Patents

Literature

852results about How to "Excellent piezoelectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

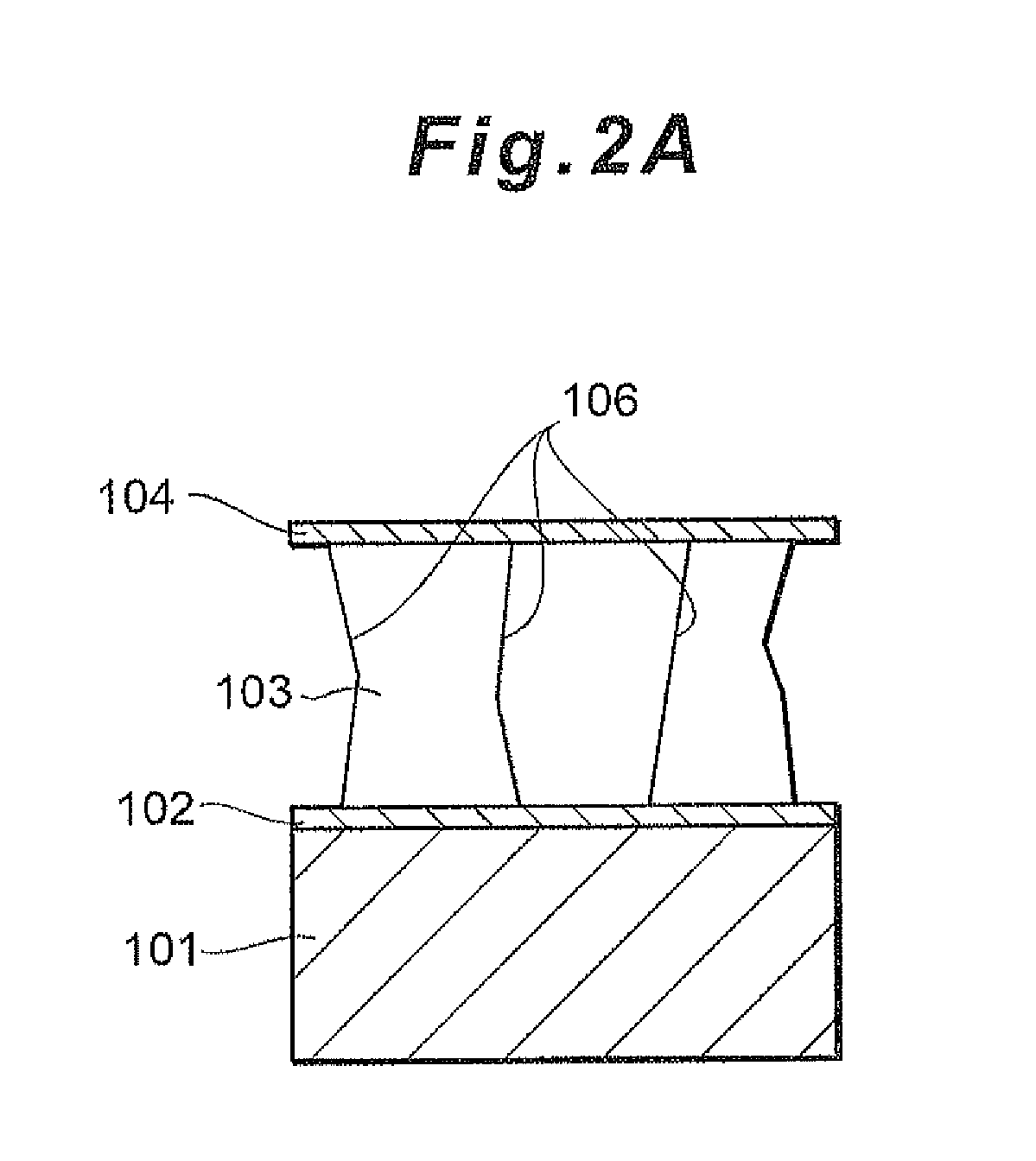

Piezoelectric vibration energy harvesting device

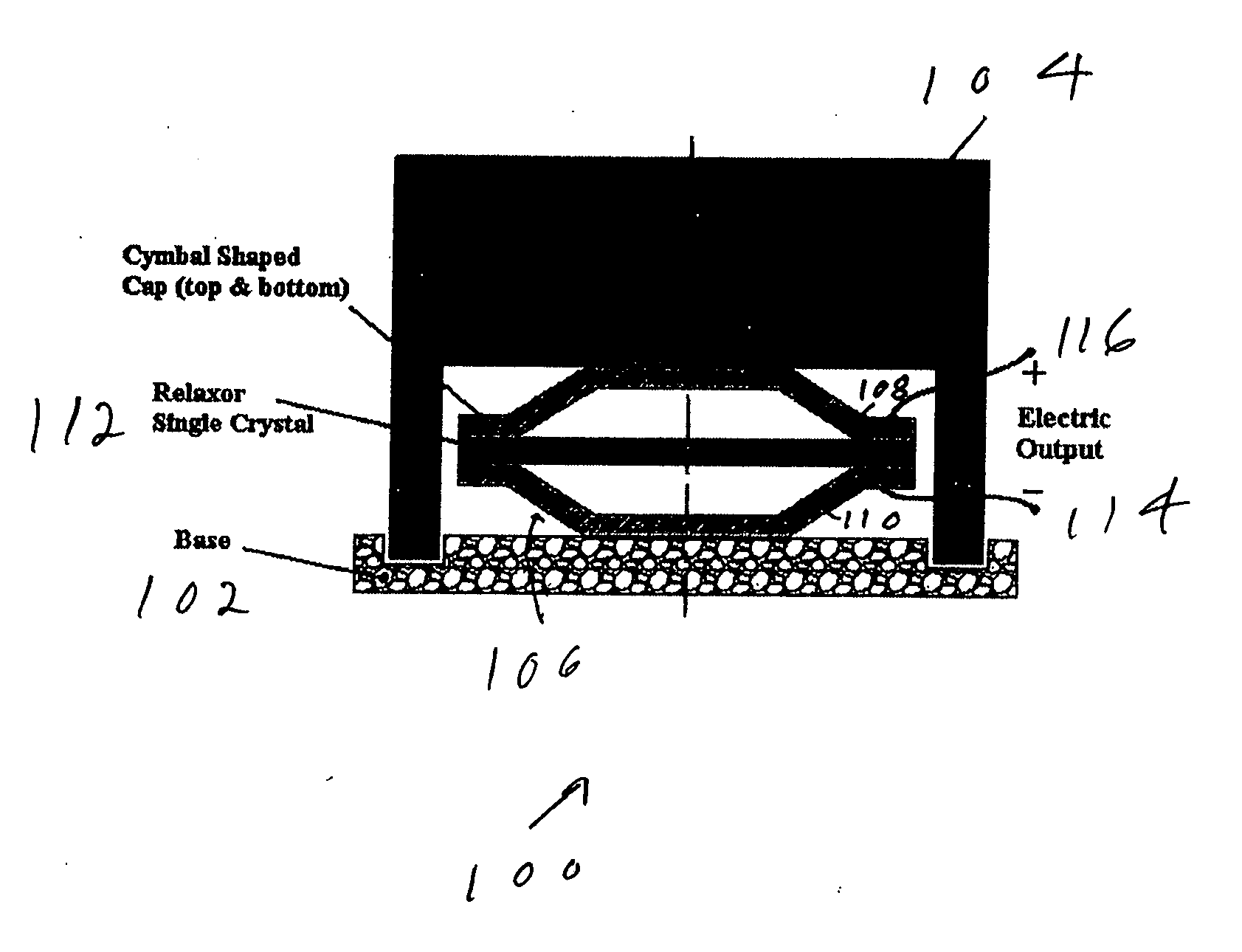

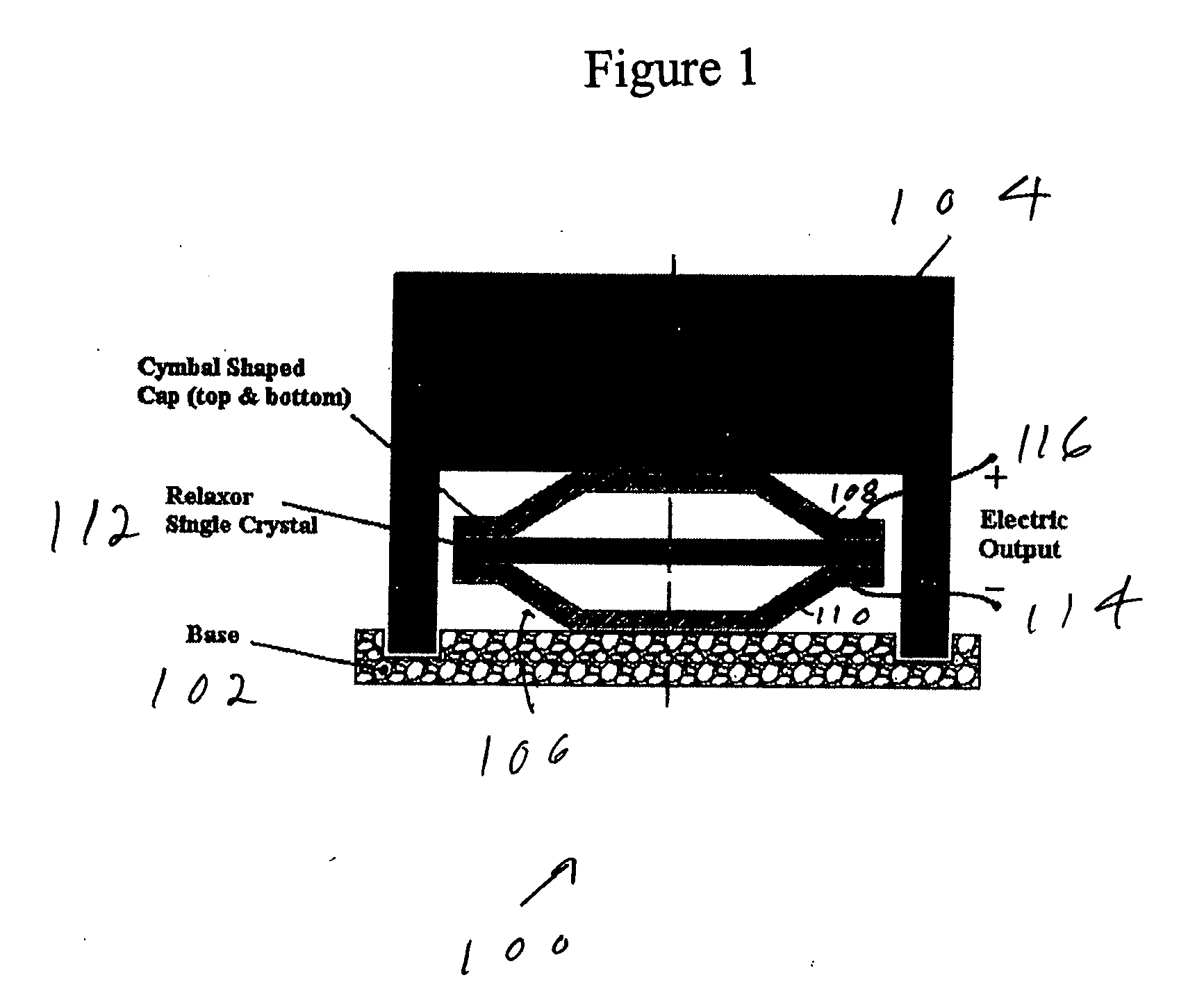

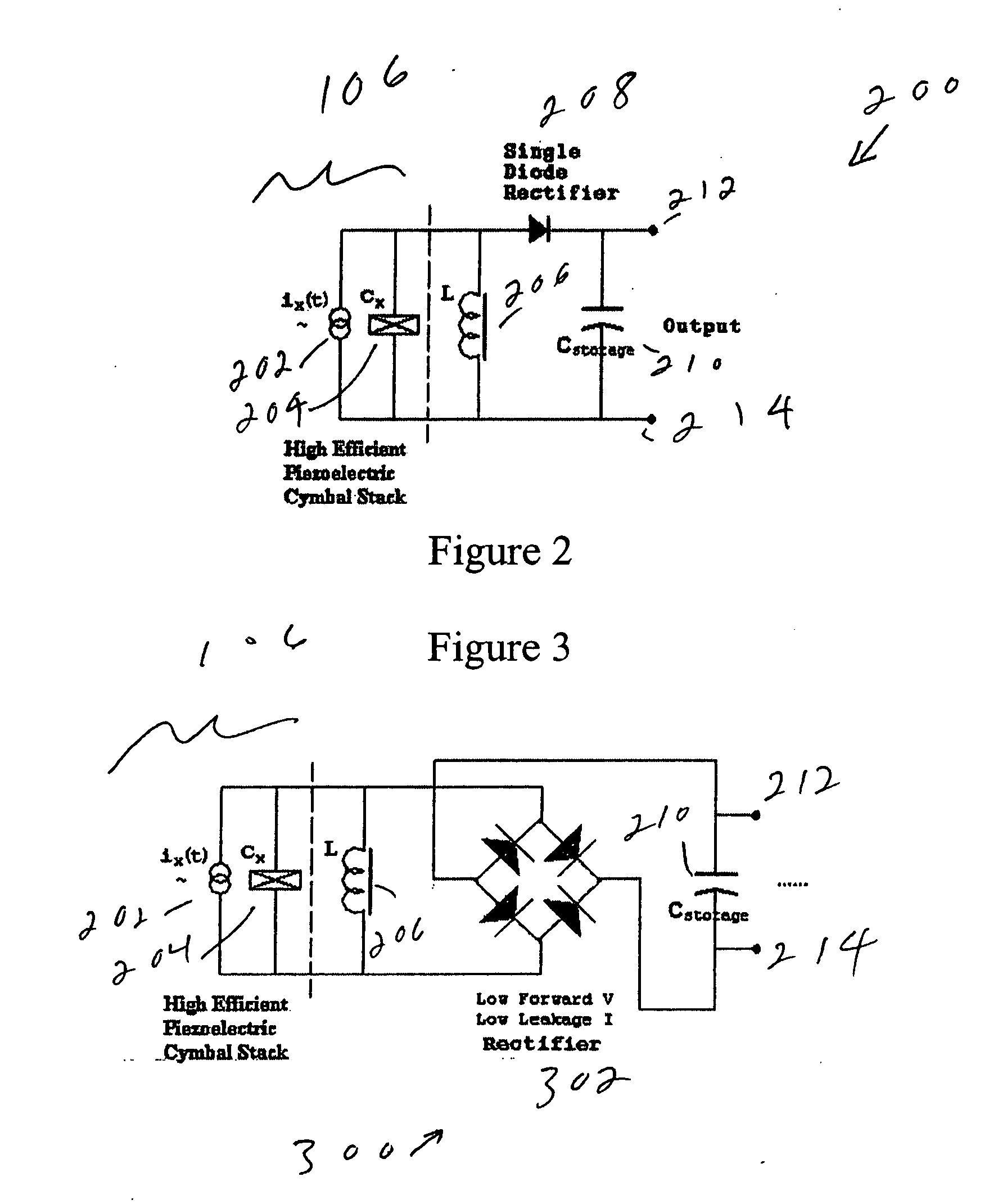

InactiveUS20050134149A1Efficient HarvestingSmall sizePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringVibration energy harvesting

A piezoelectric vibration energy harvesting device which is made up of a first mass, a second, a first spring coupled to the first mass, and a second spring coupled to the second mass. A piezoelectric element is bonded between the first mass and the second spring, so that a stress applied to the second spring is applied to the piezoelectric element

Owner:WILCOXON RES

Piezoelectric material and piezoelectric device

ActiveUS20070241642A1Excellent piezoelectric propertiesSufficient amount of distortionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMaterials science

Owner:SEIKO EPSON CORP

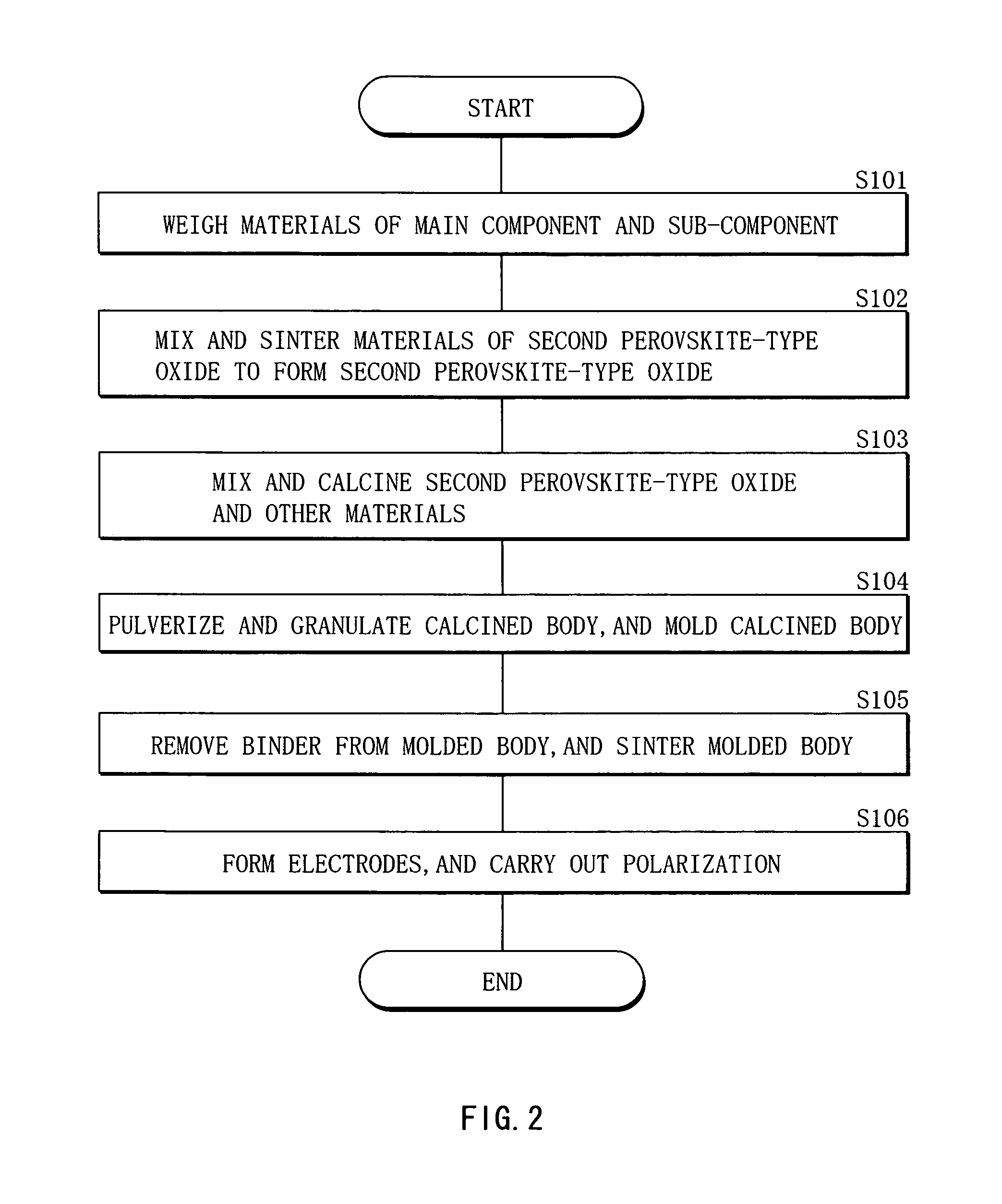

Piezoelectric ceramic composition and method of production of same, piezoelectric element, and dielectric element

InactiveUS20040058797A1Excellent piezoelectric propertiesIncrease temperaturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionRheniumIridium

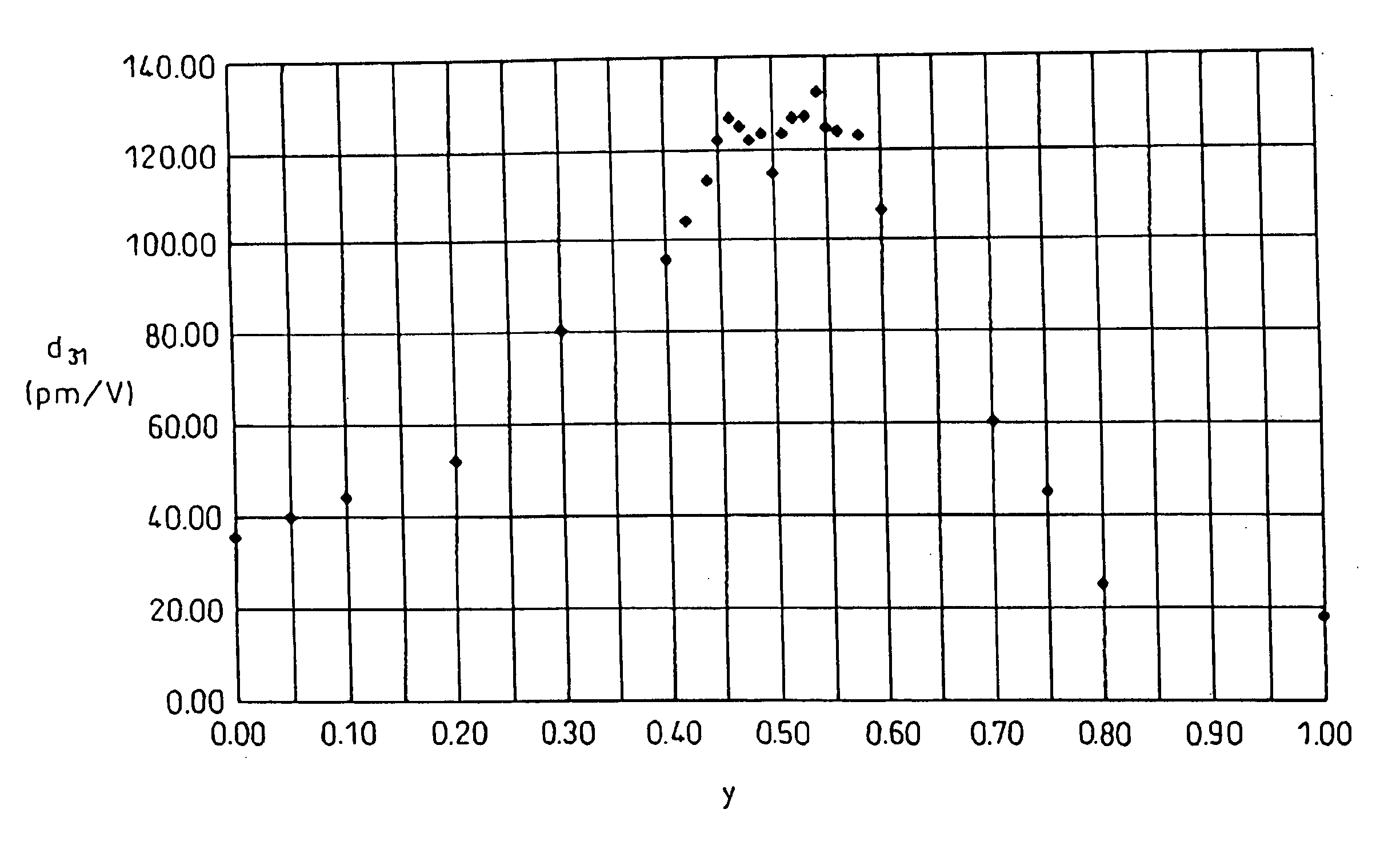

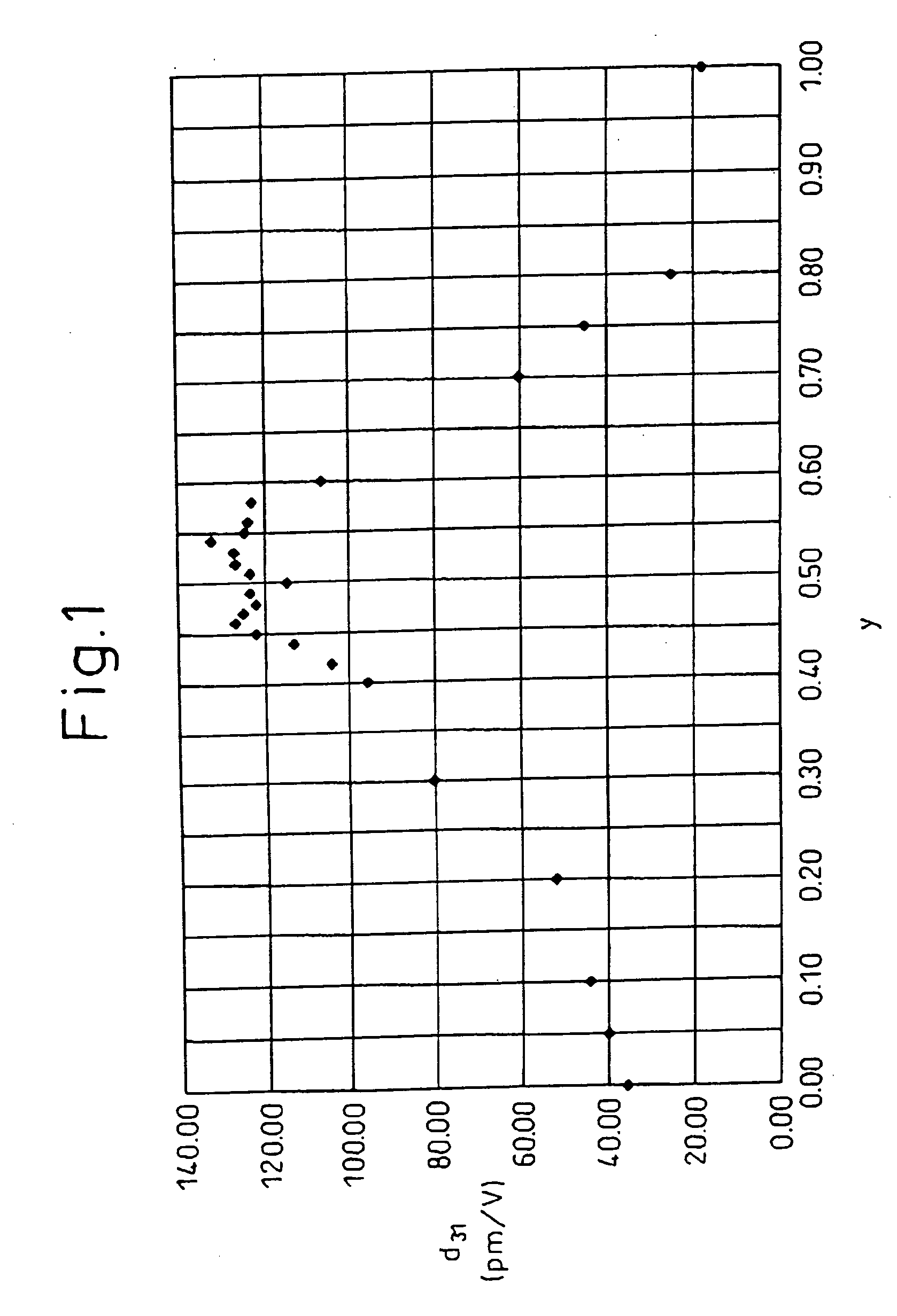

A piezoelectric ceramic composition not containing lead, able to be sintered at ordinary pressure, and superior to the past in at least one of the properties unique to piezoelectric ceramic compositions such as the piezoelectric d31 constant, that is, a piezoelectric ceramic composition having a compound of a general formula {Lix(K1-yNay)1-x}(Nb1-z-wTazSbw)O3 where x, y, z, and w are in the ranges of 0<=x<=0.2, 0<=y<=1, 0<z<=0.4, and 0<w<=0.2 as a main ingredient, where the piezoelectric ceramic composition contains at least one metal element selected from (1) palladium, silver, gold, ruthenium, rhodium, rhenium, osmium, iridium, and platinum, (2) nickel, iron, manganese, copper, and zinc, or (3) magnesium, calcium, strontium, and barium as an added element, and a method of production of the same and a piezoelectric element and dielectric element utilizing that piezoelectric ceramic composition.

