Patents

Literature

219results about How to "Speed up the installation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

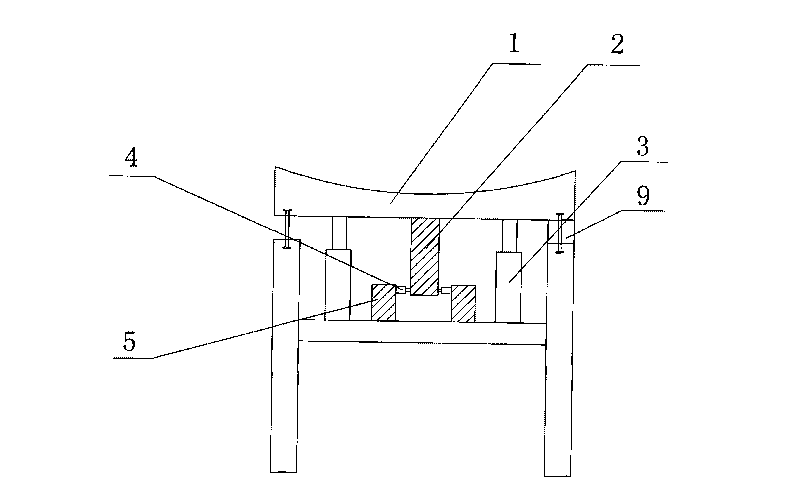

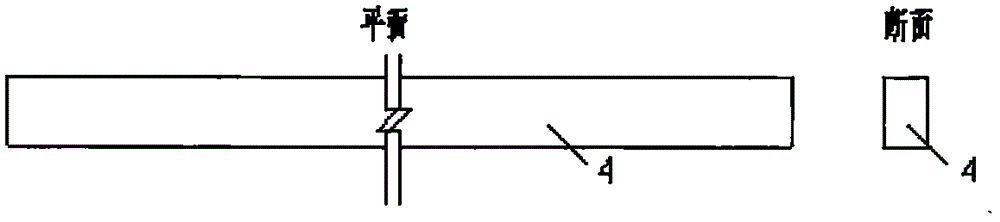

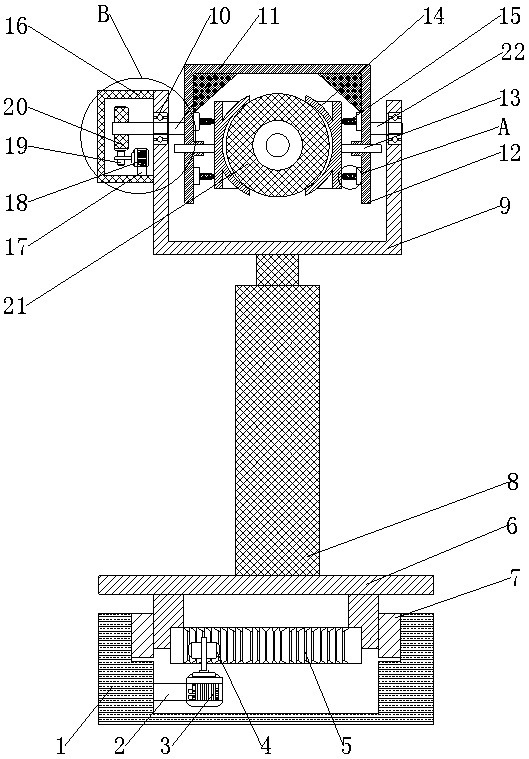

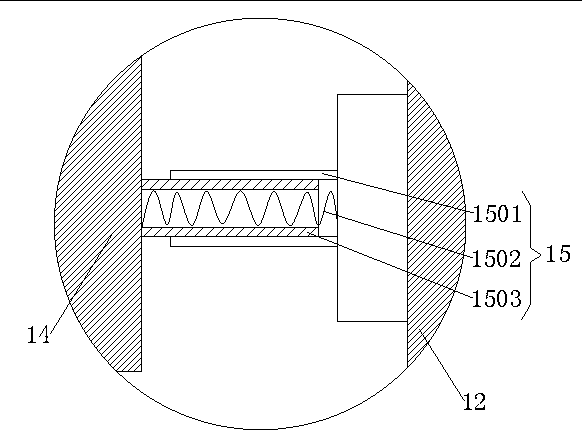

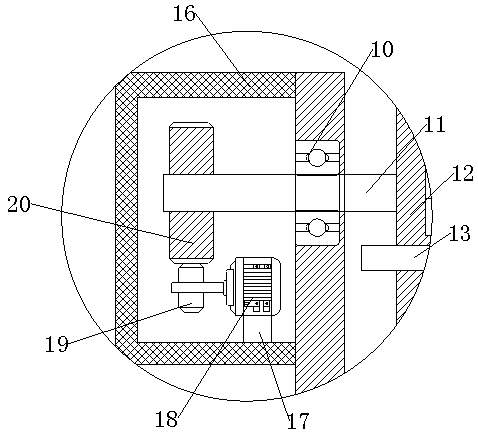

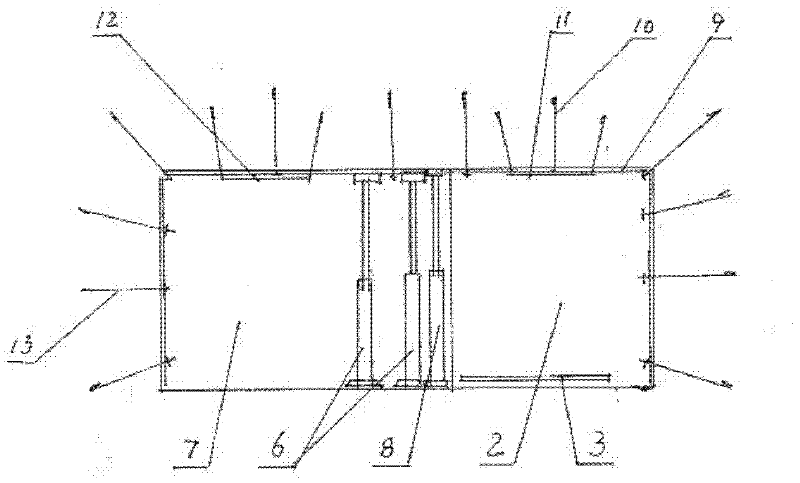

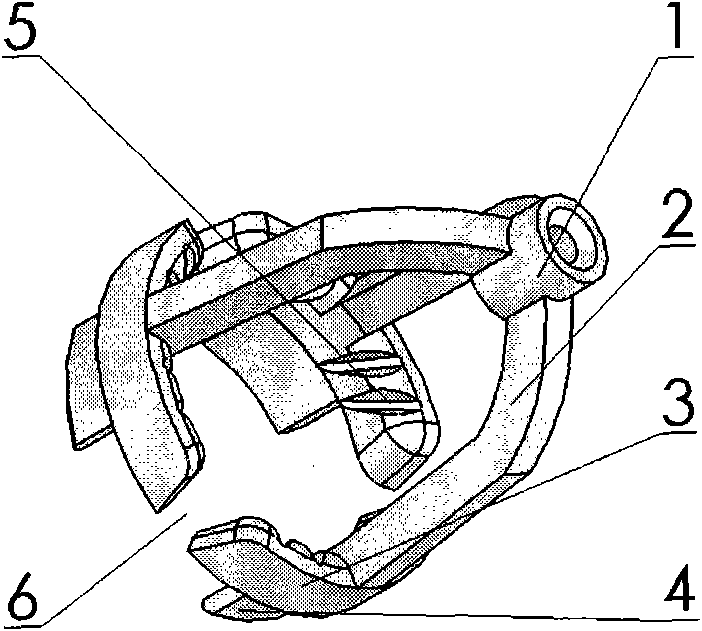

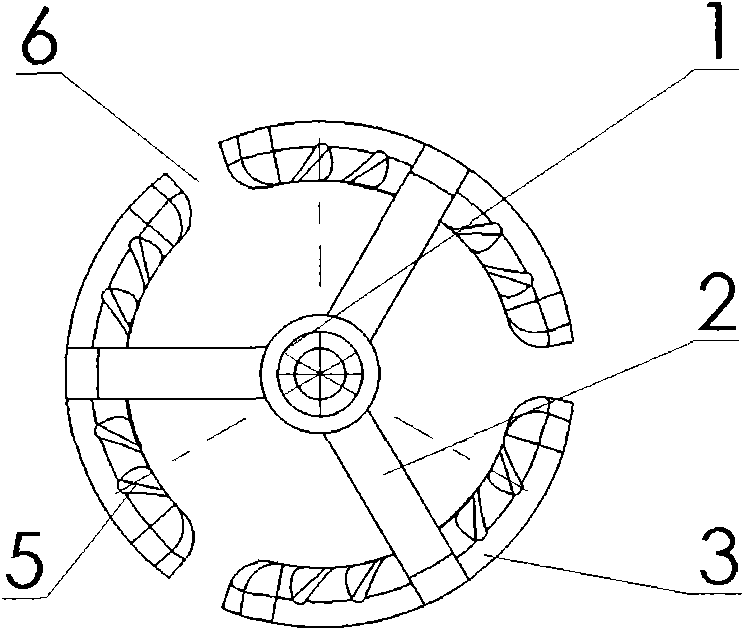

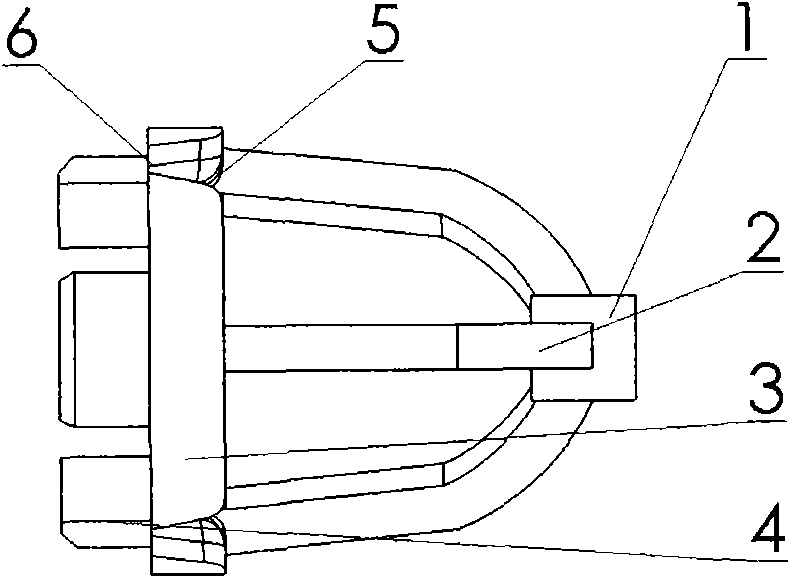

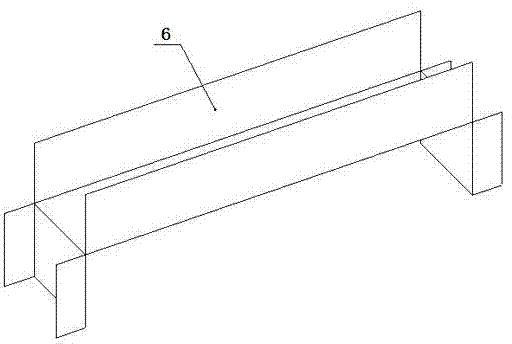

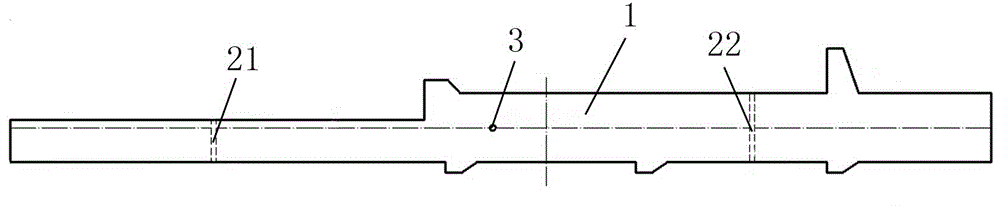

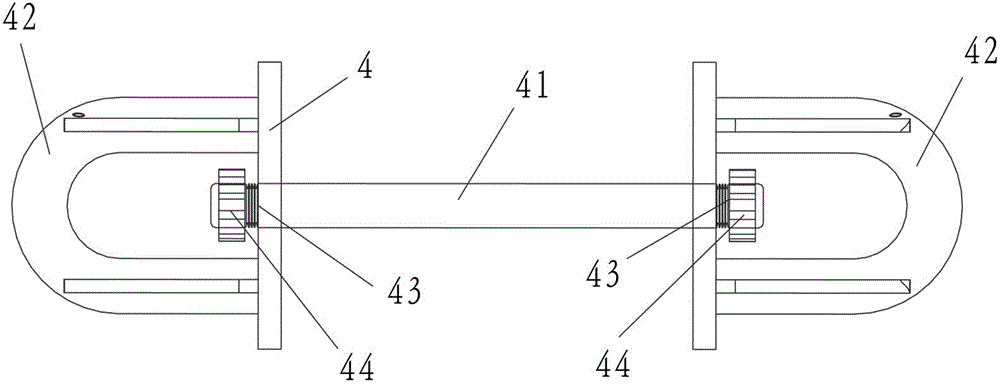

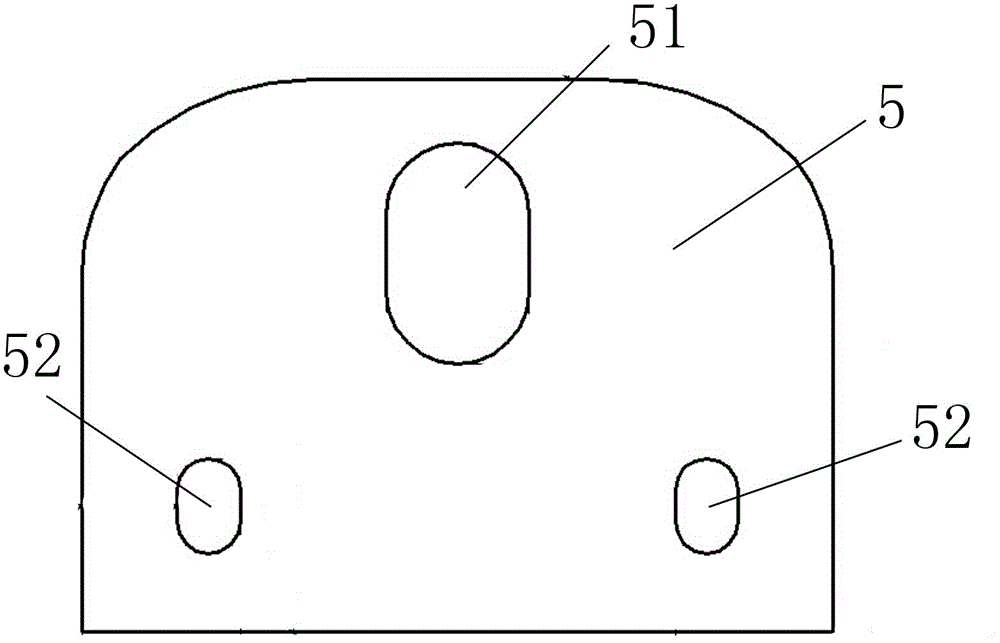

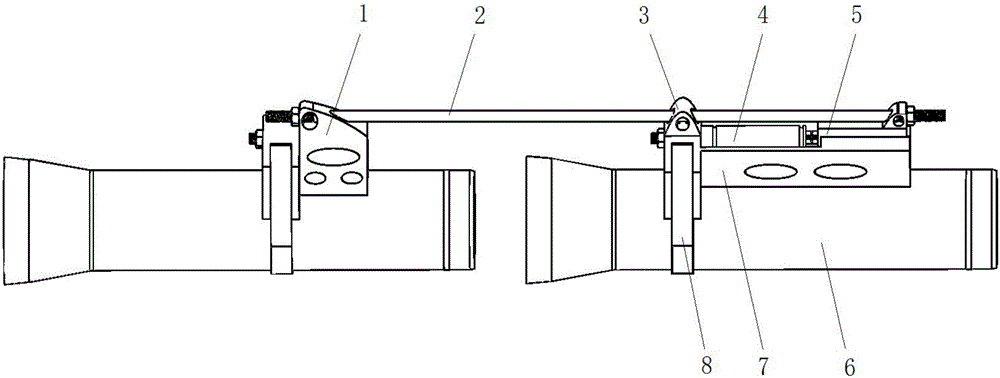

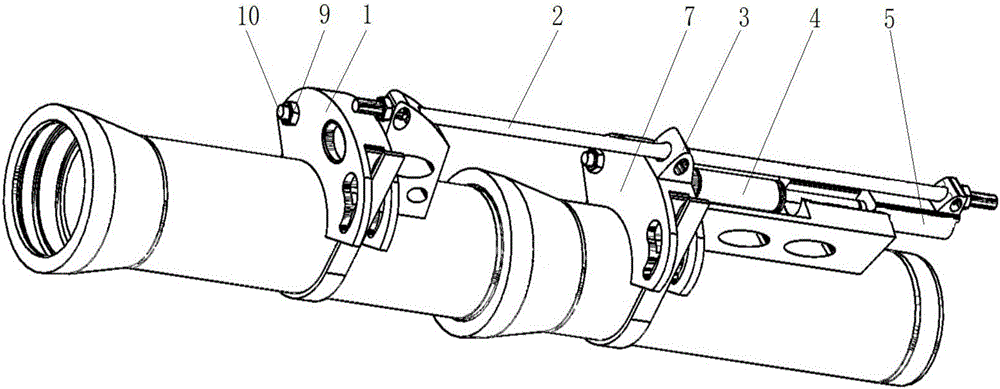

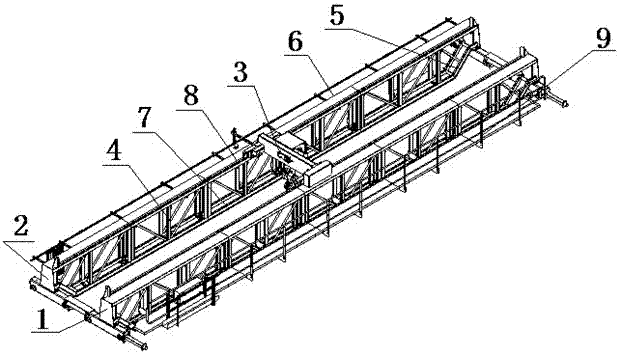

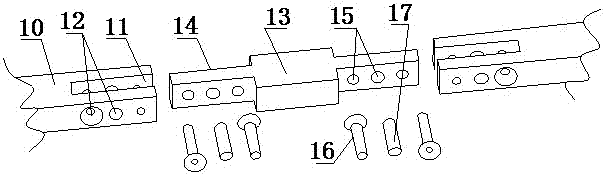

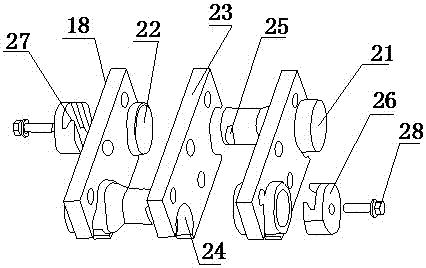

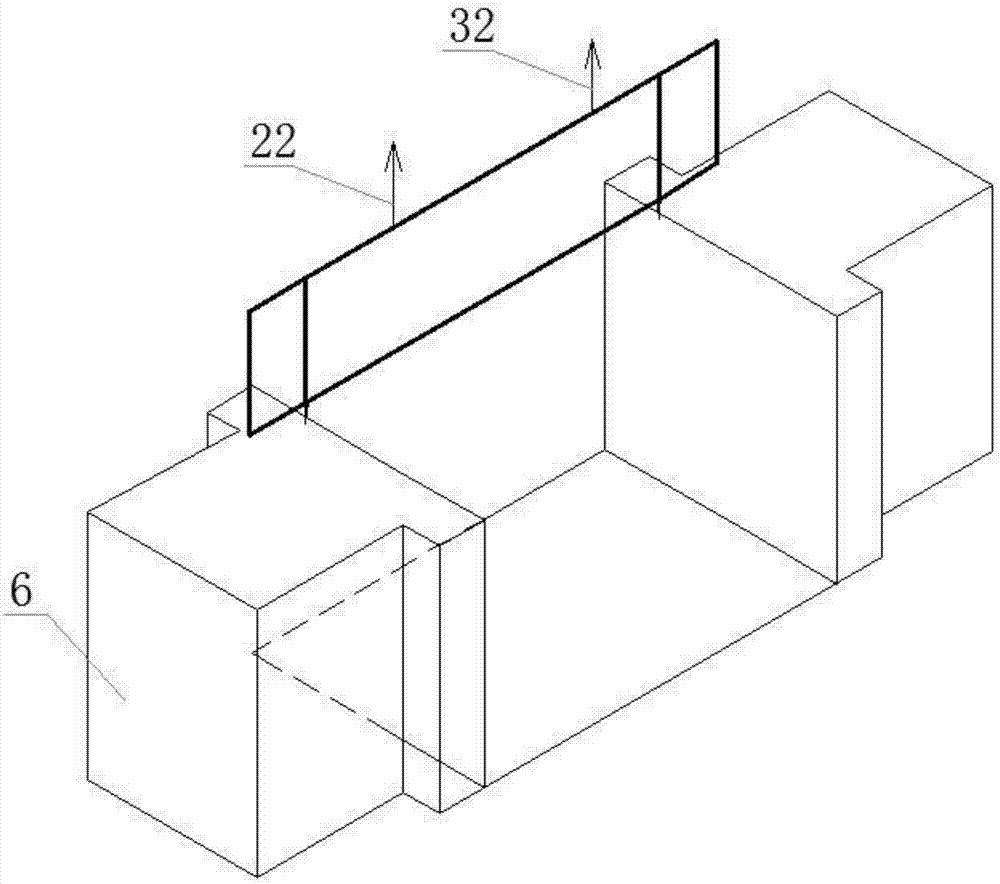

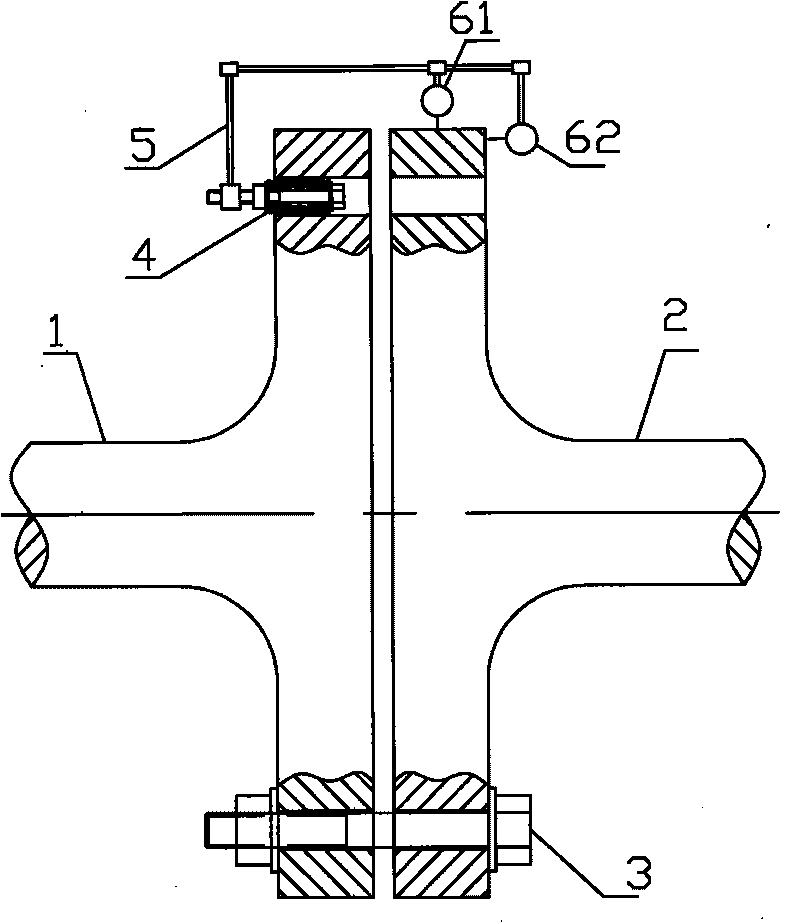

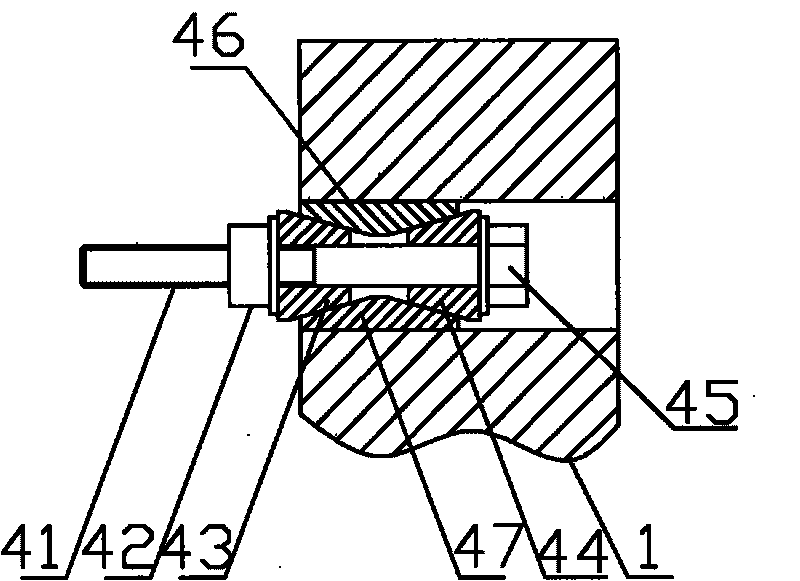

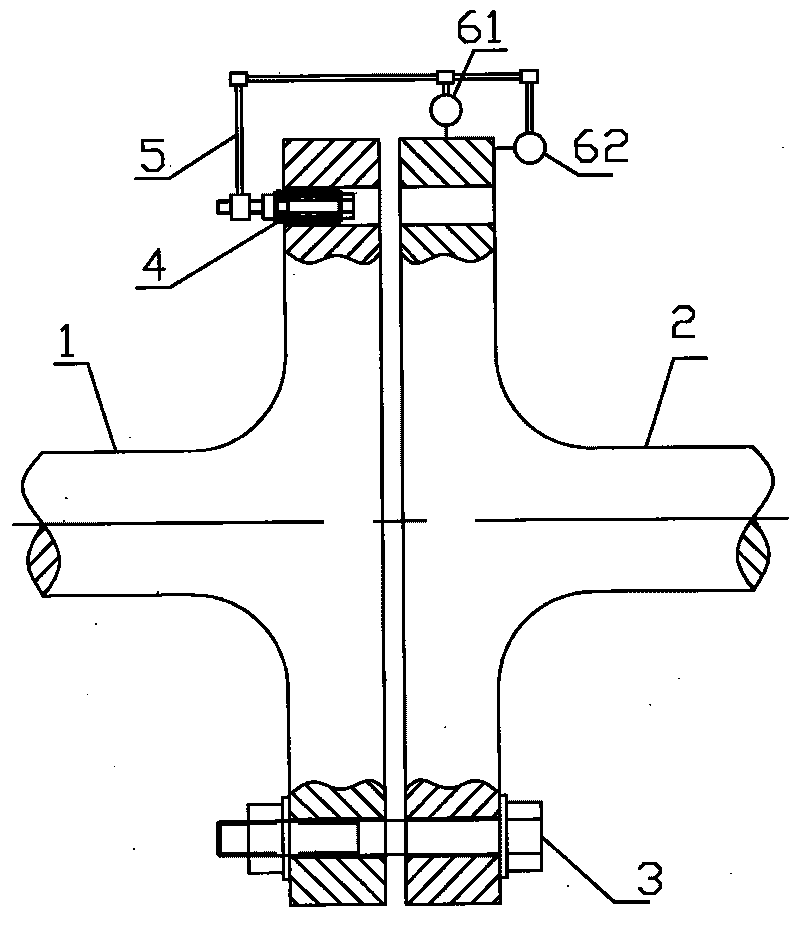

Connecting device of steel column butt joint and installing method

InactiveCN101906849ASpeed up the installation processReduce temporary fixturesStrutsBuilding material handlingButt jointSteel columns

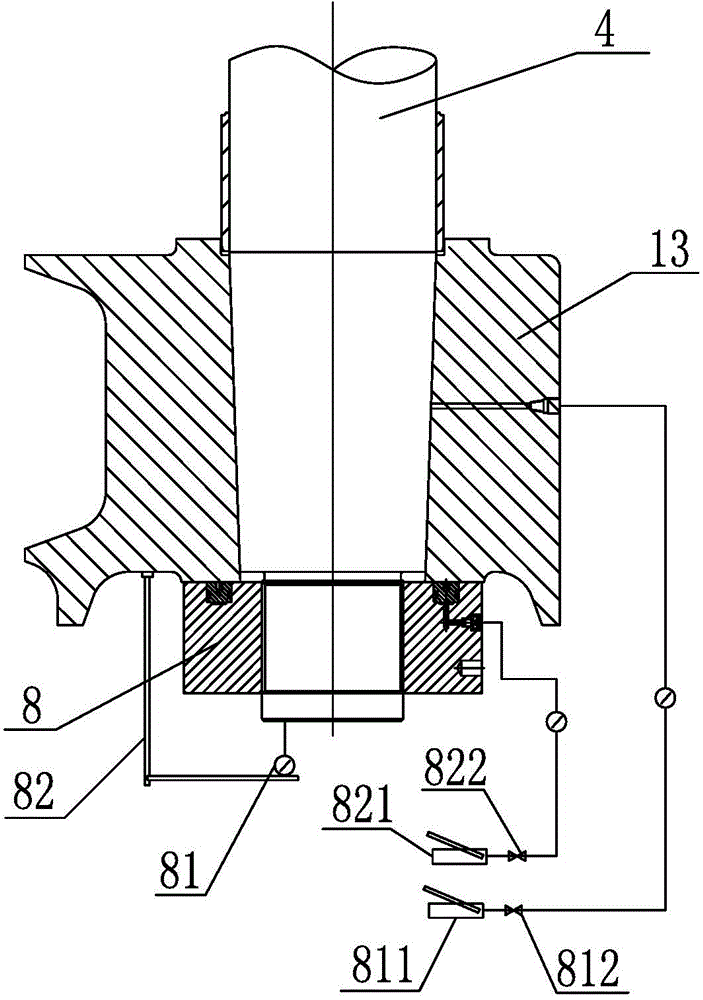

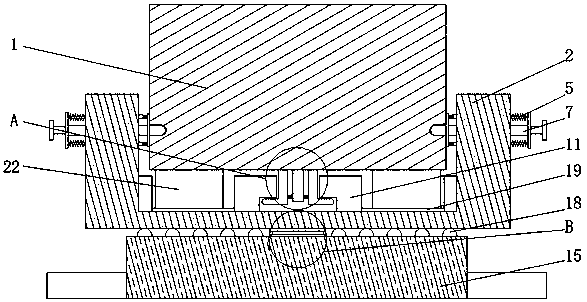

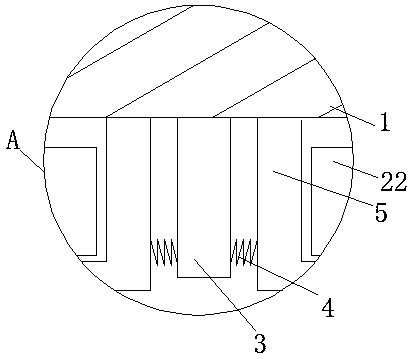

