Patents

Literature

175 results about "Sphalerite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sphalerite ((Zn, Fe)S) is a mineral that is the chief ore of zinc. It consists largely of zinc sulfide in crystalline form but almost always contains variable iron. When iron content is high it is an opaque black variety, marmatite. It is usually found in association with galena, pyrite, and other sulfides along with calcite, dolomite, and fluorite. Miners have also been known to refer to sphalerite as zinc blende, black-jack and ruby jack.

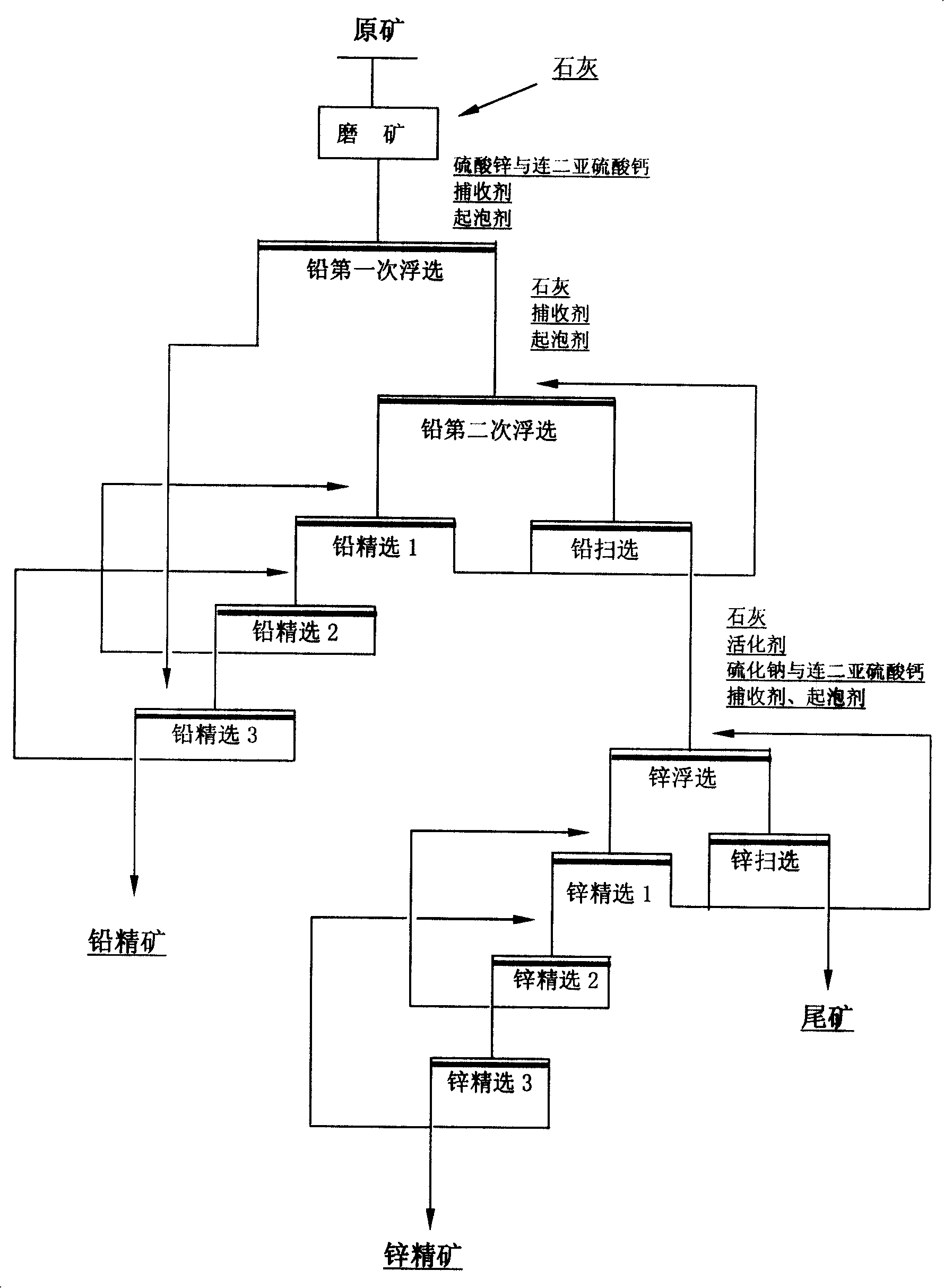

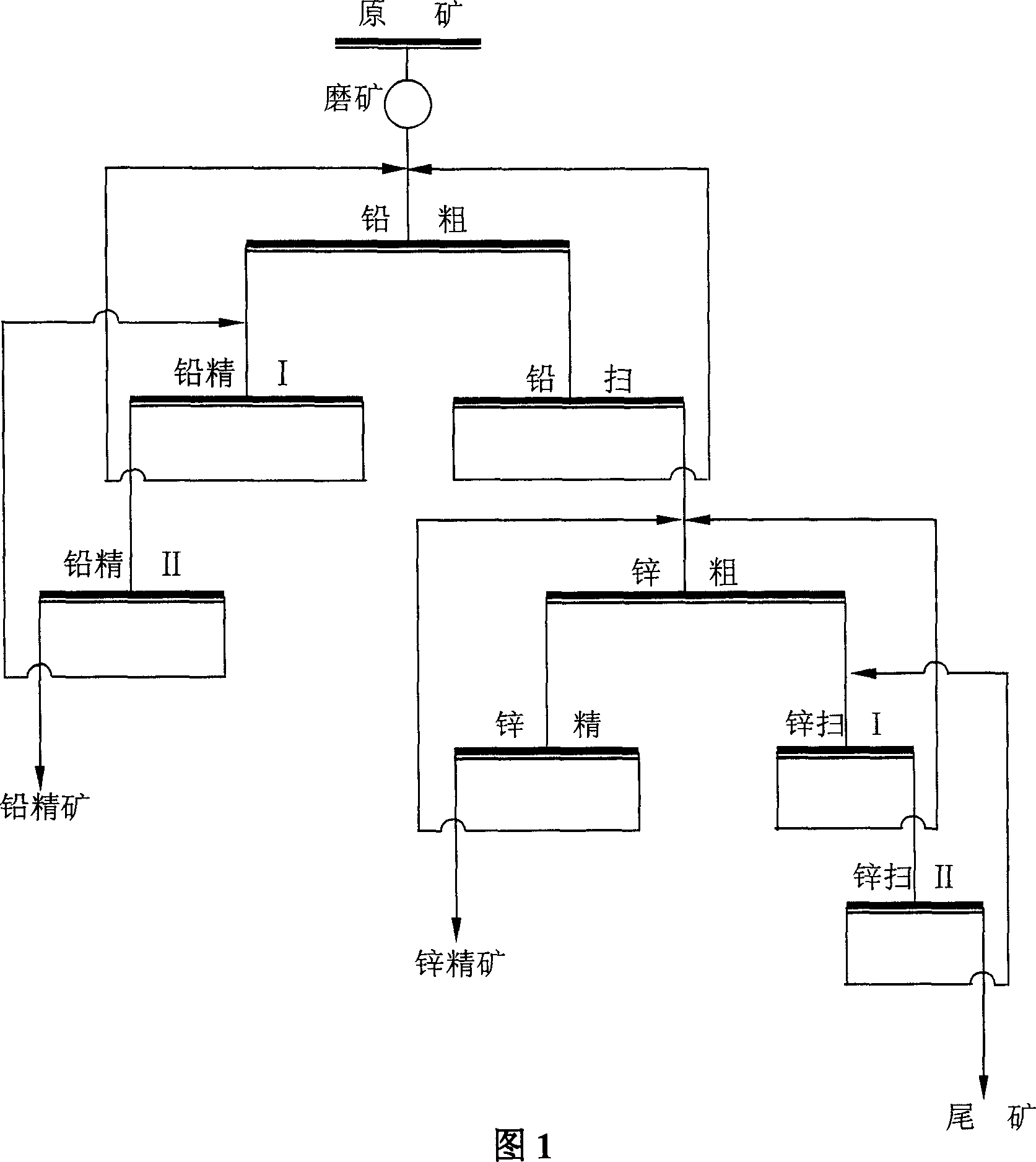

Complex plumbum, zinc, silver vulcanizing ore containing newboldite and pyrrhotite floatation method

The invention discloses a lead and zinc flotation method to ferreous blende and pyrrhotite typed complex lead zinc silver sulphide ore, mainly comprising lead ore branch flotation which controls the electrochemical conditions of the flotation and the zinc and sulfur flotation separation which controls the electrochemical conditions of the flotation. The invention has the advantages of implementing the lead-zinc sulfur separation by adopting twice branch flotation, carrying out fast flotation to the lead ore by using a novel composite catching agent to the galena and silver ore with easy floating coarse grains under the conditions of higher ore pulp potential and low pH; the normal flotation of the lead ore with difficultly floated fine grains is carried out under the conditions of lower ore pulp potential and high pH. The pH of the ore pulp is adjusted to more than 12 by lime for the gangue after the lead is floated; the iron blende is activated by bluestone; the iron blende is recovered by the catching agent with the same type of the lead sulfide floatation, thus leading the property of the lead flotation waste water to be basically consistent with that of the zinc flotation waste water and being beneficial for the circular application of floatation waste water.

