Patents

Literature

169results about How to "Meet printing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

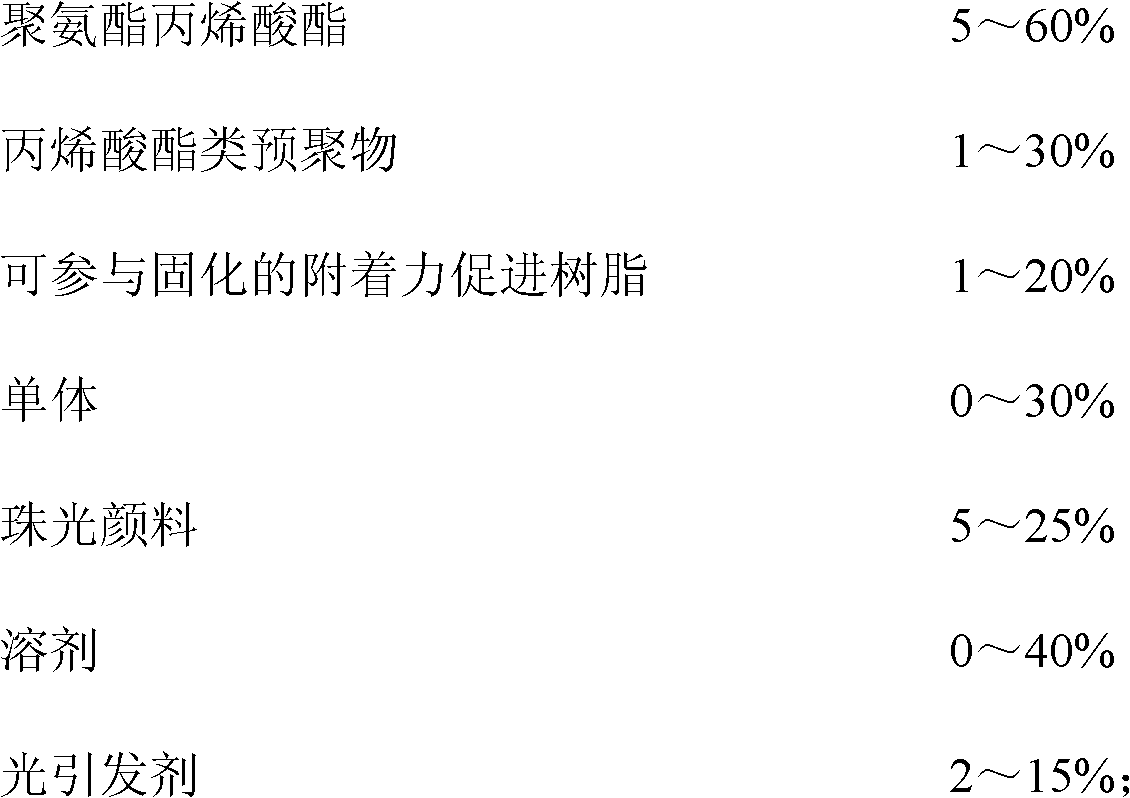

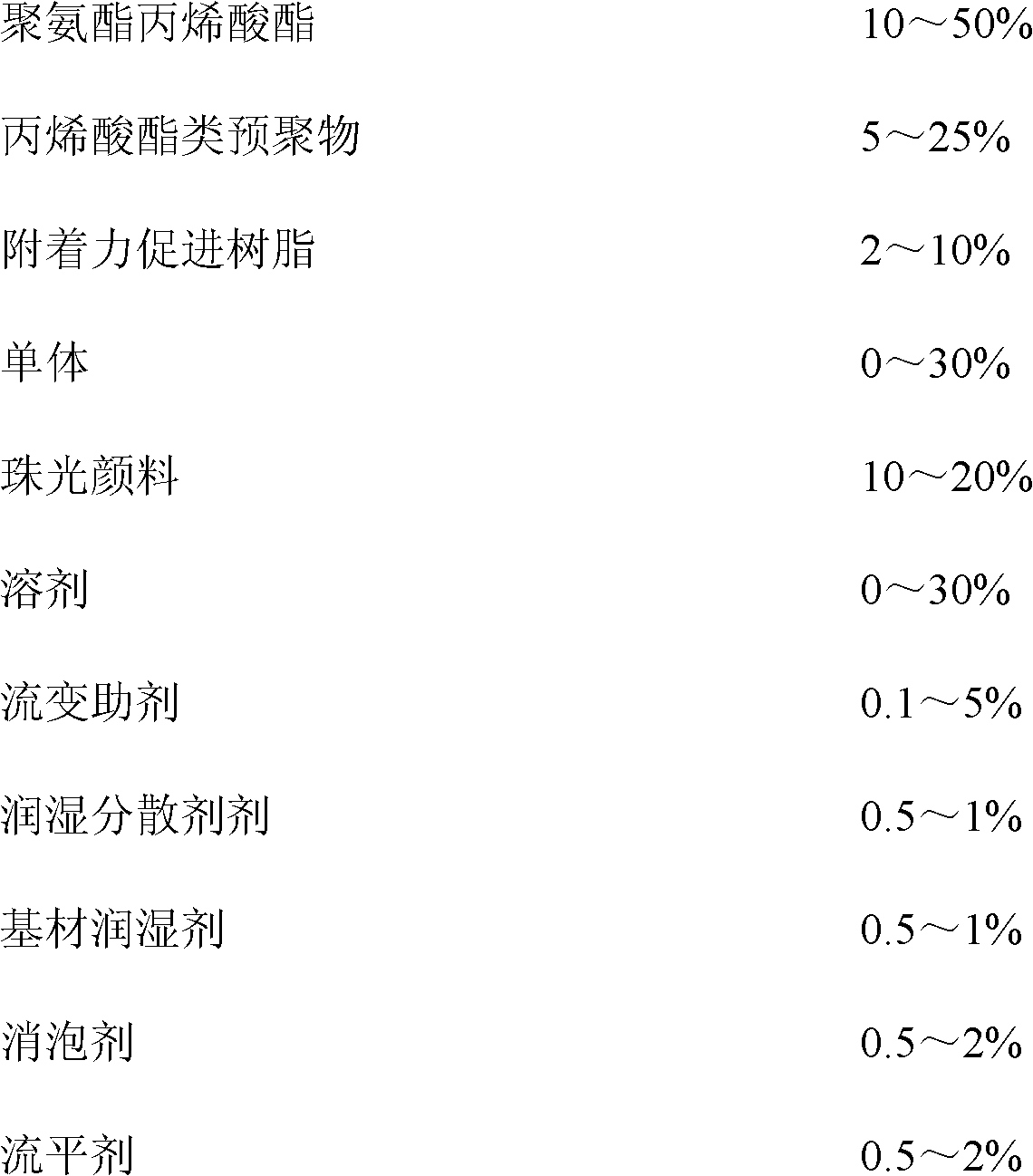

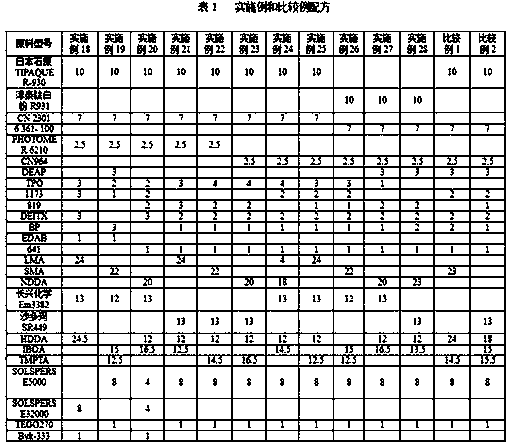

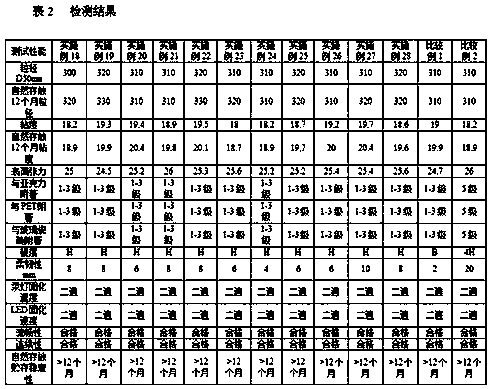

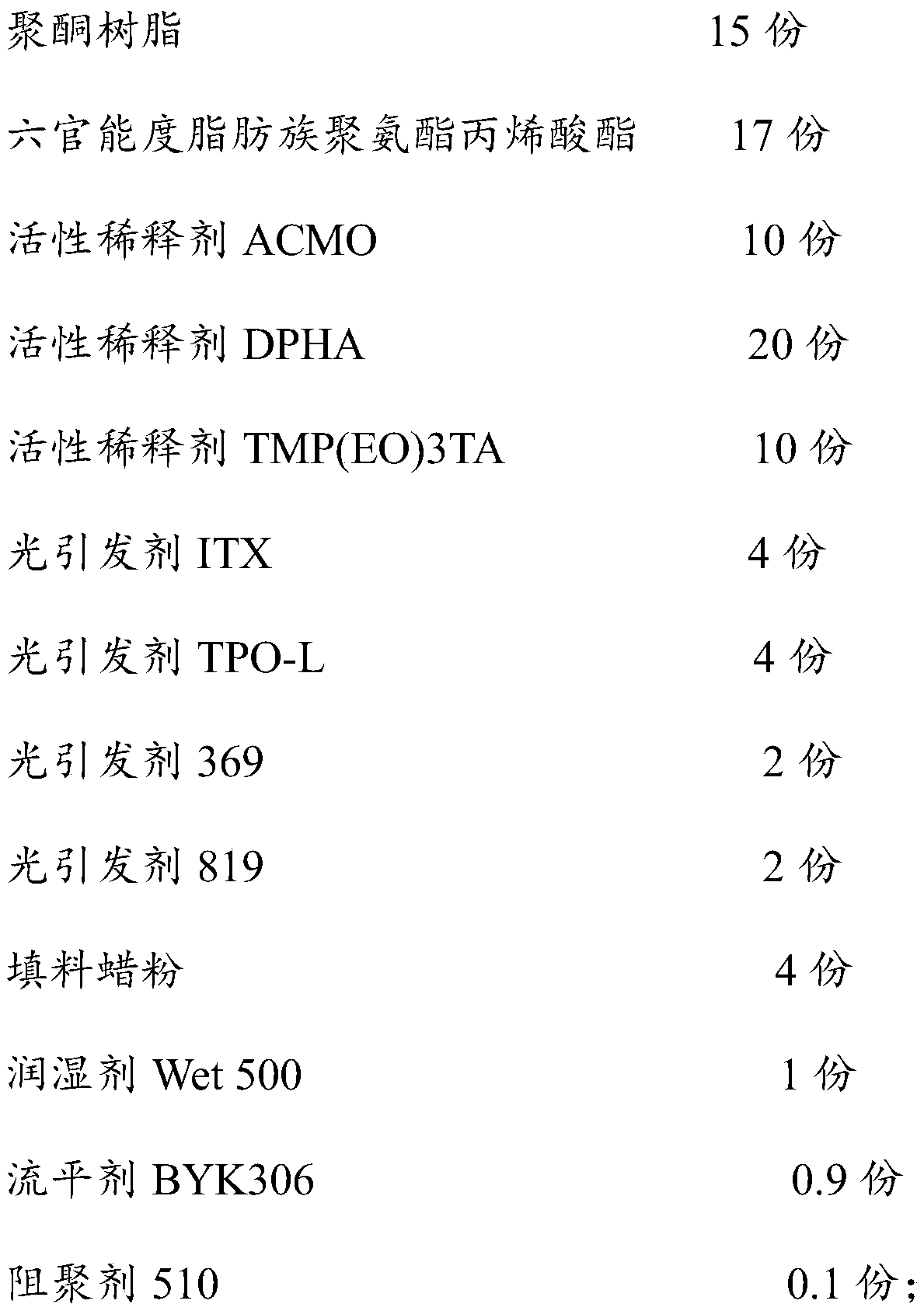

Photo-curing silk screen pearly-luster ink applicable to different printing substrates and preparation method thereof

ActiveCN102634251AGood flexibility and abrasion and scratch resistanceGood acid and alkali resistanceInksSolventPrepolymer

The invention provides a photo-curing silk screen pearly-luster ink applicable to different printing substrates and a preparation method of the photo-curing silk screen pearly-luster ink. The ink is prepared from the following components in percentage by weight: 5-60% of polyurethane acrylate, 1-30% of acrylates pre-polymer, 1-20% of adhesive force accelerating resin capable of participating curing, 0-30% of monomer, 5-25% of pearly-luster pigment, 0-40% of a solvent and 2-15% of a light initiator. The photo-curing silk screen pearly-luster ink applicable to the different printing substrate disclosed by the invention can be suitable for the different printing substrates at the same time and comprises plastic substrates including paper, PET (Poly Ethylene Terephthalate), BOPP (Biaxially-oriented Polypropylene), PP (Propene Polymer), PE (Poly Ethylene) and the like, and metal substrates; an adhesive force between the photo-curing silk screen pearly-luster ink and the printed materials is good and the photo-curing silk screen pearly-luster ink has good flexibility and wear-resisting and scrape-resisting strength; the acid-resisting and alkali-resisting performance is excellent and the performance for resisting each type of solvent is good, so that the requirements on silk-screen printing can be met.

Owner:CHINA BANKNOTE INK +1

Nanometer conductive silver paste and preparing method thereof

InactiveCN104240793AGood silver powder solubilityModerate boiling pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePlasticizer

The invention relates to a nanometer conductive silver paste and a preparing method thereof. The nanometer conductive silver paste is characterized in that mass percentage content of the components are as follows: 20-90% of a silver powder, 0.01-5% of a high-molecular resin, 0.01-5% of an organic silicone oil, 0.01-10% of a thickening agent 1, 0.01-5% of a thickening agent 2, 0.01-5% of a plasticizer, 0.5-1% of a dispersant, 0.5-1% of a leveling agent, 5-20% of a solvent 1, and 5-20% of a solvent 2. The nanometer conductive silver paste of the invention has a remarkable low-temperature sintering property and saves energy. A formed circuit has advantages of high conductivity, high adhesiveness and high hardness. A selected Teslin substrate is degradable and environment-friendly. The nanometer conductive silver paste has wide application prospect in paste application fields of RFID electronic label, LED circuit board, touch screen circuit, etc.

