Patents

Literature

21833 results about "Steel structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof insulating cementitious foam comprising phase change materials

ActiveUS8070876B1Improve fire resistanceImprove high temperature resistanceSolid waste managementSynthetic resin layered productsThermal energyThermal energy storage

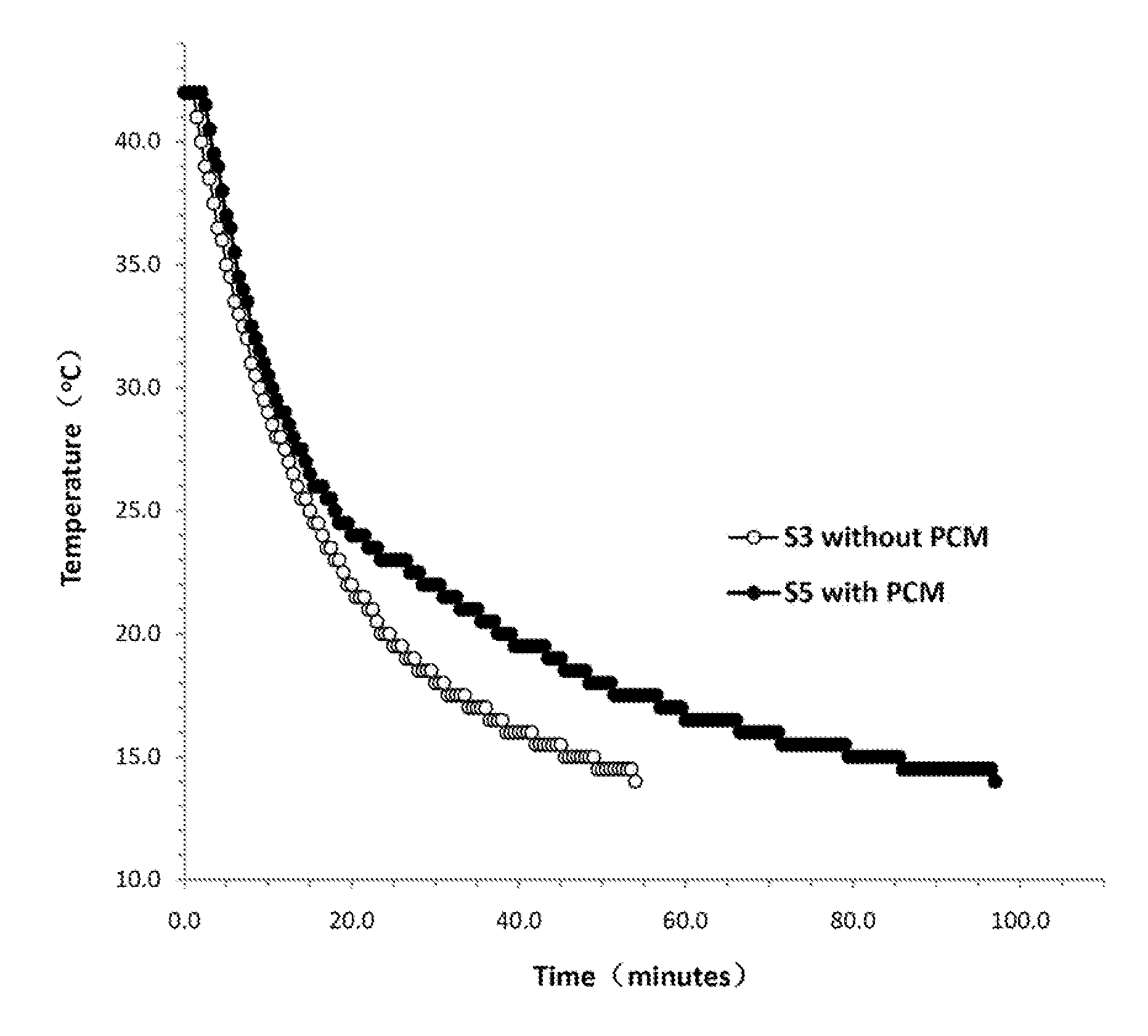

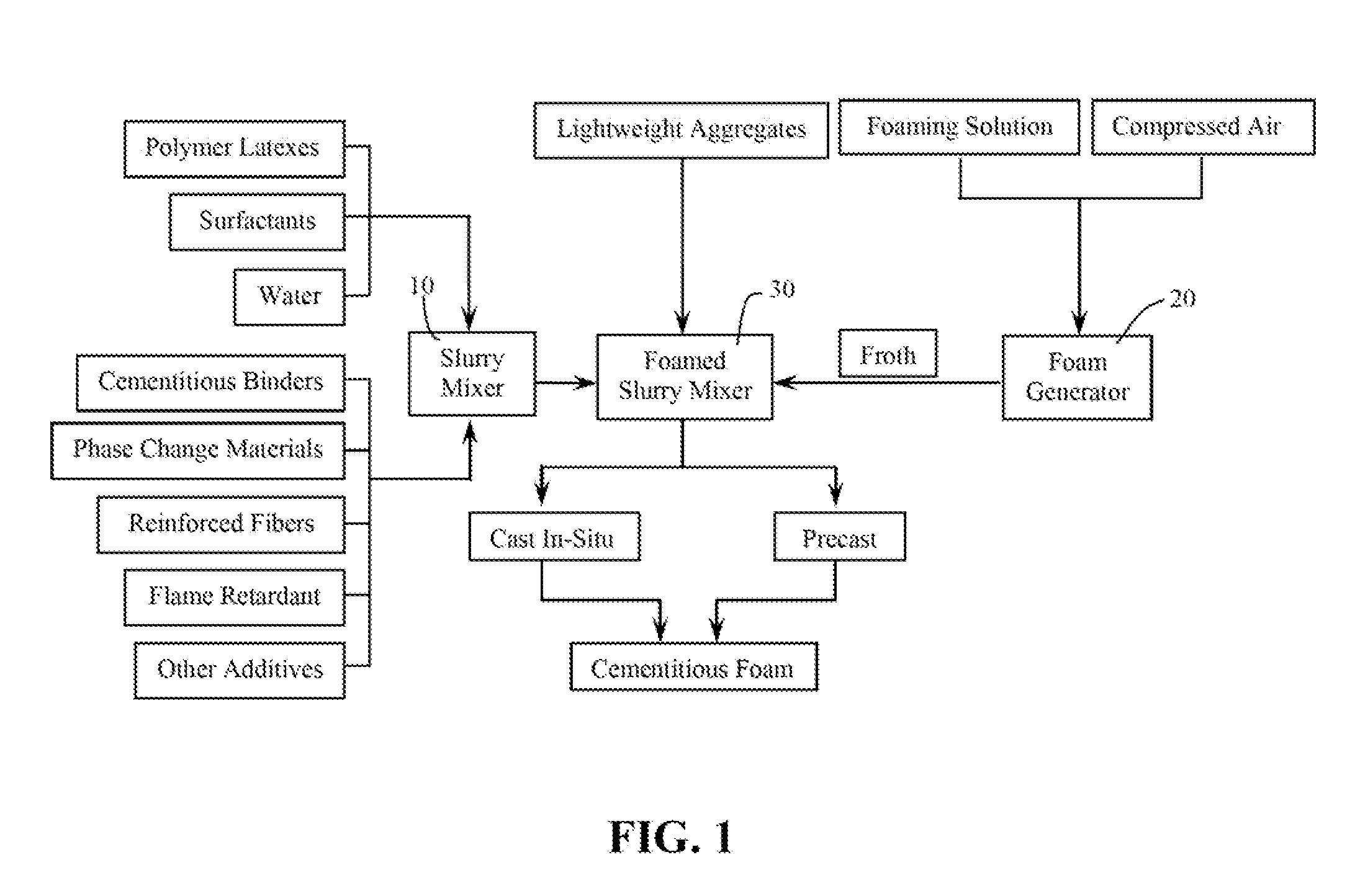

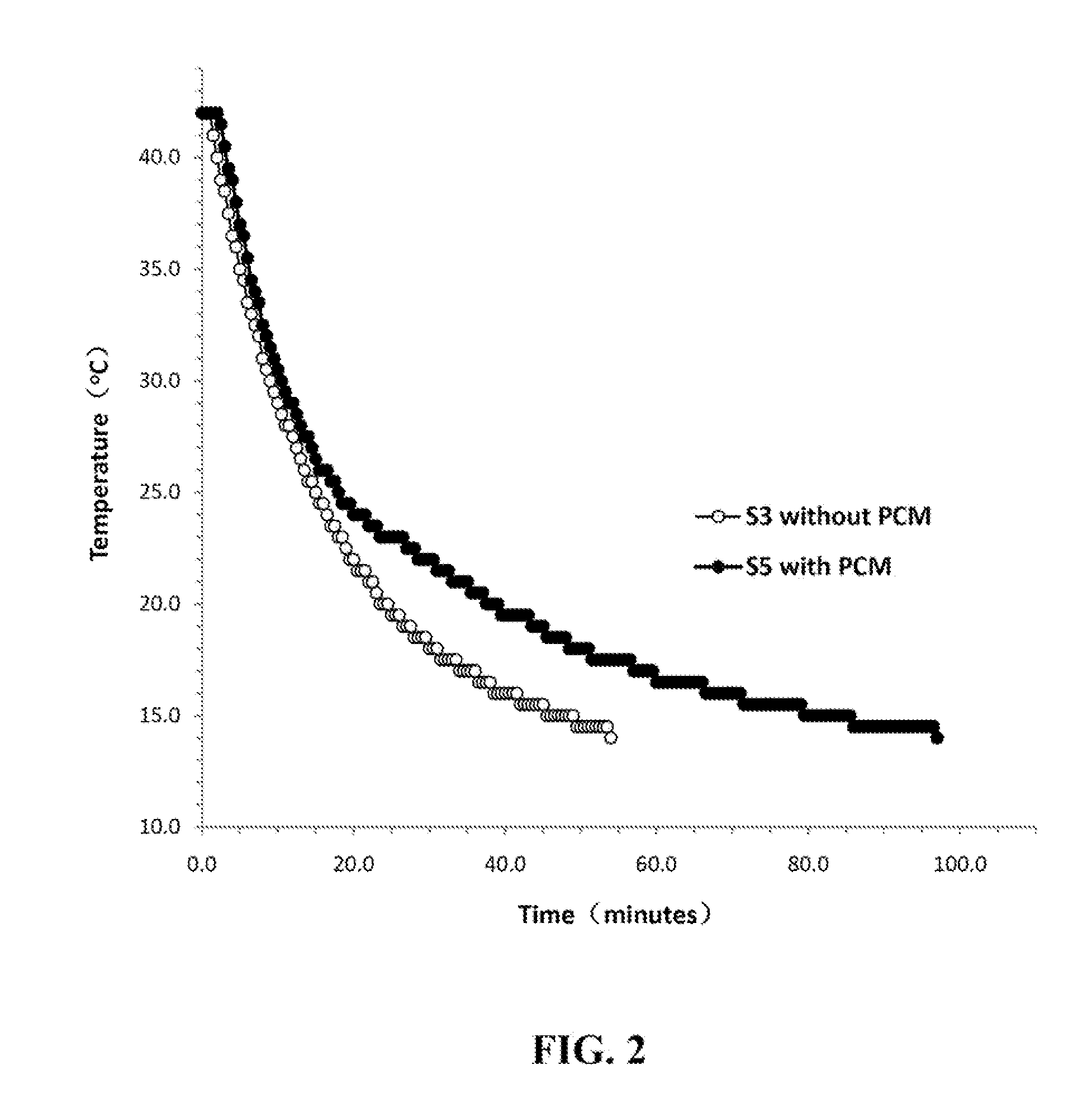

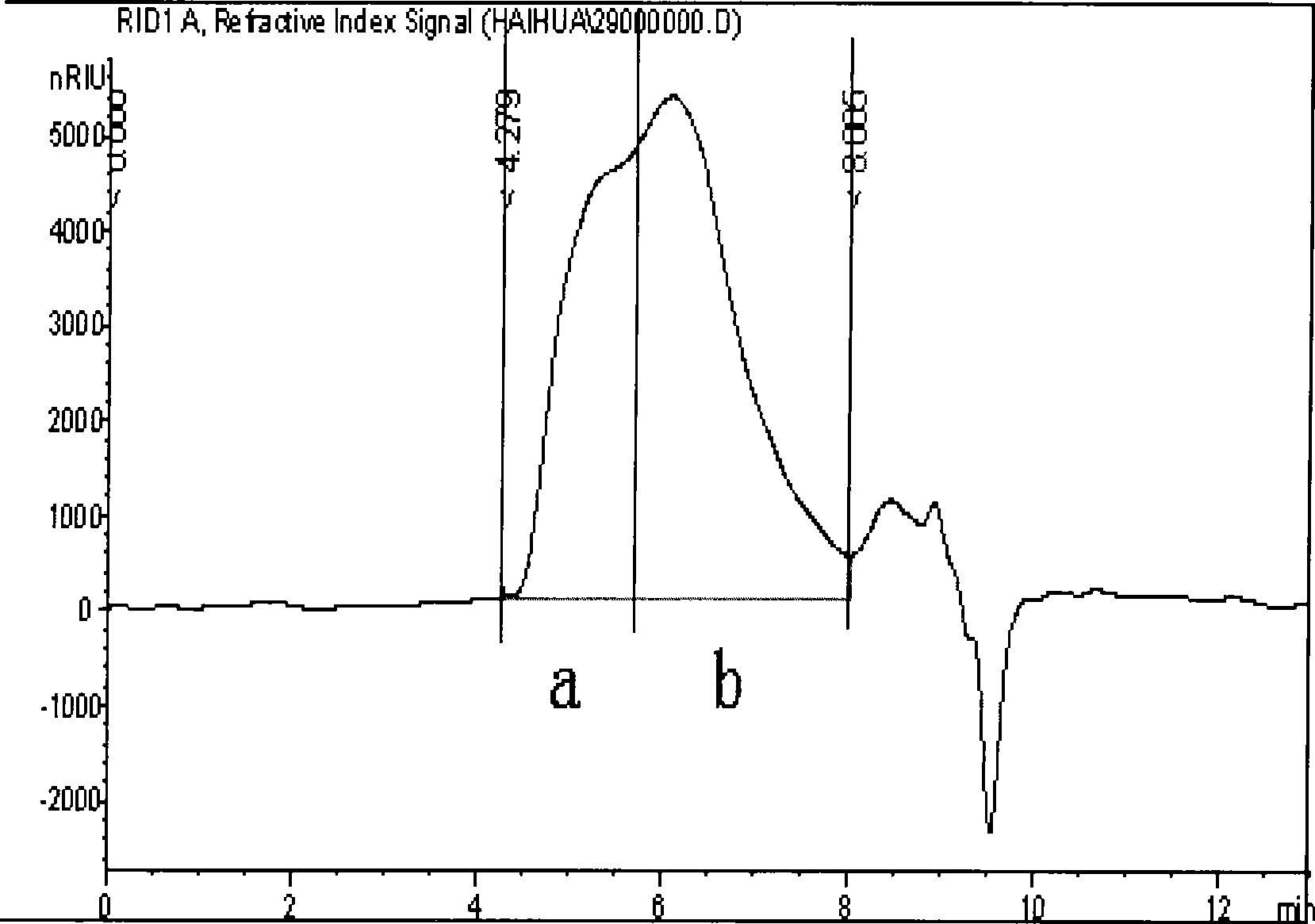

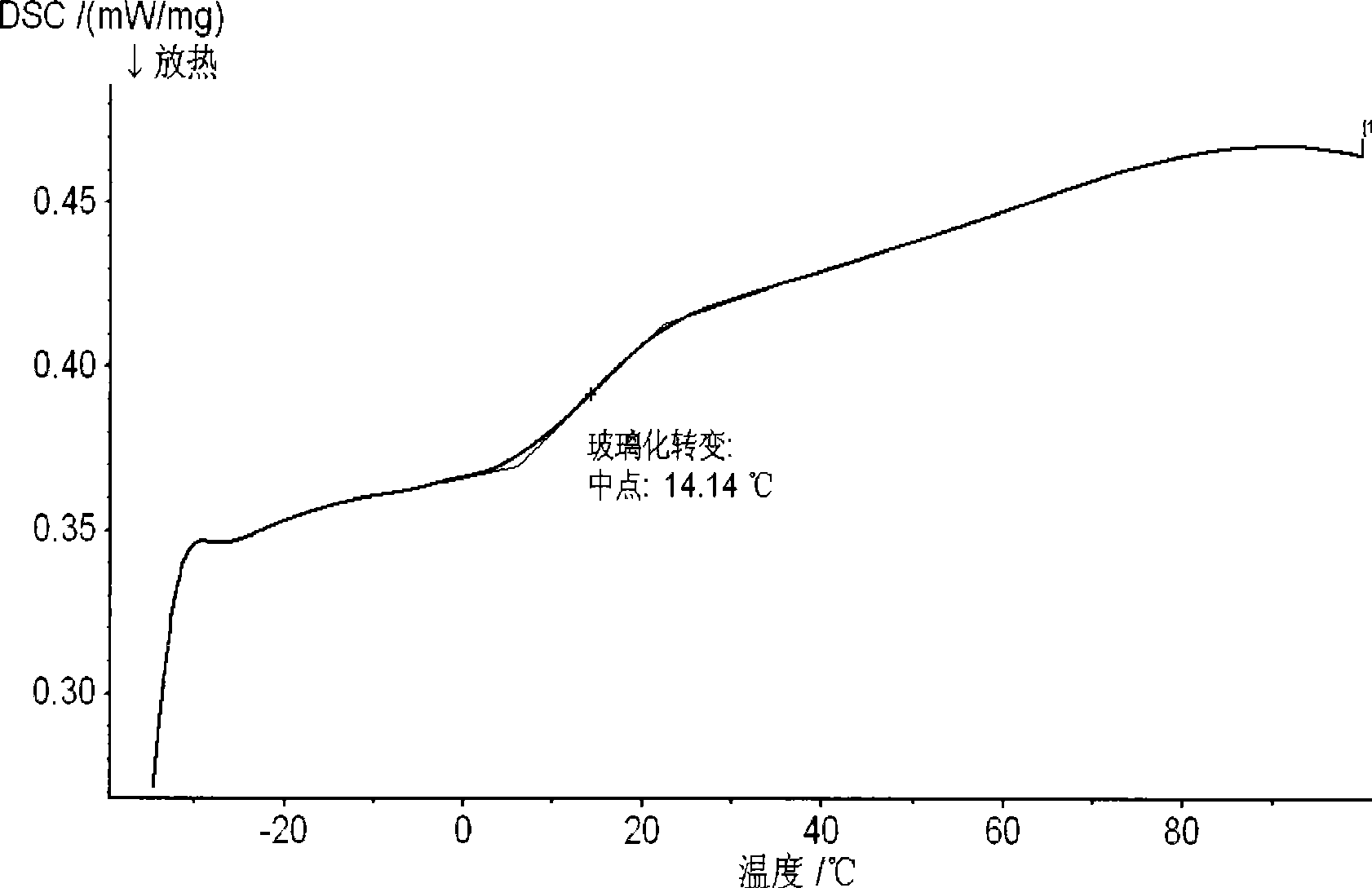

A fireproof insulating foamed cementitious composition with thermal energy storage capacity is provided for use in producing wall insulation boards, fireproof claddings for steel structures, inner cores of fire resistant wall or door panels, and the like. The composition demonstrates improved energy efficiency in which phase change materials, such as microencapsulates, are used in conjunction with a cementitious mixture of calcined gypsum and hydraulic cement, lightweight aggregates, a polymer latex, and a foaming solution to create stable air bubbles inside the cementitious matrix. The calcined gypsum and the hydraulic cement are present in a weight ratio range from about 1:3 to about 3:1. The composition may further include reinforced fibers, surfactants, inorganic flame retardants, and other additives. The presence of the phase change material not only increases energy efficiency of the cured cementitious foam material, but also improves compatibility between calcined gypsum and cement during slurry mixing and hardening.