Owner:CENT SOUTH UNIV

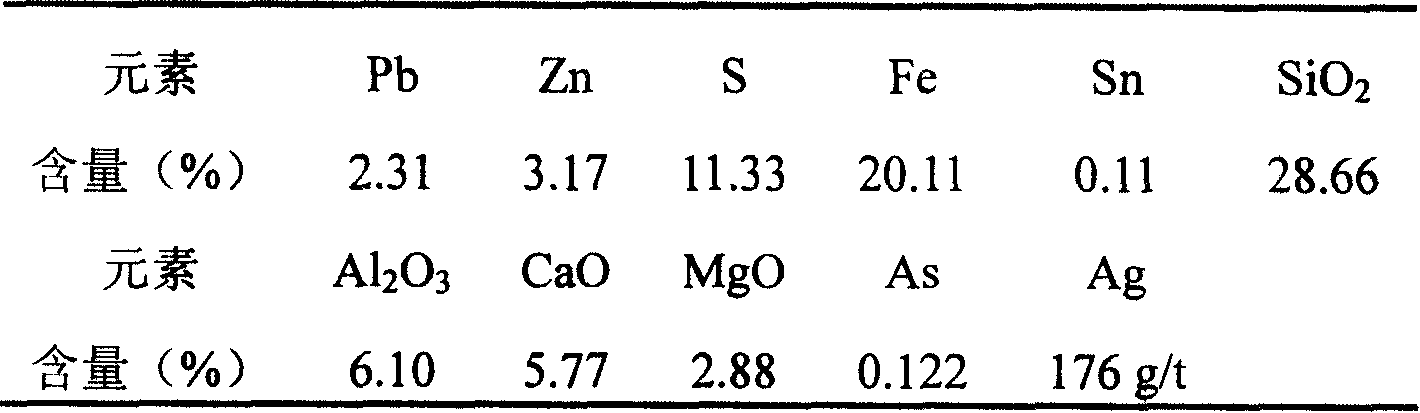

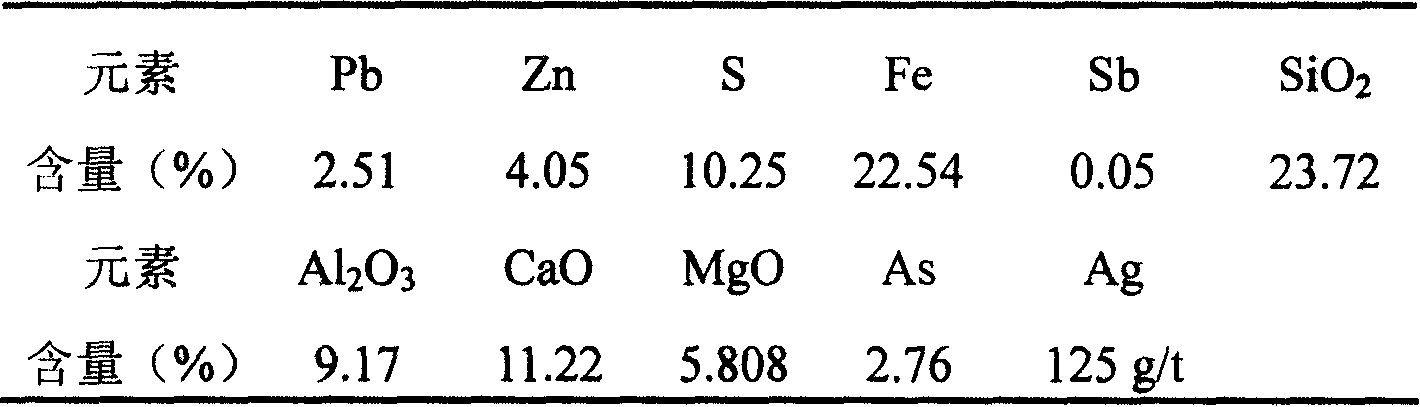

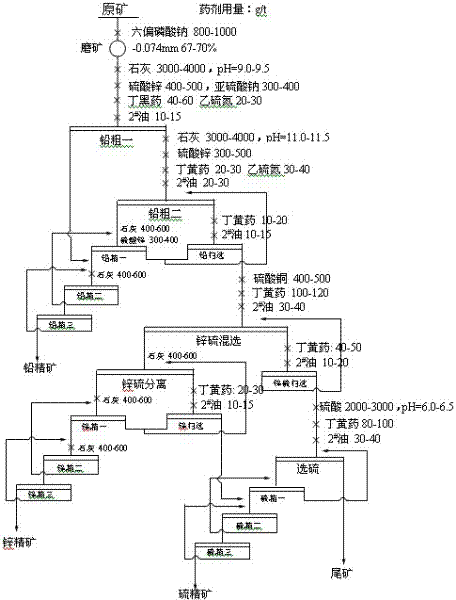

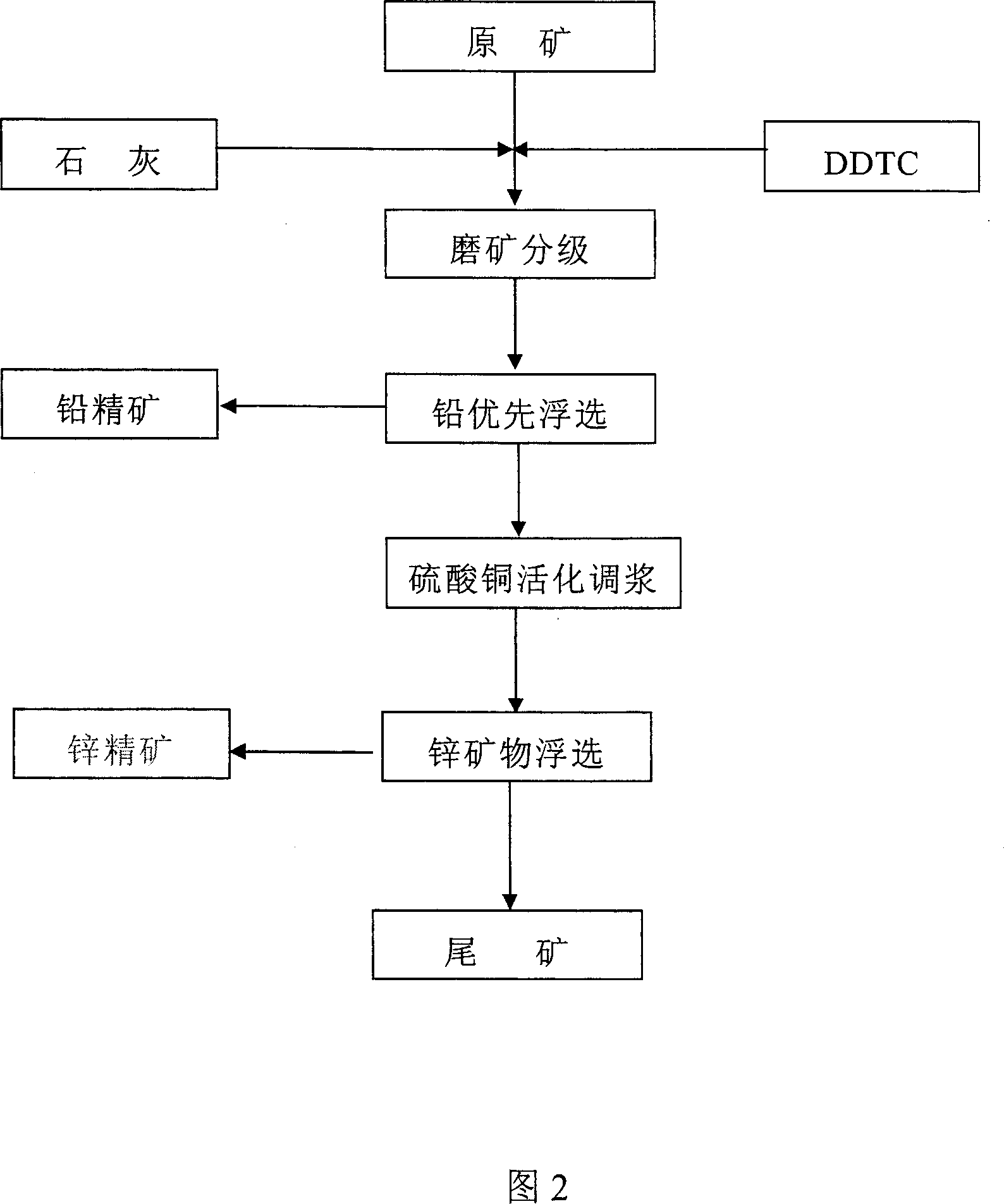

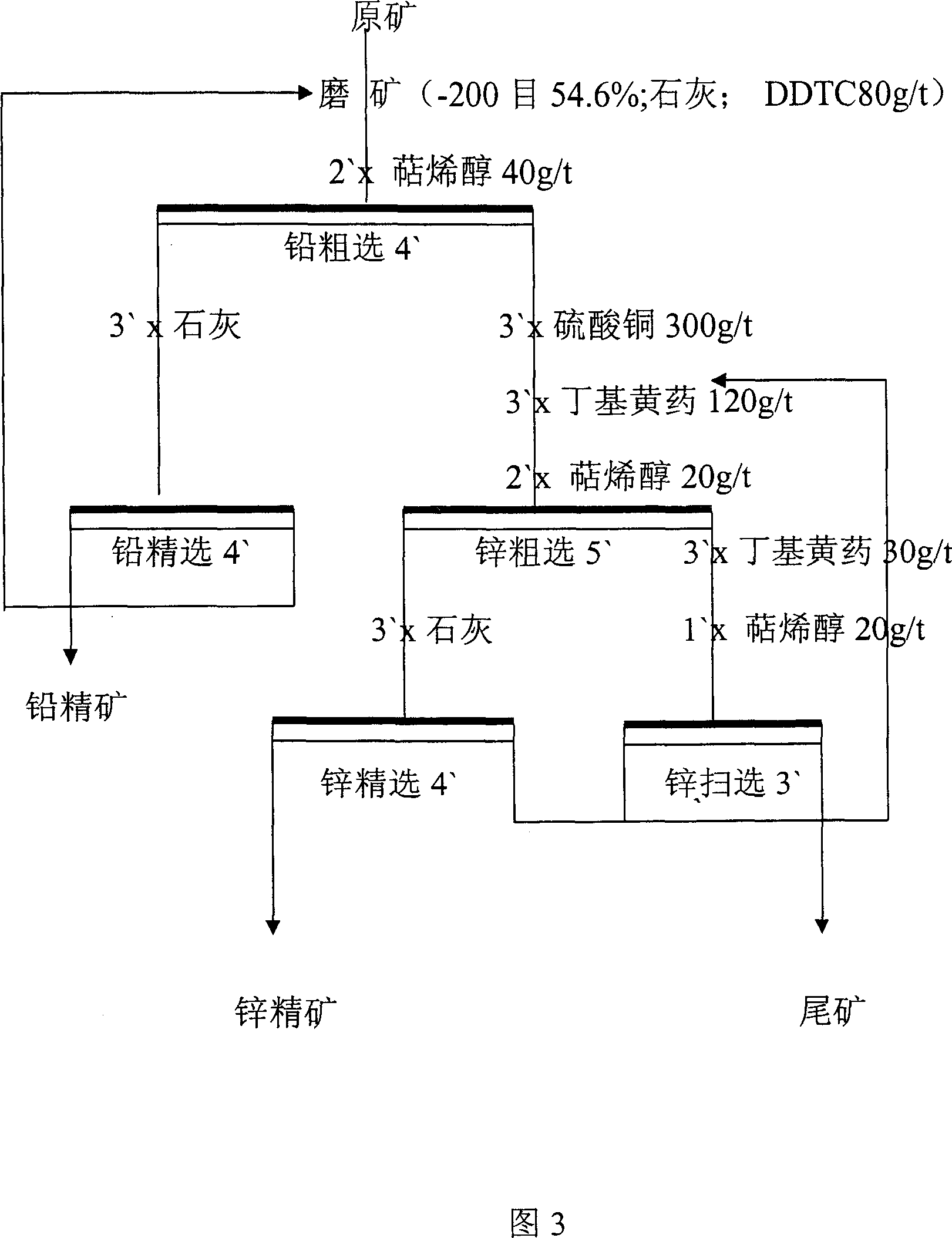

Technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity

The invention discloses a technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity. During grading of the lead and zinc sulfide ores, sodium hexametahposphate is taken as a dispersion agent and directly added into a ball mill, the ores are ground till the ores with the size of 0.074mm account for 67%-70%, lime is taken as an adjusting agent, zinc sulfate and sodium sulfite are taken as inhibitors, dithiophosphate BA and diethyldithiocarbamate are taken as collectors, and selective flotation of part of lead minerals with good floatability can be performed under low alkalinity; then xanthate and the diethyldithiocarbamate are taken as collectors, and the flotation of the lead minerals is further performed under high alkalinity; copper sulfate is added in lead flotation tailings for activation, butyl xanthate is further taken as the collector for flotation of zinc blende and part of pyrite, and zinc-sulfur separation flotation is further performed on zinc-sulfur mixed concentrate; and sulfuric acid is added in zinc flotation tailings for activation, and the xanthate is taken as the collector for flotation of the remaining pyrite. By adopting the technology, the lead-silver recovery rate can be improved, the using amount of lime and sulfuric acid can be reduced, the circulating amount of middlings can be reduced, the ore dressing cost can be reduced and the grade of the concentrate can be improved.

Owner:KUNMING UNIV OF SCI & TECH

Method of leaching copper in copper containing pyrite using bacteria

InactiveCN1556230ASulfur content risesImprove qualityProcess efficiency improvementSulfideCopper sulfide

A process for extracting Cu from the Cu-contained pyrite by bacteria features that the electrochemical catalyzing action of bacteria to different sulfide ores is used sufficiently, that is, the low-potential copper sulfide is used as corrosion anode, the high-potential pyrite or gold-silver ore is used as cathode, the bacteria are used to promote the Galvanic ell effect between them, and for the residual pyrite, the special microspirobacteria are used to suppress its oxidization. Its extraction-out rate can reach more than 75% within 4 months.

Owner:湖南世纪垠天鑫业科技有限公司

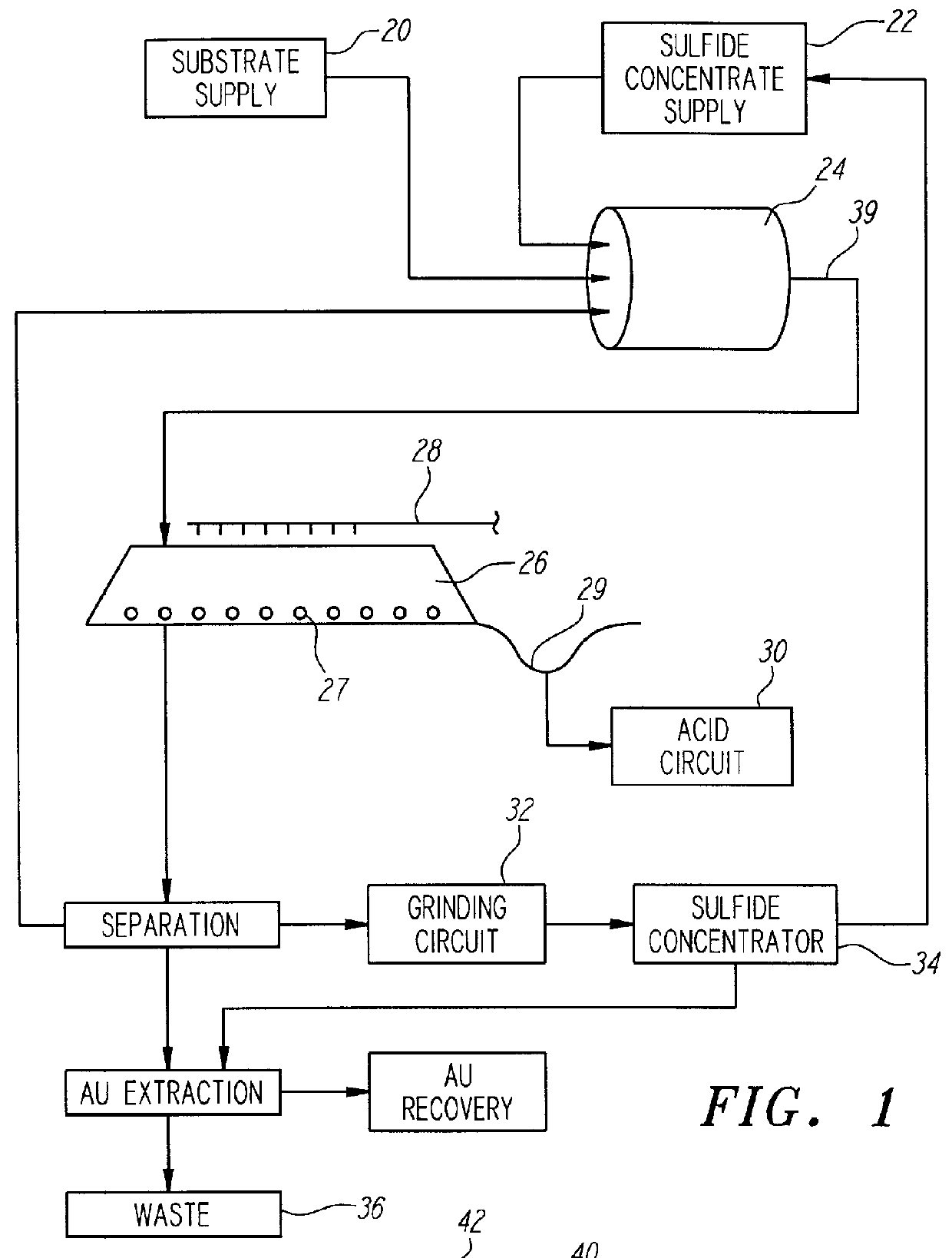

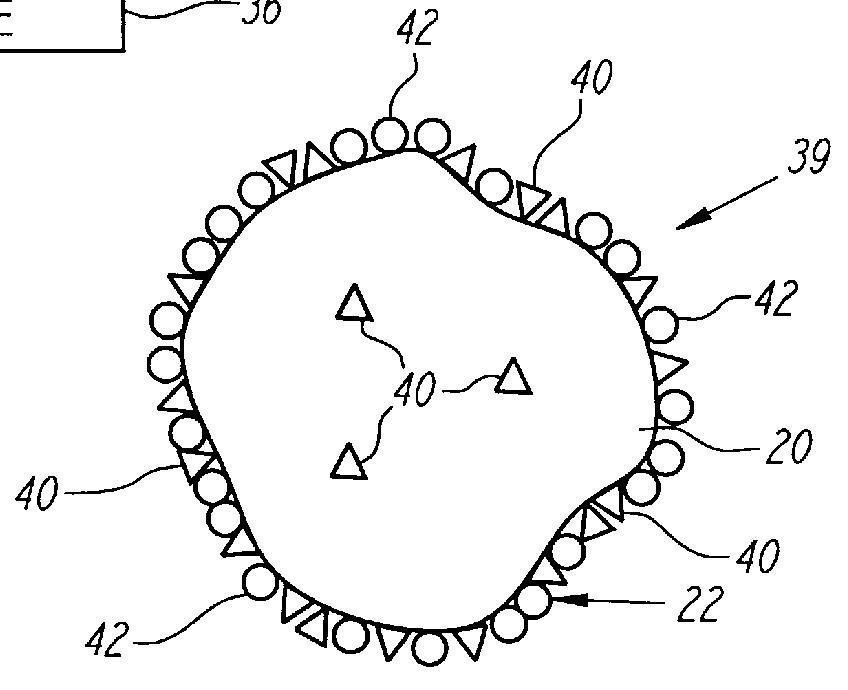

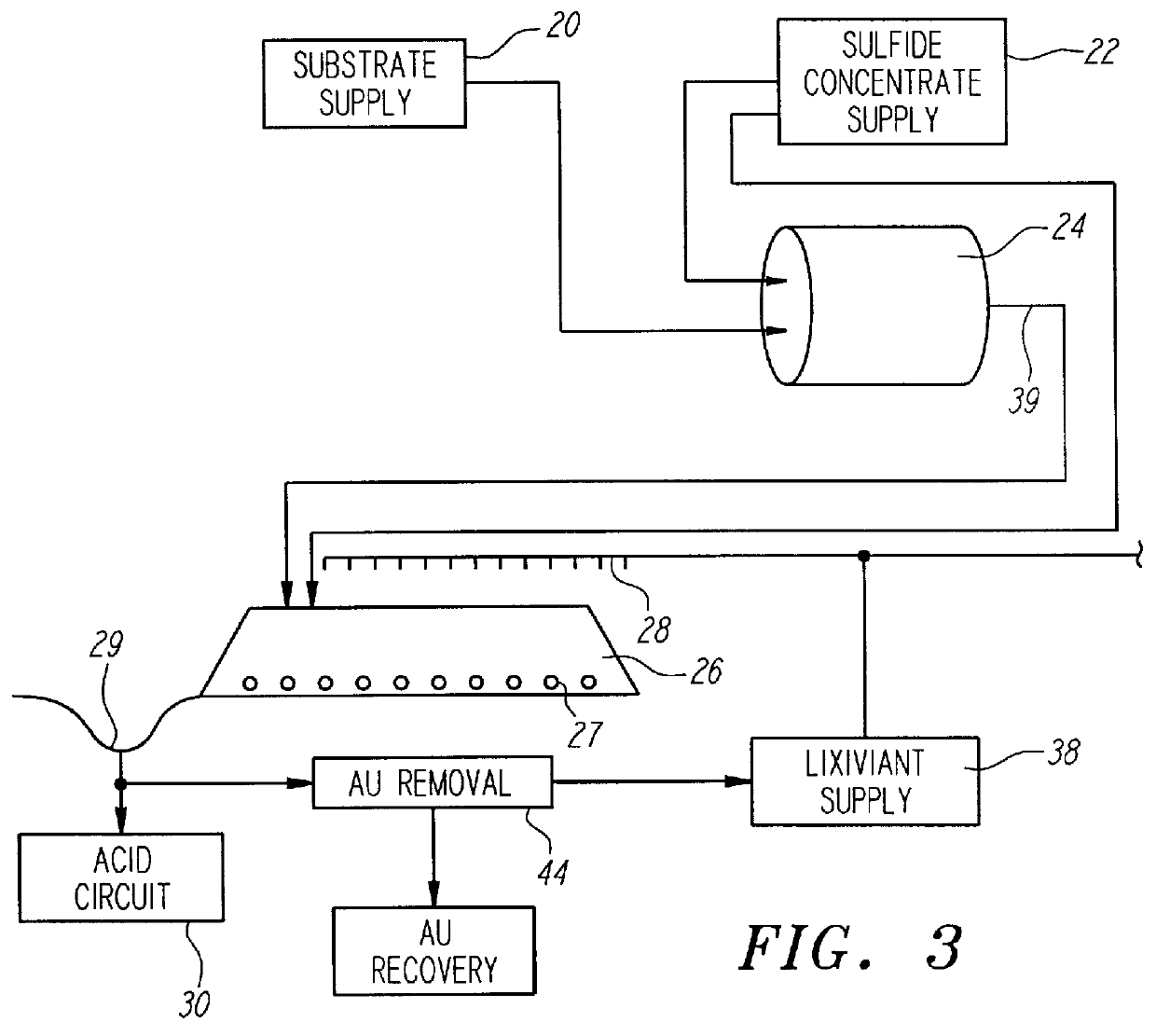

Nonstirred bioreactor for processing refractory sulfide concentrates and method for operating same

InactiveUS6083730AReduced pHIncrease equipment costSolvent extractionContaminated soil reclamationSulfide mineralsMetallic sulfide

A method of biooxidizing sulfide minerals in a nonstirred bioreactor is provided. According to the disclosed method, a concentrate of sulfide minerals is coated onto a substrate, such as coarse ore particles, lava rock, gravel or rock containing mineral carbonate as a source of CO2 for the biooxidizing bacteria. After the sulfide minerals are coated onto the substrate, a heap is formed with the coated substrates or the coated substrates are placed within a tank. The sulfide minerals are then biooxidized to liberate the metal value of interest. Depending on the particular ore deposit being mined, the sulfide mineral concentrates used in the process may comprise sulfide concentrates from precious metal bearing refractory sulfide ores or they may comprise sulfide concentrates from metal sulfide type ores, such as chalcopyrite, millerite or sphalorite. The distinction being that in the former, the metal of interest is a precious metal occluded within the sulfide minerals, whereas in the latter, the metal to be recovered is copper, nickel or zinc and is present as a metal sulfide in the sulfide concentrate.

Owner:GEOSYNFUELS LLC (US)

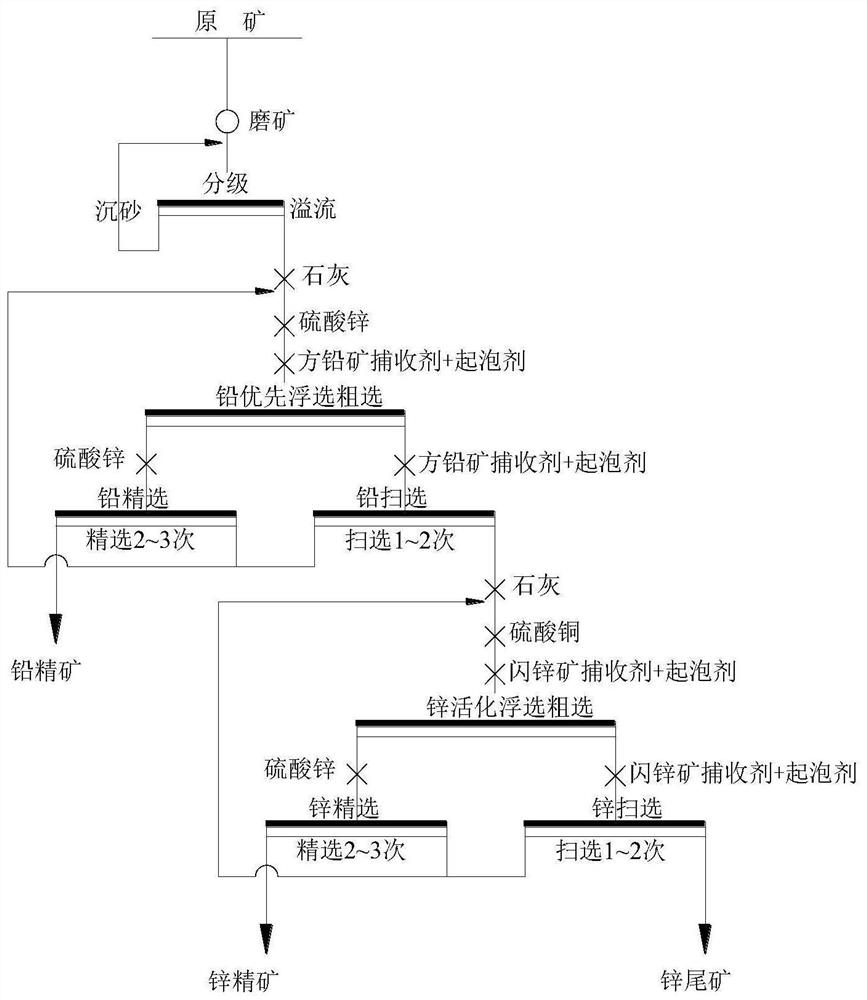

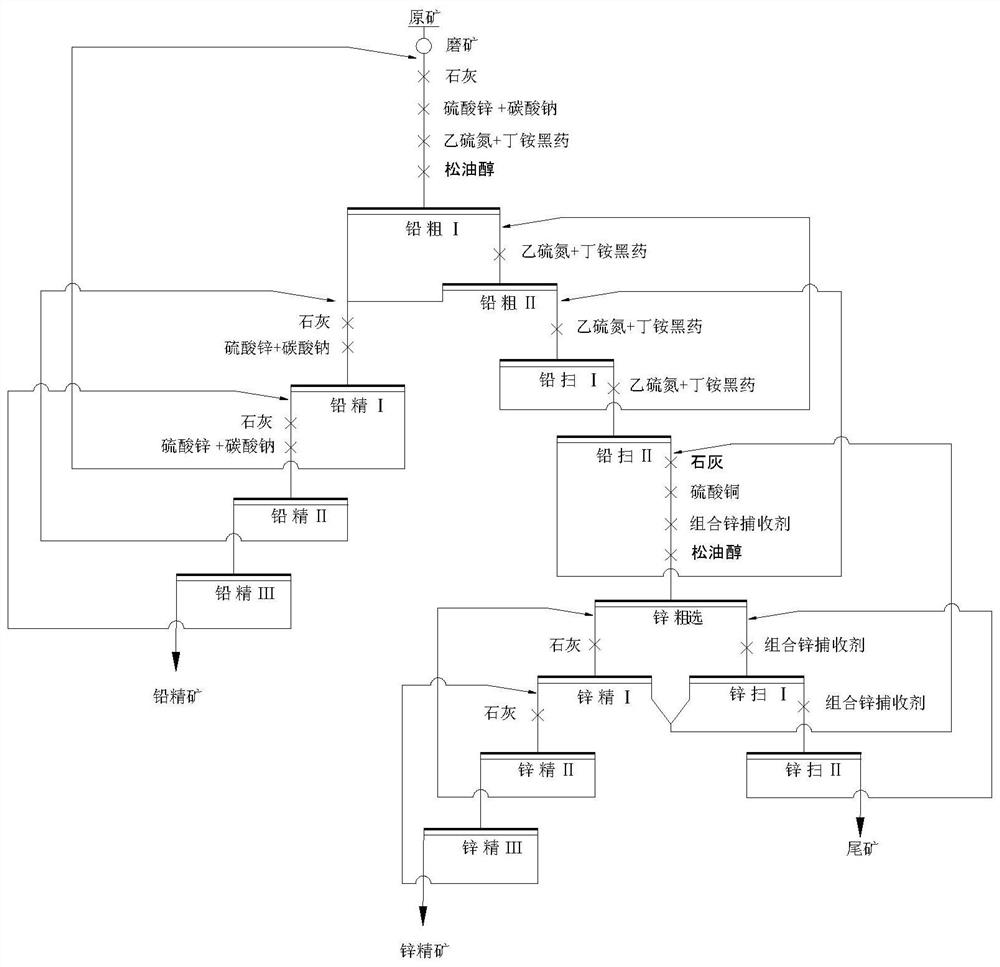

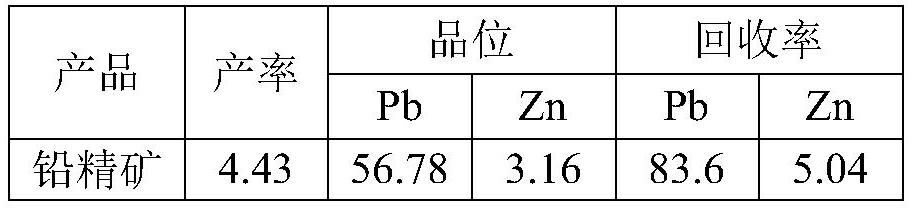

Process for increasing complicated sulfurized-lead-zinc ore dressing recovery rate

The present invention is green process of recovering complicated lead-zinc sulfide ore in high recovering rate. The technological process adopts lime to form high alkalinity and maintain the original potential of lead-zinc sulfide slurry during ore grinding floatation, sodium diethyl dithioamino formate as the selective lead mineral collecting agent, copper sulfate as the sphalerite activating agent and butyl xanthate as the zinc mineral collecting agent for optimized successive fast floatation. The present invention has raised recovering rate, low chemical consumption, simple technological process and low production cost.

