Patents

Literature

1609results about How to "Improve installation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

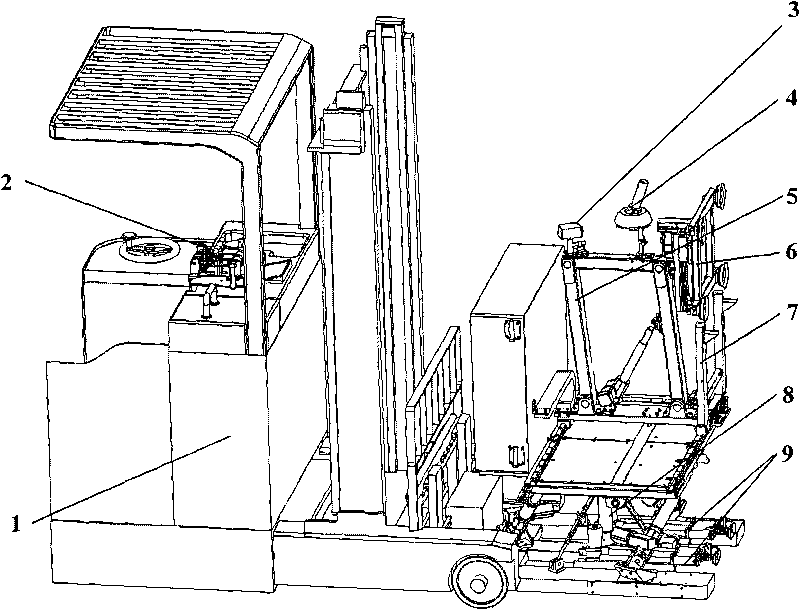

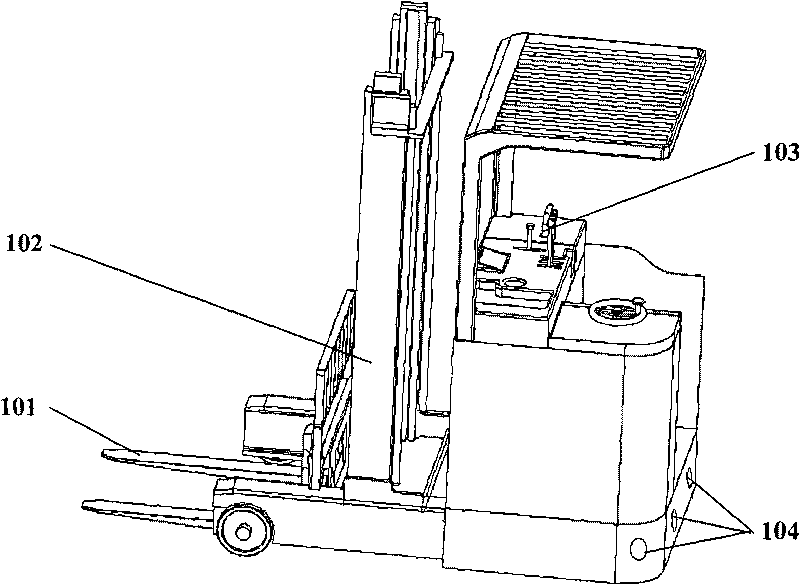

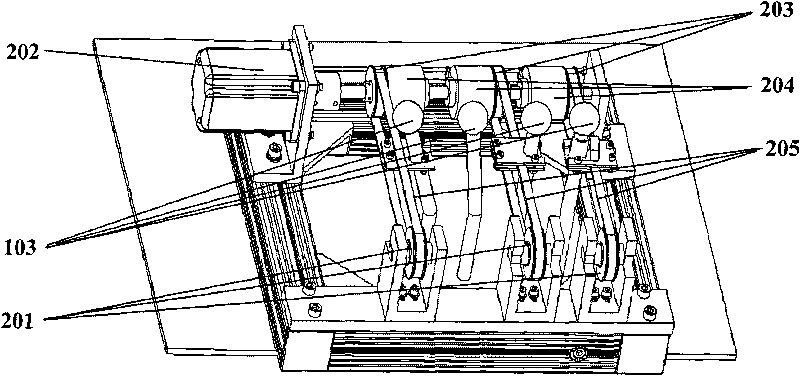

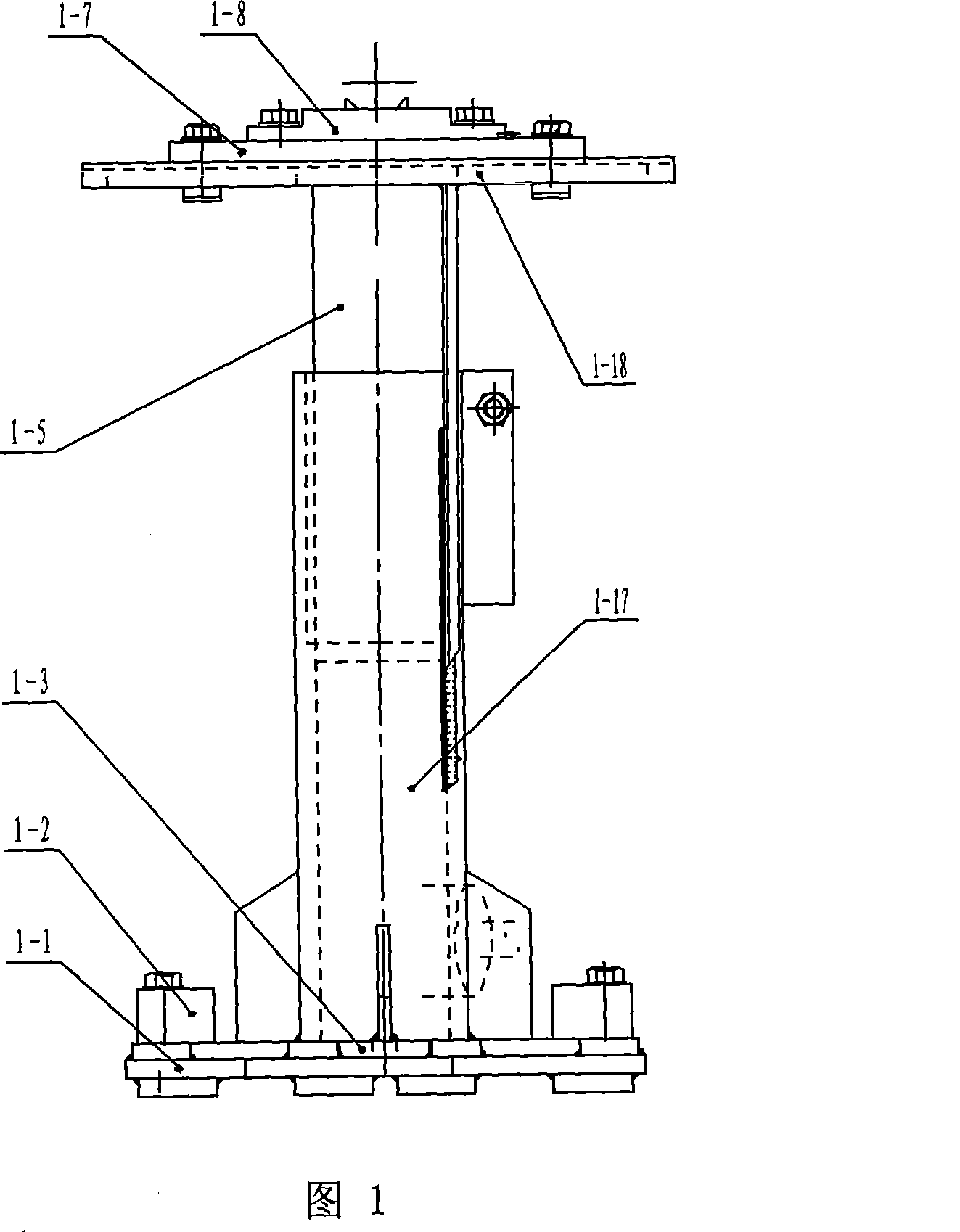

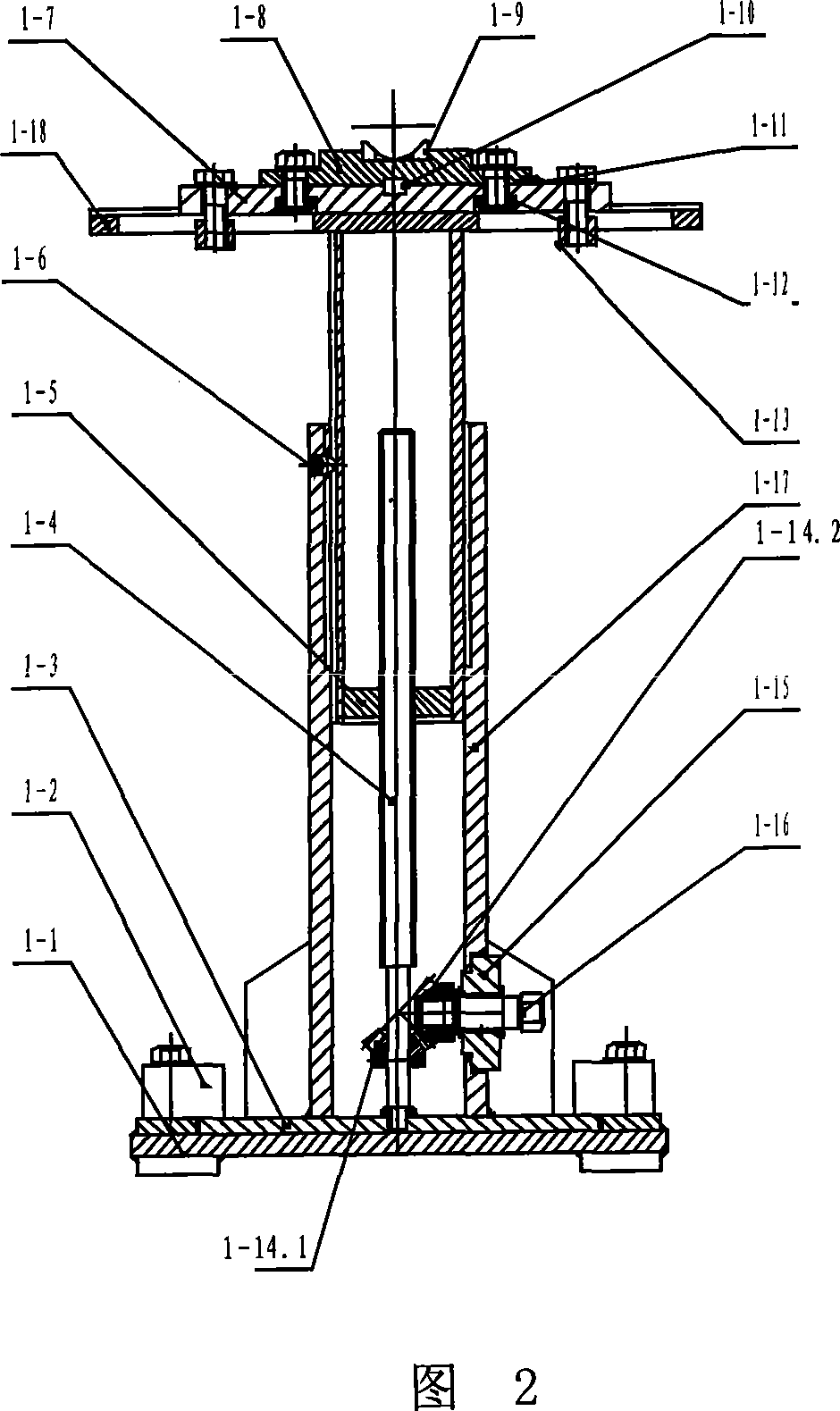

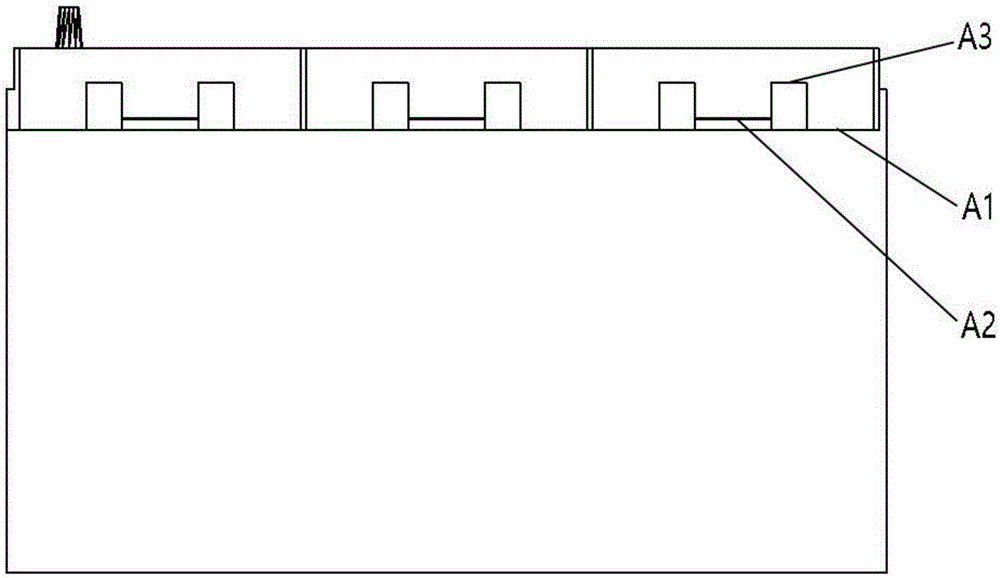

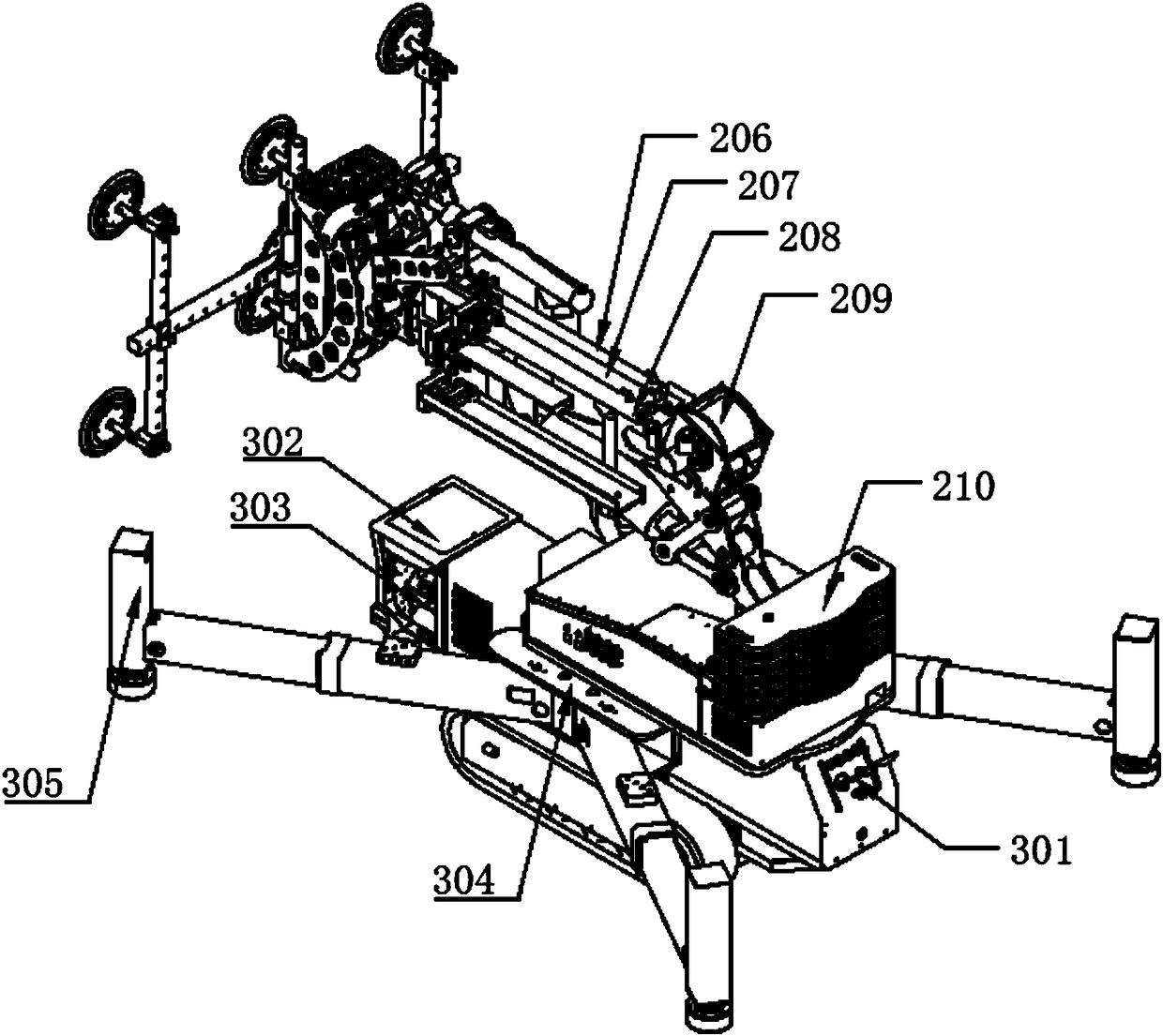

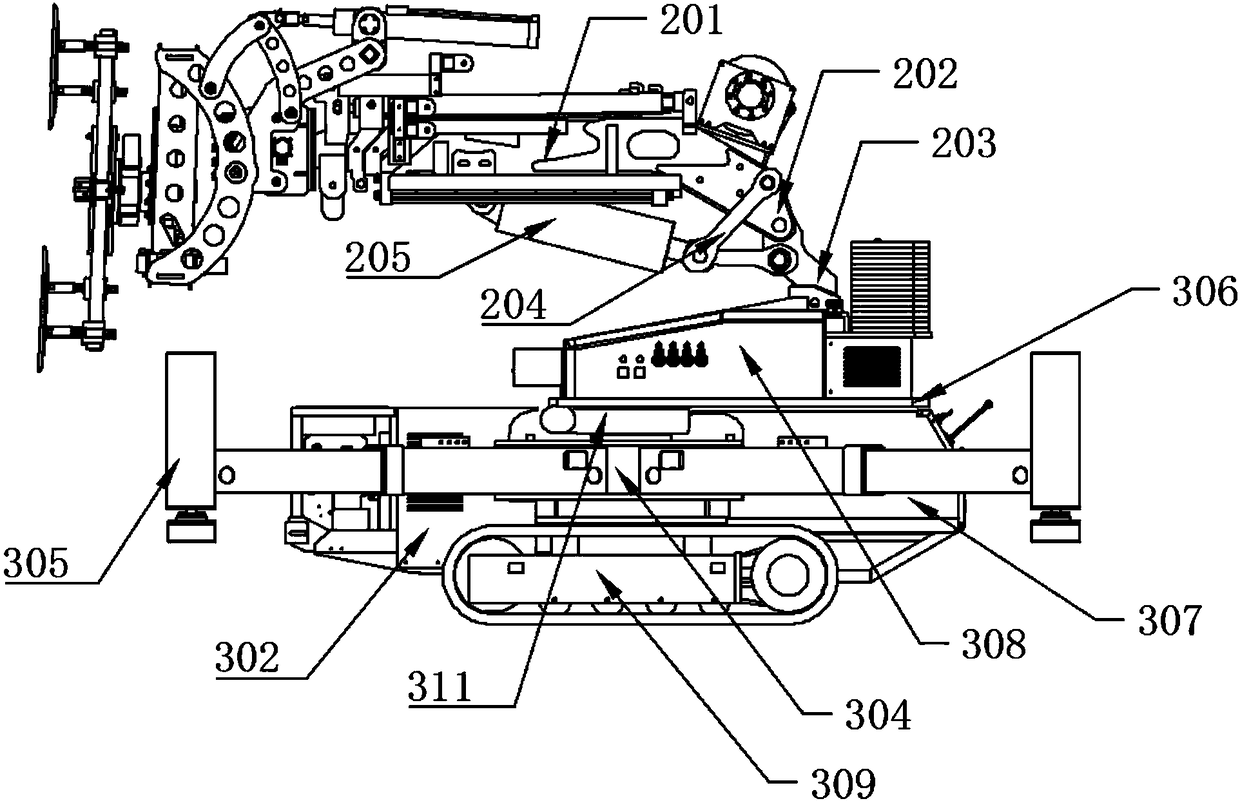

Plate dry-hanging and mounting robot

InactiveCN101691808AImprove installation qualityLabor savingLifting devicesBuilding constructionsTruckModularity

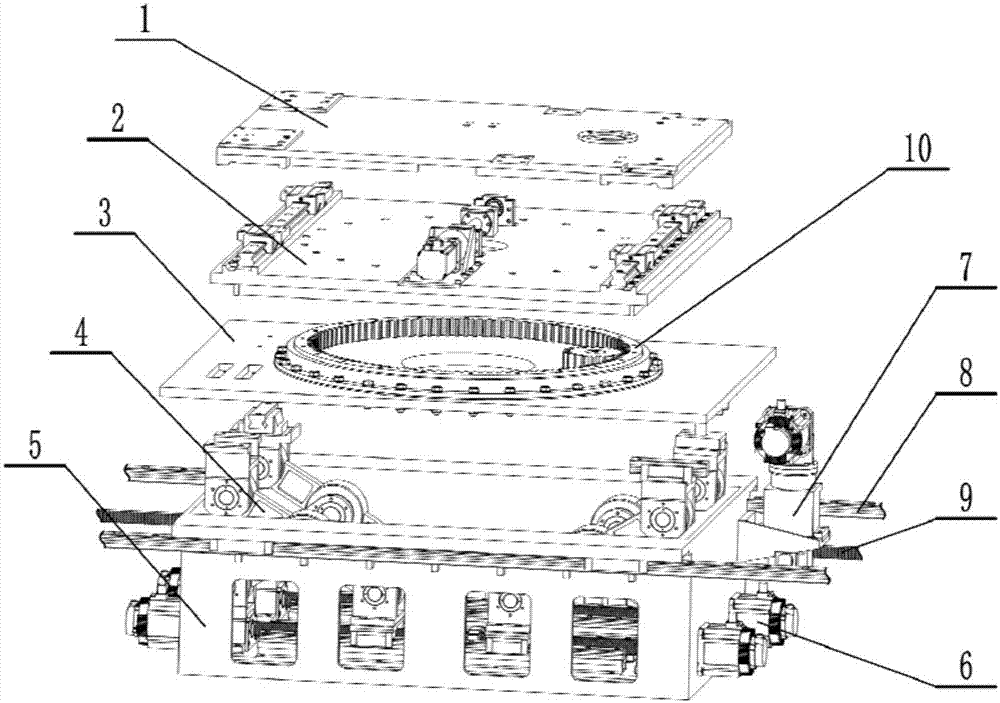

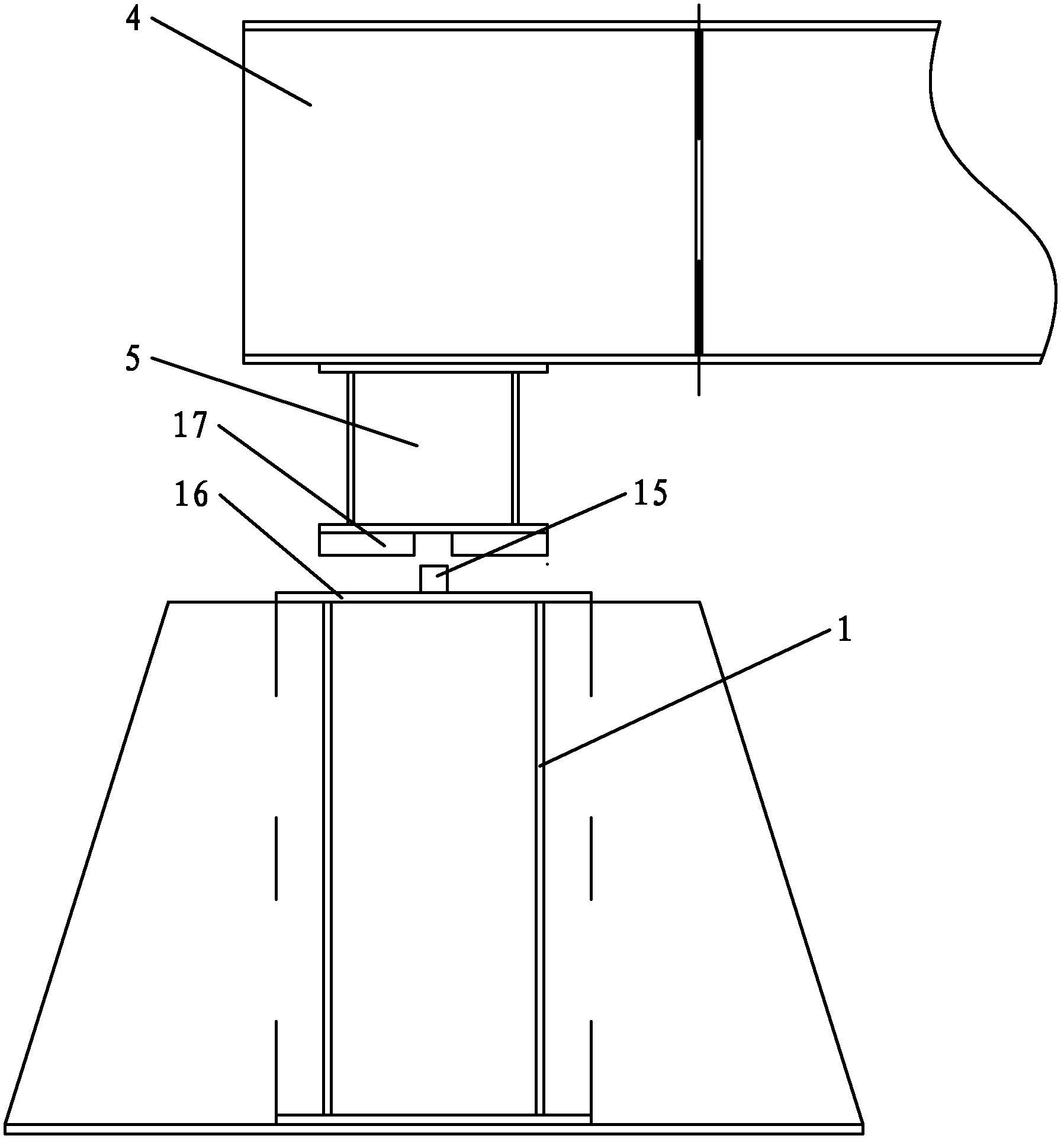

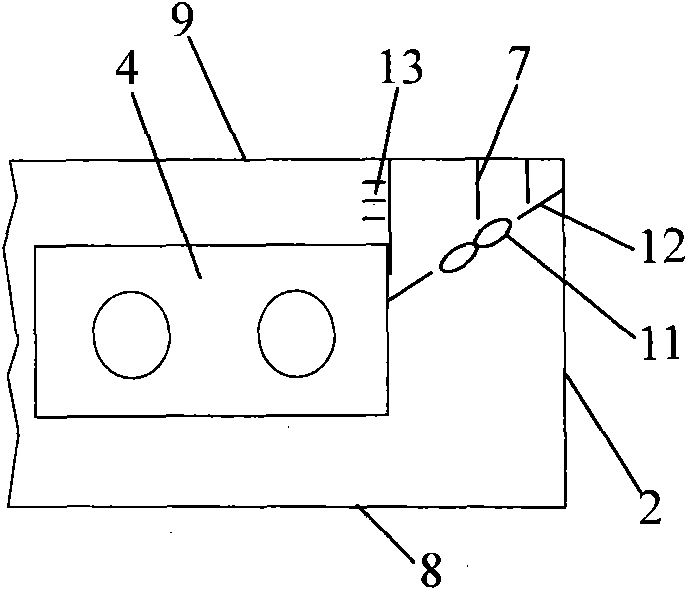

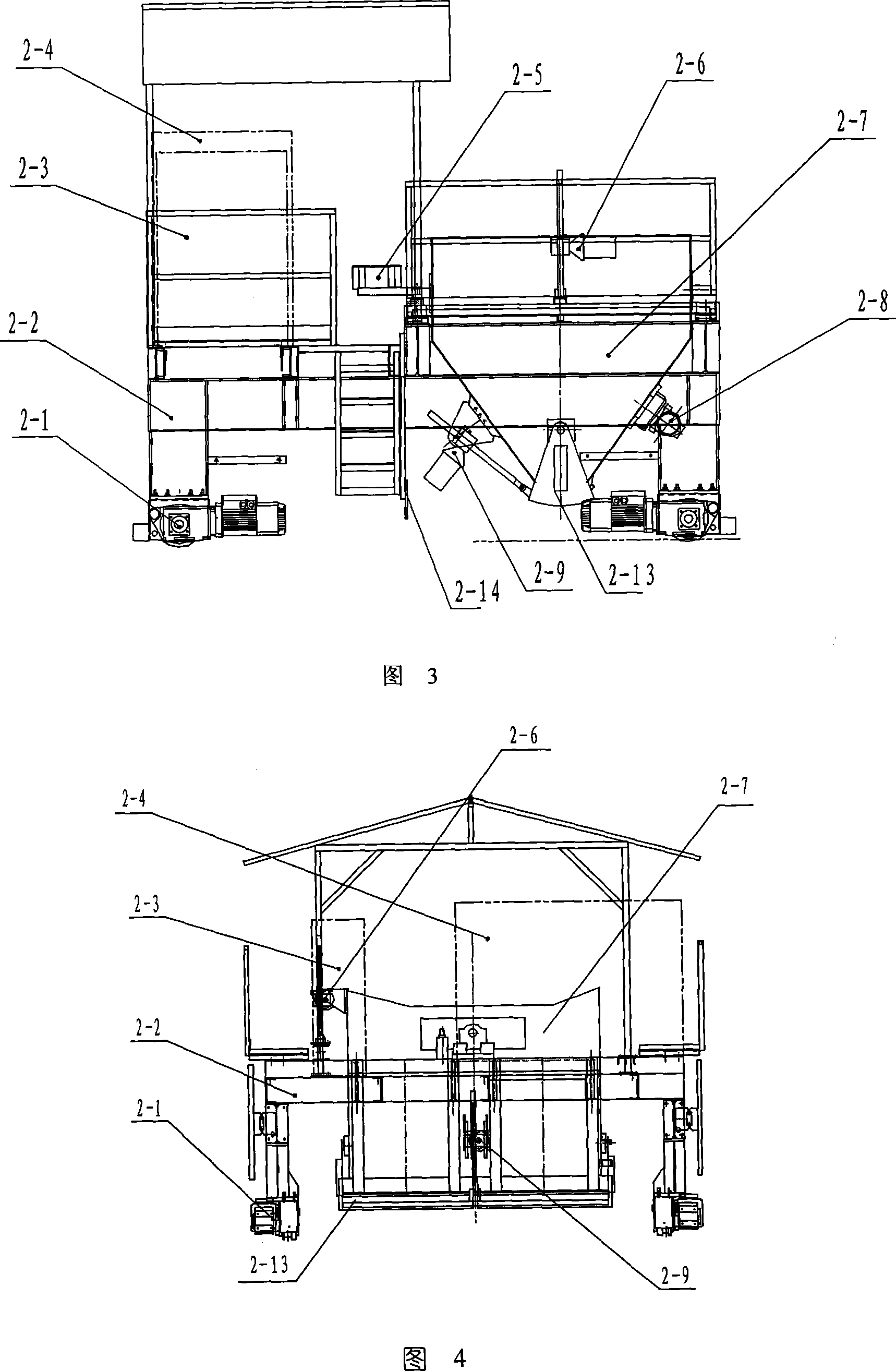

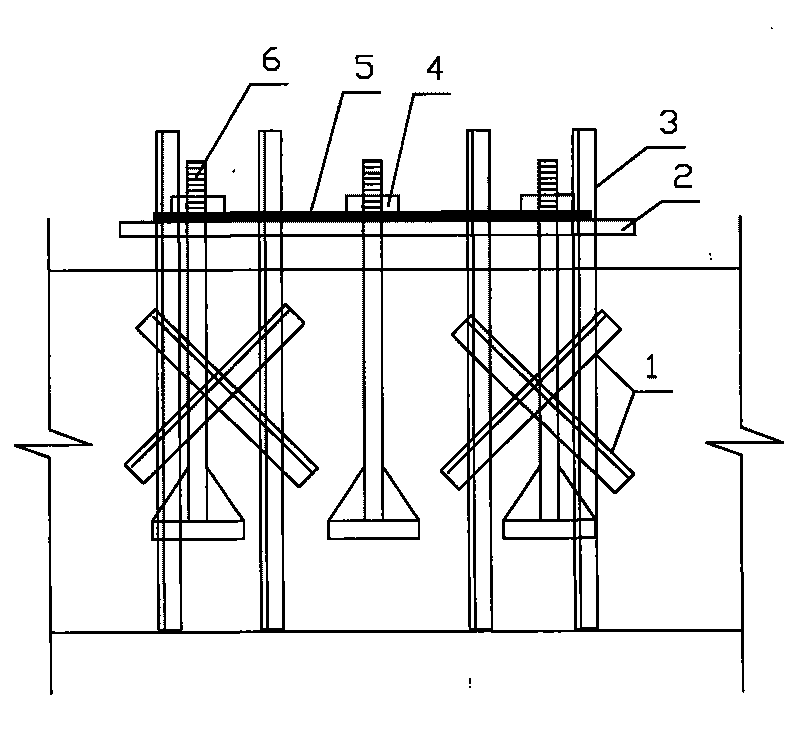

The invention relates to a plate dry-hanging and mounting robot which is characterized by being in a modular structure and comprising a movable body module, a mounting operating module, a visually-guided mounting positioning module and a motion controlling system module. The movable body module mainly comprises an improved electrical fork truck; the mounting operating module is loaded on the lifting platform of the electrical fork truck and mainly comprises a three degree-of-freedom parallel rotating platform module, a three degree-of-freedom serial moving module and an end-effector module, wherein the three degree-of-freedom serial moving module is arranged above the three degree-of-freedom parallel rotating platform module, and the end-effector module is connected with the three degree-of-freedom serial moving module; the visually-guided mounting positioning module comprise a camera, a laser distance measuring sensor, a tilt angle sensor, image acquiring software and image processing software; and the motion controlling system module comprises an industrial control computer, a motion control card, a signal acquiring card and a servo driving unit.