Owner:NANO TOP ELECTRONICS TECH

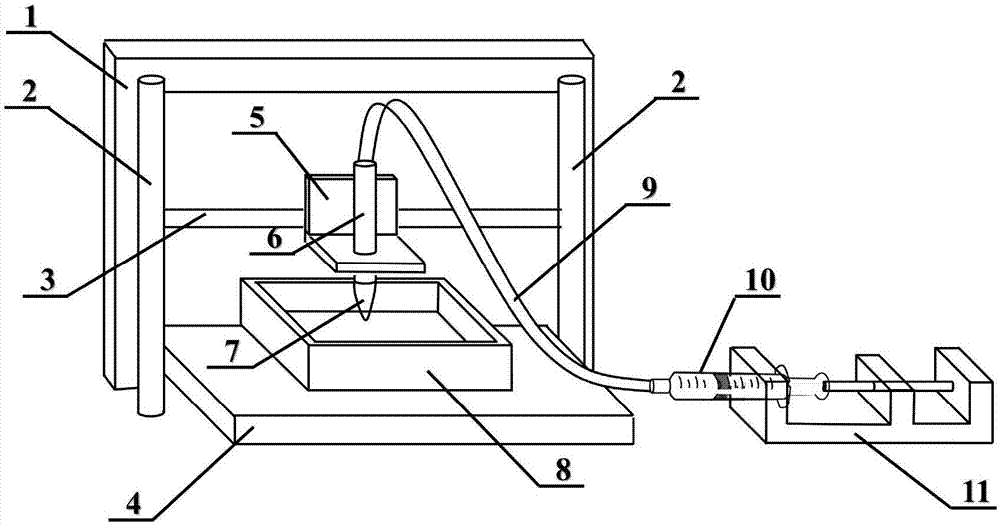

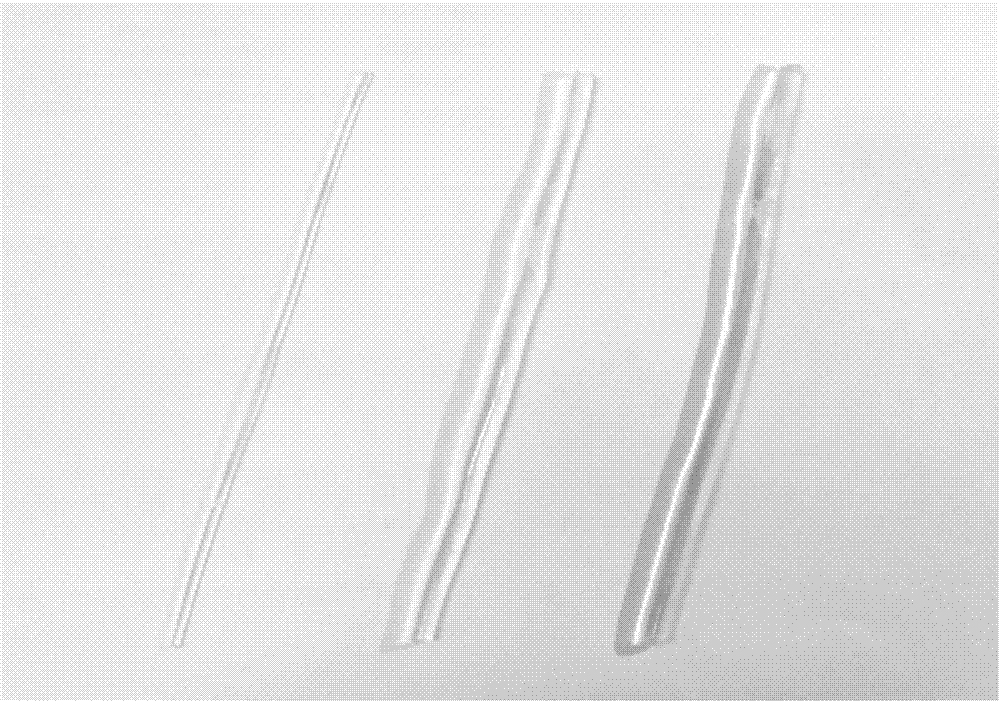

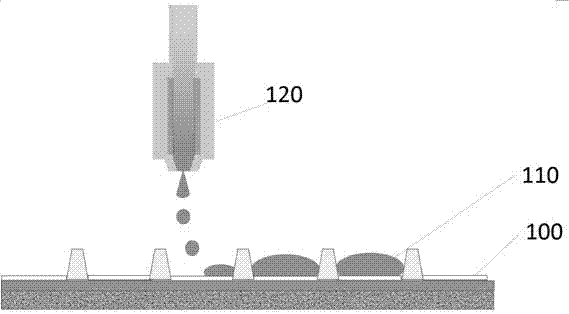

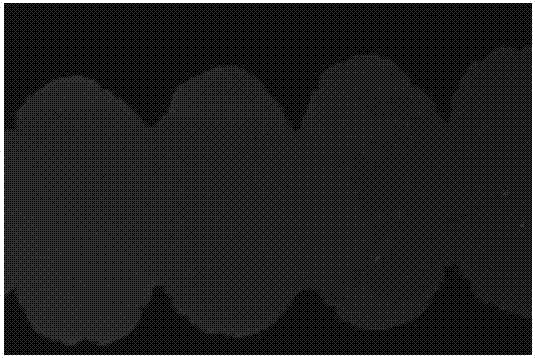

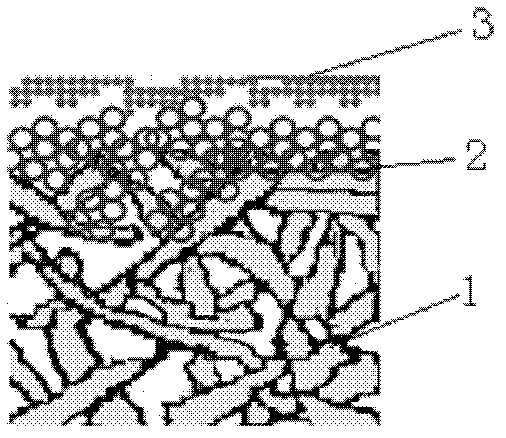

3D printer and 3D printing method of sodium alginate hydrogel

InactiveCN107139447ARealize environmental protectionAchieve securityAdditive manufacturing apparatusAdditive manufacturing with liquids3d shapesAtherion elymus

The invention discloses a 3D printer and a 3D printing method of a sodium alginate hydrogel. According to the method, a sol-like sodium alginate taken as a printing raw material is solidified through a calcium ion solution, and the sodium alginate hydrogel in a certain three-dimensional shape is obtained through 3D printing. The sodium alginate hydrogel printed by the method is in a continuous and uniform-thickness line shape and has good strength and toughness; a hydrogel model in a specific 3D shape can be prepared by the layer-upon-layer stacked printing method, the hydrogels with different colors or different functions can be obtained by adding pigments of different colors or materials with different functions. The method is simple to operate, safe and environmentally friendly, and cost is low; the method can be used for printing the sodium alginate hydrogel with a 3D structure on a large scale, and a material basis is provided for research areas such as tissue engineering, simulation robots and biosensors, which involve soft body sensing materials.

Owner:ANHUI UNIVERSITY

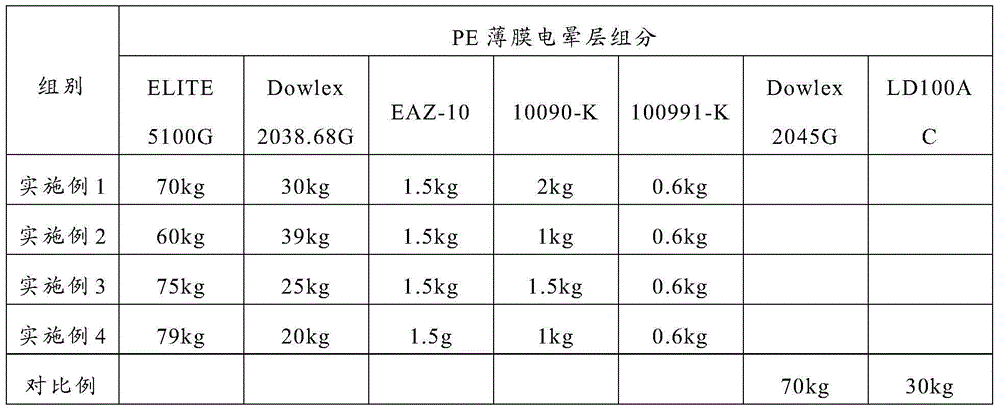

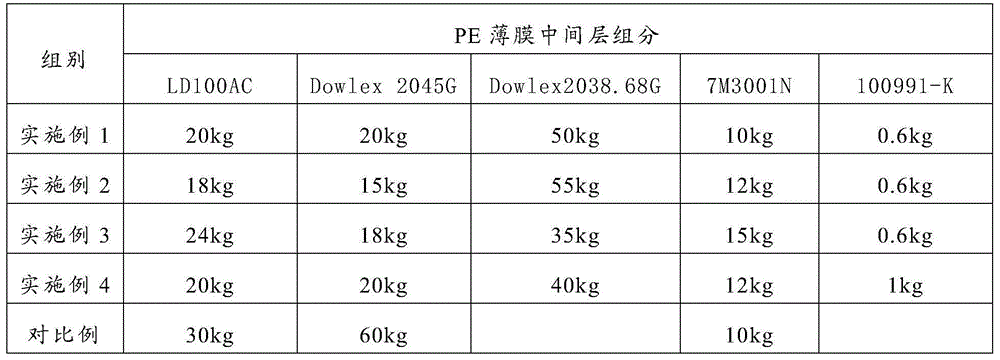

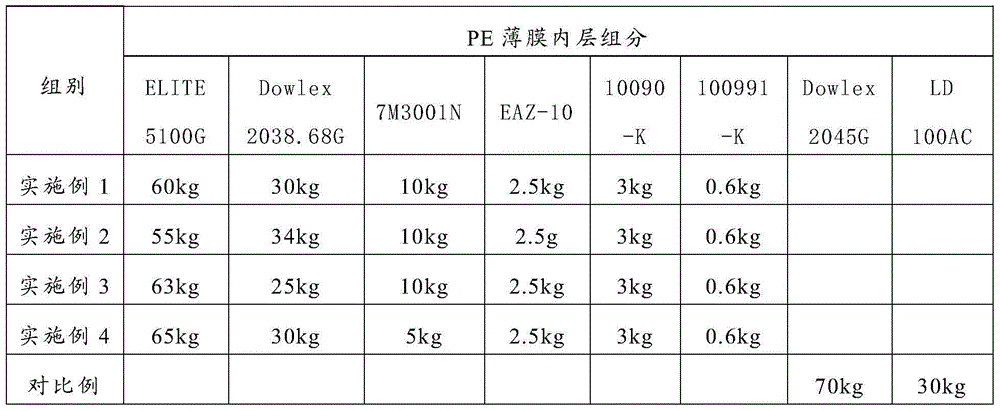

PE film and preparation method thereof

ActiveCN104476889AImprove stiffnessGood flexibilitySynthetic resin layered productsFlat articlesPliabilityMedium-density polyethylene

The invention provides a PE film which is formed by co-extruding a corona layer, a middle layer and an inner layer. The corona layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The middle layer comprises low density polyethylene resin, linear low density polyethylene resin and medium density polyethylene resin. The inner layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The corona layer and the inner layer each comprises the high-proportion metallocene linear low density polyethylene resin, so that the PE film has good heat sealing performance, and the medium density polyethylene resin added in the corona layer, the middle layer and the inner layer enable the film to have good stiffness and flexibility, and the PE film is suitable for package of hygienic products.

