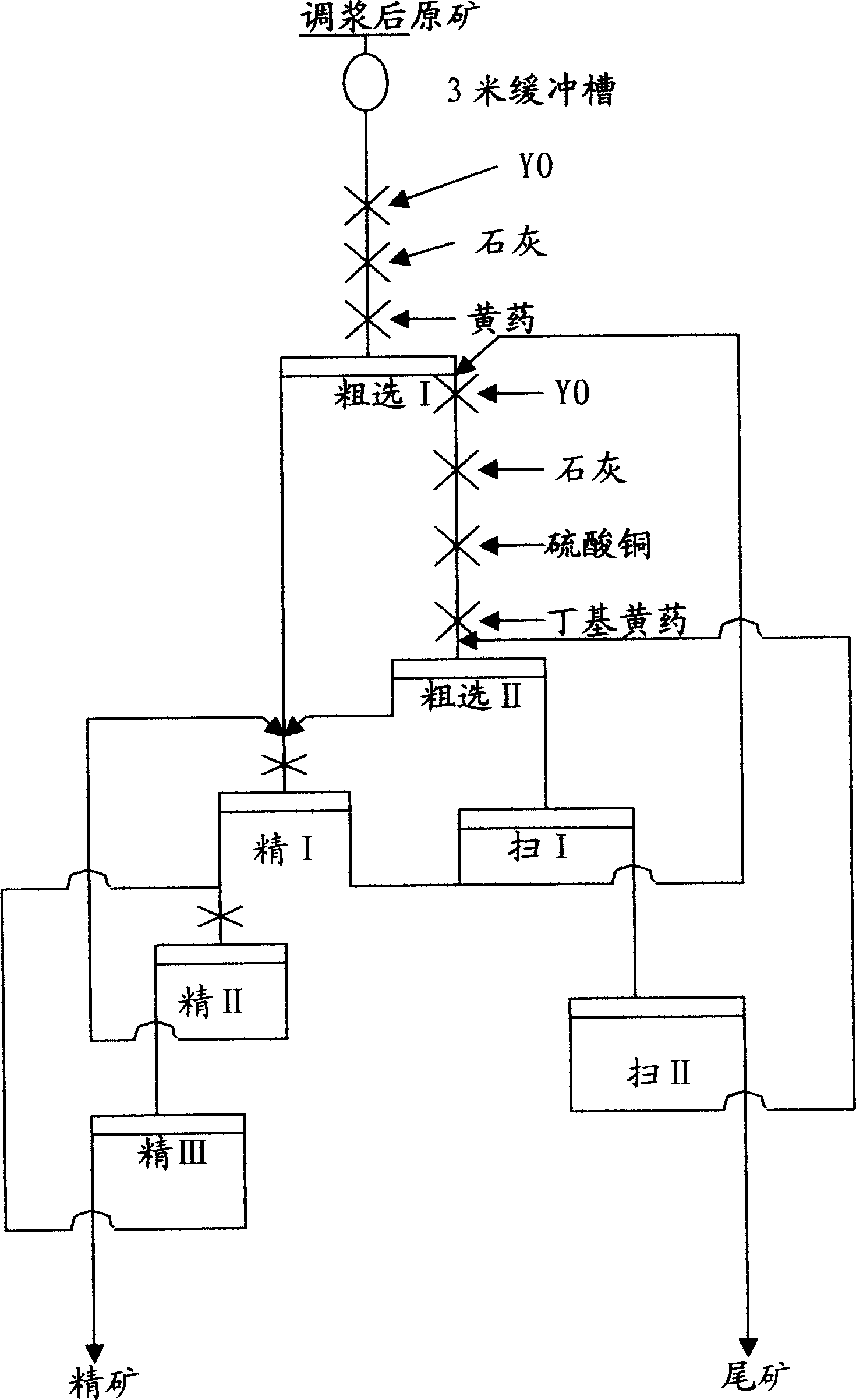

Method for floatation and recovery of lead zinc mixed concentrate from gold mine cyaniding slag tails

InactiveCN1865461AHigh recovery rateNo emissionsFlotationProcess efficiency improvementChlorinated limeSlag

The invention discloses a lead-zinc floating recycling method from gold ore cyanation tailings, which comprises the following steps: (1) predisposing: adding water in the cyanation tailings; stirring to form ore paste; adding active carbon, Y0 agent, FeSO4+ammonium persulphate in the ore paste; (2) asynchronous mixing-selecting: sending the predisposed ore paste to the floater group I to proceed first roughing separation; adding Y0 agent, limestone, butyl airpotato yam to float galena; sending the tailings in the first roughing separation to floater group II; adding Y0 agent, limestone, cupric sulfate, butyl airpotato yam to float zincblende; (3) recycling and purifying tailing water: adding chlorinated lime in the tailing water to decompose CN- less than 0.5 mg per L; recycling the tailing water.

Owner:青岛黄金铅锌开发有限公司

Reduction of lime consumption when treating refractory gold ores or concentrates

The present invention is directed to a precious metal recovery process in which basic ferric sulphates and / or jarosites are controlled by a number of mechanisms, including control of the oxidation reaction conditions in the first autoclave compartment, hot curing of the autoclave discharge slurry, and / or contacting of the autoclave feed slurry with the hot cured discharge liquid.

