Low-temperature resistant medicinal PVC modified material

A technology of modified materials and low temperature resistance, which is applied in the direction of medical containers, medical packaging, and types of packaging items. It can solve the problems of large migration of plasticizers, large precipitation of plasticizers, hardening and brittleness, etc., and achieve precipitation resistance The effect of excellent performance and excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh raw materials (kg) according to the following ratio:

[0027] PVC resin powder 100

[0028] Plasticizer: DINCH 20

[0029] TPU 5

[0030] Liquid Calcium Zinc 0.8

[0031] Tris(nonylphenyl)phosphite 0.3

[0032] Secondary Stabilizer: Epoxidized Soybean Oil 1

[0033] Polyethylene wax 0.2

[0034] The preparation method is as follows:

[0035] Mixing: Add PVC resin powder and stabilizer liquid calcium zinc to the high-speed mixer at low speed (441 rpm). When the temperature reaches 65°C, add DINCH, tris(nonylphenyl phosphite), epoxy large Soybean oil, after 1.5 minutes, turn to high speed (operating speed is 877 rpm), when the temperature reaches 90°C, add TPU, when the temperature reaches 110°C, add polyethylene wax, continue to stir until 135°C and put the material into the cold pot until the material temperature to about 30°C;

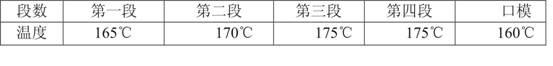

[0036] Granulation: The material cooled to about 30°C is extruded and pelletized by SJSZ-65 twin-screw extruder, and pelletized ...

Embodiment 2

[0041] Weigh raw materials (kg) according to the following ratio:

[0042] PVC resin powder 100

[0043] Plasticizer: DINCH 43

[0044] TPU 10

[0046] Tris(nonylphenyl)phosphite 0.3

[0047] Auxiliary Stabilizer: Epoxidized Soybean Oil 5

[0048] Polyethylene wax 0.4

[0049] The preparation method is as described in Example 1.

Embodiment 3

[0051] Weigh raw materials (kg) according to the following ratio:

[0052] PVC resin powder 100

[0053] Plasticizer: DINCH 50

[0054] TPU 15

[0055] Liquid Calcium Zinc 1.5

[0056] Tris(nonylphenyl)phosphite 1.2

[0057] Secondary Stabilizer: Epoxidized Soybean Oil 6

[0058] Polyethylene wax 0.8

[0059] The preparation method is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com