Patents

Literature

509 results about "Electromechanical coupling coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromechanical coupling coefficient is a numerical measure of the conversion efficiency between electrical and acoustic energy in piezoelectric materials. Qualitatively the electromechanical coupling coefficient, k, can be determined as: K⁻²=1/(energy converted per input energy)

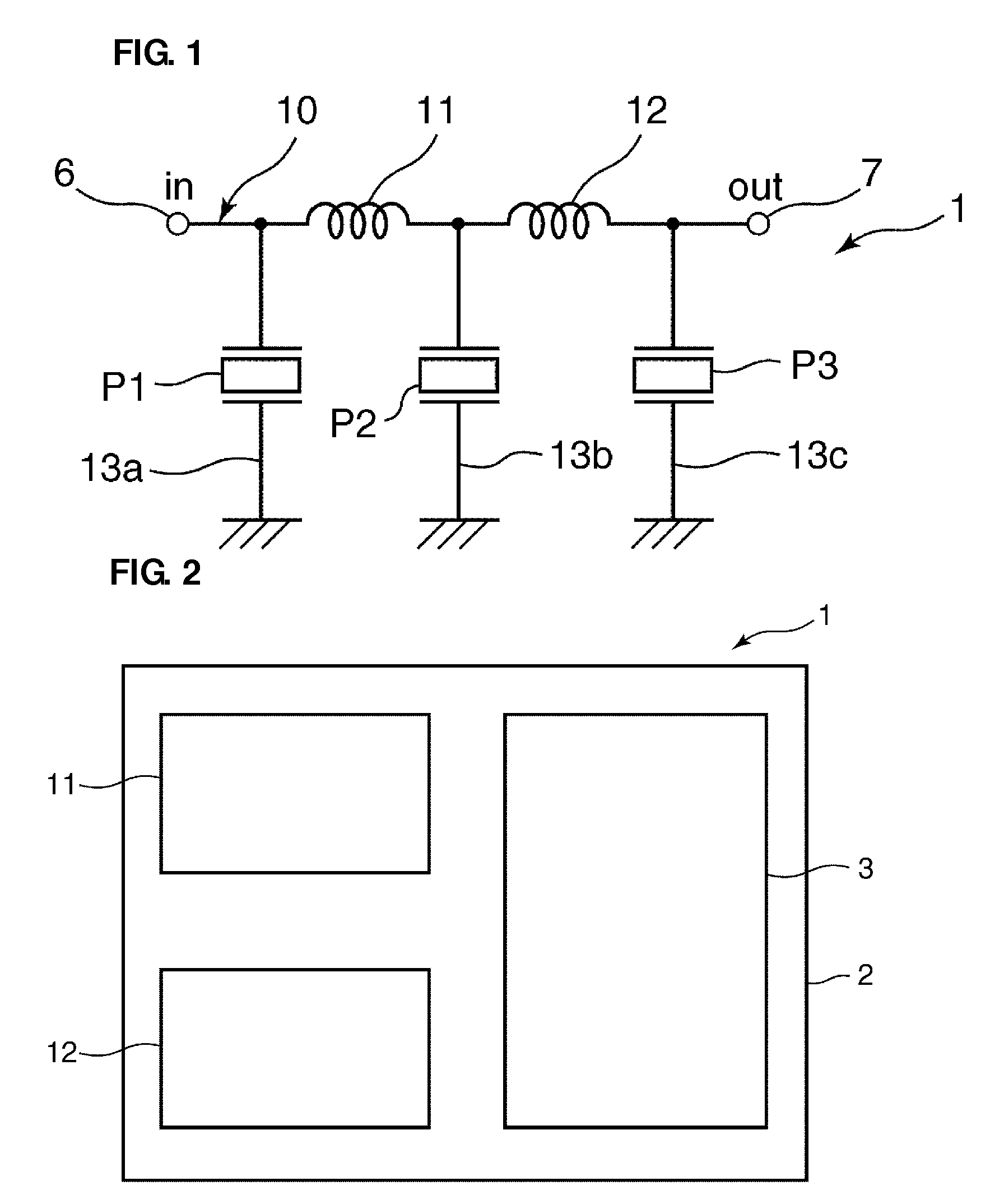

Thin film acoustic resonator and method of producing the same

InactiveUS6842088B2Improve temperature stabilityImprovement factorNanotechPiezoelectric/electrostrictive device manufacture/assemblyThin-film bulk acoustic resonatorElectromechanical coupling coefficient

Owner:MEMS SOLUTIONS INC

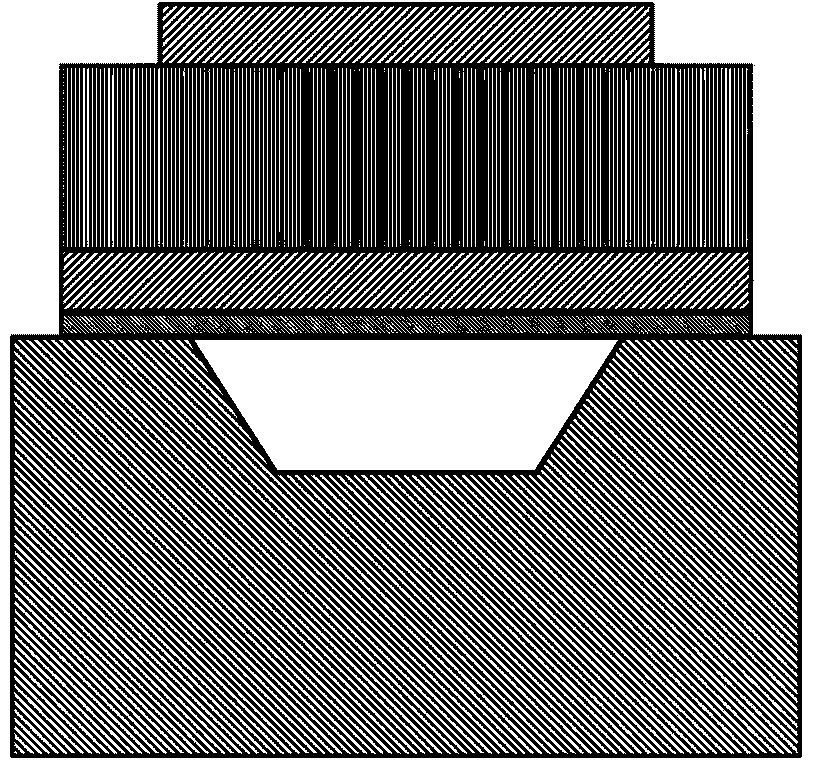

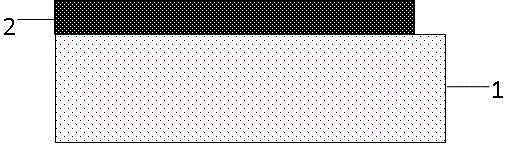

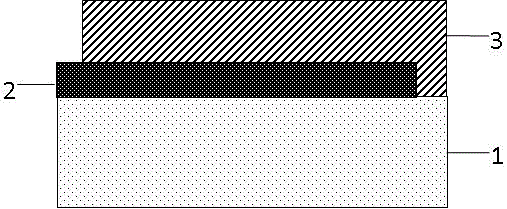

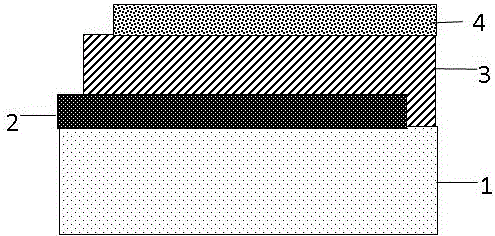

Thin film bulk acoustic resonator and method of producing the same

InactiveUS20020190814A1Improve featuresPiezoelectric/electrostrictive device manufacture/assemblyNanotechThin-film bulk acoustic resonatorElectromechanical coupling coefficient

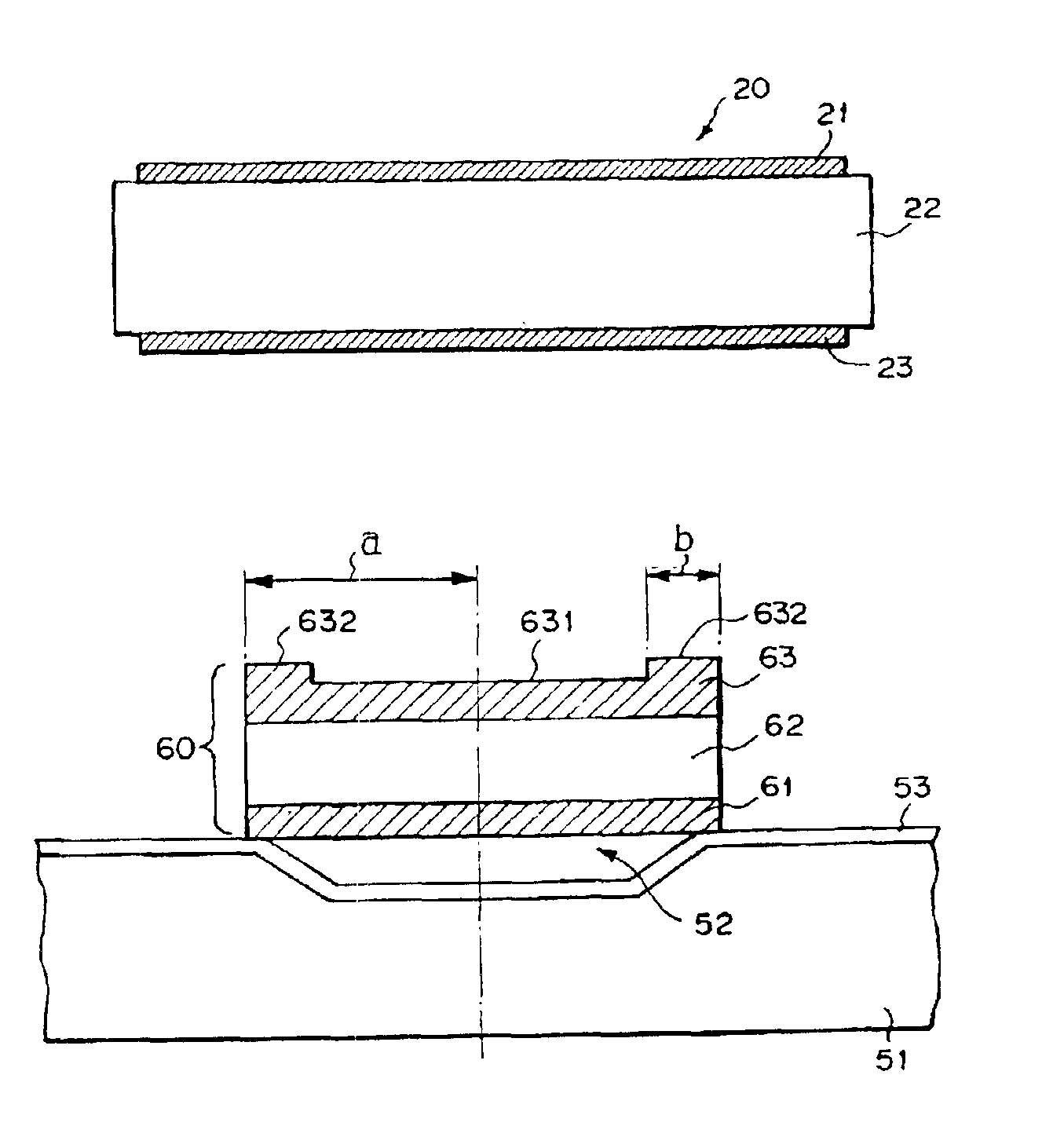

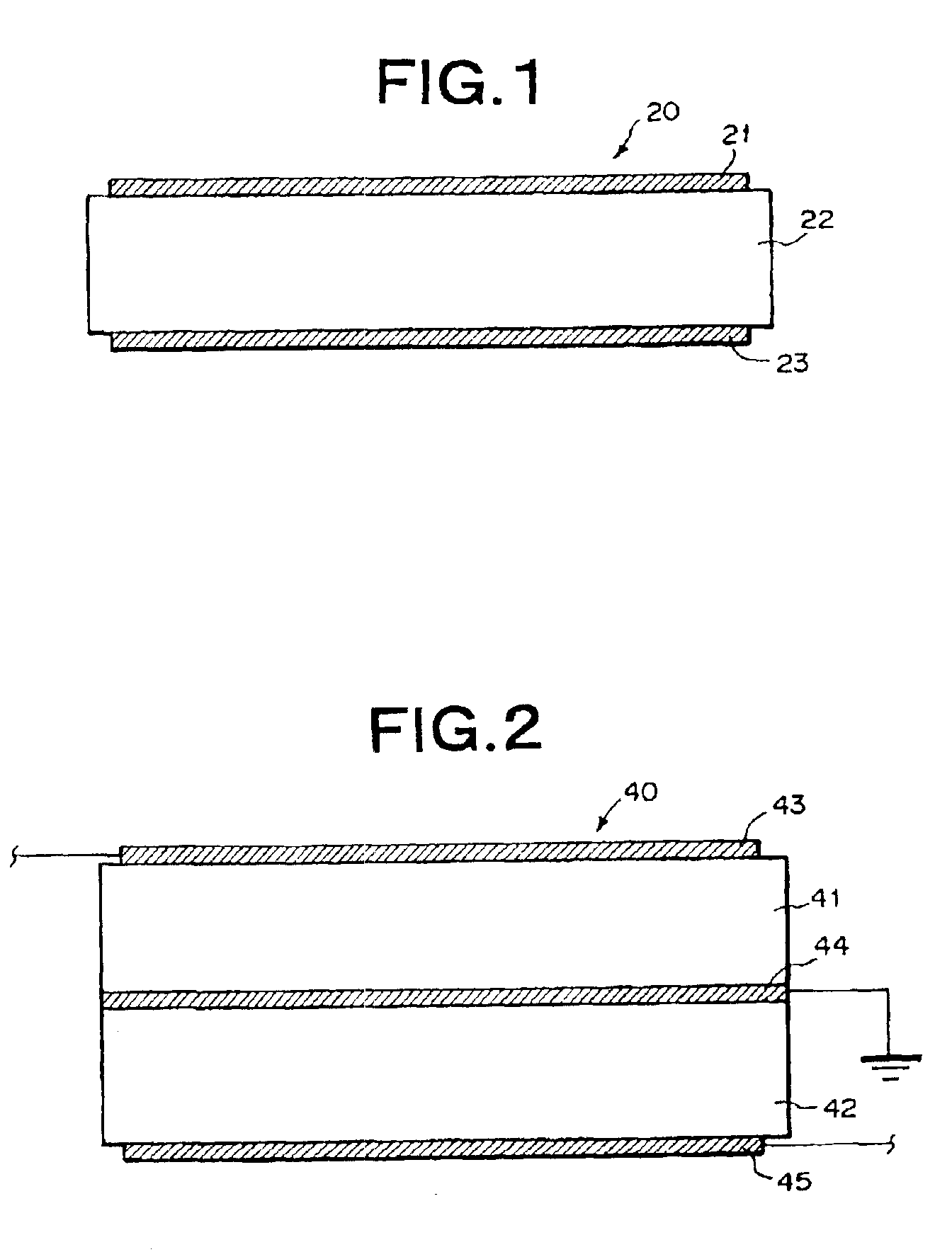

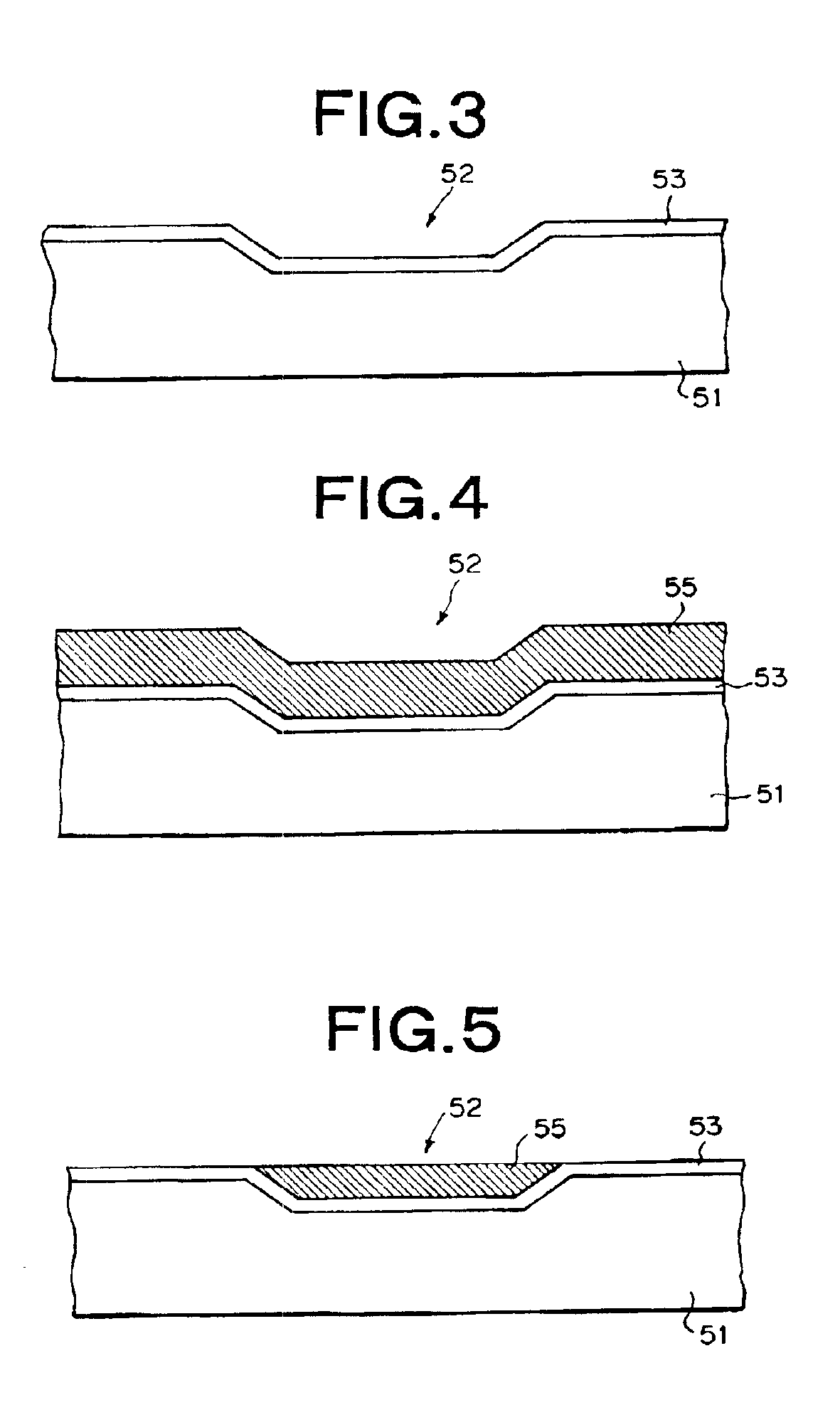

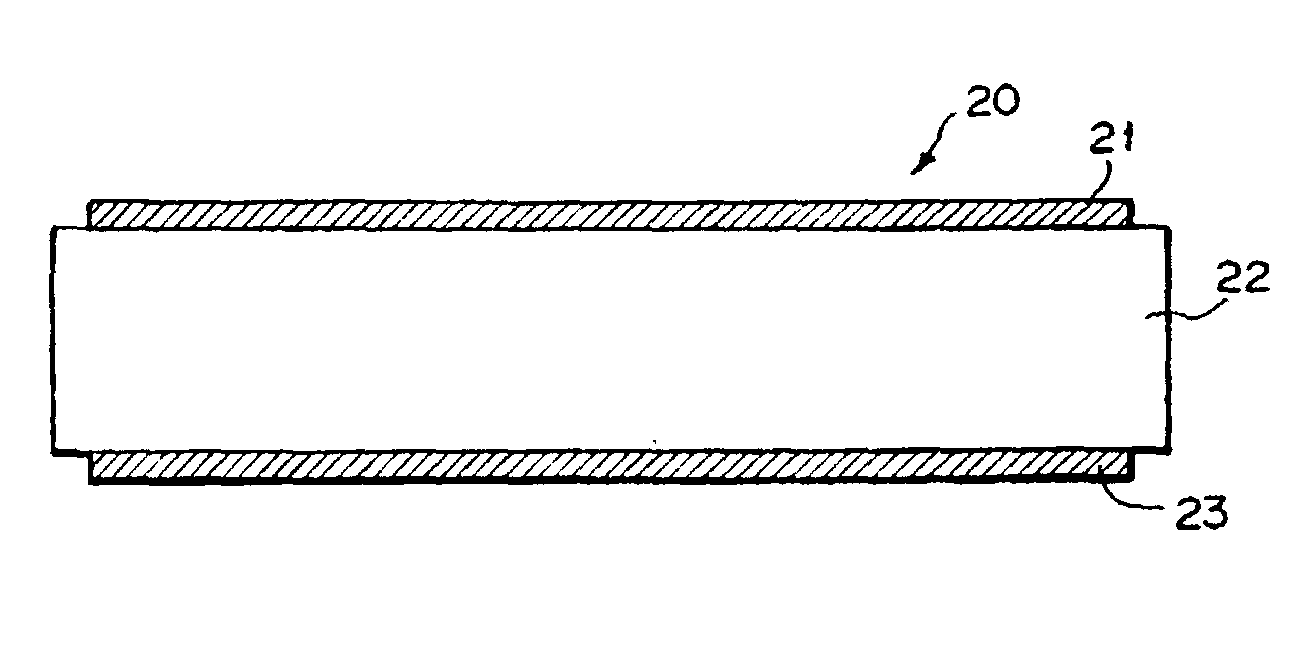

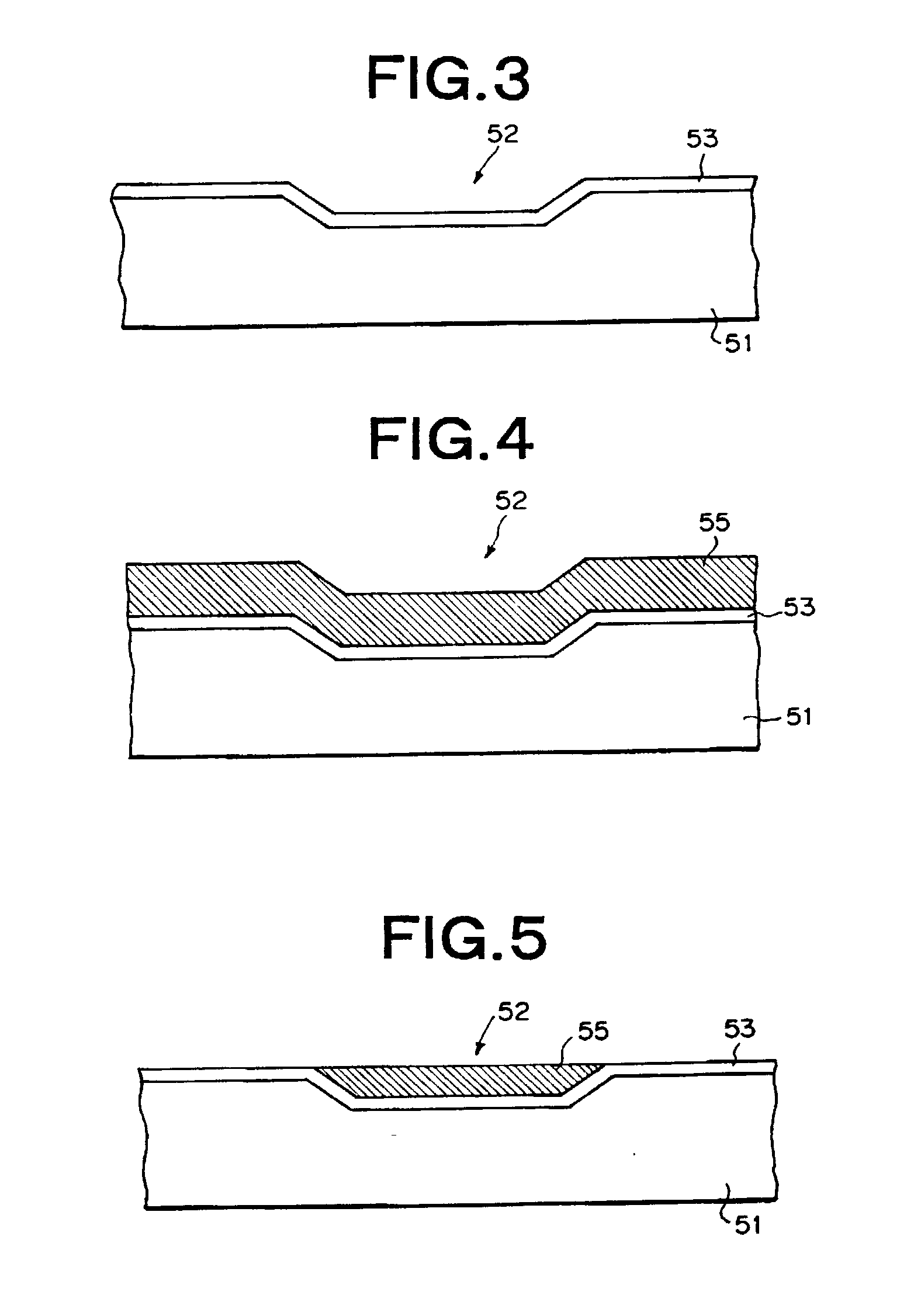

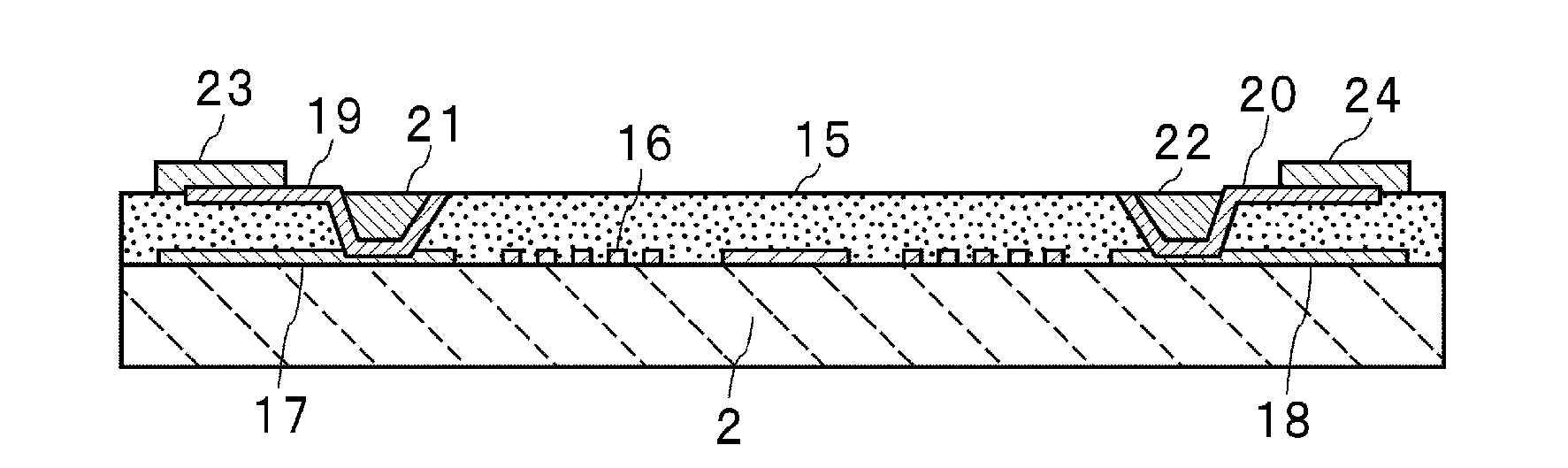

A pit (52) is formed in a substrate comprising a silicon wafer (51) on a surface of which a silicon oxide thin layer (53) is formed. A sandwich structure (60) comprising a piezoelectric layer (62) and lower and upper electrodes (61, 63) joined to both surfaces of the piezoelectric layer is disposed so as to stride over the pit (52). The upper surface of the lower electrode (61) and the lower surface of the piezoelectric layer (62) joined to the upper surface of the lower electrode are treated so that the RMS variation of the height thereof is equal to 25 nm or less. The thickness of the lower electrode (61) is set to 150 nm or less. According to such a structure, there is provided a high-performance thin film bulk acoustic resonator which are excellent in electromechanical coupling coefficient and acoustic quality factor.

