Patents

Literature

35results about How to "Moderate boiling point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer conductive silver paste and preparing method thereof

InactiveCN104240793AGood silver powder solubilityModerate boiling pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePlasticizer

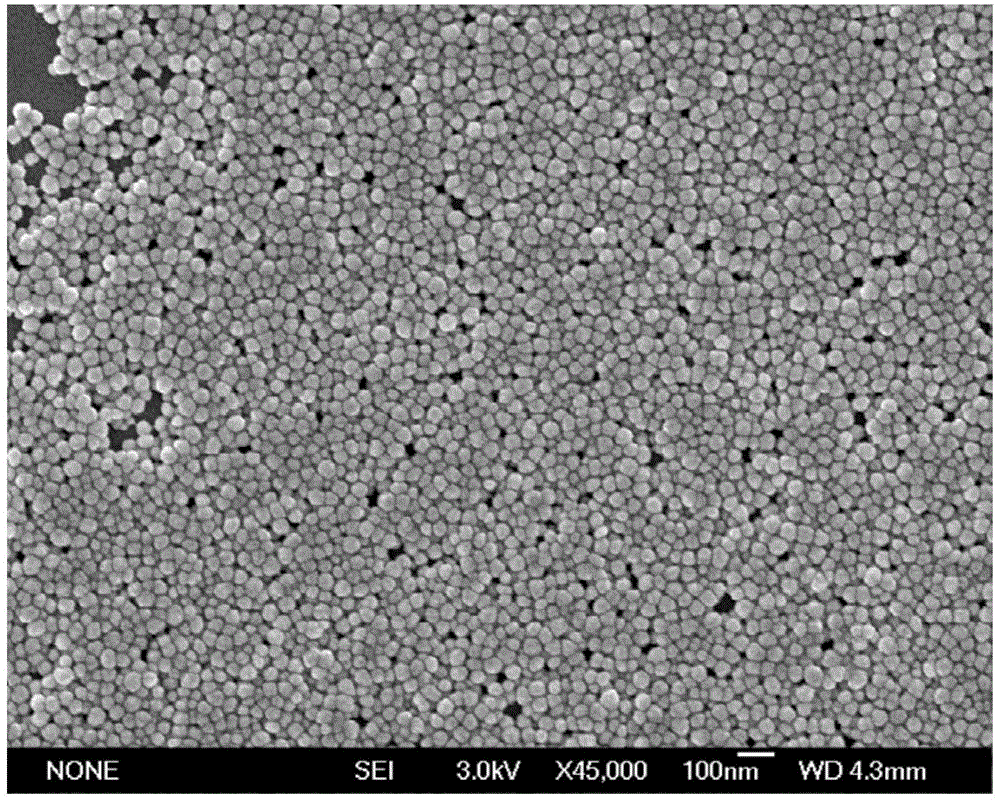

The invention relates to a nanometer conductive silver paste and a preparing method thereof. The nanometer conductive silver paste is characterized in that mass percentage content of the components are as follows: 20-90% of a silver powder, 0.01-5% of a high-molecular resin, 0.01-5% of an organic silicone oil, 0.01-10% of a thickening agent 1, 0.01-5% of a thickening agent 2, 0.01-5% of a plasticizer, 0.5-1% of a dispersant, 0.5-1% of a leveling agent, 5-20% of a solvent 1, and 5-20% of a solvent 2. The nanometer conductive silver paste of the invention has a remarkable low-temperature sintering property and saves energy. A formed circuit has advantages of high conductivity, high adhesiveness and high hardness. A selected Teslin substrate is degradable and environment-friendly. The nanometer conductive silver paste has wide application prospect in paste application fields of RFID electronic label, LED circuit board, touch screen circuit, etc.

Owner:NANO TOP ELECTRONICS TECH

Solvents containing cycloakyl alkyl ethers and process for production of the ethers

InactiveUS20050065060A1Moderate boiling pointPromote decompositionSurface-active detergent compositionsDetergent mixture composition preparationAlcoholChemical reaction

The present inventions are (A) a solvent comprising at least one cycloalkyl alkyl ether (1) represented by the general formula: R1-O-R2 (wherein R1 is cyclopentyl or the like; and R2 is C1-10 alkyl or the like); (B) a method of preparations the ethers (1) characterized by reacting an alicyclic olefin with an alcohol in the presence of an acid ion-exchange resin having a water content of 5 wt % or less. The solvent is useful as cleaning solvent for electronic components, precision machinery components or the like, reaction solvent using various chemical reactions, extraction solvent for extracting objective organic substances, solvent or remover for electronic and electrical materials, and so on. The process enables industrially advantageous production of the objective cycloalkyl alkyl ethers (1).

Owner:ZEON CORP

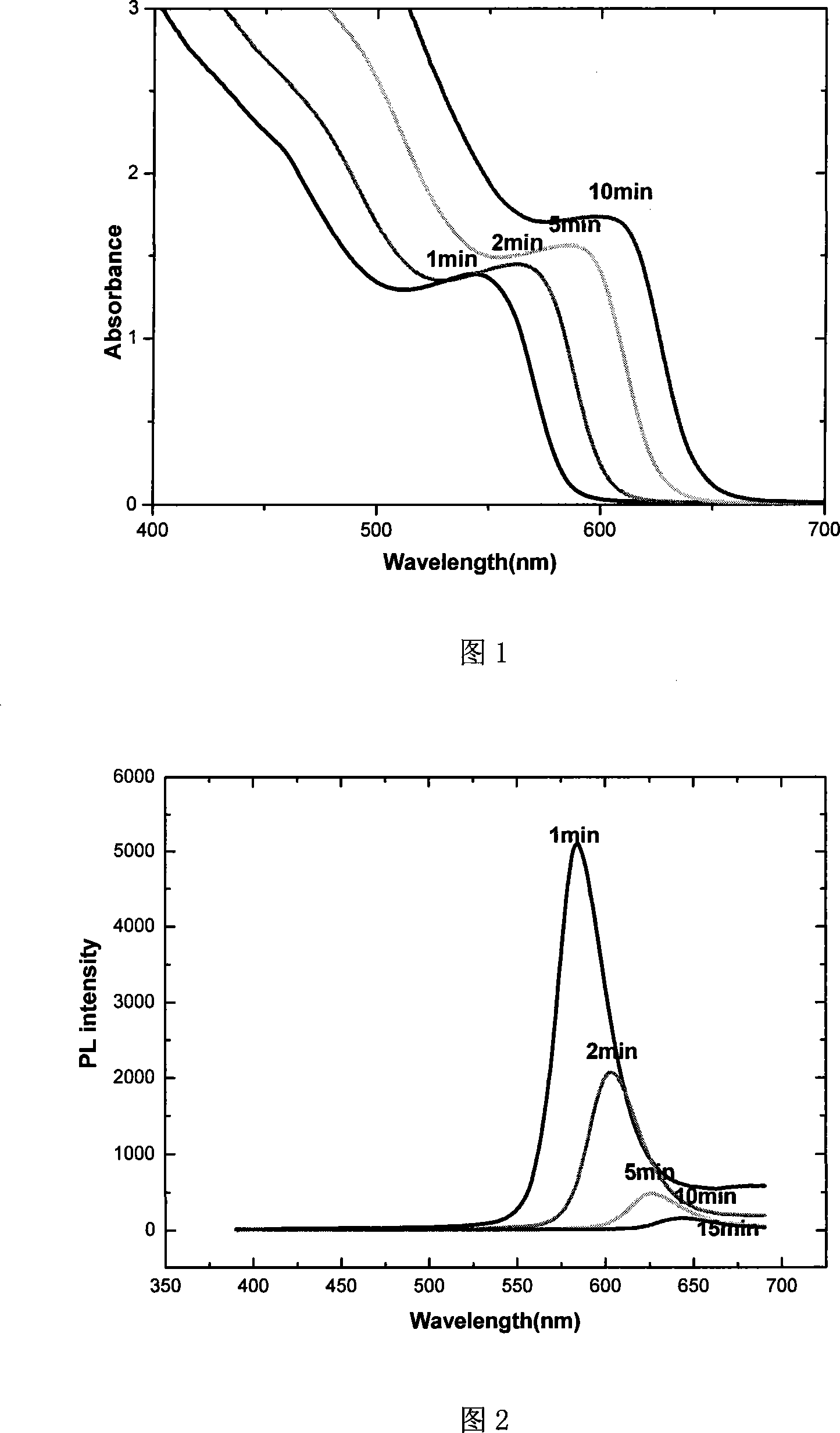

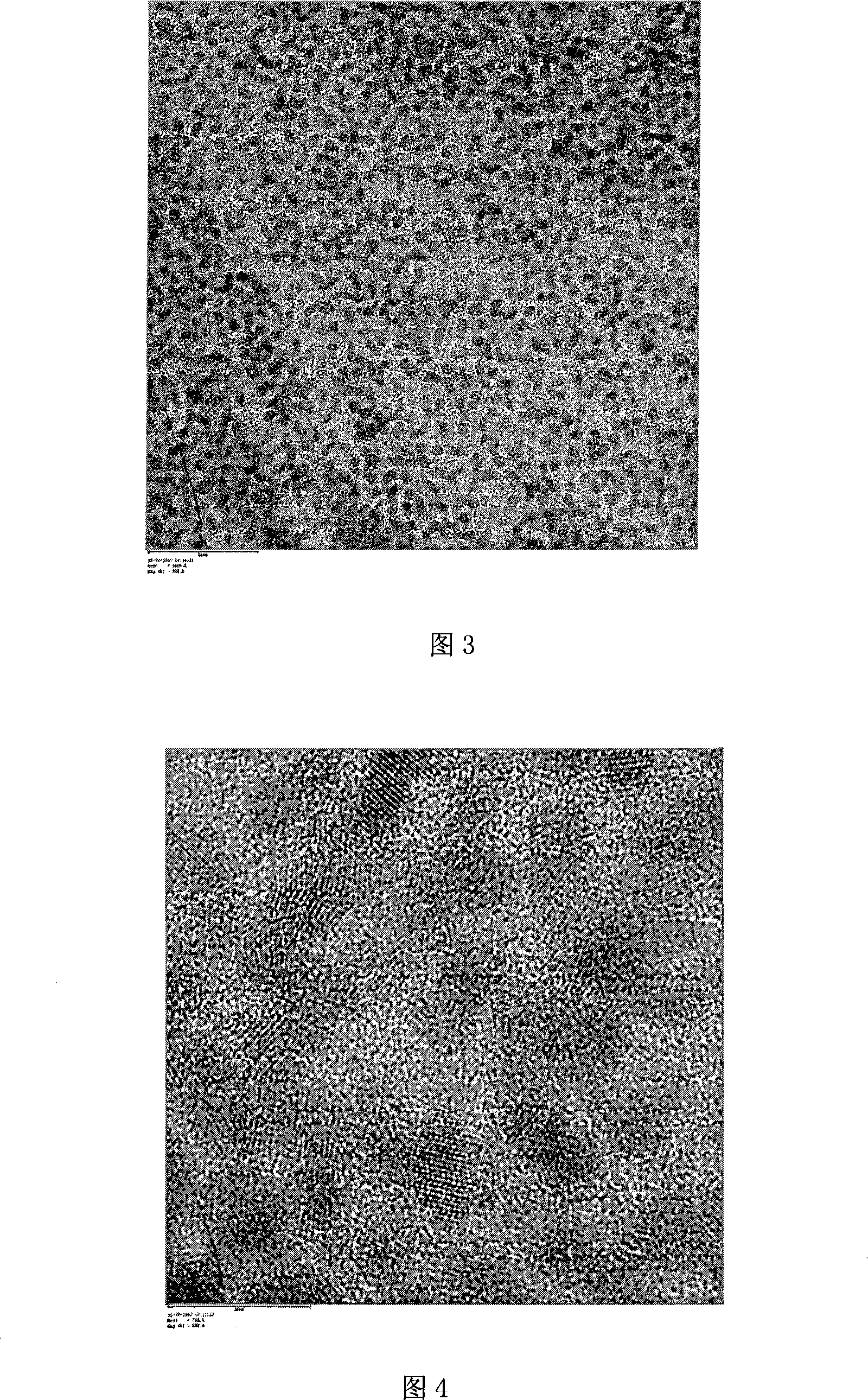

Zinc oxide-based nanoparticle ink and electroluminescent device

InactiveCN107099190AVolatileEvenly dispersedMaterial nanotechnologySolid-state devicesAlcoholNanoparticle

The invention provides zinc oxide-based nanoparticle ink. The zinc oxide-based nanoparticle ink comprises a solvent and zinc oxide-based nanoparticles uniformly dispersed in the solvent. The zinc oxide-based nanoparticle ink comprises, by mass, 0.01 to 20.00% of the zinc oxide-based nanoparticles and 80.00 to 99.99% of the solvent. The zinc oxide-based nanoparticle ink is characterized in that the solvent comprises at least one alcohol ether ester compound. The zinc oxide-based nanoparticle ink can solve the problem that the existing zinc oxide-based nanoparticle ink is not suitable for ink-jet printing and has poor film-forming quality. The invention provides an electroluminescent device. An electron transport layer of the device is prepared from the zinc oxide-based nanoparticle ink through ink-jet printing.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

