Patents

Literature

393results about How to "Avoid welding deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

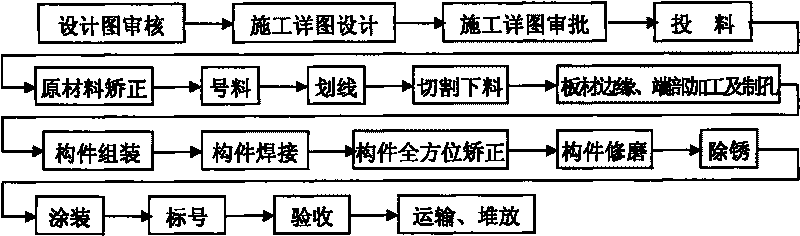

Manufacturing method for box type pillar beam

ActiveCN102896472AAdvanced preparation technologyReasonable preparation processArc welding apparatusNumerical controlSlag (welding)

The invention relates to a manufacturing method for a pillar beam for the building field and especially relates to the manufacturing method for a box type pillar beam. The manufacturing method comprises the processes of steel check, line marking, cutting, material receiving, assembling, welding, finishing, coating, and marking. The manufacturing method comprises the following steps: splicing big plates and cutting the box type pillar beam under numerical control; adding lining strips and leaving gaps during the grouping process of four main welding seams of the box type pillar beam; welding the four main welding seams by adopting an automatic submerged arc welding method; welding box type separating plates by adopting non-melting nozzle electro-slag welding; keeping the welding seams of the non-melting nozzle electro-slag welding under an abreast state; machining after grouping the separating plates of the box type pillar beam; and end-milling the two ends of the box type pillar beam. According to the manufacturing method, during a manufacturing process of the box type pillar beam, an advanced box type separating plate non-melting nozzle electro-slag welding technology is adopted; the welding and the assembling are alternately performed; the welding sequence is scientific and reasonable; multiple measures are simultaneously taken for preventing welding deformation; the precise equipment is adopted for processing the end part, so that the manufacturing technology for the box type pillar beam is more advanced and reasonable; and the manufacturing method is suitable for the box type pillar beams in various cross section sizes and plate thicknesses.

Owner:CHINA 22MCC GROUP CORP

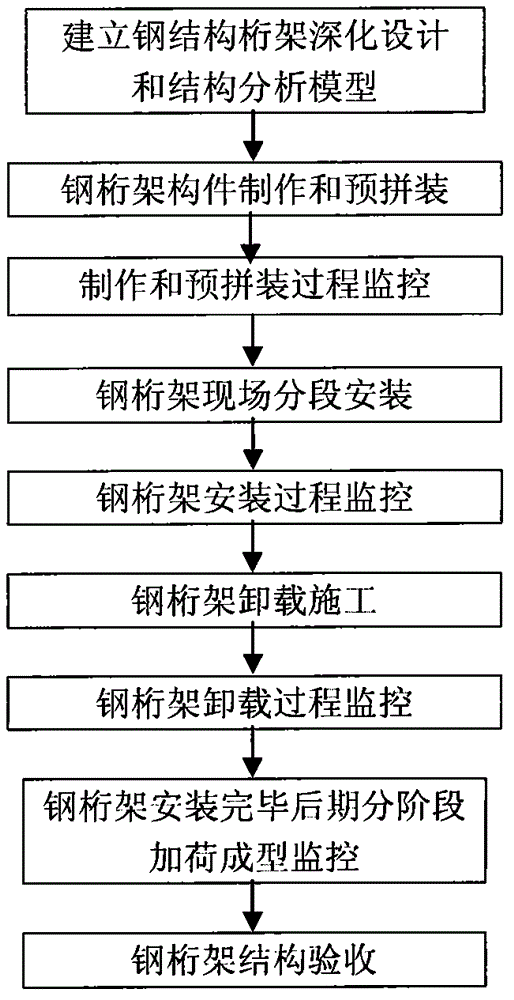

Method for installing abnormal-shaped extremely-large overhung steel truss under process monitoring construction

InactiveCN104631838AEasy to installEven by forceBuilding material handlingSupporting systemStructure analysis

The invention discloses a method for installing an abnormal-shaped extremely-large overhung steel truss under process monitoring construction. The installing method includes the steps that a steel structure truss deepening design and structure analysis model is built; steel truss parts are manufactured and pre-assembled, and the manufacturing process and the pre-assembling process are monitored; the steel truss is installed in site in a sectioned mode, and the steel truss installation process is monitored; unloading construction is carried out on the steel truss, and the steel truss unloading process is monitored; loading forming is monitored in the later period after the steel truss is installed in a staged mode; the structure of the steel truss is checked and accepted. The installation technology that a temporary supporting system and altitude spread assembling are combined is adopted, the large-span abnormal-shaped space lattice pipe truss is accurately installed, and the truss is evenly stressed and is not prone to deformation in the installation process. Heat accumulation, welding stress and welding deformation are prevented with the altitude spread roof-member method.

Owner:YONGSHENG CONSTR GRP

Method for manufacturing and installing guide rail in container ship cargo hold

InactiveCN101885368AImprove installation accuracyAvoid welding deformationVessel partsEngineeringSlipway

The invention discloses a method for manufacturing and installing a guide rail in a container ship cargo hold, which comprises the following steps of: (a) manufacturing the guide rail; (b) two-dimensional preassembly: assembling and welding a processed guide plate and the guide rail on a platform by using a doubling plate as a basal plane; (c) hoisting and boarding: installing an eye ring of the guide rail on the guide rail a quarter away from the upper end, respectively installing one eye ring at the left side and the right side of the guide plate, correspondingly reinforcing the eye rings from the back side, and hoisting the whole guide rail to a slipway; adding a toggle plate behind the doubling plate to reinforce the guide rail with low intensity; and after manufacturing the guide rail of a following ship in two segments, connecting the two segments into one guide rail after correction, and hoisting the assembled guide rail; (d) slipway installation: marking, and installing the guide rail; and (e) packaging and testing. In the method, the guide rail is firstly preassembled on the platform by using the doubling plate as the basal plane, and then, the whole guide rail is hoistedonto the slipway and installed. The invention has simple and reasonable method, convenient construction and high guide rail installation accuracy. The upward and downward hoisting and the reasonable arrangement of containers in the cargo hold can be ensured, and thus, the working efficiency and the ship manufacturing quality are increased.

