Patents

Literature

4720 results about "Phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phthalates (US: /ˈθæleɪts/, UK: /ˈθɑːleɪts/), or phthalate esters, are esters of phthalic acid. They are mainly used as plasticizers, i.e., substances added to plastics to increase their flexibility, transparency, durability, and longevity. They are used primarily to soften polyvinyl chloride (PVC).

Curable composition

InactiveUS20090182091A1Less discolorationGood adhesivenessOther chemical processesEster polymer adhesivesSilylenePlasticizer

The present invention has its object to provide a curable composition which comprises a guanidine compound as a non-organotin type catalyst, is less discolored, has good surface curability, depth curability, strength rise and adhesiveness, and can retain the curability even after storage; the above object can be achieved by a curable composition which comprises: (A) an organic polymer containing a silyl group capable of crosslinking under siloxane bond formation, the silyl group being a group represented by the general formula (1): —SiX3 (1) (wherein X represents a hydroxyl group or a hydrolyzable group and the three X groups may be mutually the same or different), (B) a guanidine compound (B-1) as a silanol condensation catalyst, and (C) a plasticizer, wherein the content of the component (B-1) is not lower than 0.1 part by weight but lower than 8 parts by weight per 100 parts by weight of the component (A), and a non-phthalate ester plasticizer accounts for 80 to 100% by weight of the (C) component plasticizer.

Owner:KANEKA CORP

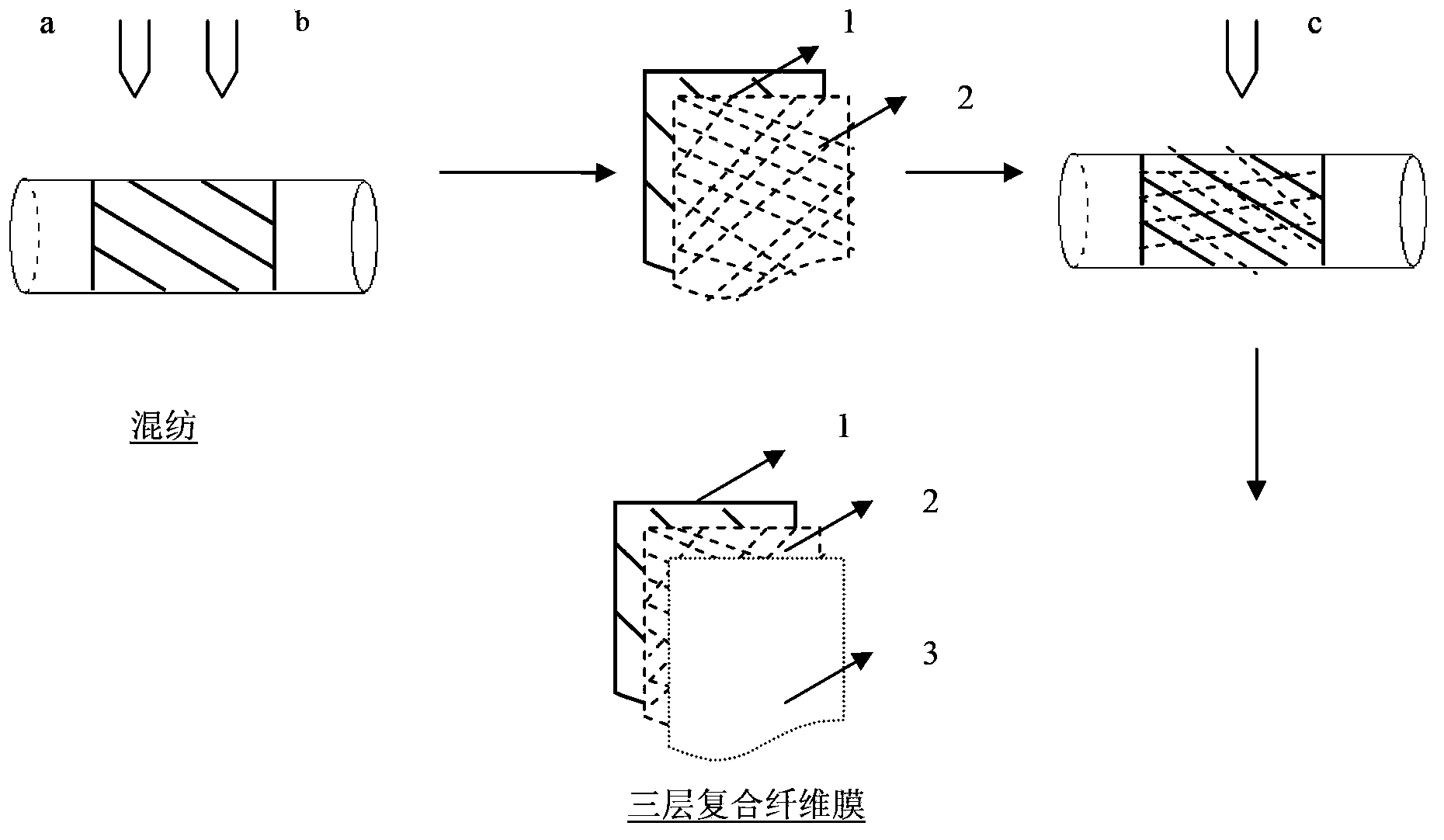

Antibacterial composite nanometer fiber high-efficiency air filtering material and preparation method thereof

ActiveCN103520999AGood air filtration efficiencyImprove adhesionSynthetic resin layered productsFiltration separationFiberComposite nanofibers

The invention relates to an antibacterial composite nanometer fiber high-efficiency air filtering material and a preparation method thereof, and belongs to the field of preparation of air filtering materials. The antibacterial composite nanometer fiber high-efficiency air filtering material sequentially comprises a non-woven fabric support layer, a filter layer and a nanometer fiber filter layer, wherein the filter layer is obtained by blending antibacterial fibers and micrometer fibers. When harmful air which contains bacteria and viruses passes through the antibacterial composite nanometer fiber high-efficiency air filtering material, the antibacterial composite nanometer fiber high-efficiency air filtering material disclosed by the invention can achieve antiviral and antibacterial effects and has high filter efficiency effect on tiny particles contained in air; the antibacterial composite nanometer fiber high-efficiency air filtering material disclosed by the invention has the advantages of antibacterial effect, and high filter efficiency and relatively lower resistance on the tiny particles contained in air, can achieve the filter efficiency on oily DOP (Dioctyl-Phthalate) particles with the grain diameters of 0.3 micrometers at 99.99% and achieve the filter efficiency on sodium chloride particles of 0.07-0.2 micrometers more than 99.99%, has the advantages of light weight, softness, and the like in practical application and can be used for preparing antibacterial protective articles, such as a mask, a protective mask and application protective clothes.

