Patents

Literature

1589 results about "Dibutyl tin dilaurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyltin dilaurate (DBTDL) is an organotin compound that is used as a catalyst. It is a colourless oily liquid. In terms of its structure, the molecule consists of two laurate groups attached to a dibutyltin(IV) center. The molecular geometry at tin is tetrahedral.

Polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy and preparation method thereof

InactiveCN101831168AImprove flame retardant performanceImprove mechanical propertiesEpoxyFire retardant

The invention provides a polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy and a preparation method thereof. The polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy comprises a component A and a component B, wherein the component A consists of phenolic resin, brominated epoxy resin, phosphorated flame retardant polyether polyol, organosilicon foam stabilizer, catalyst dimethylethanolamine, catalyst dibutyltin dilaurate, flame retardant and foaming agent 1,1-dichloro-1-fluoroethane, and the component B is flame retardant polyisocyanate curing agent. The invention also provides a preparation method of the exterior wall thermal insulation material. The polyurethane rigid foam exterior wall thermal insulation material has excellent mechanical property and high flame retardancy, overcomes the problem that the fireproof flame retardancy and the mechanical property of the traditional polyurethane rigid foam thermal insulation materials are mutually in contradiction and is suitable for exterior wall thermal construction of a building with higher fireproof level requirement.

Owner:SHANGHAI COLLODIN MATERIAL TECH DEV CO LTD

Polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer and preparation method thereof

InactiveCN102181060AEasy to manufacturePrecise control of relative contentDibutyl tin dilauratePolyethylene glycol

The invention relates to a polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer and a preparation method thereof. The molecular weight of polyvinyl alcohol is 20,000-80,000; the molecular weight of a polypeptide chain segment is 4,000-8,000; and the molecular weight of a polyethylene glycol chain segment is 350-750. The preparation method comprises the following steps of: (1) synthesizing a polypeptide homopolymer which contains an end-NCO radical: adding the polypeptide homopolymer, diisocyanate, dibutyltin dilaurate serving as a catalyst and dimethyl sulfoxide serving as a solvent into a reactor for reacting to obtain a target product; (2) synthesizing a polyvinyl alcohol-polypeptide graft copolymer: adding the polypeptide homopolymer which contains the end-NCO radical, the solvent and the catalyst into the reactor, adding polyvinyl alcohol and reacting to obtain a target product; and (3) synthesizing a polyvinyl alcohol-polypeptide-polyethylene glycol graft copolymer: adding the polyvinyl alcohol-polypeptide graft copolymer, the solvent and the catalyst into a drying reactor, adding polyethylene glycol monomethyl ether and reacting to obtain a target product.

Owner:SHANDONG UNIV OF TECH

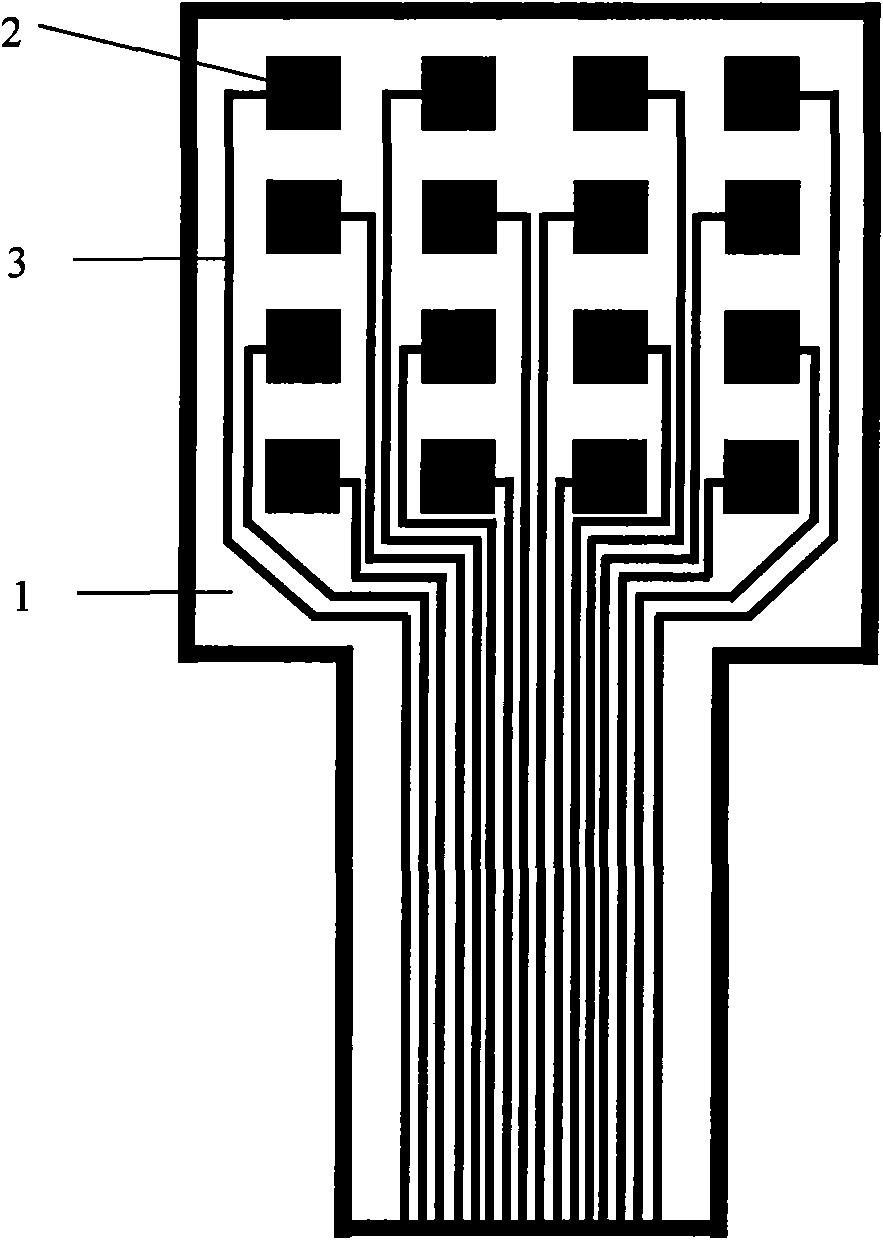

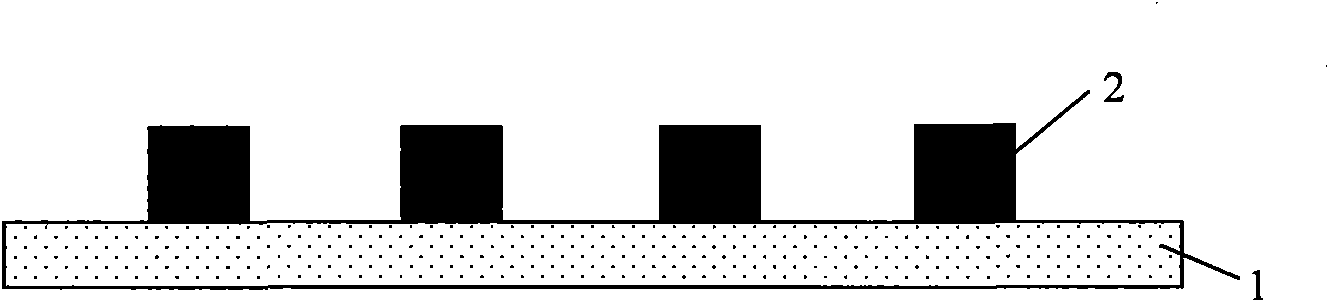

Development method of flexible pressure-sensitive element based on carbon nano-tube filled high polymer composite material

InactiveCN101885463ALarge aspect ratioHigh sensitivityDecorative surface effectsChemical vapor deposition coatingCarbon nanotubeCopper foil

The invention relates to a development method of a flexible pressure-sensitive element based on a carbon nano-tube filled high polymer composite material, which belongs to the technical field of sensors. The method comprises the following steps of: 1. pressure-sensitive material preparation: dispersing carbon nano-tubes into polydimethylsiloxane by utilizing ultrasonic vibration and mechanical stirring methods, and preparing a thin and flexible pressure-sensitive material by using tetraethoxysilane as a crosslinking agent and dibutyltin dilaurate as a catalyst with a spin coating method; 2. pressure-sensitive element packaging, wherein a two-stage sandwich structure is adopted, the first-stage sandwich structure comprises two layers of packaging films and the pressure-sensitive material positioned in the middle; and in the second-stage sandwich structure, each layer of packaging film comprises two layers of polyimide films as well as a copper foil electrode and a lead which are embedded in the two layers of polyimide films. The pressure-sensitive element developed by the invention has good flexibility, high precision, thin thickness, simple process and low cost and is applicable to the fields of pressure monitoring of structures between narrow curved surface layers in the fields of military industry and civil use and artificial electronic skin development and the like.