Owner:DENSO CORP +1

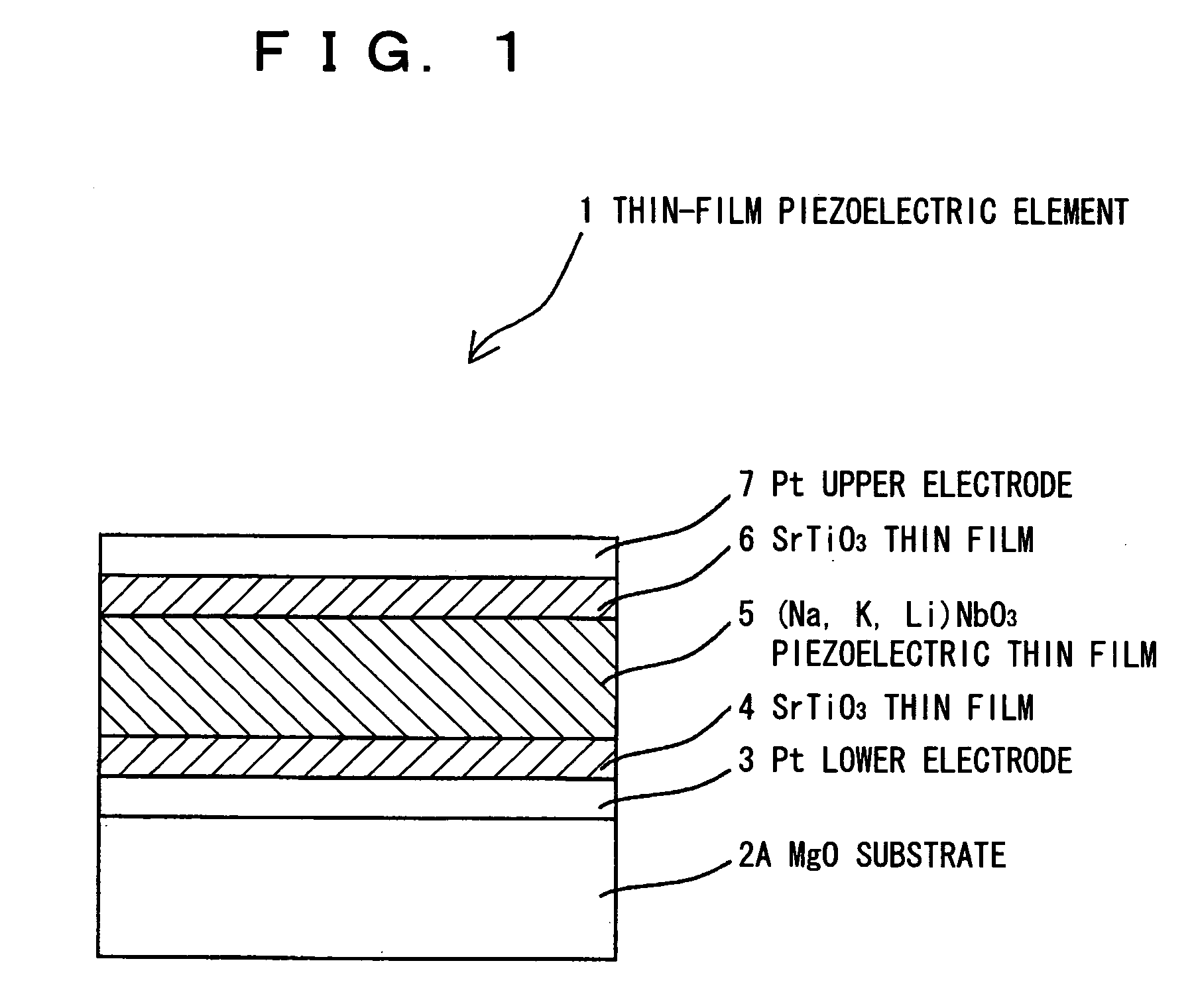

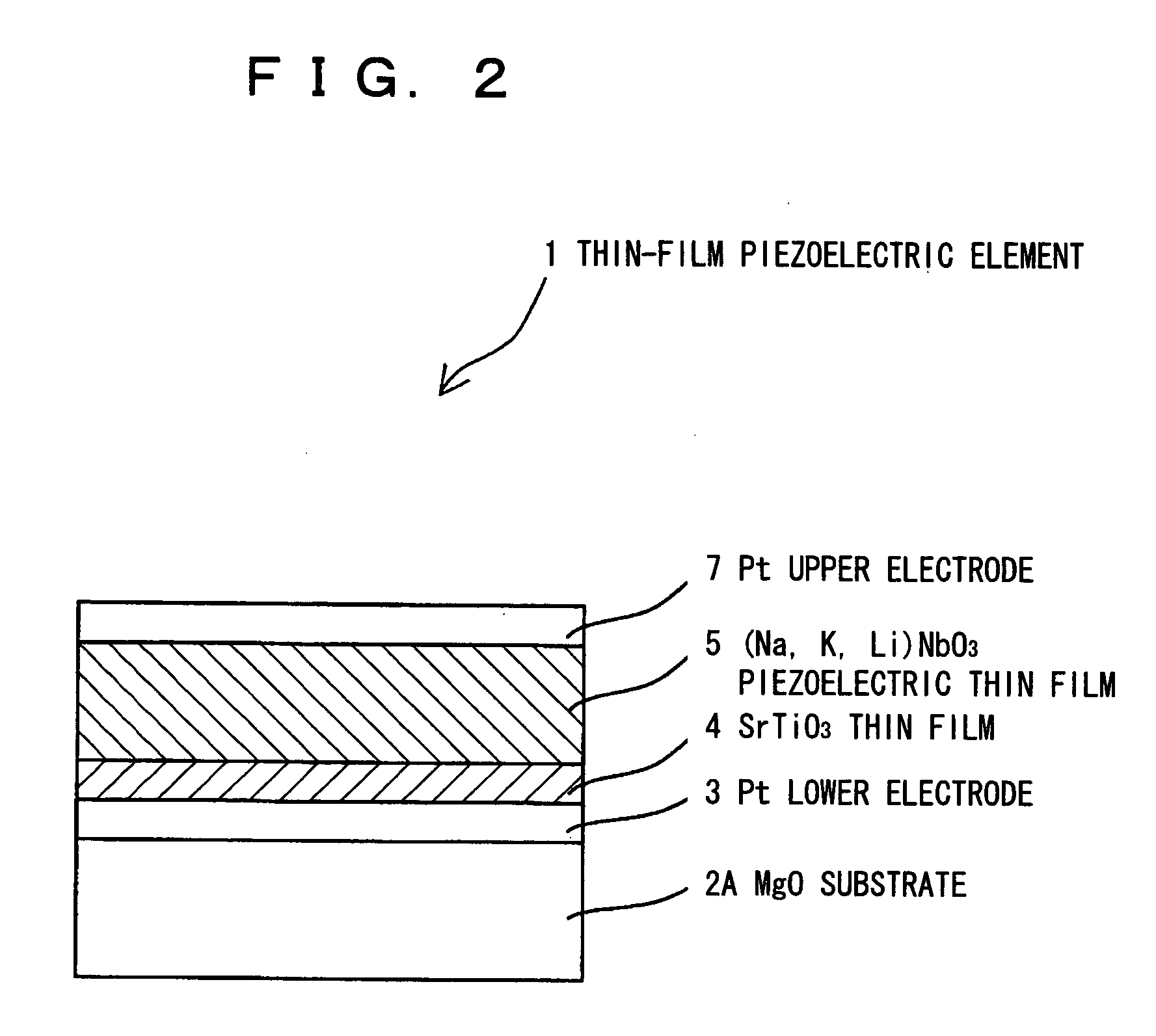

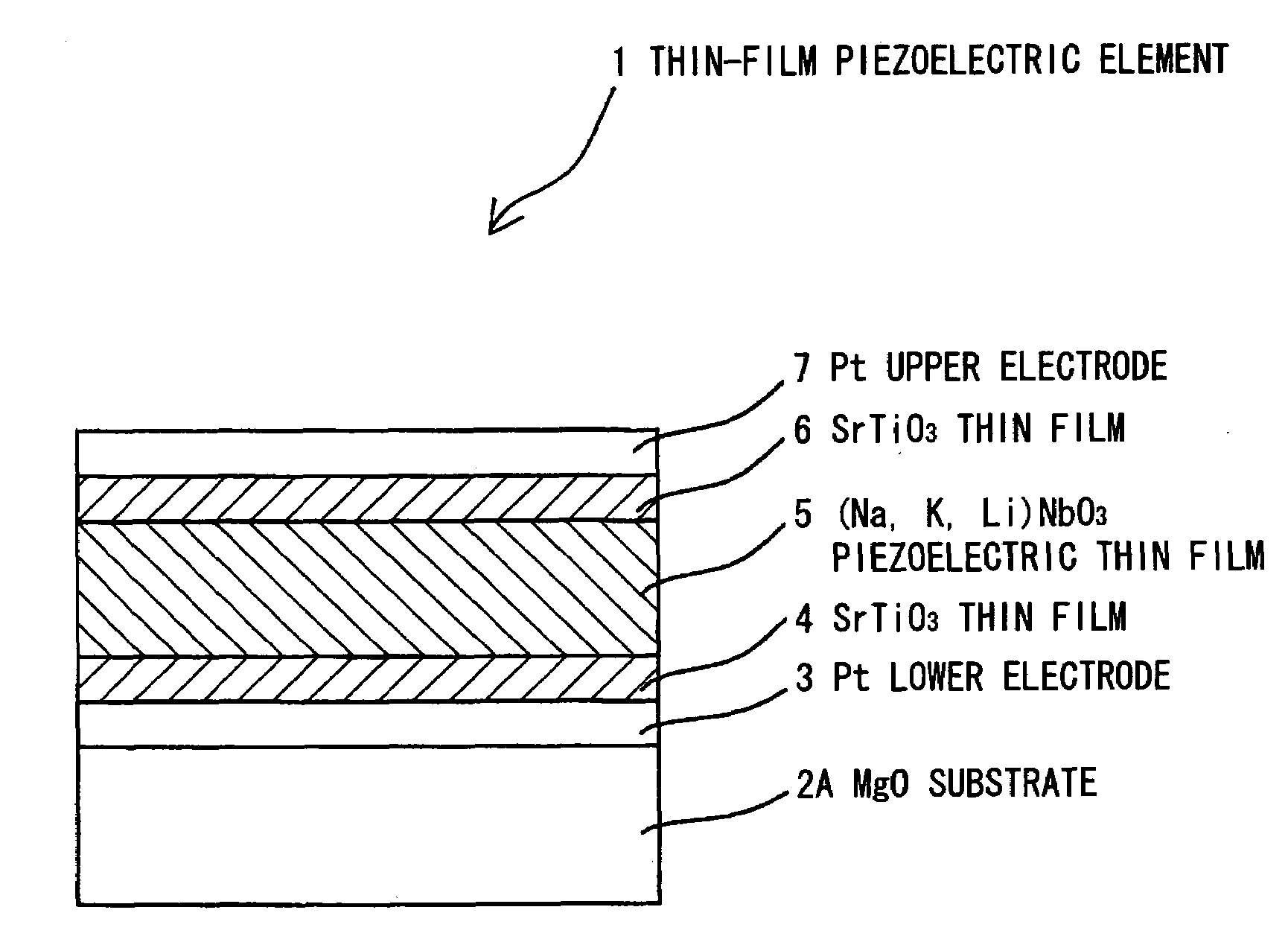

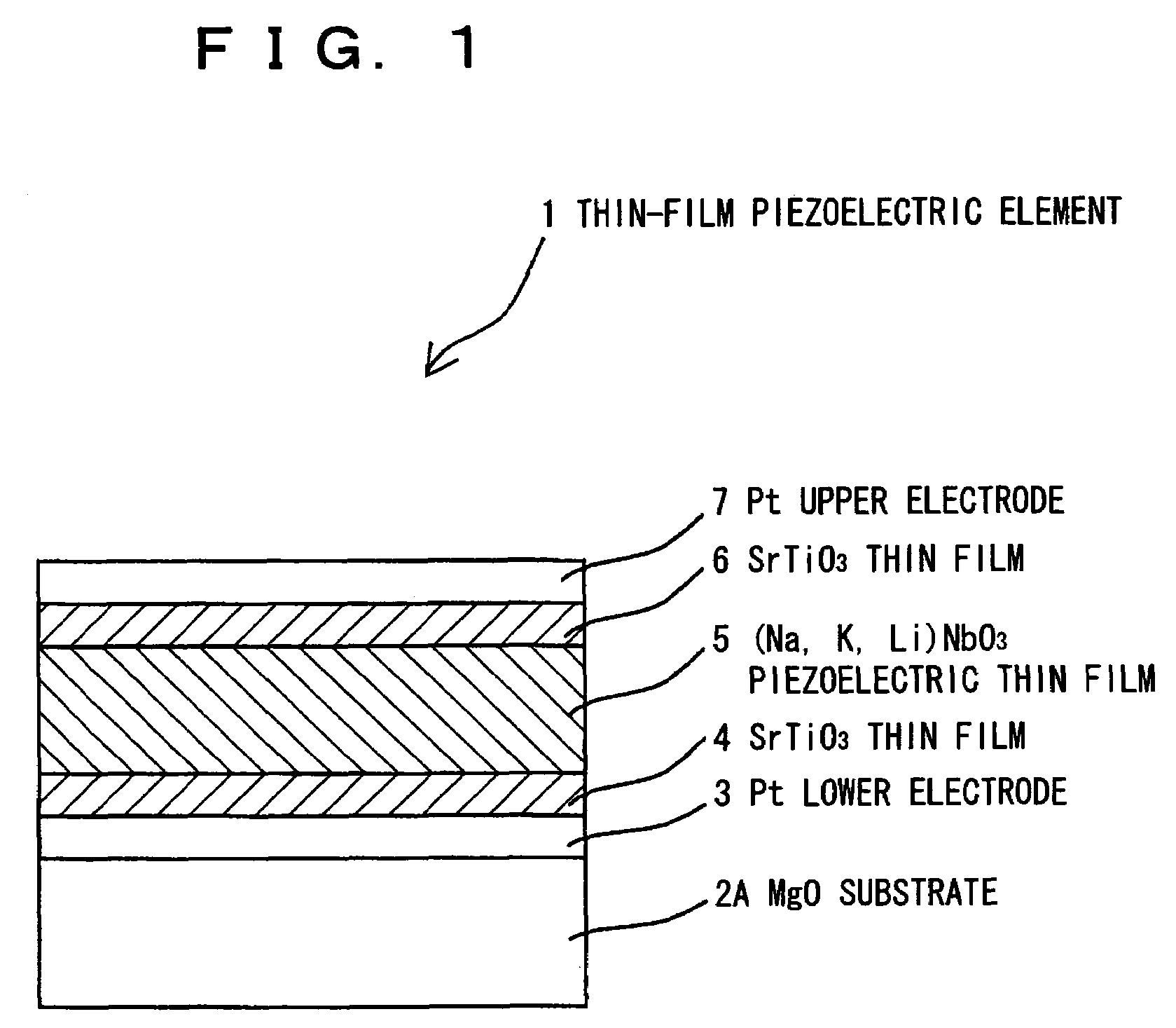

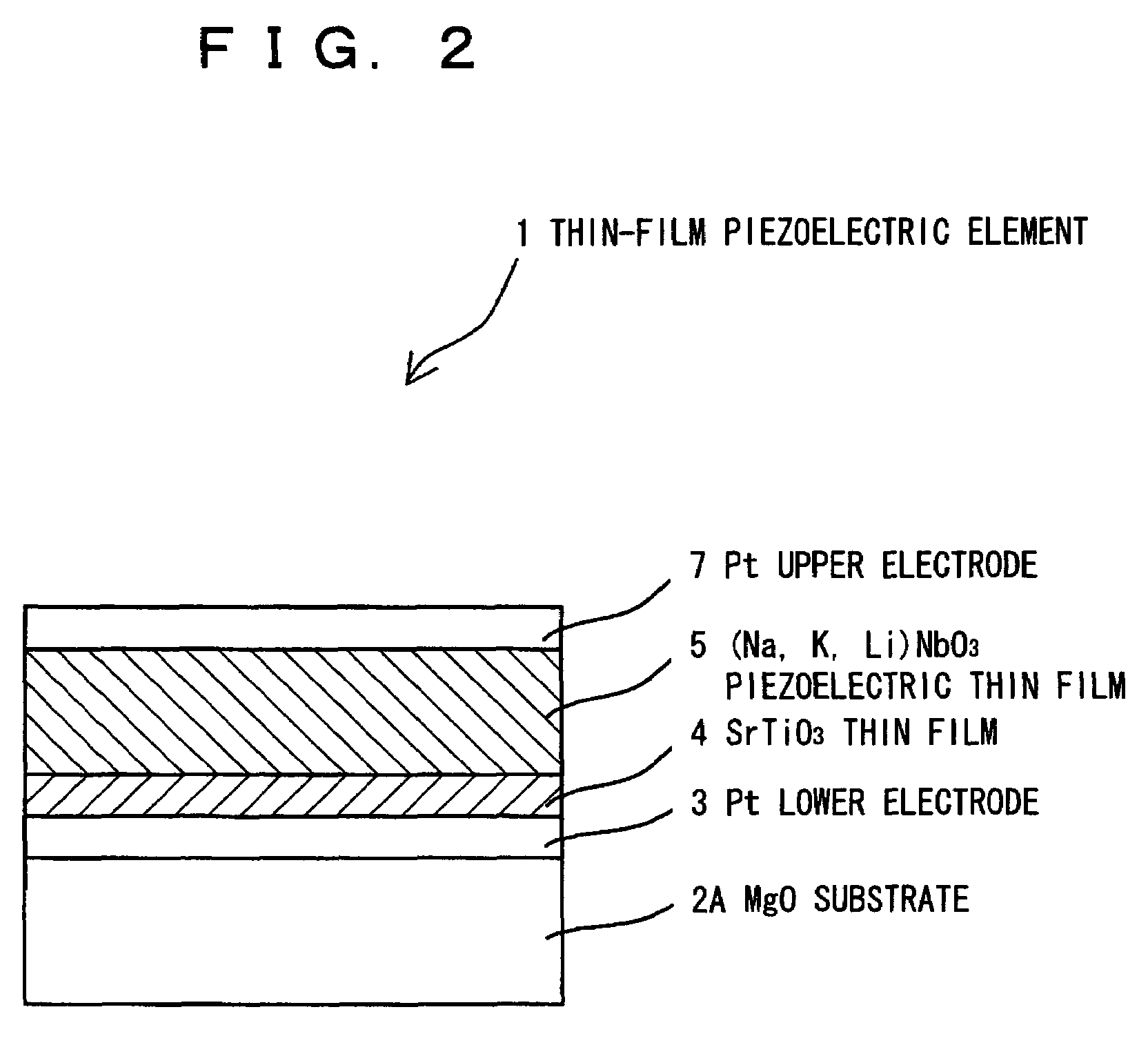

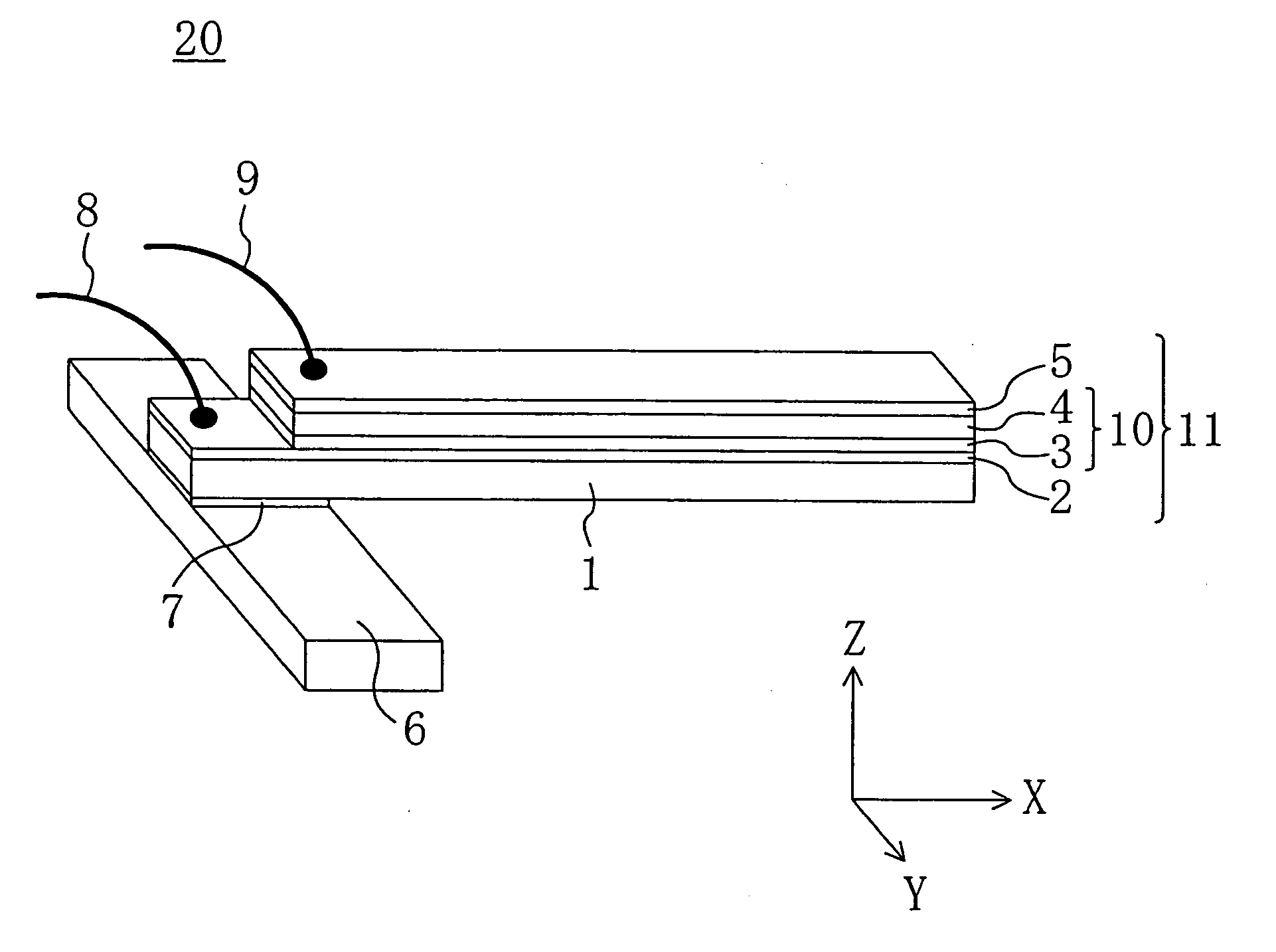

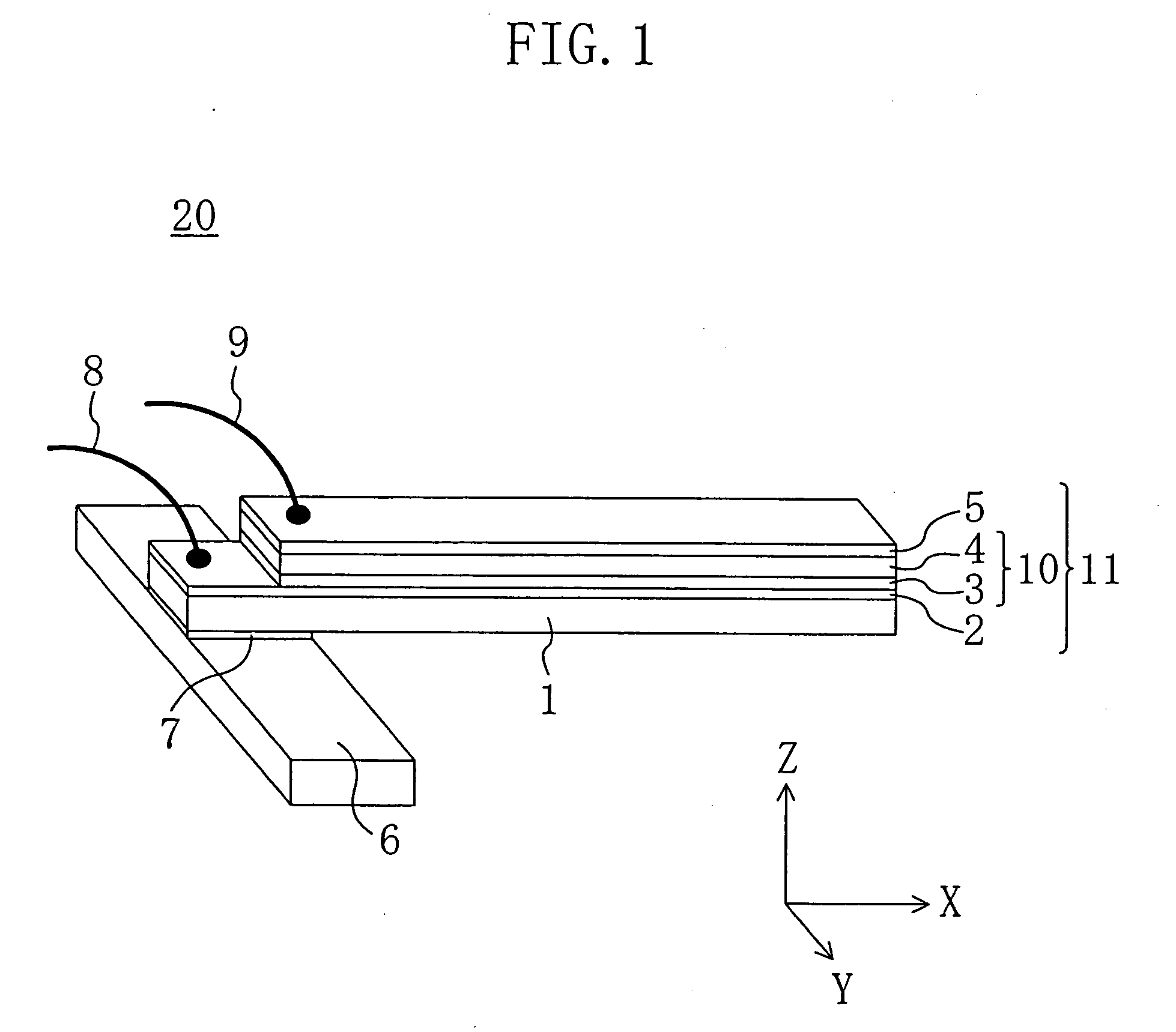

Piezoelectric thin film element

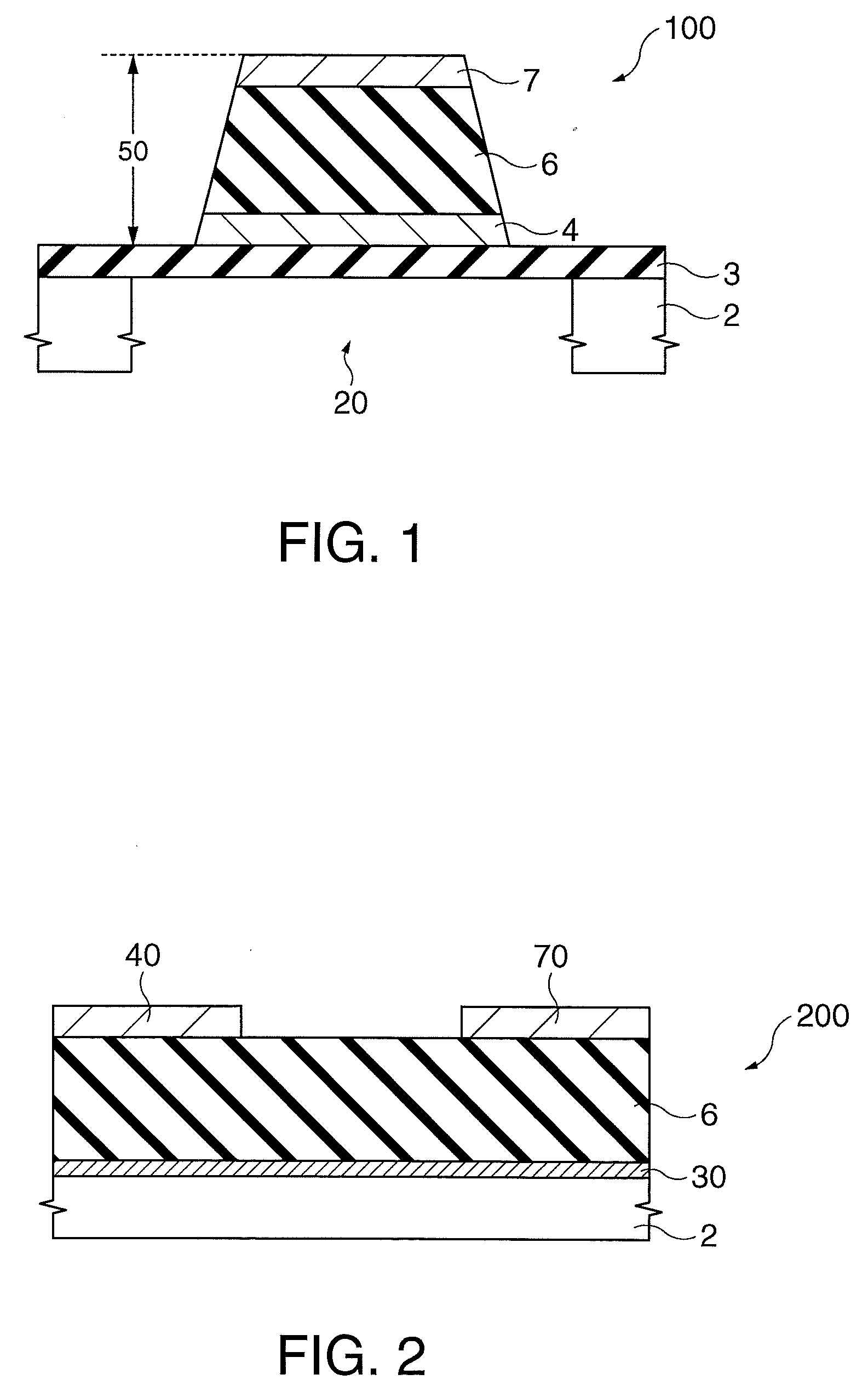

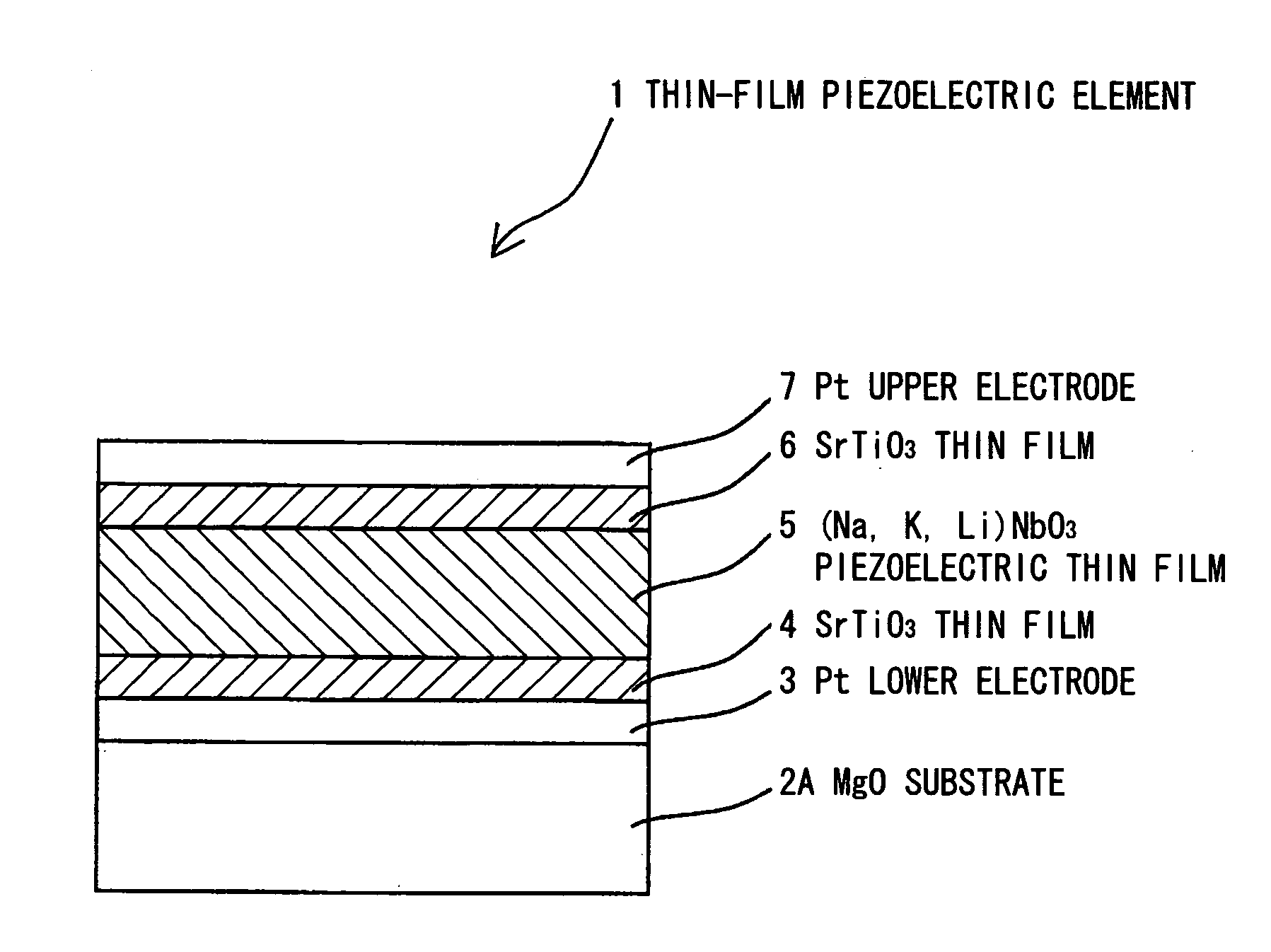

InactiveUS20070024162A1Excellent dielectric strength voltageExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric strengthDielectric thin films

A thin-film piezoelectric element has a substrate, a lower electrode, a piezoelectric portion, and an upper electrode that are sequentially formed on the substrate. The piezoelectric portion has a dielectric thin film that has an alkali niobium oxide-based perovskite structure expressed by general formula (NaxKyLiz)NbO3 (0<x<1, 0<y<1, 0≦z<1, x+y+z=1), and a high voltage-withstand dielectric that has a dielectric strength voltage greater than that of the dielectric thin film.