Owner:BEIJING INST OF CLOTHING TECH

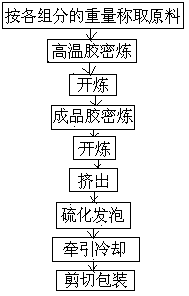

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

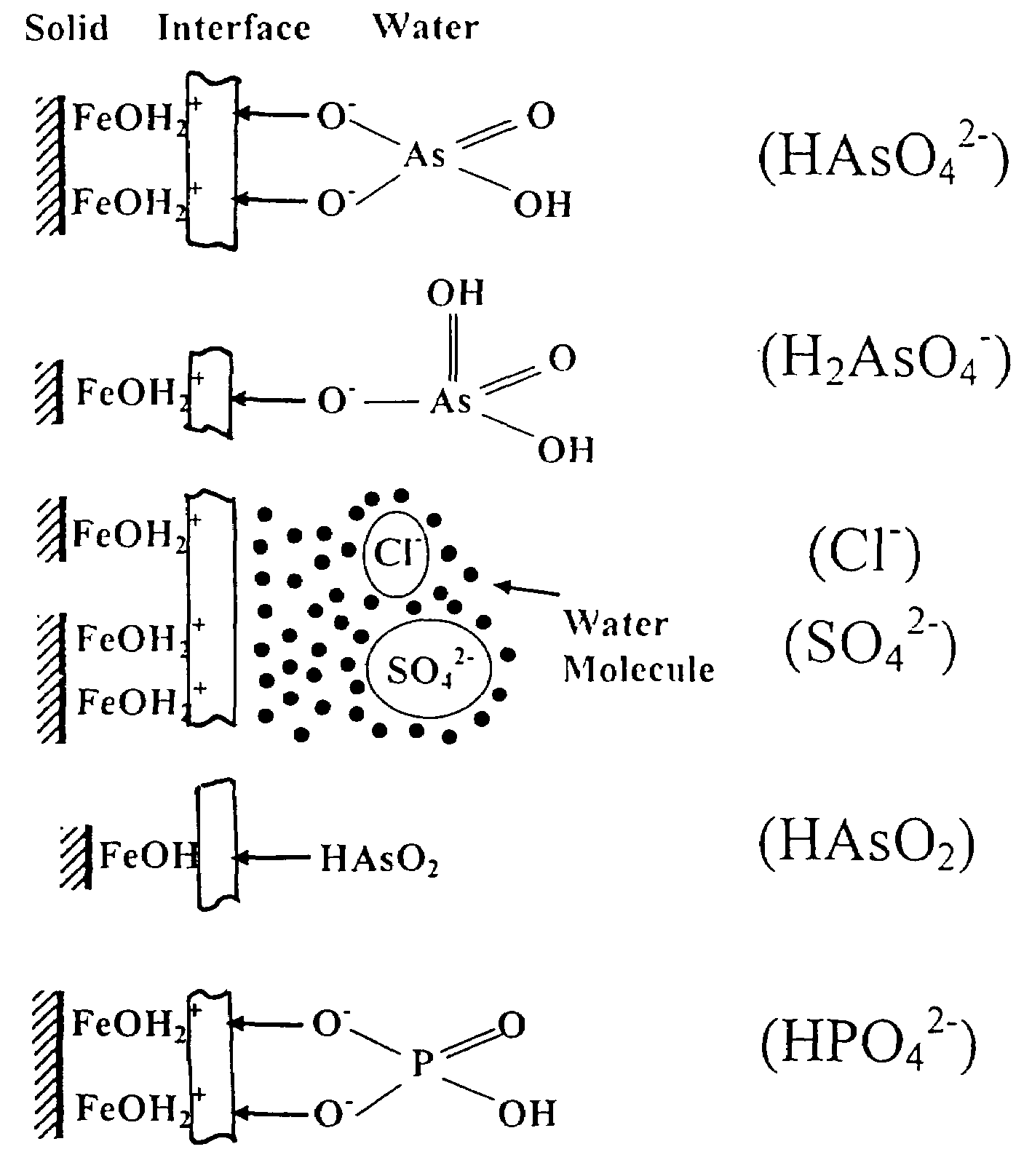

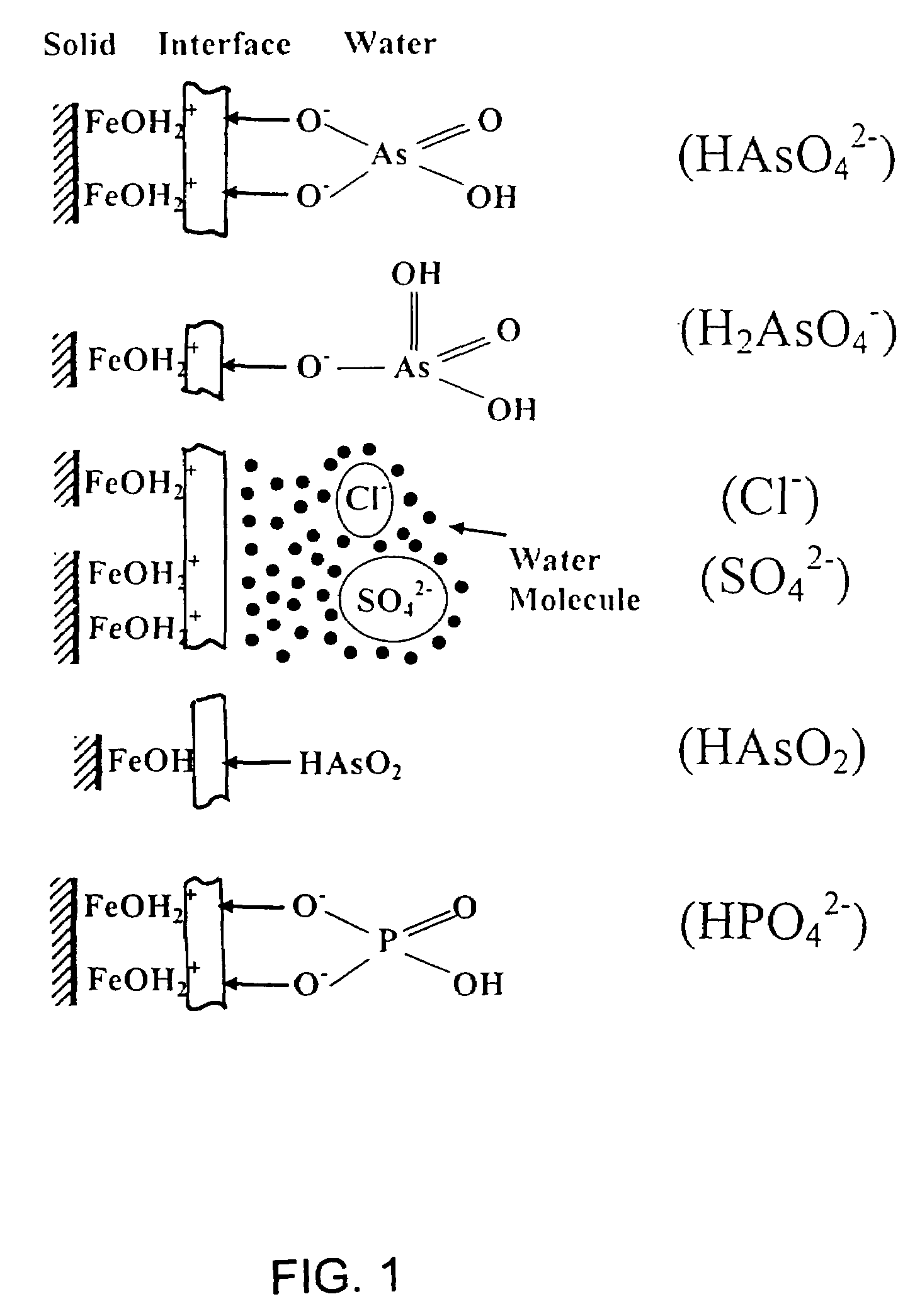

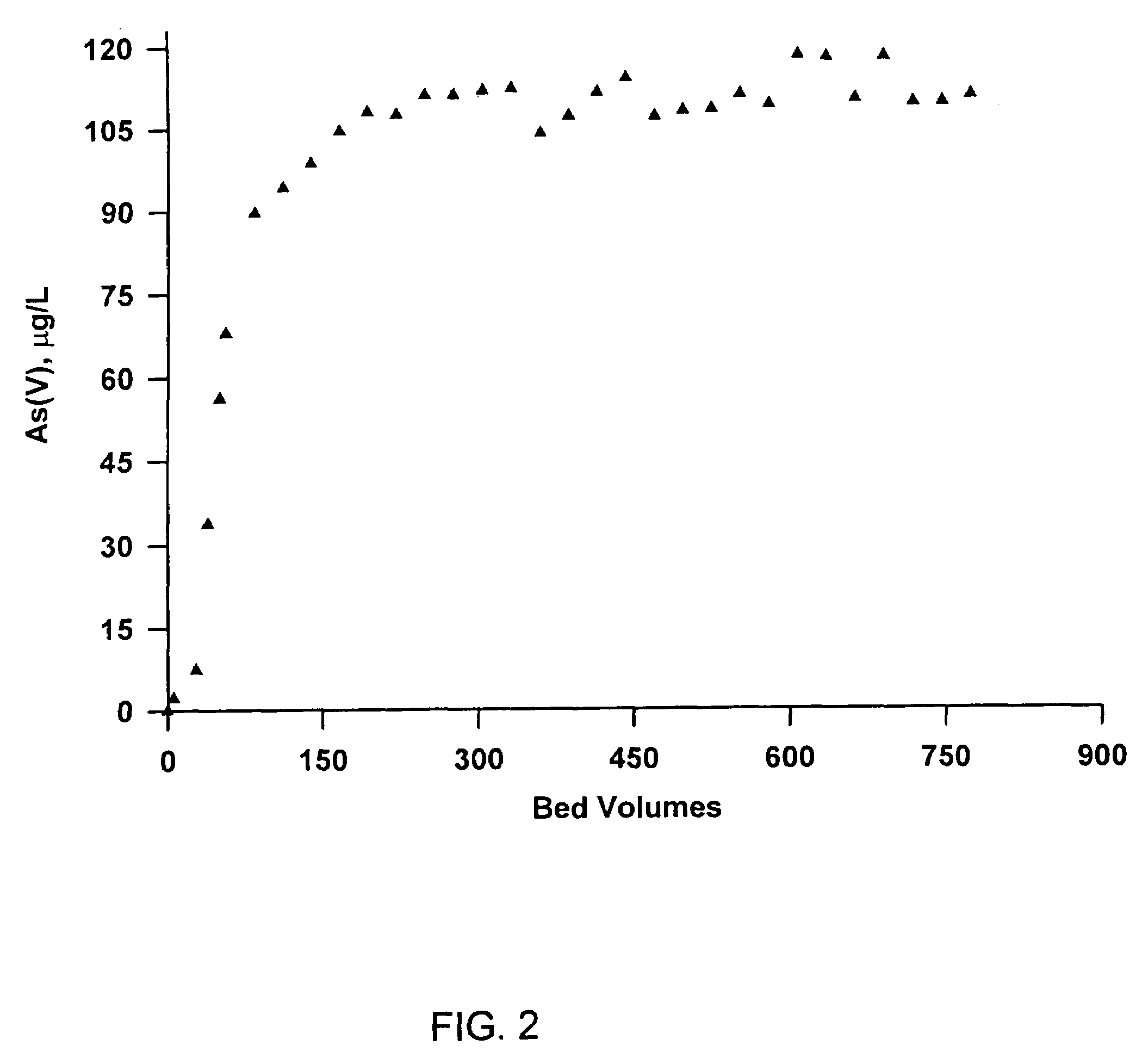

Hybrid anion exchanger for selective removal of contaminating ligands from fluids and method of manufacture thereof

ActiveUS7291578B2Improve material performanceImprove physical strengthOther chemical processesWater contaminantsPhosphateIon-exchange resin

Owner:ARUP K SENGUPTA

Glycerin triester plasticizer

InactiveUS6652774B2Improve heat resistanceReduce volatilityOrganic compound preparationOther chemical processesArylPolymer resin

The present invention provides a phthalate-free plasticizer for polymer resins. The phthalate-free plasticizer according to the invention includes a mixture of different triesters of glycerin, at least one of which meets the formula:wherein at least two of R1, R2, and R3 are different alkyl or aryl groups. Phthalate-free plasticizers according to the invention can be made by esterifying glycerin with a mixture of acids in the presence of a catalyst. Preferably, the mixture of acids includes at least two selected from the group consisting of alkyl acids and aryl acids, with each acid in the mixture containing up to about 11 carbon atoms, and more preferably from about 4 to about 9 carbon atoms each. The plasticizer according to the invention can be used to modify the properties of a wide variety of polymers including vinyl polymers, rubbers, polyurethanes, and acrylics, and has superb thermostability and low volatility.

Owner:POLYMER ADDITIVES INC DBA VALTRIS SPECIALTY CHEM

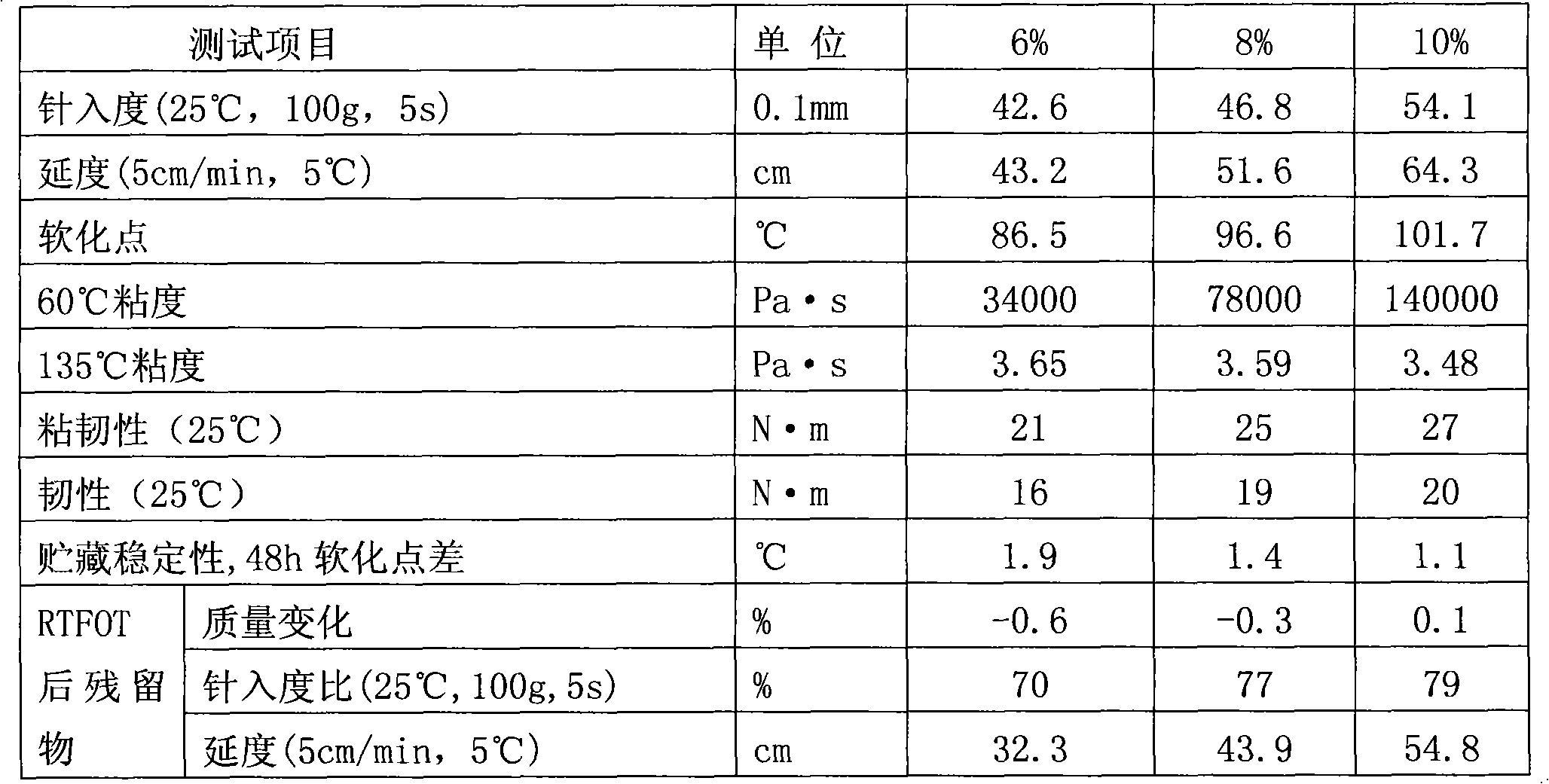

High viscosity high elasticity asphalt modifier and preparation method thereof

ActiveCN101613515AImprove adhesionImprove high temperature stabilityBuilding insulationsPolymer sciencePetroleum

The invention belongs to the technical field of asphalt modifier, in particular relates to a high viscosity high elasticity asphalt modifier and a preparation method thereof. The high viscosity high elasticity asphalt modifier is characterized in that the high viscosity high elasticity asphalt modifier is prepared by raw materials of a primary modifier, a tackifier, an anti-ageing component, a plastifying component and a stabilizer with the mass proportioning being 100:20-40:18-32:15-30:2-5 sequentially; the primary modifier is of phenylethylene-butadiene-phenylethylene segmented copolymer; the tackifier is petroresins or abietic resin; the anti-ageing component is activated rubber powder; the plastifying component is dioctyl phthalate or dibutyl phthalate; and the stabilizer is sulfur. The asphalt modifier prepared by the method can improve high temperature stability, low temperature anti-cracking performance, anti-ageing performance and elasticity restoration capability of asphalt.

