Patents

Literature

504results about How to "Guaranteed clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

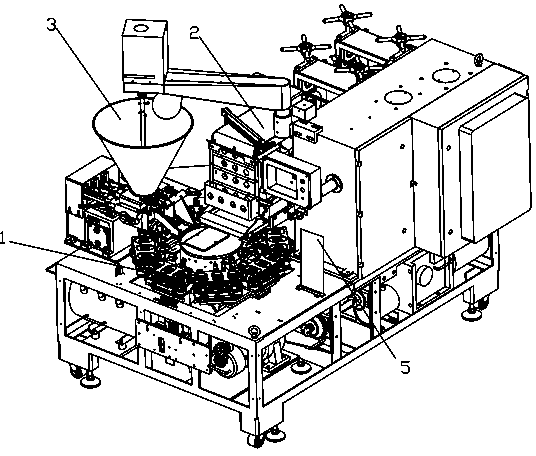

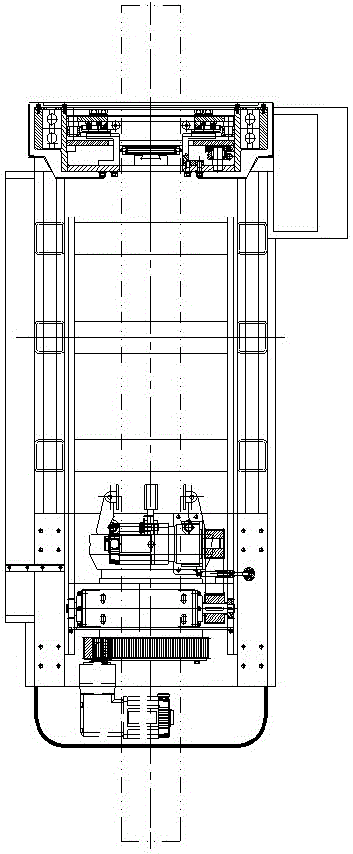

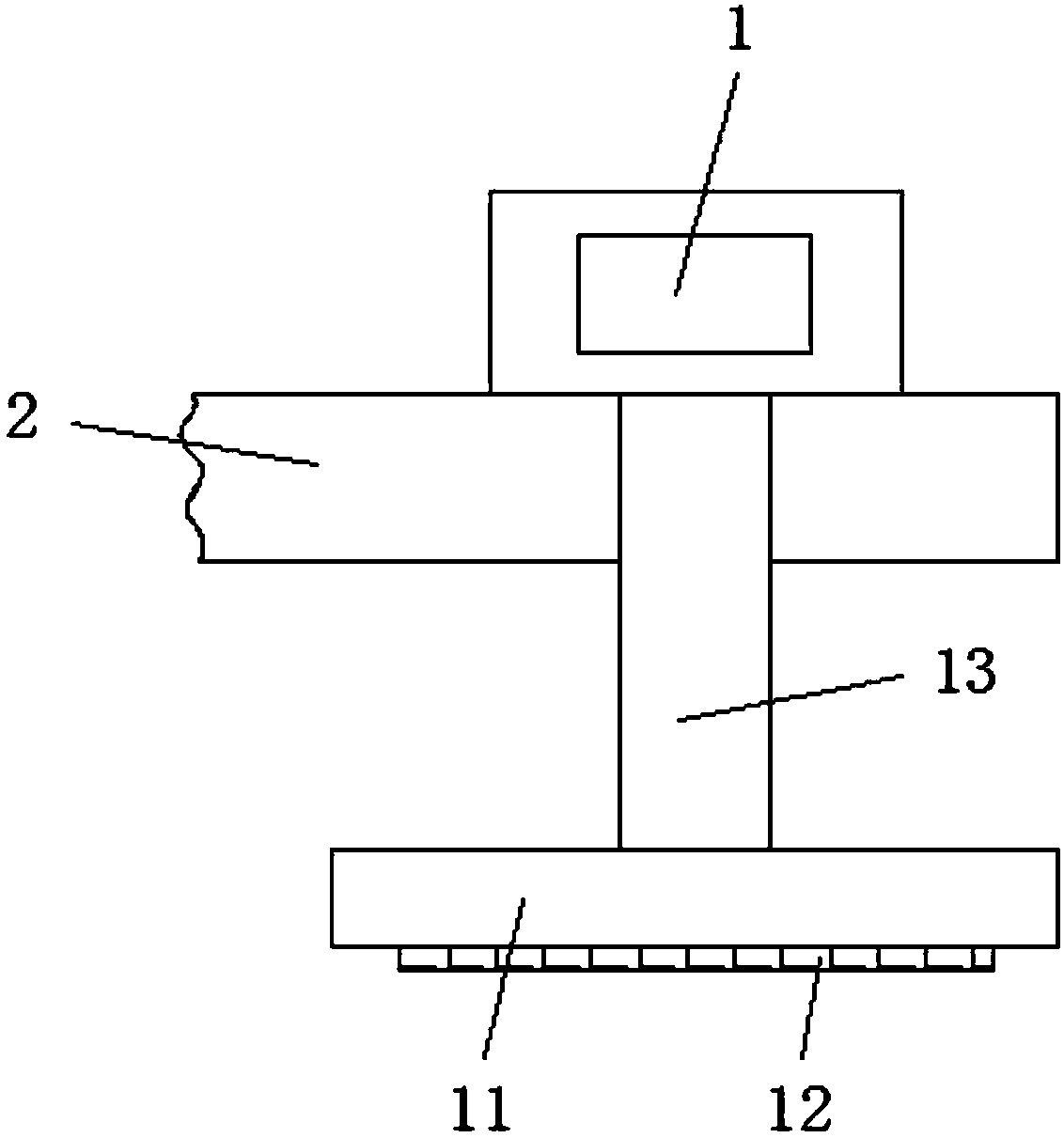

Stuffed food forming method

The invention belongs to the technical field of food processing and in particular relates to a stuffed food forming method. The stuffed food forming method comprises the following steps: 1, allowing a wrapper receiving plate to be positioned at a wrapper receiving station of an annular rail, and conveying the wrapper to the wrapper receiving plate at the wrapper receiving station through a wrapper conveying device; 2, moving the wrapper receiving plate and a die assembly device to a stuffing injection station on the annular rail, and injecting the stuffing on the surface of the wrapper through a stuffing injection device; 3, mutually closing die assembly blocks which are positioned on the die assembly device below the wrapper receiving plate and are opposite to each other, coating and forming stuffed foods, and continuously keeping the two closed die assembly blocks be in the state; and 4, simultaneously moving the wrapper receiving plate and the die assembly device to a taken-out station on the annular rail, so that the wrapper receiving plate is opened, and the die assembly blocks which are always positioned in a closed state are separated. According to the die assembly device in the method, continuous pressing force can be provided for the stuffed foods in the processing process, the tightness on the joint part of the wrapper of the stuffed foods can be guaranteed, the wrapper is not open after being pressed for a long time, and the forming rate of the stuffed foods is guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

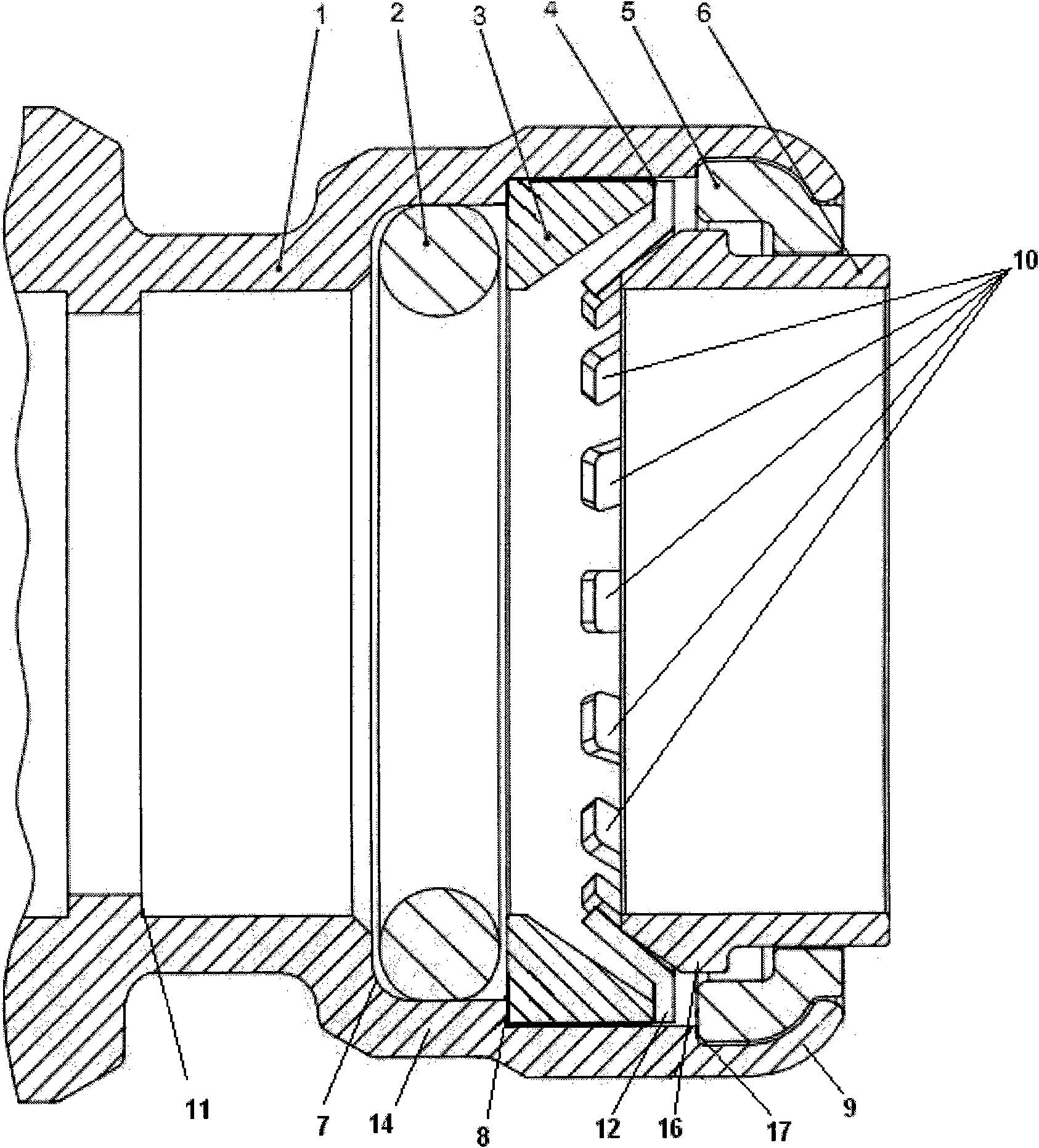

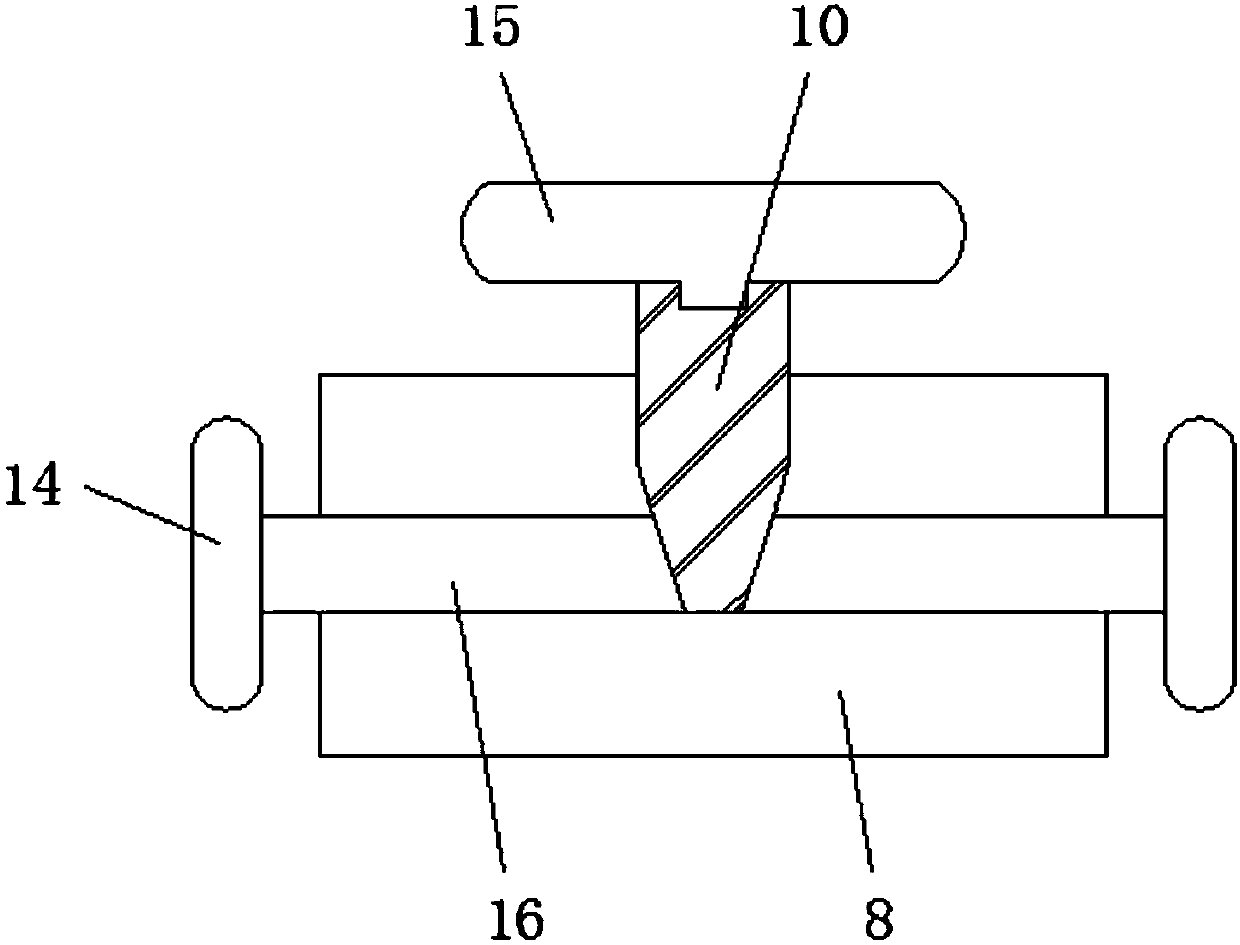

Quick pipeline connecting method and joint using same

The invention discloses a quick pipeline connecting method and a joint using the same. The joint comprises a joint body, wherein a clamping ring, a conical base and an O-shaped sealing ring are sequentially arranged inside the joint body along the pipeline insertion direction; when the pipeline is inserted into the joint, a flange arranged on the clamping ring is deflected; and when the pipeline expands under increased pressure after the introduction of a liquid, the O-shaped sealing ring expands axially under the action of pressure, and the clamping ring is driven to move along a direction opposite to the pipeline insertion direction by pushing the conical base to clamp the pipeline. The invention also discloses a quick pipeline joint adopting the quick connecting method. The joint has the advantages of capabilities of making an elastic pipe body (such as a PEX pipe body) easier to insert and ensuring that the elastic pipe body does not loosen easily after being inserted and expanded due to increased pressure caused by the introduction of the liquid, high air tightness and connecting reliability.

Owner:LA CASA ANGELA HLDG

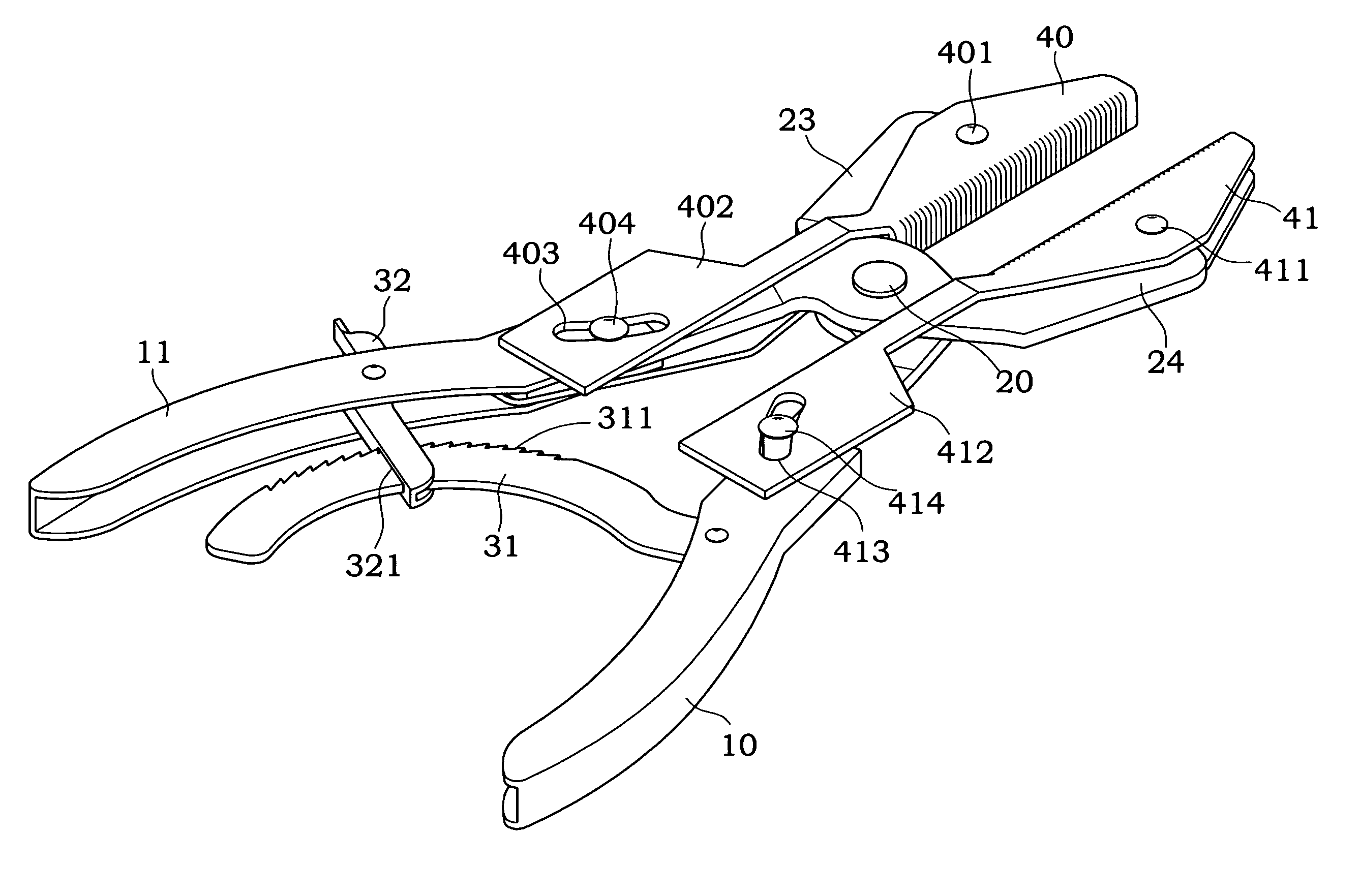

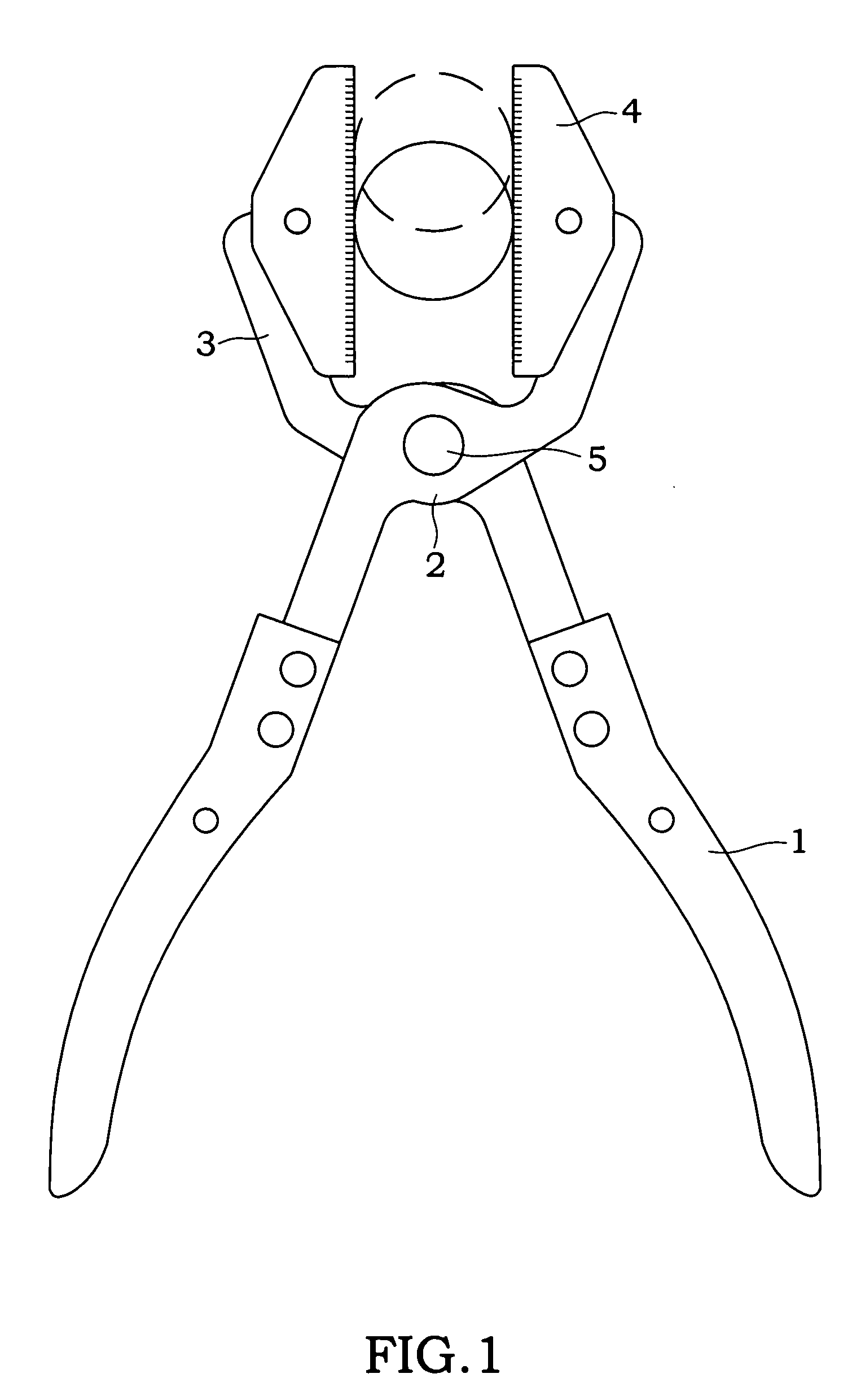

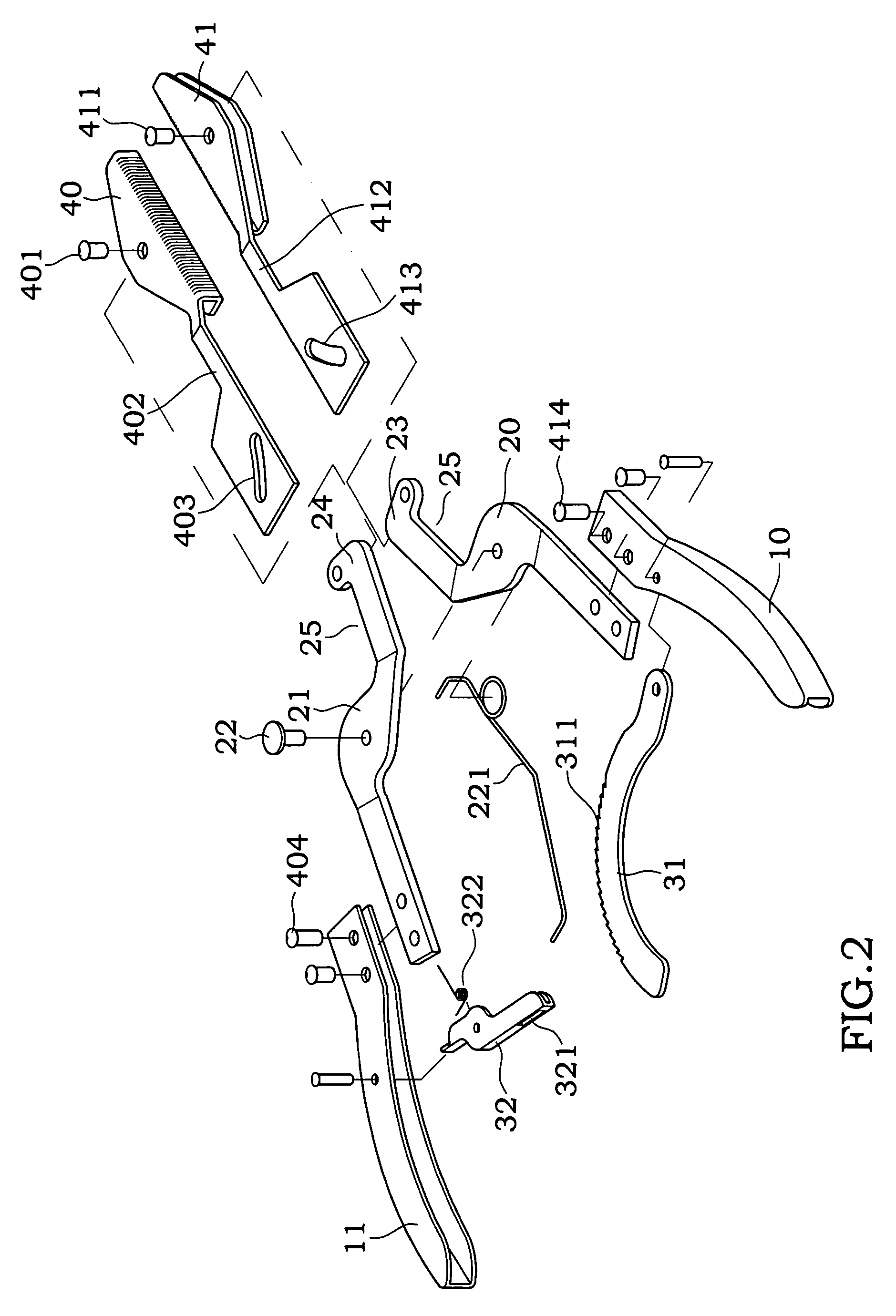

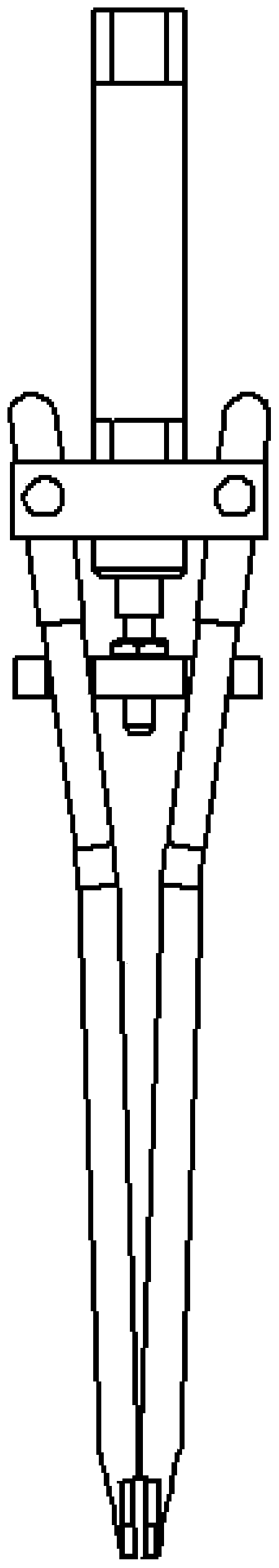

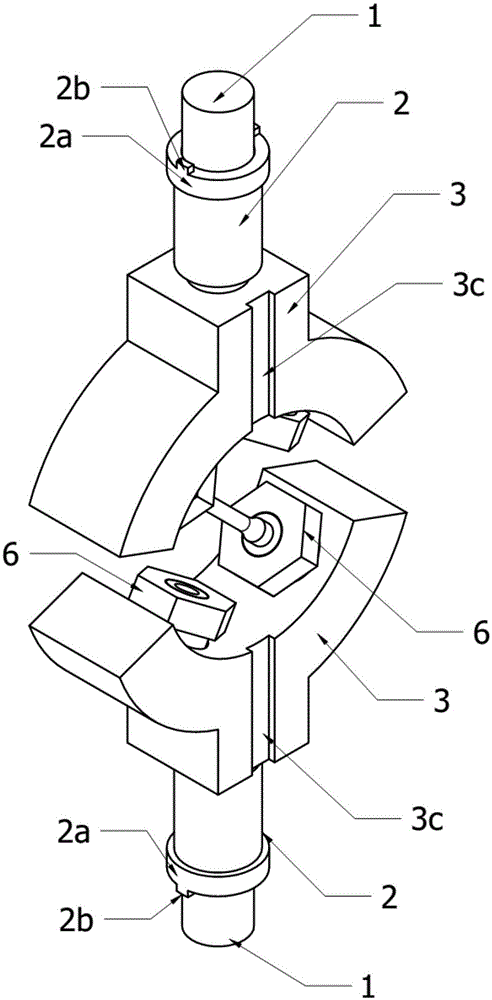

Pipe wrench assembly

InactiveUS20060162509A1The method is simple and convenientGuaranteed clamping effectPliersPipe wrenchEngineering

An improved pipe wrench assembly includes a first and a second arms, a first and a second movable wrench members disposed on the front ends of the first and second arms respectively, a guide plate separately extended from the rear ends of the first and second movable wrench members, a sliding groove disposed on the guide plate, and an insert pin pivotally coupled in the sliding groove; wherein another end of the insert pin of the first movable wrench member is fixed to a second handle and another end of the insert pin of the second movable wrench member is fixed to a first handle. With the insert pin and the sliding groove, the first and second movable wrench members can produce a parallel clamping movement when the pipe wrench is clamped and released.