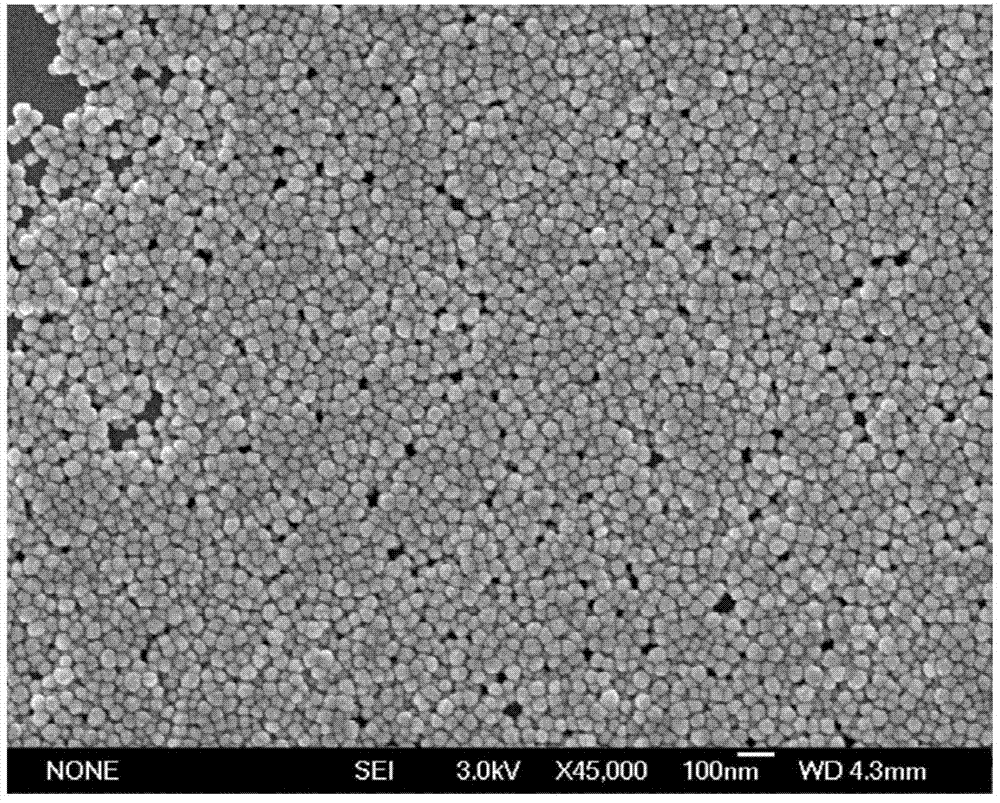

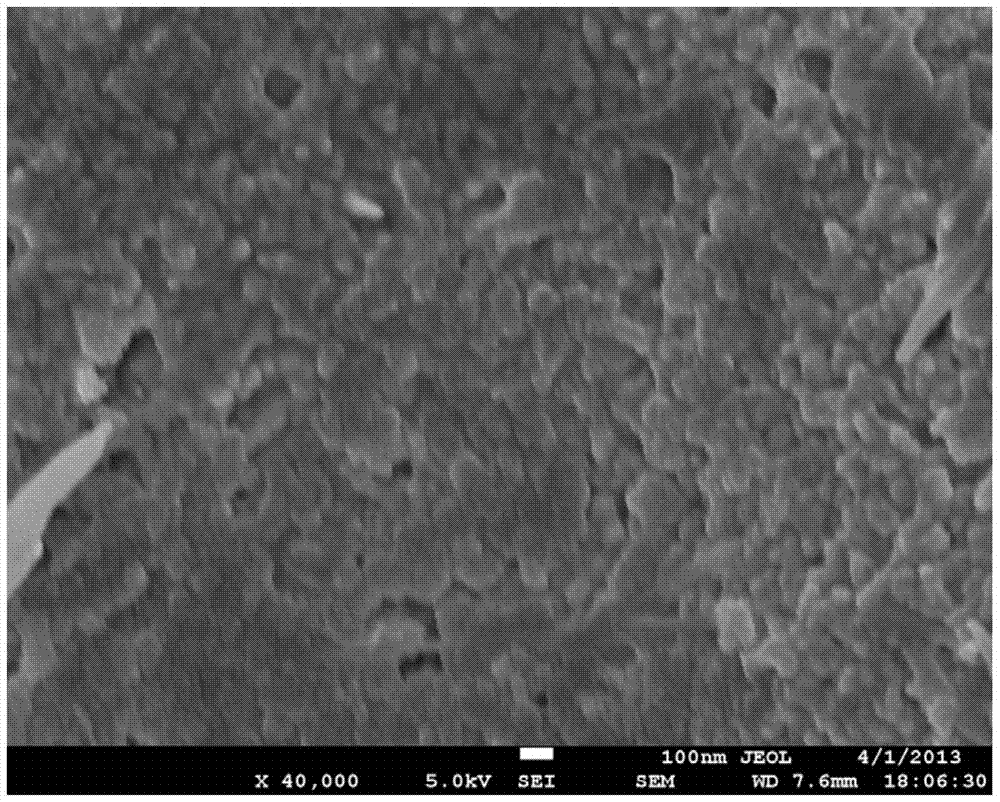

Ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof

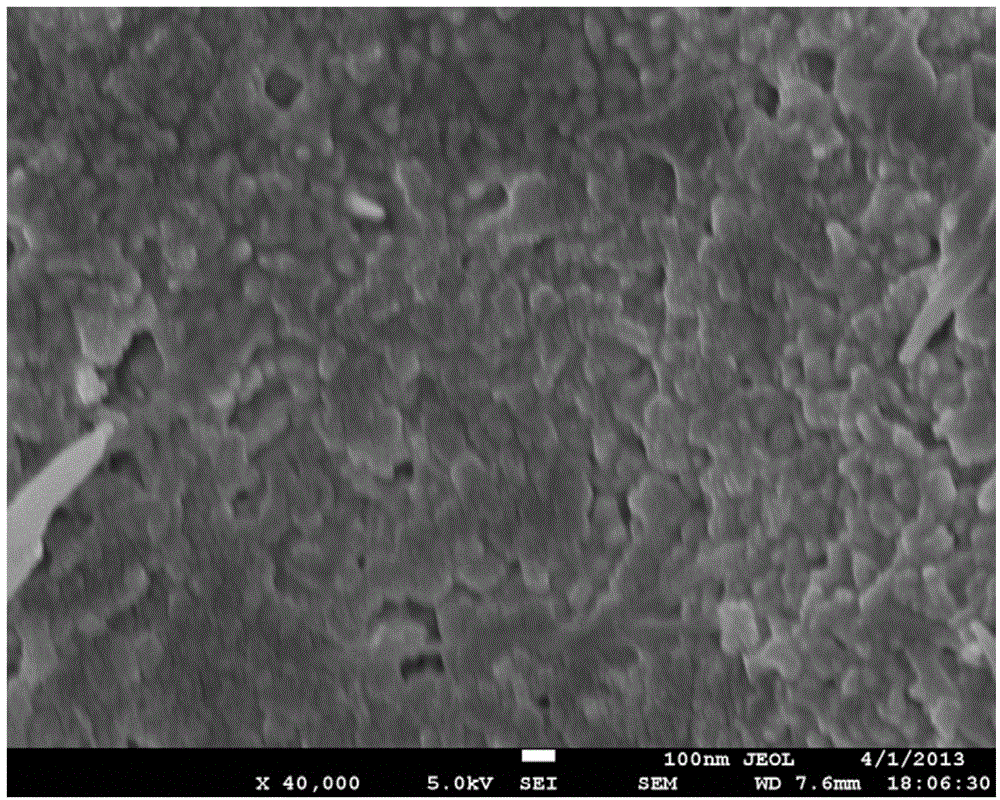

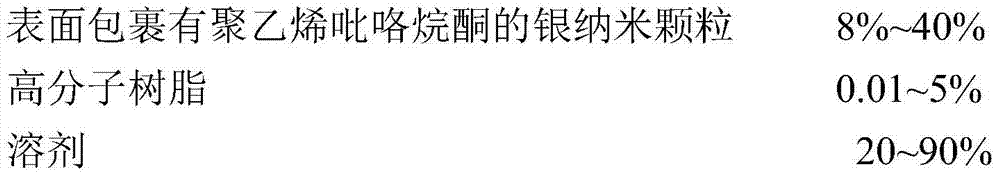

The present invention relates to an ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof. According to the present invention, silver nanoparticles with polyvinylpyrrolidone wrapped on the surface, a polymer resin, a solvent, a surfactant, a preservative, an antifoaming agent and a humectant are uniformly mixed to obtain the ink-jet printing electric conduction ink; the ink-jet printing electric conduction ink can be printed on a printed circuit board so as to prepare the pattern of an electric conduction trace, a treatment liquid is coated on the printed circuit board having the electric conduction trace pattern, and the electric conduction trace pattern printed through the ink-jet printing electric conduction ink is subjected to chemical sintering through the treatment liquid at a room temperature so as to obtain the electric conduction trace having good electric conduction property; and the ink-jet printing electric conduction ink has characteristics of low cost, excellent printing suitability and excellent durability, and can be matched with the room temperature sintering method of the present invention so as to make the printed electric conduction pattern achieve the good electric conduction property at the room temperature.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Selenium precursor fluid and method for preparing cadmium selenide or zinc selenide quantum dots by using the same

InactiveCN101186825ANarrow size distributionGood monodispersityLuminescent compositionsZinc selenideMorpholine

Provided is a selenium precursor liquid which is achieved by the preparation of heating and dissolving the elemental selenium in oleoyl morpholine under the protection of inert gas. The process for the preparation of cadmium selenide or zinc selenide quantum dots with the selenium precursor liquid is to generate pyrolytic reaction by stirring and mixing the selenium precursor liquid and fatty acid cadmium or fatty acid zincum precursor liquid under the protection of inert gas at a temperature of 150 DEG C to 330 DEG C, and the last is to separate and purify the mixture with low carbon alcohols. The dissolving capacity of the oleoyl morpholine for the elemental selenium is strong, the compatibility of the oleoyl morpholine with other green common solvents is perfect, which can increase the volume productivity of selenide nanocrystalline, thereby achieving quantum dots with relatively narrower size and higher quality.

Owner:HEFEI UNIV OF TECH

Solvents containing cycloakyl alkyl ethers and process for production of the ethers

InactiveUS7494962B2Moderate boiling pointPromptly decomposed in the atmosphereDetergent mixture composition preparationHydroxy compound preparationChemical reactionAlcohol

Owner:ZEON CORP

Solvents containing cycloalkyl alkyl ethers and process for production of the ethers

InactiveUS20080312125A1Moderate boiling pointPromptly decomposed in the atmosphereSurface-active detergent compositionsDetergent mixture composition preparationChemical reactionIon exchange

The present inventions are (A) a solvent comprising at least one cycloalkyl alkyl ether (1) represented by the general formula: R1—O—R2 (wherein R1 is cyclopentyl or the like; and R2 is C1-10 alkyl or the like); (B) a method of preparations the ethers (1) characterized by reacting an alicyclic olefin with an alcohol in the presence of an acid ion-exchange resin having a water content of 5 wt % or less. The solvent is useful as cleaning solvent for electronic components, precision machinery components or the like, reaction solvent using various chemical reactions, extraction solvent for extracting objective organic substances, solvent or remover for electronic and electrical materials, and so on. The process enables industrially advantageous production of the objective cycloalkyl alkyl ethers (1).

Owner:ZEON CORP

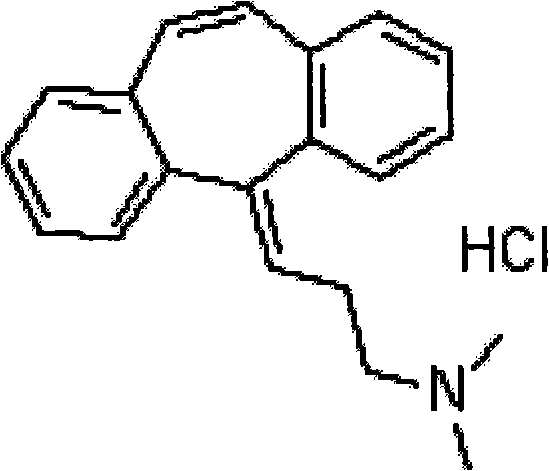

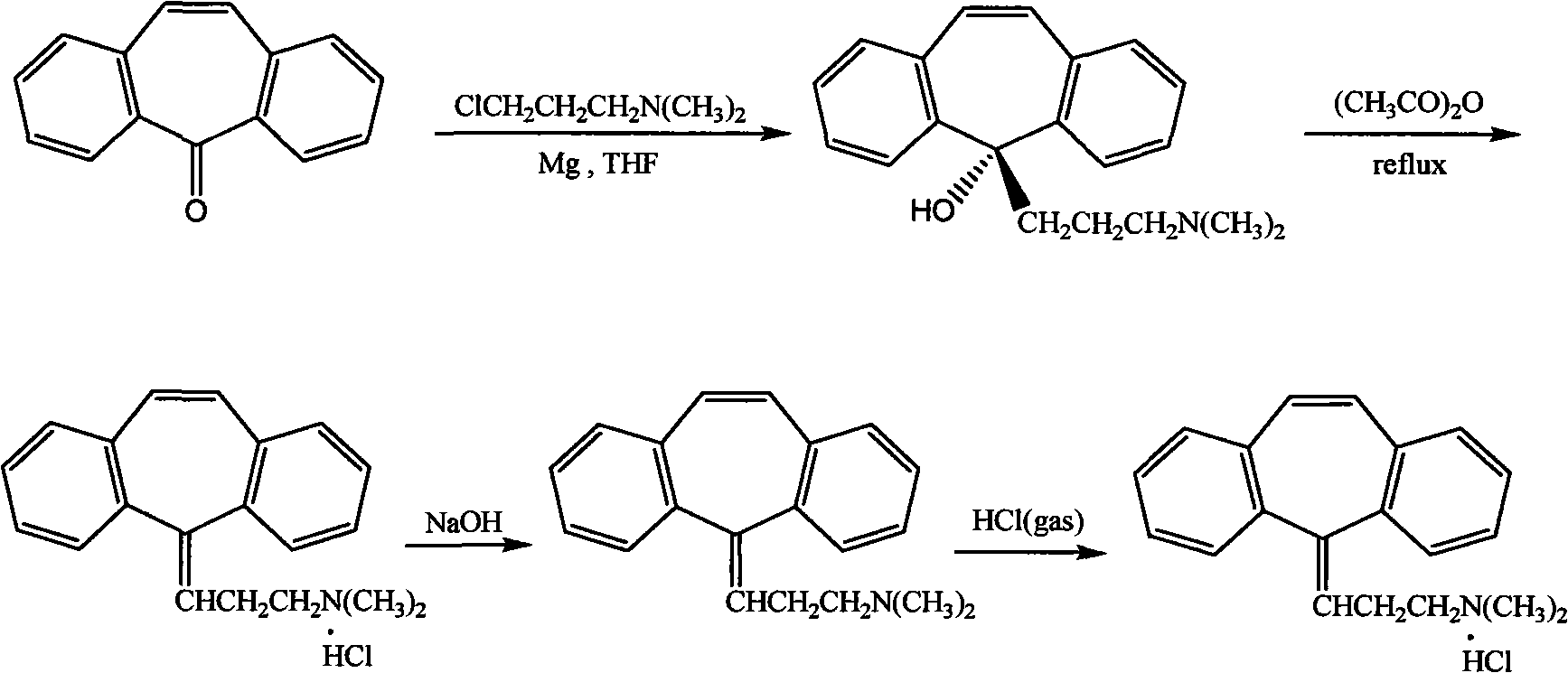

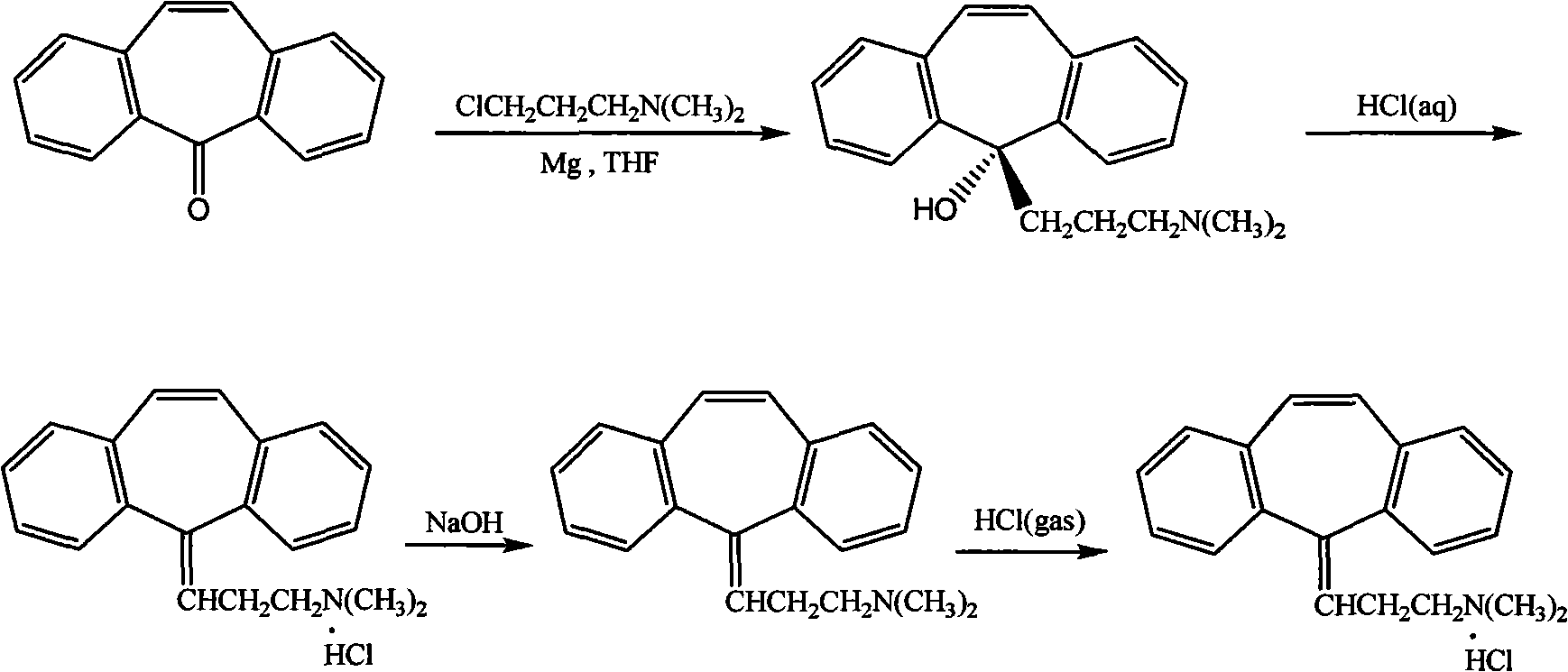

Method for refining cyclobenzaprine hydrochloride

InactiveCN101260046AHigh yieldImprove securityAmino compound purification/separationMuscular disorderOrganic layerEthyl acetate

The invention provides a refinement method for hydrochloric acid cyclobenzaprine, which is safer and more reliable, and can increase the productive efficiency. The refinement method of the hydrochloric acid cyclobenzaprine is as follows: firstly, coarse products of 5- (3- dlmethyl ammonium)- dibenzanthracene (a,d) cycloheptatriene-5-alcohol(cyclobenzaprine intermediate) are dissolved in hydrochloric acids with the concentration of between 1 and 37 percent and heated at a temperature of between 50 and 95 DEG C for 1 to 5 hours, and added in with sodium hydroxide(or other sodium salts) for neutralization so as to make a solution become basic; secondly, an aether / ethyl acetate mixed solution is used for extraction, and the organic layer is filled with dried hydrochloric acid gases for 1 to 5 hours, and coarse products of cyclobenzaprine hydrochloride are separated out; thirdly, coarse products of cyclobenzaprine hydrochloride are recrystallized by absolute isopropanol, and the use level is that each 10g of coarse products is mixed with 30 to 100ml of absolute isopropanol, and the coarse products are filtered, and filter cakes are washed to be nearly white by using acetone, aether or tetrahydrofuran, and coarse products filtered are dried to obtain finished products of cyclobenzaprine hydrochloride, and the content of hydrochloric acid cyclobenzaprine is more than 99.8 percent.

