Patents

Literature

2832 results about "Welding deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basic forms of welding deformation include shrinkage deformation, angular distortion, bending deformation, wave deformation and twist deformation, etc. During the welding process, welding pieces of uneven heating and cooling, is the root cause of the welding stress and deformation.

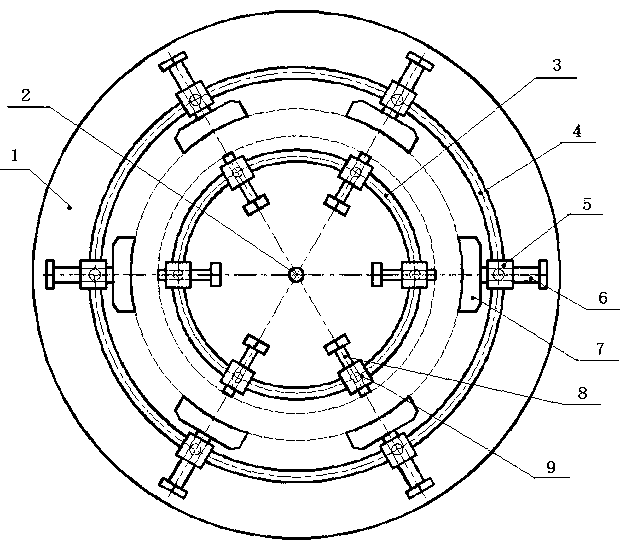

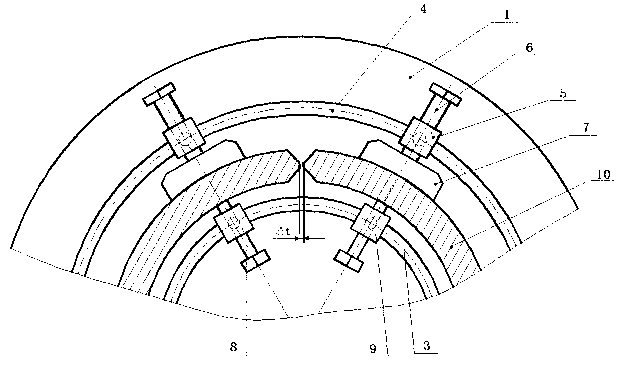

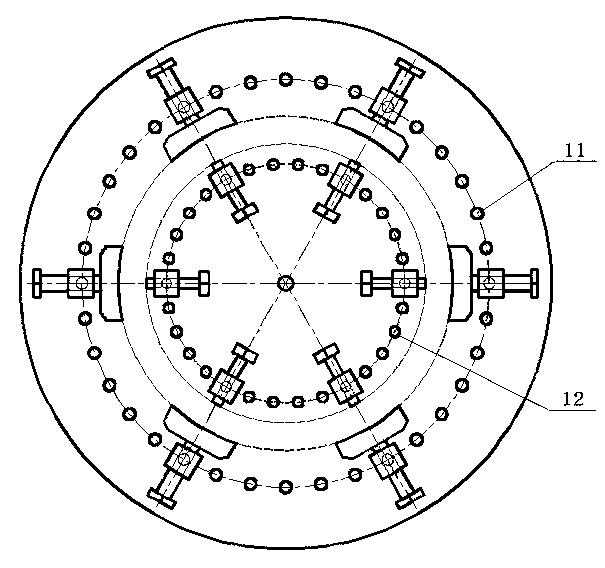

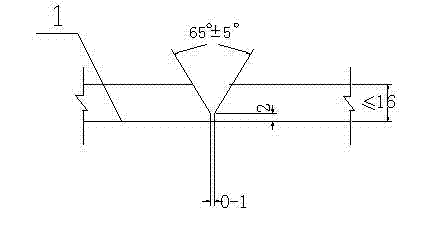

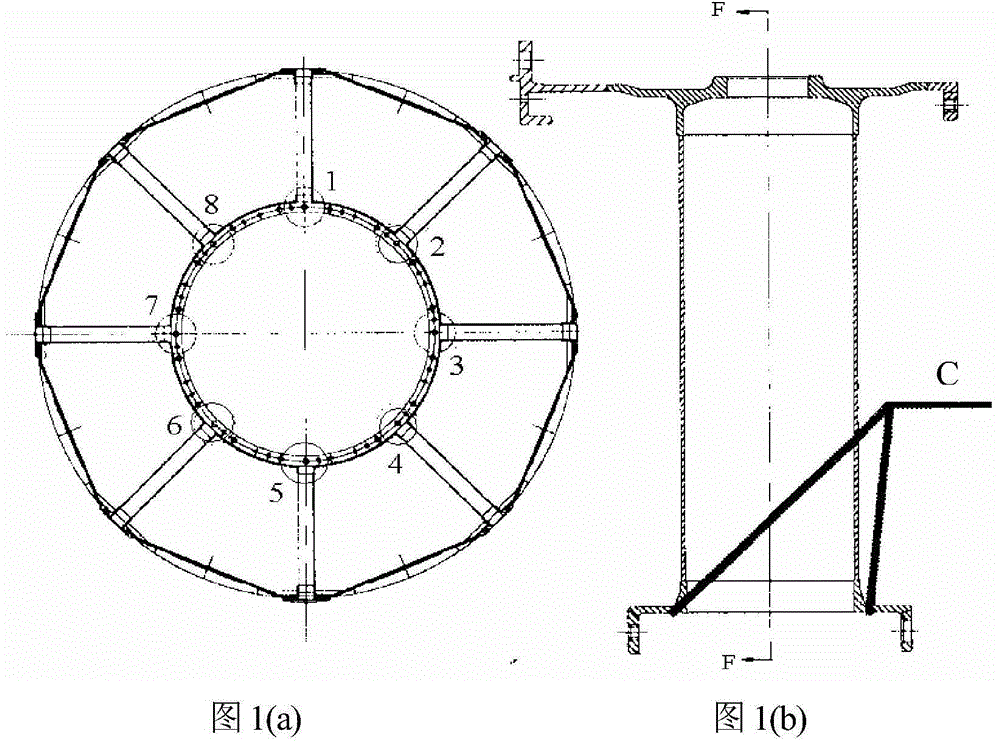

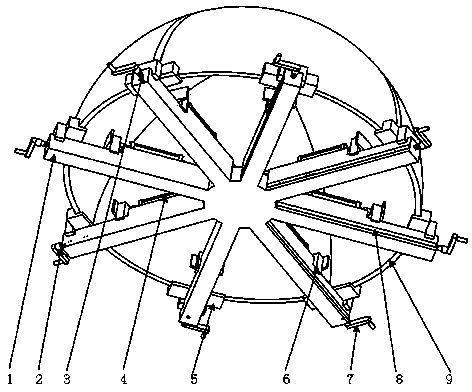

Pre-welding shaping auxiliary mold of large-scale steel cylinder and welding method

ActiveCN103273252AAvoid mechanical shaping processGuaranteed accuracy requirementsWelding/cutting auxillary devicesArc welding apparatusStructural engineeringWeld seam

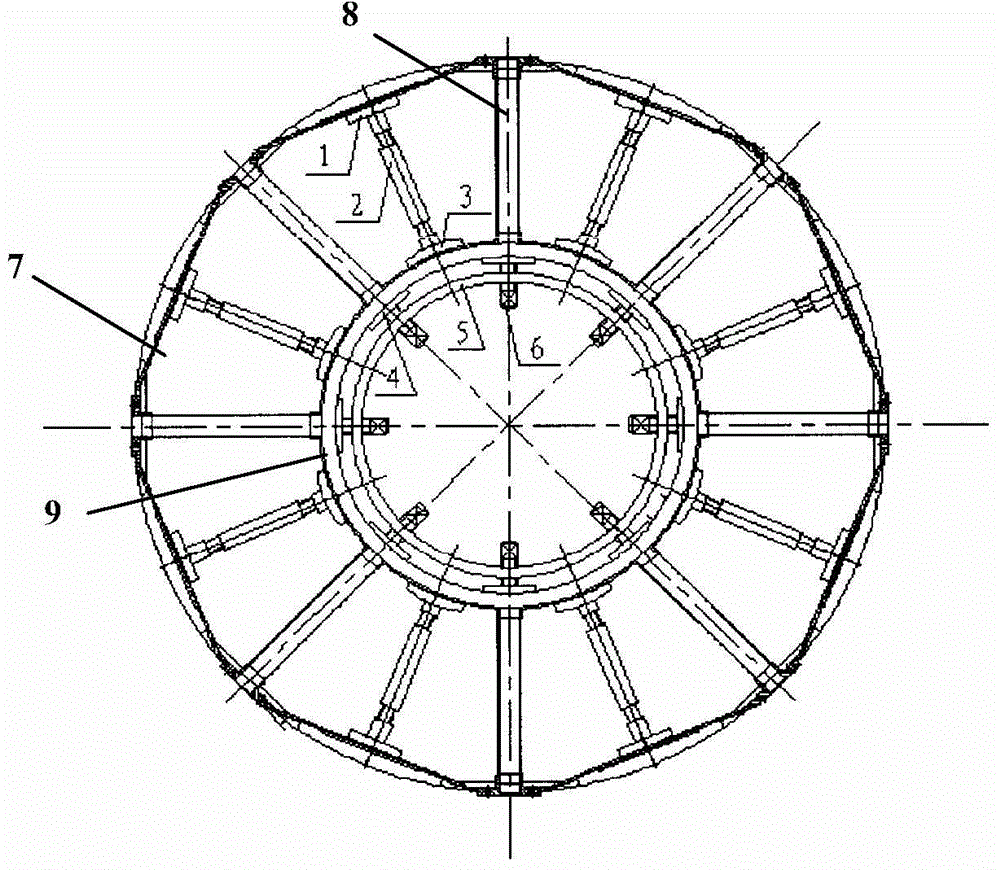

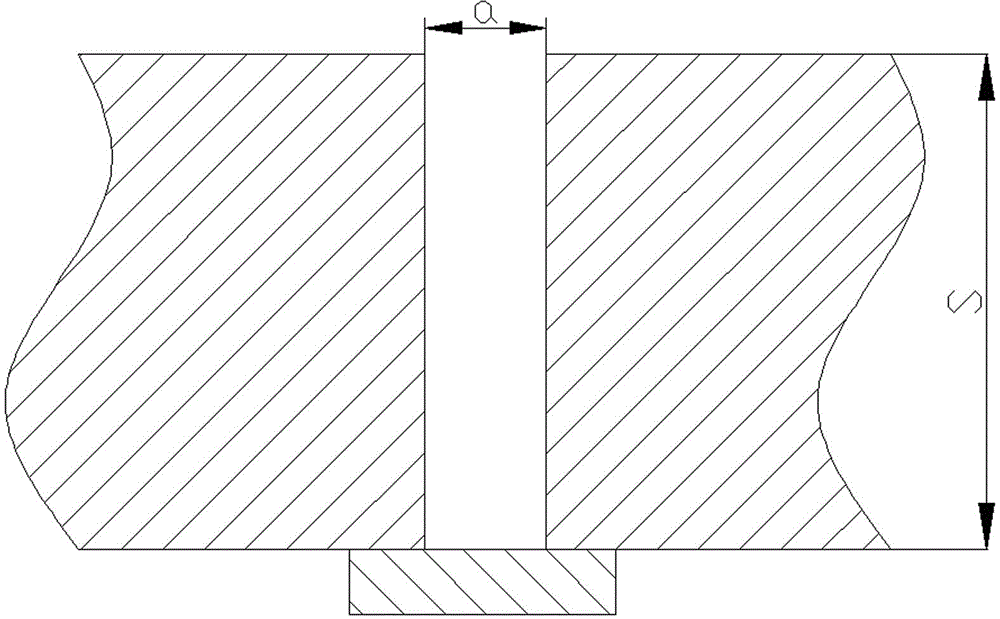

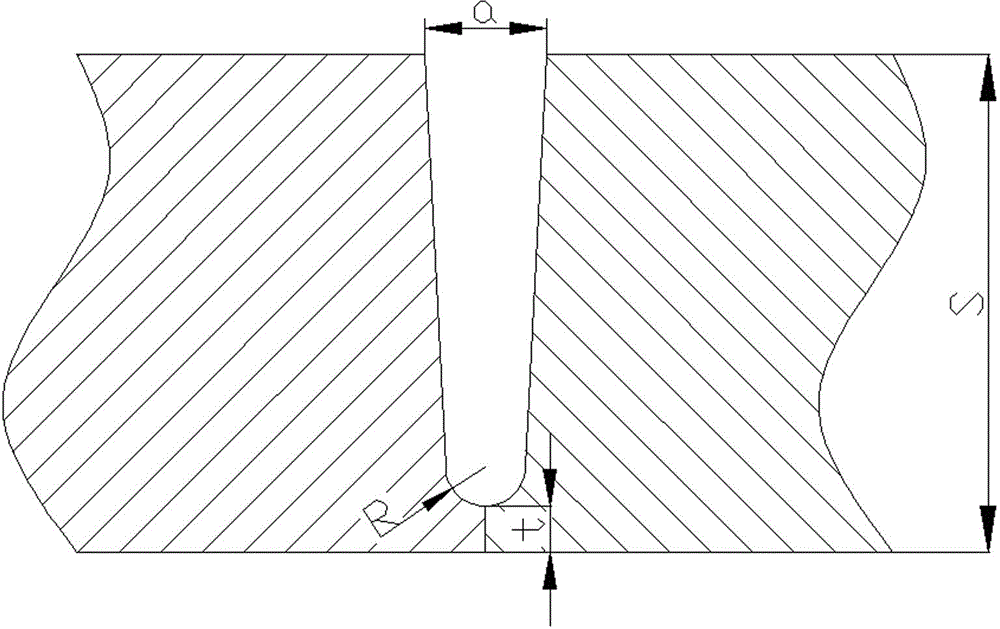

The invention relates to the technical field of forming, assembling and welding of a large-scale supporting cylinder on a lightering platform on the sea, and provides a pre-welding shaping auxiliary mold of the large-scale steel cylinder and a welding method. The shaping mold is composed of a welding platform, a fixing column, a slide way, an outer lead screw, an outer arc locating block, an inner ejector rod and the like. The outer circle of the cylinder is shaped through an adjusted rigid restrained position; shaping accuracy of the cylinder is ensured through the lead screw, a seam width positioning wedge, a process support and the like; a welding process of the cylinder is made; tack welding is firstly conducted on a longitudinal seam, then the longitudinal seam is integrally welded, and the welding sequence is that welding is conducted from the middle towards the two ends at intervals; sectionalized barrel bodies are welded in an assembled mode and through an X-type double-face groove, the butt-jointing groove faces upwards, the inner side of the cylinder is welded firstly when welding is started, carbon arc air gouging back gouging is conducted on a welding seam in the outer side after the cylinder is turned over, and then the outer side of an annular welding seam is welded. Slight welding deformation is achieved through adjustment of a rigidity restraint positioning block and changes of the welding sequence, and requirements for welding accuracy of the cylinder are met.

Owner:JIANGSU DINSON HEAVY IND +1

Manufacturing method for box type pillar beam

ActiveCN102896472AAdvanced preparation technologyReasonable preparation processArc welding apparatusNumerical controlSlag (welding)

The invention relates to a manufacturing method for a pillar beam for the building field and especially relates to the manufacturing method for a box type pillar beam. The manufacturing method comprises the processes of steel check, line marking, cutting, material receiving, assembling, welding, finishing, coating, and marking. The manufacturing method comprises the following steps: splicing big plates and cutting the box type pillar beam under numerical control; adding lining strips and leaving gaps during the grouping process of four main welding seams of the box type pillar beam; welding the four main welding seams by adopting an automatic submerged arc welding method; welding box type separating plates by adopting non-melting nozzle electro-slag welding; keeping the welding seams of the non-melting nozzle electro-slag welding under an abreast state; machining after grouping the separating plates of the box type pillar beam; and end-milling the two ends of the box type pillar beam. According to the manufacturing method, during a manufacturing process of the box type pillar beam, an advanced box type separating plate non-melting nozzle electro-slag welding technology is adopted; the welding and the assembling are alternately performed; the welding sequence is scientific and reasonable; multiple measures are simultaneously taken for preventing welding deformation; the precise equipment is adopted for processing the end part, so that the manufacturing technology for the box type pillar beam is more advanced and reasonable; and the manufacturing method is suitable for the box type pillar beams in various cross section sizes and plate thicknesses.

Owner:CHINA 22MCC GROUP CORP

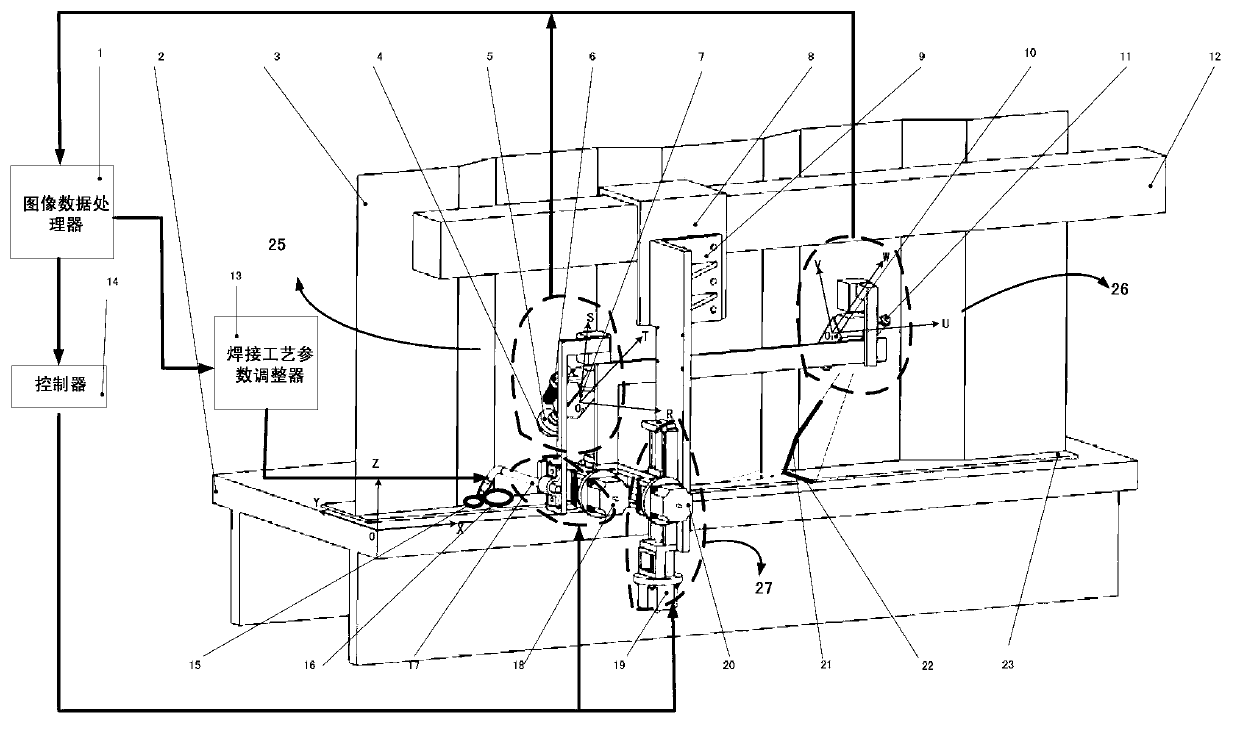

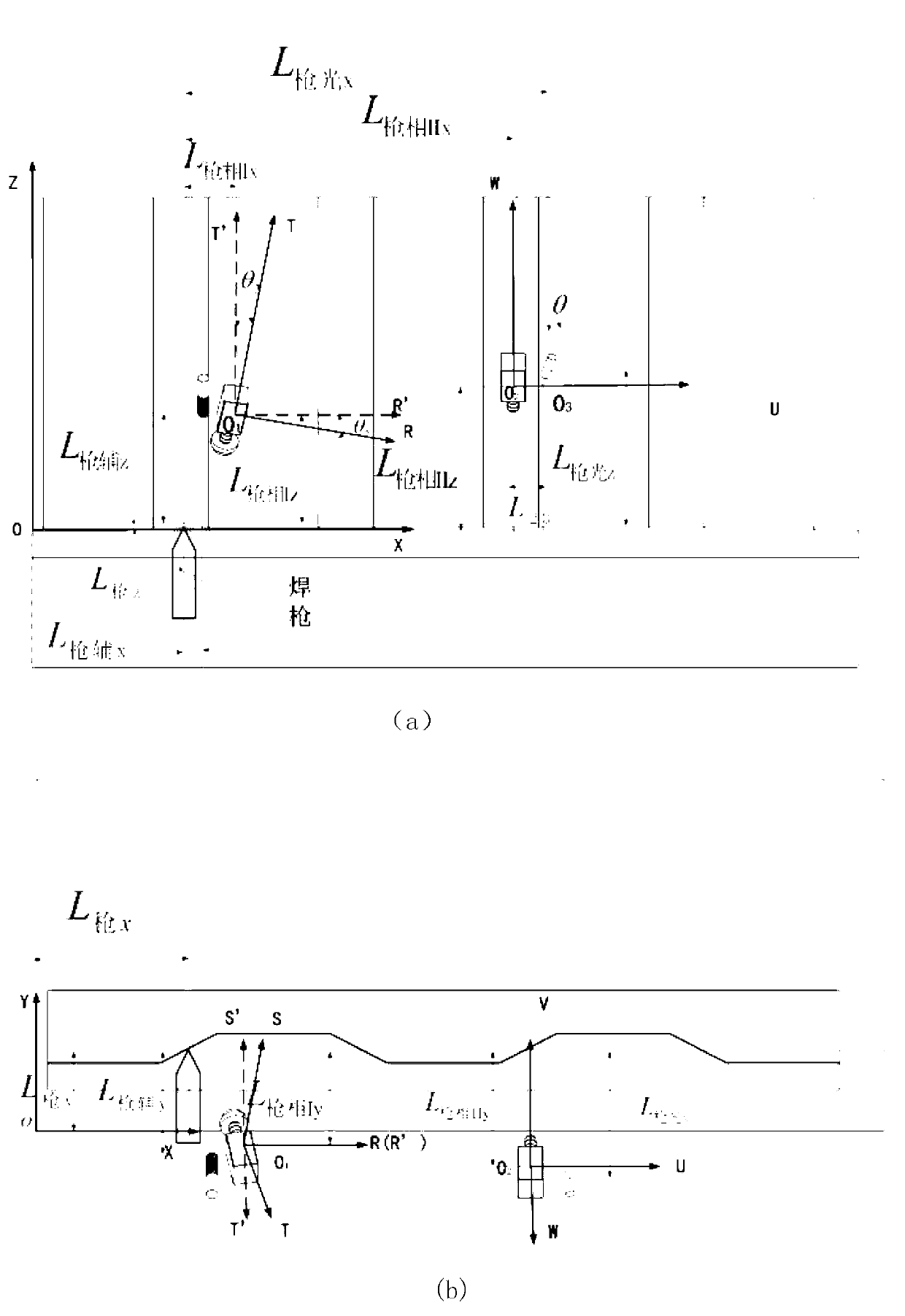

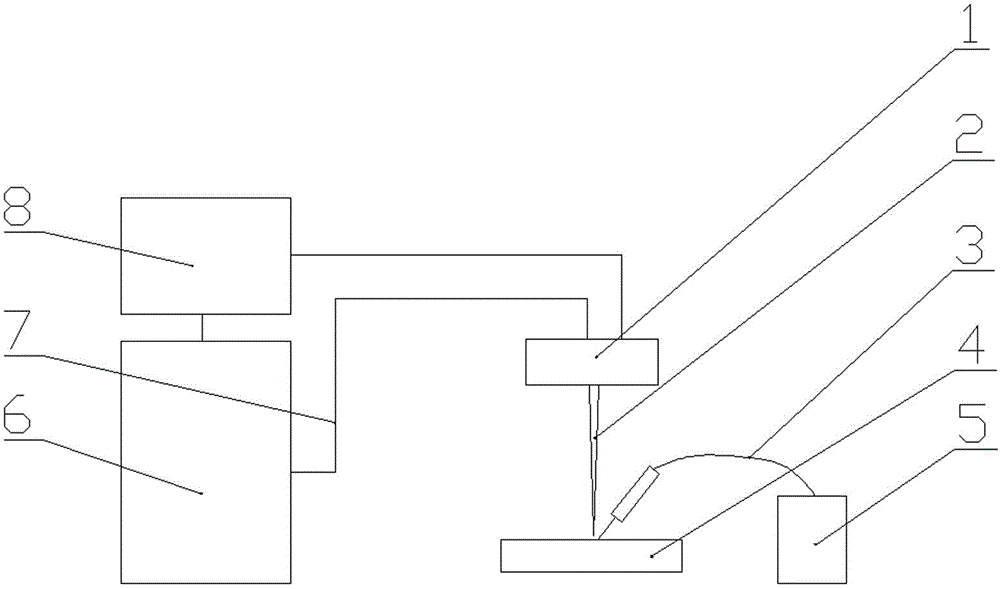

Visual tracking monitoring system and method in automatic corrugated thin plate fillet weld welding

ActiveCN103273171ARealize intelligent tracking and monitoringImprove adaptabilityArc welding apparatusFillet weldMonitoring system

The invention discloses a visual tracking monitoring system and method in automatic corrugated thin plate fillet weld welding. The visual tracking monitoring system and method in the automatic corrugated thin plate fillet weld welding comprises a welding gun, a system installing frame, a welding technological parameter adjuster, a vision device I, a vision device II, an image data processor, a welding gun drive device, a tracking drive device and a controller. The vision device I and the vision device II are respectively connected with the image data processor; the image data processor is respectively connected with the controller and the welding technological parameter adjuster; the controller is respectively connected with the welding gun drive device and the tracking drive device. According to the visual tracking monitoring system and method in the automatic corrugated thin plate fillet weld welding, binocular vision devices are adopted, the front vision device II is used for leading the movement of the welding gun, the direct-sight vision device I monitors a weld pool and welding joints before the weld pool and conducts adjustment on welding gun track deviation caused by factors such as thermal welding deformation and welding wire bending.