Owner:NORTHEASTERN UNIV

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

Bi-component high-strength polyurethane waterproofing paint

ActiveCN101100582AImprove performanceQuality improvementAntifouling/underwater paintsPaints with biocidesExtensibilityToluene diisocyanate

A dual-component high-strength polyurethane water proof coating contains A and B components; A component consists of polyether dibasic alcohol 120-200 proportion, polyether trivalent alcohol 40-180 proportion, toluene diisocyanate 47-80 proportion, dibutyl ester 1.5-3 proportion, and tartaric acid 0.1-1 proportion. B component consists of filling oil 50-90 proportion, paraffin chloride 20-50 proportion, dibutyl ester 10-30 proportion, 3,3-dichloro-4,4-diphenyl-methane-diamine 45-70 proportion, poly-ether trivalent alcohol 60-360 proportion, hydrated magnesium silicate 50-60 proportion, kaolin 10-50 proportion, heavy calcium carbonate 50-60 proportion, iron oxide brown or carbon black 3.5-4.5 proportion, de-foaming agent 0.2-0.5 proportion, and dibutyltin dilaurate 0.2-0.5 proportion. It's convenient and cheap, has excellent adhesion, strength and extensibility and more solid content and no environmental pollution. It can be used for foundation construction and municipal traffic engineering.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

