Patents

Literature

45 results about "Zincite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zincite is the mineral form of zinc oxide (ZnO). Its crystal form is rare in nature; a notable exception to this is at the Franklin and Sterling Hill Mines in New Jersey, an area also famed for its many fluorescent minerals. It has a hexagonal crystal structure and a color that depends on the presence of impurities. The zincite found at the Franklin Furnace is red-colored, mostly due to iron and manganese dopants, and associated with willemite and franklinite.

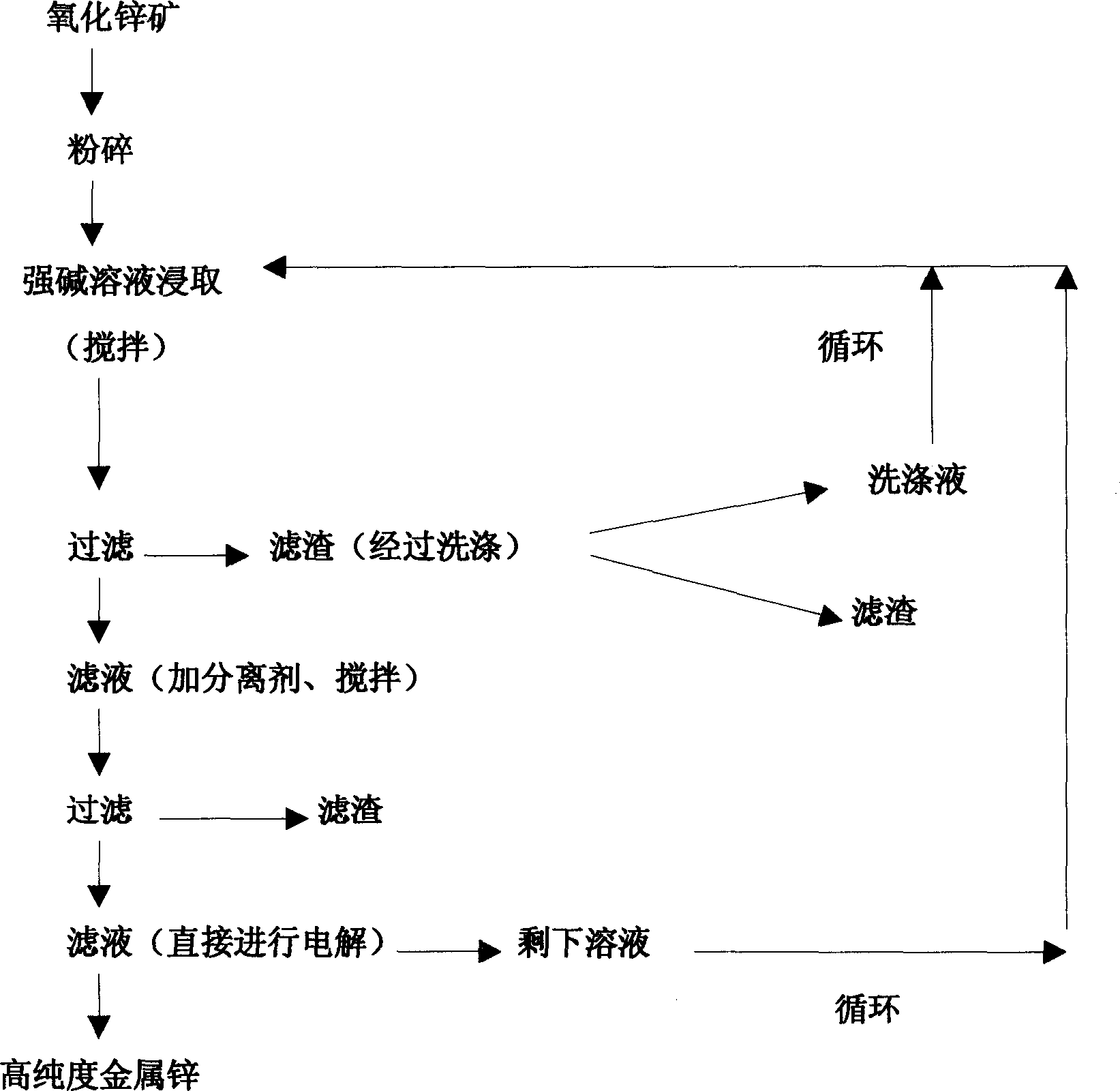

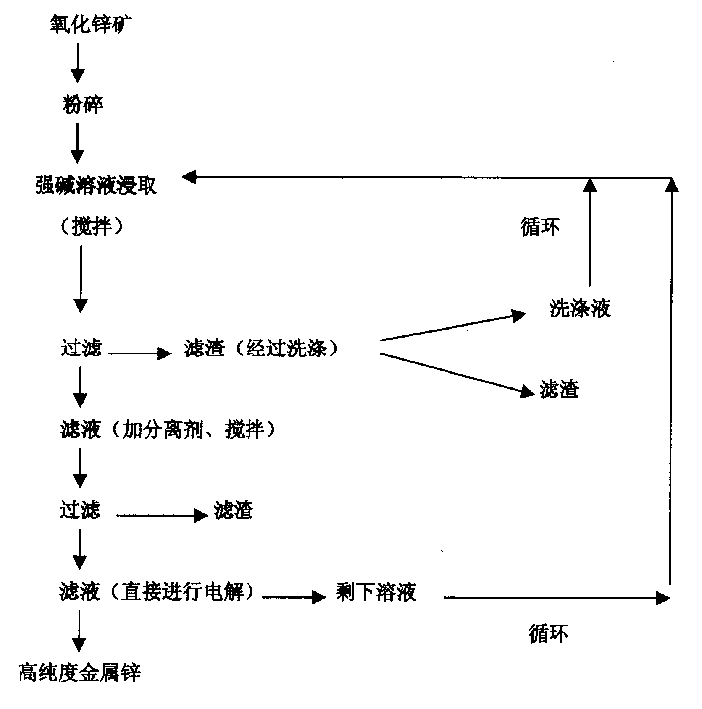

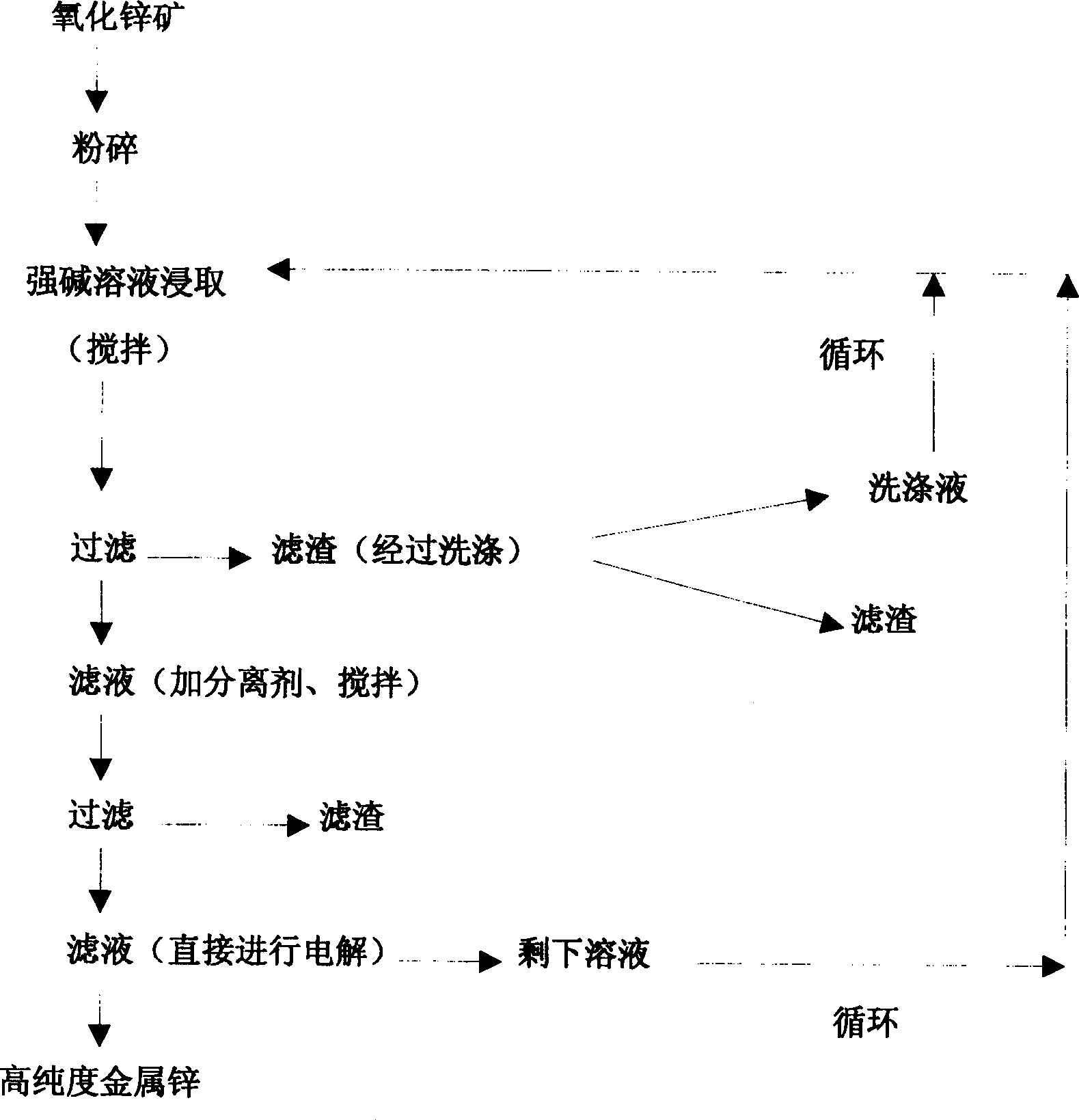

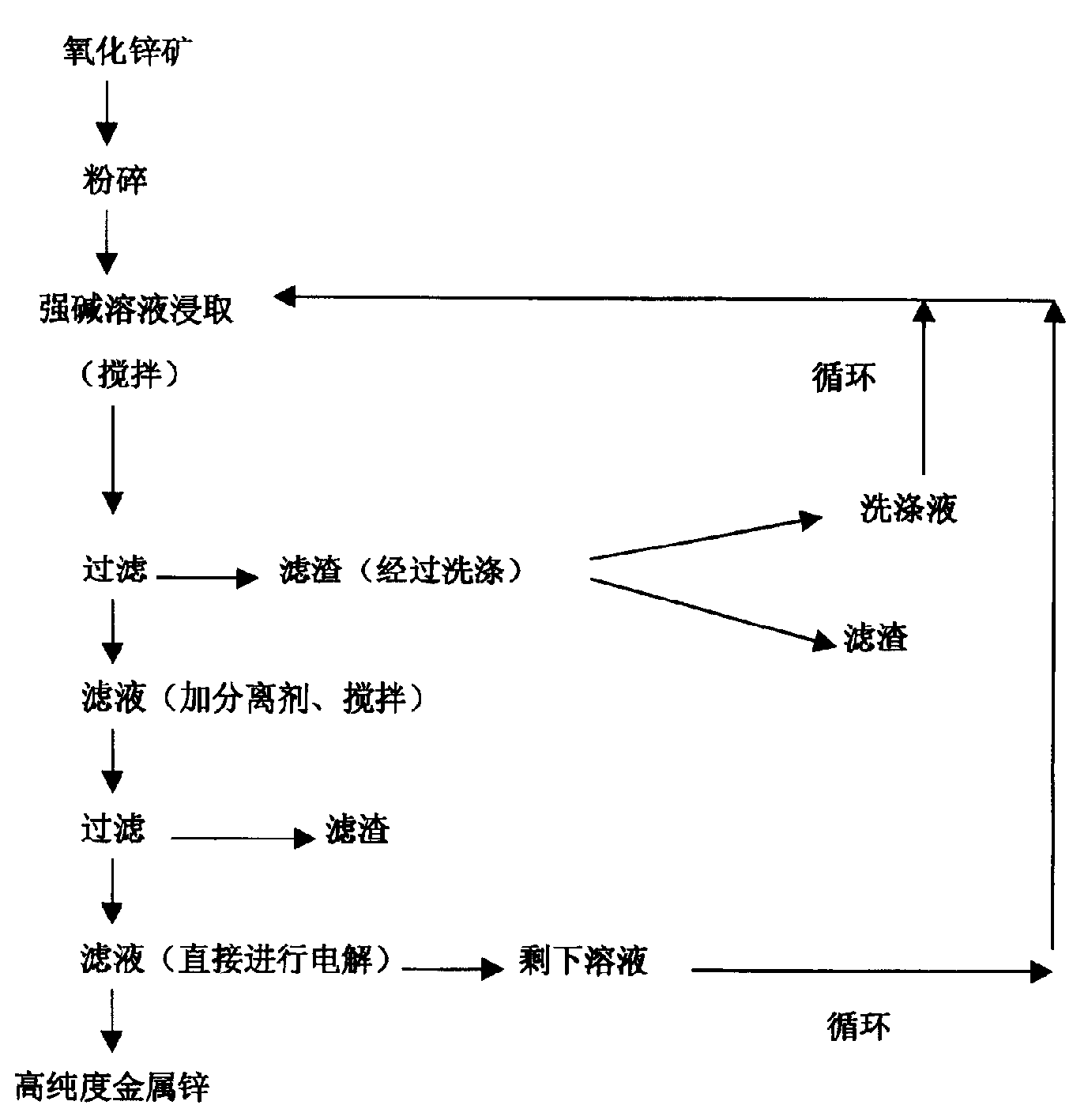

Method for producing high purity metal zinc from zinc oxide ore

The method for producing high-purity metal zinc by using low-grade zincite ore as raw material includes the following steps: firstly, pulverizing zincite ore into the zincite ore powder whose grain size is 0.1-1mm, soaking in strong alkaline solution, slowly stirring for 60-100 min, at 10-100 deg.C to extract the zinc and lead from zincite ore, filtering, discharging filter residue for making brick or burying, then adding dispersing agent whose added quantity is 0.1-5 times (mole ratio) lead content into the filtrate containing zinc and lead, stirring for 60-100 min., filtering, precipitatingseparated lead and electrolyzing the filtrate containing zinc, finally, depositing and obtaining metal zinc whose purity is above 99.95% on the cathode.