Owner:SUMITOMO CHEM CO LTD

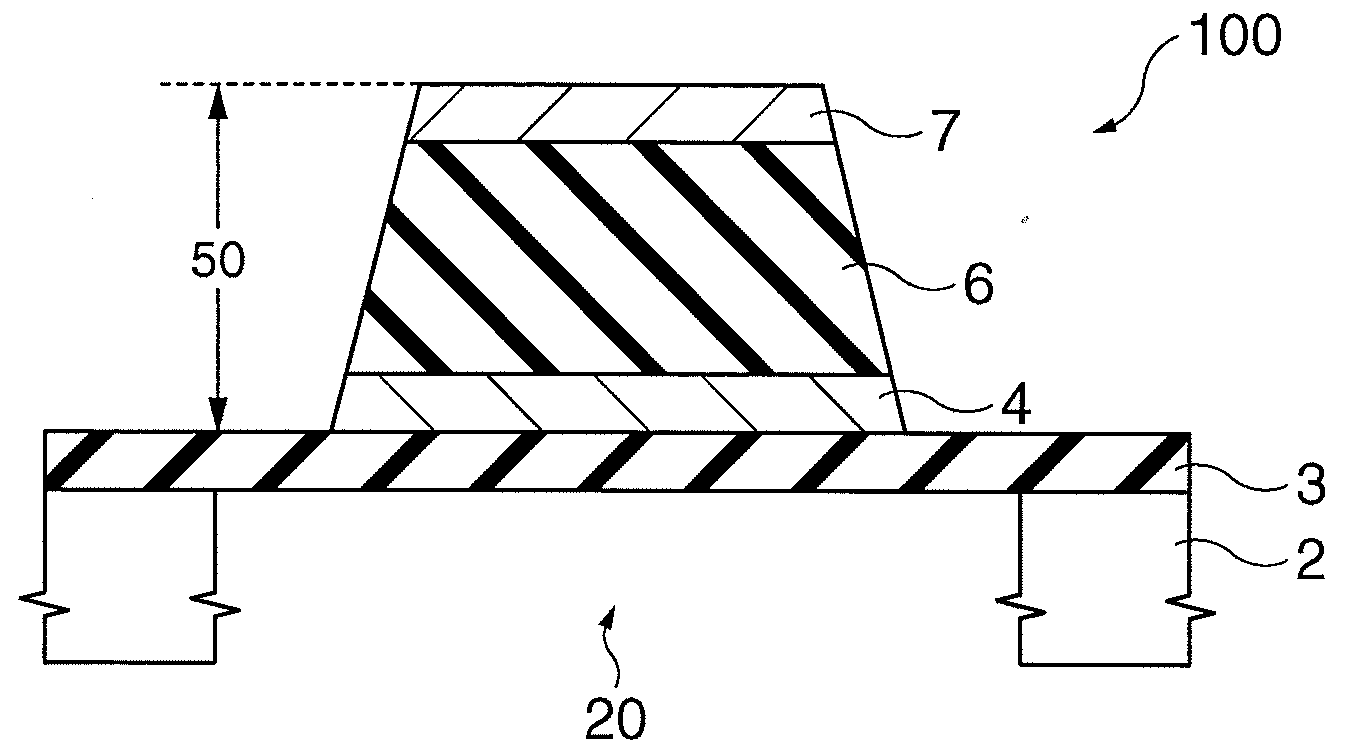

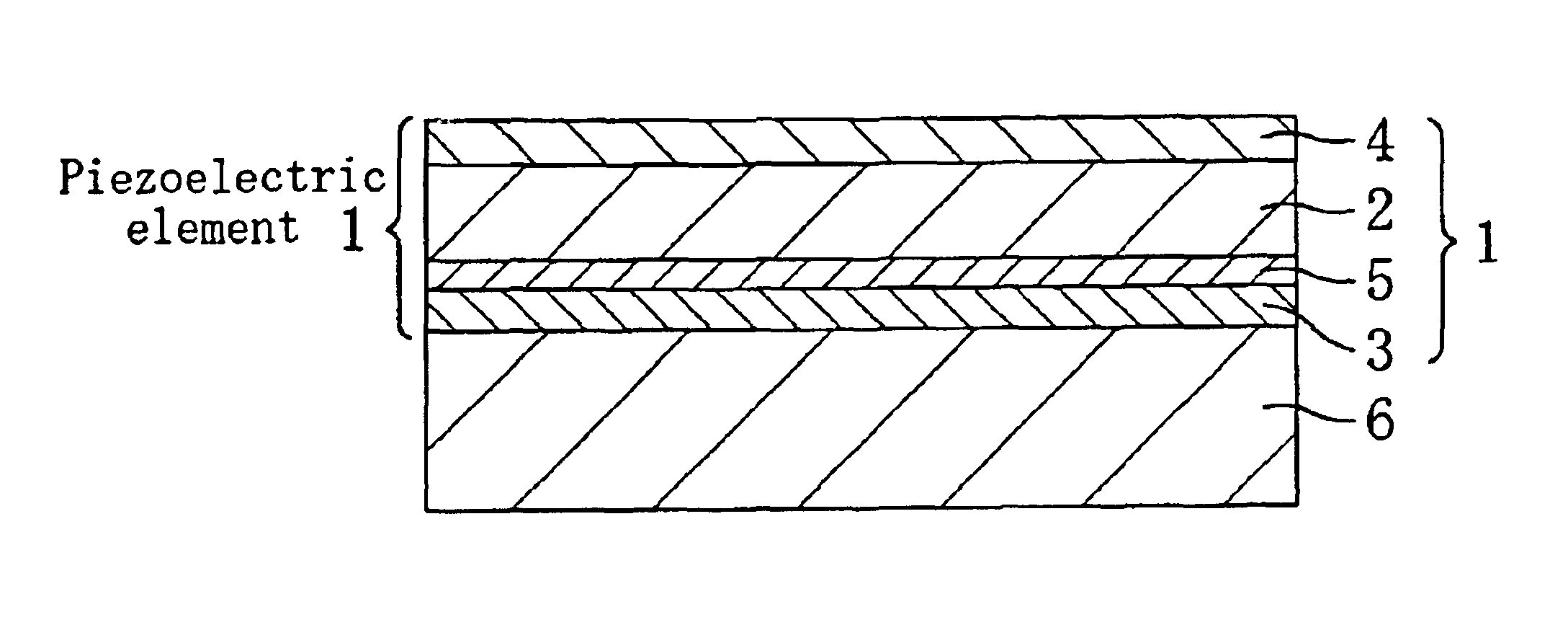

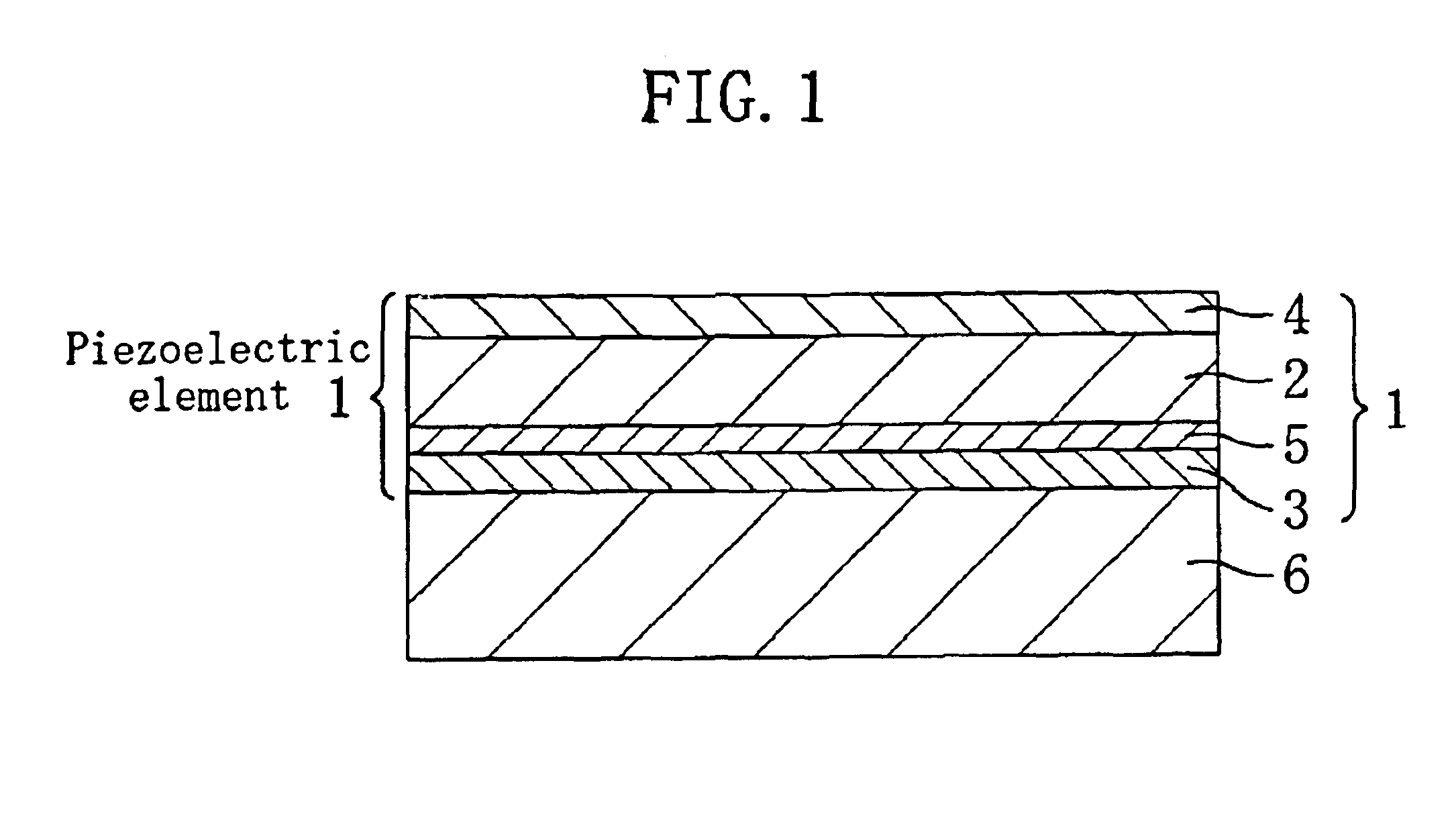

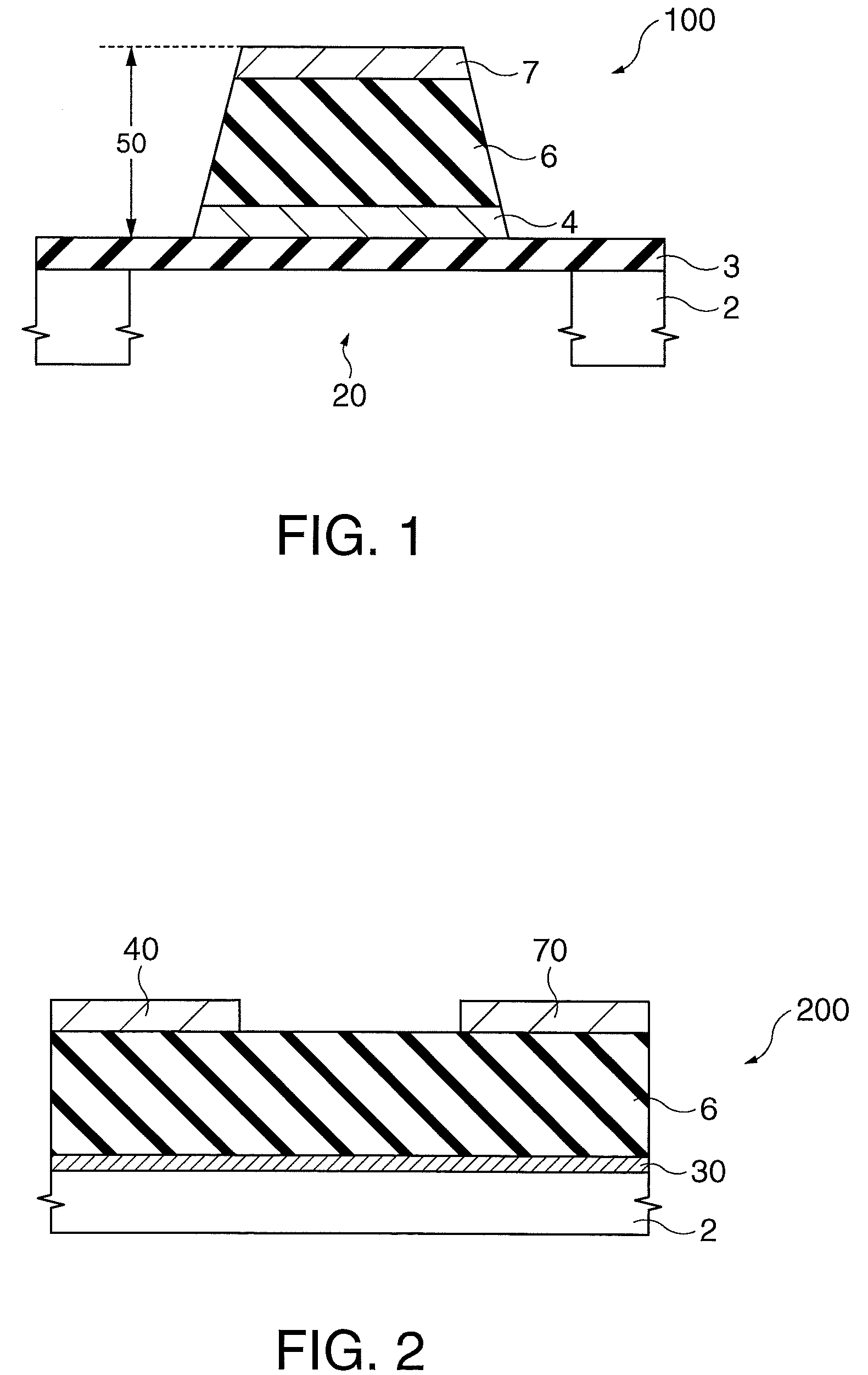

Piezoelectric element, actuator, and inkjet head

InactiveUS6903491B2Function increaseExcellent piezoelectric propertiesPiezoelectric/electrostriction/magnetostriction machinesPrintingSingle crystal substrateSingle crystal

A piezoelectric element includes: a piezoelectric film made of PZT; a pair of electrodes (a lower electrode and an upper electrode) arranged with the piezoelectric film being interposed therebetween; and a base film made of PLT having a thickness of about 50 nm to 200 nm and provided between the piezoelectric film and the lower electrode. The piezoelectric element, as a whole, is provided on a substrate, which may be a stainless steel substrate (polycrystalline), a heat-resistant glass substrate (amorphous), a silicon substrate (single crystal), etc. A piezoelectric element having a good piezoelectric characteristic can be provided on a substrate other than a single crystal substrate.

Owner:PANASONIC CORP

Ternary system sodium-bismuth titanate lead-free piezoelectric ceramics

InactiveCN101200370AExcellent piezoelectric propertiesPracticalDevice material selectionElectricityVolumetric Mass Density

The invention discloses a triple system (Na,Bi)TiO3-based lead-free piezoelectric ceramic material, the formula of the disclosed lead-free piezoelectric ceramic component is denoted with (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO3-yBi(Me)O3 and (1-x-y)(Bi0.5Na0.5)TiO3-x(Bi0.5K0.5)TiO-yBi(Me)O3+zM(a)O(b), in the formula x,y and z denote molar fractions, wherein x is bigger than or equal to 0 and smaller than or equal to 1.0, y is bigger than or equal to 0 and smaller than or equal to 0.2, z is bigger than or equal to 0 and smaller than or equal to 0.1, Me is trivalent metal element, M(a)O(b) is one or more oxides, wherein M is +1 to +6 valence and is an element that can be integrated with oxygen to form a solid oxide. The lead-free piezoelectric ceramic has high ceramic density and excellent performance, piezoelectric constant d33 can reach above 180pC per N, Kp can reach above 0.36. The lead-free piezoelectric ceramic adopts traditional electronic ceramic preparation process, and has low sintering temperature, simple and stable manufacture process and is suitable for industrialization production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Piezoelectric Ceramic Composition, Method for Manufacturing the Same, and Piezoelectric Ceramic Electronic Component

ActiveUS20080061263A1Excellent piezoelectric propertiesHigh constantPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallurgyElectronic component

A piezoelectric ceramic composition includes a primary component represented by the formula (1-x)(K1-a-bNaaLib)m(Nb1-c-dTacSbd)O3-xM1nM2O3, and 0.1 to 10 moles (preferably 1.5 to 10 moles) of at least one specific element selected from the group consisting of In, Sc, Y, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Yb, and Lu with respect to 100 moles of the primary component, wherein M1 is Ca, Sr, or Ba M2 is Ti, Zr, or Sn; and x, a, b, c, d, m, and n satisfy 0.005≦x≦0.1, 0≦a≦0.9, 0≦b≦0.3, 0≦a+b≦0.9, 0≦c≦0.5, 0≦d≦0.1, 0.9≦m≦1.1, and 0.9≦n≦1.1. Preferably, Mn, Ni, Fe, Zn, Cu, or Mg is further added. As a result, at both a very low and a high electric field, a high piezoelectric d constant can be stably obtained with a high efficiency.

Owner:MURATA MFG CO LTD

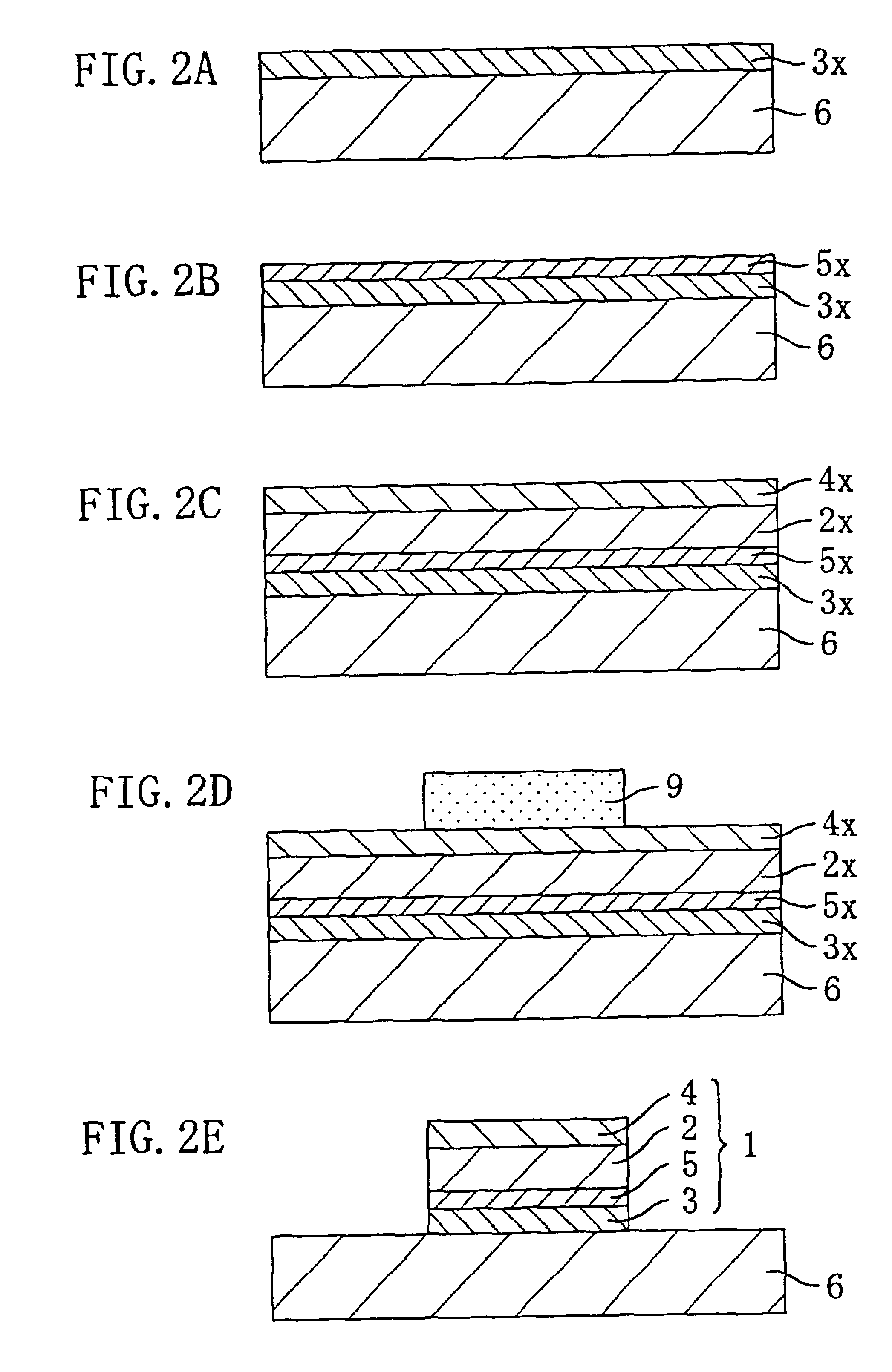

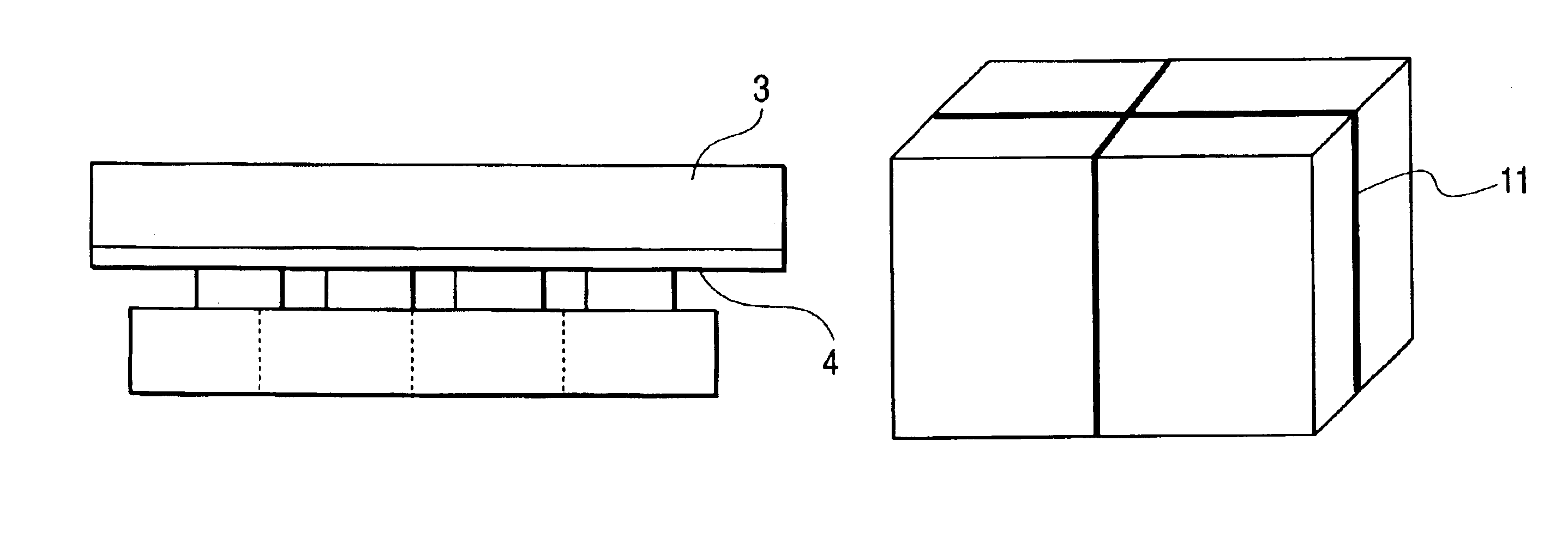

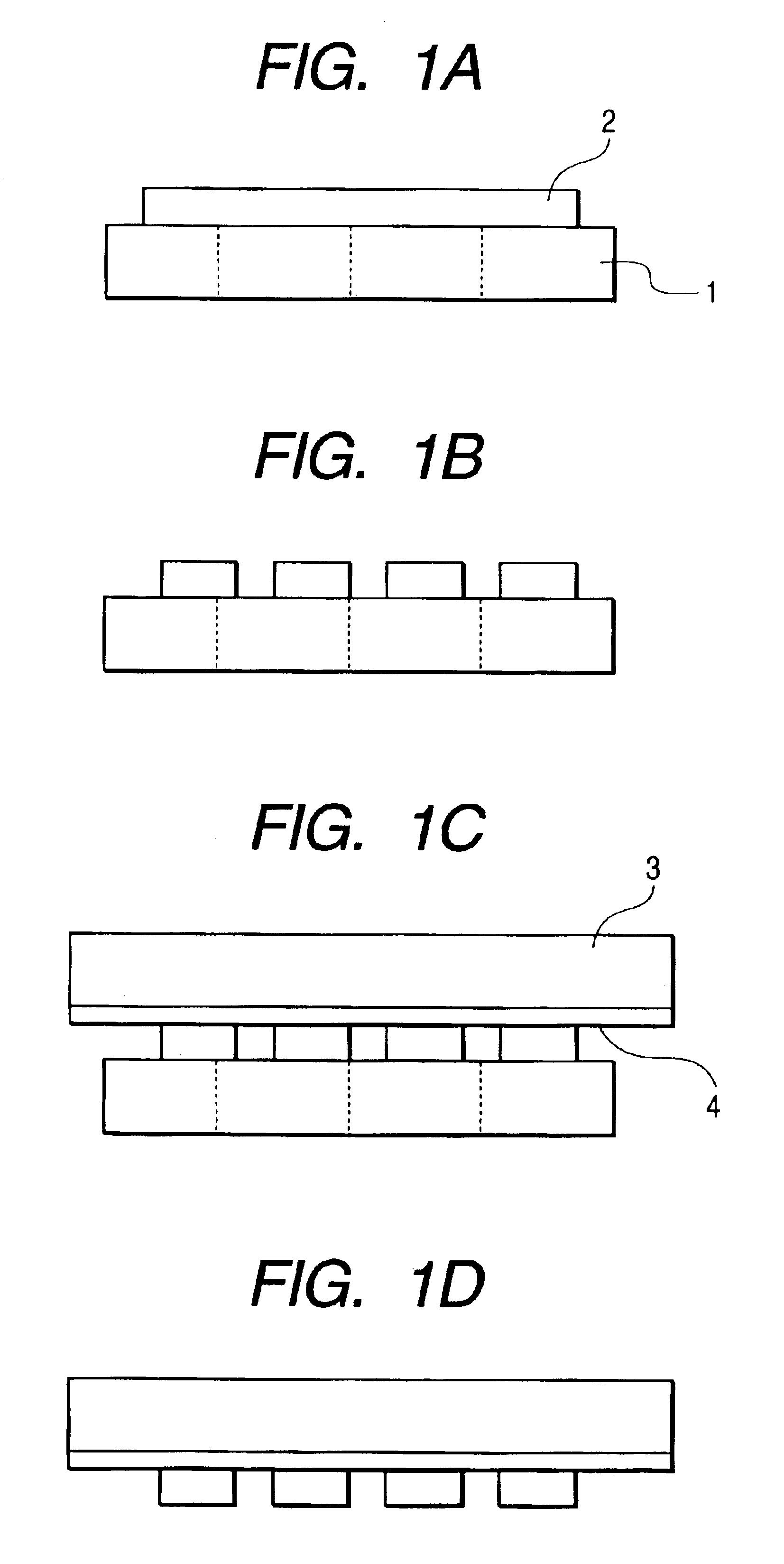

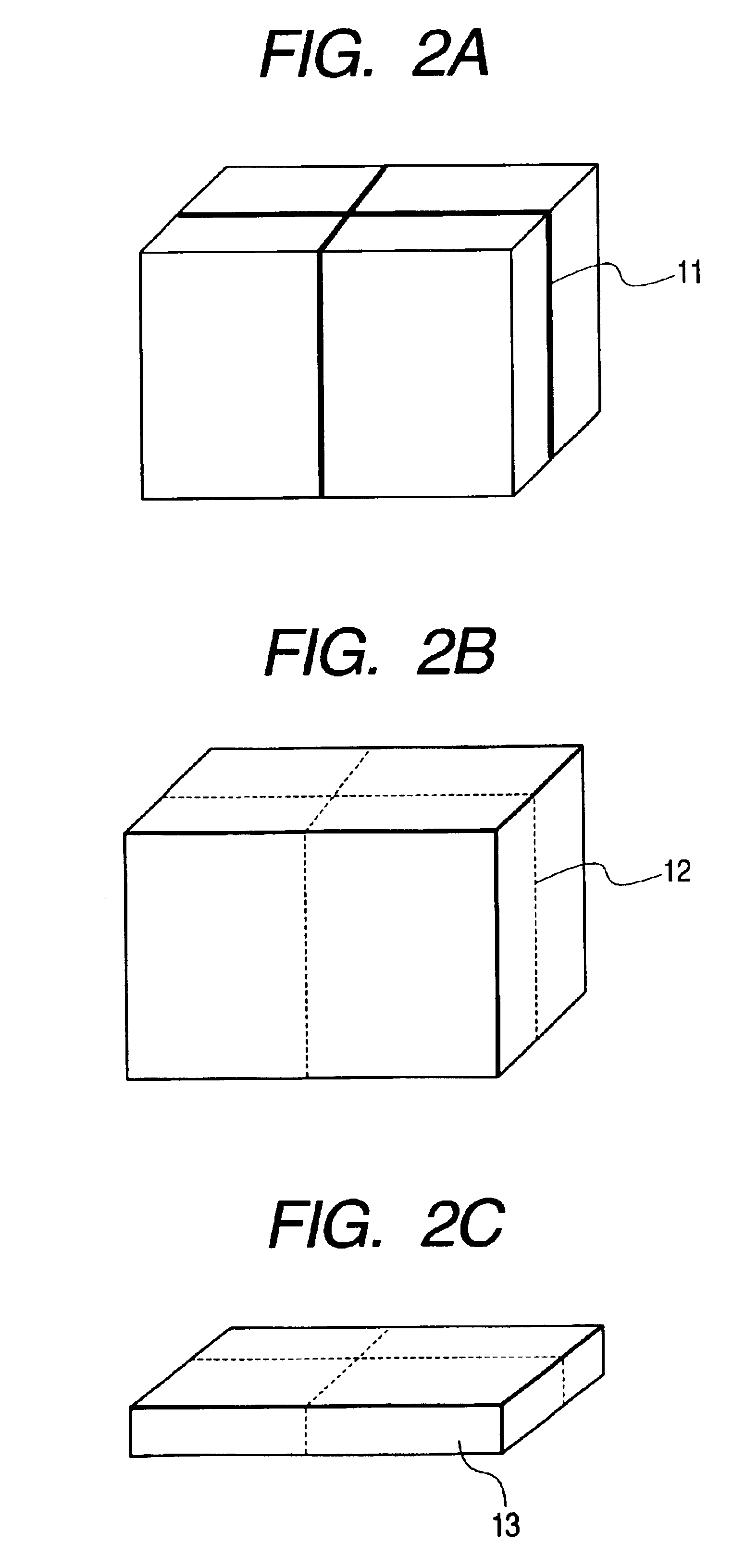

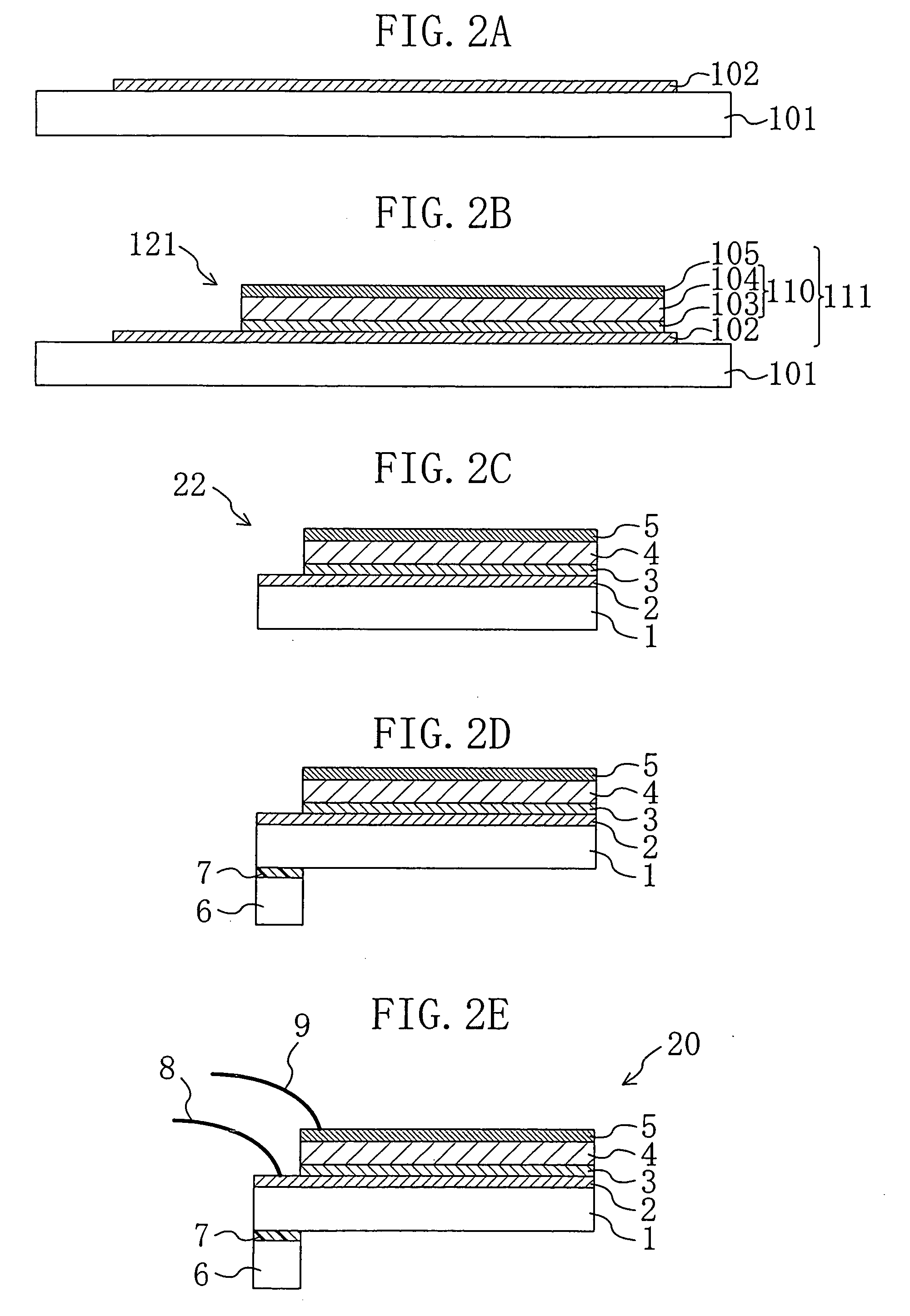

Method of manufacturing actuator and ink jet head

InactiveUS6927084B2Maintain good propertiesExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblySemiconductor/solid-state device manufacturingDiaphragm structureSingle crystal substrate

A method of manufacturing an actuator comprises the steps of bonding a piezoelectric film formed on a single crystal substrate to a diaphragm structure member and removing the single crystal substrate therefrom to manufacture the actuator. The single crystal substrate is a substrate having bonded portions where a plurality of single crystal substrates are bonded together.

Owner:CANON KK

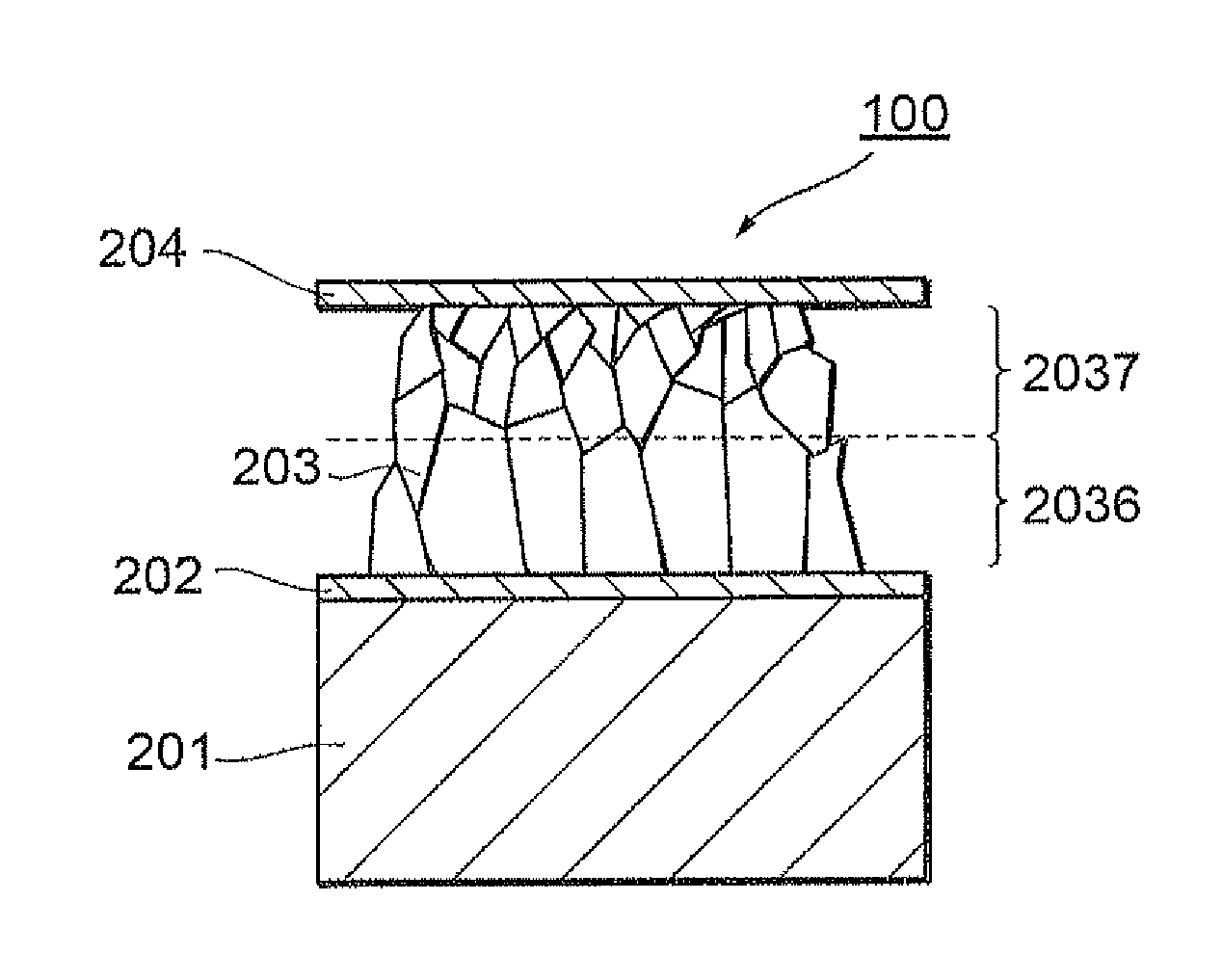

Thin-film piezoelectric element, thin-film piezoelectric actuator, thin-film piezoelectric sensor, hard drive disk, and inkjet printer

ActiveUS20140339961A1Leakage currentReduce leakage currentInking apparatusPiezoelectric/electrostriction/magnetostriction machinesHard disc drivePiezoelectric actuators

A thin film piezoelectric element according to the present invention includes a potassium sodium niobate thin film having a structure in which a plurality of crystal grains are present in a film thickness direction; and a pair of electrode films sandwiching the potassium sodium niobate thin film. When the potassium sodium niobate thin film is divided into three regions of the same thickness in the film thickness direction and average crystal grain sizes A1, A2, and A3 of the respective regions are determined, a ratio m / M of the smallest average crystal grain size m among A1, A2, and A3 to the largest average crystal grain size M among A1, A2, and A3 is 10% to 80%. The region having the smallest average crystal grain size m lies next to one of the pair of electrode films.

Owner:TDK CORPARATION

Piezoelectric thin film element

InactiveUS7323806B2Excellent dielectric strength voltageExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric thin filmsDielectric strength

A thin-film piezoelectric element has a substrate, a lower electrode, a piezoelectric portion, and an upper electrode that are sequentially formed on the substrate. The piezoelectric portion has a dielectric thin film that has an alkali niobium oxide-based perovskite structure expressed by general formula (NaxKyLiz)NbO3 (0<x<1, 0<y<1, 0≦z<1, x+y+z=1), and a high voltage-withstand dielectric that has a dielectric strength voltage greater than that of the dielectric thin film.