Owner:永新股份(黄山)包装有限公司

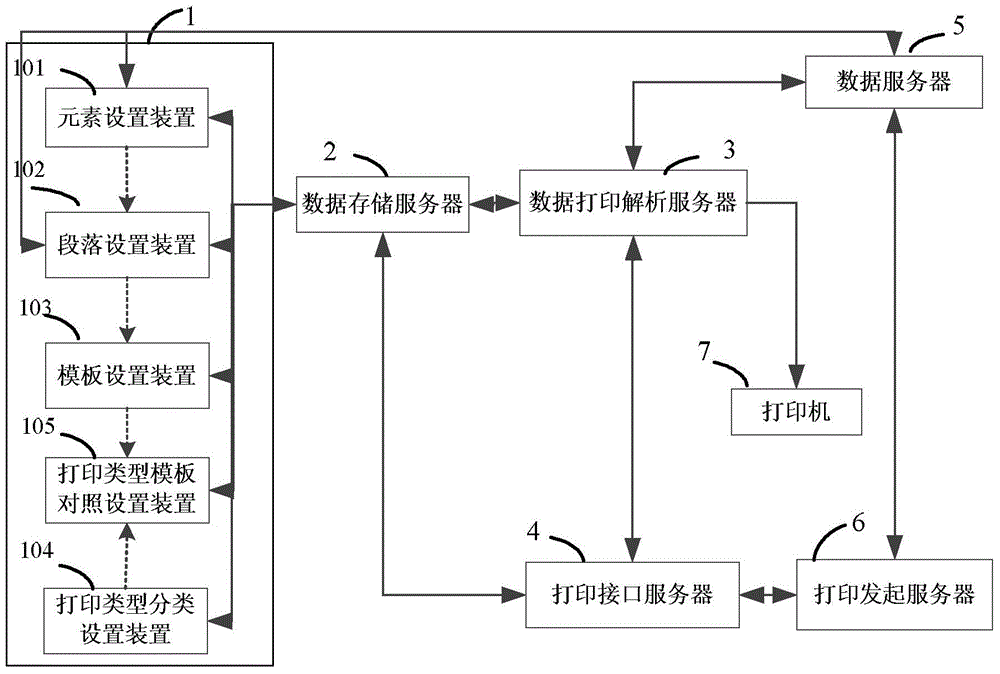

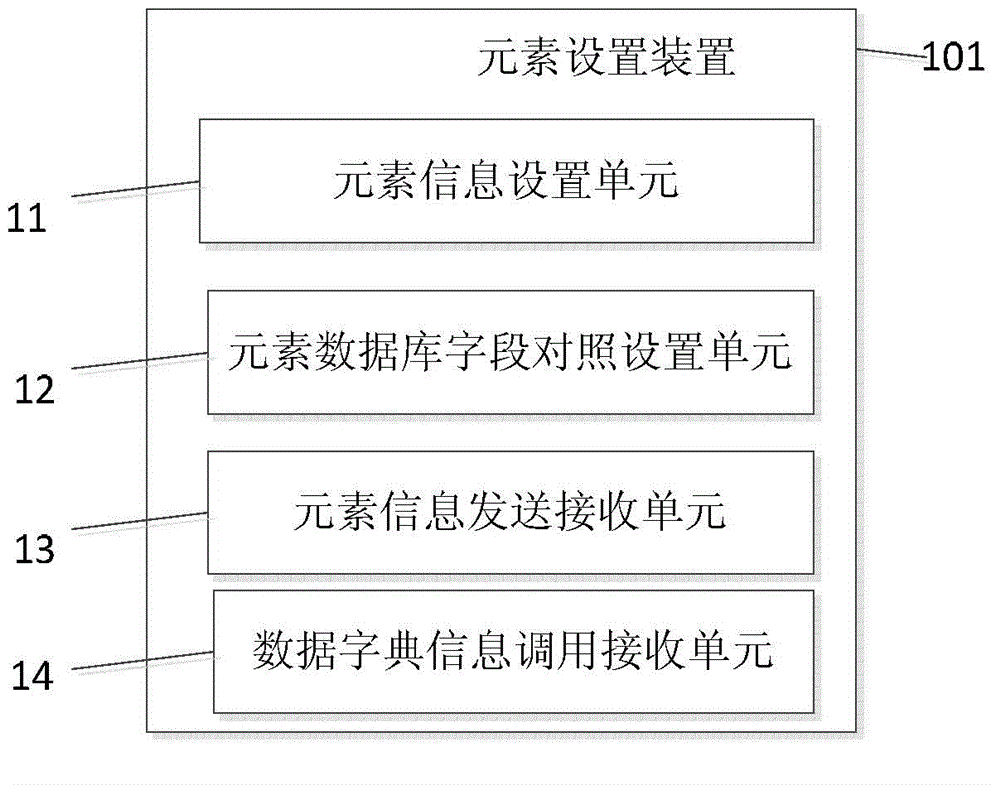

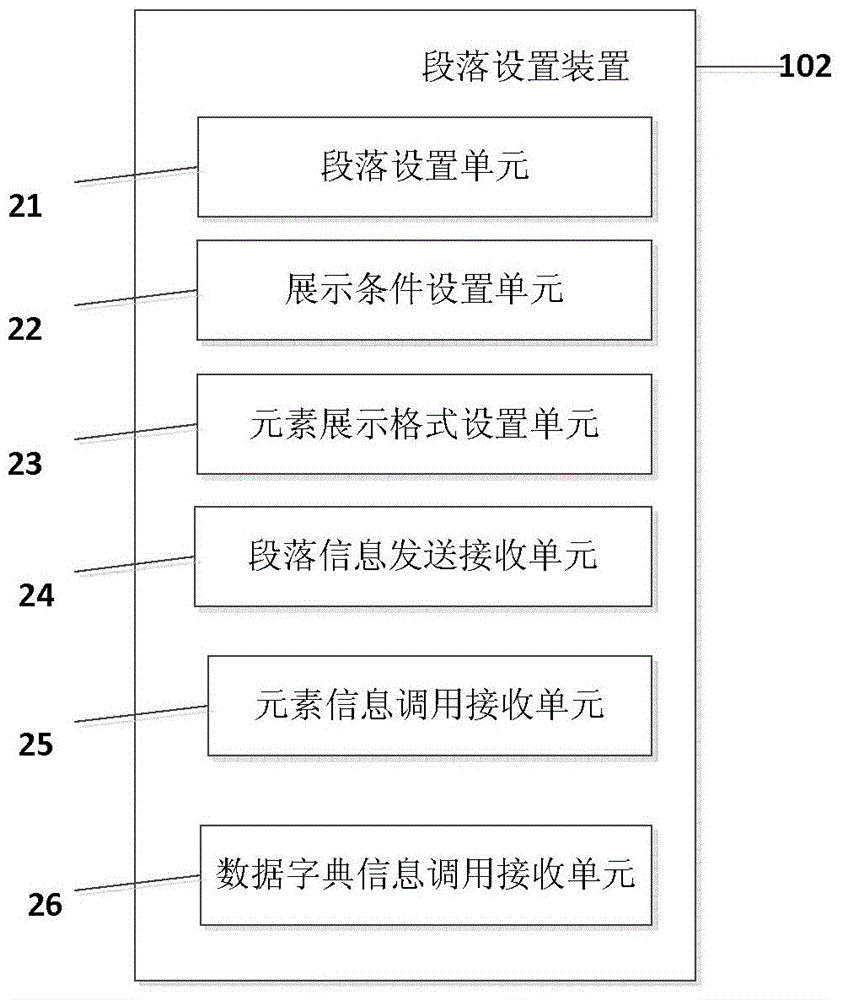

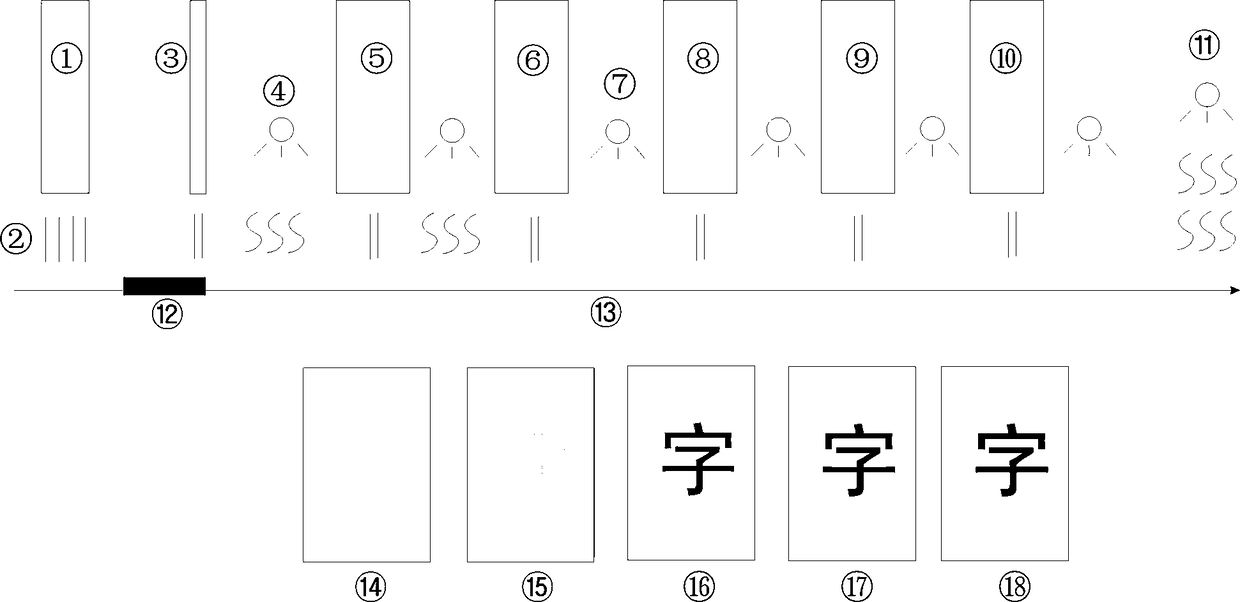

Data printing method and system

ActiveCN103955345AAvoid consumption and wasteOvercoming Inefficient Response to Print Request ChangesDigital output to print unitsResource consumptionFinancial transaction

The invention provides a data printing method and a data printing system. The data printing method comprises the steps that printing information is configured; template list information capable of being used is obtained according to printing types; a printing template is selected according to the printing types; predefined template basic data, paragraph information and element information are obtained according to the template number; paragraphs conforming to conditions generate paragraph information required to be supplemented and typed in; the paragraph information required to be supplemented and typed in is subjected to type-in operation, and transaction printing supplementary data is generated; the paragraphs conforming to conditions are sequentially subjected to analysis to generate final printing data; the finial printing data is sent to a printer server for printing. The data printing method and the data printing system have the advantages that data is converted into information and elements, a customized data printing method is built through using elements, clauses, templates and transaction, the defects of low-efficiency response to printing requirement change and resource consumption waste in the prior art are overcome, and the precise, efficient and stable data printing is realized.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

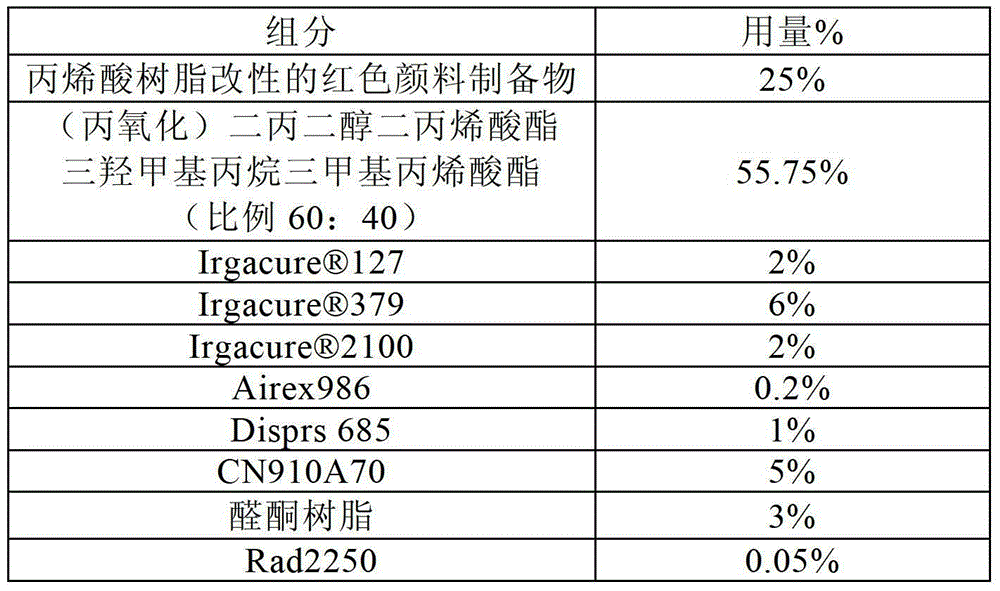

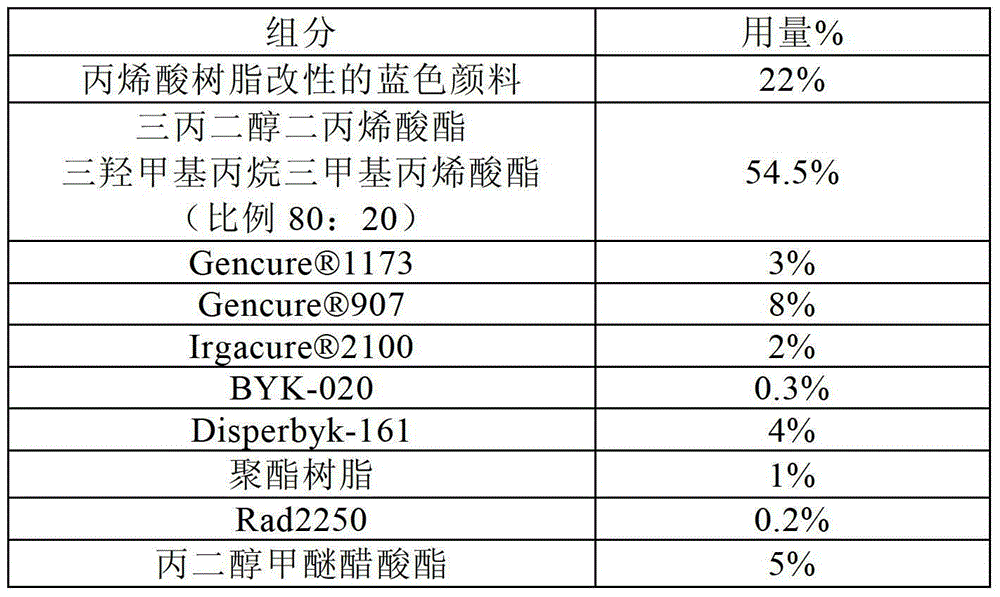

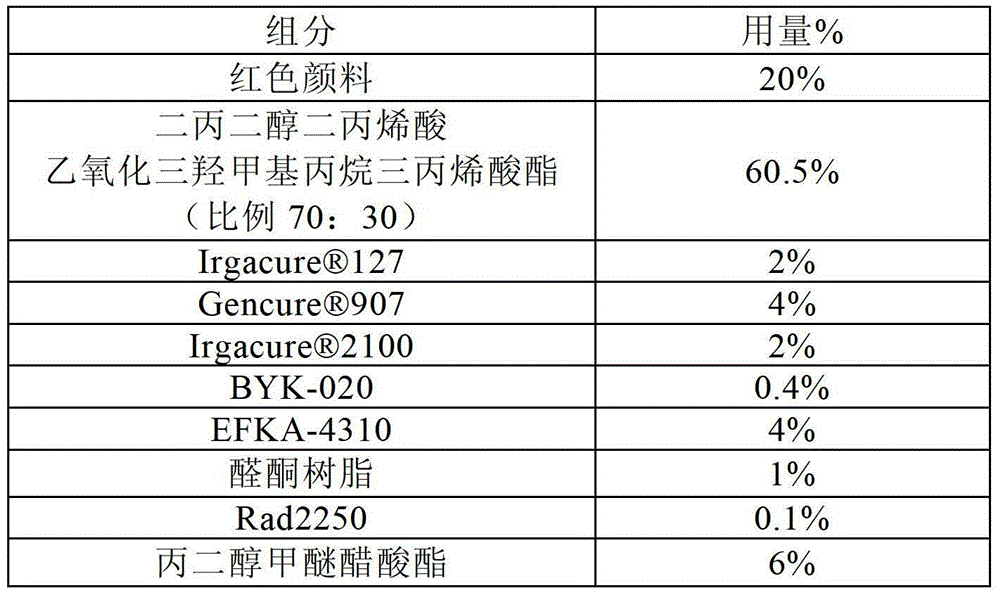

Ultraviolet curing printing ink as well as preparation method and security product thereof

