Alcohol aqueous gravure plastic composite printing ink and preparation method thereof

An alcohol-based, gravure technology, applied in the field of ink, can solve the problems of water resistance and resolubility, achieve good resolubility, meet the requirements of printing use, and have the effect of low toxicity

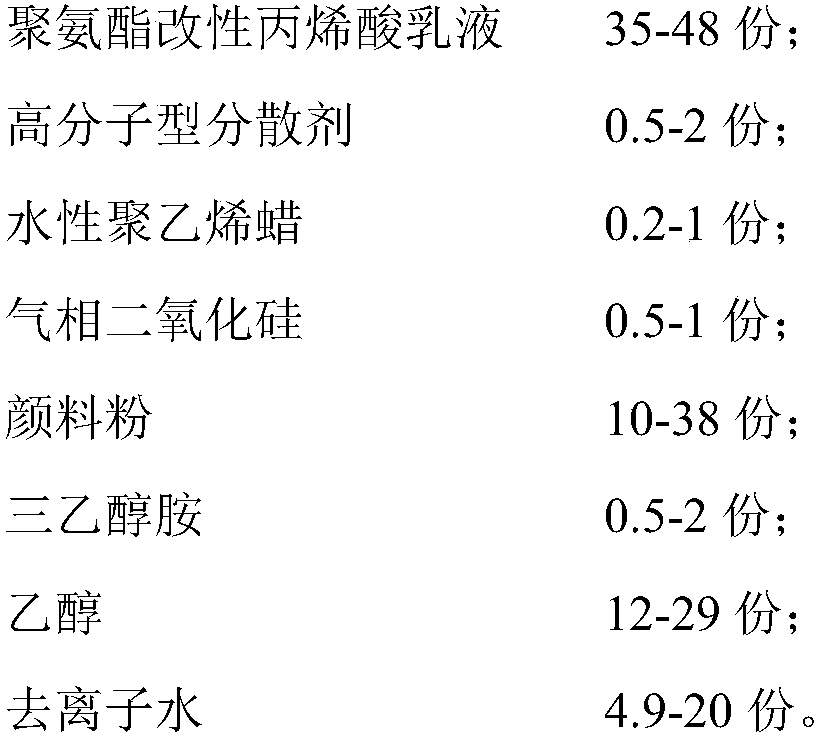

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

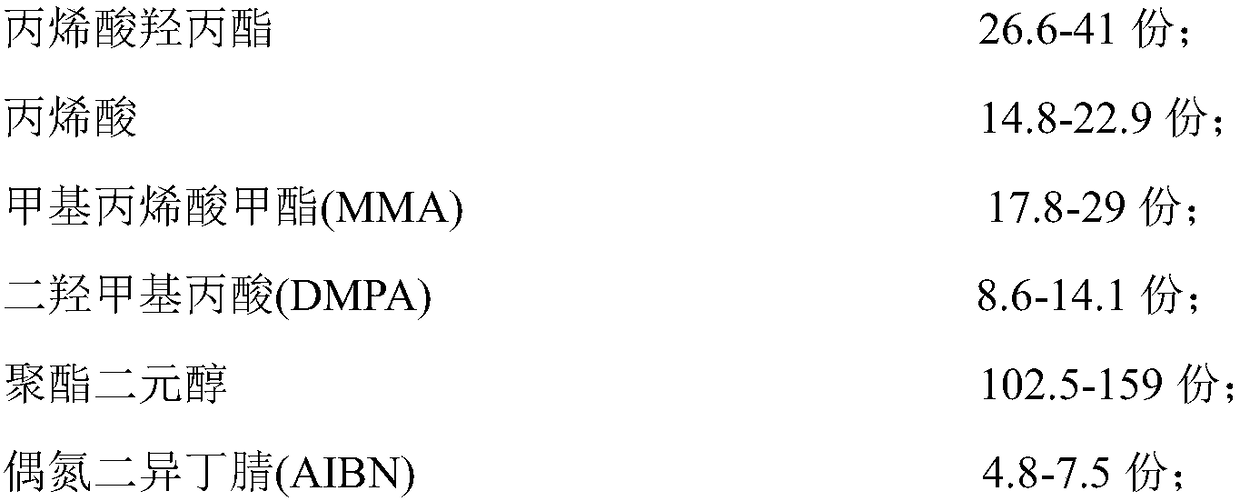

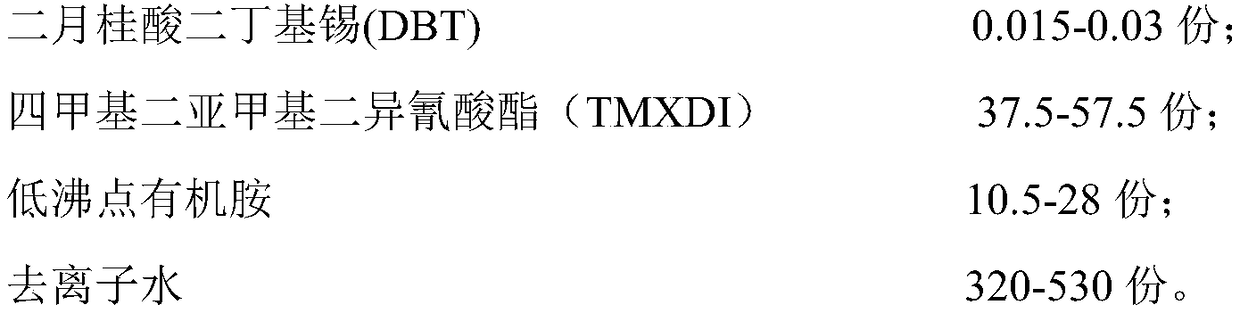

Method used

Image

Examples

Embodiment 1

[0028] 1. Hydroxypropyl acrylate, dimethylolpropionic acid (DMPA) and polyester diol (molecular weight 500) are dehydrated under reduced pressure;

[0029] 2. Add 26.7g of dehydrated hydroxypropyl acrylate, 14.8g of acrylic acid, and 18.0g of methyl methacrylate into a four-necked flask. The temperature is raised to 62℃, and 4.9g of azobisisobutyronitrile (AIBN After the dripping is completed, the reaction is continued for 2.5 hours, and 8.7g of dimethylolpropionic acid (DMPA) after dehydration and 102.5g of polyester diol (molecular weight 500) are added and reacted for 1.5 hours;

[0030] 3. The temperature is raised to 85°C, nitrogen is introduced, and 37.8 g of tetramethyl dimethyl diisocyanate (TMXDI) mixed with two drops of dibutyl tin dilaurate (DBT) (TMXDI) are added dropwise. After the addition is complete, continue the reaction For 2.5 hours, add a small amount of acetone to adjust the system viscosity, and measure the -NCO group every 30 minutes. When the -NCO group does...

Embodiment 2

[0035] 1. Hydroxypropyl acrylate, dimethylolpropionic acid (DMPA), polyester diol (molecular weight 500) are dehydrated under reduced pressure;

