Assembly positioning tool for side beam dressing welding

A technology for positioning tooling and side beams, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult to effectively control the welding quality, time-consuming and laborious positioning and welding process, deviation of axle hinge seat welding posture, etc. problems, to achieve the effect of reducing the work of days off, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

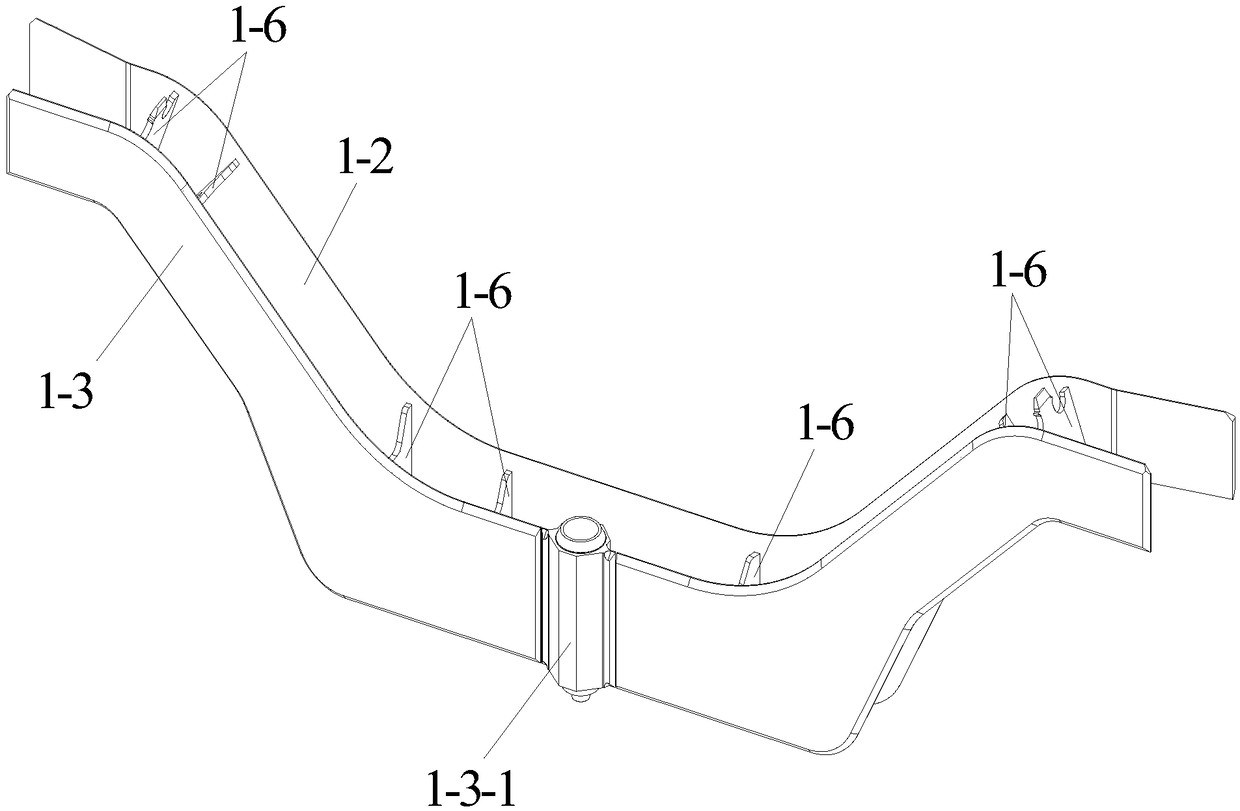

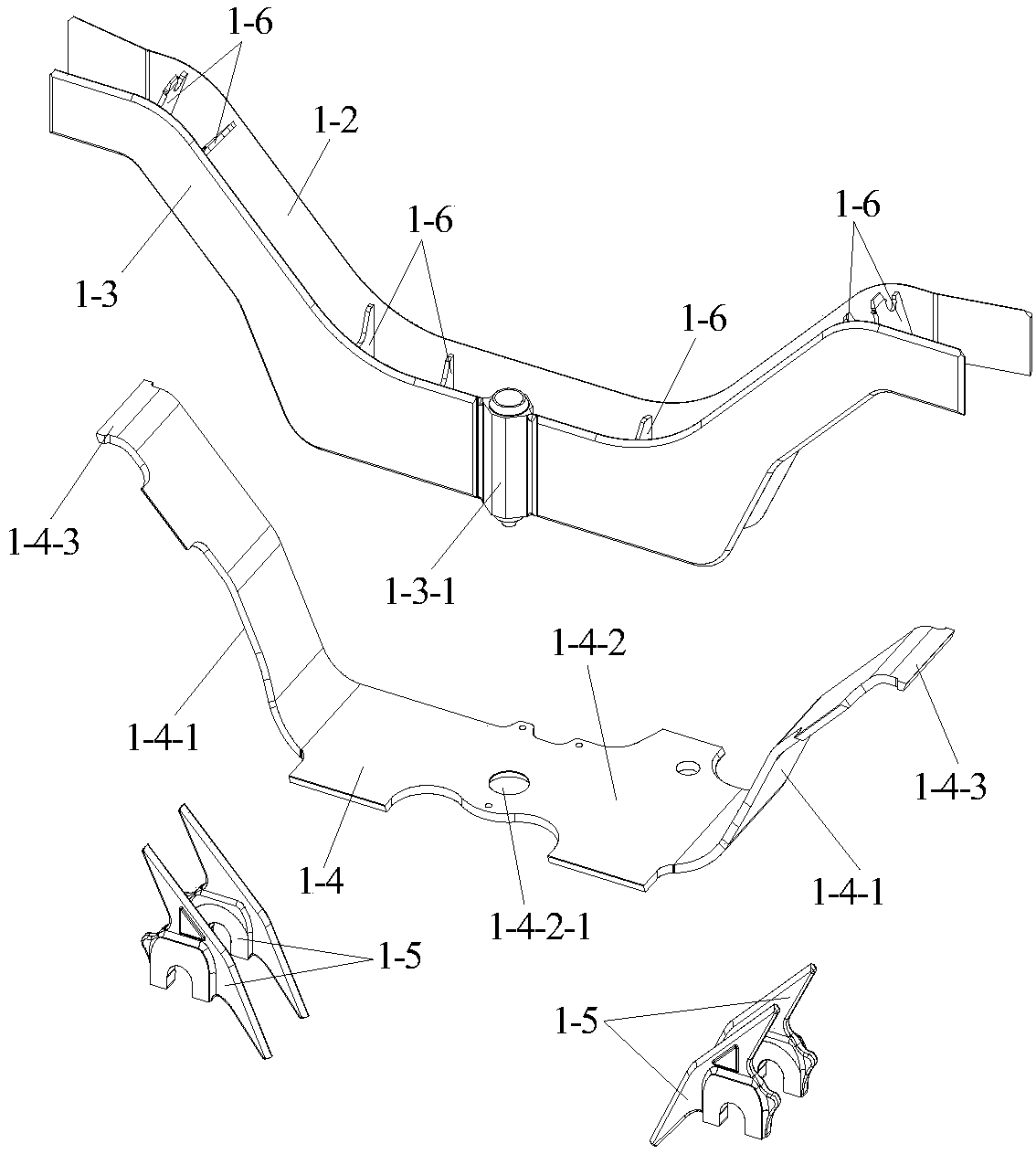