Owner:青海西部矿业科技有限公司

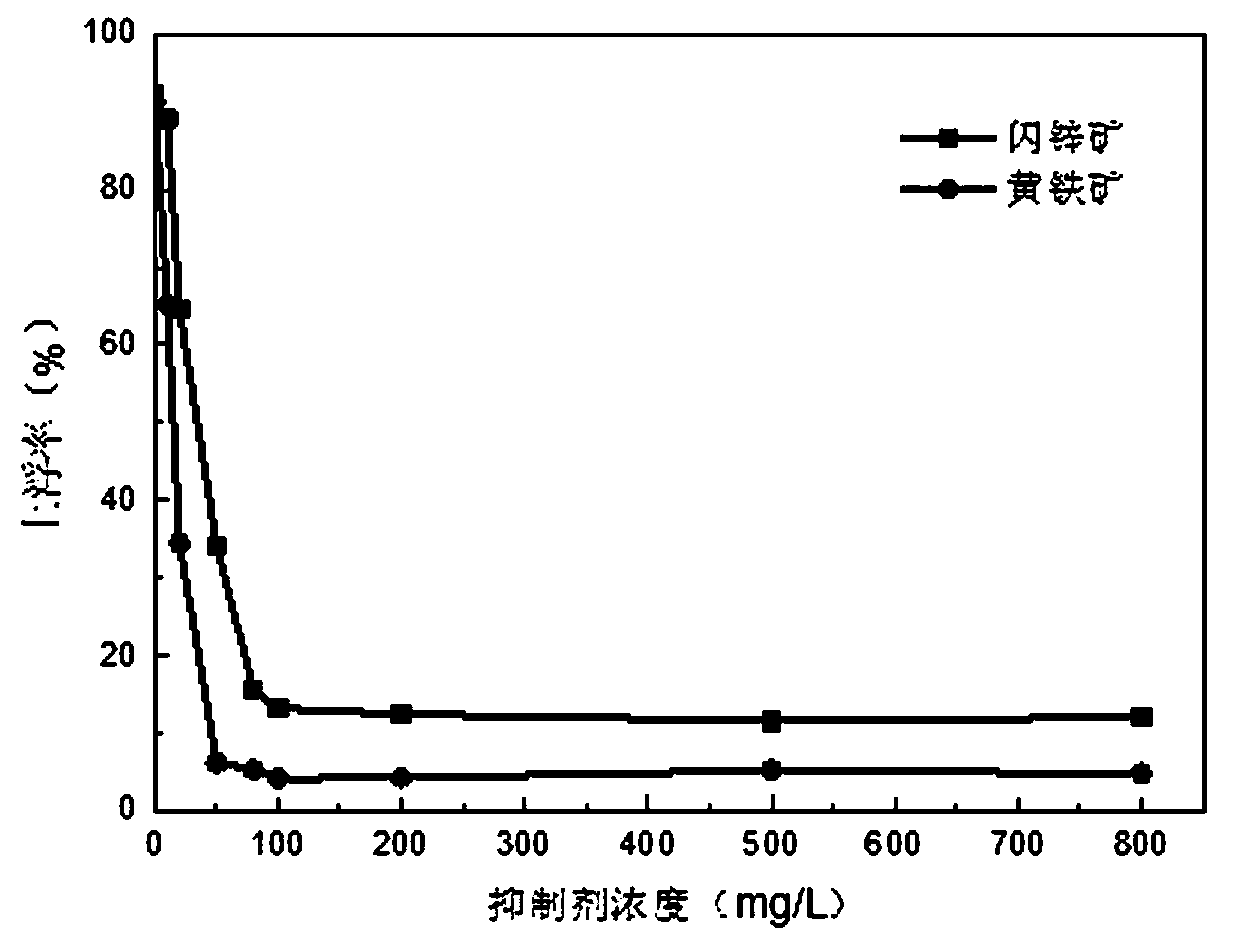

Flotation separation inhibitor and separation method of galena, pyrite and sphalerite

InactiveCN103909020AEfficient separationPlay a synergistic roleFlotationEcological environmentSeparation technology

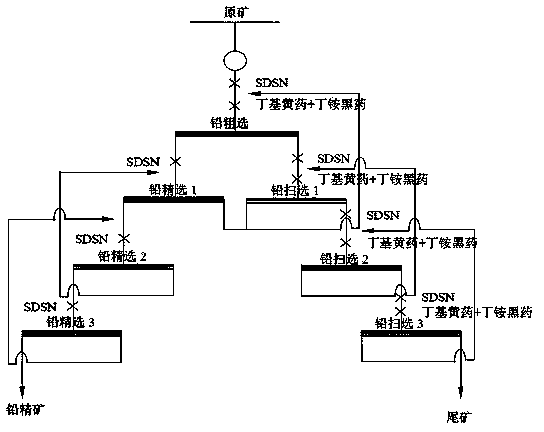

The invention discloses a flotation separation inhibitor and separation method of galena, pyrite and sphalerite, and belongs to the technical field of mineral processing. The method includes adopting raw ores of sulfide lead-zinc mine as raw material, and adding SDSN (dimethyl dithiocarbamate : 2-(methylthio)ethylamine = 1-3:1)to serve as inhibitor of the pyrite and the sphalerite so as to perform lead and zinc sulphur flotation separation after the raw ores are grinded. Compared with an existing lead and zinc sulphur separation technology, the composite inhibitor SDSN has the advantages that selectivities of the pyrite and the sphalerite are high, inhibiting capability is high, usage is fewer, and adding is facilitated. The the pyrite and the sphalerite can be inhibited well, efficient separation of the galena and the zinc sulphur is implemented, the problems that according to the traditional lime or cyanide method, the recovery rate of associated gold, silver and other precious metals in the lead-zinc sulfide mine is low and ecological environment is seriously damaged are overcome, and an efficient and environment-friendly flotation separation method is provided for complex sulfide lead-zinc mine separation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Beneficiation method for separating chalcopyrite, galena, zinc blende and ironpyrite

The invention discloses a flotation separation method for chalcopyrite, galena, zinc blende and ironpyrite by a composite inhibitor which comprises sodium pyrosulfite, sodium sulfite and ferrous sulfate, has an inhibition effect on the galena, the zinc blende and the ironpyrite under the condition of a natural pH value, and is easy to degrade and activate after inhibition during a separation process of the chalcopyrite, the galena, the zinc blende and the ironpyrite. According to the flotation separation method, the flotation is performed under the condition of a neutral medium, the adopted composite inhibitor has the inhibition effect on three metal sulphide ores of the galena, the zinc blende and the ironpyrite; environment pollution caused by adoption of heavy metal salt inhibitors is prevented; pipeline scaling caused by adoption of lime is prevented; and the inhibiting capacity of the composite medicament is relatively weaker and added segmentally, an activation difficulty of follow-up operation due to overinhibition in a flotation process is prevented, and the improvement of the metal recovery rate is further facilitated.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for floatation and recovery of lead zinc mixed concentrate from gold mine cyaniding slag tails

InactiveCN1865461AHigh recovery rateNo emissionsFlotationProcess efficiency improvementChlorinated limeSlag

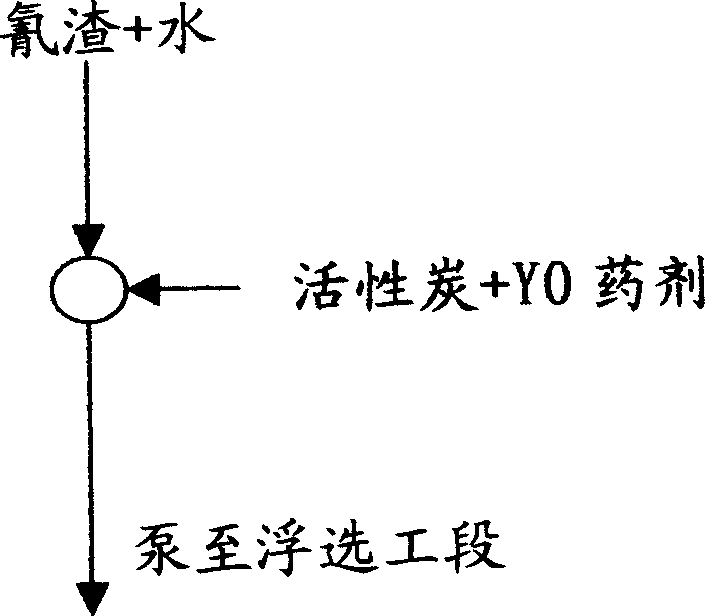

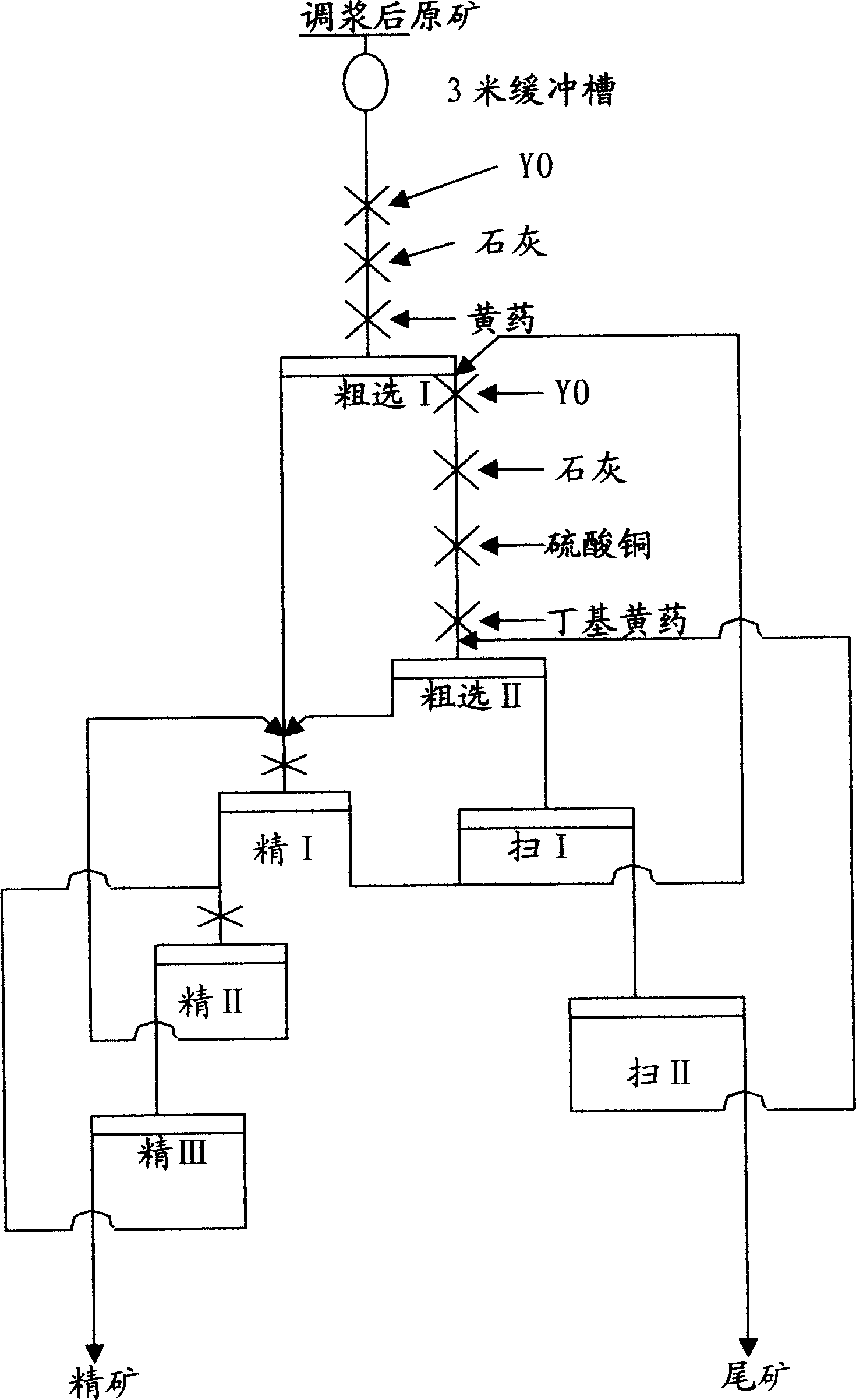

The invention discloses a lead-zinc floating recycling method from gold ore cyanation tailings, which comprises the following steps: (1) predisposing: adding water in the cyanation tailings; stirring to form ore paste; adding active carbon, Y0 agent, FeSO4+ammonium persulphate in the ore paste; (2) asynchronous mixing-selecting: sending the predisposed ore paste to the floater group I to proceed first roughing separation; adding Y0 agent, limestone, butyl airpotato yam to float galena; sending the tailings in the first roughing separation to floater group II; adding Y0 agent, limestone, cupric sulfate, butyl airpotato yam to float zincblende; (3) recycling and purifying tailing water: adding chlorinated lime in the tailing water to decompose CN- less than 0.5 mg per L; recycling the tailing water.

Owner:青岛黄金铅锌开发有限公司

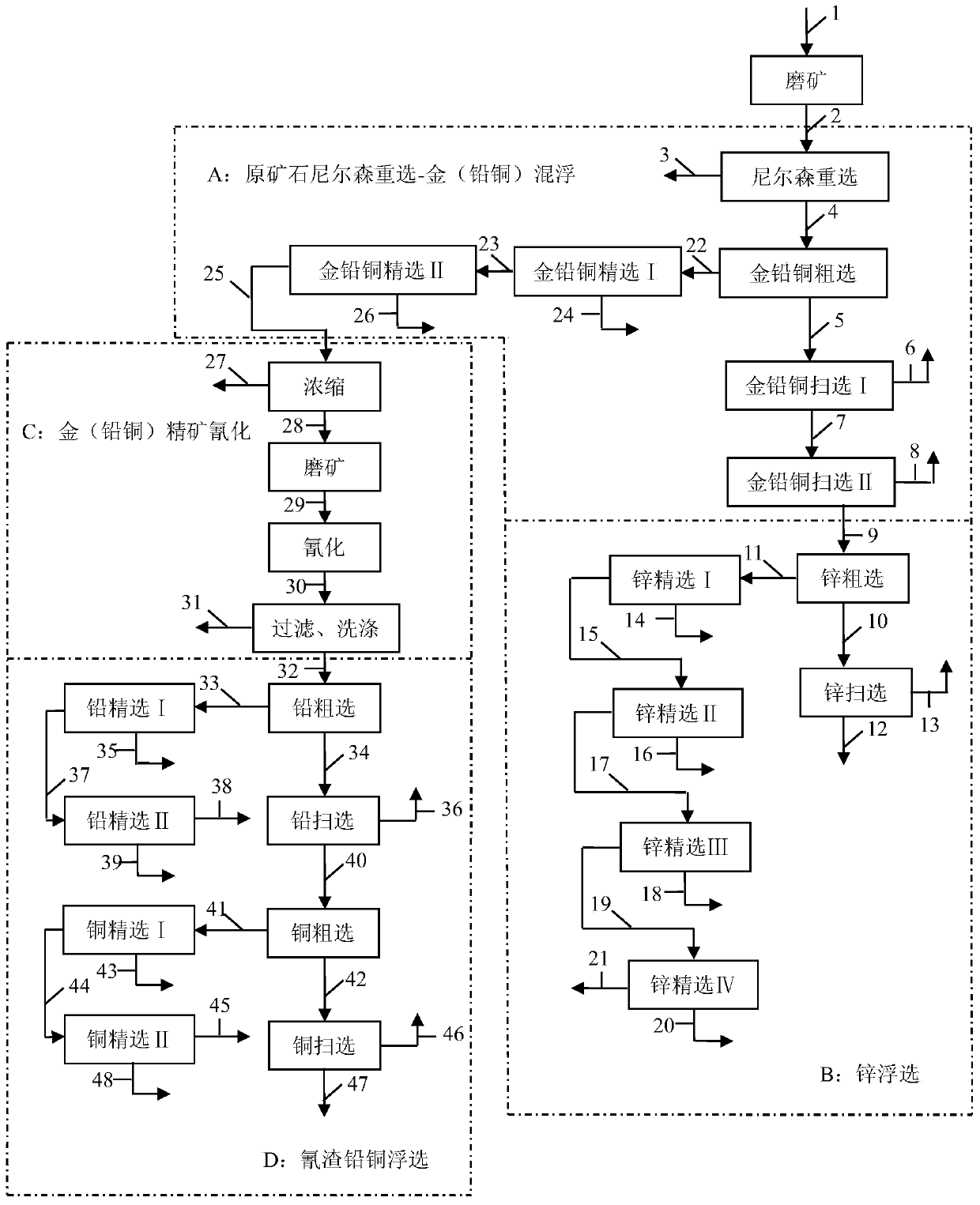

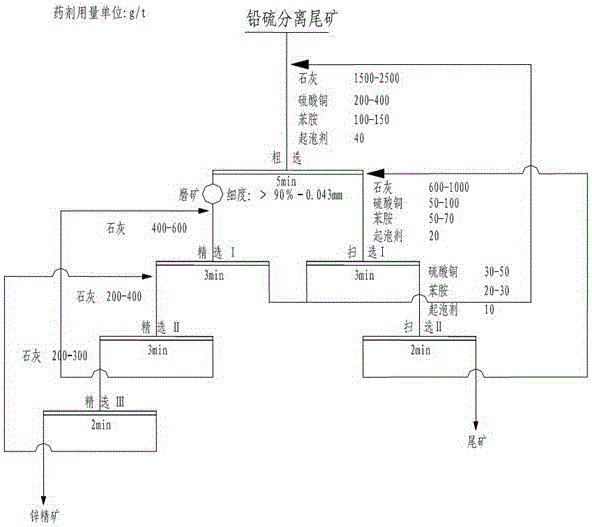

Beneficiation method for complex multi-metal sulfide electrum comprehensive recovery

The invention provides a beneficiation method for complex multi-metal sulfide electrum comprehensive recovery. According to the technical scheme, an efficient re-separation technology of Knelson concentrators is adopted according to the property and the characteristic of multi-metal sulfide electrum, and coarse gold particles are recovered in the early stage; through composite reagents of sodium sulfite, zinc sulfate and sodium silicate, slurry is highly dispersed, sphalerite and pyrite are inhibited intensively, and a novel collecting agent BK301 is adopted for synchronous flotation enrichment of gold, lead and copper minerals; copper sulfate is adopted for activation, and a fine separation technology is performed many times under high alkalinity (the pH of ore pulp ranges from 11 to 12), influences of slurry are effectively eliminated, and active separation on the sphalerite is achieved; for high-viscosity micro-fine particle cyanidation slag, the composite reagents of lime and zinc sulfate are used for intensively inhibiting copper and sulfur, and optimized lead separation is performed; the adjusting agent sodium pyrophosphate is used for efficient activated separation of copper, and therefore lead separation and copper separation are separately performed.