Owner:HEBEI UNIV OF TECH

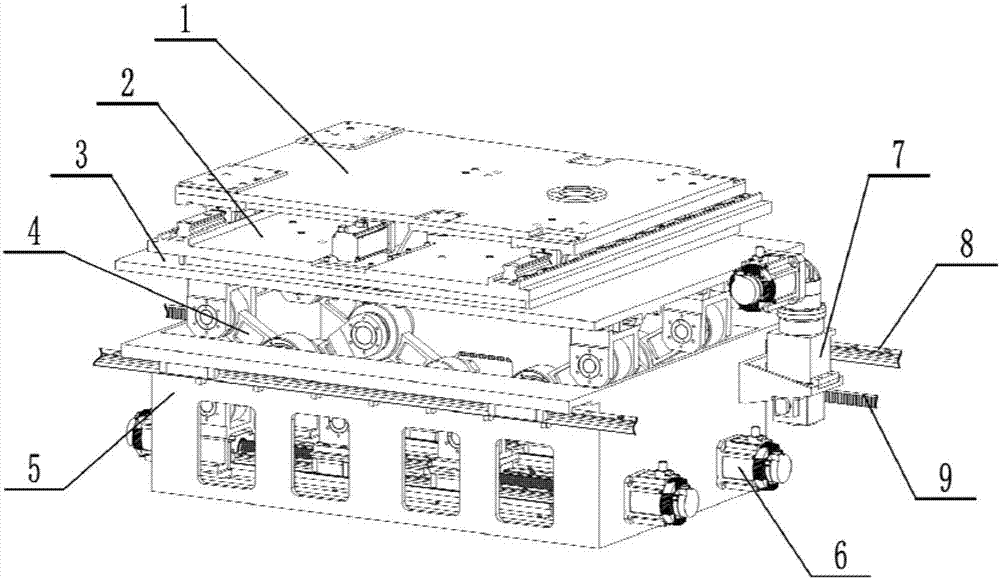

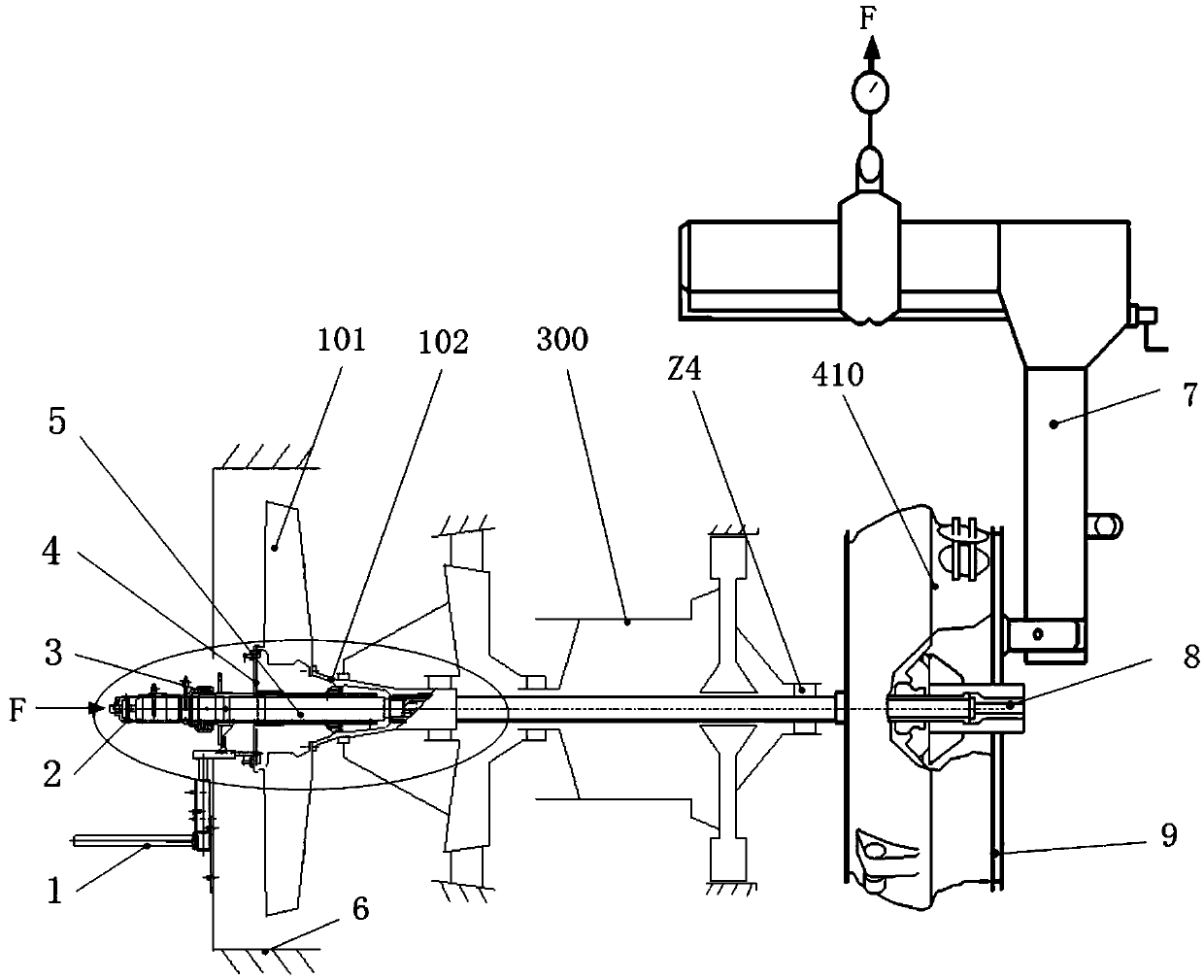

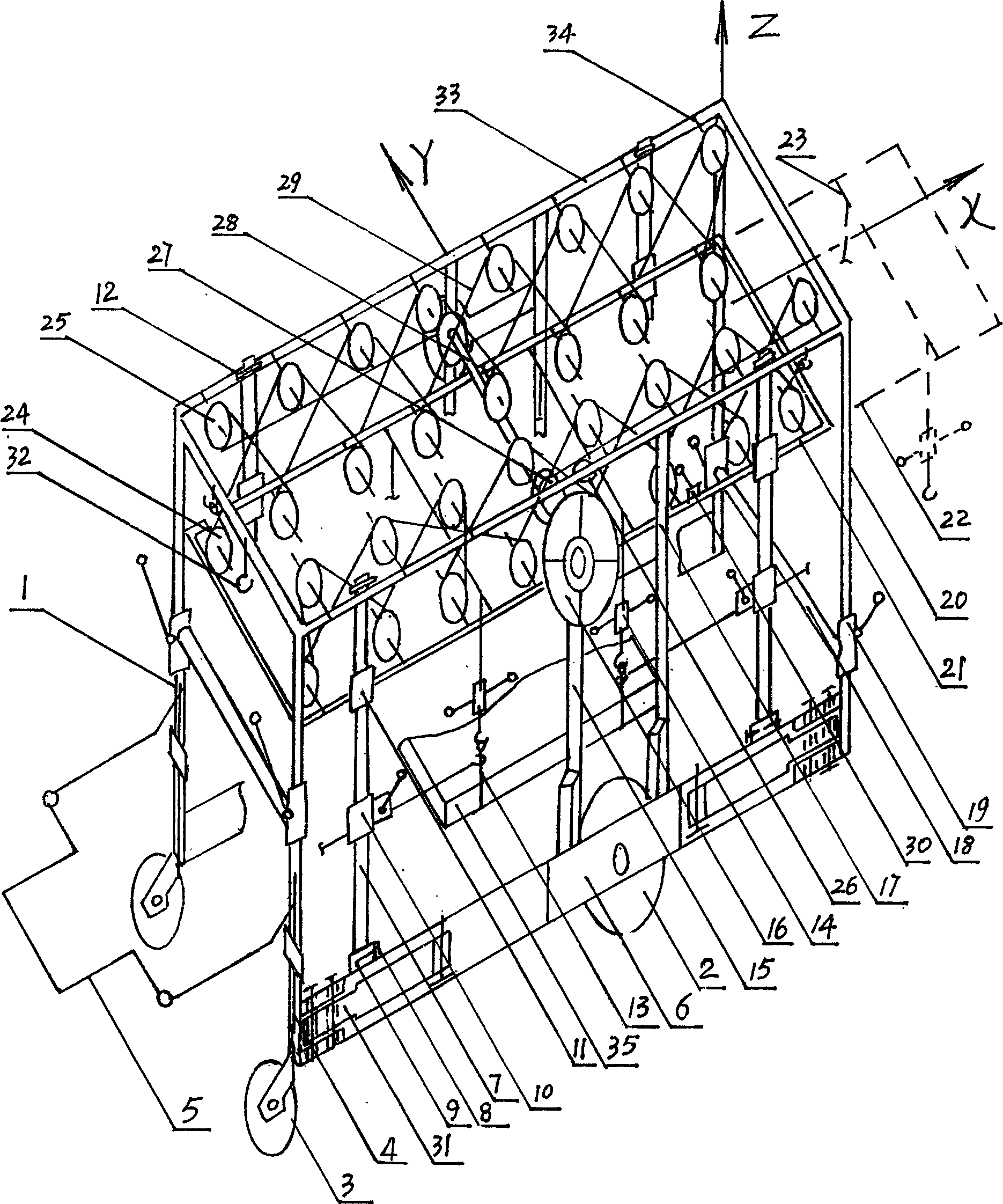

Six-axis attitude adjusting platform for installation for complete set of engine for aircraft engines

ActiveCN107352043AImprove installation efficiencyImprove installation qualityAircraft assemblyElectric machineryDegrees of freedom

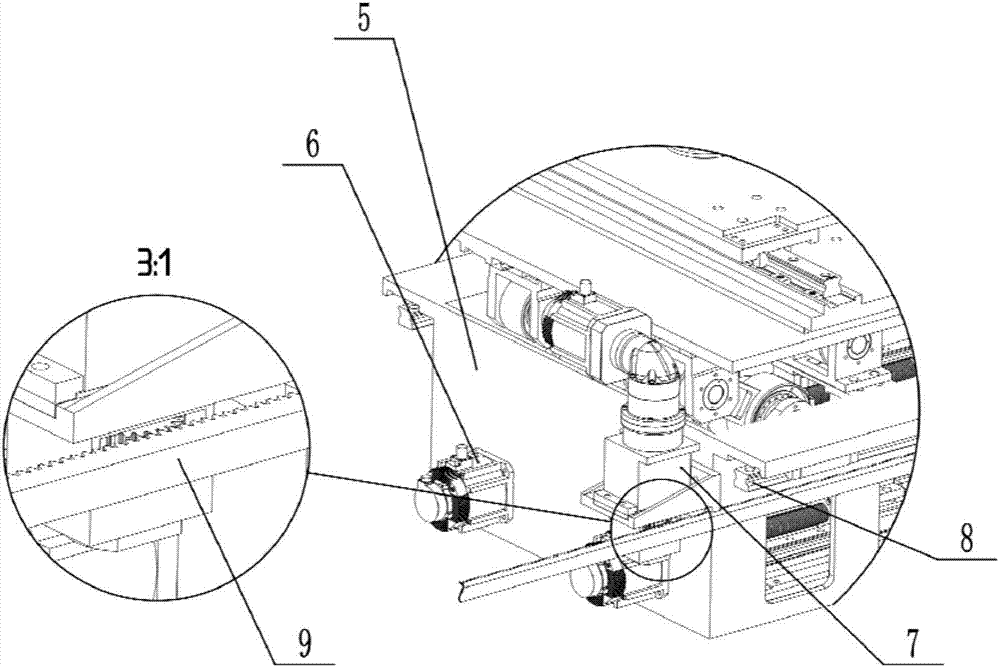

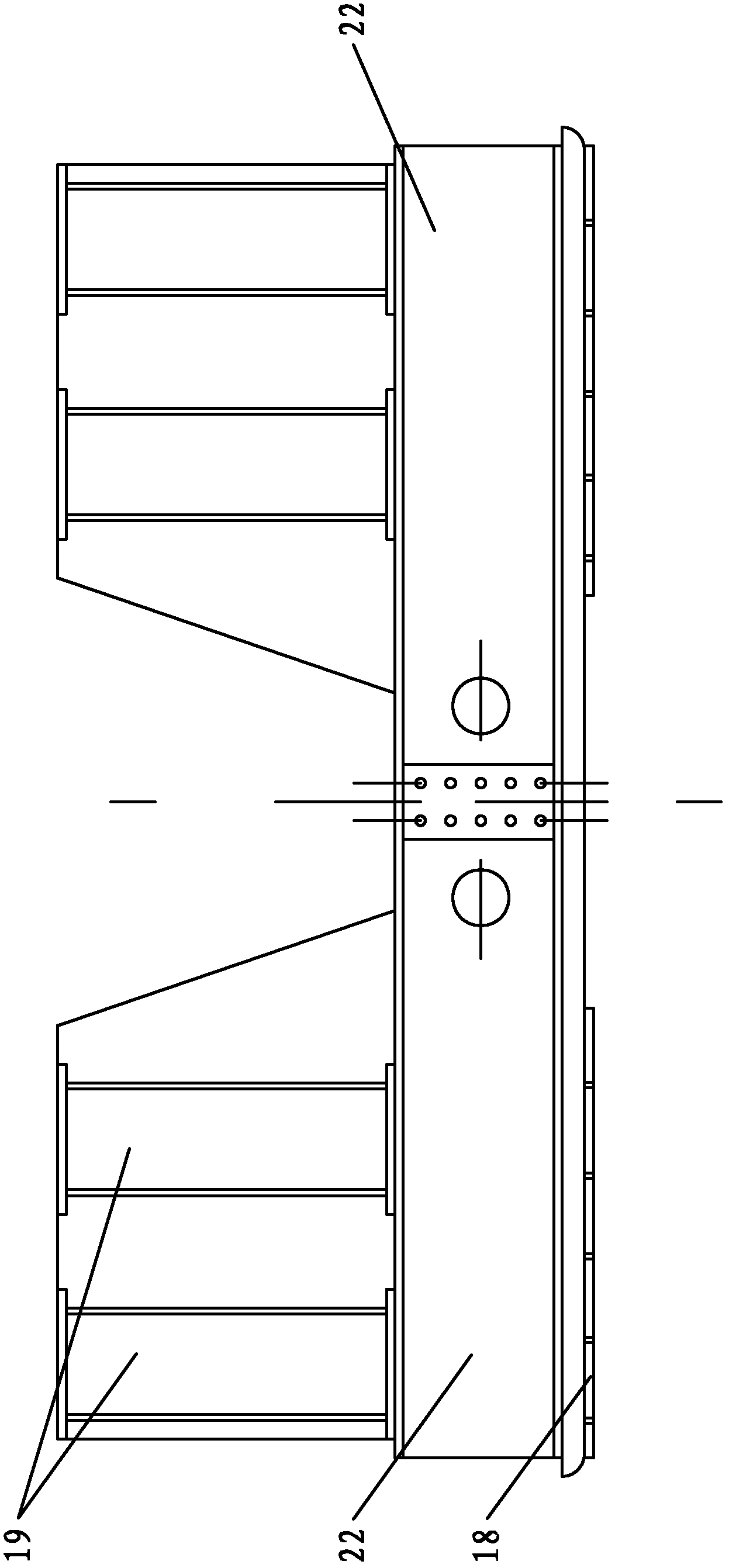

The invention discloses a six-axis attitude adjusting platform for installation for a complete set of engines for aircraft engines. The six-axis attitude adjusting platform comprises an operation table, a Y-axis translation mechanism, a C-axis slewing mechanism, four sets of herringbone hinge mechanisms, a cradle type platform frame and an X-axis propelling mechanism. According to the six-axis attitude adjusting platform disclosed by the invention, improvement is performed based on a conventional multi-axis attitude adjusting platform, so that the adjustable freedom degree is increased, and adjusting of the position attitude in six space freedom degree directions of the engines (namely X-axis horizontal propelling, Y-axis horizontal moving, Z-axis vertical lifting, A-axis left-to-right pitching, B-axis front-to-rear pitching, and C-axle horizontal rotating) is realized. Through the adoption of the six-axis attitude adjusting platform disclosed by the invention, in the mounting process of the aircraft engines, the adjusting of the position attitude in six space freedom degree directions is realized; the adjustable freedom degree is high, so that the mounting attitude of each engine is accurate; and the adjusting of the position attitude in the six free degrees of each engine adopts a servo motor to perform digital controlled attitude adjusting, so that the attitude adjusting accuracy and the attitude efficiency are improved; and the mounting efficiency and the mounting quality of the aircraft engines are further improved.

