Patents

Literature

759 results about "Quartz substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

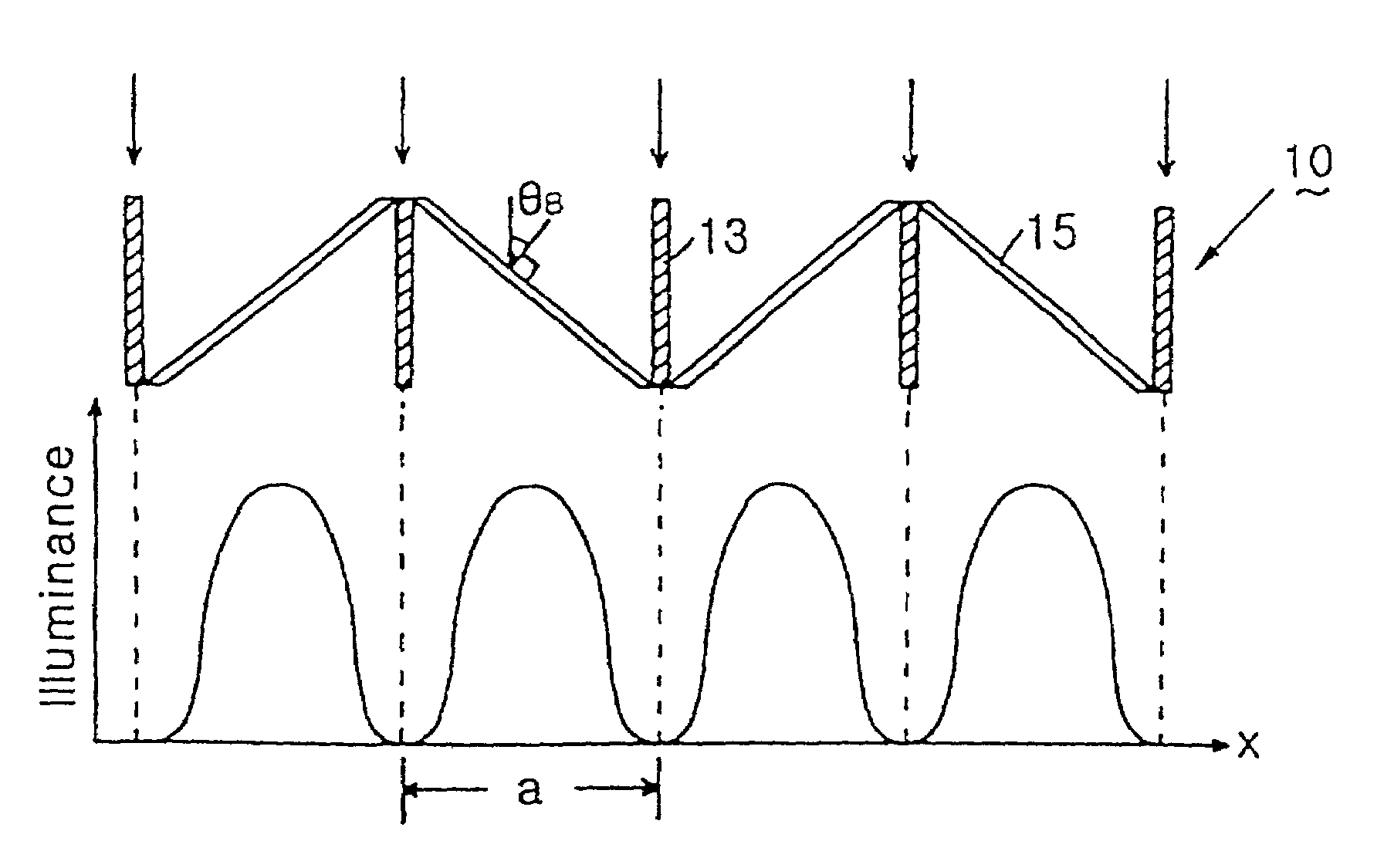

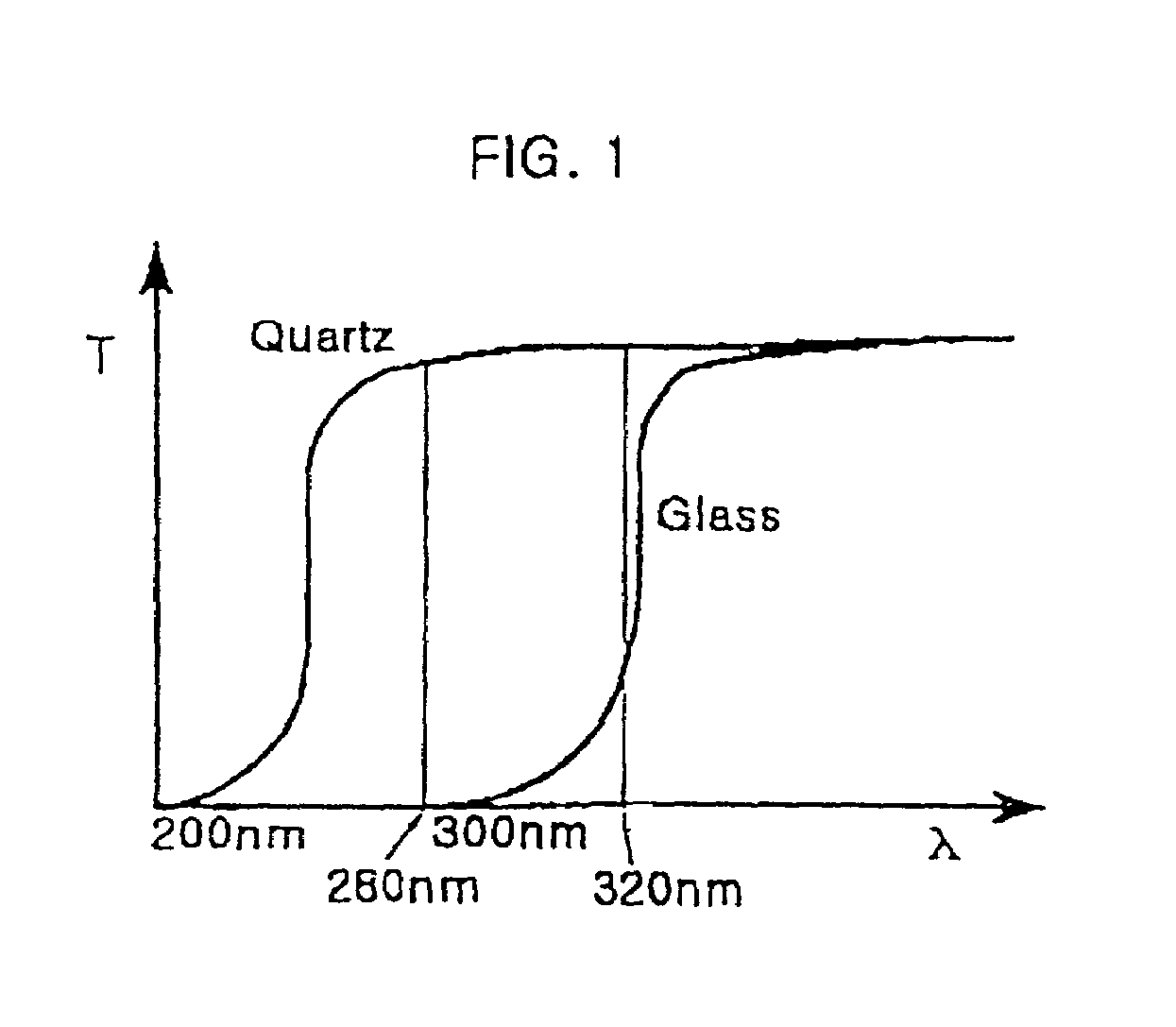

Shin-Etsu quartz substrates are most commonly used as photomask substrates for optical lithography and other applications that require ultra-high purity and high precision polished substrates. As far as polished substrates are concerned, quartz substrates have an advantage over regular glass substrates because they offer much better light...

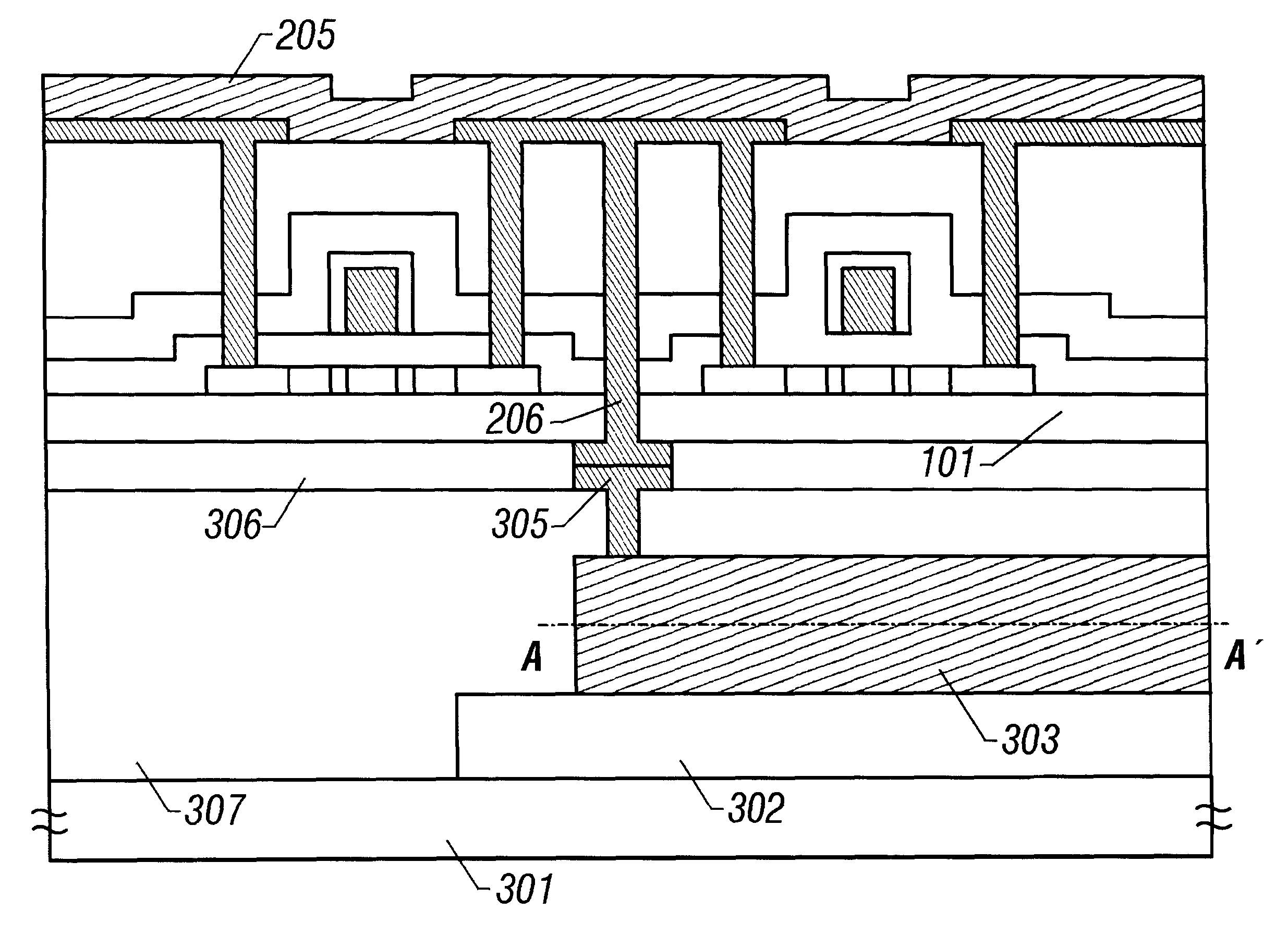

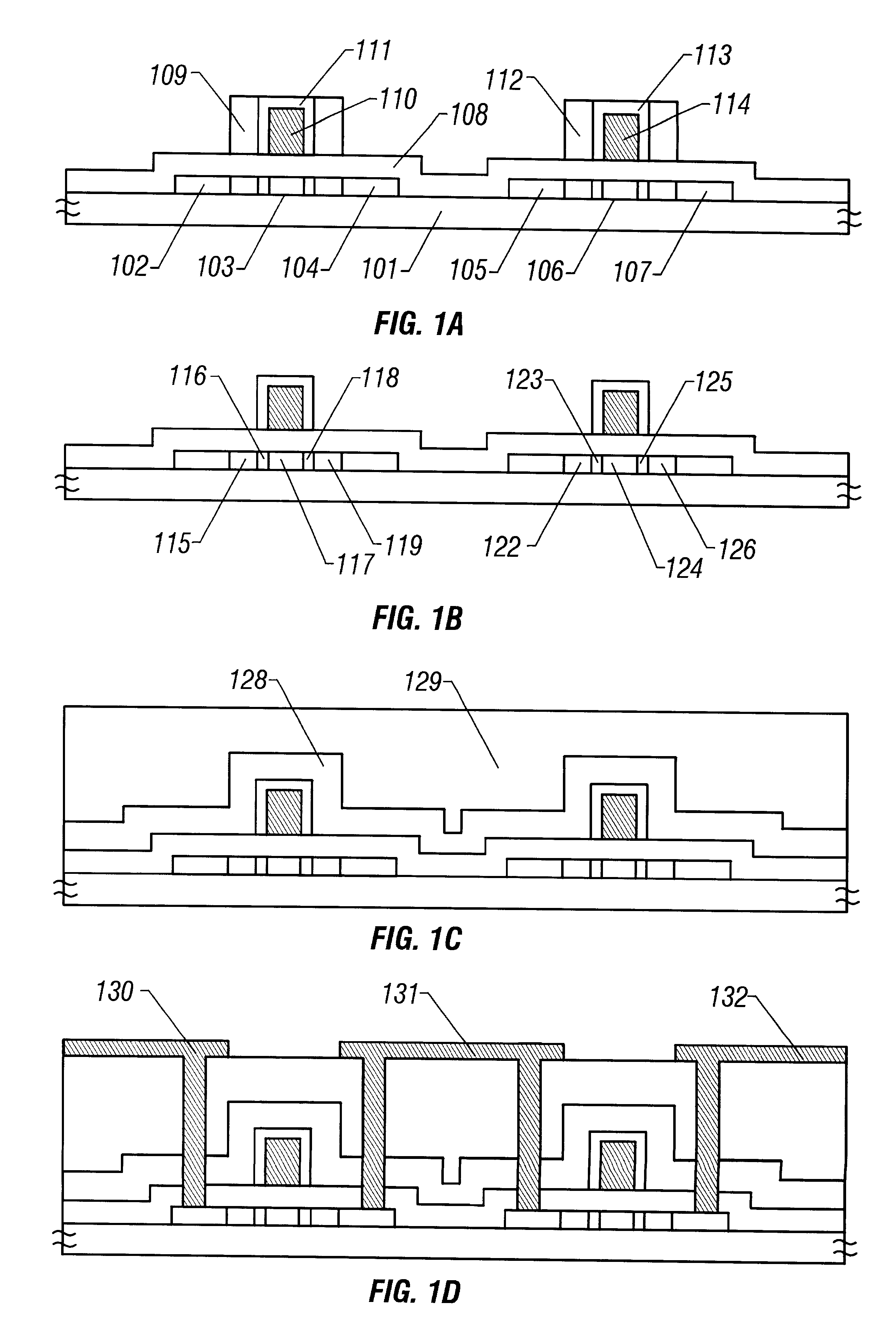

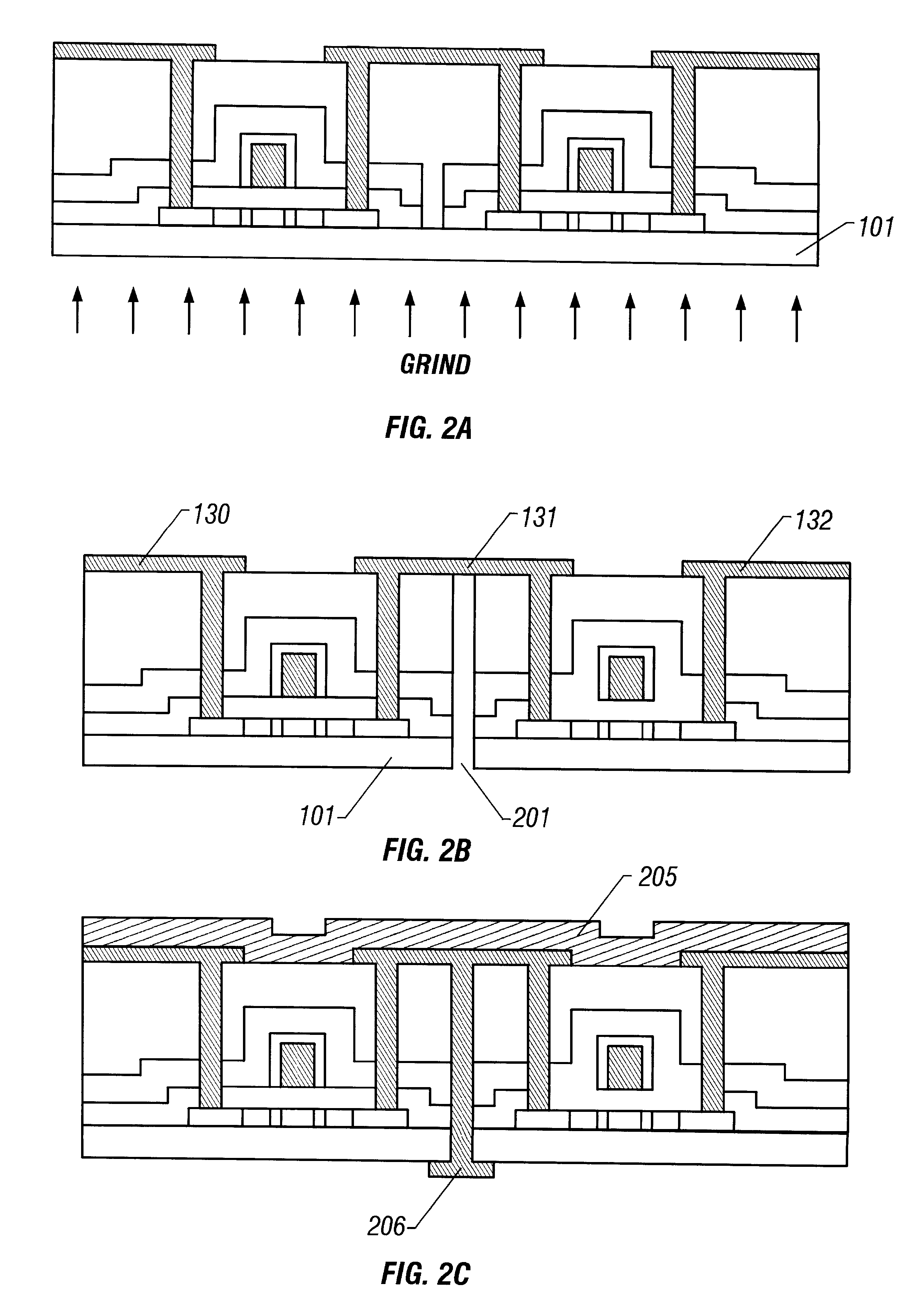

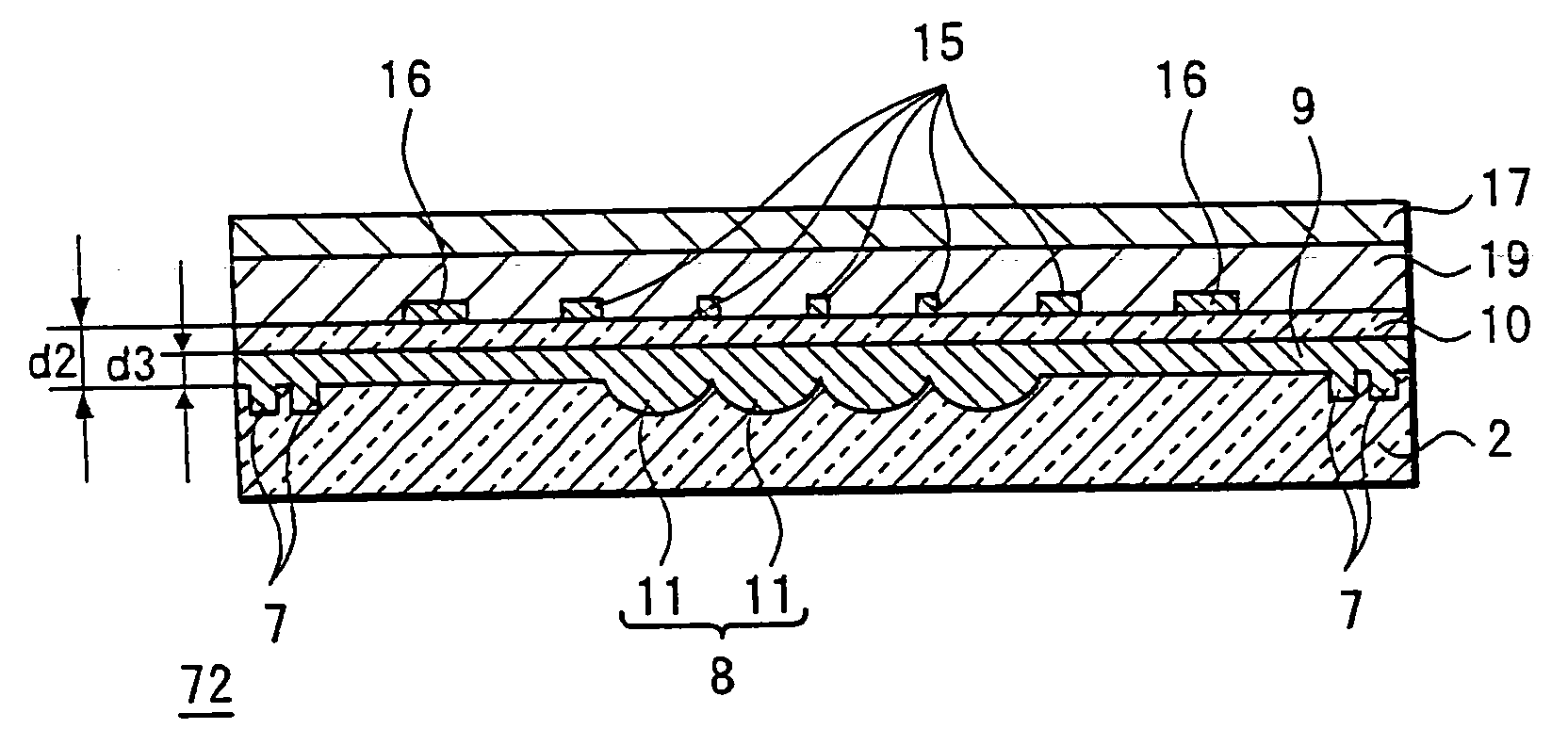

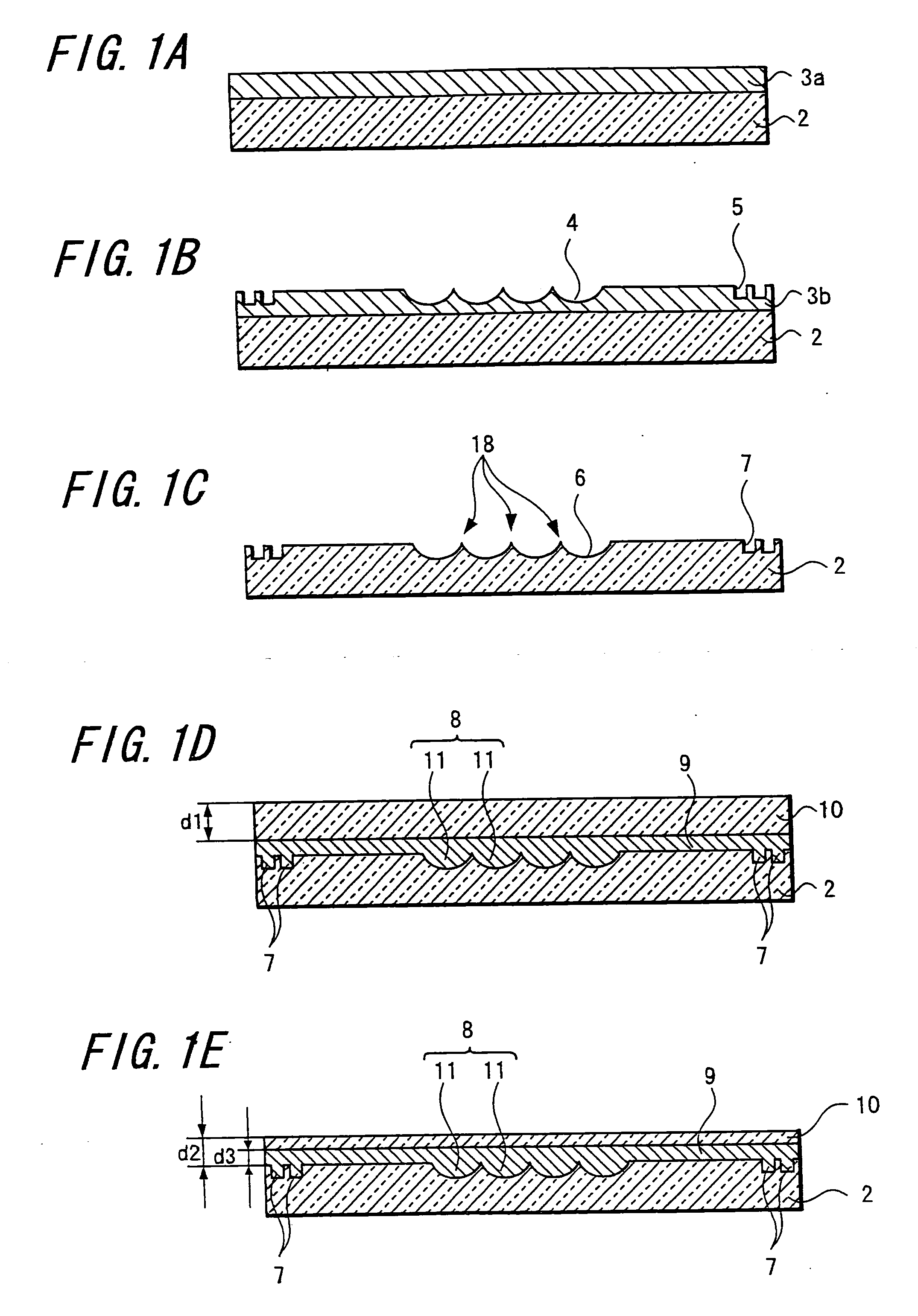

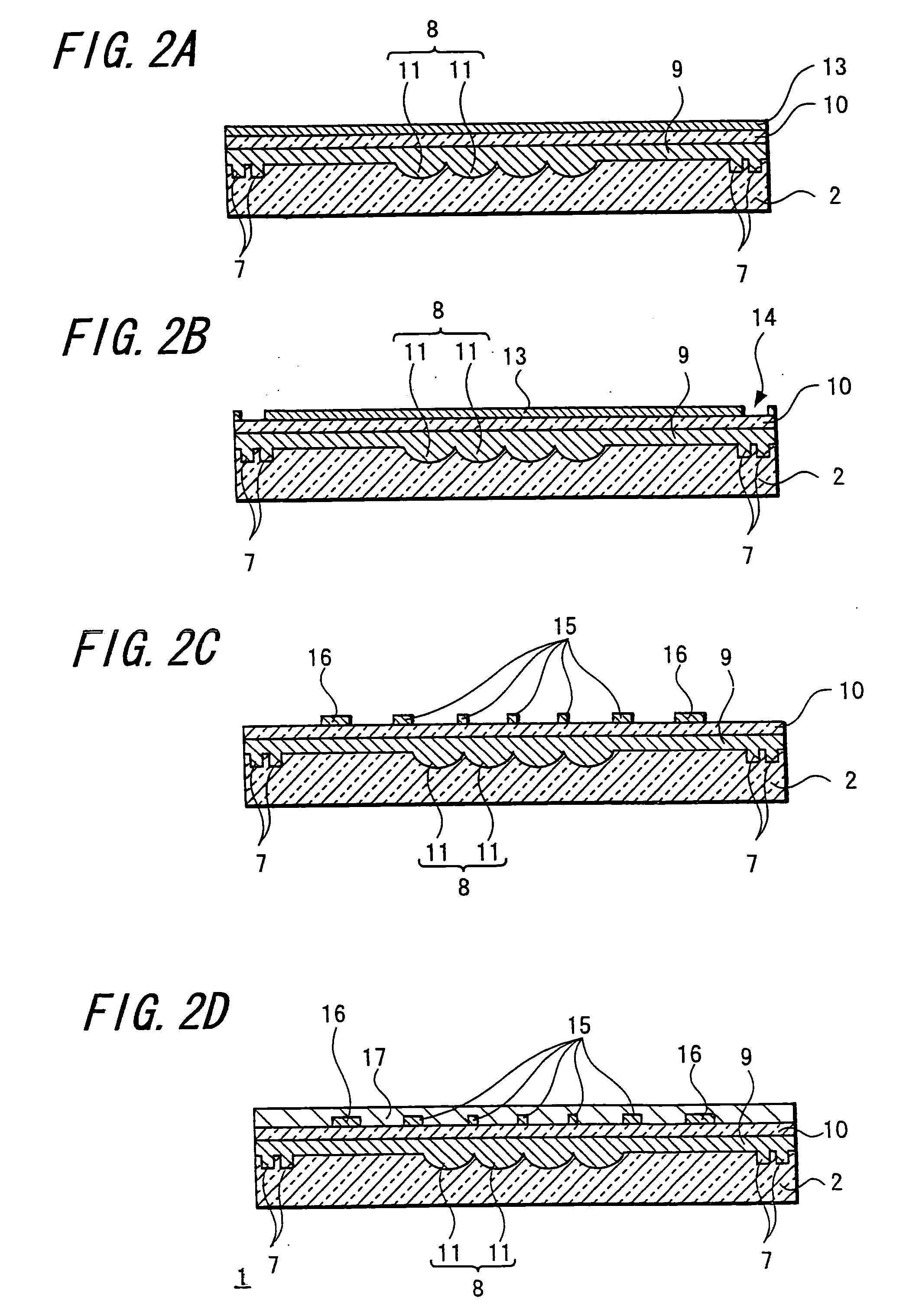

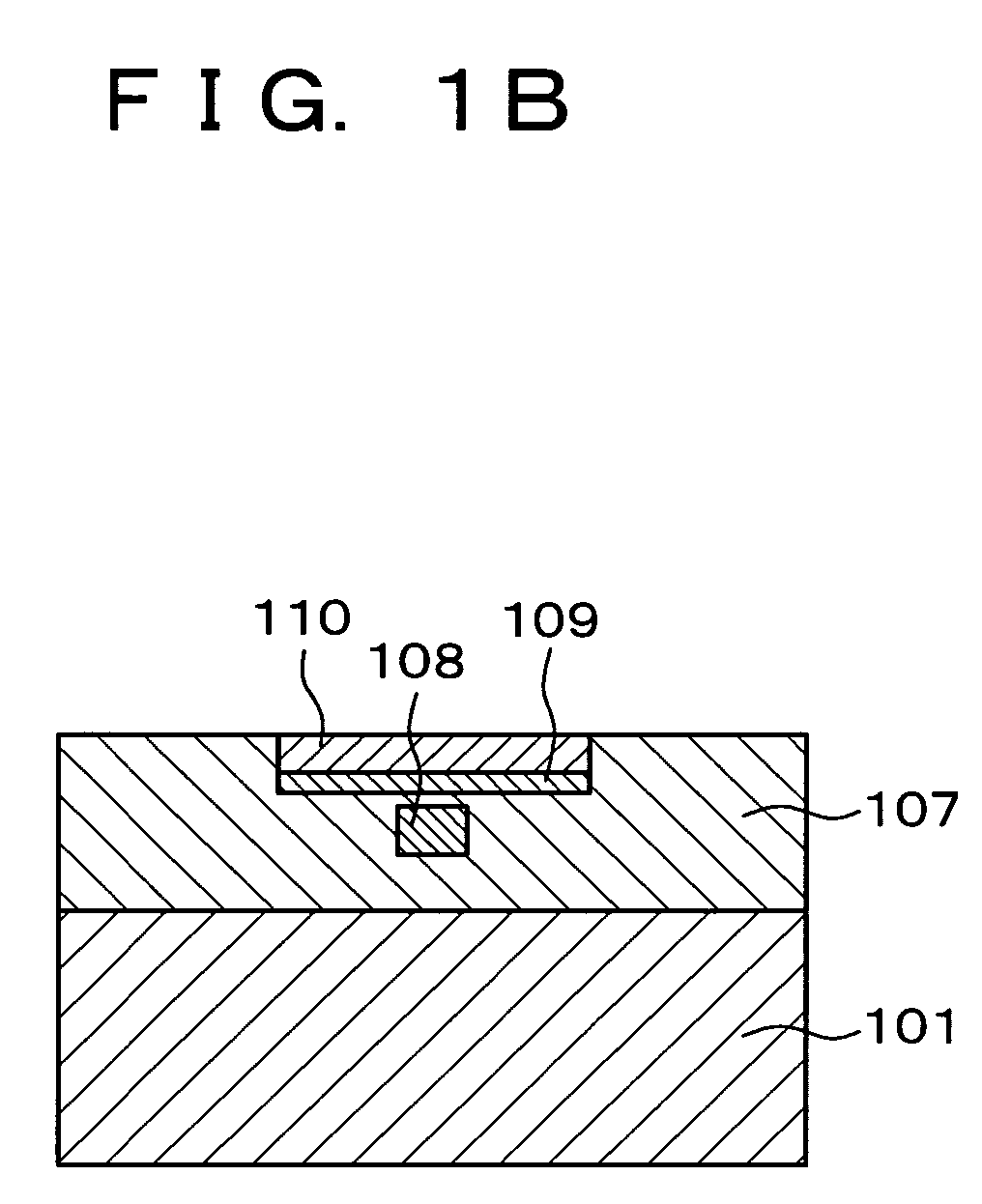

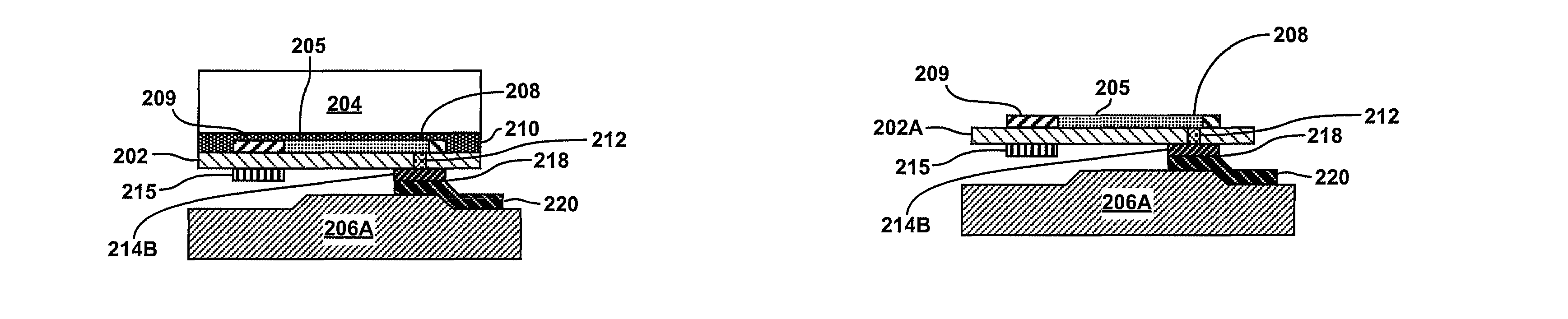

Semiconductor apparatus and fabrication method of the same

InactiveUS7067392B2Inhibit deteriorationImprove thermal conductivityTransistorFinal product manufactureDevice formThin-film diode

It is an object of the present invention to provide a semiconductor device capable of preventing deterioration due to penetration of moisture or oxygen, for example, a light-emitting apparatus having an organic light-emitting device that is formed over a plastic substrate, and a liquid crystal display apparatus using a plastic substrate. According to the present invention, devices formed on a glass substrate or a quartz substrate (a TFT, a light-emitting device having an organic compound, a liquid crystal device, a memory device, a thin-film diode, a pin-junction silicon photoelectric converter, a silicon resistance element, or the like) are separated from the substrate, and transferred to a plastic substrate having high thermal conductivity.