Owner:WANG CHING SHU

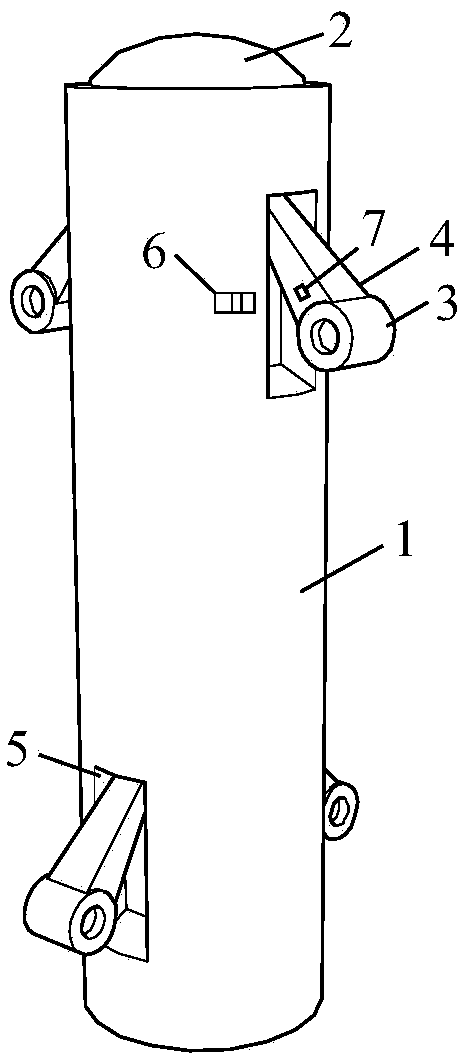

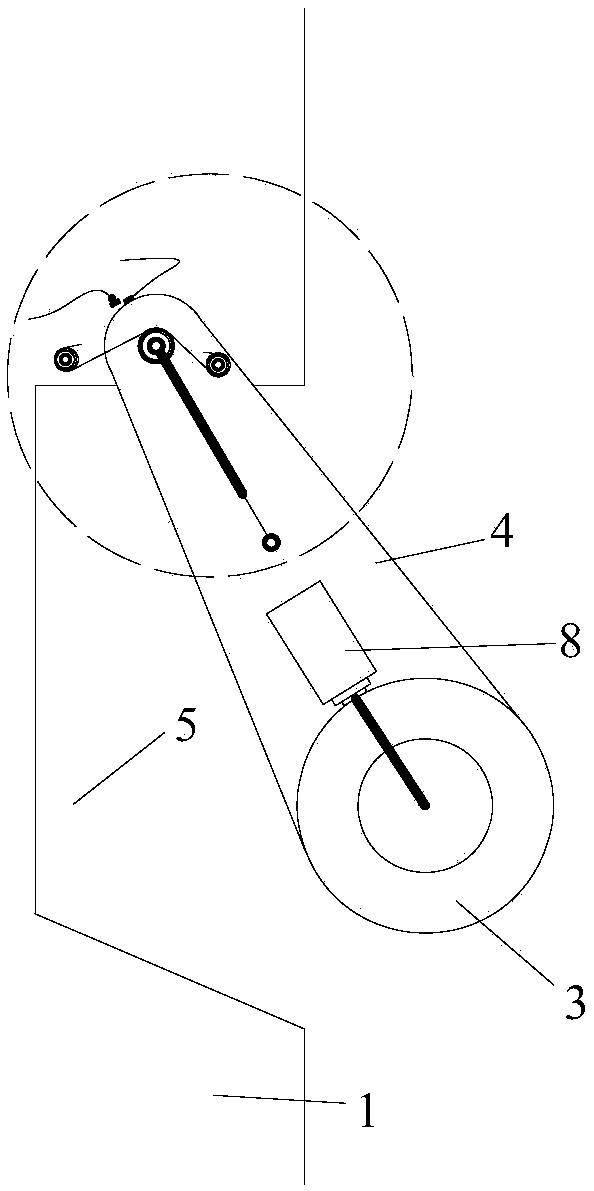

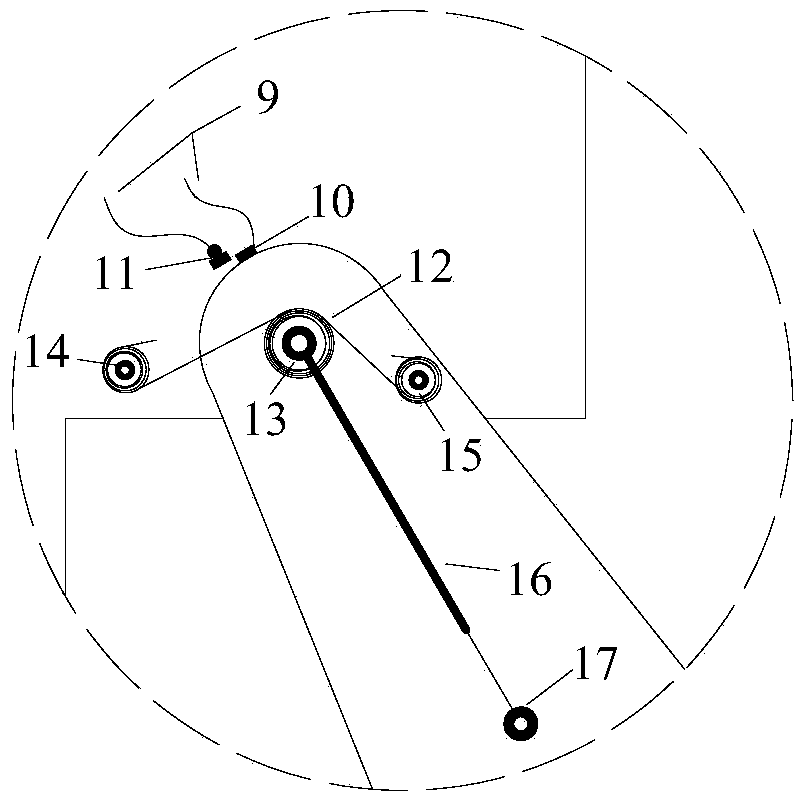

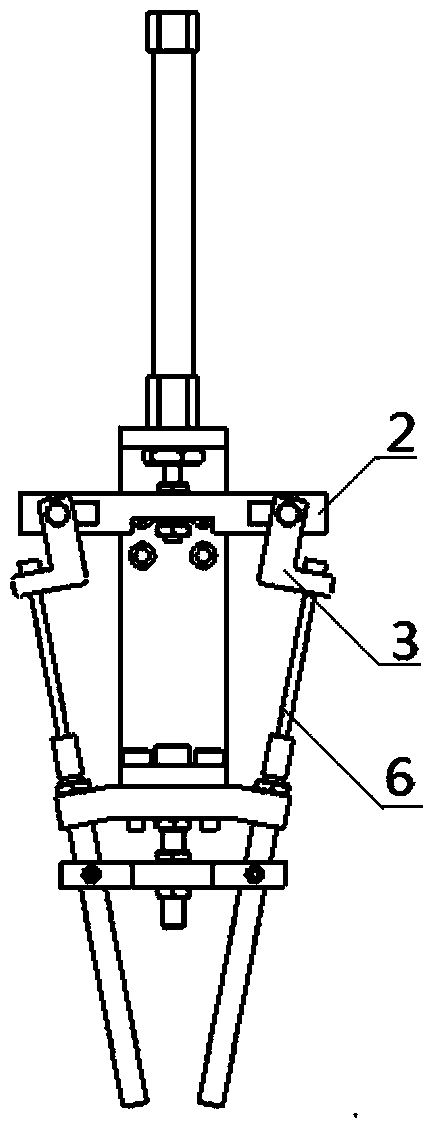

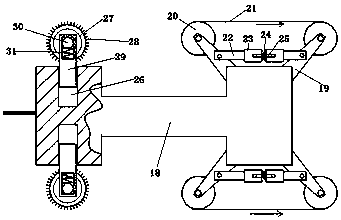

Self-propelled peeping probe adapted to different diameters of drill holes and peeping method thereof

The invention discloses a self-propelled peeping probe adapted to different diameters of drill holes and a peeping method thereof. The probe comprises a peeping probe body, a camera, walking wheels, rocker arms connected to the walking wheels, and an operating host. The rock arms can achieve a certain angle of damping opening and closing under the effects of internal torsion springs and gas springs and have alarm functions, and the rocker arms can be fixed in grooves of a peeping probe side through locking holes and locking blocks. The self-propelled function of the peeping probe in a drill hole can be achieved through an internal power supply, a driving motor, a video processing module, a control module, a WIFI module and the external operating host. The peeping probe has the advantages of centered drill hole, self-propelling and less workers in operation in a drilling peeping operation process, the complexity in a conventional drilling peeping operation is reduced, a push rod and a video transmission line are removed, auxiliary accessories are greatly reduced, and a new solution is provided for determining the fracture of a rock mass through drilling peeping in underground engineering.

Owner:CHINA UNIV OF MINING & TECH

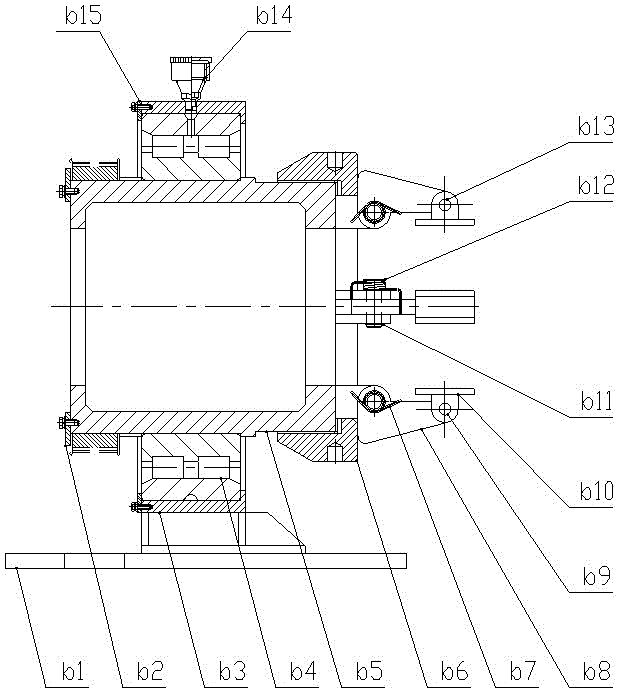

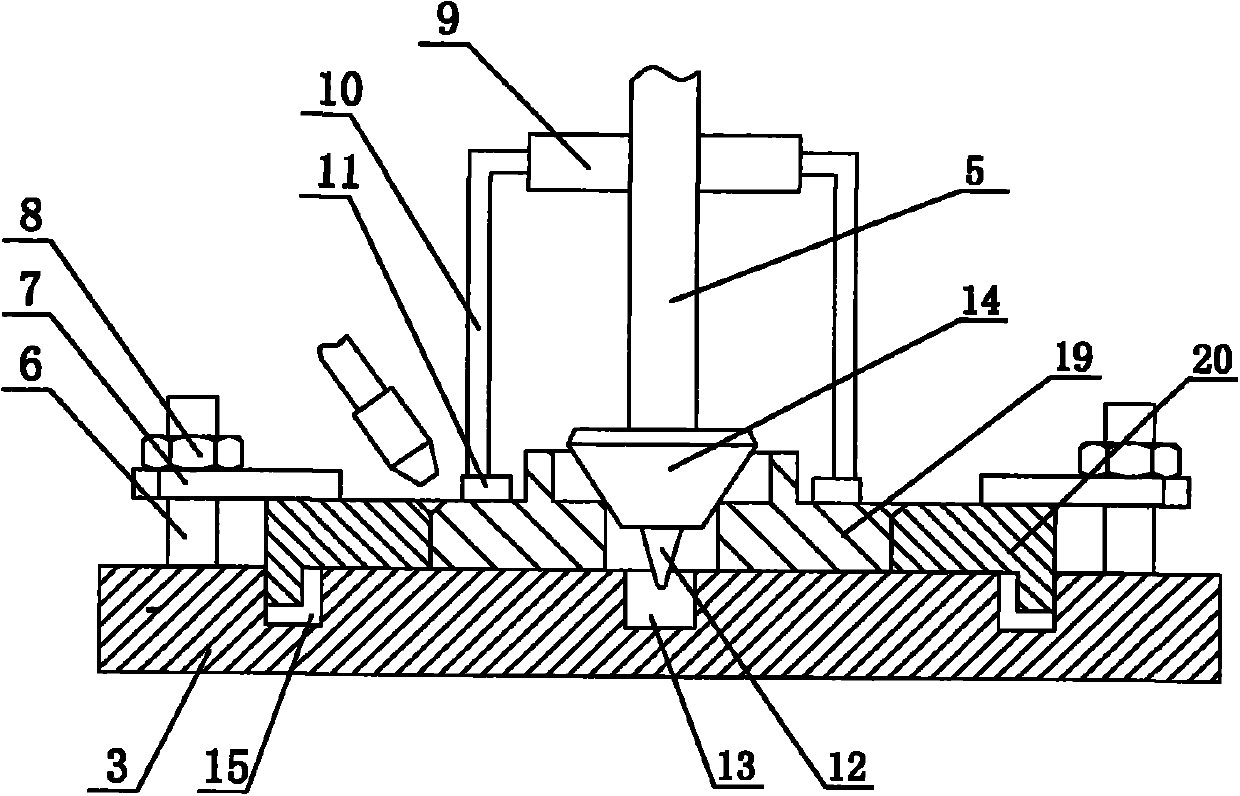

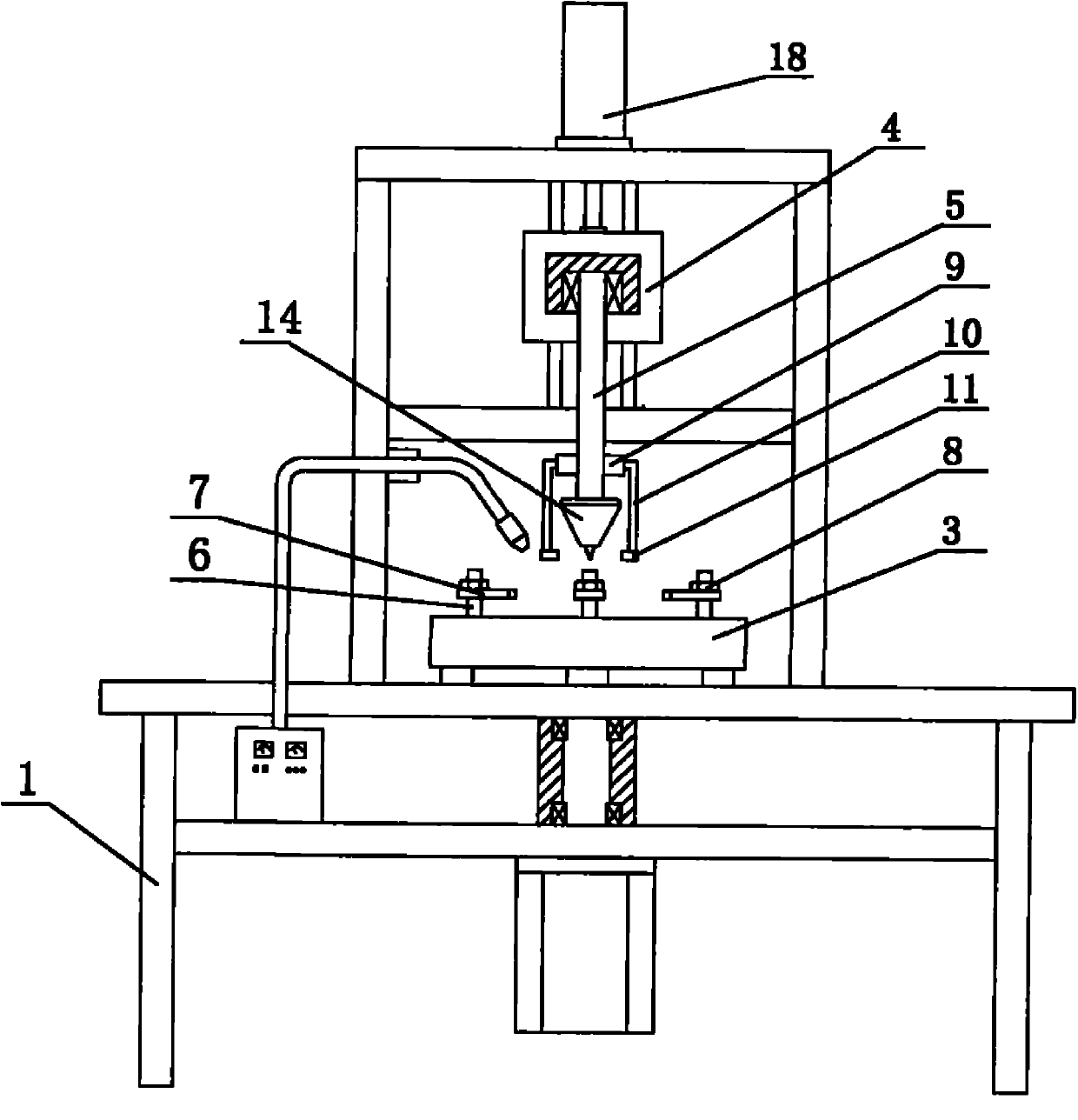

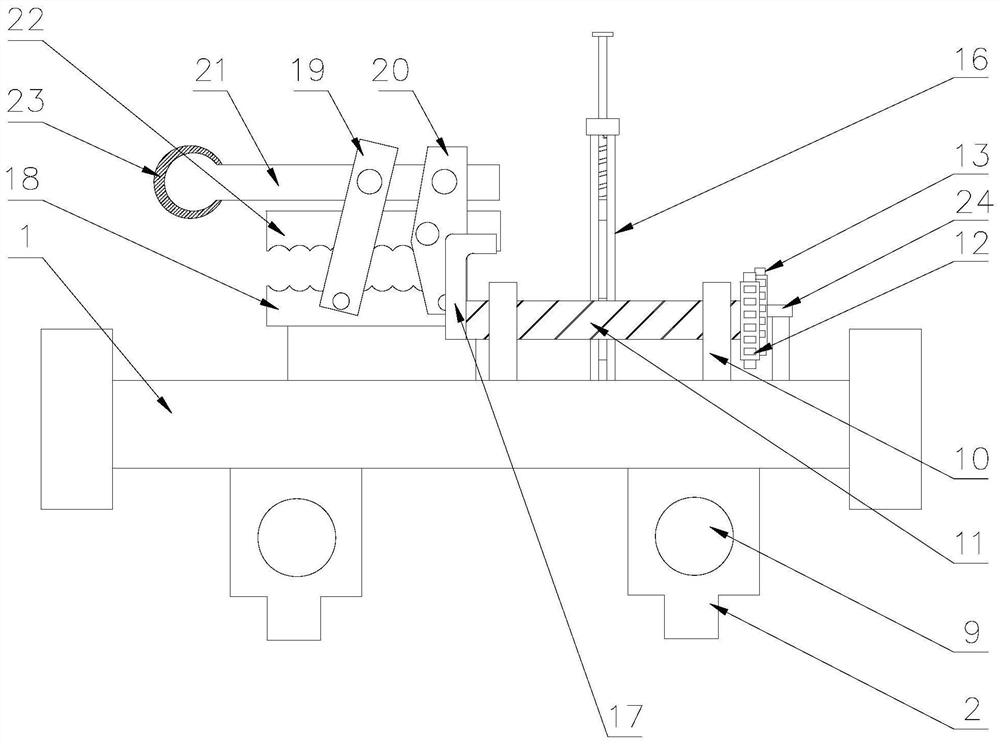

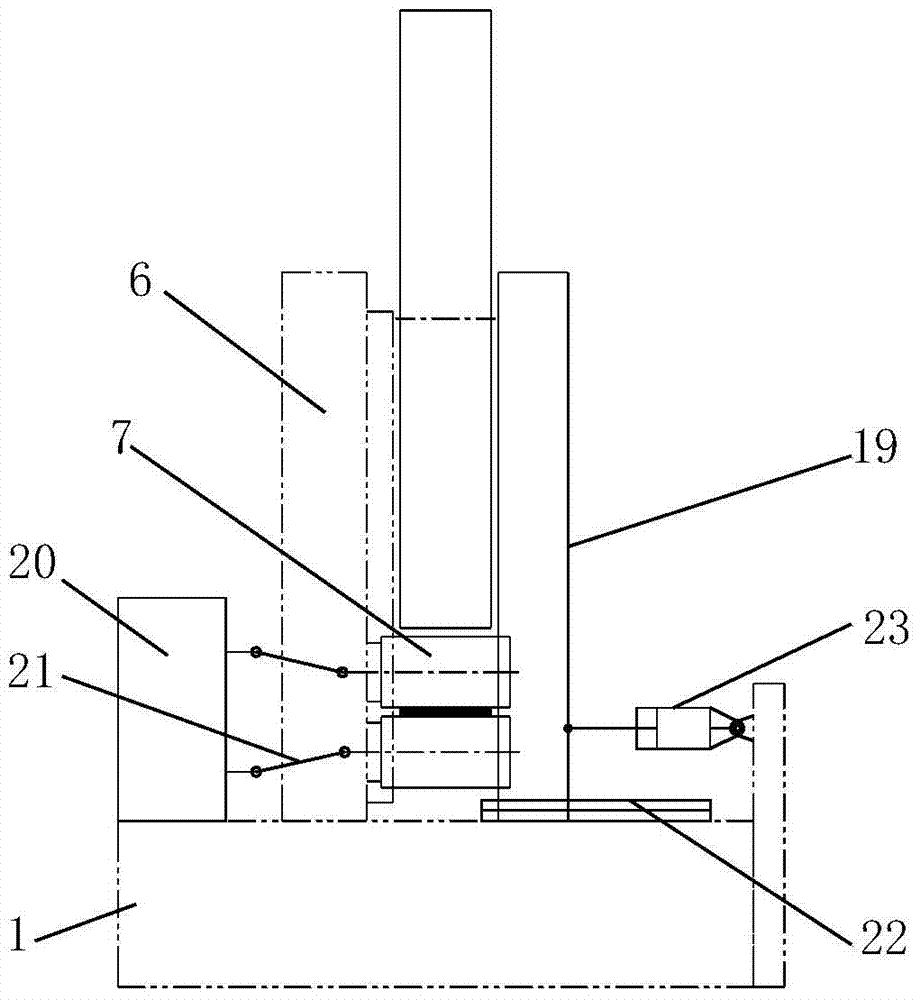

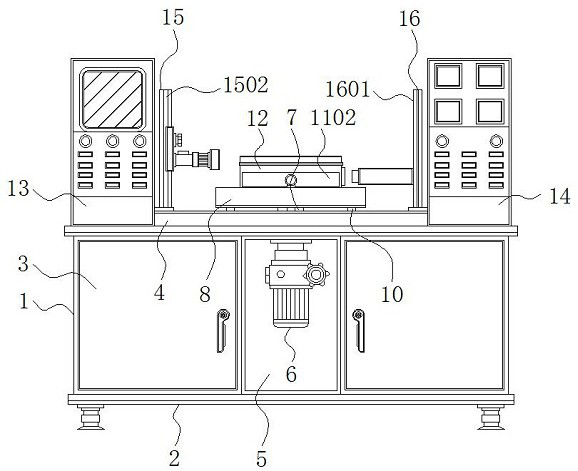

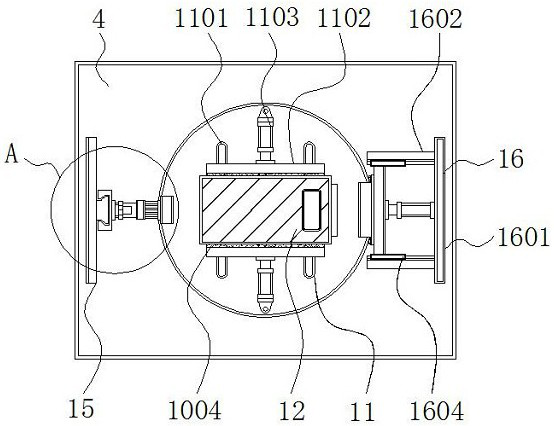

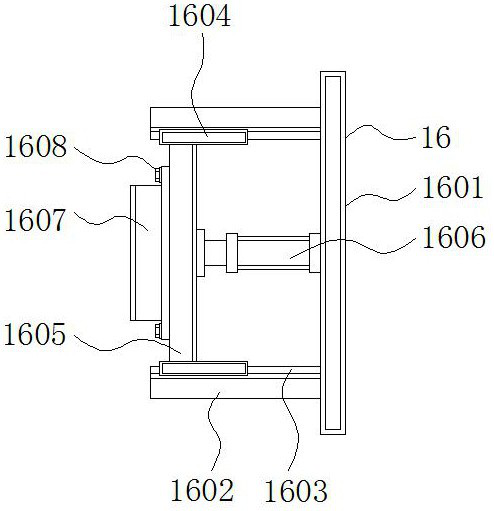

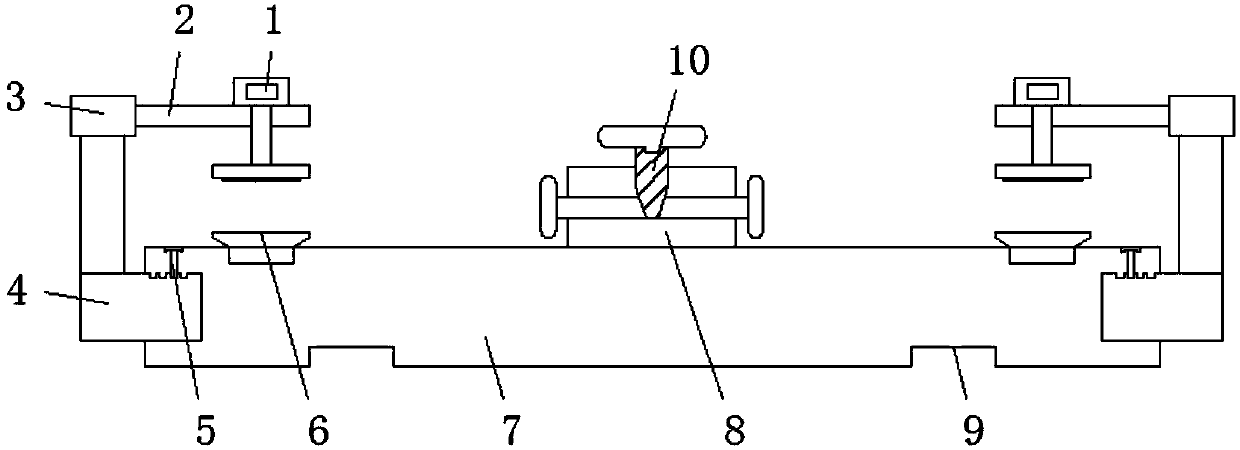

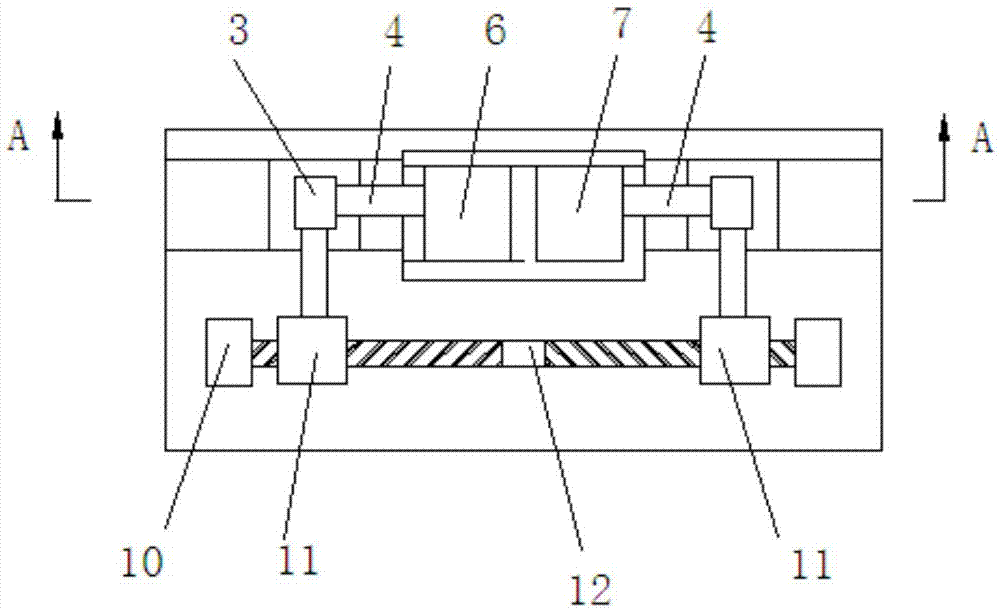

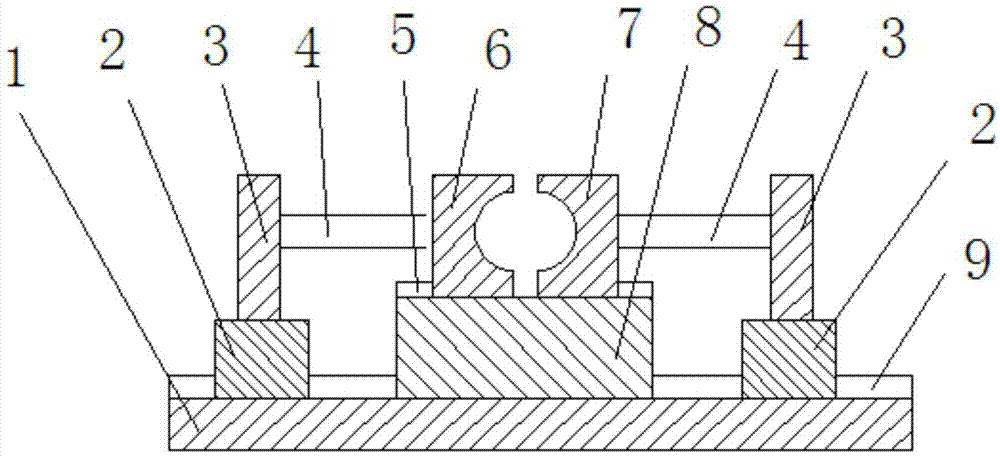

Equipment for processing valve

ActiveCN104827077AAvoid shakingGuaranteed clamping effectWork clamping meansPositioning apparatusHydraulic cylinderIndustrial engineering

The invention discloses equipment for processing a valve. The equipment comprises a hole drilling mechanism and a clamping mechanism, wherein the clamping mechanism comprises a clamping post and a hydraulic cylinder; a first sleeve ring is arranged on the clamping post; N clamping units are arranged along the axial direction of the clamping post; each clamping unit comprises a first connecting rod, a second connecting rod and a clamping plate used for being attached to the inner surface of the valve; one end of each first connecting rod is hinged to one end of the corresponding clamping plate, and the other end of each first connecting rod is hinged to the clamping post; one end of each second connecting rod is hinged to one end, far away from the first connecting rod, of the corresponding clamping plate, and the other end of each second connecting rod is hinged to the first sleeve ring; the first sleeve ring is in transmission connection with the hydraulic cylinder; the hole drilling mechanism comprises a drill bit; the drilling direction of the drill bit is parallel to the axial direction of the clamping post. The equipment has the advantages that the clamping plate can be used for clamping the valves with different diameters; the applicability and the processing precision are high; the support mechanism is designed, and is used for supporting the edge of a flange, and the sealing performance when the flange is connected with an external pipeline is ensured.