Owner:JIANG HAIHONG

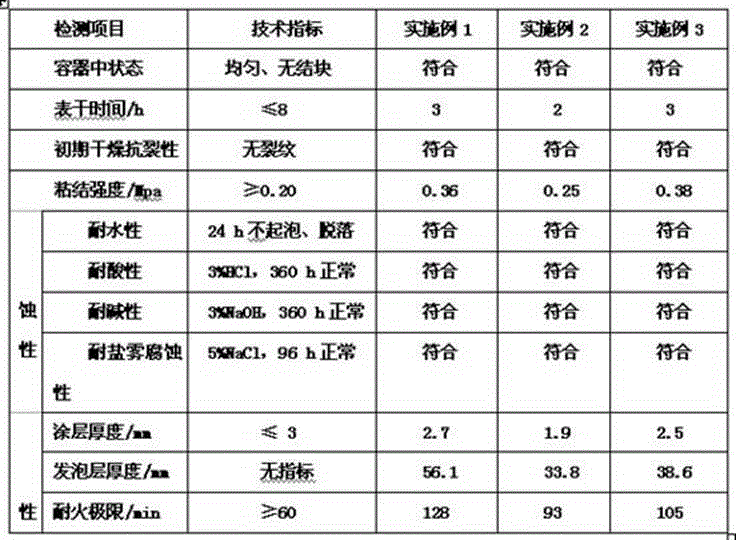

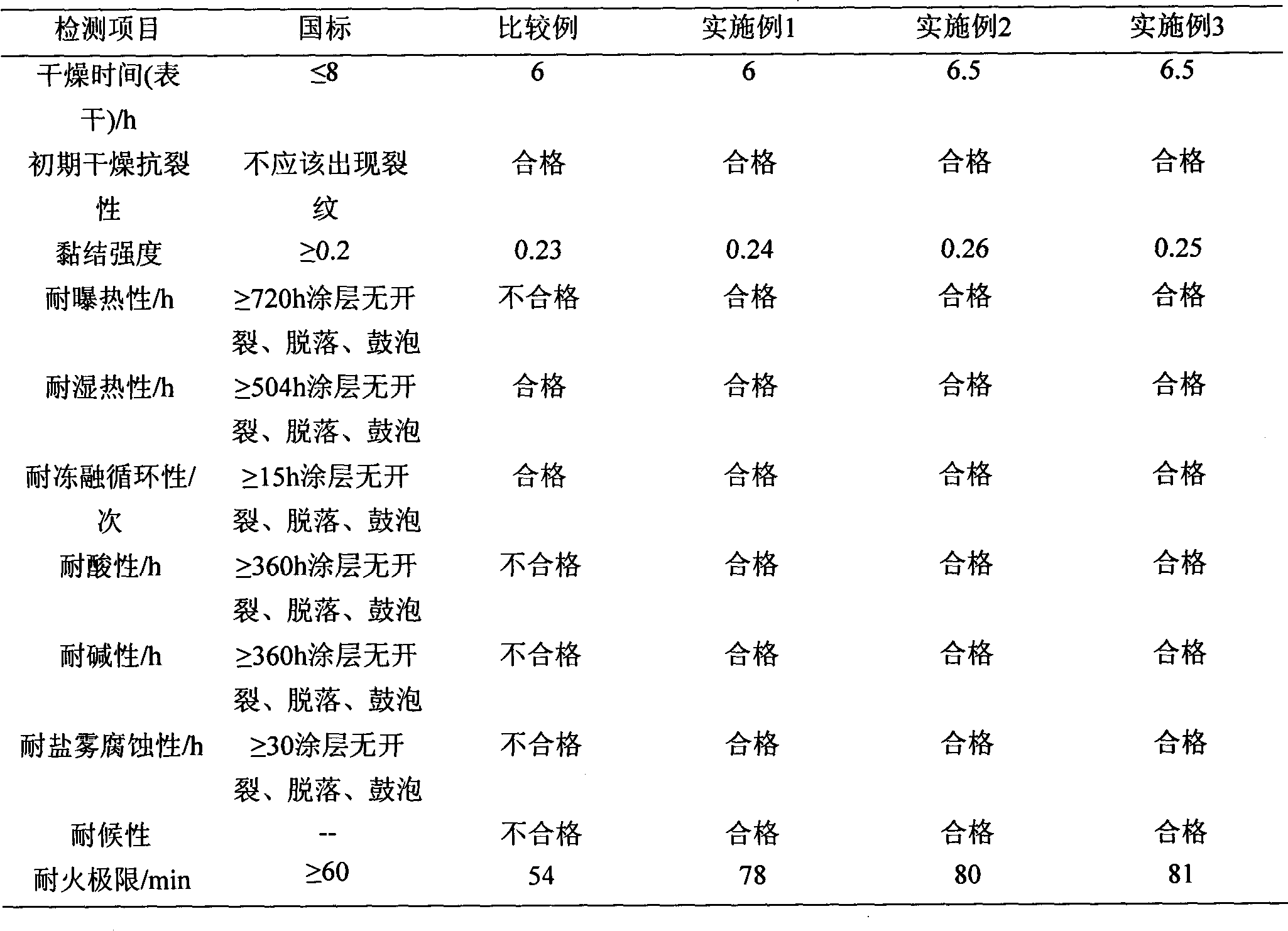

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

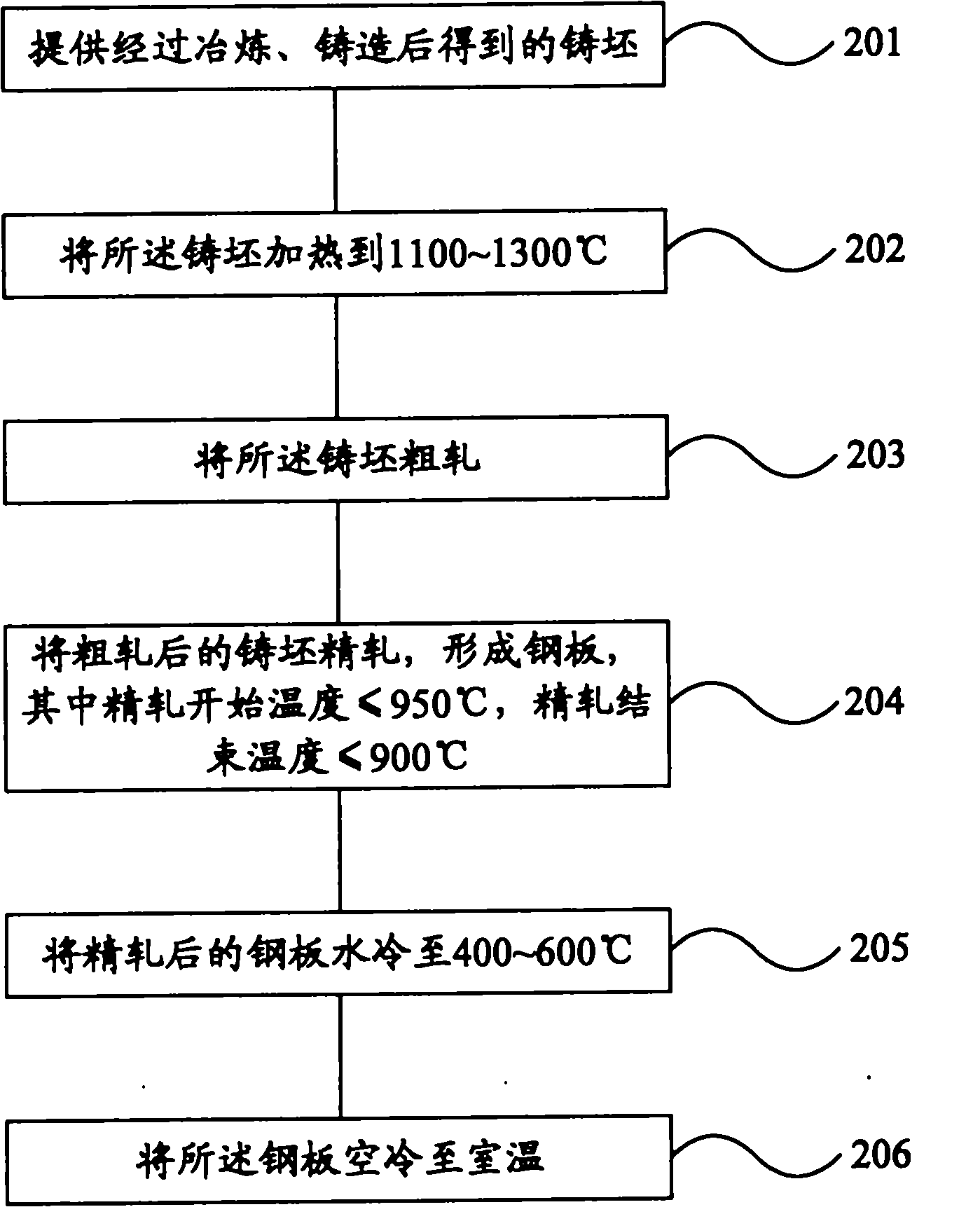

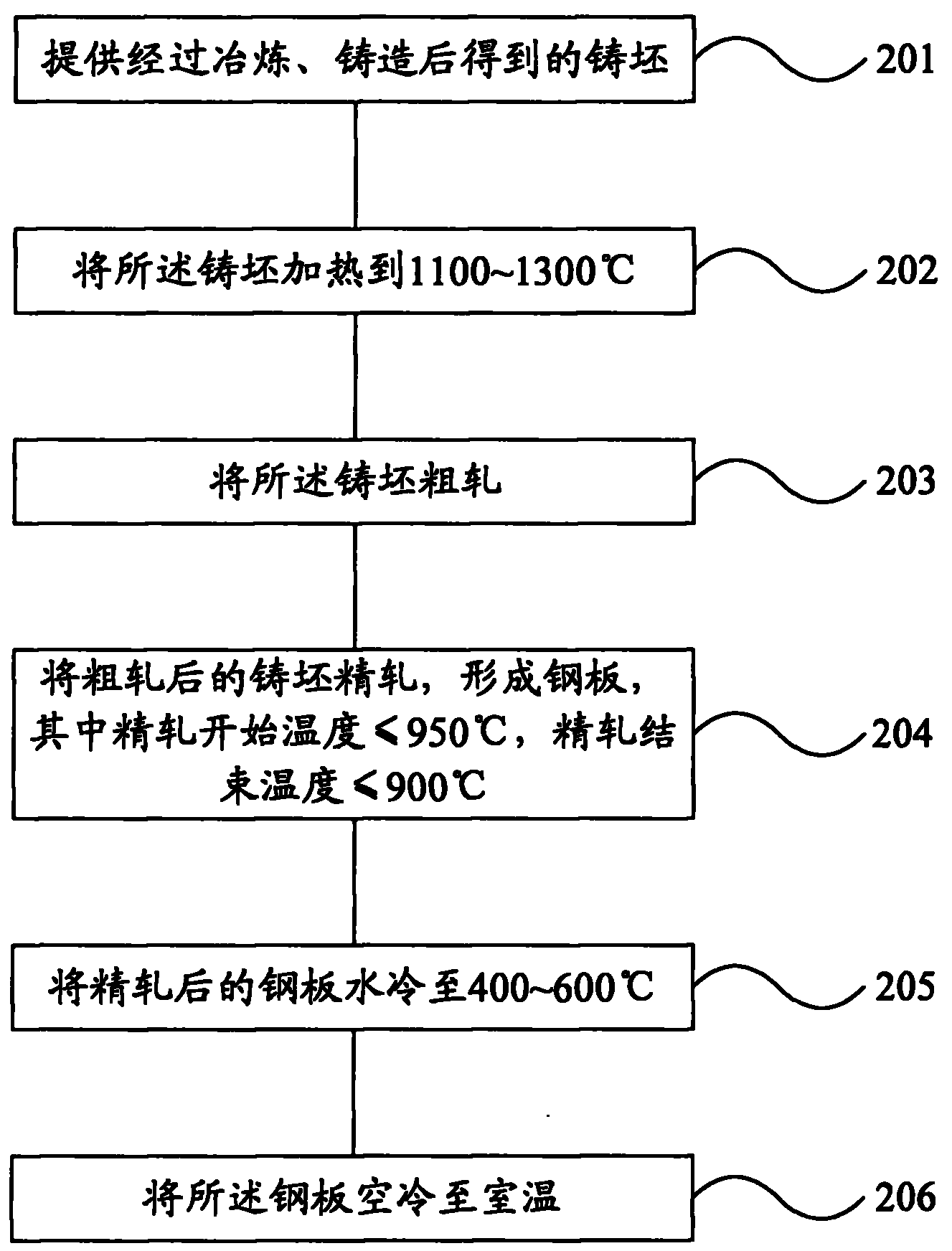

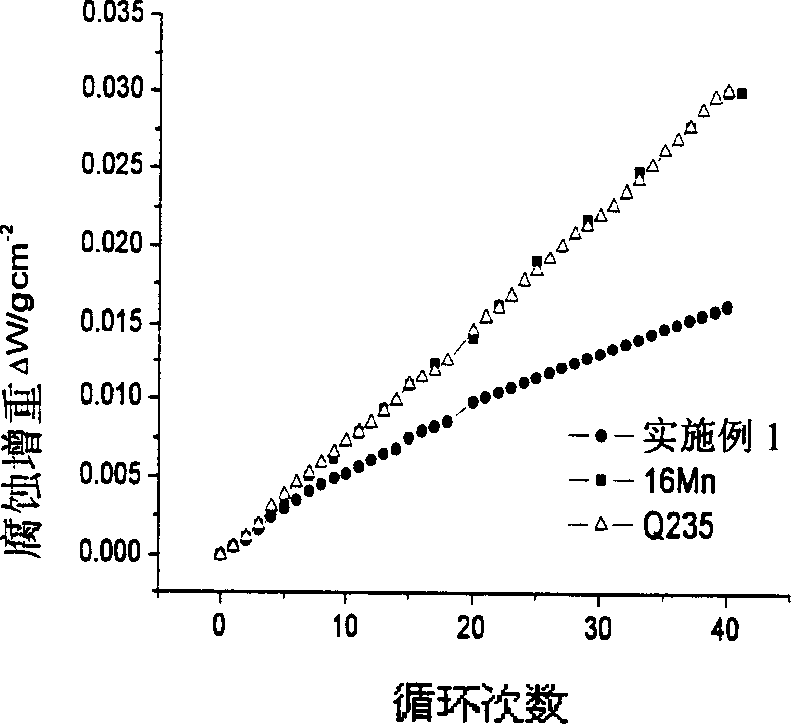

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Expanding fire-proof paint

InactiveCN1380368AGood fire and heat insulationGood adhesionFireproof paintsFoaming agentAcrylic resin

The expansive fire-resisting paint contains the components of acrylic resin, catalyst, carbon-forming agent, foaming agent, fire-resisting agent, reinforcing agent, pigment filling material, adjuvantand smoke inhibiting agent, and is characterized by that it utilizes the modification of acrylic resin, surface treatment of catalyst and addition of smoke inhibiting agent to raise comprehensive property of paint. When the paint film is heated and expanded, it can be formed into fire-resistant carbonized layer with three-D space structure, and can release fire-resisting gas to prevent flame fromspreading. Said paint is suitable for steel structure, and material and electric cable, etc.

Owner:MARINE CHEM RES INST

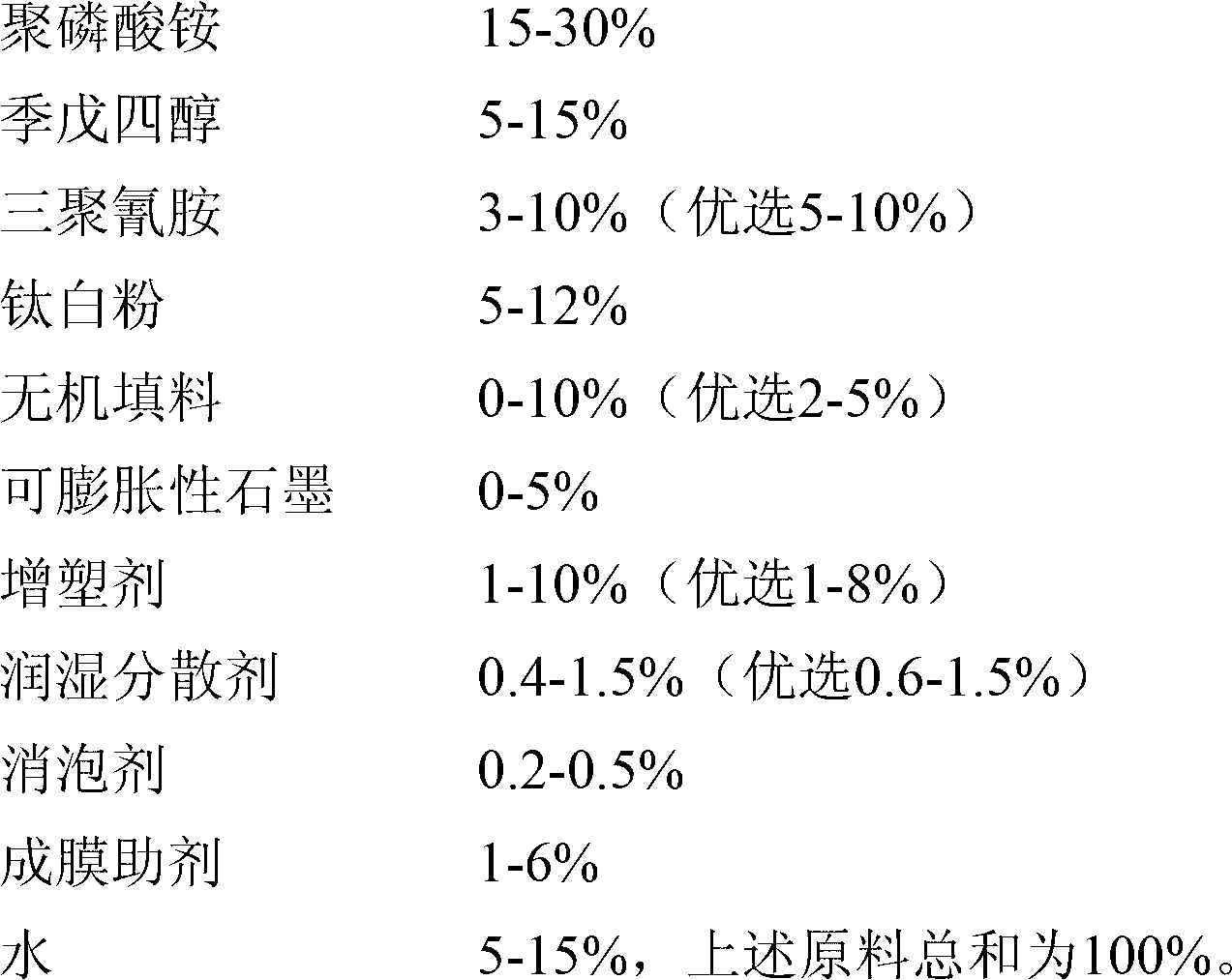

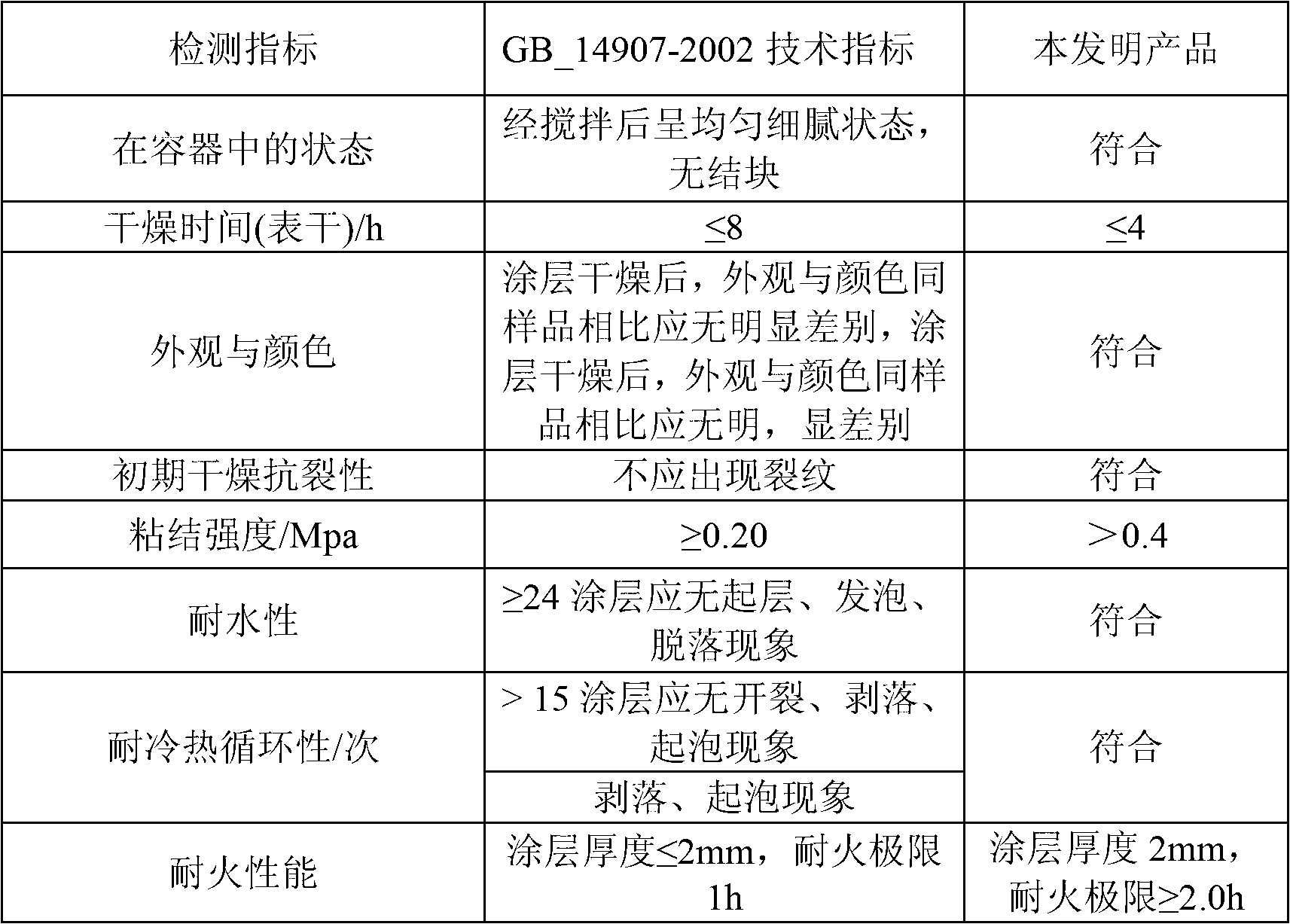

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

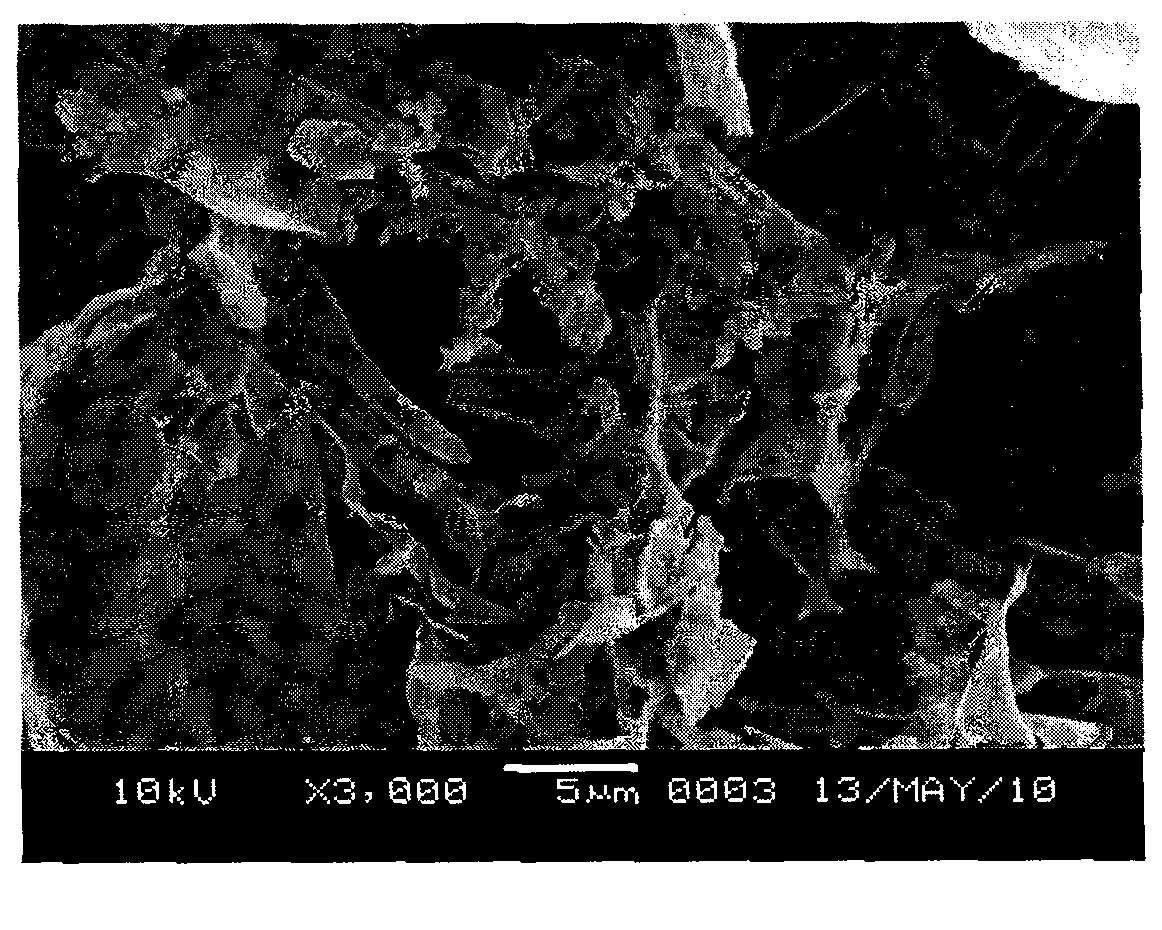

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

InactiveCN101857760AGuaranteed expansion heightHas anti-rustFireproof paintsAnti-corrosive paintsAcrylic resinRust

The invention relates to an aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and a preparation method thereof. The fire-proof anti-corrosive paint is prepared by adding ammonium polyphosphate, pentaerythritol, melamine, titanium white, expandable graphite, a preservative, a ceramic filler, an antifoaming agent, a dispersing agent, a plasticizer and the like into organic silicon-modified acrylic resin emulsion serving as a film forming base material. The paint has the advantages of high fire-proof performance, anti-corrosion and anti-rust function, and high water resistance, acid-alkali resistance and corrosion resistance, capability of meeting the requirements of various steel structures on the fire-proof and anti-corrosion performance, environmental friendliness, low cost, and readily available raw materials, so the paint can be widely applied to fire-proof protection of various steel structures.