Owner:SOUTH CHINA UNIV OF TECH

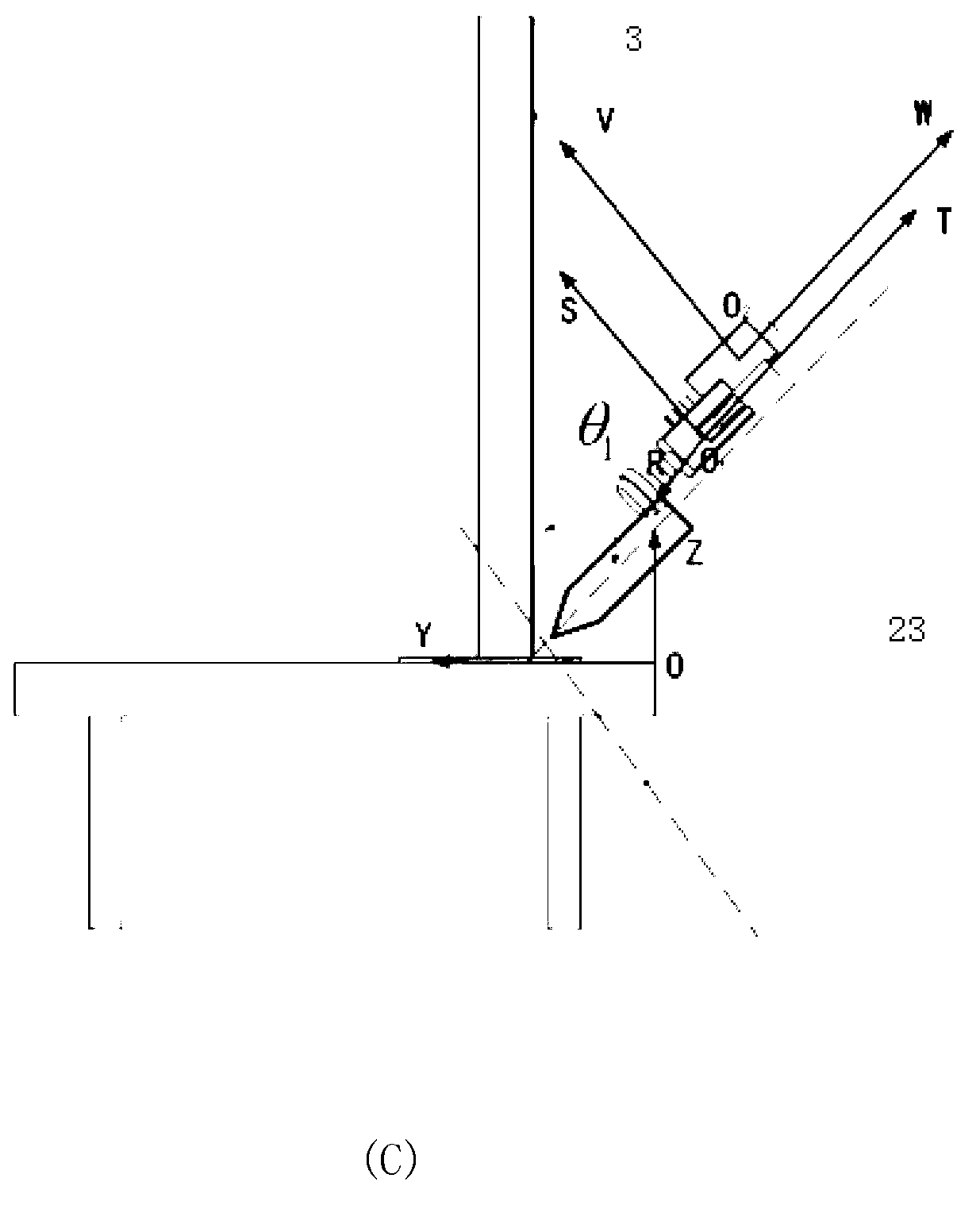

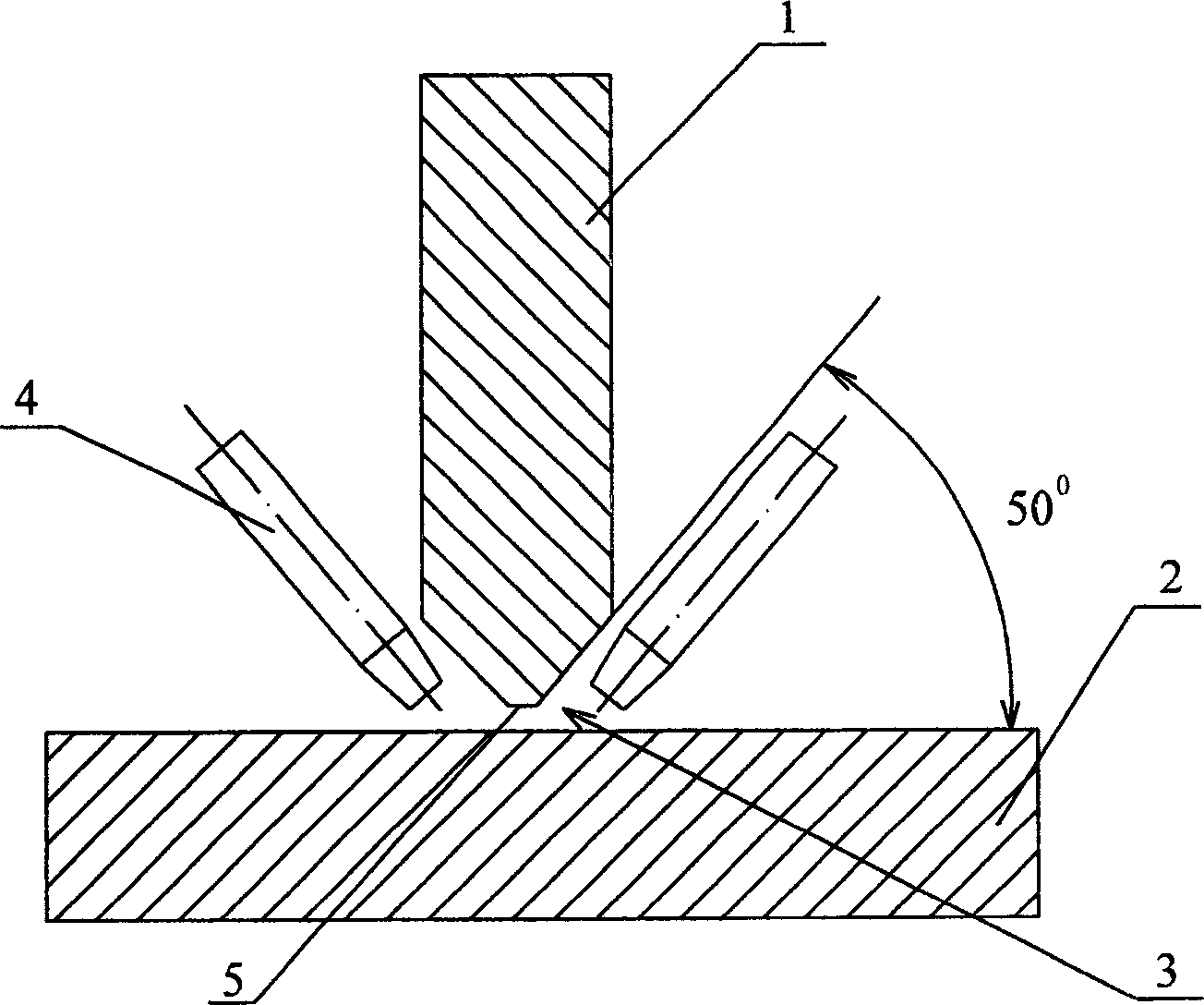

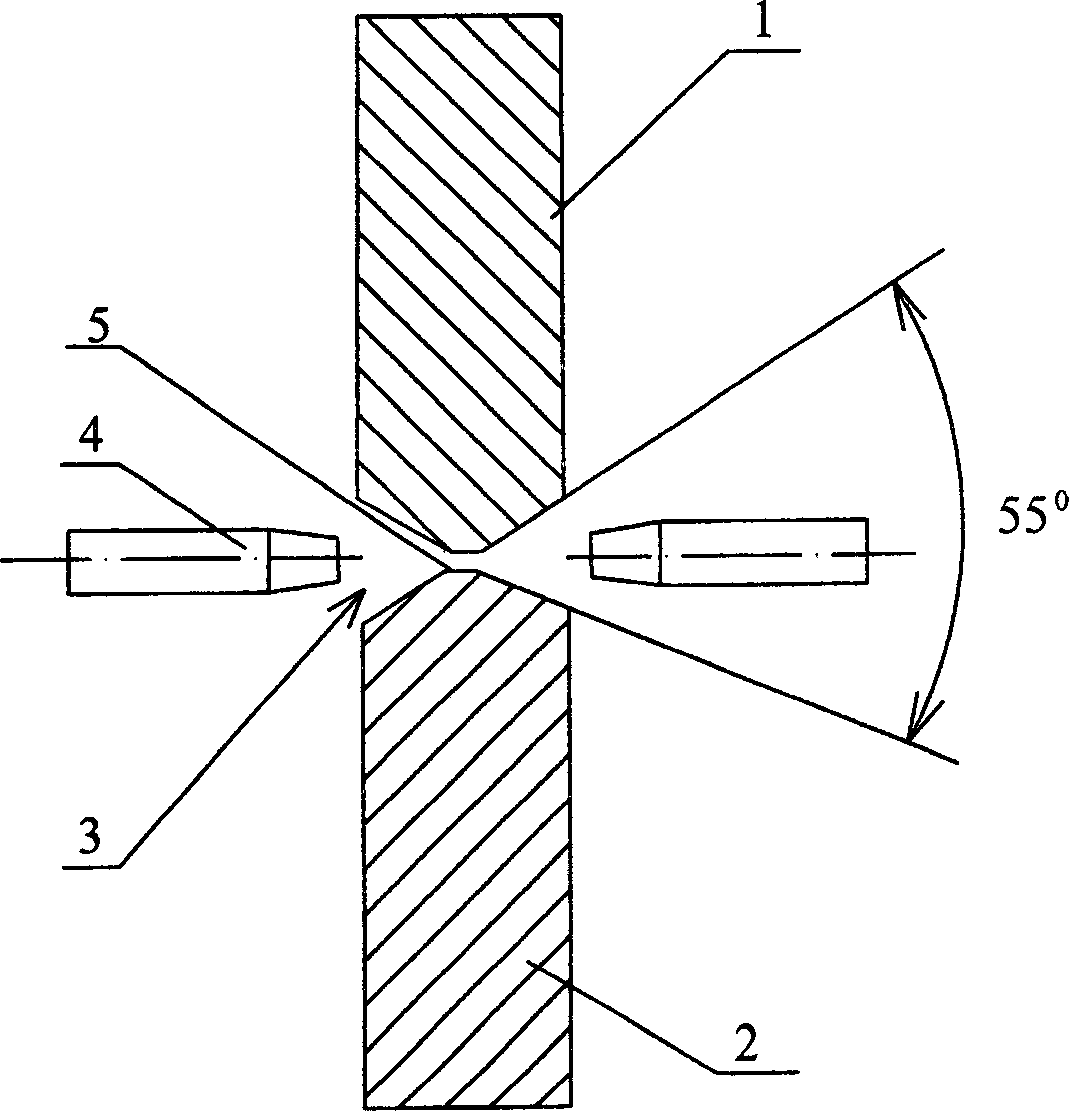

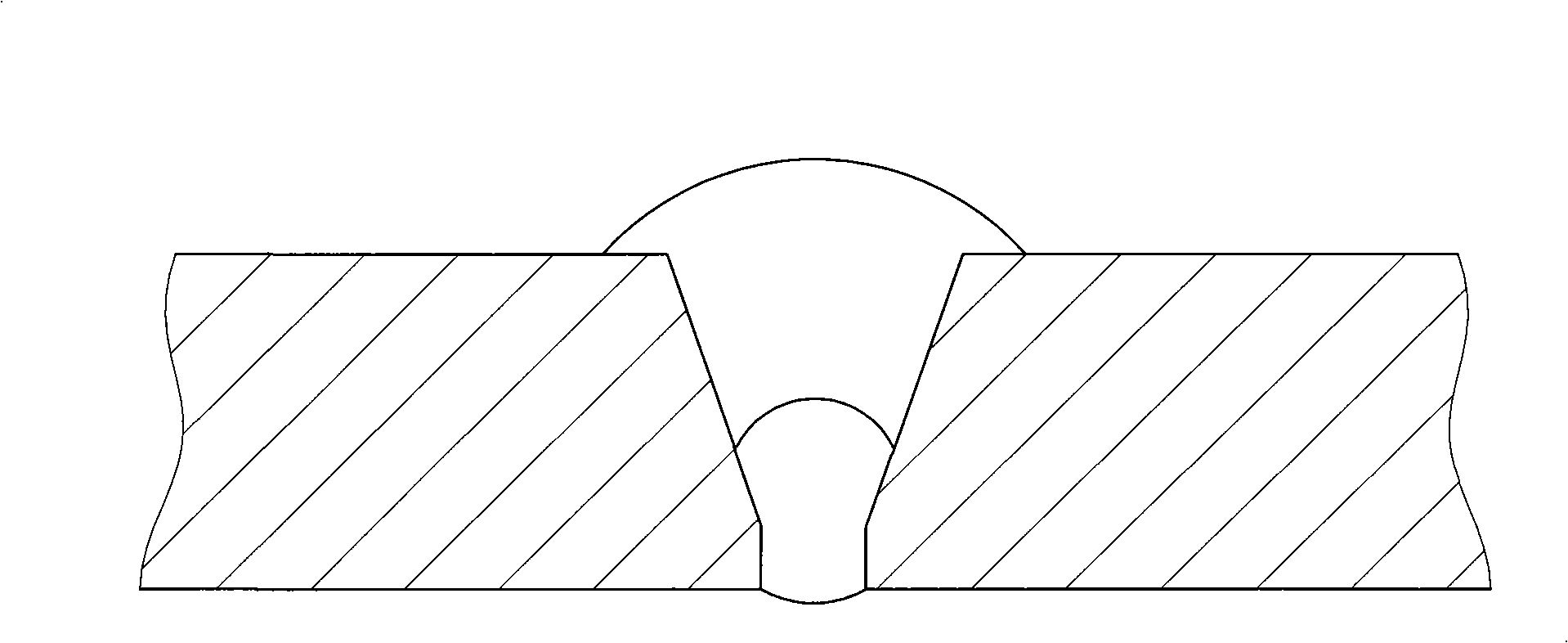

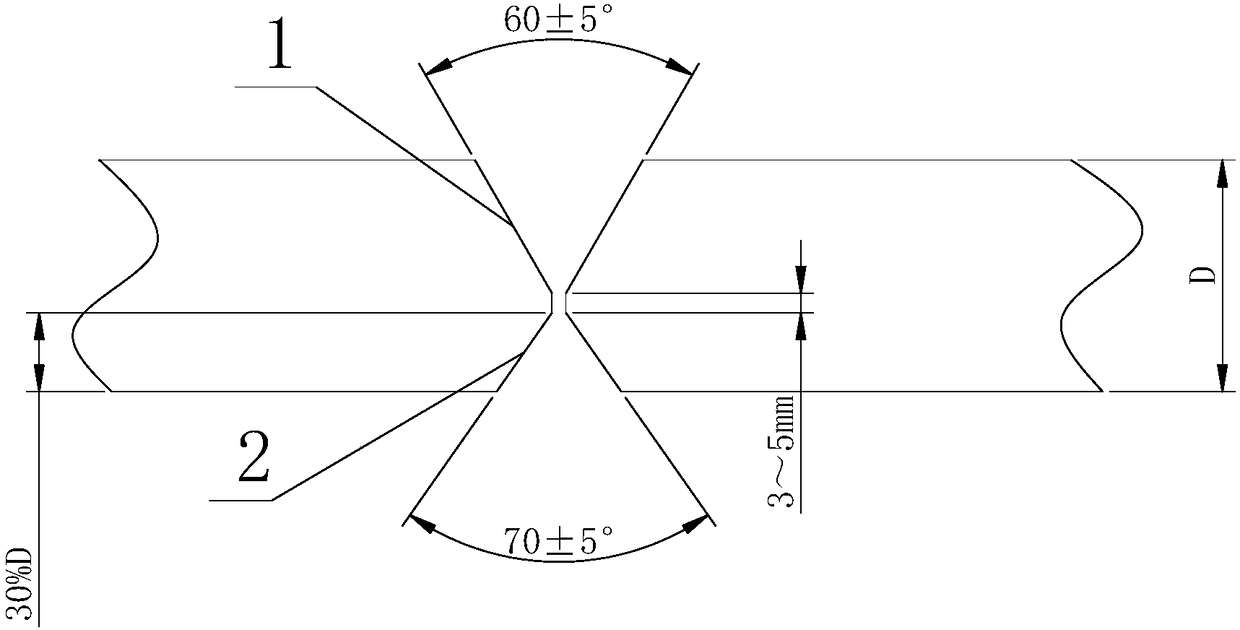

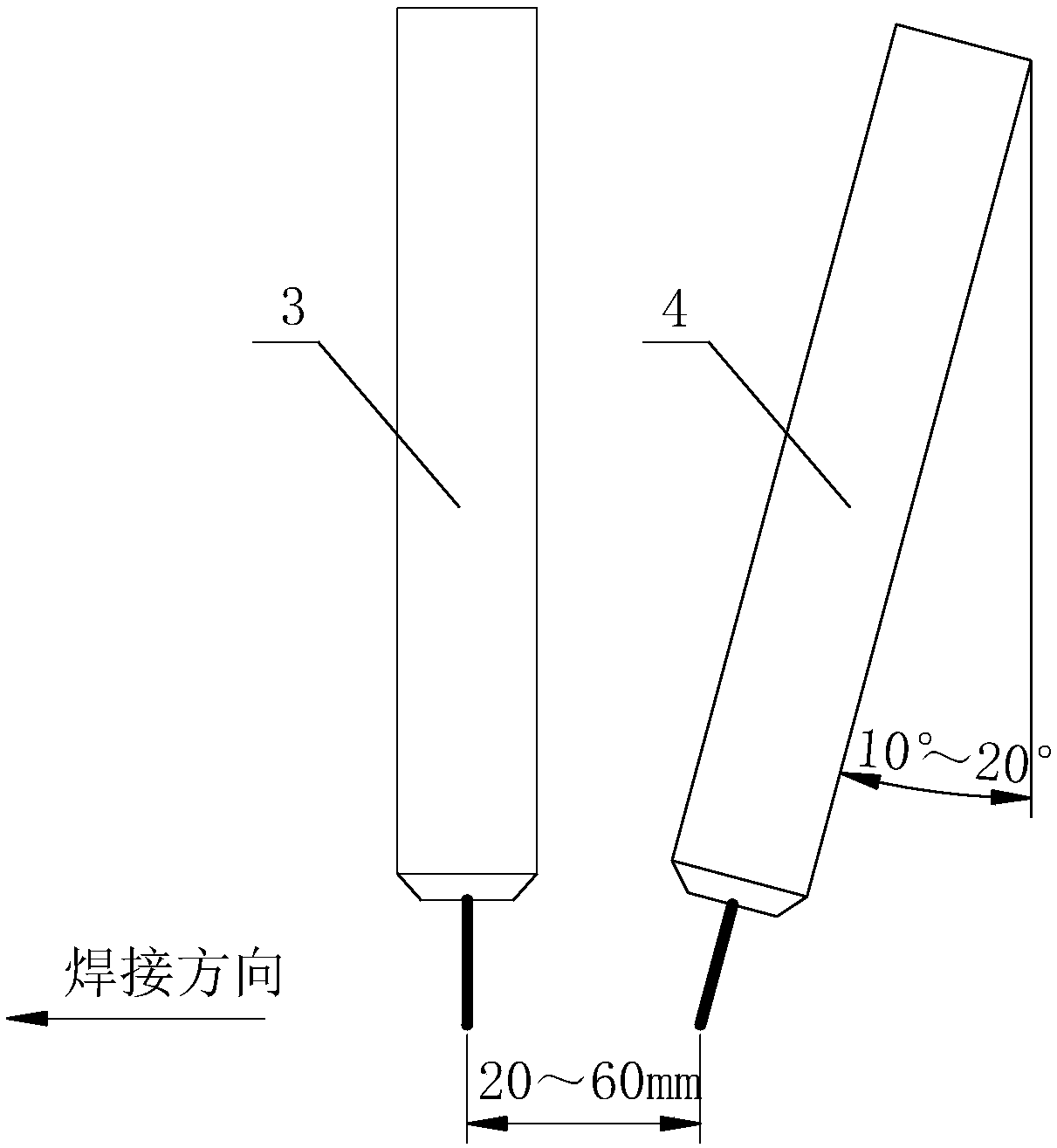

Double sides double arc welding method

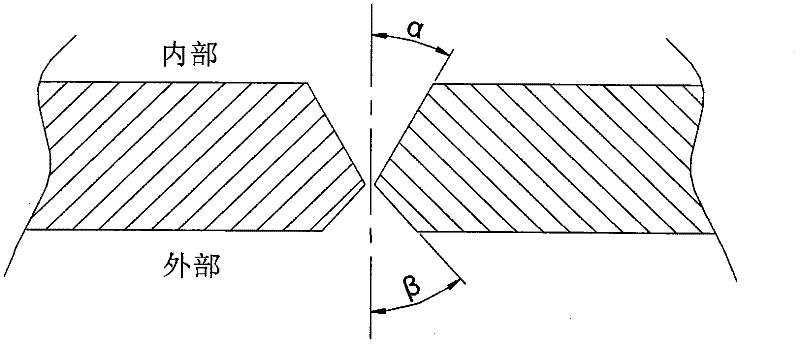

ActiveCN1603045AReduce stressGuarantee welding qualityArc welding apparatusWorkpiece edge portionsJoint stressWelding deformation

The invention relates to a double side dual-arc welding method. It includes the following steps that the work-piece connection part waited for welding is made both sides welding groove; the both sides welding groove and its both sides surface is ground and cleaned out before the welding; the two independent electric arcs elicited by two welding guns of the two welding machines are conducted both sides dual-arc symmetry bottoming welding respectively at the both sides welding groove; after the bottoming welding, the two independent electric arcs are conducted both sides dual-arc filling welding respectively at the both sides welding groove. The invention avoids the carbon arc-air gouging back gouging process, simplifies the welding process, so that the automation welding can be realized. It avails to practice gas shielded welding, ensure the welding quality, reduce the welding deformation, and decrease joint stress. The method can apply to important metal structural parts welding.

Owner:渤海造船厂集团有限公司

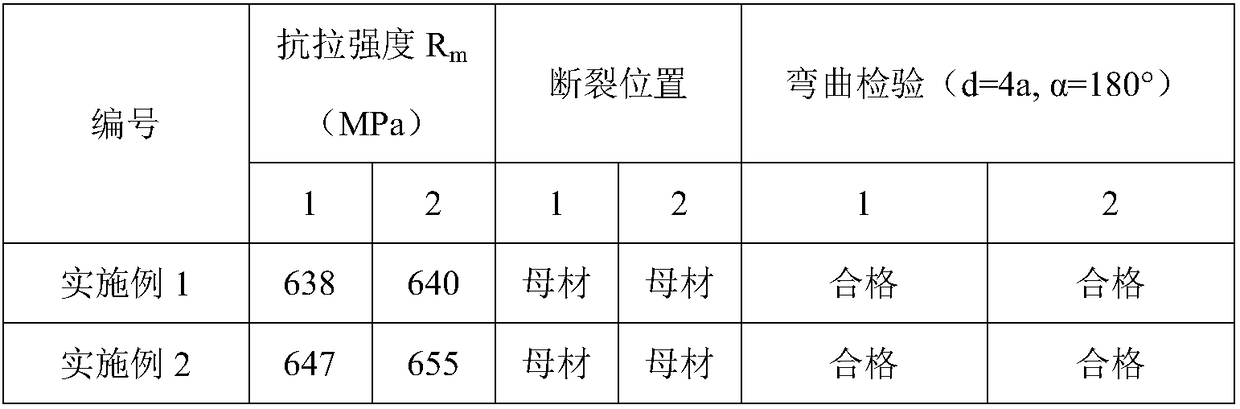

Welding technique for rolled steel

The invention relates to a welding process of ASTM A572 GR65 steel, which adopts mixed gas protection welding of argon and carbon dioxide for carrying out the backing welding and adopts the mixed gas protection welding of argon and carbon dioxide for filling and cover surface welding under the operating environment with temperature above 5 DEG C, and the operation is carried out according to the following steps: (1) the determination of parameters of the welding process; (2) the preparation before the welding: groove preparation and contra-aperture assembly; (3) the requirements of the assembly of the tack welding; (4) the backing welding by the mixed gas protection welding of argon and carbon dioxide; (5) the filling and the cover surface welding by the mixed gas protection welding of argon and carbon dioxide. The invention provides the welding process of the ASTM A572 GR65 steel which can prevent the welded steel pipes generating low-plastic quenched structure, prevent the overheating during the austenitic transformation, strengthen the austenitic stability and lower the welding deformation which is reduced by the welding stress.