The invention provides ultraviolet curing printing ink as well as a preparation method and a security product thereof. The ultraviolet curing printing ink has a particle size less than 500nm and comprises the following components in percentage by weight: 10-25% of colouring agent, 55-75% of compound active monomer, 0-5% of prepolymer, 8-15% of compound photoinitiator, 0.1-0.5% of defoaming agent, 1-4% of wetting dispersant, 0.5-3% of adhesive force enhancing resin, 0.03-0.5% of radiation curing auxiliary and 0-10% of solvent. The invention also provides a preparation method and a security product of the ultraviolet curing printing ink. The ultraviolet curing printing ink is prepared by selecting and matching a printing ink system, viscosity, adhesive force, colour saturation and the like of the prepared ultraviolet curing printing ink can be well matched with micro pattern printing, and the effect of improving the colour saturation and anti-counterfeiting level of a printed pattern and a printed product is realized.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

Method for printing drawing paper with AutoCAD format in batch

InactiveCN101587428ARealize automatic identificationMeet printing requirementsDigital output to print unitsComputer science

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

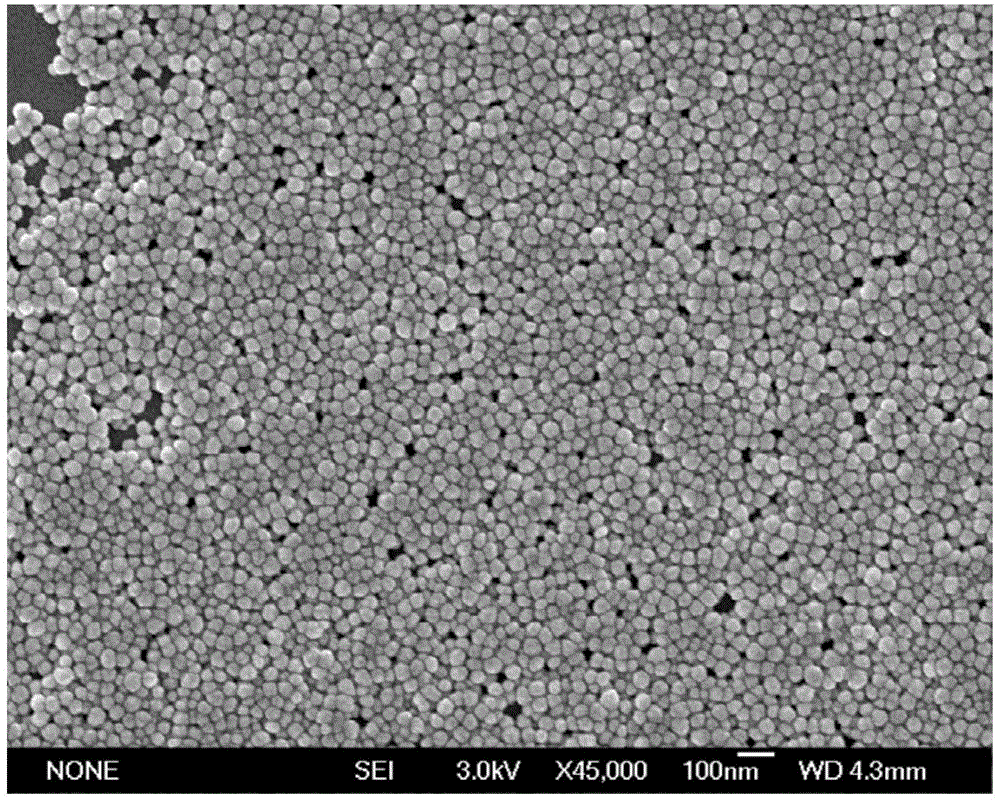

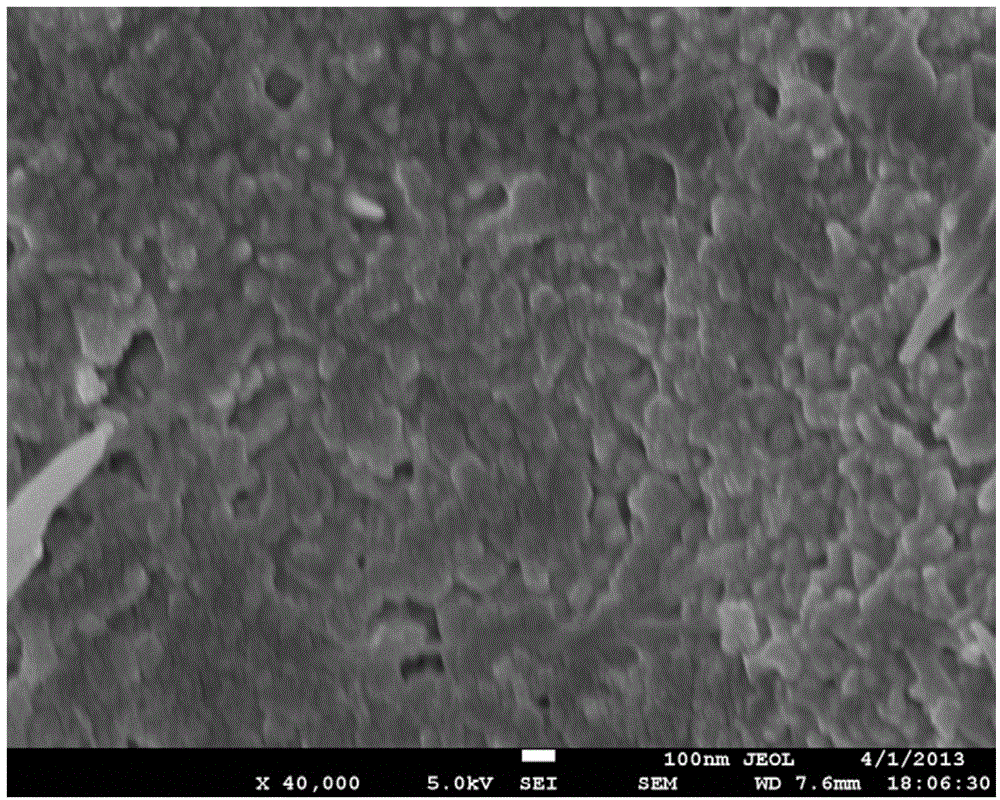

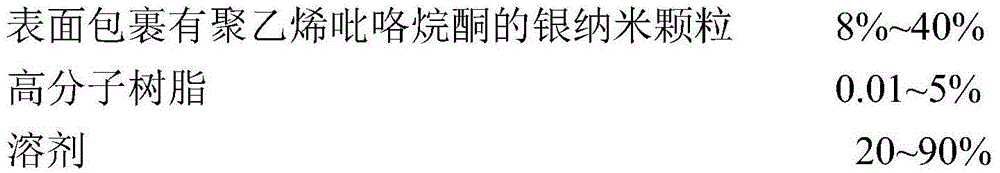

Ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof

The present invention relates to an ink-jet printing electric conduction ink capable of being subjected to room temperature sintering, and applications thereof. According to the present invention, silver nanoparticles with polyvinylpyrrolidone wrapped on the surface, a polymer resin, a solvent, a surfactant, a preservative, an antifoaming agent and a humectant are uniformly mixed to obtain the ink-jet printing electric conduction ink; the ink-jet printing electric conduction ink can be printed on a printed circuit board so as to prepare the pattern of an electric conduction trace, a treatment liquid is coated on the printed circuit board having the electric conduction trace pattern, and the electric conduction trace pattern printed through the ink-jet printing electric conduction ink is subjected to chemical sintering through the treatment liquid at a room temperature so as to obtain the electric conduction trace having good electric conduction property; and the ink-jet printing electric conduction ink has characteristics of low cost, excellent printing suitability and excellent durability, and can be matched with the room temperature sintering method of the present invention so as to make the printed electric conduction pattern achieve the good electric conduction property at the room temperature.

Owner:INST OF CHEM CHINESE ACAD OF SCI

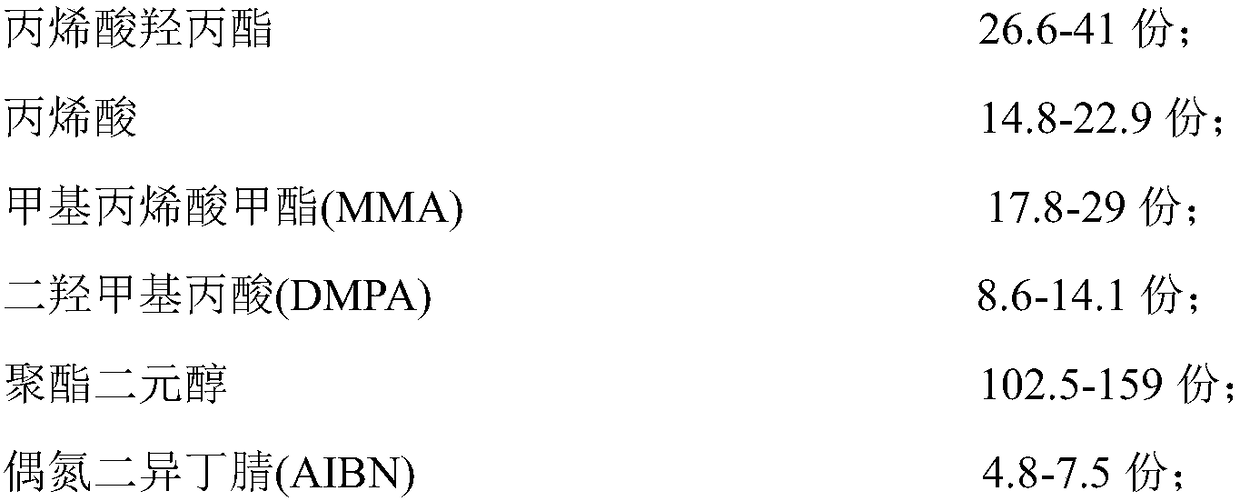

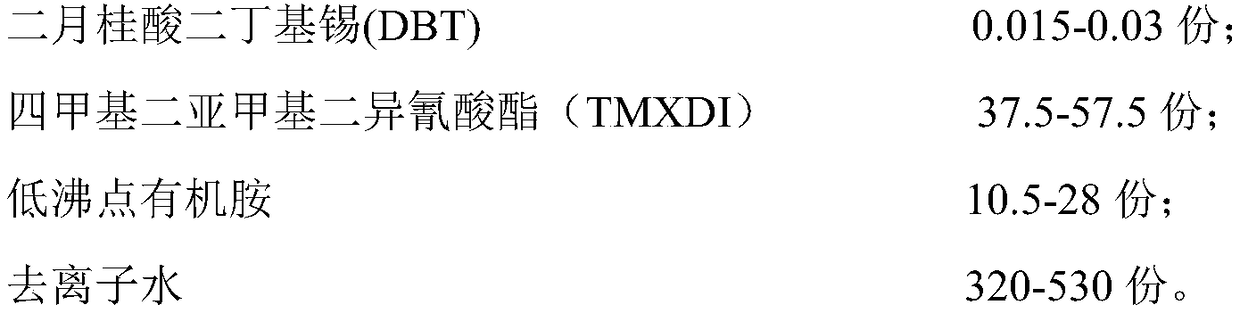

Casein type aqueous ink and method for preparing same

The invention discloses a cheese water-type ink and its process for preparing. The method is as follows: polymerizing arbowax or polyester diol, dimethylol propionic acid and isophorone diisocyanate under accelerating effect of catalyst, stopping heating after 3-5 hours; adding triethylamine to neutralize after cooling, and adding water to prepare polymer solution with 20-40 % of solid content, adding drainable clay, stirring to obtain clay intercalation polyurethane, dissolving dry casein into the water in alkali condition, preparing to obtain aqueous solution of dry casein with 10-20 % of solid content; mixing intercalation polyurethane with aqueous solution of dry casein evenly to produce junction material of water-type ink, and adding pigments, alcohol, anti-fungus agent and water, grinding, adjusting viscosity to obtain water-type ink. The invention selects renewable natural resources as its main film forming matter, so it is environment-friendly and can save energy; the said water-type ink is of simple process and reasonable cost; and the quality of the obtained ink meets the requirement of the decorative laminate printing.

Owner:SUN YAT SEN UNIV

Surface glued newsprinting paper and manufacturing method thereof

The present invention discloses a surface-sized news-paper and its making method. It includes the following steps: using bleached sulfate needle wood pulp (BKP), beating, then mixing it with Italia poplar alkaline hydrogen peroxide hot-ground mechanical wood pulp (APMP) and bleached mechanical grindstone ground wood pulp (GP), according to mixing ratio blending them into mixed pulp, adding auxiliary material and making them into raw material pulp for making paper. The standard quantity of said news-paper is 45-49 g / sq.m, brightness (ISO) is 57-63%, opaqueness is greater than 91%, transverse tearing index is greater than 5.5mV, sq.m / g, surface strength is greater than 0.5 m / s, and breaking length longitudinal is greater than 4000 m.

Owner:YUEYANG FOREST & PAPER CO LTD

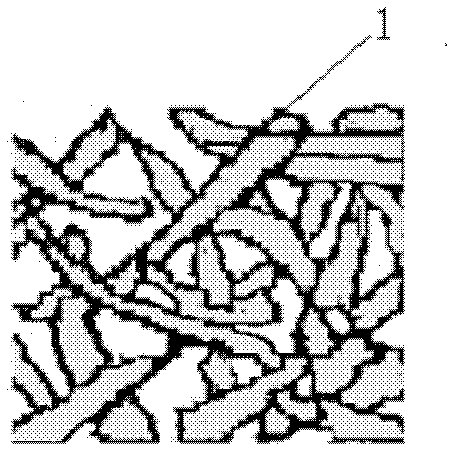

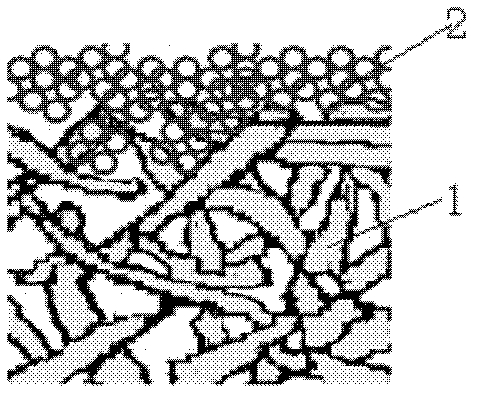

Water-based ink, and preparation method and safe product thereof

The invention provides a water-based ink, and a preparation method and a safe product thereof. The particle size of the water-based ink is less than or equal to 300nm. The water-based ink comprises the following components in percentage by weight: 15-25% of colorant, 60-80% of pure water, 3-15% of water-based resin emulsion, 1-5% of polymer dispersant, 0.1-0.5% of defoaming agent, 0.1-3% of substrate wetting agent and 0.1-1% of associated polyurethane thickener. The invention also provides a preparation method and a safe product of the water-based ink. The water-based ink is prepared by selecting and matching the water-based resin system, colorant and related adjuvants. The ink can have favorable adhesive force and dryness in micrpattern printing, especially can satisfy the requirements for micrpattern array printing in microlens array optical anti-counterfeiting elements, and achieves the effect of enhancing the color saturation and anti-counterfeiting level of the printed pattern printing products.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

Quantum dot ink based on ink-jet printing

The invention specifically relates to quantum dot ink based on ink-jet printing, belonging to the technical field of electro-optic display devices. The quantum dot ink comprises quantum dots and an organic solvent, wherein the organic solvent is a single solvent or a mixed solvent which is a low-polarity or non-polar solvent, and the mass content of the solvent accounts for 40-99.9 wt% of the quantum dot ink. The ink provided by the invention has good dispersibility and stability and proper boiling point, surface tension and viscosity, can meet the requirements of quantum dot ink-jet printing, achieves uniform film-forming, and is beneficial for industrialization of quantum dot pixelated displays.