Owner:PLACER DOME TECHN SERVICES

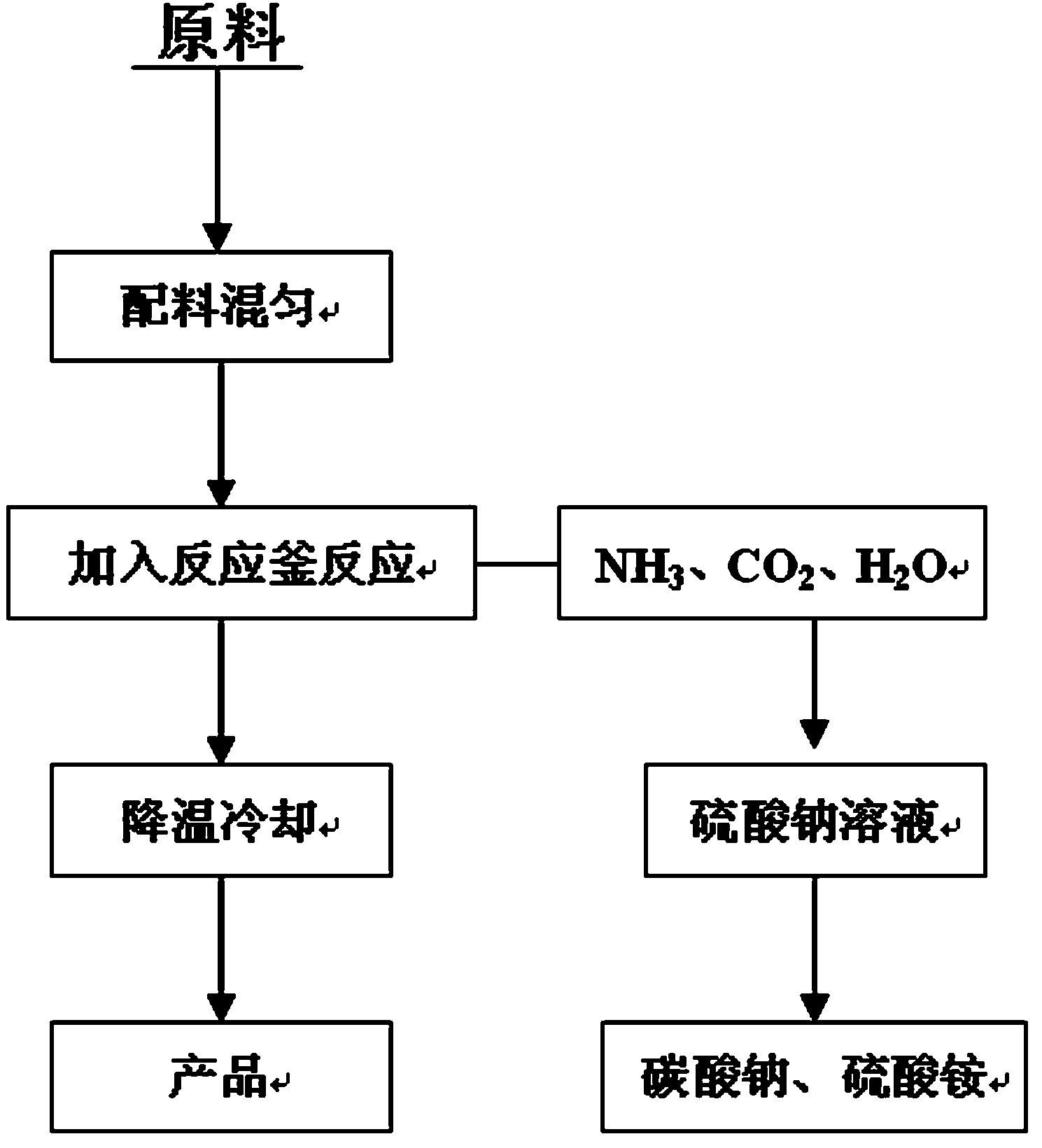

Beneficiation reagent, synthesis method and method for comprehensively utilizing generated waste gases

The invention discloses a beneficiation reagent, a synthesis method and a method for comprehensively utilizing generated waste gases. The beneficiation reagent is formed by solid-phase synthesis of inorganic or organic raw materials and comprises the following raw materials in parts by weight: 300 to 700 parts of a nitrogen-containing compound, 500 to 800 parts of chlorine salt, 400 to 650 parts of carbonate, 80 to 160 parts of strong alkali, 50 to 500 parts of cyanide complex double salt, 0 to 300 parts of cyanate, 5 to 20 parts of potassium sulfide, 50 to 200 parts of carbon and 0 to 100 parts of lime nitrogen. The beneficiation reagent is prepared by the following steps: mixing the raw materials uniformly; adding the mixed raw materials into a reaction kettle; quickly heating to 500 to 1,200 DEG C; maintaining high temperature for 1 to 2 hours; and cooling and crushing to obtain the product. Ammonia gas and carbon dioxide generated in a synthesis process are absorbed by a sodium sulfate solution to generate byproducts sodium carbonate and ammonium sulfate. The invention has the advantages of low production cost, simple operation, low toxicity and easy control. The product can be widely applied to leaching of noble metals such as gold oxide ores and silver oxide ores, floatation inhibitors and metal heat treatment and electroplating industries.

Owner:YUNNAN KEENLY NEW MATERIAL

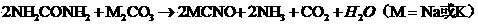

Method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings

The invention discloses a method for recycling gold and micro-fine particle antimony minerals in antimony-containing gold ore flotation tailings. By the adoption of the method, the technical problem that if the antimony-containing gold ore flotation tailings are subjected to cyanide leaching directly, the cost is high, and the gold recovery rate is low is solved. Meanwhile, efficient recovery of associated antimony minerals can also be achieved. The method is characterized by comprising the steps that the tailings are rated, the tailings with the particle size being larger than 0.038 mm are subjected to regrinding and size mixing, copper sulfate, lead nitrate and ammonia carbonate are added sequentially as a mixed activating agent, sodium n-butylxanthate and ammonium butyl aerofloat serve as a collecting agent, No.2 oil serves as a foaming agent, and gold and the antimony minerals are recycled through flotation; and water is directly added into the tailings with the particle size being smaller than 0.038 mm for size mixing, grinding is not needed, sodium hexametaphosphate, copper sulfate, lead nitrate, ammonia carbonate, sodium n-butylxanthate, No.25 aerofloat, kerosene (or diesel oil) and No.2 oil are added in sequence, wherein the sodium hexametaphosphate serves a dispersing agent, the copper sulfate, lead nitrate and ammonia carbonate serve as an activating agent, the n-butylxanthate and No.25 aerofloat serve as a collecting agent, the kerosene (or diesel oil) serves an emulsifying agent, and the No.2 oil serves as a foaming agent, and gold and the micro-fine particle antimony minerals are recycled through flotation. The technique is reasonable, procedures are simple, the gold and antimony recovery rate is high, and industrialized implementation is easy.