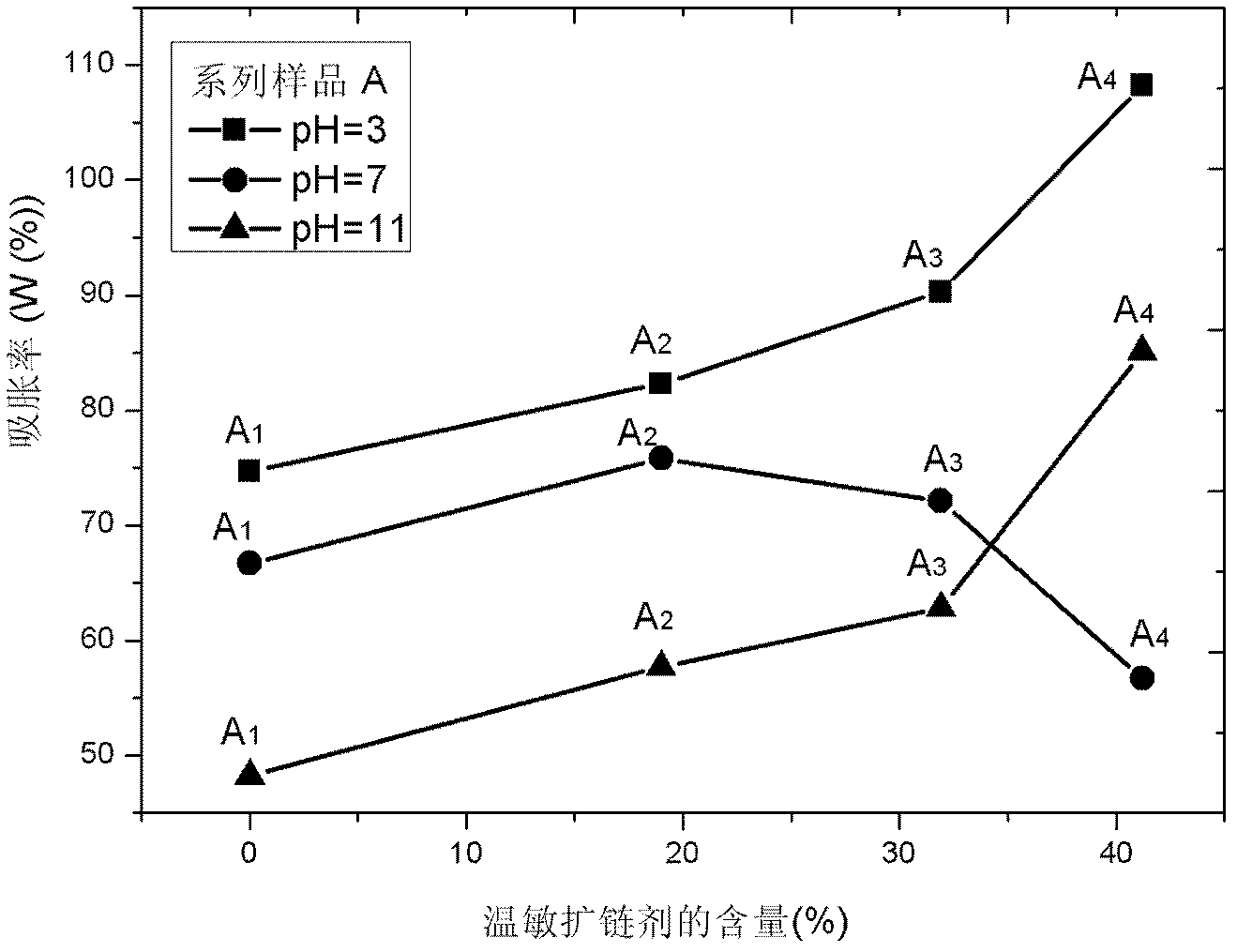

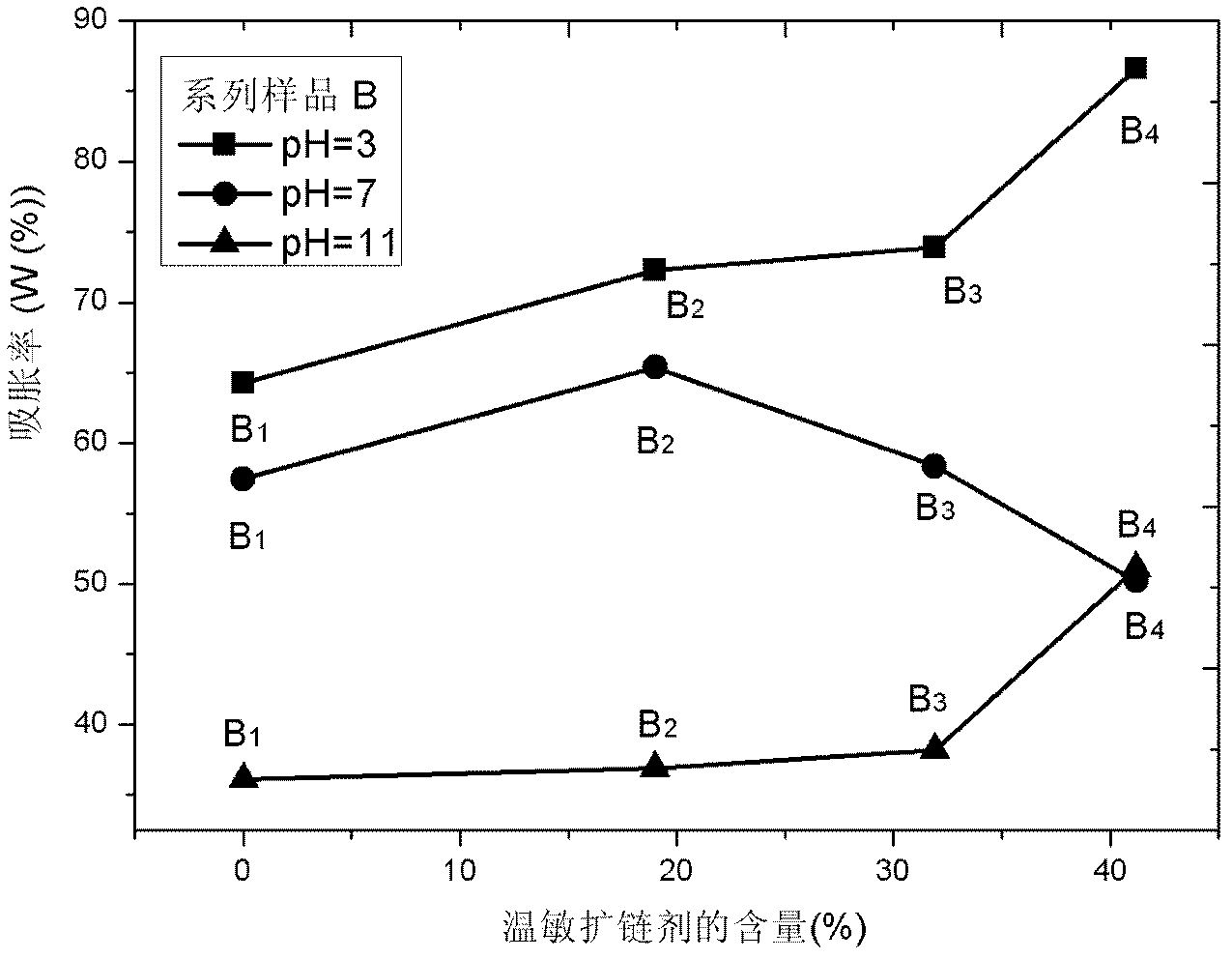

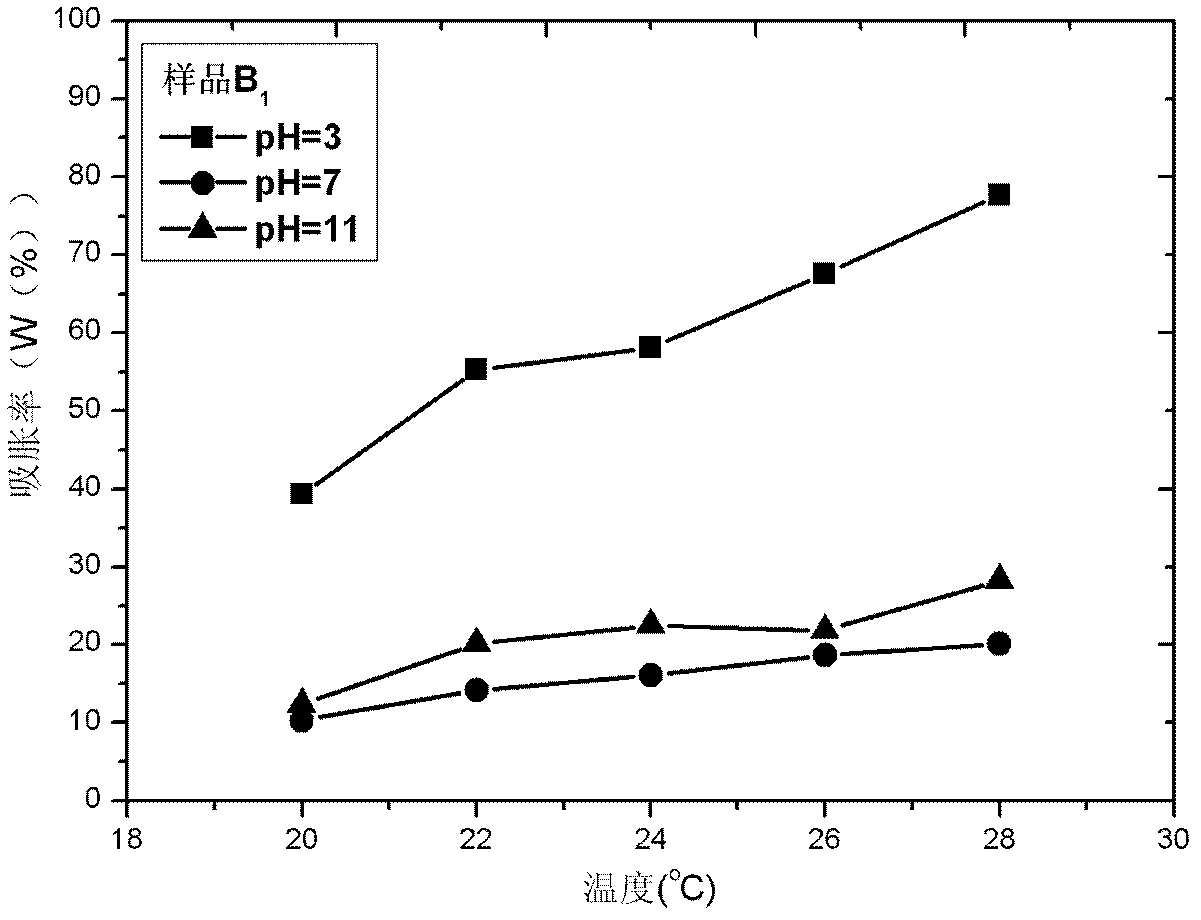

Thermo-sensitive chain extender and polyurethane hydrogel with double sensitivity of temperature and pH

The invention discloses a thermo-sensitive chain extender and polyurethane hydrogel with double sensitivity of temperature and pH. The hydrogel is prepared by the following methods: mixing 15-20.6 percent of polyethylene glycol, 6.7-9.2 percent of polyhydric carboxylic acid, 25.2-34.6 percent of multi-isocyanate and dibutyltin dilaurate used as a catalyst to perform pre-condensation polymerization reaction; adding organic solvent to stop reaction to obtain a pre-polymer; adding 15.3-36.5 percent of a thermo-sensitive chain extender to perform chain extension reaction; adding 3.1-4.3 percent of polyhydric alcohol amine stop end after the pre-polymer is subjected to the chain extension; and then, adding 11.6-19.4 percent of a curing crosslinking agent to perform crosslinking reaction to obtain polyurethane hydrogel with double sensitivity of temperature and pH. The thermo-sensitive chain extender is prepared by the method, and a method for introducing the thermo-sensitive chain extenderin polyurethane is provided, and the softness and hardness of the material are controlled in a post-crosslinking mode, so that the defects that introduction of groups and cross-linking solidity are carried out at the same time in the conventional way of excitation of double bonds are overcame, and the polyurethane hydrogel with double sensitivity of temperature and pH is prepared.