Owner:SEMICON ENERGY LAB CO LTD

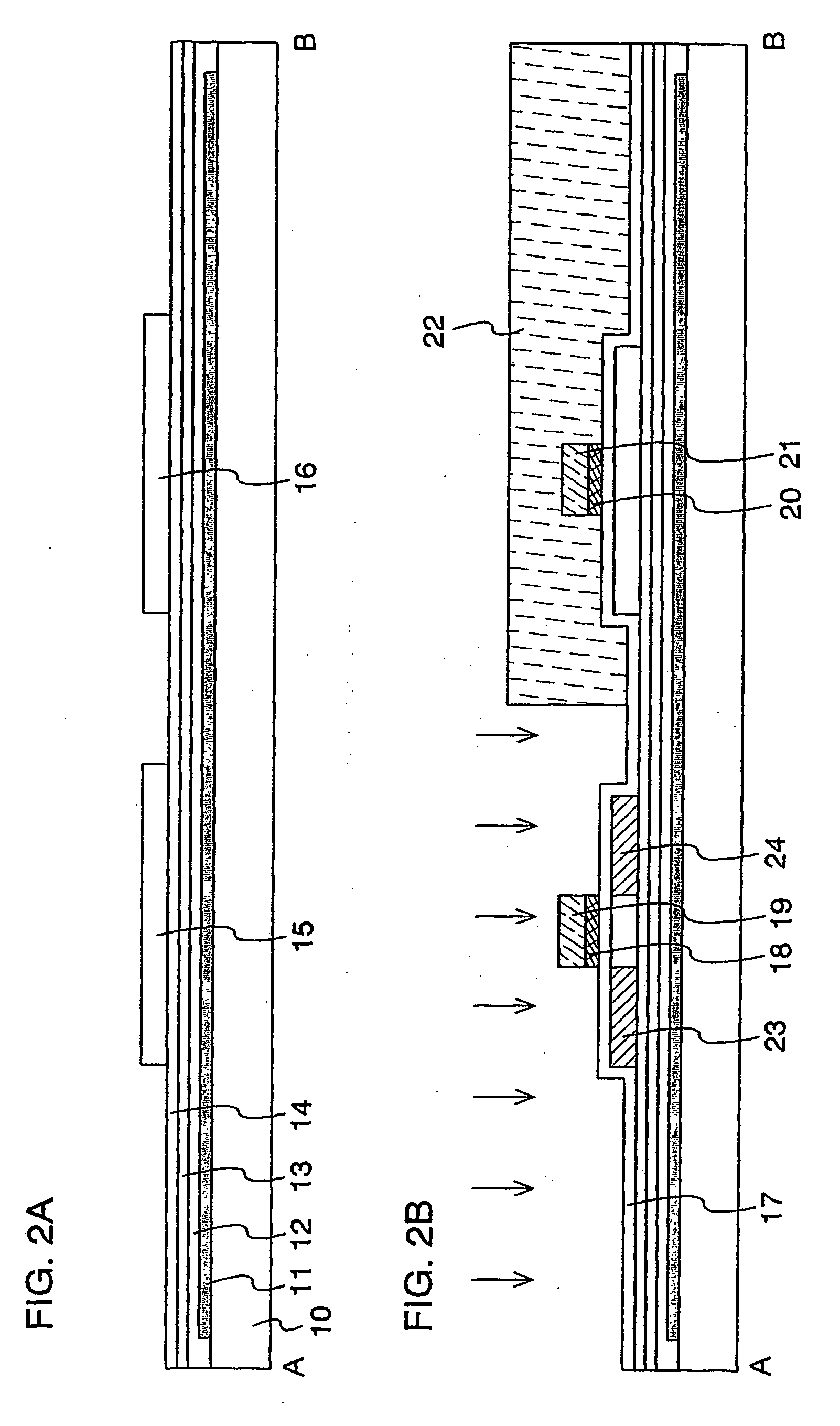

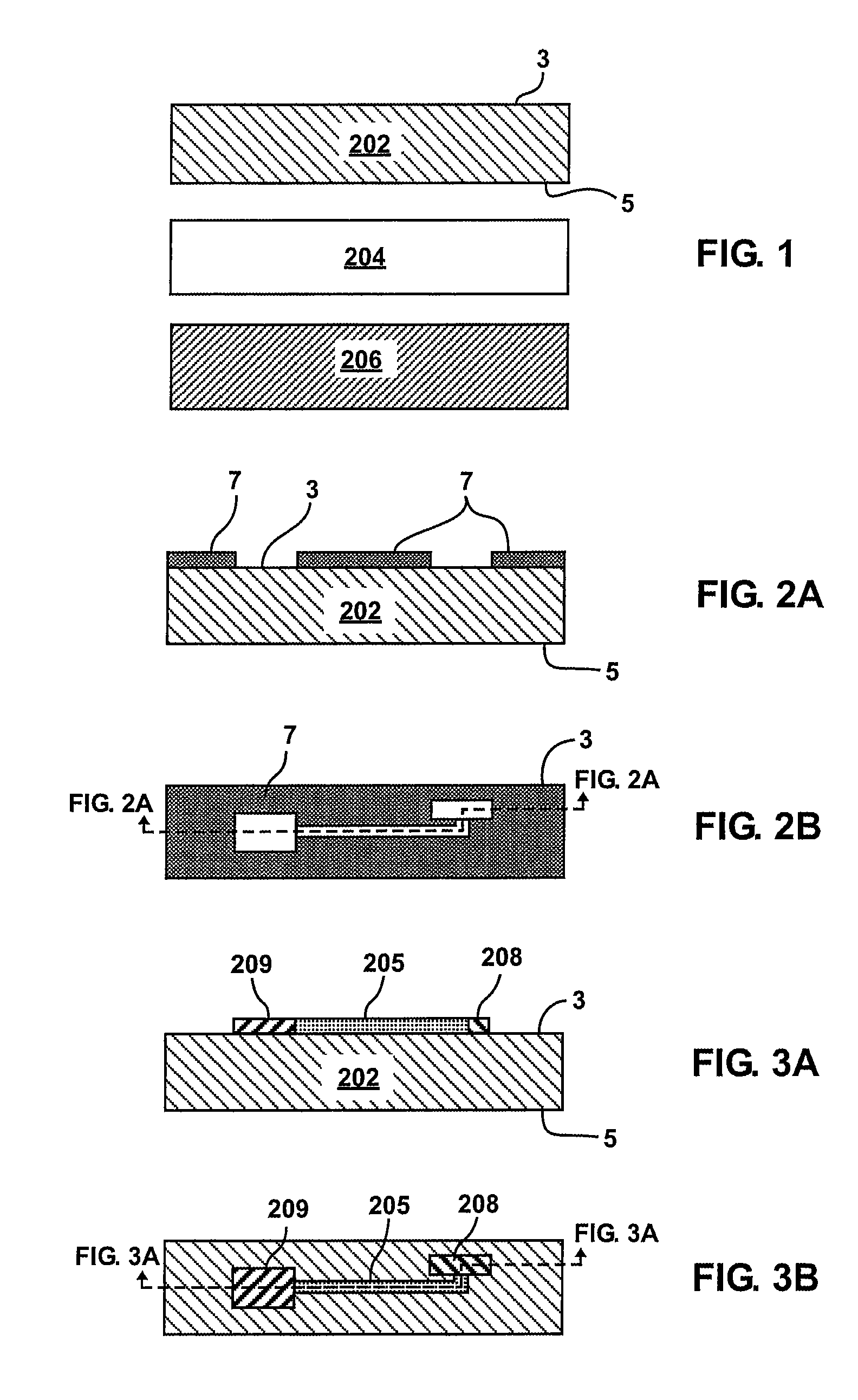

Soi substrate and method for manufacturing soi substrate

InactiveUS20100289115A1Prevent transfer defectIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingThermal expansionSoi substrate

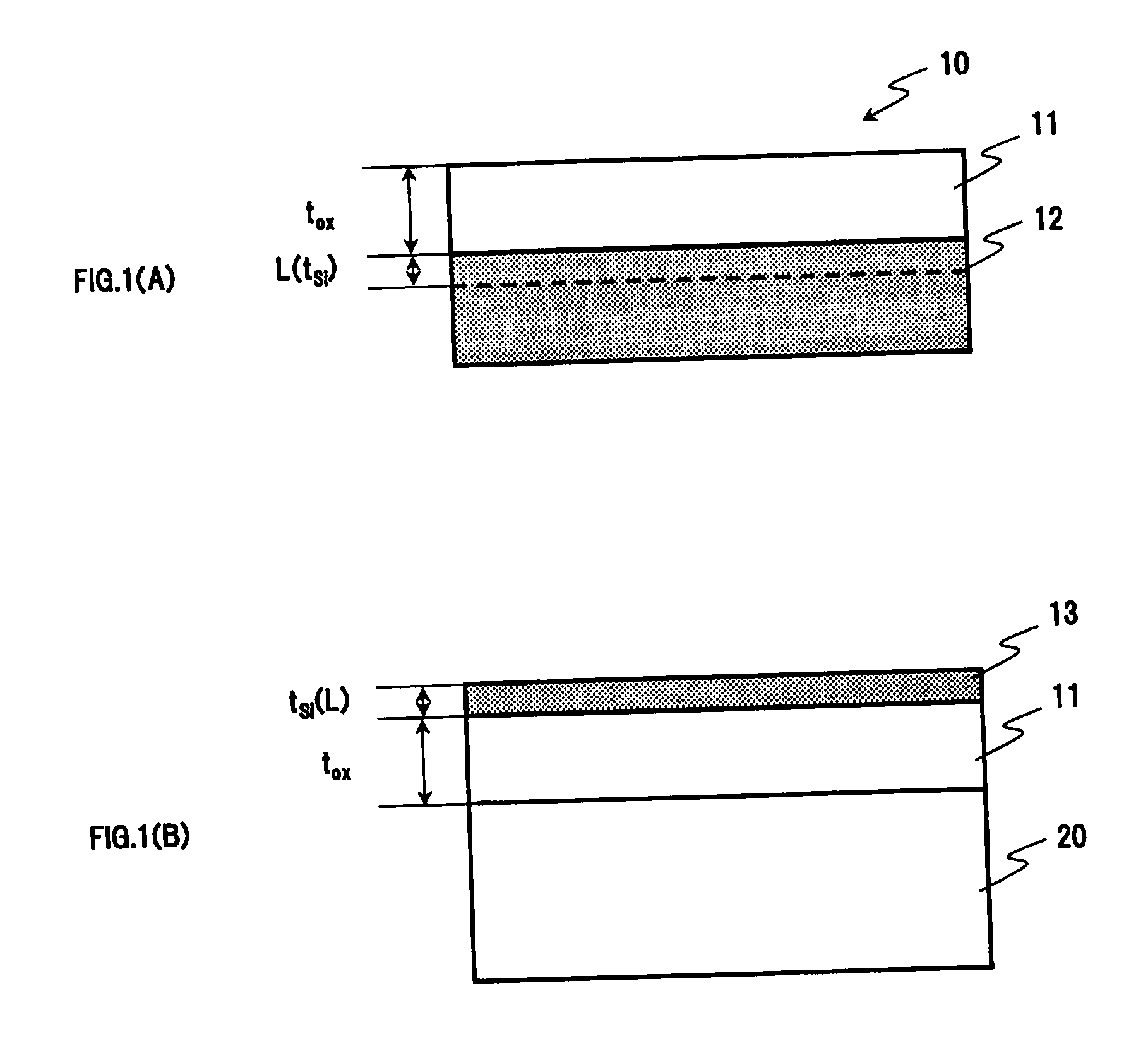

An oxide film having a thickness “tox” of not less than 0.2 μm is provided on the bonding surface of a single-crystal silicon substrate. In a method for manufacturing an SOI substrate according to the present invention, a low-temperature process is employed to suppress the occurrence of thermal strain attributable to a difference in the coefficient of thermal expansion between the silicon substrate and a quartz substrate. To this end, the thickness “tox” of the oxide film is set to a large value of not less than 0.2 μm to provide sufficient mechanical strength to the thin film to be separated and, at the same time, to allow strain to be absorbed in and relaxed by the relatively thick oxide film to suppress the occurrence of transfer defects during the step of separation.

Owner:SHIN ETSU CHEM IND CO LTD

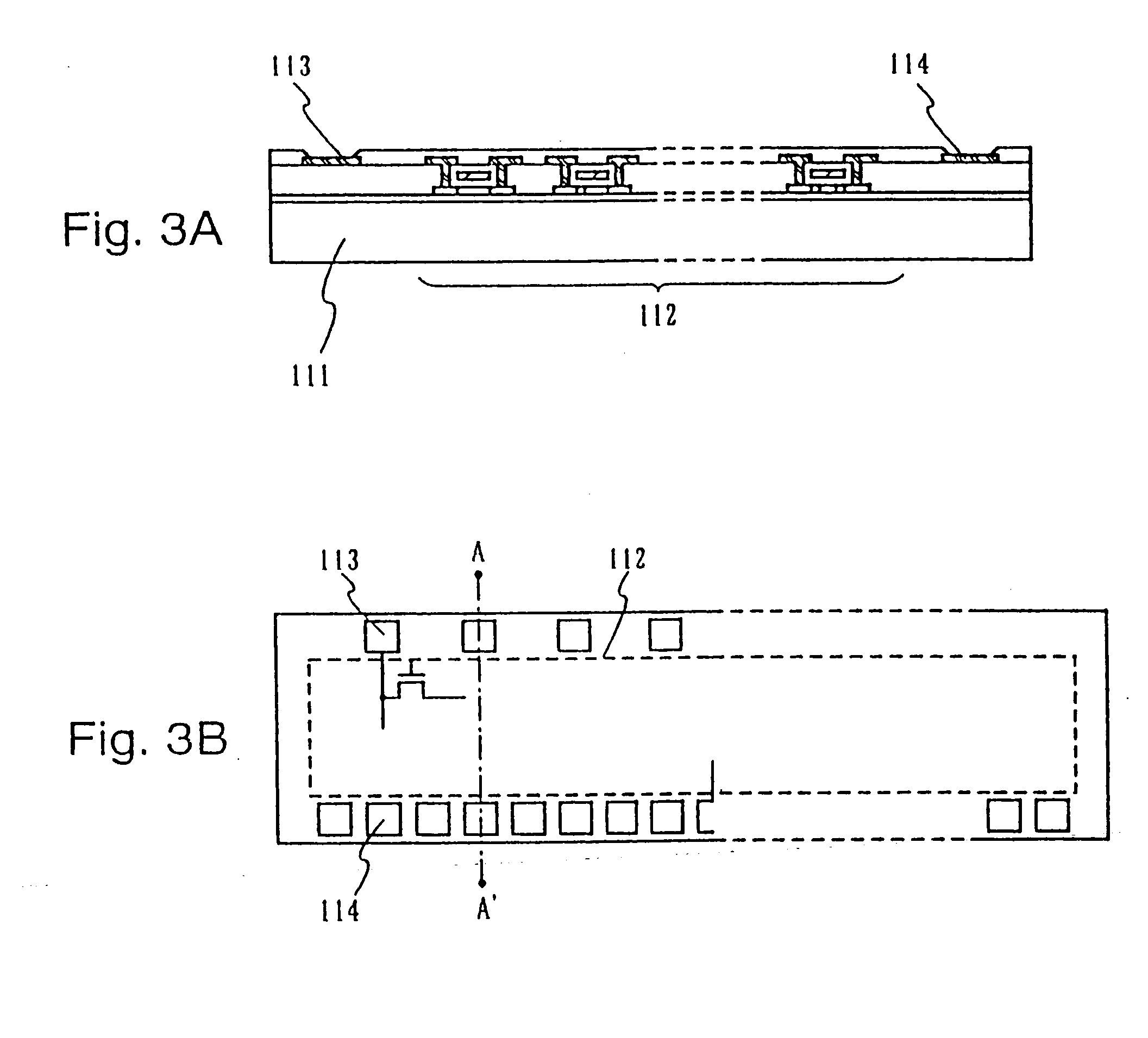

Method of producing semiconductor device and soq (silicon on quartz) substrate used in the method

ActiveUS20100123134A1Improve inspection efficiencyReduce the possibilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsQuartz substrateSilicon

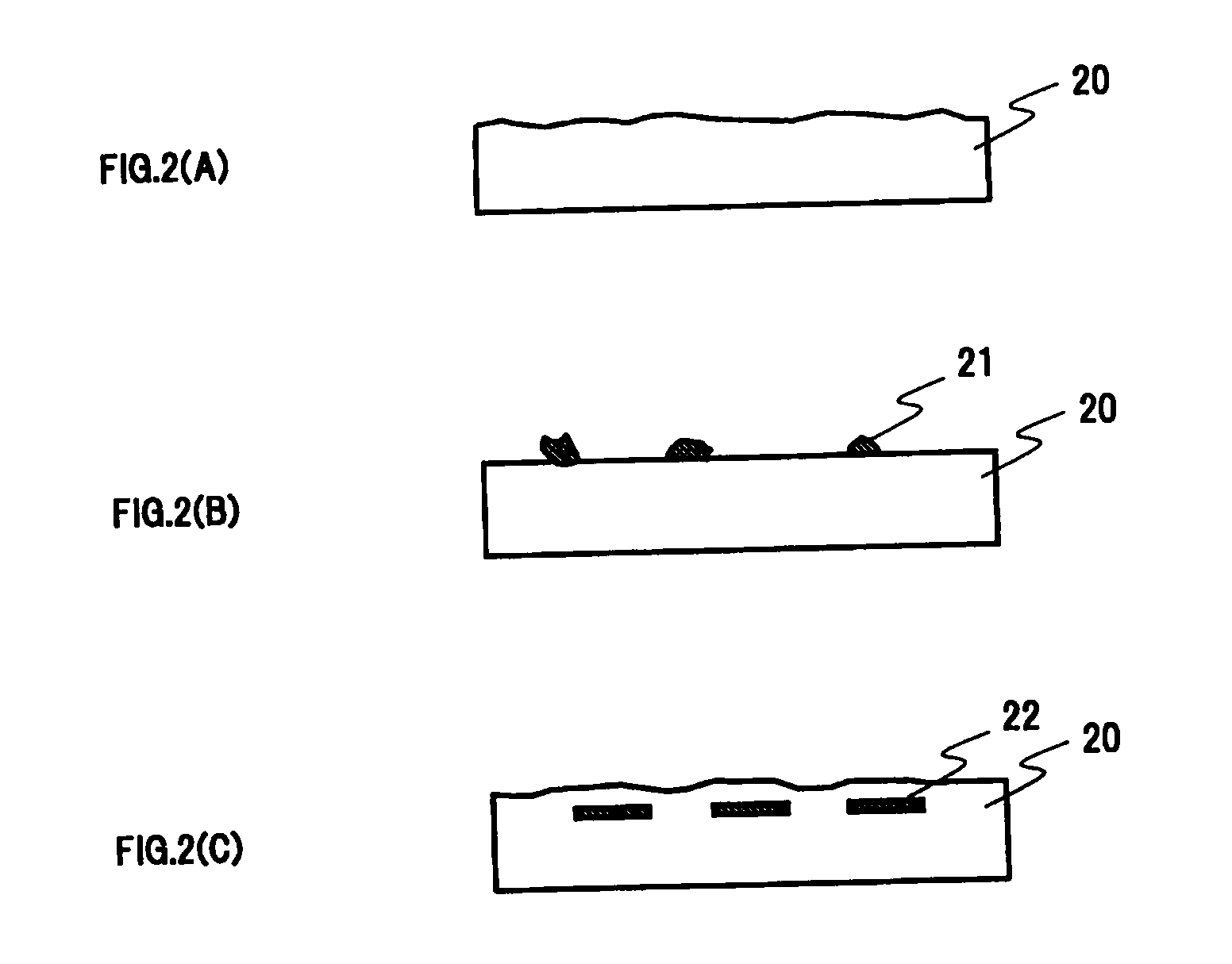

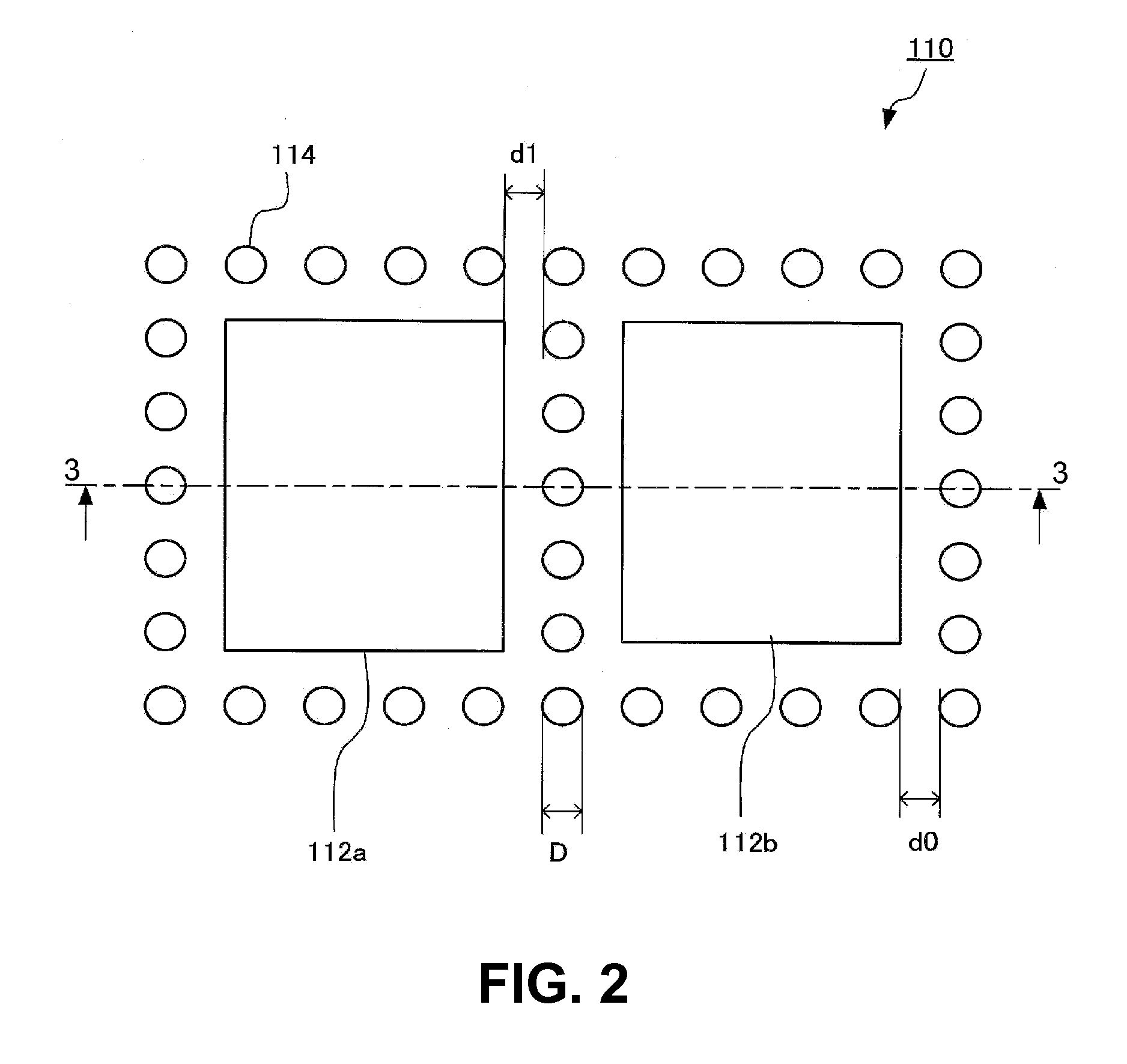

A method of producing a semiconductor device includes the steps of preparing an SOQ (Silicon On Quartz) substrate in which a semiconductor layer is formed on a quartz substrate; forming a plurality of semiconductor device forming regions in the SOQ substrate; forming a crack inspection pattern in the SOQ substrate; inspecting the crack inspection pattern to detect a crack in the crack inspection pattern in a first inspection step; and inspecting the semiconductor device forming regions to detect a crack in the semiconductor device forming regions in a second inspection step when the crack is detected in the crack inspection pattern in the first inspection step.