Owner:WUHAN MUNICIPAL CONSTR GROUP

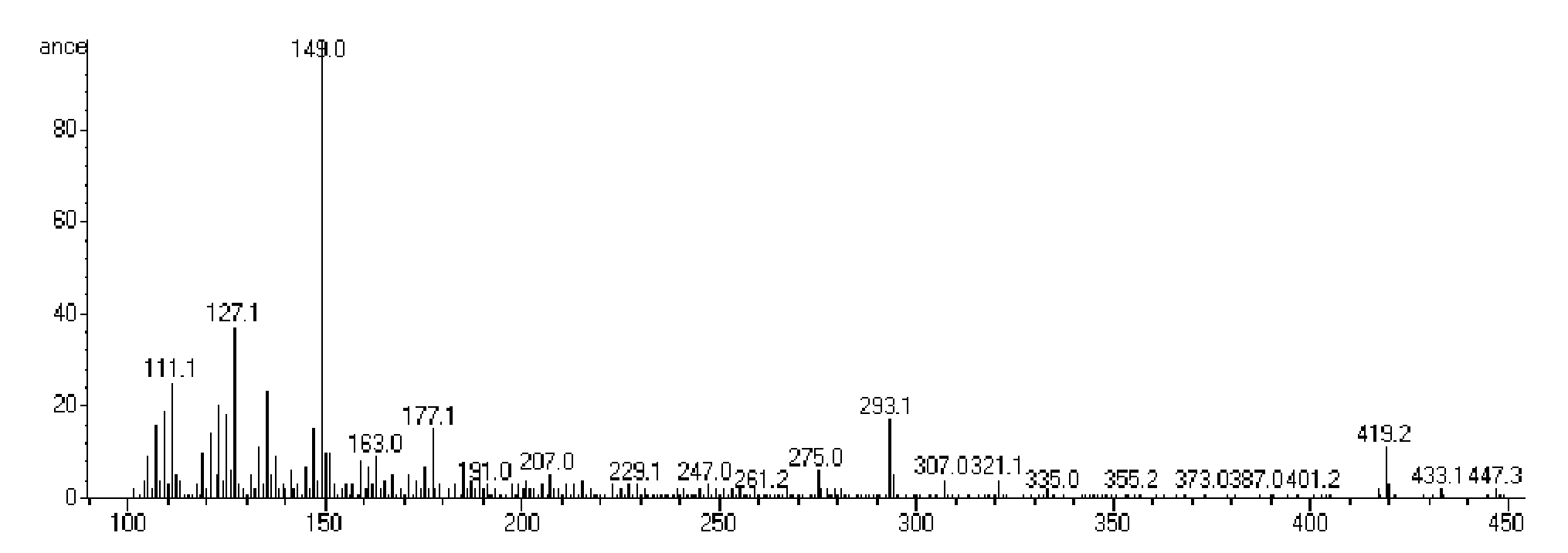

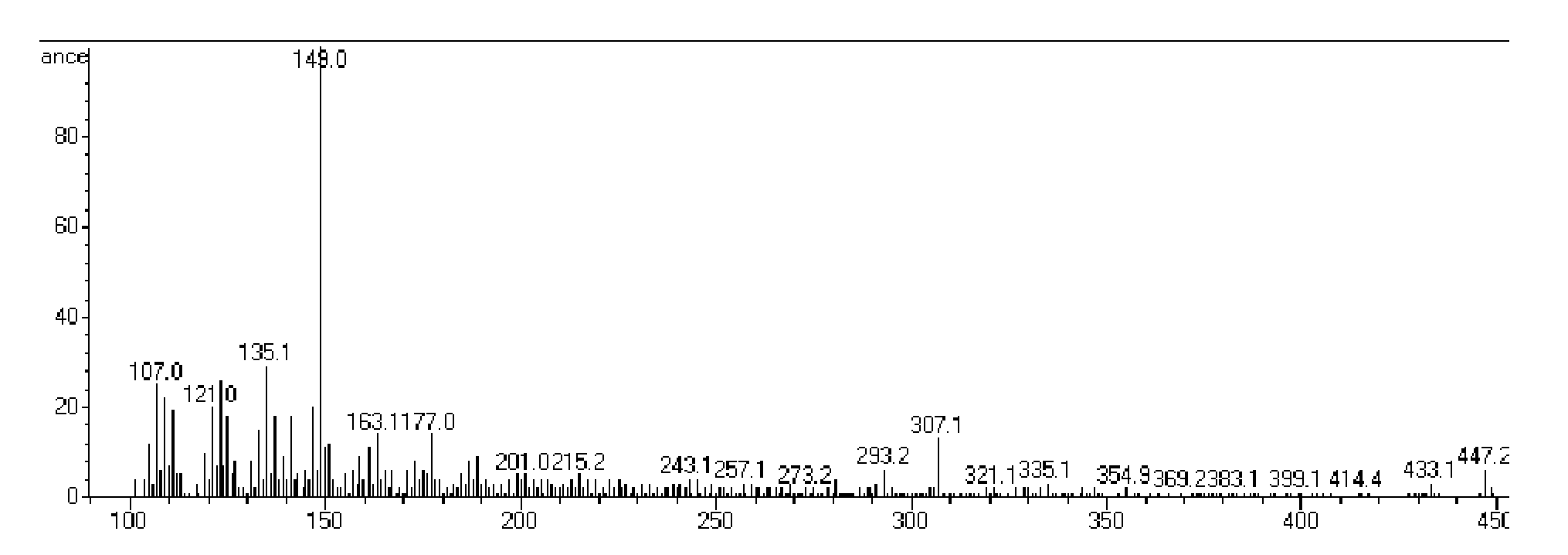

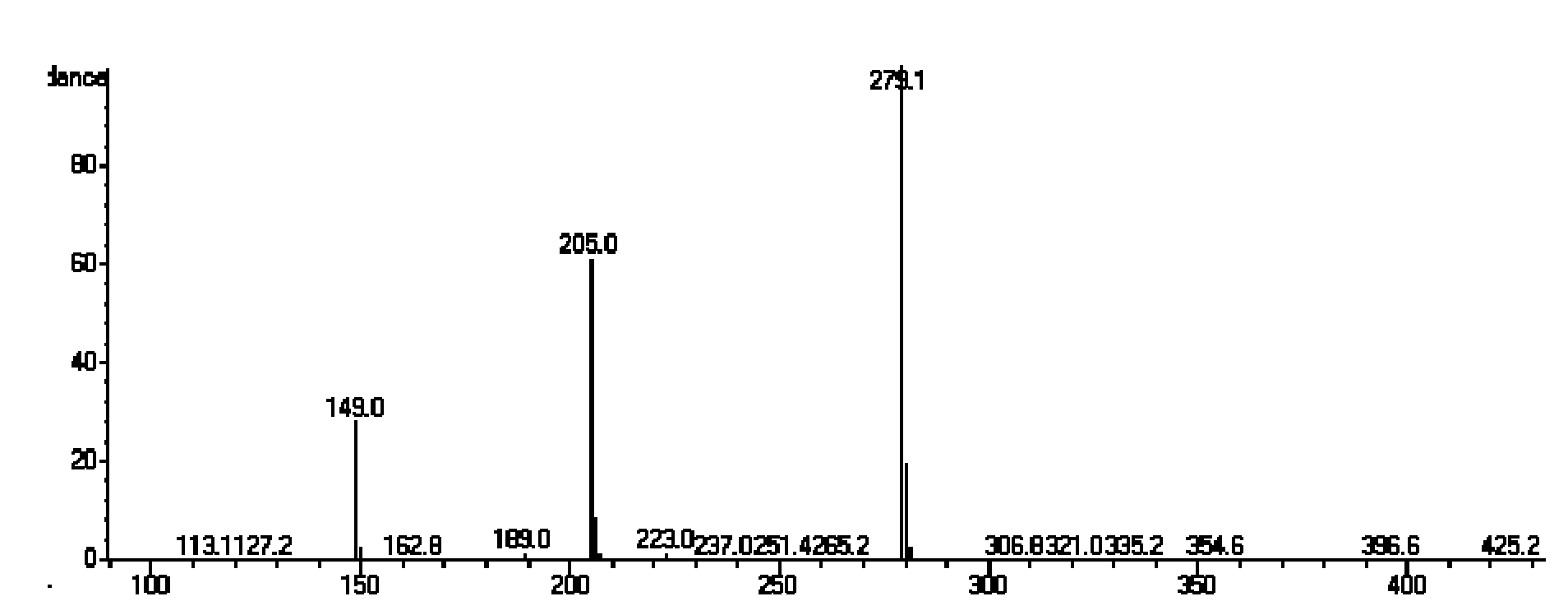

Detection method of phthalate plasticizer

InactiveCN101858897AImprove accuracySolve problems that cannot be accurately qualitative and quantitativeComponent separationPreparing sample for investigationOrganic solventThermal ionization mass spectrometry

The invention discloses a detection method of a phthalate plasticizer, comprising the following steps: 1. pretreatment: putting a sample to be detected into an organic solvent, and then dissolving and treating to obtain the solution to be detected in which the plasticizer is dissolved; and 2. content determination of the plasticizer: utilizing a gas chromatogram method and a chemical ionization mass spectrometry method to detect the type and the content of the plasticizer in the detected solution, wherein, the chemical ionization reagent used in the chemical ionization mass spectrometry method is composed of isobutane, methane or ammonia. The detection method of the phthalate plasticizer provided by the invention has high qualitative and quantitative accuracy and high quantitative detection sensitivity.

Owner:深圳出入境检验检疫局玩具检测技术中心

Ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material and preparation method thereof

ActiveCN101875747ALower embrittlement temperatureMeet construction requirementsPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

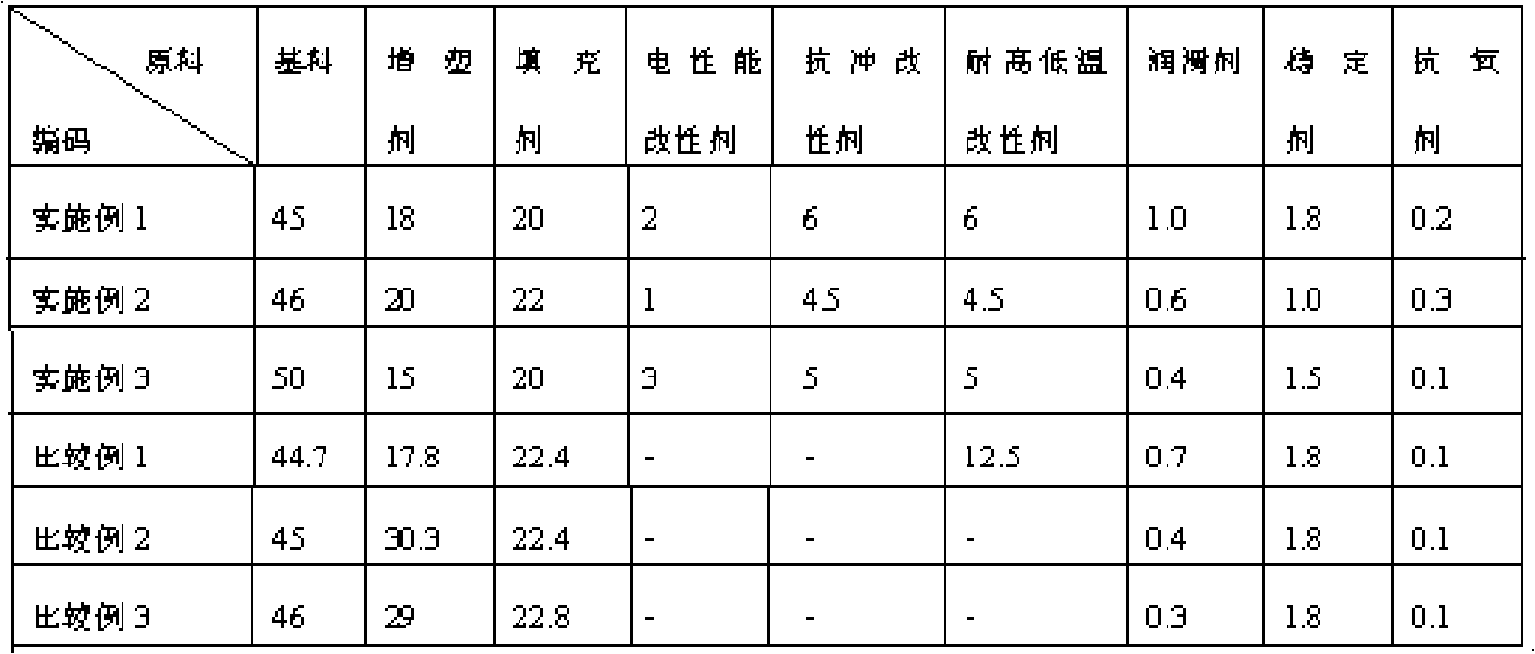

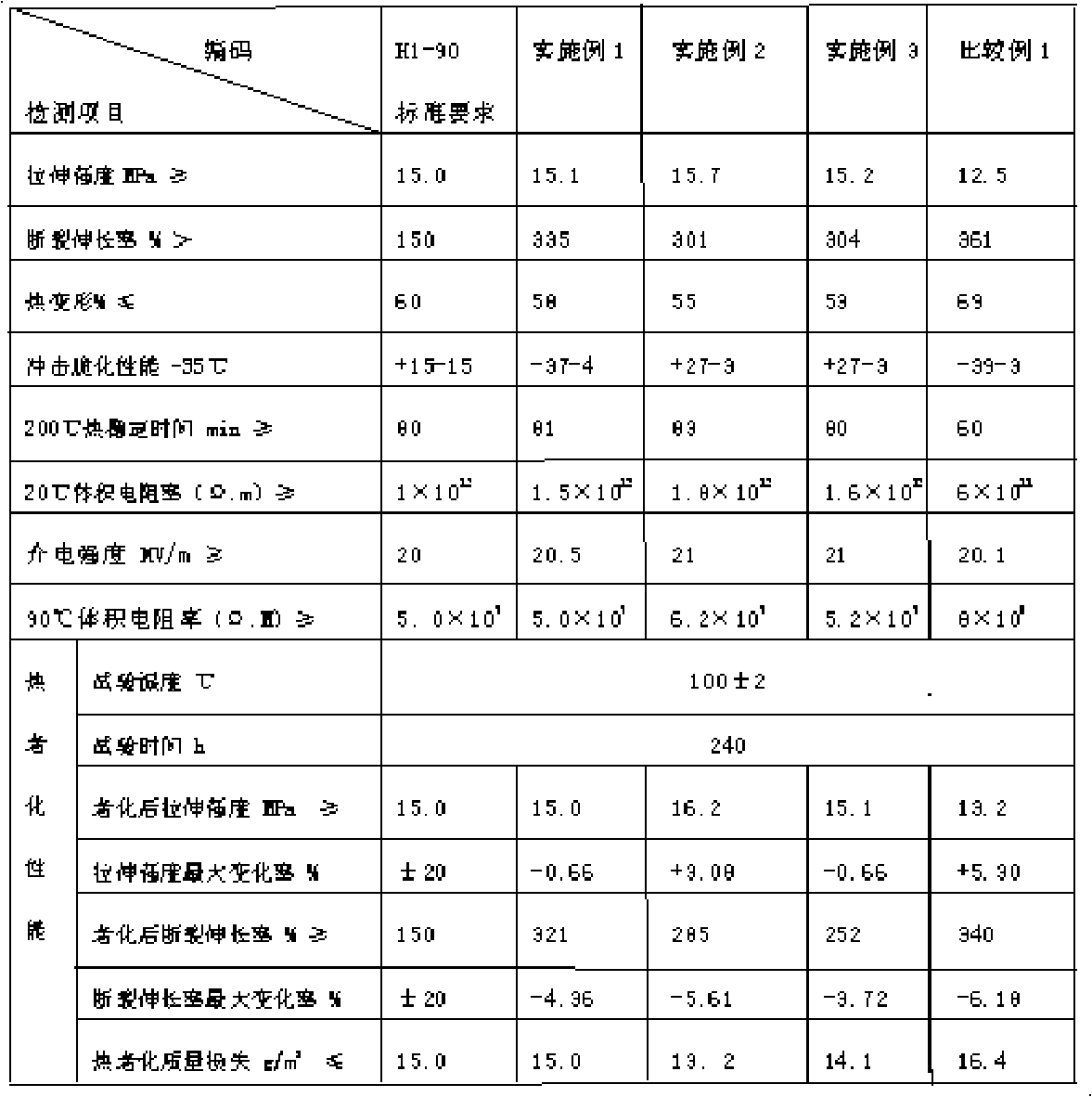

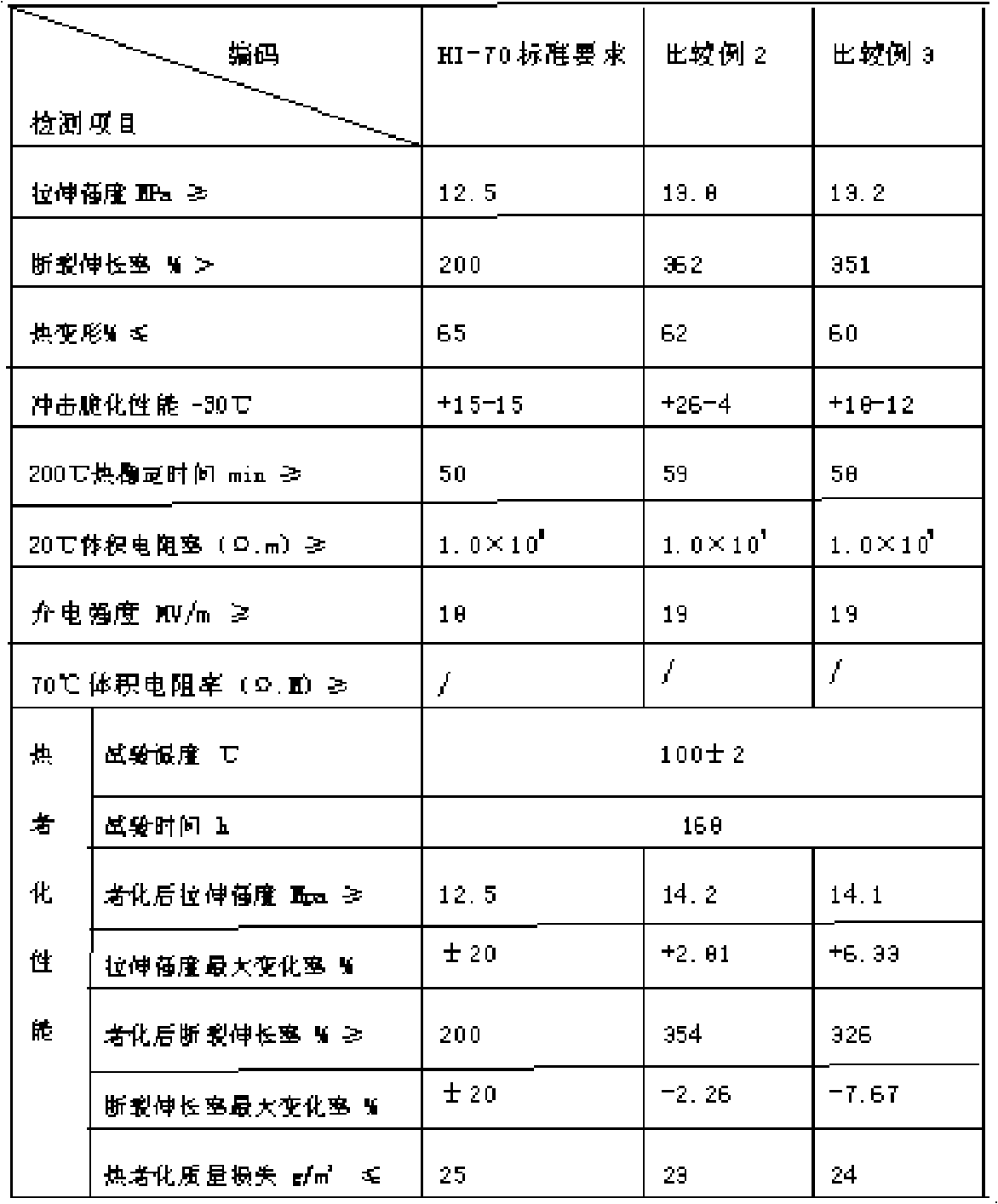

The invention discloses an ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material, belonging to the field of materials. The cable material is mainly prepared from the following raw materials in percentage by weight: 45-50% of PVC resin, 15-20% of plasticizer, 20-25% of filler, 1-3% of electrical property modifier, 9-15% of impact resistant and high and low temperature resistant modifier, 0.4-2.2% of lubricant, 1.0-2.0% of stabilizer and 0.1-0.3% of antioxidant, wherein the plasticizer is a mixture of more than two of phthalate, terephthalate or trimellitate; and the lubricant is a mixture of a composite lubricant and oxidized polyethylene wax. The invention also provides a preparation method of the cable material. The cable material provided by the invention has the advantages of low brittle temperature and good insulating property, wherein the brittle temperature can reach -35 DEG C; and simultaneously, the preparation method of the cable material is simple and is convenient for industrialized production.