Owner:FUZHOU UNIV

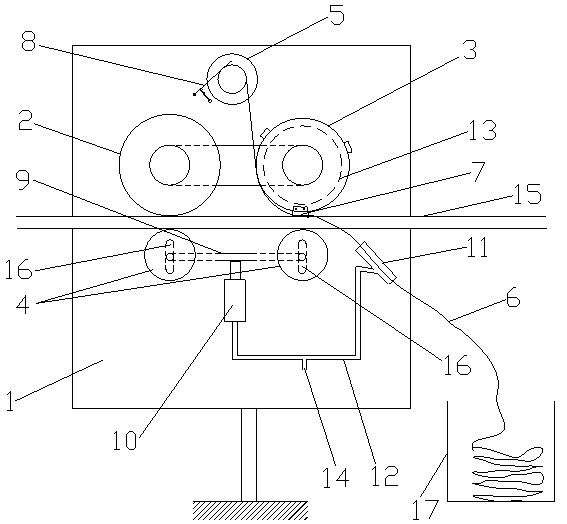

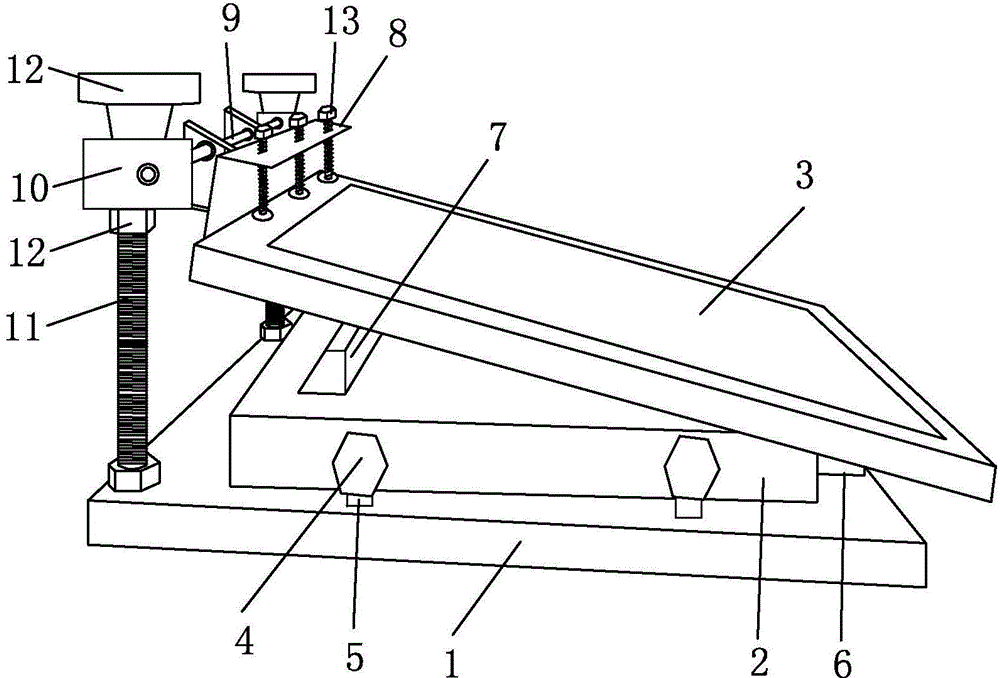

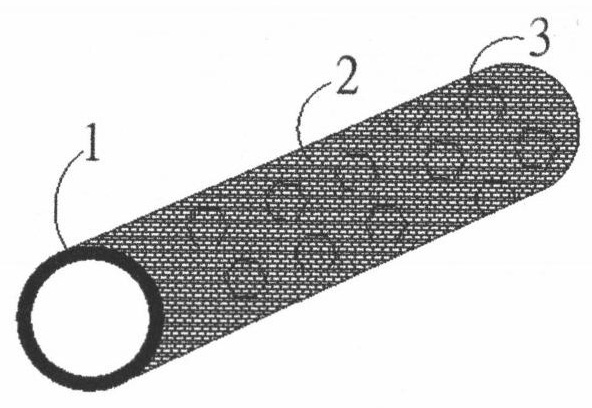

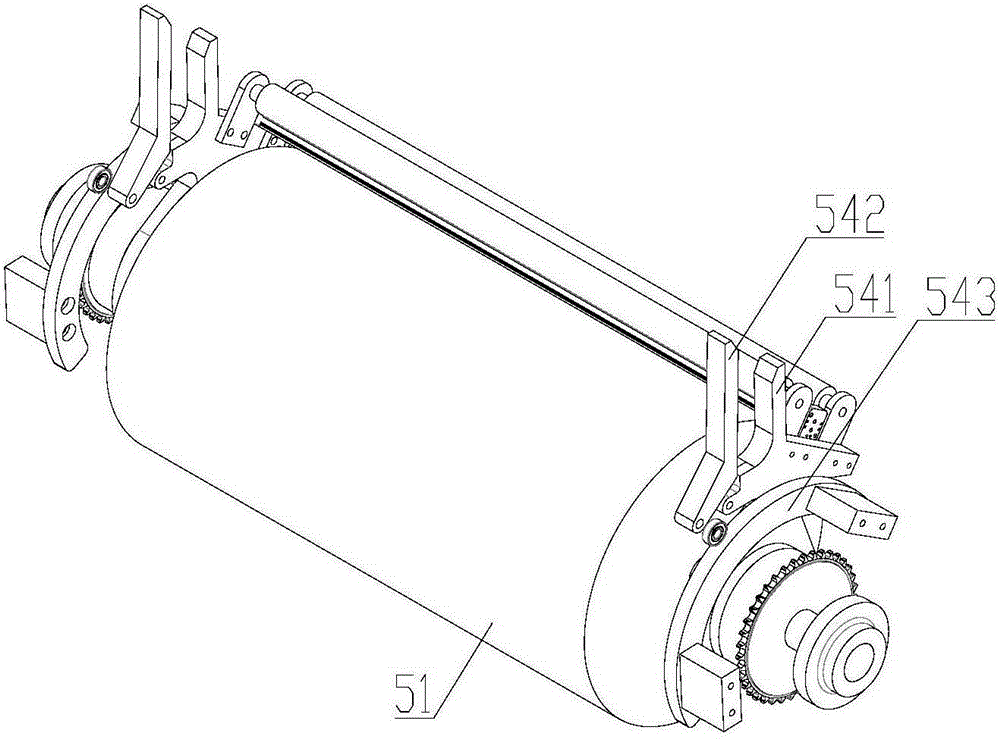

Electric and optical cable metering and printing device

ActiveCN103192600AReduce consumptionReduce manufacturing costRotary pressesEngineeringContact friction

The invention discloses an electric and optical cable metering and printing device which comprises a base plate. A friction transmission metering wheel, a printing wheel and a printing belt reel is mounted on the upper half of the base plate, two cable support wheels are mounted on the lower half of the base plate, and electric or optical cables are respectively clamped between the friction transmission metering wheel and one of the cable support wheels and between the printing wheel and the other cable support wheel. Printing belts on the printing belt reel wind around the rim of the printing wheel and are penetratingly arranged between the printing wheel and electric or optical cables. The friction transmission metering wheel rotates by contact friction with the electric or optical cables, the printing wheel is driven to rotate by belt transmission, printing blocks are arranged on the printing wheel, a belt pressing rod is arranged on the printing belt reel, and a cylinder is arranged below a connecting shaft connecting the two cable support wheels. The electric and optical cable metering and printing device can meter the electric and optical cables and print on the same, printing belt consumption and production cost are reduced, the distances between the printing wheel and the cable support wheels are adjusted conveniently, and requirements for printing of the electric and optical cables different in specifications are met.

Owner:SUZHOU SHENGXIN OPTOELECTRONICS TECH

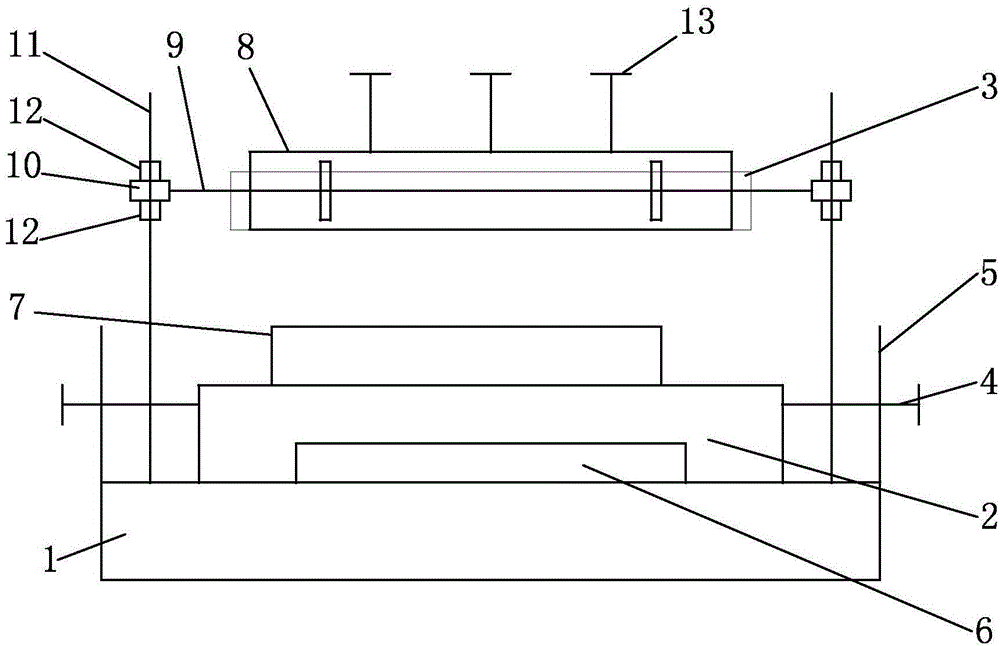

Universal printing tool

The invention discloses a universal printing tool. A tool fixing plate is disposed above a tool baseplate, puller bolts are arranged on the left side and the right side of the tool fixing plate symmetrically, the end of each puller bolt horizontally penetrates a corresponding mounting lug to be butted against the side wall of the tool fixing plate, and a fixing plate positioning stop plate is further fixedly arranged above the tool baseplate; the rear end of a printing screen is locked together with a screen clamp through fastening bolts, a horizontal bar is sleeved with the screen clamp movably, a mounting block is arranged at each of the left and right ends of the horizontal bar, each mounting block is vertically inserted into a corresponding height adjusting screw, each height adjusting screw is sleeved with two locking units so as to lock each mounting block on the corresponding height adjusting screw, and the lower end of each height adjusting screw is fixed on the tool baseplate. The universal printing tool is simple in structure, ingenious in design, convenient to operate and high in product consistency and universality, and printing requirements of products of different styles and specifications can be met by only replacing a tool positioning plate and the printing screen.

Owner:重庆凯隆模具塑胶有限公司

Pine-soot ink and preparation method thereof

InactiveCN103183982AImproved color stabilityNo chromatic aberrationInksBiotechnologyBletilla striata

The invention relates to pine-soot ink and a preparation method thereof, and belongs to the technical field of block printing. The pine-soot ink comprises the following components in part by weight: 90-100 parts of pine soot, 15-16 parts of strong flour, 5-6 parts of bone glue, 2-2.5 parts of grain wine, 2-2.5 parts of vinegar, 0.3-0.5 part of borneol, 0.7-1 part of Chinese angelica, 0.5-0.6 part of green wingceltis bark, 0.8-1 part of bletilla and a small amount of musk. The pine-soot ink is good in color stability, a printed finished product has no color difference, is not too bright or gloomy, and has unique primitive simplicity; the pine-soot ink does not deteriorate and offodor; when being used, the pine-soot ink is not bright when being thick and is not gloomy when being thin; the longer the pine-soot ink is stored, the thicker the book fragrance is; and the requirements of block printing are completely met, and the pine-soot ink is the only selection as the ink for fine block printing products.

Owner:YANGZHOU ANCIENT WIRE BOUND IND CO LTD

Polyamide coating agent for printing of label tape

InactiveCN102079944AHigh bonding strengthHigh color fastnessPolyamide coatingsAntistatic agentAlcohol

The invention discloses a polyamide coating agent for the printing of a label tape. The polyamide coating agent comprises the following components: methanol, calcium chloride, polycaprolactam, carbon black, alcohol-soluble black dye and an antistatic agent. After the alcohol-soluble black dye is used, the coating agent is black and the solidified coating is black; the polyamide coating agent is suitable for the coating formed by the wet method; and after the coating is solidified and dried, the bonding strength of the coating is high, the color fastness is high and the coating meets the printing requirements of common textiles and label tapes.