Owner:MEMS SOLUTIONS INC

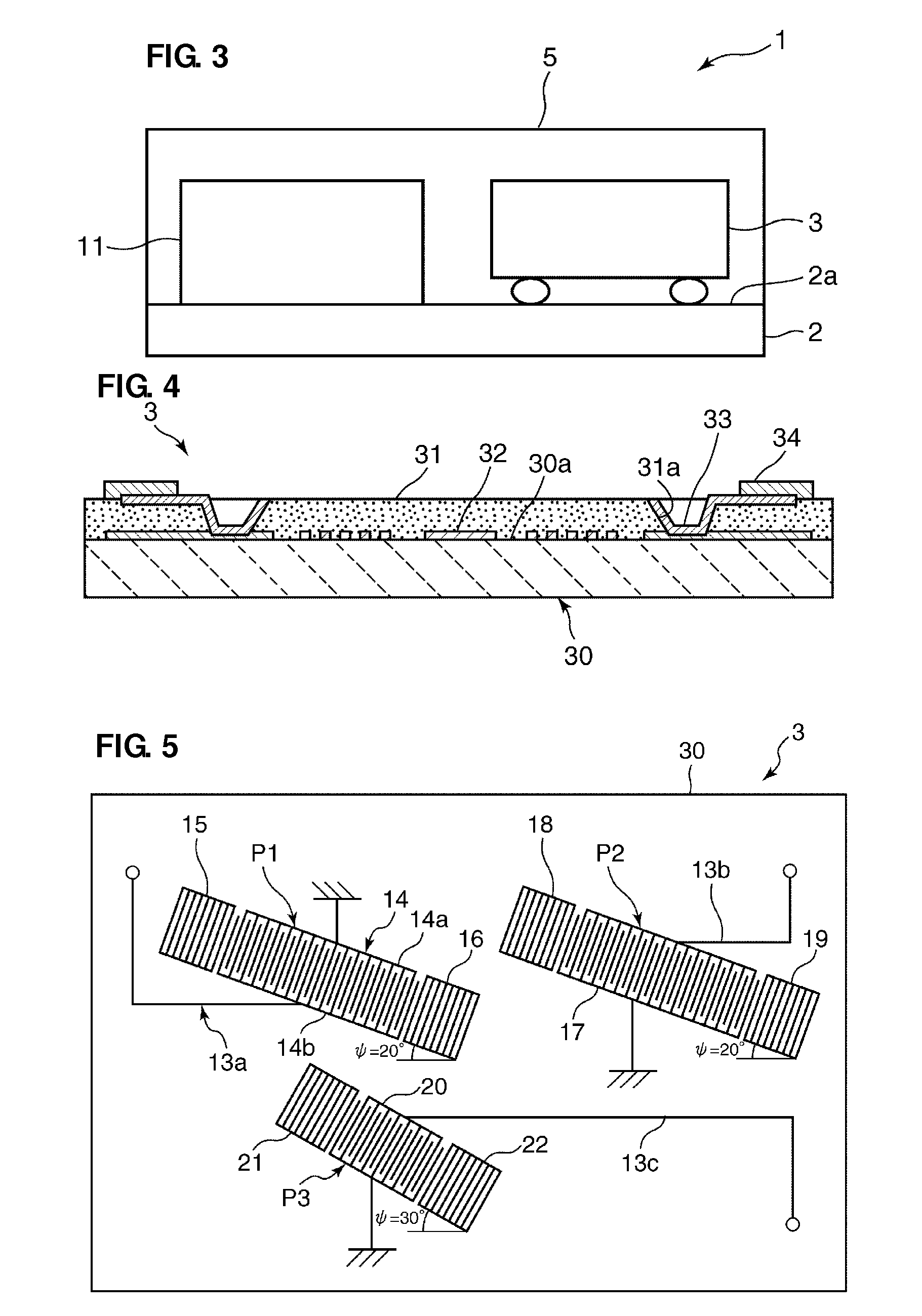

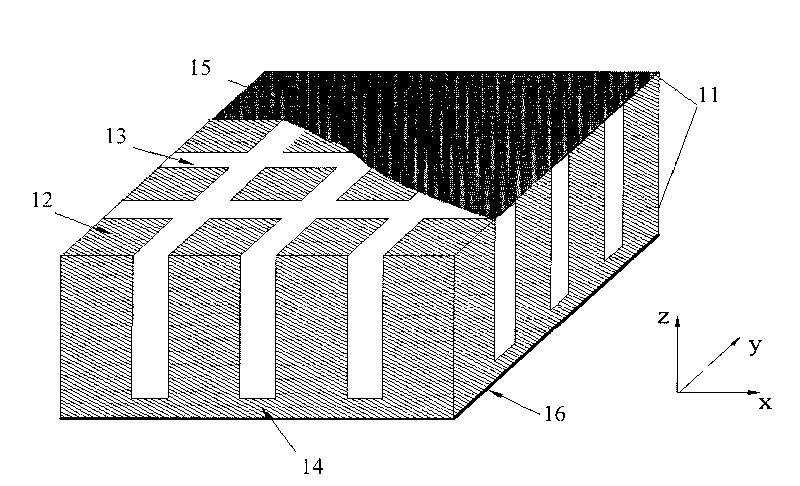

Film bulk acoustic resonator

InactiveUS6936837B2Maximum couplingHigh bandwidthImpedence networksBulk negative resistance effect devicesThin-film bulk acoustic resonatorAlkaline earth metal

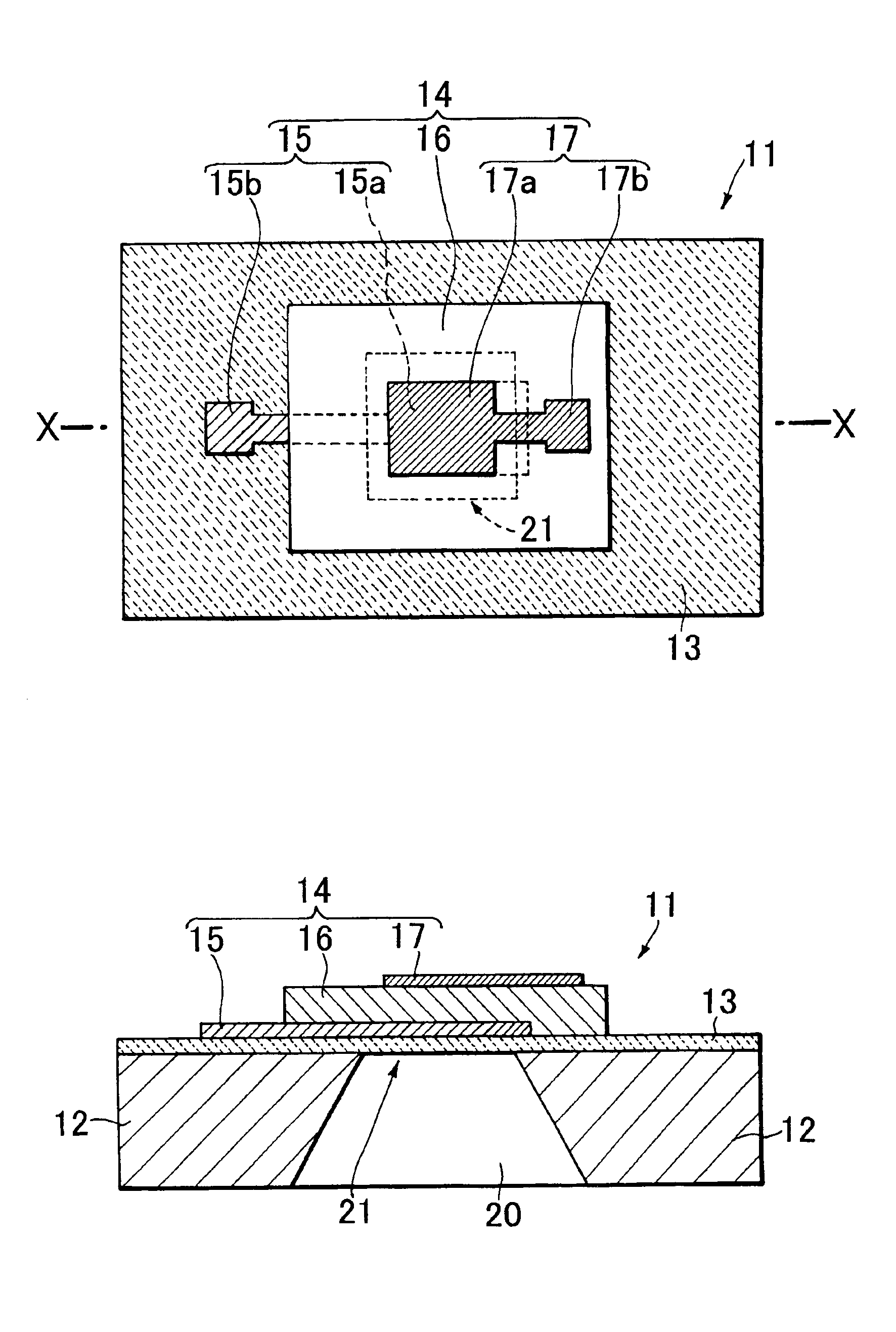

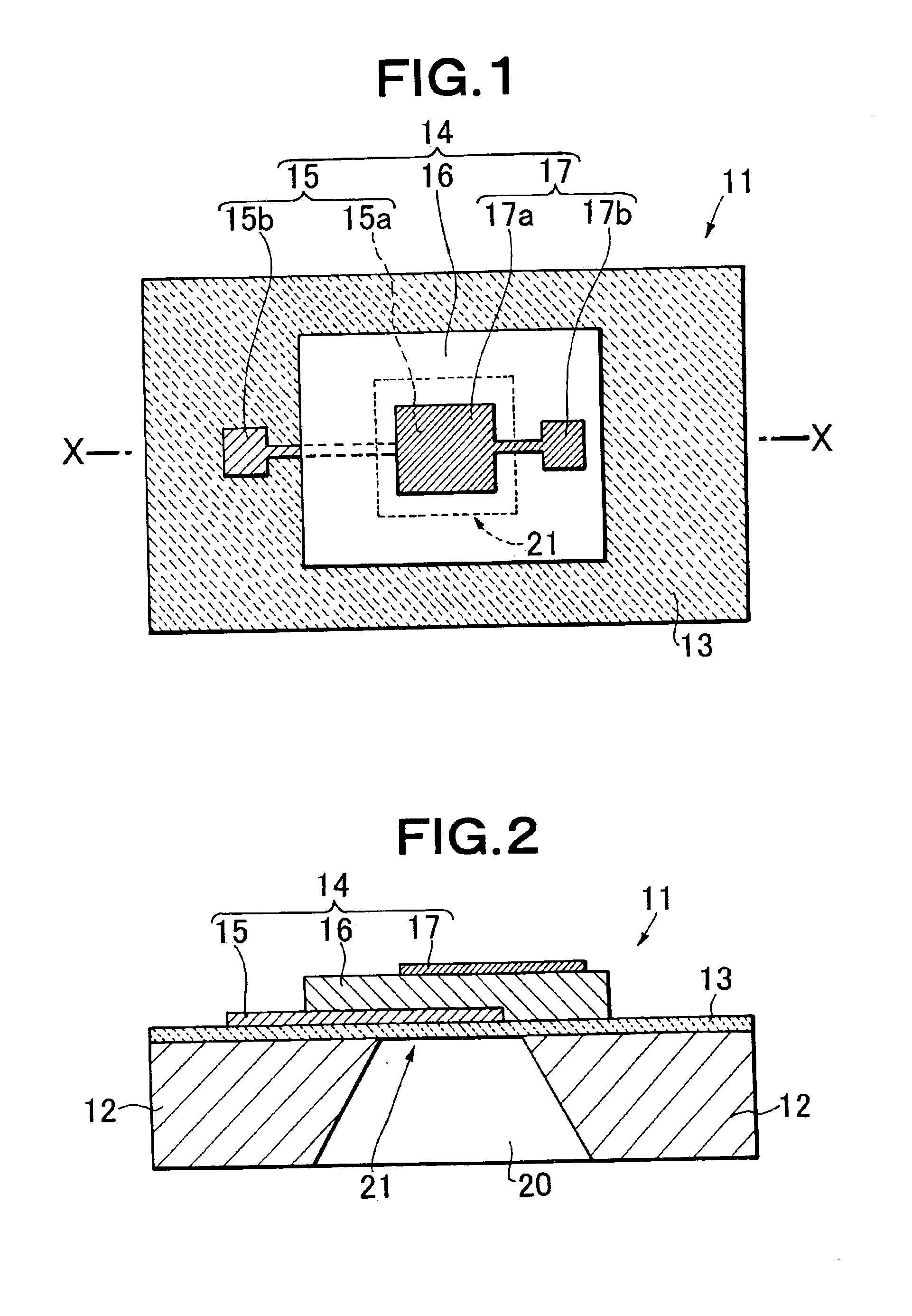

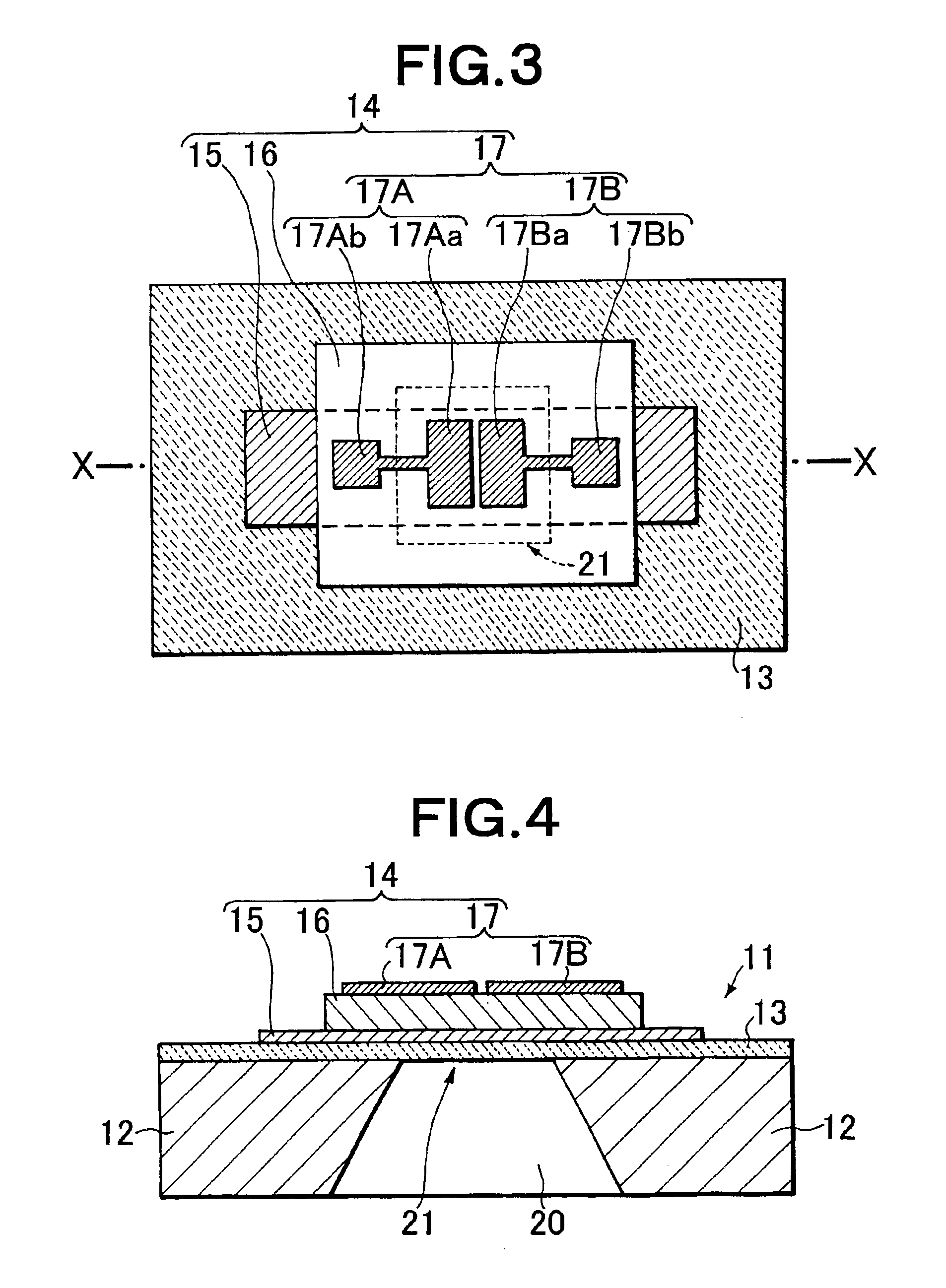

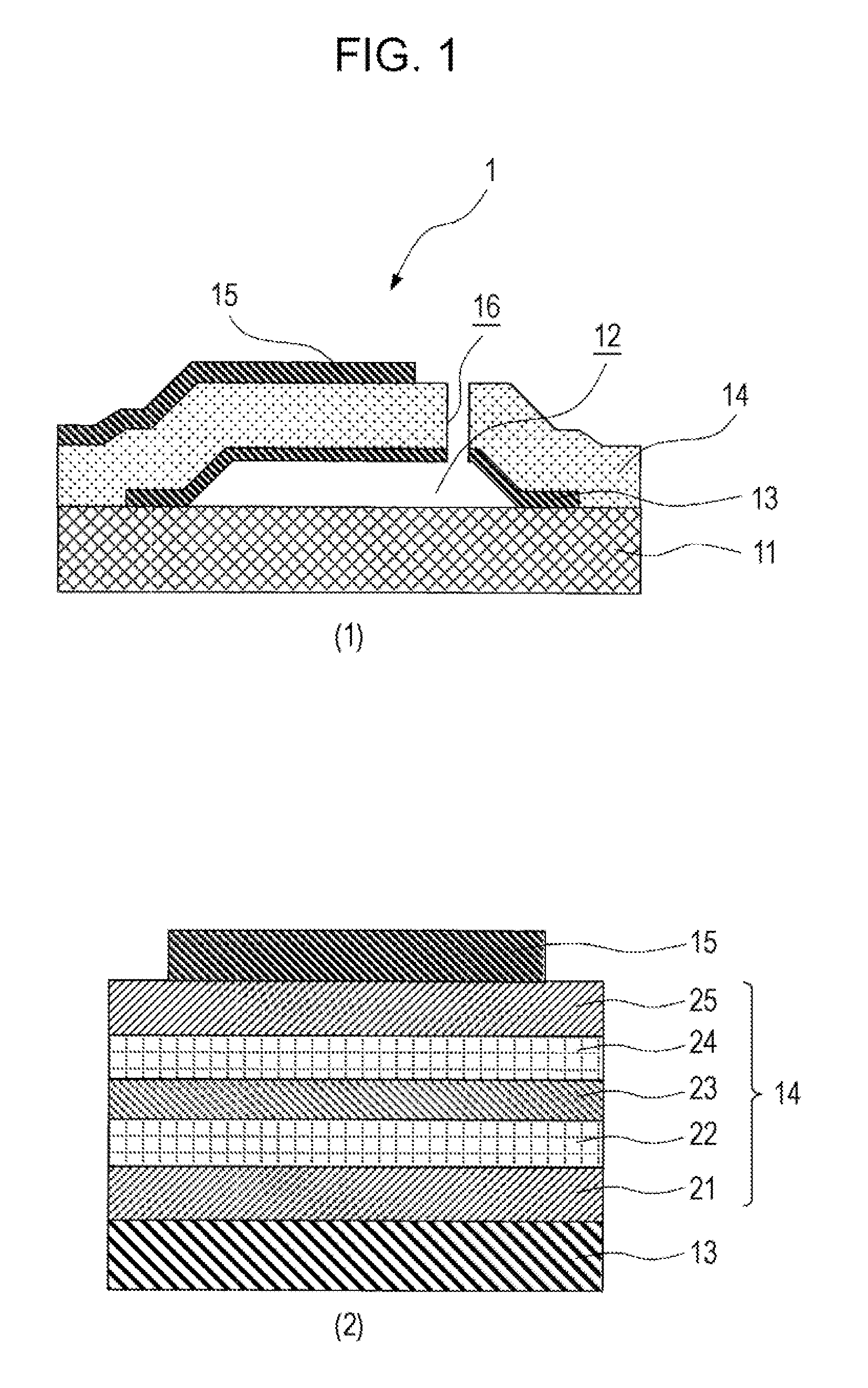

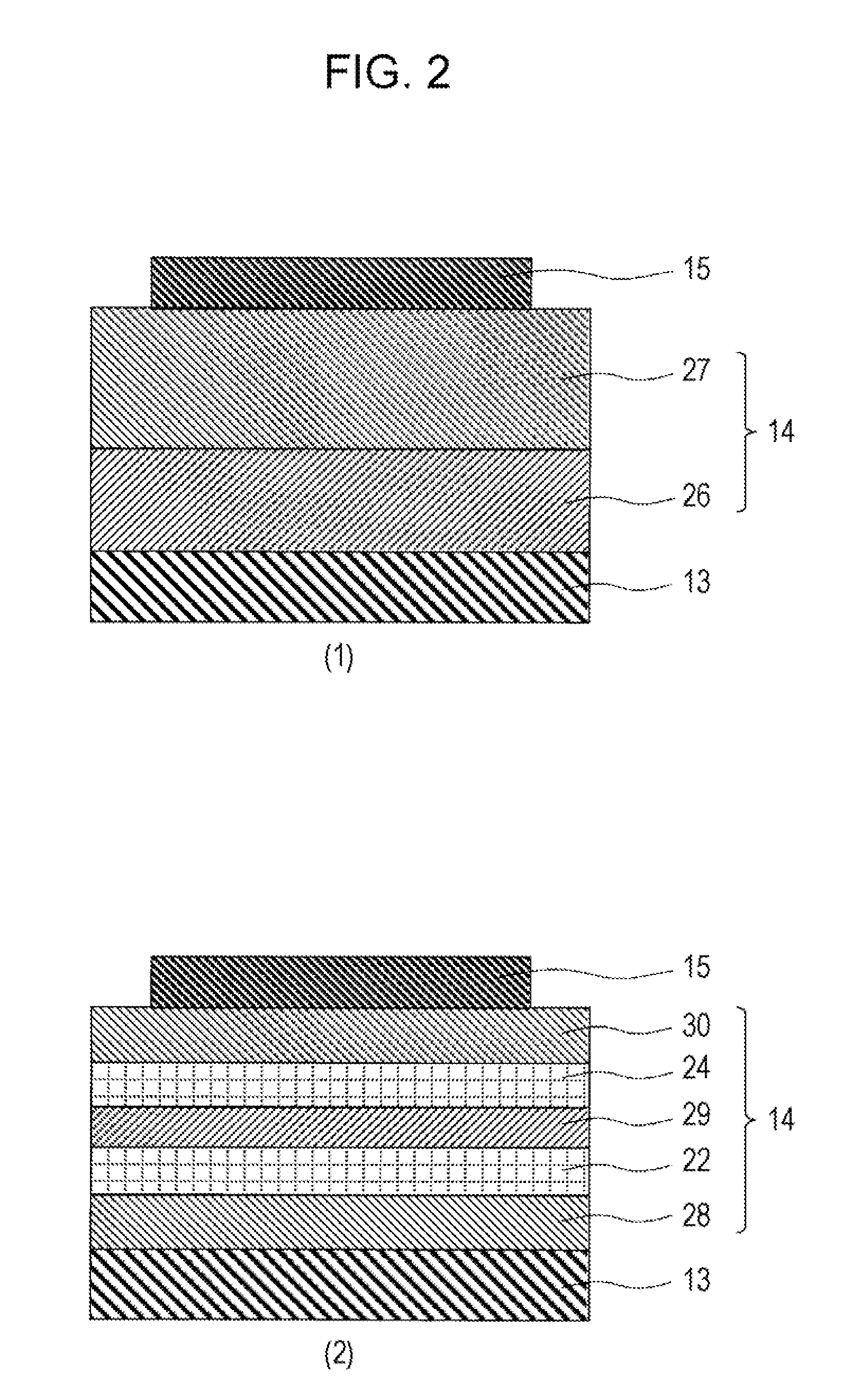

A thin film bulk acoustic resonator comprises a substrate (12) of a silicon single crystal, a base film (13) formed on the substrate (12) and composed of a dielectric film mainly containing silicon oxide, and a piezoelectric stacked structure (14) formed on the base film (13). A vibratory section (21) composed of a part of the base film (13) and a part of the piezoelectric stacked structure (14). The piezoelectric stacked structure (14) includes a lower electrode (15), a piezoelectric film (16), and an upper electrode (17) formed in this order from below. The substrate (12) had a via hole (20) in the region corresponding to the vibratory section (21). The via hole forms a space for allowing vibration of the vibratory section (21). The piezoelectric film (16) is an aluminum nitride thin film containing 0.2 to 3.0 atom % of alkaline earth metal and / or a rare earth metal. Thus, the thin film bulk acoustic resonator has a high performance such as a large electromechanical coupling coefficient, an excellent acoustic quality factor (Q) and an excellent frequency-temperature characteristic.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

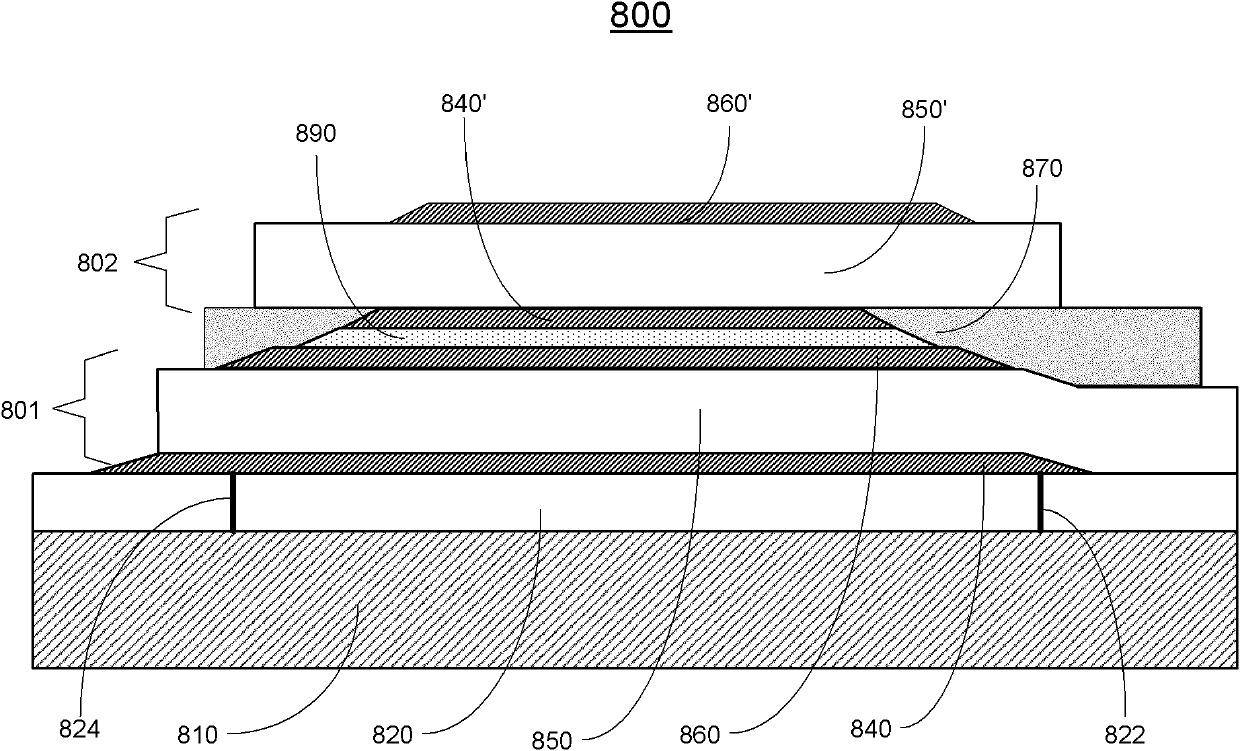

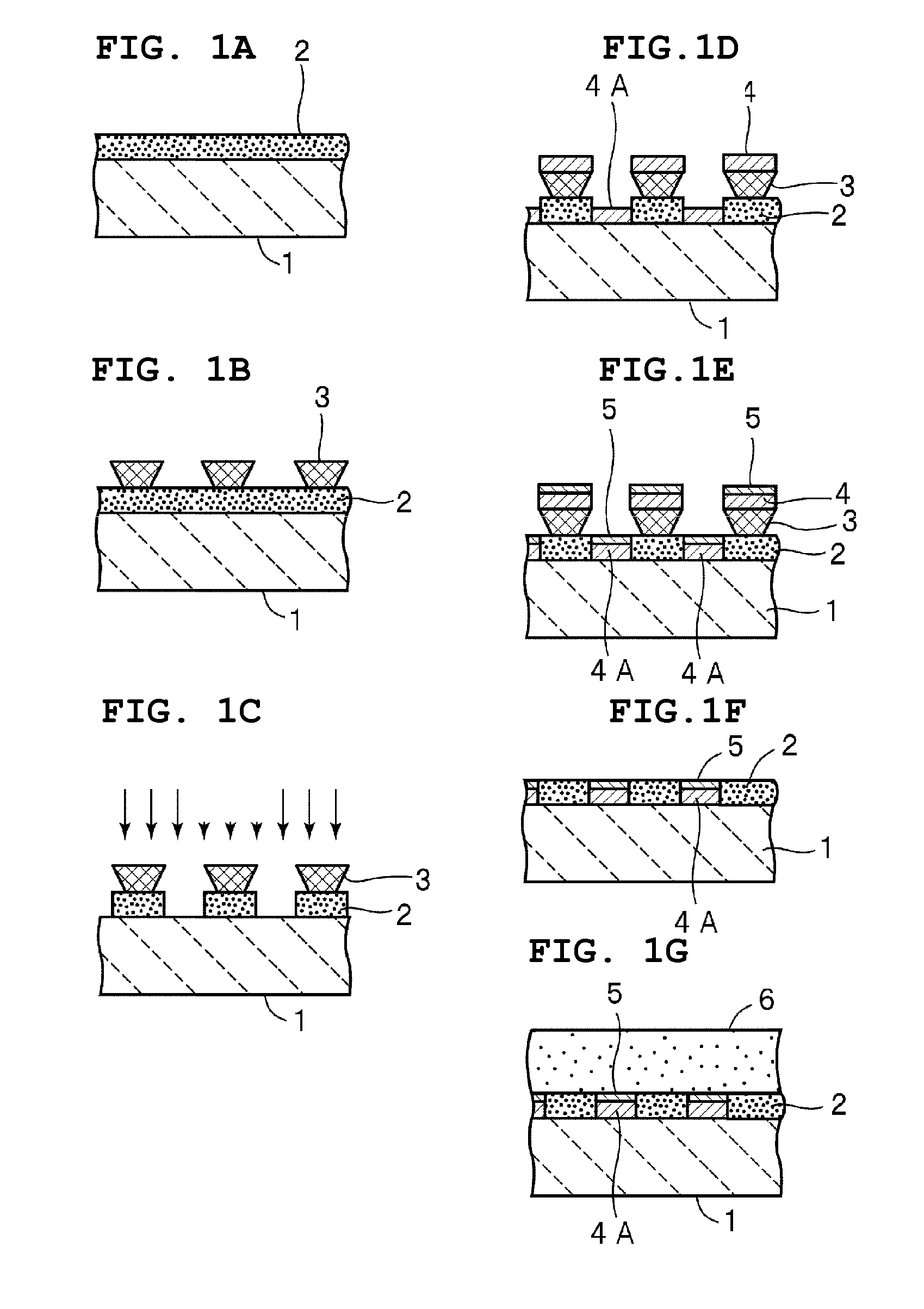

Method for manufacturing a vibrating MEMS circuit

ActiveUS9369105B1Low temperature coefficientAccurate shapePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectromechanical coupling coefficientCrystal orientation