Owner:昆明同越科技开发有限公司

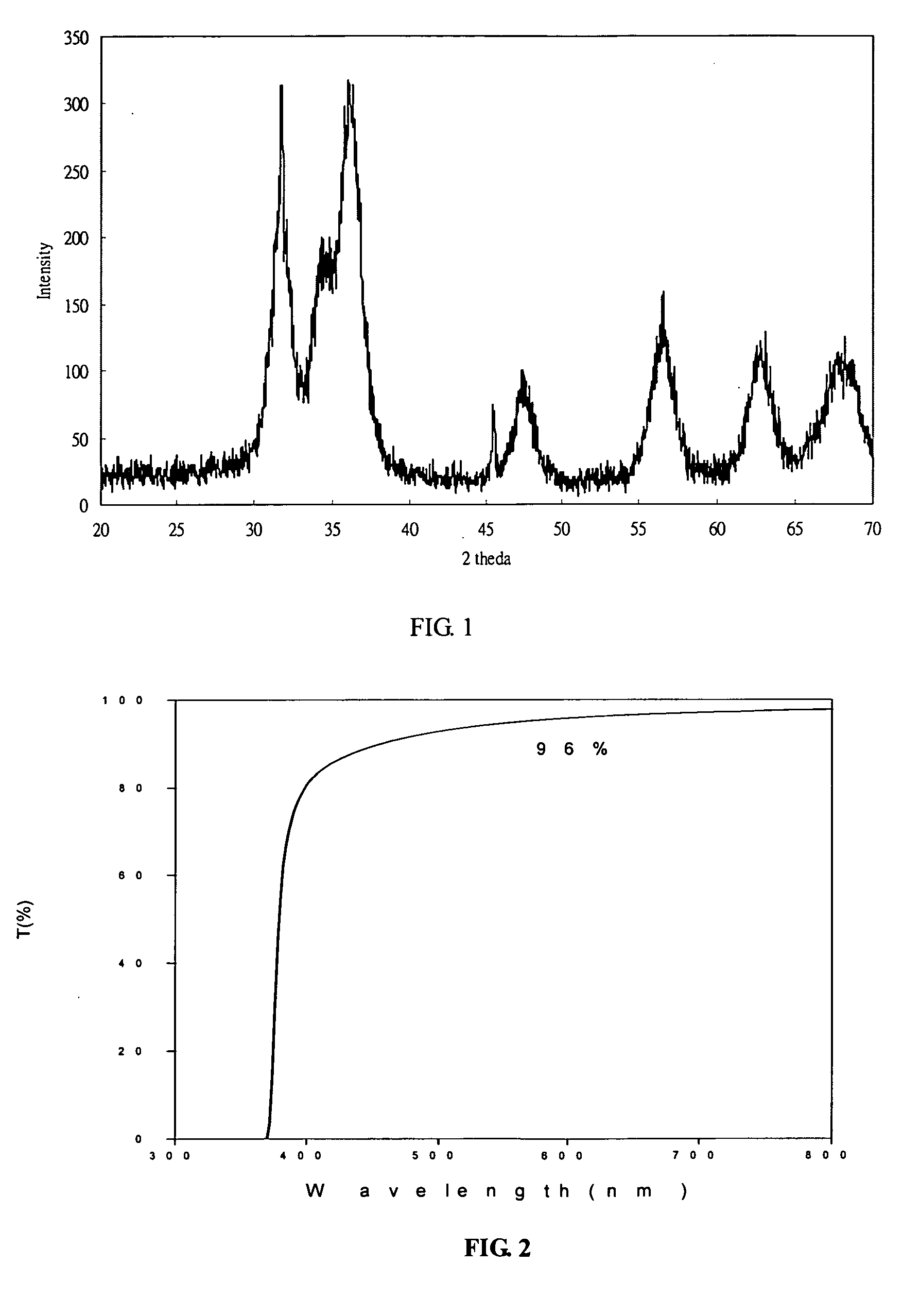

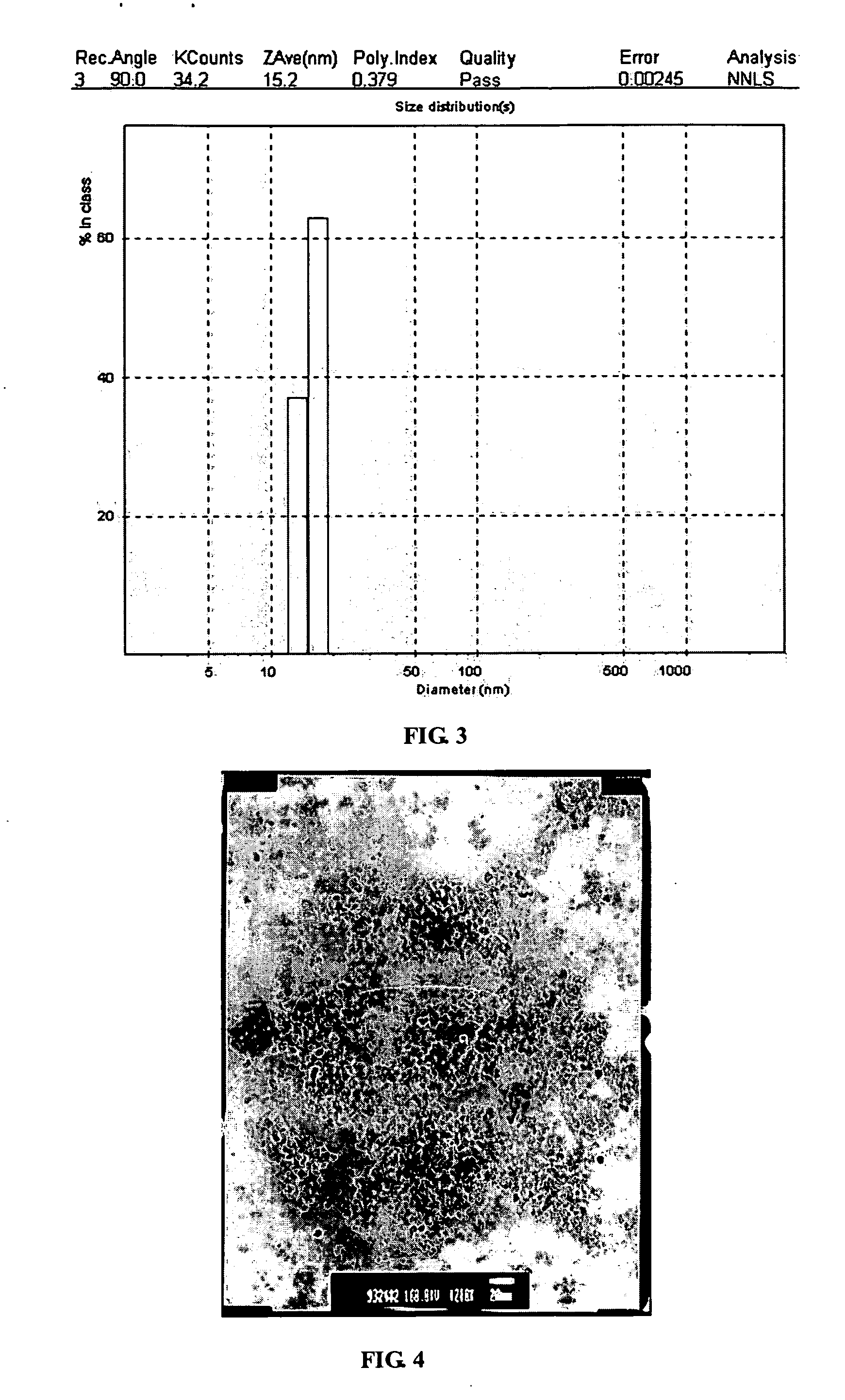

Preparation method for nanometer grade zinc oxide crystalline (zincite) sol

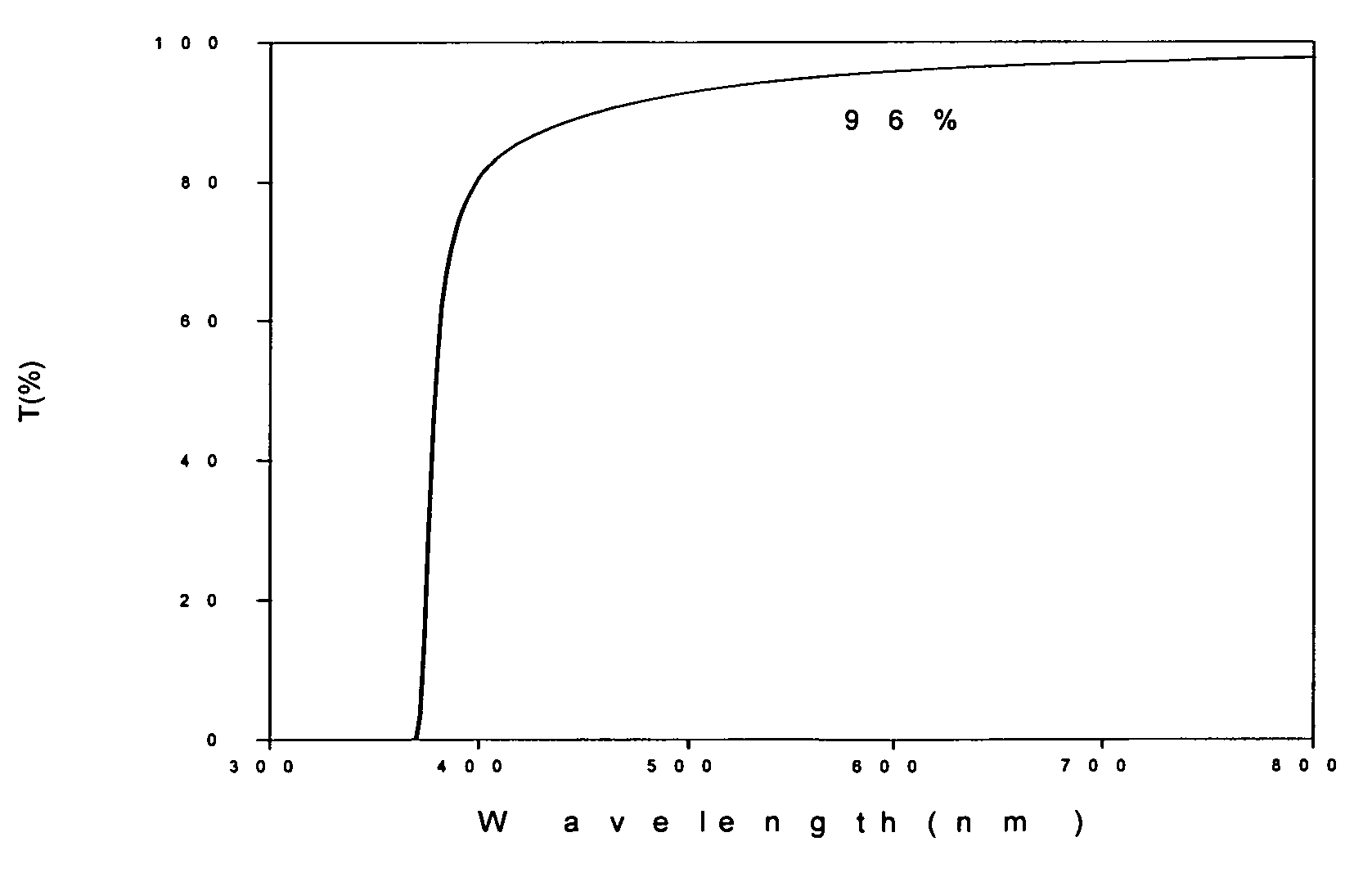

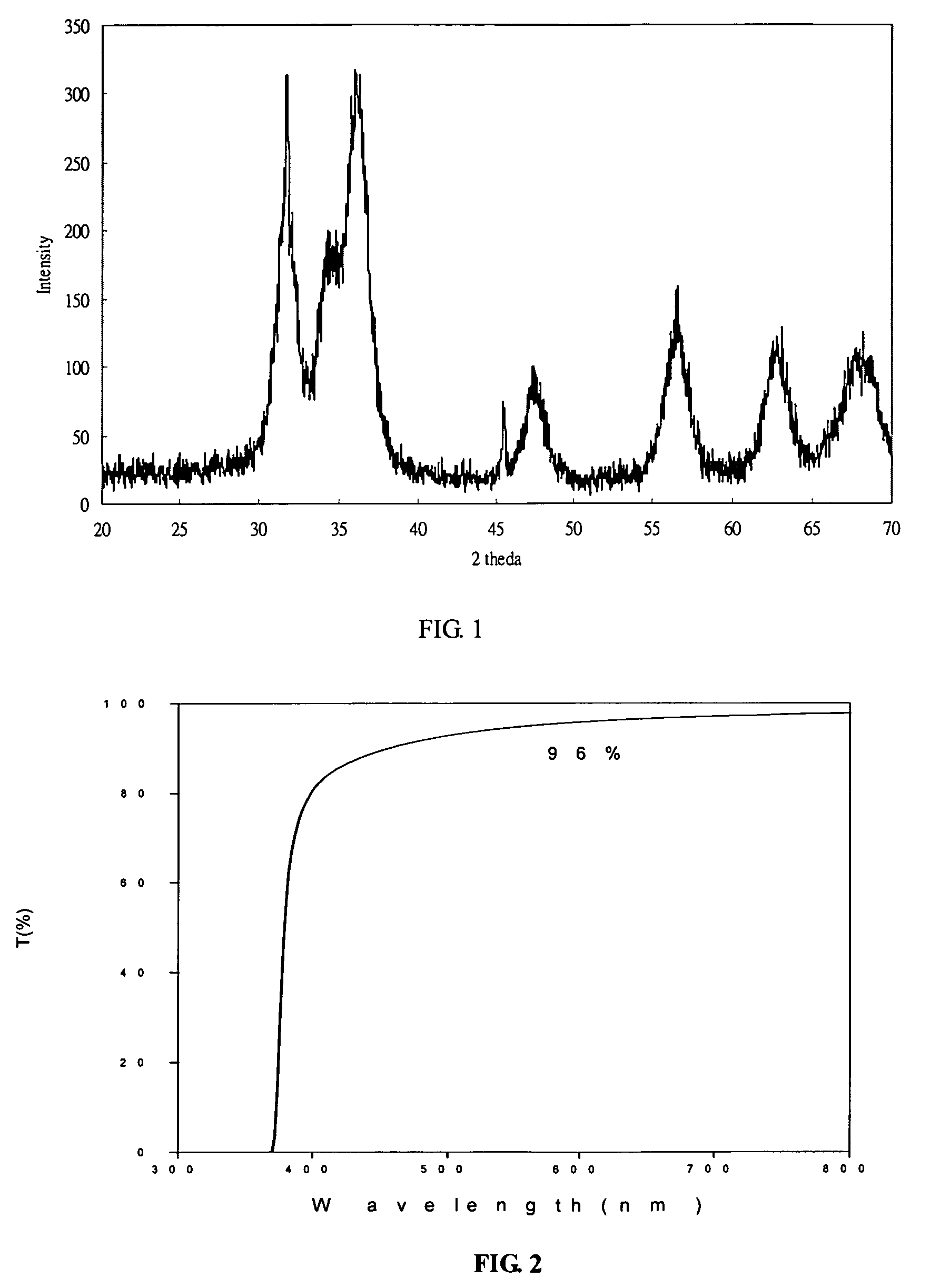

InactiveUS20060222586A1Less preferredIncreased toxicityMaterial nanotechnologyPigmenting treatmentNanoparticleZincite

An environmentally friendly method for preparing zinc oxide (zincite) nanoparticle sol having more than 90% visible light transmission at 20 wt % solid; comprises of the neutralizing, under specific pH, an inorganic zinc salt with an inorganic alkali, both dissolved in ethylene glycol, and thermally aging the precipitates afterward.