Owner:DALIAN UNIV OF TECH

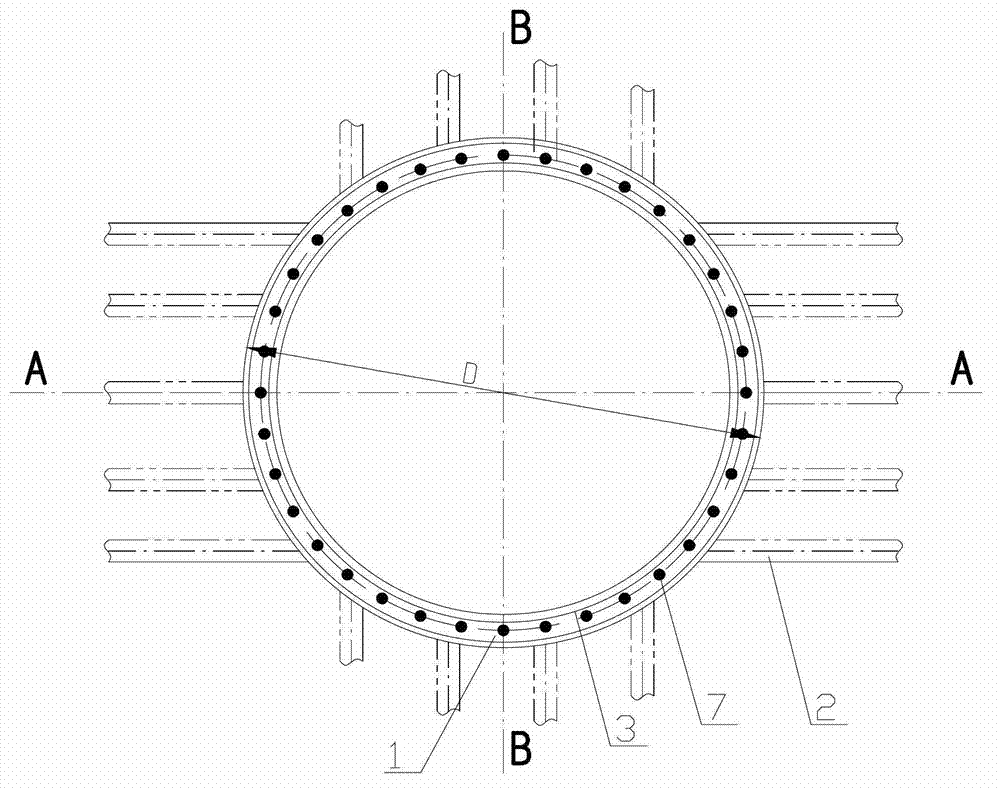

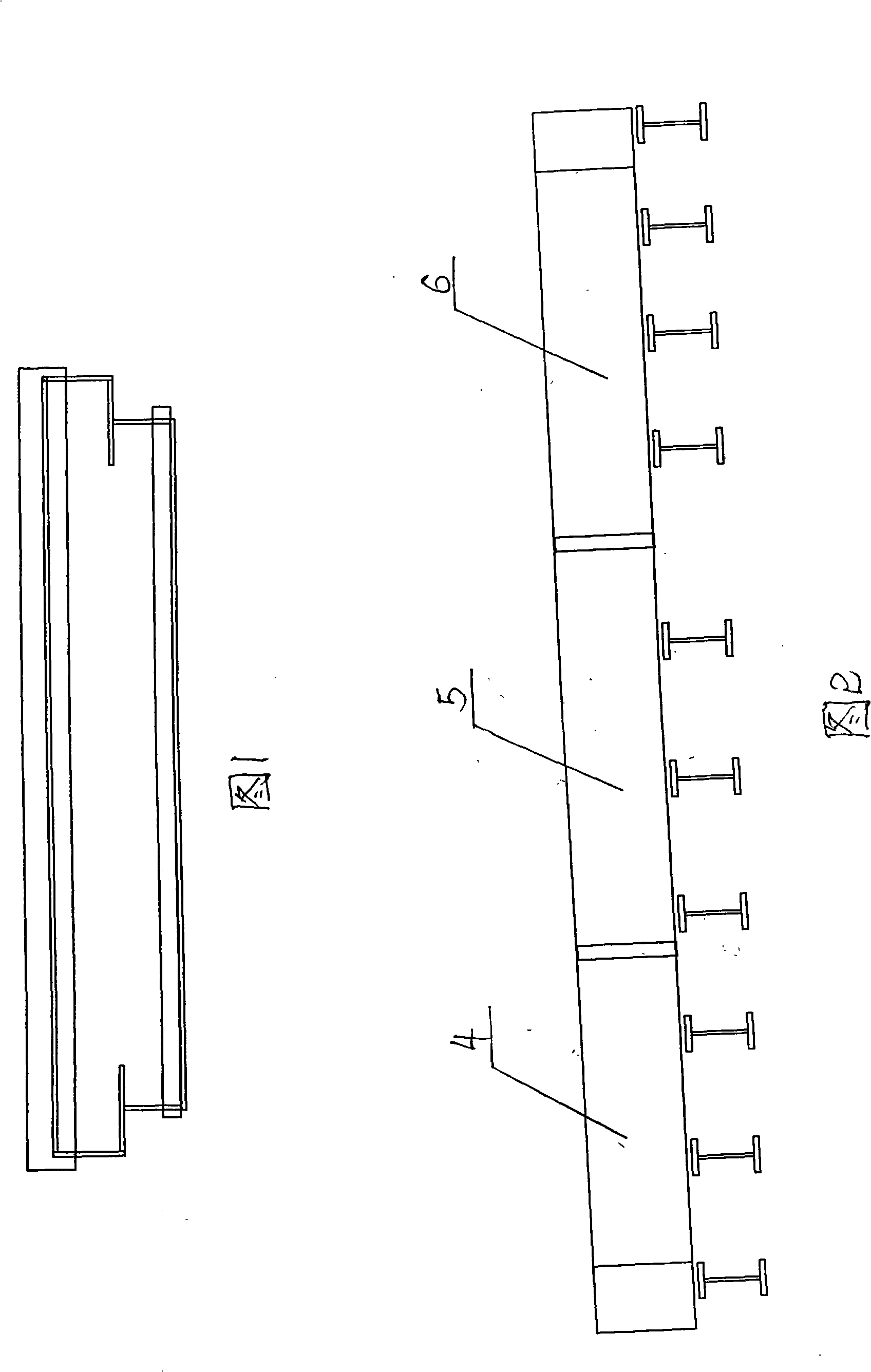

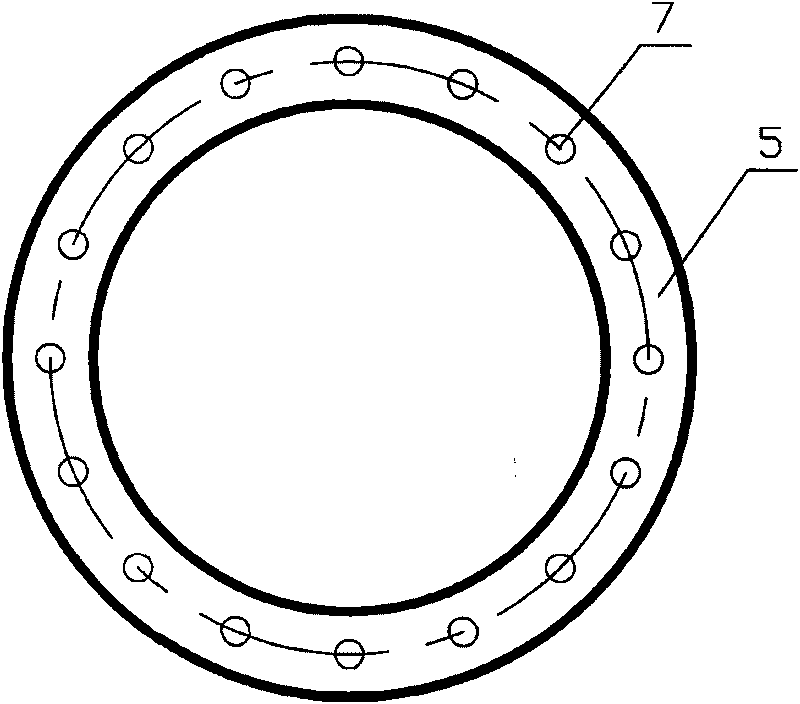

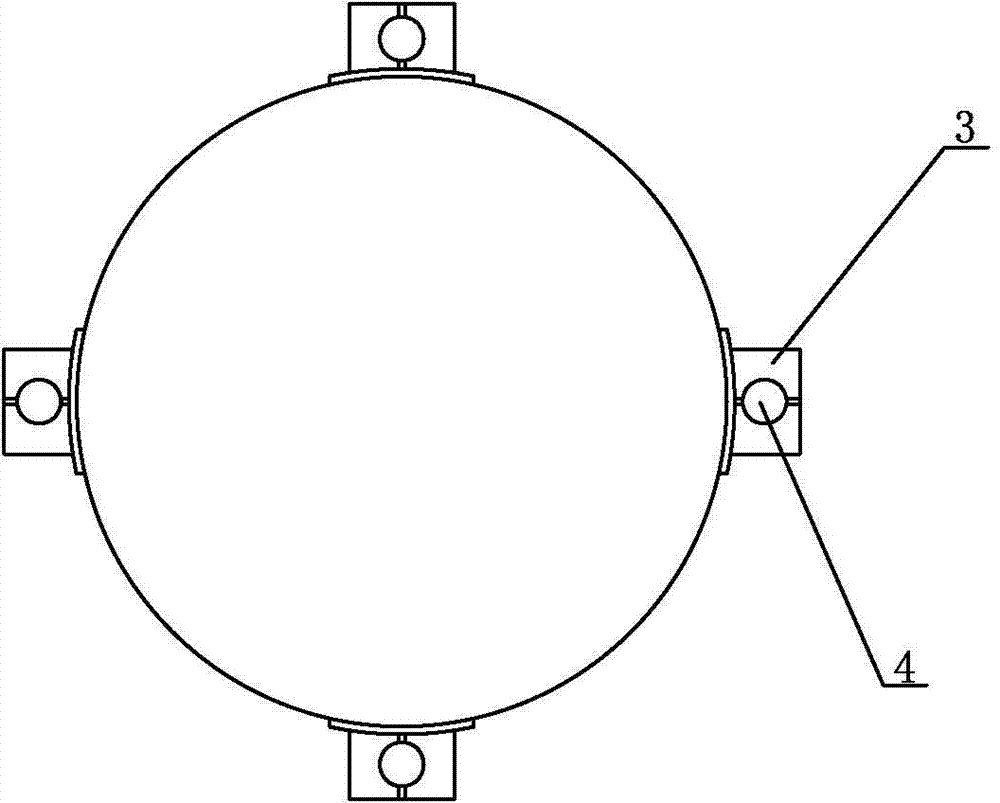

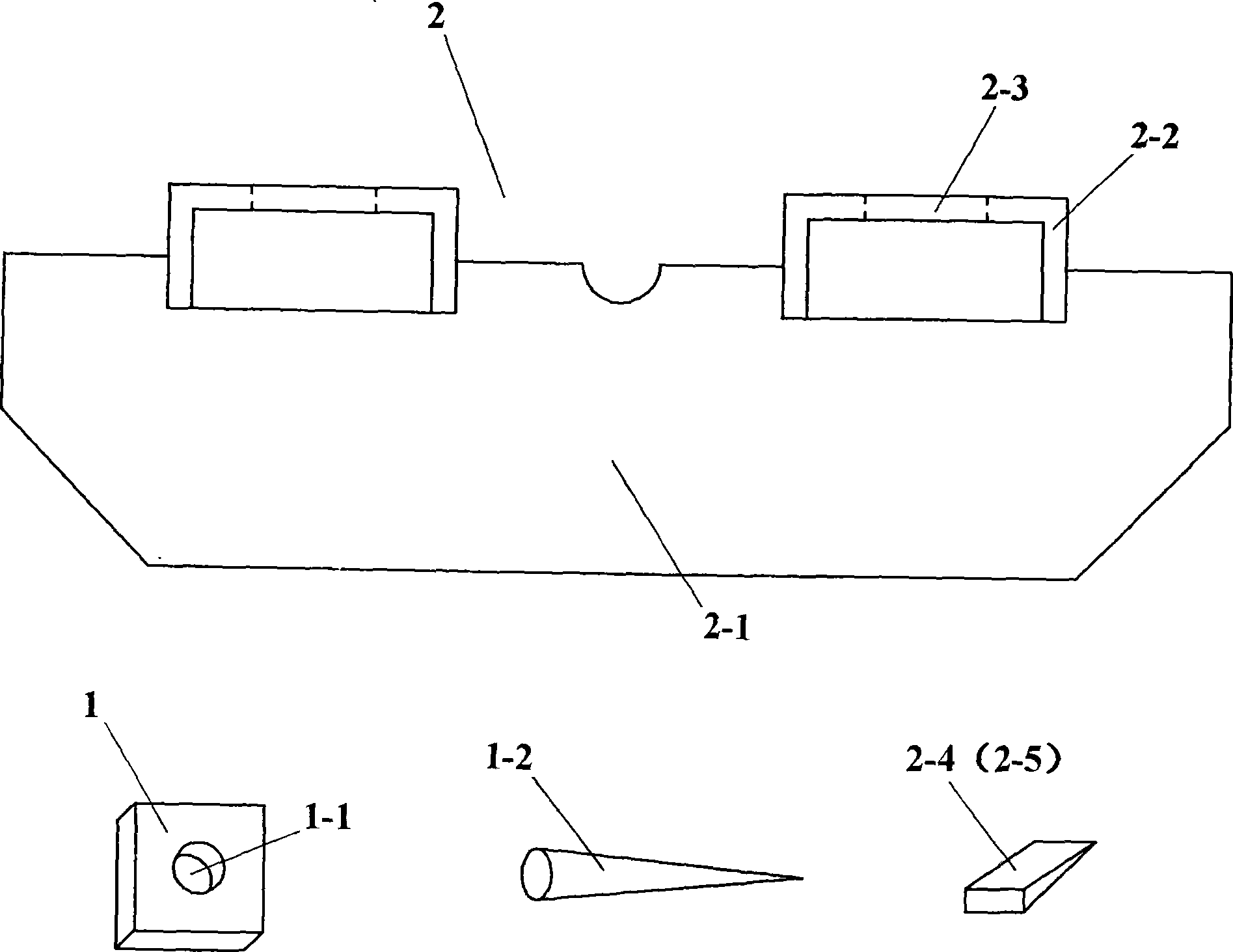

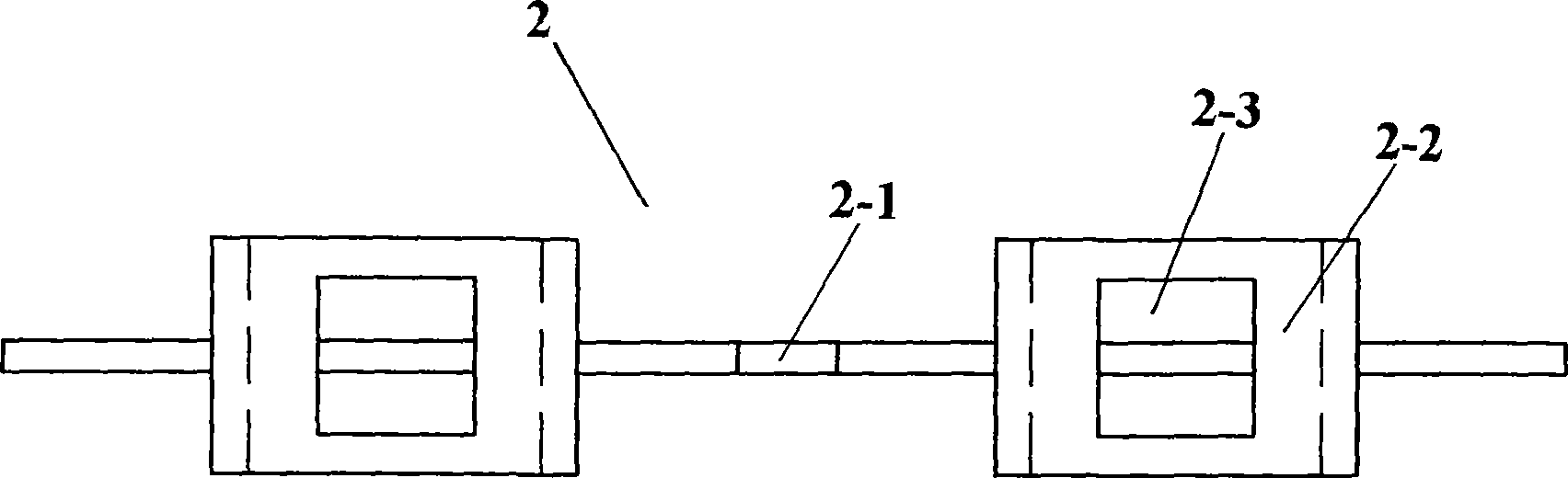

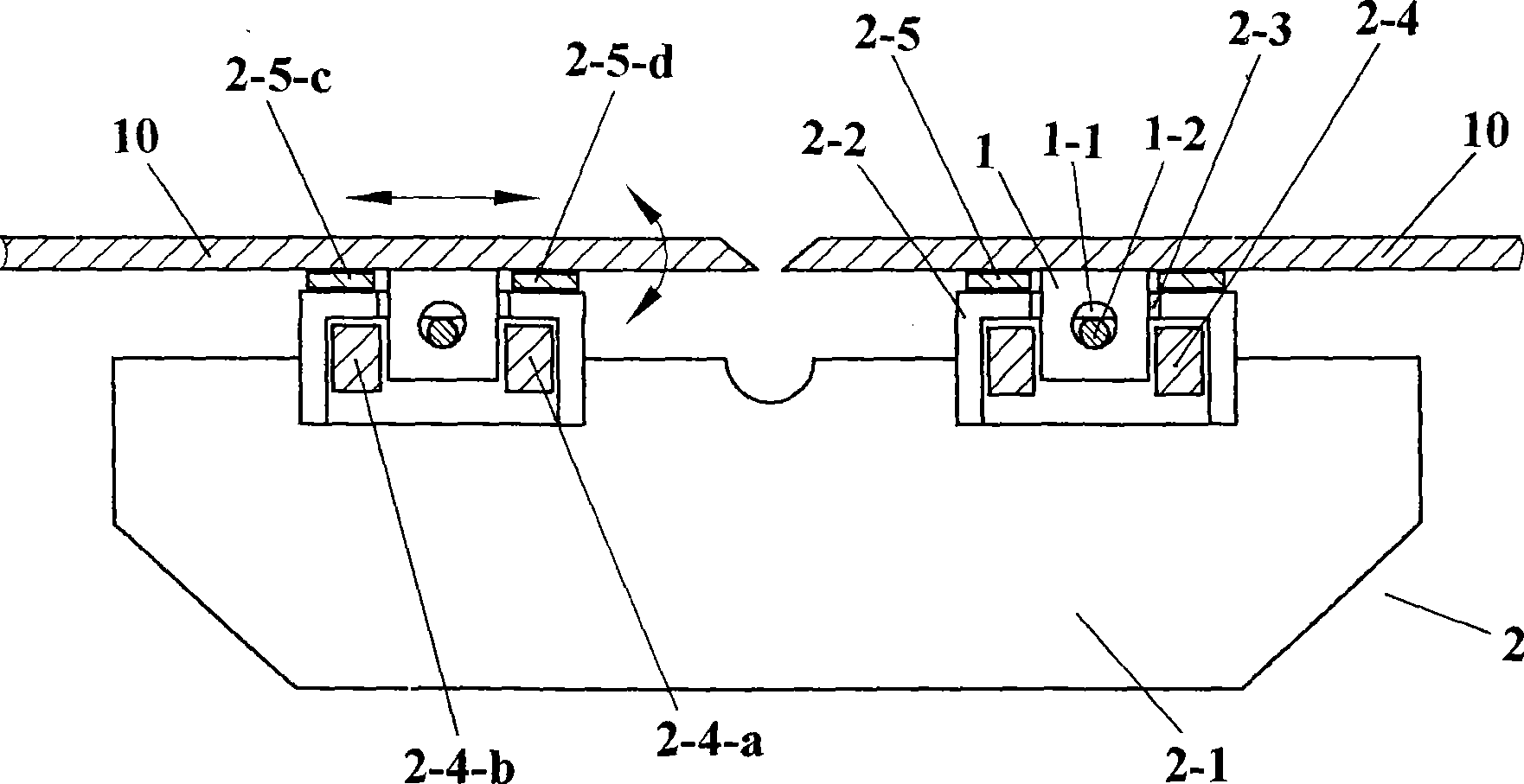

Full rotation steering oar device installation method

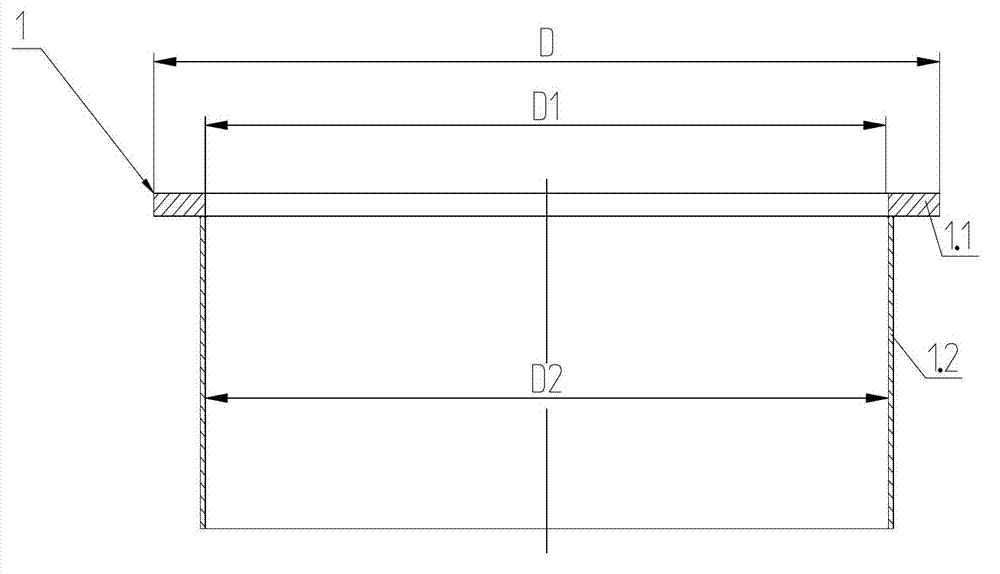

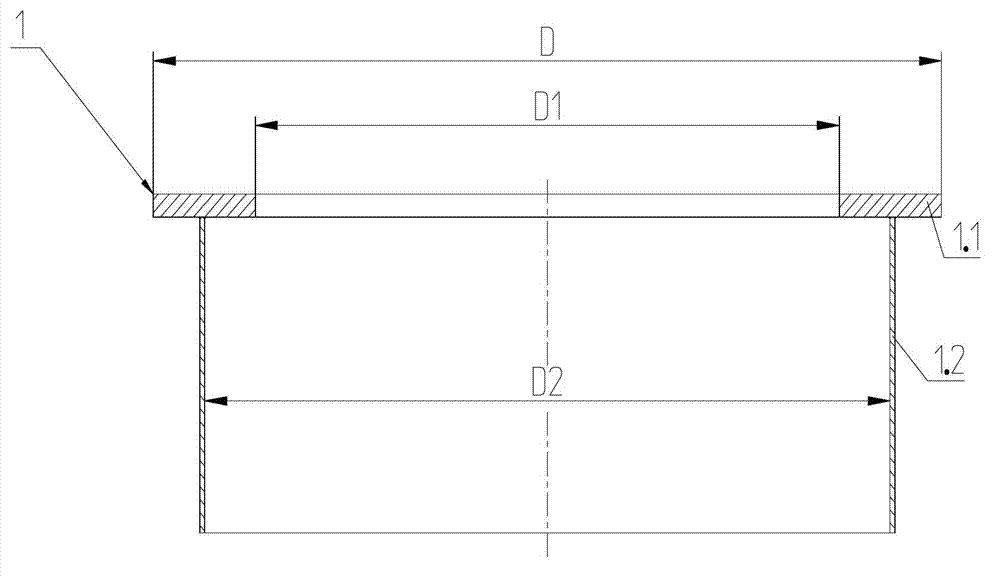

ActiveCN102923252AImprove ergonomicsSave investment in tooling equipmentVessel partsMarine engineeringFlange

The invention discloses a full rotation steering oar device installation method. A hull base of a full rotation steering oar which is installed in a trunk flange mode is cut into tapered unit bodies (indicated as the figure). The tapered unit bodies are transported to a workshop and high-precision mounting matching surfaces, screw holes and seal ring grooves are machined on the tapered unit bodies through a large vertical lathe. Next, the machined tapered unit bodies are lifted on a ship and replaced according to cutting steel marks and then the steering oar is installed so as to meet the requirement for shafting layout design, installation quality of the steering oar and sealing reliability. The full rotation steering oar device installation method abandons a traditional construction method, is labor-saving and effort-saving, improves work efficiency, and saves expensive tooling equipment investment. Secondly, the machined tapered unit bodies can be assembled with the steering oar, and then lifted on the ship and carries out replacement and installation. Installation quality and work efficiency of the steering oar are further improved and requirements of modern shipbuilding are met.

Owner:湖南湘船重工有限公司

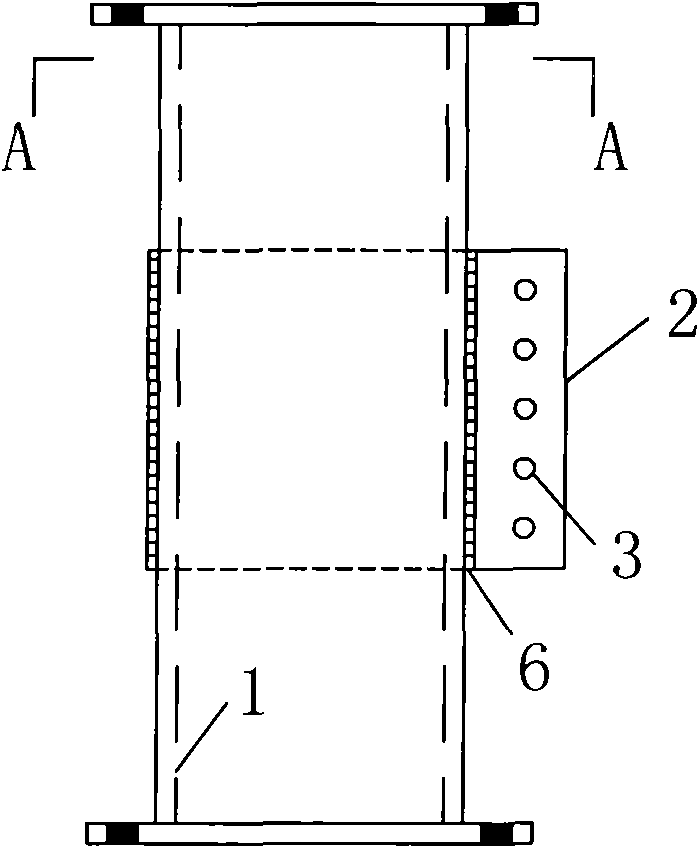

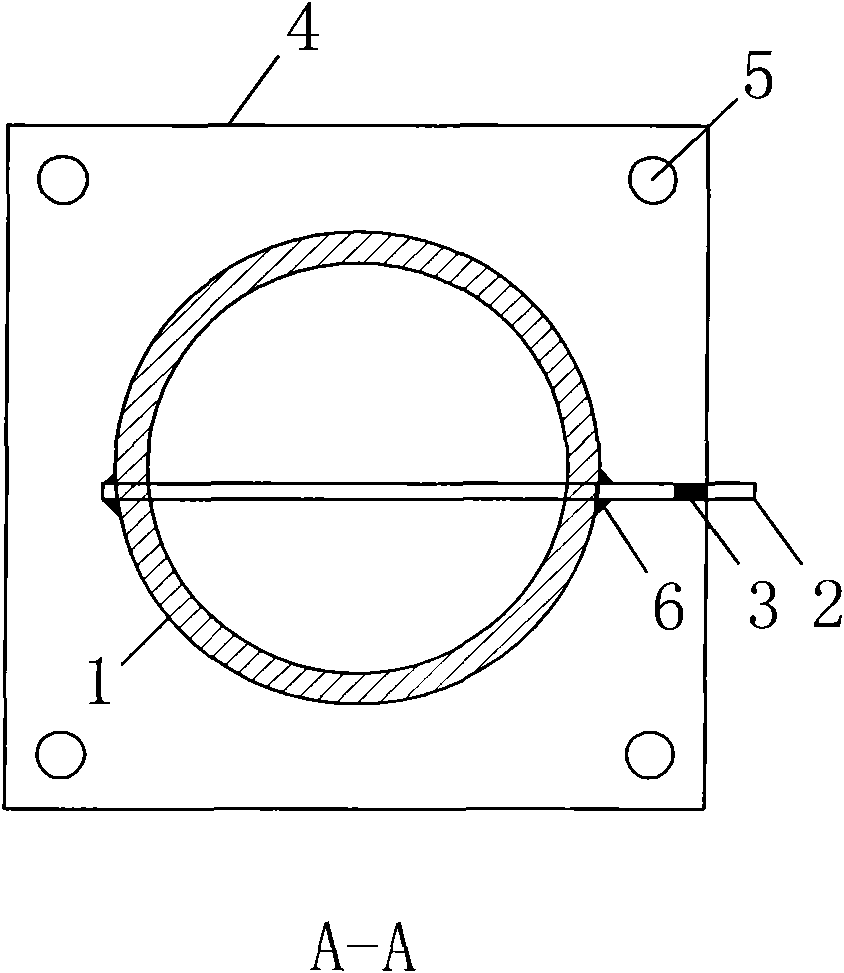

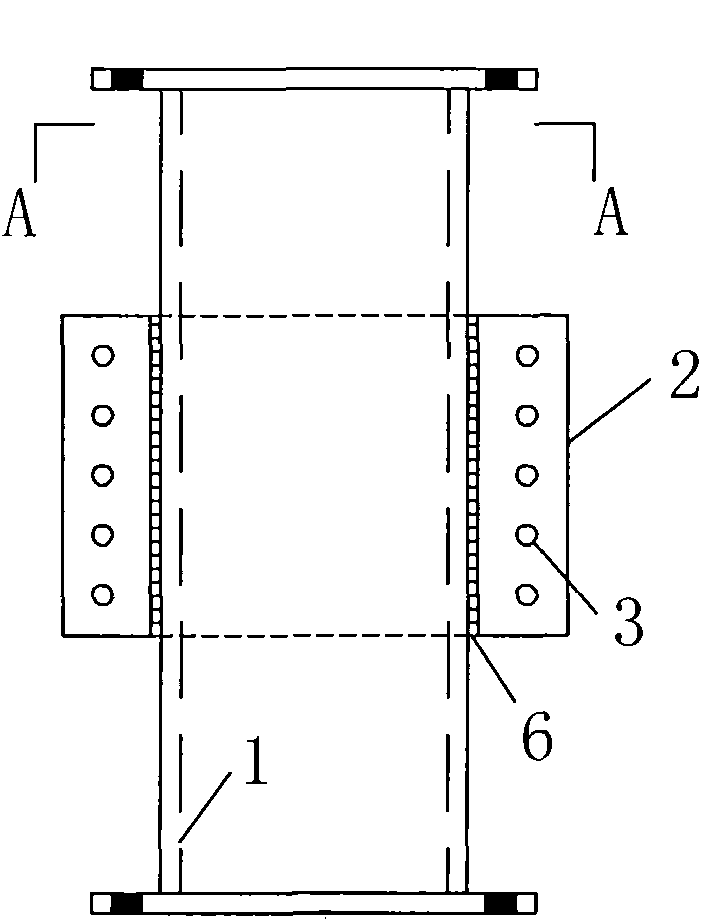

Standardized node connector of steel structure

InactiveCN101922183ADifficulty of SimplificationIncrease productivityBuilding constructionsCarrying capacityAgricultural engineering

The invention discloses a standardized node connector of a steel structure, comprising a steel column and a connection board. The connection board is fixedly connected on the side surface of the steel column; the free end of the connection board is a bolt connector; both ends of the steel column are fixedly connected with a flange on which a connection hole is arranged; the steel column is provided with a vertical through seam matched with the connection board; the connection board penetrates through the vertical through seam; and the connection board is fixedly welded with the penetrated part of the steel column. The invention has standard structure and convenient use as well as strong carrying capacity, can be applied in industrialized production and is very beneficial to promotion and application.

Owner:HENAN AUSPIC TECH

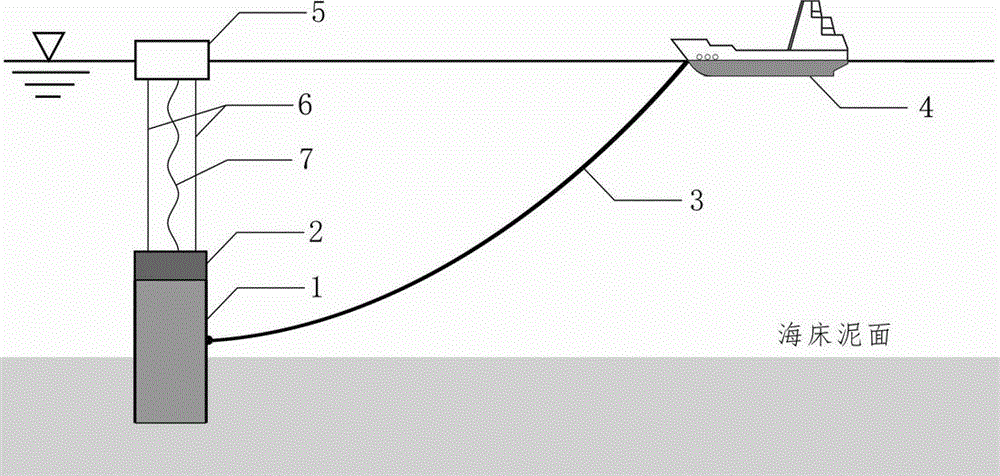

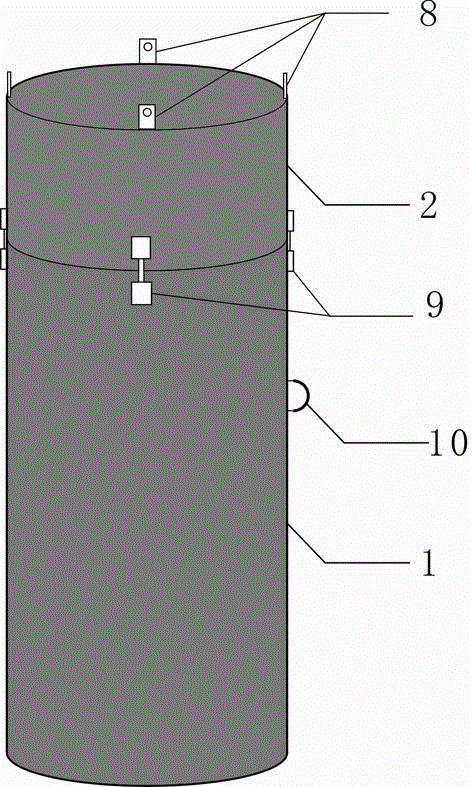

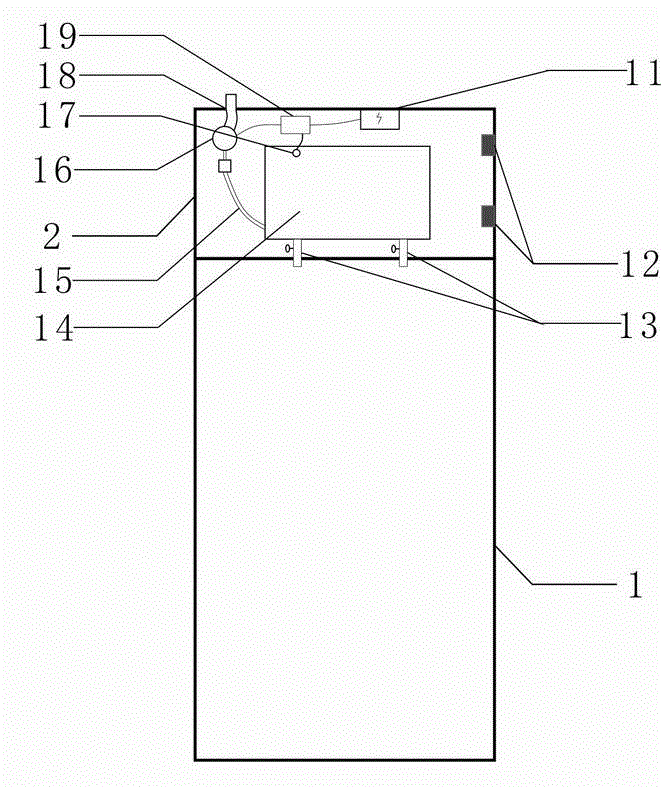

Deepwater suction type barrel-shaped foundation intermittent penetration equipment and installation method

The invention provides deepwater suction type barrel-shaped foundation intermittent penetration equipment and an installation method. A suction type barrel-shaped foundation is mechanically connected with a negative-pressure tank; and the negative-pressure tank can serve as a carrier of such installation equipment as a submersible pump, a sensor and electronic equipment to overcome limitations of a deepwater environment to installation conditions. The equipment in the negative-pressure tank allows to control applied suction in an intermittent form, so that the disturbance to a seabed soil mass can be effectively reduced under the condition of not prolonging the installation time, the development of a soil plug in a suction type barrel-shaped foundation is restrained, and the installation quality is improved.

Owner:ZHEJIANG UNIV

Hydraulic hoisting, slipping and emplacing method and equipment for large scale press components

ActiveCN102530732AConstruction safetyPrecise positioningLoad-engaging girdersTravelling cranesStructural engineering

Owner:中国机械工业建设集团有限公司 +1

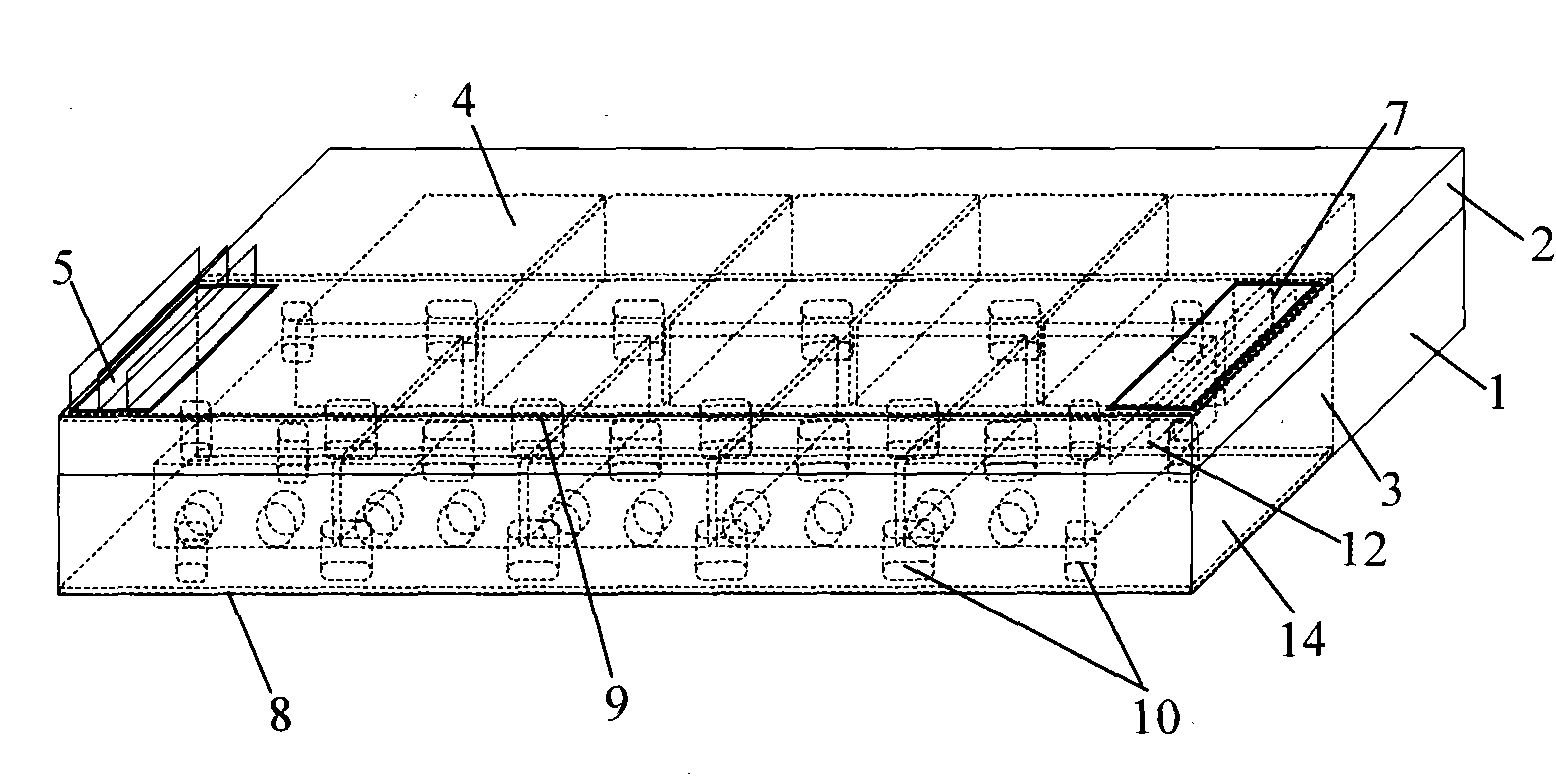

Heat exchange structure of power battery box

InactiveCN101789518AMeet the demanding requirements of operating temperatureImprove performanceCell temperature controlAcute angleWorking temperature

The invention relates to a heat exchange structure of a power battery box, wherein a temperature monitoring element is arranged in a battery module of a battery pack; the battery pack is erected in the middle of a battery box; a top space, a bottom space and a side surface space are respectively positioned between the upper surface, the lower surface and the side surface of the battery pack and the top, the bottom and the side surface of the battery box; a heating element is arranged in the battery box; a first air door and a second air door are arranged on the battery box; an air driving element is arranged in the battery box towards the second air door and at an acute angle with the second air door; and a control unit is electrically connected with the first air door, the second air door, the air driving element, the heating element and the temperature monitoring element. The invention has ingenious design, simple structure, low cost, convenient operation and both cooling and heating, thereby solving the problem of heat management of the battery box of an all-electric hybrid power vehicle, meeting the strict requirements of a battery on working temperature, enhancing the property of the battery and being suitable for large-scaled popularization and application.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

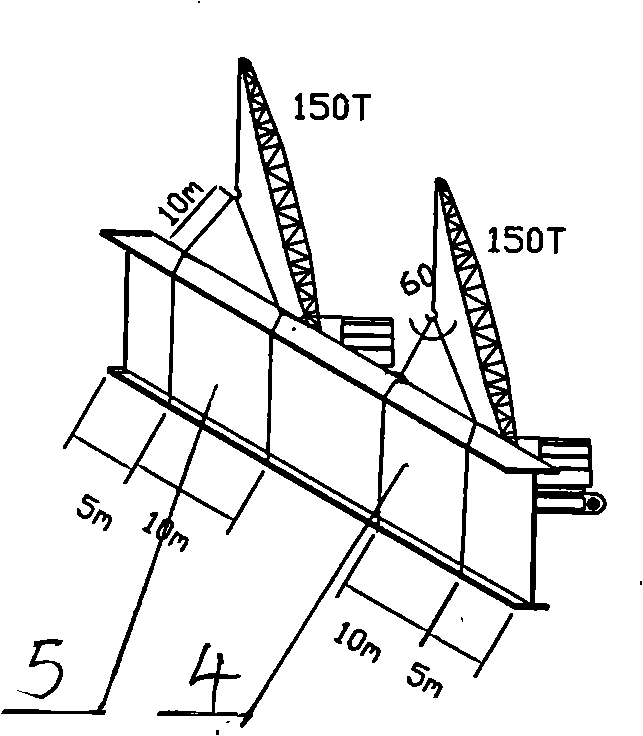

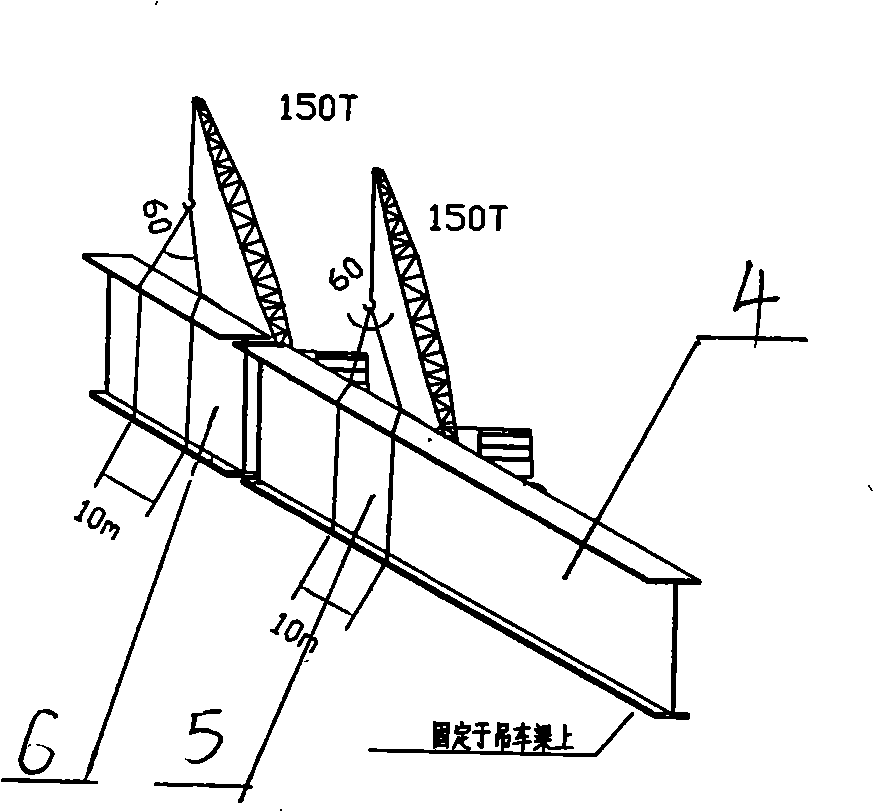

Giant crane beam mounting method

The invention relates to a construction method, in particular to a method for installing super-large crane beams, solving the technical problems of the prior art in the installation of large-span and large-mass crane beams. The method for installing the super-large crane beams comprises the following steps: a temporary bracket is first put up on the ground at one third of the span of a crane beam installation position; a crane beam is assembled on site; a left-segment crane beam component and a middle-segment crane beam component which are welded together are integrally lifted in place by use of two cranes; the left-segment crane beam component is partially fixed with a steel column connecting part; the other end of the middle-segment crane beam component falls on the bracket; a right-segment crane beam component is lifted to the height in accordance with the middle-segment crane beam component by use of another crane; and the right-segment crane beam component and the middle-segment crane beam component are paired and welded in the air. The method is applicable to the installation of the crane beam of which the length is over 60 meters and the mass is over 220 tons. The method has the advantages of high safety performance, short construction period, convenient construction operation and good engineering quality.