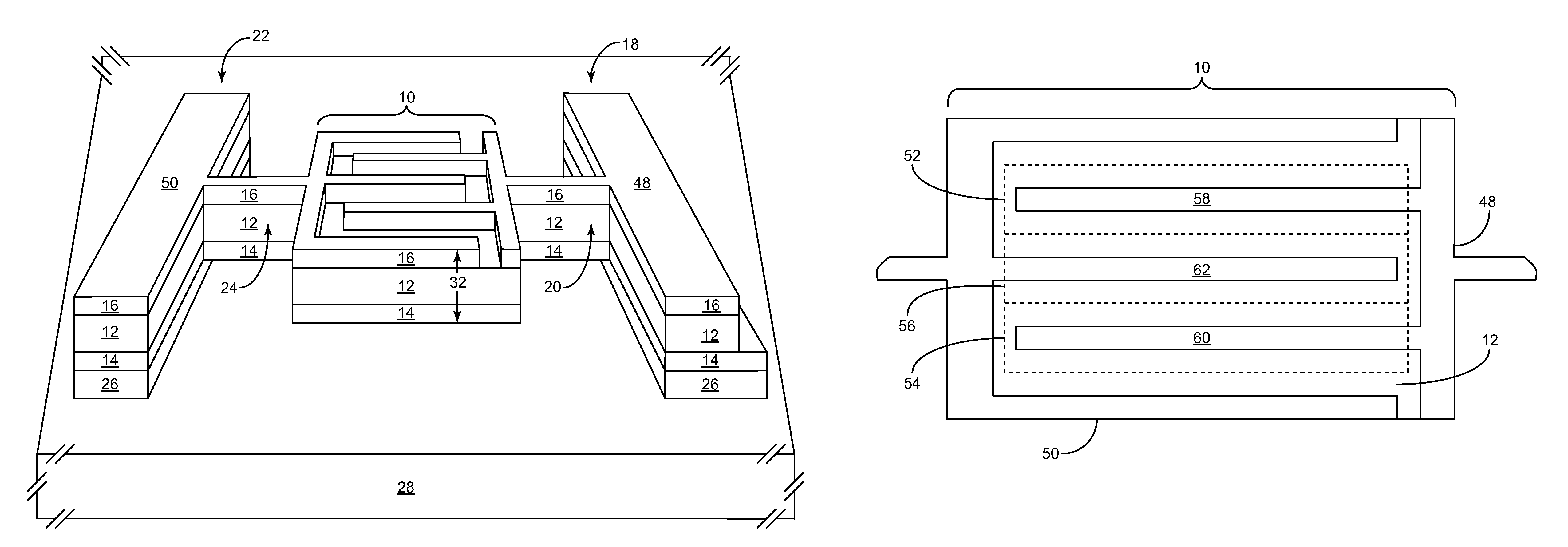

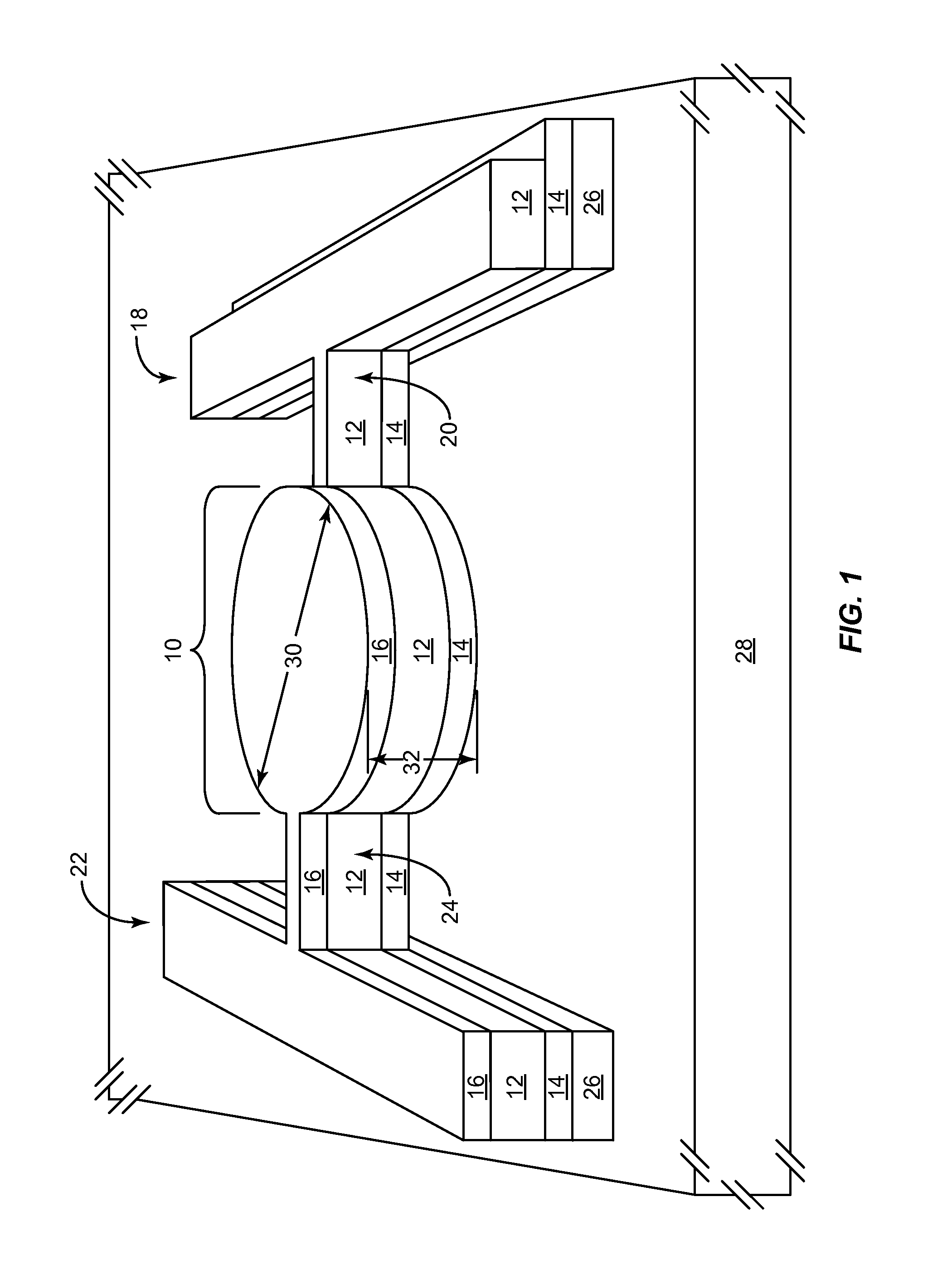

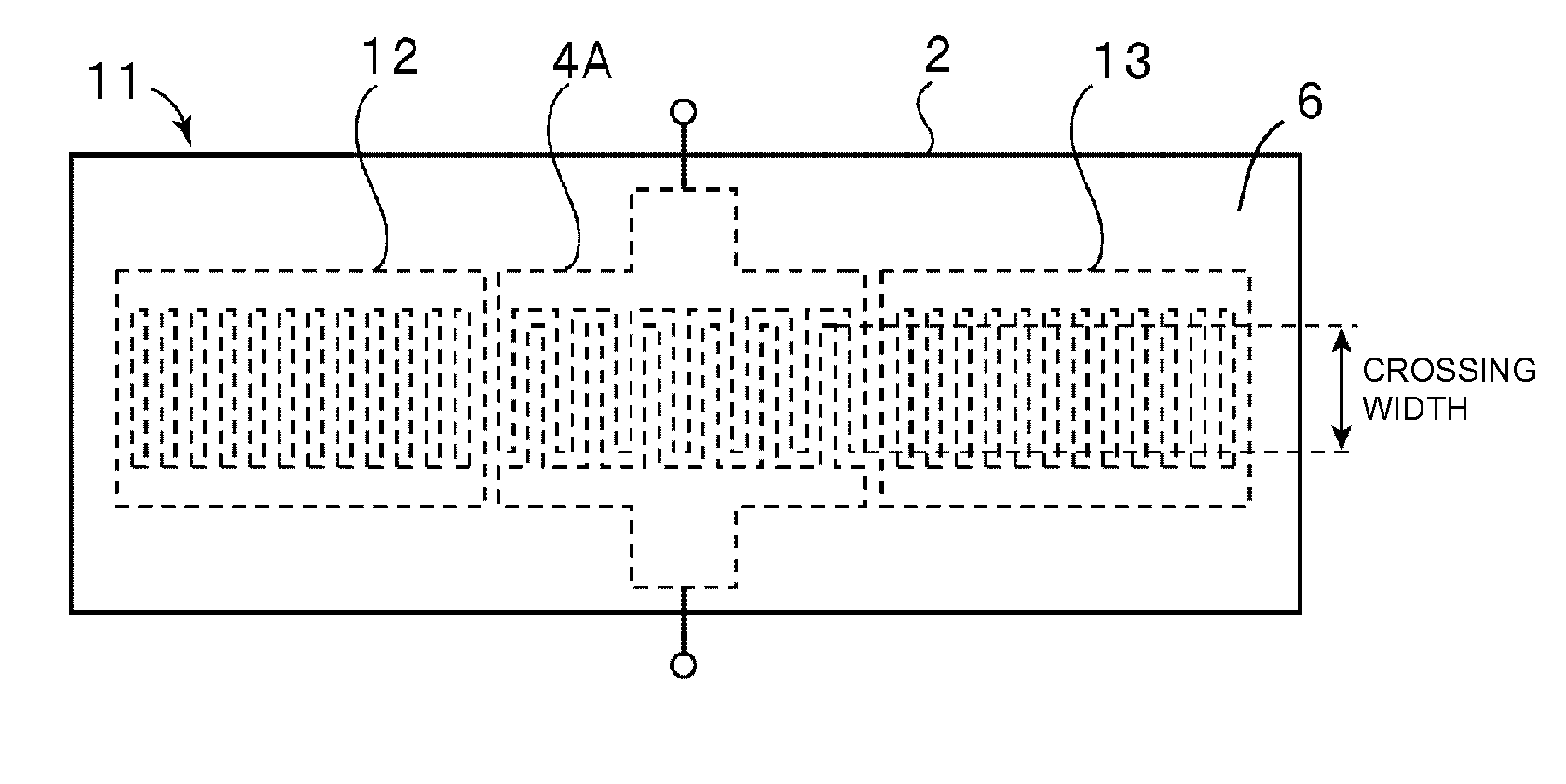

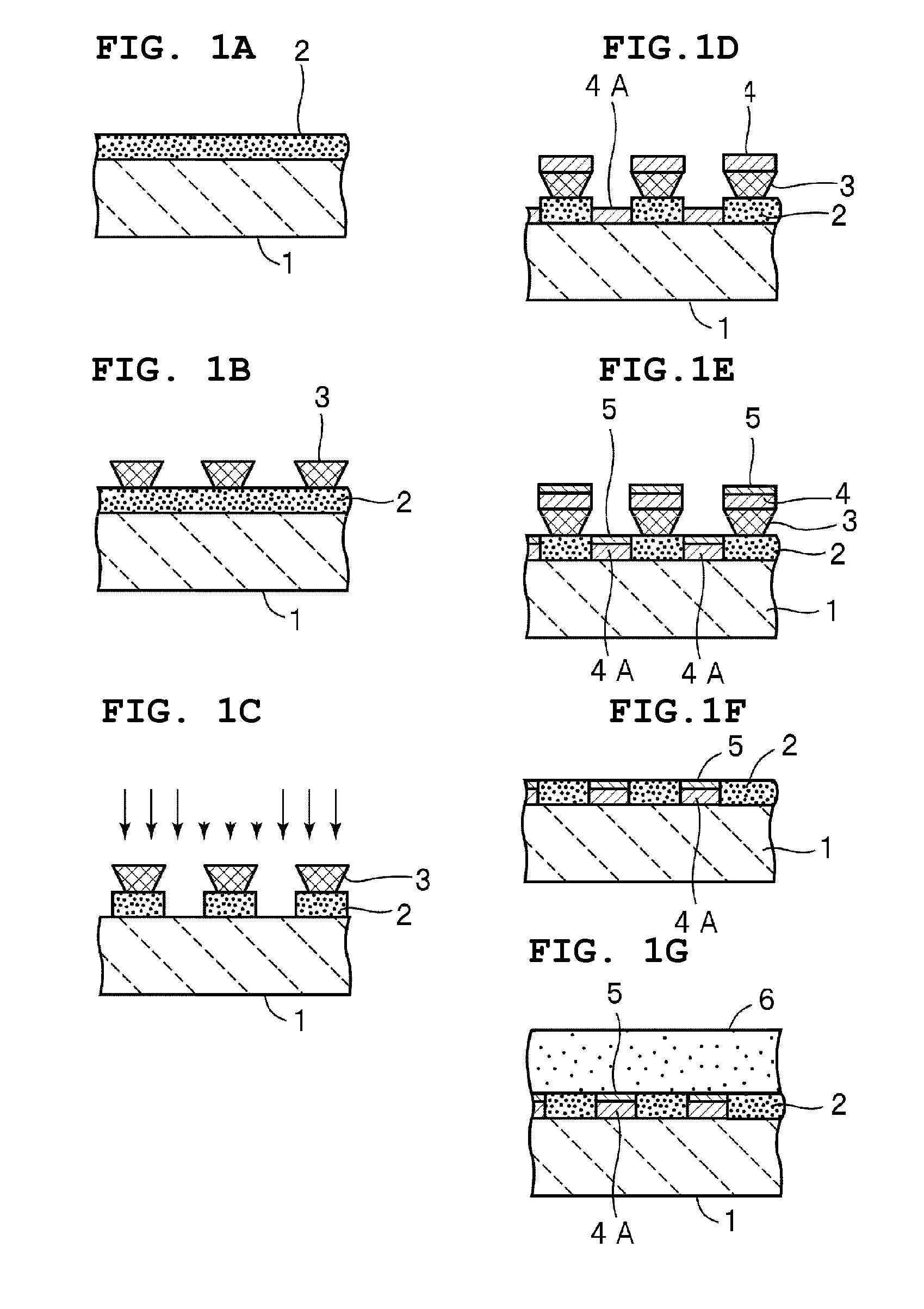

A method for making a micro-electro-mechanical systems (MEMS) vibrating structure is disclosed. The MEMS is supported by a MEMS anchor system and includes a single-crystal piezoelectric thin-film layer that has a specific non-standard crystal orientation, which may be selected to increase an electromechanical coupling coefficient, decrease a temperature coefficient of frequency, or both. The MEMS vibrating structure may have dominant lateral vibrations or dominant thickness vibrations. The single-crystal piezoelectric thin-film layer may include Lithium Tantalate or Lithium Niobate, and may provide MEMS vibrating structures with precise sizes and shapes, which may provide high accuracy and enable fabrication of multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

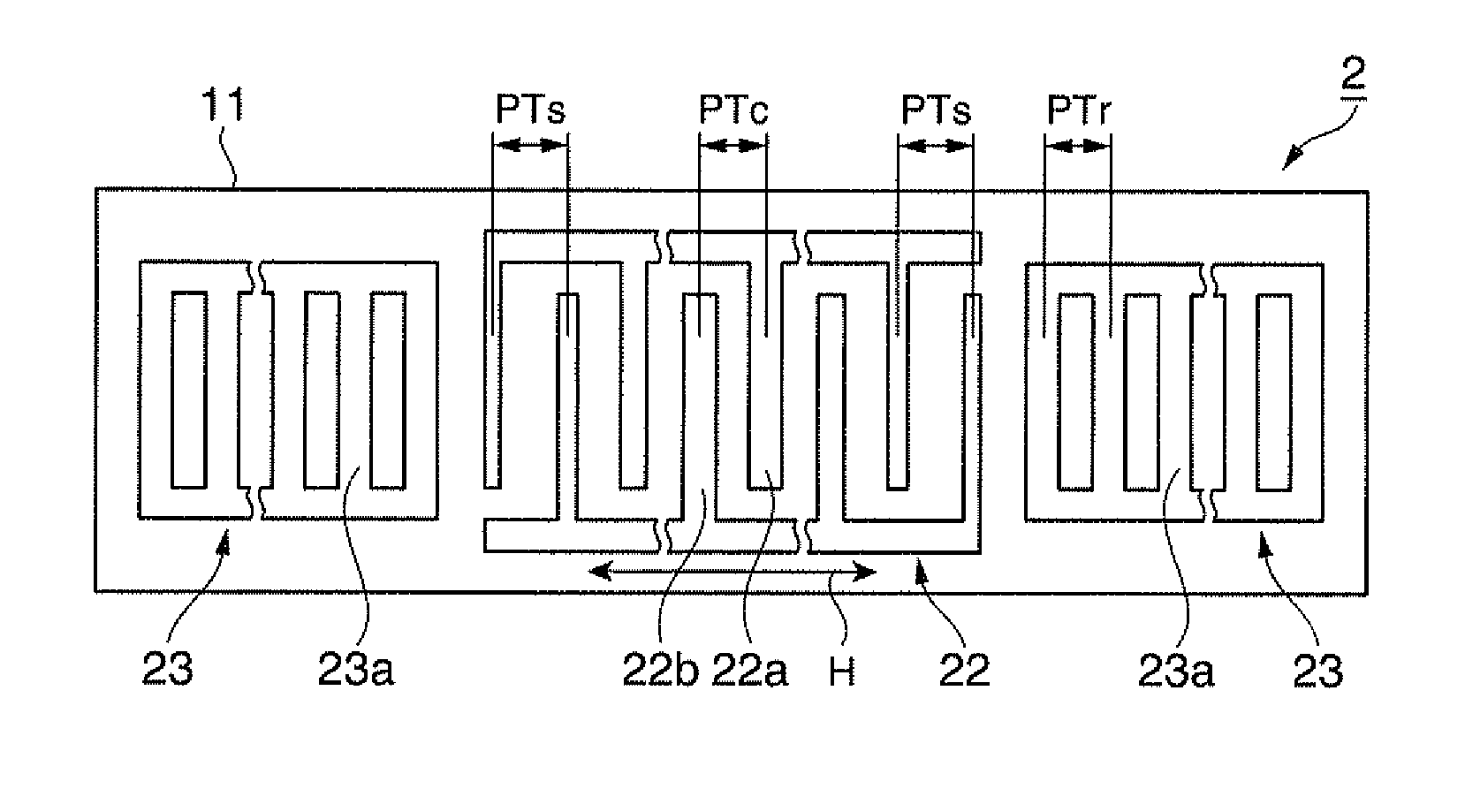

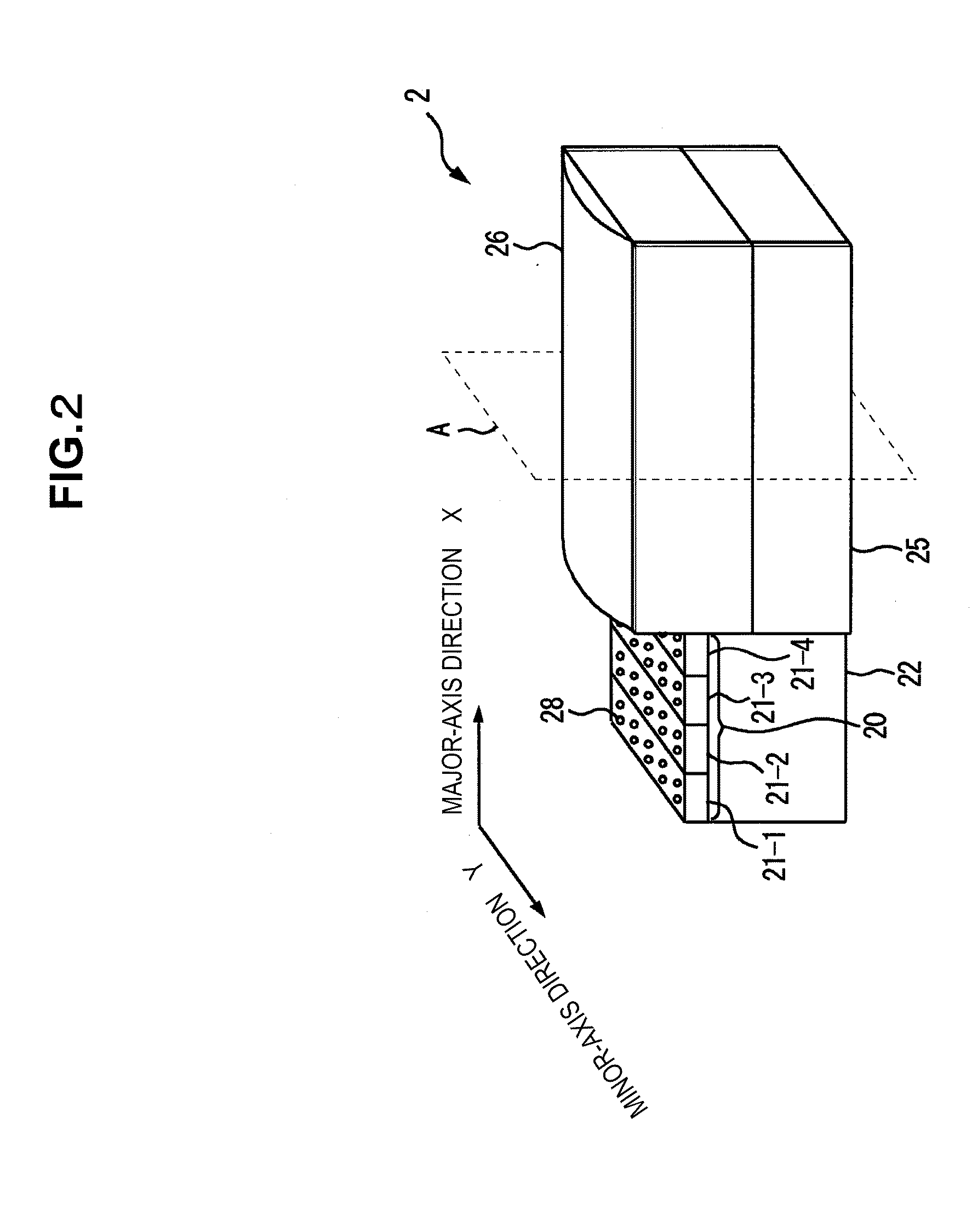

Ultrasonic probe and ultrasonic diagnostic apparatus using the same

ActiveUS8758253B2Prevent leakageUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientAcoustic lens

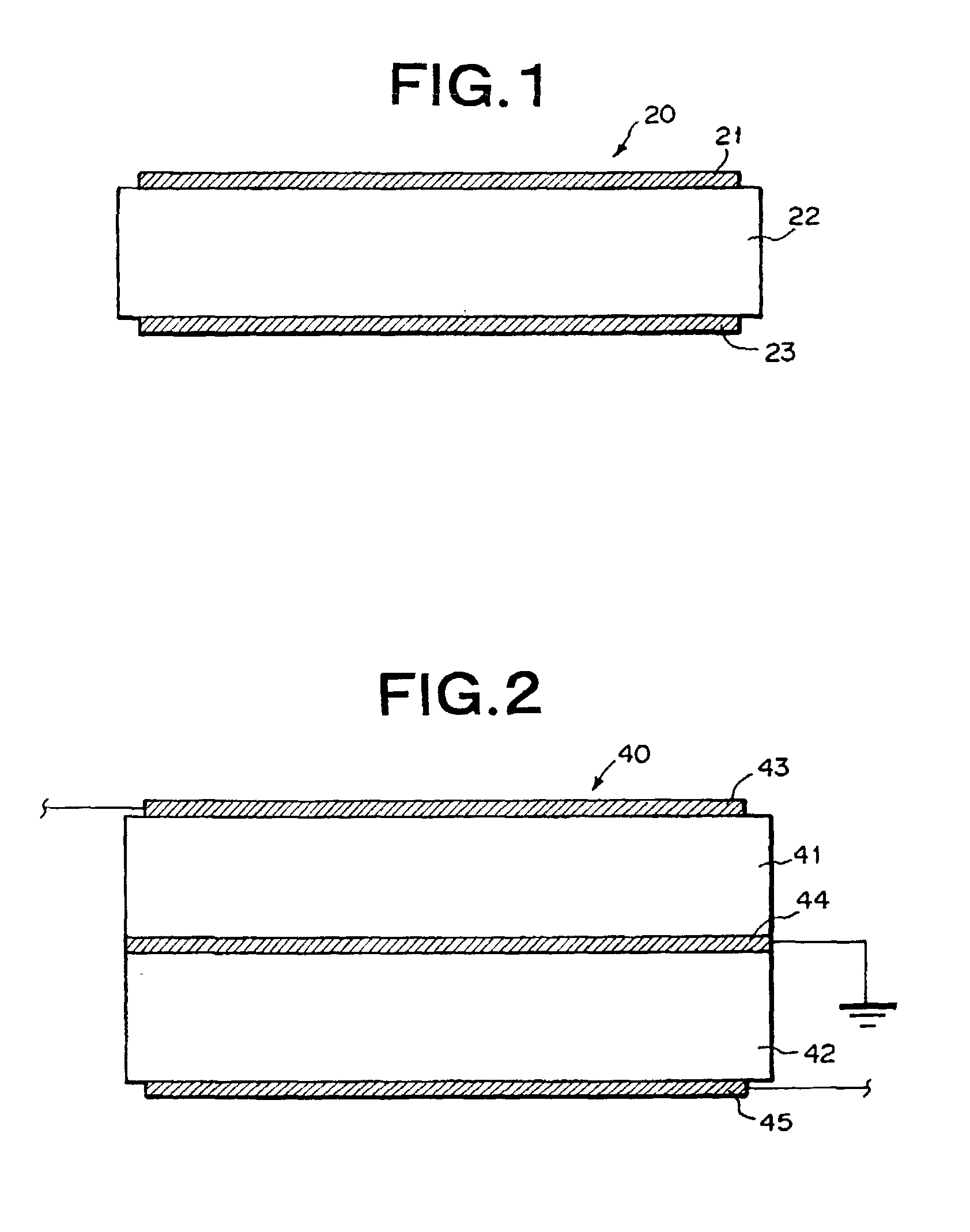

An ultrasonic probe is disclosed which includes a cMUT chip having a plurality of vibration elements whose electromechanical coupling coefficient or sensitivity is changed according to a bias voltage and transmitting and receiving ultrasonic waves, an acoustic lens arranged above the cMUT chip, and a backing layer arranged below the cMUT chip. An electric leakage preventing unit is provided at the ultrasonic wave transmission / reception surface side of the acoustic lens or between the acoustic lens and the cMUT chip. The electric leakage preventing unit can be, for example, an insulating layer such as a ground layer. Such a structure makes it is possible to provide an ultrasonic probe capable of preventing electric leakage from the ultrasonic probe to an object to be examined so as to improve the electric safety and an ultrasonic diagnostic apparatus using the probe.