Owner:KUNMING UNIV OF SCI & TECH

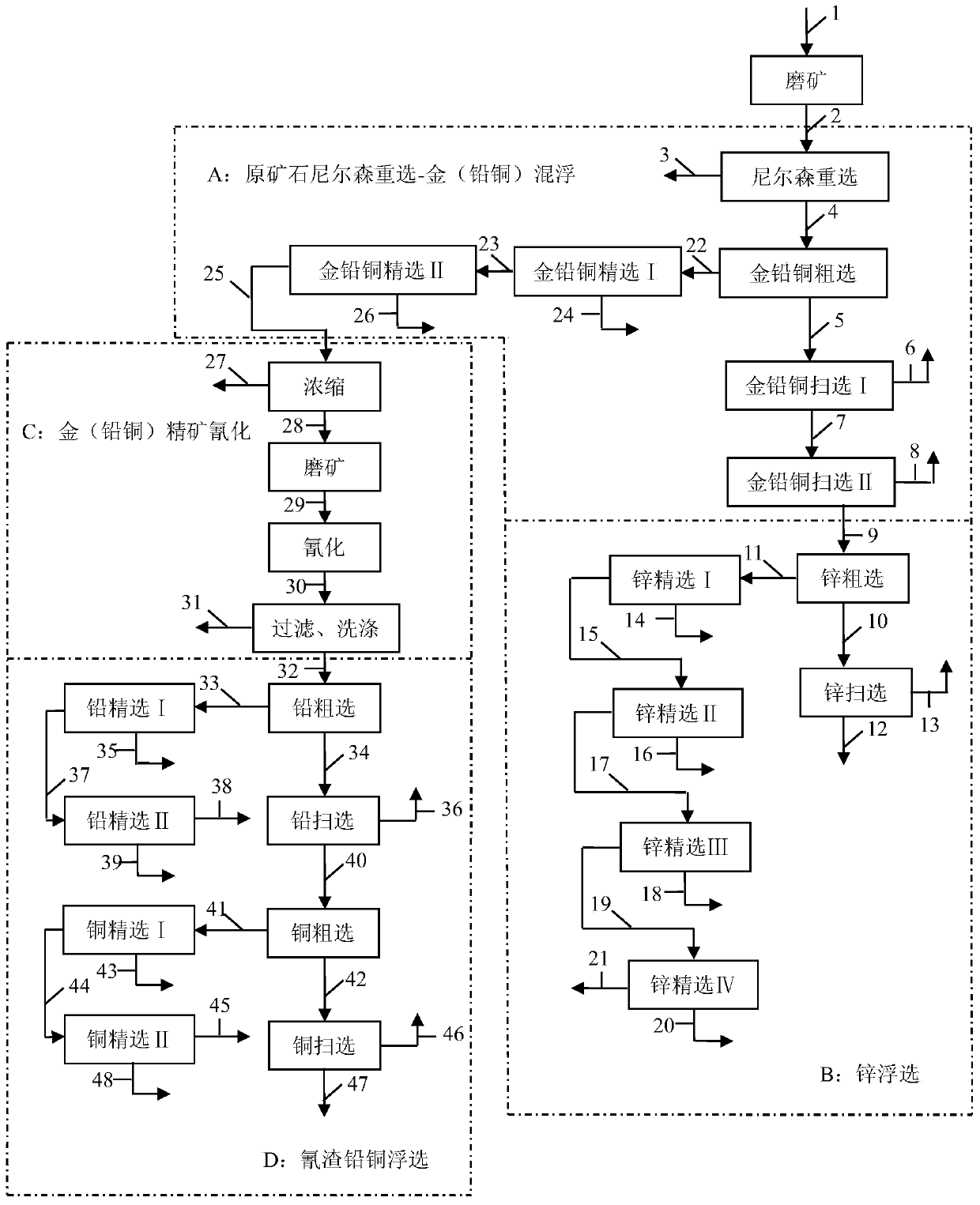

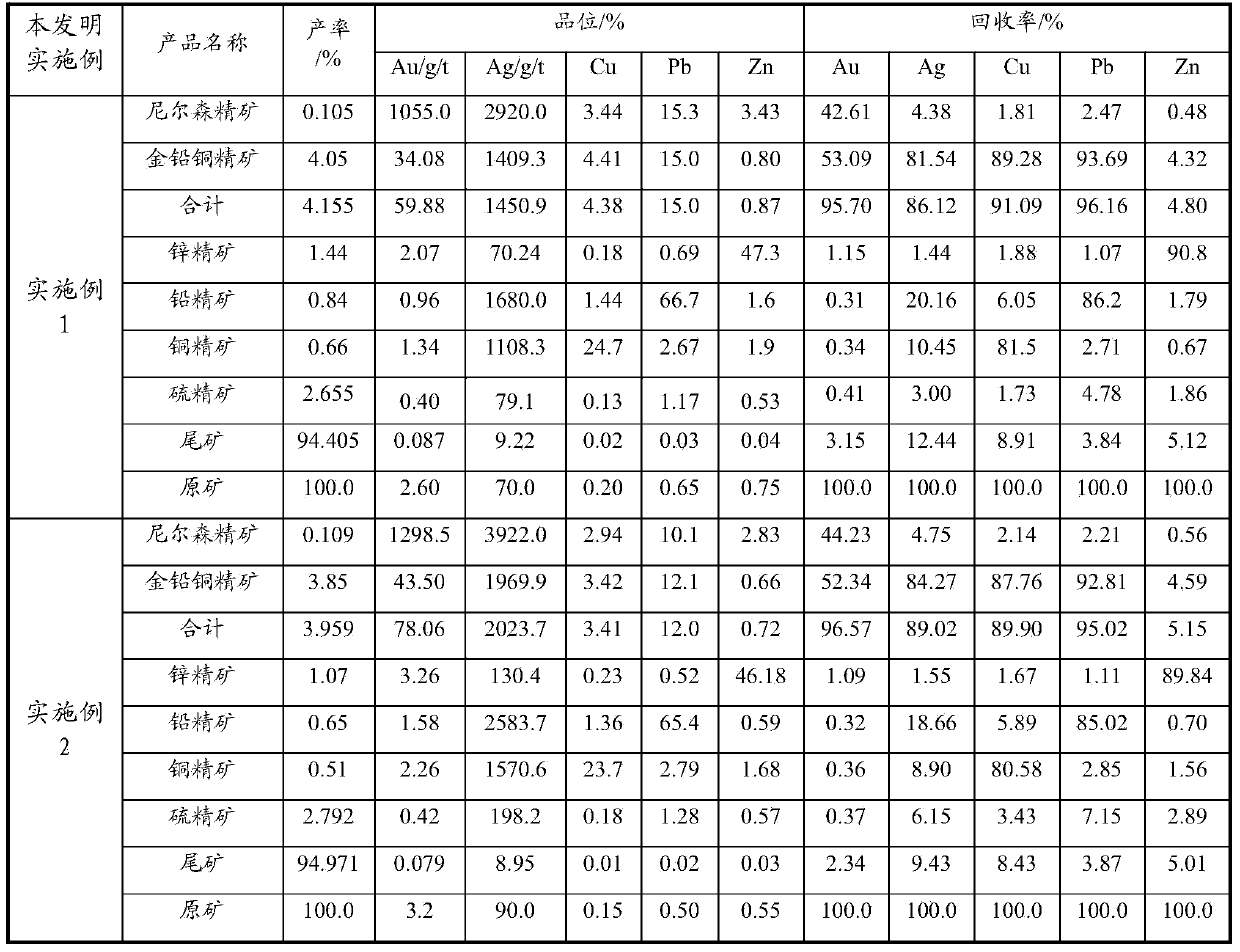

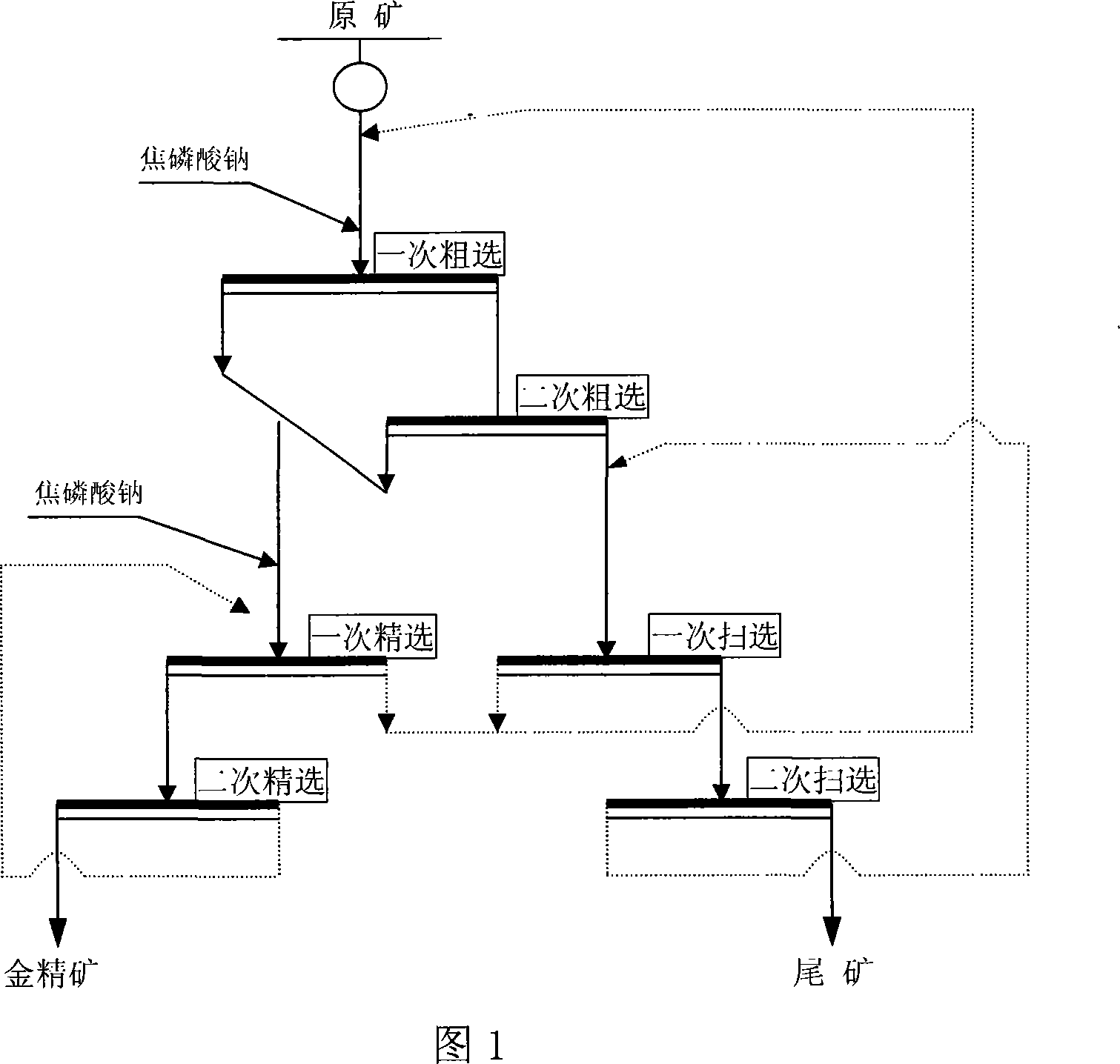

Beneficiation method for complex multi-metal sulfide electrum comprehensive recovery