Owner:SOUTH CHINA UNIV OF TECH

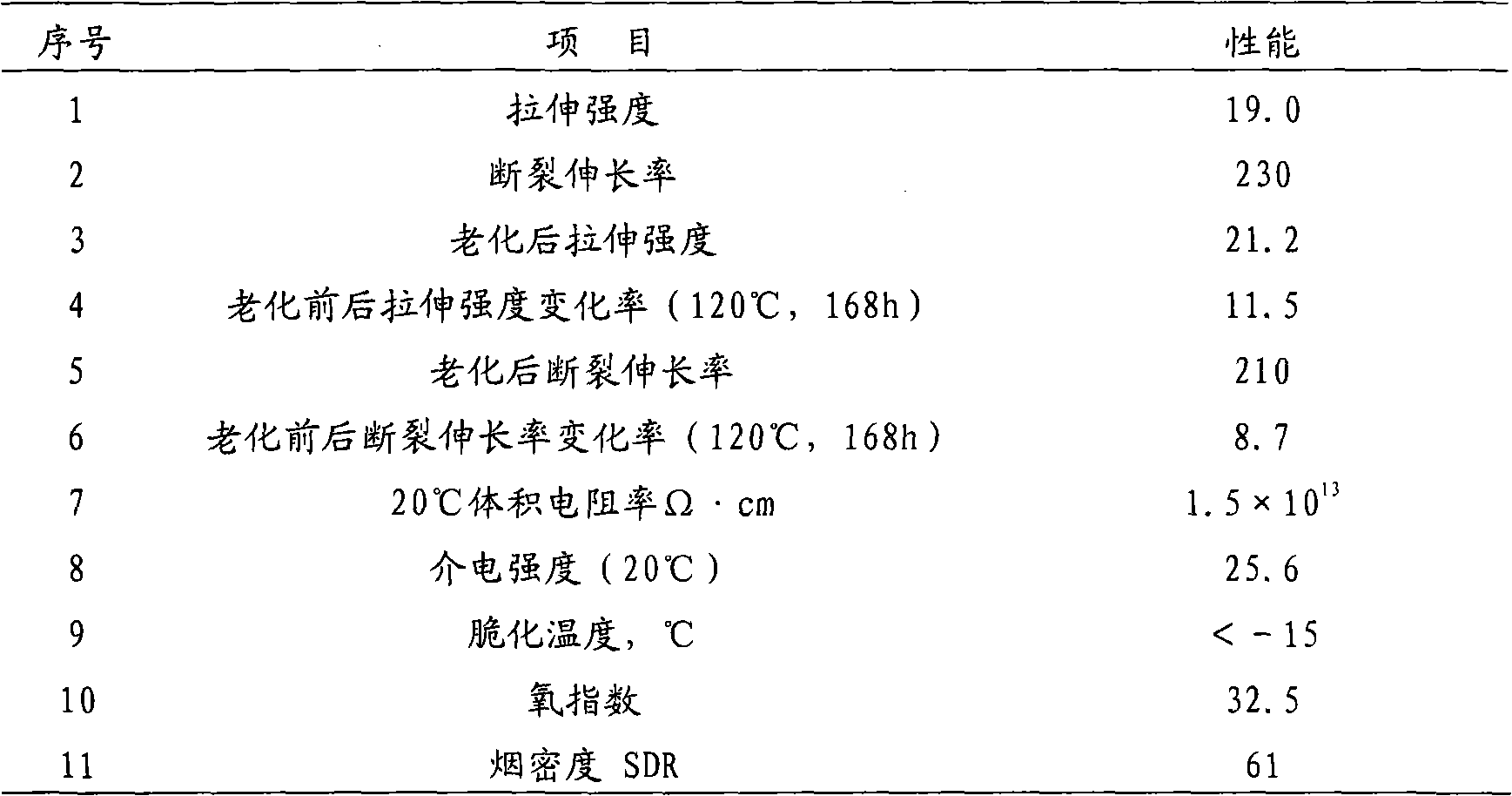

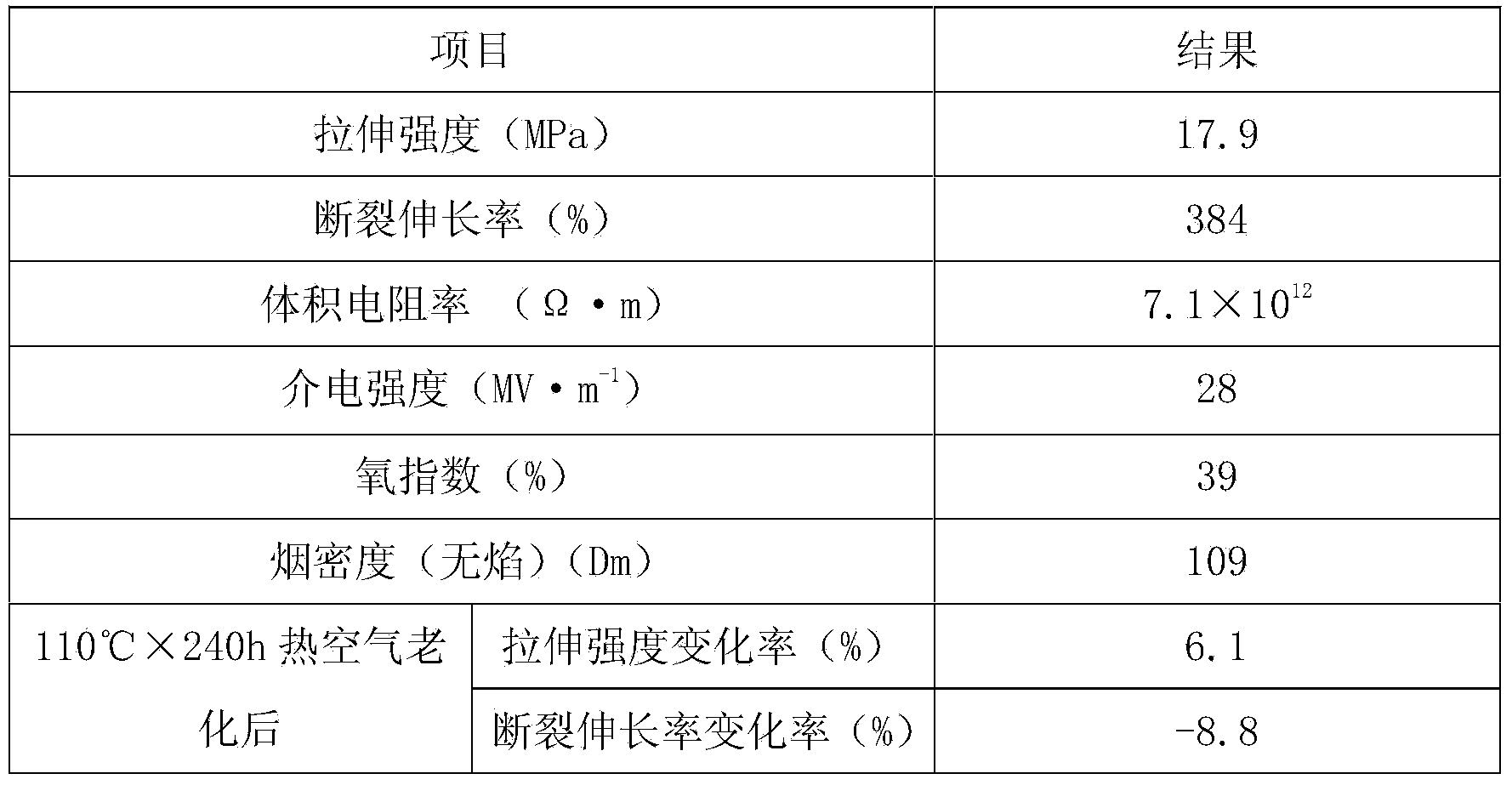

Silicone hydride crosslinked non-halogen flame-proof smoke-restraining polyvinyl chloride cable material and manufacturing process thereof

InactiveCN101319079AEasy to processPromote degradationInsulated cablesInsulated conductorsPolyvinyl chlorideFire retardant

The invention discloses a silane crosslinking HFFR flame retardant polyvinyl chloride cable material and a preparation technique thereof. The compositions by weight portion of the cable material are: 100 portions of polyvinyl chloride resin, 10 to 100 portions of a plasticizer, 0.5 to 10 portions of a silane cross-linking agent, 0.5 to 6 portions of a heat stabilizer, 30 to 100 portions of a metal hydroxide flame retardant, 1 to 10 portions of a metallic compound flame retardant synergist, 0.1 to 5 portions of a preventing cross-linking agent, 0.1 to 5 portions of a lubricant, 0.1 to 0.5 portion of an antioxidizer, 0.05 to 0.1 portion of dibutyl tin dilaurate and appropriate amount of a colorant. The cable material has the characteristics that the mechanical property is good, the mechanical intensity is increased by 20 to 30 percent compared with the uncrosslinked PVC cable material, the heat resistance is good, the electrical property is good, the specific volume resistance is increased by 3 to 5 times compared with the uncrosslinked PVC cable material, the insulating property of the cable is improved and the aging property is good.

Owner:LIAOCHENG UNIV

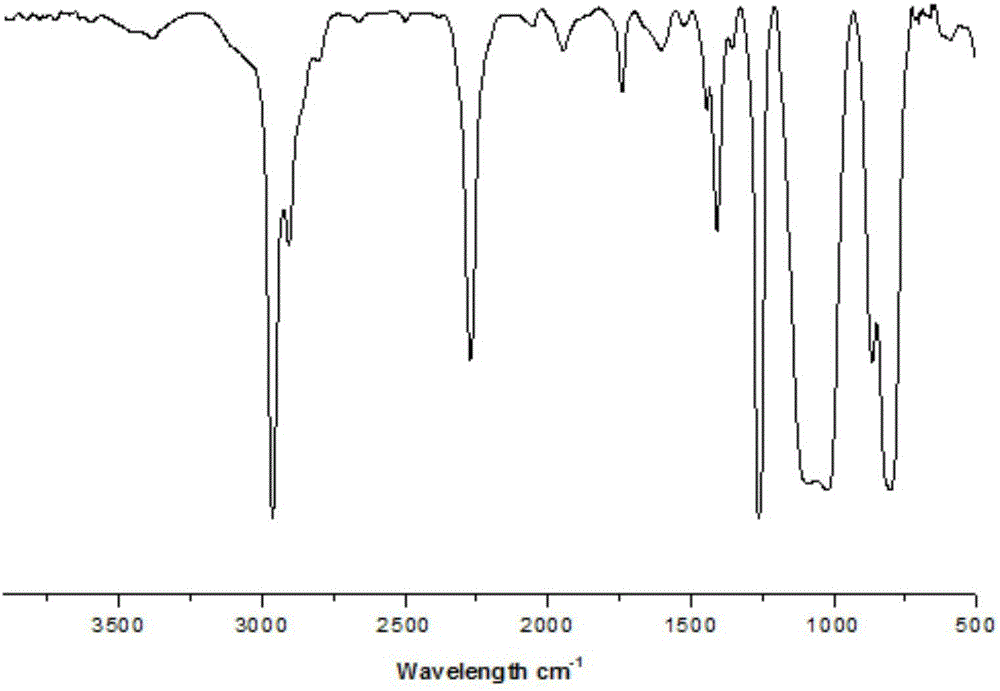

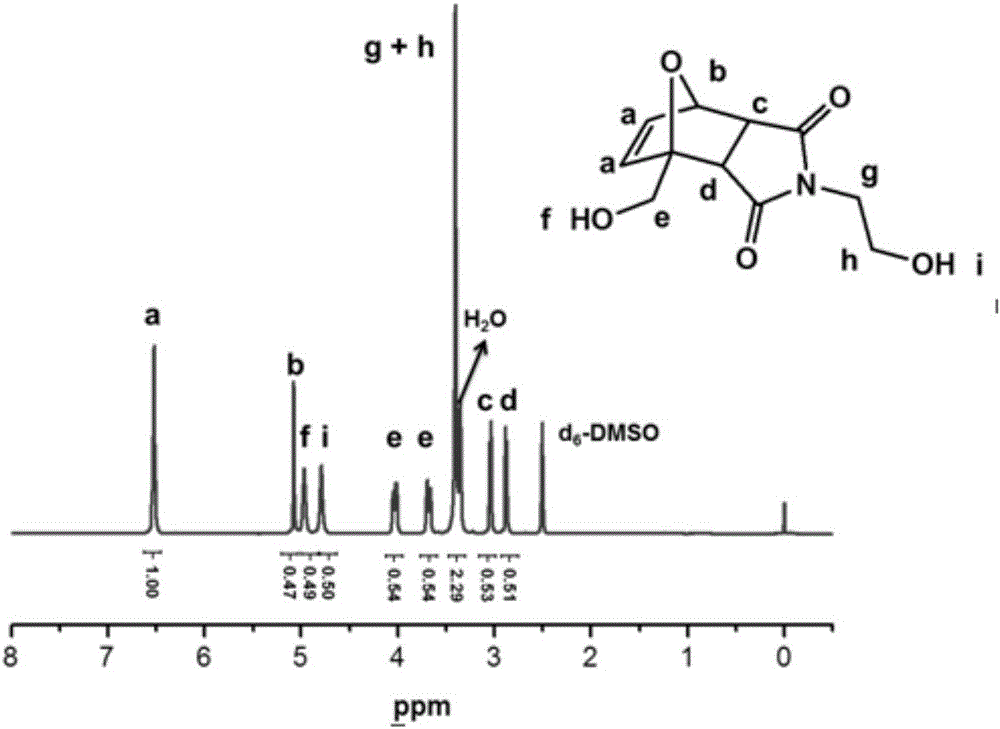

Polysiloxane-carbamate elastomer containing Diels-Alder bond and preparation method of polysiloxane-carbamate elastomer

InactiveCN105949422AHigh tensile strengthHigh elongation at breakOrganic chemistryElastomerPolyester

The invention relates to the field of materials, in particular to a polysiloxane-carbamate elastomer containing a Diels-Alder bond and a preparation method of the polysiloxane-carbamate elastomer. The polysiloxane-carbamate elastomer is prepared from a cross-linking agent, isocyanato-terminated polydimethylsiloxane, isocyanato-terminated polyester or polyether, diol containing the Diels-Alder bond as well as a catalyst dibutyltin dilaurate through curing after a reaction in anhydrous 1,4-dioxane under the protection of nitrogen. The elastomer has a microphase separation structure, multiple plastic micro-areas are formed in the elastomer, and on one hand, the micro-areas are taken as physical crossing points to improve tensile strength; on the other hand, the plastic micro-areas generate plastic deformation in a stretching process to increase elongation at break. The method adopts easily available raw materials, a synthesis process requires no special conditions or equipment, a synthesis technology is simple and easy to control, and the yield is high.

