Method for welding tower in vertical assembling mode by utilizing jacks and crane

A jack and crane technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of difficult to control verticality, verticality, misalignment, and instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In this embodiment, 60000Nm 3 The welding of the tower in the cold box of the / h air separation device is taken as an example to further illustrate the technical solution of the present invention, and the material of the tower is 5083.

[0025] Specific steps are as follows:

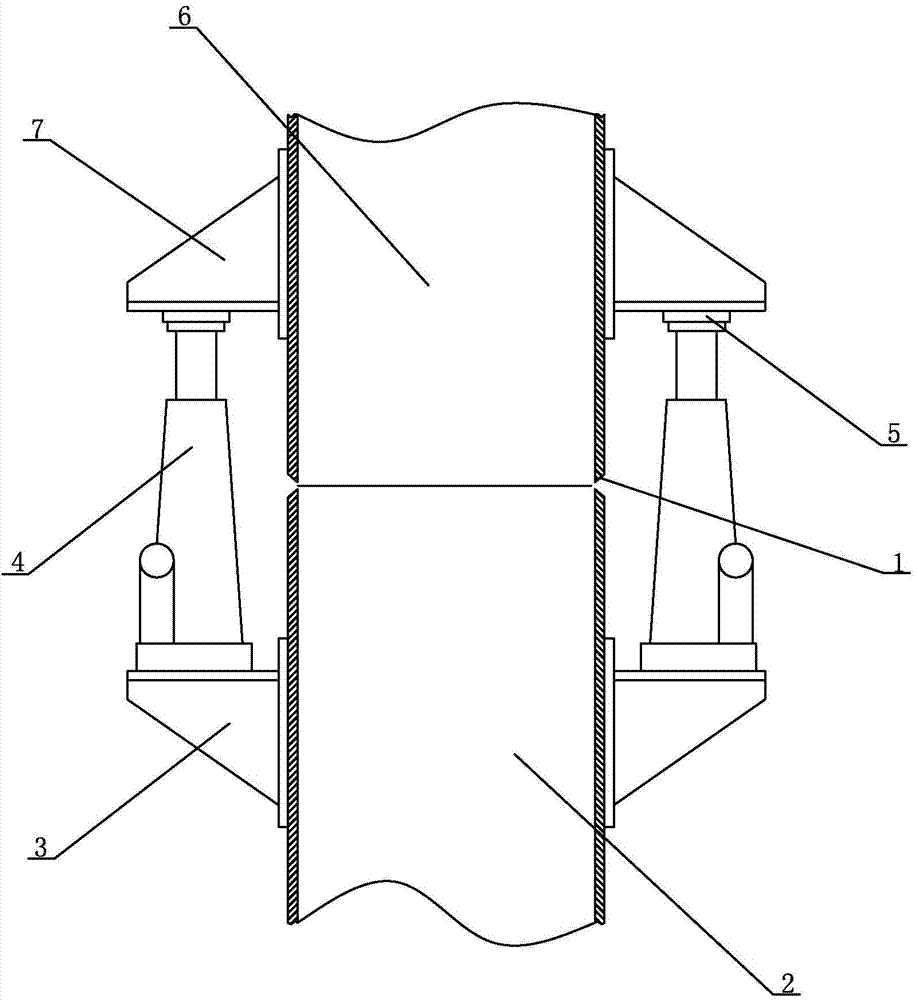

[0026] First, check the straightness of each section of the tower, cut off the head of each section of the tower according to the cutting line of the tower, and cut groove 1 at the end of each section of the tower. The form of groove 1 can be In the form in the prior art, in order to ensure the subsequent accurate assembly gap and verticality, the groove is polished to make it more tidy.