Owner:EAST CHINA MINING EQUIP CO LTD

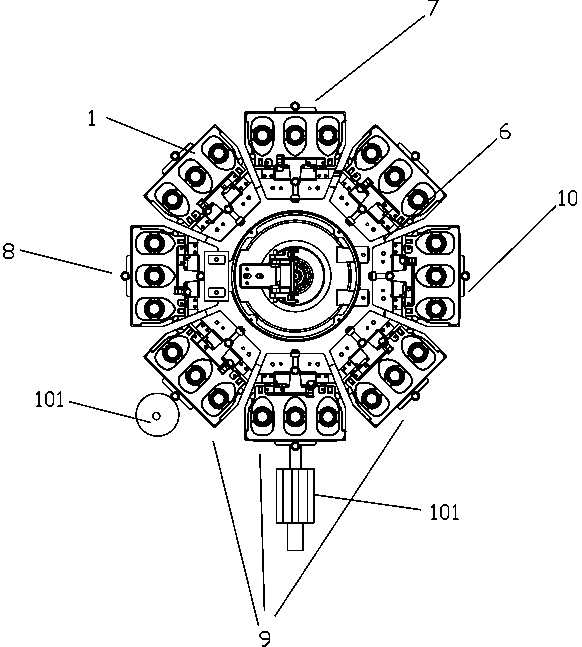

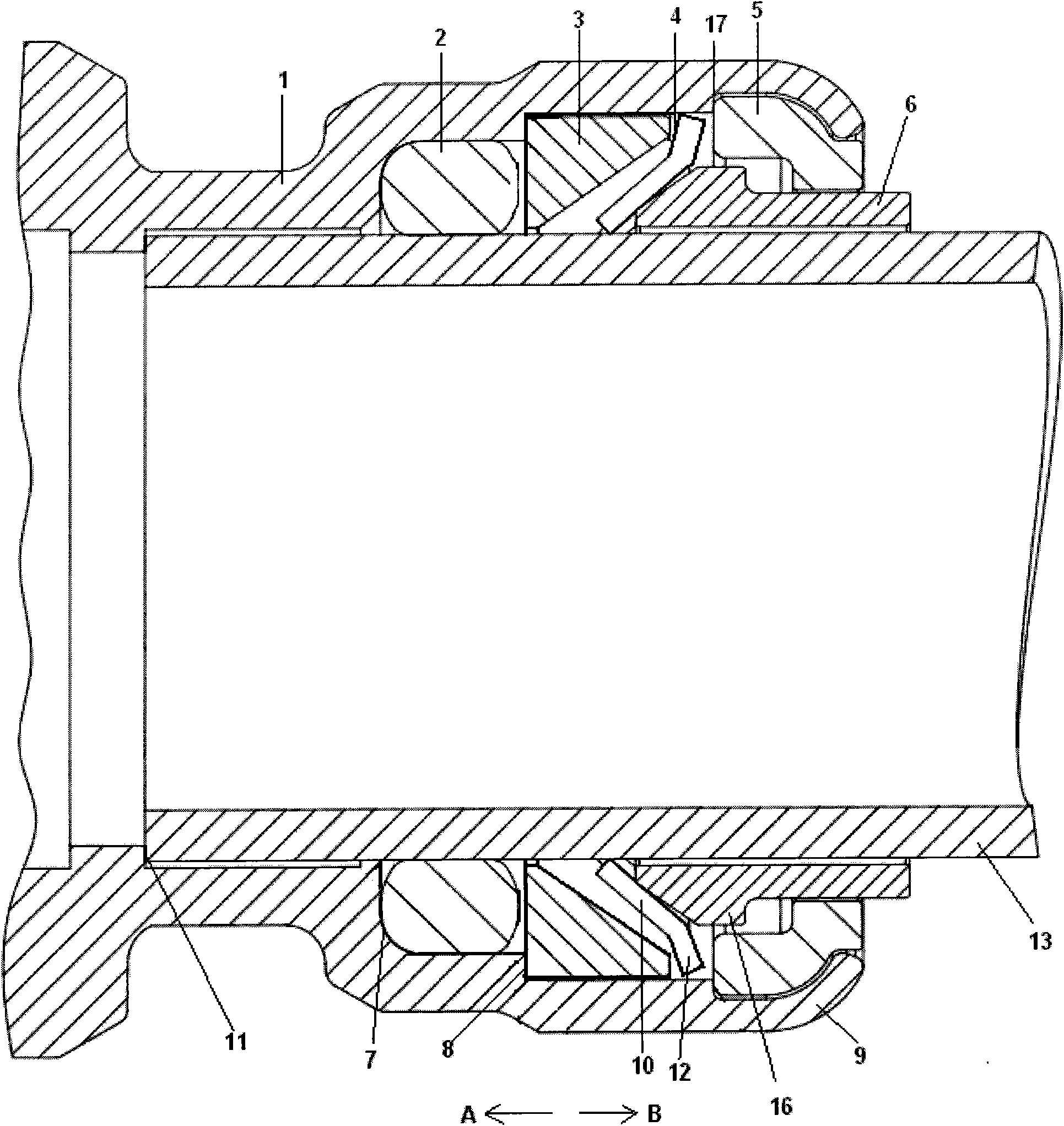

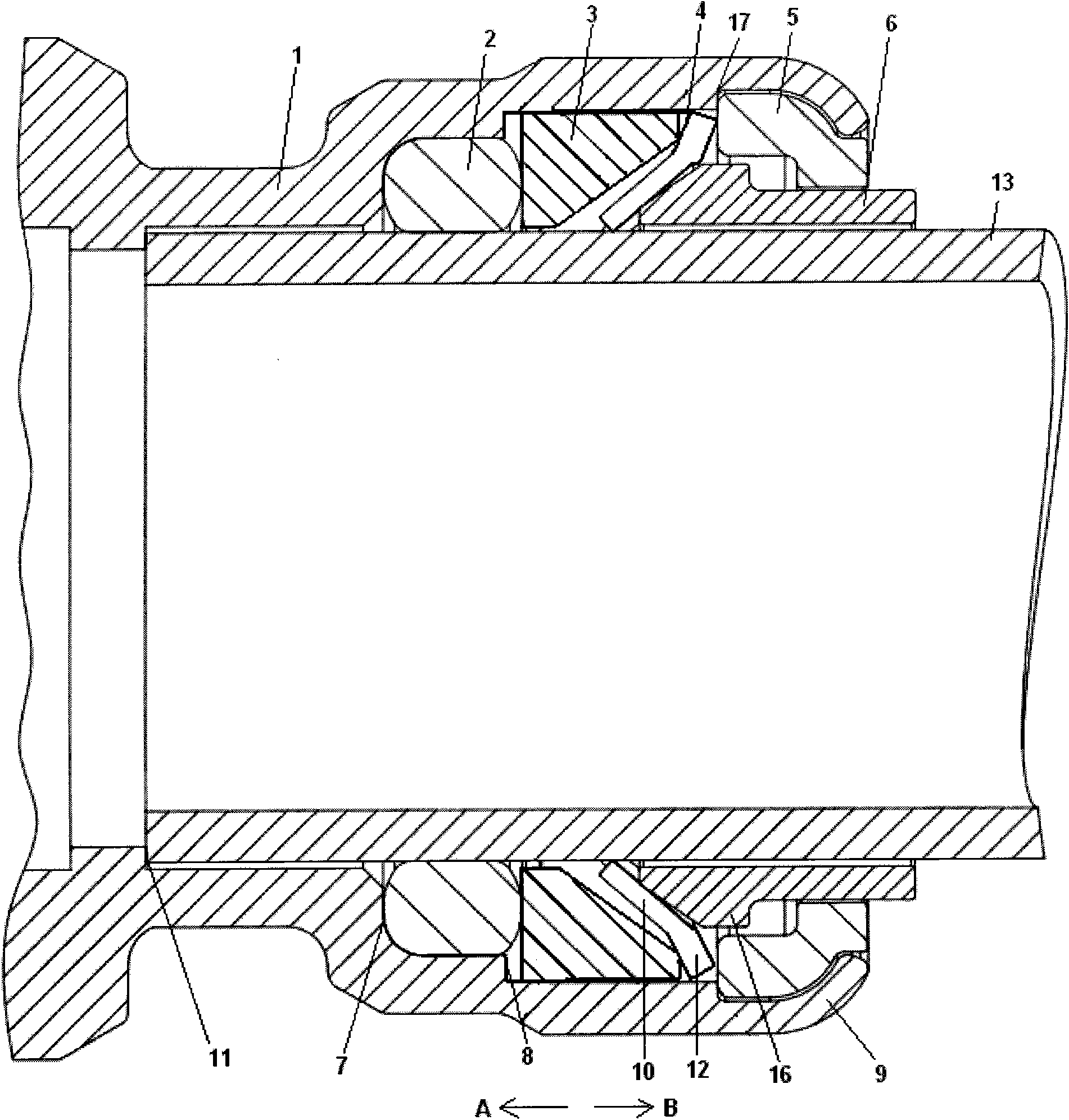

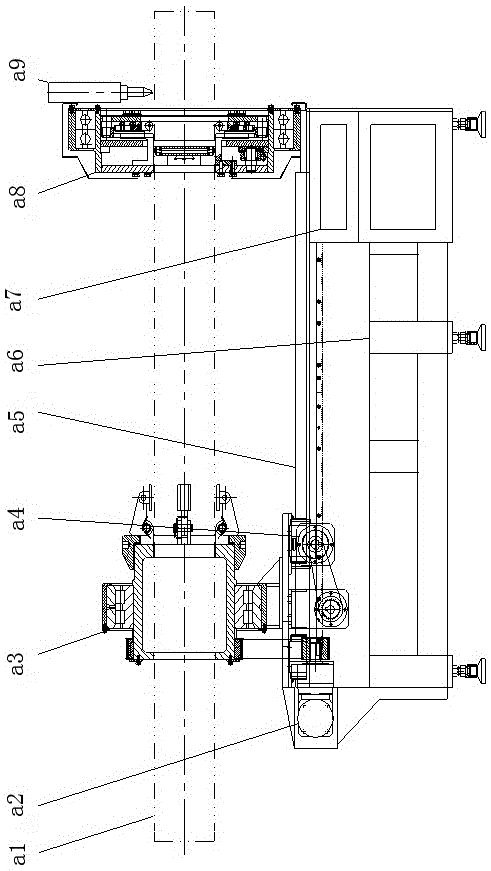

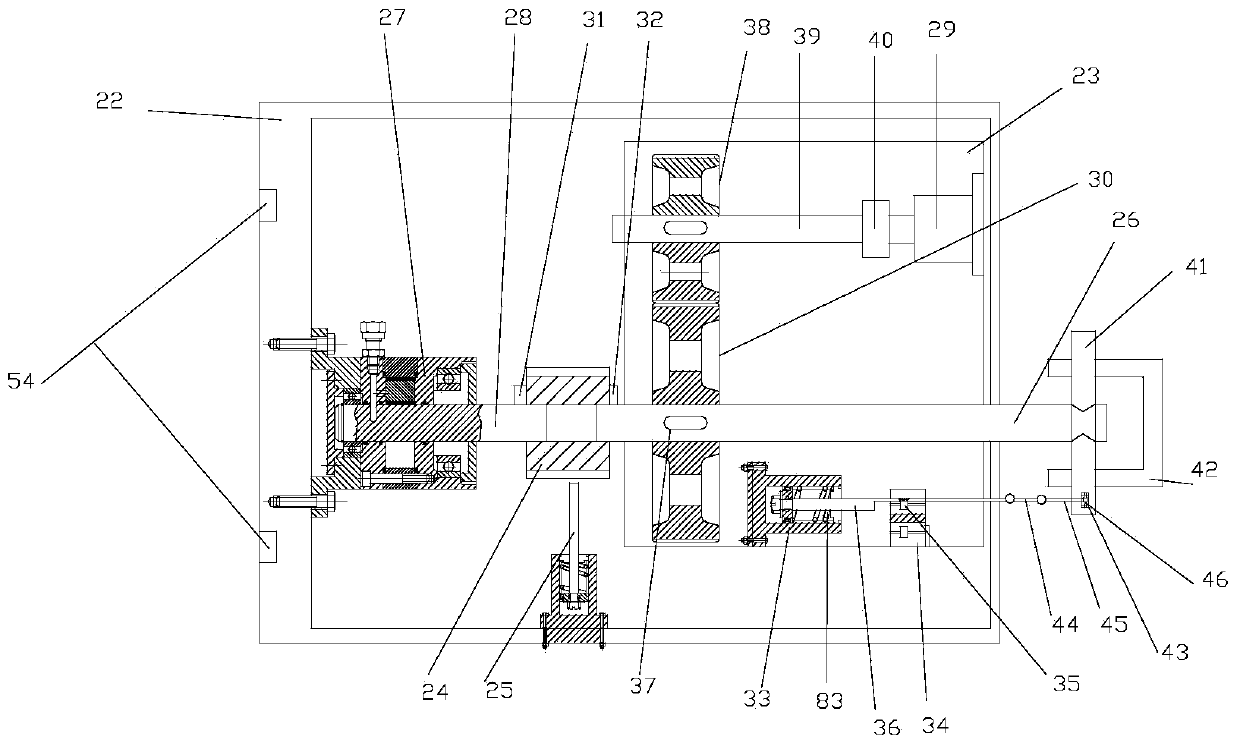

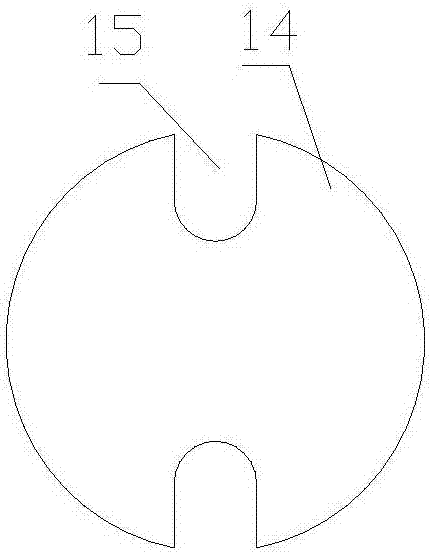

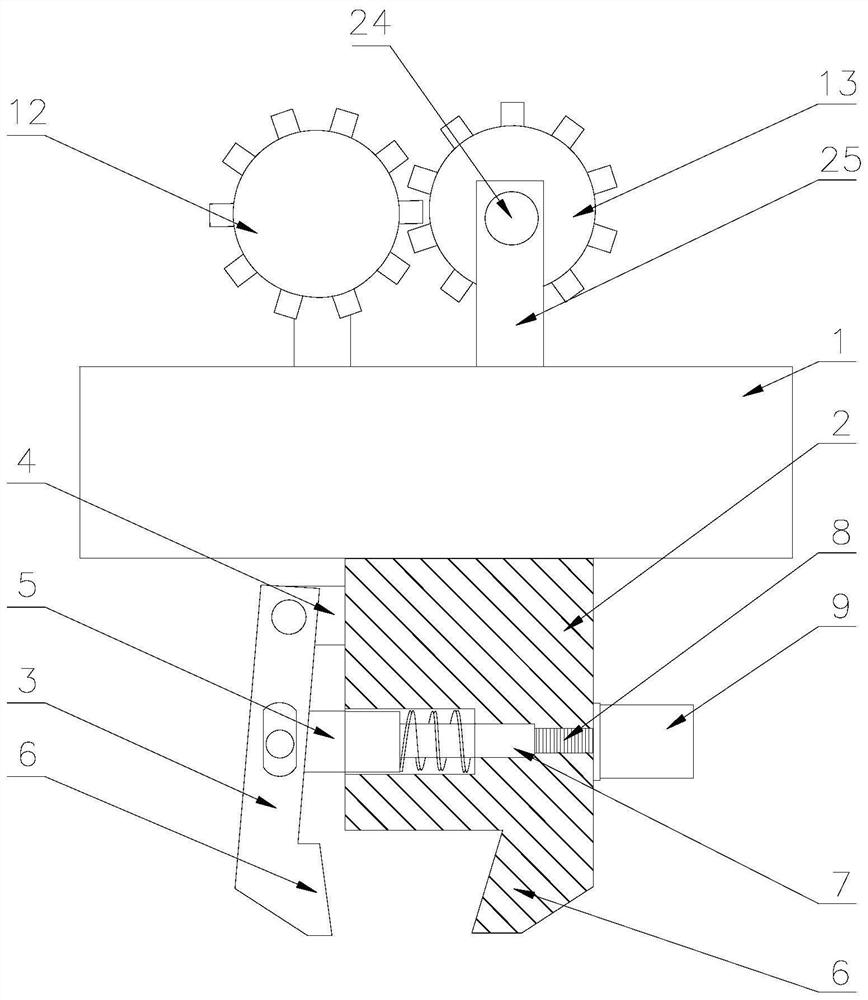

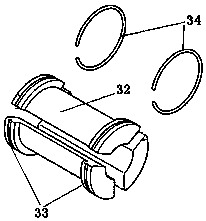

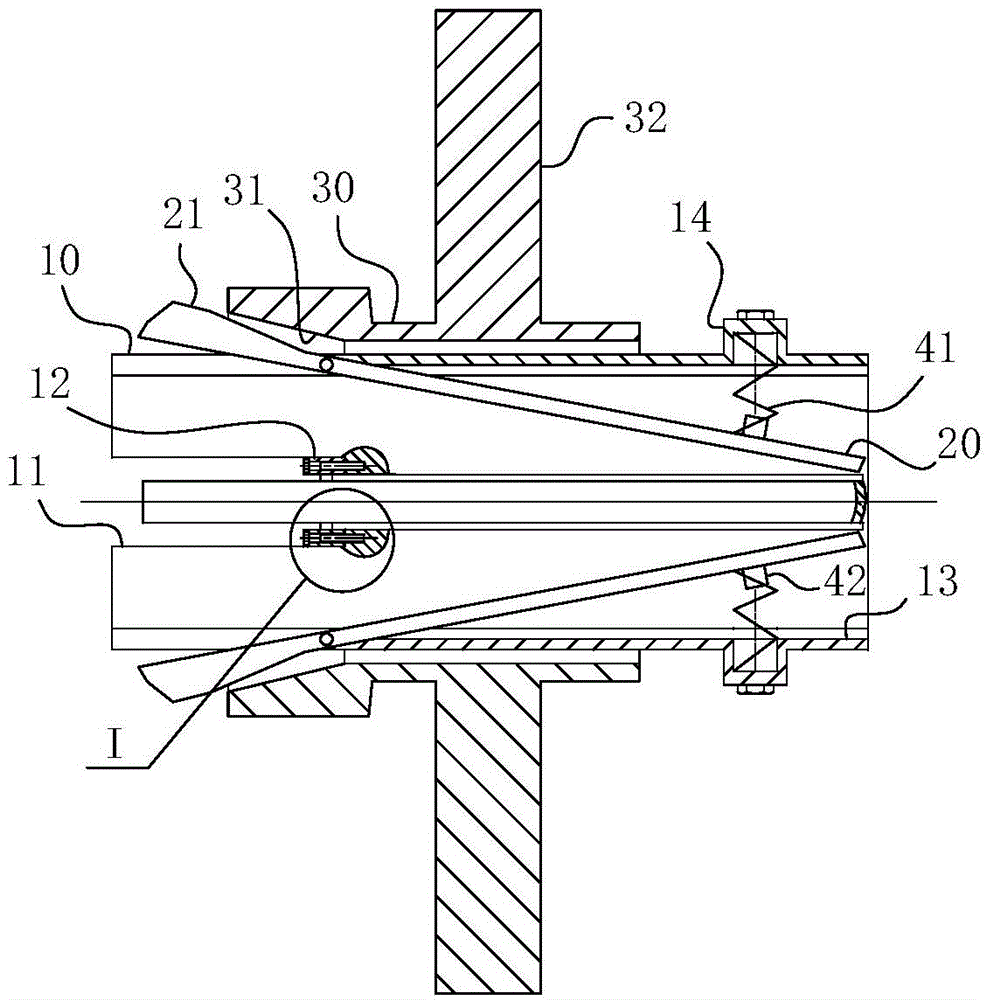

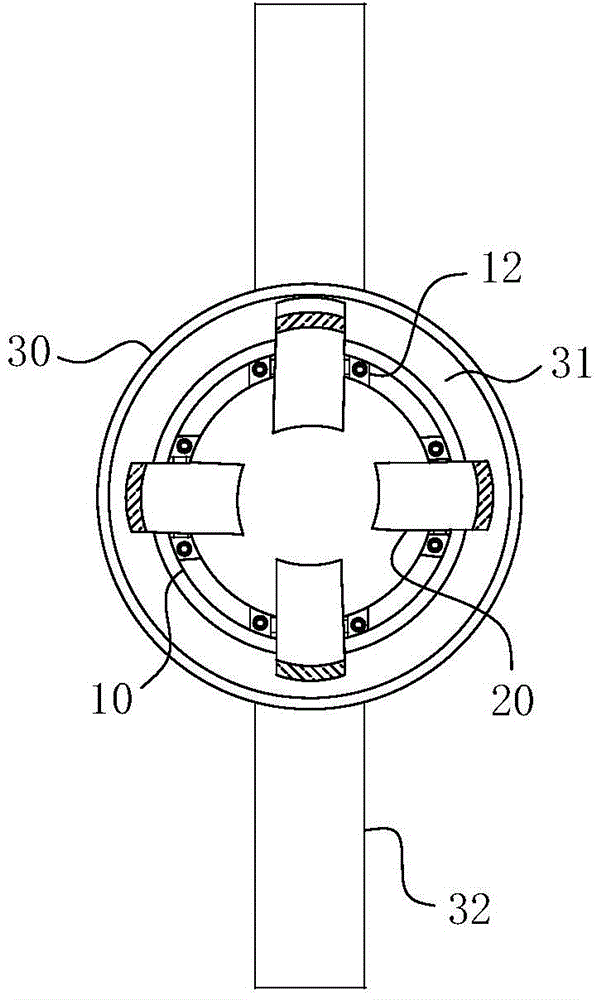

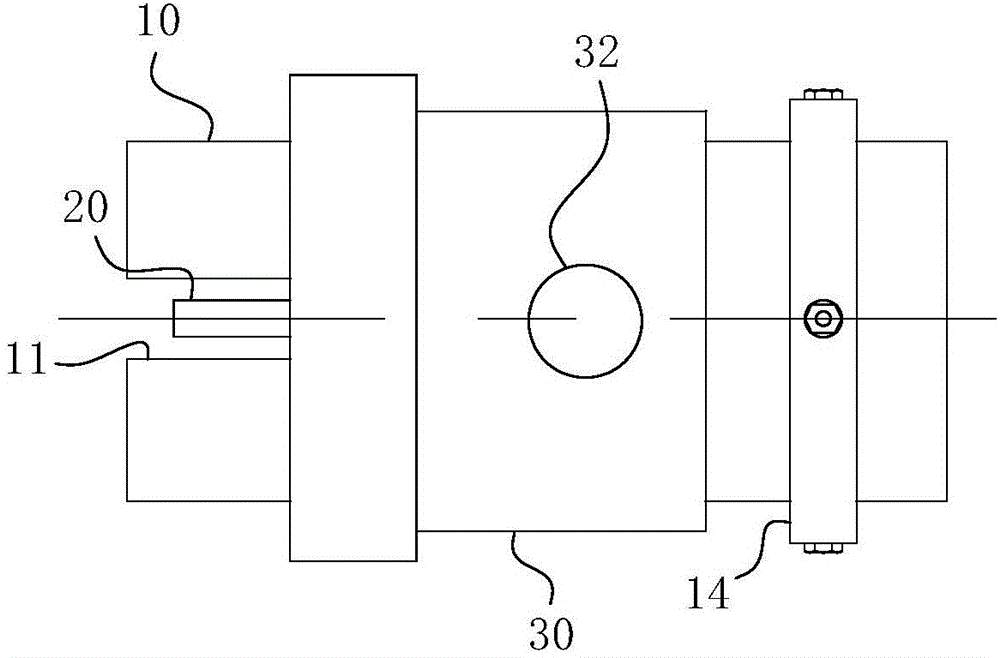

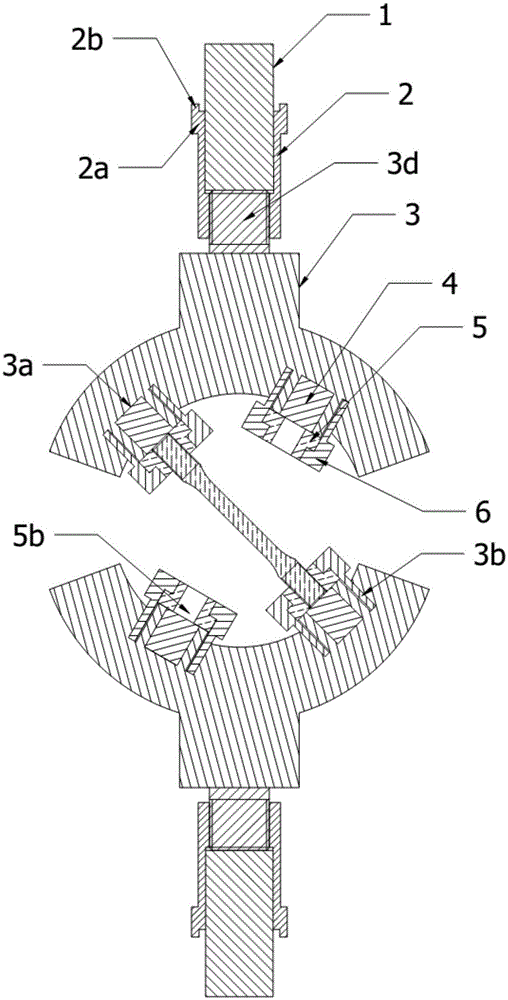

Rotary chuck and laser pipe cutting machine

ActiveCN105014295ARealize the function of rotating and walkingSmooth rotationWelding/cutting auxillary devicesAuxillary welding devicesCoil springEngineering

The invention discloses a rotary chuck which comprises bearing pedestals, a cylindrical roller bearing, a roller core, a lock disc, coil springs, clamping jaw blocks, first pin shafts, clamping jaw mats, a second pin shaft and a stopping lock. The roller core is fixed in the bearing pedestals through the cylindrical roller bearing, and a through hole allowing a workpiece to penetrate is formed in the roller core. The rear ends of the clamping jaw blocks are fixed to the front end of the roller core, and the clamping jaw blocks rotate with the second pin shaft as the axis. The second pin shaft is a hinge shaft of the roller core and the clamping jaw blocks, the coil springs for keeping the clamping jaw blocks expanding outwards are arranged on the second pin shaft, and the front ends of the clamping jaw blocks are hinged to the clamping jaw mats through the first pin shafts. The lock disc is in threaded connection with the roller core, and the clamping jaw blocks are driven to rotate around the second pin shaft through mutual movement of the lock disc and the roller core. The stopping lock capable of fixedly connecting the bearing pedestals and the roller core is arranged on the bearing pedestals. According to the rotary chuck, the pipe machining operating speed is greatly improved, and the rotary chuck is a great contribution to the social machining and manufacturing industry.