Owner:ZHEJIANG DEYU TECH

Magnesium hydroxide composite flame retardant material and preparation method thereof

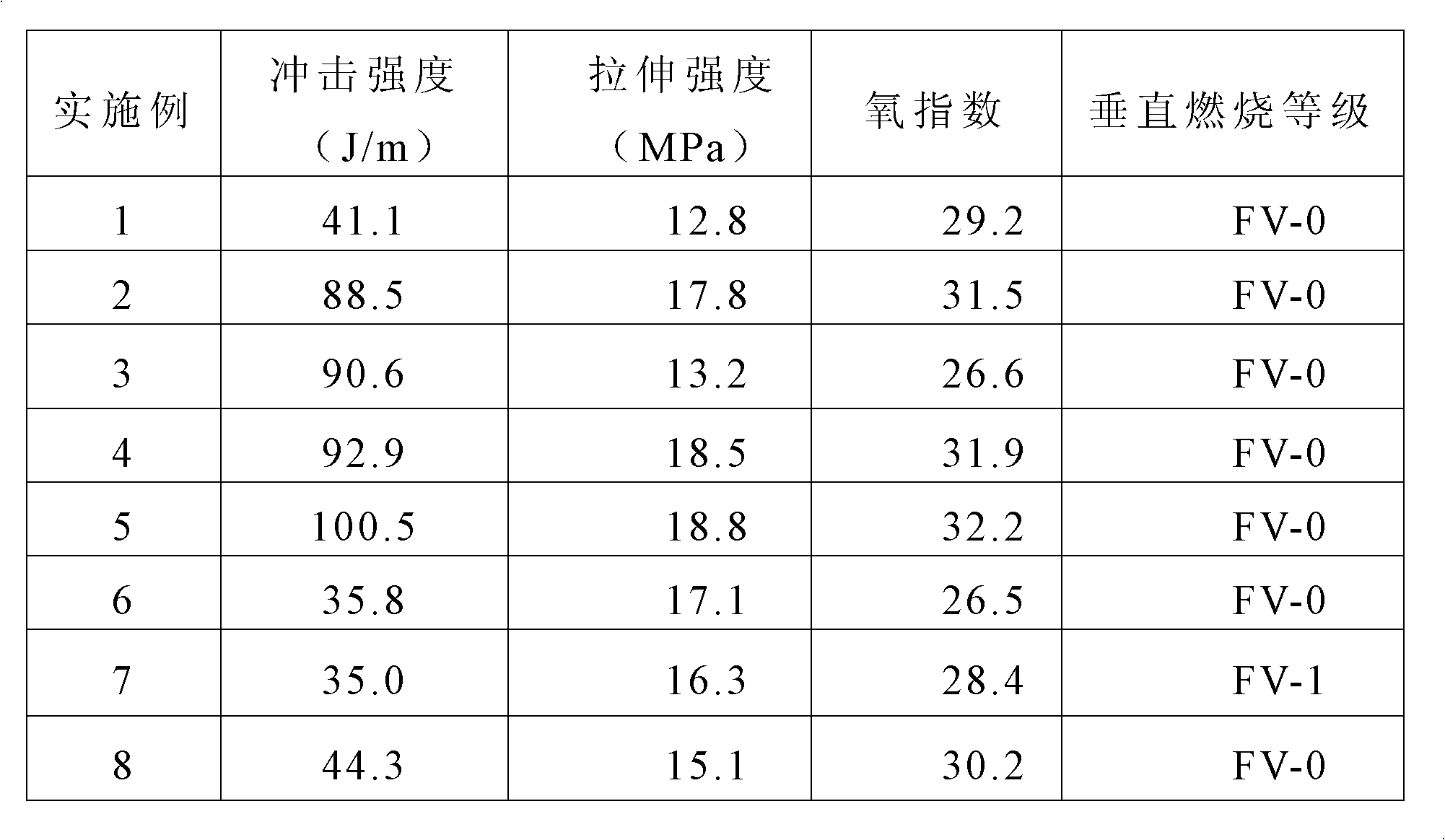

The invention discloses a magnesium hydroxide flame-retardant composite material and a preparation method thereof. The flame-retardant material comprises the following components in parts by weight: 20-100 parts of high polymer, 40-80 parts of magnesium hydroxide and 5-20 parts of toughening agent, wherein the high polymer is one or more of polyethylene, polyvinyl chloride, polypropylene, polystyrene, polyamide, polyformaldehyde, rubber or nylon; and the toughening agent is one or more of dioctyl phthalate, poly(ethylene-octene) elastomer, tricresyl phosphate, styrene-butadiene-styrene block copolymer, hydrogenated styrene-butadiene-styrene block copolymer or styrene-isoprene-styrene block copolymer. Practice proves that the magnesium hydroxide flame-retardant composite material has the advantages of strong shock resistance, high tensile strength and high oxygen index. The preparation method of the composite material is simple in operation, has low cost and high production efficiency,and can be widely used in the field of engineering plastics.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket and preparation method thereof

The invention discloses a nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket. Raw materials for the nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket comprise, by weight, 135 to 145 parts of chlorosulfonated polyethylene rubber CSM2305, 10 to 15 parts of butyl rubber CBK139, 10 to 15 parts of Lanxess 2470 EPDM rubber, 2 to 5 parts of phthalate, 3 to 5 parts of propanediol sebacate polyester, 2 to 5 parts of n-butyl methacrylate, 3 to 4 parts of zinc oxide, etc. The gasket provided by the invention has the advantages of good high temperature resistance, sealing performance and flame resistance, excellent resistance to corrosion, small changes in its volume and hardness when working in mediums like an acid, an alkali and oil for a long time, no adherency onto the surface of a metal, a small friction coefficient, good wear resistance, flexibility of bonding with a sealing surface, good resistance to weathering ageing and ozone ageing, durability, etc.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

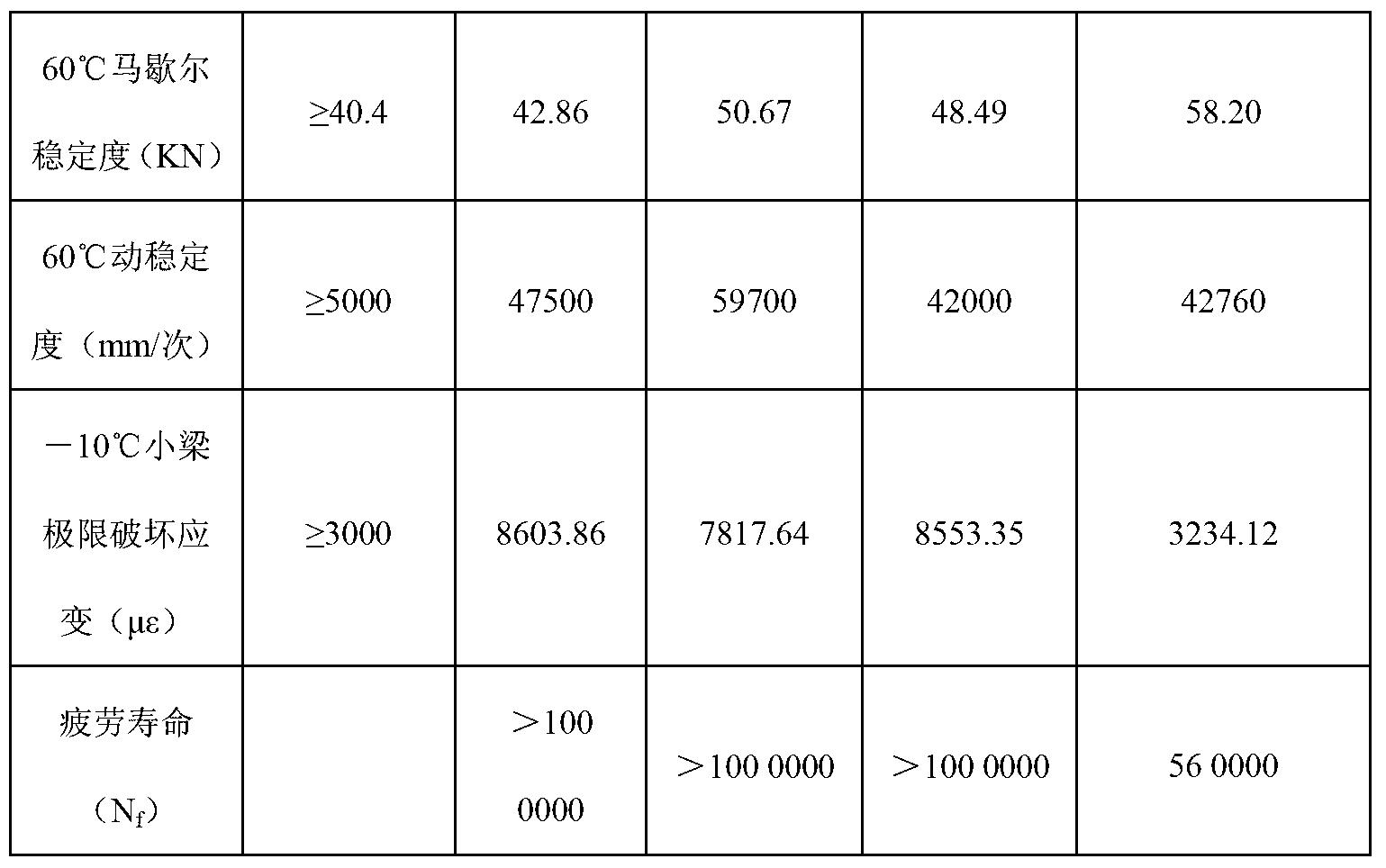

Composite modified asphalt and preparation method thereof

ActiveCN103232717AGood compatibilityHigh temperature and low temperature performanceBuilding insulationsEpoxyBridge deck

The invention relates to composite modified asphalt. The composite modified asphalt is prepared from the following raw materials in percentage by weight: 23.1-45.5% of polyurethane modified epoxy resin, 5-10% of compatibilizer, 5-10% of plasticizer, 5-10% of curing agent and 40-60% of road petroleum asphalt, wherein the polyurethane modified epoxy resin is terminal-amino polyurethane modified epoxy resin, terminal-isocyanato polyurethane modified epoxy resin or imidazolyl-terminal-capped polyurethane modified epoxy resin, the compatibilizer is naphthalene oil, asphalt tar or a mixture of naphthalene oil and asphalt tar, the plasticizer is dioctyl phthalate, dibutyl phthalate or a mixture of dioctyl phthalate and dibutyl phthalate, the curing agent is a modified aromatic amine curing agent, and the road petroleum asphalt is 70# petroleum asphalt, 90# petroleum asphalt or 110# petroleum asphalt. The road performance of concrete adopting the polyurethane epoxy resin composite modified asphalt further meets the requirements of technical specifications and surpasses that of the similar imported product Japan Epoxy, so that the composite modified asphalt can be widely applied to the construction of steel bridge deck pavement, and has great significance in opening a market for domestic epoxy asphalt materials.

Owner:重庆市智翔铺道技术工程有限公司

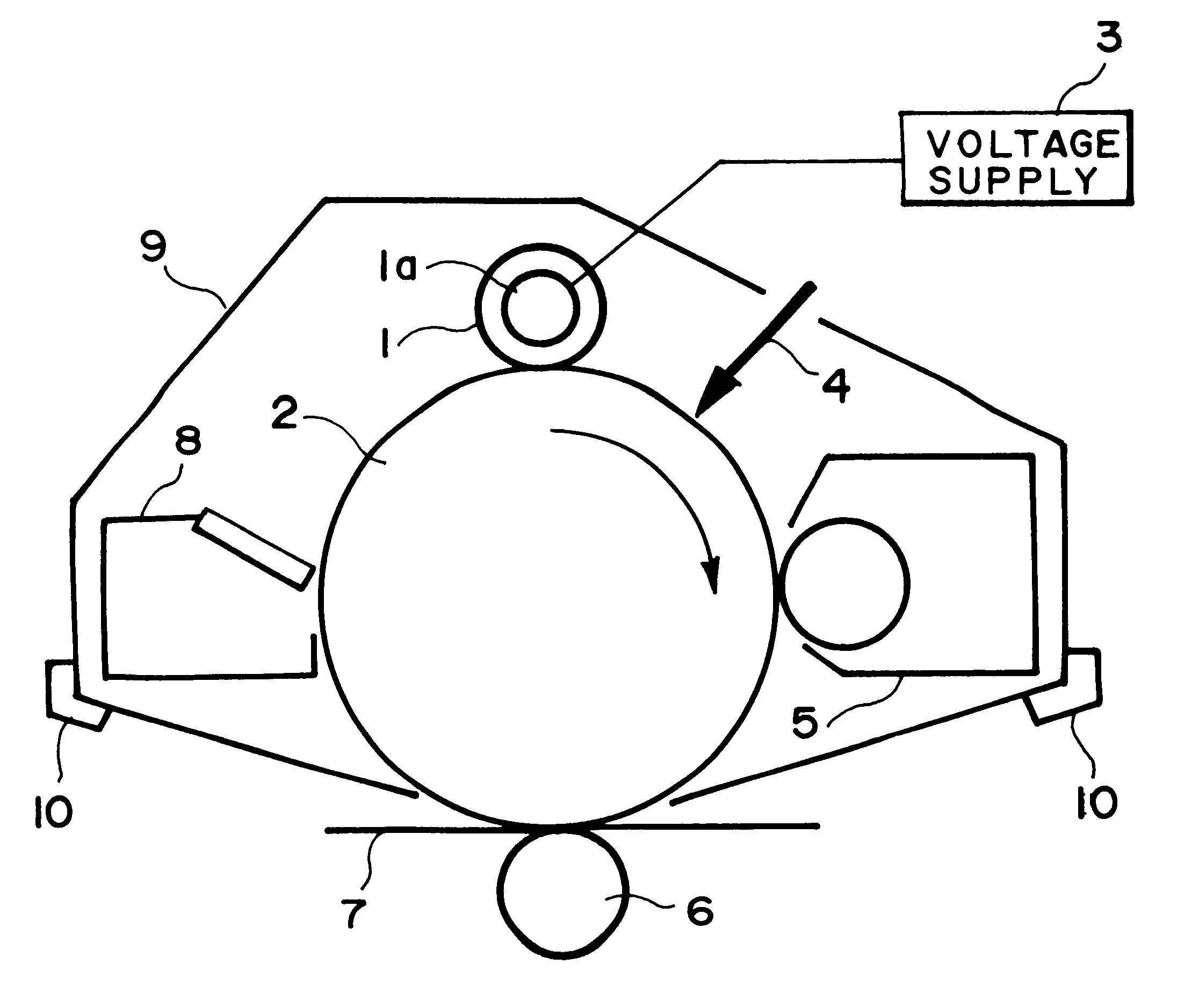

Conductive roller, process cartridge and image forming apparatus

InactiveUS6558781B1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolymer scienceAmmonium compounds

An electroconductive roller is capable of exhibiting stable conductivity regardless of environmental change and is accompanied by small bleed-out of additives. The conductive roller includes an electroconductive support, an electroconductive elastic layer coating the support and a resistance layer coating the elastic layer; wherein the elastic layer comprises at least one species of rubber selected from the group consisting of acrylonitrile-butadiene rubber, epichlorohydrin rubber and chloroprene rubber, an ether oxygen containing alkyl phthalate derivative, a quaternary ammonium perchlorate compound and a fatty oil, and the ether oxygen-containing alkyl phthalate derivative, quaternary ammonium perchlorate compound and fatty oil are contained in a total amount of 0.1-20 wt. parts per 100 wt. parts of the rubber. The conductive roller is suitably used as a contact charging member in an electrophotographic apparatus.

