Patents

Literature

269results about How to "Easy to sinter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric ceramic composition and method of production of same, piezoelectric element, and dielectric element

InactiveUS20040058797A1Excellent piezoelectric propertiesIncrease temperaturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionRheniumIridium

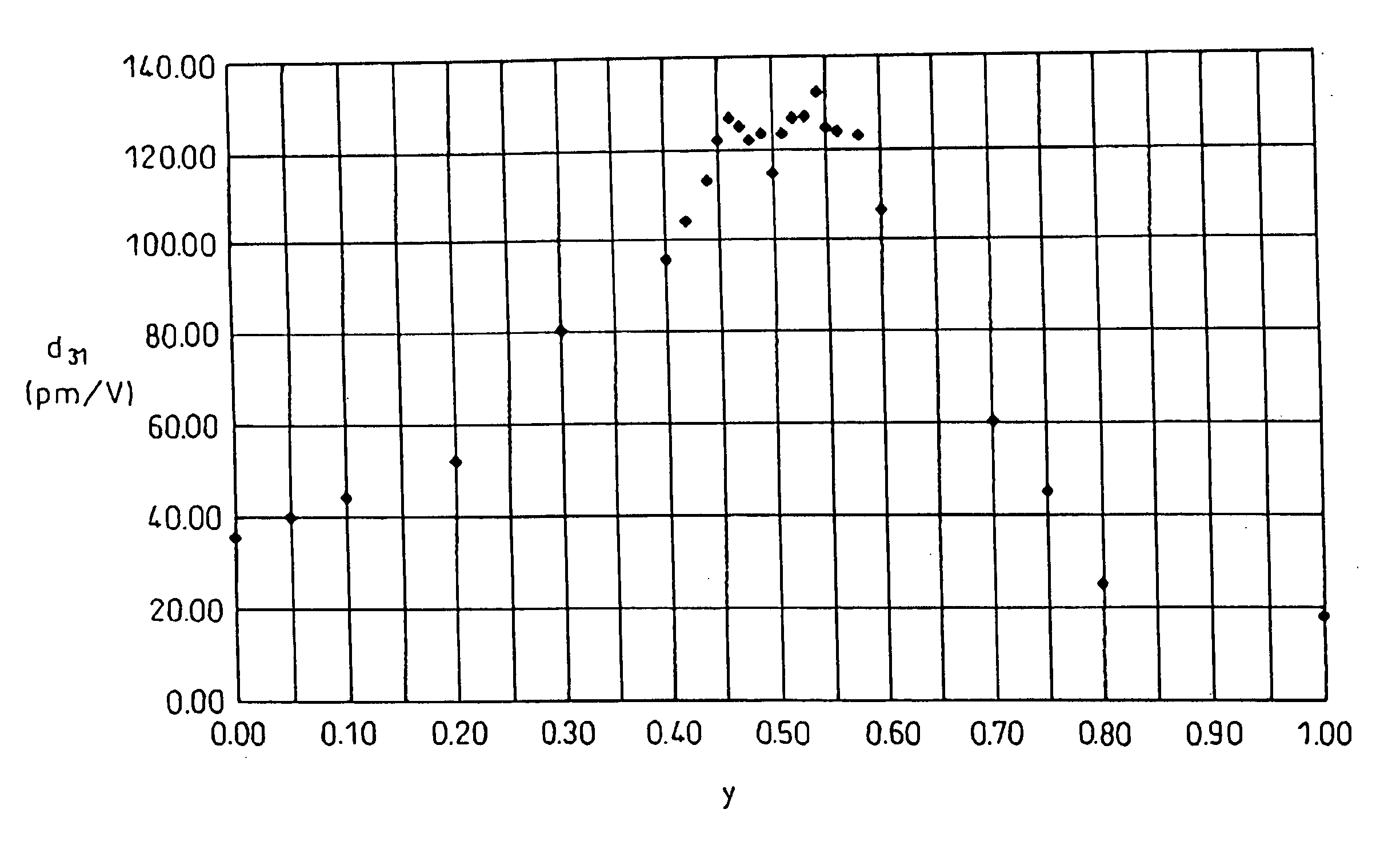

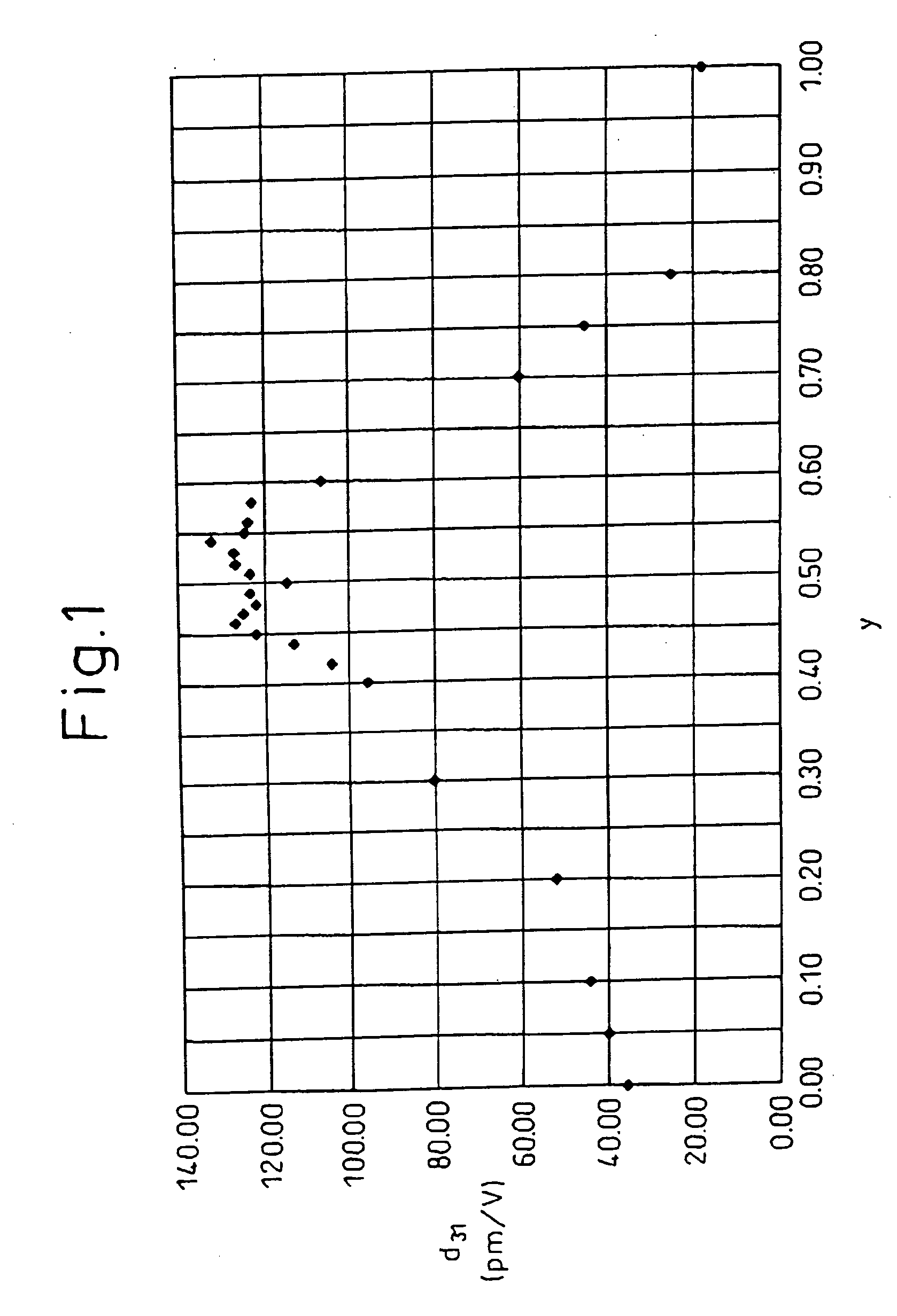

A piezoelectric ceramic composition not containing lead, able to be sintered at ordinary pressure, and superior to the past in at least one of the properties unique to piezoelectric ceramic compositions such as the piezoelectric d31 constant, that is, a piezoelectric ceramic composition having a compound of a general formula {Lix(K1-yNay)1-x}(Nb1-z-wTazSbw)O3 where x, y, z, and w are in the ranges of 0<=x<=0.2, 0<=y<=1, 0<z<=0.4, and 0<w<=0.2 as a main ingredient, where the piezoelectric ceramic composition contains at least one metal element selected from (1) palladium, silver, gold, ruthenium, rhodium, rhenium, osmium, iridium, and platinum, (2) nickel, iron, manganese, copper, and zinc, or (3) magnesium, calcium, strontium, and barium as an added element, and a method of production of the same and a piezoelectric element and dielectric element utilizing that piezoelectric ceramic composition.