Owner:HEADWAY ADVANCED MATERIALS

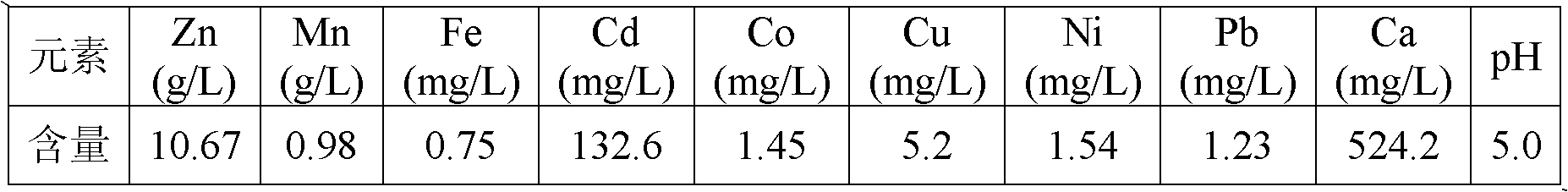

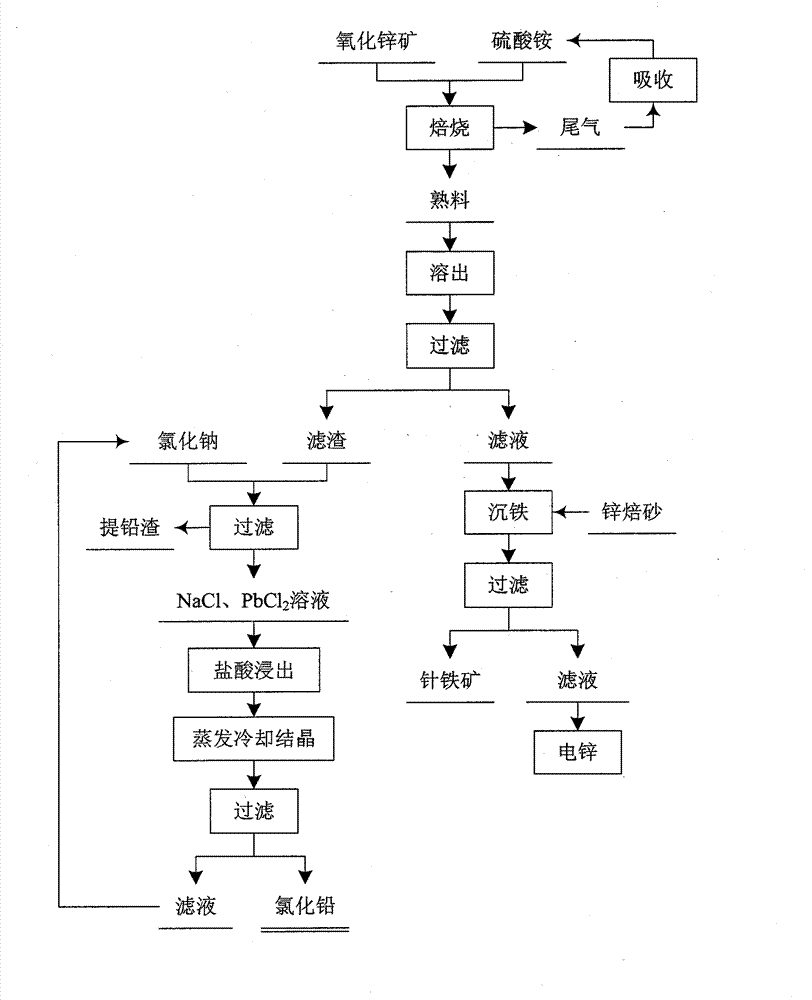

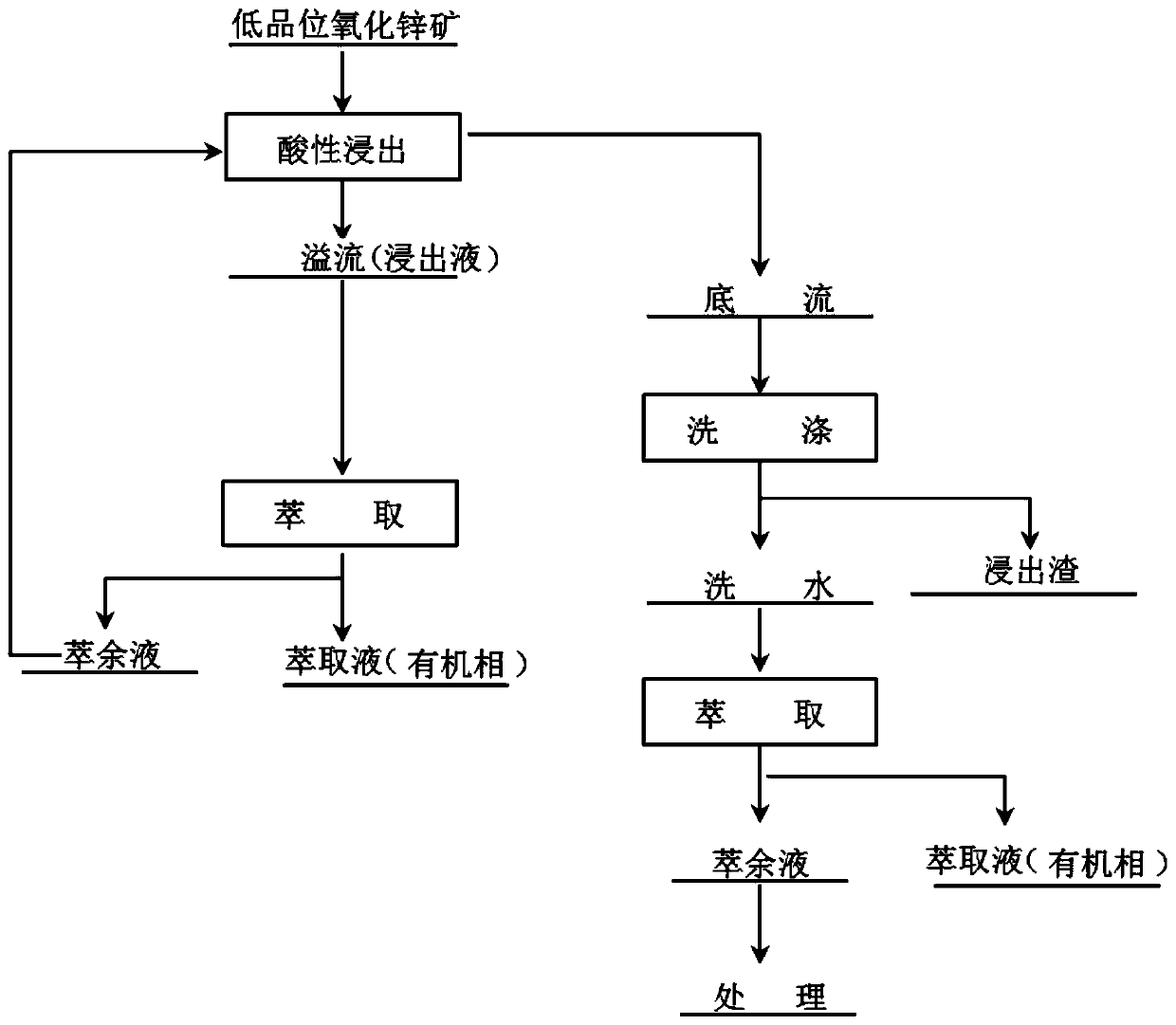

Method for recycling zinc from zinc leaching slag cleaning solution

The invention discloses a wet process for recycling zinc from a zinc leaching slag cleaning solution, belonging to wet processing methods for zinc ore, in particular relating to a method for further recycling zinc from zinc slag generated by a zinc hydrometallurgy system. The method comprises the following steps of: washing leaching slag or rinsing the leaching slag with dilute acid; then preparing an organic phase by taking P204 as an extractant and kerosene as a diluent to extract a water phase; preparing a solution containing zinc and sulphuric acid; eluting impurities in the loaded organic phase; back-extracting the loaded organic phase with waste electrolyte and sulphuric acid; shifting zinc in the organic phase into a water phase again; carrying out deoiling treatment on all water phases in contact with the organic phase; and finally, adding a back-extracted solution as a new solution into a zinc electrodeposition system. The method has the advantages of simplicity of operation and high metal recovery rate, can effectively recycle zinc included in the zinc leaching slag so as to save resources and avoide environment pollution, and can be well linked with a zinc hydrometallurgy process so that the recovery rate of zinc is increased.

Owner:KUNMING UNIV OF SCI & TECH +1

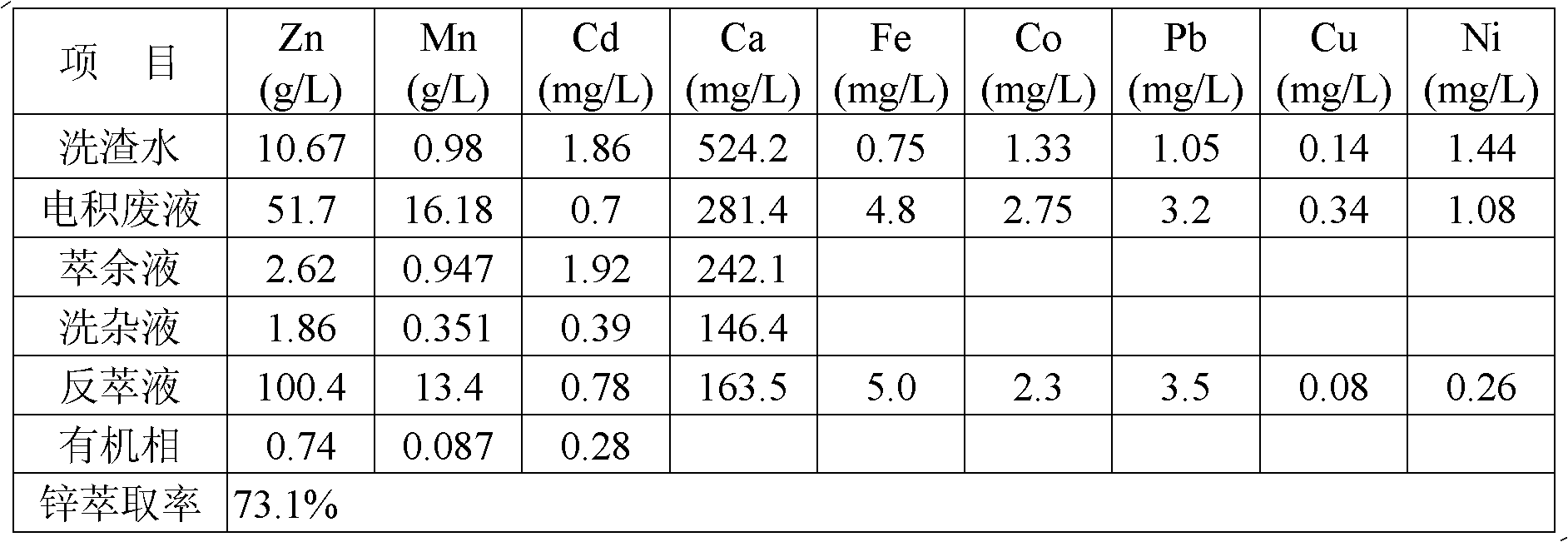

Method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate

InactiveCN106552715AImprove the level of comprehensive utilizationRelieve stressFlotationSulfur productFoaming agent

The invention discloses a method for recycling sphalerite from separated tailings of lead-sulfur bulk concentrate. The method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate comprises the steps that firstly, water is added to the separated tailings of the lead-sulfur bulk concentrate, and the mass percent concentration of a pulp is adjusted to be 25%-32%; secondly, an appropriate amount of lime is added so that the pH value of the pulp can be adjusted, and pyrite is inhibited at the same time; thirdly, copper sulfate is added as an activating agent to activate the sphalerite; and finally, a collecting agent, aniline, and a foaming agent are added for flotation of the sphalerite, the flotation procedure comprises one-time rough flotation, two-time scavenging and three-time concentration (after the concentrate obtained through rough flotation is ground to the extent that the ores reaching the grain level of >-0.043 mm account for 90%, concentration is conducted ), and effective concentration of the sphalerite is achieved. According to the sphalerite obtained through the method, the zinc grade is higher than 40%, and the recovery rate of zinc is higher than 80%. By the adoption of the method for recycling the sphalerite from the separated tailings of the lead-sulfur bulk concentrate, the zinc lost in the lead-sulfur separated tailings, namely sulfur products, can be well recycled, the comprehensive recovery rate of zinc is improved, and the economic benefits of a concentrating plant are increased.

Owner:KUNMING UNIV OF SCI & TECH

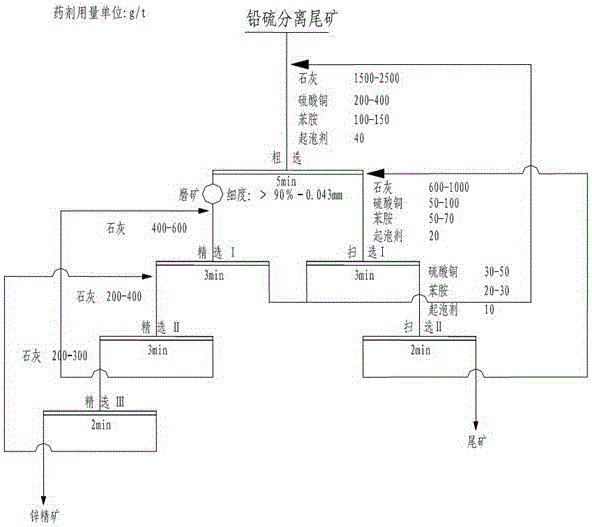

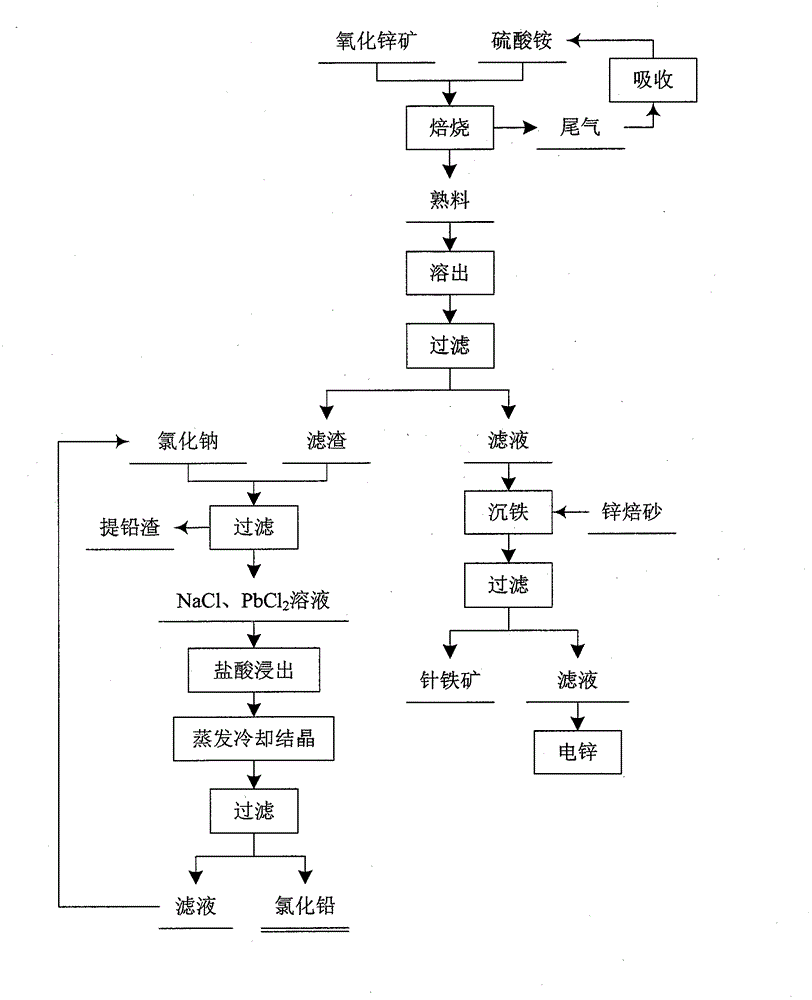

Method for preparing lead chloride and zinc sulfate by using mid low grade zinc oxide ores and zinc oxide-lead oxide paragenetic ores

The invention discloses a method for preparing lead chloride and zinc sulfate by using mid low grade zinc oxide ores and zinc oxide-lead oxide paragenetic ores, comprising the following steps: (1) crushing zinc ores and levigating, then mixing the levigated zinc ores with ammonium sulfate and roasting; (2) dissolving out clinkers obtained by roasting, carrying out iron precipitation and aluminium precipitation on the obtained filtrate, and further separating lead from the residues of zinc extraction; (3) boiling down a zinc sulfate solution obtained after iron precipitation and aluminium precipitation for electrolysis; and (4) leaching the residues of zinc extraction with an NaCl solution to obtain a filtrate, condensing the filtrate, cooling down and crystallizing out PbCl2 crystals, and returning the NaCl solution to the leaching process. According to the invention, circulation utilization is realized.

Owner:NORTHEASTERN UNIV

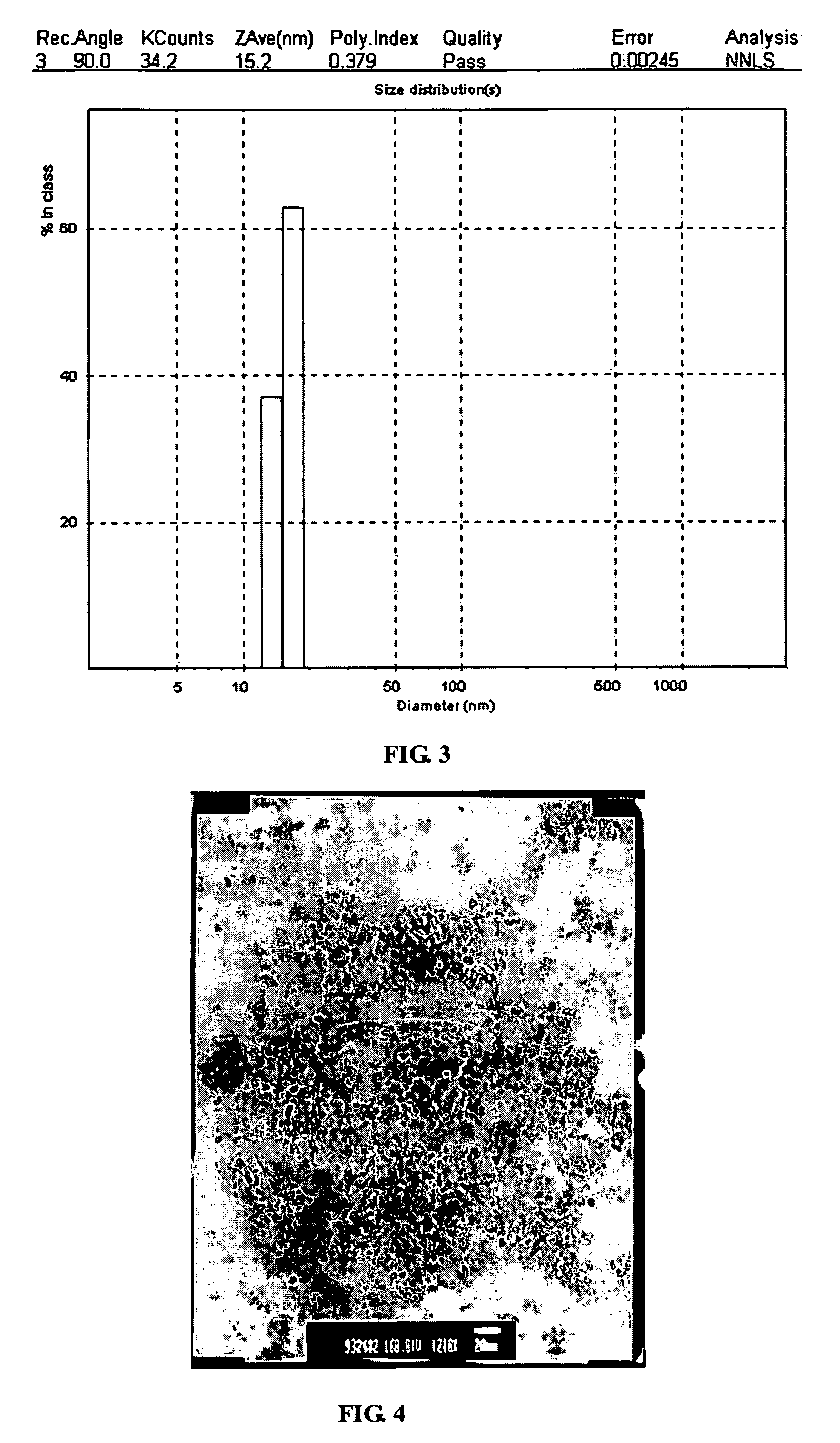

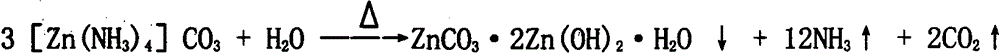

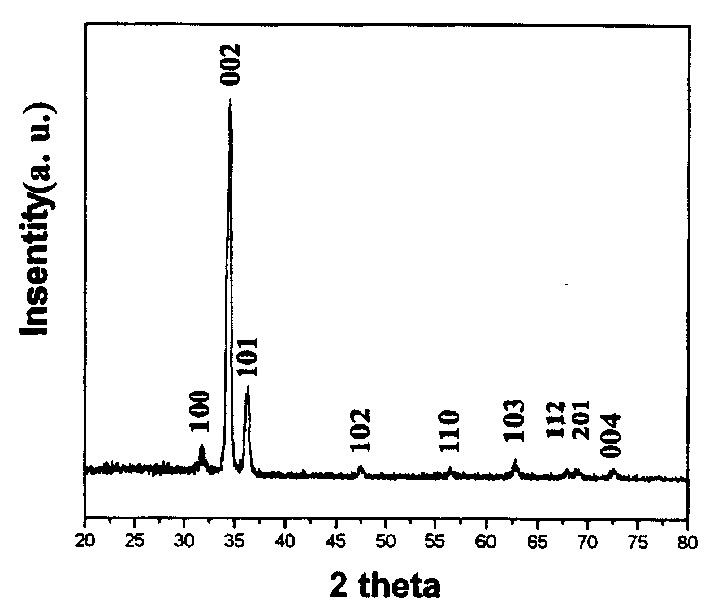

Method for producing high-purity nano zinc oxide from low-grade zinc oxide ores

ActiveCN102839282AFast leachingFully recycleZinc oxides/hydroxidesProcess efficiency improvementEnvironmental resistanceBrick