Owner:FUJIFILM HEALTHCARE CORP

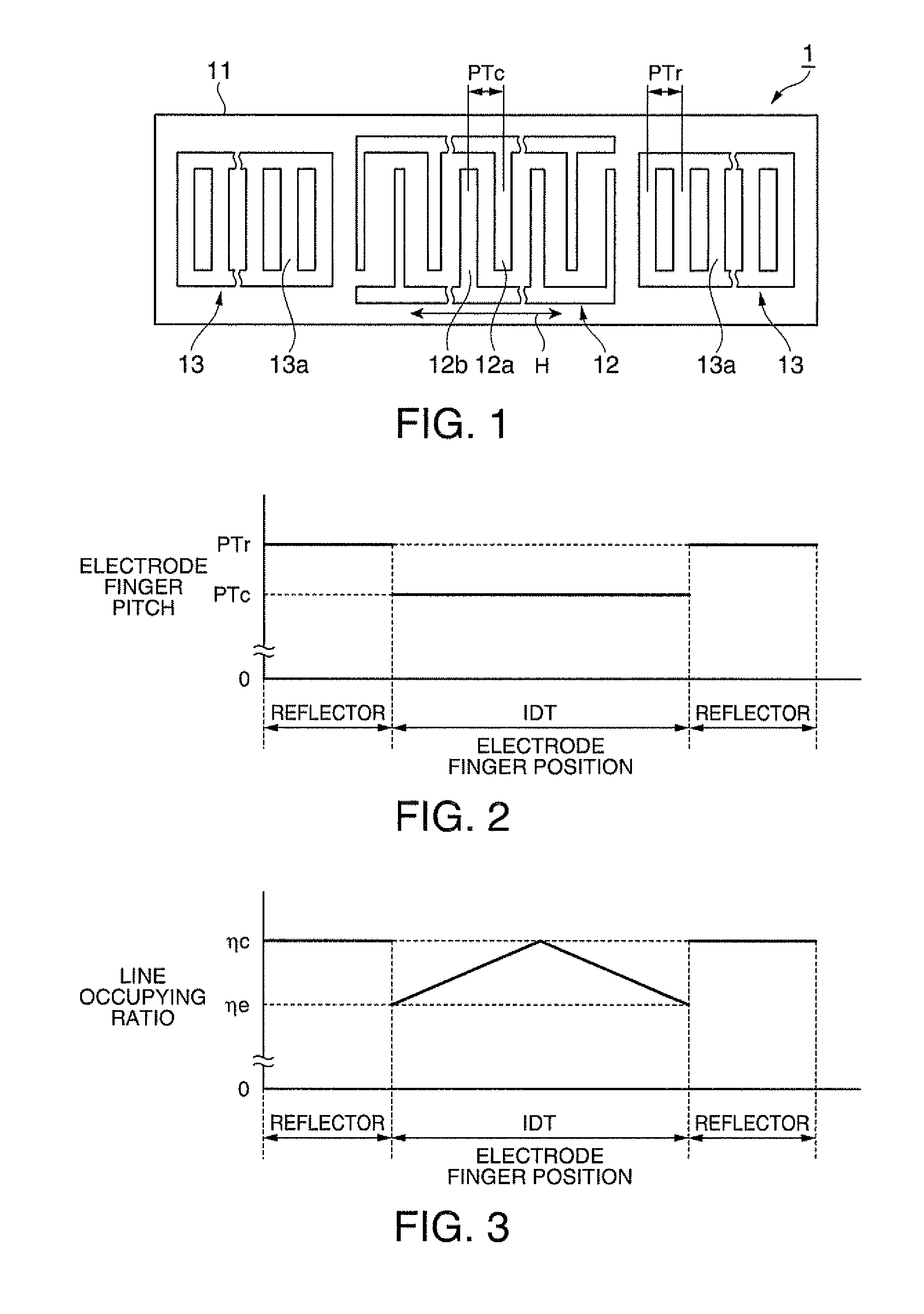

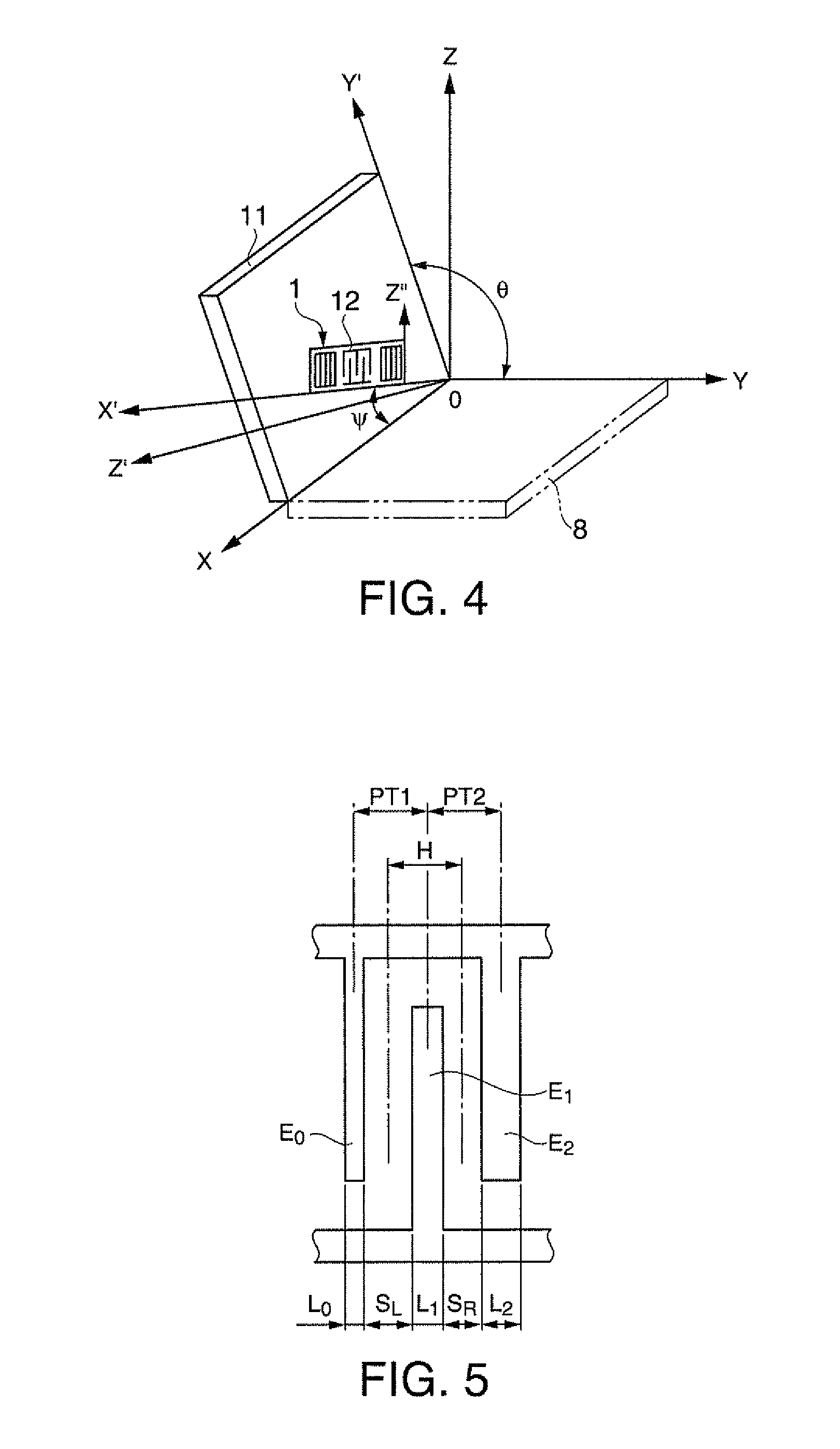

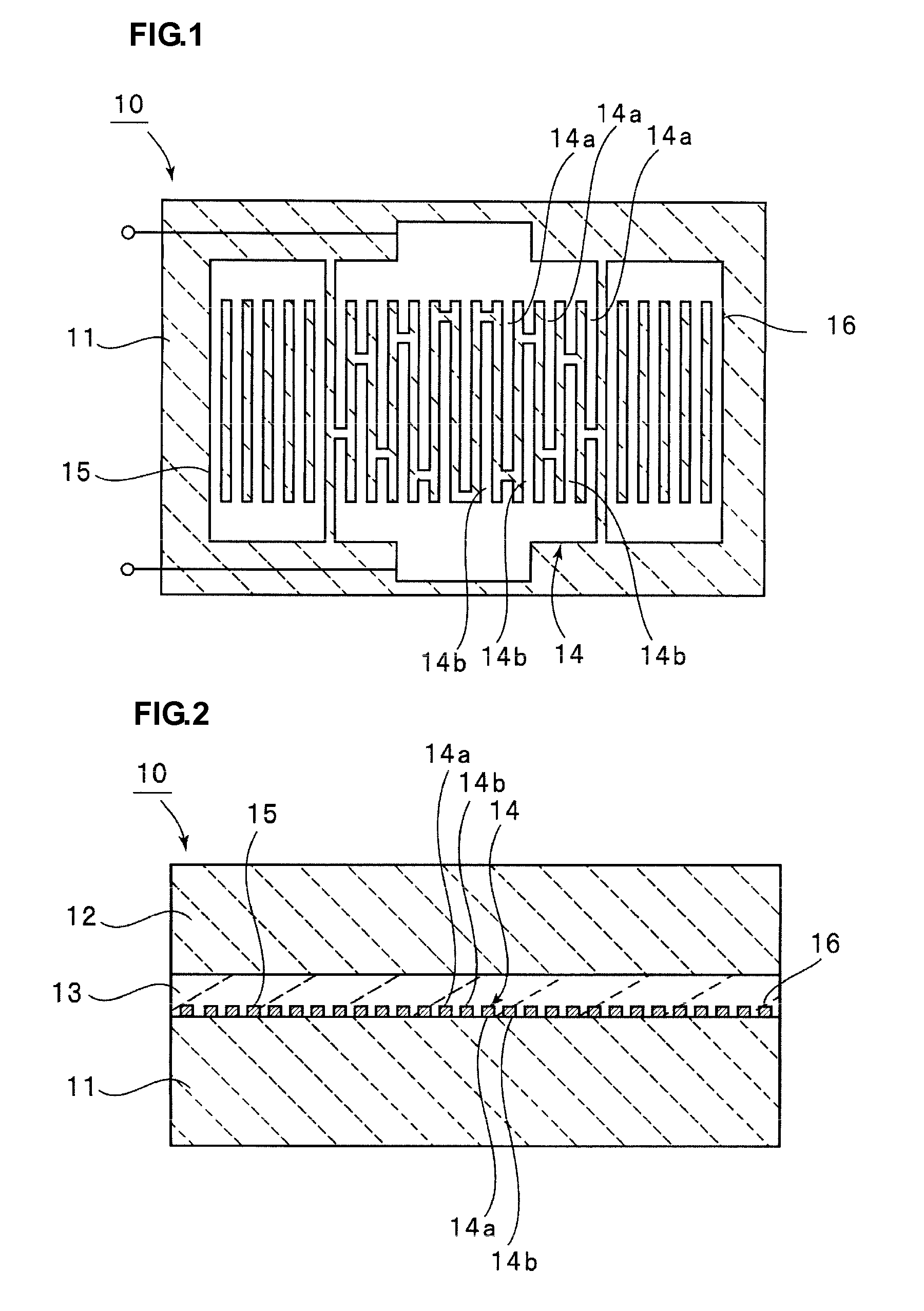

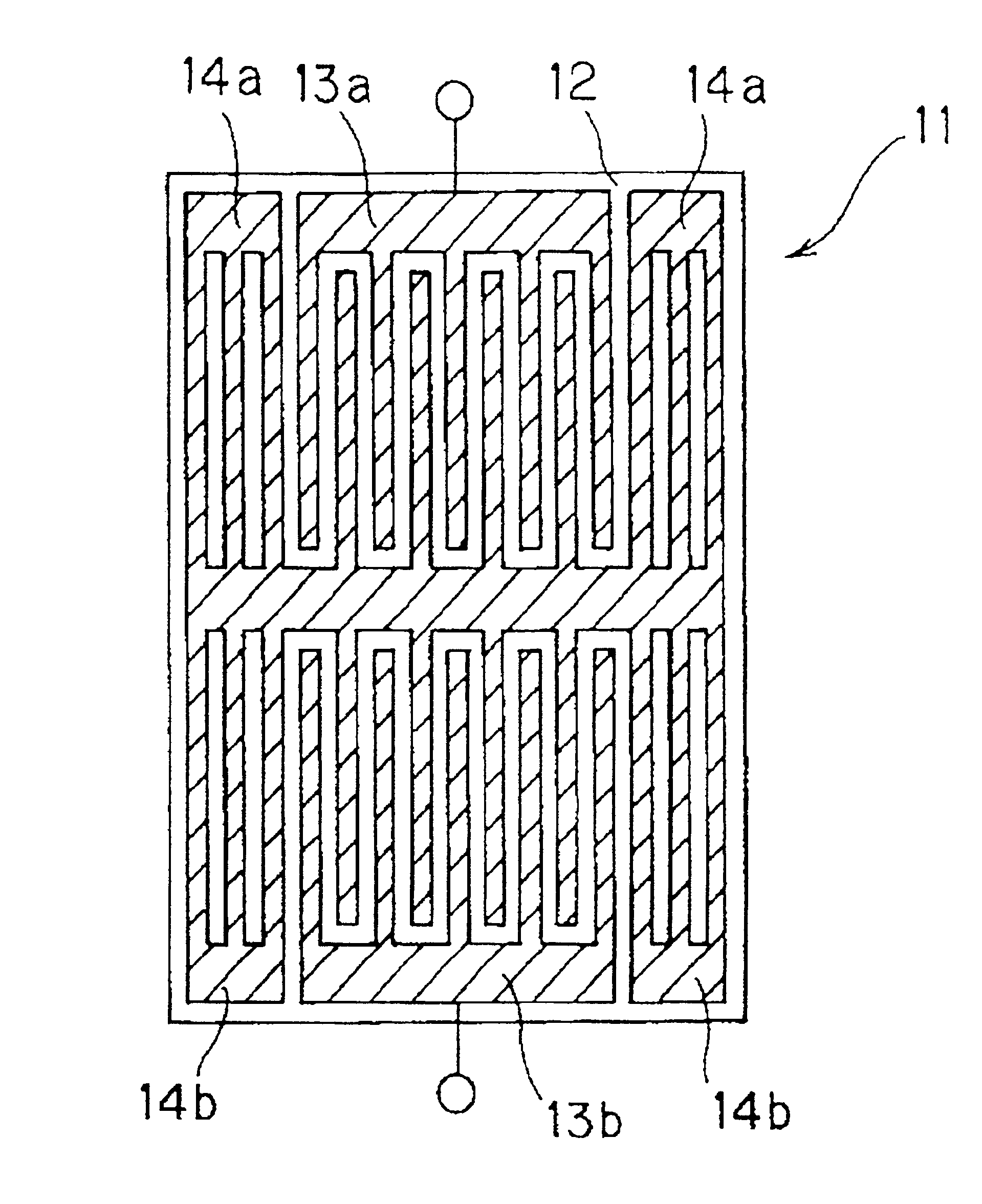

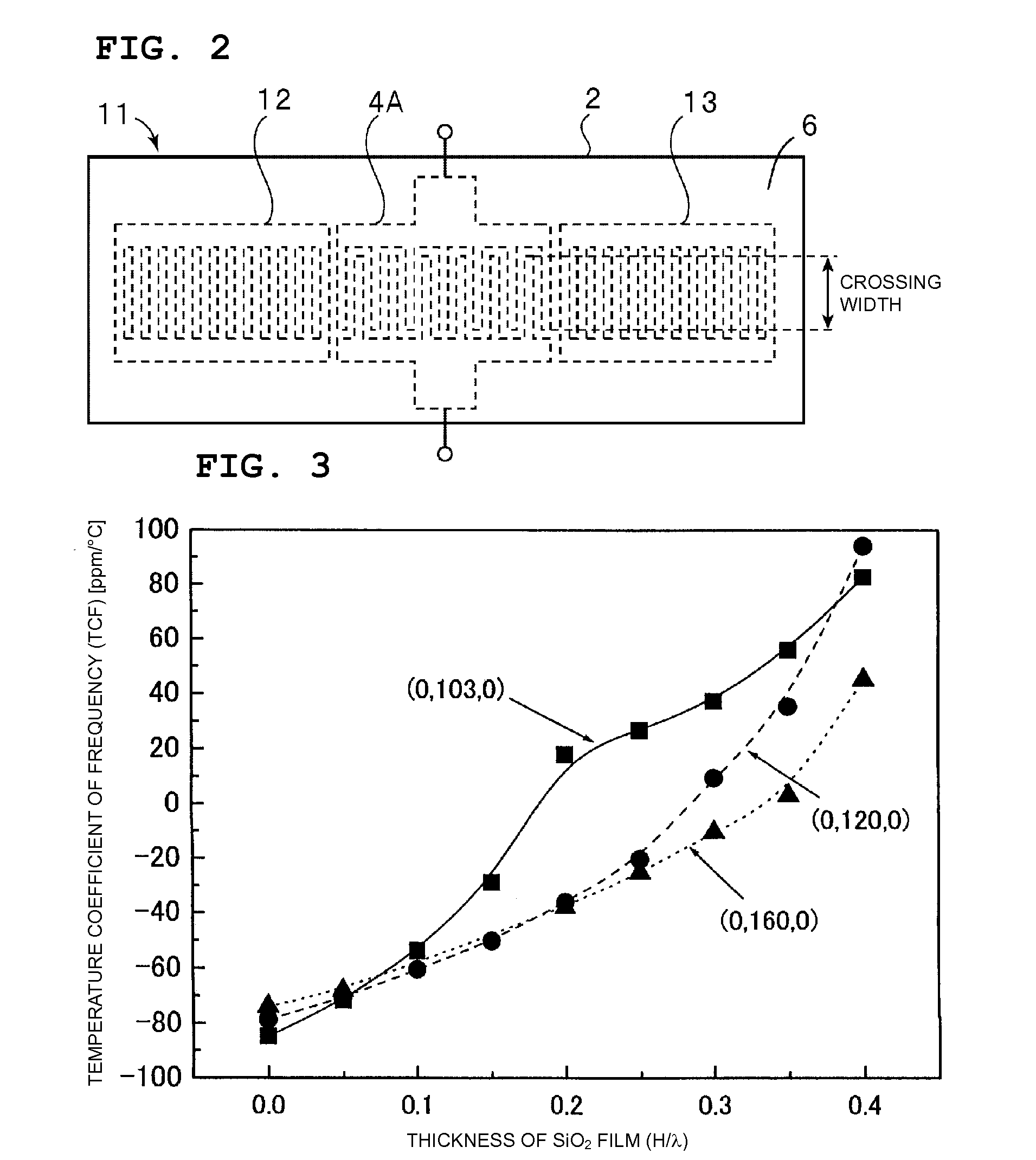

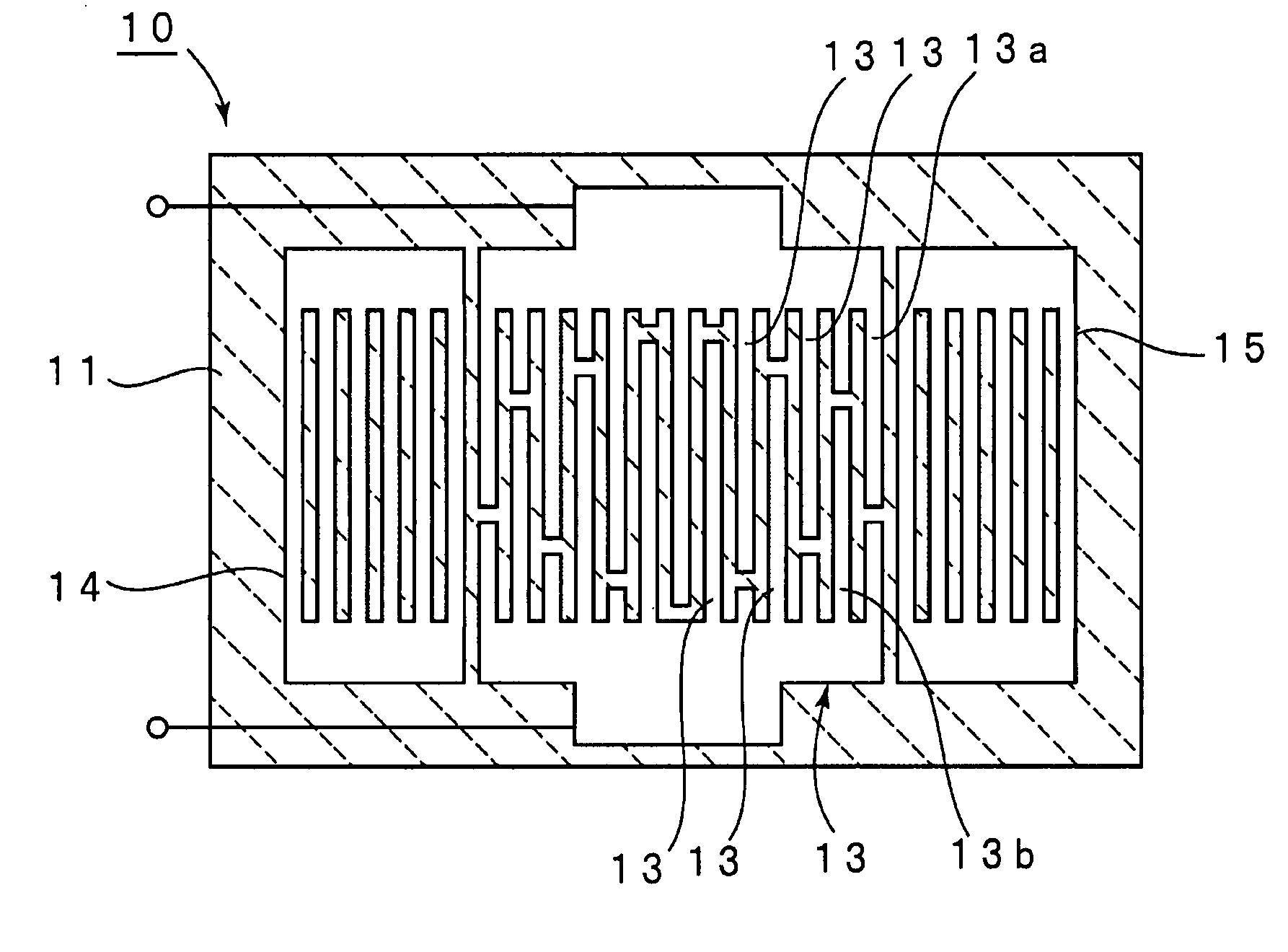

Surface acoustic wave resonator, surface acoustic wave oscillator, and surface acoustic wave module unit

ActiveUS8344815B2Improve confinementExcellent CIPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectromechanical coupling coefficientSurface acoustic wave oscillators

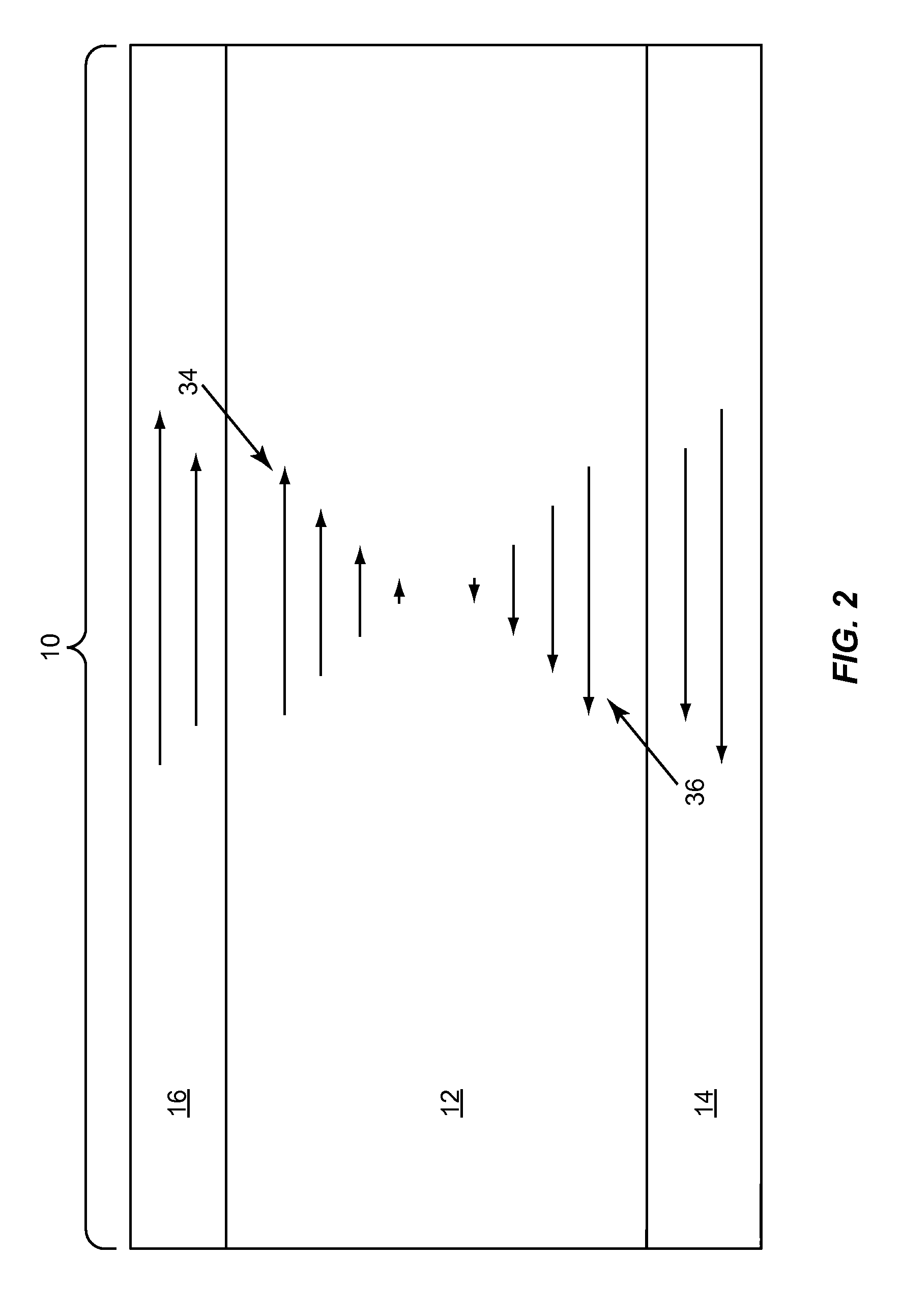

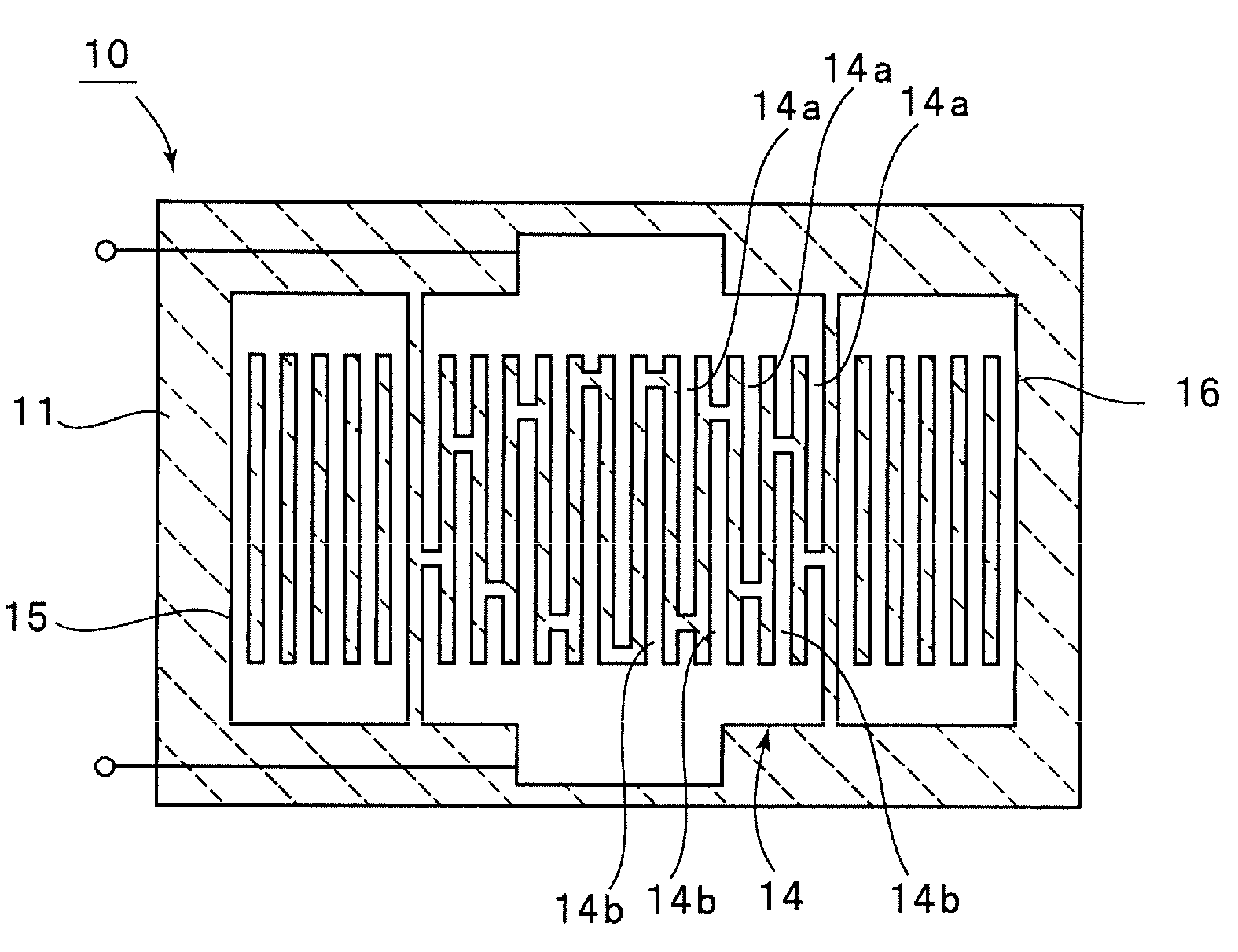

In a surface acoustic wave resonator in which an IDT having electrode fingers for exciting surface acoustic waves is formed on a crystal substrate, the line occupying ratio causing the maximum electromechanical coupling coefficient and the line occupying ratio causing the maximum reflection of the surface acoustic waves in the IDT are different from each other, the center of the IDT has the line occupying ratio causing an increase in electromechanical coupling coefficient in comparison with the edges of the IDT, and the edges of the IDT have the line occupying ratio causing an increase in reflection of the surface acoustic waves in comparison with the center of the IDT.

Owner:SEIKO EPSON CORP

Piezoelectric film bulk acoustic resonator and preparation method thereof

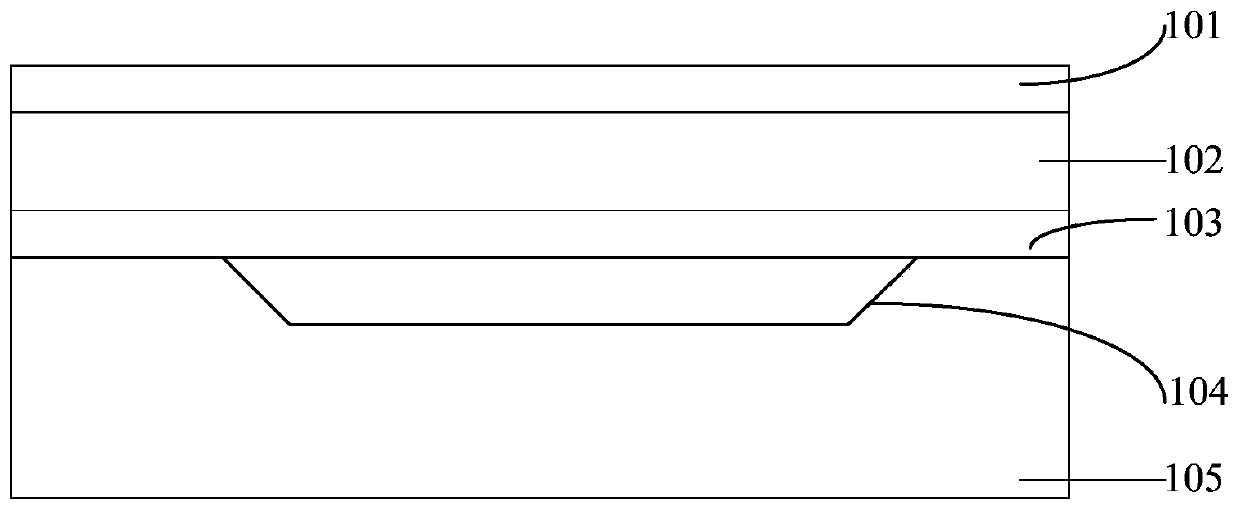

InactiveCN103873010AReduce complexityAvoid overthrowingImpedence networksElectromechanical coupling coefficientCvd graphene

The invention discloses a piezoelectric film bulk acoustic resonator and a preparation method thereof. The resonator comprises a substrate, an air cavity, a bottom electrode layer, a piezoelectric layer and a top electrode layer, wherein grapheme is used as the electrode layers of the device; a support layer is not needed in the structure of the device, and the air cavity is formed between the grapheme bottom electrode layer and a groove of the substrate; the piezoelectric layer is arranged on the bottom electrode layer, and the top electrode layer is arranged on the piezoelectric layer. A preparation process of a sacrificial layer is adopted, so the dependence of the traditional process on high-precision chemical-mechanical polishing equipment is overcome, the grinding time is shortened, and the flat surface of sacrificial layer is quickly obtained. The piezoelectric film bulk acoustic resonator has the advantages that the structure is novel, the high Q (quality) value and high electromechanical coupling coefficient can be obtained, and the piezoelectric film bulk acoustic resonator can be applied to the manufacturing of filters, duplexes and multiplexes in subsequent radio frequency communication systems, and can also be combined with different sensitive films to manufacture high-performance sensors.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

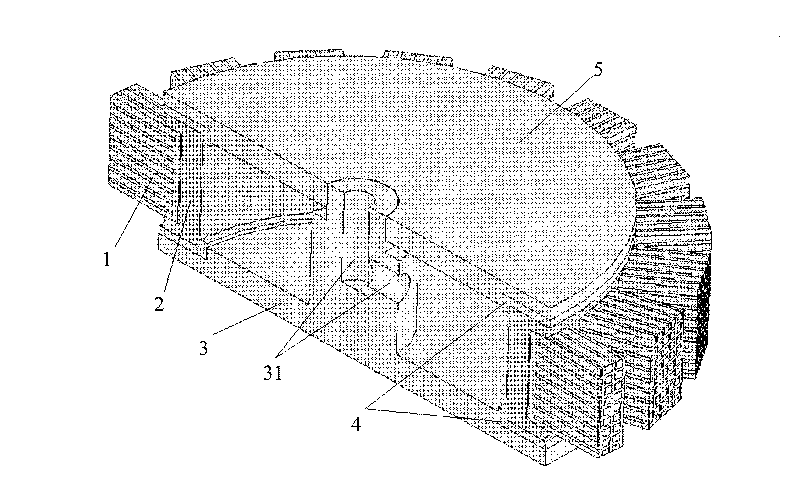

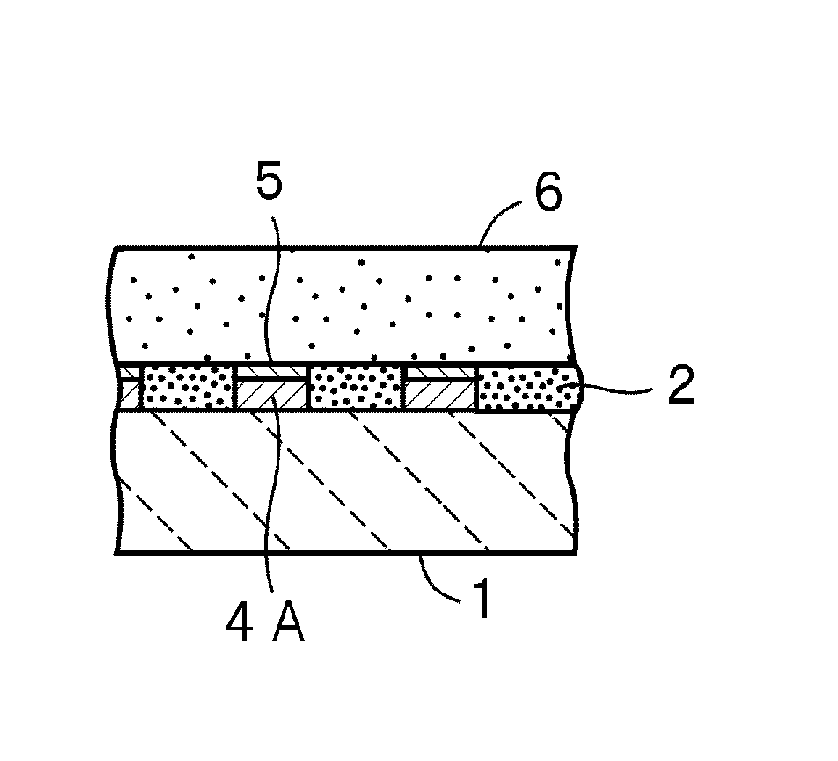

Acoustic resonator and its fabricating method

InactiveUS20100148637A1Improve the overall coefficientSignificant occurrencePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientUltimate tensile strength

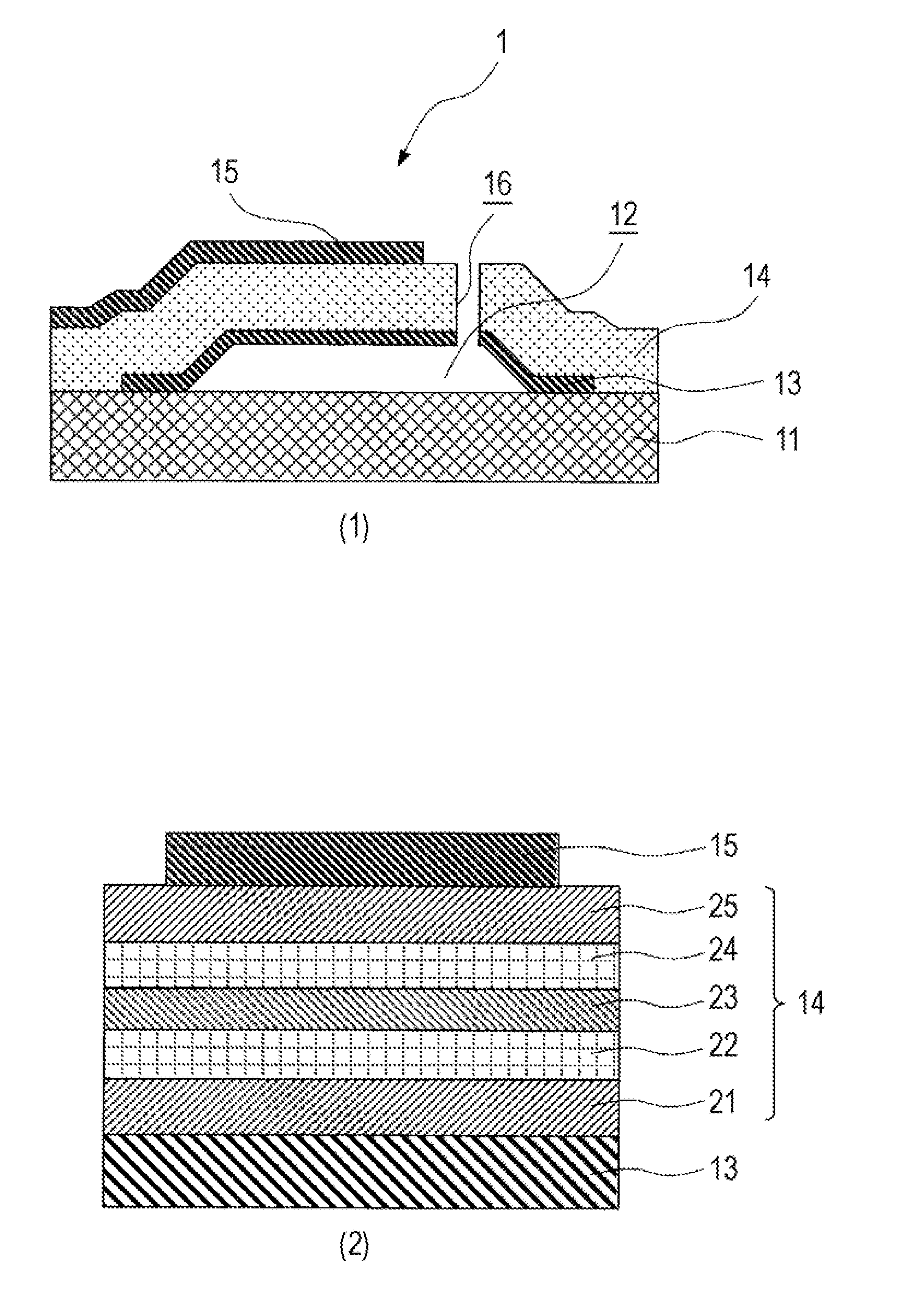

A piezoelectric layer has a multilayer structure including a tensile stress layer and a compression stress layer. The mechanical strength of the piezoelectric layer is increased to prevent the occurrence of cracks and to realize a high electromechanical coupling coefficient. An acoustic resonator 1 includes a first electrode 13 including at least one conductive layer, a piezoelectric layer 14 including a plurality of layers, the piezoelectric layer 14 being formed adjacent to the top face of the first electrode 13, and a second electrode 15 including at least one conductive layer, the second electrode 15 being formed adjacent to the top face of the piezoelectric layer 14. The piezoelectric layer 14 includes a tensile compression layer 23 in which tensile stress is present and compression stress layers 21 and 25 in which compression stress is present. The tensile stress in the tensile stress layer 23 and the compression stress in the compression stress layers 22 and 25 are adjusted to cancel each other.