Owner:HUZHOU KAIEN COATING

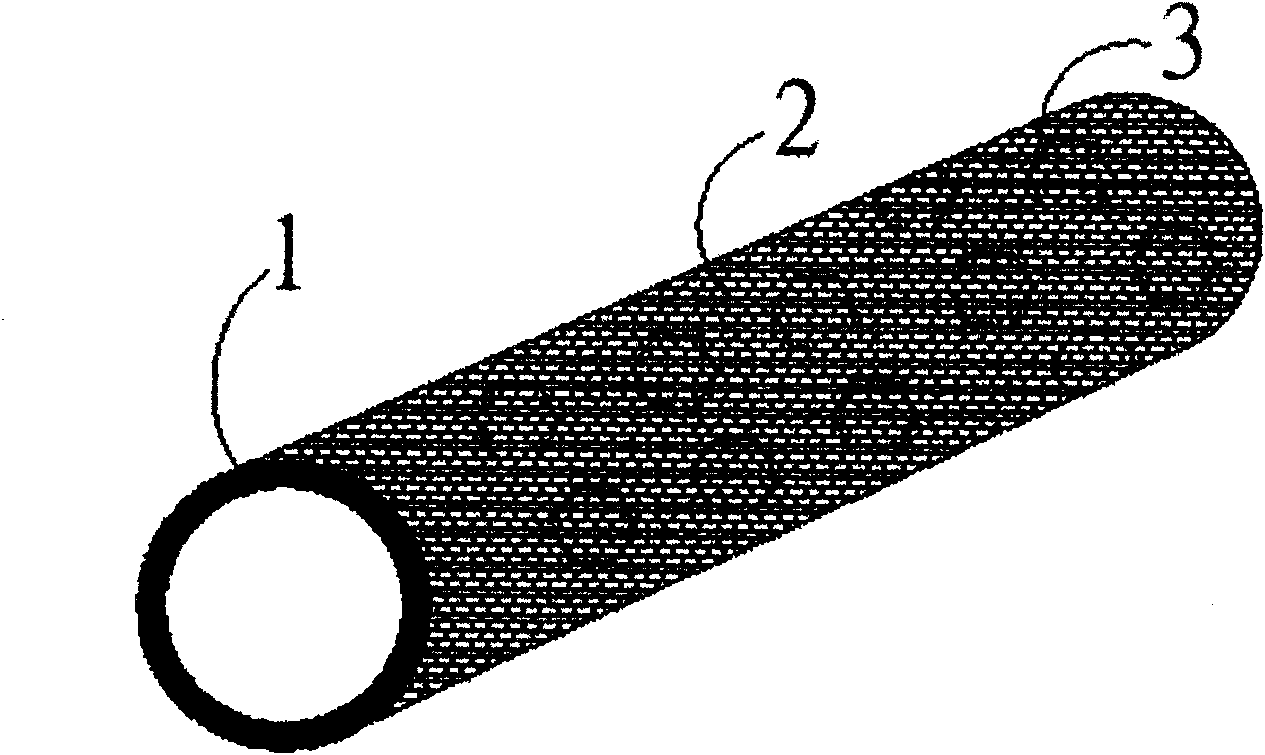

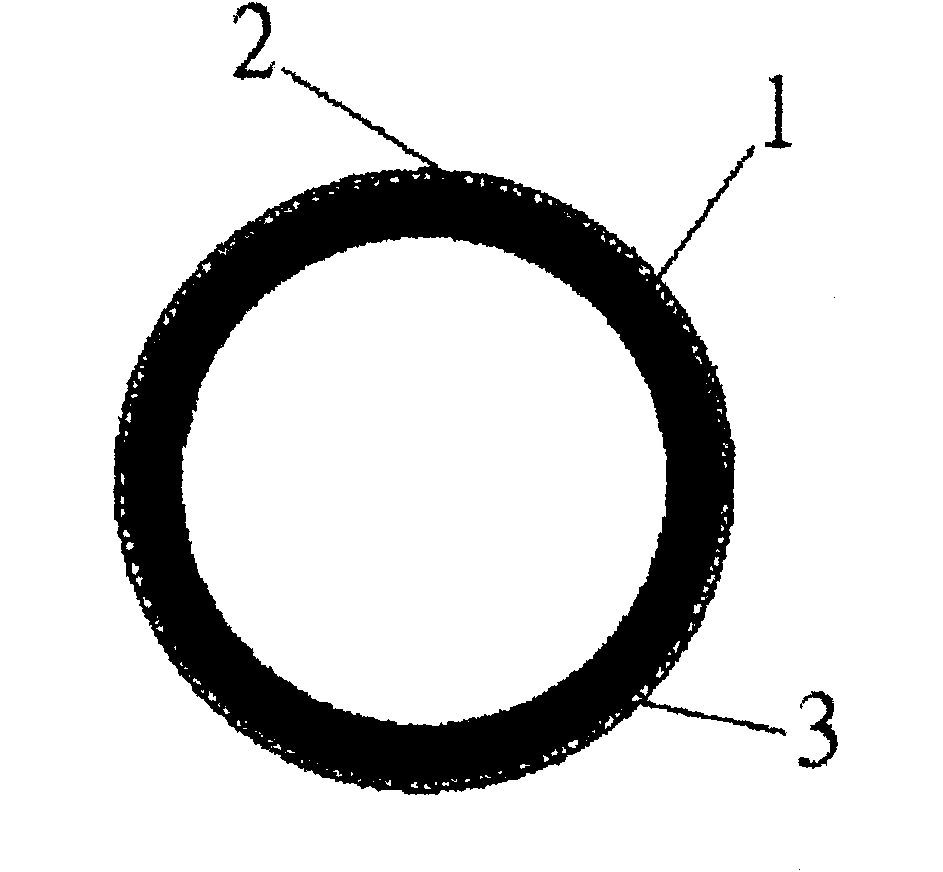

Novel material intaglio roller

InactiveCN101870191AHigh activityMeet printing requirementsPlate printingRotary pressesSurface layerEpoxy resin composite

Owner:东莞东运机械制造有限公司

Cigarette packet wrinkle printing method

The invention provides a cigarette packet wrinkle printing method. According to the method, high-speed printing adaption, special effect UV fission varnish and a web gravure printing machine are improved, and a UV wrinkling device capable of adjusting the horizontal distance from a printing stock is additionally arranged between a printing gravure cylinder and a UV curing device. The method includes the steps of forming the effect of different wrinkles under the action of the wrinkling device by using the UV fission varnish and then performing UV curing; printing special effects, such as snowflakes and wrinkles on the web gravure printing machine at the speed of 150-180 m / min (about 18000-21000 pieces / hour). By means of the cigarette wrinkle printing method, different special cigarette packet wrinkle effects can be produced according to the needs, the process is optimized, the operation is simple, the product quality is stable, the use amount of ink is reduced to effectively reduce material costs, and the production efficiency is relatively 6 times higher than that of silkscreen printing.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

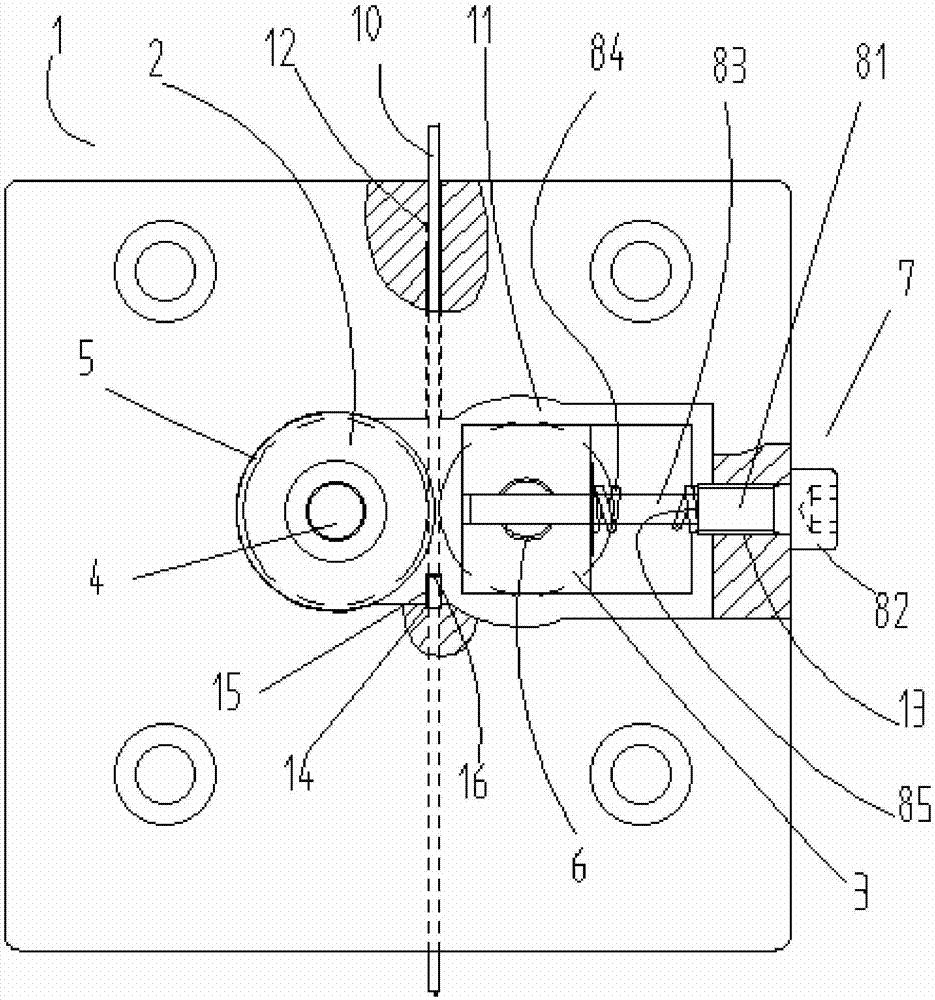

3D printer wire feeding structure

InactiveCN105437550AEasy to replaceEasy to replace and maintainAdditive manufacturing apparatusDrive wheelElectric machinery

The invention discloses a 3D printer wire feeding structure. The 3D printer wire feeding structure comprises a fixed base; the fixed base is connected with a wire feeding motor; a cavity is formed in middle of the fixed base; a wire feeding driving wheel is arranged on one side in the cavity, and a driven wheel structure is arranged on the other side in the cavity; the driving wheel is connected with a driving wheel shaft; the driving wheel shaft is supported on the inner wall of the cavity of the fixed base through a bearing; the driven wheel is connected with a driven wheel shaft; a printing wire channel is formed in the fixed base in the perpendicular direction; the driven wheel shaft is connected with a driven wheel shaft horizontal position adjusting structure; and the driving wheel is matched with the driven wheel to convey printing wires to a printing head part. The 3D printer wire feeding structure is simple and compact in structure, is convenient for disassembly, replacement and maintenance, can conveniently and precisely adjust a shaft distance between the driving wheel and the driven wheel through the horizontal position adjusting structure, and can reliably convey the printing wire materials to a melting position of the printing head part for timely melting to satisfy the printing requirements.

Owner:UNIV OF JINAN

Double-lamp-curing white UV inkjet ink and preparation method thereof

The invention discloses double-lamp-curing white UV inkjet ink. The double-lamp-curing white UV inkjet ink is prepared from the following raw materials, in percentages by mass: 5-15% of a nanoscale pigment, 3-10% of a polyester acrylate oligomer, 2-5% of a polyurethane acrylate oligomer, 5-20% of a photoinitiator, 15-45% of a single-functional or two-functional reactive monomer containing -(CH2)n-structure in the molecular chain, wherein n>=5, 5-30% of an ethoxylated or propoxylated active monomer with three or more of functional groups, 20-60% of other active monomers, and 5-15% of an auxiliary agent. The UV inkjet ink provided by the invention does not contain organic solvents and has the characteristics of greenness and environmental protection; the ink can be cured instantaneously under irradiation of a mercury lamp and an LED lamp, the surface is not sticky, and requirements of double-lamp printing are satisfied; and the ink has good continuity and fluency, good storage stability, good flexibility, no cracking, no brittleness, moderate hardness, high film strength, good adhesion to a substrate and wide adaptability.

Owner:LUCKY HUAGUANG GRAPHICS

Coating newsprint and making method thereof

InactiveCN102587193AEasy to manufactureReduced whiteness requirementsCoatings with pigmentsPaper/cardboardFiberRegenerating fibers

The invention provides coating newsprint and a making method thereof. The newsprint has the following specifications: the fixed weight is 45-49g / m<2>, whiteness is 59-63%, transverse tear index is larger than 5.5m N.m<2> / g, opaqueness is larger than 95%, surface strength is larger than 1.0m / s, average smoothness of the front side and the back side is larger than 60S, the smoothness difference of the front side and the back side is less than 20%, and the longitudinal breakage length is larger than 1500m. The making method of the coating newsprint comprises the following steps of: preparing 100% regenerated fiber deinked pulp completely made from No.8 waste paper and adding auxiliary materials including retention aid, dyes and cationic starch to obtain material pulp; distributing pulp by using a headbox, forming at a neat part, carrying out composite squeezing in a four-roller three-pressing region, primary drying, surface mineral pigment coating and finishing, post-drying, reeling by using reeling machine and external re-reeling. The making method is simple, the coat of coating newsprint per ton is reduced by 250-280 yuan; the surface whiteness of the product is greatly improved, the surface of the product is smooth and fine, the ink absorption rate of the product is moderate; the printability is improved; ink consumption during printing can be reduced 10-15wt%; the printed pictures have bright color and clear wire marks; and the made coating newsprint can meet printing requirements of common newspapers and periodicals and high-quality colored newspapers and periodicals.

Owner:WUHAN CHENMING HANYANG PAPER

Method for printing Chinese art paper through offset press

ActiveCN103753991AMeet printing requirementsRealize printingOther printing apparatusManufacturing technologyPaperboard

The invention discloses a method for printing Chinese art paper through an offset press. By means of a supporting and mounting mode, the light and thin Chinese art paper is combined with a paperboard or printable plastic film, so that the Chinese art paper has certain stiffness and meets the printing requirement of the offset press, then the printed Chinese art paper is separated from the paperboard or the printable plastic film through the printing and tearing processes, and accordingly the Chinese art paper process is finished, printing of the Chinese art paper is achieved, and the user requirements of Chinese art paper printing are met. The whole manufacturing technology is unique, novel, and rigorous and scientific in operation step, and the printed Chinese art paper can be mounted and stored for a long time and is particularly suitable for being used for manufacturing various archaistic volumes or painting albums.