Owner:MCC TIANGONG GROUP

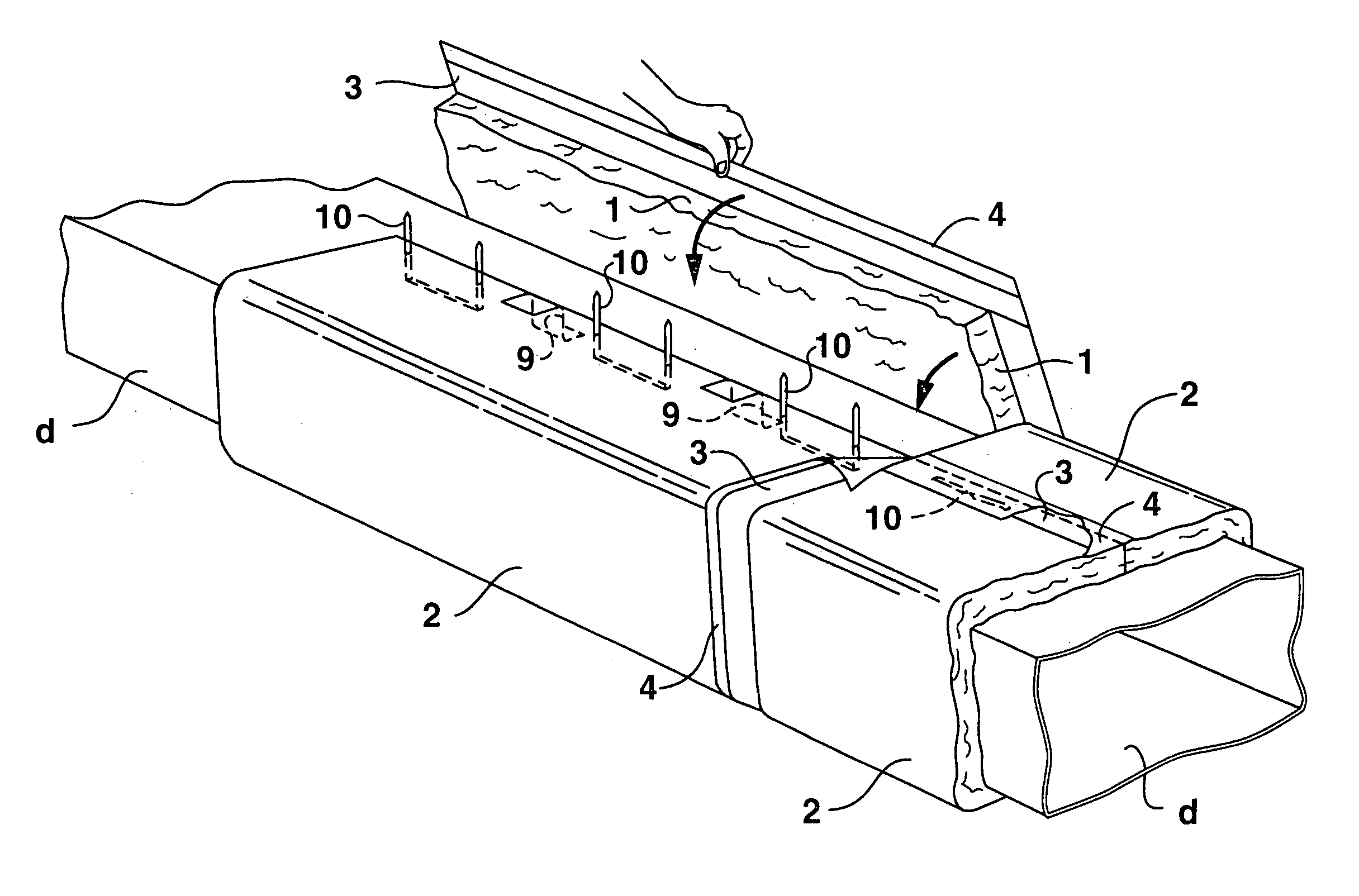

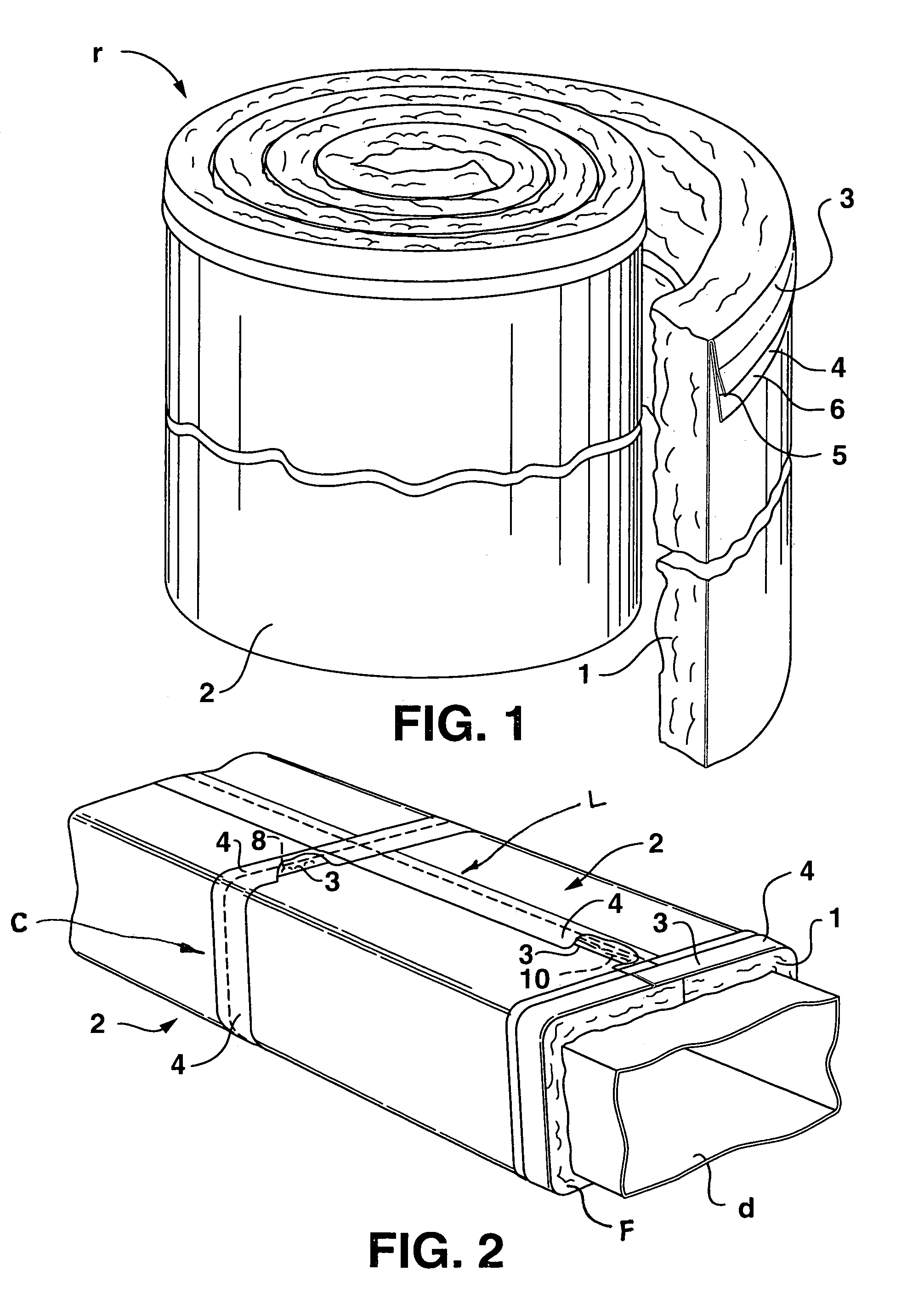

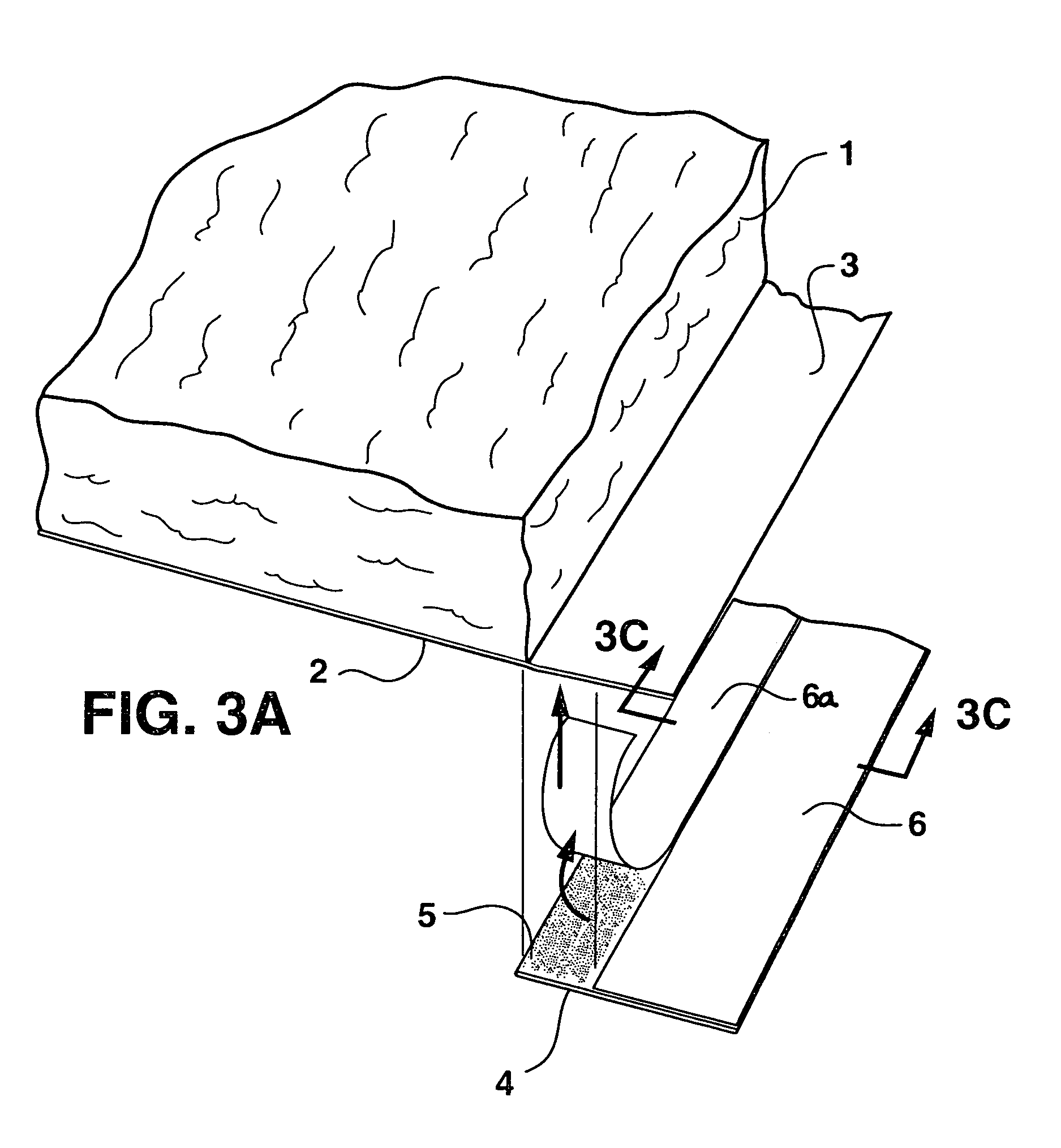

Prefabricated insulation for HVAC ductwork and other fluid conduits

InactiveUS6935379B1Improve insulation installationLow costThermal insulationLayered productsVapor barrierEngineering

An improved insulation and an improved method for preparing and installing sheets of insulation having a vapor-barrier jacket or “finish” to ductwork and other fluid conduits or other surfaces. Anchor tabs are provided on the insulation, as are also studs for anchorage and mechanical attachment. Pressure sensitive tape with a split release strip is applied to the sheets prior to the installation of the sheets to the ductwork or other fluid conduits. The pressure sensitive tape is for sealing of any penetrations in the vapor-barrier by the mechanical attachment devices and for sealing of the edge of the vapor barrier jacket flange to the adjacent piece vapor-barrier jacket. The insulation is configured such that during storage and shipment, the jacket attachment flanges are positioned to avoid crumpling.

Owner:BUCHANAN SR MARVIN C

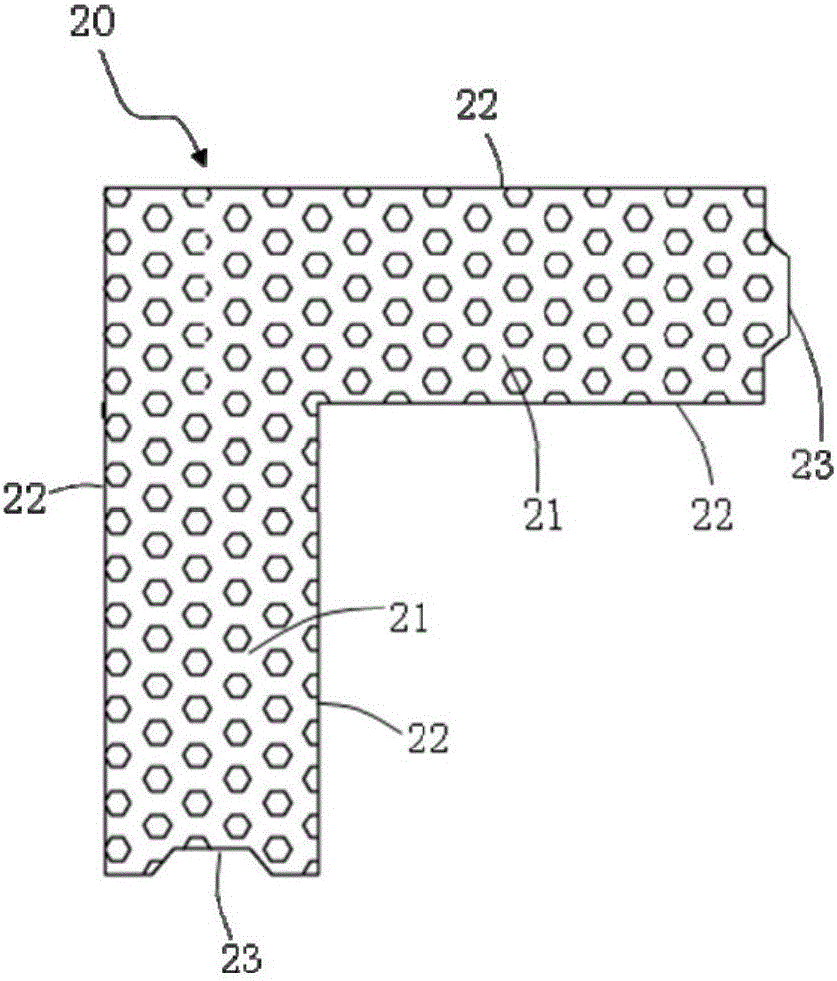

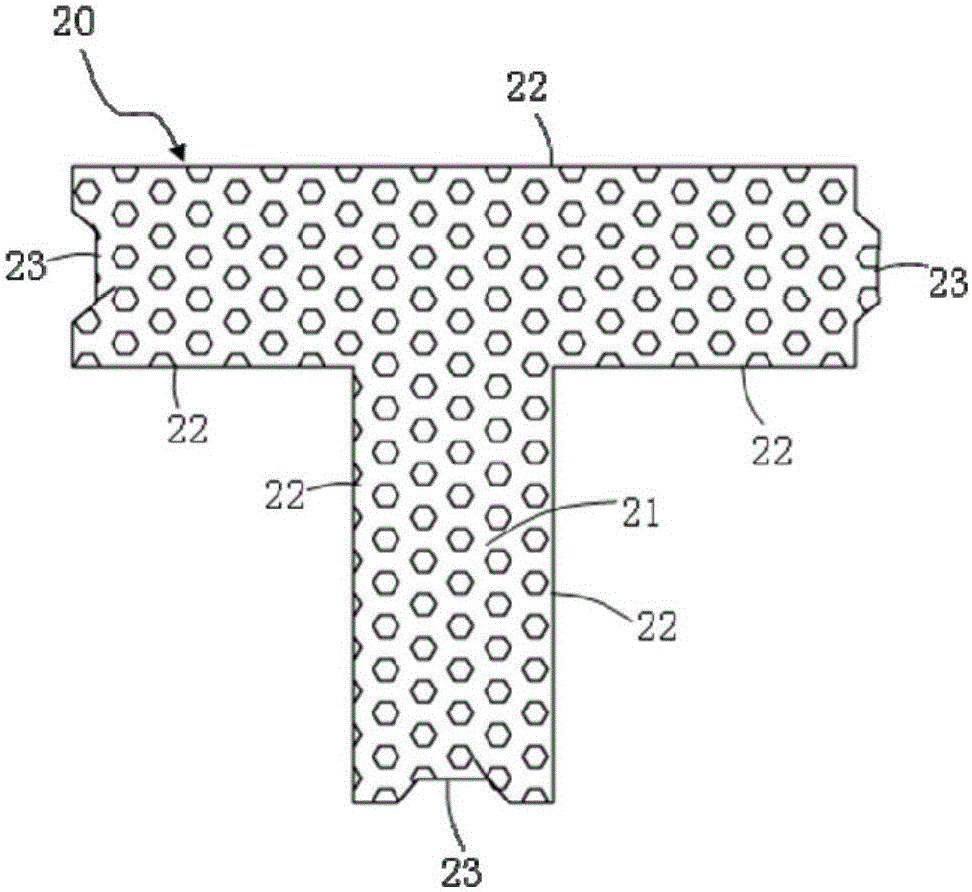

Light-weight partition wall structure and installing method thereof

The invention provides a light-weight partition wall structure and an installing method thereof. The light-weight partition wall structure is mainly characterized in that the part of a partition wall turning corner is prefabricated into an integrally formed turning corner component; a square steel pipe filled with polyphenyl granule cement is prefabricated into a construction column; and a ring beam formed by matching square steel with a U-shaped clamp element is used as a component of a light-weight partition wall, so that the technical problems of the existing polyphenyl granule light-weight ribbon board partition wall are solved; and the technical effects of shortening the construction period and practically improving the installing quality of the light-weight partition wall are achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

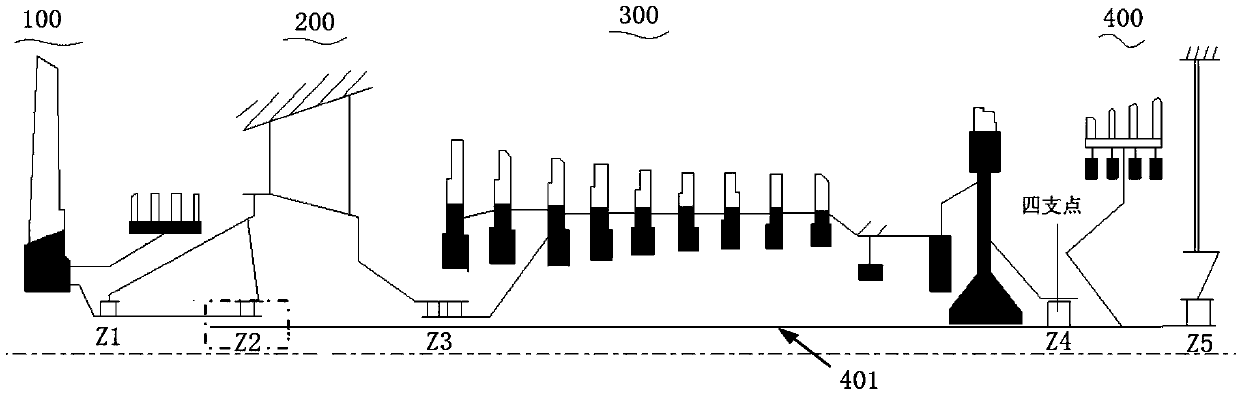

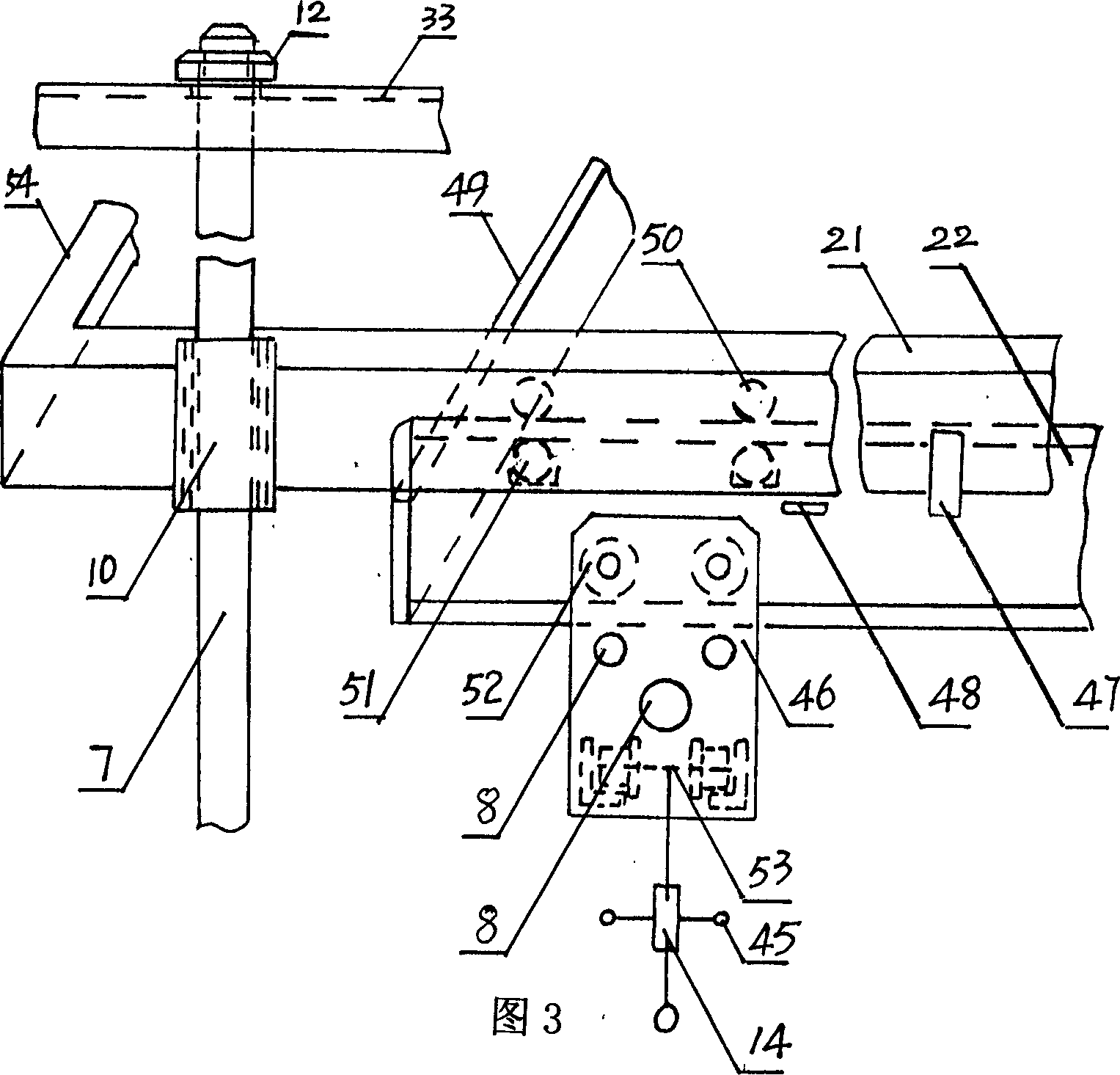

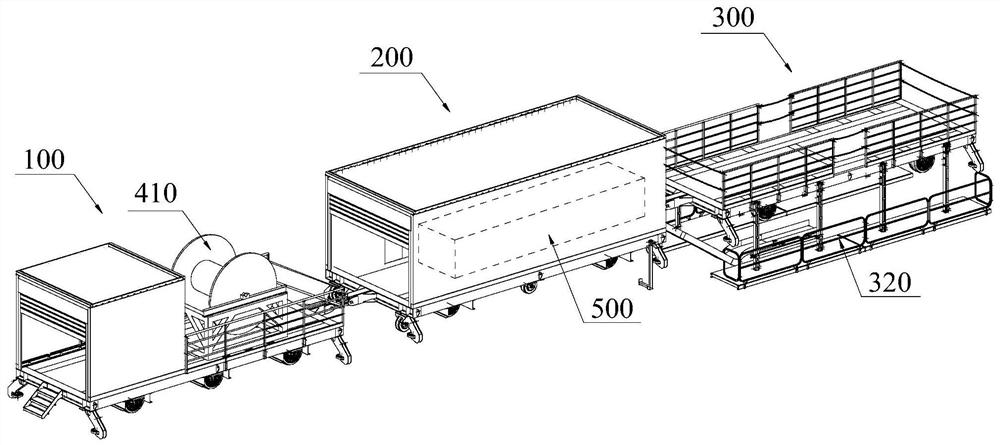

Laying construction method and device for double-block type ballastless track sleeper

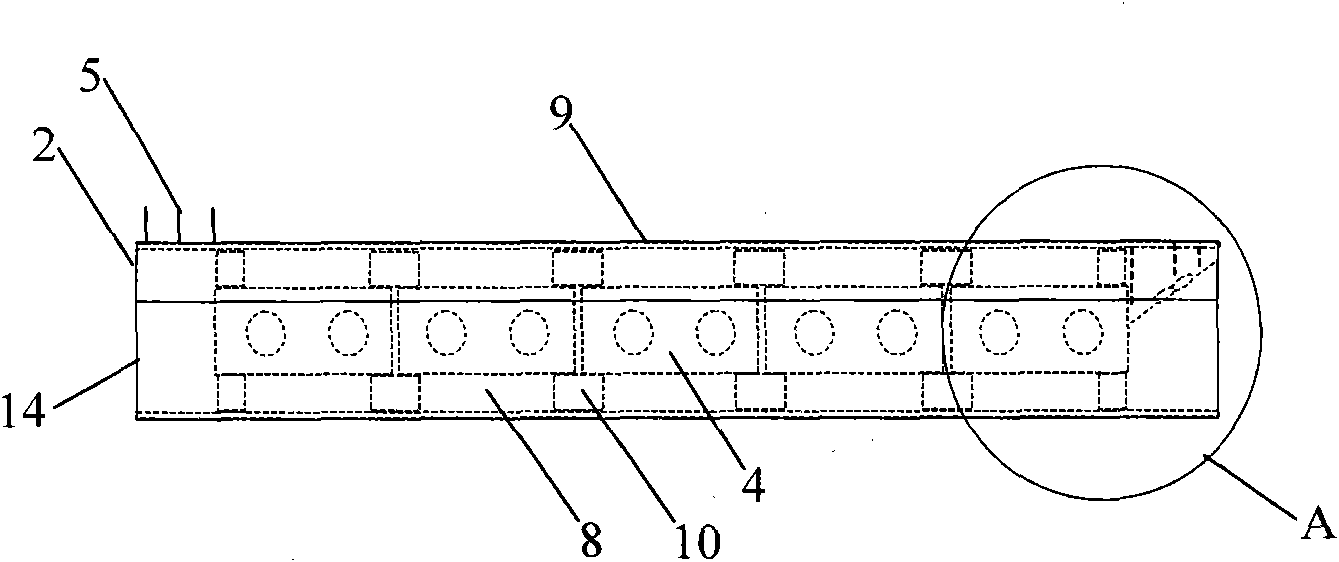

InactiveCN101215814ARealize continuous layingImprove installation qualityBallastwayRailway track constructionTrackwayArchitectural engineering

The invention discloses a high-speed railway double-block ballastless rail sleeper laying construction method and devices, which comprises: a concrete loading layer is laid on a roadbed layer, formwork rails are symmetrically fixed on both sides of the concrete loading layer, support legs are arranged outside the formwork rail, rail bed concrete is cast between two formworks for evenness; a beam is put on a pair of support legs to be constructed, a fixing frame to be combined with the sleeper is put on two adjacent beams, simultaneously the sleeper is imbedded into rail bed concrete for consolidating into one part through vibration mode, and so on for the next sleeper laying; the fixing frame is separated from the sleeper and the fixing frame, and the beams are offered to the construction equipment for recycle use after the sleeper and rail bed concrete are initially solidified; after the concrete is totally consolidated, the rail formworks, support legs are dissembled and recycled for use. The method of the invention satisfies the ballastless rail construction accuracy requirement and mechanic recycling operation mode, and greatly improves the sleeper laying efficiency and quality.