The invention discloses a method for producing high-purity nano zinc oxide from low-grade zinc oxide ores, which comprises the following steps: leaching with an ammonia water-ammonium bicarbonate solution; adding 0.3-0.5kg of sodium fluosilicate into per cubic meter of the ammonia water-ammonium bicarbonate solution; performing ammonia pre-evaporation; then performing purification and impurity removal; and finally refining. According to the invention, the ammonia method is used for the treatment of electrolyzing low-grade zinc oxide ores, and the existing ammonia method is adaptively improved, so that zinc in the low-grade zinc oxide ores can be sufficiently recycled. Through the treatment of the technical means of the invention, the purity of zinc oxide obtained by calcining at 350-450 DEG C can be up to 99.7% or above; the nano zinc oxide product of which the particle size is 10-50nm has a high economic value; the treatment method is low in energy consumption and high in efficiency, and realizes the cyclic utilization of the leaching agent; and the final leaching residue subjected to leaching treatment does not destroy the original mineral composition structure, and can be still used for brick making and other purposes, thereby achieving the dual goals of economy and environment friendliness.

Owner:SICHUAN JUHONG TECH

High-efficiency blende flotation method

The invention relates to an ore dressing method, in particular to a high-grade blende flotation method. The method comprises the main steps that (1) after being subjected to slurry mixing by a stirring bucket, high-grade blende is divided into two paths to flow into slurry pipes for first roughing operation and second roughing operation; and (2) the first roughing operation and the second roughing operation adopt batch flotation, and zinc concentrate is obtained by combining produced concentrate. As for the high-grade blende, the lead content is 6.5% or over, the zinc content is 15.5% or over, and the zinc concentrate grade is 51.0% or over, specifically, the grade lead content of the lead zinc ore industry is 1.0%, and the zinc content of the lead zinc ore industry is 2.0%. The controllable division method is adopted specific to the problem that the grade of selected ore fluctuates severely, the amount of ore pulp for operation is adjusted according to the grade of selected raw ore, the problem that single roughing operation is high in load and low in concentration ratio is solved, the concentrate grade meeting the technical requirements is obtained, the metal recovery rate is increased, and the grading speed of target minerals is increased.

Owner:YILIANG CHIHONG MINING IND

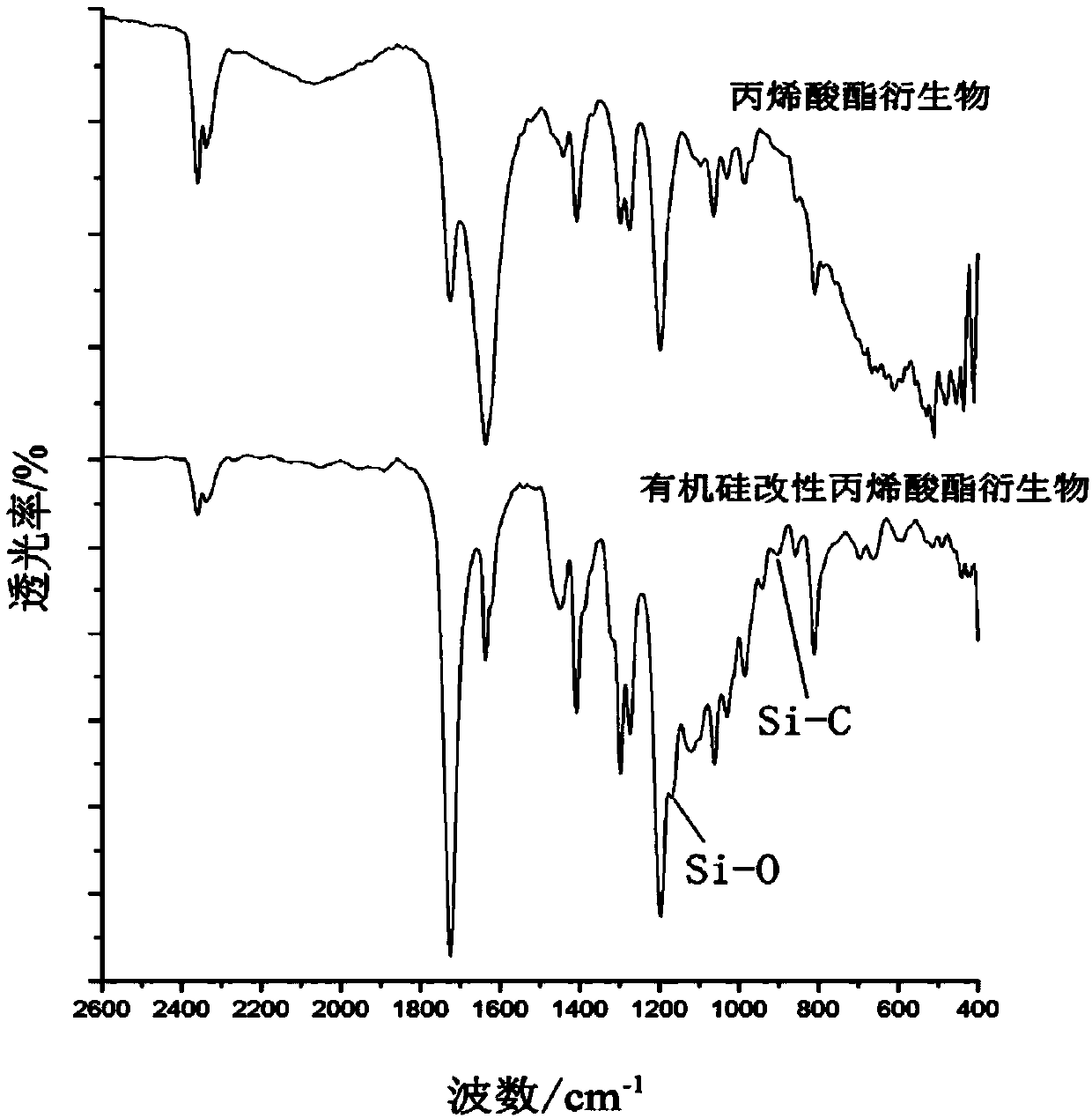

White-resistant pulp used for physical reserve printing by reactive dye

ActiveCN107747241AImprove stabilityThe solution is not easy to storeDyeing processTextile printerAdhesive

The invention belongs to the technical field of textile printing and dyeing, and especially relates to a white-resistant pulp used for physical reserve printing by a reactive dye. The white-resistantpulp comprises the following raw materials by mass percentage: 1-3% of citric acid, 2-4% of sodium trichloroacetate, 3.5-5% of thickening powder, 20-23% of a photosensitive organosilicon-modified acrylic acid ester derivative adhesive, 14-27% of a covering agent, and the balance of deionized water. The reserve printing effect can be obtained through physical shielding effect, the organosilicon-modified acrylic acid ester adhesive capable of rapidly forming a film at low temperature and having no absorption on the reactive dye is used, and is mixed with zincite powder capable of preventing diffusion of the reactive dye, greatly diluting and covering color of the reactive dye, and an acidic printing paste is added for thickening.

Owner:SHENYANG POLYTECHNIC UNIV

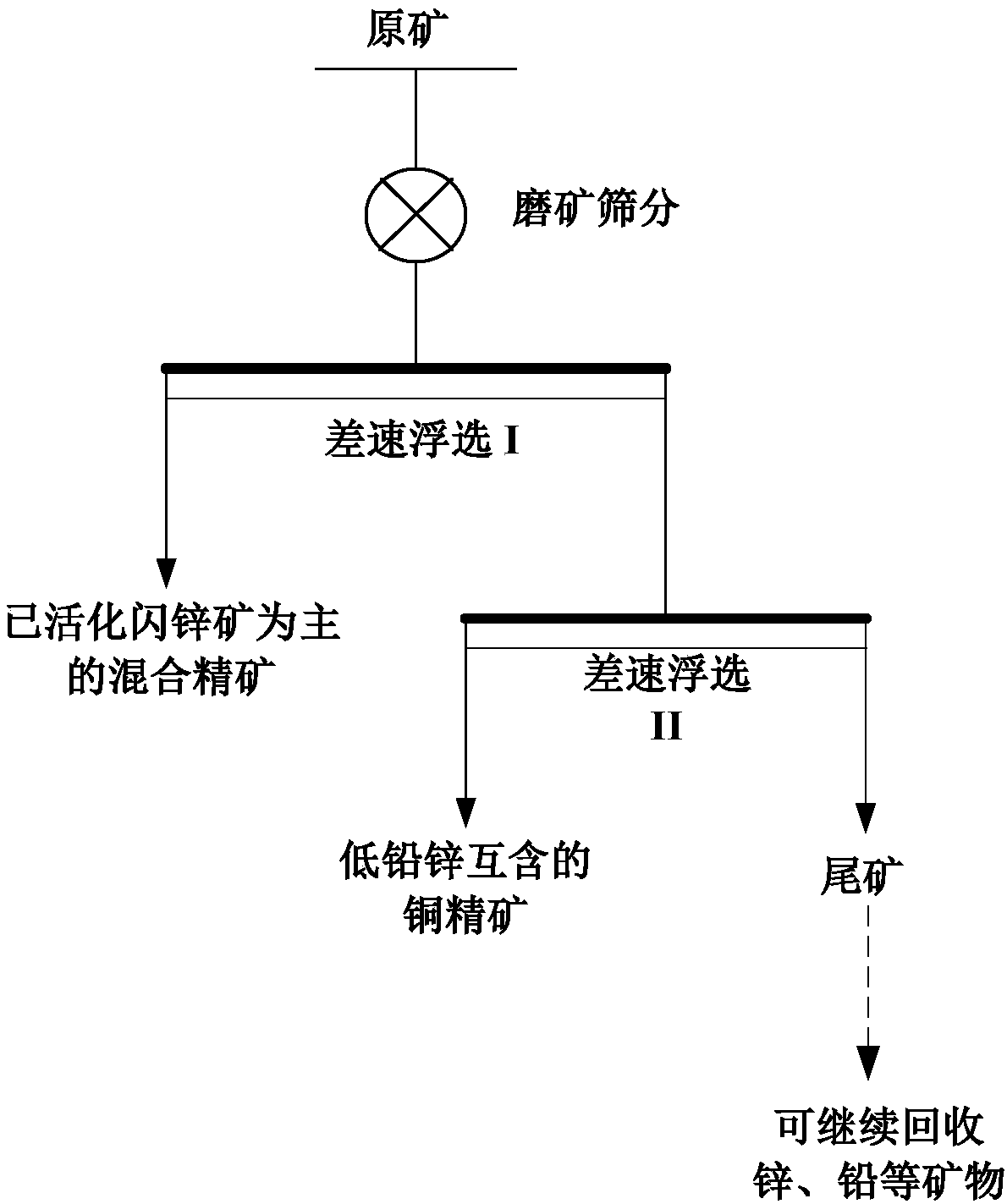

Partial zinc blende activated complex copper-lead-zinc sulfide ore differential flotation separation method

The invention discloses a partial zinc blende activated complex copper-lead-zinc sulfide ore differential flotation separation method. The method comprises the steps that by adding a flotation rate regulator and a pH regulator, the flotation rate of copper pyrites and non-activated zinc blende is lowered, the activated zinc blende flotation rate is increased, and bulk concentrate adopting the activated zinc blende as the main component is obtained through differential flotation; on the basis of the flotation rate regulator and the pH regulator, the flotation rate difference between the copperpyrites and the non-activated zinc blende is increased, high-grade copper concentrate is obtained through flotation separation preferentially, and zinc blende and a small amount of galena can continueto be recycled in nonfloat. The method achieves mineral individuation and differential flotation separation, high-grade copper concentrate can be obtained, meanwhile, the comprehensive recycling rateof copper zinc in sample ore is increased, the flow technology is easy to implement, the economic benefits are remarkable, and comprehensive recycling of hard-dressing complex copper-lead-zinc sulfide ore resources is effectively achieved.