Owner:CANON KK

High cold resistance polyvinyl chloride cable material and preparation method thereof

InactiveCN101260214AEasy to useExpand the usable rangeInsulated cablesInsulated conductorsPolyvinyl chlorideEngineering

The invention provides a polyvinyl chloride (PVC) cable material used in gelid state (minus 50 DEG C to minus 70 DEG C) and a preparation method of the cable material. During use, the cable material does not split and can be bent normally, thereby greatly increasing the application range of products. Moreover, the cable material is made from the following raw materials in portions by weight: PVC of 80 to 100 portions, dioctyl phthalate of 20 to 40 portions, dioctyl sebacate of 60 to 80 portions, dioctyl butane dicarboxylic acid of 4 to 8 portions, light activated calcium carbonate of 20 to 40 portions, lubricant of 1 to 3 portions , Ca-Zn composite stabilizer of 4 to 8 portions, antioxidant 1010 of 1 to 4 portions, frost resisting agent K175C of 0.5 to 5 portions and nitrile butadiene rubber of 20 to 50 portions.

Owner:WUXI DONGTIAN CABLE

Environment-friendly rubber plastic heat-insulating material and its preparation method

The invention relates to an environment-friendly rubber plastic heat-insulating material and its preparation method, and the rubber plastic heat-insulating material is prepared from butyronitrile rubber (NBR), antimonous oxide (Sb2O3), zinc oxide, sulfur, dioctyl-phthalate (DOP), epoxidized soybean oil (ADDA), mercaptobenzothiazole (M), anti-aging agent (4020), antioxidant (AST-500), protective wax (HGB-3), ethylene-vinyl acetate copolymer (EVA), dicumyl peroxide (DCP crosslinking agent), polyethylene glycol (PEG), stearic acid, aluminum hydroxide, foaming agent-dinitrosopentamethylene tetraamine (H), diphenylguanidine (D), pigment, anti-aging agent (RD), anti scorching agent (PVI), and the like. By limited use of raw materials containing chlorine ion components and cooperation of a new vulcanization foaming technology, environment-friendly and heat-insulating performances of the product can be stabilized, the prepared environment-friendly rubber plastic heat-insulating material has no corrosion performance in use, the material life is prolonged, metal pipes in refrigeration equipment can be effectively protected, and maximized performance of the product can be performed.