Owner:DENSO CORP +1

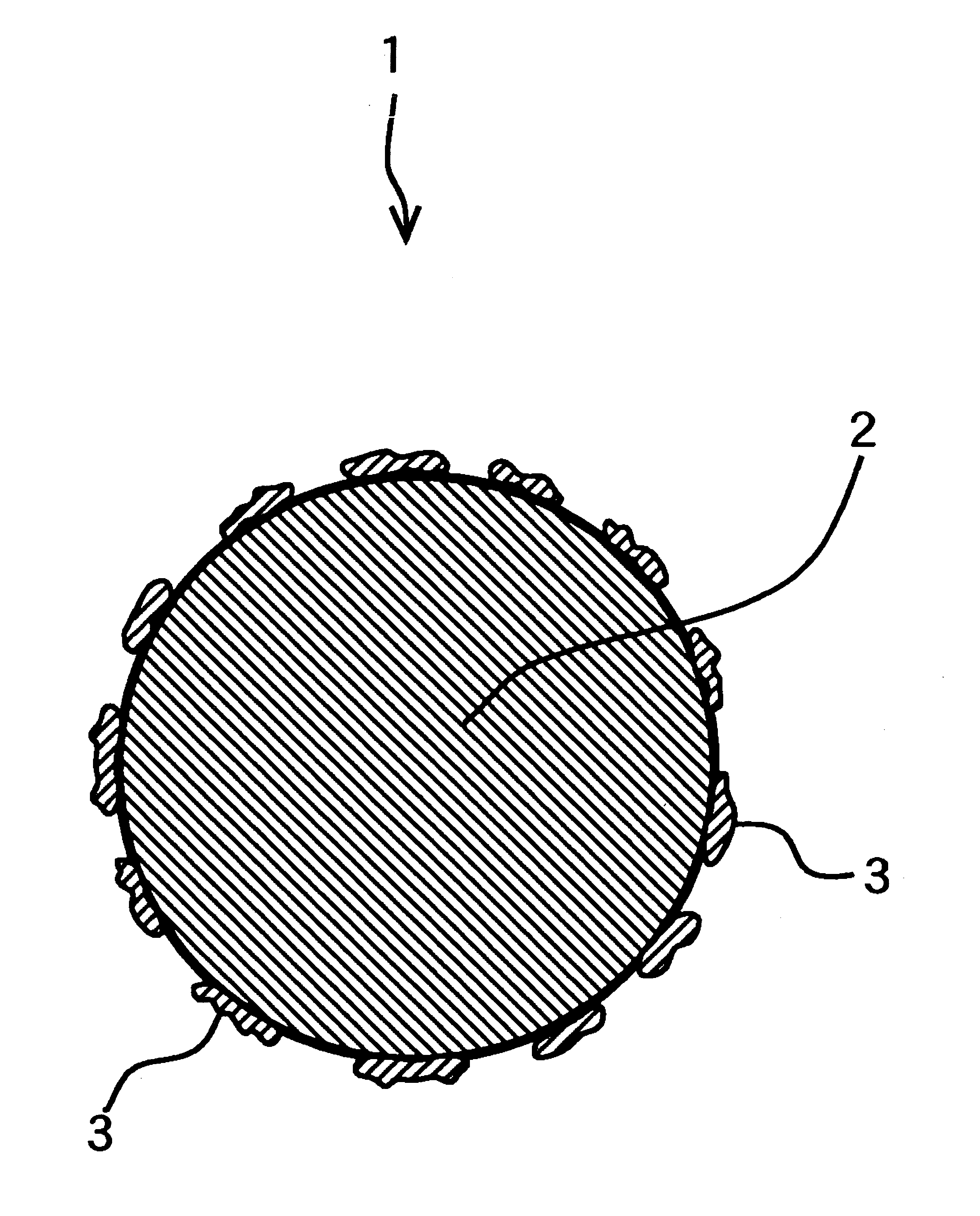

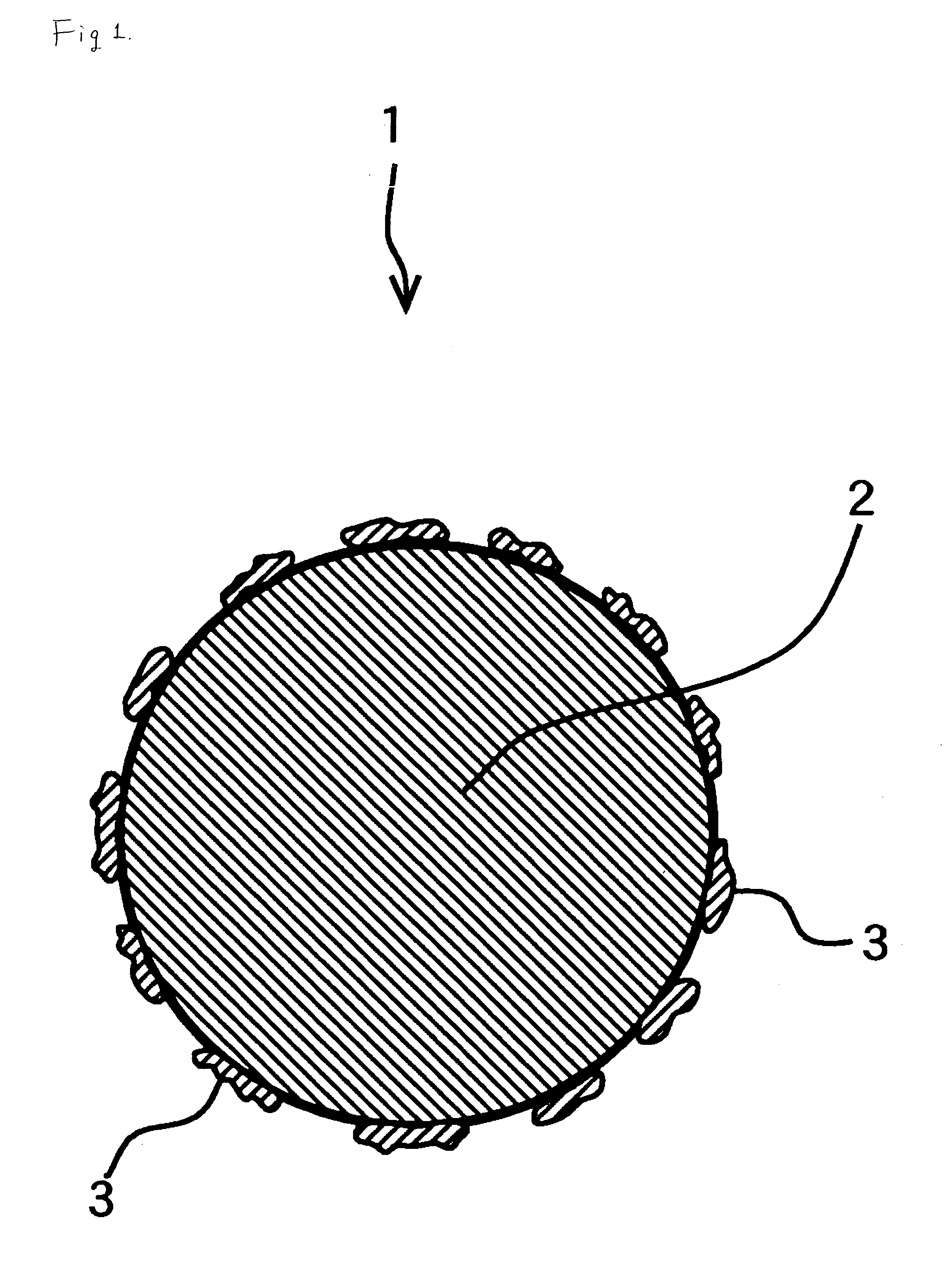

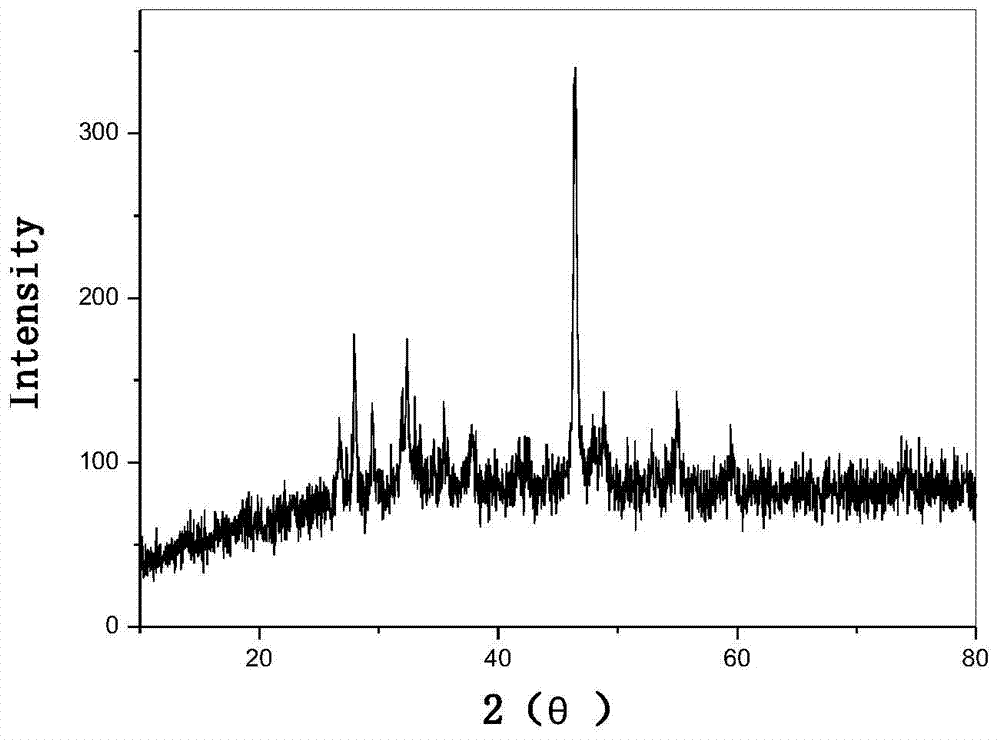

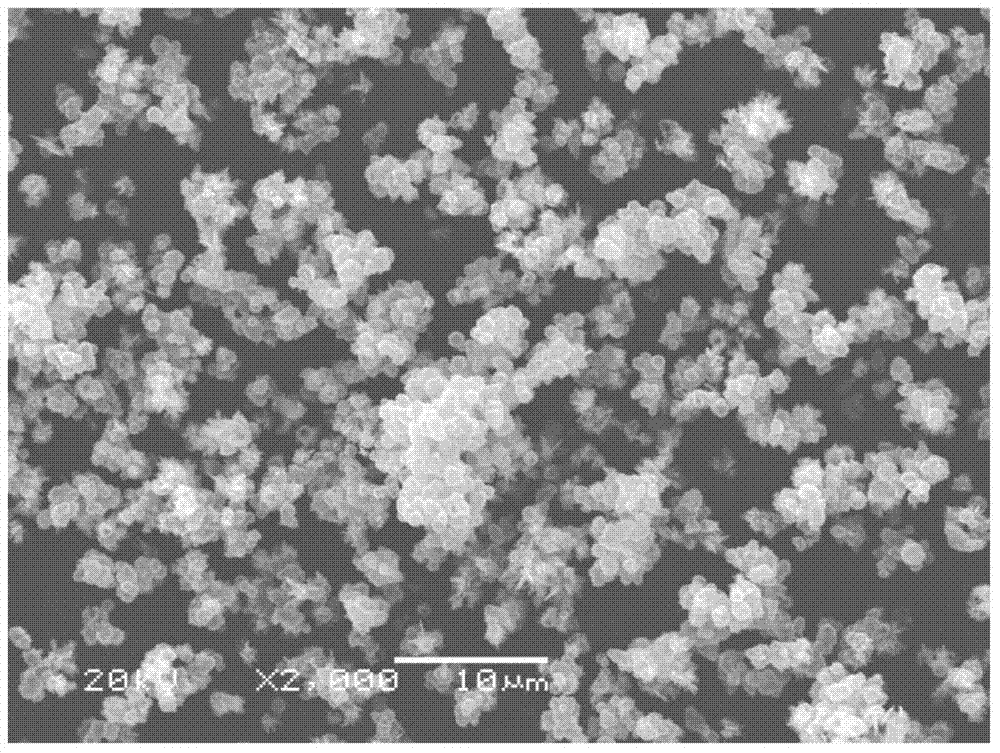

Silver powder made of silver particles, each to which fine silver particles adhere and process of producing the same

InactiveUS20050183543A1Easy to sinterProcess stabilityTransportation and packagingSemiconductor/solid-state device detailsDispersed mediaMetallurgy

This invention is a silver powder having a low-temperature sintering performance and dispersibility, which allows the powder particles to be agglomerated to a small degree and be nearly in the monodisperse state. Employed is silver powder of fine silver particles each to which fine silver particles adhere, wherein fine silver particles of nano-order particle size are adhered to the surface of each silver powder particle. The powder particles of the silver powder of fine silver particles each to which fine silver particles adhere have excellent dispersibility. In the production of the silver powder of fine silver particles each to which fine silver particles adhere, a process of including the steps of: adding a silver nitrate and a neutralizing agent into a slurry of silver powder in a dispersing medium; dissolving the mixture while stirring to allow fine silver oxide particles to be precipitated on the surface of each silver powder particle; washing the resultant silver powder; and exposing the fine silver oxide particles to UV rays to reduce the same to fine silver particles.

Owner:MITSUI MINING & SMELTING CO LTD

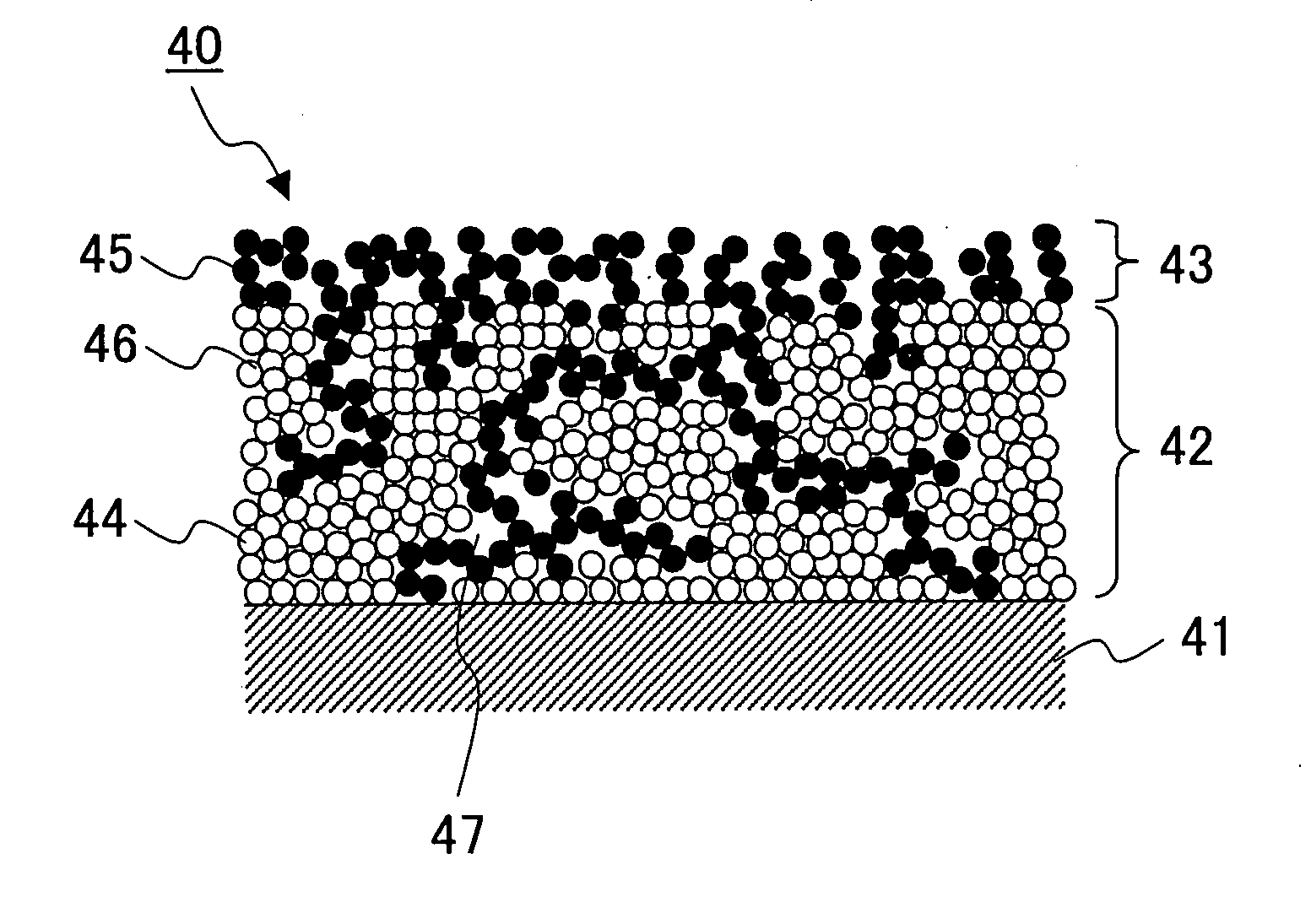

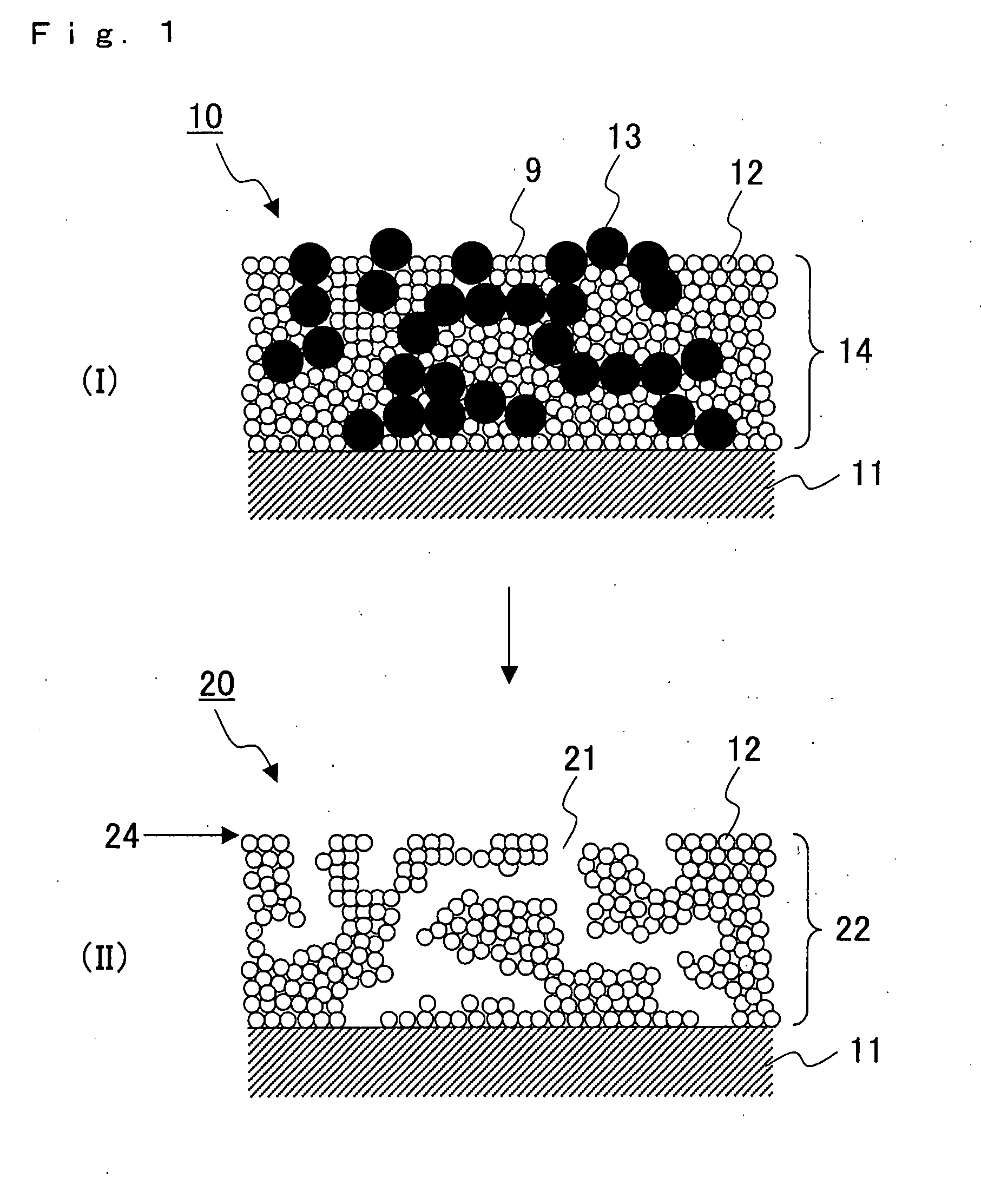

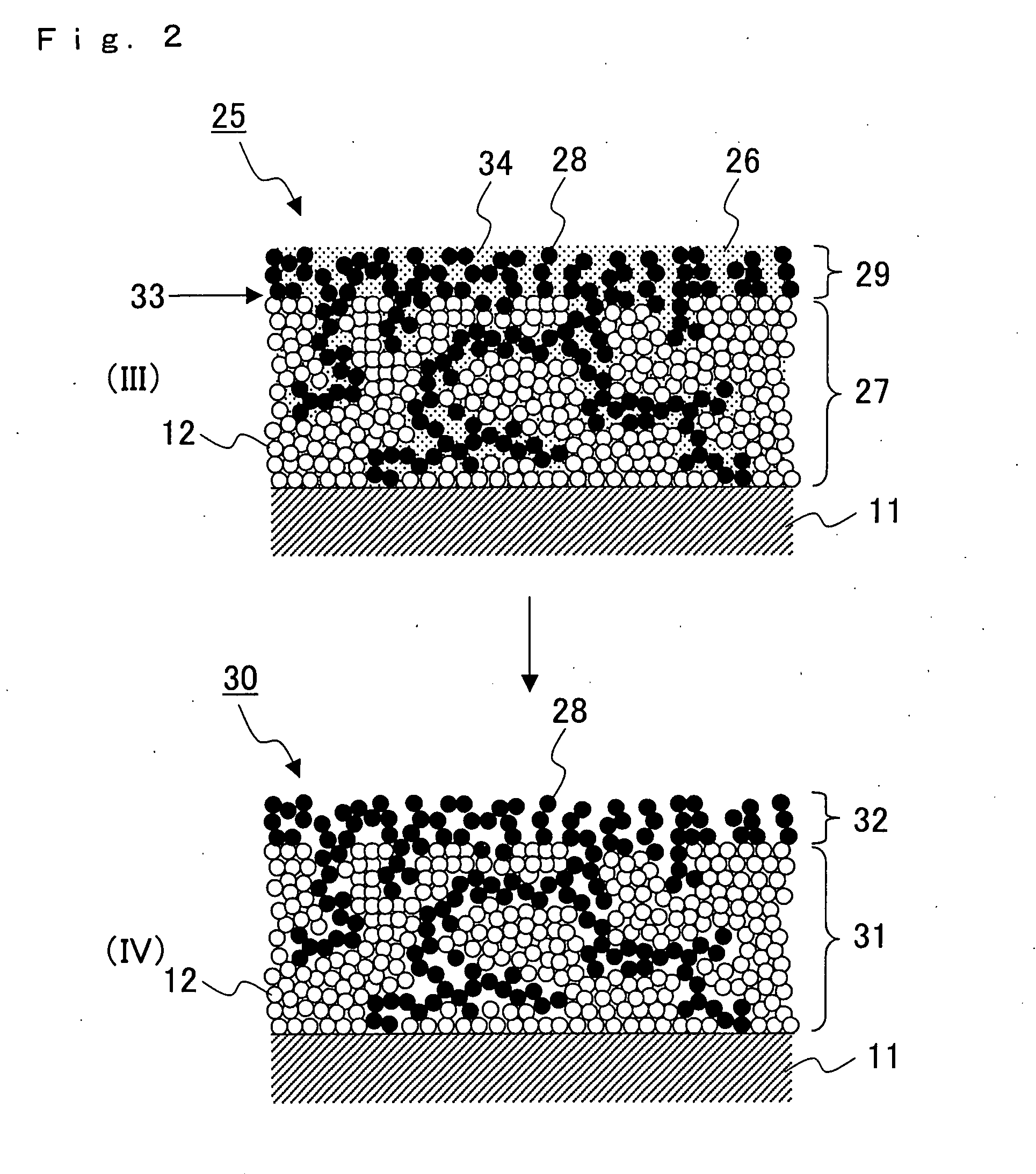

Solid Oxide Type Fuel Battery Cell and Process for Producing the Same

InactiveUS20080102337A1Small conductivityAdd three-phase interfaceSolid electrolytesFinal product manufactureFuel cellsSlurry

A process for producing a cell for solid oxide fuel cells comprising a porous electrolyte layer-forming step of obtaining an electrolyte substrate in which a porous electrolyte layer is formed by applying a slurry for forming an electrolyte layer containing an electrolyte substance powder and a pore-forming agent to the surface of an electrolyte substrate and burning the electrolyte substrate, and an electrode layer-forming step of obtaining an electrolyte substrate in which an electrode substance-filled porous electrolyte layer and an electrode layer are formed by applying a slurry for forming an electrode containing an electrode substance powder, a mixture of an electrode substance powder and an electrolyte substance powder, or a composite material powder of an electrode substance and an electrolyte substance, onto the surface of the porous electrolyte layer of the electrolyte substrate on which the porous electrolyte layer is formed, and burning the electrolyte substrate in which the porous electrolyte layer is formed. According to the present invention, a process for producing a cell for solid oxide fuel cells which can increase the three-phase interface of the porous electrolyte layer and exhibits only a small conductivity reduction of the electrolyte layer can be obtained.