Owner:ZHEJIANG SHENGDA STEEL TOWER +2

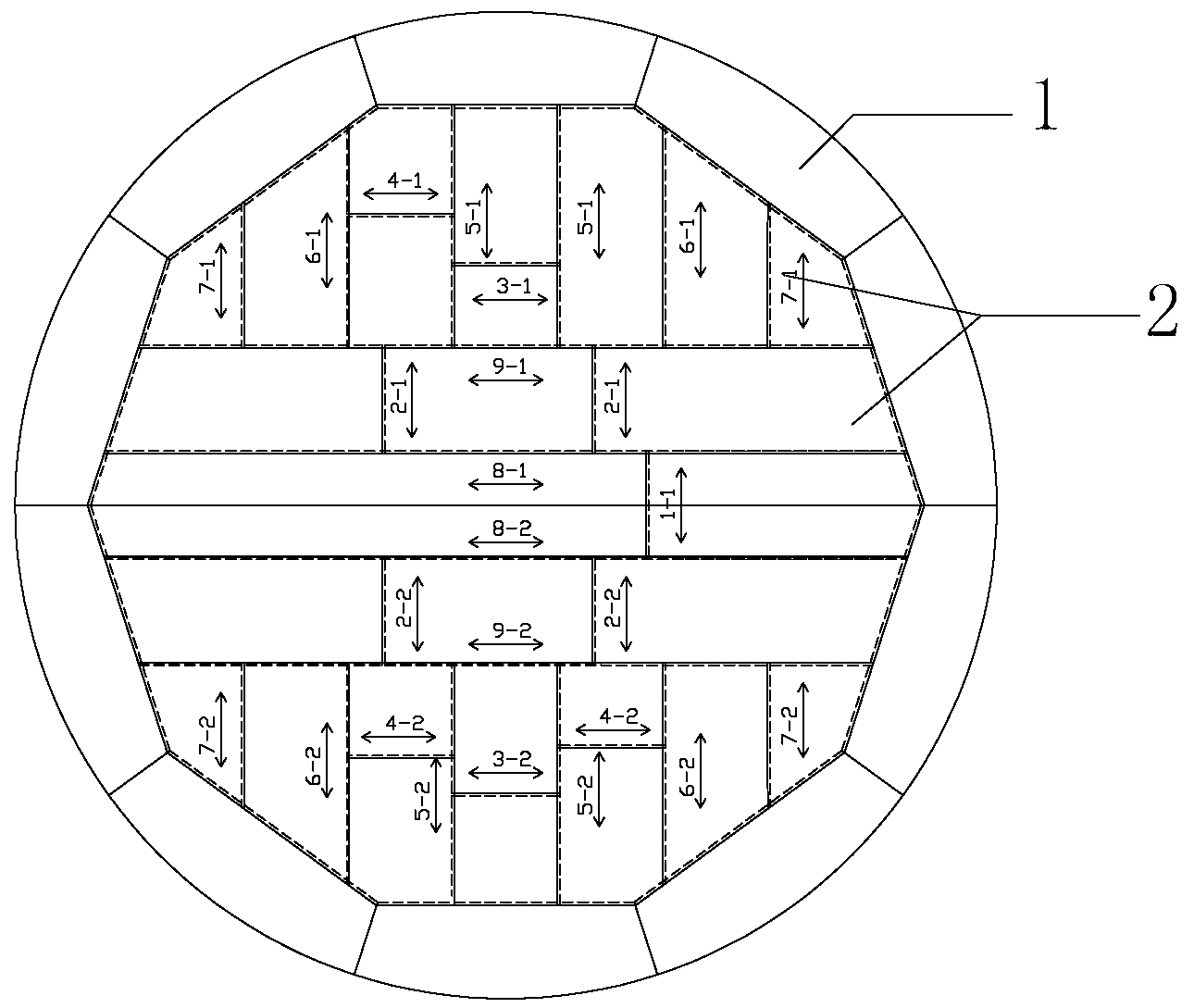

Girth welding technology for vacuum container

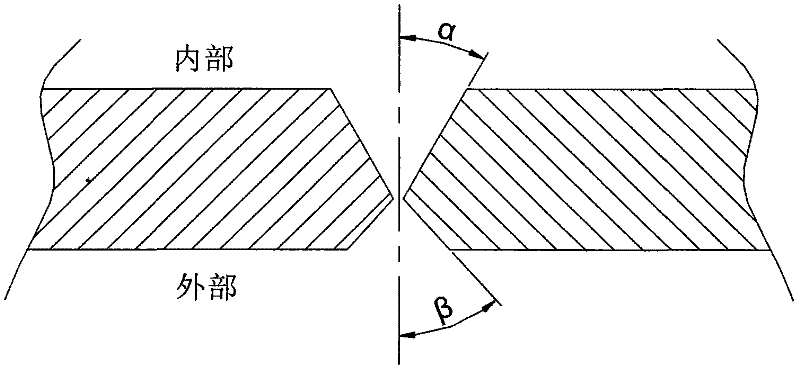

ActiveCN102357741AGuaranteed absolute penetrationAvoid the phenomenon of localized high temperatureArc welding apparatusWorkpiece edge portionsShielded metal arc weldingButt welding

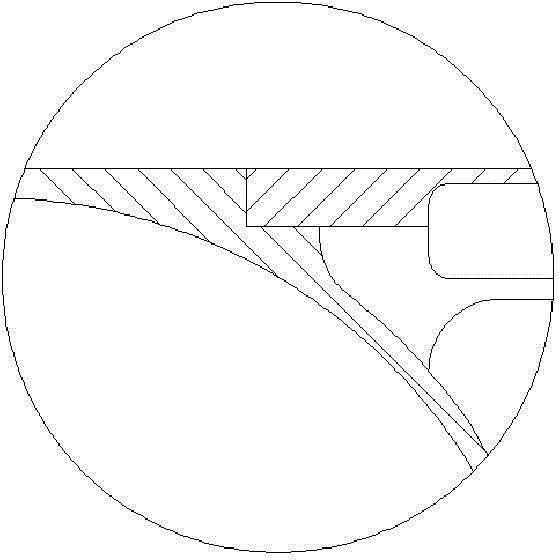

The invention discloses a girth welding technology for a vacuum container, which comprises the following steps: processing beveled edges, assembling and welding. In the step of processing the beveled edges, a 14mm thick 0Cr18Ni9 austenitic stainless steel material is selected as a cylinder base material, X-shaped beveled edges are adopted, an inside beveled edge is processed for 10mm with a single-side angle of 32.5 degrees, an outside beveled edge is processed for 4mm with a single-side angle of 35 degrees, and no truncated edge is left. In the step of assembling, reserved clearances of 2.0-2.5mm are assembled, argon tungsten-arc welding is adopted to position, a positioning welding length is 10-15mm, an interval is 200mm, and then a 'strut having a shape of Chinese character 'mi' which is used for adjusting the roundness of a cylinder is welded in the cylinder. In the step of welding, an argon arc welding double-gun butt-welding method is used for bottoming the interior of the cylinder, two layers are filled in an inner welding bead of the cylinder in the manner of manual arc welding, an external welding bead is covered in the manner of submerged-arc welding, and finally, the inner welding bead is covered in the manner of manual arc welding. The girth welding technology can be used for controlling the welding deformation and has the advantages that the method is simple and is easy to realize.

Owner:无锡市创新低温环模设备科技有限公司

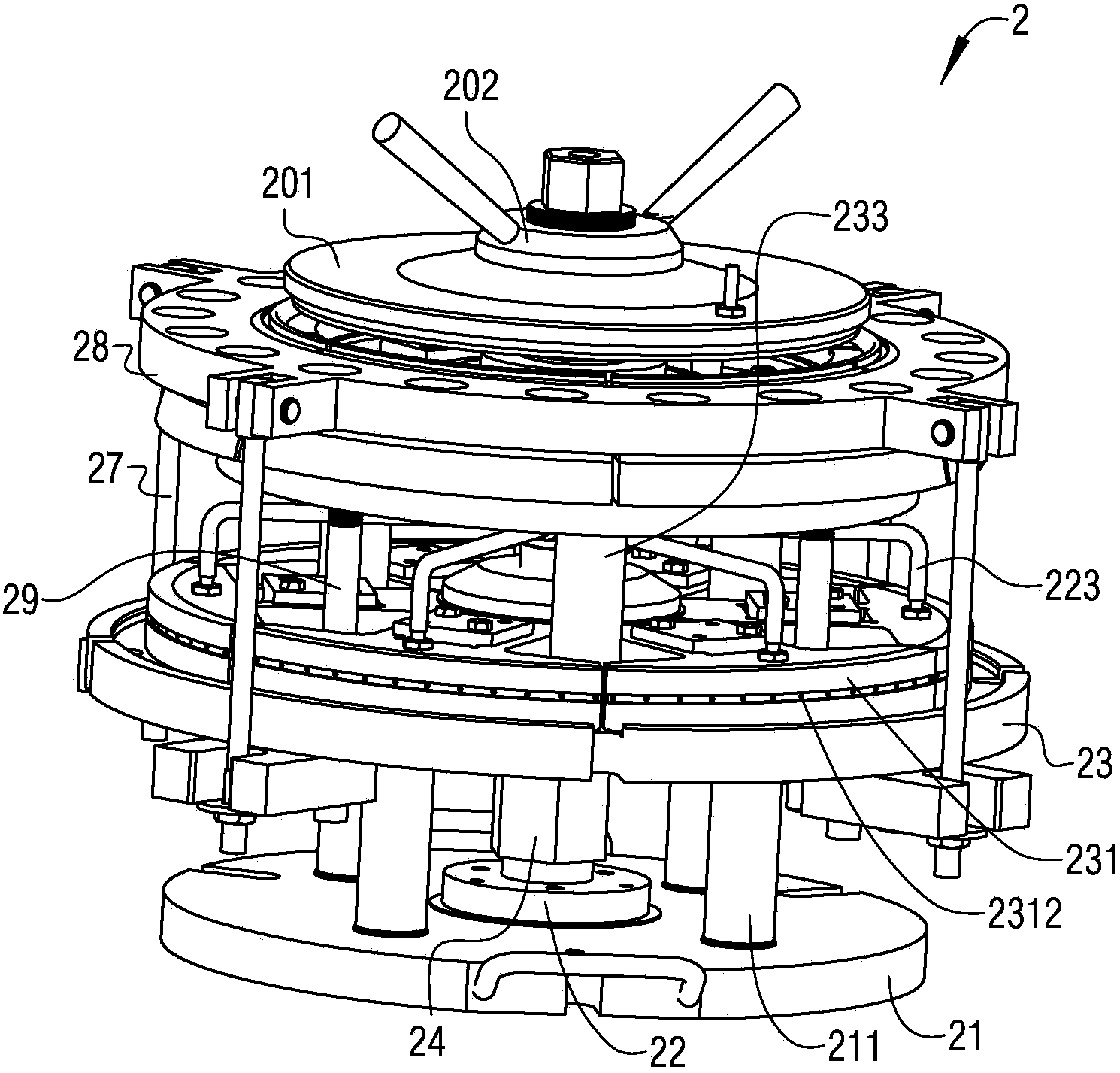

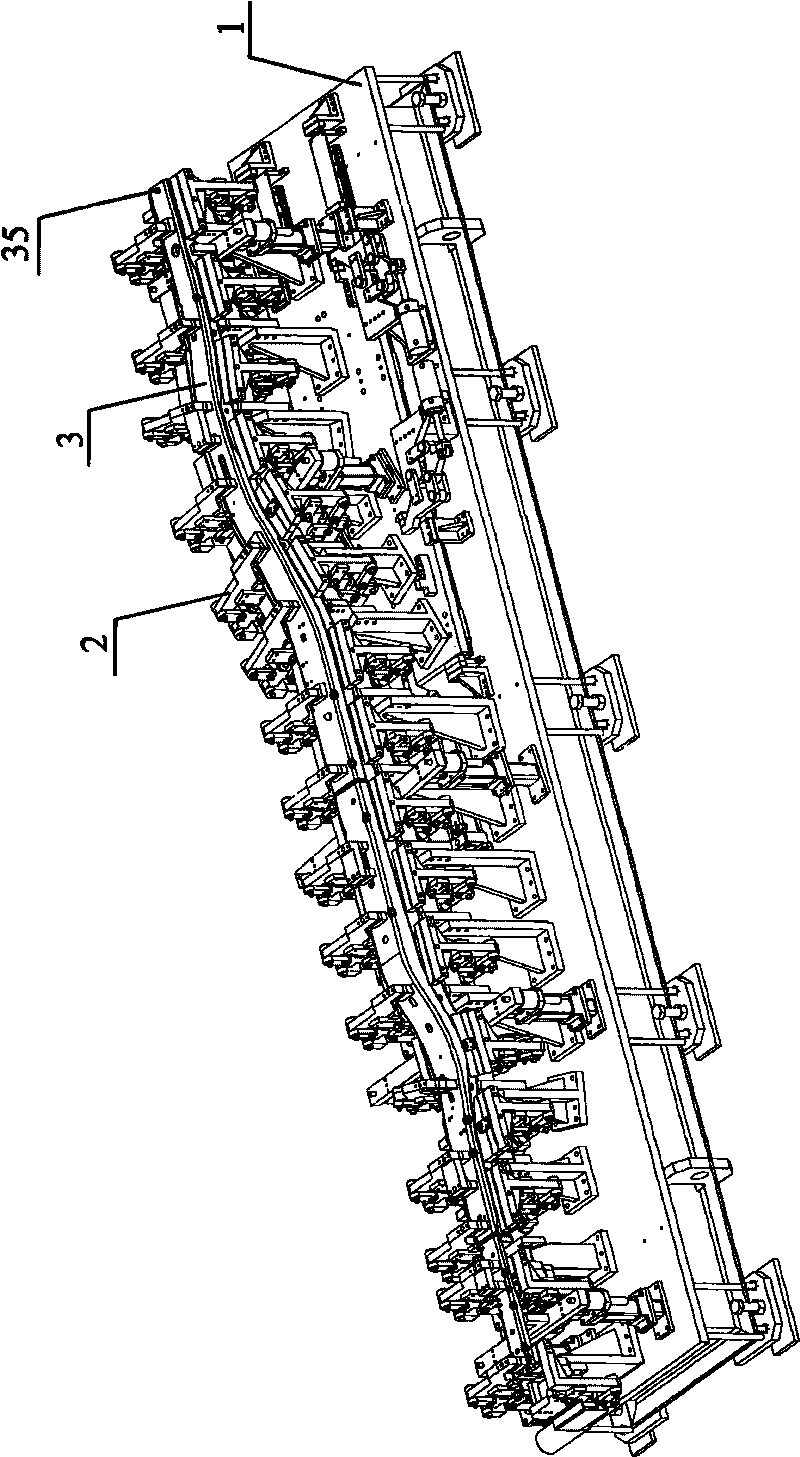

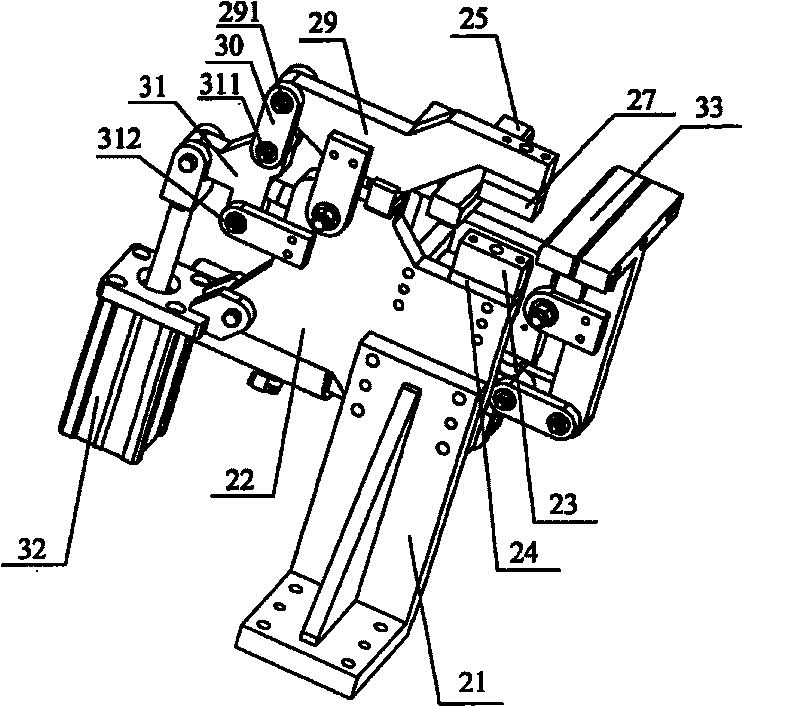

Method and tooling for controlling deformation of nickel-based ageing-strengthening high-temperature alloy casing welding assembly

ActiveCN103551770AAvoid fatigue crackingMeet reliabilityWelding/cutting auxillary devicesAuxillary welding devicesWelding residual stressElectron

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

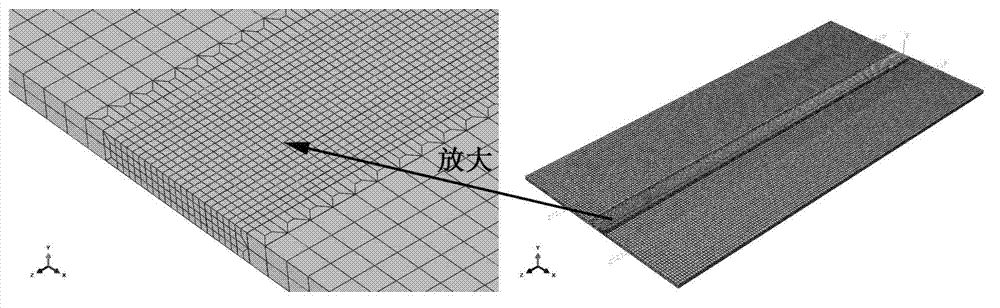

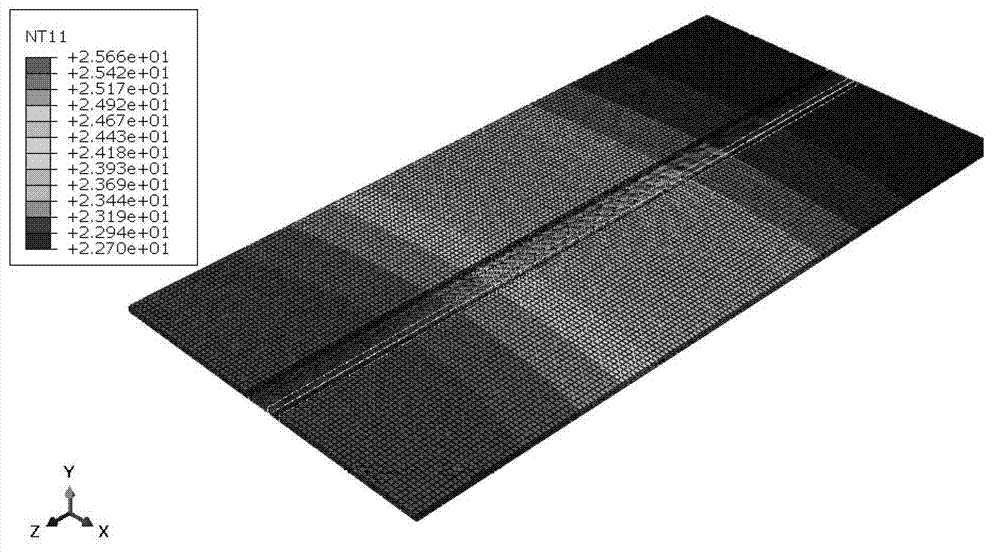

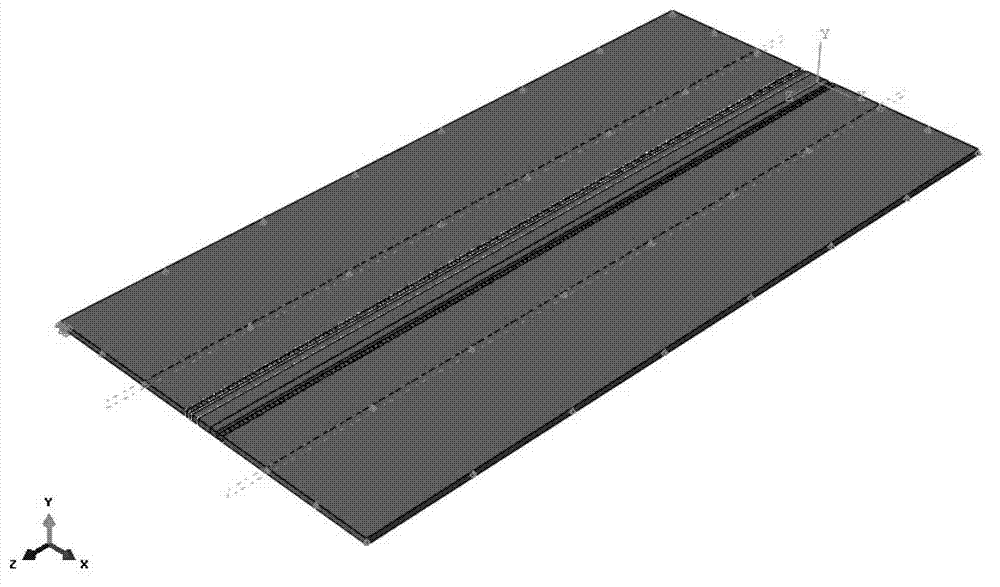

ABAQUS-based finite element simulation method of correcting welding deformation through ultrasonic shot-peening

The invention discloses an ABAQUS-based finite element simulation method of correcting welding deformation through ultrasonic shot-peening. The method includes: firstly, utilizing the finite element software ABAQUS to simulate the welding process of a certain-sized aluminum alloy sheet to obtain the distribution of the welding residual stress and the deformation;and secondly, reading in a stress force and deformation grid and performing the simulative computation of a shot-peening shape correction process on the basis of the welding stress and deformation. The ABAQUS-based finite element simulation method of correcting the welding deformation through the ultrasonic shot-peening takes the limits that the complexity of mechanism of the shot-peening process and the influence of various variable factors result in great difficulties in optimizing shot-peening process parameters and the method which purely relies on experimental data and experience consumes much time and money into consideration, so that the ABAQUS-based finite element simulation method is introduced to assist the selection of the ultrasonic shot-peening process parameters and the strain of the stress and the change of the deformation are analyzed to explain the mechanism of the shape correction.