Owner:北京东方之彩印刷有限公司

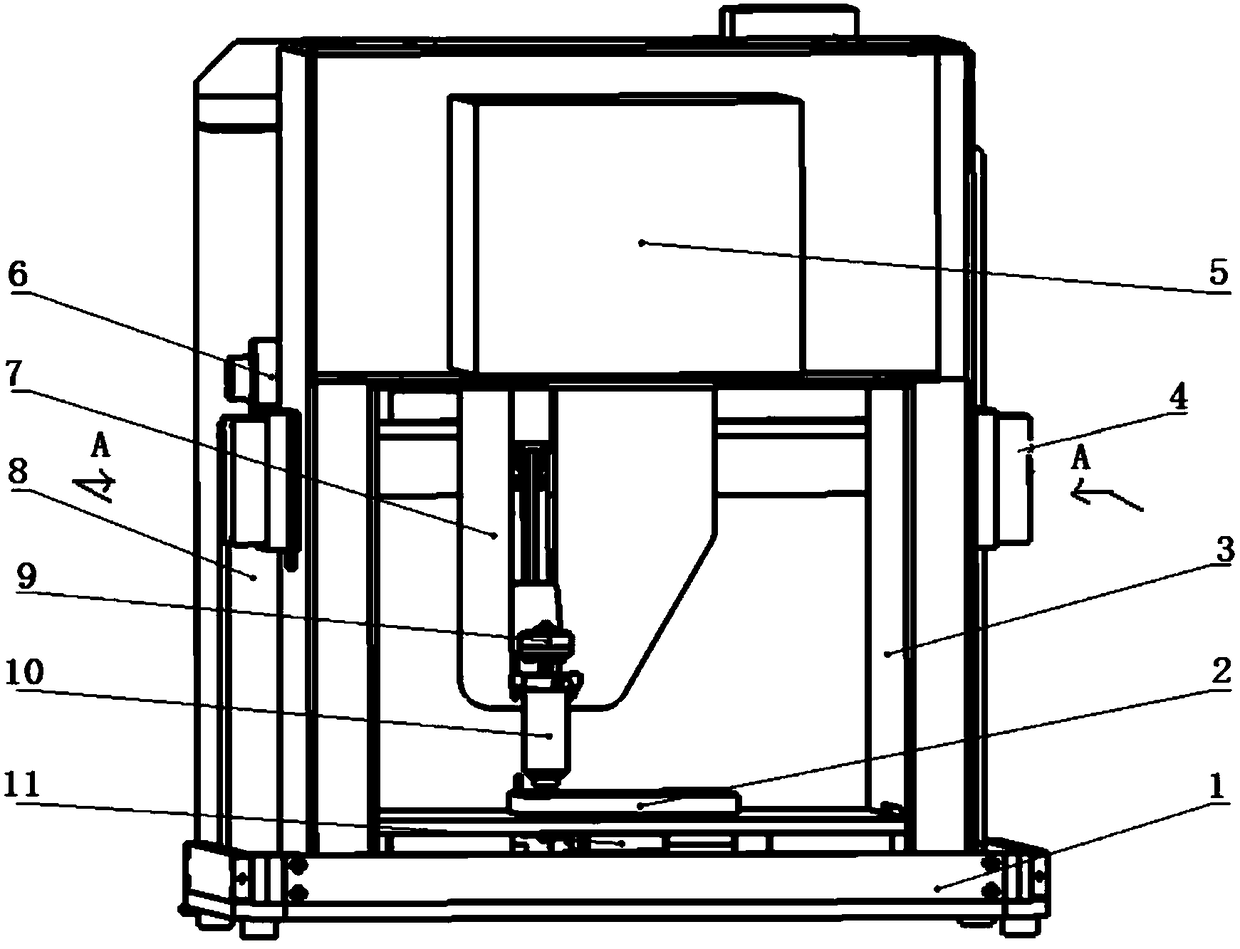

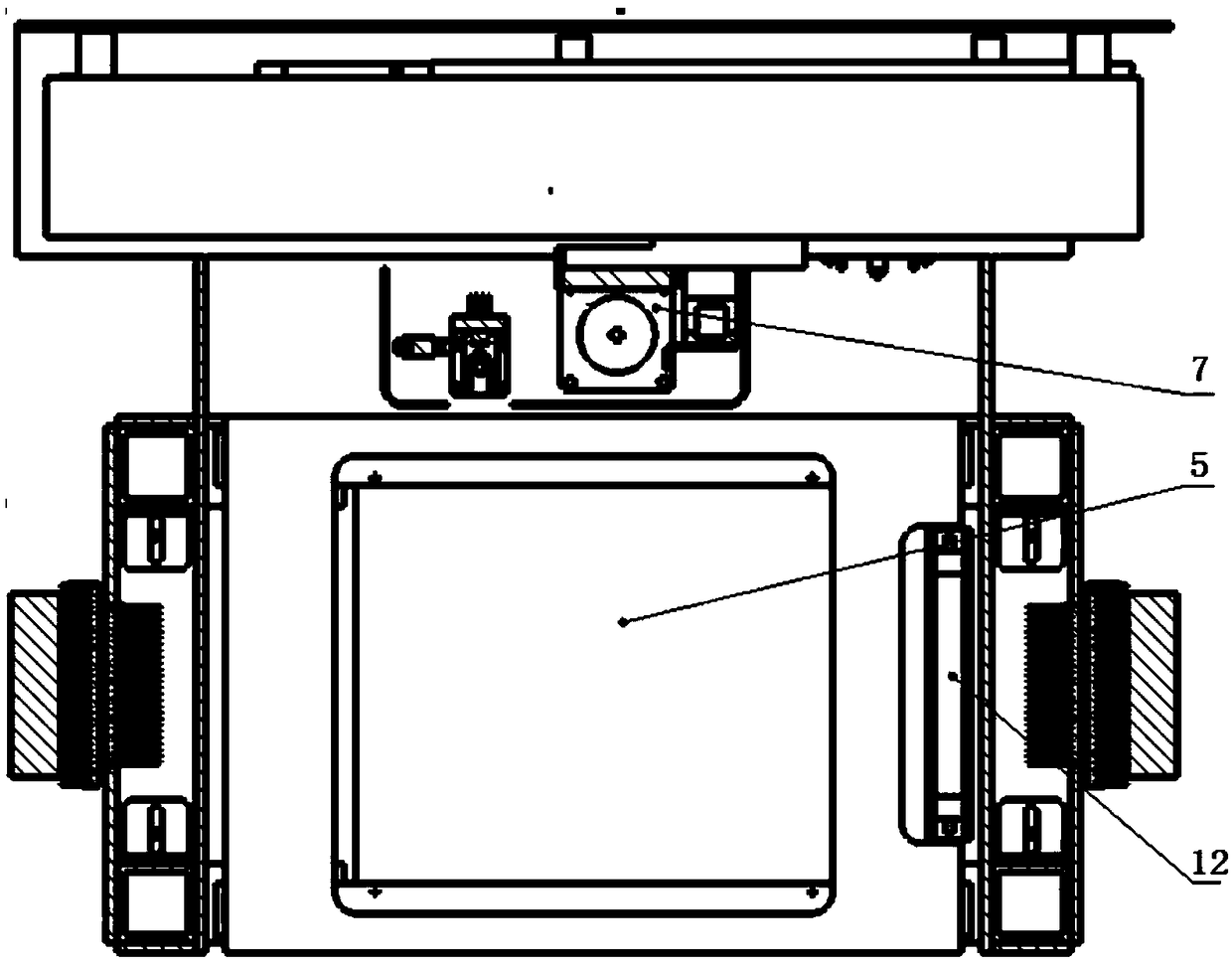

Biological 3D printing device with clean sterilization temperature control function

ActiveCN109109316AGet rid of dependenceMeet printing requirementsAdditive manufacturing apparatusTissue/virus culture apparatusAir filtrationTemperature control

The invention discloses a biological 3D printing device with a clean sterilization temperature control function, and belongs to the technical field of biological 3D printing. The biological 3D printing device comprises: an incubator arranged on a base, wherein the incubator is provided with an air inlet and an air outlet; a printing structure is arranged in the incubator for printing a three-dimensional model on a printing platform; an air outlet of an air filtering structure is communicated with the air inlet of the incubator through an air duct, an air inlet of the air filtering structure iscommunicated with the air outlet of the incubator, the air filtering structure is used for sucking the air in the incubator for filtering; a temperature control structure is arranged between the airoutlet of the air filtering structure and the air duct for cooling the filtered air; a disinfecting and sterilizing structure is arranged on the top of the incubator for disinfecting and sterilizing the cooled air, and the air enters the incubator through the air duct via the air inlet. The biological 3D printing device is free from dependence on a biological safety cabinet, is more convenient touse, and has a wide application range.

Owner:哈尔滨汇恒科技有限公司

BOPP environment-friendly type inner printing ink and preparation method thereof

The invention belongs to the technical field of printing ink application, and concretely discloses a BOPP environment-friendly type inner printing ink. The BOPP environment-friendly type inner printing ink comprises the following raw materials by weight percentage: 22-25% of resin liquid A, 8-10% of a pigment, 3-10% of a filling material, 2-5% of modified rosin, 0.3-1% of a dispersant, 8-10% of ethyl acetate, and 40-50% of n-propyl acetate. The BOPP environment-friendly type inner printing ink and a preparation method have the beneficial effects that on one hand, printing adaptability is good,viscosity resistance is good, combined strength is high, and printing requirements of a plurality of composite technologies can be satisfied; on the other hand, low-chlorinity chlorinated polypropylene is used for removing a benzene solvent, a standard of a non-benzene printing ink is achieved, and the ideal combined strength can be achieved.

Owner:JIANGSU SHENCAI PRINTING PACKAGING MATERIAL CO LTD

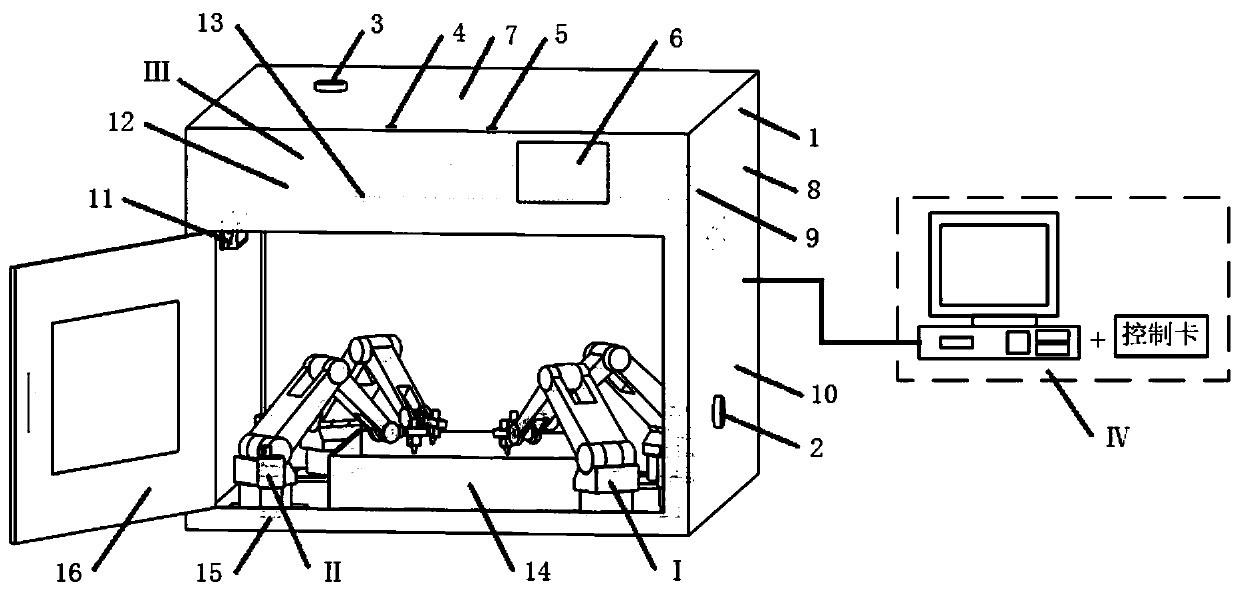

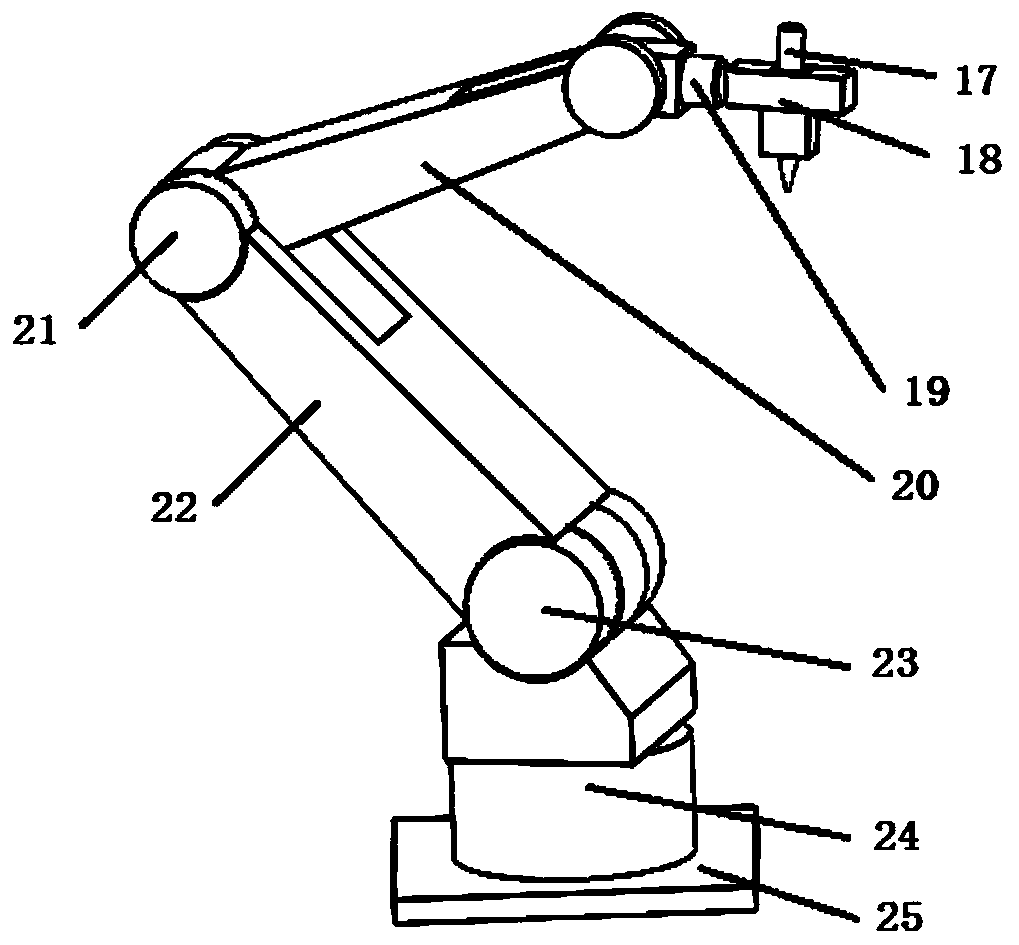

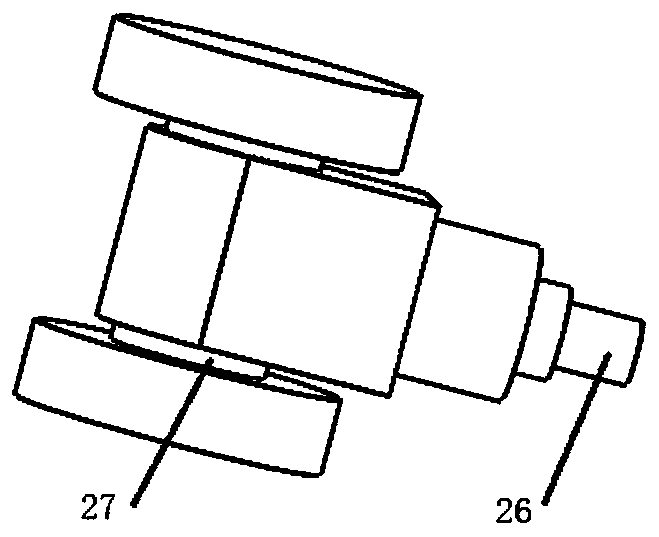

Biological 3D printing device suitable for multiple materials of gradient structure