Owner:LAPIS SEMICON CO LTD

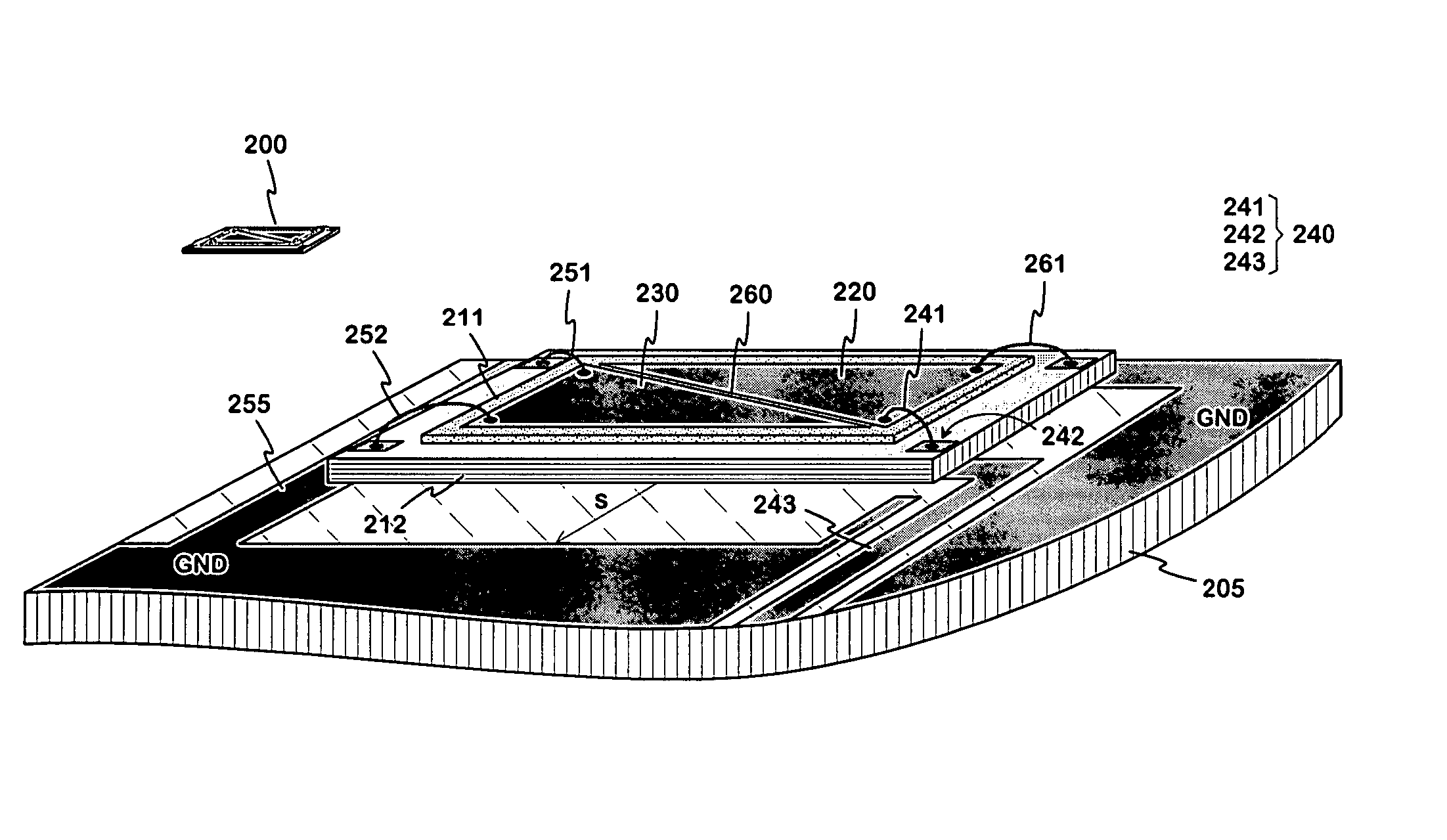

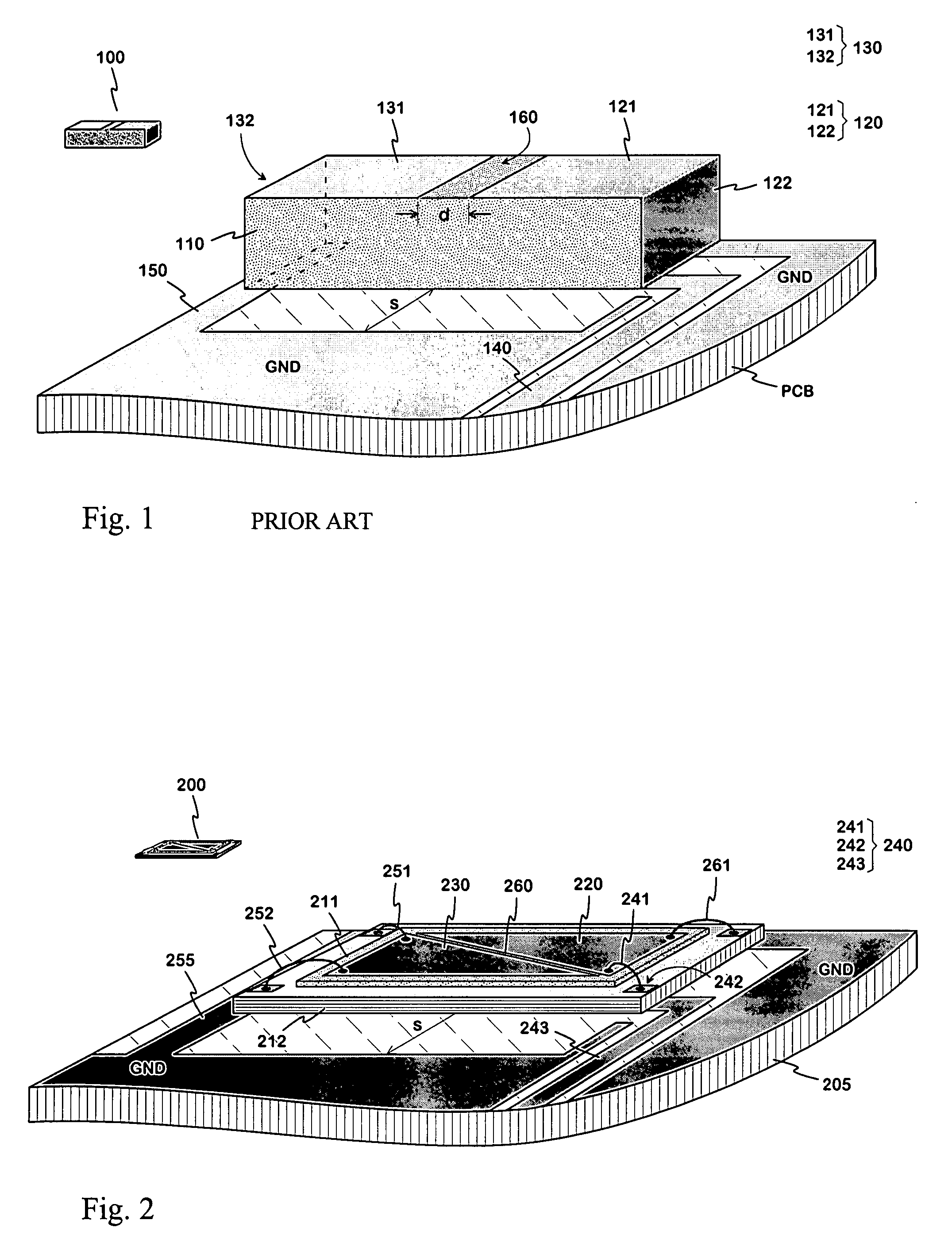

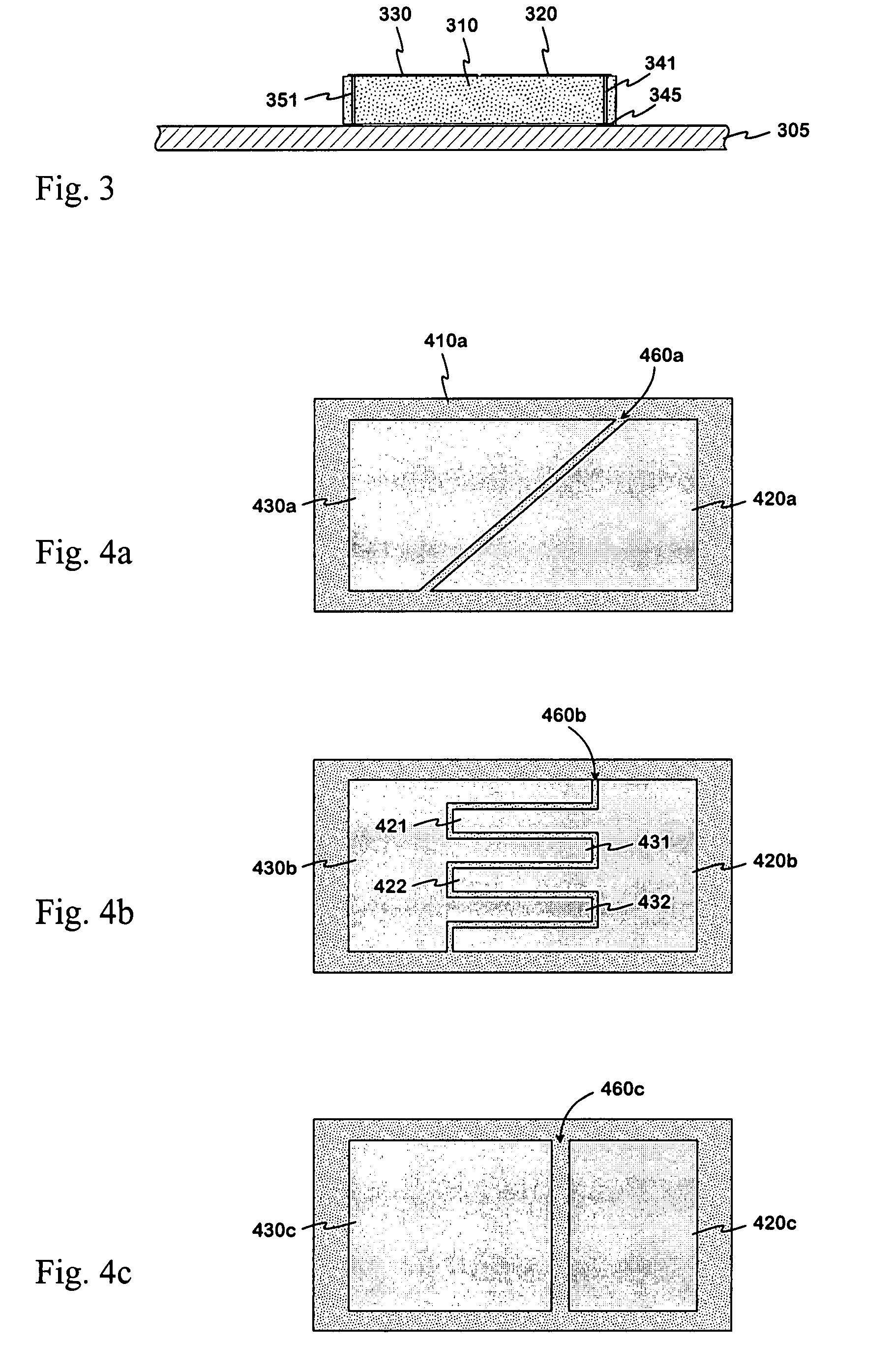

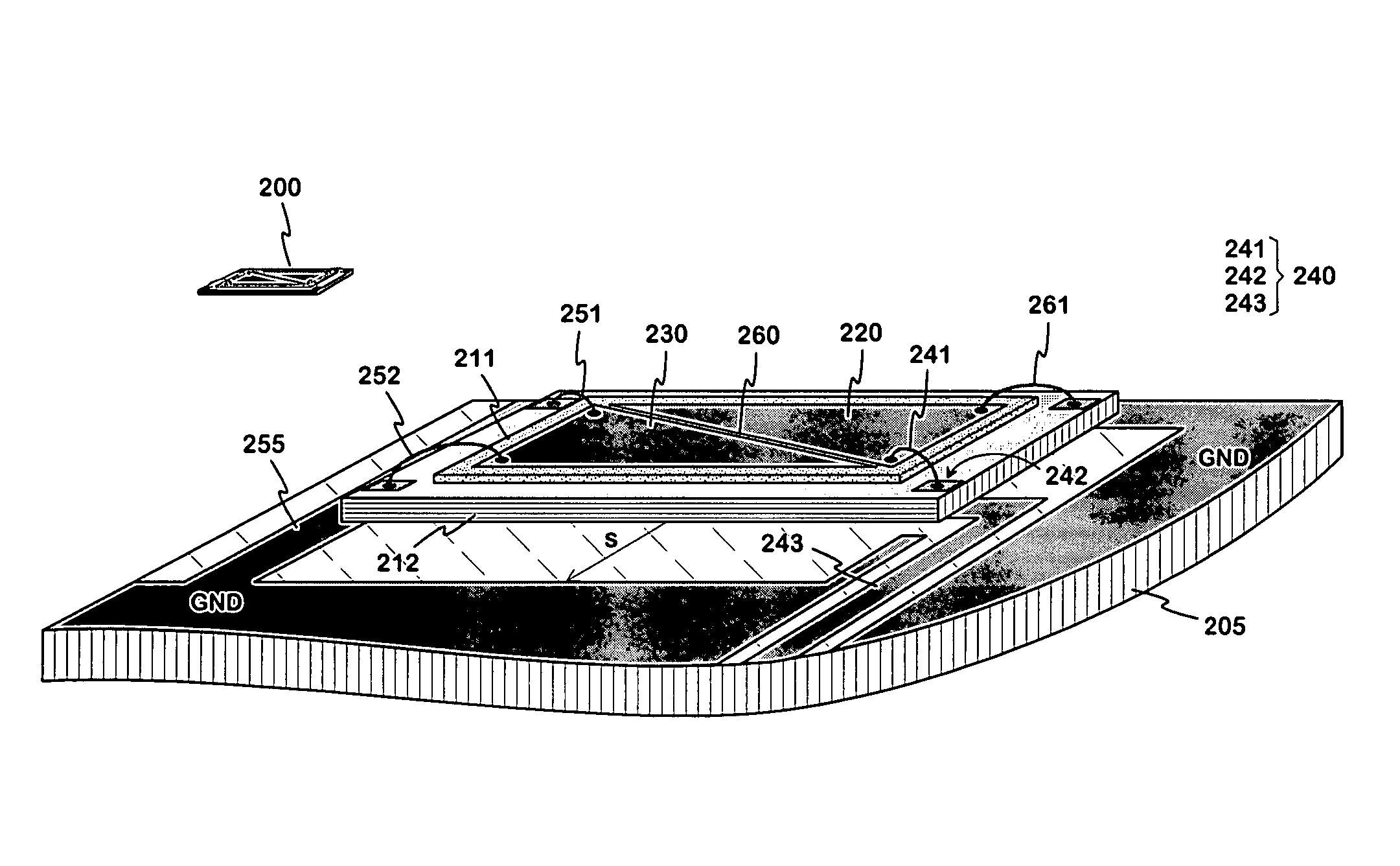

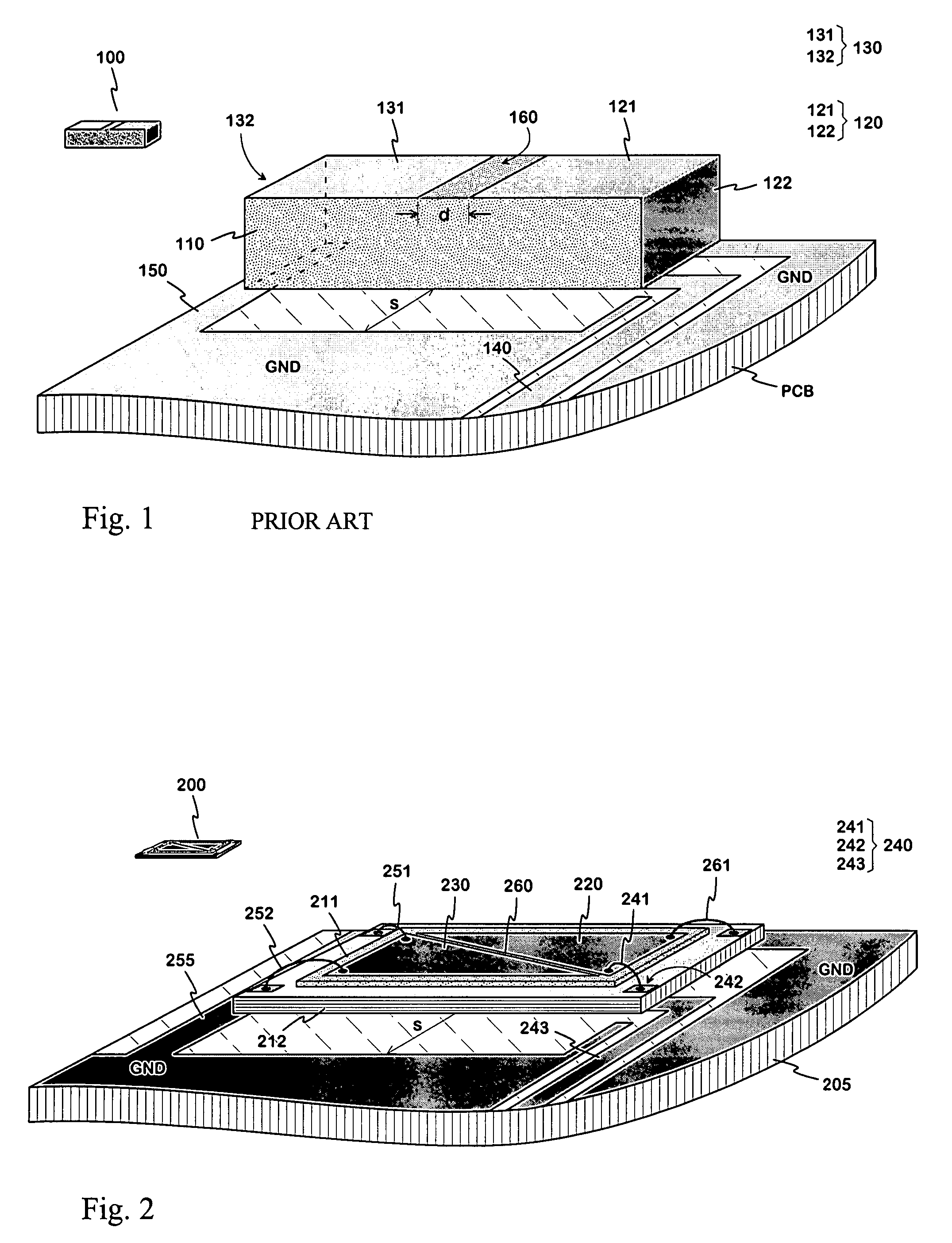

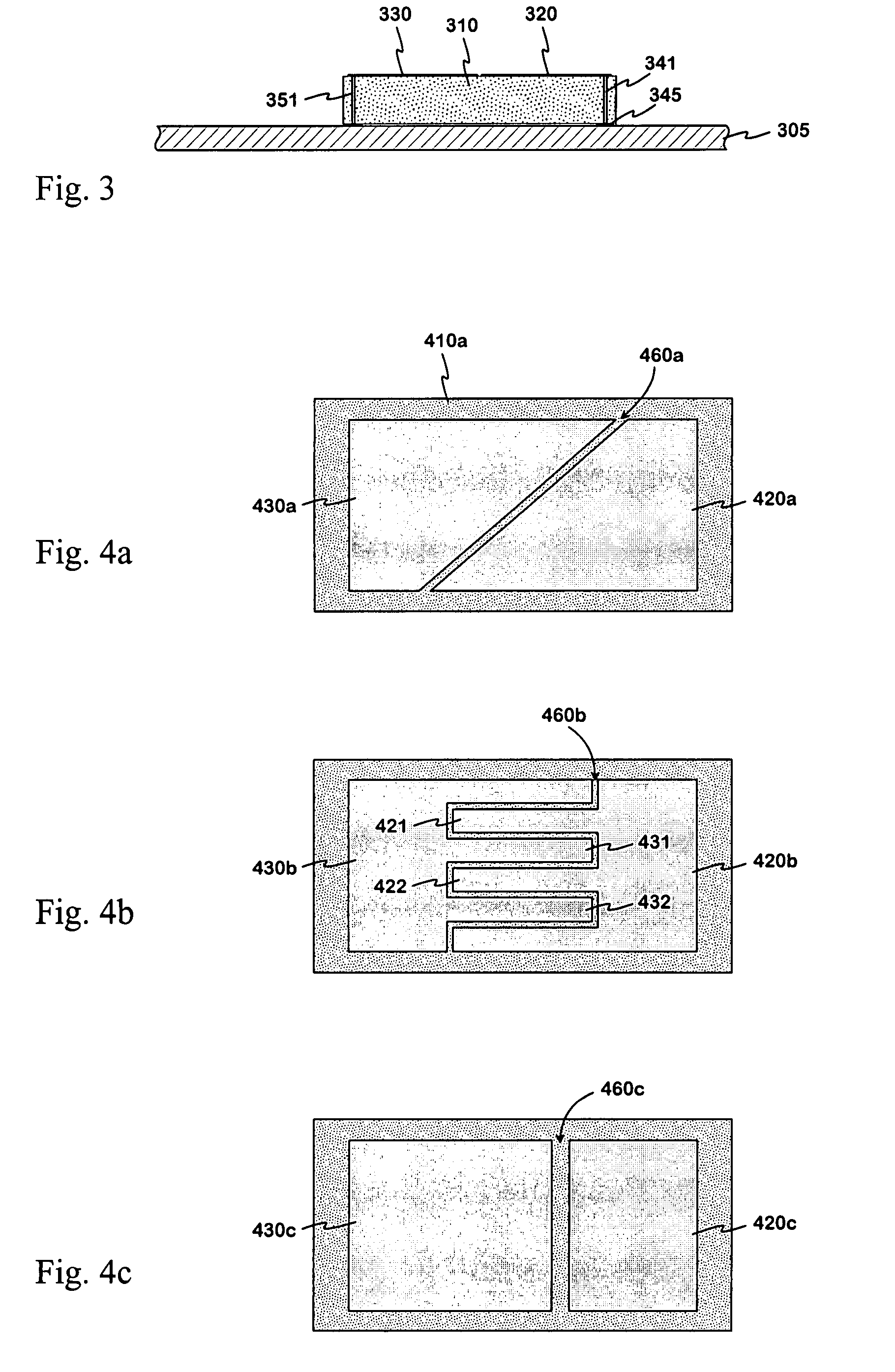

Antenna component and methods

InactiveUS20080088511A1High dielectric constantEfficient preparationSimultaneous aerial operationsRadiating elements structural formsElectrical conductorDielectric substrate

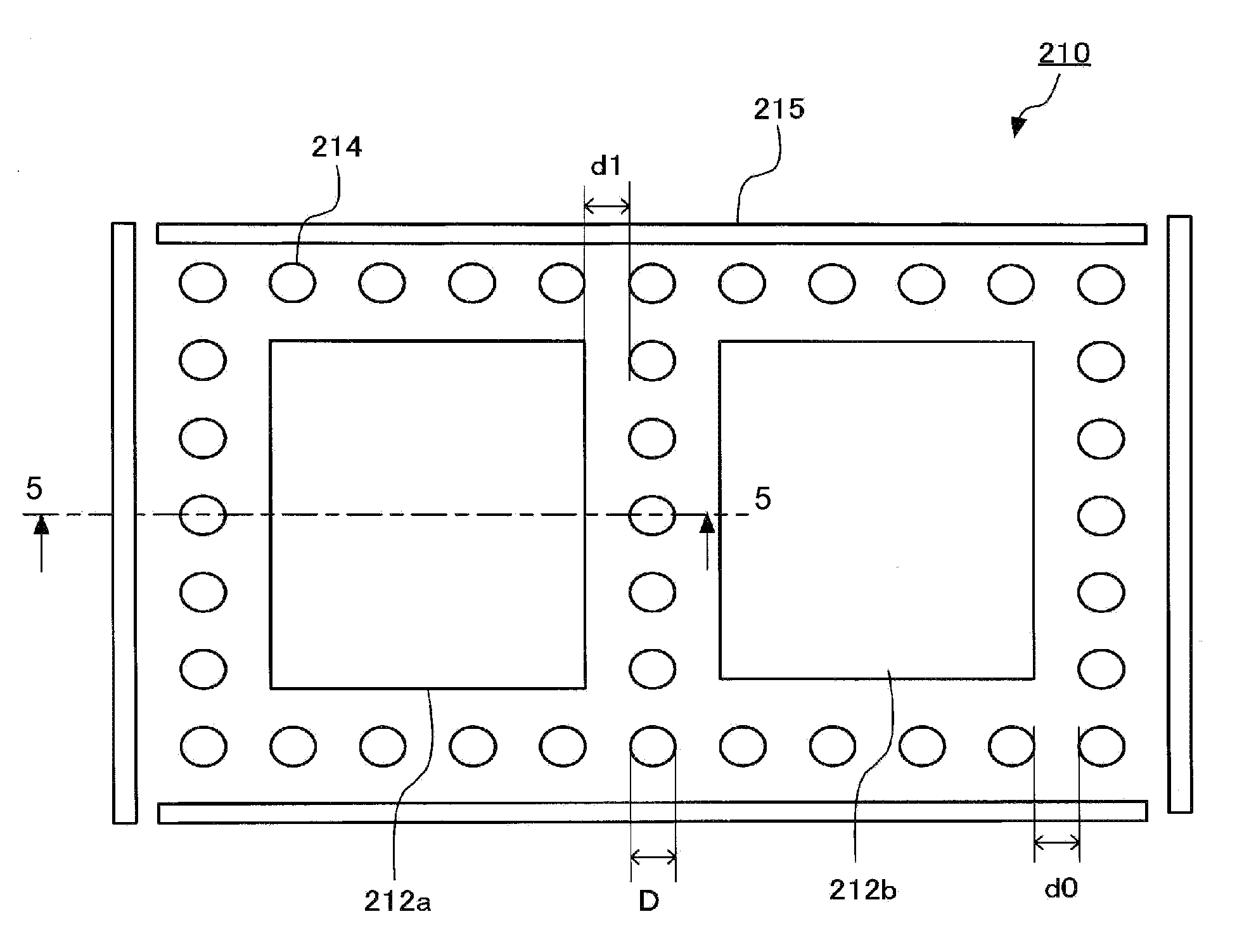

An antenna component (200) with a dielectric substrate and two radiating antenna elements. The elements are located on the upper surface of the substrate and there is a narrow slot (260) between them. The antenna feed conductor (241) is connected to the first antenna element (220), which is connected also to the ground by a short-circuit conductor (261). The second antenna element (230) is parasitic; it is galvanically connected only to the ground. The component is preferably manufactured by a semiconductor technique by growing a metal layer e.g. on a quartz substrate and removing a part of it so that the antenna elements remain. In this case the component further comprises supporting material (212) of the substrate chip. The antenna component is very small-sized because of the high dielectricity of the substrate to be used and mostly because the slot between the antenna elements is narrow. The efficiency of an antenna made by the component is high.

Owner:PULSE FINLAND

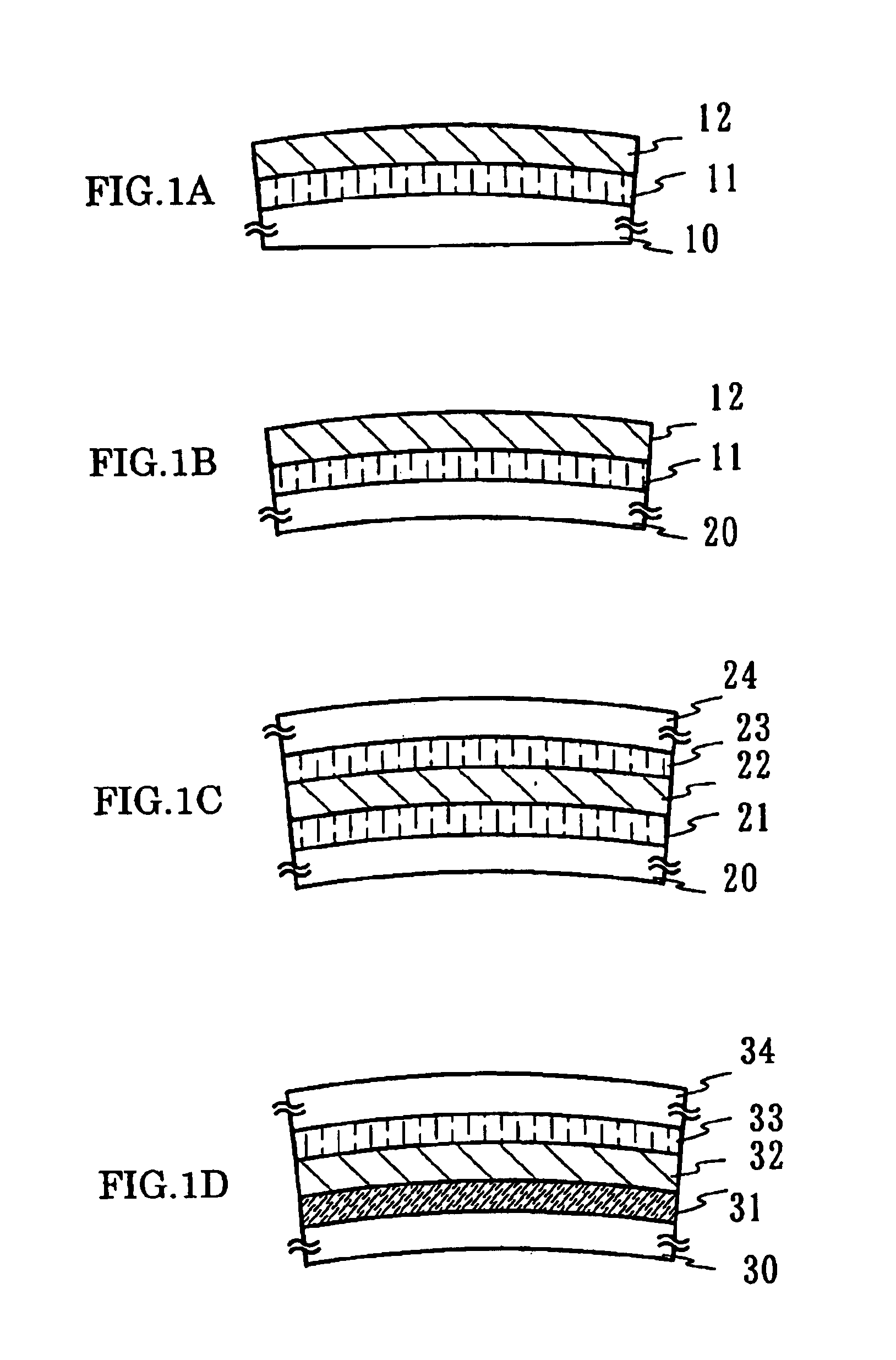

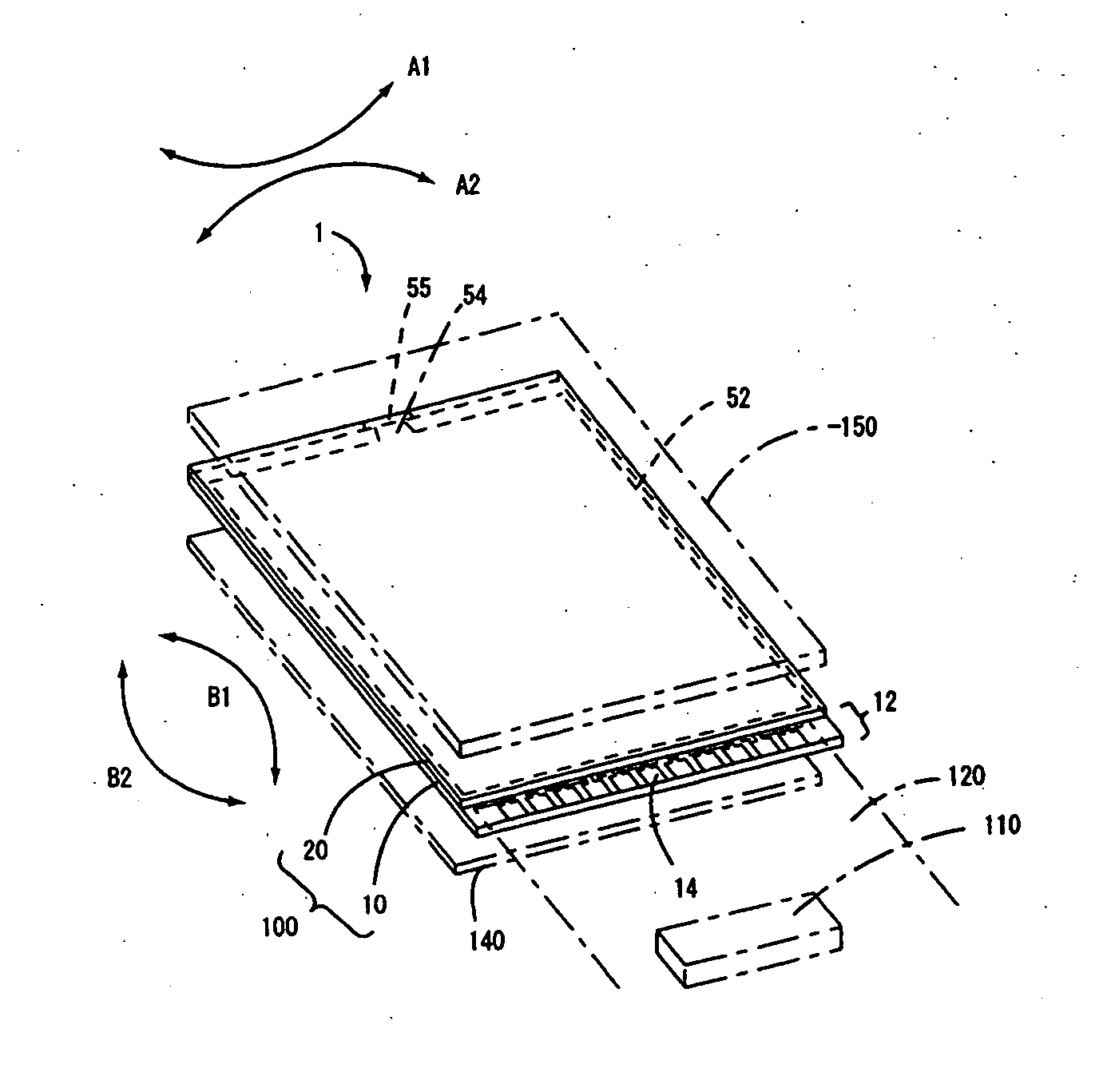

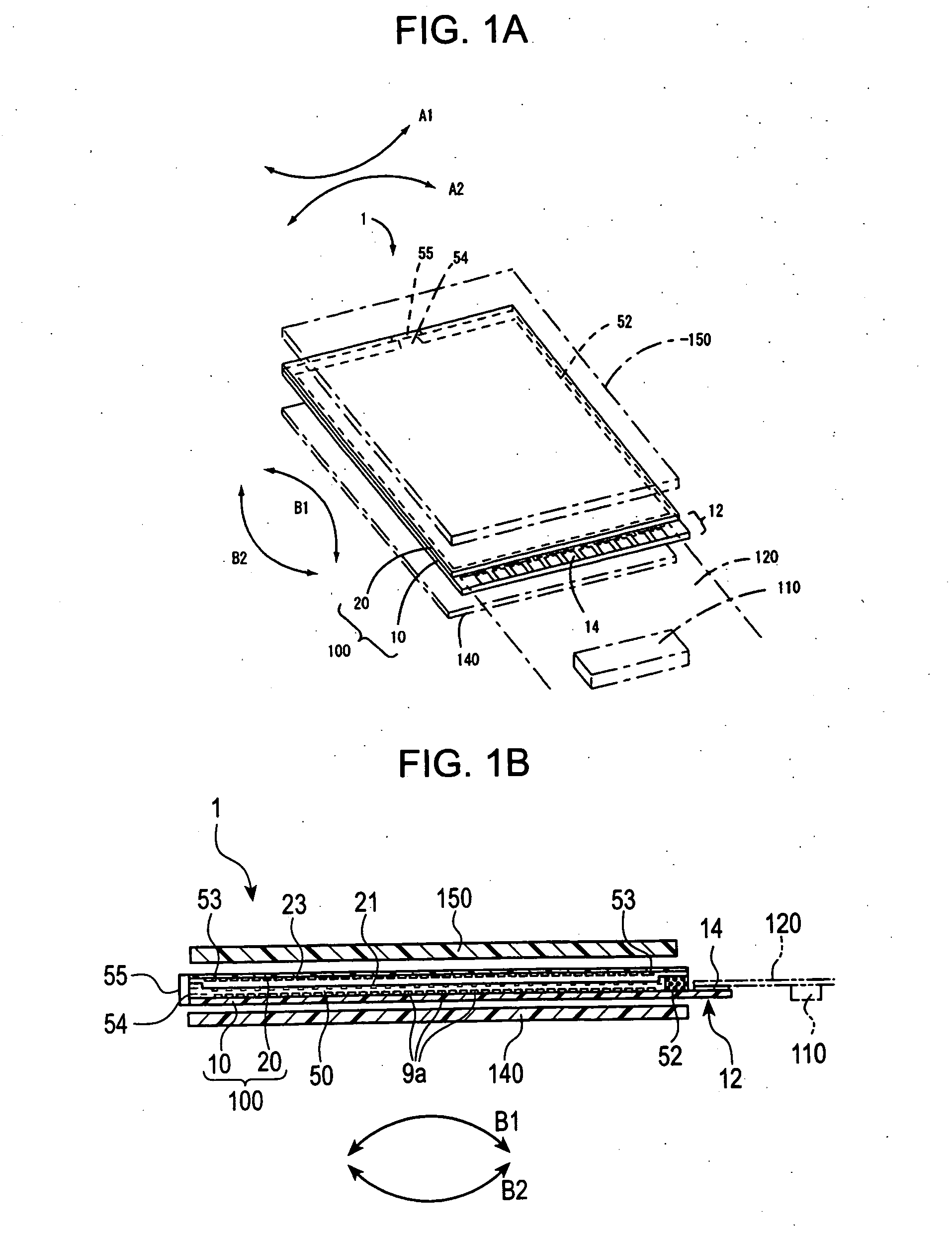

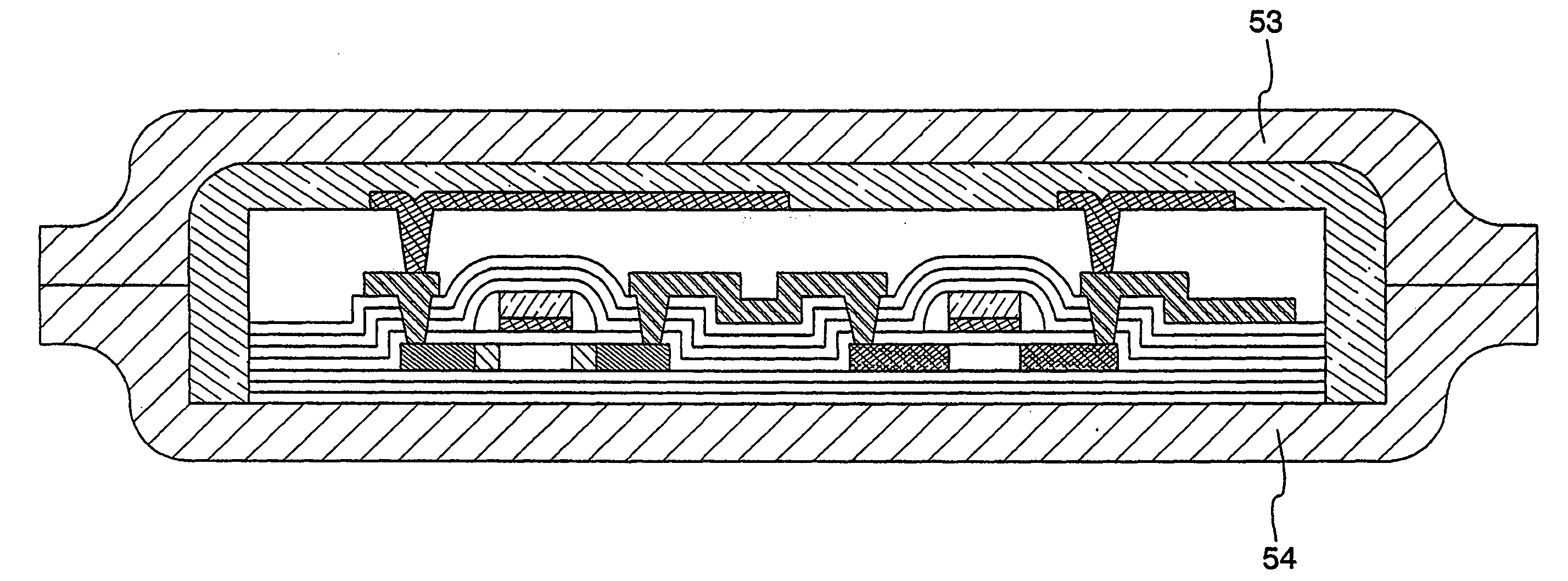

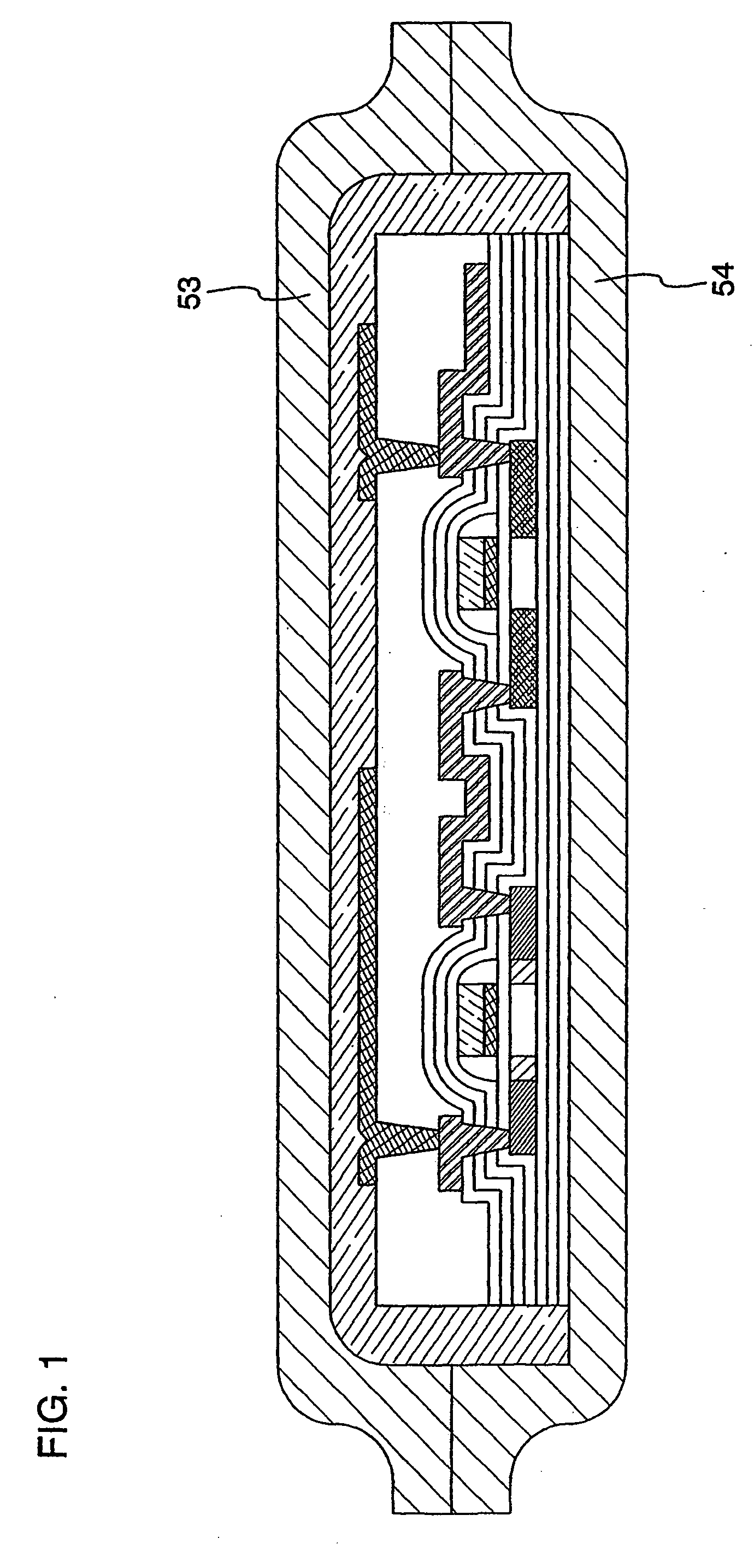

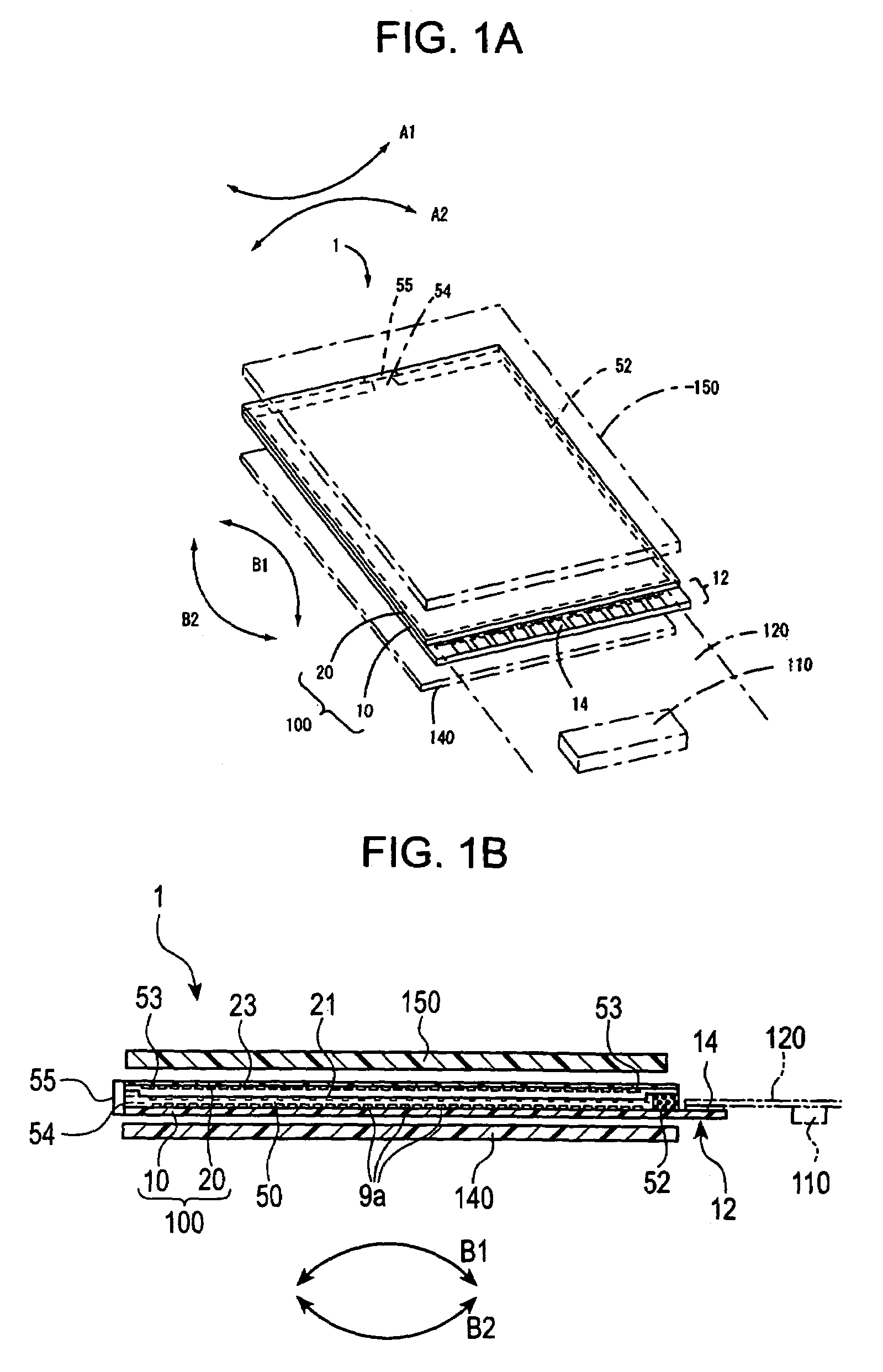

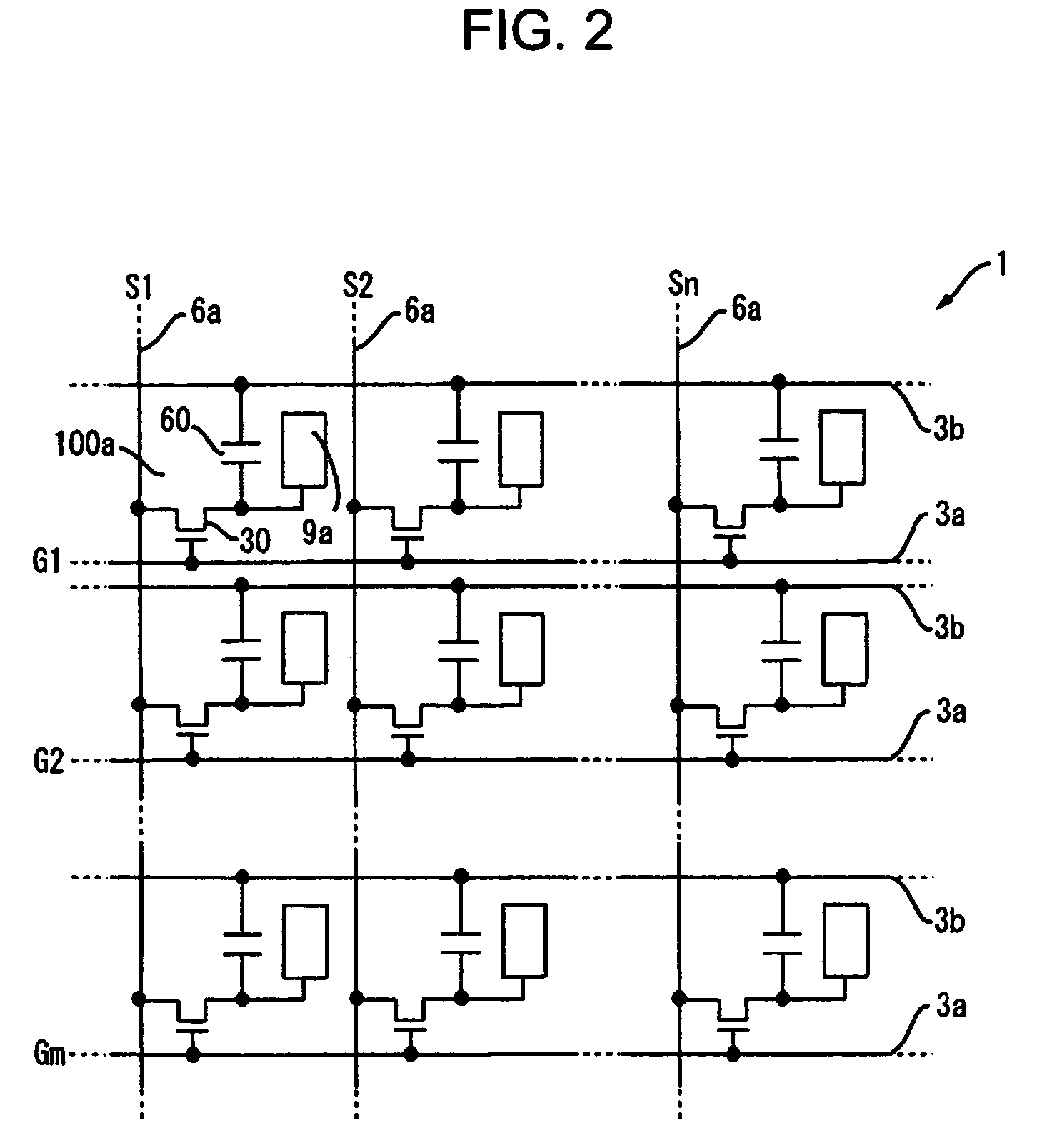

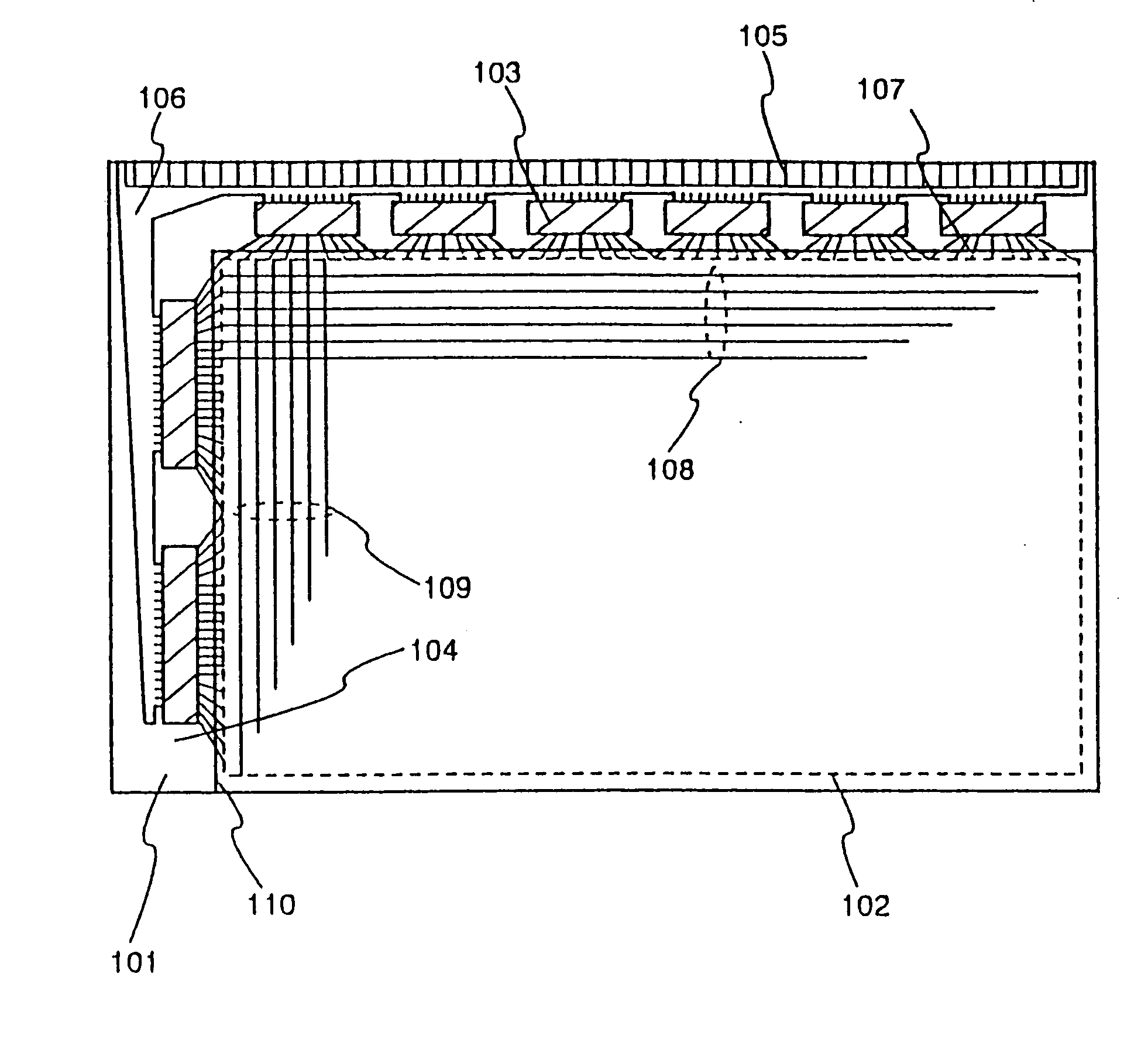

Electro-optical device, method of manufacturing the same, and electronic apparatus

