Patents

Literature

71 results about "Piano wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piano wire, or "music wire", is a specialized type of wire made to become springs or (as the name implies) to be used as piano strings. It is made from tempered high-carbon steel, also known as spring steel, which replaced iron as the material starting in 1834.

High-carbon steel wire rod with high strength and high toughness

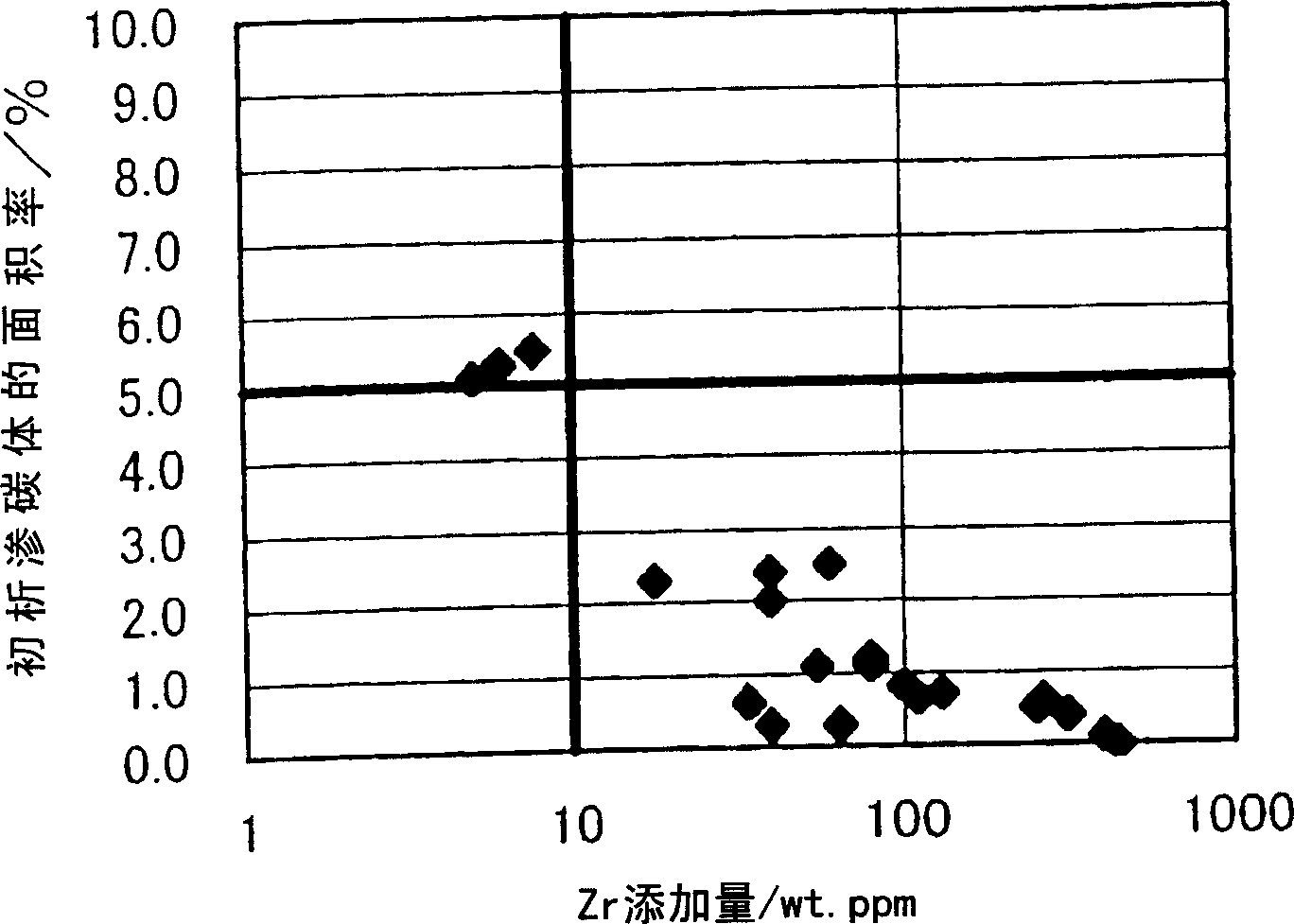

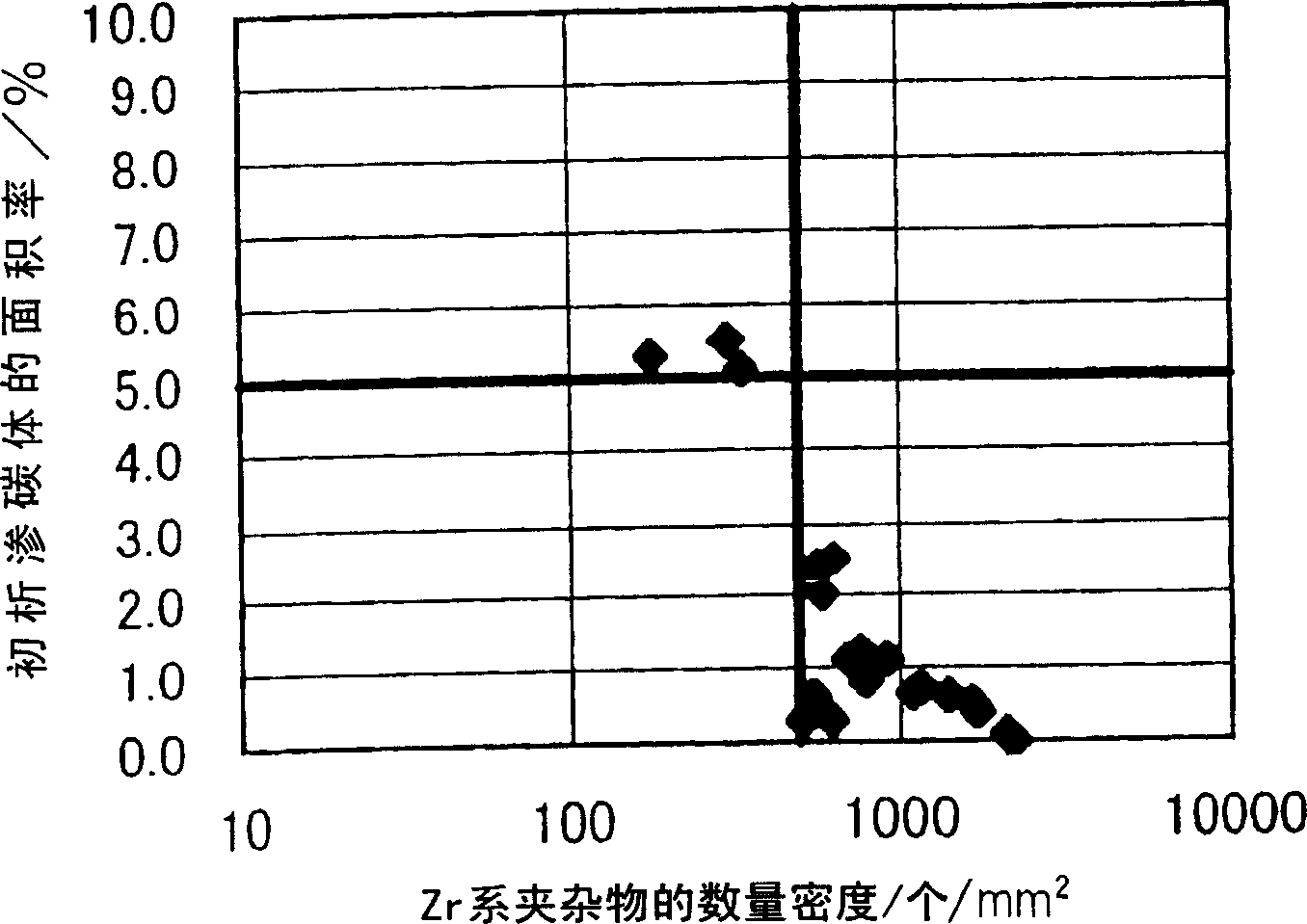

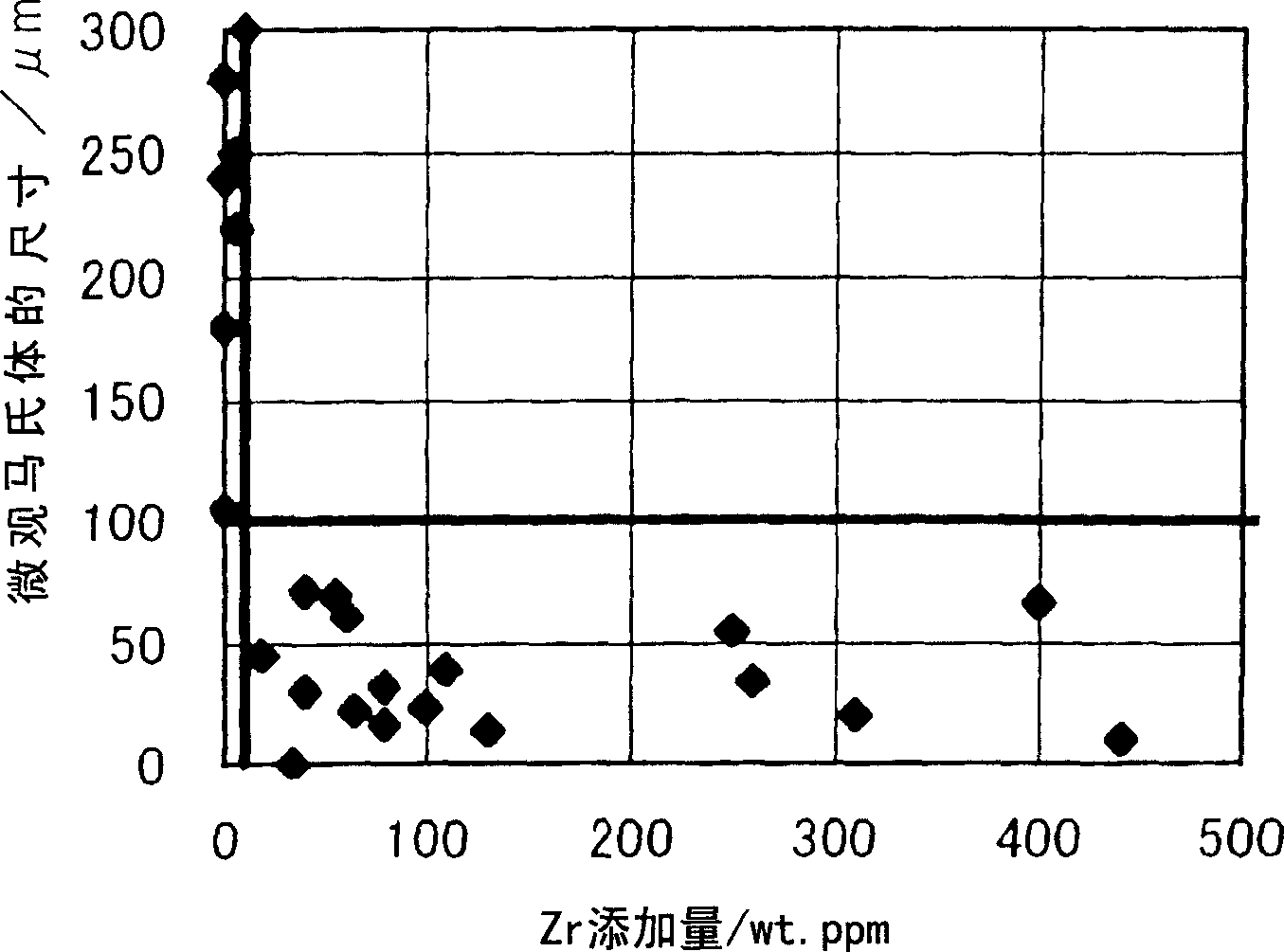

InactiveCN1745187ALimit precipitationIncrease equiaxed ratioFurnace typesHeat treatment furnacesHigh carbonNumerical density

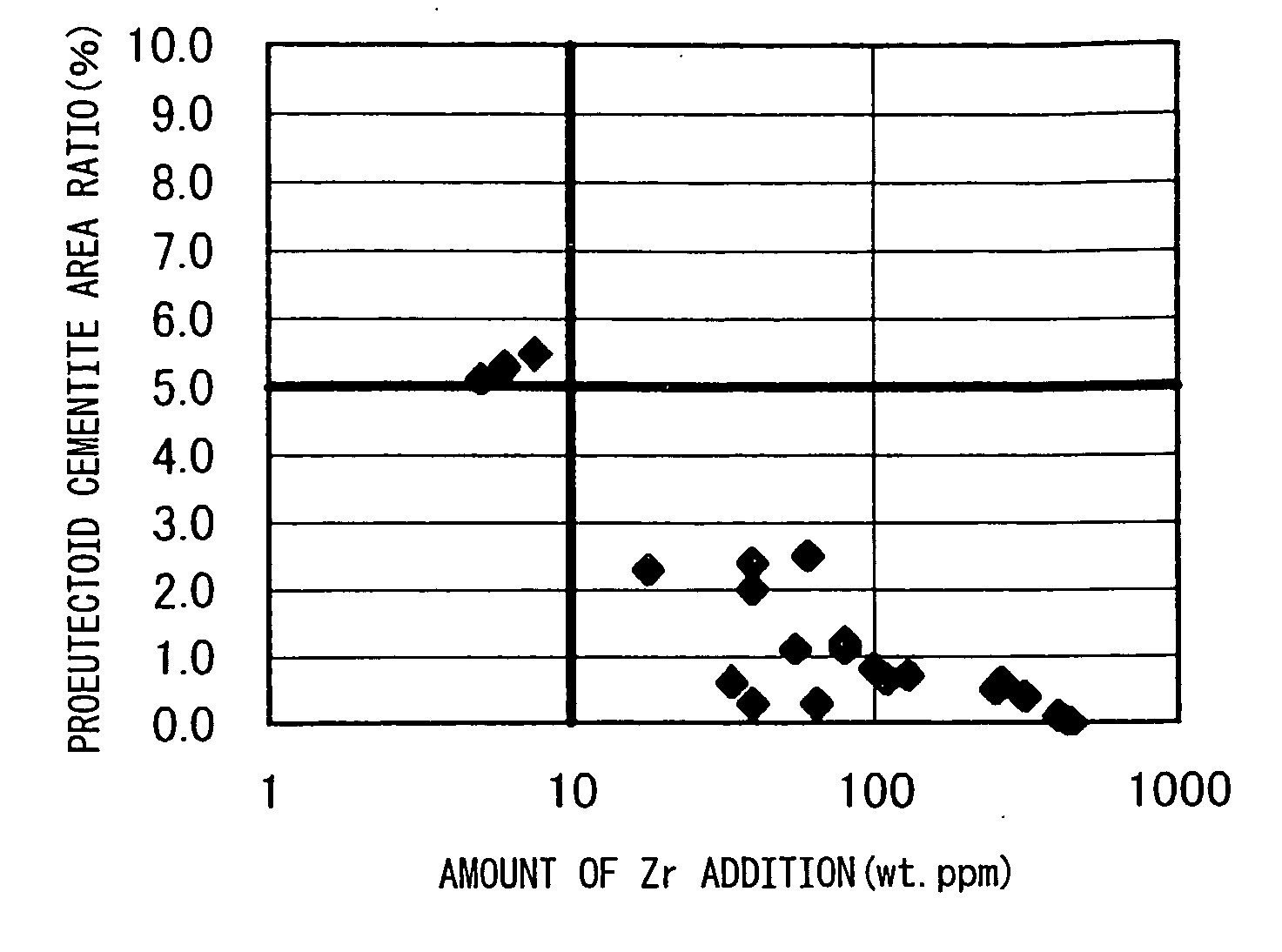

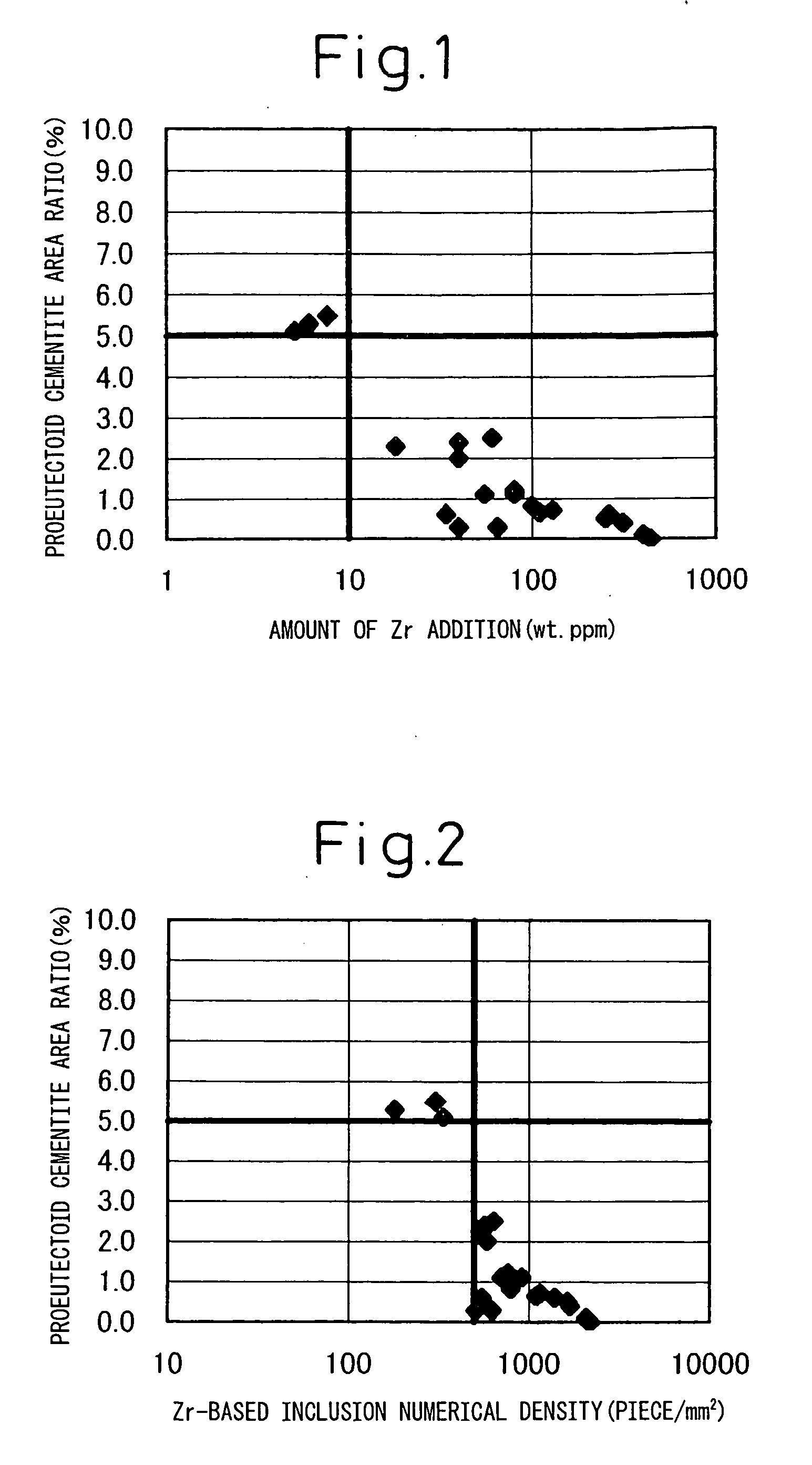

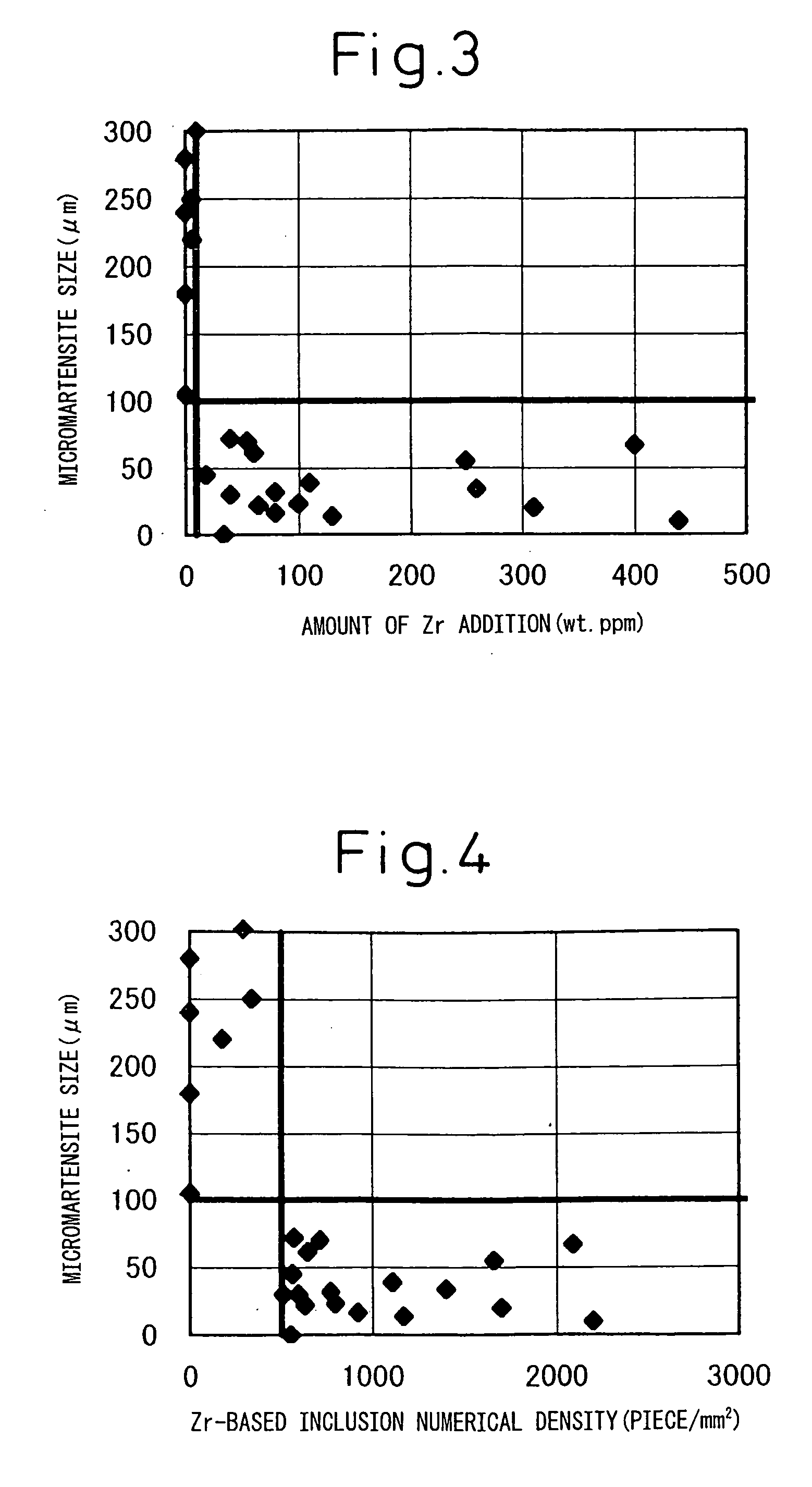

It is intended to provide a high strength high toughness steel wire suitable for use in PC steel wires, zinc plated steel twisted wires, steel wires for springs, suspension bridge cables, etc. A piano wire rod or hard steel wire rod of 170 kgf / mm<2> or greater tensile strength and 30% or more rupture drawing, having a structure composed mainly of pearlite, wherein the average value of pro-eutectoid cementite area ratio in a central region extending from the center of the wire rod to less than 20% of the radius of the wire rod is 5% or below or wherein the micromartensite size in C-section is 100 mum or less is obtained by subjecting a hard steel wire rod whose steel chemical components, chemical composition of contained inclusions, size and numerical density have been specified to hot rolling and subsequently to either directly patenting treatment or, via reaustenitization, patenting treatment.