Owner:TIANJIN UNIV

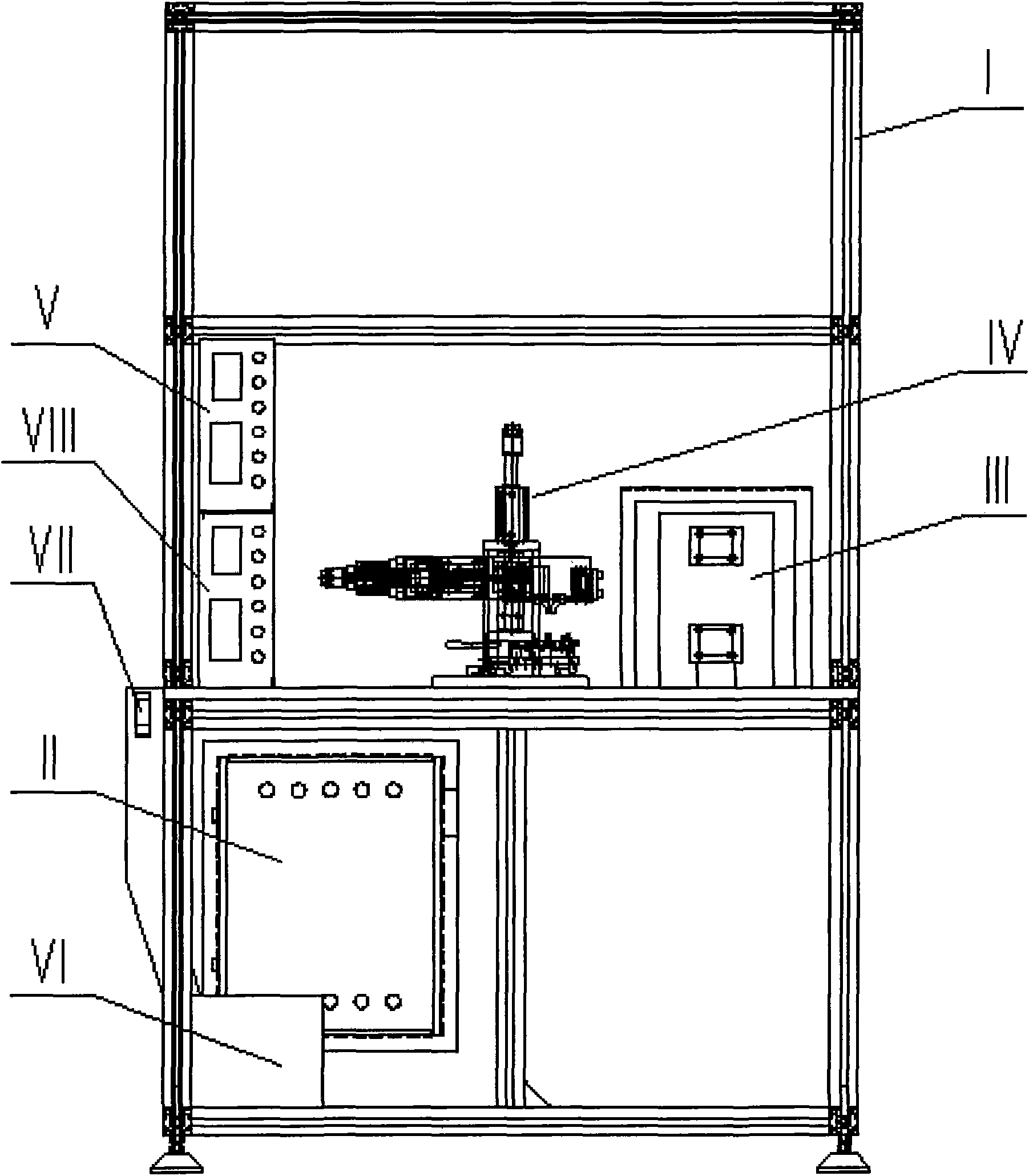

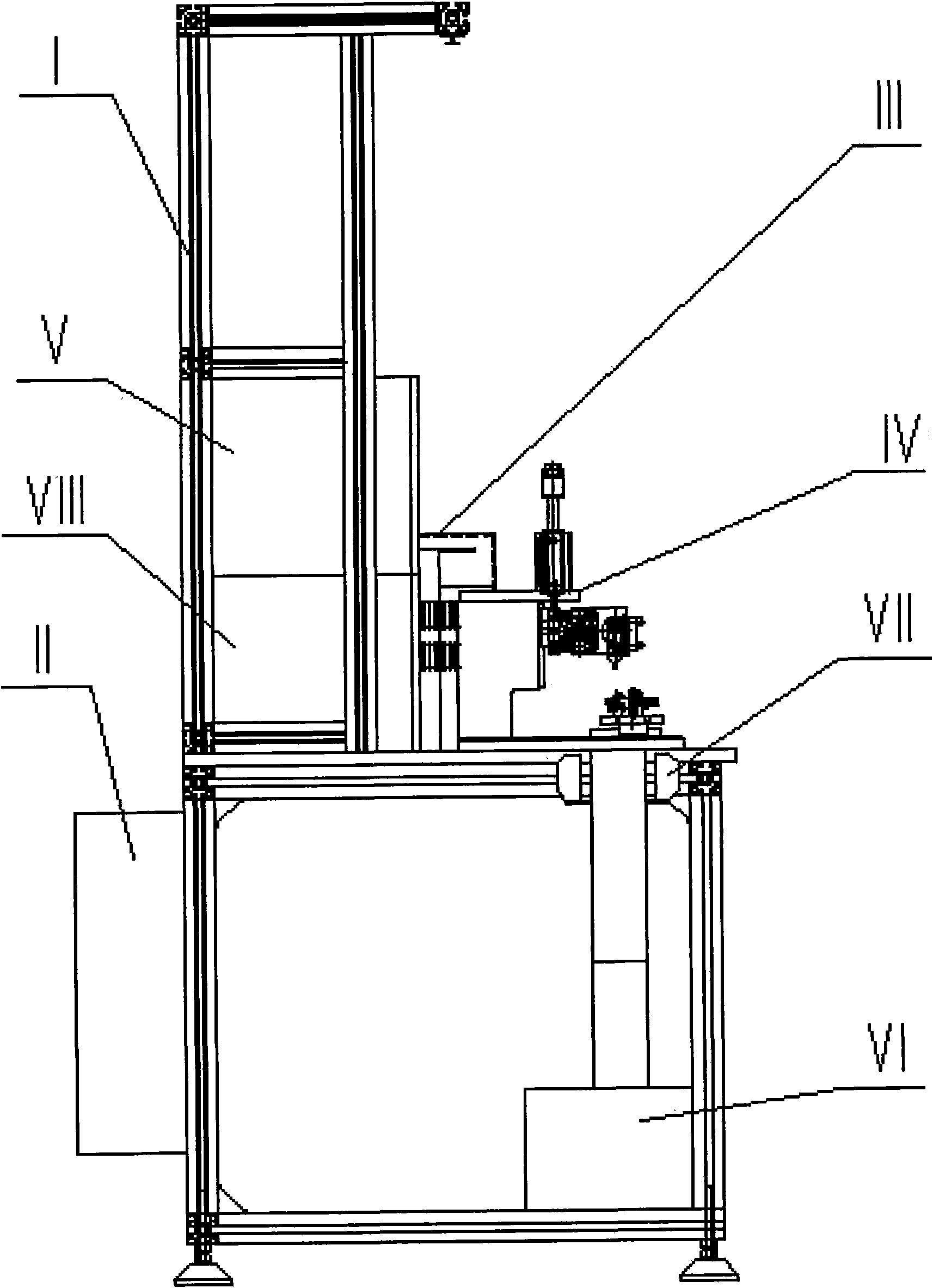

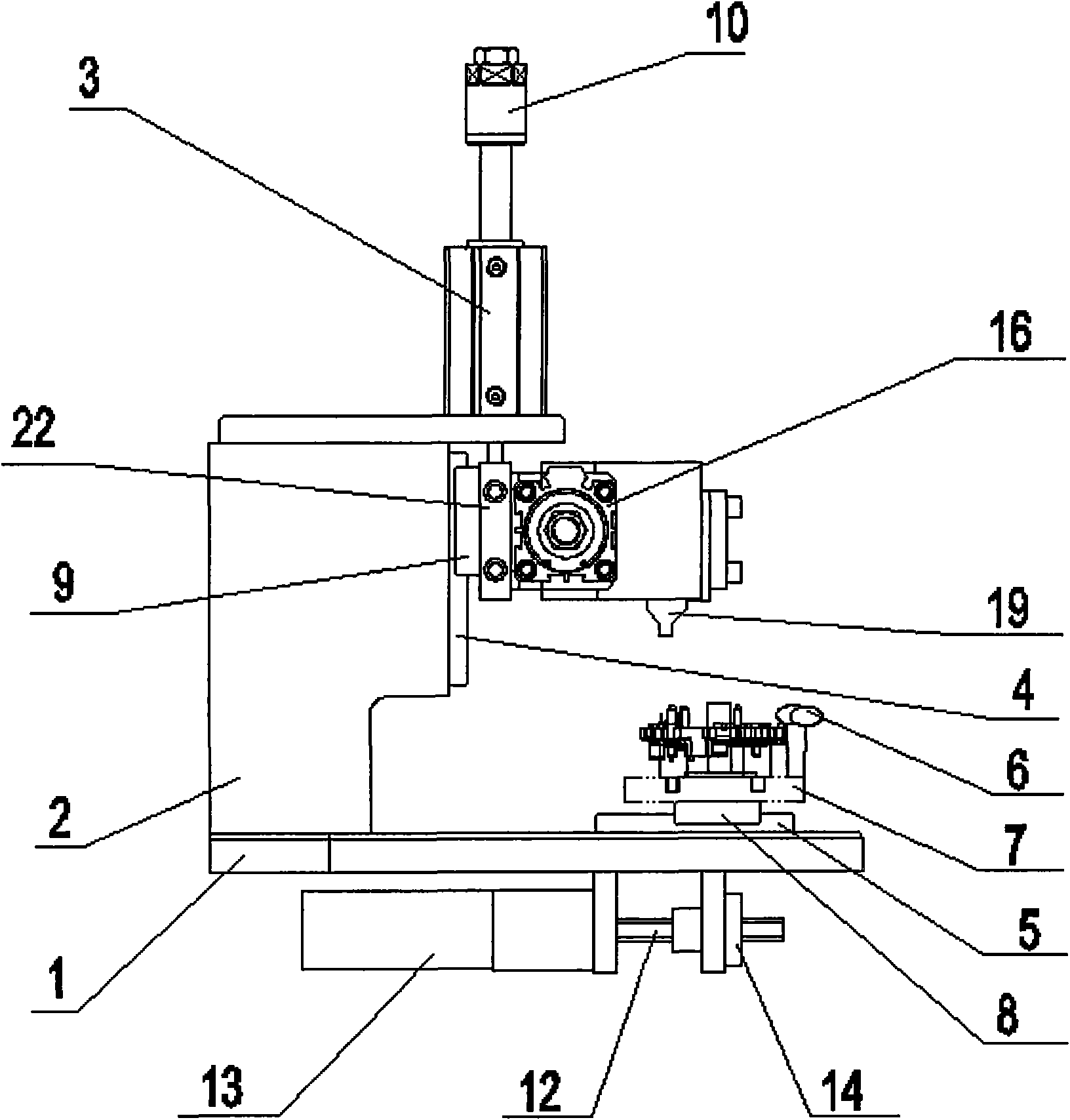

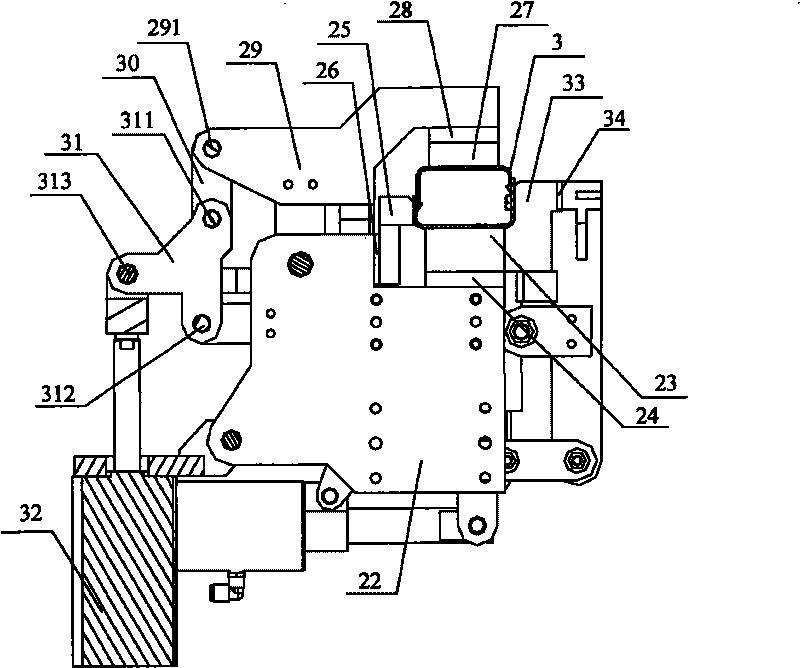

Resistance welding equipment and welding control method

ActiveCN101590562AHigh degree of automationIncrease visibilityWelding monitoring devicesElectrical resistance and conductanceTransformer

The invention provides resistance welding equipment and a welding control method. The resistance welding equipment consists of a frame, an electric cabinet and a PLC system, a welding transformer, an action mechanism, a welder controller, a waste box, an optical fiber sensor and a sensor controller, wherein the action mechanism consists of a baseplate, a main frame, a vertical cylinder, a main linear guide rail, a linear guide rail, a positioning manual press claw, a positioning fixture, a linear bearing, a main linear bearing, a positioning nut, an adjusting pressure spring, a screw mandrel, a servomotor, a coupler, a displacement sensor, a clamping cylinder, a pressure sensor, a left electrode, a right electrode, left and right linear guide rails, left and right linear bearings, an auxiliary frame, a connecting rod and a clamping pressing plate. The pressure sensor and a tracking system are adopted to collect pressure signals, the displacement sensor and the tracking system are adopted to collect displacement signals, and a PLC operational program is adopted for control, so that the welding of metal workpieces adopts dynamic on-line control to comprehensively monitor various welding control points in the whole process, and the welding deformation is controlled between 0.01 and 0.45mm to ensure welding quality.

Owner:镇江泛沃新能汽车技术股份有限公司

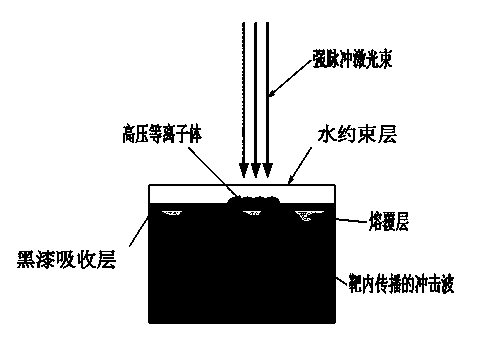

Method for prolonging life of pump shells and blades by carrying out laser strengthening micro-cracks

InactiveCN103409758AExtended service lifeImprove fatigue strengthMetallic material coating processesHeat-affected zoneLaser processing

The invention discloses a method for prolonging life of pump shells and blades by carrying out laser strengthening, which relates to the technical fields of machinery manufacturing and laser processing application. The method adequately combines the characteristics of laser cladding with laser shock strengthening, i.e., the method comprises the steps of performing laser cladding repair on micro-cracks at first, and then performing laser shock strengthening treatment on a cladding layer, thus effectively solving the problem that the pump shells and blades are easy to generate internal defects such as cracks and air holes in the laser cladding repair process, and avoiding the problems of welding deformation, large heat influence area, easy generation of heat cracks and the like in a conventional processing method; the method disclosed by the invention is capable of generating a high-amplitude residual compressive stress on the surface of a material, effectively improving the fretting fatigue resistance of the material, comprehensively improving the mechanical properties of the material, and greatly prolonging the fatigue life of the material, thus achieving the purposes of prolonging the life and improving the reliability and safety.

Owner:JIANGSU UNIV

Cartridge receiver welding method and clamp applied to same

ActiveCN104162759AGuaranteed sizeGuaranteed contourWelding/cutting auxillary devicesArc welding apparatusPunchingButt joint

The invention provides a cartridge receiver welding method. The cartridge receiver welding method includes the following steps that during installation, it is guaranteed that an upper installation side and a lower installation side are higher than the wall of a cartridge receiver by 0-0.2 mm; manual argon arc welding positioning welding is conducted, and weld joint rolling and profile correction are conducted by a bench worker; through automatic argon arc welding and weld joint rolling and profile correction which are conducted by the bench worker, punching is conducted at the positions, to be welded and corresponding to twelve bosses, of the wall of the cartridge receiver through laser cutting; manual argon arc welding positioning welding is conducted on the twelve bosses, weld joints are leveled by the bench worker, and it is guaranteed that the bosses at the butt joint positions are higher than the wall of the cartridge receiver by 0-0.2 mm; manual argon arc welding is conducted on the twelve bosses; weld joints are leveled by the bench worker, the profile tolerance of a part is corrected, and it is guaranteed that gaps between the part and a model is not larger than 0.5 mm; welding of the cartridge receiver is completed. According to the cartridge receiver welding method, welding deformation can be well controlled, and therefore it is guaranteed that the size and the profile tolerance of the finished cartridge receiver meet requirements. The invention further provides a special clamp applied to the welding method.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

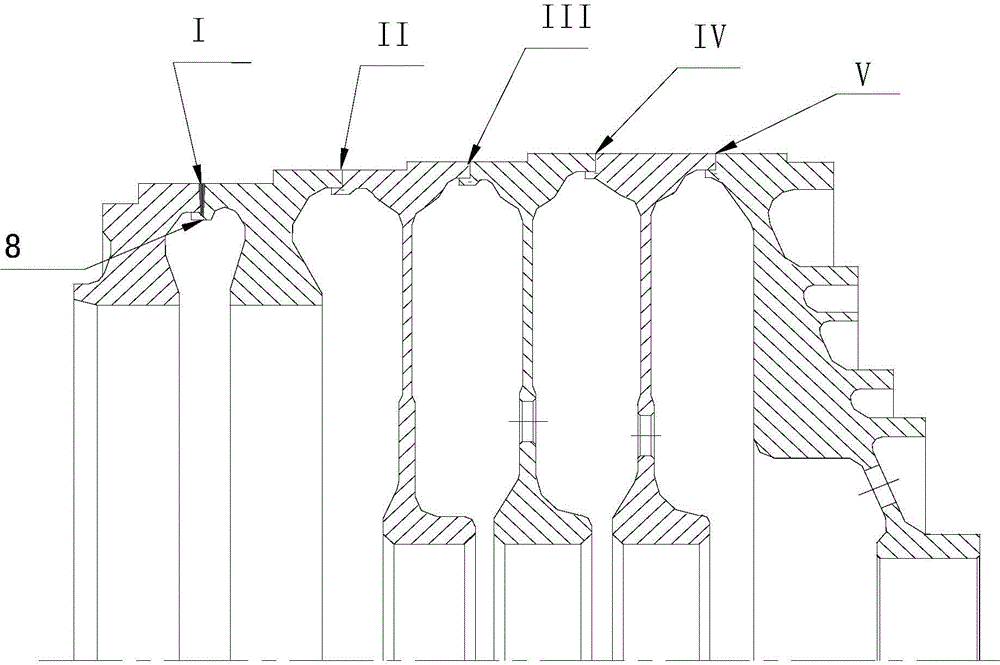

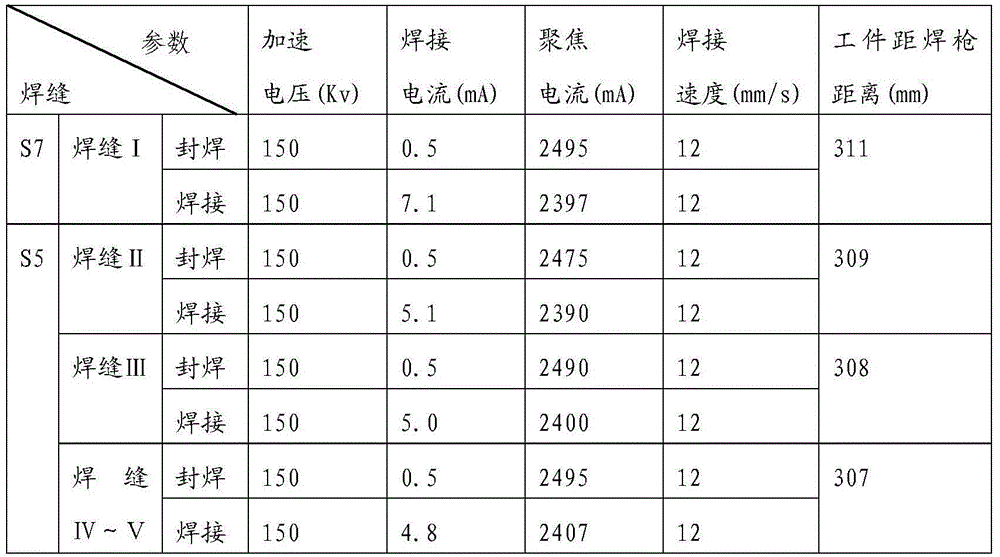

Vacuum electronic beam welding method for titanium-alloy rotor component

ActiveCN104057198AGuarantee welding qualityMeet the design requirementsElectron beam welding apparatusWelding/soldering/cutting articlesGas compressorWeld seam

The invention relates to a vacuum electronic beam welding method for a titanium-alloy rotor component. Five welding seams of a rotor of a gas compressor are welded by an electronic beam welding process. The vacuum electronic beam welding method has the advantages that reasonable welding sequence and welding parameters are adopted for controlling the welding deformation and the quality of the welding seams, the technical difficulties of poor whole rigidity, larger welding amount and difficult control for welding deformation and the like of a product are overcome, the quality of the welding seams is ensured, and the design requirement is met.

Owner:HARBIN DONGAN ENGINE GRP

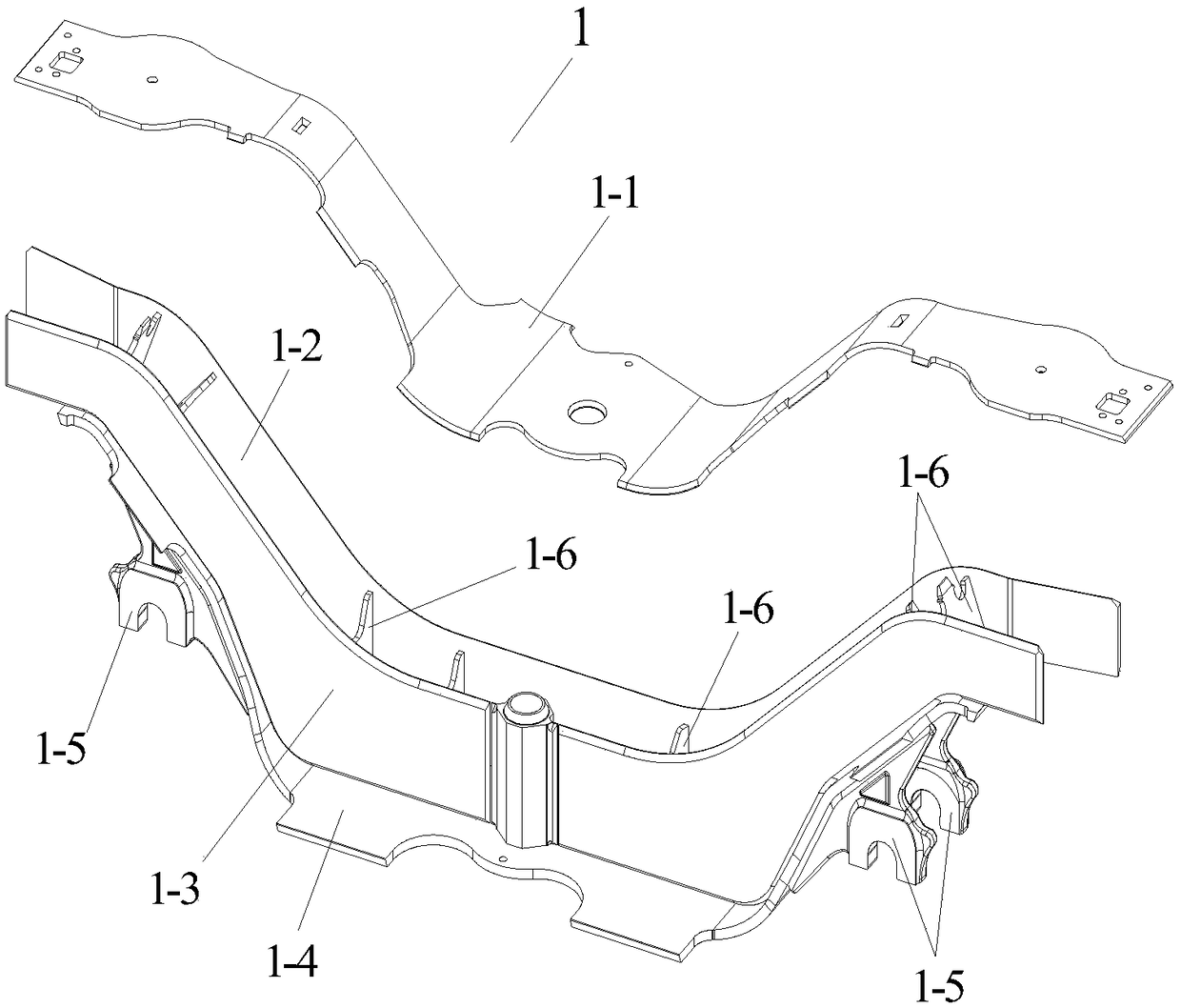

Weld positioning device

ActiveCN101733606AControlling Distortion ProblemsImprove quality statusWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention provides a weld positioning device. In order to prevent distortion in the process of welding, a frame rail to be welded is clamped in a positioning track formed by a plurality of positioning mechanisms; and the frame rail is clamped in a split fixing way in an all-surrounding mode. In order to reduce welding deformation in an upward direction and a downward direction of the frame rail in the process of designing the weld positioning device, a reversible deformation measure is designed on the weld positioning device in advance according to deformation tendency. A positioning molded surface in the weld positioning device is arranged into a convex design with higher middle part and lower both ends by aiming at the deformation tendency of bent both ends of a frame rail assembly so as to reduce welding deformation. The weld positioning device can effectively solve the problem of distortion in the process of welding the frame rail and improves quality state of frame rail products.

