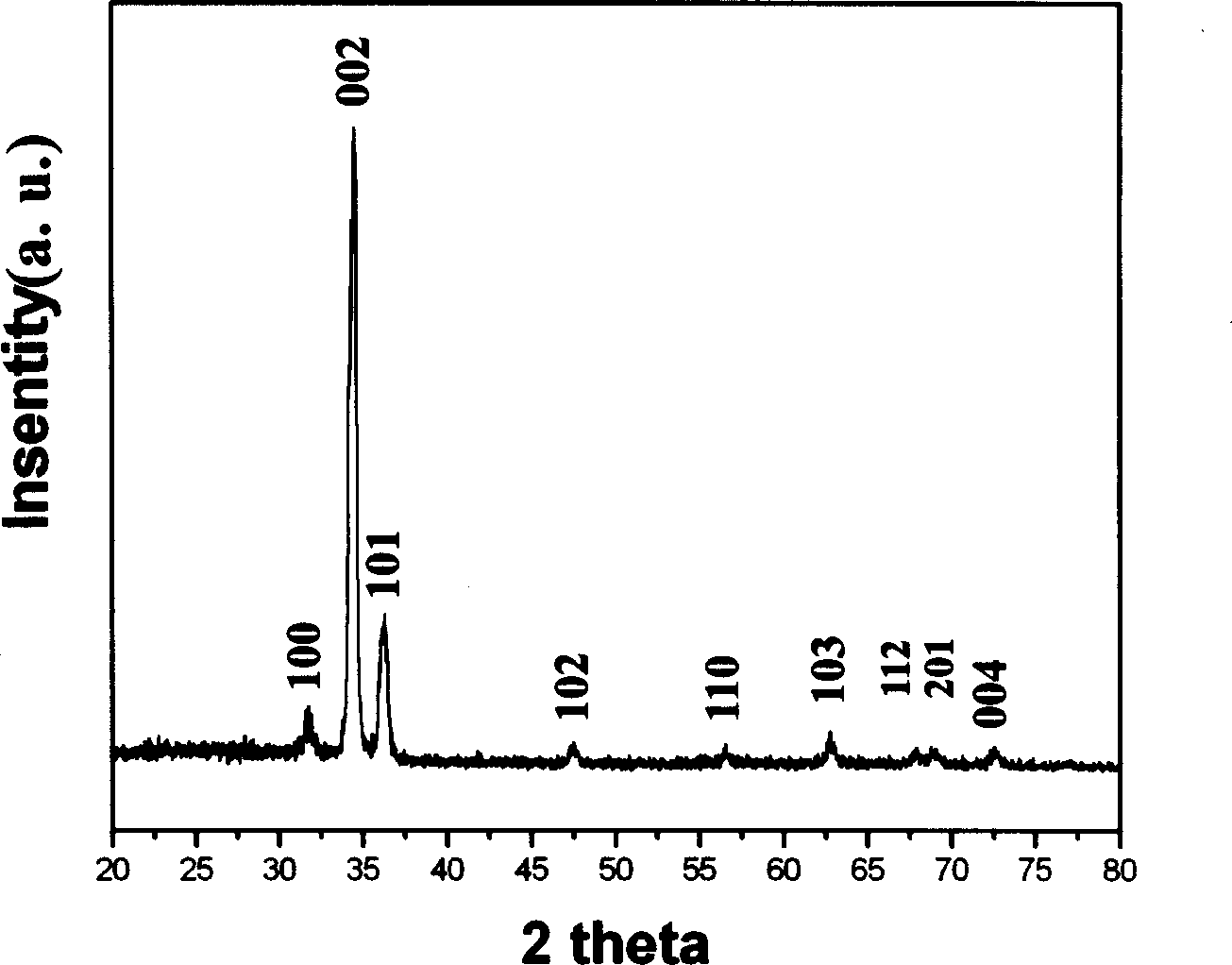

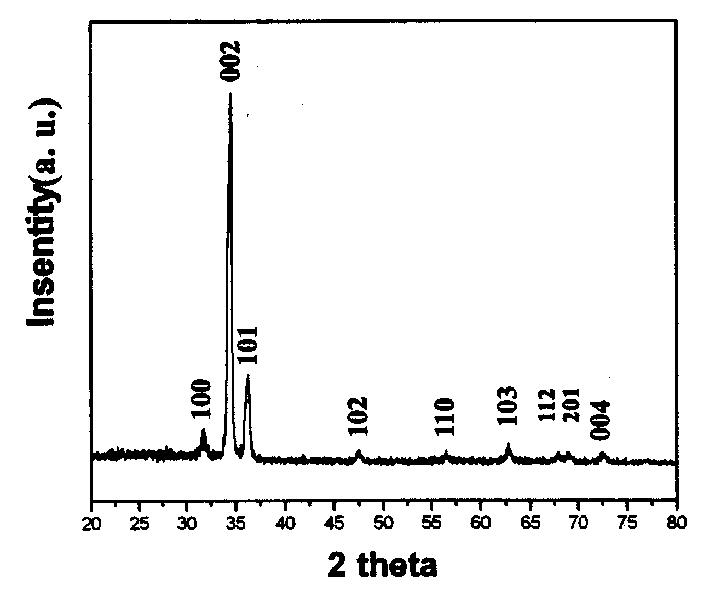

Methof for preparing 3-D orientation zinc oxide film

A zinc oxide film, three-dimensional orientation technology, applied in zinc oxide/zinc hydroxide, liquid chemical plating, semiconductor/solid-state device manufacturing, etc., can solve the problems of high reaction temperature, complex equipment, low efficiency, etc. Low, good uniformity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