ActiveCN110936605AImprove survival rateGet rid of dependenceManufacturing driving meansManufacturing heating elementsHydraulic pumpBiological materials

The invention discloses a biological 3D printing device suitable for multiple materials of a gradient structure and belongs to the field of medical instrument quick manufacturing and molding. According to the biological 3D printing device, mechanical arm 3D motion units are arranged in a thermotank and used for driving spray heads to do X, Y and Z-direction 3D motion in biological fluid on the upper portion of the interior of a forming box to conduct biological 3D printing; a hydraulic unit is arranged in the thermotank; an inlet pipe communicates with a hydraulic pump and the bottom of the forming box, and an outlet pipe extends in conformance to the mechanical arm 3D motion units and communicates with the hydraulic pump and the spray heads; the biological liquid at the bottom of the forming box is pumped to the spray heads through the hydraulic pump; a sensor and assistance unit is used for monitoring and adjusting the internal environment of the thermotank; a control and data processing unit is used for controlling operation of the mechanical arm 3D motion units and the hydraulic unit and receiving and processing monitoring data provided by the sensor and assistance unit. The biological 3D printing device has the advantages of high automation degree, greenness, low carbon, high efficiency and wide effective utilization space and has important significance on achievement of control over the temperature gradient of a biological material.

Owner:HUAZHONG UNIV OF SCI & TECH

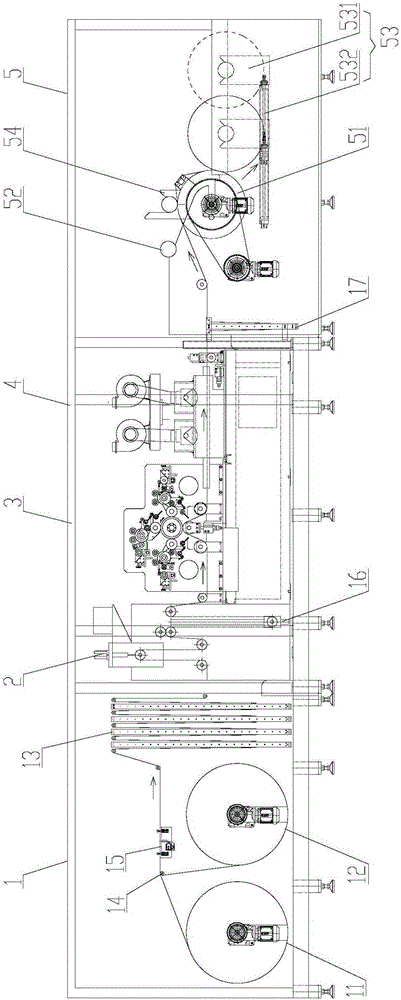

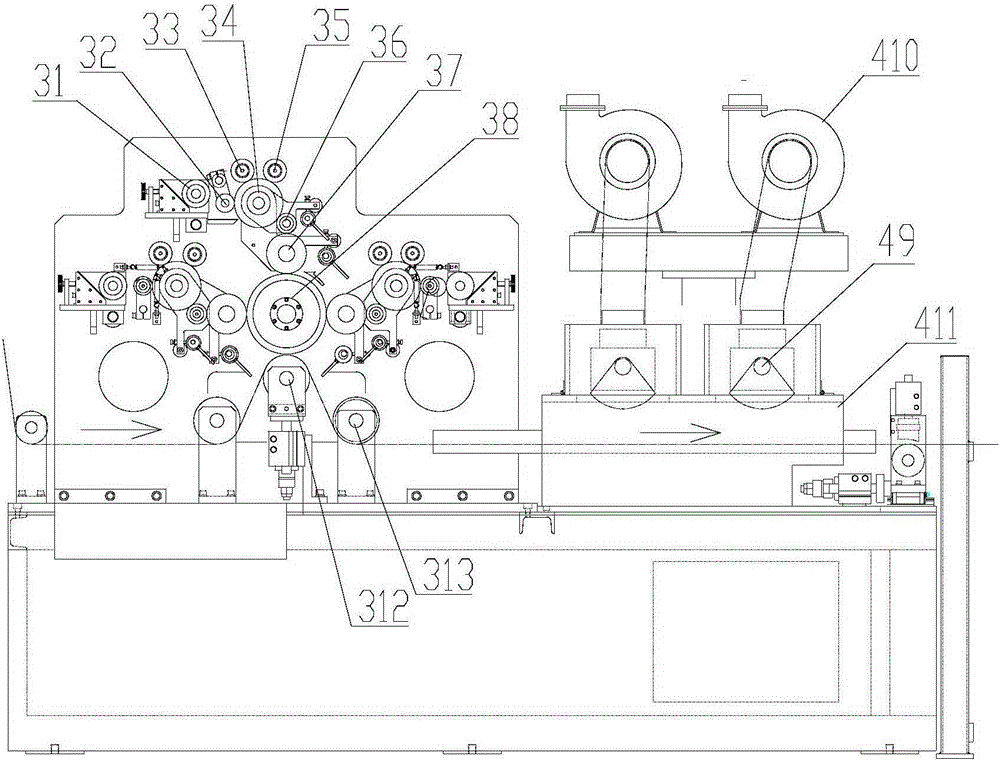

Ultraviolet (UV) continuous printing device for transfusion bag film material

ActiveCN105216445AReduce wasteEasy to stickRotary pressesPrinting press partsUltravioletFilm material

The invention discloses an ultraviolet (UV) continuous printing device for a transfusion bag film material. The UV continuous printing device comprises a continuous film supplying device, a corona treatment device, a UV printing device, a UV drying device and an automatic continuous film coiling device which are sequentially arranged in the film material conveying direction, wherein the continuous film supplying device is used for conveying the to-be-printed film material continuously to the subsequent devices; and the automatic continuous film coiling device is used for coiling the printed and dried film material again into film rolls. By adopting the printing device disclosed by the invention, continuous UV printing can be realized; film changing and film coiling can be realized without halt, so that full-automatic printing is realized; the UV printing technology is adopted, so that the defect of heat transfer printing is completely overcome; and particularly, the requirements of a pharmaceutical enterprise for the printing effect, the printing quality and the printing efficiency can be met.

Owner:SHINVA MEDICAL INSTR CO LTD

BOPP thermosensitive membrane and production method thereof

InactiveCN109957129AImprove bindingGuarantee the performance requirements of high-definition printingNon-fibrous pulp additionSynthetic resin layered productsPaper basedRubbing

The invention discloses BOPP thermosensitive membrane and a production method thereof. The BOPP thermosensitive membrane comprises BOPP base membrane, a base coat layer, a chromogenic layer and a protective layer, wherein the base coat layer, the chromogenic layer and the protective layer are sequentially arranged on the BOPP base membrane. The production method of the BOPP thermosensitive membrane comprises the following steps of (1) selecting BOPP membrane as a coating base material; (2) producing base coat layer coating layer; (3) producing chromogenic layer coating liquid; (4) producing protective layer coating liquid; and (5) pumping the coating liquid of the various layers into coating machine material grooves respectively, and adopting a measuring bar coating method for sequentiallycoating the base coat layer, the chromogenic layer and the protective layer over the paper base material. The product has high-definition printing performance, and the printing requirements of printers with different energy are met; the product has excellent resistance to dry and wet rubbing and three proofing performance, and can be used in environments in contact with water and oil for a long time; and before and after printing, the product can be repeatedly rubbed without coating shedding, and no developed images are lost, so that information fidelity in practical use is guaranteed.

Owner:JIANGSU WANBAO RUIDA HI TECH CO LTD

LED (light-emitting diode)-UV (ultraviolet) ink with special snow effects and preparation method of ink

The invention discloses an LED (light-emitting diode)-UV (ultraviolet) ink with special snow effects and a preparation method of the ink. The ink comprises, by weight, 27-52 parts of ultraviolet curable resin, 30-50 parts of activated diluents, 10-16 parts of photo-initiators, 0-10 parts of pigments, 3-8 parts of fillers and 1-2 parts of auxiliaries. The ink is cured and dried by an LED-UV light source, the wave band of the LED-UV light source can be 365nm, 375nm or 395nm, and curing power is higher than or equal to 8W / cm<2>. Compared with common UV ink, the ink has the advantages of high drying speed, good adhesive force, energy conservation, environmental protection and the like.

Owner:深圳市深赛尔股份有限公司

Functional ink for ink-jet printing as well as preparation method and application

The invention relates to functional ink for ink-jet printing on the surfaces of special base materials (glass, ceramic and metal) as well as a preparation method and application. The functional ink isprepared from the following ingredients in parts by weight: 5-20 parts of epoxy resin 1#, 10-30 parts of epoxy resin 2#, 1-10 parts of a curing agent, 0.5-5 parts of an accelerant, 25-50 parts of a solvent 1#, 1-15 parts of a solvent 2# and 0.05-2 parts of an adjuvant. The invention further relates to a preparation method, performance parameters and an application method of the functional ink. The functional ink contains the epoxy resin, the curing agent, the accelerant, the solvent and other adjuvant in a proper weight proportion and has the characteristics of excellent stability and high-temperature rapid curing, and adhesive film cured by the functional ink has extremely good adhesive force, water resistance, tenacity and rigidity. The functional ink is particularly suitable for the surfaces of the special base materials such as glass, ceramic and metal and has functions as a transition layer between the surfaces of the base materials and a UV (ultraviolet) ink layer, so that the UV (ultraviolet curing) ink-jet technology can be more broadly applied to industrial production in the fields of printing and packaging as well as embellishment and decoration.

Owner:施莹莺

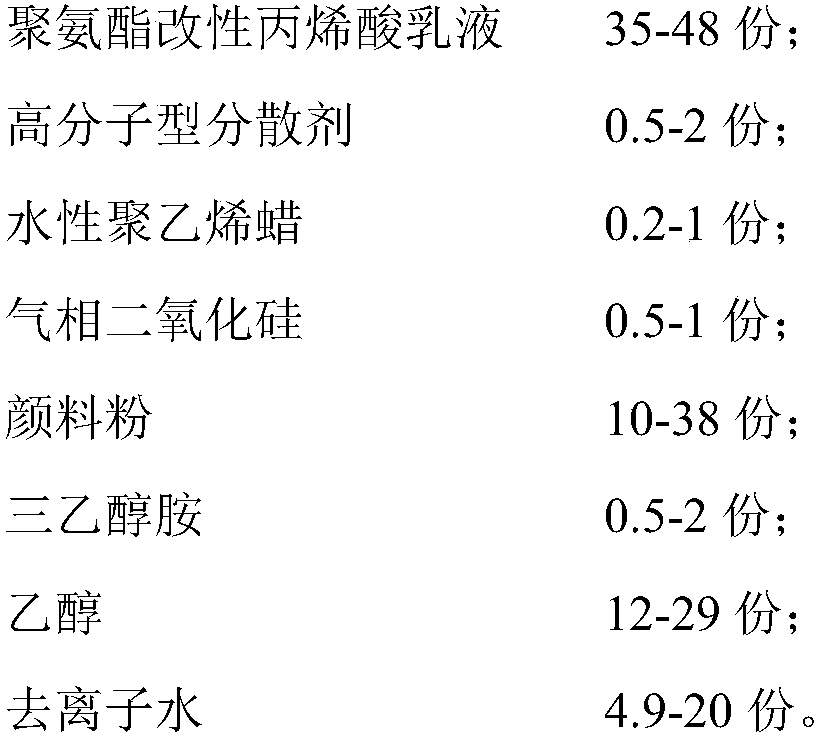

Alcohol aqueous gravure plastic composite printing ink and preparation method thereof

The invention provides alcohol aqueous gravure plastic composite printing ink. The alcohol aqueous gravure plastic composite printing ink comprises the following components in parts by mass: 35 to 48parts of polyurethane modified acrylic acid emulsion, 0.5 to 2 parts of a macromolecular type dispersing agent, 0.2 to 1 part of water-based polyethylene wax, 0.5 to 1 part of fumed silica, 10 to 38 parts of pigment powder, 0.5 to 2 parts of triethanolamine, 12 to 29 parts of ethanol and 4.9 to 20 parts of deionized water. End sealing is conducted by utilizing organic amine with a low boiling point, the organic amine with the low boiling point is introduced, the amine with the low boiling point is volatized slowly at normal temperature, a large amount of hydrophilic groups still exist in resin, and high dissolubility is achieved in an alcohol water system; when the resin is prepared into the printing ink and passes through a drying oven, escape of the amine with low boiling point on the resin is accelerated, so that the resin hydrophilic groups are greatly reduced, volatilization of water is accelerated, the printing ink is water-resistant after being dried, the printing ink on a printing plate is still at normal temperature, a large amount of hydrophilic groups still exist, high re-dissolubility is still achieved within a period of time and the printing use requirement is met.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com