Owner:THE TOKYO ELECTRIC POWER CO INC

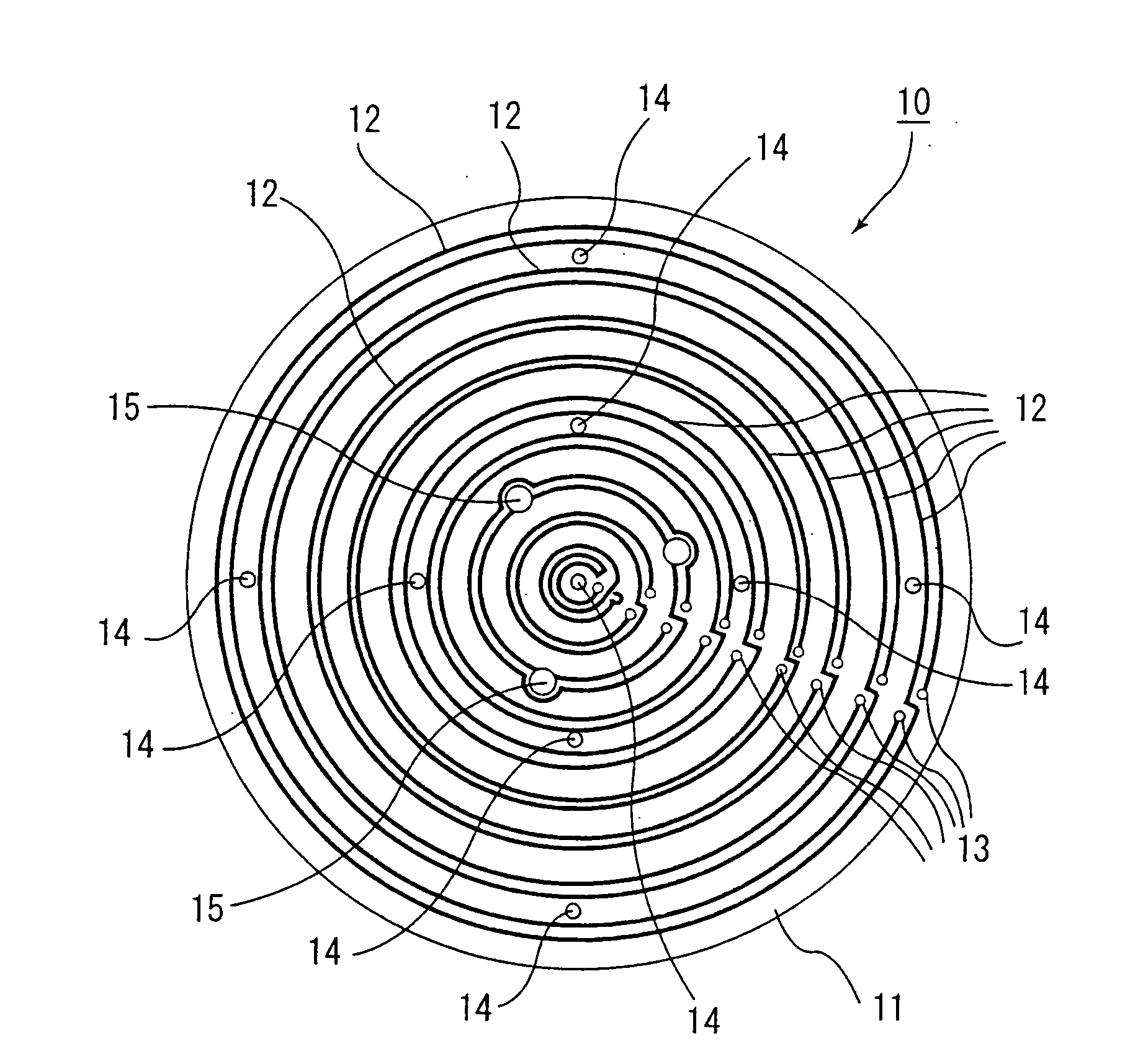

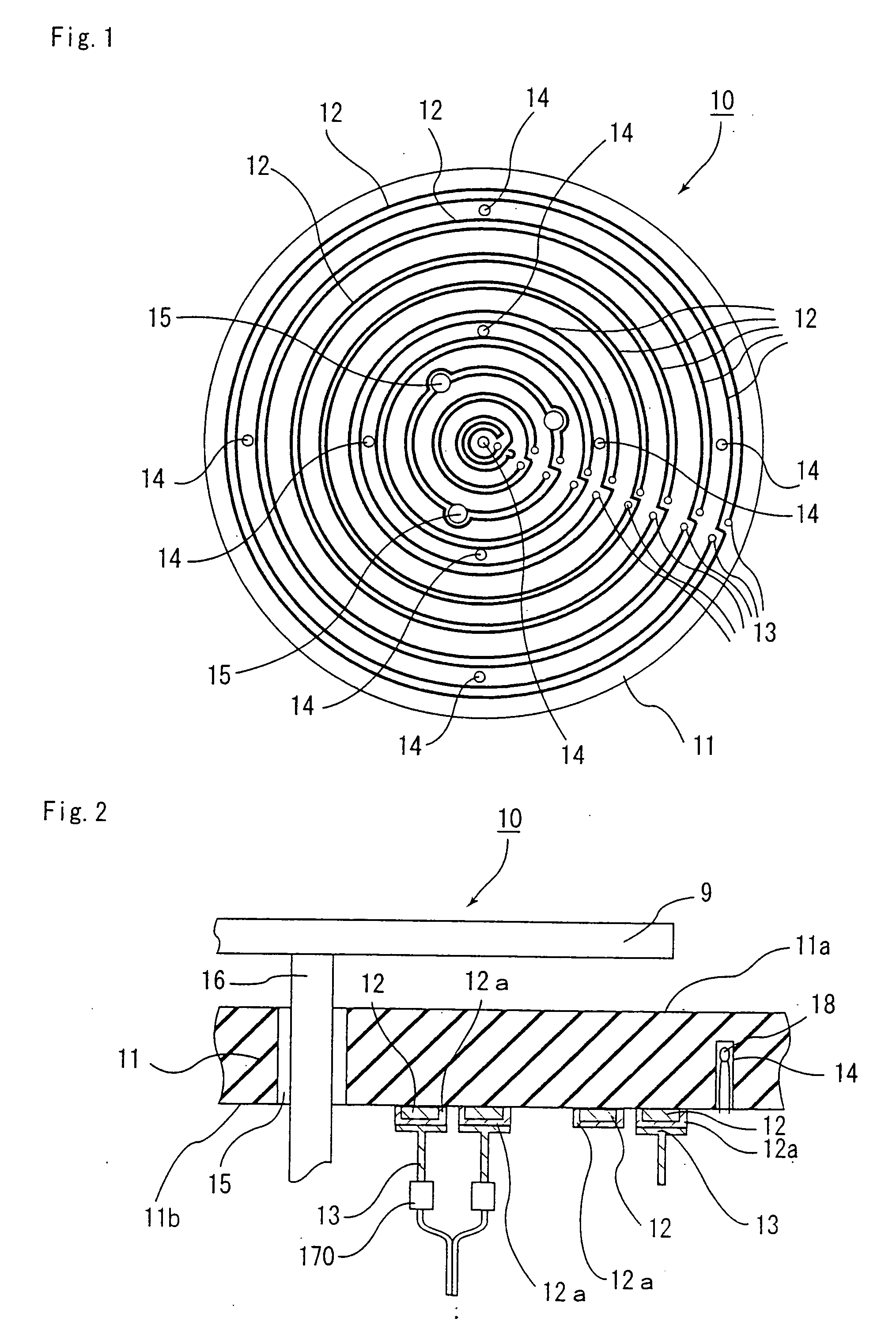

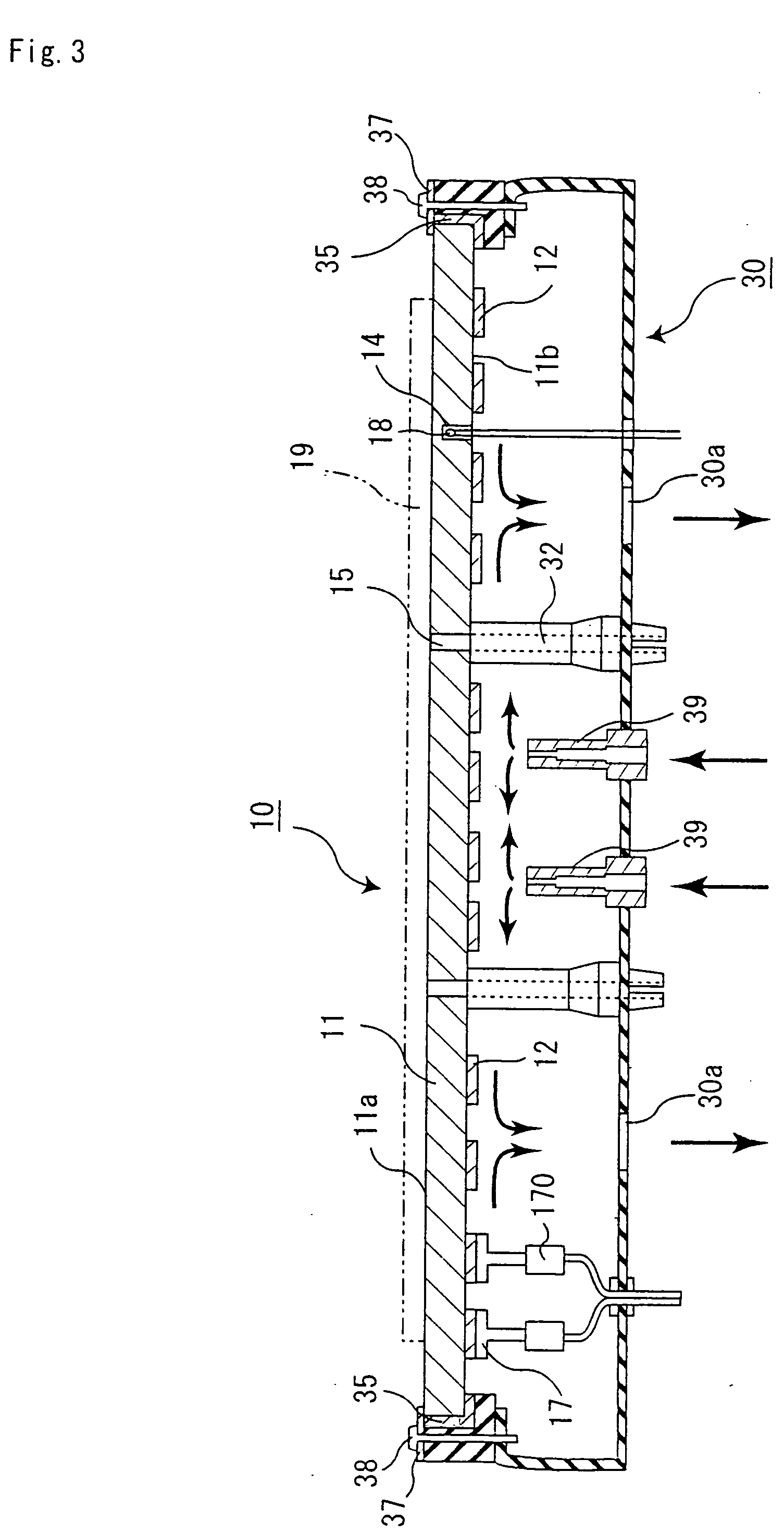

Hot plate

InactiveUS20050258164A1Temperature controlImprove control abilityVacuum evaporation coatingSputtering coatingThermal conductivityThermal efficiency

An object of the present invention is to provide a hot plate which is superior in thermal conductivity, is superior in temperature-rising / dropping property, particularly in temperature-dropping property, and has high cooling thermal efficiency at the time of cooling. The hot plate of the present invention is a hot plate comprising: a ceramic substrate; and a resistance heating element formed on the surface of said ceramic substrate or inside said ceramic substrate, wherein said ceramic substrate has a leakage quantity of 10−7 Pa·m3 / sec (He) or less by measurement with a helium leakage detector.

Owner:IBIDEN CO LTD

High-strength calcium hexa-aluminate light heat insulation material and preparation method thereof

The invention relates to a high-strength calcium hexa-aluminate light heat insulation material and a preparation method thereof. The preparation method is characterized by using 70-85wt% of Al2O3 fine powder, 2-8wt% of rho-Al2O3 micro powder and 13-22wt% of nano CaCO3 as raw materials, adding a water reducer accounting for 0.05-0.30wt% of the raw materials and water accounting for 20-80wt% of the raw materials and mixing the materials for 30-150 minutes, thus obtaining a premix; then adding foam to the premix, mixing the materials for 3-8 minutes, moulding the mixture by casting and naturally drying the product; then roasting the product at 90-110 DEG C for 24 hours and insulating the product at 1430-1650 DEG C for 3-6 hours, thus obtaining the high-strength calcium hexa-aluminate light heat insulation material, wherein the addition amount of the foam in the premix is 0.1-2.0L per kg of raw materials. The high-strength calcium hexa-aluminate light heat insulation material has the characteristics of energy conservation, environment friendliness, easiness in demoulding of green bodies and easiness in sintering, has stable properties, low content of impurities, low volume density, high strength and low heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