The invention provides a beneficiation method for complex multi-metal sulfide electrum comprehensive recovery. According to the technical scheme, an efficient re-separation technology of Knelson concentrators is adopted according to the property and the characteristic of multi-metal sulfide electrum, and coarse gold particles are recovered in the early stage; through composite reagents of sodium sulfite, zinc sulfate and sodium silicate, slurry is highly dispersed, sphalerite and pyrite are inhibited intensively, and a novel collecting agent BK301 is adopted for synchronous flotation enrichment of gold, lead and copper minerals; copper sulfate is adopted for activation, and a fine separation technology is performed many times under high alkalinity (the pH of ore pulp ranges from 11 to 12), influences of slurry are effectively eliminated, and active separation on the sphalerite is achieved; for high-viscosity micro-fine particle cyanidation slag, the composite reagents of lime and zinc sulfate are used for intensively inhibiting copper and sulfur, and optimized lead separation is performed; the adjusting agent sodium pyrophosphate is used for efficient activated separation of copper, and therefore lead separation and copper separation are separately performed.

Owner:ZIJIN MINING GROUP

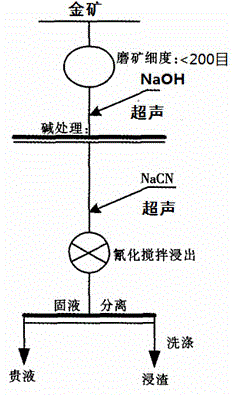

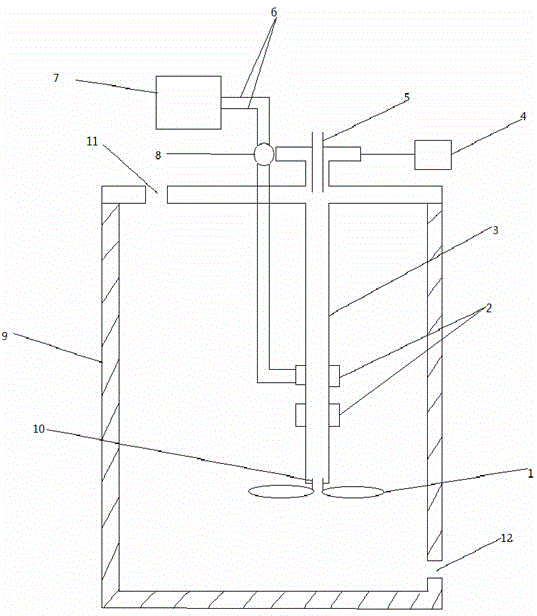

Ultrasonic intensified leaching method for refractory gold ores and ultrasonic intensified gold leaching stirrer

InactiveCN104131160AAccelerated gas stirringReduce disassemblyProcess efficiency improvementImpellerGas phase

Belonging to the technical field of wet metallurgy, the invention relates to an ultrasonic intensified leaching method for refractory gold ores and an ultrasonic intensified gold leaching stirrer. The method includes: firstly crushing gold ores to prepare an ore pulp, and then subjecting the ore pulp to pretreatment and leaching processes, in which ultrasonic intensified treatment is adopted. The ultrasonic intensified gold leaching stirrer includes a trough body, a feed inlet, a discharge port, a stirring structure, an ultrasonic structure and a ventilation structure. In the pretreatment and leaching processes, the method employs the ultrasonic method to perform intensified treatment on refractory gold ores, especially by adopting the ultrasonic method in the pretreatment process, the reaction time is shortened, and the leaching effect is intensified. The transmission shaft and stirring impellers of the ultrasonic intensified gold leaching stirrer deviate from the trough body center, thus effectively preventing the swirling phenomena, being beneficial to uniform mixing of solid-liquid-gas phase, and increasing the mass transfer rate.

Owner:KUNMING UNIV OF SCI & TECH

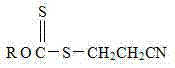

Collecting agent for low-grade refractory gold ores

The invention discloses a collecting agent for low-grade refractory gold ores. The collecting agent comprises the following materials by weight: 45-55 parts of cyanoethyl diethyl dithionocarbamate, 30-40 parts of allyl alkyl xanthate, and 10-15 parts of liquid ammonium dibutyl dithiophosphate. The collecting agent has dual attributes, such as collecting and bubbling, the selectivity is good, the collecting capacity is strong, and the concentrate grade and the recovery rate can be effectively improved in a pH value range of from 8 to 8.5, thereby being the high-efficiency collecting agent for low-grade refractory gold ores.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Ore separating method for low-grade oxide gold ore

InactiveCN1440837AHigh recovery rateImprove permeabilityProcess efficiency improvementWet separationLower gradeLow graded

The ore separating method for raising the recovering rate of low-grade oxide gold and with high mud content and containnig coarse gold grain has the three kinds of technological process of heap leaching, gravitational separation and charcoal leaching combined. After crushing, washing ore, sieving, secondary crushing and twice grading, the coarse one grains enter heap leaching system directly white the fine ore grains enter the charcoal leaching system; preliminary vibration chute is set before the grading machine to retain coarse gold grains via gravitational separation. The said method has gold core recovering rate obviously higher than that of single heap leaching method and can utilize the precious resource fully.

Owner:ZIJIN MINING GROUP

Closed-circuit method for improving refractory gold ore concentrate quality and recovery rate

A closed-loop method for the gold ore difficult to dress to increase the grade and recovery rate of gold ore concentrate includes such steps as dissolving sodium pyrophosphate (Na4P2O7.10H2O) in water to obtain solution, adding it to crude ore slurry while stirring to obtain the primary ore concentrate, adding said solution while stirring to obtain the primary fine ore concentrate, refining to obtain the final ore concentrate, and returning all failings back for further dressing.