Owner:ZIJIN MINING GROUP

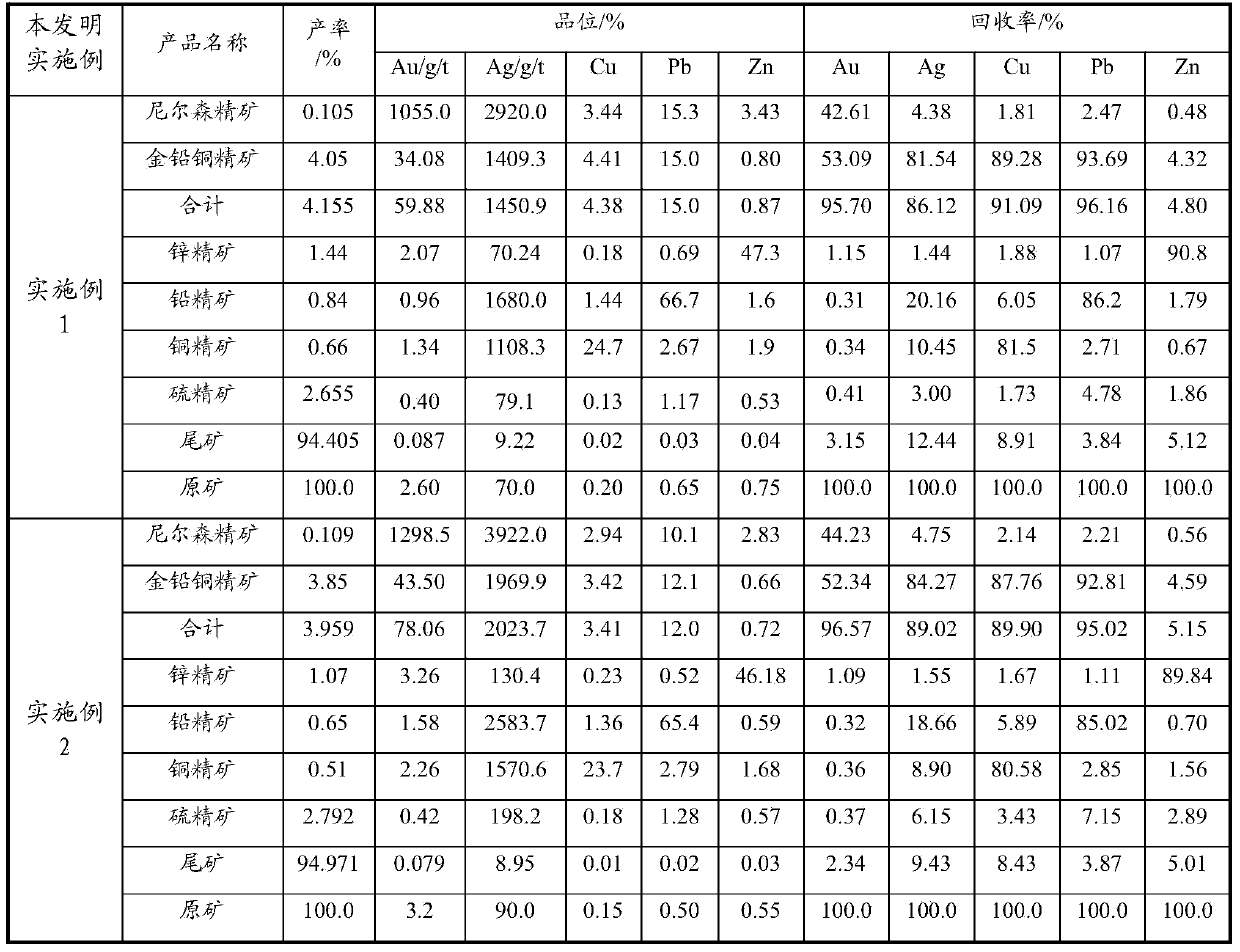

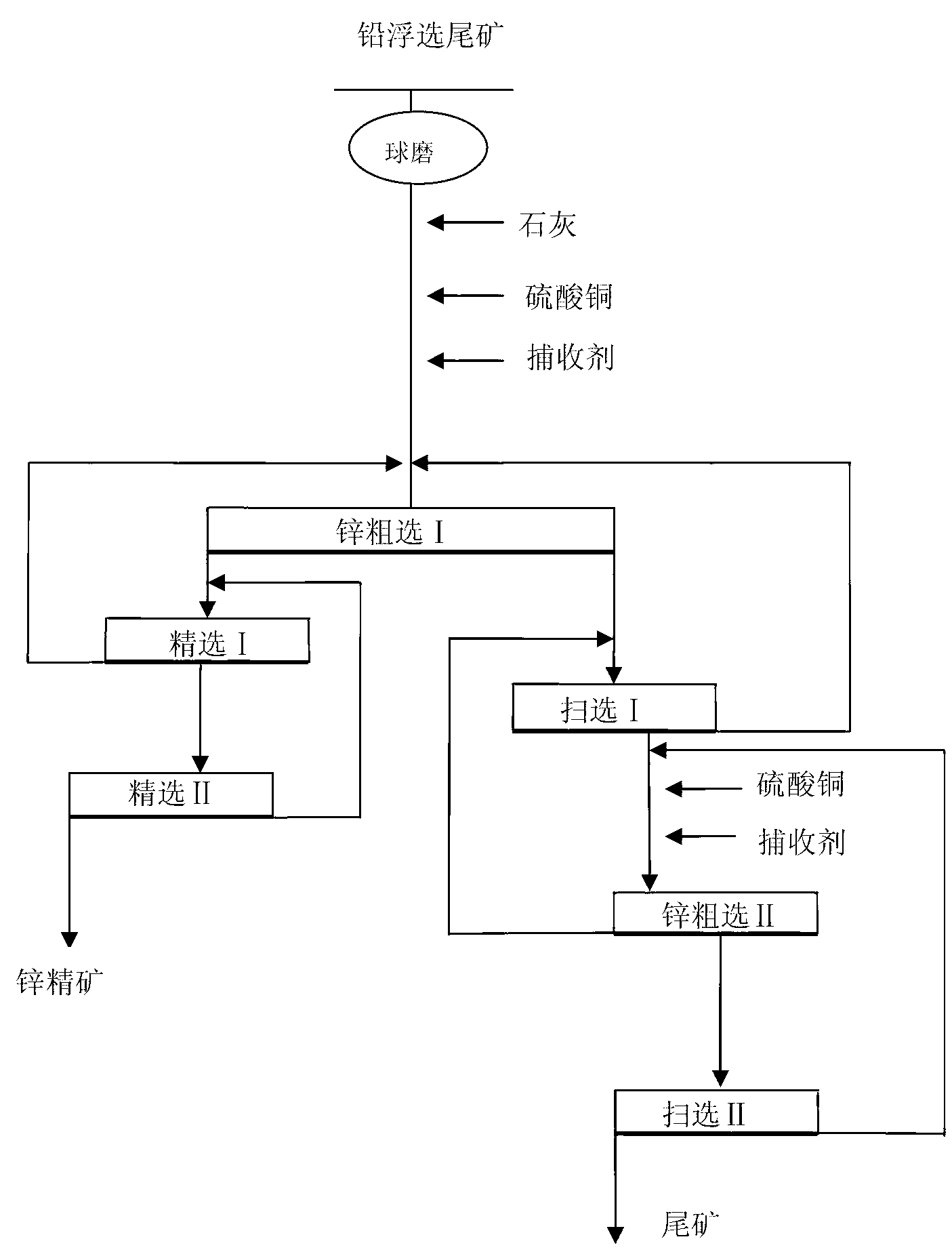

Method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate

InactiveCN106552715AImprove the level of comprehensive utilizationRelieve stressFlotationSulfur productFoaming agent

The invention discloses a method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate. The method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate comprises the steps that firstly, water is added to the separated tailings of the lead-sulfur bulk concentrate, and the mass percent concentration of a pulp is adjusted to be 25%-32%; secondly, an appropriate amount of lime is added so that the pH value of the pulp can be adjusted, and pyrite is inhibited at the same time; thirdly, copper sulfate is added as an activating agent to activate the sphalerite; and finally, a collecting agent, aniline, and a foaming agent are added for flotation of the sphalerite, the flotation procedure comprises one-time rough flotation, two-time scavenging and three-time concentration (after the concentrate obtained through rough flotation is ground to the extent that the ores reaching the grain level of >-0.043 mm account for 90%, concentration is conducted ), and effective concentration of the sphalerite is achieved. According to the sphalerite obtained through the method, the zinc grade is higher than 40%, and the recovery rate of zinc is higher than 80%. By the adoption of the method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate, the zinc lost in the lead-sulfur separated tailings, namely sulfur products, can be well recycled, the comprehensive recovery rate of zinc is improved, and the economic benefits of a concentrating plant are increased.

Owner:KUNMING UNIV OF SCI & TECH

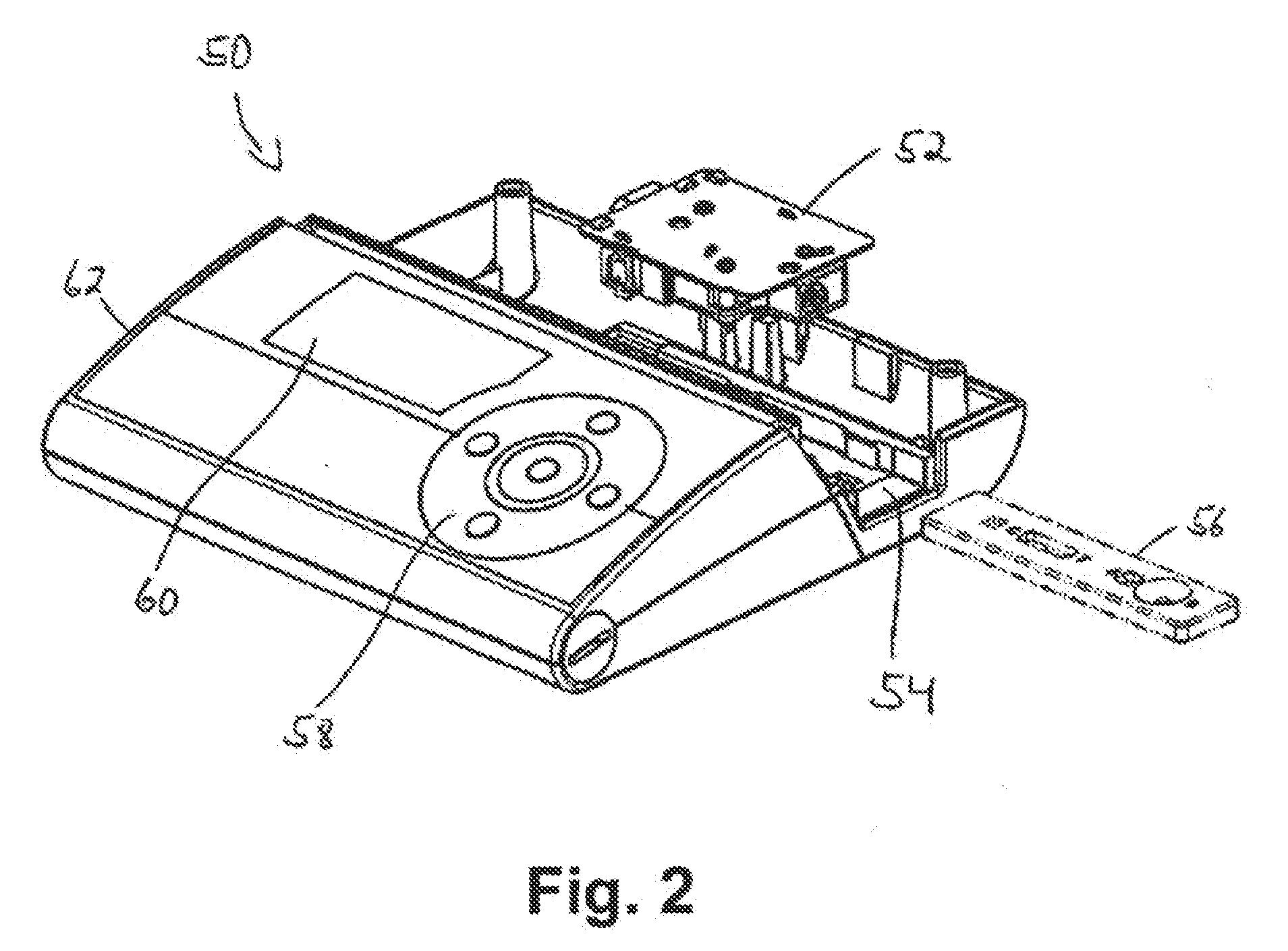

Fluorescence standard, and the use thereof

InactiveUS8704158B2Improve homogeneityOptical radiation measurementBioreactor/fermenter combinationsFluorescenceApatite

Owner:QIAGEN LAKE CONSTANCE GMBH

Fluorescence standard, and the use thereof

InactiveUS20110076687A1Improve homogeneityBioreactor/fermenter combinationsPhotometry using reference valueFluorescenceApatite

The invention concerns fluorescence standards, and in particular fluorescence standards for calibrating optical detectors. According to the invention, a fluorescent mineral or mixtures of minerals are employed for use as a fluorescence standard. The fluorescent mineral can be a naturally occurring mineral or a synthetically produced mineral. Preferred fluorescent minerals for use as fluorescence standards are corundum, fluorite, turquoise, amber, zircon, zoisite, iolite or cordierite, spinel, topaz, calcium fluorite, sphalerite or zincblende, calcite or calcspar, apatite, scheelite or calcium tungstate, willemite, feldspars, sodalite, a uranium mineral, a mineral containing Al3+, and in particular ruby and sapphire.

Owner:QIAGEN LAKE CONSTANCE GMBH

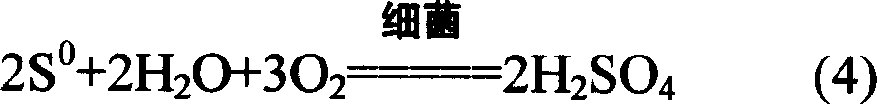

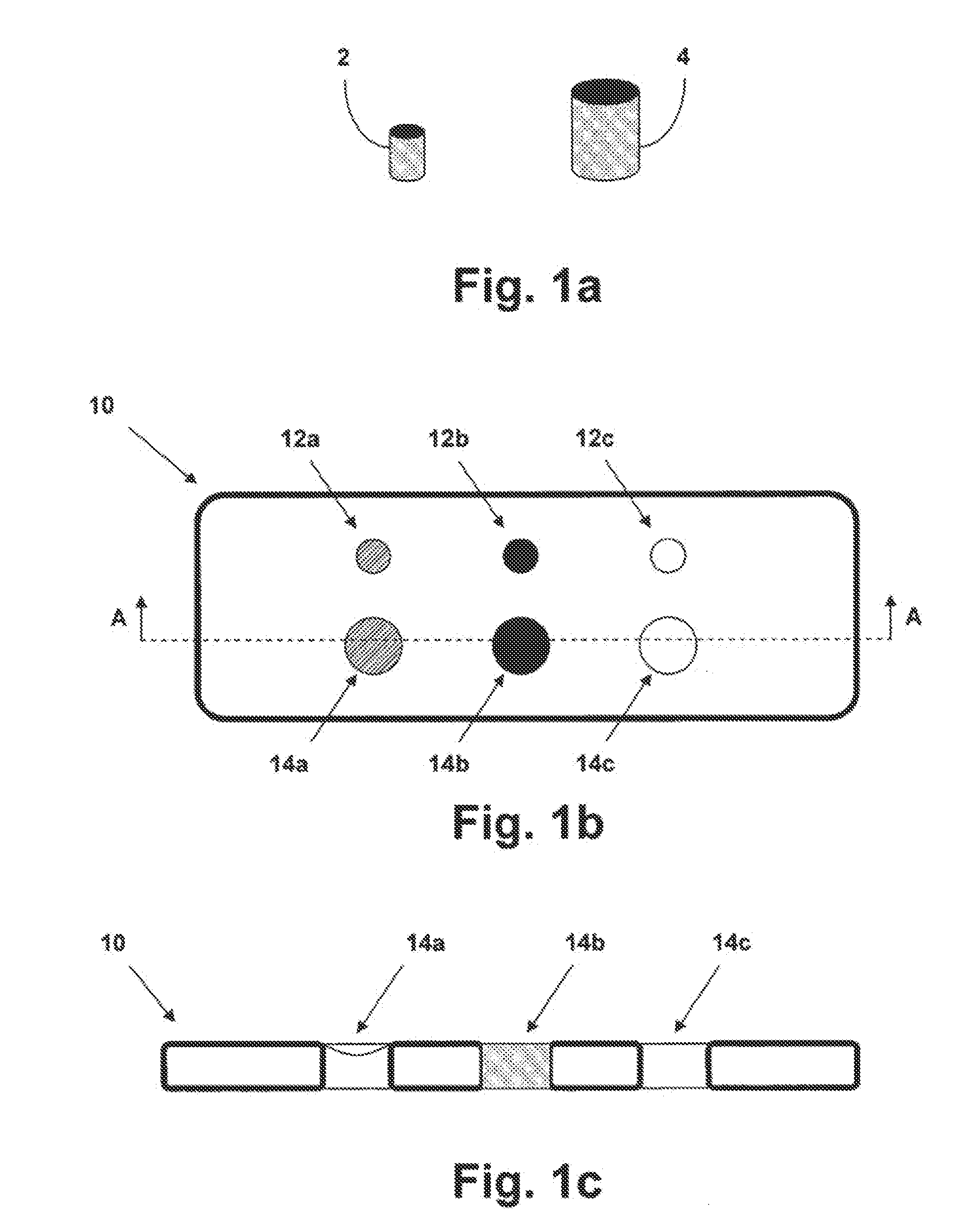

Method for reinforcing microbiological leaching effect of zinc blende

InactiveCN105734285APromote oxidative decompositionImprove leaching rateProcess efficiency improvementChemical factorHigh pressure