Owner:YANGFAN GROUP

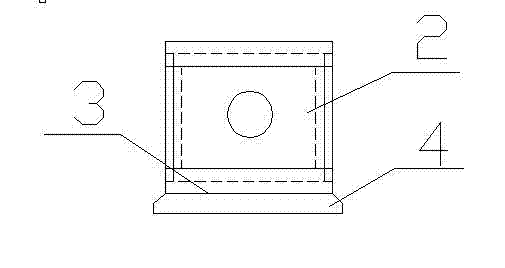

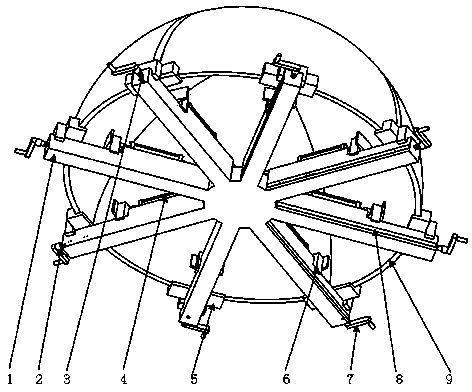

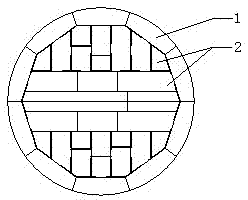

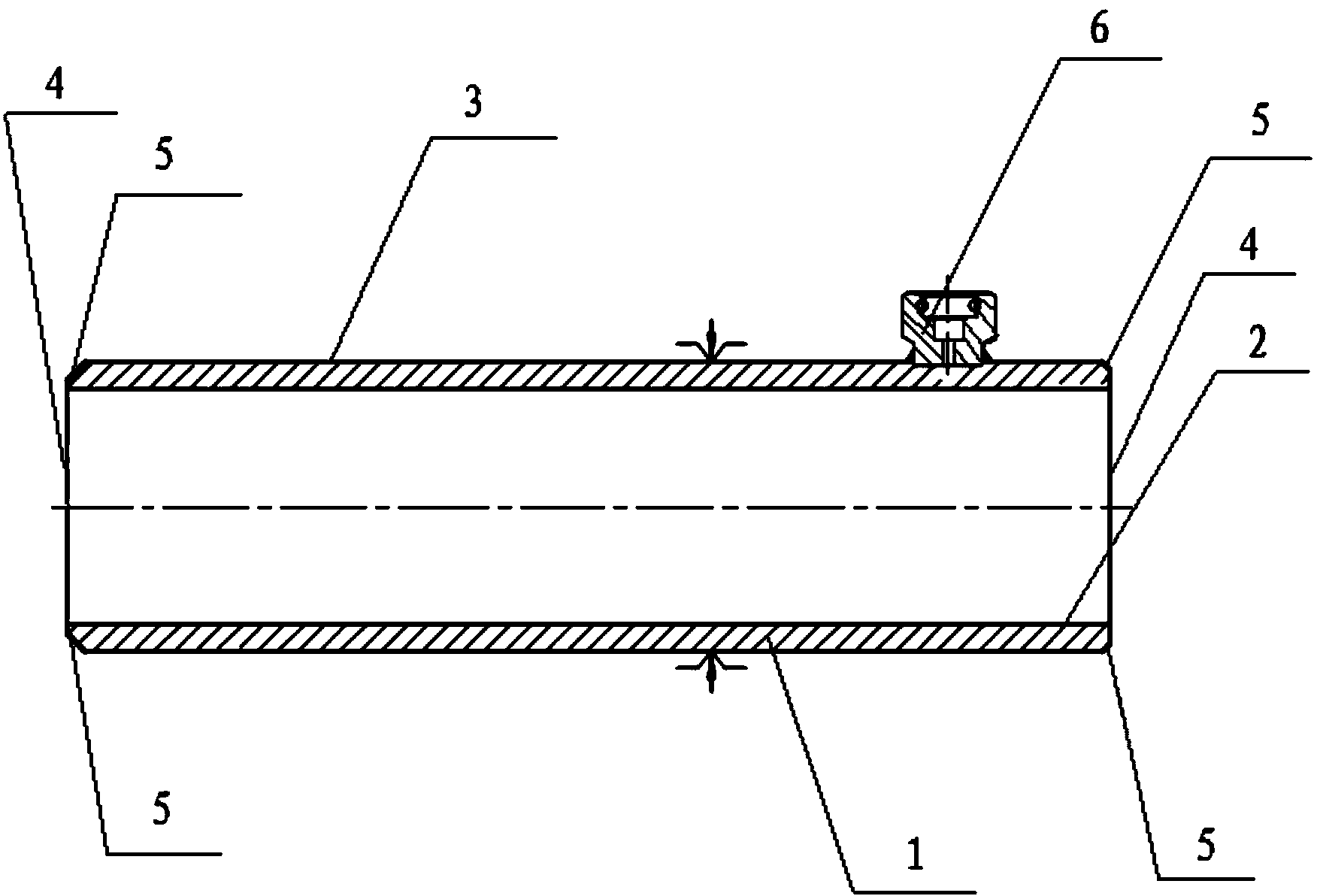

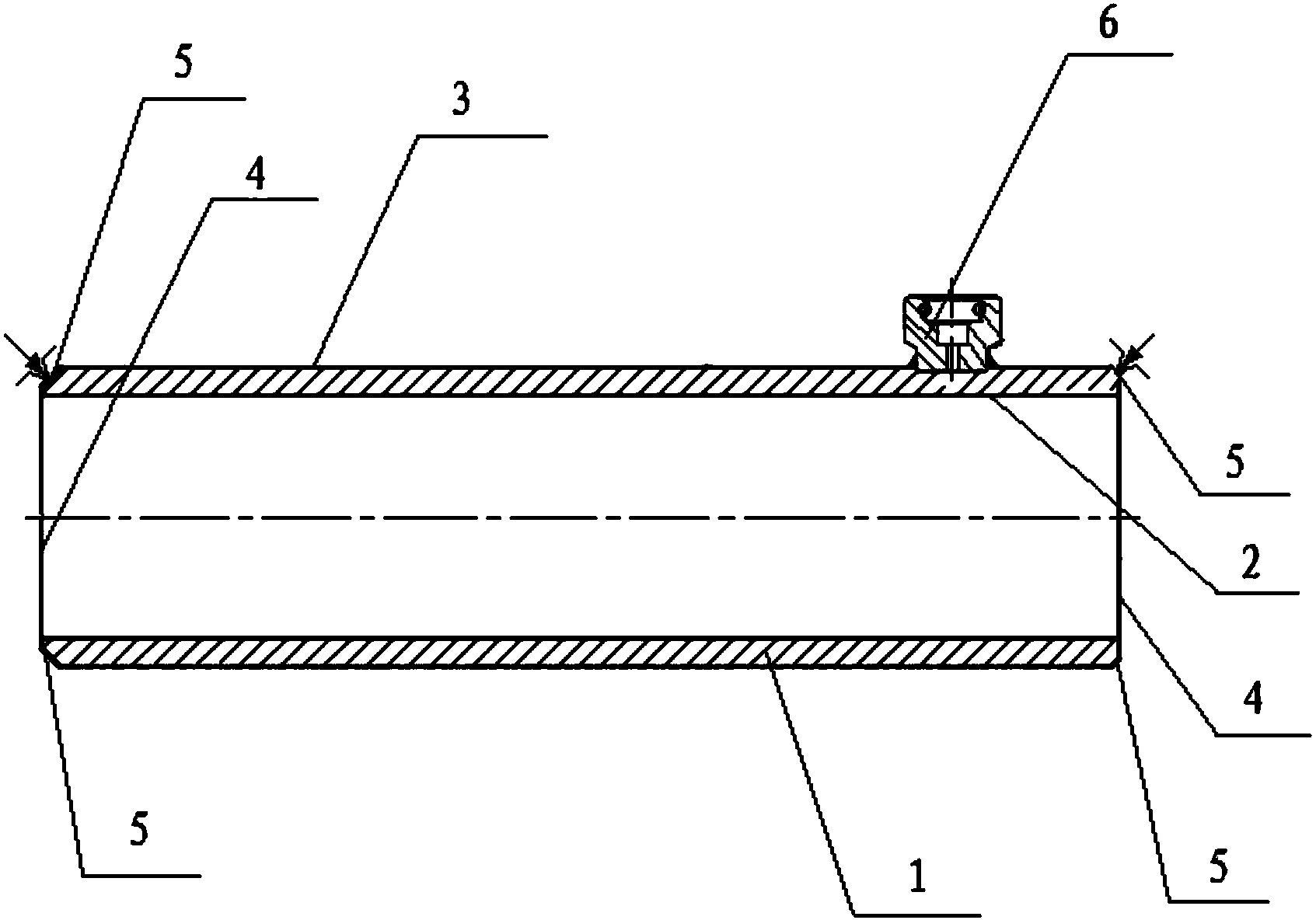

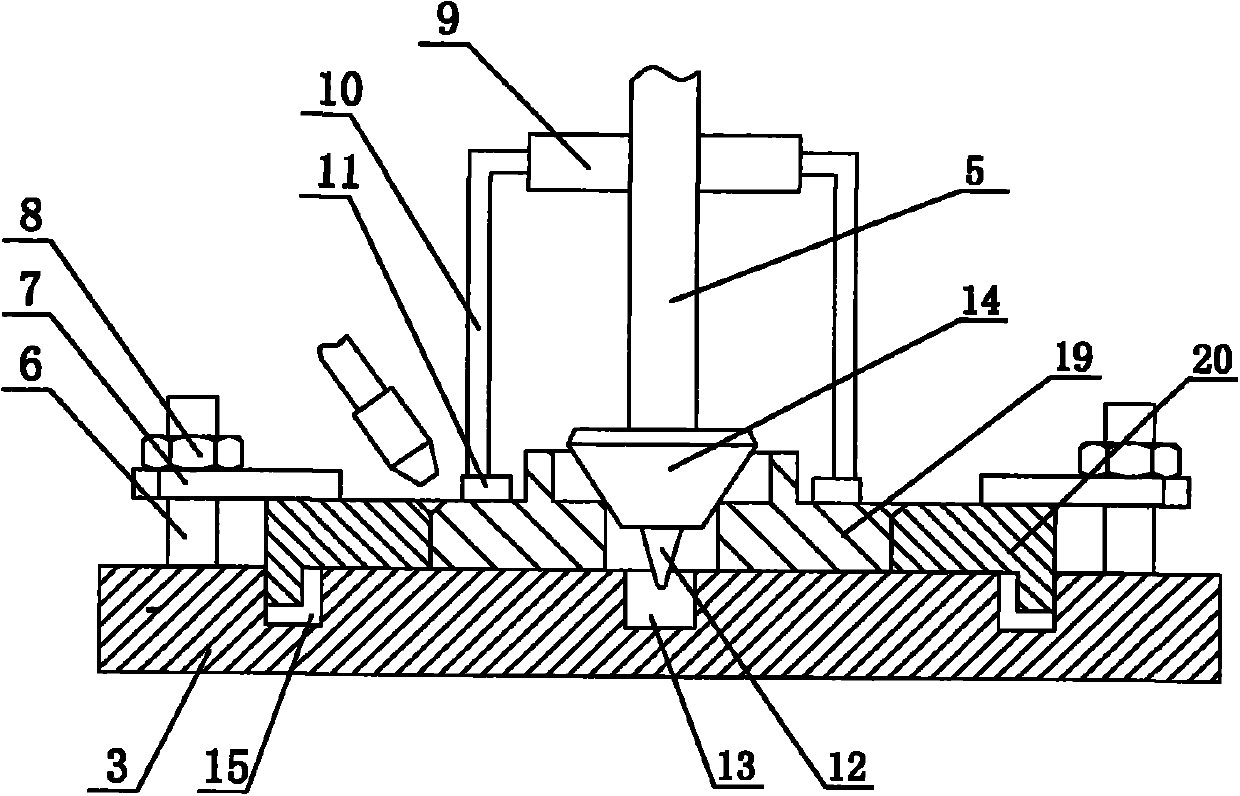

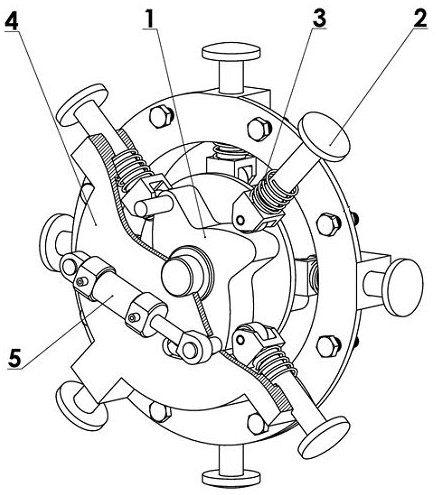

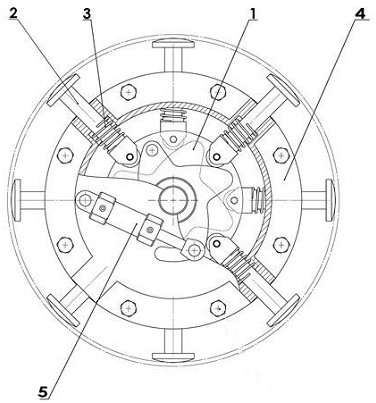

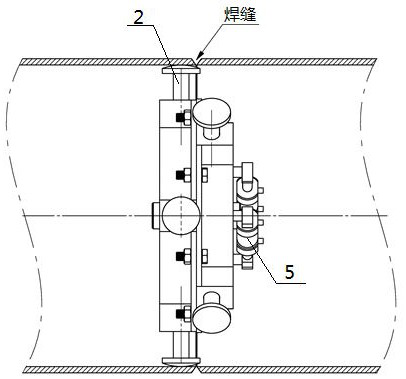

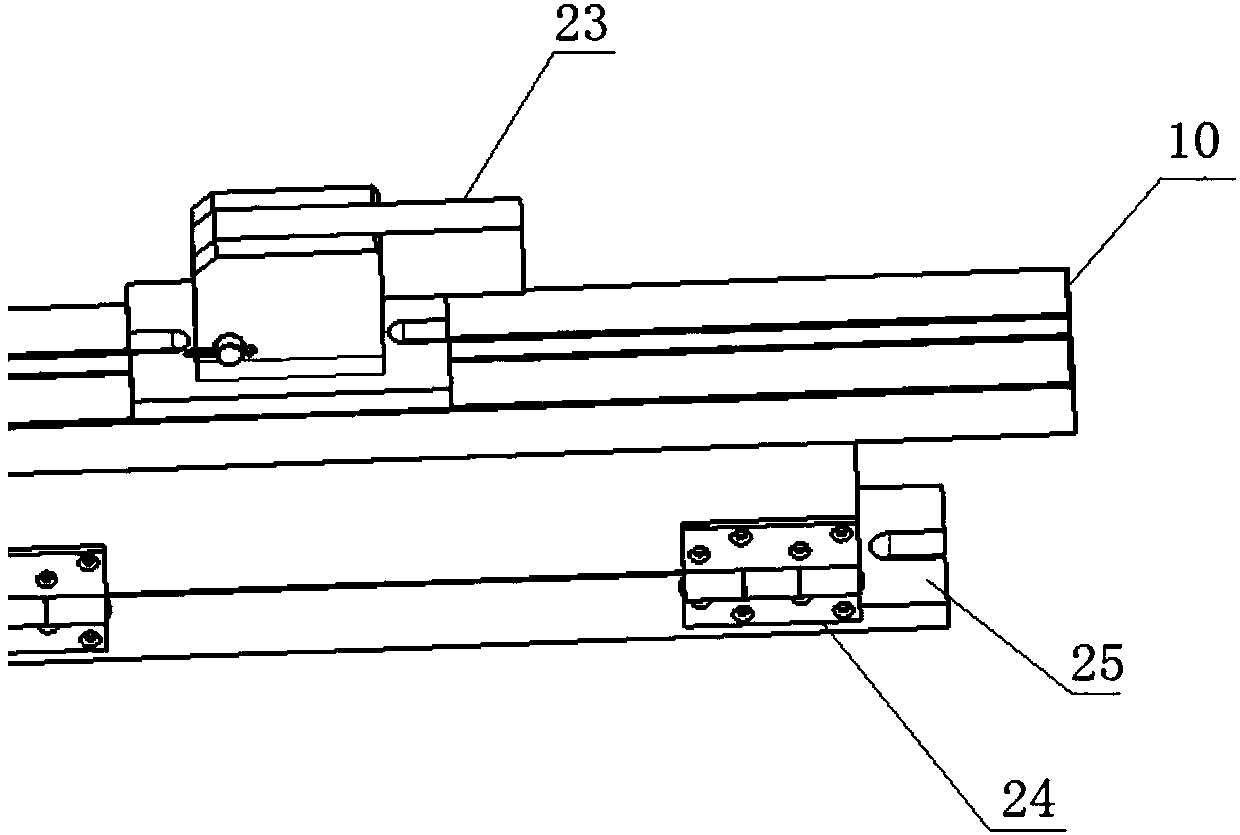

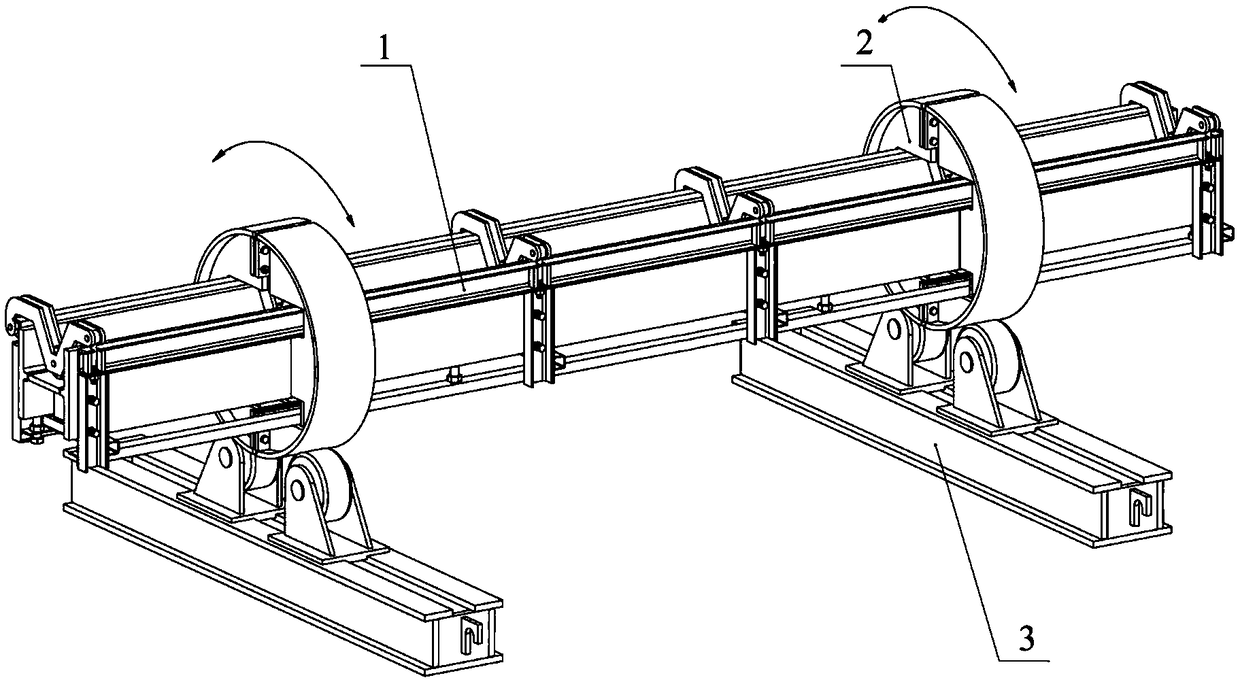

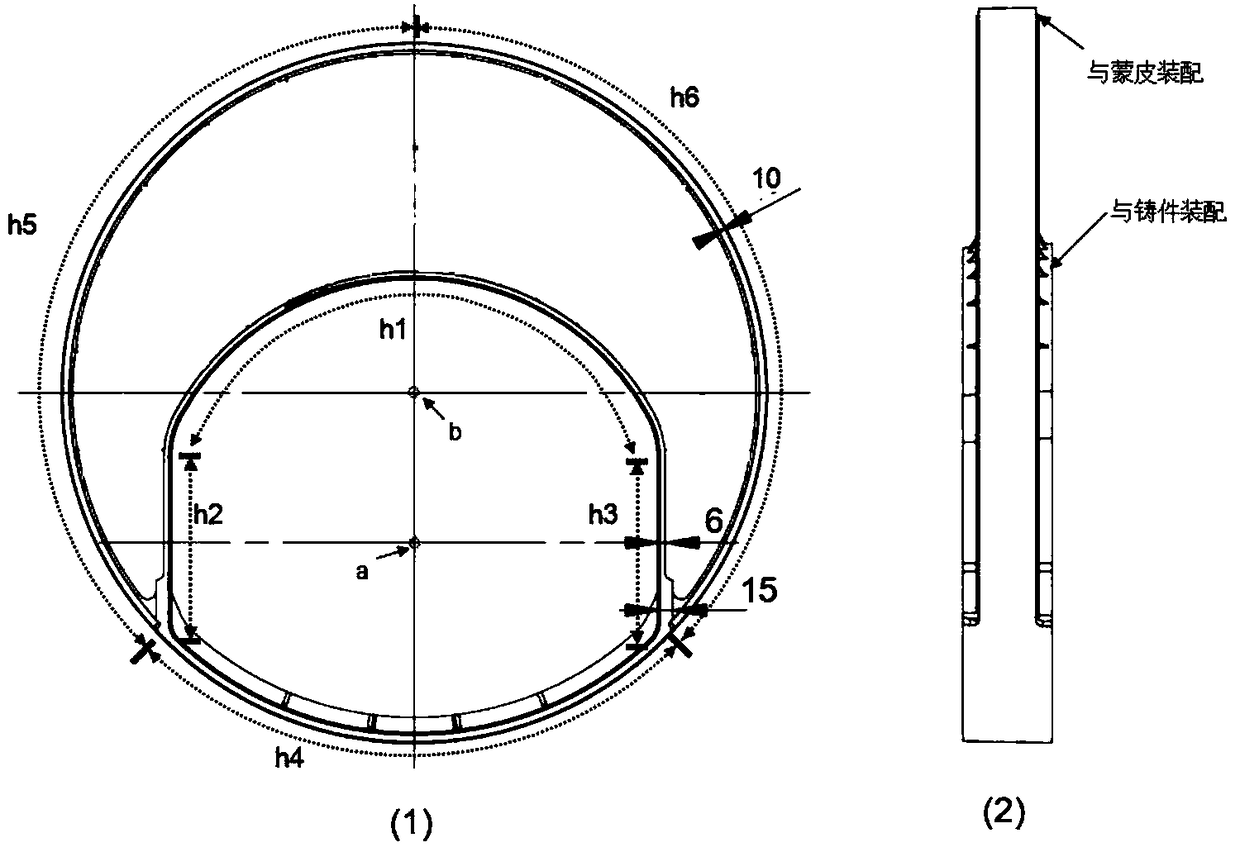

Assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers

ActiveCN103862215AGuaranteed sizeGuaranteed reliabilityWelding/cutting auxillary devicesFurnace typesStress relievingBall screw

The invention relates to an assembly welding tool device and method commonly used for large curved surface end sockets of pressure containers. The assembly welding tool device comprises a supporting base plate, a ball screw, grouped rolling bearings, a movement air cylinder, external locating blocks, internal locating blocks, a manual rocker and a graduated scale, wherein the ball screw and an executive component drive most of the external locating blocks and most of the internal locating blocks to move along guide rails of the supporting base plate so as to carry out integrated locating clamping fixation on the curved surface end sockets. According to the assembly welding tool device and method commonly used for the large curved surface end sockets of the pressure containers, in the manufacturing process of the pressure containers, tool locating of the large end sockets can be achieved, welding deformation is prevented, the curved surface end sockets are placed on the assembly welding tool device to be clamped in an assembly locating mode, spot fixation is carried out on weld joints, and then welding operation is carried out on the internal weld joints and the external weld joints; after welding is accomplished, the curved surface end sockets are naturally cooled to have the normal temperature, postwelding is carried out on the curved surface end sockets, stress relieving is carried out on the curved surface end sockets, labor intensity of workers is reduced, the production and manufacturing cycle of products is shortened, and the production cost is reduced.

Owner:哈尔滨市黎明锅炉容器封头有限公司

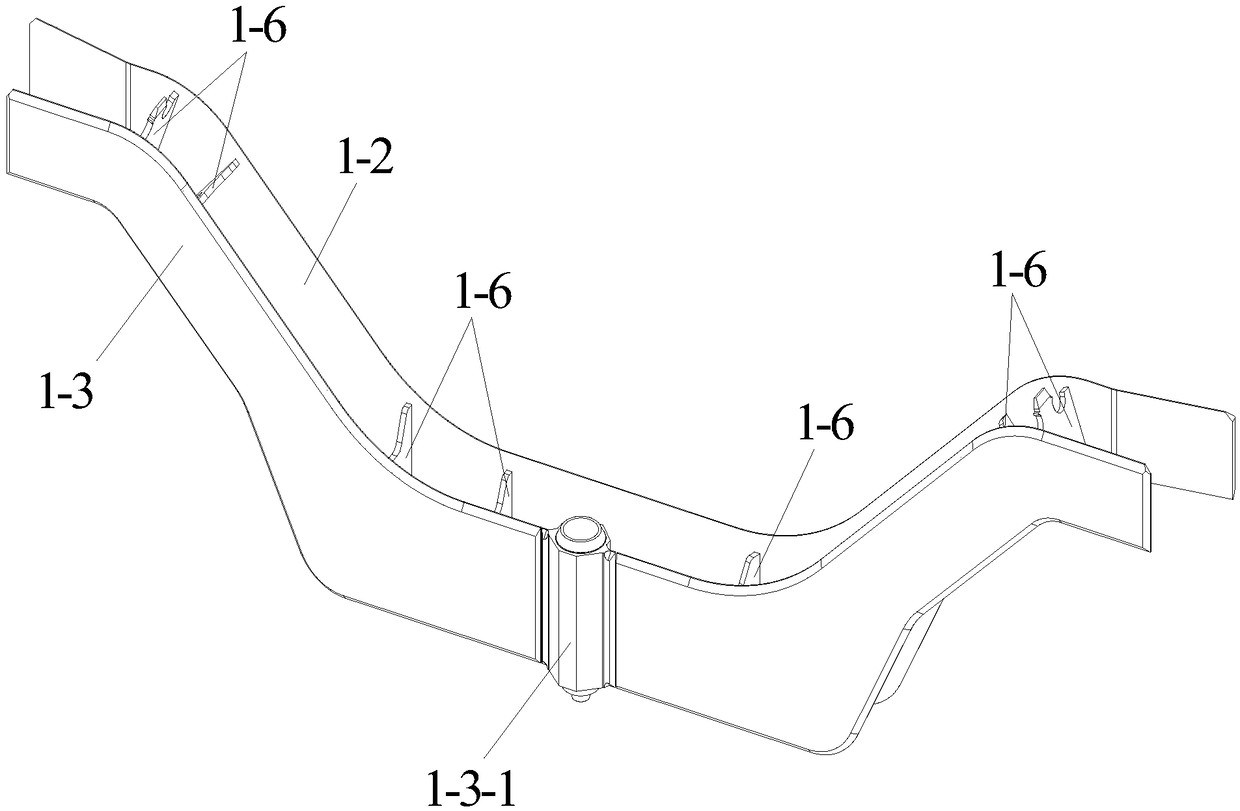

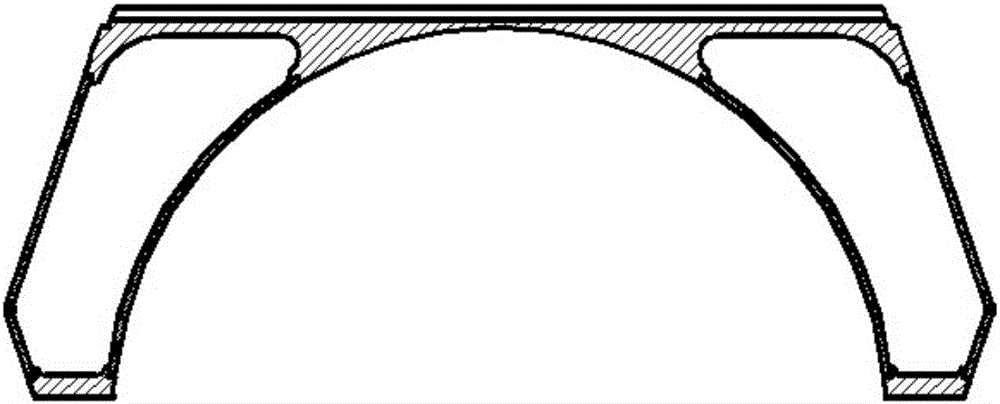

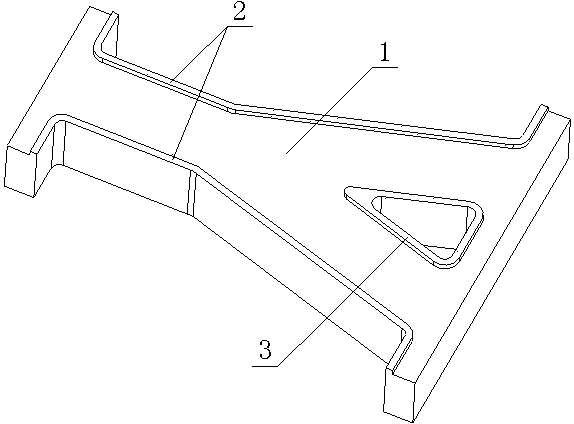

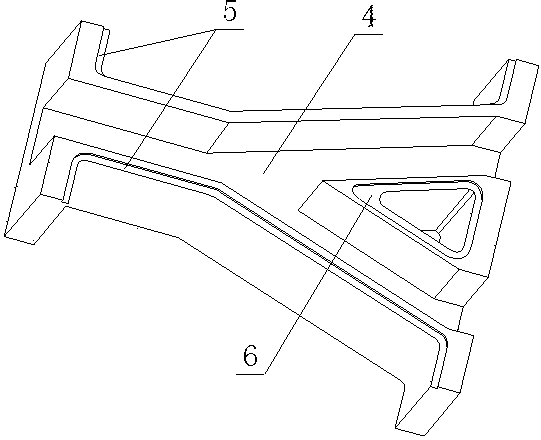

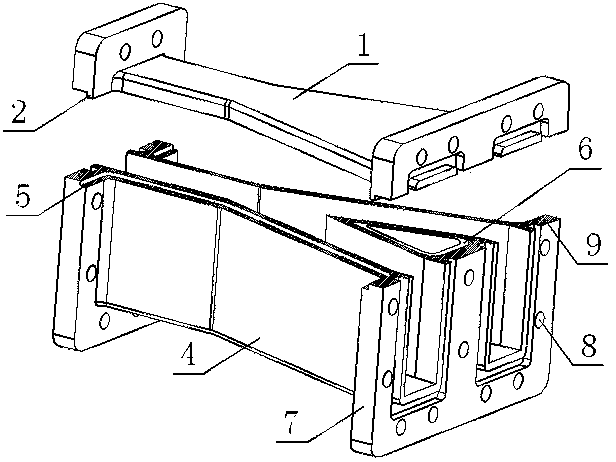

Assembly positioning tool for side beam dressing welding

ActiveCN108817797AThe way is simple and fastAvoid welding deformationWelding/cutting auxillary devicesAuxillary welding devicesBogieEngineering

The invention relates to an assembly positioning tool for side beam dressing welding and belongs to the field of auxiliary clamping devices for welding assembly positioning of track vehicle bogie sidebeam devices. The assembly positioning tool includes a base platform, two side beam end positioners, two axle hinged support gate arch positioners and a plurality of side beam upper edge vertical squeezers. Each axle hinged support gate arch positioner and one corresponding side beam upper edge vertical squeezer jointly form a side beam end positioning device. The lower ends of the plurality of side beam upper edge vertical squeezers are fixedly connected to the middle portion of the base platform, and the two side beam end positioning devices are symmetrically fixedly connected to the two ends of the base platform. The assembly positioning tool for side beam dressing welding can completely omit mapping and scribing operation during the side beam assembly, and a component positioning modeis simple, convenient, accurate and reliable and can effectively restrain welding deformation at each position of a bird wing-shaped side beam, the repair work after the welding is reduced, and thusthe production efficiency and product quality can be greatly improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Converse construction process for middle-high steel structure building

ActiveCN101691787AAvoid welding deformationGuaranteed stiffnessBuilding material handlingFloor slabSystem construction

The invention relates to a converse construction process for the middle-high steel structure building, belonging to the steel structure system construction field and aiming at solving the problems that the construction surfaces are less, the construction efficiency is low, the construction period is long and the manufacturing of the steel structure components can not meet the integral mounting quality standard requirements because the steel floorslabs and the steel structure frameworks are constructed synchronously during the construction of the prior steel structure building. The converse construction process for the middle-high steel structure building comprises the following steps: refining and enlarging the connection nodes of the steel structure frameworks; processing and assembling the steel structure components according to the enlarged construction drawing; transporting and stacking the steel structure components; mounting the steel structure frameworks; and moungin the steel floorslabs. Because the converse construction process of mouting the main structures of all the steel structure frameworks before the mouting the steel floorslabs is adopted, the steel structure frameworks and the steel floorslabs can be constructed on the same plane and can be constructed in a vertical and cross way without mutual influence, the construction speed can be accelerated, and the construction efficiency can be improved. The converse construction process is simple, convenient, economical, reasonable, safe and reliable, ensures high mounting precision and can be applied to the construction of various middle-high steel structure buildings.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +1

Vacuum electron beam welding method for special-shaped thin-walled metal plate welding structure cabin

InactiveCN106392294AAvoid cutting effectReduced solder assembly requirementsElectron beam welding apparatusPower flowSlag

The invention belongs to a vacuum electron beam welding method aiming at a special-shaped thin-walled metal plate welding structure cabin. The vacuum electron beam welding method comprises the following steps: firstly, preparation before welding; secondly, welding and assembling; thirdly, electron beam welding; fourthly, quality inspection after welding. The vacuum electron beam welding method has the advantages that: chemical cleaning and mechanical cleaning are performed before welding, so that the defects, such as air holes and slag inclusion, are formed by welding seams because of oil contamination and oxidant on the surface of a workpiece can be effectively avoided; pre-welding is performed by using a focalized small current electron beam, so that the welding and assembling requirements of the cabin can be reduced, and an electron beam cutting effect caused by an overlarge butt gap can be avoided; meanwhile, a welding seam can also be preheated, and the possibility of the air holes and cracks of a joint can be reduced; the formation of a welding seam surface can be improved by performing typical welding by using a focalized large current electron beam, so that one-time welding formation can be realized, and the welding deformation caused by modification welding is avoided. The formation of the welding seam can be improved and the possibility of air holes of the joint can be reduced by using scanning electron beam current.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