Owner:CENT SOUTH UNIV

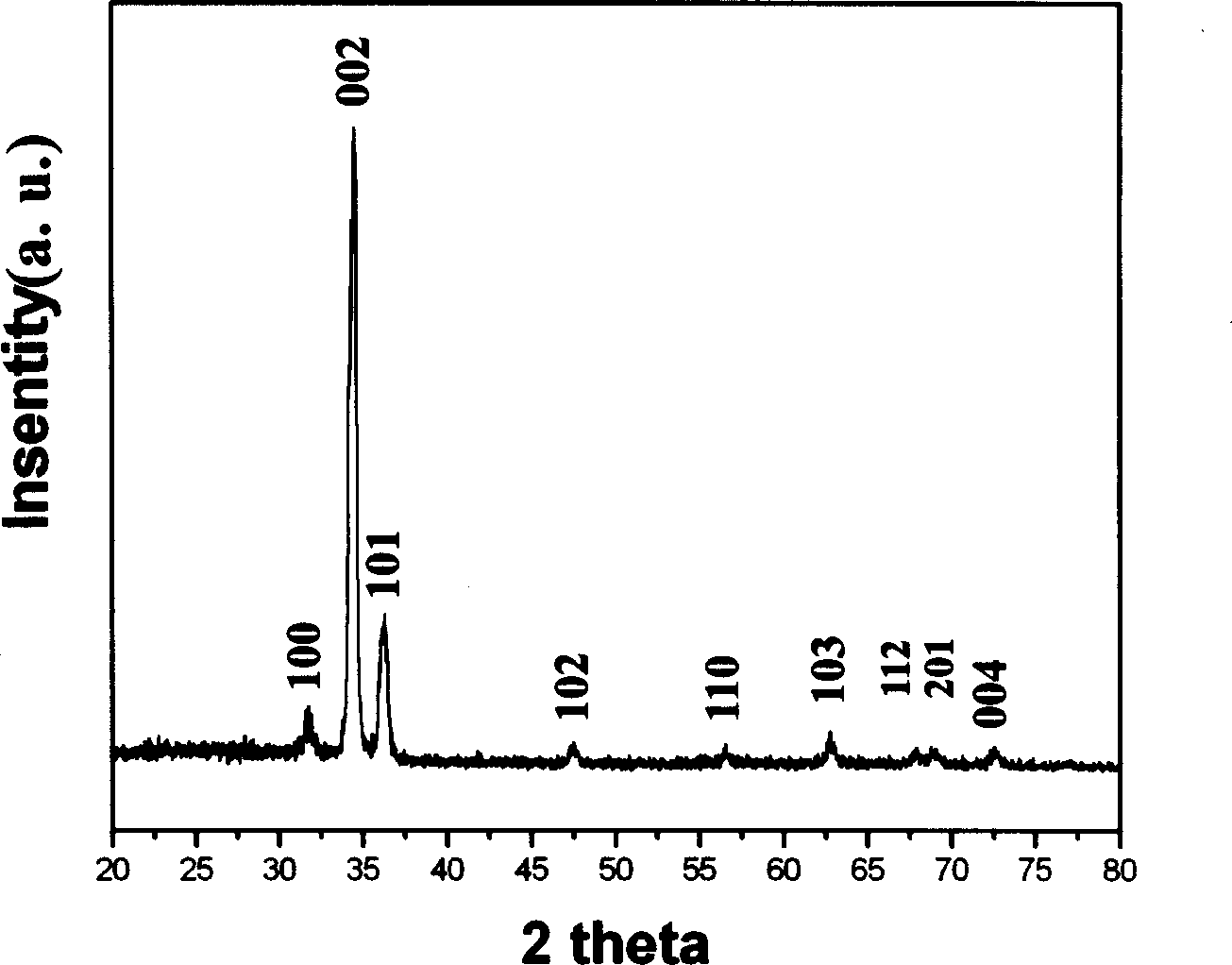

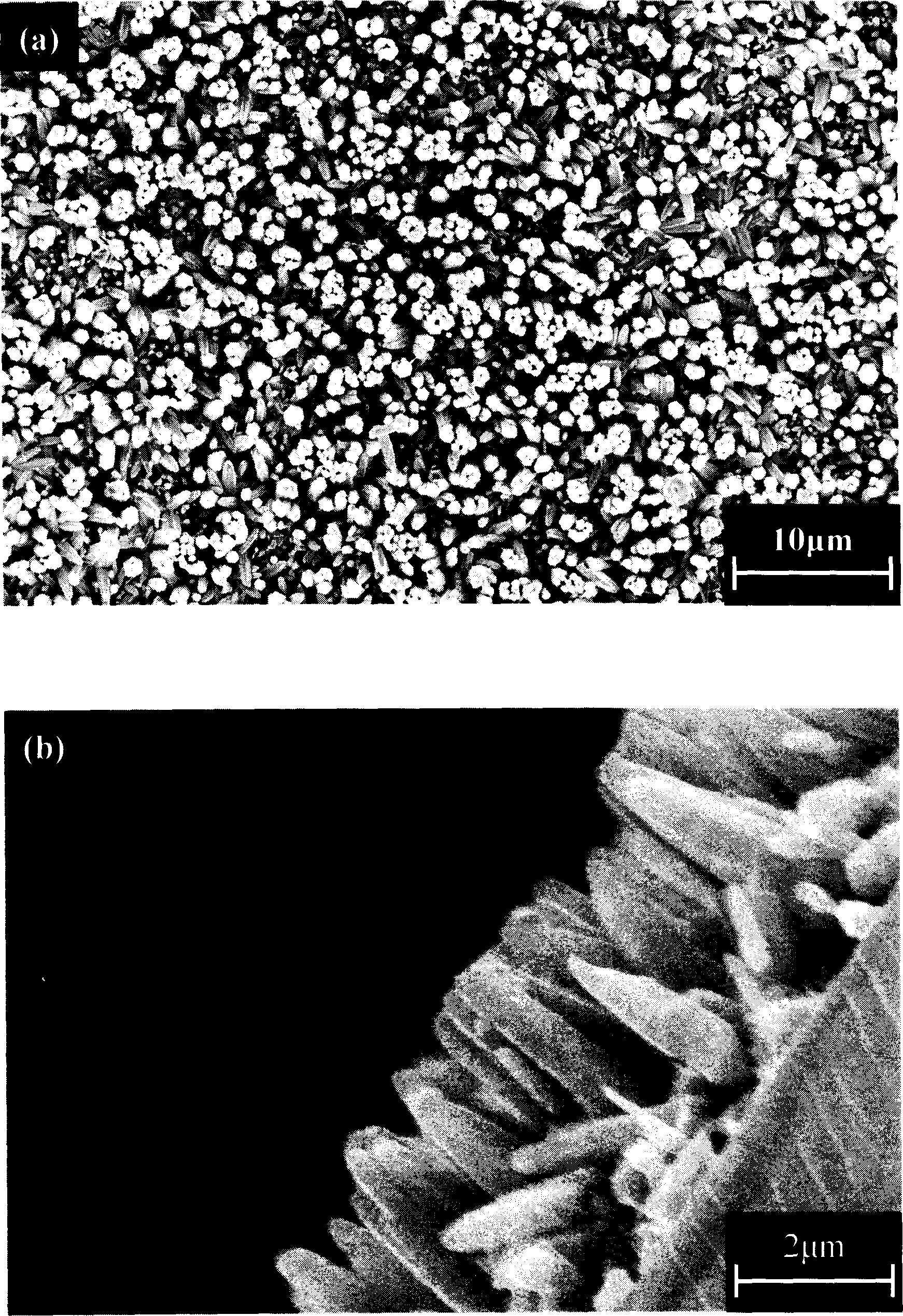

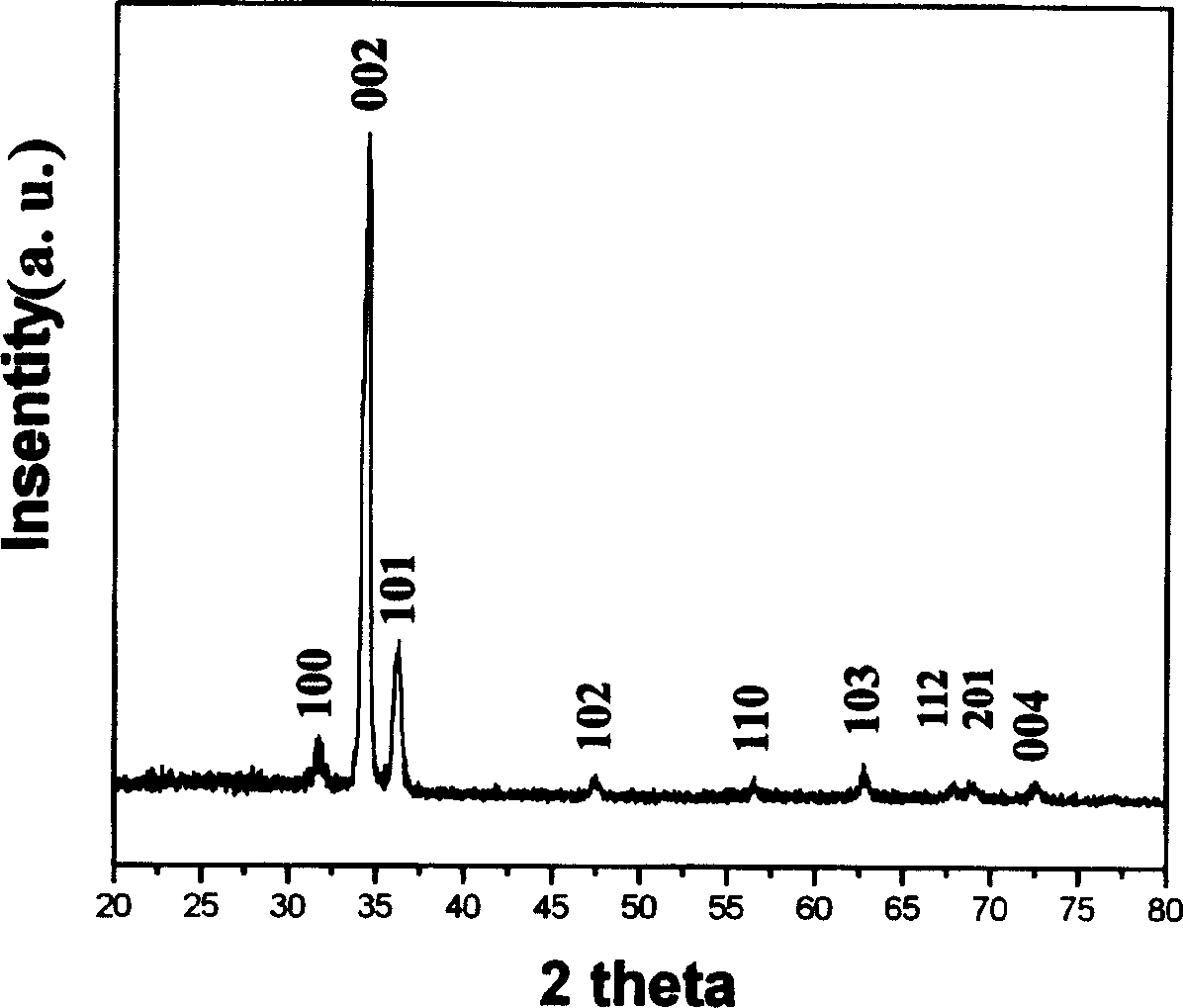

Methof for preparing 3-D orientation zinc oxide film

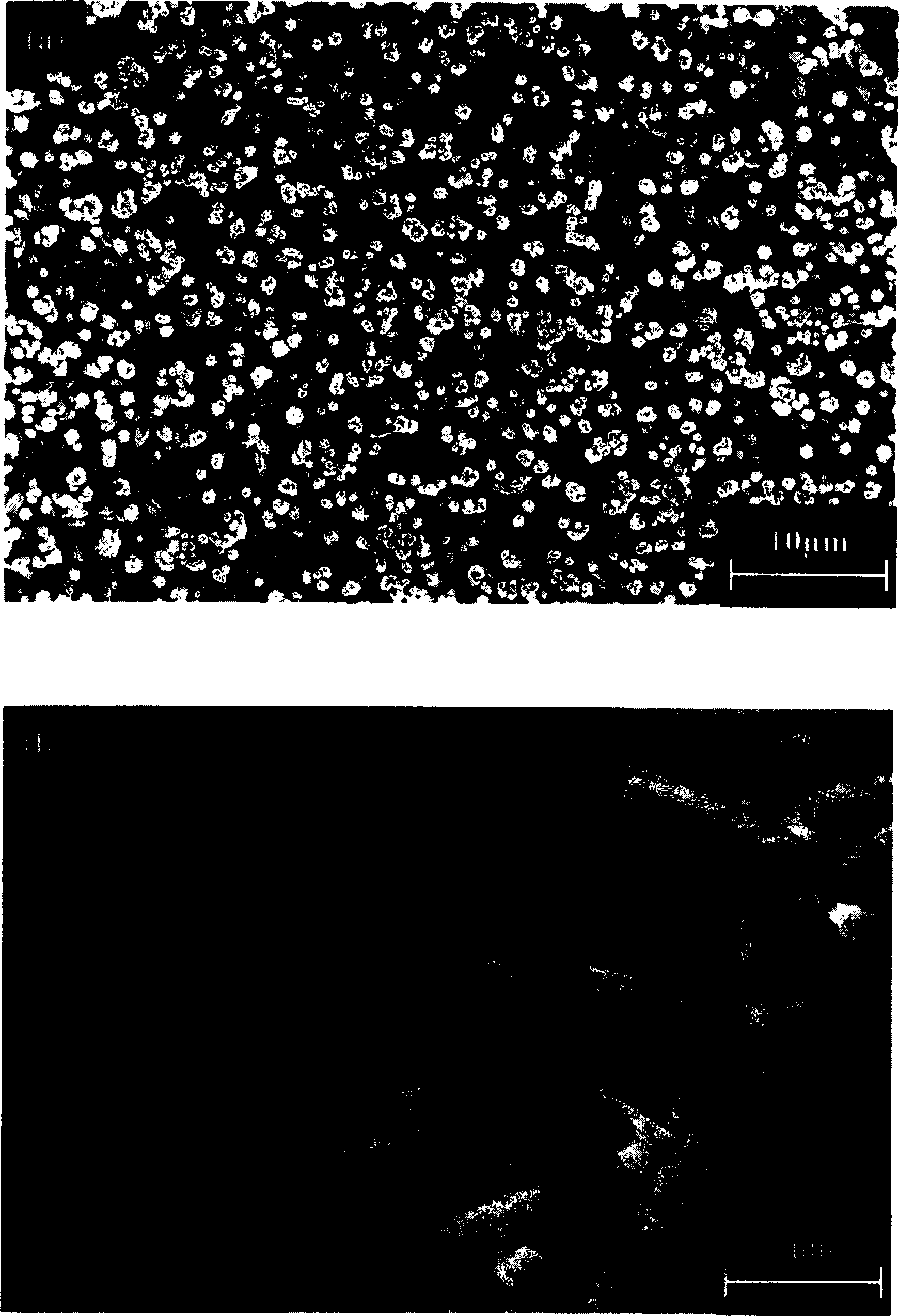

InactiveCN1450599AImprove uniformityUniform growthZinc oxides/hydroxidesSemiconductor/solid-state device manufacturingMicrometerZincite

A preparation method for three-D orientation zincite film is first of all to dissolve zincic salt, ammonia water, and amine salt in deionized water in a certain proportion to form film growing reaction liquid, then, to immerse the processed baseplate in a prepared film growing reaction liquid for 30-60 minutes with temperature of 94-97 deg.C to get densified zincite film with 3-D array after 30-60 minutes reaction. The film is composed of 3-D array micrometer rods with the mean size of 200 nm, 5 um long.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method for nanometer grade zinc oxide crystalline (zincite) sol

InactiveUS7528177B2Less preferredIncreased toxicityMaterial nanotechnologyPigmenting treatmentNanoparticleTransmittance

An environmentally friendly method for preparing zinc oxide (zincite) nanoparticle sol having more than 90% visible light transmission at 20 wt % solid; comprises of the neutralizing, under specific pH, an inorganic zinc salt with an inorganic alkali, both dissolved in ethylene glycol, and thermally aging the precipitates afterward.

Owner:HEADWAY ADVANCED MATERIALS

Method for preparing lead chloride and zinc sulfate by using mid low grade zinc oxide ores and zinc oxide-lead oxide paragenetic ores

The invention discloses a method for preparing lead chloride and zinc sulfate by using mid low grade zinc oxide ores and zinc oxide-lead oxide paragenetic ores, comprising the following steps: (1) crushing zinc ores and levigating, then mixing the levigated zinc ores with ammonium sulfate and roasting; (2) dissolving out clinkers obtained by roasting, carrying out iron precipitation and aluminium precipitation on the obtained filtrate, and further separating lead from the residues of zinc extraction; (3) boiling down a zinc sulfate solution obtained after iron precipitation and aluminium precipitation for electrolysis; and (4) leaching the residues of zinc extraction with an NaCl solution to obtain a filtrate, condensing the filtrate, cooling down and crystallizing out PbCl2 crystals, and returning the NaCl solution to the leaching process. According to the invention, circulation utilization is realized.

Owner:NORTHEASTERN UNIV LIAONING

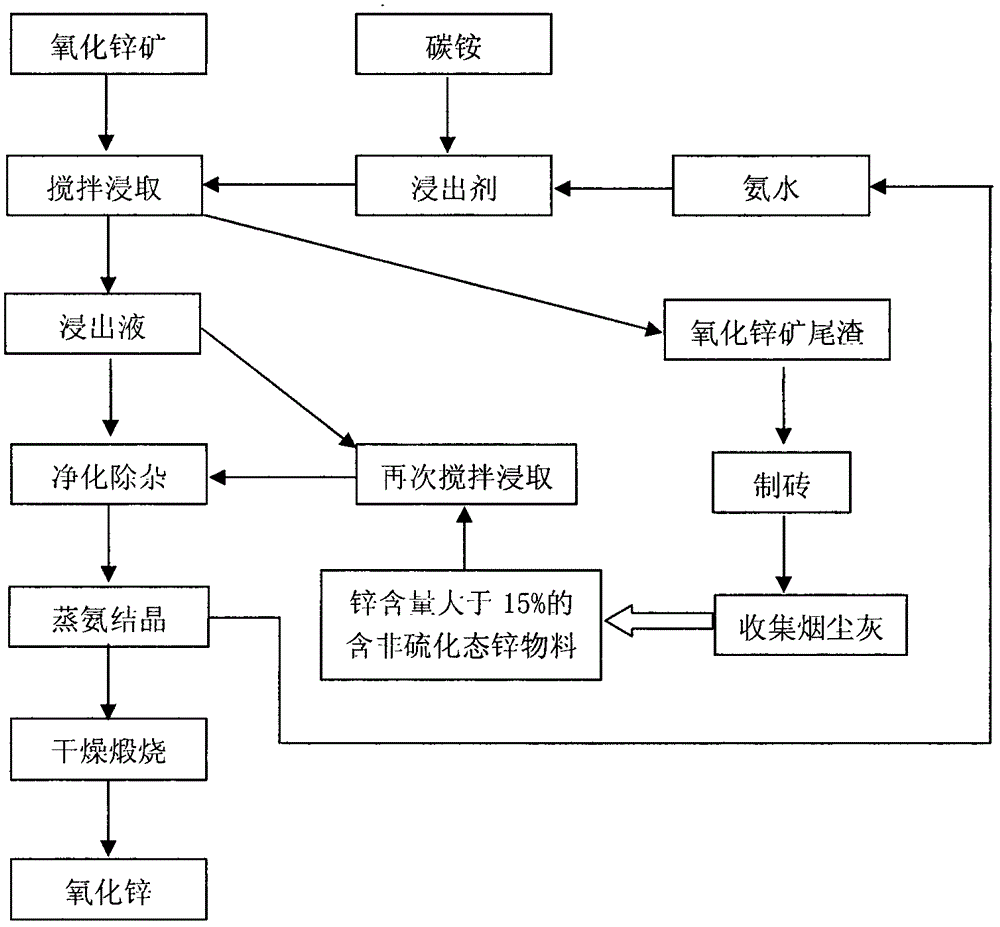

Comprehensive utilization method for zinc oxide ore

InactiveCN106115767AIncreased zinc concentrationReduce energy consumptionMaterial nanotechnologyZinc oxides/hydroxidesBrickZincite

The invention relates to a method for production of zinc oxide products from zinc oxide ore and comprehensive utilization of tailings. According to the method, zinc in the zinc oxide ore is leached by using an ammonia process, then a nonsulfided zinc-containing material with zinc content of 15% or more is added to improve the concentration of zinc in leachate so as to allow zinc oxide ore with a lower grade to be applicable to ammonia-process smelting, and purification, impurity removal, ammonia vaporization, crystallization, drying and calcining are successively carried out to prepare the zinc oxide product; and all or a part of the zinc oxide tailings obtained after leaching are added into brick-making raw materials for brick-making, flue dust is collected during sintering of bricks and then cooled so as to obtain a crude zinc oxide product, and the crude zinc oxide product is returned to the procedure of leaching so as to produce zinc oxide. The method provided by the invention employs a conventional process, the content of prepared zinc oxide is greater than 95%, and the extraction rate of oxidative zinc is more than 85%; and flue dust tailings obtained after extraction are used for preparing bricks via a frequently-used method, so high benefits, environmental protection and comprehensive utilization of the zinc oxide ore are realized.