Owner:厦门紫金矿冶技术有限公司

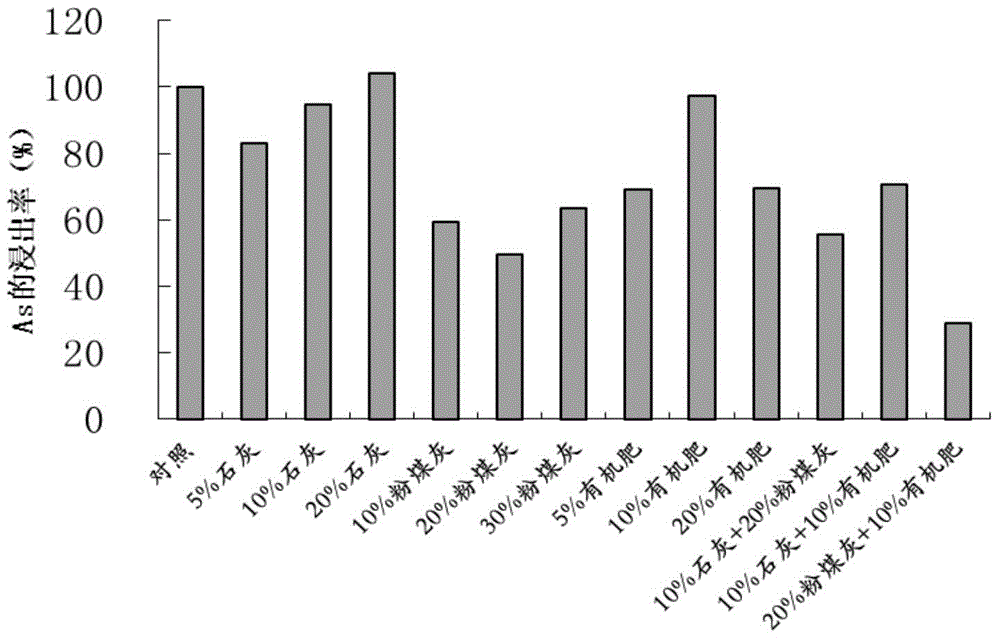

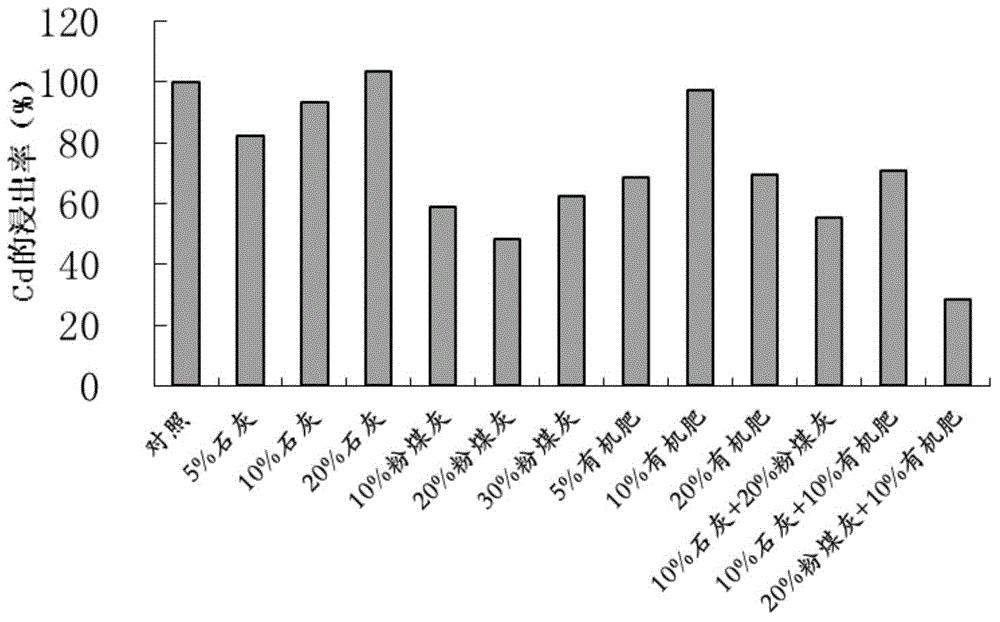

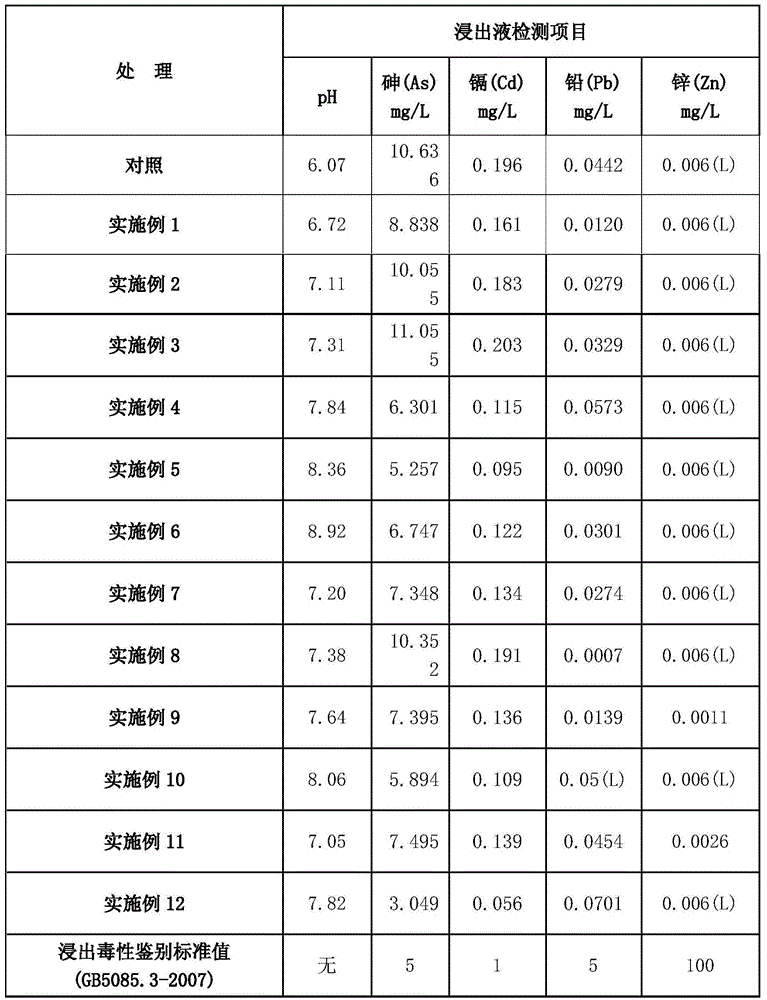

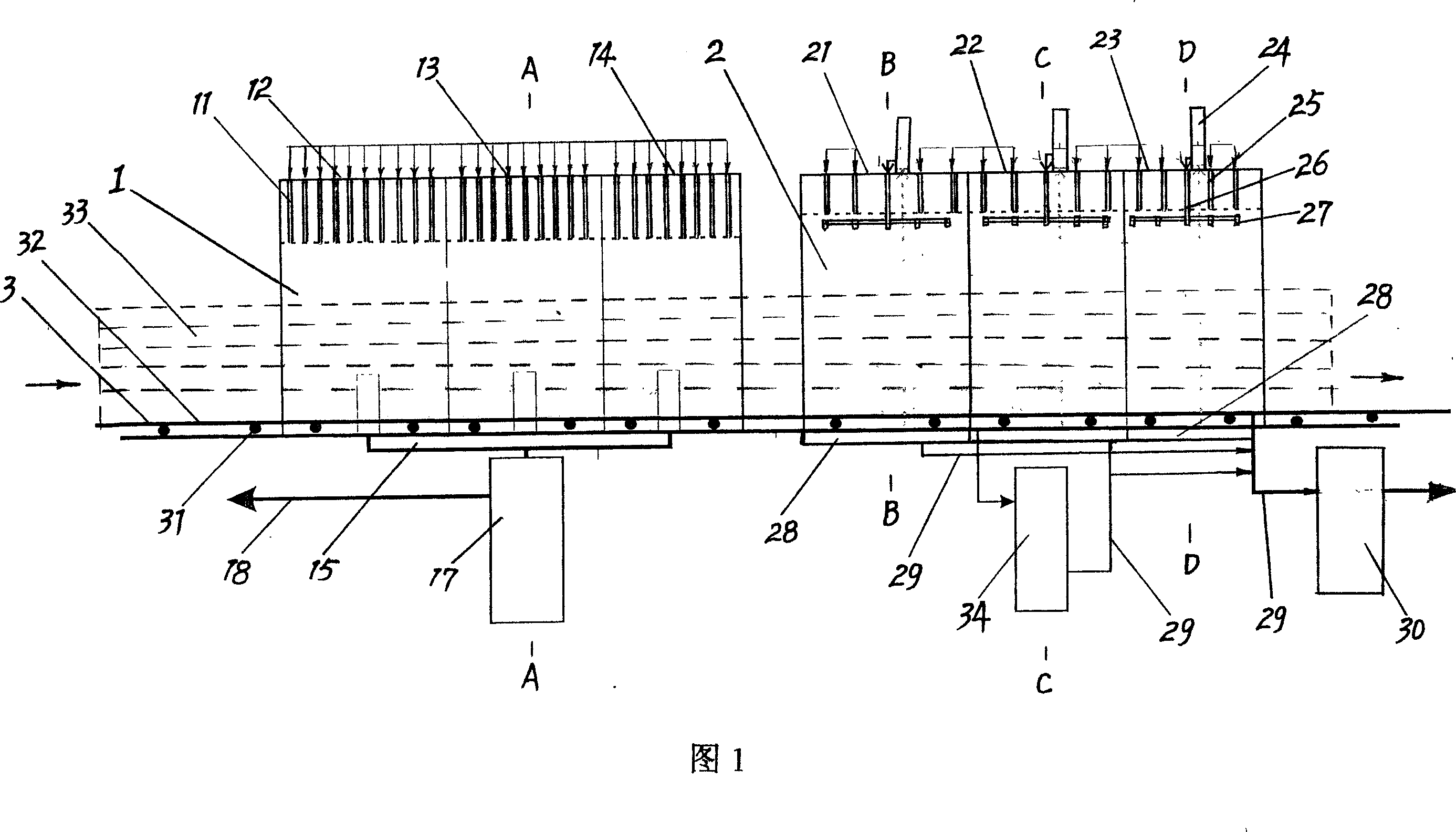

Comprehensive treatment method of slag heap of acidified gold ore containing heavy metal

