LED (light-emitting diode)-UV (ultraviolet) ink with special snow effects and preparation method of ink

A special effect and ink technology, applied in the field of LED-UV ink with snowflake special effect and its preparation, can solve the problems of normal patterning, difficulty in drying, and few varieties, and achieve the effect of reducing curing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing LED-UV ink with snowflake special effects, comprising the steps of:

[0032] a: Weigh the following components by weight percentage: 27-52 parts of UV curable resin, 30-50 parts of reactive diluent, 10-16 parts of photoinitiator, 0-10 parts of pigment, 3-8 parts of filler, auxiliary agent 1 to 2 servings.

[0033] b: Put the raw materials such as ultraviolet curing resin, photoinitiator, reactive diluent, filler, auxiliary agent into the airtight container according to the proportion, and stir in the mixer with the rotation speed of 400-600rpm in the temperature range of 40-50°C for 20-20~ 30min, the raw materials are mixed and pre-dispersed, and stirred evenly;

[0034]c: use a three-roll mill to grind the dispersed raw materials in step a to 10-15um, and obtain LED-UV ink with special snow effect.

Embodiment 1

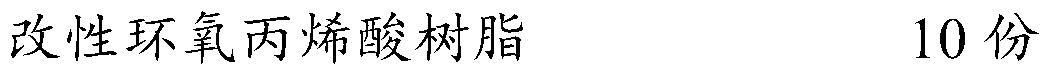

[0037] Take the following components respectively by weight proportion (parts):

[0038]

[0039]

[0040] Put the UV curable resin, photoinitiator, reactive diluent, filler, additive and other raw materials into the airtight container according to the proportion, and stir in the mixer with the speed of 400-600rpm in the temperature range of 40-50°C for 20-30min. The raw materials are mixed and pre-dispersed, stirred evenly, and finally ground to a fineness of 10-15um, and the LED-UV ink with the special effect of snowflakes is obtained.

Embodiment 2

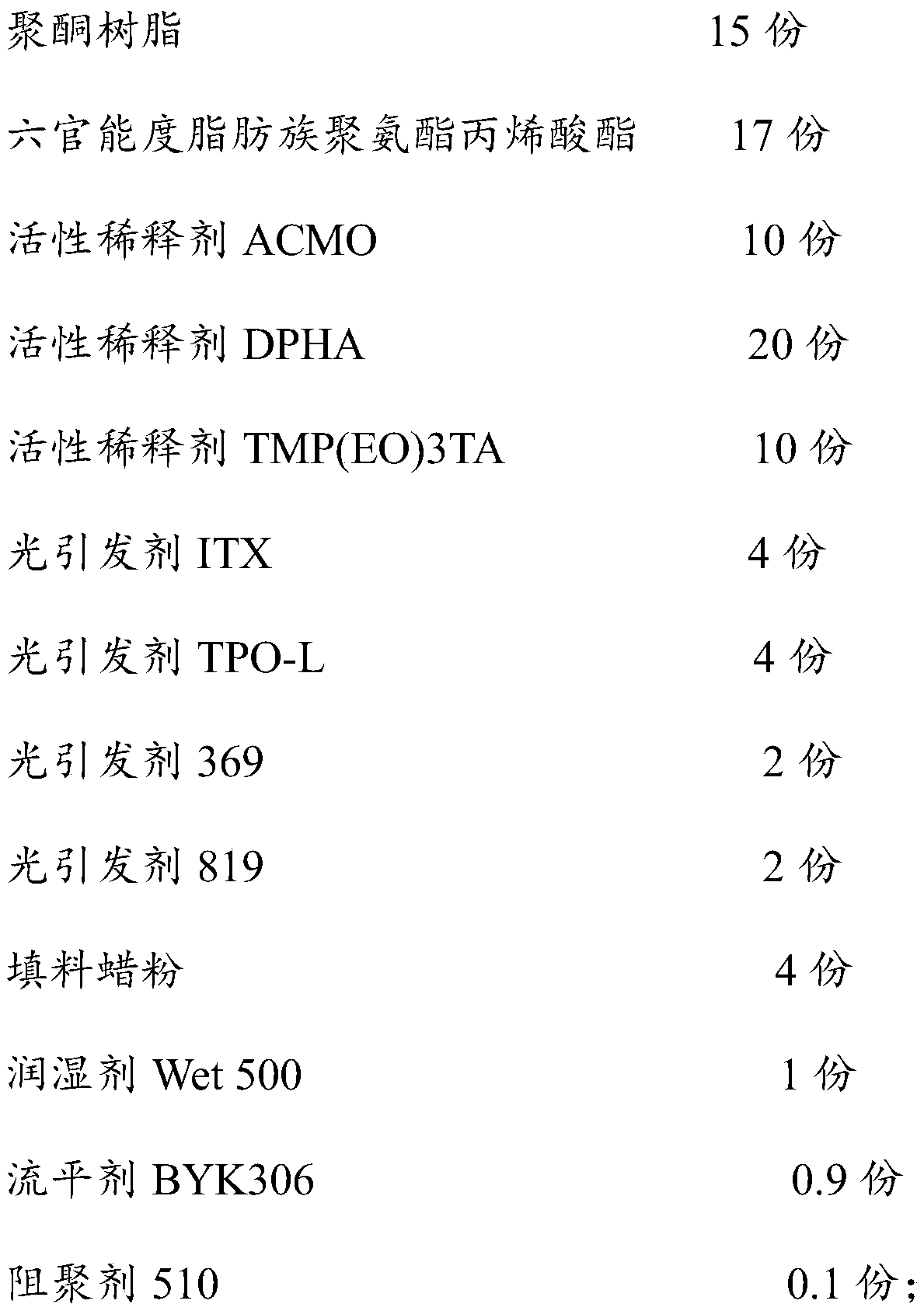

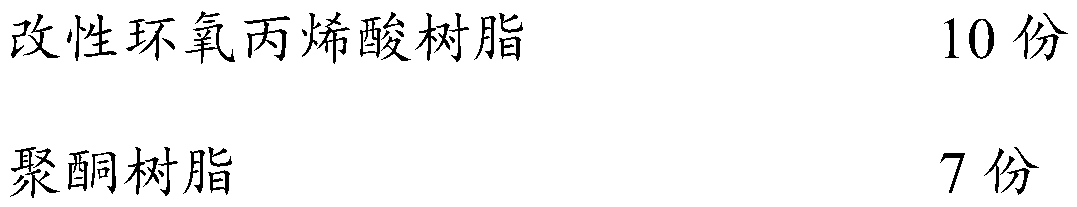

[0042] Take the following components respectively by weight proportion (parts):

[0043]

[0044]

[0045] Put the UV curable resin, photoinitiator, reactive diluent, filler, additive and other raw materials into the airtight container according to the proportion, and stir in the mixer with the speed of 400-600rpm in the temperature range of 40-50°C for 20-30min. The raw materials are mixed and pre-dispersed, stirred evenly, and finally ground to a fineness of 10-15um, and the LED-UV ink with the special effect of snowflakes is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com