Owner:NANJING HAILING TRADITIONAL CHINESE MEDICINE RES CO LTD +1

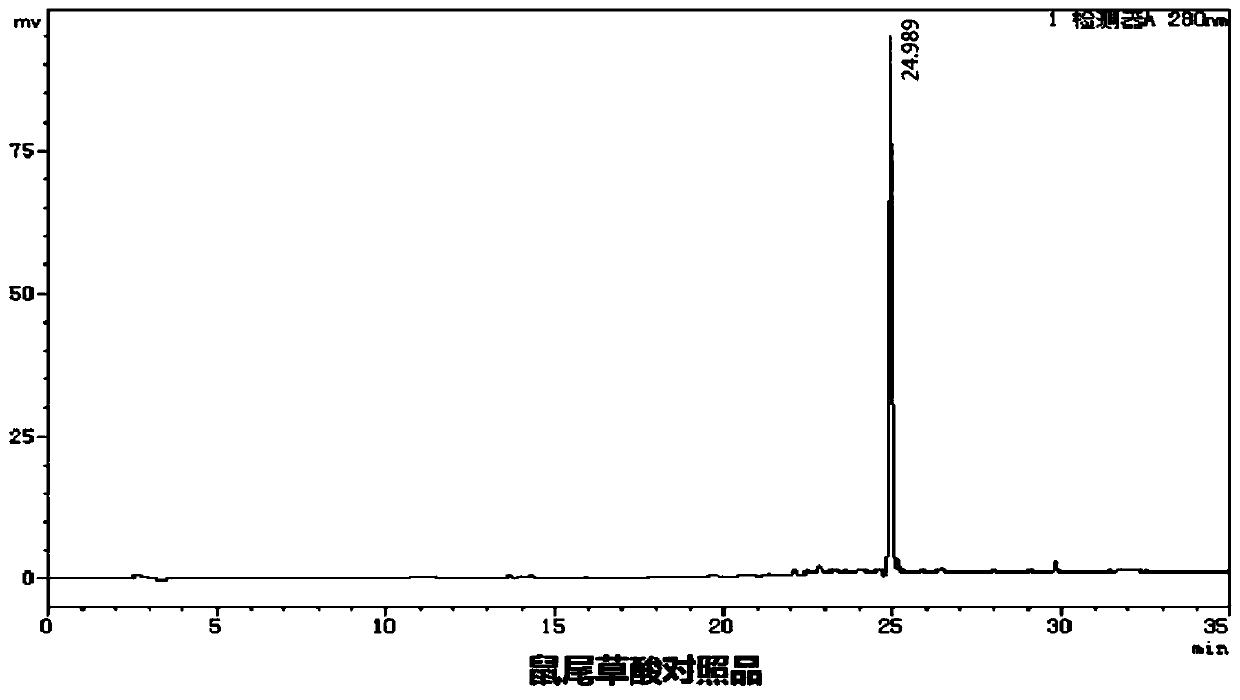

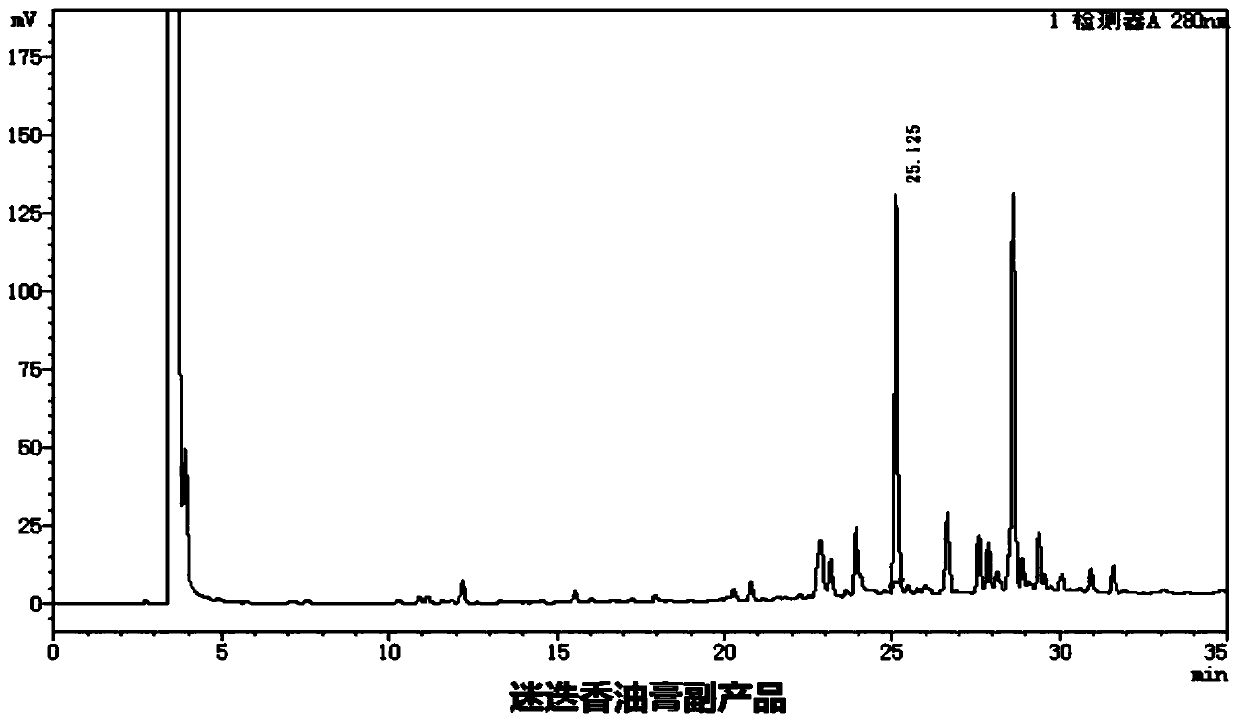

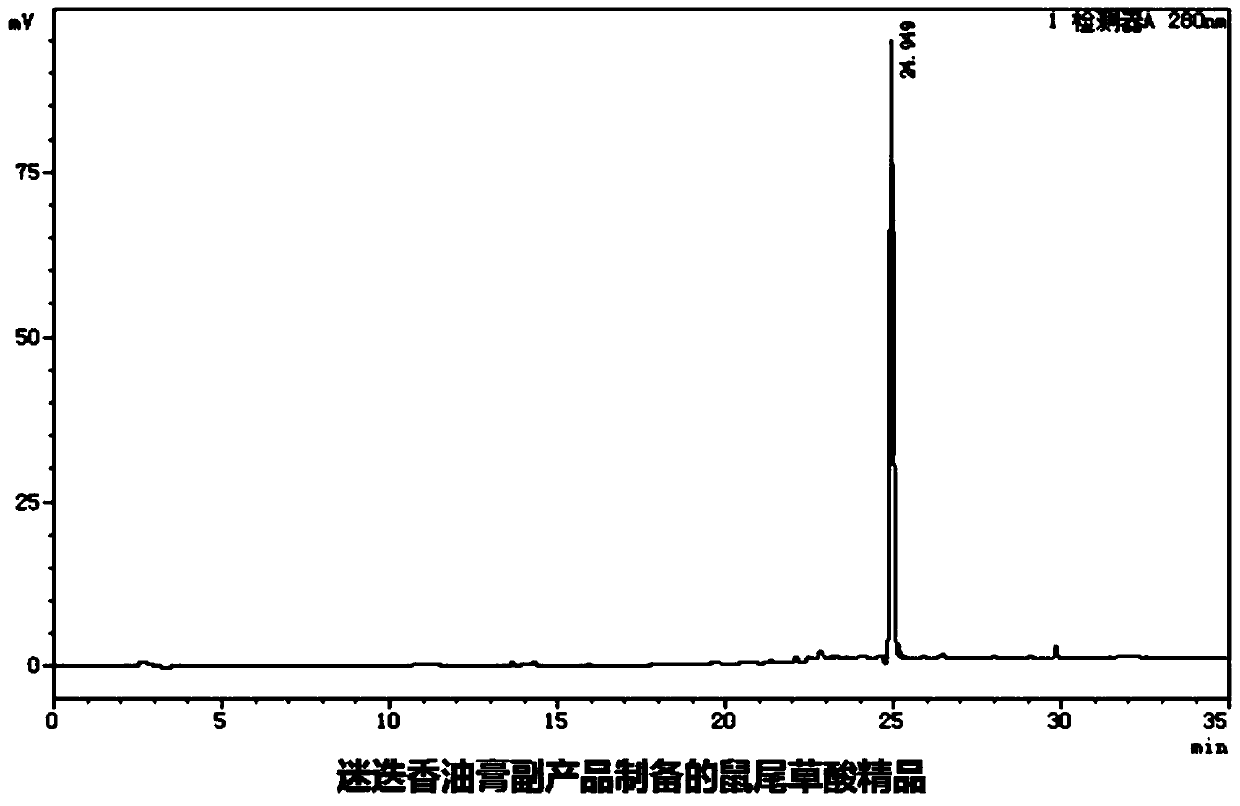

Method for preparing high-purity carnosic acid from rosemary oil paste byproduct

ActiveCN110845328AEasy to operateHigh yieldCarboxylic compound separation/purificationAgainst vector-borne diseasesActivated carbonProcess engineering

The invention discloses a method for preparing carnosic acid from a rosemary oil paste byproduct, and the method comprises the following steps: preparing an R67 extract, preparing the rosemary oil paste byproduct, preparing rosemary oil paste particle powder, carrying out solid-liquid extraction on the rosemary oil paste powder, concentrating the extract, and crystallizing to prepare crude carnosic acid dry powder, remove impurities from the crude carnosic acid product by activated carbon adsorbing, and refining carnosic acid to prepare a carnosic acid product with carnosic acid content of 95-98%. The method has the characteristics of simplicity in operation, high efficiency, recyclability of the extract, environmental friendliness, high product yield and the like.

Owner:湖南德诺贝莱健康产业有限公司

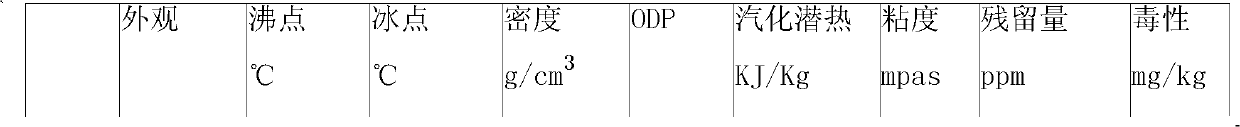

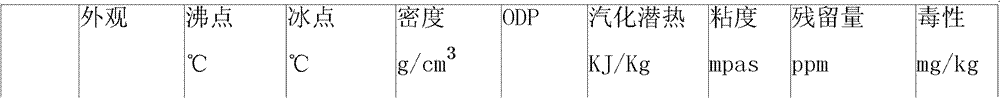

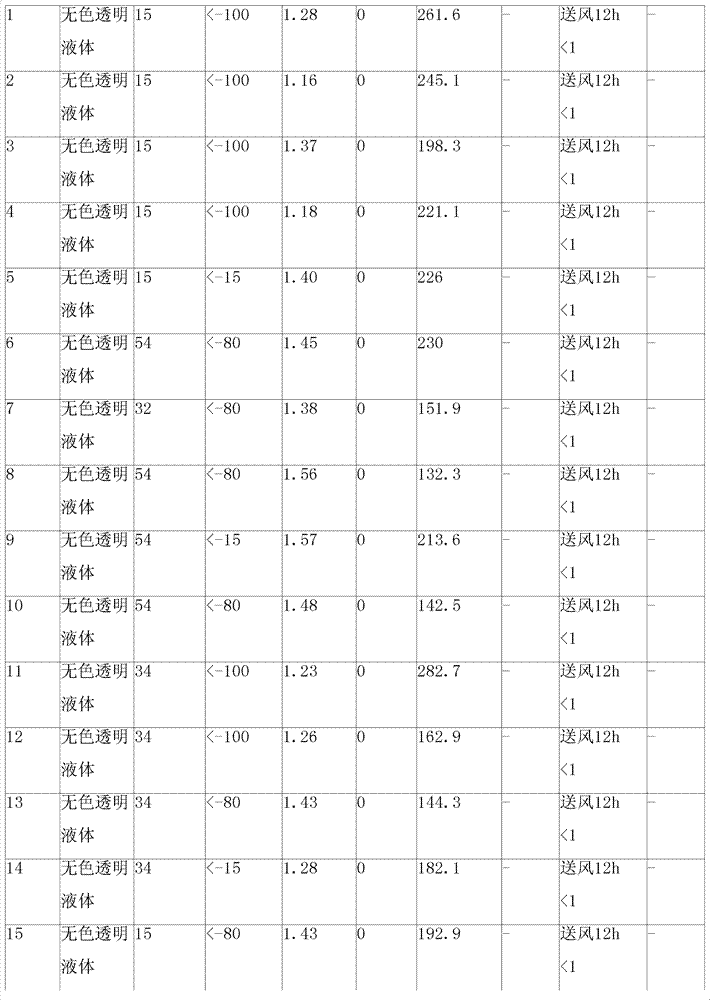

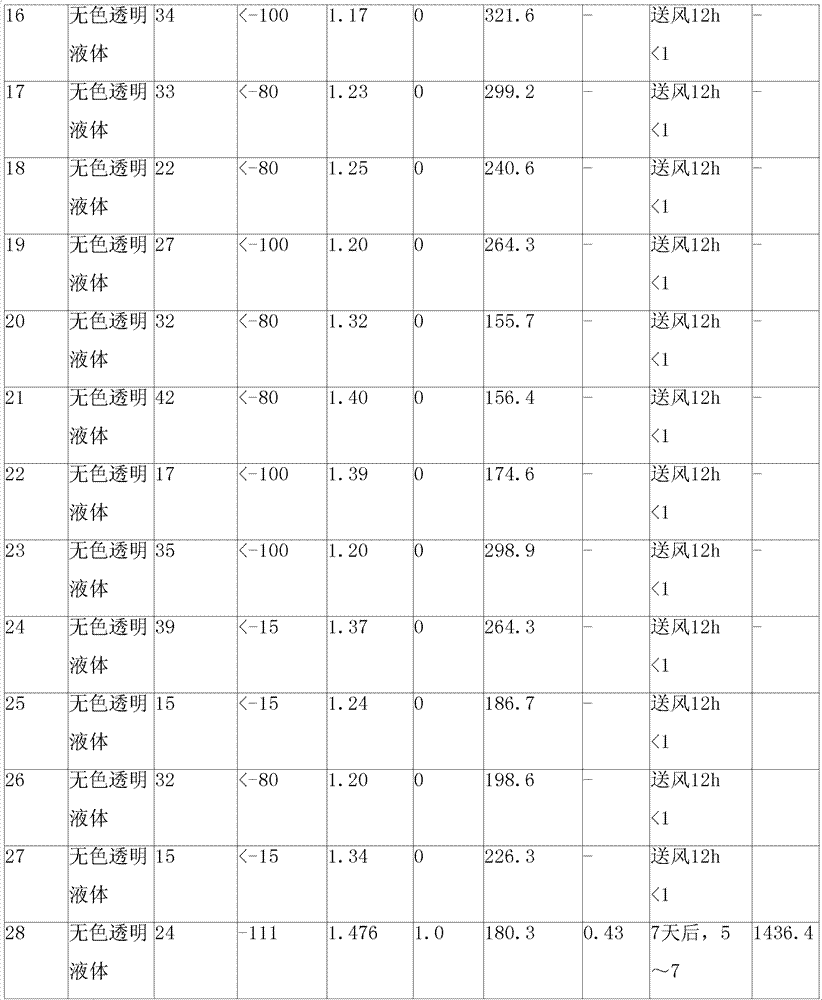

Environment-friendly cut tobacco expanding agent composition

InactiveCN101766328AHigh decomposition temperatureGood chemical stabilityTobacco treatmentAlkaneAlcohol

