Method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate

A technology for mixing concentrate and sphalerite, applied in solid separation, flotation and other directions, can solve problems such as sphalerite loss, achieve the effect of small investment, improve comprehensive utilization level, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

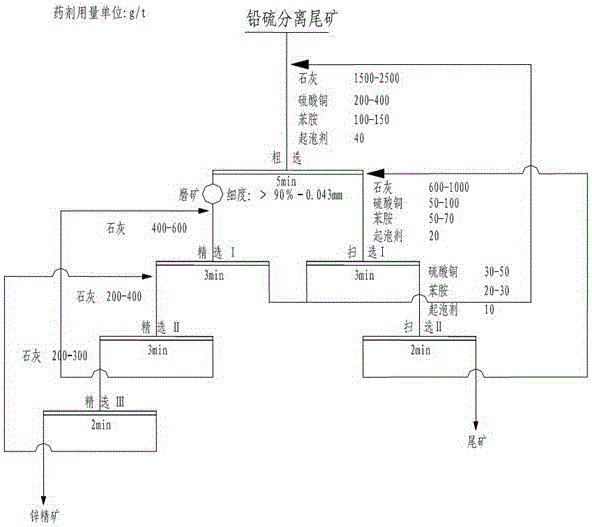

Image

Examples

Embodiment 1

[0020] In this example, a lead-zinc ore sample in Zhaotong, Yunnan Province is taken as an example. After separation of lead and sulfur, the tailings contain 3.02% zinc, pH value is 10, and the fineness is -0.074mm, accounting for 85% fineness.

[0021] (1) First add water to the tailings of the lead-sulfur mixed concentrate separation to a mass percentage concentration of 30%.

[0022] (2) Add sulfur inhibitor lime 1500g / t, adjust the pH value of the pulp at 11; after lime action for 3 minutes, add an appropriate amount of activator copper sulfate, the dosage is 400g / t; after activator action for 3 minutes, add capture The amount of aniline as a collecting agent is 150g / t, and the amount of foaming agent 24K is 45g / t. After acting for 1min, inflate the foam to scrape out the foam, and obtain the rougher concentrate and rougher tailings.

[0023] (3) Add sulfur inhibitor lime 600g / t, activator copper sulfate 100g / t, collector aniline 70g / t, and foaming agent 24K at 25g / t to th...

Embodiment 2

[0028] In this example, a lead-zinc ore sample in Qujing, Yunnan Province is taken as an example. After the separation of lead and sulfur, the tailings contain 2.11% zinc, a pH value of 10, and a fineness of -0.074 mm, accounting for 80% of the fineness.

[0029] (1) First add water to the tailings of the lead-sulfur mixed concentrate separation to a mass percentage concentration of 32%.

[0030] (2) Add sulfur inhibitor lime 1800g / t, adjust the pH value of the pulp at 11; after 3 minutes of lime action, add an appropriate amount of activator copper sulfate, the dosage is 240g / t; after activator action for 3 minutes, add capture The amount of aniline as a collector is 120g / t, and the amount of foaming agent MIBC is 40g / t. After acting for 1min, inflate the foam to scrape out the foam, and obtain the rougher concentrate and rougher tailings.

[0031] (3) Add sulfur inhibitor lime 700g / t, activator copper sulfate 80g / t, collector aniline 60g / t, and foaming agent MIBC 20g / t to th...

Embodiment 3

[0036] In this example, a lead-zinc ore sample in Xichang, Sichuan Province is taken as an example. After separation of lead and sulfur, the tailings contain 1.62% zinc, have a pH value of 10, and have a fineness of -0.074 mm, accounting for 80% of the fineness.

[0037](1) First add water to the tailings of the lead-sulfur mixed concentrate separation to a mass percentage concentration of 35%.

[0038] (2) Add sulfur inhibitor lime 2500g / t, adjust the pH value of the pulp at 12; add an appropriate amount of activator copper sulfate, the dosage is 200g / t after lime action for 4 minutes; The amount of aniline as a collecting agent is 100g / t, and the amount of foaming agent 730 A is 35g / t. After acting for 2 minutes, inflate the foam to scrape out the foam, and obtain roughing concentrate and roughing tailings.

[0039] (3) Add sulfur inhibitor lime 1000g / t, activator copper sulfate 50g / t, collector aniline 50g / t, and foaming agent 730A at 15g / t to the roughing tailings slurry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com