Owner:EAST CHINA UNIV OF SCI & TECH

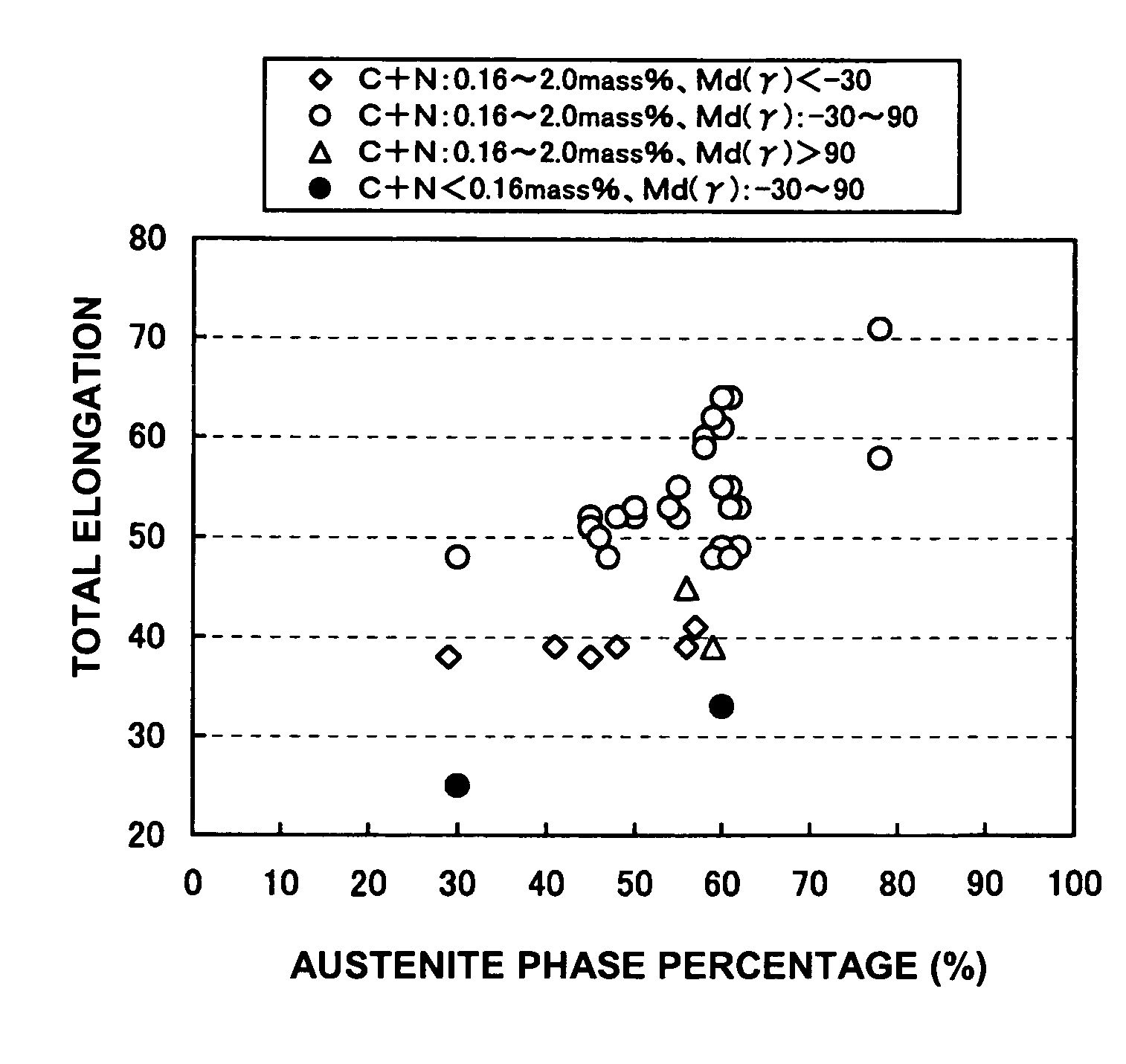

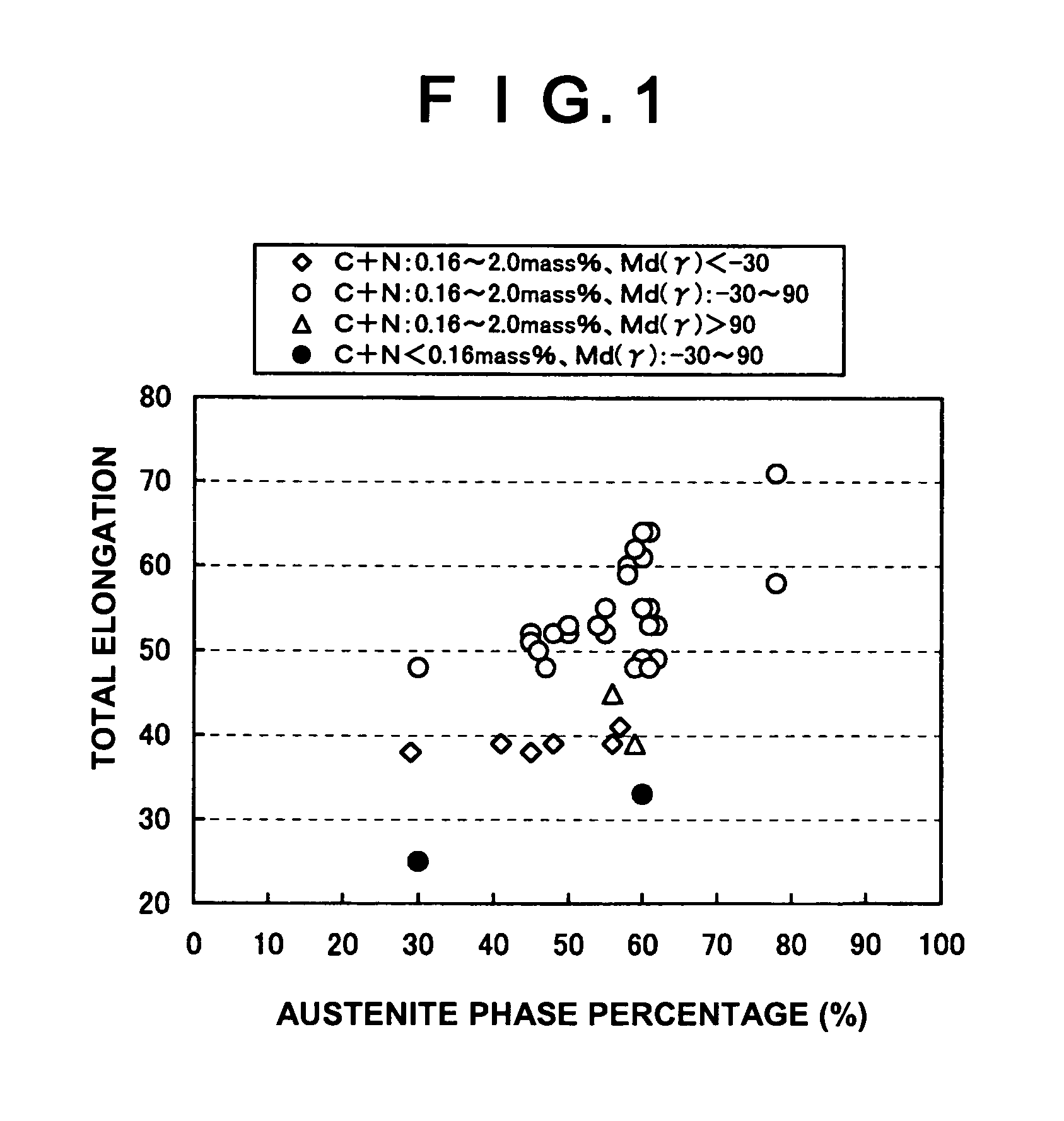

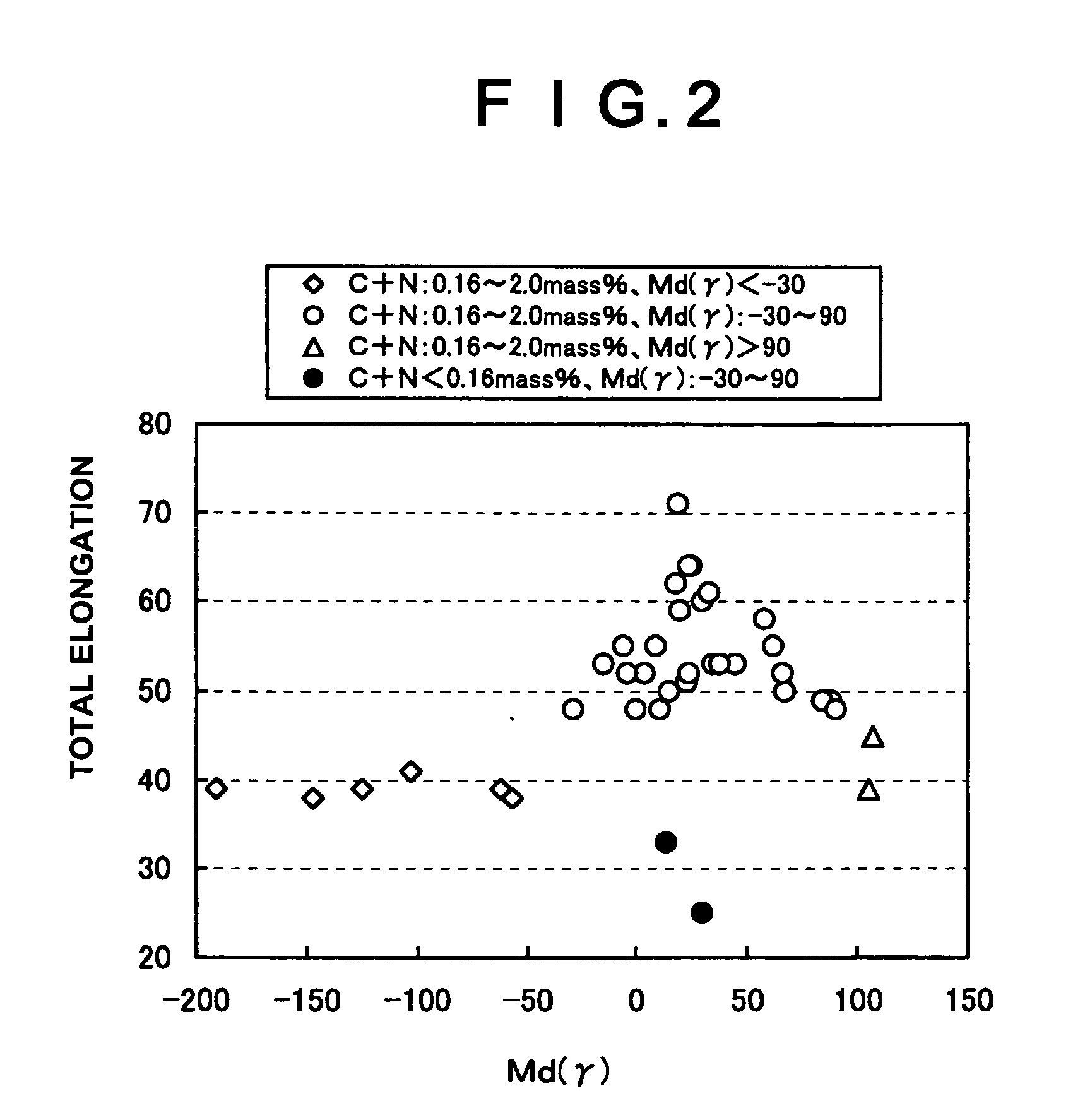

Austenitic-ferritic stainless steel

A low Ni and high N austenitic-ferritic stainless steel is disclosed. It includes an austenitic-ferritic stainless steel having high formability and punch stretchability, crevice corrosion resistance, corrosion resistance at welded part, or excellent intergranular corrosion resistance, from a stainless steel structured by mainly austenite phase and ferrite phase, and consisting essentially of 0.2% or less C, 4% or less Si, 12% or less Mn, 0.1% or less P, 0.03% or less S, 15 to 35% Cr, 3% or less Ni, and 0.05 to 0.6% N, by mass, by adjusting the percentage of the austenite phase in a range from 10 to 85%, by volume. Furthermore, it includes an austenitic-ferritic stainless steel having higher formability by adjusting the amount of (C+N) in the austenite phase to a range from 0.16 to 2% by mass.

Owner:JFE STEEL CORP

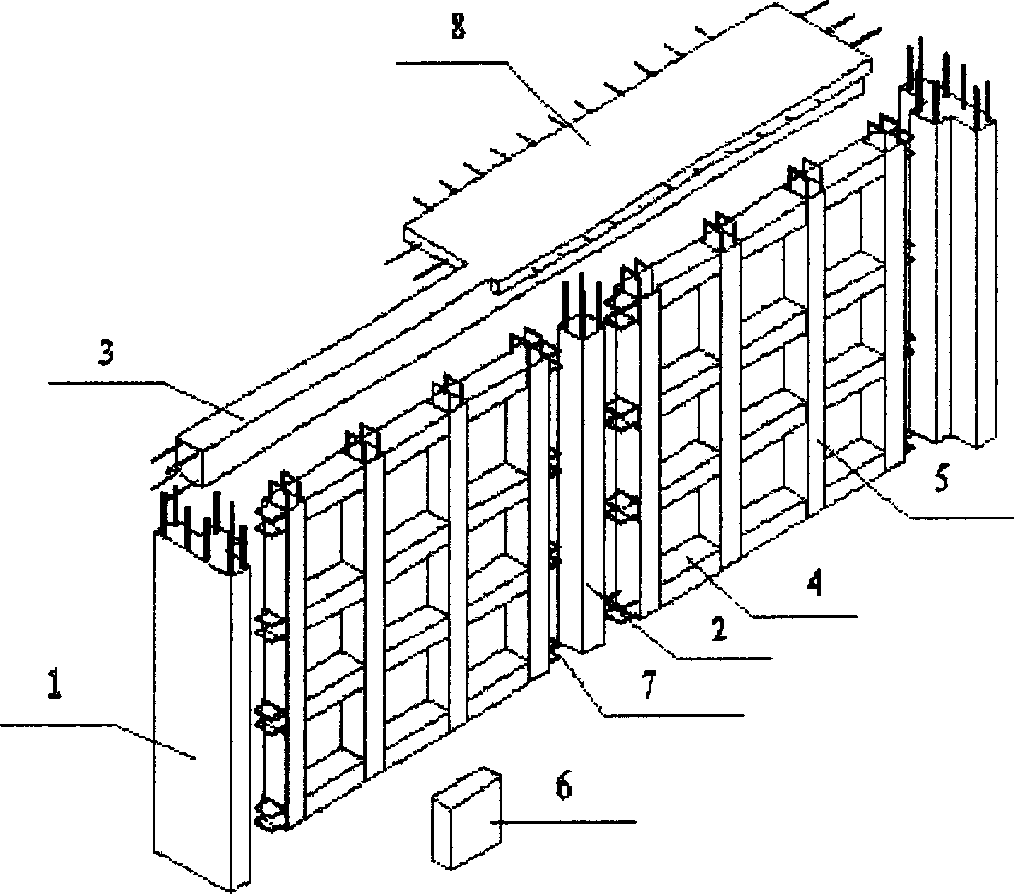

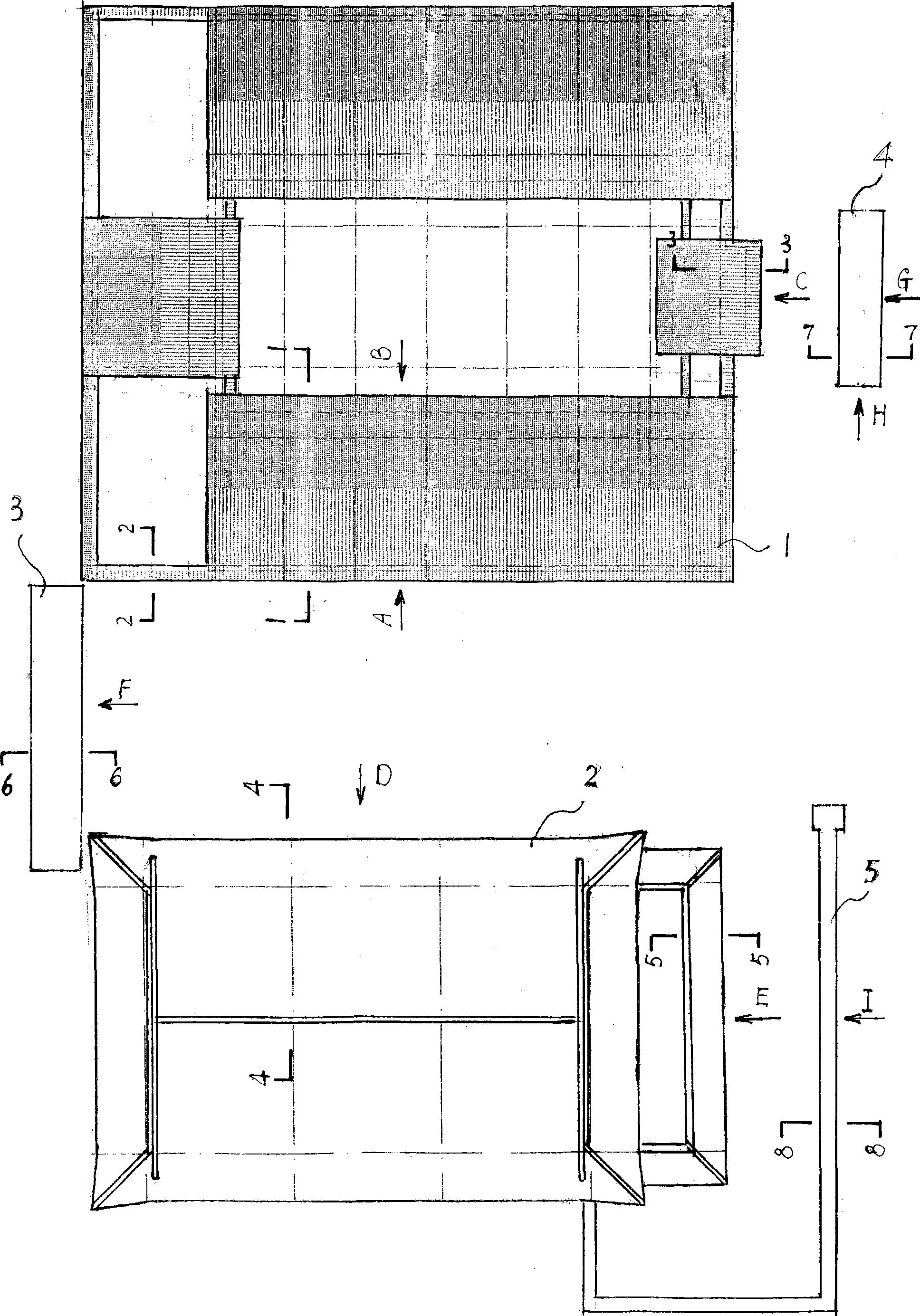

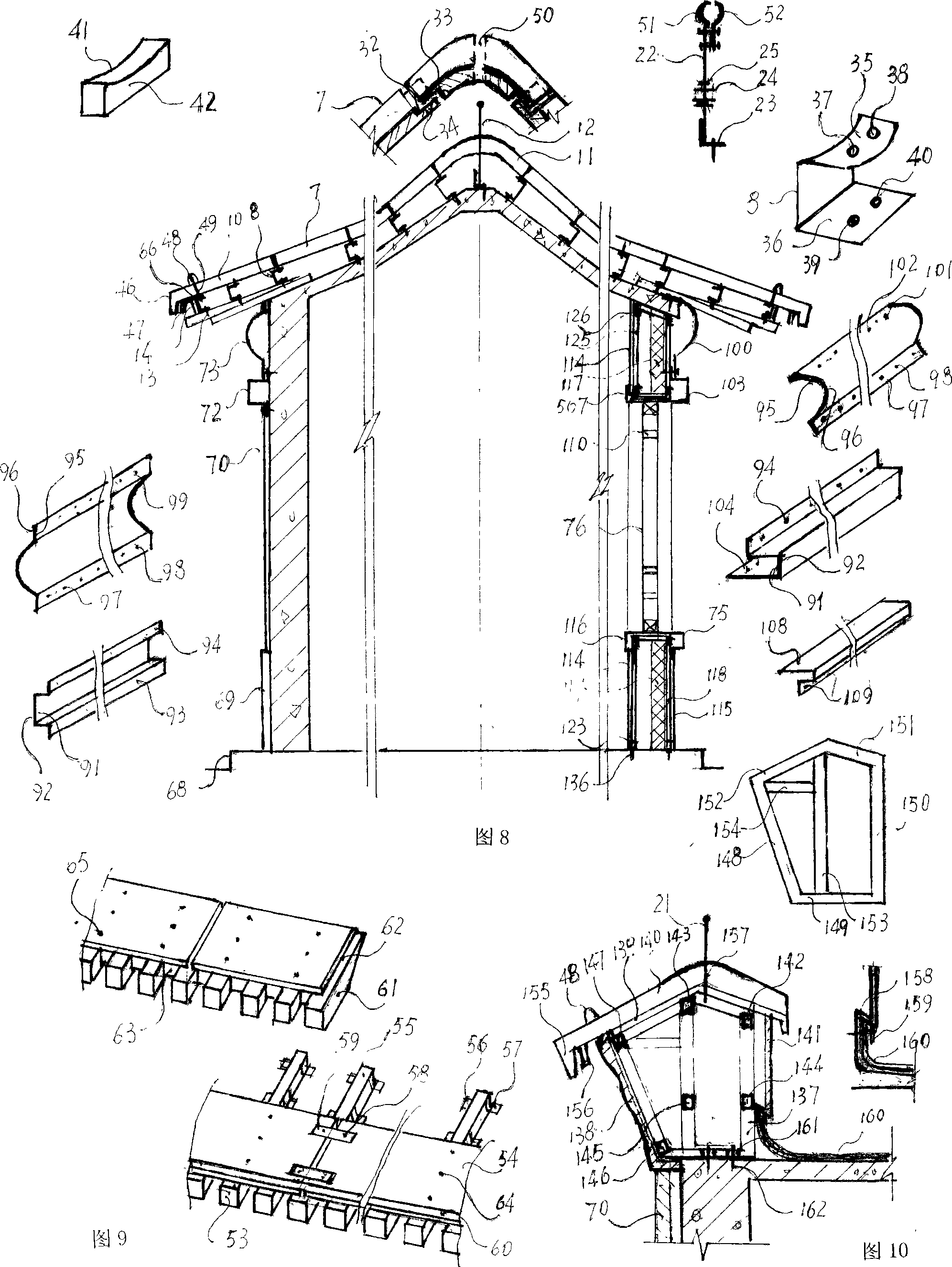

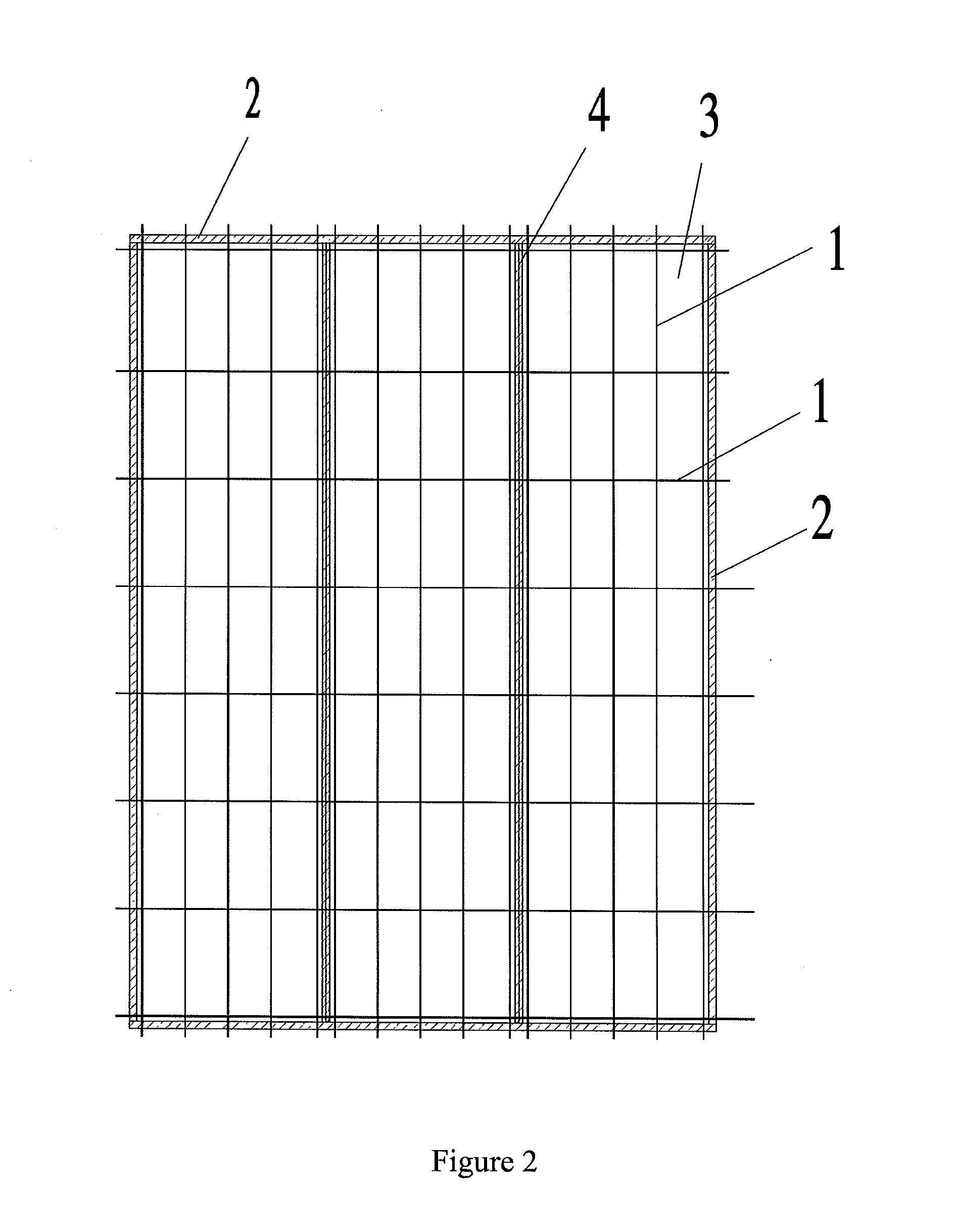

Multi-rib structure system and its connection construction method

InactiveCN1804263AAchieve graded releaseMeet the energy-saving requirements of light buildingsWallsFloor slabPre stressing

The invention relates to a ribbed structure which comprises a ribbed composite wall plate, a hidden frame and a floor. Wherein, the ribbed composite wall plate is a network construction element formed by reinforced steel concrete and light material and divided by the reinforced steel concrete beam as rib beam and rib post in small sections with embedding light material stuffing blocks into the grid; the ribbed composite wall plate also comprises the goatee bar extending from the rib beam and rib post, which is four steel bars with certain anchoring length extending from each rib beam and post and is longitude steel bar whose end is a hook in connection to hook hidden frame; or else the goatee bars are two U-shape closed ring extending from each rob beam an post and is inserted with longitude steel bars in connection; the hidden frame is formed by outer frame post, connection post, and hidden beam which are embedded outside the ribbed composite wall plate while using common concrete, profiled bar concrete or steel structural beam and post; the stuffing material is made from light material with certain strength, volume weight and little elastic modulus; and the floor can select on-situ irrigating concrete, on-sit or prefabricated ribbed composite floor, pre-stress layered floor or special-shaped pre-stress hollow floor.