The invention relates to a stabilized and ecological remediation comprehensive treatment method of slag heap of acidified gold ore containing heavy metal, and belongs to the technical field of heavy metal pollution treatment in an ore field. The method comprises the following steps: adding a certain amount of lime, coal ash and organic sludge compost into 0-20cm soil at the upper layer of the slag heap of the gold ore containing heavy metal, mixing the ore slag and the additive according to a certain ratio and stirring so as to mix evenly, adding water into the ore slag, pouring, maintaining at the natural condition for 15-30 days so as to stabilize the slag heap of the gold core containing heavy metal; then, planting heavy metal tolerant plants including ciliate desert-grass, ramie and vetiver grass, so as to further remediate the heavy metal polluted slag heap ecologically. The method can effectively stabilize heavy metal, such as arsenic and cadmium in the gold ore slag, neutralize acid in the ore slag, improve the pH of soil in the ore field, reduce the leaching of heavy metal, enhance the soil structure, increase the soil fertility, and achieve the ecological recovery of the heavy metal polluted ore slag field.

Owner:GUANGDONG XIFU ENVIRONMENTAL PROTECTION TECH +1

Integral gold refining kiln oxidizing roasting process for refractory gold ore

InactiveCN1932052ALarge amount of processingWide adaptabilityProcess efficiency improvementTunnel kilnSulfur

The present invention provides integral kiln type oxidizing, roasting and gold refining process for refractory gold ore. The roasting, the cyanating and the gold refining are completed in the same tunnel kiln. The present invention has low investment, simple apparatus making, short technological process, easy control, high gold leaching rate, high S and As oxidizing rate, low production cost, easy waste treatment and other advantages.

Owner:云南省地质科学研究所

Method for smelting and recovering lead and gold from reduction and sulfur fixation molten pool based on refractory gold ores and lead-containing residue raw materials