Owner:NIPPON STEEL CORP

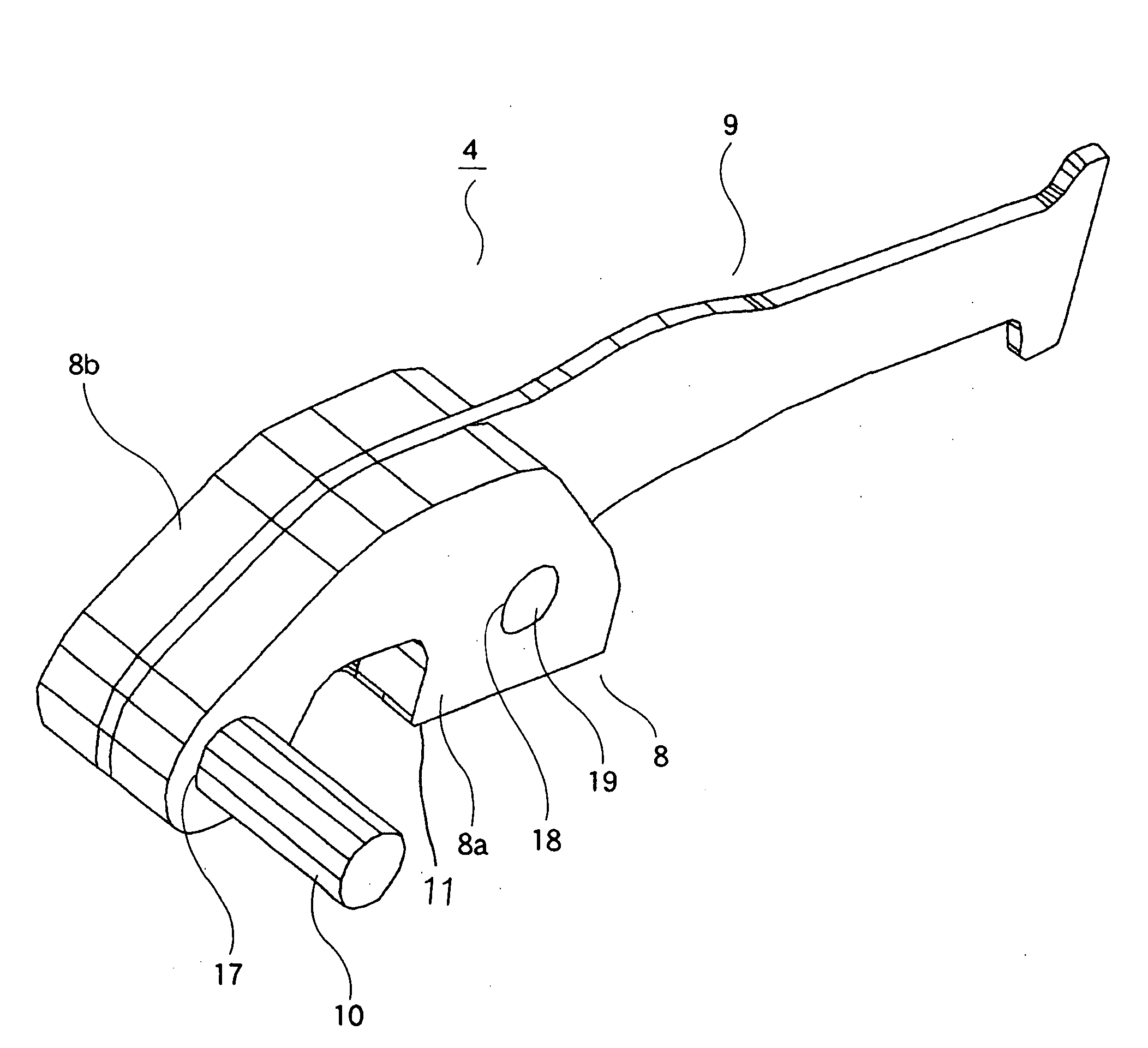

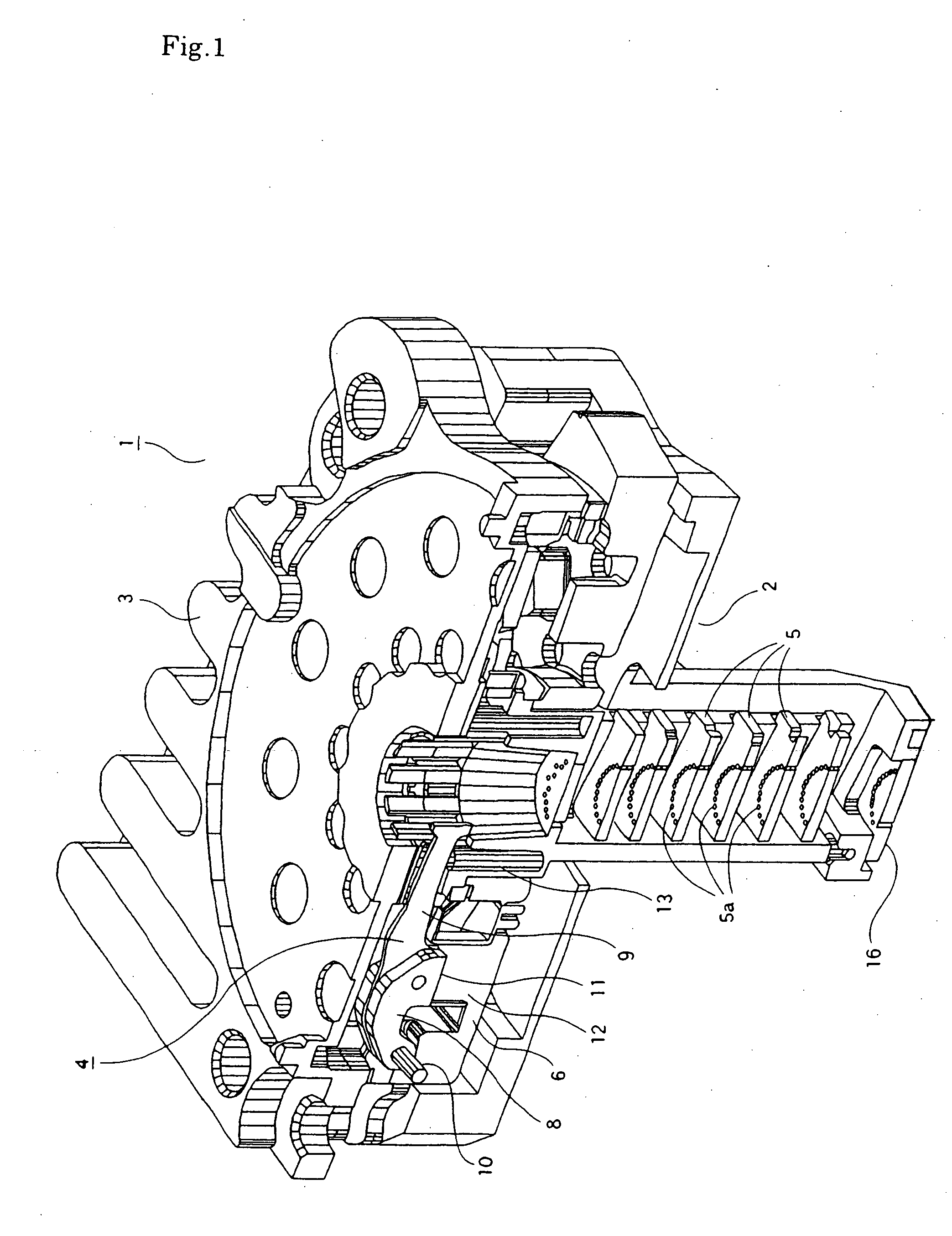

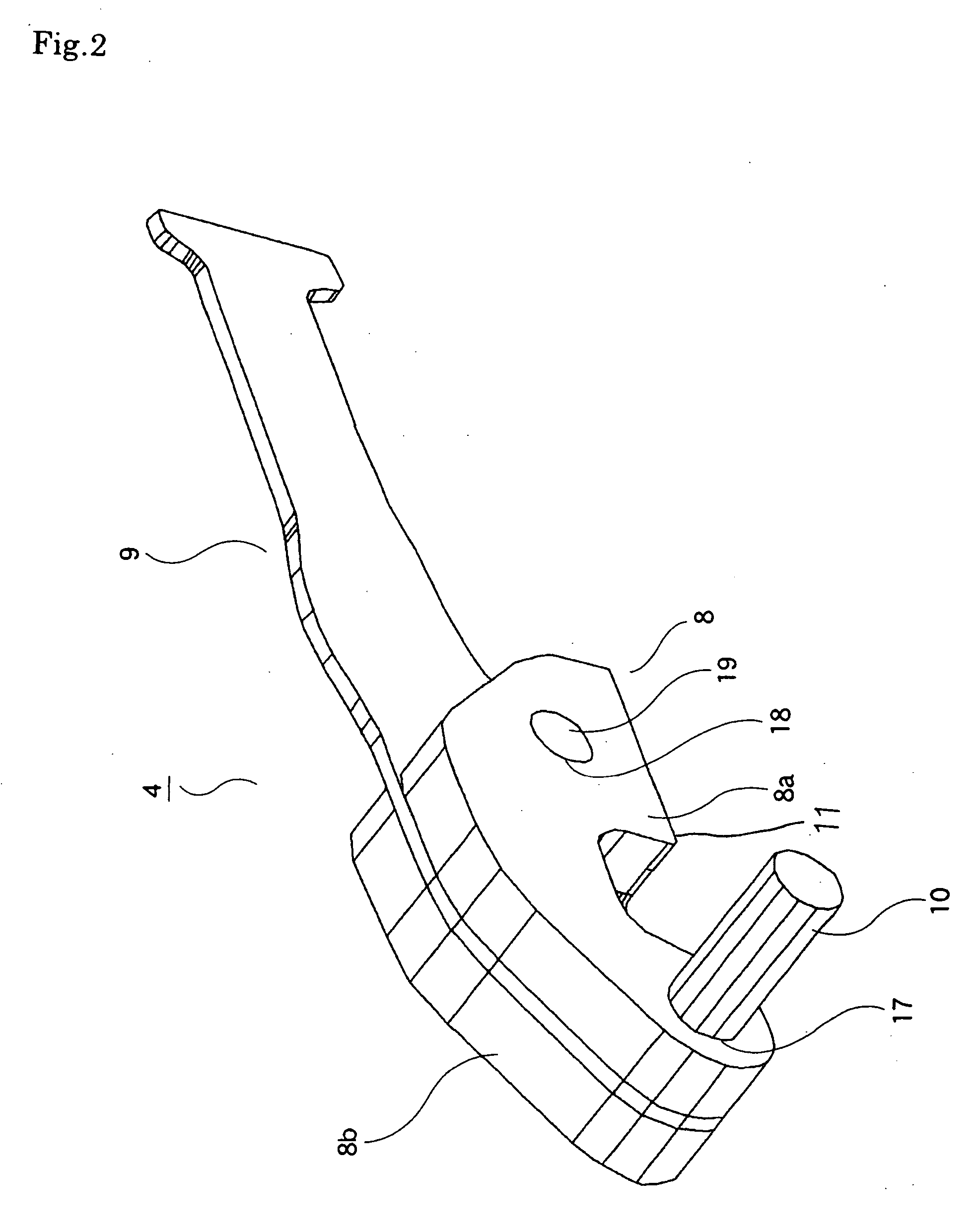

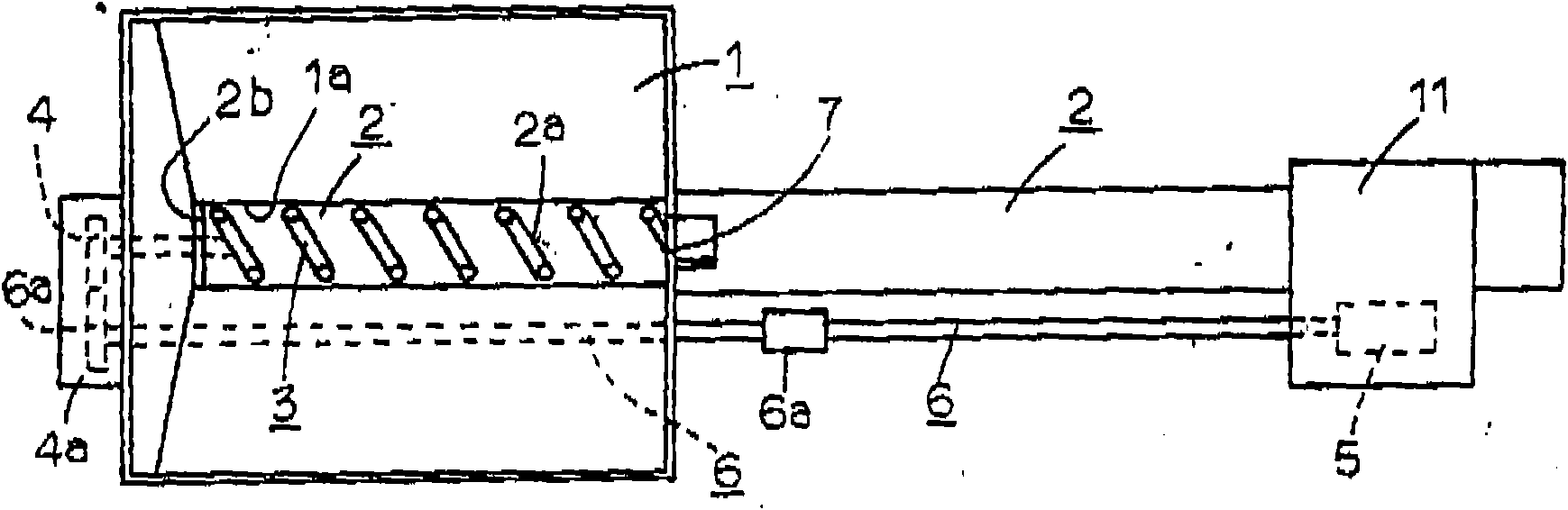

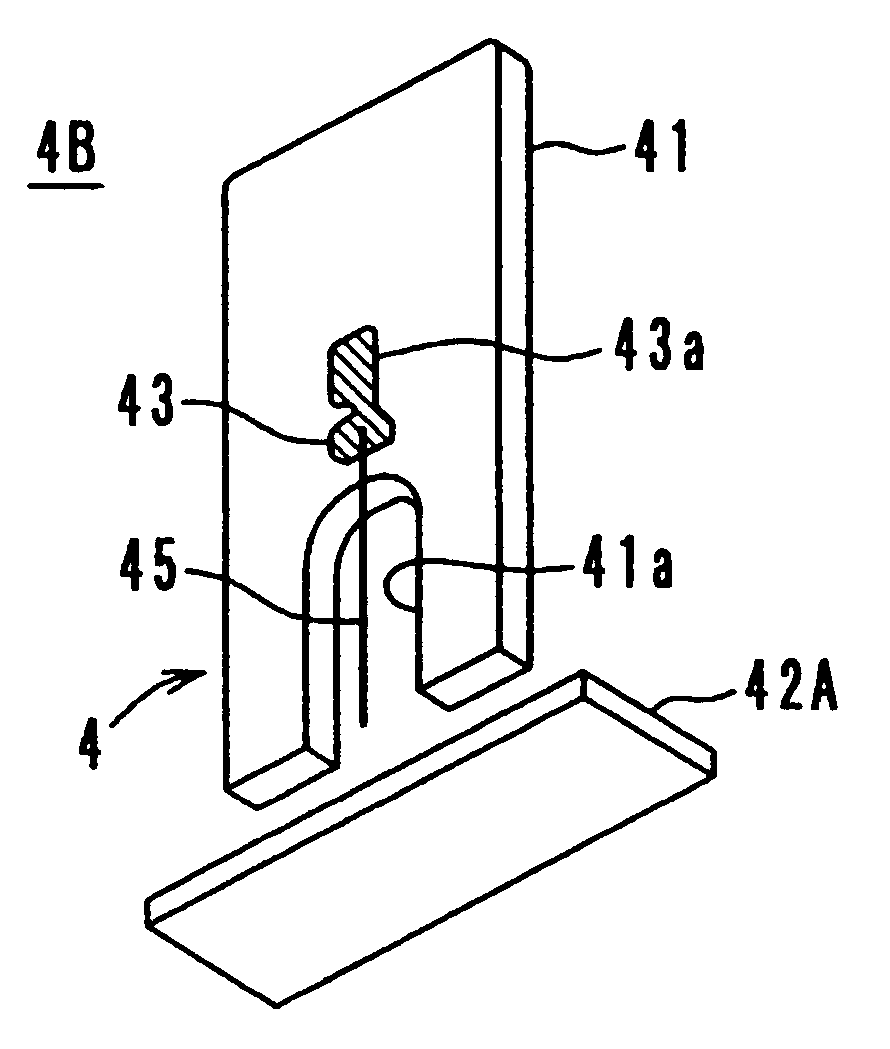

Dot head and method of manufacturing armature structure for dot head

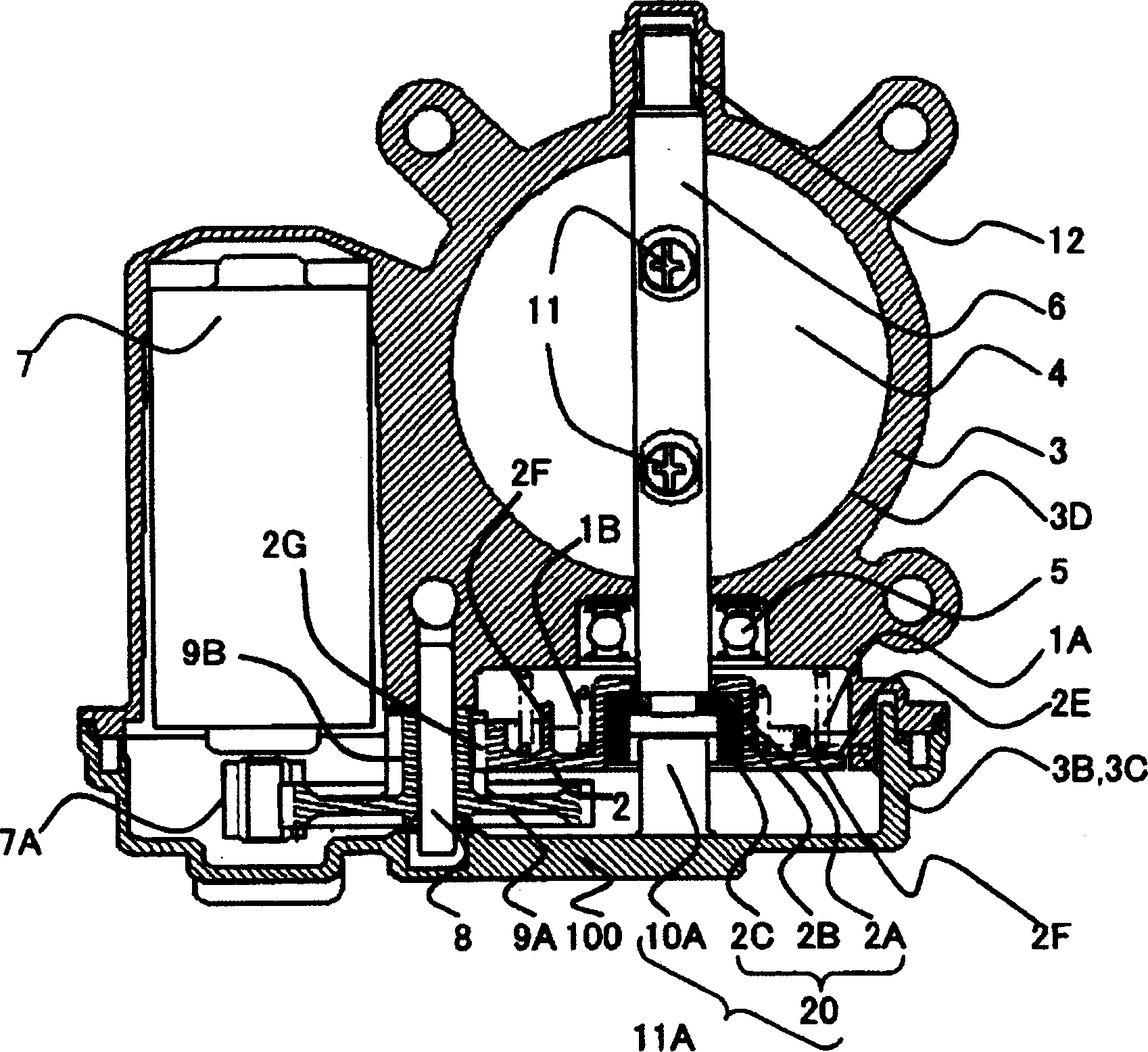

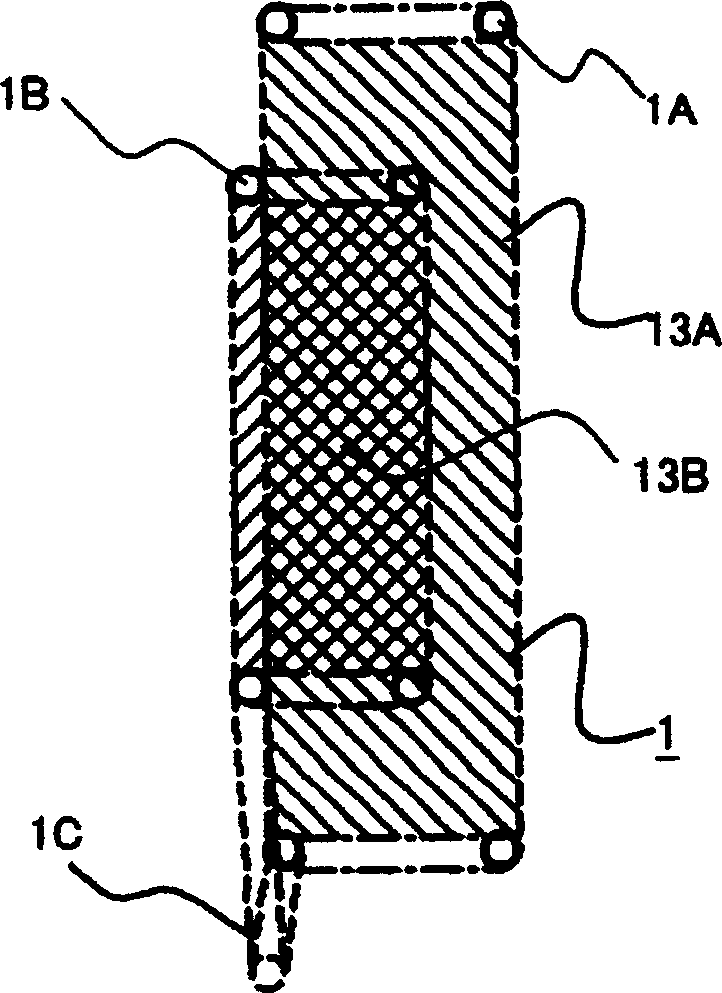

According to a dot head of the invention, an armature structure for moving a printing needle forward and backward has the efficiency that the magnetic characteristics is excellent and mechanical intensity is high. The armature structure is manufactured in a manner that an arm member, which is formed by subjecting a plate-shaped material excellent in abrasion resistance performance and having a high intensity to a plating processing using born etc., is sandwiched at a portion thereof from both sides in a stacked manner by two armature members each of which is formed by subjecting a plate-shaped material excellent in magnetic characteristics to a plating processing using born etc. A pin formed by subjecting a piano wire to a plating processing using boron etc. is inserted with a small pressure into common through holes of the two armature members and the arm member thus stacked thereby to provisionally assemble them. A pair of electrodes are made in contact to the portions including the slightly-pressed-in pin near the pin of the provisionally assembled two armature members and the arm member, and a current is supplied to the electrodes in a state that the portions are sandwiched by the electrodes thereby to melt and harden the plated portions using boron etc. to integrate the two armature members and the arm member.

Owner:TOSHIBA TEC KK

High strength, high toughness, high carbon steel wire rod and method of production of same

InactiveUS20060137776A1High strengthImprove toughnessHot-dipping/immersion processesFurnace typesHigh carbonNumerical density

The present invention provides a high strength, high toughness steel wire rod useful for a PC steel wire, galvanized steel strands, spring use steel wire, cables for suspension bridges, etc. By hot rolling, then directly patenting or reaustenitizing, then patenting a high carbon steel wire rod of a specific chemical composition of the steel and chemical composition, size, and numerical density of inclusions, piano wire rod or high carbon steel wire rod having a structure of mainly pearlite, having an average value of the proeutectoid cementite area ratio of 5% or less in a center region of less than 20% of the wire rod diameter from the center of the wire rod, having a micromartensite size of the C section of 100 μm or less, having a tensile strength of the 170 kgf / mm2 class or more, and having a drawing ratio at break of 30% or more is obtained.

Owner:NIPPON STEEL CORP

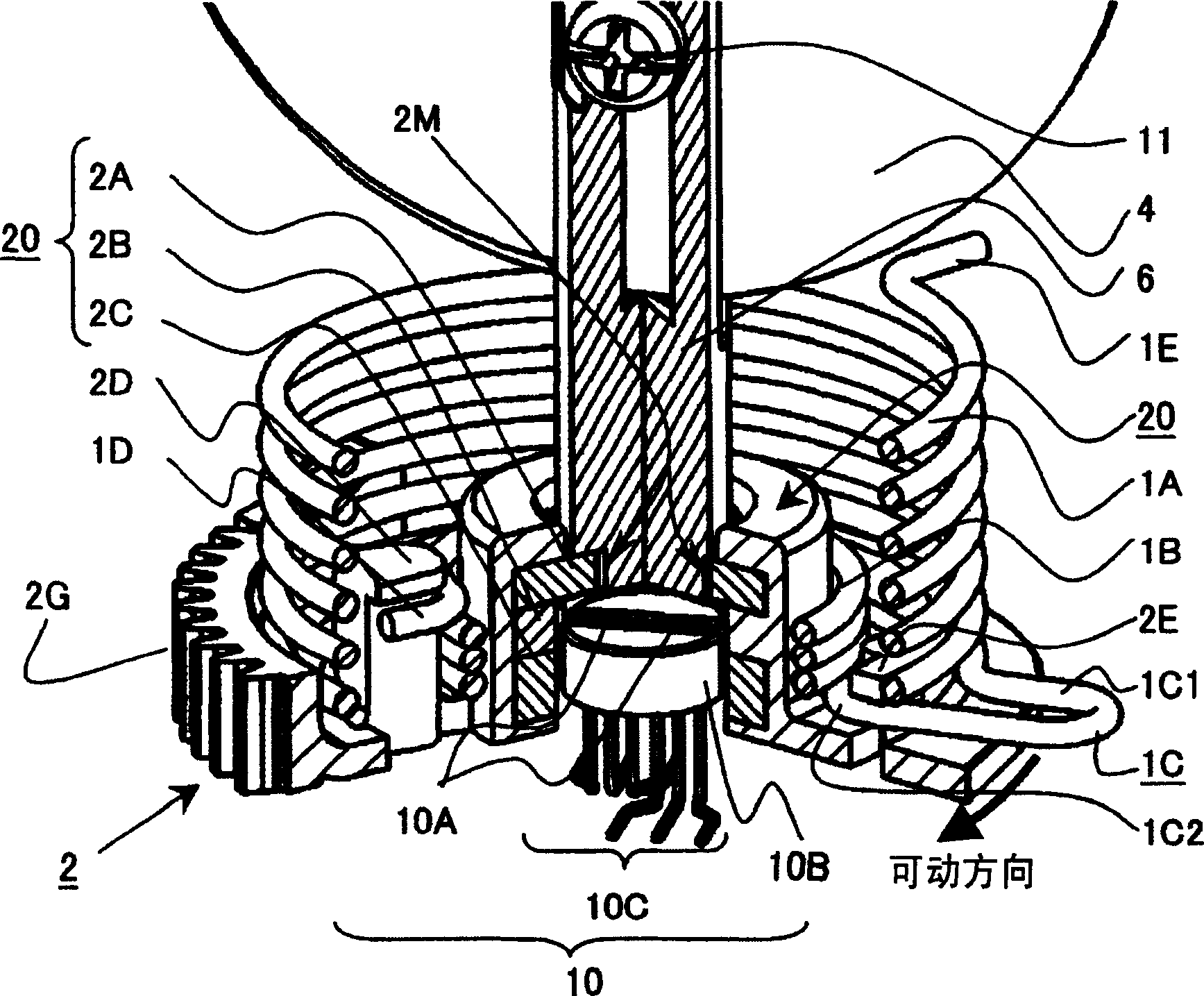

Motor-driven throttle valve control device for internal combustion engine

InactiveCN1847632ASave configuration spaceContributes to downsizing and weight reductionEngine controllersMachines/enginesMotor driveGear wheel

The invention relates to a spring to ensure default opening is constituted by a single piano wire where a return spring (1A) with a larger coil diameter and a default spring (1B) with a smaller coil diameter are connected via a connection arm formed with a spring hook (1C). The spring with a smaller coil diameter is inserted in the spring with a larger coil diameter thereby the springs are overlapped in an axial direction as a duplex-winding spring structure. Further, a magnetic sensor (11A) is provided in a position inside the both spring with a larger coil diameter and spring with a smaller coil diameter.

Owner:HITACHI LTD

Diamond wire saw and rapid production method thereof

ActiveCN103388170AIncreased chance of collisionIncrease capture rateElectrolytic coatingsChemical platingHeat treated

The invention discloses a diamond wire saw and a rapid production method thereof. The surfaces of diamond grits are respectively coated with a nickel layer by chemical plating, the nickel layers are fixed on a copper-plated piano wire substrate pre-plated with a nickel layer through electroplating, and then the nickel layers are thickened, so that the diamond grits are solidified more firmly. The rapid production method of the diamond wire saw comprises the following steps of: 1, removing greases and oxides on the surfaces of diamond grits, and carrying out sensitization, activation and chemical nickel plating on the diamond grits; 2, removing greases and oxides on the surface of a metal substrate, and pre-plating nickel layers as buffer layers; and 3, carrying out composite electroplating, thickened electroplating and heat treatment on the diamond wire saw. According to the invention, diamond grits are subjected to chemical nickel plating to achieve an effect of electric conduction, so that the diamond grits carry out sequential movement under the action of an electric field, and chemical consolidation is realized; and in addition, intense agitation is introduced in an electroplating process, so that high-current / density electroplating is realized, and a highly efficient and rapid method is provided for the industrial production of diamond wire saws.

Owner:江西核工业兴中科技有限公司

Piano wire-optoelectronic differentiator

The invention relates to a piano wire-photoelectric differential instrument, which is characterized in that: it mainly consists of a measuring seat, a differential cylinder, a connection body and an edge detector; one end of the differential cylinder is fixed on the measuring seat, while the other is connected with the edge detector through the connection body. The invention achieves the advantages of reasonable structure, high detection speed, high sensitivity, simple operation and high work efficiency.

Owner:浙江富春江水电设备股份有限公司

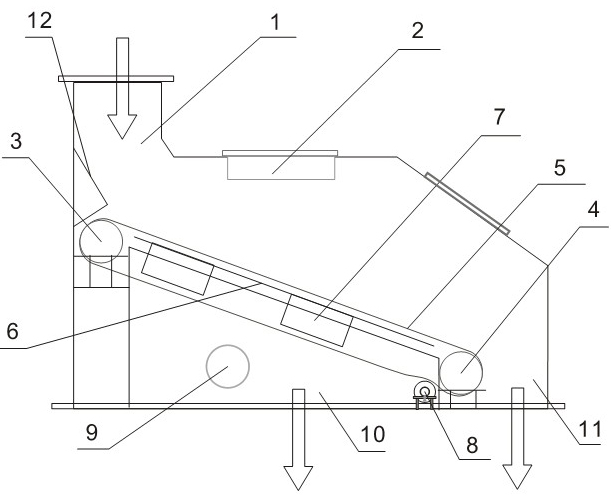

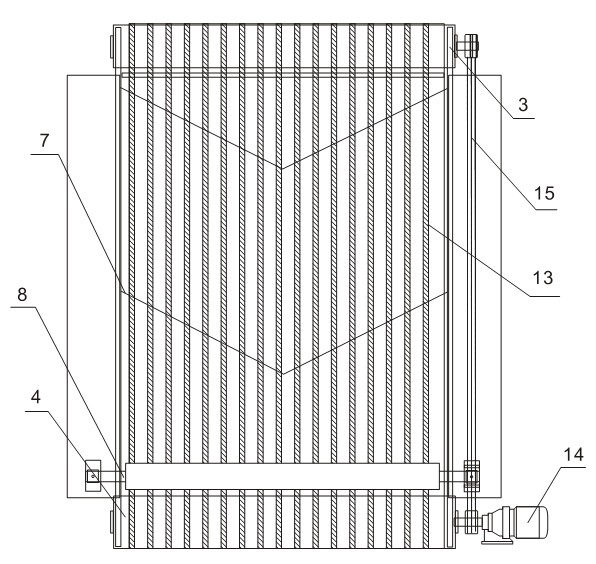

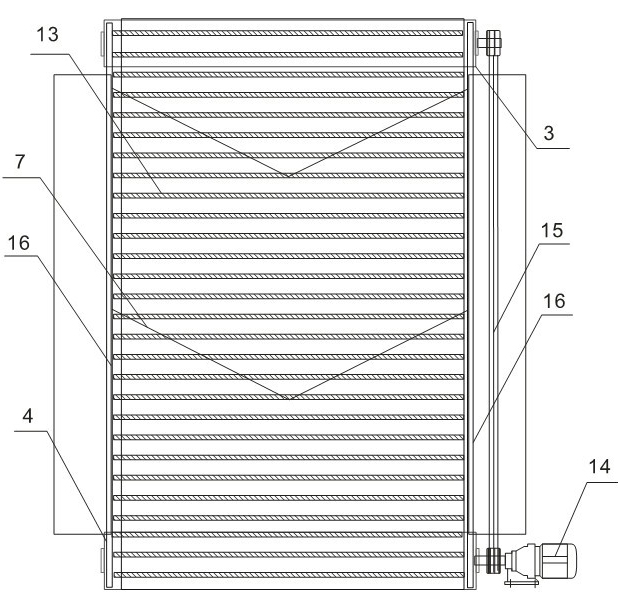

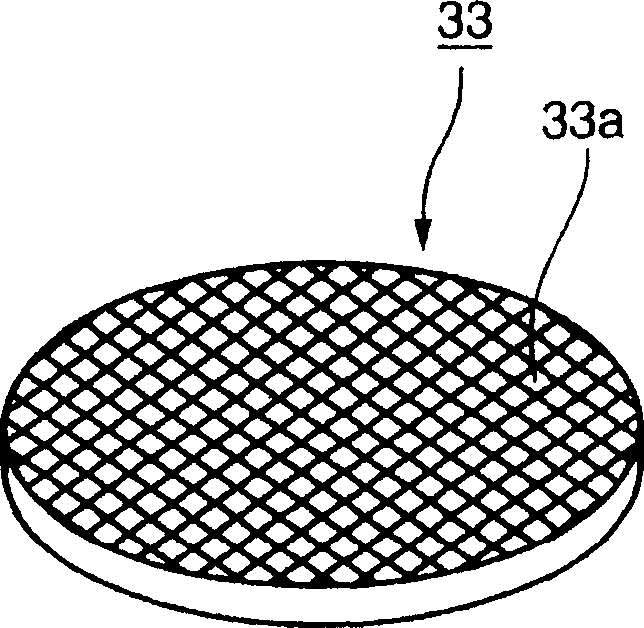

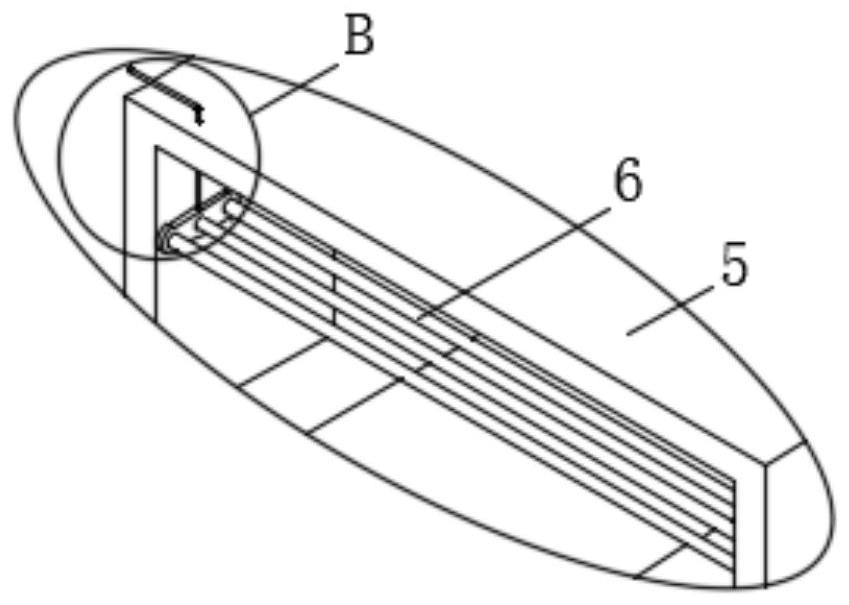

Efficient screening distributor

ActiveCN101985122ASolve the non-adjustable particle sizeSolve the non-adjustable tension of the screen surfaceSievingScreeningPiano wireElectrical and Electronics engineering