The invention relates to an environment-friendly cut tobacco expanding agent composition, which comprises the following components in percentage by weight: 50-99 percent of hydrofluoroalkane and 1-50 percent of alcohol or ether or alkane, wherein the hydrofluoroalkane is one or any combination of several kinds of pentafluoropropane, pentafluorobutane, decafluoropentane or methoxyl heptafluoropropane, preferably 80-99 percent of hydrofluoroalkane and 1-20 percent of alcohol or ether or alkane; and more preferably, 90-99 percent of hydrofluoroalkane and 1-10 percent of alcohol or ether or alkane. The environment-friendly cut tobacco expanding agent composition has favorable chemical stability; and the ozone depletion potential (ODP) index of the environment-friendly cut tobacco expanding agent composition is zero which is far lower than CFC-11, so the environment-friendly cut tobacco expanding agent composition is beneficial to the environmental protection.

Owner:北京航天科创技术开发有限公司 +1

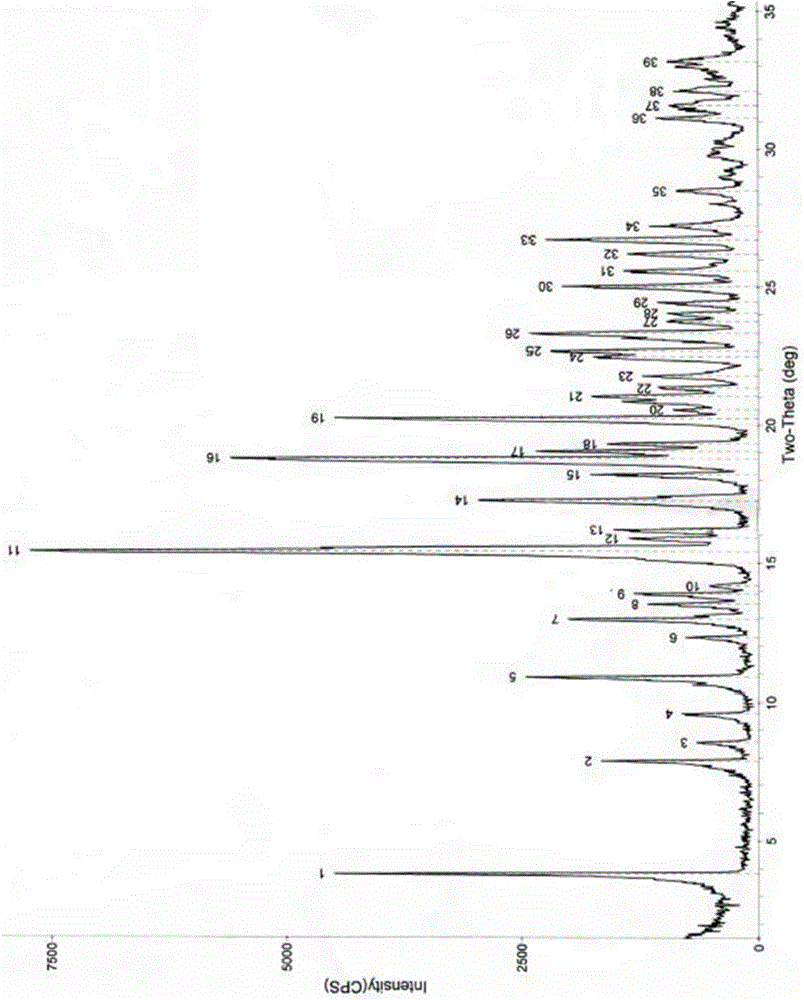

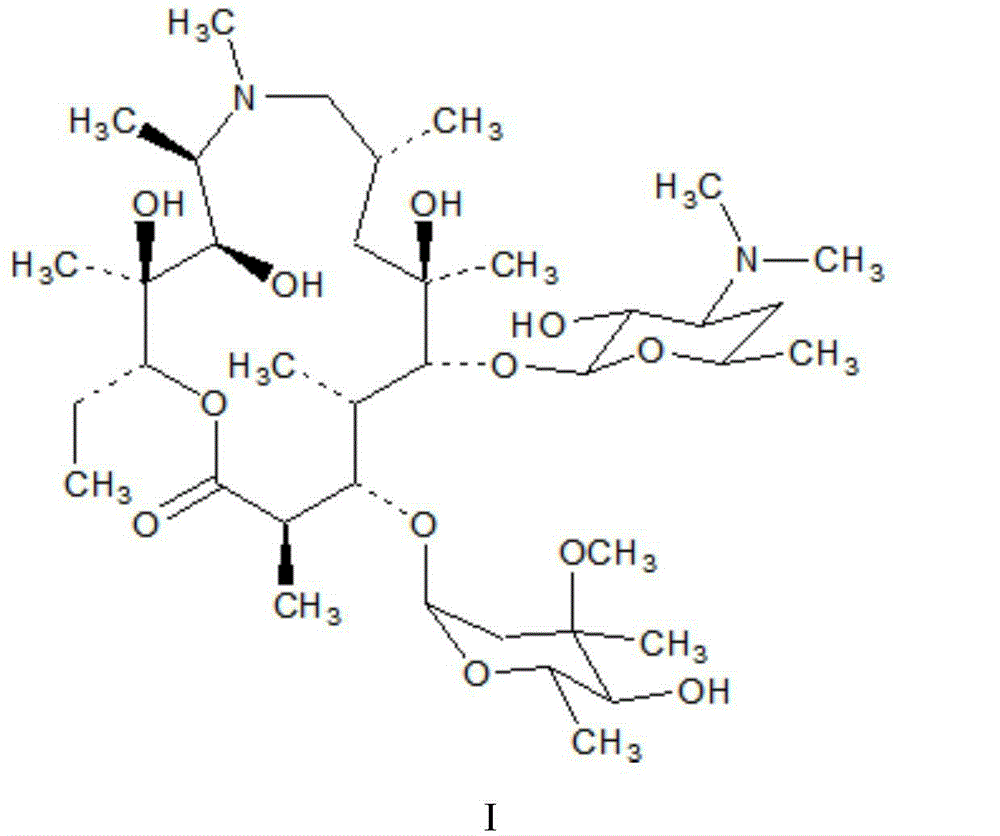

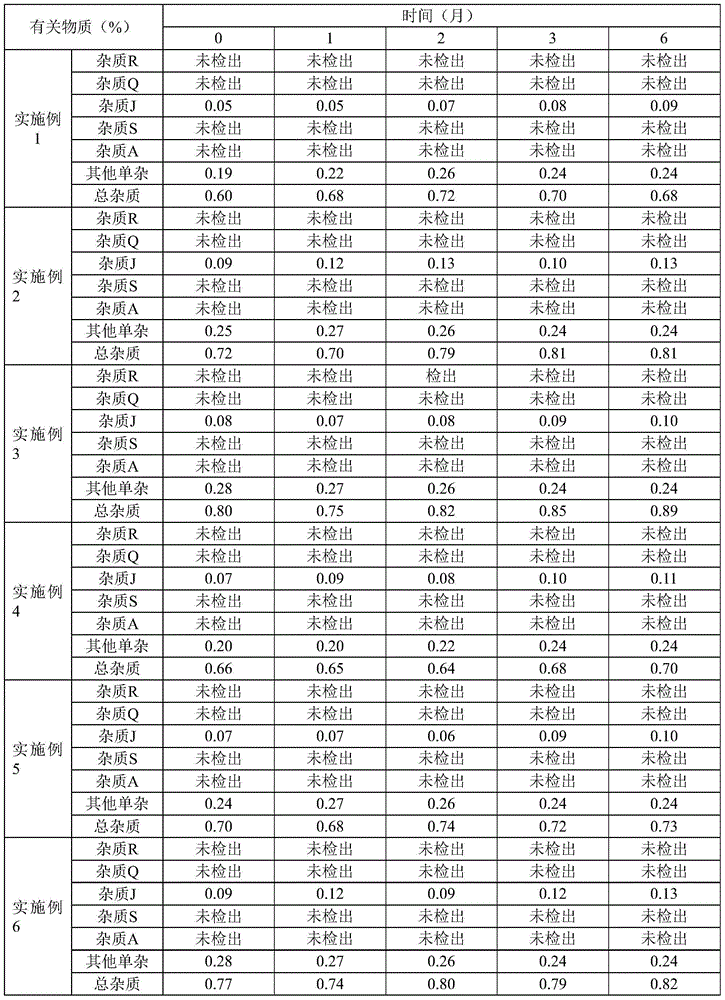

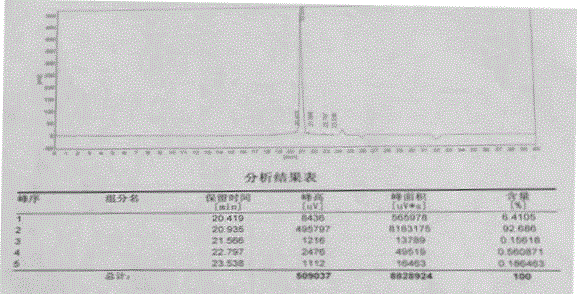

Azithromycin new crystal-form compound and preparation method thereof

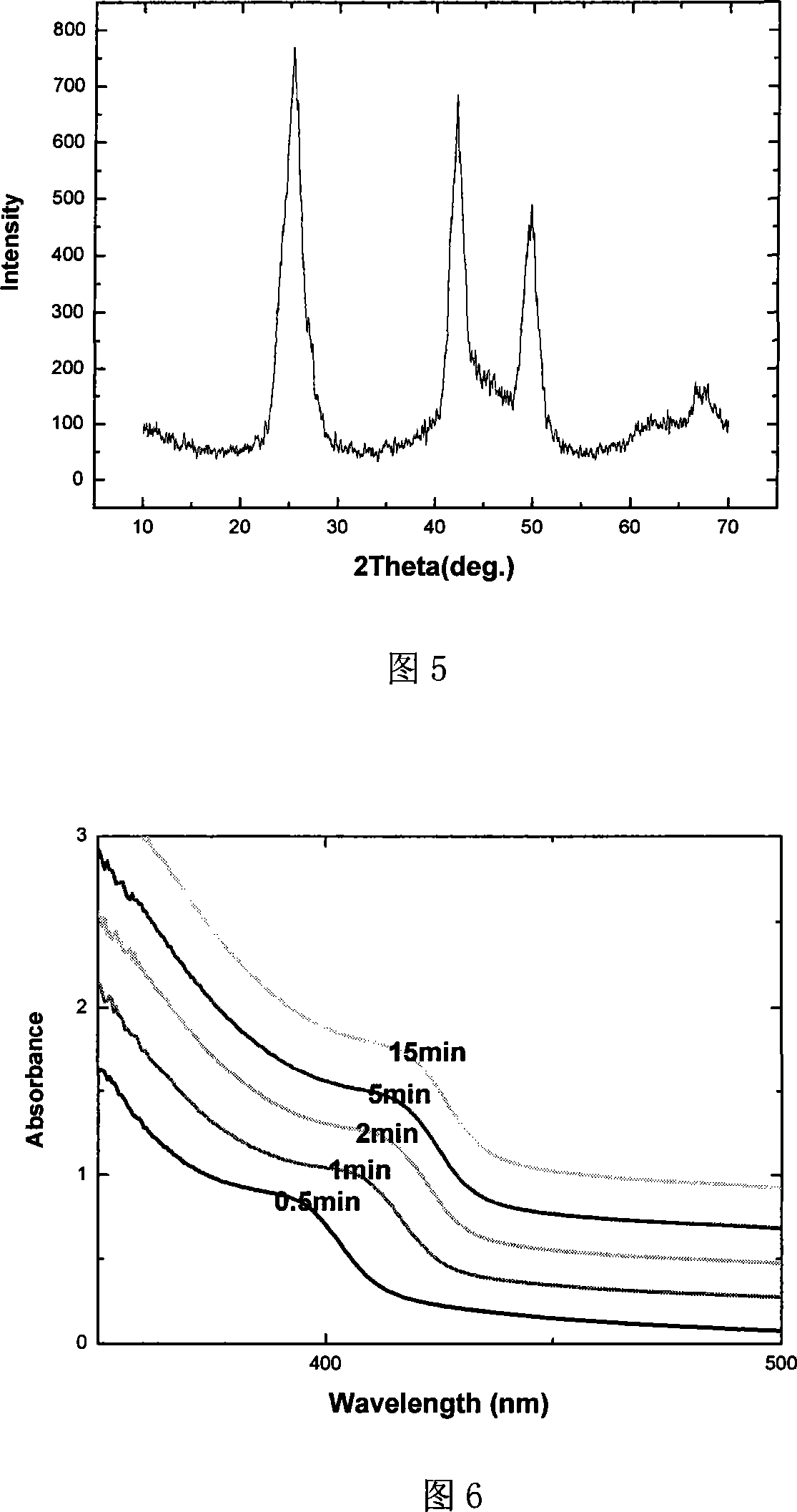

ActiveCN104910222AImprove stabilityImprove performanceSugar derivativesSugar derivatives preparationAzithromycinX-ray

The invention relates to an azithromycin new crystal-form compound and a preparation method thereof, belonging to the technical field of medicine. According to the azithromycin new crystal-form compound provided by the invention, an X-ray powder diffraction diagram has characteristic peaks at the positions that the reflection angle 2theta is 3.8+ / -0.2 degrees, 15.4+ / -0.2 degrees, 17.2+ / -0.2 degrees, 18.7+ / -0.2 degrees, 20.1+ / -0.2 degrees and 23.2+ / -0.2 degrees. The azithromycin new crystal-form compound provided by the invention is subjected to a stability test under the conditions that the temperature is 40+ / -2 DEG C and the relative humidity is 75+ / -5 percent. The test result shows that the content of each related substance of the azithromycin new crystal-form compound provided by the invention is not changed obviously, and excellent quality stability is achieved. The repose angle measuring result shows that the azithromycin new crystal-form compound has excellent fluidity and is more suitable for medicine preparation and long-time storage.