Owner:BEIQI FOTON MOTOR CO LTD

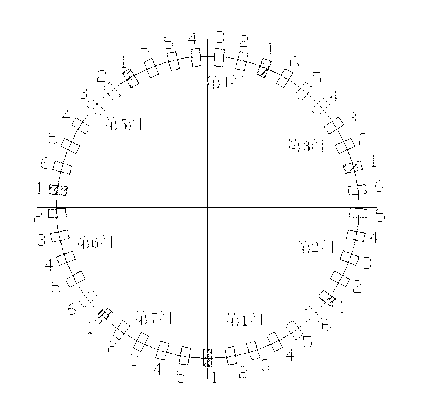

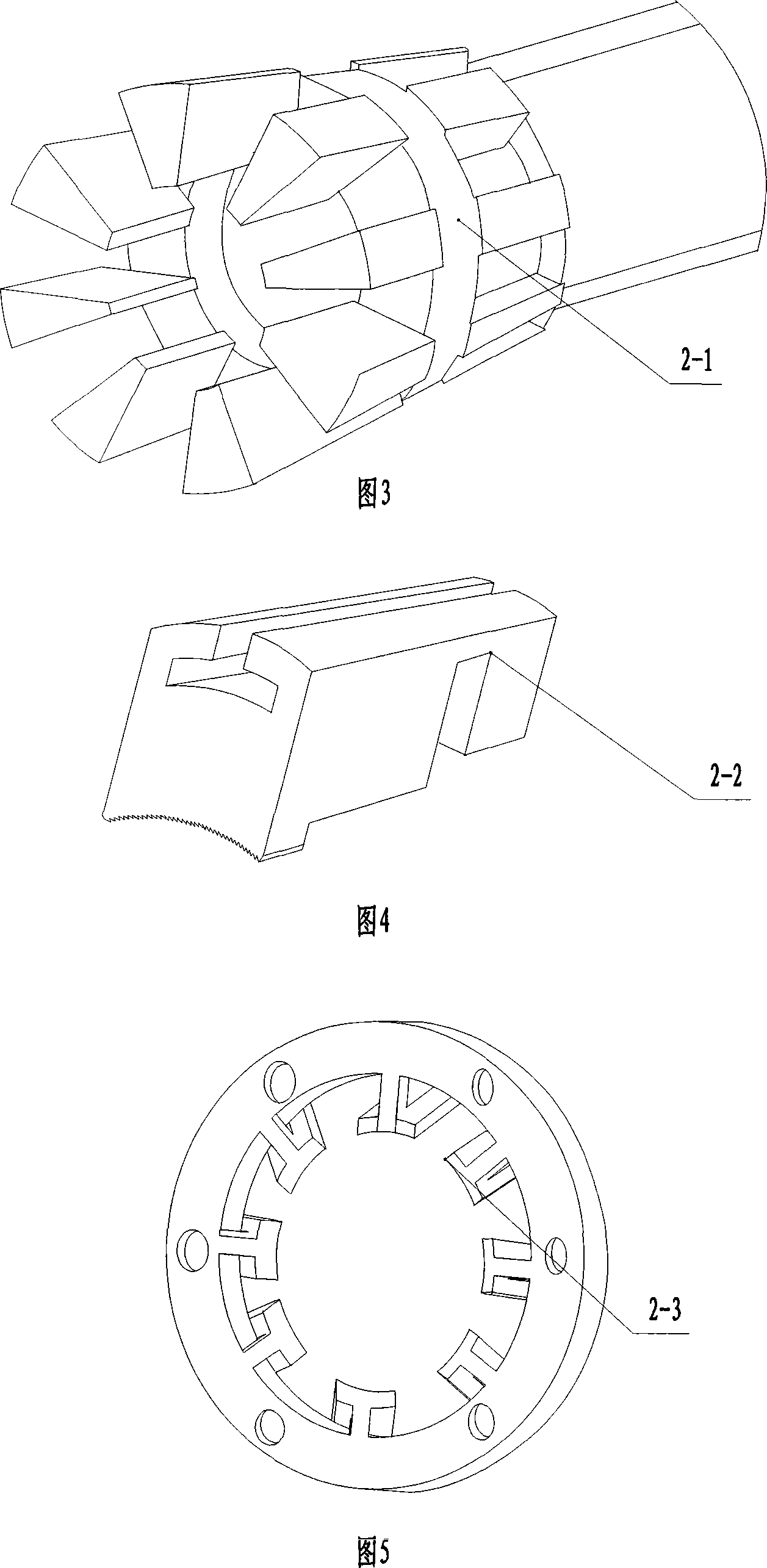

Assembling precision control method of single-body blades in blisk of electron beam welding structure

InactiveCN102837160AImprove assembly accuracy before weldingBreak through the key technical difficulties that the weld seam gap is less than 0.1mmWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld line

The invention belongs to the field of machining and particularly relates to an assembling precision control method of single-body blades in a blisk of an electron beam welding structure. The method disclosed by the invention comprises the following steps of: firstly, machining the single-body blades; designing convex technical circular platforms at blades tip parts of blade blanks; utilizing five coordinate milling centers to simultaneously mill welding surfaces and blade body modeled faces of the blades; dividing the single-body blades into seven groups to be clamped on a specific welding clamp, so as to finally control an assembling error to be within 0.05 mm; and after assembling, carrying out subsequent electron beam welding. According to the assembling precision control method disclosed by the invention, a reasonable blade forging blank structure design, integrated precise machining of blade references and welding surfaces, predication before welding of welding deformation of the blades, pre-compensation before welding, reasonable design of an assembling and welding clamp, and precise assembling of the blades on the clamp before welding, and the like are applied, so that the assembling precision of the blades before the welding is greatly improved, and the key technical difficulty that the gap between welding lines is ensured to be less than 0.1mm before electron beams are welded is broken through; and the after-welding precision of the blisk of the electron beam welding structure is controlled, an industrial blank is filled and the researching cost and the researching period are reduced at the same time.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Submerged-arc welding process for T-type joint for extra thick steel plate

ActiveCN102240841AImprove welding qualityReduce the deterioration of mechanical propertiesArc welding apparatusCrazingThick plate

The invention discloses a submerged-arc welding process for a T-type joint for an extra thick steel plate and belongs to the technical field of welding of extra thick plates. The process comprises the following steps of: before welding, pre-heating the extra thick steel plate to 100 to 150 DEG C; removing pollutants of oxides, greasy dirt and the like on the surface of the groove of the extra thick steel plate; bottoming the extra thick steel plate by submerged-arc welding; forming systematical grooves and after the front face of the extra thick steel plate is bottomed, welding and filling; performing back gouging on the reverse side of the extra thick steel plate and welding and filling the reverse side; and filling welding wires on the front side of the extra thick steel plate and covering the side. The problems that manual bottoming efficiency is low, labor intensity is high, and heat cracking, undercutting, mechanical slag inclusion, large working amount of back gouging of the reverse side and the like are easily caused by submerged-arc welding bottoming when the T-type joint of the extra thick plate of which the thickness is 50 to 150mm is welded are solved; by the selection of an appropriate groove form, the welding sequence, and welding process parameters, and slow cooling measures, slag is easy to clean in a filling weld pass, the working amount of back gouging is reduced, the welding deformation is reduced, the welding residual stress is reduced and the quality of a weld joint is guaranteed; and the submerged-arc welding process is easy to operate and implement, and is convenient to popularize.

Owner:SHOUGANG CORPORATION

Narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials

InactiveCN105149786ASimplify the welding processPrecise control of single layer fill heightWelding/soldering/cutting articlesMetal working apparatusLaser processingThick plate

The invention belongs to the technical field of laser processing, and particularly relates to a narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials. The method aims at solving the problems that in the thick plate welding process, wire filling is difficult, and molten drop transition is not stable. According to the narrow-gap laser-scanning multi-layer self-melting welding method based on a prefabricated filling layer, a laser scanning welding technology and narrow-gap multi-layer filled welding are skillfully combined, therefore, a laser wire filling multi-layer welding mode for thick plate structure parts is converted into a laser self-melting multi-layer welding mode, and the single-layer filling height of a weld joint in a narrow-gap groove can be precisely controlled; due to the fact that the prefabricated filling layer can prevent the weld joint from shrinking, welding deformation can be further reduced, the thick plate welding process is greatly simplified, and the welding efficiency and the welding quality are improved. The method is suitable for narrow-gap laser welding of thin plates or thick plates of different thicknesses.

Owner:HARBIN INST OF TECH

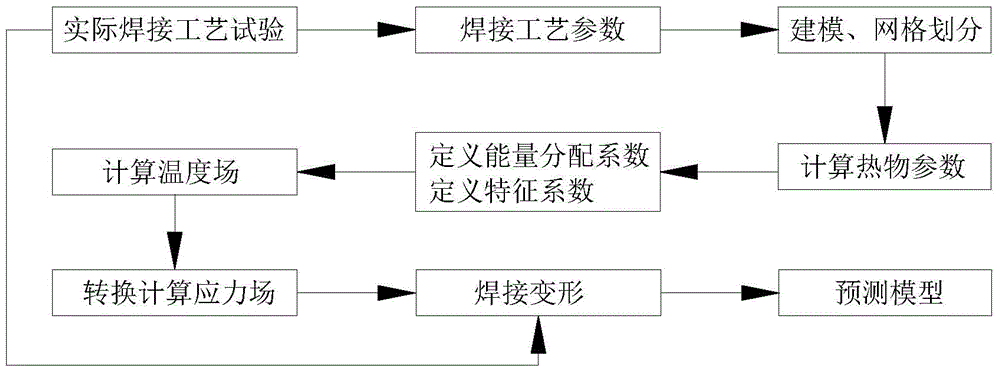

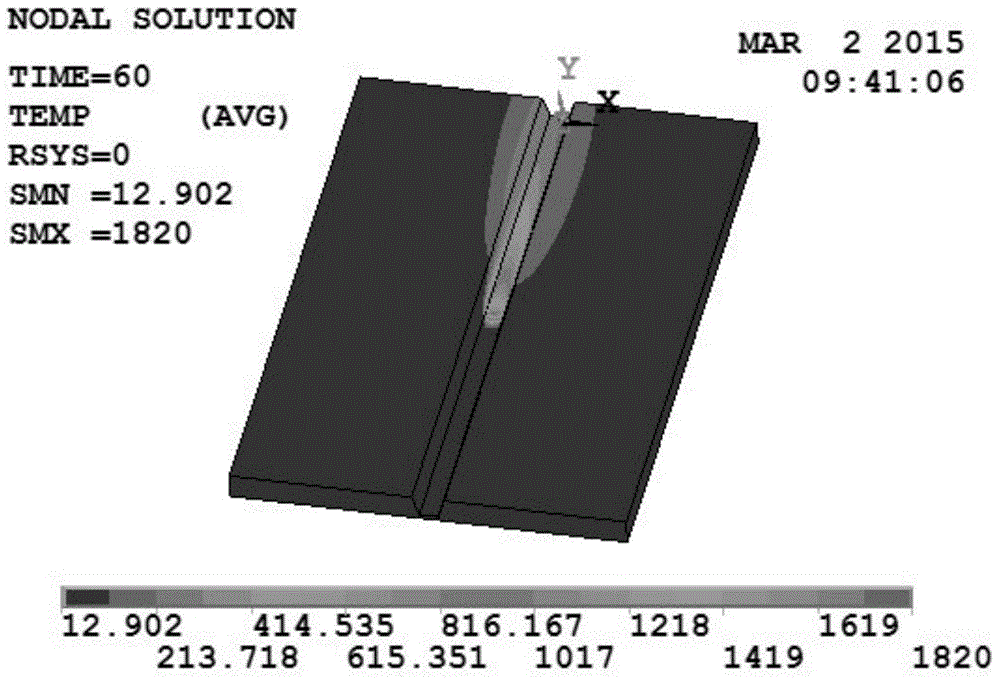

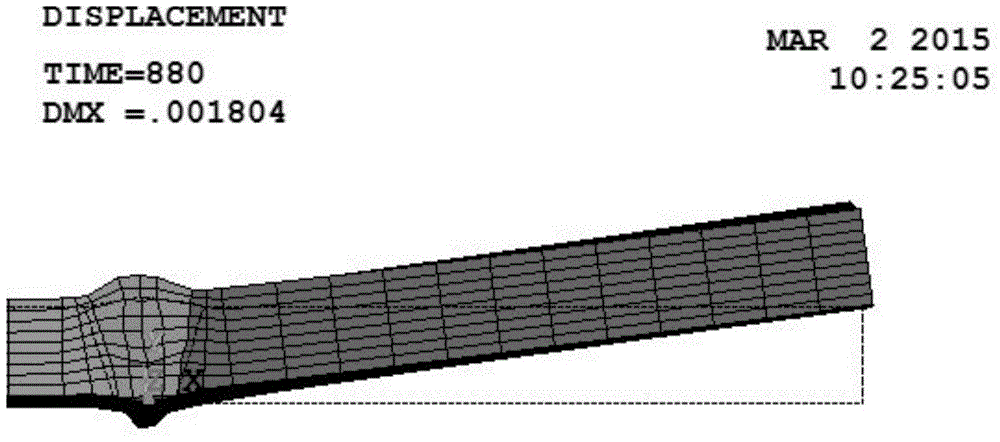

ANSYS-based duplex stainless steel and dissimilar steel welding deformation prediction method

InactiveCN104809291AReduce the number of welding procedure testsSave manpower and material resourcesWelding/cutting auxillary devicesAuxillary welding devicesElement modelWorkload

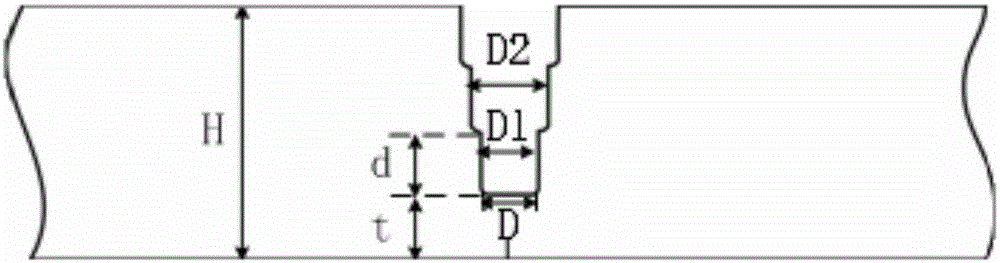

The invention provides an ANSYS-based duplex stainless steel and dissimilar steel welding deformation prediction method. The method comprises the following steps: (1) determining welding process parameters; (2) establishing a finite element model and carrying out grid partitioning; (3) determining thermal physical parameters of a welding material; (4) determining a heat source model; (5) calculating a temperature field; (6) calculating a stress field, and calculating welding deformation of duplex stainless steel and dissimilar steel. Compared with the prior art, the ANSYS-based duplex stainless steel and dissimilar steel welding deformation prediction method has the advantages that the deformation after welding of SAF2507 super duplex stainless steel and Q235 low-carbon dissimilar steel is successfully predicted; a thermal treatment scheme after welding is formulated according to a prediction result; the quantity of experiments for a welding process is reduced; manpower and materials are saved; a technical specification is provided for working procedures of previous lofting and feeding in a product manufacturing process; the workload of a working procedure of later machining is reduced.

Owner:JIN TONG LING TECH GRP CO LTD

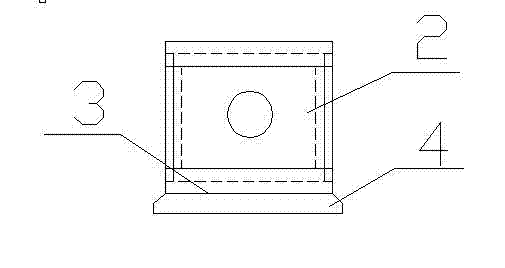

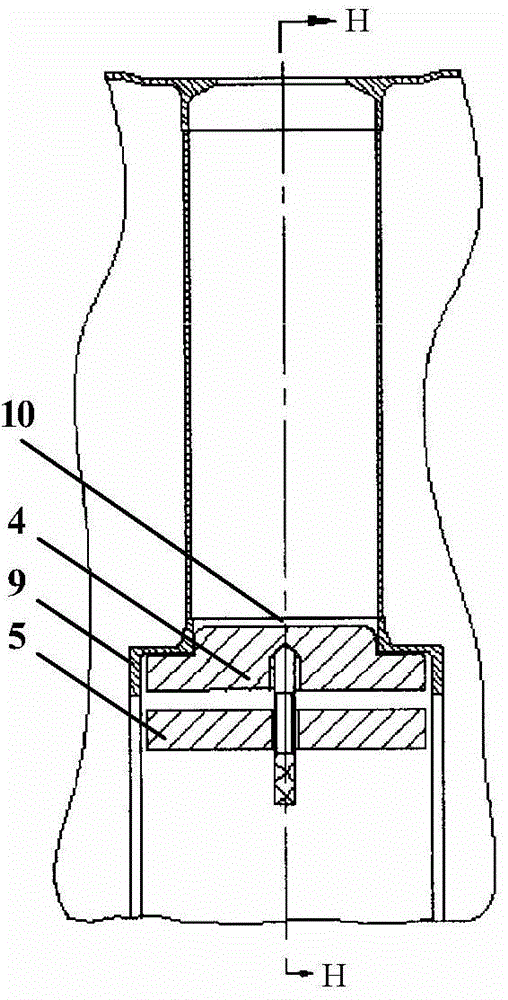

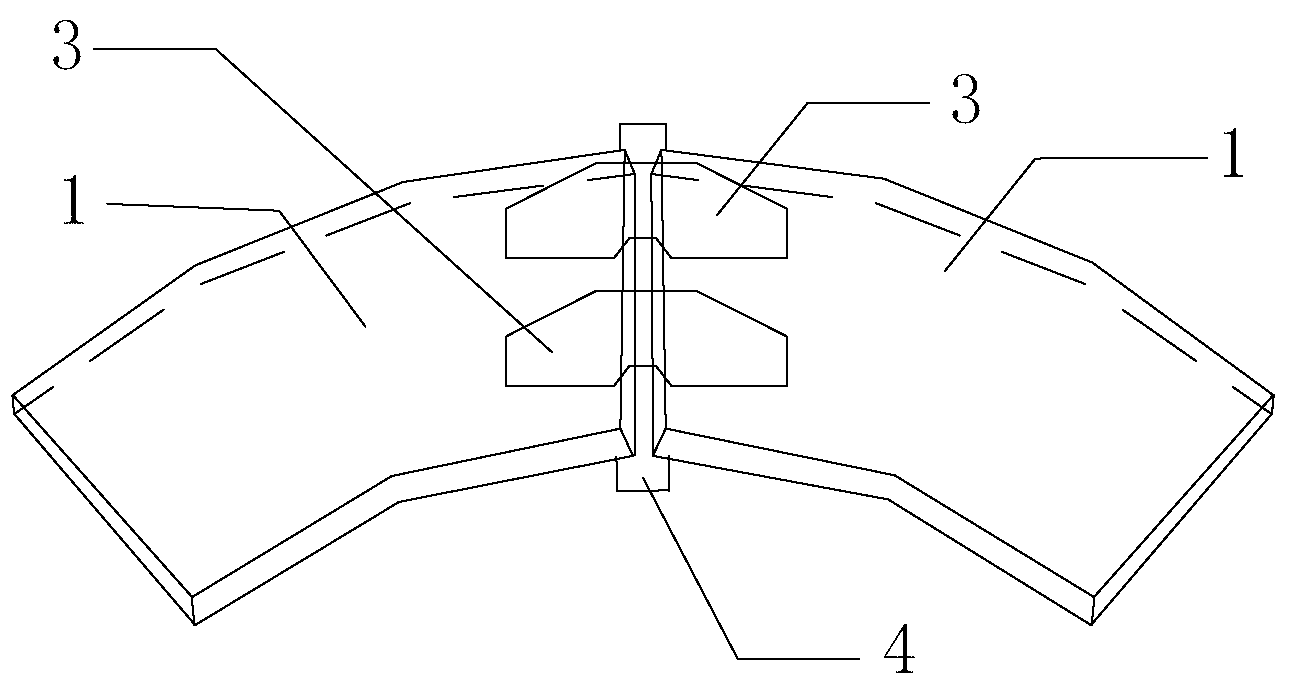

Butt welding positioning device for thin-walled cylinder with seal head

InactiveCN102416549ASolve the problem of joint positioningAccurate coaxial positioningWelding/cutting auxillary devicesAuxillary welding devicesButt weldingProcess equipment

The invention discloses a butt welding positioning device for a thin-walled cylinder with a seal head, and belongs to the technical field of process equipment. The device is mainly technically characterized by comprising a pressing plate, a pipe sleeve, a pull rod, a support body, a cone, a bulging block, a copper cushion block, a countersunk screw, a band spring, an adjusting nut, a gasket and a locking nut, wherein the pressing plate is adjusted by the adjusting nut to position a workpiece; the cone is pulled by the pull rod to jack and bulge the three-flap bulging block; the bulging block centers, bulges and clamps the workpiece to be welded; the taper of the inner wall of the bulging block is the same as that of the external surface of the cone; and a radial annular groove is formed on the surface of the copper cushion block. The assembly positioning problem of the thin-walled cylinder with the seal head and a thin-walled hollow cylinder during butt welding can be effectively solved, welding deformation is effectively reduced, and the device has the advantages that: the device has a simple structure, is convenient to assemble and disassemble and is operated and used reliably.

Owner:江南工业集团有限公司

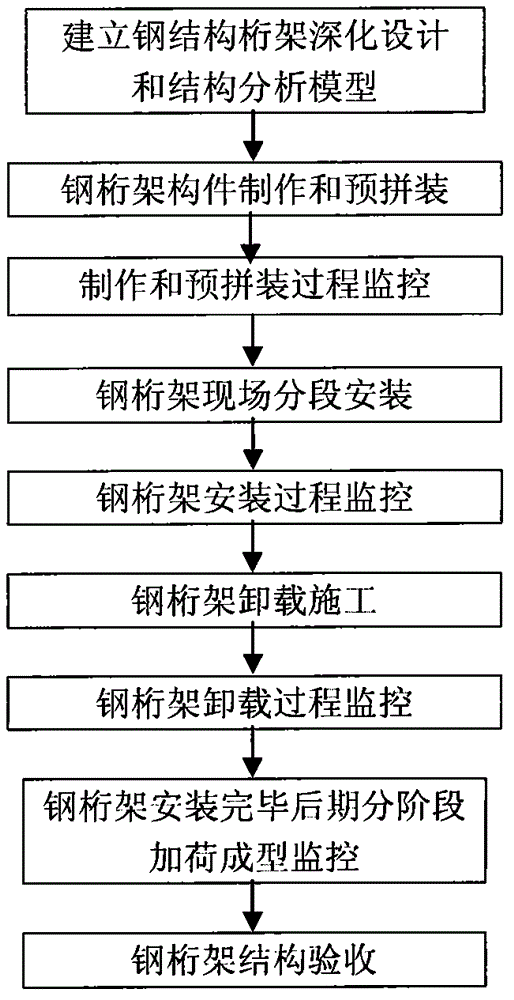

Method for installing abnormal-shaped extremely-large overhung steel truss under process monitoring construction

InactiveCN104631838AEasy to installEven by forceBuilding material handlingSupporting systemStructure analysis

The invention discloses a method for installing an abnormal-shaped extremely-large overhung steel truss under process monitoring construction. The installing method includes the steps that a steel structure truss deepening design and structure analysis model is built; steel truss parts are manufactured and pre-assembled, and the manufacturing process and the pre-assembling process are monitored; the steel truss is installed in site in a sectioned mode, and the steel truss installation process is monitored; unloading construction is carried out on the steel truss, and the steel truss unloading process is monitored; loading forming is monitored in the later period after the steel truss is installed in a staged mode; the structure of the steel truss is checked and accepted. The installation technology that a temporary supporting system and altitude spread assembling are combined is adopted, the large-span abnormal-shaped space lattice pipe truss is accurately installed, and the truss is evenly stressed and is not prone to deformation in the installation process. Heat accumulation, welding stress and welding deformation are prevented with the altitude spread roof-member method.