The invention discloses an efficient screening distributor which comprises a feed inlet (1), an upper rolling shaft (3), a lower rolling shaft (4), a piano wire screen surface (5), a fixed piano wire screen (6), a coal wiper (7), a tension device (8), a distribution plate (12), a motor (14) and a transmission device (15), wherein, the piano wire screen surface (5) is composed of a plurality of filtering ropes (13) arranged in parallel, and the piano wire screen surface (5) surrounds the upper rolling shaft (3) and the lower rolling shaft (4) to form an upper screen surface and a lower screen surface which are connected end to end and can perform gyratory motion; and the fixed piano wire screen (6) is positioned below the upper screen surface of the piano wire screen surfaces (5). The efficient screening distributor solves the problems of the existing screening distributor, such as unadjustable particle size, unadjustable tension of the screen surfaces, channel blockage caused by materials, difficult coal unloading, low screening efficiency, uneven distribution, failure in removal of iron castings from the materials and the like; and the efficient screening distributor has the advantages of rational structure, low operating cost and the like, and is convenient to maintain and overhaul.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

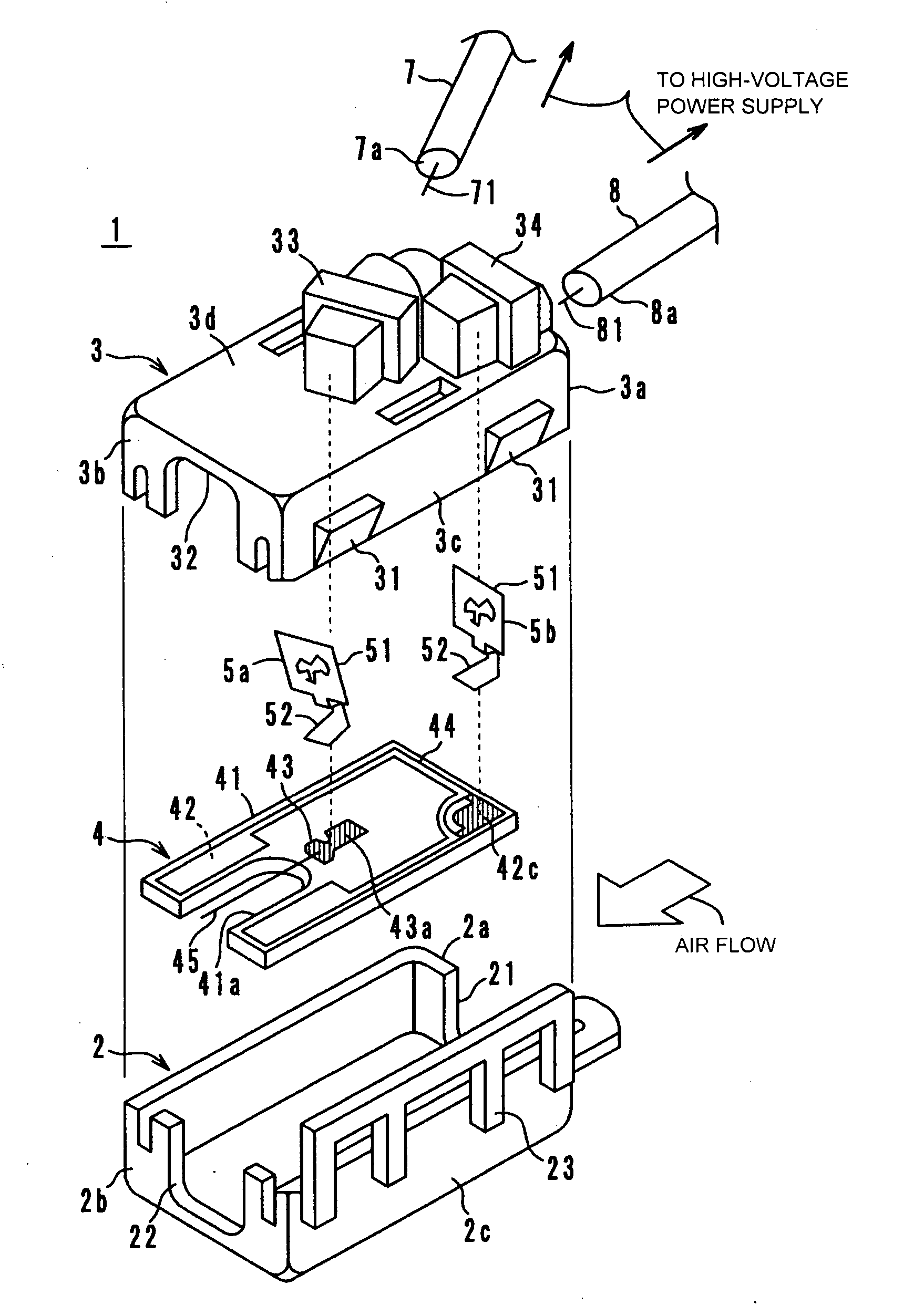

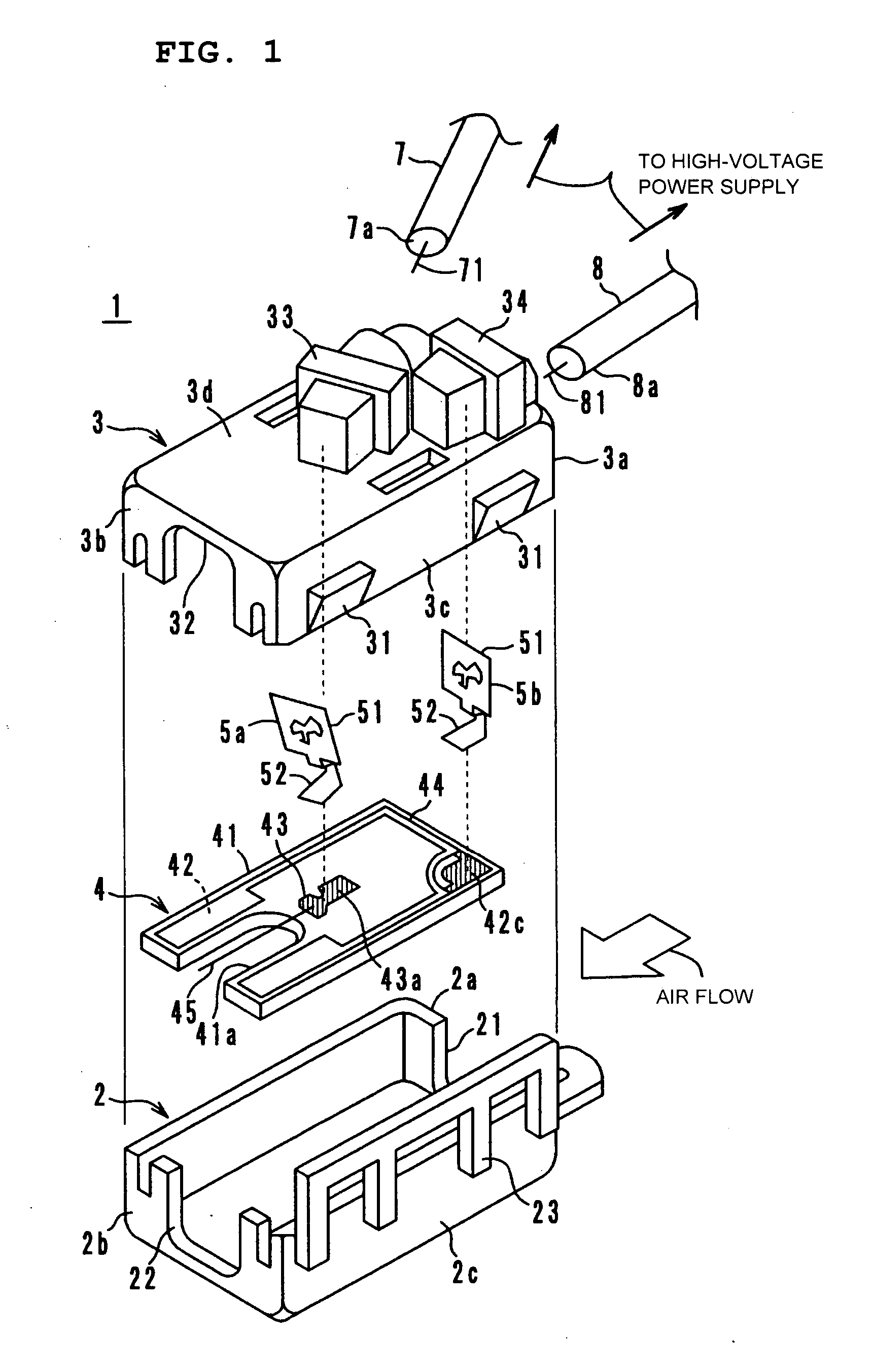

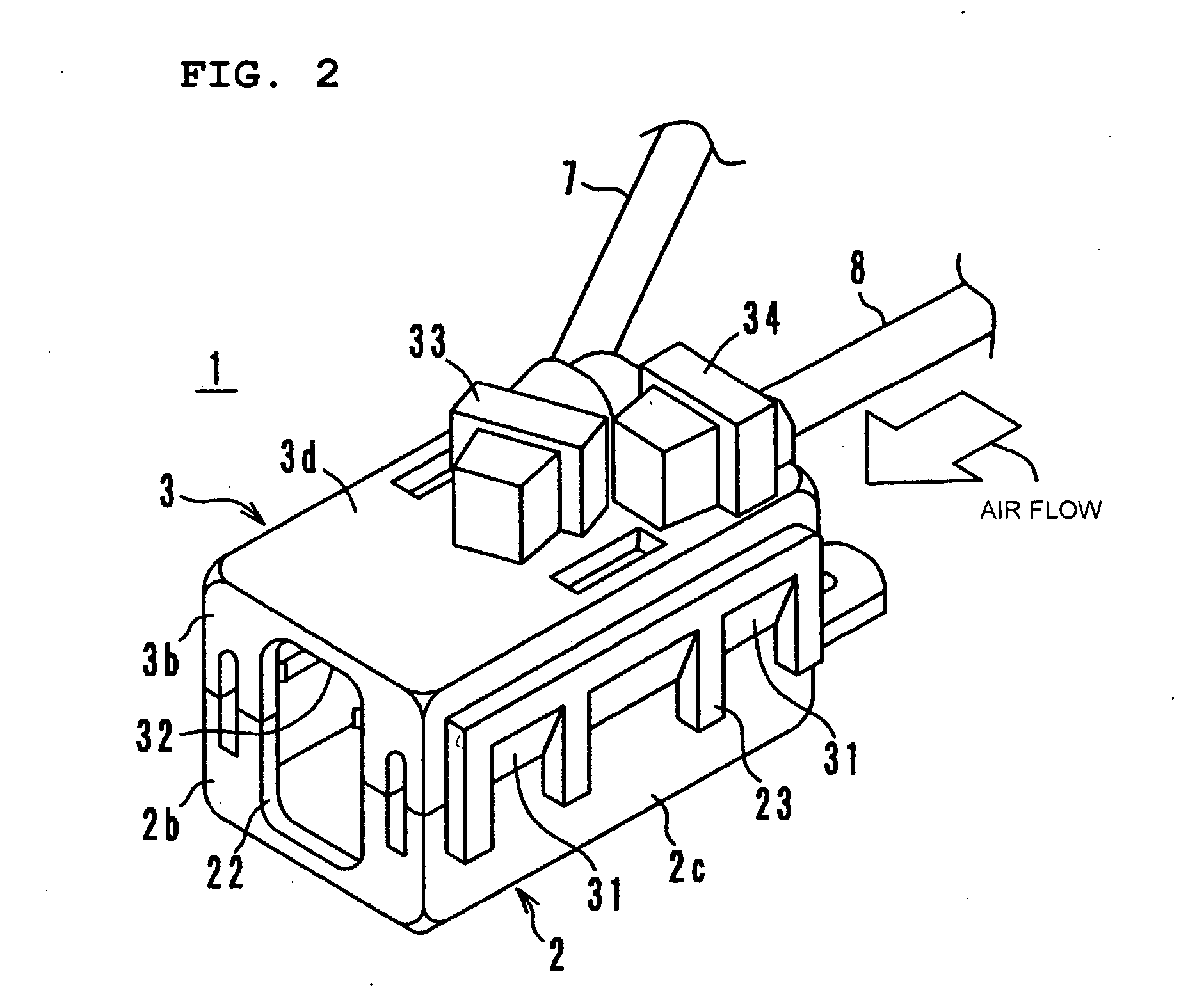

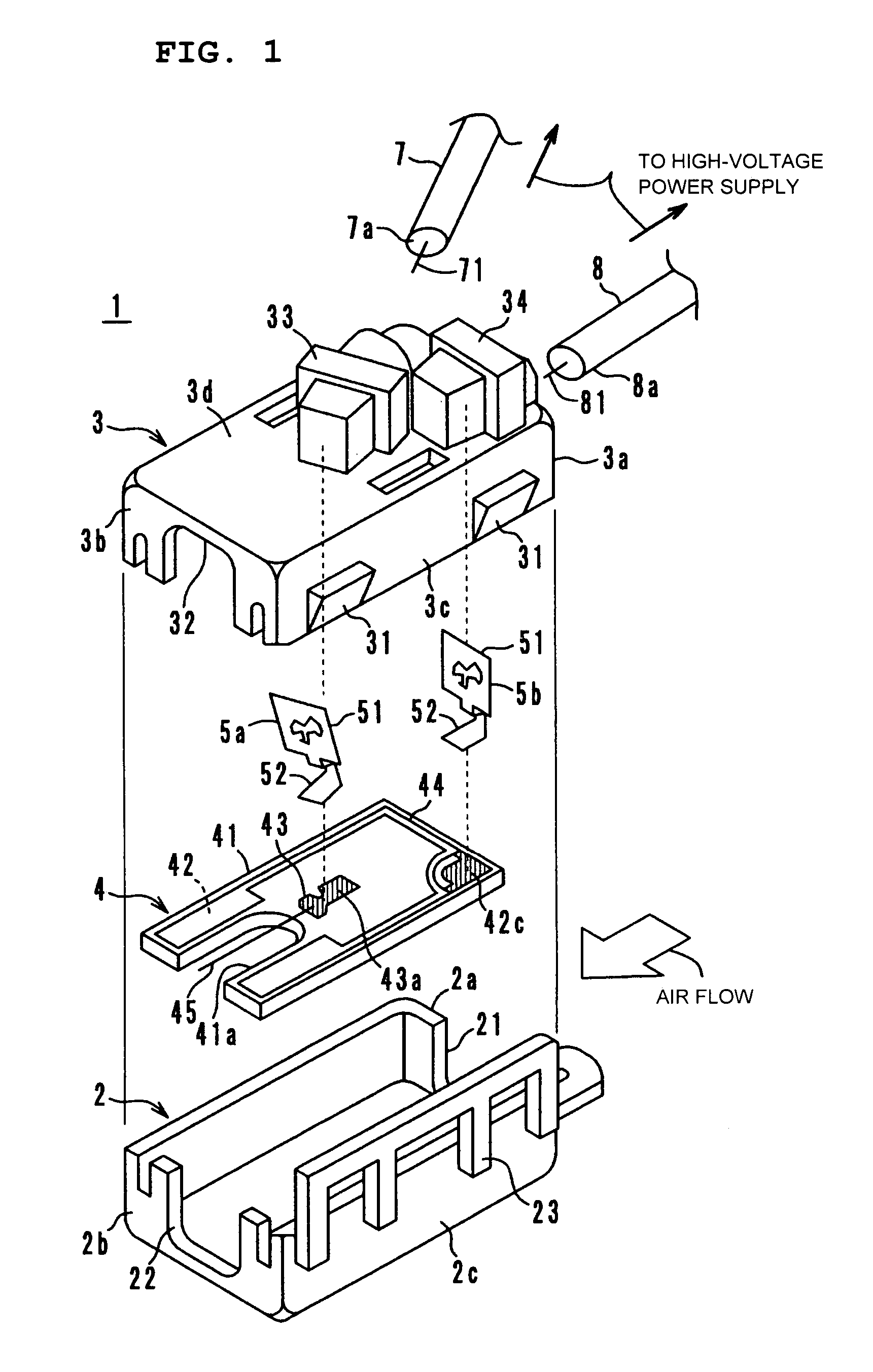

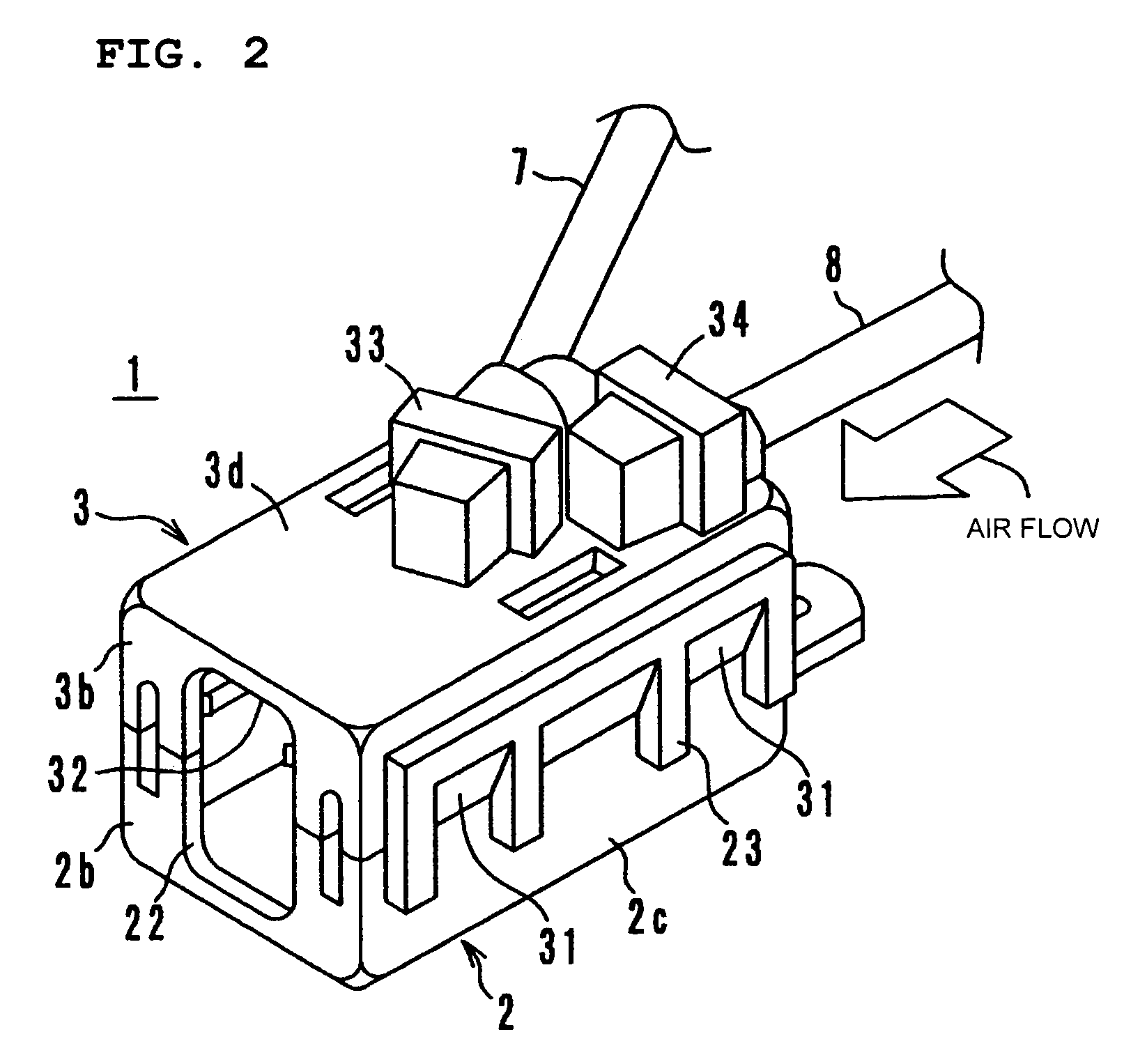

Ion-generating component, ion-generating unit, and ion-generating apparatus

ActiveUS20050036266A1Improve concentrationEasy to produceMechanical apparatusLighting and heating apparatusPiano wireTitanium

An ion-generating component has, on an insulating substrate, a ground electrode, a high-voltage electrode, an insulating film provided on the surface of the ground electrode, and a wire electrode. A cutout is formed by cutting out one side of the insulating substrate. The root of the wire electrode is soldered to the high-voltage electrode, and the leading end thereof is positioned near the cutout. The wire electrode is made of an ultrafine wire having a diameter of about 100 μm or less, for example, a piano wire, a tungsten wire, a stainless wire, or a titanium wire.