Owner:CSPC OUYI PHARM CO LTD

Benzylation method for monosaccharide glucoside

ActiveCN105153251AEasy post-processingEasy to operateSugar derivativesSugar derivatives preparationSolventToluene

The invention discloses a benzylation method for monosaccharide glucoside. The method includes the steps of sequentially adding monosaccharide glucoside, sodium hydride, methylbenzene and benzyl chloride to a reactor, raising the temperature to the reaction temperature of 60-130 DEG C, preserving heat till the reaction is completed, and conducting postprocessing on reaction liquid after the reaction ends to prepare a benzylation product of monosaccharide glucoside, wherein the benzylation product of monosaccharide glucoside is a product generated by conducting benzylation on all hydroxide radicals -OH on monosaccharide glucoside to generate -O-Bn, and Bn represents benzyl groups. Reaction solvent and extraction solvent are both methylbenzene, the postprocessing operation is simplified, the byproduct methylbenzene in the reaction process is consistent with the reaction solvent, recycled methylbenzene can be directly used as reaction solvent for the next batch without water removal, and the aims of simplifying operation, reducing sodium hydride and benzyl chloride unit consumption, effectively reducing generation of byproduct dibenzyl ether and reducing pollution are achieved.

Owner:浙江合糖科技有限公司

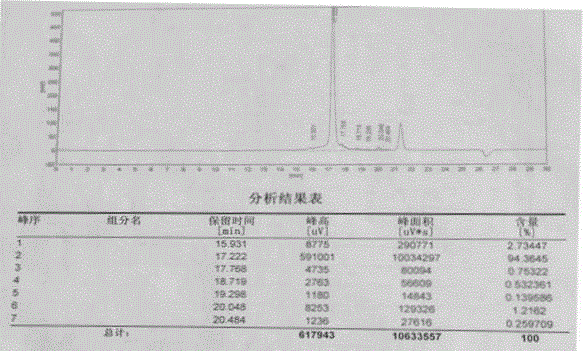

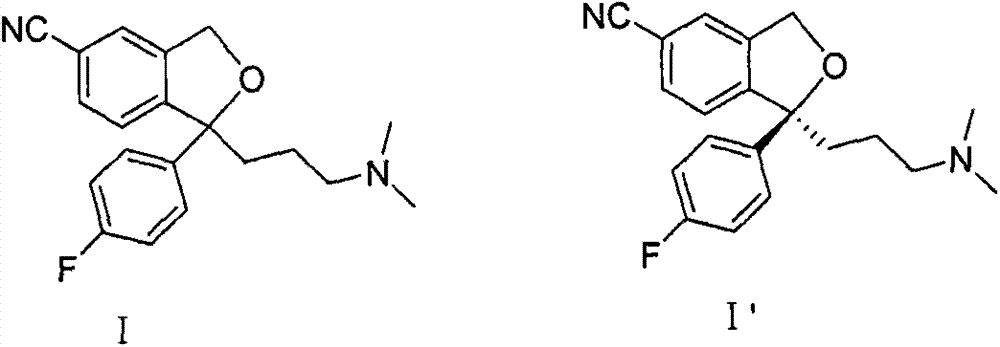

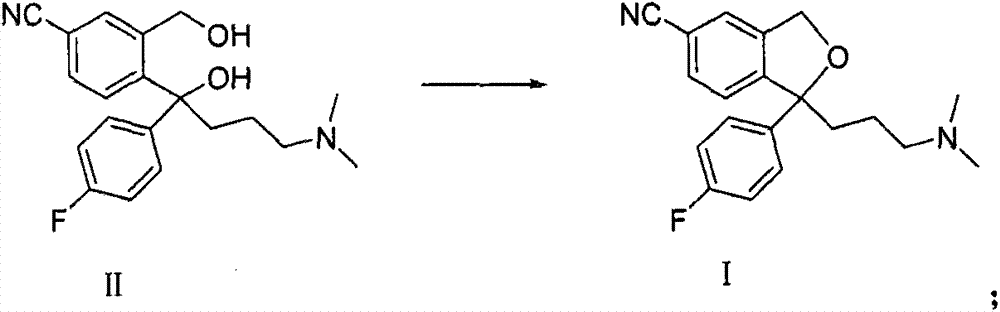

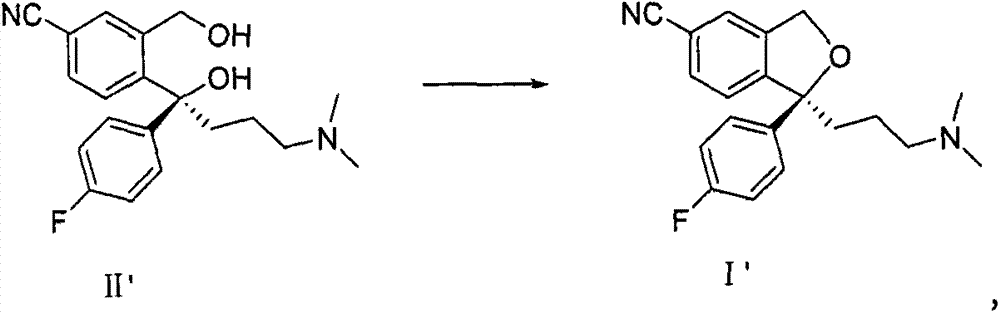

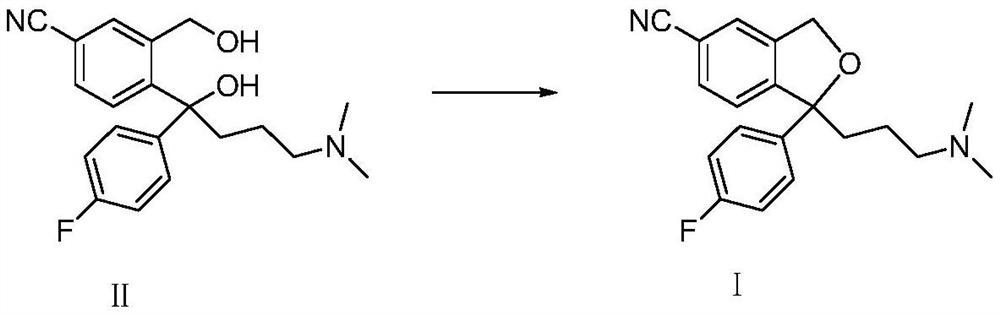

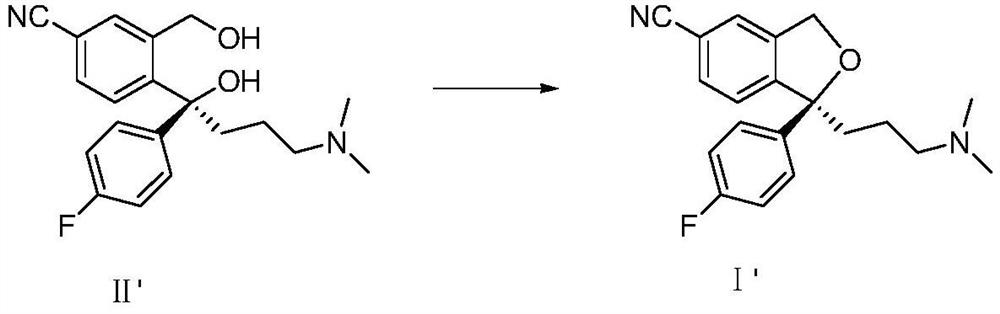

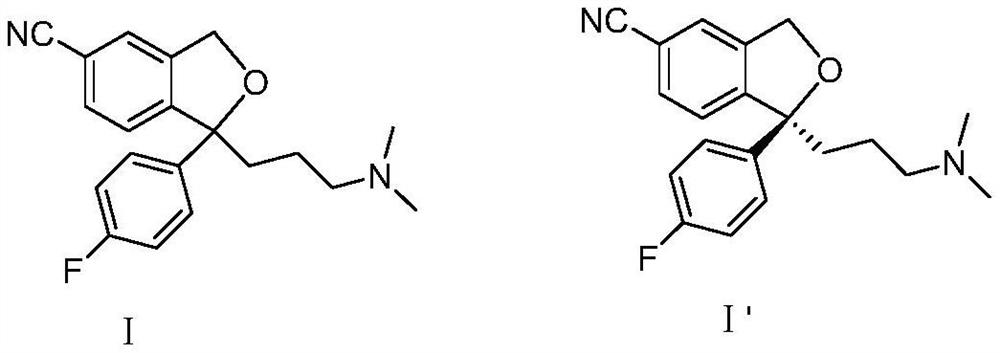

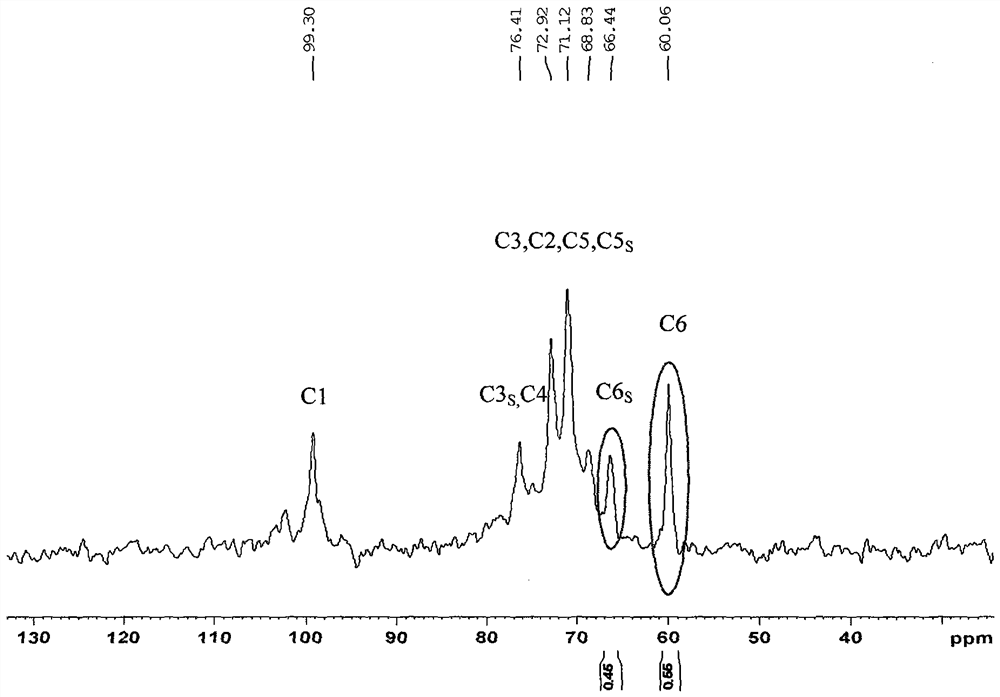

Method for preparing citalopram and S-citalopram

The invention relates to a method of preparing citalopram and S-citalopram by carrying out cyclization reaction on a diol compound (II) or S-diol compound (II') in a nixed solvent of a C4-C7 ketone solvent and water and aryl sulfonyl chloride or alkyl sulfonyl chloride under an alkaline condition. The solvent used by the invention is great in solubility to reactants and products, so that the use level of the solvent is reduced, the yield is improved and meanwhile the method is good in post-treatment extraction effect and simple and convenient to operate. The compounds (II and II') are as shown in the specification.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

Novel application of hexafluoroisobutylene

InactiveCN108586792AEffective protectionLow vapor phase thermal conductivityFoaming agentBoiling point

The invention provides an application of hexafluoroisobutylene as a foaming agent in polyurethane foaming. The hexafluoroisobutylene can be used as a new generation of foaming agent and meets the following requirements: the ozone depletion potential (ODP) is 0, the global warming potential (GWP) is as low as possible, the foaming agent is not flammable, the boiling point is suitable, the gas-phaseheat conduction coefficient is low, the foaming agent is safe and reliable, and the like. The hexafluoroisobutylene can effectively protect the earth that we depend on for existence, and achievementsare gained for the present and benefits are gained for the future. The foaming agent and composite foaming agent can be applicable to the foaming of hard polyurethane insulation materials in the fields of household appliances, building heat preservation, cold-chain transportation, industrial heat preservation and the like. The hexafluoroisobutylene is not flammable, so that safety improvement oforiginal foaming equipment is not required in any aspects.

Owner:张振宽

Environment-friendly cut tobacco expanding agent composition

InactiveCN101766328BHigh decomposition temperatureGood chemical stabilityTobacco treatmentAlkaneAlcohol

The invention relates to an environment-friendly cut tobacco expanding agent composition, which comprises the following components in percentage by weight: 50-99 percent of hydrofluoroalkane and 1-50 percent of alcohol or ether or alkane, wherein the hydrofluoroalkane is one or any combination of several kinds of pentafluoropropane, pentafluorobutane, decafluoropentane or methoxyl heptafluoropropane, preferably 80-99 percent of hydrofluoroalkane and 1-20 percent of alcohol or ether or alkane; and more preferably, 90-99 percent of hydrofluoroalkane and 1-10 percent of alcohol or ether or alkane. The environment-friendly cut tobacco expanding agent composition has favorable chemical stability; and the ozone depletion potential (ODP) index of the environment-friendly cut tobacco expanding agent composition is zero which is far lower than CFC-11, so the environment-friendly cut tobacco expanding agent composition is beneficial to the environmental protection.