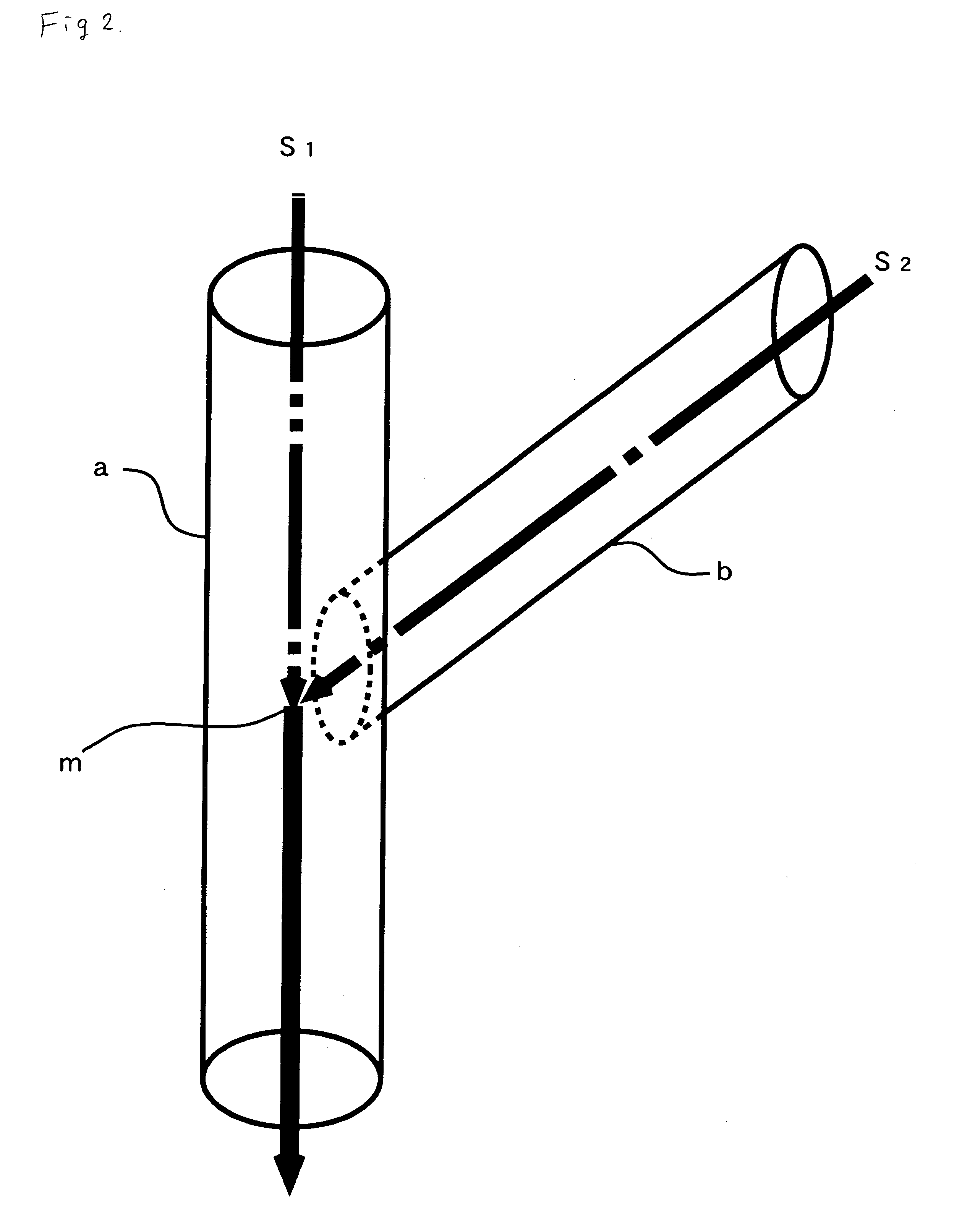

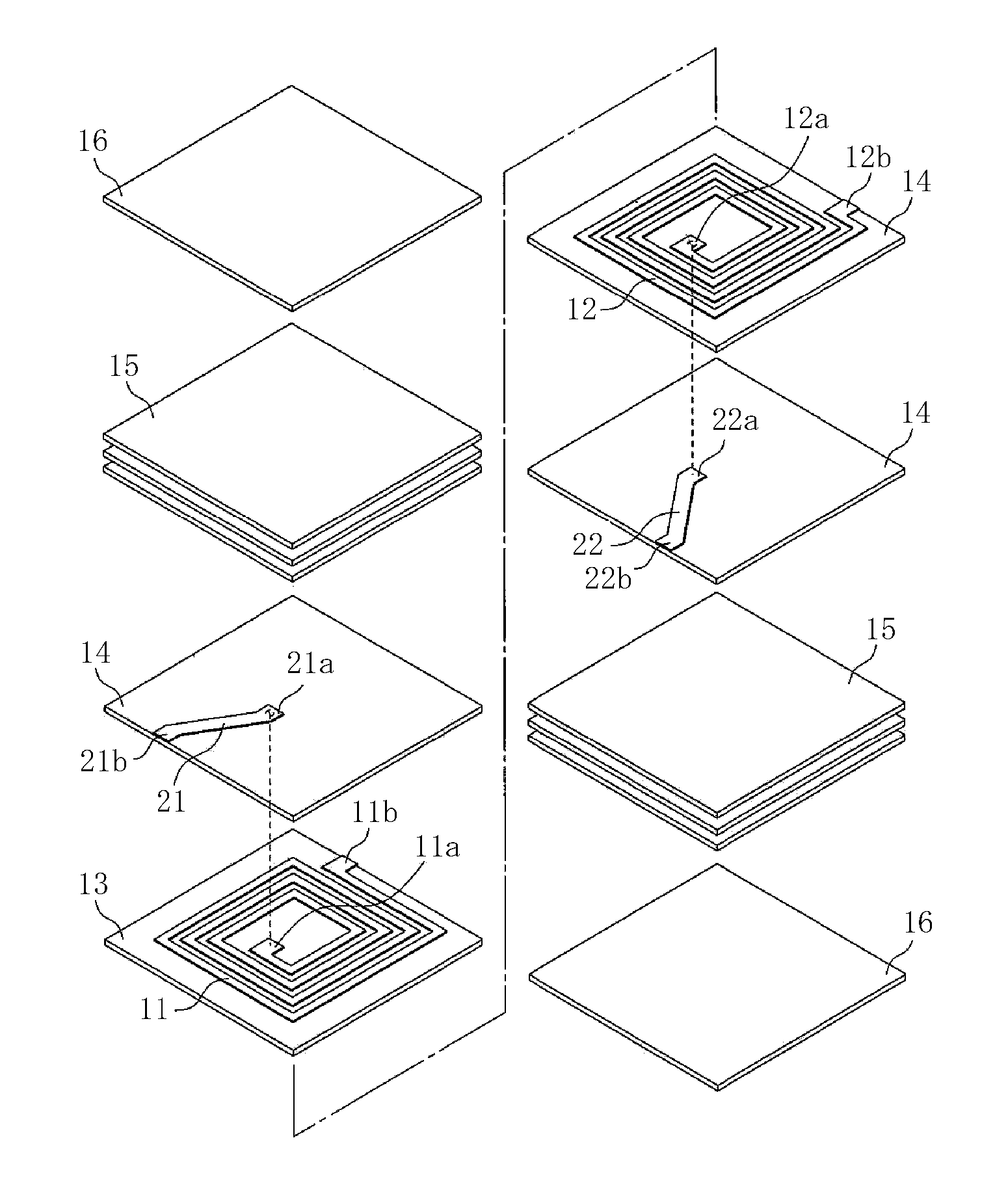

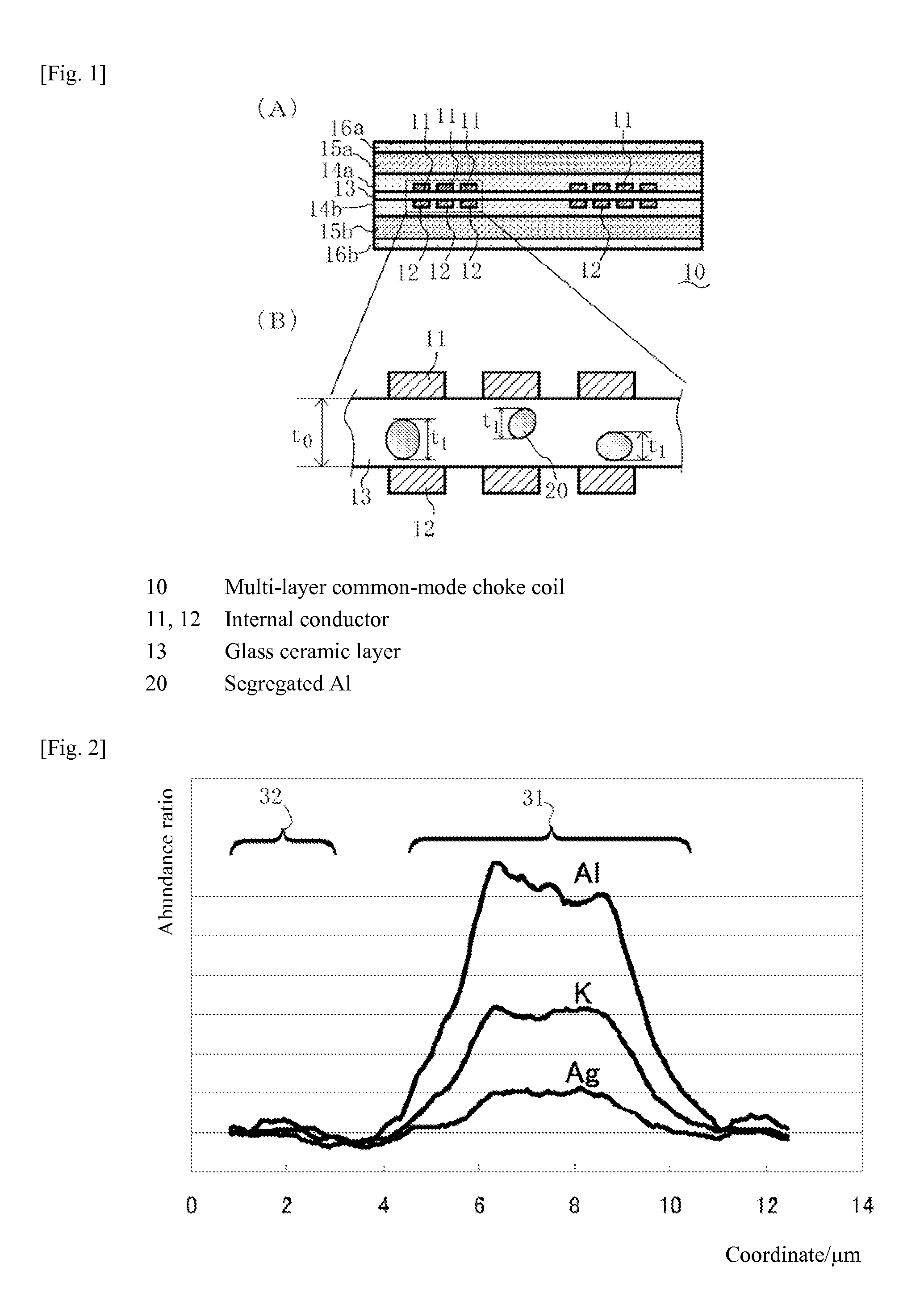

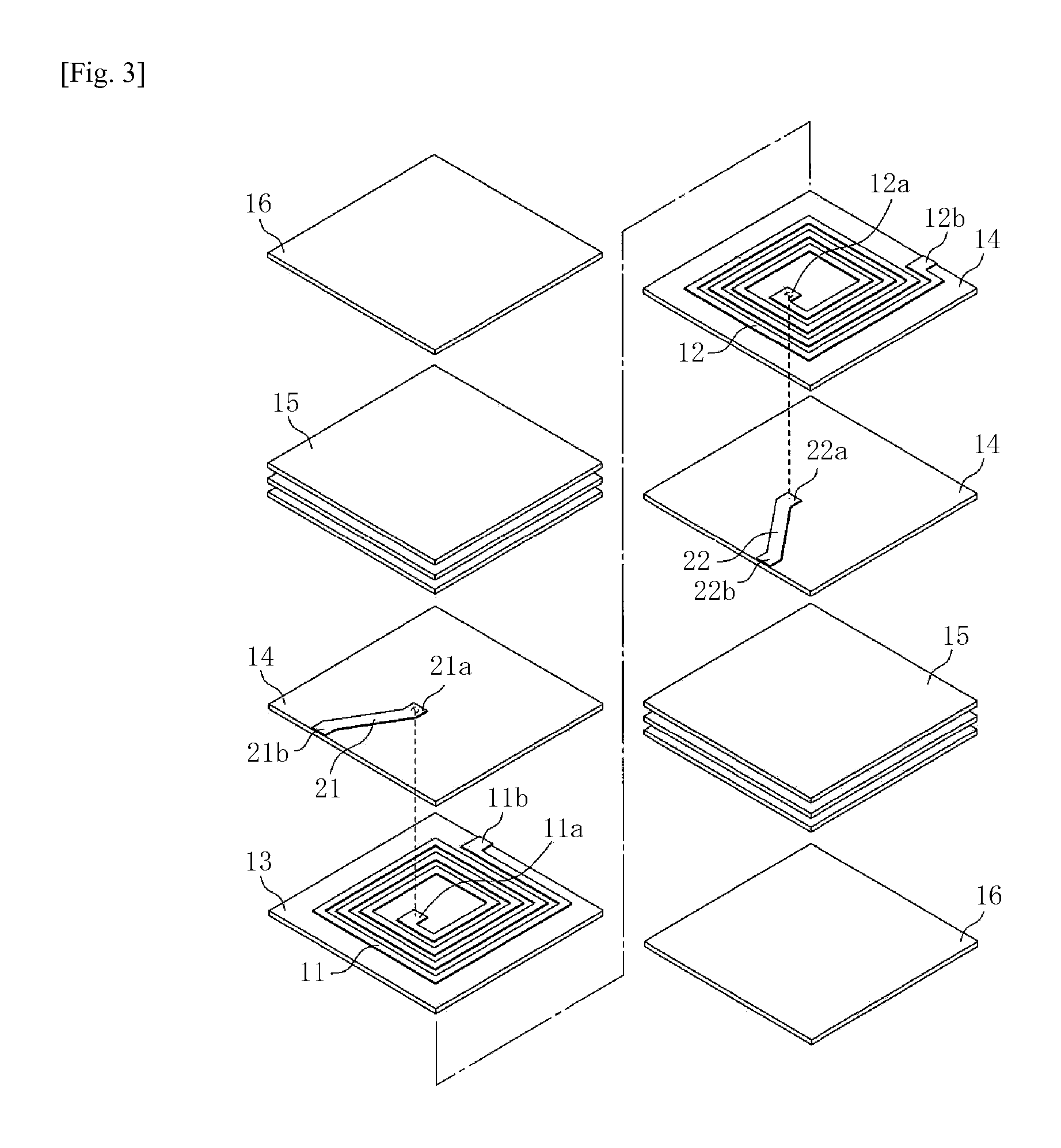

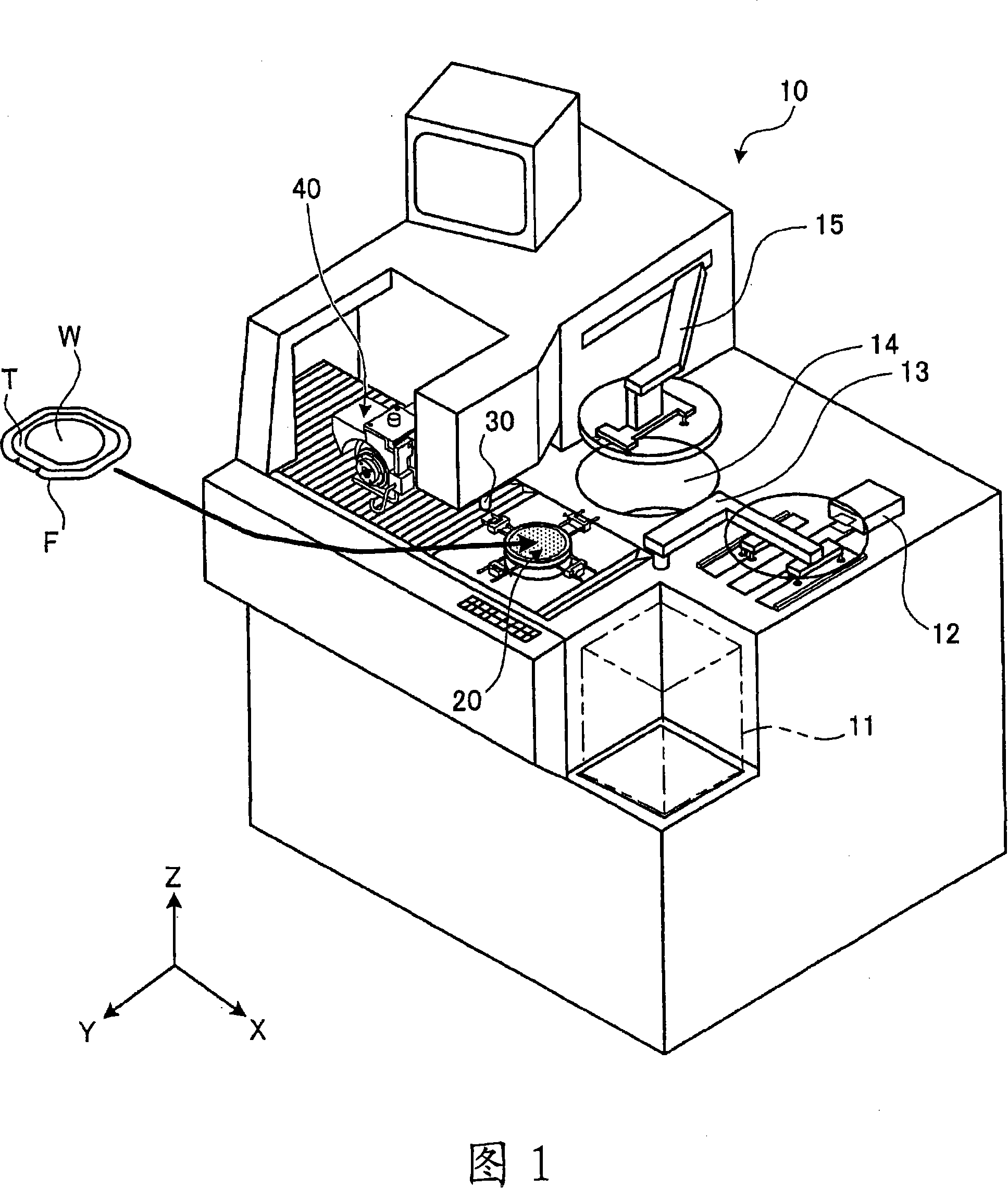

Laminated common-mode choke coil

ActiveUS20130154786A1Insulation property be lowerHigh insulation reliabilityCoilsFixed signal inductancesManufacturing engineeringElectrical conductor

A laminated common-mode choke coil offering higher insulation reliability has a glass ceramic layer, two spiral internal conductors facing each other and sandwiching the glass ceramic layer in between, and insulation layers sandwiching the two internal conductors, wherein the glass ceramic layer contains segregated Al regions and the maximum dimension t1 of each segregated Al region in the glass ceramic layer, in the layer-thickness direction, is no more than 80% of the distance t0 between the two internal conductors.

Owner:TAIYO YUDEN KK

Preparation method of polycrystalline cubic boron nitride (PcBN) composite material

The invention relates to a preparation method of a polycrystalline cubic boron nitride (PcBN) composite material, which comprises the following steps: by using nonstoichiometric titanium nitride (TiNX, 0.3<=x<=0.6) as the basic component of a binder in the PcBN composite material, constituting a binder with one or both of aluminum nitride (AlN) and titanium carbide (TiC), and sintering with monocrystalline cubic boron nitride (cBN) under the conditions of high temperature and high pressure to prepare the PcBN composite material, wherein the pressure is 4-6.5GPa, the temperature is 1400-1650 DEG C, and such pressure and temperature are kept for 1-25 minutes. Since the PcBN composite material is prepared from the cBN and the binder mainly composed of the nonstoichiometric titanium nitride (TiNX, 0.3<=x<=0.6), the polycrystal does not contain any simple substance element or alloy phase, thereby avoiding the existence of soft spot. The hardness of the obtained PcBN composite material is up to 38-55GPa, and the fracture toughness is up to 3.31-4.12MPa.m1 / 2.