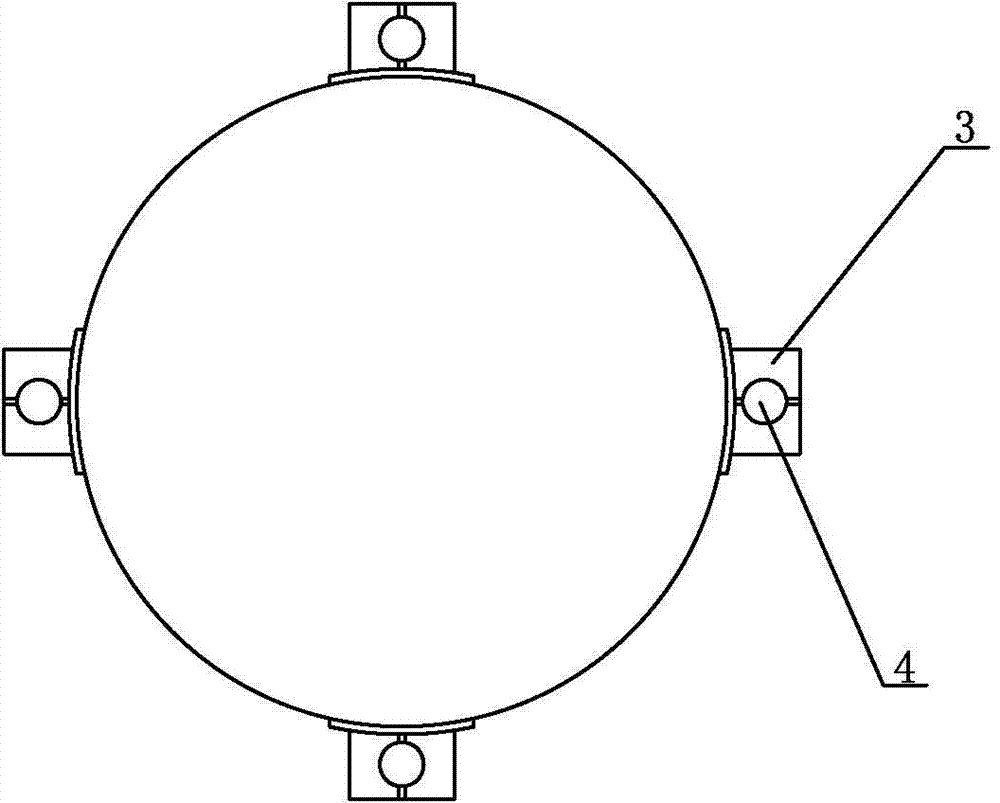

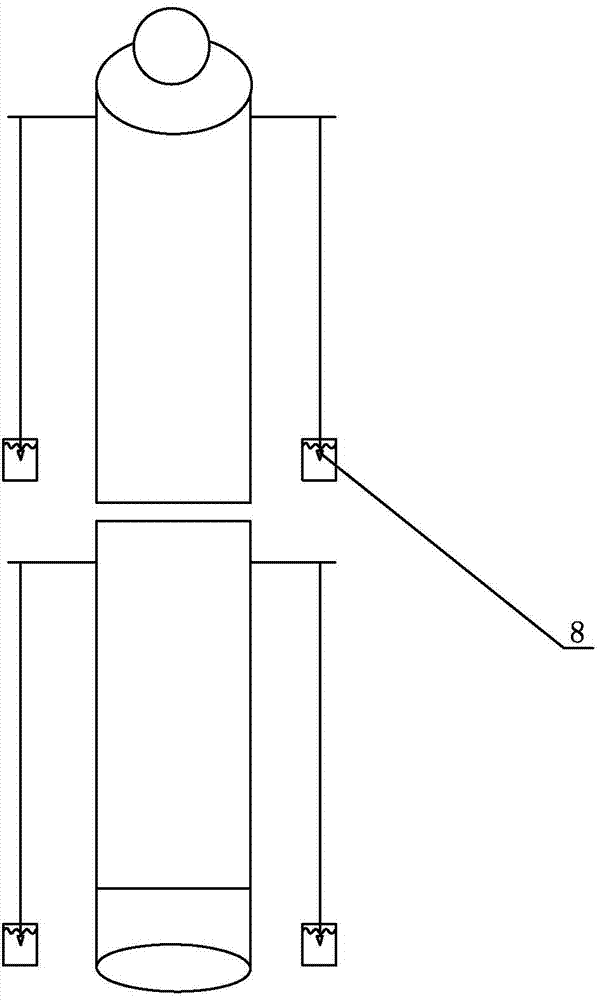

[0027] Then, fix the lower tower 2 below the butt weld of the tower to the foundation (such as a tower frame, etc.), and check the verticality of the lower tower 2, such as image 3 , 4 As shown, the plumb line is hung at the 0°, 90°, 180° and 270° positions of the top of the lower tower 2 of each section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com