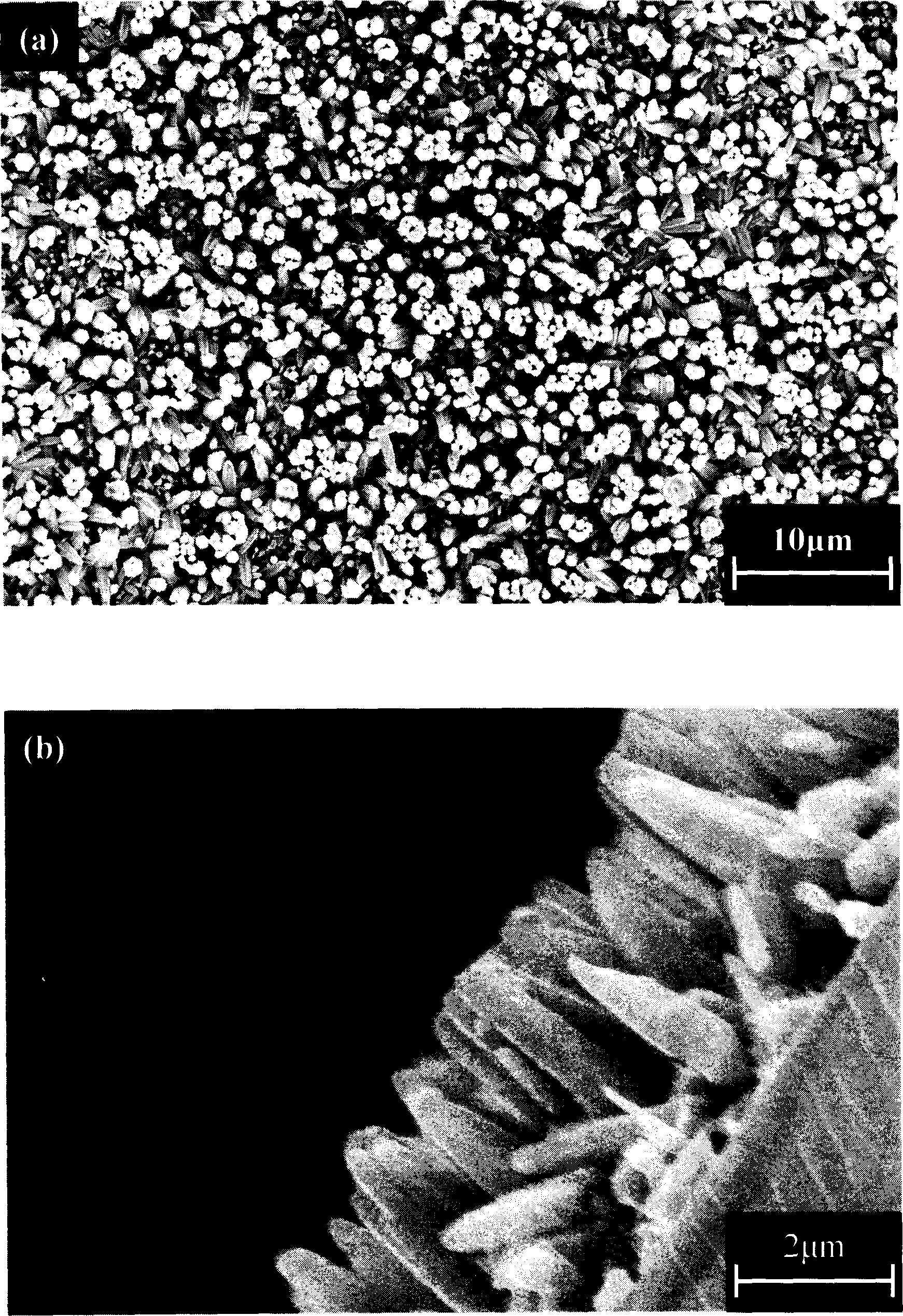

Embodiment 1

[0017] ①In a 100mL tetrafluoroethylene plastic bottle, dissolve 0.01mol zinc nitrate and 0.002mol ammonium chloride in 95mL deionized water, stir until completely dissolved, then add 5ml 25% ammonia water, continue stirring while adding, the solution is clear Afterwards, a reaction liquid for growing a zinc oxide film is prepared.

[0018] ②Immerse a quartz substrate with a length of 50mm and a width of 20mm into boiling concentrated sulfuric acid, soak for 10 hours, then immerse in acetone solution, ultrasonicate for 30 minutes, rinse with a large amount of deionized water, and finally put it in a vacuum oven to dry.

[0019] ③Immerse the quartz substrate processed according to step ② into the reaction solution prepared according to ①, soak for 30 minutes, then place the reaction bottle in an oil bath, and raise the reaction temperature to 95°C at a speed of 10°C / min , keep for 30 minutes. The quartz substrate is then immersed in ice water to cool. After cooling, immerse th...

Embodiment 2

[0022] ①In a 100mL tetrafluoroethylene plastic bottle, dissolve 0.01mol zinc acetate and 0.002mol ammonium chloride in 95mL deionized water, stir until completely dissolved, then add 5ml 25% ammonia water, continue stirring while adding, the solution is clear Afterwards, a reaction liquid for growing a zinc oxide film is prepared.

[0023] ②Immerse a glass piece with a length of 50mm and a width of 20mm into boiling concentrated sulfuric acid, soak it for 10 hours, then immerse it in acetone solution, ultrasonicate it for 60 minutes, rinse it with a large amount of deionized water, and finally put it in a vacuum oven to dry.