Owner:YANSHAN UNIV

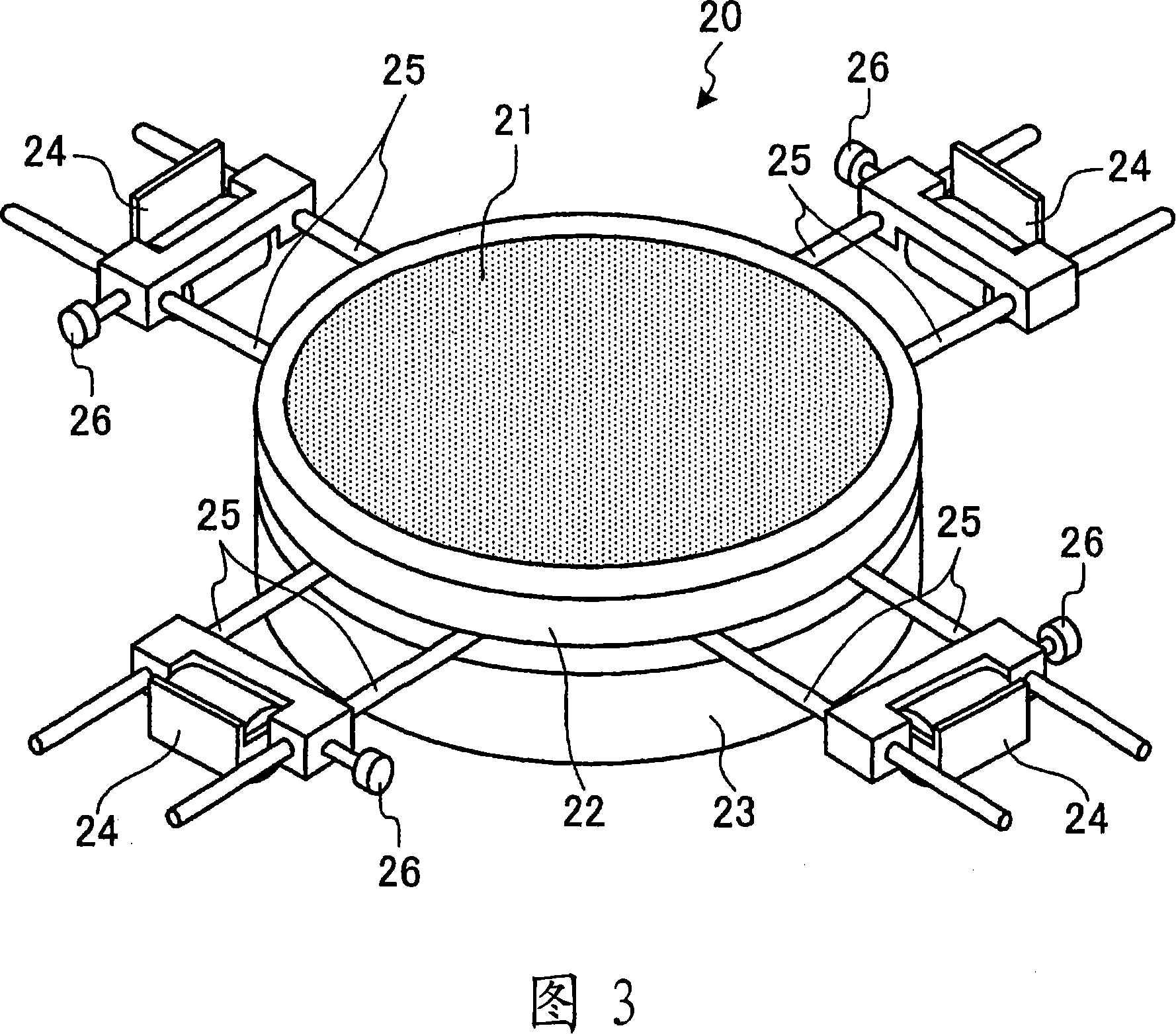

Processing device and suction plate bench

InactiveCN101140892AEliminate bendingDecreased upper surface accuracySemiconductor/solid-state device manufacturingPositioning apparatusThermal expansionTortuous retinal vessels

The present invention provides a processing device and a sucking disc worktable for preventing occurrence of the phenomena such as tortuosity of the sucking disc worktable due to temperature variation, fracture or deviation from frames of aspiration maintenance parts, even in case of realization of major diameter of crystal plates and the sucking disc worktable. The aspiration maintenance part (21) of the sucking disc worktable (20) is made of a porous ceramic whose main component is zirconium oxide having coefficient of linear thermal expansion of 9.0x10 <-6> DEG C approximately similar to that (10.4x10 <-6> DEG C) of stainless steel forming the frame body (22). Therefore, problems such as tortuosity of the sucking disc worktable due to temperature variation, fracture or deviation from the frames of the aspiration maintenance parts can be eliminated; in case of realization of major diameter of crystal plates and the sucking disc worktable, even temperature variation exists, precision drop of supine surfaces of the sucking disc worktable can be restrained, and crystal plates can be processed with high accuracy.

Owner:DISCO CORP

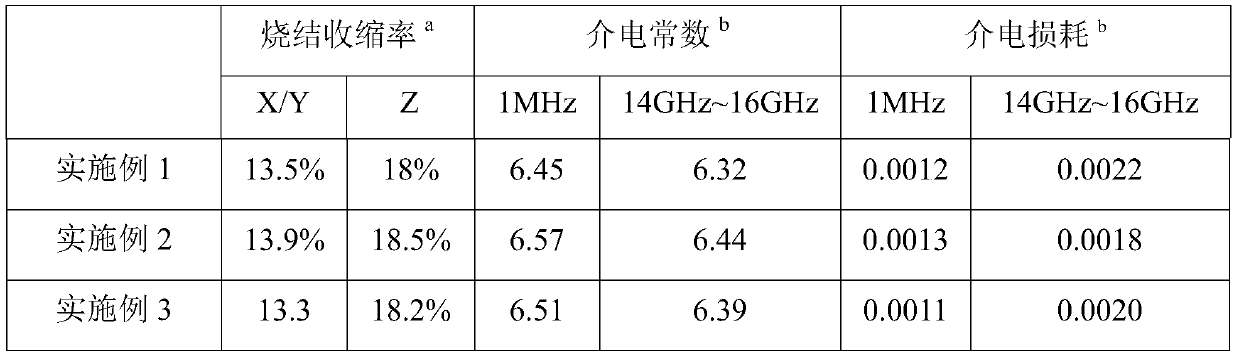

Low-dielectric LTCC green tape as well as preparation method and use thereof

The invention discloses a low-dielectric LTCC green tape as well as a preparation method and use thereof. The low-dielectric LTCC green tape is composed of a powder, a solvent, a dispersing agent, a binder and a plasticizer, wherein the powder is in a mass fraction of 40-60%, and prepared from 10-40wt% of a glass material, 1-10wt% of a low melting point oxide sintering aid and the balance of a ceramic material; the chemical composition of the ceramic material is Zn2-xSiO4-x, where x=0.05-0.3. In the present invention, the problem of low-temperature sintering ofZn2-xSiO4-x ceramic is solved byadding the crystallizable glass material and the sintering aid together, and the mechanical properties and the high-frequency electrical characteristics of the system can be improved.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

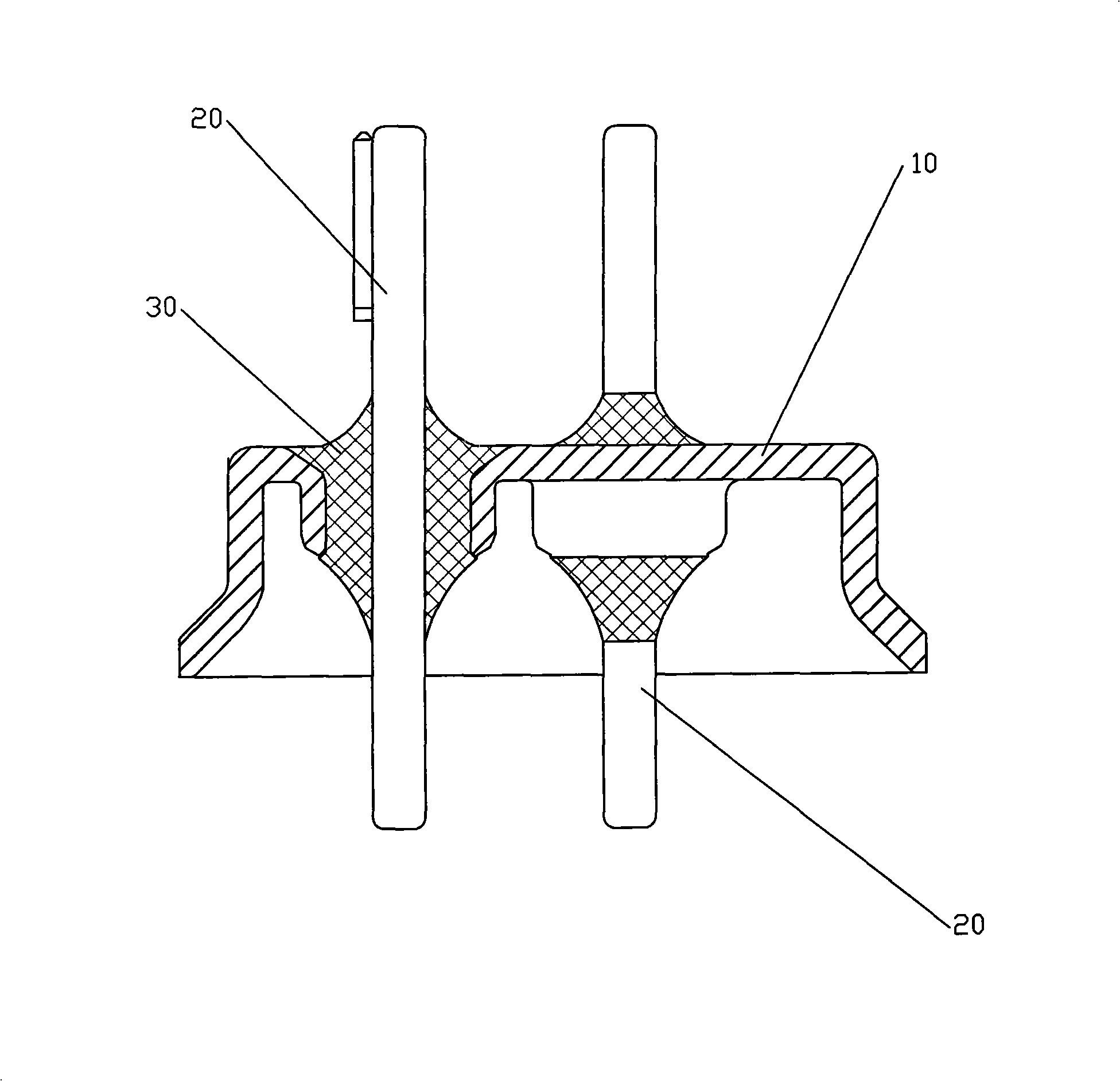

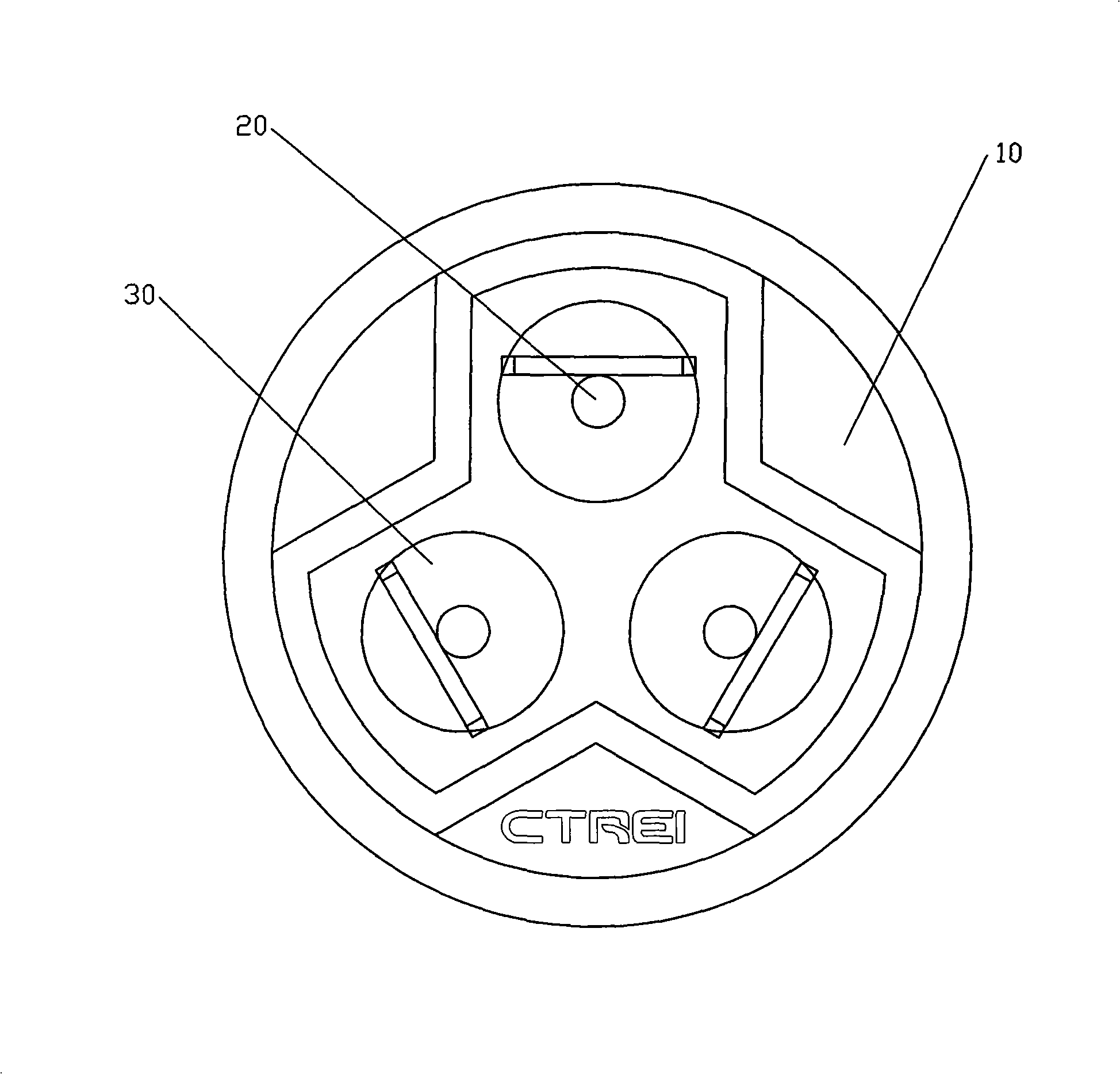

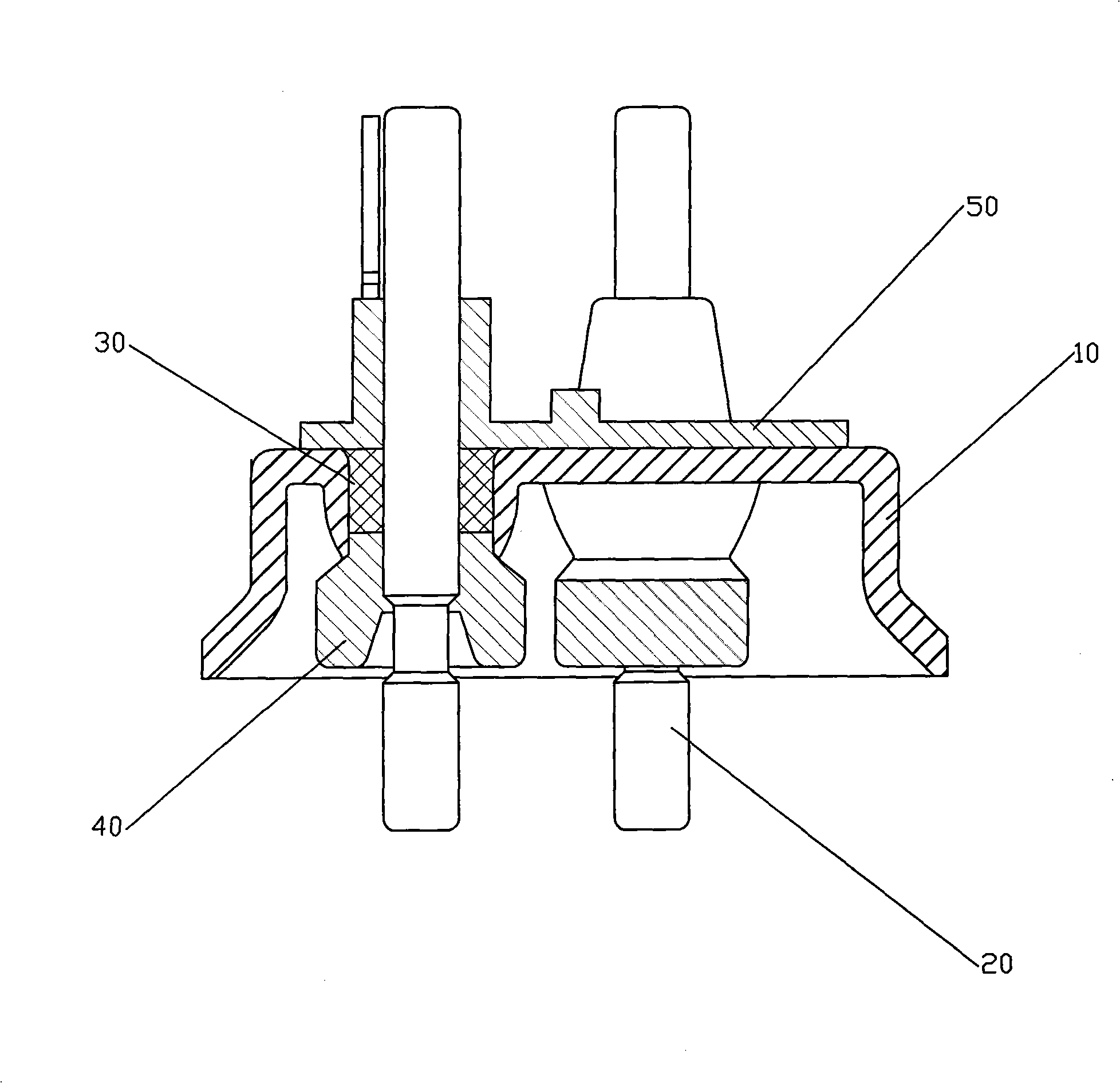

Connector post of refrigeration compressor

ActiveCN101404360AEasy to sinterPorcelain forming temperature rangeElectrically conductive connectionsCeramicsRefrigeration compressorSilicon oxide

The invention relates to a terminal part of a compressor, in particular to a binding post of a cold compressor of highly reliable ceramic insulation medium connection. The binding post comprises an end cover which is welded with a shell of the compressor, and a conductive pillar that is sealed and connected with the end cover by glass; wherein, the glass is used for playing the role of insulation and sealing, the conductive pillar is provided with an insulator separating the surface of the glass from the air, and the insulator is made of the following materials: 92-96% of aluminium oxide, 2-3% of silicon oxide, 1-3% of calcium oxide, 0.5-1.0% of bismuth oxide and 0.5-1.0% of antimony oxide. The binding post has the advantages that specially prepared aluminum oxide ceramics is adopted to replace steatite ceramics (or forsterite) to be taken as the insulator, so that the creep age distance is prolonged, and the phenomenon of overflash is avoided in the low vacuum environment, thereby effectively avoiding the serious result of compressor explosion. At the same time, the expansion of microcrack is prevented, and the probability of air leakage is effectively reduced, so that good connecting effect is formed.