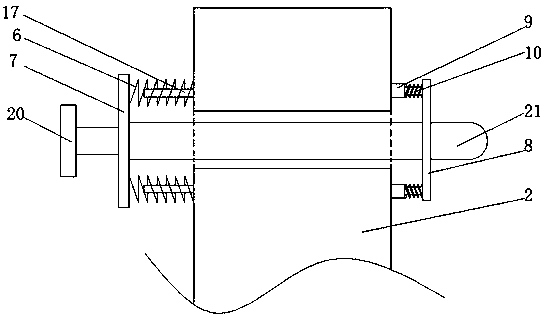

The invention discloses a connecting device of a steel column butt joint and an installing method, belonging to the field of steel structure construction. The connecting device comprises two lug plates, two connecting clamp plates and bolts, wherein bolt holes are arranged on the two lug plates; the two connecting clamp plates are provided with bolt holes corresponding to the bolt holes on the two lug plates; and the two lug plates are arranged between the two connecting clamp plates and are fixedly connected into an integral structure through the bolts and the connecting clamp plates. The invention also provides an installing method of an incline steel column butt joint. The connecting device can be used in the butt joint of incline steel columns and is fixed on the butt joint of an upper steel column and a lower steel column to ensure that the upwards-inclining upper steel column is temporally fixed on the lower steel column through the connecting device without arranging a rigid support and pulling a cable wind rope and other temporary fixed facilities, thereby reducing the temporary fixed facilities used in the butt joint of incline steel column members, improving the installation progress of the construction of the steel structure, and shortening the construction period.