Owner:CRRC LUOYANG CO LTD +1

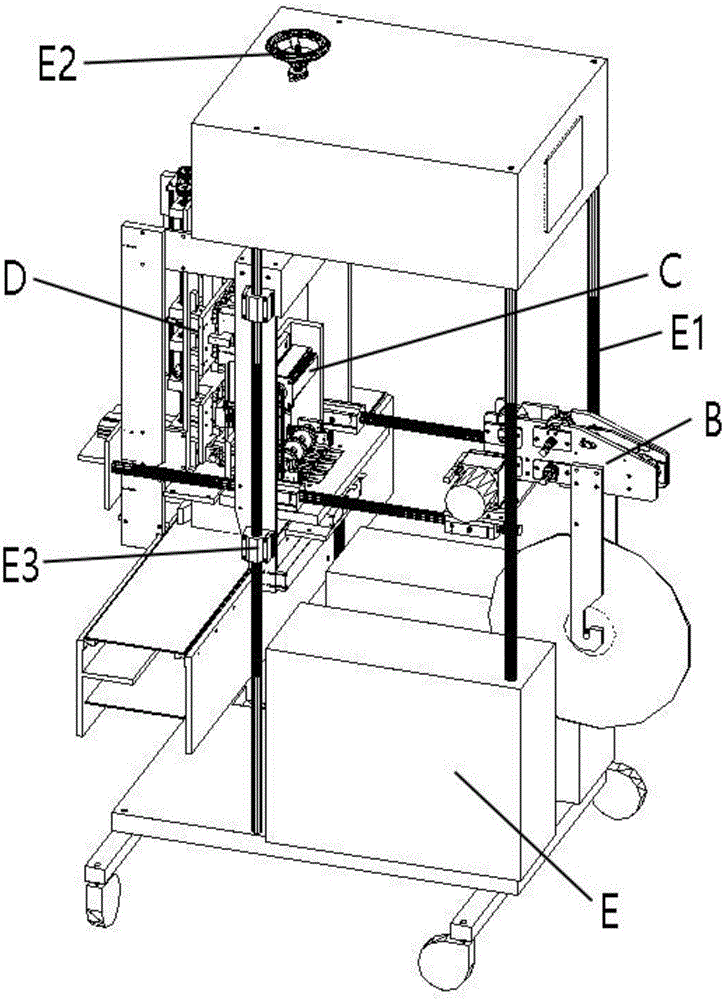

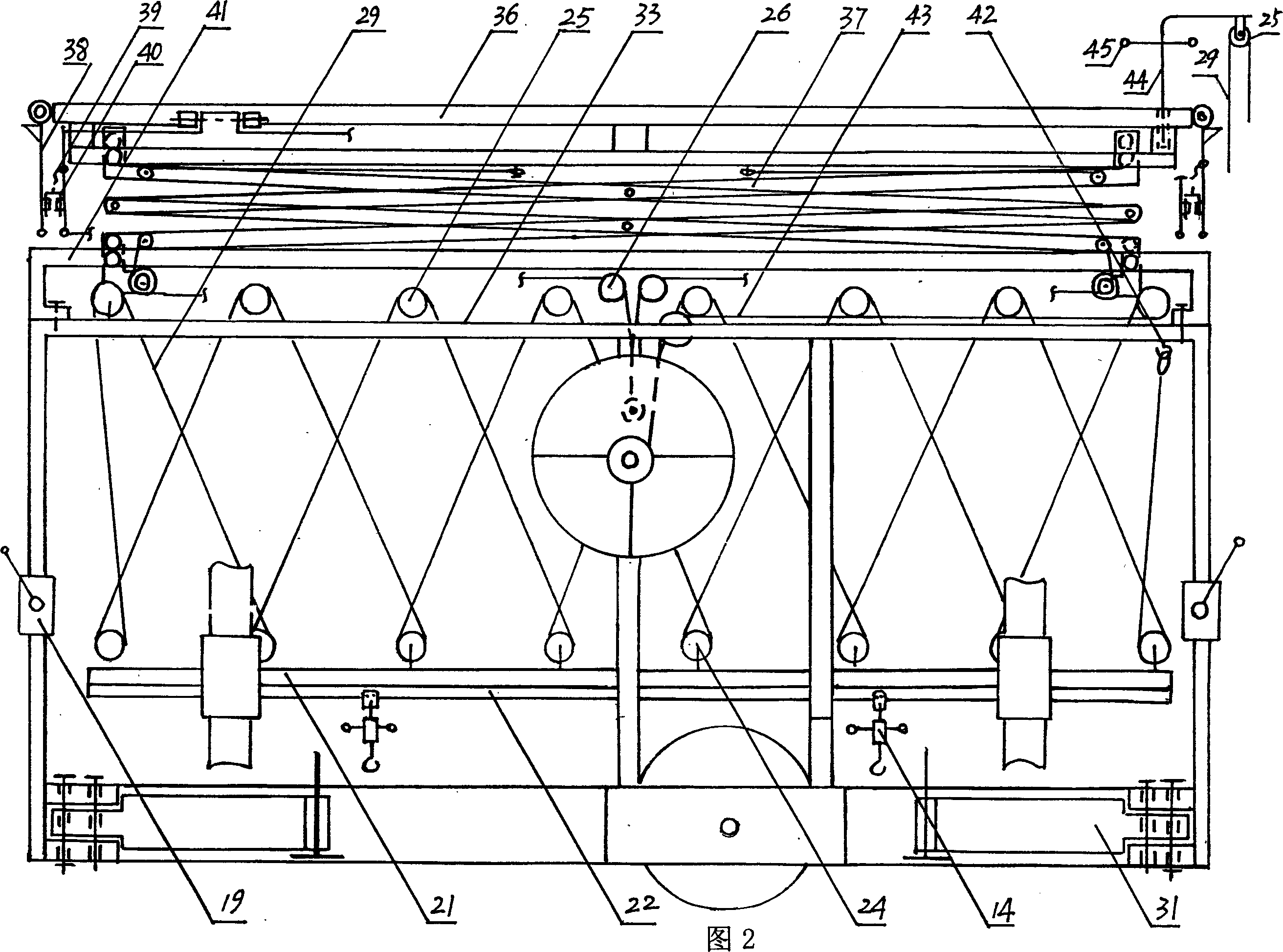

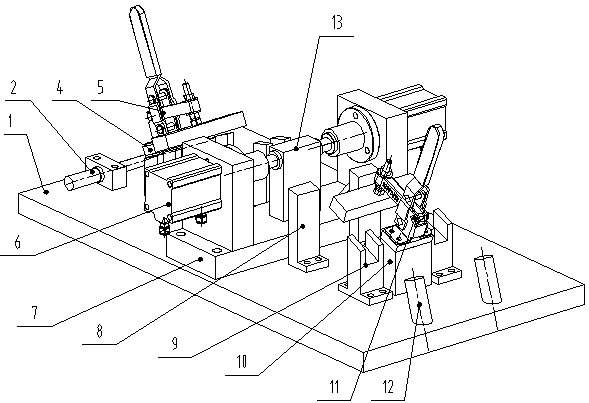

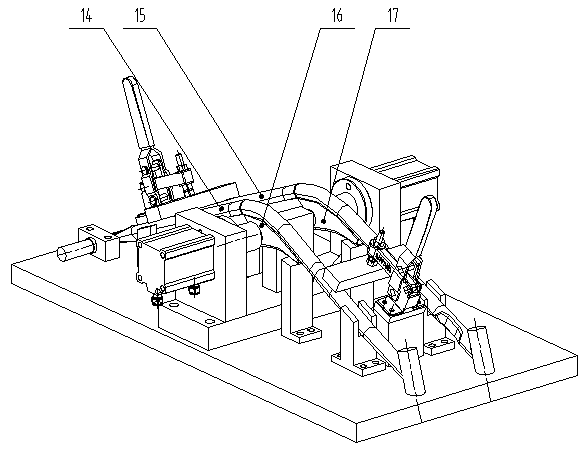

Numerical control assembly device for automobile radiator core production line

ActiveCN104259858ASave human effortImprove work efficiencyAssembly machinesNumerical controlProduction line

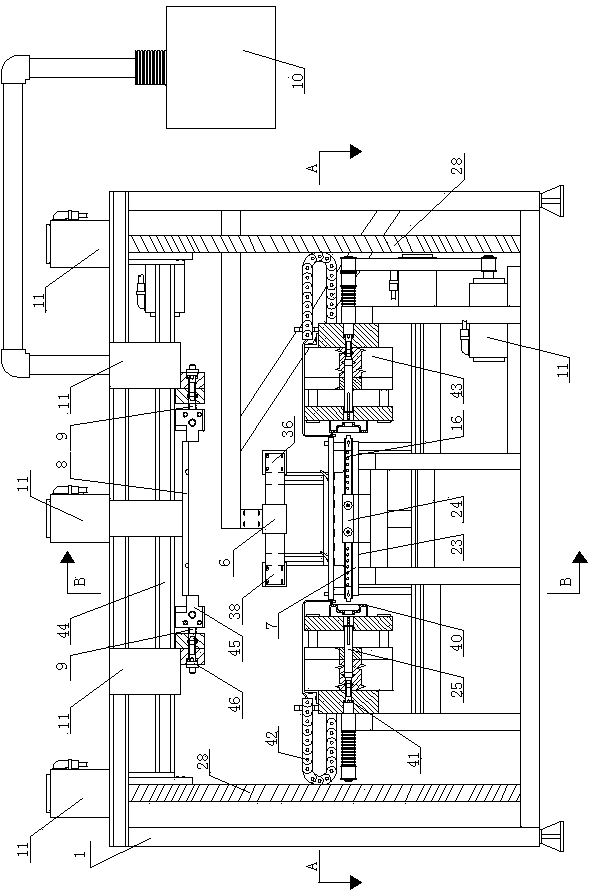

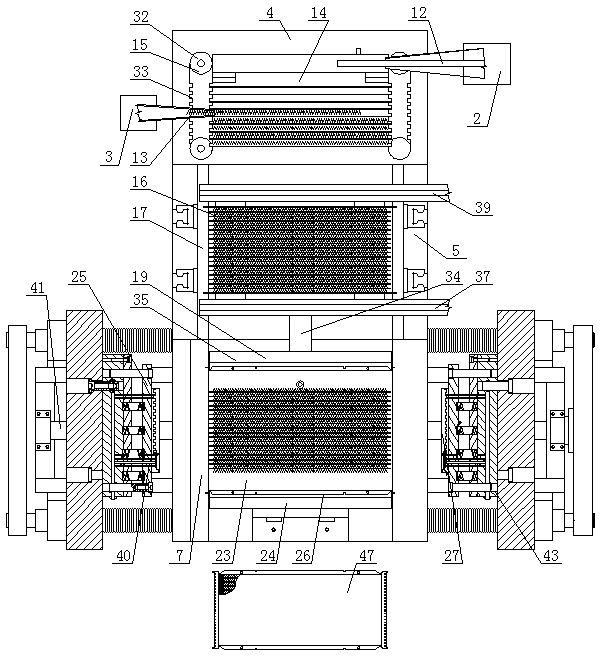

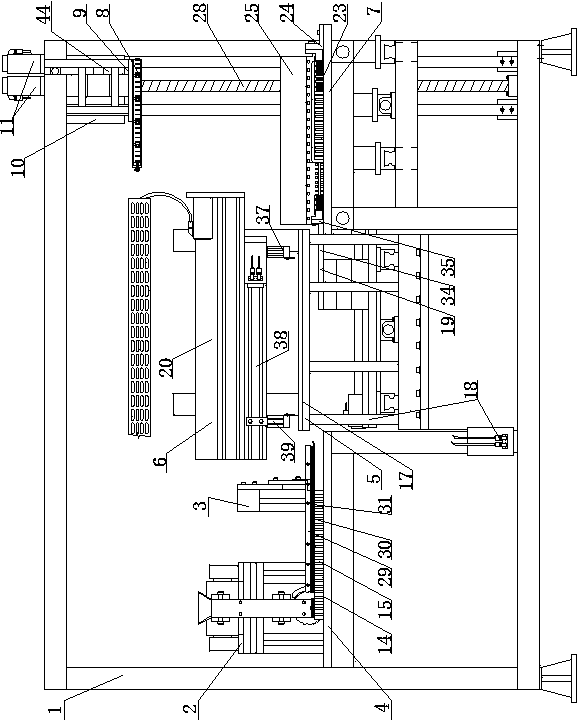

The invention discloses a numerical control assembly device for an automobile radiator core production line, belongs to a core assembly device, and aims to solve the problems of low efficiency and low precision existing in the prior art. According to the adopted technical scheme, the device comprises a rack, a radiating tube conveying device, a radiating belt turning and conveying device, a radiating tube and radiating belt automatic arrangement table, a core lifting conveying table, a front and rear manipulator assembly automatic operation mechanism, a radiator core assembly table, a core pressing device, a belt tidying device, a controller and a servo motor, wherein the radiating tube conveying device, the radiating belt turning and conveying device, the radiating tube and radiating belt automatic arrangement table, the core lifting conveying table, the front and rear manipulator assembly automatic operation mechanism, the radiator core assembly table, the core pressing device, the belt tidying device, the controller and the servo motor are arranged on the rack; the radiating tube and radiating belt automatic arrangement table, the core lifting conveying table and the radiator core assembly table are arranged on the rack from back to front in sequence; the radiating tube conveying device and the radiating belt turning and conveying device are positioned on the left and right sides of the radiating tube and radiating belt automatic arrangement table respectively; the front and rear manipulator assembly automatic operation mechanism is arranged above the core lifting conveying table; the core pressing device and the belt tidying device are positioned above the radiator core assembly table; the controller is adopted for control.

Owner:山东厚丰汽车散热器有限公司

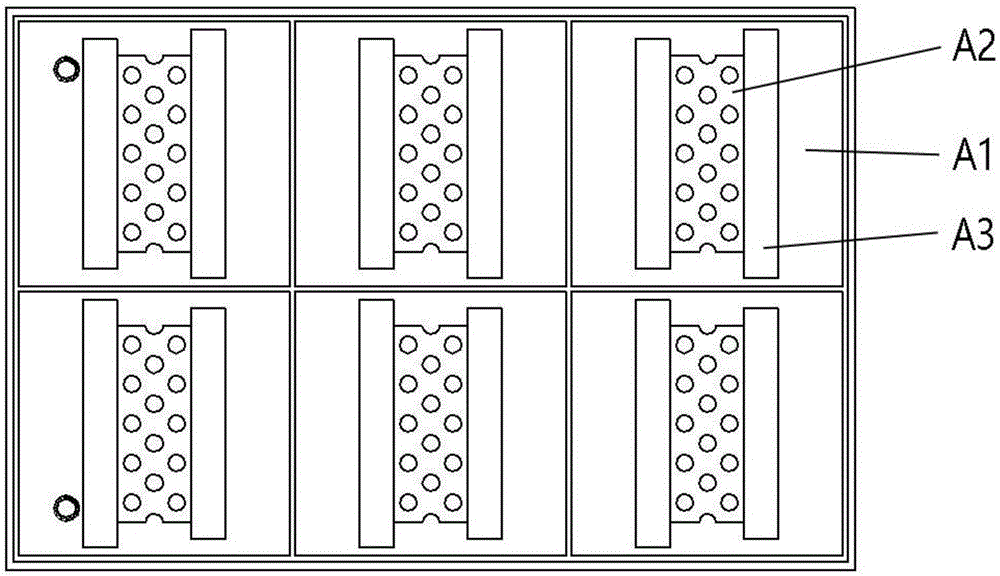

Fully-automatic assembling machine for protective meshes of storage batteries

InactiveCN106450415ASolve labor intensitySolve efficiency problemsAssembling battery machinesFinal product manufactureFully automaticTape drive

The invention provides a fully-automatic assembling machine for protective meshes of storage batteries. The assembling machine comprises a splitting part, a cutting-off part and an assembling part, wherein the splitting part comprises a splitting machine frame, a material tape channel, a splitting knife and a power device; the cutting-off part comprises a cutting-off machine frame, a plurality of narrow material tape channels for narrow protective mesh material tapes to pass through are horizontally arranged on the cutting-off machine frame, and a narrow material tape driving device and a cutting-off device are also arranged in the travelling direction of the narrow protective mesh material tape; the assembling part comprises an assembling machine frame, a mesh clip, a push rod, a mesh clip driving device, a push rod driving device, a mesh tray, a tray driving device, a clip groove clamping device and a storage battery clamping device; and the cutting-off part is arranged in front of the assembling part, and the splitting part is arranged in front of the cutting-off part. The whole working process of the assembling machine has full automation, high efficiency, low labor intensity and stable assembling quality.

Owner:JIANYANG CHAONENG ELECTRONICS

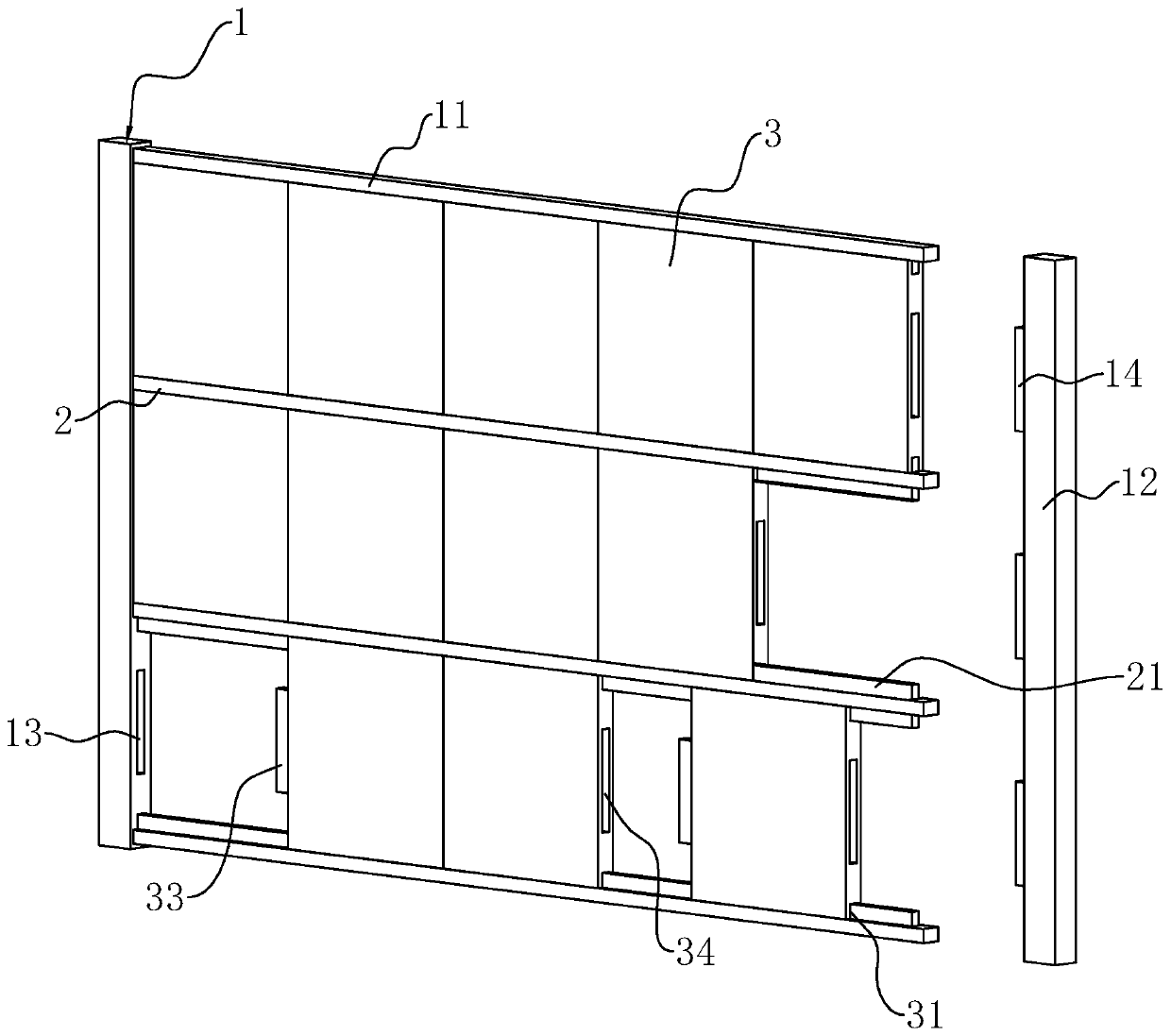

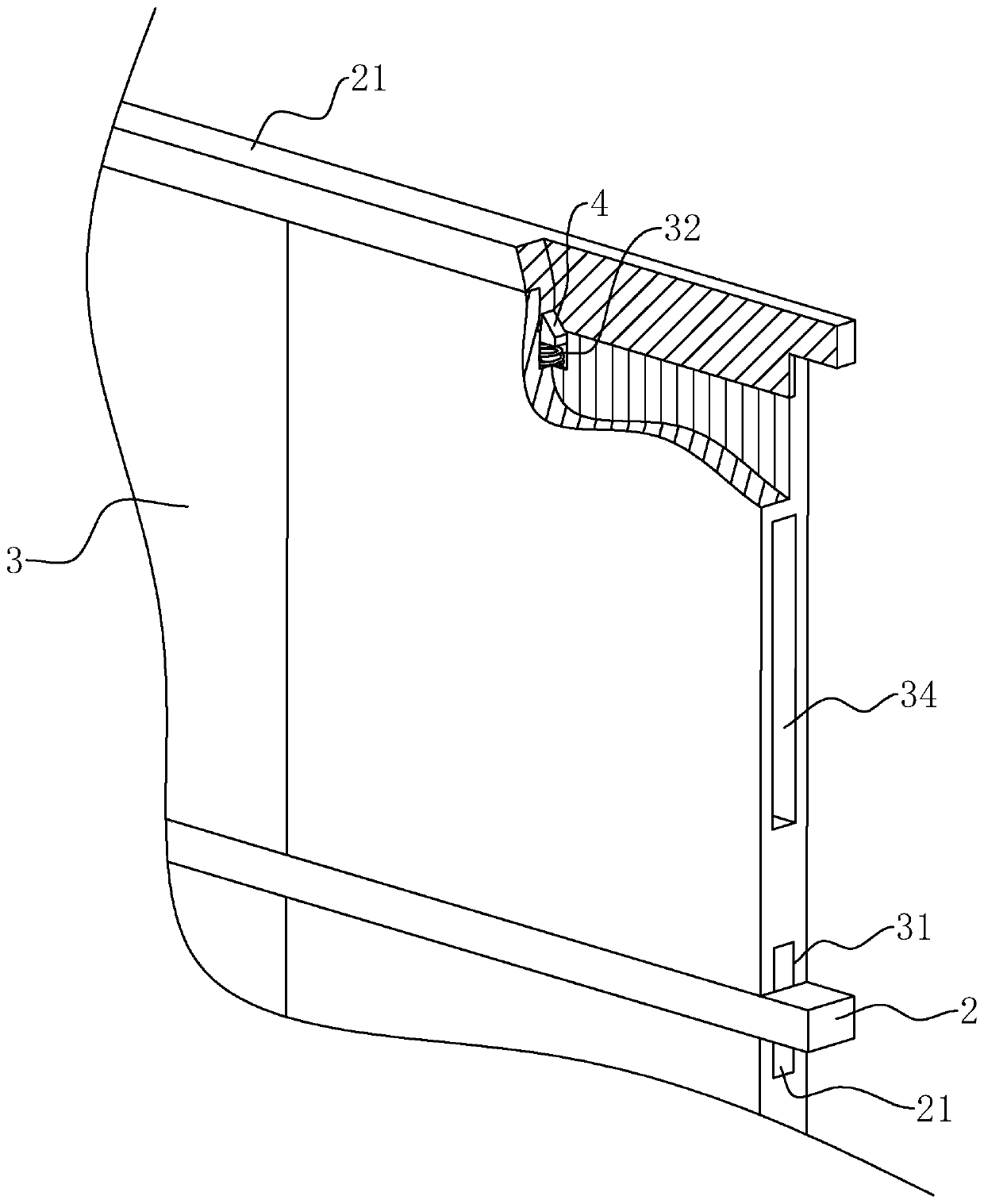

Fabricated ceramic tile wall surface and construction method thereof

InactiveCN109898774ATo achieve the locking effectTo achieve the purpose of directional slidingCovering/liningsKeelSurface construction

The invention discloses a fabricated ceramic tile wall surface and a construction method thereof, and relates to the technical field of building decoration. The fabricated ceramic tile wall surface comprises a main keel with the inner surface installed on a wall body and a plurality of ceramic tile templates installed outside the main keel, a plurality of bearing keels are equidistantly arranged on the main keel, and the bearing keels are arranged parallel to the ground surface; the multiple ceramic tile templates are spliced mutually and are slidably arranged between the upper bearing keel and the lower bearing keel in the length direction of the bearing keels, telescopic buckles are arranged on the side edges of the ceramic tile templates, lock holes corresponding to the telescopic buckles in a one-to-one mode are correspondingly formed in the bearing keels in the length direction, and the telescopic buckles of the ceramic tile templates are correspondingly connected to the inner parts of the lock holes in a clamped mode. The fabricated ceramic tile wall surface has the effects that the rapid installing is realized, the disassembling after the installing is convenient, the construction period is short, and the decoration efficiency and the ceramic tile wall surface construction quality are improved.

Owner:浙江屹立建设有限公司

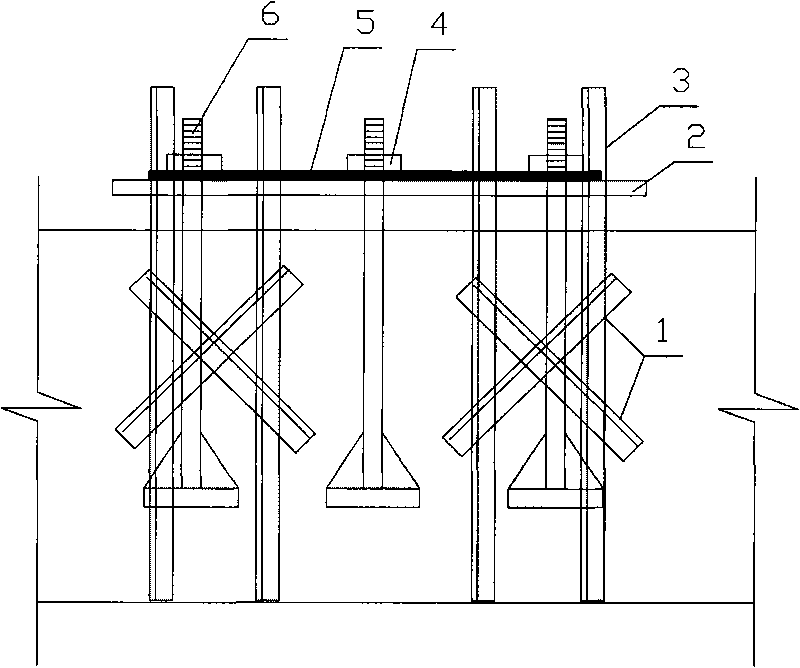

Method for integrally fixing and installing foundation bolts with large diameter

InactiveCN101705693AImprove installation qualityGuaranteed installation accuracyFoundation engineeringAnchor boltTransverse beam

The invention discloses a method for integrally fixing and installing foundation bolts with large diameter, which comprises the following steps of: (1), manufacturing a supporting steel plate in a partition way; (2), determining the central positions of bolt positioning holes on the supporting steel plate; (3), processing the bolt positioning holes on the partitions of the supporting steel plate; (4), installing an upright post and a transverse beam of a fixing rack in situ; (5), splicing the partitions of the supporting steel plate on the transverse beam of the fixing rack, fixing the partitions of the supporting steel plate with the transverse beam of the fixing rack after regulating to enable the positions of the bolt positioning holes on the partitions of the supporting steel plate to be consistent with the design positions of bolts, and welding all the partitions of the supporting steel plate into a whole; (6), installing the bolts in a hung way, enabling the bolts to penetrate through the positioning holes from the lower part of the supporting steel plate, installing nuts on the bolts and centring the elevations of the bolts by utilizing the nuts; and (7), after centring the elevations of all the bolts completely, fixing the bolts with the fixing rack by knot pulling bars and welding the fixing rack firmly. The bottoms of the bolts are fastened by one-time regulation and centring so as to complete the integral fixation and installation of the bolts, and the invention has high efficiency and low cost.