Owner:YONGSHENG CONSTR GRP

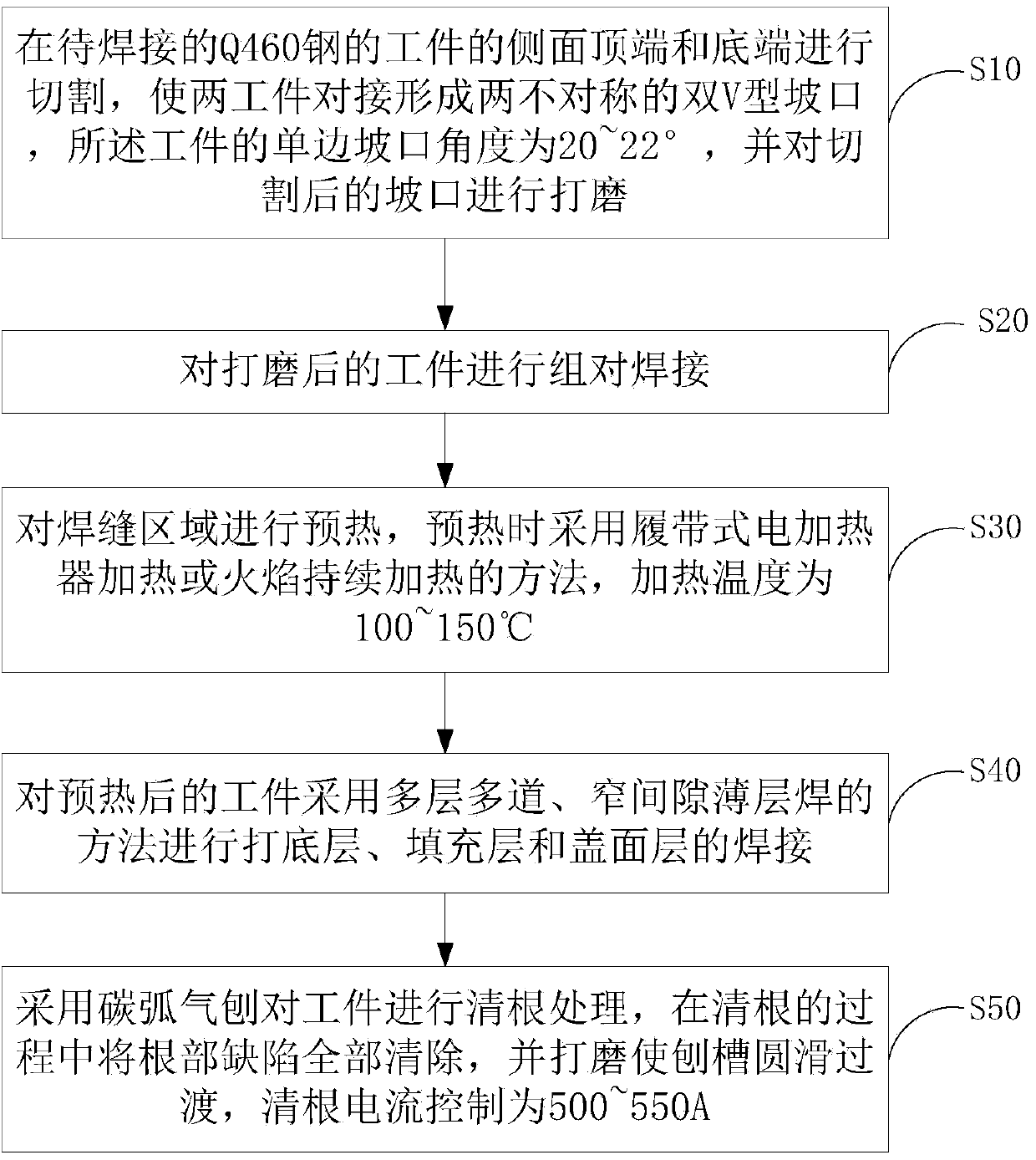

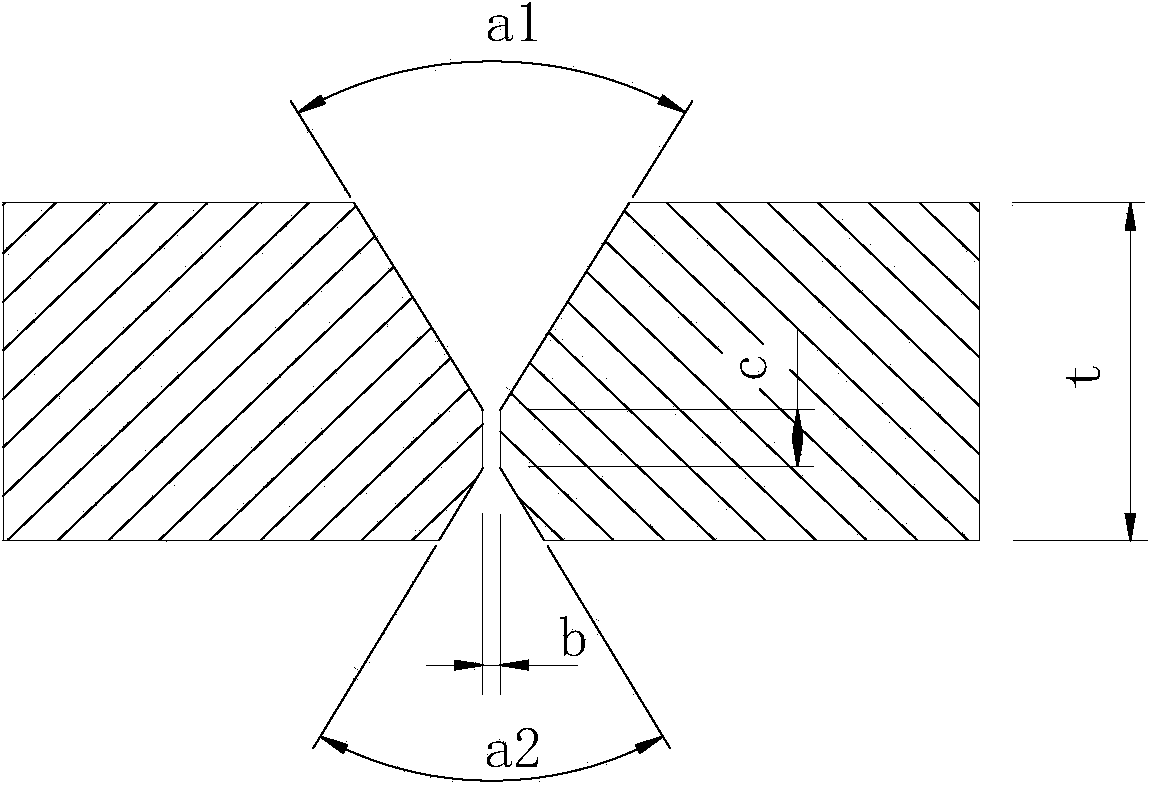

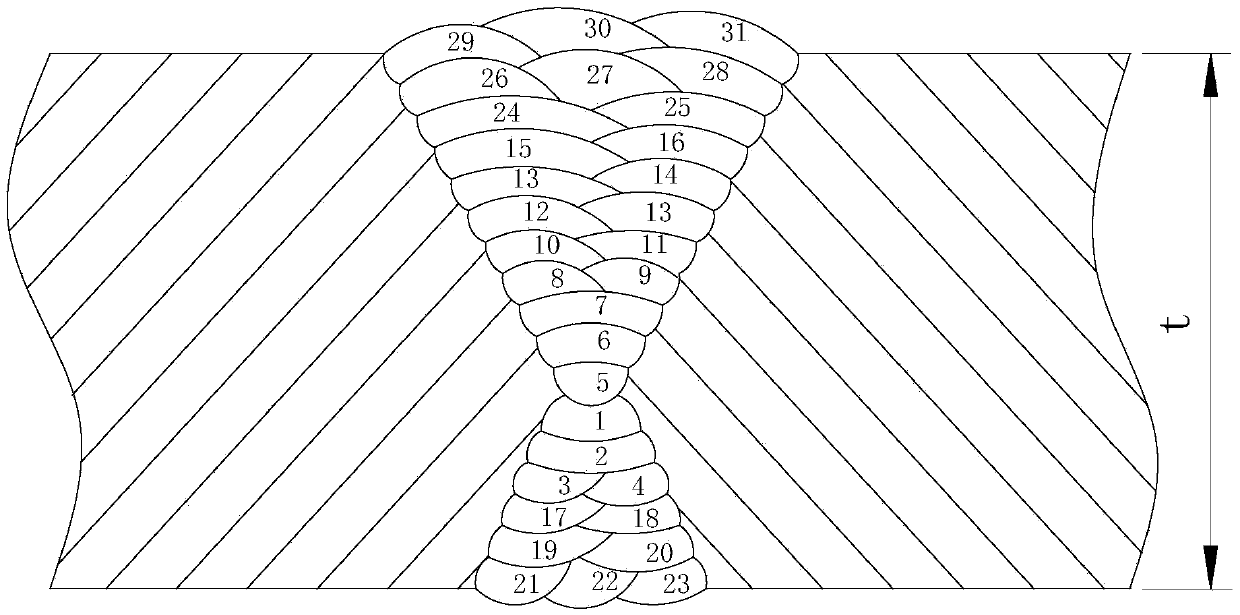

Q460 steel thick plate welding process

InactiveCN104209625AGuarantee welding qualityImprove mechanical propertiesArc welding apparatusWelding/soldering/cutting articlesSurface layerThick plate

The invention discloses a Q460 steel thick plate welding process, which comprises the following steps that the top end and the bottom end of the side surface of a Q460 steel workpiece to be welded are cut, so that two workpieces are in butt joint for forming two asymmetric double-V-shaped grooves; the ground workpieces are subjected to pairing welding; welding seam regions are preheated; the preheated workpieces are subjected to priming layer, filling layer and cover surface layer welding by a multilayer multi-pass and narrow-gap thin layer welding method; carbon arc air gouging is adopted for back chipping processing, and back defects can be totally chipped in the back chipping process. The Q460 steel thick plate welding process disclosed by the invention has the advantages that the welding quality of a Q460 steel thick plate is improved, and the generation of welding stress and welding deformation is reduced.

Owner:WUHAN YIYE STEEL STRUCTURE

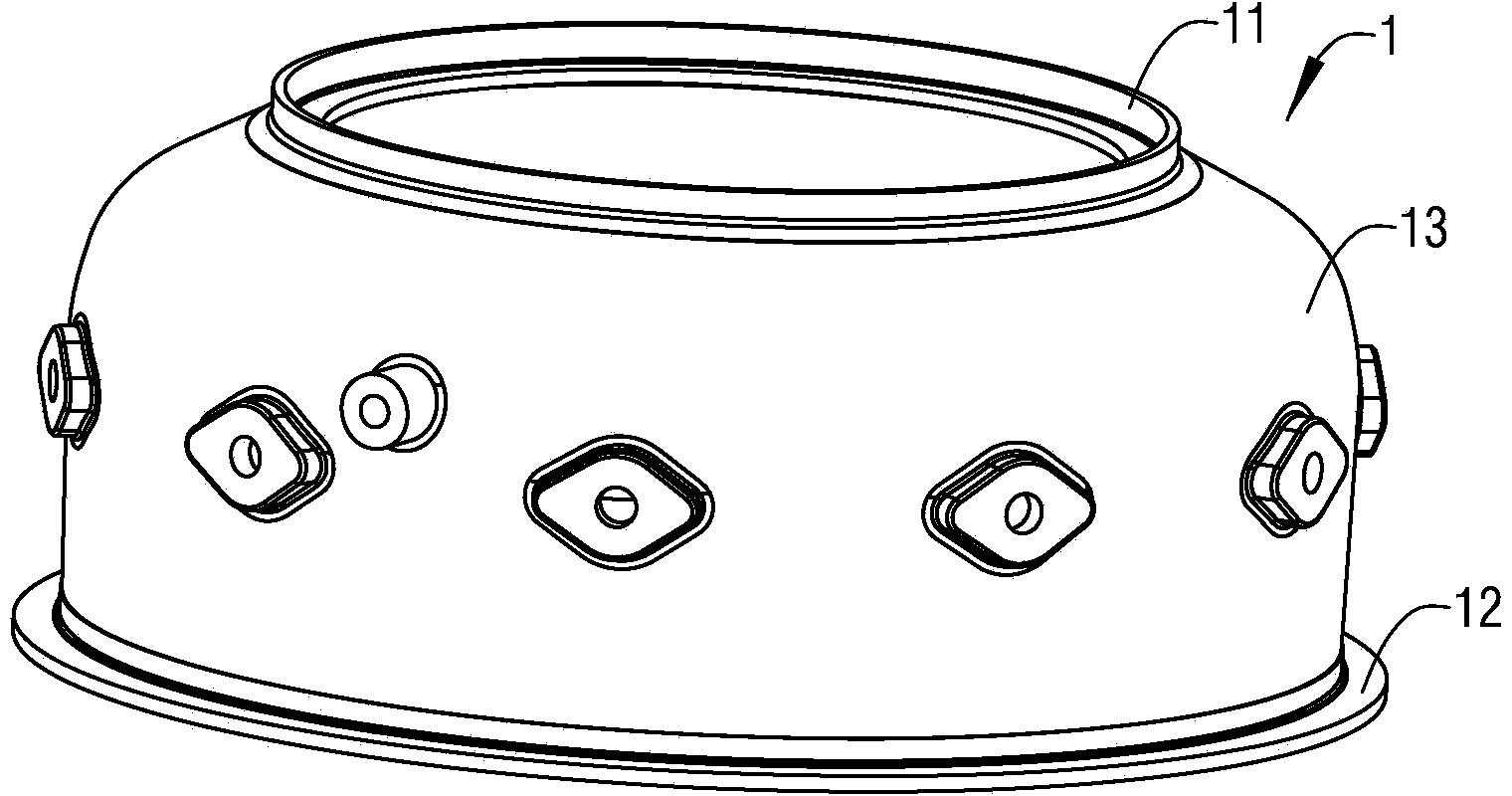

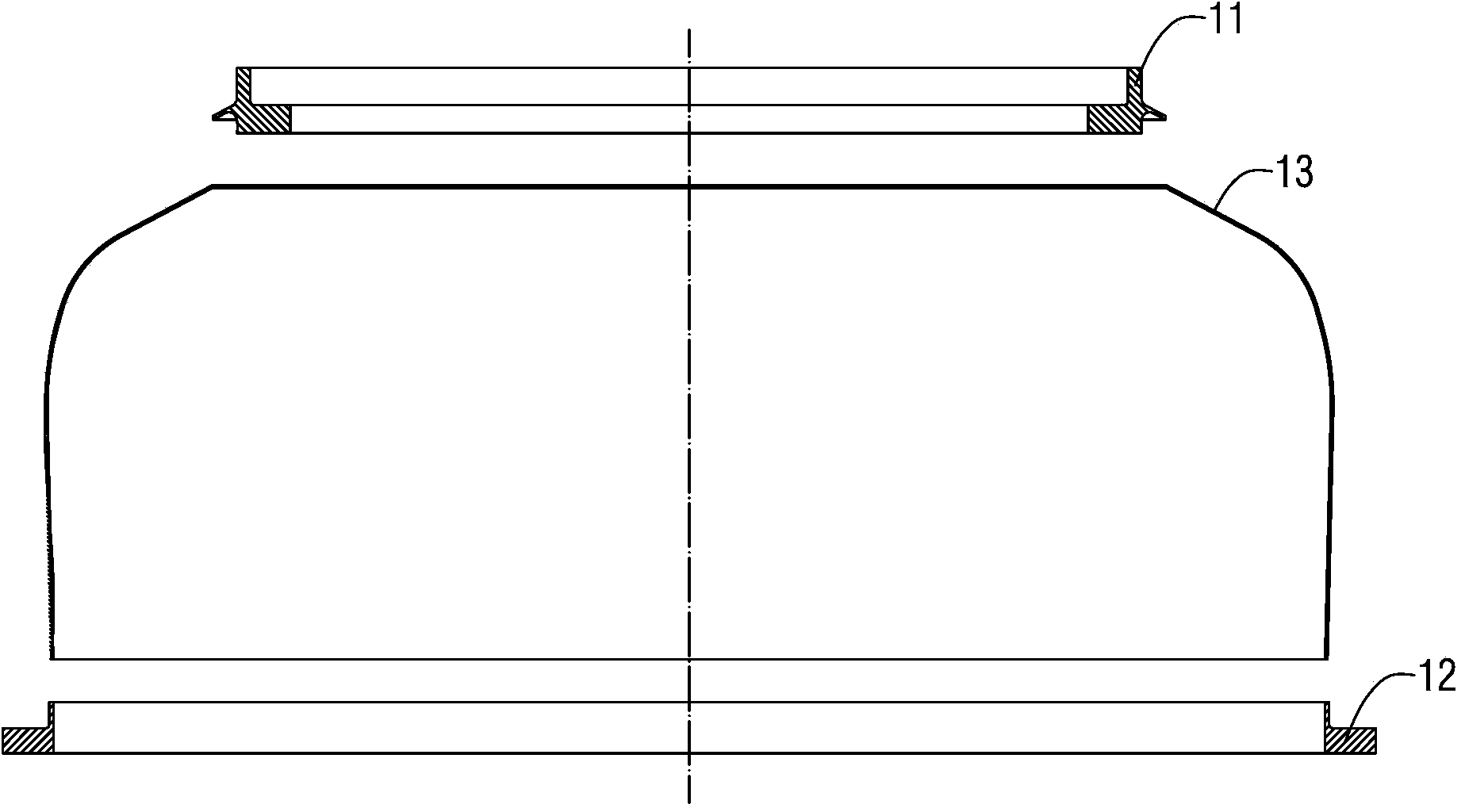

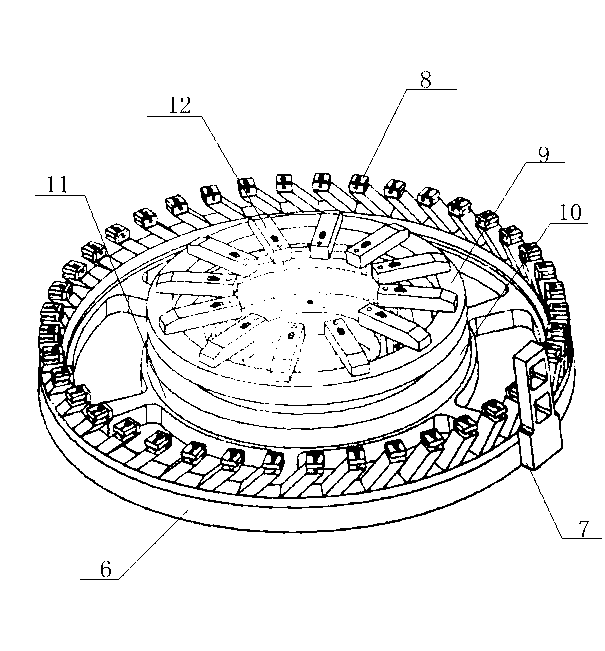

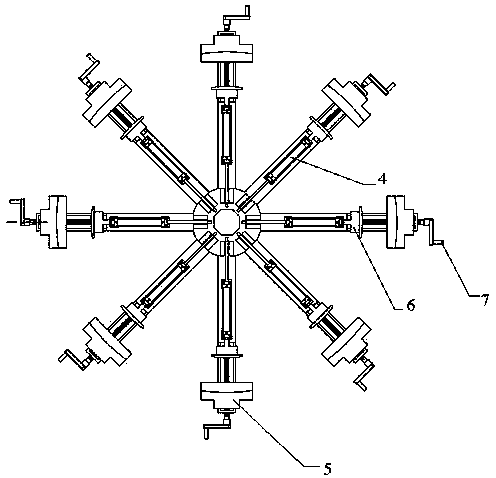

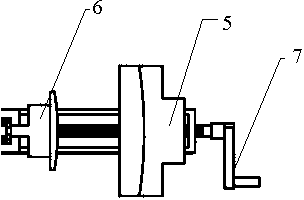

Assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers

ActiveCN103862215AGuaranteed sizeGuaranteed reliabilityWelding/cutting auxillary devicesFurnace typesStress relievingBall screw

The invention relates to an assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers. The assembly welding tool device comprises a supporting base plate, a ball screw, grouped rolling bearings, a movement air cylinder, external locating blocks, internal locating blocks, a manual rocker and a graduated scale, wherein the ball screw and an executive component drive most of the external locating blocks and most of the internal locating blocks to move along guide rails of the supporting base plate so as to carry out integrated locating clamping fixation on the curved surface end sockets. According to the assembly welding tool device and method commonly used for the large curved surface end sockets of the pressure containers, in the manufacturing process of the pressure containers, tool locating of the large end sockets can be achieved, welding deformation is prevented, the curved surface end sockets are placed on the assembly welding tool device to be clamped in an assembly locating mode, spot fixation is carried out on weld joints, and then welding operation is carried out on the internal weld joints and the external weld joints; after welding is accomplished, the curved surface end sockets are naturally cooled to have the normal temperature, postwelding is carried out on the curved surface end sockets, stress relieving is carried out on the curved surface end sockets, labor intensity of workers is reduced, the production and manufacturing cycle of products is shortened, and the production cost is reduced.

Owner:哈尔滨市黎明锅炉容器封头有限公司

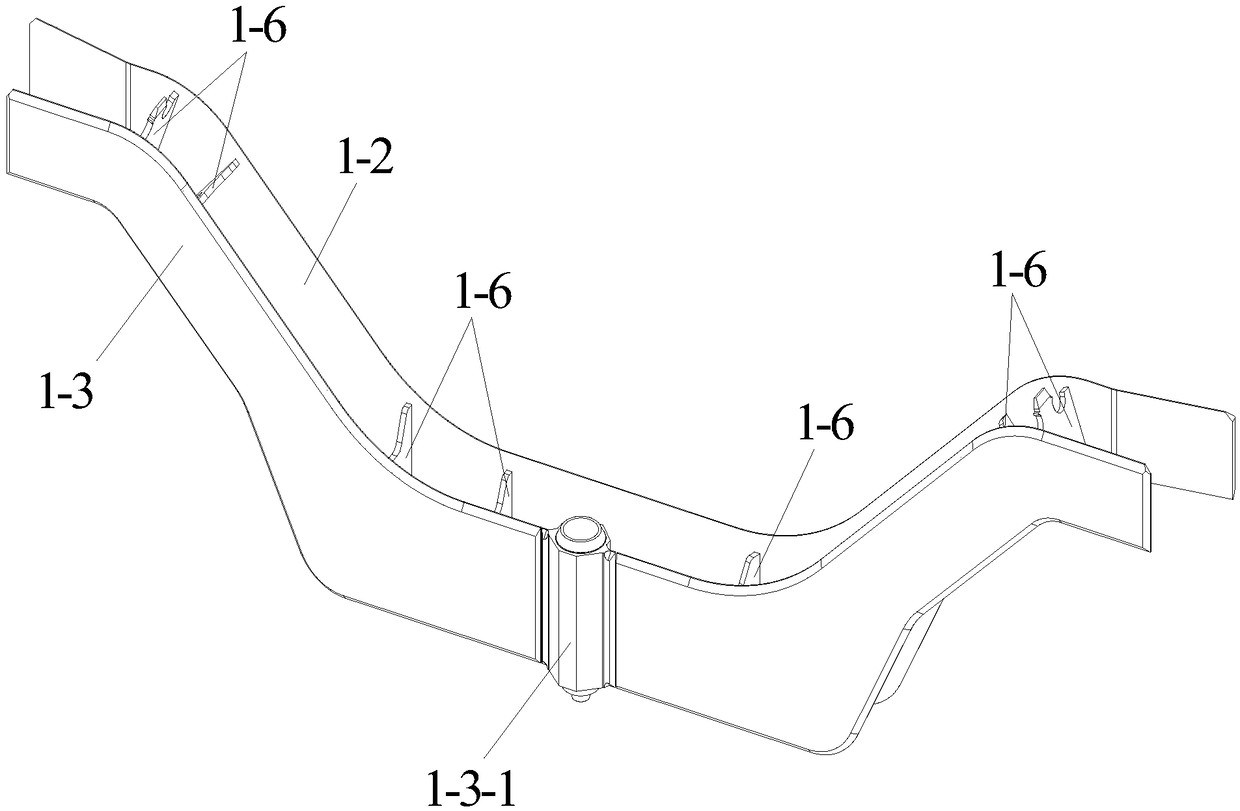

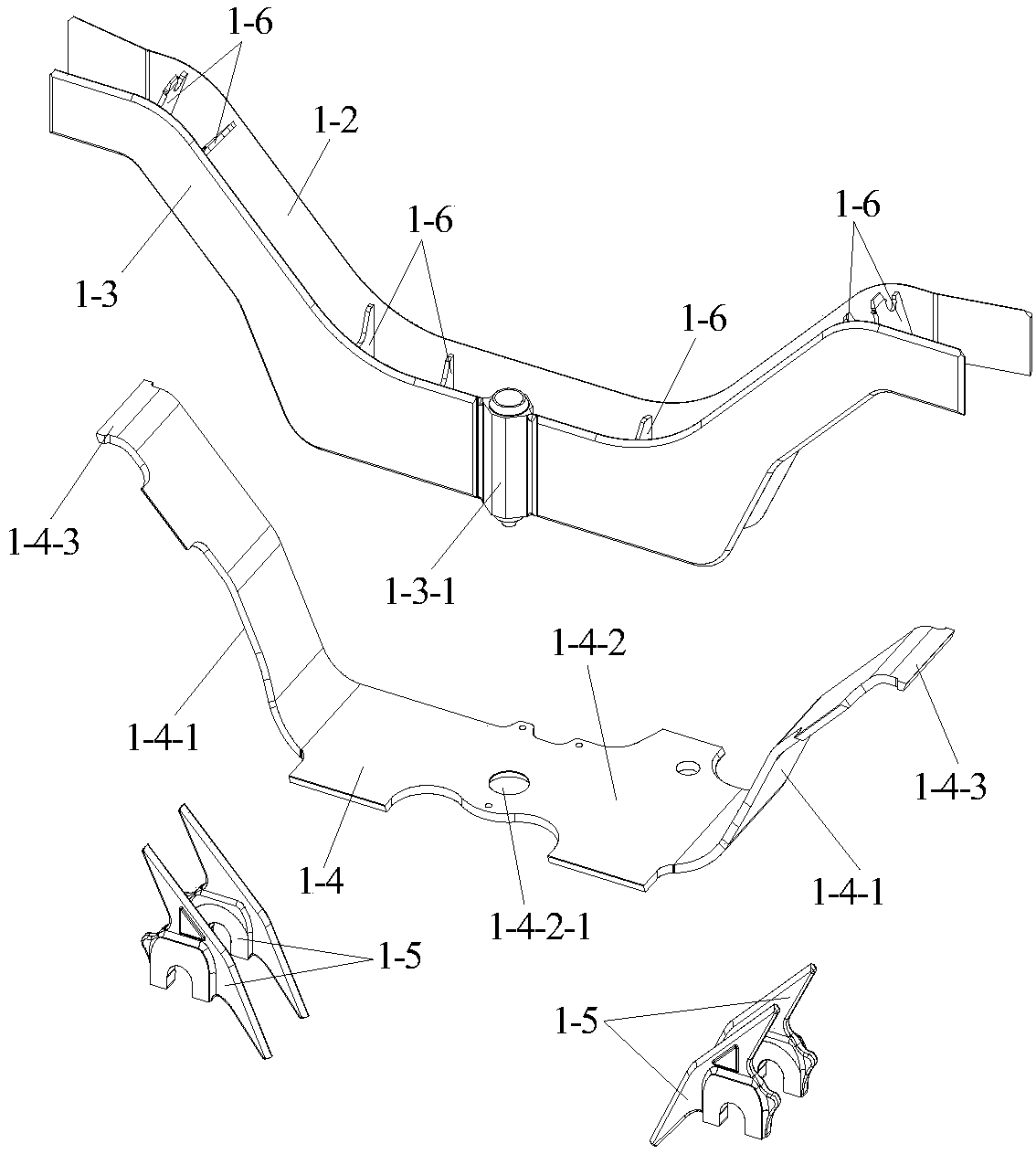

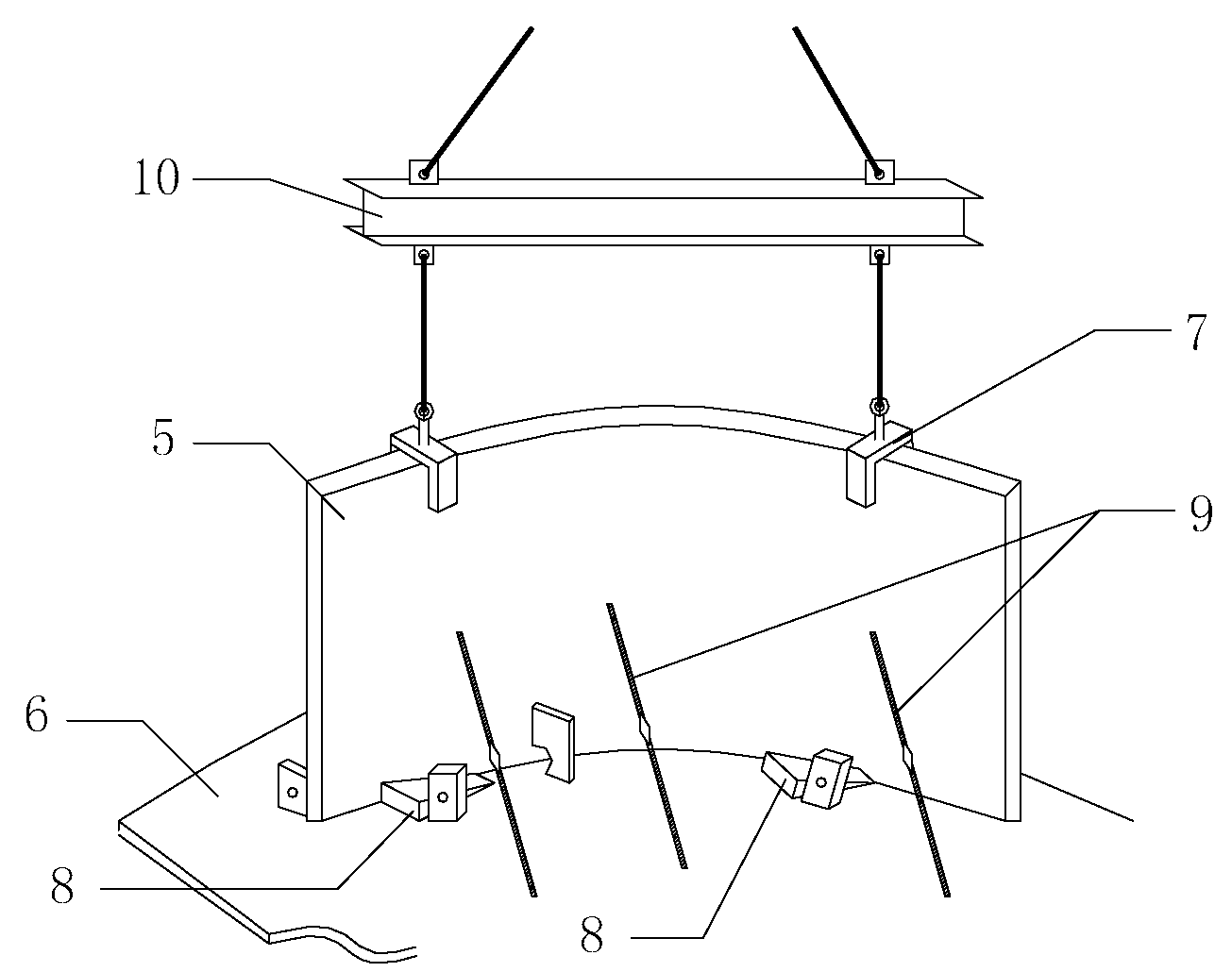

Assembly positioning tool for side beam dressing welding

ActiveCN108817797AThe way is simple and fastAvoid welding deformationWelding/cutting auxillary devicesAuxillary welding devicesBogieEngineering