Owner:SICHUAN UNIV

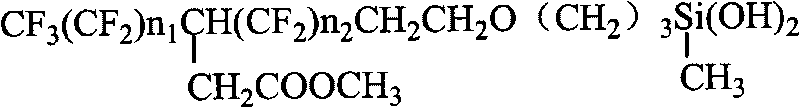

Aqueous fluorine-containing acrylate modified polyurethane coating, preparation method and application thereof

The present invention belongs to the field of polymer material synthesis, relates to aqueous polyurethane acrylate emulsion modification, and especially to an aqueous fluorine-containing acrylate modified polyurethane coating, a preparation method and an application thereof. The preparation method comprises: dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding diisocyanate in a dropwise manner; adopting dibutyltin dilaurate as a catalyst, and adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt, then adding deionized water to prepare an aqueous polyurethane acrylate prepolymer emulsion; and finally adding hexafluorobutyl acrylate and azodiisobutyronitrile to prepare the aqueous fluorine-containing acrylate modified polyurethane coating. The synthesized emulsion of the present invention has the following advantages that: dispersion is uniform; stability is good; water resistance and mechanical property of the cured film are substantially improved; elasticity and mechanical property of polyurethane are provided; ultraviolet resistance, nuclear radiation resistance, flexibility, excellent surface properties, water resistance and corrosion resistance of the fluorine-containing material are provided; and the coating can be adopted as coatings for building and furniture.

Owner:BOMEX CHEM SHANGHAI

Coloring agent for textile fabric

The invention discloses a coloring agent for a textile fabric. The coloring agent consists of the following ingredients in parts by weight: 1 to 2 parts of polypropylene glycol, 2 to 3 parts of tetracarboxydiphthalic ether dianhydride (ODPA), 1 to 2 parts of zinc stearate, 4 to 5 parts of trimethylolpropane, 4 to 5 parts of mica powder, 5 to 6 parts of butyl methacrylate, 4 to 5 parts of dibutyltin dilaurate, 3 to 4 parts of polyurethane, 6 to 7 parts of iron oxide red, 1 to 2 parts of dibutyl phthalate, 3 to 4 parts of ethyl acetate, 3 to 4 parts of an initiator, 5 to 6 parts of closed blocked isocyanate, 5 to 6 parts of water and 2 to 3 parts of polyvinylpyrrolidone. The coloring agent for the textile fabric is easy for coloring and unlikely to fade.

Owner:江苏金牛华尔车服饰有限公司

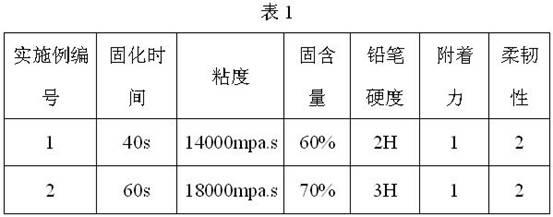

Elastic handfeel paint

InactiveCN101921538AAvoid it happening againIncrease productivityPolyurea/polyurethane coatingsDibutyl tin dilauratePolyester resin

The invention relates to an elastic handfeel paint, comprising a hydroxy component A and a curing agent component B, wherein the hydroxy component A is prepared by the following raw materials by weight percent: 35-38% of hydroxy linear saturated polyester resin, 0.1-0.3% of dibutyltin dilaurate catalyst, 0.5-1% of levelling agent, 6.5-7% of extinction powder, 2-3% of polyurethane modified wetting and dispersing agent, 2-3% of nano pigment and 48-53% of mixed solvent; and the curing agent component B is prepared by the following raw materials by weight percent: 60-80% of HDI tripolymer and 20-40% of anhydrous butyl acetate. The hydroxy component A and the curing agent component B are mixed to obtain the polyurethane elastic handfeel paint, wherein the equivalent weight ratio of -NCO in the HDI tripolymer of the curing agent component B to -OH in the hydroxy linear saturated polyester resin of the hydroxy component A is 1.05:1.2. The elastic handfeel paint has an intrinsic color, thus being free of secondary spraying.

Owner:DONGGUAN PAINT KEY PRECISE INDAL

Stain-resistant and oil-resistant wallpaper and preparation method thereof

The invention discloses stain-resistant and oil-resistant wallpaper. The stain-resistant and oil-resistant wallpaper comprises a substrate layer, a stain-resistant layer and an oil-resistant layer, wherein the outer periphery of the substrate layer is coated with the stain-resistant layer, and the outer periphery, far away from the substrate layer, of the stain-resistant layer is coated with the oil-resistant layer; the oil-resistant layer is prepared from the raw materials: acrylic perfluoroalkyl ester, alkyd resin, polyester resin, perfluoroalkyl acrylate, butyl acrylate, hydroxyethyl acrylate, aluminum tripolyphosphate, nano zinc borate, potassium persulfate, hydroxymethyl cellulose, nano zinc oxide, nano titanium dioxide, diatomite, magnesium hydroxide, aluminum oxide, organobentonite, sericite powder, perfluorocarbon, ferric phosphate, sodium molybdate, sodium persulfate, chlorinated paraffin, silane coupling agent KH-560, dibutyltin dilaurate, octadecyl trimethyl ammonium chloride, polyethylene glycol, fluorosilicon oil, a thickener, an antifoamer, a curing agent and modifying auxiliaries. The invention further provides a preparation method of the stain-resistant and oil-resistant wallpaper. The prepared wallpaper has excellent stain resistance and oil resistance.

Owner:安徽易有墙纸有限公司

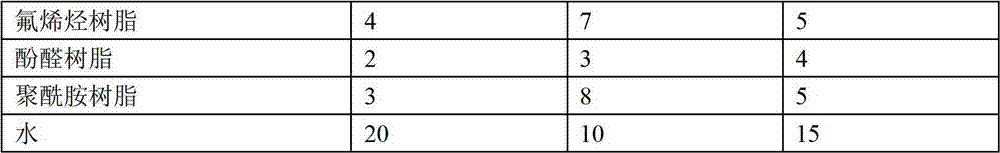

Waterproof coating

ActiveCN102850909AImprove liquidityIncrease breathabilityPolyamide coatingsEpoxy resin coatingsEpoxyAcrylic resin

