Ultra-thin weather-proof and anit-cracking organosilicon fire-proof paint

A fire-resistant coating and anti-cracking technology, applied in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor fire resistance, easy cracking and falling off, and low thickness in a single construction, to overcome poor weather resistance and enhance UV resistance. , The effect of improving fire resistance and vibration resistance and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

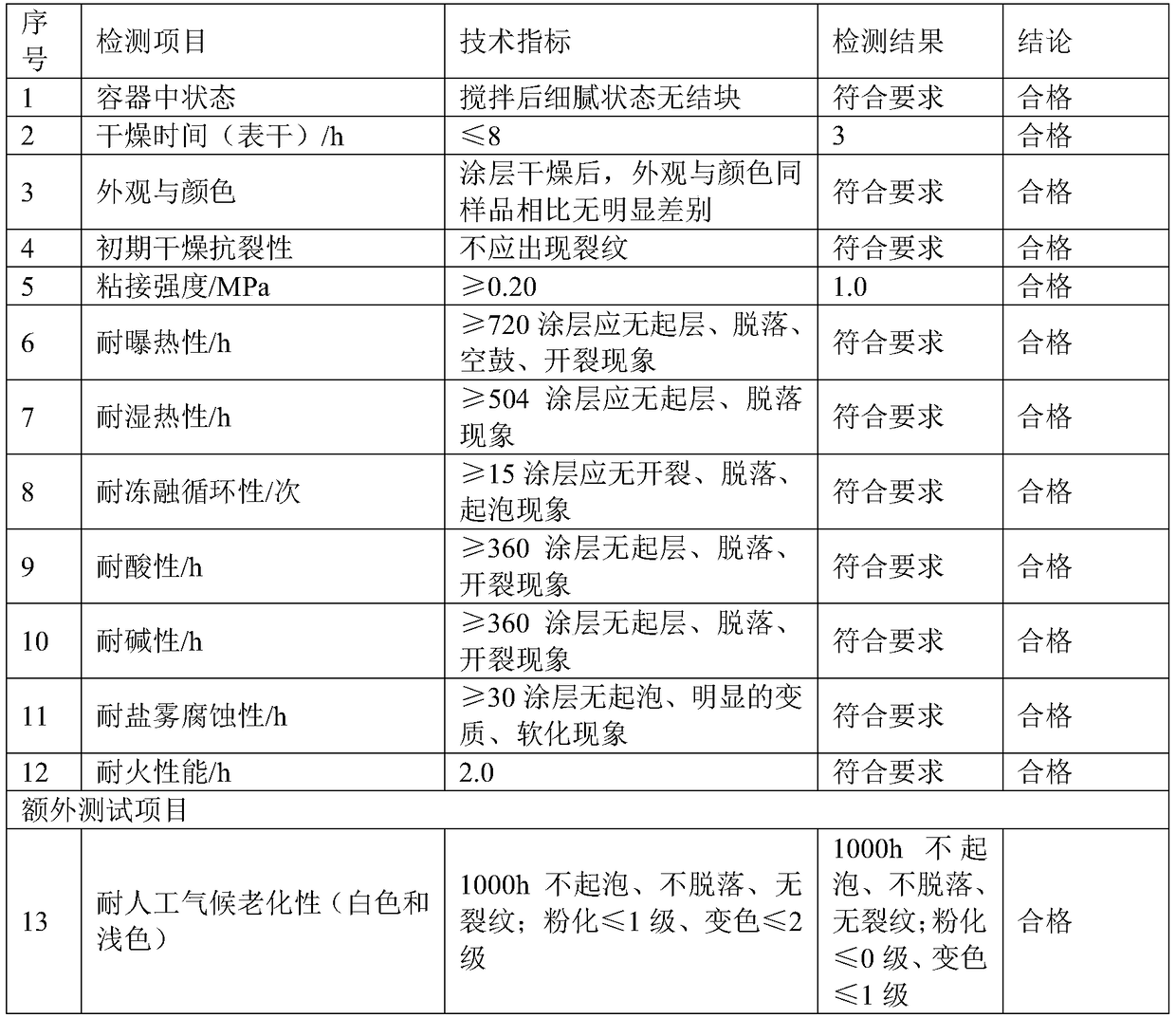

Examples

Embodiment 1

[0034] An ultra-thin weather-resistant and anti-cracking silicone fireproof coating, prepared from the following raw materials in terms of mass percentage: nano-modified polysiloxane oligomer: 32%; trifunctional silicone crosslinking agent: 5.5%; Four-functional silicone crosslinking agent: 2.8%; hydrophobic fumed silica: 5%; titanium dioxide: 5%; ammonium polyphosphate: 20.5%; melamine: 8.5%; surface-coated pentaerythritol: 9.5%; Aluminum: 2%; glass fiber powder: 2.5%; hydroxyl silicone oil: 4%; aminosilane coupling agent: 1.5%; epoxy silane coupling agent: 1%; catalyst: 0.2%.

[0035] The nano-modified polysiloxane oligomer is prepared by the following method: adding ether into a three-necked flask with a reflux condenser and a magnetic stirrer; adding metered dimethyl methoxy base silane, methylphenyldimethoxysilane and nano-titanium oxide powder; magnetically stirred for 10 minutes and then ultrasonicated for 2 hours, then gradually raised the temperature to 70°C, and slow...

Embodiment 2

[0041] An ultra-thin weather-resistant and anti-cracking silicone fireproof coating, prepared from the following raw materials in terms of mass percentage: nano-modified polysiloxane oligomer: 25%; trifunctional silicone crosslinking agent: 7%; Four-functional silicone crosslinking agent: 5%; hydrophobic fumed silica: 5%; titanium dioxide: 5.2%; ammonium polyphosphate: 21%; melamine: 9%; surface-coated pentaerythritol: 9%; Aluminum: 2%; glass fiber powder: 6%; hydroxyl silicone oil: 3%; aminosilane coupling agent: 2%; epoxy silane coupling agent: 0.5%; catalyst: 0.3%.

[0042] The nano-modified polysiloxane oligomer is prepared by the following method: adding ether into a three-necked flask with a reflux condenser and a magnetic stirrer; adding metered dimethyl methoxy base silane, methylphenyldimethoxysilane and nano-titanium oxide powder; after magnetic stirring for 30 minutes, ultrasonication for 1 hour, the temperature was gradually raised to 80 ° C, and the catalyst tetra...

Embodiment 3

[0050] An ultra-thin weather-resistant and anti-cracking silicone fireproof coating, prepared from the following raw materials in terms of mass percentage: nano-modified polysiloxane oligomer: 30%; trifunctional silicone crosslinking agent: 5%; Four-functional silicone crosslinking agent: 3%; hydrophobic fumed silica: 5.9%; titanium dioxide: 5%; ammonium polyphosphate: 20%; melamine: 8%; surface coating pentaerythritol: 10%; Aluminum: 3%; glass fiber powder: 2%; hydroxyl silicone oil: 5%; aminosilane coupling agent: 1%; epoxy silane coupling agent: 2%; catalyst: 0.1%.

[0051] The nano-modified polysiloxane oligomer is prepared by the following method: adding ether into a three-necked flask with a reflux condenser and a magnetic stirrer; adding metered dimethyl methoxy base silane, methyl phenyl dimethoxy silane and nano-titanium oxide powder; magnetic stirring and mixing for 20 minutes, ultrasonication for 1.5 hours, gradually raising the temperature to 75 ° C, and slowly add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Salt spray resistance time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com