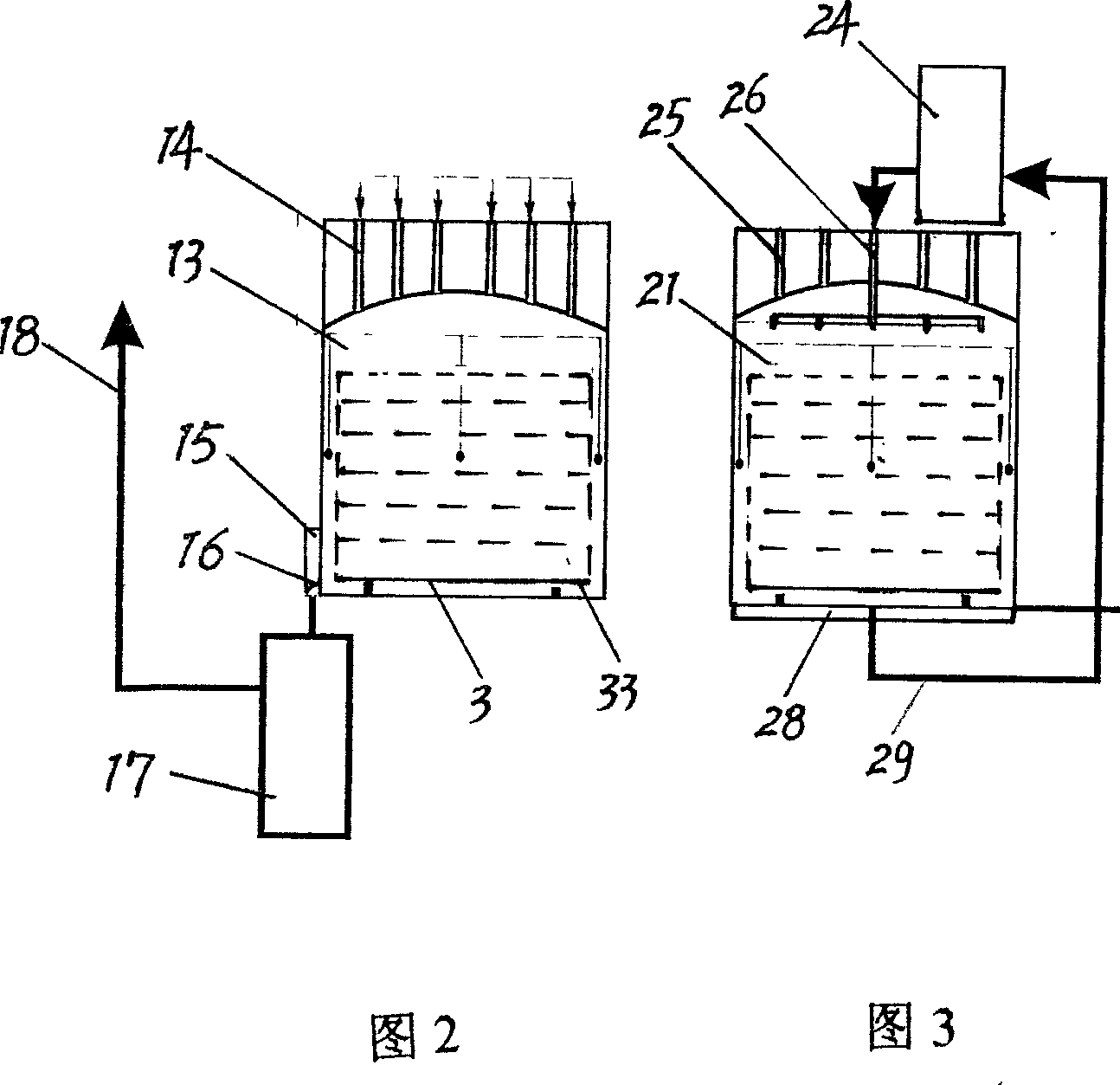

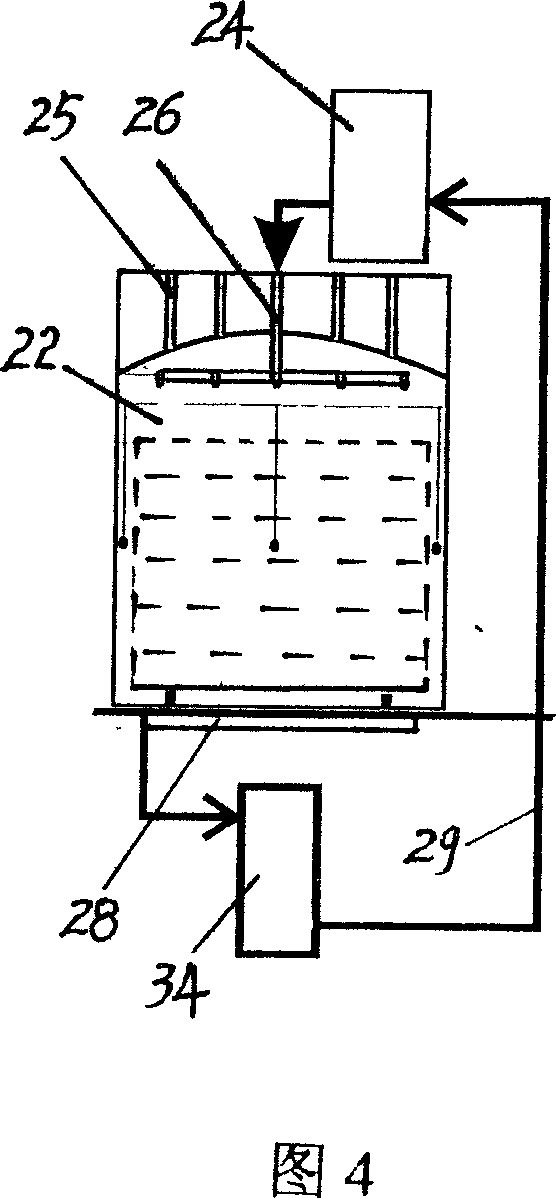

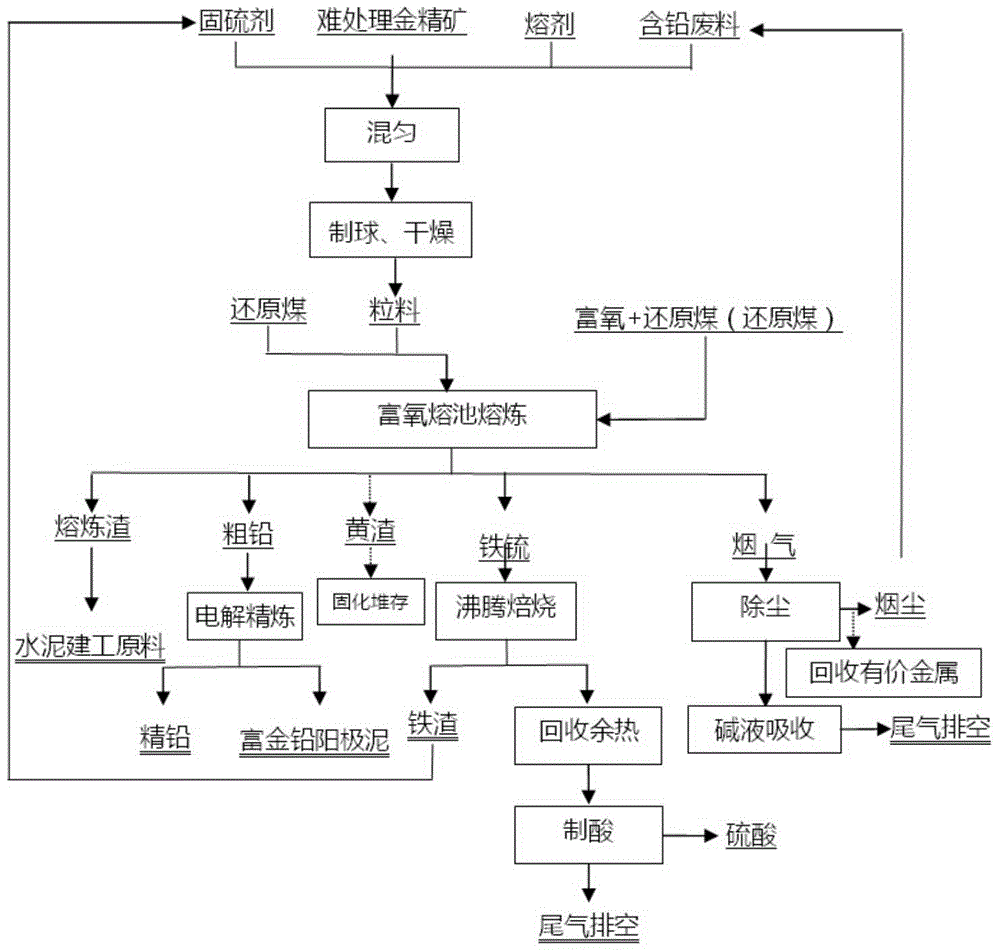

ActiveCN104313328AAchieve recyclingSimple processPhotography auxillary processesProcess efficiency improvementSlagOxygen

The invention discloses a method for smelting and recovering lead and gold from a reduction and sulfur fixation molten pool based on refractory gold ores and lead-containing residue raw materials. The method comprises the following steps: after mixing the refractory gold ores, the lead-containing material, an iron-containing sulfur-fixing agent and flux powder, granulating and drying to obtain aggregates; mixing the aggregates with a carbon reducing agent, adding into an oxygen bottom blowing furnace and introducing oxygen-enriching to smelt to obtain smelting slag, coarse lead, iron matte and smoke; mainly recovering gold and lead from coarse lead, wherein the gold recovery rate is greater than 99% and the lead recovery rate is greater than 95%; using smelting slag as a high silicon material of cement or construction; recovering valuable metals from smoke and emptying; and boiling and roasting iron matte, recovering scum and preparing acids by using sulfur dioxide tail gas, so that resources are comprehensively recycled. The method is simple to operate and low in cost and can be used for satisfying industrial production.

Owner:CENT SOUTH UNIV

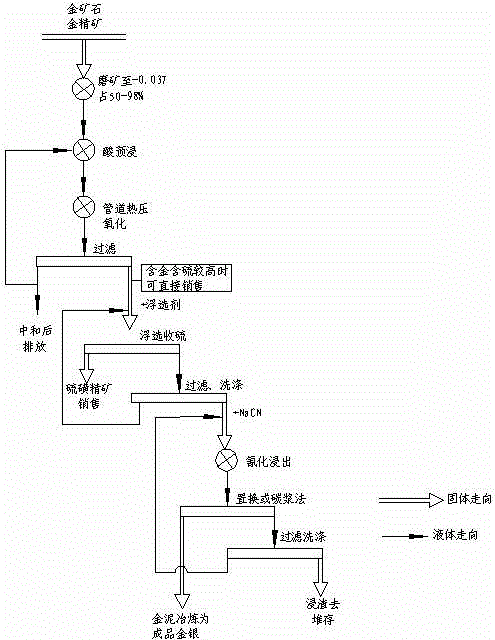

Method for recovering gold and silver from refractory gold ores

InactiveCN104818380AReduce pollutionAchieve recyclingProcess efficiency improvementBiological oxidationGold ore

The invention discloses a method for recovering gold and silver from refractory gold ores, and belongs to the field of metallurgy. The method includes two steps: firstly, pre-oxidizing and breaking inclusions of the gold and the silver in a hot-pressing manner, oxidizing organic carbon in the ores, and recovering sulfur in the ores; secondly, recovering the gold and the silver in presoaked residues by cyanidation or other non-cyanide leaching. The gold and the silver are recovered from the refractory gold ores by the method, the recovery rate of the gold and the silver is higher than 90% and increased by 40 percentage points as compared with that of a conventional cyanidation method, and the recovery rate of the sulfur is higher than 50%. By the aid of the scheme, production cost is about 400 Yuan / ton. Compared with biological oxidation, two-stage roasting and conventional hot-pressing oxidation processes, investment and the production cost can be reduced, the recovery rate is increased, multi-element comprehensive recovery is realized, environmental pollution is reduced, and economic and social benefits are obvious.