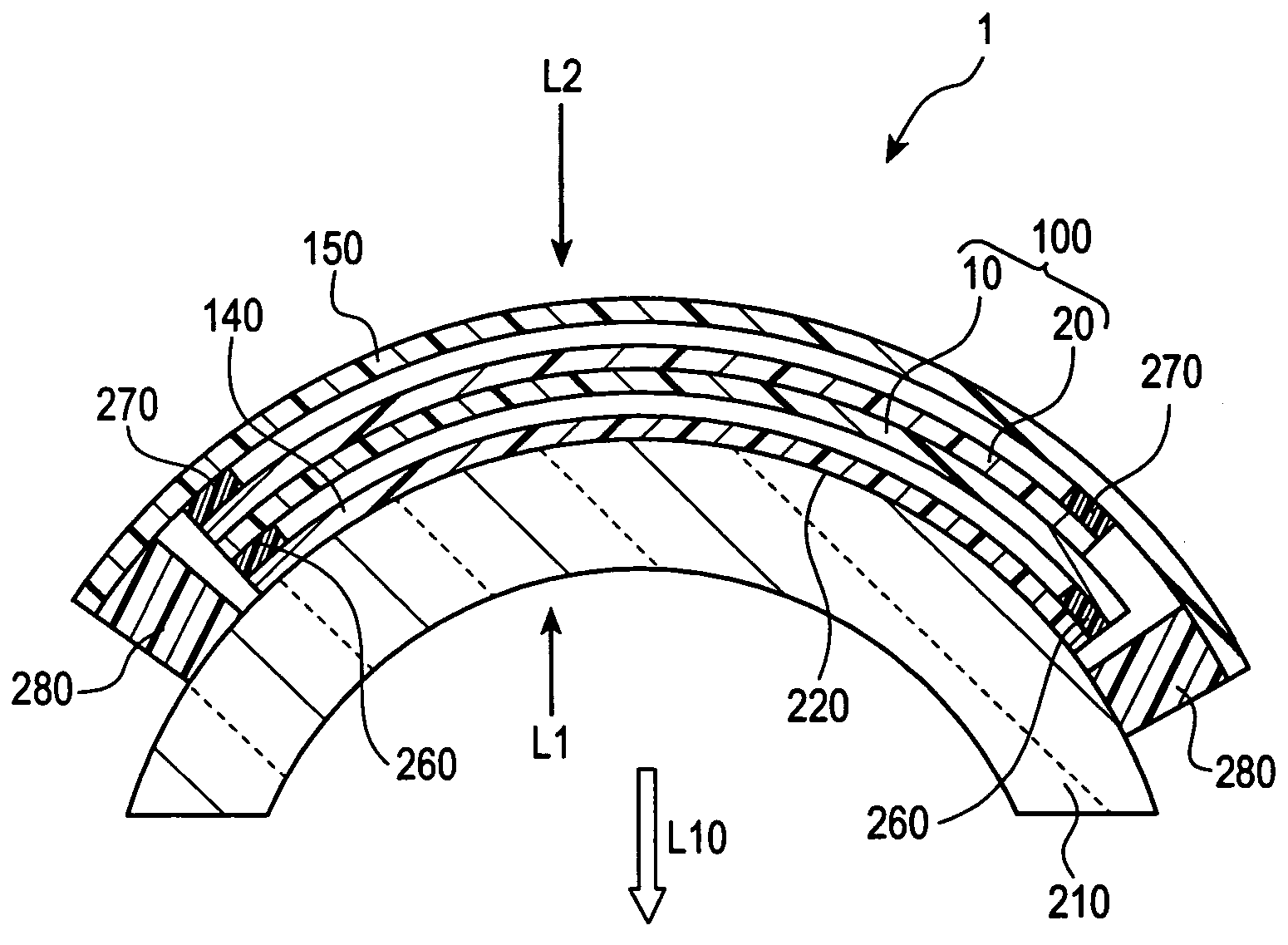

ActiveUS20050117197A1Uniform lightQuality improvementStatic indicating devicesOptical waveguide light guideEngineeringQuartz substrate

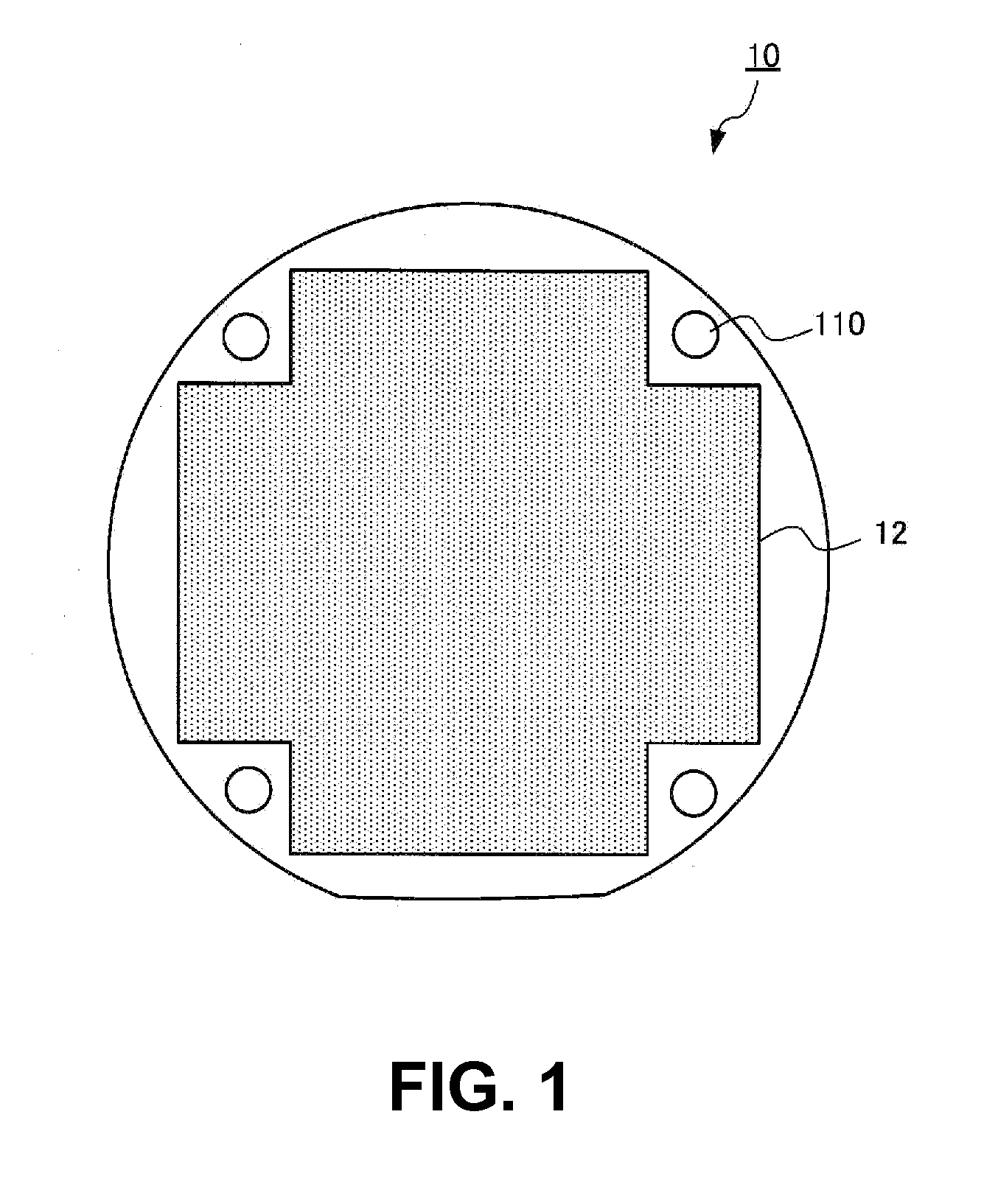

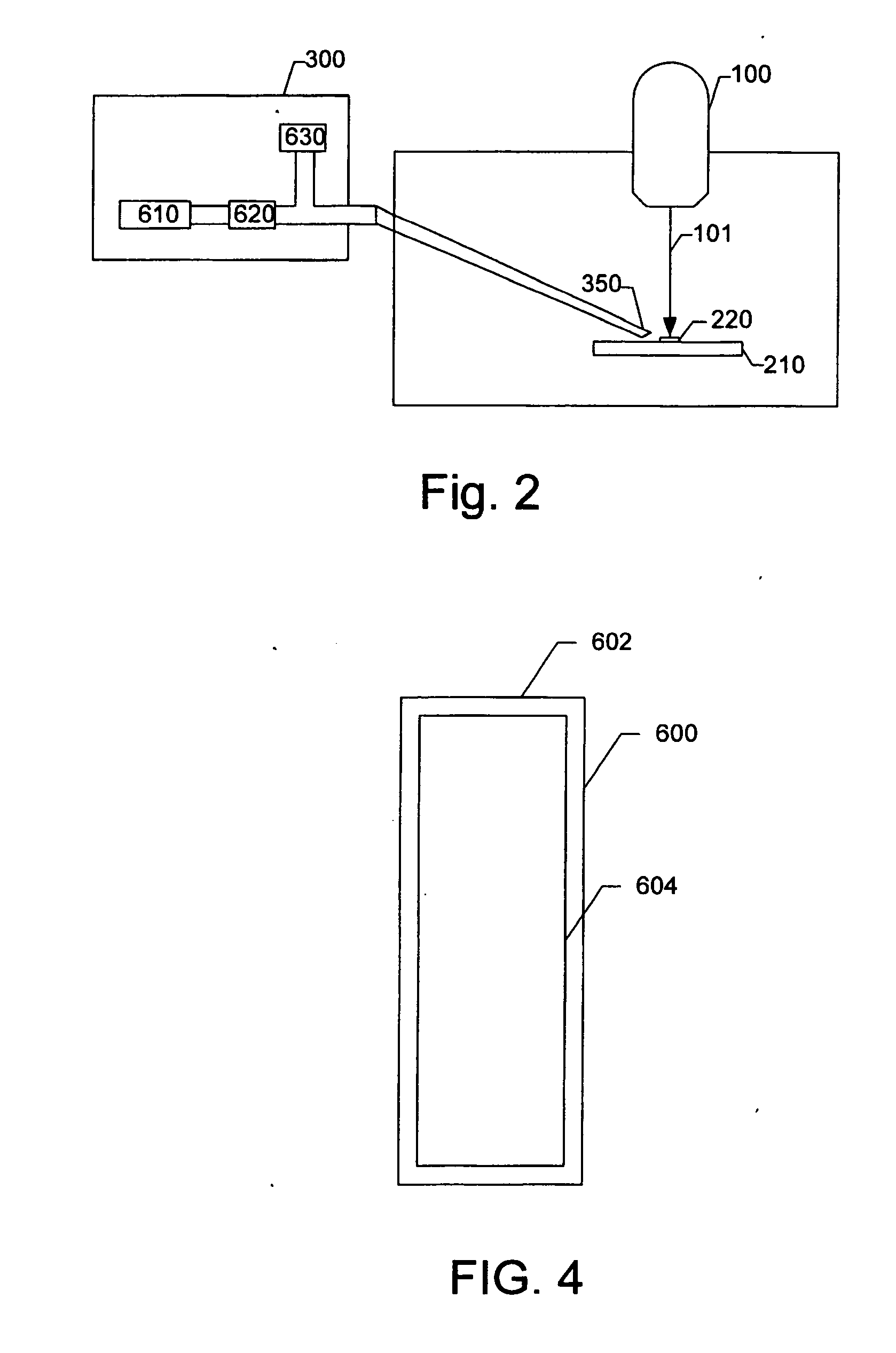

A method of manufacturing an electro-optical device having a curved display surface with high reliability is provided. A liquid crystal panel 100 comprising a TFT array substrate 10 and a counter substrate 20, each composed of a glass substrate or a quartz substrate, is thinned down to, for example, a thickness of 25 μm by a polishing process or an etching process. Subsequently, a first polarizing plate 140, first spacers 260, the liquid crystal panel 100, second spacers 270, and a second polarizing plate 150 are superposed on a base 210 having a curved surface 220 in this order, and then the outer circumference of the second polarizing plate 150 is pressed against the base 210 while curving the second polarizing plate 150 along the curved surface 220 of the base 210. Then, in order to maintain such a curved state, the second polarizing plate 150 is fixed to the base 210 by a double-faced tape 280.

Owner:SEIKO EPSON CORP

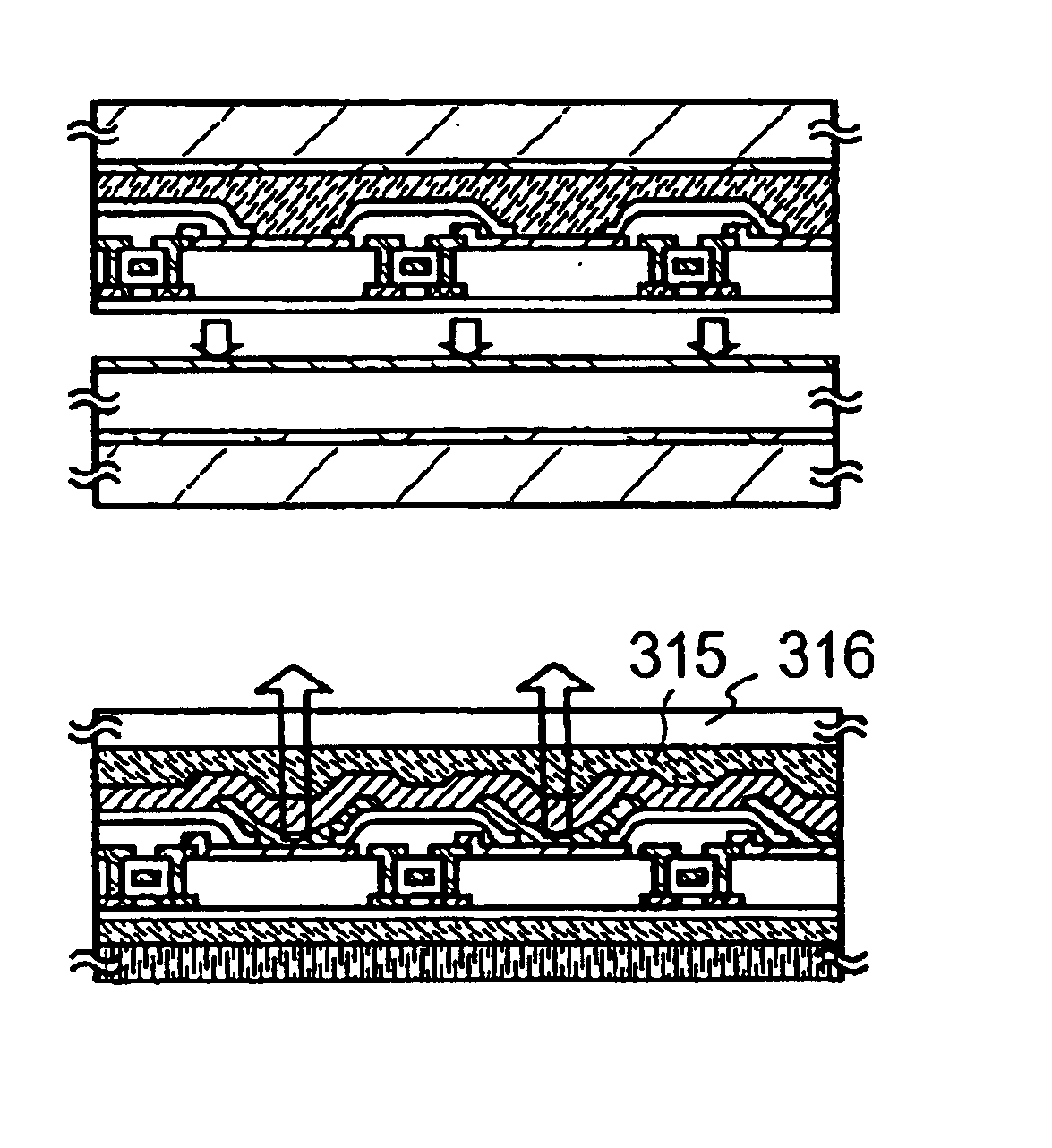

Wireless Chip And Manufacturing Method Thereof

ActiveUS20080093464A1Easily processed into flexible shapeLow costTransistorSolid-state devicesMiniaturizationEngineering

It is an object of the present invention to reduce the cost of a wireless chip, further, to reduce the cost of a wireless chip by enabling the mass production of a wireless chip, and furthermore, to provide a downsized and lightweight wireless chip. A wireless chip in which a thin film integrated circuit peeled from a glass substrate or a quartz substrate is formed between a first base material and a second base material is provided according to the invention. As compared with a wireless chip formed from a silicon substrate, the wireless chip according to the invention realizes downsizing, thinness, and lightweight. The thin film integrated circuit included in the wireless chip according to the invention at least has an n-type thin film transistor having an LDD (Lightly Doped Drain) structure, a p-type thin film transistor having a single drain structure, and a conductive layer functioning as an antenna.

Owner:SEMICON ENERGY LAB CO LTD

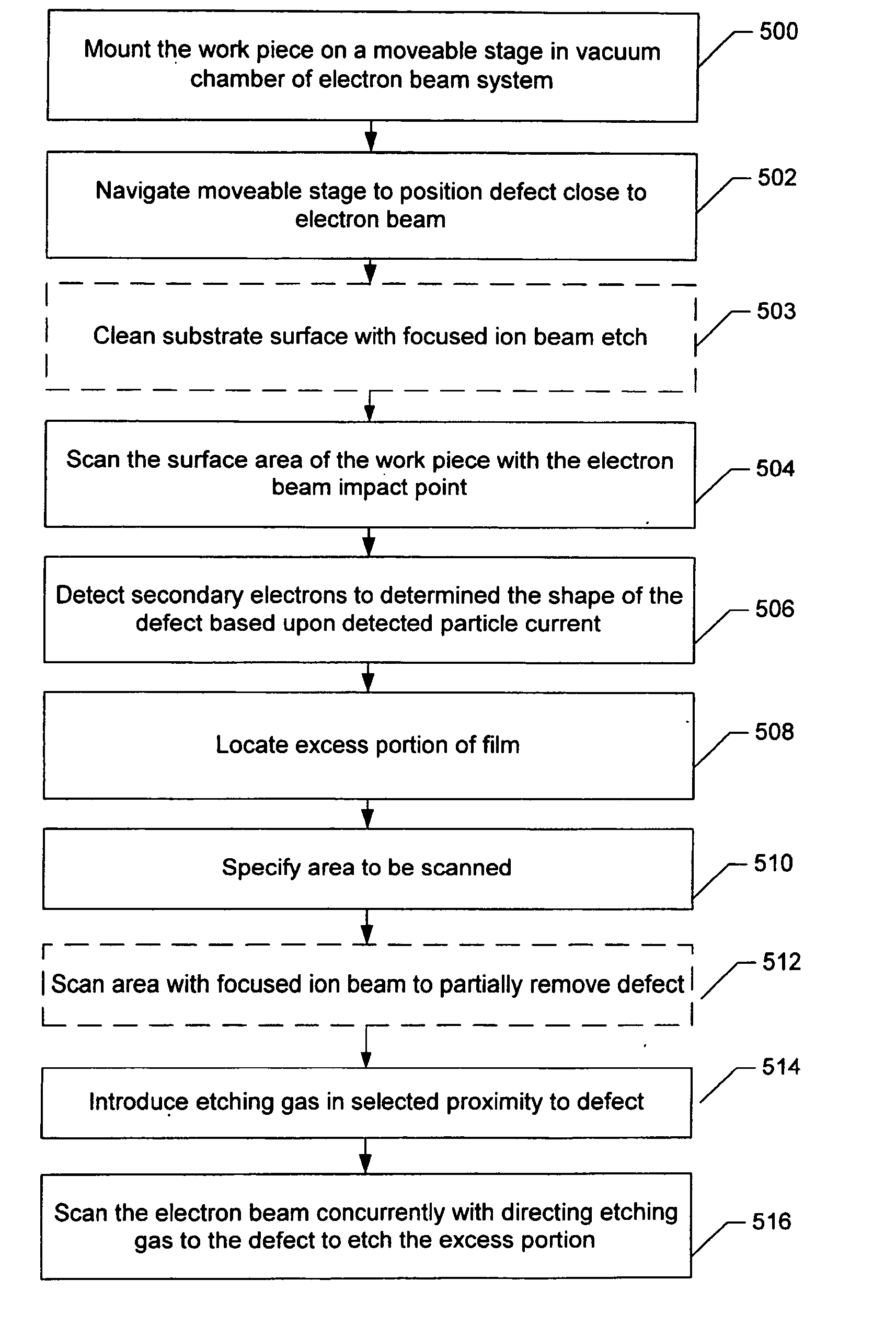

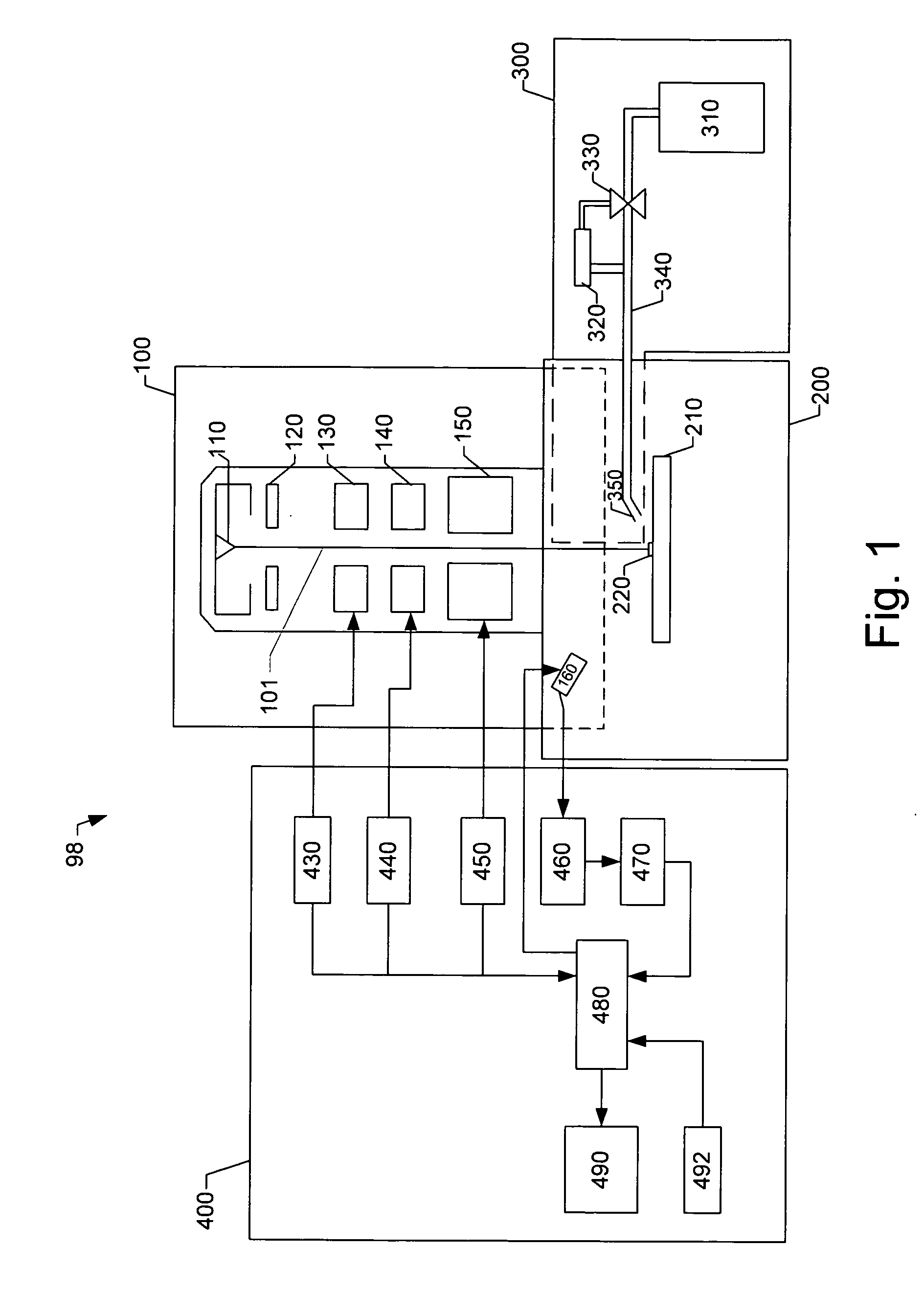

Beam-induced etching

A method and apparatus for local beam processing using a beam activated gas to etch material are described. Compounds are disclosed that are suitable for beam-induced etching. The invention is particularly suitable for electron beam induced etching of chromium materials on lithography masks. In one embodiment, a polar compound, such as ClNO2 gas, is activated by the electron beam to selectively etch a chromium material on a quartz substrate. By using an electron beam in place of an ion beam, many problems associated with ion beam mask repair, such as staining and riverbedding, are eliminated. Endpoint detection is not critical because the electron beam and gas will not etch significantly the substrate.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Hybrid circuit and electronic device using same

InactiveUS6331722B1Improve thermal conductivityRelieve pressureTransistorImpedence networksRf filtersRF module

There is disclosed a hybrid circuit in which a circuit formed by TFTs is integrated with an RF filter. The TFTs are fabricated on a quartz substrate. A ceramic filter forming the RF filter is fabricated on another substrate. Terminals extend through the quartz substrate. The TFTs are connected with the ceramic filter via the terminals. Thus, an RF module is constructed.

Owner:SEMICON ENERGY LAB CO LTD

Large scale polarizer and polarizer system employing it

InactiveUS7016113B2Simple processSimplify a driving system of the polarizerPolarising elementsSpectral modifiersPolarizerOptoelectronics

A large scale polarizer comprises one or more quartz substrate parts formed as a rectangle, a triangle, or a parallelogram, and a polarizer holder supporting the quartz substrate part. The polarizer holder may be in a lattice structure holding a plurality of quartz substrate parts. A polarizer system employing the large scale polarizer comprises a lens making an incident light to a parallel light, the large scale polarizer, and a moving control part coupled to and moving the large scale polarizer.

Owner:LG DISPLAY CO LTD

Electro-optical device, method of manufacturing the same, and electronic apparatus

ActiveUS7190503B2Good weather resistanceImprove reliabilityStatic indicating devicesOptical waveguide light guideEngineeringQuartz substrate

A method of manufacturing an electro-optical device having a curved display surface with high reliability is provided. A liquid crystal panel 100 comprising a TFT array substrate 10 and a counter substrate 20, each composed of a glass substrate or a quartz substrate, is thinned down to, for example, a thickness of 25 μm by a polishing process or an etching process. Subsequently, a first polarizing plate 140, first spacers 260, the liquid crystal panel 100, second spacers 270, and a second polarizing plate 150 are superposed on a base 210 having a curved surface 220 in this order, and then the outer circumference of the second polarizing plate 150 is pressed against the base 210 while curving the second polarizing plate 150 along the curved surface 220 of the base 210. Then, in order to maintain such a curved state, the second polarizing plate 150 is fixed to the base 210 by a double-faced tape 280.

Owner:SEIKO EPSON CORP

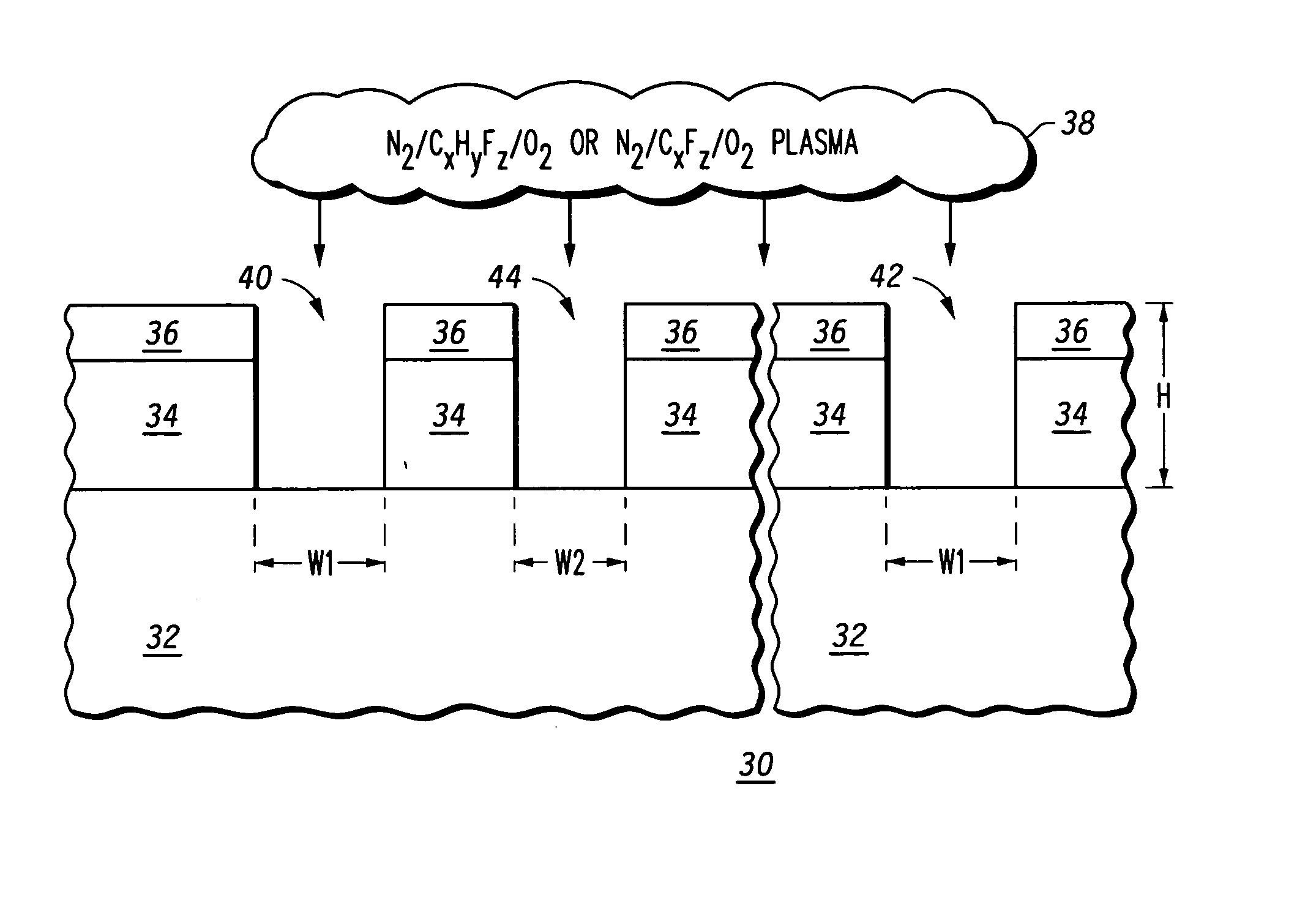

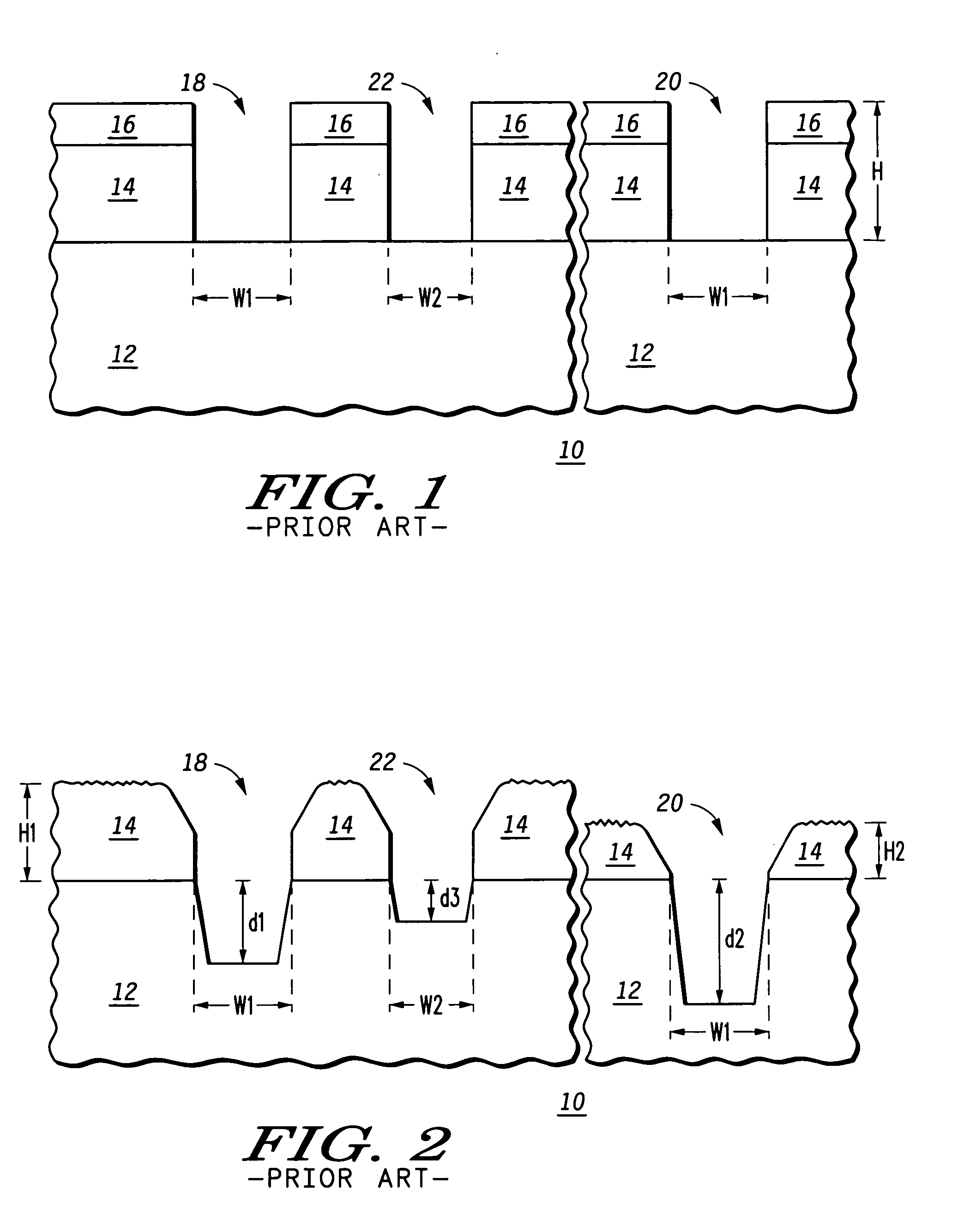

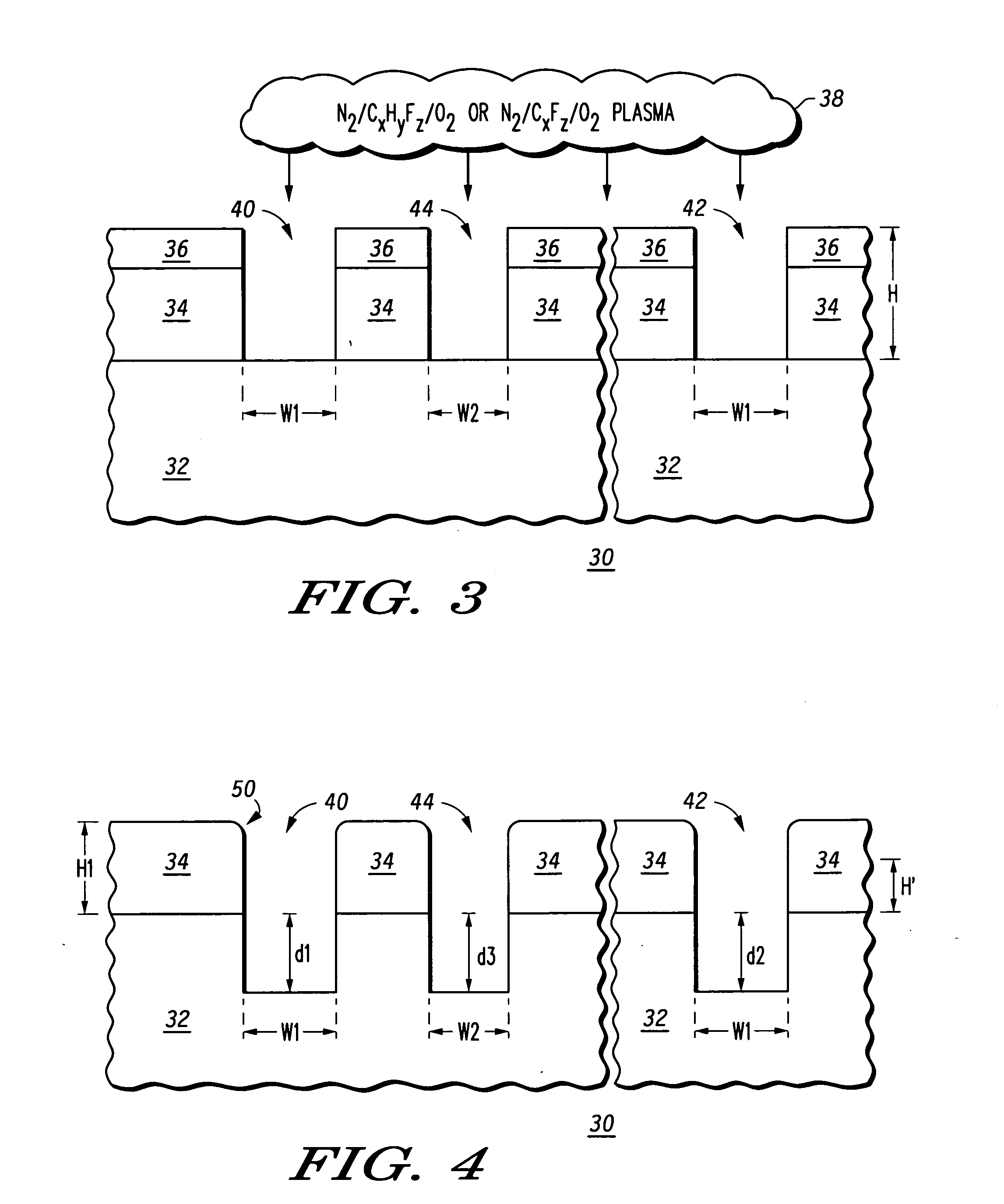

Method for etching a quartz layer in a photoresistless semiconductor mask

ActiveUS20050164514A1Decorative surface effectsSemiconductor/solid-state device manufacturingRoundingLithographic artist

A chromeless phase lithography mask (30) that does not require photoresist to manufacture has a quartz substrate (32) is etched by using a plasma (38) containing one of a nitrogen augmented hydro-fluorocarbon oxygen mixture and a nitrogen augmented fluorocarbon oxygen mixture. Various hydro-fluorocarbons or fluorocarbons may be used. The nitrogen addition results in etched openings in the quartz substrate that have substantially vertical sidewalls in a uniform manner across the substrate. Surface roughness is minimized and edges of the openings are well-defined with minimal rounding. The etch rate is rendered controllable by reducing bias power without degrading a desired vertical sidewall profile.