Owner:JINAN G WEIKE SCI & TECH

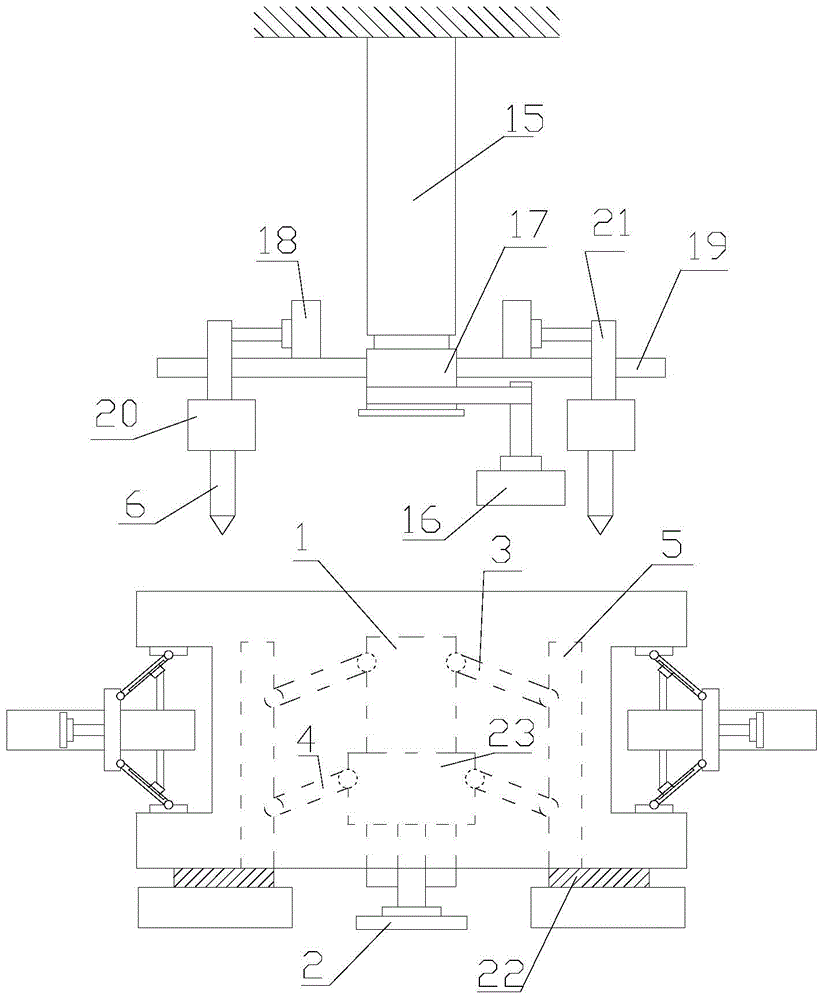

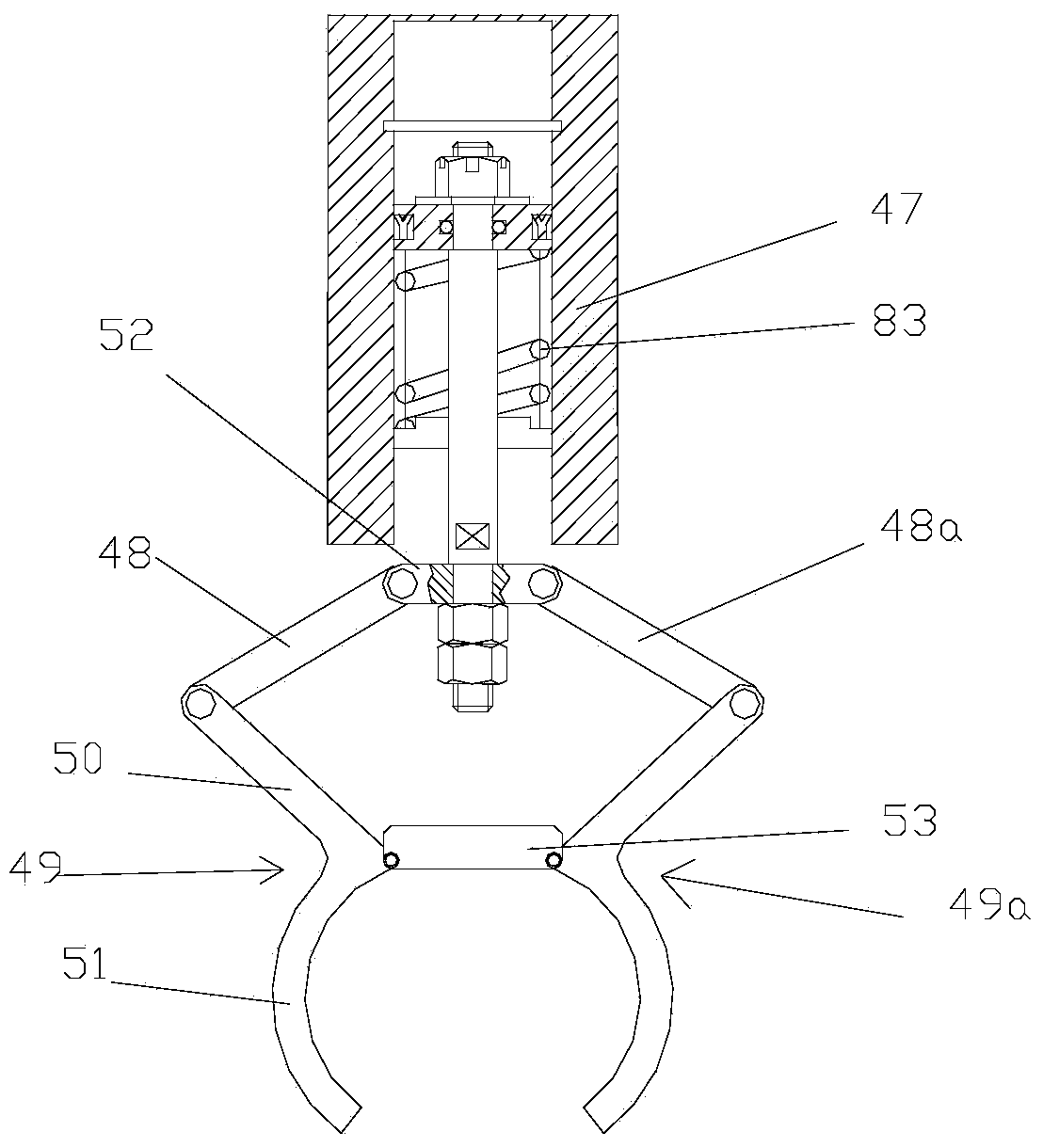

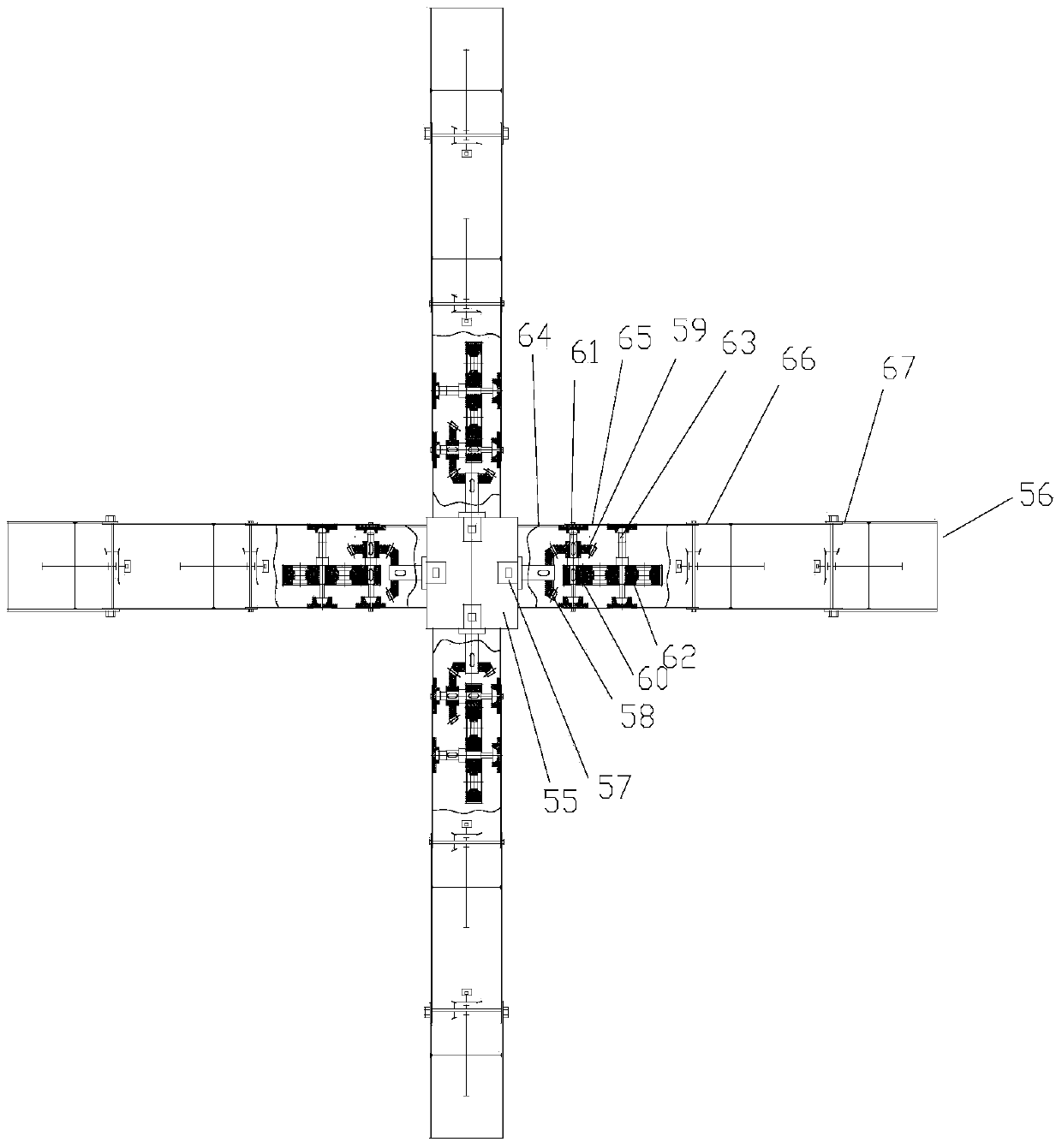

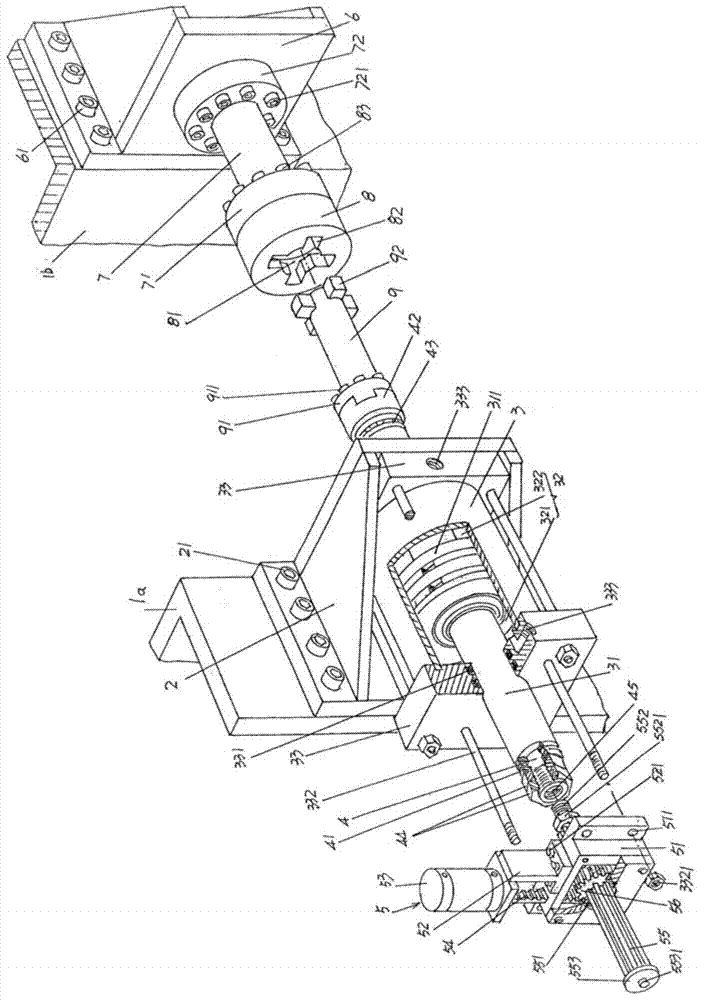

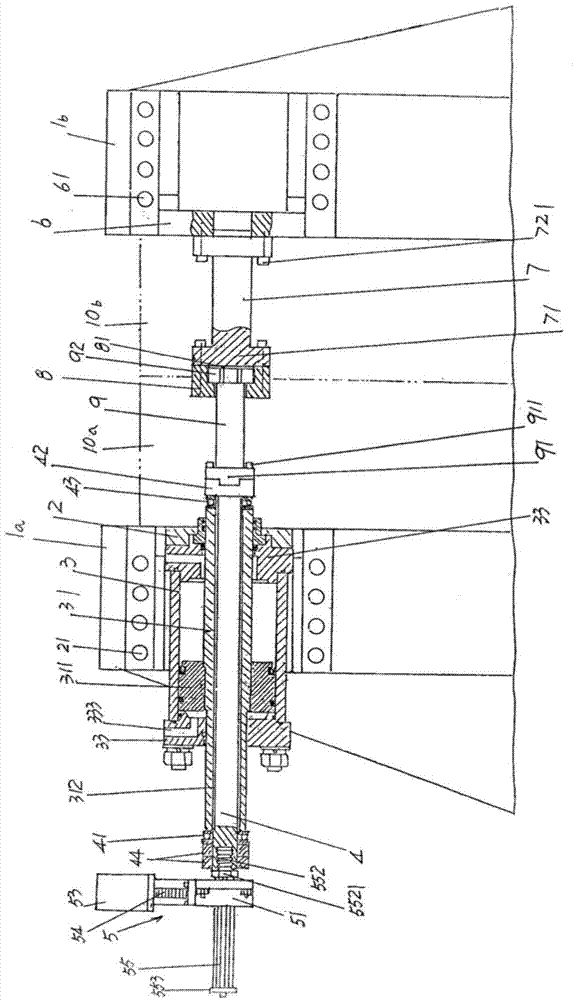

Heavy-load precision redundant three-arm mechanical hand based on traveling crane

ActiveCN104308859AHigh positioning accuracySolve the contradiction between overloading and precisionProgramme-controlled manipulatorJointsAutomatic controlManipulator

The invention discloses a heavy-load precision redundant three-arm mechanical hand based on a traveling crane. The three-arm mechanical hand comprises a base, a clamp assembly and an automatic control system, wherein the clamp assembly comprises a mounting seat used for mounting mechanical arms, a gripping mechanical hand used for gripping a workpiece, and a carrying mechanical hand used for carrying the gripped workpiece; the gripping mechanical hand comprises a heavy-load mechanical hand used for gripping a heavy workpiece, and a light-load mechanical hand used for gripping a light precision workpiece. According to the three-arm mechanical hand, the gripping mechanical hand adopts a redundant mechanical arm structure, the heavy-load mechanical hand is used for loading a heavy object, the light-load mechanical hand is used for carrying a precision device, and the two gripping mechanical hands can cooperatively carry and mount the workpiece in space, so that the problem of conflict between heavy load and precision in the field of mechanical hands is solved; in addition, due to the carrying mechanical hand, the disadvantage that a traveling crane needs to run a round trip for carrying a part at present is overcome, the labor intensity of workers is greatly reduced, the production efficiency of workshops is improved, and the energy consumption is greatly reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

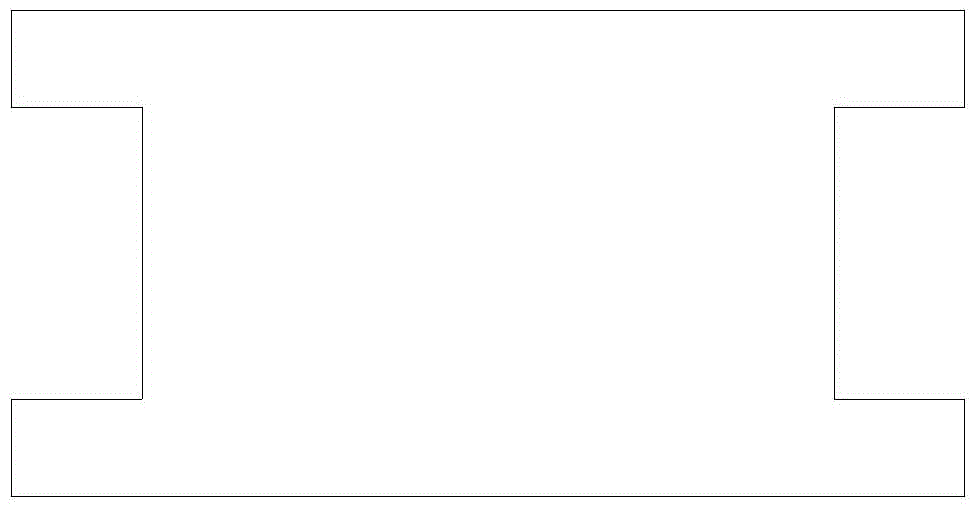

Mould locking device structure of hollow plastic product forming machine

The invention discloses a mould locking device structure of a hollow plastic product forming machine, which belongs to the technical field of plastic product forming machines. The hollow plastic product forming machine comprises left and right mould bases. The mould locking device structure comprises a pair of deflection rod displacement action cylinder bases, a deflection rod displacement action cylinder, a deflection rod, a deflection rod rotating actuating mechanism, a pull rod base, a pull rod, a pin lock and a pin lock key, wherein the deflection rod displacement action cylinder bases are fixed on one side, which faces to the right mould base, of the left mould base; the deflection rod displacement action cylinder is fixed on the deflection rod displacement action cylinder bases and is provided with a piston; the deflection rod is arranged in a deflection rod hole; the deflection rod rotating actuating mechanism is arranged the left one in the pair of deflection rod displacement action cylinder bases of the deflection rod displacement action cylinder and is connected with the left end of the deflection rod; the pull rod base is fixed on one side, which faces to the left mould base, of the right mould base, and the pull rod base and the deflection rod displacement action cylinder bases correspond to each other; the pull rod is fixed on the pull rod base; the pin lock is fixed on the pull rod; the left end of the pin lock key is connected with a tabling joint of the deflection rod, and the right end of the pin lock key is matched with the pin lock. The mould locking device structure provided by the invention has the advantages that the module combining effect of left and right half modules is guaranteed, the service life is prolonged, and the integral structure is simple.

Owner:SUZHOU TONGDA MACHINERY

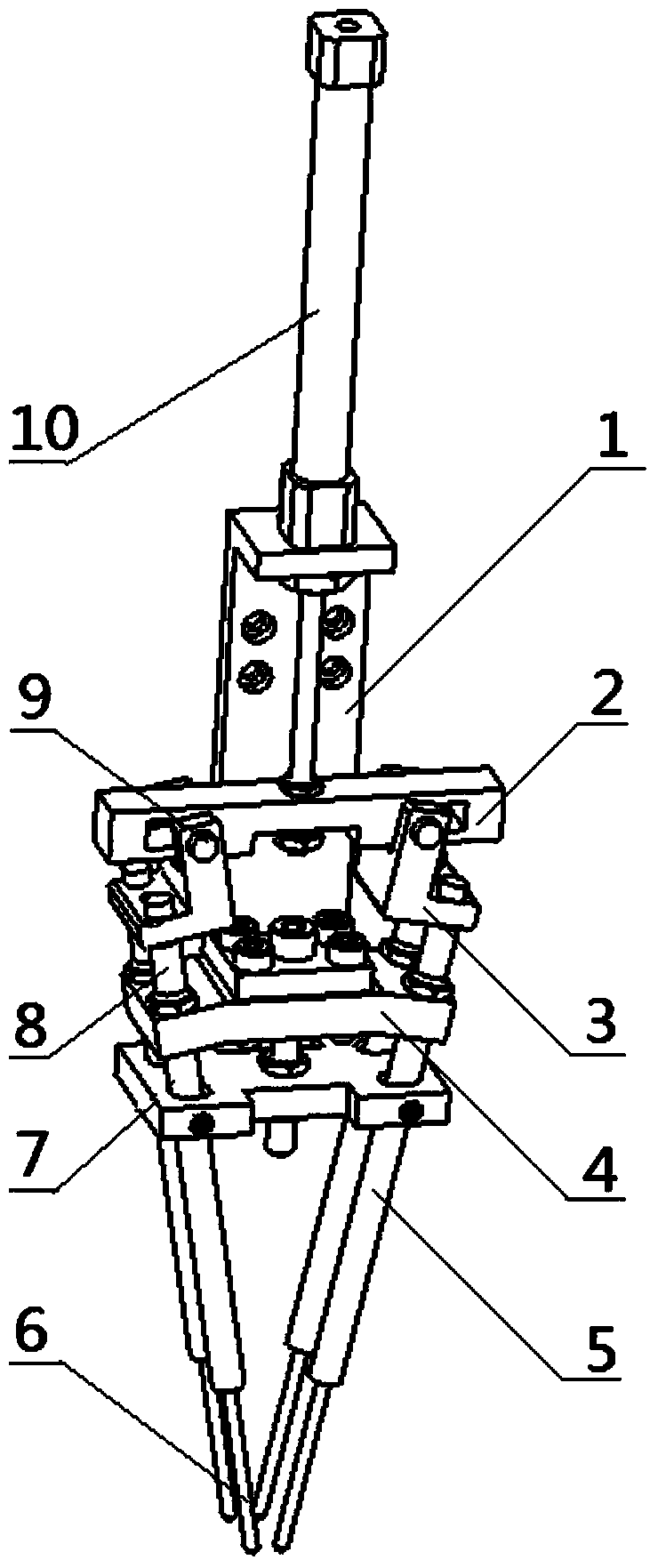

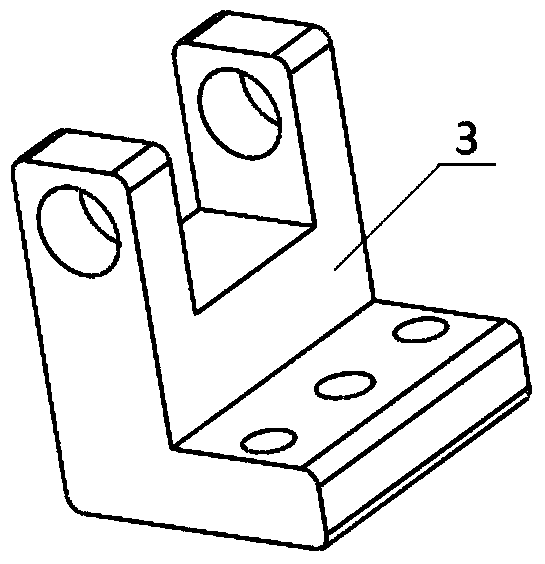

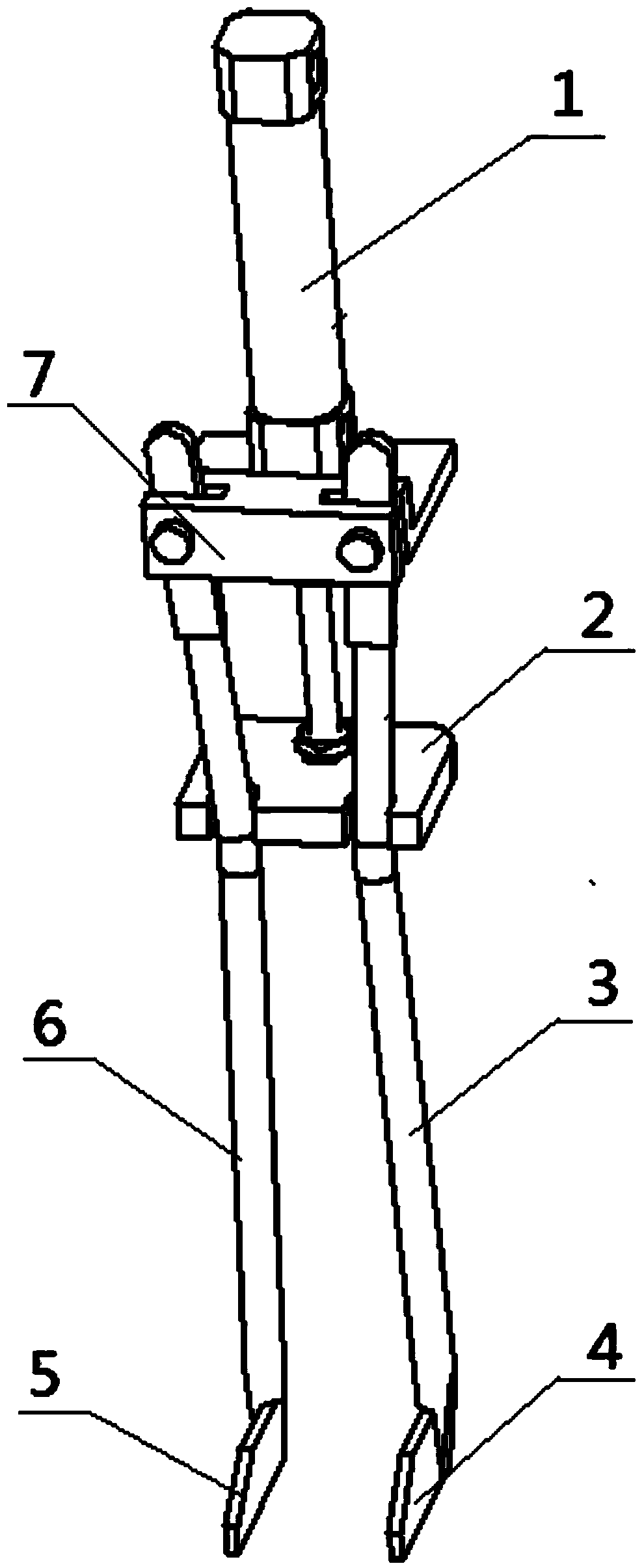

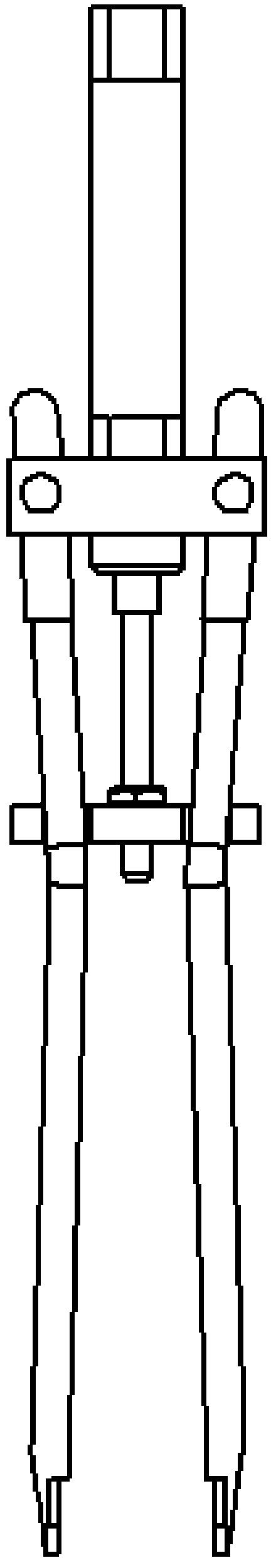

Oblique type hole tray seedling transplanting paw

The invention relates to an oblique type hole tray seedling transplanting paw which comprises a machine frame, a sliding platform, steel needle fixing plates, a sleeve fixing plate, sleeves, steel needles, a reinforcing plate, buffering sleeves, hinge pins and an air cylinder. The air cylinder is fixed on the upper portion of the machine frame, the middle of the sliding platform is fixed on the end portion of a pushing rod of the air cylinder, and the two hinge pins are fixed on the upper portions of the two steel needle fixing plates respectively and are installed in long holes in the two sides of the sliding platform. The middle of the sleeve fixing plate is fixed at the bottom of the machine frame, the four sleeves are fixed at the four corners of the sleeve fixing plate respectively, the lower portions of the four steel needles are installed in the four sleeves respectively, and the upper portions of the four steel needles are fixed on the lower portions of the steel needle fixing plates on the two sides respectively. Four long holes are formed in the four corners of the reinforcing plate respectively, the reinforcing plate is located on the lower portion of the sleeve fixing plate, the sleeves penetrate through the long holes in the four corners of the reinforcing plate, and the four buffering sleeves are arranged on the four steel needles 6 in a sleeved mode to be installed on the upper portion of the sleeve fixing plate. The form that the steel needles insert and take hole tray seedlings by a certain angle is adopted in the oblique type hole tray seedling transplanting paw, practicability is high, structure is simple and stable, and the degree of automation is high.

Owner:BEIJING UNIV OF TECH

Cable processing equipment

InactiveCN107481814AImprove flexibilityGuaranteed peeling effectBasic electric elementsApparatus for removing/armouring cablesInsulation layerEngineering

The invention discloses cable processing equipment comprising a clamping mechanism used for clamping a cable, a processing mechanism used for removing an insulation layer on the cable, and a first recycling mechanism used for recycling the cable core; the processing mechanism is arranged between the clamping mechanism and the first retrieve mechanism, and comprises N processing units; the processing unit comprises a crossbar having a cylinder and a connecting rod; the cylinder output end is provided with a blade; the cylinder drives the blade to radially move along the cable; the cylinder is hinged to the crossbar; one end of the connecting rod is hinged to the cylinder, and the other end is connected with the crossbar in a slide manner. The cable processing equipment uses a flattening unit to properly extrude and flatten the cable, thus flattening the cable bending portions, and effectively removing the cable skin; the processing mechanism can flexibly enable the blade to destroy the cable insulation layer according to different angles, thus ensuring the peeling effect.