Owner:北京航天科创技术开发有限公司 +1

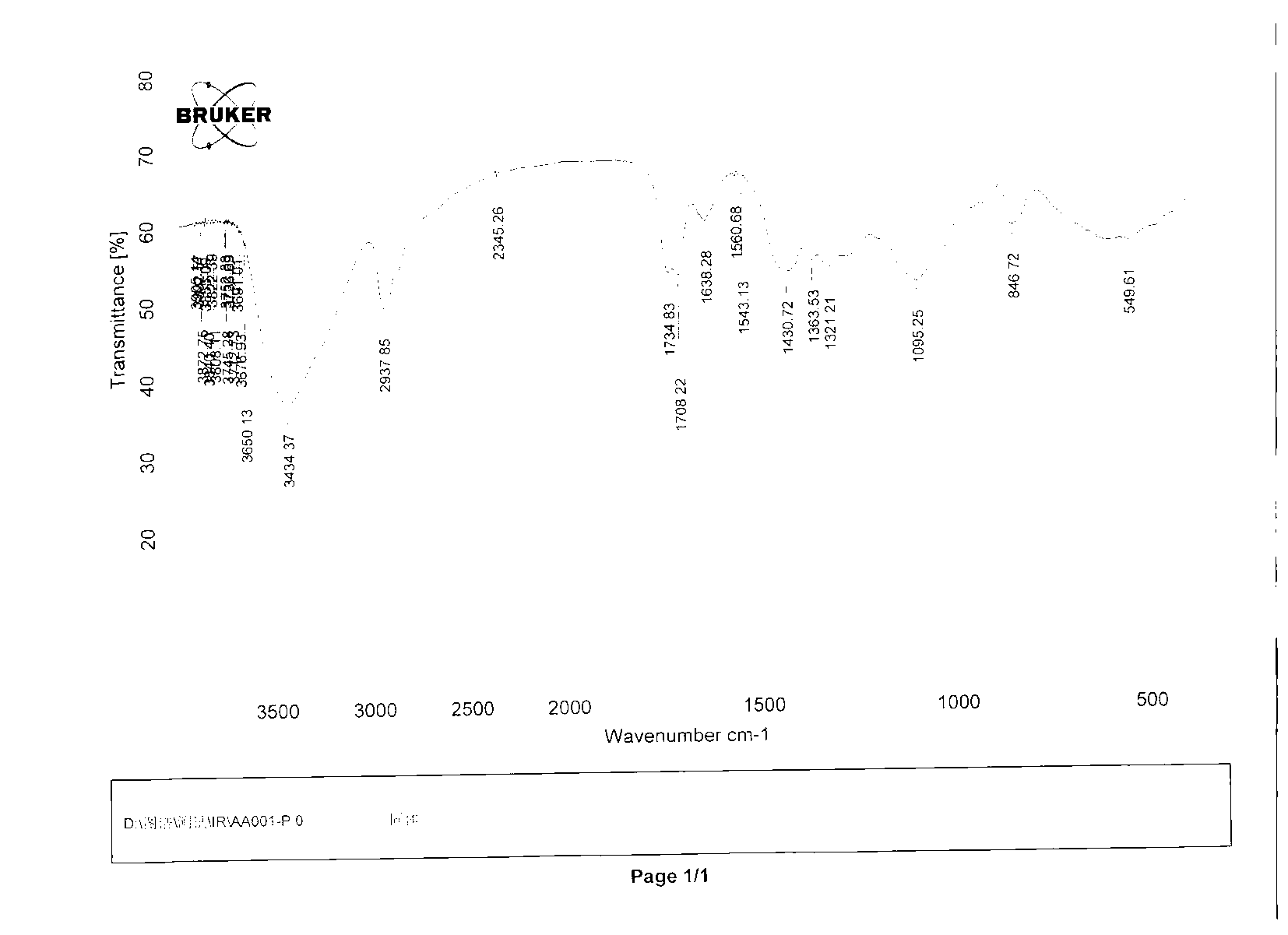

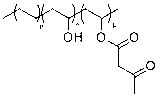

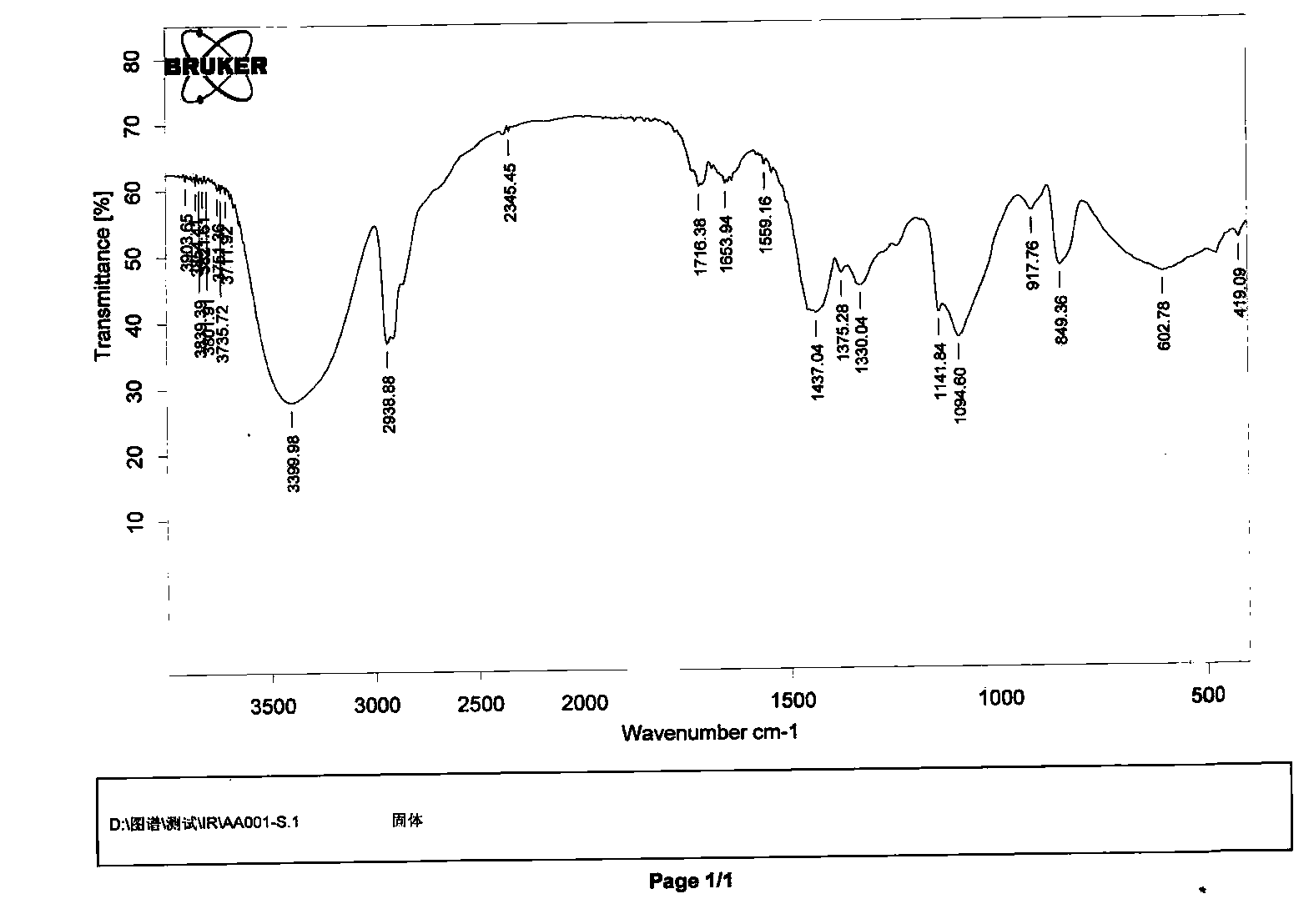

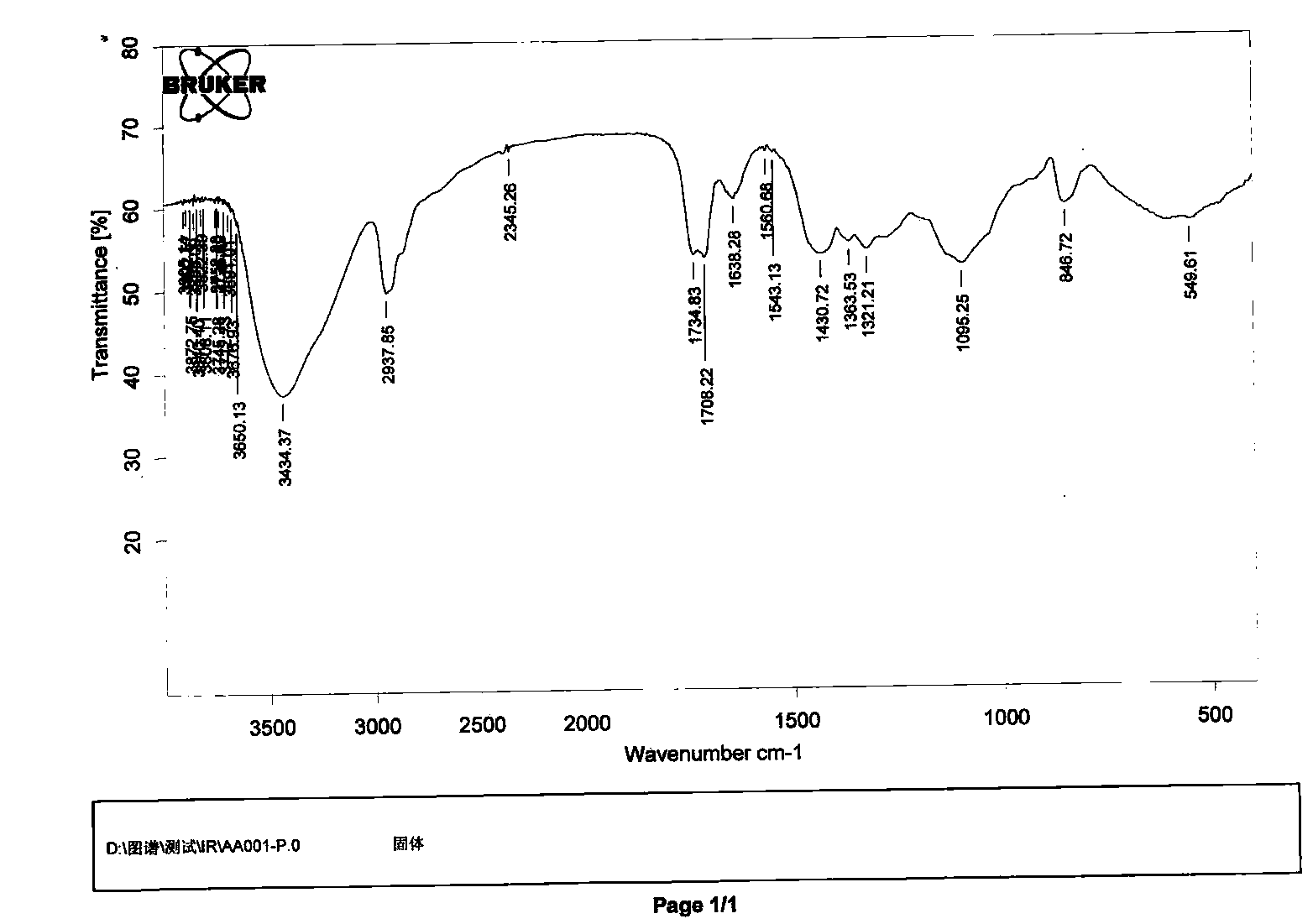

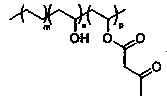

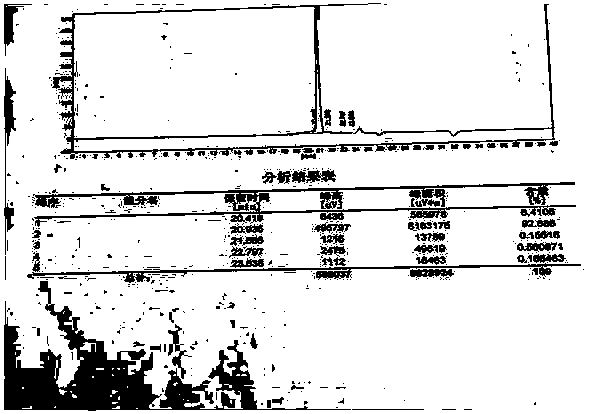

Preparation method of acetoacetyl modified ethylene-vinyl alcohol copolymer

The invention discloses a preparation method of an acetoacetyl modified ethylene-vinyl alcohol copolymer. Commercial ethylene vinyl alcohol (EVOH) is used as a raw material, the ethylene content in the EVOH is 20%-40%, the vinyl alcohol content in the EVOH is 60%-80%, and by virtue of the modification by diketene, the acetoacetyl content in the obtained modified copolymer is 0.60-2.20mol / kg. The preparation method disclosed by the invention comprises the following two steps of: (1) dissolving the ethylene-vinyl alcohol copolymer in an organic solvent to react with the diketene under the catalytic action of an organic base; and (2) adding an organic solvent after the reaction is ended to precipitate the product. The acetoacetyl modified ethylene-vinyl alcohol copolymer obtained prepared the invention is white solid powder, and is good in product quality and water solubility.

Owner:石家庄万尚医药科技有限公司 +1

Circulation method for preparing expanded cut tobacco

ActiveCN101617854BImprove whole yarn rateIncrease elasticityTobacco preparationFinal product manufactureVacuum pumpingProcess engineering

The invention discloses a circulation method for preparing expanded cut tobacco, comprising the following steps: (1) putting cut tobacco into a preheated impregnating tank, then carrying out vacuum-pumping; (2) spraying liquid expanding agent to the cut tobacco; (3) filling gas expanding agent to the impregnating tank; (4) impregnating; (5) first, recycling the liquid expanding agent, then recycling the gas expanding agent; and (6) expanding the impregnated cut tobacco, and carrying out operations in step (2) or / and step (3) by the liquid expanding agent and the gas expanding agent recycled in step (5). The method of the invention has mild condition and greatly reduced requirement for devices, by fully recycling the expanding agents, the cost is lowered, the complete set of devices has low energy consumption and high automation, continuous mass production can be carried out, all performance indexes of the obtained expanded cut tobacco are high, the expanded efficiency of the cut tobacco is high, and the recycling rate of the expanding agents is high.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

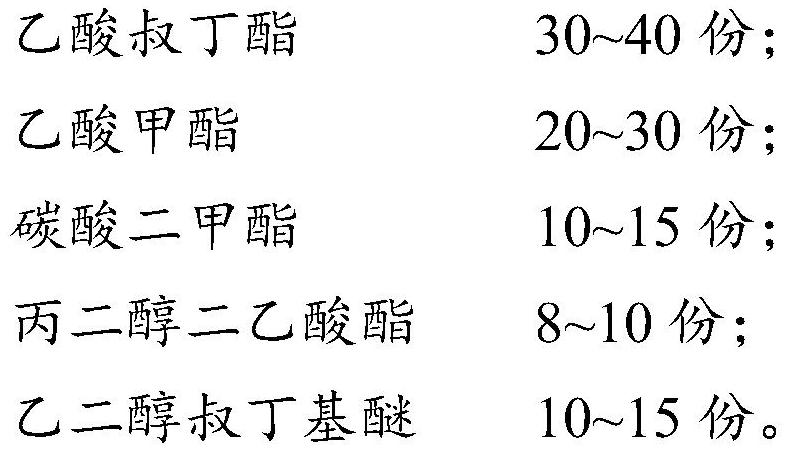

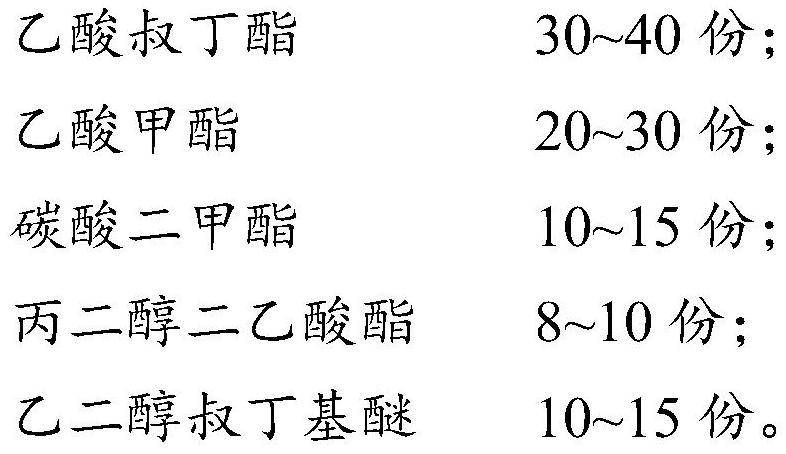

Coating material diluent containing solvent not participating in photochemical reaction, and preparation method and application thereof

InactiveCN111793380AEmission reductionConducive to labor protectionCoatingsHalohydrocarbonChemical reaction

The invention belongs to the technical field of coating material diluents, and provides a coating material diluent containing a solvent not participating in a photochemical reaction. The coating material diluent comprises the following components in parts by weight: 30-40 parts of tert-butyl acetate, 20-30 parts of methyl acetate, 10-15 parts of dimethyl carbonate, 8-10 parts of propylene glycol diacetate and 10-15 parts of ethylene glycol tert-butyl ether. The invention further provides a preparation method and application of the coating material diluent containing the solvent not participating in the photochemical reaction. According to the invention, the coating material diluent disclosed by the invention is a low-toxicity environment-friendly coating material diluent, does not containharmful substances such as benzene, halogenated hydrocarbon, formaldehyde and the like, is beneficial to labor protection, does not participate in a photochemical reaction after volatilization, does not cause photochemical pollution, effectively reduces VOC emission and plays a role in protecting the environment; and the cost of the coating material diluent is lower than that of a benzene-containing diluent, and the universality is obvious.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