Owner:NXP USA INC

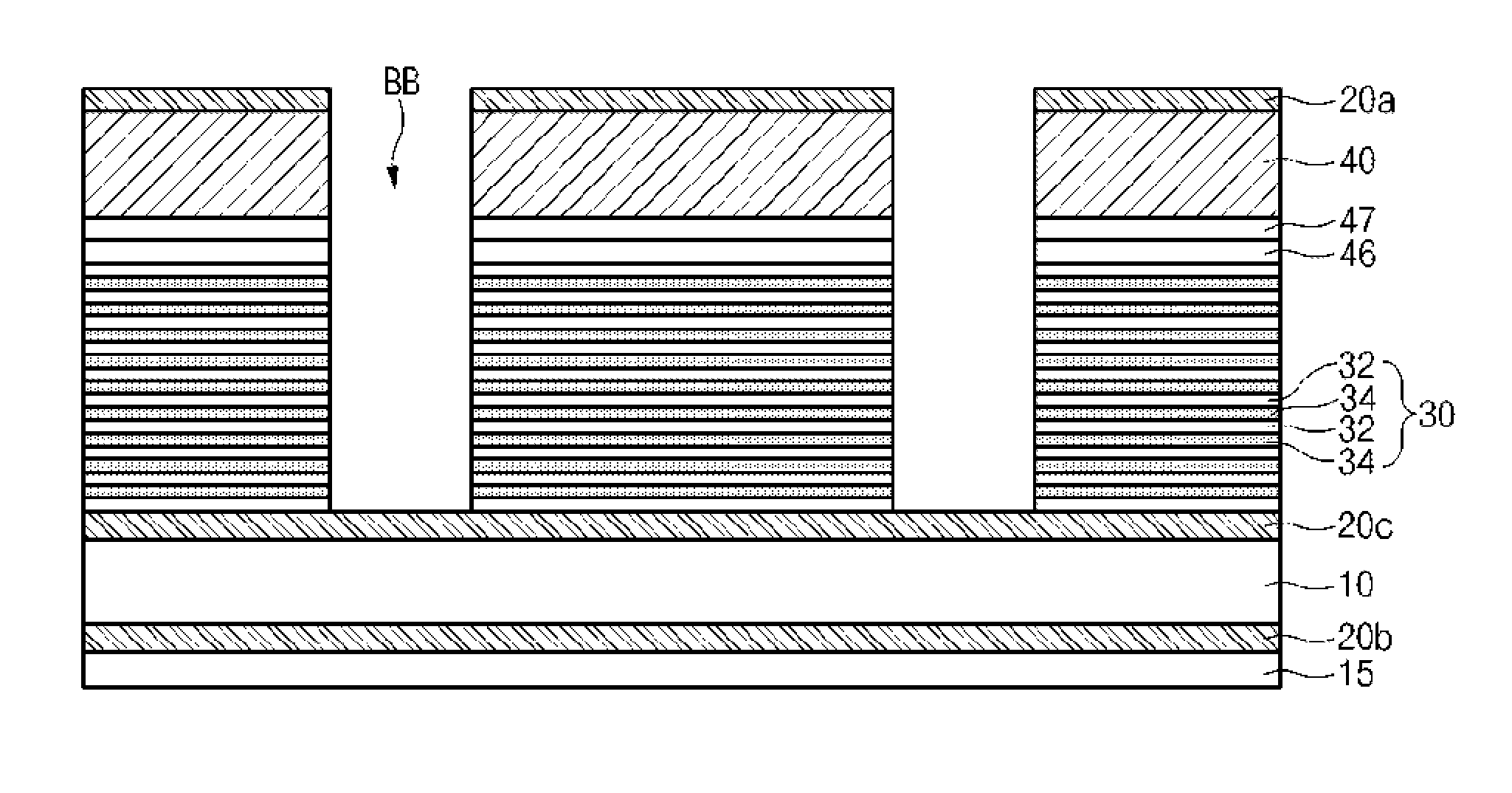

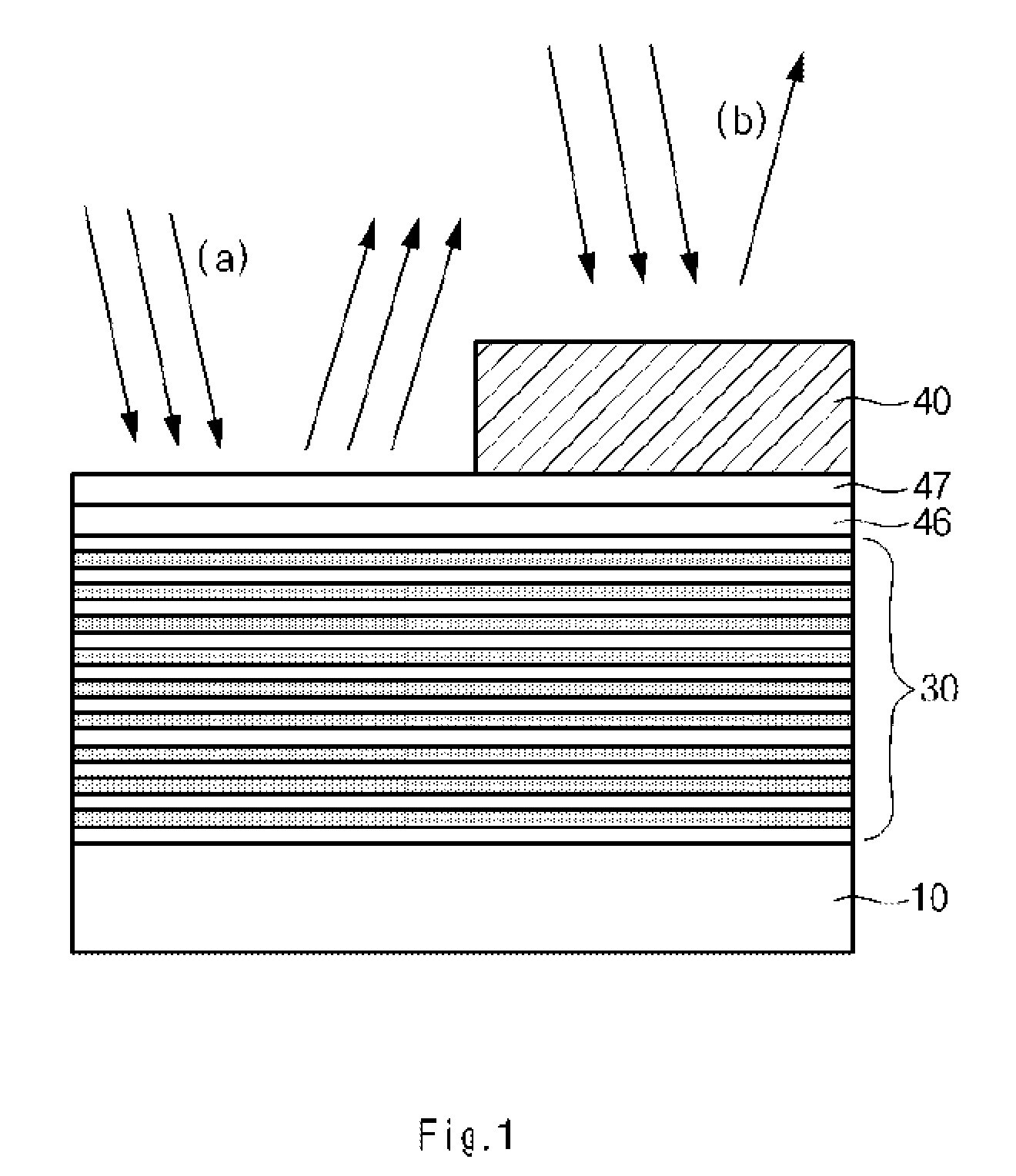

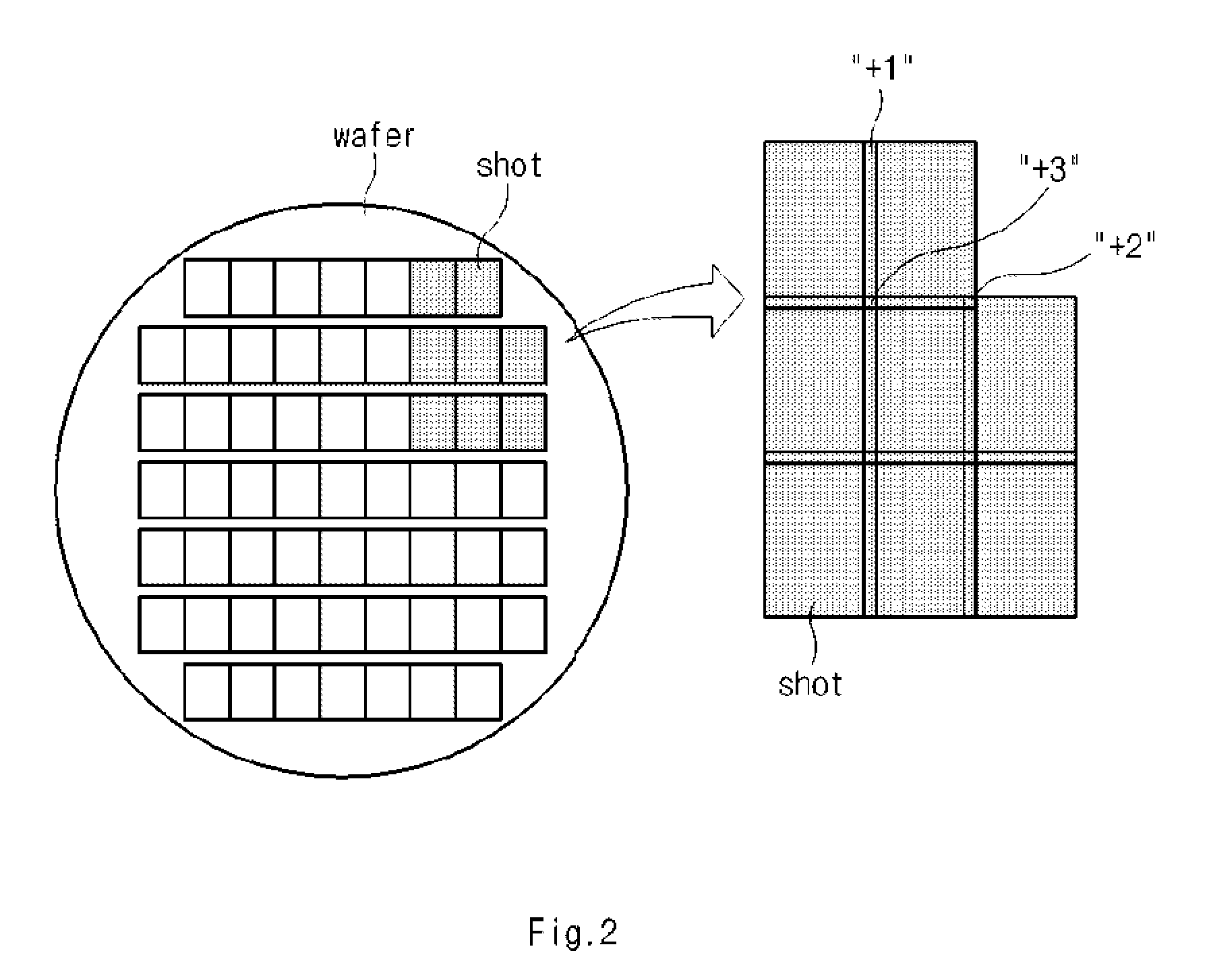

Extreme ultra violet (EUV) mask

ActiveUS8802335B2Avoid defectsReduce reflectionOriginals for photomechanical treatmentUltravioletExtreme ultraviolet

An extreme ultra violet (EUV) mask is disclosed, which prevents defects from shot overlap encountered in wafer exposure as well as reflection of unnecessary EUV and DUV generated in a black border region, such that a pattern CD is reduced and defects are not created. The EUV mask includes a quartz substrate, a multi-layered reflection film formed over the quartz substrate to reflect exposure light, an absorption layer formed over the multi-layered reflection film, a black border region formed over the quartz substrate that does not include the multi-layered reflection film, and a blind layer formed in a position including at least one of over the absorption layer, over the quartz substrate, and below the quartz substrate.

Owner:SK HYNIX INC

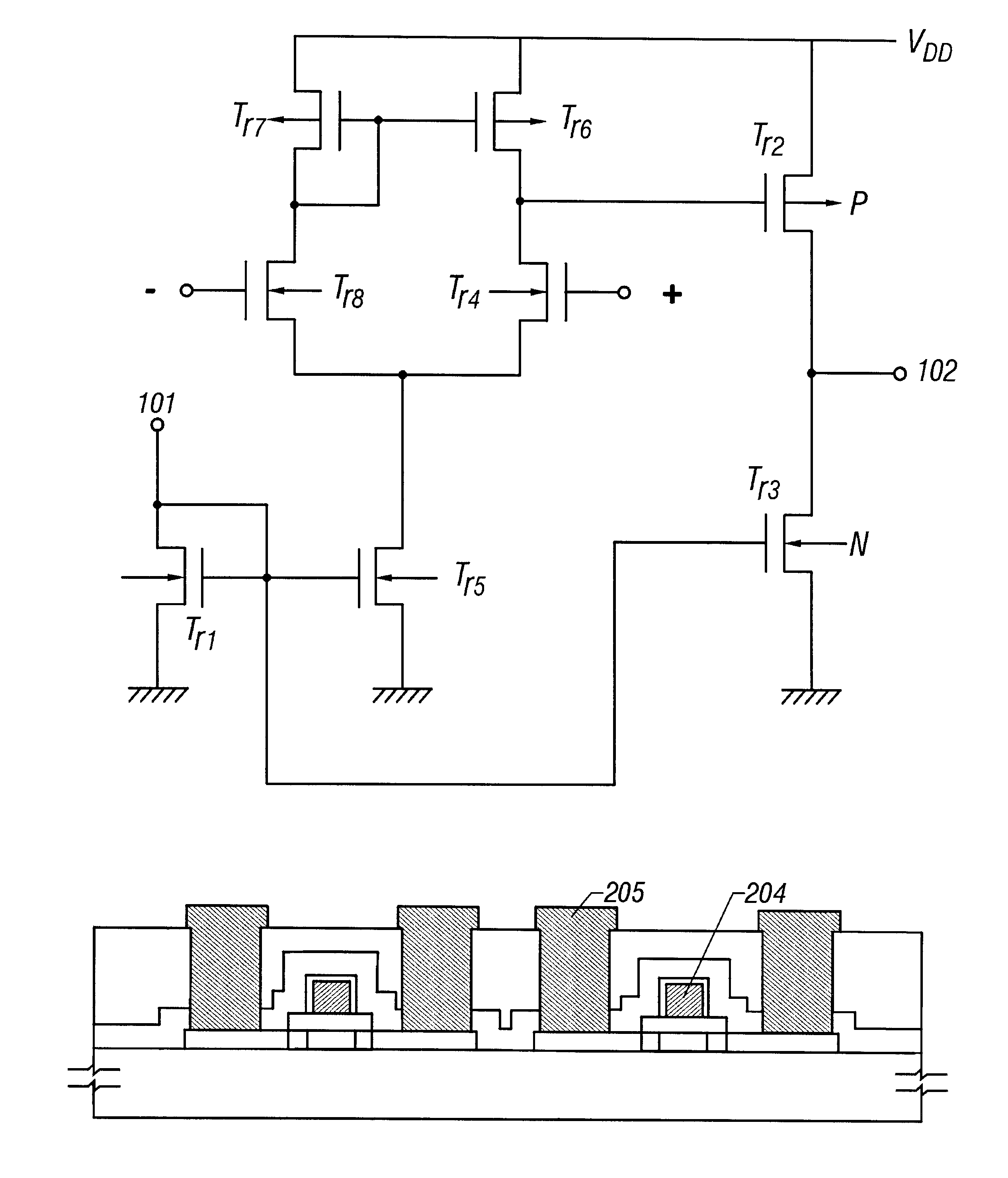

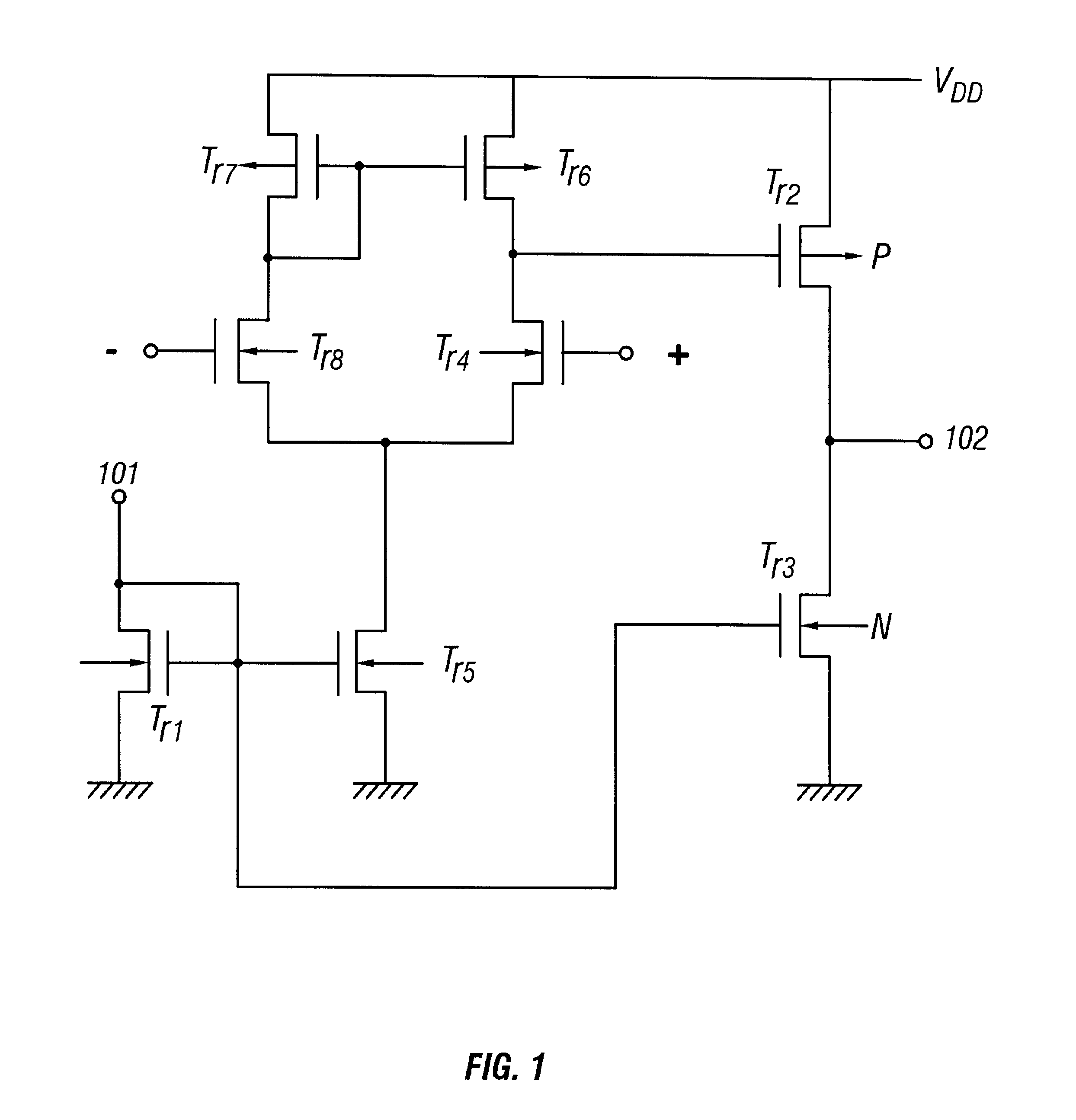

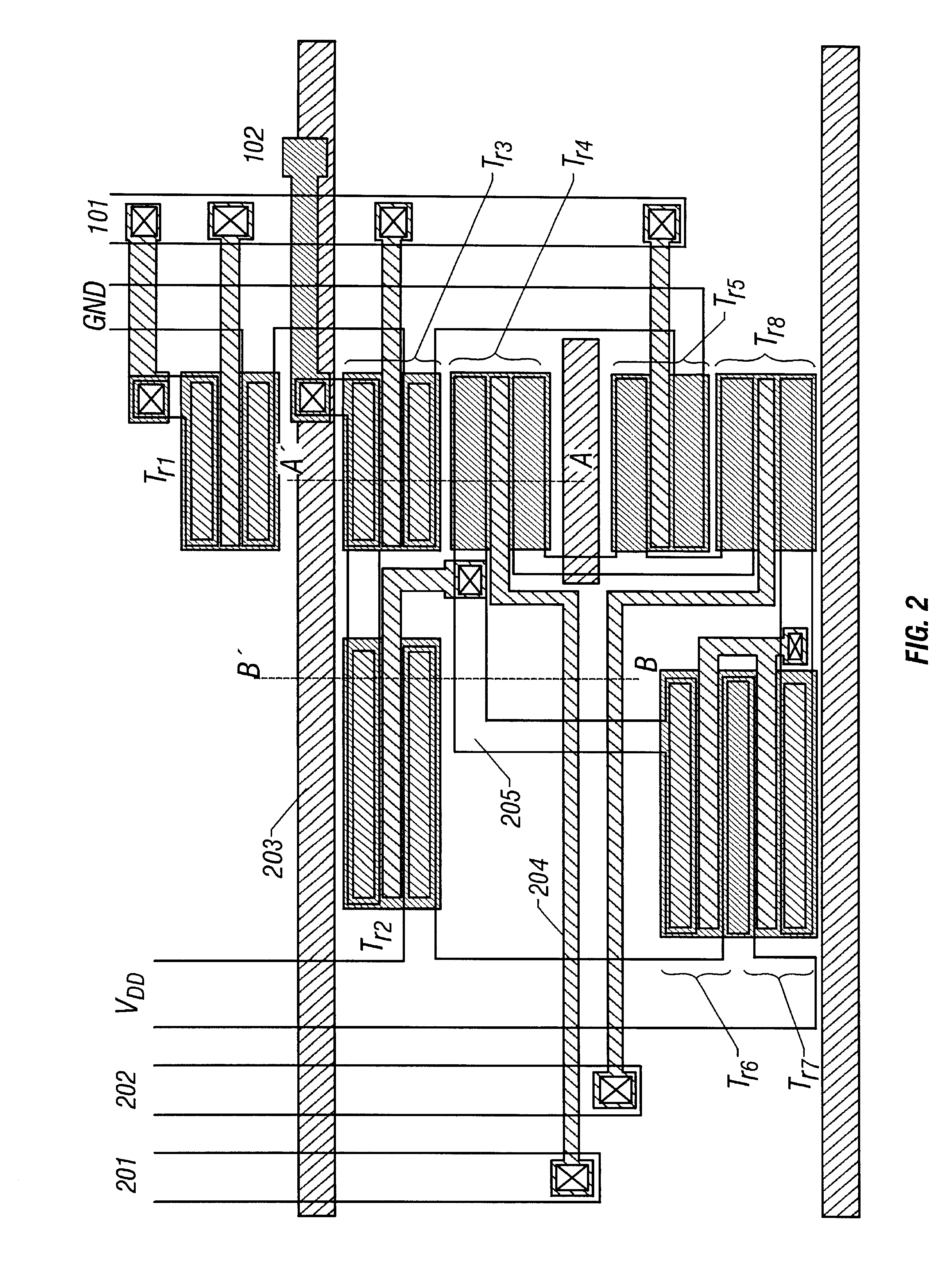

Thin film circuit with improved carrier mobility

InactiveUS6331718B1Eliminate the effects ofIncrease speedTransistorSolid-state devicesHemt circuitsCharge carrier mobility

A practical operational amplifier circuit is formed using thin film transistors.An operational amplifier circuit is formed by thin film transistors formed on a quartz substrate wherein 90% or more of n-channel type thin film transistors have mobility at a value of 260 cm2 / Vs or more and wherein 90% or more of p-channel type thin film transistors have mobility at a value of 150 cm2 / Vs or more. The thin film transistors have active layers formed using a crystalline silicon film fabricated using a metal element that promoted crystallization of silicon. The crystalline silicon film is a collection of a multiplicity of elongate crystal structures extending in a certain direction, and the above-described characteristics can be achieved by matching the extending direction and the moving direction of carriers.

Owner:SEMICON ENERGY LAB CO LTD

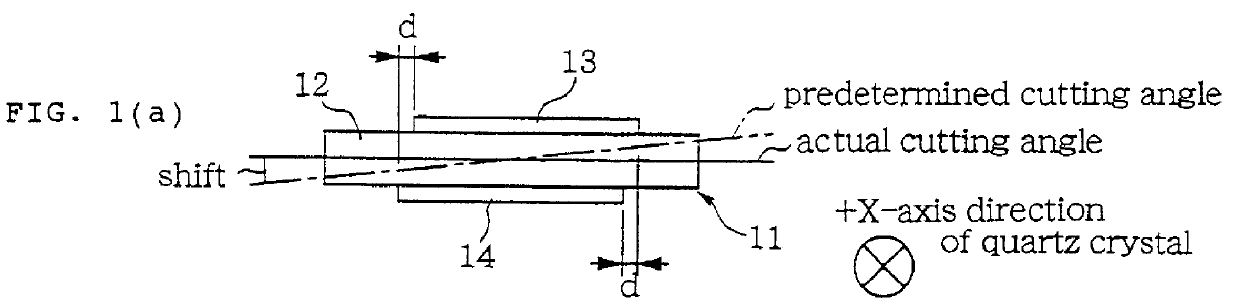

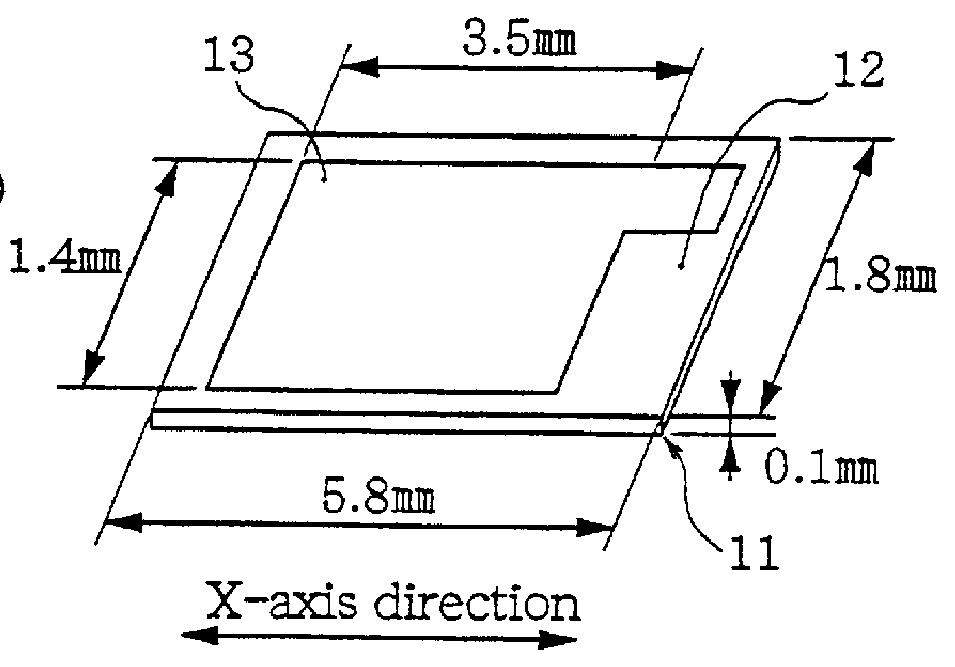

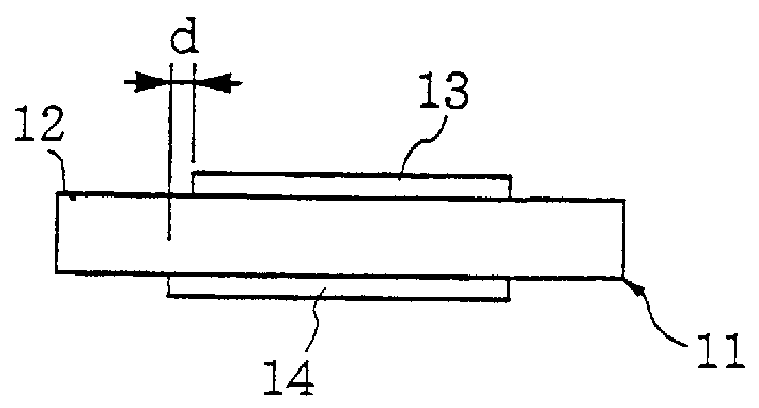

At-cut crystal resonator

InactiveUS6114801AImprove productivityEasy to correctPiezoelectric/electrostriction/magnetostriction machinesImpedence networksProduction rateIndustrial equipment

PCT No. PCT / JP98 / 01526 Sec. 371 Date Dec. 14, 1998 Sec. 102(e) Date Dec. 14, 1998 PCT Filed Apr. 2, 1998 PCT Pub. No. WO98 / 47226 PCT Pub. Date Oct. 22, 1998In an AT-cut quartz resonator having excitation electrodes formed on two principal surfaces of an AT-cut quartz substrate, the two electrodes are displaced a predetermined amount apart in a direction orthogonal to the X-axis direction so that a frequency deviation in a temperature range of from -10 DEG C. to 50 DEG C. is less than + / -2.5 ppm. Further, in an AT-cut quartz resonator in which vertically opposed electrodes on both principal surfaces of a quartz substrate are slightly displaced apart in opposite directions along the Z' axis of quartz crystal, a balancing load is formed on a piezoelectric substrate on the side opposite to the direction of displacement of the electrodes. Thus, the present invention dispenses with the need for raising the ratio of conforming to nonconforming quartz substrates by eliminating variations in their cutting angle, but makes it possible to use nonconforming quartz substrates to offer customers low-cost quartz resonators of oscillation frequencies following various specs, by making easy, simple structural modifications of slightly changing the electrode arrangement or structure, or by making simple improvements to the conventional quartz resonator manufacturing process. In the manufacture of oscillators for use in consumer-electronics equipment, it is possible to fulfill any particular specs without inserting a temperature compensating circuit in the oscillation circuit. In regards to industrial equipment, any adjustments need not be made to the temperature compensating circuit in the oscillation circuit, and this improves the productivity of various communications equipment and various electronics equipment and reduces their manufacturing costs.