Owner:SUMITOMO CHEM CO LTD

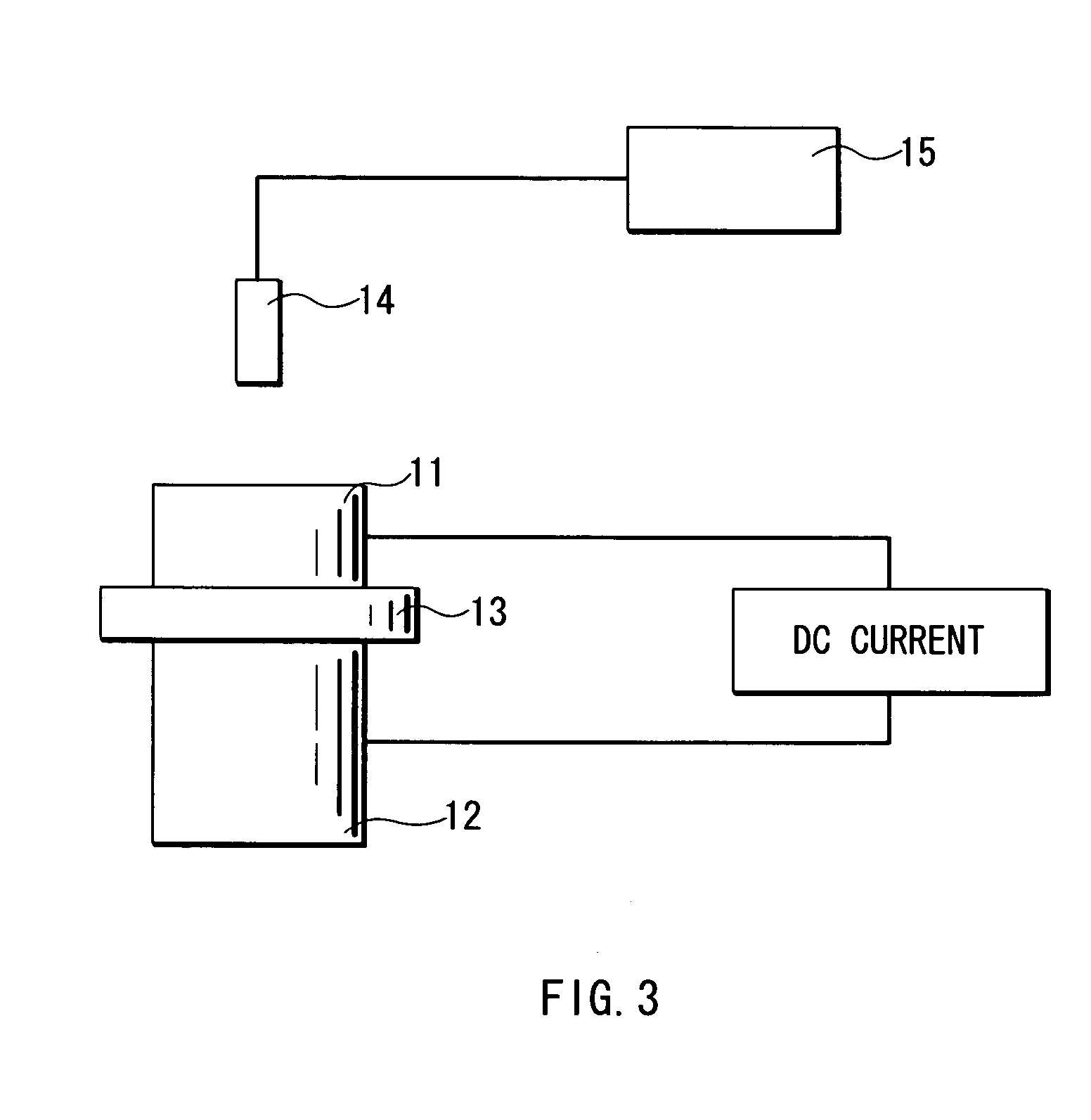

Ternary system relaxation ferroelectric single crystal material and preparation method thereof

InactiveCN101985775ASmall sizeQuality improvementPolycrystalline material growthFrom frozen solutionsBridgman methodSingle crystal

The invention discloses a ternary system relaxation ferroelectric single crystal material. The material comprises the following chemical components: xPb(In1 / 2Nb1 / 2)O3-yPb(Mg1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein the x is equal to 0.1-0.45, and the y is equal to 0.1-0.5. A preparation method of the single crystal material PIMNT is an improved Bridgman method and comprises the following steps of: processing raw materials, melting by raising the temperature, and performing crucible degrowth and crystal cooling growth. The prepared single crystal material overcomes the defects of over low Curie point of PMNT single crystals, difficult crystallization and difficult batch growth of the PINT single crystals in the prior art, has high piezoelectric performance and pyroelectric performance, higher temperature stability and wide application prospect and adds a new product in the field.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Niobic acid sodium potassium lithium radical leadless piezo-electric ceramic and preparation method thereof

InactiveCN101062864AExcellent piezoelectric propertiesImprove ferroelectric propertiesCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesLithiumPotassium

The invention discloses a preparing method of niobic acid sodium potassium lithium group leadless piezoelectric ceramic in green energy source material domain, which comprises the following steps: expressing component of niobic acid sodium potassium lithium group as non-stoichiometric ratio general formula (NaaKbLic)(NbxTaySbz)O3 or -nM; expressing a, b, c as A bit element; expressing x, y, z as mole fraction of B bit element; setting the selective rage as (0<=a<=1. 5, 0<=b<=1. 5, 0 C04B 35 / 495 C04B 35 / 64 H01B 3 / 12 H01L 41 / 187 1 6 1 2007 / 5 / 28 101062864 2007 / 10 / 31 100465131 2009 / 3 / 4 2009 / 3 / 4 2009 / 3 / 4 University of Science and Technology Beijing Beijing 100083 Zhang Boping Zhao Pei Li Songjie Ding Xiaonian Zhang Hailong liuru e 11207 The Patent Agency of Beijing University of Science and Technology No.30 Xueyuan Road, Beijing 100083

Owner:UNIV OF SCI & TECH BEIJING

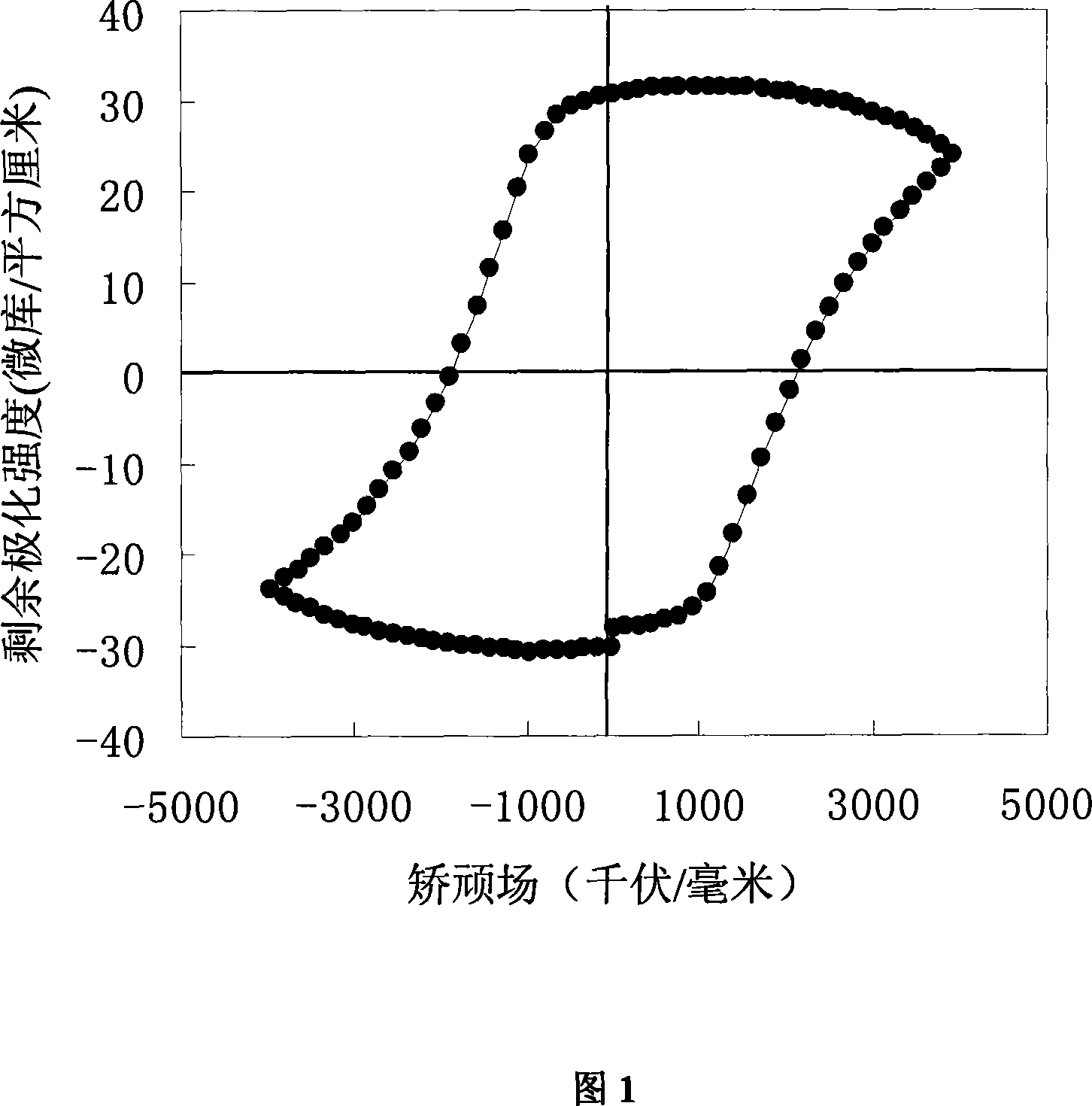

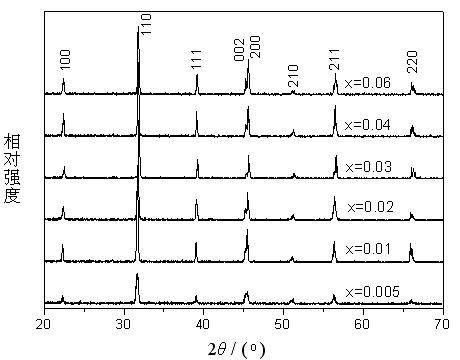

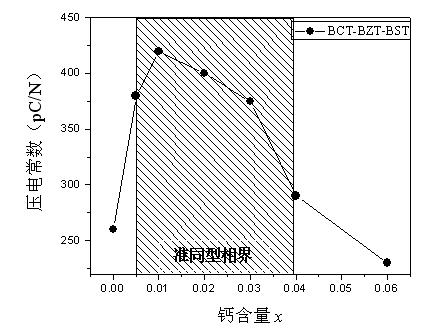

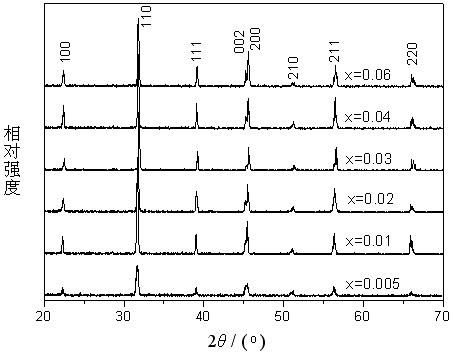

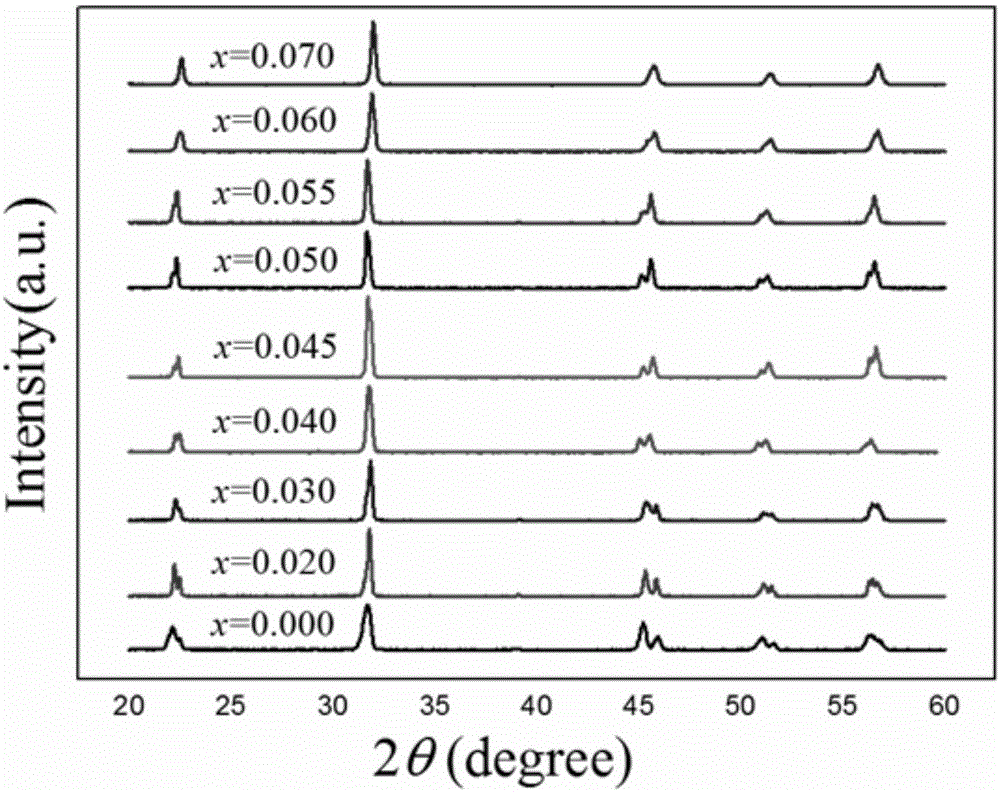

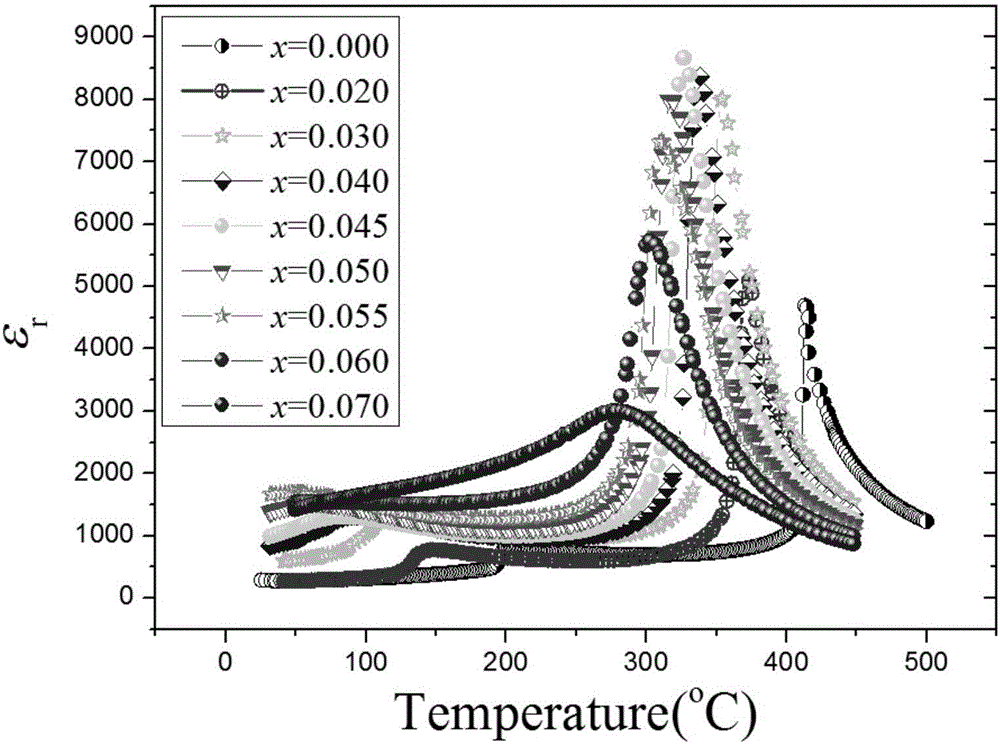

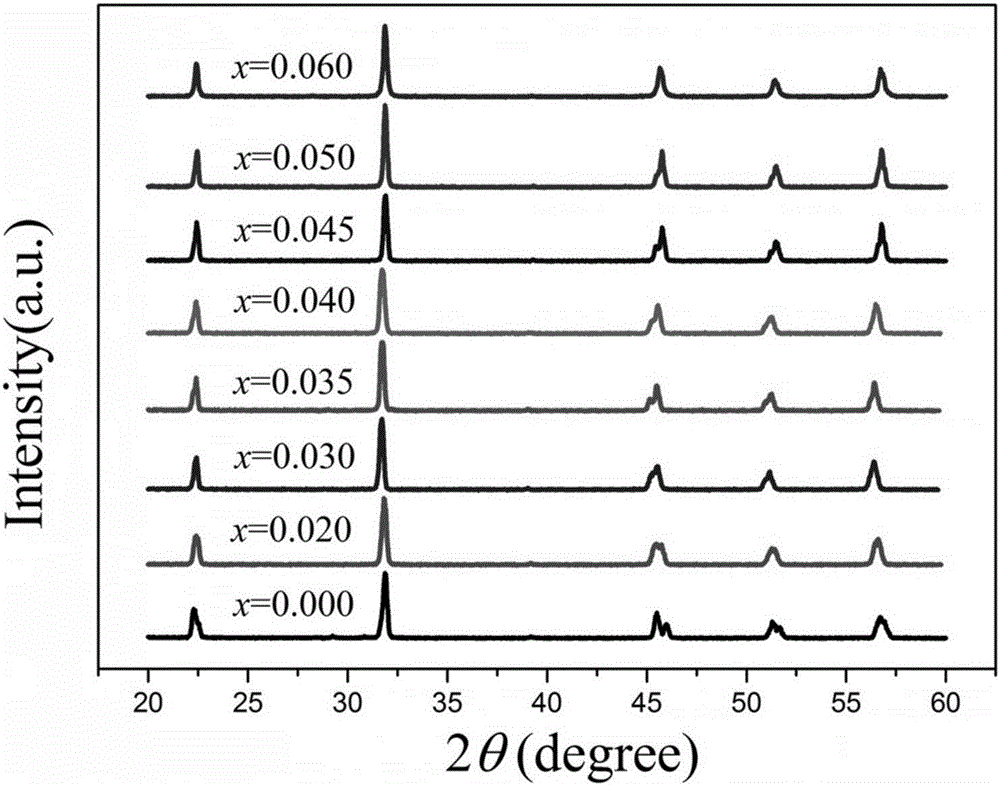

BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

InactiveCN102531578AExcellent piezoelectric propertiesThe preparation process is stableBarium titanateElectromechanical coupling coefficient

The invention belongs to the field of a lead-free piezoelectric material and discloses BCT-BZT-BST (barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is characterized by having the following material components: Ba0.8-xCaxTi0.8O3-0.1BaTi0.9Sn0.1O3-0.1BaTi0.8Zr0.2O3, wherein x is in the range of 0.005 to 0.06. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is prepared from industrial raw materials by adopting a conventional piezoelectric ceramic preparation technology. The system is a perovskite phase. When x is in the range of 0.005 to 0.04, the BCT-BZT-BST ternary system lead-free piezoelectric ceramic is in morphotropic phase boundary region, has excellent piezoelectric property, has a piezoelectric constant d33 value of 420pC / N and an electro-mechanical coupling coefficient of 44 percent, and has a stable preparation process and wide application prospect.

Owner:LIAOCHENG UNIV

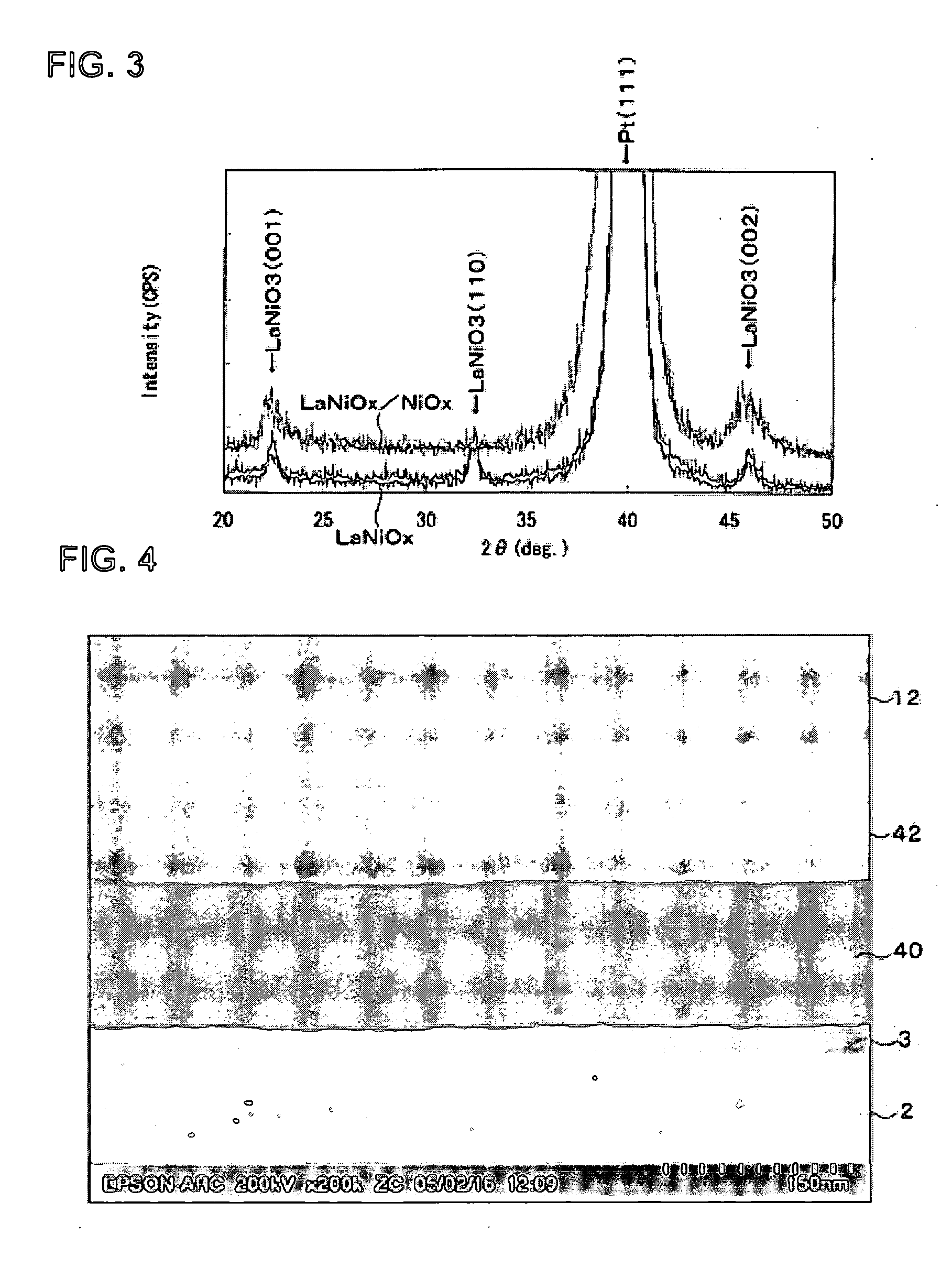

Piezoelectric element and method for manufacturing the same, ink jet recording head and ink jet printer

InactiveUS20060214542A1Excellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusOptoelectronicsLanthanum

A method for manufacturing a piezoelectric element includes the steps of forming a first electrode above a substrate, forming, above the first electrode, a piezoelectric layer composed of a piezoelectric material having a perovskite structure, and forming a second electrode above the piezoelectric layer, wherein the step of forming the first electrode includes forming a layer containing nickel, and forming, above the layer containing nickel, a lanthanum nickelate layer that is oriented to a cubic (100).

Owner:SEIKO EPSON CORP

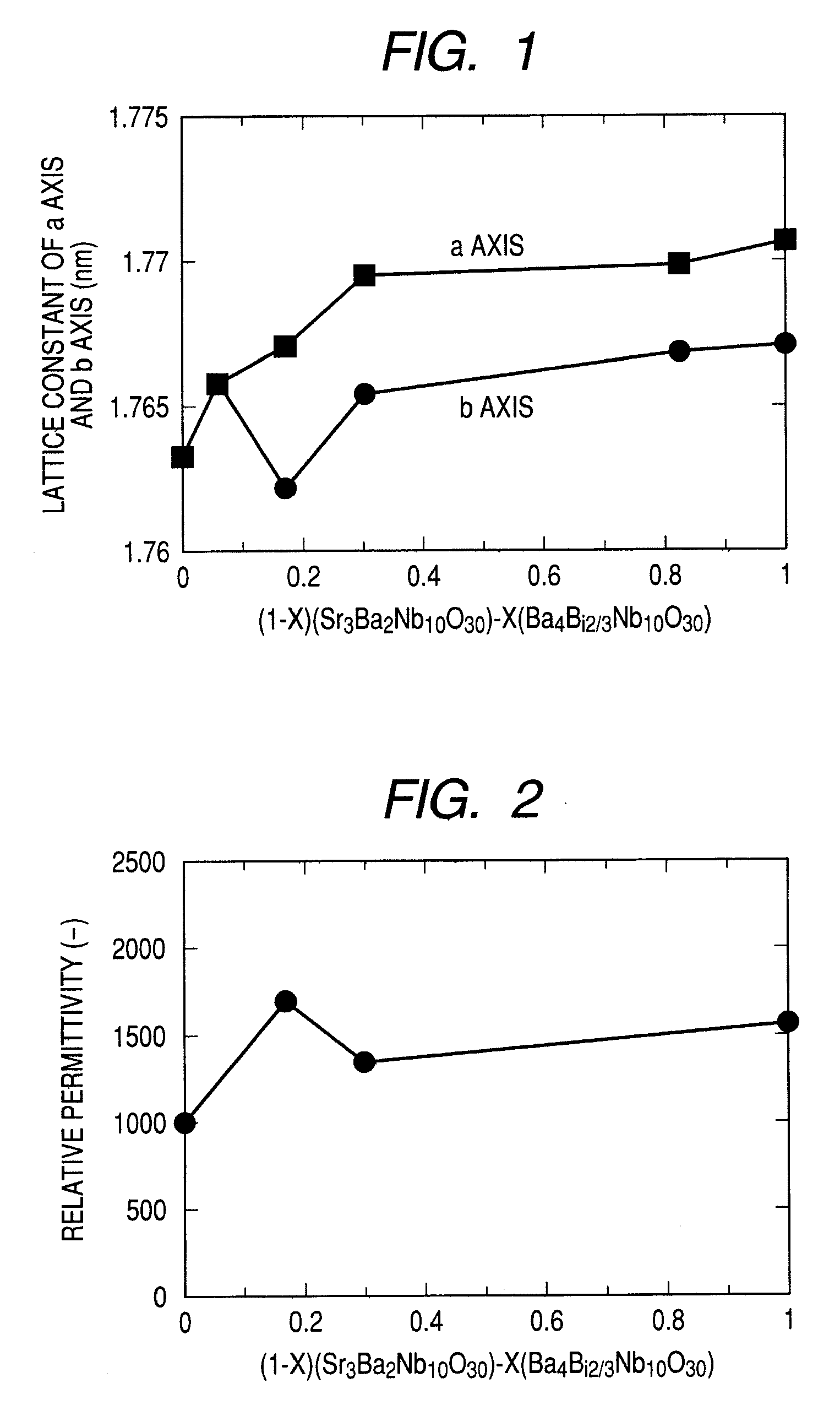

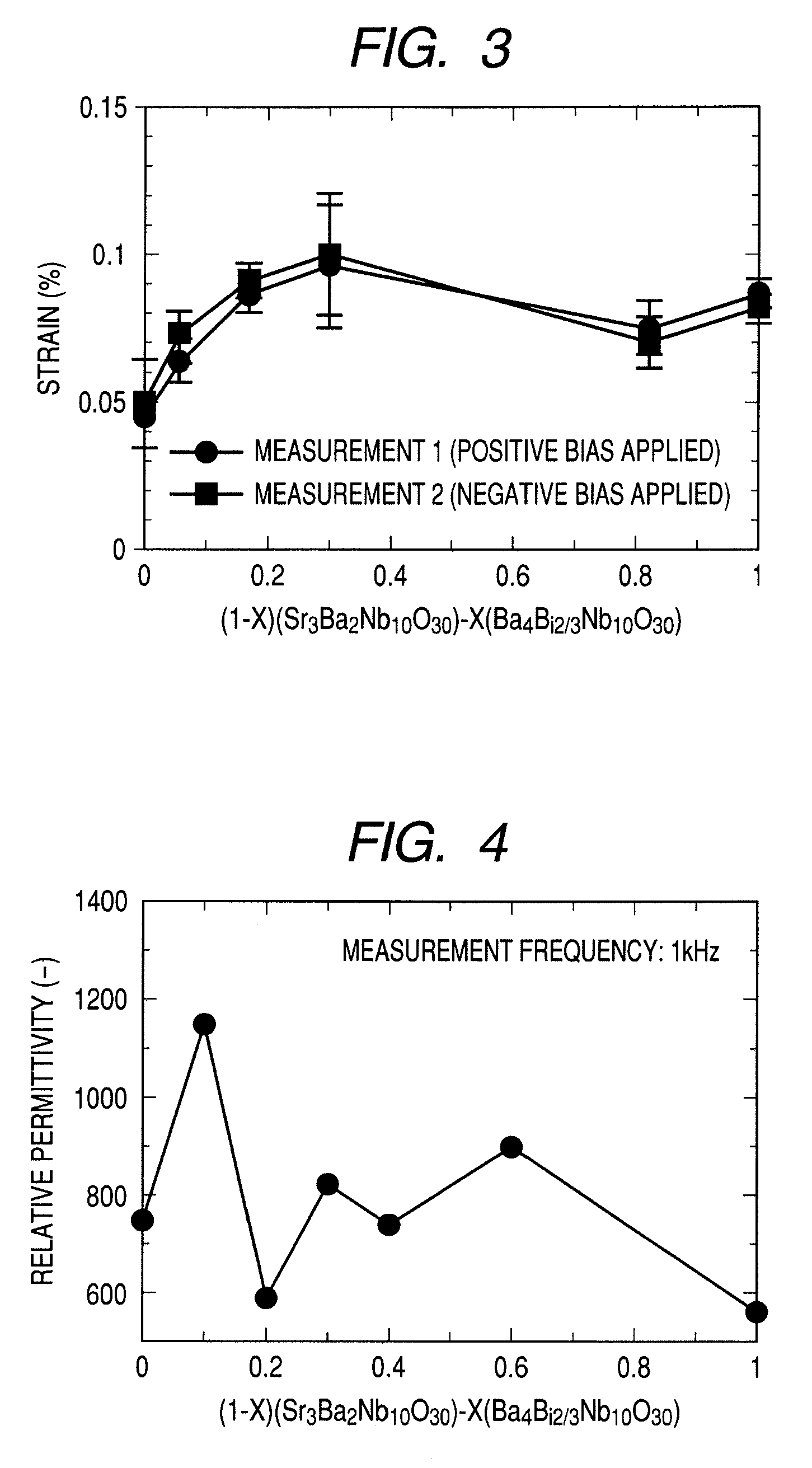

Piezoelectric material

ActiveUS20100025618A1Excellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyVacuum evaporation coatingTungstenMaterials science

Provided is a piezoelectric material which includes a compound free of lead and alkali metal and has a good piezoelectric property. The piezoelectric material where tungsten bronze structure oxides being free of lead and alkali metal and represented by AxB10O30 and A′x′B′10O30 are combined to form a morphotropic phase boundary has good piezoelectric property. The AxB10O30 is b(Ba5−5αBi10α / 3Nb10O30)+(1−b)(Ba4Ag2Nb10O30) (0≦b≦1 and 0<α≦0.4), and the A′x′B′10O30 is c(Sr5Nb10O30)+d(Ca5Nb10O30)+e(Ba5Nb10O30) (0≦c≦0.8, 0≦d≦0.4, 0.1≦e≦0.9, and c+d+e=1).