Owner:李果

Method for producing high-purity zinc oxide by ammonia method using low-grade zinc oxide ores

ActiveCN102863008AGood dispersionImprove liquidityZinc oxides/hydroxidesEnvironmental resistanceBrick

The invention discloses a method for producing high-purity zinc oxide by an ammonia method using low-grade zinc oxide ores. The method comprises the following steps of: adding 3-5% of slaked lime to low-grade zinc oxide ores to be treated for performing mixing and activation before leaching, controlling water in the mixture at 8-10% by mass percentage, adding 0.3-0.5kg of sodium fluorosilicate to per cubic meter of leaching agent, and preferably adding surfactant and dicyandiamide, wherein an ammonia pre-distillation step can be further added simultaneously, therefore, on the one hand, the leaching speed and the leaching rate of zinc in the low-grade zinc oxide ores are increased, and on the other hand, a lower calcination temperature is preferred, zinc oxide with a greater specific surface area and with the purity up to 99.7% and more can be obtained, and the obtained zinc oxide has high economic value; in addition, the treatment method is low in energy consumption and high in efficiency, and the leaching agent can be recycled. The final leaching residues after performing leaching treatment do not damage the original composition and structure of minerals and can still be used to brick-making, thereby achieving economical and environmental-friendly dual purposes.

Owner:SICHUAN JUHONG TECH

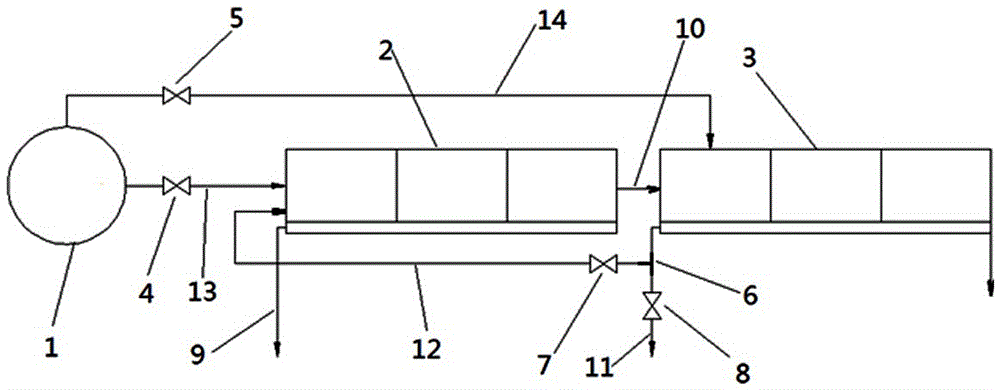

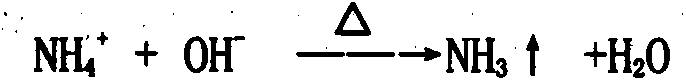

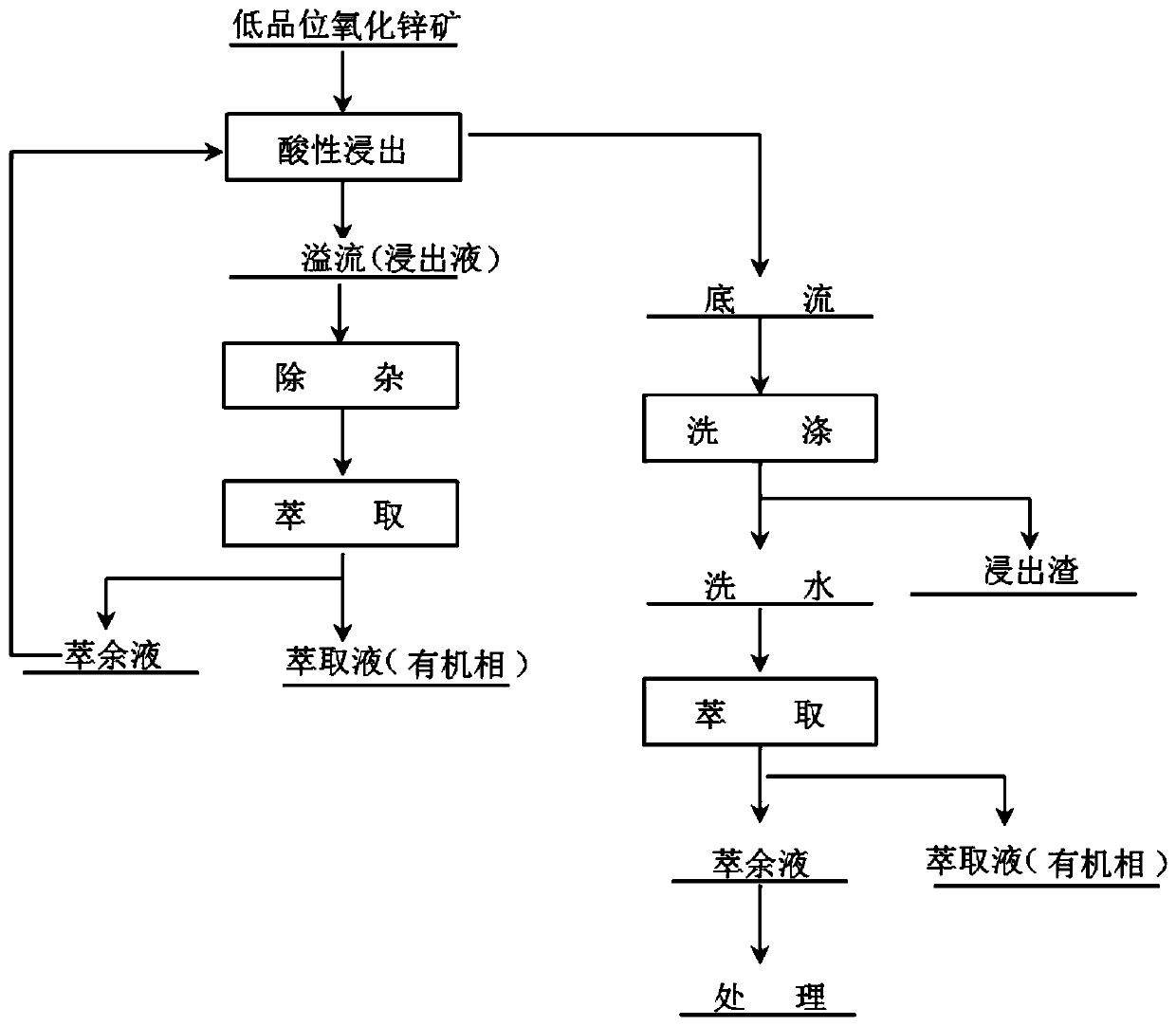

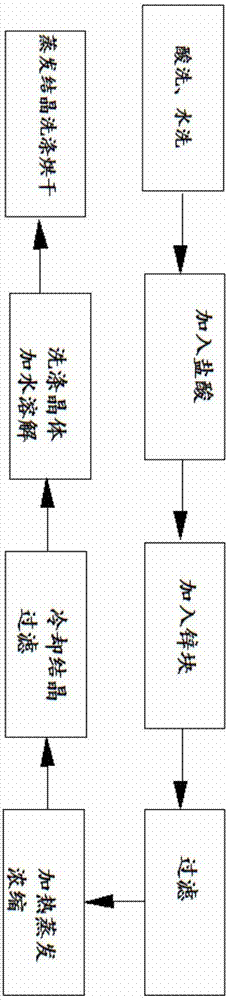

Method for conducting wet processing on low-grade zinc oxide ore

InactiveCN105648473AEasy to handleHigh recovery ratePhotography auxillary processesThree levelKerosene

The invention provides a method for conducting wet processing on low-grade zinc oxide ore and relates to the technical filed of nonferrous metallurgy, in particular to a method for producing high-quality electric zinc from the low-grade zinc oxide ore. The method, provided by the invention, for conducting wet processing on the low-grade zinc oxide ore is wide in application range and high in recovery rate. The method comprises the steps that 1, the zinc oxide ore is fed into a crusher to be crushed and then subjected to fine grinding to below 200 meshes; 2, the ground zinc oxide ore is fed into a leaching pool, water is added for neutral leaching, and stirring is started; 3, a filter press is used for conducting solid-liquid separation on a solution obtained after neutral leaching, leaching residues are fed into an acid leaching pool, and sulfuric acid is added for acid leaching; 4, after acid leaching is finished, solid-liquid separation is conducted through the filter press, a leaching solution is fed to an extraction working procedure, three-level extraction and two-level reverse extraction are adopted, and the organic phase components are 50% of P204 and 260# kerosene; and 5, a solution obtained after extraction is fed into an electrolytic cell for electrolysis, Pb-Ag-Ca-Sr four-element alloy is adopted for an anode, and an aluminum plate is adopted for a cathode.

Owner:许亚夫

Low-grade zinc oxide extraction method

The invention provides a low-grade zinc oxide extraction method. The weight percentage of the zinc element in the low-grade zinc oxide is 1-13wt%, the extraction method comprises the following steps of leaching low-grade zinc oxide and sulfuric acid to obtain a leachate; extracting the leachate to obtain a zinc-containing extracting solution and an acid-containing raffinate; wherein in the leaching treatment step, the dosage of sulfuric acid corresponding to each ton of low-grade zinc oxide is 200-300 kg, and the liquid-solid ratio is (4-6): 1. According to the low-grade zinc oxide extractionmethod, the leaching of impurity metals in the low-grade zinc oxide ores can be inhibited by controlling the concentration of the sulfuric acid and the liquid-solid ratio of the reaction raw materials, so that the purity of the leachate can be improved, and the recovery rate of the zinc element can be improved by virtue of the extraction treatment; on the basis, the invention solves the problem that low-grade zinc oxide ores are difficult to be enriched by beneficiation, the concentration of the zinc in the leaching solution is low and cannot be directly recycled after the leaching solution isdirectly leached.

Owner:CHINA ENFI ENGINEERING CORPORATION

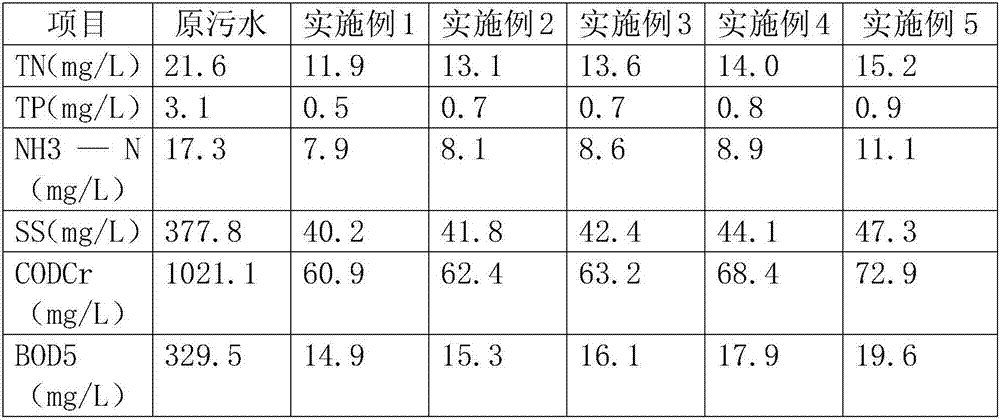

Papermaking sewage treatment agent and preparation method thereof

InactiveCN107445275AEffective coagulationImprove adsorption capacityOther chemical processesWaste water treatment from plant processingSodium BentoniteZincite

The invention belongs to the field of sewage treatment and in particular relates to a papermaking sewage treatment agent. The papermaking sewage treatment agent is prepared from the following raw materials in parts by weight: 60 to 70 parts of shell powder, 8 to 10 parts of zinc chloride, 10 to 15 parts of polyaluminum chloride, 10 to 15 parts of polyacrylamide, 3 to 5 parts of bentonite, 5 to 7 parts of zincite powder and 5 to 8 parts of trioctylamine; a preparation method of the treatment agent comprises the following steps: weighing all the raw materials in parts by weight according to the requirement; after the shell powder is subjected to pre-treatment including curing and the like, putting the shell powder and the other raw materials into a reaction kettle together; pre-heating, mixing and stirring for 2h to 3h under the condition that the temperature is 65 DEG C to 75 DEG C; then raising the temperature to 100 DEG C to 110 DEG C, and standing and keeping heat for 1h to 2h; then discharging a product, naturally cooling and sealing and packaging. A processing method of the papermaking sewage treatment agent disclosed by the invention is simple; suspended matters, inorganic salt and organic matters in papermaking sewage can be effectively coagulated and adsorbed and the treatment efficiency of the sewage is improved.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

Method for producing high purity metal zinc from zinc oxide ore

The method for producing high-purity metal zinc by using low-grade zincite ore as raw material includes the following steps: firstly, pulverizing zincite ore into the zincite ore powder whose grain size is 0.1-1mm, soaking in strong alkaline solution, slowly stirring for 60-100 min, at 10-100 deg.C to extract the zinc and lead from zincite ore, filtering, discharging filter residue for making brick or burying, then adding dispersing agent whose added quantity is 0.1-5 times (mole ratio) lead content into the filtrate containing zinc and lead, stirring for 60-100 min., filtering, precipitating separated lead and electrolyzing the filtrate containing zinc, finally, depositing and obtaining metal zinc whose purity is above 99.95% on the cathode.