Owner:TOYO TSUSHINKI

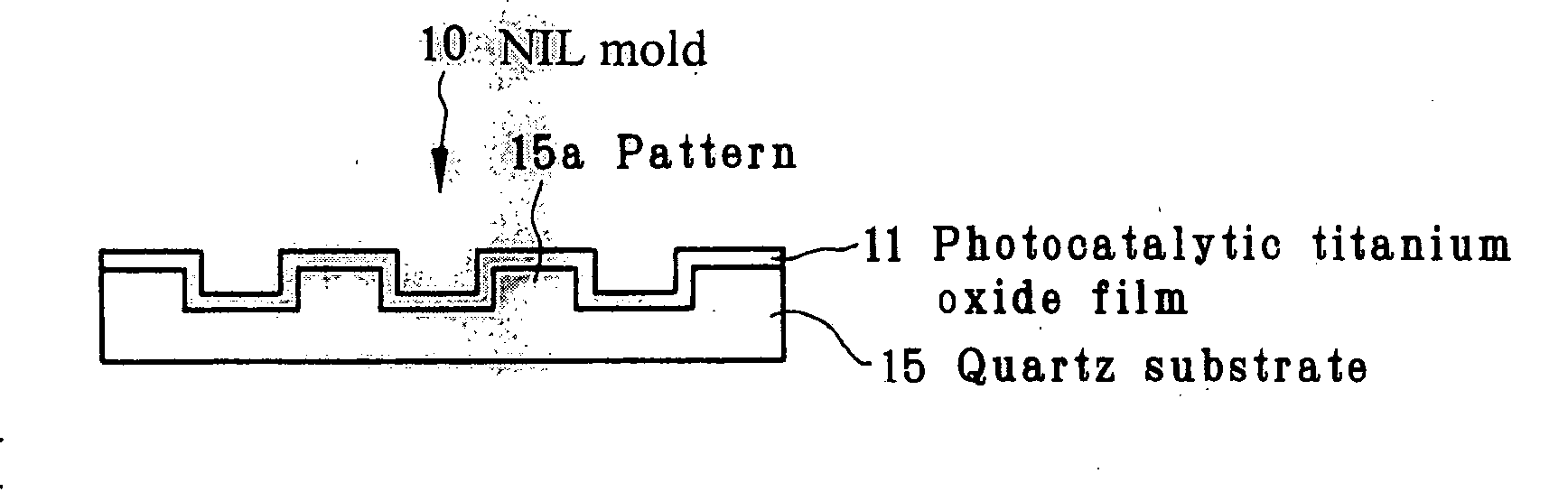

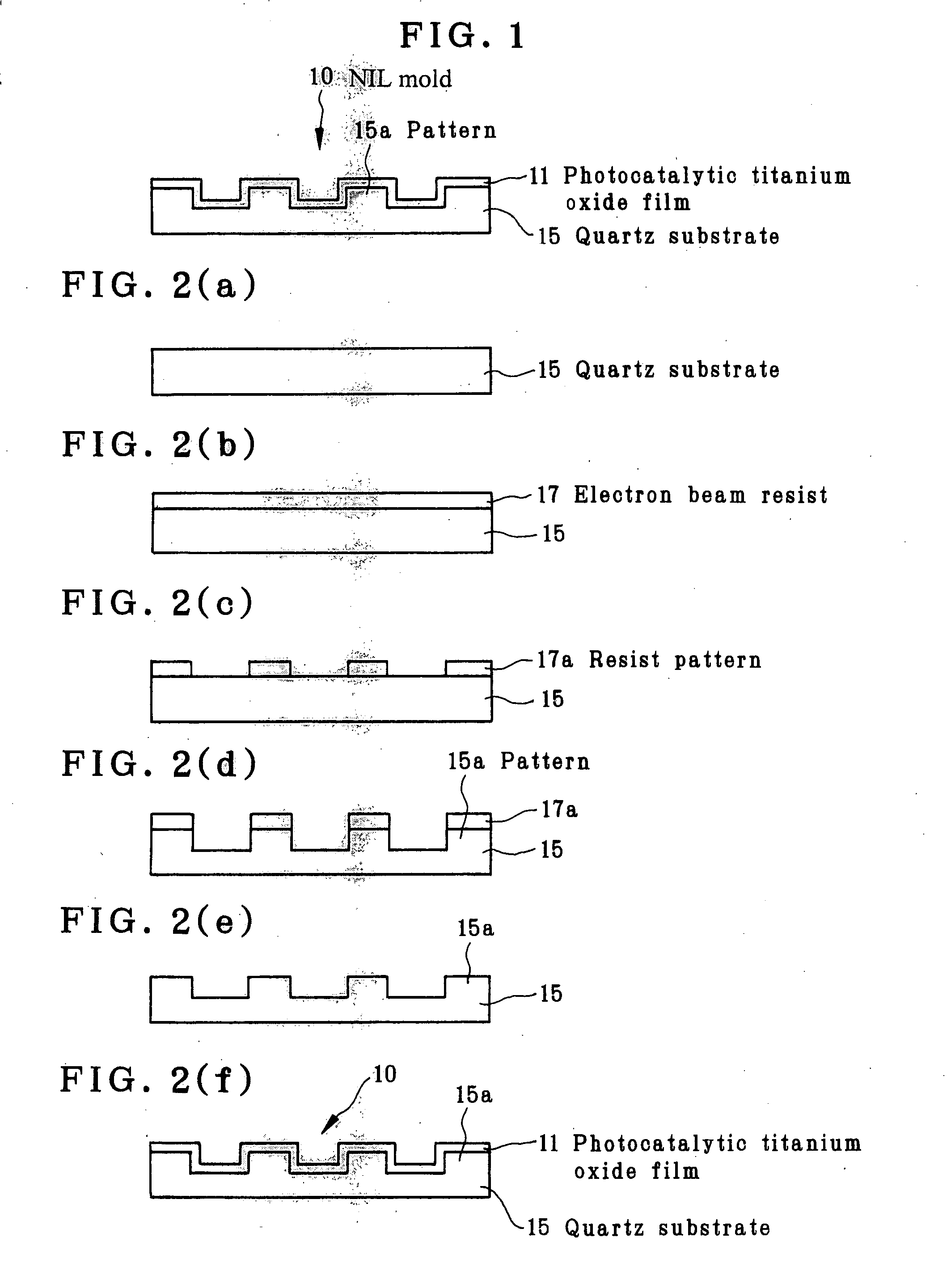

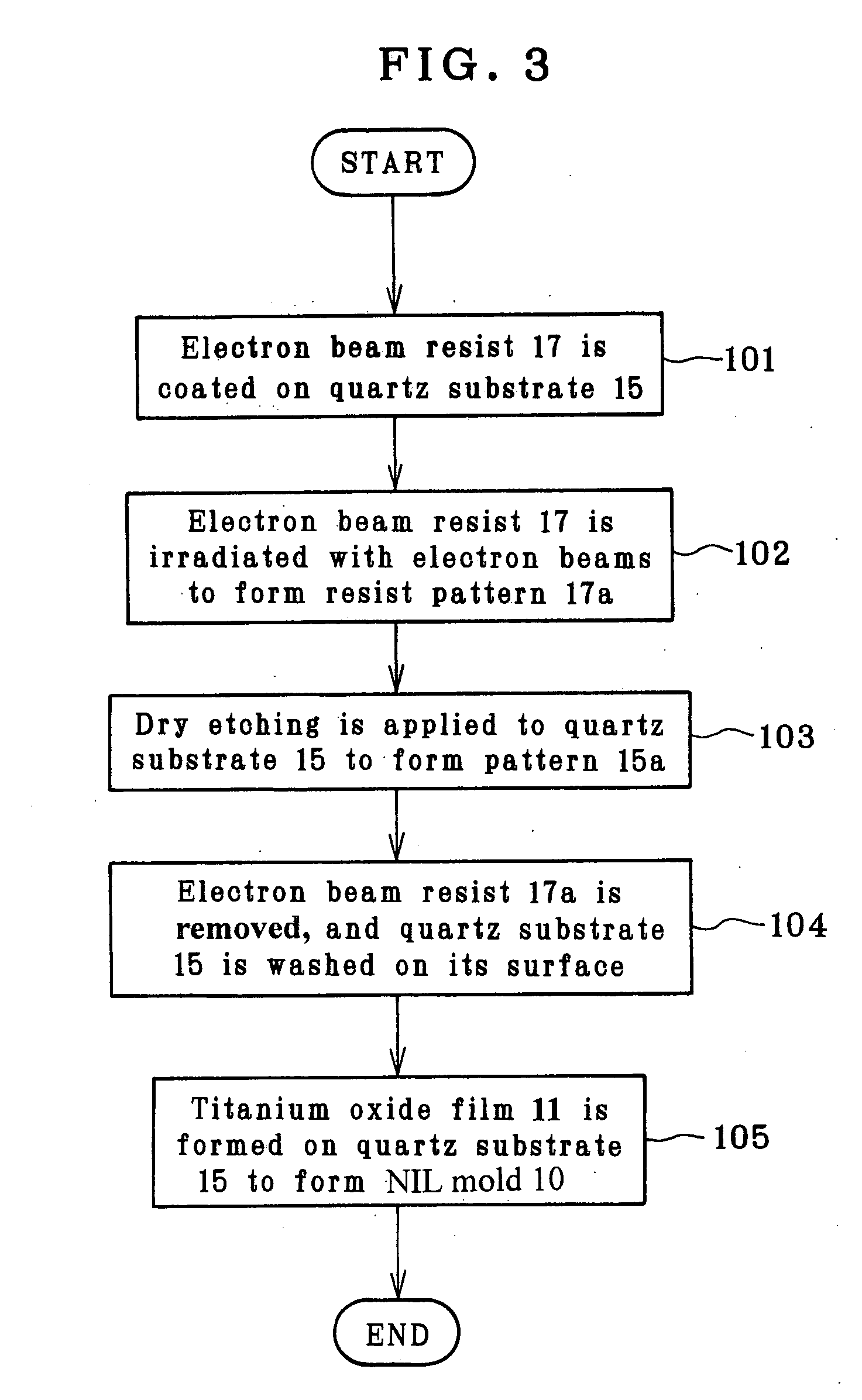

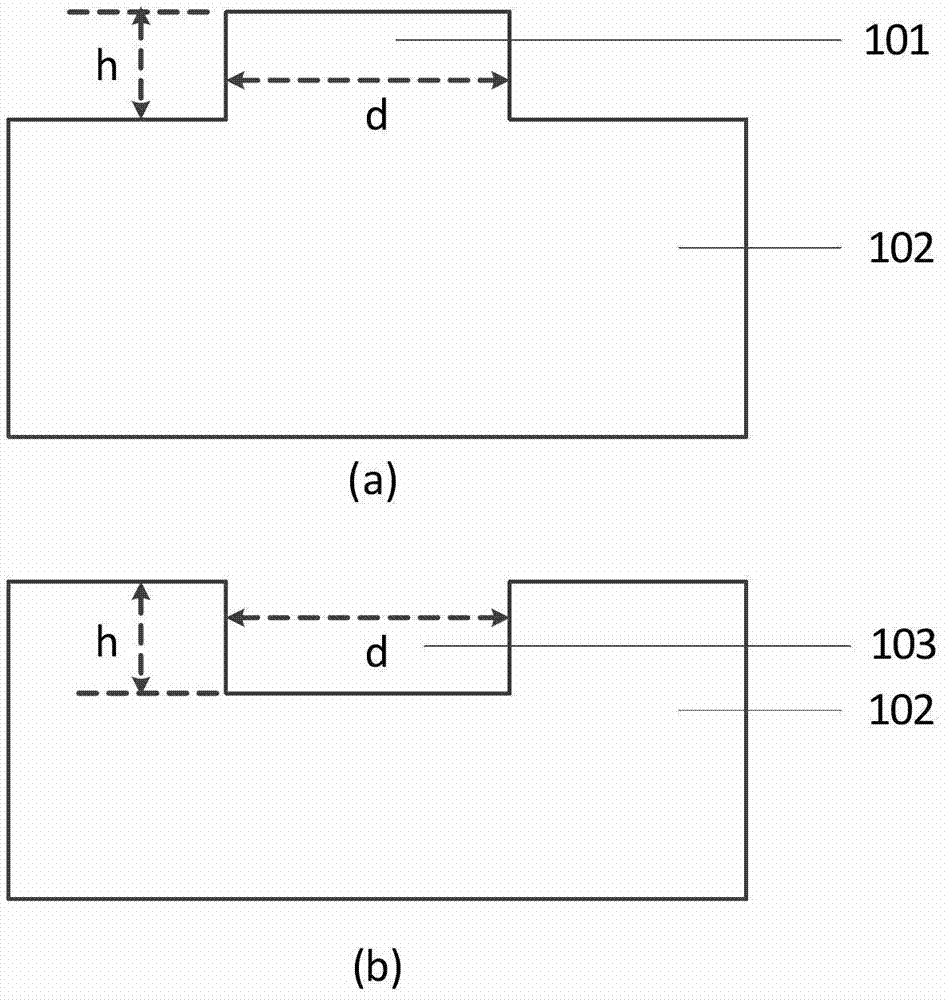

Mold for photocuring nano-imprint and its fabrication process

InactiveUS20070267764A1Improve reliabilityImprove robustnessNanoinformaticsFoundry mouldsCarbon monofluorideUltraviolet lights

The invention relates to a mold that has an improved releasability for a photocured resin and an improved robustness. First, an electron beam resist 17 is coated on a quartz substrate 15 having the nature of being transmissive to ultraviolet light. A resist pattern 17a is formed by irradiation with electron beams. Thereafter, the quartz substrate is dry etched using etching gas such as carbon tetrafluoride to form a pattern 15a on the quartz substrate 15. A photocatalytic titanium oxide film 11 is formed as by sputtering on the surface of the quartz substrate 15 with the pattern 15a formed on it to fabricate an NIL mold 10.

Owner:DAI NIPPON PRINTING CO LTD

Method for preparing graphene

The invention discloses a method for preparing graphene. The method comprises the following steps of: 1) raising the temperature of a substrate in a non-oxidizing atmosphere to be between 800 and 1,200 DEG C and keeping the temperature for 10 to 20 minutes; and 2) keeping the temperature in step 1) unchanged, aerating a carbon source and hydrogen into a reaction system in step 1), reacting on thesubstrate treated in step 1) by a chemical vapor deposition method, closing the carbon source after the reaction is finished, and cooling to room temperature in the non-oxidizing atmosphere to obtainthe graphene. The graphene can be discrete nano sheets, and can also be continuous graphene films. A quartz substrate on which the graphene grows can be directly used for high-performance transparentconductive electrodes. A silicon substrate, on which the graphene grows, with a silicon dioxide layer can be directly used for assembly of electronic devices without transfer, is simple in a process,and is compatible with the conventional semiconductor industry.

Owner:TANWENG BEIJING TECH CO LTD

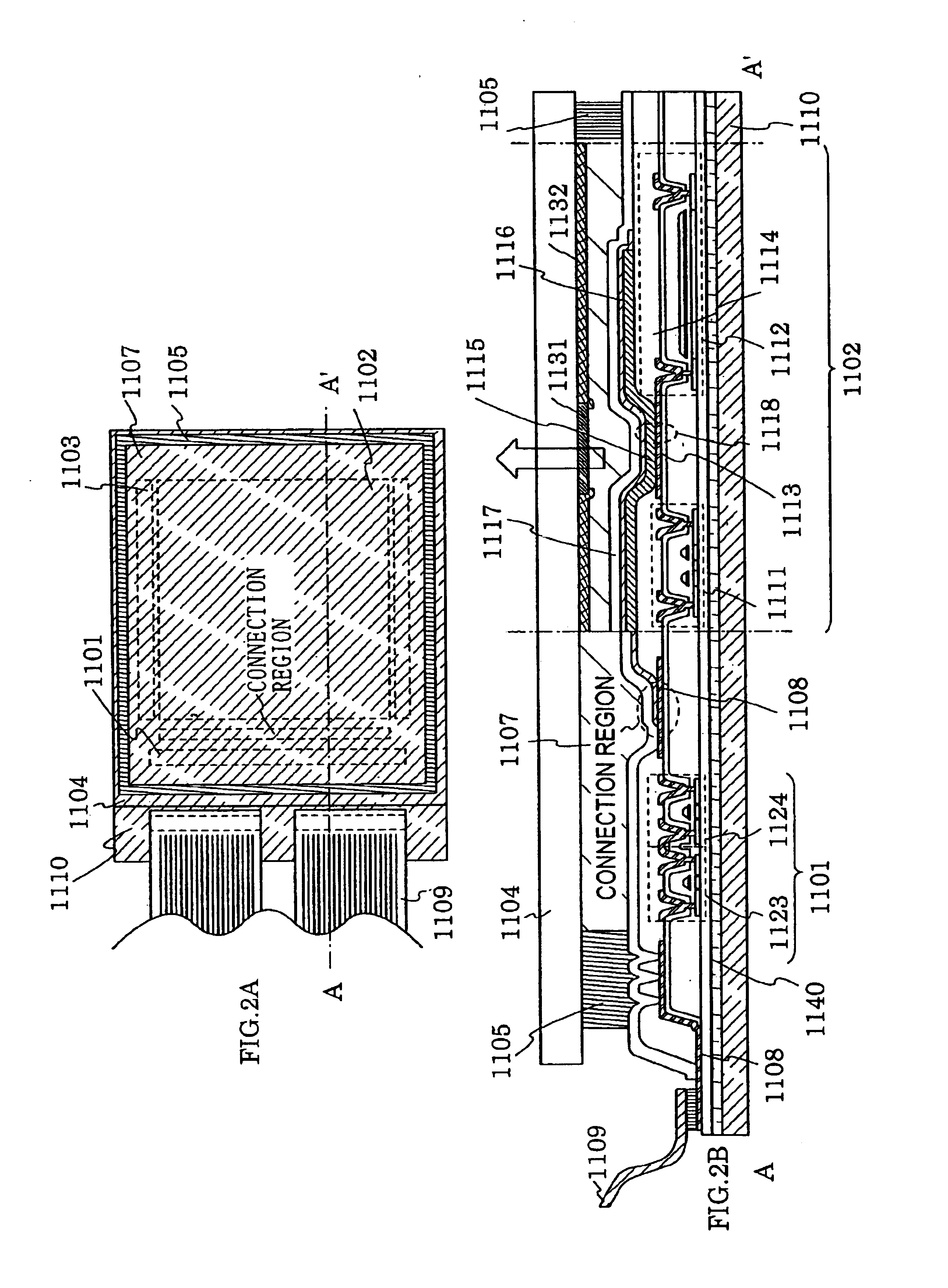

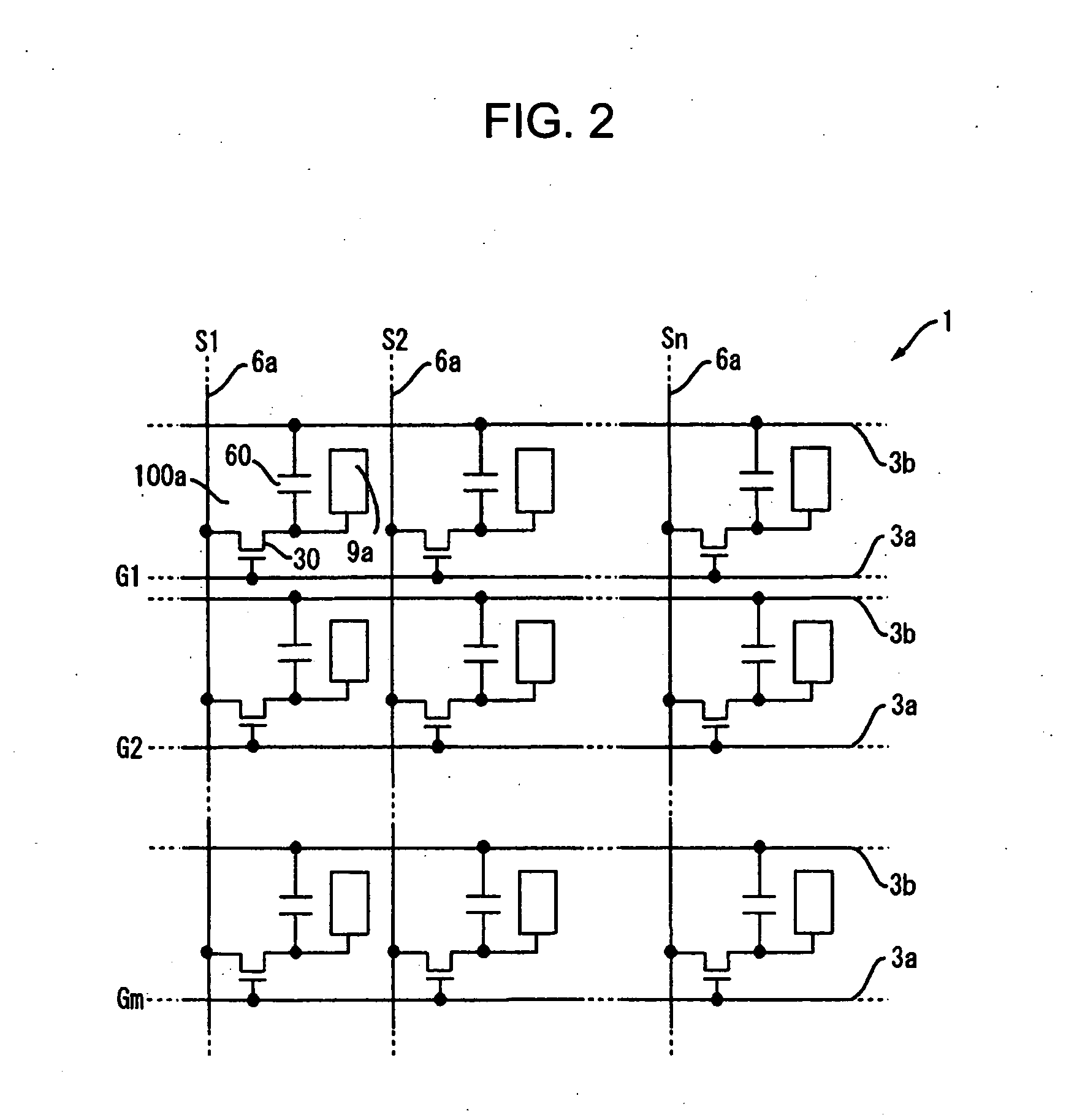

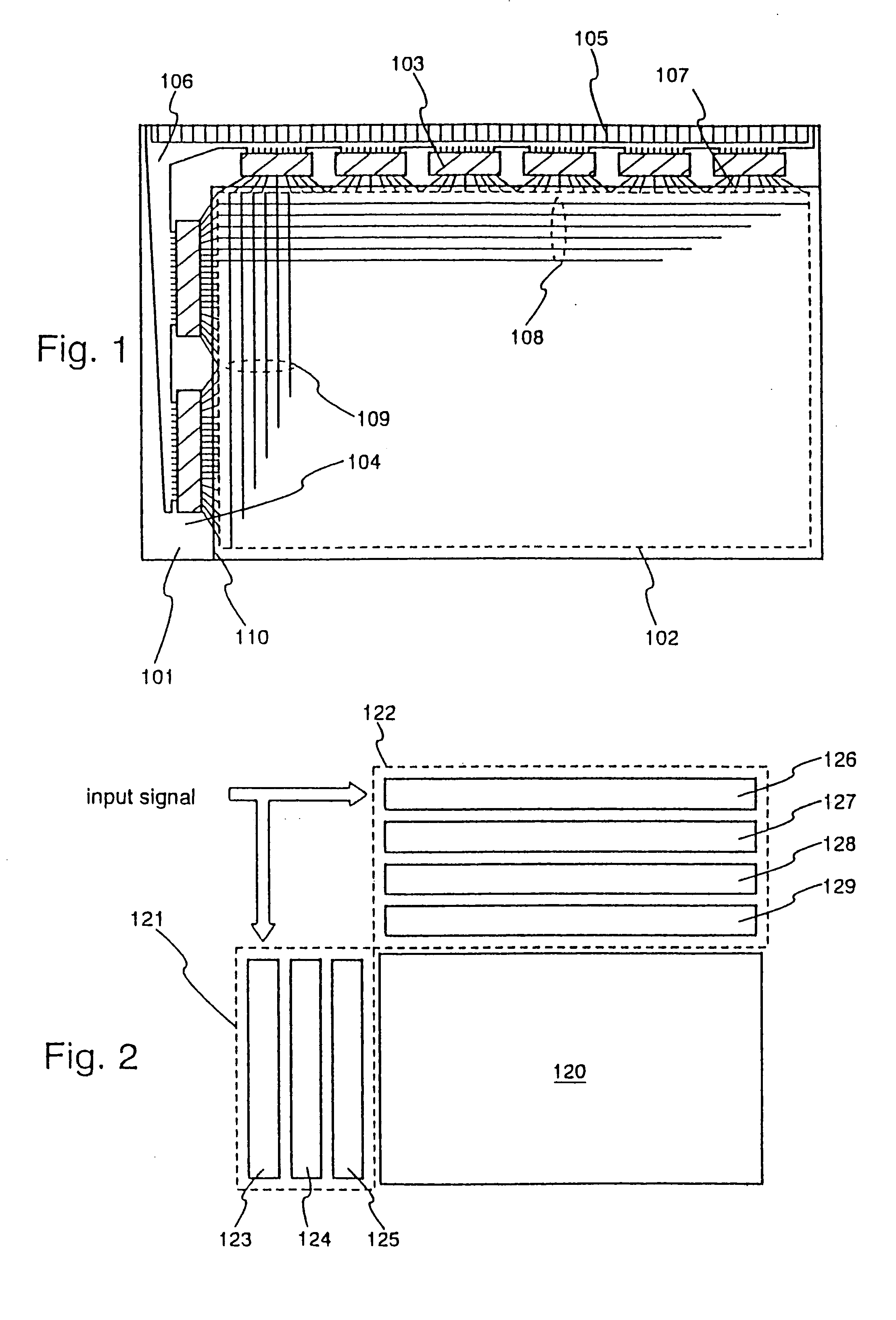

Semiconductor device and a method of manufacturing the same

InactiveUS20050121672A1Improve reliabilityReduce frequencyTransistorSemiconductor/solid-state device detailsShift registerDriver circuit

To form a driver circuit to be mounted to a liquid crystal display device or the like on a glass substrate, a quartz substrate, etc., and to provide a display device mounting driver circuits formed from different TFTs suited for their respective operational characteristics. A stick driver circuit on the scanning line side and a stick driver circuit on the data line side are different in structure, and have different TFTs in which the thickness of a gate insulating film, the channel length and other parameters are varied depending on required circuit characteristics. In the stick driver on the scanning line side, which is composed of a shift register circuit, a level shifter circuit, and a buffer circuit, the buffer circuit has a TFT with a thick gate insulating film because it is required to have a withstand voltage of 30 V. The stick driver circuit on the data line side, which is composed of a shift register circuit, a latch circuit, a level shifter circuit, and a D / A converter circuit, is driven at a high frequency, and hence its shift register circuit and latch circuit have thin gate insulating films and the channel length thereof is shorter than that of the TFT of the buffer circuit.

Owner:SEMICON ENERGY LAB CO LTD

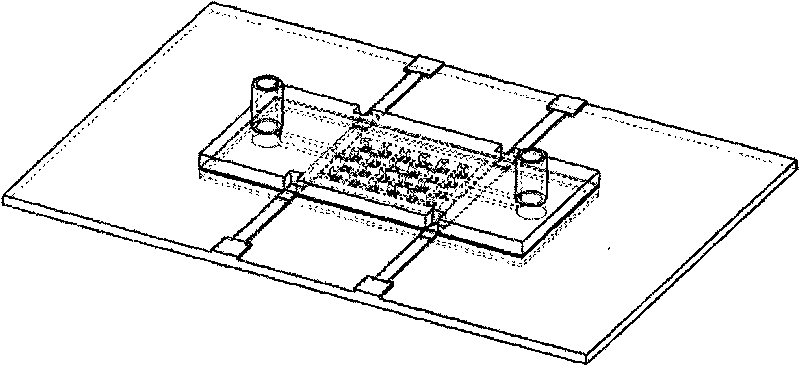

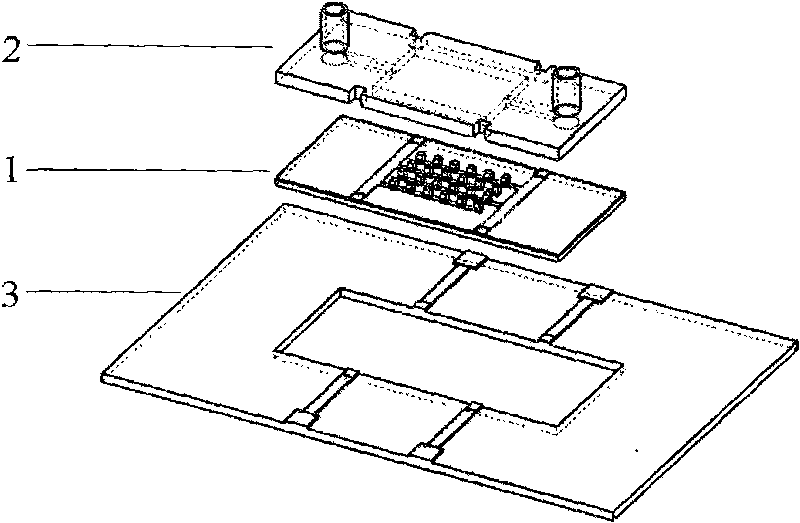

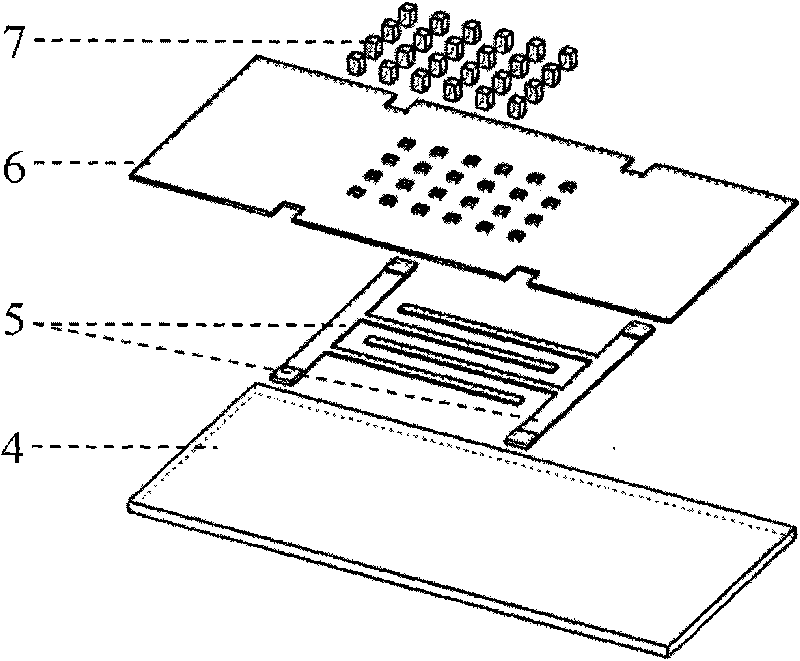

Cell electrofusion chip device based on columnar microelectrode array and electrofusion method

InactiveCN101693875AHigh fusion throughputSolving this conundrum of mobilityHybrid cell preparationStress based microorganism growth stimulationElectricitySignal on

The invention provides a cell electrofusion chip device based on a columnar microelectrode array, which consists of a columnar microelectrode array chip, a printed circuit board and a flow passage control module. The columnar microelectrode array chip consists of a quartz substrate layer, a metal lead layer, a polymer insulated layer and a columnar microelectrode layer sequentially from bottom to top, wherein the metal lead layers of the columnar microelectrode array chip is electrically connected with the periphery printed circuit board in a bonding way, leads outside electrical signals onto a columnar microelectrode, and leads a gradient electric field with enough strength to be formed between adjacent columnar microelectrodes; and the flow passage control module covers the columnar microelectrode array chip. In the invention, by loading electrical signals on the columnar microelectrode, queue and fusion among cells are controlled; simultaneously, the superiority that the columnar microelectrode array benefits the flow of the cells in chamber-tracts is utilized for realizing continuous stream fusion of the cells; and with the combination of the design of the array columnar microelectrode, the continuous, high-efficient and high-throughput fusion of the cells in the device is realized.

Owner:CHONGQING UNIV

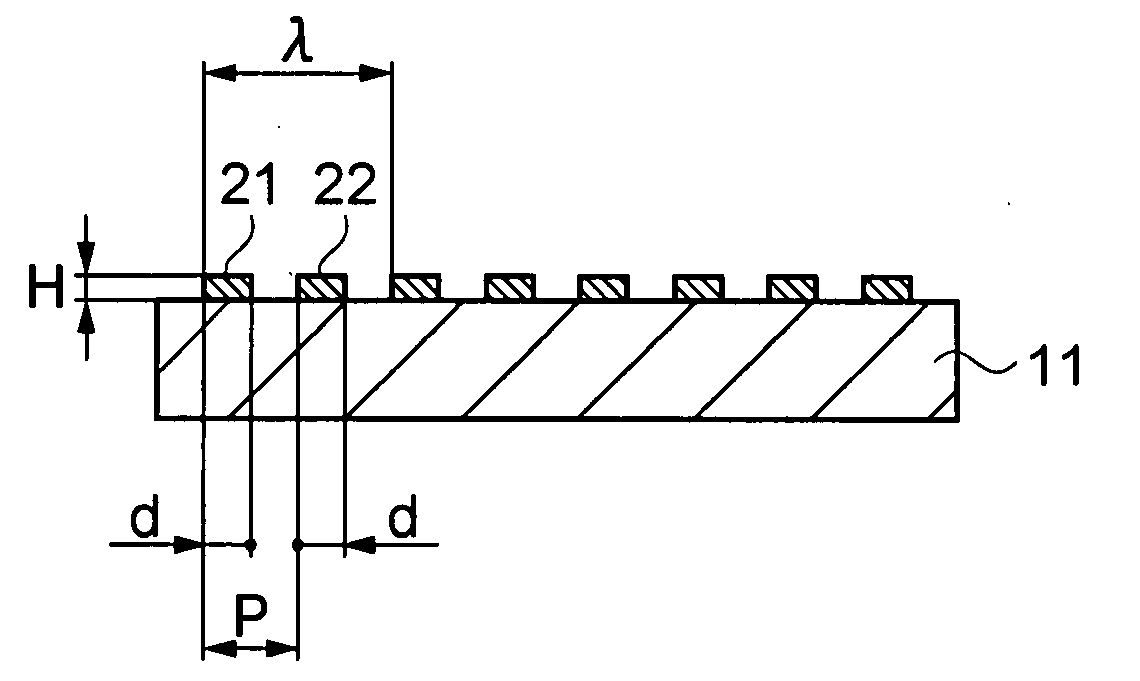

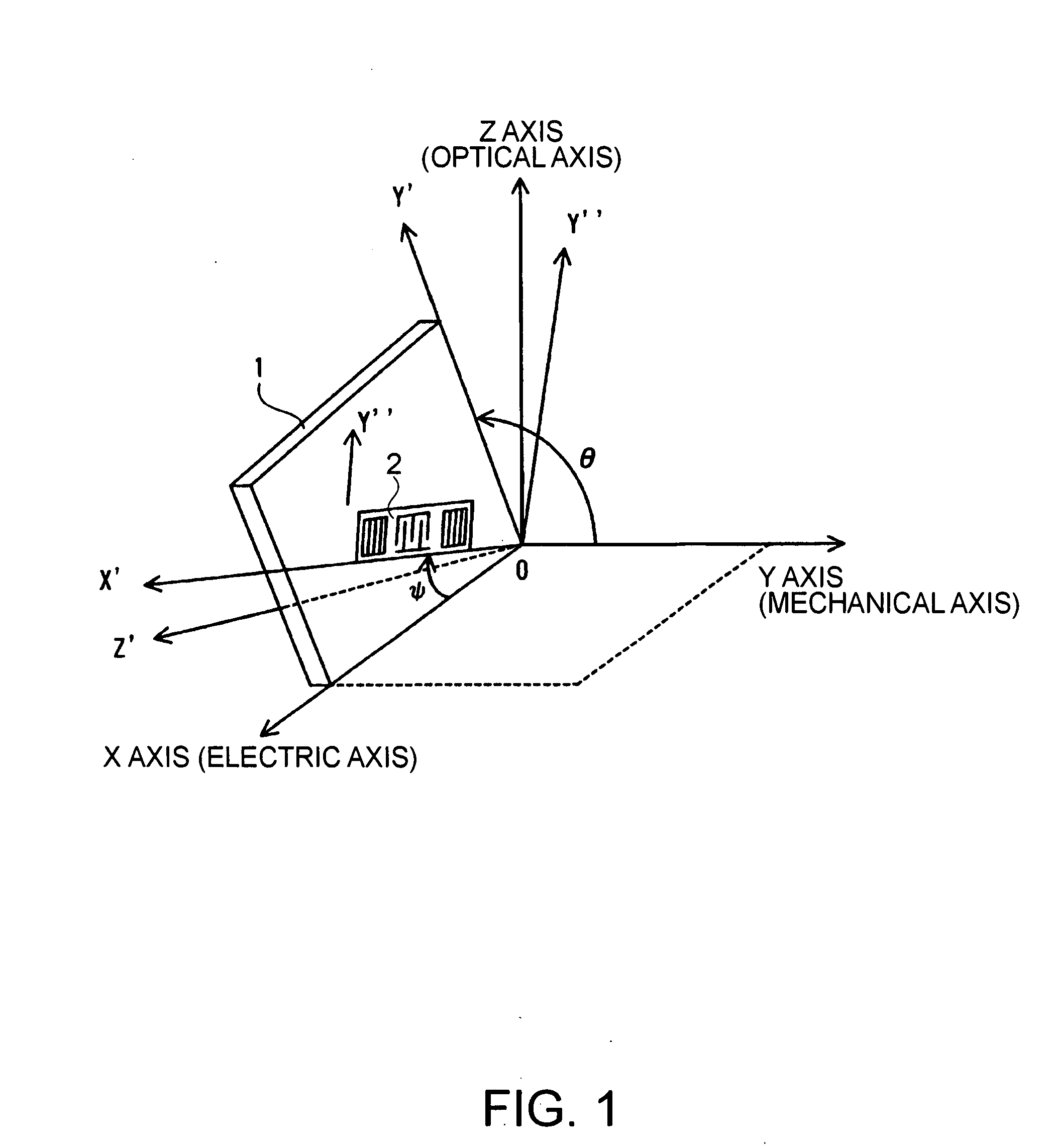

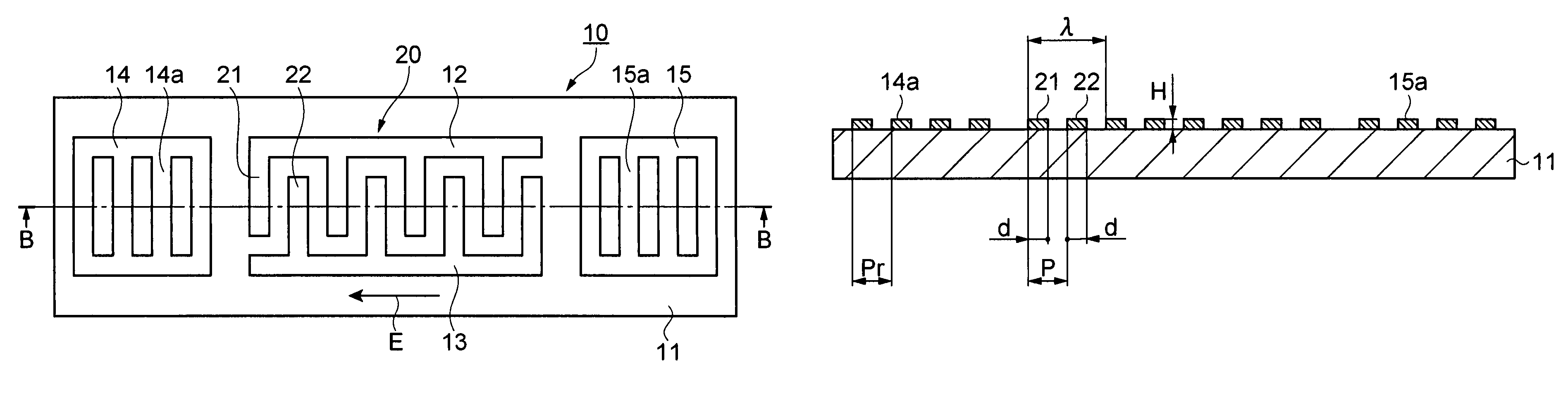

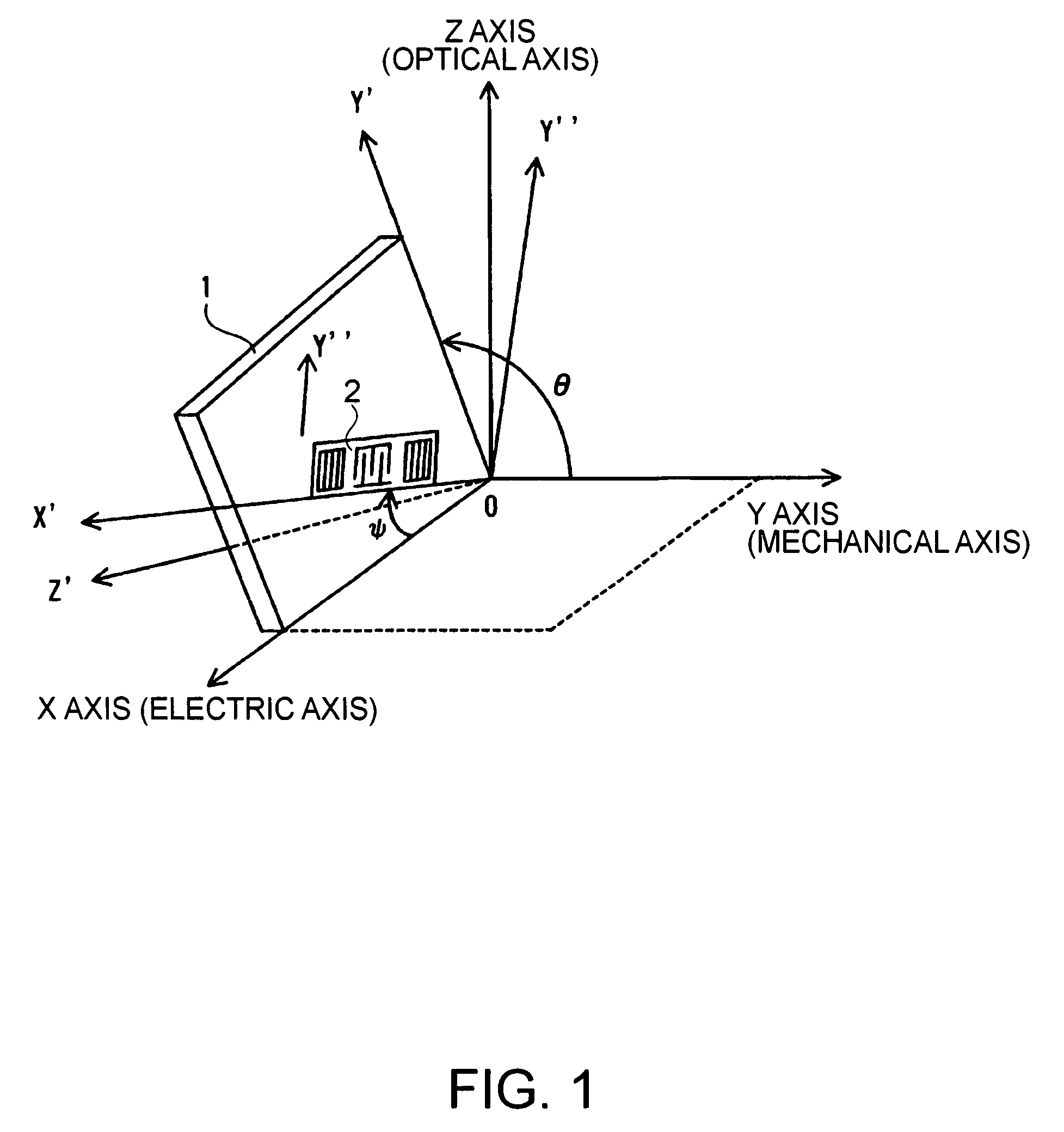

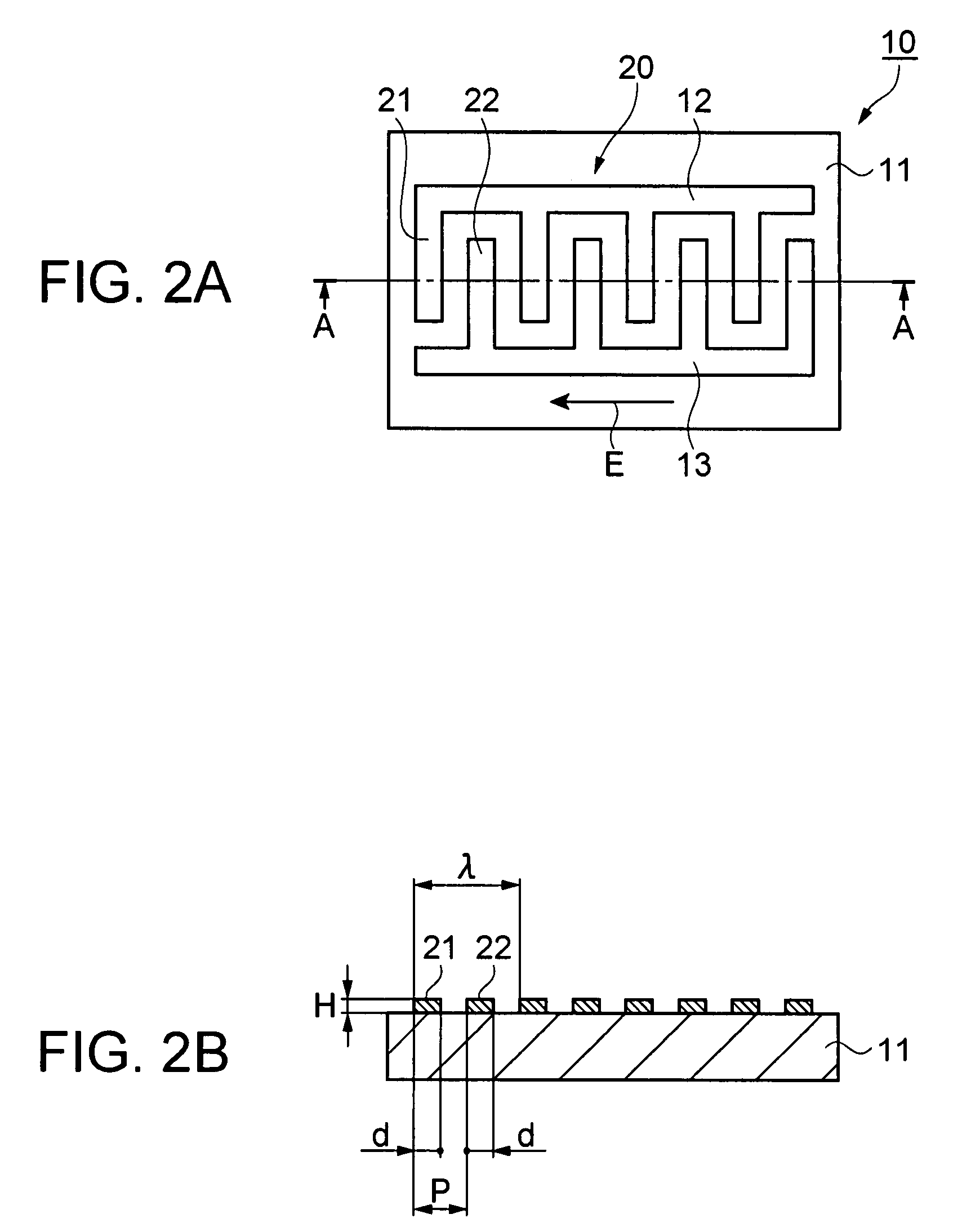

Surface acoustic wave device and electronic apparatus

InactiveUS20070182278A1Excellent frequency temperature characteristicsHigh frequencyImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcoustic waveSurface acoustic wave

