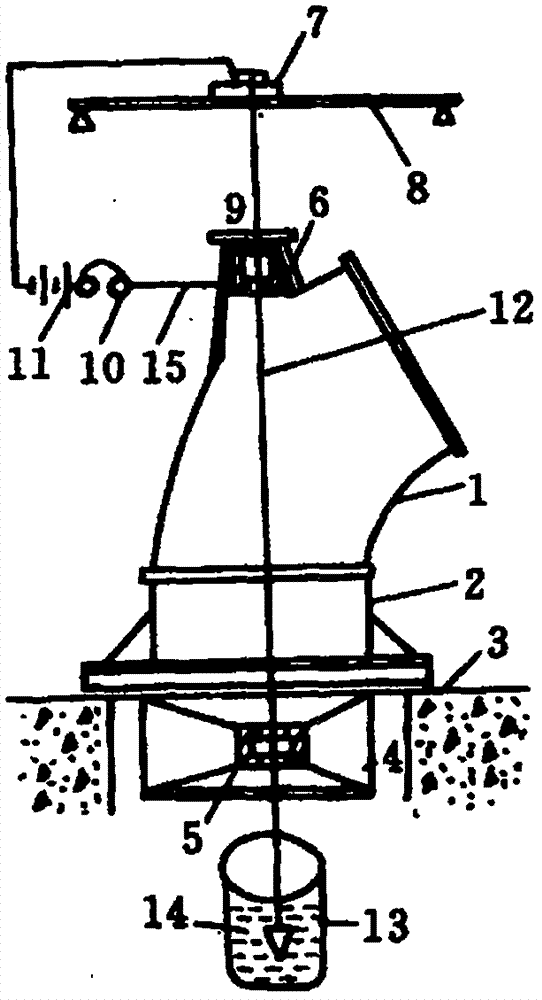

Concentricity measuring device for vertical type axial-flow pump unit

A measuring device and vertical shaft technology, applied in mechanical measuring devices, measuring devices, using mechanical devices, etc., can solve problems such as bearing heating, uneven bearing force, and inability to operate the unit, ensuring installation quality and speeding up installation. effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] When installing the vertical axial flow pump, assemble the guide vane body of the vertical axial flow pump and the intermediate connecting pipe of the vertical axial flow pump, and measure the level of the intermediate connecting pipe with a horizontal beam and a square level to meet the horizontal error requirements. At the same time, use a square level to measure the level of the guide vane body on the flange surface of the guide vane body of the vertical axial flow pump. It is required that the flange surface of the intermediate connecting pipe is level with the flange surface of the lower guide bearing of the vertical axial flow pump. Install the outlet elbow of the vertical axial flow pump on the connecting pipe in the middle of the vertical axial flow pump. Measure the vertical concentricity of the upper guide bearing of the vertical axial flow pump and the lower guide bearing of the vertical axial flow pump by electrical method. When measuring, put the center sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com