Owner:CHINA CONSTR SCI & IND CORP LTD

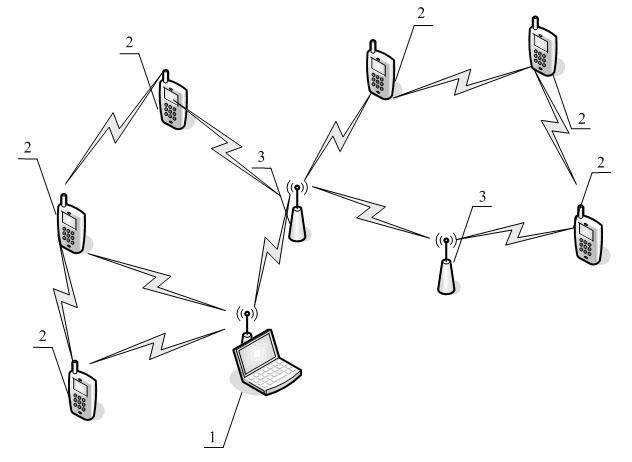

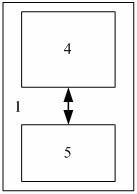

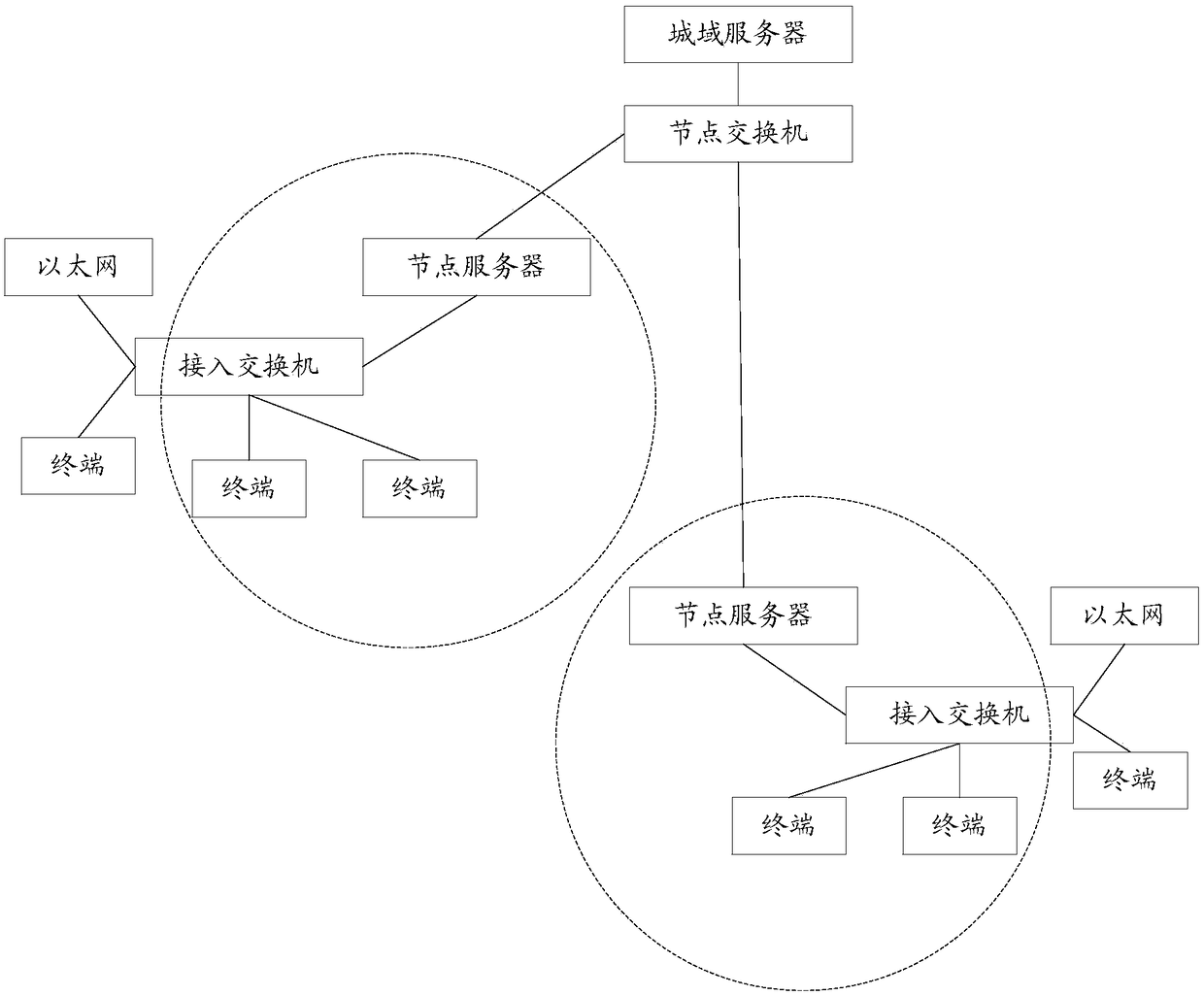

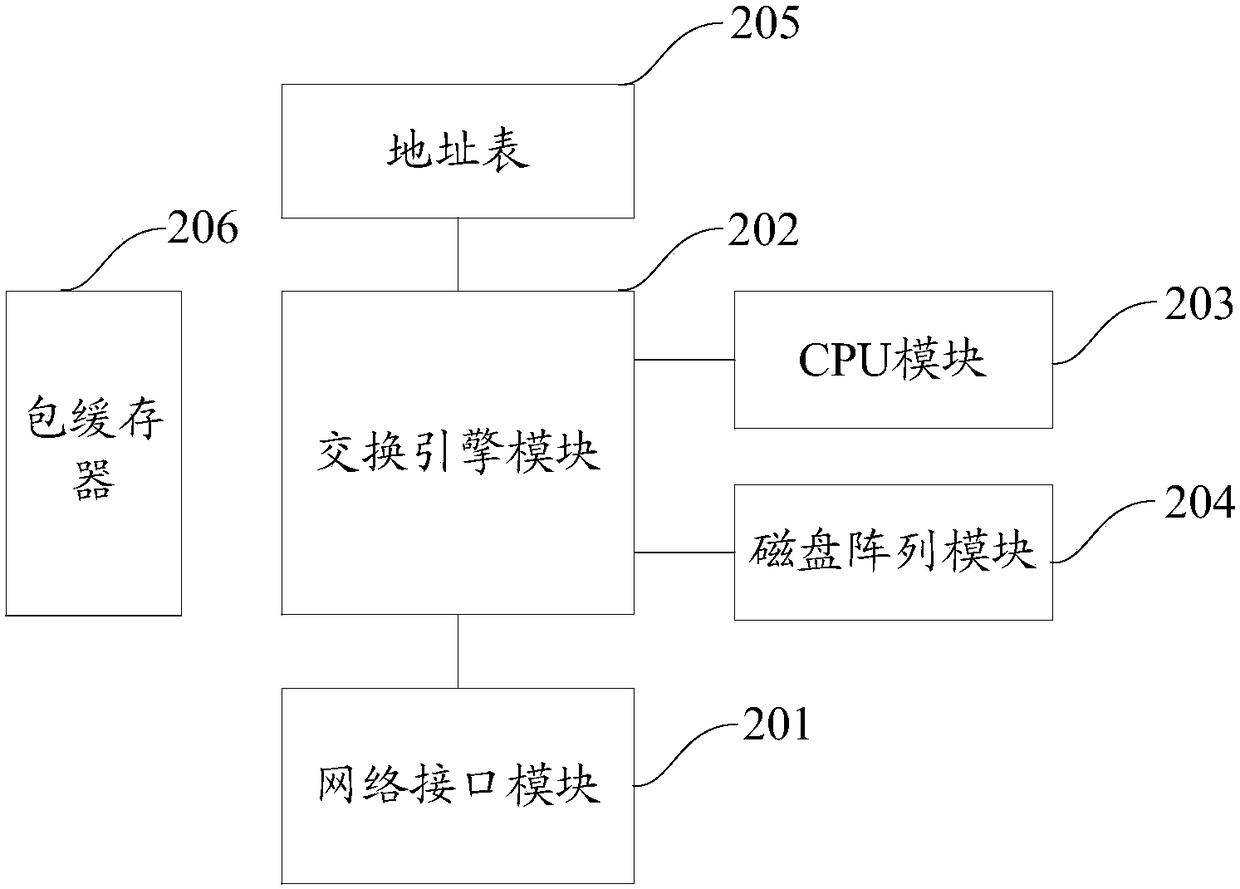

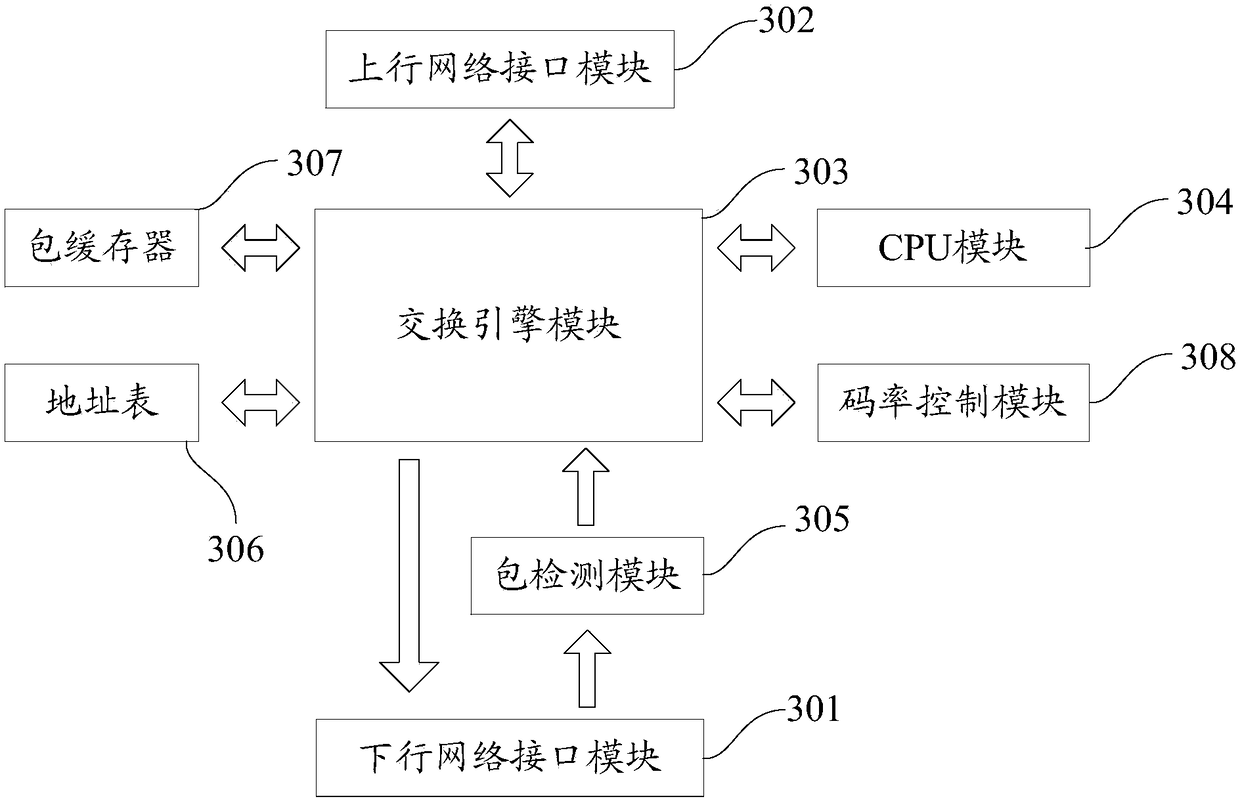

Fireman individual-soldier system on basis of wireless Mesh network framework

InactiveCN102104991AReduce volumeReduce stepsNetwork topologiesWireless mesh networkVital sign detection

The invention relates to a fireman individual-soldier system on the basis of a wireless Mesh network framework. The system consists of a wireless monitoring mainframe, a plurality of wireless individual-soldier sub-machines and a plurality of wireless repeaters, wherein the wireless monitoring mainframe consists of a monitoring module and a wireless center node module; and each wireless individual-soldier sub-machine consists of a central processing unit module, a positioning module, a vital sign detection module, a distress call module, an environment condition detection module, a carried equipment detection module and a wireless terminal node module. When the fireman individual-soldier system is applied particularly, firemen wear the wireless individual-soldier sub-machines to enter a fire site or other accident sites and a chief officer monitors information such as postures, motion tracks, vital signs, environment conditions, carried equipment conditions and the like through the wireless monitoring mainframe, so that the intelligence support of a command decision is provided for the chief officer in time and a scientific basis can also be provided for daily tactical training. By the fireman individual-soldier system, the modernization, automation and intellectualization levels of a fire command are improved and the battle damage rate of the firemen can also be effectively reduced.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY

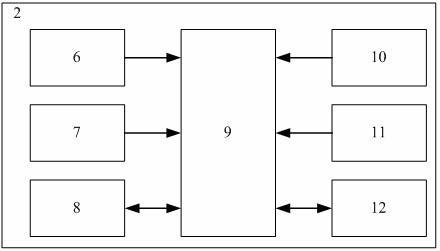

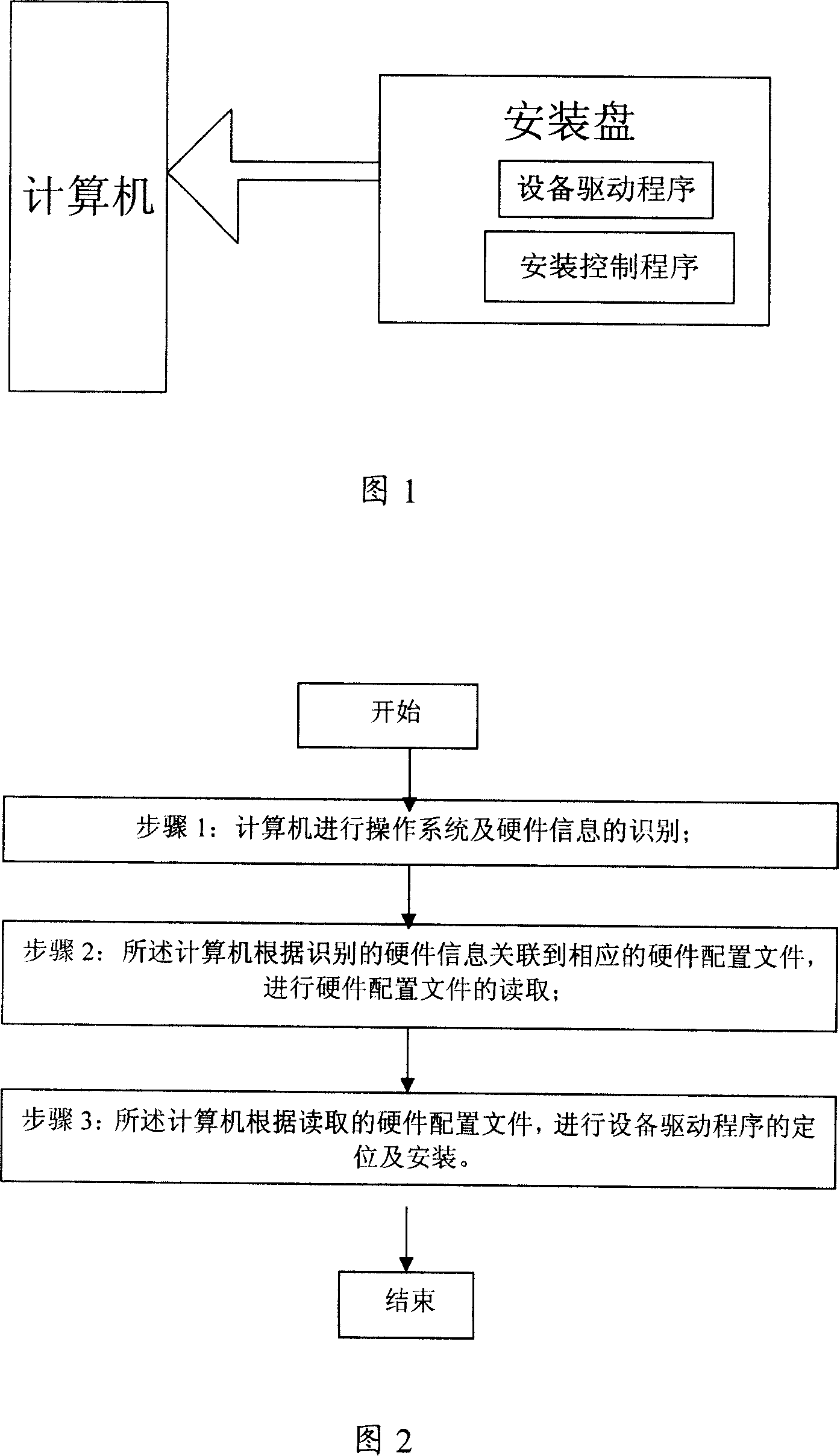

System and method for automatic installation of device driver

InactiveCN101135973AChange the installed statusSpeed up the installation processProgram loading/initiatingOperational systemSoftware engineering

Owner:EVOC INTELLIGENT TECH

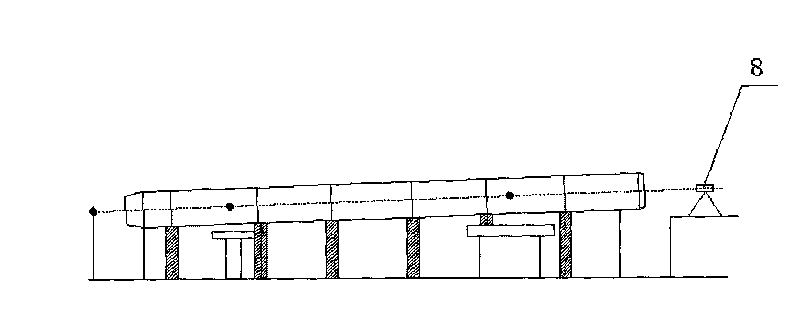

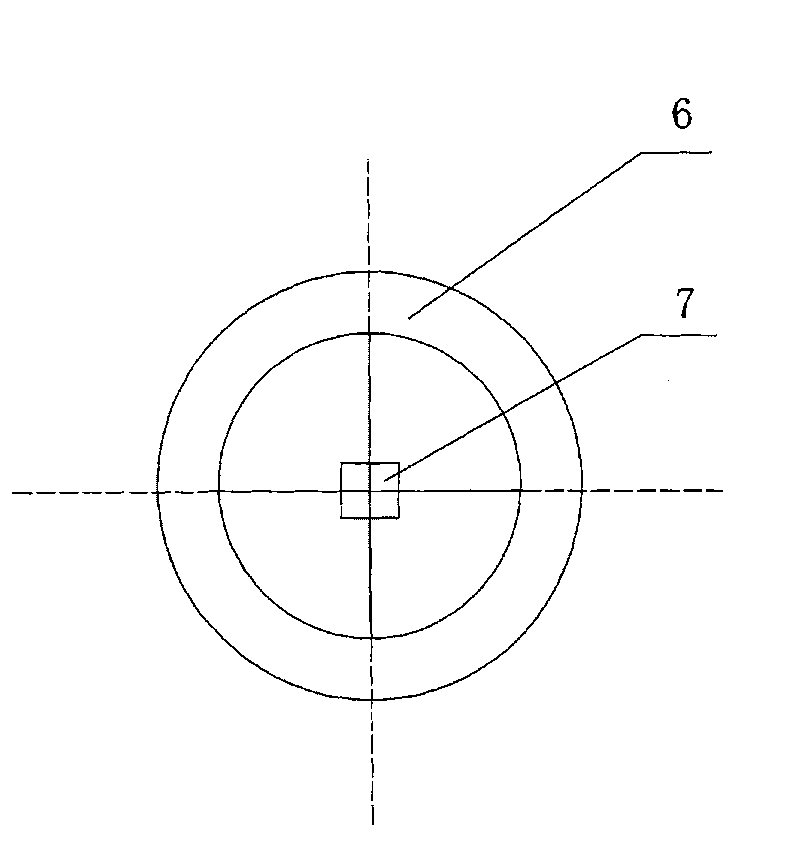

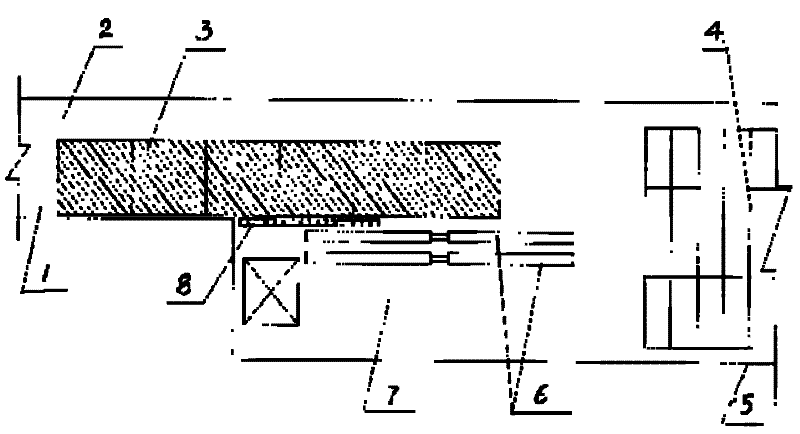

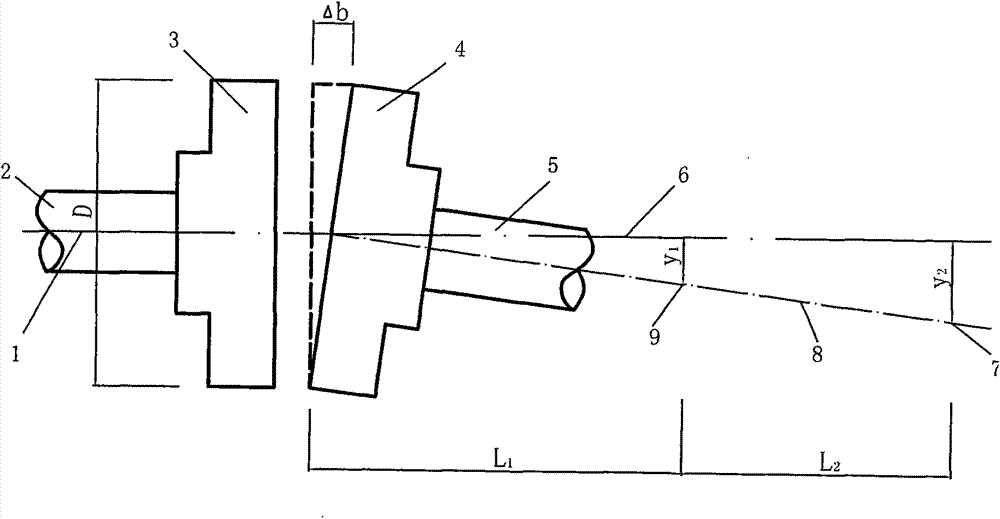

Adjustment method for center line of rotary kiln cylinders

InactiveCN101749940ASpeed up the installation processReduce installation costsRotary drum furnacesRotary kilnMechanical engineering

The invention relates to an adjustment method for a center line of rotary kiln cylinders, which comprises the steps as follows: a bolt is in butting connection at the inner sides of the cylinders between adjacent cylinders so as to lead connectors of the adjacent cylinders to be centered; then (1) a center line is marked through an infrared measuring instrument to lead a driving end base seat and a cylinder center line on the driving end base seat to be a line, other cylinders take the line as reference for adjustment; and (2) each section of cylinder is adjusted through adjusting a crescent base, the deviation of a central point of each cylinder and the reference line is measured through the infrared measuring instrument, each section of cylinder is adjusted according to the deviation value so as to lead the central points at both sides of each section of cylinder to be on the reference line. Compared with the prior art, the adjustment method has the advantages that the method is used for high-altitude installation of the rotary kiln, the positioning and centering installation method is adopted, the hoisting centering is completed at one time, and the center line deviation of the rotary kiln cylinders is greatly reduced.

Owner:ANGANG CONSTR CONSORTIUM

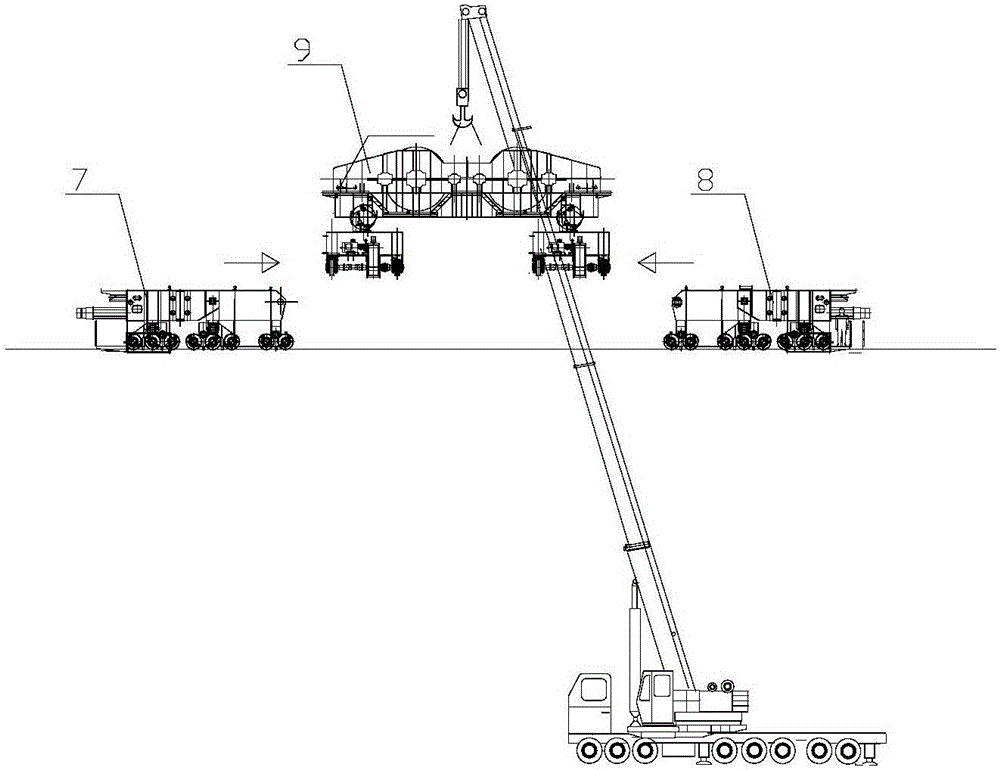

Installing method for bridge crane in enclosed environment workshop

The invention discloses an installing method for a bridge crane in an enclosed environment workshop, and belongs to the technical field of hoisting device installing. The installing method includes the steps that a crane beam rail in the original workshop is retested, and a main beam supporting frame used for containing and assembling a main beam is manufactured; devices on the main beam are assembled through an auxiliary crane, the main beam is hoisted through a large crane, after the main beam is installed, end beams of the main beam are not connected, two large cranes are located on the two sides of the end beams, and hoisting lugs of two truck-mounted cranes are arranged at the ends of a main trolley; after the main trolley is evenly hoisted to be in place, assembling is carried out; and installing of the main beam bridge crane is completed. According to the installing method, the requirement for a site in the workshop is not high, the roof of the workshop does not need to be dismantled, the large crane is not used, ground assembling is rapid, hoisting is once achieved, the working efficiency is high, and the upper-air operational quantity is small; and the installing method has the beneficial effects that the practical hoisting time is short, the practicability is high, and the like.