Owner:张伟晓

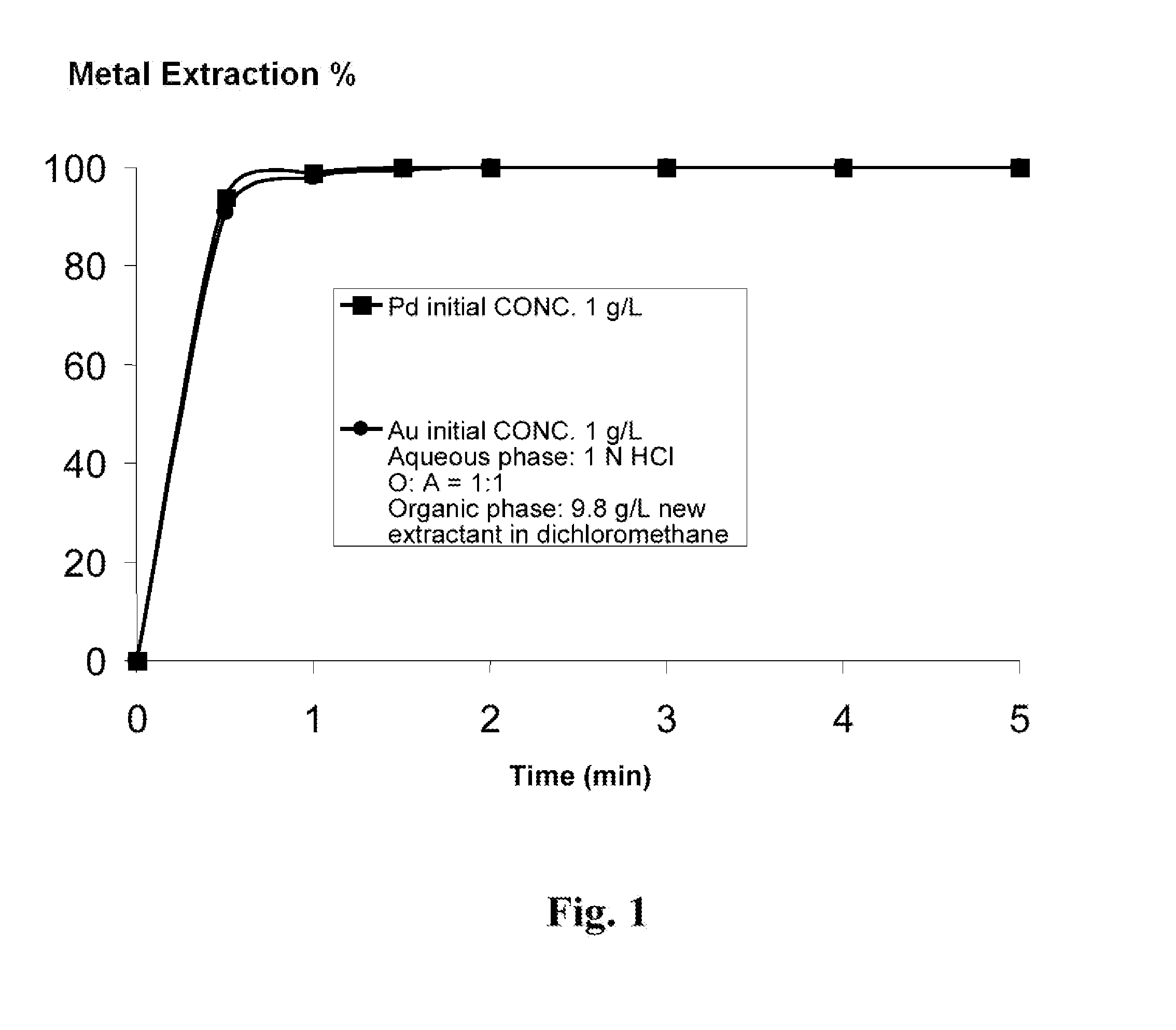

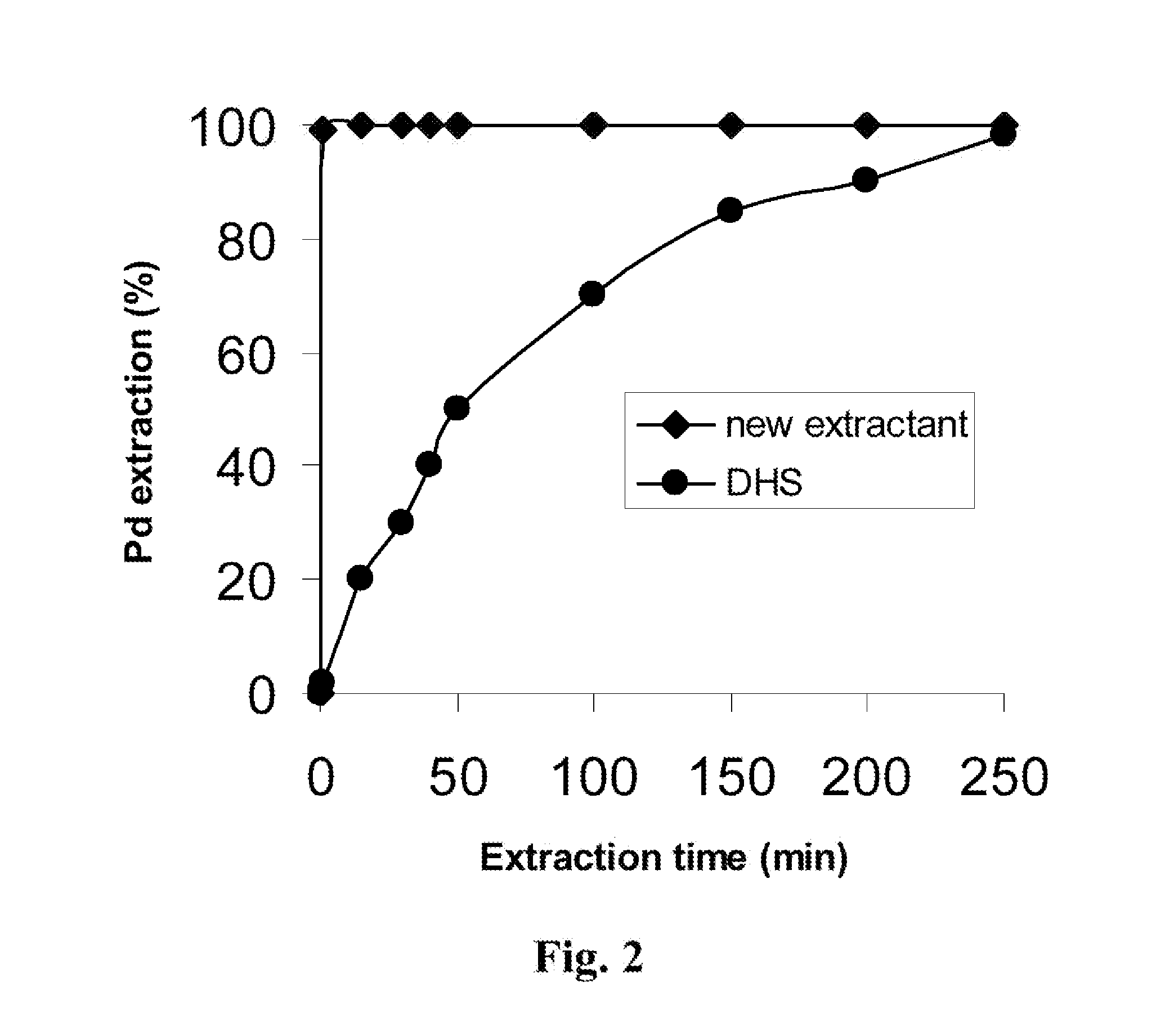

Method and Technique Employing a Novel Extractant to Enhance Recovery of Gold and Palladium from Hydrochloric Acid Media

InactiveUS20120228151A1Speed up the processEliminate needOrganic chemistryPhotography auxillary processesSolventHydrochloric acid

An extraction component enabling the concurrent recovery of gold and / or palladium selectively from a hydrochloric acid media containing the base metals and other contaminants. The disclosed extractant disclosed eliminates the conventional multi-step process for such extraction by providing for an extraction method which uses a single solvent extraction reagent. Further enhancing the conventional multi step process, the conventional scrubbing stage is eliminated by a single stripping stage. The resulting solutions can be obtained from leaching many types of material such as copper anode slimes, the treatment of scrap such as electronic circuit boards and plating effluents, PGM, or refractory gold ores.

Owner:MORADI LOGHMAN +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com