Owner:周良文

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

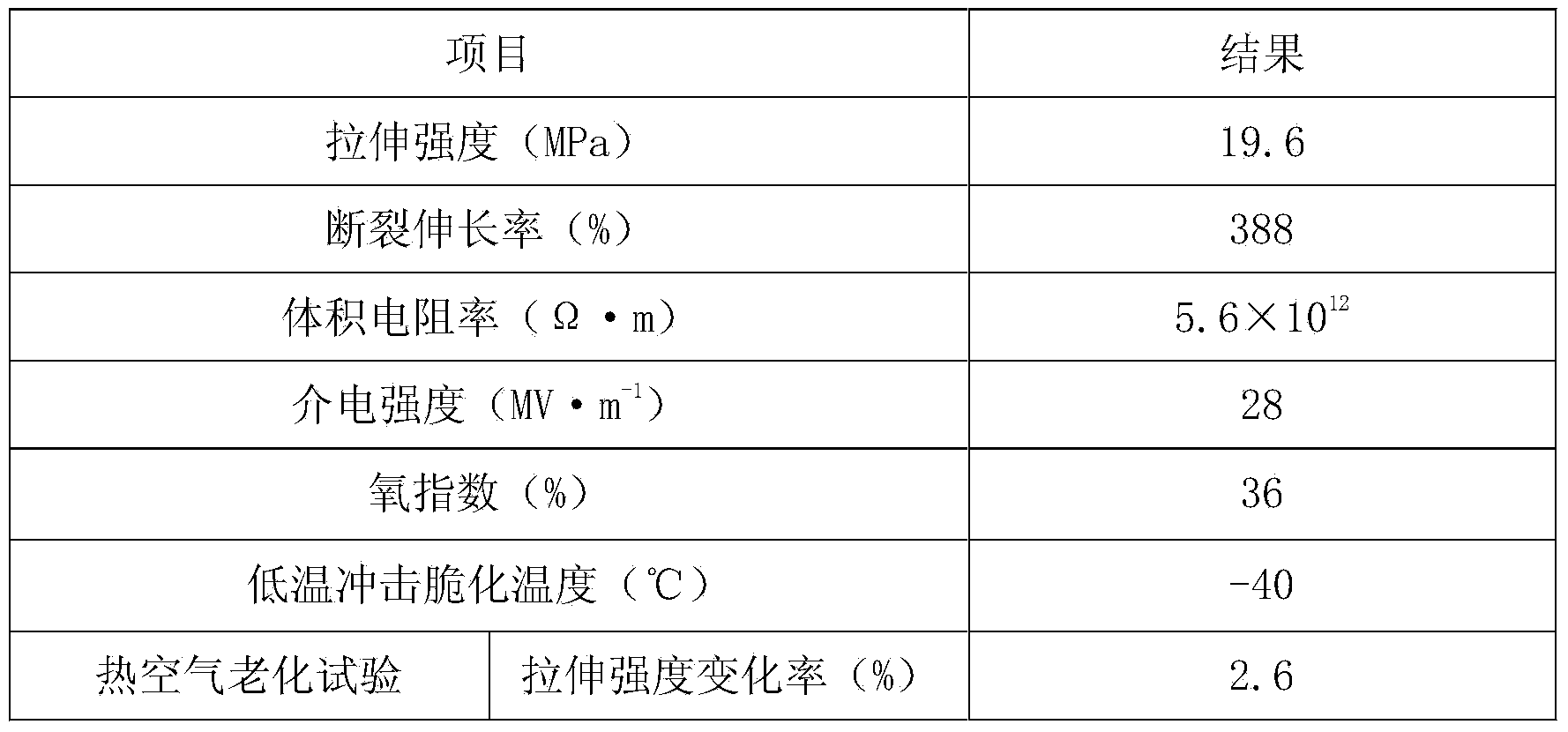

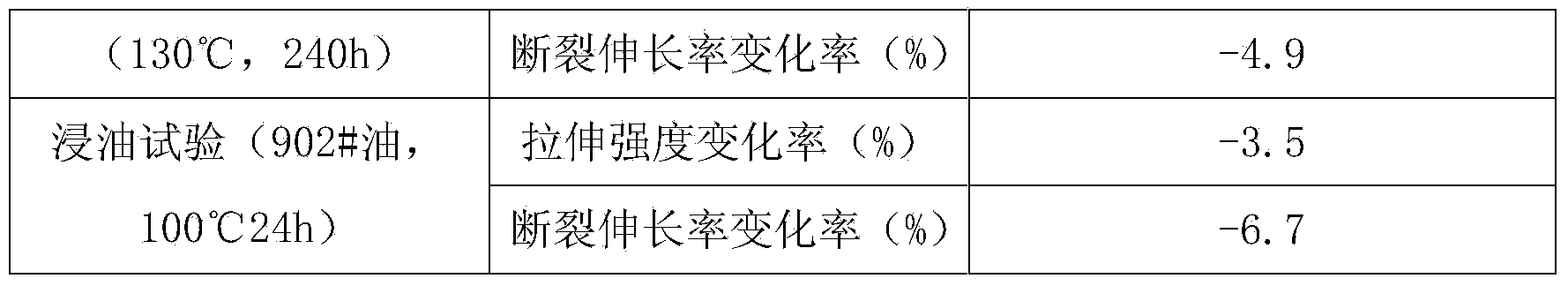

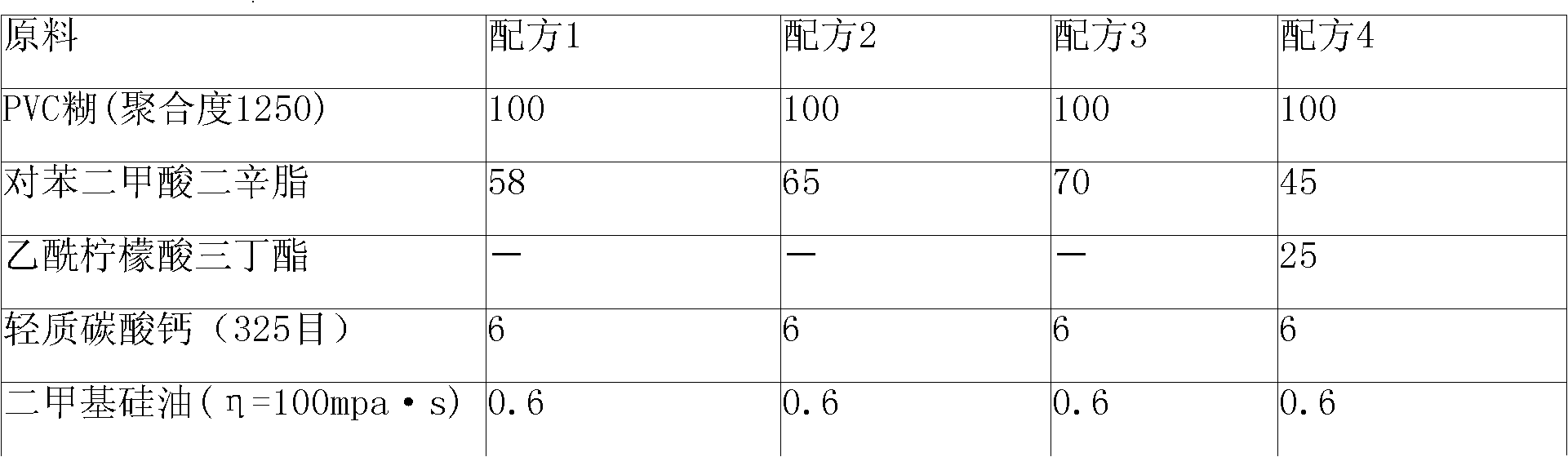

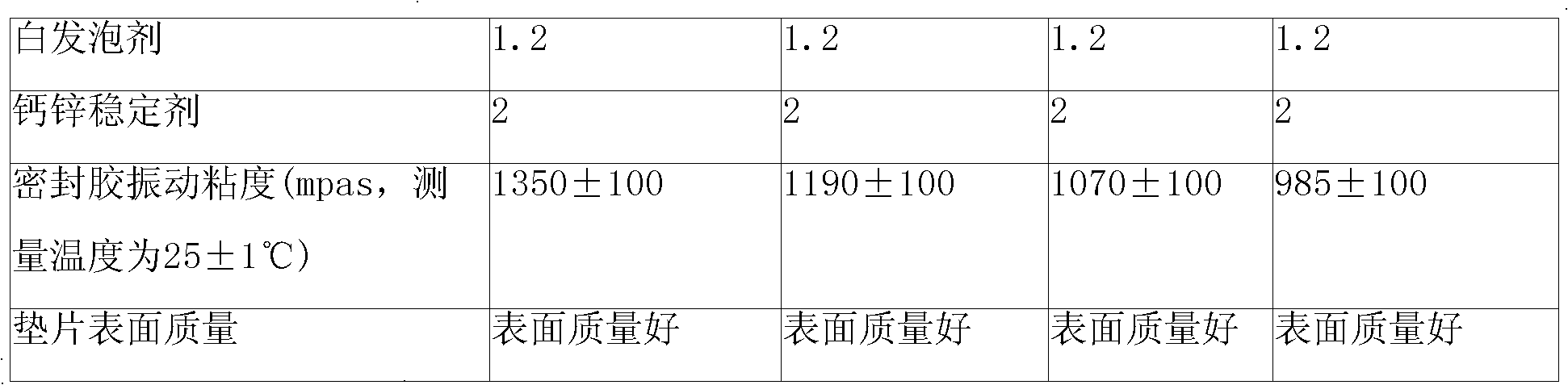

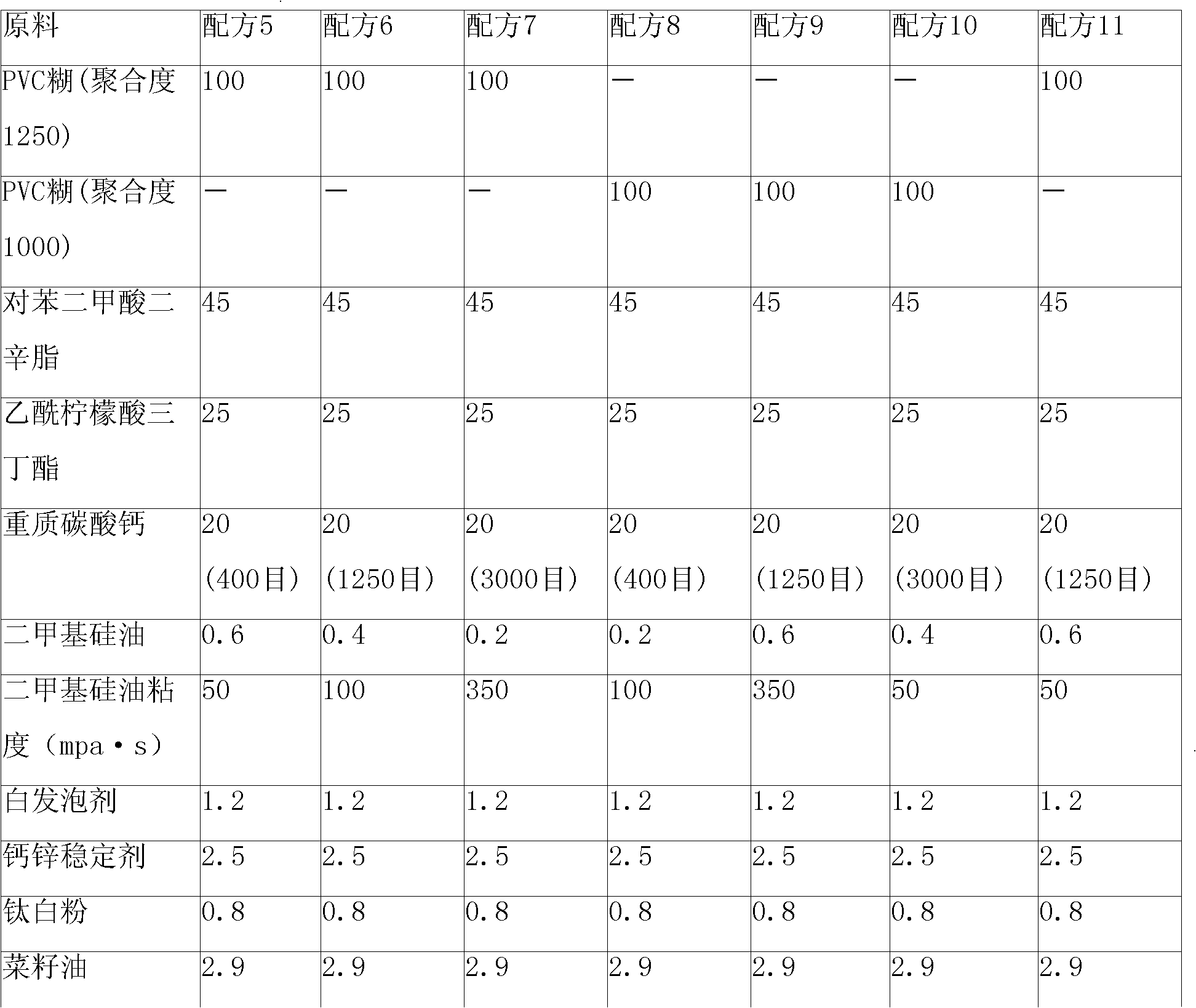

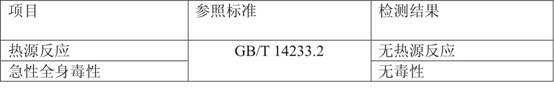

Asepsis environment-protecting polycinyl chloride bottle cap sealant and method for preparing same

InactiveCN101338171ALow priceImprove sealingOther chemical processesAdhesivesPolyvinyl chlorideRapeseed

The invention discloses a nontoxic environment protection polyvinyl chloride sealing gel and a preparation method thereof. The gel is made of pvc paste resin, dioctyl phthalate, acetyl tri-n-butyl citrate, heavy calcium carbonate, calcium-zinc stabilizer, white foaming agent, titanium dioxide, dimethicone and rapeseed oil. Phthalic ester plasticizer is not comprised. The gel meets the requirements of the food safety, and corresponds with the RoHS instruction. The gel is a foot and environmental friendly sealing gel. The using amount of fillings is added. The production cost is lowered. The nontoxic and environmental friendly sealing gel has the advantages of low price, high temperature resistance, good sealing effect and convenient engagement.

Owner:贵州省复合改性聚合物材料工程技术研究中心 +1

Temperature-resistant, corrosion-resistant and high-adhesion adhesive and preparation method thereof

ActiveCN102559120AImprove impact resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseThermoplastic

The invention discloses a temperature-resistant, corrosion-resistant and high-adhesion adhesive and a preparation method thereof, and belongs to the technical field of adhesives. The temperature-resistant, corrosion-resistant and high-adhesion adhesive consists of two components, i. e., an adhesive A and an adhesive B, in the weight ratio of 100:1-10, wherein the adhesive A consists of chemical plasticizing vinyl ester resin, a polymerization inhibitor, a low shrinkage agent, a free radical curing solvent, gas-phase silicon dioxide, inorganic filler, a coupling agent, a defoaming agent, color paste or paint, a promoter and a promotion additive; and the adhesive B consists of phthalic ester, peroxide and inertial powder filler. The adhesive provided by the invention has the performance of heat resistance, corrosion resistance, penetration resistance, adhesion, positioning, impact resistance and the like, can be formed into different types at normal temperature, and medium and high temperature, is easy and convenient to operate, can bring the unique advantage of the adhesive into full play on some occasions requiring to paying attention to corrosion resistance, adhesion, heat resistance and the like, and is suitable for mutual adhesion among a continuous cellulose material, a concrete material, a metal material, stone, FRP (Fiber Reinforce Plastic), thermoplastic plastic and the like.

Owner:浙江天和树脂有限公司 +1

Low-temperature resistant medicinal PVC modified material

ActiveCN101979434AOvercome crackingExcellent resistance to precipitationInfusion devicesPharmaceutical containersAntioxidantPlasticizer

The invention discloses a low-temperature resistant non-dioctyl phthalate (DOP) plasticized medicinal PVC (polyvinyl chloride) modified material. The material is characterized by comprising 100 parts of PVC powder, 5 to 15 parts of TPU (thermoplastic polyurethane), 20 to 50 parts of plasticizer which is Diisononyl cyclohexane-1,2-dicarboxylate (DINCH), 0.8 to 1.5 parts of stabilizer, 0.3 to 1.2 parts of antioxidant, 1 to 6 parts of epoxy soybean oil and 0.2 to 0.8 part of lubricating agent. The material has excellent low-temperature resistance, does not contain DOP and is suitable for manufacturing disposable medicinal transfusion film bags; and the plasticizer has excellent precipitation resistance.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

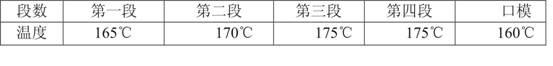

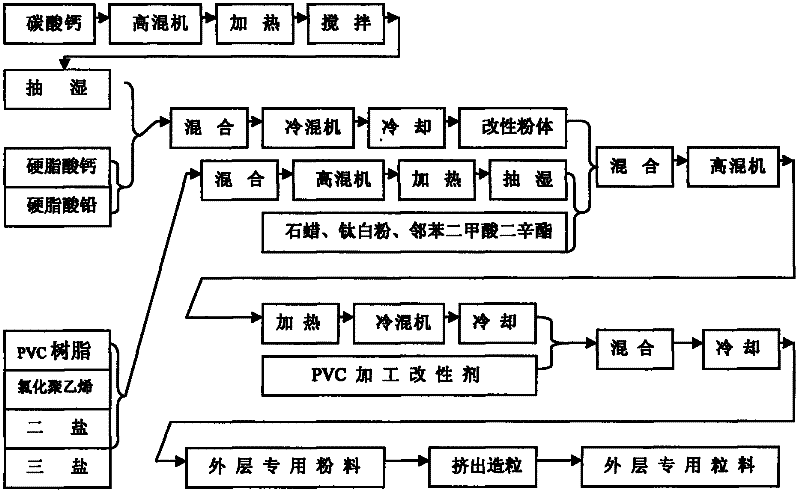

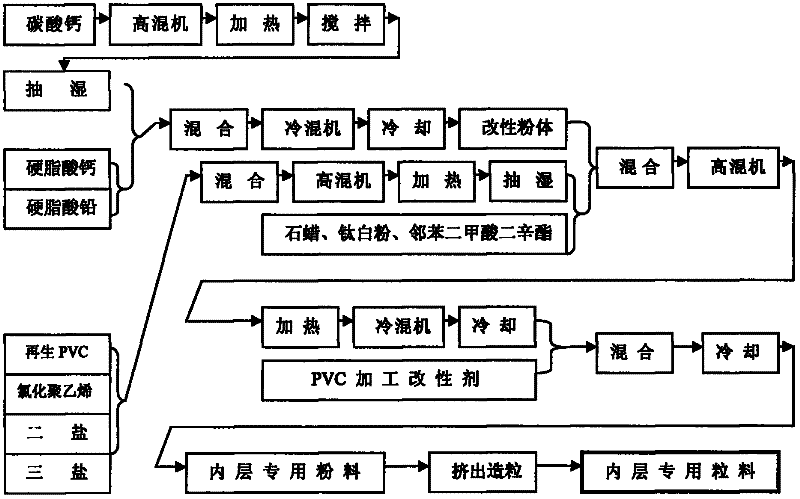

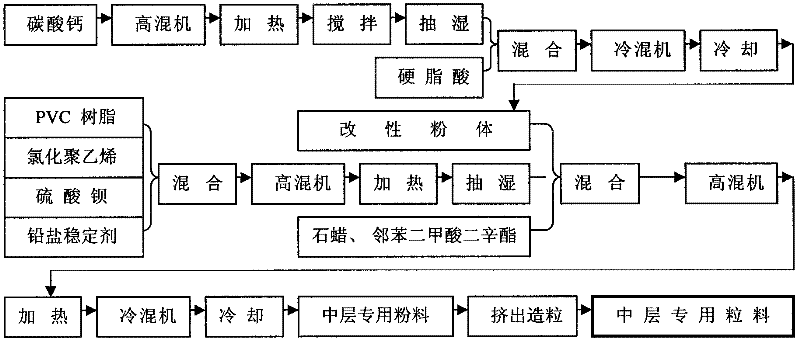

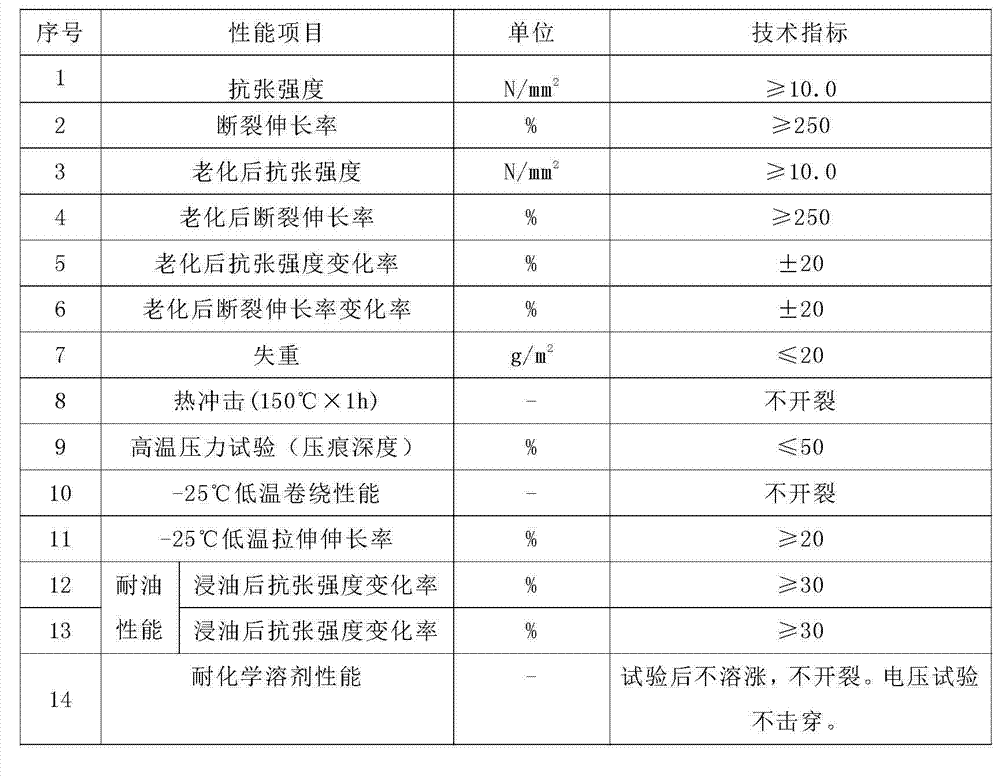

Three-layer noise reduction drainage pipe and manufacture method thereof

InactiveCN102313084AHigh strengthReduce impact noiseDomestic plumbingRigid pipesManufacturing cost reductionPolyvinyl chloride

The invention discloses a three-layer noise reduction drainage pipe, which comprises a drainage pipe body, wherein the drainage pipe body is a three-layer co-extrusion composite pipe formed by an impact-resistance outer layer, a noise reduction middle layer and an impact-resistance inner layer through co-extrusion. The noise reduction middle layer is a sound-absorbing middle layer or a sound insulation middle layer made of expandable polyvinyl chloride composition materials. The above layers are prepared with the following materials. The impact-resistance outer layer is made of polyvinyl chloride resin, chlorinated polyethylene, dibasic lead phosphite, tribasic lead sulfate, calcium stearate, lead stearate, paraffin, PVC processing and modifying agent, active light calcium carbonate, titanium dioxide and dioctyl phthalate. The sound-absorbing middle layer is made of polyvinyl chloride resin, chlorinated polyethylene, lead salt stabilizer, calcium stearate, stearic acid, paraffin, dioctyl phthalate, active light calcium carbonate and barium sulfate. The sound insulation middle layer is made of polyvinyl chloride resin, methacrylic ester polymer and inorganic foaming agent. Compared with the outer layer, the impact-resistance inner layer comprises the same components with the outer layer, except that PVC is adopted instead of polyvinyl chloride resin. The noise of the drainage pipe can be effectively reduced and the intensity of the drainage pipe is enhanced.

Owner:ZHEJIANG SANLENG PLASTIC

Ultra-permeable PVC (polyvinyl chloride) film and preparation method thereof

The invention discloses an ultra-permeable PVC (polyvinyl chloride) film which comprises the following raw materials by weight percentage: 60%-80% of PVC sizing material, 5%-10% of zinc powder, 1.5%-2% of oil, 10%-30% of plasticizer DOP (dioctyl-phthalate) and 2%-4% of cadmium barium zinc compound stabilizer. A preparation method of the ultra-permeable PVC film comprises the following steps of: burdening, banburying, refining in an open way, filtering, extruding, calendaring by six rollers, introducing purified water, drying, shaping, refrigerating, coiling and packing. The PVC film obtained by the invention is small in thickness which can be less than 1.2mm, nontoxic, high in photo-permeability, impact-resistant, tear-resistant, free from combustion, and free from moisture absorption, thereby being particularly suitable for the requirement of various high-speed automatic packaging machinery. Therefore, the film disclosed by the invention can be widely used for the package for the printing industry, the furniture, the drug, the articles of everyday use and the like, and plays a part in moisture resistance and dust resistance.