Owner:CHINA MCC17 GRP

Railway large-bore tunnel overhead contact built-in sliding chute construction method

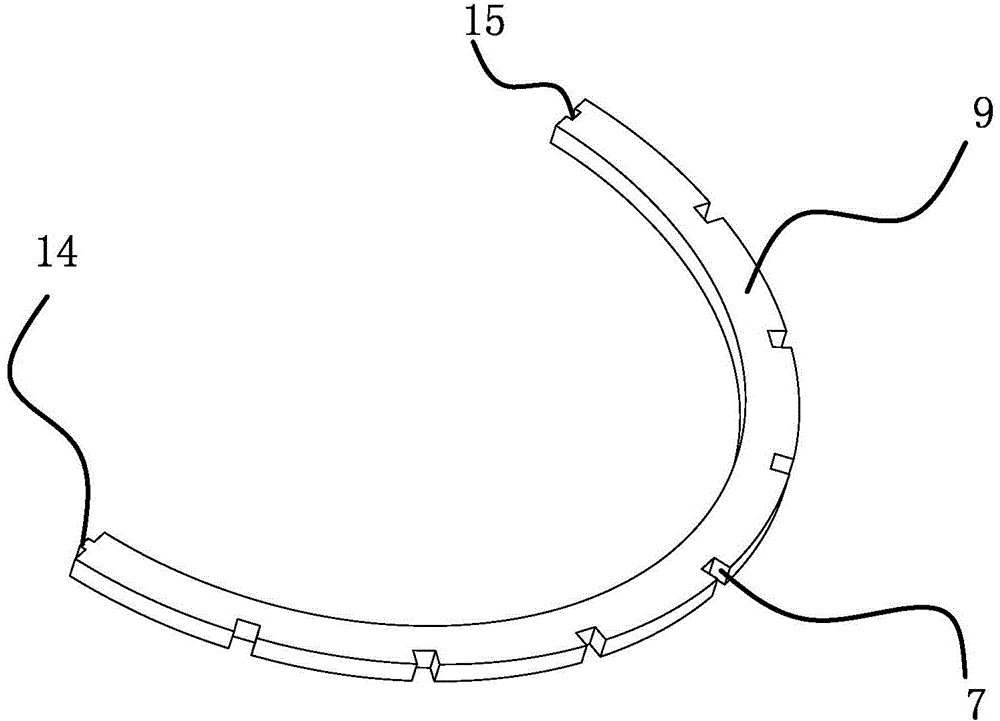

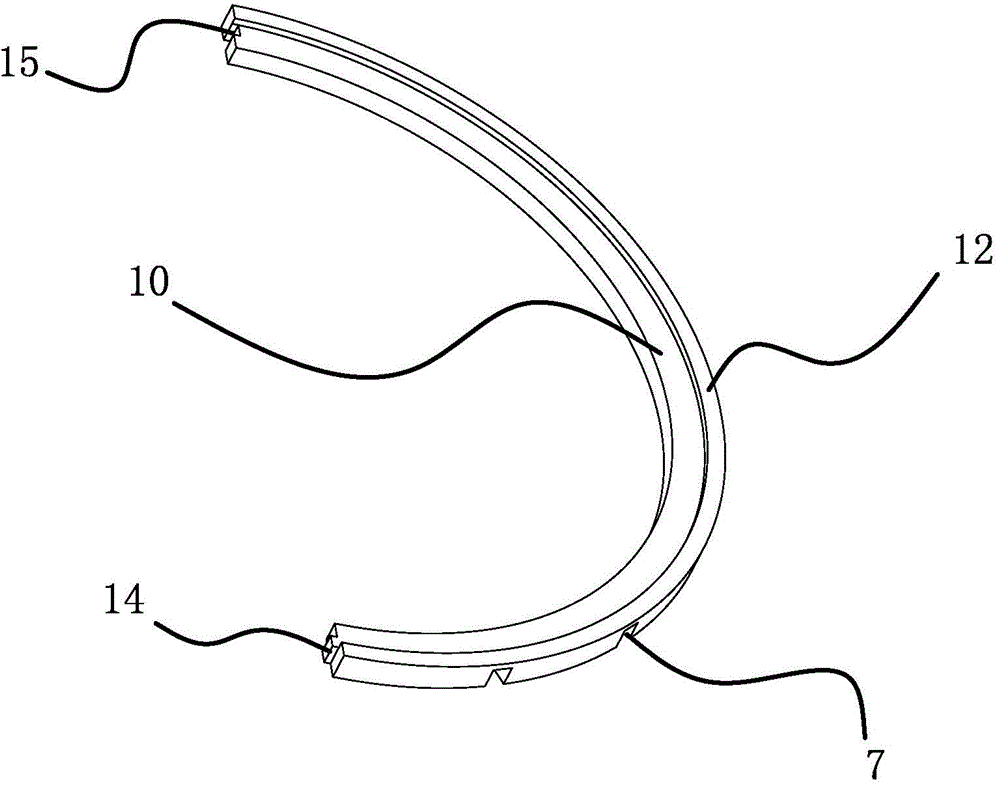

ActiveCN101182774ASpeed up the installation processImprove bindingUnderground chambersTunnel liningRailway tunnelHydraulic cylinder

The present invention relates to the art of railway tunnel construction technology, in particular to a built-in sliding chute construction method of a contact net of a railway large cross-section tunnel, which solves the problems of the prior chemical anchoring method, such as slow installation progress, low security and durability and unsmooth appearance. (1) a lining loop wheel machine template is provided with an opening; (2) the lining loop wheel machine is positioned; (3) after positioning the lining loop wheel machine, the stroke of a hydraulic cylinder of an arc control liner car template of the lining loop wheel machine is adjusted to the minimum position; (4) the hoop reinforcement in the position of the sliding chute and surrounding the sliding chute is dismantled; (5) the position of the sliding chute is adjusted on the lining loop wheel machine template so as to make both ends of the sliding chute aiming at a positioning hole and then fix the sliding chute and the lining loop wheel machine template through a T-head bolt; (6) then the dismantled hoop reinforcement is arranged; (7) the lining loop wheel machine is lifted and poured with reinforced cement. The present invention has the advantages of simple operation and strengthening, enhanced work efficiency, tight combination of built-in piece and concrete, smooth and pleasing appearance, no need of equipment and staff addition, thus greatly reducing the cost.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Bridge jacking counter-force device suitable for narrow and small space between beam bottom and cover beam

InactiveCN105735149AAvoid secondary damageSpeed up the installation processBridge erection/assemblyBridge strengtheningHoopingMaterial resources

The invention discloses a bridge jacking reaction force device suitable for the narrow space between the bottom of the beam and the cover beam. The platform structure on the side, the high-strength bolt hoop used to connect the load-bearing beam and the platform structure, and the clamping device used to fix the entire device and the cover beam. The two load-bearing beams cross the narrow gap between the beam slab and the cover beam, the load-bearing beams are reliably connected to the platform structure through high-strength bolt hoops, and the entire reaction force device is reliably connected to the cover beam through the clamping device. The jack is placed on the platforms on both sides and the bridge jacking operation can be carried out. The bridge jacking device of the present invention has the advantages of small self-weight, high bearing capacity, and wide application range. It can save a lot of manpower and material resources when used in the jacking of hollow slab bridges in the narrow space between the beam bottom and the cover beam.

Owner:CCCC ROAD & BRIDGE BEIJING TECH CO LTD

Camera fixing device for security and protection monitoring engineering

InactiveCN107830334AFunctionalWide camera rangeClosed circuit television systemsStands/trestlesRotary stageEngineering

The invention discloses a camera fixing device for security and protection monitoring engineering. The camera fixing device comprises a fixed base, wherein a first motor seat is arranged at the lowerpart of the left side wall in the fixed base; a first motor is arranged at the right end of the first motor seat; a first gear is arranged on an output shaft of the first motor in a sleeving manner; the first gear is meshed with an annular internal gear; a rotating table is arranged outside the annular internal gear in a sleeving manner; first bearings are arranged at the lower part of the rotating table in a sleeving manner; the first bearings are fixed on the fixed base; a telescopic rod is arranged at the top of the rotating table; a lifting seat is arranged at the top of the telescopic rod. By the additional arrangement of a rotating device, the camera fixing device has a rotating function, so that a camera has a wider camera range; through the additional arrangement of the telescopicrod and the lifting seat, the camera fixing device has a height adjustment function, so that the device is more flexible, and a security and protection monitoring device can be located more precisely.

Owner:西安龙之梦网络信息有限公司

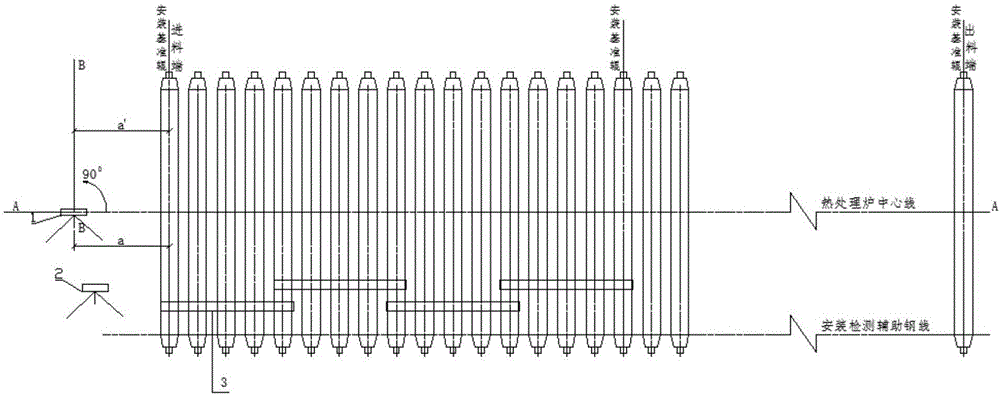

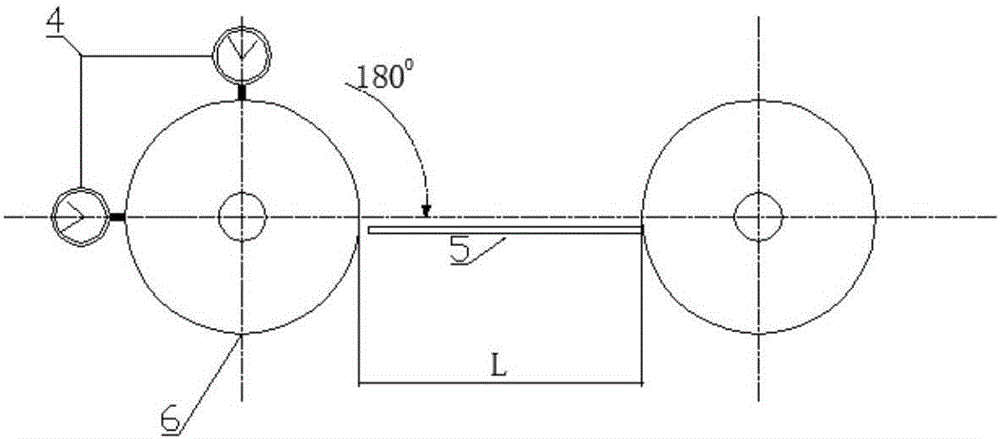

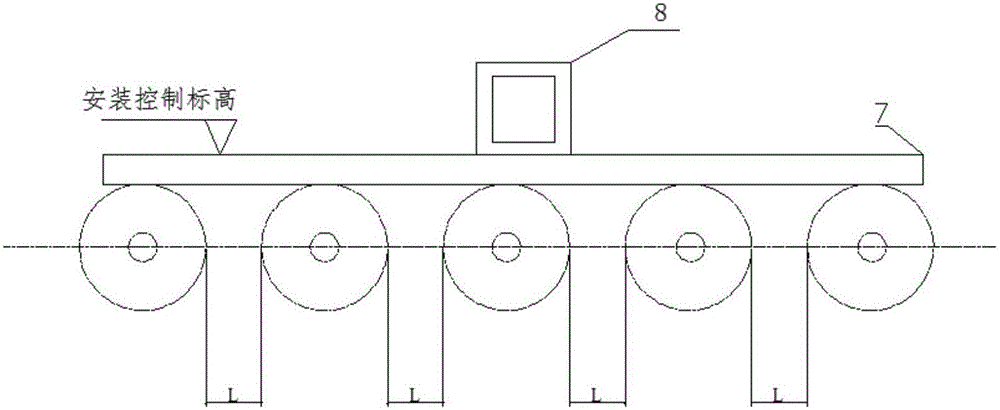

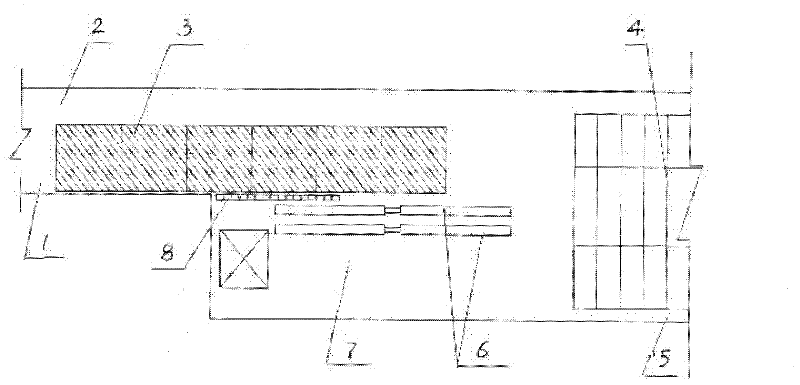

Conveying roller mounting precision control method of roller bottom heat treatment furnace

ActiveCN106834643AImprove installation efficiencyFast installationFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention discloses a conveying roller mounting precision control method of a roller bottom heat treatment furnace. The method comprises the steps of roller way assembly, lifting, finish adjustment of a standard roller way, finish adjustment of a nonstandard roller way, installation of a roller way driving device and overall adjustment of the roller ways. The method reasonably sets a standard roller, divides different mounting working surfaces, adjusts the precision of working rollers mounted on the working surfaces with all mounting control precision indexes of the standard roller way as basis, improves the mounting efficiency, accelerates the mounting speed, guarantees the mounting quality, is clear in mounting sequence, is precise in positioning, and prevents the problems of rework and work delaying. The method reasonably uses such auxiliary mounting tools as 5 m steel flat rulers, can realize overall adjustment of one set of several roller ways, accelerates the mounting progress, and meanwhile, can adopt a superposition progressive mode to guarantee non-overproof mounting errors.

Owner:TIANJIN 20 CONSTR

Fast installation method of ten-million-ton scale fully mechanized caving face equipment

InactiveCN102392667ARealize parallel operationSpeed up the installation processMine roof supportsAnchoring boltsMode of transportTon

The invention discloses a fast installation method of ten-million-ton scale fully mechanized caving face equipment and belongs to sinking and driving engineering of mines. The method is innovatively characterized in that open-off cuts on a working surface are widen to improve the transportation mode and installation method of a hydraulic support and the supporting mode of the open-off cuts. By virtue of the improvements, the installation time of the ten-million-ton scale fully mechanized caving face equipment is realized, the construction period is shortened and the installation progress of the working surface is accelerated.

Owner:SHANDONG XINJULONG ENERGY

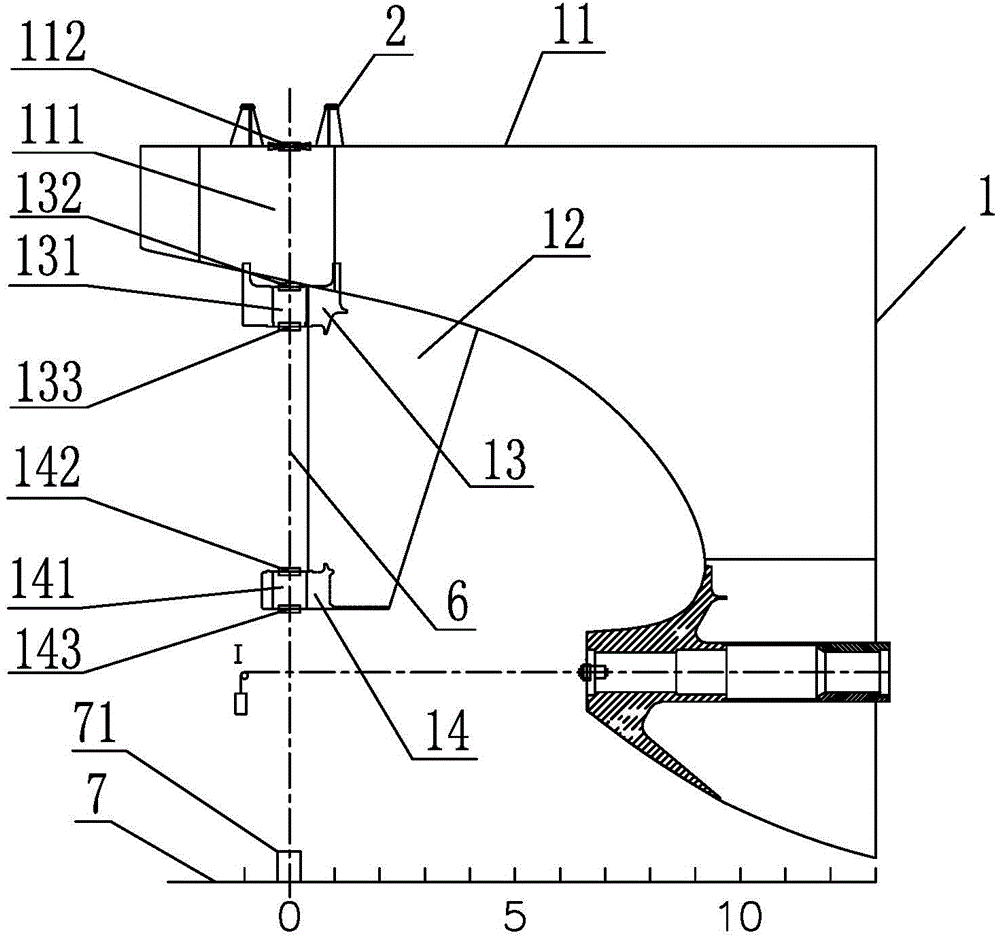

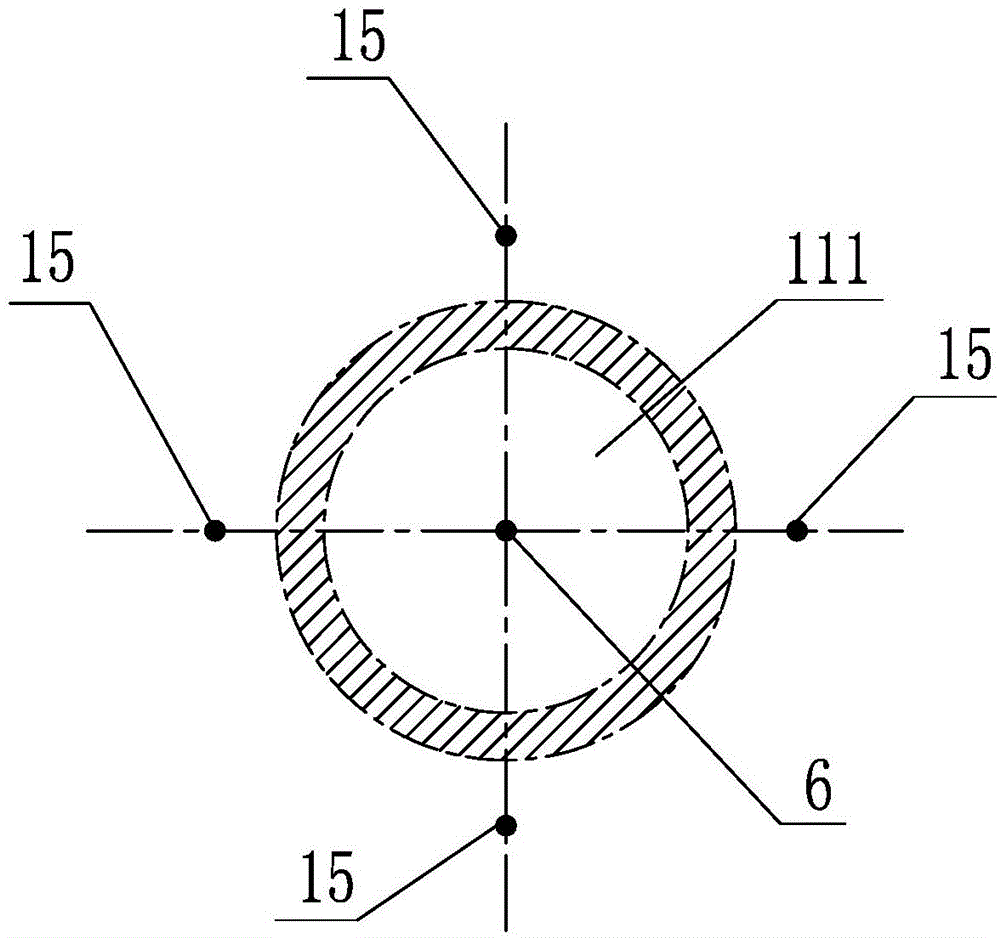

Mounting method of semi-suspension rudder in semi-ship floating condition

ActiveCN106184609AGuaranteed installation accuracySpeed up the installation processVessel partsEngineeringMechanical engineering

The invention provides a mounting method of a semi-suspension rudder in a semi-ship floating condition. The mounting method comprises the following main steps of: before semi-ship floating is performed, determining a center line of a rudder system through a reference target, an auxiliary target and a lighting device; punching a borehole mark and a reset mark, and boring holes in a lower rudder bearing and a lower rudder lug through the borehole mark; after hole boring is completed, mounting a machined rudder stock liner on the lower rudder bearing, and mounting a processed rudder pintle liner on the lower rudder lug; mounting a rudder machine base; after the operations are completed, performing semi-ship floating; after semi-ship floating is completed, firstly, resetting the center line of the rudder system; and then, connecting the semi-suspension rudder with a rudder stock in a matched manner through the matching of the rudder stock and a hydraulic nut, so that quick mounting of the semi-suspension rudder is achieved. Through the mounting method disclosed by the invention, design sizes in a drawing can be guaranteed at a construction site, and construction can be performed according to the drawing, so that the mounting accuracy is guaranteed, and the ship construction efficiency is improved effectively.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Intelligent camera convenient to install

PendingCN108036161AEasy to installEasy to put inClosed circuit television systemsStands/trestlesEngineering

The invention relates to the technical field of electronic monitoring, and discloses an intelligent camera convenient to install. The intelligent camera convenient to install comprises an intelligentcamera body and an installing base, the bottom of the intelligent camera body is inserted into the surface of the installing base, the bottom of the intelligent camera body is fixedly connected with afixing block, the fixing block is fixedly connected with the surface of one side of a pressure plate through a reset spring, the top of the pressure plate is fixedly connected to the lower surface ofthe intelligent camera body, the surface of one side of the installing base is fixedly connected with one side of a limiting plate through an extension spring, an insertion rod is fixedly connected to one side of the limiting plate, and one end of the insertion rod sequentially penetrates the installing base and the connecting plate and extends to the exterior of the connecting plate. Through cooperation of the pressure plate and the reset spring, the structure is simple, installation and operation processes are simple and convenient, the intelligent camera body can be conveniently installedby a worker, time and labor are saved, the insertion rod is released to be inserted into a clamping groove, and falling of the intelligent camera body is effectively prevented.