Owner:姚谦峰

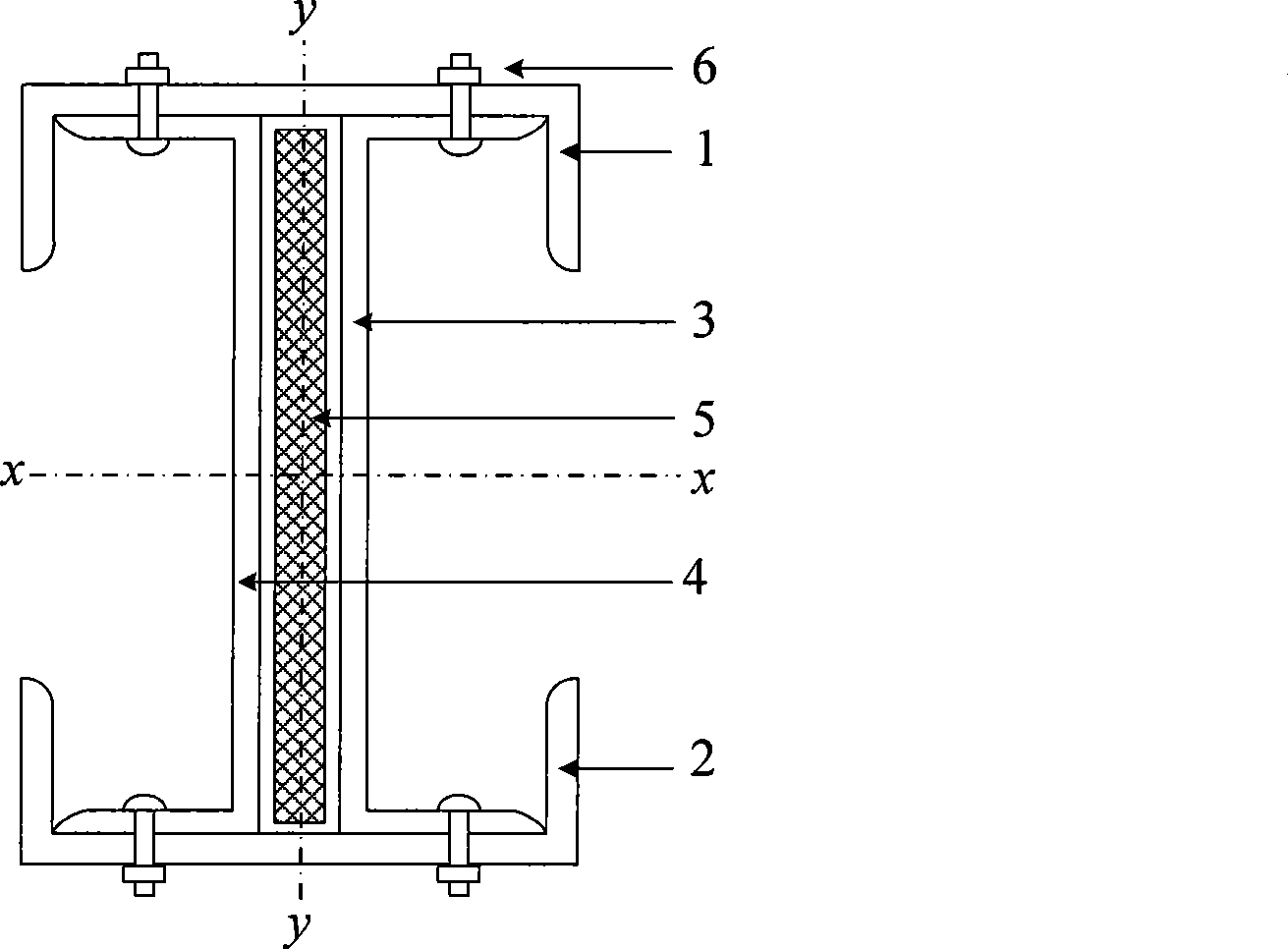

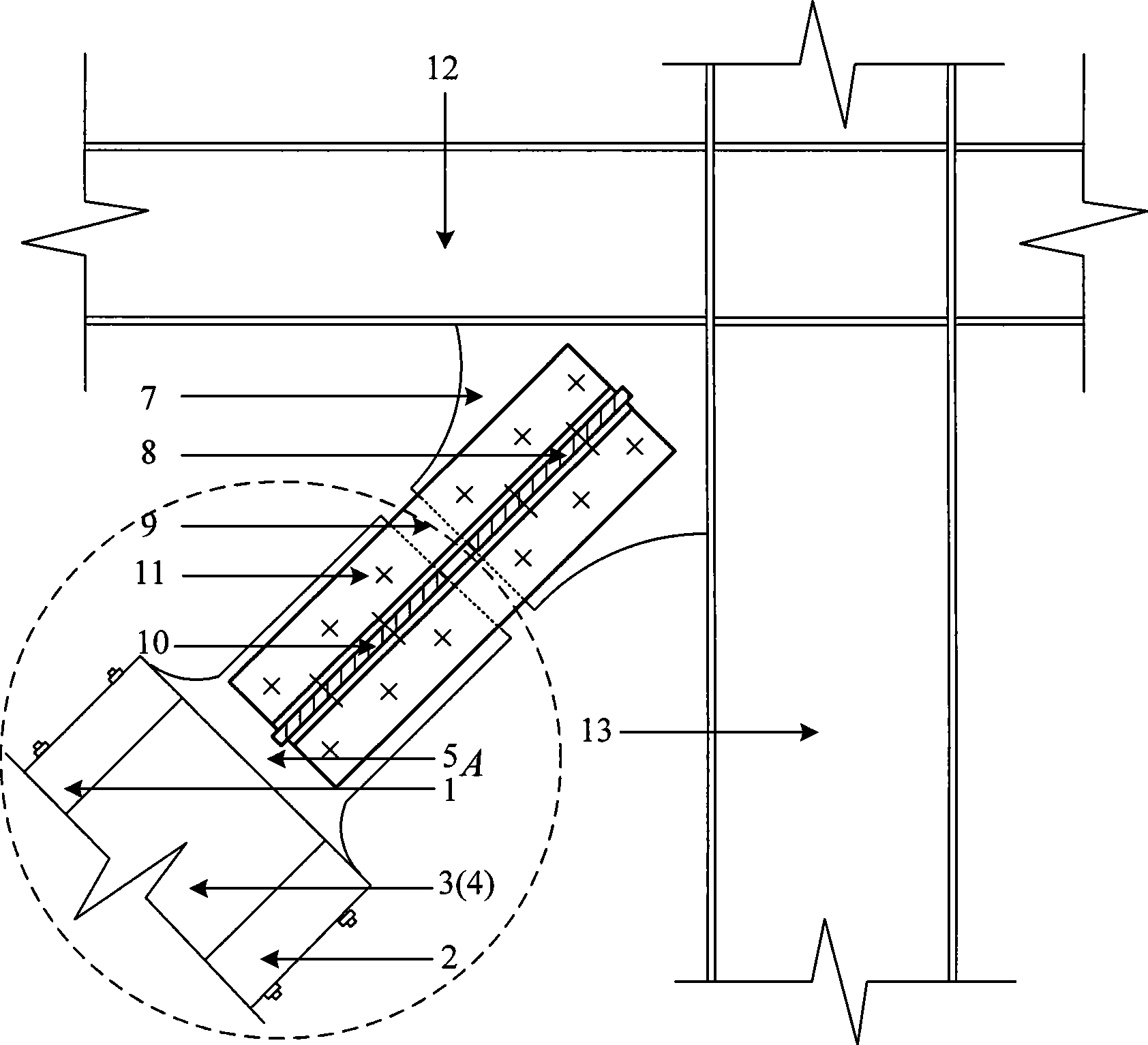

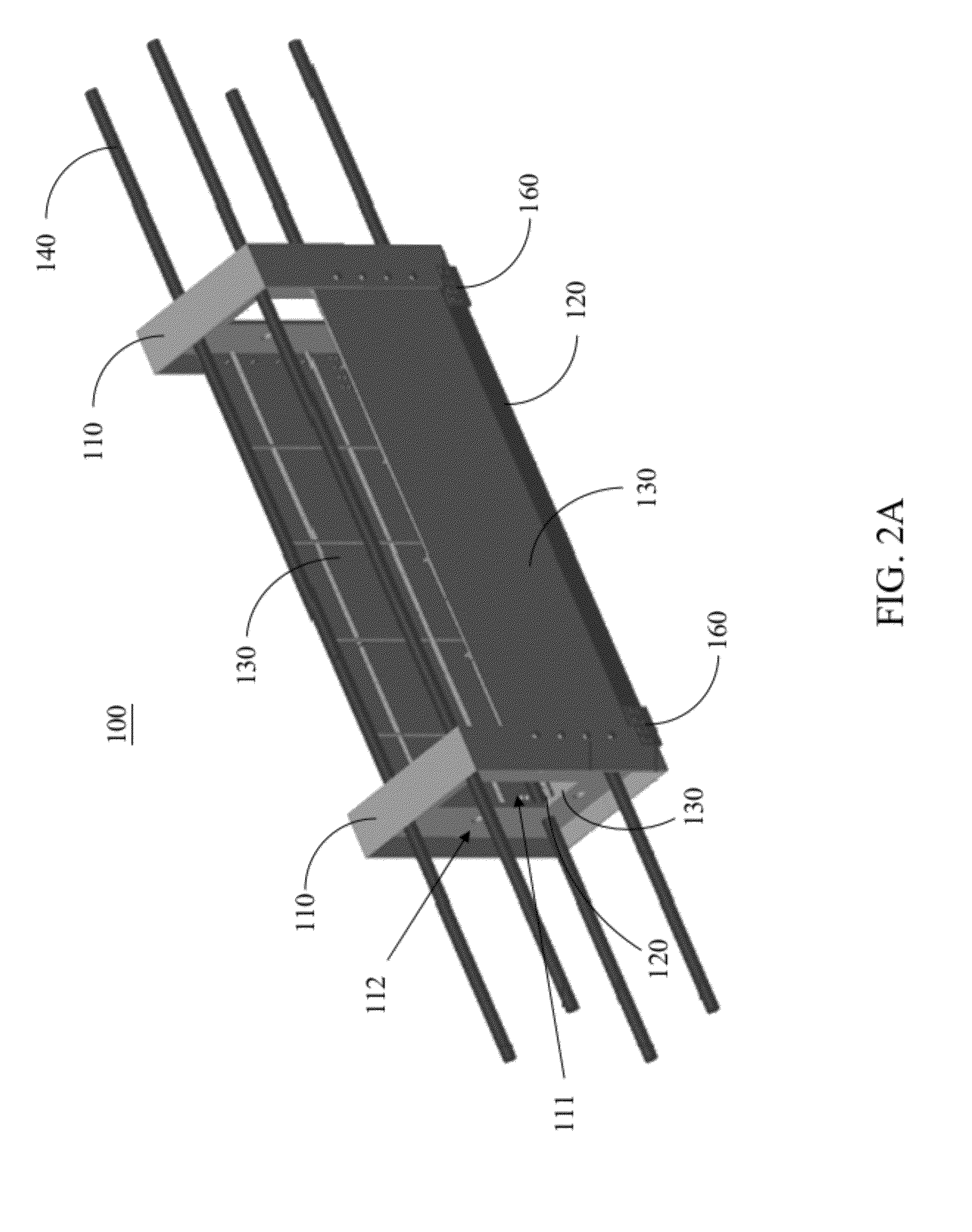

All-steel buckling-preventing energy-consuming brace

The invention relates to an all-steel buckling-preventing energy-consuming brace, which belongs to the technical field of structural engineering. The brace is characterized in that the buckling-preventing energy-consuming brace consists of four hot-rolled groove-shape section steels and a kernel linear steel plate; the four hot-rolled groove-shape section steels are connected through high-strength bolts to form a peripheral constraint component capable of forming a constraint mechanism to the kernel linear steel plate; and a certain gap is reserved between the kernel steel plate and the peripheral constraint component and is coated with unbonded material so as to guarantee the smooth slippage between the two and play a role in anticorrosive protection. The all-steel buckling-preventing energy-consuming brace provided by the invention can provide good effect of resisting lateral force for a plurality of high-rise steel structures, and can achieve total cross-section yielding under the action of large earthquakes so as to effectively consume energy. In addition, as the buckling-preventing energy-consuming brace is an all-assembled component, the brace has the advantages that the brace is easy to machine and install, capable of effectively reducing structural construction cost and excellent in performance.

Owner:TSINGHUA UNIV

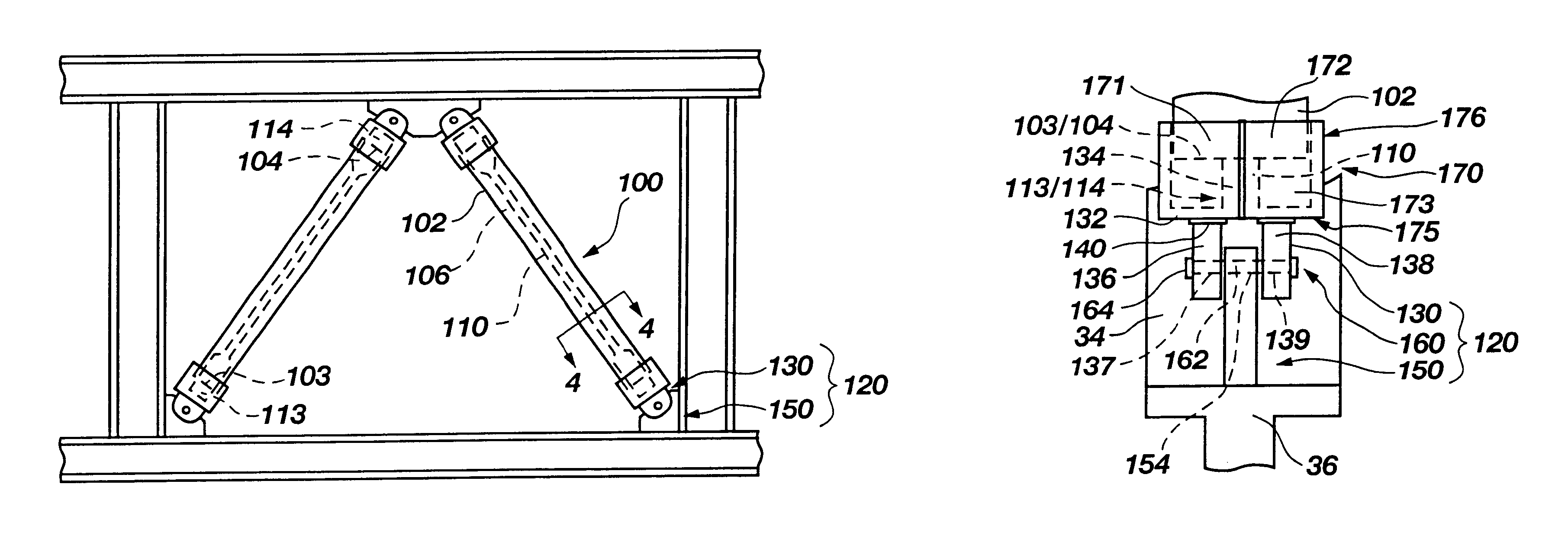

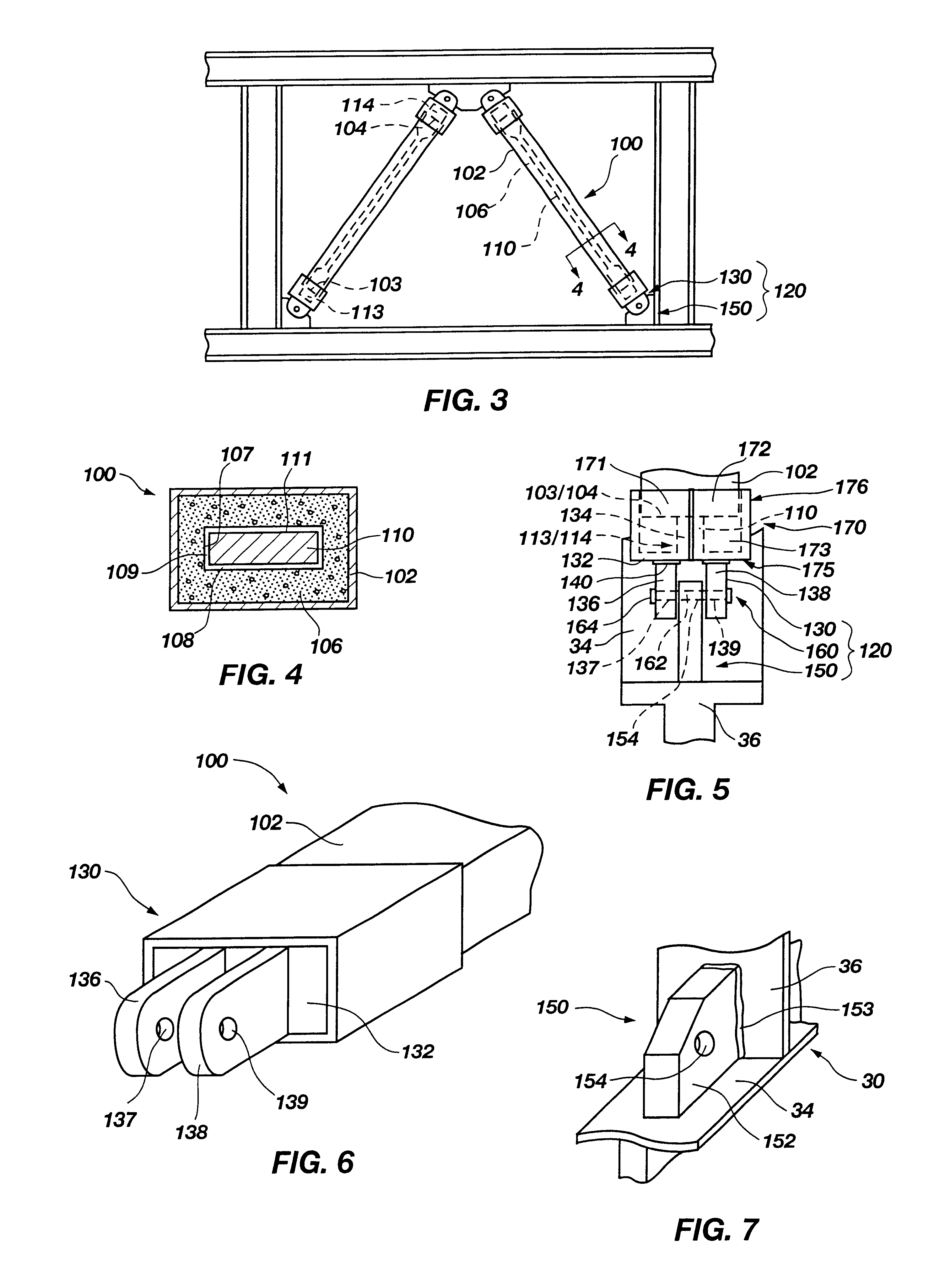

Pin and collar connection apparatus for use with seismic braces, seismic braces including the pin and collar connection, and methods

InactiveUS6837010B2Easy ArticulationThe process is simple and fastYielding couplingRopes and cables for vehicles/pulleyCouplingEngineering

A nonrigid connection apparatus includes a frame-side member securable to a steel structural frame, a brace-side member securable to a seismic brace, and a coupling element that nonrigidly secures the frame-side and brace-side members to each other. By way of example, the nonrigid connection element may provide a hinge-type connection, which substantially isolates a seismic brace from nonaxial loads. As another example, the nonrigid connection element may be a ball-and-socket type connection, which substantially isolates a seismic brace from nonaxial loads and absorbs any shear and moment applied thereto when the seismic brace drifts out of an intended plane of the steel structural frame. The nonrigid connection element may also include a collar to stabilize the brace-side member and prevent shears and moments from causing the same to buckle in an unintended direction. Methods of installing and using the nonrigid connection apparatus are also disclosed.