Owner:CHAOZHOU THREE CIRCLE GRP

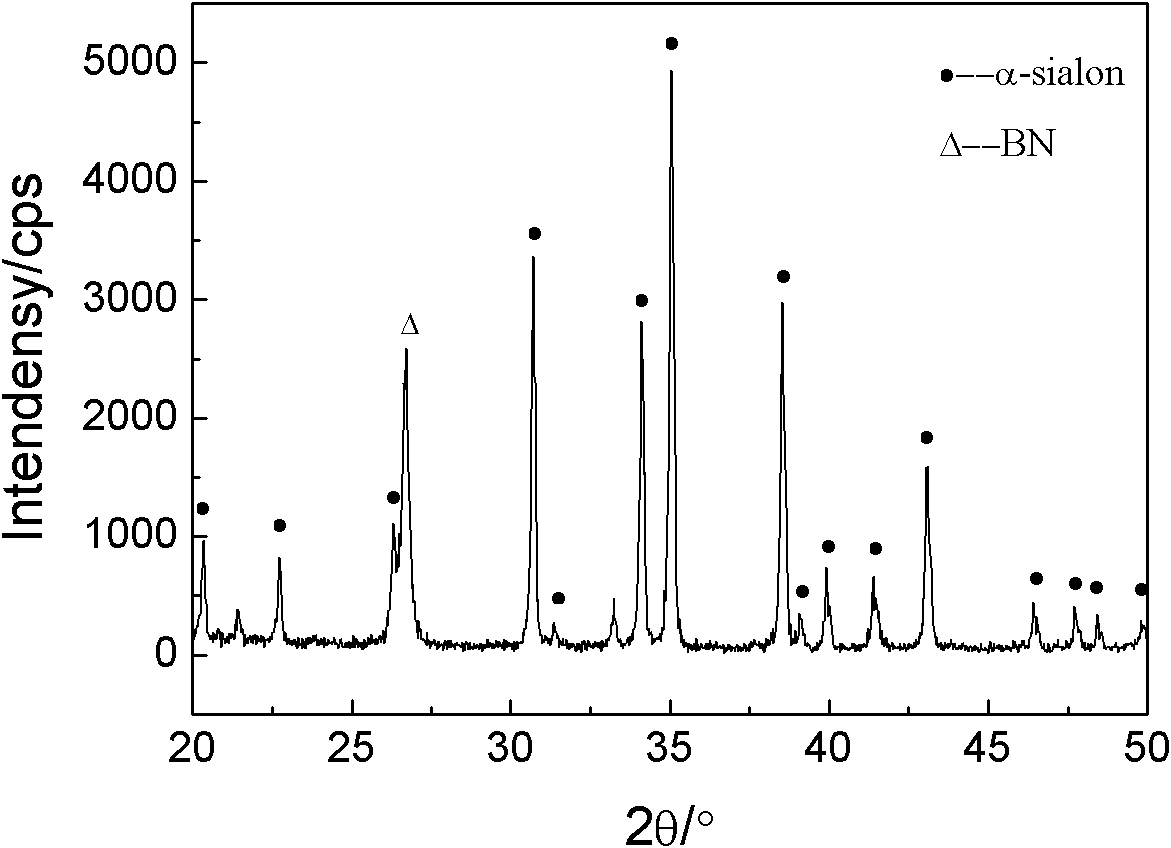

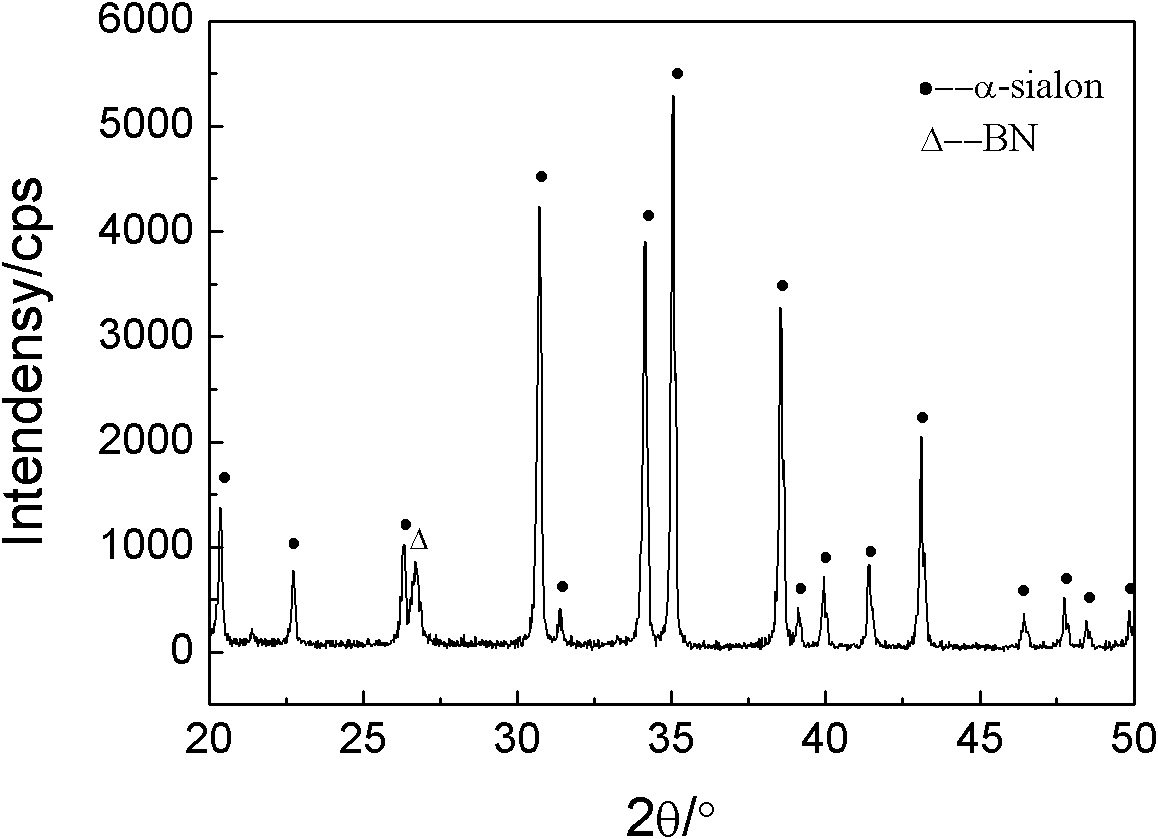

Alpha-SiAlON/BN composite ceramic material and preparation method thereof

The invention relates to an alpha-SiAlON / BN composite ceramic material and a preparation method thereof. The preparation method comprises the following steps: adopting the hot pressing sintering technology and alpha-silicon nitride powder, aluminum nitride powder, alumina powder and yttrium oxide powder as raw materials to design components according to the general formula of alpha-SiAlON, namelyYm / 3Si12-(m+n)Alm+nOnN16-n, wherein m and n are the parameters of the selected components; and adding hexagonal boron nitride, performing ball milling to the raw powder, drying, granulating, filling in a graphite mould, heating in a heating rate of 10-40 DEG C / min under dynamic nitrogen atmosphere to 1800-1950 DEG C, and sintering for 30-120min under 15-35MPa. The alpha-SiAlON / BN composite ceramic prepared by the method of the invention is characterized by high temperature resistance and high high-temperature strength.

Owner:DALIAN MARITIME UNIVERSITY

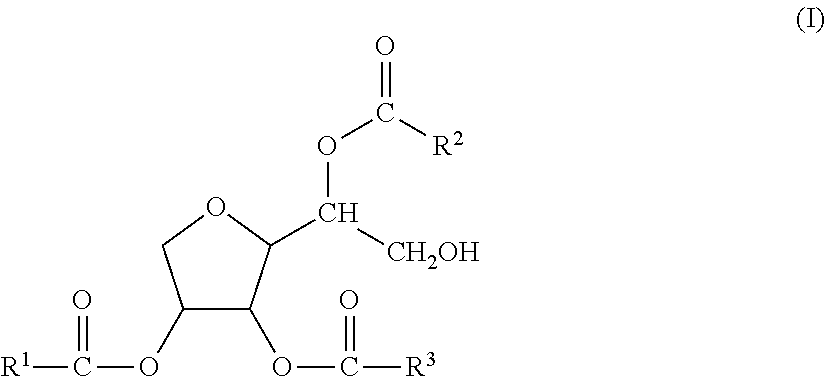

Metal nanoparticle paste, electronic component assembly using metal nanoparticle paste, LED module, and method for forming circuit for printed wiring board

InactiveUS20130265735A1Improve dispersion stabilityMechanical strengthConductive materialPrinted circuit aspectsHemt circuitsCarboxylic acid

Disclosed is a metal nanoparticle paste that uses the low-temperature sintering characteristics of metal nanoparticles to easily obtain a metal bond with excellent conductivity and mechanical strength, and which can form a wiring pattern with excellent conductivity. The metal nanoparticle paste is characterized by containing (A) metal nanoparticles, (B) a protective film that coats the surface of the metal nanoparticles, (C) a carboxylic acid, and (D) a dispersion medium.

Owner:TAMURA KK +1

Environment-friendly converter bedding-face repairing material and preparation method thereof

The invention discloses an environment-friendly converter bedding-face repairing material and a preparation method thereof. The repairing material comprises the following ingredients by weight percent: 30 to 65 percent of sintering magnesium sand, 10 to 45 percent of waste magnesite-chrome bricks, 1 to 10 percent of asphalt powder, 5 to 15 percent of tar, 1 to 5 percent of ethanol, 1 to 5 percent of N-methyl-2-pyrrolidinone and 0 to 5 percent of o-xylene. The preparation method comprises the following steps: 1) pre-crushing the sorted sintering magnesium sand and recycled waste magnesite-chrome bricks; 2) uniformly mixing the pre-crushed sintering magnesium sand and waste magnesite-chrome bricks to obtain a mixed coarse material; 3) finely crushing the mixed coarse material to obtain a mixed fine material; 4) uniformly mixing the mixed fine material and asphalt powder in a stirring machine; 5) adding tar, ethernol, N-methyl-2-pyrrolidinone and o-xylene, and stirring the mixture for 10 to 25 minutes. The practices prove that the converter repairing material has good mobility, can be sintered easily, has long service life and generates little smoke when sintered.

Owner:武汉钢铁有限公司

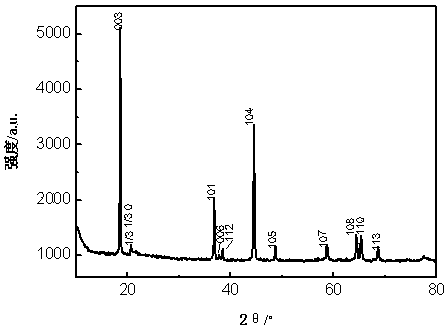

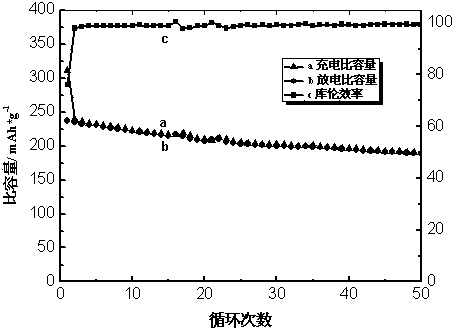

Preparation method of cathode material of lithium-rich ternary compound lithium ion battery

InactiveCN103956477AUniform precipitationSimple processCell electrodesSecondary cellsWater bathsNickel salt

The invention discloses a preparation method of a cathode material of a lithium-rich ternary compound lithium ion battery. The molecular formula of the cathode material is Li1.2Ni0.13Co0.13Mn0.54O2. The preparation method comprises the steps of firstly, stirring an organic precipitant in constant temperature water bath to dissolve the organic precipitant in an organic solvent to obtain a solution I; after that, ultrasonically dissolving soluble cobalt salt, nickel salt, manganese salt and lithium salt in deionized water to obtain a solution II; then, dropwise adding the solution II into the solution I at constant speed, and carrying out a reaction at the temperature of 40-80 DEG C for 2h-4h; drying at 100-120 DEG C; and heating the obtained solid powder in a high temperature tube furnace system by stages, calcining, and cooling the product to room temperature along with the furnace to obtain the lithium-rich ternary compound lithium ion battery cathode material which is good in electrochemical performance and uniform in particles, and has a spherical or ellipsoidal morphology feature. The preparation technology is simple and suitable for industrial scale production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