Owner:TIANJIN 20 CONSTR

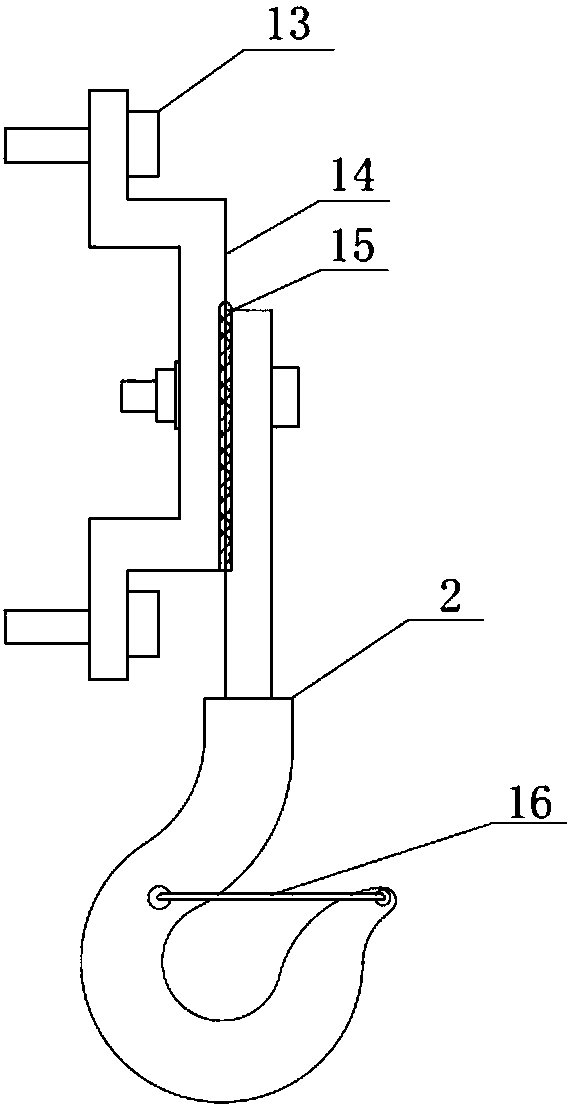

Rope terminal assembly and an elevator

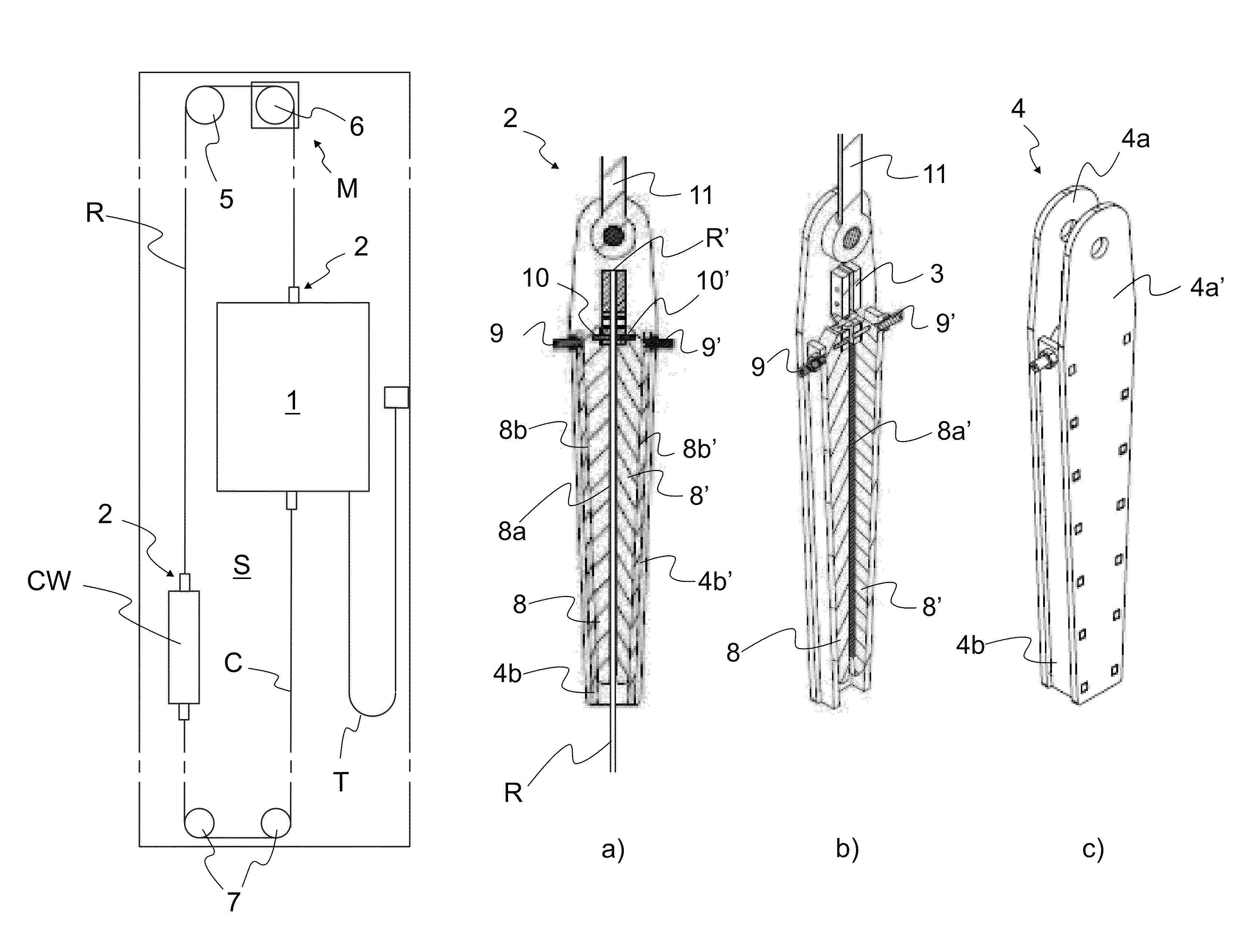

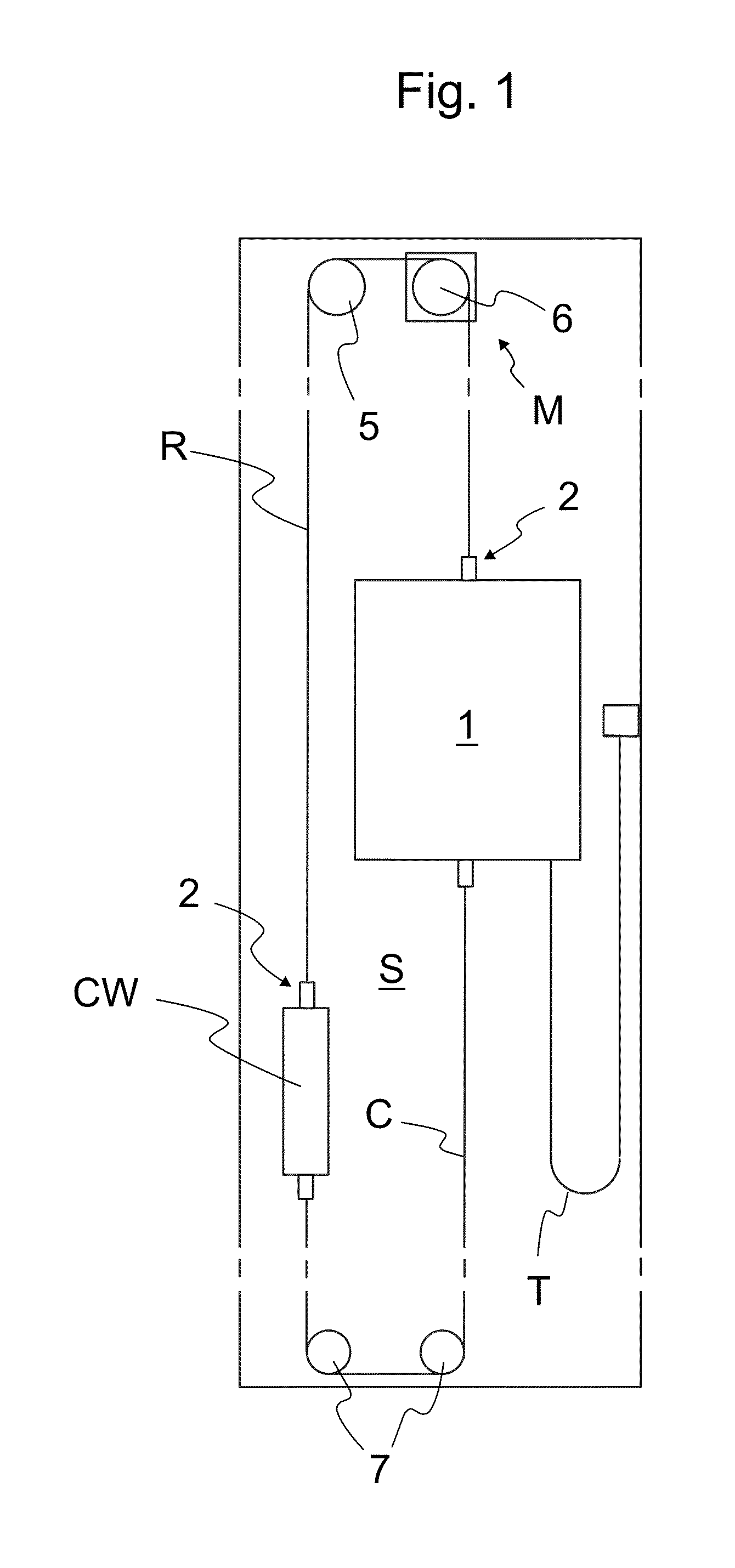

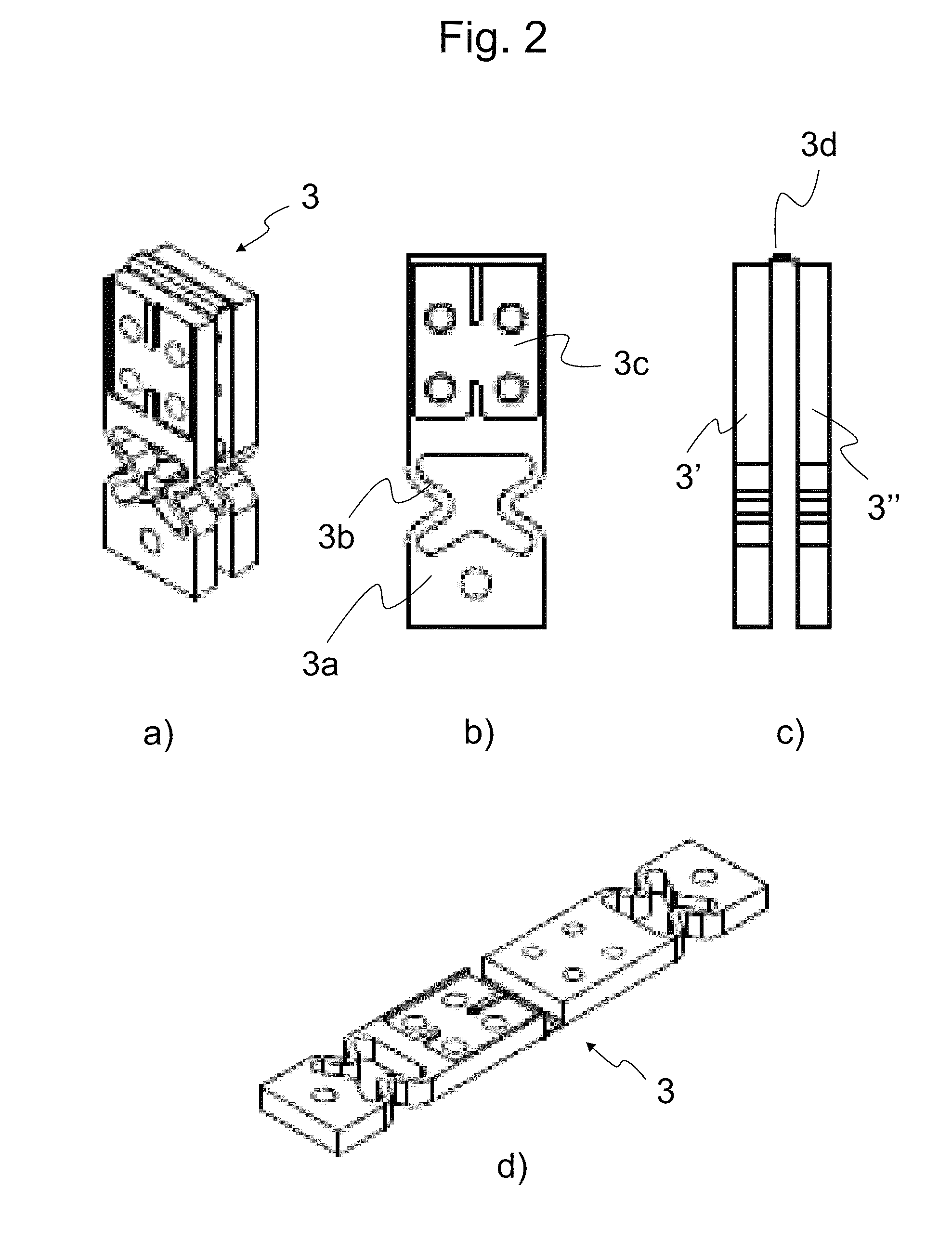

ActiveUS9422134B2Improve installation qualityCost-effectiveRopes and cables for vehicles/pulleyElevatorsMechanical engineering

A rope terminal assembly of an elevator fixing an elevator rope to a fixing base such as an elevator unit, the elevator being suitable for transporting passengers and / or goods, includes an elevator rope, whose width is larger than its thickness in a rope transverse direction, with at least one end having an end face, a rope end block attached to the rope end, one or more wedge elements, a wedge housing, where the terminal assembly includes a rope gap through which the elevator rope passes and the wedge element is arranged to wedge between the rope and the wedge housing thus locking the elevator rope in the gap, and the rope end block is attached on the end face side of the elevator rope with respect to the wedge element, and an elevator.

Owner:KONE CORP

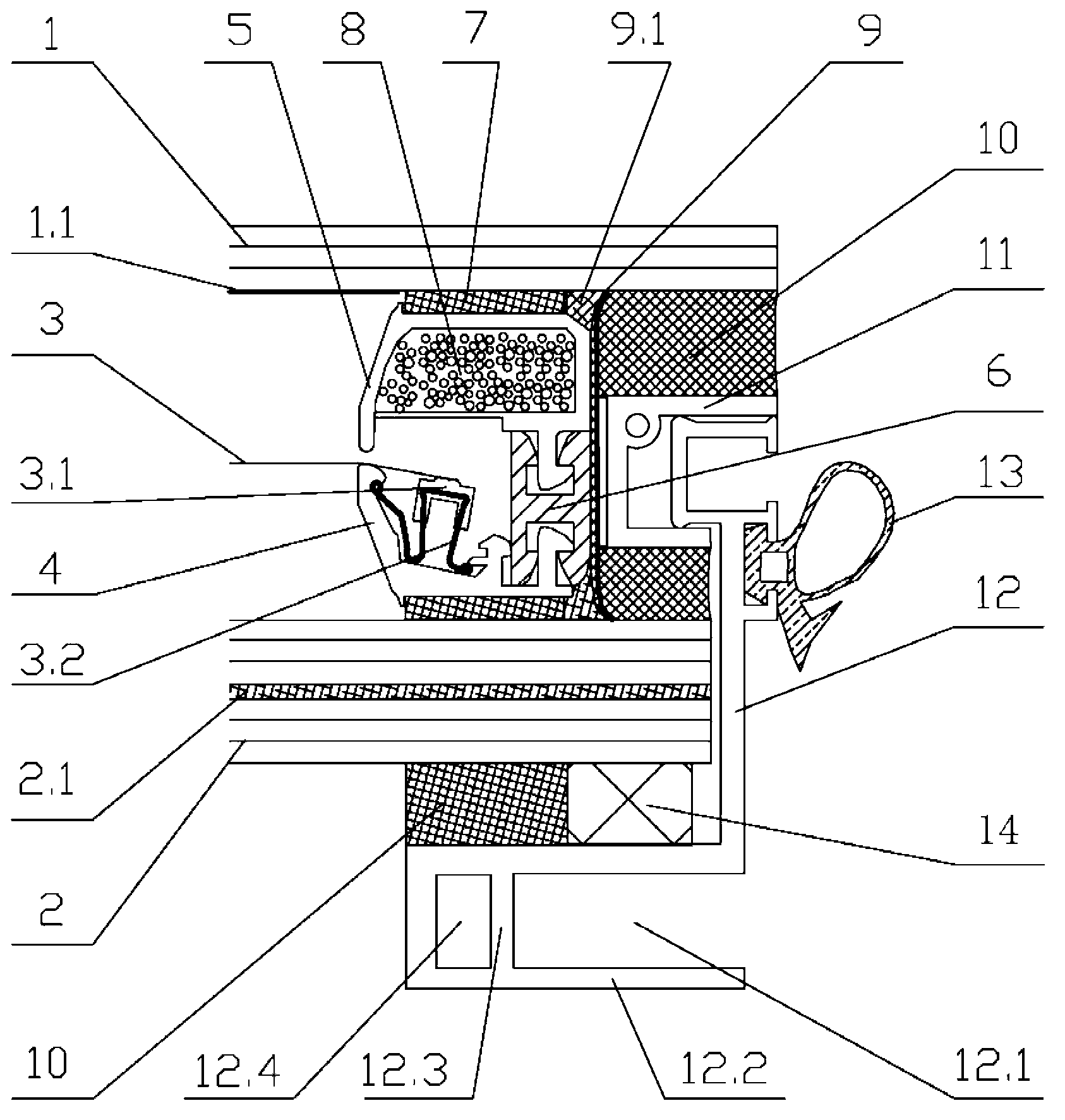

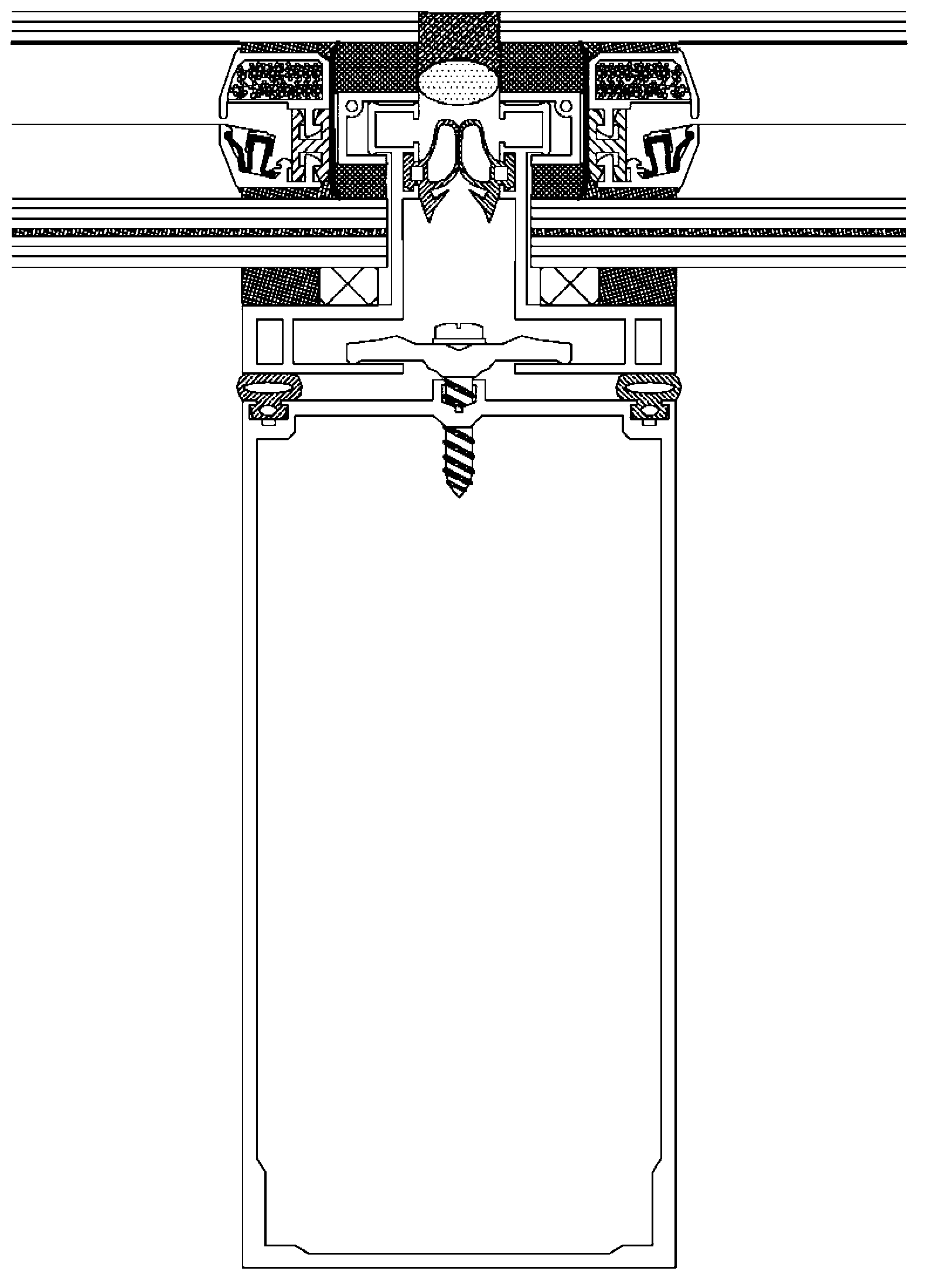

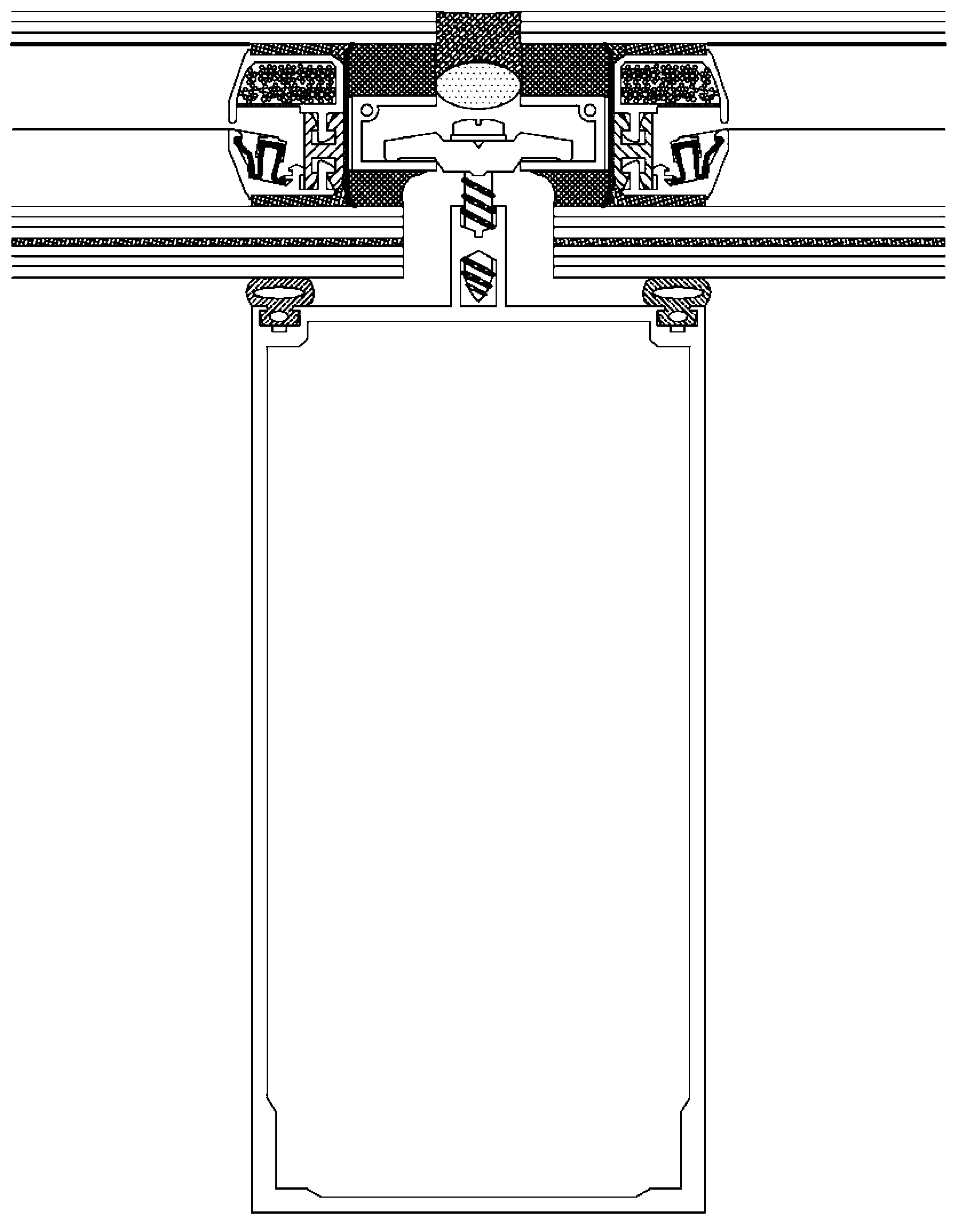

Double-hollow glass ceiling module with film suspended therein

ActiveCN103074966AConvenient lightingImprove heat insulationRoof covering using slabs/sheetsWallsMoisture condensationThermal deformation

The invention discloses a double-hollow glass ceiling module with a film suspended therein. An optical control film serves as a middle layer, and an internally suspended film structure frame, a mounting structure frame, a reinforcing separating strip and glass are sealed into an integral double-hollow glass plate. An inner structure frame and an outer structure frame are made from a novel heat-isolating material with a coefficient of thermal expansion similar to that of the glass. The internally suspended film structure frame is structurally connected through a heat-isolating bridge. A butyl rubber tape on the outer surface of the internally suspended film structure frame serves as a first sealing layer. A second sealing layer consists of the external reinforcing separating strip and a silicone structural sealant, the whole structure is always consistent to the thermal deformation of the glass, so that the sealing capability of the whole system is more reliable, and the heat-isolating property, the moisture condensation-preventing property, the sound-isolating property and the like are greatly improved. Dirt is not easily accumulated on the outer surface of a mounted ceiling, so that the ceiling is convenient to clean and maintain. The double-hollow glass ceiling module has a flexible assembling and mounting way, and can be applied to different vertical surfaces of an outer building rail.

Owner:伟视幕墙(淮安)有限公司

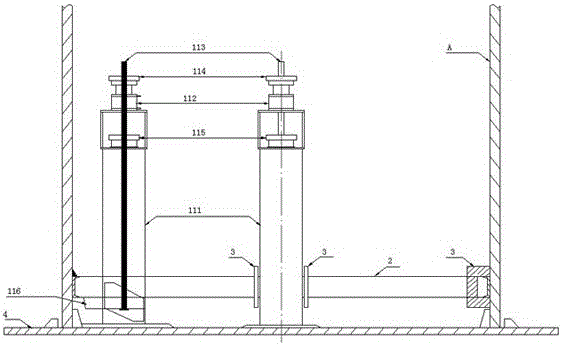

Method for welding tower in vertical assembling mode by utilizing jacks and crane

ActiveCN103567601AGuaranteed stabilityImprove installation qualityWelding/cutting auxillary devicesAuxillary welding devicesCarrying capacityPower flow

The invention discloses a method for welding a tower in vertical assembling mode by utilizing jacks and a crane. The method includes the following steps that firstly, the straightness of all sections of the tower is checked, an end socket of each section of the tower is cut off, and grooves are formed in the end portions of opposite openings of all sections of the tower in a cutting mode; secondly, a lower tower is fixed on a foundation, and the perpendicularity and the elevation of the lower tower are aligned; thirdly, a plurality of first supporting tools are evenly distributed on the peripheral wall of the lower tower, the jacks are distributed on the first supporting tools respectively and adjusted to the same horizontal position, and force measuring instruments are arranged on the jacks; fourthly, a plurality of second supporting tools are evenly distributed on the peripheral wall of the upper tower; fifthly, the upper tower is craned by the crane so that all the second supporting tools can be arranged on the jacks correspondingly, stress on the tops of the jacks is adjusted, the grooves of the end portions of the upper tower and the lower tower are assembled, the perpendicularity of the upper tower and the assembling gap of the upper tower and the lower tower are adjusted, the total carrying capacity of the jacks is N, the carrying capacity of the crane is F, and the weight of the upper tower is Q which is kept to be equal to N+F; sixthly, several welders use the same welding current and meanwhile perform symmetric welding, and therefore welding joints are welded in a multi-layer mode.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