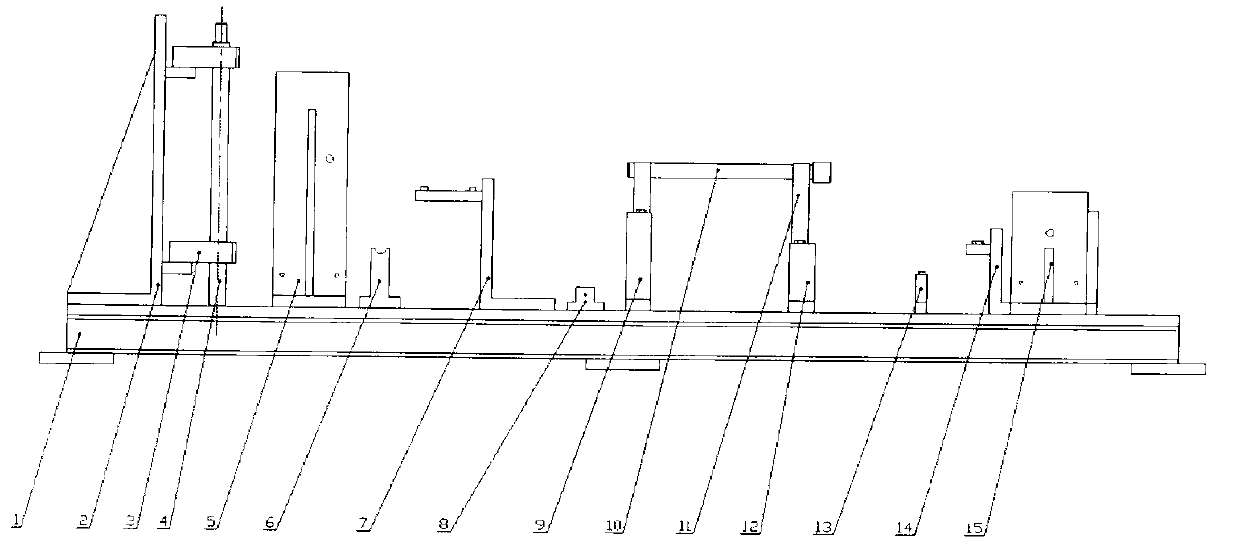

Integrated welding-die mechanism for rear frames of small-sized wheel loaders and medium-sized wheel loaders

InactiveCN103273242AGuaranteed accuracyMeet mass production requirementsWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses an integrated welding-die mechanism for rear frames of small-sized wheel loaders and medium-sized wheel loaders. The integrated welding-die mechanism for the rear frames of the small-sized wheel loaders and the medium-sized wheel loaders comprises a welding-die base, wherein a hinged plate support, a pair of front fixing plates, a pair of gearbox installing locating plates, a pair of front engine installing hole fixing plates, a pair of rear engine installing hole fixing plates, two front-and-back swing frame hole blocks, a front-and-back swing frame hole locating pin roll, a gear pump installing base limiting plate, a pair of left-and-right longitudinal beam locating bases and a pair of rear tail plate limiting blocks are arranged on the welding-die base in sequence, the front-and-back swing frame hole locating pin roll is arranged between the front-and-back swing frame hole blocks, two vertically-arranged middle limiting plates are arranged on the hinged plate support, and a hinged plate hole locating core rod is arranged on the two middle limiting plates. The integrated welding-die mechanism for the rear frames of the small-sized wheel loaders and the medium-sized wheel loaders can ensure accuracy of assembled and welded assemblies, prevent welding deformation, meet requirement for mass production of the loaders, greatly improve efficiency of assembly, and ensure strength of welding, and meanwhile stress deformation of components cannot happen after the components are welded.

Owner:ANHUI ZHONGDING FEICAI VEHICLE

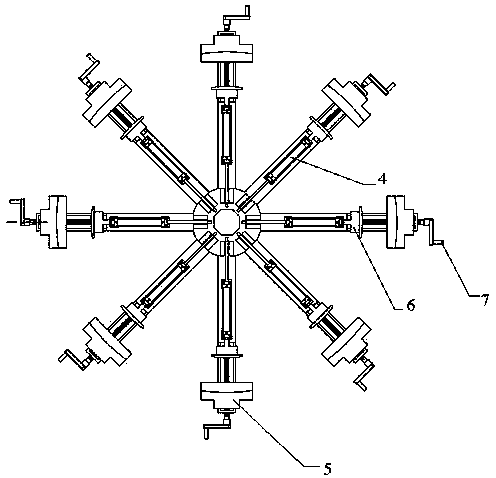

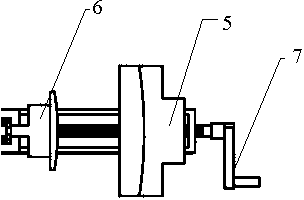

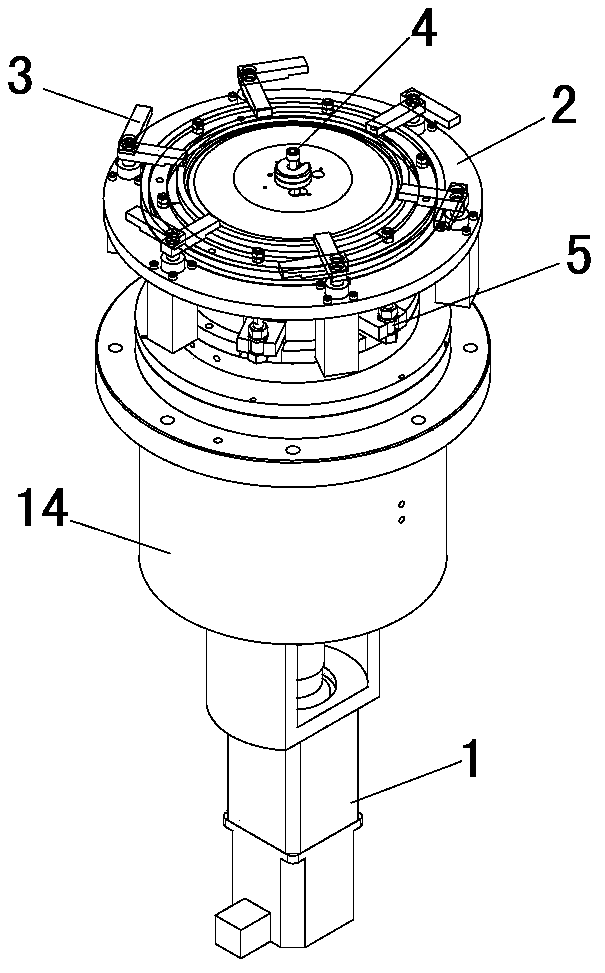

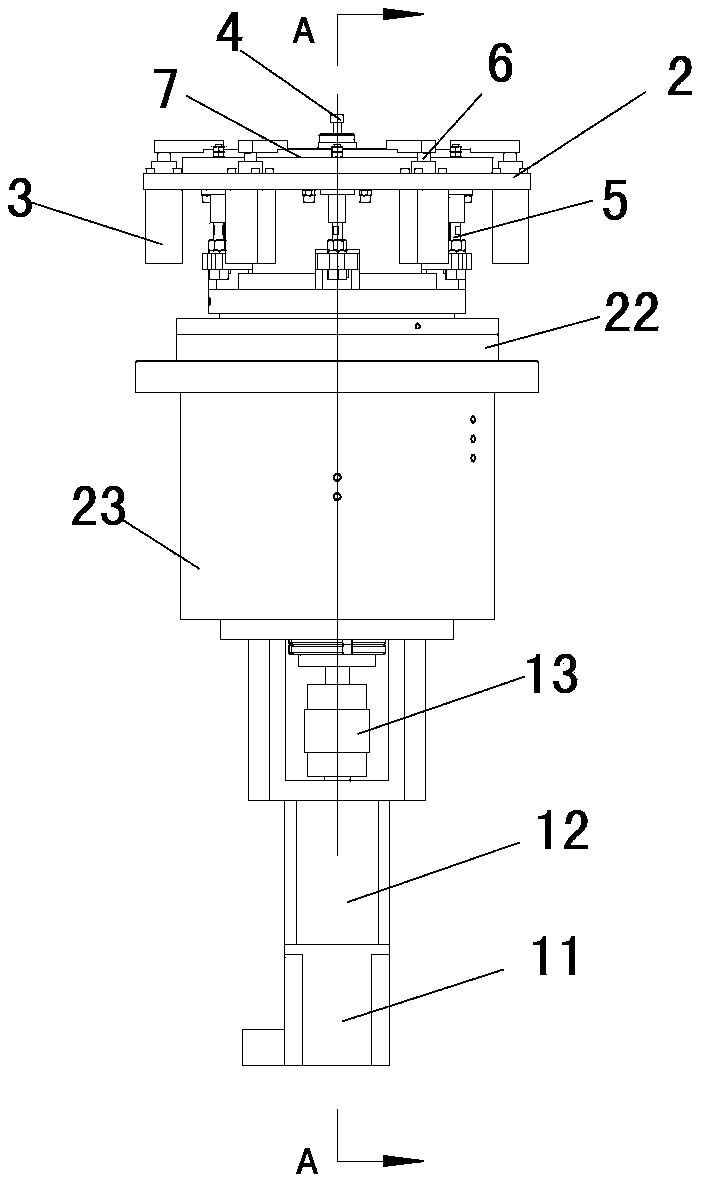

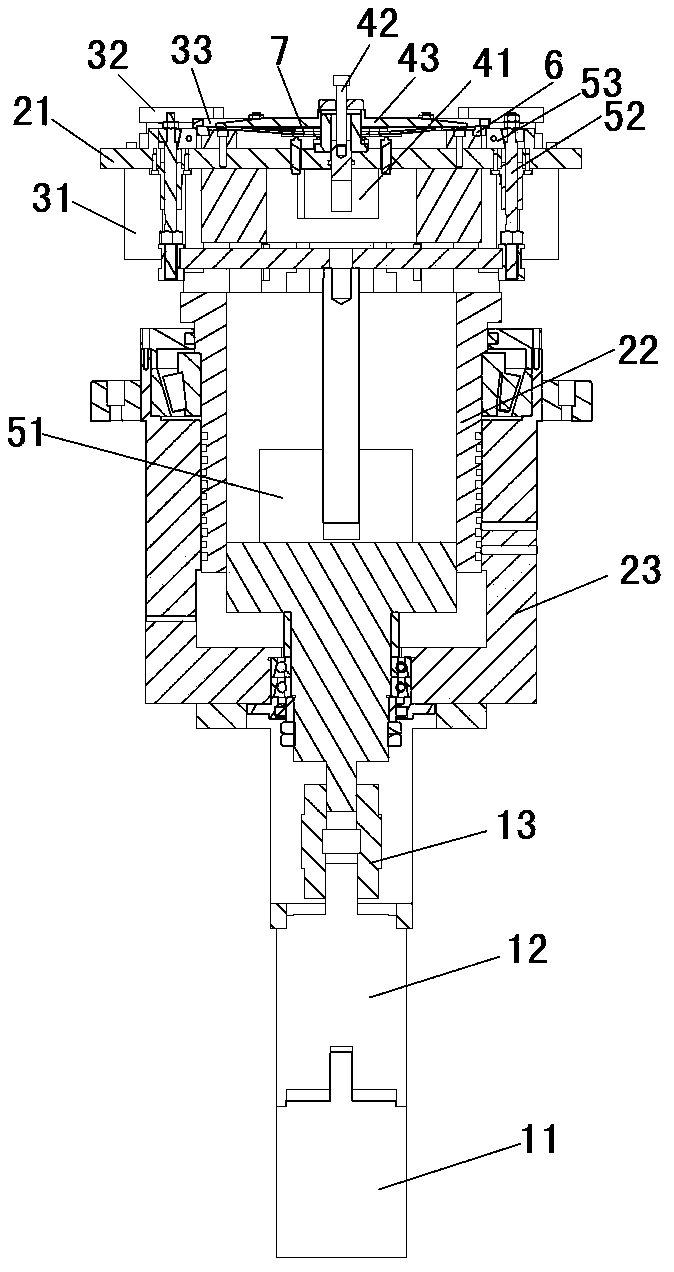

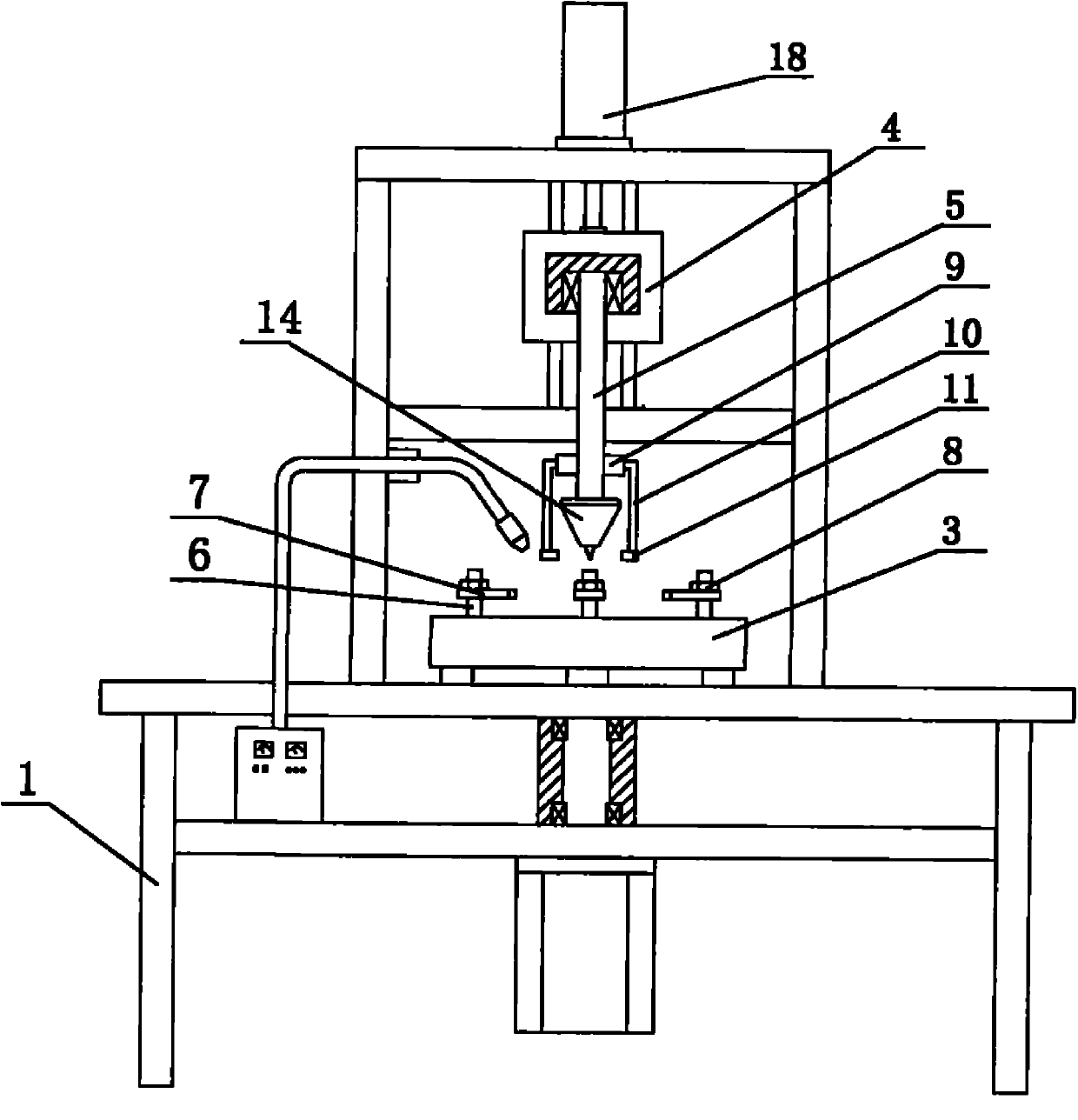

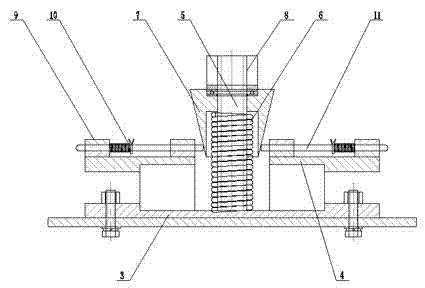

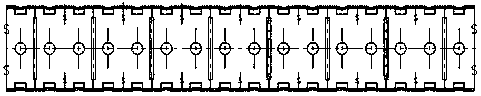

Laser welding fixture for gear

InactiveCN103506761AReduce complexityAvoid welding deformationWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

A laser welding fixture for a gear comprises a power rotating mechanism, a welding platform, a gear ring clamping mechanism, a wheel disc clamping mechanism and a gear ring tightening mechanism. The welding platform is in fixed transmission connection with the power rotating mechanism, the gear ring clamping mechanism is installed on the welding platform and used for clamping a gear ring axially, the wheel disc clamping mechanism is installed on the welding platform and used for clamping a wheel disc axially, and the gear ring tightening mechanism is arranged on the welding platform and used for clamping the gear ring radially. According to the laser welding fixture for the gear, the gear ring contracts and is clamped through the gear ring tightening mechanism in the radial direction, and therefore the concentricity of the gear ring can be guaranteed; the gear ring is clamped through the gear ring clamping mechanism in the axial direction, so that the end face accuracy of the gear ring is guaranteed, and the anti-splash protection effect is achieved at the same time; the wheel disc is clamped through the wheel disc clamping mechanism in the axial direction, so that welding deformation of the wheel disc is prevented, and welding accuracy is improved. The whole laser welding fixture for the gear can effectively prevent welding deformation, protect the gear, and improve welding accuracy and welding efficiency.

Owner:上海团结普瑞玛激光设备有限公司

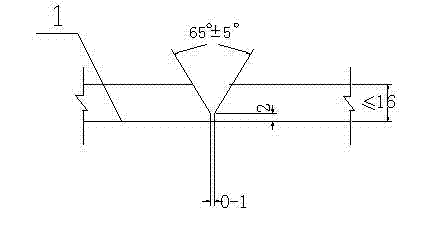

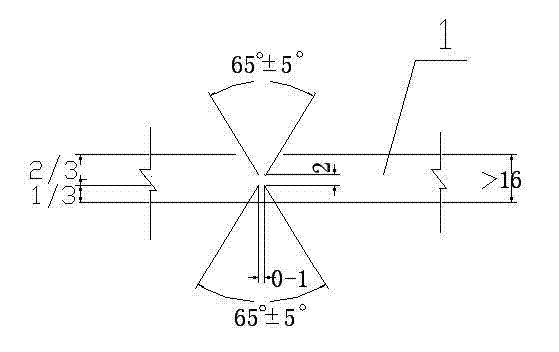

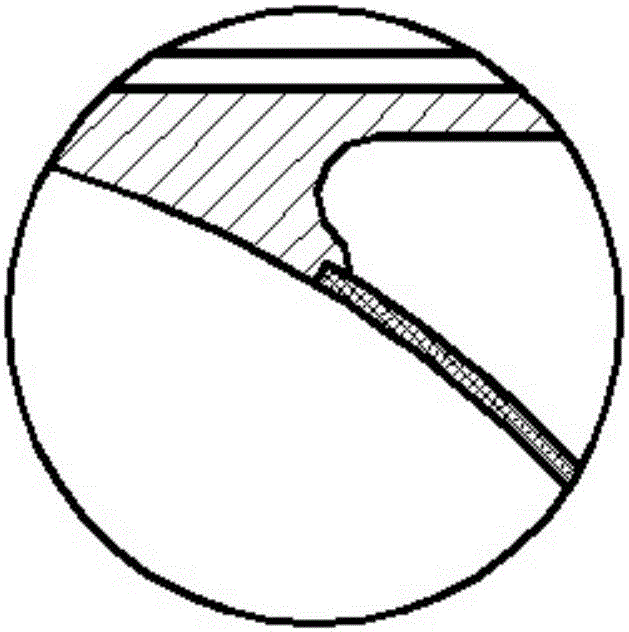

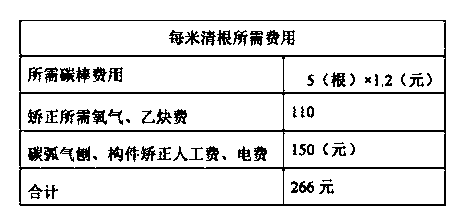

Full penetration fillet weld back-gouging-free welding technology

InactiveCN104259634AImprove rigidityImprove deformation resistanceArc welding apparatusWorkpiece edge portionsFillet weldEngineering

The invention belongs to the technical field of steel structure welding and provides a full penetration fillet weld back-gouging-free welding technology. The welding technology comprises the following steps of: 1) processing a groove of a web plate and decreasing the welding groove as much as possible, 2) fabricating a welding body, ensuring an inclination angle of the welding body to allow a center line of a welding wire to be located on a bisector of an included angle between the groove of the web plate and a wing plate during welding, 3) assembling and placing the web plate and the wing plate on the welding body in a push-against manner, ensuring the straightness and planeness of the web plate and the wing plate and accurately controlling focuses of the web plate and the wing plate, 4) selecting an appropriate welding wire material according to performance of a base material, and carrying out carbon dioxide gas shielded welding on a weld on the reverse side of the groove of the web plate to form a welding backing plate for later groove welding, 5) carrying out union melt welding as the first U-shaped groove welding, and 6) carrying out layered filling welding via the union melt welding, and finally carrying out cosmetic welding, wherein the groove of the web plate is a unilateral U-shaped or V-shaped groove.

