Easily repaired steel-structure beam-column node

A technology of beam-column joints and steel structures, which is applied to building components, building structures, and earthquake resistance, can solve problems such as difficulties and joint repairs, and achieve the effects of simple repairs, difficult repairs, and insufficient ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

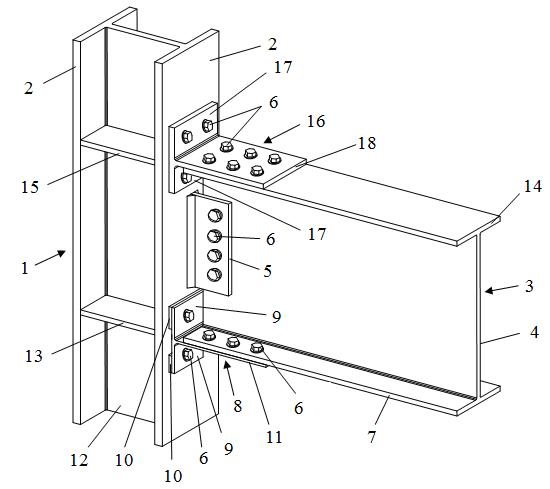

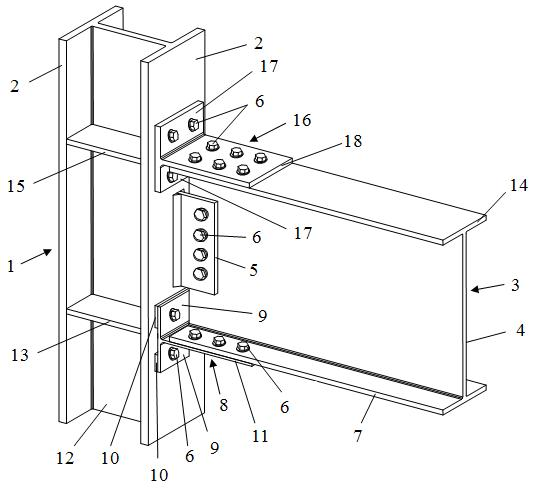

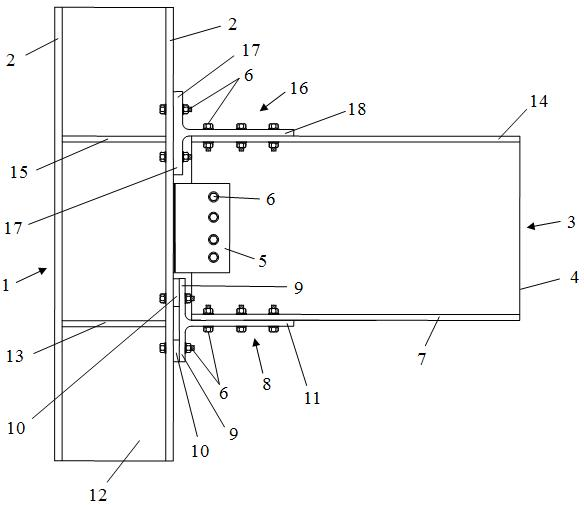

[0028] The present invention provides a beam-column node of an easily repairable steel structure, which comprises a vertical H-shaped steel column 1 and an H-shaped steel beam 3 whose end is vertically connected to the side panel 2 of the H-shaped steel column. The connecting end of the plate 4 and the H-shaped steel column side panel 2 is connected through a reinforced connecting plate 5 fitted with the H-shaped steel beam web 4 and high-strength bolts 6 passing through the reinforced connecting plate 5, and the reinforced connecting plate 5 and The H-shaped steel column flank plates 2 are welded together, and the two sides of the connecting end of the H-shaped steel beam bottom flank plate 7 are locked and connected to the H-shaped steel column 1 through a T-shaped connecting plate 8 and through high-strength bolts 6 respectively. The T-shaped connecting plate 8 is placed horizontally, and its longitudinal upper and lower ends 9 are locked and connected with the H-shaped stee...

Embodiment 2

[0033] On the basis of the specific embodiment 1, the top side panel 14 of the H-shaped steel beam 3 is connected with a reinforced concrete member 19 covering the upper periphery of the H-shaped steel column 1 (see Figures 4 to 6). In order to jointly deform the H-shaped steel beam 3 and the reinforced concrete member 19 and reduce the effect of shear force, a shear stud 20 is provided between the H-shaped steel beam 3 and the reinforced concrete member 19 (see Fig. 5 and Fig. 6 ).

Embodiment 3

[0035] The difference between this specific embodiment and specific embodiment 1 is that: the top side panel 14 of the H-shaped steel beam 3 and the side panel 2 of the H-shaped steel column 1 are connected by a full-penetration weld 21 (see FIGS. 7 to 9 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com