Owner:HENAN HAOWEI INTELLIGENT TECH CO LTD

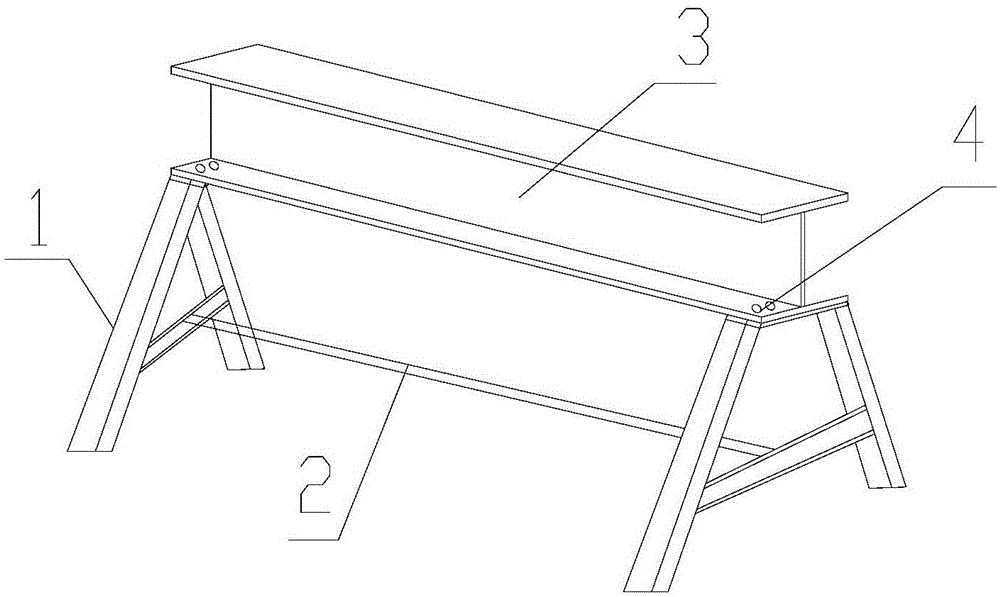

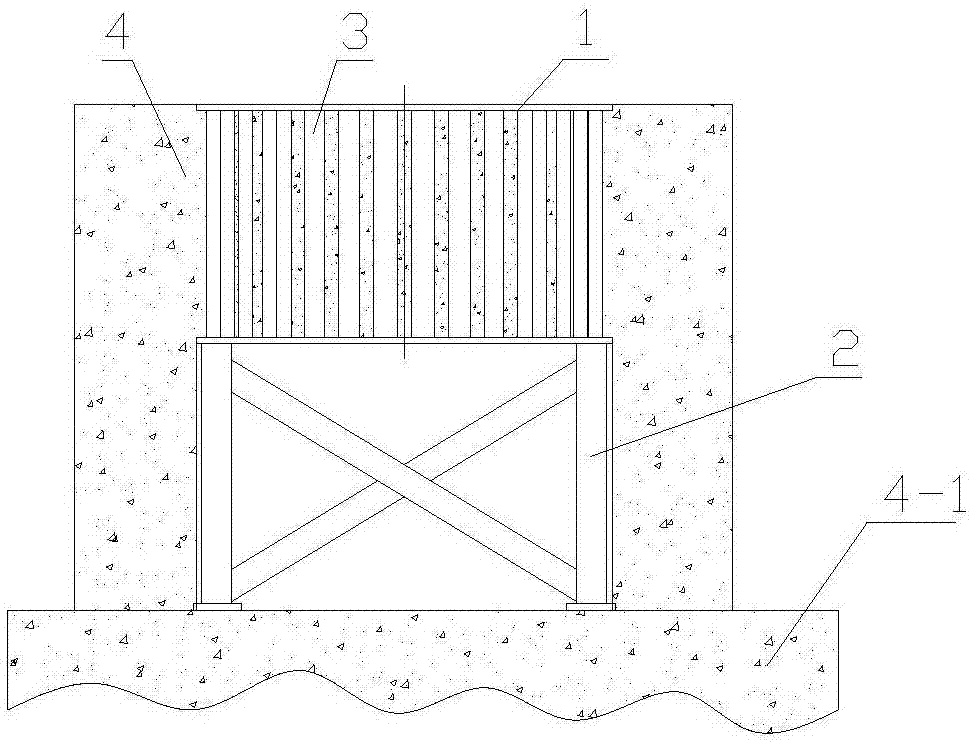

Welding deformation flatness correction method of finished steel crane beam

The invention discloses a welding deformation flatness correction method of a finished steel crane beam. The welding deformation flatness correction method includes the following steps: a, an arc correction tool and a deflection control tool are made; b, a crane beam is placed on the deflection control tool; c, the arc correction tool is placed at a local area between two stiffening rib plates of the crane beam, and correction is performed by using a roasting mode; and d, the arc correction tool is moved to the place between the adjacent stiffening rib plates after the local area is corrected, correction is performed sequentially by using a roasting mode until specified quality standard is achieved. The welding deformation flatness correction method of the finished steel crane beam adopts the measure, can reduce labor intensity of workers, improves efficiency, shortens time for the crane beam to occupy field space, accelerates installation progress, and reduces installation cost.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

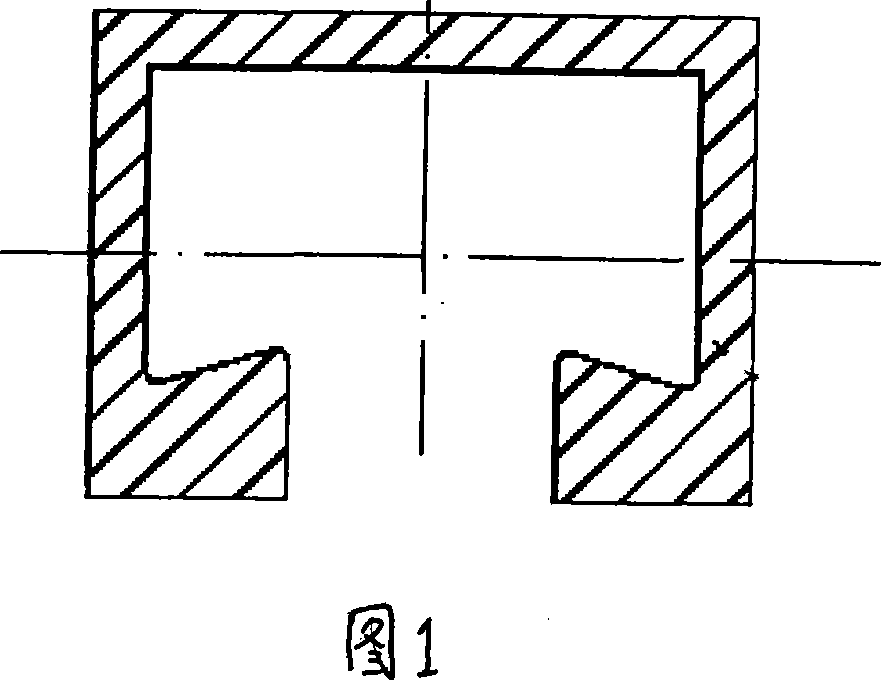

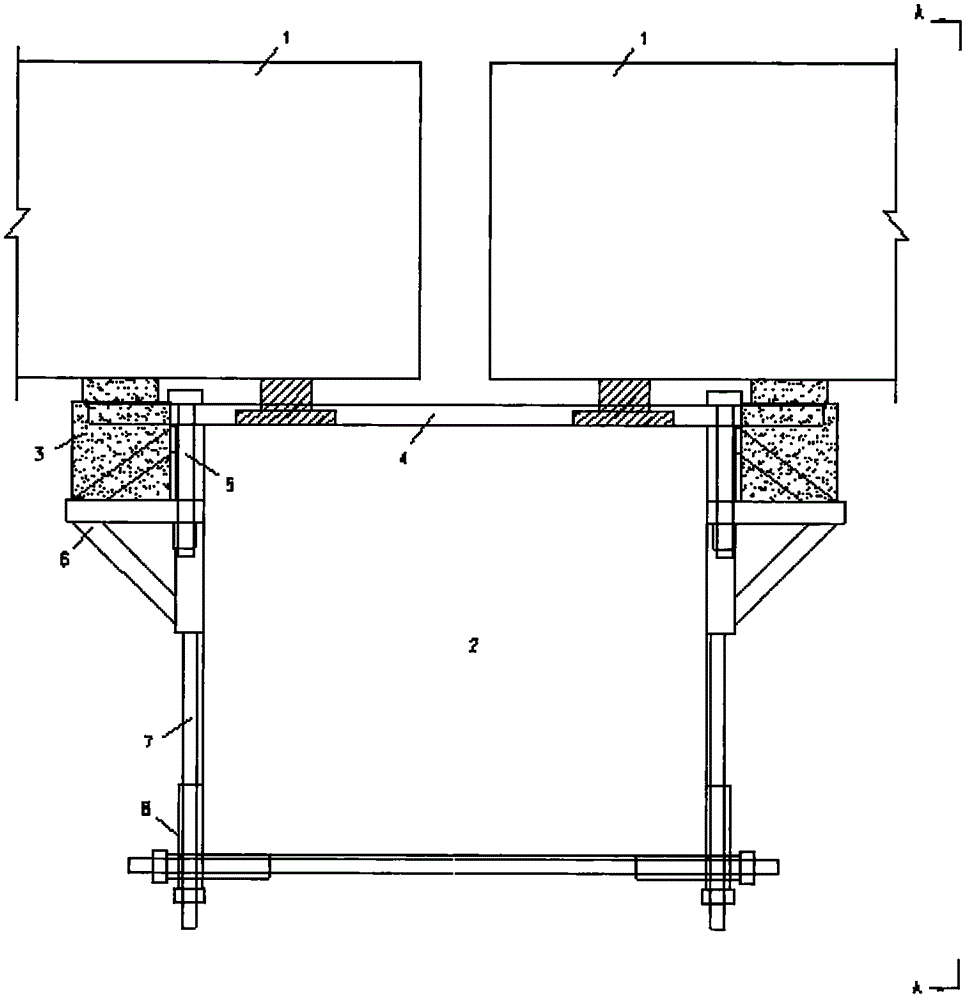

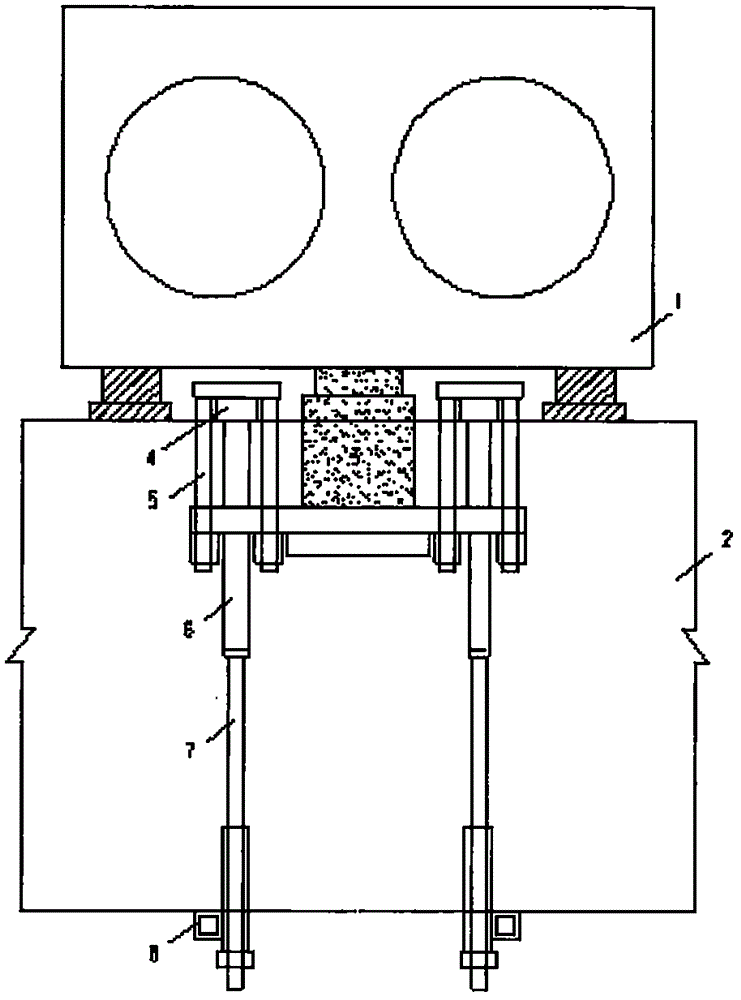

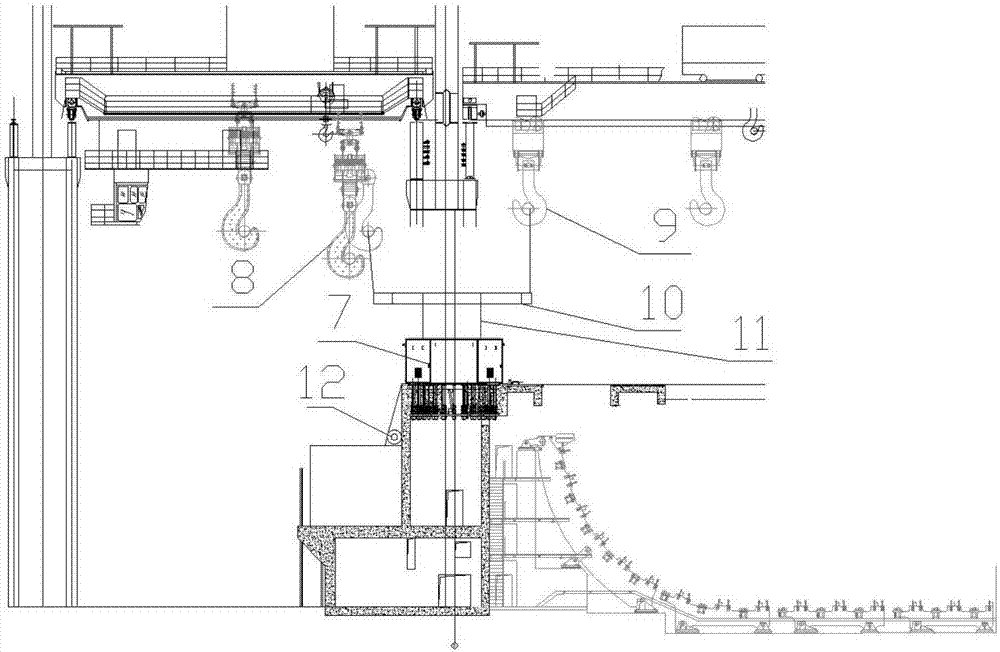

Combination hoisting mounting method of continuous casting ladle turret

The invention belongs to a building construction method, and discloses a combination hoisting mounting method of a continuous casting ladle turret. The combination hoisting mounting method is characterized in that by employing the advantage that the ground in a factory building is wide, a part of components of the continuous casting ladle turret are assembled on the ground off-line, the components of the continuous casting ladle turret are transferred by adopting a sliding device, and are hung by a shoulder pole for hoisting, concrete is prevented from leaking into sleeves of foundation bolts by adopting an anti-leakage device, and a travelling crane of a molten steel receiving bay and a travelling crane of a casting bay that are arranged in the factory building are used jointly to hoist the various components of the continuous casting ladle turret in position. The combination hoisting mounting method comprises the following steps: one, a fixing bracket is arranged and anchor pieces are mounted; two, slurry of a foundation seat is prepared, and the sliding device is arranged; three, a base of the continuous casting ladle turret is hoisted; four, a revolving body is mounted; five, an upper part revolving support body is assembled and mounted; and six, accessories are mounted. The combination hoisting mounting method is fast in progress and high in precision, the construction efficiency is improved, and the construction cost is reduced.

Owner:CHINA MCC17 GRP

Inner diversion type self-tightening hanging part of heat exchange tube

InactiveCN101839670AHigh trafficIncreased turbulenceCleaning heat-transfer devicesHeat transfer modificationSoftware engineeringScale control

The invention discloses an inner diversion type self-tightening hanging part of a heat exchange tube, mainly comprising a hollow shaft, a connecting rod, a support table and an extension end, wherein the hollow shaft, the support table and the extension end are respectively a concentric cylindrical body with an inner hole, the diameter of the inner hole of the hollow shaft is a little bigger than the diameter of a rotary shaft, the hollow shaft and the support table are fixedly connected through the connecting rod, the outer diameter of the extension end is a little bigger than the inner diameter of the heat exchange tube, the diameter of the support table is equal to the diameter of the extension end, the outer diameter of the support table is bigger than the outer diameter of the heat exchange tube and smaller than the center distance of two nearest heat exchange tubes in a heat exchanger, the support table is fixedly connected with the extension end, a section of notch is respectively arranged at the middle position of two adjacent connecting rods on the support table and the extension end, the notches of the support table and the extension end are beneficial to the stretching of the extension end in the radial direction and are beneficial to the installation of the hanging part and the tightening in the heat exchange tube, the notch of the extension end is beneficial to reducing the resistance to a fluid and saving the cost, and a diversion surface of the support table and a spiral groove structure have certain effects of heat transfer enhancement and scale control and removal.

Owner:BEIJING UNIV OF CHEM TECH

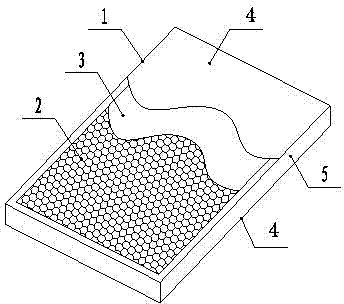

Installation construction process of honeycomb lightweight partition wall boards

The invention discloses an installation construction process of honeycomb lightweight partition wall boards. The process comprises the steps of wall position paying-off, wall cushion construction, installation of keels along the top, keels along the ground, keels along foundation columns and keels along the wall, wall board installation and filling of joints among the wall boards. According to the construction process, the double-layer honeycomb lightweight low-carbon composite partition wall boards are used for an internal partition wall of a building, and can also be used as a wall maintaining material of a house; and according to different wall surface using requirements, the installed product surface can be directly plastered, brushed with coating, stuck with wallpaper or stuck with ceramic tiles.

Owner:YUNNAN JUHE CONSTR GROUP

Hanging method of special-shaped reinforced concrete prefabricated column

The invention discloses a hanging method of a special-shaped reinforced concrete prefabricated column. The method comprises the steps that (1) a hanging starting point position on a special-shaped column is computed; (2) a turning hanging point position on the special-shaped column is computed; (3) sleeve pipes are buried at the hanging starting point and the turning hanging point in advance; (4) long-rod screws penetrate into the pre-buried sleeve pipes of the turning hanging point respectively; (5) special-shaped column demoulding and turning are carried out; (6) preparing before hanging of the special-shaped column is carried out; (7) hanging of the special-shaped column is carried out; (8) a special-shaped column foot is stabilized and is inserted into a cup-shaped foundation; (9) special-shaped column aligning is carried out; (10) a crowbar is used for prying a wedge, or a hammer is used for striking the wedge, so that the center line of the column body is aligned with the center line of the cup bottom; (11) crane unhooking is carried out, and the special-shaped column is placed to the cup-shaped foundation bottom; (12) the wedge on the periphery is tightly stricken; (13) special-shaped column perpendicularity correction is carried out; and (14) grouting is carried out immediately after correction is carried out. During component prefabricating, a hanging hole is reserved, and the shortcomings that hanging point sliding and component corner damage which can happen easily through a conventional binding method are overcome.