[0036] 2. Add 30.6g of dehydrated hydroxypropyl acrylate, 16.9g of acrylic acid, and 20.3g of methyl methacrylate into a four-necked flask. The temperature is raised to 60°C, and 5.4g of azobisisobutyronitrile (AIBN) is slowly dissolved in drops. After the dripping of the acetone solution is completed, the reaction is continued for 3 hours, and 9.7g of dimethylolpropionic acid (DMPA) after dehydration and 117.5g of polyester diol (molecular weight 500) are added and reacted for 1.5 hours;

[0037] 3. Warm up to 90℃, blow in nitrogen, drop by drop 41.5g of tetramethyl dimethyl dimethyl diisocyanate (TMXDI) mixed with two drops of dibutyl tin dilaurate (DBT), continue the reaction after the addition is complete For 3 hours, add a small amount of acetone to adjust the system viscosity, and measure the -NCO group every 30 minutes. When the -N...

Embodiment 3

[0042] 1. Hydroxypropyl acrylate, dimethylolpropionic acid (DMPA), polyester diol (molecular weight 500) are dehydrated under reduced pressure;

[0043] 2. Add 33.2g of dehydrated hydroxypropyl acrylate, 18.4g of acrylic acid, and 21.7g of methyl methacrylate into a four-necked flask. The temperature is raised to 60℃, and 5.9g of azobisisobutyronitrile (AIBN) is slowly dissolved in drops. After the addition of the acetone solution, continue to keep the temperature for 2.5 hours, add 11.1g of dimethylolpropionic acid (DMPA) after dehydration, 127.5g of polyester diol (molecular weight 500), and react for 2 hours;

[0044] 3. Warm up to 85℃, blow in nitrogen, drop by drop 45.4g of tetramethyl dimethyl dimethyl diisocyanate (TMXDI) mixed with two drops of dibutyl tin dilaurate (DBT), and continue the reaction after the addition is complete For 3 hours, add a small amount of acetone to adjust the viscosity of the system, and measure the -NCO group every 30 minutes. When the -NCO group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com