Owner:SONY CORP

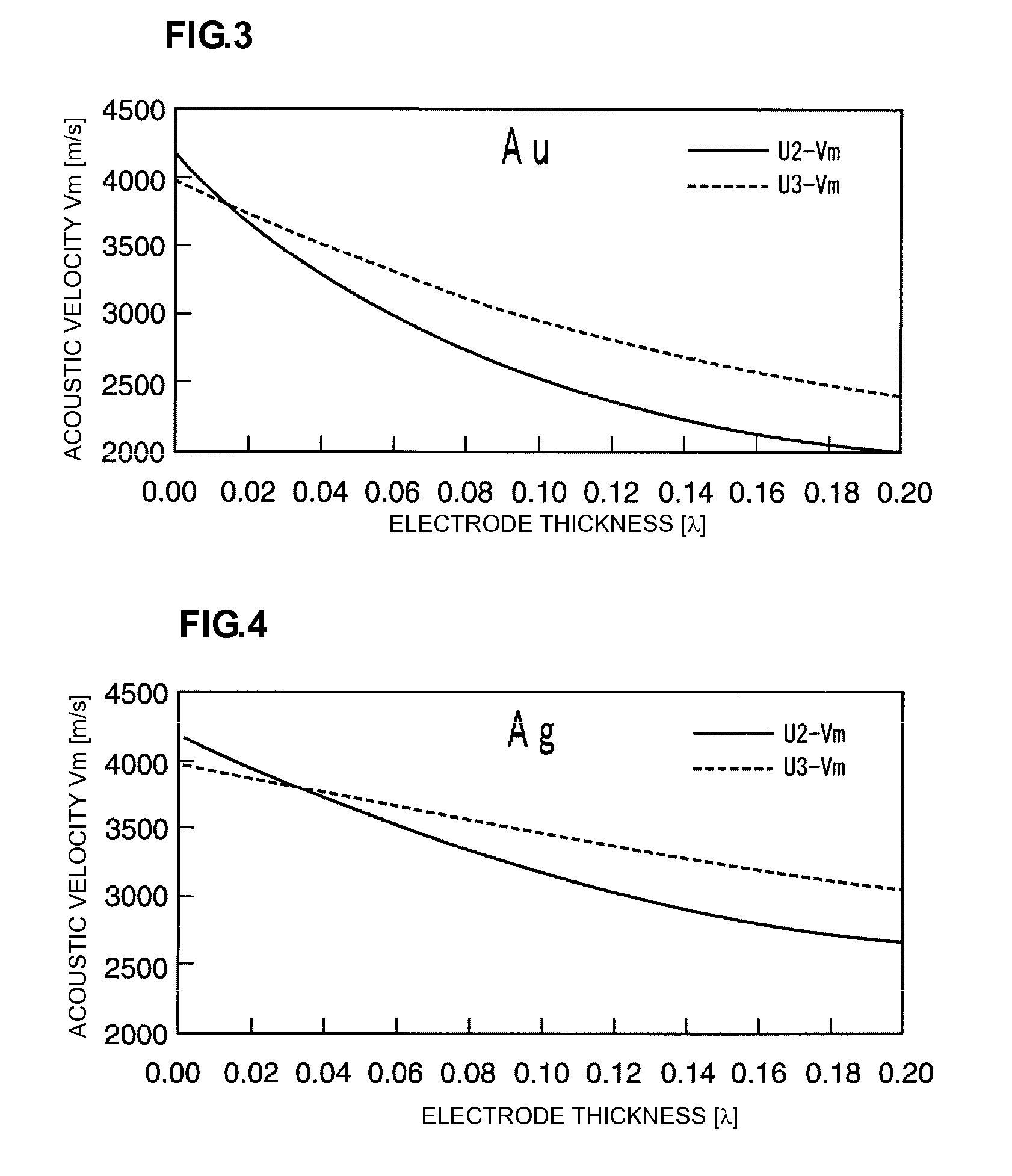

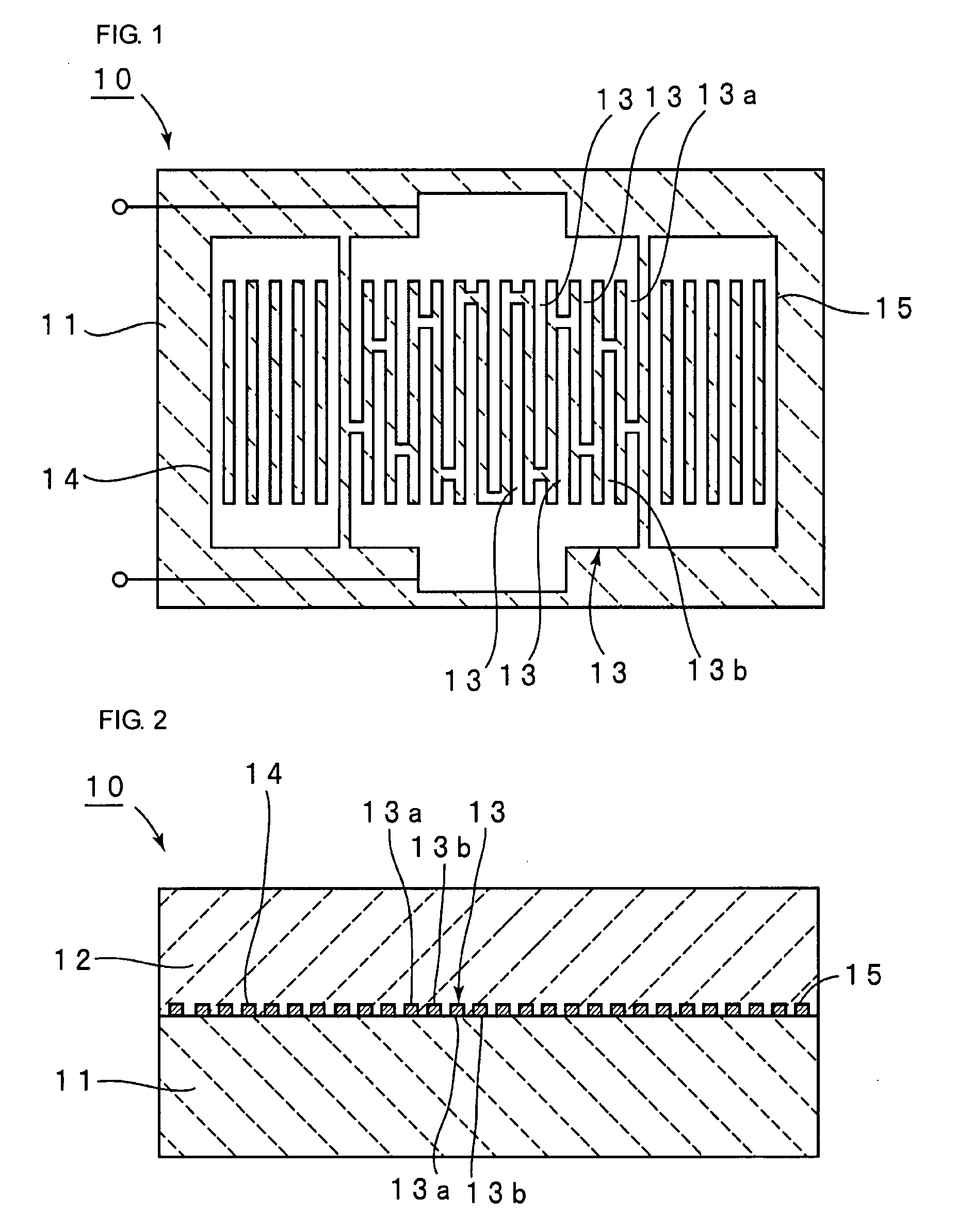

Surface acoustic wave device

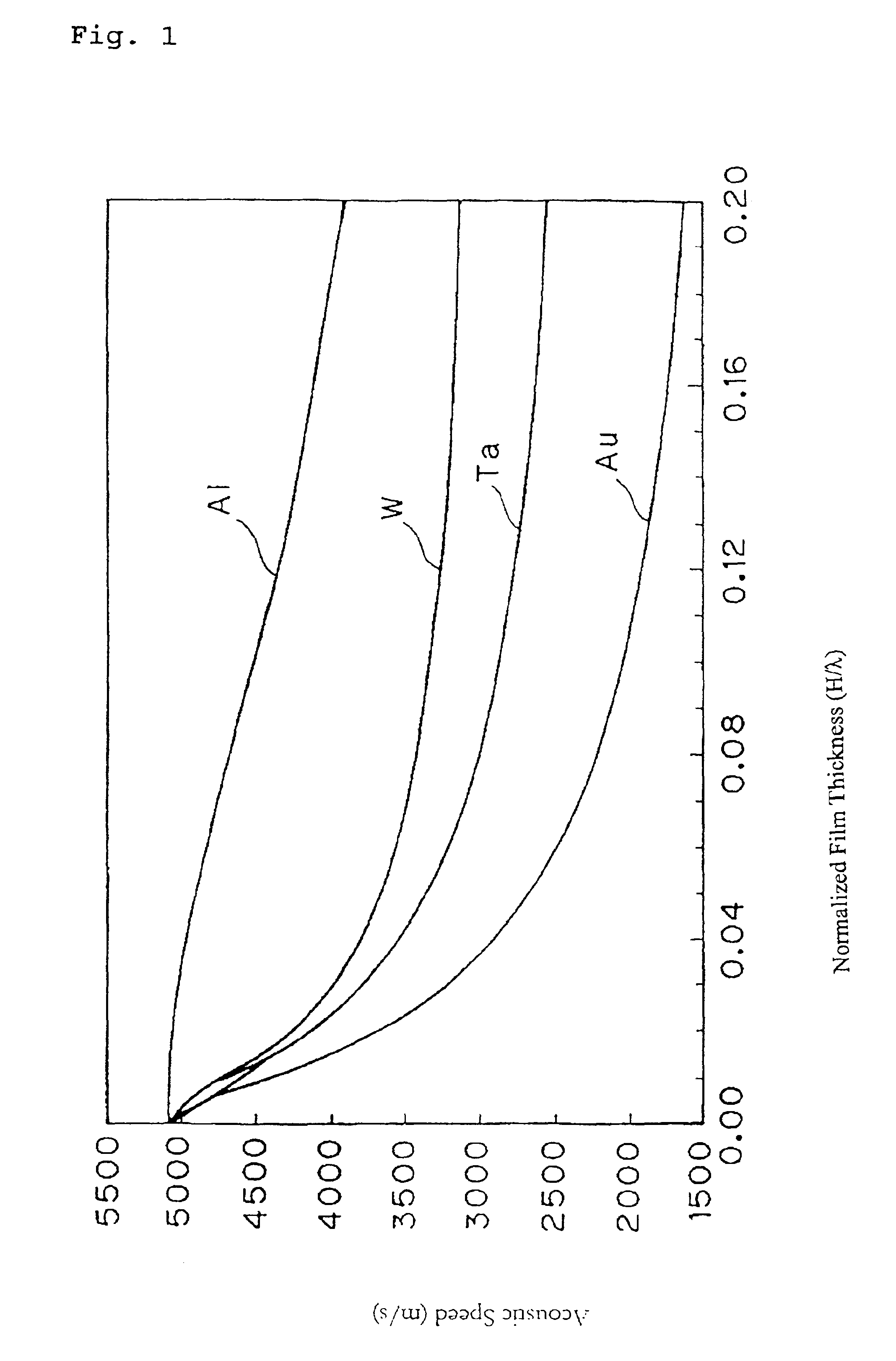

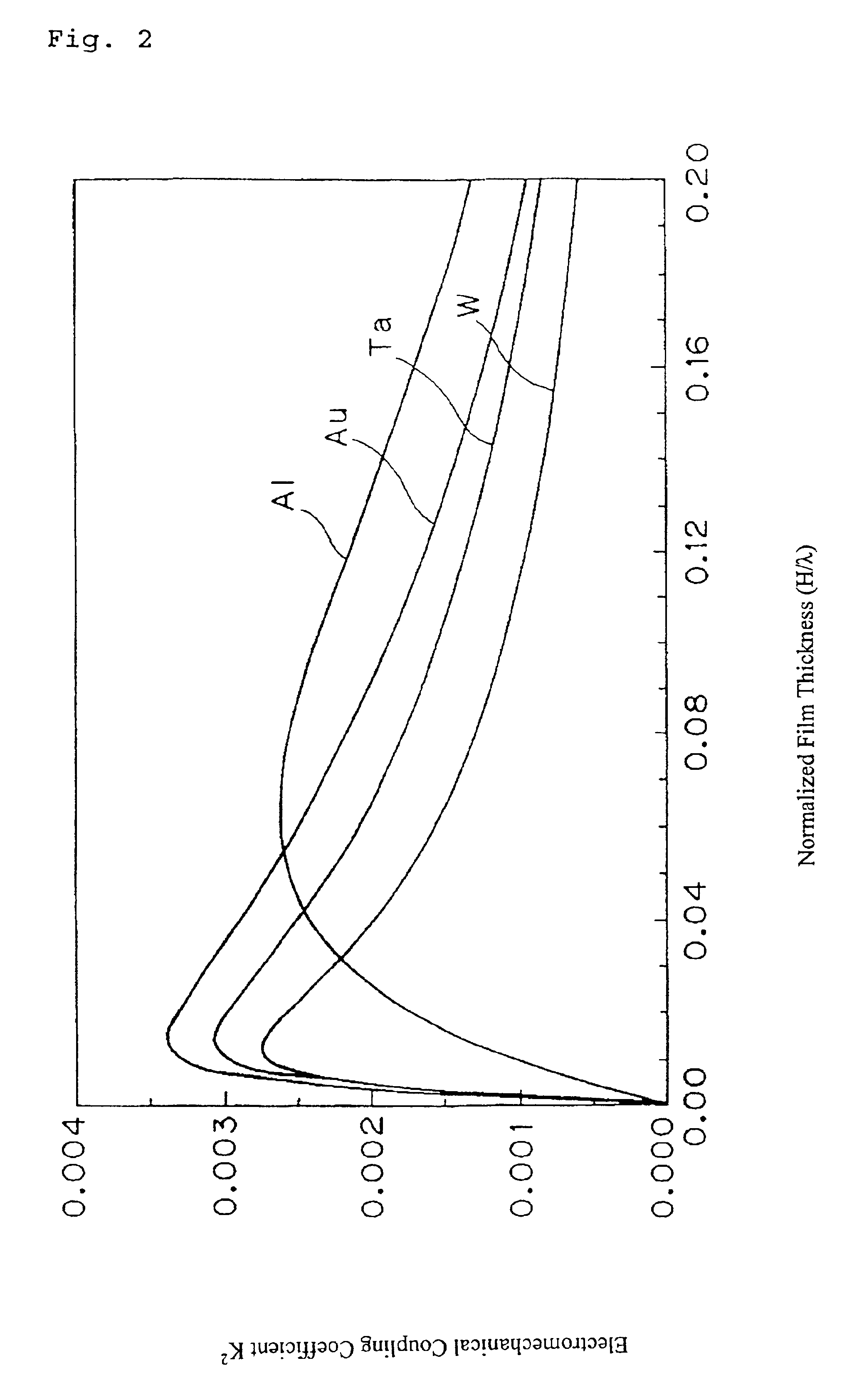

ActiveUS20070096592A1Improve featuresHigh reflection coefficientImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientAcoustic wave

A surface acoustic wave device includes a piezoelectric substrate made of LiNbO3 having an electromechanical coupling coefficient k whose square is at least about 0.025, at least one electrode that is made of a metal whose density is greater than that of Al or an alloy primarily including the metal or that is composed of laminated films made of a metal whose density is greater than that of Al or an alloy primarily including the metal and another metal, the electrode being disposed on the piezoelectric substrate, a first insulating layer disposed in a region other than a region where the at least one electrode is disposed, the thickness of the first insulating layer being substantially equal to that of the electrode, and a second insulating layer covering the electrode and the first insulating layer. The density of the electrode is at least about 1.5 times greater than that of the first insulating layer.

Owner:MURATA MFG CO LTD

Boundary acoustic wave device

ActiveUS20090115287A1Efficiently vibrational energyLow boundary acoustic wave propagation lossImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientAcoustic wave

A boundary acoustic wave device efficiently traps the vibrational energy of boundary acoustic waves and exhibits a high electromechanical coupling coefficient, and is consequently not affected by higher-order modes. The boundary acoustic wave device includes a first medium having piezoelectric characteristics, a non-electroconductive second medium, and a third medium through which slow transverse waves propagate at a lower acoustic velocity than slow transverse waves propagating through the first and second media. The first medium, the third medium, and the second medium are stacked in that order. An IDT is disposed between the first medium and the third medium. The IDT includes a metal layer made of a metal having a density ρ in the range of about 3000 kg / m3 to about 21500 kg / m3. The IDT has electrode fingers arranged at a pitch of λ and has a thickness H1 satisfying the relationship 0.006λ≦H1≦0.2λ, and the third medium has a thickness H2 satisfying the relationship H1<H2≦0.7λ.

Owner:MURATA MFG CO LTD

Body wave resonator and processing method thereof

ActiveCN101908865ASimple structureEasy to processImpedence networksElectromechanical coupling coefficientBody waves

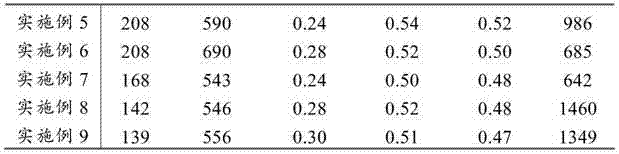

The invention relates to a body wave resonator and a processing method thereof. The body wave resonator comprises an acoustic mirror arranged on or embedded in a substrate and provided with a first edge and a second edge, a dielectric layer which is arranged on the substrate and in full contact with the two edges of the acoustic mirror, a first electrode which is arranged on the acoustic mirror and composed of a first terminal part, a second terminal part and a main part which is arranged between the first and the second terminal parts, a piezoelectric layer which is arranged on the first electrode and composed of a main part, a first terminal part and a second terminal part, and a second electrode which is arranged on the piezoelectric layer and consists of a main part and a second part, wherein the main part is located above the main part of the piezoelectric layer and connected with the second part, so that the connected joint of the main part and the second part is arranged between the first edge and the second edge of the acoustic mirror, and an air gap is formed between the second part of the second electrode and the first terminal part of the piezoelectric layer. The body wave resonator has simple structure and convenient processing, and can improve the quality factor, effective electro-mechanical coupling factor and static discharge resistance capacity.

Owner:ROFS MICROSYST TIANJIN CO LTD

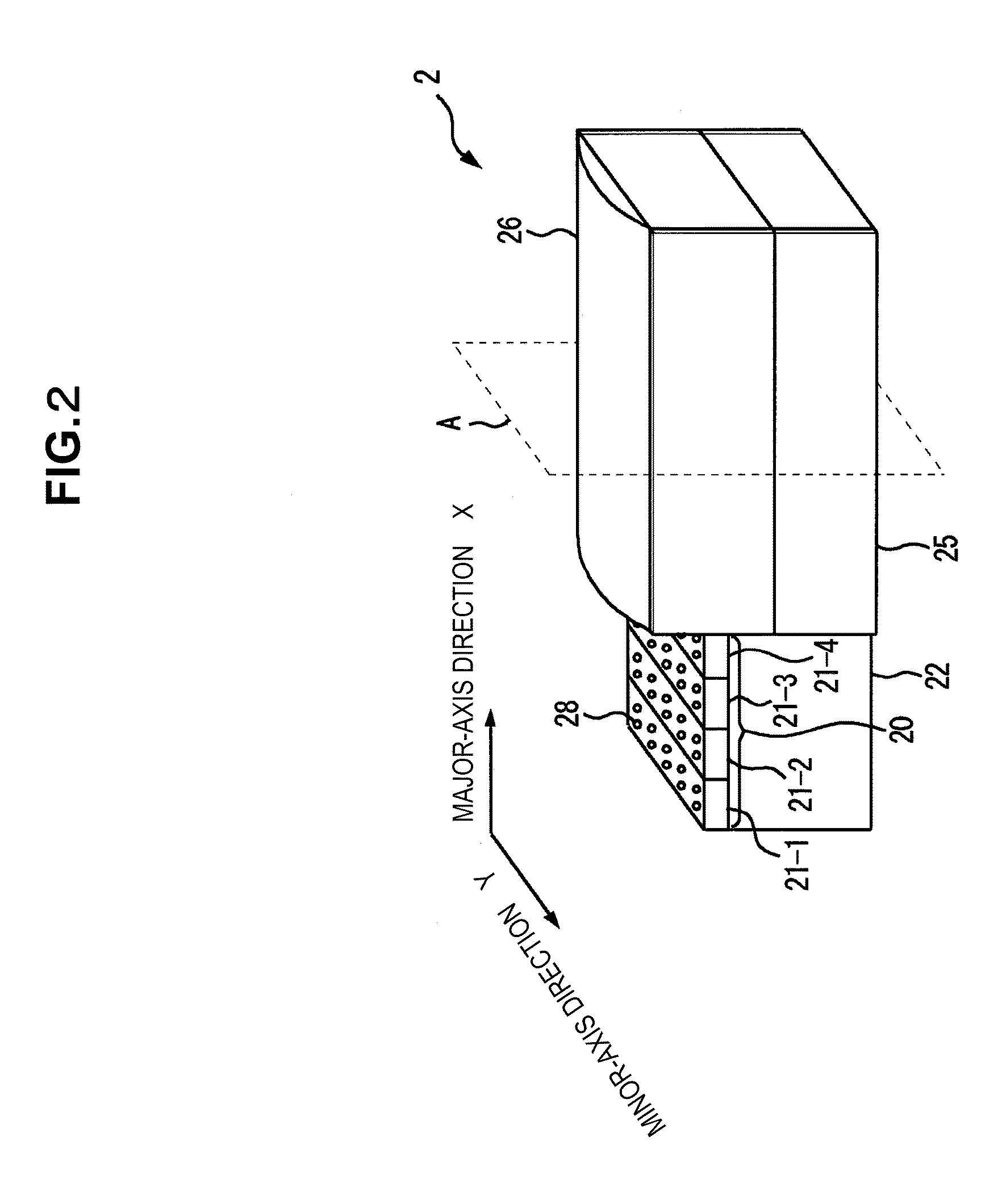

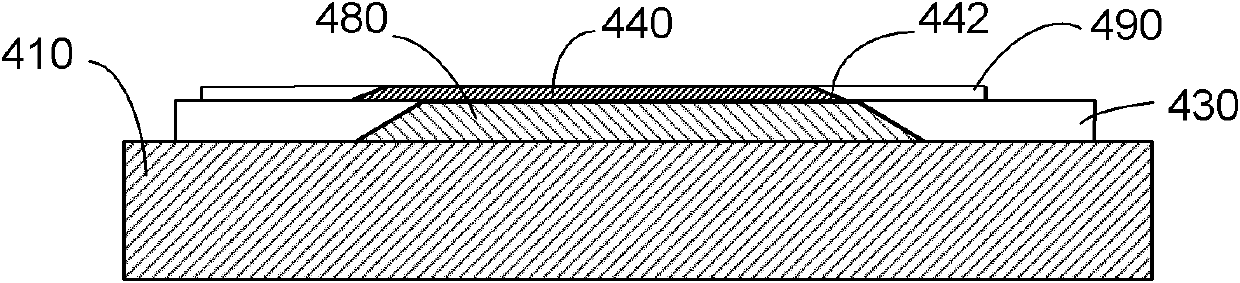

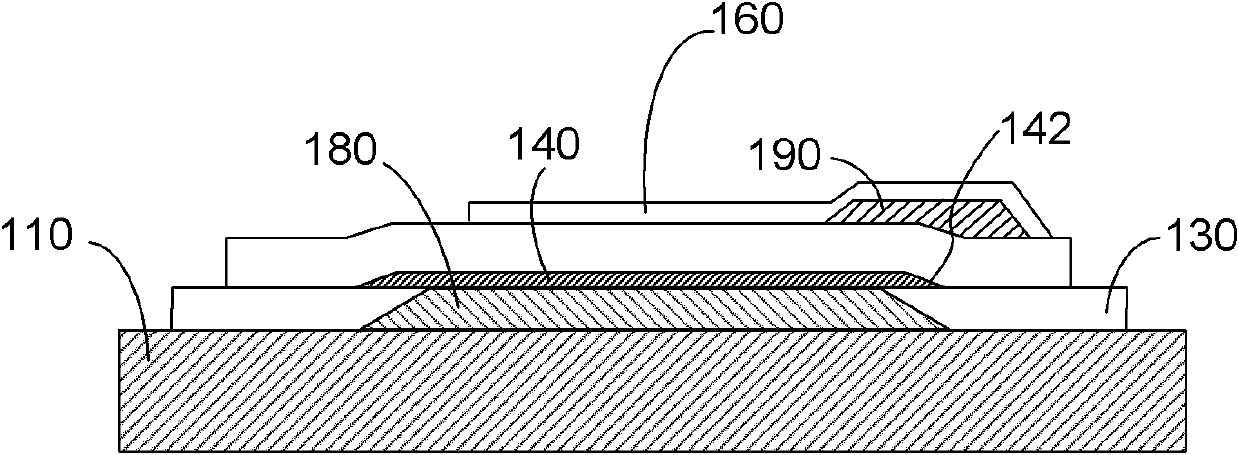

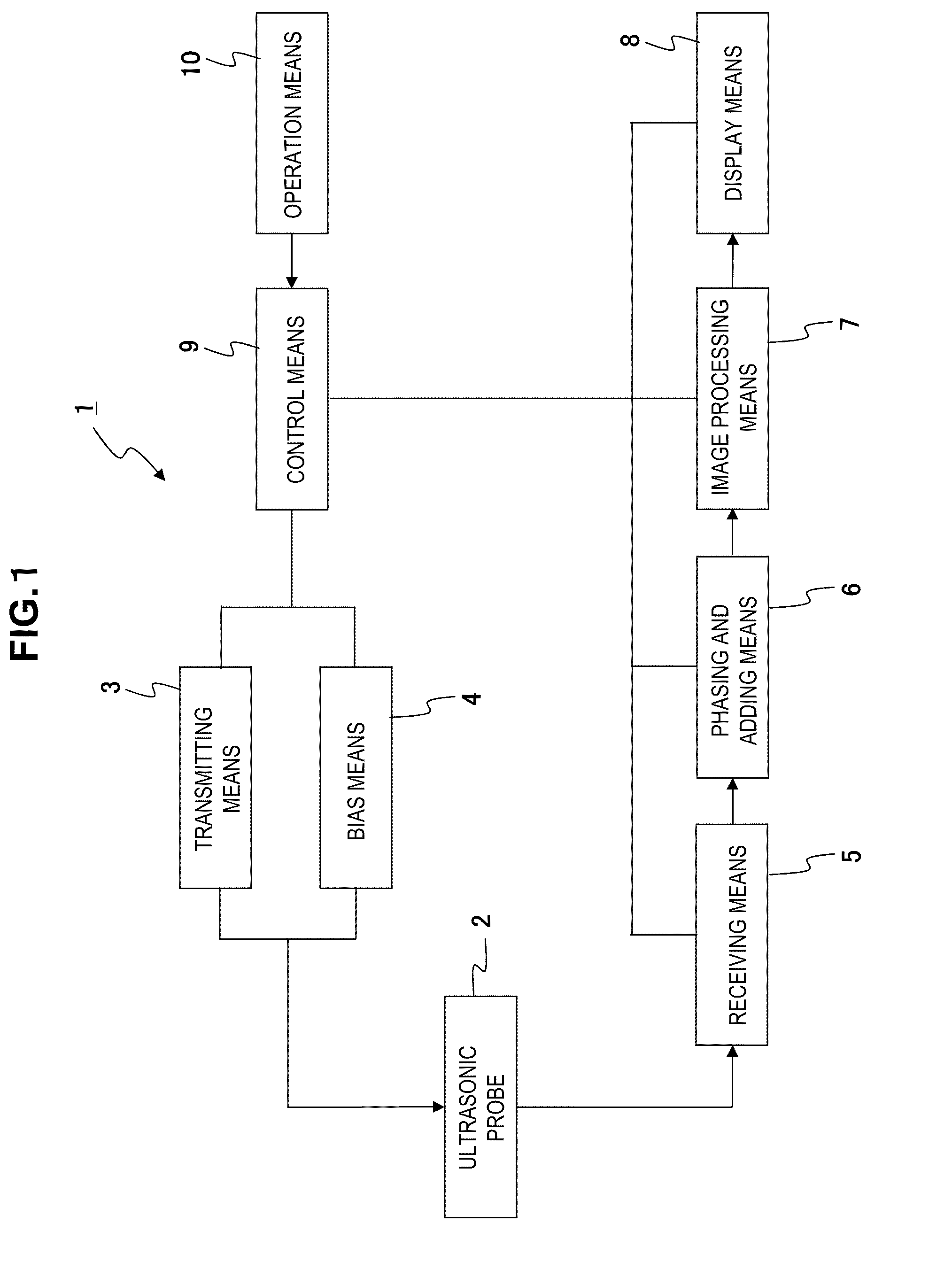

Ultrasonic probe, method for manufacturing the same and ultrasonic diagnostic apparatus

InactiveUS20110071396A1Avoid dysfunctionMaterial analysis using sonic/ultrasonic/infrasonic wavesElectrical transducersElectromechanical coupling coefficientAdhesive

An ultrasonic probe is provided with a CMUT chip having a plurality of transducer elements that change electromechanical coupling coefficients or sensitivities in accordance with a bias voltage to transmit and receive ultrasonic waves, an electric conducting layer formed on the ultrasonic irradiation side of the CMUT chip, an acoustic lens arranged on the ultrasonic irradiation side of the CMUT chip, an insulating layer formed in the direction opposite to the ultrasonic irradiation side of the acoustic lens, a housing unit that stores the CMUT chip in which the electric conducting layer and the insulating layer are fixed with an adhesive and the acoustic lens, wherein the insulating layer is formed by the material that includes at least either silicon oxide or paraxylene to prevent a solvent of the adhesive from soaking into the adhered portion.