Owner:CHINA SIXTH METALLURGICAL CONSTR

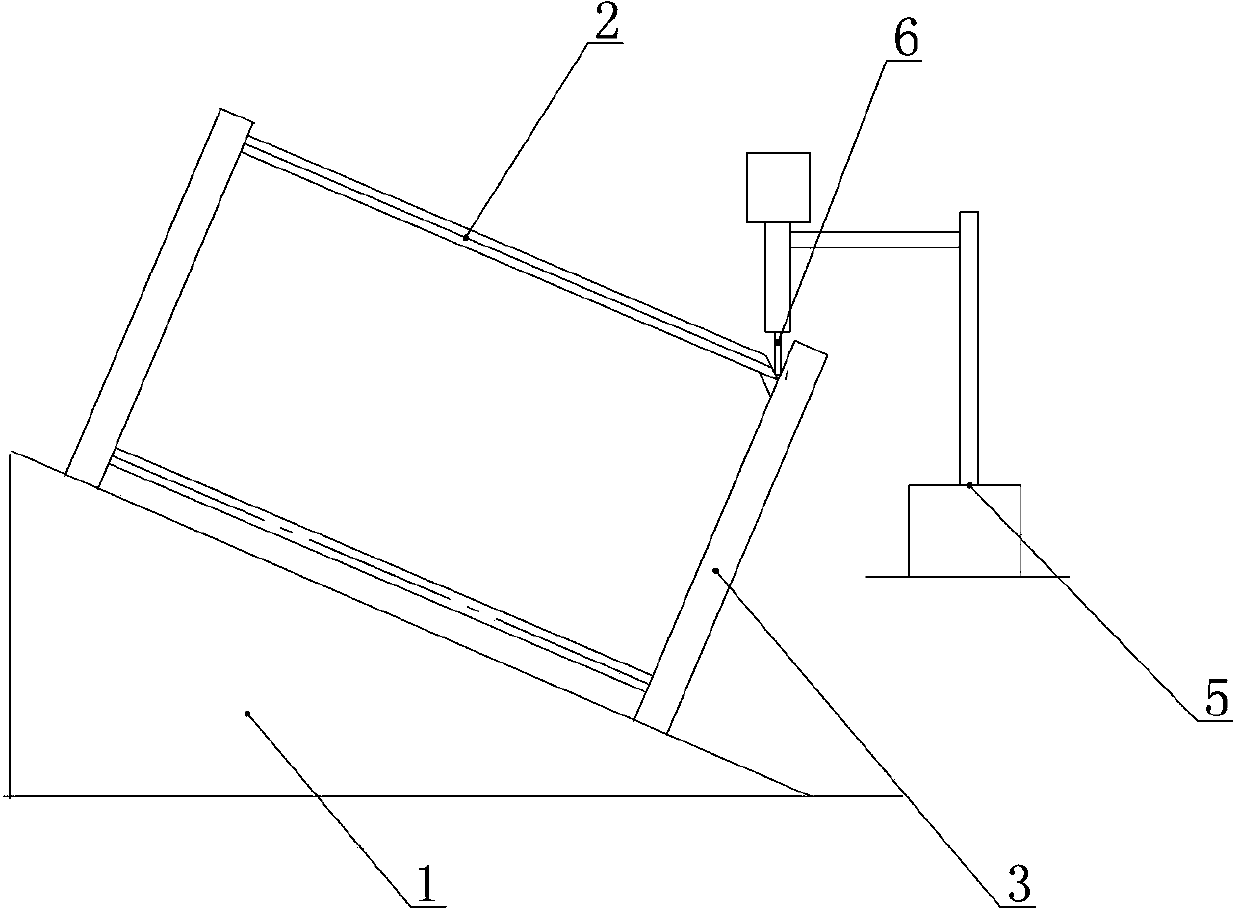

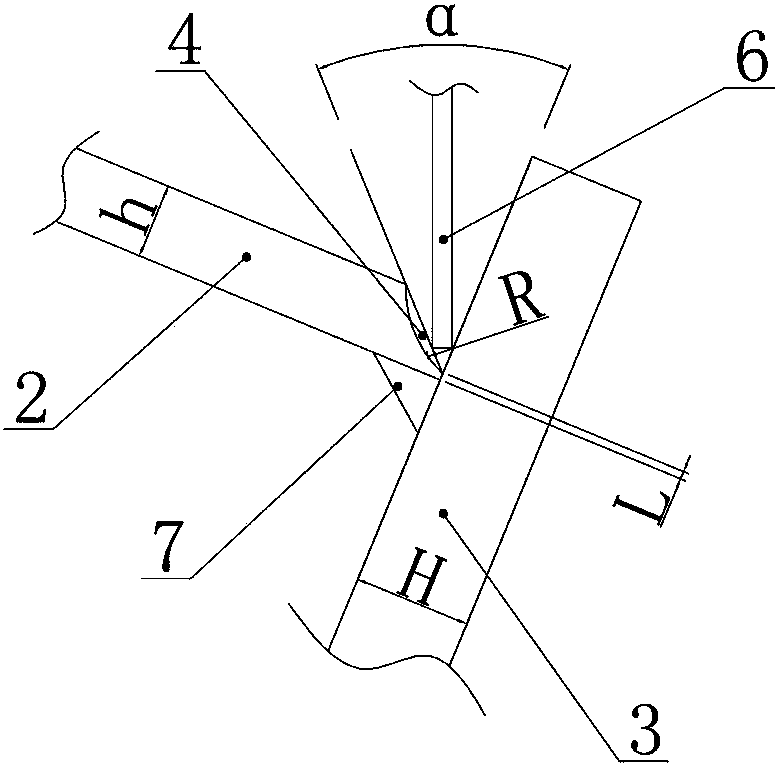

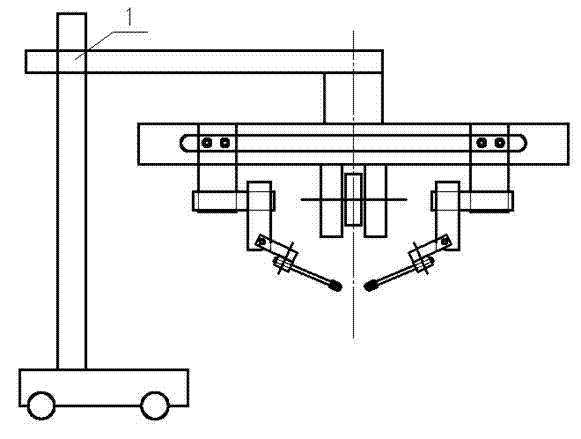

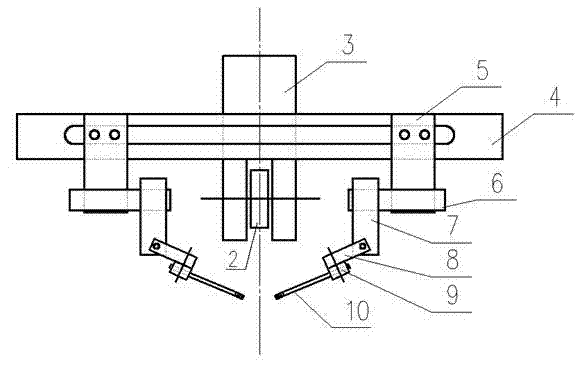

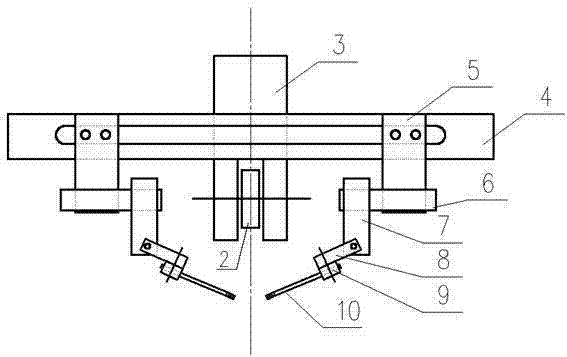

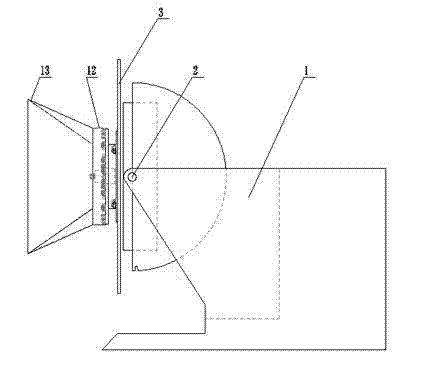

Automatic welding device for annular symmetrical fillet welds

ActiveCN102642069ACounteracts welding stressAvoid welding deformationArc welding apparatusEngineeringWelding

The invention relates to an automatic welding device for annular symmetrical fillet welds. The automatic welding device comprises a supporting device, a fixed connection arm and a horizontal slide rail, wherein the fixed connection arm is fixedly connected with the horizontal slide rail in a vertical cross manner, one side of the fixed connection arm is fixed on the supporting device, and the other side of the fixed connection arm is provided with a rotatable guide wheel; the horizontal slide rail is provided with two welding gun positioning devices which can move along the horizontal slide rail, and the two welding gun positioning devices are symmetrically arranged by taking the fixed connection arm as a center; each welding gun positioning device comprises a vertical coarse adjuster, a horizontal fine adjuster, a vertical fine adjuster, a left-and-right rotator and a back-and-forth rotator; and the back-and-forth rotators are provided with two welding gun heads. According to the automatic welding device for the annular symmetrical fillet welds, the two welding gun positioning devices are adopted to be symmetrically arranged, so that the two welding gun heads can simultaneously weld on both sides, the welding stress can be offset, and the welding deformation is prevented; and meanwhile, the manual welding of the fillet welds is replaced by the automatic welding device disclosed by the invention, so that the production efficiency is increased, the labor intensity and manufacturing cost are lowered, and meanwhile, the welding quality of the fillet welds is improved.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Tank of benzene hydrogenation engineering and manufacturing and mounting method thereof

ActiveCN104843357AImprove welding qualityAvoid welding deformationLarge containersUnderwater structuresBenzeneRadar

The invention discloses a tank of a benzene hydrogenation engineering. The tank is a vertical cylindrical steel storage tank, and comprises a breather valve (24), a waveguide pipe (25), a light transmission hole (26) and an inner floating disc (27); the vertical cylindrical steel storage tank is characterized by being provided with a tank vault; the breather valve (24) and the light transmission hole (26) are arranged on the tank vault; the waveguide pipe (25) is a round pipe type radar waveguide pipe, and extends into the bottom from the top of the tank; a flange is arranged at the top of the waveguide pipe for mounting a radar liquid level meter and measuring a real-time liquid level of the tank to remotely transfer to a central control room; and the inner floating disc (27) is a general self-floating assembled inner floating disc sold on the market, and is horizontally arranged in the vertical cylindrical steel storage tank. The tank of the benzene hydrogenation engineering and a manufacturing and mounting method thereof improve the tank welding quality and prevent the welding deformation caused by thinner wall plates of the tank, and have unique statuses of becoming the instruction classics of tanks and manufacturing and mounting operations thereof in industries.

Owner:MCC5 GROUP CORP SHANGHAI

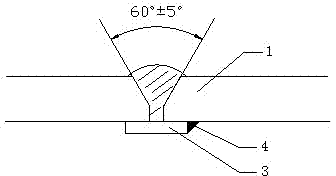

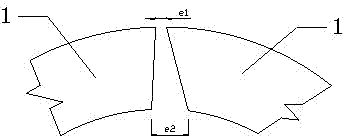

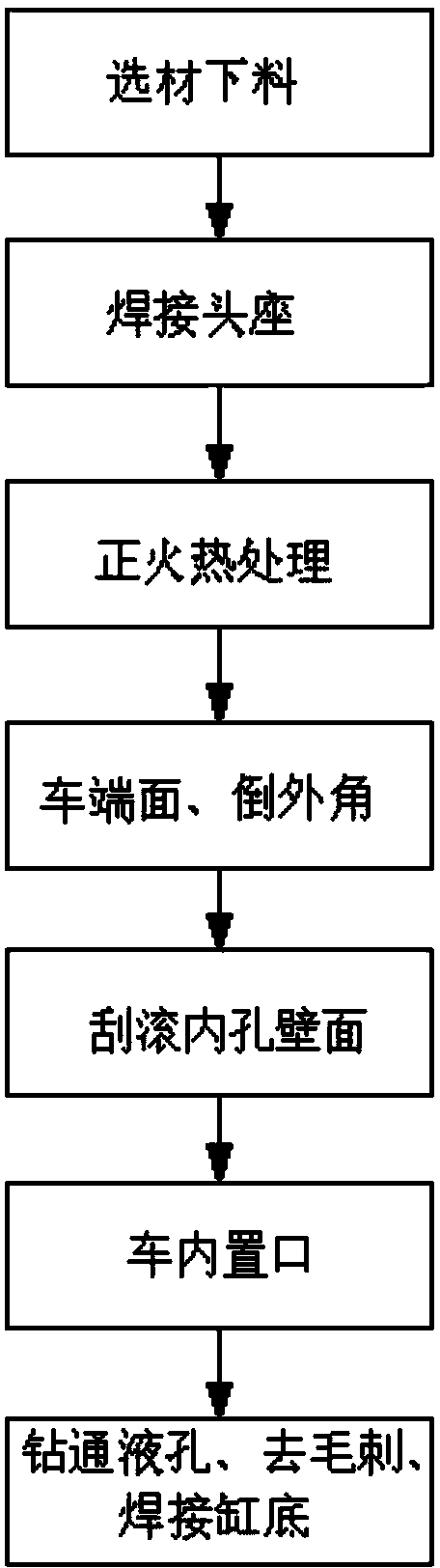

Machining process of hydraulic support lifting jack cylinder

InactiveCN104043950AThe process steps are simpleEliminate welding internal stressLifting devicesJackscrewEngineering

The invention relates to a machining process of a hydraulic support lifting jack cylinder, in particular to a machining process of the hydraulic support lifting jack cylinder through a cold drawn pipe made of 27SiMn. The machining process comprises the steps that firstly, the pipe made of the 27SiMn is selected as machining raw materials of the cylinder, after the pipe is detected qualified, the size is determined, blanking is carried out, and the cylinder is obtained; secondly, a headstock is welded to the cylinder; thirdly, normalization heat treatment is carried out on the cylinder; fourthly, the end surfaces of the cylinder are turned, and the cylinder is chamfered; fifthly, the wall surface of an inner hole of the cylinder is machined in a scraping and rolling mode; sixthly, a built-in opening of the cylinder is turned; seventhly, a hydraulic hole is drilled in the cylinder, burrs on the cylinder are removed, the bottom of the cylinder is welded in a rotary mode, and the hydraulic support lifting jack cylinder is obtained. The machining process of the hydraulic support lifting jack cylinder has the advantages of being simple in process step, eliminating inner stress of welding, prolonging the service life of products, improving production efficiency and lowering production cost.

Owner:河南伟彤重型装备制造有限公司

Welding deformation control fixture for welding of large-scale thin wall storage box structure and welding method

ActiveCN102699515AImprove rigidityDesign Approaches to Avoid Adverse ConsequencesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention provides a welding deformation control fixture for the welding of a large-scale thin wall storage box structure and a welding method. The fixture comprises a front cover and a rear cover, wherein the shape of the front cover is consistent with that of a storage box front bottom and the front cover can cover the storage box front bottom; the shape of the rear cover is consistent with that of a storage box rear bottom and the rear cover can cover the storage box rear bottom; the end parts of both the front cover and the rear cover are provided with outer edges which protrude and extend outward; and the insides of the outer edges are tightly attached to the outer surface of a transition region of the storage box front bottom and are ring-shaped wedge surfaces. According to the method, the storage box front bottom and the storage box rear bottom are respectively connected with both ends of a storage box flange by an electronic beam welding mode. The fixture provided by the invention adopts a design method that the dead weight of the fixture is acted on a thick welded junction region of the storage box structure, so that the disadvantageous effects of the fixture on the thin region in the welding process are effectively avoided; and by utilizing the fixture, the integral rigidity of the thin wall storage box structure can be improved in the welding process and the welding deformation can be effectively prevented.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

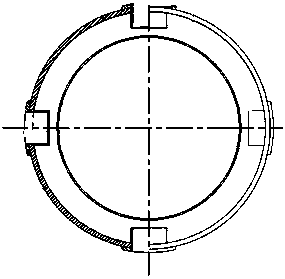

Ring set welding tool

InactiveCN103495828AGuaranteed concentricityGuaranteed clamping effectWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringEngineering

The invention discloses a ring set welding tool. The ring set welding tool comprises a work platform connected to a machine frame, the work platform is provided with an annular groove, an annular protrusion of an outer ring is inserted into the annular groove, the work platform is provided with an outer ring fixture, the machine frame is further provided with a support, the support is driven by a vertical power mechanism to slide vertically, located above the work platform, and is rotationally connected with a supporting arm extending downwards, the supporting arm is provided with an inner ring fixture, and an inner ring locating mechanism is arranged between the downward-extending end of the supporting arm and the work platform. The ring set welding tool has the advantages that an inner ring and the outer ring can be effectively clamped.