Owner:MURATA MFG CO LTD

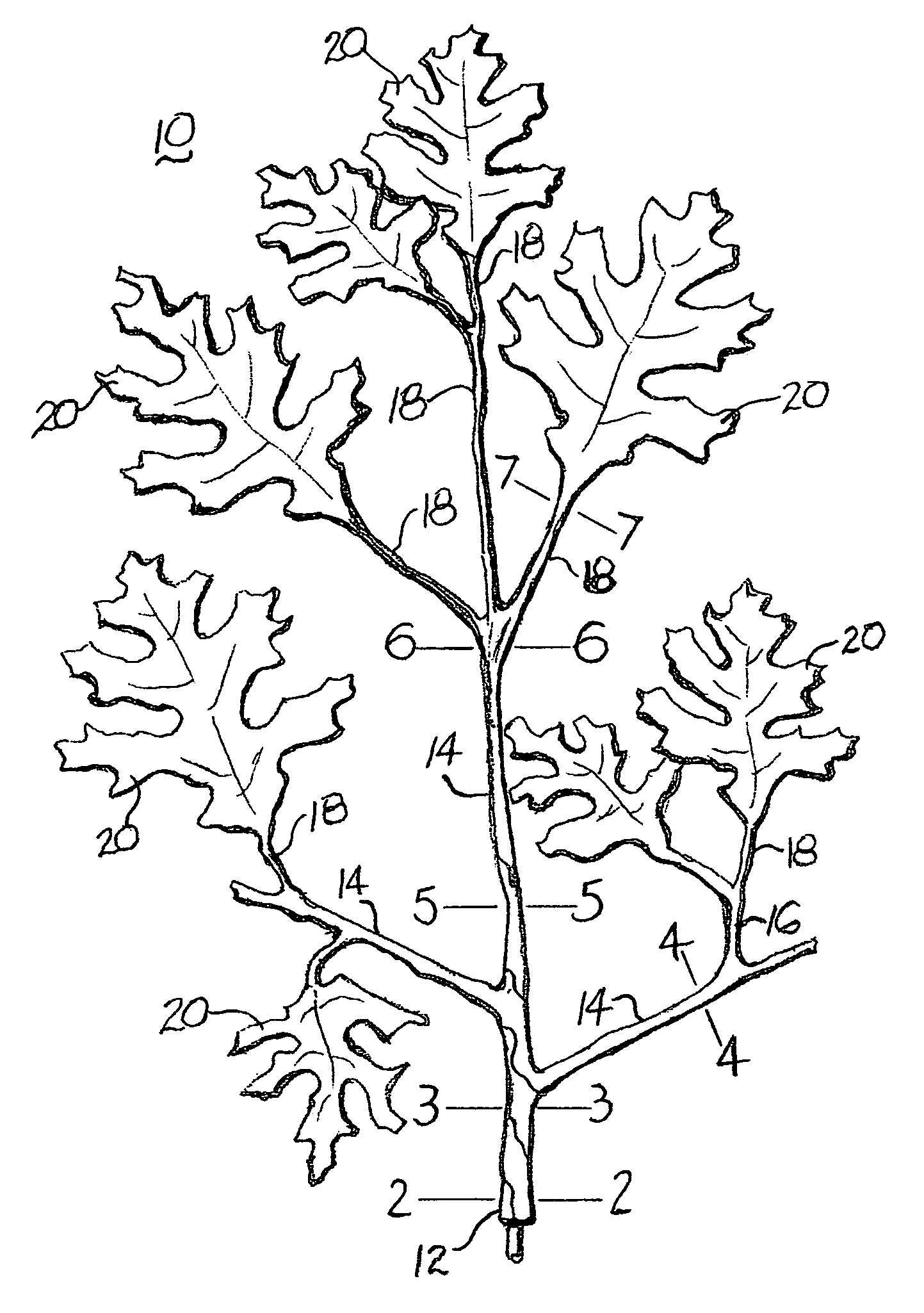

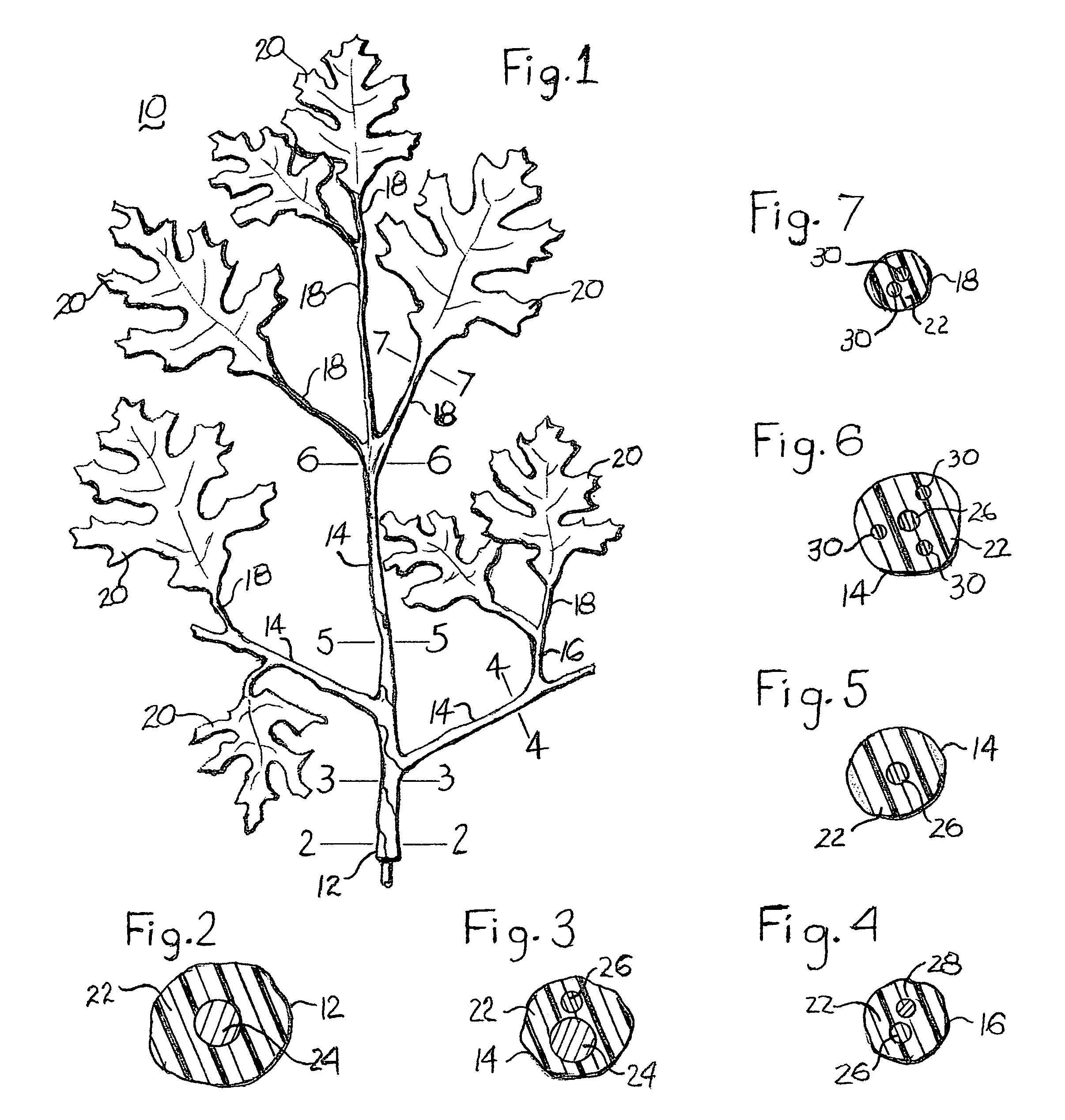

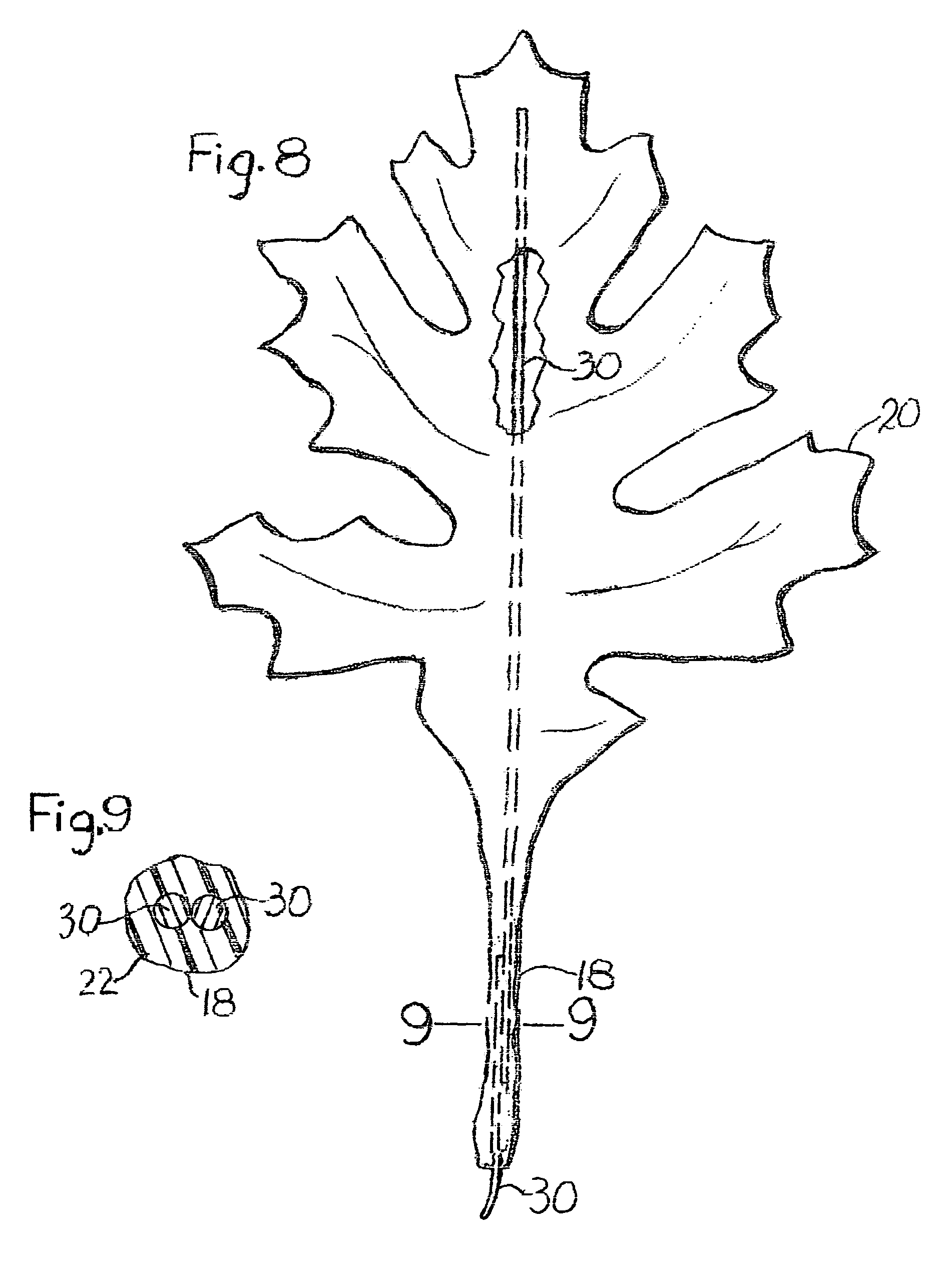

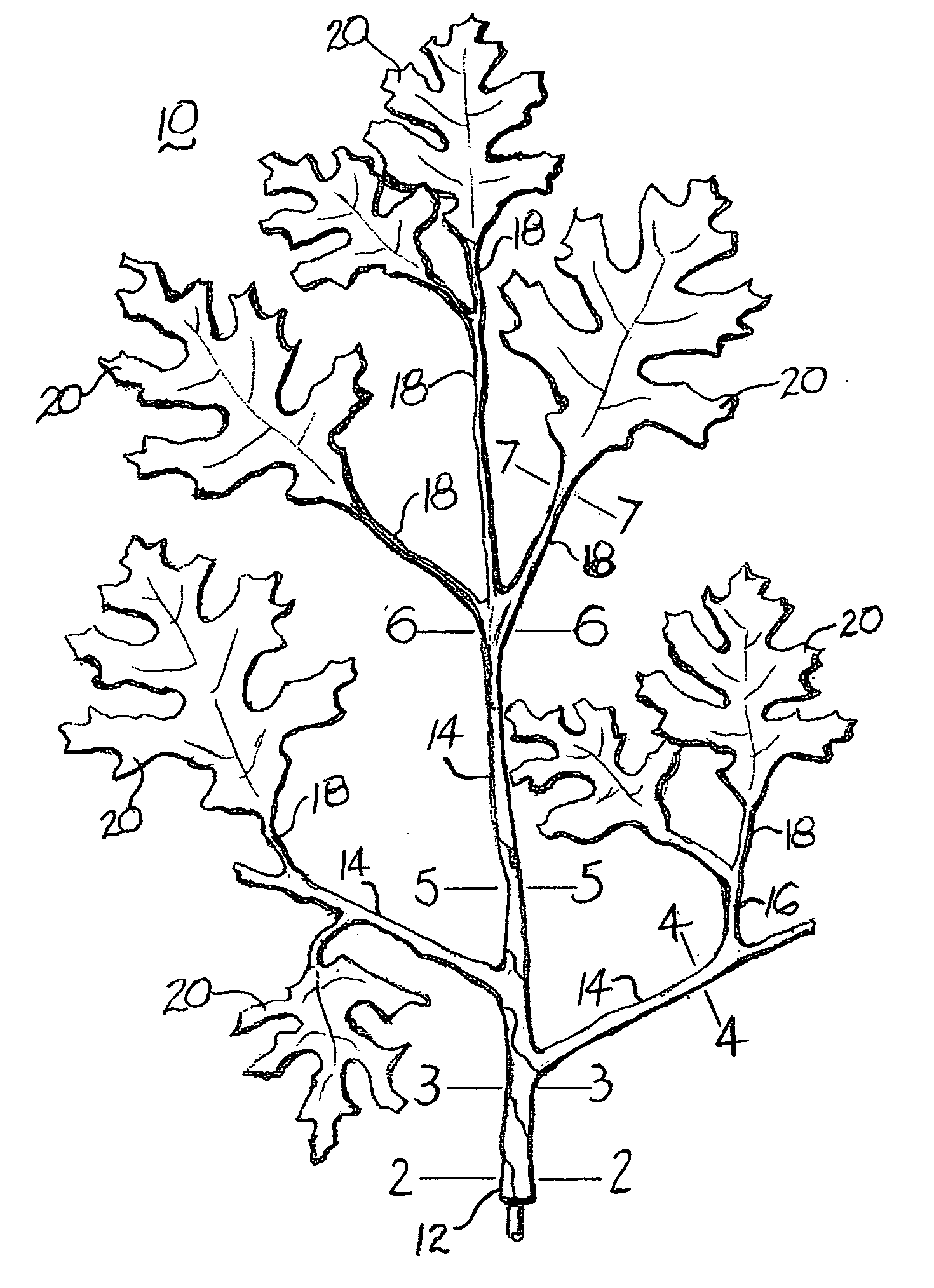

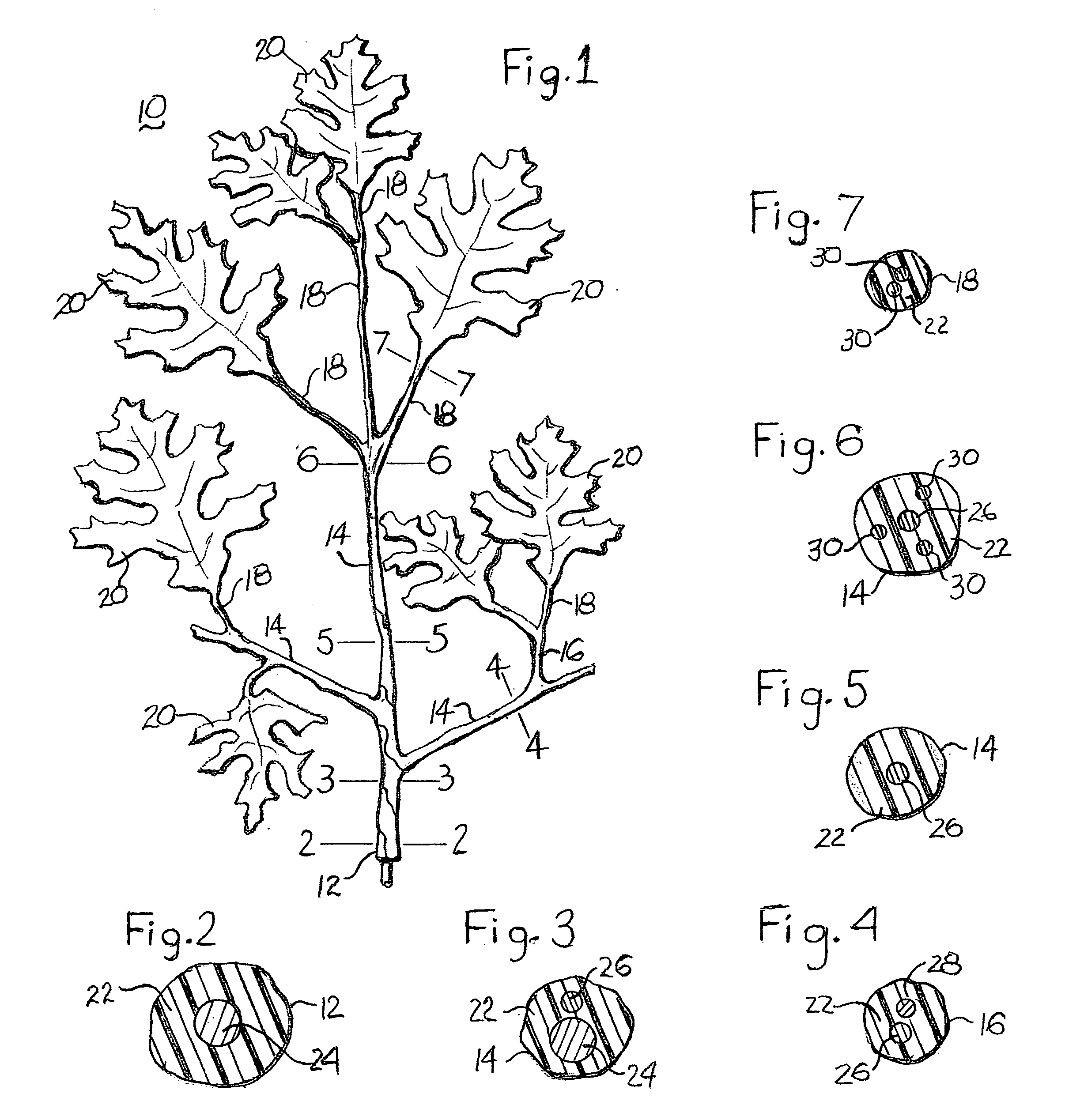

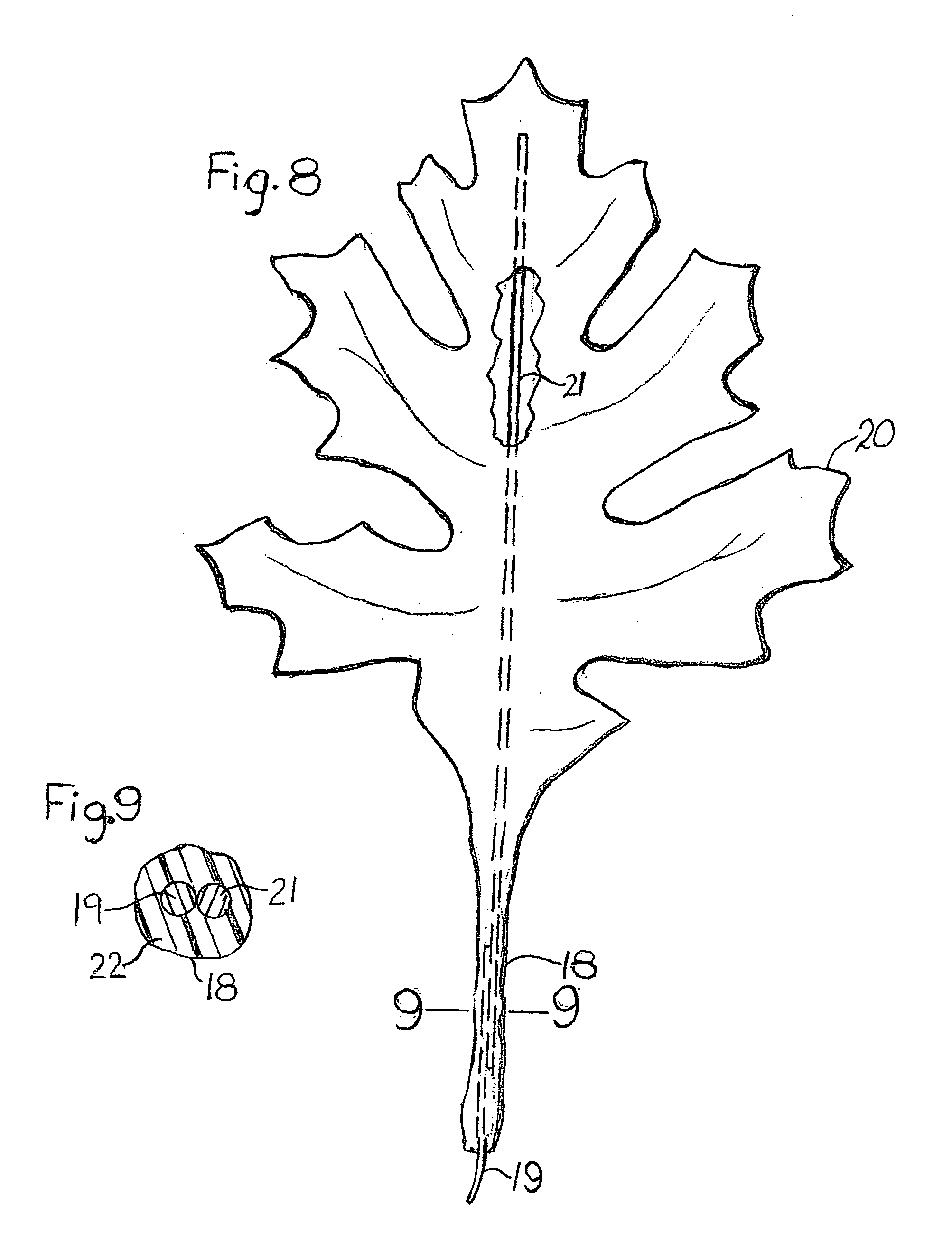

Artificial foliage

ActiveUS7371442B2Sufficient degree of elasticitySolve the lack of ductilityDead plant preservationArtificial flowers and garlandsPiano wireEngineering

An artificial foliage structure with wire cores embedded in its leafy parts causing these parts to “spring back” upon removal of compressive loading acting thereupon. These wire cores may be made of hard, springy steel such as piano wire or small diameter spring wire. Thicker, woody limbs and branches have embedded therein heavier wire cores that are sufficiently soft to be given a set solely by manually applied bending force.

Owner:AMERICAN PRIDE OUTDOORS LLC

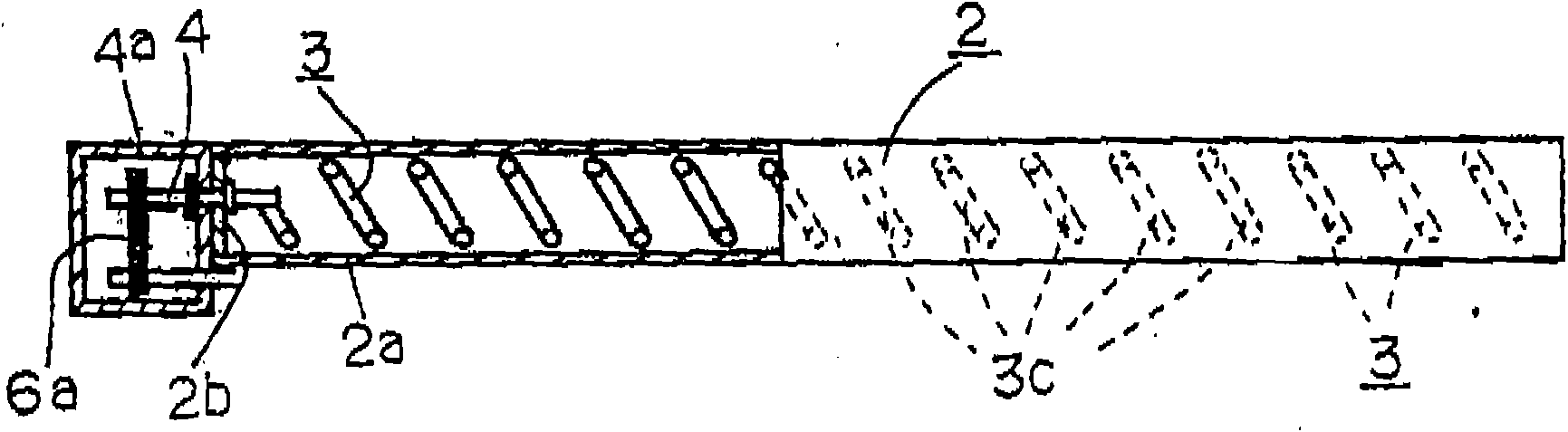

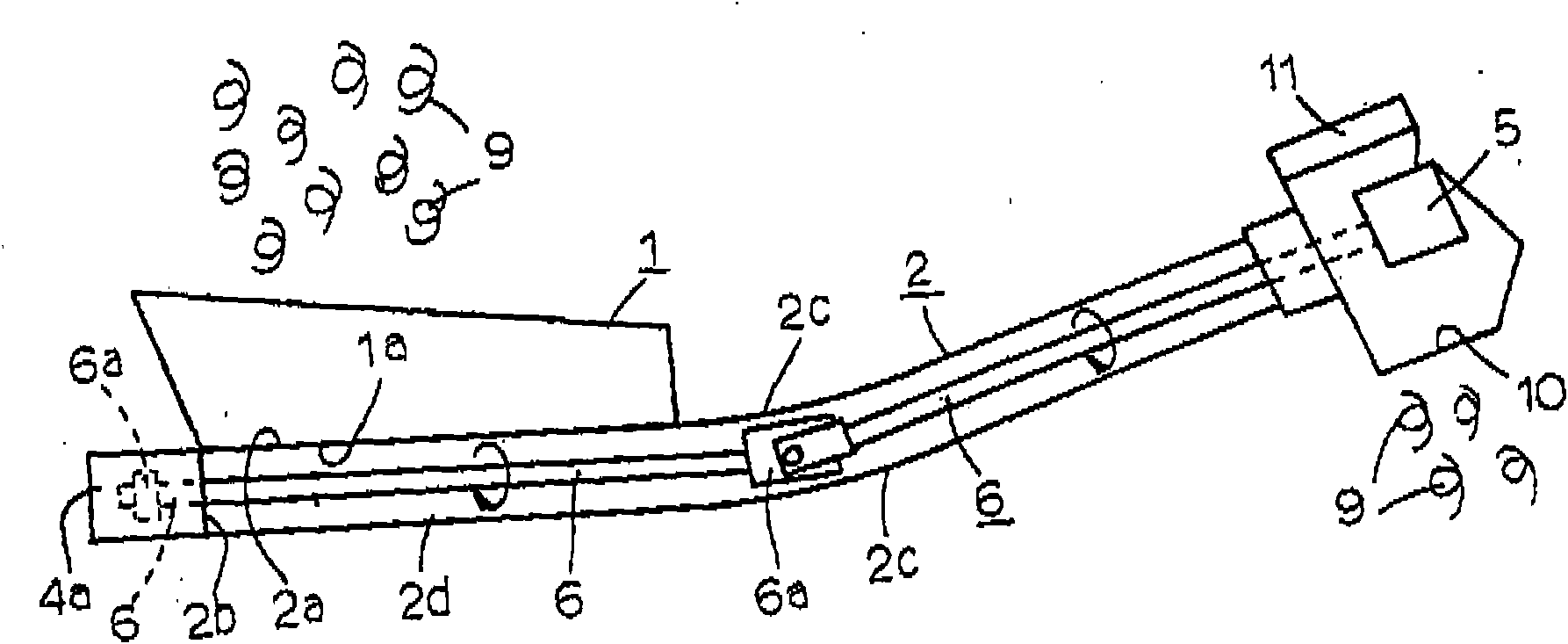

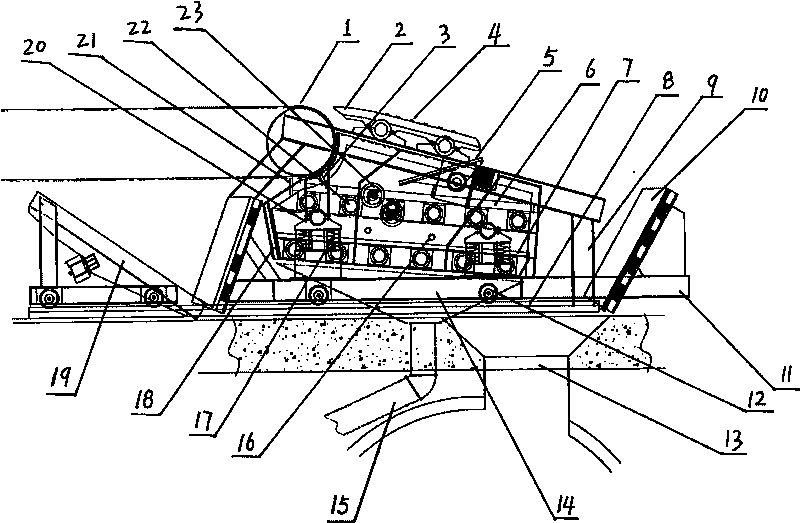

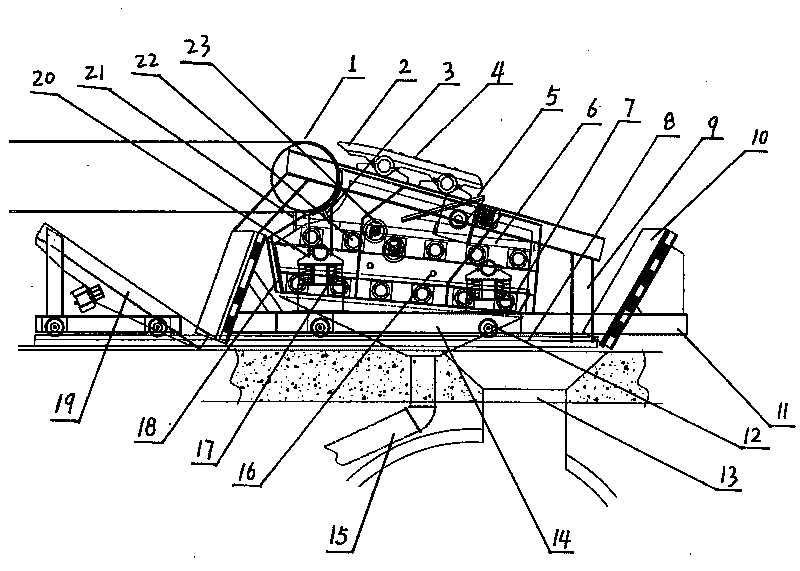

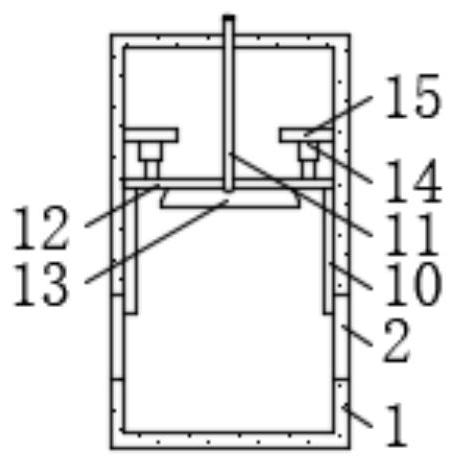

A overflow type material rolling and chipping conveyor that separates cutting scrap with cutting lubricant

ActiveCN101554703AImprove performanceCongestion without jamCharge manipulationPackagingUniversal jointPiano wire

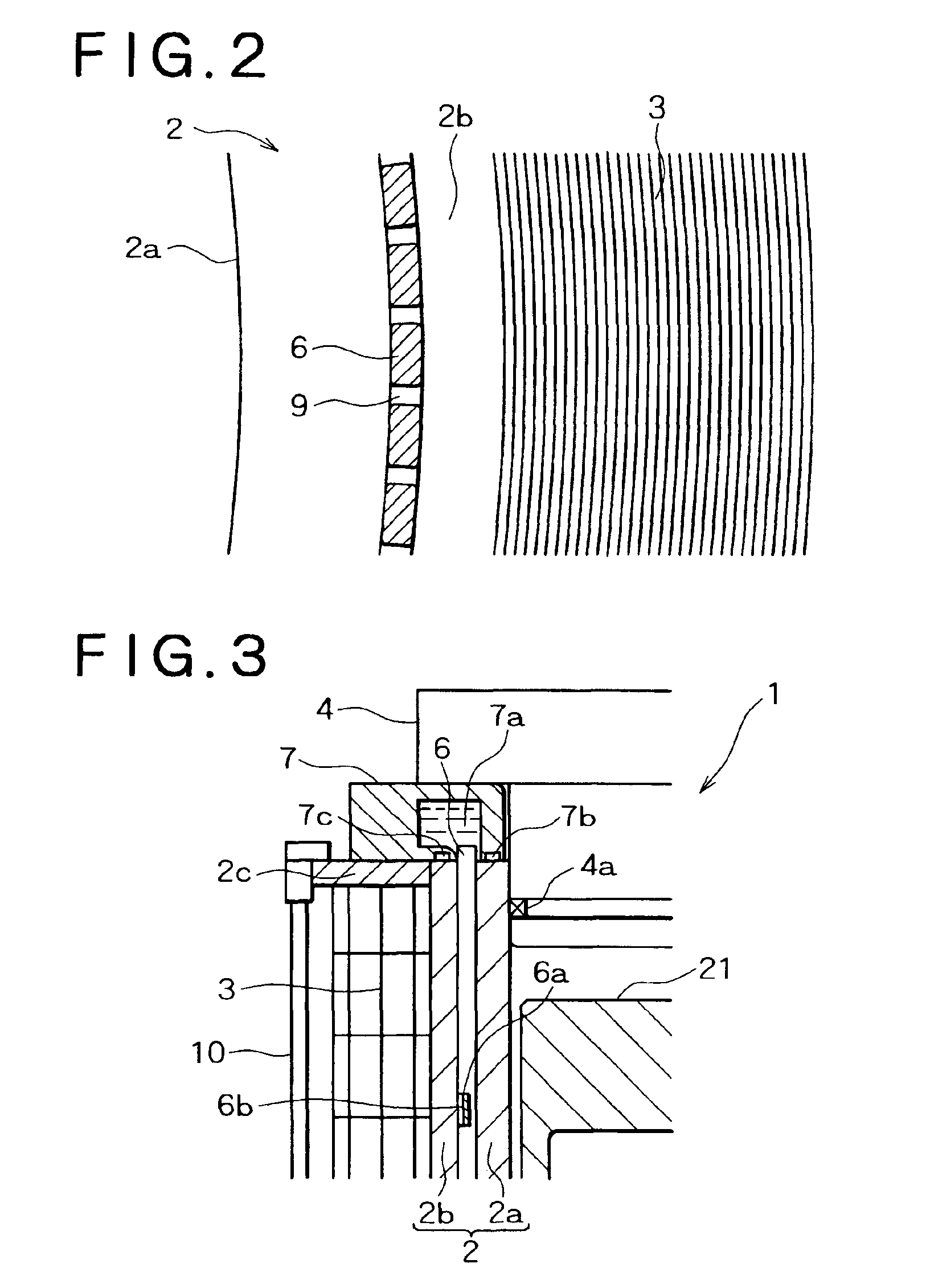

The present invention provides a overflow type material rolling and chipping conveyor that separates cutting scrap with cutting lubricant, which relates to material of material used in adverse environment and a bending structure; a tube (2) is provided with a inlet (2a) of the cutting scrap and the cutting lubricant that stick to opening of a scoop (1); area around the inlet of the cutting scrap and the cutting lubricant is in horizontal status; front-end of the tube bends upwards from 10 DEG to 30 DEG and bending radius R is from 500 mm to 1000 mm. The material covers the tube all over and is collected in the tube, material quality is piano wire of SWP-B of JIS standard. A universal joint combines with one end of the material near to inlet of the cutting scrap and the cutting lubricant, and makes the material rotate. The pipe wall holds the universal joint, and closes end of the tube close to the universal joint. An electric motor makes the universal joint rotates. An outlet of the cutting lubricant is set on above scoop, bottom of the cutting lubricant outlet lies in location of such horizontal plane: cutting lubricant that put into tube through the scoop up to oil mass of bending section of material collected in the tube.