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

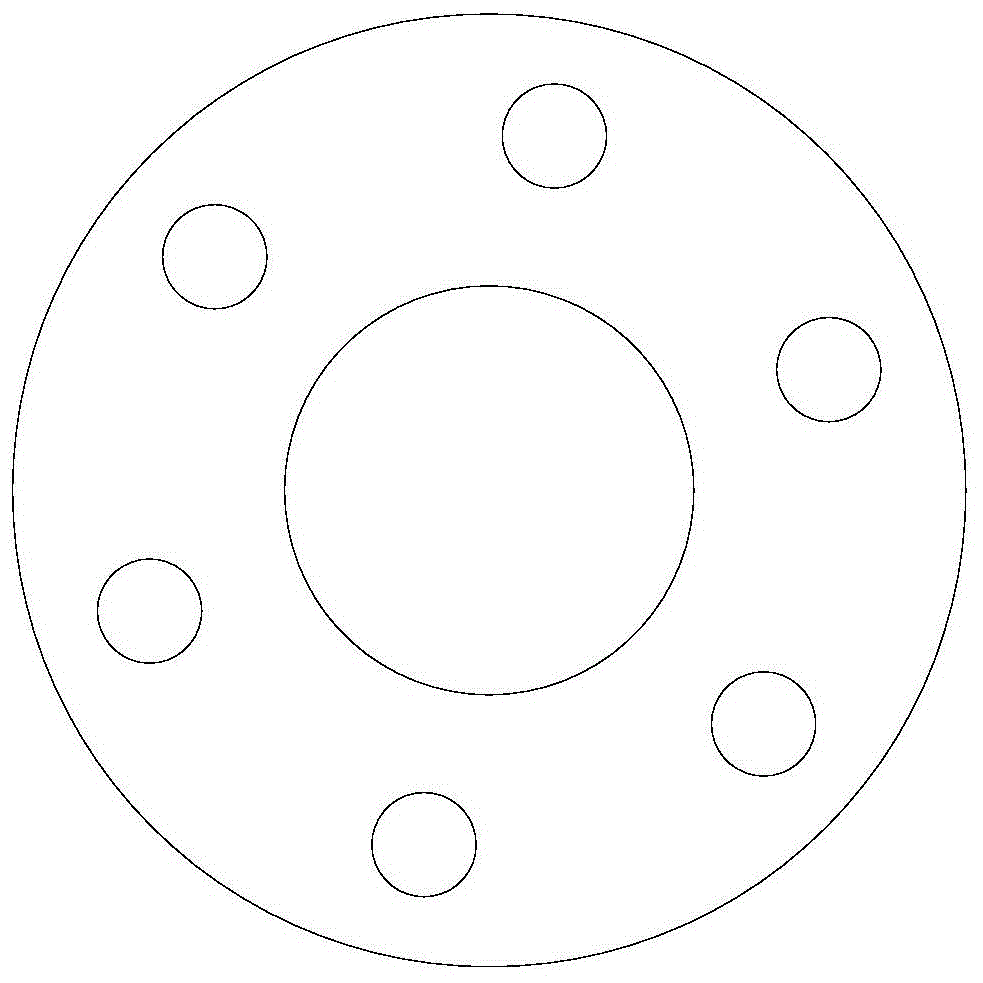

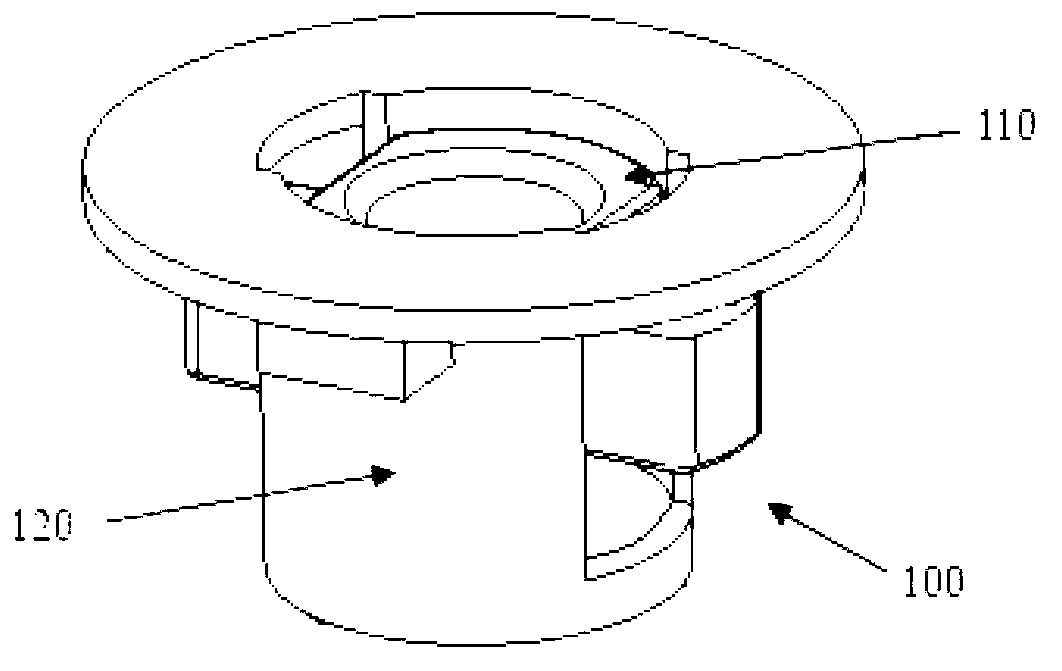

Ring set welding tool

InactiveCN103495828AGuaranteed concentricityGuaranteed clamping effectWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringEngineering

The invention discloses a ring set welding tool. The ring set welding tool comprises a work platform connected to a machine frame, the work platform is provided with an annular groove, an annular protrusion of an outer ring is inserted into the annular groove, the work platform is provided with an outer ring fixture, the machine frame is further provided with a support, the support is driven by a vertical power mechanism to slide vertically, located above the work platform, and is rotationally connected with a supporting arm extending downwards, the supporting arm is provided with an inner ring fixture, and an inner ring locating mechanism is arranged between the downward-extending end of the supporting arm and the work platform. The ring set welding tool has the advantages that an inner ring and the outer ring can be effectively clamped.

Owner:SHANDONG ZHENGTAI HEAVY IND TECH

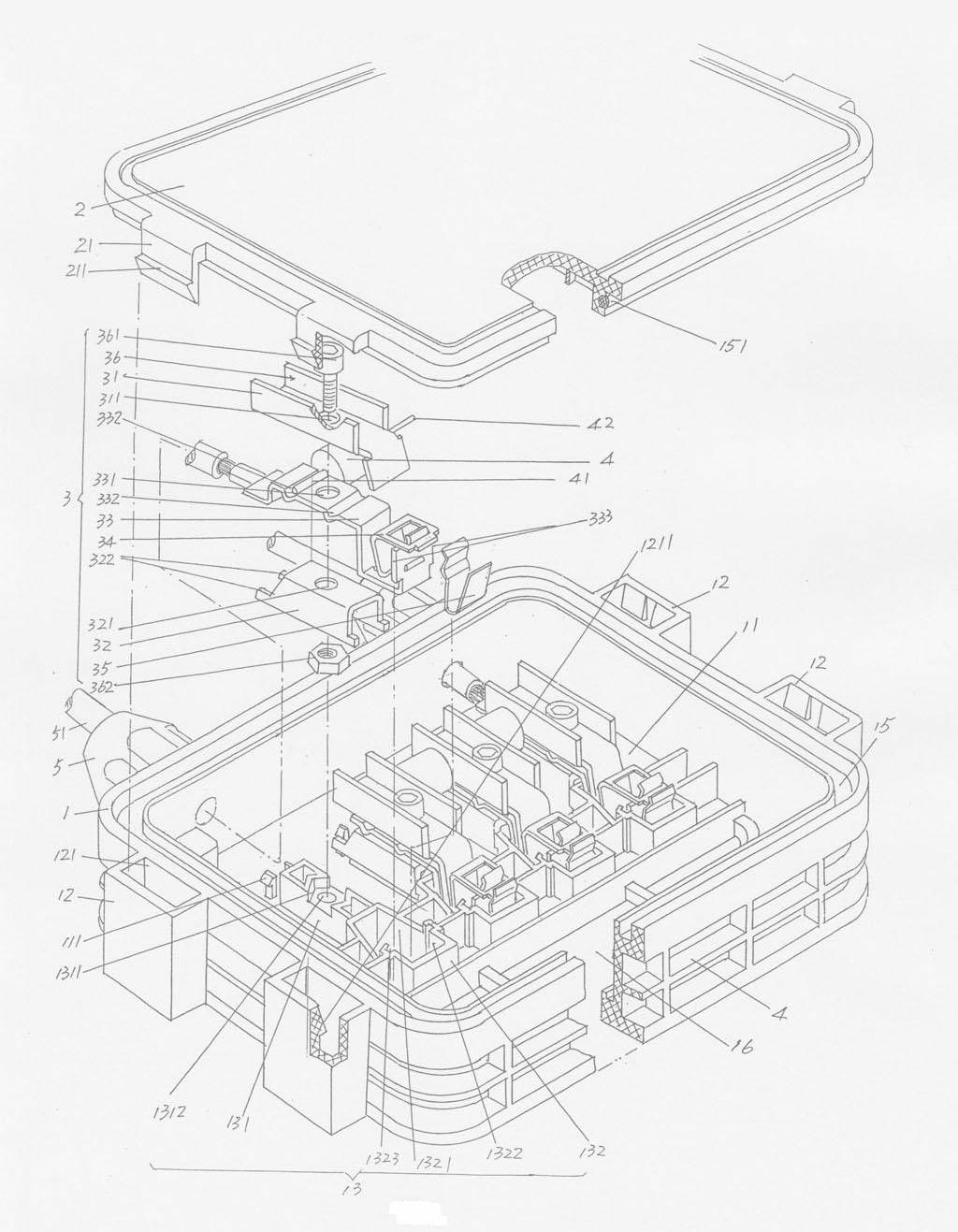

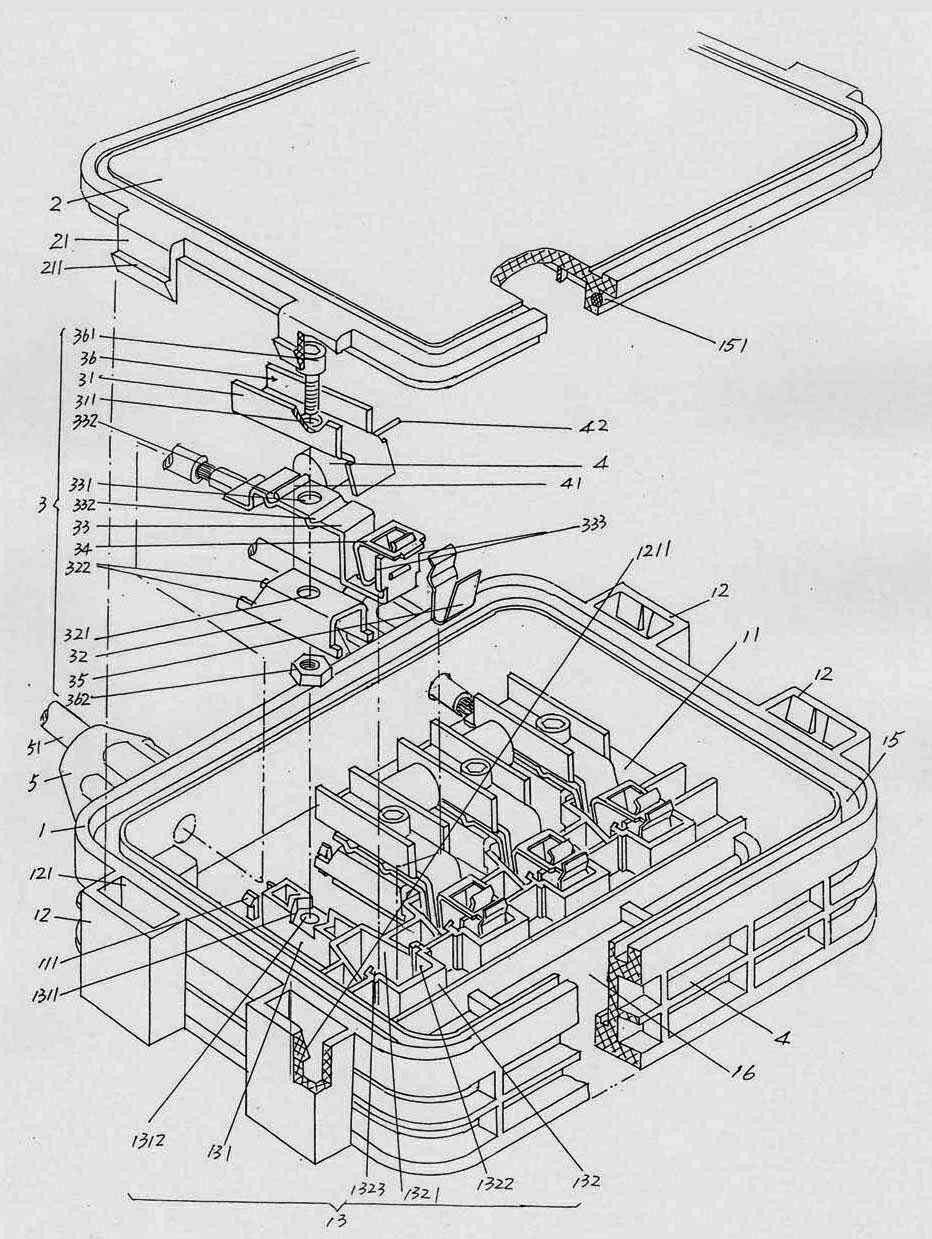

Junction box of solar photovoltaic component

InactiveCN102169913APrecise positioningReduce contact resistancePhotovoltaicsCoupling contact membersEngineeringSolar battery

The invention discloses a junction box of a solar photovoltaic component and belongs to the technical field of solar battery components. The junction box comprises a junction box body, a box cover, a group of bypass diodes and a group of conductive connection mechanisms, wherein the junction box body is provided with a box cavity and an embedding pin seat; the box cover is provided with an embedding pin; the group of bypass diodes are provided with first pins and second pins and arranged in the box cavity; the group of conductive connection mechanisms are arranged in the box cavity; and at least one bypass diode is arranged between each two adjacent conductive connection mechanisms. The junction box is characterized in that: a conductive connection mechanism seat is formed in the box cavity; the conductive connection mechanism seat comprises a lower pressing plate seat and a conductive connecting plate fitting seat; and the conductive connection mechanisms comprise upper and lower pressing plates, a conductive connecting plate, a first wire clamp and a second wire clamp. The junction box has the advantages of reducing contact resistance and temperature rise, prolonging the service life of each bypass diode, always guaranteeing the clamping effects on the first and second pins of the bypass diodes without influence of deformation of the heated junction box body, shortening the length of the embedding pin, and contributing to enhancement of the rigidity of the embedding pin to avoid breakage.

Owner:苏州恒宏模塑科技有限公司

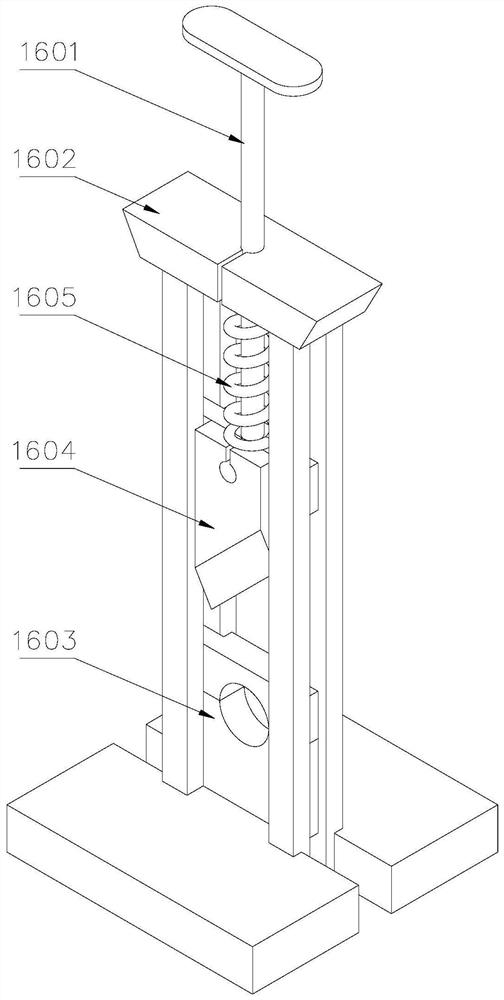

Cable tensioning device for high-altitude power construction

ActiveCN111799700AReduce work intensityProtect construction safetyApparatus for overhead lines/cablesElectric machineSupport plane