Owner:昆明同越科技开发有限公司

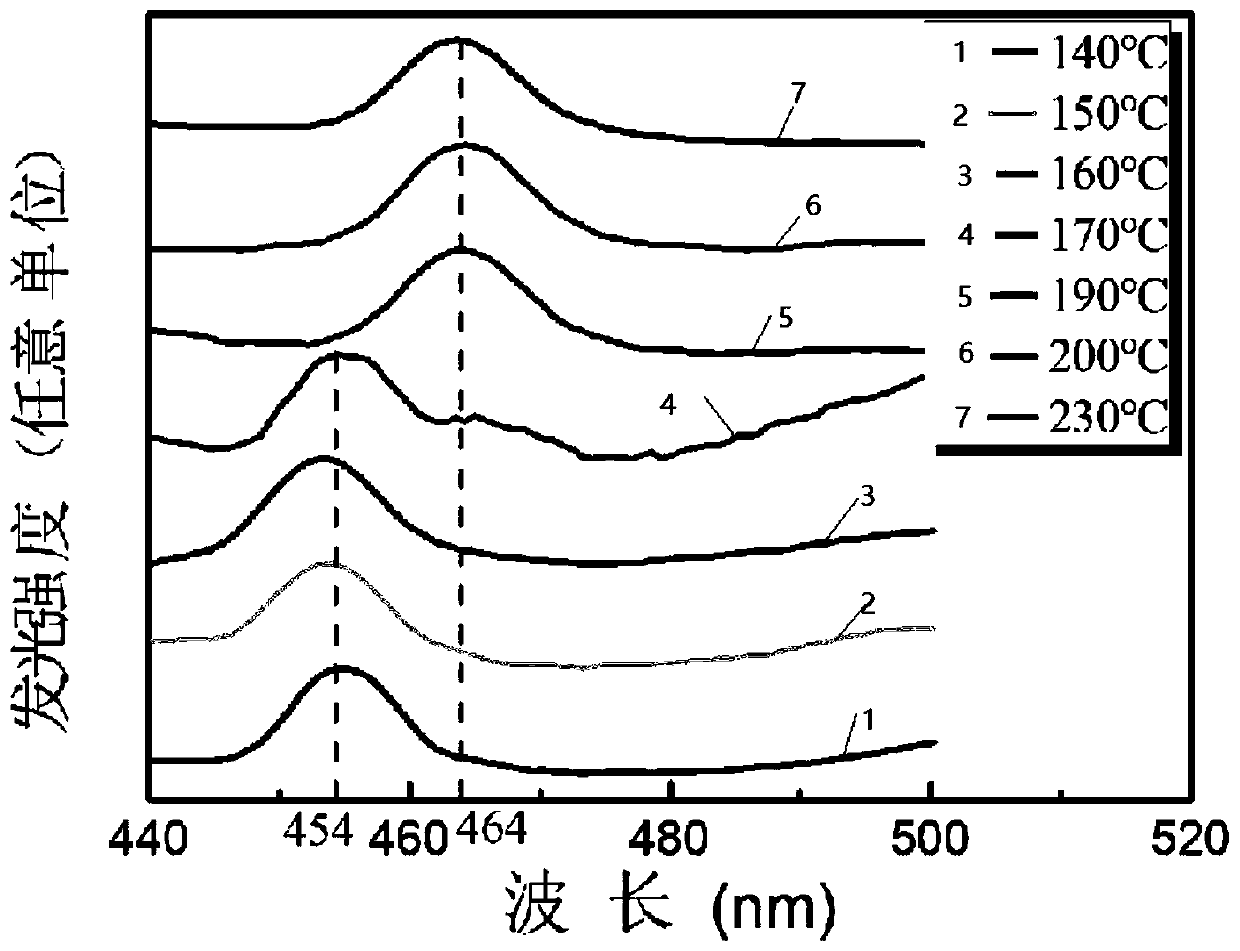

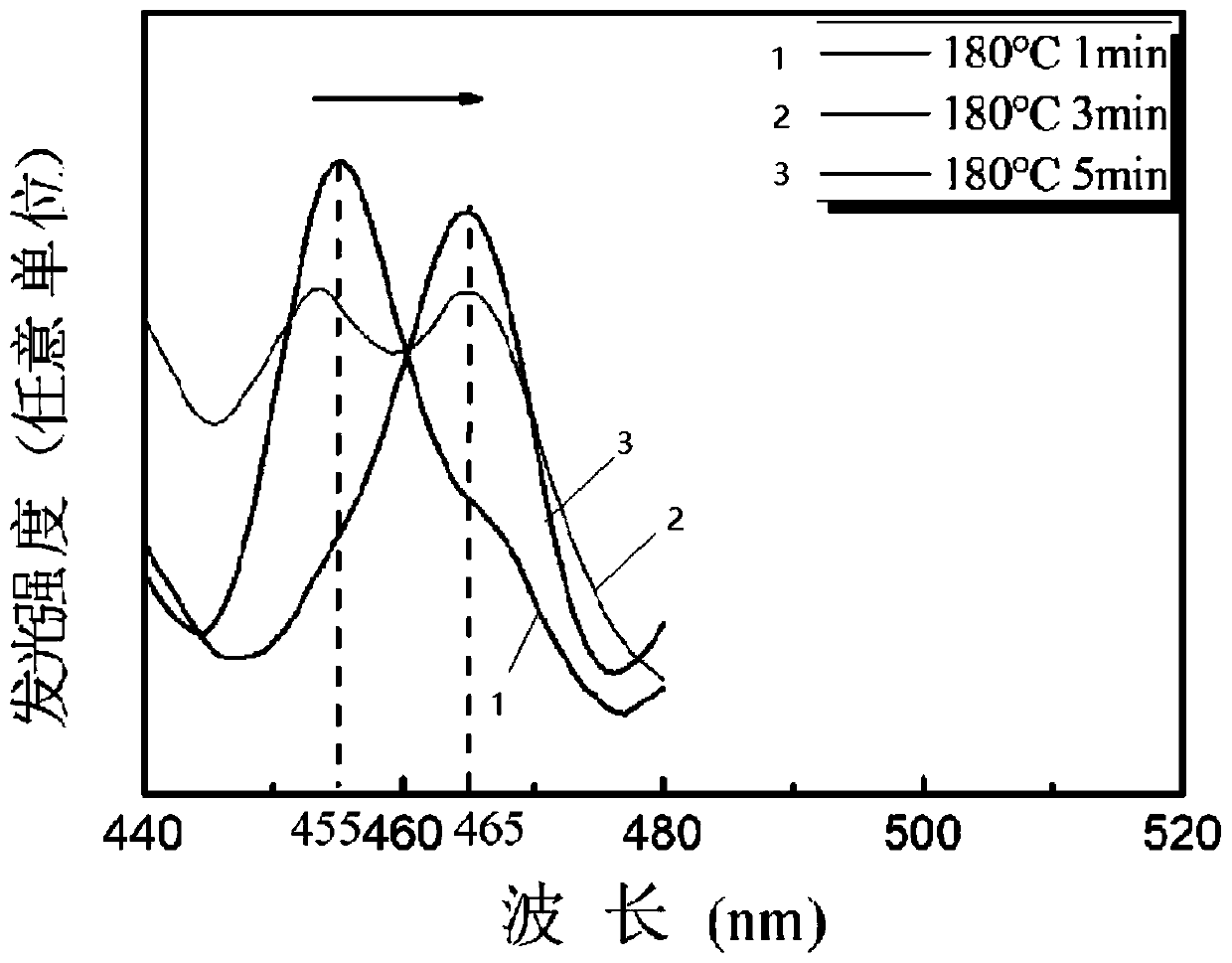

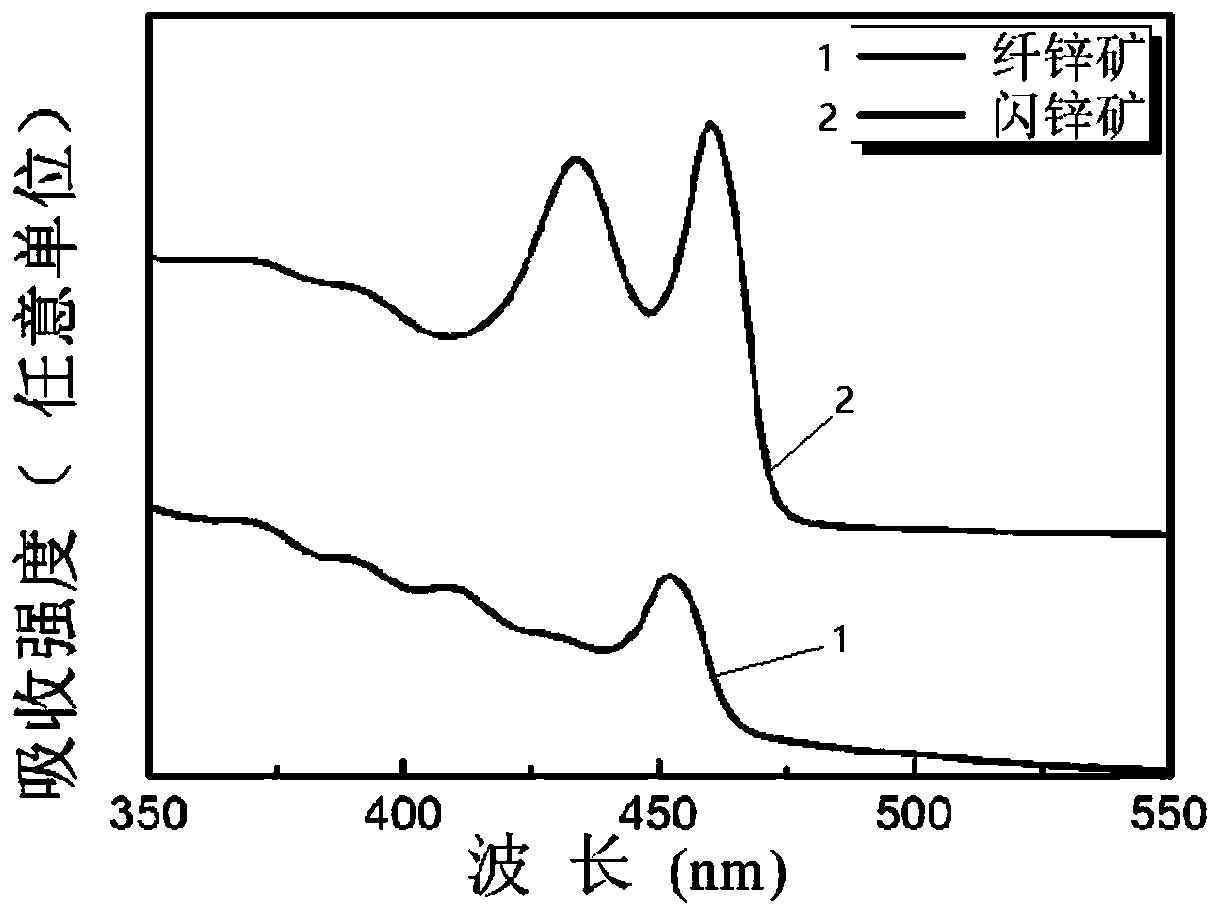

Blue light CdSe nanosheet crystal form regulation and control method

ActiveCN109896507AModulate the emission peakAdjust the sizeNanoopticsLuminescent compositionsReaction temperatureCadmium acetate

The invention discloses a blue light CdSe nanosheet crystal form regulation and control method. According to the blue light CdSe nanosheet crystal form regulation and control method, reaction temperature is reduced, and reaction time is prolonged based on conventional blue light CdSe nanosheet synthesis, wherein the CdSe nanosheet is prepared through adding of cadmium acetate dihydrate, selenium powder, and oleic acid into octadecene (ODE), and degrassing at inert atmosphere. The advantages are that: accurate regulation and control of reaction temperature and reaction time are adopted, so thatstructure mutual conversion of synthesized nanosheet between face centered cubic zinc blende structure and hexagonal wurtzite structure is realized, and nanosheet crystal structures, emission peaks,and sizes can be adjusted and controlled preferably; and in addition, Se-ODE is taken as the selenium source in conventional wurtzite synthesis technology, in the blue light CdSe nanosheet crystal form regulation and control method, Se powder is taken as a selenium instead of Se-ODE, Se-ODE synthesis time is about 6h, when Se powder is adopted, reaction time is only 3min to 1h, and unreacted Se powder can be precipitated directly, so that centrifugation purification is more convenient.

Owner:合肥净龙环保科技有限公司

Method of producing calcium zincate by means of zinc-containing raw ore

InactiveCN108622925ARealize economic and environmental protection utilizationEfficient extractionZinc compoundsZincateDistillation

The invention relates to a method of producing calcium zincate by means of zinc-containing raw ore. The method includes: an extraction step, an optional purification step, a decarbonization step, a calcium zincate synthesis step, a rinsing step, and a drying step. In the method, wet-leaching and synthetic technologies are combined, thus achieving economical and environment-friendly utilization ofultralow-grade zinc ore. The method is wide in application range, is free of ammonia distillation and is simple, can greatly reduce energy consumption, and can avoid problems of safety risk due to high-temperature and high-pressure and equipment corrosion, solves a problem of environmental protection of influence on process water balance since steam brings excessive water into an ammonia circulation process and solves a problem of recovery rate and grade of fine products of the technology. The method is low in pollution and is recyclable in assistant materials. For the first time, synthesis ofthe calcium zincate is achieved under the zinc-ammonia environment in the method.

Owner:CHONGQING DONGQUN TECH CO LTD

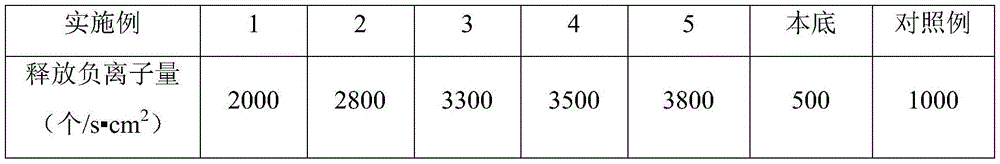

Anion composite powder suitable for building materials

The invention discloses an anion composite powder suitable for building materials. The anion composite powder is prepared from, by mass, 30-80 parts of schorl powder, 20-40 parts of zincite powder, 1-8 parts of calcium stearate, 1-5 parts of zinc oxide, 1-8 parts of cerium oxide, 0-30 parts of rare earth, 1-30 parts of iron sesquioxide, 1-8 parts of monazite powder and 1-8 parts of sodium hexametaphosphate. According to the anion composite powder in the technical scheme, a preparing technology is simple, and the price of the raw materials is low; an anion plate has perdurability, efficiency and the environment-friendly performance, the prepared anion plate can efficiently and stably release anions with the density of 2,000-3,800 per s.cm<2>, air can be purified, indoor peculiar smells and harmful gas can be removed, and the anion composite powder is an environment-friendly anion additive.

Owner:ZHUO DA NEW MATERIAL TECH GRP

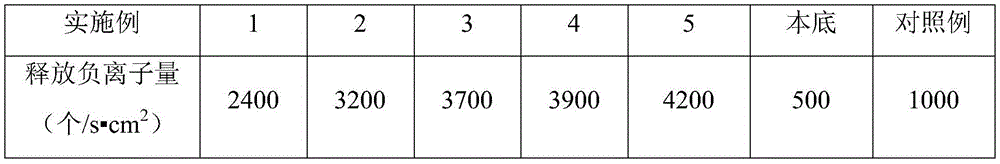

Negative ion composite powder suitable for building materials

InactiveCN105601146ASimple preparation processSuitable for mass productionSolid waste managementRare earthMonazite

The invention discloses negative ion composite powder suitable for building materials. The negative ion composite powder is prepared from, by mass, 30-80 parts of black tourmaline powder, 20-40 parts of zincite powder, 1-8 parts of calcium stearate, 1-5 parts of zinc oxide, 1-8 parts of cerium oxide, 0-30 parts of rare earth, 1-30 parts of ferric oxide, 1-8 parts of waterborne acrylic acid, 1-8 parts of monazite powder and 1-8 parts of sodium hexametaphosphate. According to the technical scheme, the preparation process is simple, raw materials are low in price, a negative ion plate has durability, high efficiency and environment friendliness, the made negative ion plate can release 2400-4200 negative ions per second.cm<2> efficiently and stably, purify air and eliminate indoor peculiar smells and harmful gases, and the composite powder is an environment-friendly negative ion additive.

Owner:ZHUO DA NEW MATERIAL TECH GRP

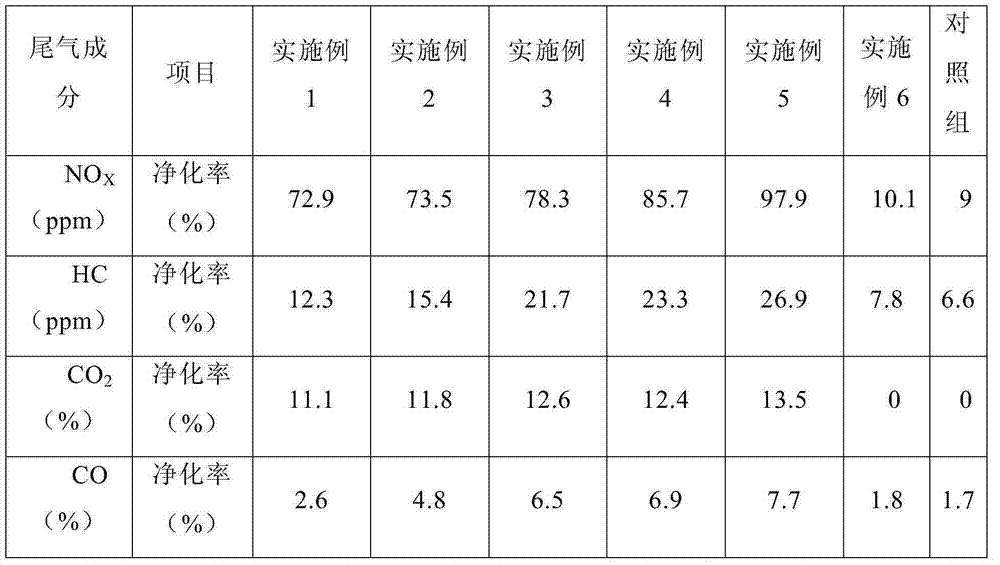

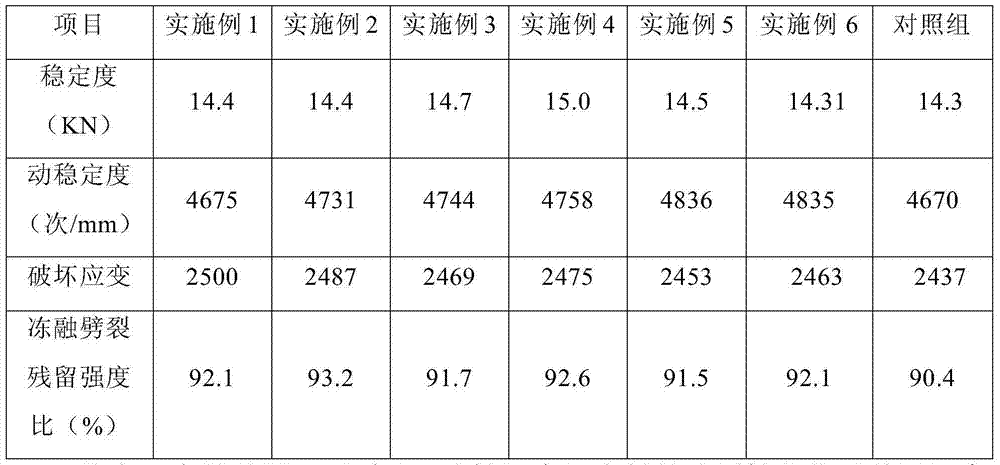

Asphalt concrete modifier and application thereof

The invention relates to an asphalt concrete modifier and its application. The modifier contains willemite. The asphalt concrete modifier also contains zincite and stannite. The zincite is nanoscale zincite powder. The stannite is nanoscale stannite powder. It shows through researches that willemite can be used as a modifier which can be used to enhance pavement performance during paving of an asphalt mixture. It shows through further researches that zincite and stannite can obviously raise adsorption function of the asphalt mixture and can adsorb harmful gas in automobile exhaust. Meanwhile, compatibility between zincite, willemite and stannite and the asphalt concrete can be raised after JL-G02FX amino-terminated polyol ester is added into a surface modifier of the asphalt concrete, and ultrafine inorganic powder modified asphalt has good storage stability.