Owner:ZHEJIANG JINXIN CONSTR ENG

Portable spigot and socket pipeline jointing machine

The invention discloses a portable spigot and socket pipeline jointing machine which comprises a fixed pull rod seat, a pull rod, a sliding hole, a retractor device, a sliding pull rod seat, a water feeding spigot and socket pipe and a spigot and socket pipe thrust jointing machine seat. One end of the pull rod is fixedly connected with the fixed pull rod seat, and the other end of the pull rod is fixedly connected with the sliding pull rod seat. The sliding pull rod seat is connected inside a sliding groove formed in one end of the spigot and socket pipe thrust jointing machine seat in a sliding manner while one end of the sliding pull rod seat is fixedly connected with the output end of the retractor device. The retractor device is fixedly connected inside the spigot and socket pipe thrust jointing machine seat. The automatic jointing machine formed by the fixed pull rod seat, the pull rod, the retractor device and the spigot and socket pipe thrust jointing machine seat is simple in structure, portable and easy to operate, and saves time, labor, and human resource. Only two people can easily complete the onerous installation used to be finished by seven to eight persons. The installation speed is increased, working efficiency and installation quality are improved, and the occurrence of hidden dangers is prevented.

Owner:中铁电气化局集团北京建筑工程有限公司

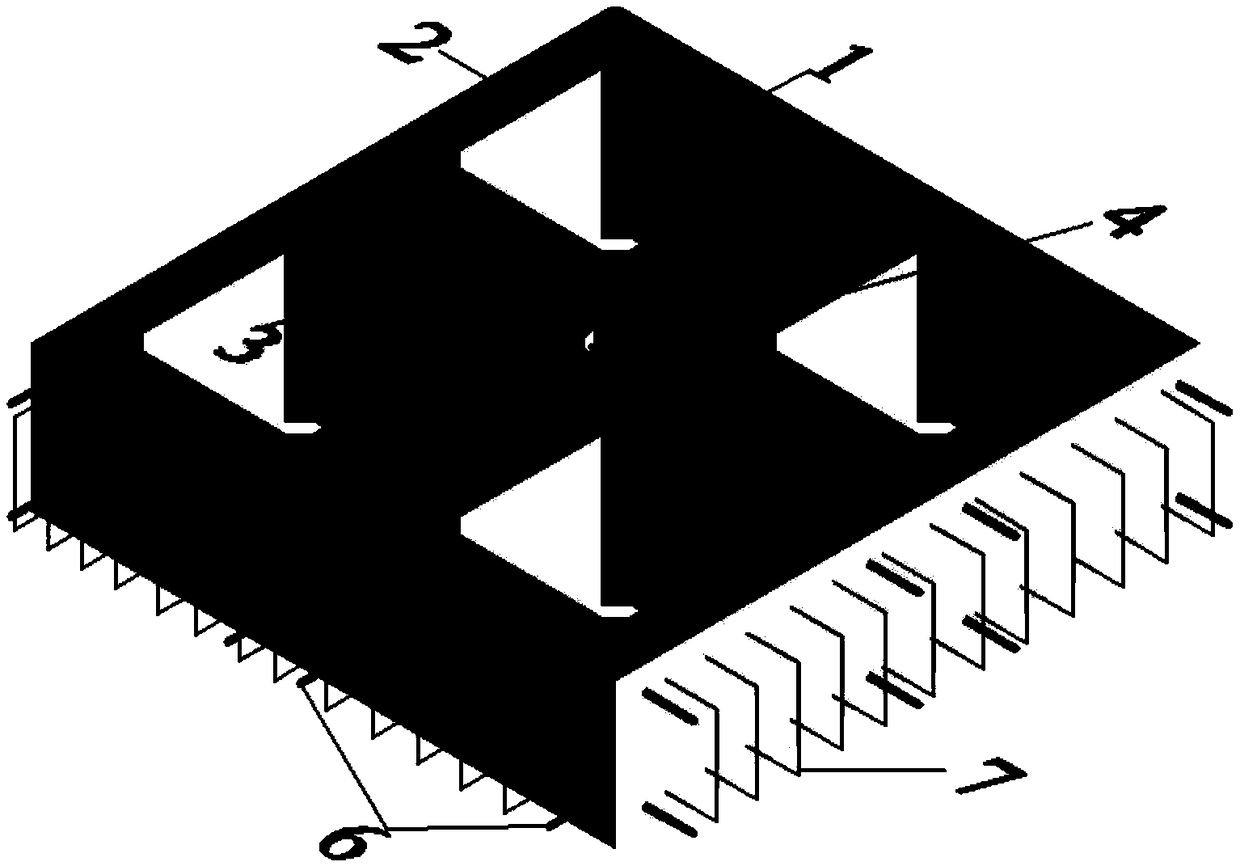

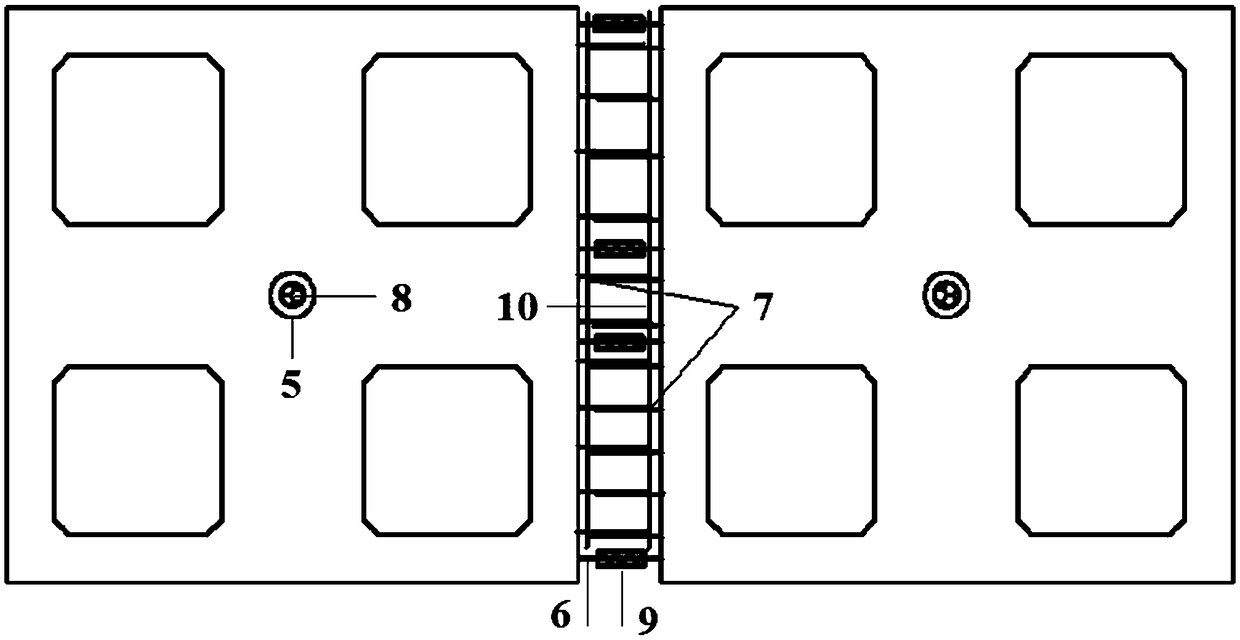

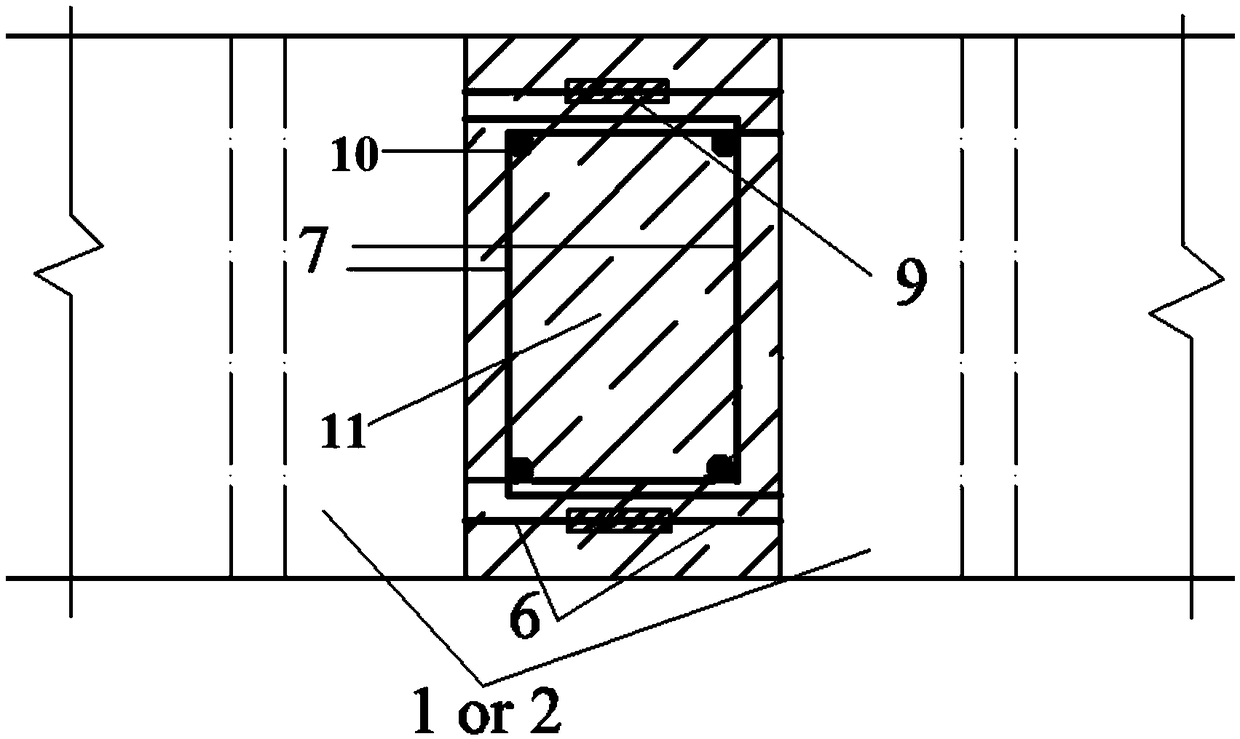

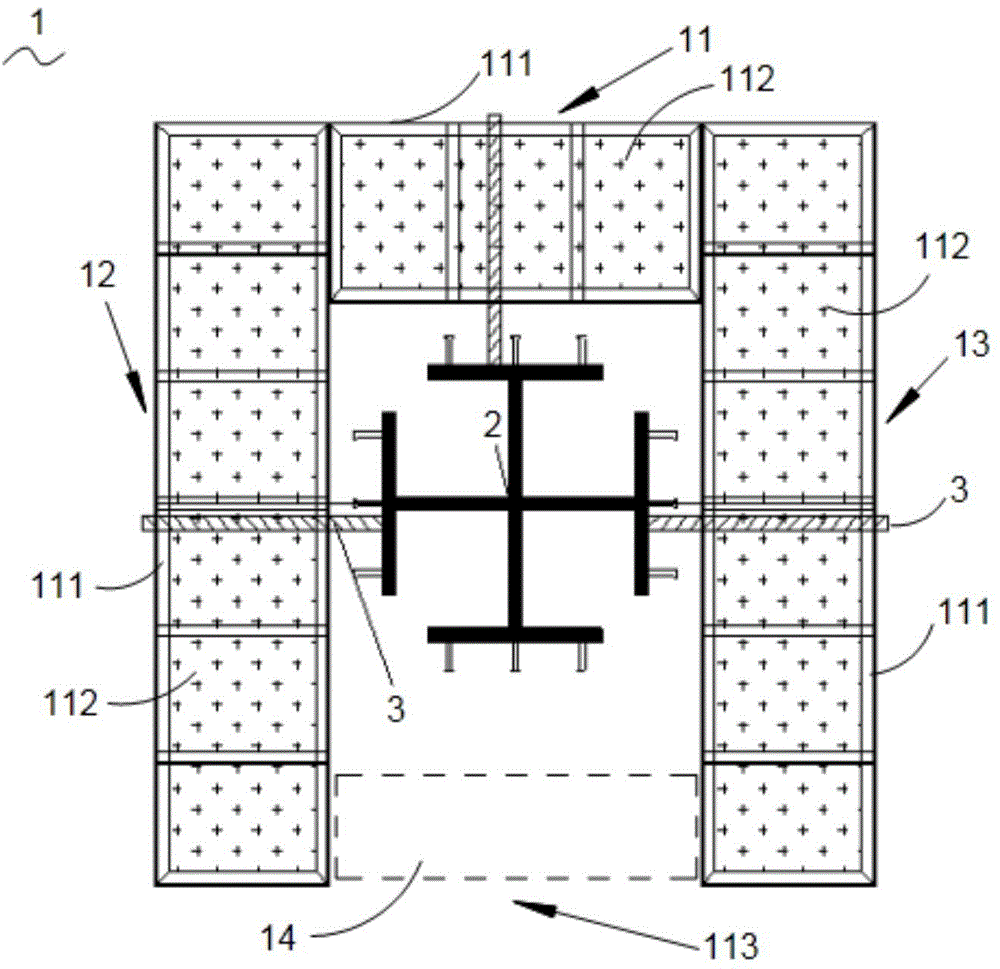

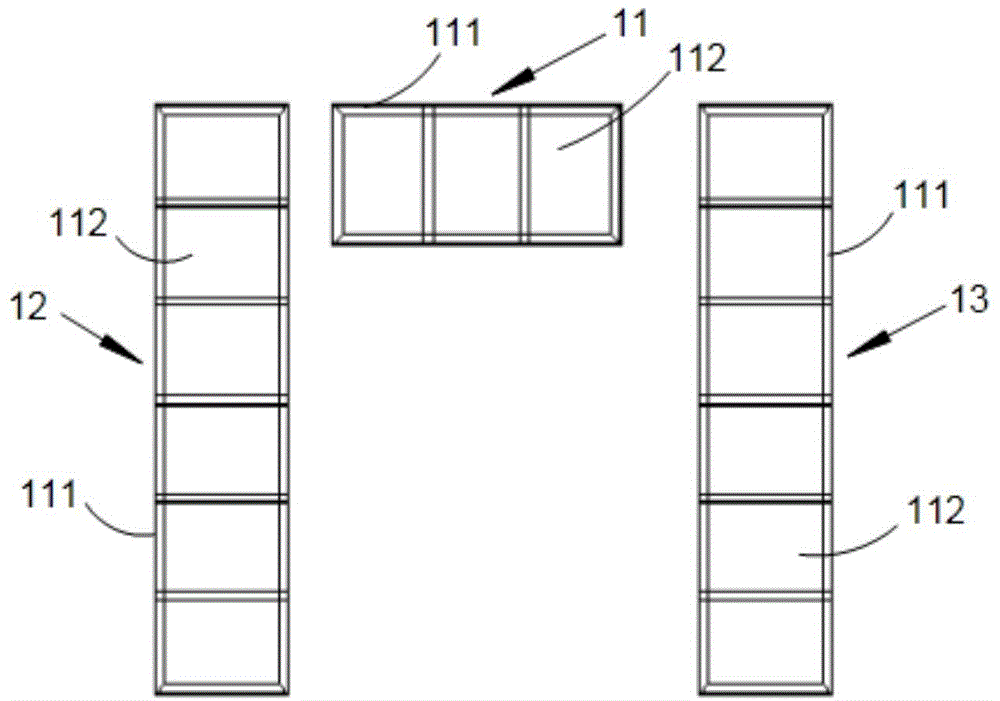

Prefabricated lattice beam structure for slope reinforcement and assembly overall construction method

The invention discloses a prefabricated lattice beam structure for slope reinforcement and an assembly overall construction method. According to the method, reinforced concrete lattice beams shaped like Chinese characters 'tian' are prefabricated in a PC component factory, then the prefabricated lattice beams serve as basic assembly units to be safely assembled in a slope construction site sectionby section and layer by layer along with excavating or filling, and the prefabricated lattice beam structure can be applied to reinforcement treatment of cut slopes and also applied to reinforcementtreatment of fill slopes; the prefabricated lattice beams can be assembled downwards from the top faces of the slopes and also assembled upwards from slope toe lines; and after the prefabricated lattice beams are mounted and assembled in place, concrete of reserved space between the adjacent prefabricated lattice beams is poured and tamped, and post-poured superimposed longitudinal and cross beamsare formed. Thus, the prefabricated lattice beam structure for slope reinforcement and the assembly overall construction method are beneficial for achieving lattice beam slope reinforcement rapid andsafe assembly overall construction and worthy of being popularized.

Owner:NANHUA UNIV

BIM-based ground fresh air and floor heating system pipeline assembly and intelligent control method

InactiveCN110410951ASpeed up the installation processImprove installation efficiencyMechanical apparatusLighting and heating apparatusFresh airMaterials processing

The invention discloses a BIM-based ground fresh air and floor heating system pipeline assembly and an intelligent control method, and belongs to the technical field of building modeling intelligent control. The method comprises the following steps of establishing a ground fresh air and floor heating system BIM model; integrating with a project building and electromechanical BIM model, and correcting a three-dimensional model of the ground fresh air and floor heating system; deriving the size of a reserved hole of the system; exporting a pipeline buckle detail list; exporting a system construction drawing and a material processing detail list; installing and accepting the system; collecting environmental data; transmitting the environmental data to a BIM server; converting the environmental data into a three-dimensional data model and displaying the three-dimensional data model in a display screen; and intelligently controlling the intelligent control system through the three-dimensional data model. According to the method, the installation accuracy and efficiency of the system can be improved, reworking is avoided, and a more comprehensive, more efficient and more intelligent system monitoring and control method is provided for the ground fresh air and floor heating system.

Owner:CHINA MCC17 GRP

Axial clearance adjustment method for pumping unit

InactiveCN104295533AReduce thicknessGuaranteed installation qualityPump componentsPump controlEngineeringAnchor bolt

Provided is an axial clearance adjustment method for a pumping unit. According to a measurement result of an axial clearance, the sizes, supposed to be obtained after measurement, of a front anchor and a rear anchor of a motor are calculated accurately and quickly, that is to say, the thicknesses of pads which need to be added to or removed from a front anchor bolt and a rear anchor bolt of the motor are worked out, the axial clearance can meet the installation accuracy requirement, the installation quality of the pumping unit is guaranteed, and the installation progress is accelerated.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Installation method and device for Articulated Naturality Web application

InactiveCN108632331AReduce the frequency of typing commandsLower technical barriersTransmissionWeb applicationThe Internet

An embodiment of the invention provides an installation method and an installation device for an Articulated Naturality Web application (ANW). An ANW server in the ANW has an installation script and an installation file of the ANW application. The installation method comprises the steps of: starting the installation script; installing the installation file of the ANW application in the ANW serverby means of the installation script; and starting the ANW application in the ANW server by means of the installation scrip if the installation file is installed successfully. On the one hand, the installation script executes most of installation operations of the ANW application, the technical threshold of installation is lowered, and the frequency of inputting commands by a user is reduced, thereby speeding up the installation progress, reducing the probability of errors, and increasing the probability of successful installation; on the other hand, the installation file already exists in theANW server and does not need to be downloaded from the Internet, thereby reducing communication with the Internet and reducing the difficulty of installation.

Owner:VISIONVERA INFORMATION TECH CO LTD

Integral main beam structure for double main beam hoisting equipment

InactiveCN107445056AImprove assembly efficiencyHigh split efficiencyLoad-engaging girdersStructural engineering

The invention discloses an integral main beam structure for double main beam hoisting equipment. The integral main beam structure comprises a first main beam and a second main beam which are of the same structure, and the first main beam and the second main beam are arranged in parallel; hoisting trolley equipment is arranged between the first main beam and the second main beam, wherein the first main beam is a truss composed of an upper cover plate, a lower cover plate and trolley tracks; the upper cover plate is arranged on the upper plane of the truss, and the lower cover plate is arranged on the lower plane of the truss; the upper surface of the first main beam is provided with the upper cover plate, and the lower surface of the first main beam is provided with the lower cover plate; the trolley tracks are located on the upper surface of the upper cover plate; one side, deviating from the second main beam, of the first main beam is provided with a maintenance platform, and one side, deviating from the first main beam, of the second main beam is provided with a hoisting trolley power supply system. The inventory specifications of plates and sectional materials are reduced, and quick transport and assembly of combined double beams can be achieved.