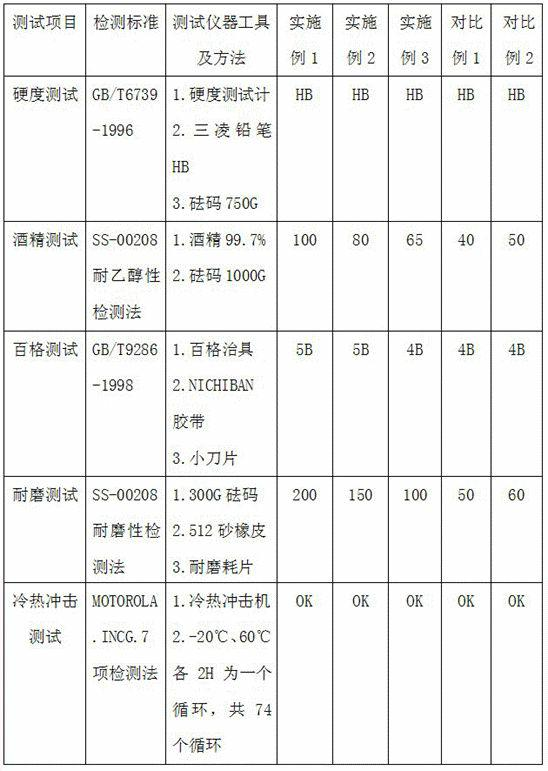

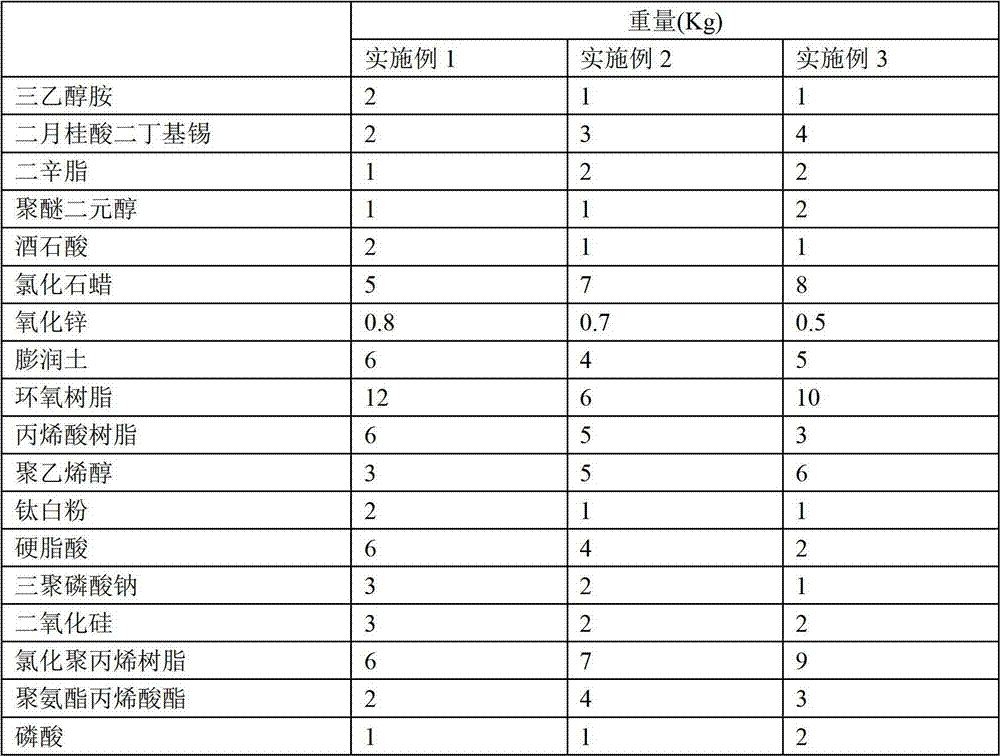

The invention provides a waterproof coating, which belongs to the technical field of coatings. The waterproof coating comprises, by weight, 1 to 2 parts of triethanolamine, 2 to 4 parts of dibutyltin dilaurate, 1 to 2 parts of DOP, 1 to 2 parts of polyether glycol, 1 to 2 parts of tartrate, 5 to 8 parts of chlorinated paraffin, 0.5 to 0.8 part of zinc oxide, 4 to 6 parts of bentonite, 6 to 12 parts of epoxy resin, 3 to 6 parts of acrylic resin, 3 to 6 parts of polyvinyl alcohol, 1 to 2 parts of titanium dioxide, 2 to 6 parts of stearic acid, 1 to 3 parts of sodium tripolyphosphate, 2 to 3 parts of silica, 6 to 9 parts of chlorinated polypropylene resin, 2 to 4 parts of polyurethane acrylate, 1 to 2 parts of phosphoric acid, 4 to 7 parts of fluoro-olefin resin, 2 to 4 parts of phenolic resin, 3 to 8 parts of polyamide resin and 10 to 20 parts of water. The waterproof coating provided by the invention has excellent waterproof performance and strong adhesion with a substrate.

Owner:苏州市德莱尔建材科技有限公司

Wear-resistant and heatproof modified polyurethane rubber cable material

InactiveCN105602238AImprove performanceGood wear resistance and heat resistancePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl alcohol

The invention discloses a wear-resistant and heatproof modified polyurethane rubber cable material which comprises the following raw materials: modified polyurethane, acrylate rubber, ethylene-propylene-diene monomer, nitrile butadiene rubber, epoxy resin, polyether glycol, toluene diisocynate, polyvinyl alcohol, diisobutyltin dilaurate, polyvinyl chloride, hydroxyl-terminated polybutadiene, hydroxyl-terminated polyalcohol, isocyanate, vinyltriethoxysilane, dibutyltin dilaurate, silicone oil, a carbon nanotube, organic modified montmorillonoid, nano alumina powder, talc powder, bamboo carbon fiber, chlorinated paraffin, silicon dioxide, zinc oxide, stearic acid, nano aluminum hydroxide, a flame retardant, an anti-aging agent, a plasticizer, an antioxidant and an accelerant. The modified polyurethane rubber cable material disclosed by the invention has excellent wear-resistant and heatproof properties.

Owner:ANHUI DUJIANG CABLE GROUP

Preparation method of light-resistant waterborne polyurethane

The invention discloses a preparation method of light-resistant waterborne polyurethane, which comprises the steps of mixing polytetramethylene ether glycol with diisocyanate in the presence of a dibutyltin dilaurate catalyst, stirring at 70-90 DEG C for reaction for 2-4h, obtaining a polyurethane prepolymer, adding a hydrophilic chain extender, a polyhydroxyl compound and butanone into the polyurethane prepolymer, stirring at 70-90 DEG C for reaction for 1.0-3.5 h, adding triethylamine for neutralizing, stirring for reaction for 40-60min, adding water for emulsification to form hydrophilic polyurethane, adding a nano emulsion into a hydrophilic polyurethane system, shearing and stirring for 40-60min under the condition that a pH value is 7, and obtaining light-resistant waterborne polyurethane. Prepared light-resistant waterborne polyurethane is environment-friendly and low in price, and can meet the demand of a market on a property of light-resistant polyurethane.

Owner:上海力太化学有限公司

Coating compositions having extended pot life and shortened cure time and combination of chemicals used therein

InactiveUS6084026AExtension of timeRaise the ratioSynthetic resin layered productsPolyurea/polyurethane coatingsCarbamateDibutyl tin dilaurate

A combination of chemicals suitable for extending pot life and shortening cure time of a pot mix of a thermosetting composition is disclosed. The combination of chemicals includes a catalyst, such as, dibutyl tin dilaurate; carboxylic or sulfonic acid; and an extender compound, such as 2,4 pentanedione. The combination is generally included in a polymeric component of the urethane composition. The extended pot life provides the user with longer open time during which to efficiently apply a coating of the pot mix over a wide variety of substrate surfaces while still producing coatings that cure quickly upon application.

Owner:ROHM & HAAS CO

Method for preparing biodegradable polyurethane rigid foam from bamboo waste liquefaction products

InactiveCN101362818ARealize the purpose of turning waste into treasureReduce dependencePolymer scienceReaction temperature

The invention discloses a method for preparing biodegradable rigid polyurethane foam with liquefaction products of bamboo waste, which comprises the following steps: 1 mass portion of crude glycerin / polyethylene glycol liquefying solvent and 0.02-0.04 mass portion of concentrated sulfuric acid are added into a reaction vessel, heated till the temperature reaches 120-180 DEG C after a reflux condensation tube is connected to the reaction vessel; 0.2-0.5 mass portion of crushed and dried bamboo waste is added, reacted for 90-180min with stirring, taken out and cooled and neutralized by MgO till being neutral; 1 mass portion of liquefaction products of bamboo waste, 0.02-0.08 portion of a dibutyl tin dilaurate / triethylene diamine mixed catalyst, 0.02-0.06 portion of silicone oil, 0.02-0.1 portion of water and 0.1-0.15 portion of fire retardant are added into a container, premixed for 20-30s when stirred at 2,000r / min, added with sufficient PAPI with the molar ratio between isocyanato-NCO in PAPI and hydroxyl group-OH in bamboo waste liquefaction products being 0.6-1.2, stirred for 10s-15s at 1,000r / min, put into a mould, foamed with standing at room temperature, placed for slaking and mould separating at room temperature for 24h-72h after reaction. The method fully utilizes resources, reduces liquefaction cost, and has a mild reaction temperature and stable liquefaction products; the performance of obtained foam meets the national standard and biodegradability.

Owner:NANCHANG UNIV

Weather-proof polyolefin wire cable material and preparation method thereof

InactiveCN104109276AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsEpoxyPolyolefin

The invention discloses a weather-proof polyolefin wire cable material and a preparation method thereof, the cable material comprises the raw material by weight: 60-80 parts of LDPE, 15-25 parts of EVA, 10-15 parts of SEBS, 14-18 parts of magnesium hydroxide, 2-4 parts of stearic acid, 1-2 parts of zinc oxide, 5-10 parts of zinc borate, 1-2 parts of lead sulfate tribasic, 1-2 parts of vinyltriethoxysilane, 4-8 parts of octyl epoxy stearate, 0.5-1 part of light stabilizing agent GW-4800.5, 1-1.5 parts of anti-oxidant 215, 0.5-1 part of dibutyltin dilaurate, 0.5-1 part of dicumyl peroxide, 20-25 part of aluminum silicon black, 10-15 parts of nano barite, 5-10 parts of nano diatomite and 4-8 parts of composite filling material. The polyolefin cable material has excellent flame retardation performance, physical and mechanical properties and weatherability, can be widely used in electric power cable, communication cable, control cable, optical cable , subway cable, insulation or sheath, electronic wire, automobile and the like, and has the advantages of environmental protection and durable performance.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

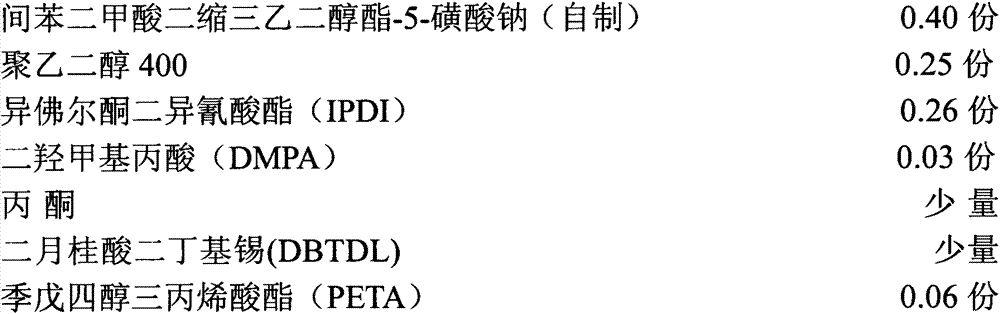

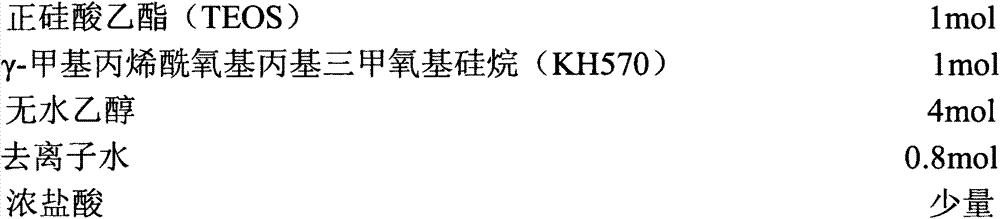

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Method of preparing fluorinated polyurethane paint and fluorinated polyurethane anticorrosive paint