Owner:FOSHAN WEIMING PLASTICS

Butyronitrile-PVC (polyvinyl chloride) compound elastomer insulation material for wires and cables and preparation method of butyronitrile-PVC compound elastomer insulation material

InactiveCN103205034ALower surface energyGood dispersionRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxElastomer

The invention discloses a butyronitrile-PVC (polyvinyl chloride) compound elastomer insulation material for wires and cables and a preparation method of the butyronitrile-PVC compound elastomer insulation material. The butyronitrile-PVC compound elastomer insulation material comprises, by weight, 100-120 parts of butyronitrile rubber, 30-40 parts of PVC resin, 2-3 parts of accelerant TMTD, 1-2 parts of accelerant DM, 1-2 parts of antiager, 2-3 parts of antiager MB, 6-8 parts of paraffin, 8-12 parts of zinc oxides, 1-1.5 parts of stearic acid, 10-15 parts of DOP (dioctyl-phthalate), 2-4 parts of gas-mixed carbon black, 30-40 parts of precipitated white carbon black and 50-60 parts of modified nano calcium carbonate. The insulation material produced has the advantages of good mechanical and physical performance, insulation performance, good high and low temperature resistance, oil resistance, solvent resistance, wear resistance, ozone resistance, ageing resistance and the like, is long-lasting, durable, environment-friendly, pollution-free and capable of meeting the requirements of modern wires and cables completely.

Owner:ANHUI HUAJIN CABLE GROUP

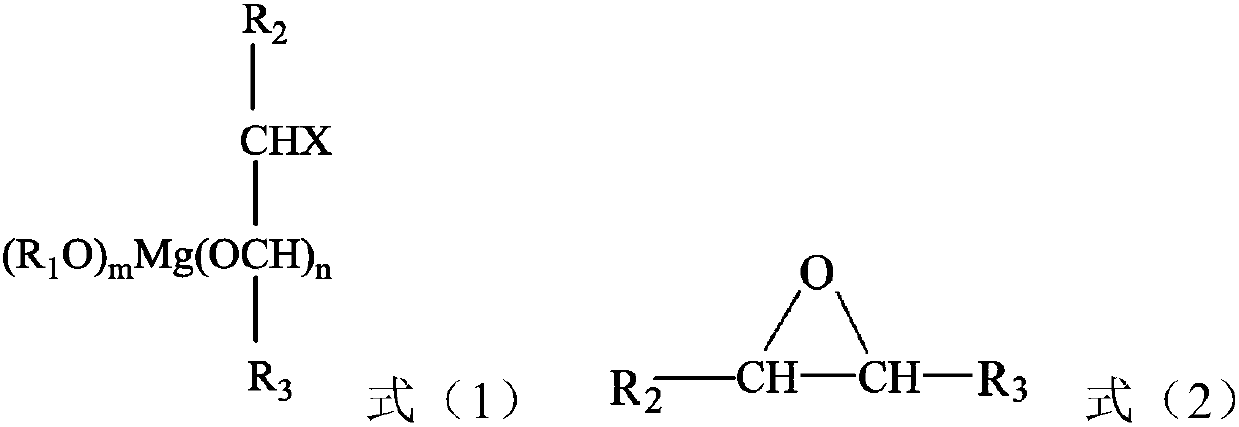

Catalyst component for olefin polymerization, and preparation method thereof, and catalyst for olefin polymerization, and applications thereof

ActiveCN107629153AHigh stereospecificityNarrow molecular weight distributionSolid componentResponse sensitivity

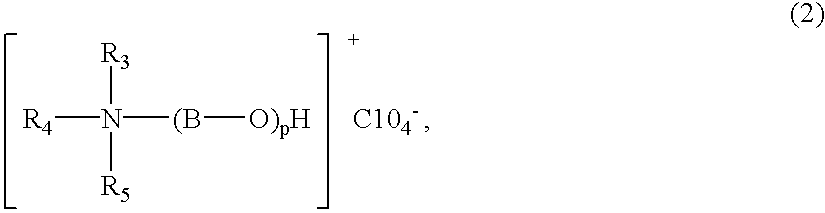

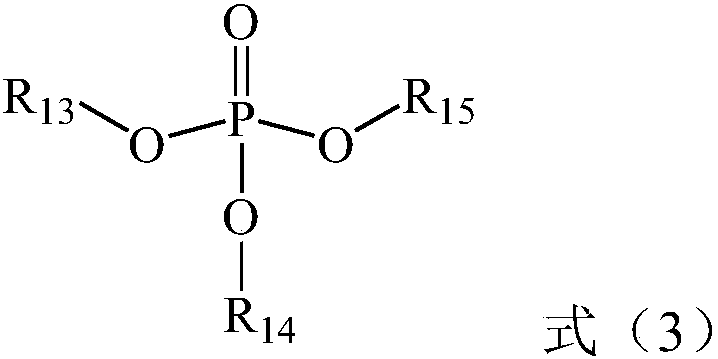

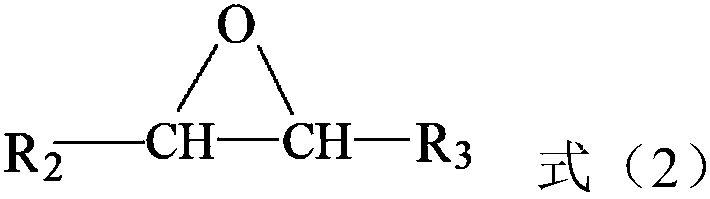

The present invention relates to the field of olefin polymerization, and particularly provides a catalyst component for olefin polymerization, and a preparation method thereof, and a catalyst for olefin polymerization, and applications thereof. The catalyst component for olefin polymerization contains the product obtained by carrying out a reaction on a solid component, at least a titanium compound and an internal electron donor, wherein the internal electron donor contains a phosphate compound and a diether compound, the phosphorus content (calculated as the phosphorus element) in the catalyst component is not more than 0.06 wt% by using the total weight of the catalyst component as the reference, and the solid component contains a magnesium compound represented by a formula (1) and an alkylene oxide compound represented by a formula (2). According to the present invention, the catalyst component does not contain phthalate compounds (plasticizers), has high hydrogen response sensitivity and high stereospecificity, and can be used in olefin polymerization so as to obtain the polymer having narrow molecular weight distribution. The formulas (1) and (2) are defined in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

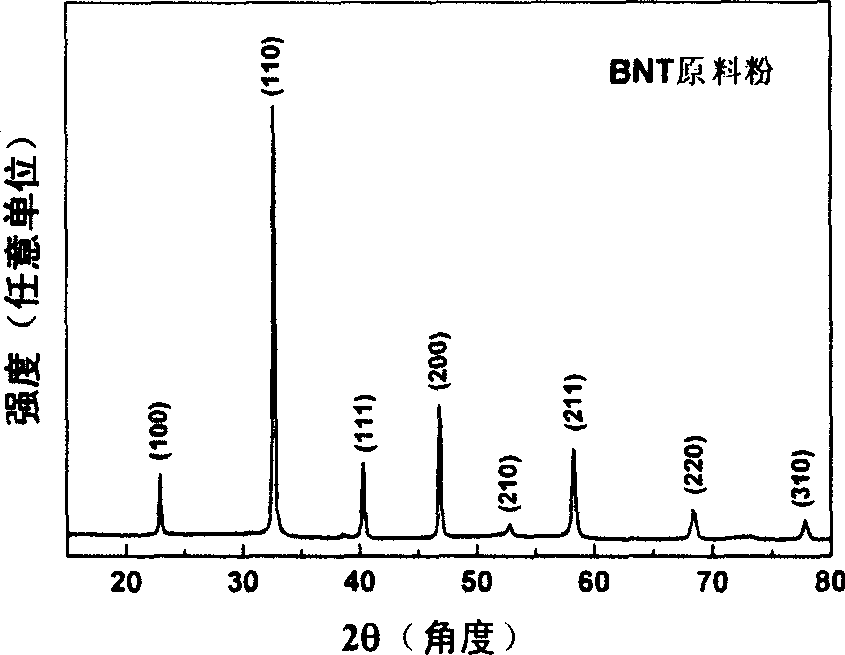

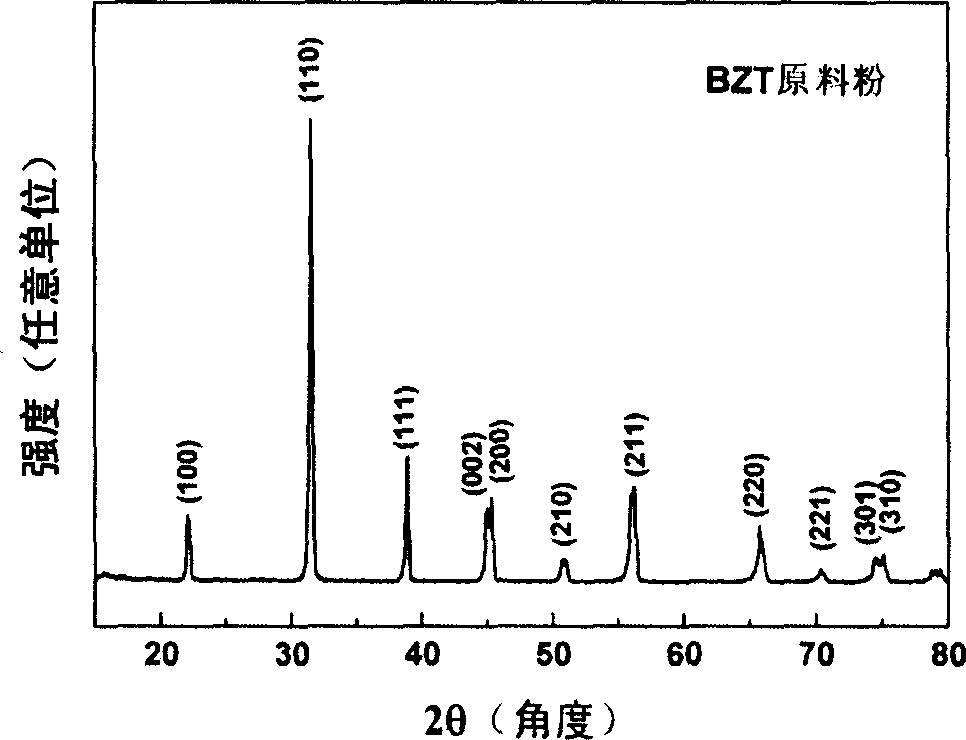

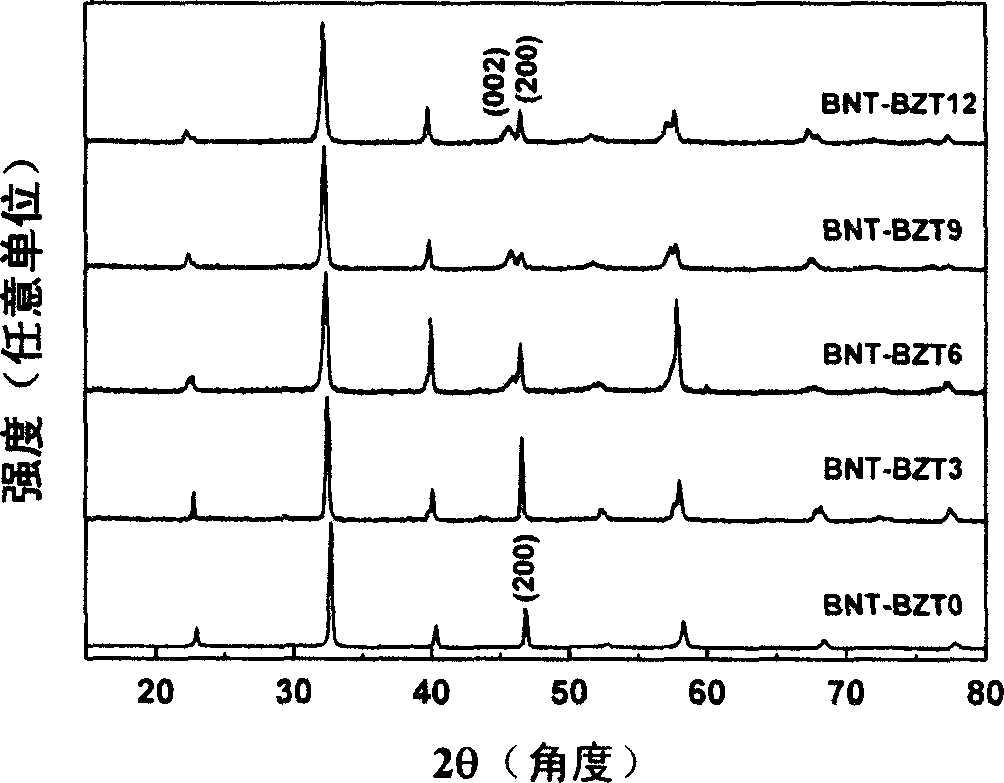

Sodium bismuth phthalate-barium zirconium phthalate leadless piezoelectric ceramic and its preparation method

InactiveCN1623954AExcellent piezoelectric propertiesReduce leakage currentPiezoelectric/electrostrictive/magnetostrictive devicesHigh densitySodium titanate

A non-Pb piezoelectric bismuth sodium titanate-barium zirconate titatate ceramics, (Bi0.5Na0.5)TiO3-xBa(Ti1-yZry)O3 (BNT-BZT), is prepared by two-step sinter method. Its advantages are high density, low leakage current in polarizing procedure, and high piezoelectric and ferroelectric performance.

Owner:TSINGHUA UNIV +1

Special N-phthalate reinforced soft polyethylene plastics for circulation loop and preparation method thereof

The invention discloses special N-phthalate reinforced soft polyethylene plastics for a circulation loop, which comprises the following ingredients by weight parts: 100 weight parts of PVC resin powder, 20 to 50 weight parts of N-phthalate plasticizers, 5 to 35 weight parts of auxiliary stabilizing agents, 0.5 to 5.0 weight parts of stabilizing agents, 0.1 to 2.0 weight parts of lubricating agents and 0.1 to 1.0 weight part of antioxidants. The invention also discloses a preparation method of the special N-phthalate reinforced soft polyethylene plastics for the circulation loop. The method comprises the following steps: carrying out high-speed mixing on ingredients; using a double-screw extruding machine for plastification; and using a single screw for cooling and forming to obtain rubber grains. The recipe of the invention is suitable for the manufacture of the circulation loop, particularly the varieties with high processing precision and long operation time and the varieties needing ray sterilization.