Owner:长春市兴泰起重机械有限公司

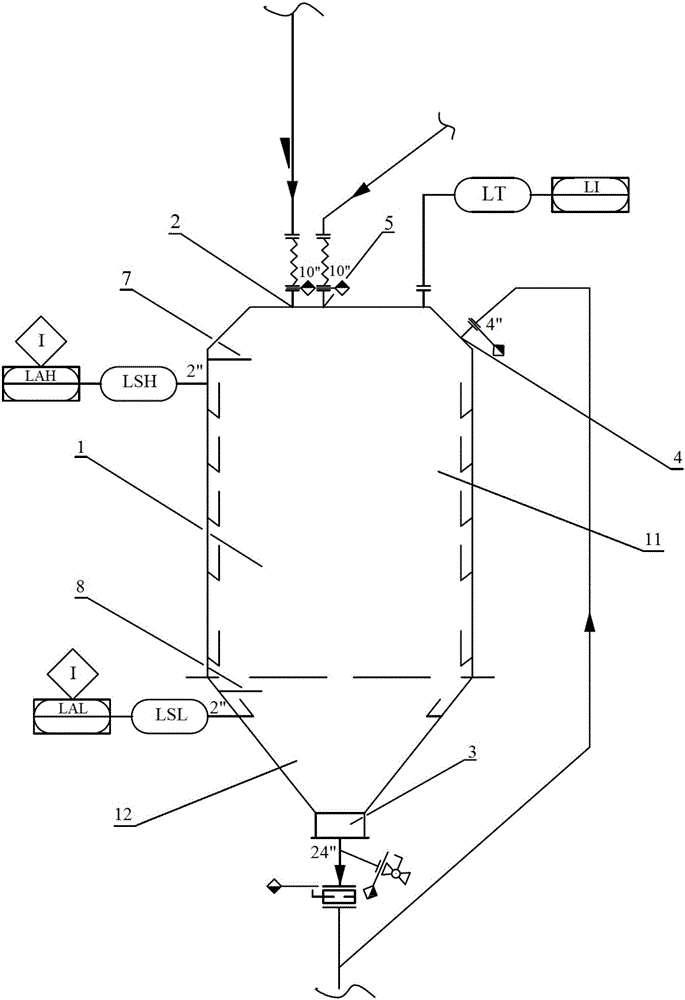

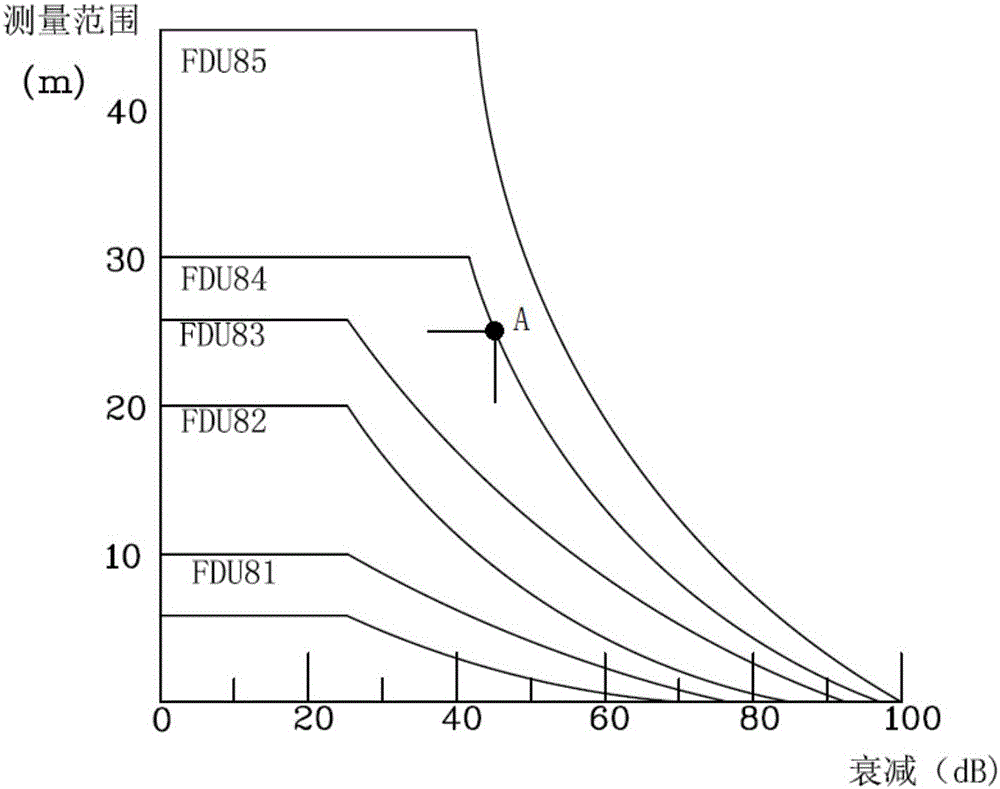

Homogenizing stock bin and detecting method for material level of materials in homogenizing stock bin

InactiveCN105668066ASpeed up the installation processReduce procurement costsLarge containersMachines/enginesEngineering

Owner:JILIN DESIGNING INST OF CNPC NORTHEAST REFINING & CHEM ENG

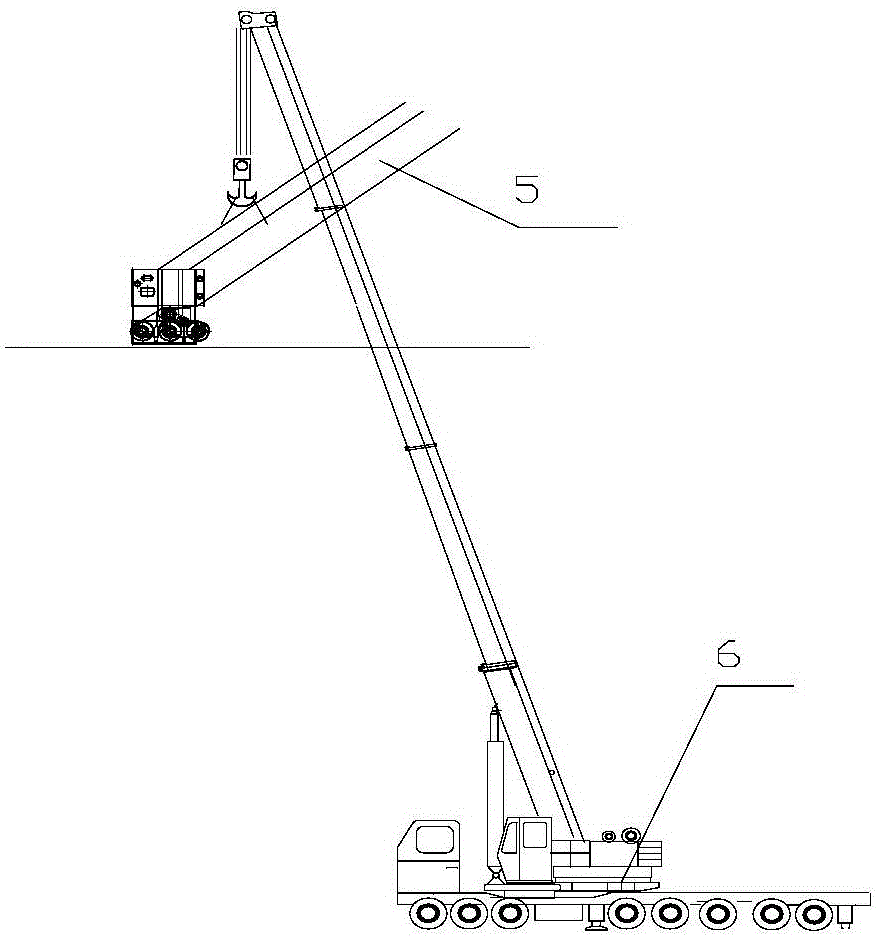

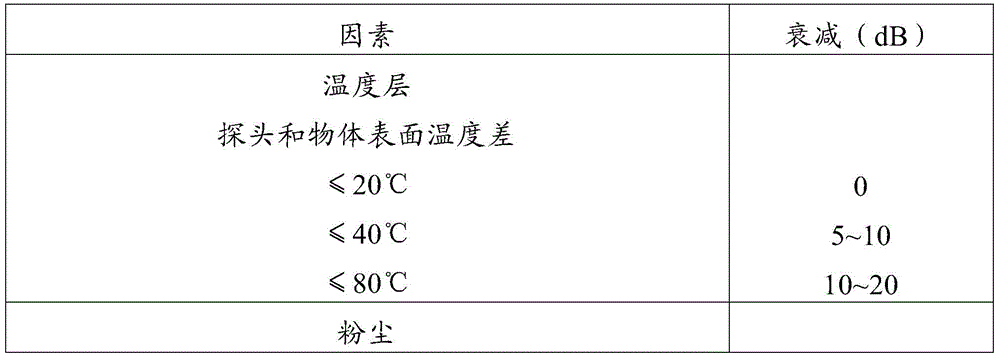

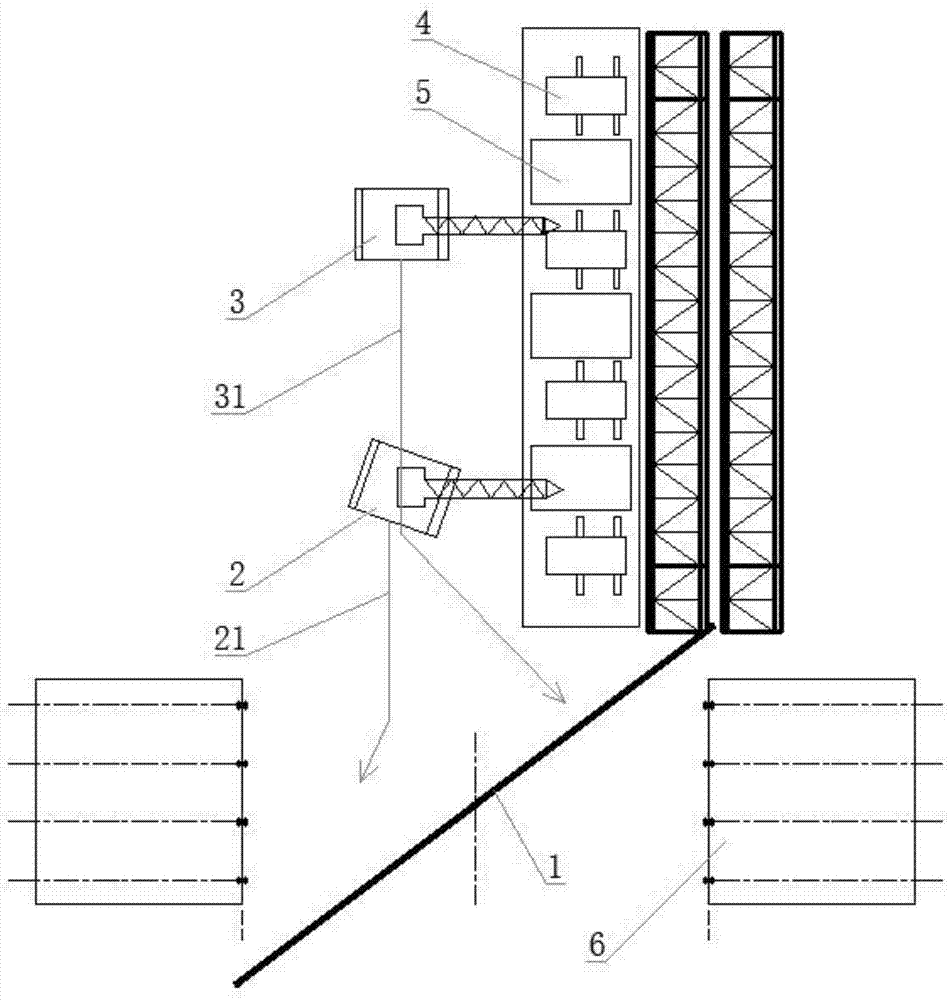

Installation method of large-span steel trusses

InactiveCN106869319AFast installationImprove securityBuilding material handlingLong spanSupport point

The invention discloses a large-span steel truss installation method, which belongs to the technical field of steel structure installation, and comprises the construction steps of preparation work→steel truss assembly→first long-span steel truss hoisting→subsequent steel truss installation. The large-span steel truss installation method of the present invention cannot meet the installation requirements for the assembly and hoisting site, especially for the large-span steel truss in a restricted space or cantilevered outside the support point, the installation progress is faster, the safety effect is better, and it is more economical The construction cost reduces safety risks, the ground assembly is convenient and fast, the installation progress and quality are effectively improved, the actual hoisting time is shorter, and the practicability is stronger.

Owner:CHINA MCC17 GRP

Measurement method for centering coupling

InactiveCN101762228AAvoid inaccuraciesAvoid damageMechanical measuring arrangementsVertical deflectionCoupling

The invention discloses a measurement method for centering a coupling. The method comprises the following steps that: 1, symmetrical positions of left and right couplings are connected together by bolts; 2, a tensioning device provided with a screw rod is fixedly arranged in an erection bolt hole of the left coupling; 3) the end part of the screw rod is sleeved with a dial indicator bracket; 4, a dial indicator contacted with the circumferential surface and the end surface of the right coupling is fixedly arranged on the dial indicator bracket; 5, the couplings are turned back by 90 degrees, 180 degrees and 270 degrees from the zero position in turn to measure the circumferential clearance and the end clearance of each position respectively; and 6, the center of the coupling is adjusted according to the measured data. The measurement method has the advantages of effectively solving the problem that the measuring instrument is inaccurate due to the poor rigidity of the dial indicator bracket, outside slight vibration and shaking of the couplings in the rotating process during measurement and avoiding the influence of large diameter of the coupling and vertical deflection of the coupling from a shaft when the coupling is assembled on the centering accuracy.

Owner:GUANGDONG IND EQUIP INSTALLATION

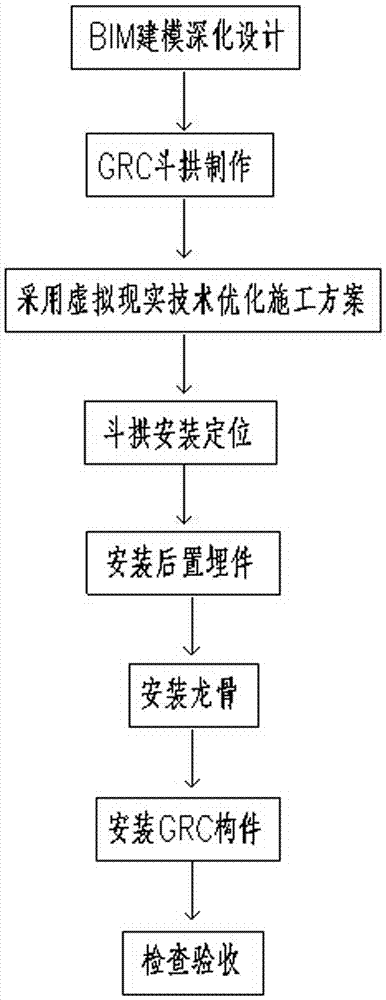

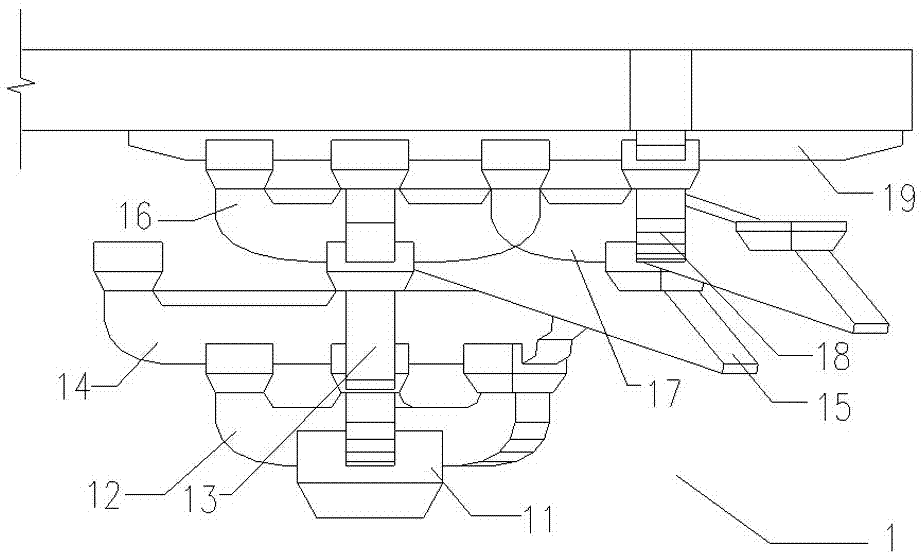

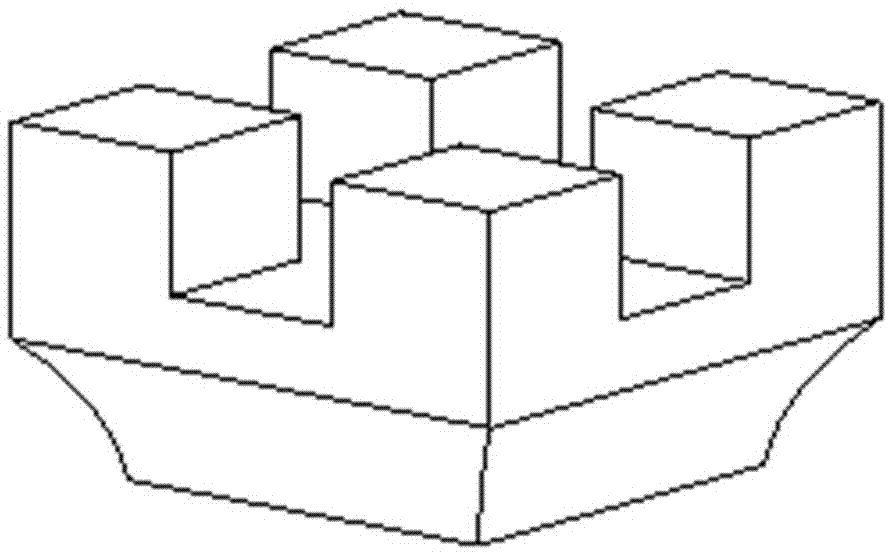

Tang-dynasty ancient architecture imitated bucket arch installing and constructing method

ActiveCN107227852AEnable intuitive analysisSpeed up the installation processGeometric CADAdditive manufacturing apparatusKeelEngineering

The invention discloses a tang-dynasty ancient architecture imitated bucket arch installing and constructing method. A bucket arch is a GRC bucket arch. The constructing method of the bucket arch comprises the following steps that 1, BIM modeling and design deepening are performed; 2, the bucket arch is manufactured; 3, a virtual reality technology is adopted to optimize a construction scheme; 4, the bucket arch is installed and positioned; 5, embedded parts are arranged after installation; 6, keels are installed; 7, GRC members are installed; 8, checking and inspection are performed. The construction difficulty of a bucket arch installing project is effectively reduced, the bucket arch installing progress is accelerated, and the construction quality of bucket arch installing is effectively guaranteed.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

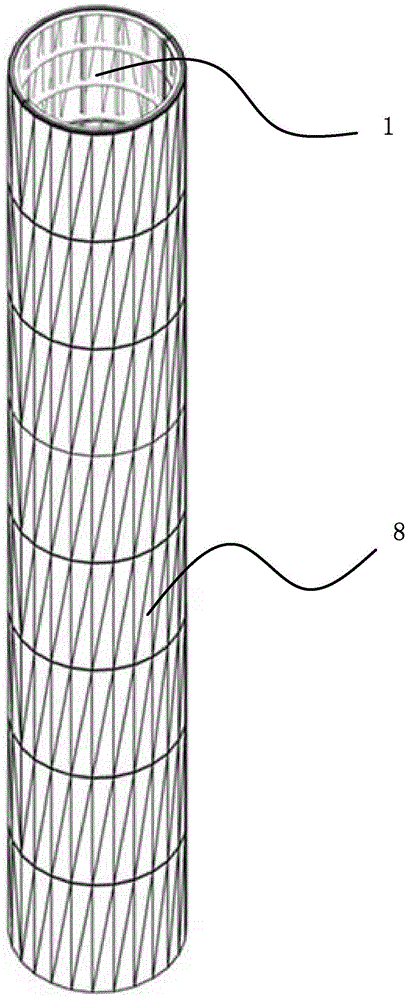

Wood veneer cylinder and manufacturing process thereof

InactiveCN104805975AIncrease manufacturing difficultyIncrease labor costCovering/liningsWood veneerHigh density

The invention provides a wood veneer cylinder and a manufacturing process thereof, and belongs to the technical field of building. The wood veneer cylinder comprises a plurality sections of hollow and cylindrical connecting cylinders, wherein the upper and lower end surfaces of the connecting cylinders are mutually attached and stacked into a straight tube shape, each connecting cylinder comprises a keel frame and a circular arc-shaped high-density plate, each high-density plate covers the outer side of the corresponding keel frame, each keel frame comprises an annular whole circle keel and a straight strip-shaped straight keel, each whole circle keel is formed by splicing two semicircular keels, a plurality of clamp grooves in uniform distribution are formed in the circumferential direction of the semicircular keels, the straight keels can be clamped and embedded in the clamp grooves, the high-density plates and the keel frames are bonded together through glue water, and a layer of straight vein decoration surface is also pasted on the outer layer of each high-density plate. The invention also provides the manufacturing process of the wood veneer cylinder, the process comprises two links including factory processing and in-site assembly, the cost is reduced, the keel frame structure is simple, and can be conveyed to a site to be spliced after being processed in a factory, the efficiency is high, and the cost is low.