The invention relates to an assembly positioning tool for side beam dressing welding and belongs to the field of auxiliary clamping devices for welding assembly positioning of track vehicle bogie sidebeam devices. The assembly positioning tool includes a base platform, two side beam end positioners, two axle hinged support gate arch positioners and a plurality of side beam upper edge vertical squeezers. Each axle hinged support gate arch positioner and one corresponding side beam upper edge vertical squeezer jointly form a side beam end positioning device. The lower ends of the plurality of side beam upper edge vertical squeezers are fixedly connected to the middle portion of the base platform, and the two side beam end positioning devices are symmetrically fixedly connected to the two ends of the base platform. The assembly positioning tool for side beam dressing welding can completely omit mapping and scribing operation during the side beam assembly, and a component positioning modeis simple, convenient, accurate and reliable and can effectively restrain welding deformation at each position of a bird wing-shaped side beam, the repair work after the welding is reduced, and thusthe production efficiency and product quality can be greatly improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

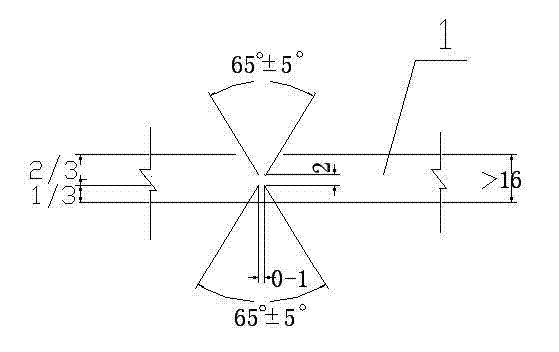

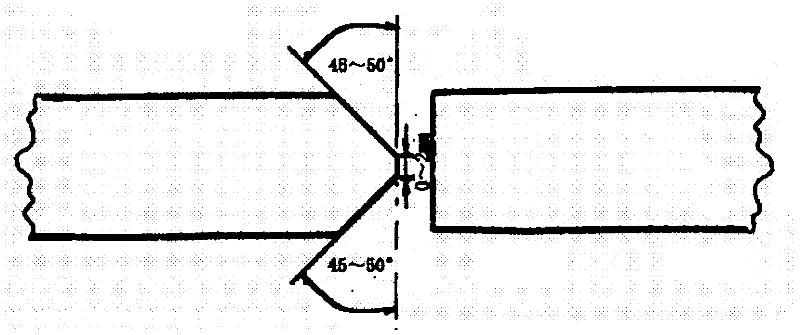

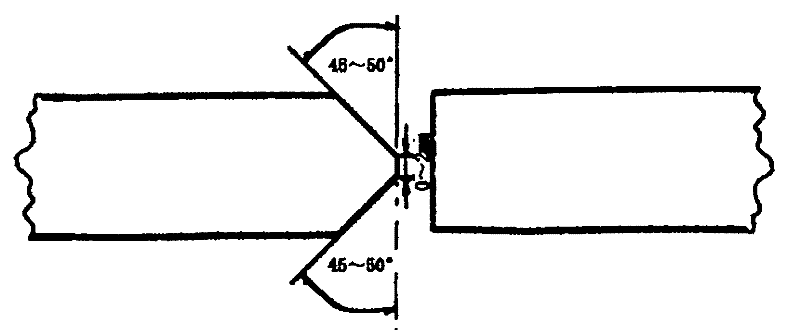

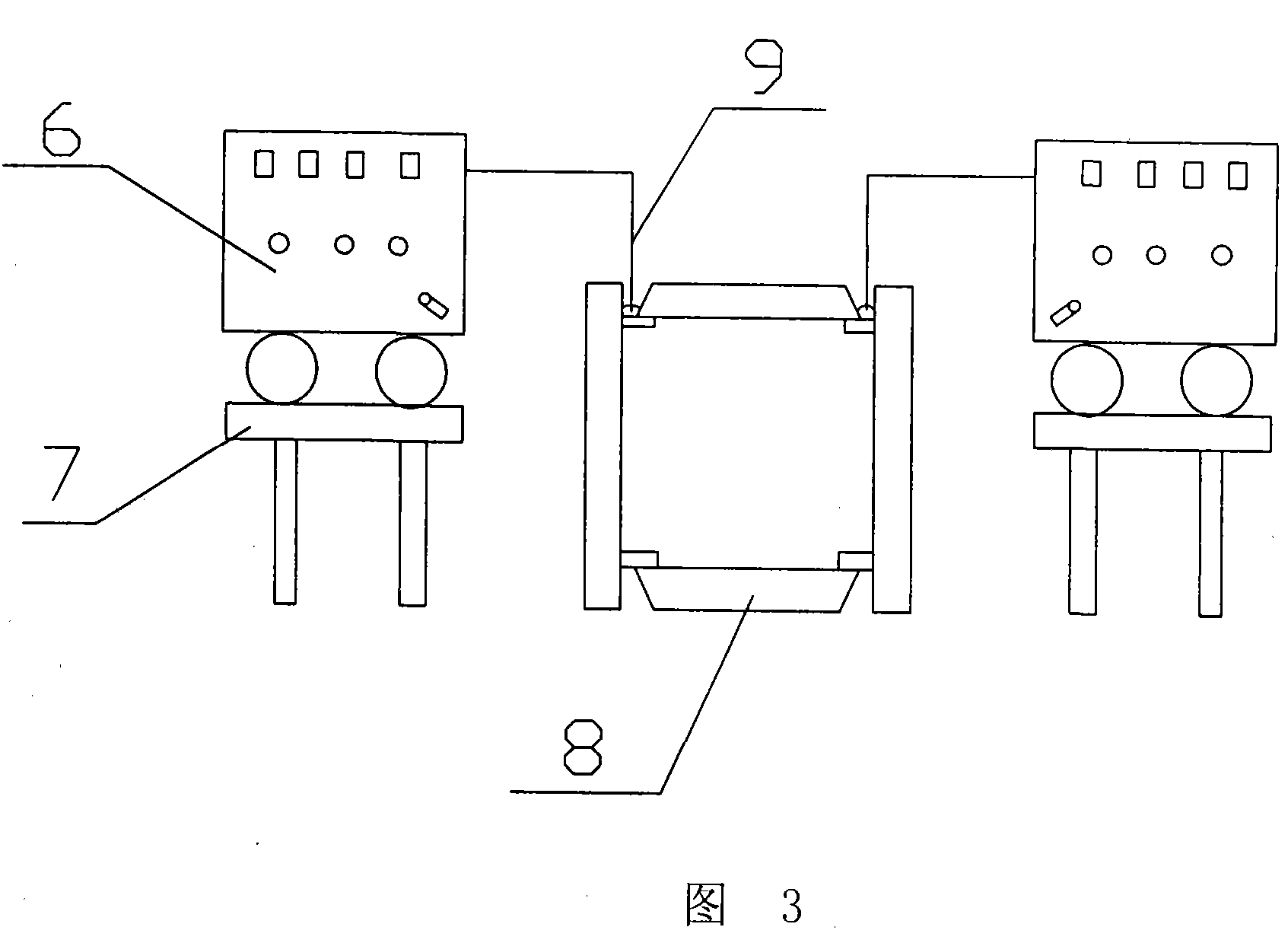

Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

The invention relates to a welding technique, especially a combined welding process combining small bevel angle full-automatic CO2 gas shielded protection welding with unionmelt welding, comprising following steps: (1) opening a corresponding small angle bevel on the weldment with a bevel angle of 25+50DEG; (2) paring, ensuring welding space of 8+20mm; (3) grounding welding by using full-automatic CO2 gas shielded protection welding; (4) performing filling in and capping welding by using unionmelt welding. The advantages of the invention are: (1) small bevel angle welding, saving material and improving productivity; (2) grounding welding by using unionmelt welding, the electrical arc heat quantity is centralized, the heated area is small, the welding speed is quick, head affection range is contracted, and welding deformation is small; (3) crackle generation tendency is decreased; (4) bottom slag cleaning is avoided to prepare for narrow gap welding and welding efficiency is increased; (5) filling in and capping are performed by using unionmelt welding, so that welding speed and external appearance forming quality are assured.

Owner:MCC JINGTANG CONSTR

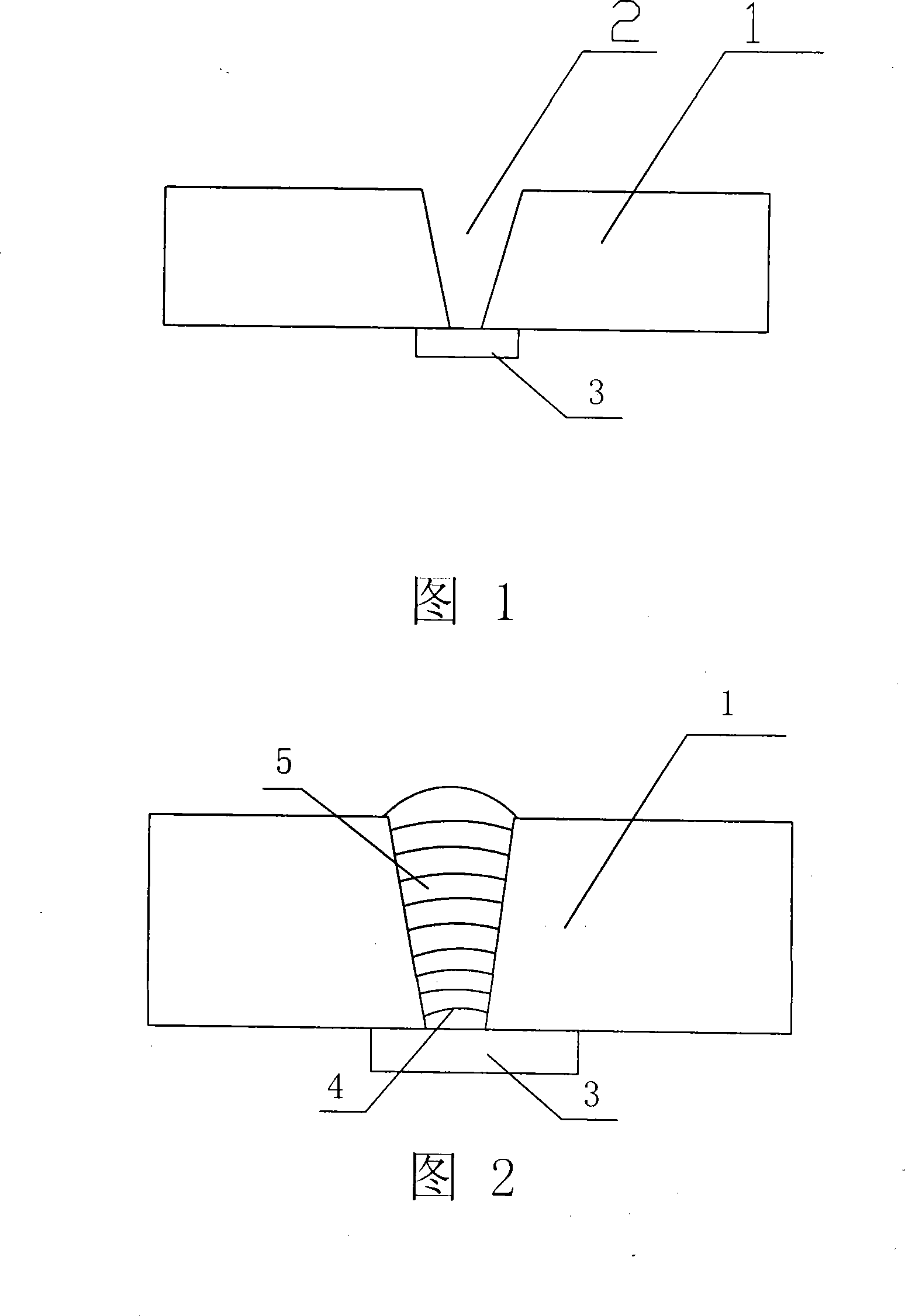

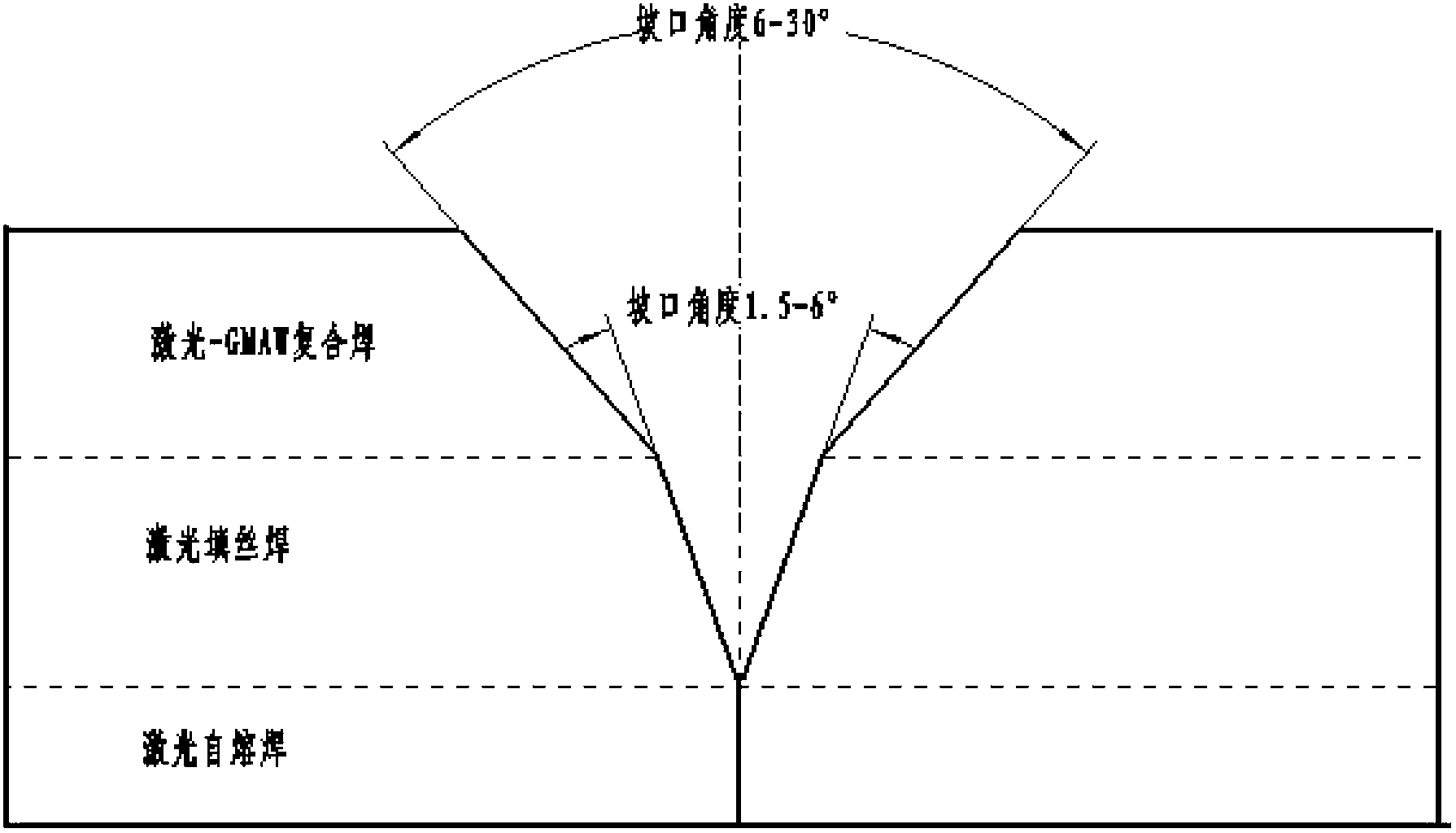

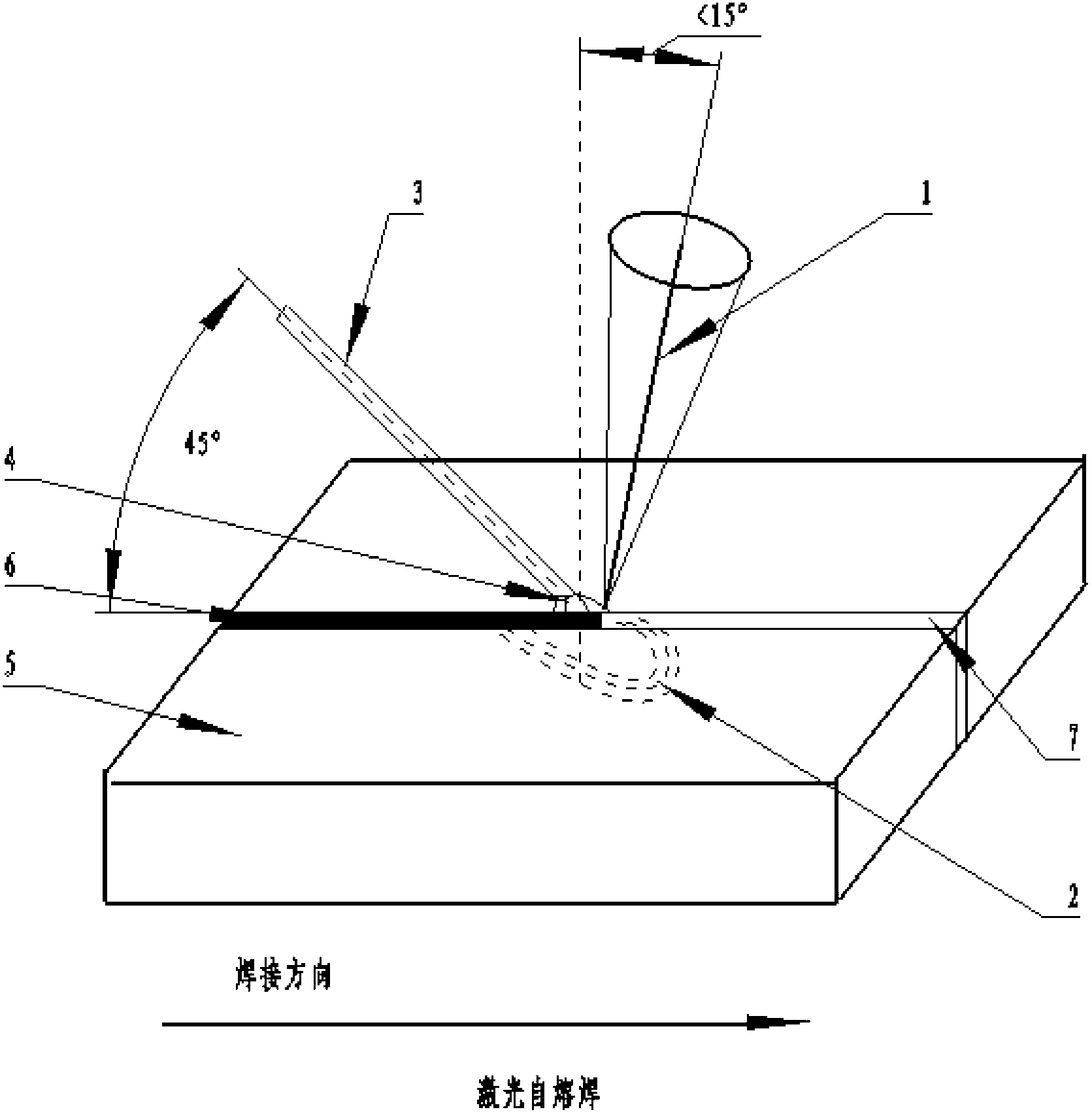

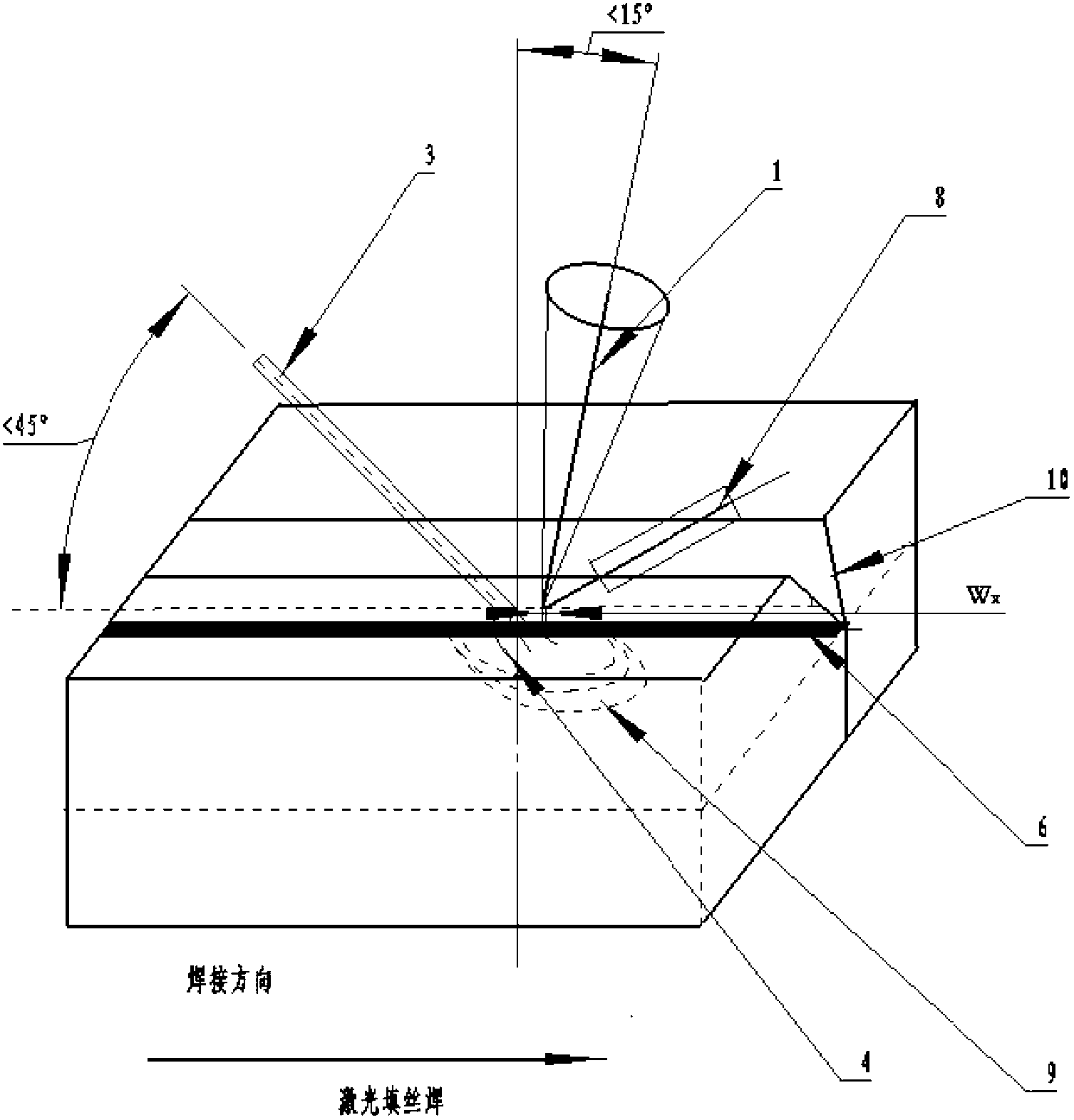

Narrow gap multi-pass laser welding method for thick plate

InactiveCN103008895AReduce consumptionImprove welding productivityLaser beam welding apparatusWorkpiece edge portionsThick plateGas metal arc welding

The invention discloses a laser welding method for a thick plate. A gap is reserved on the thick plate or a divided edge with a blunted edge is performed, a laser autogenous welding is adopted at the welding bead part for welding a pass for bottoming, then, the laser wire filling welding is carried out, a welding wire and a laser beam maintain an included angle being 15 degrees to 75 degrees, the welding wire extends into the divided edge gap from the front of the laser beam, when the filling wire welding cannot fully fill the divided edge gap, the laser-GMAW (gas metal arc welding) composite welding is finally carried out, and the welding of the thick plate is completed. The preserved gap value is respectively smaller than or equal to 0.5mm, the width of the performed welding bead used for the wire filling welding is smaller than or equal to 2.5mm, and the width of the performed welding bead used for the composite welding is smaller than or equal to 10mm. The laser welding method has the advantages that the problem of high-efficiency and high-quality welding of the thick plate is solved, so high-quality and efficient thick plate welding joints with small welding deformation and high gap bridging capability are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

Vacuum electron beam welding method for thin-wall titanium alloy box structure with multiple cabin sections

ActiveCN104858542AControl welding deformationWeld Quality ControlElectron beam welding apparatusWelding/soldering/cutting articlesEngineeringTitanium alloy

The invention belongs to the field of welding technologies and particularly relates to a vacuum electron beam welding method for a thin-wall titanium alloy box structure with multiple cabin sections. All the cabin sections are welded by adopting the method of integral assembling and one-shot clamping, a reasonable welding sequence and reasonable welding parameters are selected, welding deformation and weld joint quality are controlled, and the technical difficulties that products are poor in integral rigidity and welding deformation is difficult to control are overcome. According to the scheme, a welded joint, achieving single face welding, double face forming and back face spatter avoiding, of a thin-wall titanium alloy box is achieved, and welding quality meets the requirements of the primary national military standard GJB1718A-2005 Electron Beam Welding. After the multiple sections of the box are spliced and welded, the appearance precision requirements that cylindricity is smaller than 1.0 mm-1.5 mm and coaxiality is smaller than 2 mm-3 mm, and meanwhile the hydraulic pressure strength and the airtight strength of the box meet product use requirements.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Double-wire submerged arc welding method for high heat input energy welding of high-strength super-thick steel plates

InactiveCN109014513AImprove performanceSimple methodArc welding apparatusWelding/cutting media/materialsSheet steelEngineering

The invention relates to a double-wire submerged arc welding method for the high heat input energy welding of high-strength super-thick steel plates. Double-wire submerged arc welding is carried out on the steel plates of which the thickness is larger than 50mm without carrying out preheating before welding or carrying out heat treatment after welding. The total welding heat input energy of double-wire submerged arc welding is controlled at 100+ / -5kJ / cm, interlayer temperature is controlled between 100DEG C and 150DEG C, and the welding groove type belongs to a non-symmetrical X type. The double-wire submerged arc welding method has the advantages that the method is simple, easy to operate and efficient, saves energy and is particularly suitable for guiding the building construction of a large steel structure; and the quality of welding joints is excellent, the deformation degree of the welded plates is very small, welding defects are effectively avoided, welding deformation is controlled, the welding efficiency is increased, and the welding operation intensity is reduced.