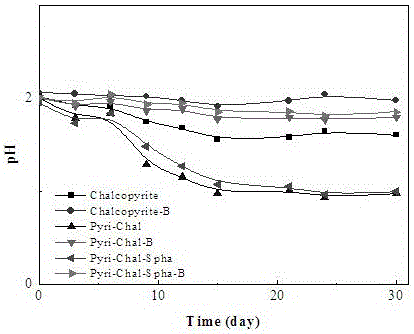

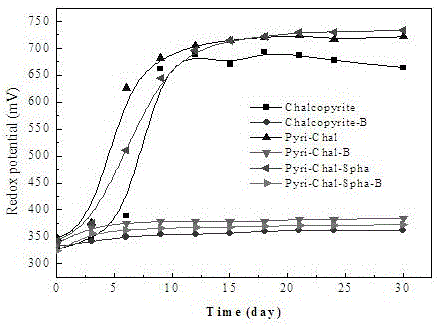

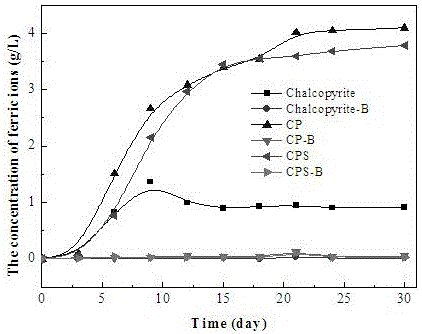

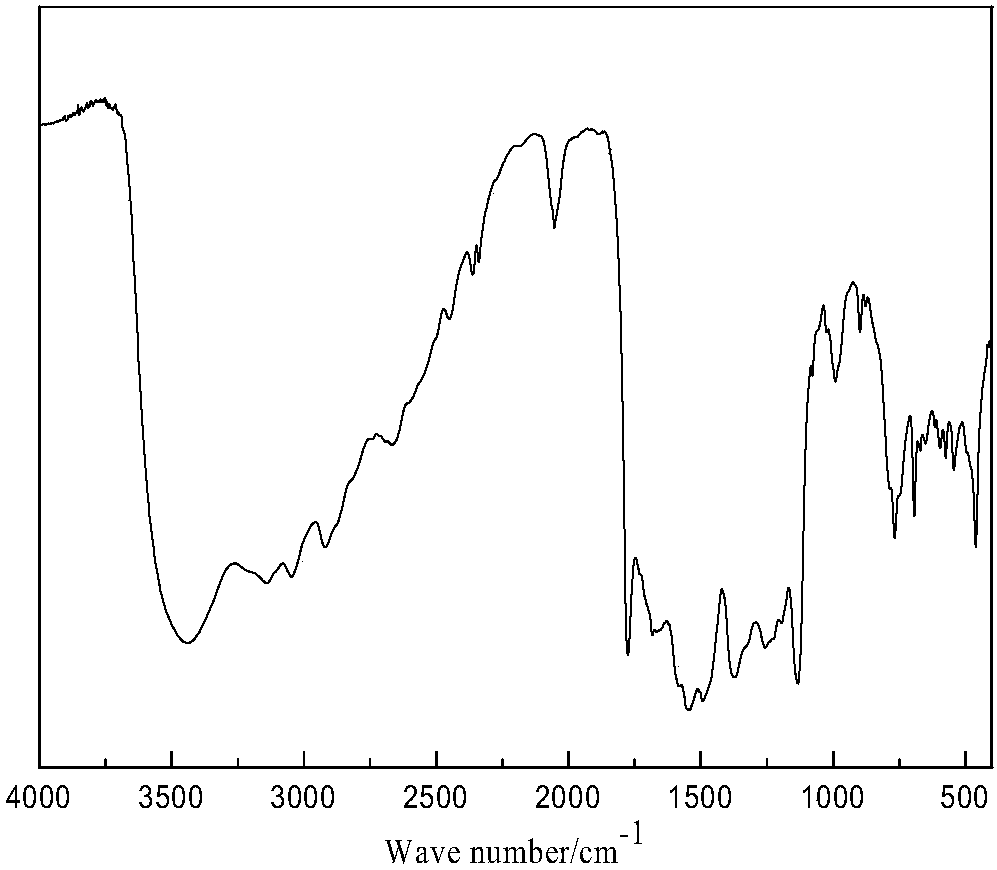

The invention discloses a method for reinforcing the microbiological leaching effect of zinc blende. The method comprises the steps of 1, smashing zinc blende sample ore into particles and smashing iron pyrite sample ore and / or copper pyrite sample ore to be added into particles; 2, sterilizing a culture medium, the zinc blende and iron pyrites and / or copper pyrites to be added at high temperature and high pressure; 3, adding the sterilized zinc blende into a shake flask containing the culture medium, then adding the iron pyrites or the copper pyrites into the shake flask and carrying out inoculation of mineral leaching microorganisms; 4, placing the shake flask in the step 3 on a constant-temperature shaker for cultivation; 5, measuring the leaching efficiency of zinc in the leaching process. According to the method, by adding the iron pyrites in a microbiological leaching system of the zinc blende, the pH value in solutions is low, the concentration of iron ions is high, the redox potential is high, oxygenolysis of the zinc blende is reinforced under the synergistic effect of the microorganisms and physical and chemical factors, and the leaching efficiency of the zinc can be improved obviously. The method provides technological guidance for efficient leaching of the zinc blende.

Owner:CENT SOUTH UNIV

Method for reinforcing leaching of chalcopyrite microorganisms

InactiveCN105861823AHigh static potentialImprove solubilityProcess efficiency improvementMicroorganismChalcopyrite

The invention discloses a method for reinforcing leaching of chalcopyrite microorganisms. The method comprises the steps that (1) a chalcopyrite sample, a pyrite sample and a blende sample are crushed into particles; (2) a culture medium, chalcopyrite, blende to be added and / or pyrites to be added are subjected to high-temperature and high-pressure sterilization; (3) the sterilized samples are put into a shake flask with the culture medium according to the requirement, and the microorganisms in bioleaching are inoculated; (4) the shake flask in the step (3) is placed in a constant-temperature shaking table to be cultured; and (5) the leaching efficiency of copper in the leaching process is measured. By adding the pyrites and the blende in a chalcopyrite microorganism leaching system, pH of a solution is low, the concentration of iron ions and the redox potential are high, oxygenolysis of the chalcopyrite is reinforced under the synergistic effect of biological, physical and chemical factors, and the leaching rate of the copper is increased. Compared with microorganism leaching results obtained without adding any minerals, the leaching rate of the copper is increased by 5.0%-5.5%. The method provides technological guidance for efficient leaching of the chalcopyrite.

Owner:CENT SOUTH UNIV

Mineral processing process for multi-metal sulfide minerals containing secondary copper

The invention relates to a mineral processing process for multi-metal sulfide minerals containing secondary copper, and belongs to the technical field of mineral processing. According to the method of the mineral processing process for multi-metal sulfide minerals containing the secondary copper, iron powder with the particle size of 1 mm to 150 mm is selected for preparing suspension liquid with the concentration of 1 percent to 10 percent; iron powder with the amount of 0.1 to 1 percent of the mass of solid ore in the ore pulp is added to a mill or an agitator tank, and subsequently conventional flotation method is carried out to obtain final concentrate products; the iron power added into the mill and ore particles form primary batteries, dissociative copper ions in the ore pulp are replaced, excitation of the dissociative copper ions on blende and pyrite is reduced, the floatability difference among the minerals is enlarged, the phenomenon that concentrate products containing one another is reduced, and therefore the index of mineral separation products is improved. The method has the advantages of being good in flotation index, saving chemical, and simplifying mineral processing flow.

Owner:WUPING ZIJIN MINING CO LTD

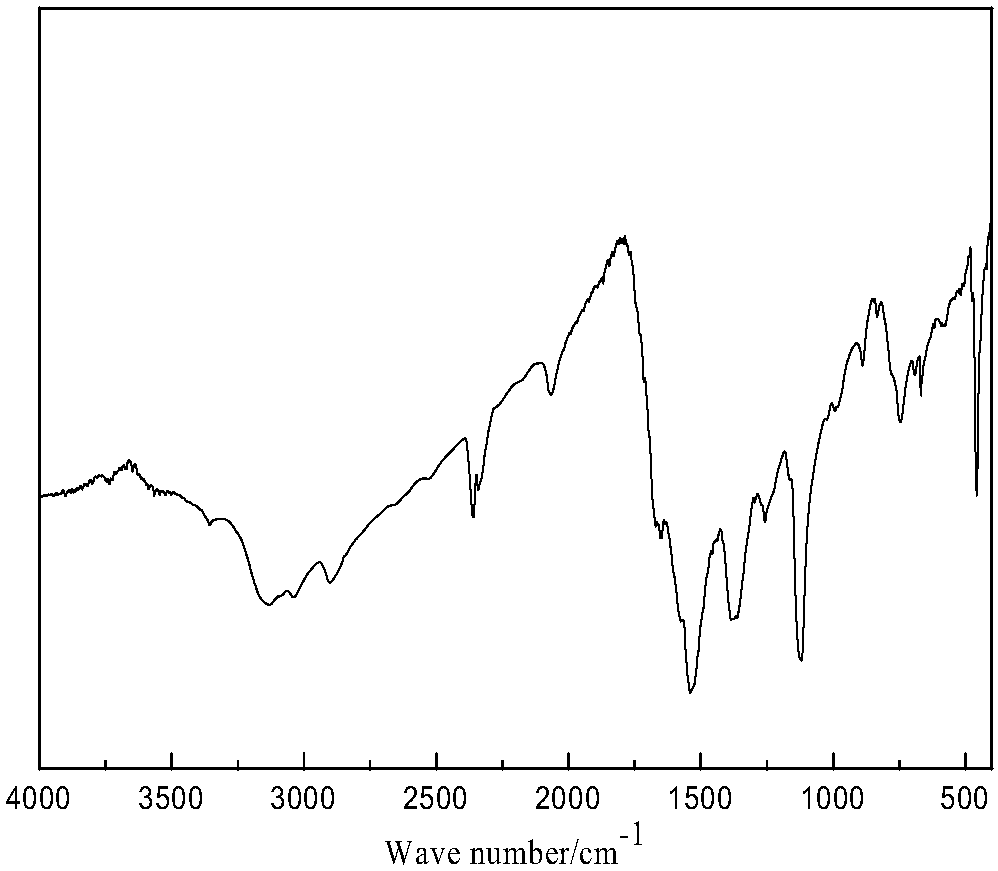

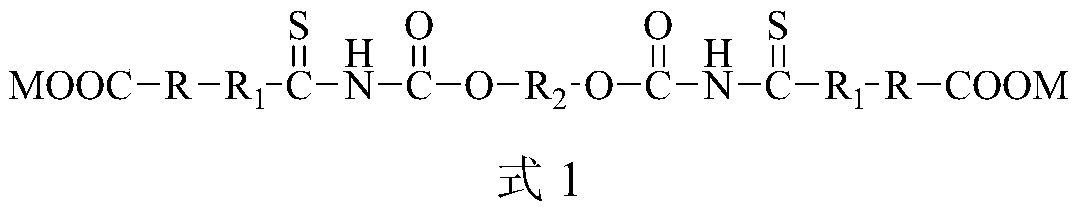

Ether-based double-sulfur amine ester derivative or ether-based bis-thiourea derivative and preparation method and application thereof

ActiveCN105801458ASpecial molecular structureHas surfactant propertiesOrganic chemistryFlotationChloroformateNickel sulfide

The invention provides an ether-based double-sulfur amine ester derivative or an ether-based bis-thiourea derivative and a preparation method and application thereof. The molecular structure of the ether-based double-sulfur amine ester derivative or the ether-based bis-thiourea derivative contains a large quantity of thioamide or thiourea or thioacid amide ether or other lipophilic groups and carboxyl hydrophilic groups. The preparation method includes the steps that bis-chloro-carbonic ester and thiocyanate are subjected to a substitution reaction, an intermediate product containing bis-acyl bis-isothiocyanate is generated, the intermediate and an alcohol compound or an amine compound or a phenol compound are subjected to an addition reaction, and then the ether-based double-sulfur amine ester derivative or the ether-based bis-thiourea derivative is obtained. The preparation method is simple, the prepared product directly serves as a non-molybdenum sulphide ore inhibitor, and floatation separation of molybdenum sulfide ore and the non-molybdenum sulphide ore can be effectively achieved. The preparation method is especially suitable for separation of molybdenite and copper sulphide ore, galena, sphalerite, pyrite, arsenopyrite, jamesonite concentrate, nickel sulfide ore, bismuth sulfide ore and the like, and the grade of molybdenum concentrate is improved.

Owner:CENT SOUTH UNIV

Non-copper sulphide ore inhibitor and application thereof

ActiveCN110918263AEnhanced inhibitory effectEfficient flotation separationFlotationSulfide mineralsGalena

The invention relates to the technical field of non-ferrous metal beneficiation, in particular to a non-copper sulphide ore inhibitor and application thereof. The non-copper sulphide ore inhibitor isprepared from the following components in parts by mass: 1-3 parts of xanthan gum, 1-2 parts of pectin and 1-2 parts of arabic gum. The non-copper sulphide ore inhibitor is simple in preparation, lowin cost and green and environment-friendly and has a quite high inhibition effect on molybdenite, galena, sphalerite, pyrite and other sulphide ores in the copper bulk concentrate. With application ofthe inhibitor, efficient flotation separation of chalcopyrite and other sulfide minerals can be achieved.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD

Manufacturing process of iron oxide red transmutation glazed porcelain

The invention discloses a manufacturing process of iron oxide red transmutation glazed porcelain. The iron oxide red transmutation glazed porcelain comprises a green body and an iron oxide red glaze,wherein the green body is prepared from the following raw materials: Dehua feldspar, Dehua quartz, Dehua kaolin, sillimanite, szaibelyite, boehmite, sphalerite, zinc oxide and zirconium oxide. By limiting the composition of the green body and improving the basic formula of the glaze, a plurality of orange plaques with the sizes of broad beans and peas are distributed on the glaze surface of the fired iron oxide red transmutation glazed porcelain.

Owner:福建省德化县东盛陶瓷有限公司

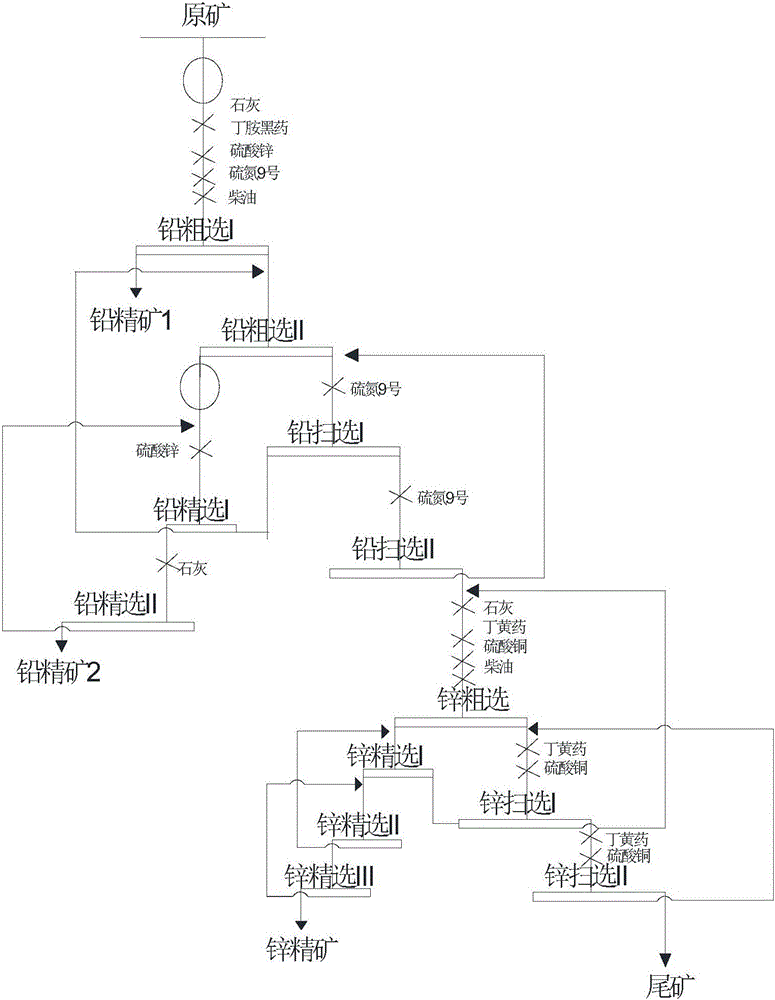

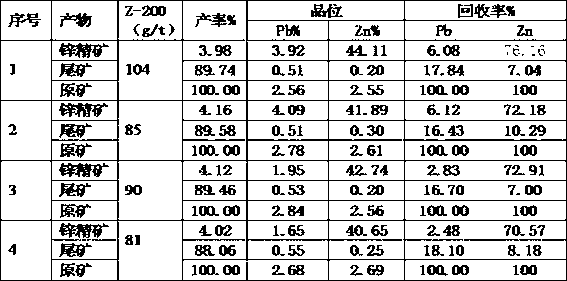

Beneficiation process of lead-zinc-silver ore and flotation reagent thereof

The invention provides a beneficiation process of a lead-zinc-silver ore. The ore grinding fineness of a raw ore in the ore grinding operation is 50-60% of -200 meshes; the lead roughing in the lead selection operation is firstly performed for the raw ore after ball milling; a diesel adding step is added before the lead roughing; the zinc roughing in the zinc selection operation is performed for the raw ore after the lead selection operation; and a diesel adding step is added before the zinc roughing. The beneficiation process of the lead-zinc-silver ore eliminates pyrite inhibitor sodium sulfite in a traditional flotation reagent, reduces the cost, facilitates increment of the lead, zinc and silver yields, prevents bad groove deflection phenomenon in the flotation process when the oxidation degree of the lead-zinc-silver ore is higher, and is high in capturing capacity of a sphalerite by diesel.

Owner:西藏金和矿业有限公司

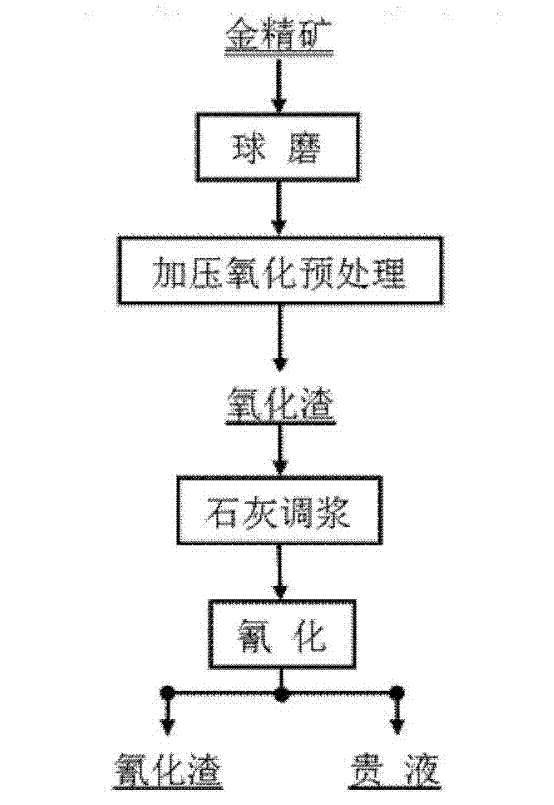

Pressurization, water immersion and oxidation preprocessing cyaniding gold extraction method for difficult-processing gold concentrates

InactiveCN102925716AReduce usageReduce maintenance costsProcess efficiency improvementWater immersionSulfur containing

The invention relates to a pressurization, water immersion and oxidation preprocessing cyaniding gold extraction method for difficult-processing gold concentrates, which aims at the gold concentrates with higher sulfur-containing, mainly containing iron pyrite, concomitant with copper pyrite, zinc blende and the like, and comprises the following steps: performing ball-milling on the raw material gold concentrates, performing size mixing, cyaniding for gold extraction after pressurization, water immersion and oxidation preprocessing to obtain a pregnant solution with gold-containing of 0.010 g / L-0.040 g / L, and the gold cyanide leaching rate reaches 96% of a smelting indicator. In the invention, the initial media are neutral, an acid or alkali reagent is not needed, and only the neutral additive lignosulphonate is needed, so that the process cost is reduced, and the extremely high gold recovery rate is realized at the same time.