Owner:HITACHI MEDICAL CORP

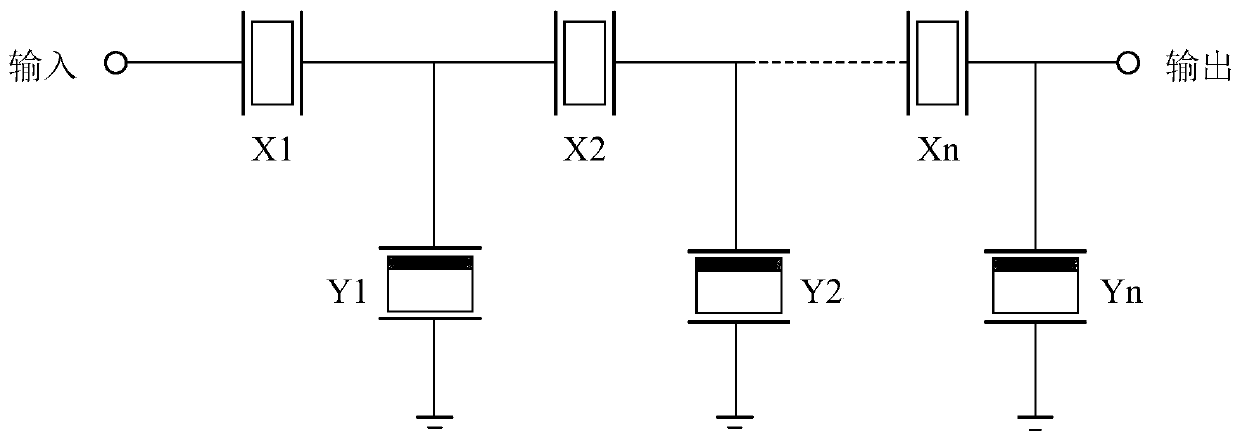

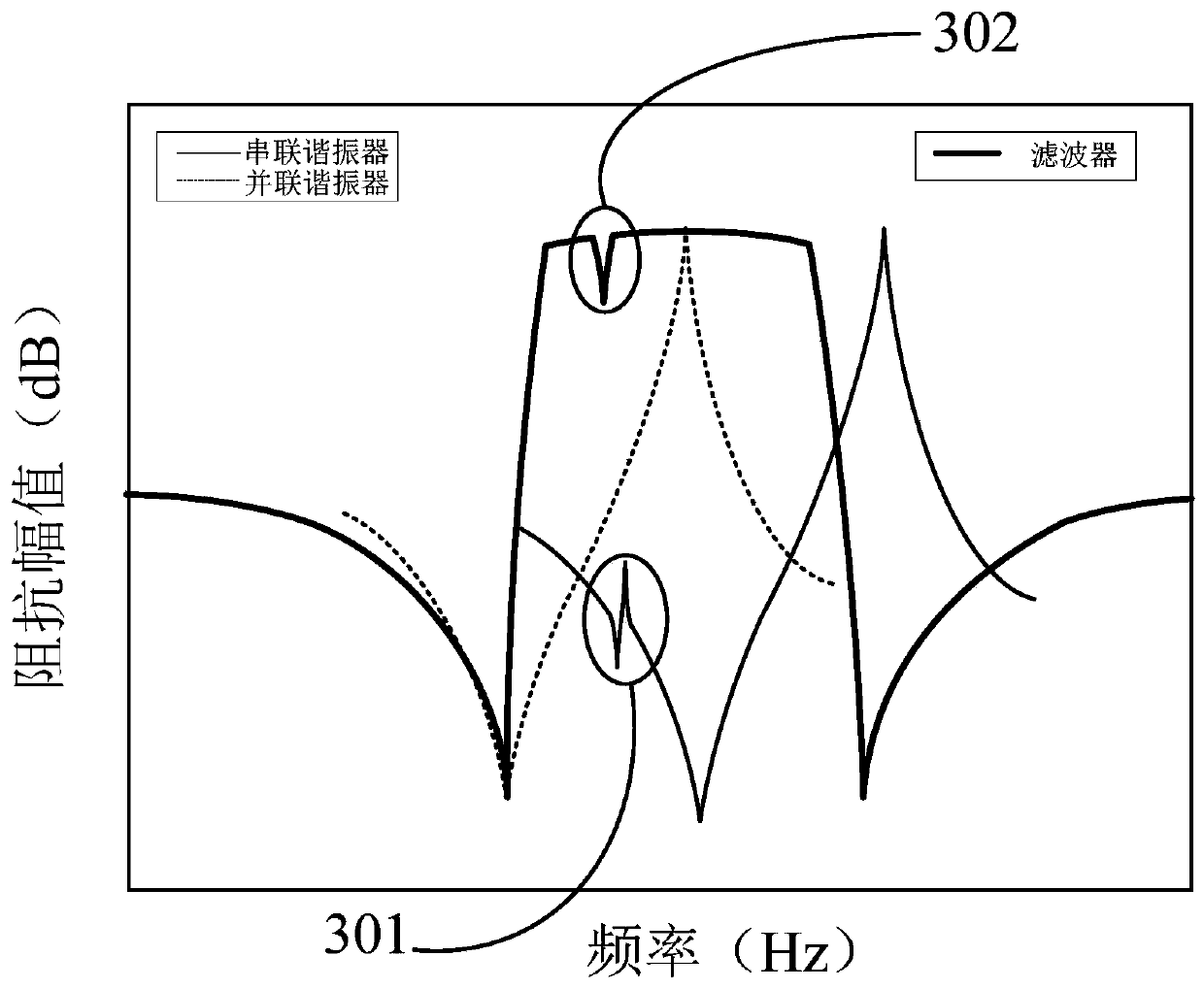

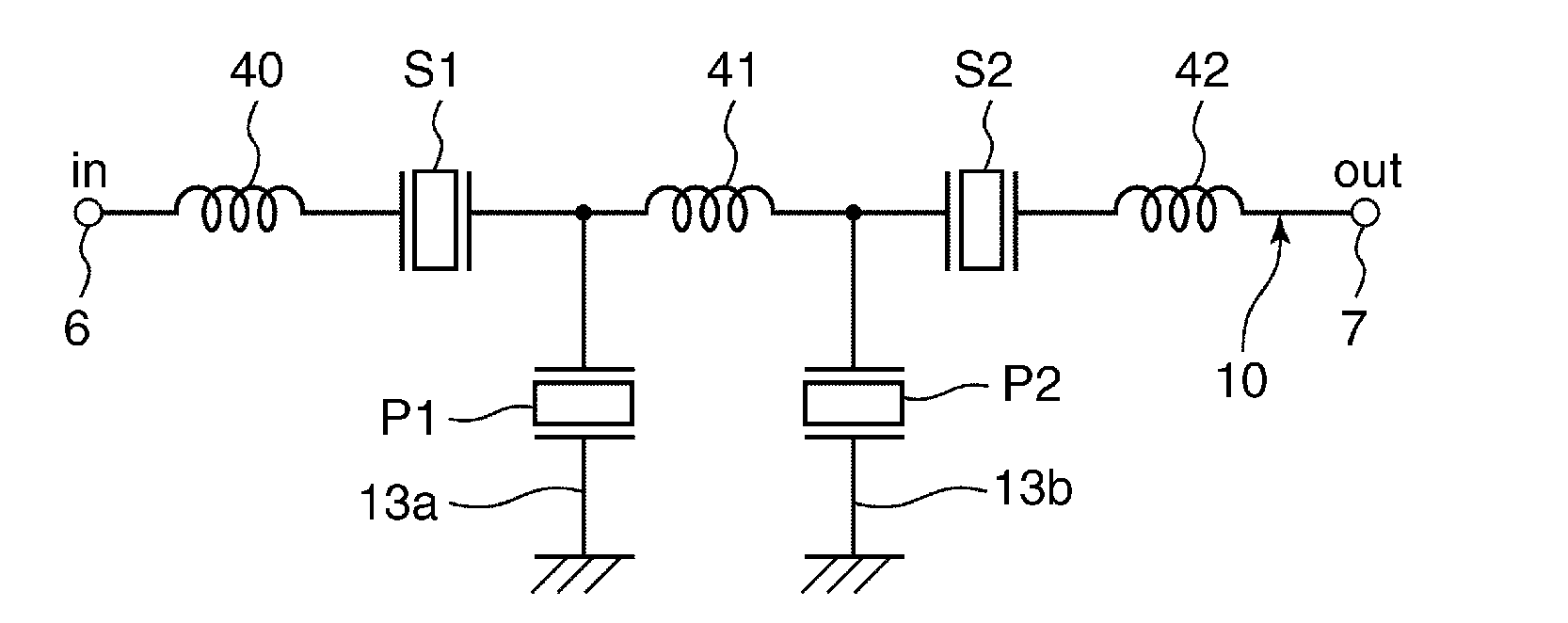

Acoustic wave filter device

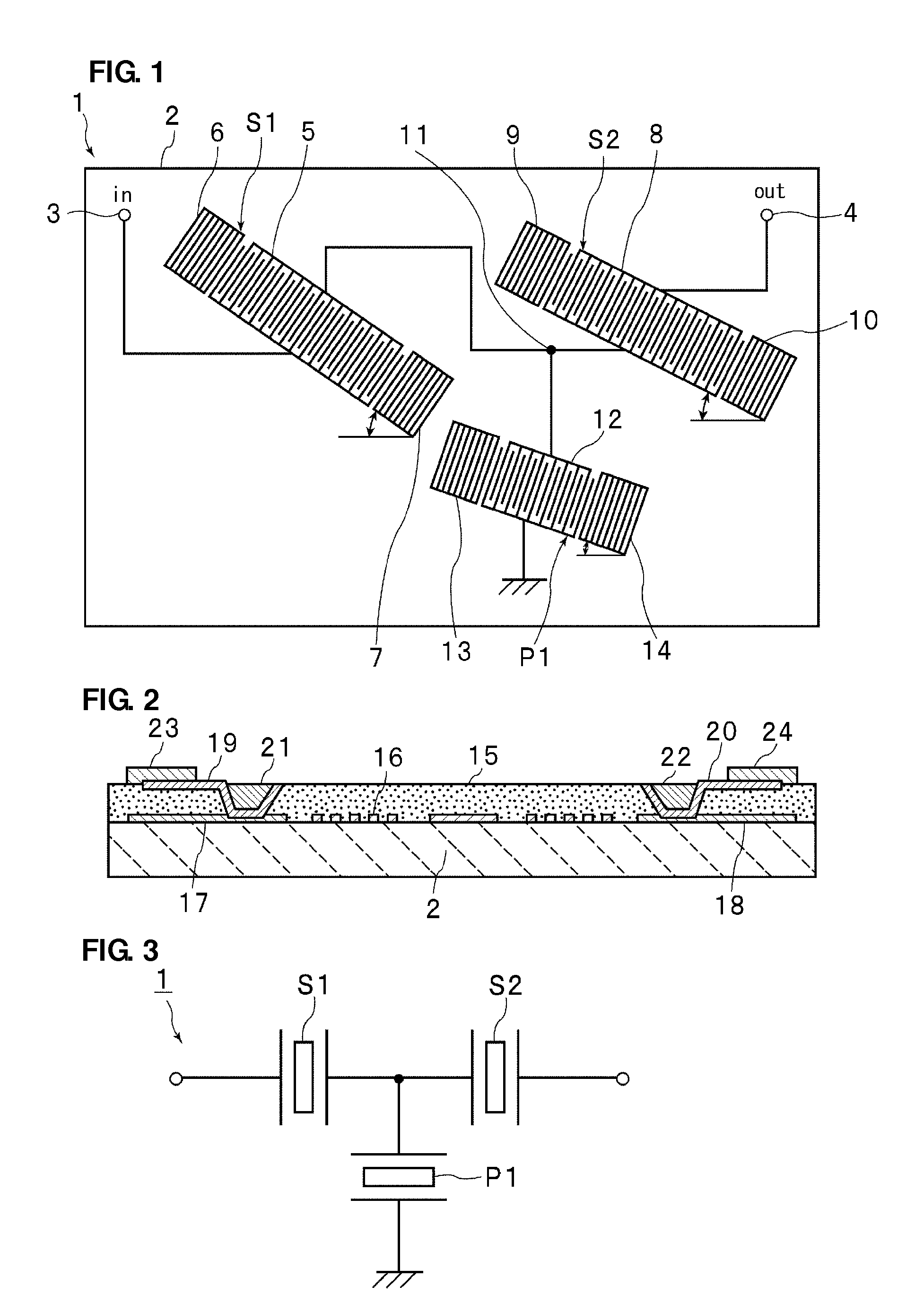

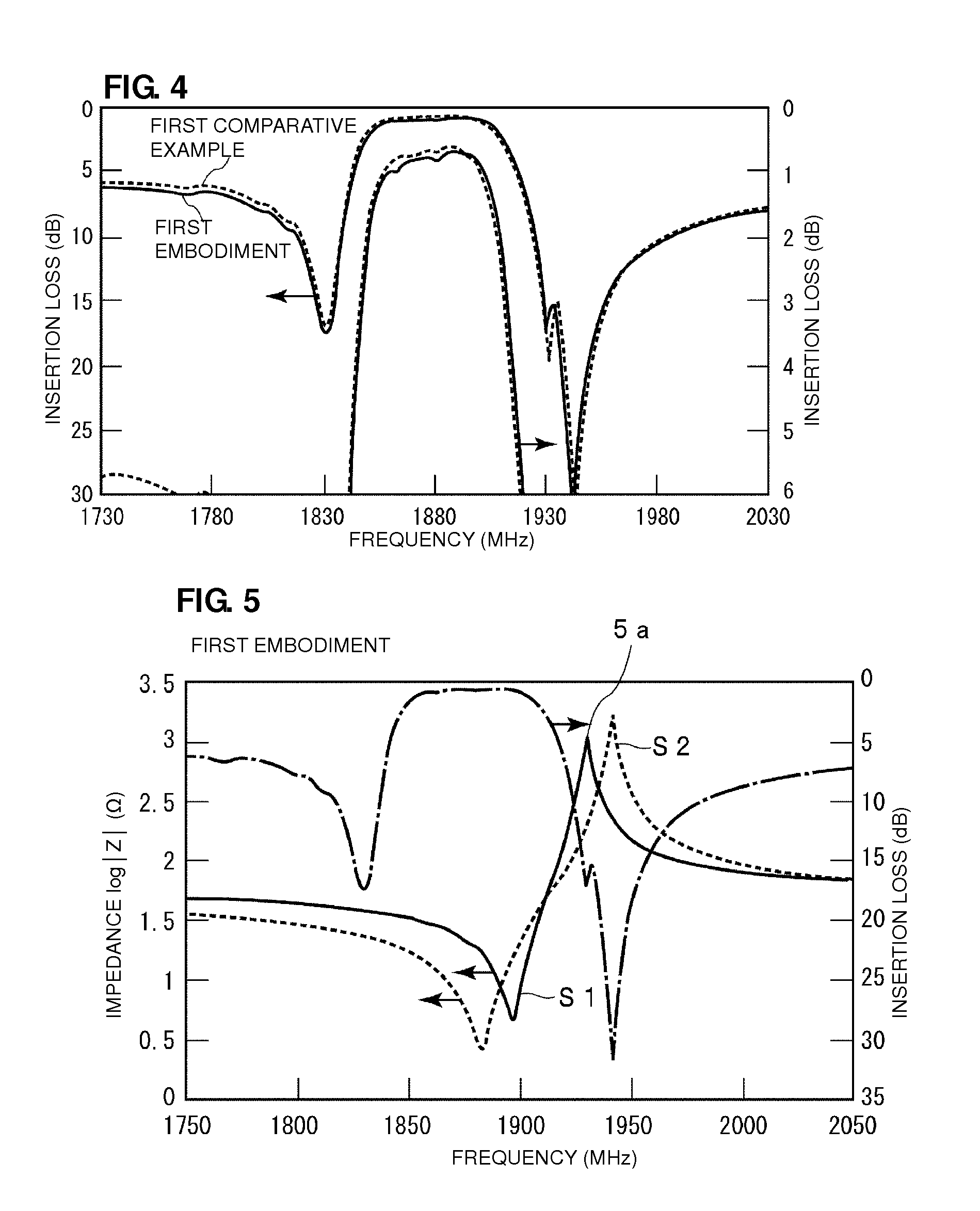

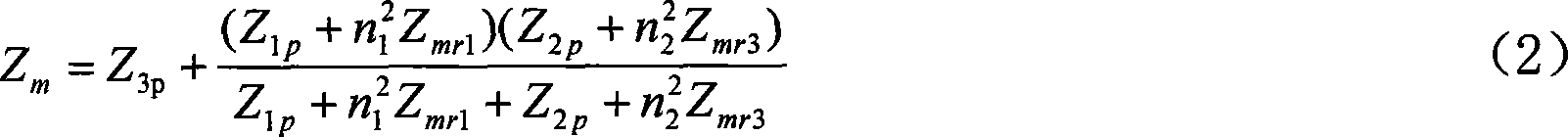

ActiveUS20100207707A1Outstanding steepnessReduce lossImpedence networksUltrasound attenuationElectromechanical coupling coefficient

An acoustic wave filter device is capable of increasing the steepness of a filter characteristic at a boundary between a passband and an attenuation band and achieving a low loss in the passband. The acoustic wave filter device has a ladder circuit configuration including a plurality of series arm resonators and at least one parallel arm resonator. The anti-resonant frequency of the series arm resonator is different from that of the series arm resonator. The series arm resonator having the lowest anti-resonant frequency has a resonant frequency located in the passband and an electromechanical coupling coefficient less than an average of electromechanical coupling coefficients of the series arm resonators.

Owner:MURATA MFG CO LTD

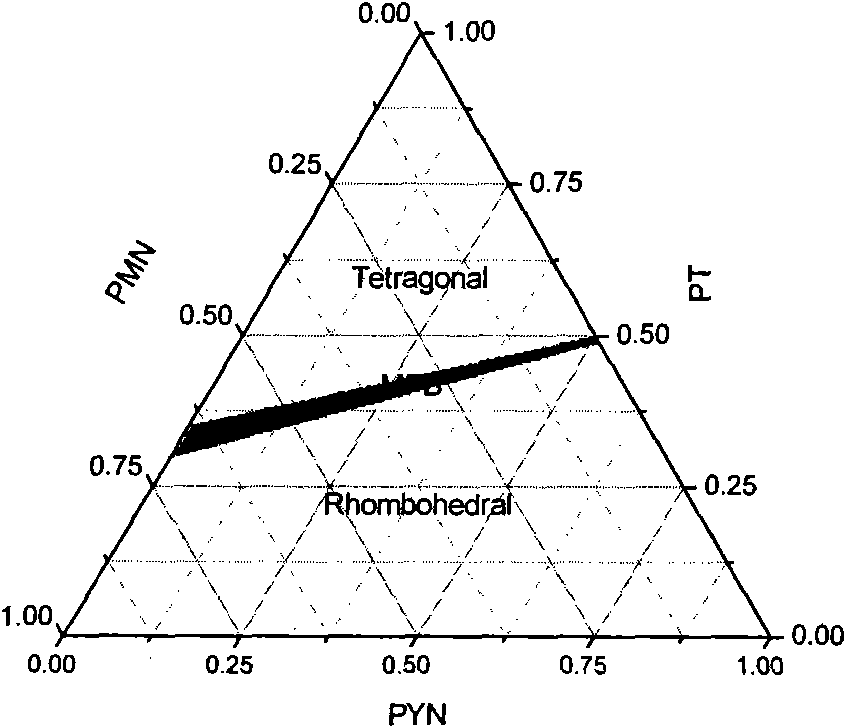

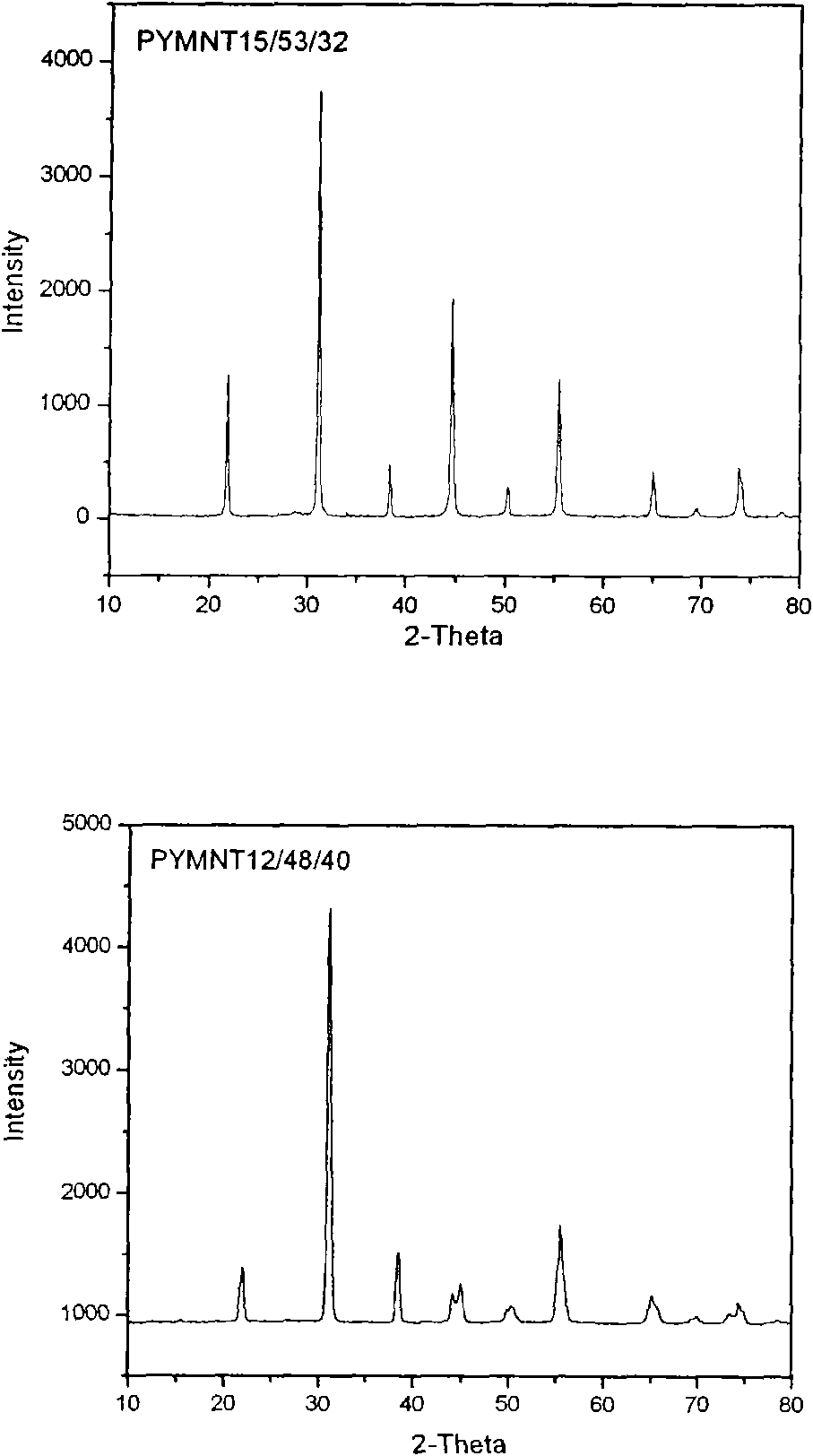

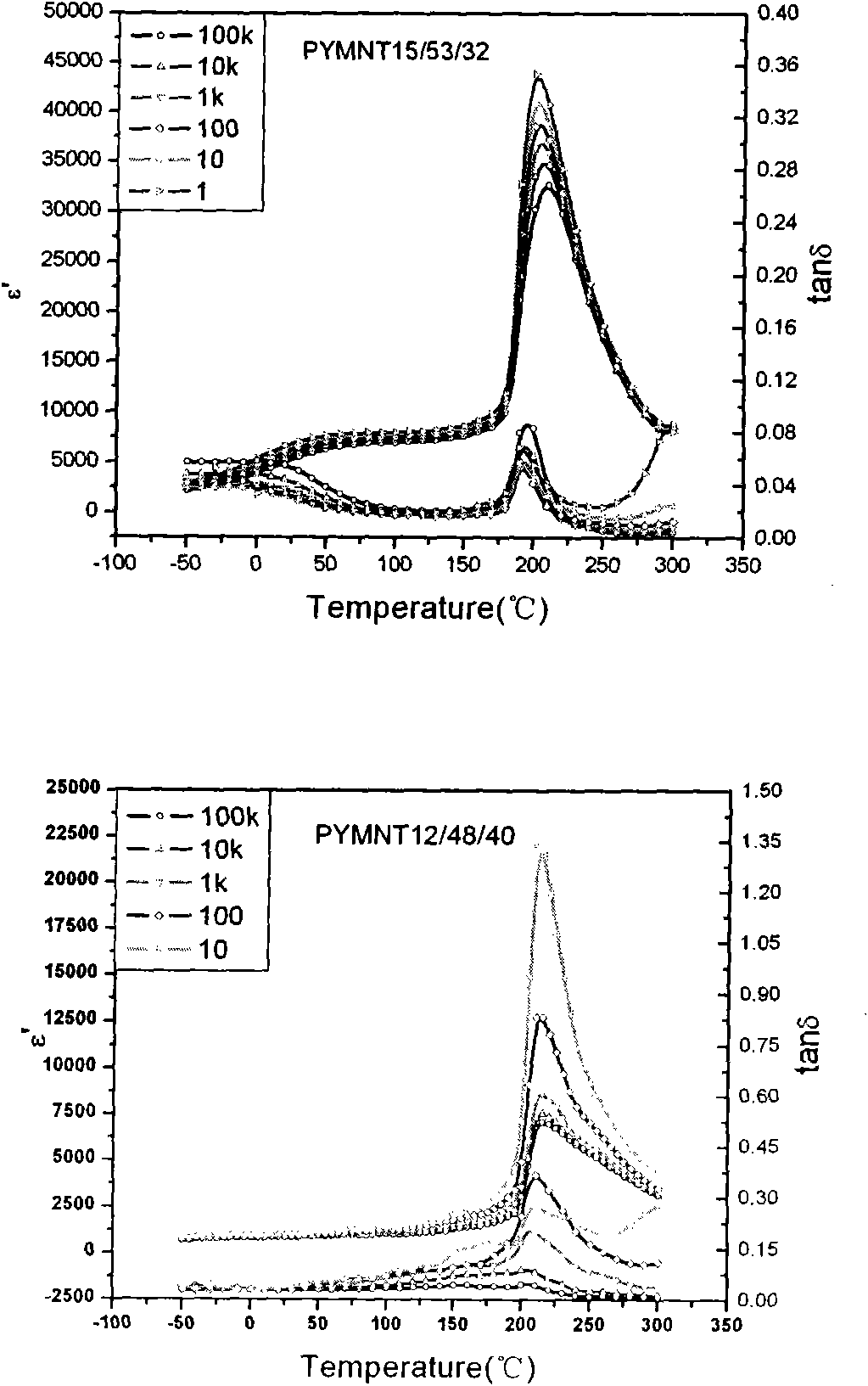

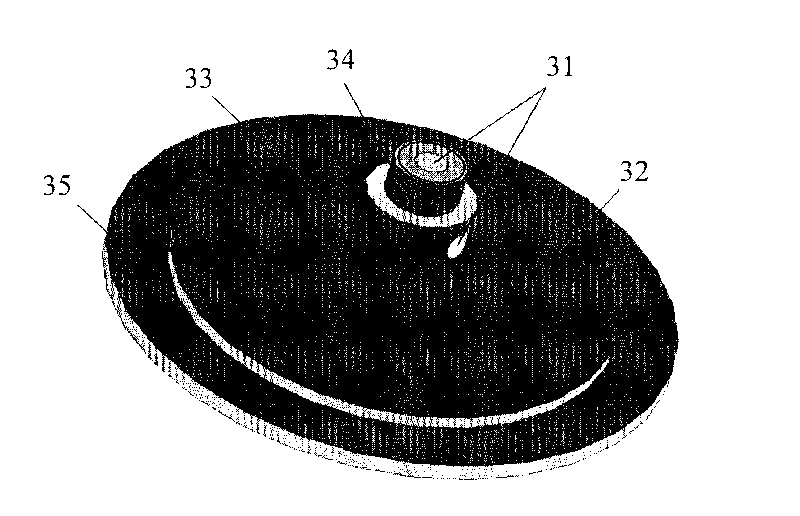

Novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate

InactiveCN102051685APolycrystalline material growthFrom melt solutionsCrystal rotationSingle crystal

The invention relates to the growth, the structures and the properties of novel ferroelectric single-crystal lead ytterbium niobate-lead magnesium niobate-lead titanate. The crystal belongs to a perovskite structure, has an MPB region and has a chemical formula of (1-x-y)Pb(Yb1 / 2Nb1 / 2)O3-xPb(Mg1 / 3Nb2 / 3)O3-yPbTiO3 which is short for PYMNT or PYN-PMN-PT. By adopting a top crystal-seeded method, the crystal with large size and high quality can grow under the conditions that the growth temperature of the crystal is 950-1100 DEG C, the crystal rotation speed is 5-30rpm, and the cooling speed is 0.2-5 DEG C / day, and the grown crystal exposes a 001 natural growth surface. Through X-ray powder diffraction, the system is confirmed as the perovskite structure; and through ferroelectric, dielectric and piezoelectric measurement, the ferroelectricity, the dielectric property and the piezoelectricity of the crystal are analyzed. The crystal has high Curie temperature and trigonal-tetragonal phase transition temperature, large piezoelectric constant and electromechanical coupling factor, high dielectric constant and low dielectric loss and better heat stability. The crystal can be widely applied to devices in the piezoelectric fields of ultrasonically medical imaging, sonar probes, actuators, ultrasonic motors, and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

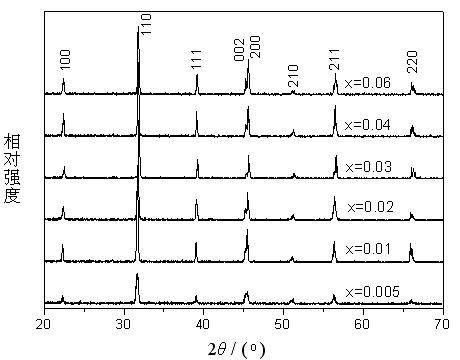

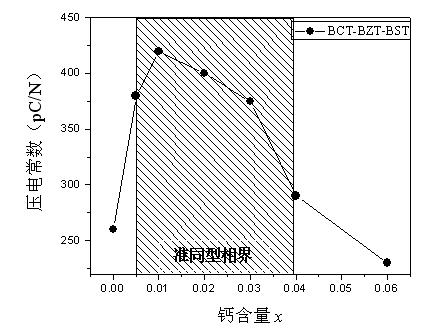

BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

InactiveCN102531578AExcellent piezoelectric propertiesThe preparation process is stableBarium titanateElectromechanical coupling coefficient

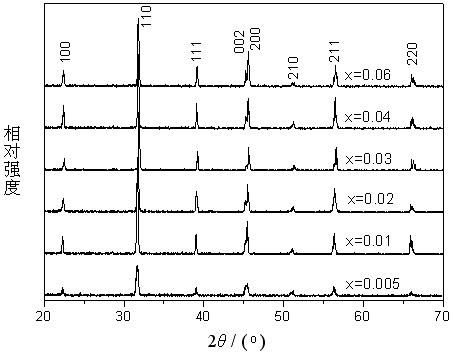

The invention belongs to the field of a lead-free piezoelectric material and discloses BCT-BZT-BST (barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is characterized by having the following material components: Ba0.8-xCaxTi0.8O3-0.1BaTi0.9Sn0.1O3-0.1BaTi0.8Zr0.2O3, wherein x is in the range of 0.005 to 0.06. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is prepared from industrial raw materials by adopting a conventional piezoelectric ceramic preparation technology. The system is a perovskite phase. When x is in the range of 0.005 to 0.04, the BCT-BZT-BST ternary system lead-free piezoelectric ceramic is in morphotropic phase boundary region, has excellent piezoelectric property, has a piezoelectric constant d33 value of 420pC / N and an electro-mechanical coupling coefficient of 44 percent, and has a stable preparation process and wide application prospect.

Owner:LIAOCHENG UNIV

Resonator and trapezoidal filter

The invention relates to the field of communication, and provides a resonator and a trapezoidal filter. The resonator comprises a substrate, a bottom electrode, a piezoelectric layer, a top electrode,a sound wave reflection structure and a protrusion structure used for adjusting the passband performance of the filter. The piezoelectric layer is located between the top electrode and the bottom electrode, and the protruding structure is located on the surface, away from the piezoelectric layer, of the top electrode, or located on the surface, below the top electrode, of the piezoelectric layer,or located on the upper surface, below the piezoelectric layer, of the bottom electrode, or located below the bottom electrode. The acoustic reflection structure is located between the substrate andthe bottom electrode. Compared with the prior art, the method is simple, the left clutter in the impedance frequency characteristic curve of the series resonator is moved leftwards through the convexstructure design, so that the defects in the passband of the filter are moved into the stop band of the filter, thereby improving the performance of the filter, and the piezoelectric layer is doped with rare earth elements, so that the reduction of the electromechanical coupling coefficient of the resonator caused by the convex structure design can be made up.

Owner:TIANJIN UNIV +1

Band rejection filter

ActiveUS20110090026A1Improve clarityLarge attenuation amountMultiple-port networksUltrasound attenuationElectromechanical coupling coefficient

An inexpensive compact band rejection filter realizes a high sharpness of a filter characteristic at ends of passbands and has a large attenuation. In the band rejection filter, at least one of a plurality of elastic wave resonators, which contributes to formation of a transition band, has a propagation angle larger than those of the other elastic wave resonators. Accordingly, the at least one of the plurality of elastic wave resonators which contributes to the formation of the transition band has an electromechanical coupling coefficient that is smaller than electromechanical coupling coefficients of the other elastic wave resonators.

Owner:MURATA MFG CO LTD

Surface acoustic wave device and electronic device using the same

InactiveUS6946930B2Increase reflectionSmall sizePiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectromechanical coupling coefficientAcoustic wave

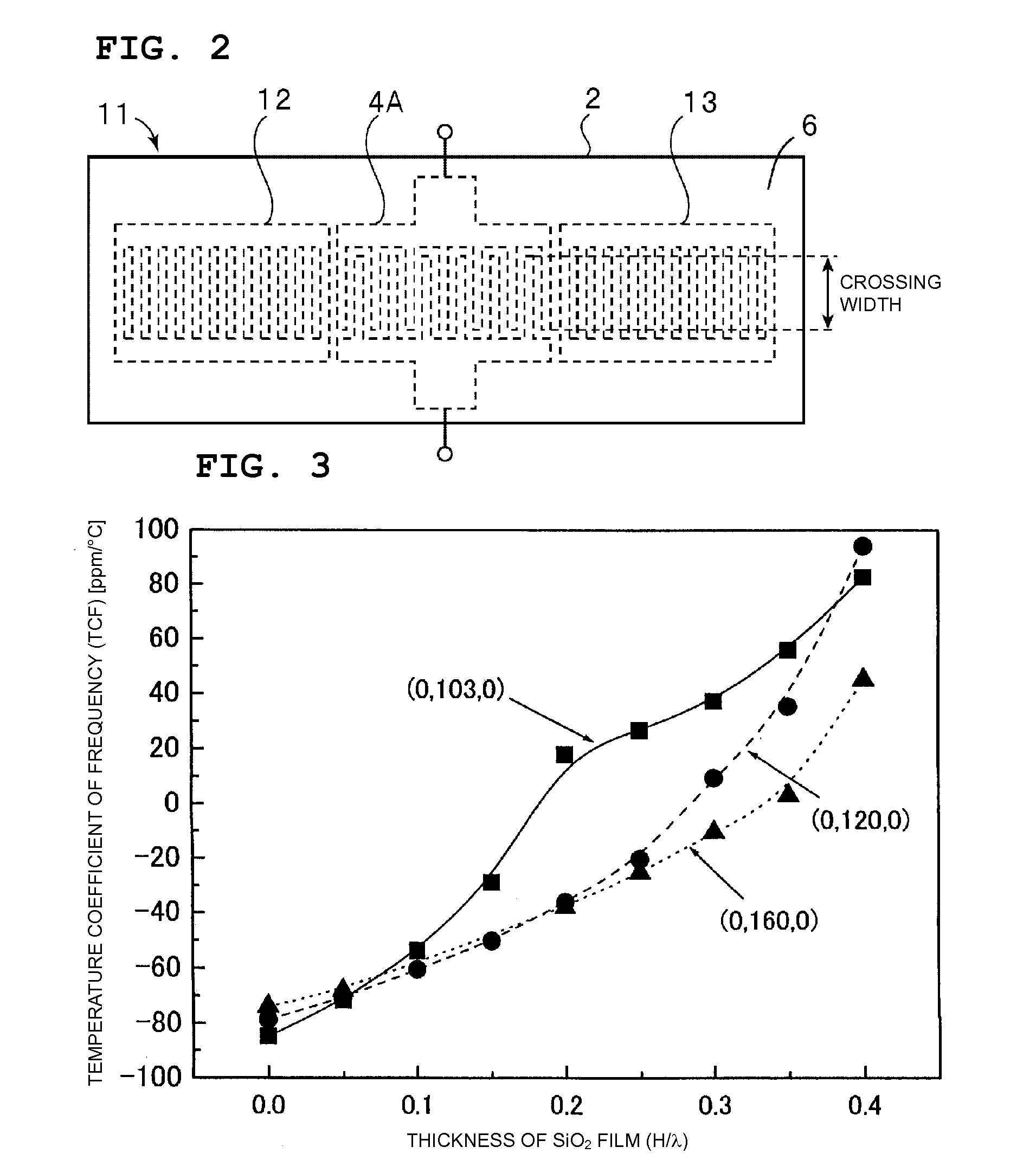

A reliable SAW device has excellent reflection and a small size, which is achieved by reducing the number of fingers defining reflectors, such that losses due to a large electromechanical coupling coefficient are small and the film thickness of electrodes has much less effect on frequencies of the device. In the SAW device having pluralities of first fingers and second fingers, disposed on a quartz substrate, constituting an IDT for exciting SH waves and reflectors for reflecting the SH waves, respectively, the first and second fingers made mainly from Al are disposed on the ST-cut 90° X-propagation quartz substrate with the Euler angles (0°, θ, 90°±2°), wherein the angle θ is within the range of about 110° to about 150°, and a normalized film thickness (H / λ) of the fingers is within in the range of about 0.025 to about 0.135.

