Measurement method for centering coupling

A measurement method and backrest wheel technology, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., to achieve the effects of faster installation progress, higher safety, and avoiding external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

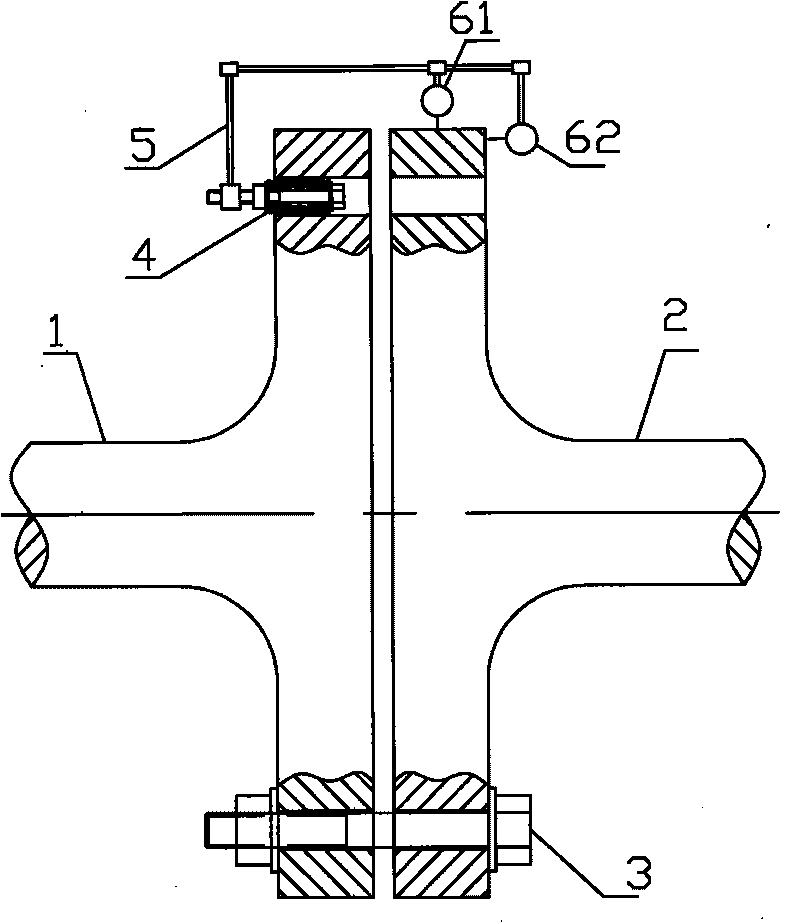

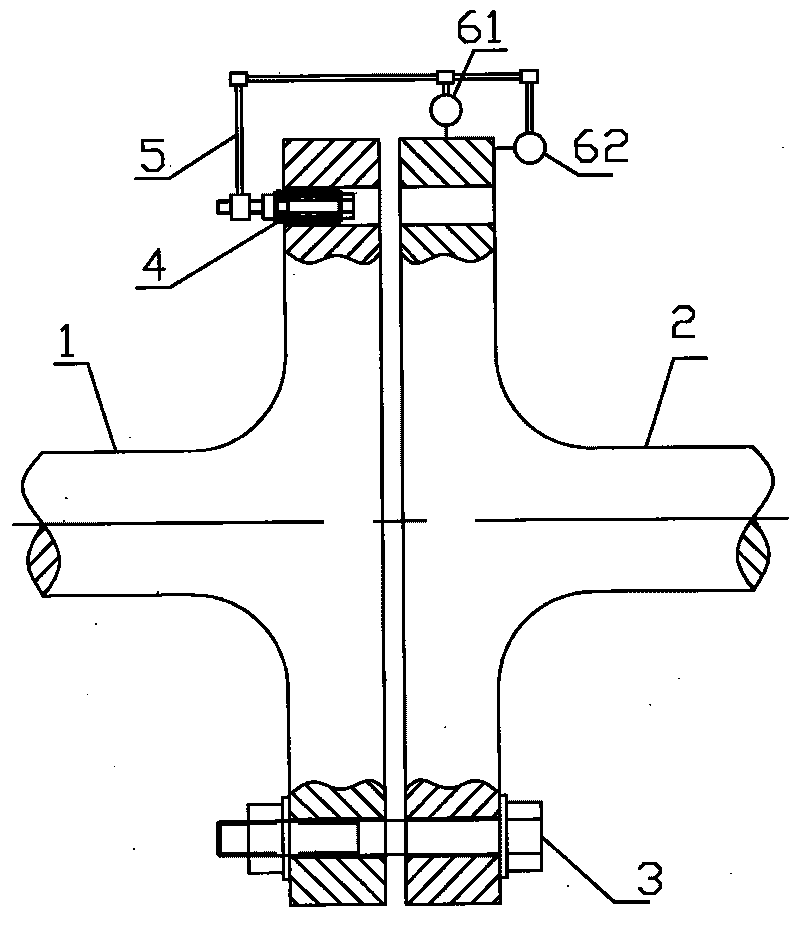

[0019] refer to figure 1 , a method for measuring the center of a backrest wheel, the method comprising the steps of:

[0020] 1: Connect and install the symmetrical positions of the left and right backrest wheels 1 and 2 together with bolt 3;

[0021] 2: The expansion device 4 with the screw rod 41 is fixedly installed in the mounting bolt hole of the left back wheel 1;

[0022] 3: Sleeve the dial indicator bracket 5 at the end of the screw rod 41;

[0023] 4: Dial indicators 61 and 62 in contact with the circumferential surface and end surface of the right back wheel 2 are fixedly installed on the dial indicator bracket 5;

[0024] 5: Turn the back wheel, turn 90°, 180°, 270° sequentially from the zero position, and measure the circumferential clearance and end clearance at each position respectively;

[0025] 6: Adjust the center of the backrest wheel according to the measured data.

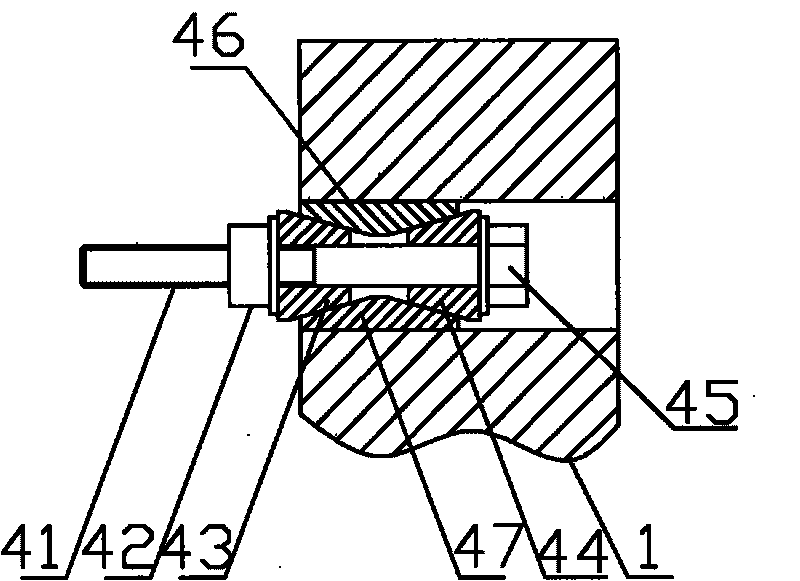

[0026] refer to figure 2 , the expansion device 4 described in step 2 includes a scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com