Owner:YUNNAN GOLD MINING GRP

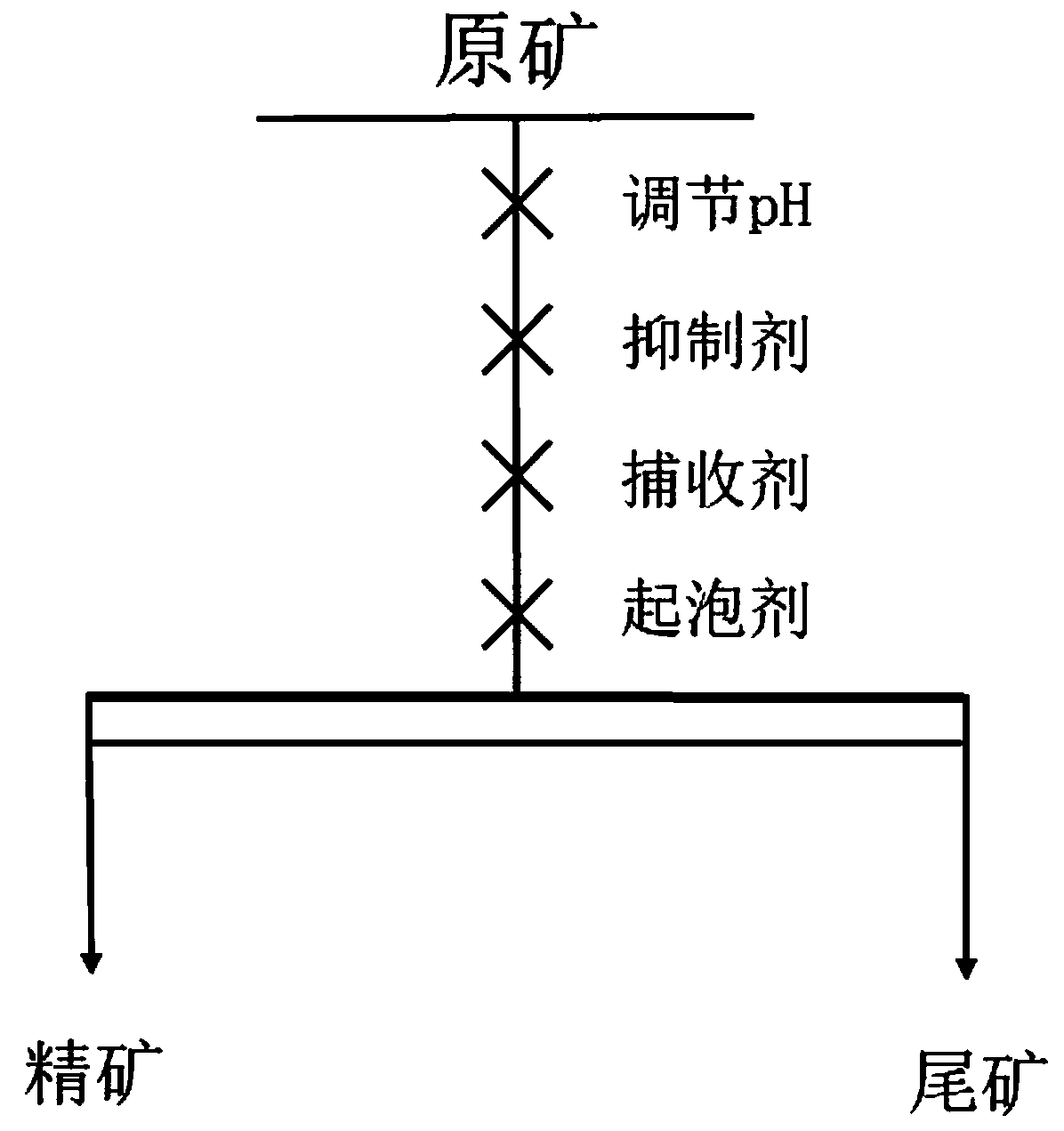

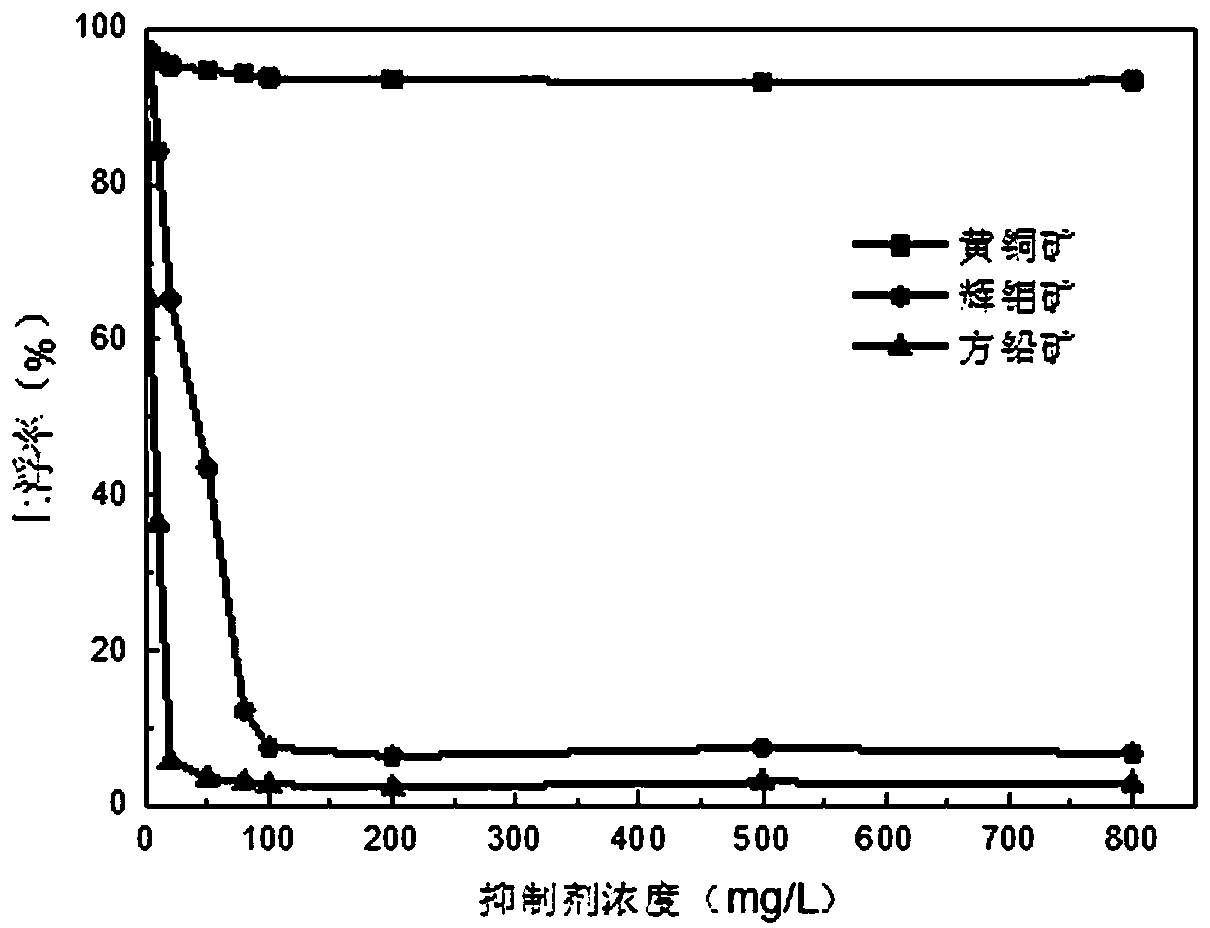

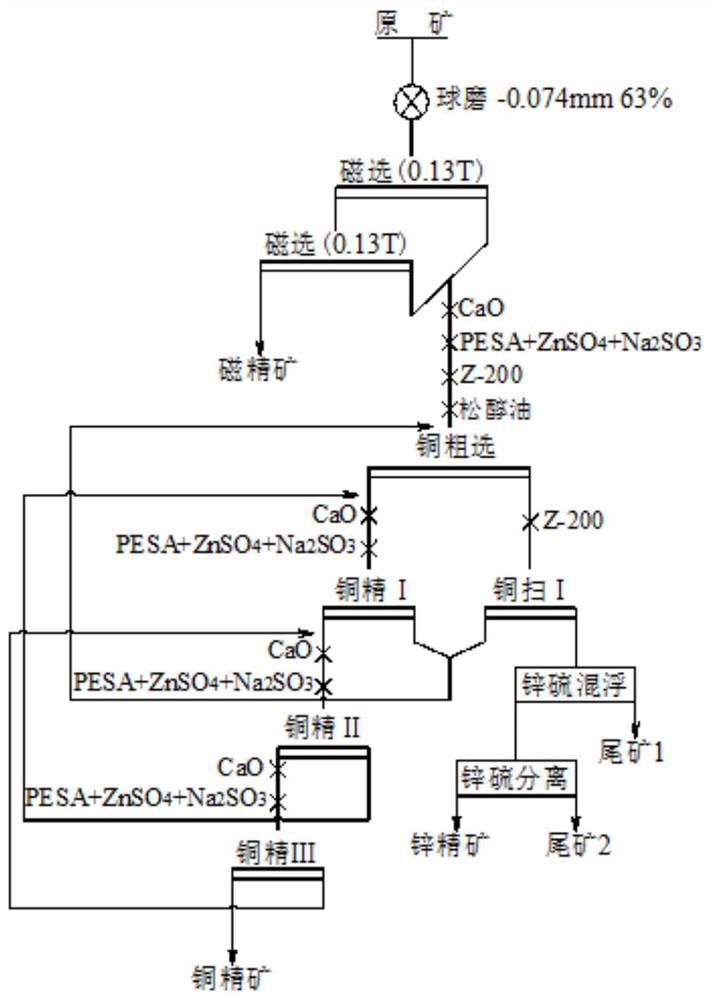

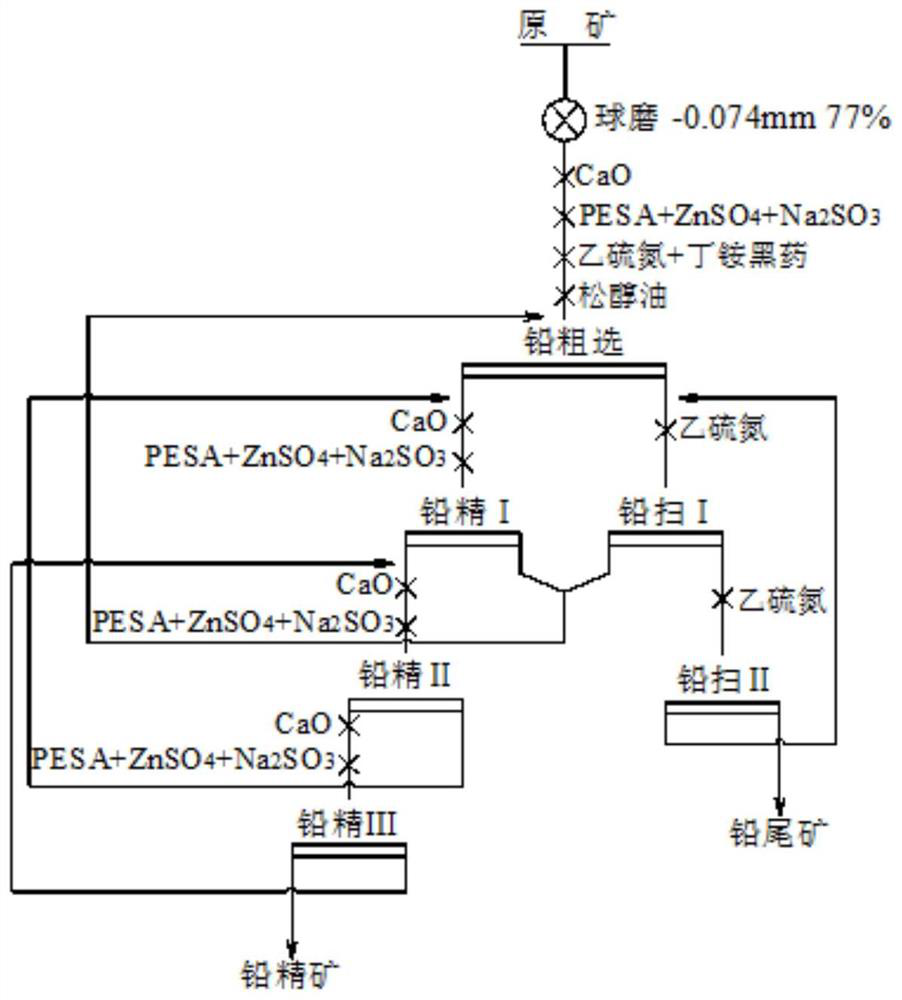

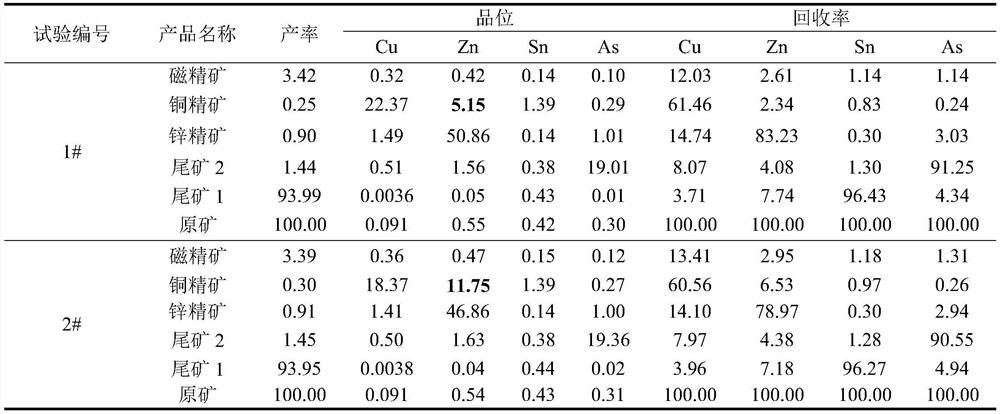

Combined inhibitor for zinc sulfide ore and application thereof

ActiveCN111715410AEfficient inhibitionDoes not affect planktonicFlotationMagnetic separationSulfite saltCarboxylic acid

The invention discloses a combined inhibitor for zinc sulfide ore and application thereof. The combined inhibitor comprises the following active components: polyepoxysuccinic acid (PESA), zinc sulfateand sodium sulfite in a mass ratio of (0.25-2): (25-100): (10-50). According to the principle of mixed medication, the water-soluble micromolecular carboxylic acid (PESA) and conventional inhibitorsincluding Na2SO3 and ZnSO4 are combined according to the certain mass ratio, and through the synergistic effect of the agents, the dosage of the combined inhibitor is reduced compared with the dosagesof the agents used alone, and the inhibition performance of the combined inhibitor is also remarkably enhanced. The combined inhibitor can efficiently and selectively inhibit activated iron / sphalerite, basically does not influence flotation of chalcopyrite / galena, and achieves the purpose of selective separation; the novel combined inhibitor is formed by combining the PESA and the conventional inhibitors, and is simple to prepare and easy to industrially implement; and the PESA is an excellent water treatment agent and can complex heavy metal ions in beneficiation wastewater, so the difficulty of wastewater reuse is greatly reduced.

Owner:CENT SOUTH UNIV

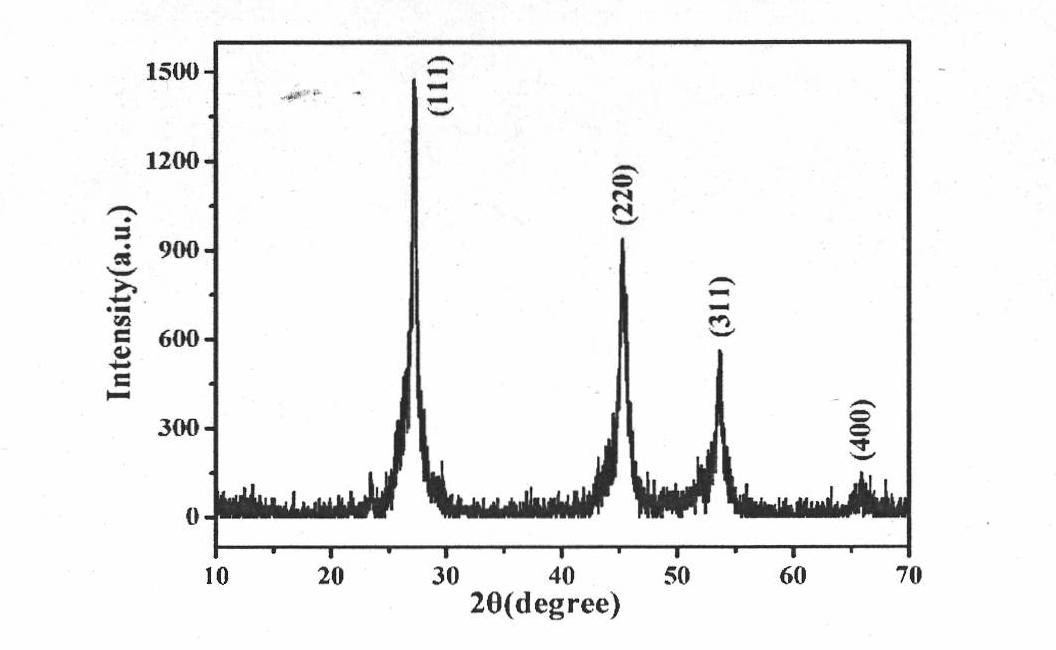

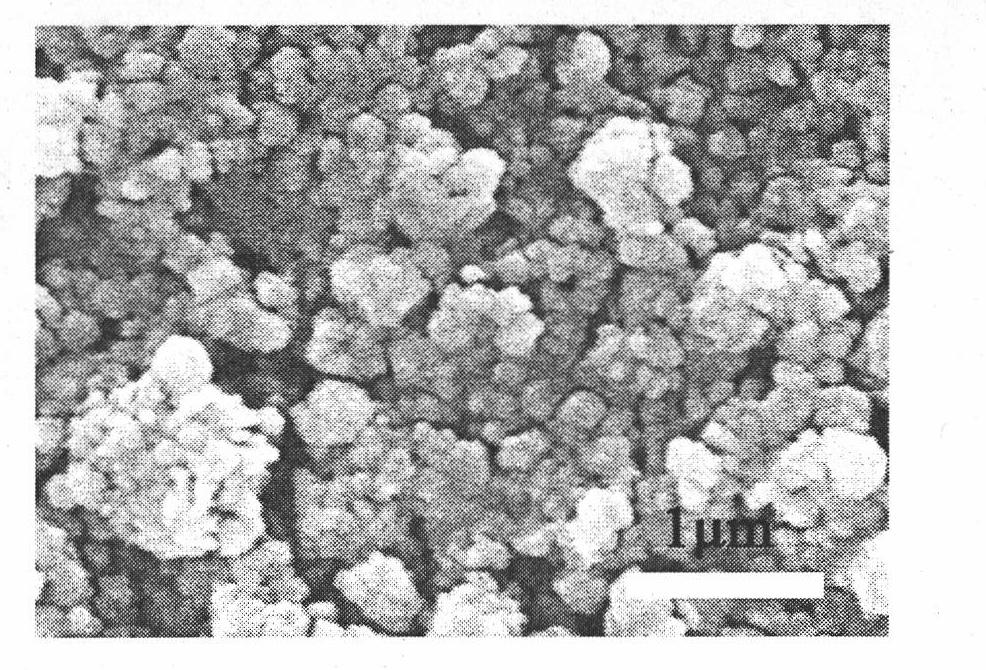

Solvothermal controllable method for preparing ZnSe and ZnTe nano materials

InactiveCN102040201ASimple processNanotechnologyBinary selenium/tellurium compoundsEthanolaminesSolvent

The invention discloses a solvothermal controllable method for preparing ZnSe and ZnTe nano materials. The method comprises the following steps of: placing a Se source or Te source of an analytical reagent in an polytetrafluoroethylene inner lining; adding an ethanolamine solvent to ensure that the solution is 80 percent based on the total volume of the polytetrafluoroethylene inner lining; performing magnetic stirring for several minutes; adding the Zn source of the analytical reagent again; performing magnetic stirring uniformly and then sealing a reaction kettle; and placing in a baking oven at the temperature of 200 DEG C and reacting for 24 hours, after completing the reaction, cleaning to obtain a product. The ZnSe and ZnTe nano materials with a blende or wurtzite structure can be controllably synthesized successfully in one step in the same system by changing the Se source or the Te source through a simple solvothermal method under the mild condition for the first time. The method has the characteristics of simplicity, low cost, high yield, high uniformity of products, high controllability, environment friendliness and easiness in popularization and is suitable for large-scale production.