Owner:武藤 诚典

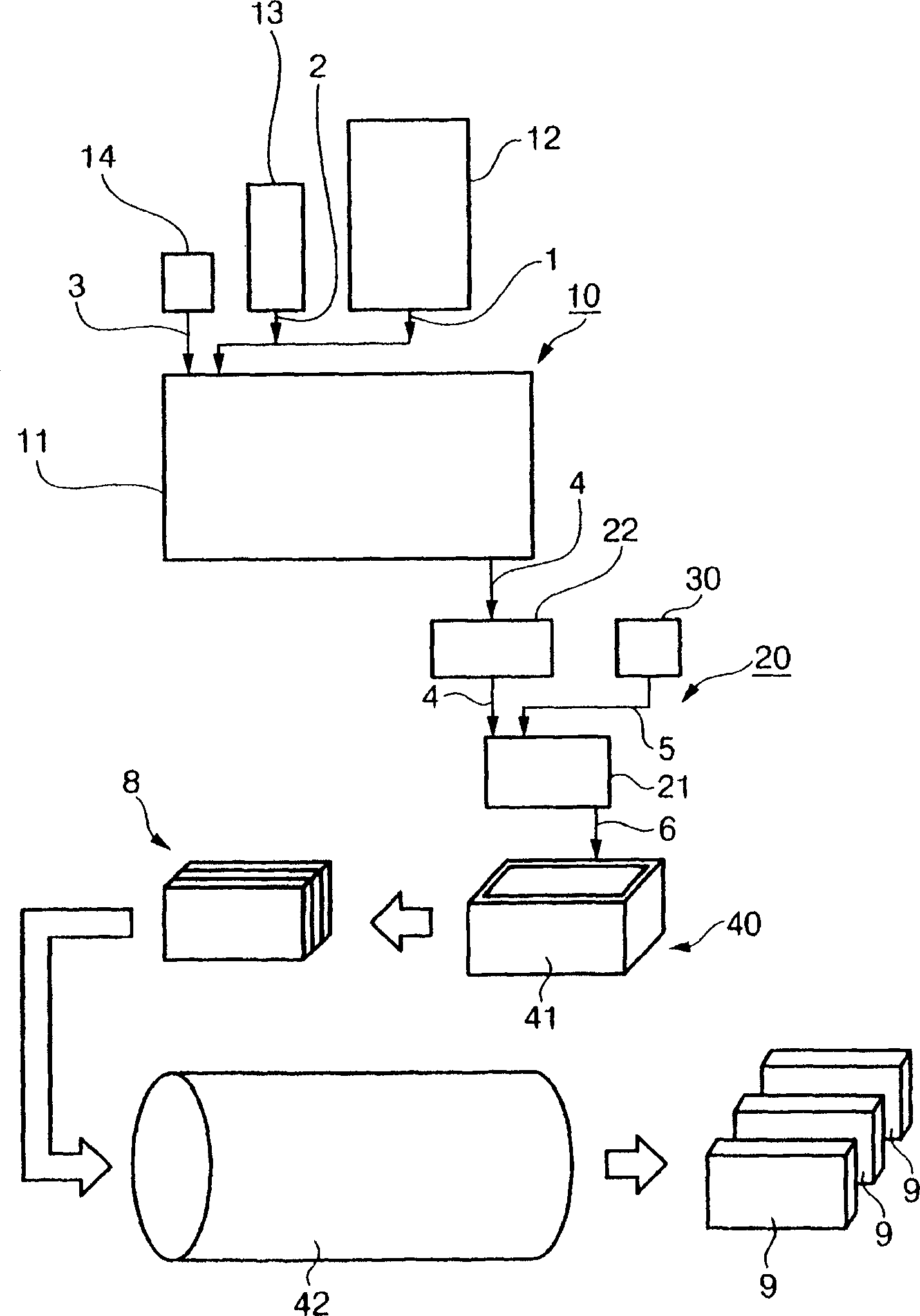

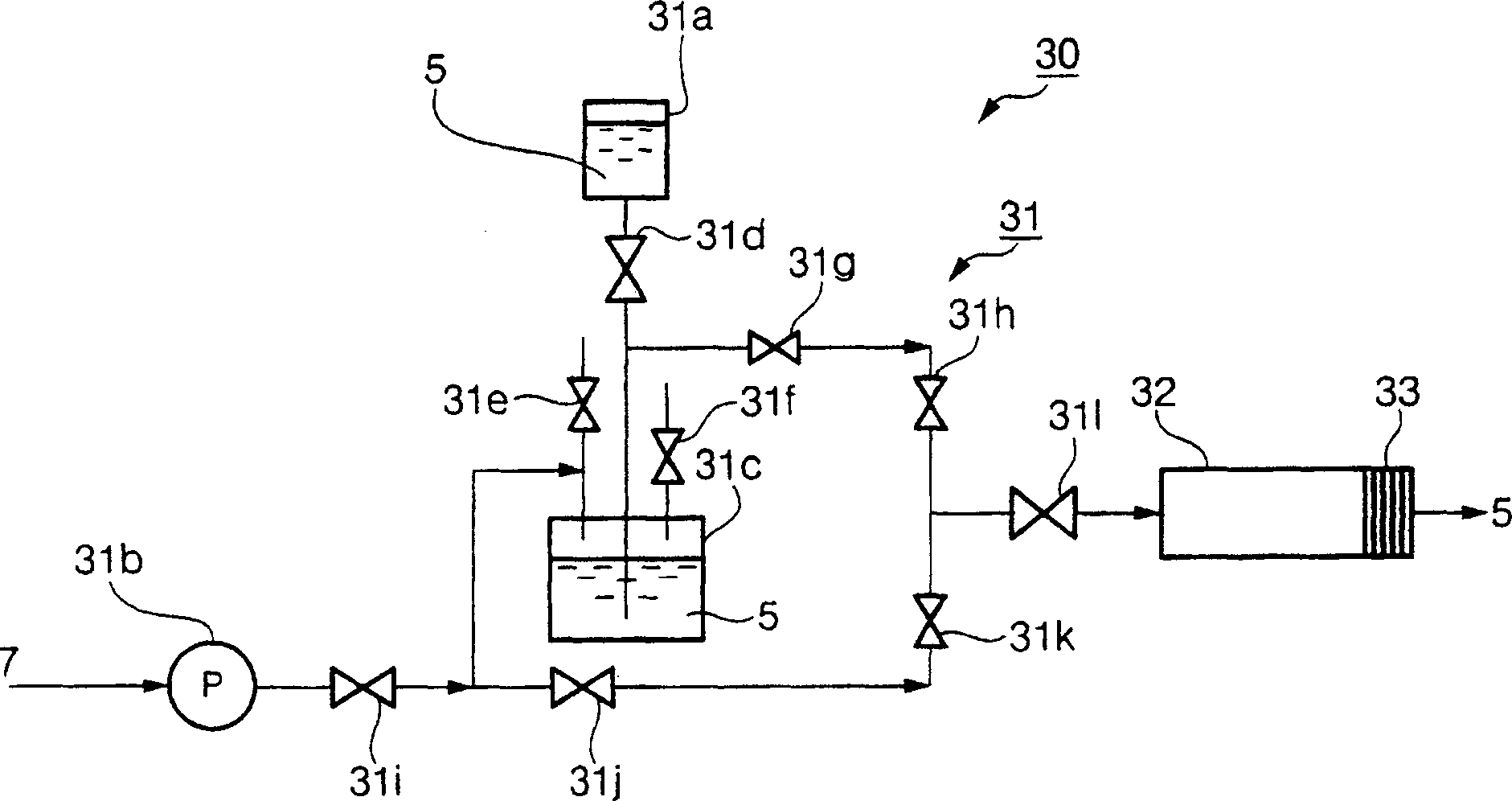

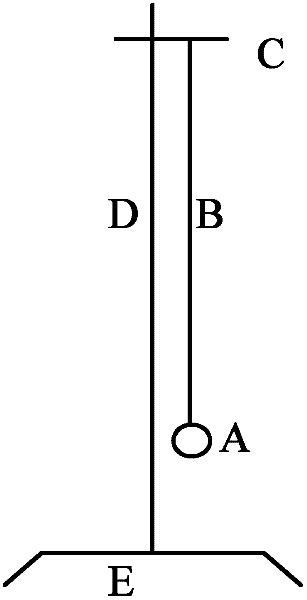

Porous body, its producing process & foaming apparatus used for the same production

InactiveCN1421419AUniform sizeImprove bending strengthSolid waste managementCeramicwareFoaming agentPiano wire

The invention provides a process of producing a porous body which exhibits sufficient strength although it is obtained by using fly ash as a main component. The porous bodies 9 are obtained by feeding fly ash 1, cement 2 and water 3 from respective feeders 12-14 of a main raw material slurry producing unit 10 into a mixer 11, then mixing the raw materials to prepare a main raw material slurry 4 having a viscosity of 200-1,200 cp, feeding the main raw material slurry 4 from a feeder 22 of a foamed slurry production unit 20 to a mixer 21, at the same time, feeding a protein-based foaming agent from a foaming unit 30 into the mixer 21, after stirring for producing a foamed slurry 6, pouring the foamed slurry 6 into a molding flask 41 of a porous body forming unit 40 so as to cast, subjecting to preliminary steam curing, removing a cured material from the molding flask 41, cutting the formed body 8 removed from the mold into pieces each having a predetermined size using a piano wire, and curing the pieces in a curing unit 42.

Owner:MITSUBISHI HEAVY IND LTD +1

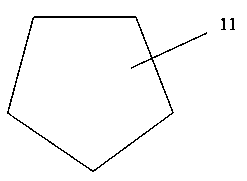

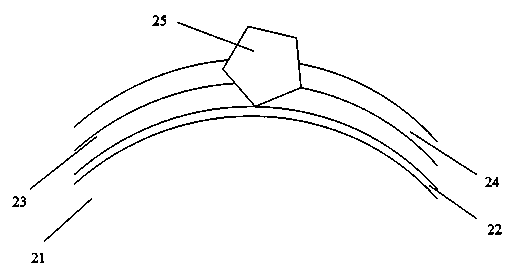

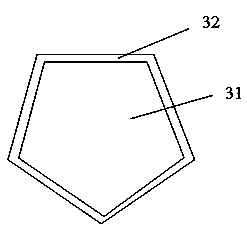

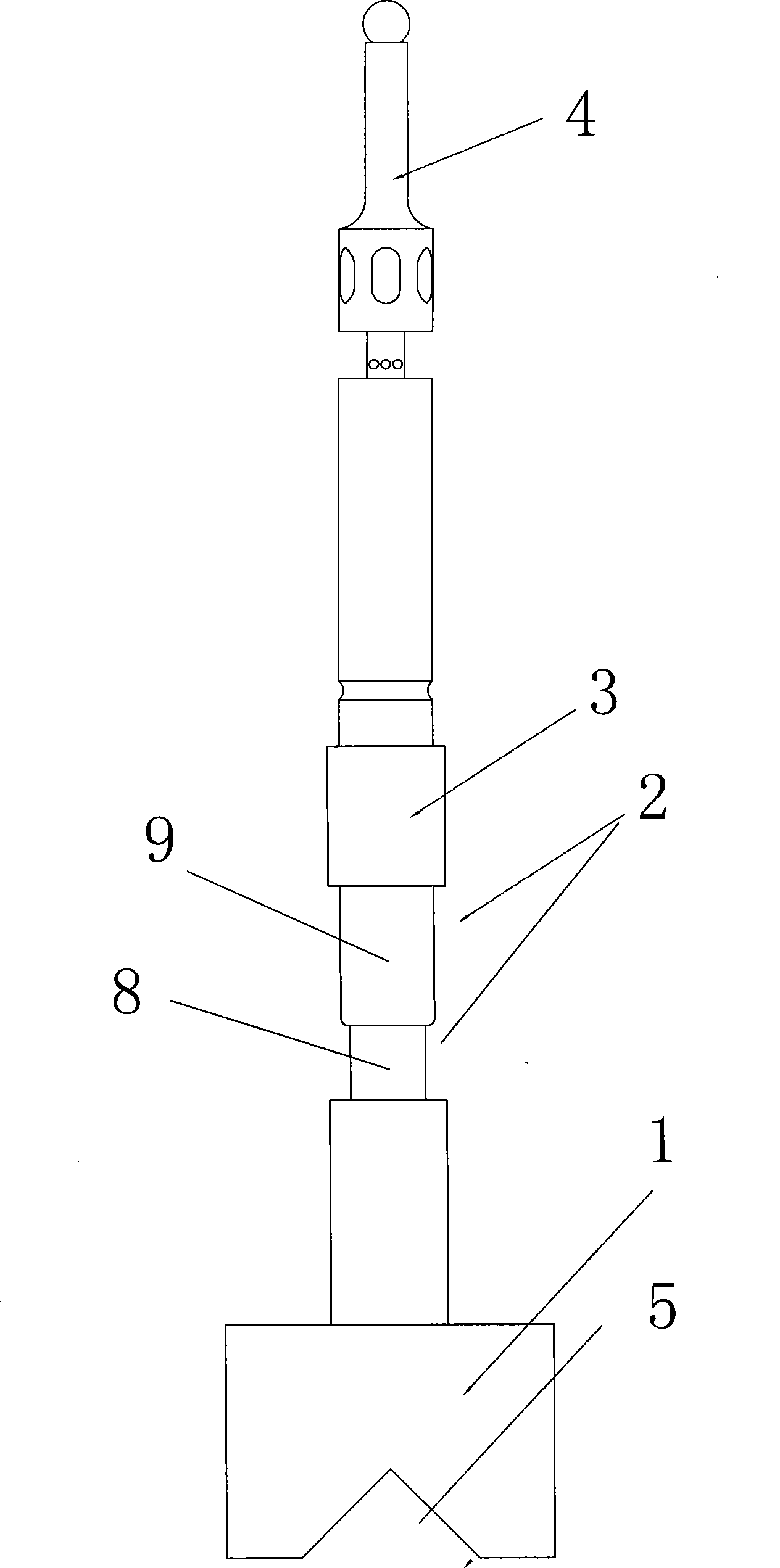

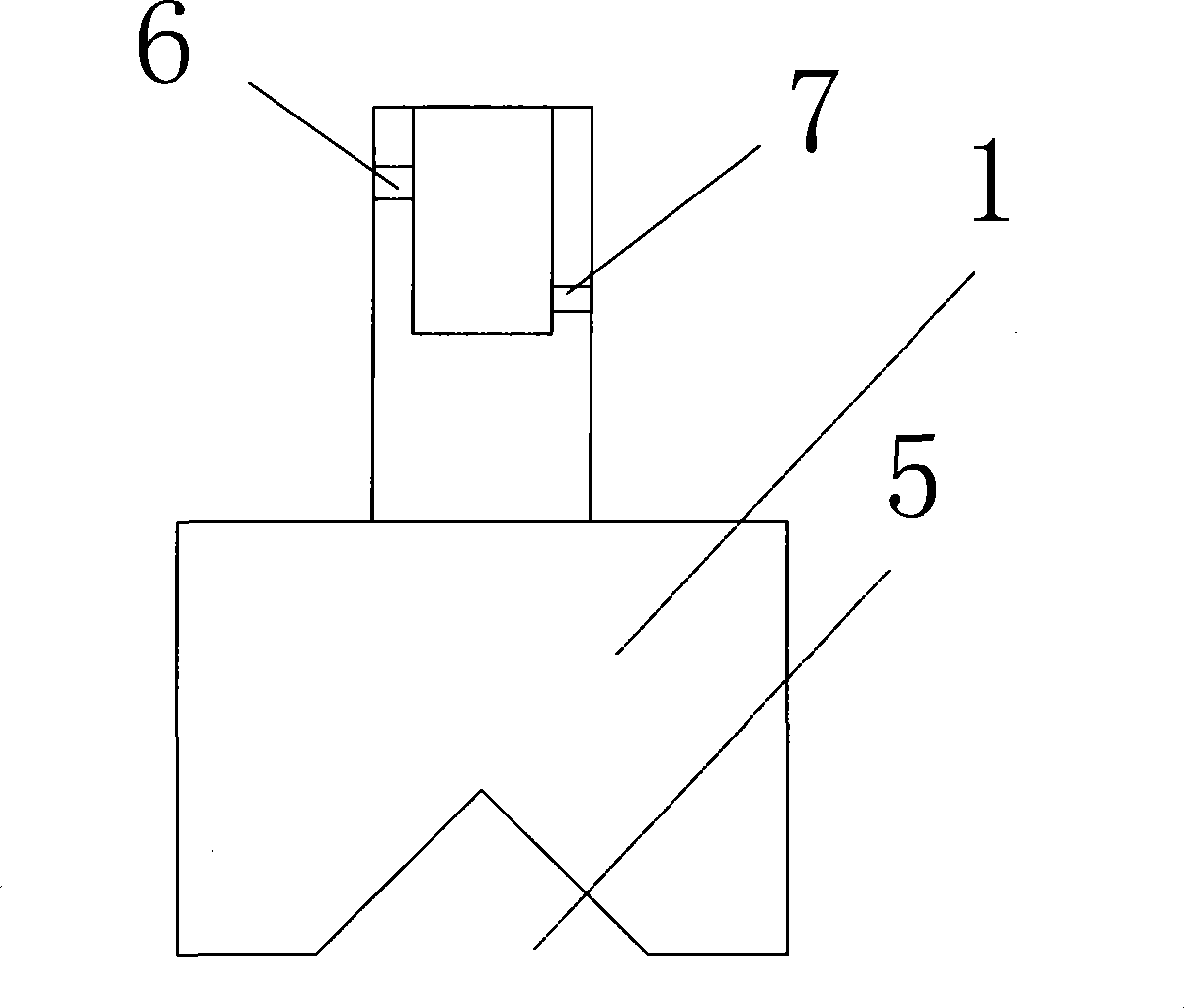

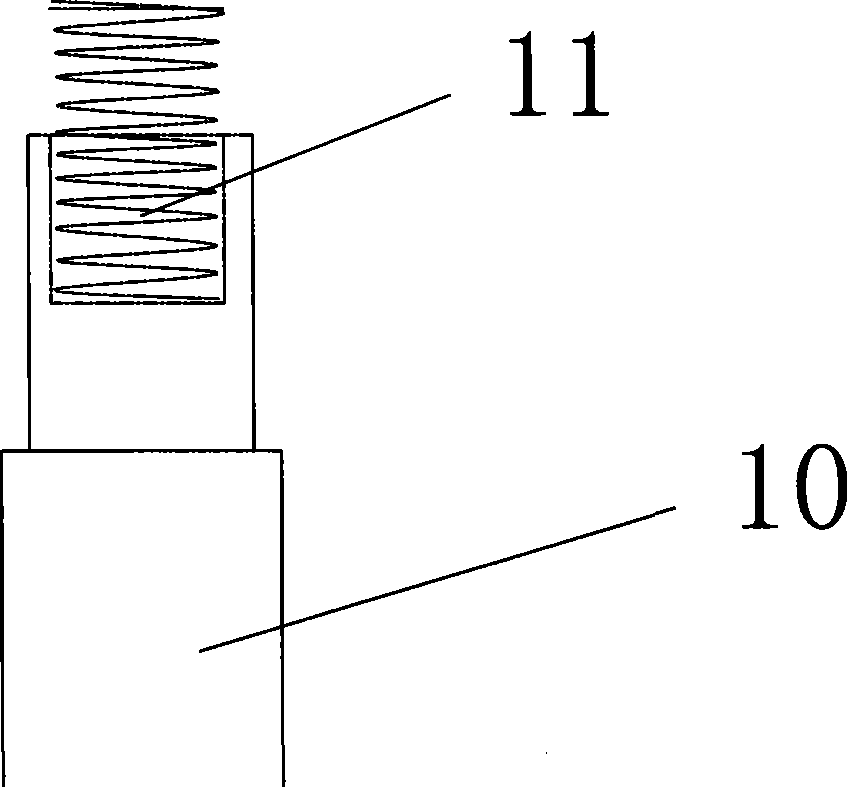

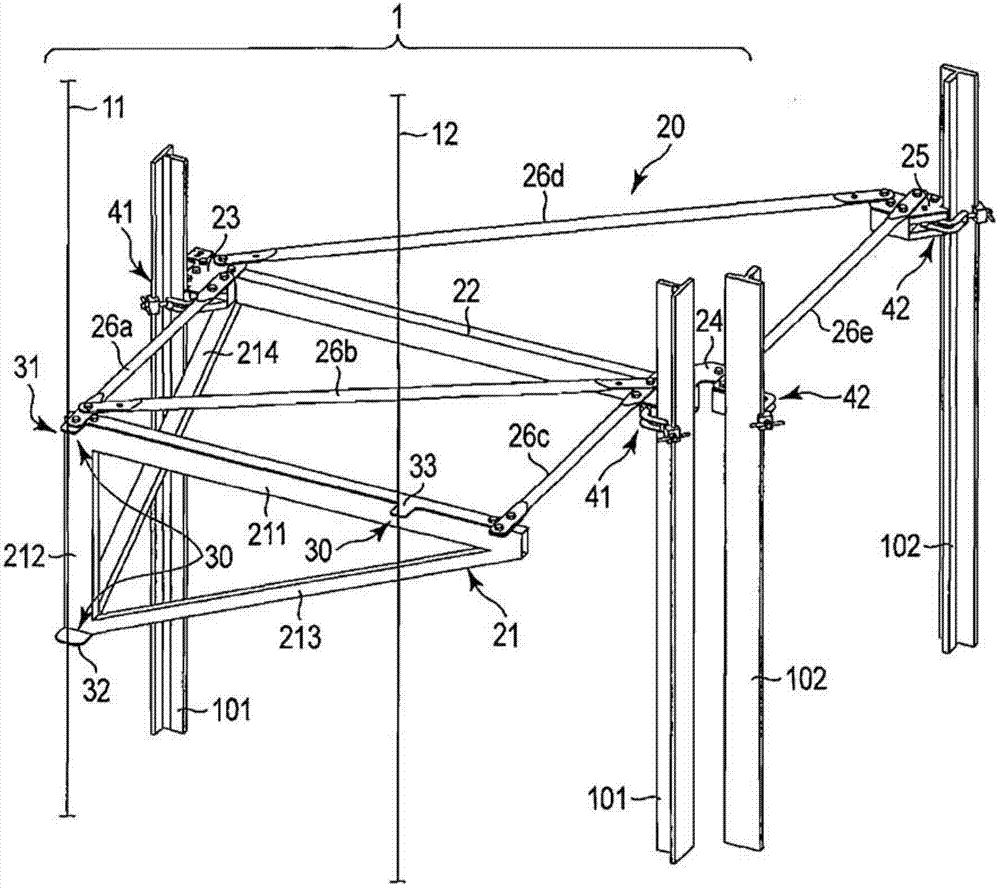

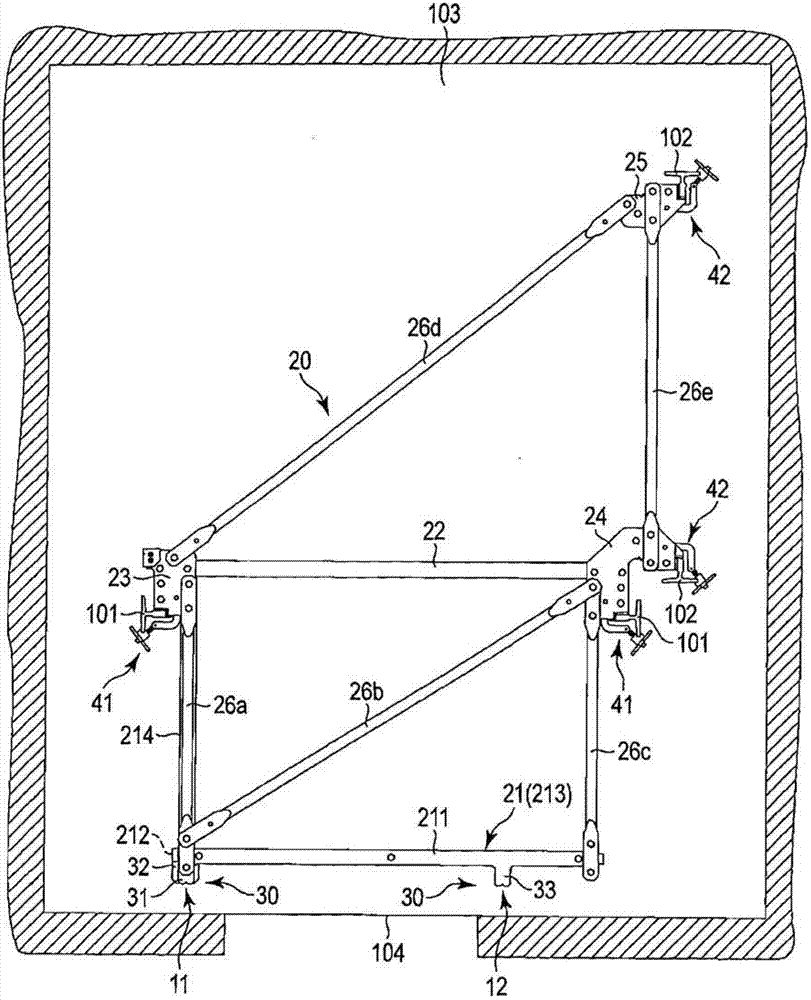

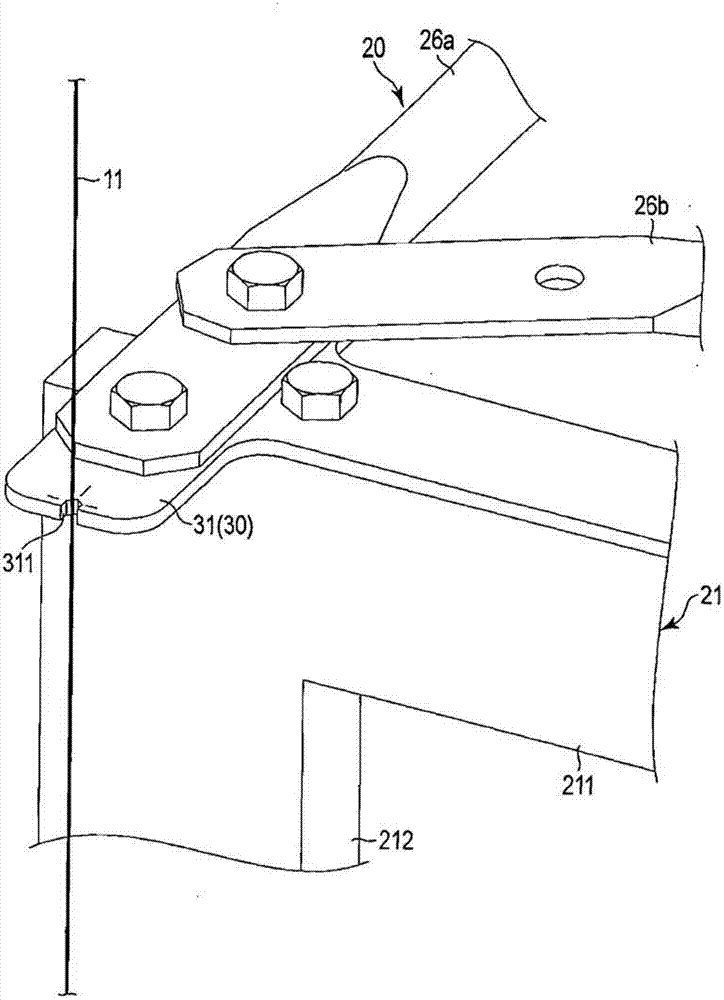

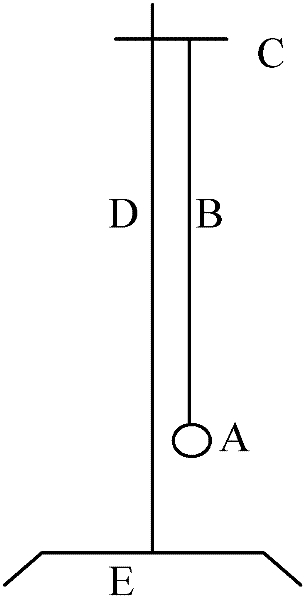

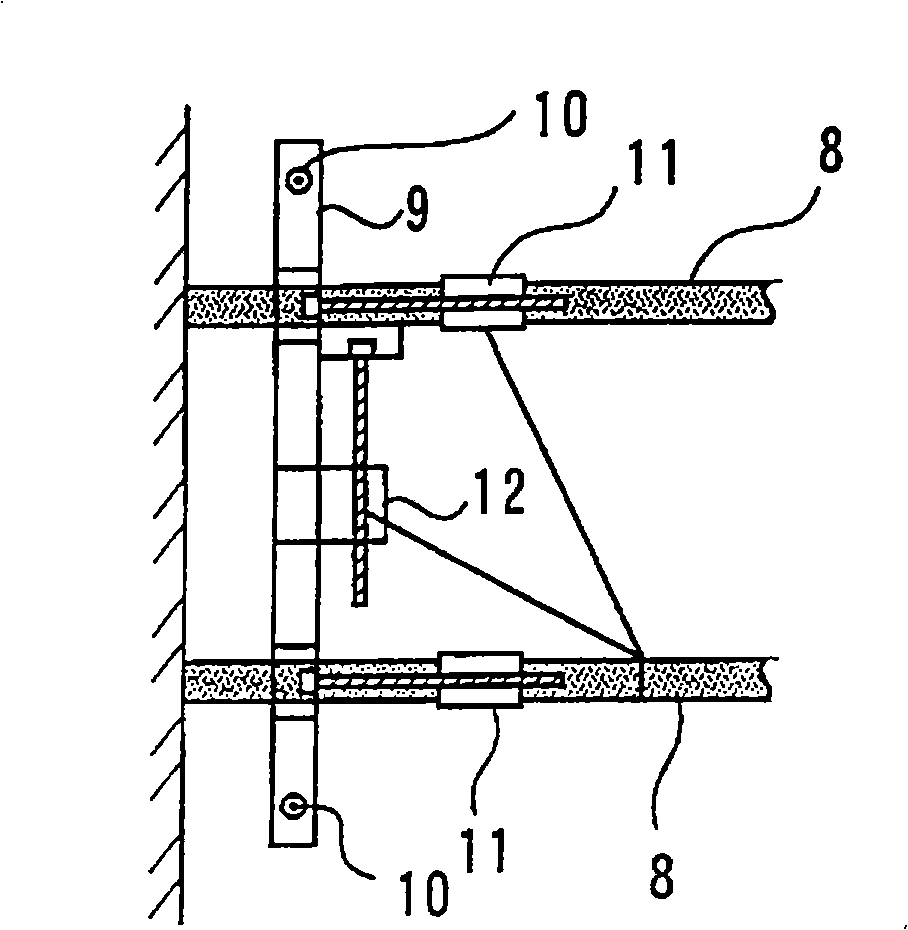

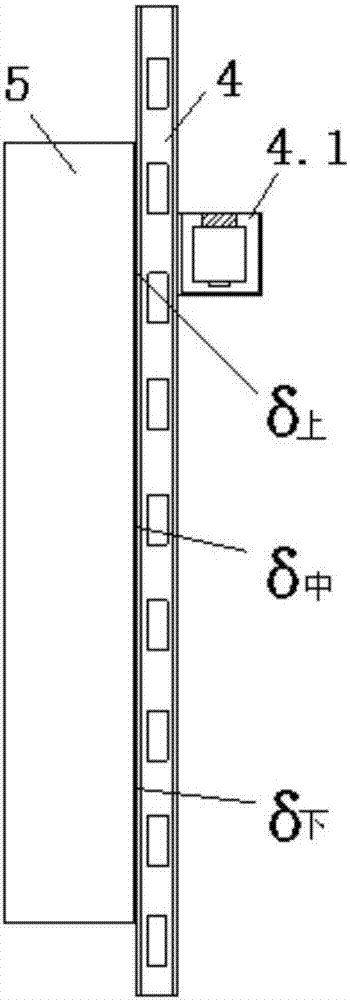

Center fixture of elevator guide rail

The apparatus (1) has a preset piano wire (11) and a specific piano wire (12) which are installed in the both sides of the hall door opening portion of the hoist way of the lift in parallel along a perpendicular direction. A preset clamp (41) holds a pair of guide rail for buckets which guides a cage. A specific clamp (42) holds a pair of guide rail for weights which guides a counterweight. A rail holding jig (20) is positioned by using gauge portion (30) that combines a relative position with respect to the three places of preset piano wire and specific piano wire.