Owner:YANGZHOU KAIER CHEM

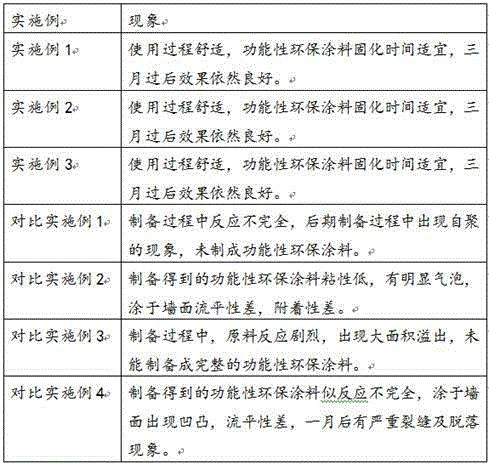

Method for preparing functional environmentally-friendly paint

The invention relates to a method for preparing a functional environmentally-friendly paint. The preparation method comprises: adding 10-100 parts of glycerol, 10-100 parts of pentaerythritol, 5-80 parts of trimethylolpropane, 20-200 parts of phthalate, 3-60 parts of adipic acid, 10-80 parts of trimellitic anhydride, and 15-150 parts of maleic acid into a reactor; heating the reactor to make the substances therein react; after a complete reaction, adding in 0.03-3 parts of a defoamer; cooling the reactants, and gradually adding in 0.05-2 parts of hydrogenated castor oil and 0.05-2 parts of a polymerization inhibitor during the cooling process; adding in 8-95 parts of styrene to modify a product; and adding in 4-60 parts of triethylamine, 3-70 parts of a solvent, 15-230 parts of a pigment and a filler, 0.01-2 parts of a leveling agent, 0.5-6 parts of a catalyst, 3-7 parts of a first solid additive, 1.5-6 parts of a second solid additive, 6-9 parts of a first composite modifier, 7-11 parts of a second composite modifier, and 8-14 parts of a third composite modifier to obtain the functional environmentally-friendly paint. The functional environmentally-friendly paint prepared by the method is stable in performance, little in environmental effect, and suitable for large-scale popularization.

Owner:ANJI QILONG NEW BUILDING MATERIAL

Sodium silicate sand with high wet-compressive strength and preparation method thereof

InactiveCN103567356AImprove wet compressive strengthEasy to moldFoundry mouldsFoundry coresSlagStearic acid

The invention discloses sodium silicate sand with high wet-compressive strength and a preparation method thereof. The sodium silicate sand with high wet-compressive is prepared from the following raw materials in parts by weight: 55-75 parts of silica sand, 30-40 parts of carborundum, 10-15 parts of limestone, 5-8 parts of bentonite, 3-6 parts of bauxite, 4-7 parts of modified sodium silicate, 2-3 parts of Arabic gum powder, 1-2 parts of dioctyl phthalate, 3-4 parts of lithium slag powder, 2-3 parts of talcum powder, 1.5-2.5 parts of gypsum, 1-2 parts of triisopropanolamine, 0.5-1 part of stearic acid and 3-5 parts of water. The sodium silicate sand disclosed by the invention is high in wet-compressive strength, easy to draw and repair, so that process requirements of drawing and then curing are completely satisfied. Moreover, the sodium silicate sand has good mobility, low gas evolution rate, good gas permeability and good collapsibility, can be used for remarkably improving the quality of a casting piece and lowering the rejection rate of the casting piece.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Calcium/zinc thermal stabilizer polyvinyl chloride transparent hard film and preparation method thereof

The invention discloses a calcium / zinc thermal stabilizer polyvinyl chloride transparent hard film and a preparation method thereof. The hard film is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 1.0-1.5 parts of calcium / zinc thermal stabilizer, 0.7-1.2 parts of organic thermal stabilizer, 0.3-0.8 part of organic auxiliary stabilizer, 0.8-1.2 parts of processing aid, 0-5 parts of non-orthophenyl plasticizer, 0.6-0.9 part of internal lubricant and 0.2-0.4 part of external lubricant. The calcium / zinc thermal stabilizer is successfully applied to a polyvinyl chloride transparent hard film; the film is a non-toxic hard film; a new approach is provided for application of the calcium / zinc thermal stabilizer to the polyvinyl chloride transparent hard film; and by adopting the non-orthophenyl plasticizer, harm of heavy metal and the conventional phthalate plasticizer is avoided, so that a polyvinyl chloride product is more environmentally-friendly.

Owner:JIANGSU GUANGHUI PACKAGE +2

Tea polyphenol liposoluble microcapsules and preparation method thereof

InactiveCN103330213ASmall droplet sizeSmall particle sizeTripeptide ingredientsAntinoxious agentsPhenolic content in teaPolyphenol

The invention relates to microcapsules and a preparation method thereof, particularly to tea polyphenol liposoluble microcapsules and a preparation method thereof, wherein a core material of the tea polyphenol liposoluble microcapsules comprises tea polyphenol and reduced glutathione, a mass ratio of the tea polyphenol to the reduced glutathione is 95-99:1-5, a wall material of the tea polyphenol liposoluble microcapsules is one or a plurality of materials selected from arabic gum, dextrin, corn syrup, ethyl cellulose, methylcellulose, and hydroxypropyl methylcellulose phthalate, and a mass weight ratio of the core material to the wall material is 1:1-4. The tea polyphenol liposoluble microcapsule preparation method comprises the following steps: respectively preparing a core material emulsion liquid and a wall material solution, adding the core material emulsion liquid to the wall material solution, carrying out high speed stirring, homogenizing, and carrying out spray drying to obtain the tea polyphenol liposoluble microcapsules. The tea polyphenol liposoluble microcapsules have characteristics of fine average particle size and slow tea polyphenol release, such that anti-oxidation and absorption utilization efficiency of the tea polyphenol are substantially improved.

Owner:ZHEJIANG MINGHUANG NATURAL PRODS DEV

Fabric treatment composition comprising a core-shell particle bound to a phthalate-containing polymer

InactiveUS8158571B2Increase depositionOrganic detergent compounding agentsDetergent perfumesPolyesterPolyol

A particle (preferably a core-shell encapsulate) comprising a benefit agent (preferably a perfume), said particle being bound to a non-cationic deposition aid which is substantive to polyester, wherein the non-cationic deposition aid is a polymer derivable from dicarboxylic acids and polyols. Preferably the polymer comprises units derived from (poly)ethylene glycol and terephthalate, most preferably selected from the group comprising PET / POET, PEG / POET, PET / PEG and phthalate / glycerol / ethylene glycol polymers. The invention also provides a method for producing improved benefit agent particles which comprises the step of covalently linking or co-polymerising a deposition aid which is substantive to polyester to a particle comprises the benefit agent. The particles find particular utility in laundry treatment compositions comprising (a) anionic and / or nonionic surfactant, or (b) cationic fabric conditioner and further comprising core-shell particles, wherein said particles have, incorporated in the shell a polyester-substantive deposition aid which is a phthalate containing polymer and incorporated in the core a perfume.

Owner:CONOPCO INC D B A UNILEVER

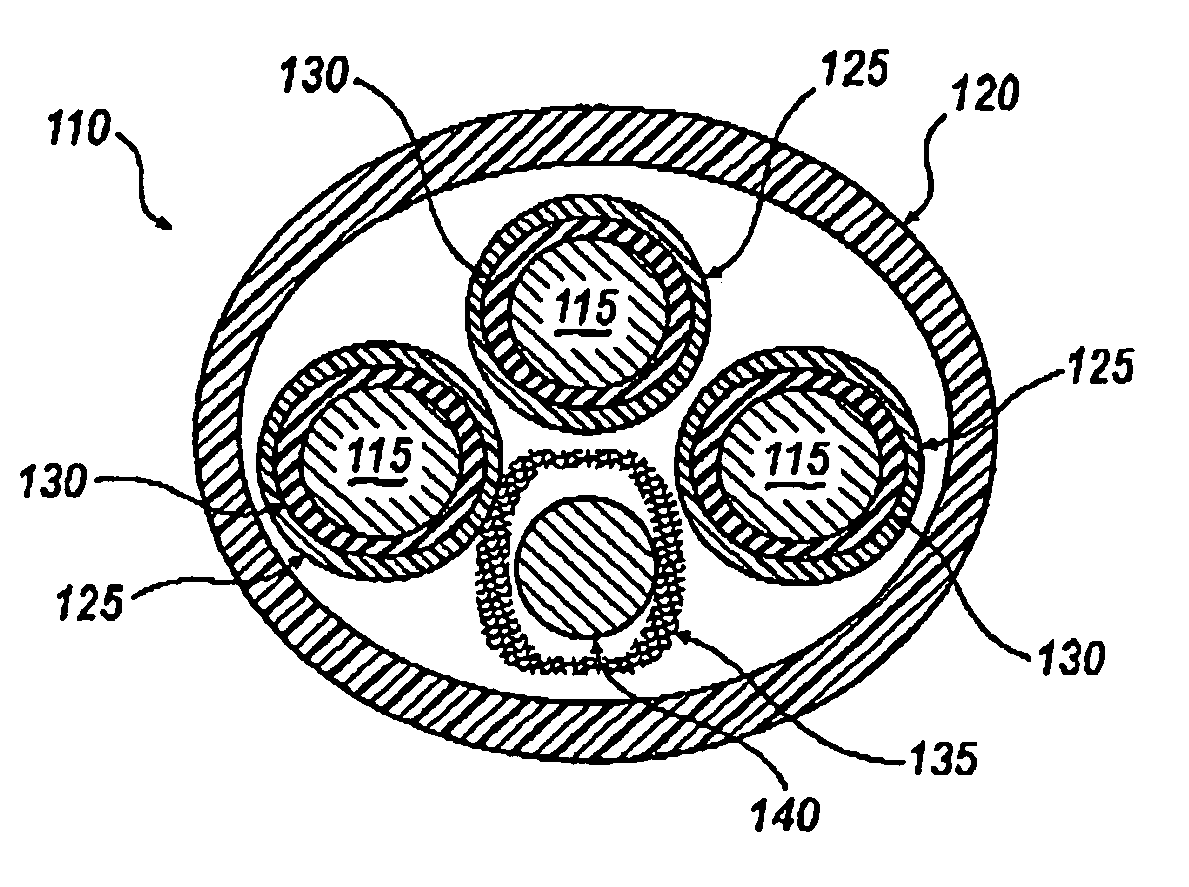

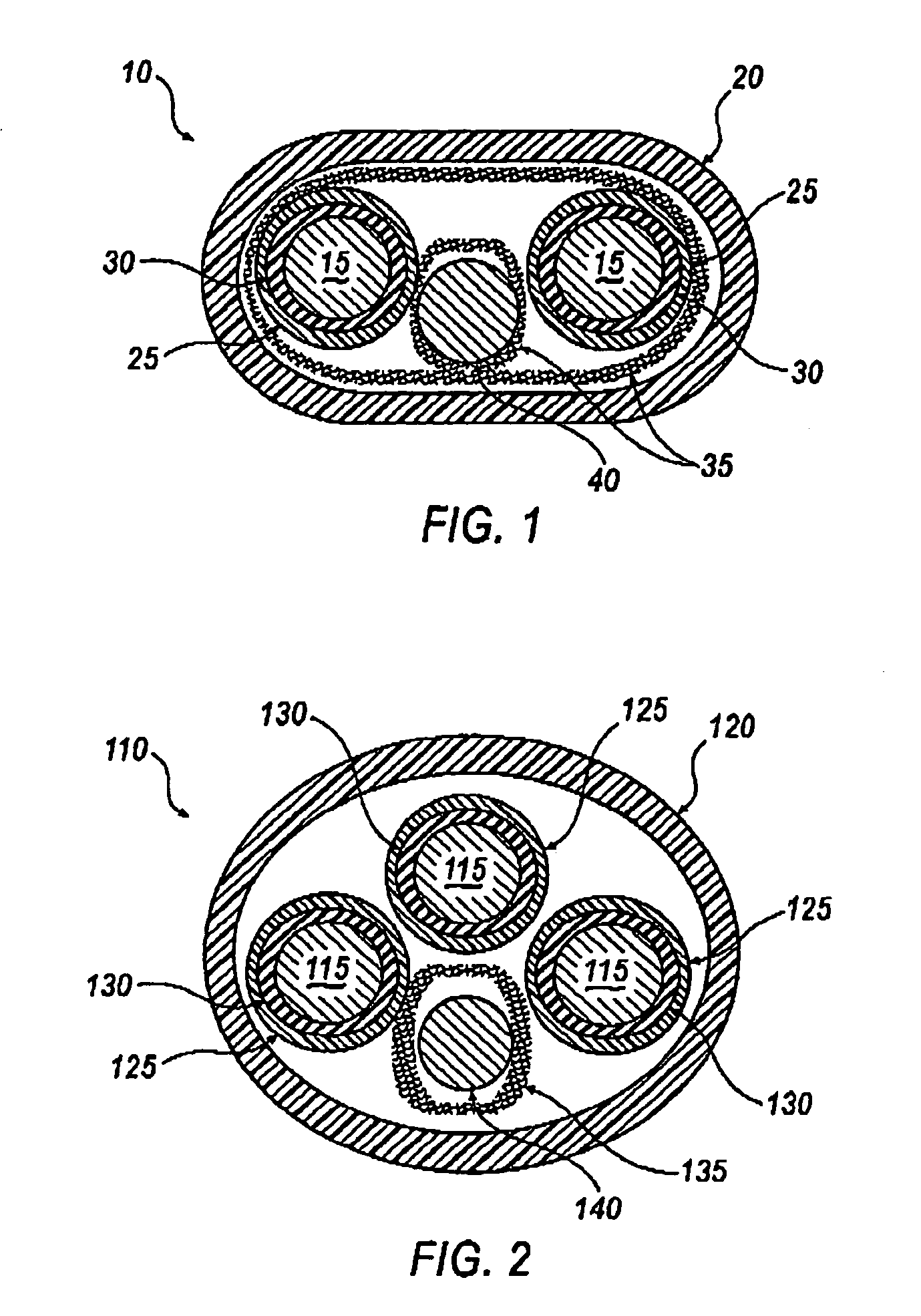

Non-lead jacket for non-metallic sheathed electrical cable

InactiveUS7129415B1Easy to pullReduce frictionPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorPlasticizer

A non metallic (NM) jacket has from about 40% to about 50% by weight of a polyvinyl chloride resin; from about 20% to about 35% by weight of a filler; from about 0.1% to about 0.5% by weight of an unsaturated primary amide derived from erucic acid; from about 20% to about 30% by weight of a phthalate-based plasticizer; and from about 0.5% to about 5% by weight of a lead-free heat-stabilizing system; wherein 100% is the weight of the jacket. Methods for improving the slip characteristics of a lead-free NM jacket for an electrical conductor are also provided.

Owner:SOUTHWIRE CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com