Owner:XINJIANG UNIVERSITY

Magnetic aluminum nitride thin film material of sphalerite structure and preparation method and application thereof

ActiveCN105483615AHigh curie temperatureGood stability at room temperatureNitrogen compoundsVacuum evaporation coatingSemiconductor materialsHexagonal crystal system

The invention discloses a magnetic aluminum nitride thin film material of a sphalerite structure and a preparation method and an application. In Sc-doped aluminum nitride, the crystal structure of the Sc-doped aluminum nitride is the sphalerite structure, and Sc elements occupy the position of part of Al elements in crystal lattice. The molar ratio of Sc to Al is 76:24. The molar ratio of the Al elements and the Sc elements to nitrogen elements is 1:1. The material prepared through the method is a diluted magnetic spin semiconductor material with sphalerite, the Curie temperature of the material of the sphalerite structure is high, the room temperature stability is good, and the spin injection efficiency is high; the crystal structure of reported diluted magnetic semiconductor GaN belongs to a hexagonal crystal system, the magnetism is weak and close to the super paramagnetic properties, and therefore application prospects are broad.

Owner:TSINGHUA UNIV

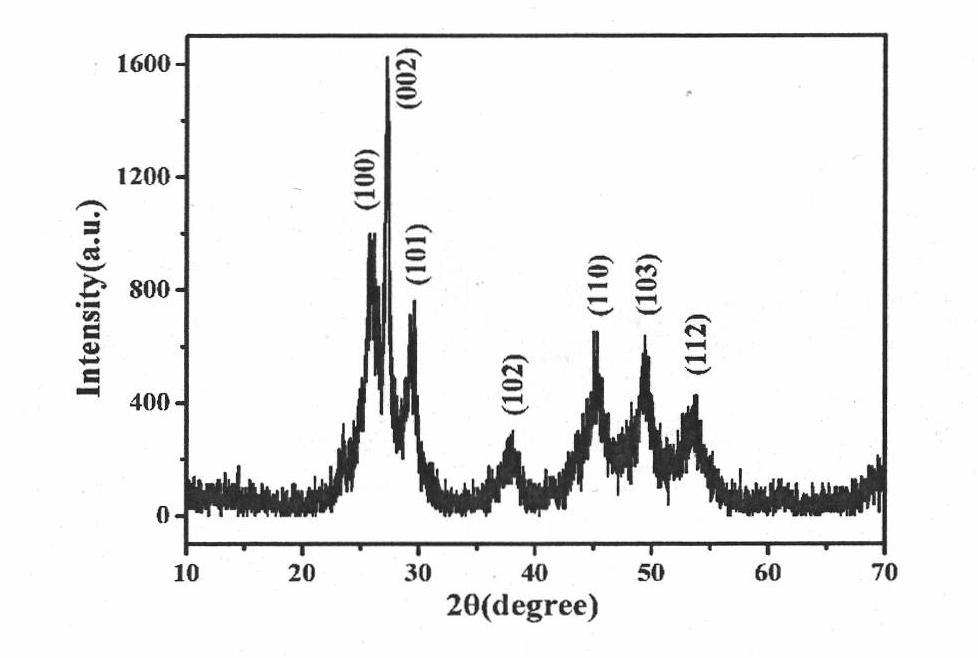

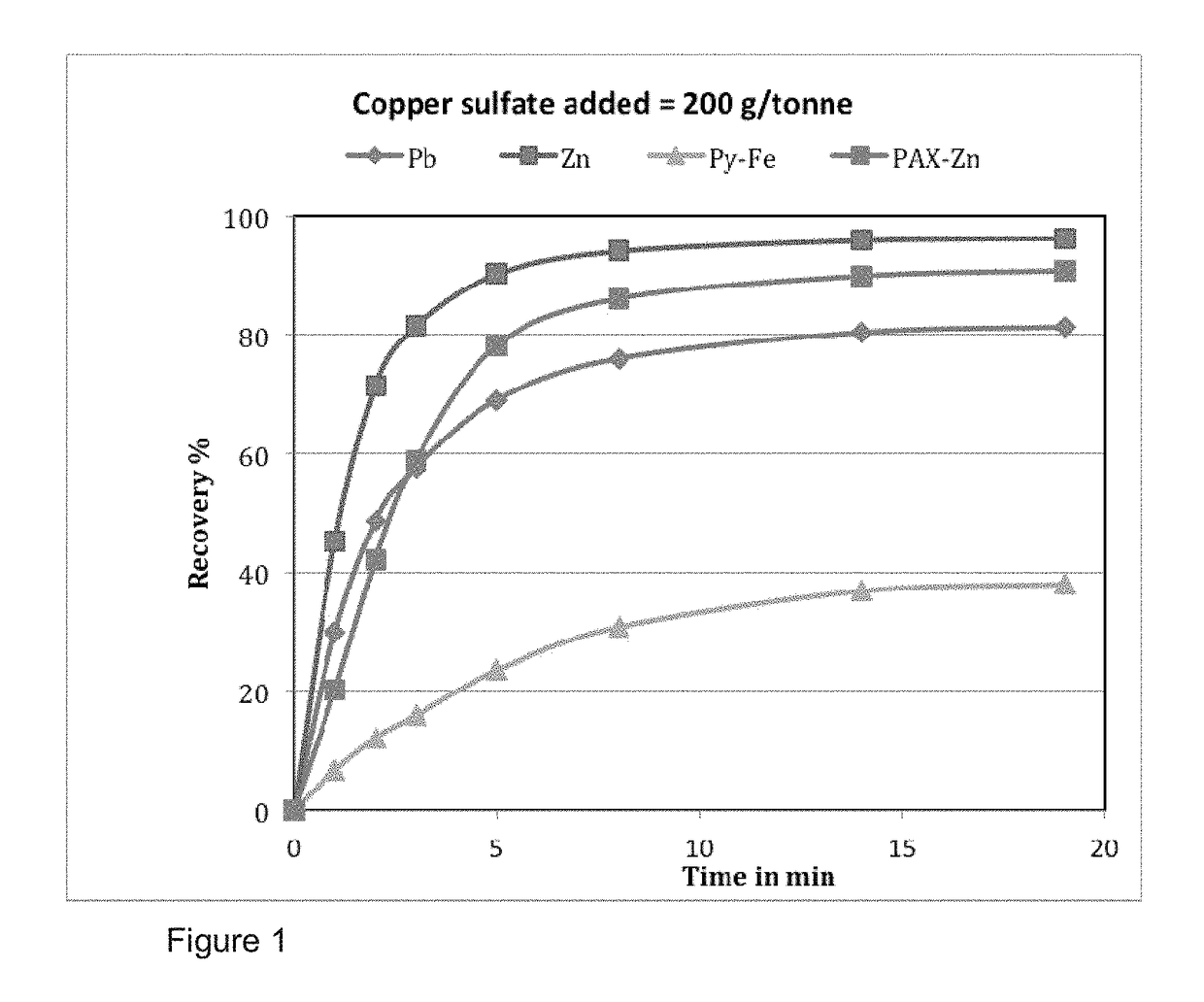

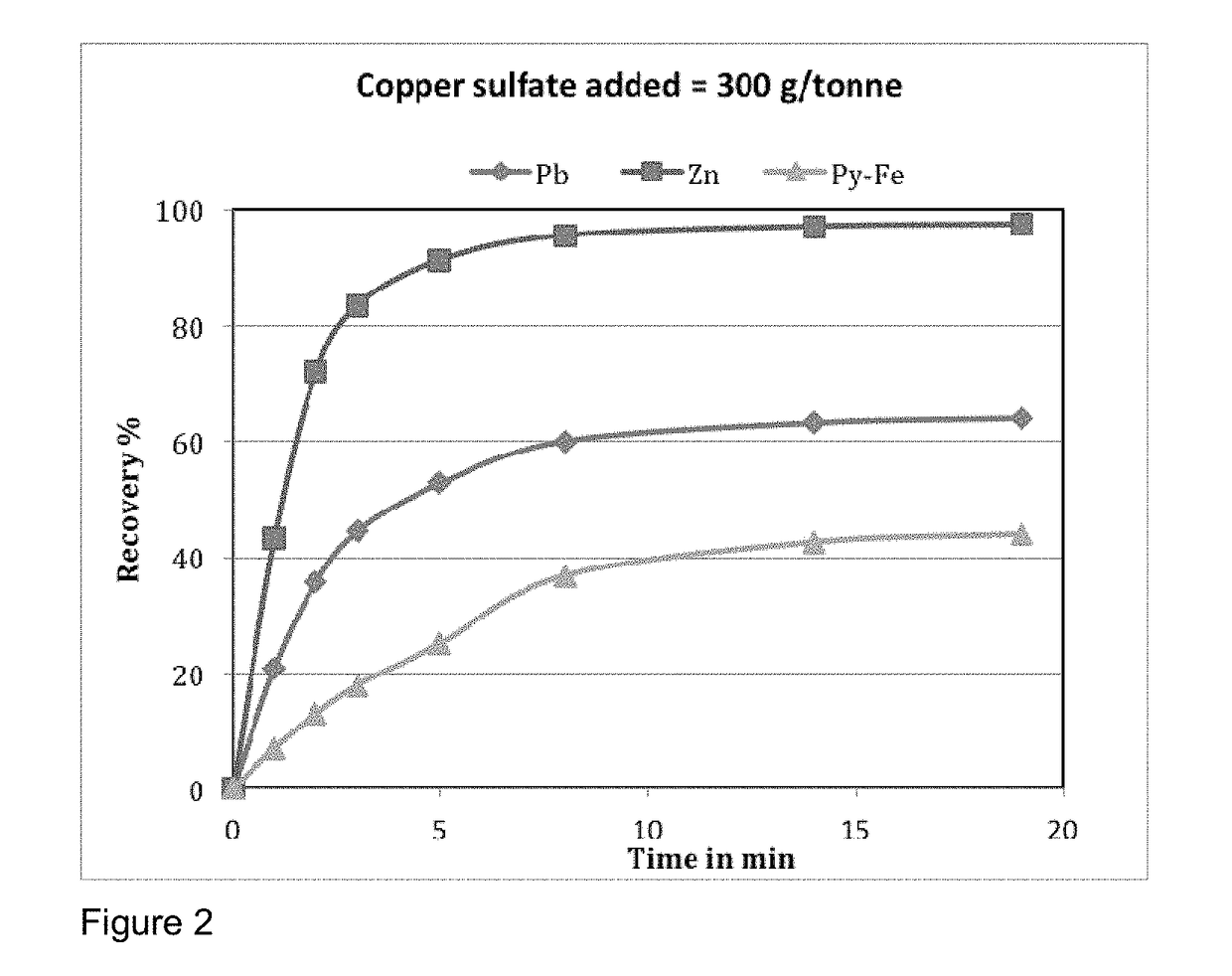

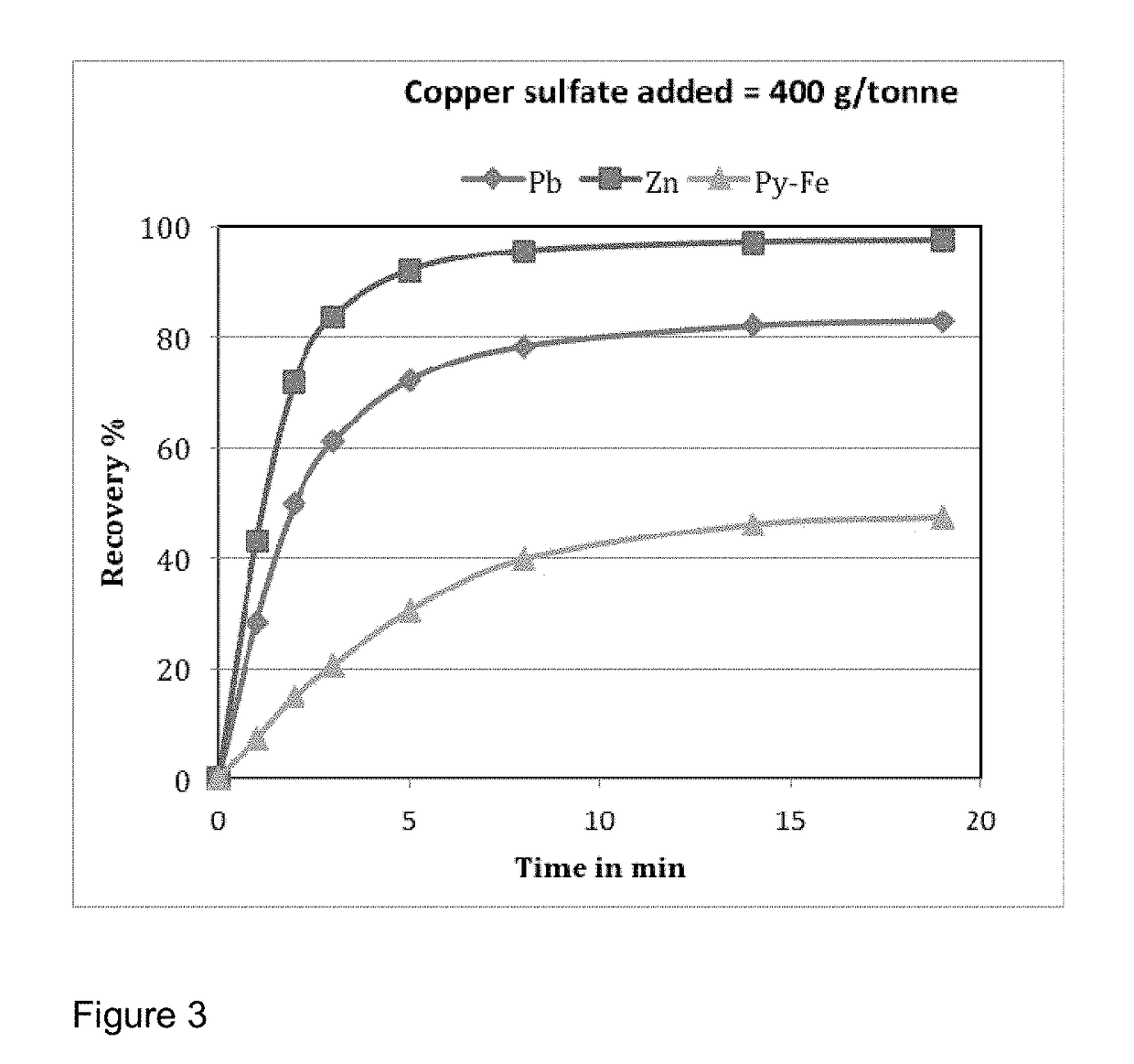

Flotation of sphalerite from mixed base metal sulfide ores either without or with largely reduced amount of copper sulfate addition using 2-(alkylamino)ethanethiols as collectors

The main objective of the invention was to develop a new flotation collector that could eliminate or reduce the amount of copper sulfate used in the flotation of sphalerite. Different series of collectors such as cupferrons, arylhydroxamic acids and amino mercaptans or amino thiols were synthesized and tested. Amino mercaptans / aminothiols were found to be very effective in floating sphalerite from a lead-zinc ore using only 10-15% of copper sulfate used with conventional xanthate collector. The present invention does not require any alteration in the current mill practices. This warrants only changing the flotation collector in zinc flotation stage from, for example, potassium amyl xanthate (PAX) to the new collector.