Owner:COREBRACE LLC

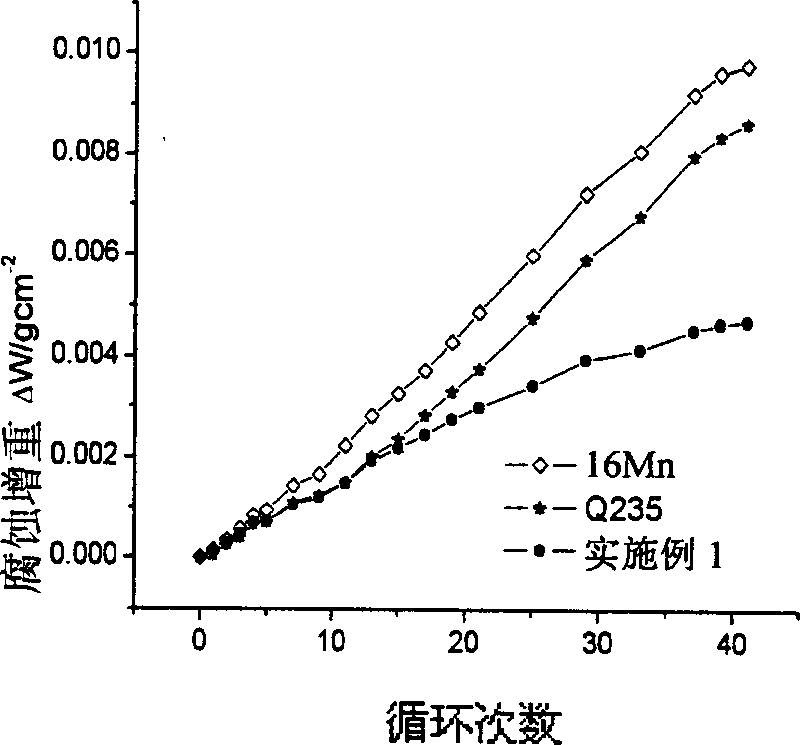

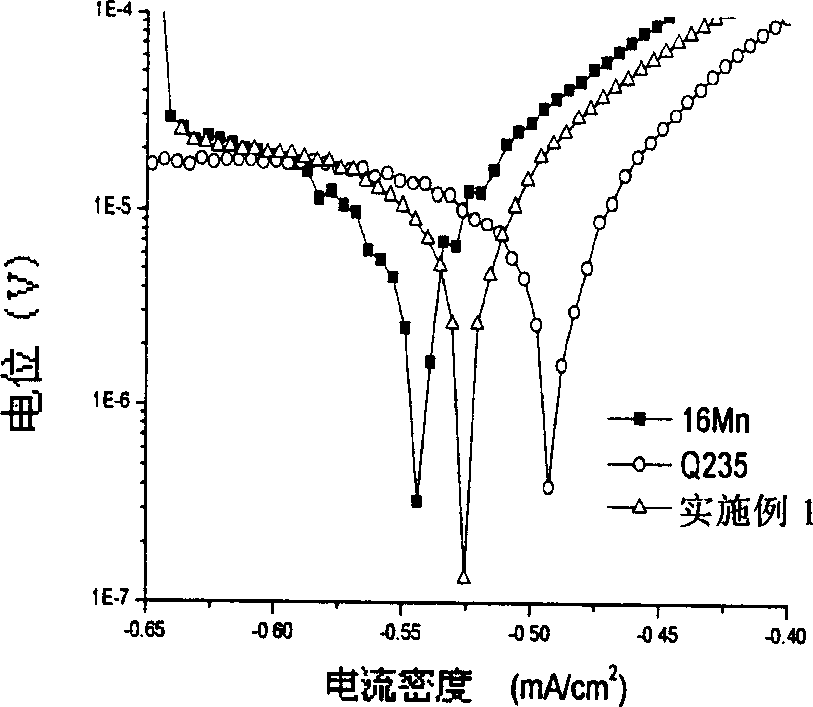

Economy type weathering-resistant steel

The invention relates to economic air corrosion prevention low-alloy carbon constructional steel in the field of low-alloy constructional steel. It is mainly used in the steel structure which is used in air such as railroad, carriage, bridge and tower and so on. The alloying component and the percentage by weight of the weather fastness steel is as following: C: 0.12-0.21, Si: 0.2-2.0, Mn: 0.7-2.0, S <=0.036, P<=0.034, Cu: 0.10-0.40, Al<0.2, and other iron and impurity elements.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Super-thick film anticorrosion coating of splash zone marine steel structure

InactiveCN101987937ASimple construction processLow construction costAnti-corrosive paintsEpoxy resin coatingsEpoxyFluorocarbon

Owner:MARINE CHEM RES INST

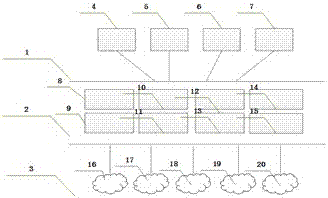

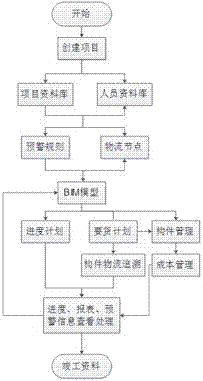

Steel structure BIM information management method and system based on cloud server

InactiveCN107038554ALow hardware requirementsReduce procurement costsCo-operative working arrangementsOffice automationInformatizationData acquisition

The invention discloses a steel structure BIM information management method and system based on a cloud server. Based on the visualization of the three-dimensional project model, the method utilizes data collection, real-time monitoring, analysis and forecasting means to timely grasp the project and the progress, to monitor the early warning and to analyze and predict the project operation condition by unified management of the data, business flow, progress, cost and the like of the project life cycle, so that the enterprise project management mode is improved, and the construction of streamlined and informatization enterprise management mode is promoted. The system integrates a project data subsystem, a business flow subsystem, a BIM application subsystem, an early warning subsystem, a reporting subsystem, a background maintenance subsystem, a mobile terminal and a cloud server, and intelligently manages the project from the design, construction and operation of the life cycle, thereby shortening the project construction period, reducing the management cost and promoting the healthy development of the enterprise.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

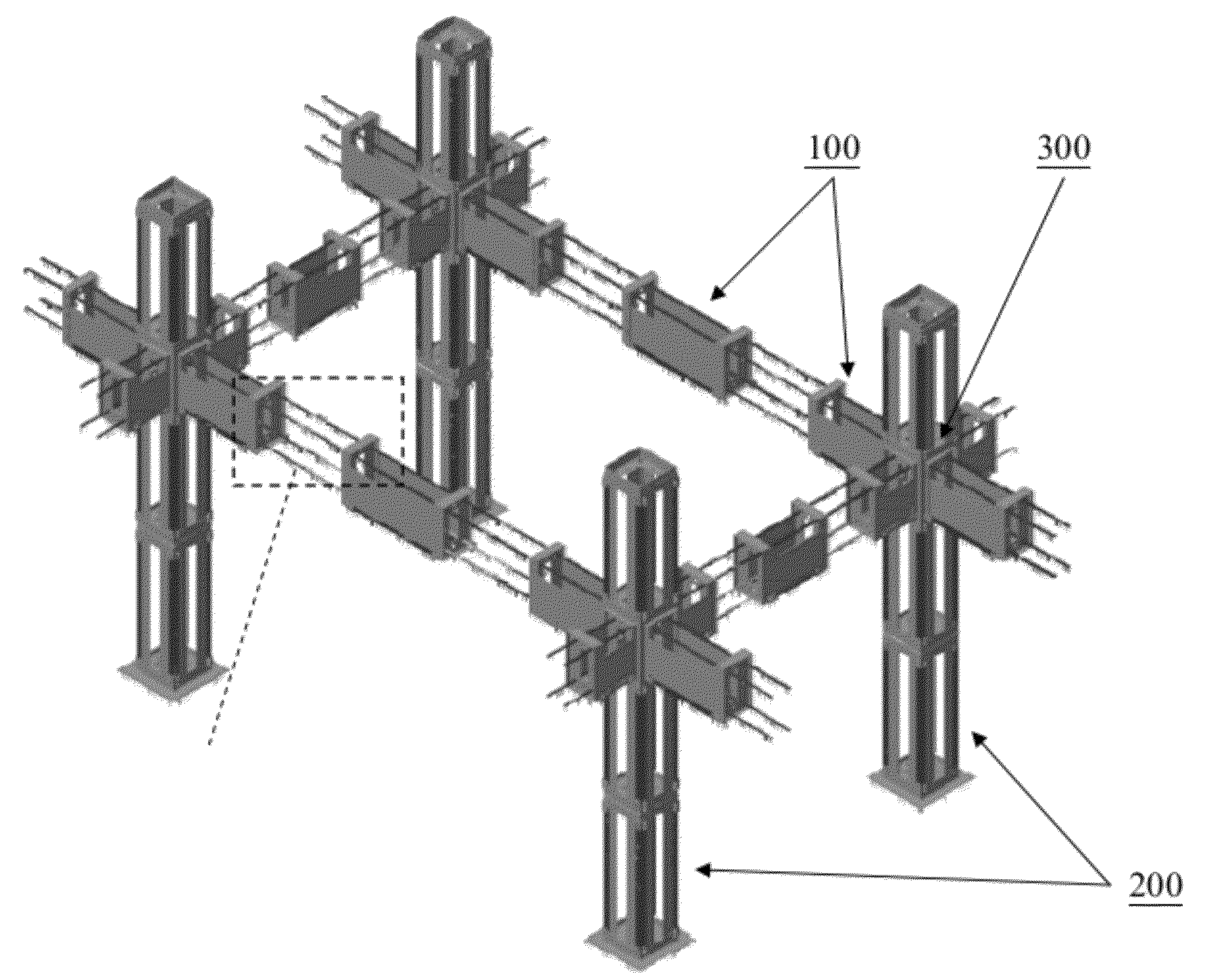

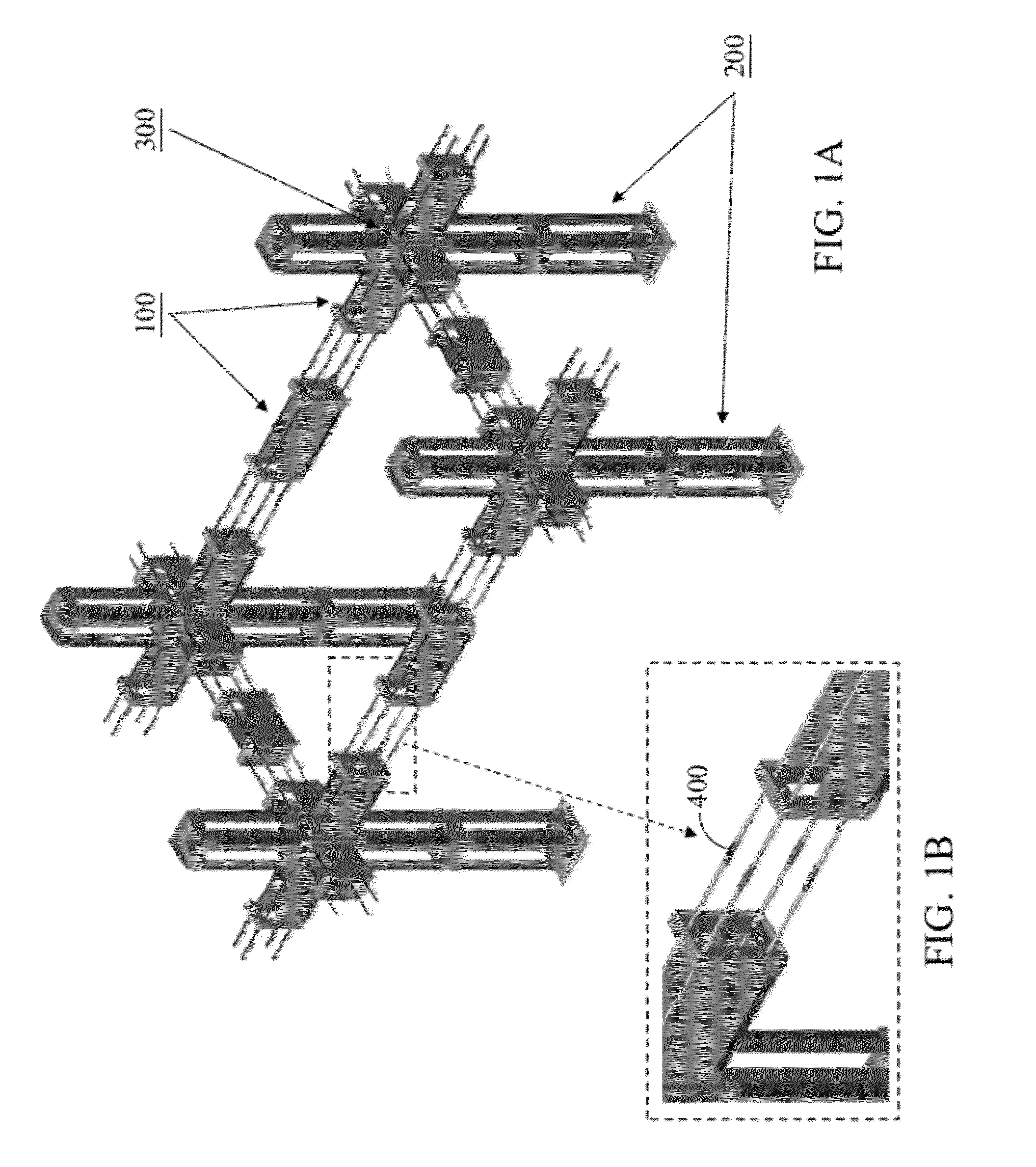

Architectured reinforcement structure

InactiveUS20120304584A1Easy constructionReduced isolationTowersBuilding constructionsReinforced concreteHoneycomb

This invention presents a modified reinforced concrete structure, which has a steel structure composed of a beam steel box unit, column steel box unit, and beam-column joint steel box unit with lap jointing reinforced steels. The side plate and / or end plate of the steel box has through holes for concrete flowing therebetween. In this way, the workability of concrete grouting and tamping are improved, and the phenomena of hive, segregation, or floating can be avoided. It can also enhance the performance of beam-column joints (e.g. with better confinement ability, etc.). Applying the invention, the efficiency and accuracy of constructing beam-column joints can be increased, and in addition to better ensure the structural safety, it can also reduce construction manpower and schedule.

Owner:NAT TAIWAN UNIV OF SCI & TECH

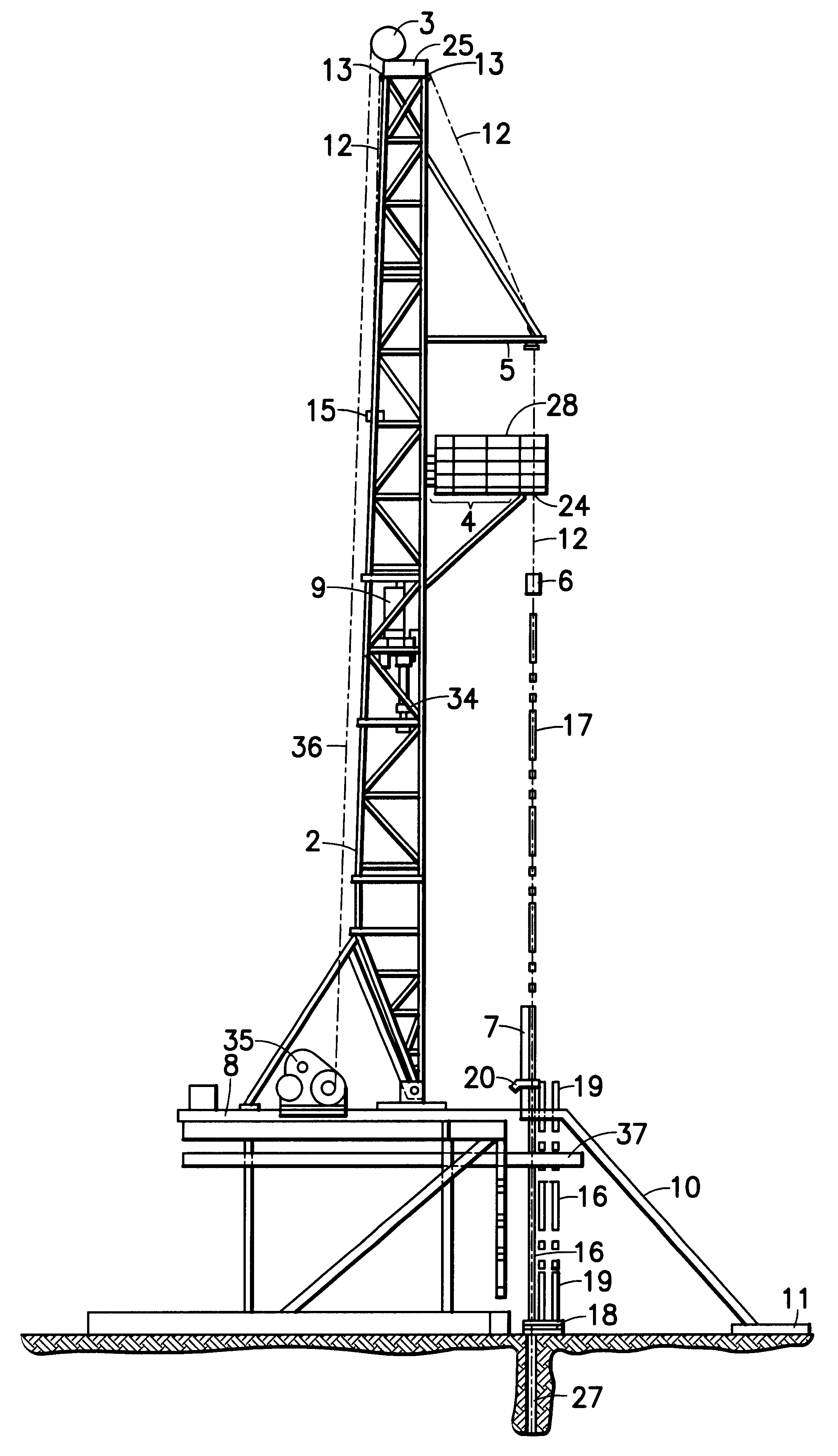

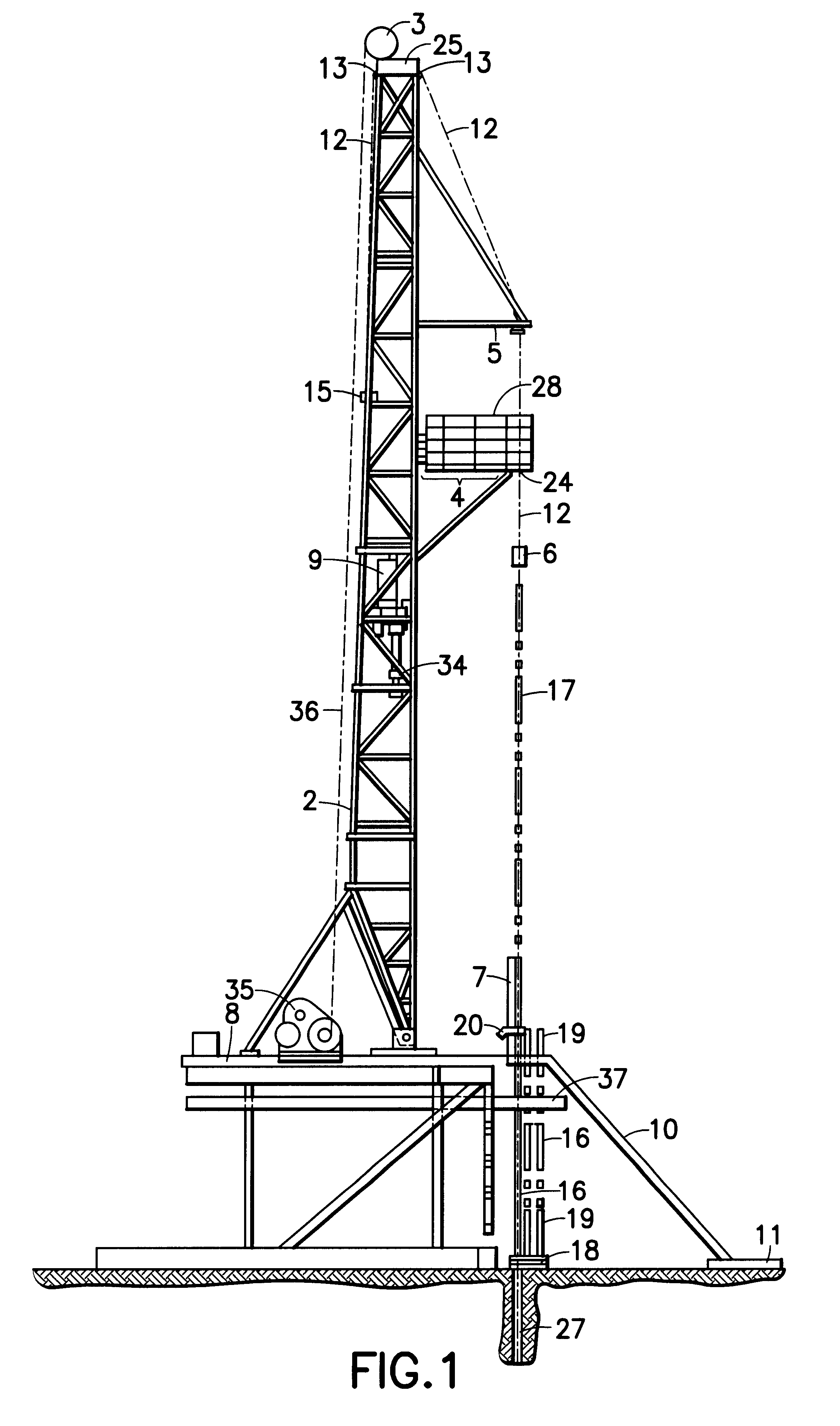

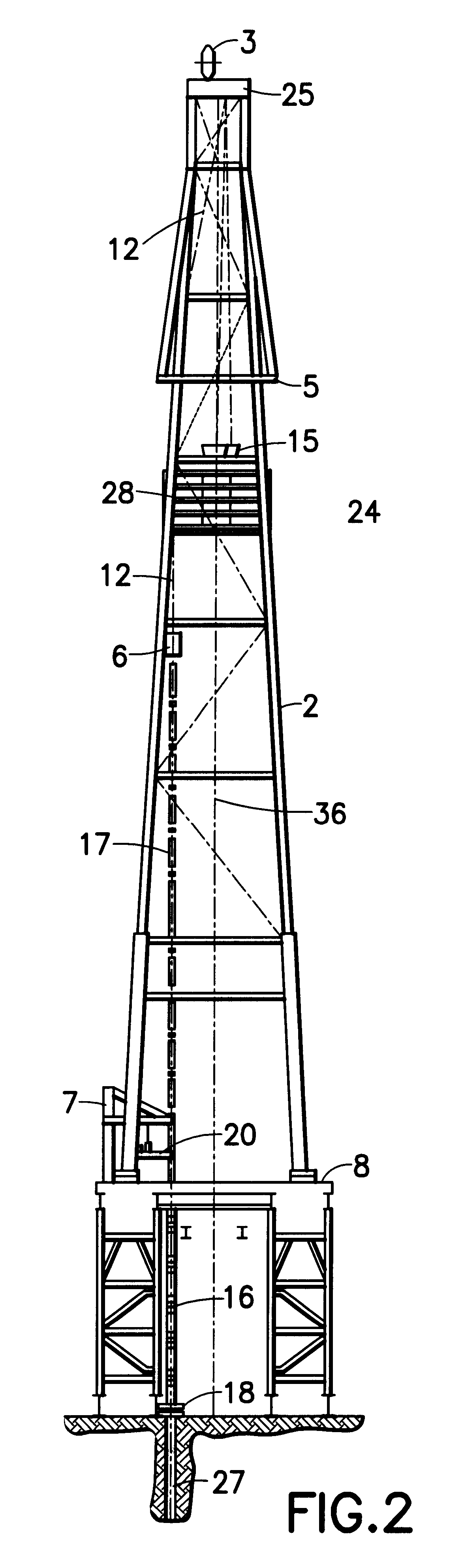

Apparatus for handling pipes in drilling rigs

InactiveUS6513605B1Improve performanceImprove securityDrilling rodsFluid removalWell drillingEngineering

The invention relates to a method and an apparatus for handling pipes, such as rods and drilling strings, in drilling rigs and drilling installations for sinking boreholes, in particular on hydrocarbon reservoirs. The apparatus according to the invention for handling pipes and drilling strings in a drilling installation having a steelwork structure with a set-down platform, a working platform, a lifting device, a drill drive and a pipe connecting device is defined in particular by the fact that there is arranged on the drilling installation a wireline, a two-axis crane which is connected to the wireline and to the steelwork structure and an extension element, which is arranged on the outside of the racking platform and has a passage to the racking platform, and also by the fact that a set-down and make-up device, arranged beside or on the working platform, is provided for vertical pipes, it being possible for the set-down and make-up device to be accessed by the wireline.