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

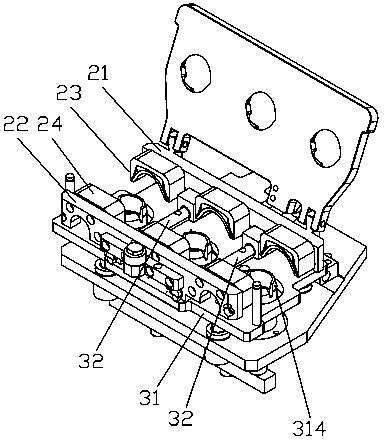

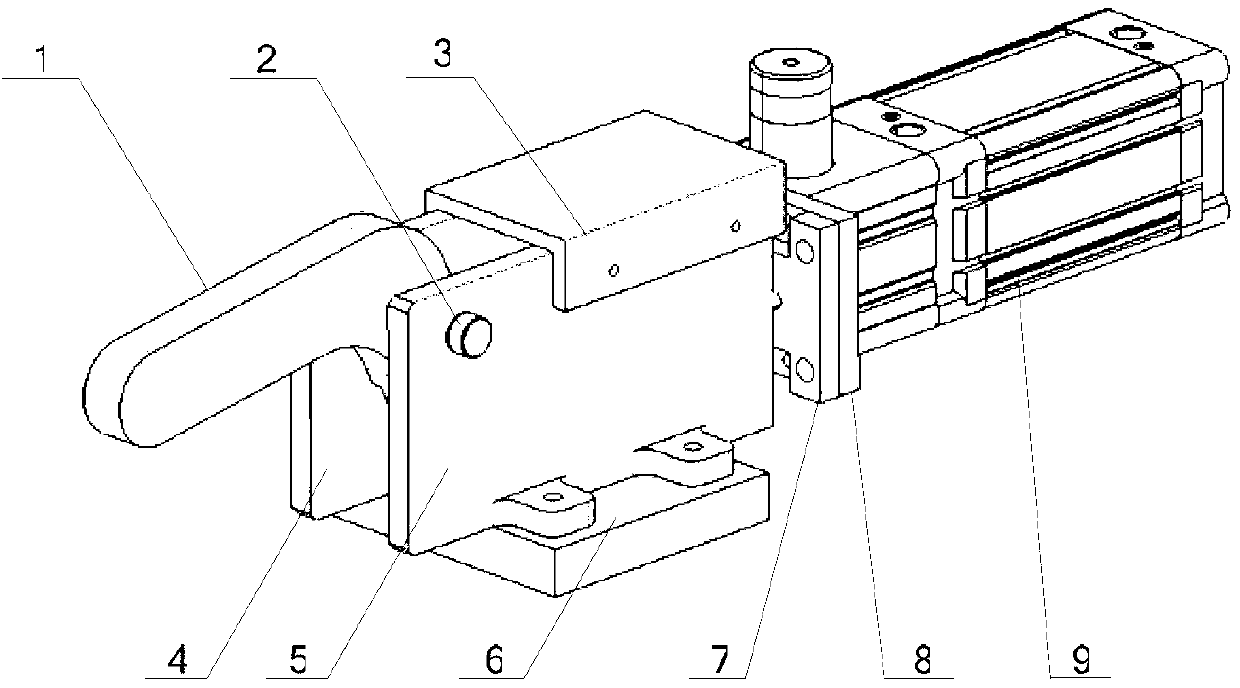

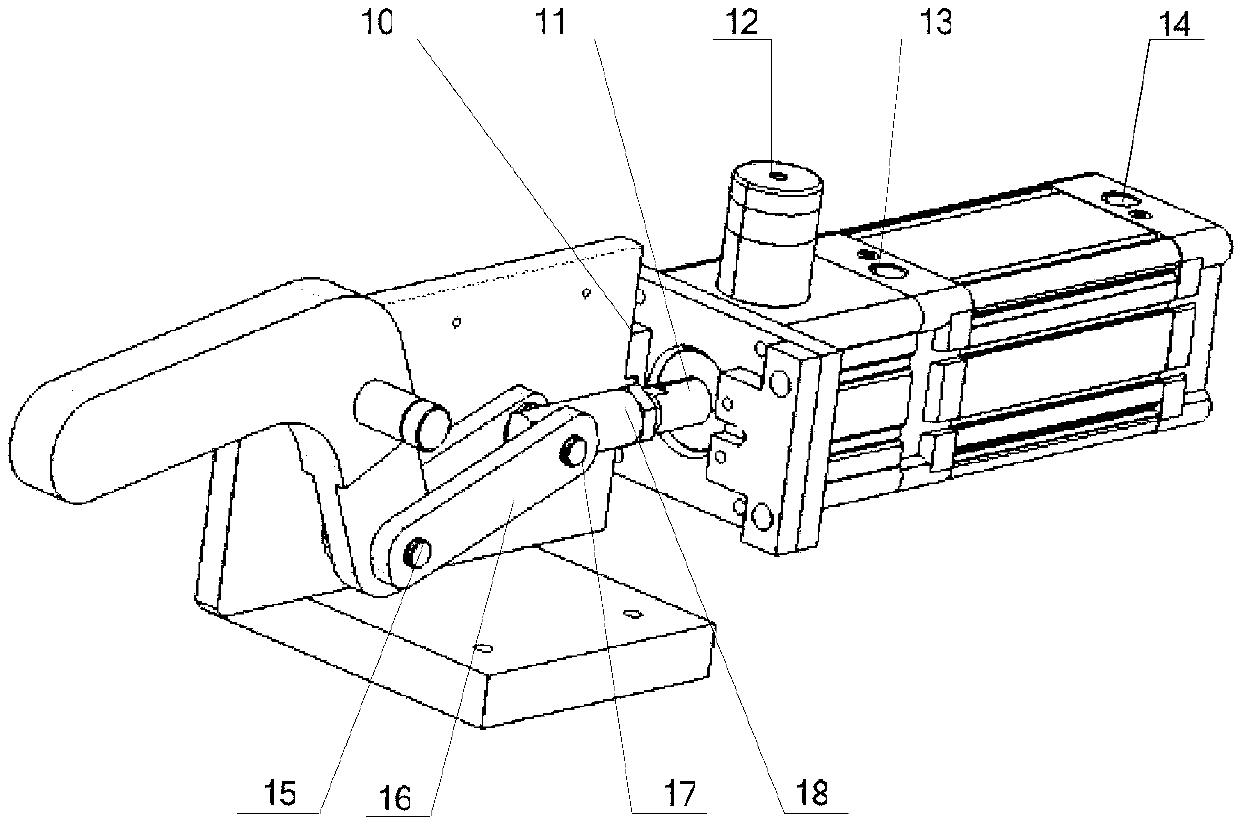

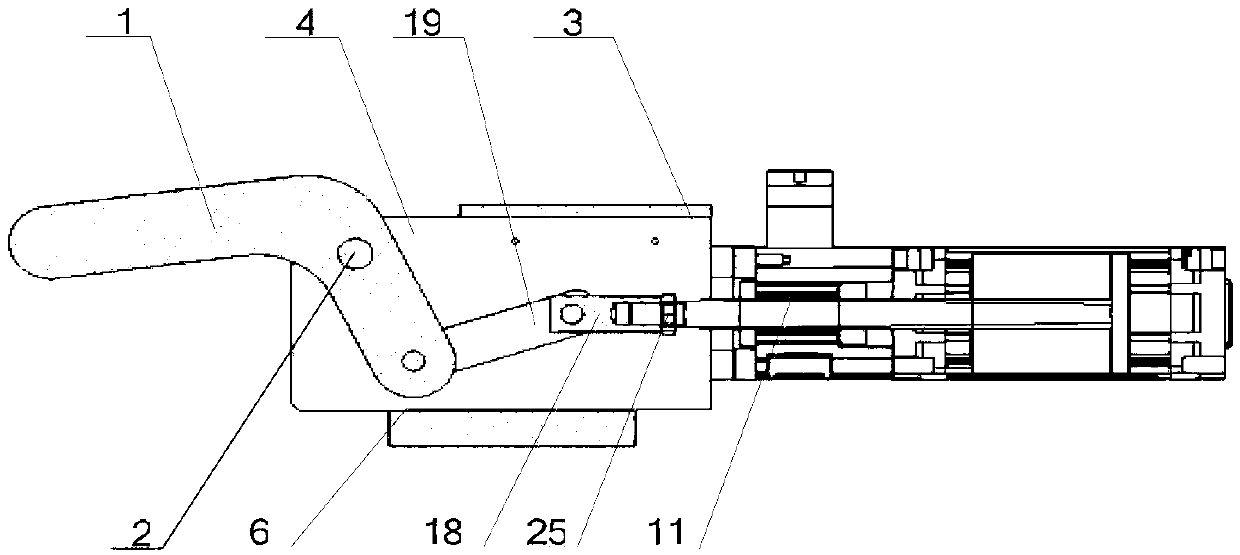

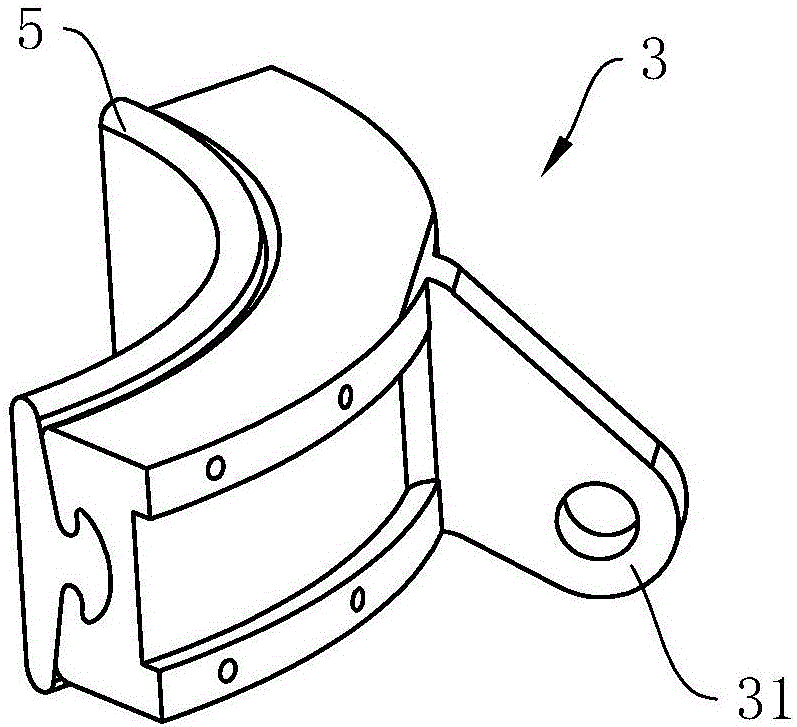

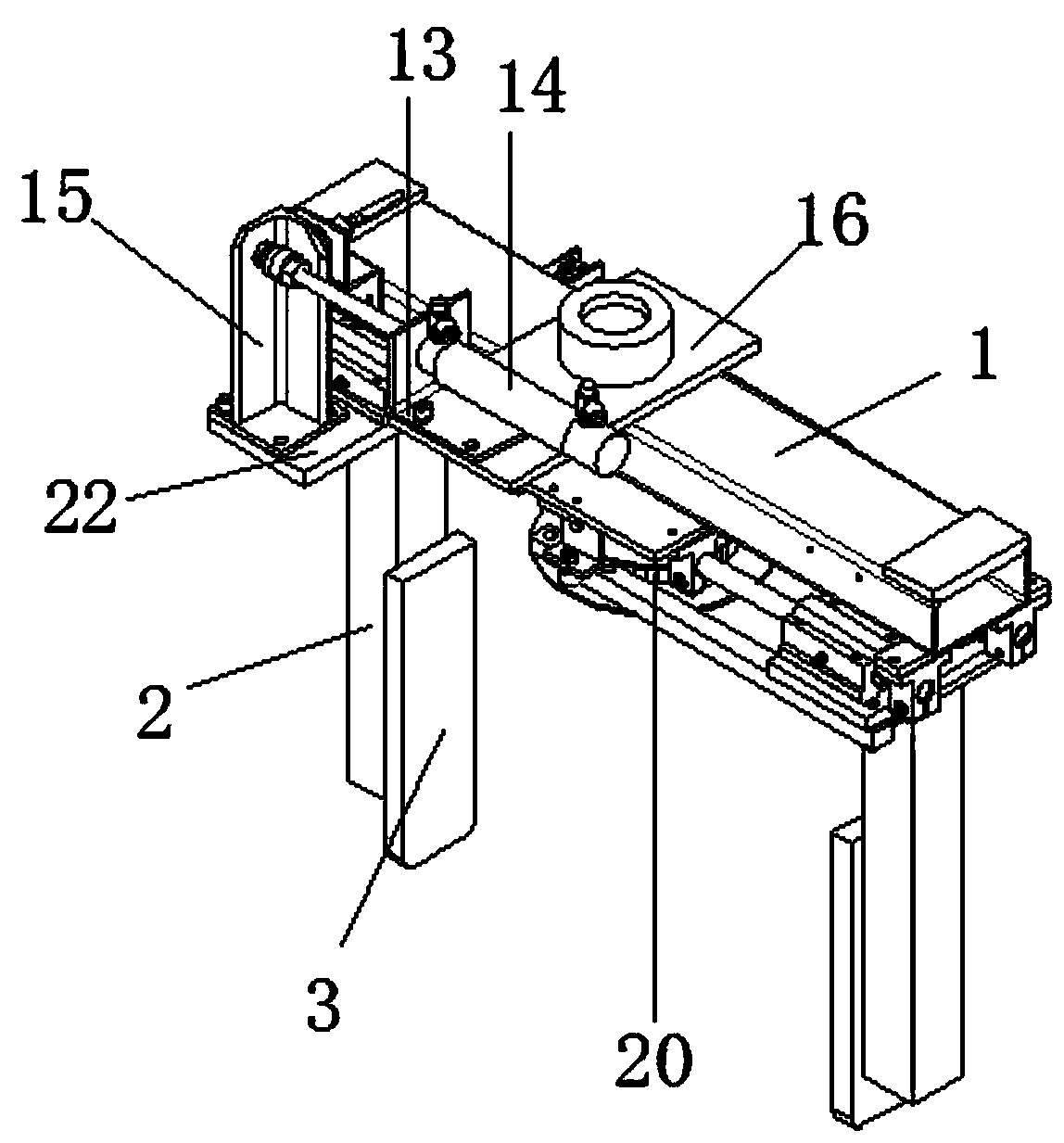

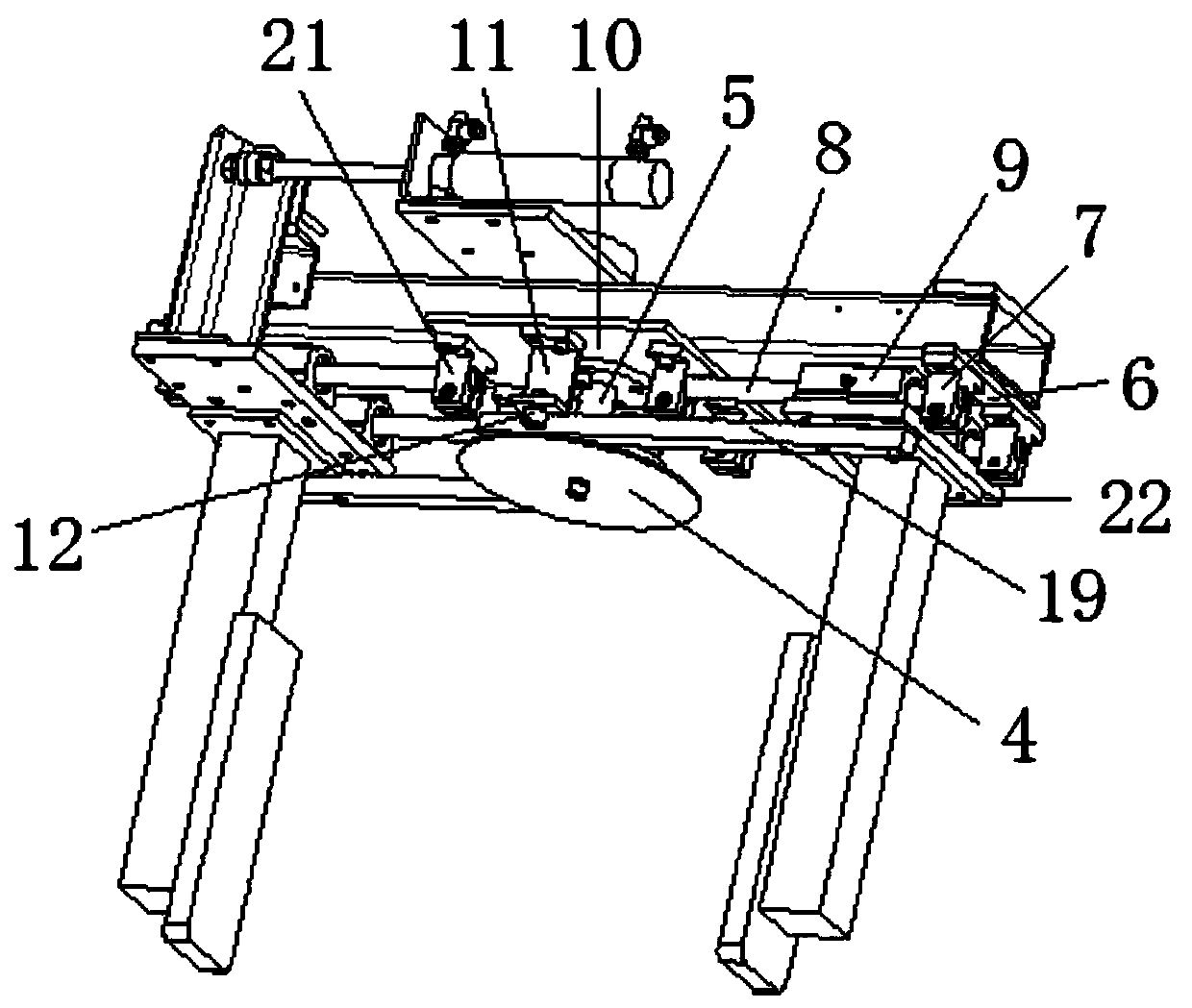

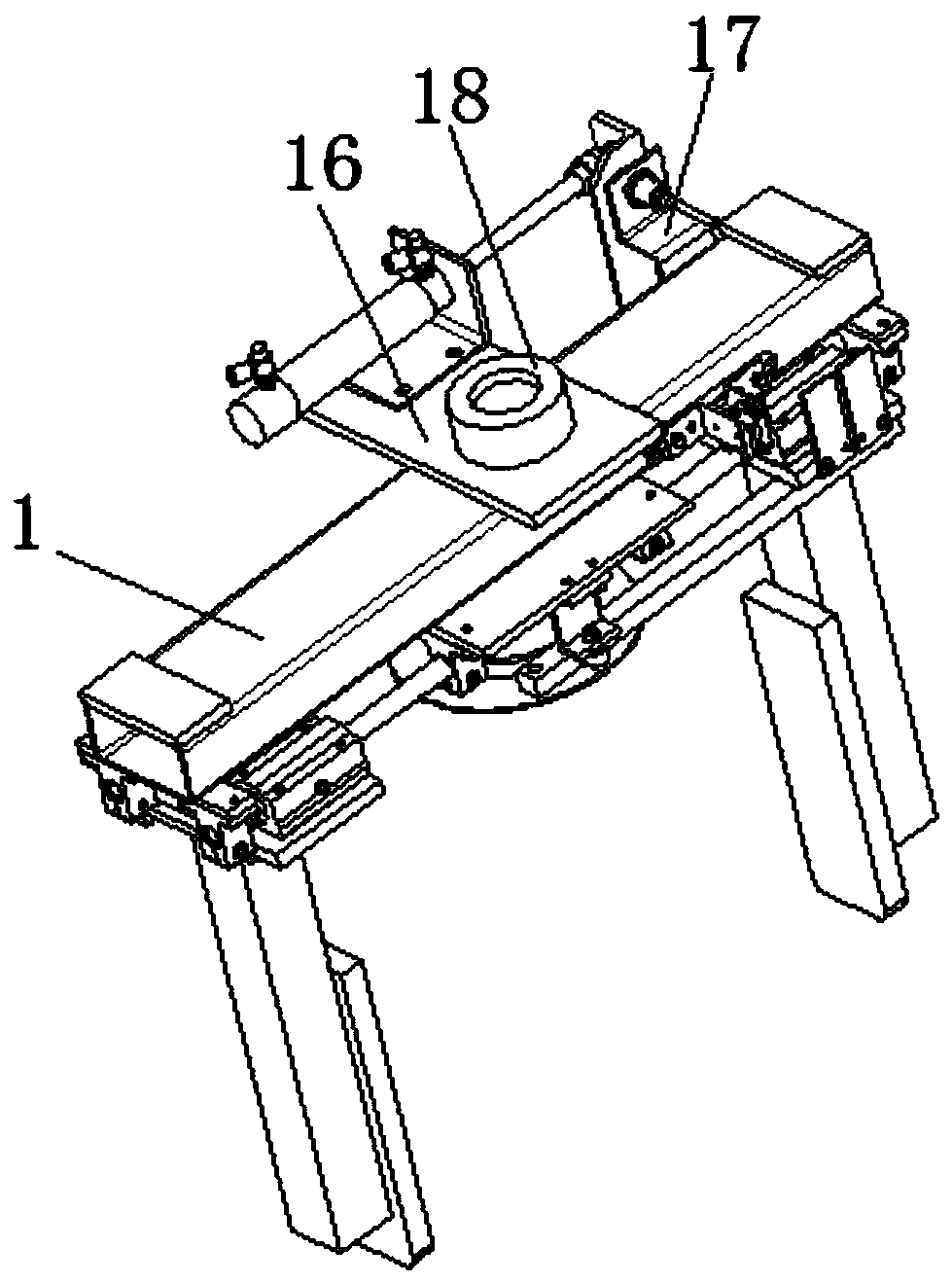

Clamp holder for small enclosure frame in aircraft panel assembly

InactiveCN103341833AEase of loading and unloadingSimple structureWork holdersAircraft assemblyAssembly lineEngineering

The invention discloses a clamp holder for a small enclosure frame in aircraft panel assembly. The clamp holder for the small enclosure frame in the aircraft panel assembly comprises a clamping head assembly, an air cylinder assembly and a flange, wherein the clamping head assembly is fixed on the front portion of the air cylinder assembly, and is connected with locating blocks in a matched mode through the flange, a pressing rod is installed between two fixing arms through a pressing rod rotary shaft, the pressing rod is connected with one end of a left connecting rod and one end of a right connecting rod, the other end of the left connecting rod and the other end of the right connecting rod are connected with a push rod, the push rod is fixedly connected with a piston rod of an air cylinder, and the air cylinder assembly is matched with the two locating blocks through the flange to form a body structure of the clamp holder for the small enclosure frame with the fixing arms. Due to the fact that the air pressure clamp holder is adopted to achieve clamping and location of the small enclosure frame in the process of the aircraft panel assembly, an assembly jig model is simplified, the operation of clamping and the operation of location are simplified, the small enclosure frame can be conveniently placed on an assembly jig and can be conveniently taken off from the assembly jig, the effect of clamping can be ensured, and meanwhile a foundation is laid for achieving digitization assembly of a panel assembly. The clamp holder for the small enclosure frame in the aircraft panel assembly is simple in structure and stable in working, greatly reduces the manual operating rate, and well improves stability of clamping.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

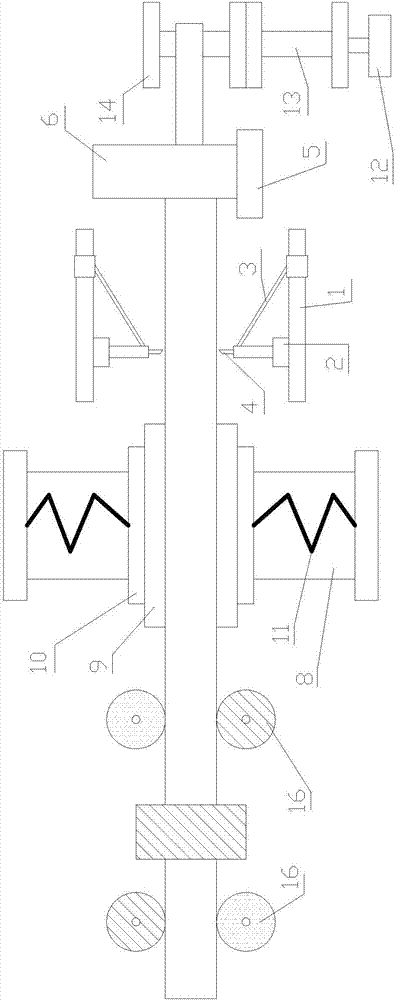

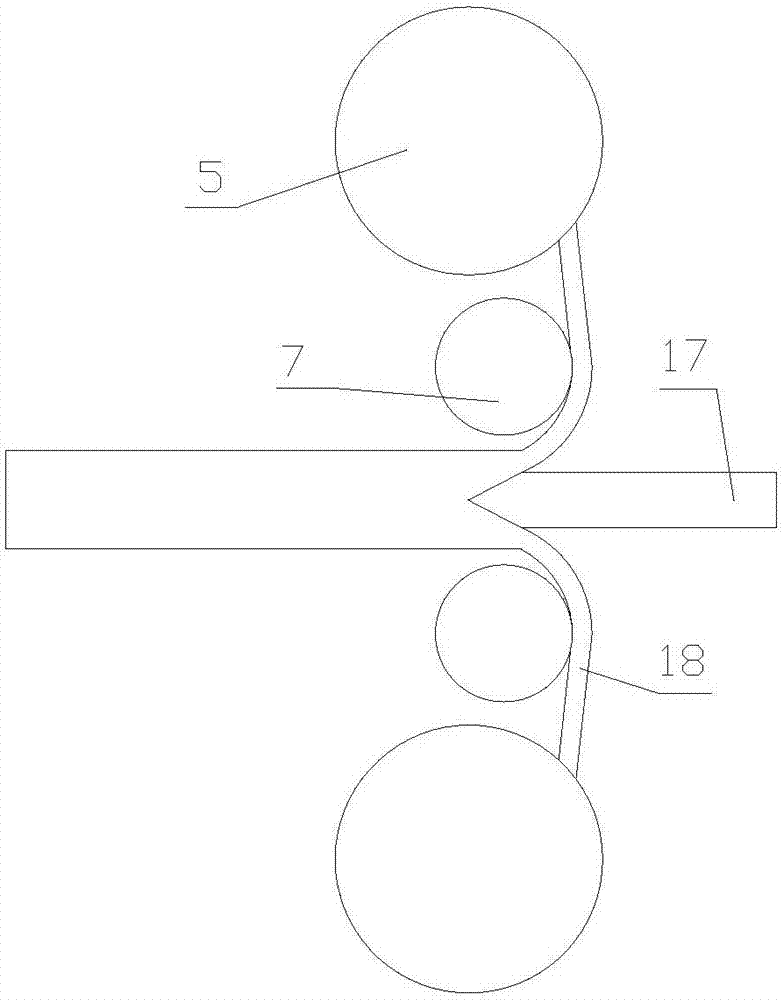

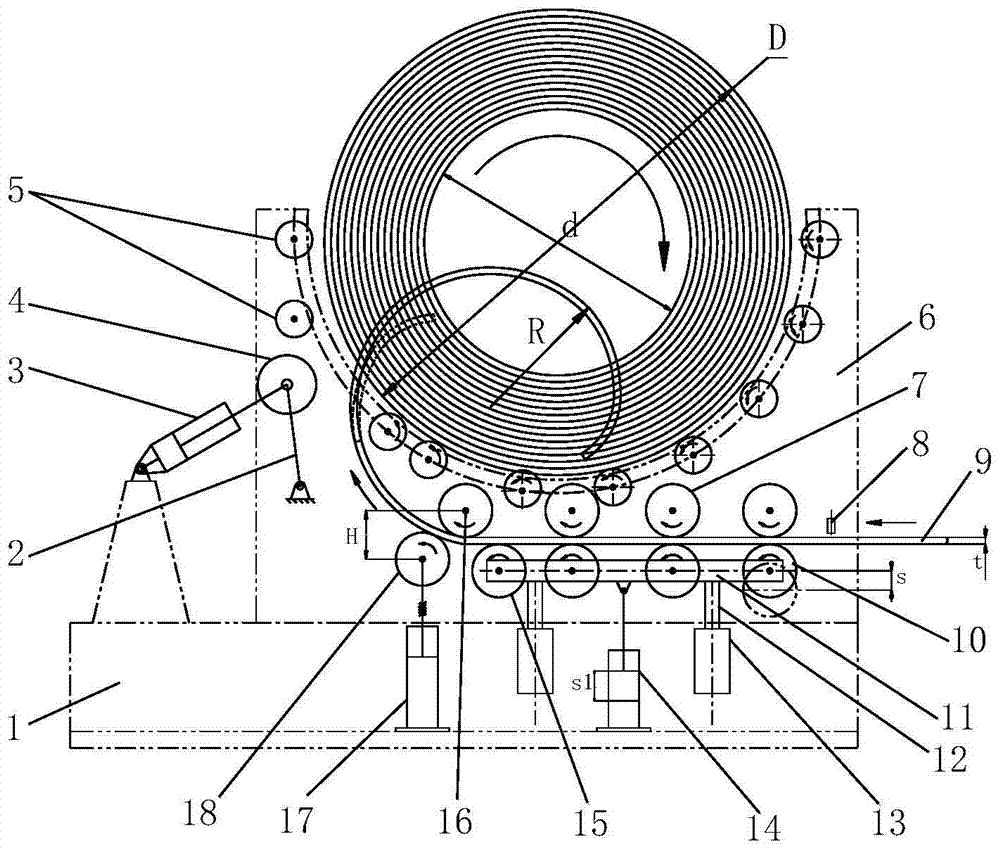

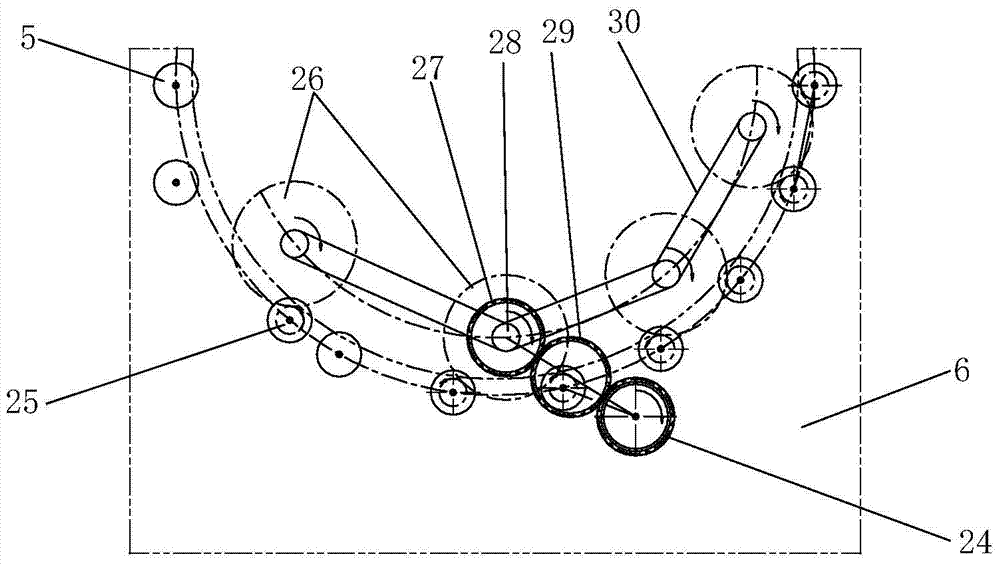

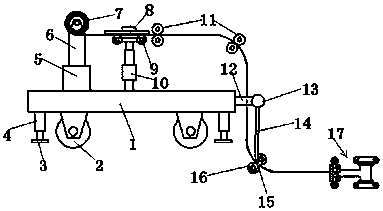

Single-row multilayer winding machine for strip product

ActiveCN103693476ASimple structureNovel and reasonable designWebs handlingWinding machineEngineering

The invention discloses a single-row multilayer winding machine for a strip product. The single-row multilayer winding machine for the strip product comprises a rack and a first striker plate arranged on the rack. Bottom pinch rolls, a bending supporting roll and a bending roll are arranged on the first striker plate in sequence along the moving direction of the product; top pinch rolls matched with the bottom pinch rolls and used for pinching the product are respectively arranged above the bottom pinch rolls; the first striker plate is provided with a bending fixed roll matched with the bending supporting roll and the bending roll and used for bending the product upwards; the rack is provided with a power mechanism used for driving the top pinch rolls, the bottom pinch rolls, the bending supporting roll, the bending fixed roll and the bending roll to rotate; the first striker plate is hinged to a plurality of supporting rolls used for supporting the whole roll of product; the supporting rolls are arranged at intervals along the bending radian of the bottom part of the whole roll of product. According to the single-row multilayer winding machine for the strip product, the product can be effectively wound, and therefore the transportation and the packaging of the product are facilitated, the storage space of the product is saved, and the use of the product at the construction site is also facilitated.

Owner:XIAN METALWK HYDRAUMATIC MACHINERY

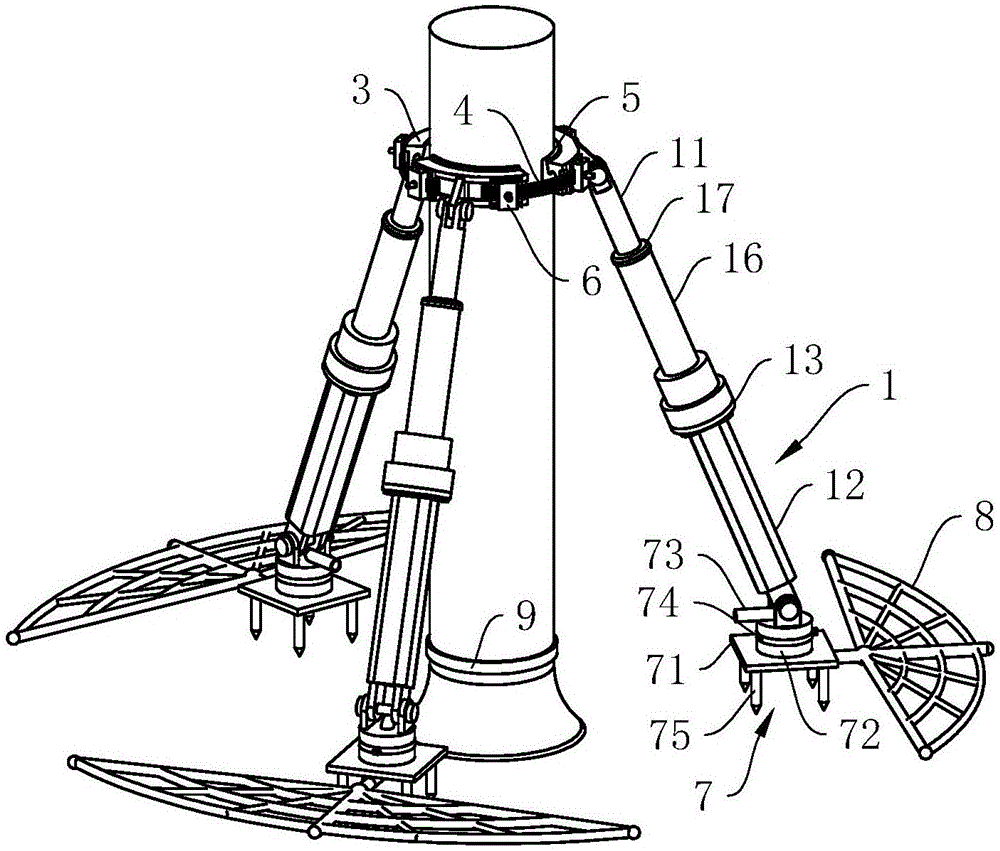

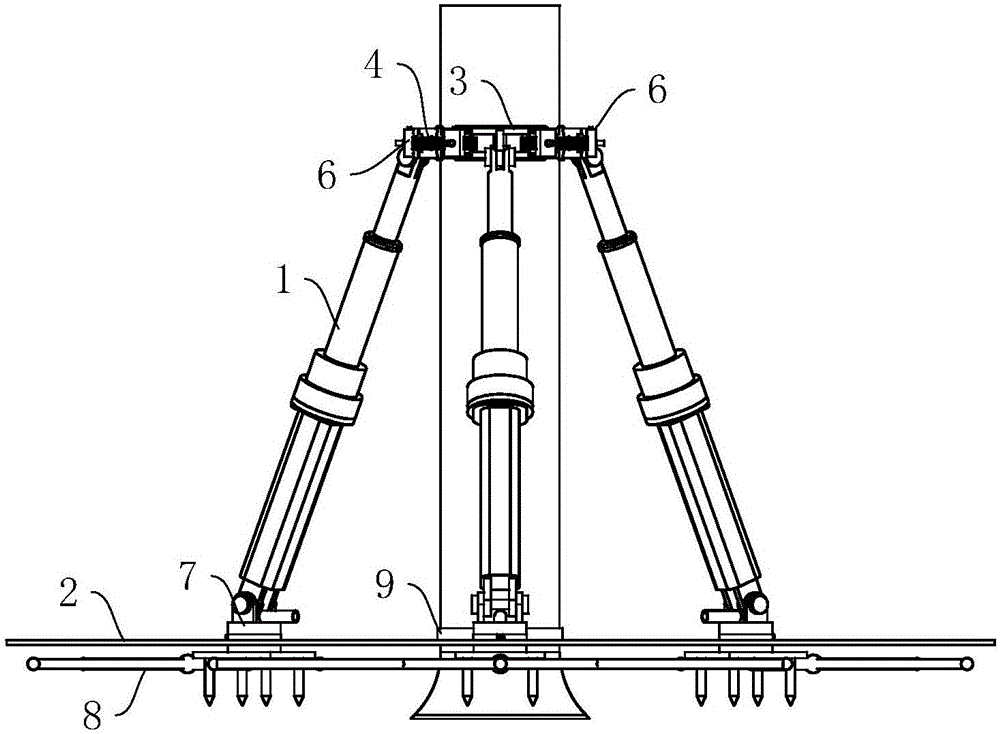

Saline-alkali soil tree protecting device

InactiveCN106550853AEffective protectionGuaranteed clamping forceCultivating equipmentsAlkali soilEngineering

The invention relates to the technical field of saline-alkali soil nursery stock protection, and provides a saline-alkali soil tree protecting device which comprises a supporting frame and a mulching film. The supporting frame comprises at least three clamp hoops, a clamp hoop ribbon which is adjusted and fixed through a ribbon locking device is connected between every two adjacent clamp hoops, and a supporting rod is hinged to a hinging part of a clamp hoop hinging lifting lug on each clamp hoop. Each supporting rod comprises an inner supporting rod body and an outer supporting rod body connected with the inner supporting rod body in a sleeving mode, wherein a directional locking device is arranged at the upper end of the outer supporting rod body, a supporting rod base is hinged to the lower end of the outer supporting rod body, a water injecting pipe penetrates through the supporting rod base, and the output end of the water injecting pipe communicates with a water seepage and ventilation pipe network. Each base table is sleeved with a mulching film tightening clamp hoop, and a tree base is sleeved with a mulching film binding band. The supporting height and surrounding diameter of the saline-alkali soil tree protecting device can be automatically adjusted along with growth of a tree, the tree is effectively supported and protected, the breathing requirement of the root is met, watering and fertilizer and pesticide applying can be conveniently conducted on the tree, and the mulching film can be effectively protected.

Owner:WEIFANG UNIVERSITY

Cable laying apparatus

InactiveCN108110680AGuarantee normal progressGuaranteed clamping effectApparatus for laying cablesRolling speedAutomation

The invention discloses a cable laying apparatus. According to the cable laying apparatus, the laying efficiency can be improved, and complete automation of cable laying is realized; propulsion is performed by employing propulsion belts so that the propulsive force is large; a boosting wheel is provided, and the boosting wheel is provided with fine needles so that the wall-holding force of the boosting wheel during rolling can be guaranteed, the propulsion of the propulsion belts is guaranteed, and the propulsion effect is greatly improved; and the applicability is high, the requirement of diameters of various laying pipelines can be met, the rolling speed of the boosting wheel and the speed of the propulsion belts can be consistent during usage, and long-distance cable laying can be wellrealized.

Owner:陈龙

Photovoltaic inverter detection device with limiting structure and convenient for multi-directional adjustment

InactiveCN112034293AGuaranteed stabilityGuaranteed fluencyElectrical testingMaterial analysis by optical meansEngineeringControl theory

The invention relates to the technical field of the photovoltaic inverter detection devices, and discloses a photovoltaic inverter detection device with a limiting structure and convenient for multi-direction adjustment. The device comprises a main body, a clamping mechanism and a power-on detection mechanism, a pedestal is fixed at the lower end of the main body, and storage cabinets are arrangedat two sides of the front end of the main body; and a workbench is arranged in the center of the upper end of the main body, a middle frame is arranged in the middle of the front end of the main body, and a servo motor is arranged at the top end of the inner side of the middle frame. The lower end of a clamping block and the inner side of a limiting sliding groove, which are matched mutually, canensure the tightness and stability of connection between the two, so the clamping block can keep enough stability in the process of being pushed by an air cylinder, the clamping effect of the clamping block on the photovoltaic inverter body is guaranteed, and meanwhile the stability of the clamping block on the photovoltaic inverter main body is further improved in cooperation with an anti-skid layer arranged on one side of the clamping block, therefore, the photovoltaic inverter main body can carry out two detection processes of outer tube and electrification.

Owner:东莞市达盛机电设计有限公司

Motor end cover clamping tool

InactiveCN107855963AEasy to handleImprove the stability of useWork holdersManufacturing dynamo-electric machinesHydraulic cylinderContact pad

The invention discloses a clamping tool for a motor end cover, which comprises a clamping platform, positioning grooves are symmetrically opened on both sides of the lower surface of the clamping platform, a center column is welded at the center of the upper surface of the clamping platform, and the center Both sides of the column are symmetrically equipped with a transmission rod and a matching top plate. The center of the upper surface of the transmission rod is threaded with a fastening pin, and the upper surface of the fastening pin is clamped with a rotating handle. The two sides of the clamping table The side is snap-connected with the telescopic rod through positioning pins, and the upper surface of the telescopic rod is rotationally connected with the rotating rod through a bearing. , the lower surface of the upper pressing plate is fixed with a contact gasket, and the upper surface of the clamping platform is symmetrically provided with lower pressing plates on both sides. In the present invention, the overall structure design of the clamping tool is simple and reasonable, the connection between parts is stable, the operation is flexible and convenient, and it has strong practicability.

Owner:扬州洁晨机电科技有限公司

Cable pulling device

ActiveCN104158108AEasy to moveFacilitate human or mechanical force applicationCable installation apparatusEngineeringMechanical engineering

The invention belongs to the field of cable installation matching equipment and particularly relates to a cable pulling device. The cable pulling device comprises an annular sleeving part and a clamping part. The profile of the clamping part is a cone cage-shaped fence. Each clamp rod on the clamping part can synchronously leave or approach the axis of the annular sleeving part along the radial direction of the annular sleeving part in a reciprocating manner. The minimal inner diameter of the clamping part is smaller than the outer diameter of a to-be-pulled cable body, and the maximal inner diameter is larger than or equal to the outer diameter of the to-be-pulled cable body. The outer wall of the annular sleeving part is provided with a handle part. A large-diameter port of the annular sleeving part, at the clamping part, is provided with notch grooves. The profile of each clamp rod is straight, each clamp rod is positioned in one notch groove, and a body of each clamp rod is hinged to groove walls at two sides. The axis of a hinged shaft formed by each clamp rod and one notch groove is vertical to the axis of the annular sleeving part. The cable pulling device also comprises an elastic reset unit. The cable pulling device is convenient to use and high in operational efficiency, and can effectively solve a problem that distortion of a cable body is accumulated when a traditional cable is pulled.