Owner:SHANDONG ZHENGTAI HEAVY IND TECH

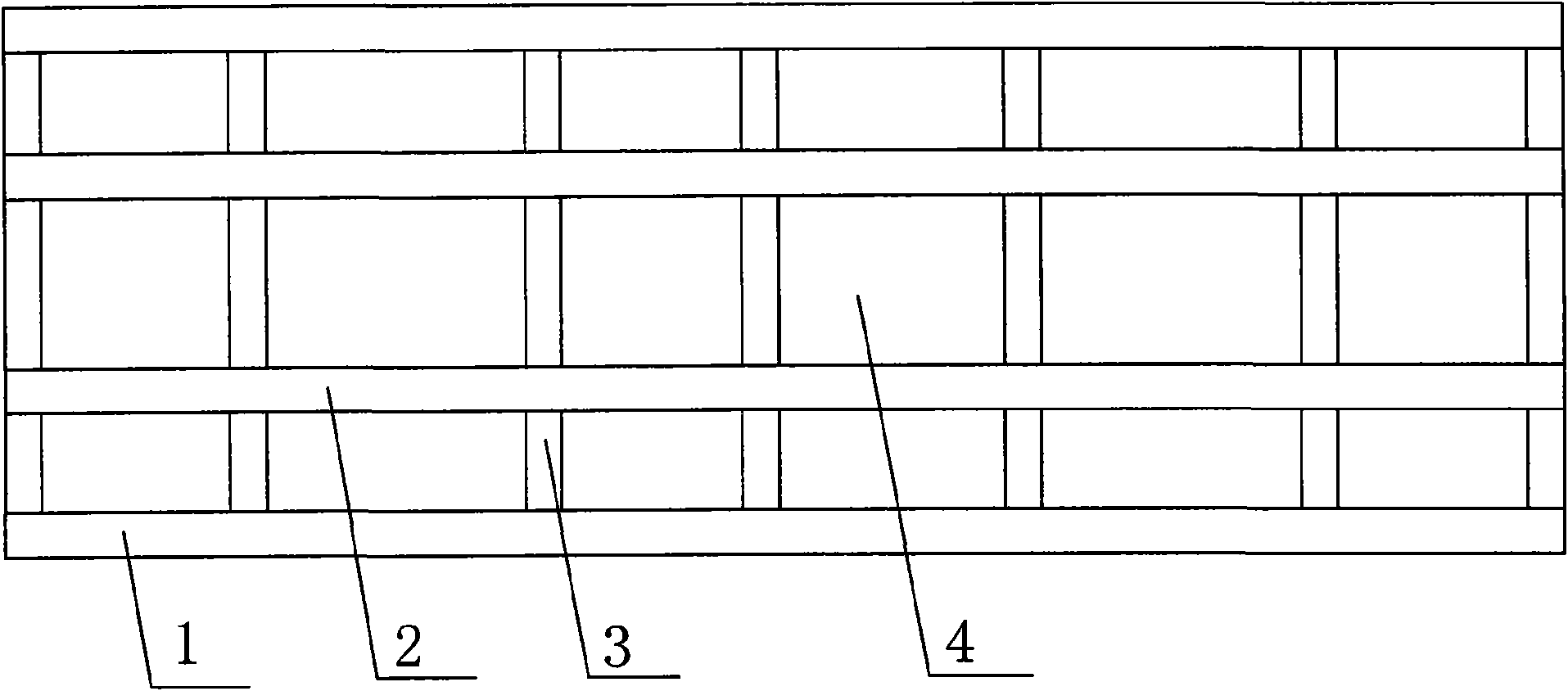

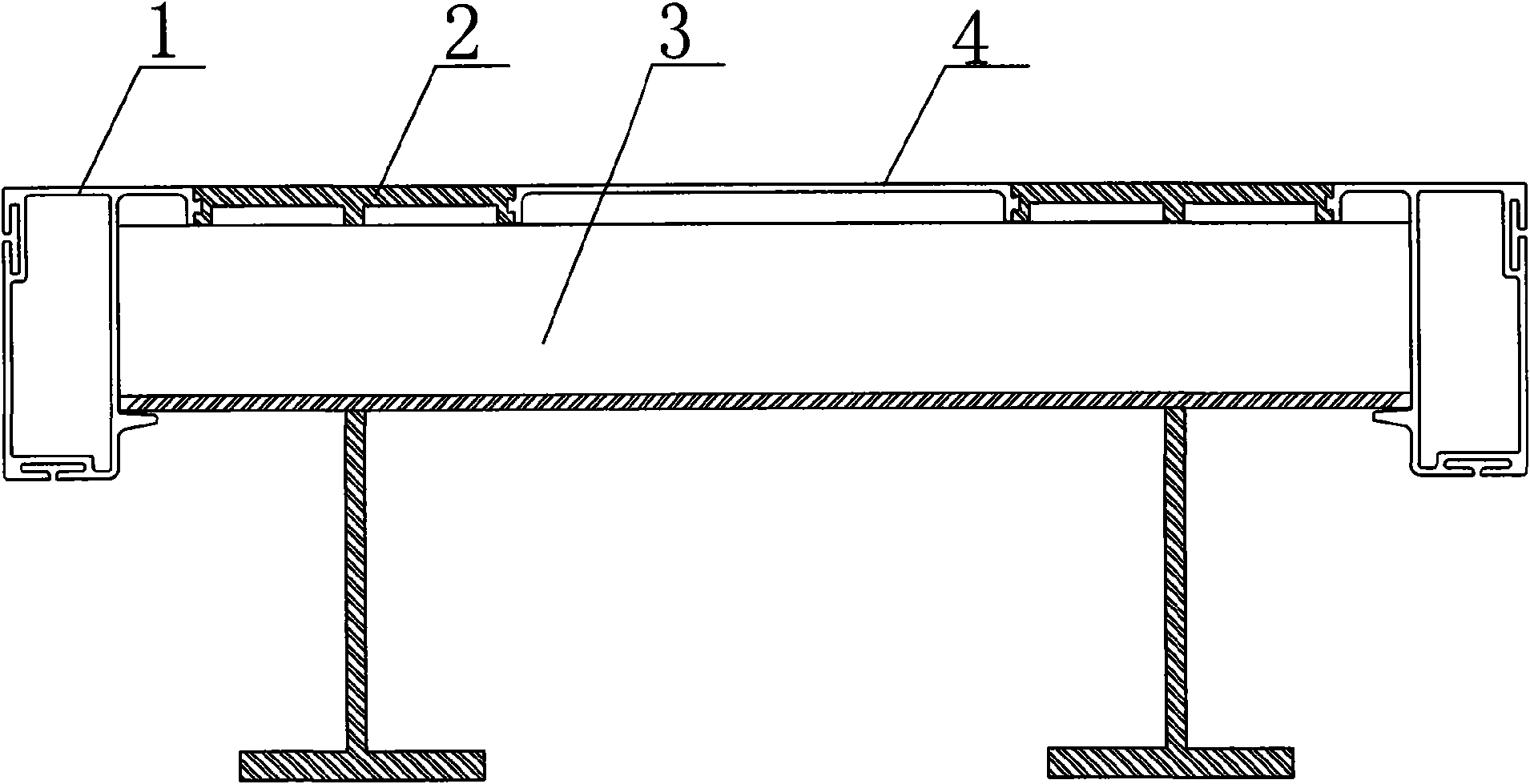

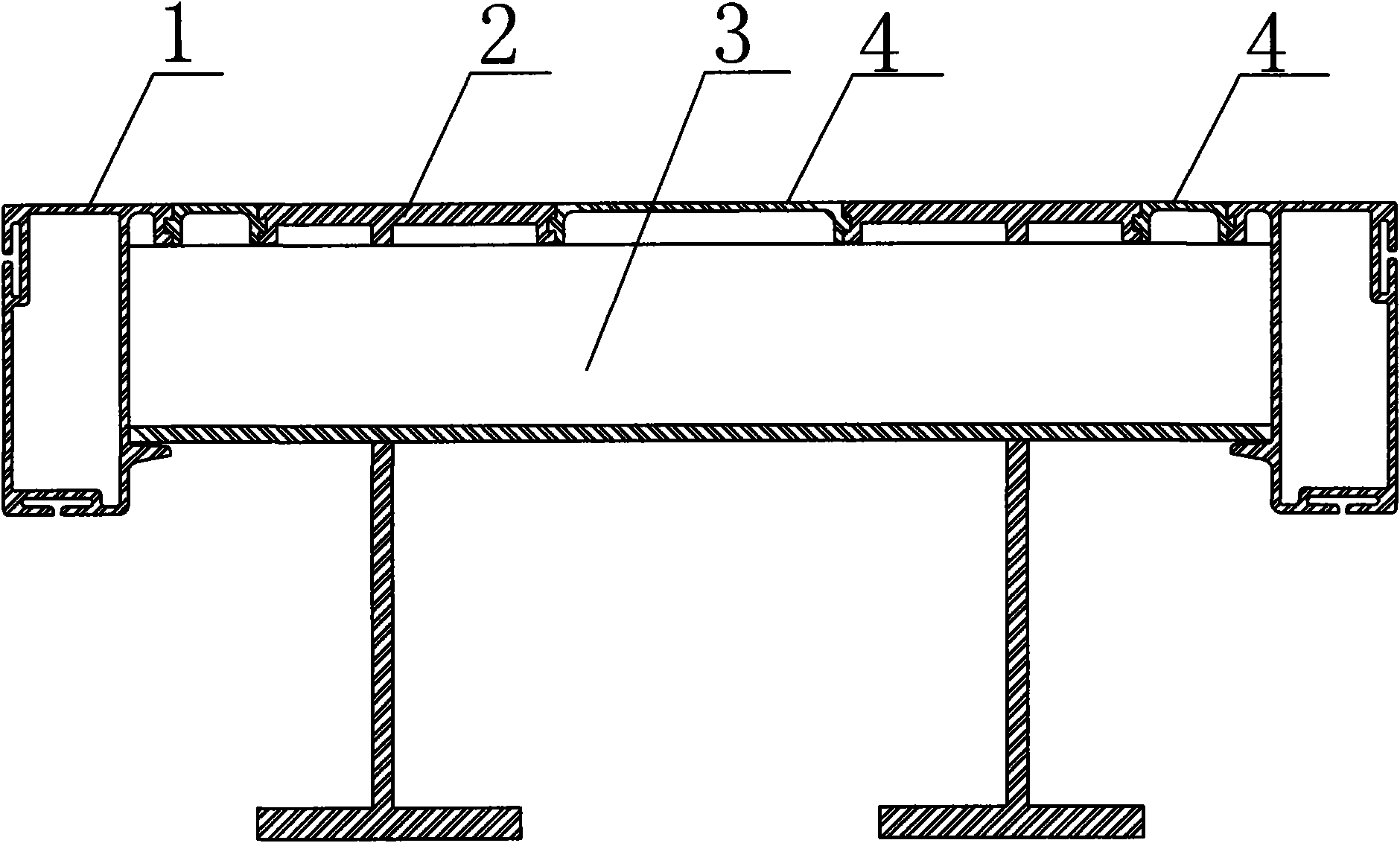

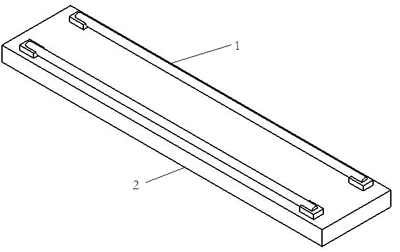

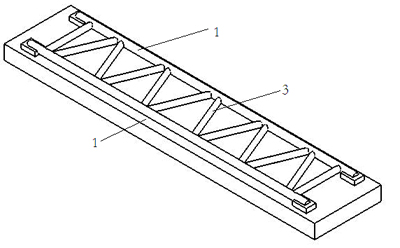

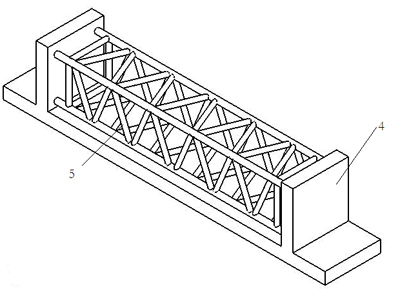

Joggling type vehicle bottom plate assembly

InactiveCN101628590AAvoid welding deformationWon't happenUnderstructuresSuperstructure subunitsEngineeringTongue and groove

The invention relates to a joggling type vehicle bottom plate assembly which comprises edge beams, longitudinal beams and transverse beams. The joggling type vehicle bottom plate assembly is characterized in that the upper parts of the edge beams and the longitudinal beams are provided with planes; one side edge of the edge beams is provided with a joggling groove structure along the length direction, and both side edges of each longitudinal beam are provided with joggling groove structures along the length direction; the edge beams are connected with the longitudinal beams by a joggling groove along the transverse direction of a vehicle body so as to form a plane on the upper surface or the edge beams are connected with the longitudinal beams and the longitudinal beam is connected with the longitudinal beam in such a way that both side edges are provided with transition connecting plates in the joggling groove structure by the joggling groove along the transverse direction of the vehicle body so as to form the plane on the surface; and the transverse beams are connected with the edge beams and the longitudinal beams. The invention prevents the welding deformation of the bottom plate assembly and eliminates welding stress, and the strength and the working reliability of the bottom plate assembly are not influenced by welding, particularly the vehicle bottom plate made of an aluminum magnesium alloy material has more obvious effect; no harmful gas is generated in the assembly process of the bottom plate assembly, thereby being beneficial to environmental protection; the assembly process is simple, the production efficiency is high, and the manufacture cost is reduced.

Owner:王景峰

Active welding method for filler wire welding

InactiveCN101244489ASuppresses phenomena such as grain coarseningHigh strengthWelding/cutting media/materialsSoldering mediaActive agentWelding deformation

The invention relates to an active welding method applying to the filler wire welding, belonging to the material engineering technical field, which is characterized in that: the active agent is equably packaged in welding wire or is coated on the surface of welding wire. When the invention is applied to magnesium alloy welding, the active agent is composed of MnCl2, CaCl2, MnO2, and ZnO and the weight proportion is MnCl2: 10% to 40%, CaCl2: 5% to 20%, MnO2; 15% to 30% and ZnO: 20% to 60%. The active agent addition quantity lies on the surface area of welding wire, 0.2 to 0.8mg / mm2. The active welding method has the advantages that: the invention overcomes the difficulty of wire fill and weld joint moulding; the weld joint of the invention is uniform and beautiful; the welding penetration of the invention is one to three times of the ordinary filler wire welding; the welding times of thick panels are reduced; the welding deformation is efficiently depressed; the intensity of weld joint is improved; the welding craft is simplified; the productivity is improved.

Owner:DALIAN UNIV OF TECH

Welding device and process method for section-increased cantilever crane body assembly positioning welding

InactiveCN101941129AAvoid the inconvenience of scribing vertical assembly tack weldingAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCantilever

The invention provides a head and tail-type rotatable positioner tool with a lifting platform, and a process method for section-increased cantilever crane body assembly positioning welding adopting the tool. In the method, the lifting platform and the head and tail-type rotatable positioner are adopted; the assembly positioning welding of an overall section-increased cantilever crane body is finished in limited ground space, which saves fussy operations of welding piece by piece and assembling finally in conventional welding; simultaneously, the welding of all ventral tubes is performed on a horizontal plane, which saves a trouble in lineation vertical assembly in the conventional welding; moreover, the welding process of the overall positioning welding is finished under the restriction of a tool, which effectively avoids cantilever crane distortion and welding distortion caused by overturning; and therefore, the welding quality and the welding efficiency of the section-increased cantilever crane body are improved fundamentally.