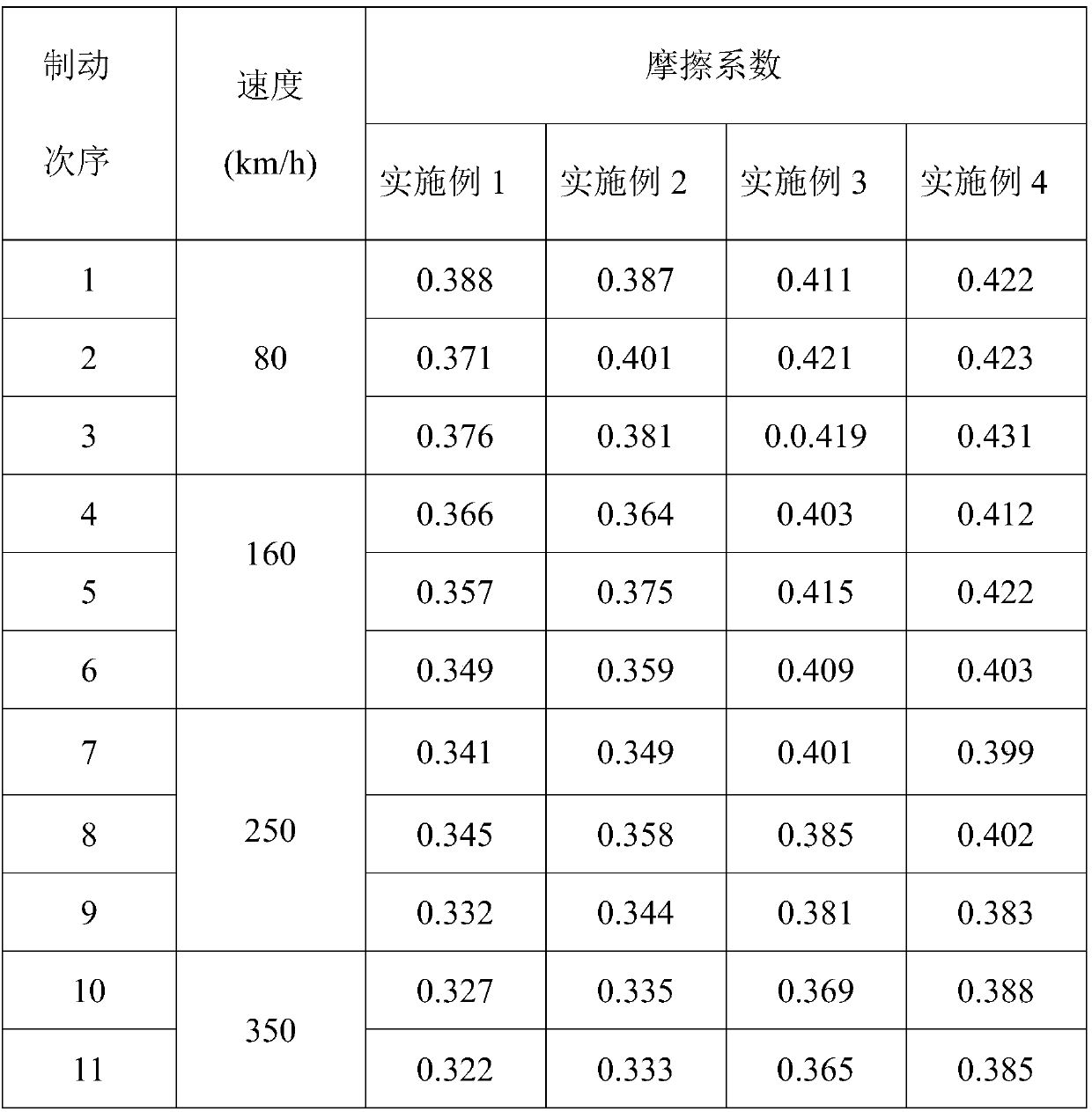

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

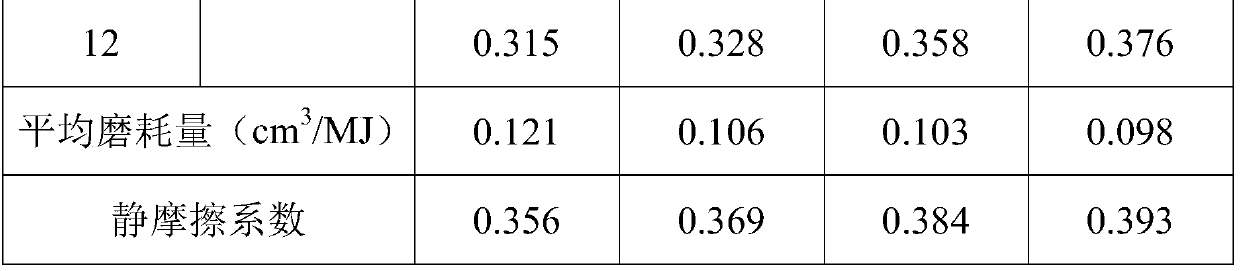

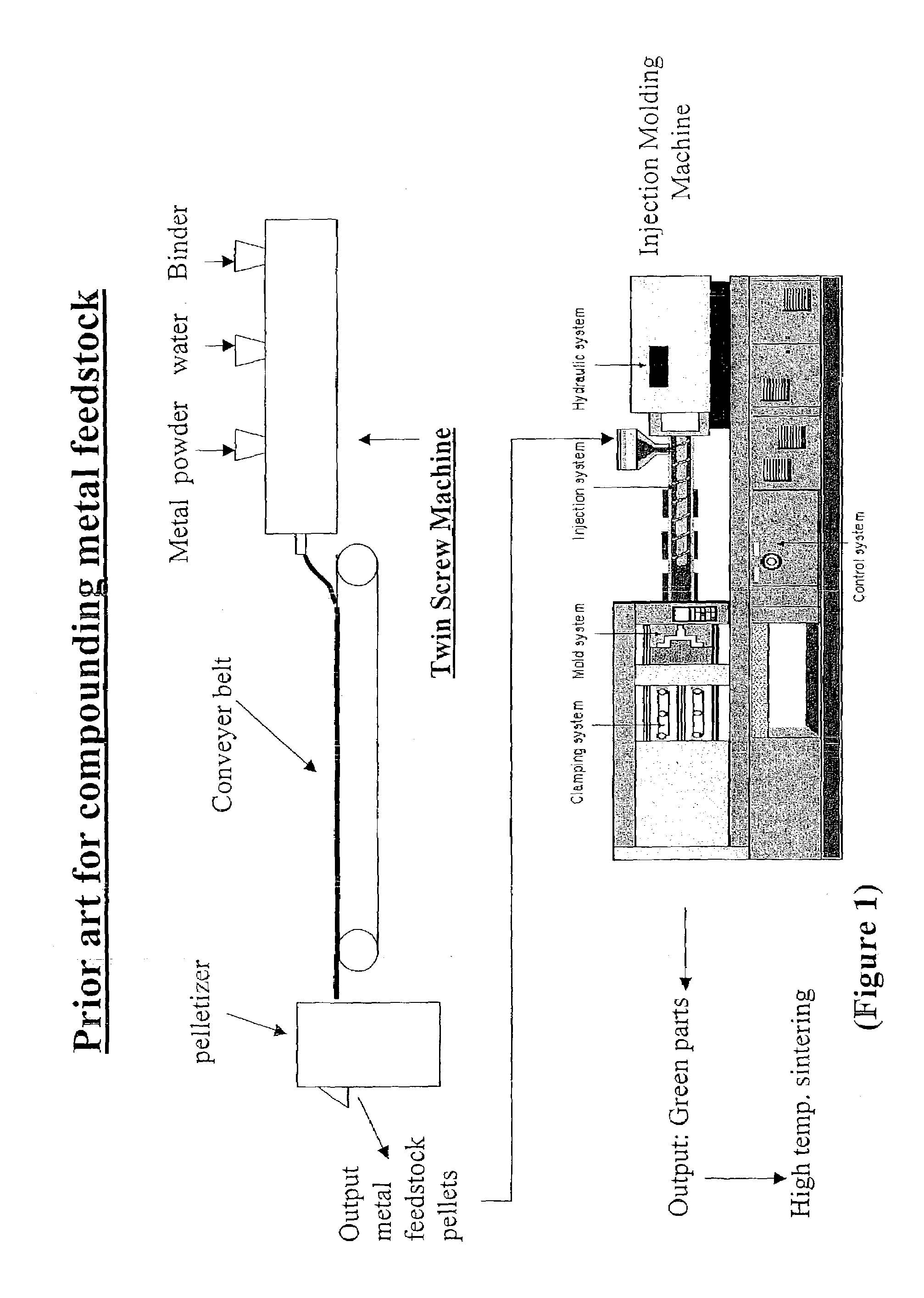

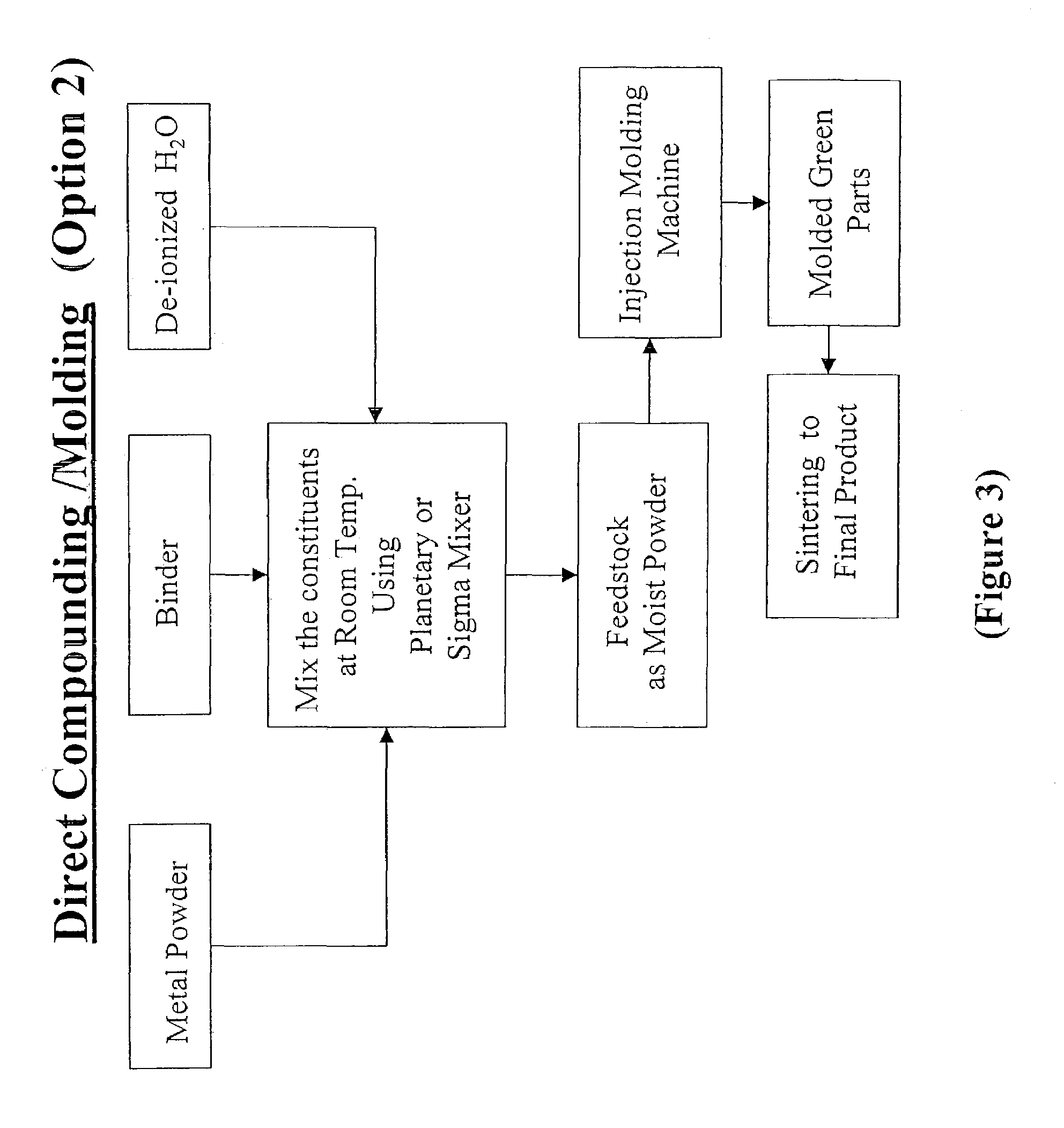

Aqueous binder formulation for metal and ceramic feedstock for injection molding and aqueous coating composition

ActiveUS6986810B1Easy and low costEasy and low and techniqueFireproof paintsAntifouling/underwater paintsGelatinMetal

Owner:UNITED MATERIALS TECH

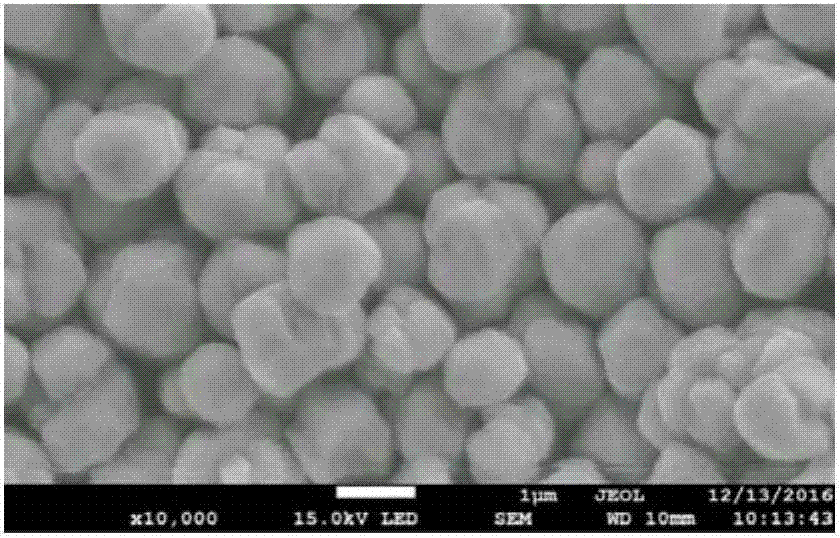

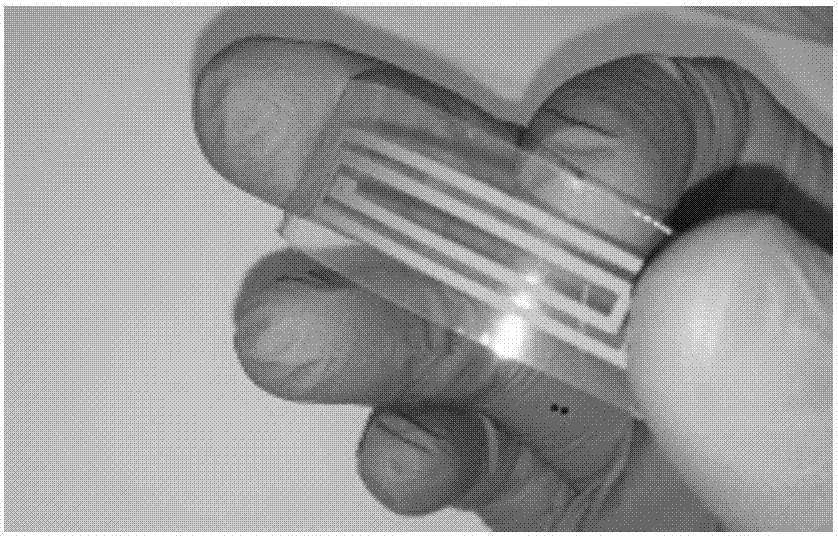

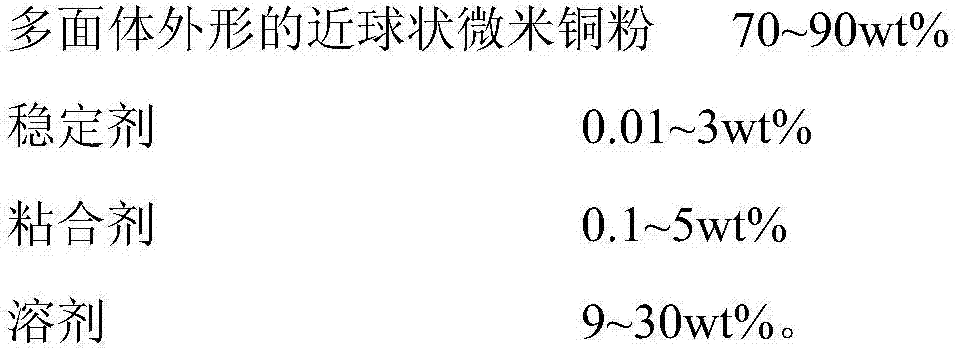

Copper conductive slurry and preparation method and application thereof

ActiveCN106981324AIncrease contact areaEasy to sinterConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialSolventEnvironmentally friendly

The invention provides copper conductive slurry. The copper conductive slurry is prepared from the following raw materials and components in parts by weight: 70wt% to 90wt% of approximately spherical micron copper powder of polyhedron appearance, 0.01wt% to 3wt% of a stabilizer, 0.1wt% to 5wt% of a binder and 9wt% to 30wt% of a solvent. In the invention, the slurry adopts the proximately spherical micron copper powder with high single crystal content, and the copper powder is large in contact area, easy to sinter and high in specific conductance; the used copper powder is 0.5 to 3 microns in particle size, and can meet the using requirement of fine circuits; flash sintering is directly carried out after silk-screen printing, and the copper conductive slurry is simple in technology and is applicable to large-scale production; the stabilizer is added in the system, copper oxide is reduced in the sintering process, the content of the copper oxide in a copper line is reduced, a conductive circuit with low copper oxide content is obtained, and the conductive slurry adopts the aqueous binder, so that the copper conductive slurry has the characteristics of being environmentally-friendly, energy-saving and easy to clean.

Owner:江西安缔诺科技有限公司

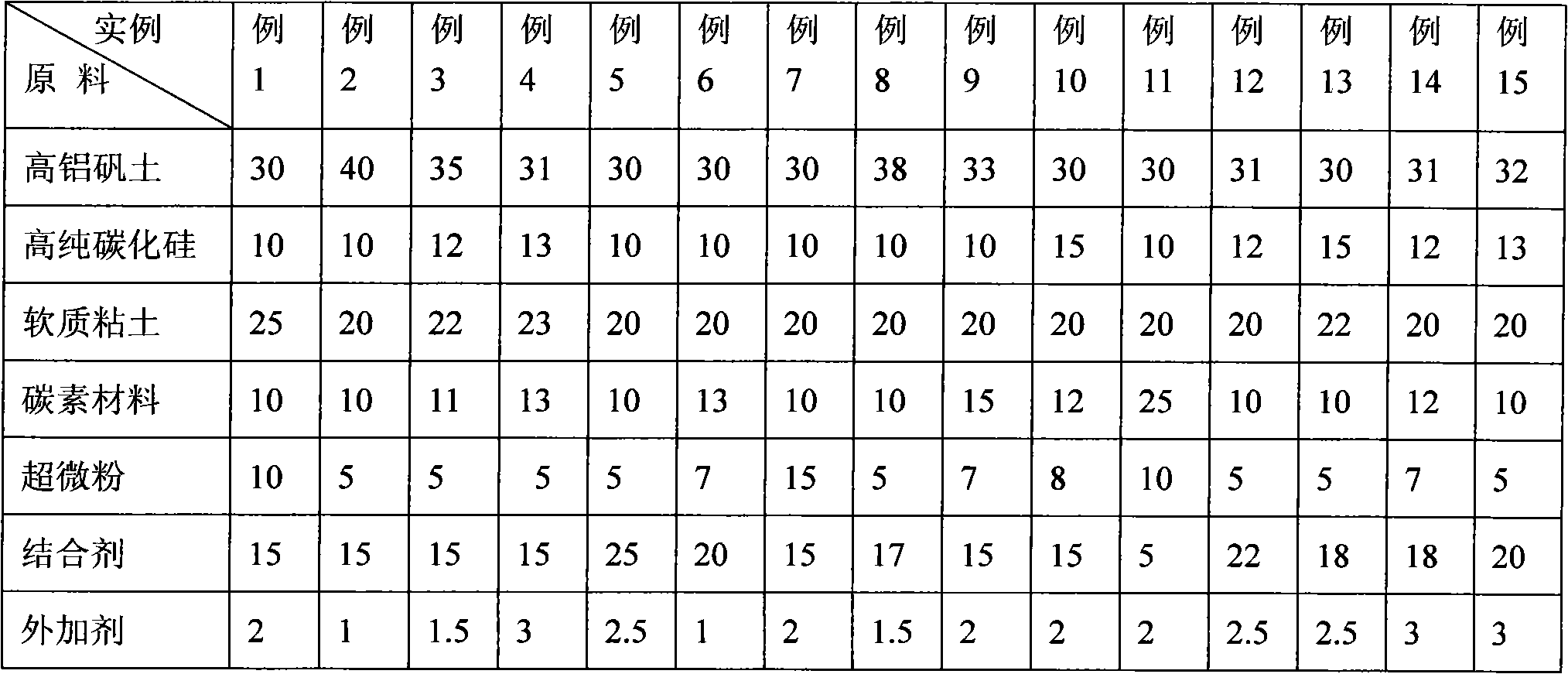

Anhydrous stemming for blast furnace

The invention relates to an anhydrous stemming for a blast furnace. The anhydrous stemming is prepared from the following raw materials in percentages by weight: 30-40 percent of high-alumina bauxite, 10-15 percent of high-purity silicon carbide, 20-25 percent of soft clay, 10-25 percent of carbonaceous material, 5-15 percent of submicron powder, 15-25 percent of binding agent, and additionally silicon metal powder addictives accounting for 1-3 percent of the total weight of the raw materials. The anhydrous stemming has the advantages of favorable high-temperature fire performance, linearity change ratio of lower than 0.3 percent under the condition of 1400 DEG C*2h, breaking strength of more than or equal to 10MPa, high intensity, slag-iron resistant scouring, easy sintering, excellent work performance, less pollution and low production cost, and is beneficial to environment protection as well as popularization and application.

Owner:HENAN HUAXI FURNACE REFRACTORY

Chemical-bonding aluminum-magnesium repairing material for steel ladle working lining

The invention discloses a chemical-bonding aluminum-magnesium repairing material for a steel ladle working lining. The chemical-bonding aluminum-magnesium repairing material is composed of a dry material and an additional binder, wherein the dry material consists of the following components in percent by weight: 75%-80% of high-aluminum aggregate, 10%-15% of sintered magnesite fine powder, 1%-5% of aluminum oxide micro powder and 1%-5% of clay, wherein the high-aluminum aggregate and the sintered magnesite fine powder are essential components; the aluminum oxide micro powder is a clinkering aid; addition amount of the binder accounts for 5%-10% of the weight of the dry material. The prepared chemical-bonding aluminum-magnesium repairing material for the steel ladle working lining has the advantages of being good in adhesion, quick in adhesive strength development, small in temperature influence, moderate in hardening speed, free from special-purpose maintenance, not easy to sinter under a high temperature, and the like, is especially suitable for repairing under a thermal state, and can effectively resist scouring and erosion of molten steel and steel slag to achieve an effect of protecting the working lining. Moreover, service life of the steel ladle is prolonged, consumption of a ton-steel refractory material is lowered, and safety of the steel ladle can be well guaranteed.