Owner:STATE GRID CORP OF CHINA +1

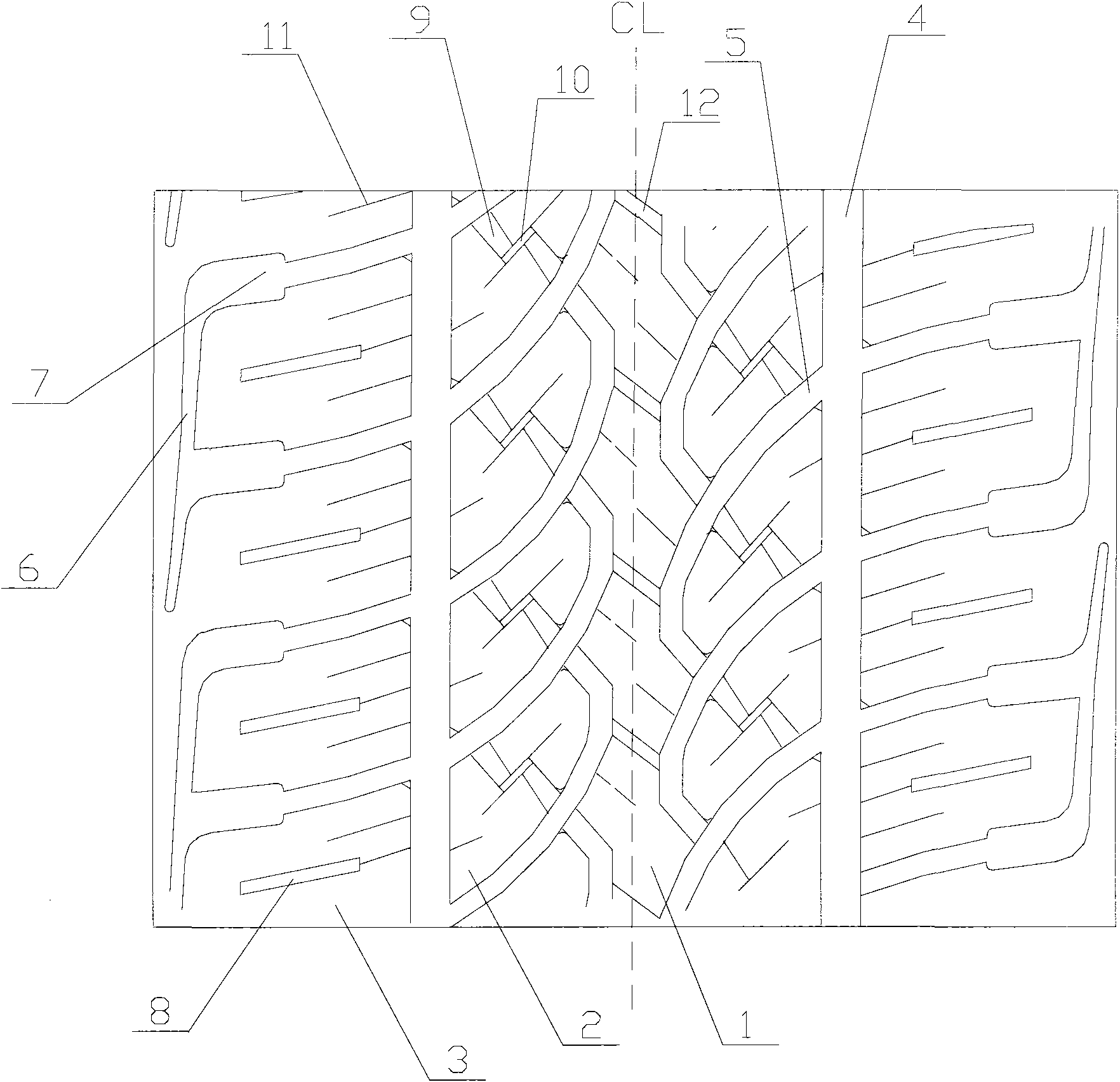

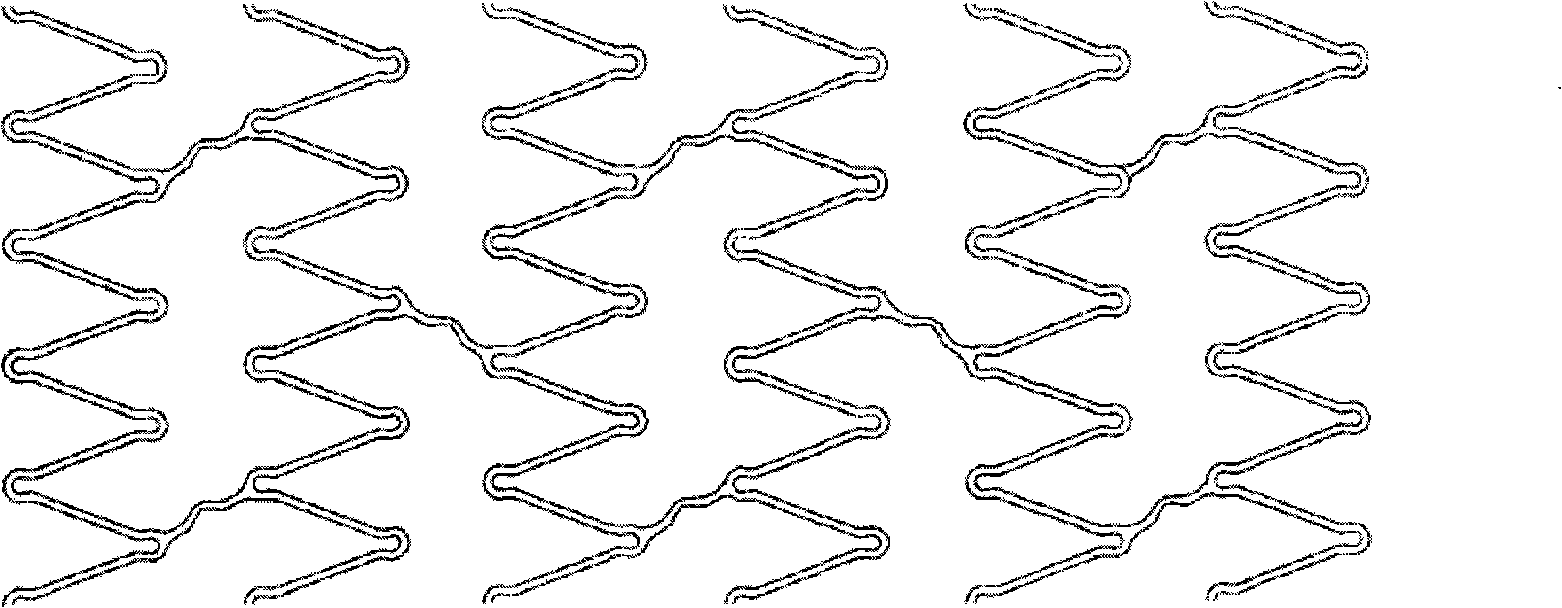

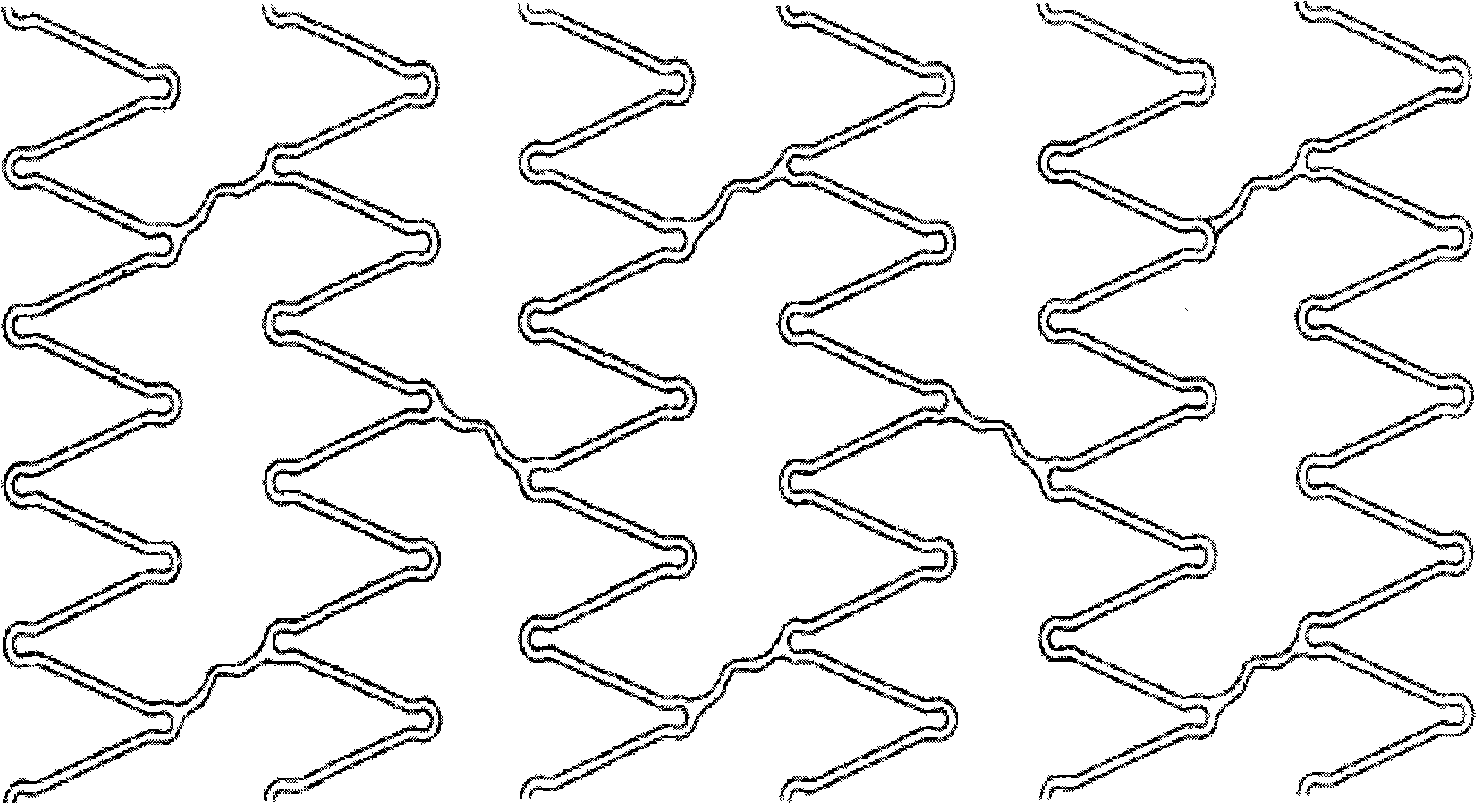

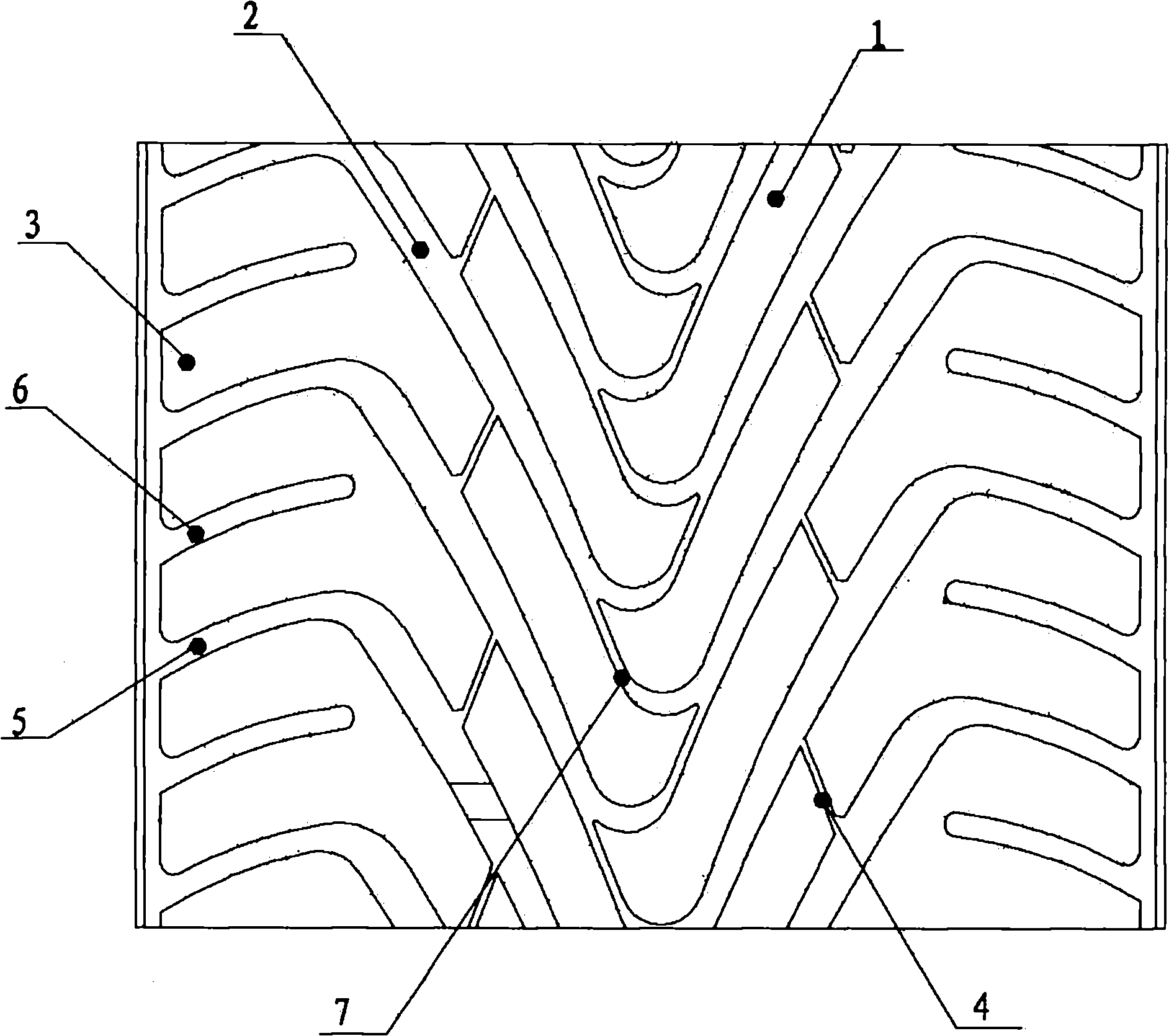

Tire tread of sedan meridian tire

ActiveCN101607512ASufficient braking forceImprove maneuverabilityTyre tread bands/patternsTire beadCentral line placement

The invention relates to a sedan tire structure, in particular to a tire tread pattern structure of a sedan tire. The tire tread of the sedan meridian tire comprises central pattern blocks, lateral pattern blocks and tire shoulder pattern blocks, wherein the central pattern blocks are the longitudinal pattern blocks; the lateral pattern blocks and the tire shoulder pattern blocks are regularly arranged on the left side and the right side of the central pattern blocks from inside to outside in sequence; the central pattern blocks are positioned on the central line position of the tire tread; the same arched pattern ditch is spaced between the central pattern blocks and the lateral pattern blocks, between the two adjacent lateral pattern blocks, and between the two adjacent tire shoulder pattern blocks respectively; an inclined lateral pattern ditch is spaced between the two adjacent central pattern blocks; and a longitudinal circumferential pattern ditch is spaced between the lateral pattern blocks and the tire shoulder pattern blocks. The tire tread of the tire adopts mixed patterns, and has the advantages of sufficient braking force, good control performance and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

Stem-gripping type potted seedling transplanting claw

The invention relates to a stem-gripping type potted seedling transplanting claw, belonging to the field of agricultural automatic seedling transplanting equipment. The stem-gripping type potted seedling transplanting claw disclosed by the invention is composed of a driving cylinder, a push frame, a left arm, a left claw, a right claw, a right arm and a fixed frame; the fixed frame is in an L-shaped structure; the driving cylinder is installed on the fixed frame; the push frame is installed at the tail end of a push rod of the driving cylinder; two long holes are formed in the push frame; both the upper and lower sections of the left arm and the right arm are provided with a folded corner respectively; the upper ends of the left arm and the right arm are symmetrically hinged onto the fixed frame through a pin shaft respectively; the upper parts of the folded corners of the left arm and the right arm respectively penetrate through the two long holes in the push frame; the left claw and the right claw are fixedly connected with the tail ends of the left arm and the right arm respectively. The seedling injury rate is reduced while the stronger gripping capability is ensured in a manner of griping stems; the whole structure is only singly driven; the stem-gripping type potted seedling transplanting claw disclosed by the invention is simple in structure, high in automation degree and strong in practicability and reliability.

Owner:BEIJING UNIV OF TECH

Self-expanding medicament stent and preparation method thereof

InactiveCN102114273APrevention of late blood clot problemsGuaranteed gripStentsSurgeryPercent Diameter StenosisSynthetic Polymeric Macromolecules

The embodiment of the invention discloses a self-expanding medicament stent and a preparation method thereof, and the self-expanding medicament stent is characterized by comprising a self-expanding nickel and titanium alloy super-elastic stent body; a medicament coating is coated on the self-expanding nickel and titanium alloy super-elastic stent body; the medicament coating is formed by mixing a medicament capable of inhibiting restenosis with a polymer according to the weight ratio; the polymer has biological degradable property and comprises at least one of PLA (polylactic acid), PGA (polyglycolic acid), PLGA (poly(lactic-co-glycolic acid)) and other artificially synthesized polymer materials or chitosan, algae salt type, bioprotein and other natural polymers. The self-expanding medicament stent disclosed by the embodiment of the invention takes a metal stent as the basis, and the micro-roughening treatment is performed on the surface, thereby increasing the binding force between the surface and the coating and simultaneously promoting the endothelialization of blood vessels.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

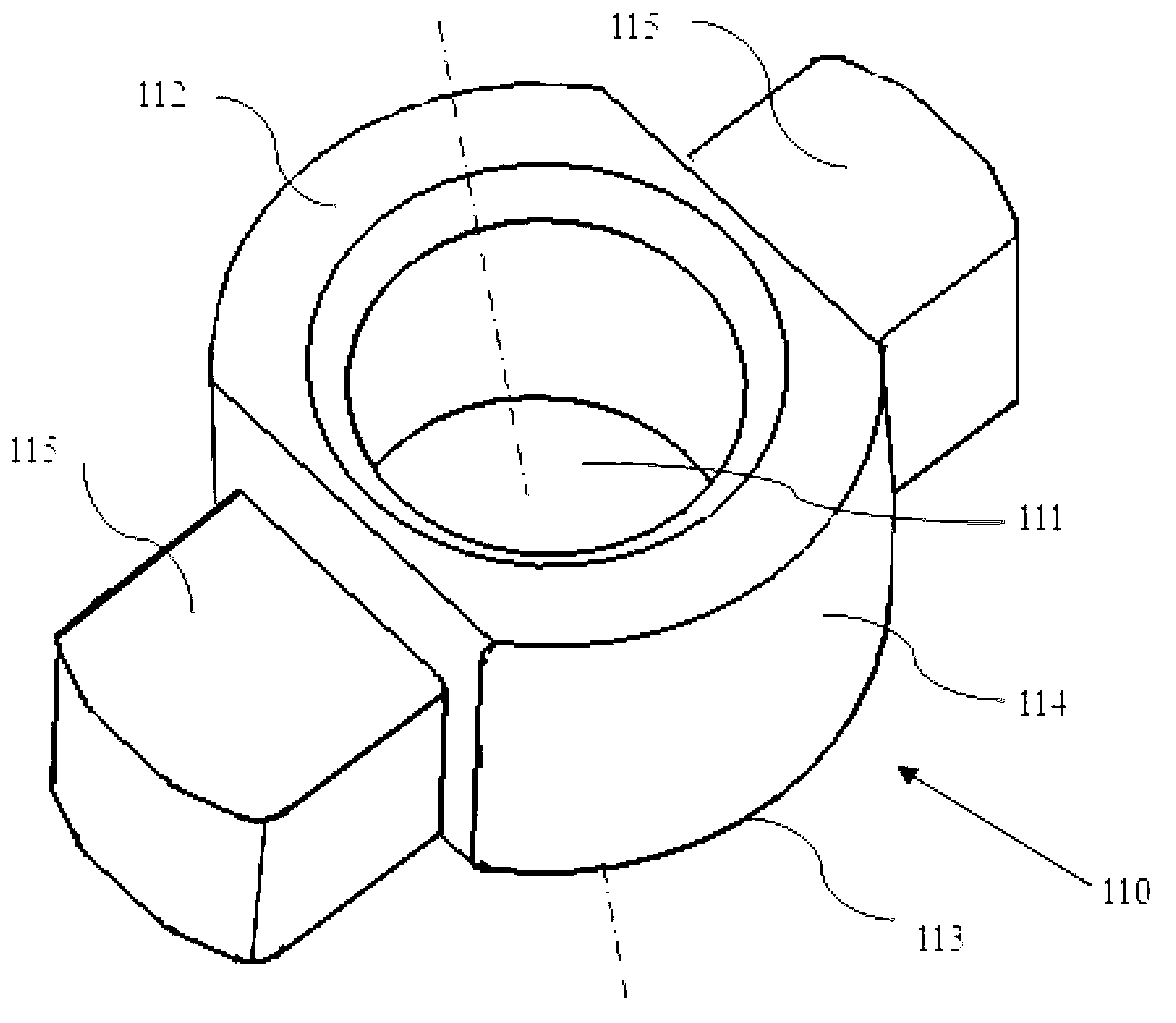

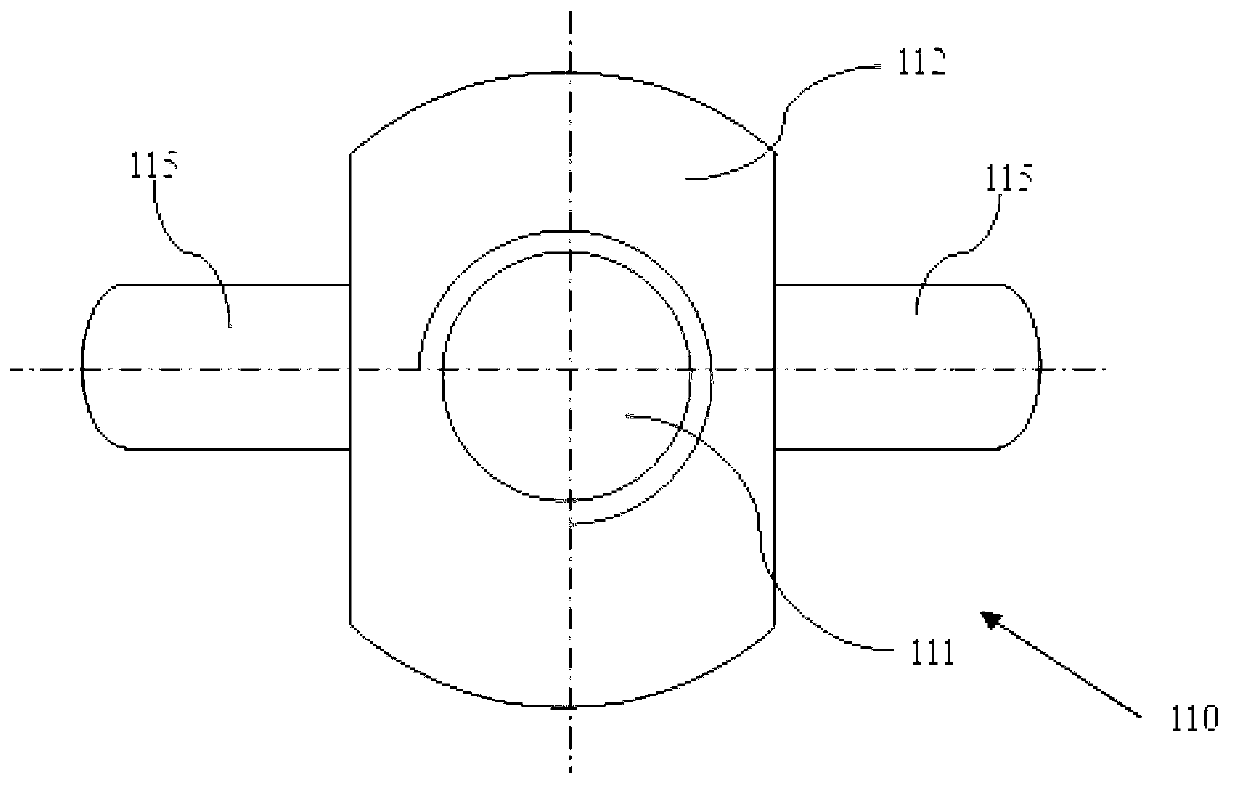

Buckle-type nut component

The invention provides a buckle-type nut component comprising a nut body and a tubular unit. A protruding wing-shaped unit is arranged on the side wall of the nut body, and the outer wall of the tubular unit is provided with a flange arranged in a circumference direction. A limit groove, extending axially from one end of the tubular unit and penetrating through a plain on the upper surface of the flange and the plain on the lower surface of the flange, is reserved in the tubular unit. One end of the limit groove is open, while the other end of the limit groove is sealed. The wing-shaped unit of the nut body enters the limit groove from an open end of the limit groove, and extends out of the limit groove, so that the nut body is limited in the tubular unit, and a gap is reserved between the upper end surface of the wing-shaped unit and the lower end surface of the flange. The buckle-type nut taken place by a projection welding nut has the advantages of convenience in buckle connection operation and high intensity of connection with the nut. The nut component can be reused, and thermal deformation of a connector caused by welding is simultaneously avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Steel pipe clamping mechanism

InactiveCN105436937ASimple designStep up effect is goodPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention provides a steel pipe clamping mechanism which comprises a bottom plate; a driving mechanism, a clamping mechanism and pushing mechanisms are arranged on the bottom plate; the clamping mechanism comprises a base, a left clamping block and a right clamping block; the base is fixedly connected with the bottom plate; the left clamping block and the right clamping block are respectively and movably arranged on the top surface of the base; the pushing mechanisms comprise sliding blocks, pushing plates and pushing rods; the sliding blocks are arranged in a first sliding chute in a sliding manner; the pushing plates are fixedly connected to the top surfaces of the sliding blocks; the pushing rods are arranged horizontally; the left clamping block and the right clamping block are respectively connected with the pushing rods and the pushing plates; the driving mechanism comprises a supporting frame and a bi-directional screw rod; the supporting frame is arranged on the bottom plate; the bi-directional screw rod and the first sliding chute are arranged in parallel; the bi-directional screw rod is rotationally connected onto the supporting frame; a left spiral part and a right spiral part of the bi-directional screw rod are in threaded connection with the connecting blocks respectively; the two connecting blocks and the pushing mechanisms are arranged correspondingly; and each connecting block is fixedly connected with one corresponding pushing plate.