Owner:BENTEC DRILLING & OILFIELD SYST

Room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and preparation method thereof

ActiveCN103087612AImprove anti-corrosion performanceFast curingAnti-corrosive paintsEpoxy resin coatingsSurface-active agentsChemistry

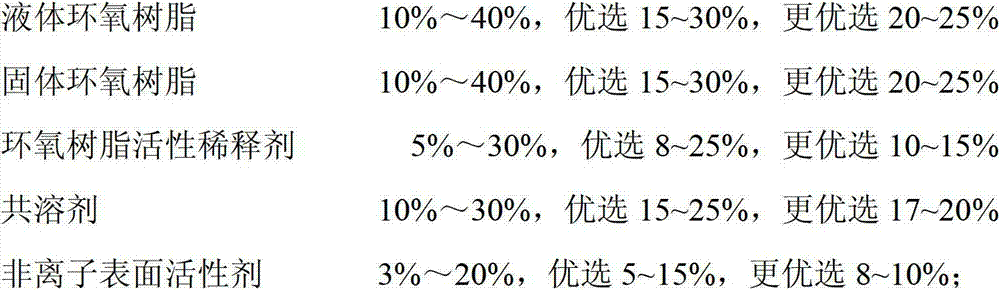

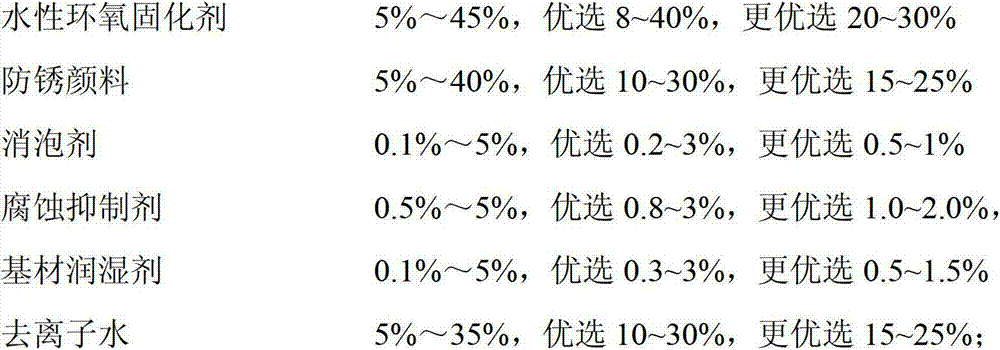

The invention provides a room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and a preparation method for the coating. The coating comprises A and B two components, wherein the A component consists of liquid epoxy resin, solid epoxy resin, an epoxy resin reactive diluent, a cosolvent, and a non-ionic surface active agent; the B component consists of a waterborne epoxy curing agent, an anticorrosive pigment, a foam killer, a corrosion inhibitor, a substrate wetting agent and de-ionized water, and during application, mass proportion of the A component to B component is 1:3-6. The coating is high in curing speed of coated film, the surface is dried in 30min at room temperature without being roasted; the coating has high early hardness, and the hardness can reach 3H in 48 hours; and in addition, the coating is good in thermal resistance stability, low in VOC (Volatile Organic Compound) content, excellent in anti-corrosion performance, and is capable of replacing a solvent type two-component epoxy coating to be applied to the anti-corrosion of a steel structure.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Aqueous environmental protection ultration expansion type steel structure fireproof paint and its preparation method

InactiveCN1824716ADecorativeReduce dosageFireproof paintsLiquid spraying apparatusAdditive ingredientPhosphate

The present invention provides a water environment-protecting superthin expanded type steel structure fire-retardant coating. Said fire-retardant coating uses water as dispersion medium, uses flake expandable graphite as expansion reinforcing material, uses one or several kinds of emulsions of acrylic emulsion and others as film-forming material, and its expansion system adopts the ingredients of polyammonium phosphate, pentaerythritol and tripolycyanamide. Said invention also provides its preparation method and concrete steps.

Owner:北京首纳东方科技有限公司

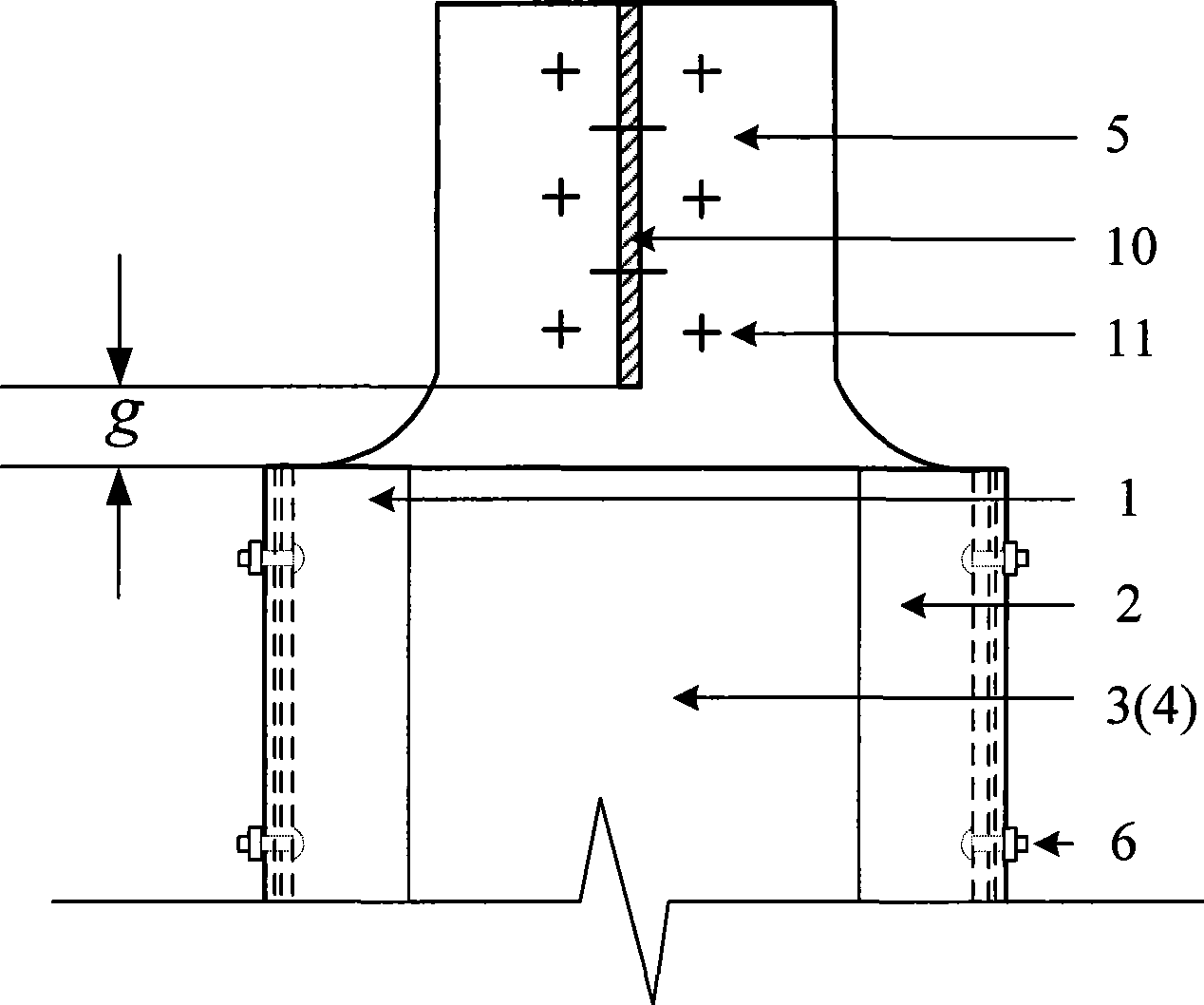

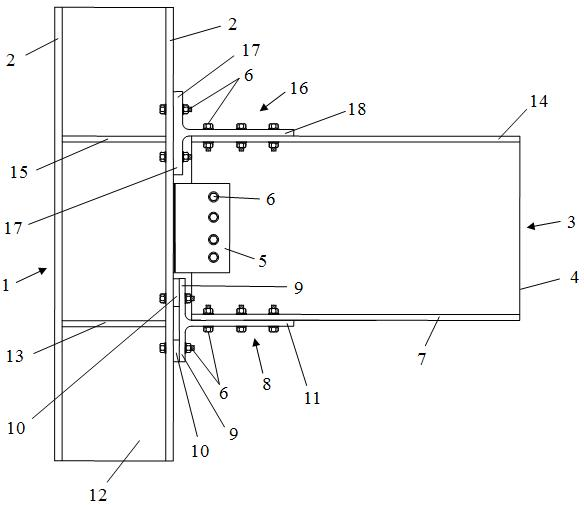

Easily repaired steel-structure beam-column node

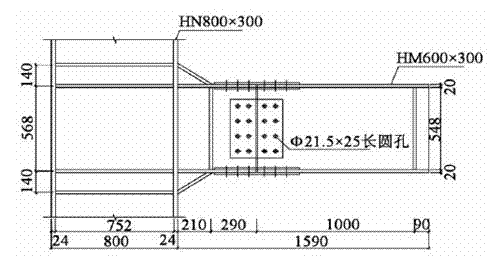

InactiveCN101812872ASolve the lack of ductilitySolve the problem prone to brittle failureShock proofingHigh intensitySteel columns

The invention relates to an easily repaired steel-structure beam-column node, in particular to an easily repaired steel-structure beam-column node which is applied in the field of structural engineering and particularly used in high-intensity earthquake-proof areas. The node comprises an upright H-shaped steel column and an H-shaped steel beam of which the end part is vertically connected on a side wing plate of the H-shaped steel column, and is characterized in that: connecting ends of a belly plate of the H-shaped steel beam and the side wing plate of the H-shaped steel column are connected by a reinforced connecting plate closely contacted with the belly plate of the H-shaped steel beam and high-strength bolts penetrating the reinforced connecting plate, the reinforced connecting plate is in welding connection with the side wing plate of the H-shaped steel column, and both sides of the connecting end of a bottom side wing plate of the H-shaped steel beam are in locked connection with the H-shaped steel column by a T-shaped connecting plate and penetrating high-strength bolts respectively; and the T-shaped connecting plate is transversely arranged, upper and lower ends of the T-shaped connecting plate in the vertical direction are in locked connection with the side wing plate of the H-shaped steel column by a washer and the penetrating high-strength bolts respectively, a transverse plate of the T-shaped connecting plate is supported on the lower part of the bottom side wing plate of the H-shaped steel beam and locked by the penetrating high-strength bolts. The structure can effectively avoid brittle failure, has good ductile fracture characteristic, and can be widely applied to structures of earthquake areas, particularly the high-intensity earthquake-proof areas; and the easily repaired steel-structure beam-column node of the invention also has the advantages of convenient construction and convenient after-earthquake repairing.

Owner:FUZHOU UNIV

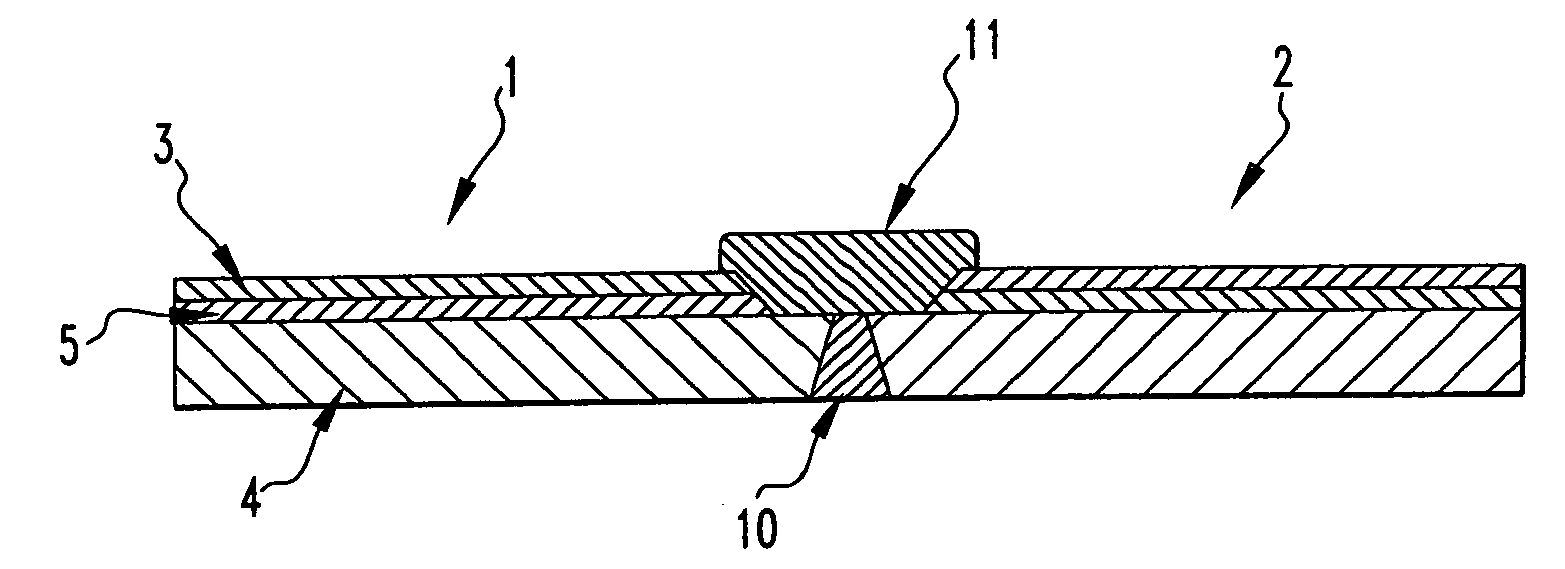

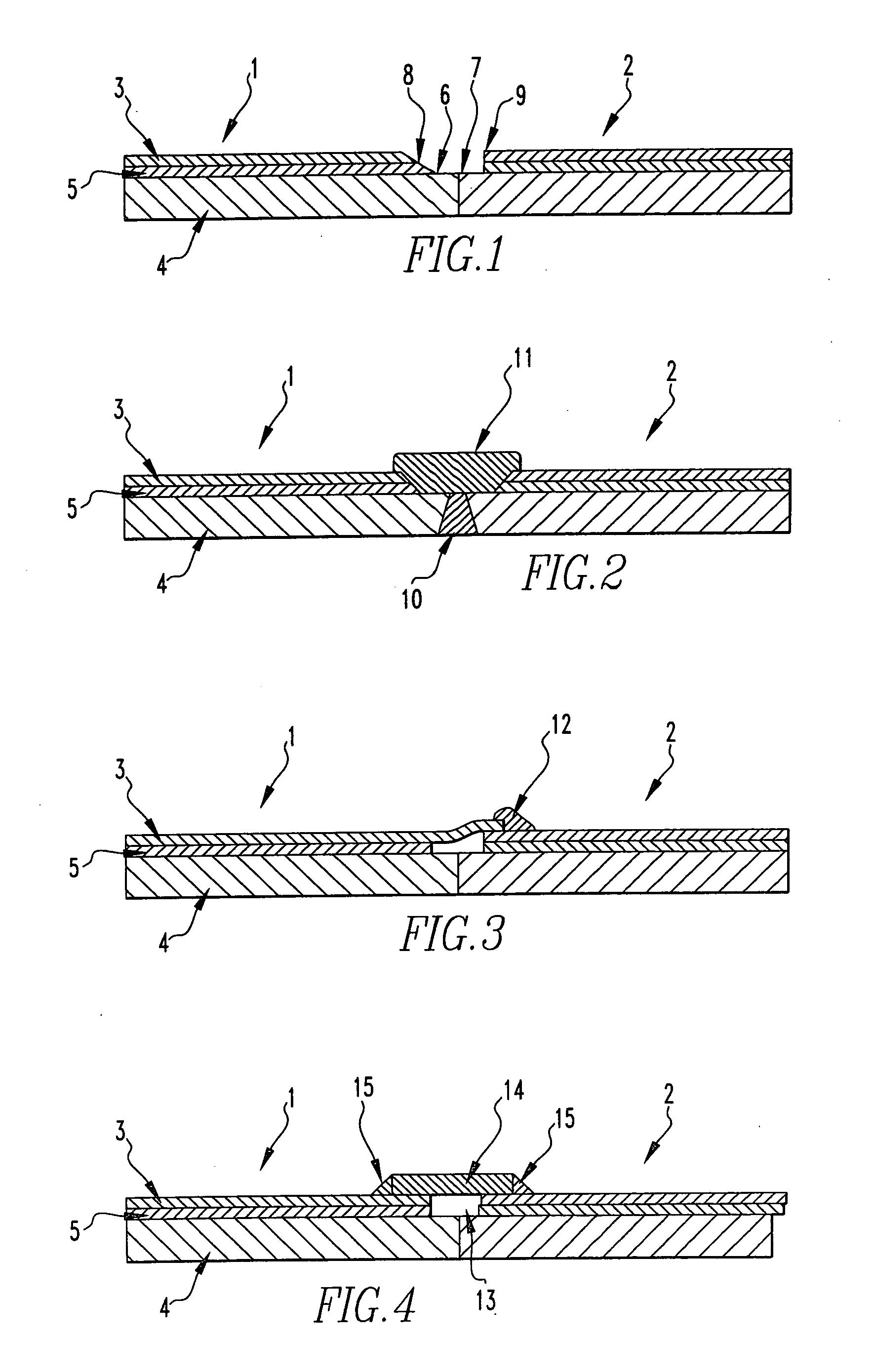

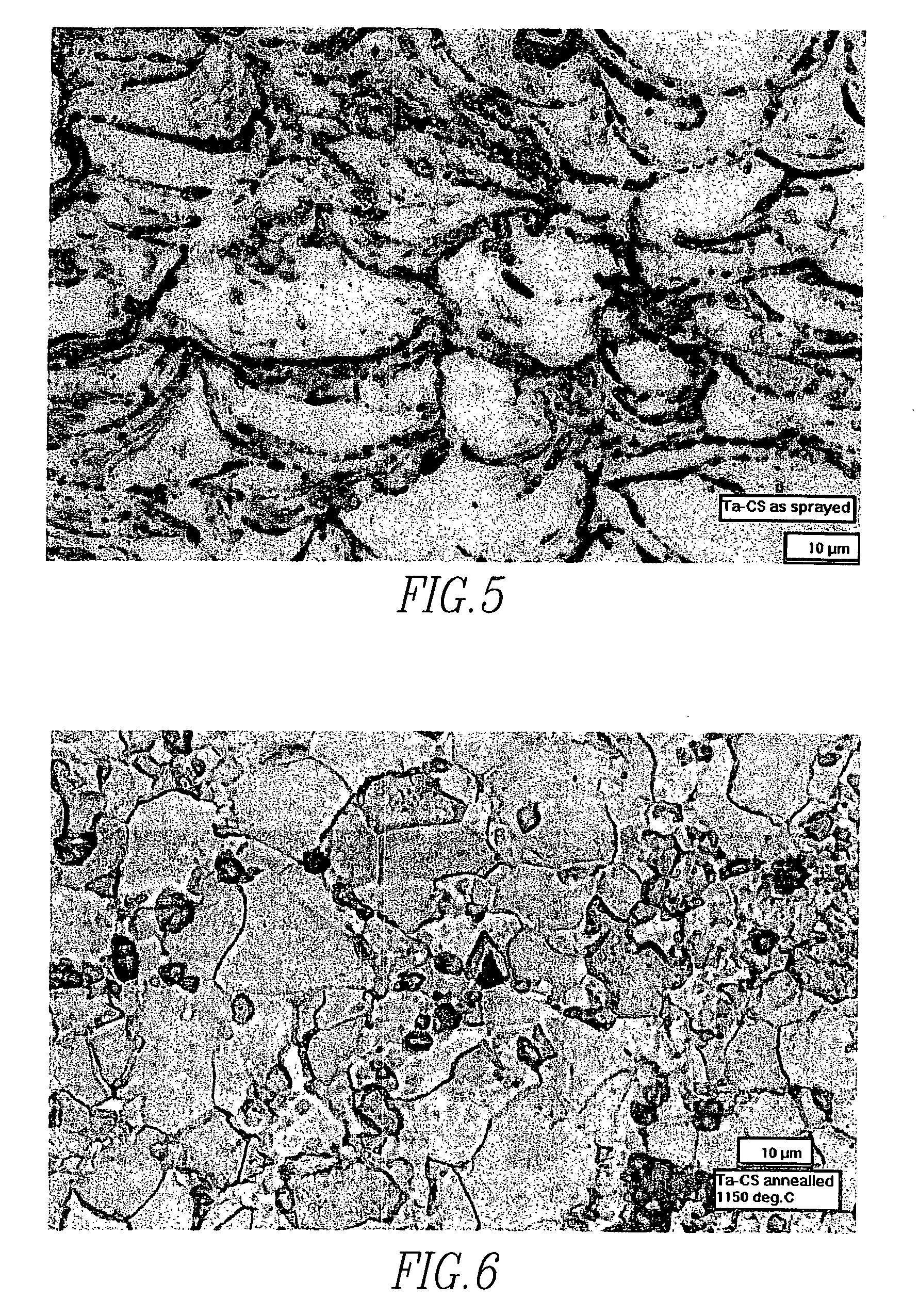

Method of joining tantalum clade steel structures

InactiveUS20080145688A1Reduce oxidationHigh densityLamination ancillary operationsLaminationTantalumEdge region

The present invention is directed to a process for joining tantalum clad steel structures. The process broadly comprises:a) providing a first tantalum clad section, said first tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,b) providing a second tantalum clad section, said second tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,c) locating said steel edge regions adjacent each other,d) welding the steel edge regions together,e) cold spraying a tantalum powder onto the welded edge regions and over the tantalum layers adjacent said edge regions thereby joining the tantalum clad steel sections.The invention is also directed to tantalum welds or joints formed by cold spraying tantalum powder.