Owner:CANON KK +3

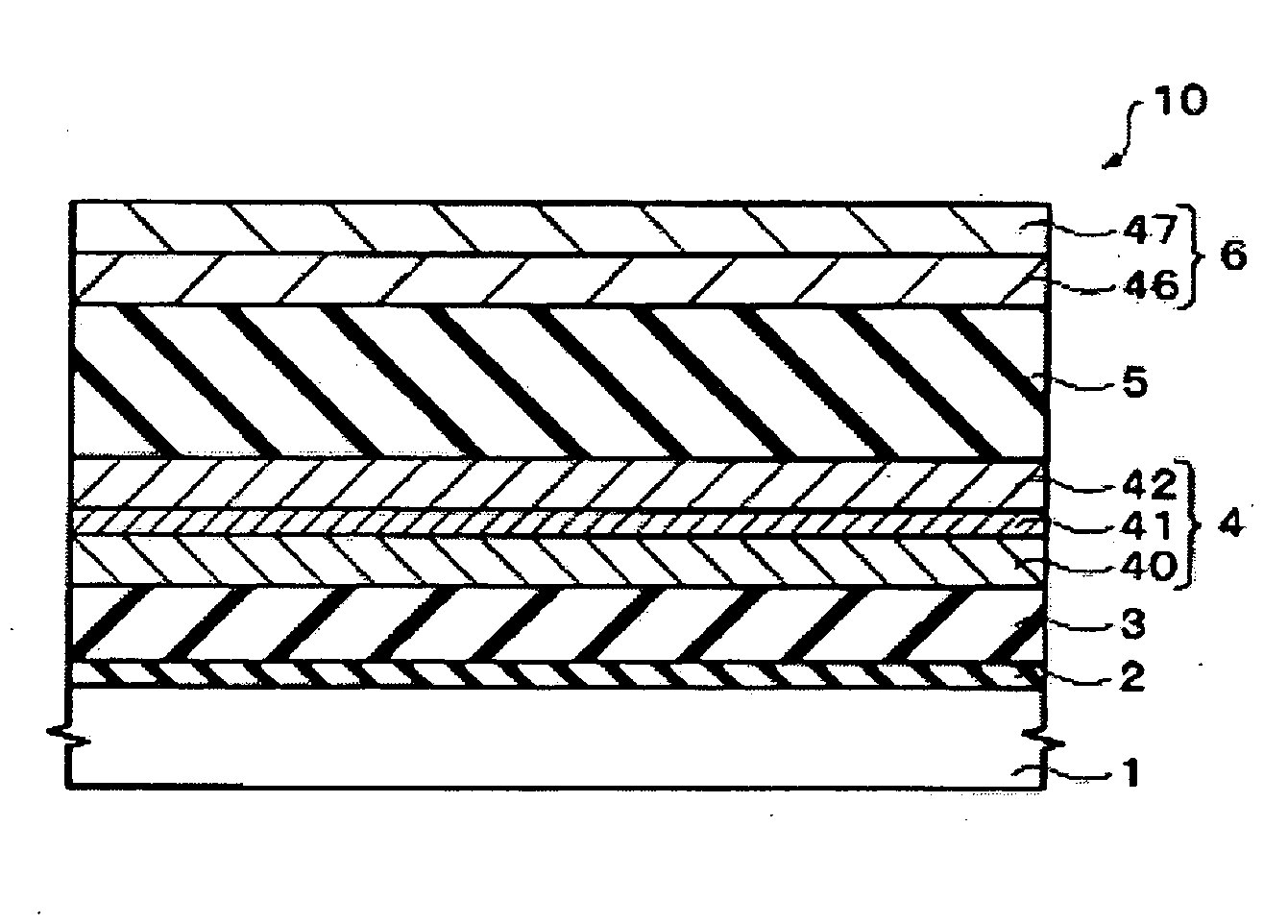

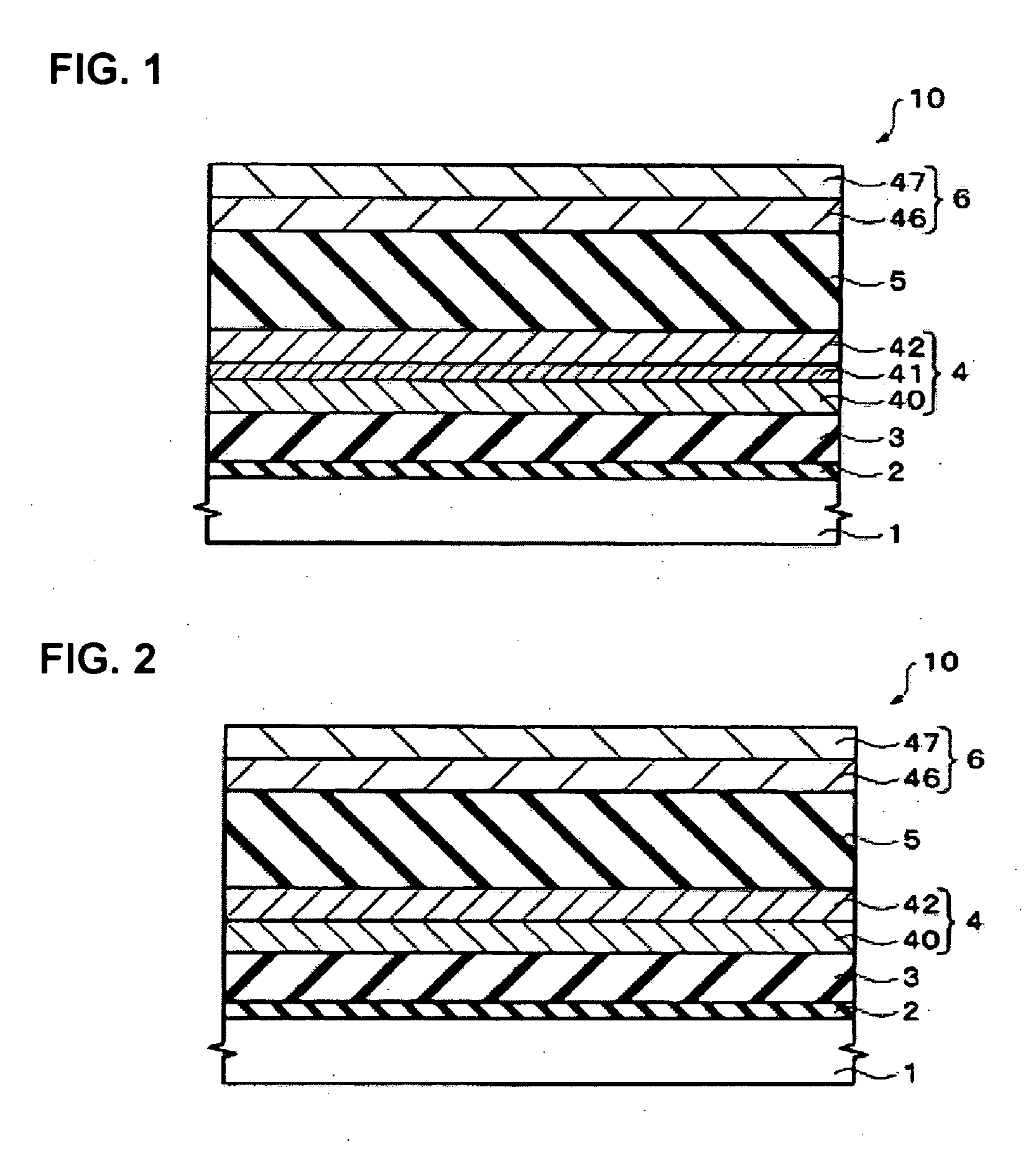

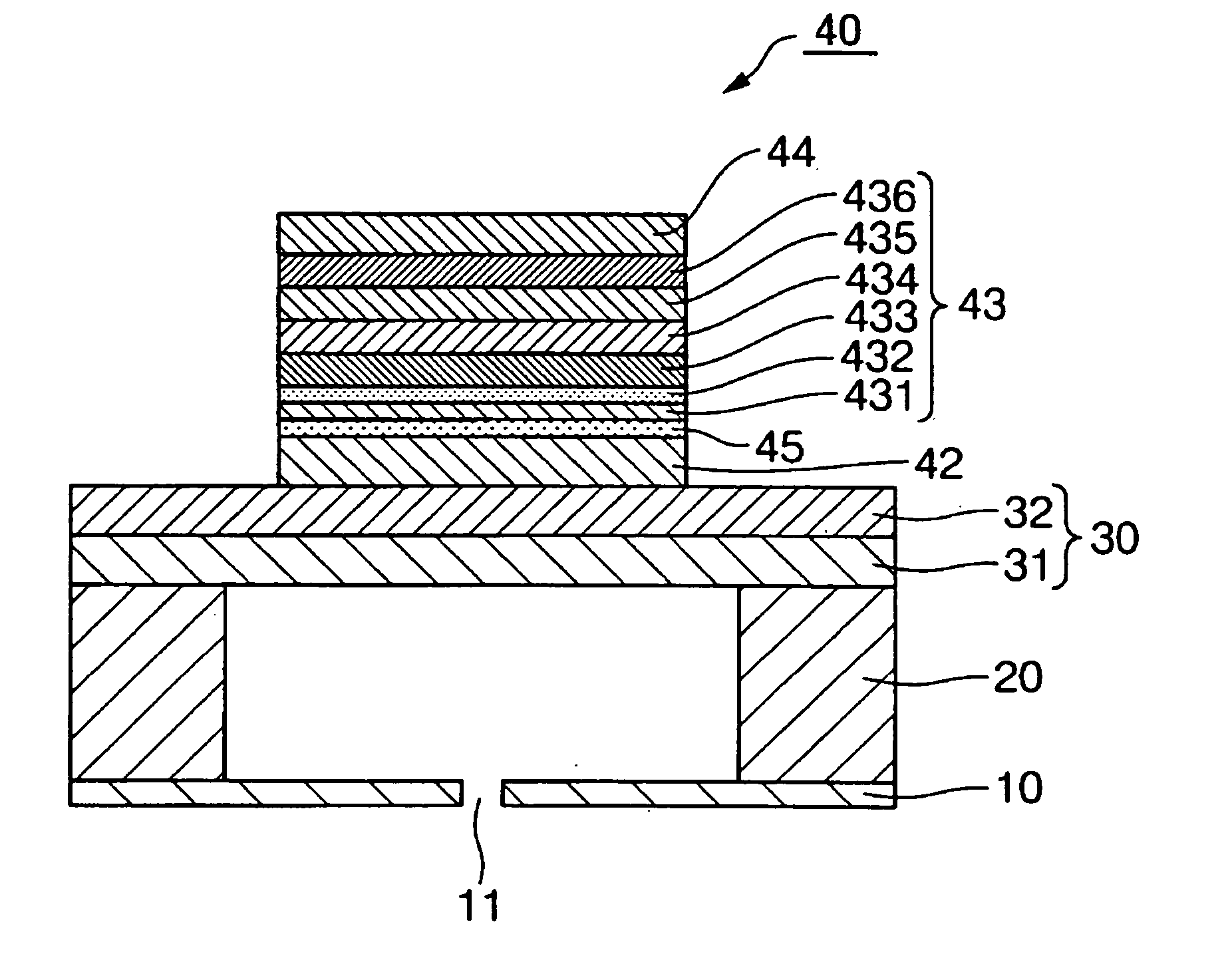

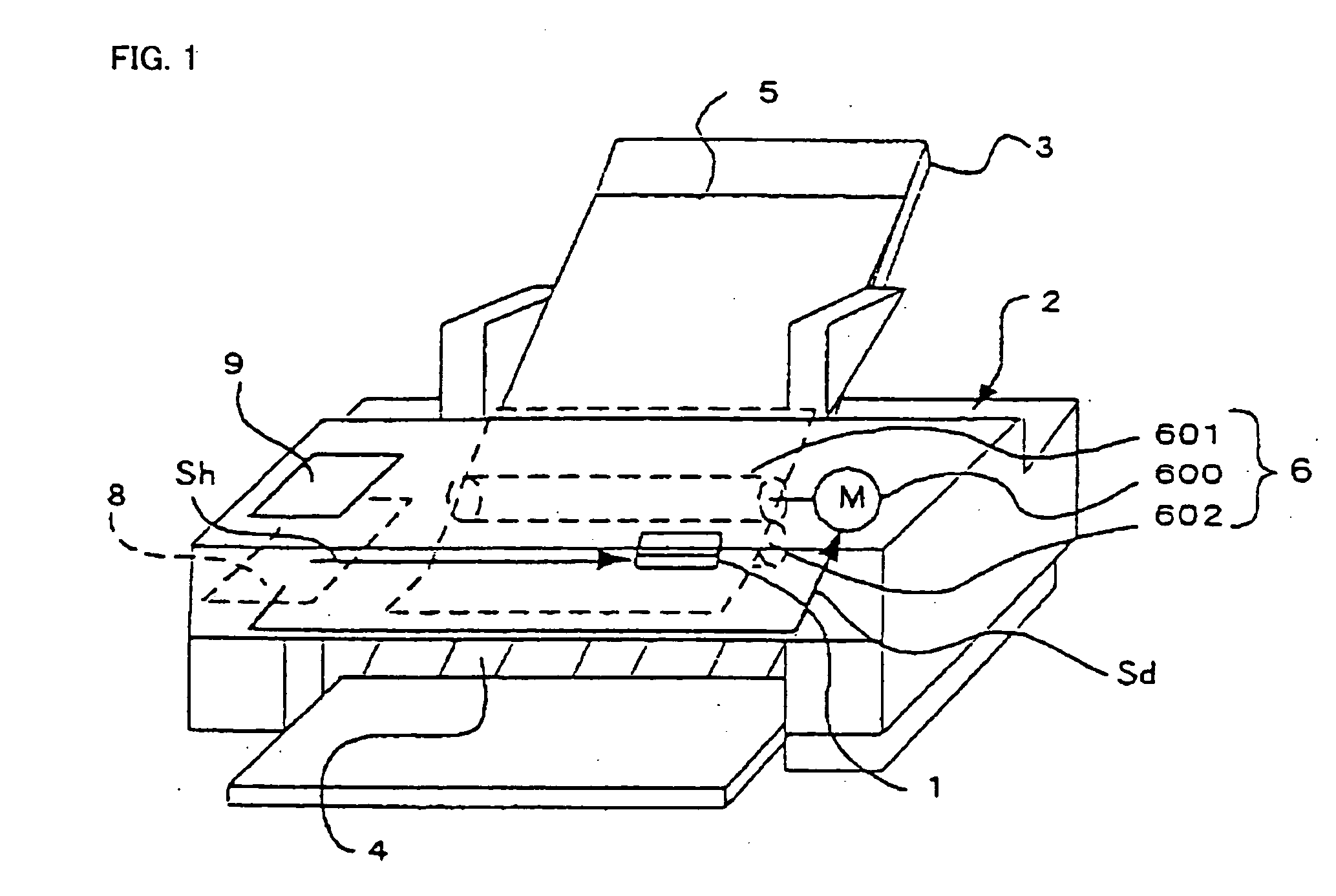

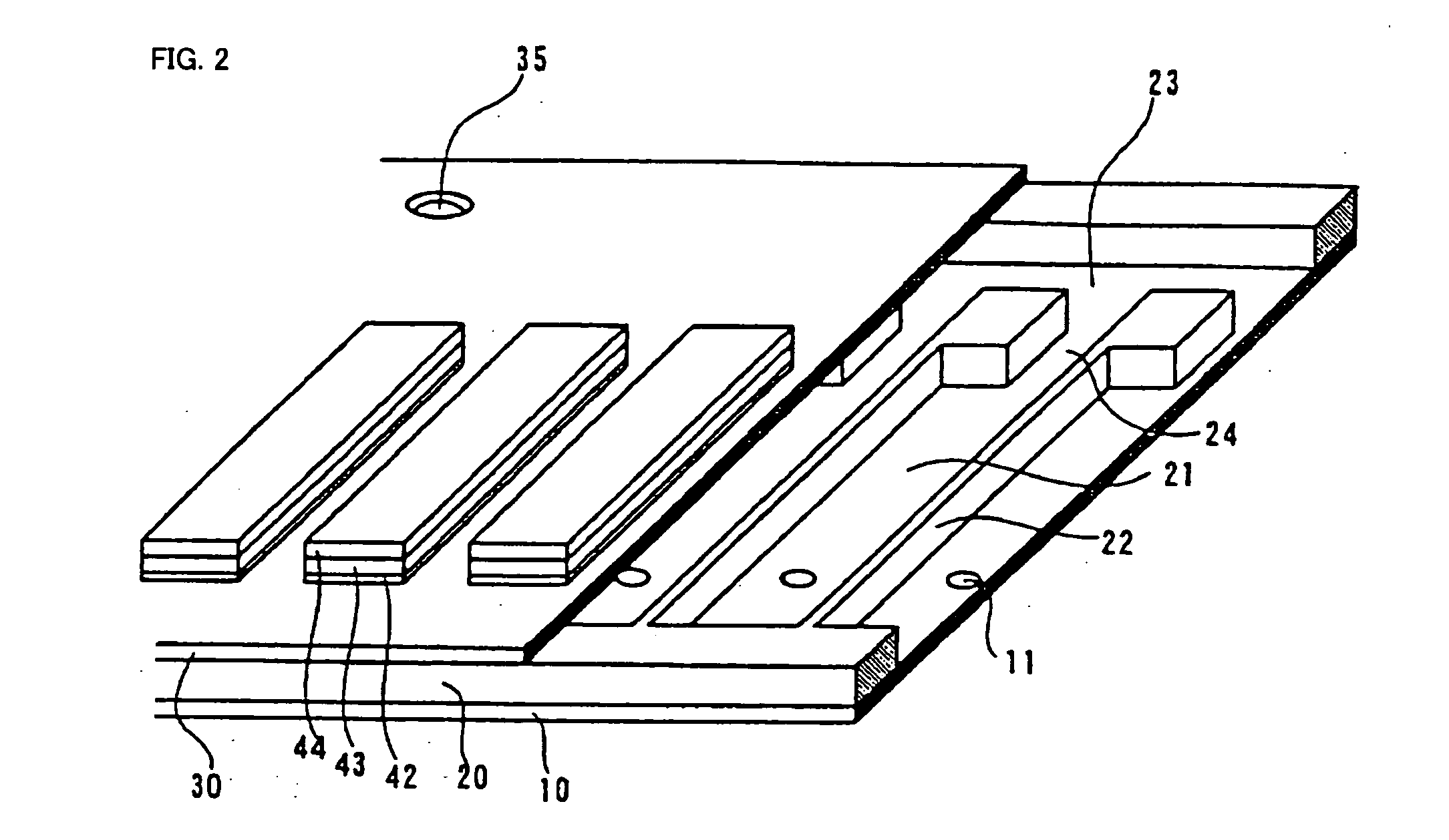

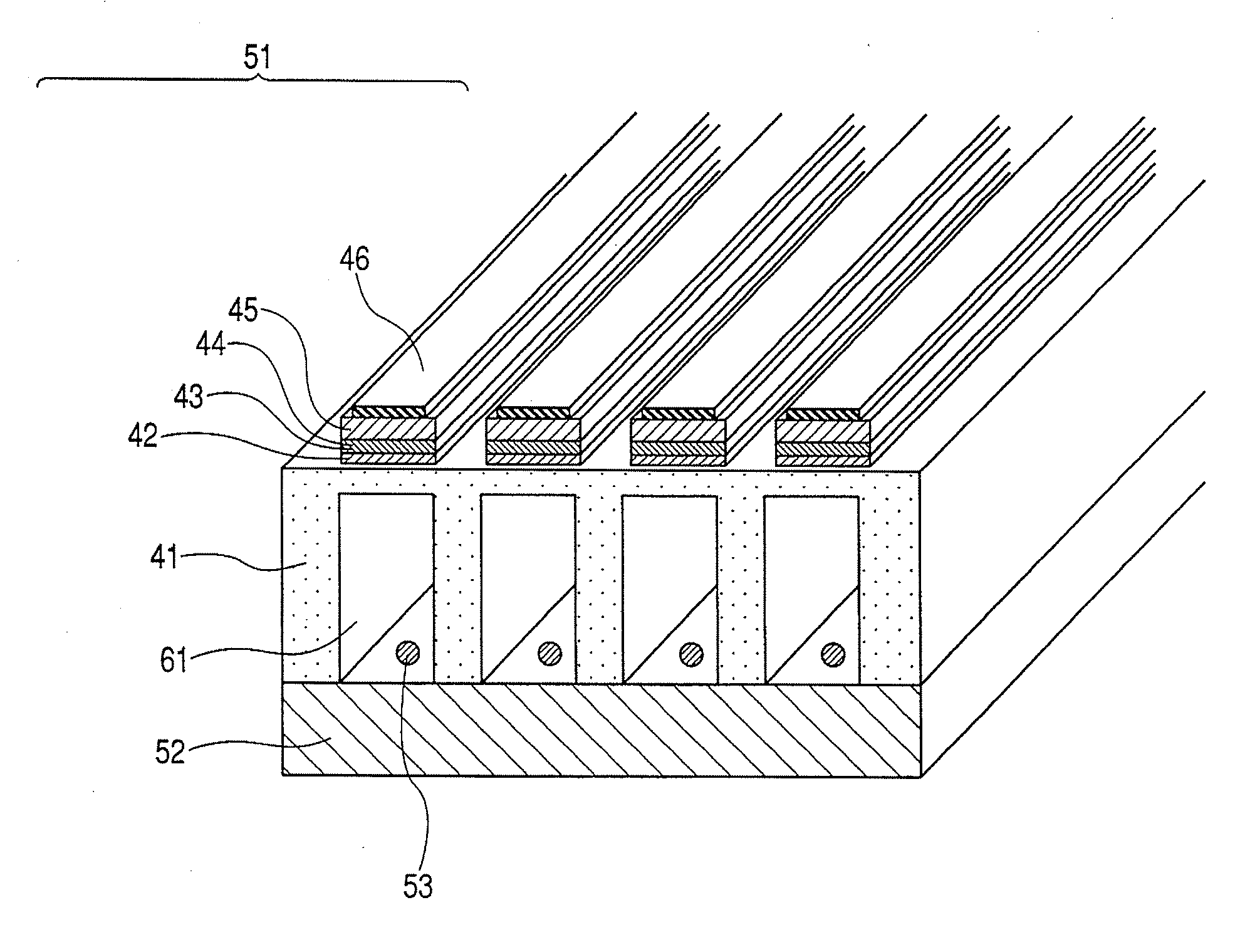

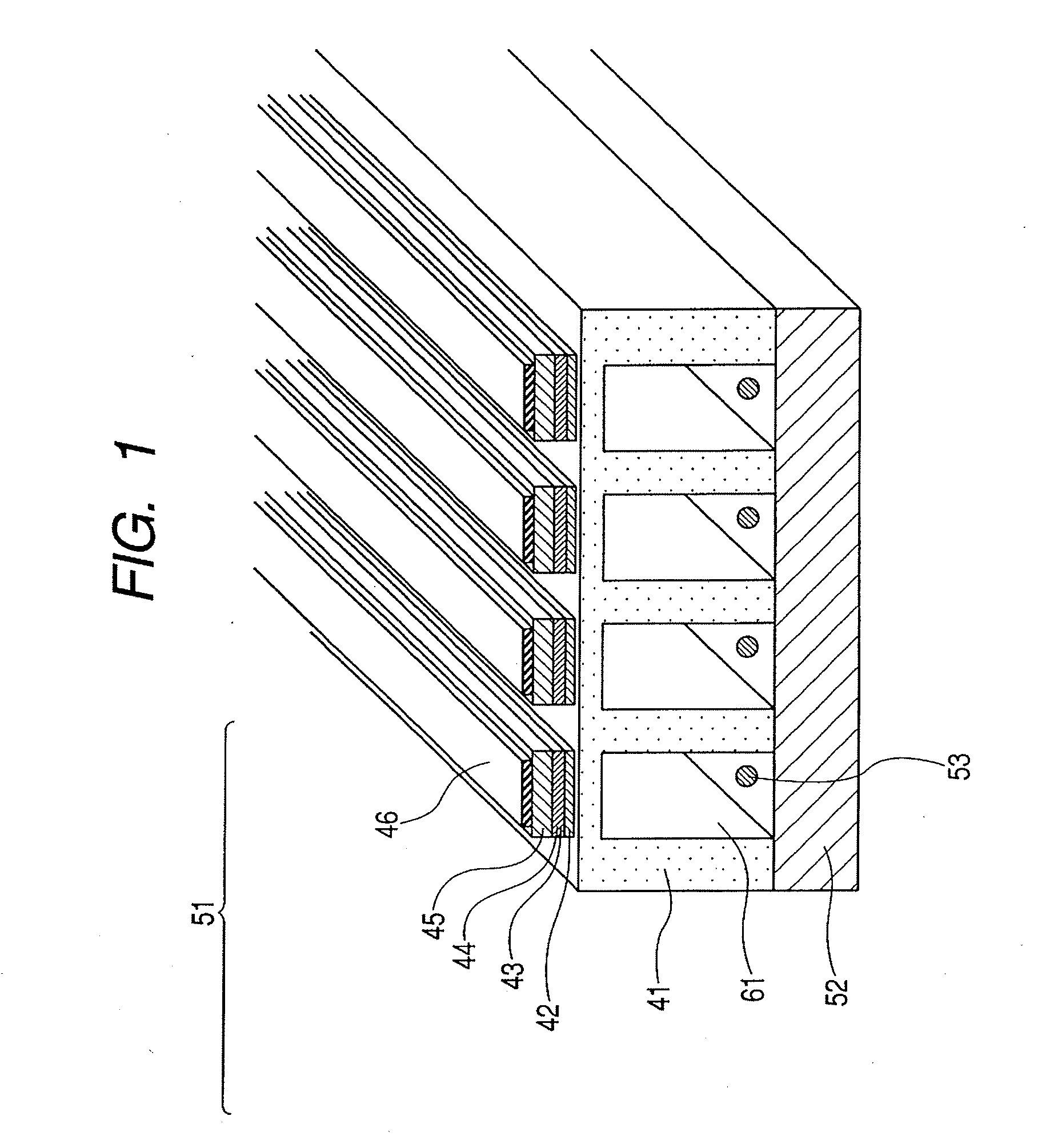

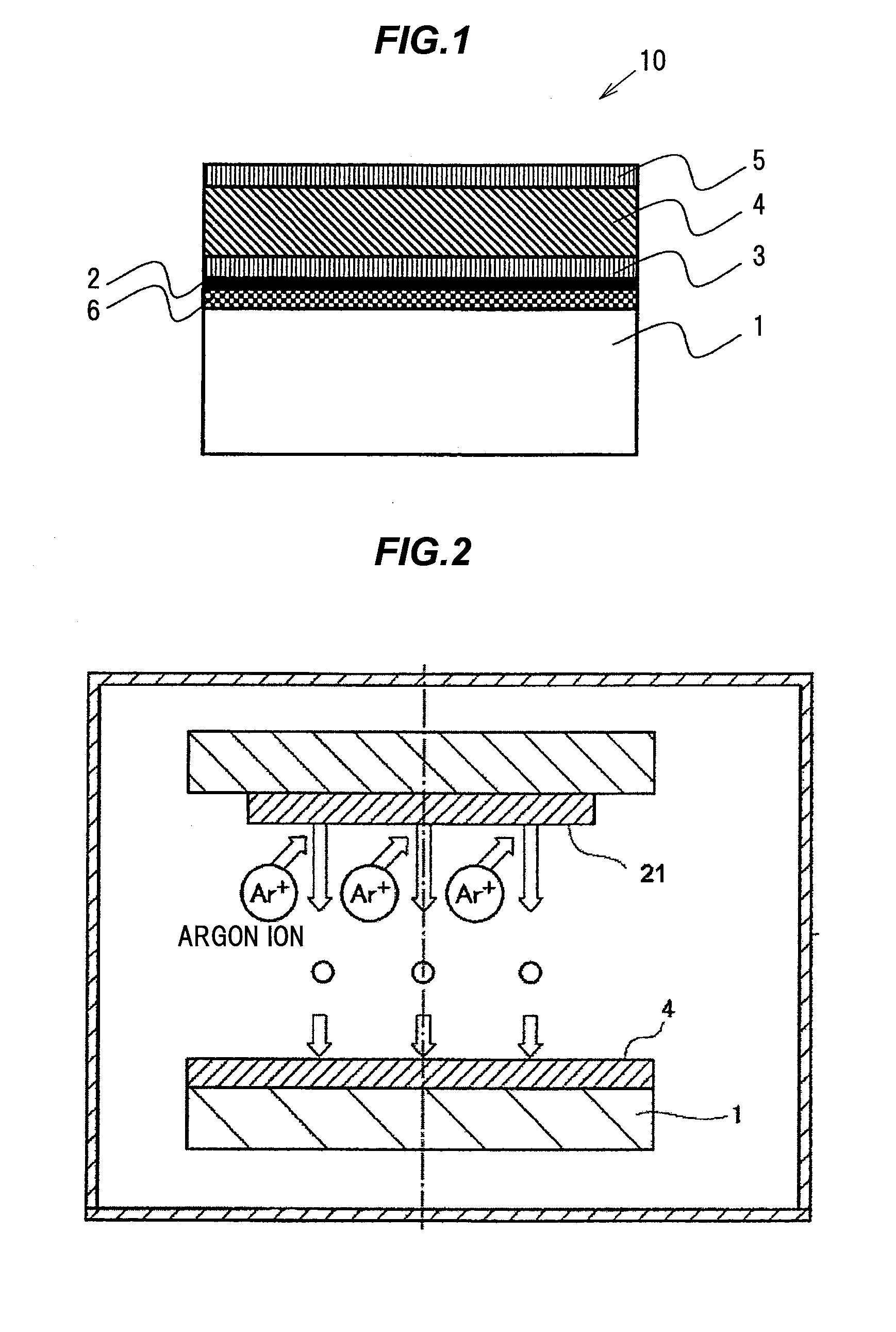

Piezoelectric thin film element, manufacturing method thereof, and liquid ejecting head and liquid ejecting apparatus employing same

InactiveUS20040090500A1Excellent piezoelectric propertiesReduce thicknessPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusEngineeringPiezoelectric thin films

The present invention provides a piezoelectric thin film element with superior piezoelectric properties in which the condition of the crystal of the piezoelectric thin film is appropriately controlled, and a manufacturing method thereof, as well as a inkjet recording head, inkjet printer, or other liquid ejecting apparatus employing the same. The piezoelectric thin film element 40 comprises a top electrode 44, a bottom electrode 42, and a piezoelectric thin film 43 formed between the top electrode 44 and the bottom electrode 42, wherein the piezoelectric thin film 43 is structured so as to comprise a first layer 431 located nearest to the bottom electrode and second layers (433-436) that are located nearer to the top electrode than the first layer and that each have a thickness greater than that of the first layer 431.

Owner:SEIKO EPSON CORP

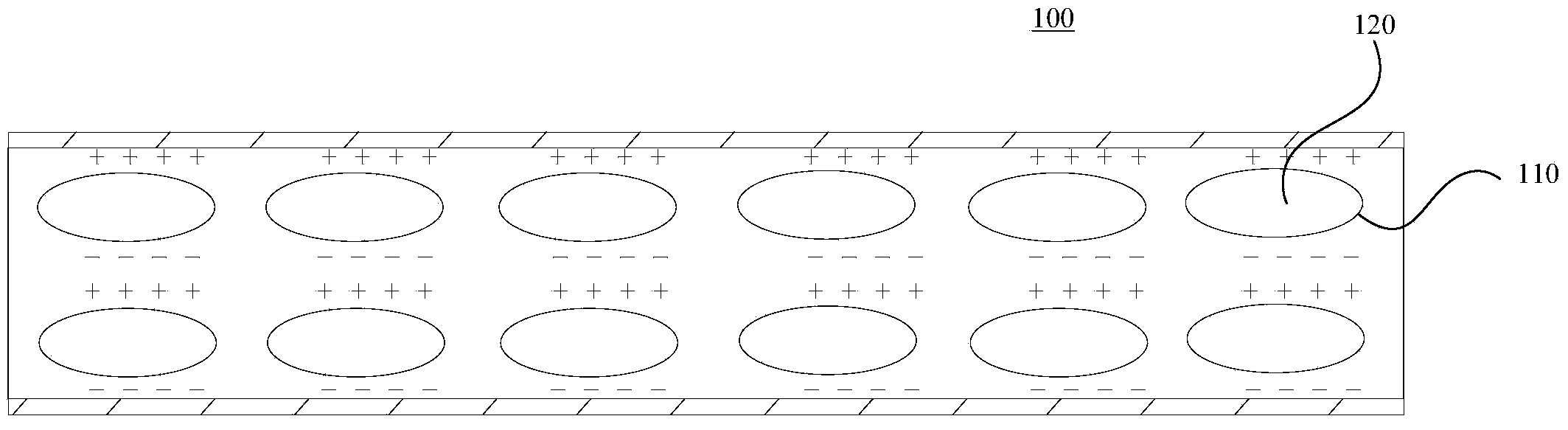

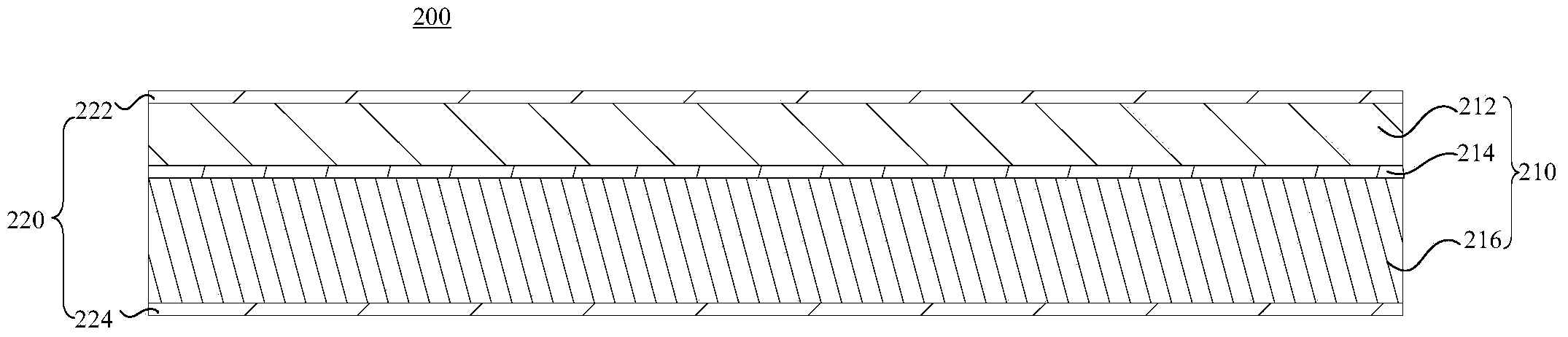

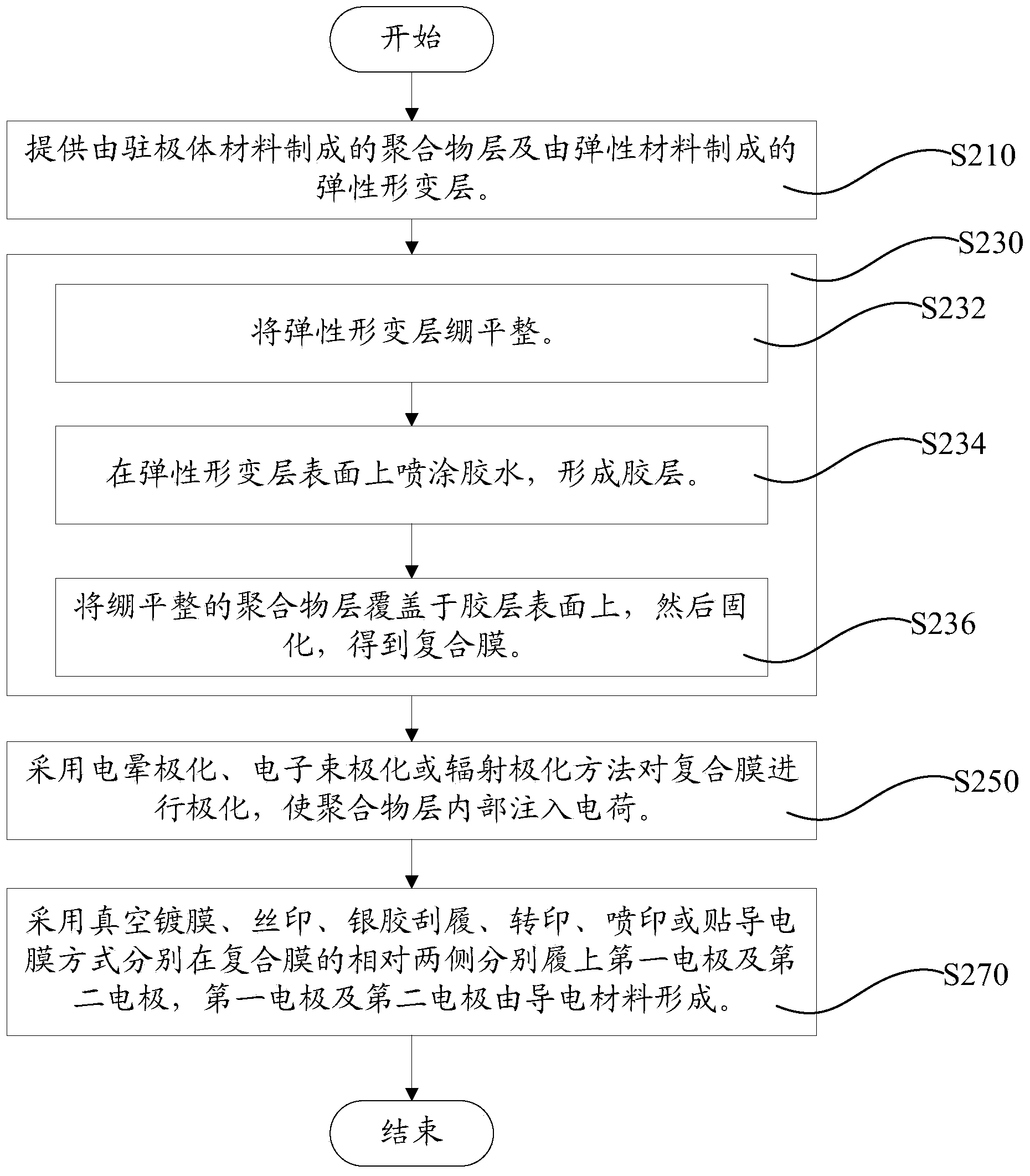

Piezoelectric electret material and preparation method thereof

ActiveCN103531706ANo storage limitExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionExternal circuitPower flow

A piezoelectric electret material comprises a composite membrane and an electrode, wherein the composite membrane comprises a polymer layer and an elastic deformation layer which are stacked sequentially; the polymer layer is made of an electret material and used for storing charge; and the elastic deformation layer is made of an elastic material. The electrode is made of a conductive material and comprises a first electrode and a second electrode formed on the two opposite sides of the composite membrane. When the piezoelectric electret material suffers an external mechanical action, the elastic deformation layer deforms, and the induced charge on the electrode is changed, so that an external circuit shows short-circuit current or open-circuit voltage, and the piezoelectric electret material has relatively good piezoelectric property. The piezoelectric electret material forms a closed hole structure without special treatment, so that the charge storage capacity in a piezoelectric electret is not limited. Simultaneously, the invention provides a preparation method of the piezoelectric electret material.