InactiveCN104293158ALower surface energyExcellent water and oil repellencyAnti-corrosive paintsPolyurea/polyurethane coatingsPolyolMixed materials

The invention provides a method of preparing fluorinated polyurethane paint. The method is characterized by comprising the following steps: a step of preparing a component A, namely adding 15-60 parts of fluorinated polyether polyol and 0.01-0.03 part of dibutyltin dilaurate into a three-necked flask with a stirring rod in sequence, and stirring for 30 minutes to obtain the component A; a step of preparing a component B, namely adding 10-40 parts of 4,4-diphenyl methane diisocyanate and 0-30 parts of collaborative anticorrosive filler into 20-60 parts of a solvent system to stir and dissolve to obtain the component B; and a step of preparing fluorinated polyurethane anticorrosive paint, namely adding the component B into the three-necked flask filled with the component A, stirring for 8-10 minutes, grinding the mixed materials in the three-necked flask until fineness is 40-50 mu m after uniformly stirring, coating a metal sheet with the grinded mixed materials and curing for 24 hours to obtain the fluorinated polyurethane anticorrosive paint.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Single-component moisture curable polyurethane waterproof coating and preparation method thereof

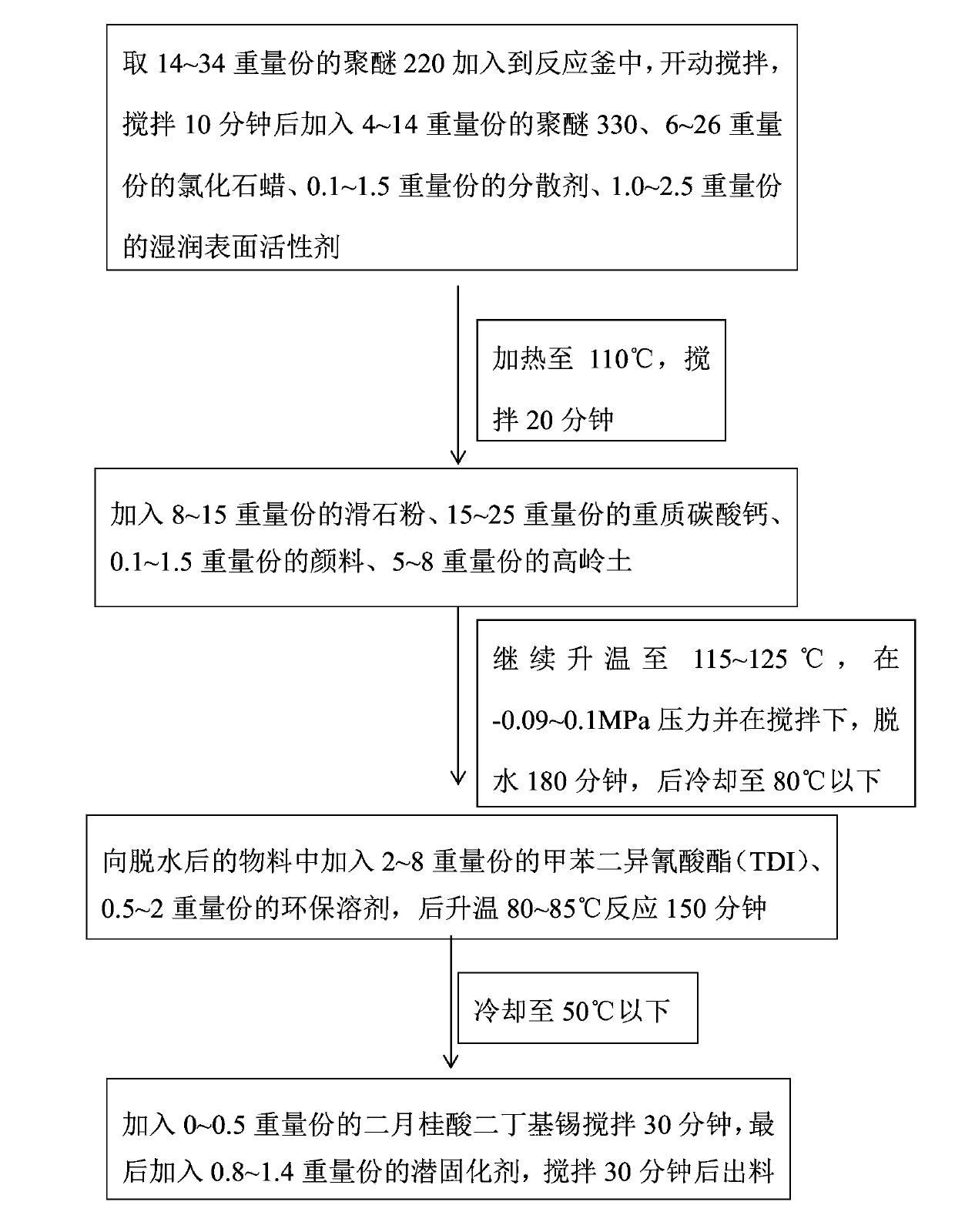

InactiveCN103965765ASolve the problem that the construction quality is difficult to guaranteeGood storage stabilityPolyurea/polyurethane coatingsToluene diisocyanateChlorinated paraffins

The invention provides a single-component moisture curable polyurethane waterproof coating and a preparation method thereof. The single-component moisture curable polyurethane waterproof coating comprises the following raw materials by weight: 14-34 part of polyether 220, 4-14 parts of polyether 330, 6-26 parts of chlorinated paraffin, 0.1-1.5 parts of a dispersing agent, 1.0-2.5 parts of a wetting surfactant, 8-15 parts of talcum powder, 15-25 parts of heavy calcium carbonate, 0.1-1.5 parts of a pigment, 5-8 parts of kaolin, 2-8 parts of toluene diisocyanate (TDI), 0.5-2 parts of environment-friendly solvent, 0-0.5 part of dibutyltin dilaurate, and 0.8-1.4 parts of a latent curing agent. In the preparation process of the polyurethane coating, the wetting surfactant and the latent curing agent are added, so that even if a fundamental plane with a lot of dust is encountered in a construction process of the coating, sand holes and other problems cannot arise. Adding of the latent curing agent can prevent the coating from undergoing micro-foaming during construction.

Owner:YANTAI DONGJU WATERPROOF THERMAL INSULATION ENG CO LTD

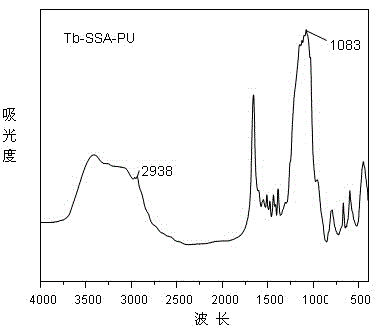

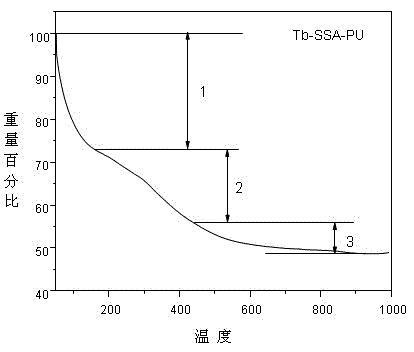

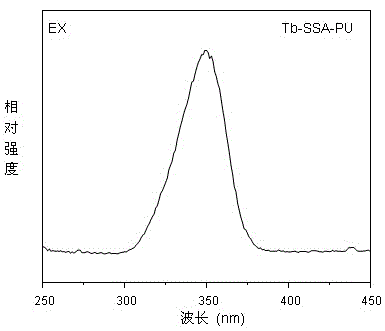

Rare-earth polyurethane high-polymer composite luminescent material and preparation method thereof

InactiveCN102876322AHigh Luminous Quantum EfficiencyImprove thermal stabilityLuminescent compositionsPolymer sciencePtru catalyst

The invention discloses a synthesis method of a rare-earth polyurethane high-polymer composite luminescent material, which comprises the following steps: after modifying a hydroxy-containing carboxylic acid organic ligand by a chemical method, and introducing rare-earth ions by a sol-gel method to obtain a binary rare-earth carboxylic acid hybrid material; and by using free hydroxy group in the hybrid material as active group and dibutyltin dilaurate (T12) as a catalyst, reacting with an organic substance diphenylmethane diisocyanate or toluene-2,4-diisocyanate with active group (isocyanate) to implement combination by a covalent bond, thereby obtaining the bonded rare-earth polyurethane high-polymer composite luminescent material which has the advantages of long fluorescence lifetime, high luminescent quantum efficiency and high heat stability. The preparation method of the rare-earth polyurethane high-polymer composite luminescent material has the characteristics of simple technique, mild reaction conditions, no need of any additive, low production cost and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Woven fabric capable of shielding UV light and imitating knitted effect and manufacturing method thereof

ActiveCN104726995AFunctional DiversificationFeel tightWoven fabricsConjugated synthetic polymer artificial filamentsDibutyl tin dilauratePolypropylene

The invention discloses woven fabric capable of shielding UV light and imitating a knitted effect. The woven fabric is formed by the way that warps and wefts are knitted by an air jet loom. The warps and the wefts comprise, by weight, 24-35 parts of isotatic polypropylene, 20-25 parts of polyester fibers, 3-5 parts of diatom ooze, 2-4 parts of nano-TiO2, 18-26 parts of waste cotton fibers, 20-26 parts of bamboo charcoal fibers, 13-16 parts of soybean protein fibers, 19-27 parts of mulberry bark fibers, 5-8 parts of EPDM, 6-9 parts of ethyl acetate, 12-17 parts of glycidyl methacrylate, 0.3-0.7 part of dibutyltin dilaurate, 2-4 parts of schisandra chinensis, 1-3 parts of folia perillae acutae, 90-110 parts of 1-butyl-3-methylimidazole acetate, 100-120 parts of 1-allyl-3-methylimidazole chlorine salt, 5-8 parts of auxiliaries and an appropriate amount of water. The woven fabric has the advantages of being tight and stiff in hand feeling, capable of achieving a visual effect, antibacterial, capable of keeping warm and the like.