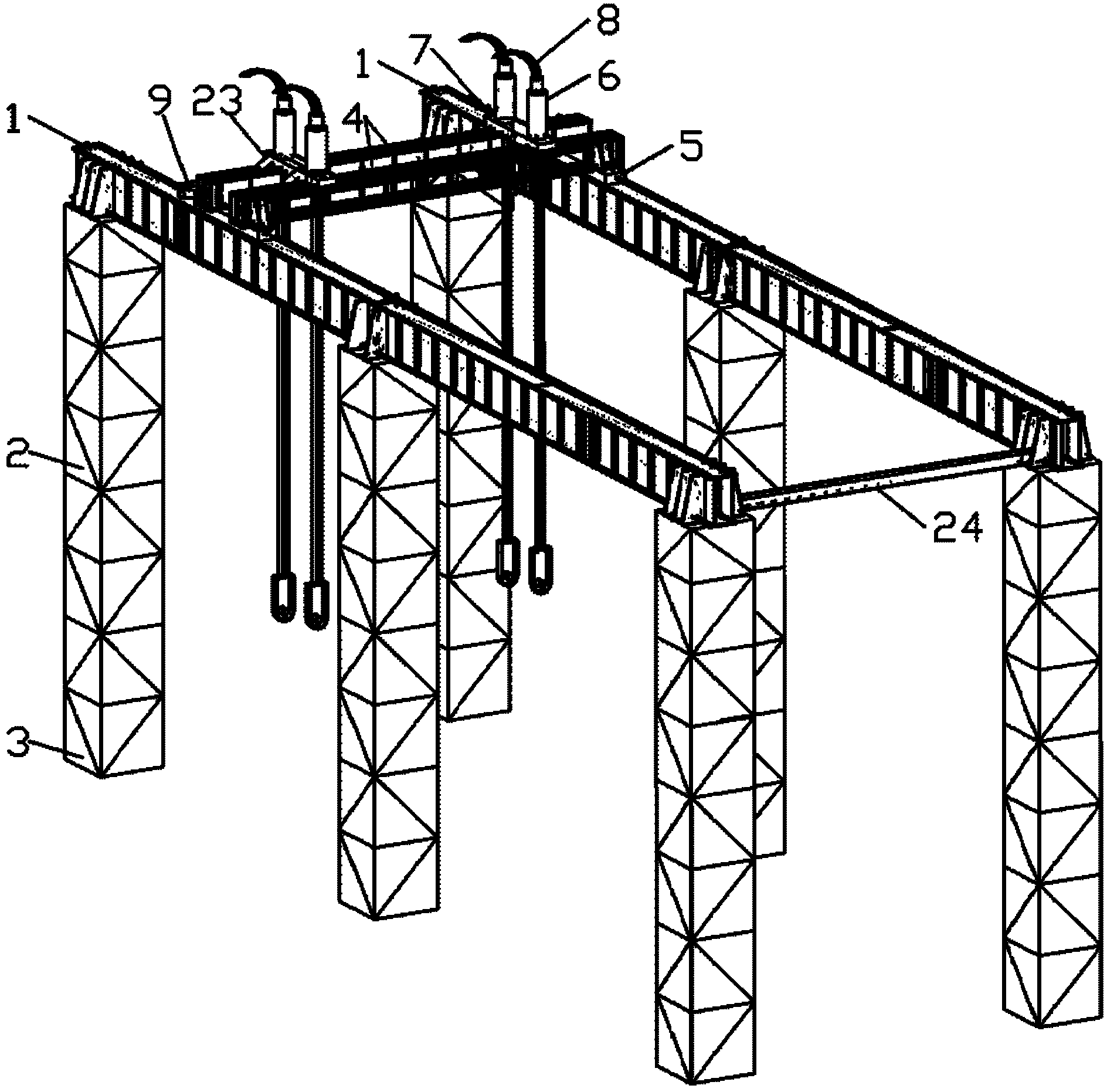

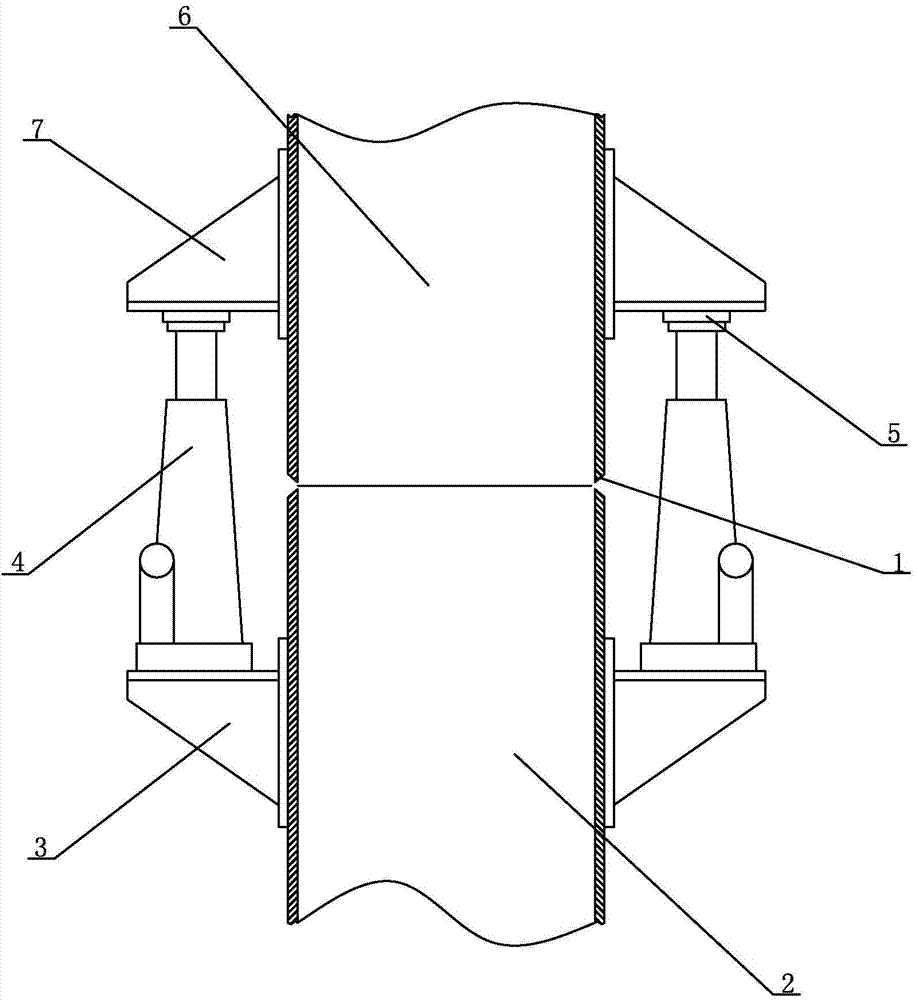

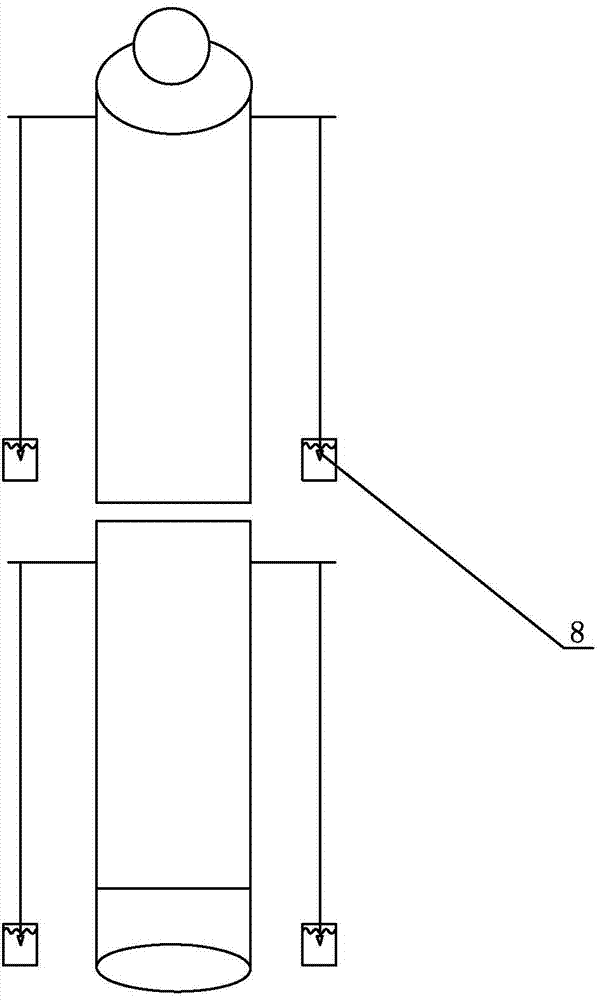

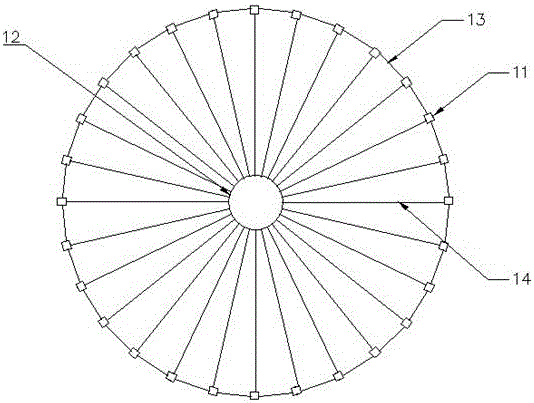

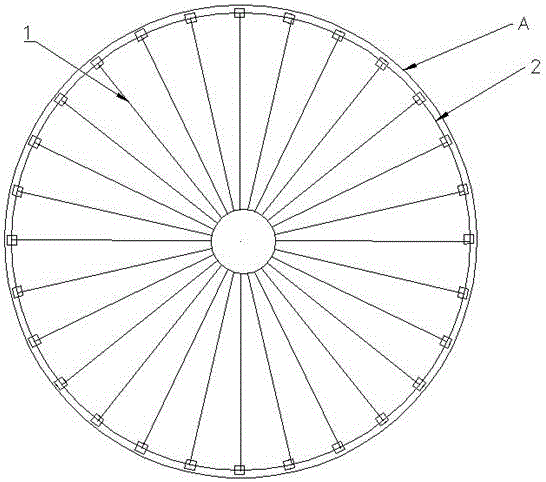

Lifting device and inverted installing method for reducing absorption tower

ActiveCN105776067AStable structureLimit tiltGas treatmentDispersed particle separationEngineeringTower

The invention discloses a lifting device used for lifting a large cylinder during inverted installing of an absorption tower. The lifting device comprises a hydraulic lifting round frame, an expansion ring attached to the inner wall of the cylinder, and door-shaped steel clamps used for fixing the expansion ring. The door-shaped steel clamps are buckled on the expansion ring and welded and fixed to the inner wall of the cylinder. The hydraulic lifting round frame comprises hydraulic lifting frames evenly arranged on the inner side of the cylinder along the circumference, a center steel pipe arranged in the center position of the cylinder, circumferential box iron sequentially connected with the hydraulic lifting frames, and radial box iron used for connecting the center steel pipe with the hydraulic lifting frames. The hydraulic lifting frames and the center steel pipe are all welded and fixed to a bottom plate. Each hydraulic lifting frame comprises a support, an oil cylinder arranged over the support, a lifting rod, an upper clamping head arranged over the oil cylinder and used for driving the lifting rod to move upwards, a lower clamping head arranged between the support and the oil cylinder and used for limiting downward sliding of the lifting rod, and a sliding pull block capable of sliding along the support. According to an inverted installing method for the reducing absorption tower, the installing procedures of the absorption tower are simplified, and the installing quality of the absorption tower is improved.

Owner:HUNAN THERMAL POWER CONSTR CO LTD OF CHINA ENERGY ENG GRP

Non-rolling construction method for vertical cylinder storage tank and fixture thereof

InactiveCN101440669ASimplify the assembly processShorten the construction periodWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsVertical cylinder

The invention relates to a plate-rolling-free construction method for a vertical cylindrical storage tank and a clamp thereof. The method comprises the following steps: during construction, not using a plate roller to roll a wall plate of the storage tank, correspondingly welding at least one vertical welding line positioning plate at two edges inside the wall plate, welding at least one wall plate positioning frame at the upper edge and the lower edge, regulating radians of most wall plates by adopting the elasticity of the most wall plates for direct installation, and regulating the width of the vertical welding lines at the joint of each wall plate, the radians of the wall plates, the vertical positioning of each wall plate, and the like by using a special vertical welding line adjusting clamp and other normal clamps, to achieve assembly installation of the wall plates at the cylindrical part of the tank. The method has the advantages of simple and easily-mastered installation construction process, simple structure and low cost of the required clamps, fewer constructors and auxiliary facilities, low intensity of labor, short construction period, low cost, good installation quality, wide application range, and the like. Compared with the plate rolling construction method, the method can save labor by more than 5 percent, can reduce the construction period and the construction cost by more than 10 percent, and has great popularization value.

Owner:CHINA GASOLINEEUM JILIN CHEM ENG & CONSTR

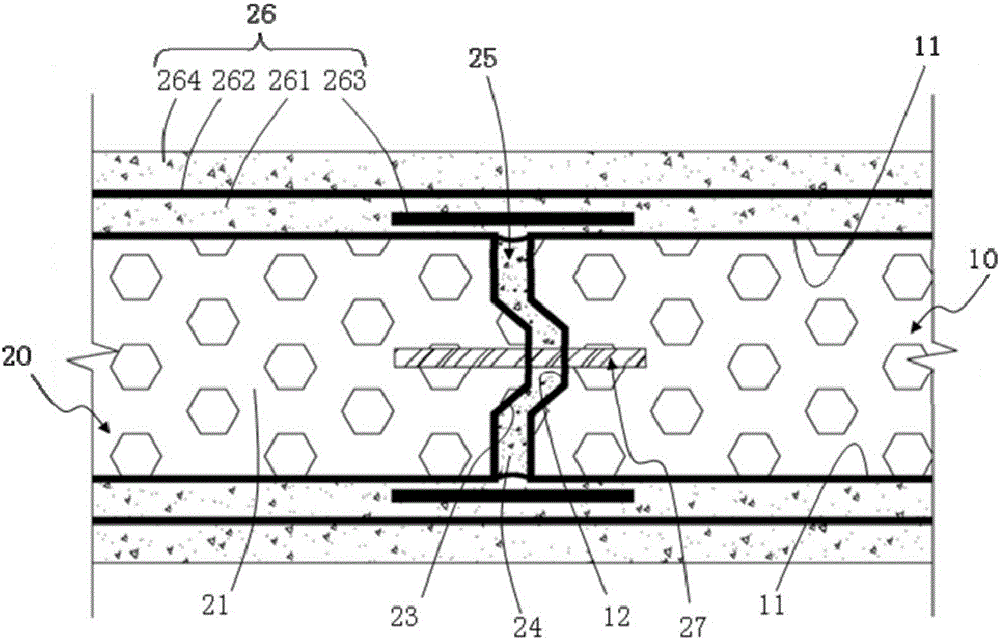

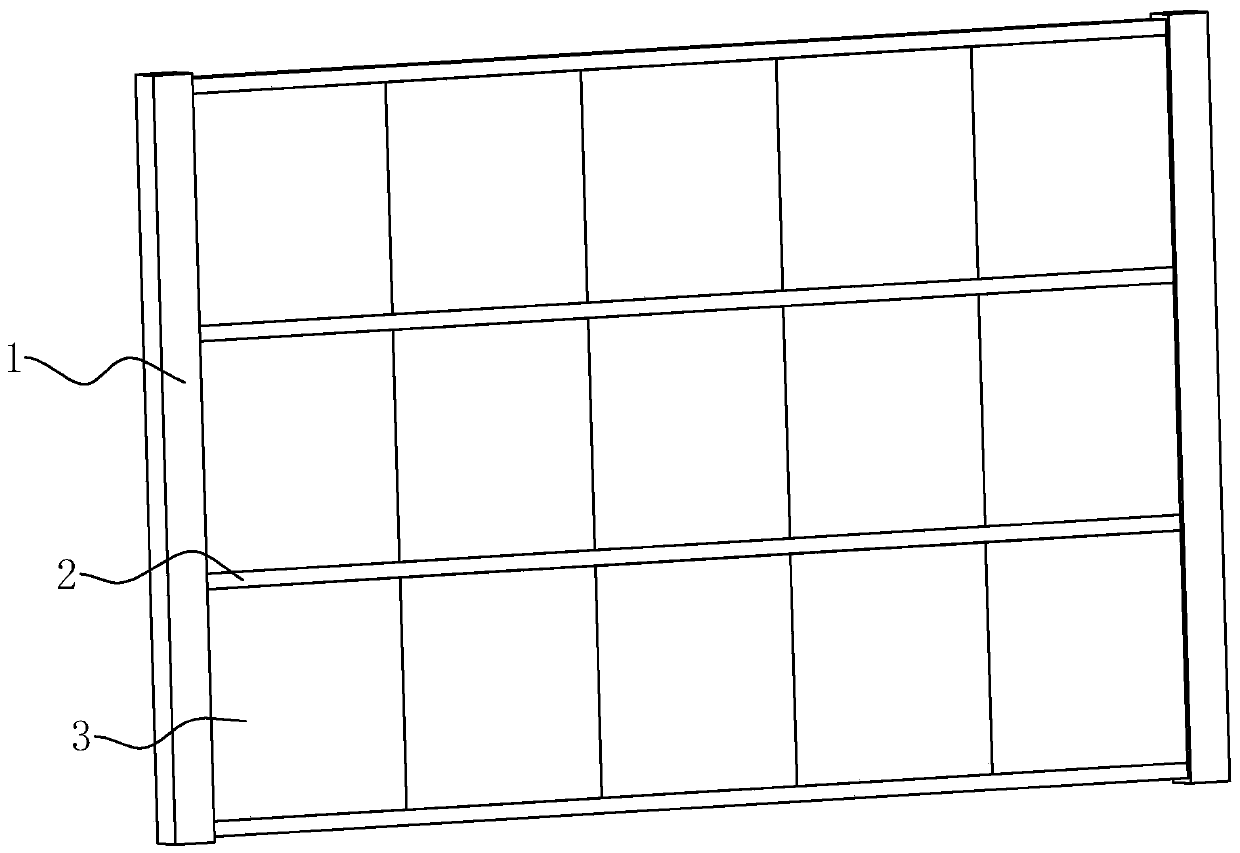

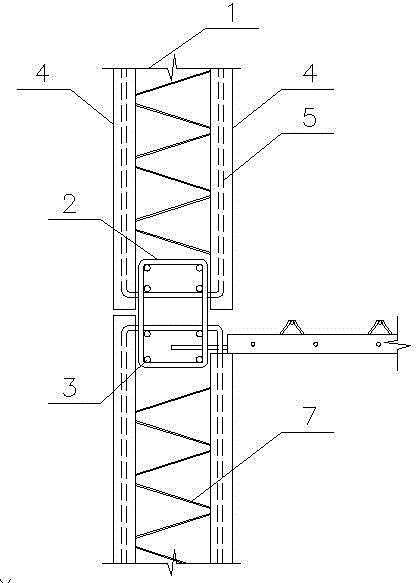

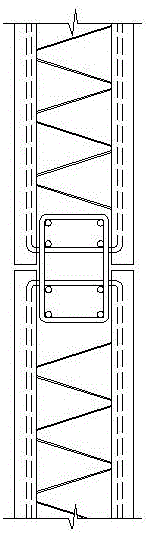

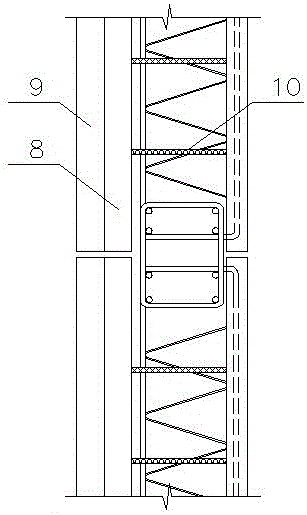

Longitudinal connection structure for superimposed slab concrete shear walls and connection method

The invention provides a longitudinal connection structure for superimposed slab concrete shear walls and a connection method, and solves the problems of a traditional longitudinal connection method for prefabricated part walls that the prefabricated part production process is complicated, field hole aligning is difficult, the loss of a grouting material during field mixing is huge, the grouting material is quick in setting and hardening, and the mixing qualities are much different during mixing. The longitudinal connection structure comprises a closed ring-shaped connecting stirrup (2), the connecting stirrup extends into an upper superimposed slab concrete shear wall (1) and a lower superimposed slab concrete shear wall (1) which are mutually connected to form a transition space together with ring-shaped longitudinal bars (5) of the upper superimposed slab concrete shear wall and the lower superimposed slab concrete shear wall, pin joint longitudinal bars (3) penetrate into the transition space in a manner of being perpendicular to the plane where the connecting stirrup is positioned, and the ring-shaped longitudinal bars of the upper superimposed slab concrete shear wall and the lower superimposed slab concrete shear wall are integrated with the pin joint longitudinal bars. The connection method is applied to the longitudinal connection structure for the superimposed slab concrete shear walls.

Owner:HUBEI YUHUI NEW BUILDING MATERIAL

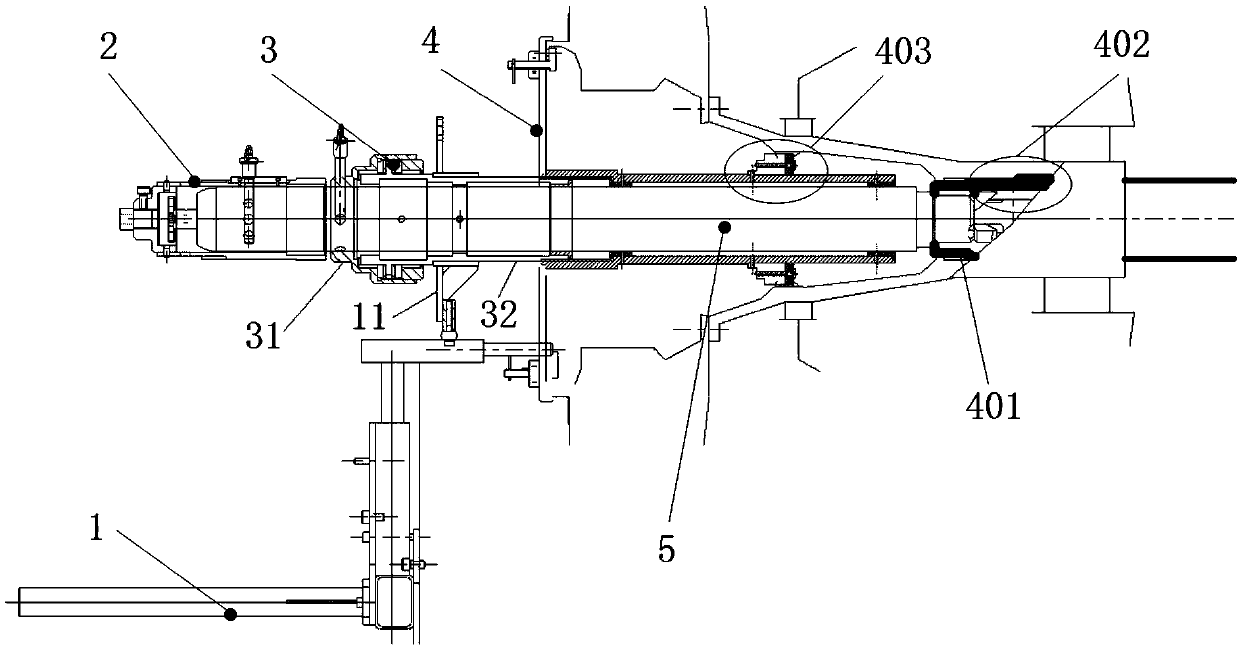

Aviation engine low-pressure turbine installation device

ActiveCN109648288AImprove installation qualityImprove reliabilityAircraft componentsMetal working apparatusAviationTurbine

The invention discloses an aviation engine low-pressure turbine installation device. The aviation engine low-pressure turbine installation device comprises a guide shaft, a transfer segment, a centring device, a pulling jacking device and a reverse twist device, wherein one end of the guide shaft is relatively fixed with a low-pressure turbine shaft; the transfer segment is arranged at the other end of the guide shaft and is angularly fixed through a connection part; the centring device is fixed with a rotor, a centring sleeve is arranged between the centring device and the guide shaft to be used for making the axis of the guide shaft coincide with that of an engine, and the centring sleeve and the guide shaft can move relatively on the axis of the engine; the pulling jacking device comprises a rotating segment axially fixed with the guide shaft and a moving segment in screw-thread fit with the centring device, and the rotating segment and the moving segment are axially fixed and can rotate relatively; and the reverse twist device is provided with a reverse twist portion, the reverse twist portion is matched with the moving segment to be used for preventing rotating of the moving segment, and the reverse twist device is relatively fixed to an engine stator casing. By means of the aviation engine low-pressure turbine installation device, the installation quality of engine four fulcrum bearings can be improved, and the engine reliability is improved; and bearing damage is reduced, and the service lives of the bearings are prolonged.

Owner:AECC SHENYANG ENGINE RES INST

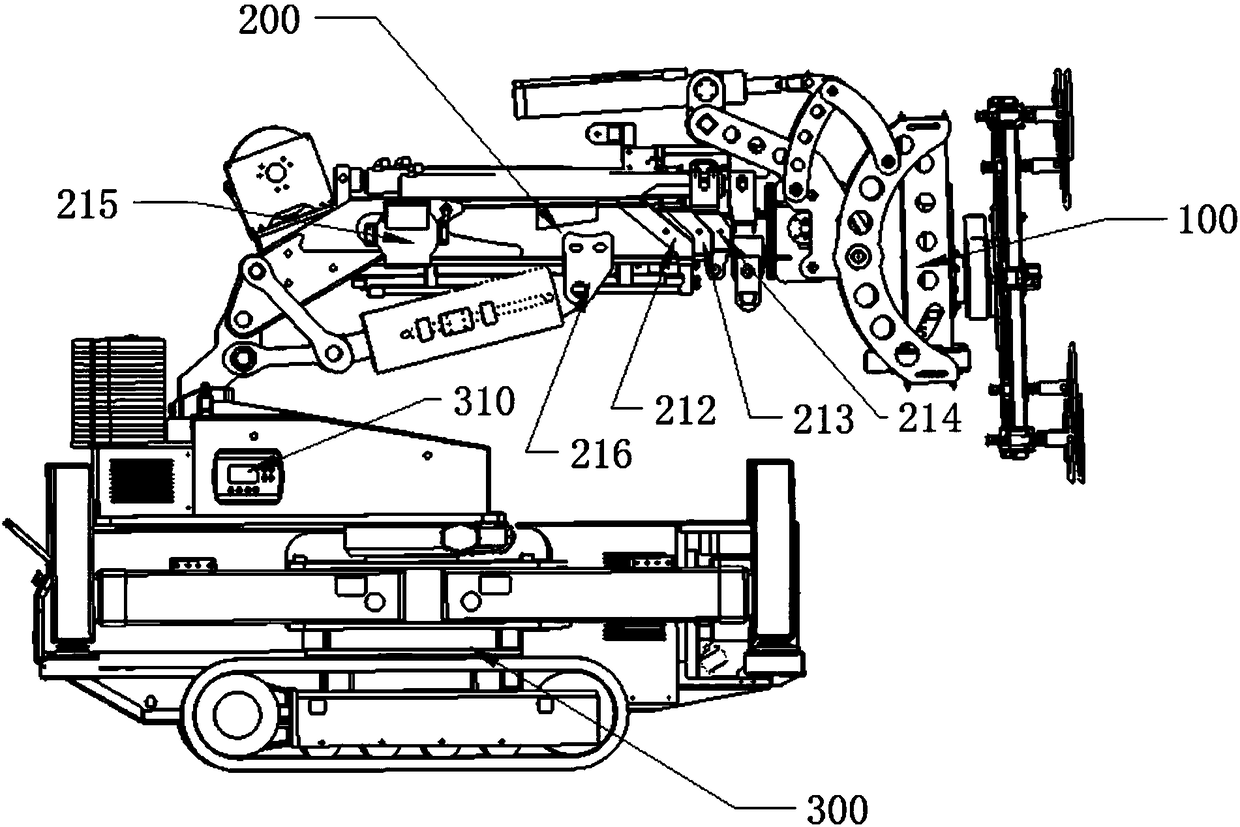

Multi-dimensional glass mounting robot

PendingCN108453697AIncrease productivityImprove production efficiencyProgramme-controlled manipulatorGripping headsEngineeringMulti dimensional

The invention discloses a multi-dimensional glass mounting robot which comprises a multi-dimensional mounting head, a telescopic mechanical arm and a rotary walking chassis, wherein the multi-dimensional mounting head is mounted on the telescopic mechanical arm; the telescopic mechanical arm is mounted on the rotary walking chassis; the multi-dimensional mounting head comprises an up-down slidingunit, a left-right rotating unit, an overturning unit, a rotary unit and a translation unit. The multi-dimensional glass mounting robot is scientific and reasonable in design and compact in structure,at least can achieve movement in eight directions, solves the problems of multi-dimensional and multi-angle mounting and carrying, and achieves the effects of efficiently and flexibly mounting and carrying by coarse and fine adjustment. The multi-dimensional glass mounting robot disclosed by the invention achieves mechanical and auxiliary automatic operations of grabbing, carrying and mounting large glass panels, so that the large panel mounting quality, the production efficiency and the benefit are improved, a lot of labor forces are saved, the labor intensity is reduced, and the construction cost is lowered.

Owner:GUANGZHOU COWEST MACHINERY EQUIP CO LTD

Multifunctional engineering installation vehicle

InactiveCN1544307AEasy to operateImprove installation qualityLifting devicesHydraulic cylinderPull force

The present invention discloses a multifunctional engineering installation vehicle used for engineering construction, which comprises a vehicular support frame, a walking and the like. In the vehicle as a gantry supporting frame structure, a extensible guide supporting frame for X axial movement is connected forwards with a Z axial direction tunable movable lift hook; at the C axial movement extensible guide supporting frame, there is an outside force acting at the Z axial direction, which can be a pull force of a armored rope or a cylinder rod clean and jerk force of the hydraulic cylinder and used for pushing the X axial movement extensible guide supporting frame for a vertical motion; a lifting platform is installed at the vehicle roof to execute pipe laying pipe laying, anti-corrosion, heat preservation, laying and maintenance of cable rope and crane span structure, and the like; the Z axial direction tunable movable lift hook inside the vehicle is used for lifting and loading articles of merchandise to realize installation of equipments; a labor saving and quick-releasing pipeline frame is allocated for carriage of pipelines; a ground tray is allocated, which is used for lifting, loading and transporting large and heavy workpieces. The multifunctional engineering vehicle is a powerful machinery for constructions, and the plurality of functions mentioned above greatly improves the installation quality, saves 2 times for the human energy and improves the work efficiency more than 10 times.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

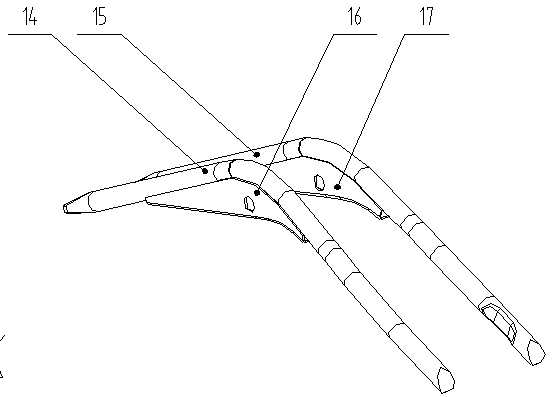

Ride-type motorcycle tail pipe assembly processing clamp and processing method thereof

InactiveCN103192216AGuaranteed positioning accuracyHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameDamper

The invention discloses a ride-type motorcycle tail pipe assembly processing clamp and a processing method thereof. The ride-type motorcycle tail pipe assembly processing clamp comprises a base plate, a damping-box fixing seat, a damping-box limiting seat, a cylinder, a tail pipe clamping groove, a tail-pipe end-face fixing pin, a tail pipe limiting pin, a rapid pressing clamp and the like structures which are arranged on the base plate. In the processing method, by the aid of the ride-type motorcycle tail pipe assembly processing clamp, the tail pipe and the damping box are positioned and then are mechanically welded to be integrated to be connected to a motorcycle frame; and positioning accuracy is improved, welding quality is improved by adopting the mechanically weld, connecting strength and positioning accuracy of the damping box are improved accordingly, and mounting quality of the damper is improved. The ride-type motorcycle tail pipe assembly processing clamp has the advantages of simple structure, reliable position, convenience in operation, low implementation cost and the like.