Owner:SHENZHEN HORN AUDIO

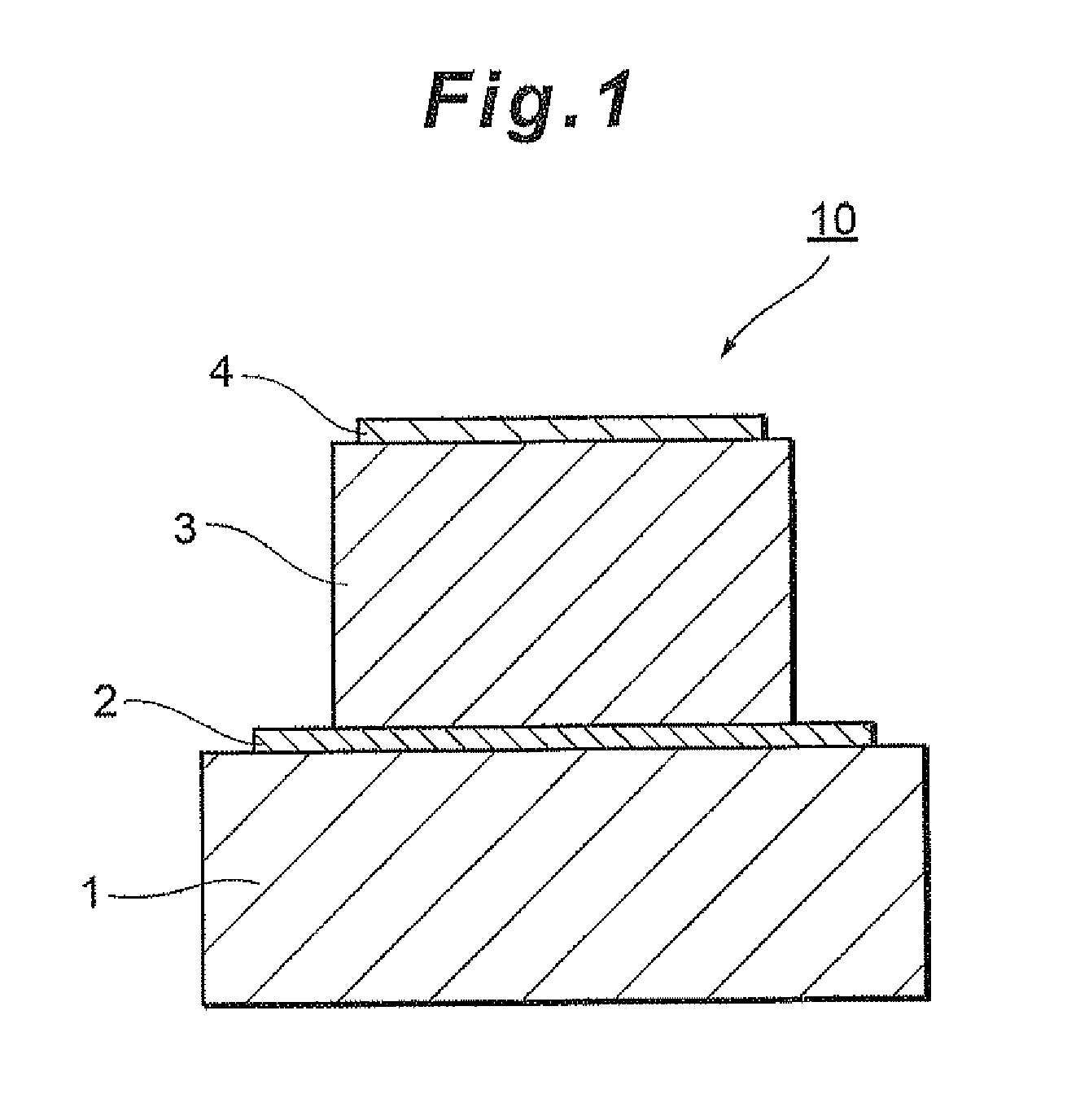

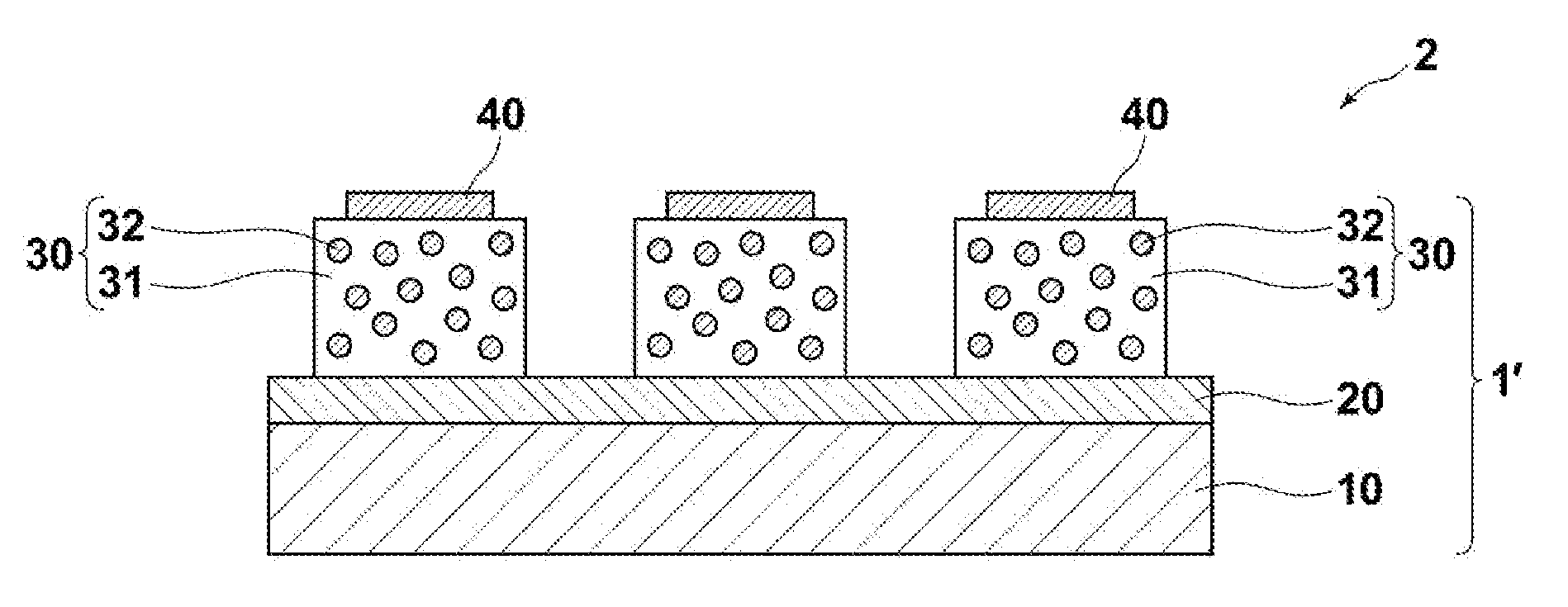

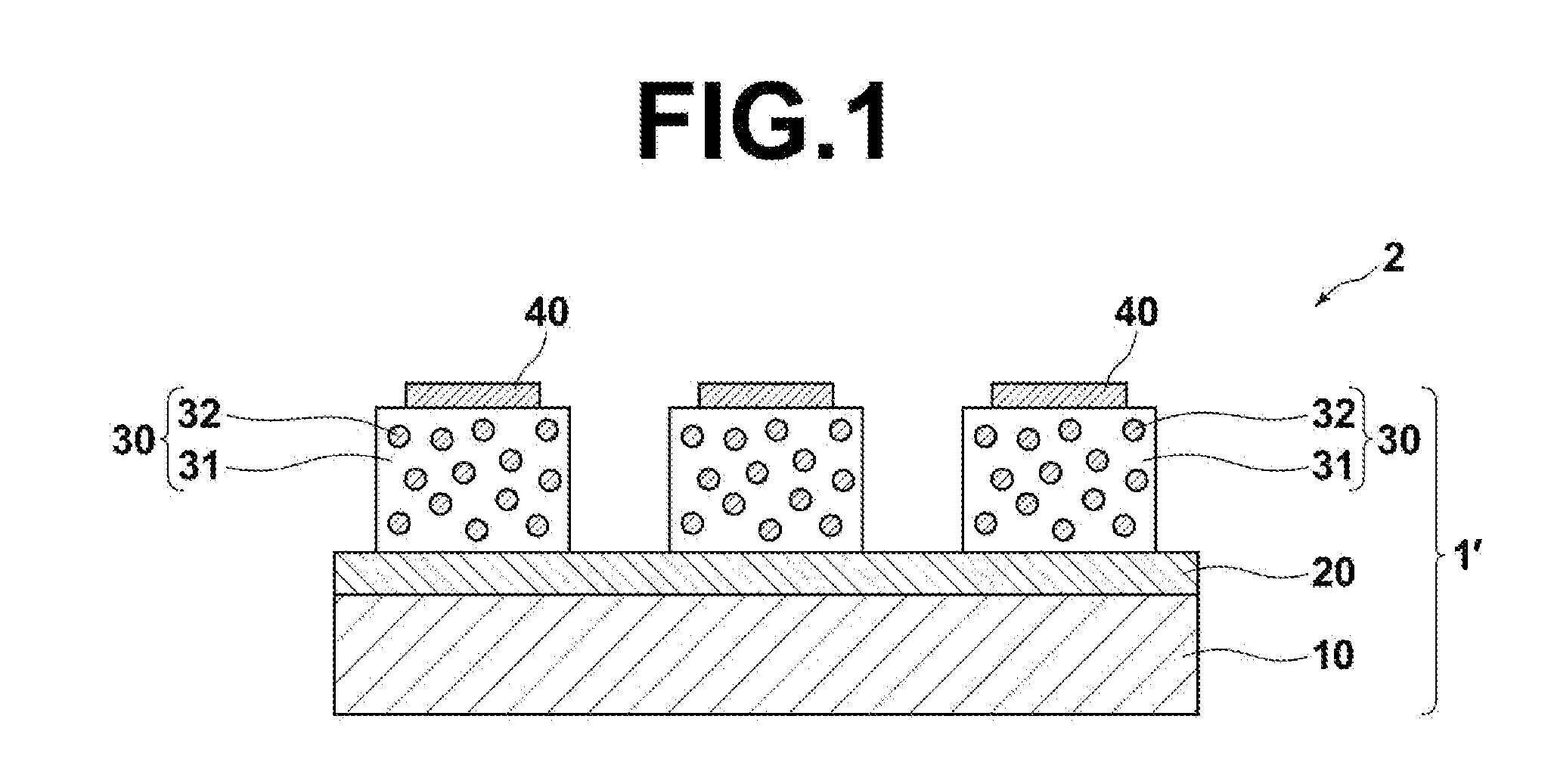

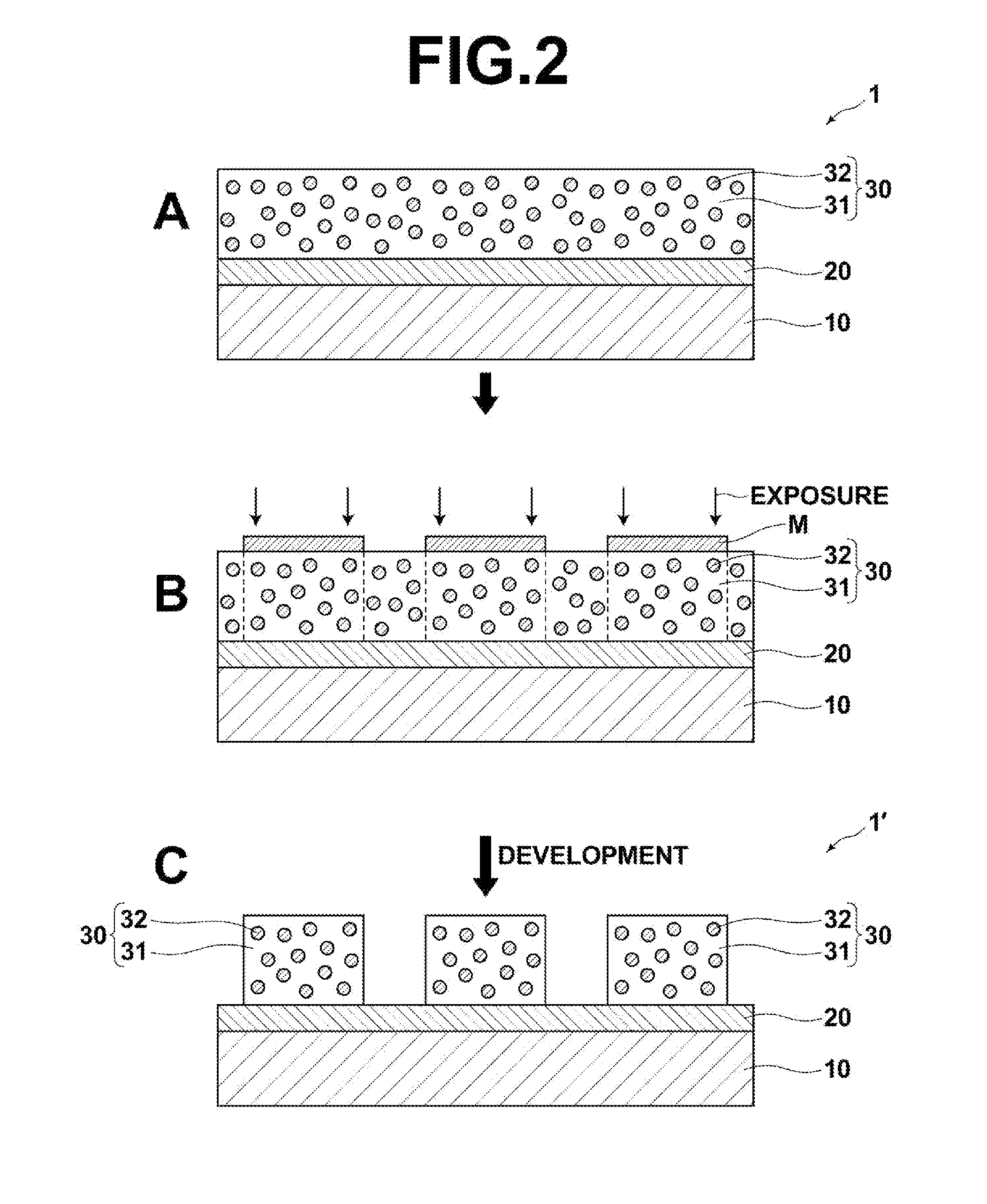

Layered structure and piezoelectric device using the same

ActiveUS20110217519A1Excellent piezoelectric propertiesImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPhotomechanical exposure apparatusResin matrixOrganic polymer

A layered structure, including a flexible resin substrate and a composite piezoelectric film formed on the resin substrate and constituted by an organic polymer resin matrix and a plurality of inorganic piezoelectric bodies dispersed in the matrix.

Owner:FUJIFILM CORP

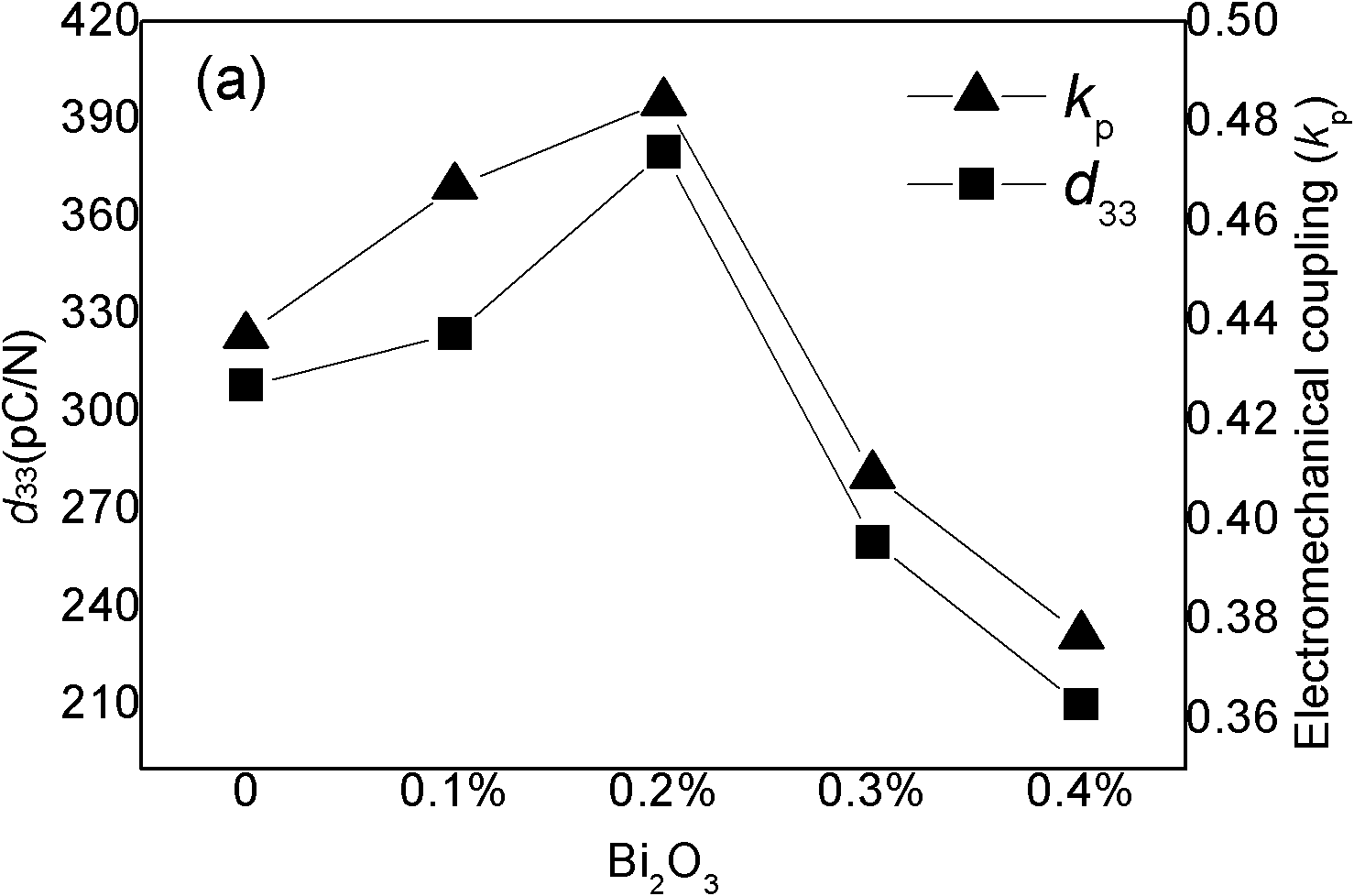

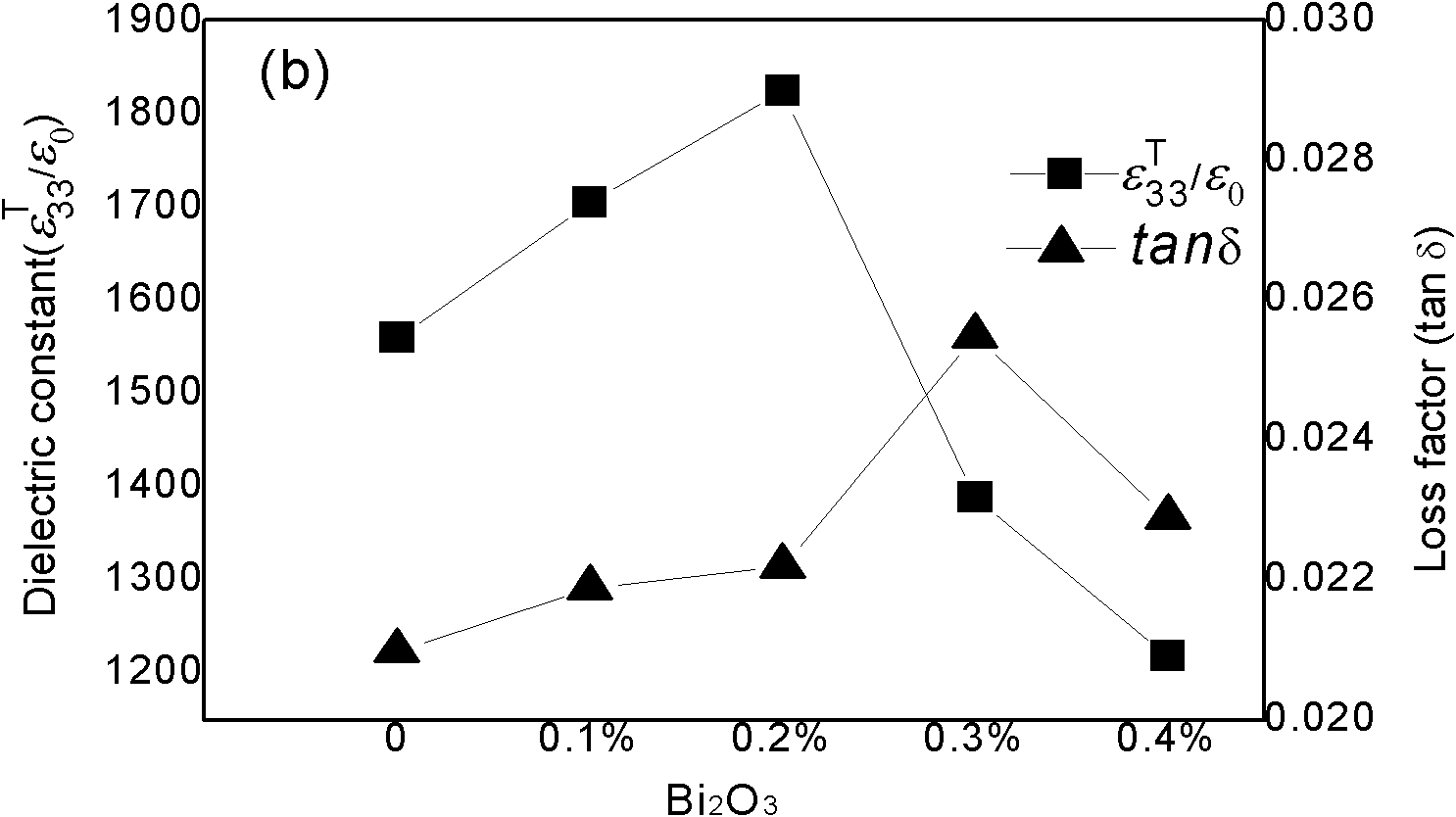

Bismuth scandate-lead titanate high-temperature piezoelectric ceramic material and preparation method thereof

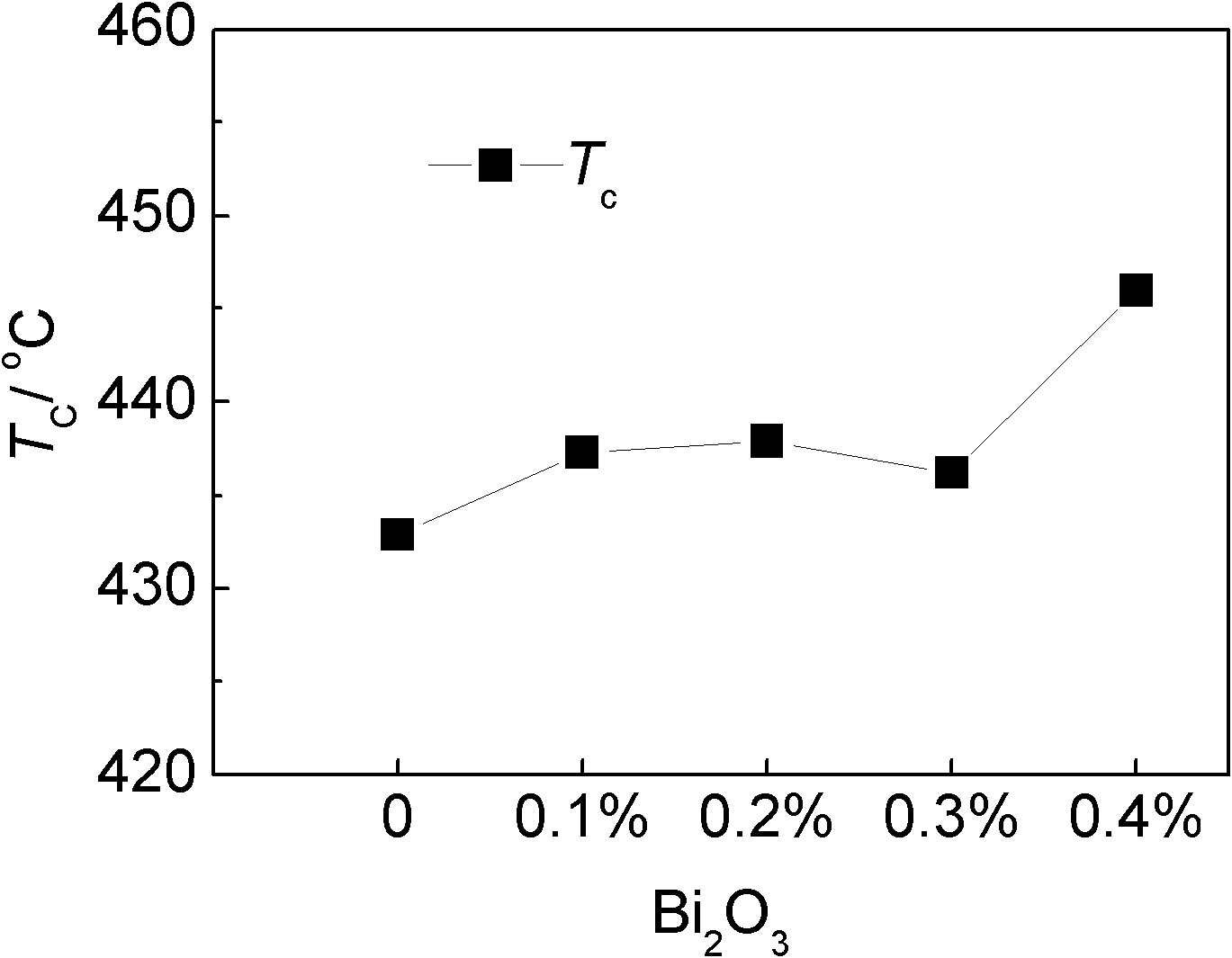

InactiveCN102180665AStoichiometric ratio is accurateLower sintering temperatureCeramic sinteringCurie temperature

The invention discloses a bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material comprises a matrix with the chemical formula of xBiScO3-(1-x)PbTiO3 and bismuth trioxide (Bi2O3) in an amount which is less than 0.4 percent of the total weight of the matrix. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material is prepared by adding excess Bi2O3 into raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3, wherein x is 0.35 to 0.38; and the using amount of the excess Bi2O3 is 0.1 to 0.4 percent of the total weight of the raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material solves the problems that ceramic sintering temperature is increased and piezoelectric and dielectric properties are reduced due to deviation of a stoichiometric ratio caused by bismuth volatilization in the sintering process of BSPT ceramic, and has high Curie temperature, excellent piezoelectric property and an actual application value in high-temperature electronic equipment. The invention also discloses a preparation method for the bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. In the preparation method, the piezoelectric ceramic material is prepared by synthesizing and sintering at lower temperature, so production cost is reduced, process steps are simplified, and the material has actual application value.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

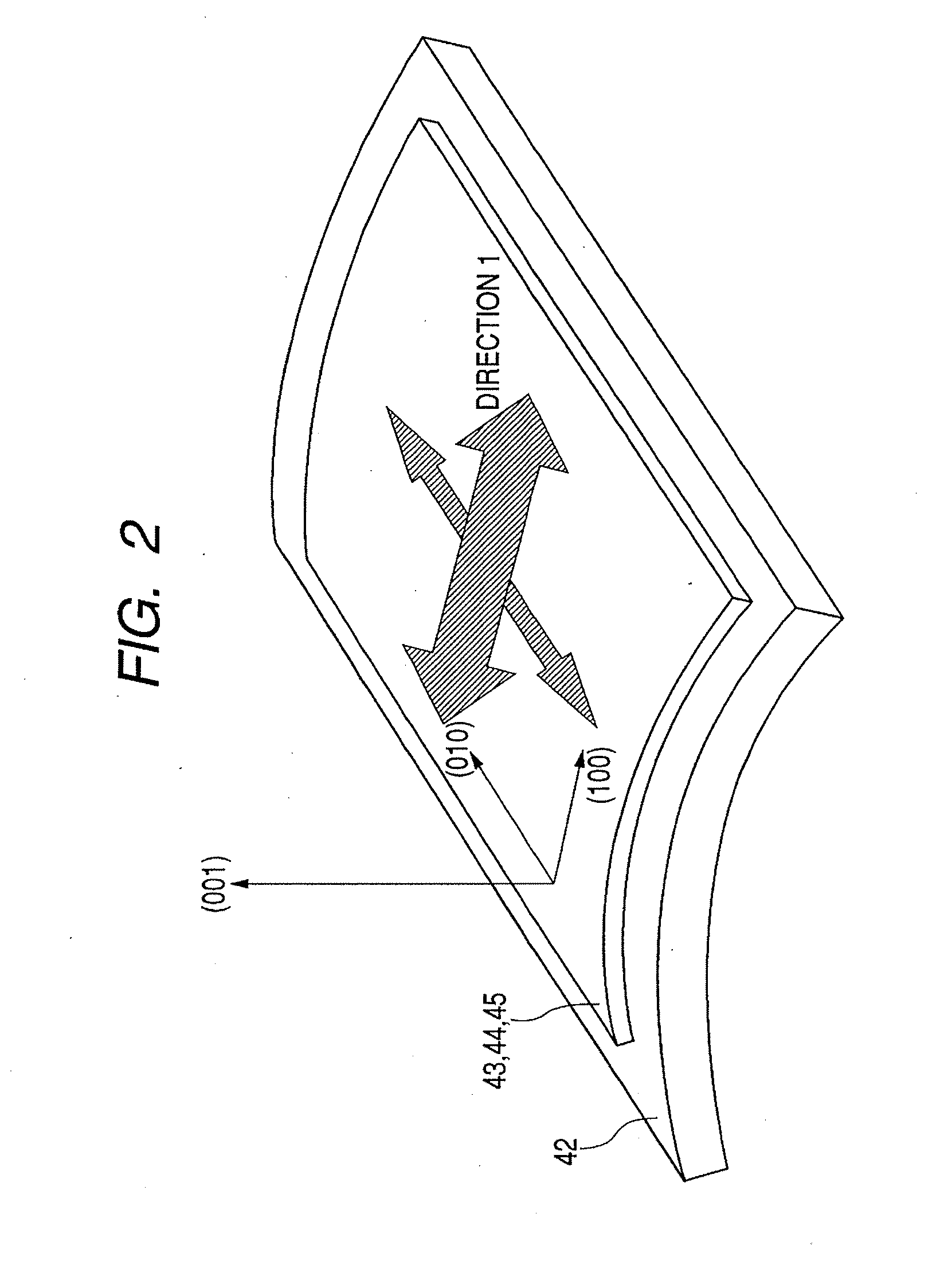

Piezoelectric element, ink jet head and producing method for piezoelectric element

InactiveUS20080012910A1Excellent piezoelectric propertiesSatisfactory durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringPlane parallel

A piezoelectric element comprises a piezoelectric film disposed on a substrate and a pair of electrodes disposed in contact with the piezoelectric film and utilizing a bending mode. The piezoelectric film includes domains constituted of a tetragonal crystal and including an a-domain which is formed by a crystal having a (100) plane parallel to the film surface of the piezoelectric film, the a-domains include an A-domain having a normal axis of (001) plane substantially parallel to a principal bending direction of the piezoelectric film and a B-domain having a normal axis of (001) plane substantially perpendicular to the principal bending direction of the piezoelectric film, and the A-domains have a volume proportion larger than 50 vol % with respect to the sum of the volume of the A-domains and the volume of the B-domains.