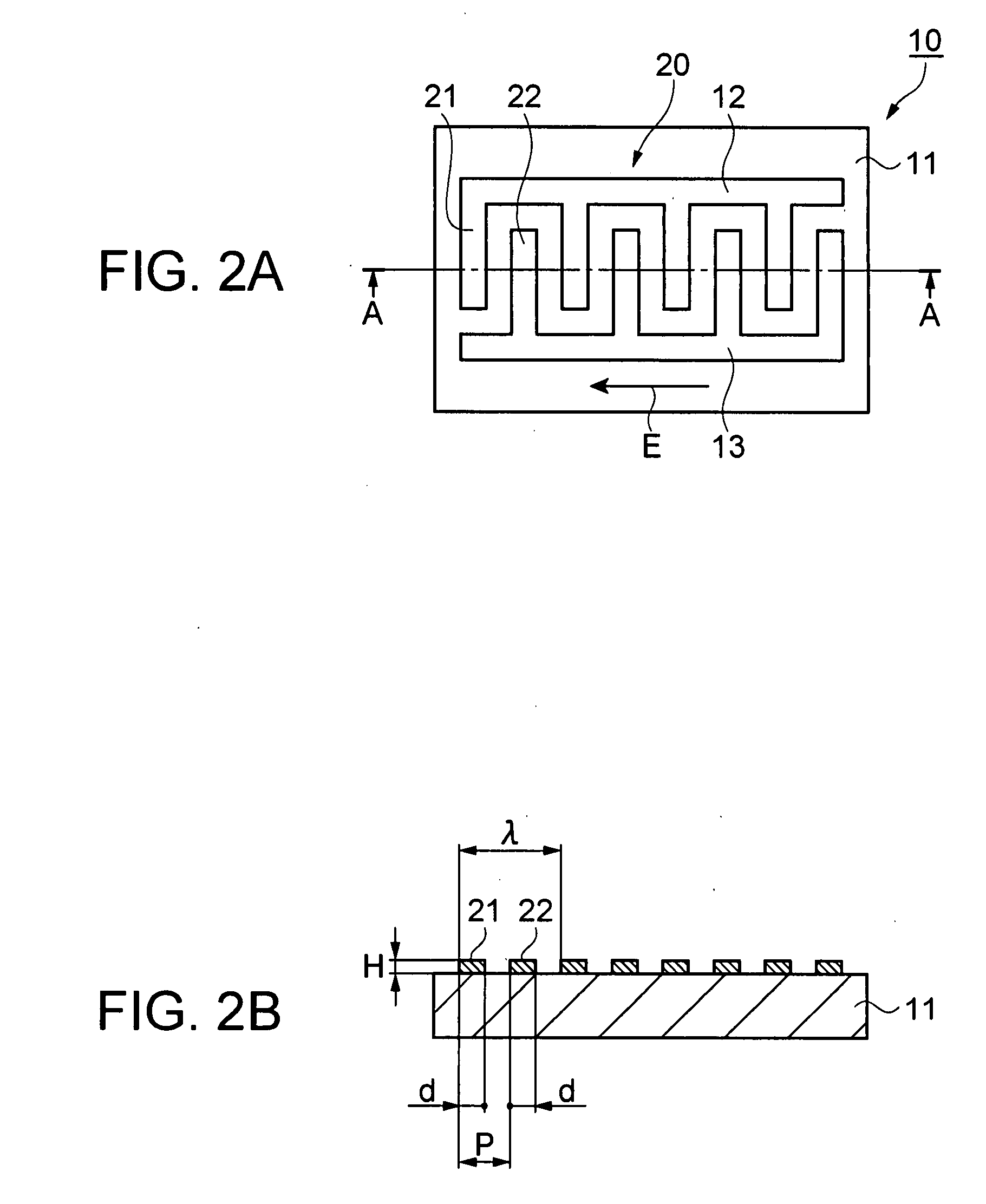

A surface acoustic wave device includes: a quartz substrate; and at least a single-type IDT electrode provided on a surface of the quartz substrate for exciting a Rayleigh surface acoustic wave in the upper limit mode of the surface acoustic wave stop band with the following relationships satisfied;φ=0, 110°≦θ≦140°, and 38°≦|ψ|≦44°, when the quartz substrate cut angles and the surface acoustic wave propagation direction are represented by Euler angles (φ, θ, ψ), and wherein the electrode thickness relative to wavelength set such thatH / λ≧0.1796η3−0.4303η2+0.2071η+0.0682, with the thickness of the IDT electrode defined as H, the width of an electrode IDT finger defined as d, the pitch between the electrode fingers of the IDT electrode as P, the wavelength of the surface acoustic wave as λ, and where η=d / P.

Owner:COLUMBIA PEAK VENTURES LLC

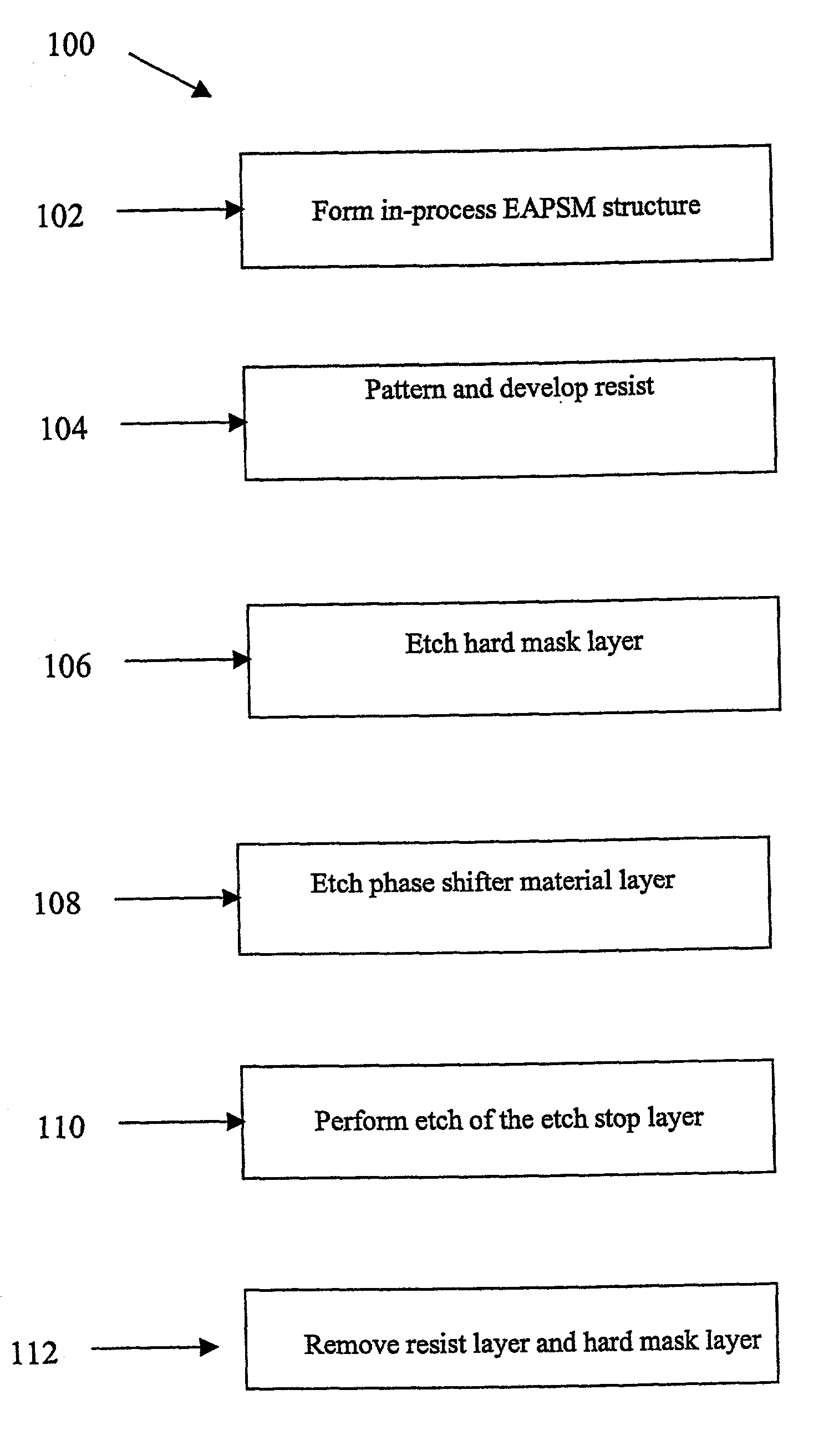

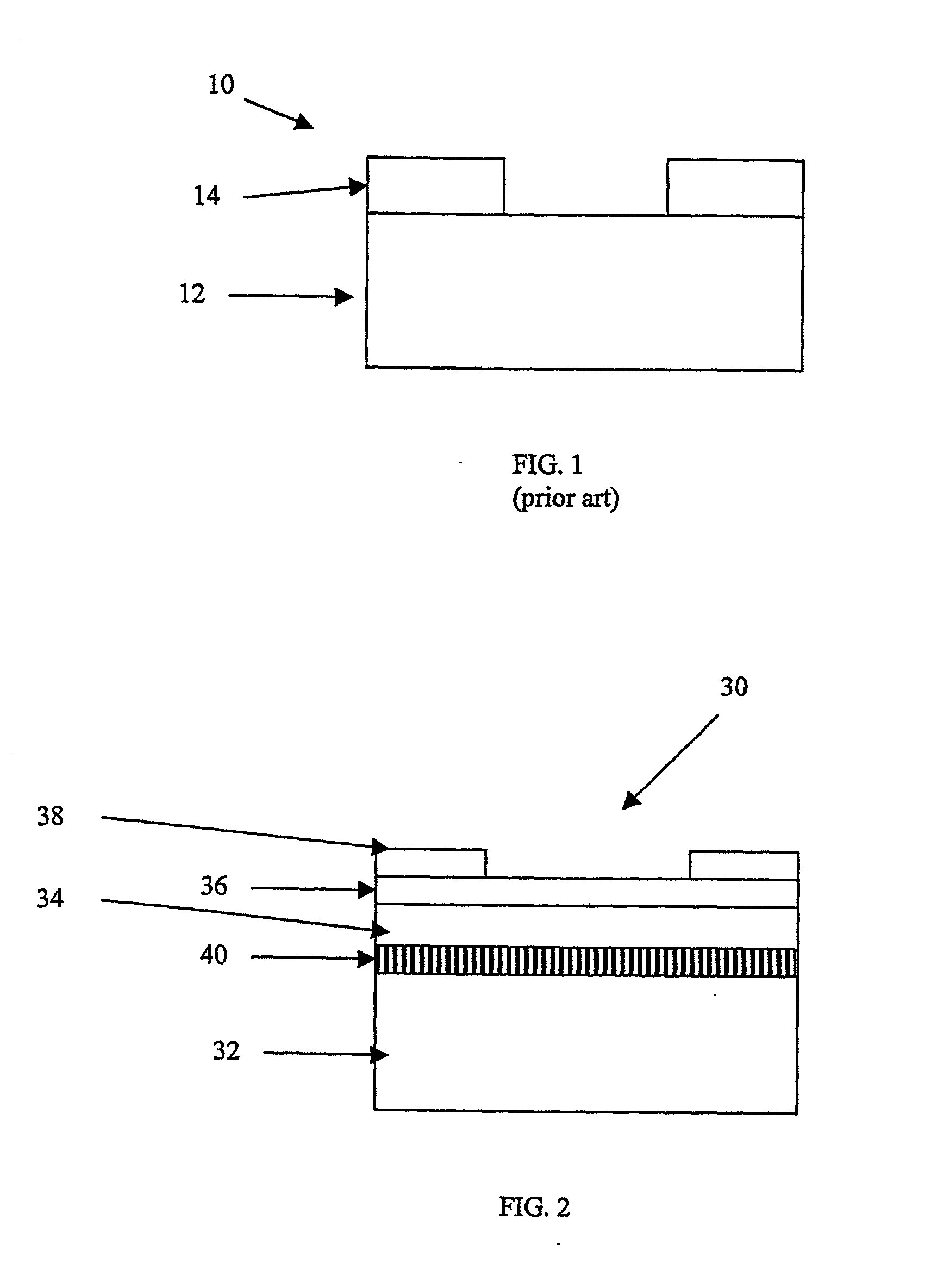

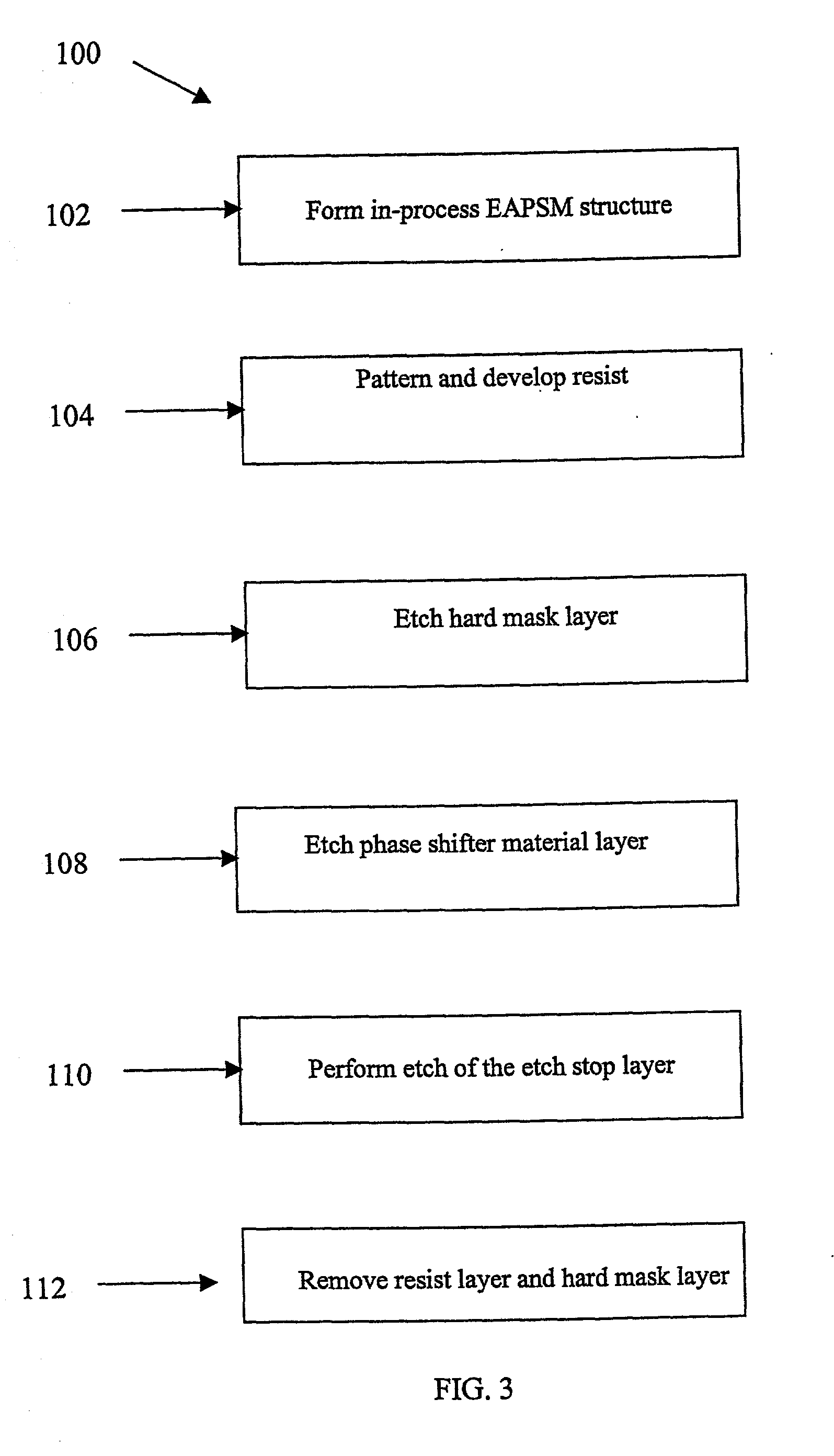

Embedded attenuated phase shift mask and method of making embedded attenuated phase shift mask

InactiveUS20020068229A1No damageDecorative surface effectsPhotomechanical apparatusPhase shiftedEngineering

An embedded attenuated phase shift mask ("EAPSM") includes an etch stop layer that can be plasma etched in a process that is highly selective to the underlying quartz substrate. Selectivity to the underlying quartz maintains a desired 180 degree phase shift uniformly across the active mask area. Conventional plasma etching techniques can be utilized without damage to the underlying quartz substrate. Alternatively, the etch stop layer comprises a transparent material that can remain intact in the mask structure.

Owner:UNAXIS USA

Microlens array substrate and production method therefor

InactiveUS20060215269A1Pattern size is accurateReduce materialNon-linear opticsLensResistImage resolution

A micro-lens substrate having a precise micro-lens array suitable for higher resolution, the micro-lens array substrate of high quality without having a distortion, and a method for manufacturing thereof are provided. In the micro-lens array substrate of the present invention, a micro-lens array formed of a plurality of consecutive concave lens-shaped micro-lenses is directly formed in a surface of a quartz substrate or glass substrate, and the micro-lens array is formed by a transfer method based on dry-etching. In the micro-lens array substrate of the present invention, a taper portion is formed toward the surface of the substrate in a peripheral portion of the micro-lens array in the quartz substrate or glass substrate. In a method for manufacturing the micro-lens array substrate of the present invention, a resist layer having a plurality of consecutive lens-shaped concave portions is formed in a surface of a quartz or glass substrate, the lens-shaped concave portion of the resist layer is transferred to the substrate by dry-etching, and a micro-lens array is formed by injecting a resin into the lens-shaped concave portion of this substrate. In addition, a taper portion is formed in a peripheral portion similarly to the formation of the lens-shaped concave portion, and a micro-lens array is formed by injecting a resin into the lens-shaped concave portion and taper portion.

Owner:SONY CORP

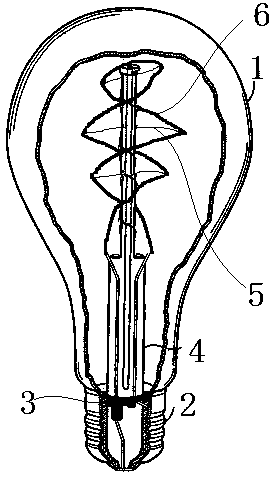

All-angle bendable LED (Light Emitting Diode) filament strip and antique LED bulb comprising same

The invention provides an all-angle bendable LED (Light Emitting Diode) filament strip. The all-angle bendable LED filament strip comprises a plurality of LED filament strip units which are connected end to end in turn; the two adjacent LED filament strip units are connected with each other through a rotating part in a rotating mode; every LED filament strip unit comprises a plurality of LED chips which are fixed on a quartz substrate; the LED chips which are located on the LED filament strip units achieve circuit communication through the rotating parts. The invention also provides an antique LED bulb. The antique LED bulb comprises a capsule, a lamp holder, a power circuit, the LED filament strip and a supporting part; the LED filament strip units which are arranged in the LED filament strip bend into the preset angle at the positions of the flexible electrical connection plates and accordingly the preset shape of the LED filament strip can be formed integrally; the supporting part comprises a plurality of antennas which are supported at the positions of the flexible electrical connection plates of the LED filament strip units so as to maintain the preset bending angle; the power circuit is fixedly arranged at the bottom of the capsule integrally after being arranged inside the lamp holder.

Owner:江苏华英光宝科技有限公司

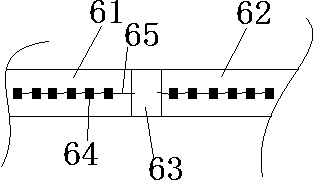

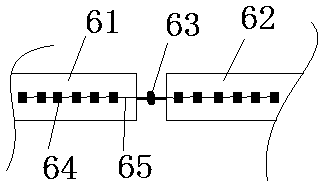

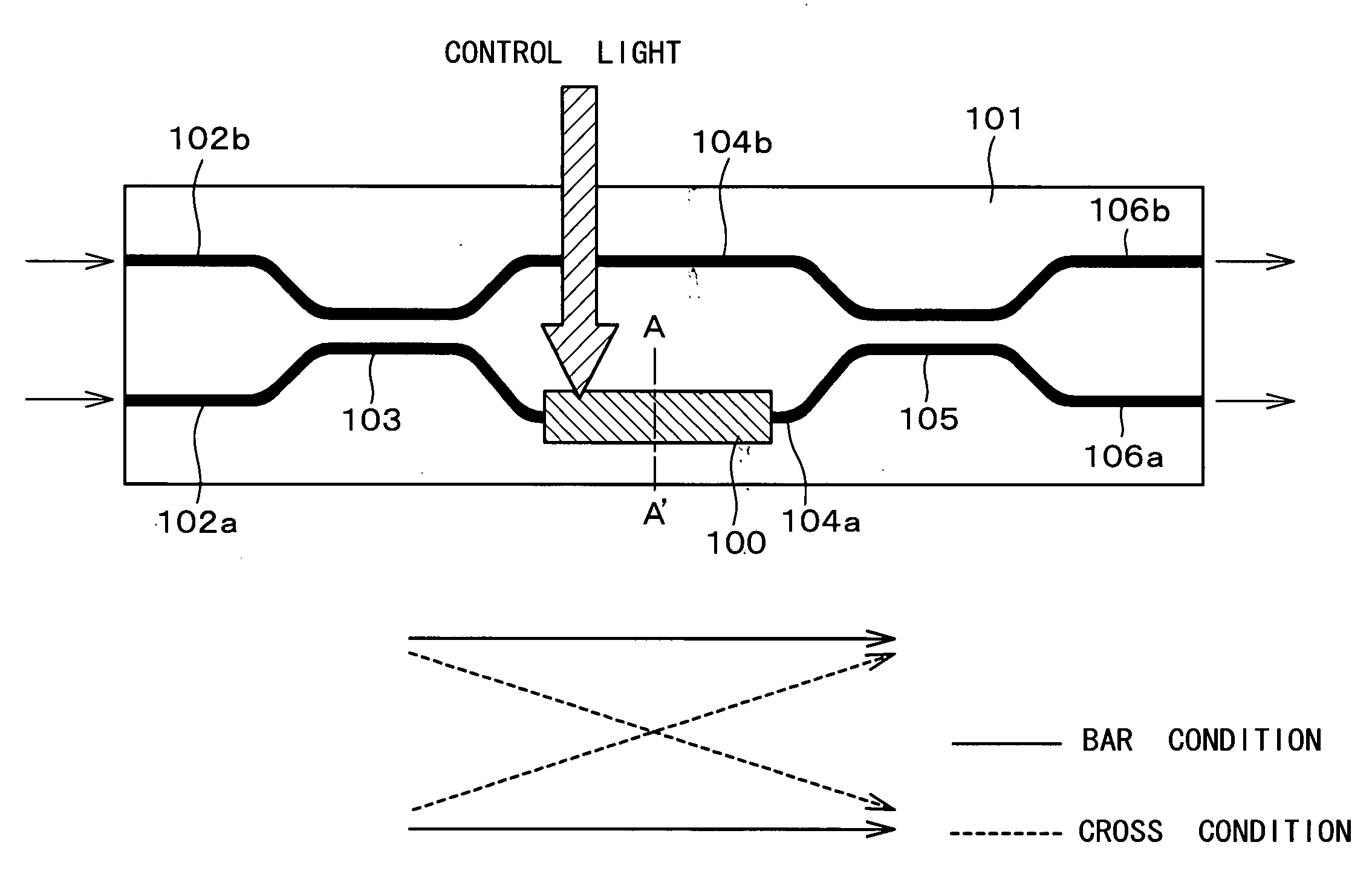

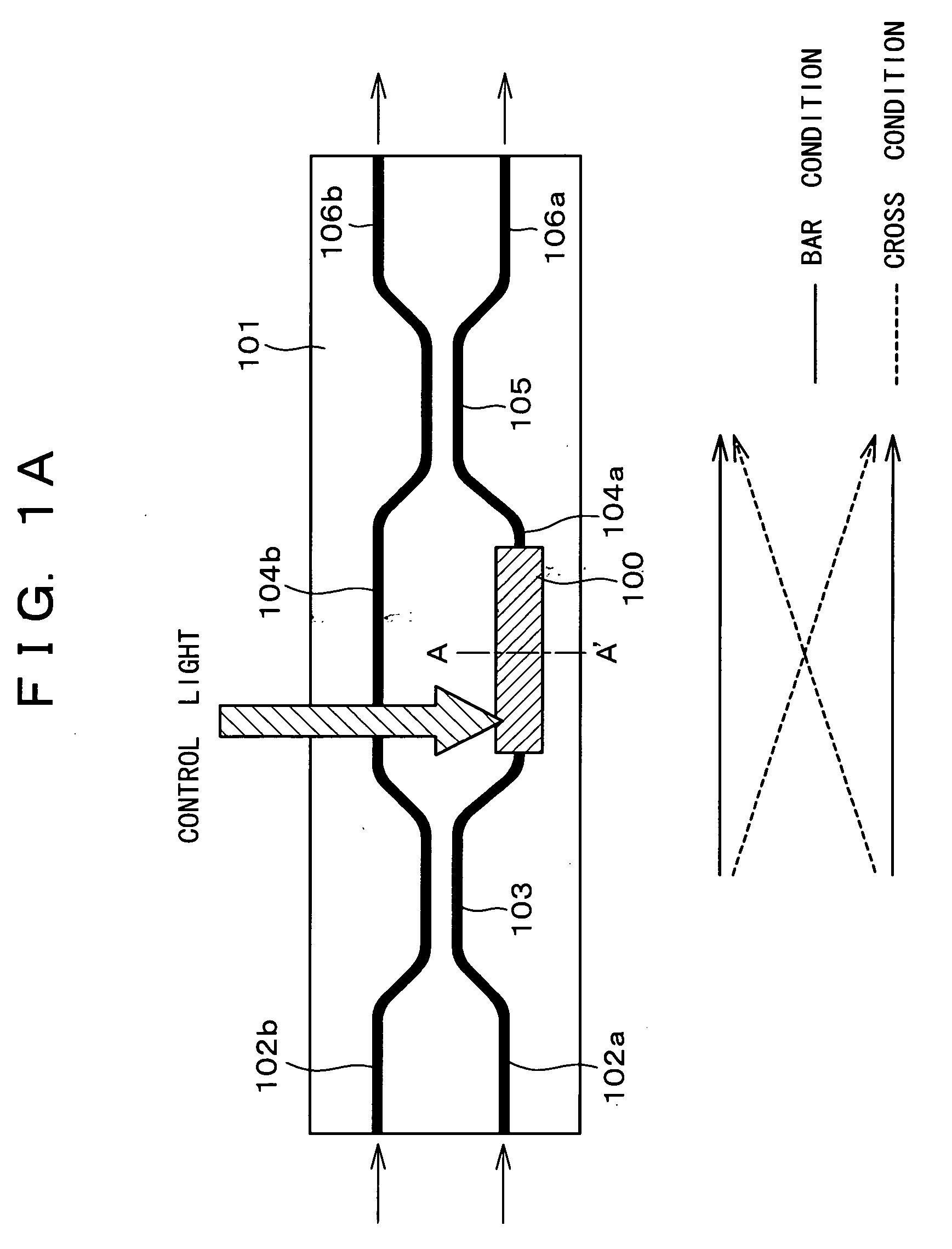

Optical switch

InactiveUS20060140535A1Reduce power consumptionIncrease speedCoupling light guidesNon-linear opticsLength waveWaveguide

In order to provide a low-loss optical switch that is low in power consumption by providing the same as a self-holding type, and high speed and highly practicable, an optical switch of the present invention is composed of a quartz substrate (101), first and second input waveguides (102a and 102b), a first directional coupler (103), first and second arm waveguides (104a and 104b) of a Mach-Zehnder interferometric circuit, a second directional coupler (105), first and second output waveguides (106a and 106b), and a phase change material portion (100). A control light (for an amorphous to crystal transition) pulse (pulse width: 20 ns, pulse intensity: 5 mW) having a wavelength of 0.78 microns is irradiated. As a result of the control light pulse irradiation, the phase change material portion (109) changes in phase to a crystal state, and the optical switch transits to a bar condition.

Owner:KEIO UNIV

Antenna component and methods

InactiveUS8378892B2High dielectric constantEfficient preparationSimultaneous aerial operationsRadiating elements structural formsElectrical conductorDielectric substrate

An antenna component (200) with a dielectric substrate and two radiating antenna elements. The elements are located on the upper surface of the substrate and there is a narrow slot (260) between them. The antenna feed conductor (241) is connected to the first antenna element (220), which is connected also to the ground by a short-circuit conductor (261). The second antenna element (230) is parasitic; it is galvanically connected only to the ground. The component is preferably manufactured by a semiconductor technique by growing a metal layer e.g. on a quartz substrate and removing a part of it so that the antenna elements remain. In this case the component further comprises supporting material (212) of the substrate chip. The antenna component is very small-sized because of the high dielectricity of the substrate to be used and mostly because the slot between the antenna elements is narrow. The efficiency of an antenna made by the component is high.

Owner:PULSE FINLAND

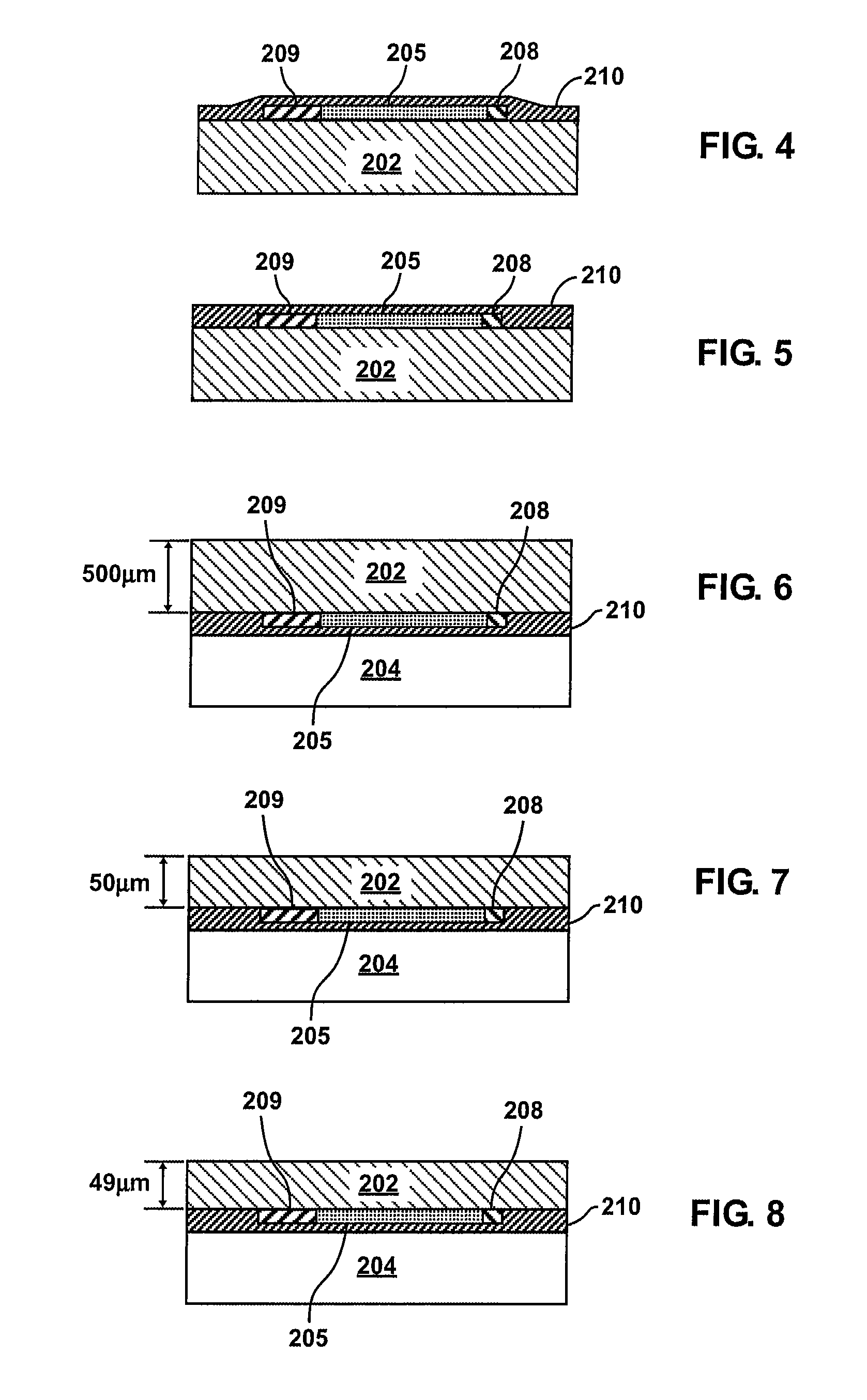

Method of fabricating an ultra thin quartz resonator component

ActiveUS7802356B1Piezoelectric/electrostrictive device manufacture/assemblyTransducer detailsInterposerQuartz resonator

A method for manufacturing a resonator is presented in the present application. The method includes providing a handle substrate, providing a host substrate, providing a quartz substrate comprising a first surface opposite a second surface, applying interposer film to the first surface of the quartz substrate, bonding the quartz substrate to the handle substrate wherein the interposer film is disposed between the quartz substrate and the handle substrate, thinning the second surface of the quartz substrate, removing a portion of the bonded quartz substrate to expose a portion of the interposer film, bonding the quartz substrate to the host substrate, and removing the handle substrate and the interposer film, thereby releasing the quartz substrate.