Owner:SHANGHAI SANY TECH

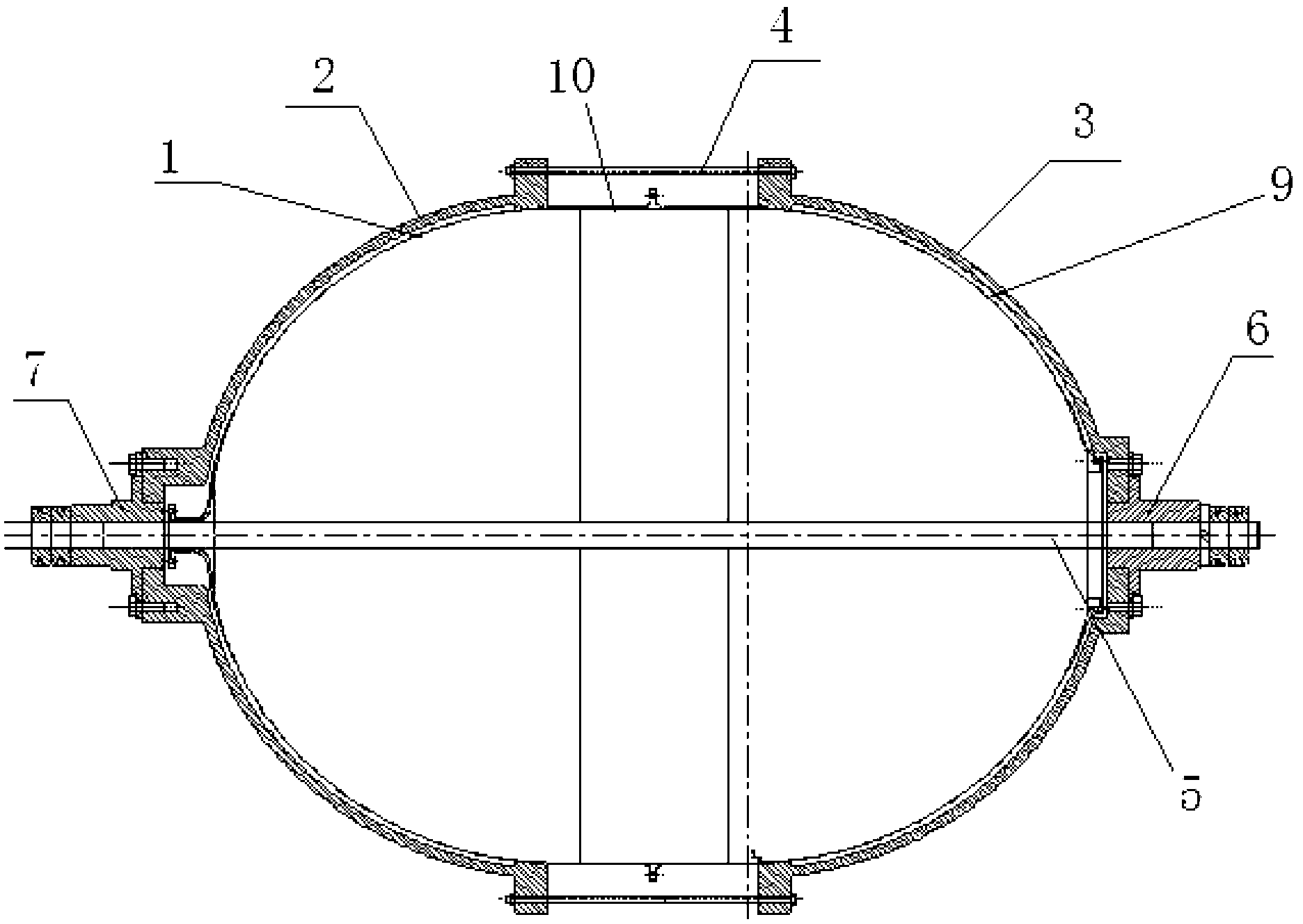

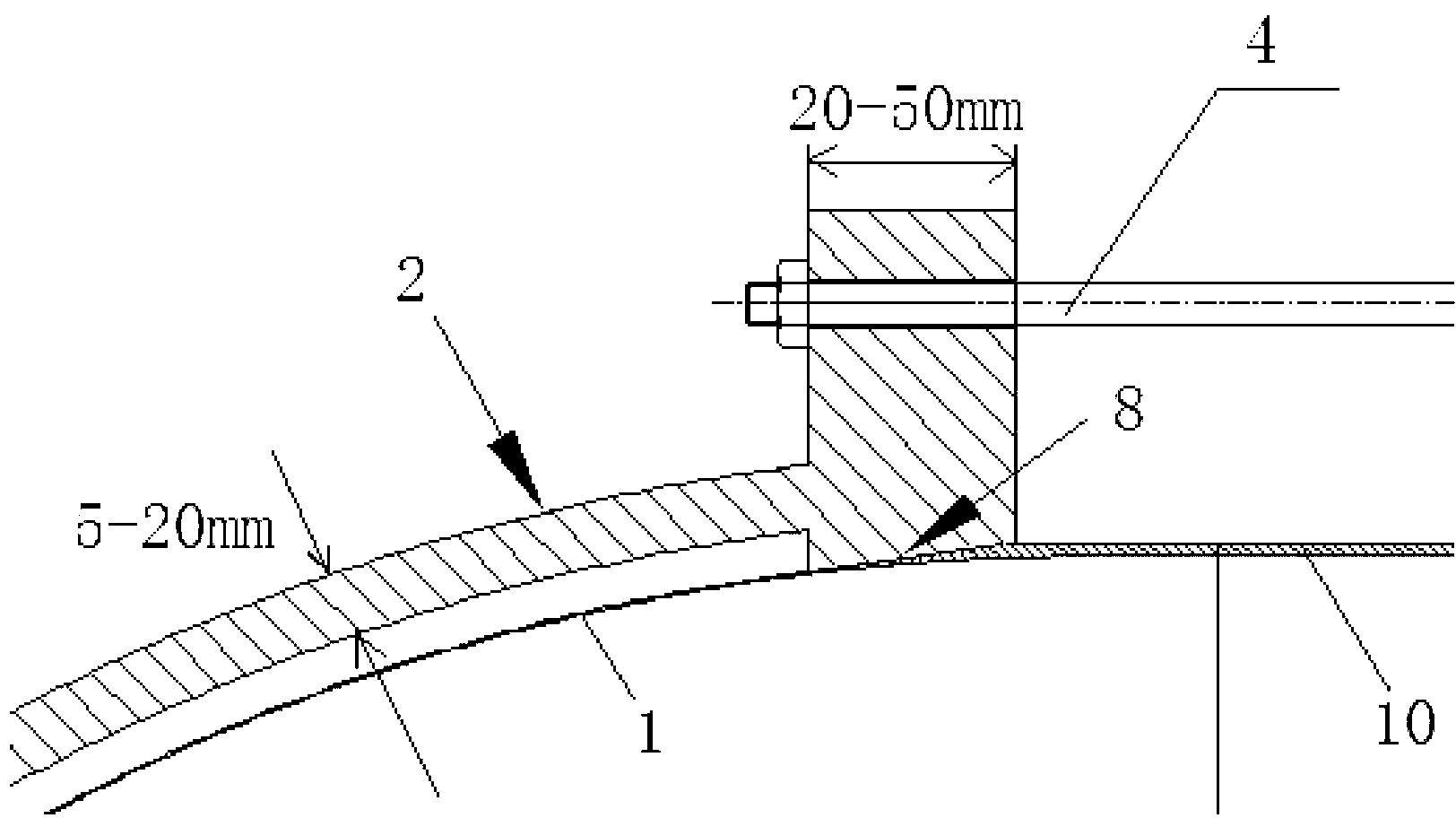

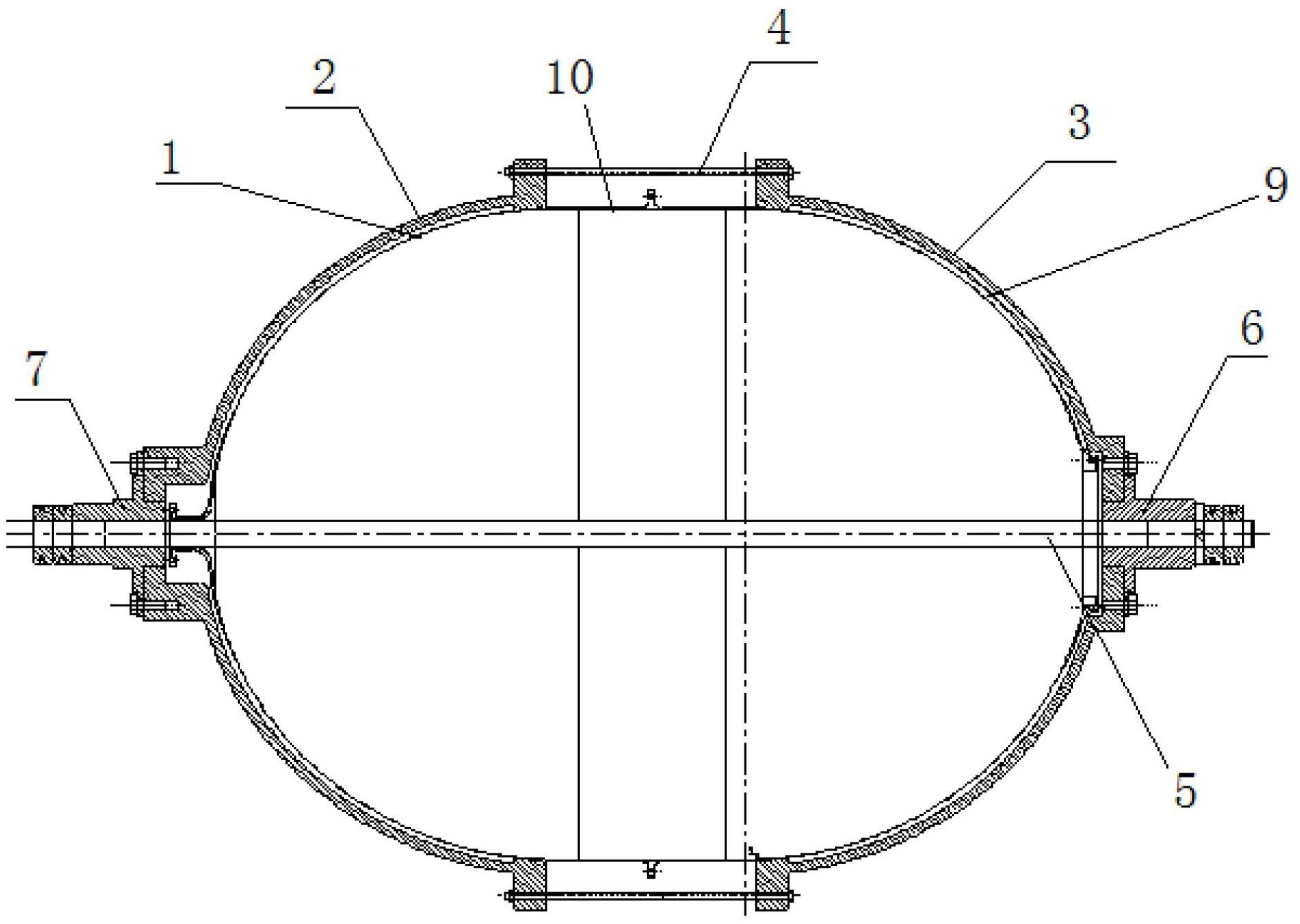

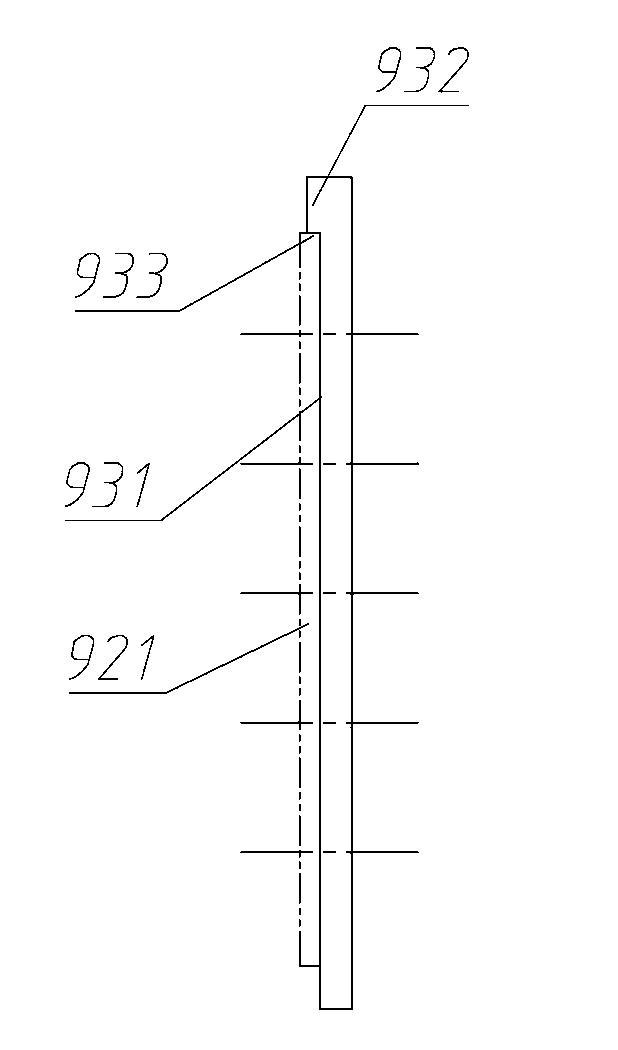

Circle supporting device for the inner side of a thin-wall metal pipeline

ActiveCN111791014AImprove general performanceGuaranteed roundnessWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention discloses a circle supporting device for the inner side of a thin-wall metal pipeline. The circle supporting device comprises a cam shaft body capable of rotating and a plurality of pushrod assemblies extending and retracting along the cam shaft body, and the cam shaft body and the push rod assemblies are covered with shells. The cam shaft body comprises a rotating shaft arranged inthe middle. The two sides of the rotating shaft are each provided with a windmill-shaped cam with a plurality of fan blades evenly distributed in the circumferential direction, and the two cams on the two sides are arranged in a staggered mode at a certain angle. Each push rod assembly is sleeved with a spring, and a reset spring clamping groove is formed in each shell. The reset spring clampinggrooves enable the springs to be in a compressed state all the time, and then one end of each push rod assembly is driven to abut against the corresponding fan blade all the time. The outer sides of the shells are provided with a hydraulic cylinder used for providing power for rotation of the cam shaft body. The circle supporting device is ingenious in design, easy and convenient to use, high in accuracy and capable of being applied to inner side anti-deformation supporting when the outer sides of metal pipelines whose inner side areas are unreachable via various paths are welded, and the inner diameter and the roundness of the pipelines are guaranteed.

Owner:YANSHAN UNIV

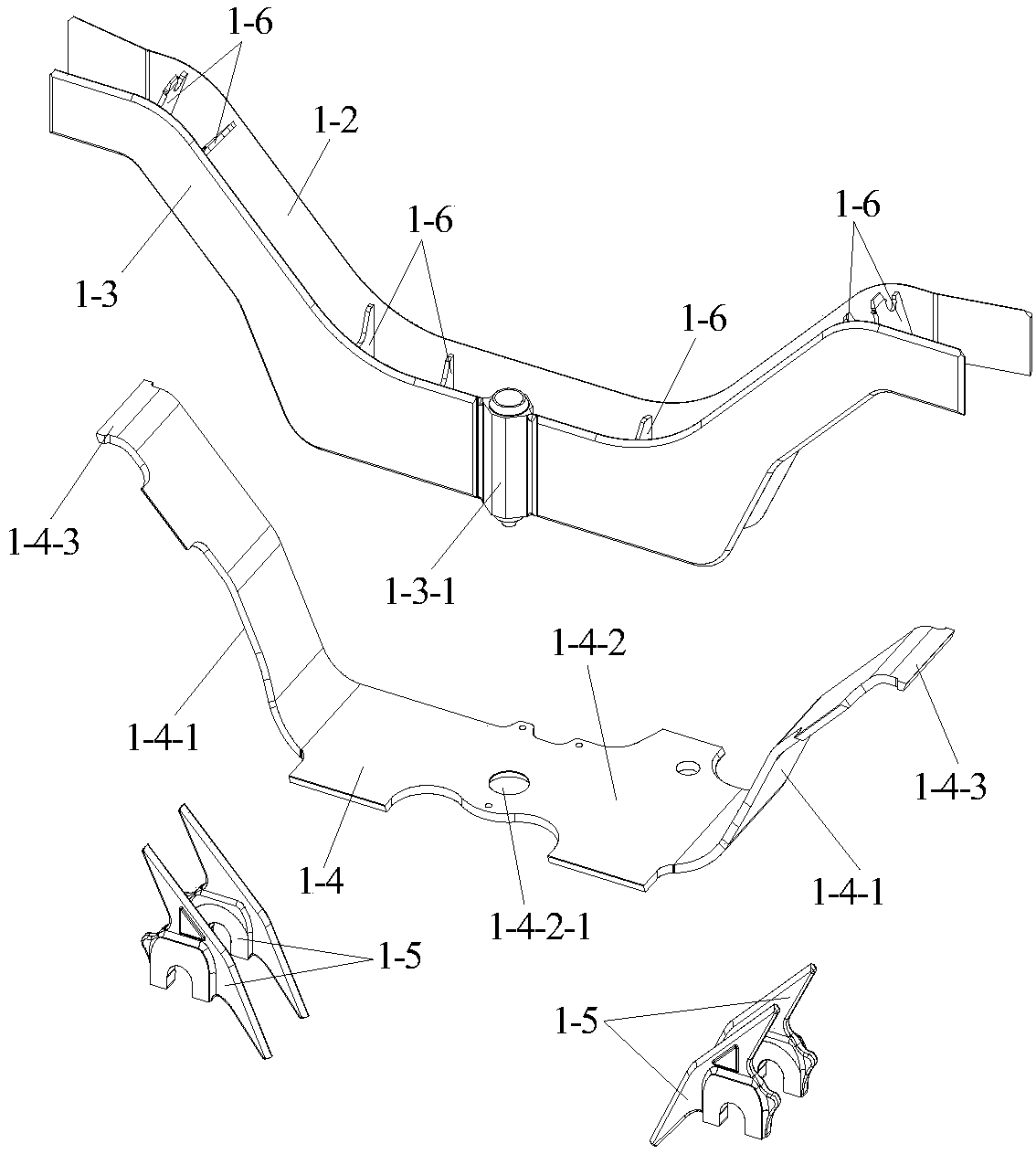

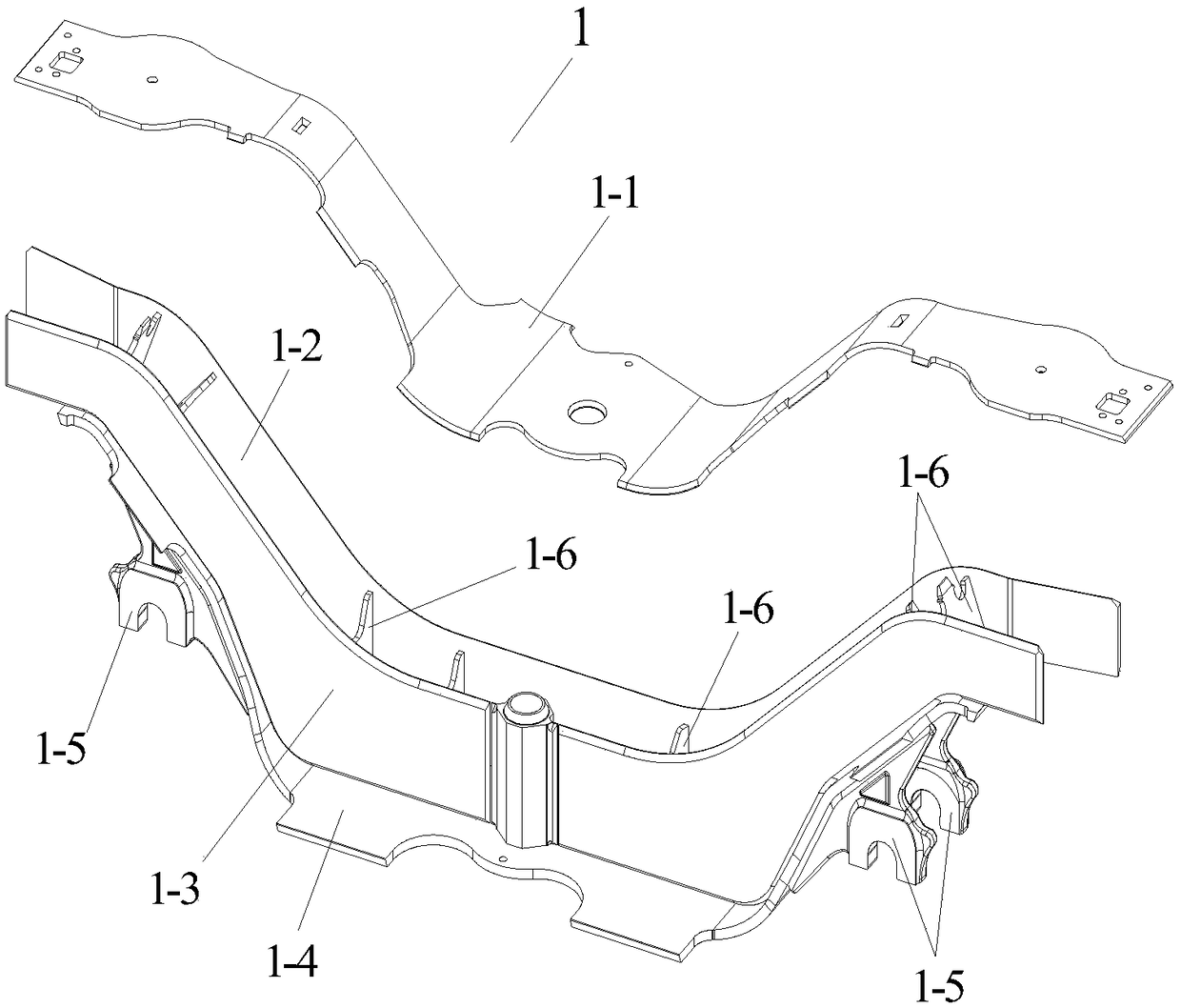

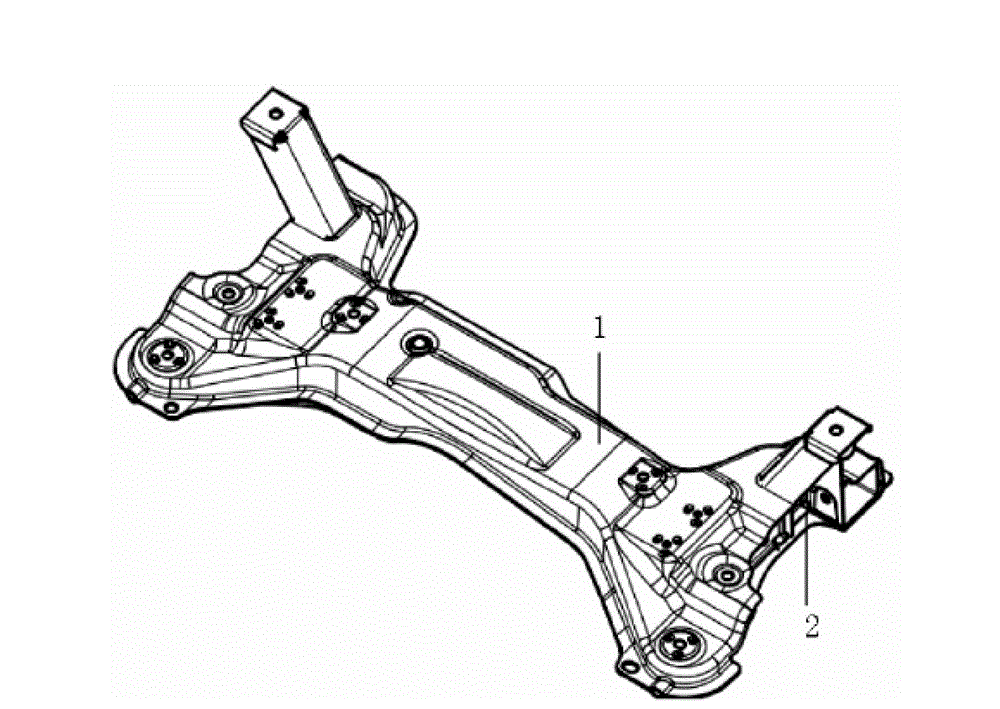

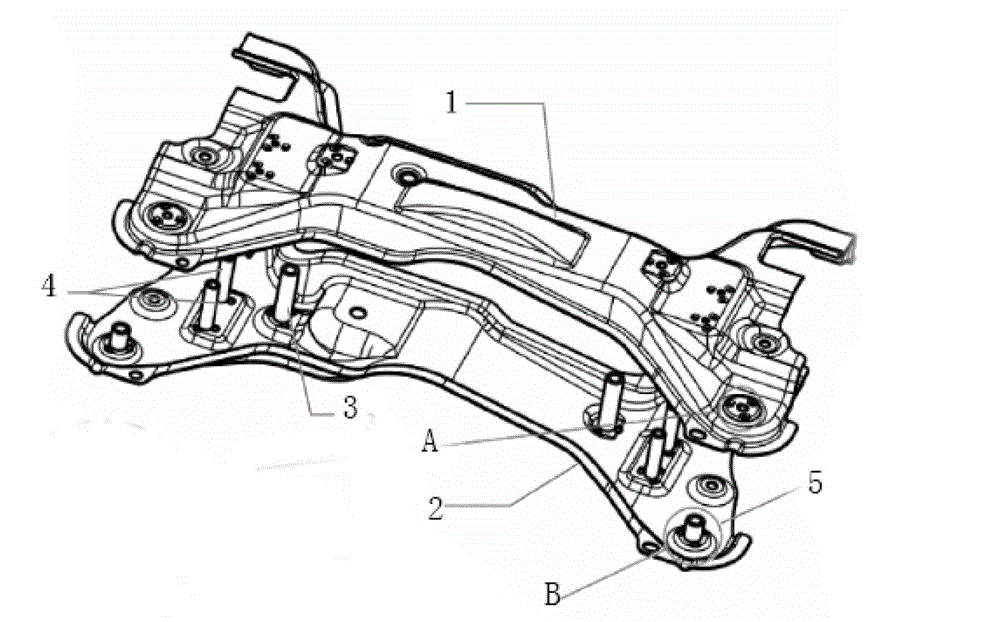

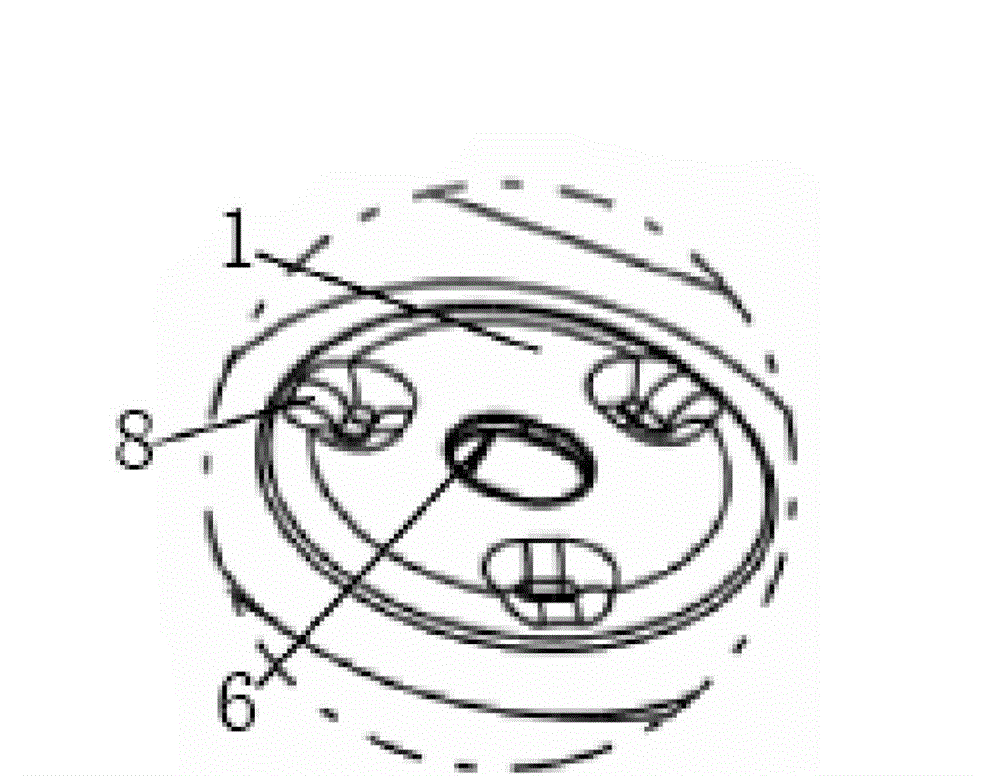

Auxiliary frame mechanism of automobile

ActiveCN103144672AGuaranteed dimensional accuracyAvoid welding deformationUnderstructuresVehicle frameEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