Owner:CANON KK

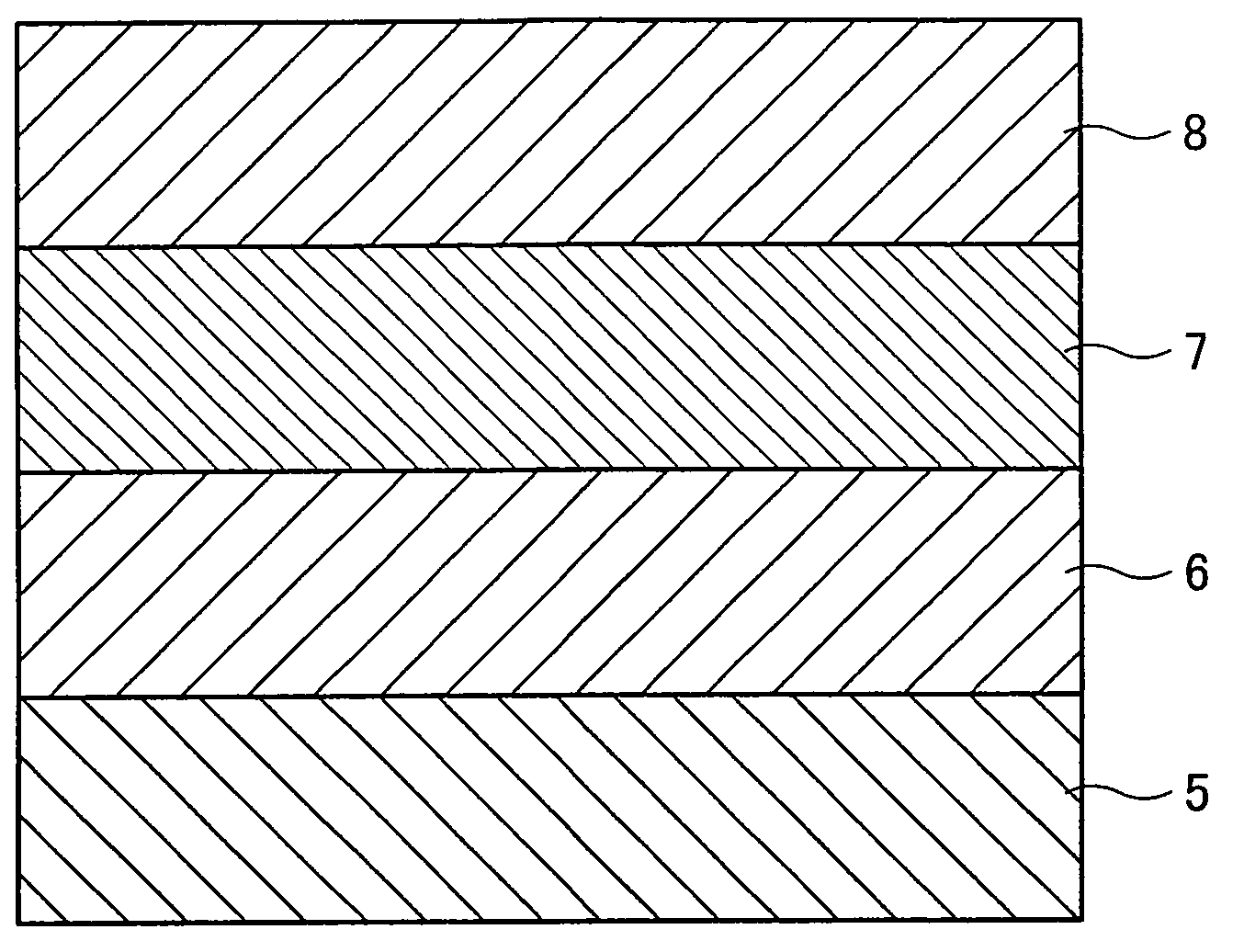

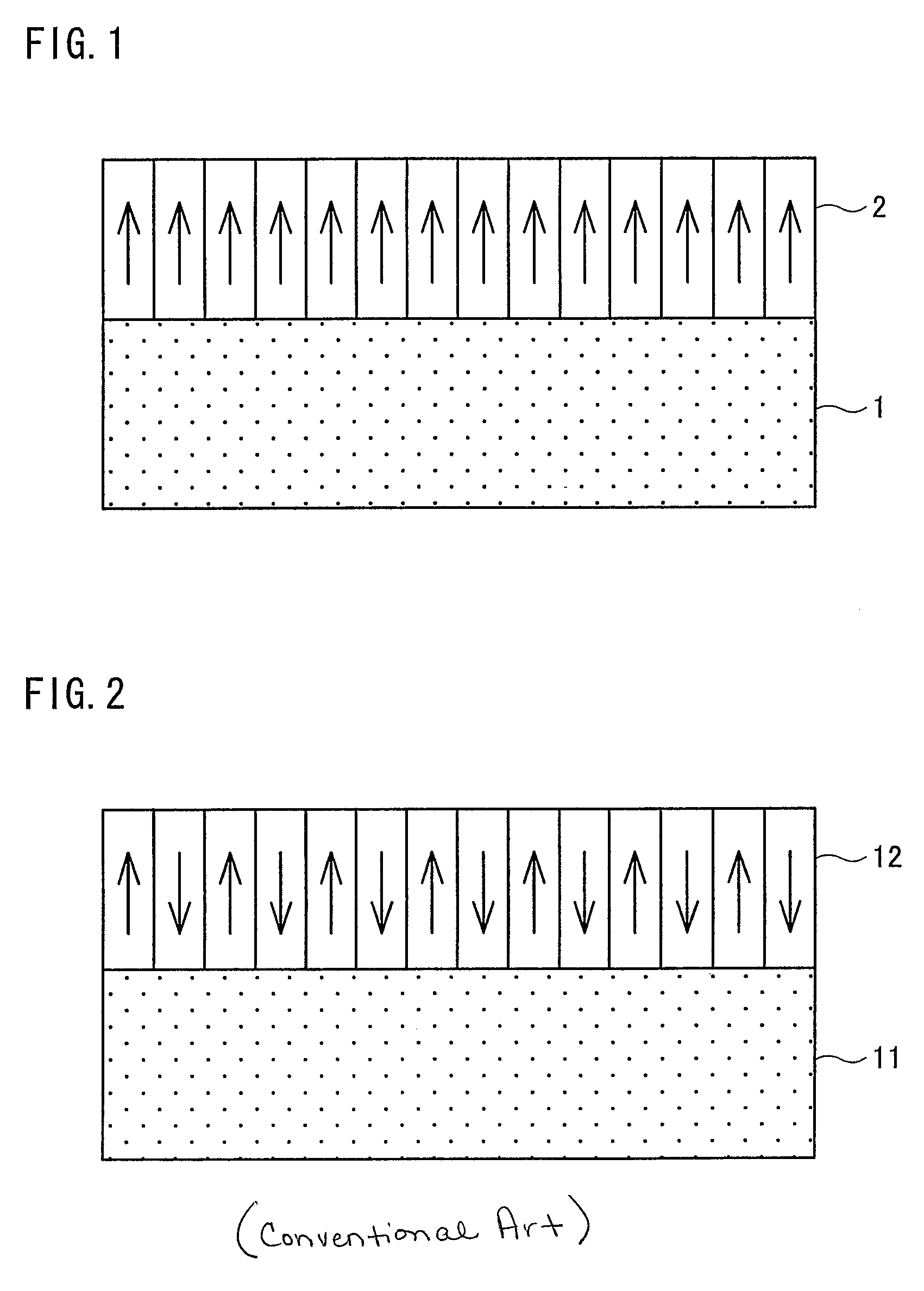

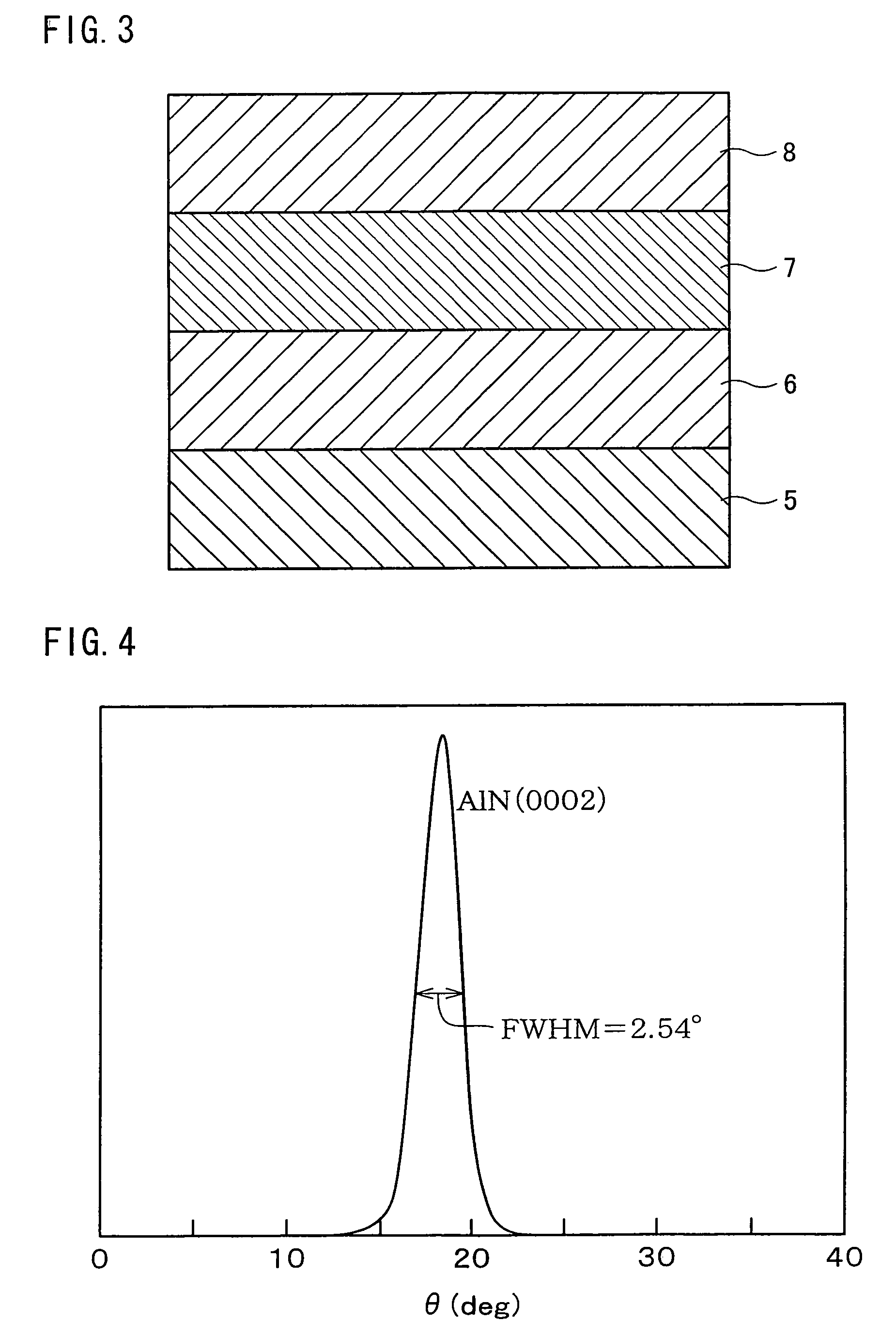

Wurtzite thin film, laminate containing wurtzite crystalline layer and their manufacturing methods

ActiveUS7642693B2High crystallinityEffective piezoelectric propertyPolycrystalline material growthPiezoelectric/electrostriction/magnetostriction machinesCelluloseWurtzite crystal structure

A thin film made of a wurtzite structure compound is manufactured by a reactive sputtering using a metal material as a target, and a nitrogen gas or oxygen gas as a reactive gas. By optimizing film-forming conditions when manufacturing the film, it is possible to obtain a wurtzite thin film whose polarization directions of crystal grains are aligned in a uniform direction. There is provided a laminate including a first wurtzite crystalline layer made of a wurtzite crystalline structure compound is formed in advance between a substrate and a functional material layer that is a ground. Thus it is possible to improve the crystallinity and crystalline orientation of a second wurtzite crystalline layer on the functional material layer.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Antimony potassium-sodium niobate leadless piezoelectric ceramics and preparation method thereof

Antimony potassium-sodium niobate leadless piezoelectric ceramics provided by the invention is a compound with its chemical formula expressed as (1-x)K1-yNayNb1-zSbzO3-x(Bi0.5-uMu)R0.5ZrO3 or (1-x)K1-yNayNb1-zSbzO3-x(Bi0.5-uMu)R0.5ZrO3-aQ, wherein x is less than or equal to 0.08 and greater than or equal to 0; y is less than or equal to 0.68 and greater than or equal to 0.4; z is less than or equal to 0.04 and greater than or equal to 0; u is less than or equal to 0.05 and greater than or equal to 0.04; M element is one of lanthanide Sm, Nd and La; R element is at least one of Na, K, Li and Ag; Q is a metallic oxide; a is molar percentage of the metallic oxide Q in the compound (1-x)K1-yNayNb1-zSbzO3-x(Bi0.5-uMu)R0.5ZrO3; and the metallic oxide Q is one of Zn oxide, Cu oxide and Mn oxide. The antimony potassium-sodium niobate leadless piezoelectric ceramics can further raise and enhance piezoelectric property of potassium-sodium niobate (KNN) leadless piezoelectric ceramics.

Owner:SICHUAN UNIV

Piezoelectric element, fabrication method for the same, and inkjet head, inkjet recording apparatus and angular velocity sensor including the same

ActiveUS20050127795A1Easy to mass produceMinimize changesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCrystal orientationPiezoelectric membrane

A piezoelectric element includes a first electrode; a piezoelectric layered film composed of a first piezoelectric film formed on the first electrode film and a second piezoelectric film that is formed on the first piezoelectric film and is controlled in crystal orientation thereof by the first piezoelectric film; and a second electrode film formed on the second piezoelectric film. Each of the first and second piezoelectric films is an aggregate of columnar grains grown unidirectionally along a thickness direction of the piezoelectric layered film. A columnar grain of the second piezoelectric film has a larger cross-sectional diameter than a columnar grain of the first piezoelectric film. A ratio l / d of the thickness l of the piezoelectric layered film to the cross-sectional diameter d of the second piezoelectric film is not less than 20 and not more than 60.

Owner:PANASONIC CORP

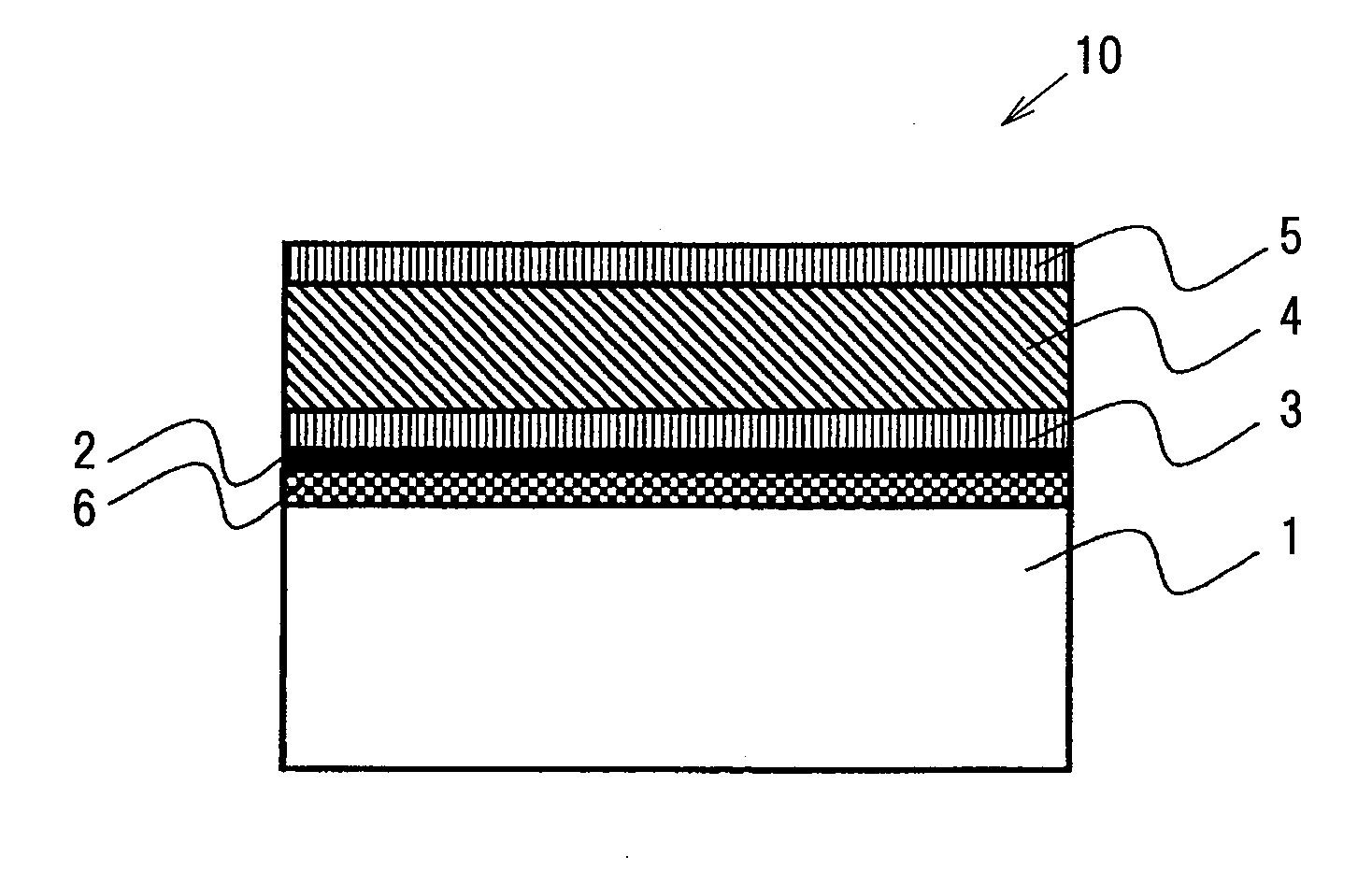

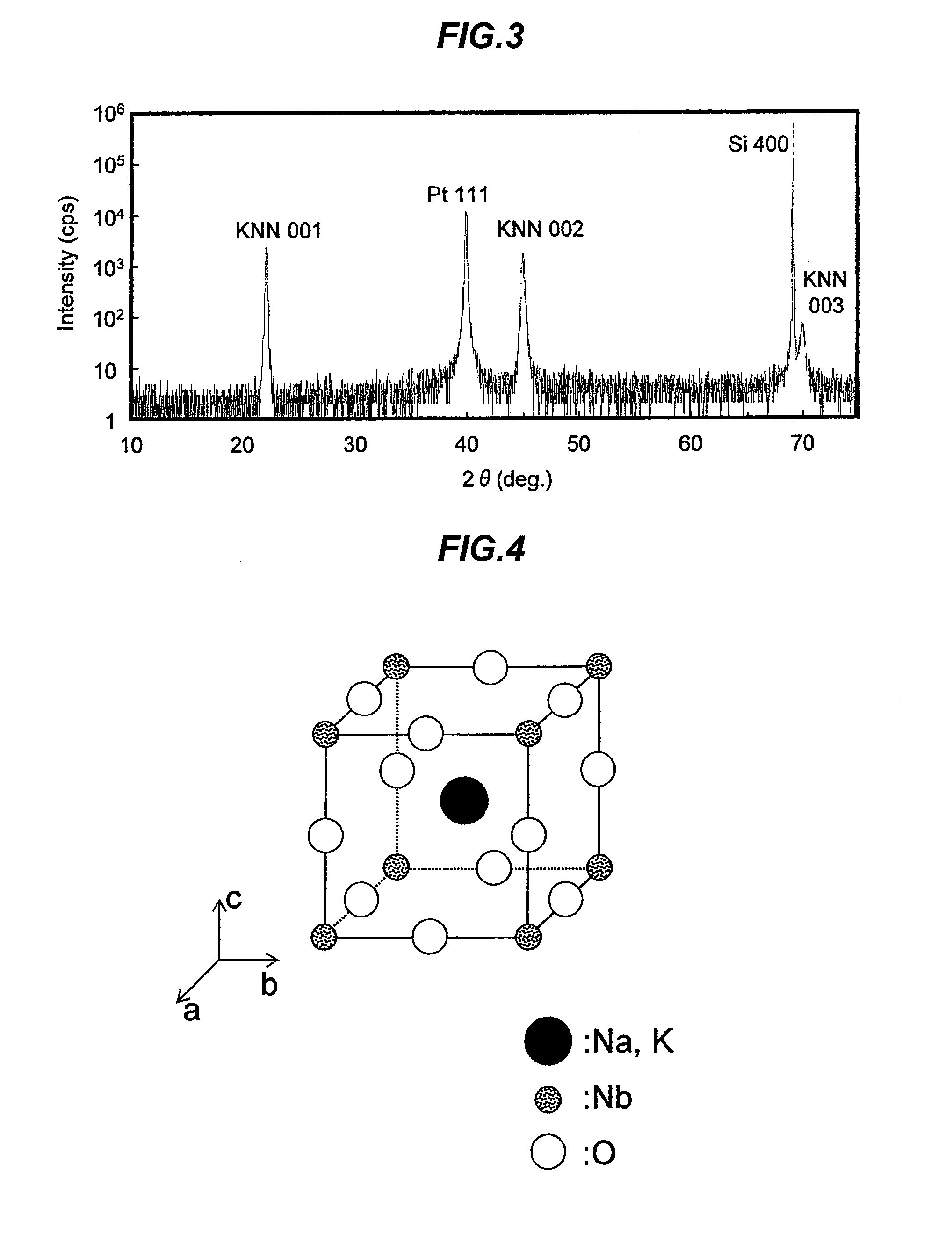

Piezoelectric element, piezoelectric device and method of manufacturing piezoelectric element

InactiveUS20140042875A1Excellent piezoelectric propertiesHigh precisionPolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyX-ray absorption fine structureElectron energy loss spectroscopy

A piezoelectric element includes a substrate, and a lower electrode layer, a piezoelectric film represented by a general formula of (NaxKyLiz)NbO3 (0<x≦1, 0<y≦1, 0≦x≦0.2, x+y+z=1) and an upper electrode layer formed on the substrate. The piezoelectric film has a crystal structure of pseudo-cubic crystal, tetragonal crystal, orthorhombic crystal, monoclinic crystal or rhombohedral crystal, or has a state that at least two of the crystal structures coexist. A difference between the maximum value and the minimum value of an energy of Na-K absorption edge measured by an electron energy loss spectroscopy or an X-ray-absorption fine-structure spectroscopy in a direction of the film thickness of the piezoelectric film is not more than 0.8 eV.

Owner:SORIN CRM +1

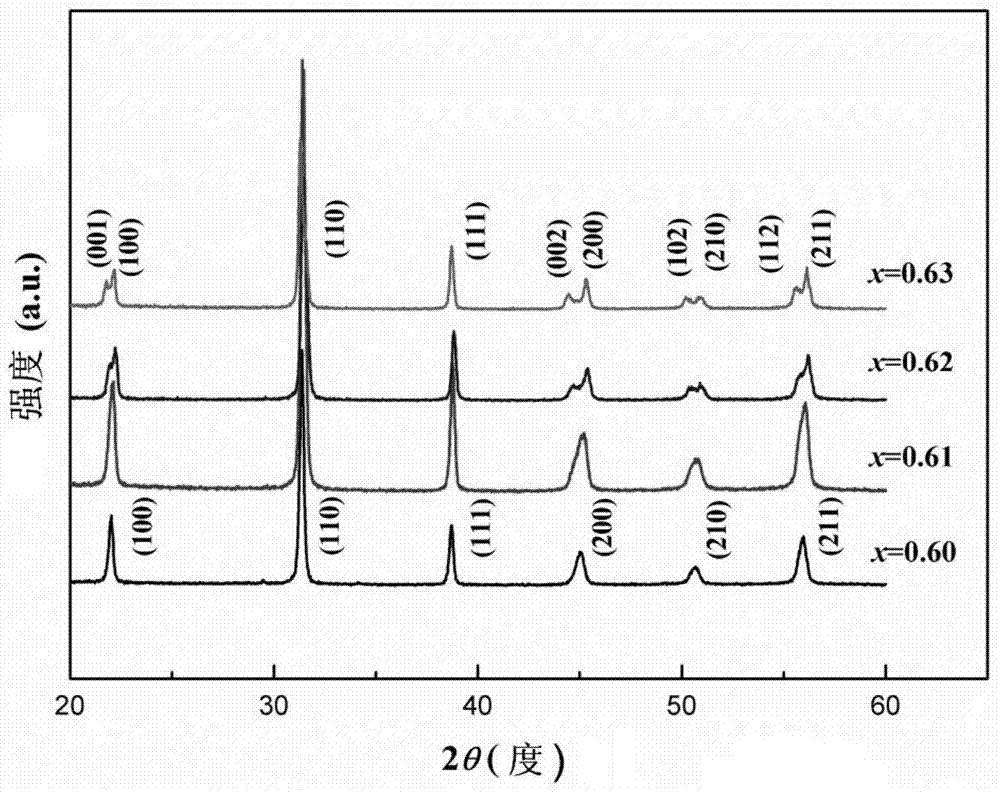

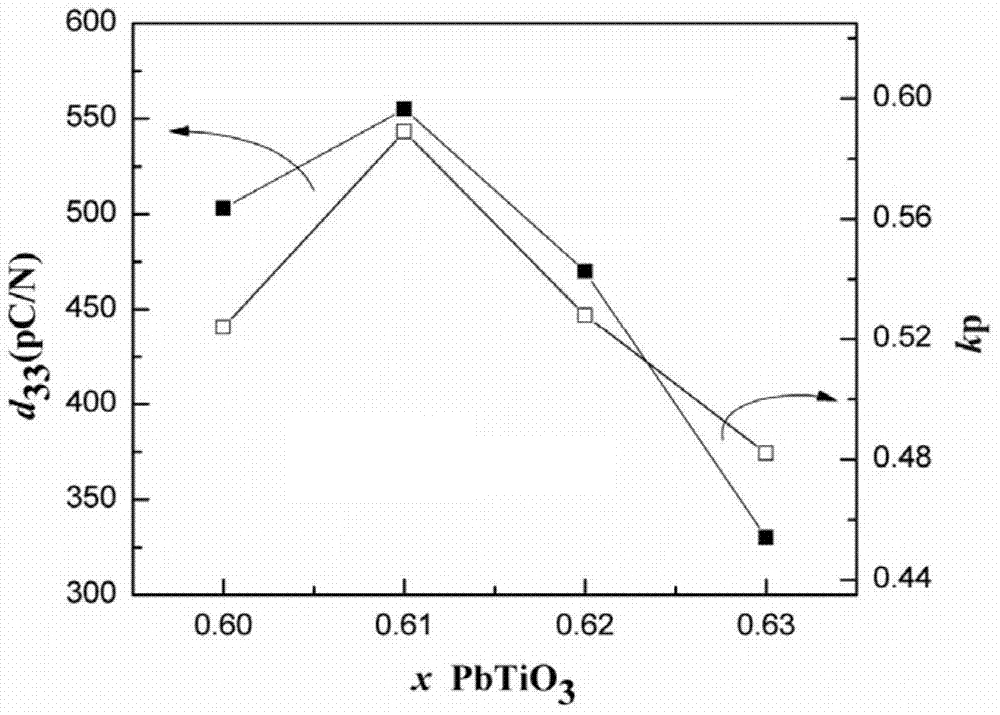

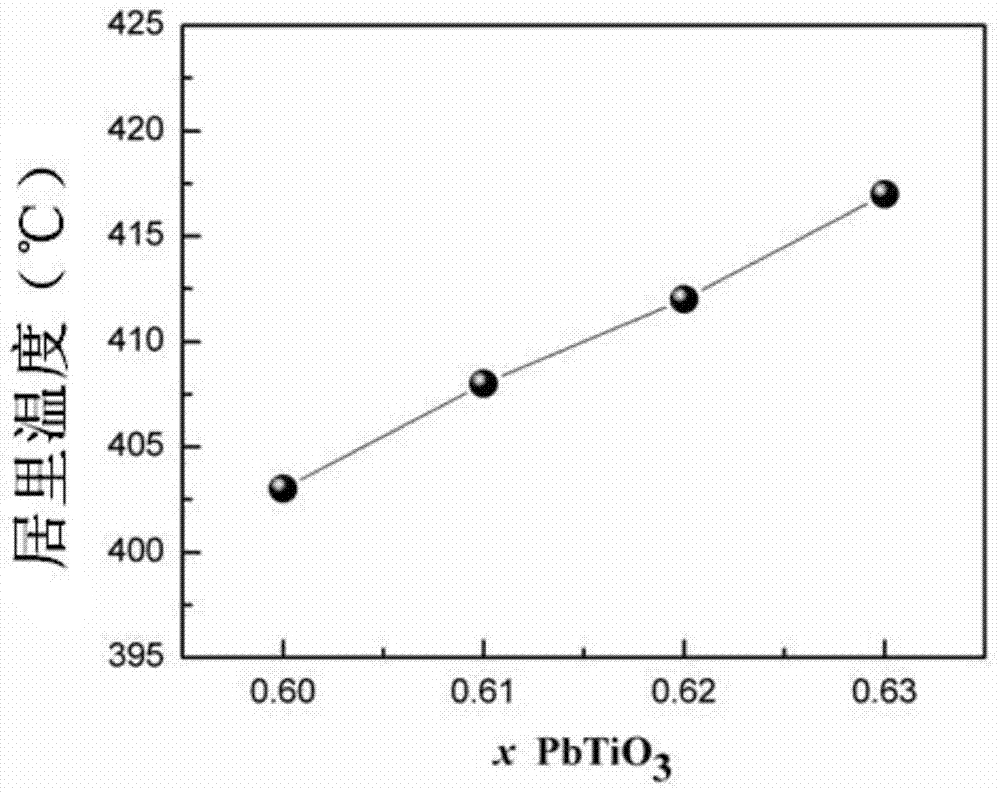

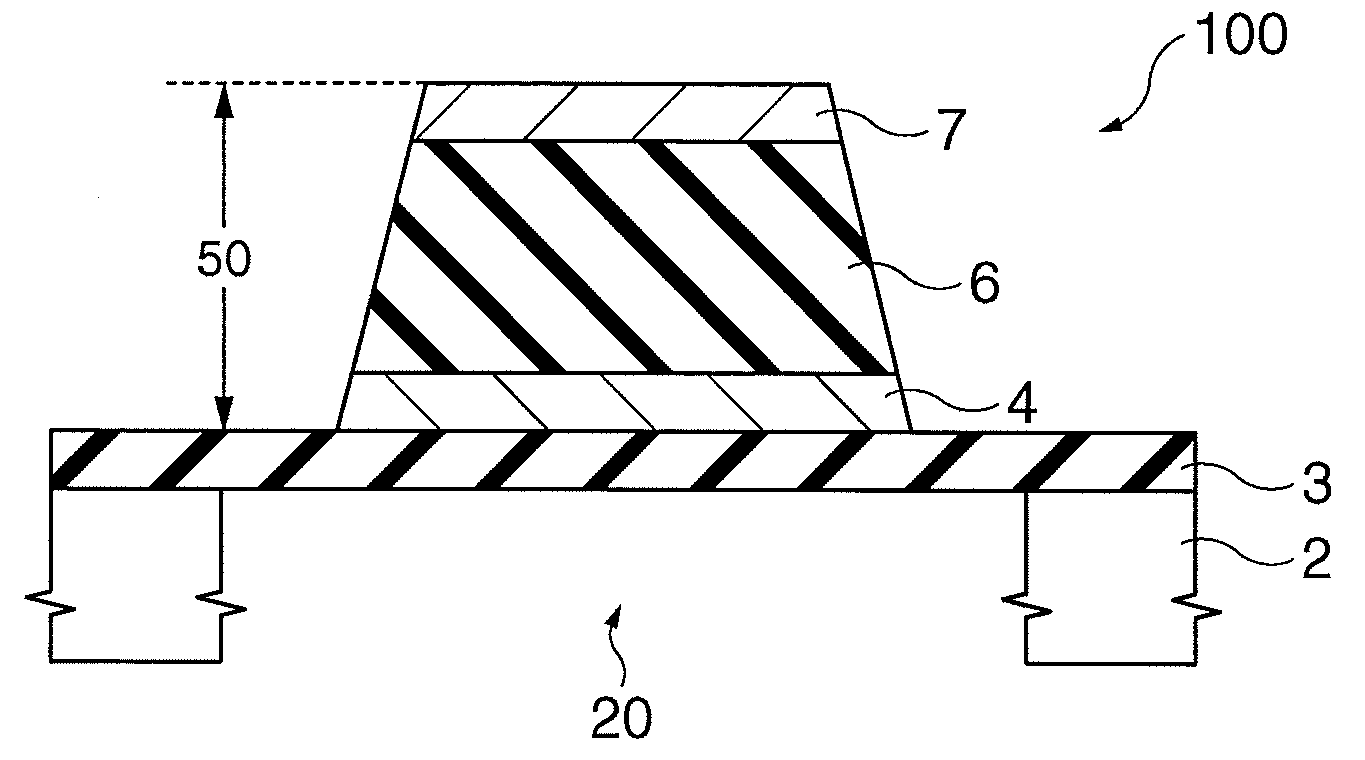

Lead tin niobate-bismuth scandate-lead titanate ternary system high temperature piezoceramic material and preparation method thereof

The invention provides a lead tin niobate-bismuth scandate-lead titanate ternary system high temperature piezoceramic material and a preparation method thereof. The structure of the material is as shown in the following general formula: 0.05Pb(Sn1 / 3Nb2 / 3)O3-(0.95-x)BiScO3-xPbTiO3, wherein x and 0.95-x respectively represent the mole percentages of PbTiO3 and BiScO3; x ranges from 0.60-0.63. The invention further provides a preparation method of the high temperature piezoceramic material. According to the lead tin niobate-bismuth scandate-lead titanate ternary system high temperature piezoceramic material provided by the invention, by changing the material system, the use amount of Sc is reduced compared with that of an existing piezoceramic material BiScO3-PbTiO3, the cost of industrial production is lowered, and under the condition that a relatively high Curie temperature is kept, the piezoelectric property of the material is further improved.

Owner:PEKING UNIV

Piezoelectric ceramic material and preparation method thereof

The invention discloses a piezoelectric ceramic material, the chemical formula of the material is as follows: Pb1.05-dSrdZrxTiyO3 + amol% La2O3 + bmol% M + cmol% SiO2, wherein, d is more than or equal to 0 and less than or equal to 0.03, x + y = 1, a is more than or equal to 0 and less than or equal to 5, b is more than or equal to 0 and less than or equal to 5, c is more than or equal to 0 and less than or equal to 1, M presents LiNbO3 or Nb2O5. The invention also discloses the preparation method of the piezoelectric ceramic material. Compared with the prior art, the advantages of the invention are as follows: replacement of doping in the PZT piezoelectric ceramic is conducted, and the preparation process which is suitable for the piezoelectric ceramic material is selected creatively, which leads the Curie point of the piezoelectric ceramic material to be greatly increased, the piezoelectric property and the dielectric property are excellent, under high temperature of 270 degrees C., the piezoelectric property and the dielectric property of the piezoelectric ceramic material is decreased very little, and the invention can be used for SMD piezoelectric ceramic buzzer.