Owner:MURATA MFG CO LTD

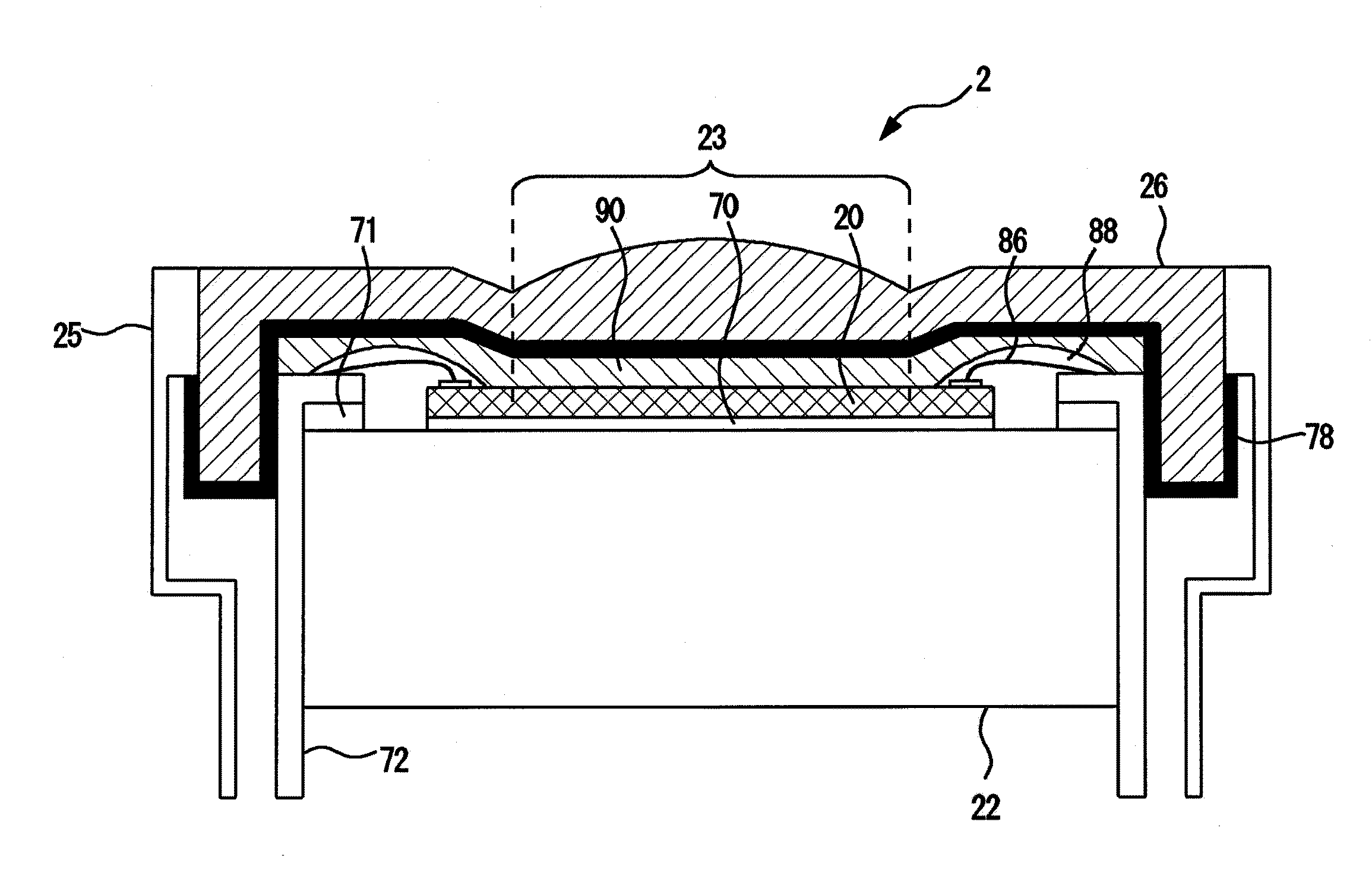

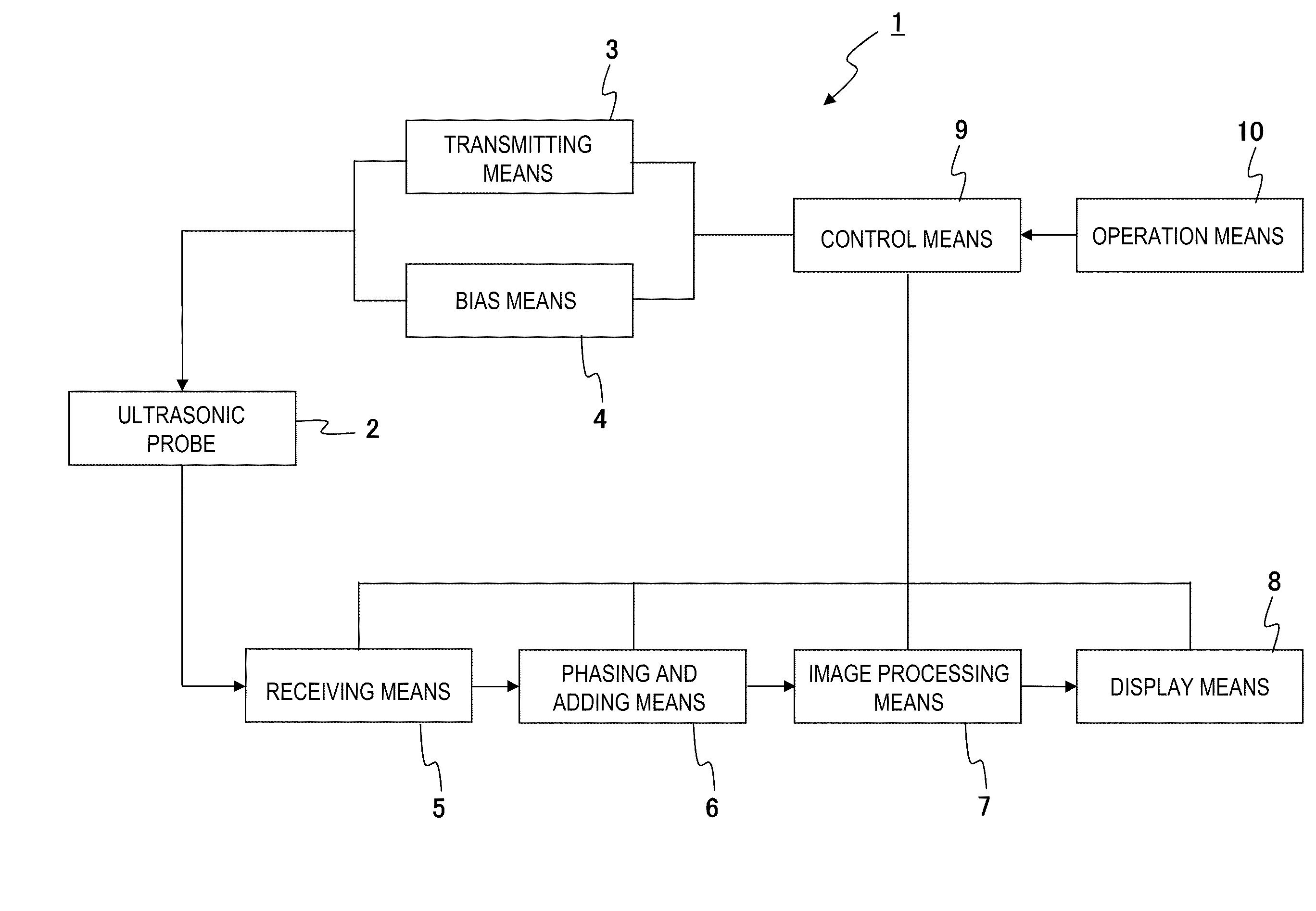

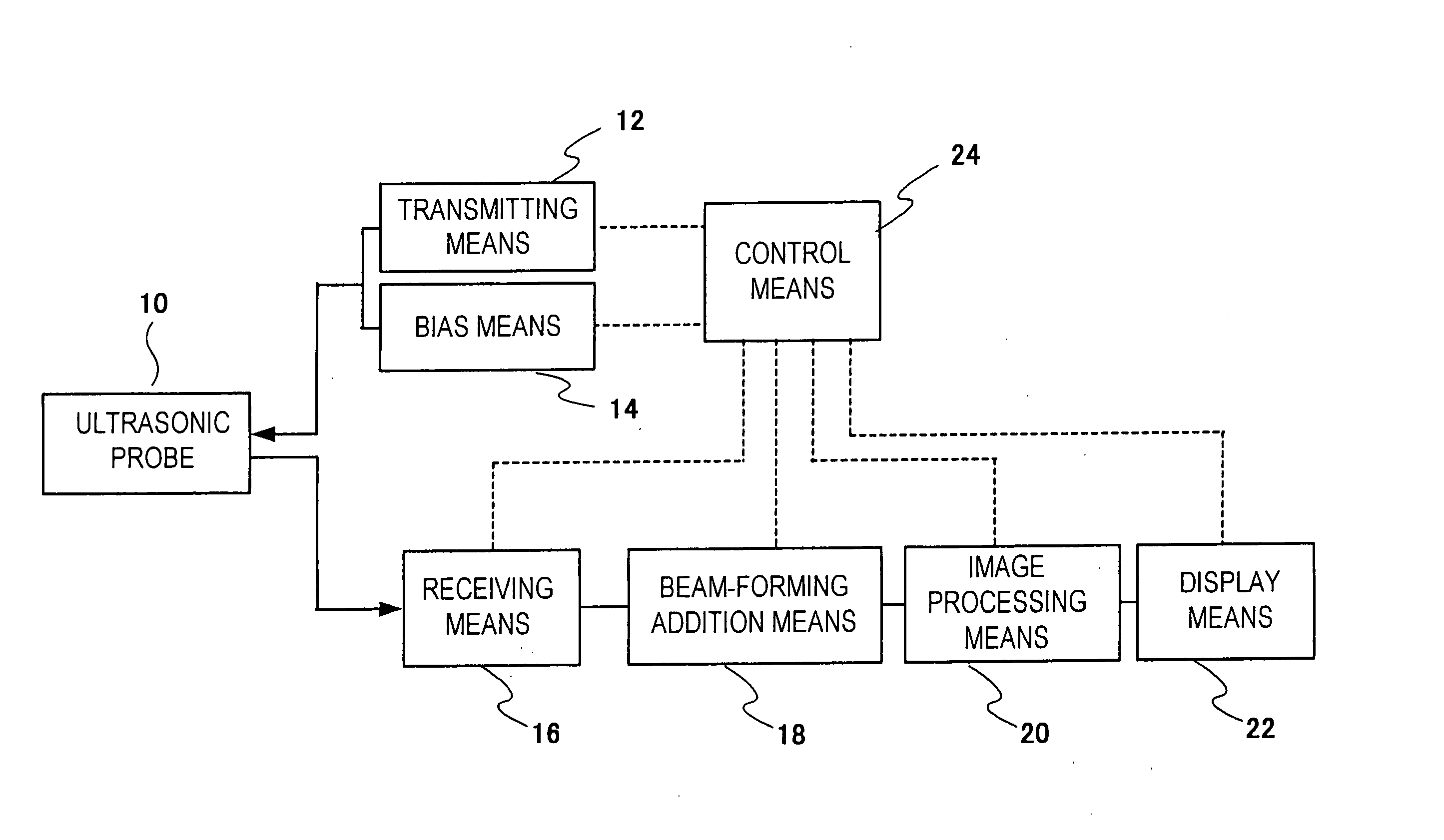

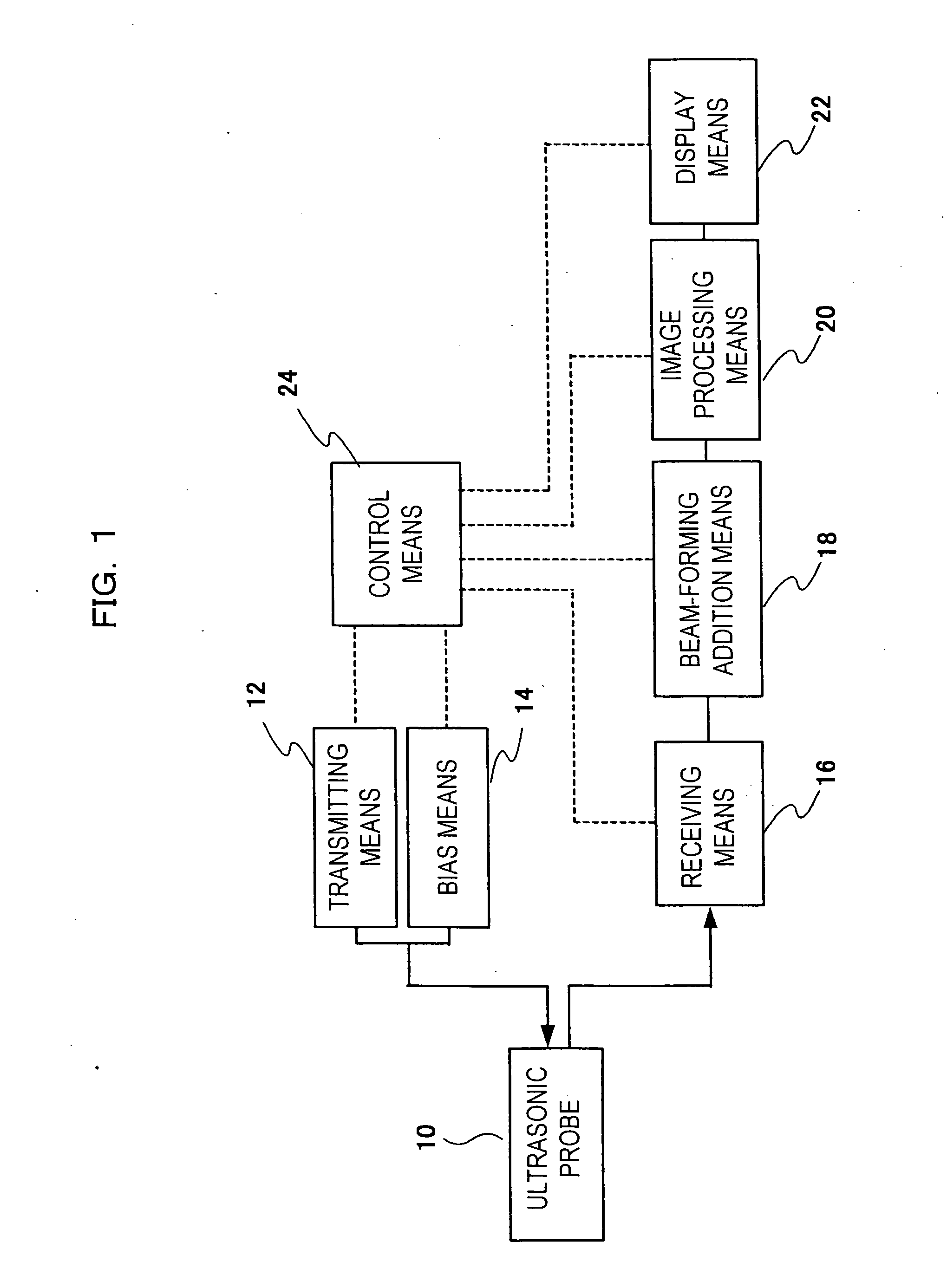

Ultrasonic probe and ultrasonic diagnostic apparatus using the same

ActiveUS20100036257A1Prevent leakageImprove securityUltrasonic/sonic/infrasonic diagnosticsSemiconductor electrostatic transducersElectromechanical coupling coefficientAcoustic lens

Provided is an ultrasonic probe including: a cMUT chip having a plurality of vibration elements whose electromechanical coupling coefficient or sensitivity is changed according to a bias voltage and transmitting and receiving ultrasonic waves; an acoustic lens arranged above the cMUT chip: and a backing layer arranged below the cMUT chip.Electric leakage preventing means is provided at the ultrasonic wave transmission / reception surface side of the acoustic lens or between the acoustic lens and the cMUT chip.The electric leakage preventing means is, for example, an insulating layer such as a ground layer.By using such a structure, it is possible to provide an ultrasonic probe capable of preventing electric leakage from the ultrasonic probe to an object to be examined so as to improve the electric safety and an ultrasonic diagnostic apparatus using the probe.

Owner:FUJIFILM HEALTHCARE CORP

Cascade and parallel piezoelectric composite material-based cylindrical transducer

InactiveCN101715157ABandwidthHigh sensitivityTransducers for subaqueous useElectromechanical coupling coefficientEngineering

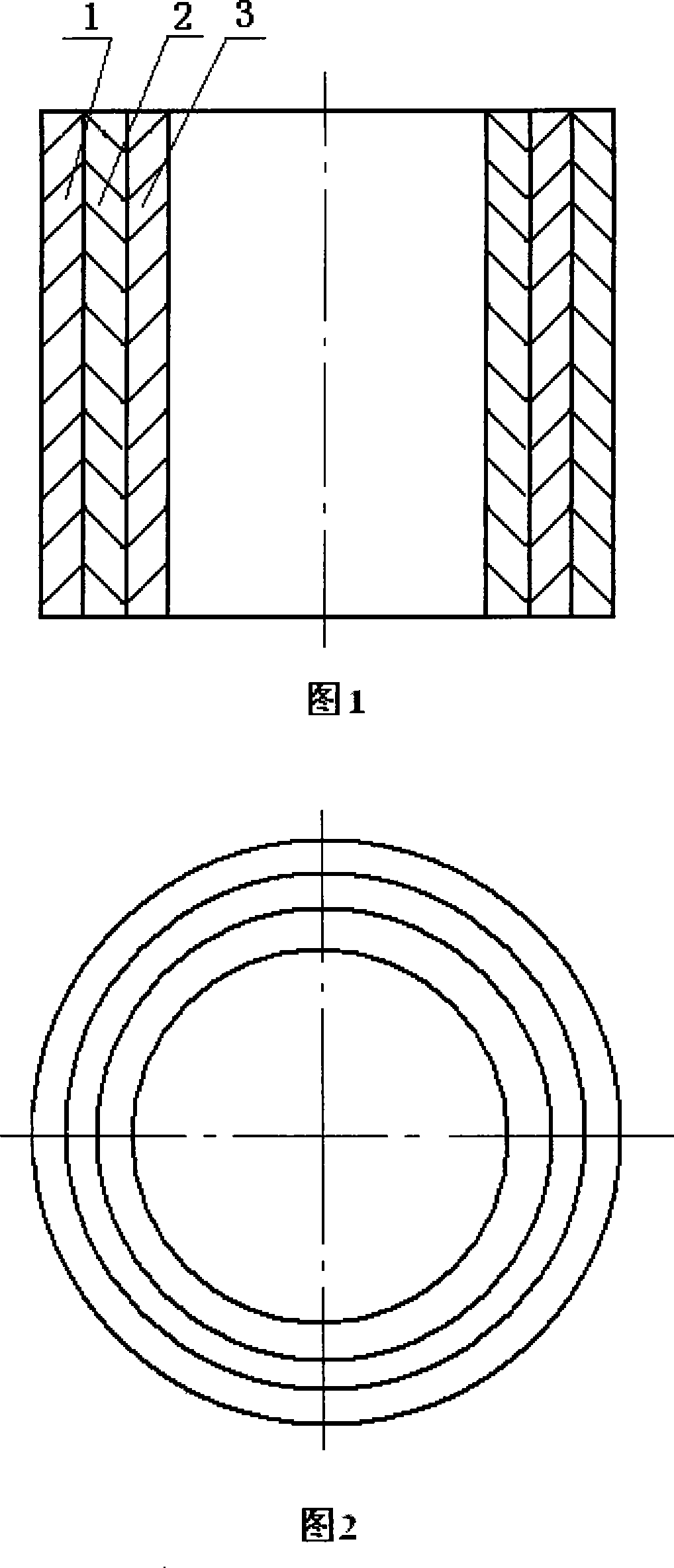

The invention discloses a cascade and parallel piezoelectric composite material-based cylindrical transducer, which comprises a support with an underpan, an annular backing, an end cover and a plurality of wafers, wherein the wafers are cascade and parallel piezoelectric composite wafers, are uniformly arranged on the outer side of the annular backing along the periphery and are polarized along the radial direction of the ring; insulating washers are cushioned on and under a tubular sensitive element consisting of the backing and the wafers; the tubular sensitive element is sleeved and fastened on the underpan of the support; and the end cover is fixed at the upper end of the support and on the insulating washer on the sensitive element. The transducer adopts a multi-wafer annular array as the sensitive element, the vibration of the wafers adopts a thickness model, the working frequency is higher than the radial vibration frequency of a round tube, and the high-frequency sound wave emission can be realized; moreover, because the wafers are mode of the cascade and parallel composite material, the electro-mechanical coupling factor of the composite material is high, the frequency band thereof is broad, and the transducer has high sensitivity and broad working frequency band; therefore, the transducer has the characteristics of high frequency, high sensitivity, broad band and level omnidirection.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Compositions for high power piezoelectric ceramics

InactiveUS20060229187A1Suitable propertyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDopantDielectric loss factor

A class of ceramic compositions according to the formula Pb(1-z)Mz(Mn1 / 3Sb2 / 3)x(ZryTi1-y)1-xO3 where M is selected to be either Sr or Ba, x is selected to be between 0.01 and 0.1, y is selected to be between 0.35 and 0.55, and z is selected to be between 0.01 and 0.10. In some embodiments of the above composition, one or more dopants is added to the compositions. The dopant(s) may be selected from the group comprising: PbO, CeO2, SnO2, Sm2O3, TeO2, MoO3, Nb2O5, SiO2, CuO, CdO, HfO2, Pr2O3, and mixtures thereof. The dopants can be added to the ceramic composition in individual amounts ranging from 0.01 wt % to up to 5.0 wt %. The preferred ceramic compositions exhibit one or more of the following electromechanical properties: a relative dielectric constant (ε) of between 1200 and 2000, a mechanical quality factor (Qm) of between 1500 and 2800; a piezoelectric strain constant (d33) of between 250-450 pC / N, a dielectric loss factor (tan δ) of between 0.002-0.008 and a thickness electromechanical coupling coefficient (kt) of between 0.45 and 0.7.

Owner:PIEZO TECH

Bi.Na.Ag Ba titanate series lead-free piezoelectric ceramics

InactiveCN1814569AImprove performancePromote polarizationPiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientDielectric loss

The invention relates to bismuth titanate natrium-silver-barium series piezoelectric ceramics with ABO3 structure. The general equation of the compound is [Bi0.5(Na1-xAgx)0.5] 1-yBayTiO3+aM alpha O beta (wt%), and in the equation, 0 alpha Obeta is one or plural doping oxide. The main constituent is 0-5 of Biw(Na1-x-y-zKxLiyAgz)1-wTiO3, M could be Na, K, Li, Ni, Zn, Cr, Co, Nb, Ta, Al, Cu, Fe, Ce, Pr, Nd, Sm, Gd, Dy, Er, Yb, In, Y, Sc, La, Ho, Lu, Sn, Sb, Mn, Ca, Ba, Sr, Mg, Si, Bi, Ag, etc. Alpha and beta mean the M element and atomicity corresponding to the relative oxide. The sintering temperature is 1100-1200 degree centigrade, keeping for 1-4 hours. The optimal value of the compound of d33 could be over 160pC / N, kp could be over 31%, dielectric loss could be below 0.03. And the technology is stable, and it would be made from traditional technology and raw material.

Owner:SICHUAN UNIV

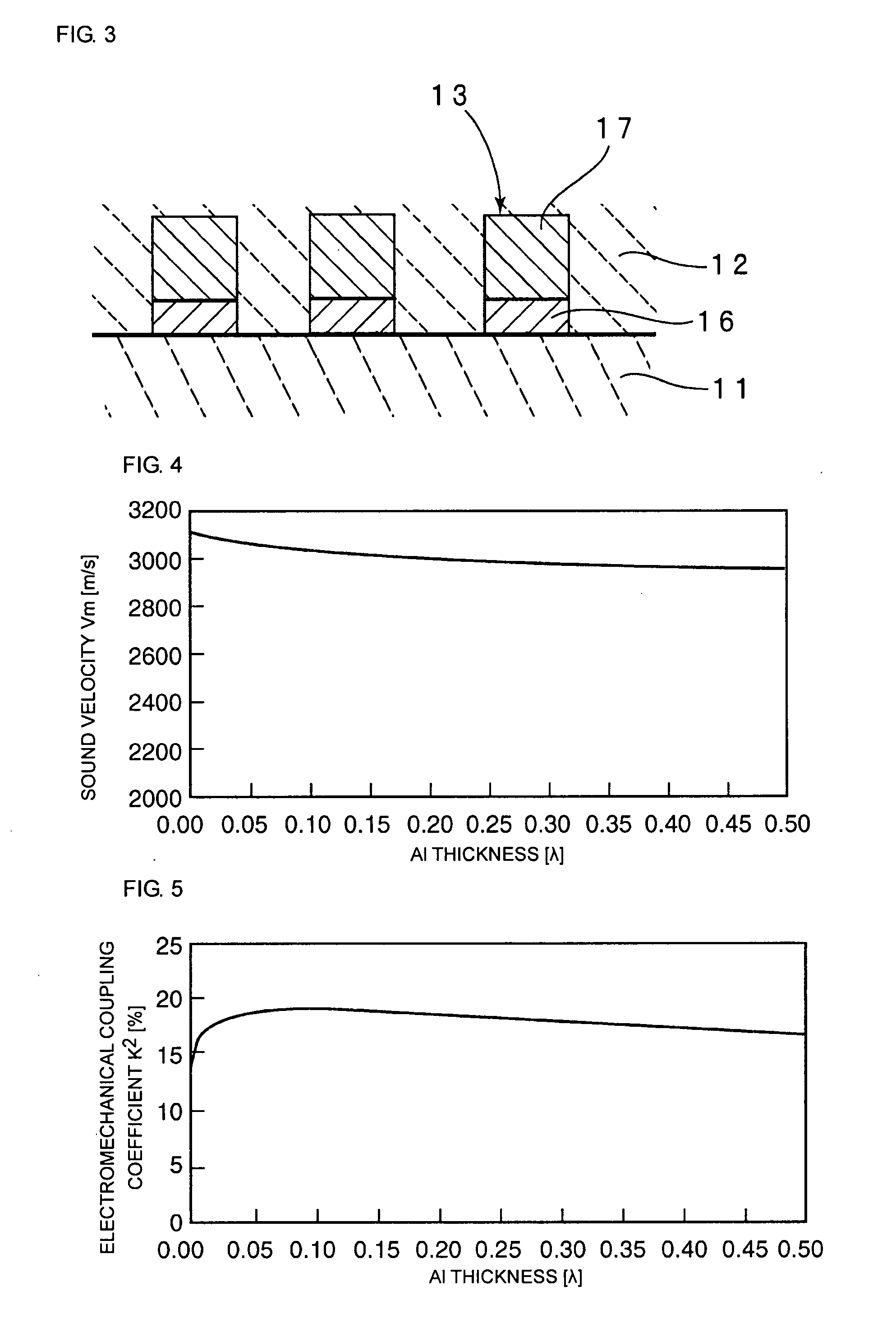

Method for preparing film bulk acoustic wave resonator on the basis of monocrystal AlN

InactiveCN105703732AHigh c-axis orientationAvoid lossImpedence networksThin-film bulk acoustic resonatorElectromechanical coupling coefficient

The invention discloses a method for preparing film bulk acoustic wave resonator on the basis of a monocrystal AlN. The method comprises the following steps of: growing (111) an oriented monocrystal Al film on a preparation substrate by using a molecular beam epitaxial growth method; growing (002) an oriented monocrystal AlN film on the oriented monocrystal Al film by using a pulse laser deposition growth method; and depositing a layer of metallic film on the AlN film to form a Al / AlN / metal sandwich piezoelectric stack structure. The piezoelectric stack structure based on monocrystal AlN prepared by the method can be used for preparing the film bulk acoustic wave resonator. The piezoelectric performance of the monocrystal AlN film is superior to that of a polycrystal AlN piezoelectric film applied to film bulk acoustic wave resonator so that the quality factor and a valid electromechanical coupling factor of a device are increased.

Owner:FOSHAN AIFO LIGHT FLUX TECH CO LTD

Bismuth sodium titanate based leadless piezoelectric ceramic and preparation technique thereof

InactiveCN101462875AImprove performanceHigh electromechanical coupling coefficientPiezoelectric/electrostrictive/magnetostrictive devicesAlkaline earth metalElectromechanical coupling coefficient

The invention discloses a sodium bismuth titanate based lead-free piezoelectric ceramic and a preparation process thereof. The general formula of the piezoelectric ceramic composition is (1-x)(Na0.5Bi0.5)1-aMaTiO3-xNaNbO3, wherein, x is the mol content of NaNbO3 in a ceramic system, a is the atom number of composite ions (Na0.5Bi0.5) which are replaced by M in (Na0.5Bi0.5)TiO3, x is not less than 0 but less than 0.3, a is more than 0 but less than 0.3, and M represents divalent alkaline earth metal elements Ba, Sr and Ca. As a secondary isostatic pressing forming method is adopted in the preparation process, the piezoelectric ceramic has the advantages of simple operation, high stability and low cost; and the method helps easily obtain high-density microcrystal ceramic materials, obviously improve the piezoelectric parameter and electromechanical coupling factor of the materials, and meet the practical requirement of the piezoelectric ceramic materials used in a micro-displacement actuator.

Owner:XIAN UNIV OF SCI & TECH

Surface acoustic wave device

ActiveUS7339304B2Improve featuresIncrease reflectionPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectromechanical coupling coefficientAcoustic wave

A surface acoustic wave device includes a piezoelectric substrate made of LiNbO3 having an electromechanical coupling coefficient k whose square is at least about 0.025, at least one electrode that is made of a metal whose density is greater than that of Al or an alloy primarily including the metal or that is composed of laminated films made of a metal whose density is greater than that of Al or an alloy primarily including the metal and another metal, the electrode being disposed on the piezoelectric substrate, a first insulating layer disposed in a region other than a region where the at least one electrode is disposed, the thickness of the first insulating layer being substantially equal to that of the electrode, and a second insulating layer covering the electrode and the first insulating layer. The density of the electrode is at least about 1.5 times greater than that of the first insulating layer.