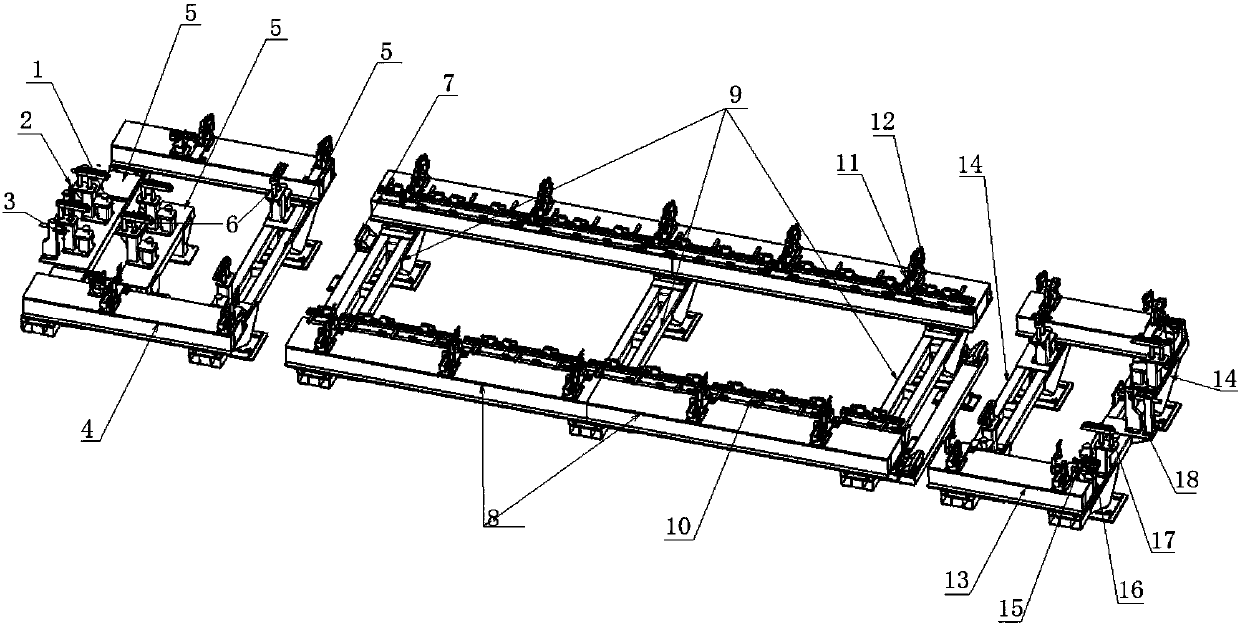

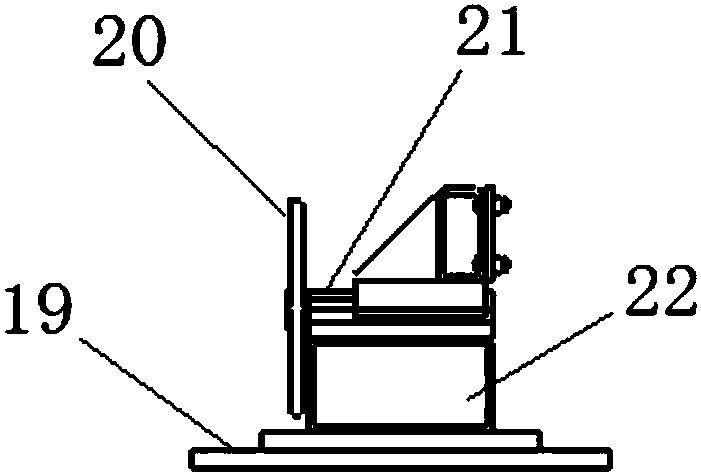

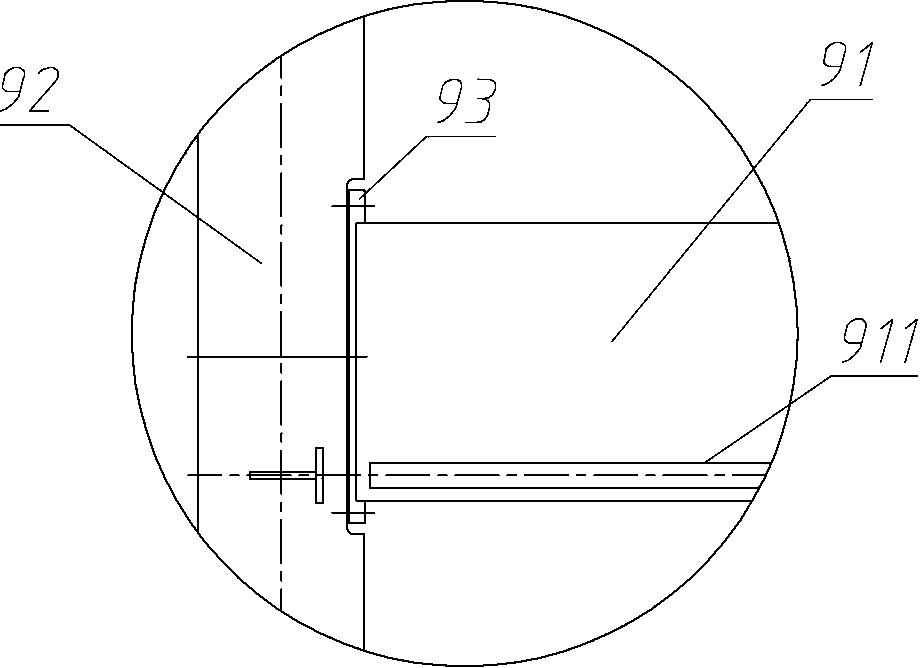

Welding tool for monorail vehicle chassis assembly

ActiveCN107790948AImprove general performanceStrong specificityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringChassis

The invention provides a welding tool for a monorail vehicle chassis assembly. The tool comprises a one-dimensional end welding frame, a middle portion welding frame and a two-dimensional end weldingframe. The one-dimensional end welding frame comprises a bottom surface supporting frame, a longitudinal beam, cross beams, a one-dimensional end limiting block and a center stay wire device, and theone-dimensional end limiting block and the center stay wire device are arranged on the cross beam at the forefront end. The middle portion welding frame comprises a bottom surface supporting frame, longitudinal beams, cross beams and a vehicle body side supporting limiting block, and the vehicle body side supporting limiting block is fixed to the bottom surface supporting frame and located on theside, close to the one-dimensional end welding frame, of the vehicle body side supporting limiting block; the longitudinal beams are provided with T-shaped groove guide rails, side beam limiting blocks and side beam pressing devices, and cross beam limiting blocks are arranged on the T-shaped groove guide rails. The two-dimensional end welding frame comprises a bottom surface supporting frame, a longitudinal beam, cross beams, a side beam side limiting block and a two-dimensional end limiting block, and the two-dimensional end limiting block is arranged on the cross beam at the tail end. The tool can be smoothly and easily demolded, and the requirements for forward installing positioning and reverse installing positioning can be simultaneously met.

Owner:南京雷尔伟新技术股份有限公司

Y-shaped power divider manufacturing technology

InactiveCN104347923AHigh dimensional accuracyQuality improvementCoupling devicesNumerical controlManufacturing technology

The invention discloses a Y-shaped power divider manufacturing technology which comprises upper cover plate processing, lower cavity processing and vacuum brazing molding and specifically comprises the steps of S31: mounting an upper cover plate and a lower cavity in trial, and guaranteeing that an edge boss (2) and an edge groove (5) as well as a Y-branch slot convex bayonet (3) and a Y-branch slot concave bayonet (6) are tightly attached; S32: performing pickling to remove impurities; S33: assembling the upper cover plate, the lower cavity and a brazing material; S34: performing vacuum brazing; S35: performing numerical control processing on the appearance of a power divider and a flange disk; S36: drilling and hinging pin holes; S37: performing electrochemical treatment; S38: testing telecommunications parameters. According to the Y-shaped power divider manufacturing technology, the welding deformation caused by multi-time manual flame welding is avoided; the upper cover plate and the lower cavity are positioned by the boss, the groove and the bayonets, so that the size consistency and the precision of the power divider are guaranteed; when the parts such as the boss, the groove and the bayonets are designed, the embedding thickness of a welding sheet is considered; furthermore, a fit clearance is increased to 0.02-0.04mm, so that the flowability of brazing material joint filling is guaranteed during welding, and the cavity size precision of the assembled power divider is guaranteed.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

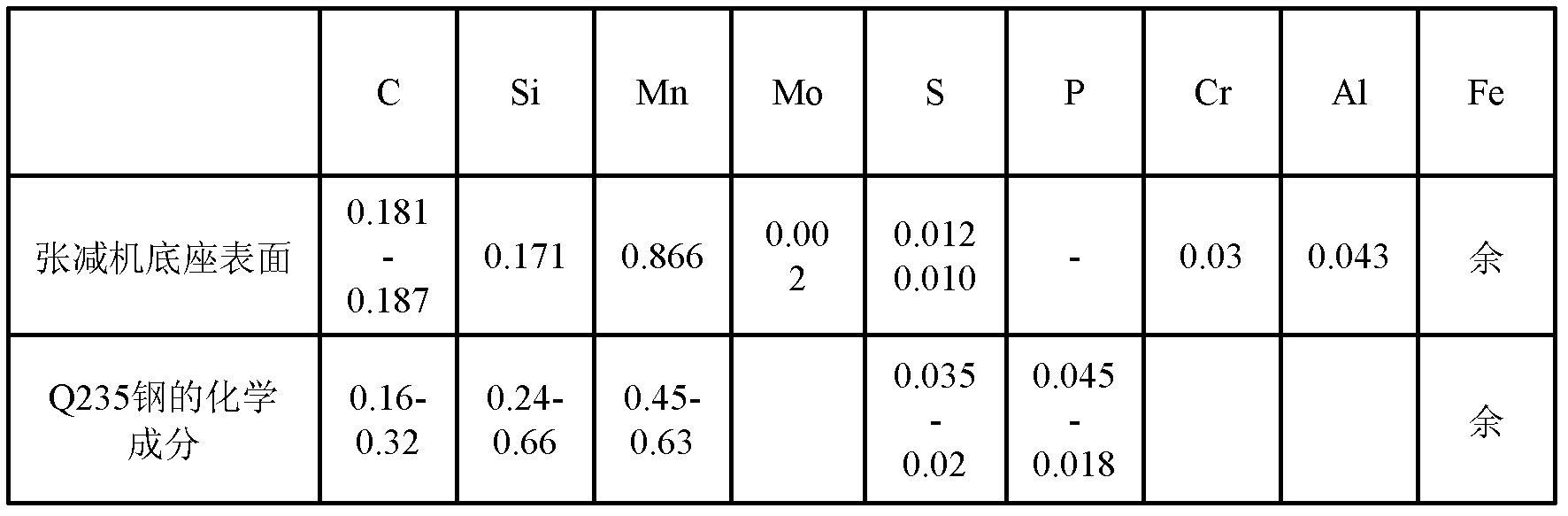

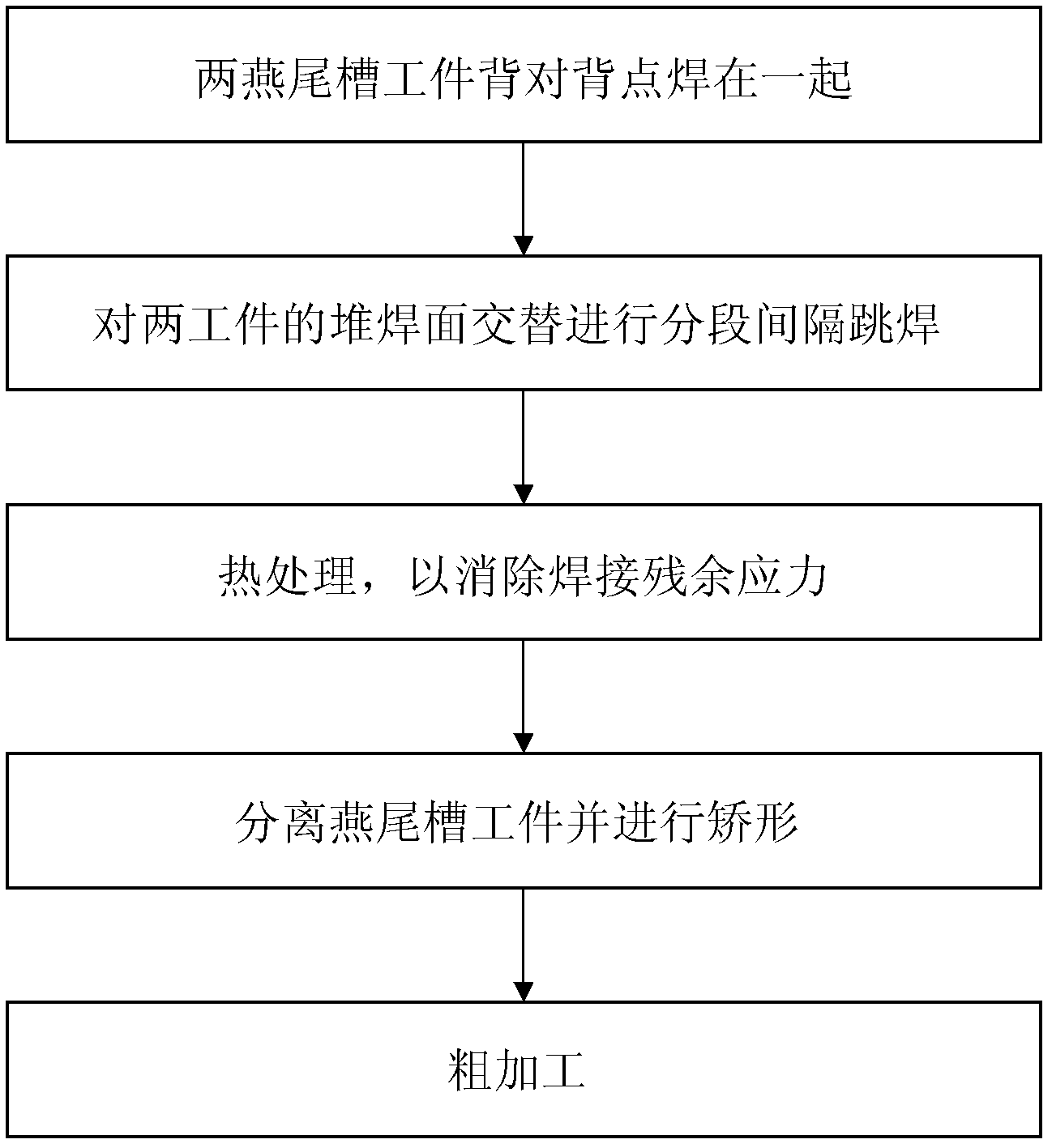

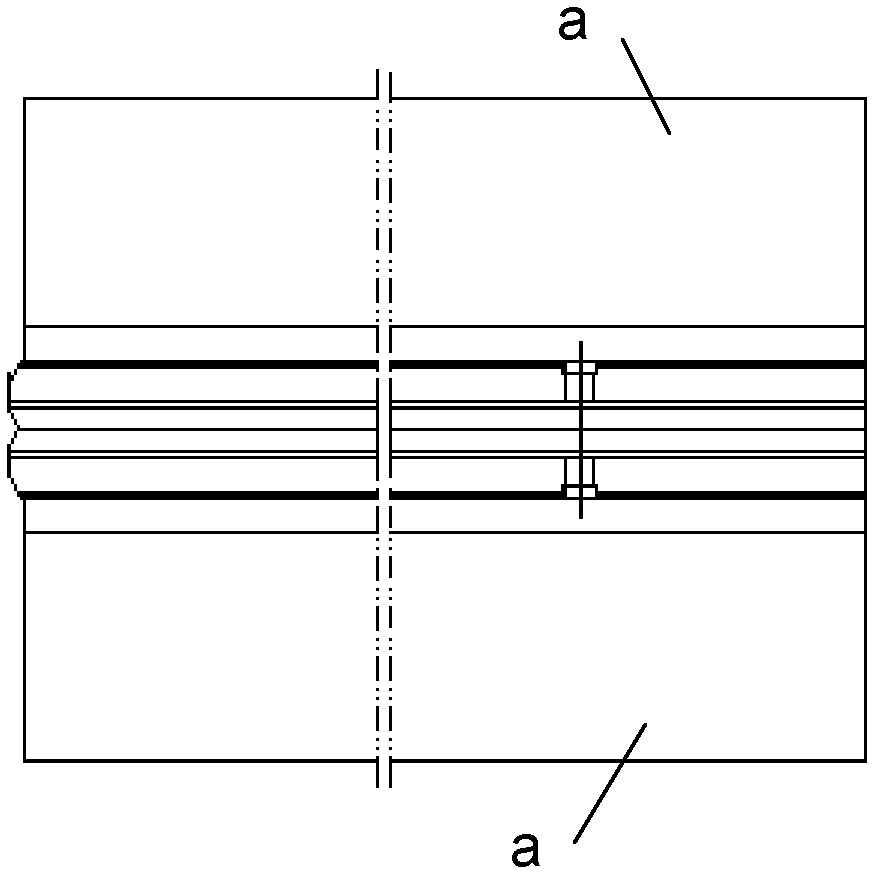

Surfacing method for antiseptic wear-resisting layer of dovetail groove

ActiveCN103008833AImprove corrosion and wear resistanceEliminate welding residual stressArc welding apparatusFurnace typesWelding residual stressEngineering

The invention discloses a surfacing method for an antiseptic wear-resisting layer of a dovetail groove. According to the method, two dovetail groove workpieces are spot-welded back to back, slant groove surfaces and horizontal groove surfaces of the upper dovetail groove workpiece and the lower dovetail groove workpiece are alternately skip-welded sectionally at intervals by ER410NiMoTi surfacing material, welding residual stress is eliminated through heat treatment, and finally the two dovetail groove workpieces are separated, corrected and roughly machined. According to the surfacing method disclosed by the invention, welding deformation can be effectively avoided, and the formed surfacing layer can improve the antiseptic wear-resisting performance of the dovetail groove.

Owner:BAOSHAN IRON & STEEL CO LTD

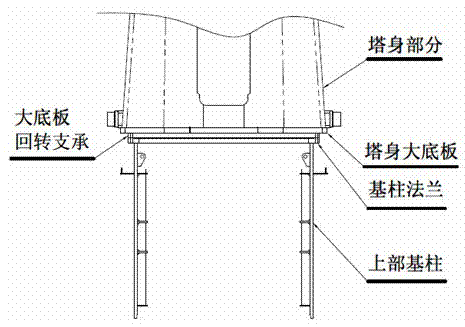

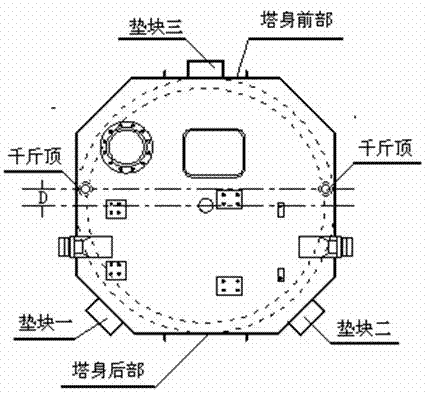

Method for controlling deformation of principal welding seam of ship crane

ActiveCN102922161AReasonable workmanshipControl welding currentWelding apparatusEngineeringWelding deformation

The invention relates to a method for controlling the deformation of a principal welding seam of a ship crane. A welding deformation controlling technique is adopted and comprises the following steps: 1) controlling welding current, improving a welding machine for welding a crane tower, installing a current-limiting device, controlling welding current of the welding machine, and reducing the input of welding heat produced by welding to a welded part; 2) reducing welding deformation due to the welding heat, adopting a symmetric welding technique, formulating a welding sequence of the symmetric welding, and scattering heat input affecting on a large base plate of the crane tower during welding; and 3) predicting deformation points, adopting a reverse deformation technique according to the predicted deformation points, and reducing the amount of deformation after the finishing of the welding. The method has the advantages of novel design, convenience and easiness in implementation, good process effect, reduction in production cost and guarantee on welding quality. Therefore, the the method has good popularization and application prospects.