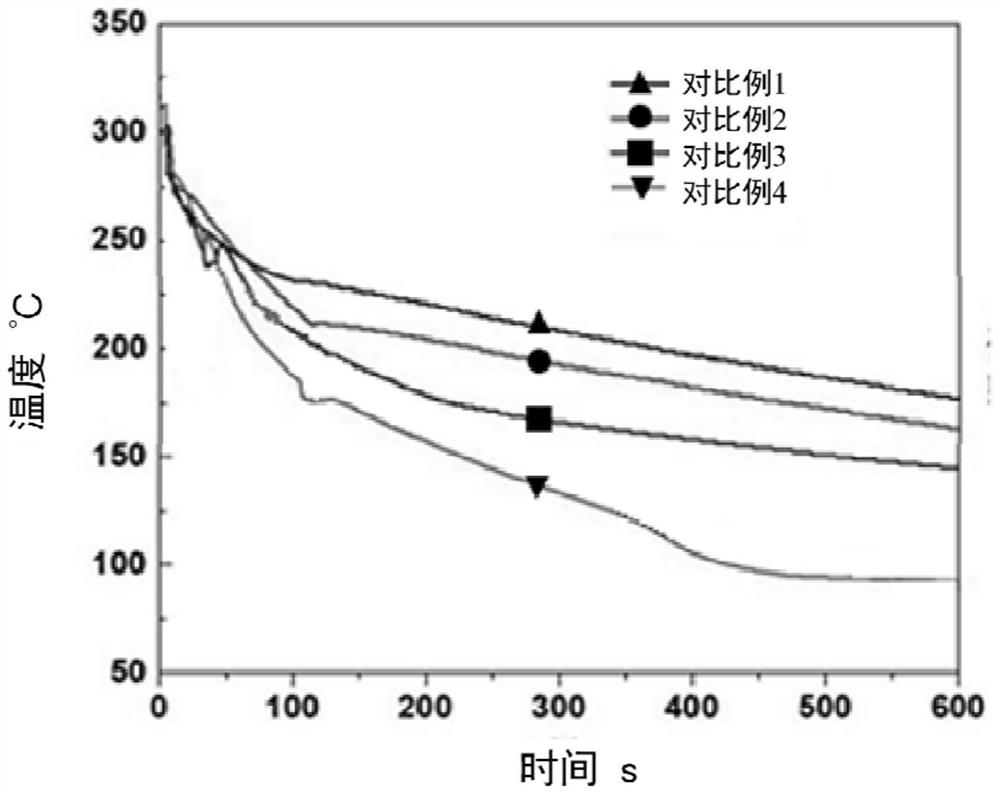

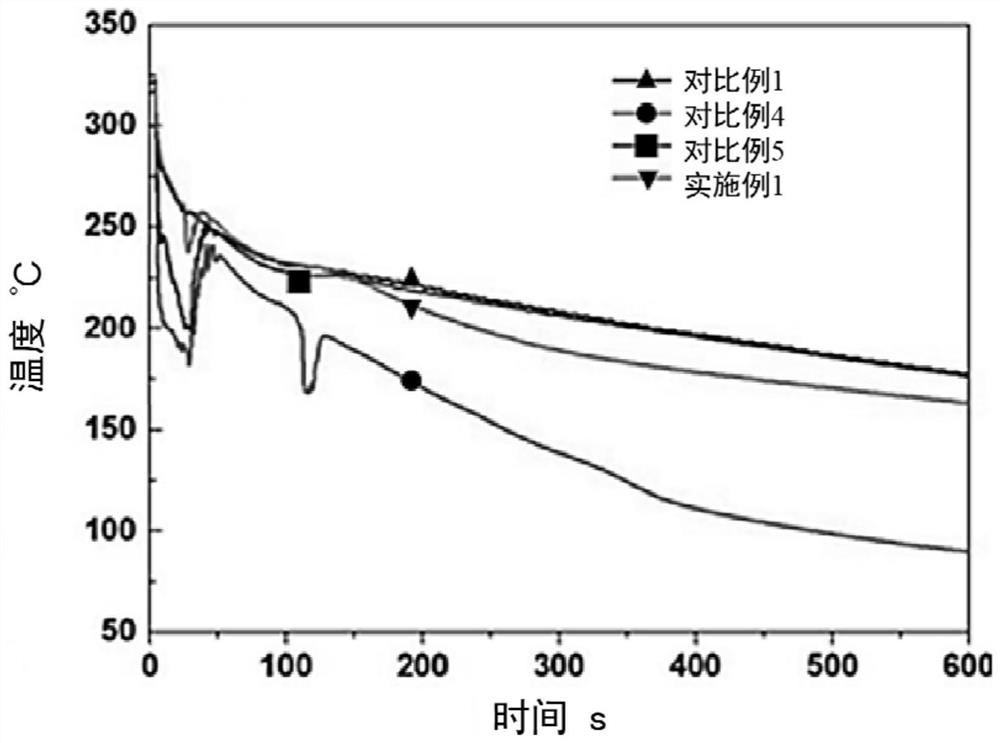

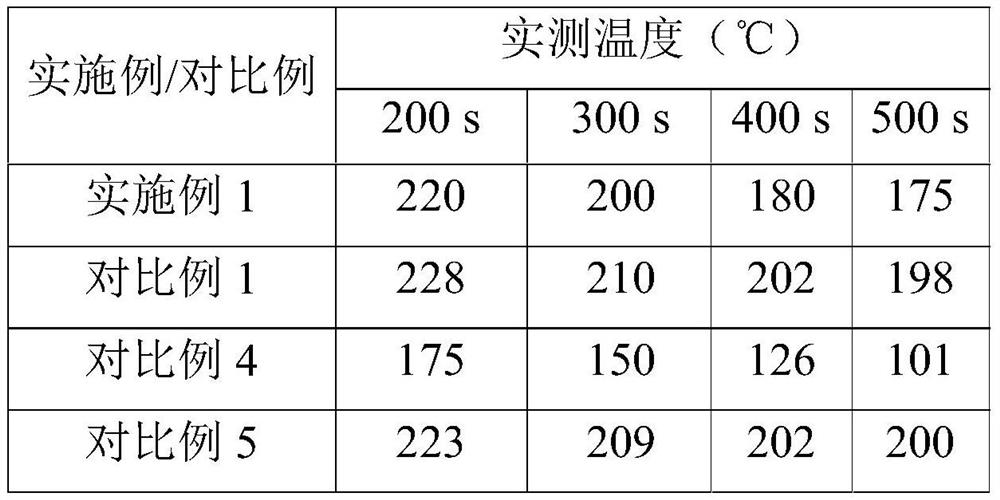

Lithium ion battery fire extinguishing agent and preparation method and application thereof

ActiveCN113350730AGuarantee the safety of useEffectively extinguishFire rescueFire extinguisherMontmorilloniteEngineering

The invention provides a lithium ion battery fire extinguishing agent which comprises a fire extinguishing material, a cooling material and an anti-corrosion material. The mass ratio of the fire extinguishing material to the cooling material to the anti-corrosion material is (0.5-2): (0.2-2): (0.1-0.3). The fire extinguishing material is a fluorine-containing organic matter of which the vaporization heat does not exceed 100kJ / kg; the cooling material is a fluorine-containing organic matter of which the vaporization heat is higher than 100kJ / kg; and the anti-corrosion material is montmorillonite loaded with activated aluminum oxide and urea. Through reasonable compounding, the lithium ion battery fire extinguishing agent has a suitable boiling point, high vaporization heat and high specific heat, has fire extinguishing and cooling performance, can prevent re-combustion while effectively and rapidly extinguishing a lithium ion battery fire, and does not corrode electrical equipment and cause secondary damage in the fire extinguishing process.

Owner:SHENZHEN POWER SUPPLY BUREAU

Composition of tobacco shred puffing agent

InactiveCN100539881CGood chemical stabilityLow ozone depletion potential ODP indexTobacco preparationEnvironmental healthOzone depletion potential

The present invention relates to a shredded tobacco expansion agent composition. The first shredded tobacco expansion agent composition of the present invention is composed of pentafluorobutane and heptafluoropropane, the second is composed of pentafluorobutane and hexafluoropropane, and the third is composed of pentafluorobutane and heptafluoropropane. Butane and pentafluoropropane, the fourth is composed of pentafluorobutane and tetrafluoroethane, and the fifth is composed of pentafluorobutane and decafluoropentane. The cut tobacco expander composition of the present invention has an ozone depletion potential (ODP) of zero, moderate boiling point, safety, low toxicity and nonflammability, and can replace CFC-11 as a cut tobacco expander in the tobacco industry.

Owner:北京航天科创技术开发有限公司 +1

A kind of preparation method of electrolyte additive

The invention provides a safe preparation method for an electrolyte additive with a low cost and a high yield and capable of large-scale preparation. The electrolyte additive is an AaXxBb compound employing fluorinated metal salt, fluorinated gas and nitrogen-containing ligands as raw materials, A is at least any one selected from Cs, Rb, Sr and Ba, X is at least any one selected from C5H5N, (C2H5)3N, CH3CN, (CH2CN)2 and (C2H4CN)2, wherein, a is more than 0 and less than 3, x is more than 0 and less than 3, and a is more than 0 and less than 3. Fluorinated metal salt is dissolved in an alcohol and ether solvent, nitrogen-containing ligands are added at a normal temperature under protection of inert gas, fluorinated gas and nitrogen are mixed and inputted into the container under circulation of a cooling medium, the reaction is carried out for 2-4h, centrifugation and washing are repeated, and the AaXxBb compound is obtained after drying. The provide preparation method can be applied to the compound synthesis field.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

A kind of method for preparing citalopram and s-citalopram

The present invention relates to diol compound (II) or S-diol compound (II ') in C 4 -C 7 In the mixed solvent of ketone solvent and water, under alkaline condition, react cyclization with arylsulfonyl chloride or alkylsulfonyl chloride to obtain citalopram and S-citalopram. The solvent used in the invention has high solubility to reactants and products, thus reducing the amount of solvent used and improving production capacity, and at the same time, the post-treatment extraction effect is good and the operation is simple and convenient.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

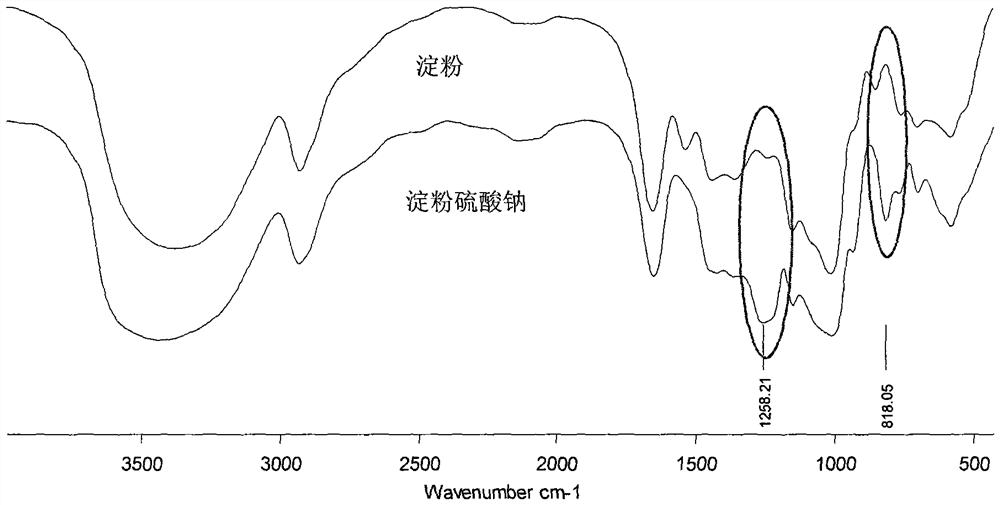

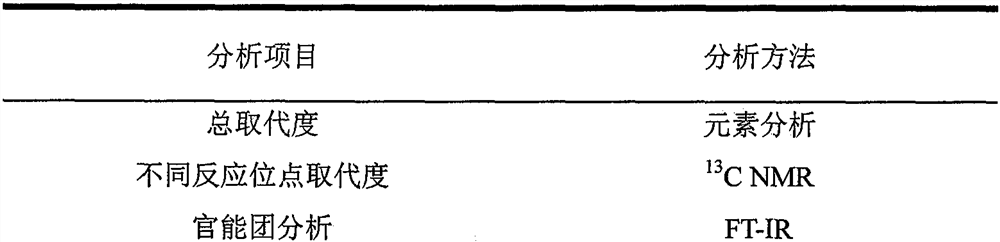

A kind of starch sulfate and its salt synthesis process

Owner:XIAMEN UNIV +1

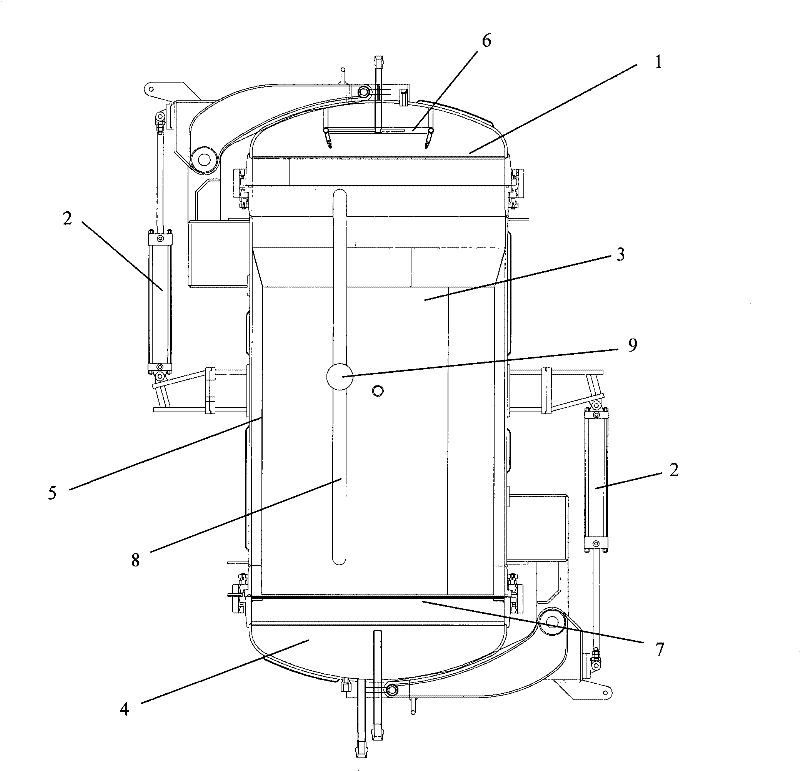

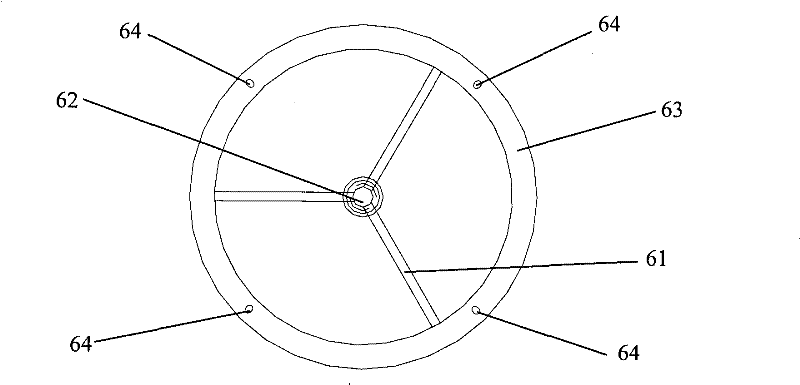

Tobacco shred immersion method and device

ActiveCN101744359BHigh energy consumptionReduce energy consumptionTobacco preparationLiquid stateAgricultural engineering

