Silicone hydride crosslinked non-halogen flame-proof smoke-restraining polyvinyl chloride cable material and manufacturing process thereof

A polyvinyl chloride cable, silane cross-linking technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of material processing performance and mechanical performance deterioration, large addition of inorganic flame retardants, and uneven cable surface. Improve the effect of degradation and product surface roughness, low smoke density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

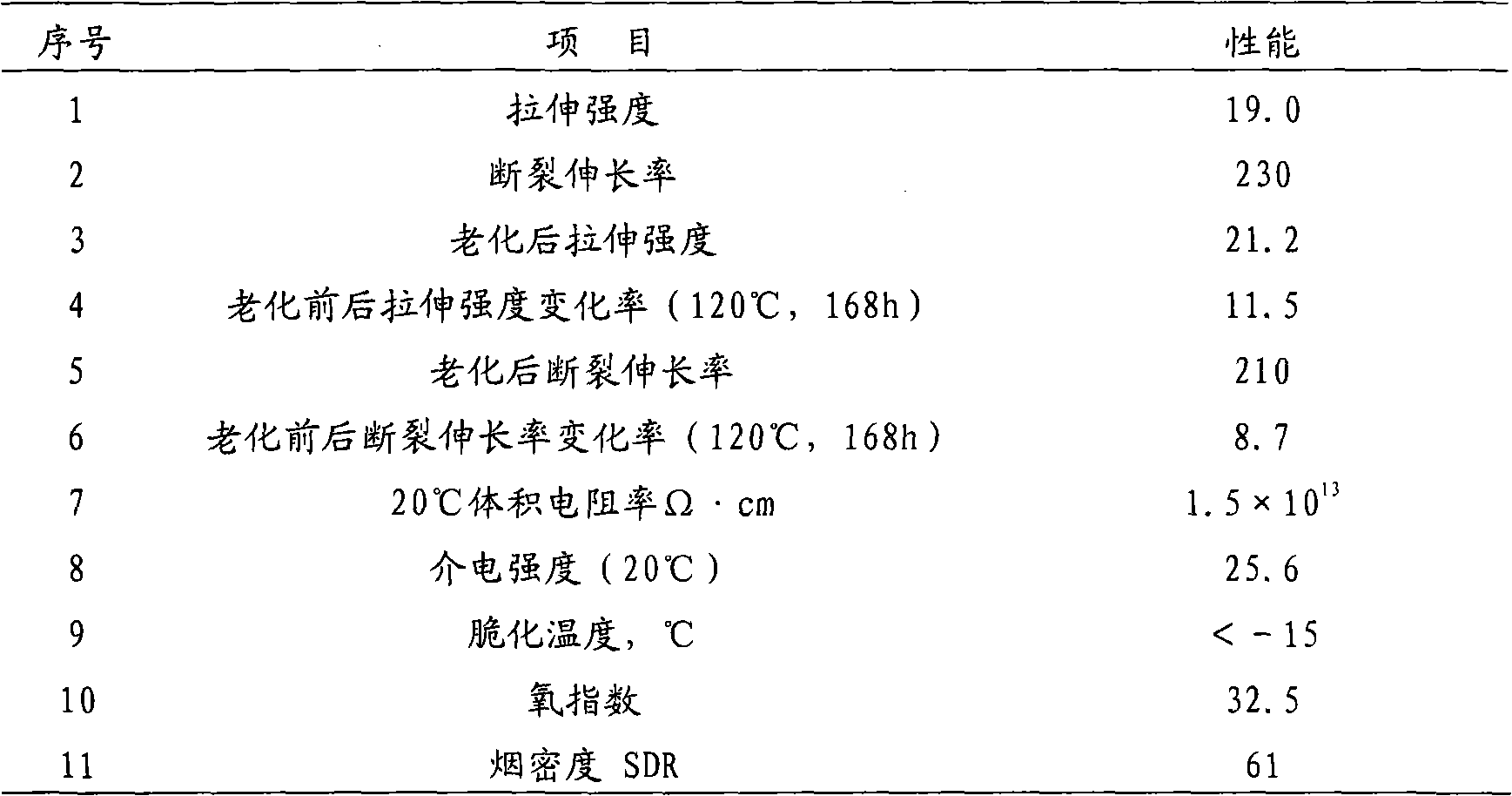

[0020] The technical solution proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but is not limited thereto.

[0021] The invention provides a silane cross-linked halogen-free flame-retardant and smoke-suppressing polyvinyl chloride cable material, which uses the following materials: PVC resin, heat stabilizer, lubricant, cross-linking agent, flame retardant and synergist, Plasticizer, anti-pre-crosslinking agent, catalyst dibutyltin dilaurate.

[0022] The plasticizer can be selected from one or more of dioctyl phthalate, dibutyl phthalate, trioctyl trimellitate, and chlorinated paraffin. Silane crosslinking agent can choose γ-aminopropyltrimethoxysilane, γ-aminopropyltriethoxysilane, β-(aminoethyl)γ-aminopropylmethyldimethoxysilane, β-( Aminoethyl)γ-aminopropylmethyldiethoxysilane, N-β-(aminoethyl)γ-aminotrimethoxysilane, N-phenyl-γ-aminopropyltrimethoxysilane, 3 - One or more of mercaptopropyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com