Owner:TOSHIBA ELEVATOR KK

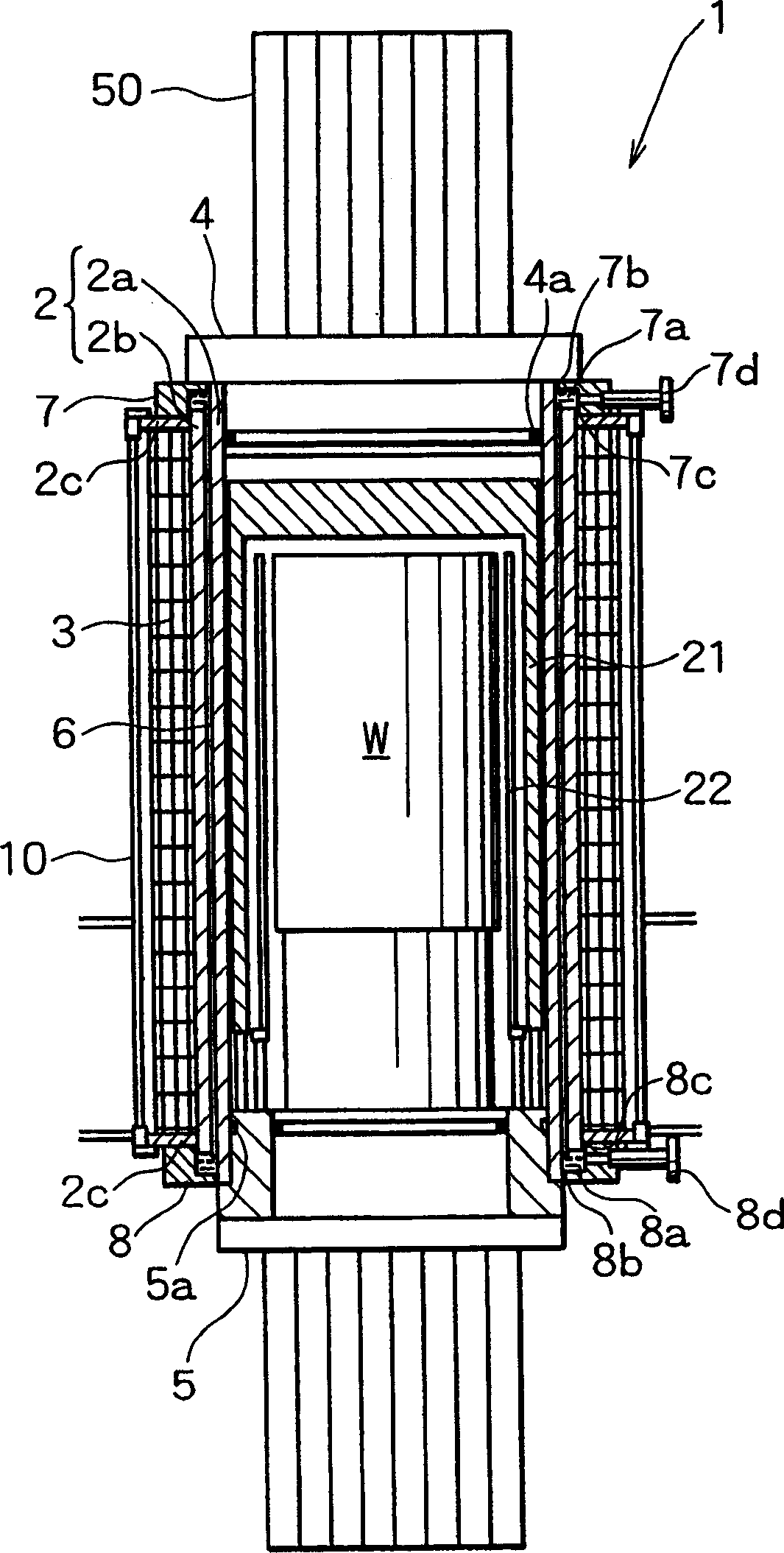

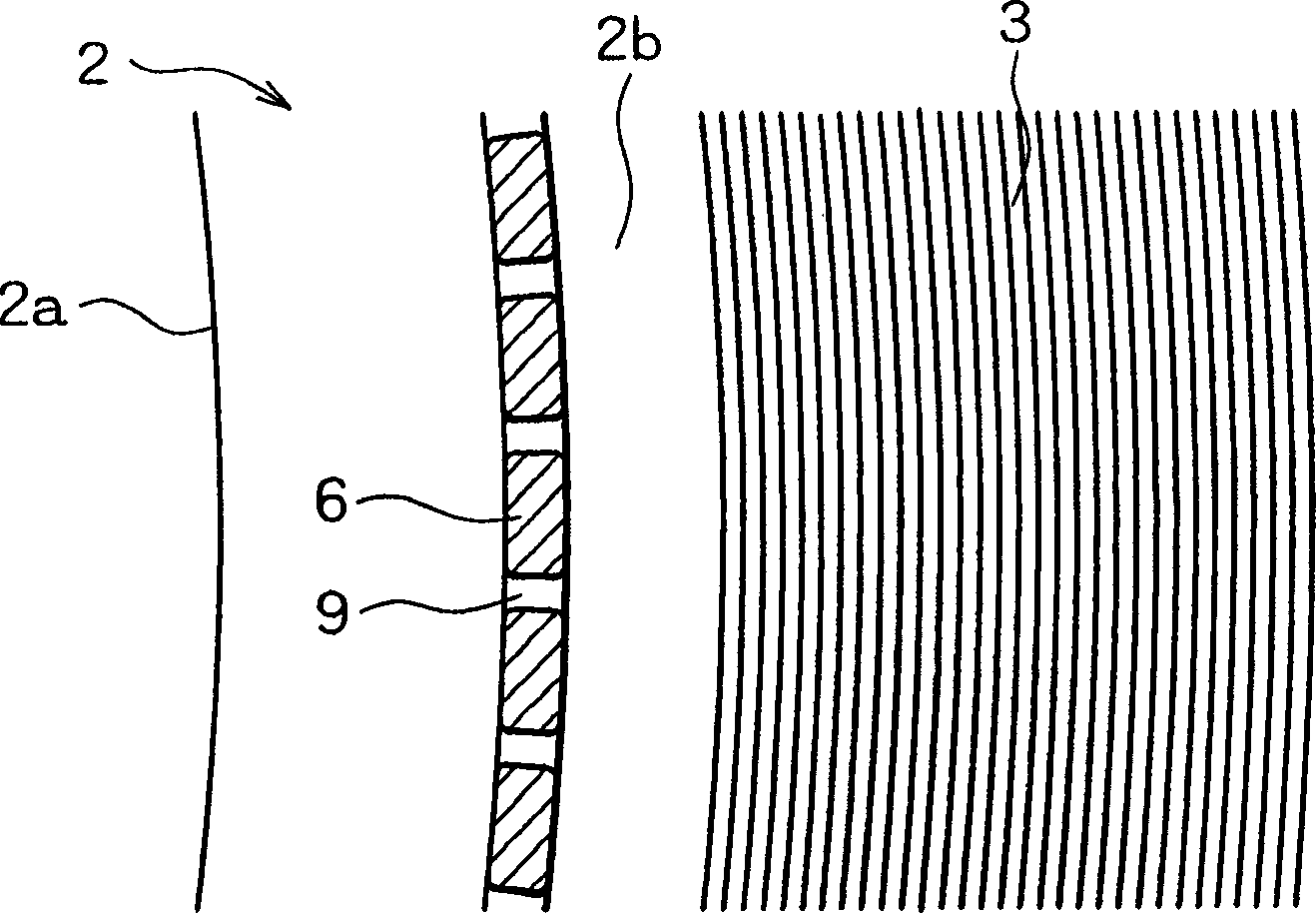

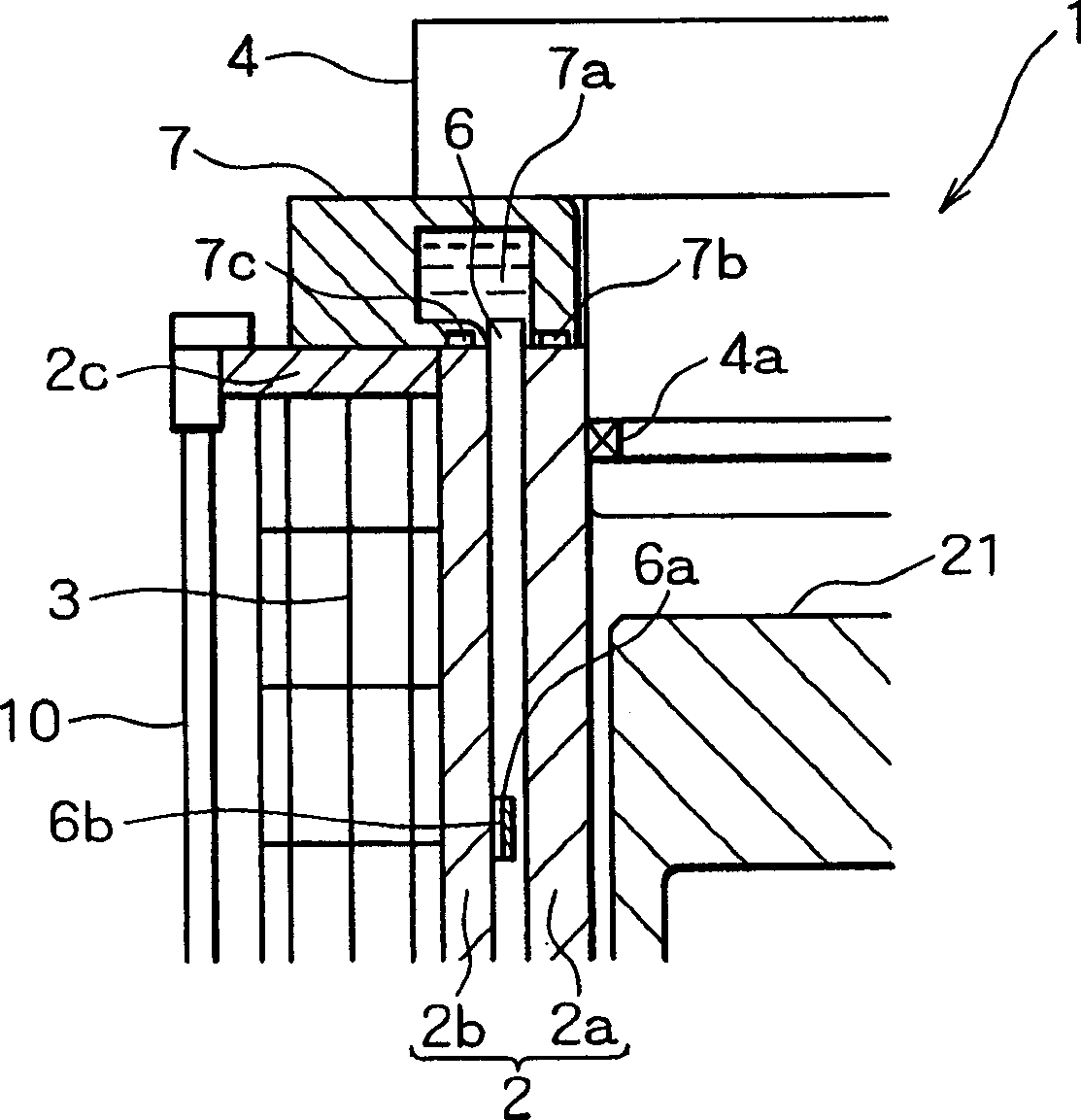

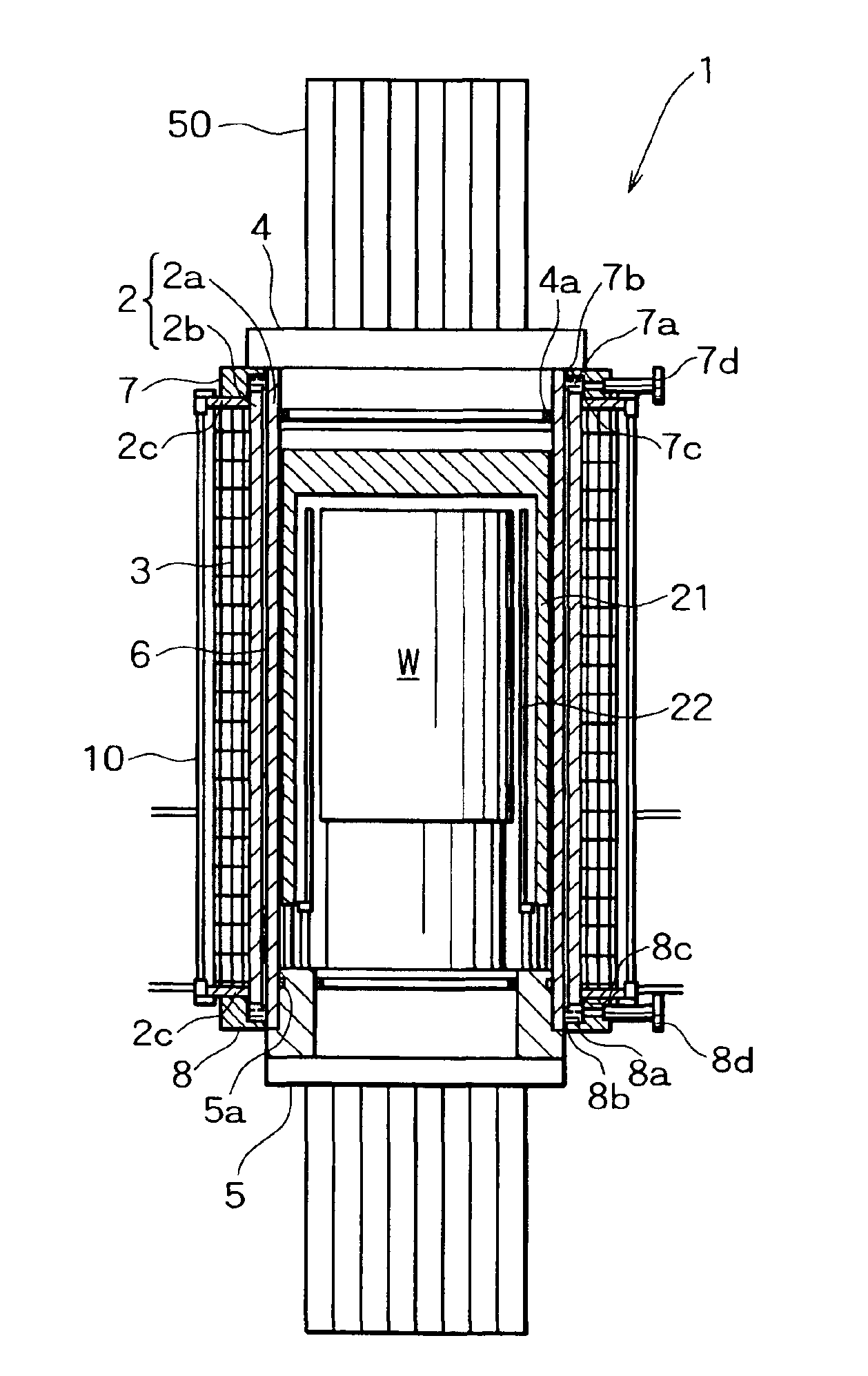

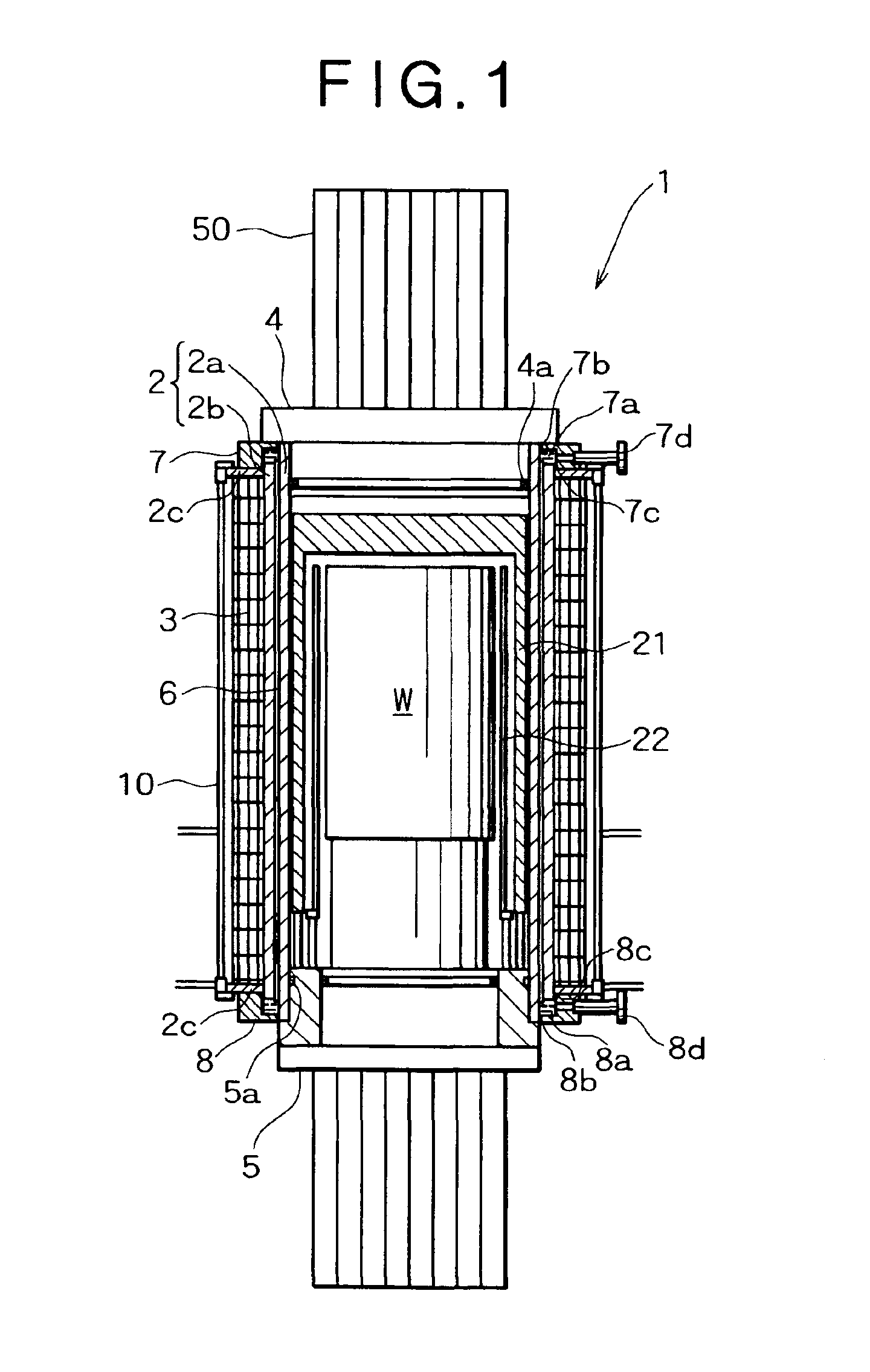

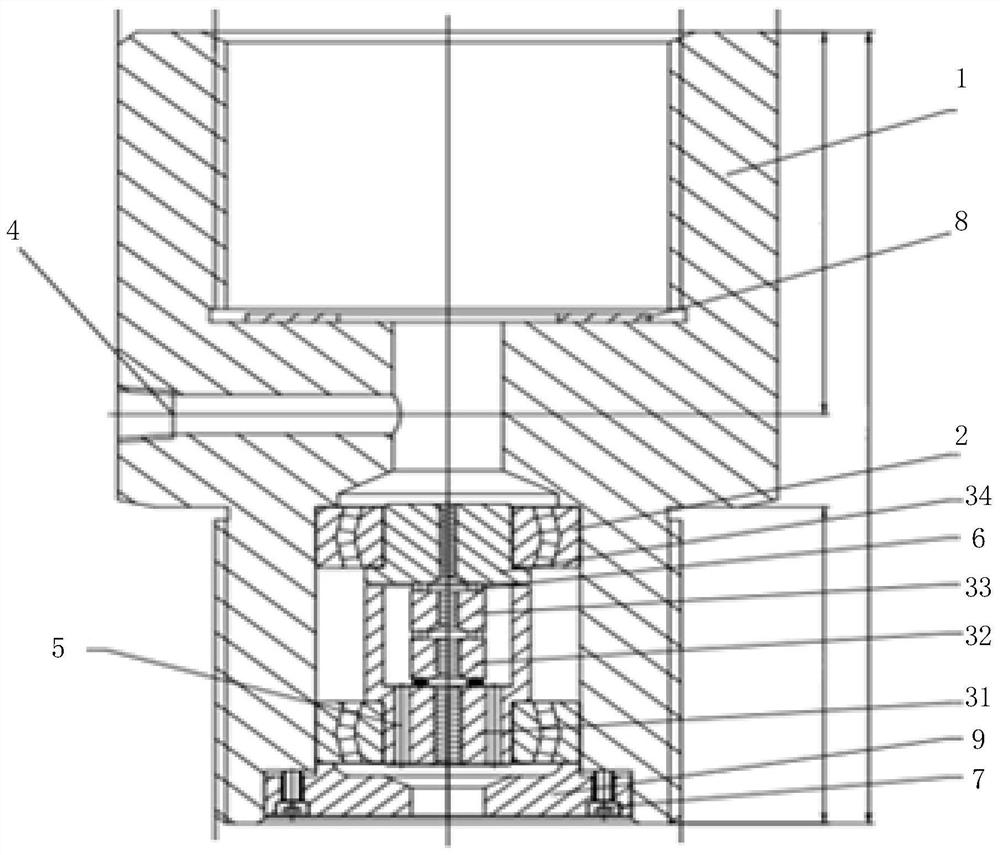

High temperature/pressure container

InactiveCN1472495AImprove cooling effectOperating cost advantageFurnace typesFurnace coolingPiano wireWater flow

In a high temperature / high pressure vessel for treating a workpiece placed in the interior of the vessel at a high temperature and a high pressure wherein piano wire is wound under tension round an outer periphery of a cylindrical body to apply a compressive residual stress to the cylindrical body and axial openings of the cylindrical body are tightly closed with upper and lower lids so that the lids can be disengaged from the openings, the cylindrical body is constituted as a two-layer cylindrical body comprising an inner cylinder and an outer cylinder which is fitted on the inner cylinder through plural spacers arranged along an outer periphery surface of the inner cylinder, allowing cooling water flow paths to be formed each between adjacent such spacers so as to extend from one end side to an opposite end side of the tow-layer cylindrical body. In this high temperature / high pressure vessel, vessel packings can be cooled effectively, the piano wire is not wet with cooling water, and the internal space of the vessel can be utilized effectively.

Owner:KOBE STEEL LTD

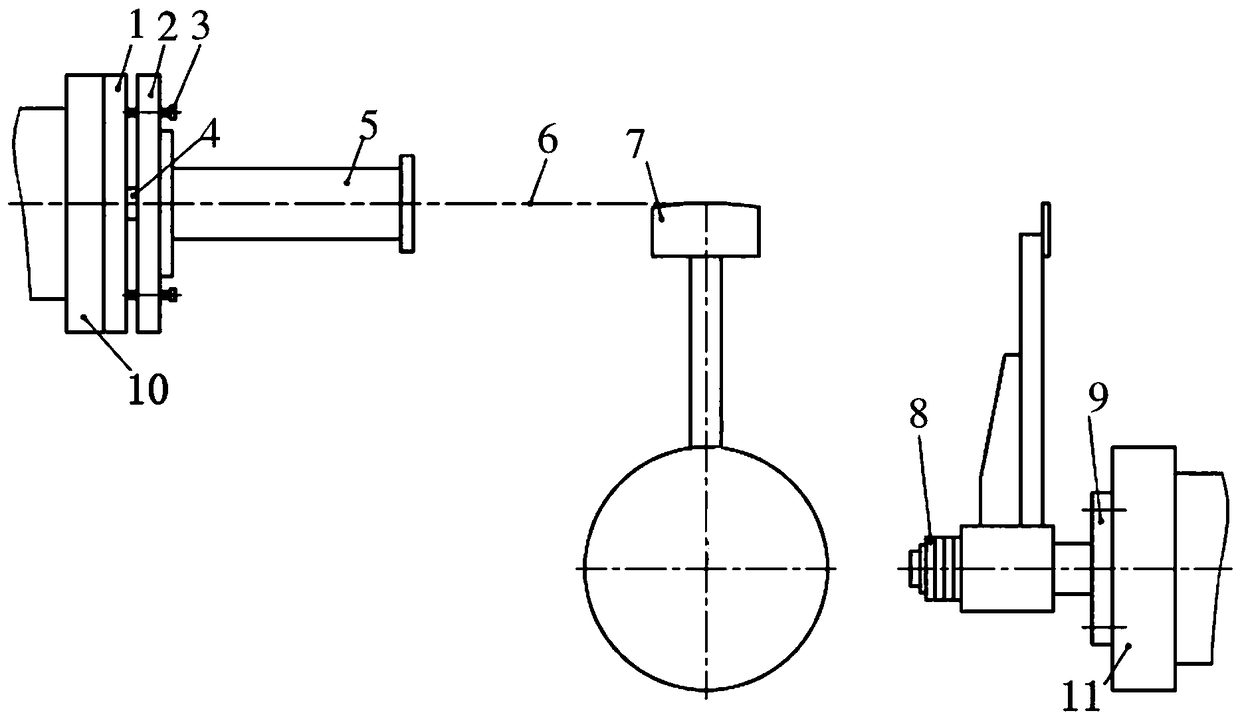

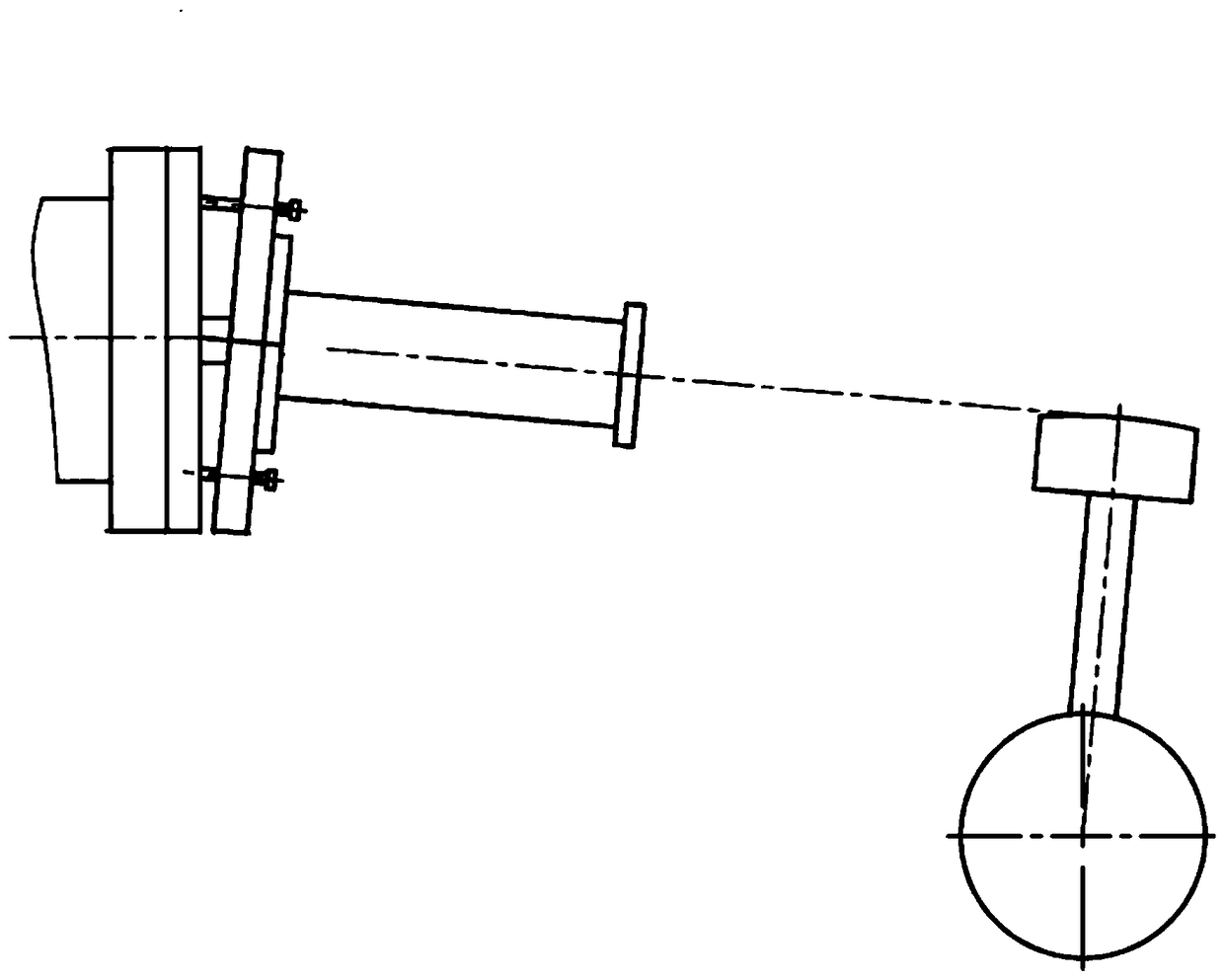

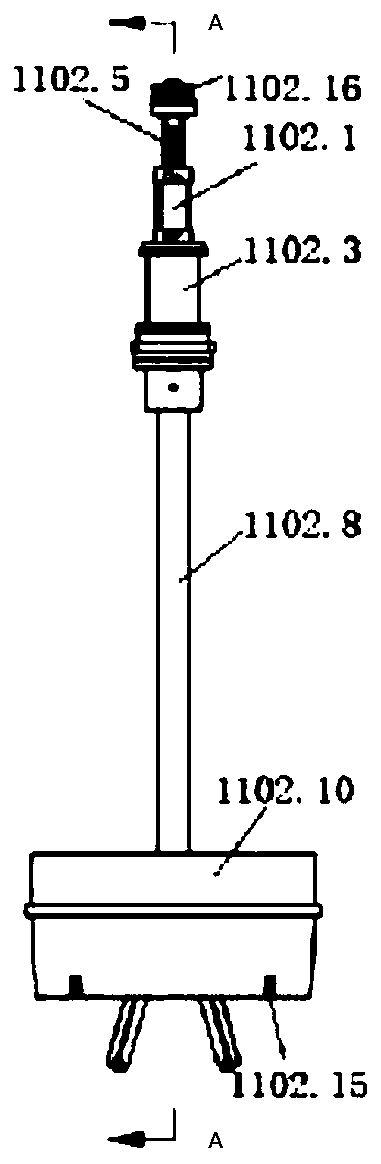

Impact type hydraulic turbine spray nozzle adjustable pad measuring device

InactiveCN108119288AAccurate measurementProven AccuracyHydro energy generationMachines/enginesPipe waterPiano wire

The invention provides an impact type hydraulic turbine spray nozzle adjustable pad measuring device which comprises an adjustable pad, a runner and a spray nozzle. The adjustable pad is arranged between a spray nozzle flange and a water distribution pipe water outlet flange. One side of the water distribution pipe water outlet flange is tightly connected with one side of a middle flange. The other side of the middle flange is connected with a swing flange. An adjusting screw is installed between the middle flange and the swing flange. A centering swing device is arranged in the center betweenthe middle flange and the swing flange. The center of the other side of the swing flange is connected with the spray nozzle. A piano wire is arranged between the center of the spray nozzle and a section disc at the front end of the runner. A gasket, a centering disc and a spindle lower flange are arranged on the other side of the runner. One end of the gasket is connected with the centering disc.The other end of the gasket is opposite to the whole runner. The other end of the centering disc is connected with the spindle lower flange. According to the device, the impact type hydraulic turbinespray nozzle adjusting pad can be accurately measured, and the installation precision of the impact type hydraulic turbine spray nozzle is guaranteed.