The invention relates to a tobacco shred immersion method and a device; the method comprises: (1) the tobacco shred is arranged in a pre-heating immersion device and then vacuumizing is carried out; (2) swelling agent with liquid state is sprayed on the tobacco shred; (3) swelling agent with gas state is filled in the immersion device; (4) immersion is carried out. The immersion device provided by the invention comprises a tank body, an upper tank cover, a lower tank cover and a hydraulic pressure opening device, a spraying device is arranged in the upper tank cover, wherein the tank body is provided with two layers of sleeves, a screen cloth is formed on the inner wall of the inner layer sleeve, and the pore diameter of the screen cloth is 1.5mm. The invention has simple structure and convenient operation, can achieve good immersion effect to the tobacco shred and can realize continuous immersion of the tobacco shred.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

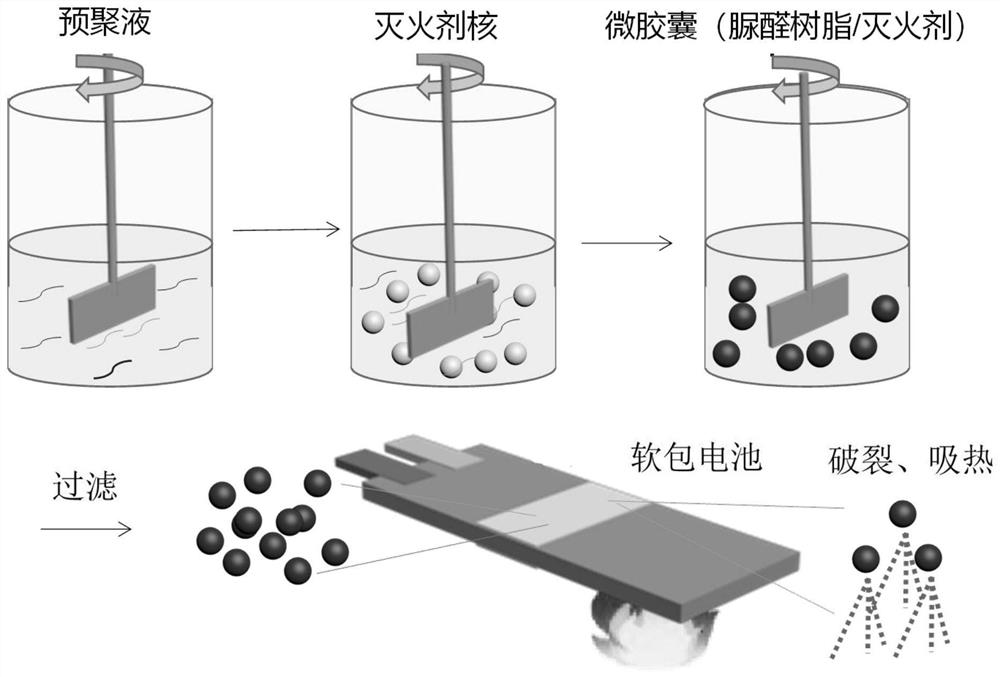

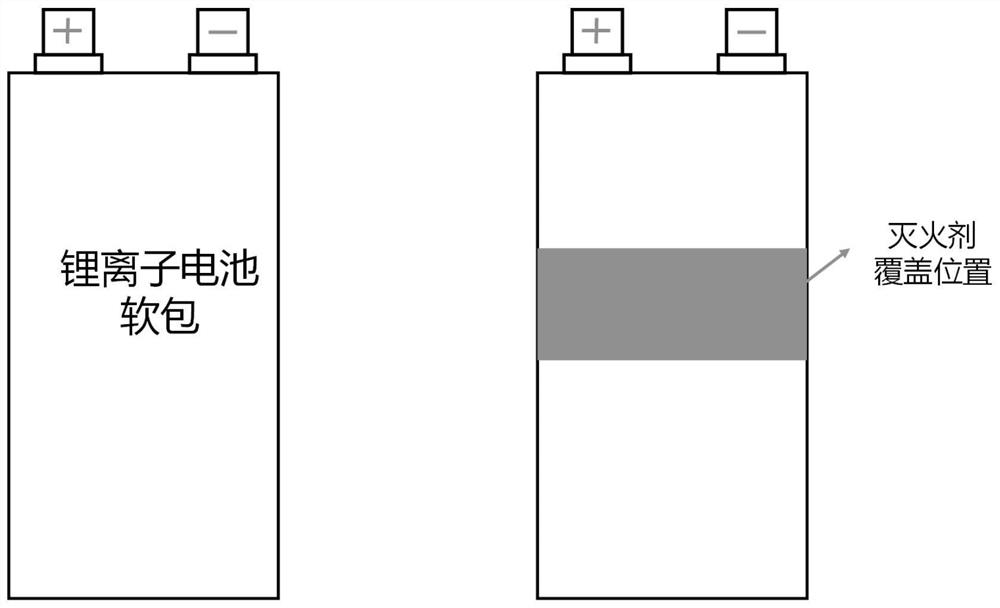

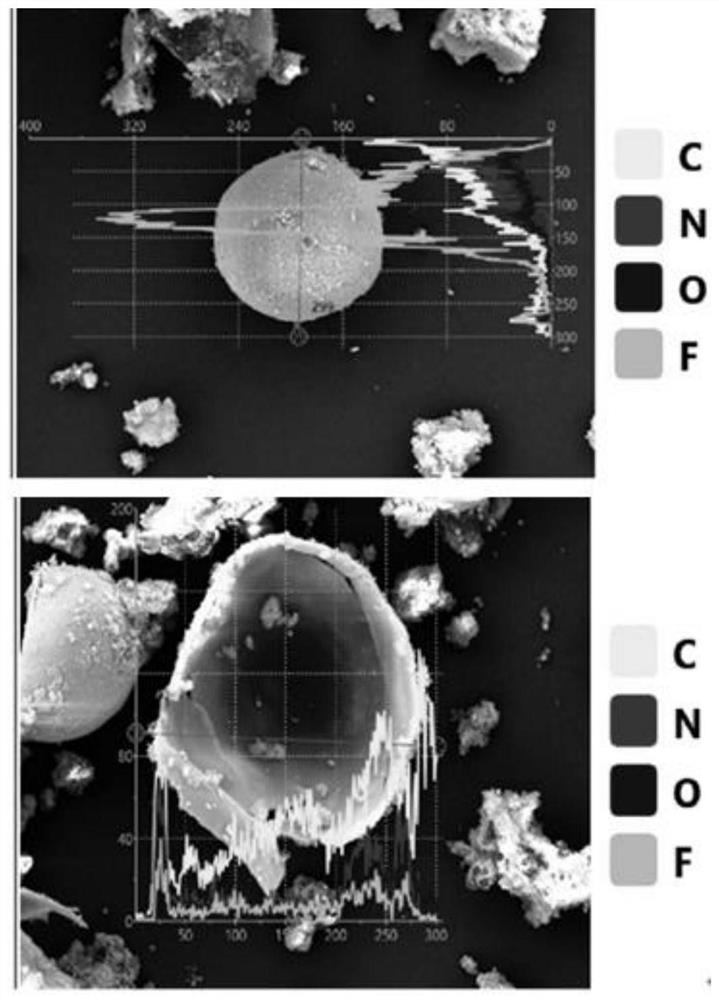

A kind of high-efficiency fire extinguishing agent and fire safety fire extinguishing process

ActiveCN113181589BAchieve microscopic precision controlGuarantee the safety of useFire rescueFire extinguisherLithium-ion batteryDefoaming Agents

The invention provides a high-efficiency fire extinguishing agent and fire safety fire extinguishing technology. The present invention prepares melamine urea-formaldehyde resin as shell material by preparing melamine urea-formaldehyde resin prepolymer and mixing it with montmorillonite, defoaming agent and perfluorohexanone and heptafluorocyclopentane as fire extinguishing materials. Perfluorohexanone and heptafluorocyclopentane are high-efficiency fire extinguishing agents with a core-shell structure as core materials; and by loading the prepared high-efficiency fire extinguishing agents on the outer surface of lithium-ion batteries, it provides effective safety protection for lithium-ion batteries and ensures Fire safety of lithium-ion batteries. Through the above method, the fire extinguishing process provided by the present invention can break the high-efficiency fire extinguishing agent when the lithium-ion battery is thermally out of control, release the fire extinguishing material, play the dual role of flame retardancy and fire extinguishing in time, and ensure the fire extinguishing effect while taking into account the cooling ability. The lithium-ion battery fire can be quickly extinguished and cooled, effectively preventing the re-ignition of the lithium-ion battery, so as to ensure the safety of the lithium-ion battery.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Method for extracting high-purity resveratrol from wild blueberry of Great Khingan by enzymolysis

InactiveCN105695516AHigh yieldHigh quality and purityOrganic chemistryOrganic compound preparationAlcoholOrganic solvent

The invention belongs to the field of natural organic chemistry, and relates to a method for enzymatically extracting high-purity resveratrol from Daxinganling wild blueberries. The invention uses the blueberry fruit picked in Daxing'an Mountains as a raw material, and obtains a high-purity resveratrol crystal powder product through a simplified process of biological enzymolysis reaction, water extraction, alcohol precipitation, deep extraction, separation, concentration and drying. The method of the invention has the characteristics of sufficient biological enzymolysis, short time consumption, low energy consumption cost, high operation safety, full use of raw materials and organic solvents, waste liquid mainly being water, good for environmental protection, and easy industrialization and application. The resveratrol crystal powder product prepared by the method of the invention has a high purity, which can reach more than 98 percent; and a high yield, which can reach 1.40 percent.

Owner:DAXINGANLING PERFECTION NOBILITY FRIGID ZONE BIO TECH CO LTD

Inkjet printing conductive ink capable of sintering at room temperature and its application

The present invention relates to an ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof. According to the present invention, silver nanoparticles with polyvinylpyrrolidone wrapped on the surface, a polymer resin, a solvent, a surfactant, a preservative, an antifoaming agent and a humectant are uniformly mixed to obtain the ink-jet printing electric conduction ink; the ink-jet printing electric conduction ink can be printed on a printed circuit board so as to prepare the pattern of an electric conduction trace, a treatment liquid is coated on the printed circuit board having the electric conduction trace pattern, and the electric conduction trace pattern printed through the ink-jet printing electric conduction ink is subjected to chemical sintering through the treatment liquid at a room temperature so as to obtain the electric conduction trace having good electric conduction property; and the ink-jet printing electric conduction ink has characteristics of low cost, excellent printing suitability and excellent durability, and can be matched with the room temperature sintering method of the present invention so as to make the printed electric conduction pattern achieve the good electric conduction property at the room temperature.

Owner:INST OF CHEM CHINESE ACAD OF SCI

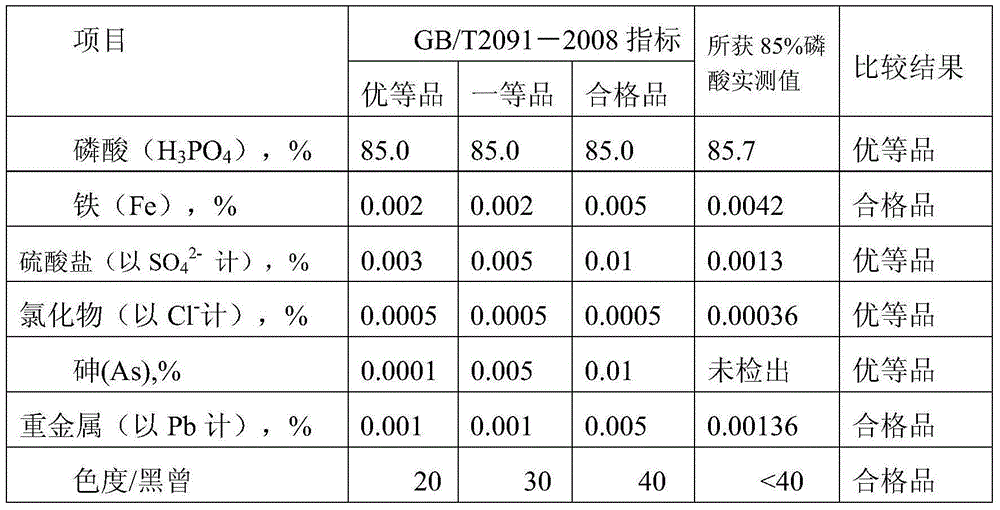

An extractant for purifying wet-process phosphoric acid and method for extracting wet-process phosphoric acid with it

ActiveCN104069646BHigh selectivitySimple production processSolid solvent extractionPhosphorus compoundsPhosphoric acidKetone

The invention discloses an extracting agent for purifying wet-process phosphoric acid and a method of extracting wet-process phosphoric acid by the extracting agent. The extracting agent comprises the following components in mass percent: 35%-95% of n-butyl alcohol, and 5%-65% of one of isooctyl alcohol, n-butyl ether, high-carbon ketone, aliphatic amine or quaternary ammonium salt. The method comprises the following steps of defluorinating and destaining crude wet-process phosphoric acid, and carrying out 6-10-level counter-current extraction according to a ratio of the extracting agent to crude phosphoric acid being (2-5) to 1, wherein sulfuric acid is added to a crude phosphoric acid inlet in the sixth or seventh level of counter-current extraction; and washing an extracting phase by using industrial phosphoric acid in which sodium carbonate is dissolved, re-extracting by using deionized water to obtain a re-extracting liquid, finally purifying the re-extracting liquid and performing concentration to obtain the industrial phosphoric acid. The extracting agent provided by the invention has the advantages that organic matters with close and moderate boiling points is subjected to binary compound, an extracting characteristic of a compound solvent is obvious, a property is stable, the extracting agent is easy to recycle and is reused for a long time, extraction is performed under room temperature and is energy-saving, crude phosphoric acid does not need to be purified in advance, the productive technology is simple, and the production cost is low.

Owner:陈锂

Acetoacetyl modified ethylene-vinyl alcohol copolymer and preparation method thereof

The invention discloses a preparation method of an acetoacetyl modified ethylene-vinyl alcohol copolymer. Commercial ethylene vinyl alcohol (EVOH) is used as a raw material, the ethylene content in the EVOH is 20%-40%, the vinyl alcohol content in the EVOH is 60%-80%, and by virtue of the modification by diketene, the acetoacetyl content in the obtained modified copolymer is 0.60-2.20mol / kg. The preparation method disclosed by the invention comprises the following two steps of: (1) dissolving the ethylene-vinyl alcohol copolymer in an organic solvent to react with the diketene under the catalytic action of an organic base; and (2) adding an organic solvent after the reaction is ended to precipitate the product. The acetoacetyl modified ethylene-vinyl alcohol copolymer obtained prepared the invention is white solid powder, and is good in product quality and water solubility.

Owner:石家庄万尚医药科技有限公司 +1

A kind of benzylation method of monosaccharide methyl glycoside

ActiveCN105153251BModerate boiling pointReduce unit consumptionSugar derivativesSugar derivatives preparationReaction temperatureBenzyl chloride

The invention discloses a method for benzylation of monosaccharide methyl glycoside: add monosaccharide methyl glycoside, sodium hydride, toluene and benzyl chloride in sequence in a reactor, heat up to a reaction temperature of 60-130°C, and keep warm until the reaction is complete , after the end of the reaction, the post-treatment of the reaction solution produces a benzylated product of the monosaccharide methyl glycoside; the benzylated product of the monosaccharide methyl glycoside is that all the hydroxyl-OH on the monosaccharide methyl glycoside are all benzylated to generate ‑O ‑Bn product, Bn represents benzyl. Both the reaction solvent and the extraction solvent of the present invention are toluene, which simplifies the post-processing operation. The by-product toluene in the reaction process is consistent with the reaction solvent, and the recovered toluene can be directly used as the next batch of reaction solvent without removing water, thereby simplifying the operation. The purpose of reducing the unit consumption of sodium hydride and benzyl chloride, effectively reducing the generation of by-product dibenzyl ether, and reducing pollution.

Owner:浙江合糖科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com