Owner:GLAS TRUST +1

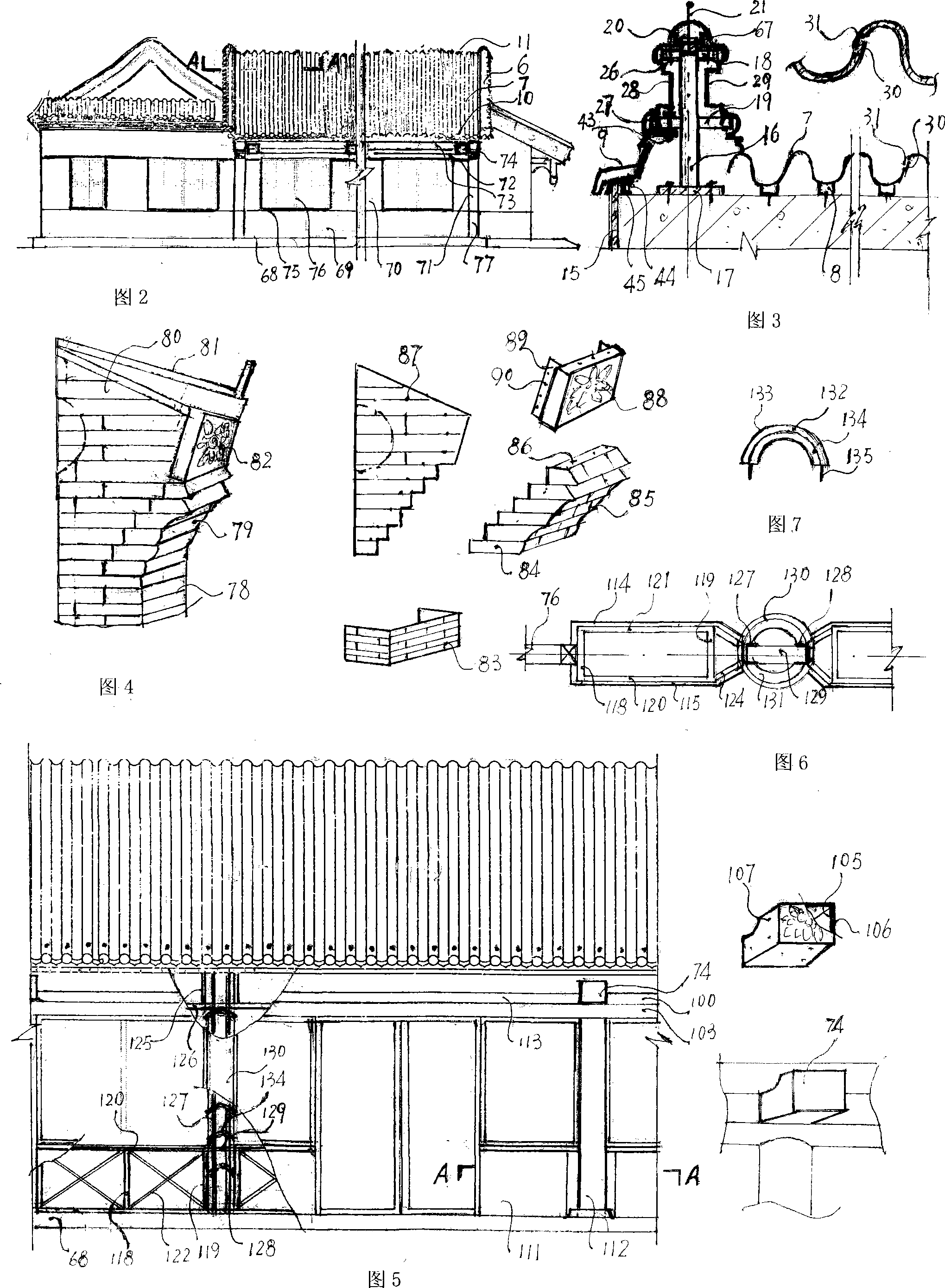

Novel energy-conserving emission reduction pseudo-classic architecture and construction method thereof

InactiveCN101457546AEliminate deforestationEliminate the destruction of vegetationBuilding roofsRoof covering using tiles/slatesRoof tileEaves

The invention relates to a novel archaized building which has the advantages of energy conservation and emission reduction and a construction method thereof. The invention is applicable to various archaized buildings, and the novel archaized building is characterized by comprising a Chinese round-ridge gabled roof 1, a gable and hip roof 2, a wall body, a flat roof eaves cap, a festoon gate, a verandah 3, a screen wall 4, a courtyard wall 5 and the like; completely based on the external shapes of the existing archaized buildings, the novel archaized building adopts lightweight steel construction as a structural support framework or a support member bar of purlins, square-columns, beams, rafters, pillars, the wall body and roofing tiles, and adopts modern construction materials such as thin steel plates, aluminium alloy plates, GRC or glass fiber reinforced plastic and the like which are made into various novel components and parts such as purlins, square-columns, pillars, the wall body and roofing tiles; factory production (including painting and colored drawing) is carried out, and the novel components and parts are assembled on-site and replace the existing traditional archaized building materials such as wooden beams, pillars, rafters, soil calcined tiles and the like as well as the retarded construction technology, thus achieving the aim of energy conservation and emission reduction, clean construction and installation, increment of working efficiency, reduction of erection time and cost reduction.

Owner:冯刚克

Method for high altitude installation of large span steel truss

InactiveCN101255768ASolve quality problemsSolve many disadvantages such as long construction periodBuilding material handlingSUSPENDING VEHICLEFalsework

The present invention relates to a method for installing a large span steel truss on high altitude. The method comprises the steps of arranging embedded part on the structure girder at two sides of the designed position of the steel truss, then installing extensible guide on the embedded part, and at last assembling a specialized steel structure tackle. Firstly, a large tonnage hoisting machine is used for hanging the steel truss which is wholly assembled underground to two tackles that are arranged on station. Afterwards, the steel trust is parallelly moved to the installation position through the synchronous slippage of two tackles on the extensible guide. Lastly, the two-end capitals of the designing position of the steel truss are installed with an independent holding pole, a chain block and a pulley assembly. These hoisting apparatuses are used for hanging the longeron from the tackle. The longeron of the lengthened part is cut and the steel truss is installed to the position according to the design requirement. Compared with the traditional high altitude dispersed splitting method for building whole surface of scaffold, the installing method provided by the invention subtly settles many abuses of difficulty for controlling the construction quality, long construction period and the like in the traditional method. The manpower and considerable material transportation are saved and the construction quality can be effectively guaranteed. Various requirements of the designing and constructing are excellently and rapidly satisfied.

Owner:NINGBO CONSTR +1

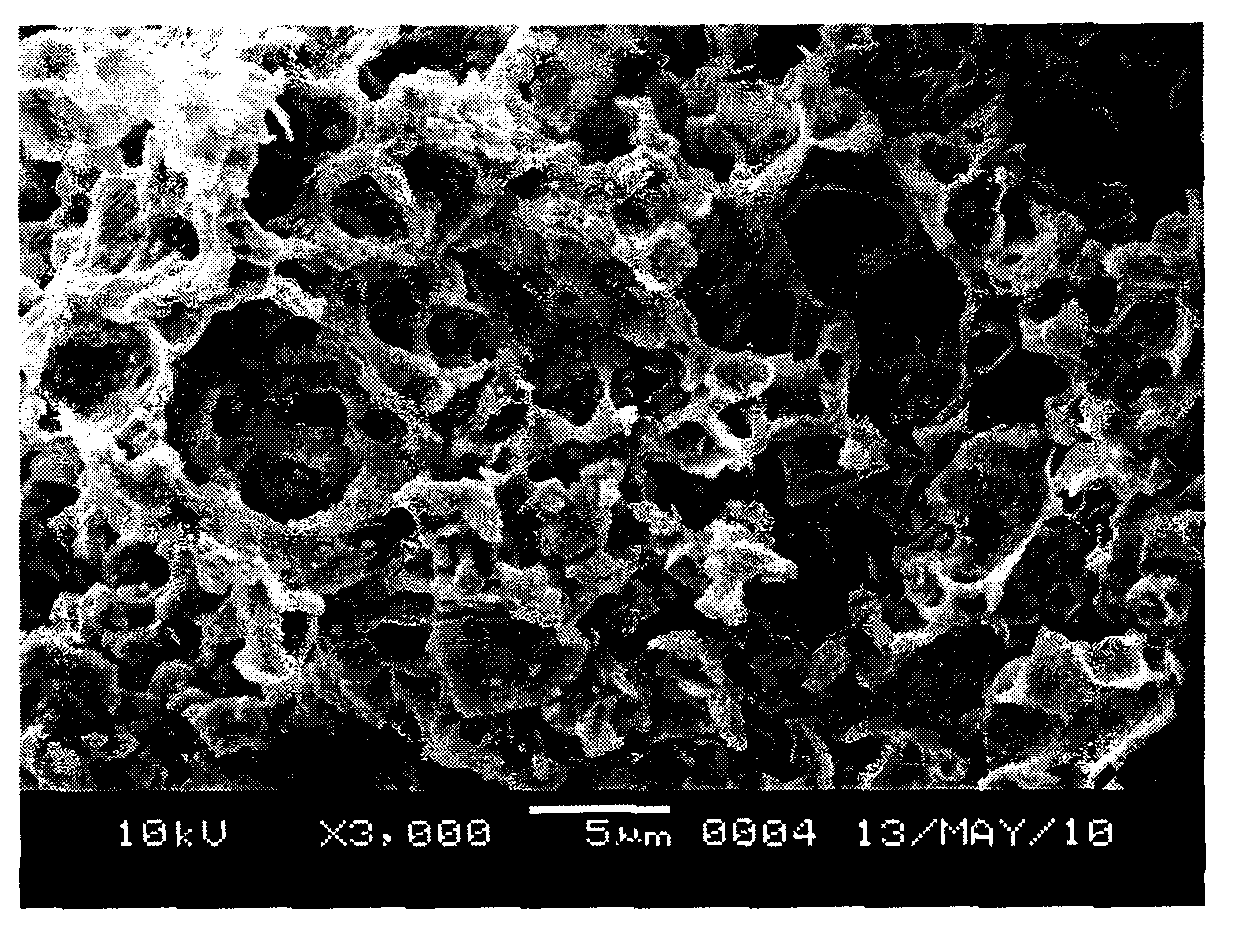

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

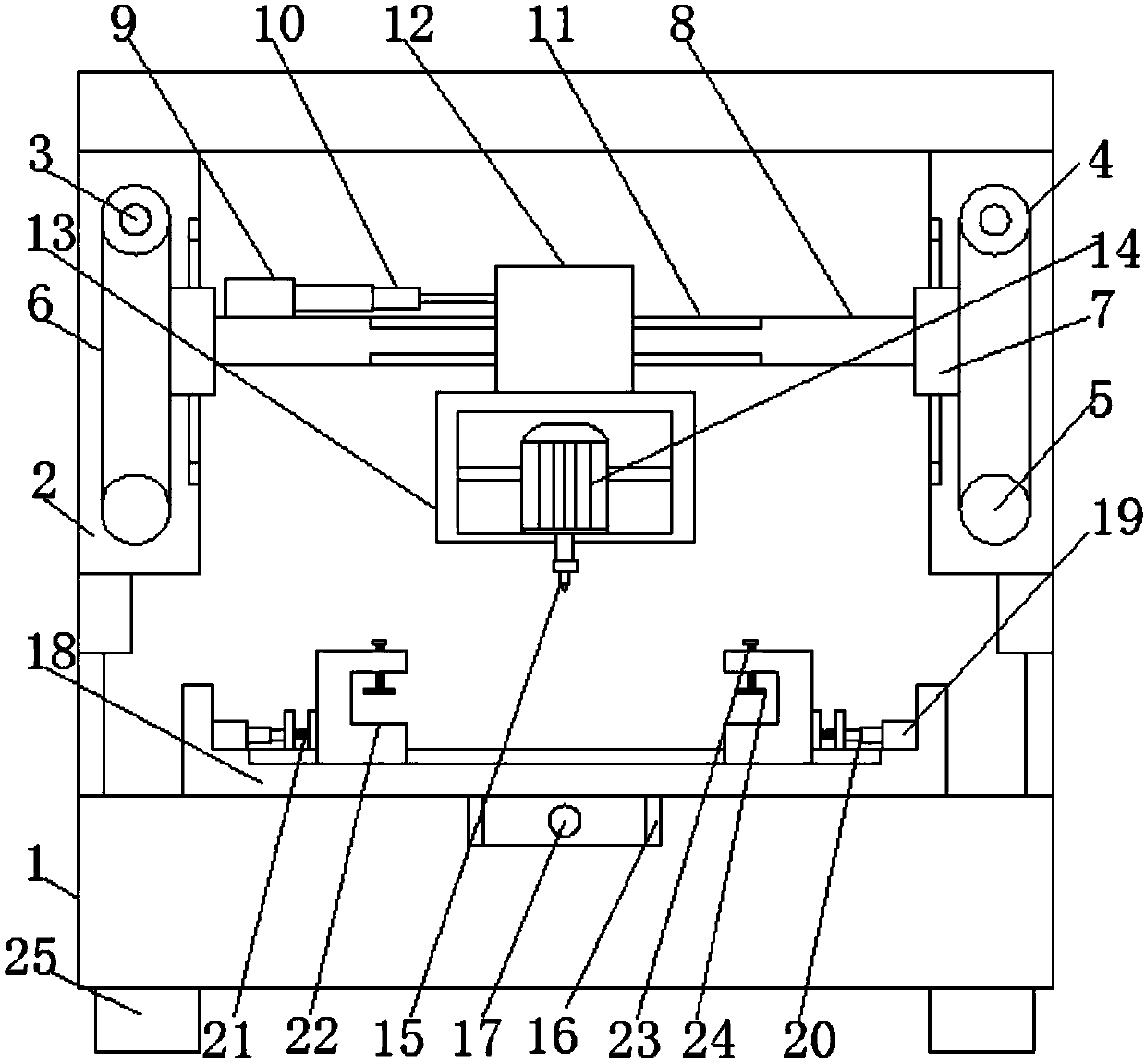

Steel structure drilling device

InactiveCN107824828AAvoid distortionAvoid stickingFeeding apparatusPositioning apparatusDrive wheelArchitectural engineering

The invention discloses a drilling device for a steel structure, which comprises a machine body. Both sides above the inner wall of the machine body are provided with organic casings. One motor, the output shafts of the two first motors are fixedly sleeved with driving wheels, the inner chambers of the two casings are provided with driven wheels, and belts are movably connected between the two driving wheels and the driven wheels, and the two belts Both of them are fixedly connected with fixed blocks, and the two fixed blocks are slidably connected to the inner wall of the through groove, and a support frame is fixedly connected between the two fixed blocks, and the left side of the top of the support frame is provided with a first cylinder. The invention solves the problem that the drill cannot be displaced laterally by adding a device for lateral movement to the drill, and achieves the purpose of the clamp device being able to move forward and backward by setting the turntable and the screw rod, and solves the problem that the existing steel structure drilling cannot be clamped at one time Problem with drilling multiple times.

Owner:余骆杨

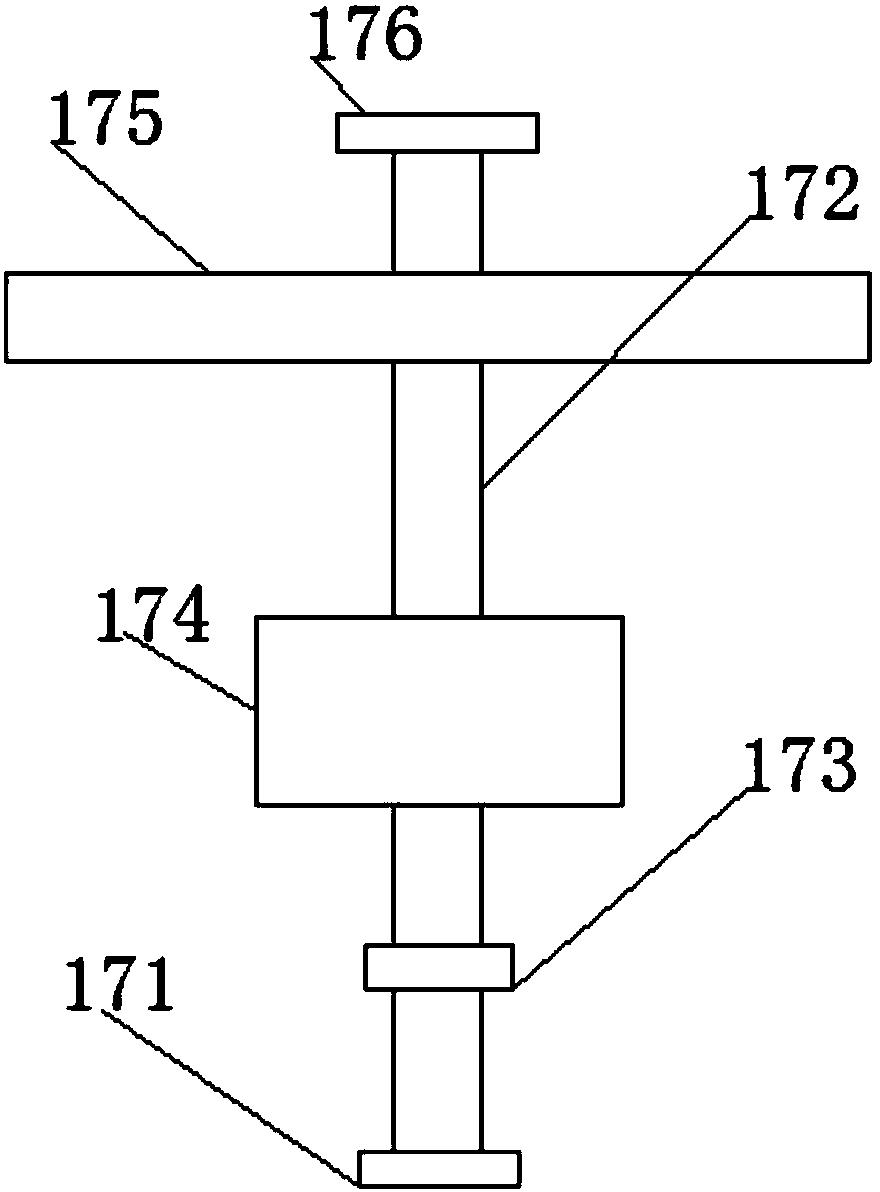

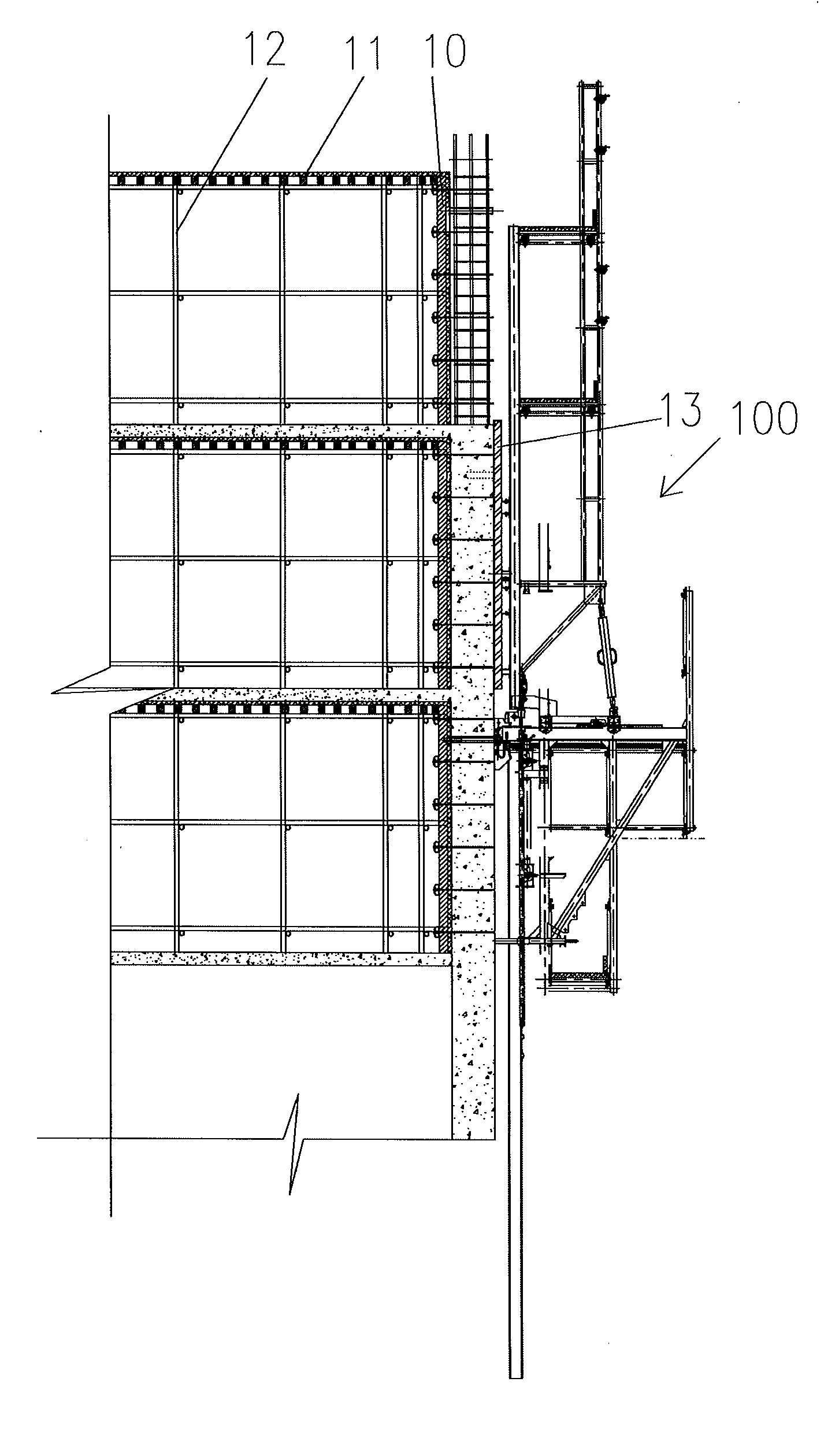

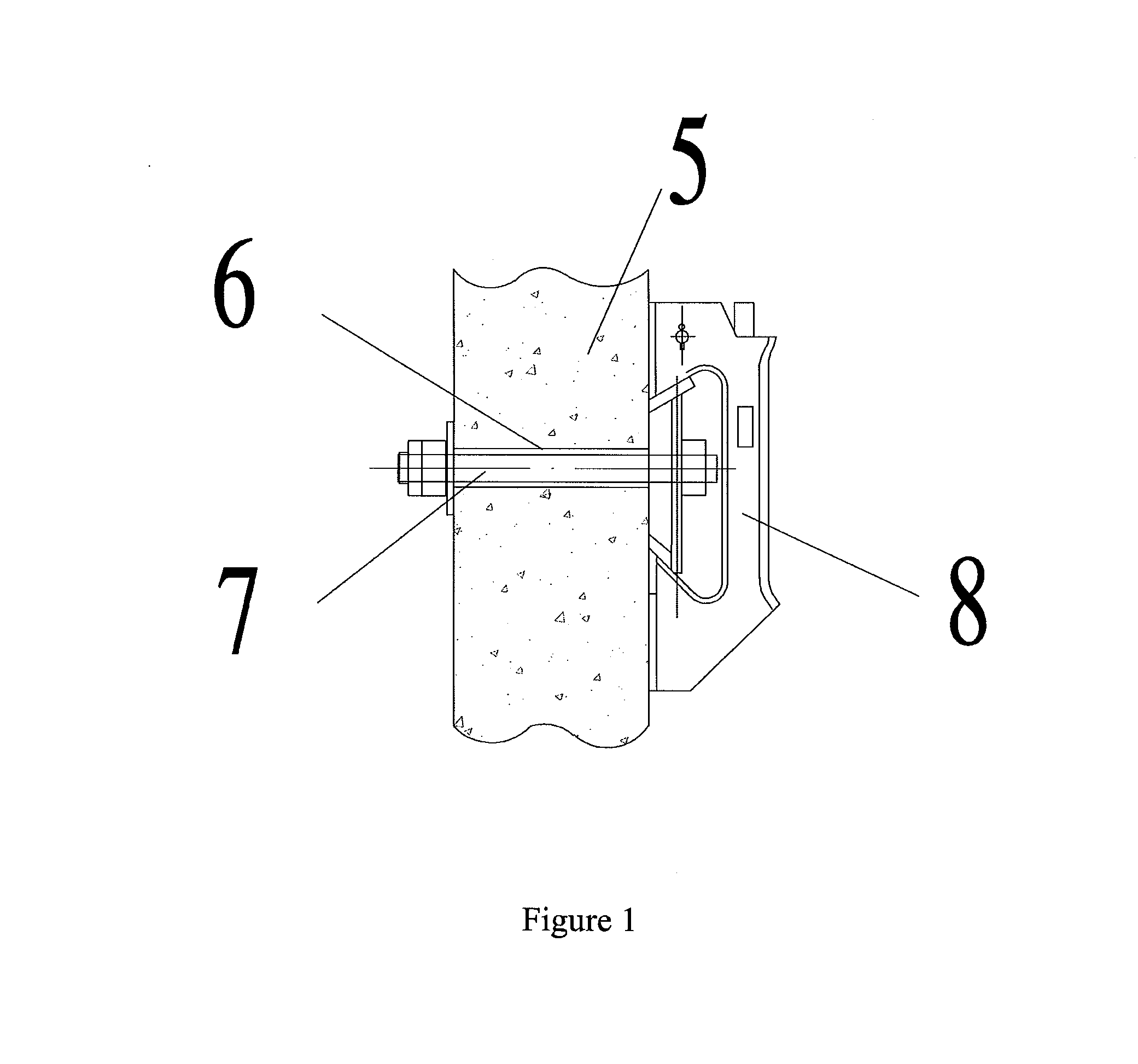

Constructing method for concrete cylinder of construction steel bar of high-rise steel structure