Owner:SHENYANG GETAI HYDROPOWER EQUIP

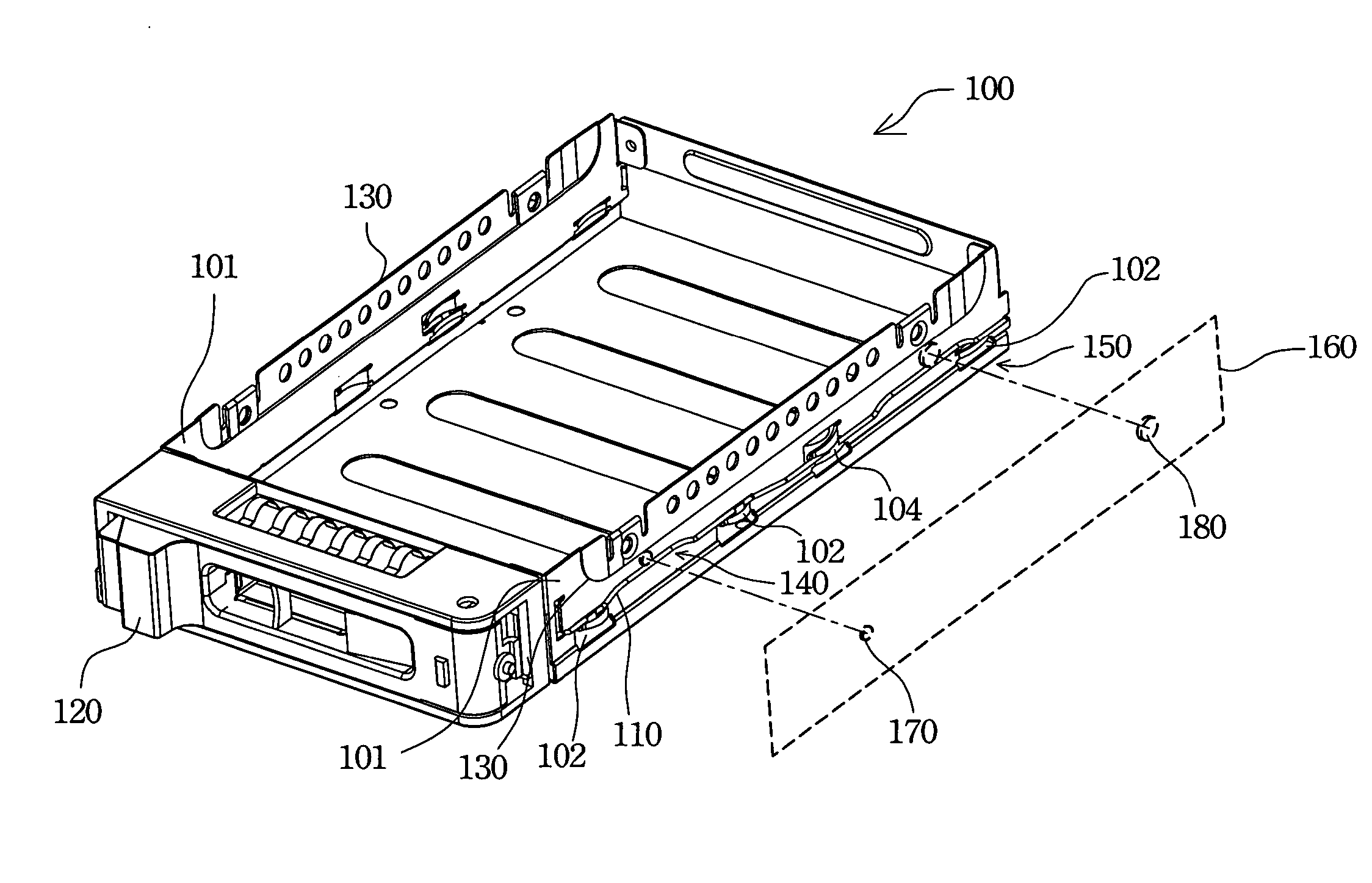

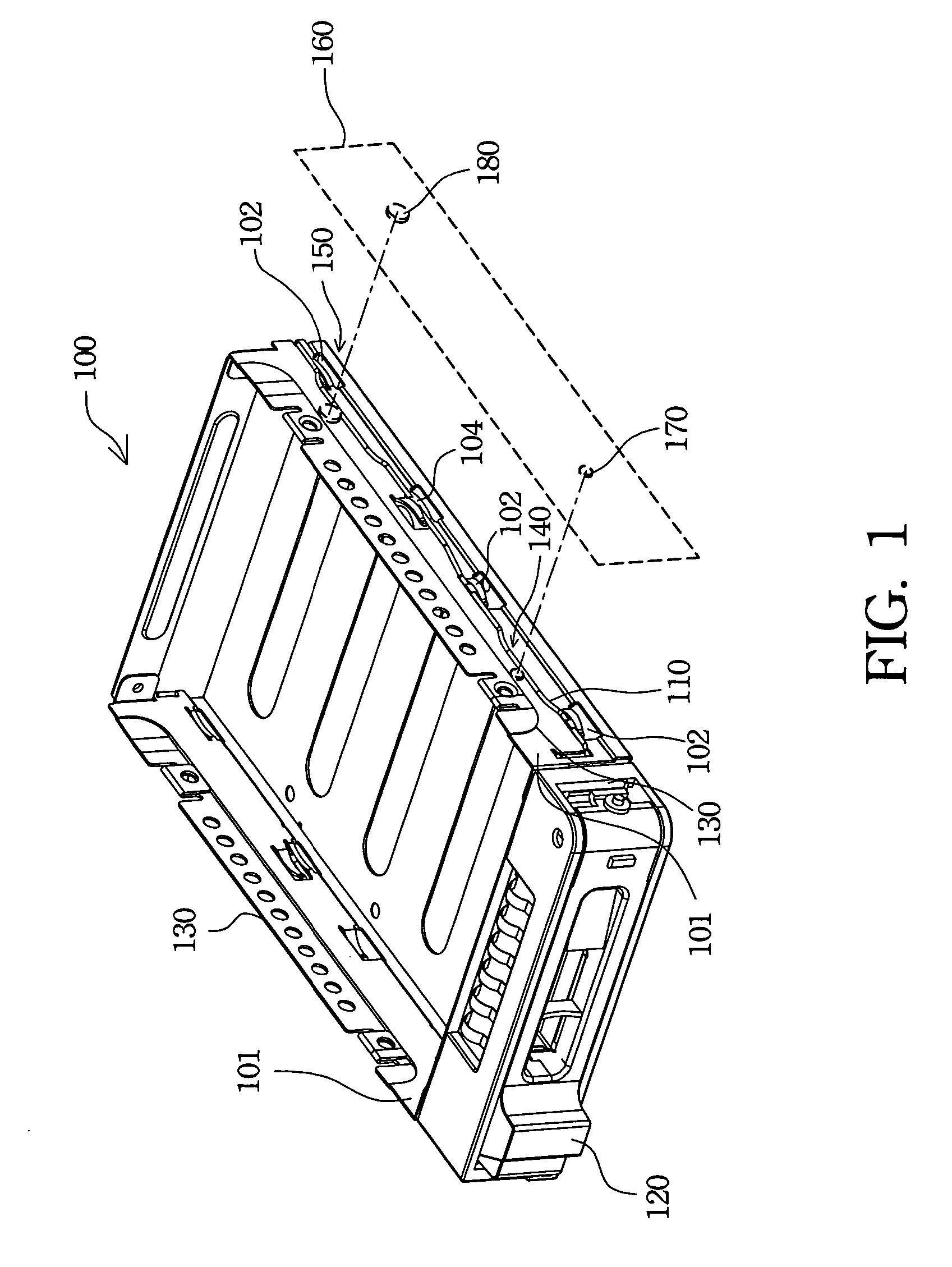

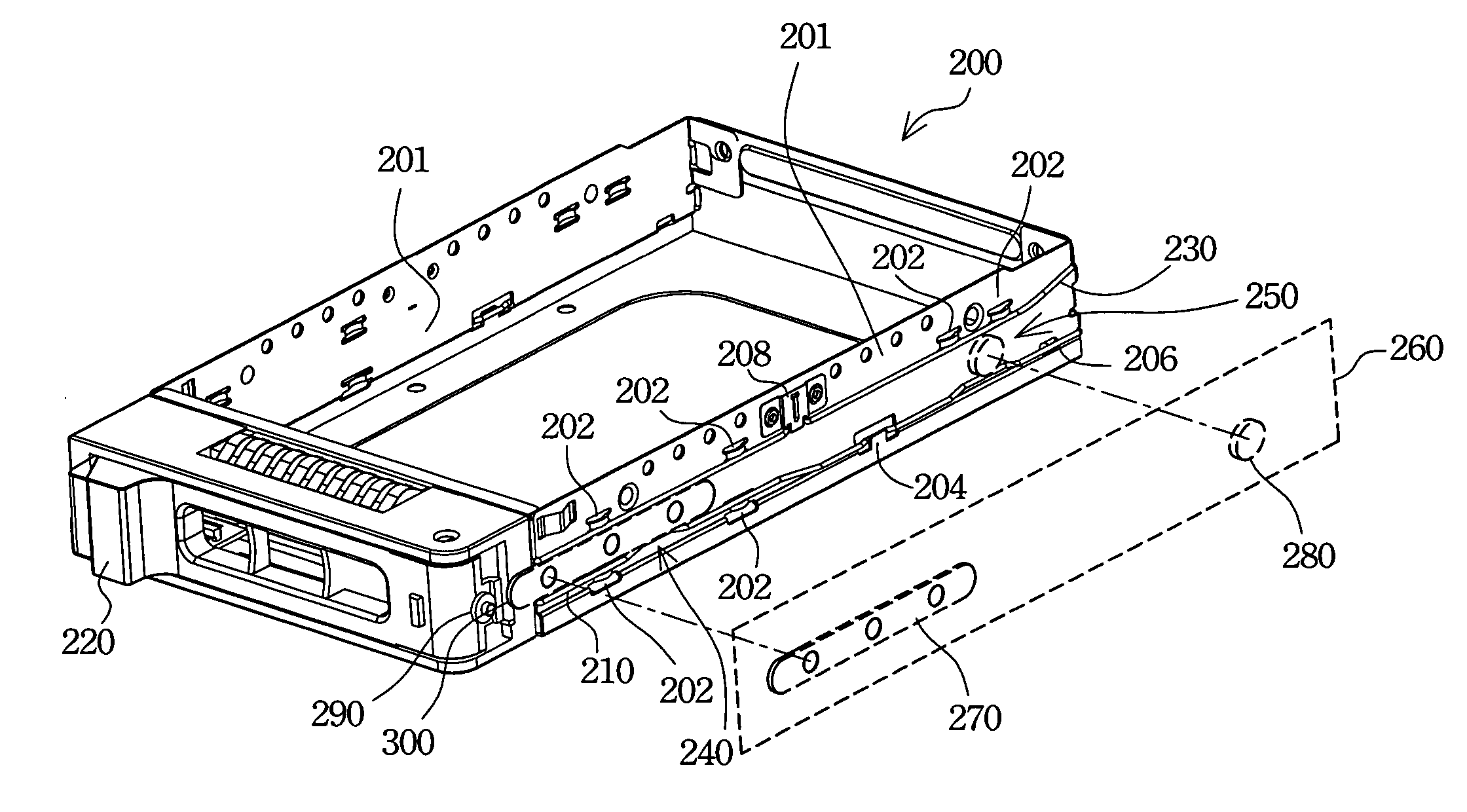

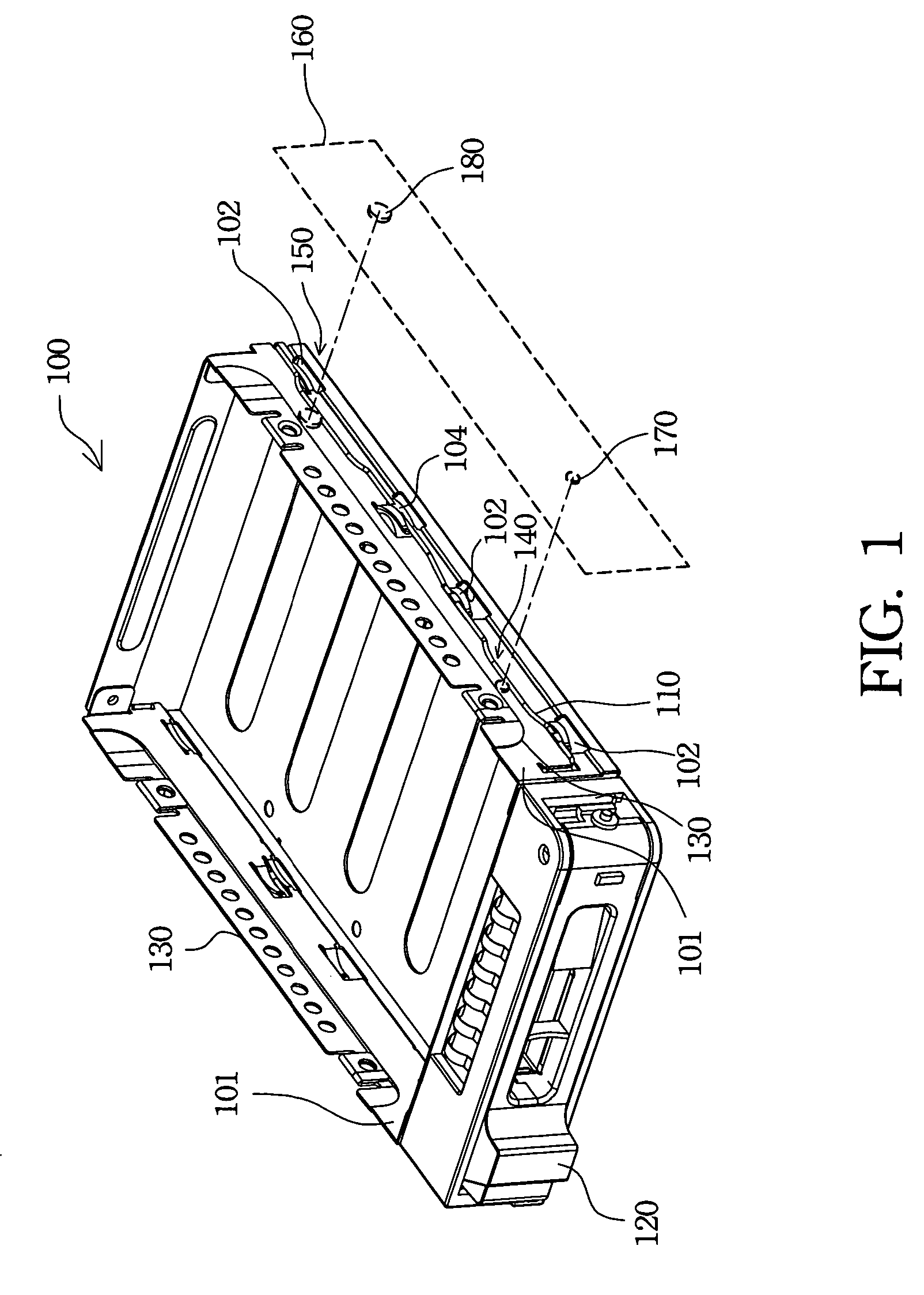

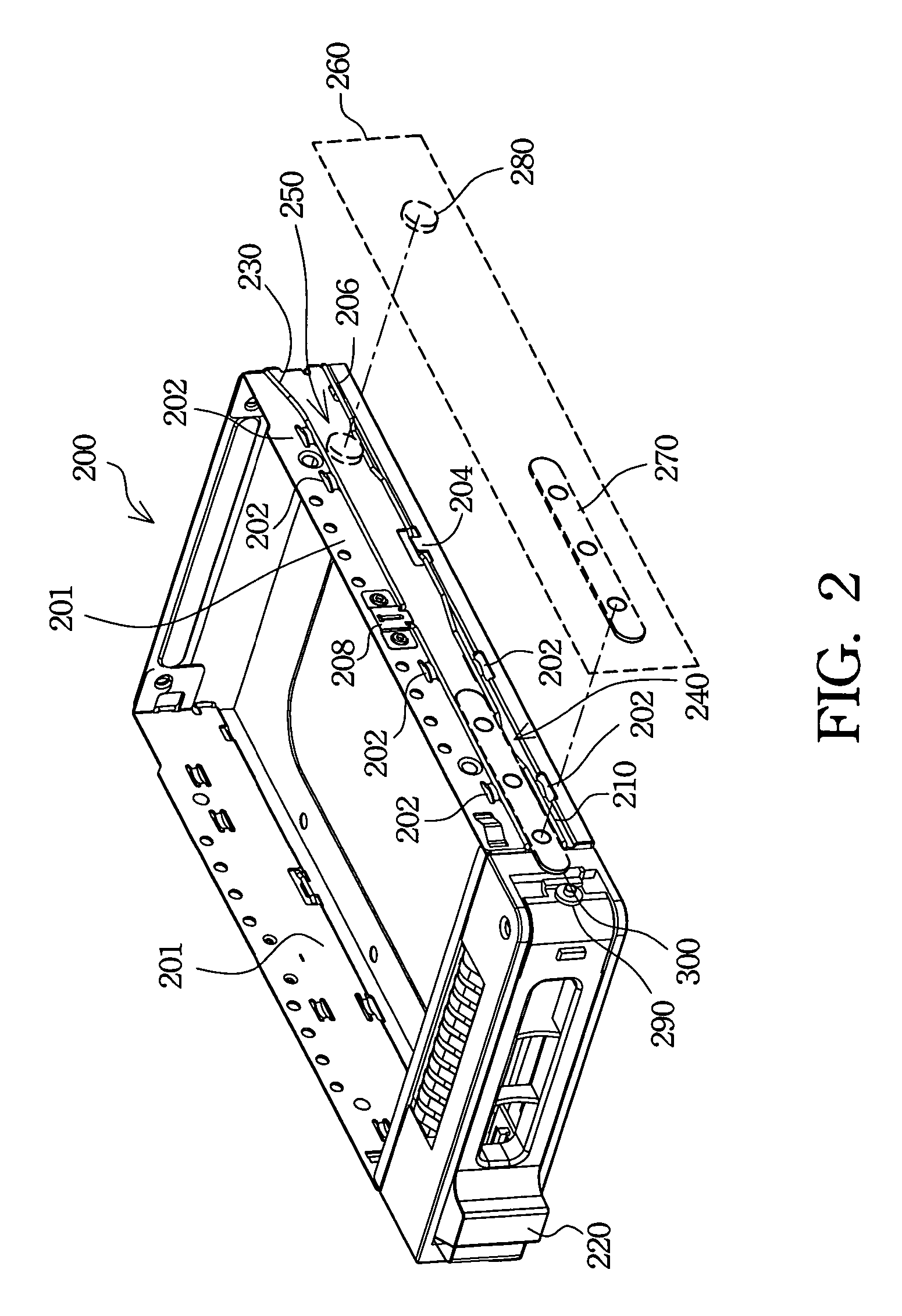

Removable hard disk module

ActiveUS20050013109A1Space utilizationIncrease reliability lifeEngagement/disengagement of coupling partsCarrier constructional parts dispositionWire rodPiano wire

A removable hard disk module is described. The removable hard disk module has a module sidewall, a first slide rail, and a second slide rail. The first slide rail and the second slide rail are fixed on the module sidewall and the second slide rail is disposed above the first slide rail. The first slide rail is made of a linear material such as a piano wire or the like. The second slide rail is directly formed on the module sidewall or made of the linear material. The removable hard disk module further includes a handle with a withdrawal post to push a support stud on a module fixing device for withdrawing the removable hard disk module from the module fixing device when the handle is opened.

Owner:QUANTA COMPUTER INC

Moving dehydration device for underground water coal

InactiveCN101732923AEasy to dehydrateImprove dehydration effectSievingScreeningPiano wireEngineering

The invention discloses a moving dehydration device for underground water coal. The device comprises an arc grate screen, a hydraulic baffle, two layers of elastic rod screens, three layers of piano wire screens, a track, a grate screen bracket, a coal flow baffle, a chassis, wheels, a milling coal hole, an undersize hopper, an undersize water pipe, a screen frame and a vibration exciter, wherein the screen frame is fixed on the chassis; the chassis is provided with the wheels; the wheels are positioned on the track; the two layers of the elastic rod screens and the three layers of the piano wire screens are respectively arranged in the screen frame; the upper part of the two layers of the elastic rod screens is provided with the fixed arc grate screen; the arc grate screen is supported by the grate screen bracket; the grate screen bracket is fixedly connected on the chassis; the lower part of the screen frame is fixedly provided with the undersize hopper; the undersize hopper is connected with the undersize water pipe; the lower right part of the screen frame is fixedly provided with the milling coal hole; and the chassis on the upper right part of the milling coal hole is fixedly provided with the coal flow baffle. The moving dehydration device for the underground water coal has the characteristics of compact structure, lump coal impact resistance, good dehydration effect, stable and reliable working and the like.

Owner:HENAN POLYTECHNIC UNIV

Steel wire and manufacturing method therefor

InactiveUS7560628B2Improve sound qualityStringed musical instrumentsFurnace typesPianoChemical composition

A steel wire (e.g., a piano wire) for use in a stringed musical instrument is designed to have a specific chemical composition in which phosphorus content ranges from 0.015 weight percent to 0.050 weight percent, wherein the total decarburized layer depth of a decarburized layer formed on the surface, which is subjected to decarburized depth measurement using a microscope method as defined in the Japanese Industrial Standard JIS G 0588, is reduced to 2 μm or less. Other chemical substances included in the chemical composition of the steel wire are preferably defined in the standard JIS G 3502 regarding chemical compositions of piano wires. In manufacturing, a rolled steel material is subjected to wire drawing and patenting under prescribed conditions, wherein the sound quality realized by the steel wire installed in a stringed musical instrument can be noticeably improved by adopting both chemical composition control and total decarburized layer depth control.

Owner:YAMAHA CORP

Artificial foliage

ActiveUS20060008598A1Sufficient degree of elasticitySolve the lack of ductilityDead plant preservationArtificial flowers and garlandsPiano wireEngineering

An artificial foliage structure with wire cores embedded in its leafy parts causing these parts to “spring back” upon removal of compressive loading acting thereupon. These wire cores may be made of hard, springy steel such as piano wire or small diameter spring wire. Thicker, woody limbs and branches have embedded therein heavier wire cores that are sufficiently soft to be given a set solely by manually applied bending force.

Owner:AMERICAN PRIDE OUTDOORS LLC

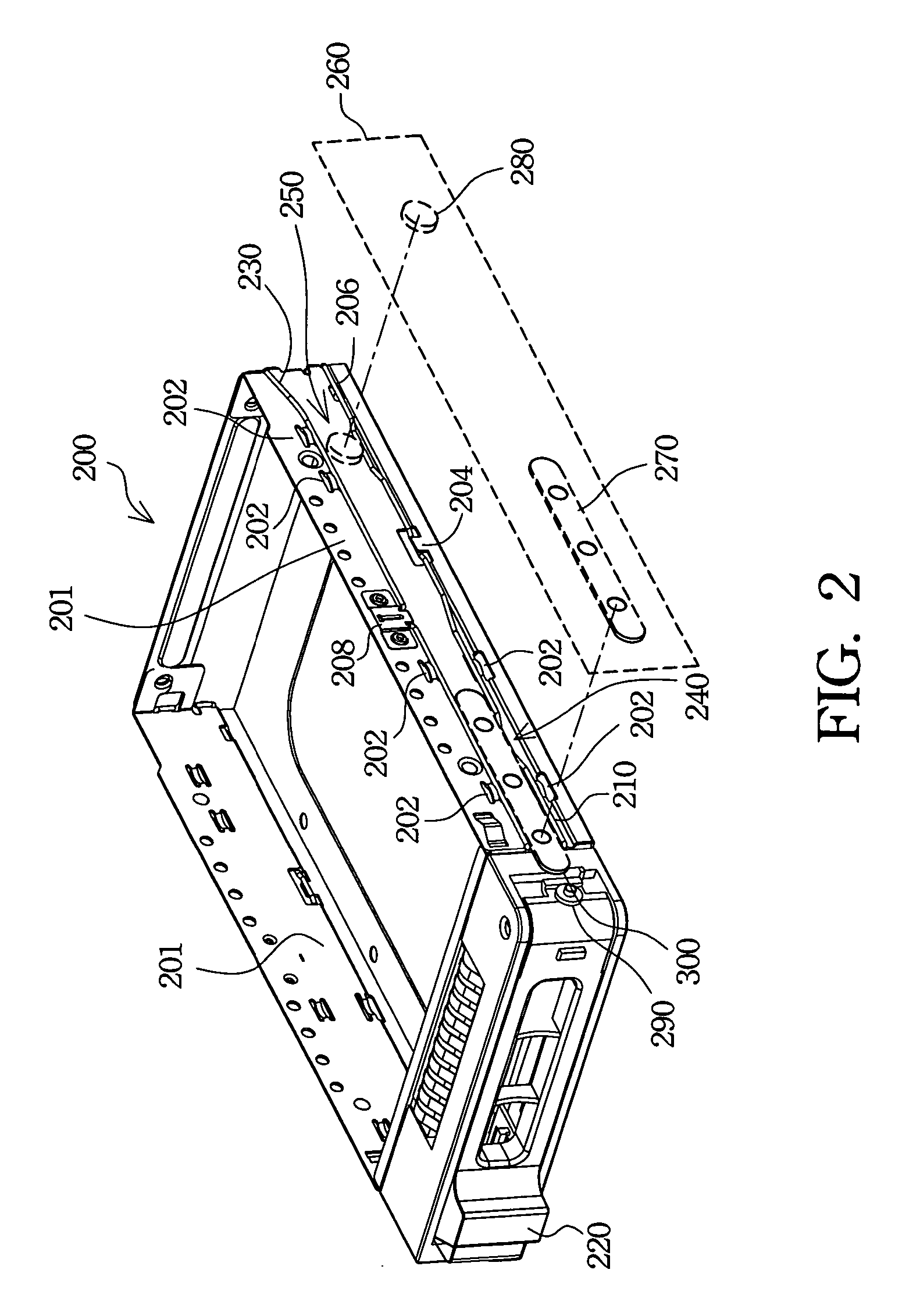

Removable hard disk module

ActiveUS7068501B2Space utilizationIncrease reliability lifeEngagement/disengagement of coupling partsCarrier constructional parts dispositionPiano wireComputer engineering

A removable hard disk module is described. The removable hard disk module has a module sidewall, a first slide rail, and a second slide rail. The first slide rail and the second slide rail are fixed on the module sidewall and the second slide rail is disposed above the first slide rail. The first slide rail is made of a linear material such as a piano wire or the like. The second slide rail is directly formed on the module sidewall or made of the linear material. The removable hard disk module further includes a handle with a withdrawal post to push a support stud on a module fixing device for withdrawing the removable hard disk module from the module fixing device when the handle is opened.

Owner:QUANTA COMPUTER INC

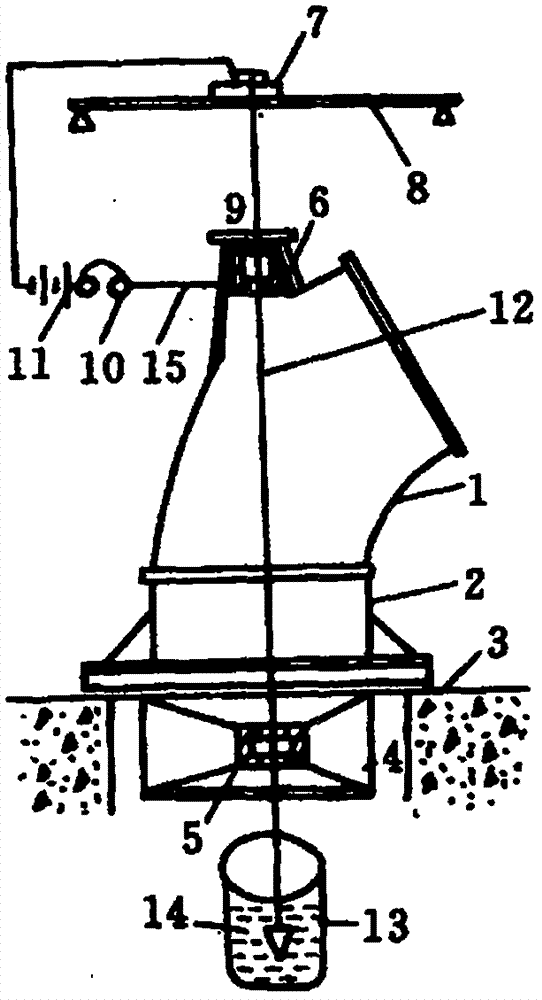

Tool and method for measuring rotational inertia of table tennis ball

InactiveCN102494844AIndirect measurement is convenient and accurateStatic/dynamic balance measurementPiano wireMoment of inertia

The invention relates to a method for measuring the rotational inertia of a table tennis ball, which includes the steps: hanging a piano wire B with the diameter of 0.15mm on a cross bar C; hanging a disk with a mass M and a radius R below the piano wire B, recording the turn number n and the time t of rotation of the disk, computing the rotational period T0=t / n of the disk at the moment and obtaining the rotational inertia I0 of the disk M by means of the formula I0=1 / 2MR2; hanging the table tennis ball to be measured below the piano wire B and similarly measuring the rotational period TS of the table tennis ball; and obtaining the rotational inertia IS=A2I0 of the table tennis ball below the piano wire according to the equation of the torsion constant and the rotational period K=T2I / (4 pi 2), wherein A=T0 / TS. The invention further provides a tool for measuring the rotational inertia of the table tennis ball. The method breaks through the limitations of original computational formulas, and only the rotational period is measured creatively, so that measurement of the rotational inertia of the table tennis ball has more rules to follow and is more convenient and more operable.

Owner:CHANGZHOU UNIV

Piano wire-drawing and matte coating process

The invention discloses a piano wire-drawing and matte coating process. The process comprises the following steps of: (1) spraying poly ethylene (PE) paint onto each piano workpiece and polishing the piano workpiece with sand paper from the crude sand paper to the fine sand paper until 600# sand paper is used; (2) spraying nitrolacquer onto each piano workpiece, polishing the piano workpiece withthe sand paper and cleaning the workpiece; (3) polishing each piano workpiece with a non-woven fabric and cleaning the workpiece; (4) polishing each piano workpiece with a steel wool and cleaning theworkpiece; (5) coating wax on the piano workpieces with colors except black; and (6) wiping each piano workpiece with 'Chachakelin' (a foam with extremely high detergency), and wiping the piano workpiece until the piano workpiece is dry, thus finishing the process. The surface of the processed piano is uniform, straight, fine and soft in sanded textures.

Owner:PEARL RIVER PIANO GROUP

Concentricity measuring device for vertical type axial-flow pump unit

InactiveCN107024167AAccurately measure and calculateGuaranteed installation qualityMechanical measuring arrangementsAxial-flow pumpMeasurement device

The invention provides a concentricity measuring device for a vertical type axial-flow pump unit. If the axis of a vertical motor and the axis of a vertical type axial-flow pump are not in the same vertical line, a bearing is not uniformly stressed during operation. During operation, the bearing generates heat and the pump unit generates the vibration and the noise. When the condition gets severer, the pump unit might not run. Therefore, during the installation of the vertical type axial-flow pump unit, the concentricity of the vertical type axial-flow pump unit might be measured. During the particular application process, an internal dial gauge, an upper guide bearing of a vertical type axial-flow pump, a lower guide bearing of the vertical type axial-flow pump, a headset, a battery and a centering device are connected to form an electrical loop through insulated flexible wires. The measurement is conducted repeatedly, and then the shortest length of a measuring rod at each point is obtained as the distance between a piano wire and the sidewall of a guide bearing. Meanwhile, the measured data of each point is recorded into a table. According to a measurement record, the concentricity deviation value of a component can be calculated. When the concentric deviation value does not meet the requirement, the installation of the vertical type axial-flow pump is adjusted. In this way, the concentric deviation value is adjusted to meet the installation requirement. The installation quality of the vertical type axial-flow pump unit is ensured.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Ion-generating component, ion-generating unit, and ion-generating apparatus

ActiveUS7199993B2Improve concentrationEasy to produceMechanical apparatusLighting and heating apparatusPiano wireTitanium

An ion-generating component has, on an insulating substrate, a ground electrode, a high-voltage electrode, an insulating film provided on the surface of the ground electrode, and a wire electrode. A cutout is formed by cutting out one side of the insulating substrate. The root of the wire electrode is soldered to the high-voltage electrode, and the leading end thereof is positioned near the cutout. The wire electrode is made of an ultrafine wire having a diameter of about 100 μm or less, for example, a piano wire, a tungsten wire, a stainless wire, or a titanium wire.