Owner:ANGANG STEEL CO LTD

Catalytic converter assembly welding method for vehicle exhaust system

ActiveCN103464912ASimple structureImprove accessibilityWelding/cutting auxillary devicesAuxillary welding devicesWelding residual stressWelding deformation

A catalytic converter assembly welding method for a vehicle exhaust system uses incremental part welding and includes the following steps of welding a front cone, a carrier shell and a rear cone on carrier shell subassembly welding equipment to form carrier shell subassembly, welding a front flange, a front connection tube, a middle connection tube, and the welded carrier shell subassembly on a front subassembly welding equipment to form a front subassembly, and welding flexible connection, a rear connection tube, a rear flange and the front subassembly on assembly welding equipment so as to form a catalytic converter assembly. The catalytic converter assembly welding method for the vehicle exhaust system has the advantages of greatly reducing cumulative welding residual stress caused by integrated welding and forming, avoiding deformation of complex welding on junctions of various part, improving product quality, eliminating quality problems caused by welding residual stress and a large of unqualified products owing to the welding deformation, and improving production efficiency.

Owner:保定市屹马汽车配件制造有限公司

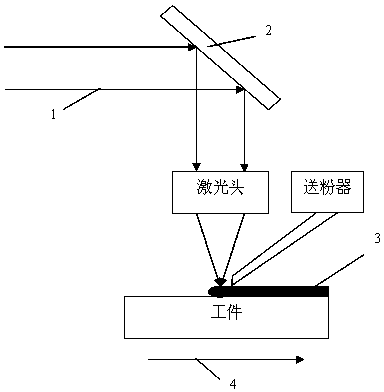

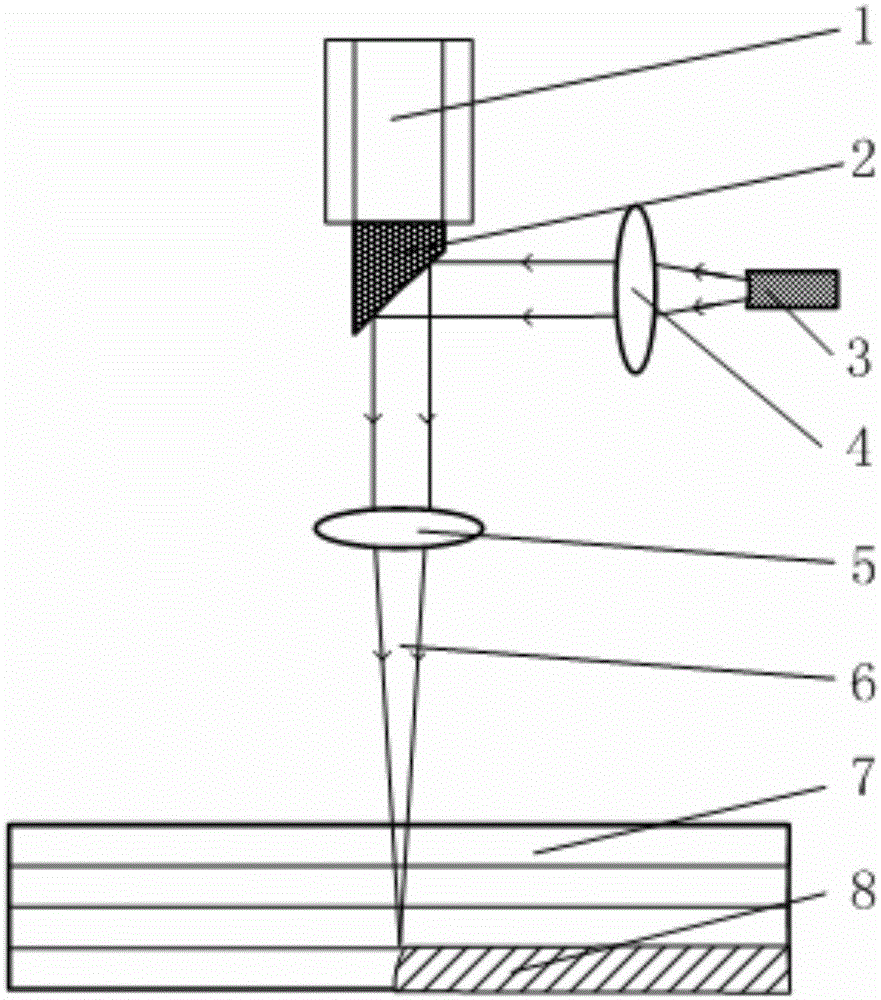

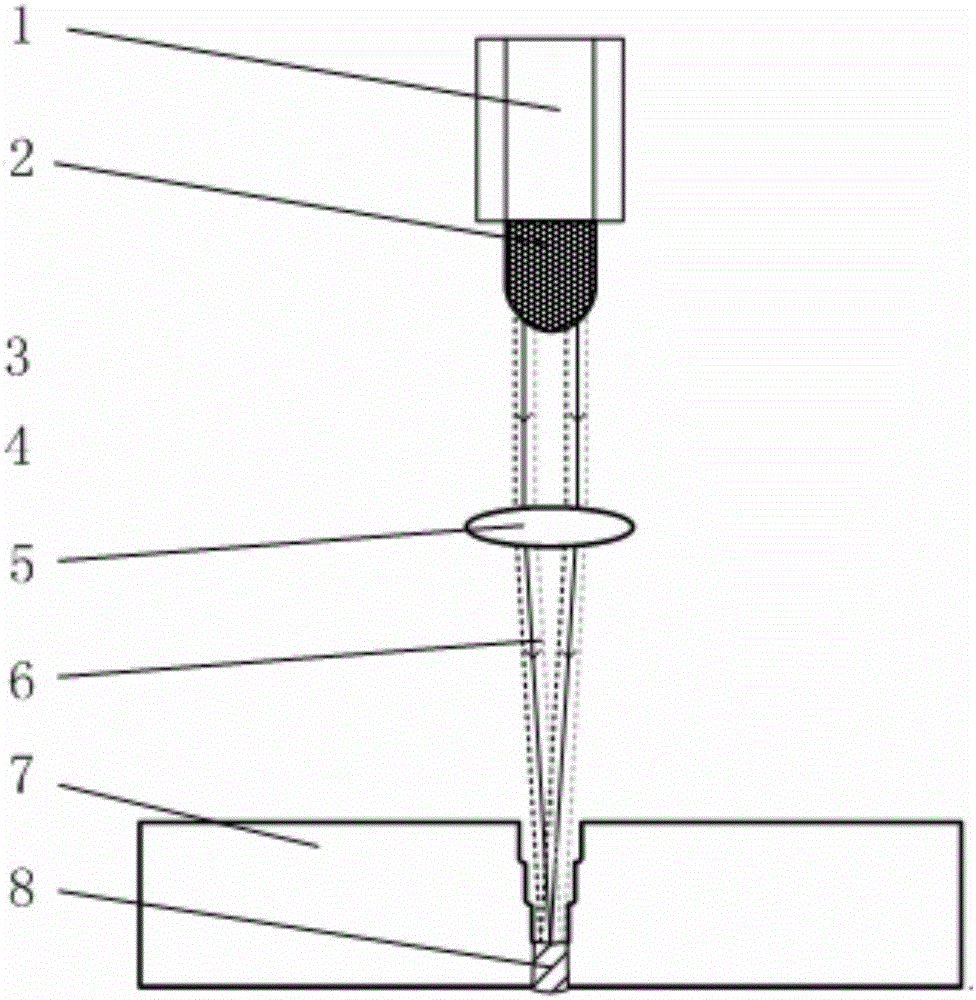

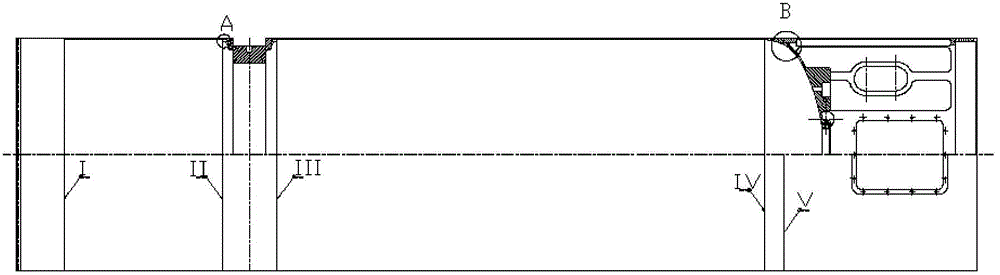

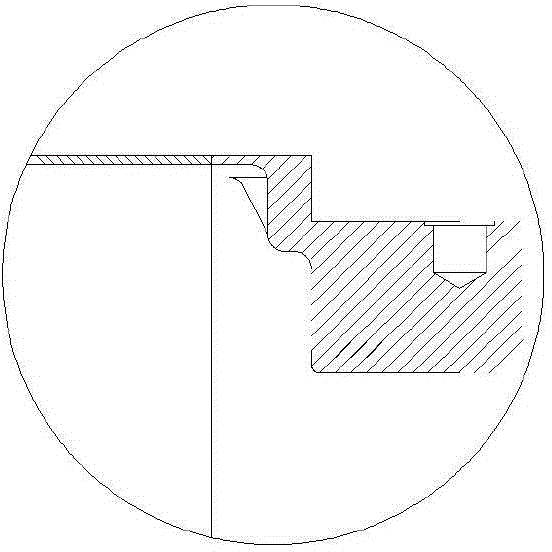

Thick-plate narrow-gap laser scanning filler wire welding method

InactiveCN104551403AHigh energy density of laserImprove welding efficiencyWorkpiece edge portionsLaser beam welding apparatusThick plateLaser scanning

The invention relates to a thick-plate narrow-gap laser scanning filler wire welding method. The method comprises the steps: firstly arranging an I-type beveled edge or a deep U-type beveled edge with a thick truncated or a deep V-type beveled edge between two thick plates to be welded, transmitting laser beams to a weld seam by adopting a scanning galvanometer, carrying out the bottoming by virtue of laser self-melting welding, and then carrying out the laser scanning filler wire welding. In the filler wire welding process, the width of the beveled edge is detected in real time by adopting a visual detection system, and the deflection angle of the scanning galvanometer is further controlled, so that the laser beams can scan back and forth at two sides of the weld seam, a weld wire stretches into a gap of the beveled edge from the front of the laser beams, and the weld wire is molten by the laser which scans back and forth; the scanning galvanometer is driven by adopting a plane travel cart or an annular guide rail to move along the weld seam, and the scanning galvanometer is adjusted as the increment of welding beads, so that the laser can be focused in the plane of the weld seam to melt the weld wire. By adopting the thick-plate narrow-gap laser scanning filler wire welding method, the welding heat input can be reduced, the weld deformation can be alleviated, a thick-plate weld joint with small weld deformation and good gap side wall fusion can be obtained, and the welding efficiency and welding quality of the thick plate can be greatly improved.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

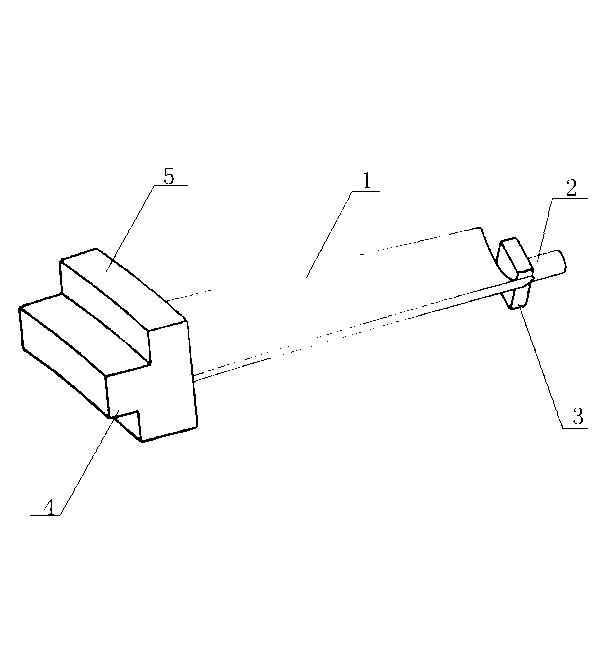

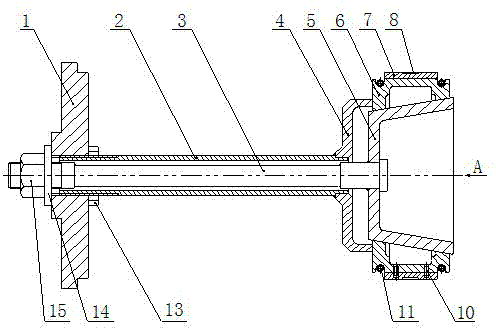

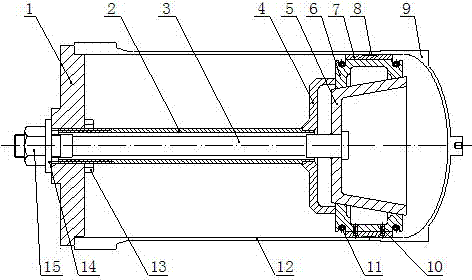

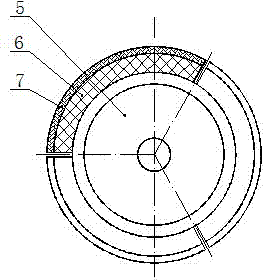

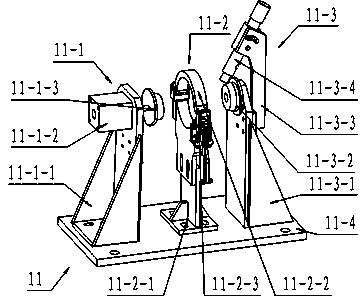

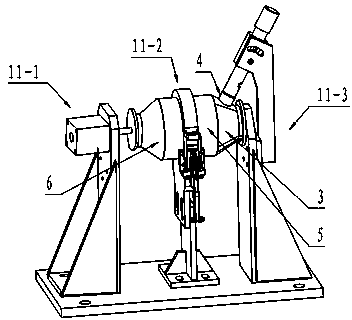

Inertia friction welding machine

InactiveCN101224522AAxial welding is convenientPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

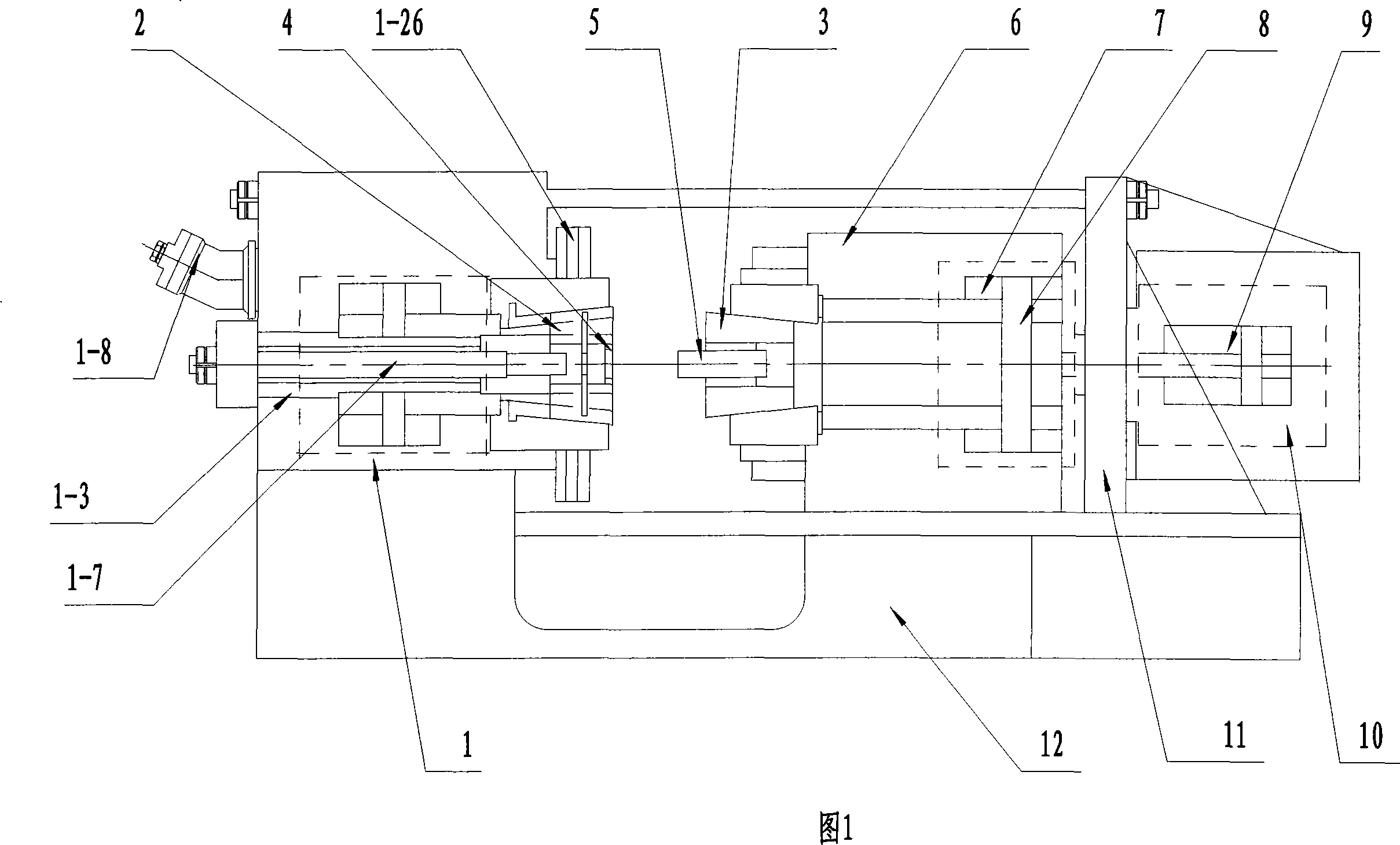

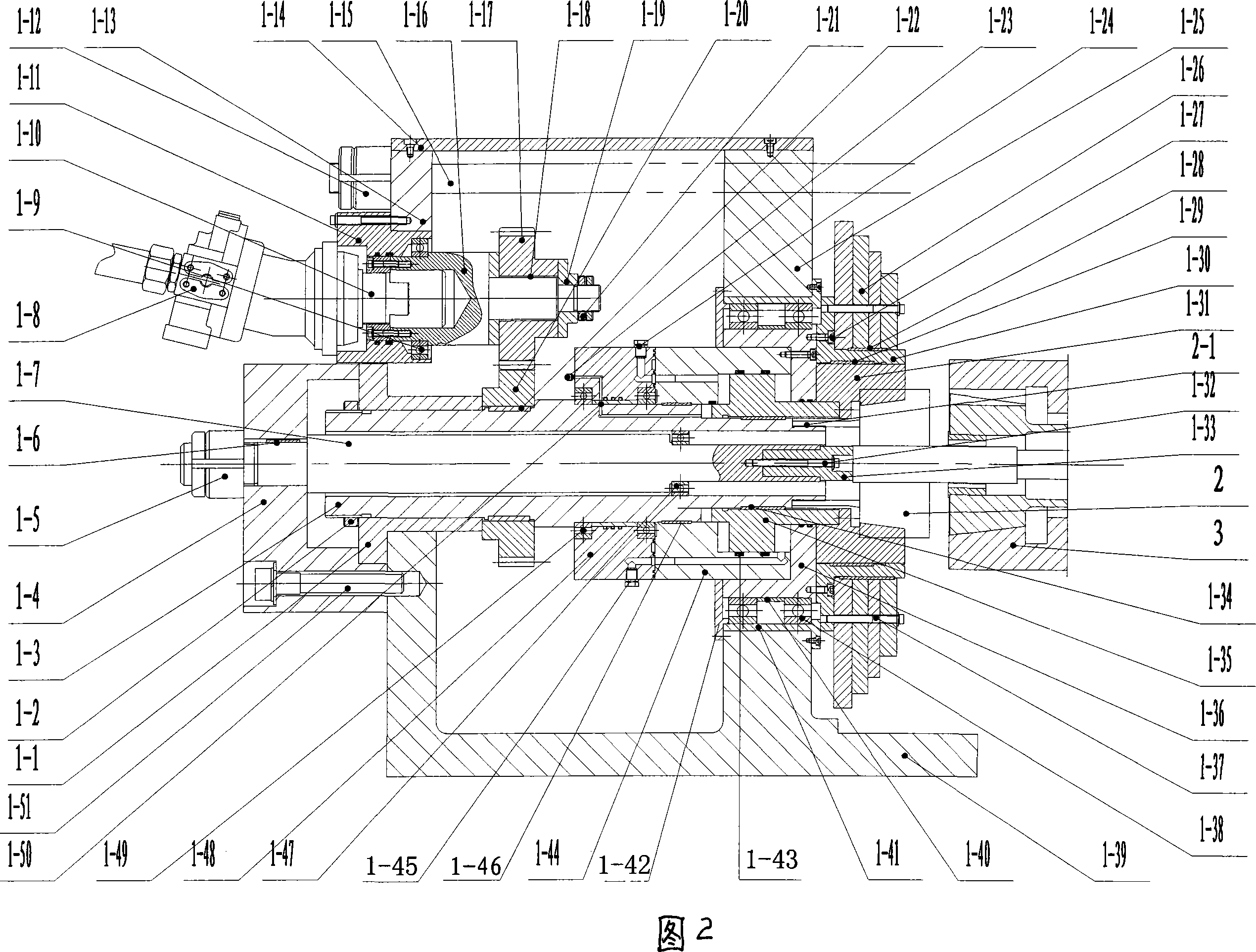

The invention relates to an inertia friction welding equipment, comprising a frame (1-39), a mainshaft box (1) which is formed by the connecting of a left bracket (1-13) and a right bracket (1-25), a transmission mainshaft (1-3) arranged in the mainshaft box (1), and a flywheel (1-26) which is rotated together with the transmission mainshaft (1-3); the invention is characterized in that the front circumference of the transmission mainshaft (1-3) is provided with a hydraulic device which rotates with the transmission mainshaft (1-3) and is pressed axially. The equipment which is provided by the invention and can be used for the radial inertia friction welding on the circumference surface of a cirque part and a cylindrical and round pipe-shaped part has simple and reasonable structure, and safe and convenient application, can realize the radial pressurization in the rotation, realizes the pre-clamping and the exact positioning of any positions of the cirque welding part, controls the welding deformation, ensures that the surface of the clamped workpiece is not damaged by the rotation inertia of the frock device in the welding process, thus greatly improving the working efficiency.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Tank fabricating and welding method

ActiveCN102848087AControl welding deformationAdvantages of making welding methodsWelding apparatusStructural engineeringSeam welding

The invention discloses a tank fabricating and welding method, which is characterized by comprising the following steps of: a. fabricating and welding a tank soleplate, wherein the step comprises: (1) paving the soleplate, and (2) welding the soleplate; and b. fabricating and welding a tank wall board, wherein the step comprises: (1) paving the wall board, and (2) welding the wall board, and the step of welding the wall board comprises: 1) temporarily not welding 300mm of the lower edge of a longitudinal weld and welding the lower edge together with a circular seam after being paired with a next sine wall board; 2) when welding the circular seam, enabling welders to be uniformly distributed on the surrounding of the tank and welded in the same direction; 3) selecting the setting distance of an anti-deformation fixture according to the thickness of the wall board before welding the circular seam, the distance of the fixture of the wall board with delta equal to 6mm being 300mm; and 4) selecting an even number of welders when welding the wall board, the levels of the welders being close, and welding with the same vertical seam and circular seam welding parameters. The tank fabricating and welding method disclosed by the invention has the advantages of simple and convenient operation, strong maneuverability and the capability of effectively controlling the welding deformation of the tank.

Owner:MCC5 GROUP CORP SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com