ActiveUS20140305070A1Construction safetyGood engineering qualityWallsBuilding repairsFalseworkReinforced concrete

A constructing method for a concrete cylinder of a construction steel bar of a high-rise steel structure adopts a constructing method of supporting inside and climbing outside. The outside of the cylinder adopts hydraulic mutual-climbing adhesive lifting scaffold creeping formwork system (100), and also has an outside wallboard mechanical formwork erection function and an outer frame protection function. For the inside of the cylinder, except that an appropriate structure is left for later processing according to a schedule requirement, beam walls all adopt a steel cylinder support to perform formwork erection, so as to greatly reduce the workload of repeatedly mounting / dismantling the scaffold and the formwork at a high place. The scaffold itself carries the formwork erection system, so formwork erection and formwork removal can be mechanized, thereby reducing the risk of formwork erection and formwork removal at a high place

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

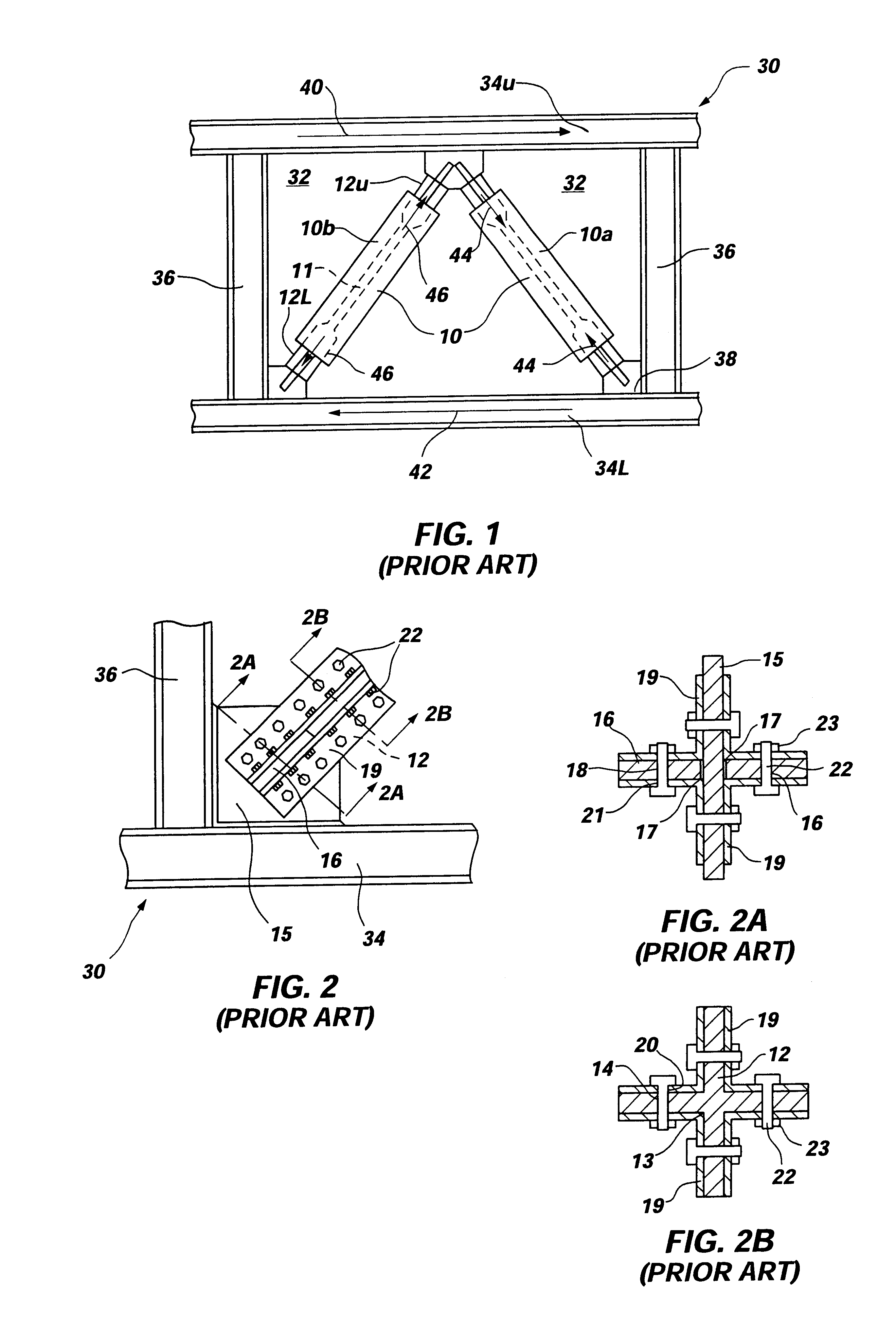

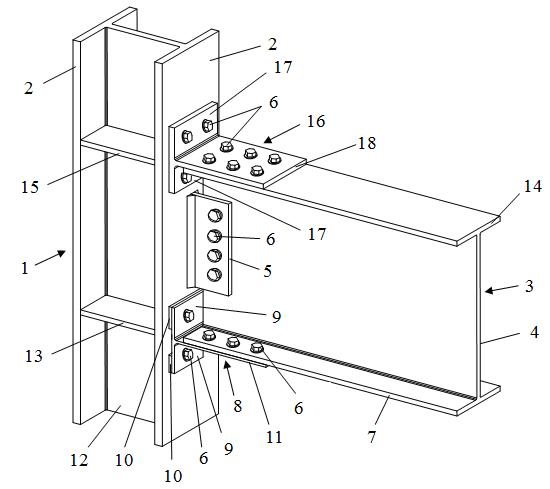

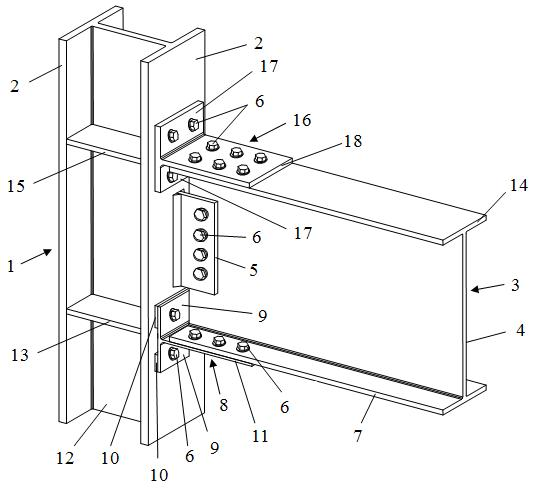

High-ductility steel structure beam column node in angle steel connection and construction method of high-ductility steel structure beam column node

ActiveCN102363979AIncreased ductile deformation capacityImprove energy consumptionBuilding material handlingShock proofingHigh intensitySteel columns

The invention relates to a high-ductility steel structure beam column node in angle steel connection and a construction method of the high-ductility steel structure beam column node. The invention is characterized in that: upper and lower flange plates of an H-shaped steel beam are respectively connected with a steel column by using flange angle steel, a flange steel cushion plate and a friction type high-strength bolt; a web plate of the H-shaped steel beam is connected with the steel column by using web plate angle steel, a web plate steel cushion plate and the friction type high-strength bolt; bolt holes in a flange angle steel branch and a web plate angle steel branch, which are connected with the H-shaped steel beam, are long circular holes; horizontal reinforcing ribs are arranged, at a joint of the steel column and the H-shaped steel beam, inside the steel column; and a gap is reserved between an end head of the H-shaped steel beam and the steel column. The high-ductility steel structure beam column node has quite high ductile deformation capacity and excellent energy-dissipation capacity; and connection welded beams are not formed on beam column members, so that the brittle failure of the steel beam or the steel column in a node area under the action of a seldom-occurring earthquake is avoided. Furthermore, the high-ductility steel structure beam column node has the advantages of convenience for construction, simple and quick in repair operation after the earthquake, low in repair cost and the like.

Owner:FUZHOU UNIV

Water thin type expanding steel structure fire-resisting paint and its preparation method

The present invention relates to a water thin expanding steel structure fire-resisting coating material and its preparation method. Said ivnention adopts a self-synthesized high melting temp. acrylate emulsion as main film-forming substance, adding proper quantity of chlorometaemulsion to raise fibre resistance of film-forming substance self-body, and on the basis of convertional ammonium polyphosphate fire-resistant adjuvant an expandable graphite as foaming material is added so as to form the invented fire-resisting coating material. Said invention can greatly raise forming rate to coating layer, the thickness of foamed layer can be up to 30-50 times that of original coating layer, and its fire-resisting limit can be up to 75 min (thickness of coating layer is 3 mm).

Owner:TONGJI UNIV

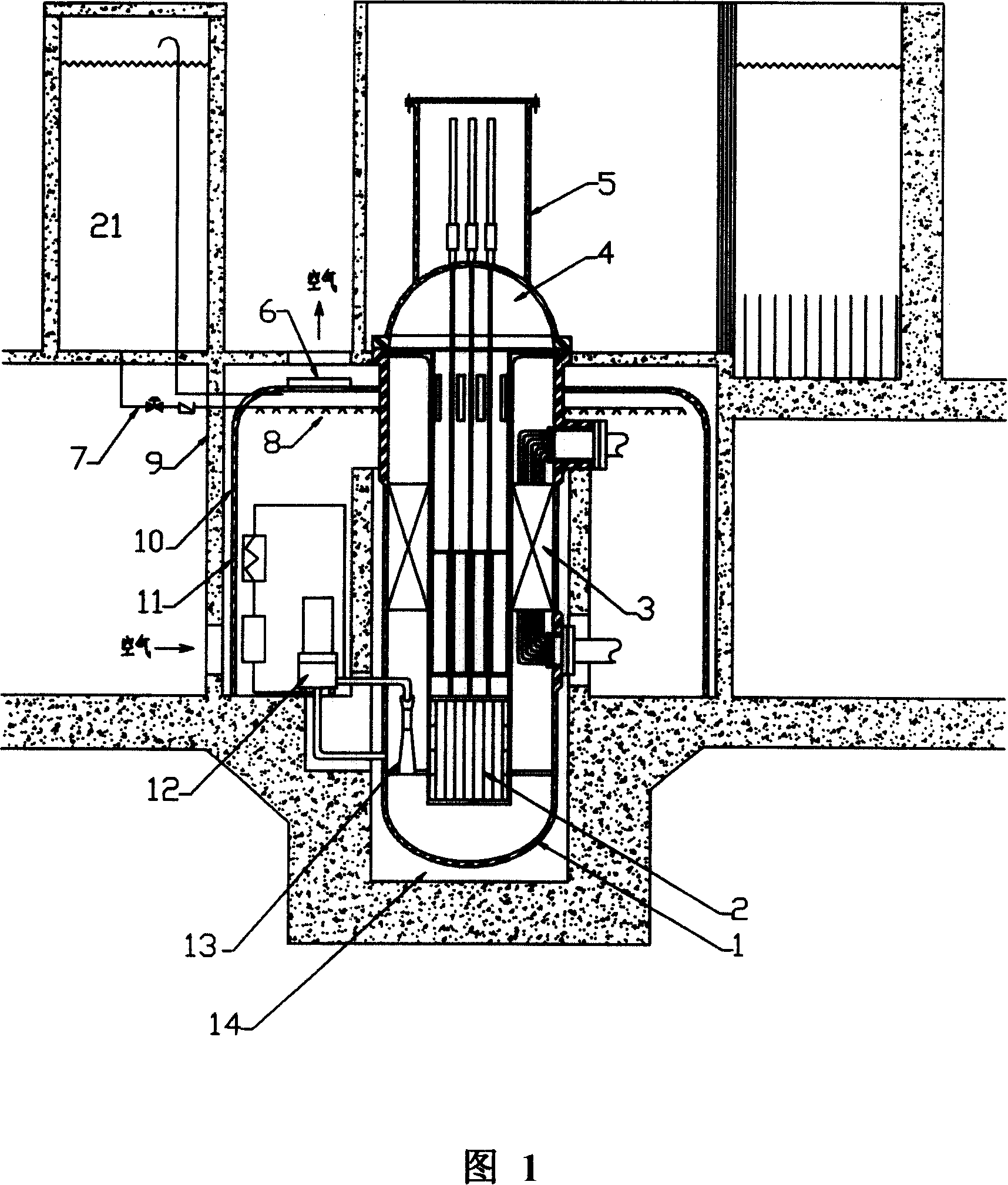

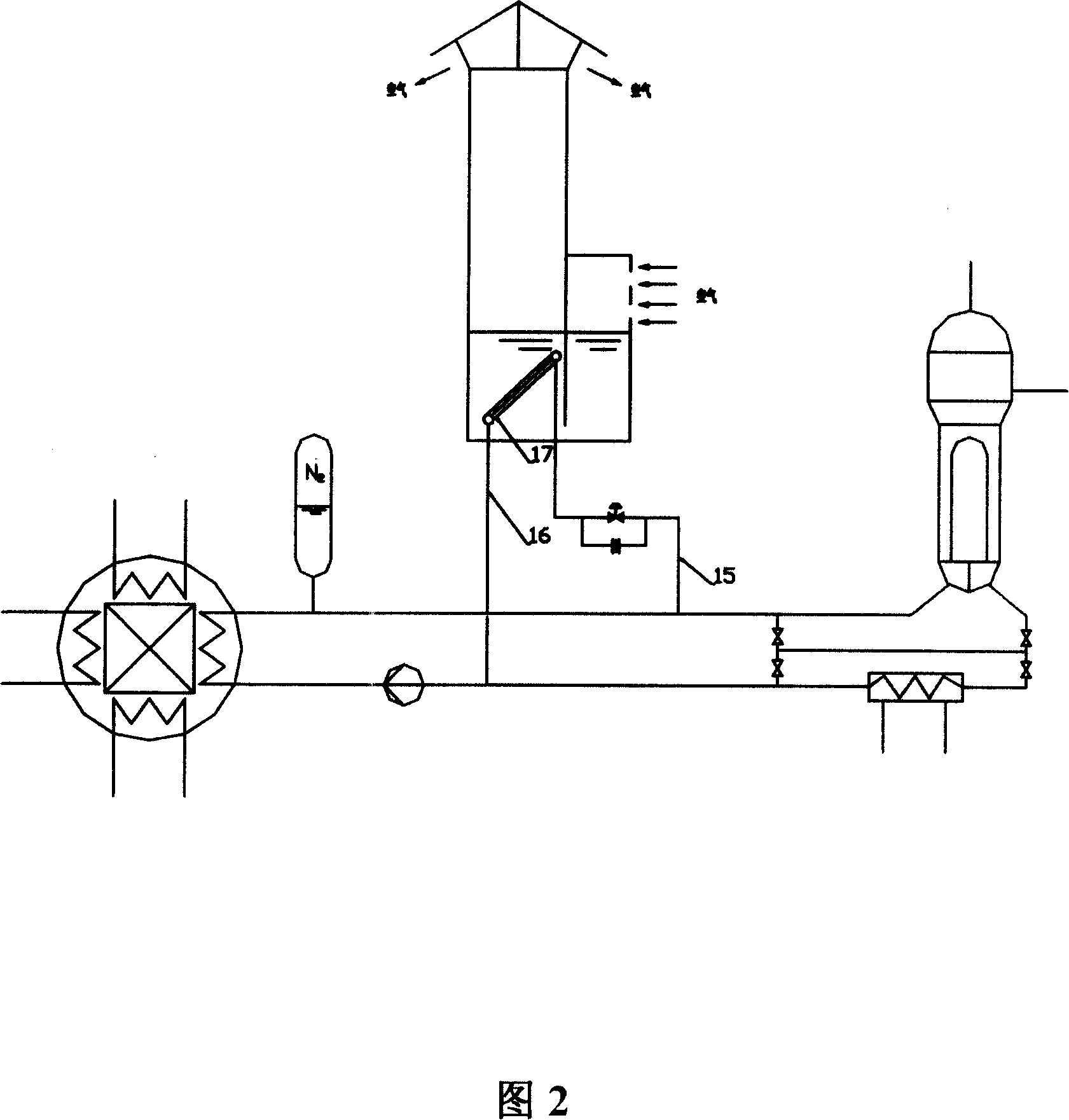

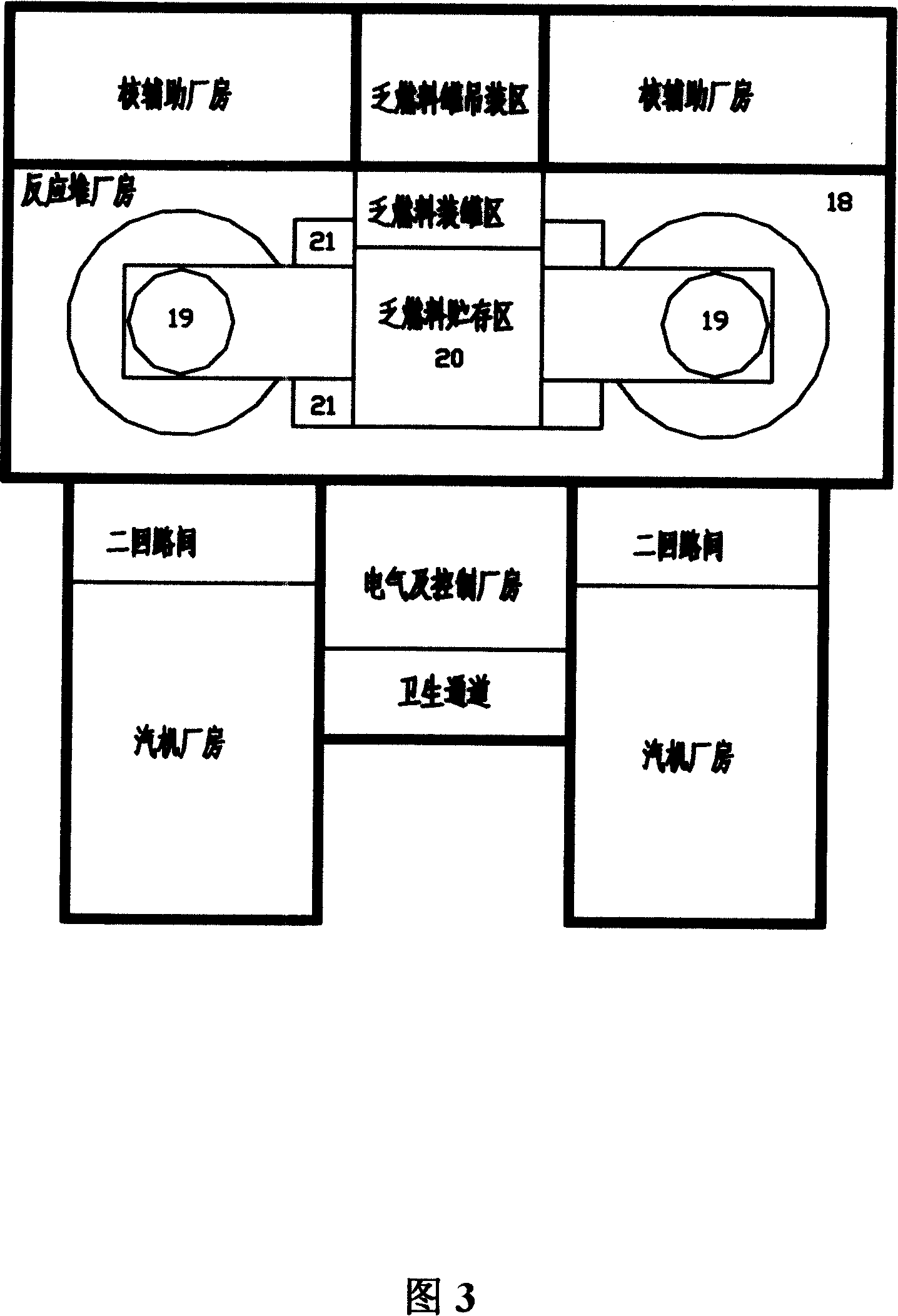

Integrated low-temperature nuclear heat supplying pile

ActiveCN101154472ASmall sizeCompact layoutIntegral reactorsNuclear energy generationReactor pressure vesselPressurized water reactor

The invention discloses an integral low-temperature nuclear heat reactor with the circuit equipment adopting integral arrangement and belonging to the low- and medium-parameter pressurized-water reactor, wherein, a reactor core adopts the mature nuclear power plant fuel component and control rod component; a main heat exchanger is of integral coil type; a voltage stabilizer is a built-in nitrogen partial pressure control voltage stabilizer; coolant circulation is completed by a built-in jet apparatus and the equipment of an external drive circuit; the drive circuit and the equipment and a main circuit auxiliary system are arranged at the circumference of a reactor pressure vessel; a containment vessel consists of a reactor body containment vessel and a reactor top containment vessel; the reactor body containment vessel which is a structure combined by a reactor vault of reinforced concrete structure and a casing of steel structure is connected with a sealed refueling water storage pool through a pipe and a valve. The thermal power of the reactor can be selected between 50MW and 500MW at will and the outlet temperature of the reactor can be selected between 100 DEG C to 200 DEG C according to application, requirement and power.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Ultrathin section steel structure fire-resisting paint and preparation thereof

The invention discloses an ultra-thin fireproof coating for a steel structure and a preparation method thereof. The coating has the characteristics of high gloss, good water resistance, strong adhesion force and so on of a solvent based ultra-thin fireproof coating, also has the advantages of water-based coatings by taking water as a medium, and satisfies the direction of developing low-pollution and environment-friendly coatings of the coating industry. The technical proposal comprises that the ultra-thin fireproof coating for the steel structure is prepared from the following components by weight portion: 10 to 35 portions of acrylic hybrid emulsion, 10 to 25 portions of dehydration and carbon-forming catalyst, 10 to 25 portions of carbon forming agent, 5 to 20 portions of foaming agent, 5 to 20 portions of flame retardant, 5 to 25 portions of pigment and filler, 3 to 10 portions of reinforcing agent, 5 to 10 portions of latent solvent, 1 to 5 portions of dispersant, 0.1 to 1 portion of foam killer, 0.2 to 2 portions of flatting agent, 0.2 to 2 portions of thickening agent, 1 to 5 portions of film forming additive, and the balance being water.

Owner:MARINE CHEM RES INST

Low-smoke superthin expansion steel structure fireproof coating and its preparing method

The invention relates to a kind of new-style low smoke super thin inflating steel structure fire protection dope and its producing method. Its components have coordinated effect when encountering fire. It inflates and froths to isolate oxygen and has good heat insulation performance. It can slow down the speed of heat transmitting to protected basic material, and prevent flame fast overspreading. The dope of the invention is mainly comprised of basic material resin, carbon forming agent, vesicant and activator. It uses certain proportion of resin as main membrane forming substance, and improves height and intensity of frothing layer through adding china padding. The frothing height can get to over 50 times. It uses china padding and smoke inhibitor to have coordinated effect and reduce smoking quantity. Advantages: simple to smear, good fire protection performance, small smoking quantity, high frothing height and high frothing intensity.

Owner:FUDAN UNIV

Segmental slipping and assembling process of overhead large-span steel structure

InactiveCN101725255AImprove installation accuracyFast constructionBuilding material handlingSpandrelSteel structures

The invention relates to a segmental slipping and assembling process of an overhead large-span steel structure, which is characterized by comprising the following steps of: firstly building a temporary track beam support, then arranging a slipping track beam and an assembling jig frame on the temporary track beam support, assembling a steel structure truss element on the jig frame according to drawing requirements, dismantling the assembling jig frame after the assembly is finished, pushing and slipping the steel structure truss element forwards along the a slipping track, moving the steel structure truss element to the expected position of the steel structure, then carrying out next span area steel structure truss element assembly on the emptied-out assembling jig frame, carrying out welding connection between the next span steel structure truss element and the previous element, slipping and pushing the steel structure truss elements to the expected position in sequence, analogizing the process in sequence till all steel structure slipping and assembly are finished, and finally unloading, landing and fixing to finish the whole installation work of the steel structure.

Owner:高申甫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com