Owner:河南海格尔高温材料有限公司

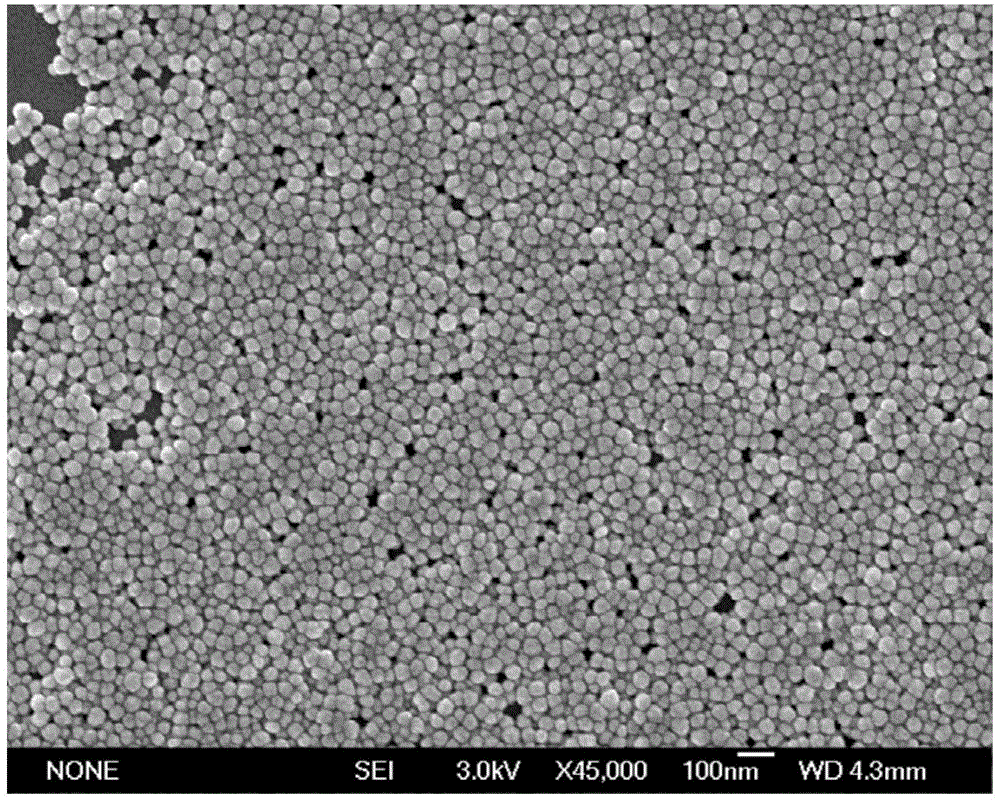

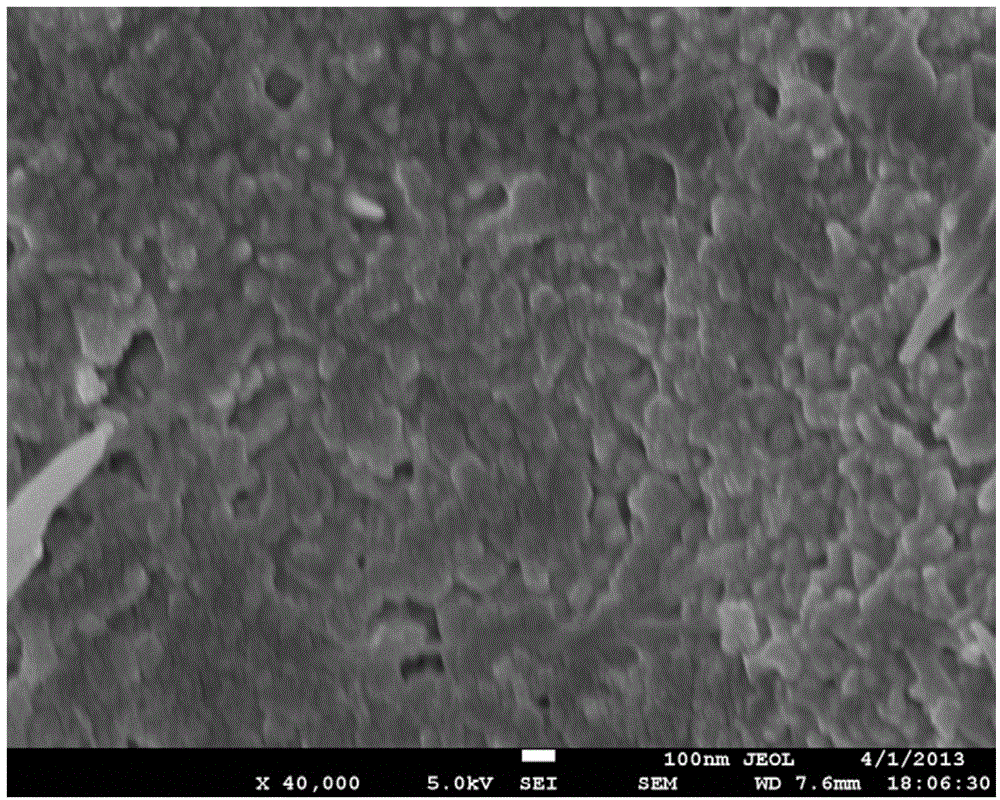

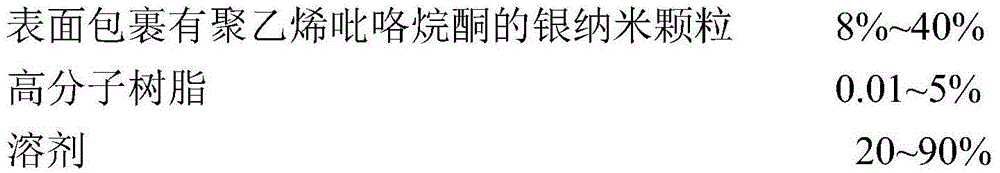

Ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof

The present invention relates to an ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof. According to the present invention, silver nanoparticles with polyvinylpyrrolidone wrapped on the surface, a polymer resin, a solvent, a surfactant, a preservative, an antifoaming agent and a humectant are uniformly mixed to obtain the ink-jet printing electric conduction ink; the ink-jet printing electric conduction ink can be printed on a printed circuit board so as to prepare the pattern of an electric conduction trace, a treatment liquid is coated on the printed circuit board having the electric conduction trace pattern, and the electric conduction trace pattern printed through the ink-jet printing electric conduction ink is subjected to chemical sintering through the treatment liquid at a room temperature so as to obtain the electric conduction trace having good electric conduction property; and the ink-jet printing electric conduction ink has characteristics of low cost, excellent printing suitability and excellent durability, and can be matched with the room temperature sintering method of the present invention so as to make the printed electric conduction pattern achieve the good electric conduction property at the room temperature.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Thermal-state mending material taking forsterite as raw material for converters and preparation method thereof

The invention relates to a thermal-state mending material taking forsterite as a raw material for converters and a preparation method thereof. The technical scheme is as follows: adopting 45-70wt% of sintered magnesia particles, 5-15wt% of graphite and 15-40wt% of forsterite fine powder as raw materials; adding simple substance silicon powder accounting for 1-10wt% of the weight of the raw materials and liquid pitch modified phenolic resin accounting for 15-25wt% of the weight of the raw materials; and stirring for 5 to 30 minutes to obtain the slurry thermal-state mending material taking forsterite as the raw material for converters. While being used, the thermal-state mending material is poured into the converter, the converter is rotated to enable the mending material to flow to the charging position, the tapping position, the bedding face and the furnace bottom of the steelmaking converter which are in need of thermal-state mending and the mending material is sintered by the heat in the converter. The material has the characteristics of abundant raw materials, low production cost, excellent hydration-proof performance, easiness in sintering at a high temperature and convenience in combination with the converter lining and is beneficial for prolonging the service life of materials of the converter lining.

Owner:北京炜润达冶金材料有限公司 +1

Composite metal powder for sintered bearing, and sintered oil-retaining bearing

InactiveCN1241250AImprove running-inImprove corrosion resistanceTransportation and packagingShaftsSurface layerIron powder

Composite metal powder for sintered bearings, prepared by coating surface layers of particles of iron powder with 10 wt.% to less than 30 wt.% of copper based on the iron powder so that the particle size of the coated iron powder is at most 80 meshes, the content of the powder of at most 350 meshes is at most 30%, and the specific surface area of the powder is 450-750 cm<SP>2< / SP> / g according to the subsieve sizer method. This metal powder can provide an oil-retaining bearing for motors, which is capable of providing a low gas-permeability without decreasing the oil content and which has a low and constant coefficient of friction, a high corrosion resistance, a high adaptability and a high durability, readily at a low cost.

Owner:PORITE +1

Method for preparing ZrB2-Al2O3 composite powder

The invention belongs to the technical field of ceramics and refractory materials, and particularly relates to a method for preparing ZrB2-Al2O3 composite powder. Fe2O3 powder and metal Al powder are taken as raw materials of a thermit, the metal Al powder, ZrO2 powder and B2O3 powder are taken as raw materials for synthesizing the ZrB2-Al2O3 composite powder, and the heat emitted by a thermit reaction is utilized to ignite a reaction for synthesizing the ZrB2-Al2O3 composite powder. The method has a simple preparation technology, does not need special equipment and atmosphere, has cheap needed raw materials and small energy consumption and using time, and is environment-friendly; and the synthesized powder has high purity, fine granularity, and low manufacturing cost.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

High-performance forsterite refractory raw material and preparation method thereof

The invention relates to a high-performance forsterite refractory raw material and a preparation method thereof. The method comprises the following steps: mixing 65-85 weight percent of fine magnesite powder with 15-35 weight percent of siliceous raw material fine powder, adding 1-10 weight percent of binding agent, and ball-milling for 1-3 hours to obtain a ball-milling material; then adding water being 3-10 weight percent of the ball-milling material into the ball-milling material, stirring, pressing to form a blank body, drying, and calcining at 1200-1400 DEG C to obtain a calcining material; grinding the calcining material to the particle size smaller than 0.045mm, and adding an additive being 0.2-2 weight percent of the calcining material and the binding agent being 1-10 weight percent of the calcining material, and ball-milling to obtain a secondary ball-milling material; and adding 3-10 weight percent of water into the secondary ball-milling material, stirring, pressing to form a blank body, drying, and secondary calcining at 1450-1650 DEG C to obtain the high-performance forsterite refractory raw material. The raw material has the advantages of wide sources, low production cost and easiness in sintering, and the prepared high-performance forsterite refractory raw material has large volume density, low porosity and stable high temperature properties.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of cuprous sulfide powder, and cuprous sulfide powder

The invention discloses a preparation method of cuprous sulfide powder and the cuprous sulfide powder. The preparation method of the cuprous sulfide powder comprises the following steps: allowing cuprous oxide and a sulfurizing agent solution to react and filtering to obtain a cuprous sulfide precursor; calcining the cuprous sulfide precursor in vacuum to obtain the cuprous sulfide powder. According to the preparation method of the cuprous sulfide powder, the cuprous oxide and the sulfuring agent react, the cuprous sulfide precursor is prepared by adopting a precipitate transformation method and is calcined in vacuum to prepare the cuprous sulfide powder. The method is rich in cheap raw materials, low in cost, simple in preparation process, mild in condition, good in controllability, high in production efficiency, easy to realize industrialization, free of pollution and wide in development prospect in the field of preparation of superfine powder; the prepared cuprous sulfide powder is high in purity, good in crystal form, good in dispersity, stable in structure, easy to coat, dope, sinter and the like, and applicable to the fields of solar batteries, seawater batteries, sensors, catalysts and the like.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Method for preparing apatite type oxide electrolyte powder

InactiveCN101186287AHigh purityEvenly distributedSolid electrolyte fuel cellsFuel cell detailsSolventMethod selection

The invention provides a preparation method of apatite oxide electrolyte powder. The preparation method chooses organic or inorganic precursor which can provide apatite electrolyte components as raw material; the raw material is dissolved in non-aqueous solvent, and the mixed solution and the complexing agent form sol and gel; at last, the apatite oxide electrolyte powder can be obtained by drying, sintering and some other technique process. The particle size is 20-400 nanometers. The preparation method has low requirement on equipment, simple technique, narrow particle distribution and high product purity and the obtained product has even particles.

Owner:HEFEI UNIV

Manufacturing method for improving sintered NdFeB magnet coercive force

ActiveCN103506626AImprove coercive forceGuaranteed compactnessInorganic material magnetismMaterials scienceMagnet

Provided is a manufacturing method for improving sintered NdFeB magnet coercive force. On the basis that the original composition ratio of a sintered NdFeB magnet is not changed, parameters of the rapid hardening process for magnet casting are changed to achieve secondary jet milling so that the average particle size of particles of the magnet can be less than or equal to2.5um, after lower-temperature sintering is controlled between 1020 DEG C and 1035 DEG C for 3.5-5.0 hours, aging treatment is carried out under 450-600 DEG C for 4-6 hours, the powder size of the magnet is lowered after rapid hardening casting and secondary jet milling technologies, surface activity is increased, the particles are easily compacted in a sintered mode, compactness of the magnet can be guaranteed and meanwhile grains can be prevented from rapidly growing up through combination of the lower-temperature sintering, magnetic performance of the magnet is improved, the coercive force is increased by 2-3kOe on average, and the price performance ratio of the magnet is remarkably increased.

Owner:NINGBO KETIAN MAGNET +1

Method for preparing low-cost sintered neodymium (Nd) iron (Fe) boron (B) by doping lanthanum (La) cerium (Ce)

ActiveCN102842400AEasy to sinterLow melting pointInorganic material magnetismCeriumVolumetric Mass Density

The invention discloses a method for preparing low-cost sintered neodymium (Nd) iron (Fe) boron (B) by doping lanthanum (La) cerium (Ce), and the method comprises following steps of (1) utilizing a quick-hardening sheet vacuum sensing smelting furnace to smelt a NdFeB material and to prepare a NdFeB alloy sheet with thickness of 0.3 to 0.5mm; (2) utilizing a hydrogen broken furnace to pulverize the NdFeB alloy sheet to NdFeB alloy powder of 110 to 150 micrometers; (3) grinding the obtained powder into NdFeB alloy powder of 3.5 to 4.5 micrometers through the airflow; (4) adding the LaGe alloy powder into the powder to be uniformly mixed; (5) utilizing a magnetic field press machine to orient and form the powder under the magnetic field, and acquiring pressed blank with density of 4.6 to 4.8 g / cm<3> through isostatic cool pressing; (6) placing the pressed blank into a vacuum sintering furnace to be sintered, and ensuring the sintered magnet of (PrNdGd)2936 to 29.65(LaCe)0.99 to 1.96(FeCoAlCu)67.63 to 68.3B1.05 to 10.6. The LaGe powder which is processed by special process is added to substitute rich neodymium phase in the NdFeB, so that the LaCe can be prevented from being excessively mixed with the NdFeB mani phase to influence the magnetic performance, and an effect for improving the product performance and reducing the product cost can be realized.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

Biomass carbon matrix environment-friendly brick and making method

InactiveCN107324773AGood environmental protection functionIncrease profitCeramic materials productionClaywaresBiomass carbonToxic gas

The invention discloses a biomass carbon matrix environment-friendly brick and a making method. The biomass carbon matrix environment-friendly brick is characterized by comprising the following components (in percentage by weight): 35-45% of biological black carbon, 55-65% of an earth material and 1-3% of molding aids, wherein the brick is made by treating the earth material, mixing with the biological black carbon, molding, drying and roasting; the biological black carbon is biological black carbon granules or powder ash made of biomasses via high-temperature carbonization; the earth material comprises 15-35% of clay, 15-25% of shale powder ash, 15-25% of coal gangue powder ash and 15-25% of coal ash; the 1-3% of molding aids comprise bentonite, fulvic acid powder and tapioca flour. The making method comprises the following steps: performing high-temperature carbonization on various types of biomass straw so as to obtain biological black carbon granules or powder ash; grinding shale, coal gangue and coal residues into a powder material; uniformly mixing with the clay and the molding aids; making bricks by using a brick making machine, drying, and sintering. Due to adoption of a biomass black carbon material, the biomass carbon matrix environment-friendly brick is capable of adsorbing toxic gases as a whole for a long time, is light and environmentally friendly, and is capable of purifying indoor polluted air and lowering cost.

Owner:湖北金日生态能源股份有限公司

High-aluminum silicon carbide casting material combined with silica sol

The invention discloses a high-aluminum silicon carbide casting material combined with a silica sol. The high-aluminum silicon carbide casting material is prepared from the following raw materials in parts by weight: 60-80 parts of bauxite with particle size of 8-0mm, 10-15 parts of silicon carbide with particle size of 180-320 meshes, 2-7 parts of alpha-Al2O3 micropowder with particle size less than 0.5mu m, 2-5 parts of kyanite with particle size of 80-120 meshes, 10-15 parts of brown corundum with particle size of 160-200 meshes, 2-5 parts of sodium tripolyphosphate and 5-10 parts of silica sol. The high-aluminum silicon carbide casting material combined with a silica sol has the beneficial effects that: the chemical activity of the silica sol is large; the casting material is easy to sinter; after middle-temperature sintering, the strength of the casting material is not reduced; the property of the casting material is greatly improved at the temperature of 1500 DEG C; the thermal shock stability of the casting material is good; and water cooling can be carried out over forty times at the temperature of 1100 DEG C.

Owner:郑州京华耐火材料实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com