Owner:力帆科技(集团)股份有限公司

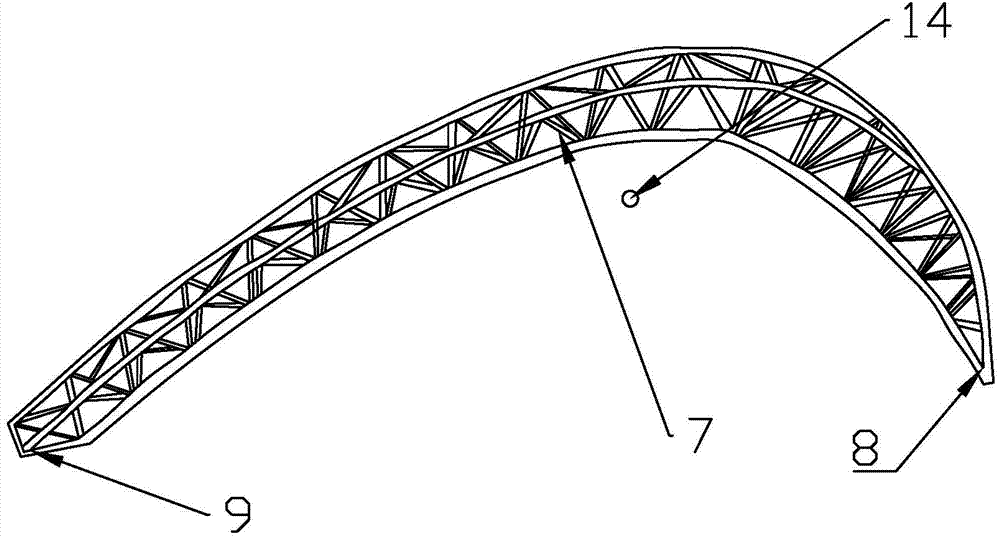

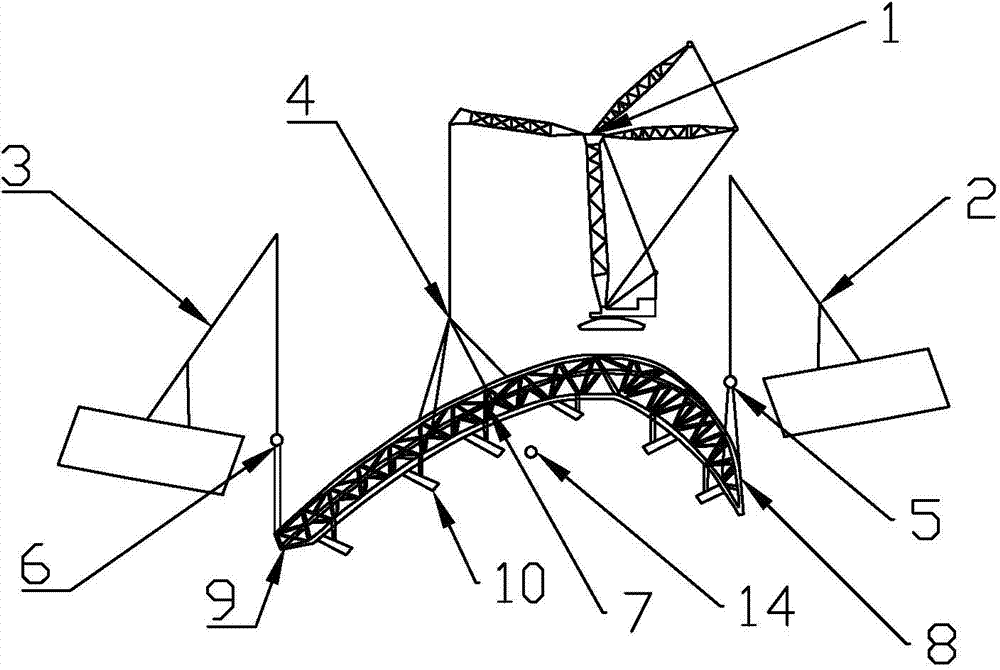

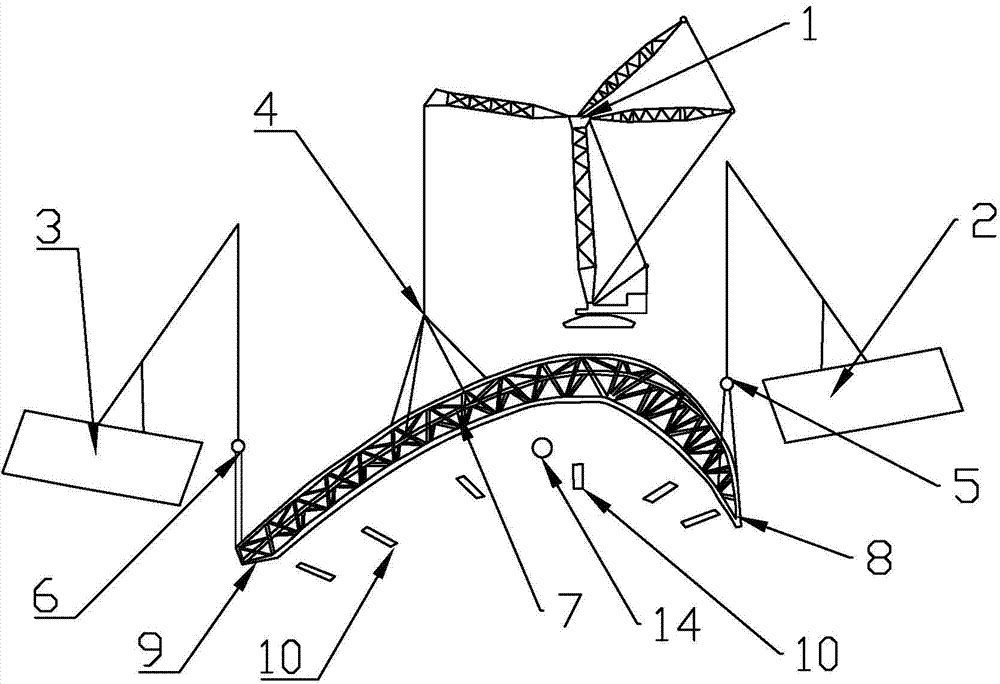

Construction method for three-crane lifting installation used for bow-shaped space truss

ActiveCN104746883ASave hoisting costsReduce split dockingBuilding material handlingButt jointGravity center

The invention discloses a construction method for three-crane lifting installation used for a bow-shaped space truss. The construction method includes the following steps of conducting simulation to determine the gravity center of the bow-shaped space truss, arranging three lifting points and three cranes, conducting separation through the three cranes, conducting carrying and correcting work after separation is completed, hoisting the bow-shaped space truss on a platform, and fixing the bow-shaped space truss to the platform. The construction method is simple, easy to achieve, high in installation efficiency, scientific, convenient and capable of saving the labor cost and greatly reducing hoisting expenses. By separating, carrying, correcting and hoisting the whole bow-shaped space truss, sectional butt joint and correction of the truss are reduced, aloft welding does not need to be conducted between sectional trusses, and therefore the installation quality and the welding quality are improved, the truss installation construction period is shortened, and truss hoisting expenses are saved.

Owner:浙江中南绿建科技集团有限公司

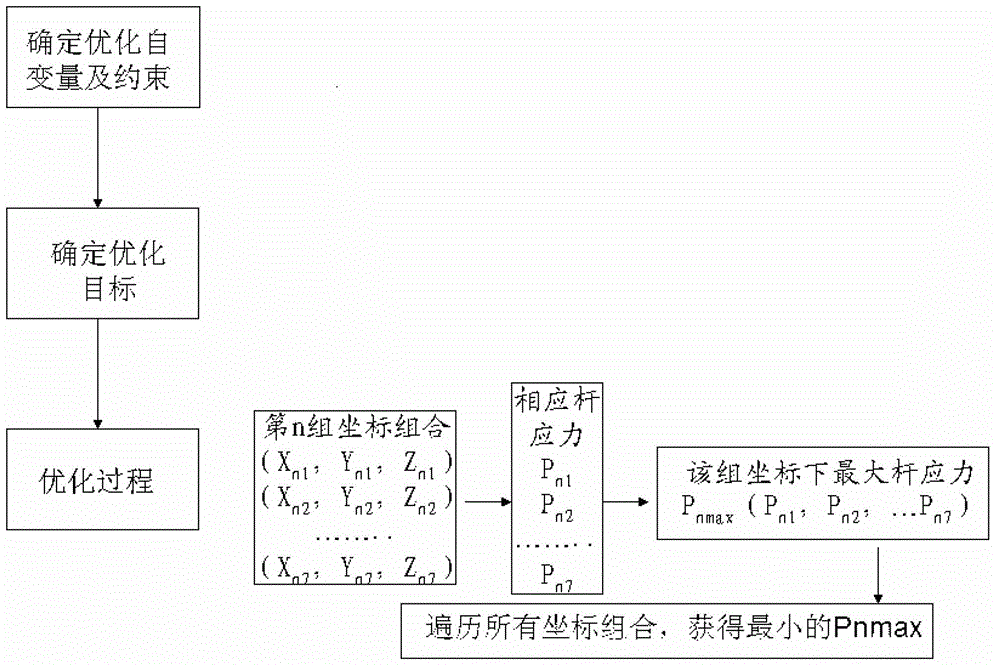

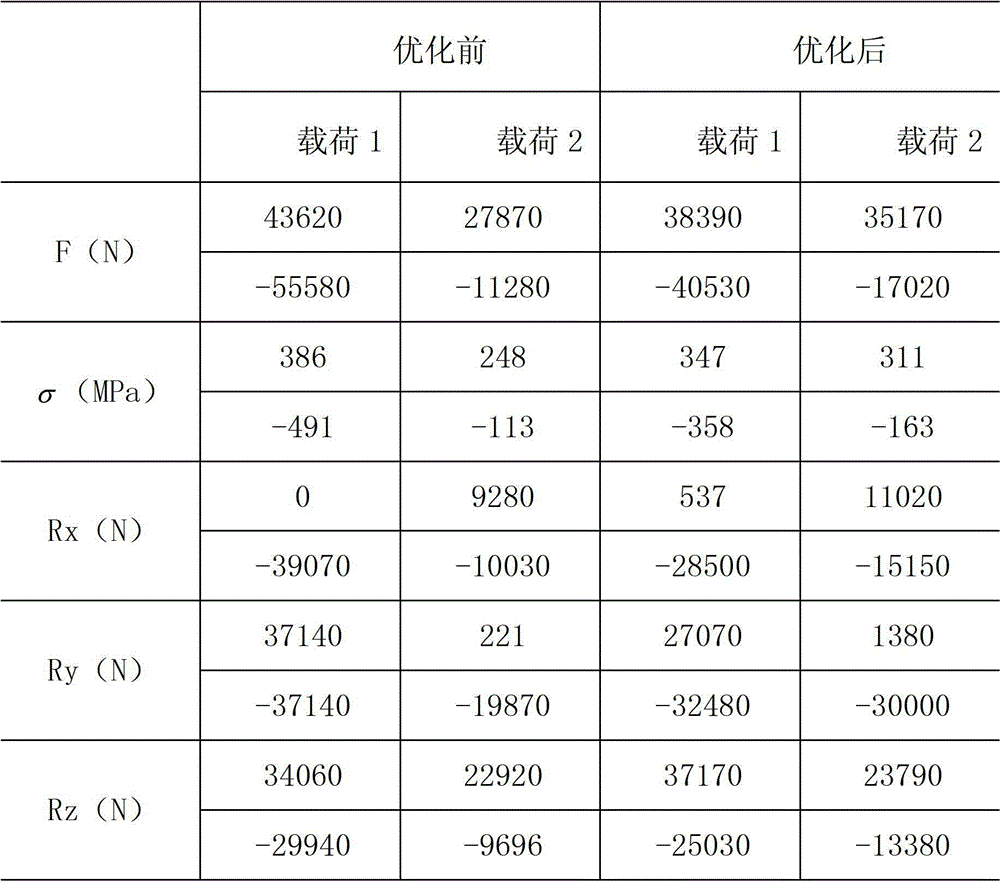

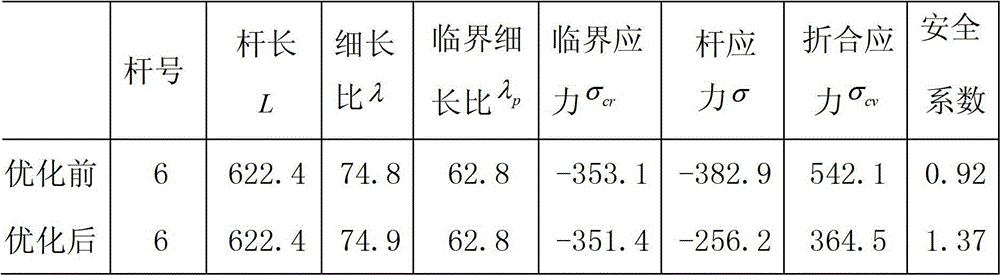

Pull rod installing layout method of airplane auxiliary power device

ActiveCN102750408AMeet layout optimization needsReduce structural weightSustainable transportationSpecial data processing applicationsJet aeroplaneSolid structure

The invention belongs to the installation technology of airplane airborne equipment and relates to an installing structure layout optimized method of an auxiliary power device. According to the pull rod installing layout method of the airplane auxiliary power device, engineering design software is utilized for structure parameterized modeling, and the data transfer from the parameterized entity structure to the finite element analysis software is realized under the invoking effect of flow process optimization control program; and in the finite element software, entities are subjected to meshing, in addition, the application of conditions of materials, restraining, loads and the like of an installing system is carried out, the structure stress or deformation of a rod system is calculated, and the optimum structure of the installing system is determined by an optimizing flow process according to optimizing targets such as the system weight, good manufacturability and the like. The method has the advantages that the installing structure with the minimum structure weight and the optimal stress form can be obtained, the structure weight is lightened, the vibration transfer is reduced, the installation efficiency and the installing quality are improved, and the layout optimization requirement of the installing system of the airplane auxiliary power device is met.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

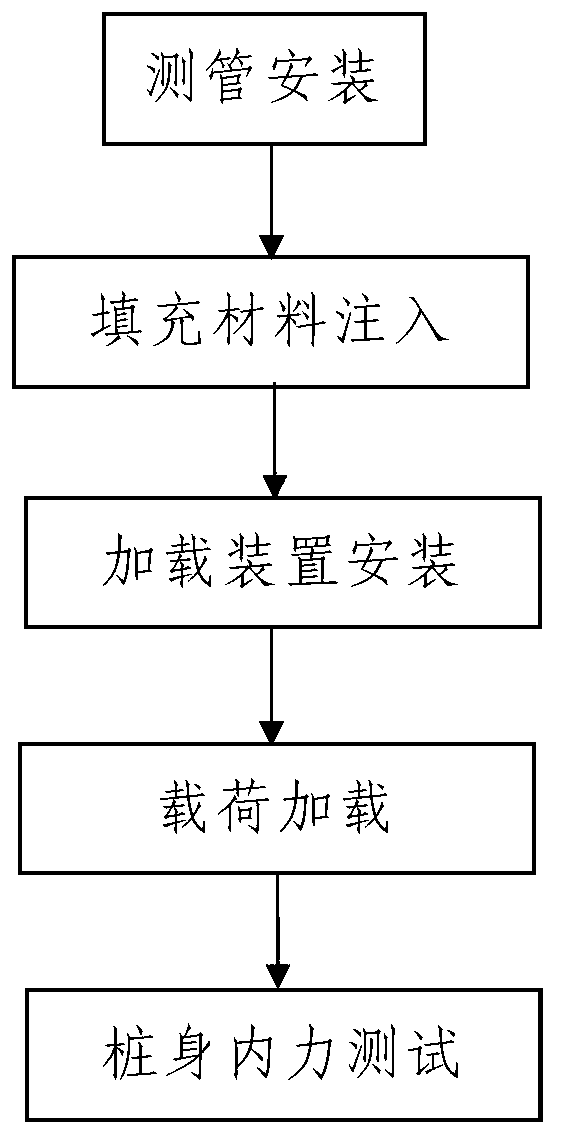

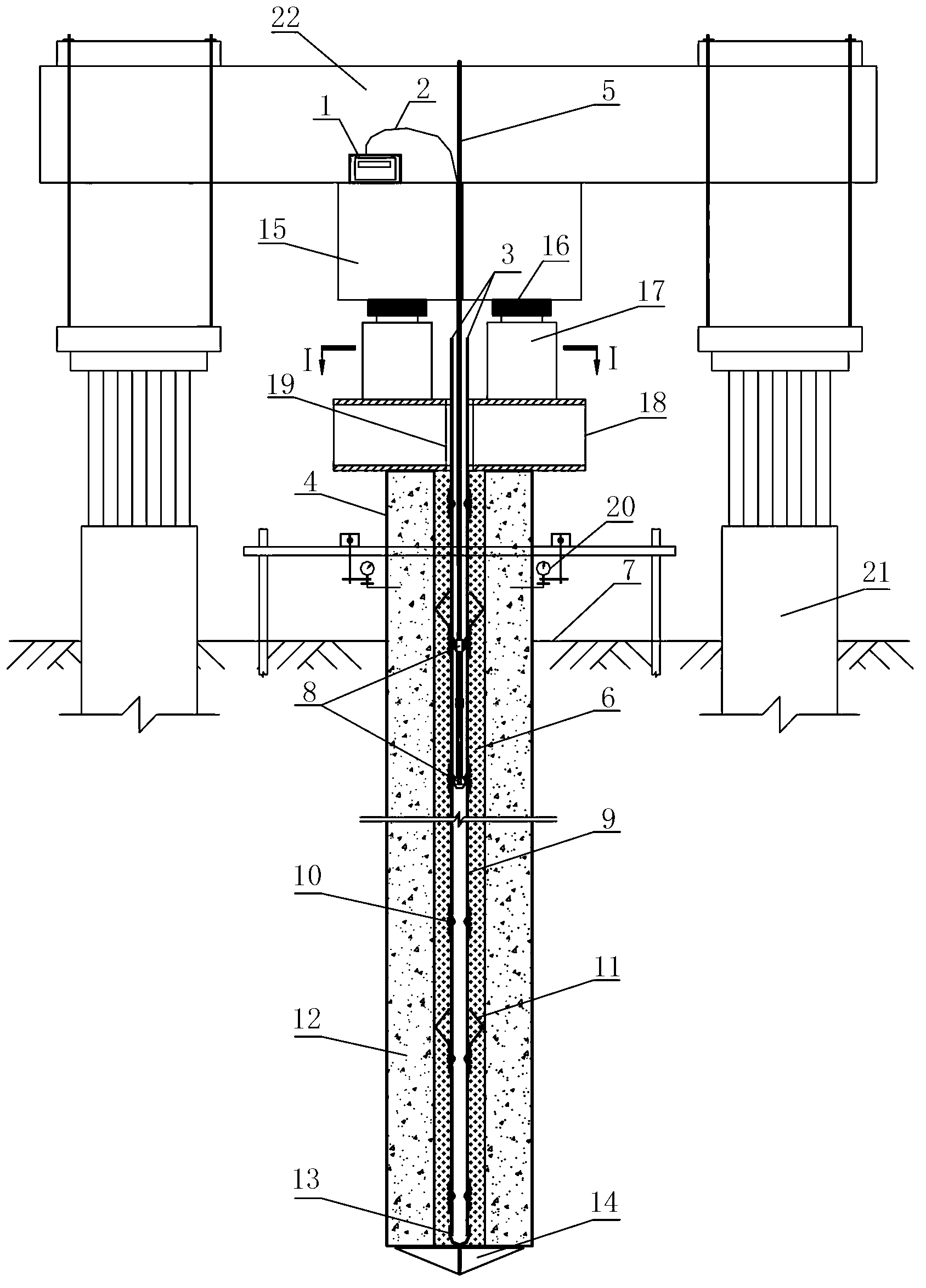

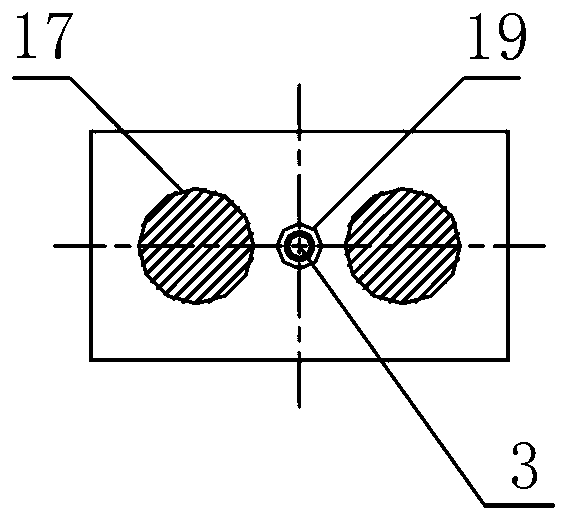

Internal force testing method for load test of pre-stress tubular pile

ActiveCN102797269AReasonable designSimple and fast operationFoundation testingMicrometerFilling materials

The invention discloses an internal force testing method for a load test of a pre-stress tubular pile. The method comprises the following steps: 1, installing a testing tube: the testing tube of a slide micrometer is installed in a constructed pre-stress tubular pile, and the testing tube is arranged in the middle of the pile core of the pre-stress tubular pile in the vertical direction; the bottom of the testing tube is sealed through a sealing cap and the testing tube is full of water; 2, injecting a filling material: the filling material is injected into the cavity between the tubular pile core of the pre-stress tubular pile and the testing tube from bottom to top by adopting grout injecting equipment, and comprises water, cement and bentonite; 3, loading an installation device; 4, loading a load; and 5, testing the internal force of a pile body: after the load is loaded and the pre-stress pile is settled and stabilized, the internal force of the pile body of the pre-stress tubular pile is tested by adopting the slide micrometer. According to the invention, the measuring method has simple steps and is convenient to implement while having high test precision and low investment, so as to obtain the internal force test result of the pre-stress tubular pile simply, conveniently, rapidly and accurately.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

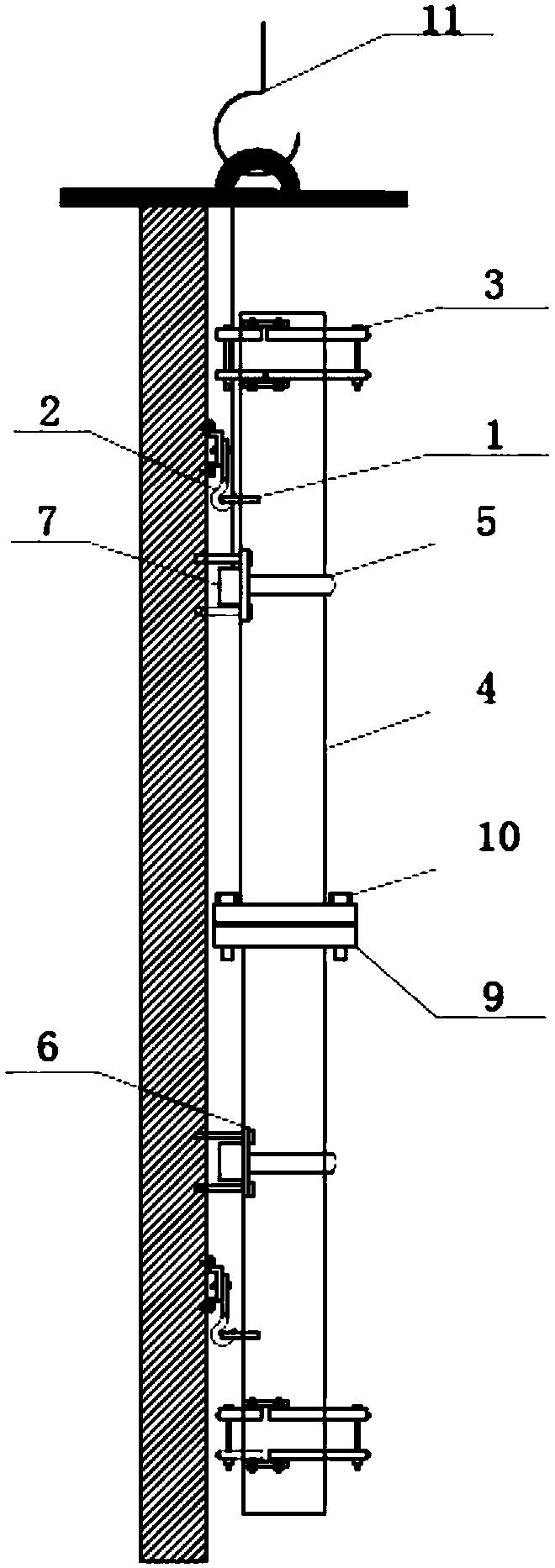

Mounting device for combined type vertical tube in high-rise tube well and mounting method thereof

PendingCN107662881AVertical fall preventionAvoid shakingPipe laying and repairLoad-engaging elementsVertical tubeStructural engineering

The invention discloses a mounting device for a combined type vertical tube in a high-rise tube well and a mounting method thereof, belonging to the technical field of mechanical and electrical installation, and aiming to solve various problems of the modularizing mounting of the present mounting device for the combined type vertical tube. The mounting device comprises a tube wall lug and a tube well pothook which are arranged in a matching manner; single pipelines are fixed on a sharing bracket through a bracket fixing plate; the bracket fixing plate is fixed on the tube well wall. The mounting method comprises the following steps: firstly, welding a lug on the outer wall of the single vertical tube; fixing the vertical tube in the sharing bracket by a hoop so as to form a vertical tube set; arranging a pothook on the corresponding position on the tube well wall; wholly hanging the vertical tube set to a floor; suspending the lug on the preset pothook; vertically splicing the verticaltube set in turn; and finally closing the opening of the pothook through a safety pin. According to the invention, the tube wall lug and the tube well pothook are utilized to realize the temporary fixing of the vertical tube set, the flexible time is supplied for the re-testing of the tube set position, and the mounting precision and quality are further improved.

Owner:SHANGHAI INSTALLATION ENG GRP

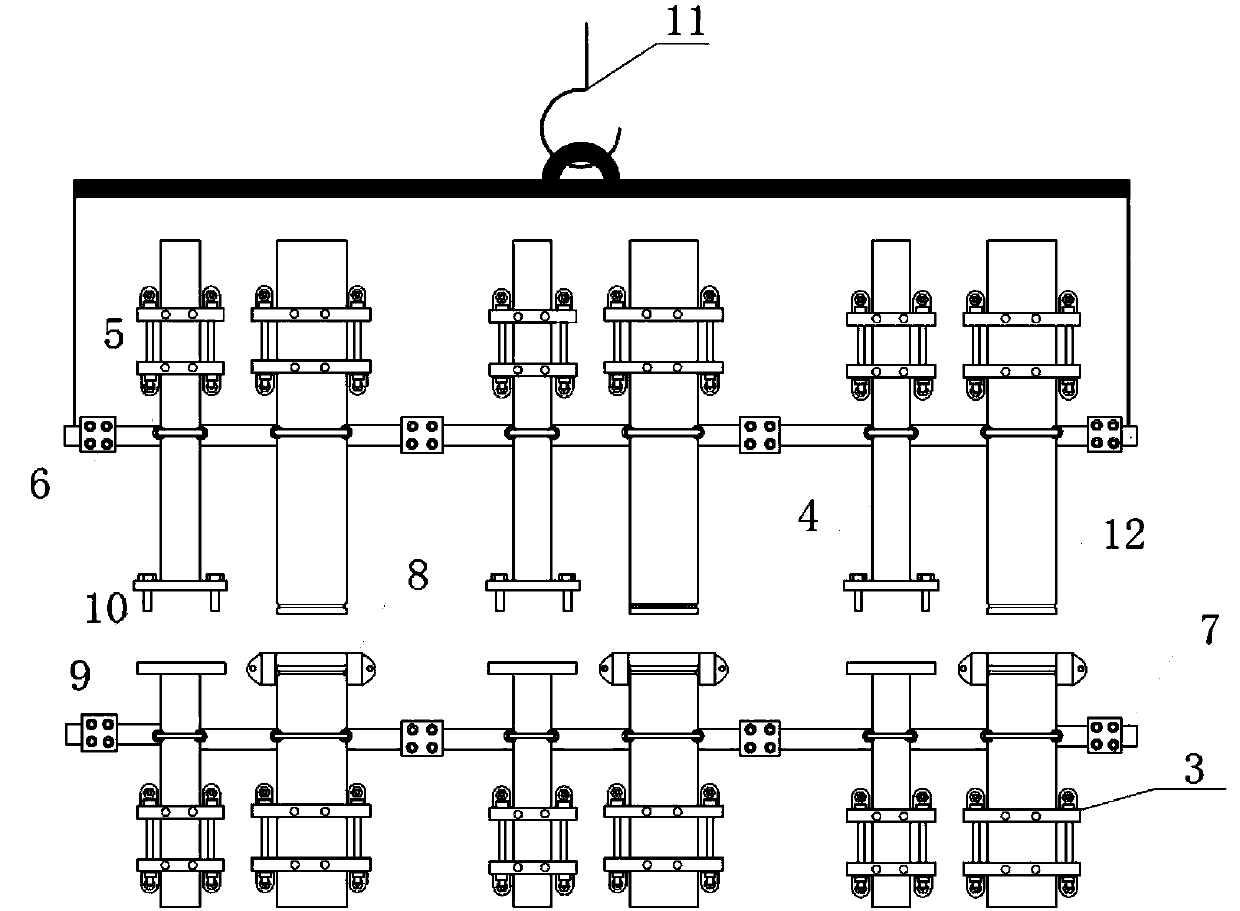

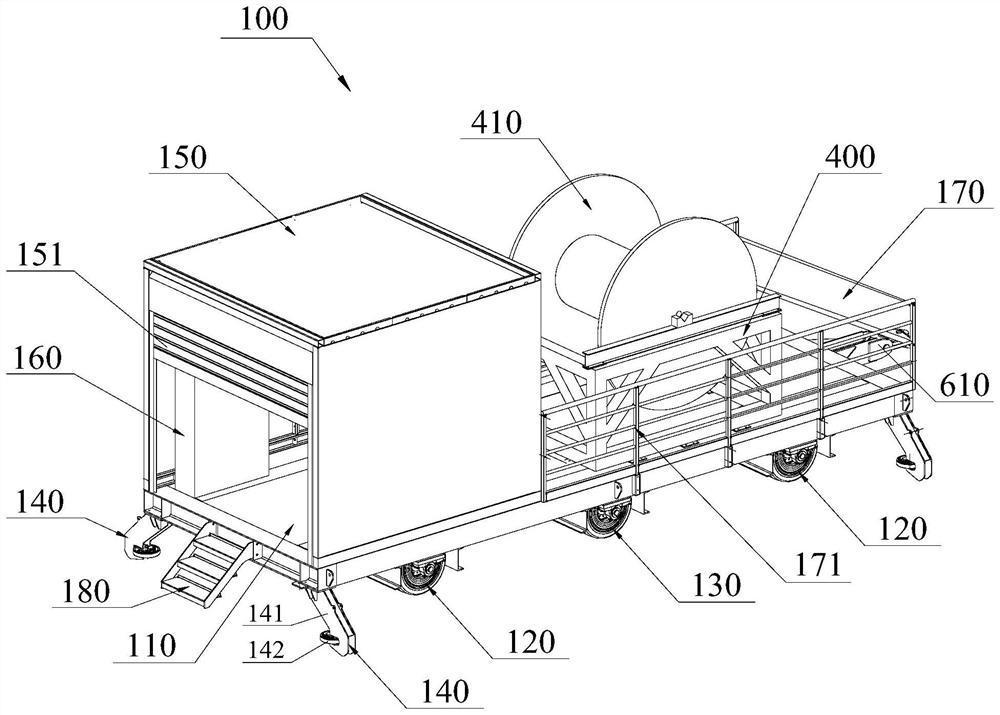

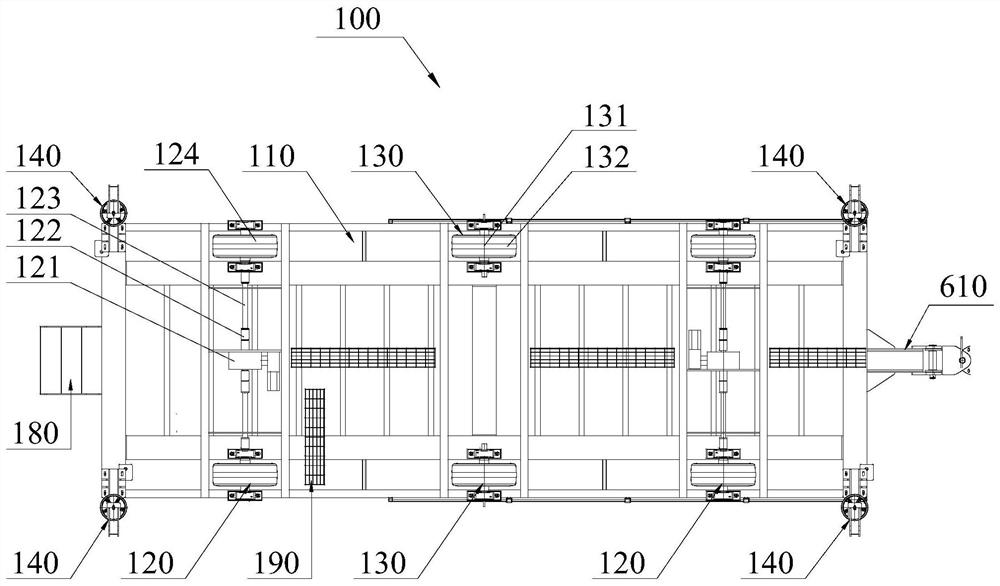

Magnetic levitation long stator coil laying vehicle system

PendingCN112688505AImprove installation efficiencyImprove installation qualityEmbedding prefabricated windingsMagnetic holding devicesStator coilElectric cables

The invention discloses a magnetic levitation long stator coil laying vehicle system. The system comprises: a first vehicle, wherein a cable reel is arranged on the vehicle body of the first vehicle; a second vehicle, wherein cable bending equipment is assembled on the vehicle body of the second vehicle and used for bending and forming the cable conveyed by the cable reel of the first vehicle into a long stator coil; and a third vehicle, wherein external hanging operation platforms for receiving the long stator coils conveyed by the second vehicle are arranged on the two sides of the vehicle body of the third vehicle. The installation efficiency of the long stator coil can be improved, the labor cost is reduced, and deformation is not likely to be caused.

Owner:SHANGHAI INSTALLATION ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com