Owner:天津建通管业有限公司

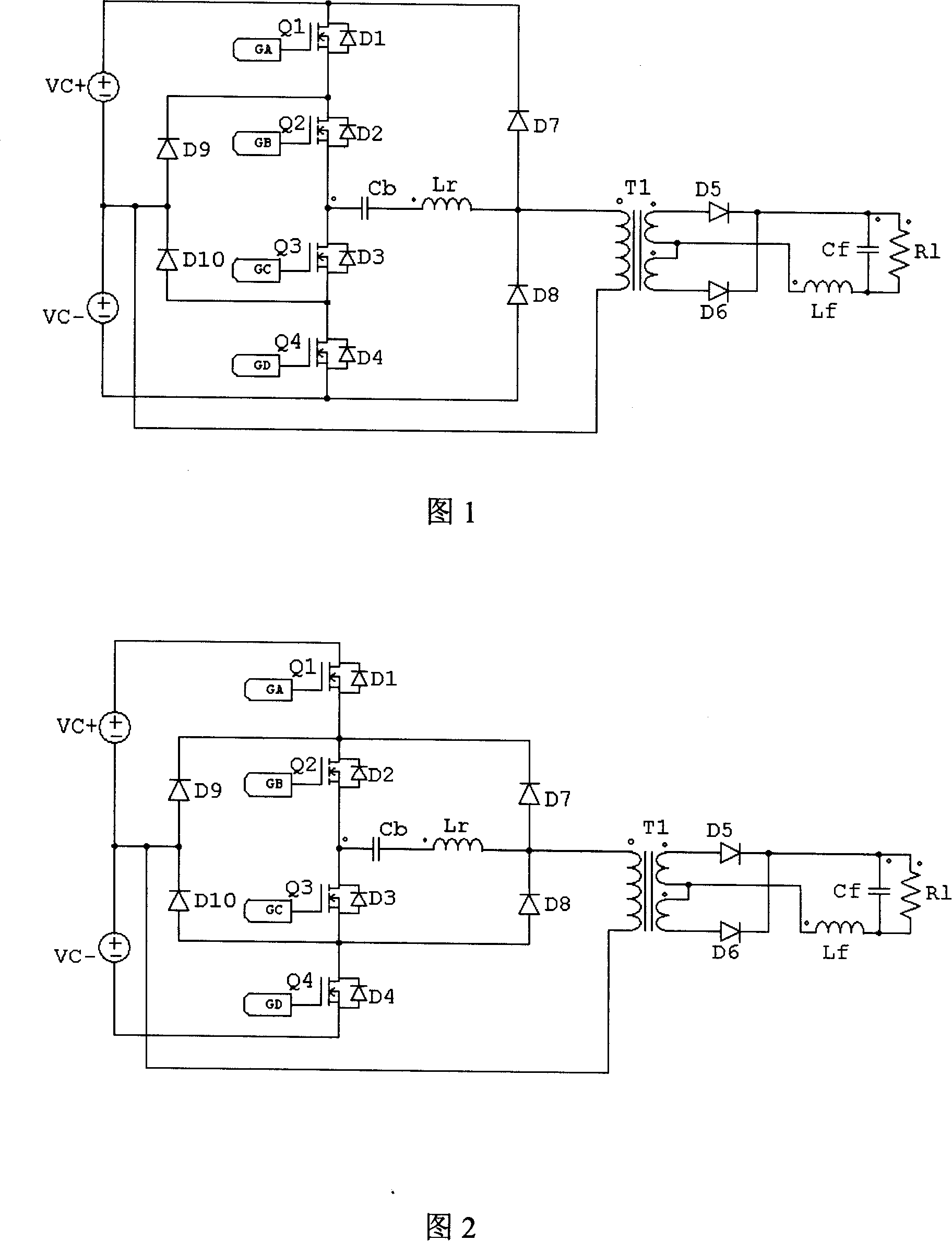

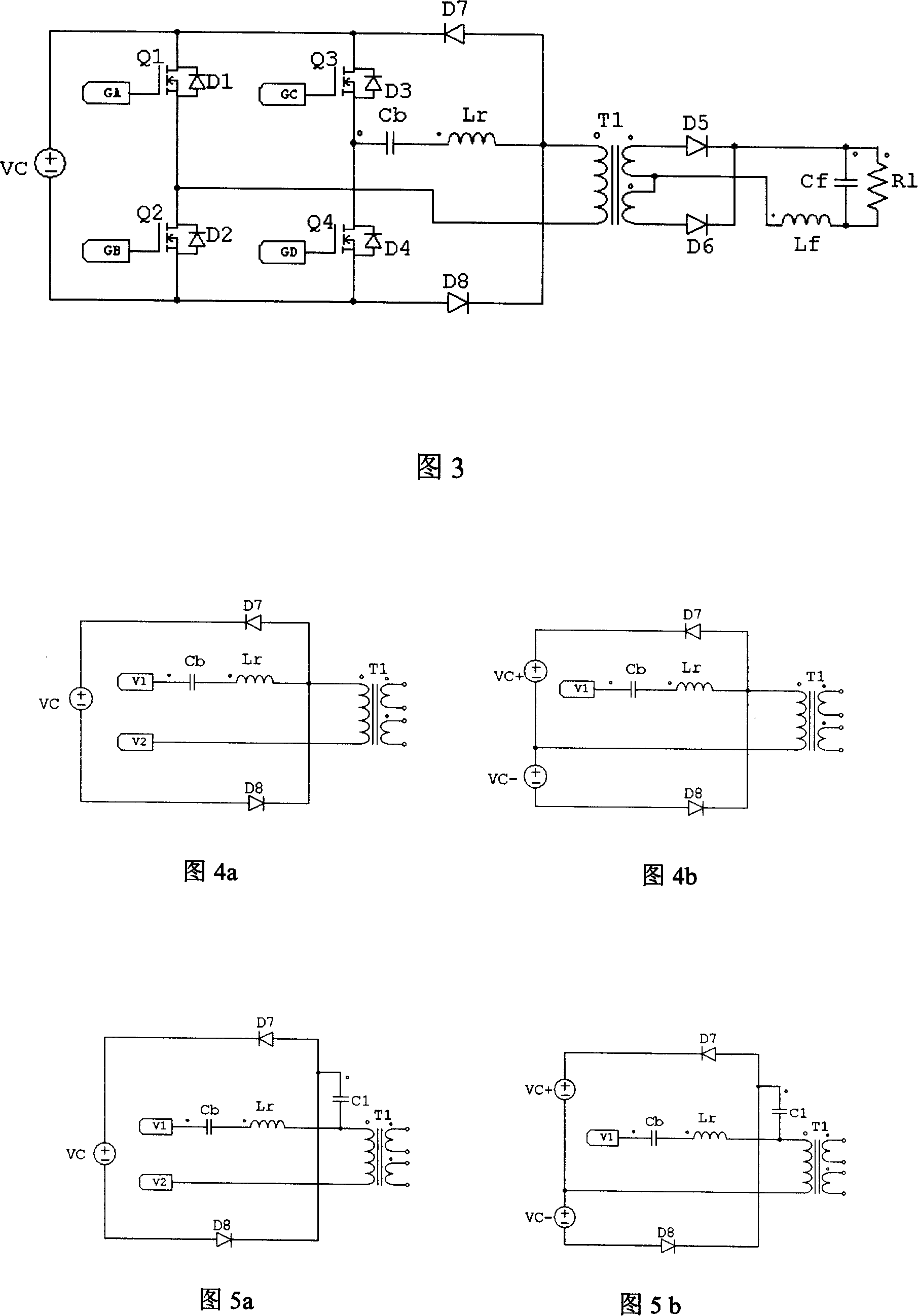

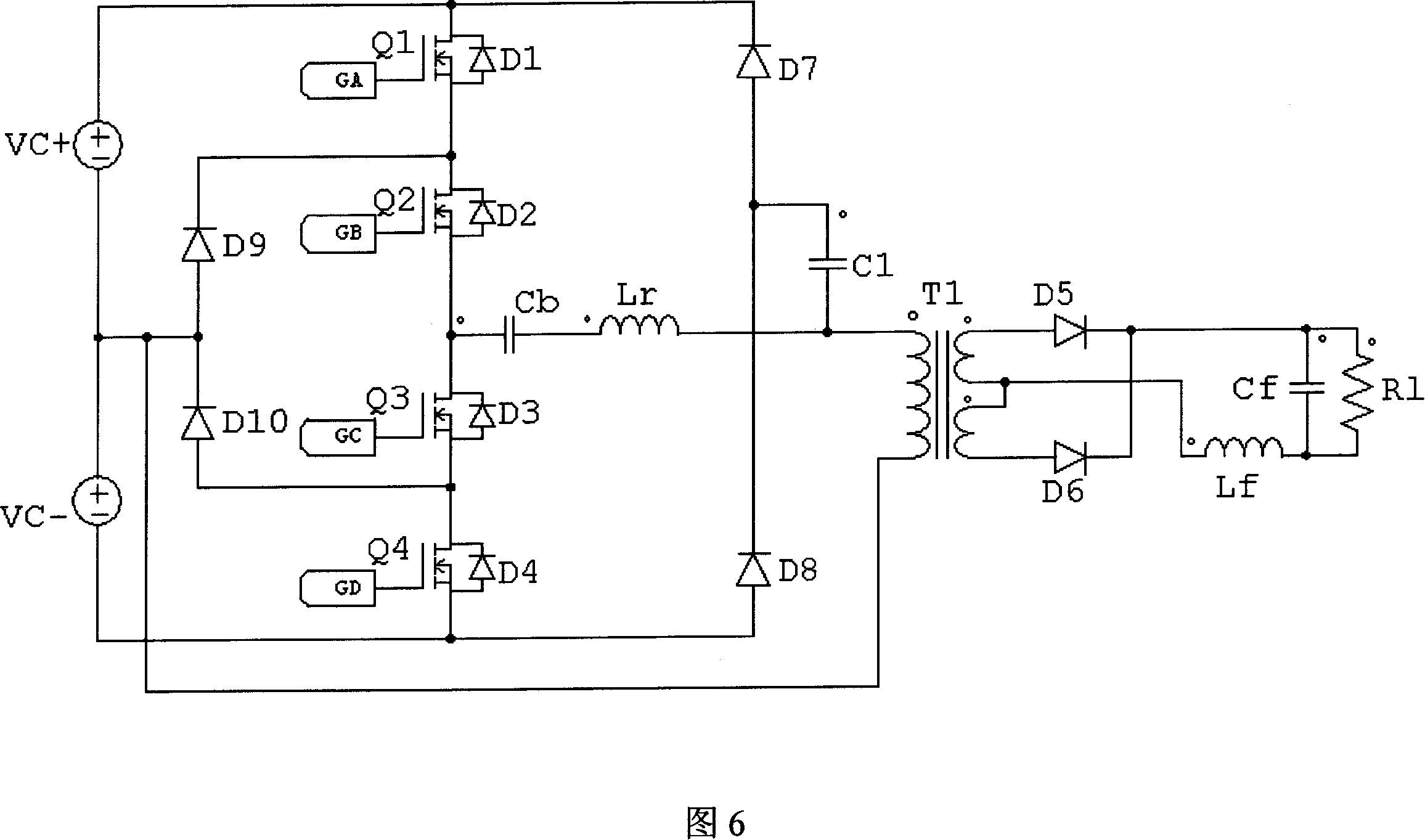

Original edge clamp circuit of DC converter

ActiveCN101127482AReduce current stressImprove reliabilityAc-dc conversionApparatus with intermediate ac conversionCapacitanceCircuit reliability

The utility model provides a primary side clamping circuit of a direct current converter. An anti-leakage capacitance is arranged between connections of the clamped point which is in the middle of a resonant inductance and a transformer, and the clamping diode, so as to cut off the release or bypass channel from a blocking capacitance through the clamping diode. Therefore, the transformer can be effectively prevented from working in magnetic biasing state under the conditions that the clamping performance is basically constant when the voltages of the positive and negative bus-bars are balanced, the voltages of the positive and negative input bus-bars are different, or driving pulses widths of positive and negative half-cycle from the switching tube are inconsistent, so that the reliability of the whole circuit is promoted, the current stress of the clamping diode is reduced. The clamping performances of two terminal voltages of the transformer and the both terminal voltages of the transformer secondary side rectifier diode are improved.

Owner:VERTIV CORP

Clamping mechanism for industrial robot

The invention discloses a clamping mechanism for an industrial robot. The clamping mechanism comprises a mounting cross rod, movable clamping rods, clamping plates and a driving air cylinder. The driving air cylinder is started to drive a movable bottom plate on one side to move through a first fixed plate, the movable bottom plate drives a straight gear to rotate through one guide rod, therefore,a movable bottom plate on the other side is driven to move through the other guide rod, and the two movable clamping rods drive the clamping plates to move oppositely or reversely for clamping or loosening. The clamping mechanism is simple in structure and convenient to operate and use; two moving bases are arranged on the movable bottom plates and slide on fixed sliding rods, so that stable movement of the movable bottom plates and the movable clamping rods is guaranteed, and the clamping effect of the clamping plates is guaranteed. A connecting lug is arranged on a sliding block, a spring is arranged between the connecting lug and a second fixing plate, so that the movable clamping rods provide buffering in the moving process, the movable clamping rods are prevented from colliding witha circular baffle during clamping, and the safety performance is high.

Owner:合肥伟达智能科技有限公司

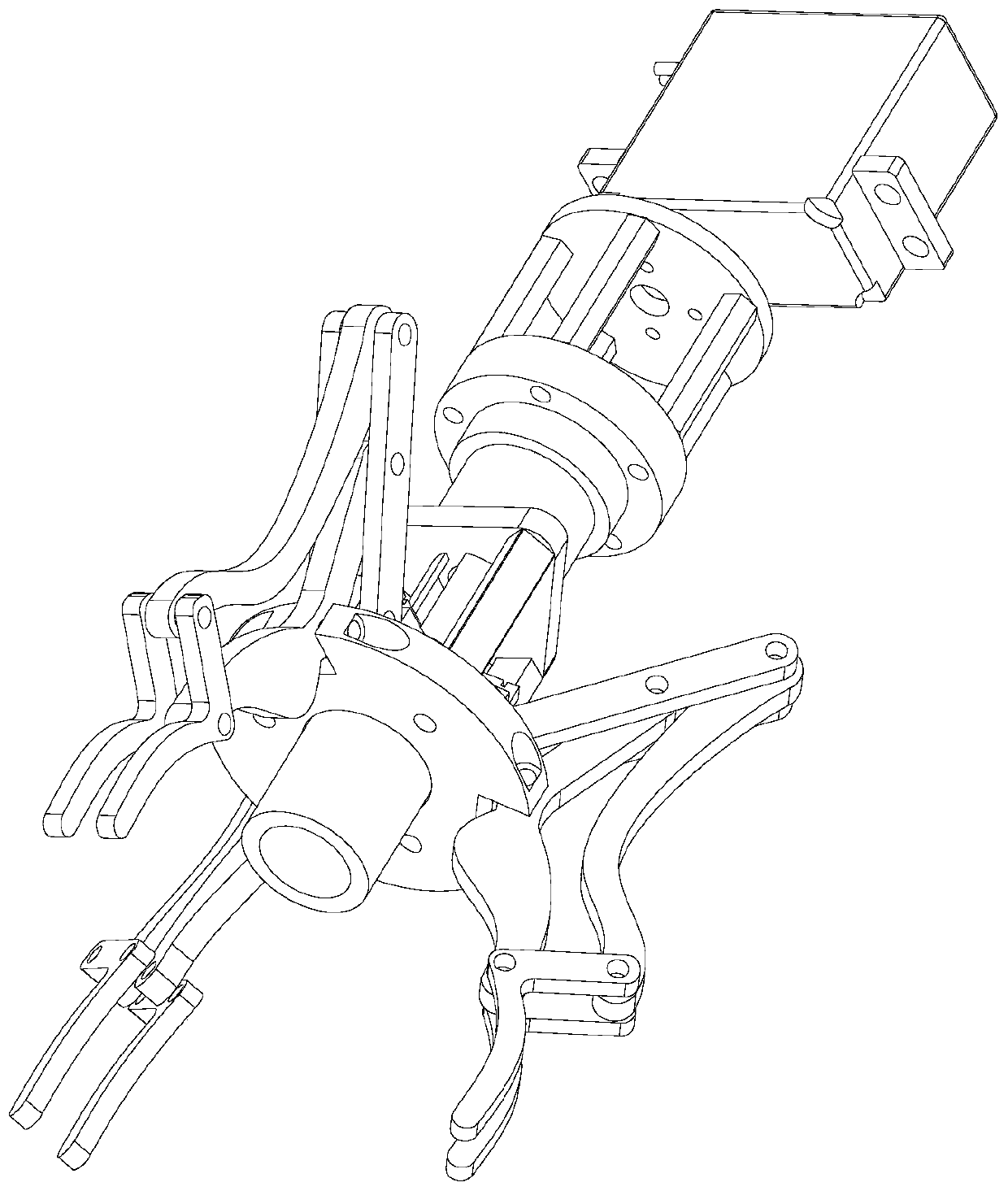

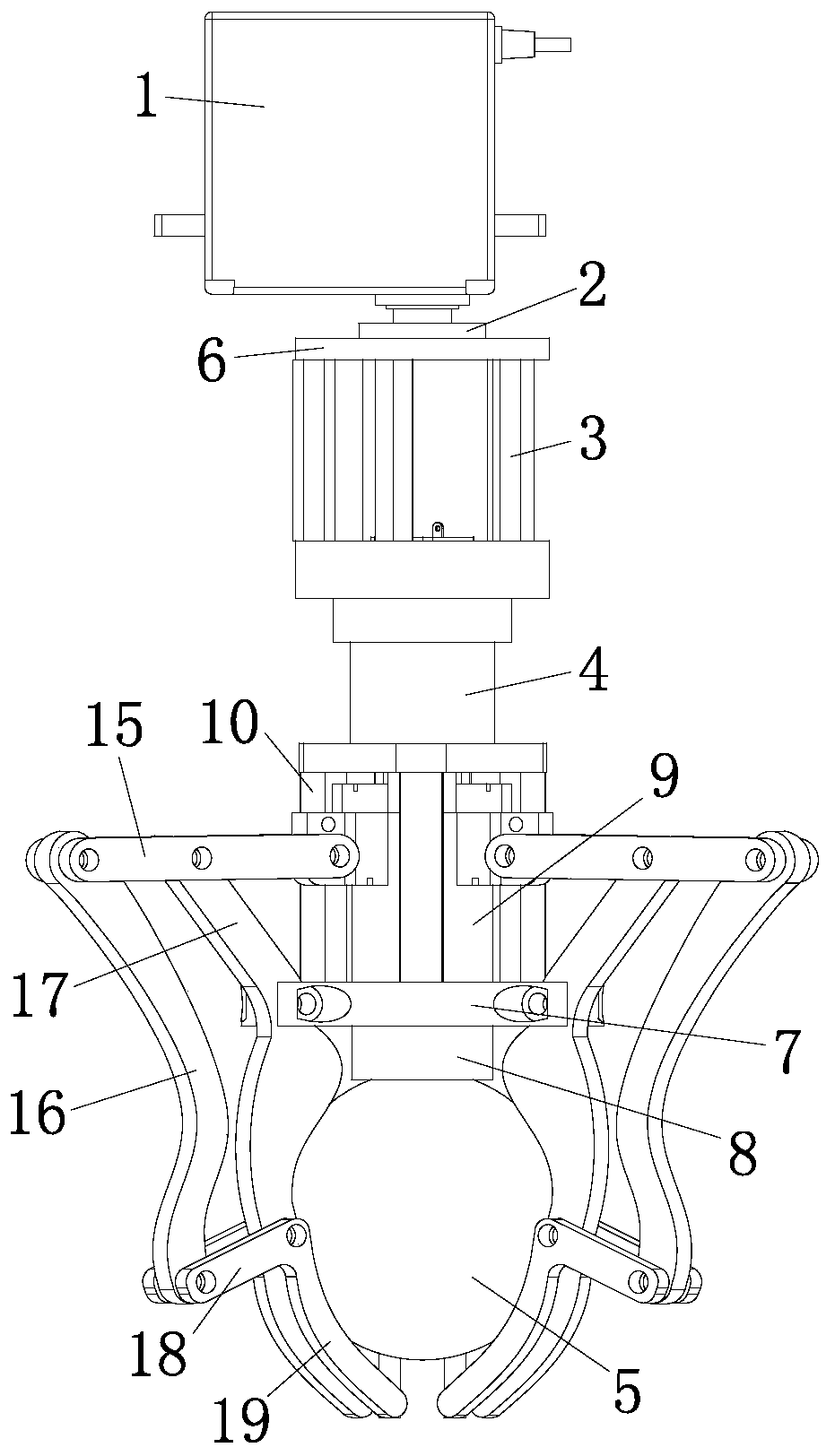

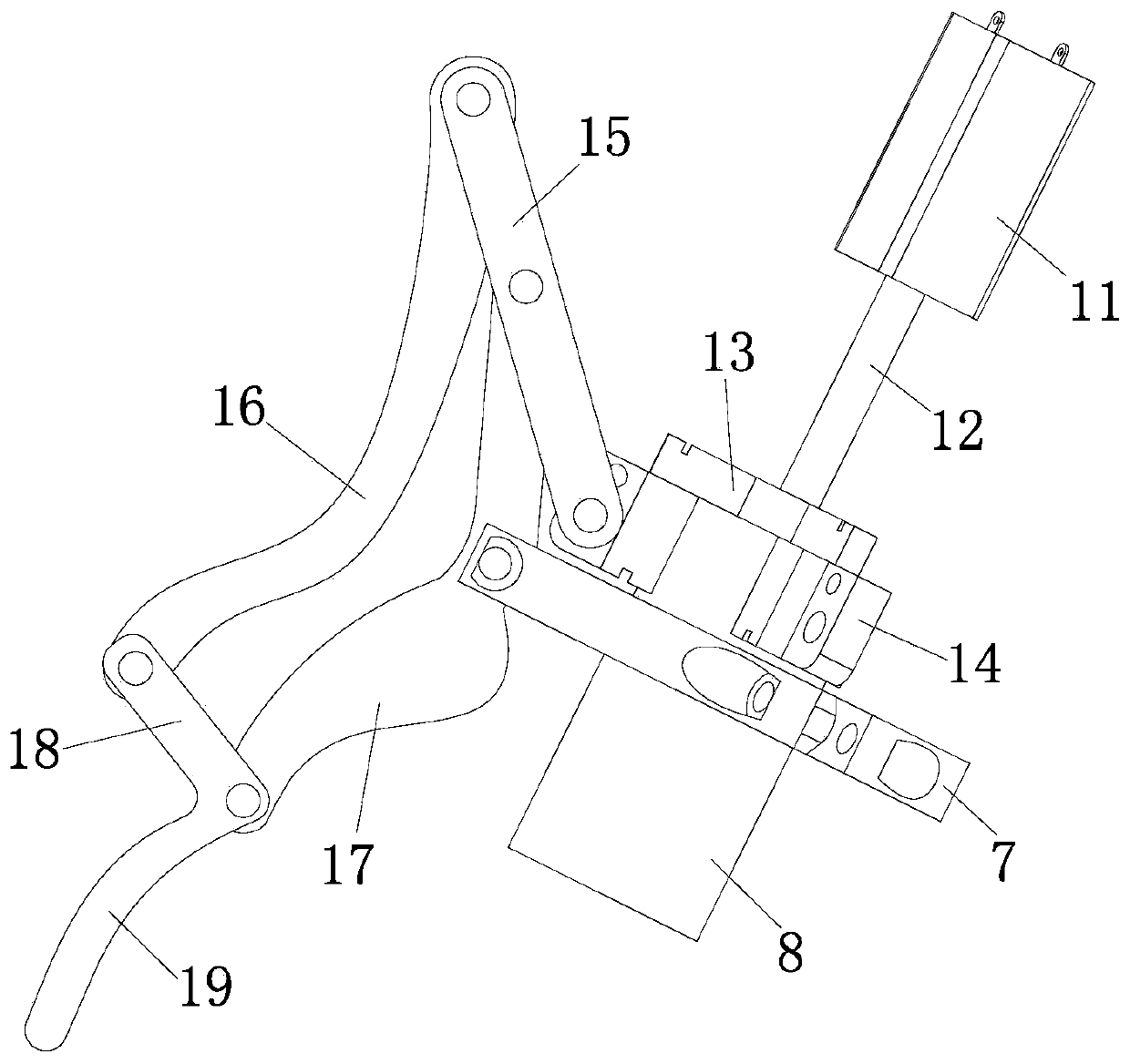

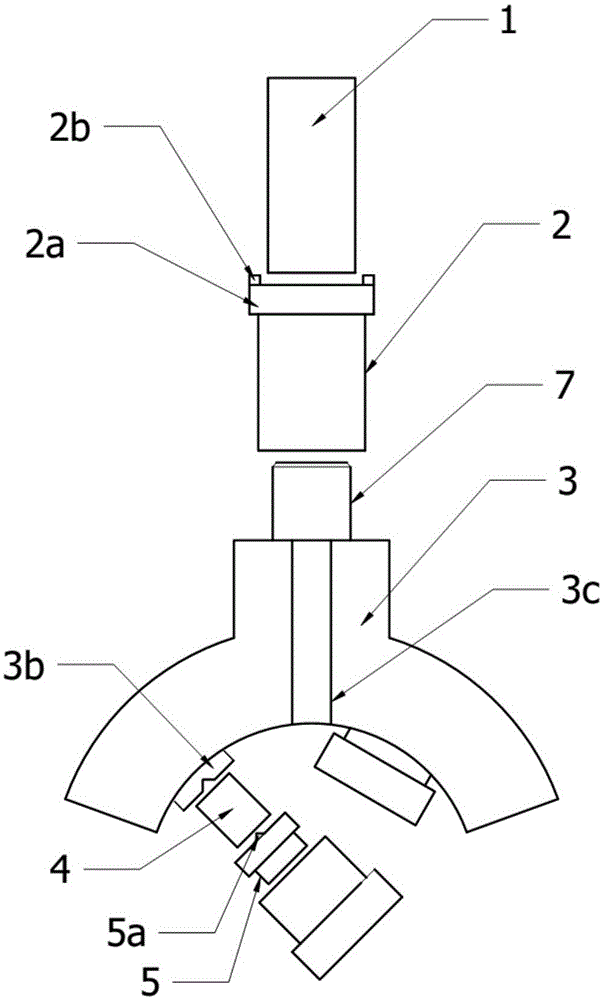

Dual-drive multi-knuckle bionic gripper

PendingCN111055301AImprove complianceIncrease success rateGripping headsElectric machineryEngineering

The invention relates to the field of robots, and aims to provide a dual-drive multi-knuckle bionic gripper. The device can integrate the advantages of a rigid connecting rod mechanism and a flexiblebionic mechanism, and has the characteristics of simple structure and high reliability. The technical scheme is as follows: the dual-drive multi-knuckle bionic gripper is characterized by comprising:a rack, a first motor used for driving the rack to rotate around the axis, a second motor arranged in the rack, a supporting table which is telescopically positioned at the front end of the rack, gripper branches arranged on the periphery of the supporting table, and a transmission mechanism used for transmitting power of the second motor to drive the supporting table and the gripper branches to move. The transmission mechanism comprises: a guide rails arranged in the rack and parallel to the length direction of the rack, a push plate capable of sliding along the guide rails, a lead screw driven by the second motor, and a nut meshed with the lead screw and fixed on the push plate. The supporting table is slidably positioned on the guide rails, a plurality of connecting blocks are arrangedon the supporting table, and the connecting blocks are connected to the push plate through elastic bodies.

Owner:ZHEJIANG SCI-TECH UNIV

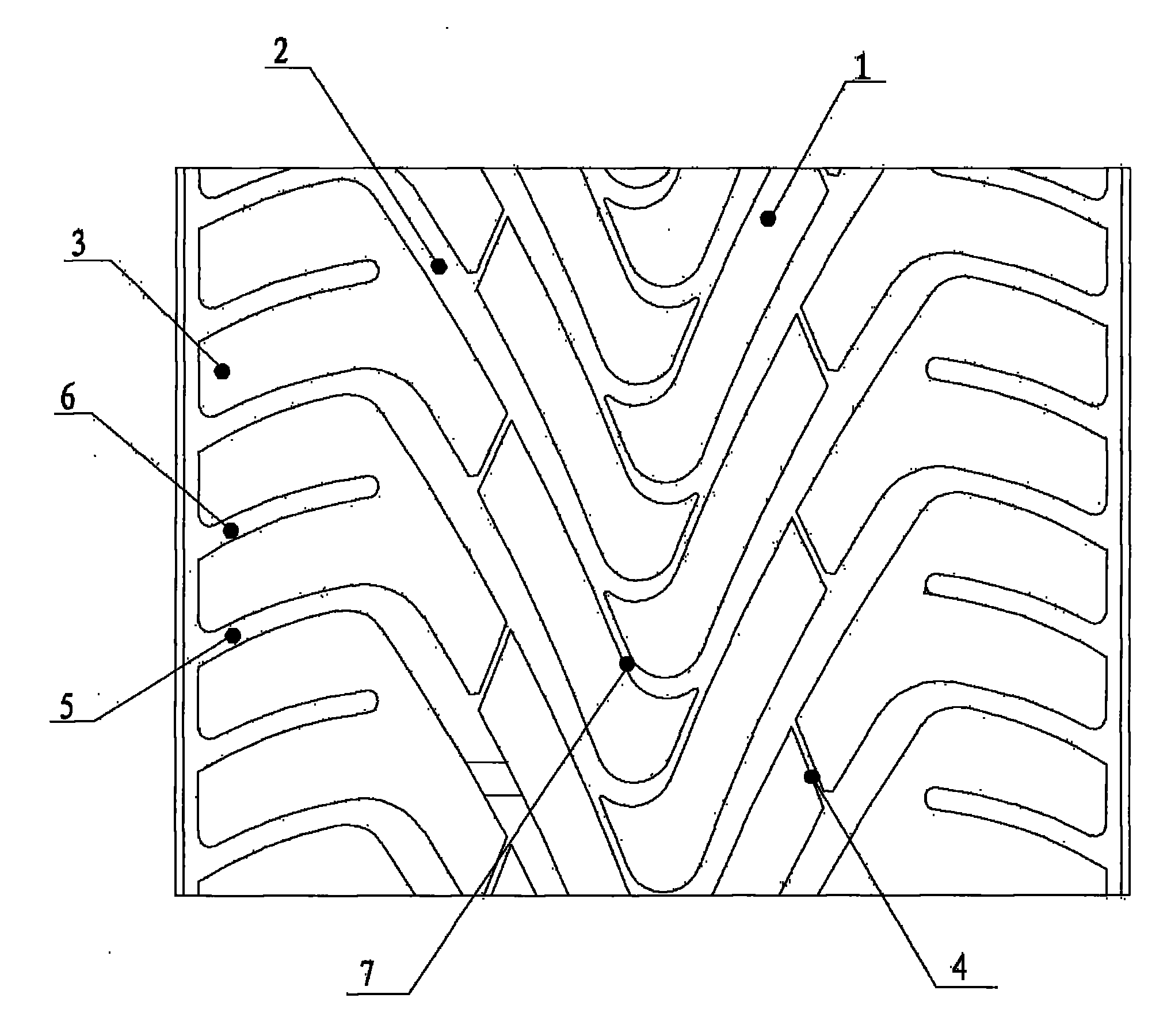

Tread pattern for radial ply tire of sedan

InactiveCN102248867ASufficient braking forceImprove maneuverabilityTyre tread bands/patternsEngineeringMixed pattern

The invention relates to an automobile tire structure, in particular to a tread pattern structure of a load-carrying automobile tire. In a tread pattern for a radial ply tire of a sedan, V-shaped pattern grooves are formed at the central position of a tire tread along the circumferential direction at intervals; central pattern blocks and tire shoulder pattern blocks are arranged in the groove wall directions of the V-shaped pattern grooves from groove bottoms to groove tops sequentially; the central pattern blocks are spaced from the tire shoulder pattern blocks through lateral pattern grooves; the two ends of the lateral pattern grooves are communicated with two adjacent V-shaped pattern grooves; the central pattern blocks are arranged in a sequentially superposed and staggered way along the circumferential direction; the inclined directions of the two adjacent central pattern blocks are symmetrical to each other relative to the central position; every two adjacent tire shoulder pattern blocks are spaced from each other through a transverse pattern groove; and the transverse pattern grooves are communicated with the V-shaped pattern grooves and are smoothly transitioned. Mixed patterns are used for the tread of the tire, and have sufficient braking force, high maneuvering performance and aesthetic and elegant appearance.

Owner:克劳斯玛菲股份有限公司

Multi-axis fatigue testing clamp of high-cycle fatigue testing machine

InactiveCN105021452AAccurately reflect the resultant forceAchieve lockingStrength propertiesTest sampleEngineering

The invention provides a multi-axis fatigue testing clamp of a high-cycle fatigue testing machine. The multi-axis fatigue testing clamp comprises two relative clamp bodies, wherein a clamping end of the rear part of each clamp body is composed of an extending main shaft and an extending sleeve; an inner thread is arranged in the front end of each extending main shaft and is matched with an outer thread of the rear part of a connection shaft at the rear end of an arc-shaped clamp; an inwards concave surface of the front end of the arc-shaped clamp is provided with a plurality of locking devices which form different angles with the vertical direction; the structure of each locking device is as follows: the inward concave surface of the arc-shaped clamp is provided with a lug boss with a blind hole; a conduction cushion block is arranged in the blind hole; a test sample connection block covers the conduction cushion block, and a limiting tooth of the test sample connection block is matched with a limiting groove in a tabletop of the lug boss; an annular groove adapted with the side wall of a locking cover is formed in the periphery of the lug boss; the locking cover covers the test sample connection block and the locking cover is connected to the lug boss through a thread; a locking cover is provided with a through hole; and the test sample connection block is provided with an inner thread through hole. The clamp is matched with the single-axis high-cycle fatigue testing machine to be tried, and can be used for carrying out high-cycle and multi-axis test researches on a test sample.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com