[0024] ③Immerse the glass substrate treated according to step ② into the reaction solution prepared according to ①, soak for 60 minutes, then place the reaction bottle in an oil bath, and raise the reaction temperature to 97°C at a speed of 20°C / min , keep for 60 minutes. The glass substrate is then cooled by immersing it in a bath of ice water. After ...

Embodiment 3

[0026] ①In a 100mL tetrafluoroethylene plastic bottle, dissolve 0.01mol zinc nitrate and 0.002mol ammonium nitrate in 95mL deionized water, stir until completely dissolved, then add 5ml of 25% ammonia water, continue stirring while adding, after the solution is clarified A reaction solution for zinc oxide thin film growth was prepared.

[0027] ② Immerse a quartz plate with a length of 50mm and a width of 20mm into boiling concentrated sulfuric acid, soak it for 8 hours, then immerse it in acetone solution, ultrasonicate it for 45 minutes, rinse it with a large amount of deionized water, and finally put it in a vacuum oven to dry.

[0028] ③Immerse the quartz substrate processed according to step ② into the reaction solution prepared according to ①, soak for 45 minutes, then place the reaction bottle in an oil bath, and raise the reaction temperature to 94°C at a speed of 15°C / min , keep for 45 minutes. The quartz substrate is then immersed in ice water to cool. After coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com