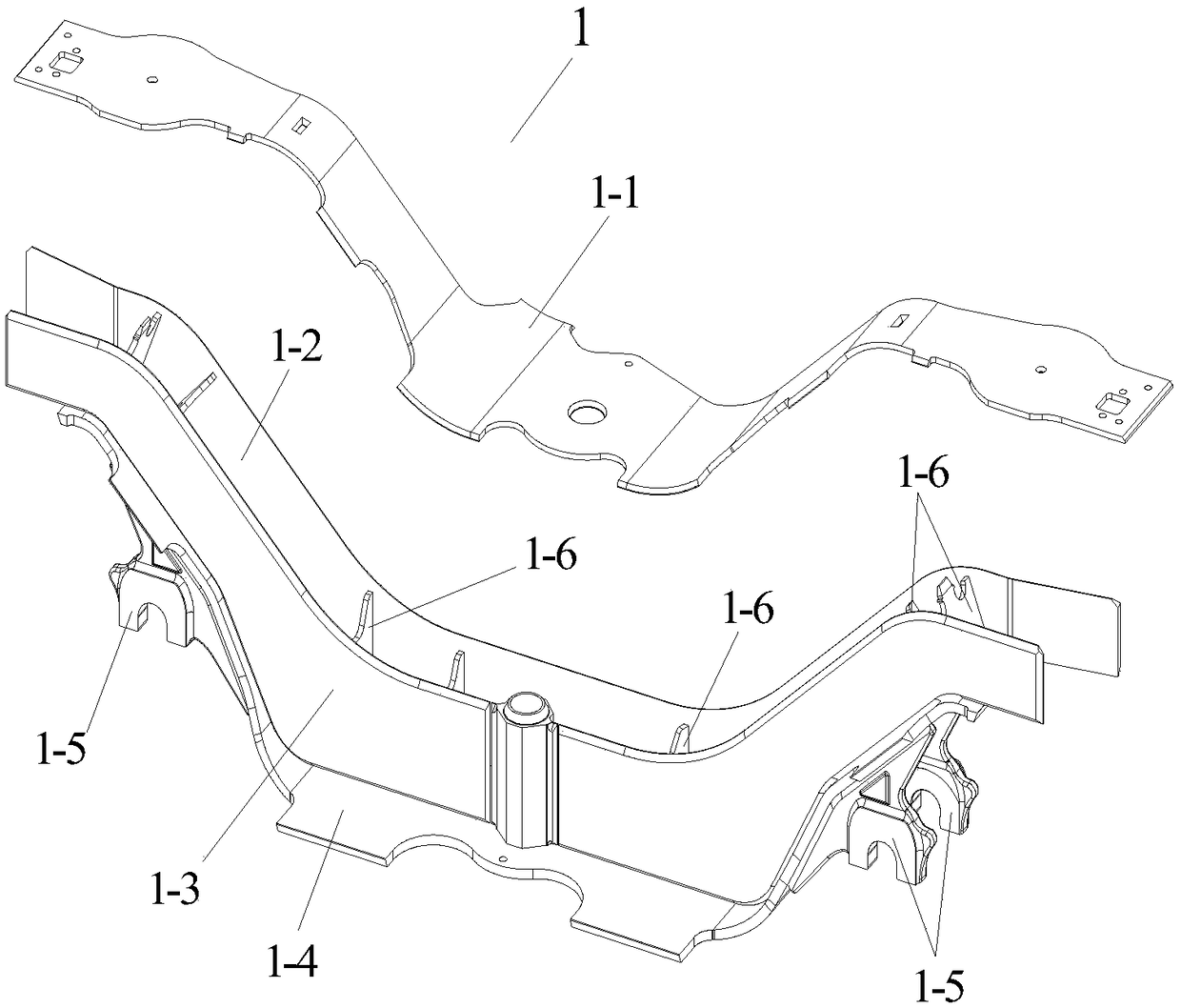

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] like Figure 7 to Figure 9 As shown, the paired positioning tooling for side beam formal welding of the present invention includes a foundation platform 2, two side beam end positioners 3, two axle hinge seat door arch positioners 4 and four side beam upper edge vertical To the compactor 5, each axle hinge seat arch positioner 4 and a corresponding side beam end positioner 3 together form a side beam end positioning device; the two side beam end positioning devices are fixed symmetrically at both ends of the base platform 2.

[0047] The basic platform 2 includes a platform plate, a positioning template 2-1 for the horizontal section of the lower cover plate, and four positioning template pressing blocks 2-2. The middle part is provided with the through hole 2-1-1 of the positioning model, and the horizontal pressing block of the positioning model pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com