Owner:WUHAN MARINE MACHINERY PLANT

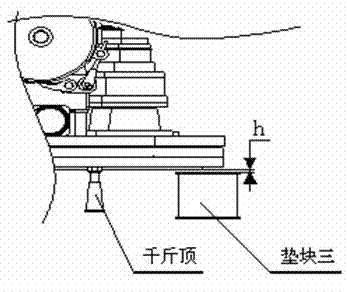

Ultra thin-wall high-temperature alloy lamination laser welding technology and clamp thereof

ActiveCN105397289ASave energyAchieve circumferential continuous weldingLaser beam welding apparatusAlloyStain

The invention discloses an ultra thin-wall high-temperature alloy lamination laser welding technology and a clamp thereof. Through cleaning parts before welding, and after removing oil stain and dirt, the clamp is adopted for assembly positioning so as to ensure tight fit of every two laminations and welding clearance, and then, 40% of the normal welding power is utilized to carry out uniform positioned welding of eight circumferential parts on each tack weld for rotating by 1 degree every time with the positioning radian being 5-8 degrees; a rotary working table rotates the laminations at the rotational indexing of 0.4-0.6 degree as the frequency, carries out welding with the welding parameters of laser power being 80+ / -5 W and welding speed being 800 m / min, and finally carries out laser repairing on non-welded local parts at 90+ / -5 W. With adoption of the ultra thin-wall high-temperature alloy lamination laser welding technology, circumferential continuous welding on the circular end faces of the laminations is realized, the leakproofness of the solder sides of the laminations is ensured, the welding penetration can be better controlled, and the part welding deformation can be prevented.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

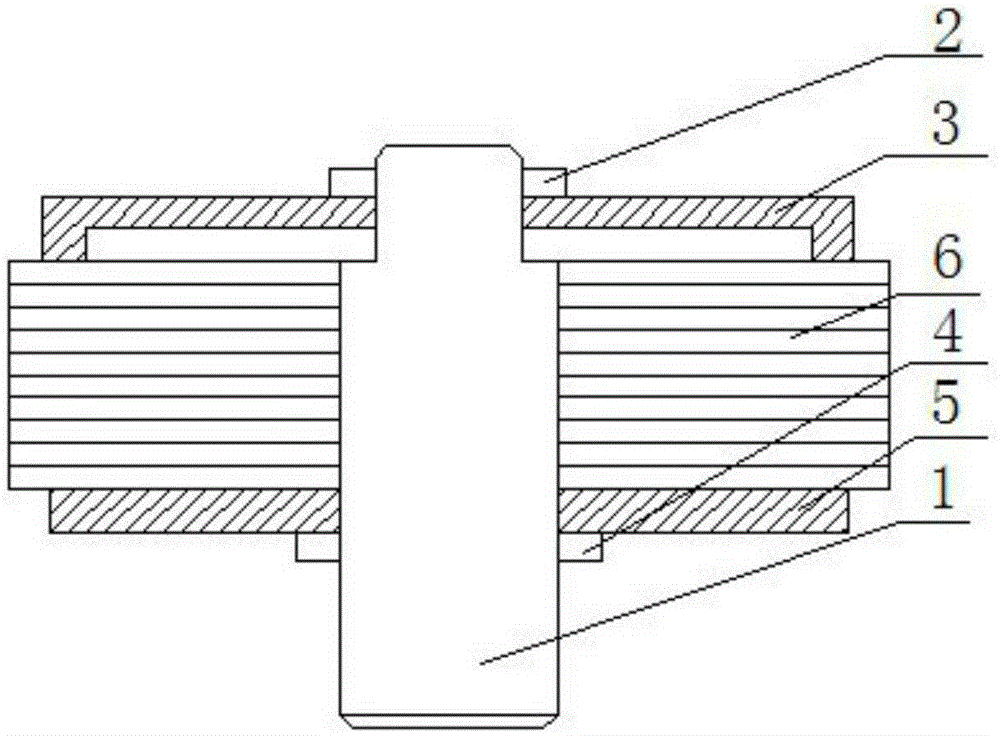

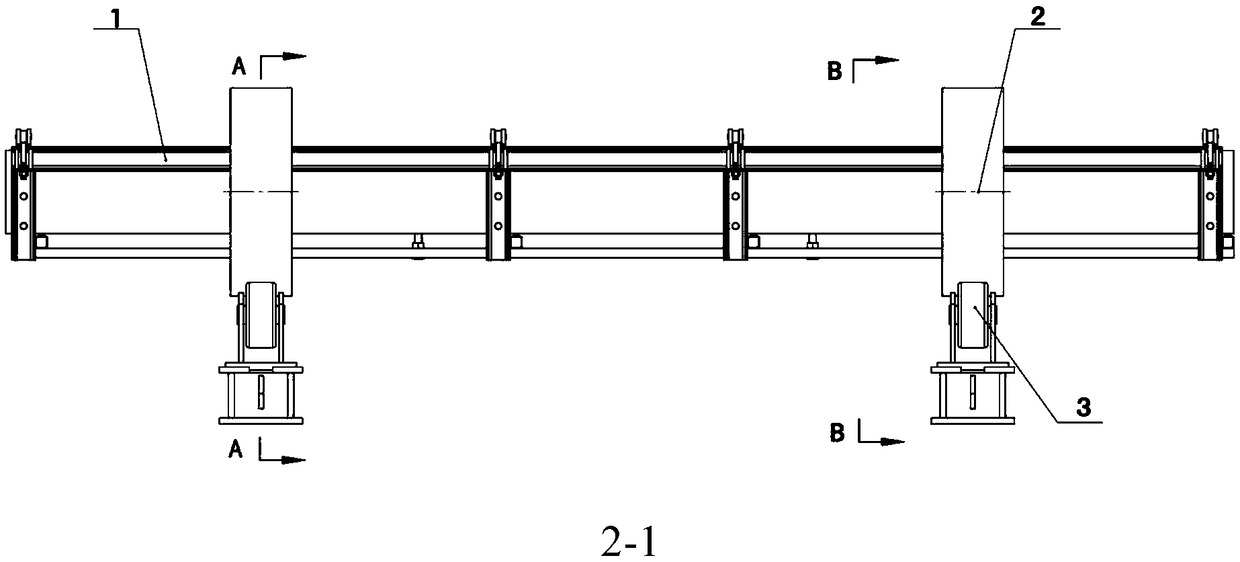

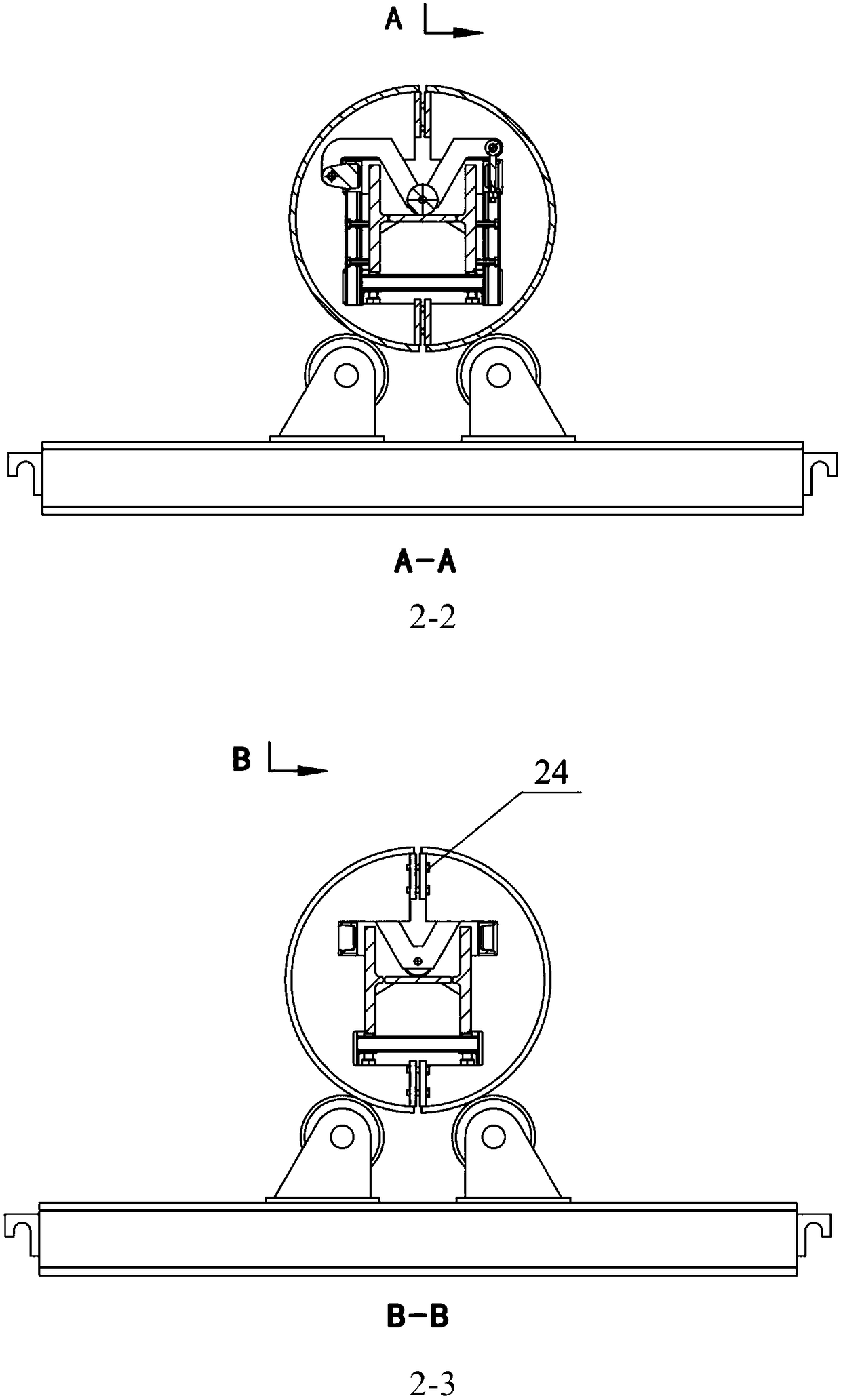

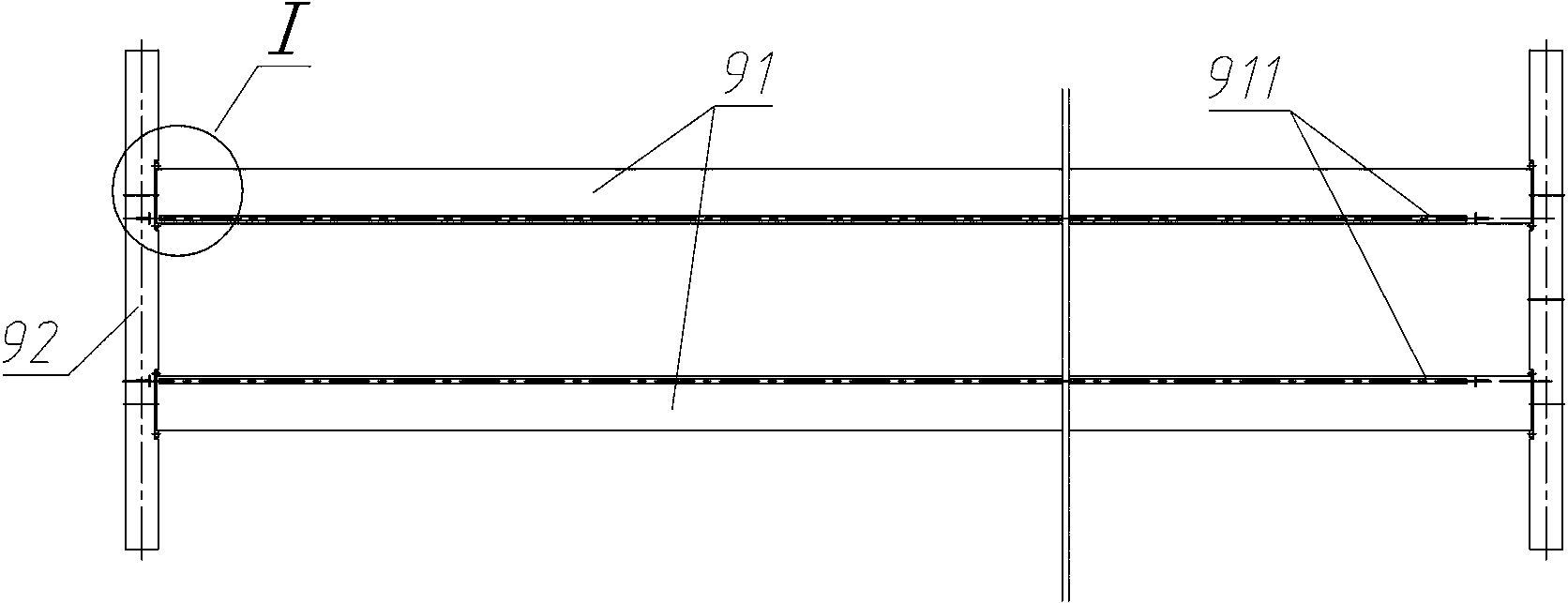

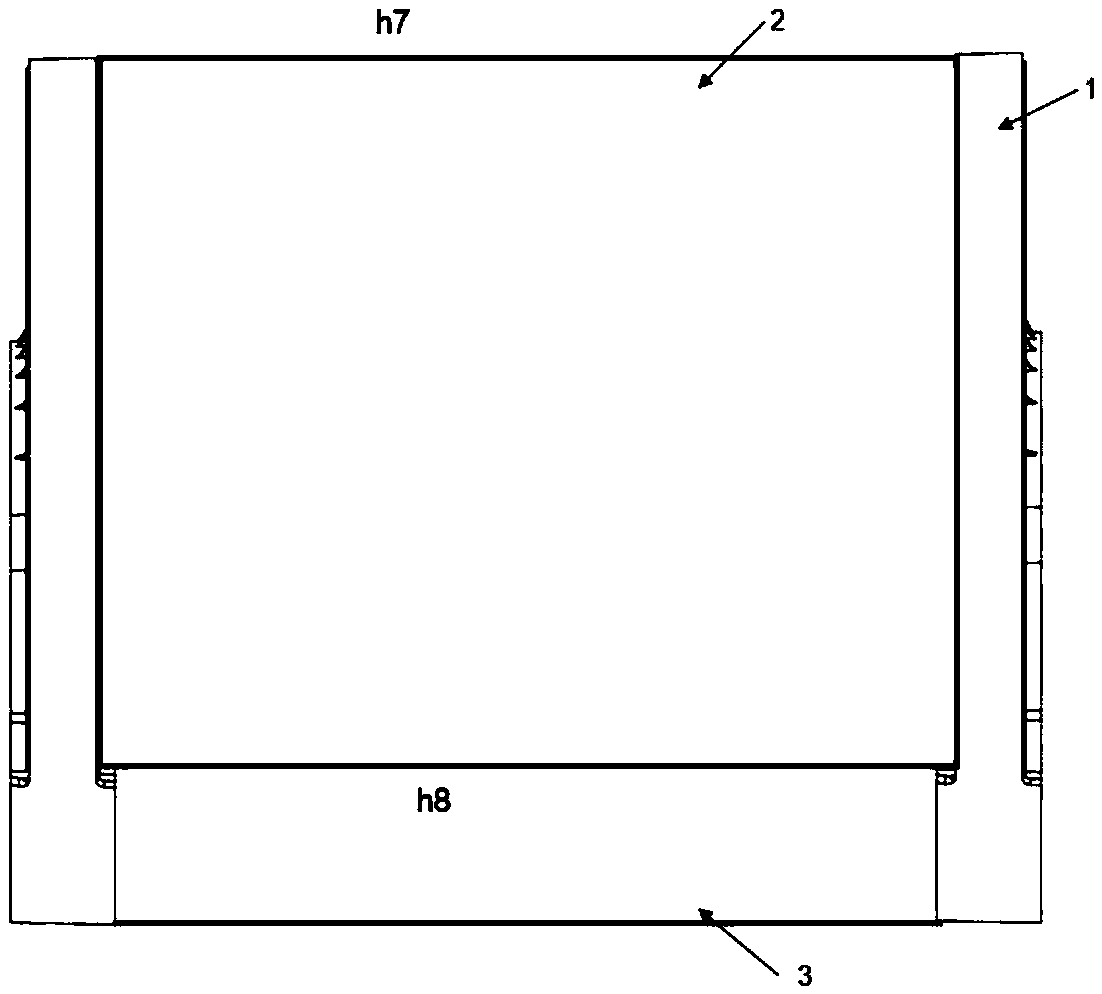

Large austenite welding H-shaped steel assembly and rotation welding device

ActiveCN109079410ANovel structureIngenious designWelding/cutting auxillary devicesAuxillary welding devicesFixed positionAustenite

The invention discloses a large austenite welding H-shaped steel assembly and a rotation welding device. The device comprises an assembly frame (1) used for assembly and fixed-position welding of H-shaped steel plates, the two ends of the assembly frame (1) are provided with rotation supporting assemblies (2) so that the H-shaped steel can stably rotate in the welding process, and welding deformation is prevented. The welding device is ingenious in design, easy to operate, high in universality, high in welding quality and low in welding difficulty.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Girder machining method and girder machining device for crane and crane span collecting-mounting method

ActiveCN103481026AEliminate welding distortionGuarantee assembly qualityWork benchesOther workshop equipmentStructural engineeringWelding deformation

The invention relates to a girder machining method and a girder machining device for a crane and a crane span collecting-mounting method. The girder machining method for the crane comprises the following steps of step 1, welding girder hanging plates onto corresponding positions of two ends in the length direction of the girder, and enabling the side faces of the girder hanging plates to face the outside of the length direction of the girder; step 2, placing a girder bracket onto a corresponding girder support, fixing by a girder fixing device on the girder support, and utilizing corresponding machining equipment to machine a pressing plane used for being pushed and matched with corresponding matching faces on end beams; step 3, machining thread connecting holes penetrating through the girder hanging plates along the thickness direction in set positions of the girder hanging plates; finally, jointing the end beams with the girder and fixing the end beams and the girder by bolts. By adopting the technical scheme, the collecting-mounting quality of a crane span is prevented from being influenced by welding deformation.

Owner:HENAN WEIHUA HEAVY MACHINE

Vacuum electron beam welding method for special-shaped complex large-thickness fuel loading bin

ActiveCN109262131AImprove welding qualityInhibition formationElectron beam welding apparatusEngineeringWeld line

The invention discloses a vacuum electron beam welding method for a special-shaped complex large-thickness fuel loading bin. Before welding, acid pickling and mechanical grinding are adopted for a workpiece joint region, firstly, two end frames and a casting are assembled, and after completion, point fixing and normal welding are performed; then, two skins and an end frame are assembled, and pointfixation and normal welding are performed after completion; finally, point fixation and welding of a welding line are performed between the skins and the skin and the casting. In the welding process,upper-heater low-current electronic beams are adopted for point fixation, upper-heater large-current electronic beams are adopted for normal welding, and meanwhile X and Y direction beam flows are applied for scanning. The fuel bin welding line manufactured by adopting the welding method meets the requirement for GJB1718A-2005 'electron beam welding' first-stage joints, the welding deformation issmall, and the integrated profile tolerance is controlled within 1.5 mm.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Bidirectional adjustable cylindrical welding anti-deformation fixture

ActiveCN102896455AAvoid welding deformationImprove molding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a bidirectional adjustable cylindrical welding anti-deformation fixture which comprises a rotary table, a central compressing component and more than three groups of movable supporting components, wherein the central compressing component is arranged on the rotary table, the rotary table is in a rotation state around the central compressing component, the more than three groups of movable supporting components are uniformly distributed on the rotary table around the central compressing component, and the central compressing component props against the more than three groups of movable supporting components so that the movable supporting components are simultaneously extended outwards or simultaneously retracted. According to the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention, the central compressing component drives the movable supporting components to prop against and fix a cylinder workpiece, and the rotary table capable of rotating in plane and space drives the cylinder workpiece to rotate in two directions by supporting the movable supporting components so that the cylinder workpiece is located and welded; in addition, the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention has the advantages of simple structure, convenience in operation, low cost and good welding effect; and the welded workpiece has less possibility of deformation.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

Construction process for lifting leg pile of offshore living platform

The invention relates to a construction process for a lifting leg pile of an offshore living platform. The construction process is characterized by comprising the following steps of joint pipe manufacturing, unit section butt joint, segment butt joint, T-shaped frame assembly and welding, external web plate assembly and welding, pile leg cylinder curved surface hole making and sealing, sand blasting coating and pile insertion assembly. According to the construction process, each pile leg segment is of a cylinder structure, a plurality of cylinder segments are spliced and assembled into a segment, the construction efficiency is improved, and the construction cost is reduced; vertical reinforcing ribs and T-shaped reinforcing rings play the roles of longitudinal and transverse fixing and reinforcing, structural pipes play the role of transverse reinforcing in cylinders, and the strength of a pile leg structure is ensured; and the construction accuracy of a rack plate is improved by restricting the main indexes such as straightness, tooth spacing and common normal spacing of the rack plate, so that the support and stability of the pile leg are improved, and welding deformation or weldcracking is avoided.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com