Owner:CHANGAN UNIV

Ceramic material radiator

InactiveCN108147819AWith environmental heat conduction functionWith radiation heat conduction functionLighting heating/cooling arrangementsZinciteRadiant heat

The invention discloses a ceramic material radiator. The radiator is prepared by grinding and injection molding of the following raw materials in parts by weight: 96-116 parts of aluminum nitride, 1.5-3.5 parts of magnesium oxide, 10-20 parts of silicon micro powder, 8-12 parts of kaolin, 8-12 parts of zincite powder, 5-7 parts of titanium dioxide, and 8-12 parts of an injection molding substance.The ceramic material radiator provided by the invention not only has an environmental heat conduction function of a metal material, but also has a radiant heat conduction function, so that the radiator has more excellent heat conduction performance and insulating performance, and makes bulbs safer.

Owner:何明俊

Surface Treatment Method of Bright Engine Cylinder Head

ActiveCN105200508BClean appearanceAnti-corrosion and anti-mildew effectTectorial membraneElectrolysis procedure

The invention discloses a bright engine cylinder cover surface treatment method. The bright engine cylinder cover surface treatment method comprises the following steps of electrolysis procedure: performing electrolysis on a cylinder cover in electrolyte arranged in an electrolytic bath; soaking procedure: soaking the electrolyzed cylinder cover in protection liquid; and solidifying procedure: solidifying the soaked cylinder cover so that a protection film is formed on the surface of the cylinder cover. The electrolyte contains sodium sulfate with concentration of 18g / L, zincite with concentration of 3.5g / L, sodium superoxide with concentration of 4g / L, sodium alkyl sulfonate with concentration of 1g / L, and the balanced water. By the engine cylinder cover surface treatment method, the surface of the cylinder cover can be clean, burnt-on sand of an inner duct of the cylinder cover can be removed, a black or grey surface caused by shot blasting is avoided, the protection film capable of preventing mildew spots is obtained, and has good discoloration resistance and corrosion resistance, the bright and attractive cylinder cover can be obtained, and the cylinder cover has effects of preventing corrosion and mildew spots.

Owner:WUHU YONGYU AUTOCAR INDAL

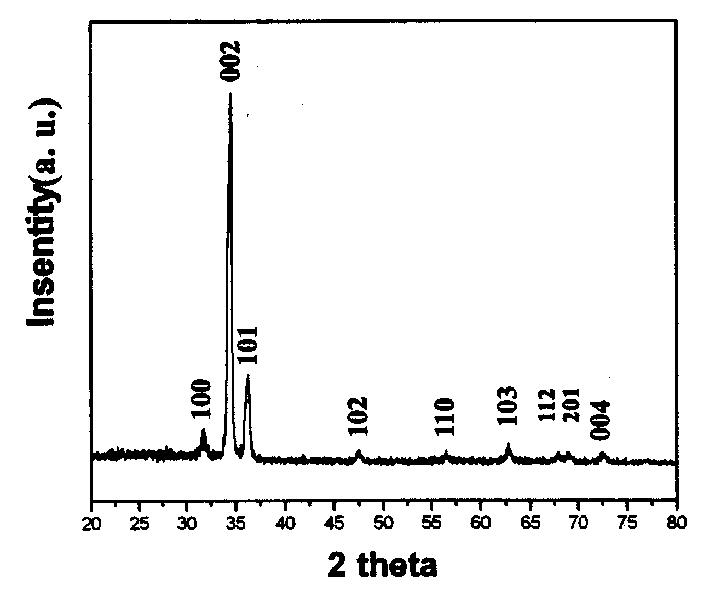

Methof for preparing 3-D orientation zinc oxide film

InactiveCN1188901CImprove uniformityUniform growthZinc oxides/hydroxidesSemiconductor/solid-state device manufacturingMicrometerZincite

Owner:SHANGHAI JIAOTONG UNIV

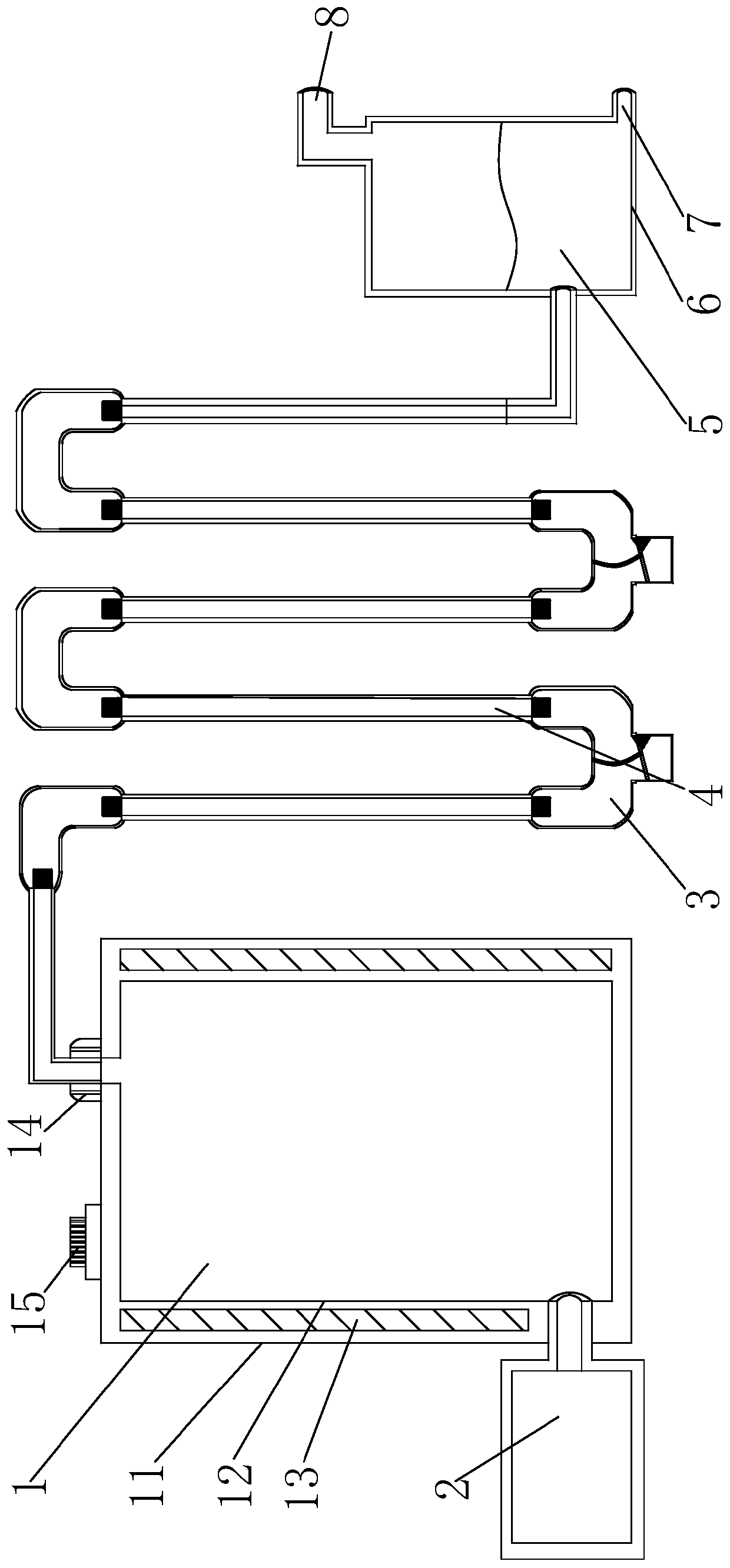

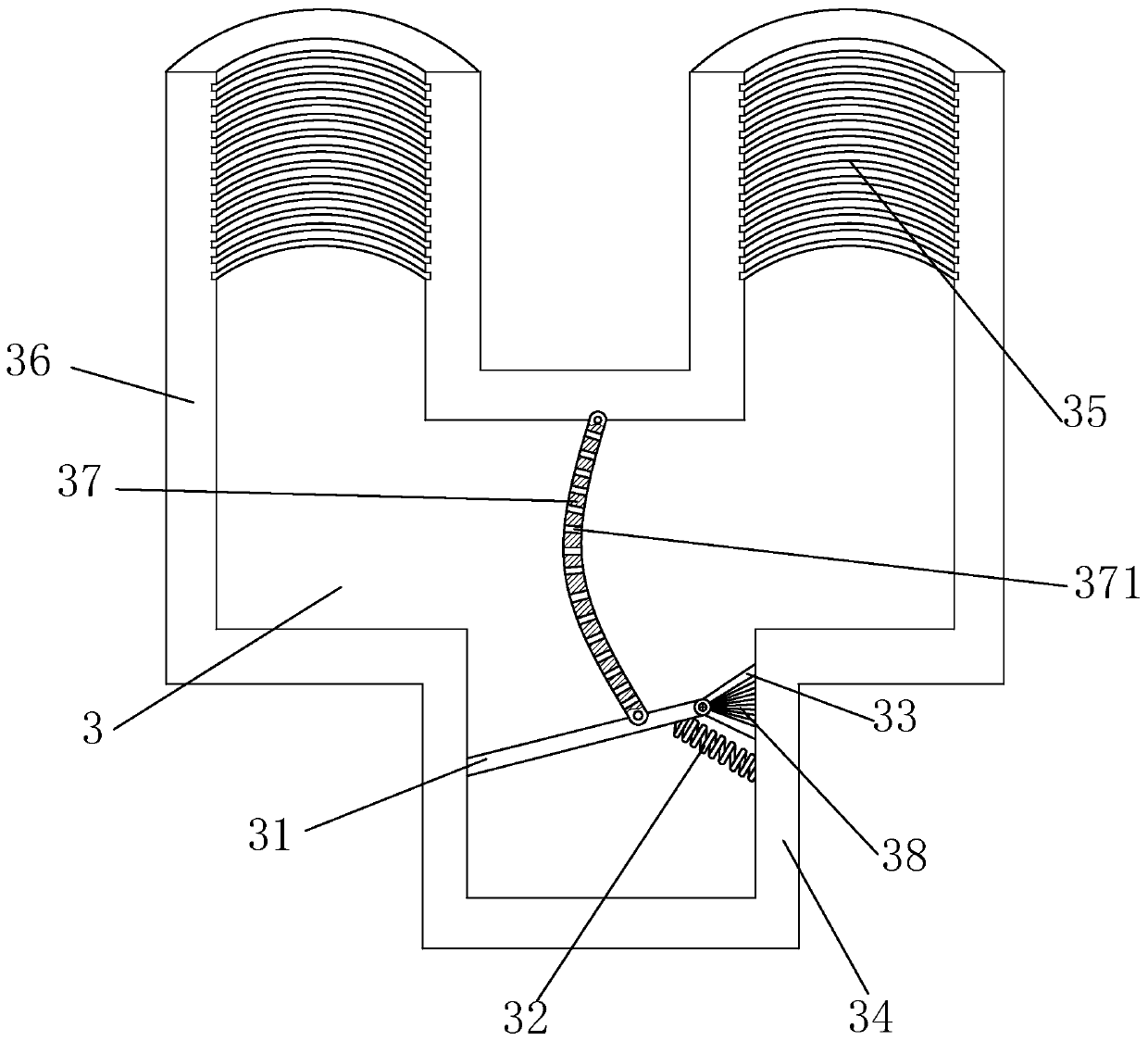

High-ferric polymetallic zinc ore smelting furnace

ActiveCN110160359AEasy to replaceSlow dischargeIncreasing energy efficiencyCrucible furnacesStraight tubeAtmospheric pressure

The invention discloses a high-ferric polymetallic zinc ore smelting furnace. The high-ferric polymetallic zinc ore smelting furnace comprises a furnace body, a curved tube, a straight tube, a filtrate, a filter box and a water outlet, wherein a fan body is fixed at the lower end of one side of the furnace body, and the straight pipe is fixed at the upper end of the furnace body; and the other endof the straight pipe is fixedly provided with the curved tube, the other end of the curved tube is fixedly provided with the filter box, and the upper end of the interior of the filter box is fixedlyprovided with an air outlet. According to the high-ferric polymetallic zinc ore smelting furnace, disassembling and assembling can be better achieved, aged and blocked pipelines can be conveniently replaced, and the replacement inconvenience and economic loss caused by replacement of the whole pipelines due to aging and blocking are avoided; and the phenomena that due to the fact that particles are accumulated for a long time, the curved pipe is blocked, exhaust of waste gas is too low, the smelting efficiency is reduced, and the air pressure in the smelting furnace is too high, the explosionof the smelting furnace is caused, economic losses caused by the damage of the smelting furnace are caused, and the life safety of surrounding people can be threatened seriously are avoided.

Owner:安徽友进冠华新材料科技股份有限公司

Method for producing high-purity nano zinc oxide from low-grade zinc oxide ores

ActiveCN102839282BFast leachingFully recycleZinc oxides/hydroxidesProcess efficiency improvementEnvironmental resistanceBrick

The invention discloses a method for producing high-purity nano zinc oxide from low-grade zinc oxide ores, which comprises the following steps: leaching with an ammonia water-ammonium bicarbonate solution; adding 0.3-0.5kg of sodium fluosilicate into per cubic meter of the ammonia water-ammonium bicarbonate solution; performing ammonia pre-evaporation; then performing purification and impurity removal; and finally refining. According to the invention, the ammonia method is used for the treatment of electrolyzing low-grade zinc oxide ores, and the existing ammonia method is adaptively improved, so that zinc in the low-grade zinc oxide ores can be sufficiently recycled. Through the treatment of the technical means of the invention, the purity of zinc oxide obtained by calcining at 350-450 DEG C can be up to 99.7% or above; the nano zinc oxide product of which the particle size is 10-50nm has a high economic value; the treatment method is low in energy consumption and high in efficiency, and realizes the cyclic utilization of the leaching agent; and the final leaching residue subjected to leaching treatment does not destroy the original mineral composition structure, and can be still used for brick making and other purposes, thereby achieving the dual goals of economy and environment friendliness.

Owner:SICHUAN JUHONG TECH

Preparation method of activator

The invention provides a preparation method of an activator, which comprises pickling zinc ore, washing with water, adding hydrochloric acid, adding zinc block, filtering, heating, evaporating and concentrating, cooling and crystallizing and filtering, adding water to dissolve the washed crystal, evaporating and crystallizing, washing and drying to obtain a finished product . The method is simple and practical, has low manufacturing cost, and is suitable for mass production of the product.

Owner:佛山市诚新泰不锈钢制品有限公司

Bright engine cylinder cover surface treatment method

ActiveCN105200508AClean appearanceAnti-corrosion and anti-mildew effectTectorial membraneElectrolysis procedure

The invention discloses a bright engine cylinder cover surface treatment method. The bright engine cylinder cover surface treatment method comprises the following steps of electrolysis procedure: performing electrolysis on a cylinder cover in electrolyte arranged in an electrolytic bath; soaking procedure: soaking the electrolyzed cylinder cover in protection liquid; and solidifying procedure: solidifying the soaked cylinder cover so that a protection film is formed on the surface of the cylinder cover. The electrolyte contains sodium sulfate with concentration of 18g / L, zincite with concentration of 3.5g / L, sodium superoxide with concentration of 4g / L, sodium alkyl sulfonate with concentration of 1g / L, and the balanced water. By the engine cylinder cover surface treatment method, the surface of the cylinder cover can be clean, burnt-on sand of an inner duct of the cylinder cover can be removed, a black or grey surface caused by shot blasting is avoided, the protection film capable of preventing mildew spots is obtained, and has good discoloration resistance and corrosion resistance, the bright and attractive cylinder cover can be obtained, and the cylinder cover has effects of preventing corrosion and mildew spots.

Owner:WUHU YONGYU AUTOCAR INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com