Owner:LAKEHEAD UNIVERSITY

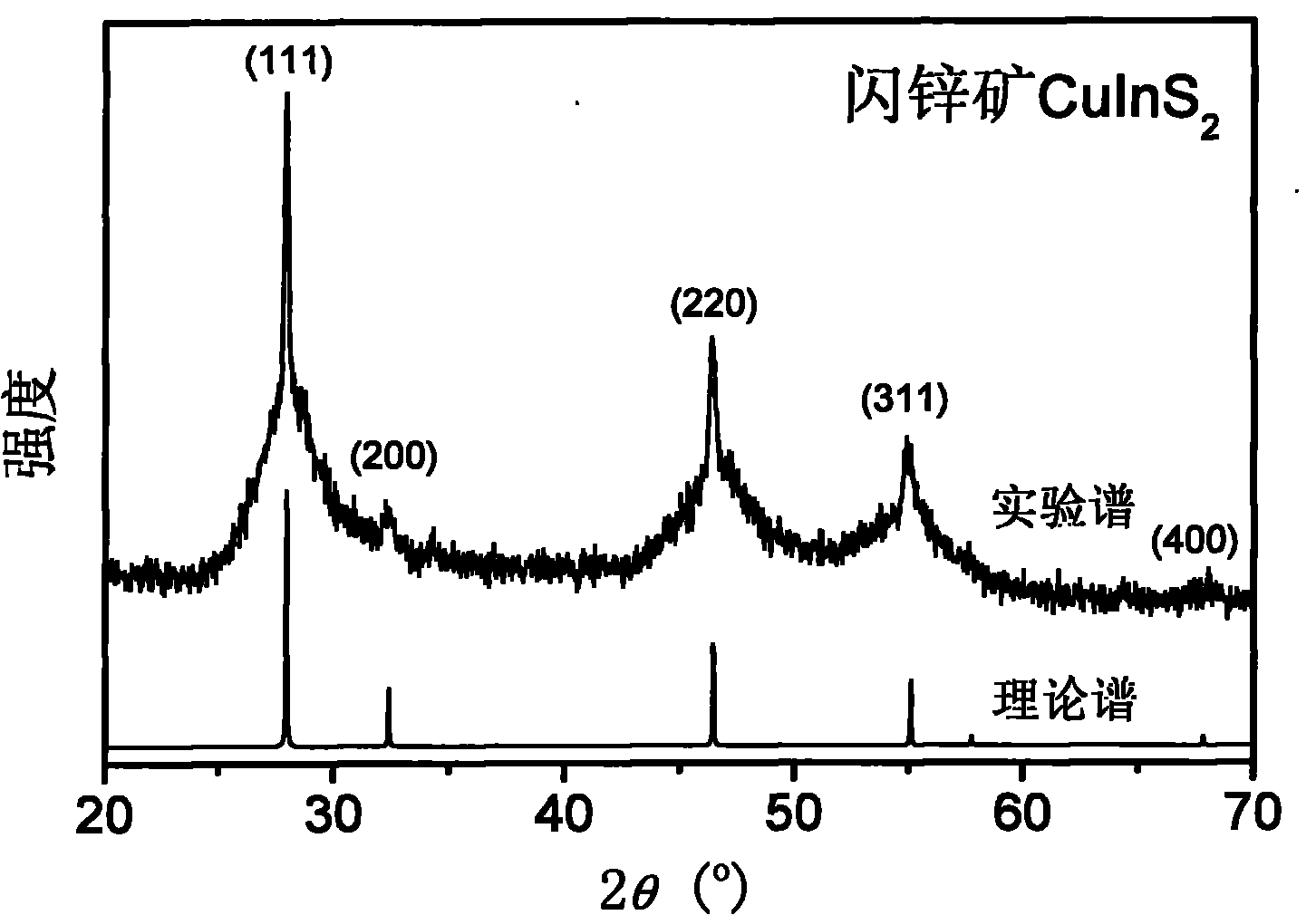

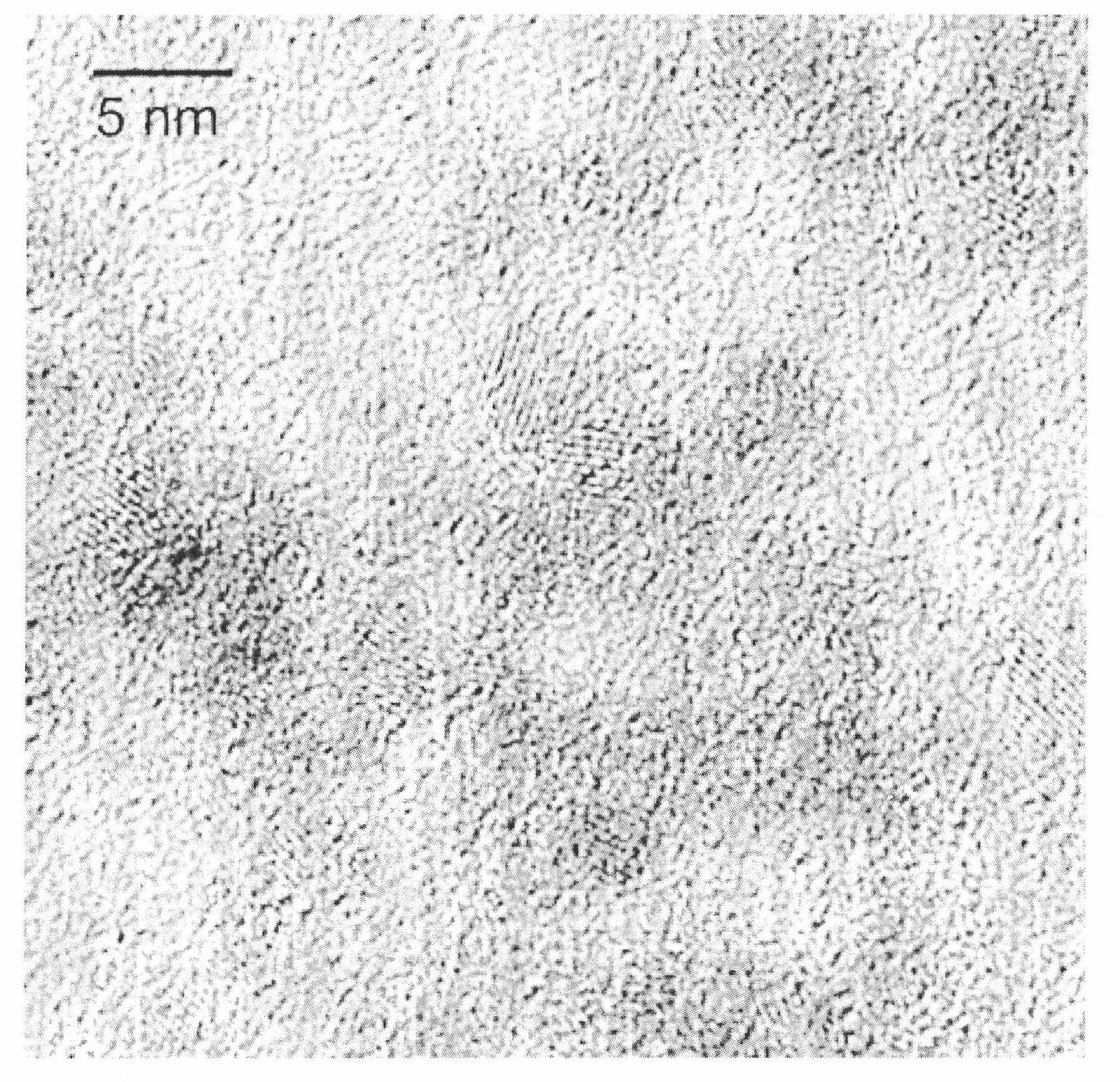

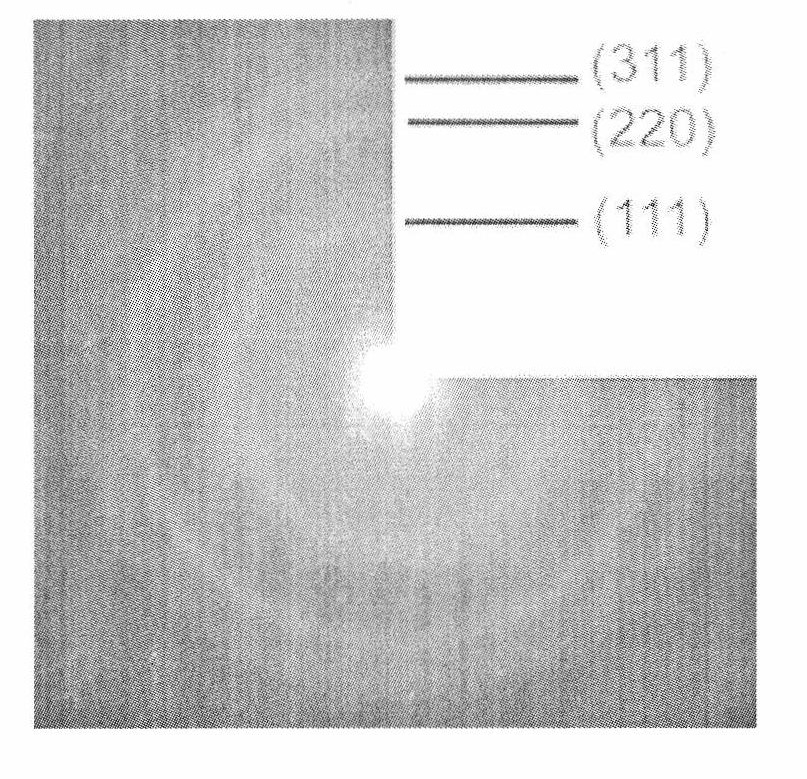

CuInS2 quantum dots with sphalerite structure and wurtzite structure and preparation method thereof

InactiveCN101805014AUniform particle size distributionEasy to makeGallium/indium/thallium compoundsSolventSolvothermal reaction

The invention discloses CuInS2 quantum dots with a sphalerite structure and a wurtzite structure and a preparation method thereof. The CuInS2 quantum dots of which the grain sizes are between 2 and 5 nanometers are synthesized through a solvent hot reaction by using environmental-friendly ethanol as a solvent; and the CuInS2 quantum dots of two crystal forms, namely the CuInS2 quantum dots with the sphalerite structure and the wurtzite structure are prepared by changing the variety of a surfactant, namely thiophenol or mercaptan. The prepared quantum dots have the good dispersibility in an organic solvent, and have important application value in fields of optical materials, coating materials, photovoltaic materials, organic-inorganic composite materials and the like.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Process for selecting marmatite from high ferric sulphide ore

The invention relates to mineral processing process, in particular to process for selecting marmatite from high ferric sulphide ore. The process includes the steps of ore grinding, roughing I, fine selecting and primary tailing disposing. The process for selecting marmatite from high ferric sulphide ore can effectively reduce usage of lime, achieves the purposes of energy conservation and environment protection, improves recovery rate and grade of the marmatite, can well separate the marmatite from the high ferric sulphide ore, improves indium-containing grade, and achieves comprehensive utilization effects of ore resources.

Owner:云南澜沧铅矿有限公司

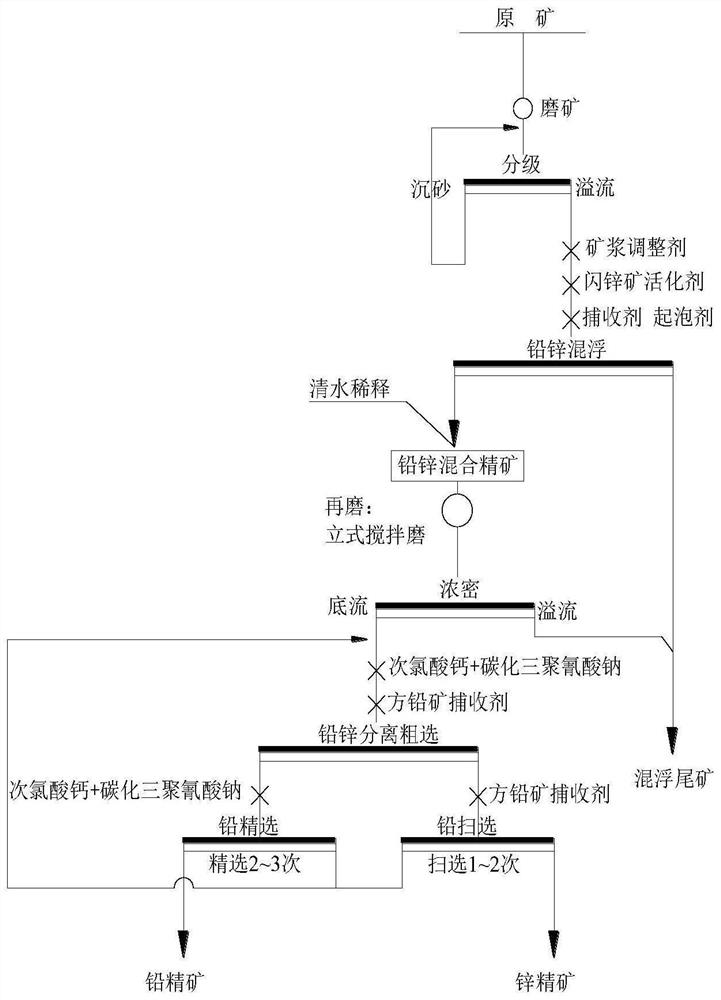

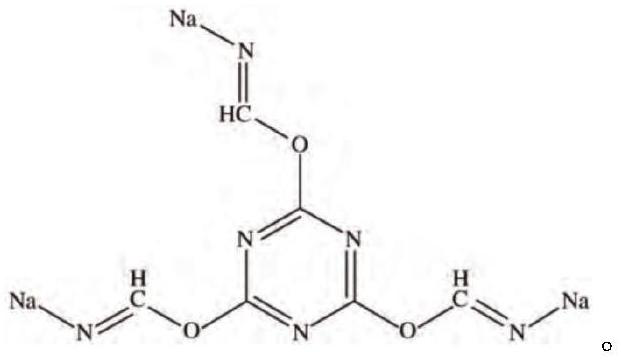

Flotation separation method of refractory lead-zinc sulfide ore and sphalerite inhibitor of refractory lead-zinc sulfide ore

The invention discloses a flotation separation method of refractory lead-zinc sulfide ore and a sphalerite inhibitor of the refractory lead-zinc sulfide ore, the sphalerite inhibitor is a composition of calcium hypochlorite and carbonized sodium cyanurate, the mass ratio of calcium hypochlorite to carbonized sodium cyanurate is 1: (2 to 4), and the inhibitor composition can have a strong inhibition effect on sphalerite. The invention further provides a flotation separation method of the refractory lead-zinc sulfide ore, the refractory lead-zinc sulfide ore is subjected to ore grinding and grading treatment and size mixing, a sphalerite activating agent, a flotation collecting agent and a foaming agent are added, then inflation flotation is conducted, lead-zinc bulk concentrate dense underflow is obtained through regrinding and thickening, and the sphalerite inhibitor and a galena collecting agent are added for flotation separation; and the separated lead rough concentrate is subjected to sphalerite inhibition and repeated concentration to obtain lead concentrate, the galena collecting agent is added into the separated lead rough concentrate for repeated lead scavenging to obtain zinc concentrate, and therefore the refractory lead-zinc sulfide ore is economically and efficiently separated and enriched, and the method has wide industrial application prospects.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD +1

Low-sulfur type copper-lead-zinc polymetallic ore sequential preferential flotation separation method

The invention discloses a low-sulfur type copper-lead-zinc polymetallic ore sequential preferential flotation separation method. According to the technical scheme, flotation of copper is carried out before flotation of lead. In the preferential flotation of copper, a combined inhibitor T-9 is used, and effective separation of valuable element copper in ore from lead and zinc is realized under the condition of pH 6-7. In the preferential flotation of lead, an inhibitor F-8 is used, and floating of zinc mineral is effectively inhibited. The T-9 reduces floatation activity of lead and zinc minerals and effectively increases floatability difference between copper and lead and zinc minerals, and the composition is nontoxic and harmless and is green and pollution-free. The inhibitor F-8 has a good inhibiting effect on sphalerite, has high activity to galena and silver mineral, has a certain collecting effect on galena, and is good for reducing mutual Inclusion of lead and zinc in the product. By the method, the target minerals copper, lead and zinc are effectively separated, thus achieving the purpose of comprehensive recovery and utilization of mineral resources.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

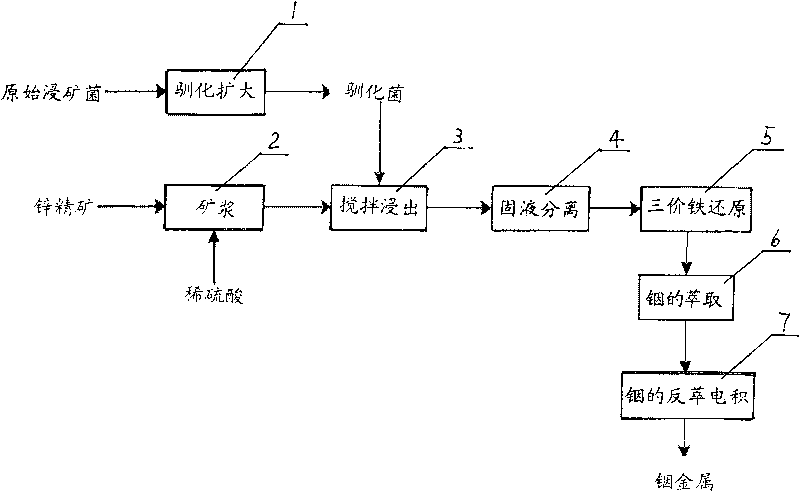

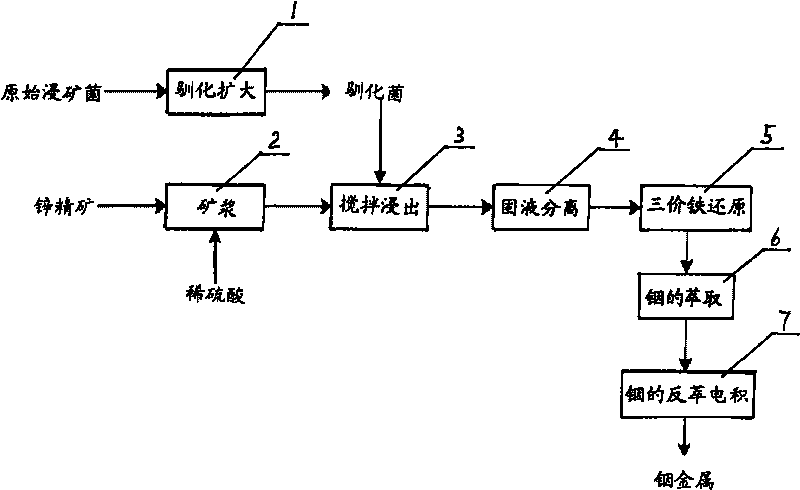

Leaching-ore bacteria and biological indium extraction process in sphalerite concentrate ore

The invention provides leaching-ore bacteria and a biological indium extraction process in a sphalerite concentrate ore. The name of the leaching-ore bacteria is Leptospirillum ferrooxidans Retech-SPL-1, the preservation register number of the leaching-ore bacteria is CCTCC NO:M 208162, the preservation data is on October 17th in 2008, the preservation unit of the leaching-ore bacteria is China Center for Type Culture Collection, and the address of China Center for Type Culture Collection is in the Wuhan University. The biological indium extraction process in the sphalerite concentrate ore comprises the following steps: carrying out acclimatisation and amplification culture on the leaching-ore bacteria; putting the cultivated leaching-ore bacteria in a stirring pot containing ore pulp; completing the leaching process by aerating and stirring; and sending leaching solution obtained by the leaching step to the step of iron removing and indium extracting back-extraction electrodeposition. The invention has the advantages of being benefit for environment protection and also being used for developing the low grade indium resource which is not easily comprehensively utilized by the conventional beneficiation and metallurgy technology, enlarging the utilization range of the indium mineral resource and improving the comprehensive utilization of the indium.

Owner:有研资源环境技术研究院(北京)有限公司

Combined zinc collecting agent for flotation of lead-zinc sulfide ore and application thereof

The invention discloses a combined zinc collecting agent for flotation of lead-zinc sulfide ore and application thereof. The combined zinc collecting agent comprises the following active components inparts by weight: 10-30 parts of ammonium dibutyl dithiophosphate, 30-50 parts of ethyl thiocarbamate and 30-50 parts of 2-aminothiophenol. According to the efficient combined collecting agent for sphalerite flotation, the combined collecting agent is composed of ammonium dibutyl dithiophosphate, ethyl thiocarbamate and 2-aminothiophenol and is easy to obtain, low in price, small in dosage and free of pollution. The ammonium dibutyl dithiophosphate is weak in collecting capacity, but has foamability, high sulfur and nitrogen collecting capacity and certain lead sulfide ore and zinc sulfide orecollecting capacity; compared with a conventional collecting agent butyl xanthate, 2-aminothiophenol has good flotation effect of on marmatite even under the condition that copper ion activation is not used, and has poor lead sulfide ore flotation effect; however, 2-aminothiophenol is a weakly acidic compound, and cannot fully react with zinc sulfide ore when a pH value is relatively low; and therefore, the components of the combined collecting agent can supplement each other.

Owner:CENT SOUTH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com