Owner:NINGBO KEPO ELECTRONICS

Piezoelectric material and piezoelectric device

ActiveUS7586234B2Excellent piezoelectric propertiesSufficient amount of distortionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMaterials science

Owner:SEIKO EPSON CORP

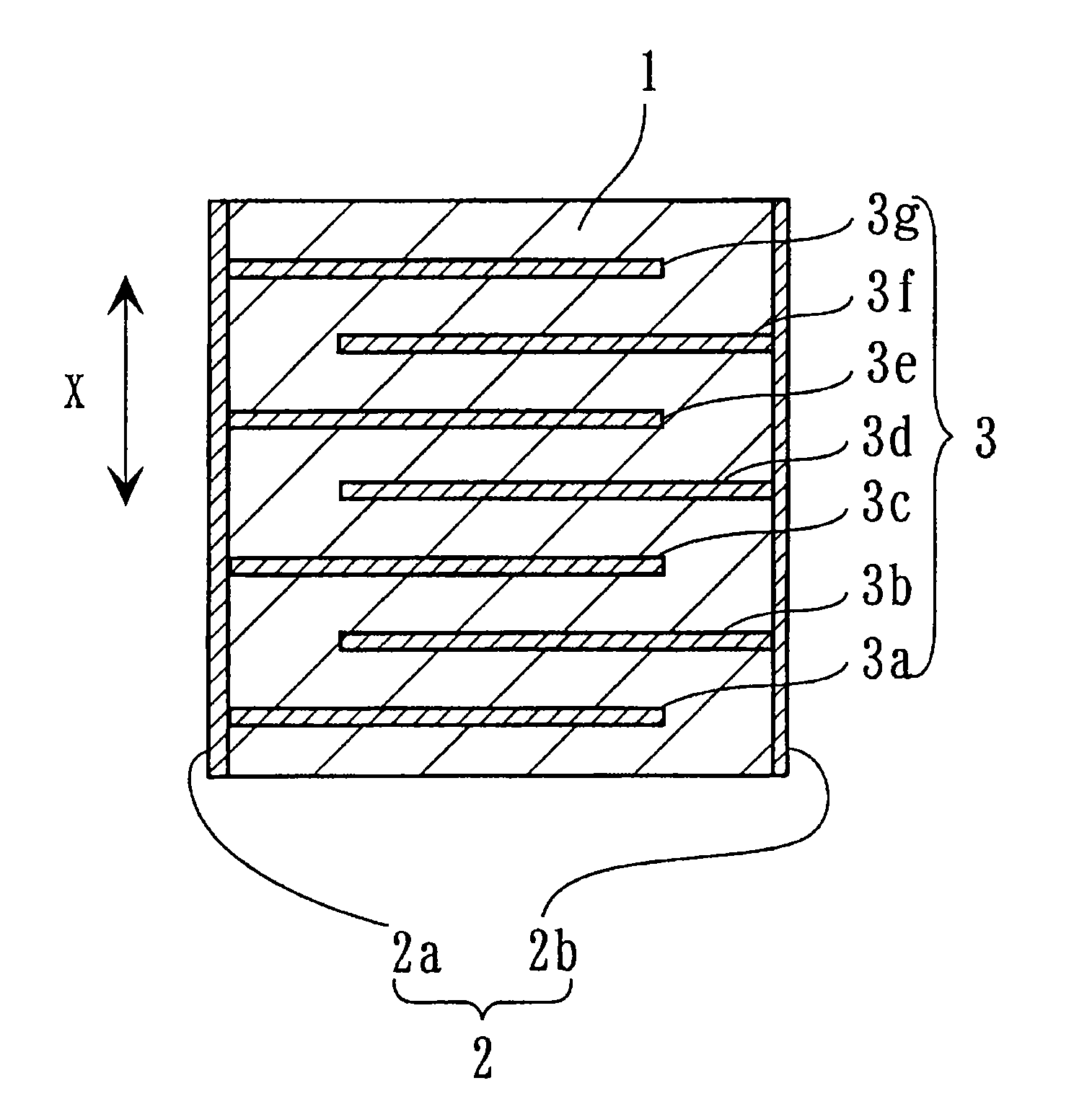

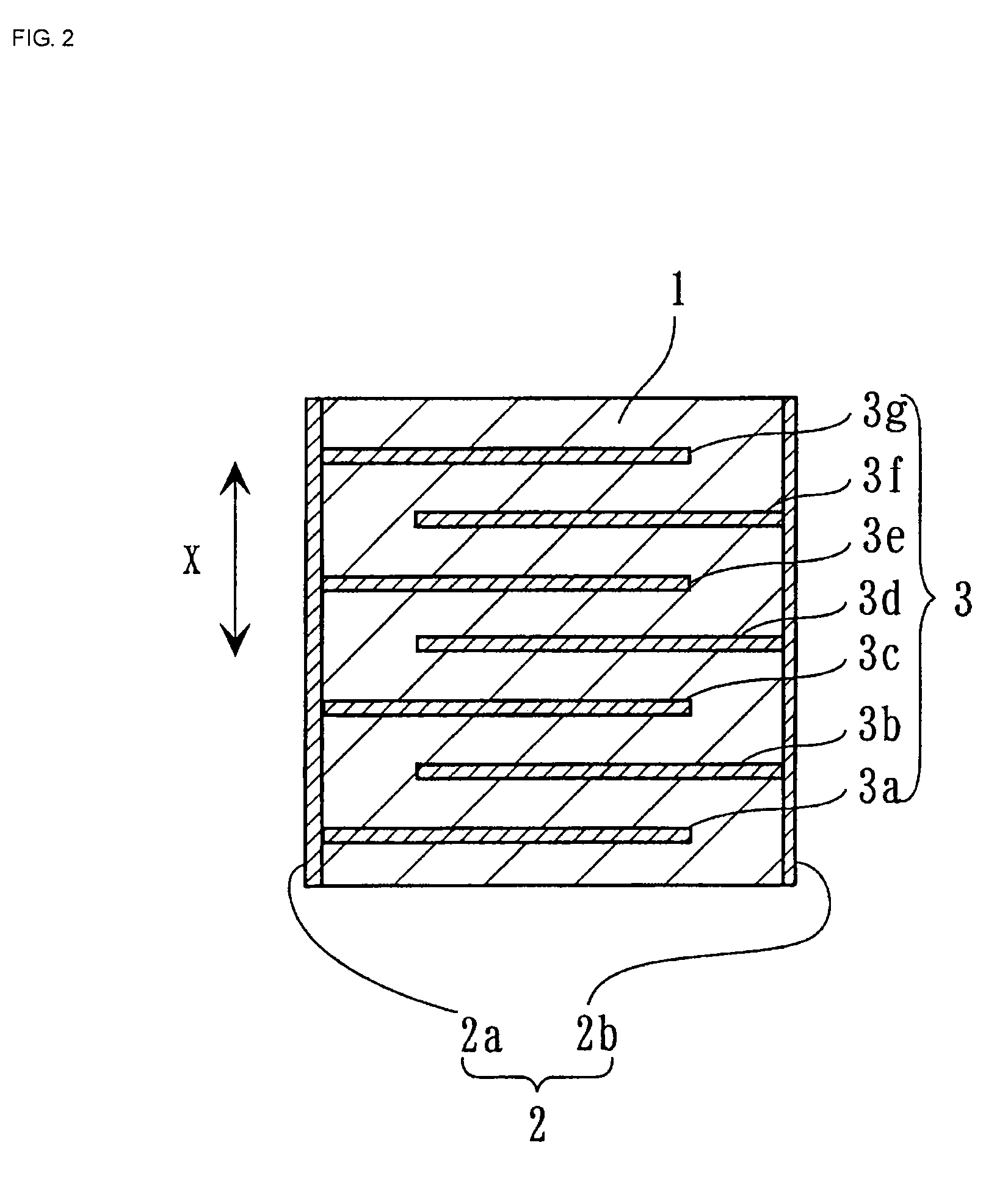

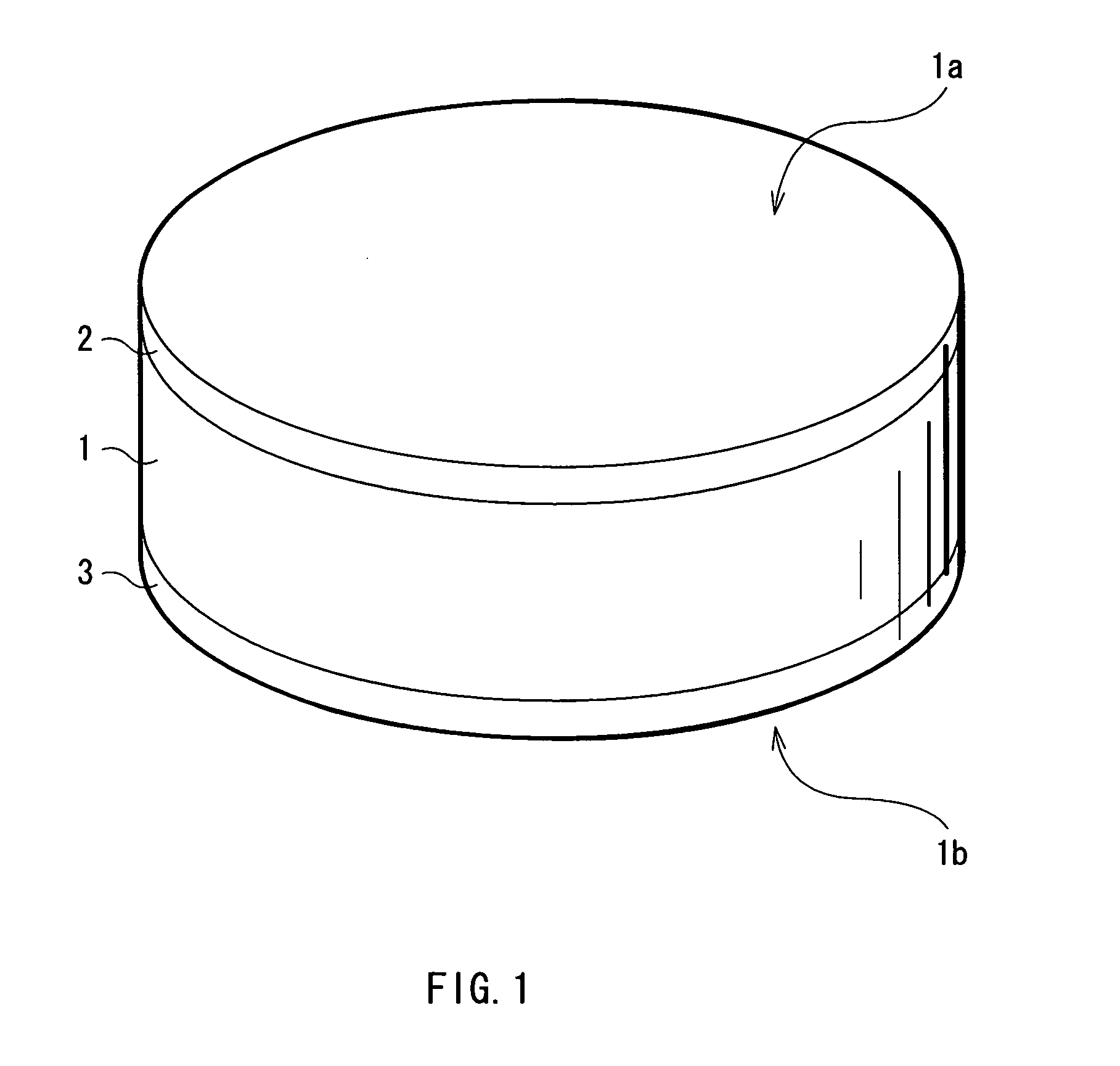

Piezoelectric ceramic and method of manufacturing the same

InactiveUS20070152183A1Improve piezoelectric performanceImprove sintering performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionAlkaline earth metalCurie temperature

There is provided a piezoelectric ceramic having a wider operating temperature range, being capable of obtaining a larger amount of displacement, being easily sintered, and being superior in terms of low emission, environment and ecology. A piezoelectric substrate (1) includes (1−m−n){(Na1-x-yKxLiy)(Nb1-zTaz)O3}+m{(M1)ZrO3}+n{M2(Nb1-wTaw)2O6} as a main component. M1 and M2 each represent an alkaline-earth metal element, and the values of x, y, m and n are preferably within a range of 0.1≦x≦0.9, 0≦y≦0.1, 0<m<0.1 and 0<n≦0.01, respectively. Thereby, a higher Curie temperature and a larger amount of displacement can be obtained, and sintering can be more easily performed. At the time of sintering, after (M1) ZrO3 is formed, other materials are mixed.

Owner:TDK CORPARATION

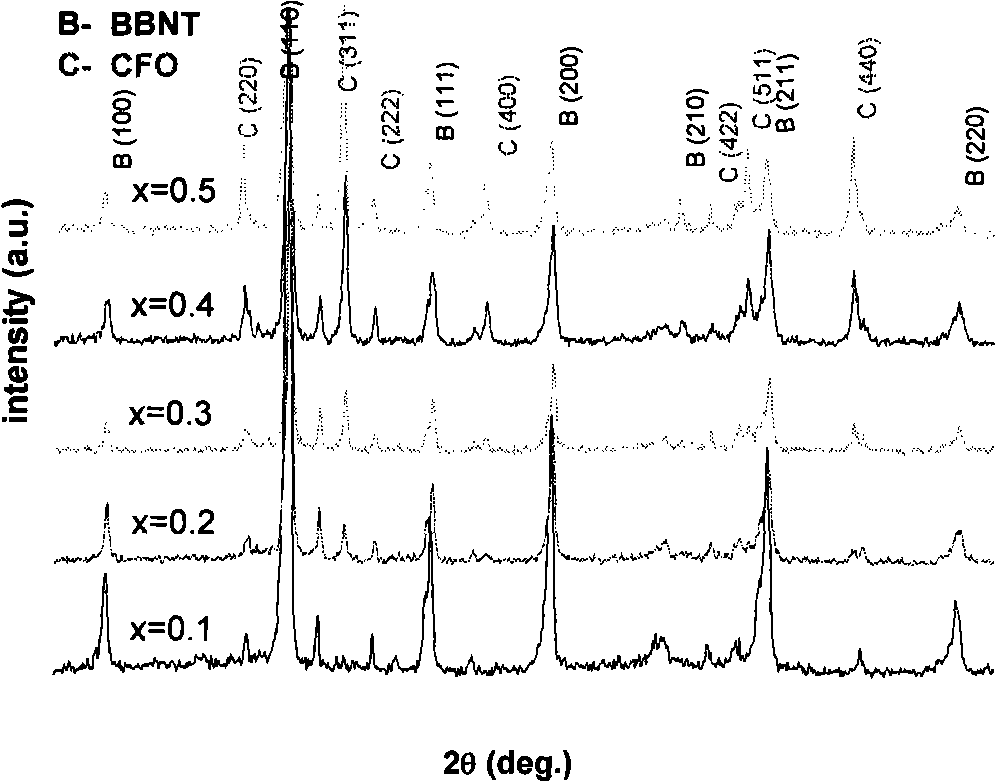

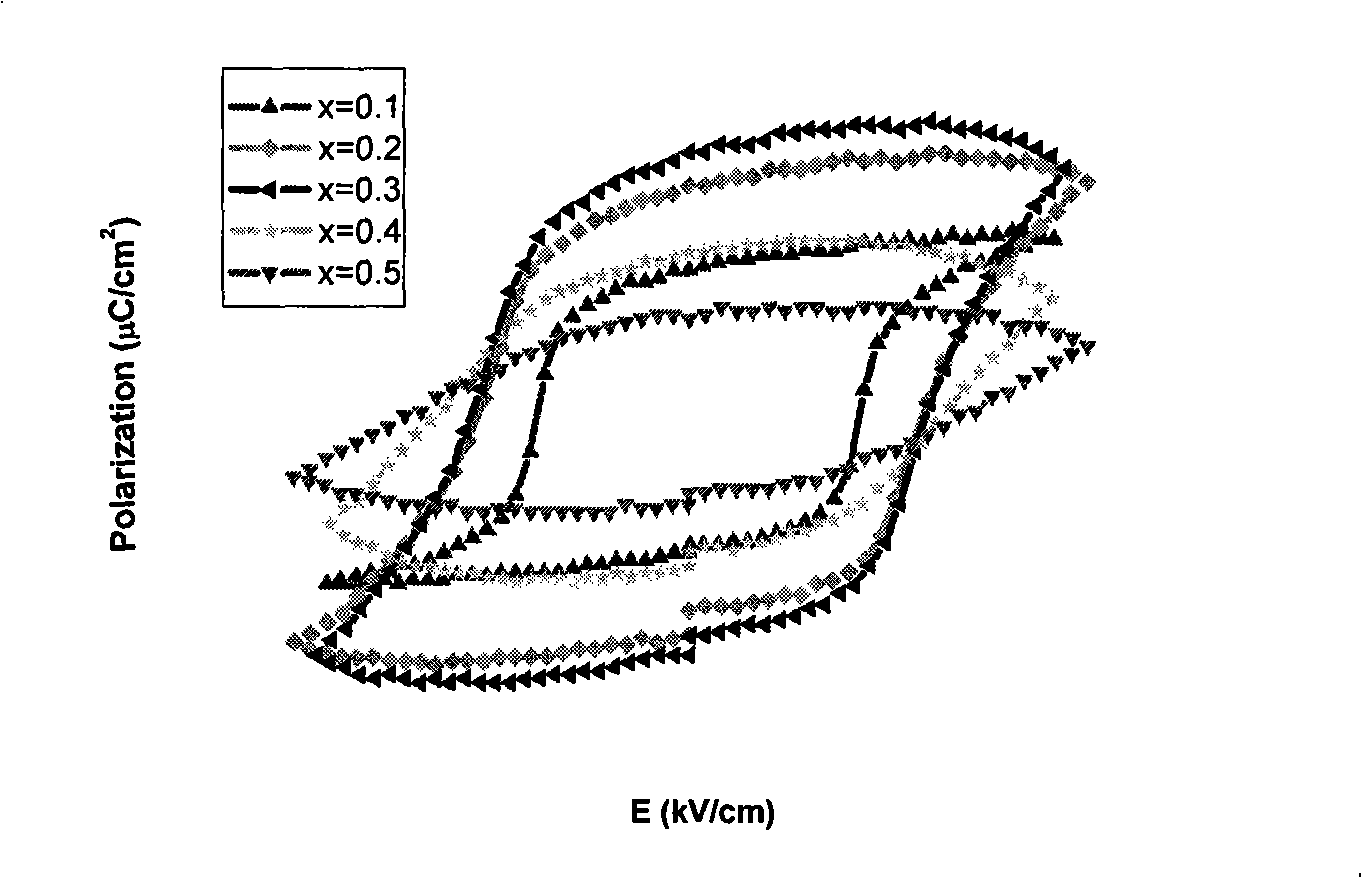

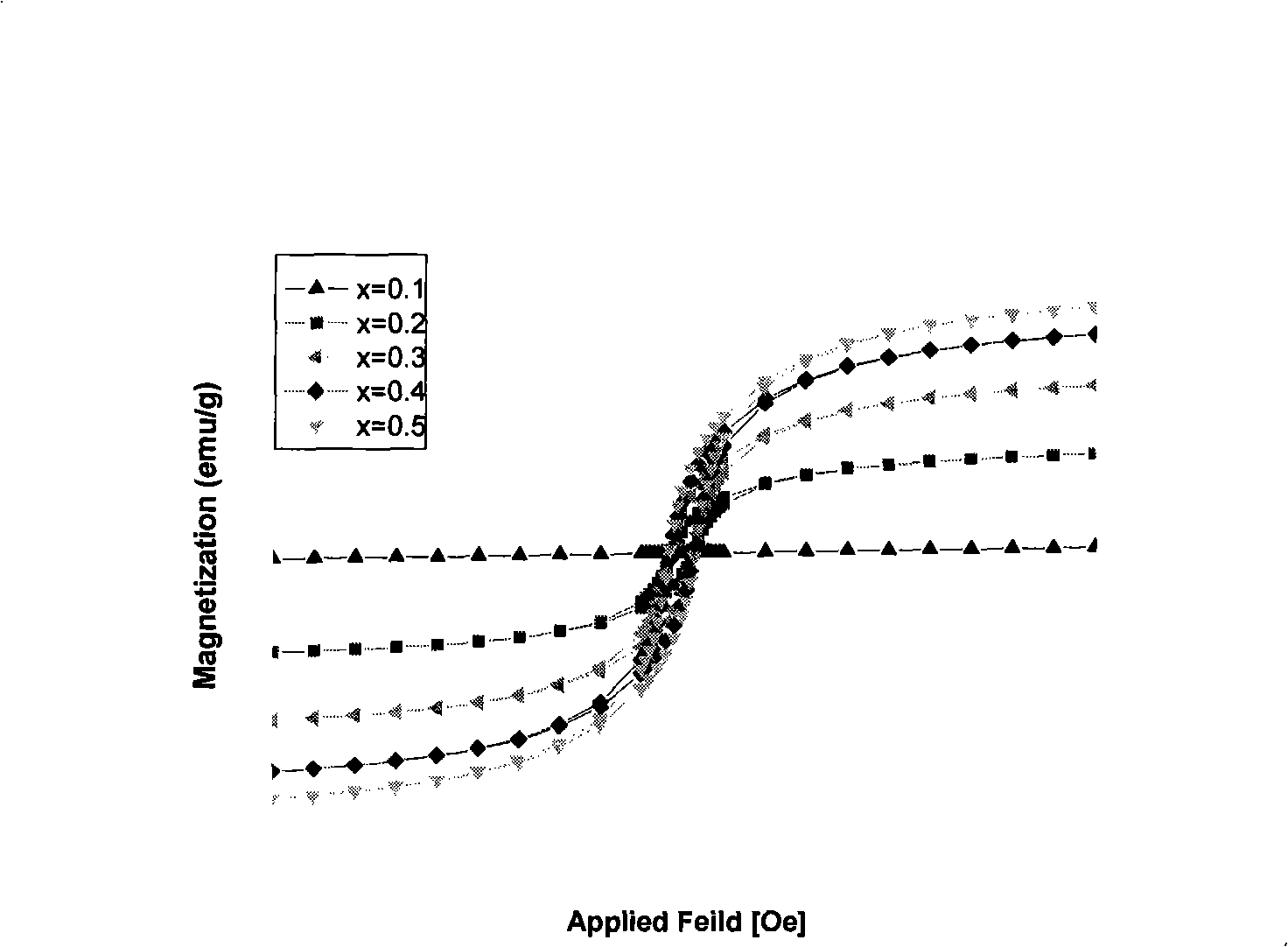

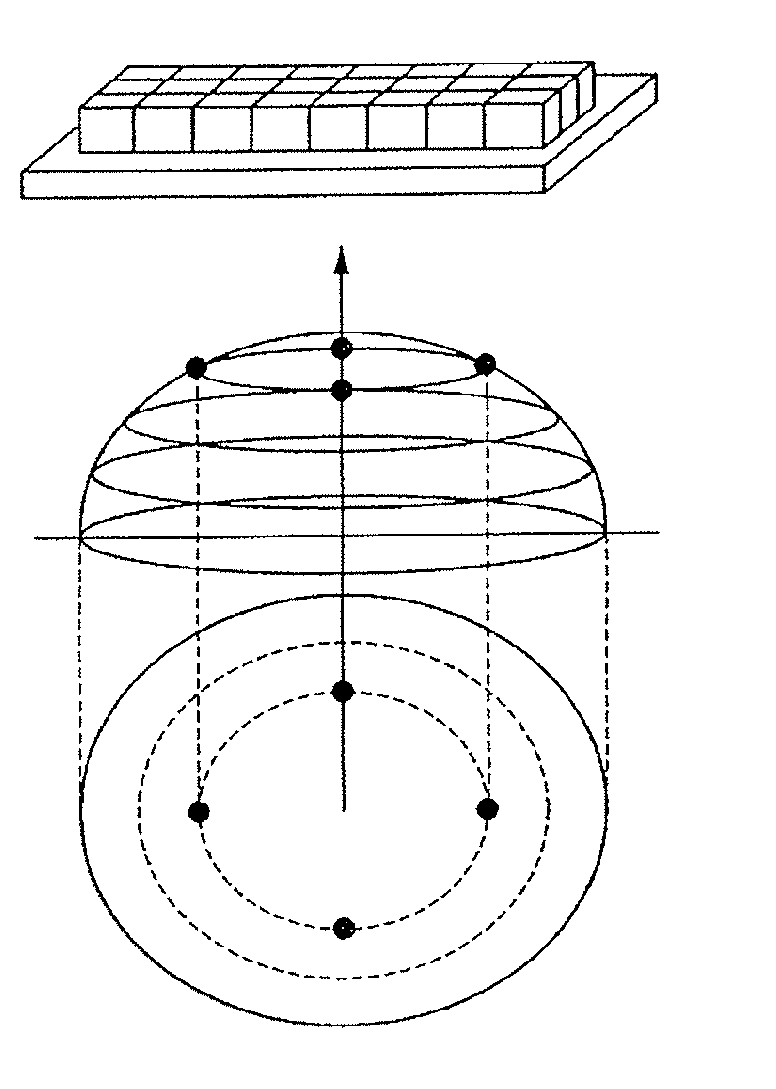

(1-x)(ba,bi,na)tio3-xcofe2o4 composite multi-iron ceramic and preparation method thereof

InactiveCN101265084AImprove ferroelectric propertiesExcellent piezoelectric propertiesCompression moldingAdhesive

The invention relates to a composite multiferroic ceramic (1-x)(Ba, Bi, Na)TiO3-xCoFe2O4, wherein x is more than or equal to 0.1 but less than or equal to 0.5. A production method of the composite multiferroic ceramic is also disclosed. The method comprises the following steps: 1) weighing Bi2O3, Na2CO3, BaTiO3, Co2O3 and Fe2O3 at the given ratio mentioned above, grinding and mixing thoroughly; 2) mixing the fine powder obtained in the step 1) with a binder and mixing thoroughly; 3) compression-molding the powder obtained in the step 2) under 10-20 MPa to obtain sheet with a thickness of 2.0 plus or minus 10% mm; and 4) in a sealed container, placing the sheet obtained in the step 3) over the fine powder obtained in the step 1), covering the sheet with the fine powder, placing the sealed container loading the sheet and powder in a heating furnace, and sintering, to obtain the composite multiferroic ceramic (1-x)(Ba, Bi, Na)TiO3-xCoFe2O4, wherein the sintering temperature is 1000-1250 DEG C and the sintering time lasts 2-3 hours. The product is free of lead and environment-friendly. The production equipment and process are simplified.

Owner:NANJING UNIV

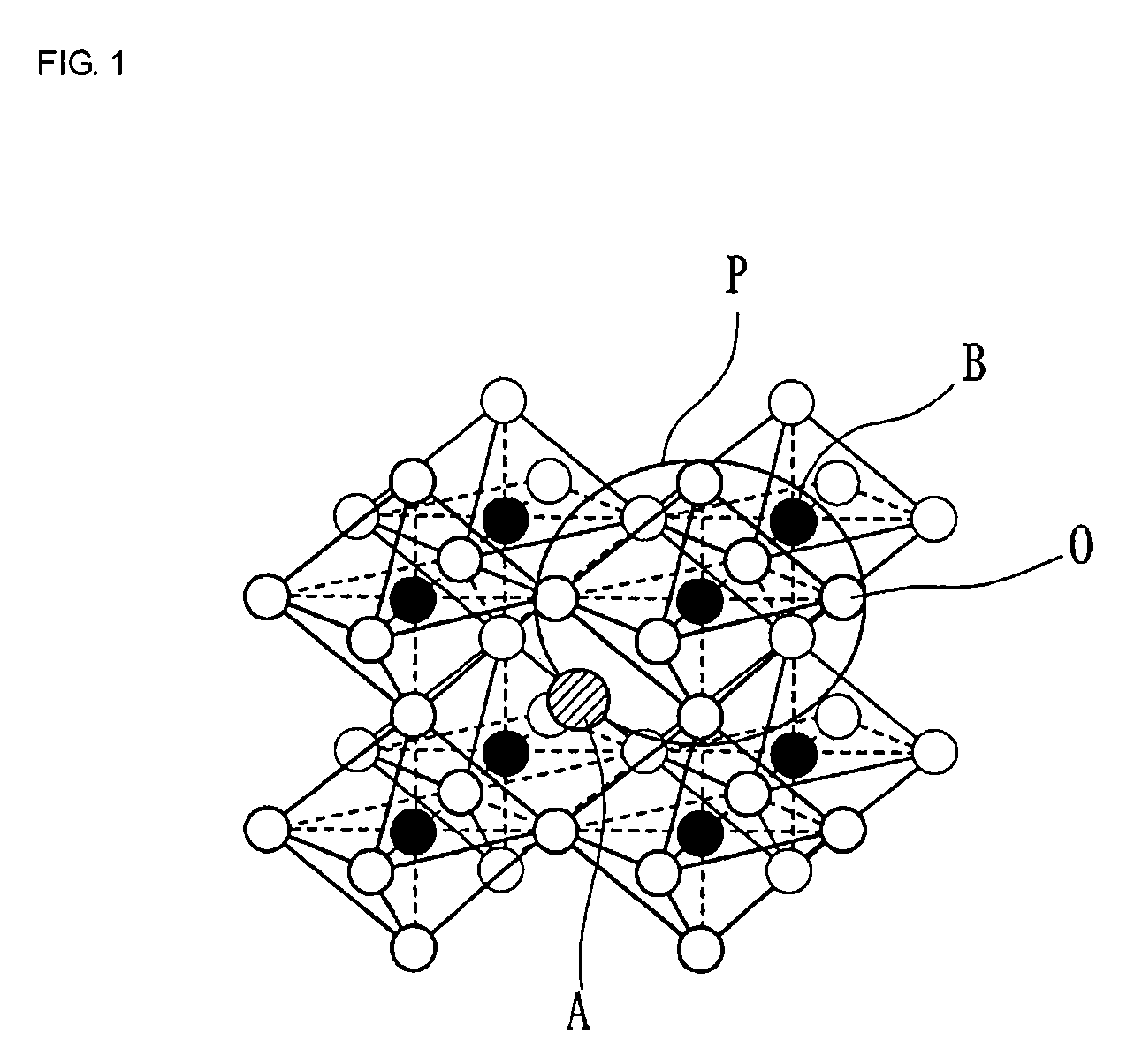

Piezoelectric substance and manufacturing method thereof, piezoelectric element and liquid discharge head using such piezoelectric element and liquid discharge apparatus

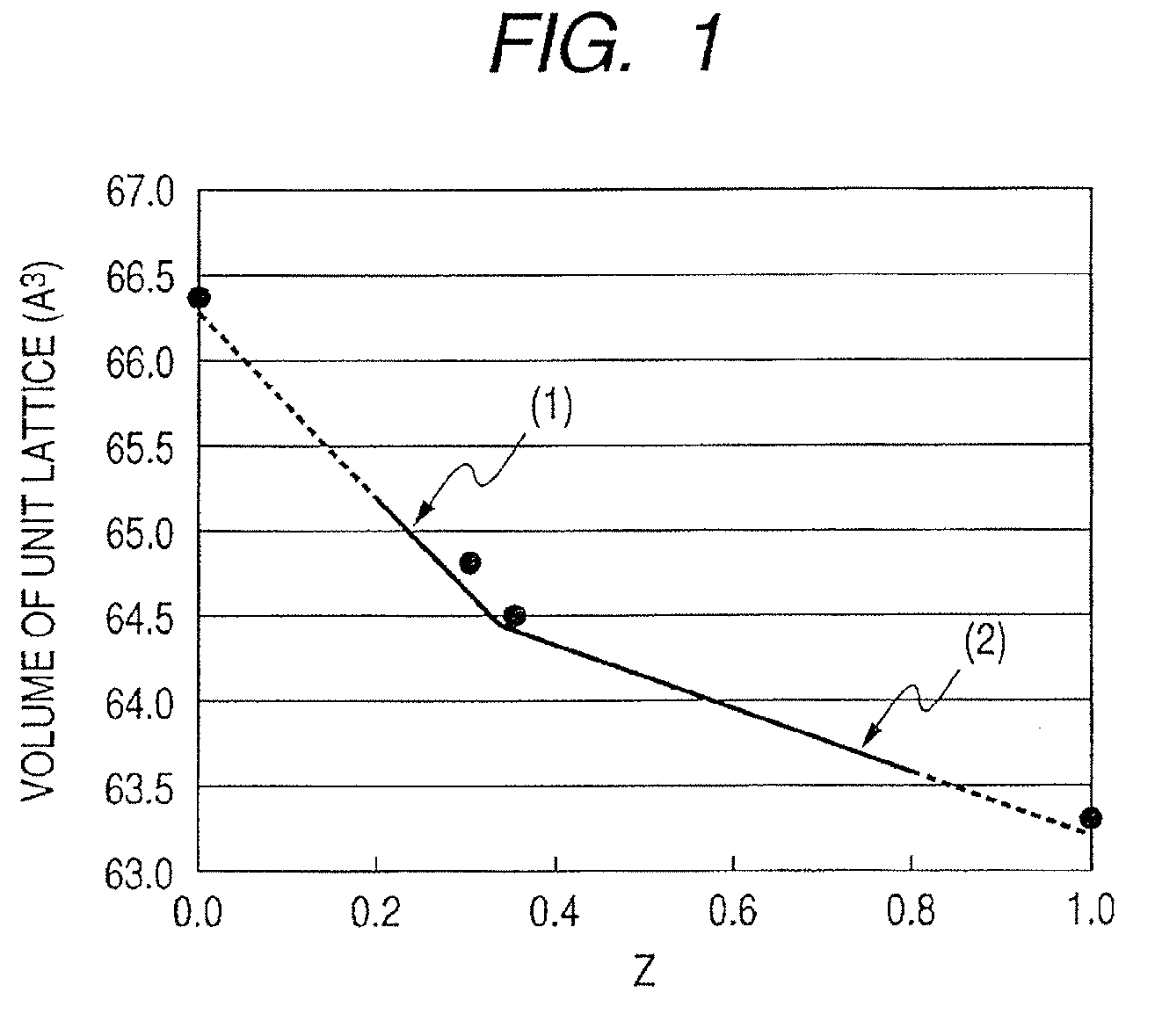

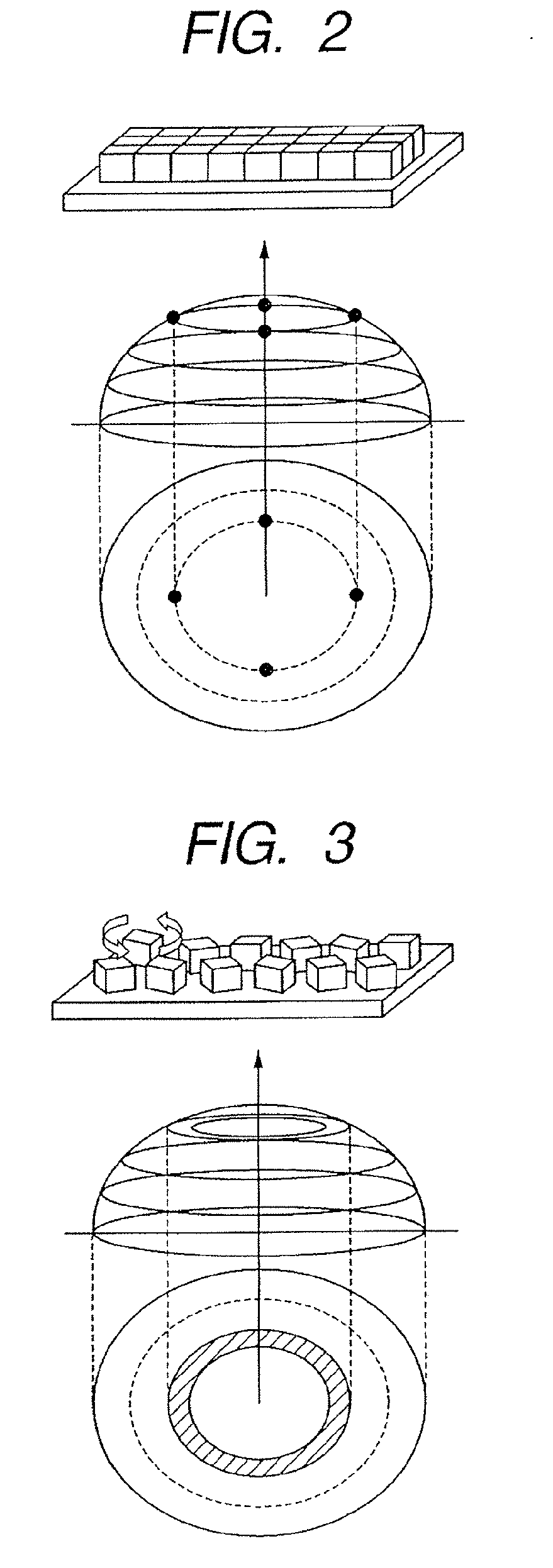

InactiveUS20070046154A1Excellent piezoelectric propertiesImprove discharge performancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesSingle crystalUniaxial crystal

The present invention provides a piezoelectric substance of single crystal or uniaxial crystal type in which three lattice lengths a, b and c of a unit lattice of the piezoelectric substance are smaller than lattice length a0, b0 and c0 of a unit lattice of a bulk state of single crystal having the same temperature and same composition, respectively, and a volume of the unit lattice of the piezoelectric substance is smaller than a volume of the unit lattice of the bulk state of single crystal having the same temperature and same composition.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com