Owner:ZHEJIANG SENLAN JIUDING FURNITURE MFG CO LTD

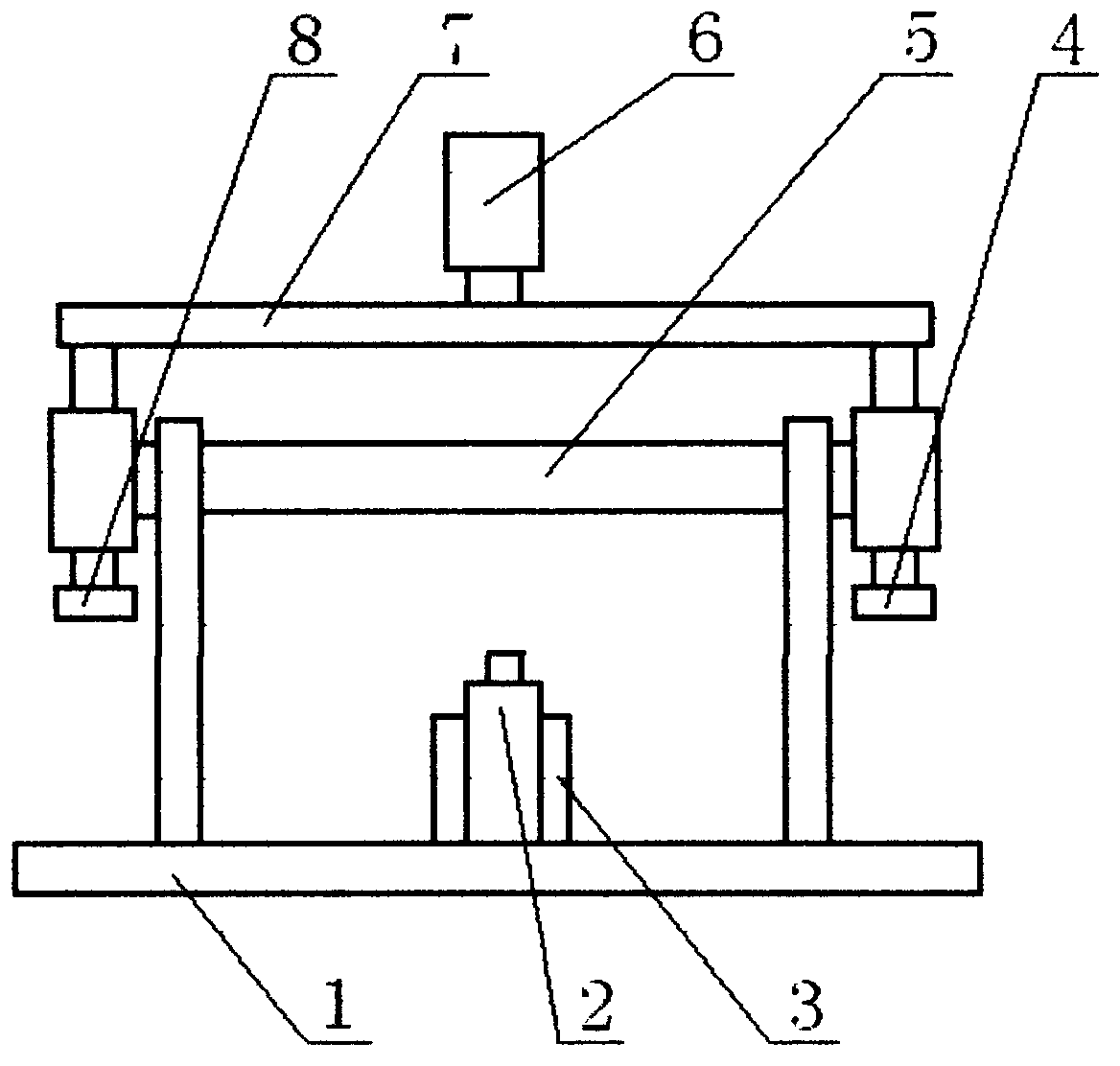

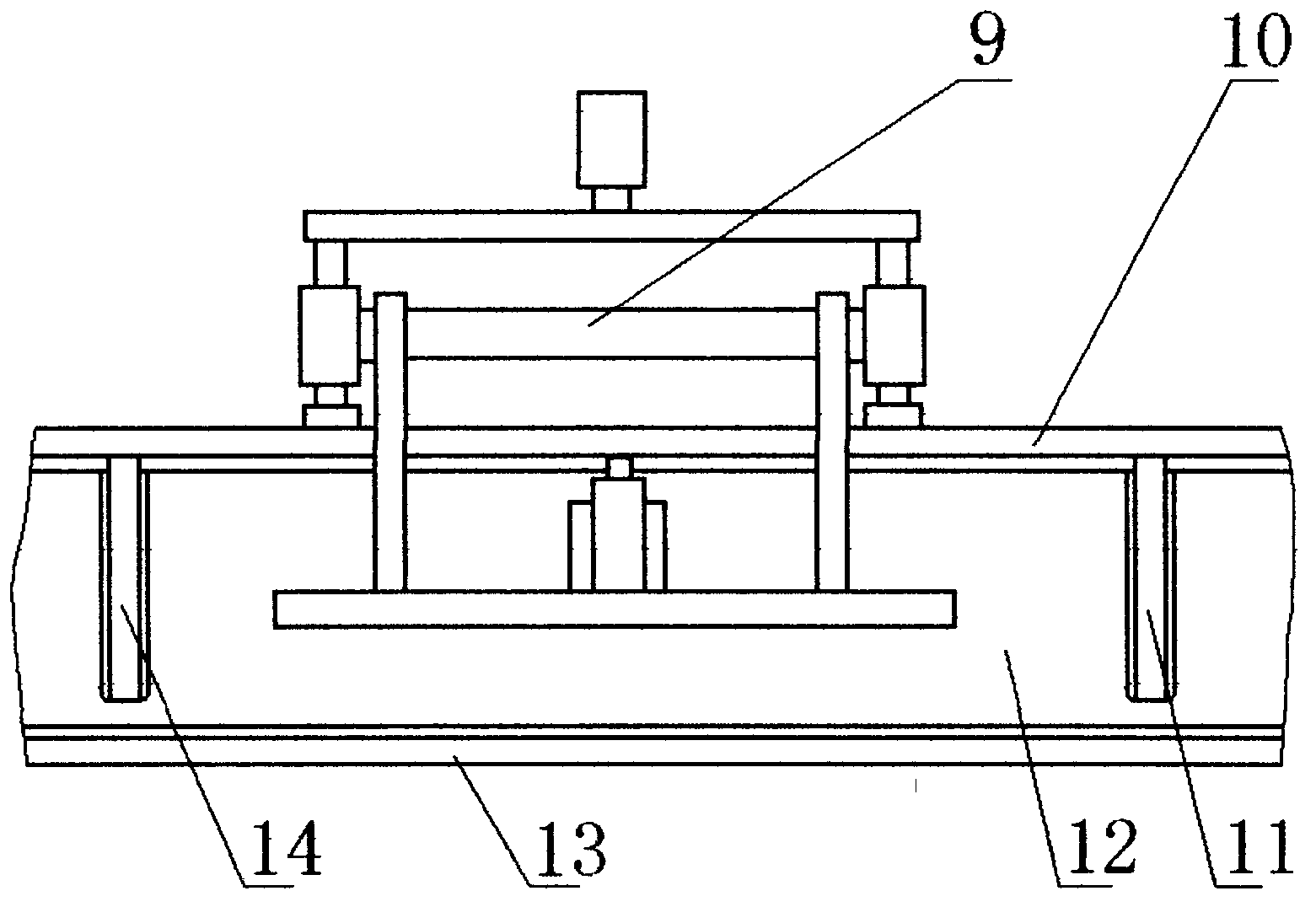

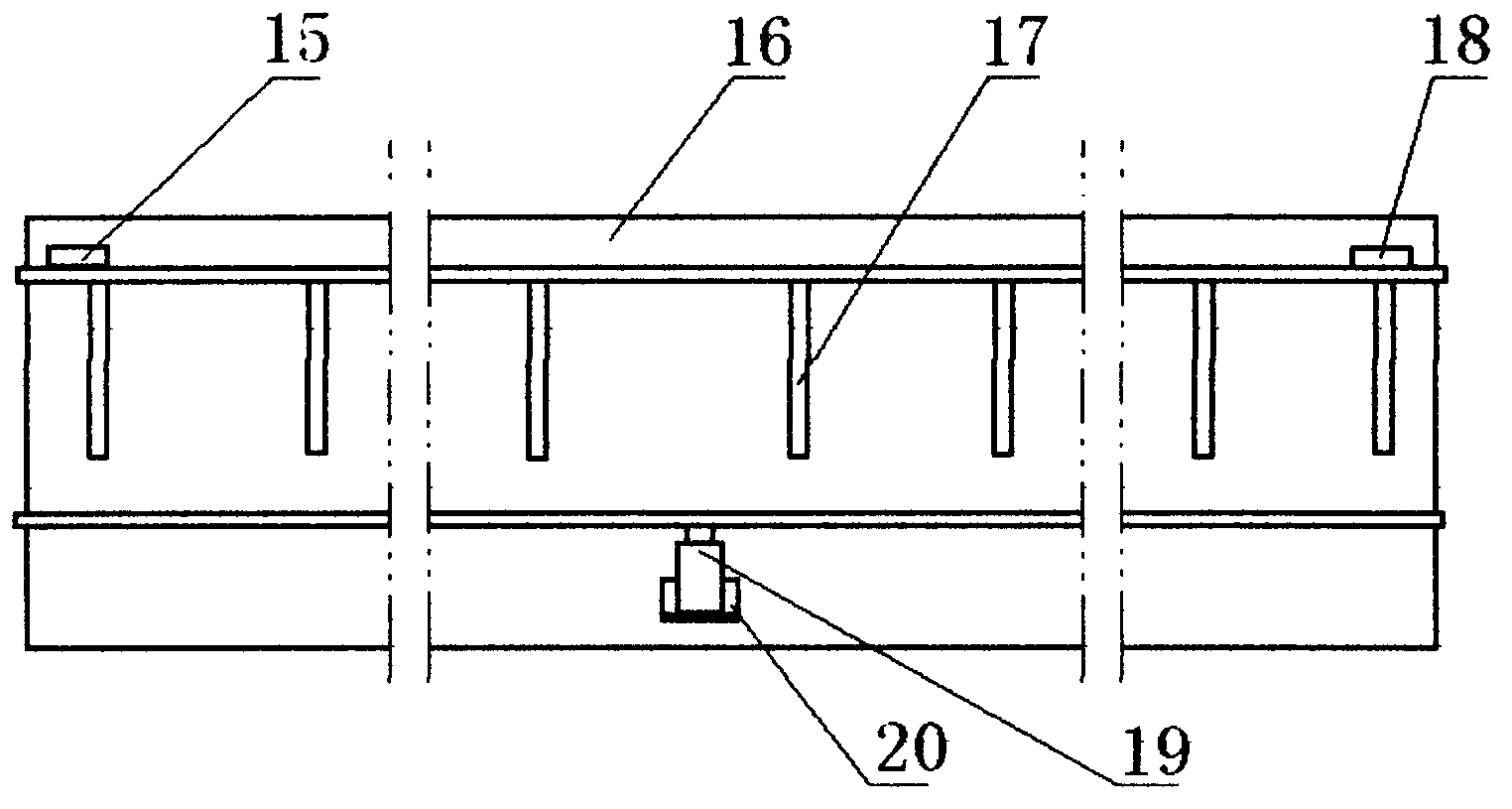

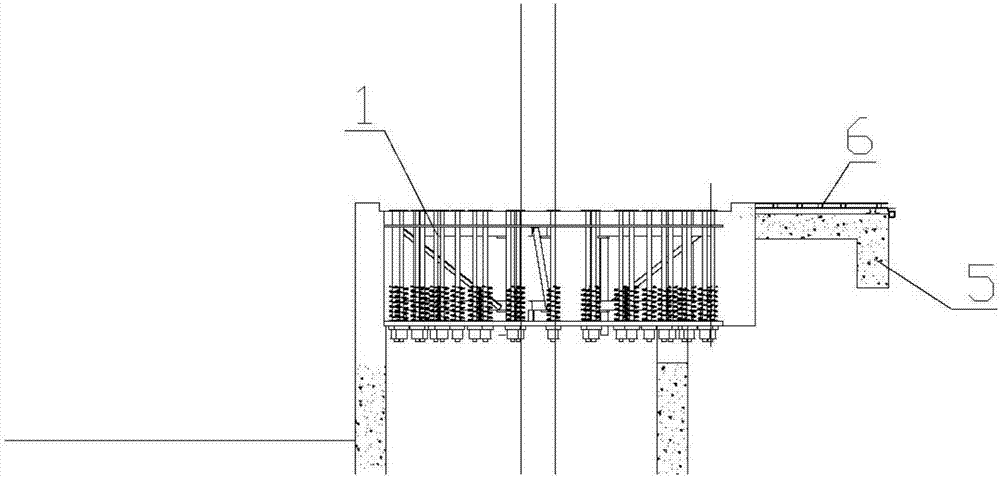

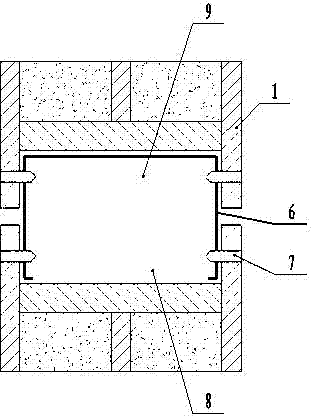

Steel column mounting operation platform and mounting method thereof

InactiveCN104631844ASpeed up the installation processReduce safety in placeBuilding material handlingSteel columnsRisk factor

A steel column mounting operation platform comprises a first construction operation platform, a second construction operation platform and a third construction operation platform. The first construction operation platform further comprises a bearing frame for forming a peripheral closed structure, and a bearing plate arranged on the bearing frame. The second construction operation platform and the third construction operation platform are arranged on the two sides of the first construction operation platform respectively to form an n-shaped structure, the second construction operation platform and the third construction operation platform further comprise bearing frames and bearing plates, the bearing frames are used for forming peripheral closed structures, and the bearing plates are arranged on the bearing frames. By means of the steel column mounting operation platform, the steel column mounting progress is effectively quickened, risk factors in the turning and dismounting process are reduced, in the welding process, personnel are safely in place, a windproof device can be portably erected on the periphery, the platform is beneficial to improvement of quality, cost is saved, and an existing steel pipe rental fee, turning and dismounting labor cost and the like are reduced.

Owner:SHANGHAI MECHANIZED CONSTR GRP

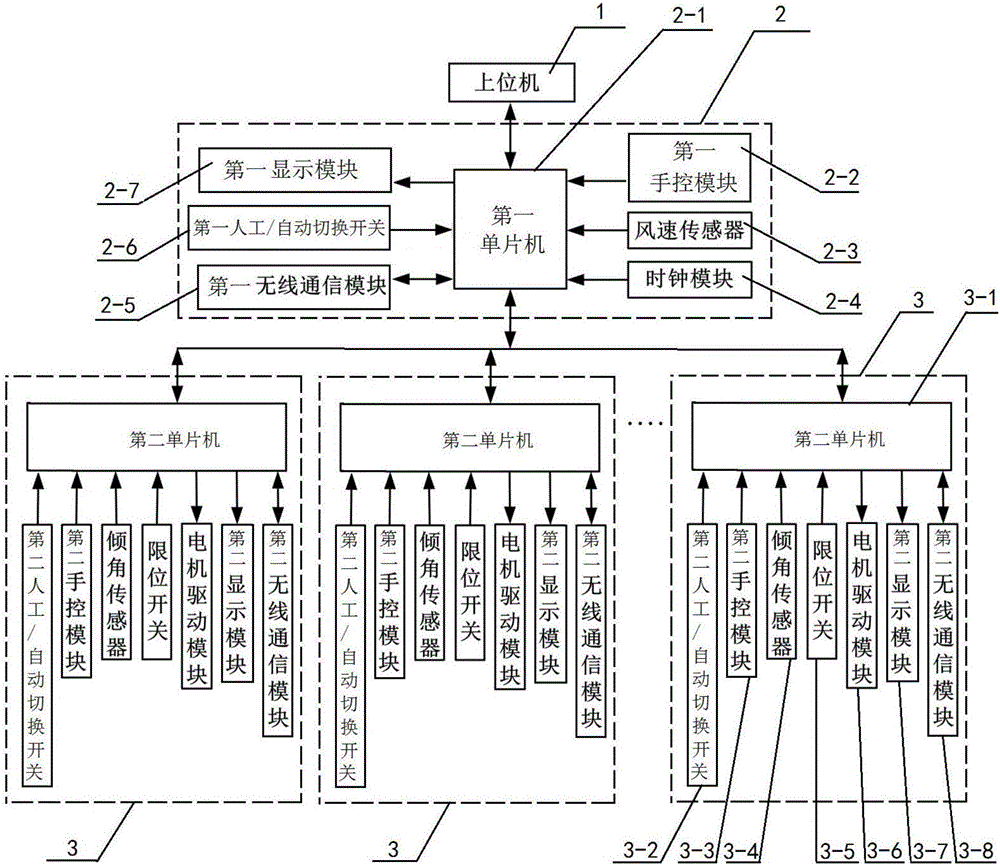

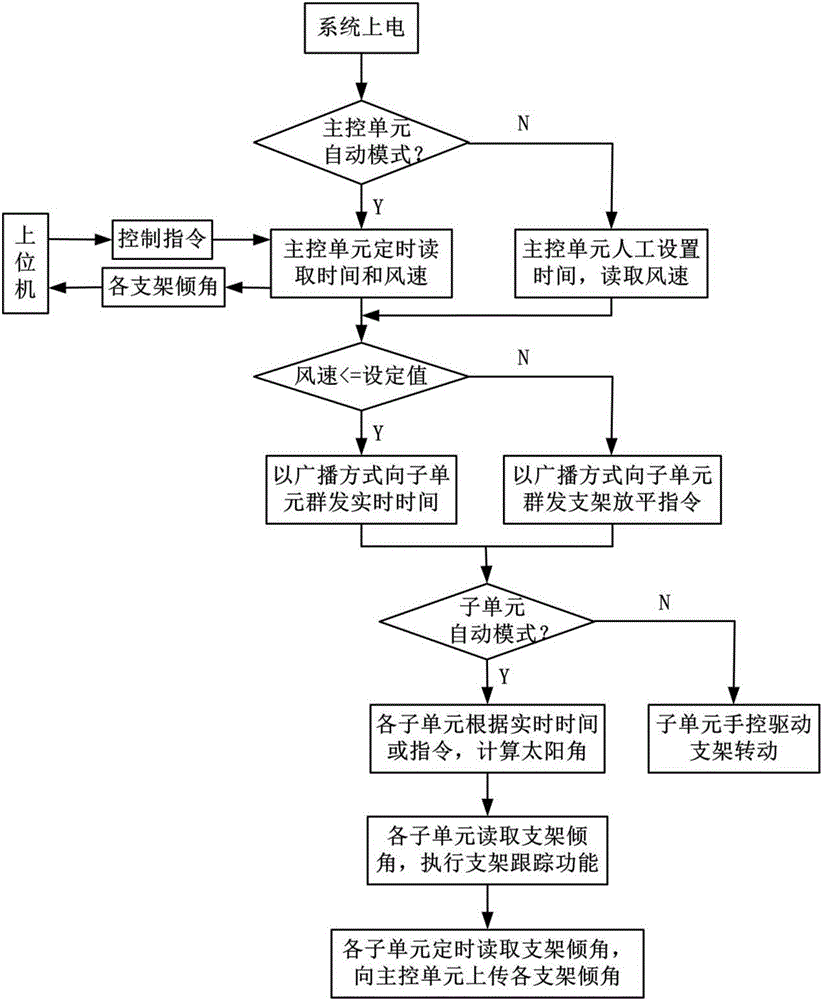

Photovoltaic tracking support group control system and method based on wireless communication

PendingCN106054944ACost-effectiveConvenient on-site constructionControl using feedbackMicrocontrollerMicrocomputer

The invention provides a photovoltaic tracking support group control system based on wireless communication, and the system comprises an upper computer, a main control unit, and a plurality of photovoltaic tracking support drive subunits. The main control unit comprises a first single-chip microcomputer, a first manual / automatic change-over switch, a first wireless communication module, a first hand-operated module, a wind speed sensor, and a clock module. Each photovoltaic tracking support drive subunit comprises a second single-chip microcomputer, a second manual / automatic change-over switch, a second wireless communication module, a second hand-operated module, an inclination angle sensor, and a motor drive module. The upper computer is in bidirectional connection with the first single-chip microcomputers, and the first wireless communication modules are in wireless communication connection with the second wireless communication modules. The system achieves a purpose that one main control unit achieves the wireless control of a plurality of tracking supports through the wireless mesh network technology based on Zigbee, carries out the angle tracking control of a photovoltaic tracking support group, reduces the cost, and also greatly reduces the installation and debugging cost.

Owner:石坤 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com