Owner:安徽省中日农业环保科技有限公司

High temperature-resistant ultralow temperature-cured epoxy polyester powdery coating

InactiveCN103275597AReasonable formulaLow curing temperaturePowdery paintsEpoxy resin coatingsEpoxyLow temperature curing

The invention discloses a high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating solves the problem that the existing low temperature-cured epoxy polyester powdery coating has poor heat resistance and poor thermal conductivity so that in curing, temperatures in a coating film prepared from the existing low temperature-cured epoxy polyester powdery coating are not different and coating curing rates are not different and thus the coating film produces orange peel phenomenon and even crazes and coating film surface-effects are influenced. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating is prepared from 30 to 40wt% of epoxy resin, 15 to 20wt% of polyester resin, 0.5 to 1.5wt% of polyarylene sulfide resin, 10 to 15wt% of titanium dioxide, 2 to 5wt% of nano-metal powder subjected to surface treatment, 0.5 to 1wt% of dibutyltin dilaurate, 1 to 3wt% of an assistant, 1 to 5wt% of sodium fluoride, 15 to 20wt% of a filling material and 10 to 15wt% of a pigment. The high temperature-resistant ultralow temperature-cured epoxy polyester powdery coating has a low curing temperature, good heat resistance, and physical and mechanical properties and chemical resistance satisfying industrial requirements.

Owner:HANGZHOU GOLDEAGLE PLASTIC POWDER

Preparation method of antibacterial type soft polyurethane foaming plastic

InactiveCN103467702AGood antibacterial and bactericidal performanceStable heat resistancePolymer scienceButanediol

The invention discloses a preparation method of an antibacterial type soft polyurethane foaming plastic. The preparation method is characterized by comprising the following technical steps: a, adding metered polyether glycol N330 and 1,4-butanediol, a catalytic amount of dibutyltin dilaurate and tripolycyanamide to a reaction kettle, filling nitrogen or an inert gas into the reaction kettle for protection, heating at 40-60 DEG C, sufficiently stirring for 6-8 hours, and reducing temperature to 25 DEG C; b, adding polyisocyanate, silicone oil, triethylamine, nanometer zinc oxide and a right amount of water to a product obtained from the step a, and stirring at high speed till foaming; c, when a large quantity of white foams appear, immediately injecting the white foams into a mould, aging at 40-60 DEG C for 60-150 minutes, and demoulding to obtain a soft polyurethane foaming plastic product. The obtained polyurethane soft foaming plastic has the advantages of good antibacterial and bactericidal property, stability in heat-resistant property, no bactericide separation, safety, environment protection, simpleness and convenience for production process and suitability for industrialized production.

Owner:NANJING NIANJI REFRIGERATION FOOD

Method for preparing ultraviolet photocuring polyurethane resin based on polybasic isocyanate and polybasic hydroxy polyacrylate

InactiveCN102050938AThe synthesis process is simpleLong storage periodPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention relates to a method for preparing ultraviolet photocuring polyurethane resin based on polybasic isocyanate and polybasic hydroxy polyacrylate. The method comprises the following steps of: 1) adding monohydroxy acrylic ester, butanol and dibutyltin dilaurate into a constant-pressure dropping funnel; 2) regulating the temperature of an oil bath pot to be between 20 and 50 DEG C after dropping is finished in the step 1), reacting for 1 to 2 hours and stopping the reaction; 3) adding 20 to 30 weight parts of polyhydroxy acrylic resin and 0.5 to 1.5 weight parts of inhibitor 4-methoxy phenol into a reaction product obtained in the step 2); and 4) adding 5 to 15 weight parts of active monomer thinner according to the solid content to obtain a product. The method has the advantages of performing polyfunctional monomer premature crosslinking, introducing more double bonds, and improving the crosslinking and relative molecular weight of a paint film; and the product has high mechanical properties and greatly improved corrosion resistance.

Owner:NANCHANG HANGKONG UNIVERSITY +1

Method for preparing fire-retarding aqueous polyurethane

The invention discloses a method for preparing fire-retarding aqueous polyurethane, which comprises the following steps of: reacting a polyhydroxyl phosphorus compound and hexamethylene diisocyanate in the presence of a dibutyltin dilaurate catalyst for 1 to 3h to obtain a polyurethane prepolymer; adding hydrophilic chain extender containing 1.5 to 3 percent by total weight of polyurethane prepolymer of carboxyl and a butanone solvent which is 10 to 20 percent by the total weight of polyurethane prepolymer into the polyurethane prepolymer, reacting for 2 to 3h, adding triethylamine, neutralizing the reaction solution for 20 to 40min, and adding water for emulsification to form hydrophilic polyurethane; and adding bentonite dispersion liquid and phospholipid into the hydrophilic polyurethane, and shearing and stirring for 30 to 80 minutes under a condition of a pH value of 7 to obtain the fire-retarding aqueous polyurethane. The polyurethane has greatly improved fire retardance and mechanical property.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Anti-pollution flashover coating and preparation method thereof

ActiveCN101735727AWith flame retardant synergistic effectAdd lessFireproof paintsAntifouling/underwater paintsAluminium hydroxideSilicon dioxide

The invention discloses an anti-pollution flashover coating and a preparation method thereof. The anti-pollution flashover coating consists of the following compositions in part by weight: 20 to 40 parts of hydroxyl-terminated polyorganosiloxane, 4 to 8 parts of modified silicon fluorine resin, 1 to 3 parts of small molecular siloxane, 3 to 6 parts of nanometre silicon dioxide, 1 to 3 parts of decabromdiphenylethane (DBDPE), 1 to 3 parts of wollastonite, 4 to 8 parts of aluminium hydroxide, 1 to 2 parts of pigment, 1 to 6 parts of crosslinker, 0.02 to 1 part of catalyst and 30 to 60 parts of solvent, wherein the small molecular siloxane is trimethyl end-capped polydimethylsiloxane; the catalyst is dibutyltin dilaurate or stannous octoate; and the solvent is a mixed solvent of dimethylbenzene and butyl acetate in a weight ratio of 3:1-5:1. The prepared coating has the advantages of high flame retardant grade and good anti-pollution effect.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Preparation method of light-resistant water-based polyurethane coating

InactiveCN103436155AGood compatibilityGood light fastnessPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method of a light-resistant water-based polyurethane coating. The preparation method comprises the following steps of: mixing bisphenol S and diisocyanate in the presence of a dibutyltin dilaurate catalyst, and stirring to react at 60-85 DEG C for 1.5-3.5 hours to obtain a polyurethane prepolymer A; adding a hydrophilic chain extender with carboxyl content accounting for 1.2%-4.6% of the weight of A into A, then adding a solvent which accounts for 15%-35% of the weight of A, and stirring to react under the condition of 80-95 DEG C for 1.0-4.0 hours; adding triethylamine according to the condition that the mole ratio of COOH / NH2 is 0.6:(1-1.6):1 for neutralization, stirring to react for 30-70 minutes, and adding water for emulsification to form the light-resistant water-based polyurethane coating. The prepared light-resistant water-based polyurethane is environmentally-friendly and low in cost and can meet the requirement of the market on the property of light-resistant polyurethane.

Owner:HESHAN YIXIN CHEM CO LTD

Preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials

The invention discloses a preparation method for waterborne polyurethane with improved fire resistance by virtue of nano materials. Under the condition that a dibutyltin dilaurate catalyst exists, PTMG and IPDI (isophorone diisocyanate) are mixed for reaction at the temperature of 75-95 DEG C for 1.5-3.5 hours, so that polyurethane prepolymer can be obtained; a hydrophilic chain extender, of which the weight of carboxyl groups is 1.2-3.2 % of that of the polyurethane prepolymer, and an acetone solvent, of which the weight is 12-25% of that of the polyurethane prepolymer, are added into the polyurethane prepolymer for reaction at 65-85 DEG C for 1.5-3.5 hours, then, triethylamine is added for neutralization reaction for 30-50 minutes, and water is added for emulsification, so that polyurethane emulsion A can be formed; nano material emulsion, with the weight being 5-10% of that of the polyurethane emulsion A, is added into the polyurethane emulsion A, and the mixture of the nano material emulsion and the polyurethane emulsion A is subject to shear agitation for 20-50 minutes under the condition that the pH value is 7, as a result, the fire resistance waterborne polyurethane can be obtained. The prepared fire resistance polyurethane is environment-friendly and low is price, and can meet the low cost requirement on fire resistance leather products by the market.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com