Owner:MURATA MFG CO LTD

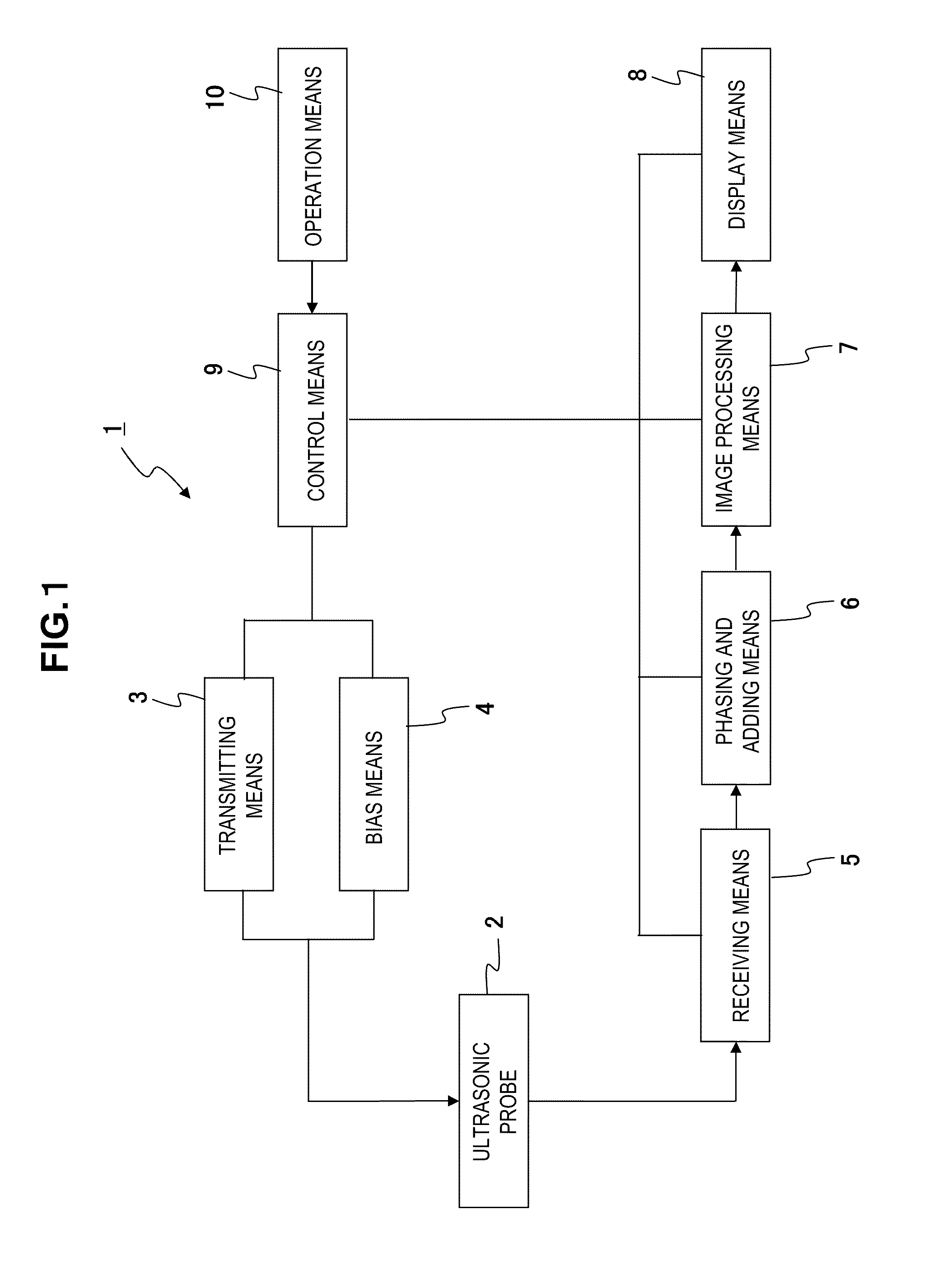

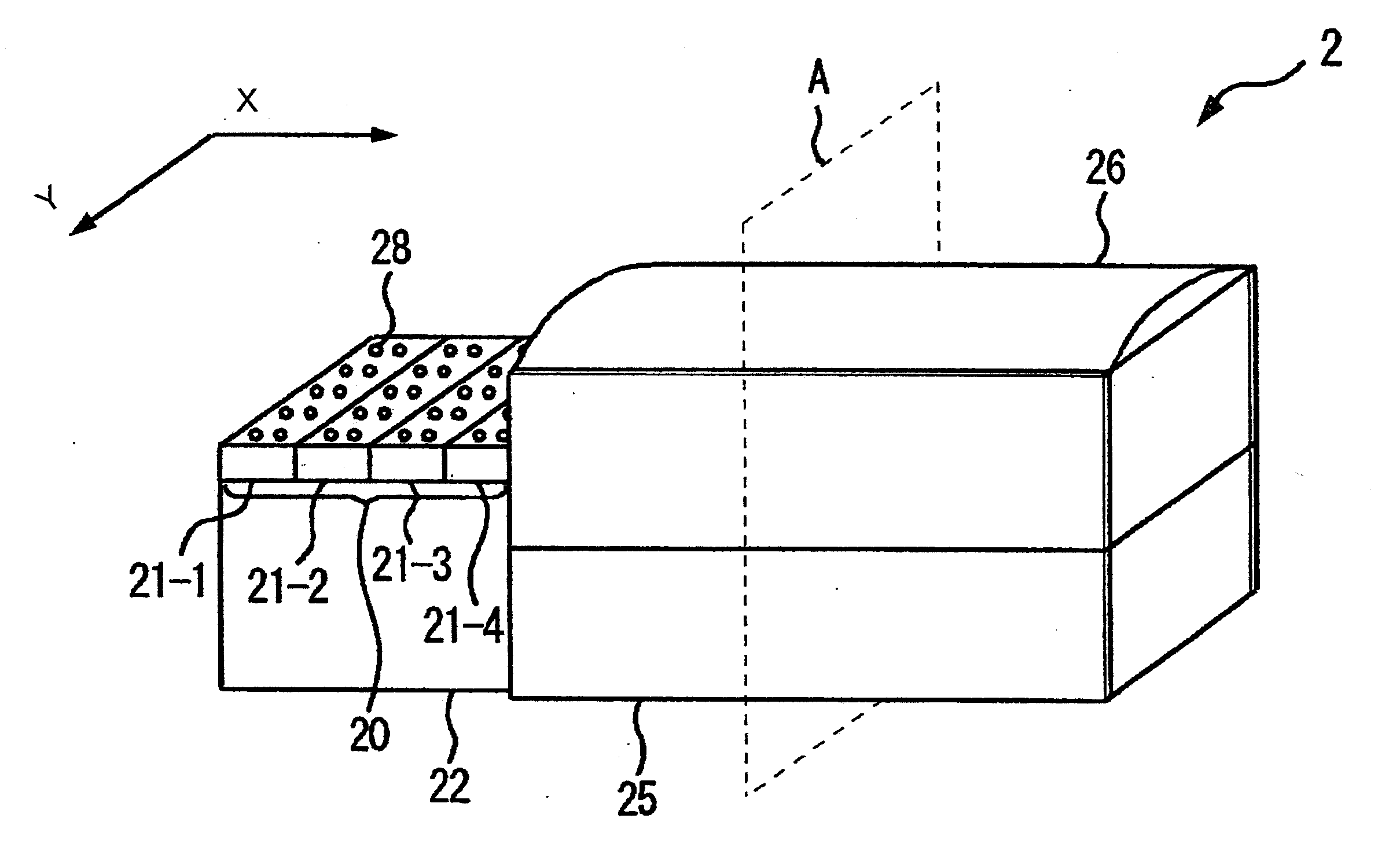

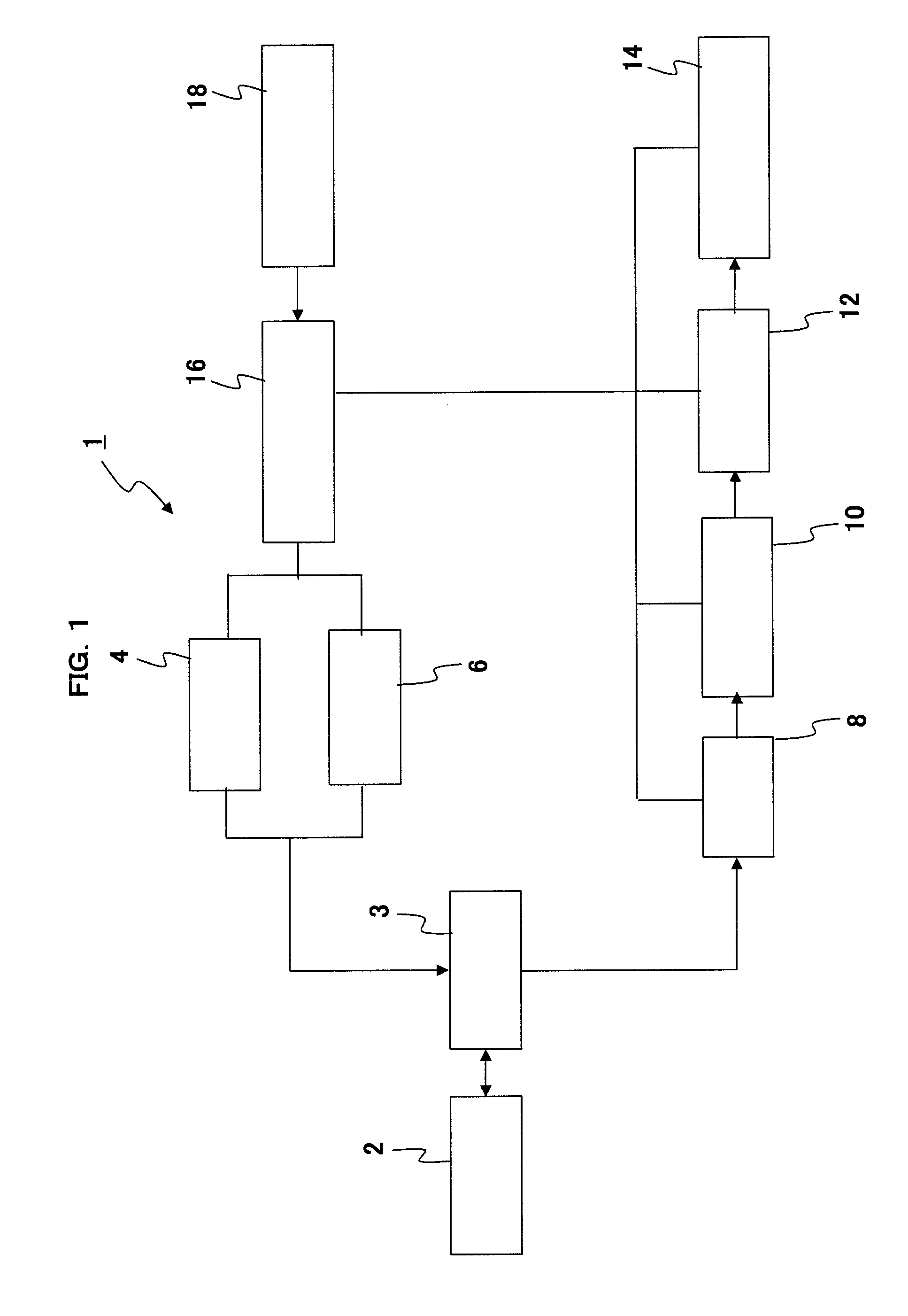

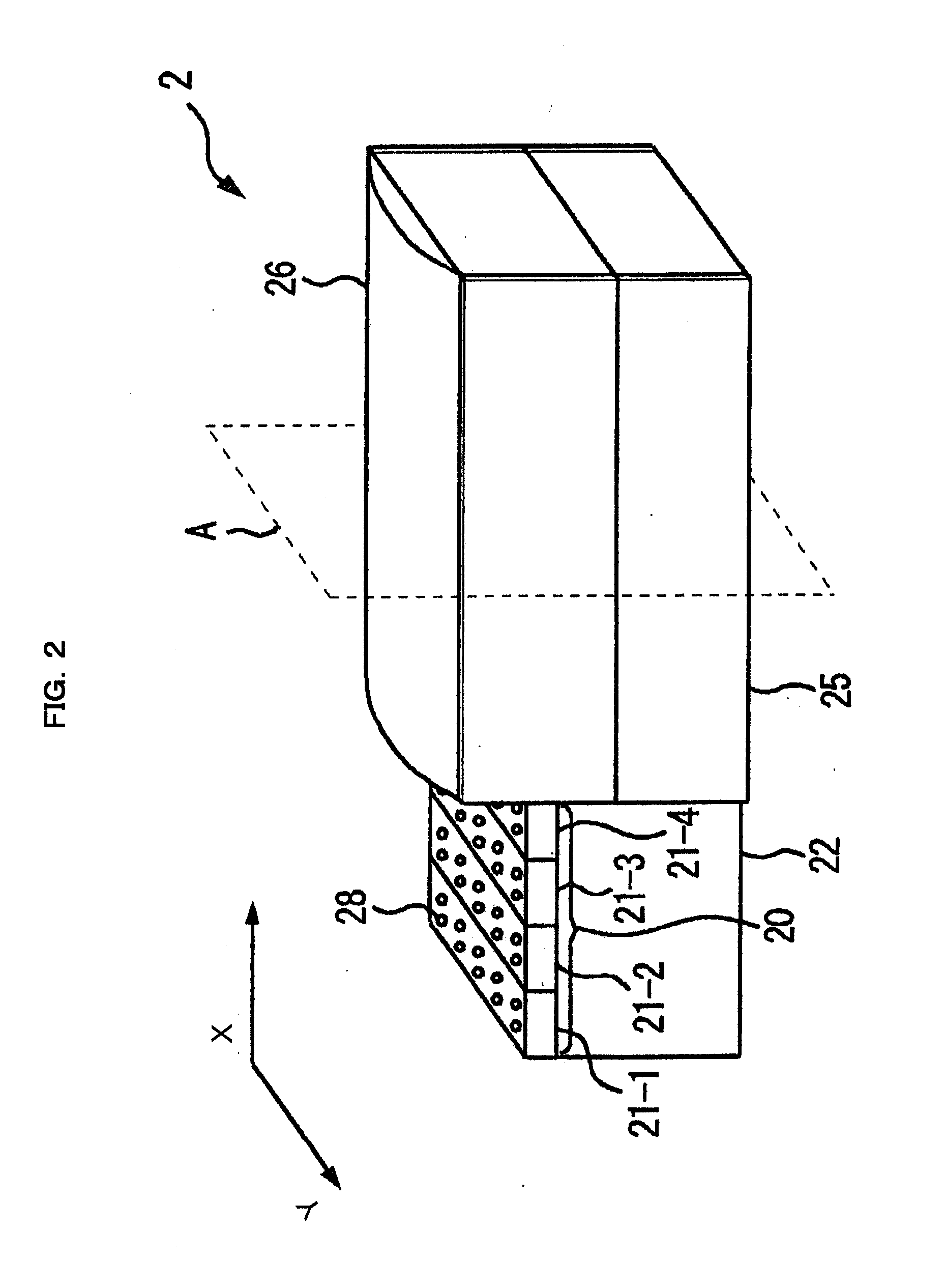

Ultrasonic probe, ultrasonographic device, and ultrasonographic method

InactiveUS20070016020A1High resolutionSmall coefficientUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationElectromechanical coupling coefficientTransducer

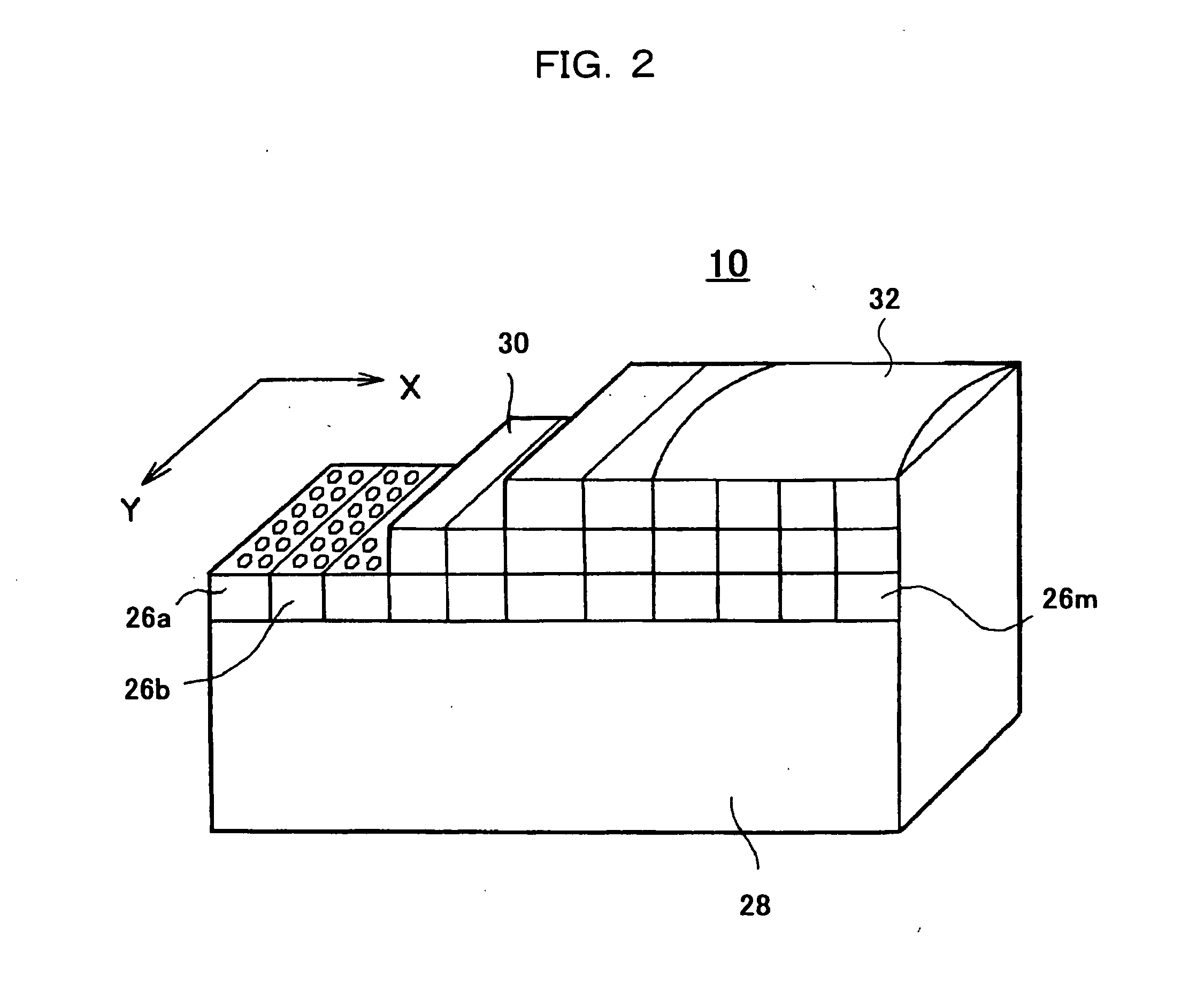

An ultrasonic probe 10 is formed by arranging a plurality of transducers 26a to 26m for converting drive signals into ultrasonic waves to transmit the waves to an object to be inspected, and receiving ultrasonic waves generated from the object to convert the waves into electrical signals. Each of the transducers 26a to 26m has a plurality of oscillation elements 34-1 to 34-30, and each of the oscillation elements 34-1 to 34-30 has a characteristic in which the electromechanical coupling coefficient changes in accordance with the strength of the direct-current bias applied by being superposed on the drive signals. Electrodes 35, 36, and 37 of each of the oscillation elements 34-1 to 34-30 are connected to terminals 49-1 and 49-2 to which the drive signals are applied.

Owner:HITACHI MEDICAL CORP

Piezoceramic material and preparation method thereof

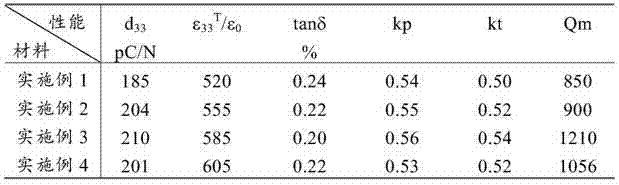

The invention discloses a piezoceramic material and a preparation method thereof. The piezoceramic material has the chemical general formula of Pb1-xMx(Sb1 / 2Nb1 / 2)y(Mn1 / 3Sb2 / 3)z(ZreTif)1-y-zO3+awt.%Fe2O3+bwt.%Sm2O3+cwt.%MnO2+dwt.%Al2O3, wherein M is Sr<2+> and / or Ba<2+>, x=0.02-0.1, y=0.01-0.1, z=0.01-0.1, e=0.40-0.60, f=0.40-0.60, f meets the condition that e+f=1, a=0-0.4, b=0-0.5, c=0-1.0, d=0-1.0, and the content of at most one of dopants in the four dopants including Fe2O3, Sm2O3, MnO2 and Al2O3 is equal to 0. The piezoceramic material disclosed by the invention has the main performances as follows: d33=210Pc / N, epsilon33T / epsilon0=585, tan delta=0.20%, kp=0.56, kt=0.54, and Qm=1210. Compared with a common power transmitted piezoceramic material, the piezoceramic material disclosed by the invention is lower in dielectric constant, smaller in dielectric loss and higher in mechanical quality factor and electromechanical coupling coefficient and is a power transmitted piezoceramic material with favorable performance, low dielectric constant and high mechanical quality factor.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Sandwich type radial direction vibrating piezoelectric ceramic ultrasonic transducer

InactiveCN101111098AOptimization parametersRaise the resonant frequencyPiezoelectric/electrostrictive transducersElectromechanical coupling coefficientOmni directional

The present invention relates to a radial vibration sandwich piezoelectric ceramic ultrasonic transducer. A piezoelectric ceramic ring is arranged between a metal inner ring and a metal outer ring, the upper end surfaces of the metal inner ring, the metal outer ring and the piezoelectric ceramic ring are in the same plane, and lower end surfaces are also in the same plane. The metal inner ring and the metal outer ring can adopt steel rings, aluminum rings, brass or purple copper rings, titanium rings, aluminum nickel copper alloy rings and titanium alloy rings. The present invention realizes the high efficiency work of a radial composite transducer through a radial prestress impressed by the inner and outer metal rings, and realizes the parameter optimization of the transducer through reasonably designing the geometry size of the inner and outer metal rings simultaneously, such as resonance frequency, frequency bandwidth as well as electromechanical coupling coefficient. The present invention can be used for the high efficiency omni-directional acoustic source underwater and all kinds of supersonic processing high efficiency supersonic source in liquid.

Owner:SHAANXI NORMAL UNIV

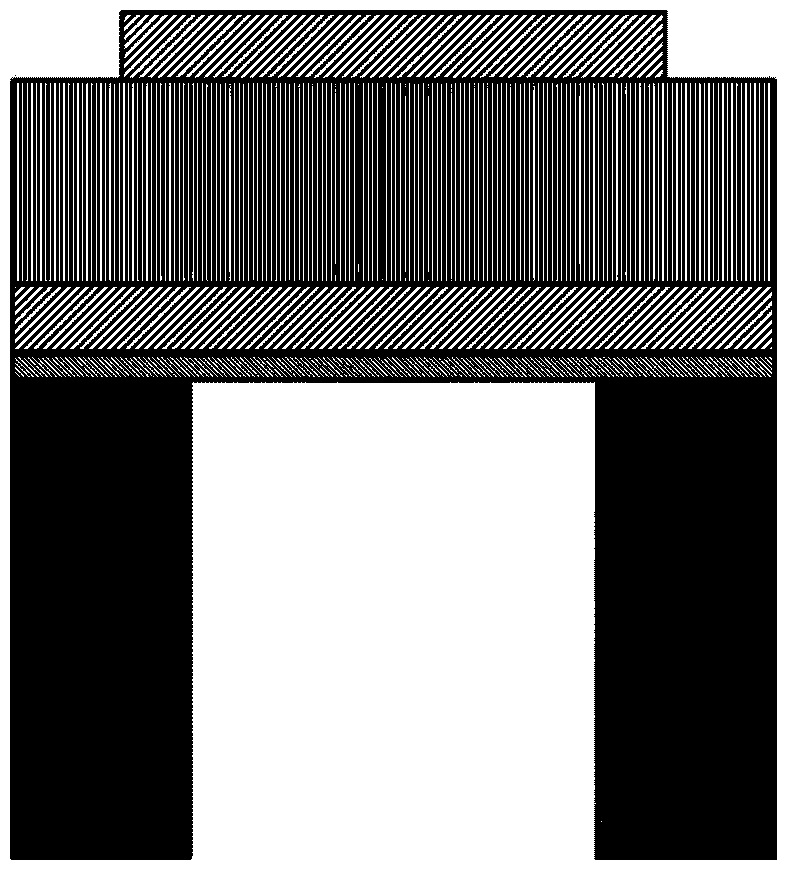

Boundary acoustic wave device

ActiveUS20070159026A1Well formedReduce lossImpedence networksPiezoelectric/electrostriction/magnetostriction machinesHigh densityElectrical conductor

A boundary acoustic wave device is provided in which an increase in the conductor resistance can be suppressed and a satisfactorily high electromechanical coupling coefficient K2 can be achieved even when the frequency is increased. The boundary acoustic wave device includes a first medium, a second medium, and an IDT provided therebetween. In the boundary acoustic wave device, a plane that separates the IDT into two equal parts in the thickness direction is defined as a boundary plane, the energy of boundary acoustic waves that is present at the first medium side of the boundary plane is represented by E1, and the energy that is present at the second medium side of the boundary plane is represented by E2. Furthermore, under the condition that an IDT including only the conductive layer having the highest density among the plurality of conductive layers constituting the IDT is configured so that the sound velocity of boundary acoustic waves when the IDT includes the plurality of conductive layers is equal to the sound velocity of boundary acoustic waves when the IDT includes only the conductive layer having the highest density, the energy of boundary acoustic waves that is present at the first medium side of the boundary plane is represented by E1′ and the energy that is present at the second medium side of the boundary plane is represented by E2′. In this case, the relationship E1 / E2>E1′ / E2′ is satisfied.

Owner:MURATA MFG CO LTD

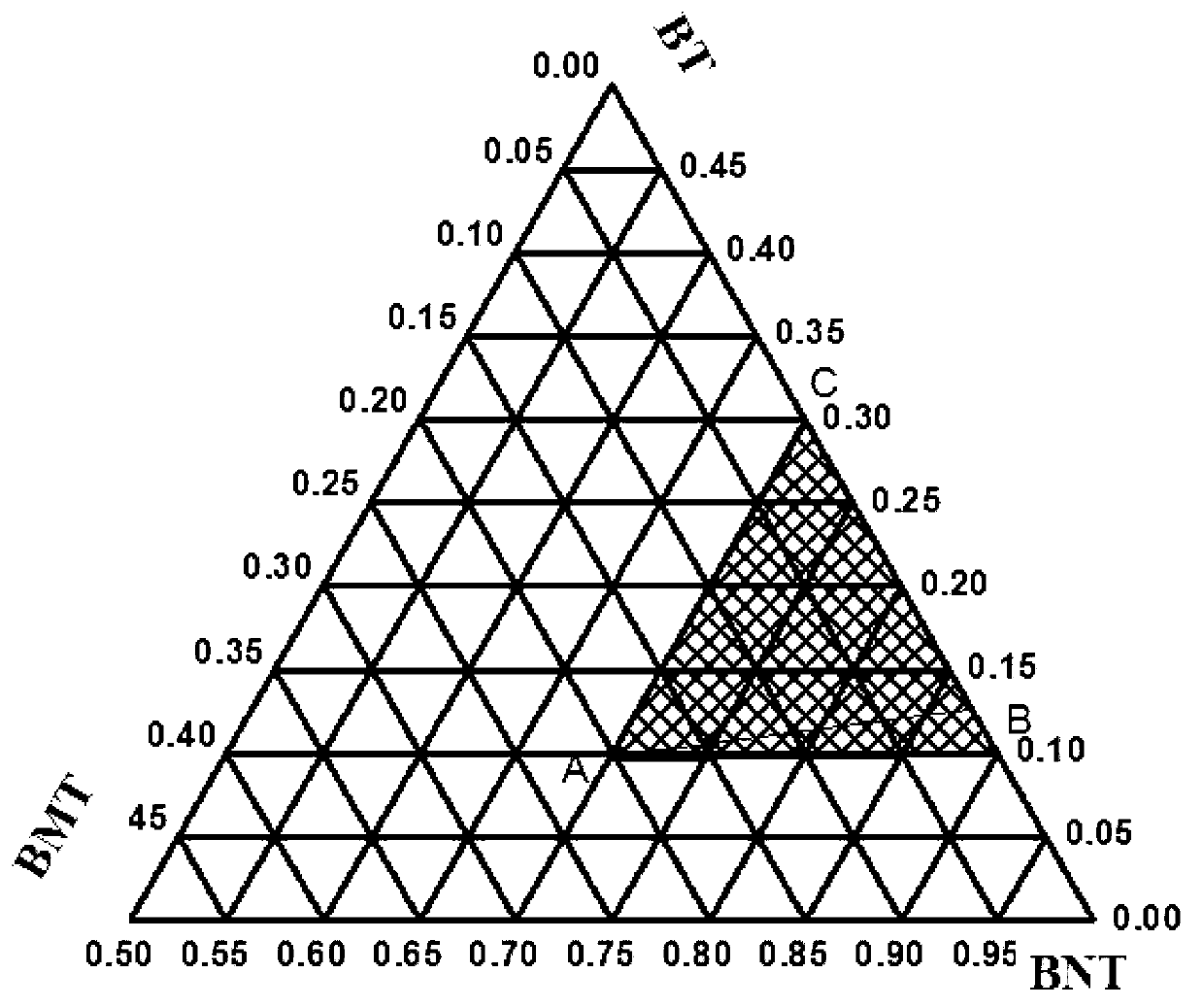

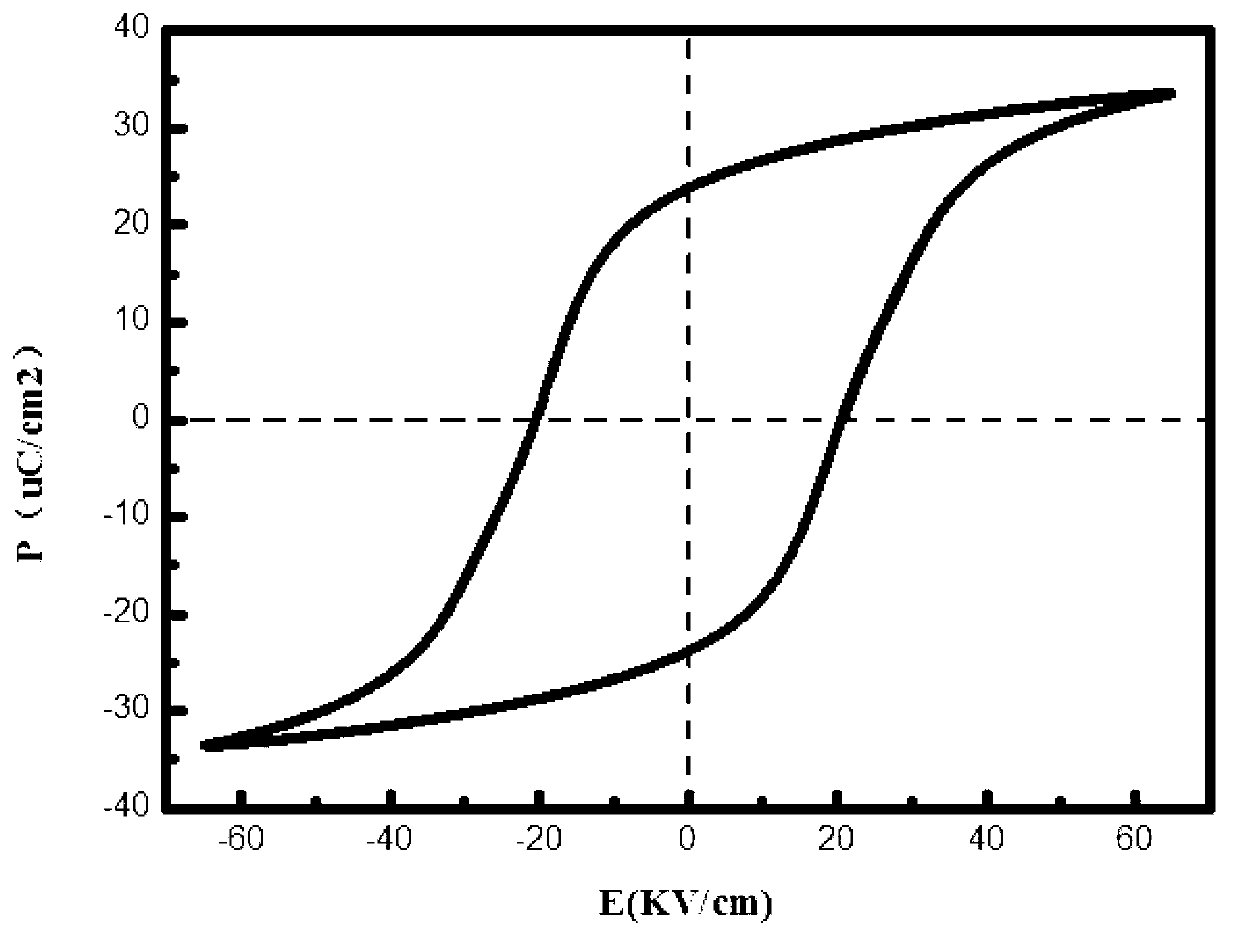

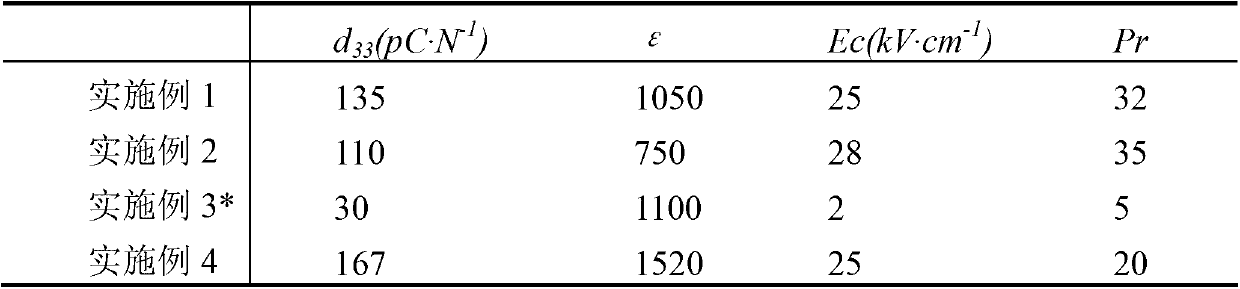

Bi0.5Na0.5TiO3-BaTiO3-BiMg0.5Ti0.5O3 lead-free piezoelectric ceramic material

The invention provides a Bi0.5Na0.5TiO3-BaTiO3-BiMg0.5Ti0.5O3 lead-free piezoelectric ceramic material, relates to a multicomponent system lead-free piezoelectric ceramic compound and belongs to the perovskite structure piezoelectric ceramic field. The composition provided by the invention can be expressed by a general formula of xBi0.5Na0.5TiO3-yBaTiO3-zBiMg0.5Ti0.5O3, wherein the numeric area of x, y and z is indicated by the shadow area of a ternary phase diagram (the area comprises the boundary line). The lead-free piezoelectric ceramic composition further contains oxide Bi2O3; and the content of oxide Bi2O3 is 1% of the content of Bi ions in the composition. The coercive field of the system changes with the three-component system components between 20kV / cm and 40 kV / cm; the piezoelectric coefficient d33 and the electromechanical coupling coefficient Kp are increased with the increase of the value of y in the polarizable component range; d33 is unequal from 100pC / N to 170 pC / N, while Kp is from 0.1 to 0.3. Besides, the depolarization temperature of the ceramics is slightly reduced between 80 DEG C and 120 DEG C with the increase of y.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com