Owner:MURATA MFG CO LTD

High temperature/high pressure vessel

ActiveUS6960318B2Use of internal spaceEfficient use ofFurnace typesHeat treatment furnacesPiano wireWater flow

In a high temperature / high pressure vessel for treating a workpiece placed in the interior of the vessel at a high temperature and a high pressure wherein piano wire is wound under tension round an outer periphery of a cylindrical body to apply a compressive residual stress to the cylindrical body and axial openings of the cylindrical body are tightly closed with upper and lower lids so that the lids can be disengaged from the openings, the cylindrical body is constituted as a two-layer cylindrical body comprising an inner cylinder and an outer cylinder which is fitted on the inner cylinder through plural spacers arranged along an outer periphery surface of the inner cylinder, allowing cooling water flow paths to be formed each between adjacent such spacers so as to extend from one end side to an opposite end side of the tow-layer cylindrical body. In this high temperature / high pressure vessel, vessel packings can be cooled effectively, the piano wire is not wet with cooling water, and the internal space of the vessel can be utilized effectively.

Owner:KOBE STEEL LTD

Low-resistivity spring-free jig and manufacturing method thereof

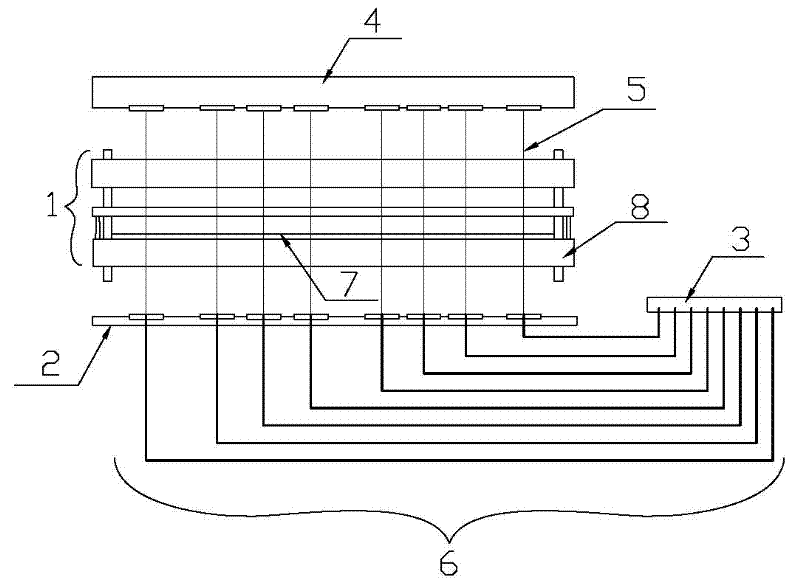

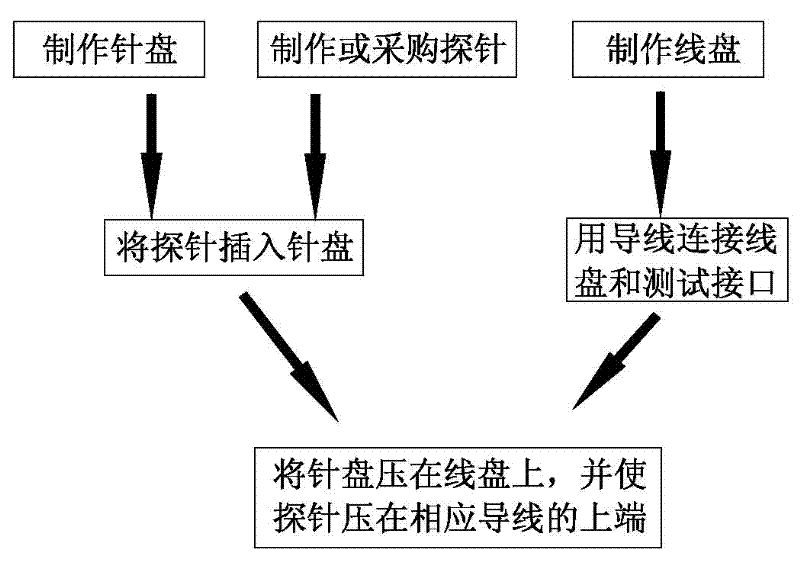

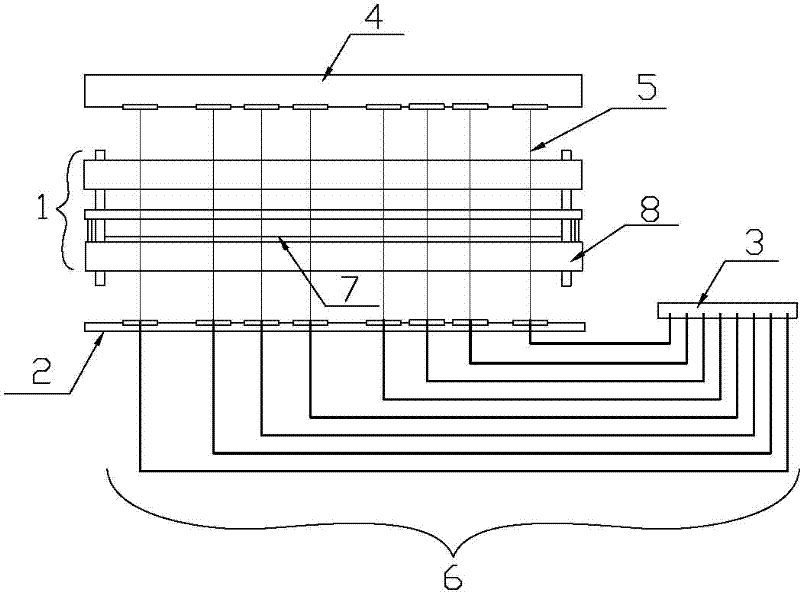

ActiveCN102419383AReduce contact resistanceImprove test accuracyElectrical measurement instrument detailsElectrical testingHigh densityPiano wire

The invention relates to a low-resistivity spring-free jig and a manufacturing method thereof. The conventional jig cannot meet the requirements of high density and low resistance values of a printed circuit board during testing. Therefore, the low-resistivity spring-free jig comprises a needle disc, a wire coil and a testing interface, wherein the needle disc consists of one or more insulating boards and is provided with a through hole corresponding to a testing point of a board to be tested, and a probe is arranged in the through hole; the wire coil consists of one or more insulating boards and is provided with a hole corresponding to the through hole on the lower surface of the needle disc, a conducting wire is arranged in the hole, and the other end of the conducting wire is connected to the testing interface; the probe has the diameter of between 0.015 and 0.15mm and is made of a piano wire or a rhenium-tungsten wire; the needle disc is pressed on the wire coil; and the probe is pressed at the upper end of a corresponding conducting wire. The invention also relates to a method for manufacturing a corresponding jig. The low-resistivity spring-free jig has the advantages of simple structure, low resistance value and high density and is widely applied in the process of detecting various printed circuit boards.

Owner:珠海拓优电子有限公司

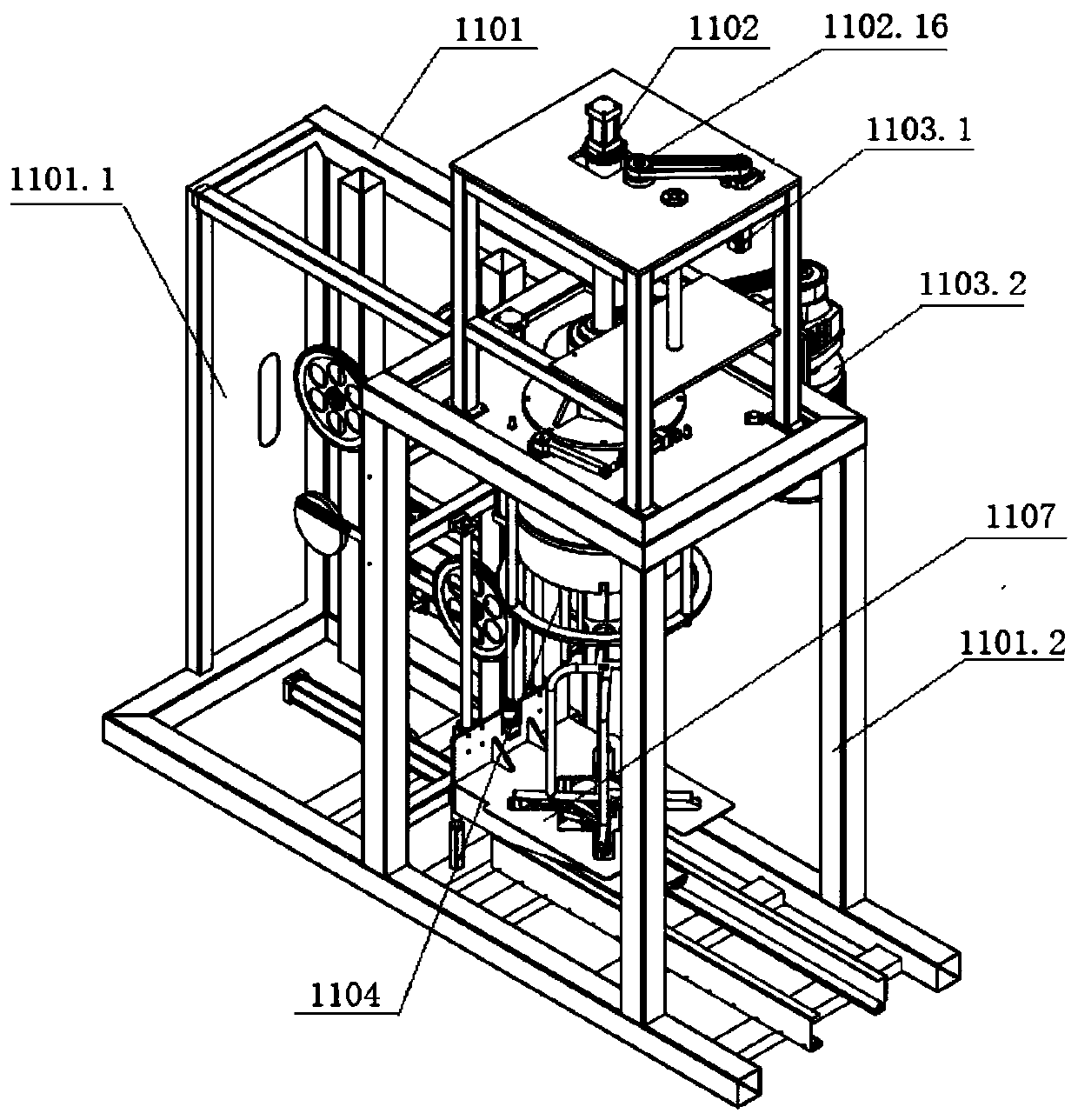

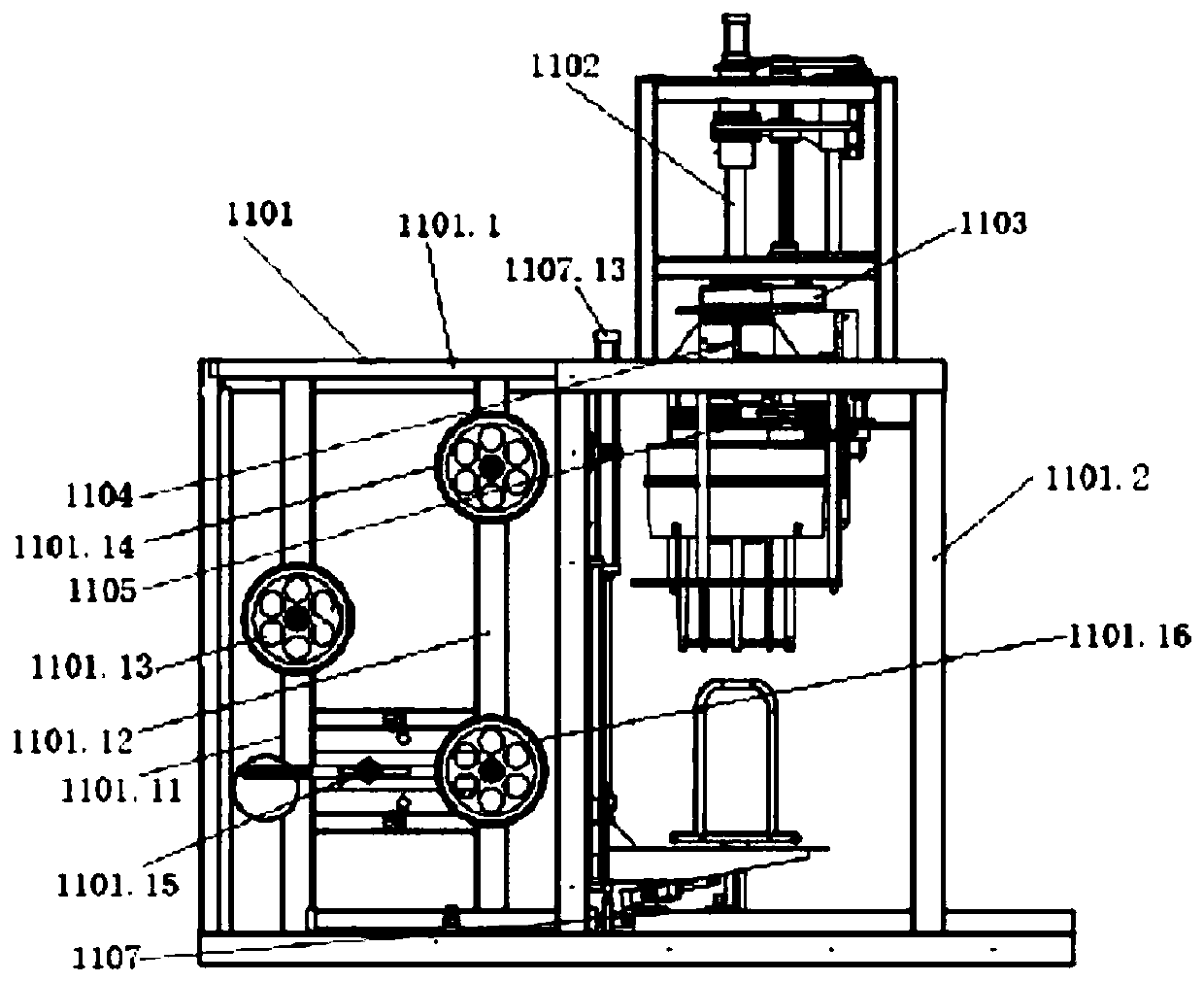

Piano wire winding mechanism for automobile seat system

The invention relates to a piano wire winding mechanism for an automobile seat system. The piano wire winding mechanism comprises a rack. The rack comprises a left rack body and a right rack body. Theleft rack body is vertically provided with a first connecting rod and a second connecting rod. The first connecting rod is provided with a first wire feeding wheel, and the second connecting rod is provided with a second wire feeding wheel and a third wire feeding wheel. The right rack body is provided with an elevating telescopic assembly, a power assembly, a coiling block assembly and a wire unloading assembly. The piano wire winding mechanism can solve the problem that in the rolling process of a traditional steel wire winding device, extrusion force is generated between steel wires.

Owner:无锡熠卿锋金属科技有限公司

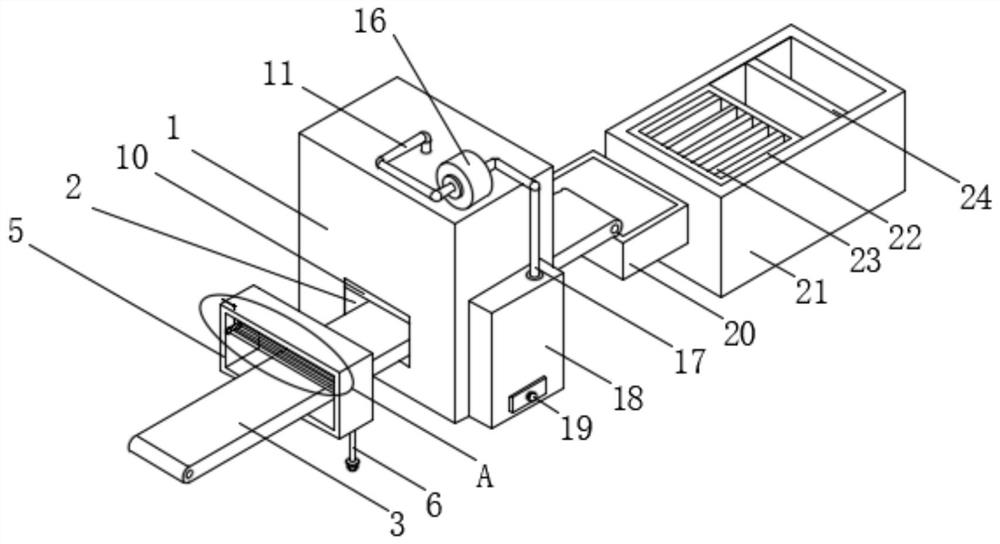

Solar cell preparation combination method and preparation device

PendingCN111952416AEfficient removalImprove dust removalElectrolysis componentsFinal product manufactureElectrolysisElectrical battery

The invention discloses a solar cell preparation combination method and preparation device, and belongs to the technical field of solar cell preparation. The device comprises an impurity removal chamber, a through hole is formed in the side surface of the impurity removal chamber, an electric transmission belt is inserted into the through hole, and an electrostatic electret chamber is arranged atthe periphery of the electric transmission belt; and an anode piano wire mounting seat is arranged on the inner side wall of the electrostatic electret chamber. According to the invention, through themutual cooperation of the designed electrolyte solution, the electrostatic electret chamber, the positive piano wire, the electrolytic reaction generation chamber, the molybdenum net cage and the molybdenum net partition plate, fallen fluff in the suede can be effectively removed, and the dust in the suede is driven by the fluff to move towards the direction of the probe, so the dust removal andfluff removal efficiency is high; the electrolytic reaction generation chamber can be prevented from having more impurities in the electrolytic reaction process, a phosphorosilicate glass layer formedon the surface of the silicon wafer plate can be effectively removed, the effect is higher compared with acid pickling, and a diffusion dead layer on the surface of the silicon wafer plate can be effectively removed.

Owner:阳光中科(福建)能源股份有限公司

Safety protection device for piano wire

The invention discloses a safety protection device for a piano wire. The safety protection device comprises a blowout prevention pipe connection segment, a bearing support segment, a rotary stepwise decontamination segment, a liquid injection segment and a dirt drain hole, wherein the upper end of the blowout prevention pipe connection segment is connected with a blowout prevention pipe; the lowerend of the blowout prevention pipe connection segment is connected with a shaft gas production tree shaft mouth flange; the five parts of the safety protection device are of cylindrical structures, and are all arranged inside the blowout prevention pipe connection segment; the blowout prevention pipe connection segment, the bearing support segment and the rotary stepwise decontamination segment are sleeved sequentially from outside to inside; the rotary stepwise decontamination segment comprises a first rotating body, a second rotating body, a third rotating body and a fourth rotating body which are connected sequentially from bottom to top, and is used for removing dirt from the piano wire stepwise, and draining the removed dirt through the dirt drain hole; and the liquid injection segment is arranged on the blowout prevention pipe connection segment transversely, and is used for lubricating and cooling the piano wire after being injected with liquid. The safety protection device caneffectively remove sundries attached to the piano wire, and cool the piano wire.

Owner:PETROCHINA CO LTD

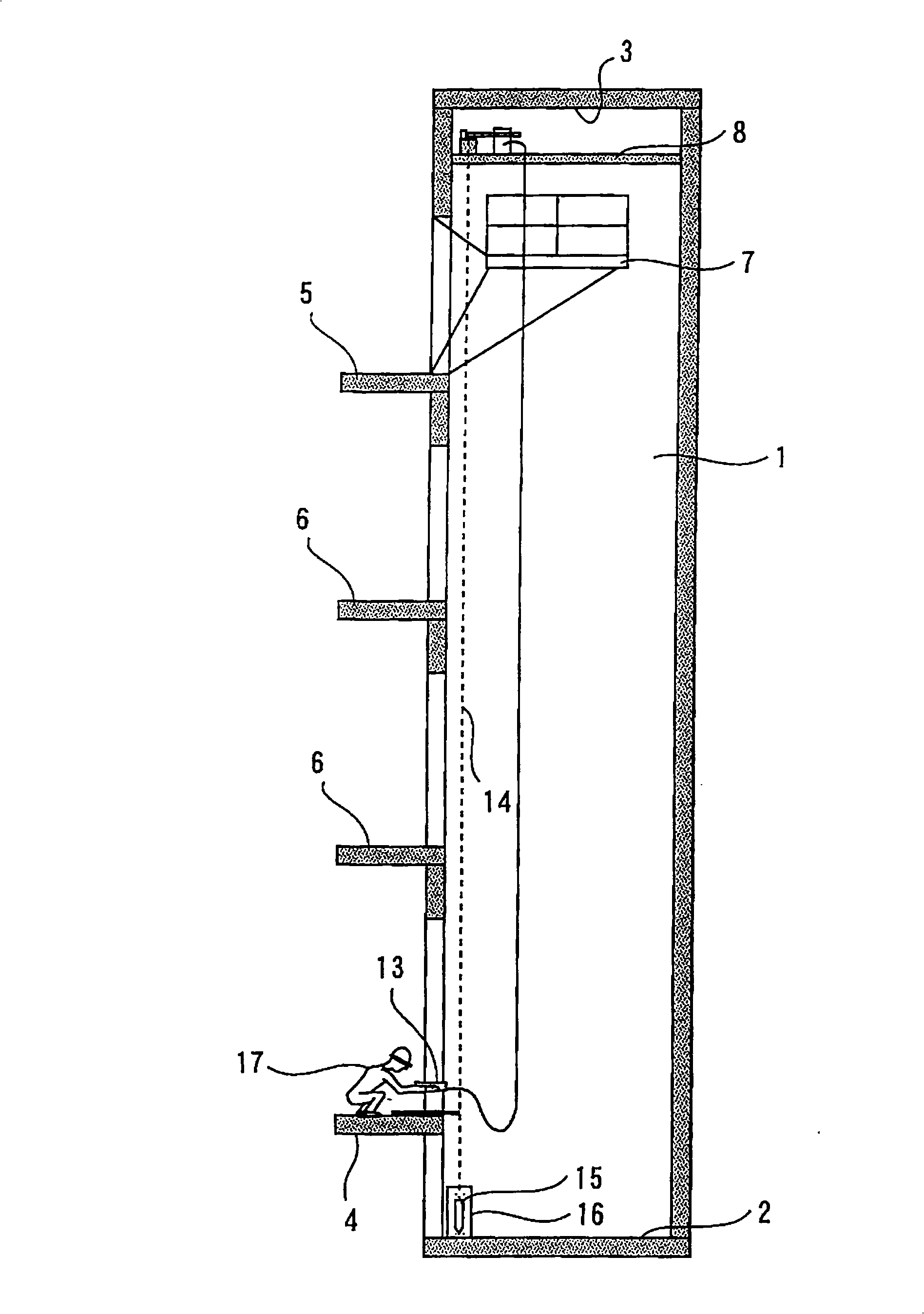

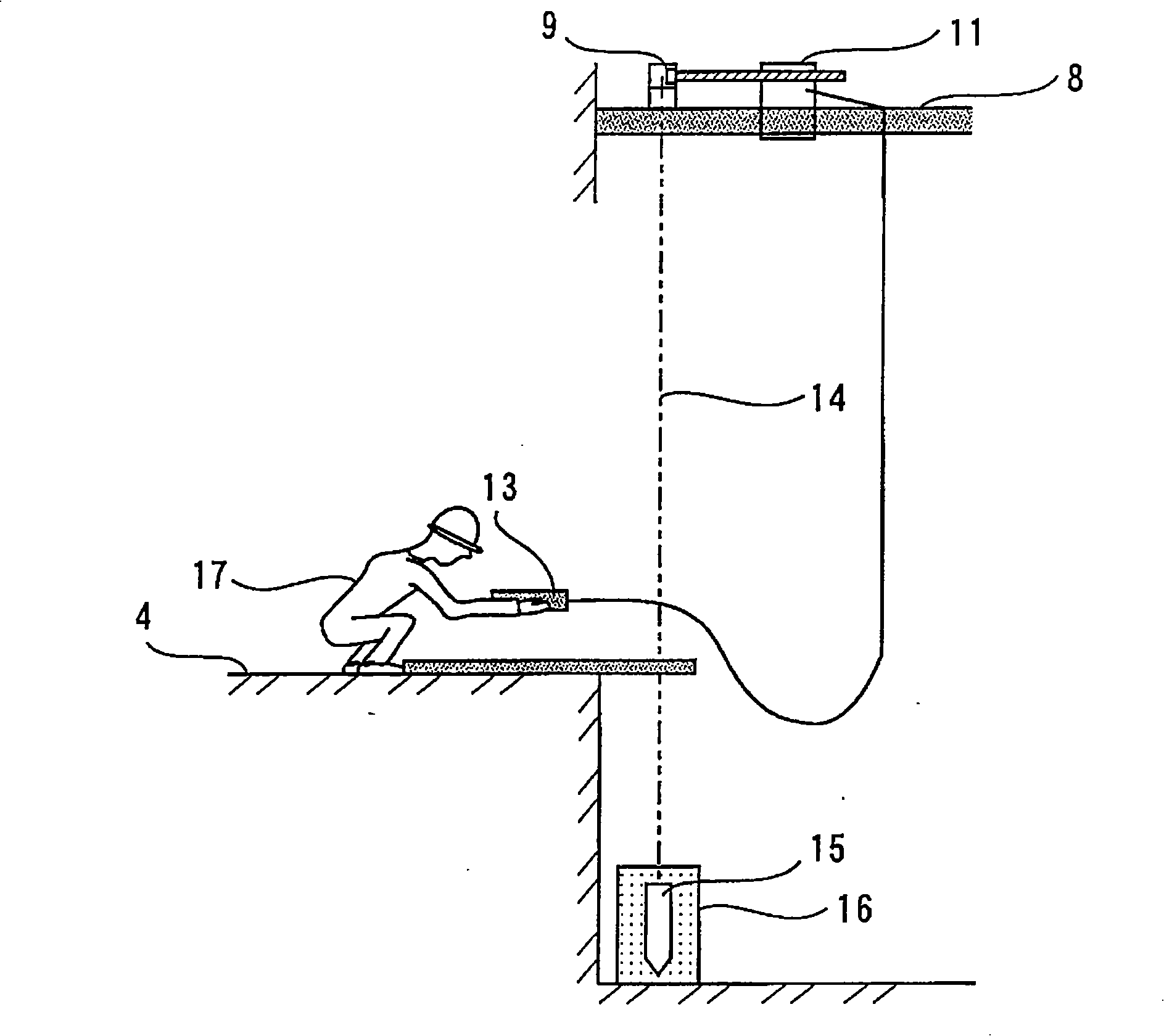

Automatic location apparatus of benchmark template for elevator and method thereof

The invention relates to an elevator used reference template automatic positioning device which can reduce the operator in elevation direction reference positioning while installing an elevator and reduce cost. The device comprises: a template supporting mechanism (8) disposed on the top of the lifting path (1); a reference template (10) disposed cross the template supporting mechanisms equipped with a piano wire dropping unit (10) on each end; a reference template automatic positioning device (11, 12) disposed on the reference template for adjusting and controlling the planar motion in the directions of perpendicular and parallel to the lift block side; a remote control device (13) capable of operating and controlling the automatic positioning device from the bottom the lift block; piano wires (14) hung from the reference template and having a suspended weight (15) installed on lower end; and a suspended weight stilling resting watering containing (16) disposed in the lifting path pit and immersing the lower end of the suspended weight for preventing it from swinging.

Owner:MITSUBISHI ELECTRIC BUILDING SOLUTIONS CORP

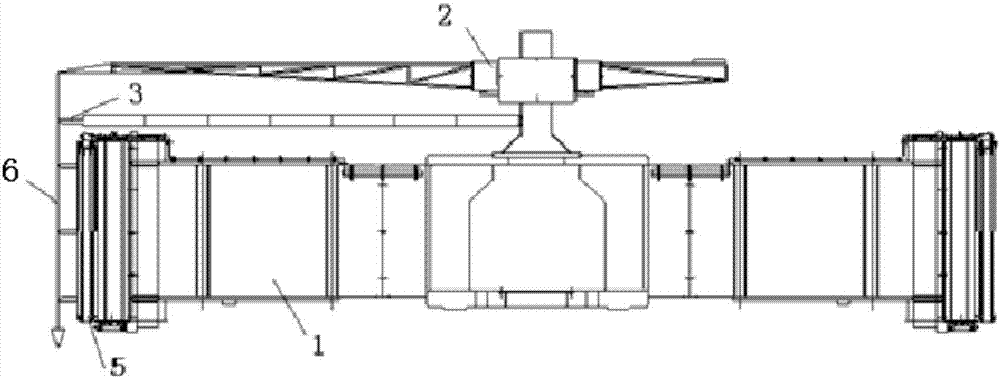

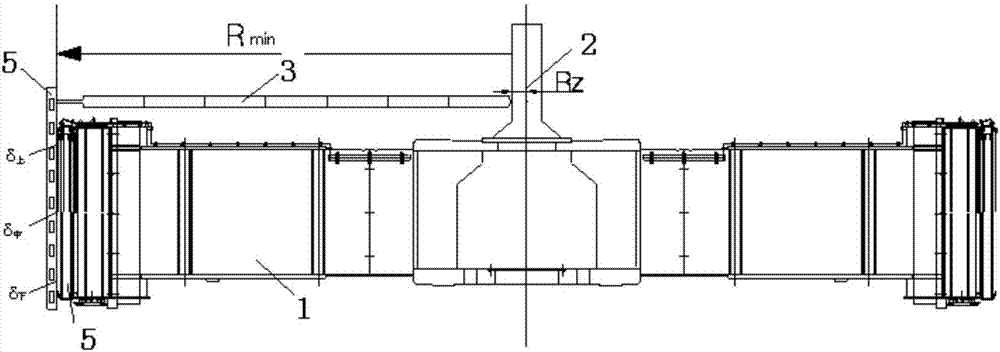

A measuring device for the absolute radius of a hydro-generator rotor and a method thereof

PendingCN107462132AImprove accuracyImprove work efficiencyMechanical diameter measurementsPianoMeasurement device

The invention provides a measuring device for the absolute radius of a hydro-generator rotor. The device comprises a rotor (1), a roundness measurement rack center pillar (2), an inside micrometer (3), an I-shaped straight edge (4), and a magnetic pole (5). The roundness measurement rack center pillar (2) is arranged at the right center of the rotor (1); the center point of the roundness measurement rack center pillar (2) coincides with the center point of the rotor (1); the outer edge of the rotor (1) is provided with the magnetic pole (5); the outer side of the magnetic pole (5) is provided with the I-shaped straight edge (4); the two ends of the I-shaped straight edge (4) extend out of the upper vertex and the lower vertex of the magnetic pole (5). The device solves the problem of large workload and error in the prior art where piano wires are used and reduces the workload.

Owner:重庆大唐国际彭水水电开发有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com