Owner:HRL LAB

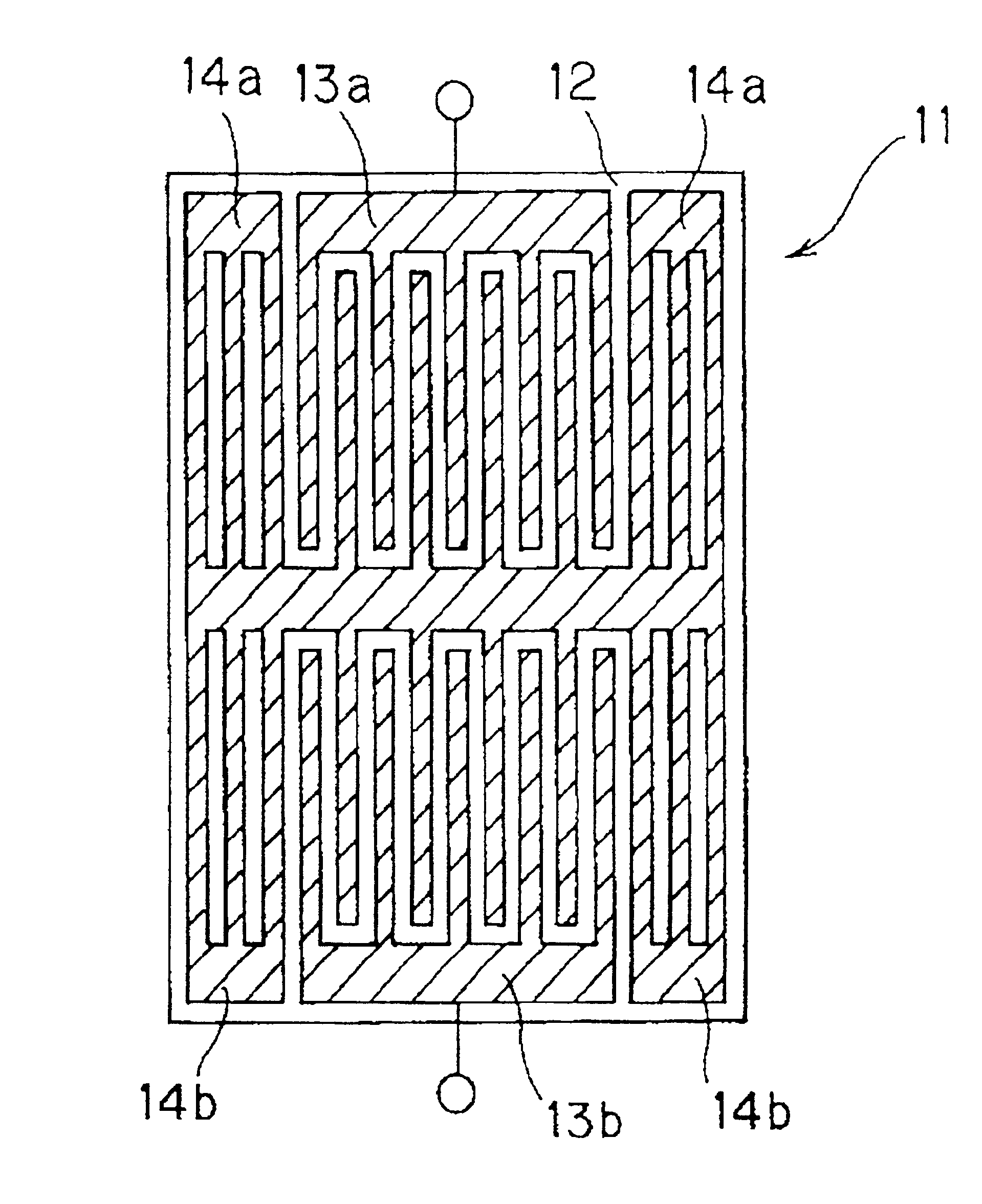

Surface acoustic wave device and electronic device using the same

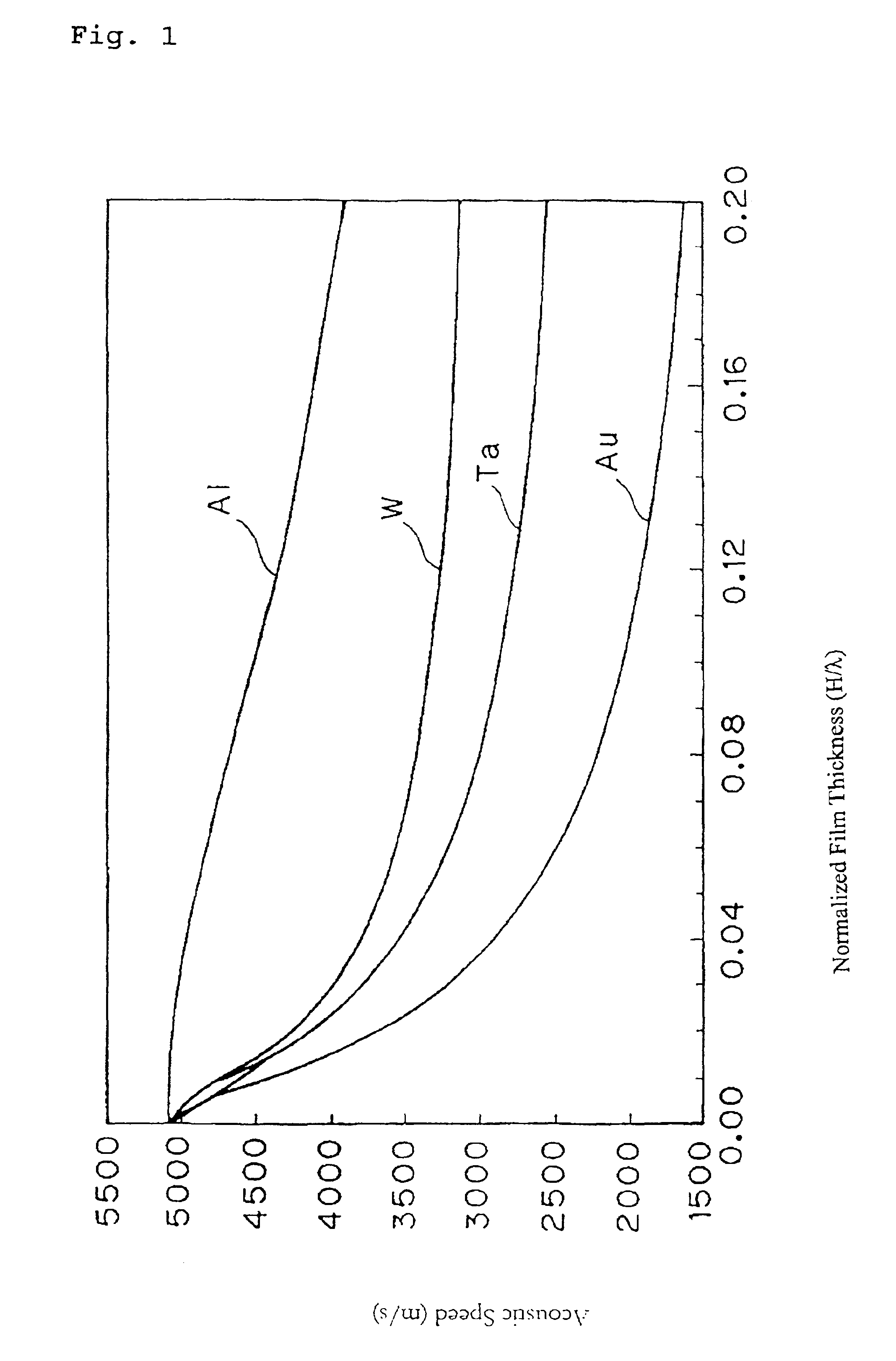

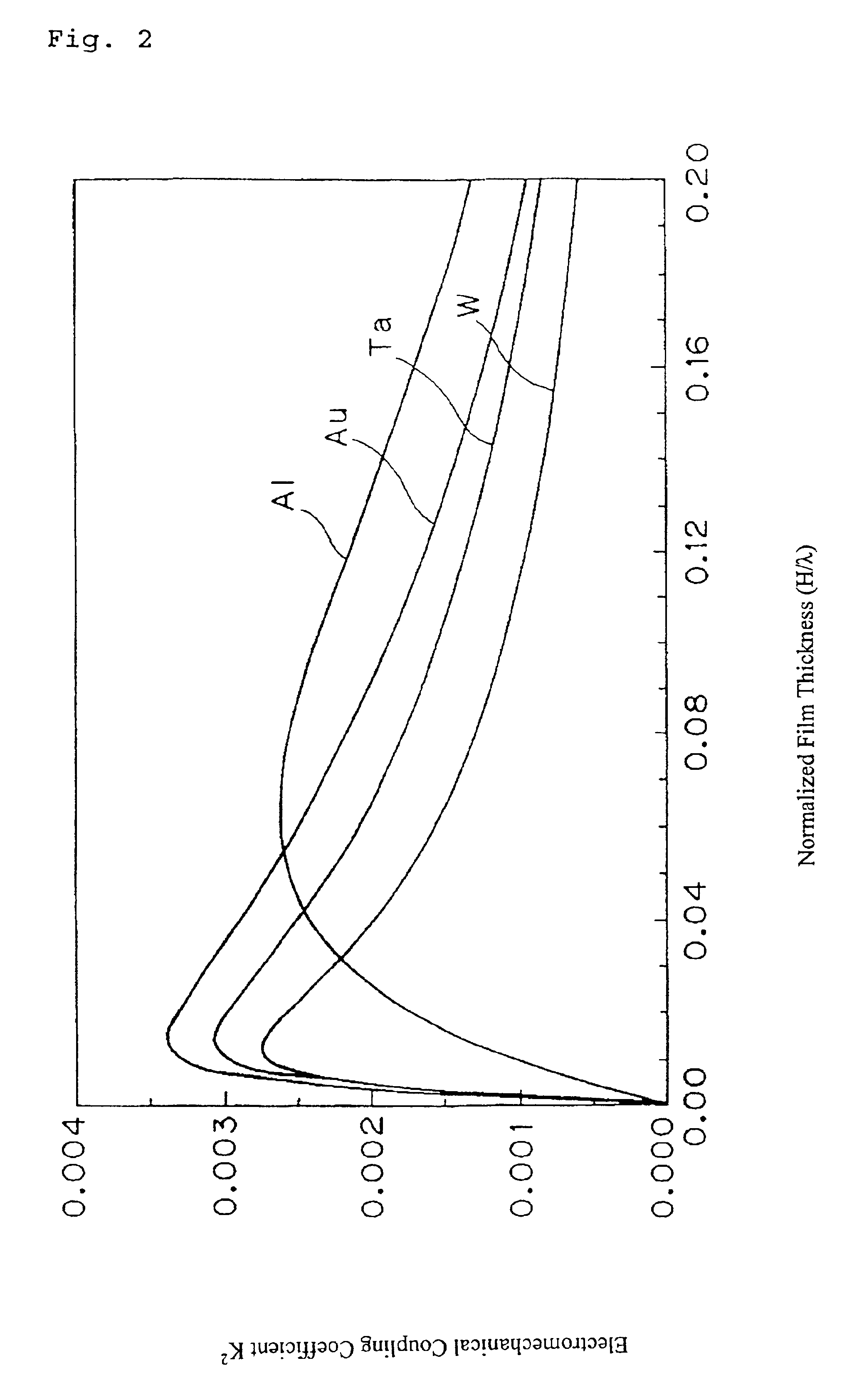

InactiveUS6946930B2Increase reflectionSmall sizePiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectromechanical coupling coefficientAcoustic wave

A reliable SAW device has excellent reflection and a small size, which is achieved by reducing the number of fingers defining reflectors, such that losses due to a large electromechanical coupling coefficient are small and the film thickness of electrodes has much less effect on frequencies of the device. In the SAW device having pluralities of first fingers and second fingers, disposed on a quartz substrate, constituting an IDT for exciting SH waves and reflectors for reflecting the SH waves, respectively, the first and second fingers made mainly from Al are disposed on the ST-cut 90° X-propagation quartz substrate with the Euler angles (0°, θ, 90°±2°), wherein the angle θ is within the range of about 110° to about 150°, and a normalized film thickness (H / λ) of the fingers is within in the range of about 0.025 to about 0.135.

Owner:MURATA MFG CO LTD

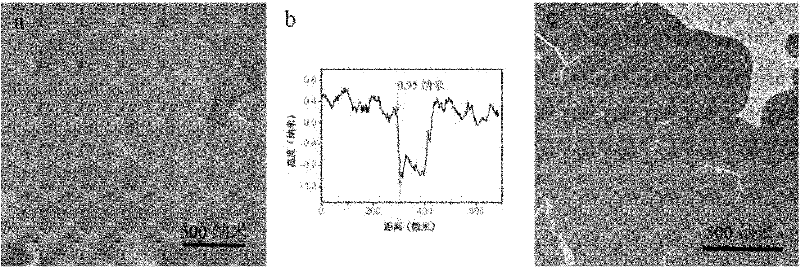

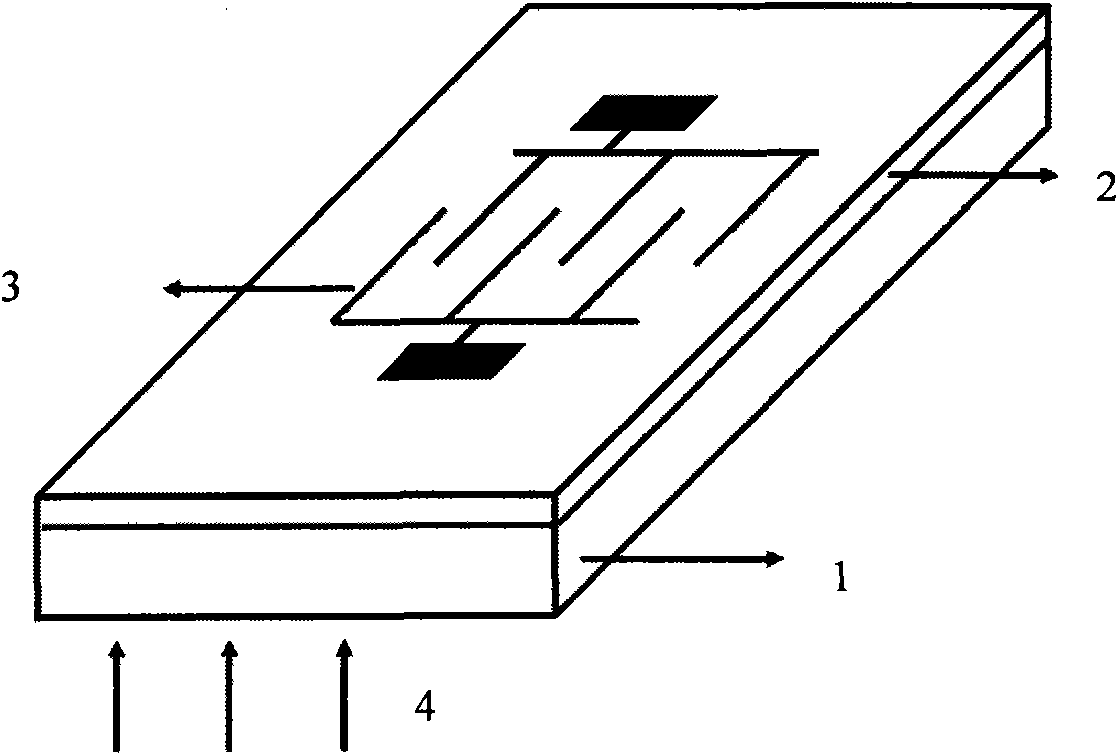

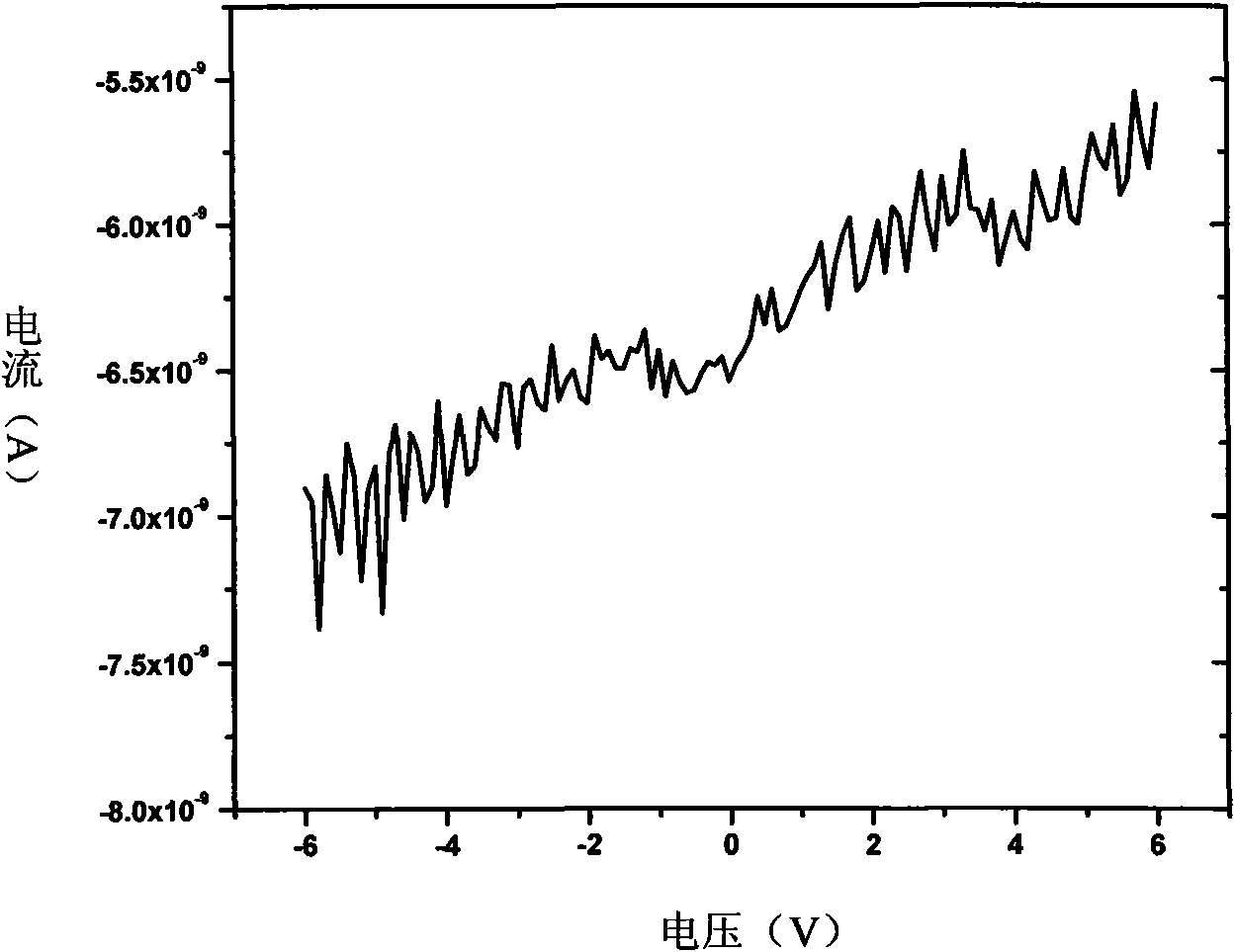

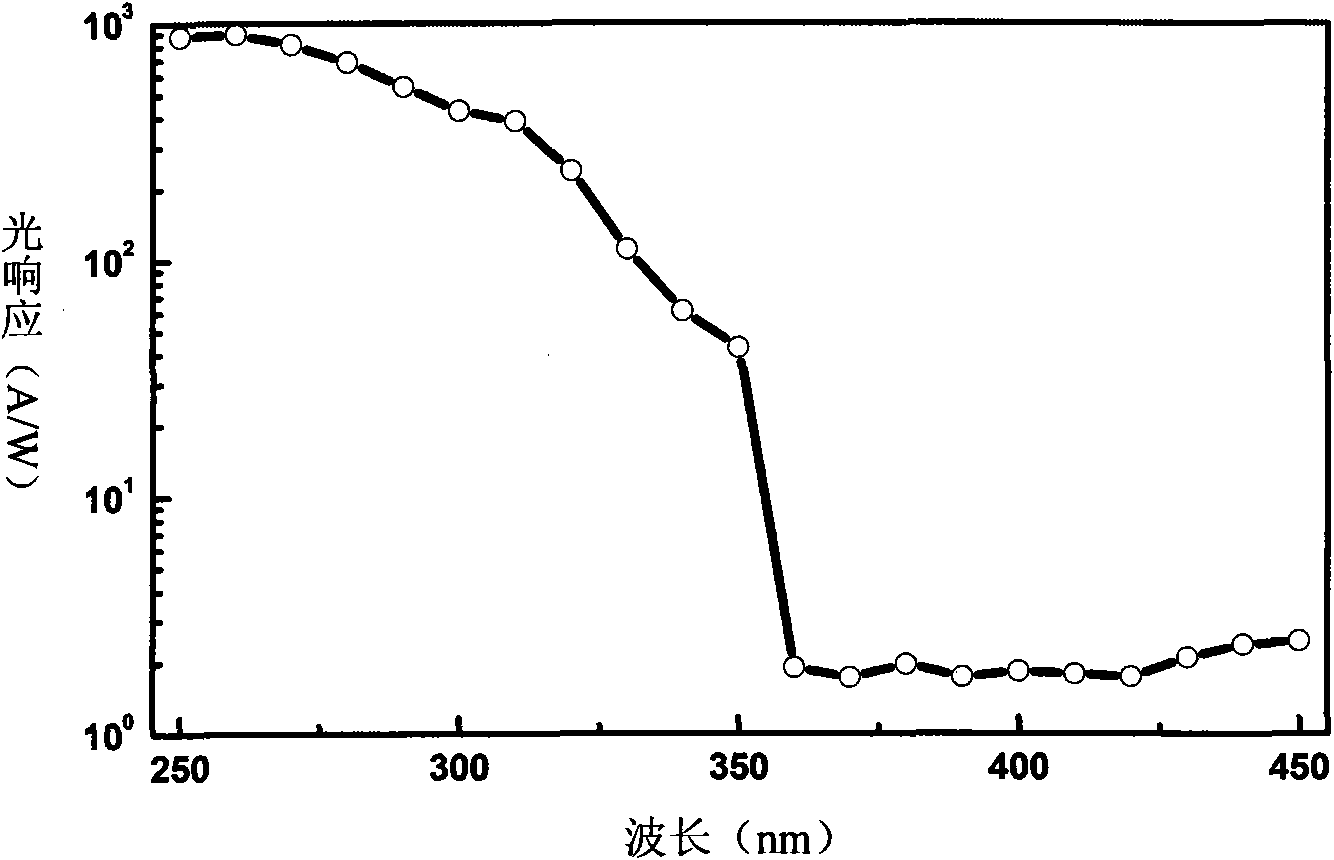

Back incident-type TiO* UV detector and preparation method thereof

InactiveCN101562208AStrong absorption propertiesTo achieve the purpose of detectionFinal product manufactureVacuum evaporation coatingSchottky barrierUltraviolet

The invention belongs to the field of semiconductor optoelectronic detectors, in particular relates to a back incident-type UV detector with quartz as a substrate, nano-TiO2 thin film as a basic UV detection material and Ni as a metal electrode, and a preparation method thereof. The detector takes the quartz as the substrate and adopts an M-S-M (metal-semiconductor-metal) structure. The method for manufacturing the UV detector comprises the steps of adopting a sol-gel technique to grow a TiO2 nanometer thin film on the quartz substrate, evaporating a layer of thin Ni on the prepared TiO2 thin film by a magnetron sputtering method to achieve electrode contact, and adopting lithography technology to obtain Ni inserted-finger shape electrodes. The UV detector in an MSM planar double schottky barrier structure adopts a back incident-type working mode and can greatly improve responsiveness. The detector has good detection performance for the UV rays 250 to 350 nm in wavelength.

Owner:JILIN UNIV

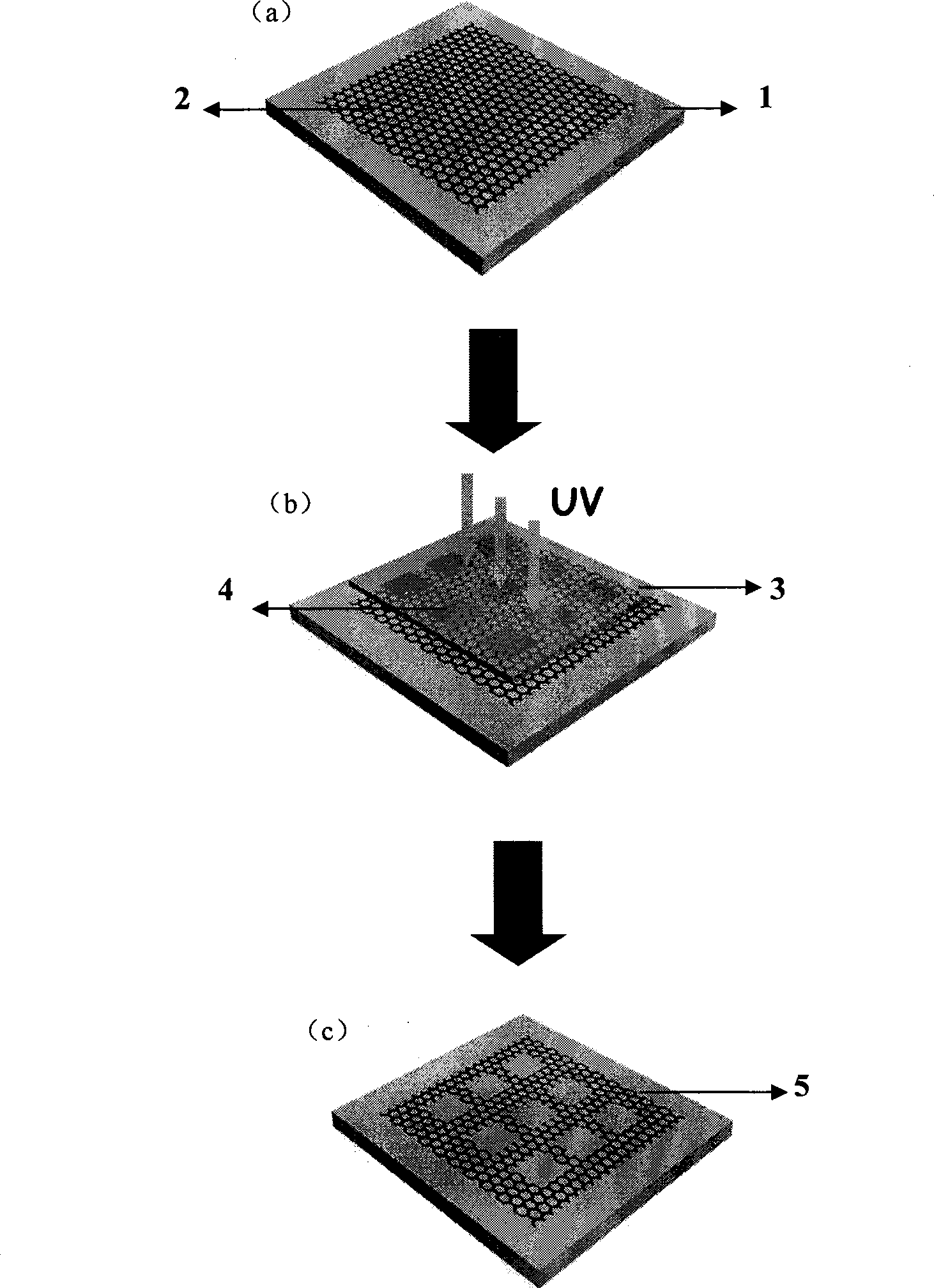

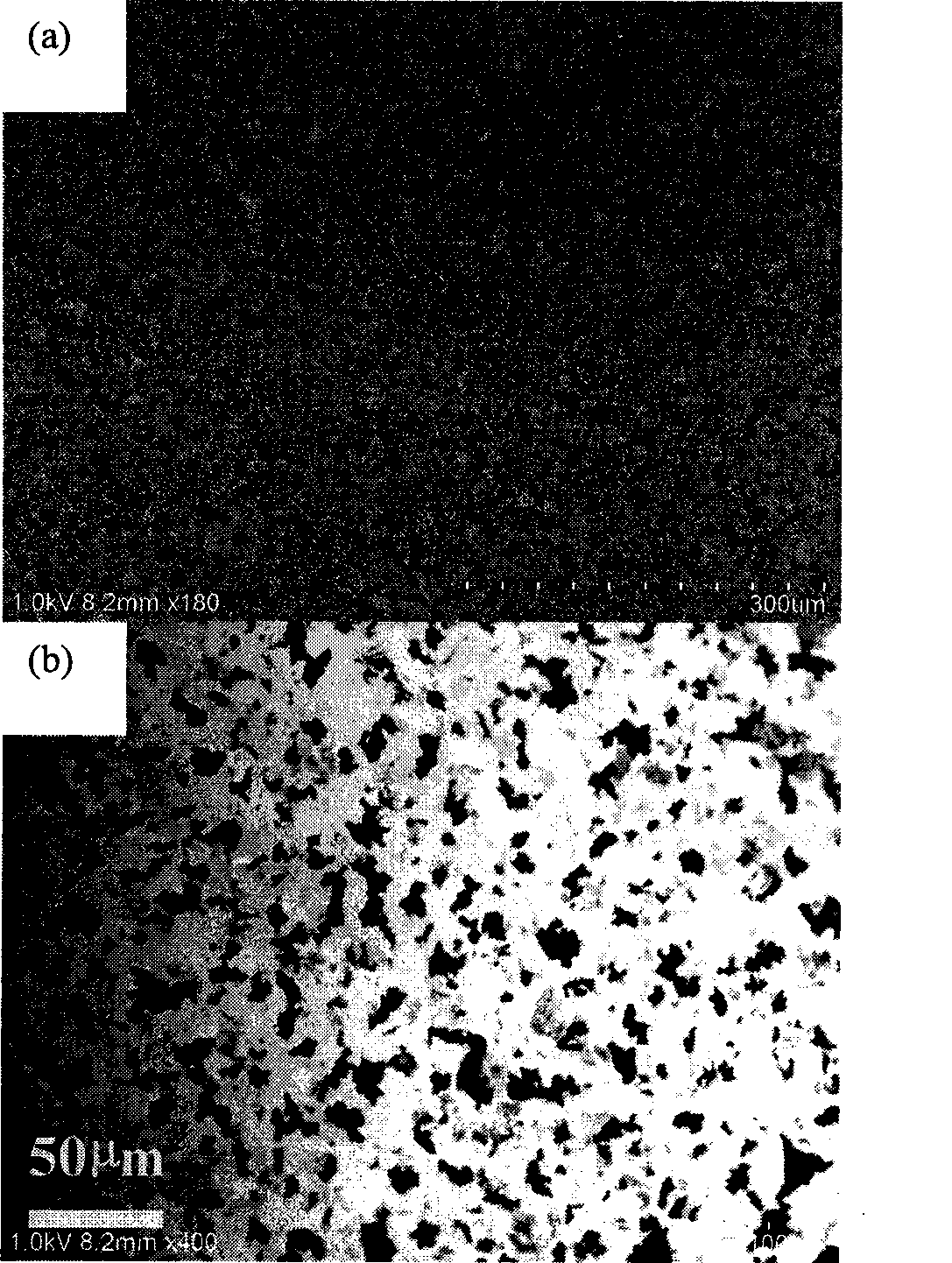

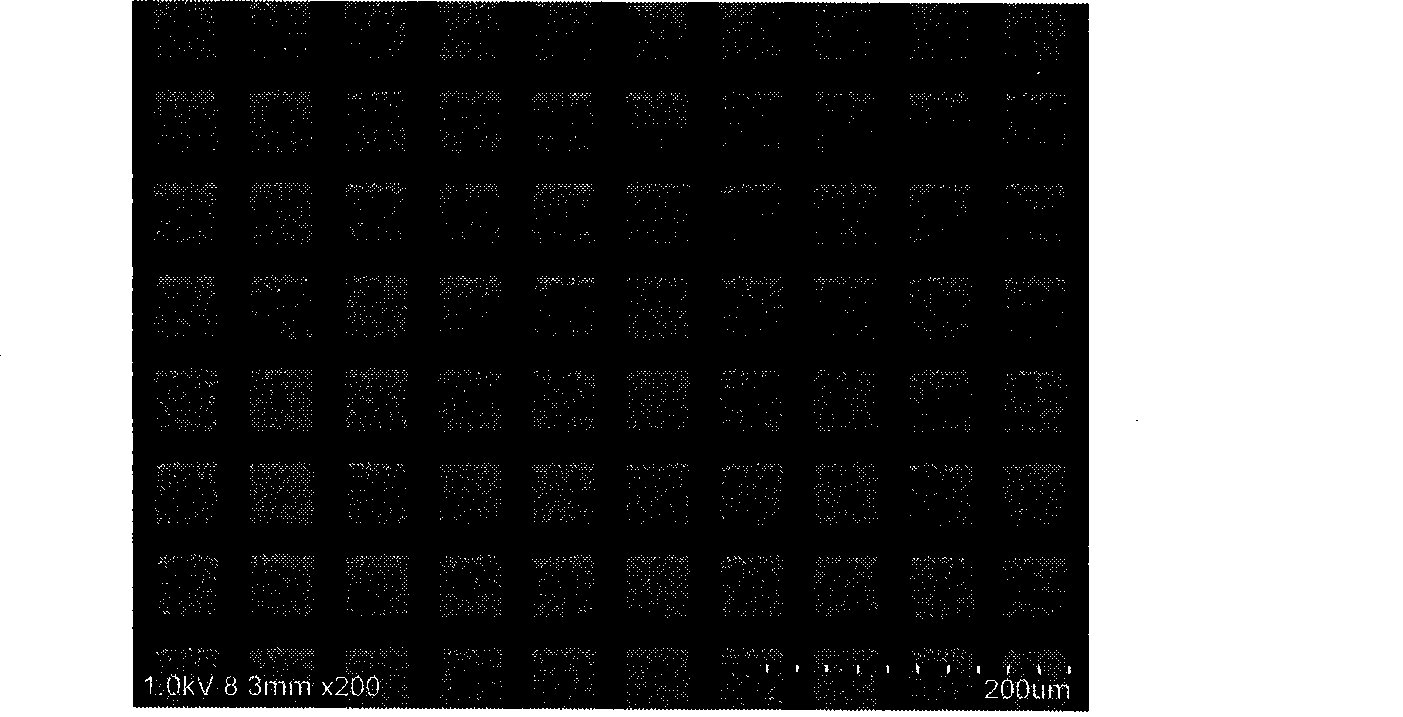

Method for cutting graphite alkene by titanium dioxide photocatalysis

InactiveCN101503174AAchieve arbitrary patterningThe method is simpleNanostructure manufacturePhysical/chemical process catalystsNano structuringPhotocatalytic reaction

The invention discloses a method for cutting graphene by using titanium dioxide through photocatalysis. The method comprises the steps: 1) a graphene lamellar layer is prepared on a substrate; 2) a convex titanium dioxide nano structure layer is constructed on a quartz substrate to obtain titanium dioxide mask; 3) the titanium dioxide nano structure layer of the titanium dioxide mask is contacted with the graphene lamellar layer and irradiated by ultraviolet light, and the titanium dioxide mask has photocatalysis reaction under the irradiation of the ultraviolet light and can simultaneously cut the graphene to obtain patterned graphene. The method avoids the use of solution phase, has high efficiency and mild reaction condition, and is not limited by the substrate, thus being compatible with the existing semiconductor technique and laying foundation for the development of graphene surface flexible electronic devices.

Owner:PEKING UNIV

Surface acoustic wave device and electronic apparatus

InactiveUS7696675B2Excellent frequency temperature characteristicsHigh frequencyImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcoustic waveSurface acoustic wave

A surface acoustic wave device includes: a quartz substrate; and at least a single-type IDT electrode provided on a surface of the quartz substrate for exciting a Rayleigh surface acoustic wave in the upper limit mode of the surface acoustic wave stop band with the following relationships satisfied;φ=0°, 110°≦θ≦140°, and 38°≦|ψ|≦44°, when the quartz substrate cut angles and the surface acoustic wave propagation direction are represented by Euler angles (φ, θ, ψ), and wherein the electrode thickness relative to wavelength set such thatH / λ≧0.1796η3−0.4303η2+0.2071η+0.0682, with the thickness of the IDT electrode defined as H, the width of an electrode IDT finger defined as d, the pitch between the electrode fingers of the IDT electrode as P, the wavelength of the surface acoustic wave as λ, and where η=d / P.

Owner:COLUMBIA PEAK VENTURES LLC

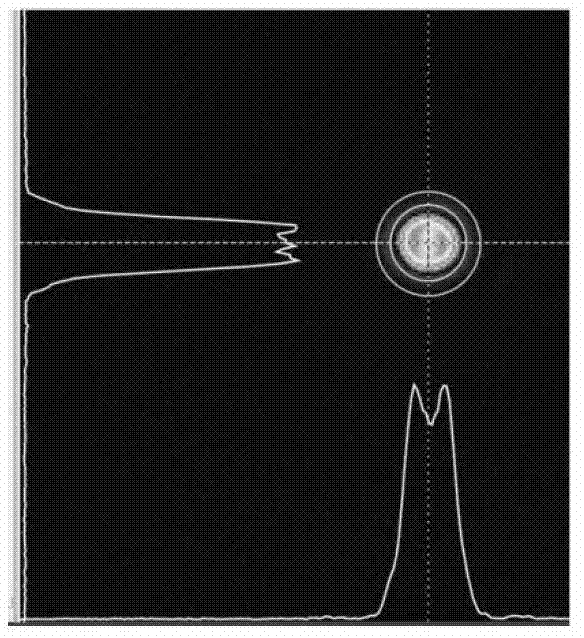

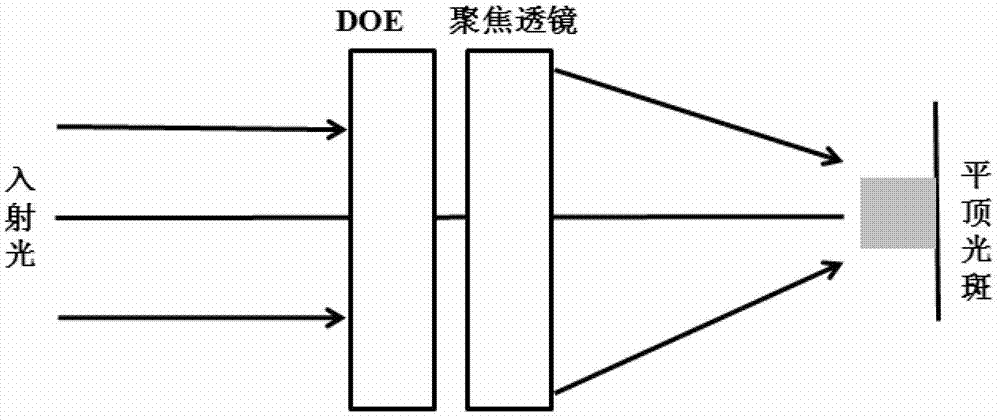

Diffractive optical element for shaping gauss beam into flat-topped beam, and preparation method thereof

ActiveCN103399406AImprove energy transmittanceEasy to usePhotomechanical exposure apparatusMicrolithography exposure apparatusGaussian beamTransmittance

The invention provides a new diffractive optical element for shaping a gauss beam into a flat-topped beam, and the diffractive optical element is called DOE for short; the invention also provides a preparation method of the DOE. Grooves or steps with different shapes and sizes are prepared in the center of a quartz substrate, and the DOE is then arranged at the different positions of a light path and is matched with a beam expanding collimation lens and a focusing lens, so that the flat-topped beam can be realized. The DOE has the outstanding advantages of being high in energy transmittance, less sensitive to the incident laser mode change, and simple and flexible in installation and use.

Owner:北京润和微光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com